Page 1

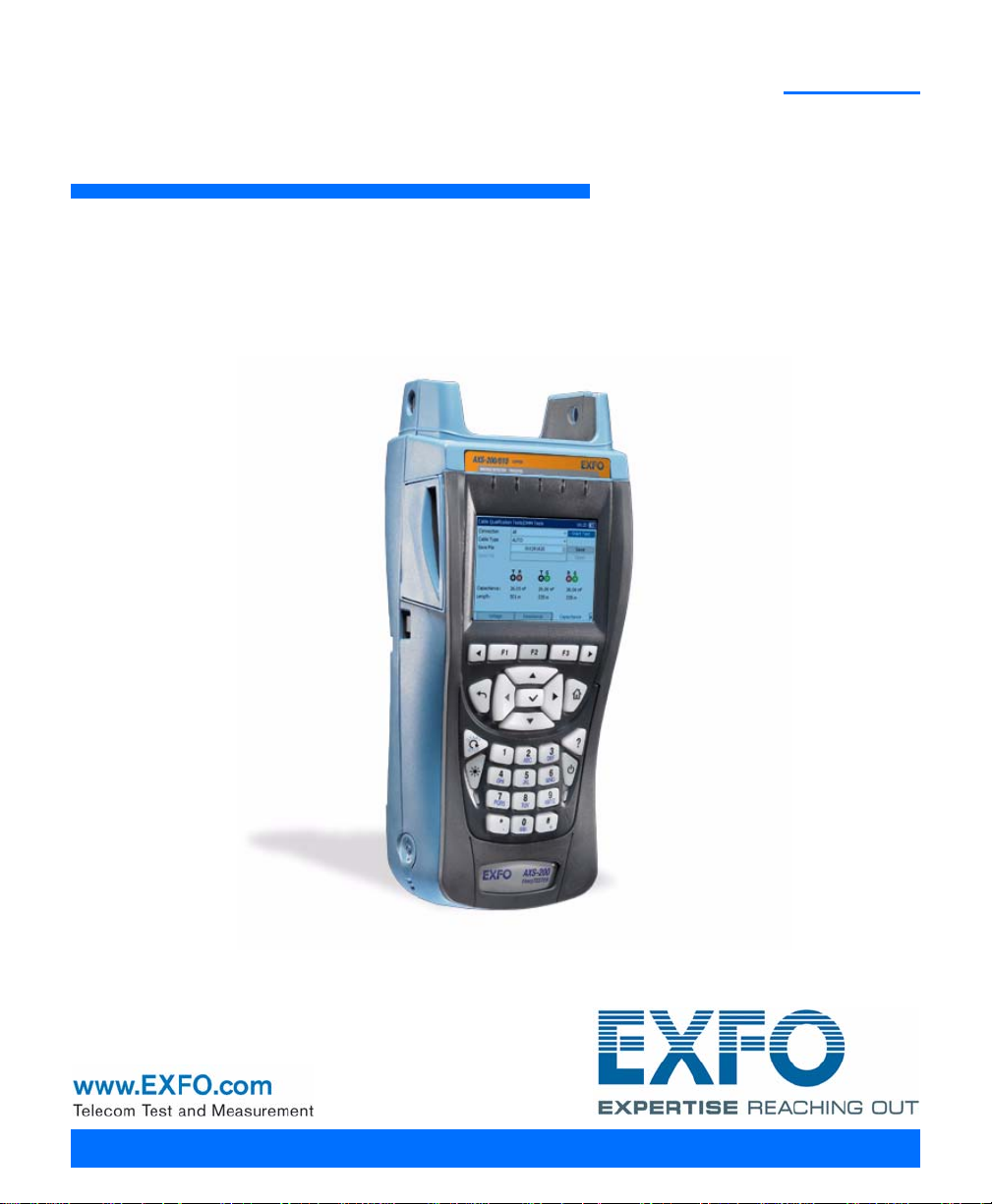

AXS-200/610

Copper Test Module

User Guide

Page 2

Copyright © 2008–2009 EXFO Electro-Optical Engineering Inc. All rights

reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or

otherwise, without the prior written permission of EXFO Electro-Optical

Engineering Inc. (EXFO).

Information provided by EXFO is believed to be accurate and reliable.

However, no responsibility is assumed by EXFO for its use nor for any

infringements of patents or other rights of third parties that may result from

its use. No license is granted by implication or otherwise under any patent

rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North

Atlantic Treaty Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without

notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence

or absence of such identification does not affect the legal status of any

trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and

practices.

Version number: 4.0.0

ii AXS-200/610

Page 3

Contents

Contents

Certification Information ........................................................................................................v

1 Introducing the AXS-200/610 Copper Test Module .................................... 1

Main Features .........................................................................................................................1

Typical Applications ................................................................................................................2

Cable Connections ..................................................................................................................2

LED Indicators .........................................................................................................................3

Electrical Safety Information ...................................................................................................3

VDSL2 .....................................................................................................................................4

Navigating through the AXS-200/610 .....................................................................................5

Conventions ............................................................................................................................6

2 Getting Started with Copper Qualification Tests ....................................... 7

POTS Dialing ...........................................................................................................................7

Regional Settings ..................................................................................................................10

Saving Results .......................................................................................................................17

Reading Saved Results ..........................................................................................................20

3 Auto CQ/Video-DSL Rate Prediction .......................................................... 23

CQ Auto Test .........................................................................................................................23

Configuring CQ Auto Tests ....................................................................................................24

Running CQ Auto Tests and Viewing Results .........................................................................35

Video-DSL Rate Prediction ....................................................................................................43

Configuring Video-DSL Rate Prediction .................................................................................43

Running Video-DSL Rate Prediction Tests and Viewing Results .............................................49

4 POTS Auto Test ............................................................................................ 61

5 DMM Tests .................................................................................................. 63

DMM ....................................................................................................................................63

In Service Pair Detection Test .................................................................................................72

Rectified Loop (Corrosion) Detection Test .............................................................................73

Water Detection Test .............................................................................................................73

Resistive Balance ...................................................................................................................74

6 Fault Location Tests .................................................................................... 77

TDR Test ................................................................................................................................77

RFL Single Pair (2 wire) Test ...................................................................................................80

RFL Separate Good Pair (4 wire) Test .....................................................................................83

Loop Mapper Test .................................................................................................................86

Copper Test Module iii

Page 4

Contents

7 VF Tests ........................................................................................................91

Receive Tone (RX) ..................................................................................................................92

Send Tone (TX) ......................................................................................................................93

Tracing Tone ..........................................................................................................................94

VF Noise ...............................................................................................................................95

Impulse Noise .......................................................................................................................96

Power Influence ....................................................................................................................98

Longitudinal Balance ............................................................................................................99

Load Coil Detection ..............................................................................................................99

8 Wideband Tests .........................................................................................101

Receive Tone (RX) ................................................................................................................102

Send Tone (TX) ....................................................................................................................103

PSD Noise ...........................................................................................................................104

Spectral Detective Test ........................................................................................................108

Impulse Noise Test ..............................................................................................................111

Impulse Noise Histogram ....................................................................................................113

Attenuation Test .................................................................................................................116

Longitudinal Balance ..........................................................................................................118

Data Rate Prediction ...........................................................................................................120

9 Maintenance ..............................................................................................129

General Maintenance ..........................................................................................................129

Battery Charging and Replacing .........................................................................................129

Recycling and Disposal (Applies to European Union Only) ..................................................130

10 Troubleshooting ........................................................................................131

Solving Common Problems .................................................................................................131

Contacting the Technical Support Group ............................................................................132

Transportation ....................................................................................................................133

11 Warranty ....................................................................................................135

General Information ...........................................................................................................135

Liability ...............................................................................................................................136

Exclusions ...........................................................................................................................136

Certification ........................................................................................................................136

Service and Repairs .............................................................................................................137

EXFO Service Centers Worldwide ........................................................................................138

A Technical Specifications ............................................................................139

Index ...............................................................................................................141

iv AXS-200/610

Page 5

Certification Information

Certification Information

F.C.C. Information

Electronic test equipment is exempt from Part 15 compliance (FCC) in

the United States. However, compliance verification tests are

systematically performed on most EXFO equipment.

Information

Electronic test equipment is subject to the EMC Directive in the European

Union. The EN61326 standard prescribes both emission and immunity

requirements for laboratory, measurement, and control equipment.

This unit has undergone extensive testing according to the European Union

Directive and Standards.

CSA Information

This unit is certified by the CSA (certificate number 162451) and was

evaluated according to applicable CSA and UL standards (as confirmed by

“C-US” mark) as well as applicable IEC standards for use in Canada, the

United States, and other countries.

Copper Test Module v

Page 6

Certification Information

Application of Council Directive(s): 73/23/EEC - The Low Voltage Directive

89/336/EEC - The EMC Directive

And their amendments

Manufacturer’s Name: EXFO Electro-Optical Engineering Inc.

Manufacturer’s Address: 400 Godin Avenue,

Quebec (Quebec)

Canada G1M 2K2

(418) 683-0211

Equipment Type/Environment: Test & Measurement / Industrial

Trade Name/Model No.: AXS-200/610

30 MHz Copper Test Set

Standard(s) to which Conformity is Declared:

EN 61010-1:2001 Safety Requirements for Electrical Equipment for Measurement,

Control, and Laboratory Use, Part 1: General Requirements.

EN 55022: 1998 +A2: 2003 Limits and Methods of Measurement of Radio Disturbance

Characteristics of Information Technology Equipment.

EN 61326:1997 +A1:1998

+A2:2001 + A3:2003

Electrical Equipment for Measurement, Control and Laboratory

Use - EMC Requirements

I, the undersigned, hereby declare that the equipment specified above conforms to the above Directive and Standards.

Manufacturer

Signature:

Full Name: Stephen Bull, E. Eng

Position: Vice-President Research and

Development

Address: 400 Godin Avenue, Quebec (Quebec),

Canada, G1M 2K2

Date: January 16, 2008

DECLARATION OF CONFORMITY

vi AXS-200/610

Page 7

1 Introducing the AXS-200/610

Copper Test Module

The AXS-200/610 Copper Test Module is a handheld device designed to test

basic twisted pair quality, identify and locate faults, perform advanced

single-ended loop tests, and troubleshoot noise and signal issues all the

way up to 30 Mhz in support of the VDSL2 standard. These measurements

offer a quick and thorough method to determine if the cable is capable of

supporting xDSL technology. In addition, the AXS-200/610 utilizes noise

measurements, longitudinal balance tests, and power spectral density tests

to assist in the installation, maintenance, and troubleshooting of copper

cables.

Main Features

³ Full 30 MHz spectrum analysis

³ Spectral detective with auto identification of disturbers

³ Single-ended testing – no remote device required

³ Loop mapper – graphical loop depiction

³ Color display with graphical analysis

³ Fully automated testing with pass or fail analysis

³ POTS and VF measurements for complete ADSL2+ and VDSL2 loop

qualification

³ Video and DSL rate prediction

³ In-service pair, rectified loop, and water detection tests

Copper Test Module 1

Page 8

Introducing the AXS-200/610 Copper Test Module

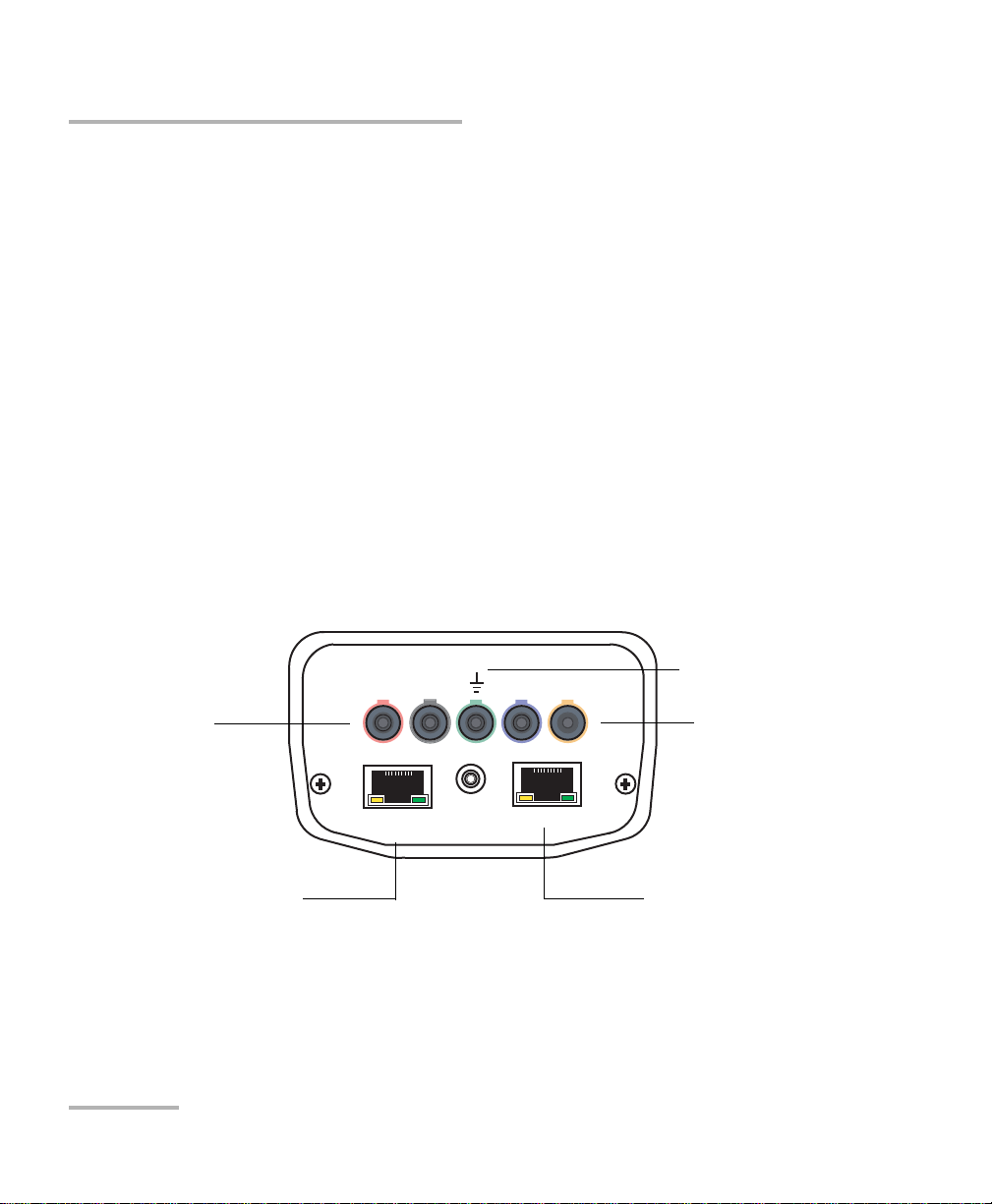

LANHeadset

DSL

WAN

RT R1T1

Primary tip/ring

3-pin connectors

Secondary tip/ring

3-pin connectors

LAN connector for

Ethernet output

WAN connector for Ethernet

and DSL input

Measuring ground

terminal

Typica l A p p l i cations

Typical Applications

The AXS-200/610 can be configured to run the following series of tests to

see if the cable is suitable for carrying digital subscriber line (DSL)

technologies:

³ Auto tests

³ POTS auto test

³ DMM tests

³ VF tests

³ Fault location tests

³ Wideband tests

Cable Connections

The graphic below shows the connectors on the AXS-200/610 device.

