LS5/SES2555

& QuickVac

VACUUM & NON-VACUUM AUTOCLAVES

Service Manual

606023

ST-SM33l

Introduction

Description

Read these Instructions before use

Keep thIs ‘Service Manual’ in a safe convenient place for future reference.

Operating controls

& display

Autoclave

components

Operation cycle

Maintenance

Part removal

& replacement

Technical data

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquires, please quote the

Model and Serial Number of your Autoclave which is shown on the Serial Number plate, the

location of which is shown below. Please ensure you include all alpha and numeric digits of the

Serial Number.

The Serial Number

F

4

L

0

S

0

4

m

VA

A

C

6

U

9

U

6

M

plate is located here

1

8

1

1

S

3

N

A

L

2

S

x

4

3

5

8

B

1

0

5

9

0

0

R

9

0

3

9

E

2

4

-

F

0

5

6

8

3

4

5

6

7

6

2

3

0

V

4

.

4

A

E

s

c

5

h

0

m

-

a

6

n

n

0

P

E

H

e

q

t

u

e

z

i

r

p

R

m

o

e

a

n

W

d

t

,

,

e

L

s

a

t

n

S

c

u

i

s

n

s

g

e

,

x

,

E

n

B

g

N

la

1

n

5

M

d

8

A

T

D

J

.

E

I

N

E

N

G

L

A

N

D

789789-1

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

T el: +44 (0) 1903 765040. Fax: +44 (0) 1903 762006.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limited .

“Eschmann Equipment” is a trading name of Eschmann Holdings Limit ed.

“LS5”, “Little Sister”, “QuickV ac” and “SES2555” are t rade marks of Eschmann Holdings Limit ed.

Patents : Patents Pending plus - Pat. US5090033 and Pat. GB2238407

Copyright © 2003

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

If the CE mark is affixed to the product, it indicates compliance with Council Directive

93/42/EEC of 14 June 1993 concerning medical devices.

Service Manual

ST-SM33l September 2003

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

CONTENTS

1 Introduction

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Description

2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Operating controls & display

3 Operating controls & display . . . . . . . . . . . . . . . . . 4

Push buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Digital displays . . . . . . . . . . . . . . . . . . . . . . . . . 5

Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4 Autoclave components

4 Autoclave components . . . . . . . . . . . . . . . . . . . . . . 5

5 Operation cycle

5 Operation Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Cycle details

6 Cycle Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Maintenance

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

7.1 Special functions . . . . . . . . . . . . . . . . . . . . 12

7.2 Protected functions . . . . . . . . . . . . . . . . . . . 12

7.3 Errors and faults . . . . . . . . . . . . . . . . . . . . . 12

Power failure . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Aborted cycles and errors . . . . . . . . . . . . . . . . 12

Reset thermostat (overheat) . . . . . . . . . . . . . . 12

7.4 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . 13

7.5 LED Function test . . . . . . . . . . . . . . . . . . . . 13

7.6 Connections, air, water and electrical . . . . . 13

7.7 Safety checks (Weekly & Annual) . . . . . . . . 13

8.17 Gauze filter . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.18 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.19 Safety valve . . . . . . . . . . . . . . . . . . . . . . . . 33

