Page 1

BV10

Performance Endpoint Unit

User Guide

Page 2

Copyright © 2010–2014 EXFO Inc. All rights reserved. No part of this

publication may be reproduced, stored in a retrieval system or transmitted

in any form, be it electronically, mechanically, or by any other means such

as photocopying, recording or otherwise, without the prior written

permission of EXFO Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

December 4, 2014

Version number:

ii BV10

3.

0.0.1

Page 3

Certification Information

Certification Information

North America Regulatory Statement

This unit was certified by an agency approved in both Canada and the

United States of America. It has been evaluated according to applicable

North American approved standards for product safety for use in Canada

and the United States.

Electronic test and measurement equipment is exempt from FCC part 15,

subpart B compliance in the United States of America and from ICES-003

compliance in Canada. However, EXFO Inc. makes reasonable efforts to

ensure compliance to the applicable standards.

The limits set by these standards are designed to provide reasonable

protection against harmful interference when the equipment is operated in

a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance

with the user guide, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely

to cause harmful interference in which case the user will be required to

correct the interference at his own expense.

Modifications not expressly approved by the manufacturer could void the

user's authority to operate the equipment.

European Community Declaration of Conformity

An electronic version of the declaration of conformity for your product is

available on our website at www.exfo.com. Refer to the product’s page on

the Web site for details.

Laser

This product complies with 21 CFR 1040.10 except for deviations pursuant

to Laser Notice No. 50, dated June 24, 2007 and with IEC/EN 60825-1.

BV10-100 and BV10-1000 iii

Page 4

Contents

Certification Information ....................................................................................................... iii

1 Introducing the BV10 ....................................................................................1

Features .................................................................................................................................1

BrixWorx for Turn Up ..............................................................................................................2

Conventions ............................................................................................................................3

2 Safety Information ......................................................................................5

Additional Laser Safety Information .......................................................................................6

Installation Instruction Warnings ............................................................................................7

Other Safety Symbols on Your Unit .........................................................................................8

3 Getting Started .............................................................................................9

Installing the BV10 in a Rack ..................................................................................................9

Connecting the Power ..........................................................................................................10

4 Physical Interfaces, LEDs, and Buttons ......................................................15

BV10 Models .......................................................................................................................15

Port Availability on BV10 .....................................................................................................16

Connecting the TEST Port Interface .......................................................................................16

Connecting the Management Interfaces ...............................................................................18

LEDs .....................................................................................................................................20

RESET and DEFAULT Buttons .................................................................................................21

5 Managing BV10 Verifier on BrixWorx ........................................................23

Configuring BV10 Verifier for BrixWorx Registry ...................................................................23

Configuring a Test .................................................................................................................24

Verifier Health Information ...................................................................................................28

6 Introducing the BV10 CLI ............................................................................29

Command Line Interface .......................................................................................................29

Connecting to the BV10 to a Console ...................................................................................30

Entering Commands .............................................................................................................33

CLI Session ............................................................................................................................37

7 CLI Command Reference ............................................................................39

Conventions ..........................................................................................................................39

Command Availability ...........................................................................................................39

Alphabetical List of CLI Commands .......................................................................................40

Operation Commands ..........................................................................................................42

Configuration Commands ....................................................................................................58

iv BV10

Page 5

8 Test Applications ........................................................................................ 73

Smart Loopback Test .............................................................................................................74

Ping Test ...............................................................................................................................76

TWAMP Light Responder Test ...............................................................................................77

UDP Echo Responder Test .....................................................................................................78

Ethernet OAM Handling Test .................................................................................................79

9 Power Failure Recovery .............................................................................. 81

10 Maintenance ............................................................................................... 83

Cleaning LC Connectors ........................................................................................................84

Recycling and Disposal (Applies to European Union Only) ....................................................84

11 Troubleshooting ......................................................................................... 85

Solving Common Problems ...................................................................................................85

Contacting the Technical Support Group ..............................................................................86

Transportation ......................................................................................................................86

12 Warranty ..................................................................................................... 87

General Information .............................................................................................................87

Liability .................................................................................................................................88

Exclusions .............................................................................................................................89

Certification ..........................................................................................................................89

Service and Repairs ...............................................................................................................90

EXFO Service Centers Worldwide ..........................................................................................91

A Specifications ............................................................................................. 93

General Specifications .........................................................................................................93

Electrical Interface ...............................................................................................................95

Optical Interface ..................................................................................................................95

B Glossary ...................................................................................................... 97

Acronym List ........................................................................................................................97

Ethernet Cables .................................................................................................................102

Index .............................................................................................................. 105

BV10-100 and BV10-1000 v

Page 6

Page 7

1 Introducing the BV10

Highly cost-effective Ethernet performance monitoring device providing

complete network visibility for mobile backhaul, Carrier Ethernet, and PTN

networks.

Features

Fully integrated in EXFO’s end-to-end mobile backhaul solution for

service turn-up, troubleshooting, and performance monitoring.

Offers complete network visibility at a third of the cost of traditional

Ethernet NID solutions.

Simple and remote management for zero-truck-roll network

maintenance.

Completely standards-based, supporting Ethernet OAM, with 802.1ag

and Y.1731 message response as a performance endpoint, as well as

TWAMP (RFC 5357).

Capability to perform full-line-rate loopback from layer 2 up to layer 4

with rates of 10/100/1000 Mbit/s.

BV10-100 and BV10-1000 1

Page 8

Introducing the BV10

BrixWorx for Turn Up

BrixWorx for Turn Up

BrixWorx for Turn Up is a system designed for Turn-Up and reflector testing

with no monitoring capability. BrixWorx for Turn Up supports a central

management system, Verifier management for the supported Verifier

models, and user management. BrixWorx for Turn Up does not support

active or passive testing.

The BV10 Verifier is designed specifically for Ethernet OAM Handling, UDP

Echo Responder, TWAMP Light Responder, and Smart Loopback test

features. These features are enabled by loading the tests on the Verifier

Information page (Additional Services section) and in some cases

specifying parameters, such as a UDP Listening port for TWAMP or the

mode for Smart Loopback.

For more information, refer to the BrixWorx for Turn Up Getting Started

guide to learn more about the features of the BrixWorx for Turn Up system

and the BrixWorx User Guide to learn more about the Verifier Information

page.

2 BV10

Page 9

Introducing the BV10

Conventions

Before using the product described in this guide, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

Conventions

IMPORTANT

Refers to information about this product you should not overlook.

BV10-100 and BV10-1000 3

Page 10

Page 11

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active.

Never look directly into a live fiber and ensure that your eyes are

protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for

operation and maintenance, other than those specified herein may

result in hazardous radiation exposure or impair the protection

provided by this unit.

IMPORTANT

When you see the following symbol on your unit , make sure

that you refer to the instructions provided in your user

documentation. Ensure that you understand and meet the required

conditions before using your product.

IMPORTANT

Other safety instructions relevant for your product are located

throughout this documentation, depending on the action to

perform. Make sure to read them carefully when they apply to your

situation.

BV10-100 and BV10-1000 5

Page 12

Safety Information

Additional Laser Safety Information

Additional Laser Safety Information

This product employs Class 1 Laser SFP. Invisible laser radiation may

be encountered at the output port. The laser classification is

reproduced on the pluggable transceiver or in its documentation.

When the LASER LED is on or flashing, the BV10 is transmitting an

optical signal on the SFP transceiver port.

WARNING

WARNING

6 BV10

Page 13

Safety Information

Installation Instruction Warnings

Installation Instruction Warnings

CAUTION

No user serviceable parts are contained inside. Contact the

manufacturer regarding service of this equipment.

IMPORTANT

All wiring and installation must be in accordance with local building

and electrical codes acceptable to the authorities in the countries

where the equipment is installed and used.

CAUTION

Electrostatic Discharge (ESD) Sensitive Equipment:

Units can be damaged by static electrical discharge. To minimize the

risk of damage, dissipate static electricity by touching a grounded

unpainted metal object

before removing, inserting, or handling the unit.

before connecting or disconnecting cables to/from the unit.

before inserting or removing SFP transceiver to/from the unit.

CAUTION

For DC version, the BV10 must be installed in Restricted Access

Locations.

IMPORTANT

Unauthorized modifications to this equipment shall void the user’s

authority to operate this equipment.