2 AXS-200/610

Page 9

Introducing the AXS-200/610 Copper Test Module

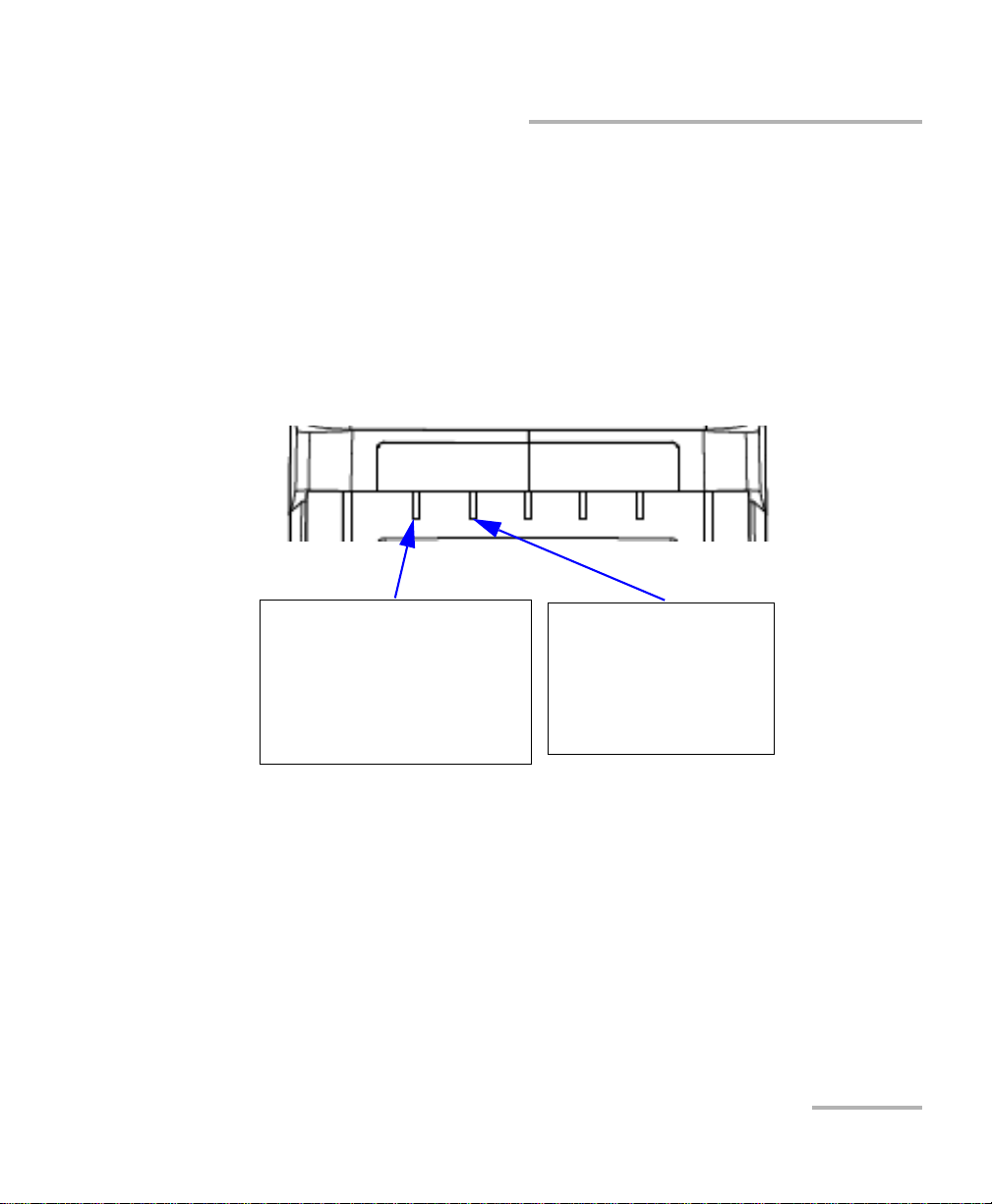

VOLTAGE DETECTED

Red indicates that a voltage is

detected on the line. This is normal if

the voice switch is connected to the

circuit under test. If the circuit is

open, foreign voltage is present -

either DC (with battery cross) or AC

(induced from electrical power lines.

PAS S/FAIL

Red indicates that test results

have failed the thresholds.

Green indicates that test results

were evaluated against the

customer-defined thresholds

and have passed.

LED Indicators

Note: When connecting a DSL cable to the WAN port, use the RJ-45 plug end of

the 26AWG cable provided with the unit. There is a 1500V maximum

transient voltage on telecom ports. Basic insulation is needed for external

telecom circuits.

LED Indicators

The graphic below illustrates the LED indicators across the top of the

AXS-200/610 unit.

Electrical Safety Information

Do not use the unit outdoors in wet locations. For information about

equipment rating for temperature, environment, and power supply, refer to

the Safety Information chapter of the AXS-200 User Guide.

Copper Test Module 3

Page 10

Introducing the AXS-200/610 Copper Test Module

VDSL2

VDSL2

Very high speed digital subscriber lines (VDSL) is a new standard that

allows extremely high speed internet access over existing copper cables.

The VDSL2 standard increases the spectrum allocation up to 30 MHz for

even higher performance than its predecessor VDSL1, and allows speeds

up to 100 Mbps symmetrical (both up and downstream). VDSL2 also calls

for support of applications such as multi-channel high definition TV

(HDTV), video on demand, video-conferencing, and VoIP using the existing

copper telephone line infrastructure. Along with that it also calls for ATM,

Ethernet, and IP compatibility, as well as multimode implementations to

permit interoperability with existing ADSL equipment.

VDSL2 gives carriers the flexibility to start rapidly deploying VDSL2

networks and offer new broadband services including triple-play services,

HDTV, VoD, high-speed data, VoIP, high-speed Internet access, video

conferencing, virtual private networks (VPNs), PBX Extension, and video

surveillance to compete with cable companies. VDSL2’s broader spectrum

combined with features like Trellis coding and multi-pair bonding allows

carriers to offer full triple-play services to a large portion of their customer

base.

4 AXS-200/610

Page 11

Introducing the AXS-200/610 Copper Test Module

Navigating through the AXS-200/610

Navigating through the AXS-200/610

Use the following general instructions to navigate through the AXS-200/610

menus and panes:

³ To navigate through the menu items use the arrow keys.

³ To confirm a choice or open a menu item press .

³ Most manual tests automatically run when they are selected from

the menu.

³ The rotating hour glass in the title bar indicates when a test is

running.

Note: The unit checks for an active circuit at

the beginning of every manual and

auto test.

³ To start/stop a test, press .

³ To view the contents of the panes

or tabs, use the F1, F2, and

F3 keys. To view any available

additional tabs use the function

arrow keys on either side of the F1 and F3 keys.

³ To cancel an action or return to the previous item or pane, press .

³ To return to the home pane, press .

Copper Test Module 5

Page 12

Introducing the AXS-200/610 Copper Test Module

Conventions

Conventions

Before using the product described in this manual, you should understand

the following conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. Do not proceed unless you

understand and meet the required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in component damage. Do not proceed unless you

understand and meet the required conditions.

IMPORTANT

Refers to information about this product you should not overlook.

6 AXS-200/610

Page 13

2 Getting Started with Copper

Qualification Tests

The AXS-200/610 is designed to test basic twisted pair quality, identify and

locate faults, perform advanced single-ended loop tests, and troubleshoot

noise and signal issues all the way up to 30 MHz in support of the VDSL2

standard. These measurements offer a quick and thorough method to

determine if the cable is capable of supporting xDSL technology. In

addition, it utilizes noise measurements, longitudinal balance tests, and

power spectral density tests to assist in the installation, maintenance, and

troubleshooting of copper cables.

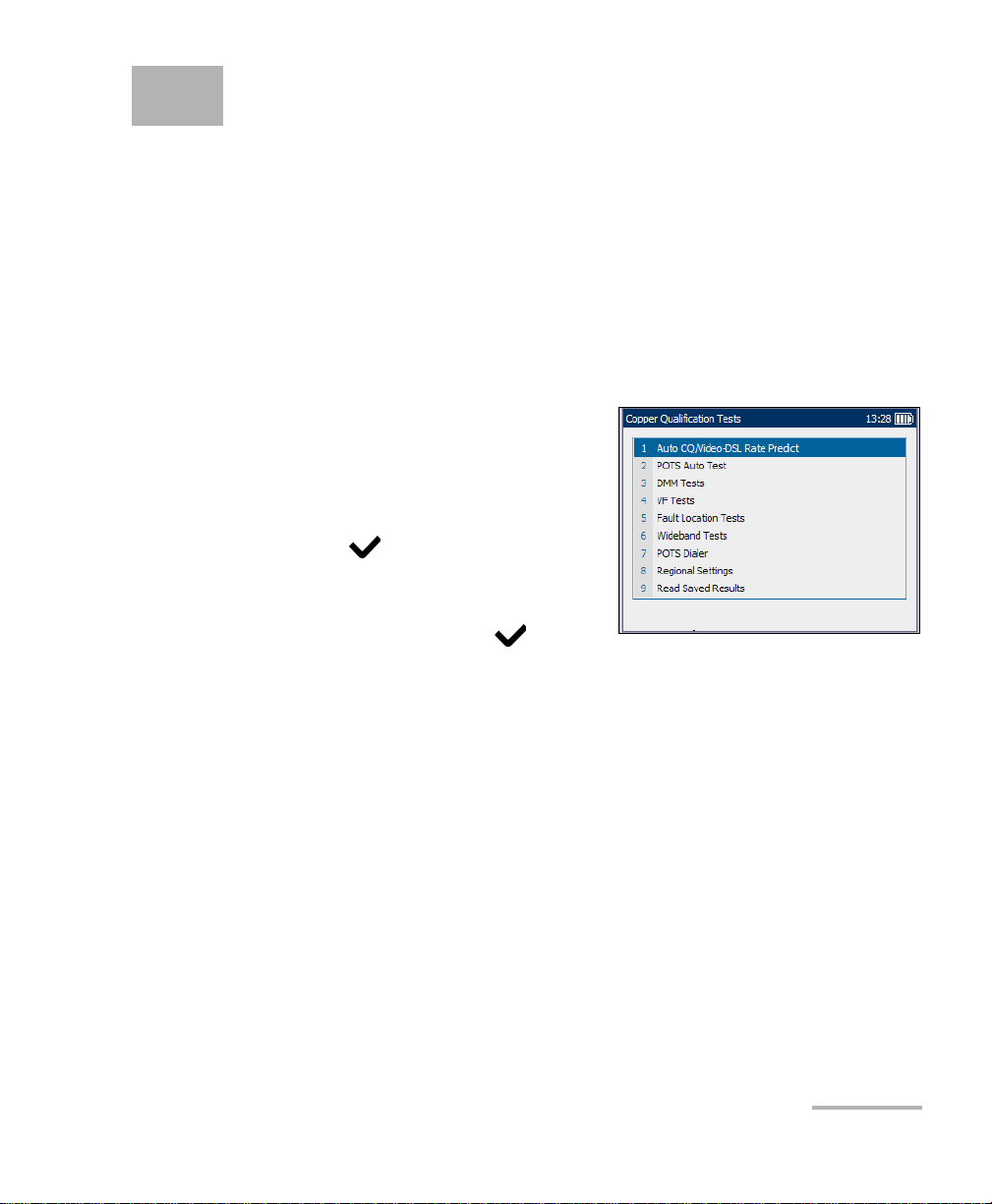

To access copper qualification

tests:

1. From the Home pane use the

up/down arrow keys to highlight

Copper Qualification Tests, then

press .

2. From the Copper Qualification

Tests pane highlight the desired

menu item, and press .