8.20 Band heater temp. sensor . . . . . . . . . . . . . 33

8.21 Mains switch . . . . . . . . . . . . . . . . . . . . . . . . 33

8.22 Band heater . . . . . . . . . . . . . . . . . . . . . . . . 33

8.23 Chamber water level sensors . . . . . . . . . . . 33

8.24 Reset thermostat (overheat) . . . . . . . . . . . . 34

8.25 Cycling thermostat . . . . . . . . . . . . . . . . . . . 34

8.26 Thermal fuse . . . . . . . . . . . . . . . . . . . . . . . 34

8.27 Display board . . . . . . . . . . . . . . . . . . . . . . . 34

8.28 Mains fuse holders . . . . . . . . . . . . . . . . . . . 34

8.29 Membrane key pad . . . . . . . . . . . . . . . . . . . 34

8.30 Reservoir level sensor . . . . . . . . . . . . . . . . 34

8.31 Water pump . . . . . . . . . . . . . . . . . . . . . . . . 35

8.32 Test probe port and pressure gauge . . . . . . 35

8.33 Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

8.34 Band heater resettable thermostat . . . . . . . 35

8.35 Vacuum pump maintenance . . . . . . . . . . . . 35

8.37 Pressure door lock . . . . . . . . . . . . . . . . . . . 36

9 Technical data

9 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Parts lists

Parts list 1

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . 39 - 41

Parts list 2

Pipes and plumbing . . . . . . . . . . . . . . . . . . . . . 43

Parts list 3

General assembly . . . . . . . . . . . . . . . . . . 45 - 47

Tables

Table 1 Key to display A2 . . . . . . . . . . . . . . . . . . . . 10

Table 2 Special functions . . . . . . . . . . . . . . . . . . . . 15

Table 3 Protected functions . . . . . . . . . . . . . . . . . . . 17

Table 4 Fault diagnosis & error number details . . . . 22

Table 5 Protected function P7 quick reference . . . . 29

8 Part removal & replacement

8 Part removal & replacement . . . . . . . . . . . . . . . . . 30

8.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

8.2 Fuse renewal . . . . . . . . . . . . . . . . . . . . . . . 30

8.3 Cover removal & replacement . . . . . . . . . . 30

8.4 Chamber solenoid valves . . . . . . . . . . . . . . 31

8.5 Reservoir . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8.6 Mains transformer . . . . . . . . . . . . . . . . . . . 32

8.7 Power board . . . . . . . . . . . . . . . . . . . . . . . . 32

8.8 Door microswitches . . . . . . . . . . . . . . . . . . 32

8.9 Door lock/open solenoids . . . . . . . . . . . . . . 32

8.10 Door lock magnetic catch . . . . . . . . . . . . . . 32

8.11 Chamber temperature sensors . . . . . . . . . . 32

8.12 Heating element . . . . . . . . . . . . . . . . . . . . . 32

8.13 Door seal . . . . . . . . . . . . . . . . . . . . . . . . . . 32

8.14 Vacuum pump . . . . . . . . . . . . . . . . . . . . . . 33

8.15 Cooling fan . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.16 Bacterial air filter . . . . . . . . . . . . . . . . . . . . . 33

