Eschmann T-20 Service manual

T20-a

OPERATION TABLE

manual Service

111707 |

T-SM47j |

Preliminary

Information

Technical data

Technical description

Safety notes

Maintenance

Part removal adjustment replacement

Read these Instructions before use

Keep these ‘Instructions’ in a safe convenient place for future reference. Read in conjunction with the Publications detailed in Section 1.1.

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and assistance during normal office hours. To avoid delays when making enquiries, please quote the Model and Serial Number of your Operation Table which is shown on the Serial Number plate, the location of which is shown below. Please ensure you include all alpha and numeric digits of the Serial Number.

The Serial Number plate is located here

Service manual

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England. Tel: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limited. “Eschmann Equipment” is a trading name ofEschmann Holdings Limited.

“T20-a” is trade mark of Eschmann Holdings Limited.

Patents : Worldwide Patents Pending.

Copyright © 2005 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying, recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however, reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

T-SM47j July 2005

CONTENTS

1.0Preliminary information

1.0 |

Preliminary information . . . . . . . . . . . . . . . . . . . |

5 |

2.0Technical data

2.1 Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.3 Movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.4 Table loading . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.5 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 2.6 Classification and symbology . . . . . . . . . . . . . . 9 2.7 Use in conjunction with other equipment . . . . . . 9 2.8 Standards compliance . . . . . . . . . . . . . . . . . . . . 9 2.9 Environmental conditions . . . . . . . . . . . . . . . . . . 9

3.0Technical description

3.1 Power supply assembly . . . . . . . . . . . . . . . . . . 13 3.2 Control electronics . . . . . . . . . . . . . . . . . . . . . . 13 3.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 13 3.2.2 Handset overview . . . . . . . . . . . . . . . . . . . . 14

4.0Safety warnings

4.1 |

‘Service position’ . . . . . . . . . . . . . . . . . . . . . . . |

16 |

4.2 |

Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

4.3 |

M10 trunk screw removal . . . . . . . . . . . . . . . . |

16 |

4.4 |

Trend and tilt actuator removal . . . . . . . . . . . . . |

16 |

4.5 |

Working with mains voltage . . . . . . . . . . . . . . . |

16 |

4.6 |

Gas springs . . . . . . . . . . . . . . . . . . . . . . . . . . . |

16 |

4.7 |

Hot parts on PCAs . . . . . . . . . . . . . . . . . . . . . |

16 |

4.8 |

Biological contamination . . . . . . . . . . . . . . . . . |

16 |

4.9 |

Connection of leads . . . . . . . . . . . . . . . . . . . . . |

16 |

4.10 |

Leaking batteries . . . . . . . . . . . . . . . . . . . . . . . |

16 |

5.0Maintenance

5.1 |

Power supply assembly . . . . . . . . . . . . . . . . . . |

17 |

5.2 |

Table fault finding . . . . . . . . . . . . . . . . . . . . . . . |

17 |

|

5.2.4 Break motion control . . . . . . . . . . . . . . . . . |

17 |

|

5.2.5 Trunk section connector blocks . . . . . . . . . |

17 |

5.3 |

Fuse location . . . . . . . . . . . . . . . . . . . . . . . . . . |

17 |

5.4 Service schedule and safety check . . . . . . . . . |

18 |

|

6.0Part removal/adjustment/ replacement

6.1 General |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

6.2 Table base and column covers . . . . . . . . . . . . |

20 |

|

6.2.2 Base covers . . . . . . . . . . . . . . . . . . . . . . . . |

20 |

|

6.2.2.1 Removal of base covers . . . . . . . . . . |

20 |

|

6.2.2.2 |

Replacing base covers . . . . . . . . . . . |

21 |

6.2.3 Access to column . . . . . . . . . . . . . . . . . . . . |

21 |

|

6.2.3.2 |

Lower column access . . . . . . . . . . . . |

21 |

6.2.3.3 |

Lower-mid column access . . . . . . . . |

21 |

6.2.3.4 |

Upper-mid column access . . . . . . . . |

21 |

6.2.3.5 Top of column access . . . . . . . . . . . . |

23 |

|

OPERATION TABLE

6.2.4 Telescopic covers . . . . . . . . . . . . . . . . . . . . 23 6.2.4.1 Removal of telescopic covers . . . . . . 23

6.2.4.2Refitting the telescopic covers . . . . . 23

6.2.5 Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 6.2.5.1 Removal of the bellows . . . . . . . . . . . 23 6.2.5.2 Replacing the bellows . . . . . . . . . . . . 24

6.3 Table base components . . . . . . . . . . . . . . . . . . |

24 |

||

6.3.2 |

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

6.3.3 |

Pedal dampers . . . . . . . . . . . . . . . . . . . . . . |

24 |

|

6.3.4 |

Front wheels . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

6.3.5 |

Castors . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

6.3.5.1 |

Castor assembly . . . . . . . . . . . . . . . . |

25 |

|

6.3.5.2 |

Castor wheels . . . . . . . . . . . . . . . . . . |

25 |

|

6.3.6 |

Brake pads . . . . . . . . . . . . . . . . . . . . . . . . |

25 |

|

6.3.7 |

Castor pillar bushes . . . . . . . . . . . . . . . . . |

29 |

|

6.3.8 |

Pedal spindle bushes . . . . . . . . . . . . . . . . |

29 |

|

6.3.9Lifting roller assembly.. . . . . . . . . . . . . . . . 29

6.3.10 Pedal catch block . . . . . . . . . . . . . . . . . . . 29 6.3.11 Pedal anti-skid pads . . . . . . . . . . . . . . . . . 29 6.3.12 Pedal catch pawl and spring . . . . . . . . . . . 29