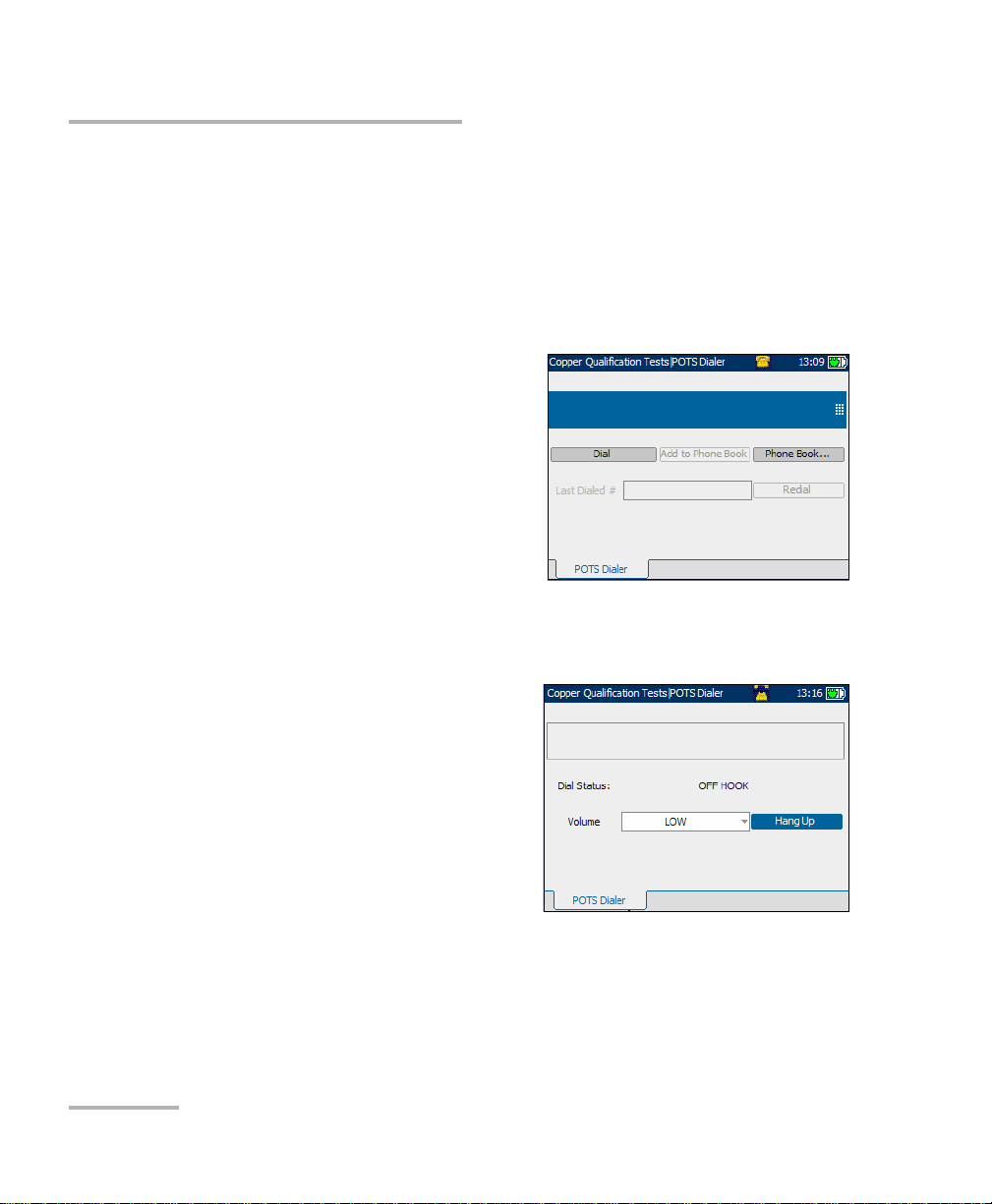

POTS Dialing

The POTS Dialer function provides a dial-up path from the AXS-200/610 to

another tester (or quiet termination or silent switchman) through a

switched circuit network. DTMF transmission is enabled via the AXS-200

keypad allowing you to place and receive POTS calls. The dialer can be

accessed from the Copper Qualification Tests pane and is also integrated

into individual test screens to give you quick access to the manual dialer

function, speed dial and last dialed lists, without exiting the current test

application.

Copper Test Module 7

Page 14

Getting Started with Copper Qualification Tests

POTS Dialing

POTS Dialer

The POTS Dialer menu item/tab allows you to use the unit as a telephone

(with a headset) and the AXS-200 keypad as a dialer keypad when the

POTS Dialer is invoked, whether in the test results screens or through the

separate dedicated POTS Dialer application.

Each parameter and button are described below:

³ NumbertoDial edit box is the

phone number you wish to dial.

You can add this number to the

Phone Book by pressing the Add

to Phone Book button.

³ Dial button is enabled whether or

not there is a number present in

the NumbertoDial edit box. If a

number is present, it will be dialed.

If not, pressing the Dial button will cause the unit to go off hook and a

new placing a call pane appears where you can manually dial a

number from the keypad.

³ Dial Status displays the

progress of dialing such as

Dial Tone Detected,

No Dial Tone, or

Busy Tone Detected.

³ Volume is used to set the

headset volume to LOW or

HIGH.

³ Hang Up button terminates

the call and you’ll be returned to the POTS Dialer pane.

8 AXS-200/610

Page 15

Getting Started with Copper Qualification Tests

POTS Dialing

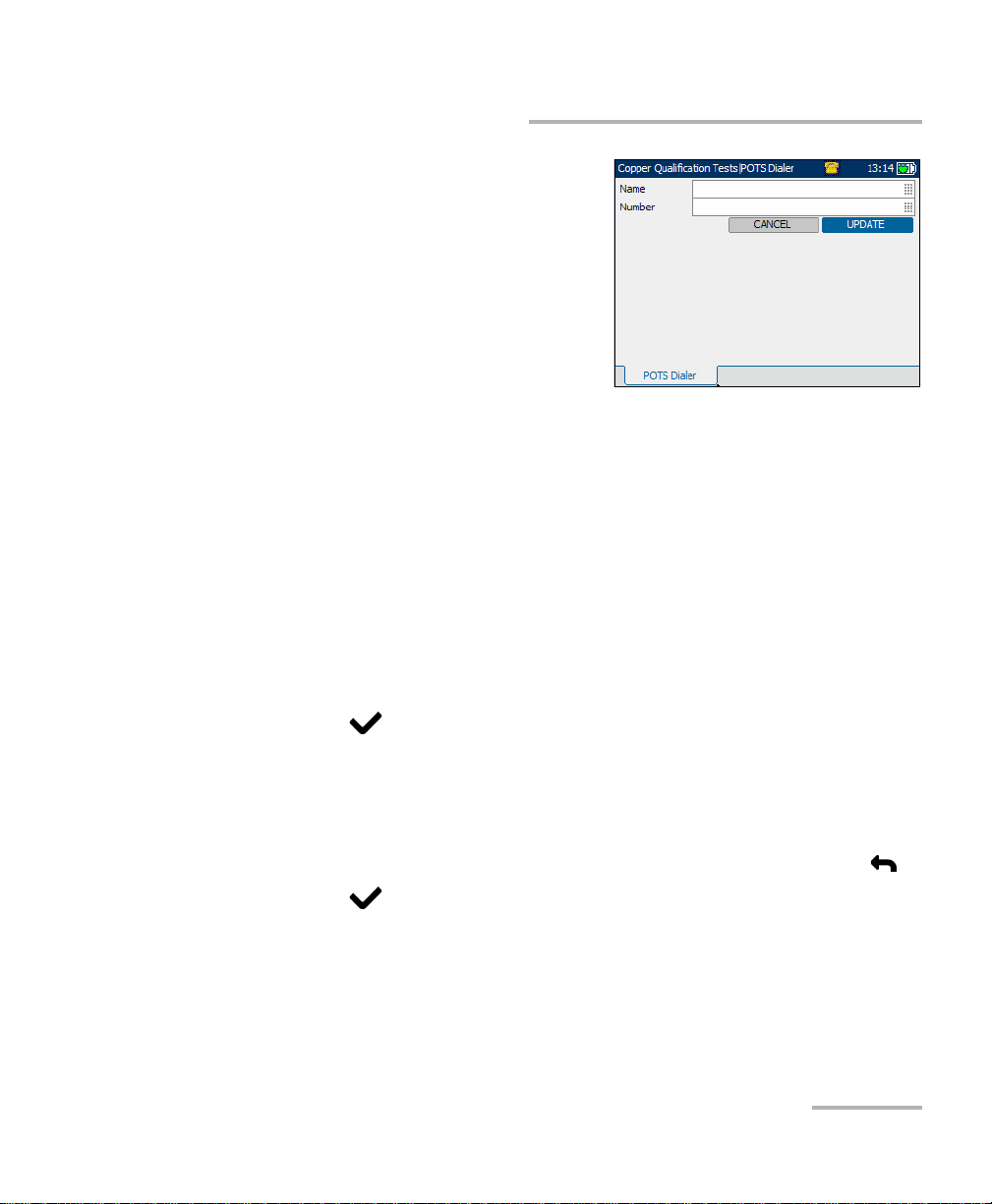

³ Add to Phone Book button enters

the number dialed into the Phone

Book by bringing up the

edit screen where you can add the

Name for the Number dialed and

save it. After pressing either the

Cancel or Update buttons, you’ll

be returned to the POTS Dialer

pane.

³ Phone Book button invokes the list of numbers to dial and supports 15

commonly called names and numbers. Names can be up to 30

characters long and numbers up to 32 digits.

³ Last Dialed # lists up to 30 last dialed numbers.

³ Redial button dials a selected phone number from the

Last Dialed # list.

³ Icon on title bar gives a live on-screen, graphical indication of on-hook

and off-hook status.

To select parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

Copper Test Module 9

Page 16

Getting Started with Copper Qualification Tests

Regional Settings

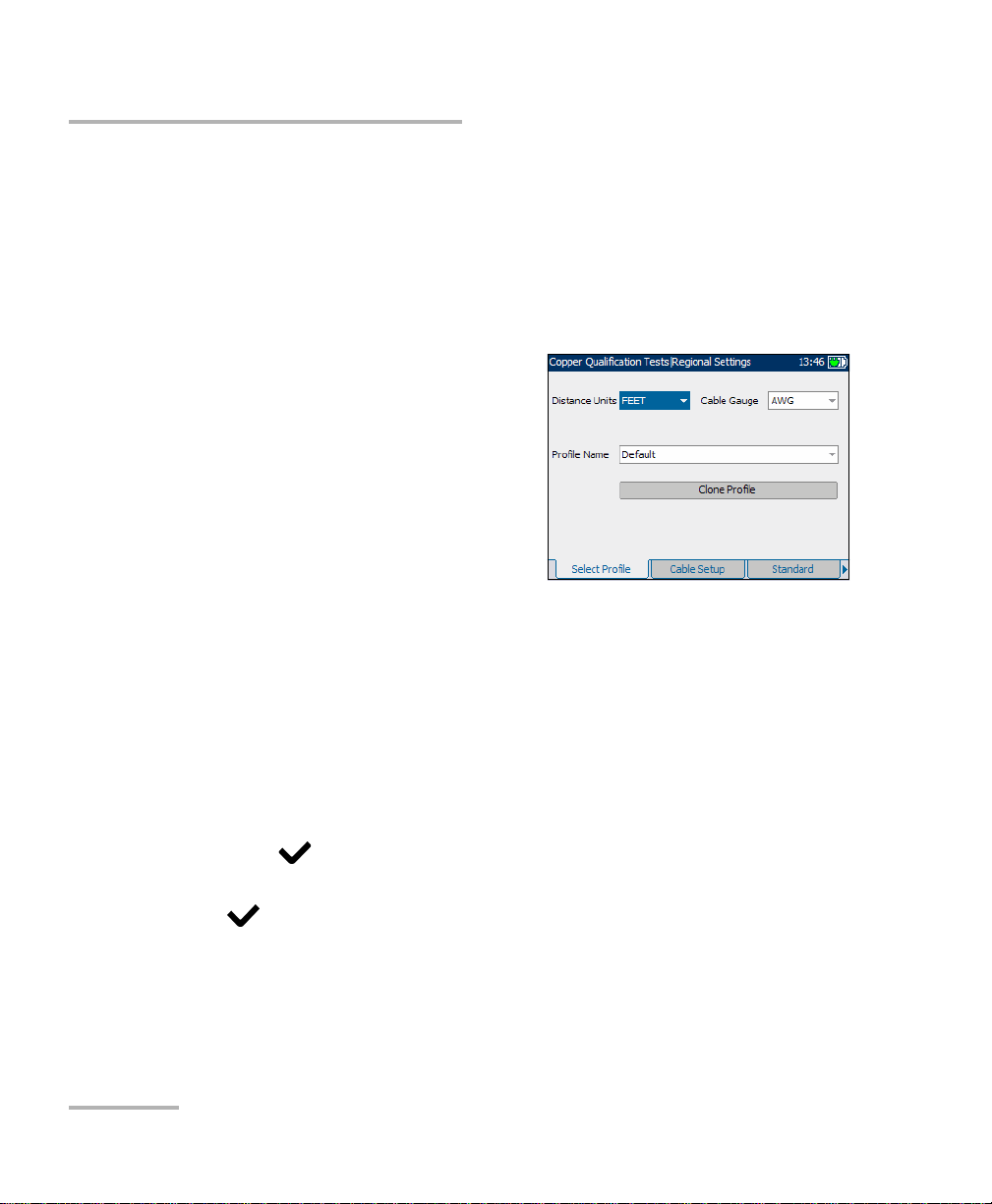

Regional Settings

Before performing copper qualification tests, set up the software settings

and values for the cables. The AXS-200/610 allows you to save standard

parameter settings to different profiles and reuse them as needed.

Select Profile

The Select Profile tab allows you to

configure the unit with specific

measurement values.

Each parameter is described below:

³ Distance Units are the units of

measurement for distances in

FEET or METER.

³ Cable Gauge is the gauge system

for measuring wire sizes in AWG (American Wire Gauge) units or mm

(metric wire size).

³ Profile Name is either Default or a list of all available profile file names

stored in the current directory.

³ Clone Profile allows you to copy an existing profile to a new one and

switch to use the new profile.

To select the parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list.

3. Use the up/down arrow keys to highlight the desired value, and press

to accept the value.