BV10-100 and BV10-1000 7

Page 14

Safety Information

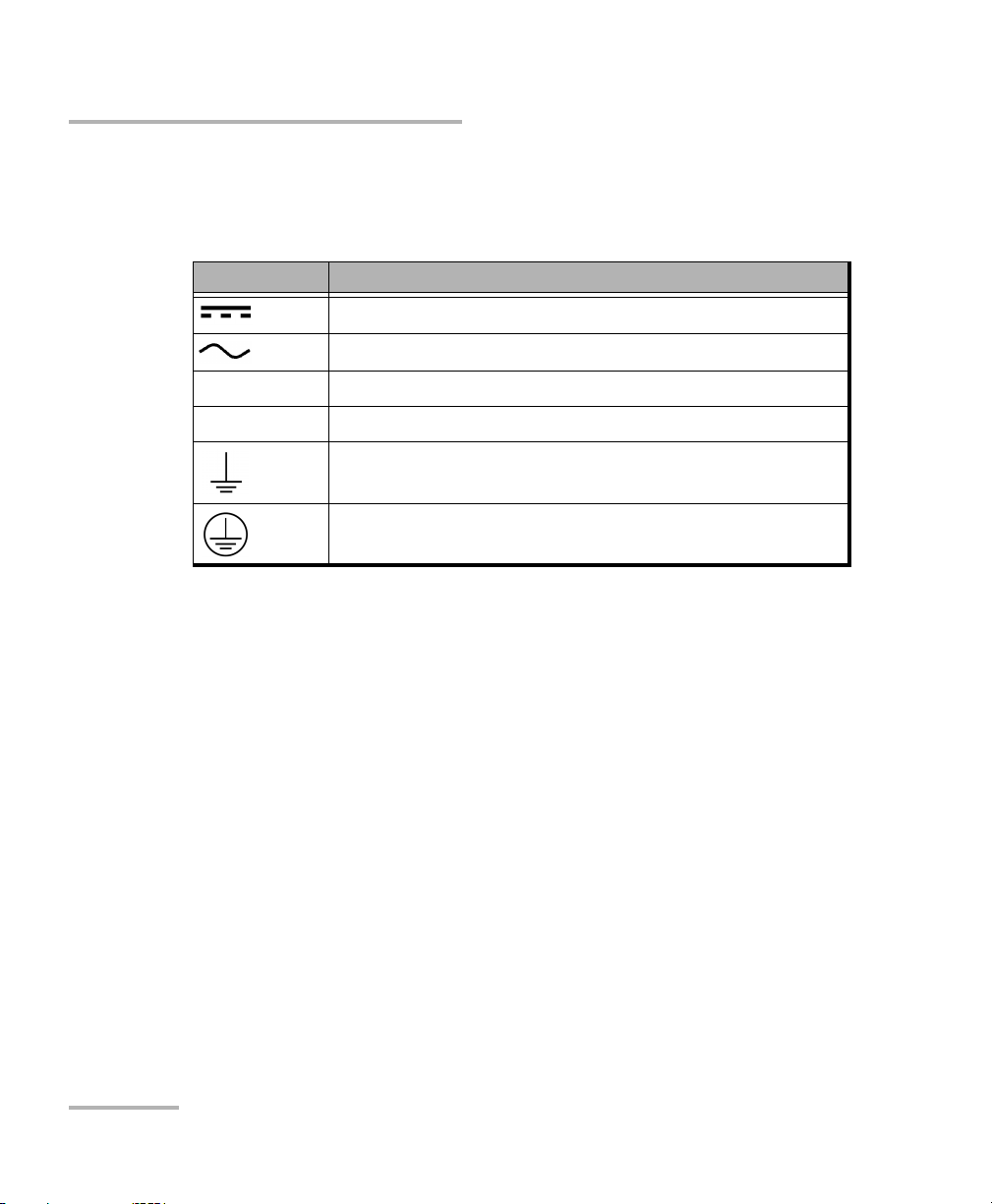

Other Safety Symbols on Your Unit

Other Safety Symbols on Your Unit

One or more of the following symbols may also appear on your unit.

Symbol Meaning

Direct current.

Alternating current.

+

–

Plus; positive polarity.

Minus, negative polarity.

The unit is equipped with an earth (ground) terminal.

The unit is equipped with a protective conductor terminal.

8 BV10

Page 15

3 Getting Started

Installing the BV10 in a Rack

The BV10 can be mounted in a rack using the rack mount accessory kit

(ordered separately). The accessory kit shelf holds up to four BV10.

To install the BV10 in a rack:

1. Attach the brackets of the supplied shelf unit to your rack using the

supplied screws.

2. If cables have been attached to the BV10, disconnect all of them as

well as the ground lug from the unit.

3. Slide the unit into the desired slot from front to back.

4. With the unit completely inserted into the slot, tighten the thumb screw

at the back of the unit.

5. Connect all cables and the ground lug, as explained in the next

sections.

BV10-100 and BV10-1000 9

Page 16

Getting Started

Connecting the Power

Connecting the Power

The BV10 is available with either an AC power supply, DC +24 V connector,

or DC –48 V connector.

As soon as the BV10 is connected to a live power supply, the POWER LED

turns on. If the POWER LED does not turn on, there is a power failure at the

source or the unit is damaged. The STATUS LED indicates whether or not

the unit is ready for use. If the STATUS LED is off the unit is booting up. If it

is green or red the unit has booted (refer to STATUS on page 20).

10 BV10

Page 17

Getting Started

AC unit ground

lug and hardware

DC unit ground

lug and hardware

Connecting the Power

Grounding the BV10

The BV10 is equipped with a ground lug and hardware attached to the

back of the unit. The grounding hardware consists of a washer with

external teeth facing the unit and a locking nut. You will need to supply a

#12 AWG wire.

WARNING

The BV10 DC version is intended to be grounded. Ensure that the unit is

connected to earth ground during normal use.

To ground the BV10:

1. Loosen the locking nut on the grounding lug.

2. Using a #12 AWG wire, twist the wire around the lug so that it is

touching the flat surface of the washer. The wire must be twisted

between the washer and the locking nut.

3. Tighten the locking nut.

4. Connect the other end of the wire to the ground distribution network.

BV10-100 and BV10-1000 11

Page 18

Getting Started

Connecting the Power

Connecting the BV10 using an AC/DC Power

Source

The typical output voltage of the external brick AC power supply is 9 V DC.

To connect the BV10 to an AC power source:

1. Connect the supplied AC power cord to the AC/DC adapter and the

other end to an AC wall outlet.

2. Connect the other end of the power supply to the DC barrel power

connector on the BV10.

Connecting the BV10 using a DC Power Source

The BV10 DC version is equipped with either +24 V DC or –48 V DC

connector.

Powering a BV10 +24 V DC unit with a –48 V power source will

permanently damage the unit. The +24 V input range is 20-32 V.

WARNING

Powering a BV10 –48 V DC unit with a +24 V power source will

permanently damage the unit. The –48 V input range is –40 to –72 V.

To connect the BV10 to a DC power source:

1. Using 14-16 AWG copper insulated wires and the supplied connector,

insert the two stripped wires into the connector and tighten the screws

firmly. Either use non-stranded wire or crimp a ferrule onto the wire.

Be sure to respect the polarity.

The positive supply wire lead must be on the right side of the

connector and the negative supply wire on the left side.

12 BV10

Page 19

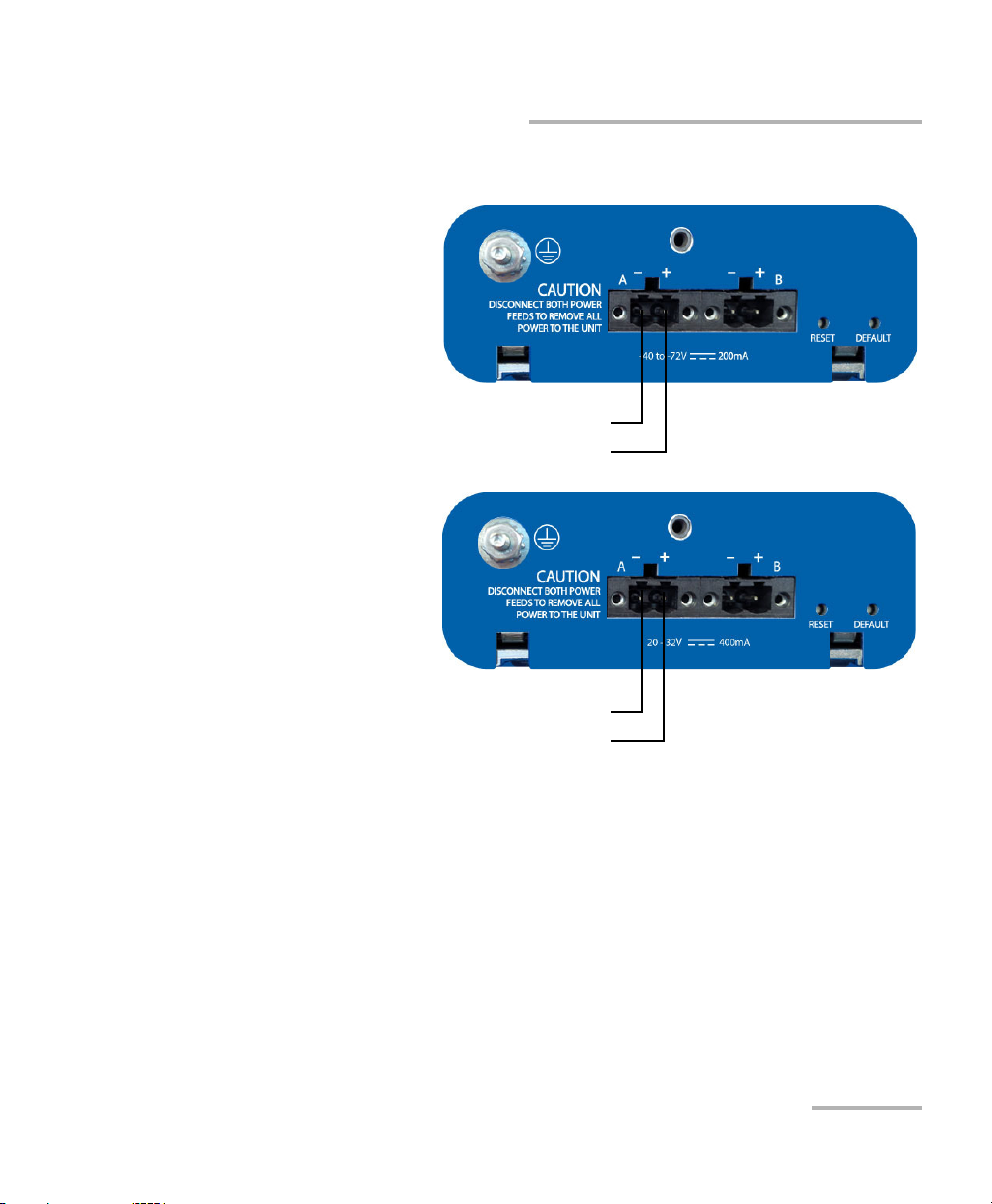

Getting Started

–48 V DC Unit

Supplied connector

Negative (

–) supply wire lead on the left

Positive (+) supply wire lead on the right

+24 V DC Unit

Supplied connector

Negative (

–) supply wire lead on the left

Positive (+) supply wire lead on the right

Connecting the Power

The following figures show the –48 V and +24 V DC units.

-

-

2. Connect the plug to one of the two DC input connectors on the BV10

unit and tighten the screws firmly.

BV10-100 and BV10-1000 13

Page 20

Getting Started

Connecting the Power

3. Connect the other end of the wires to the DC power source.

The DC input feeds to the equipment must be protected by 20 A rated

maximum breaker provided as part of the building installation.

Permanently connected equipment must have a switch or

circuit-breaker for disconnection. If the switch is not part of the kit:

Include a switch or circuit-breaker in the installation.

The switch must be located easily, and placed near the equipment.

The switch must be specified as the disconnecting device for the

4. To add a redundant DC power source on the BV10, repeat step 1

through step 3.

To avoid serious injuries as well as irreparable damages to your unit,

ALWAYS TURN OFF BOTH DISCONNECT DEVICES BEFORE OPENING OR

SERVICING THE UNIT.