6.4 |

Table column components . . . . . . . . . . . . . . . . |

30 |

|

|

6.4.2 Trendelenburg actuator . . . . . . . . . . . . . . . . |

30 |

|

|

6.4.3 Tilt actuator . . . . . . . . . . . . . . . . . . . . . . . . . |

30 |

|

|

6.4.4 Telescopic column assembly . . . . . . . . . . . . |

30 |

|

|

6.4.5 Tilt & Trendelenburg motor . . . . . . . . . . . . . . |

32 |

|

|

6.4.6 Tilt bush . . . . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

|

6.4.7 Trendelenburg bush . . . . . . . . . . . . . . . . . . . |

32 |

|

|

6.4.8 Bearing pads . . . . . . . . . . . . . . . . . . . . . . . . |

32 |

|

6.5 |

Table sections . . . . . . . . . . . . . . . . . . . . . . . . . |

33 |

|

|

6.5.1 Head and leg section . . . . . . . . . . . . . . . . . |

33 |

|

|

6.5.1.1 |

Guide pins . . . . . . . . . . . . . . . . . . . . |

33 |

|

6.5.1.2 |

Gas springs . . . . . . . . . . . . . . . . . . . |

33 |

|

6.5.1.3 |

Top cover . . . . . . . . . . . . . . . . . . . . . |

33 |

|

6.5.1.4 Gas spring release head/pin . . . . . . . |

33 |

|

|

6.5.1.5 Gas spring release handle . . . . . . . . |

35 |

|

|

6.5.1.6 |

X-ray translucent top . . . . . . . . . . . . |

35 |

|

6.5.2 Trunk sections . . . . . . . . . . . . . . . . . . . . . . . |

35 |

|

|

6.5.2.1 |

Traverse motor . . . . . . . . . . . . . . . . . |

35 |

|

6.5.2.2 |

Traverse drive belt . . . . . . . . . . . . . . |

36 |

|

6.5.2.3 |

Break motor . . . . . . . . . . . . . . . . . . . |

36 |

|

6.5.2.4 |

Break gearbox . . . . . . . . . . . . . . . . . |

36 |

|

6.5.2.5 |

Side rails . . . . . . . . . . . . . . . . . . . . . |

39 |

|

6.5.2.6 |

Top covers . . . . . . . . . . . . . . . . . . . . |

39 |

|

6.5.2.7 |

Push button components . . . . . . . . . |

39 |

|

6.5.2.8 |

Traverse rod bearing . . . . . . . . . . . . . |

39 |

|

6.5.2.9 Drive belt guide bearing . . . . . . . . . . |

41 |

|

|

6.5.2.10 |

Attachment blocks . . . . . . . . . . . . . . |

41 |

|

6.5.2.11 |

Black tops . . . . . . . . . . . . . . . . . . . . |

41 |

6.6 Electrical components . . . . . . . . . . . . . . . . . . . 41 6.6.2 Three actuator PCA . . . . . . . . . . . . . . . . 42 6.6.3 Four actuator PCA . . . . . . . . . . . . . . . . . 42 6.6.4 Infrared receiver PCA . . . . . . . . . . . . . . 42 6.6.5 Power supply assembly . . . . . . . . . . . . . 43 6.6.6 Traverse motor . . . . . . . . . . . . . . . . . . . . 43

(continued over page)