Figures

Fig.1a Control panel (SES2555/LS5) . . . . . . . . . 5 + 51

Fig.1b Control panel (SES2555/QuickVac) . . . . . 5 + 51

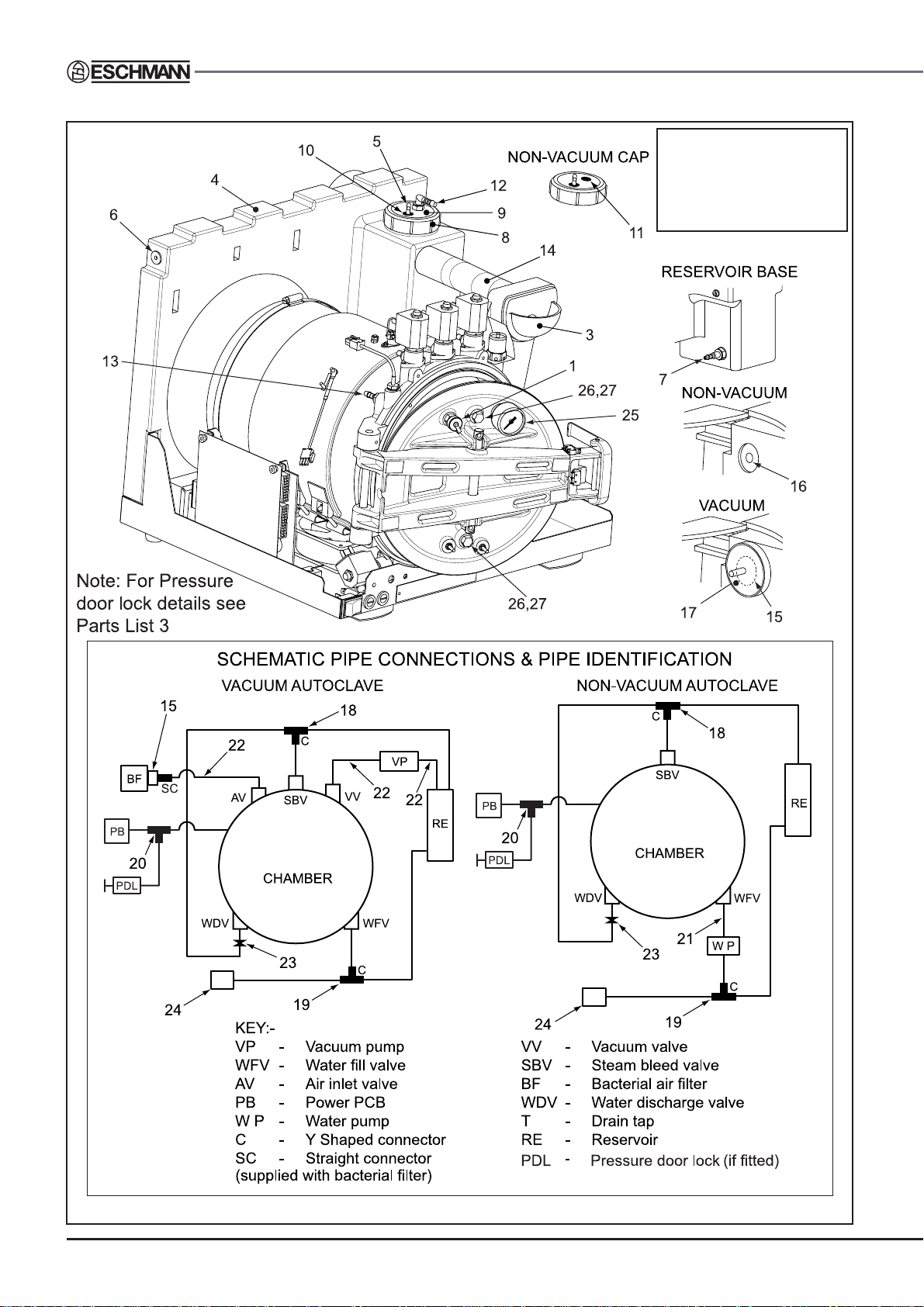

Fig.2 Main components (covers on) . . . . . . . . . . . . . 6

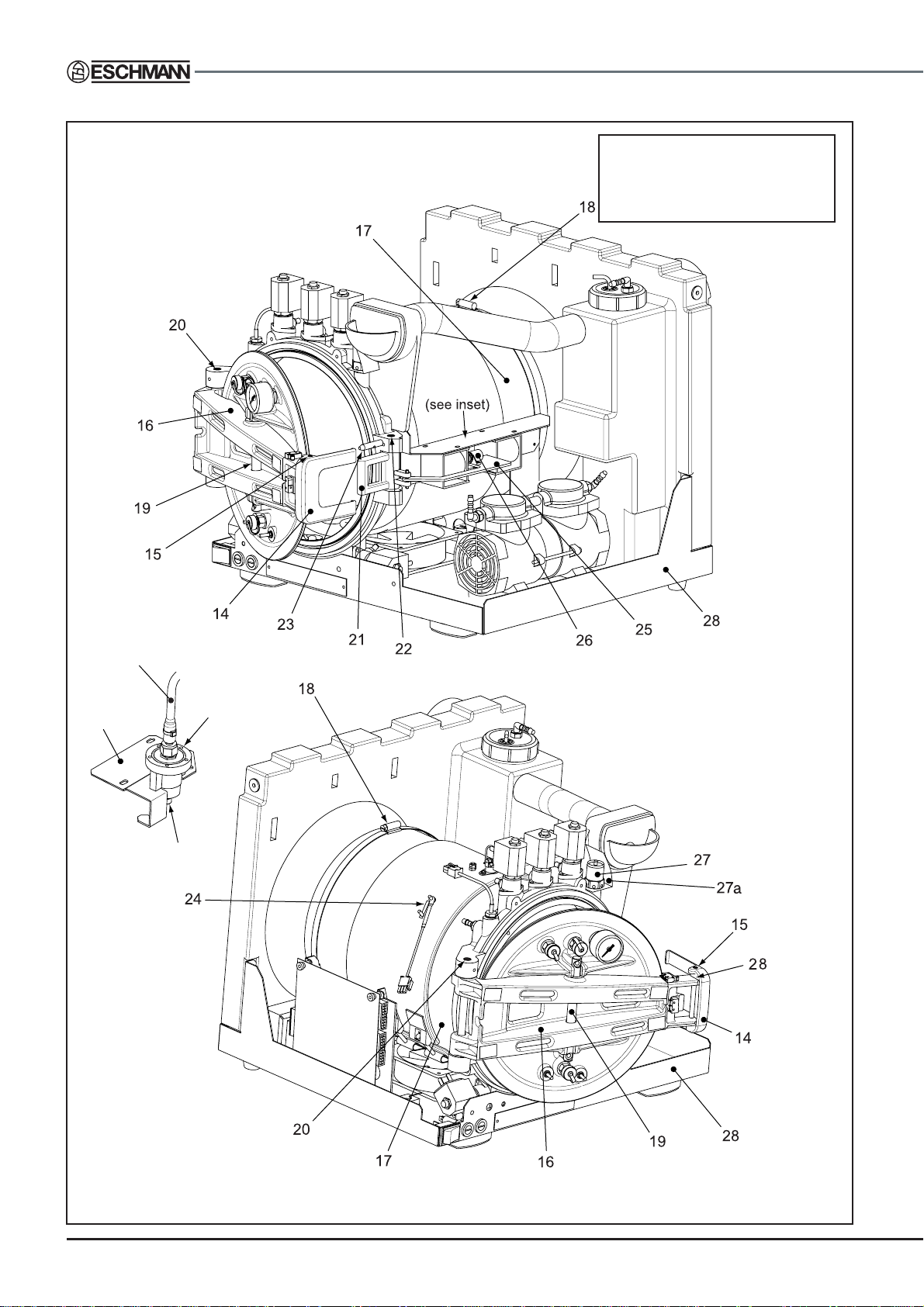

Fig.3 Main components (covers off) . . . . . . . . . . . . . 7

Fig.4 Main components (covers off, non-vacuum) . . 8

Fig.5 Pipe connections and identification . . . . . . . . 14

Fig.6 Vacuum pump part identification . . . . . . . . . . 35

Fig.7 Parts list 1 - Electrical . . . . . . . . . . . . 38 and 40

Fig.8 Parts list 2 - Pipes and plumbing . . . . . . . . . . 42

Fig.9 Sheet 1 Parts list 3 - General assembly . . . 44

Fig.9 Sheet 2 Parts list 3 - General assembly . . . 46

Fig.10 Schematic electrical diag. (non-vacuum) . . . . 49

Fig.11 Schematic electrical diag. (vacuum) . . . . . . . 50

Appendix 1

Appendix 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

ST-SM33l P3/51

1 Introduction

WARNING

Read this service manual before servicing the

autoclave and keep it in a safe convenient place

for future reference. Always have at hand the

‘Instructions for Use’ as supplied with the

autoclave and be familiar with the cautions and

warnings contained within it. The servicing of

this autoclave should be under the control of a

competent person with sterilization training.

The autoclave should only be serviced as

specified by the manufacturer and detailed

within these service instructions.

1.1 This service manual applies to the following

autoclaves, fitted with software version 1.51 or later