CAUTION

equipment.

WARNING

14 BV10

Page 21

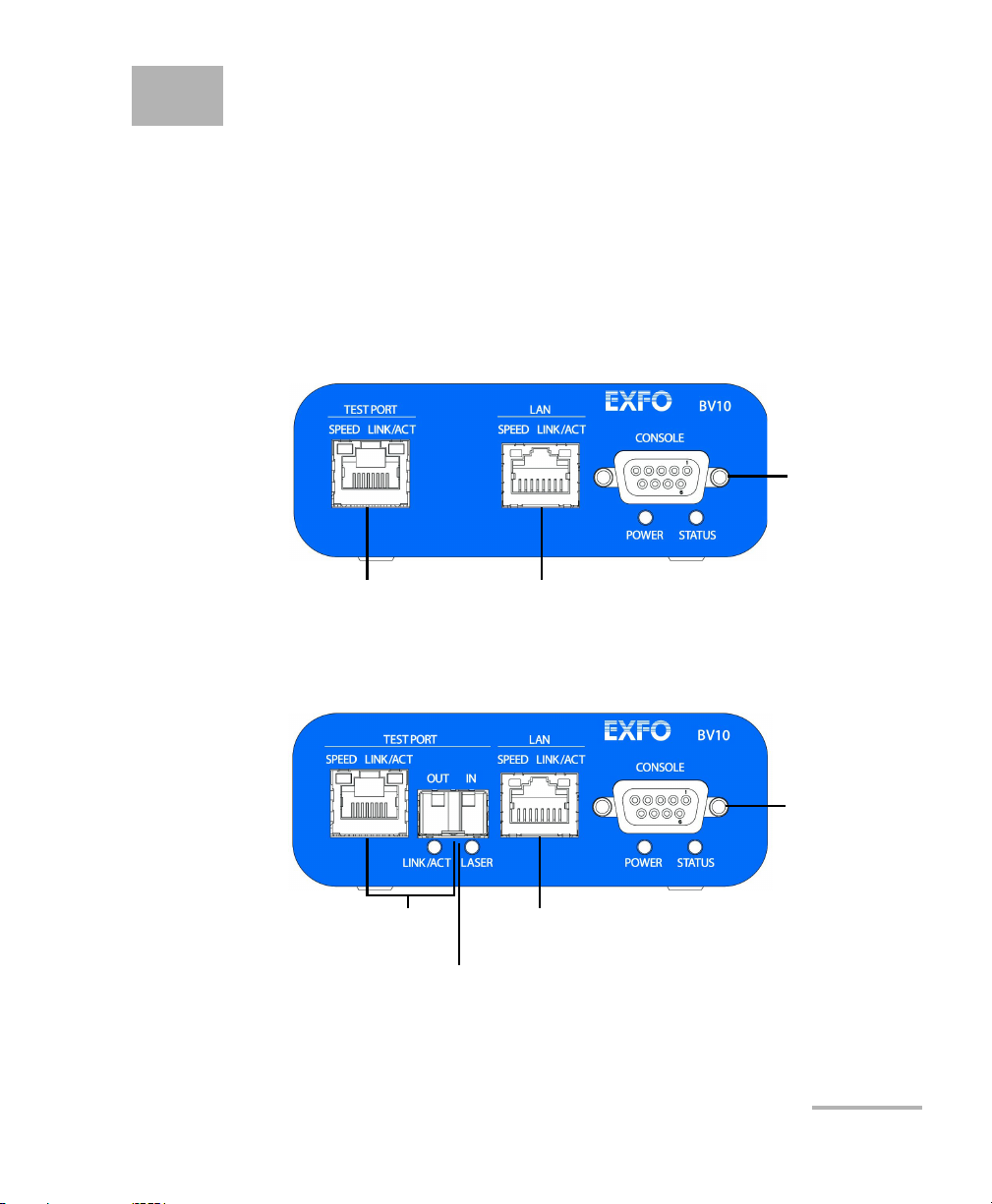

4 Physical Interfaces, LEDs, and

LANTEST

CONSOLE

LANTEST

CONSOLE

Laser radiation emitted from this port when LASER LED is on.

Buttons

This section describes all connectors (ports), LEDs, and buttons available

on the BV10-100 and BV10-1000 units.