T-SM47j |

P3/54 |

|

6.6.7 |

Break motor . . . . . . . . . . . . . . . . . . |

. . . . 43 |

Figures |

|

|

|

|

6.6.8 |

. . . .Tilt and Trendelenburg motors |

. . . . 43 |

|

|

|

|

|

6.6.9 |

Telescopic column assembly . . . . . |

. . . . 43 |

1.0 |

Identification of main parts . . . . . . . . . . . . |

. . |

. . . 6 |

|

6.6.10 |

Break potentiometer loom . . . . . . . . |

. . . 43 |

2.1 |

Major dimensions and movements . . . . . . |

. . |

. . 10 |

|

6.6.11 |

Tilt potentiometer loom . . . . . . . . . . |

. . . 43 |

2.2 |

Maximum patient weights . . . . . . . . . . . . |

. . |

. . 11 |

|

6.6.12 |

Trendelenburg potentiometer . . . . . . |

. . . 43 |

2.3 |

Maximum patient weights |

|

12 |

|

6.6.13 |

Height potentiometer loom . . . . . . . . |

. . . 43 |

. . |

|||

|

6.6.14 |

Traverse motor loom & m’switches . . |

. . . 45 |

3.1 |

Schematic diagrams . . . . . . . . . . . . . . . . |

. . |

. . 15 |

|

6.6.15 |

Connector blocks & looms . . . . . . . . |

. . . 45 |

6.1 |

Table covers general arrangement . . . . . . |

. . |

. . 22 |

|

6.6.16 |

Switch & accessory panel looms . . . |

. . . 45 |

6.2a |

Table base general arrangement (ext’l catch) |

. . 26 |

|

|

6.6.17 |

Column energy chain and loom . . . . |

. . . 45 |

6.2b |

Table base general arrangement (int’l catch) . |

. . 27 |

|

|

6.6.18 |

Break gearbox loom . . . . . . . . . . . . . |

. . . 46 |

6.2c |

Table base general arrangement (int’l catch |

|

|

|

6.6.19 |

Batteries, table & handset . . . . . . . . |

. . . 46 |

|

and increased height) . . . . . . . . . . . . . . . . . |

. |

. . 28 |

|

6.6.20 |

Fuses . . . . . . . . . . . . . . . . . . . . . . . |

. . . 46 |

6.3 |

Table column general arrangement . . . . . . . |

. |

. . 31 |

|

6.6.21 |

Table infrared code change . . . . . . . |

. . . 46 |

6.4 |

General arrangement, head & leg section. . . . . 34 |

||

|

6.6.22 |

Infrared handset code change . . . . . |

. . . 46 |

6.5 |

Table long trunk general arrangement . . . . . |

. . |

. 37 |

|

6.6.23 |

Handset service . . . . . . . . . . . . . . . . |

. . . 47 |

6.6 |

Table short trunk general arrangement |

|

38 |

|

6.6.24 |

Processor PCA . . . . . . . . . . . . . . . . |

. . . 47 |

. . |

|||

|

6.6.25 |

Standby panel and loom . . . . . . . . . |

. . . 47 |

6.7 |

Table traverse general arrangement . . . . . . |

. . |

. 40 |

|

6.6.26 |

Battery management reconditioning |

. . . . 47 |

6.8 |

Table base main electrical components . . . |

. . |

. 42 |

6.7 |

Function tests |

47 |

6.9 |

Handset button functions and serial labels . |

. . |

. 44 |

|

6.10 |

Old and new infrared Handset buttons . . . . |

. . |

. 44 |

||||

|

6.7.1 |

Batteries . . . . . . . . . . . . . . . . . . . . . |

. . . 47 |

A1 |

T20-a Schematic diagram - Base Section |

. . . . 51 |

|

|

6.7.2 |

Battery charger . . . . . . . . . . . . . . . . |

. . . 47 |

A2 |

T20-a Schematic diagram - Pedestal Section . |

. 52 |

|

|

6.7.3 |

Corded handset . . . . . . . . . . . . . . . . |

. . . 47 |

A3 |

T20-a Schematic diagram - Trunk Section |

. . . . 53 |

|

|

6.7.4 |

Infrared handset . . . . . . . . . . . . . . . . |

. . . 47 |

|

|

|

|

|

6.7.5 |

Footswitch control . . . . . . . . . . . . . . |

. . . 47 |

Appendix 1 |

|

|

|

|

6.7.6 |

Standby control panel . . . . . . . . . . . |

. . . 47 |

|

|

||

|

|

|

|

|

|||

|

6.7.7 |

Sections (head and leg) . . . . . . . . . . |

. . . 47 |

Torque conversions . . . . . . . . . . . . . . . . . . . . . . . |

. . |

. 49 |

|

|

6.7.8 |

Base pedals . . . . . . . . . . . . . . . . . . . |

. . . 48 |

|

|

|

|

|

6.7.9 |

Cycle of movements . . . . . . . . . . . . |

. . . 48 |

Appendix 2 |

|

|

|

6.8 |

. . . . . . . . . . . . . . . . . . . . . . . .Accessories |

. . . 48 |

Application software guide . . . . . . . . . . . . . . . . . . |

. . |

. 50 |

||

|

|

|

|

Appendix 3 |

|

|

|

|

|

|

|

T20-a Table schematics . . . . . . . . . . . . . . . . . . . . |

. . |

. 51 |

|

|

|

|

|

Appendix 4 |

|

|

|

|

|

|

|

Electrical safety checks . . . . . . . . . . . . . . . . . . . . |

. . |

. 54 |

|

P4/54 |

T-SM47j |

1.0PRELIMINARY INFORMATION

WARNING

Before servicing this operation table the engineer should be familiar with all the warnings and cautions contained within the ‘Instructions for use’ detailed in section 1.1.

This service manual does not provide details of how to operate the table nor does it provide information on the symbols and warning signs provided on the table. All this information is in the ‘Instructions for use’ supplied with the table. Additional copies of the ‘Instructions for use’ can be obtained from Eschmann Equipment.

Only qualified and trained engineers should service or maintain this operation table to ensure that all the built-in safety features are not compromised.

1.1 This Service Manual should be referred to for details of the T20-a Powered Operation Table, Serial Number (SN)

T2AA3A0000 or above: |

|

|

REF T20-223-2301* |

& T20-108-2301* |

|

REF T20-221-2301 |

& |

T20-106-2301 |

REF T20-221-2101 |

& |

T20-106-2101 |

* These models have Denyer style accessory side rails.

The related publications listed below provide additional information.

T-IM102 (111701) - Instructions for use T-IPL35 (111706) - Illustrated parts list

T-IM94 (111012) - ‘T’ SeriesApplication software manual T-IM56 (698907) - General accessory leaflet

The number in brackets above, is the part number for that publication.

1.2‘Instructions for use’ and ‘Service manuals’ should be readily accessible for reference prior to and when operating, cleaning, servicing, or, maintaining the operation table.

1.3The table and all accessories are not supplied sterile therefore the table and all accessories should be cleaned and disinfected in line with hospital practice and the information supplied in the ‘Instructions for Use’ before use.

1.4The manuals listed above and the Application software, are available to order from Eschmann Equipment, see inside front cover for address details.

1.5Make sure that routine servicing is carried out as detailed in the service schedule, section 5.4, by Eschmann trained or accredited engineers.

1.6The service schedule provided in this manual details a program of maintenance work to be carried out at six monthly intervals, refer to the applicable section of this

OPERATION TABLE

manual for details of how to perform these various functions. Any special adjustments required for components are detailed in the part replacement (section 6.0) for that item to save duplication. As routine the Service Schedule should be followed in the event of an additional service due to a fault developing with any aspect of the table, this will ensure that all aspects of the table are covered.

WARNING

Ensure that the correct screw torque settings are used as detailed within this manual to ensure safety and that parts are not damaged.

1.7Throughout this manual there are recommended torque settings for many of the screws. In the main, these are only provided on the illustrations. Ensure that these are checked and the correct torque settings are used where specified. These are provided to ensure safety (i.e. screws are tightened correctly) and that components are not damaged by excessively high torques.

1.8Fig. 1.0 identifies the main parts of the T20-a operation table.

1.9The table can be placed into a ‘Service Position’ that provides easy access to components within the ‘top of column’ area (ensure table is switched ‘off’ before opening top). To achieve this position first note the safety warning in section 4.1. Remove as much as possible from the table top (e.g. leg and head sections, accessories and mattresses etc.). Remove the top of column steel covers (items 13 and 14 of Fig. 6.1). Remove the four M10 screws (each side) that secure the trunk sections to the pedestal (not the M6 cap head screws that can be seen passing through the oilite bushes on each side) and allow the trunk section to pivot (short trunk down) about the oilite bush pivots (item 16, Fig. 6.3). Extreme care should be taken at all times with the table in this position, especially during transition into and out of the ‘Service Position’. Use tool number T2203 to maintain contact between the connector blocks if required when the table is in the ‘Service Position’. When returning the table out of the ‘Service Position’ ensure the eight M10 screws are tightened to the correct torque and that the covers are replaced.