(software version is displayed briefly when the autoclave

is switched ‘on’ or B1 is pressed):-

SES Little Sister 5 Autoclave (from Serial Number

L5NA3C1001) REF 87-060-01

SES Little Sister 5 Vacuum Autoclave (from Serial

Number L5SA3C1001) REF 87-060-25

SES QuickVac V acuum Autoclave (from Serial Number

LQSA3D1001) REF 87-061-47

SES 2555 Autoclave (from Serial Number S5NA3C1001)

REF 87-060-61

SES 2555 Vacuum Autoclave (from Serial Number

S5SA3C1001) REF 87-060-73

SES 2555 Vacuum Autoclave (from Serial Number

SQSA3D1001) REF 87-060-73

SES 2555 Autoclave - Australian (from Serial Number

S5NA3C1001) REF 87-061-09

SES 2555 Vacuum Autoclave - Australian (from Serial

Number S5SA3C1001) REF 87-061-21

SES 2555 Autoclave - Singapore and New Zealand (from

Serial Number S5NA3C1001) REF 87-060-85

SES 2555 Vacuum Autoclave - Singapore and New

Zealand (from Serial Number S5SA3C1001) R EF 87- 060-97

1.2 This Service Manual contains a technical

description, complete maintenance procedures and an

illustrated list of spare parts that are available from the

Eschmann After Sales Service Department.

Note: When sterilizing lubricated dental handpieces, the

reservoir water should be changed every week to prevent

contamination of the door seal, and other elastomer

components, used in the pressure system.

1.5 It is recommended that the reservoir is drained,

allowed to dry and refilled with water* every week. At every

service interval the reservoir must be removed,

thoroughly cleaned and dried (see section 8.5), and then

refilled with water*.