BV10 Models

BV10-100

BV10-1000

BV10-100 and BV10-1000 15

Page 22

Physical Interfaces, LEDs, and Buttons

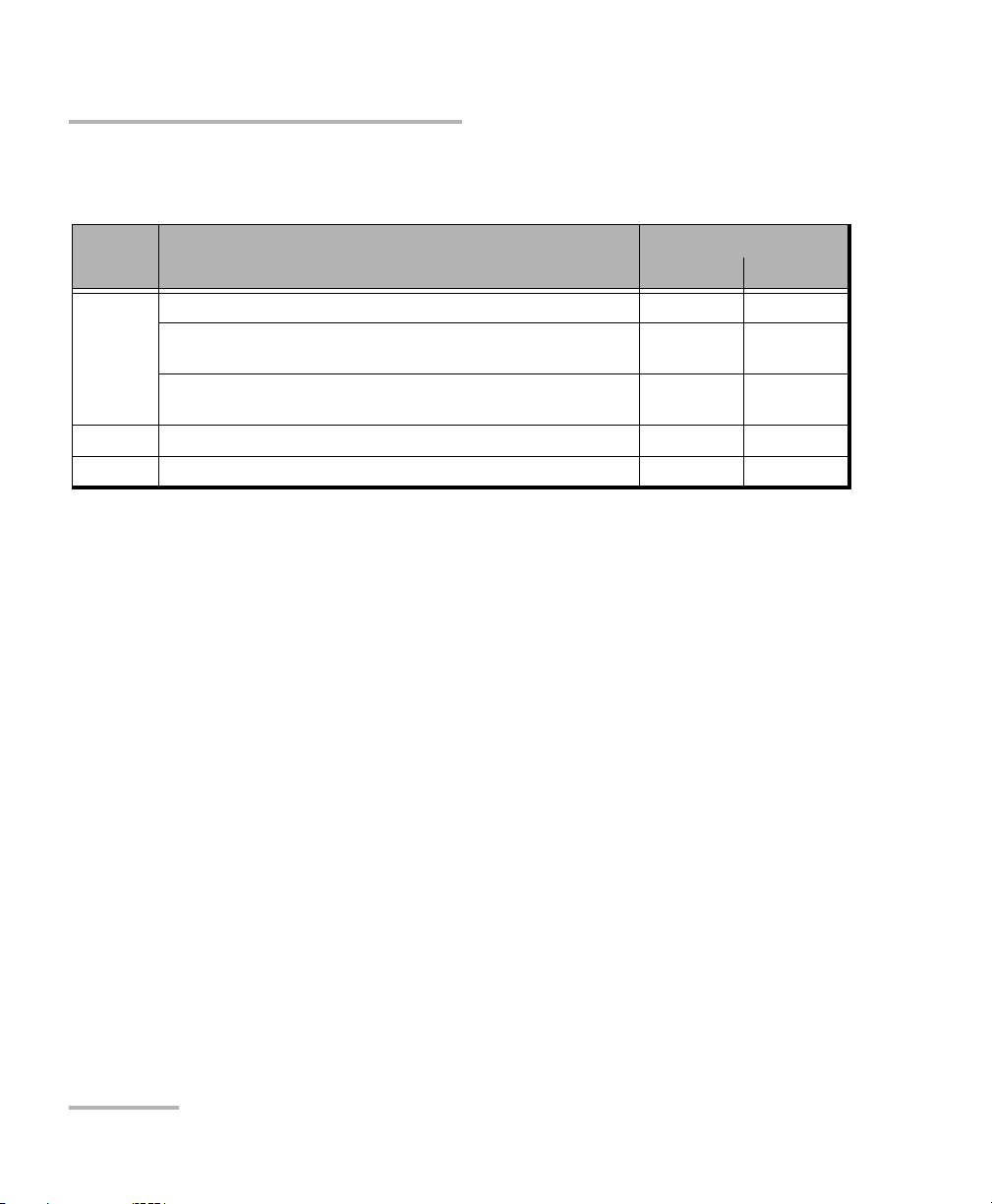

Port Availability on BV10

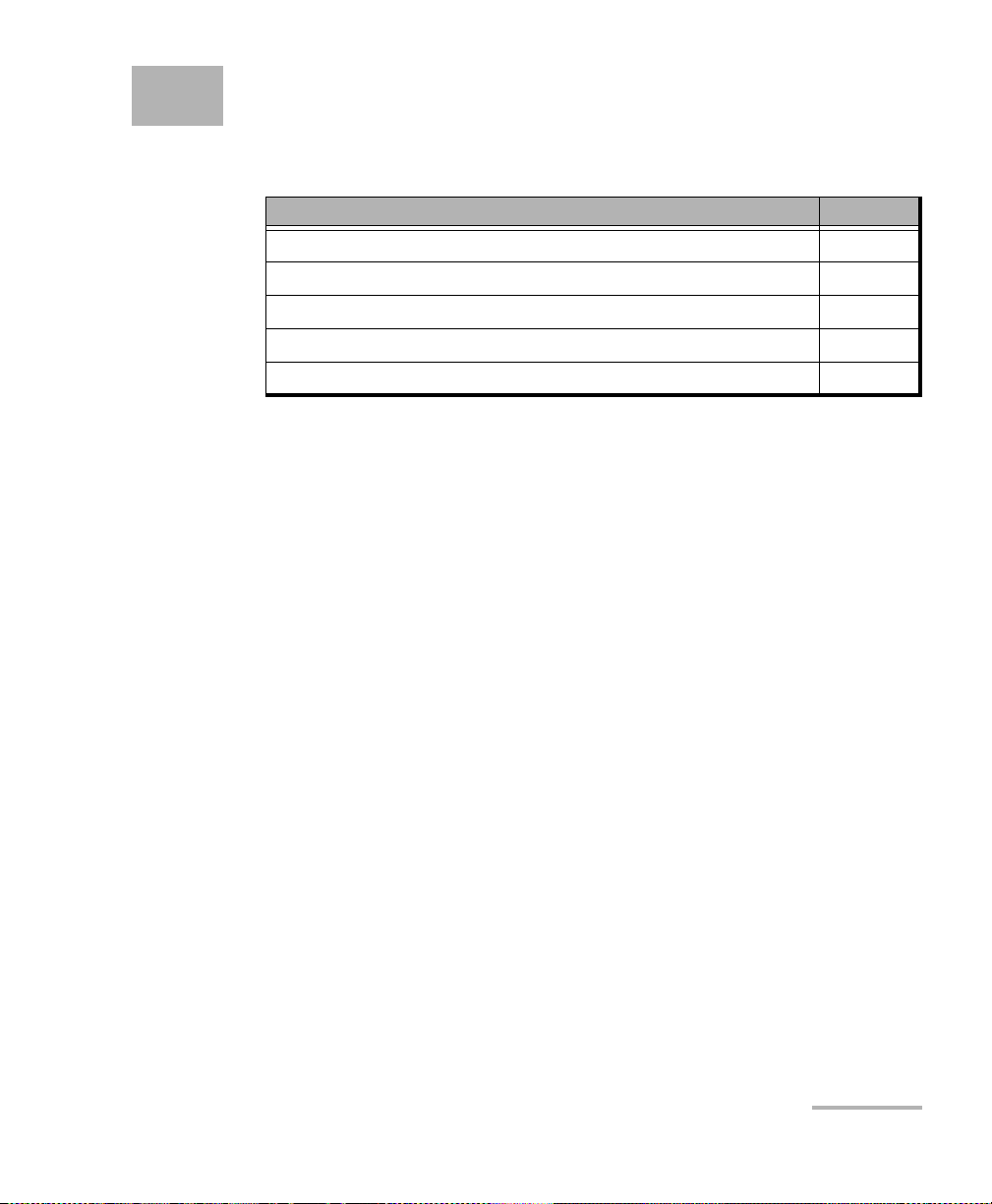

Port Availability on BV10

Port

Label

TEST PORT 10/100 Mbit/s electrical RJ45 Test port (10Base-T and 100Base-TX) X

10/100/1000Mbit/s electrical RJ45 Test port (10Base-T, 100Base-TX

and 1000Base-T)

1000 Mbit/s optical SFP Test port (1000Base-SX/LX/ZX;

850/1310/1550nm)

LAN 10/100 Mbit/s electrical Management port X X

CONSOLE RS-232 DE-9F DCE (referred as DB9) Console port X X

Description

BV10-100 BV10-1000

Model

Connecting the TEST Port Interface

The BV10-100 provides an electrical 10/100 Mbit/s Ethernet Test interface

while the BV10-1000 provides an electrical 10/100/1000 Mbit/s and an

optical 1000 Mbit/s SFP laser Ethernet Test interfaces. The two BV10-1000

Test interfaces are mutually exclusive.

RJ45 Port

Connect the 10/100/1000 Mbit/s electrical interface to be tested to the RJ45

test port. The electrical ports is RJ45 for category 5 unshielded twisted pair

(UTP). Refer to Ethernet Cables on page 102 for cable specifications.

X

X

Supported electrical rates are:

For BV10-100: 10 Mbit/s and 100 Mbit/s.

For BV10-1000: 10 Mbit/s, 100 Mbit/s, and 1000 Mbit/s.

16 BV10

Page 23

Physical Interfaces, LEDs, and Buttons

Connecting the TEST Port Interface

SFP Port (BV10-1000)

The BV10-1000 provides an optional optical port for 1000Base-SX/LX/ZX

testing capability. The optical port is a Small Form Factor Pluggable (SFP)

slot type with LC connector.

Insert an SFP module into the SFP test port slot on the BV10. Refer to

Optical Interface on page 95 for more information on supported SFP.

Carefully connect optical fibre cables to the SFP’s IN and OUT ports. To

ensure good signal quality, make sure that the optical fibre connector is

fully inserted into the optical connector port.

CAUTION

To prevent exceeding the maximum input power level please use an

attenuator when a loopback configuration is used.

BV10-100 and BV10-1000 17

Page 24

Physical Interfaces, LEDs, and Buttons

Connecting the Management Interfaces

Connecting the Management Interfaces

The management interface can be connected locally using the CONSOLE

port or remotely using the LAN Port.

LAN Port

Connecting a typical management network to the 10/100 Mbit/s Ethernet

LAN port provides remote access to the BV10 Command Line Interface

(CLI) using either Telnet or SSH session.

To connect remotely to the BV10 using the LAN port, connect both the

BV10 LAN port and the remote PC to the same Management network using

a standard straight through Ethernet cable with RJ45 connectors.

18 BV10

Page 25

Physical Interfaces, LEDs, and Buttons

Connecting the Management Interfaces

CONSOLE Port

Connecting a PC to the CONSOLE port provides local access to the BV10

using CLI commands.

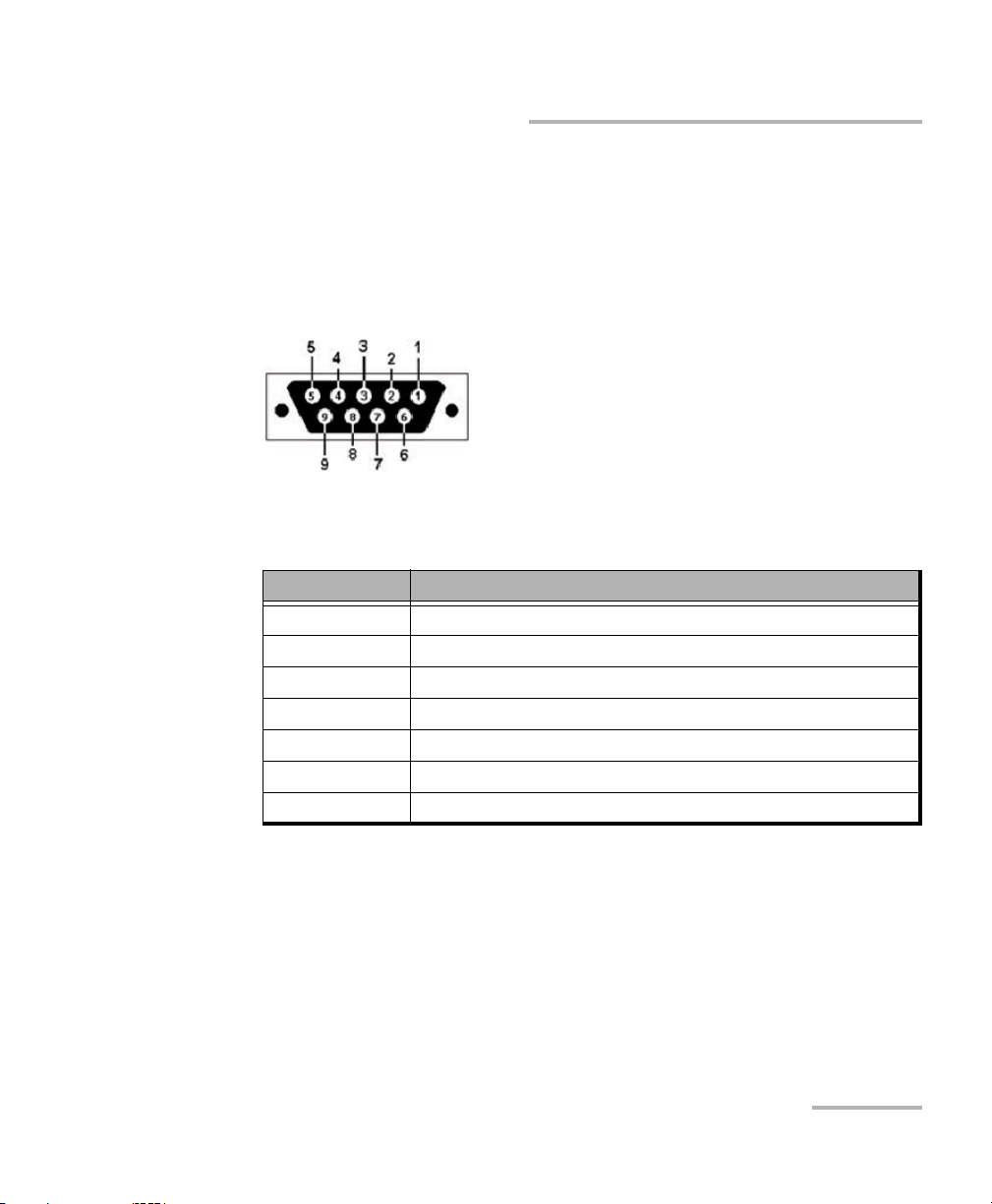

The following figure shows the DB9 (RS-232 DE-9F DCE) pinouts as viewed

from the front of the BV10.

The following table indicates the DB9 pinouts.

Pin Number Description

1, 4, and 6 Connected together inside the BV10

7 and 8 Connected together inside the BV10

5 Signal ground

2 TX (output of the BV10)

3 RX (input of the BV10)

9 Not internally connected

DB9 casing Chassis ground

To connect locally, connect a PC to the CONSOLE port using an RS-232

straight cable with a DB9 connector.

BV10-100 and BV10-1000 19

Page 26

Physical Interfaces, LEDs, and Buttons

LEDs

LEDs

POWER

On (Green) indicates that the BV10 unit is receiving power from an

external source.

Off indicates that the BV10 unit is not receiving power from the

external source or the unit is damaged.

STATUS

On (Green) indicates that the link on the test port is up.

On (Red) indicates that the link on the test port is down.

Off indicates that the unit is not yet booted.

SPEED

Off indicates 10 Mbit/s

On (Green) indicates 100 Mbit/s

On (Amber) indicates 1000 Mbit/s (BV10-1000 only)

LINK/ACT (Electrical and Optical Ports)

On (Green) indicates that the link is up; there is no activity.

Off indicates that the link is down; there is no activity.

Blinking (Green) indicates that the link is up; there is activity.

LASER

Off indicates that the laser is off.

On (Red) indicates that the laser is on.

20 BV10

Page 27

Physical Interfaces, LEDs, and Buttons

RESET

DEFAULT

RESET and DEFAULT Buttons

RESET and DEFAULT Buttons

The RESET and DEFAULT buttons are recessed on the back of the BV10 to

avoid accidental use.

-

RESET Button

The RESET button is used to reboot the BV10. Press the RESET button once

to reboot the BV10. While rebooting, the BV10 displays a series of

messages if the unit is connected to a console.