1.10The ‘Instructions for use’ (provided with the table) contain all the cleaning, disinfection and care instructions, consult this for these aspects as they are not duplicated in this manual.

CAUTION

Continued use of the table batteries when ‘critically low’ can damage the batteries. Charge batteries regularly to maintain peak performance. Do not remove the table from charge until both charging LED’s are ‘green’ to avoid false battery level indication on the handset.

T-SM47j |

P5/54 |

NOTE: The table illustrated has external pedal locking catches. Some tables have internal locking catches, see section 6.2 and 6.3 for details.

Fig. 1.0 Identification of main parts

P6/54 |

T-SM47j |

OPERATION TABLE

Key to Fig. 1.0

1Head section

2Long trunk section

3Short trunk section

4Leg section

5Leg section gas spring

6Short trunk section release button

7Long trunk section release button

8Battery fuses

9Wheel foot pedal

10Head section release bar

11Head section gas spring

12Standby control panel

13Base

14Pedestal

15Castor foot pedal

16Leg section release bar

17Mains fuses

18Connection socket for mains (ONLY use Eschmann mains cord, Part No. 391177)

19Main battery charging state LED:

|

Red |

= |

Mains ‘on’, batteries in ‘bulk’ charge |

|

Amber |

= |

Mains ‘on’, batteries in ‘top-up’ charge (duration 2 hours) |

|

Green |

= |

Mains ‘on’, batteries in ‘trickle’ charge (i.e. fully charged) |

20 |

Standby battery charging state LED (colour code as main battery above) |

||

21 |

Main table ‘On/Off’ switch ( = Off, = On) |

||

22Connection socket for Eschmann footswitch (ONLY)

23Table ‘On’ LED (green)

Bright |

= |

Table in use, micro-controllers active |

Dim |

= |

Table ready for instant use but in battery save (sleep) mode |

24Connection socket for Eschmann handset (ONLY)

25Head and leg section end blocks (use to stow UK handset)

26Accessory side rails (can also be used to stow handset*)

27Standby battery switch

* Clip on handset must match side rail type, see ‘Instructions for Use’.

Note: For location of the Serial Number plate see inside front cover.

T-SM47j |

P7/54 |

2.0TECHNICAL DATA

2.1Weights

The nominal weights of the standard table components are listed below (for 50mm mattresses):

Leg section (without mattress) |

.. |

.. 11.50kg |

||

Leg section mattress .. |

.. |

.. |

.. |

2.75kg |

Head section (without mattress) |

.. |

.. |

7.75kg |

|

Head section mattress |

.. |

.. |

.. |

2.00kg |

Table (base and column only) |

|

.. |

192.00kg |

|

Long and short trunk assembly* |

.. |

|

55.75kg |

|

Long and short trunk mattress |

.. |

.. |

7.25kg |

|

Total weight standard table .. |

.. |

.. |

279kg |

|

Lightweight leg section.. |

.. |

.. |

.. |

4.50kg |

Footrest (incl. mattress) |

.. |

.. |

.. |

7.00kg |

Width extender (incl. mattress) |

.. |

.. |

6.00kg |

|

Perineal instrument tray |

.. |

.. |

.. |

3.00kg |

*(without mattress)

2.2Dimensions

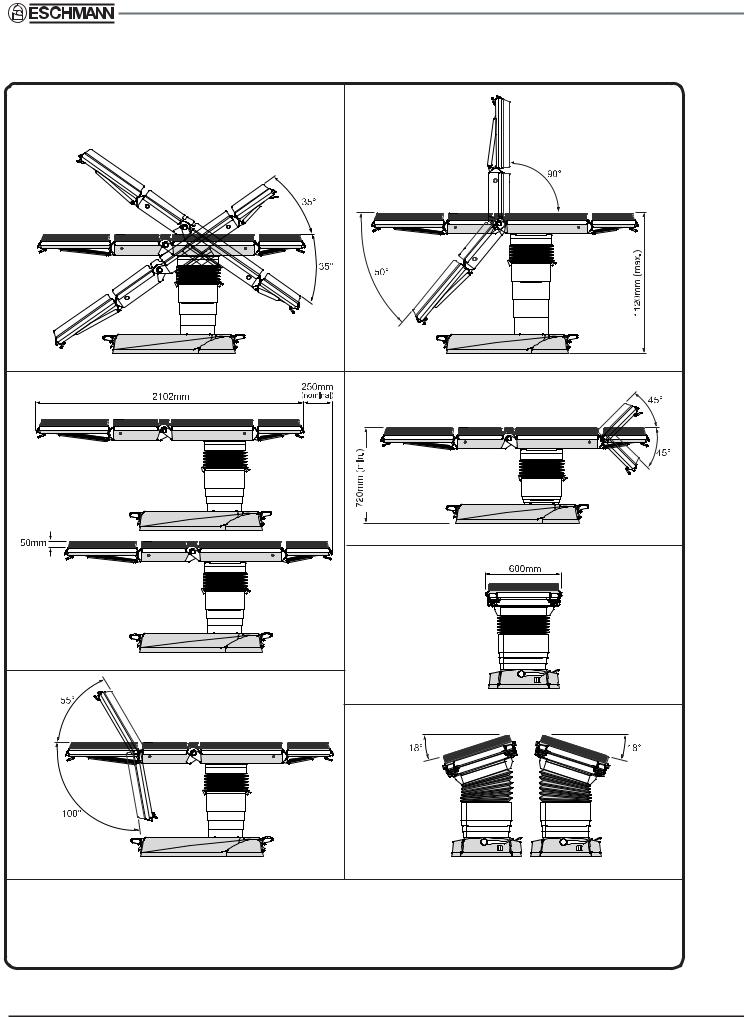

The following are the nominal major dimensions of the standard table (with head and leg sections fitted) and include the 50mm mattress and side rails if applicable (see Fig. 2.1 for illustration, the number in brackets after the item details which part):

Overall length (2) |

.. |

.. |

.. |

2102mm |

Maximum height (4) .. |

.. |

.. |

1120mm* |

|

Minimum height (5) .. |

.. |

.. |

720mm* |

|

Maximum top traverse (2) .. |

.. |

250mm |

||

Overall width (6) |

.. |

.. |

.. |

600mm |

Sidebars (Denyer) |

.. |

.. |

.. 37.8 x 5.5mm |

|

* 5mm less for Serial Numbers prefixed T2AA or T2AB

2.3Movements

The following table movements are maximums and cannot be assumed to be available in all combinations of table positioning (see Fig. 2.1 for illustration, the number in brackets after the item details which part). For example, with the table in its normal configuration and at minimum height the maximum Trendelenburg and leg section movements cannot be achieved due to the proximity of the floor. Similarly with a large amount of tilt set, maximum Trendelenburg cannot be achieved.