* DO NOT USE T A P WATER Eschmann recommend the

use of ‘Sterile Water for Irrigation’ alternatively clean

distilled or deionized water, or water treated by reverse

osmosis may be used.

2 Description

2.1 The autoclave is a portable steam unit heated by

an electric element (or elements depending on the model).

For sterilization of wrapped loads the vacuum unit creates

a vacuum in the chamber. The unit is supplied to suit the

mains electrical supply shown in the technical data section.

2.2 The autoclave is electronically controlled and has

various sterilizing programmes as detailed in the

‘Instructions for Use’. For typical sterilization cycle times,

refer to the technical data section.

2.3 The required sterilizing cycle is selected by pressing

various buttons on the control panel. LEDs illuminate to

show which temperature and cycle have been selected.

The cycle is started by pressing the start button. The

sterilizing/drying cycle proceeds automatically until

complete and the printer (if fitted) starts automatically when

the start button is pressed.

2.4 Indication of cycle status or error codes during a

cycle are provided by the digital display and printer (if fitted).

3 Operating controls & display

3.1 The following operating controls and displays are

all positioned on the front of the unit. Their use is explained

in greater detail within the ‘Instruction for Use’.

Mains switch The symbol ‘I‘ indicates ‘on’ and the symbol

‘0’ indicates ‘off’ (see 9, Fig. 2).

1.3 Ensure that routine servicing is carried out at regular

intervals by either Eschmann trained personnel or suitably

trained engineers only, otherwise the warranty could be

infringed.

1.4 Keep the ‘Instructions for Use’ and this ‘Service

Manual’ readily accessible for reference purposes prior to

and during operation, cleaning and servicing of the autoclave.

CAUTION

In common with other systems containing static

water reservoirs, water used in this unit can become

contaminated over a period of time, or following an

aborted cycle, and should be treated as a potential

risk of infection.

Push buttons (see Fig. 1a and 1b)

B1 Display change button. Press B1 to display the

cycle counter in display window D1.

B2 Cycle temperature button. Each time B2 is

pressed the cycle temperature alternates between

134°C and 121°C.

B3 Unwrapped load (with drying) cycle button.

B4 Unwrapped load (without drying) cycle button.

B5 Programme ‘P’ button. For details see Section 7.2.

B6 Cycle start button. (Always press and hold)

B7 Open door button. (Always press and hold)

B8 Single wrapped load (with drying) cycle button.

(V acuum autoclaves only)

P4/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

B9 Hollow instruments (without drying) cycle

button. (QuickV ac and later SES2555 models only)

Note: During some maintenance procedures you can

press and hold buttons to scroll display data quickly .

Digital displays (see Fig. 1a and 1b)

D1 Time, cycle counter, error number display or

minutes left during sterilization or drying phase.

For more details on the error codes see Table 4.

D2 Temperature display.

D3 Pressure display.

NOTE: Displays may show other information in special

functions mode, see the ‘Special functions table’.

Indicators (see Fig. 1a & 1b)

A1 Low water indicator.

A2 Process display indicator. (See Table 1 in the

instruction for Use).

A3 Door unlocked indicator.

A4 Door locked indicator.

NOTE: FOR EASY REFERENCE THESE FIGURES (1a & 1b) ARE REPEATED

ON A FOLD OUT AT THE BACK OF THIS MANUAL

C Selection indicators. These indicators illuminate

to show which function has been selected (cycle or

temperature).