The reboot command can also be used to reboot the BV10 (refer to reboot

on page 45).

DEFAULT Button

The DEFAULT button is used to reset the BV10 to the factory default

settings. Press the DEFAULT button once to reset the BV10 to its factory

default settings then the unit reboots by itself.

BV10-100 and BV10-1000 21

Page 28

Page 29

5 Managing BV10 Verifier on

BrixWorx

This chapter describes how to configure and use BV10 hardware on

BrixWorx. It explains the CLI commands used to communicate with the

BrixWorx registry and describes how to set up tests using the BrixWorx

user interface.

Note: When the BV10 is used in a BrixWorx environment, you must use BrixWorx

GUI rather than CLI prompt to manage the BV10 device. When you change

a reflector to run or not through the CLI, this is not updated on the BrixWorx

GUI Additional Services page. The GUI changes override the changes done

using the CLI prompt.

Configuring BV10 Verifier for BrixWorx Registry

The BV10 Verifier must be configured before you can use it in the BrixWorx

system. Once the configuration of a BV10 Verifier is complete, you must

add it to BrixWorx just like any other Verifier.

Configure the BV10 Verifier

To configure the BV10 Verifier for use in the BrixWorx system:

1. Access the CLI prompt using Telnet or SSH. To log on to the Telnet or

SSH server, use the following login information:

Login ID:

Password: exfo123

The CLI prompt name contains the BV10 model number followed by

(DEBUG). For example:

BV10-1000 (DEBUG)>

2. To configure the IP address of the local BrixWorx registry, type the

following command:

BV10-1000 (DEBUG)> server discovery local IP address

BV10-100 and BV10-1000 23

exfo

Page 30

Managing BV10 Verifier on BrixWorx

Configuring a Test

3. To configure the port of communication, type the following command:

BV10-1000 (DEBUG)> server discovery port value

The default port value is 80.

4. To save the new port value, type the following command:

BV10-1000 (DEBUG)> server discovery write

Add the BV10 to BrixWorx

Once you have configured a BV10, you must add it to BrixWorx.

Refer to the BrixWorx User Guide for more information on how to add the

BV10 Verifier to the BrixWorx system.

Configuring a Test

Only a specific set of BrixWorx tests are supported by the BV10 Verifier. All

tests supported on the BV10 Verifier are available through BrixWorx:

Ethernet OAM Handling

UDP Echo Responder

TWAMP Light Responder

Smart Loopback

SSH service

Teln e t ser vi c e

Refer to Test Applications on page 73 for more information on the tests

supported on the BV10 Verifier.

24 BV10

Page 31

Managing BV10 Verifier on BrixWorx

Configuring a Test

To configure a test on a BV10 Verifier using the BrixWorx

Operations Centre:

1. Login to BrixWorx.

2. Select Verifier s.

BV10-100 and BV10-1000 25

Page 32

Managing BV10 Verifier on BrixWorx

Configuring a Test

3. Click the name of the Verifier on which you want to configure the test.

4. Click the edit button for Additional Services. You can choose to load a

specific test or service on this page.

26 BV10

Page 33

Managing BV10 Verifier on BrixWorx

Configuring a Test

5. Enter the time interval at which you want the BV10 Verifier to report the

health information. See Verifier Health Information on page 28 for

more information.

6. Select Load for the tests that you want to configure on the BV10

Verifier.

For the TWAMP Light Responder test, you must enter the UDP port

value to load the test.

For Smart Loopback test, select Ethernet, Ethernet all unicast, IP,

or UDP-TCP to load the specific test.

Refer to Test Applications on page 73 for more information about the

tests that you can load on the BV10 Verifier.

7. To run the S S H or Te lnet s er v ice , sele c t Run.

The selected tests and services are loaded on the BV10 Verifier.

BV10-100 and BV10-1000 27

Page 34

Managing BV10 Verifier on BrixWorx

Verifier Health Information

Verifier Health Information

The BV10 Verifier runs its health status test based on the interval set in the

Status field in the Additional Services category of the Verifier’s advanced

parameters. It reports results to BrixWorx based on its polling interval. The

following figure shows an example of Verifier health information.

To display the Verifier Health page, select the Verifier Health category on

the Verifier Information page.

See Configure the BV10 Verifier on page 23 for more information on how to

set the interval for Verifier status reporting and refer to the Verifiers chapter

in the BrixWorx User Guide for information on the fields from the Verifier

Health page.

28 BV10

Page 35

6 Introducing the BV10 CLI

This chapter describes the BV10 Ethernet Performance Endpoints

Command Line Interface (CLI), its uses, and its features.

Note: Refer to CLI Command Reference on page 39 for more information on

command definition and syntax.

Command Line Interface

The Command Line Interface (CLI) allows to configure and manage the

operation of the BV10 by sending commands to the BV10 using either the

CONSOLE Port, a Telnet session (LAN or TEST Port), or Secure Shell (SSH)

session (LAN or TEST Port).

Note: Telnet and SSH provide the same functionality except SSH provides a secure

channel. Refer to console telnet|ssh server enable|disable on page 61 for

more information on enabling Telnet or SSH.

BV10-100 and BV10-1000 29

Page 36

Introducing the BV10 CLI

Connecting to the BV10 to a Console

Connecting to the BV10 to a Console

Connect the BV10 to a Console for management through CONSOLE, LAN,

or TEST port.

CONSOLE Port

A console is directly connected to the BV10 (CONSOLE Por t). The

CONSOLE port is always available for CLI use.

To use the CONSOLE port:

1. Ensure that your PC is connected to the BV10‘s CONSOLE port. Refer to

CONSOLE Port on page 19.

2. Use a terminal application to connect with the BV10 through its

CONSOLE port.

2a. Start the terminal application.

2b. Set the connection configuration to 9600bps, 8 data bits, no parity,

1 stop bit (9600/8-N-1).

2c. Establish the connection with the BV10.

30 BV10

Page 37

Introducing the BV10 CLI

Connecting to the BV10 to a Console

LAN Port

A console it connected to the BV10 (LAN port) for remote access through

the network using either Telnet or SSH session.

To use the LAN port:

1. Ensure that both your PC network interface and the BV10‘s LAN port

are connected to the same Management network. Refer to LAN Port on

page 18.

2. On your PC, run a terminal application.

3. Select Telnet or SSH connection type.

The use of Telnet server is enabled by default on the BV10.

The use of SSH server is disabled by default on the BV10 and must be

enabled as well as the password must be defined; refer respectively to

console telnet|ssh server enable|disable on page 61 and password set

password on page 61; the user name is exfo. The CLI supports SSHv2.

Encryption keys are factory generated.

4. Enter the BV10 LAN port IP address and Netmask. Default values are:

IP address: 10.10.10.10

Netmask: 255.255.0

5. Establish the connection with the BV10.

BV10-100 and BV10-1000 31

Page 38

Introducing the BV10 CLI

Connecting to the BV10 to a Console

TEST Port

In-band management activities on the TEST port is provided for basic

configuration and software upgrade tasks in situations where the

Management port is inaccessible.

It is important to note that in-band management through the TEST port

should be performed with low traffic volume so that management

responses have minimal impact on test traffic. With high traffic volume,

management responses might add jitter/latency or dropped packets to

results. When a CLI session is opened on the TEST port, the following

warning message appears:

WARNING: Session opened on the TEST Port. Any action may interfere with traffic.

Not all CLI commands are available on the TEST port.

console in-band enable|disable command controls in-band management on

The

the test port. By default, in-band management on the test port is enabled.

Refer to console in-band enable|disable on page 62 for more information.

To use the TEST port:

1. Ensure that both your PC network interface and the BV10‘s TEST port

are connected to the same Management network. Refer to Connecting

the TEST Port Interface on page 16.

2. On your PC, run a terminal application.

3. Select Telnet or SSH connection type.

The use of Telnet server is enabled by default on the BV10.

The use of SSH server is disabled by default on the BV10 and must be

enabled as well as the password must be defined; refer respectively to

console telnet|ssh server enable|disable on page 61 and password set

password on page 61; the user name is exfo. The CLI supports SSHv2.

Encryption keys are factory generated.

4. Enter the BV10 TEST port IP address and Netmask.

5. Establish the connection with the BV10.

32 BV10

Page 39

Introducing the BV10 CLI

Entering Commands

Entering Commands

Once you have connected to the BV10, you can enter CLI commands at the

command prompt. The CLI command prompt is either

BV10-1000>, depending on the BV10 model you are communicating with.

Basic Command Format

The basic format of a CLI command is:

command parameter,...

Both upper and lower case alphanumeric characters and special

characters, such as the slash (/) and colon (:) are supported. Commands

and parameters are not case sensitive.

You can specify no parameter, one parameter, or multiple parameters

separated with comma.

Abbreviating Commands

BV10-100> or

The CLI allows you to type only as much of a command that it is required to

make it unambiguous. For example,

version

because show is the only keyword that starts with sh and version is the

only keyword that starts with

ve. If it cannot be unambiguously determined,

sh ve is the equivalent of typing show

the CLI displays a list of possible commands and parameters that begin

with the partial keyword.

BV10-100 and BV10-1000 33

Page 40

Introducing the BV10 CLI

Entering Commands

Completing Commands

To submit a CLI command, press the Enter key.

The CLI command completion feature lets you type part of a command

and use the Tab key to complete the remainder of the command. Consider

the following examples.

sh <tab> resolves to show

con <tab> resolves to console

sh <tab> ve <tab> resolves to show version

Command completion works as long as what you have typed is

unambiguous – that is, there are no other CLI commands that start with the

letter or letters you have typed. Typing just

the CLI to distinguish

determined, the CLI displays a list of possible commands and parameters

that begin with the partial keyword.

When the rest of the command can be completed, it appears in its

completed form on the same line when you press the Tab key. If the

command cannot be completed, the possible values appear on the

following line when you press the Tab key.

c, for example, does not allow

console from clear. If it cannot be unambiguously

Tip: You can combine abbreviated commands with command completion

on the same line. For example, if you type

resolves to

sh version. When you then press Enter, the CLI abbreviated

command feature allows it to successfully resolve the

and displays the current software/firmware versions.

version

34 BV10

sh v <tab>, the command

sh and the v to show

Page 41

Introducing the BV10 CLI

Entering Commands

Command Editing Keys

The CLI uses common line editing key sequences, as shown in the

following table.