Max. Trendelenburg (1) |

.. |

.. |

.. |

35° |

|

Max. reverse Trendelenburg (1) |

.. |

.. |

35° |

||

Max. extension (4) |

.. |

.. |

.. |

.. |

230° |

Max. flexion (4) .. |

.. |

.. |

.. |

.. |

90° |

Head section (5) |

.. |

.. |

.. |

.. |

±45° |

Leg section (3) .. |

.. |

.. |

.. |

-100° |

+55° |

Max. lateral tilt (7) |

.. |

.. |

.. |

.. |

±18° |

2.4Table loading

See maximum patient weight distribution charts in Fig. 2.2 and 2.3 for various table positions and orientations.

Maximum section loading is stated on each item and is detailed below for reference:

Leg section |

.. |

.. |

44kg |

Head section |

.. |

.. |

22kg |

For accessories the maximum loading is stated on each item and detailed in the User Handbook supplied with them.

For specific notes on the obese patient see the ‘Instructions for Use’.

2.5Electrical

2.5.1Antistatic requirements

The table has an antistatic pathway from the table top, through an internal resistor, to the castors.

CAUTION

To complete and maintain the antistatic pathway the table must be used on an electrically conductive or antistatic floor and with mattresses supplied by Eschmann Equipment.

2.5.2Batteries

Table base:

Main batteries**:

Two, 12V 10.0Ah, sealed lead acid Backup batteries**:

Two, 12V 1.2Ah, sealed lead acid (see battery disposal caution in the ‘Instructions for Use’)

Infrared handset:

Two, 1.5V size AA Alkaline (Note: Must only be changed in accordance with the notes in the section

6.6.19.2 to ensure the IP rating is not compromised).

2.5.3Internal battery charger**

Input

100-240V a.c. 2.4A (max) 50-60Hz

Output

29.2V d.c. 2A (max.) when charge state LED red or orange, 27.6V d.c. when charge state LED green

2.5.4Fuses

2.5.4.1External fuses

Mains input fuses (item 17, Fig. 1.0)

2 x T4A (5 x 20mm) 250V

Battery fuses (item 8, Fig. 1.0)

2 x T20A (6.35 x 32mm) 500V

P8/54 |

T-SM47j |

OPERATION TABLE

Note: The right hand fuse is linked to the main batteries and the left hand fuse (i.e. nearest to the backup battery switch) is linked to the backup batteries.

2.7Use in conjunction with other equipment

Mains plug fuse |

|

||

|

.. |

.. |

10A (type is dependent on plug |

which may have been changed from that originally |

|||

supplied) |

|

|

|

2.5.4.2 |

Internal fuses** (only accessible by engineer) |

||

Battery fuses** (joining each battery pair)

2 x 30A blade type* (1 per battery pair)

2.5.5Duty cycle

This symbol is used to indicate the table’s duty cycle which, in the worst case, is ‘60s : 600s’, the ratio of the operating time to the sum of the operating time and the ensuing interval (see note below). Each motor drive has its own duty cycle and this is dependent on loading and table position as detailed below.

This symbol is used to indicate the table’s duty cycle which, in the worst case, is ‘60s : 600s’, the ratio of the operating time to the sum of the operating time and the ensuing interval (see note below). Each motor drive has its own duty cycle and this is dependent on loading and table position as detailed below.

Trendelenburg 1 : 4 (60s : 240s) at a maximum torque of 417Nm (e.g. 135kg load offset 31cm from the fulcrum, or a 300kg load offset 14cm from the fulcrum. Where this load is the patient and accessories weight and the offset is how far the loads centre of gravity is, from the centre of the column).

Traverse 1 : 4 (60s : 240s) when the table is horizontal and at the maximum load of 300kg, or at 17.5° with a patient weight of 225kg, or at 35° with a patient weight of 150kg.

Break |

1 : 10 (60s : 600s) at maximum patient |

||

weight of 300kg. |

|

|

|

Height |

1 : 4 (60s |

: 240s) |

at maximum patient |

weight of 300kg (not offset). |

|

||

Tilt |

1 : 4 (60s |

: 240s) |

at maximum patient |

weight of 300kg. |

|

|

|

Note: The duty cycles above are all for the worst case (i.e. maximum loads). For reduced loading the above duty cycles can be increased.

2.6Classification and symbology

All the symbols used on this table are shown and explained in the ‘Instructions for Use’. These detail the safety category and class of this table as marked on the table or section by the use of these symbols.

2.7.1Electrosurgical equipment (h.f.)

The T20-a operation table has been designed to minimise the possibility of accidental electrosurgery burns and can be used in conjunction with electrosurgical equipment. However, contact with any metal surfaces (e.g. table side bars, or other equipment etc.) can cause burns during electrosurgery and must be avoided.

2.7.2Defibrillation equipment

With the mains cord attached the equipment has defibrillator proof applied parts with type BF protection against electric shock.

2.7.3Other

When the T20-a is used in conjunction with other infrared controlled devices, their controllers should be checked to ensure that no interference between them and the T20-a is possible, prior to surgical intervention. Also see the ‘Instructions for Use’.