10 AXS-200/610

Page 17

Getting Started with Copper Qualification Tests

Regional Settings

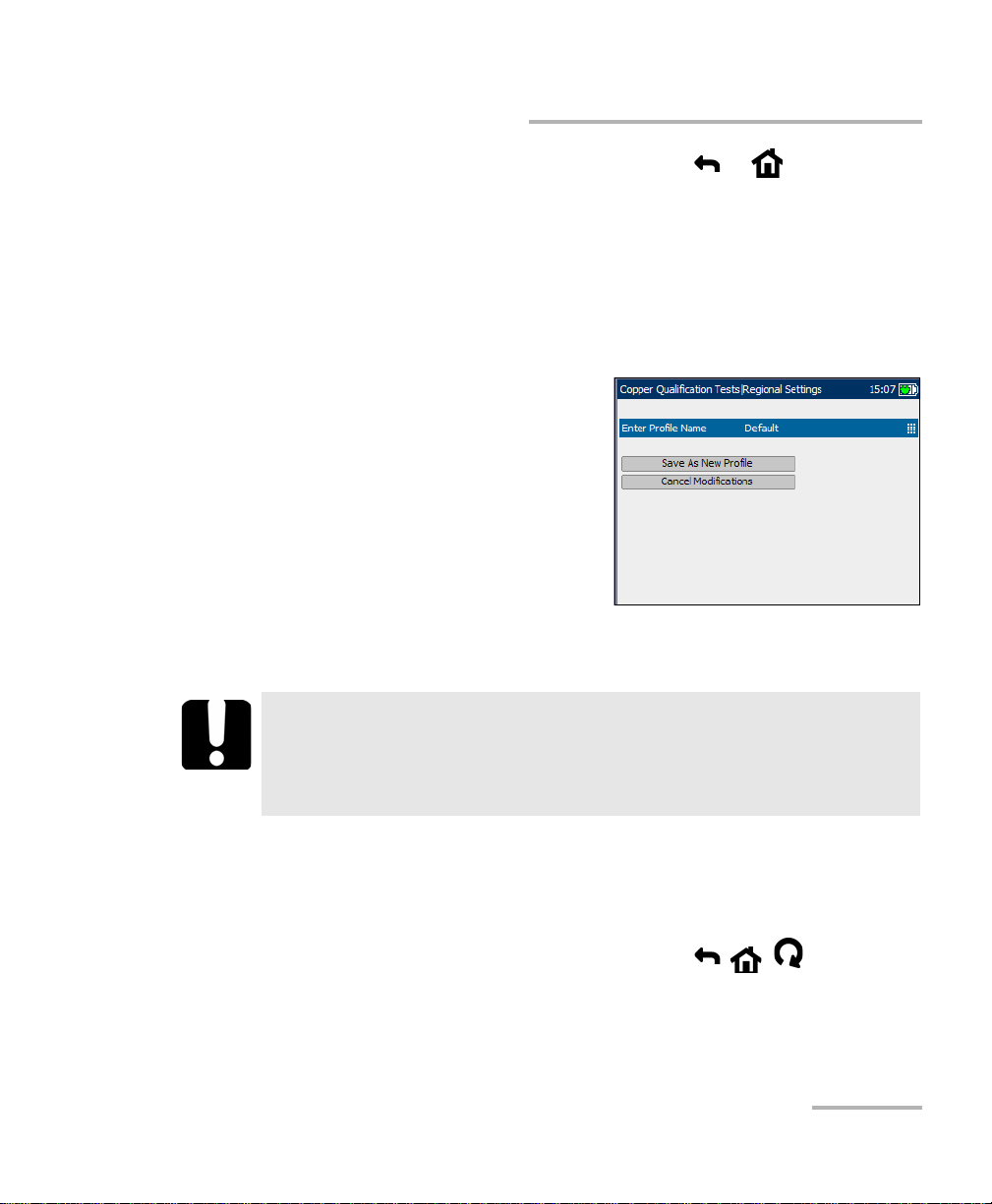

When you change the selections and press or , the

following actions should be performed:

1. If ProfileName selection is not Default then save modifications (if any)

into the current profile file and proceed with the selected action.

2. If ProfileName selection is Default and modification to the profile has

been made then enter the new name of the profile.

At power up, all settings are read from the last current profile.

³ Enter Profile Name is the new

name of the profile.

To save modifications made to a

CustomProfile:

1. Select Save as New Profile and

create and save a new

CustomProfile name in the

current directory.

2. If the file with CustomProfile

name already exists in the current directory, you will be prompted to

overwrite it.

IMPORTANT

Changes to test parameters will be lost if the unit is turned off

without first saving them to a default or custom profile. The unit

can also be left in suspend mode to avoid loss of test parameters.

To cancel modifications made to a CustomProfile:

1. Select Cancel Modifications and reload the current profile with the

default profile.

2. Proceed with the previously selected action ( , , ).

Copper Test Module 11

Page 18

Getting Started with Copper Qualification Tests

Regional Settings

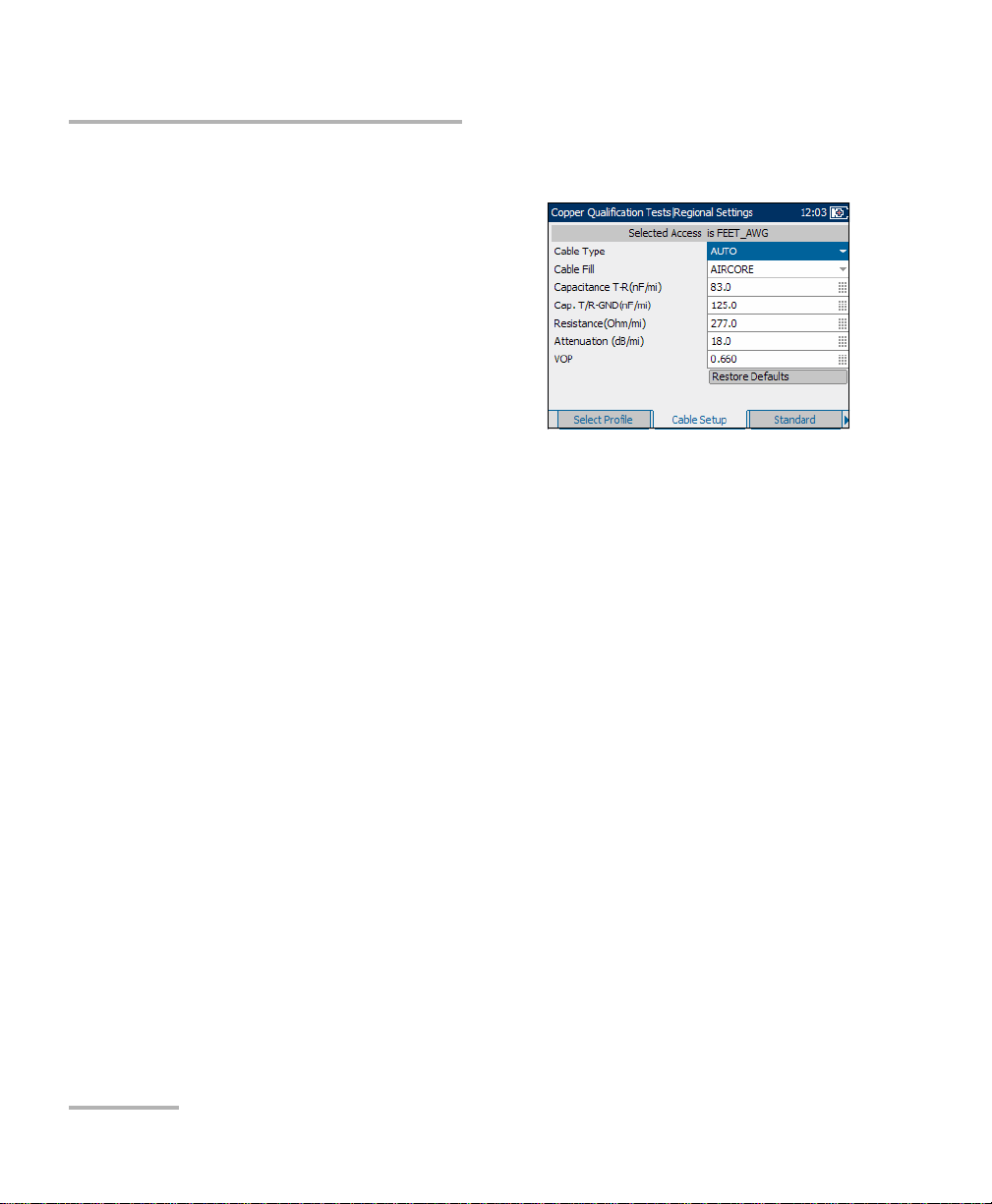

Cable Setup

The Cable Setup tab allows you to

configure parameter values for the

cable.

Each parameter and button is

described below:

³ Cable Type defines the gauge of

the cable in use. If wire gauge is

measured in American Wire

Gauge (AWG) units, the available

choices are: AUTO, 19 AWG, 22 AWG, 24 AWG, or 26 AWG. For mm

gauge wire, the available choices are: AUTO, 0.32 mm, 0.40 mm,

0.50 mm, 0.60 mm, 0.65 mm, 0.80 mm, 0.90 mm, or 1.20 mm.

³ Cable Fill allows you to select the type of material the cable can be

filled with. Changing the selection to AIRCORE, JELLY, PULP, 5PR, or

2PR influences the cable capacitance per length, automatically

updating the Cap. T/R-GND field.

³ Capacitance T-R (nF/km or nF/mi) allows you to specify a value for the

capacitance per length constant.

³ Cap. T/R-GND (nF/km or nF/mi) allows you to specify a value for the

capacitance per length to ground constant.

³ Resistance (Ohm/km or Ohm/mi) allows you specify a value for the

resistance constant of the cable.

³ Attenuation (dB/km or dB/mi) allows you to specify a value for the

reduction in signal strength or insertion loss of the cable.

³ VOP allows you to set the velocity of propagation for the cable as a

ratio of the speed of light. Enter a value between 0.400 and 0.999.

³ Restore Defaults allows you to reset cable parameters for the selected

cable to the standard default values.

12 AXS-200/610

Page 19

Getting Started with Copper Qualification Tests

Regional Settings

To select parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

To reset default cable values:

1. Press the up/down arrow keys to highlight Cable Type.

2. Press to display the list.

3. Press the up/down arrow keys to highlight the desired cable type, then

press to accept the selection.

4. Use the up/down arrow keys to highlight the Restore Defaults button,

then press . The selected cable’s default values are restored.

Copper Test Module 13

Page 20

Getting Started with Copper Qualification Tests

Regional Settings

Standard

The Standard tab allows you to set

unit parameter values for the selected

profile composed of current Distance

Units and Cable Gauge.

³ Standard allows you to specify if

the copper qualification tests

should conform to the ITU

(International

Telecommunications) or ANSI

(American National Standards Institute) standard.

³ Temp er at ur e allows you to specify the units of measurement for

temperature in F (Fahrenheit) or C (Celsius).

³ Connection allows you to specify the default type of cable connections

as T-R-G or A-B-E.

To select the parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list.

3. Use the up/down arrow keys to highlight the desired value, and press

to accept the value.