Key Sequence Result

Enter Executes the command.

Backspace Deletes the character to the left of the cursor’s position.

Delete Deletes the character to the left of the cursor’s position.

Home Moves the cursor to the beginning of the line.

End Moves the cursor to the end of the line.

<right arrow> Moves the cursor to the right one character.

<left arrow> Moves the cursor to the left one character.

Ctrl C Interrupts/cancels the command.

<up arrow> Recalls the most recently entered command; scrolls back through the command history

<down arrow> Scrolls forward through all of the commands that have been recalled using the up

Tab Completes the command or keyword. See Completing Commands on page 34 for more

Ctrl D Deletes the character at the cursor’s position.

Ctrl H Deletes the character to the left of the cursor’s position.

Ctrl I Re-displays the current line, completing the last word in the line.

Ctrl J Executes the command.

Ctrl K Deletes all characters from the cursor’s position to the end of the line.

Ctrl L Re-displays the current line.

Ctrl M Executes the command.

Ctrl N Scrolls forward through all of the commands that have been recalled using Ctrl P or the

Ctrl P Recalls the most recently entered command; scrolls back through the command history

buffer each time you press the up arrow key.

arrow.

information.

Up arrow, one command at a time.

buffer each time you repeat the key sequence.

BV10-100 and BV10-1000 35

Page 42

Introducing the BV10 CLI

Entering Commands

Key Sequence Result

Ctrl U Deletes all characters on the line.

Ctrl W Deletes the previous word.

Ctrl Y Pastes from the clipboard.

Esc B Moves the cursor to the start of the previous word.

Esc C Capitalizes the current character.

Esc D Deletes all characters in a word from the cursor’s position to the end of the word.

Esc F Moves the cursor forward one word at a time.

Esc L Lowercases the current character and those that follow in the current word.

Esc U Uppercases the current character and those that follow in the current word.

Esc Delete Deletes the previous word.

Note: Not all key sequences are available to the SSH client. Because an SSH client

buffers data before sending it to the BV10, line editing keys are interpreted

by the SSH client and not by the CLI shell on the BV10. It might be required

to press Enter after using certain keys, such as Tab and ? for example, to get

the result described in the above table.

Command History

The BV10 CLI stores commands performed during a session in a history

buffer. You can recall most recent commands from the history buffer using

either: Up arrow key, Ctrl P, Down arrow key, and Ctrl N (see above table

for more information).

36 BV10

Page 43

Introducing the BV10 CLI

CLI Session

CLI Session

All commands are available at any time once a communication session

has been established with the BV10.

All commands are executed immediately and any configuration changes

are saved automatically.

Idle Timeout

The BV10 has a security feature, called the idle timeout, that logs users out

of a CLI session and closes the connection if there has been no activity for

a specified period of time. An idle timeout can be set for each type of

access (CONSOLE port, Telnet session, or SSH session). It can also be

disabled.

Refer to console telnet|ssh|serial idle-timeout value_in_seconds on

page 62 for more information on how to configure the timeout period.

In addition to the session timeout, a communication session is

automatically closed when the connection is closed or lost (for a LAN

connection).

BV10-100 and BV10-1000 37

Page 44

Page 45

7 CLI Command Reference

This chapter describes the BV10 command line interface (CLI). The

commands are grouped under Operation and Configuration commands.

Note: When the BV10 is used in a BrixWorx environment, you must use BrixWorx

GUI rather than CLI prompt to manage the BV10 device. When you change

a reflector to run or not through the CLI, this is not updated on the BrixWorx

GUI Additional Services page. The GUI changes override the changes done

using the CLI prompt.

Note: Refer to Introducing the BV10 CLI on page 29 for more information on CLI

and its features.

Conventions

The following table lists the conventions used in this chapter to represent

command syntax.

Convention Description Example

Pipe symbol | Choice between two

or more parameters.

Square brackets [ ] Optional parameters.

Italics Variable information.

all | lan | test

Select one of the keywords:

all, lan or test.

[timeout value_in_ms]

The timeout parameter and its

value_in_ms are optional.

value

size size_in_bytes

Enter a number in place of

size_in_bytes.

Command Availability

All CLI commands can be sent through the LAN and CONSOLE ports. Only

a subset of commands can be sent through the Test port.

BV10-100 and BV10-1000 39

Page 46

CLI Command Reference

Alphabetical List of CLI Commands

Alphabetical List of CLI Commands

The following table lists the BV10 CLI commands in alphabetical order.

?44

clear statistics 50

console in-band enable|disable 62

console in-band port port_value 62

console telnet|ssh|serial idle-timeout value_in_seconds 62

console telnet|ssh server enable|disable 61

eth-oam enable|disable 72

help 43

interface lan duplex auto 65

interface lan duplex half|full 66

interface lan flow auto 66

interface lan flow rx|none 66

interface lan speed 10|100 force 65

interface lan|test address-netmask IP_address/netmask|dhcp 68

interface lan|test cable auto 67

interface lan|test gateway IP_address|none 68

interface lan|test gateway dhcp|none 69

interface lan|test speed auto 64

interface lan|test vlan value|none 67

interface test cable straight 67

interface test laser on|off 63

interface test speed 10|100|1000 auto 63

interface test speed 10|100|1000 force 64

interface lan speed 10|100 force 65

interface test speed 1000 auto 65

interface test transceiver electrical|optical 63

Command Page

40 BV10

Page 47

CLI Command Reference

Alphabetical List of CLI Commands

Command Page

interface test vlan priority value 67

load image 47

logout or exit 45

password clear 61

password set password 61

ping 53

reboot 45

server discovery local 54

server discovery network 54

server discovery port 55

server discovery universal 54

server discovery write 55

show config 59

show interface 51

show server discovery local 56

show server discovery network 56

show server discovery port 56

show server discovery universal 56

show server log 57

show statistics 49

show sysinfo 46

show version 46

smart-loopback enable|disable 70

smart-loopback mode ethernet-all-unicast|ethernet|ip|udp-tcp 70

twamp enable|disable 71

twamp udp-port value 71

udp-echo enable|disable 71

BV10-100 and BV10-1000 41

Page 48

CLI Command Reference

Operation Commands

Operation Commands

Operation commands allow to view and change the operational behavior

of the BV10. Operation commands do not change the configuration of the

unit.

The Operation commands are organized as follows:

Subgroup Command Page

Help help

?

System reboot

logout or exit

show sysinfo

Software Management show version

load image

Statistics show statistics

clear statistics

Interface Information show interface 51

Too ls pi ng 5 3

Server Discovery server discovery local

server discovery network

server discovery universal

server discovery port

server discovery write

show server discovery local

show server discovery network

show server discovery universal

show server discovery port

show server log

43

44

45

45

46

46

47

49

50

54

54

54

55

55

56

56

56

56

57

42 BV10

Page 49

CLI Command Reference

Operation Commands

Help Commands

help

Description Displays a list of top-level CLI commands with a description of each

command.

To display context sensitive help for commands that begin with a

certain string of characters (either a complete or partial keyword), use

any of the following commands at the prompt:

partial-keyword?

Displays a list of commands and parameters that begin with the

partial-keyword entered.

keyword<space>?

Displays a list of possible parameters associated with the keyword.

Syntax

Example

BV10-100 and BV10-1000 43

help

bv10-100> help

List of commands:

clear Clears Statistics

console Configure Telnet/SSH/Serial/In-Band management settings

eth-oam Enables/disables Ethernet OAM

exit/logout Logout of the CLI

help Shows help information

interface1 Configures network interface

load Upgrades system image

password Changes password

ping Ping IP address

reboot Reboots the system

show Show statistics, configurations, version, system, server information

smart-loopback Configures Smart Loopback mode

twamp Configures TWAMP

udp-echo Enables/disables UDP echo

server Configures local/network/universal registry and port information

Page 50

CLI Command Reference

Operation Commands

?

Description Displays context-sensitive help. You can enter the ? alone at the CLI

prompt, at the end of a partial keyword (command or parameter), or at

the end of a complete keyword (command) preceded by a space. The

help that is displayed varies accordingly. If you type

at the CLI prompt: displays the names of the top-level CLI

commands.

at the end of a complete or partial keyword (command or

parameter): displays the complete keyword on the next line if the

keyword is unambiguous. If the partial keyword is ambiguous,

displays the possible choices on the next line.

after a complete or partial keyword and a space: displays a list of

parameters. If the partial keyword is ambiguous, displays the

possible choices.

The question mark character is not echoed on the screen.

?

Syntax

Examples

44 BV10

?

bv10-100> ?

clear help password smart-loopback

console interface ping twamp

eth-oam load server udp-echo

exit logout show

bv10-100> c?

clear console

Page 51

CLI Command Reference

Operation Commands

System Commands

reboot

Description Restarts the BV10. Before restarting the unit, the CLI prompts for

confirmation.

The RESET button can also be used to reboot the BV10. Refer to RESET

Button on page 21 for more information.

Syntax

Example

reboot

bv10-100> reboot

Reboot system? [y|n]:

logout or exit

Description Logs out of the CLI session. The logout and exit commands are exactly

the same.

Syntax

Example

logout | exit

bv10-100> logout

BV10-100 and BV10-1000 45

Page 52

CLI Command Reference

Operation Commands

show sysinfo

Description Displays the following BV10 unit information:

Software/firmware versions

Hardware model, version, and identification

Serial number

Manufacturing date

Unit Health Status of the test port: LINK DOWN or OK (link up)

DC Feed A Status, DC Feed B Status. Applied to DC version only and

are monitored every 5 seconds.

Syntax

Example

show sysinfo

bv10-100> show sysinfo

S/W VERSION : Linux 2.6.25 #8 Wed Apr 16 14:47:51 EDT 2014

H/W : BV10-1000-AC

H/W VERSION : C

H/W ID : 800000638428

SERIAL NUMBER : 638428

MFG DATE : 23-03-12

UNIT HEALTH : OK

Software Management Commands

show version

Description Displays the current software/firmware versions.