2.8Standards compliance

The table has been designed and built to comply with the following international standards:

BS EN 60601-1: 1990 (issue 2, October 1997) BS EN 60601-1-2: 1993

BS EN 60601-2-46: 1998

BS EN 60601-1-4: 1997

2.9Environmental conditions

2.9.1Operating environment

The table has been designed to operate in the following environment:

Temperature range .. |

.. |

10°C to +40°C |

|

Pressure range .. |

.. |

.. |

69KPa to 106KPa. |

Humidity range .. |

.. |

.. |

30% to 75% RH |

|

|

|

non-condensing. |

2.9.2Transport & storage environment

The table can be transported and stored safely, in the following environment:

Temperature range .. |

.. |

-30°C to +50°C |

|

Pressure range .. |

.. |

.. |

69KPa to 106KPa |

Humidity range .. |

.. |

.. |

30% to 90% RH |

|

|

|

non-condensing. |

**NOTE: Items marked ** are to be changed with caution. During change or replacement they must only be disconnected for a maximum of 60 seconds. If battery power is removed from the table for longer than this then reconditioning of the battery management system must be carried out, see section 6.6.26.

T-SM47j |

P9/54 |

1 |

4 |

|

(see section 2.2) |

2 |

5 |

|

|

|

(see section 2.2) |

|

6 |

3 |

7 |

|

These are maximum movements for each aspect, they may not be available in certain combinations (e.g. maximum tilt and maximum Trendelenburg). Movements that could cause damage cannot be catered for (e.g. position of the leg section).

Fig. 2.1 Major dimensions and movements

P10/54 |

T-SM47j |

OPERATION TABLE

Fig. 2.2 Maximum patient weight v table position graphs

T-SM47j |

P11/54 |

Fig. 2.3 Maximum patient weight v table position graphs

P12/54 |

T-SM47j |

OPERATION TABLE

3.0TECHNICAL DESCRIPTION

See Fig. 3.1 and Appendix 3 for schematic diagrams.

3.1Power supply assembly

This assembly (Part number 111765) which is located in the table base, has no user serviceable parts and must be changed as a complete unit. The assembly includes, a Battery charger loom, a Battery charger module, a Battery management PCA, a Battery connector loom, a Chassis plate, two Battery support brackets, a Switch, two Fuses (32 x 6.35mm 20A ‘T’ type), two Fuse holders, two battery pairs and all connections, cable ties and screws etc.

3.2Control electronics

3.2.1Overview

The control electronics for the T20-a is distributed between two PCA’s (the ‘4 actuator PCA’ and the ‘3 actuator PCA’). These two PCA’s contain three distinct microprocessor daughter PCAs (two on the ‘4 actuator PCA’ and one on the ‘3 actuator PCA’).

The ‘4 actuator PCA’ (111524) is located on the column and includes the ‘main controller’ and the ‘4 actuator controller’. Each of these ‘controllers’ consists of a ‘microprocessor daughter PCA’ (111526) which have their control electronics on the ‘4 actuator PCA’.

The ‘Three actuator PCA’ (111525) is located in the long trunk section of the table and contains the ‘3 actuator controller’, another ‘microprocessor daughter PCA’ (111526) with its control electronics on the ‘Three actuator PCA’.

3.2.1.1Microprocessor daughter PCAs

The daughter PCAs consist of a Motorola MC68HC912B32 micro controller, a watchdog circuit, an RS232 line driver and an SPI UART and RS485 line driver. All the micro controllers on the T20-a require these components. The RS232 communications can be used to provide a telemetry link to custom software running on a PC. Once fitted to their respective controller boards the micro controllers are programmed with the appropriate software application.

There is a ‘main controller application’ (110442) and an ‘actuator controller application’ (110443). Both the 4- actuator and 3-actuator are programmed with the same ‘actuator controller application’ (110443). A configuration file is then downloaded to each micro controller that specifies which controllers are present on which board. It is possible to configure any actuator to any board, however the configuration of the electronics is specific to each actuator.

3.2.1.2The ‘main controller’

The ‘main controller’ provides the control and supervisory functions for the table. This consists of the interface to the infrared handset, corded handset (via RS232), footswitch and standby panel. It also controls the table power LED.

The main controller communicates with the two actuator controllers (one of which is co-located on the 4 actuator PCA) by means of an RS485 multi-drop bus. This system enables multiple slave controllers to be attached at any time. The main controller issues a health check poll message to each of the actuators (up to four of which can be controlled by the single PCA) to ensure that they are functioning correctly.

When a command is received from any of the user-input devices the main controller issues the appropriate movement commands to the required actuator (or actuator groups in the case of combined movements).

3.2.1.3The ‘4 actuator PCA’

The ‘4 actuator PCA’ is responsible for movement of four actuators on or within the table’s column. These are the ‘top and bottom height actuators’ inside the column assembly, the ‘Trendelenburg actuator’ and the ‘Tilt actuator’ mounted on the column. A number of signals control the movement of each actuator.

A PWM signal is used to set the speed of the motor; digital signals control direction (forward/reverse), a digital signal enables the drive circuit and another digital signal effects a brake on the motor by shorting the windings together. The electronics provide a digital fault signal to indicate when there is a problem with the control circuit, or an over current situation has occurred. An analogue signal is also provided on all but the ‘bottom height actuator’. The analogue signal on the top height actuator is the output from a potentiometer that indicates the combined position of the height actuators. Although the column contains two motors, there is only a single potentiometer to indicate the height of the column. This analogue signal is fed to the ‘top height actuator’; the’ bottom height actuator’ is effectively slaved to the top.

3.2.1.4The ‘Three actuator PCA’

The ‘Three actuator PCA’ is responsible for movement of the three actuators within the tables long and short trunk sections. These are the ‘left break actuator’, ‘right break actuator’ and the ‘traverse actuator’. These actuators are controlled by the same signals as on the ‘4 actuator PCA’. In terms of feedback, both the ‘left and right break actuators’ have potentiometers and the ‘traverse actuator’ has limit switches which open when the long trunk reaches either end of its movement. The ‘left and right break actuators’ are independently controlled to move at a set speed and to maintain a minimum deviation between them.