14 AXS-200/610

Page 21

Getting Started with Copper Qualification Tests

Regional Settings

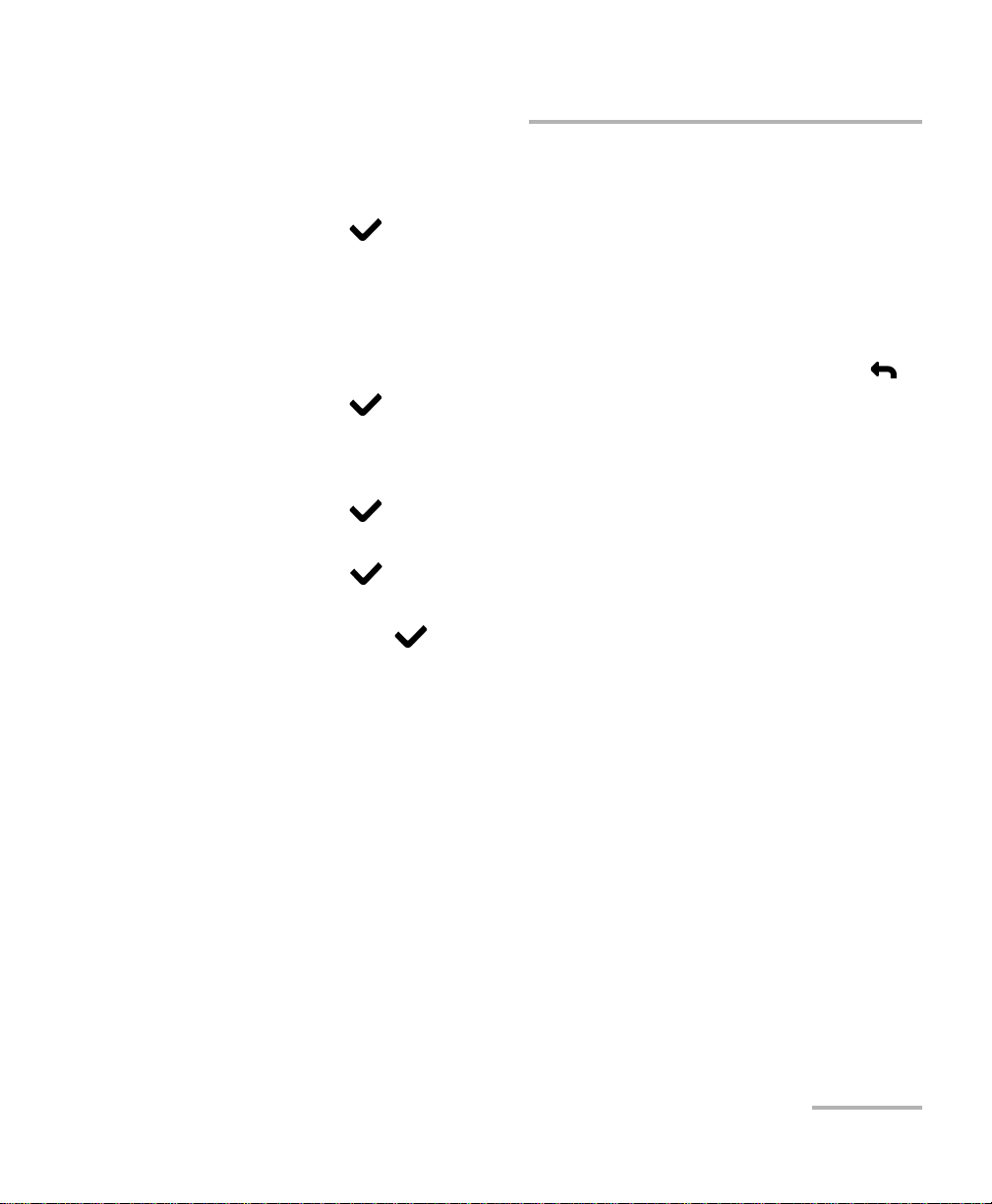

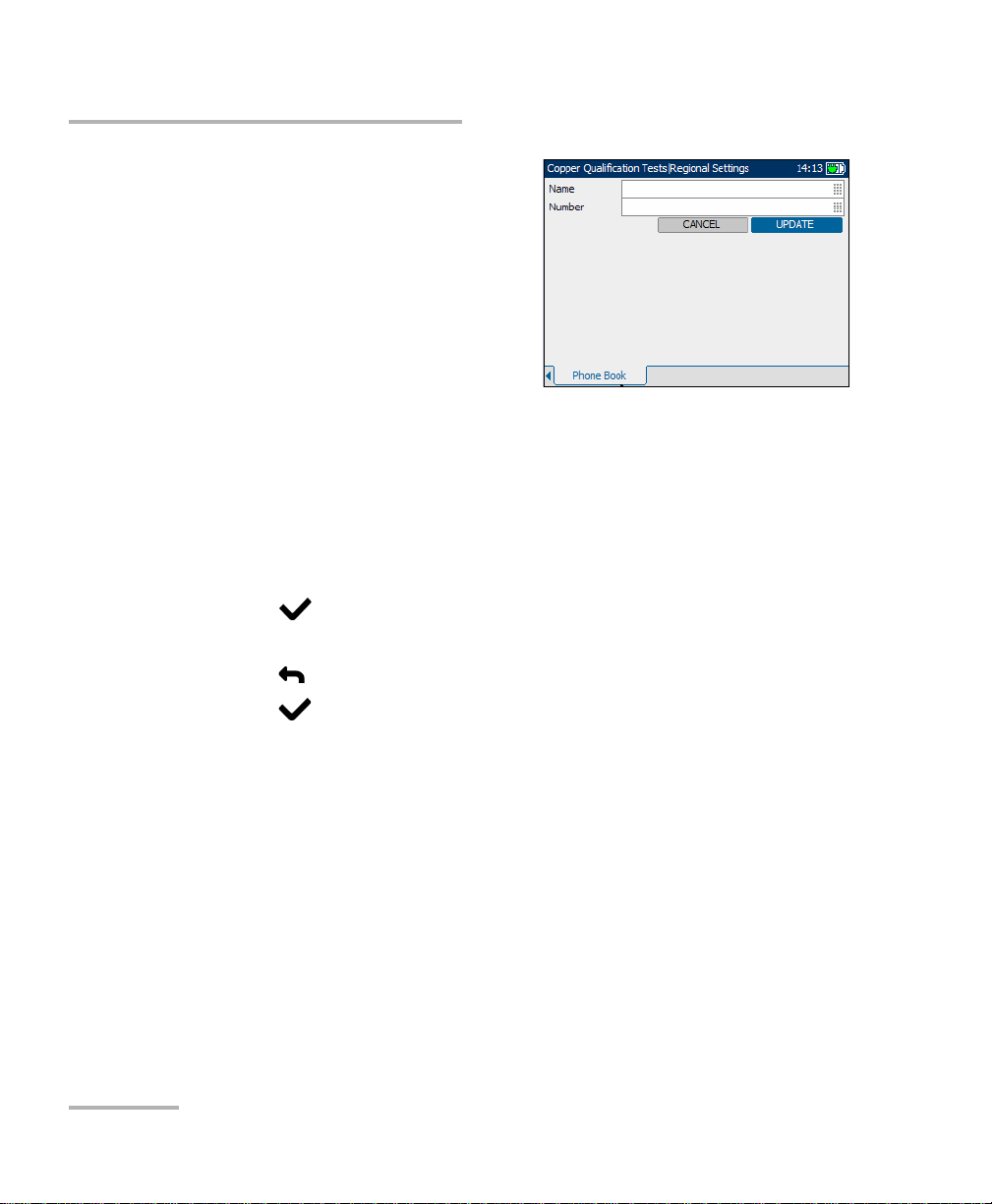

Phone Book

The Phone Book tab provides you with

a list of saved names and numbers that

will be part of the Profile.

Each parameter and button is

described below:

³ Name displays the list box of

names in a phone book list.

³ Number displays the list box of

phone numbers in a phone book list.

³ List Box can display up to 15 names/numbers. Once the list box

reaches 15 entries the New button will be disabled. The phone book

has 3 predefined entries: Milliwatt Line, Drop Battery and Quiet Line.

These entries can be edited but not removed.

To select a name/number from the current list:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to select the item.

This selection can be edited or removed. Once you leave this screen, the

selected name/number will be used to dial. All changes are automatically

saved into phone book.

³ New invokes the edit screen where a new name and number can be

entered then saved to the phone book list.

³ Edit invokes the edit screen where a name and number can be viewed

or changed.

³ Delete removes the selected entry from the phone book list.

Copper Test Module 15

Page 22

Getting Started with Copper Qualification Tests

Regional Settings

On the edit details screen, the

following controls are shown:

³ Name is the name, maximum 30

characters, assigned to the phone

number entered in the phone

book.

³ Number is the phone number,

maximum 32 digits including #,*

and comma.

³ Cancel button returns you to the phone book screen without saving

any changes.

³ Update button stores the Name and Number entered, in the phone

book.

To select and edit the controls:

1. Press the up/down arrow keys to highlight the desired entry and

press .

2. Use the alphanumeric keypad to enter a value. To cancel the entry,

press .

3. Press to accept the value.

16 AXS-200/610

Page 23

Getting Started with Copper Qualification Tests

Saving Results

Saving Results

You can save any of your results after running and viewing a test performed

with the AXS-200/610, in either text or graphical format. Each copper

qualification test includes a Save Results tab to do so.

Press the F1, F2, or F3 key to view this tab, or use the function

arrow keys on either side of the F1 and F3 keys to access it.

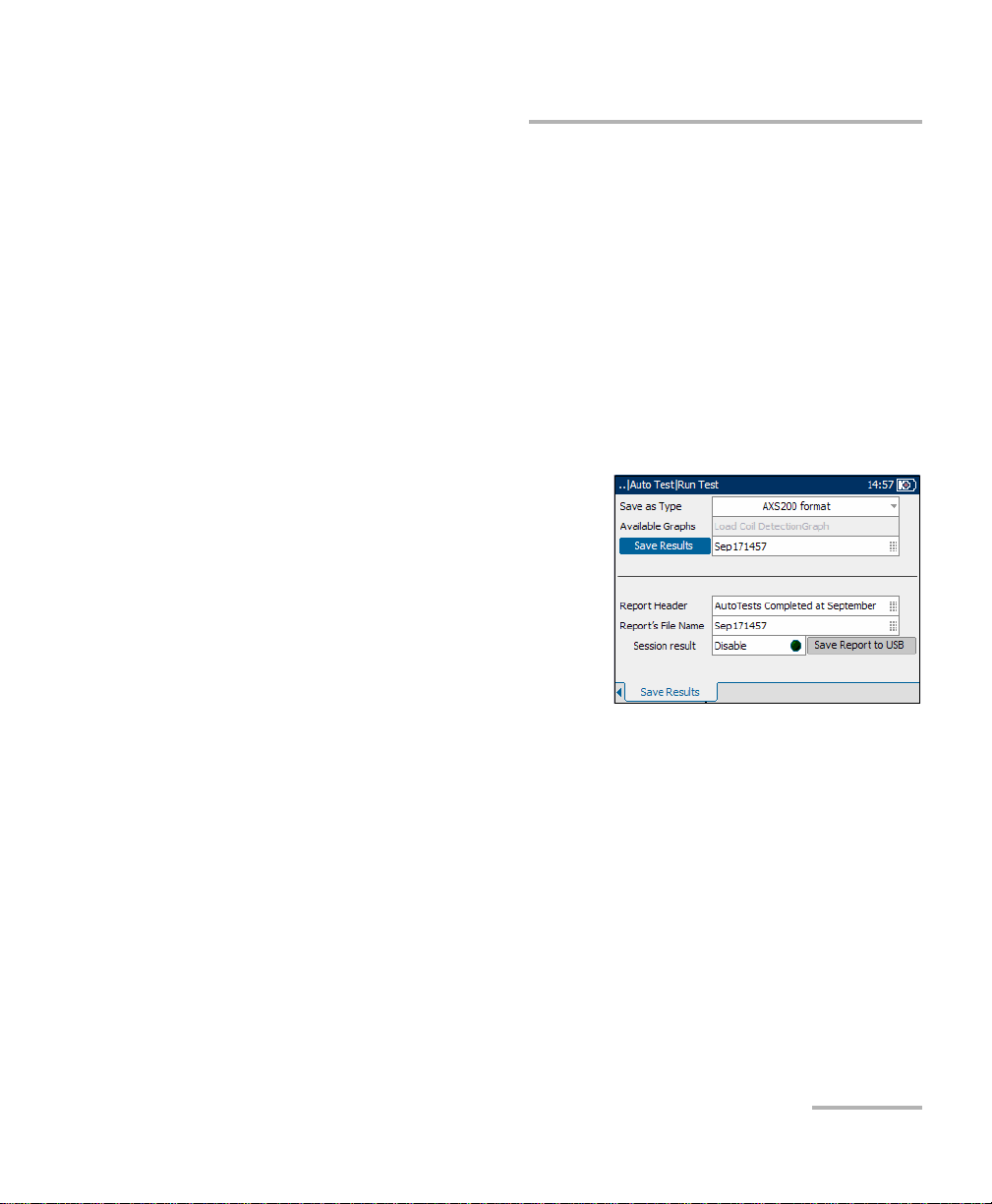

Save Results

The Save Results tab allows you to save your test results to a file or to an

HTML report.

Each entry on the pane is described as

follows:

³ Save as Type lists the following

formats to save your test results:

³ AXS200 format is a binary file

format with ext *.dat. This

format can be opened only on

an AXS200 unit. The Available

Graphs list box will be

unavailable in this case.

³ *.csv saves only graphical results.Textual results must be formatted

as a comma-separated values table for easy importation to Excel.

Results are saved to a USB.

³ *.gif stands for graphics interchange format and is one of the most

common file formats for graphic images on the World Wide Web.

Results are saved to a USB.

³ *.bmp saves graphical results in a bitmap file format. Results are

saved to a USB.

³ *.xml saves your data in a common language format to share on

the Web.

Copper Test Module 17

Page 24

Getting Started with Copper Qualification Tests

Saving Results

³ Available Graphs is enabled only if the selected format under

Save as Type is *.gif, *.csv, or *.bmp.The selection of graphs available

are: Load Coil Detection, VF Power Influence, PSD Noise,

WB Spectral Detective, WB Impulse Noise Histogram, Attenuation,

WB Long. Balance, Loop Mapper, TDR, and Auto Test. For a test that

does not have a graph, this list box is unavailable.

³ Save Results button saves the test results in internal or external

memory (depending on the Save as Type format).

³ Filename is the current date and time stamp plus you can enter any

name. If it already exists, you will be prompted to overwrite the existing

file.

³ Report Header is where you can enter any comment. The initial value

is the current test followed by the date and time stamp.

³ Report’s File Name is where you can enter any name for the HTML

filename. If the name already exists, you will be prompted to overwrite

the existing file.The default extension is .html.

The default name is generated from the current time.

³ Session result creates and saves the report for single test results when

disabled, or appends multiple results in one report when enabled.

³ Save Report to USB button saves the results to an HTML report. If a

USB memory stick is not inserted, the following warning dialogue box

appears: USB device is not detected.

³ Append to Report button appears only if Session result is Enable,

and creates an HTML report for the current test in internal memory.

18 AXS-200/610

Page 25

Getting Started with Copper Qualification Tests

Saving Results

To set parameter values and save results:

1. Press the left/right and up/down arrow keys to highlight the desired

parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow key to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

Copper Test Module 19

Page 26

Getting Started with Copper Qualification Tests

Reading Saved Results

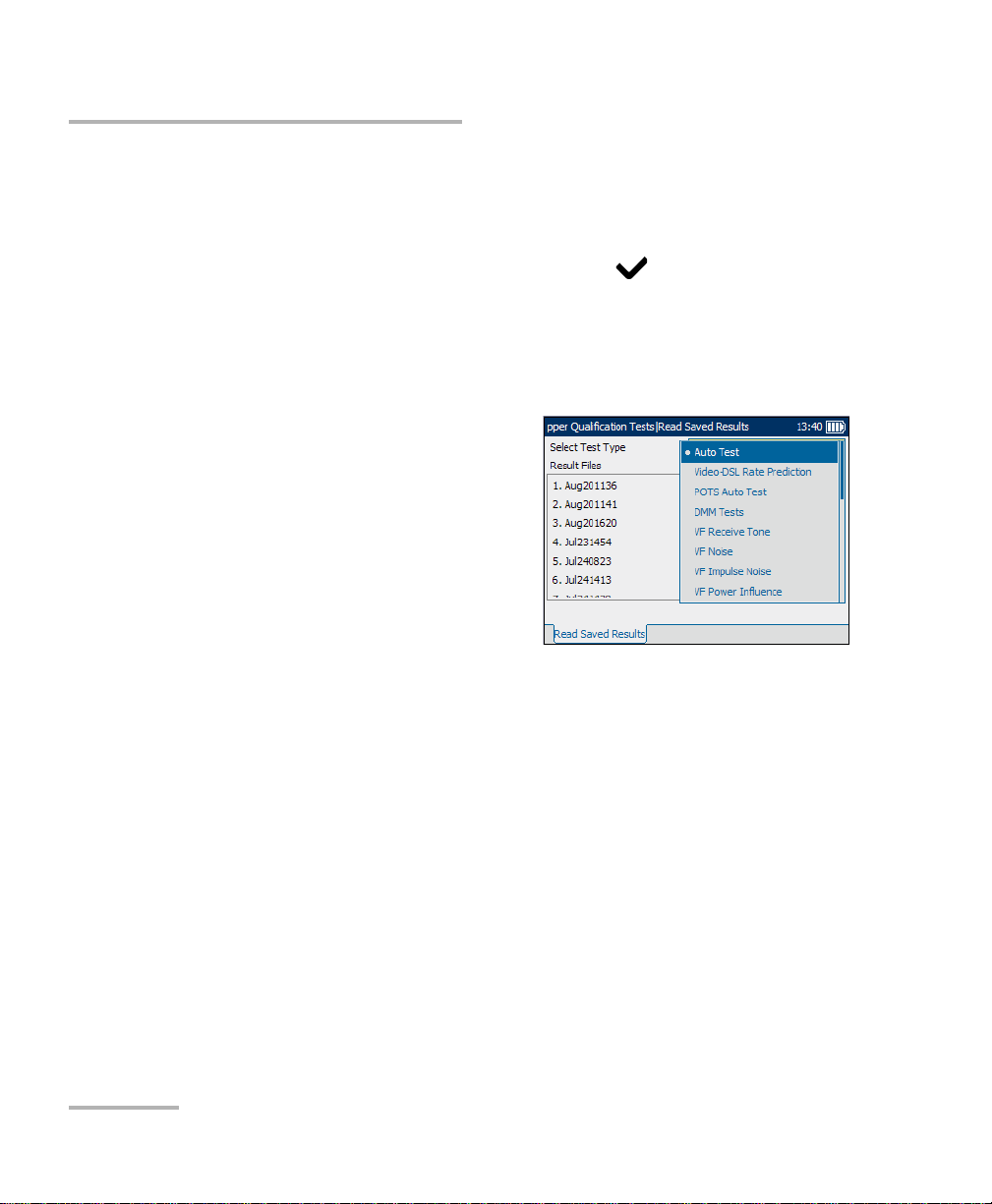

Reading Saved Results

You can view any of your saved results with the Copper Test Module, by

highlighting the Read Saved Results menu item from the

Copper Qualification Tests pane, and pressing .