Syntax

Example

show version

bv10-100> show version

S/W VERSION : Linux 2.6.25 #8 Wed Apr 16 14:47:51 EDT 2014

F/S VERSION : 4.0.1.2, Thu Aug 21 11:50:11 EDT 2014

F/W VERSION : 10021906

46 BV10

Page 53

CLI Command Reference

Operation Commands

load image

Description Loads a software upgrade/downgrade image from TFTP or FTP (using a

username and password) server. The BV10 acts as a client.

The BV10 can be upgraded or downgraded to the next or previous two

versions, preserving the unit’s settings. The unit can be upgraded or

downgraded more than two versions; however, there is no guarantee

that the unit’s settings will be preserved.

The upgrade/downgrade process preserves the unit’s current settings

such as IP parameters and Smart Loopback mode. As the software

loads, informative messages are displayed for each step, including

instructions when user input is required. If the installation fails, the unit

automatically reverts to the previous software image. Once the

software is loaded, the BV10 must be rebooted in order for the new

software image to be applicable. You can use either the RESET button

or the reboot command. Refer to RESET Button on page 21 and reboot

on page 45 for more information.

The LAN or the Test port can be used for loading a software image.

However loading a software image using the Test port stops all

applications running on the BV10, the following message is displayed

requiring a confirmation.

Test Port used to load the image. All Test Applications will be stopped during upgrade.

Are you sure you want to continue? (Y/N)

Y to stop all applications and proceed with the image loading.

Enter

N to cancel the command.

Enter

State and configuration settings are preserved and restored when the

software upgrade is complete and the BV10 is rebooted. The Ping test

remains enabled during software upgrades.

The load image command can be entered through the CONSOLE port

or the LAN/Test port running Telnet or SSH. Refer to Connecting to the

BV10 to a Console on page 30 for more information.

BV10-100 and BV10-1000 47

Page 54

CLI Command Reference

Operation Commands

load image

Syntax

Example

load image lan|test uri

The URI can use one of the following formats, depending on the server

type (TFTP or FTP) from which the unit is being updated:

tftp://192.168.1.1/image_name.img

ftp://username:password@192.168.1.1/image_name.img

bv10-100> load image lan tftp://10.17.1.75/BV-10_4.0SP1.img

WARNING: Performing image upgrade.

Please DO NOT power down!! Use CTRL-C to abort.

Shutting down processes for upgrade...done.

Transferring BV-10_4.0SP1.img from 10.17.1.75 using tftp...done(5149757 bytes).

Unpacking image file...done.

Writing to device(1)...done.

Writing to device(2)...done.

Updating configs...done.

Updating boot(1)...done.

Upgrade Successful!

*** Reboot is required! ***

48 BV10

Page 55

Statistics Commands

show statistics

Description Displays the following status and statistics:

Smart Loopback Control (enabled or disabled)

Smart Loopback operational status

Link status of the test port

DHCP Status (when DHCP is enabled)

Laser control (optical transceiver only)

Number of processed Smart Loopback packets

Number of processed Ping requests on Test port only

TWAMP Light Control (enabled or disabled)

TWAMP Light UDP listening port

Number of processed TWAMP Light packets

UDP Echo Control (enabled or disabled)

Number of processed UDP Echo packets

Ethernet OAM Global Control (enabled or disabled)

Number of processed Ethernet OAM Loopback messages

Number of processed Ethernet OAM Delay Measurement messages

Number of processed Ethernet OAM Link Trace messages

CLI Command Reference

Operation Commands

Syntax

Example

BV10-100 and BV10-1000 49

show statistics

bv10-100> show statistics

Smart Loopback Control = enabled

Smart Loopback Status

Link = 1

DHCP = enabled (lease acquired)

Smart Loopback Packets = 731

Ping Packets = 408

TWAMP Light Control = enabled

TWAMP Light UDP port = 9495

TWAMP Light Packets = 0

UDP Echo Control = enabled

UDP Echo Packets = 0

Ethernet OAM Control = enabled

Ethernet OAM Loopbacks Packets = 70

Ethernet OAM Delay Meas. Packets = 55

Ethernet OAM Link Trace Packets = 42

Page 56

CLI Command Reference

Operation Commands

clear statistics

Description Clears the counter of all statistics.

Syntax

Example

clear statistics

bv10-100> clear statistics

Clearing statistics

50 BV10

Page 57

CLI Command Reference

Operation Commands

Interface Information Command

show interface

Description Displays information about the LAN, Test, or both ports.

For the LAN and TEST ports:

IP address

Net Mask

MAC Address

Default Gateway

Speed

Duplex

Link status

Auto-negotiation status

DHCP status

VLAN

MDI/MDI-X status

Flow control

Transceiver type (Test port on BV10-1000 only)

Additional information for BV10-1000 optical port:

Laser Control

SFP vendor manufacturing information (as per SFF-8472): ID,

Part Number, Serial Number, Vendor Nam e , Connector Type

(e.g.: LC, MT-RJ...), Speed, Type (for example: SR, IR, LR),

Wavelength, and Mode (SMF or MMF).

Syntax

BV10-100 and BV10-1000 51

show interface all|lan|test

Page 58

CLI Command Reference

Operation Commands

show interface

Example

bv10-100> show interface all

LAN PORT

IP_ADDRESS = 10.17.16.32

NETMASK = 255.255.0.0

MAC_ADDRESS = 00:E0:0C:BC:E5:60

GATEWAY = 10.17.1.2

SPEED = 100Mb/s

DUPLEX = Full

LINK = yes

AUTO-NEG = on

DHCP = Disabled

VLAN = Disabled

MDI = 0

FLOW CONTROL =

TEST PORT

IP_ADDRESS = 10.16.7.138

NETMASK = 255.255.0.0

MAC_ADDRESS = 00:03:01:FF:6B:70

GATEWAY = 10.16.1.1

SPEED = 1000Mb/s

DUPLEX = Full

LINK = yes

AUTO-NEG = on

DHCP = Disabled

VLAN = Disabled

MDI = Normal

FLOW CONTROL = None

TRANSCEIVER = Electrical

52 BV10

Page 59

CLI Command Reference

Operation Commands

Tools Command

ping

Description Initiates a ping of a specified destination using the LAN or Test port and

displays the results. Refer to Ping Test on page 76 for more information.

Syntax

Example

ping destination_IP

[repetition number_of_packets | continuous]

[size size_in_bytes]

[ttl value]

[delay value_in_ms]

[timeout value_in_ms]

exit_interface

The delay parameter is the interval between packets.

exit_interface parameter can be either lan or test and is required.

The

The parameters can be entered in any order. If a parameter is not

specified, the default value is used as follows:

4 for

repetition number_of_packets

size size_in_bytes

32 for

128 for

1000 for

4000 for

bv10-100> ping 10.10.10.20 lan

PING 10.10.10.20 (10.10.10.20) from 10.10.10.180 eth0: 24(52) bytes of data.

32 bytes from 10.10.10.20: icmp_seq=1 ttl=128 time=10.0 ms

32 bytes from 10.10.10.20: icmp_seq=2 ttl=128 time=0.000 ms

32 bytes from 10.10.10.20: icmp_seq=3 ttl=128 time=0.000 ms

32 bytes from 10.10.10.20: icmp_seq=4 ttl=128 time=0.000 ms

--- 10.10.10.20 ping statistics --4 packets transmitted, 4 received, 0% packet loss, time 3010ms

rtt min/avg/max/mdev = 0.000/2.500/10.000/4.330 ms

ttl value

delay value_in_ms

timeout value_in_ms

BV10-100 and BV10-1000 53

Page 60

CLI Command Reference

Operation Commands

Server Discovery Commands

Note: The following commands are only effective when used in a BrixWorx

environment.

server discovery local

Description Sets the BrixWorx local registry IP address for communication.

Syntax

Example

server discovery local IP address

bv10-100> server discovery local 10.192.3.34

server discovery network

Description Sets the BrixWorx network registry IP address for communication.

Syntax

Example

server discovery network IP address

bv10-100> server discovery network 10.192.3.3

server discovery universal

Description Sets the BrixWorx universal registry IP address for communication.

Syntax

Example

server discovery universal IP address

bv10-100> server discovery universal 10.192.3.33

54 BV10

Page 61

CLI Command Reference

Operation Commands

server discovery port

Description Sets the BrixWorx local registry port for communication. The default

port value is 80.

Syntax

Example

server discovery port IP address

bv10-100> server discovery port 80

server discovery write

Description Changes the IP address or Port number to the new value set by the

server discovery local|network|port|universal and saves the setting.

Once the configuration is changed, the Verifier is rebooted.

Syntax

Example

server discovery write

bv10-100> server discovery write

Writing changes...

Password:

Configuration changed

Rebooting verifier

Password:

./brix-verifier: line 31: /usr/bin/whoami: No such file or directory

Stopping the Brix Verifier Agent... done

Verifier application stopped

Password:

Starting verifier application

Password:

./brix-verifier: line 31: /usr/bin/whoami: No such file or directory

Starting the Brix Verifier Agent... done

Verifier application started

BV10-100 and BV10-1000 55

Page 62

CLI Command Reference

Operation Commands

show server discovery local

Description Displays the IP address of the currently set local BrixWorx registry.

Syntax

Example

show server discovery local

bv10-100> show server discovery local

discovery-host = 10.192.3.34

show server discovery network

Description Displays the BrixWorx network registry IP address for communication.

Syntax

Example

show server discovery network

bv10-100> show server discovery network

network-host = 10.192.2.3

show server discovery universal

Description Displays the BrixWorx universal registry IP address for communication.

Syntax

Example

show server discovery universal

bv10-100> show server discovery universal

universe-host = 10.192.2.33

show server discovery port

Description Displays the currently set port number for the local BrixWorx registry.

Syntax

Example

56 BV10

show server discovery port

bv10-100> show server discovery port

discovery-port = 80

Page 63

CLI Command Reference

show server log

Description Displays the server log for the local BrixWorx registry.

Operation Commands

Syntax

Example

show server log

bv10-100> show server log

BV10-100 and BV10-1000 57

Page 64

CLI Command Reference

Configuration Commands

Configuration Commands

BV10 Configuration commands allow to view and change the configuration

of the BV10.