T-SM47j |

P13/54 |

3.2.2 Handset overview

There are two versions of handset, a cordless type (infrared handset) with an infrared emitter powered by 2 AA cells and a corded version (corded handset) with an RS232 link to the main processor on the ‘4 actuator PCA’. The latter version derives its power from the T20-a.

3.2.2.1Infrared handset

The 4 x 5 matrix keyboard is decoded using a proprietary keyboard decoder. This device is powered down and remains dormant until a key is pressed causing its clock oscillator to be initialised. The key is decoded and the 38kHz modulated signal is fed to the infrared LED via a FET. The whole system is powered via 2 AA batteries

3.2.2.2Corded handset

The 4 x 5 matrix keyboard is decoded using a proprietary keyboard decoder. This device is powered down and remains dormant until a key is pressed causing its clock oscillator to be initialised. The key is decoded and the 38kHz modulated signal is fed to a PIC processor. The processor decodes the output from the keyboard decoder into RS232. This output is fed to an RS232 line driver. The corded handset’s power is supplied directly from the T20-a, 5V power supply. The handset contains a DC-DC converter to supply 3.3V for the keyboard decoder. There are indicator LED’s to show the charge status of the table batteries (main and standby).

P14/54 |

T-SM47j |

OPERATION TABLE

PROCESSOR |

|

|

PROCESSOR |

COMMUNICATIONS |

CONTROL |

FET DRIVERS |

OVER |

||

|

|

INTERFACE |

||

|

|

CURRENT |

|

|

|

|

MANAGER |

|

12 |

|

|

|

|

|

|

POSITIONAL |

MOTOR |

44 |

4 |

|

FEEDBACK |

|

||

|

|

|

||

CONTROL FROM |

|

|

CONNECTOR 64 WAY |

|

|

|

|

|

|

HOST MICRO |

|

|

|

|

Basic control and feedback - all actuator drivers |

|

Processor PCA |

||

|

|

|

|

|

AXIS TILT |

|

|

|

|

AXIS TREND |

|

|

Keyboard |

Battery |

AXIS HEIGHT 1 |

|

POSITION ENCODERS AND |

|

|

AXIS HEIGHT 2 |

ANCILLARIES |

|

|

|

|

|

|

||

|

|

|

|

Power Management |

|

|

OVER CURRENT MANAGERS |

|

|

|

|

|

Keyboard Encoder |

|

POWER |

CONNECTORS |

|

|

|

MANAGEMENT |

INC: |

|

|

Infrared Driver / Emitter |

|

|

|

||

|

|

|

|

|

|

CONNECTORS & INTERFACES |

|

|

|

|

MICRO CONNECTORS |

|

|

|

|

|

|

Handset remote version |

|

|

Four Actuator PCA |

Keyboard |

Connector/Lead |

|

|

|

|

||

AXIS BREAK RIGHT |

|

|

|

|

AXIS BREAK RIGHT |

POSITION |

|

Power Management |

|

AXIS TRAVERSE |

MONITORS |

|

|

|

|

|

|

Keyboard Encoder |

|

|

|

OVER CURRENT |

|

Processor |

|

|

MANAGERS |

|

|

|

|

|

|

|

CONNECTORS |

|

|

|

|

POWER |

|

|

|

|

MANAGEMENT |

|

|

|

RS232 Decoder/Driver |

|

|

|

|

|

|

Three actuator PCA |

Handset corded version |

||

Fig. 3.1 Schematic diagrams

T-SM47j |

P15/54 |

4.0SAFETY WARNINGS

4.1‘Service position’

When the four M10 screws (each side) that secure the trunk sections to the pedestal are removed, to place the table in the ‘Service position’ as detailed in section 1.9, always take extreme care (and ensure table is switched ‘off’ before tilting top into or out off the ‘Service position’). When the M10 screws are removed the table trunk sections may tilt dramatically unless the sections are fully supported during screw removal. Always lower the trunk sections into (and out of) the ‘Service position’ slowly and always return the table trunk sections to the ‘normal’ position (taking care not to trap fingers) as soon as possible, replacing the eight M10 screws securely. Also remove the following before placing the table into the ‘Service position’:

Head section |

Leg section |

Trunk mattress |

All accessories |

When powering the table in the ‘Service position’ using tool T2203 (to connect the table top connector blocks) extreme care should be taken and powering the table in this position should be limited to essential testing only. It is preferable to return the table out of the ‘Service position’ before powering the table.

4.2Lifting

During some of the procedures detailed in this manual it is necessary to lift heavy assemblies. These are the long and short trunk assembly, the wrapround assembly and the telescopic assembly. These all require two people to lift safely and any procedure that requires these to be removed from the table should not be attempted if two people are not available. Other components although not heavy enough to require two people, should be handled using the correct lifting techniques to minimise personnel injury. It is advised that suitable protective footwear is worn when handling heavy parts.

4.3M10 trunk screw removal

When removing the four M10 (hexagonal head) screws that secure the trunk sections to the column, always ensure that precautions similar to those detailed in 4.1 above are taken. Remove all accessories, sections and trunk mattress and support the trunk sections during screw removal.

4.4Trend and tilt actuator removal

When the Trend and /or tilt actuators are removed the trunk sections will not be stable. Before removal follow similar precautions to those detailed in section 4.1. Remove all accessories, sections and trunk mattress and support the trunk sections during actuator removal. Replace the actuator as soon as possible.

4.5Working with mains voltage

The only time that it may be required to work with mains voltage applied to the table is whilst testing the battery charger. During this procedure ensure that normal safe

working procedures are employed for an activity that entails working with mains voltage, such as:

iReduce the amount of live work to the minimum possible.

iiUse common sense and stop working if approached, distractions can kill.

iiiEnsure the area is clear of all unnecessary personnel or warn people in the area to stay clear during live work. Also ensure that you are not entirely alone and that someone could come to your assistance if you should suffer an electric shock.

ivOnly use the correct equipment, probes and cables for the work in hand.

vMains power should be supplied via an RCD (residual current device).

viTurn off the mains power whenever possible to reduce risks.