Read Saved Results

The Read Saved Results tab allows you to select a test type and view the

results of all the files previously saved.

Selec t Te st Type provides a list of all

the copper qualification test types

available for you to select for viewing.

³ Auto Test

³ Video-DSL Rate Prediction

³ POTS Auto Test

³ DMM Tests

³ VF Receive Tone

³ VF Noise

³ VF Impulse Noise

³ VF Power Influence

³ VF Long.Balance

³ VF Load Coil

³ TDR

³ RFL-2 Wires

³ RFL-4 Wires

³ Loop Mapper

³ WB Receive Tone

20 AXS-200/610

Page 27

Getting Started with Copper Qualification Tests

Reading Saved Results

³ WB Impulse Noise

³ WB Impulse Noise Histogram

³ Spectral Detective

³ PSD Noise

³ Attenuation

³ WB Longitudinal Balance

³ WB Data Rate Prediction

³ Rect. L Detection

³ Resistive Balance

To open previously saved test results:

1. Press to open the list.

2. In the list, press the up/down arrows to select the test type.

3. Press to confirm the selection.

4. Press the down arrow to activate the Result Files list box and

press to display the list of available files.

5. Press the up/down arrows to select the desired result file.

6. Press to view the selection.

Copper Test Module 21

Page 28

Page 29

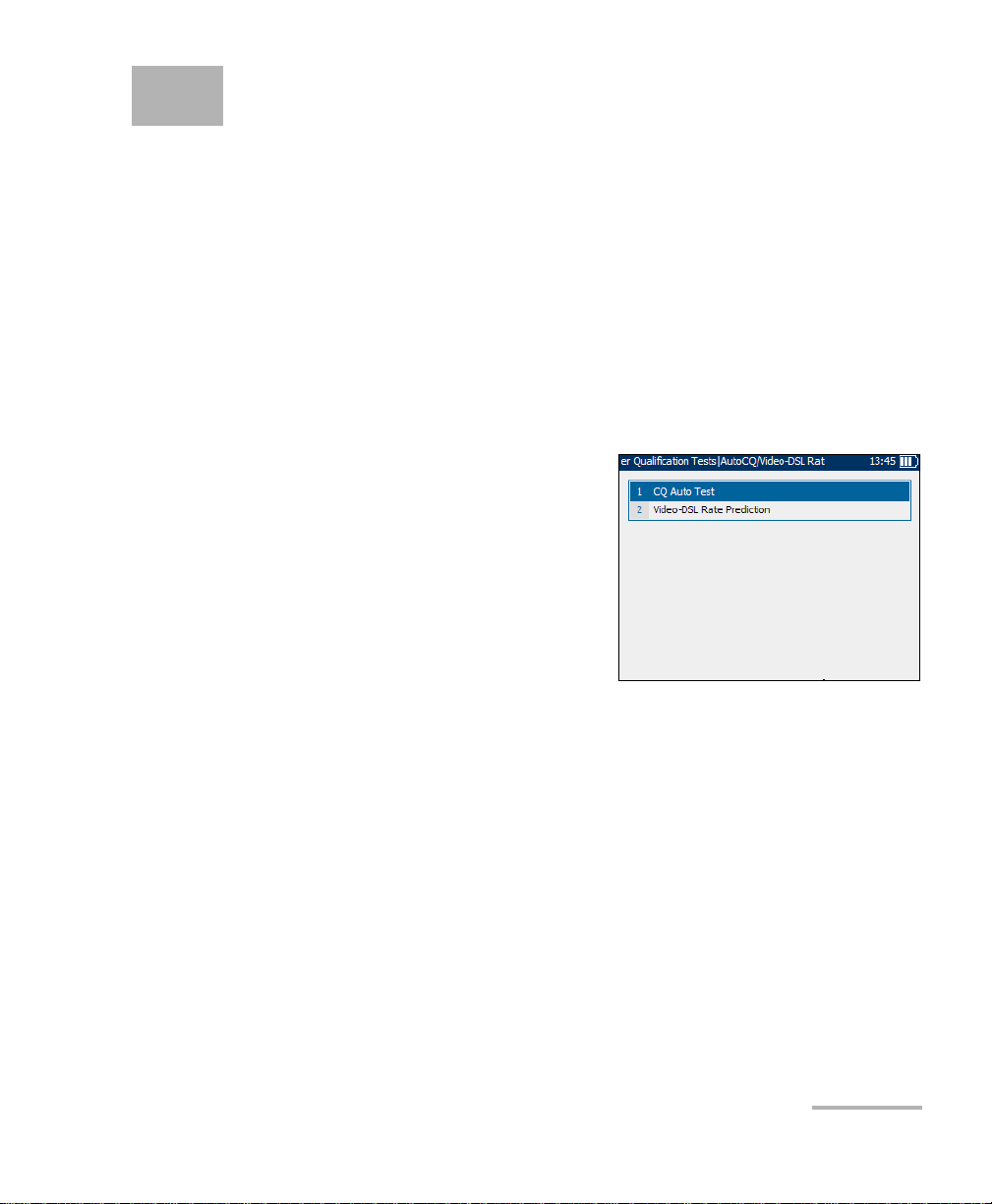

3 Auto CQ/Video-DSL Rate

Prediction

CQ Auto Test

The cable qualification auto test function allows you to automatically run

tests used in pre-qualification, installation, and maintenance of different

circuit types from POTS to VDSL2. Auto tests include a range of different

tests that compare measured results against stored threshold values to

provide pass or fail results. The results are displayed in both text and

graphical format.

The following tests can be included in the CQ auto test function:

³ AC/DC voltage and current

³ Resistance

³ Capacitance

³ Isolation

³ Load coil detection

³ Power influen c e

³ Voice frequency (VF) longitudinal

balance

³ Voice frequency (VF) noise

³ Voice frequency (VF) impulse noise

³ Voice Frequency (VF) receive tone

³ Wideband (WB) receive tone

³ Wideband (WB) longitudinal balance

³ Power spectral density (PSD) noise

³ Attenuation

³ Wideband (WB) impulse noise

³ Time domain reflectometry (TDR)

Copper Test Module 23

Page 30

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

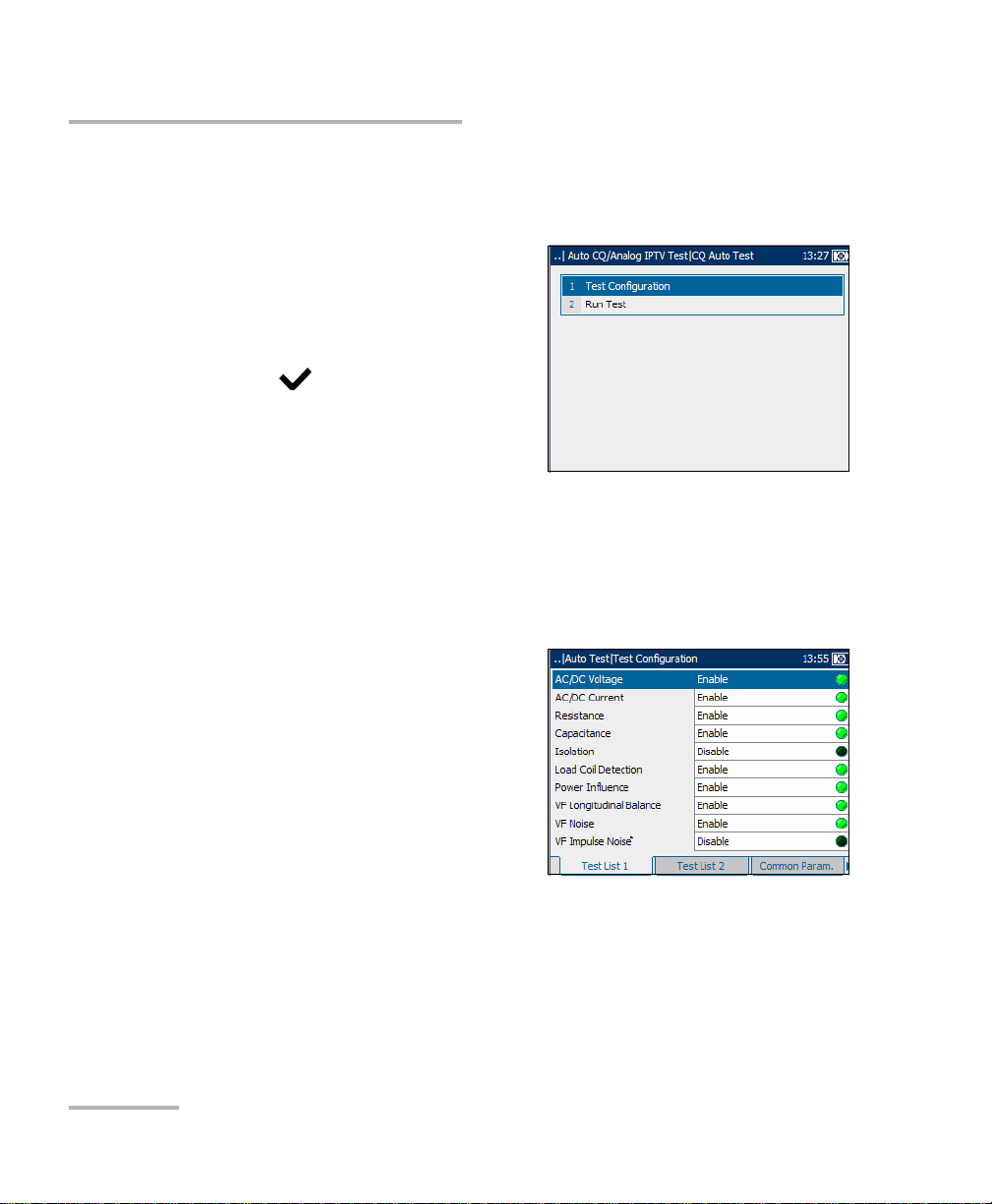

Configuring CQ Auto Tests

Parameters for auto test configuration are on the CQ Auto Test pane tabs.

To view auto test configuration

tabs:

1. From the CQ Auto Test pane use

the up/down arrow keys to

highlight Test Configuration, and

press .

2. Press the F1, F2, or F3 key to view

the various tabs. To view any

available additional tabs, use the

function arrow keys on either side of the F1 and F3 keys.

Test List 1

The Test L i s t 1 tab allows you to select the types of tests to include in the

auto test function.

The following tests are available:

³ AC/DC Voltage detects AC RMS

and DC voltages in the line. Toggle

between Enable and Disable.

³ AC/DC Current checks for AC RMS

and DC currents in the line. Toggle

between Enable and Disable.

³ Resistance measures isolation

resistance between the wires and to ground. It is also used to identify

possible faults, and to measure the resistance of the twisted pair cable

for estimating loop length. Toggle between Enable and Disable.

³ Capacitance measures the capacitance of the cable for estimating

loop length. Toggle between Enable and Disable.

24 AXS-200/610

Page 31

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

³ Isolation measures the quality of insulation or sheathing for the copper

pairs.

³ Load Coil Detection detects the presence of load coils in the line.

Toggle between Enable and Disable.

³ Power Influence measures the effects that 50 Hz and 60 Hz powerline

(AC Mains) interference has on the circuit under test. Toggle between

Enable and Disable.

³ VF Longitudinal Balance is very useful in identifying loops that will

suffer from crosstalk. Toggle between Enable and Disable.

³ VF Noise measures VF noise in the line. Toggle between Enable and

Disable.

³ VF Impulse Noise measures the random occurrences of energy spikes

in the voice frequency range that have random amplitude and spectral

content.

To select tests:

1. Press the up/down arrow keys to highlight a desired test.

2. Press to toggle between Enable and Disable.

3. Select other tests as required.

Copper Test Module 25

Page 32

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

Test List 2

The Test List 2 tab allows you to select

additional tests to include in the auto

test function.

The following additional tests are

available:

³ VF Receive Tone measures the

level and frequency of the

incoming voice signal.

³ WB Receive Tone measures the level and frequency of the incoming

wideband signal.

Note: The VF and WB Receive Tone tests are mutually exclusive. When one test is

enabled, the other is automatically disabled.

³ WB Longitudinal Balance verifies that the wideband longitudinal

balance ratios comply with applicable standards.

³ PSD Noise measures power spectral density noise.

³ Attenuation measures the amount of reduction in signal strength.

³ WB Impulse Noise measures the irregular occurrences of energy

spikes in the wideband range that have random amplitude and

spectral content.