4 Autoclave components

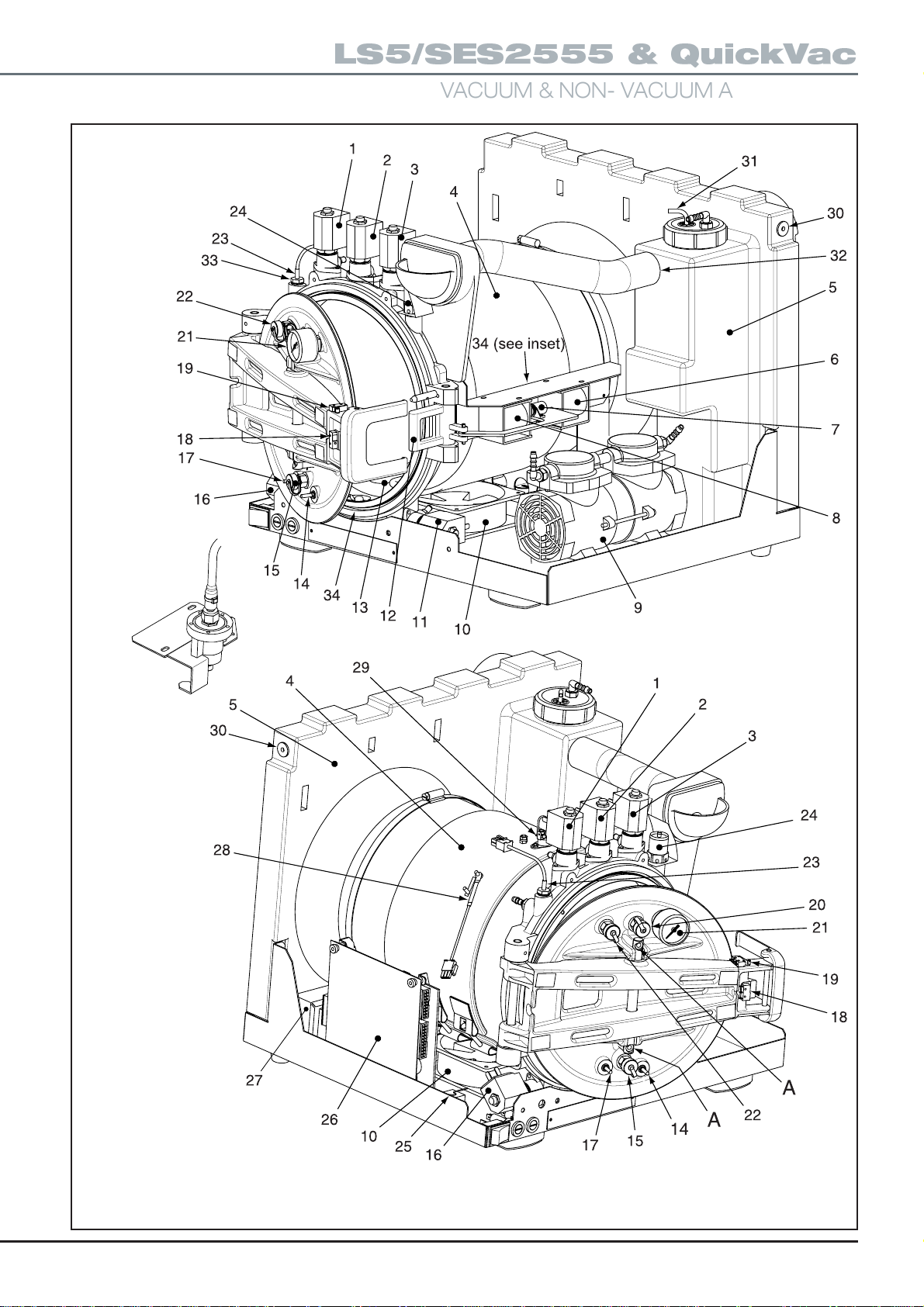

4.1 The following components and equipment are

incorporated in the autoclave. They are illustrated in Fig.2,

3 and 4. Fig.2 shows the autoclave with covers on Fig. 3

and 4 with covers off. In Fig. 2 and 3 the vacuum unit is

shown, some components are particular to the vacuum

unit only (vacuum and QuickV ac models are similar apart

from the control panel). Fig.4 shows the position of

components peculiar to the non-vacuum unit and some

common components.

Door close solenoid, Fig.3 item 8. This is operated when the

door closed microswitch (Fig.3 item 19) is actuated by

closing the door. The lock (Fig.3 item 12) holds the door

closed until the sterilizing cycle is complete. It will also

keep the door closed under all fault conditions. As

absence of power is also a ‘fault’ the unit power switch

must be set to ‘on’ in order to open the door. (See errors

and error clearing section).

Fig. 1a Control panel for SES2555 and LS5 Fig. 1b Control panel for QuickVac

and later SES2555 Models

ST-SM33l P5/51

Fig. 2 Main component identification (covers on)

Door open solenoid, Fig.3 item 6. This is operated when the

door open button B7 is pressed to release the primary

door lock, or the controller signals it to open the door

onto the secondary catch during drying on nonvacuum autoclaves.

Secondary catch, Fig.2 item 12. To ensure that the door

does not fly open should there be residual pressure in

the chamber when the open door button is operated.