4.6Gas springs

When removing or servicing the table head and leg sections gas springs refer to the warning in section 6.5.1.2. They do not require lubrication and do not attempt to open them. Also note the disposal notes provided in 6.5.1.2 (vii).

4.7Hot parts on PCAs

During service and when covers are removed note that parts of the PCAs can become hot enough to cause burns. Beware that touching these assemblies when hot could result in unexpected body movements.

4.8Biological contamination

During servicing of the table it is advised that protective gloves should be warn to avoid biological contamination. It is preferable that the table be cleaned and disinfected before service.

4.9Connection of leads

When connecting test leads to the table during service ensure that these do not constitute a tripping hazard.

4.10Leaking batteries

In the unlikely event of a battery leaking in the table base avoid spreading the contamination (sulphuric acid) and:

iWear suitable personnel protection (goggles, gloves etc.) do not smoke and avoid sparks.

iiUse a bonding agent such as sand, or sodium carbonate to absorb and neutralise the bulk of the electrolyte. Wash (and rinse well) the contaminated area with water, taking care not to splash electronics or any other table base components.

iiiDo not flush electrolyte into the sewer system but dispose of the used bonding agent and all cleaning materials in accordance with local waste regulations.

In the case of skin contact wash and rinse immediately with water. If splashed into eyes rinse well with water and seek medical advice. If acid mist is inhaled, inhale fresh air and seek medical advice.

P16/54 |

T-SM47j |

5.0MAINTENANCE

5.1Power supply assembly

This assembly (Part number 111765) which is located in the table base, has no user serviceable parts and must be changed as a complete unit (also see section 3.1).

5.2 Table fault finding

5.2.1The ‘Instructions for use’ contains a basic fault finding table that can be used to solve any minor problems. This covers the main user errors (i.e. there is no fault) that can occur when the user has not read and understood the ‘Instructions for use’. It also contains the first line of fault finding (i.e. check external fuses, try another handset, try another mains lead). The following section (5.2.2) provides a test sequence to help determine the fault (for the majority of faults that may occur) that could stop the table responding to an input via a control device. Mechanical faults are normally self evident in that a part is worn, damaged or broken. In this case refer to the appropriate section of this manual for part replacement information. Appendix 3 provides the schematic diagrammes that can also be used in fault finding.

5.2.2Follow the sequence below to identify most major faults that result in a lack of response to a control command:

1When the table is initially switched ‘on’ is the table ‘on’ LED (item 23 of Fig. 1.0) bright, dull or ‘off’ for the first few seconds.

If dull turn the table ‘off’ wait at least 10 seconds and then turn back on. If the LED is still dull or ‘off’ this indicates an electronics fault see 5.2.3.

If bright move to 2 below.

If it is flashing this also indicates an electronics fault see 5.2.3.

2Try the ‘standby control panel’ (any motion except Trendelenburg), if this fails try the ‘standby control panel’ with the backup battery switch depressed.

If the table works from the ‘standby control panel’ this indicates a fault with the control device or its connection to the table.

If the table works from the ‘standby control panel’ only when the backup battery switch is pressed this indicates a fault with the main batteries (replace the whole Power supply unit).

Now try Trendelenburg from the ‘standby control panel’, if this and only this motion works it indicates a problem with the main control PCA.

3If one of the motor groups ‘only’ has failed then this indicates a problem with its associated PCA as follows:

Break and traverse - Three actuator PCA

Tilt, Trend and Height - 4 Actuator PCA

This distinction may help in reducing the amount of diagnostics and cover removal.

OPERATION TABLE

4Remove covers and check battery fuses (see section 5.3.1 and 6.6.26). Also look to see if the PCA indicator lights are flashing ‘on’ for 1 second and ‘off’ for 1 second. If they are ‘off’ or flashing faster, this indicates an electronics fault see 5.2.3.

5If the fault is only apparent for one motion this could indicate a failed motor or failed sensor for that motion, or, an electronics fault. If the motion starts and then stops immediately this could indicate a failed sensor or an over current situation. Test motor (as detailed in section 6.6), if the motor works and no small movement is observed following a demand for that motion, it indicates an electronics fault, see 5.2.3.

5.2.3Electronic faults can only be determined with the table connected to a PC with the ‘T20 Application Software’ installed. Consult the Application Software Manual (as detailed in section 1.1) which provides guidance on fault diagnosis. Also note that when correcting electronic faults (and following some parts replacement) the table will require reprogramming, reconfiguring or recalibration. These aspects are also fully covered in the Application Software Manual.

5.2.4Break motion control

5.2.4.1The two break arms are independently controlled and are synchronised to operate within a programmed limit of each other. This control system can result in small variances that appear as a slight misalignment, this is acceptable and a part of the normal table control software routine. In the unlikely event that this deviation goes outside of the programmed limit the table break motion (only) will stop working. This can sometimes be corrected as below.

5.2.4.2Whilst observing the two break arms press (for approximately 0.5 seconds only) a break control button on the handset (B7 or B8 of Fig. 6.9) once or twice. If this makes the deviation worse press the other break control button as above once or twice. If the break motion still does not work correctly after this there could be a fault in one of the following:

Break motor

Break potentiometer Wiring to any of the above

Significant uneven table loading*

*This problem will only be evident during use and if investigated at service it will be difficult to reproduce.

5.2.5 Trunk section connector blocks

5.2.5.1 If all the top table functions stop working (e.g. break and traverse) the connector blocks (item 5, Fig. 6.7 and item 14, Fig 6.3) could be failing to connect correctly due to contamination etc. Check that a good contact is being made between the column and trunks connector blocks.

5.3 Fuse location

5.3.1 All fuse locations are identified in section 2.5.4 and Fig. 1.0. DO NOT REMOVE OR CHANGE INLINE BATTERY

FUSES UNLESS YOU HAVE READ SECTION 6.6.26.

T-SM47j |

P17/54 |

Loading...

Loading...