³ TDR test identifies and locates all types of faults as well as bridge taps

(multiple appearances) and load coils.

To s e le ct t es t s:

1. Press the up/down arrow keys to highlight a desired test.

2. Press to toggle between Enable and Disable.

3. Select other tests as required.

26 AXS-200/610

Page 33

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

Common Parameters

The Common Param. tab allows you to

set up parameters common to all tests

in the auto test function.

Each parameter is described below:

³ Cable Type defines the gauge of

the cable in use. If wire gauge is

measured in AWG units, the

available choices are: AUTO,

19 AWG, 22 AWG, 24 AWG, or

26 AWG. For mm gauge wire, the available choices are: AUTO,

0.32 mm, 0.40 mm, 0.50 mm, 0.60 mm, 0.80 mm, 0.90 mm, or

1.20 mm.

³ Temp er at ur e specifies the temperature of the cable under test in

either F (Fahrenheit) or C (Celsius) units.

³ Isolation Test Time(sec) specifies the duration of the isolation test.

To set parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

Copper Test Module 27

Page 34

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

VF Test Parameters

The VF Parameters tab allows you to

set up parameters used in the voice

frequency tests.

Each parameter is described below:

³ VF Noise Filter defines the level of

voice frequency noise filtering. If

the ANSI standard is used, the

available choices are: NONE,

C-MESSAGE, CNOTCHED,

3kHzFLAT, D-FILTER or 15 kHz. If the ITU standard is used, the

available choices are: NONE, PSOPHOMETRIC, P-NOTCHED,

3kHzFLAT, D-FILTER or 15 kHz.

³ VF Termination defines if the unit uses normal test impedance

termination or high bridging impedance when the cable is active or

terminated by other external equipment. For normal test termination

select TERMINATED, otherwise select BRIDGING.

³ Imp. Noise Filter defines the type of impulse noise filtering to use. If

ANSI standard is used, the available choices are: NONE, C-MESSAGE,

CNOTCHED, 3kHzFLAT, D-FILTER or 15 kHz. For the ITU standard,

the choices are: NONE, PSOPHOMETRIC, P-NOTCHED, 3kHzFLAT,

D-FILTER or 15 kHz.

³ Low Threshold(dBm) defines the low threshold limits for impulse

noise. Specify a value between -40 and 0.

³ Separation(dB) defines the level difference (in dB) between the low,

the mid and high thresholds. Specify a value between 1 and 6 dB.

³ Imp. Noise Measure. Time defines the time duration to measure

impulse noise. The available choices are: 1 minute, 5 minutes,

10 minutes, 15 minutes, 60 minutes, or 24 hours.

28 AXS-200/610

Page 35

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

To set parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

Copper Test Module 29

Page 36

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

WB Test Parameters

The WB Parameters tab allows you to

set up parameters used in the

wideband tests.

Each parameter is described below:

³ WB Noise Filter defines the level

of wideband noise filtering. The

available choices are: NONE,

50 kbit, ISDN-E, HDSL-F, ADSL-G,

ADSL, ADSL2+, VDSL, VDSL2-8,

VDSL2-12, VDSL2-17, or VDSL2-30.

Note: VDSL2-x filters are only available if VDSL2 is enabled in the software

options.

³ Bandwidth specifies the frequency range for the test: 2.2 MHz,

12 MHz, 17 MHz, or 30 MHz.

Note: Frequency bands in excess of 2.2 MHz are only displayed if VDSL2 is

enabled in the software options.

³ WB Termination defines if the unit uses normal test impedance

termination or high bridging impedance when the cable is active or

terminated by other external equipment. For normal test termination

select TERMINATED, otherwise select BRIDGING.

³ WB Termination Impedance defines the impedance of the dummy

load connected to the line. Select one of the following: 100 Ohm or

135 Ohm.

³ Imp. Noise Threshold(dBm) is the maximum impulse noise level.

Specify a value between -50 and 0 (-40 and 0 if any filter applied).

³ Imp. Noise Measure. Time defines the time duration to measure

impulse noise. The available choices are: 1 minute, 5 minutes,

10 minutes, 15 minutes, 60 minutes, or 24 hours.

30 AXS-200/610

Page 37

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

To set parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow key to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

Copper Test Module 31

Page 38

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

Thresholds 1

The Thresholds 1 tab allows you to set

threshold values for the auto tests.

Each parameter is described below:

³ Max. AC Voltage T-R (V) defines

the maximum AC threshold

voltage for the T-R leg of the circuit.

Specify a value between 1 and 30.

³ Max. AC Voltage to GND (V)

defines the maximum AC threshold voltage to ground for the circuit.

Specify a value between 1 and 30.

³ Max. DC Voltage T-R (V) defines the maximum DC threshold voltage

for the T-R leg of the circuit. Specify a value between 1 and 400.

³ Max. DC Voltage to GND (V) defines the maximum DC threshold

voltage to ground for the circuit. Specify a value between 1 and 400.

³ Min. Resistance T-R(MOhm): defines the minimum threshold

resistance for the T-R leg of the circuit. Specify a value between

0 and 999.

³ Min. Resistance T-G(MOhm) defines the minimum threshold

resistance for the T-G leg of the circuit. Specify a value between

0 and 999.

³ Min. Resistance R-G(MOhm) defines the minimum threshold

resistance for the R-G leg of the circuit. Specify a value between

0 and 999.

32 AXS-200/610

Page 39

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

To set a threshold value:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to select the value.

3. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

4. Press to accept the value.

Copper Test Module 33

Page 40

Auto CQ/Video-DSL Rate Prediction

Configuring CQ Auto Tests

Thresholds 2

The Thresholds 2 tab allows you to set

additional threshold values.

Each parameter is described below:

³ Min. VF Long. Balance(dB)

defines the minimum voice

frequency threshold longitudinal

balance level. Specify a value

between 10 and 80.

³ Max. VF RMS Noise defines the maximum threshold RMS noise energy

level. Specify a value between -90 and 10 dBm if the ITU standard is

used. Specify a value between 0 and 100 dBrn if the ANSI standard is

used.

³ Max. VF Power Influence defines the maximum threshold power

influence level on the circuit. Specify a value between -90 and 20 dBm

if the ITU standard is used. Specify a value between 0 and 110 dBrnC if

the ANSI standard is used.

³ Min. WB Long. Balance(dB) defines the minimum threshold

wideband longitudinal balance level. Specify a value between

10 and 80.

³ Attenuation(dB) defines the threshold wideband attenuation level.

Specify a value between 0 and 80.

To set a threshold value:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to select the value.

3. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

4. Press to accept the value.

34 AXS-200/610

Page 41

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

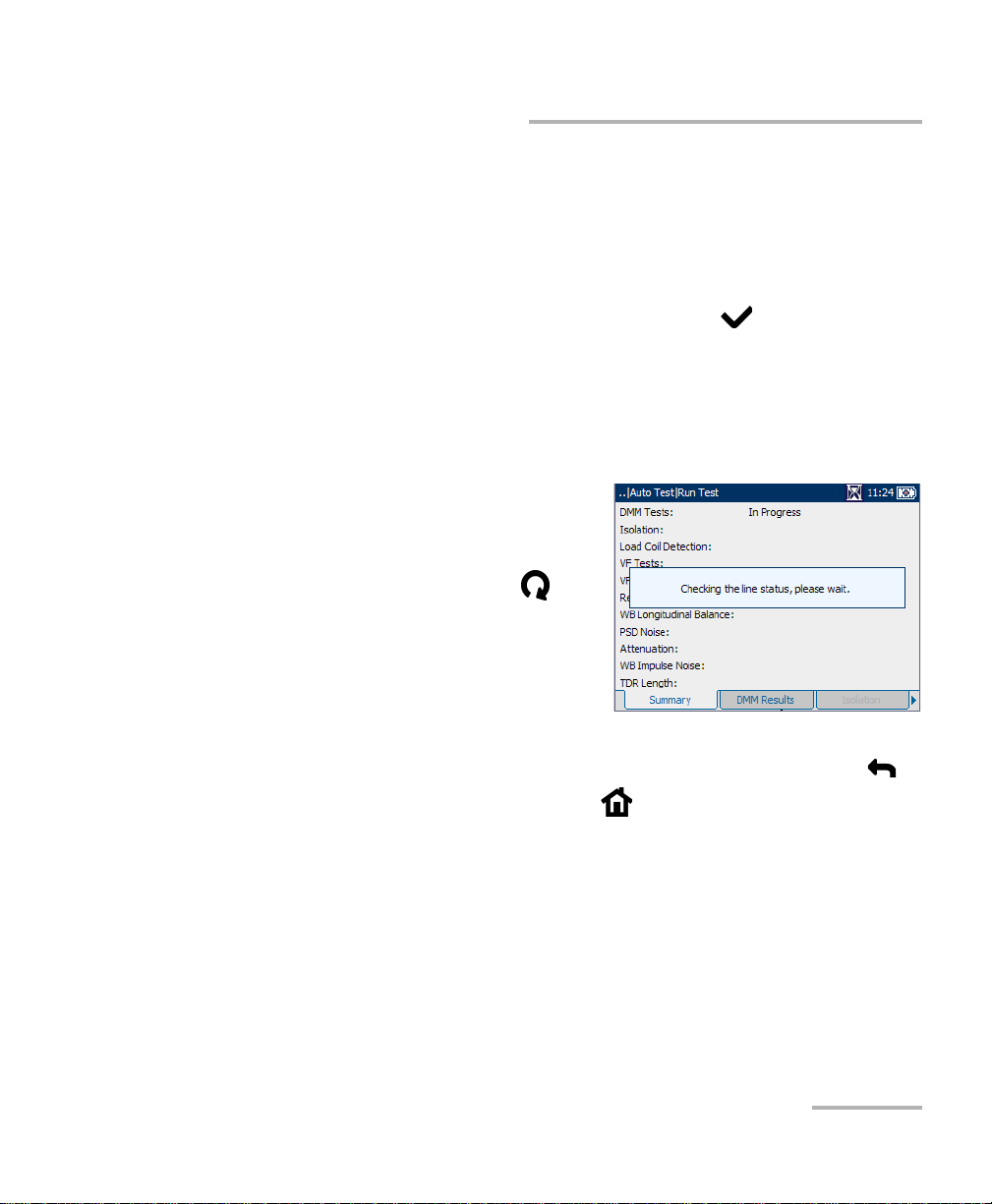

Running CQ Auto Tests and Viewing Results

Auto test results are located on the CQ Auto Test pane tabs.

To run auto tests and view results:

1. From the CQ Auto Test pane use

the up/down arrow keys to

highlight Run Test, and press .

2. Press the F1, F2, or F3 key to view

the various tabs. To view any

available additional tabs, use the

function arrow keys on either side

of the F1 and F3 keys.

Summary

The Summary tab displays the overall

PASS or FAIL status of all tests selected

for auto testing.

Copper Test Module 35

Page 42

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

DMM Results

The DMM Results tab displays the

measured values and pass or fail status

of each digital multimeter (DMM) test.

Isolation

The Isolation tab displays the

measured Resistance values from the

isolation test.

Load Coil

The Load Coil tab displays the number

of load coils in the line, and measured

values from the load coil detection test

in graphical form.

To move the screen pointer:

Press the left/right arrow keys to move

the screen pointer. The pointer value

updates dynamically.

36 AXS-200/610

Page 43

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

VF Tests

The VF Tests tab displays the

measured values and PASS or FAIL

status of the voice frequency tests.

VF Impulse Noise

The VF Impulse Noise tab displays the

measured values from the voice

frequency impulse noise tests.

Receive Tone

The Receive Tone tab displays the

current received frequency and level

values of the received tone.

Copper Test Module 37

Page 44

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

WB Longitudinal Balance

The WB Long. Balance tab displays in

graphical form the measured values

from the wideband longitudinal

balance tests.

The list and buttons on the tab are

described below:

³ (Zoom function List) allows you to

select the desired zoom function

Horizontal Zoom or Vertical

Zoom. The selected function is displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in or out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow keys to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow keys to highlight the Zoom In or Zoom Out

button as required, then press .

The graphical display zooms in or out accordingly.

5. Press repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow keys to move the screen pointer. The pointer

value updates dynamically.

38 AXS-200/610

Page 45

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

PSD Noise

The PSD Noise tab displays the RMS

Noise value from the power spectral

density (PSD) noise tests in text and

graphical form.

The list and buttons on the tab are

described below:

³ (Zoom function List) allows you to

select the desired zoom function:

Horizontal Zoom or Vertical

Zoom. The selected function is displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in or out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow keys to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow keys to highlight the Zoom In or Zoom Out

button as required, then press .

The graphical display zooms in or out accordingly.

5. Press repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow keys to move the screen pointer. The pointer

value updates dynamically.

Copper Test Module 39

Page 46

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

Attenuation

The Attenuation tab displays in

graphical form the cable length value

from attenuation tests.

The list and buttons on the tab are

described below:

³ (Zoom function List) allows you to

select the desired zoom function:

Horizontal Zoom or Vertical

Zoom. The selected function is

displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in or out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow keys to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow keys to highlight the Zoom In or Zoom Out

button as required, then press .

The graphical display zooms in or out accordingly.

5. Press repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow keys to move the screen pointer. The pointer

value updates dynamically.

40 AXS-200/610

Page 47

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

WB Impulse Noise

The WB Impulse Noise tab displays

the measured values from the

wideband impulse noise tests.

TDR

The TDR tab displays the time domain

reflectometry which is on and ready to

use upon completion of the Auto Test.

TDR first attempts to find the length of

the circuit and then searches all ranges

from shortest to longest for significant

events. Upon completion, the test

selects the nearest major event, sets

the range to match, and aligns the

cursor with the event. It remains

running (not in Fault Location Tests).

To make TDR adjustments via the keypad:

1. Press to change the mode button (top-right corner of the pane)

and function of the up/down arrow keys.

2. Press repeatedly to cycle between:

³ Zoom

³ Gain

³ Pulse Gain (Pulse Width & Gain)

³ Range

³ Cursor and Marker Selection

Copper Test Module 41

Page 48

Auto CQ/Video-DSL Rate Prediction

Running CQ Auto Tests and Viewing Results

To measure the distance/duration between reflections:

1. Press to cycle the mode and change to CursorMarker.

2. Press the left/right arrow keys to position the blue cursor (indicated by

the blue color of data above cursor).