The Configuration commands are organized into the following subgroups:

Subgroup Command Page

General show config 59

Console password set password

password clear

console telnet|ssh server enable|disable

console in-band enable|disable

console in-band port port_value

console telnet|ssh|serial idle-timeout value_in_seconds

Interface

Configuration

interface test transceiver electrical|optical

interface test laser on|off

interface lan|test speed auto

interface test speed 10|100|1000 auto

interface test speed 10|100|1000 force

interface lan speed 10|100 force

interface test speed 1000 auto

interface lan duplex auto

interface lan duplex half|full

interface lan flow auto

interface lan flow rx|none

interface lan|test cable auto

interface test cable straight

interface lan|test vlan value|none

interface test vlan priority value

interface lan|test address-netmask IP_address/netmask|dhcp

interface lan|test gateway IP_address|none

interface lan|test gateway dhcp|none

61

61

61

62

62

62

63

63

64

63

64

65

65

65

66

66

66

67

67

67

67

68

68

69

58 BV10

Page 65

CLI Command Reference

Configuration Commands

Subgroup Command Page

Test Application smart-loopback enable|disable

smart-loopback mode ethernet-all-unicast|ethernet|ip|udp-tcp

twamp enable|disable

twamp udp-port value

udp-echo enable|disable

eth-oam enable|disable

General Command

show config

Description Displays all BV10 configuration parameters as follows:

Console:

Console in-band management

a

Timeout, Telnet

Interfaces:

, Telnet Timeout, SSHa, and SSH Timeout

LAN port:

IP Address, Subnet Mask, Gateway, Auto Speed, Speed, Duplex,

Flow, MDI, VLAN ID

TEST port:

IP Address, Subnet Mask, Gateway, Auto Speed, Speed, MDI,

Transceiver, Transceiver type, VLAN ID, VLAN Priority.

Test applications:

Smart Loopback

a

TWAMP

, TWAMP port, UDP Echo

a

, Smart Loopback Mode, Ethernet OAMa,

a

, Console Passworda, Console

a

70

70

71

71

71

72

Syntax

BV10-100 and BV10-1000 59

show config

Page 66

CLI Command Reference

Configuration Commands

show config

Example

bv10-100> show config

Console

CONSOLE_IN_BAND = enabled

CONSOLE_PASSWORD = disabled

CONSOLE_TIMEOUT = 0

TELNETD_ENABLE = enabled

TESNETD_TIMEOUT = 0

SSHD_ENABLE = disabled

SSHD_TIMEOUT = 0

Interfaces

LAN_ADDRESS = 10.17.16.32

LAN_MASK = 255.255.0.0

LAN_GATEWAY = 10.17.1.2

LAN_AUTO_SPEED = on

LAN_SPEED = 10/100

LAN_DUPLEX = auto

LAN_FLOW = 0

LAN_MDI = 0

LAN_VLAN_ID = none

TEST_ADDRESS = 10.16.7.138

TEST_MASK = 255.255.0.0

TEST_GATEWAY = 10.16.1.1

TEST_AUTO_SPEED = on

TEST_SPEED = 10/100/1000

TEST_MDI = 2

TEST_TRANSCEIVER = off

TEST_TRANSCEIVER_TYPE = electrical

TEST_VLAN_ID = none

TEST_VLAN_PRIORITY = 1

Test Applications

SMART_LOOPBACK_ENABLE = enabled

SMART_LOOPBACK = UDP-TCP

ETH_OAM = enabled

TWAMP = disabled

TWAMP_PORT = 9495

UDP_ECHO = enabled

a. Enabled or disabled.

60 BV10

Page 67

CLI Command Reference

Configuration Commands

Console Commands

password set password

Description Defines a password for the BV10. By default, no password is set. The

password is case sensitive. When you enter a password, the CLI

prompts you to confirm the password by entering it again.

Syntax

Example

password set password

bv10-100> password set chidley

Please re-enter password

chidley

setting password

password clear

Description Clears the BV10 password.

Syntax

Example

password clear

bv10-100> password clear

clearing password

console telnet|ssh server enable|disable

Description Enables or disables the Telnet and/or SSH servers.

Before enabling SSH, you must set a password for the CLI (see

password set password on page 61). If you attempt to enable SSH

before setting a password, the following message is displayed:

Please set password first!

This command displays no output unless there is an error.

Syntax

Example

BV10-100 and BV10-1000 61

console telnet|ssh server enable|disable

bv10-100> console telnet server enable

Page 68

CLI Command Reference

Configuration Commands

console in-band enable|disable

Description Enables or disables in-band management on the Test port. By default,

in-band management on the Test port is enabled.

This command displays no output unless there is an error.

This command is not available through the Test port.

Syntax

Example

console in-band enable|disable

bv10-100> console in-band disable

console in-band port port_value

Description Configures the port number that can be used to communicate with the

BrixWorx server from the Test port.

Syntax

Example

console in-band port port_valueh

bv10-100> console in-band port 300

console telnet|ssh|serial idle-timeout value_in_seconds

Description Sets the idle timeout for the Telnet server, SSH server, or serial console

communication session. Each connection method can have its own

timeout.

By default, no idle timeout is set. The minimum idle timeout is 30

seconds. To disable the idle timeout, enter 0 (zero).

This command displays no output.

Syntax

console telnet|ssh|serial idle-timeout value_in_seconds

Example

62 BV10

bv10-100> console telnet idle-timeout 900

Page 69

CLI Command Reference

Configuration Commands

Interface Configuration Commands

The following commands allow setting the port interface parameters such

as the IP addressing (static IP or DHCP), auto-negotiation (speed, duplex,

flow control), VLAN support, transceiver (electrical or optical), laser (ON or

OFF), and cable (straight or auto detection).

Note: Most of the interface commands do not display output. Use the

(see page 51) and

show config (see page 59) commands to display the

show interface

BV10’s current interfaces and configuration.

Note: For the TEST port: Duplex and Flow Control are not configurable and

respectively set to Full and None.

interface test transceiver electrical|optical

Description Sets the TEST port transceiver type to either electrical or optical.

This command applies to the BV10-1000 only.

This command cannot be sent through the Test port.

Syntax

Example

interface test transceiver electrical|optical

bv10-100> interface test transceiver optical

interface test laser on|off

Description Turns the laser of the TEST optical interface on or off.

This command applies to the BV10-1000 only and is available only

when the transceiver type is set to optical.

This command cannot be sent through the Test port.

Syntax

Example

BV10-100 and BV10-1000 63

interface test laser on|off

bv10-100> interface test laser on

Page 70

CLI Command Reference

Configuration Commands

interface lan|test speed auto

Description Auto-negotiates all supported LAN (10/100) or Test (10/100/1000 for

electrical or 1000 for optical) port speeds.

This command cannot be sent through the Test port.

Syntax

Example

interface lan|test speed auto

bv10-100> interface lan speed auto

interface test speed 10|100|1000 auto

Description Auto-negotiates the specified electrical TEST port speed (10/100/1000).

This command cannot be sent through the Test port.

Syntax

Example

interface test speed 10|100|1000 auto

bv10-100> interface test speed 100 auto

interface test speed 10|100|1000 force

Description Forces the electrical TEST port speed (10/100/1000) to the specified

value; no auto-negotiation is performed.

This command cannot be sent through the Test port.

Syntax

Example

interface test speed 10|100|1000 force

bv10-100> interface test speed 1000 force

64 BV10

Page 71

CLI Command Reference

Configuration Commands

interface lan speed 10|100 force

Description Forces the LAN port speed (10/100) to the specified value; no

auto-negotiation is performed.

This command cannot be sent through the Test port.

Syntax

Example

interface lan speed 10|100 force

bv10-100> interface lan speed 100 force

interface test speed 1000 auto

Description Auto-negotiates the specified optical TEST port speed (1000).

This command cannot be sent through the Test port.

Syntax

Example

interface test speed 1000 auto

bv10-1000> interface test speed 1000 auto

interface lan duplex auto

Description Auto-negotiates the LAN duplex speed.

This command cannot be sent through the Test port.

Syntax

Example

interface lan duplex auto

bv10-100> interface lan duplex auto

BV10-100 and BV10-1000 65

Page 72

CLI Command Reference

Configuration Commands

interface lan duplex half|full

Description Sets the LAN duplex to either half or full; no auto-negotiation is

performed.

This command cannot be sent through the Test port.

Syntax

Example

interface lan duplex half | full

bv10-100> interface lan duplex full

interface lan flow auto

Description Auto-negotiates the flow control for the LAN port to either receive (rx)

or none.

This command cannot be sent through the Test port.

Syntax

Example

interface lan flow auto

bv10-100> interface lan flow auto

interface lan flow rx|none

Description Sets the flow control for the LAN port to the receive (rx) or none; no

auto-negotiation is performed.

This command cannot be sent through the Test port.

Syntax

Example

interface lan flow rx|none

bv10-100> interface lan flow rx

66 BV10

Page 73

CLI Command Reference

Configuration Commands

interface lan|test cable auto

Description Automatically detects the LAN or electrical Test port cable type:

crossover or straight through (MDI or MDI-X).

This command cannot be sent through the Test port.

Syntax

Example

interface lan|test cable auto

bv10-100> interface lan cable auto

interface test cable straight

Description Sets the electrical Test port cable as straight.

This command cannot be sent through the Test port.

Syntax

Example

interface test cable straight

bv10-100> interface test cable straight

interface lan|test vlan value|none

Description Sets the VLAN ID of the LAN or TEST port to the specified value, or

disables VLAN (none).

Syntax

Example

interface lan | test vlan value | none

bv10-100> interface lan vlan none

interface test vlan priority value

Description Sets the VLAN priority of the TEST interface.

Syntax

Example

BV10-100 and BV10-1000 67

interface test vlan priority value

bv10-100> interface test vlan priority 1

Page 74

CLI Command Reference

Configuration Commands

interface lan|test address-netmask IP_address/netmask|dhcp

Description Sets the IP address and subnet mask for the LAN or TEST port either

manually or using DHCP.

DHCP is enabled by default on the TEST port; it is disabled by default on

the LAN port.

The LAN port is set to IP address 10.10.10.10/255.255.0.0. When DHCP is

enabled, the local IP parameters are acquired from a DHCP server, as

defined in RFC2131. The CLI provides information about the DHCP

acquisition status and the lease (expiration time). For more

information, refer to show interface on page 51

The BV10 supports IPv4 addressing. The netmask value can be

specified in either dotted decimal notation or CIDR format. For

example:

192.168.1.1/255.255.255.0

192.168.1.1/24

Syntax

Example