3. Press the up arrow key to select the red marker.

4. Press the left/right arrow keys to position the marker.

5. The difference between the cursor and marker is continuously

updated and is indicated with a triangle (delta symbol) above the

graph.

To zoom in/out:

1. Press to select the Zoom function. Default mode is Zoom.

2. Press the up/down arrow keys to increase/decrease Zoom function.

The graphical display zooms in or out accordingly.

42 AXS-200/610

Page 49

Auto CQ/Video-DSL Rate Prediction

Video-DSL Rate Prediction

Video-DSL Rate Prediction

The video-DSL rate prediction test

provides an innovative way to

understand the otherwise complicated

output of electrical and attenuation

measurements, and noise tests as they

relate to the capacity to transport IPTV

video over ADSL2+ circuits. This test

performs a series of loop-quality

measurements before predicting the

ADSL2+ data rate and Video-DSL rate.

Based on current loop conditions and user-defined technology, the

video-DSL rate prediction test shows you how many streams of standard

broadcast (SB) and high definition (HD) IPTV video streams the tested

circuit could reliably carry.

Configuring Video-DSL Rate Prediction

Parameters for auto test configuration are on the Video-DSL Rate

Prediction pane tabs.

To view the test configuration

tabs:

1. From the Video-DSL Rate

Prediction pane use the up/down

arrow keys to highlight Tes t

Configuration, and press .

2. Press the F1, F2, or F3 key to view

the various tabs. To view any

available additional tabs, use the

function arrow keys on either side of the F1 and F3 keys.

Copper Test Module 43

Page 50

Auto CQ/Video-DSL Rate Prediction

Configuring Video-DSL Rate Prediction

Configuration

The Configuration tab allows you to

define the desired number of streams

and allocated bit rate per stream

before running the test.

Each parameter is described below:

³ No Of Streams is the number of

High Def. (definition) streams,

ranging from 0 to 4 and Std.

(standard) Def. streams ranging

from 0 to 10.

³ Stream Rate (Mbps) is the High Def. (HD) and Std. Def. (SD) stream

rate before running the test, ranging from 0 to 24 Mbps. Default values

are 8 Mbps for HD and 1 Mbps for SD.

³ Non-Video Data Rate (Mbps) is a data rate of non-video data typically

used by high-speed internet and VoIP services. Rates range from

0 to 24 Mbps. Default value is 1 Mbps.

³ Annex defines the modes of available ADSL Annexes from the

ITU standards.

³ A is ADSL service functioning over POTS.

³ B activates the ADSL functionality over ISDN.

³ L Mask 1 assumes an increase in ADSL2 range/distance.

³ L Mask 2 also extends the signal reach but can show an

improvement in the upstream data rate.

³ M allows increased upload speeds from 1 Mbps to 3.5 Mbps.

Available only for ADSL2 and ADSL2+.

44 AXS-200/610

Page 51

Auto CQ/Video-DSL Rate Prediction

Configuring Video-DSL Rate Prediction

³ Technology lists the following values: ADSL2+, ADSL2, or ADSL. If

Annex L is previously selected, ADSL2 is automatically set. If Annex M,

ADSL is not available.

³ Targ e t SNR is the desired signal-to-noise ratio ranging from 0 to 31 dB.

Default value is 6 dB.

To set parameter values:

1. Press the up/down or left/right arrow keys to highlight the desired

parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

Copper Test Module 45

Page 52

Auto CQ/Video-DSL Rate Prediction

Configuring Video-DSL Rate Prediction

Thresholds

The Thresholds tab allows you to set

threshold values for the auto tests.

Each parameter is described below:

³ Max AC Voltage (V) defines the

maximum AC voltage, ranging

from 1 to 20. Default value is 6.

³ Max DC Voltage (V) defines the

maximum DC voltage ranging from

1 to 20. Default value is 9.

³ Min Resistance (MOhm) defines the minimum resistance ranging

from 0.5 to 100. Default value is 3.6.

³ Max Cap. Balance (%) defines the percentage maximum capacitance

balance ranging from 0 to 20. Default value is 6.

³ Min Long Balance (dB) defines the minimum longitudinal balance

level ranging from 50 to 70. Default value is 59.

To set a threshold value:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to select the value.

3. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

4. Press to accept the value.

46 AXS-200/610

Page 53

Auto CQ/Video-DSL Rate Prediction

Configuring Video-DSL Rate Prediction

Impulse Noise Setup

The Imp. Noise Setup tab allows you to configure parameters to measure

impulse noise on the circuit under test.

Each parameter on the pane is

described below.

³ Ter mi na ti on defines if the unit

uses normal test impedance

termination or high bridging

impedance when the cable is

active or terminated by other

external equipment. For normal

test termination select

TERMINATED, otherwise select BRIDGING.

³ Termination Impedance defines the impedance of the dummy load

connected to the line. Select one of the following: 100 or 135 Ohm.

³ Noise Filter defines the level of wideband noise filtering. The available

choices are: NONE, 50 kbit, ISDN-E, HDSL-F, ADSL-G, ADSL, ADSL2+,

VDSL, VDSL2-8, VDSL2-12, VDSL2-17, or VDSL2-30.

Note: VDSL2-x filters are only available if VDSL2WB is enabled in the software

options.

³ Threshold(dBm) is the maximum impulse noise level. Specify a value

between -50 and 0 (-40 and 0 if any filter applied). Default value is -30.

³ Measurement Time defines the duration of the Impulse Noise test. The

available choices are: 1, 3, 5, 10, 15, or 60 Minutes, or 24 Hours.

Copper Test Module 47

Page 54

Auto CQ/Video-DSL Rate Prediction

Configuring Video-DSL Rate Prediction

To set parameter values:

1. Press the up/down arrow keys to highlight the desired parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

48 AXS-200/610

Page 55

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

Running Video-DSL Rate Prediction Tests and

Viewing Results

Details of the video-data rate prediction results are located on the

Video-DSL Rate Prediction pane tabs.

To run the tests and view results:

1. From the Video-DSL Rate

Prediction pane use the up/down

arrow keys to highlight Run Test,

and press .

2. Once the tests are completed,

highlight the Details button from

the Test Summary pane and

press to view the results.

3. Press the F1, F2, or F3 key to view the various tabs. To view any

available additional tabs, use the function arrow keys on either side of

the F1 and F3 keys.

Test Summary

The Test Summary tab allows you to view the pass/fail status and Details

of all tests configured for auto testing.

The available test results are the

following:

³ DMM Tests or digital multimeter

tests detect AC/DC voltages, and

measure frequency, resistance and

capacitance for the copper wire

connection.

³ Load Coils Detected is the

number load coals detected in

the line.

Copper Test Module 49

Page 56

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

³ WB Long. Balance measures the wide band longitudinal balance of

the broadband service.

³ WB PSD Noise measures the wide band power spectral density noise

on the line.

³ WB Attenuation measures the cable length value from wide band

attenuation tests.

³ WB Impulse Noise measures values from the wideband impulse

noise tests.

³ Data Rate Test predicts the maximum bit rate achievable on the

local loop based on Annex, Technology, and Tar g e t SNR selected.

³ HD Streams is the number of high definition streams carried on the

local loop. Again, the pass indicator is displayed only if the analyzed

number of HD streams matches the number set on the Configuration

tab. Otherwise the status is fail.

³ SD Streams is the number of standard definition streams carried on

the local loop. Here, the pass indicator is displayed only if the analyzed

number of SD streams matches the number set on the Configuration

tab. Otherwise the status is fail.

³ Predicted Rate displays the downstream and upstream predicted

data rates.

³ The Details button navigates you to the applicable results tab which

provides more information about a particular test.

To view more information about each available test result:

1. Press the up/down arrows to highlight the Details button alongside the

desired test result.

2. Press to select the desired Details button.

3. To return to the Test Summary pane, press .

50 AXS-200/610

Page 57

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

Video Rates

The Video Rates tab allows you to view the pass/fail status, details and

predicted data rate of the high and standard definition streams carried on

the local loop.

Configurable parameters include:

³ No of Streams is the number of

High Def. (definition) streams,

ranging from 0 to 4 and Std.

(standard) Def. streams ranging

from 0 to 10.

³ Stream Rate (Mbps) is the High

Def. (HD) and Std. Def. (SD)

stream rate before running the test,

ranging from 0 to 24 Mbps. Default values are 8 Mbps for HD and

1Mbps for SD.

³ Technology lists the following values: ADSL2+, ADSL2, or ADSL. If

Annex L is previously selected, ADSL2 is automatically set. If Annex M,

ADSL is not available.

³ Annex defines the modes of available ADSL Annexes from the

ITU standards.

³ A is ADSL service functioning over POTS.

³ B activates the ADSL functionality over ISDN.

³ L Mask 1 assumes an increase in ADSL2 range/distance.

³ L Mask 2 also extends the signal reach but can show an

improvement in the upstream data rate.

³ M allows increased upload speeds from 1 Mbps to 3.5 Mbps.

Available only for ADSL2 and ADSL2+.

Copper Test Module 51

Page 58

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

³ Targ e t SNR is the desired signal-to-noise ratio ranging from 0 to 31 dB.

Default value is 6 dB.

³ Recalculate button allows you to change the setup and re-evaluate the

rates.

To re-set parameters to view different results:

1. Press the up/down or left/right arrow keys to highlight the desired

parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

6. Press the up/down arrow keys to highlight the Recalculate button.

7. Press to recalculate rates for the new setup.

DMM Tests

The DMM tests results pane displays

the measured values on tip, ring, and

ground, and the pass/fail status of each

digital multimeter test.

52 AXS-200/610

Page 59

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

WB Longitudinal Balance

The WB Long. Balance pane displays

the results of the wideband

longitudinal balance test in graphical

form.

The buttons on the tab are described

below:

³ (Zoom function List) allows you to

select the desired zoom function:

Horizontal Zoom or Vertical

Zoom. The selected function is displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in/out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow key to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow key to highlight the Zoom In or Zoom Out

button as required, then press .

5. The graphical display zooms in or out accordingly. Press

repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow key to move the screen pointer. The pointer value

updates dynamically.

Copper Test Module 53

Page 60

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

WB PSD Noise

The WB PSD Noise pane displays the

RMS Noise value from the power

spectral density (PSD) noise tests in

text and graphical form. RMS noise

voltage measures the signal-to-noise

ratio of the circuit.

The list and buttons on the tab are

described below:

³ (Zoom function List) allows you to

select the desired zoom function: Horizontal Zoom or Vertical Zoom.

The selected function is displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in or out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow keys to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow keys to highlight the Zoom In or Zoom Out

button as required, then press .

The graphical display zooms in or out accordingly.

5. Press repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow keys to move the screen pointer. The pointer

value updates dynamically.

54 AXS-200/610

Page 61

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

WB Attenuation

The WB Attenuation pane displays the

wideband attenuation test results in

graphical form.

The list and buttons on the tab are

described below:

³ (Zoom function List) allows you to

select the desired zoom function:

Horizontal Zoom or Vertical

Zoom. The selected function is

displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in/out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow key to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow key to highlight the Zoom In or Zoom Out

button as required, then press .

5. The graphical display zooms in or out accordingly. Press

repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow key to move the screen pointer. The pointer value

updates dynamically.

Copper Test Module 55

Page 62

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

WB Impulse Noise

The WB Impulse Noise pane displays

the measured values from the

wideband impulse noise tests.

DSL Rate Tests

The DSL Rate tab allows you to view

the down/up stream Predicted Rate

based on measurements of PSD noise

and attenuation.

Configurable parameters include:

³ Annex lists the modes of available

ADSL Annexes from the

ITU standards.

³ A is ADSL service functioning over POTS.

³ B activates the ADSL functionality over ISDN.

³ L Mask 1 assumes an increase in ADSL2 range/distance.

³ L Mask 2 also extends the signal reach but can show an

improvement in the upstream data rate.

³ M allows increased upload speeds from 1 Mbps to 3.5 Mbps.

Available only for ADSL2 and ADSL2+.

³ Targ e t SNR is the desired signal-to-noise ratio ranging from 0 to 31 dB.

Default value is 6 dB.

56 AXS-200/610

Page 63

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

³ Technology lists the following values: ADSL2+, ADSL2, or ADSL. If

Annex L is previously selected, ADSL2 is automatically set. If Annex M,

ADSL is not available.

³ Recalculate button allows you to change the setup and re-evaluate the

rates.

To re-set parameters to view different results:

1. Press the up/down or left/right arrow keys to highlight the desired

parameter.

2. Press to display the list or select the value.

3. Press the up/down arrow keys to highlight the desired value.

OR

4. Press the left arrow key to erase the existing value, and then use the

alphanumeric keypad to enter a value. To cancel the entry, press .

5. Press to accept the value.

6. Press the up/down arrow keys to highlight the Recalculate button.

7. Press to recalculate rates for the new setup.

Copper Test Module 57

Page 64

Auto CQ/Video-DSL Rate Prediction

Running Video-DSL Rate Prediction Tests and Viewing Results

Signal-to-Noise Ratio

The SNR tab displays the

signal-to-noise ratio per tone in

graphical form.

The list and buttons on the tab are

described below:

³ (Zoom function List) allows you to

select the desired zoom function:

Horizontal Zoom or Vertical

Zoom. The selected function is

displayed in the box.

³ Zoom In allows you to increase the level of zoom for the selected

zoom function.

³ Zoom Out allows you to reduce the level of zoom for the selected

zoom function.

To zoom in or out:

1. Press to display a list of zoom functions.

2. Press the up/down arrow keys to highlight the desired zoom function.

3. Press to select the zoom function.

4. Use the left/right arrow keys to highlight the Zoom In or Zoom Out

button as required, then press .

The graphical display zooms in or out accordingly.

5. Press repeatedly to continue zooming.

To move the screen pointer:

Press the left/right arrow keys to move the screen pointer. The pointer

value updates dynamically.

58 AXS-200/610

Page 65