Primary door lock, Fig.3 item 12. Used to lock the door shut

during all cycles, cannot be released until Pressure

door lock (Fig.3 item 34) opens when pressure falls

below 0.2Bar(Gauge).

Door closed microswitch, Fig.3, item 19. This is used to

signal the controller that the door is properly closed.

It should operate just as the door is fully closed.

Door locked microswitch, Fig. 3, item 18. This is used to

signal the controller that the door is properly locked.

It should operate just as the door is fully locked.

Chamber pressure gauge, Fig.3 item 21. Fitted behind the

door cover, it indicates the approximate chamber

pressure (without electrical power).

Water reservoir, Fig.3 item 5. This is used to hold water

which is admitted into the chamber via the water fill

valve (Fig.3, item 11). The water reservoir also receives

hot water and steam vapour discharged from the

chamber towards the end of the cycle, via the water

discharge valve (Fig.3, item 16). The vacuum pump

(Fig.3, item 9) on vacuum units also discharges into

the water reservoir.

Reservoir water level sensor (fitted in base of reservoir

position indicated in Fig. 4 item 1). The water level

sensor in the reservoir will stop the cycle being started

if there is insufficient water in the reservoir to complete

a chamber fill. Indicator A1 will be illuminated in a low

water condition.

Gauze filter, Fig. 2 item 6. This filters the water leaving the

chamber (easily removed for cleaning).

Mains switch, Fig. 2 item 9. This switch controls mains

power to the autoclave.

Heating element, Fig.3 item 13, and Fig.4 item 4. The

heating element consists of a single immersion element

inside the chamber. The heating element is controlled

by a solid state relay on the Power PCA (Fig.3,

item 26) and protected from overheating by a manual

reset thermostat (Fig.3, item 25). Refer to

TECHNICAL DATA for heater element loading.

Power board, Fig.3 item 26. There are a number of key

functions provided by the power board:

Solid state relays (SSR) control the mains supply to

the water heater element (10A), band heater (10A)

and vacuum pump (2A).

Mechanical relay provides additional safety for heaters

and pump circuits.

Connections for display board (40-way ribbon cable,

J1), 24 volts from transformer (J2), temperature

sensors (J3), solenoid valve drives, door

microswitches and water level sensors (J4), mains to

heaters and vacuum pump (J5) and mains in (J6).

P6/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

Note: Item 34 the

‘Pressure door

lock’ is only fitted

on later units.

Note: Items 15 and

20 are shown with

‘twinlocks’ fitted, the

autoclave is supplied

with a blank plug only

Fig. 3 Main component identification (covers off) vacuum and QuickVac autoclave

cables and tubing removed for clarity.

ST-SM33l P7/51

4

1

2

3

Fig. 4 Main component identification (covers off) non-vacuum autoclave with cables,

pressure door lock and tubing removed for clarity (some parts common to vacuum autoclave).

Fuse for protecting the 24V d.c. supply (T3.15A).

Two voltage regulators.

Autoclave bleeper.

Pressure transducer with connection via pipe to

chamber neck ring.

Display board (fitted behind membrane key pad, Fig.2

item 3). The display board interfaces with the power

board to control every aspect of autoclave

management. The main features are:

7 segment displays (D1, D2 and D3 of Fig. 1) to

provide time, temperature and pressure indication

and other information for special and protected

functions and error detail.

LEDs to indicate low water, cycle status and door

status (A1, A2, A3 and A4 of Fig. 1)

LEDs to provide visual indication of cycle selection (C

of Fig. 1).

Connections to Power PCA (40 way ribbon cable, J4),

key pad (11 way ribbon cable, J3), printer (16 way ribbon

cable, J5) and serial port (10 way ribbon cable, J2).

Battery to maintain real time clock.

Microprocessor to control the autoclave. This receives

information from the front panel and all the sensors

(temperature, pressure, door microswitches, chamber

water level, reservoir level etc.). If any errors are

detected they are shown on the display, and printed

(if a printer is fitted) as error codes.

Reset thermostat (overheat). Fig.3 item 25. The reset

thermostat is fitted underneath the unit and is

connected in series with the chamber heater element.

The reset thermostat is operated by a fluid-filled

capsule clamped to the heating element, providing

protection if the temperature of the heater surface

exceeds 250°C. It will remake electrically if the reset

button underneath the cabinet is pressed, after giving

the heater element time to cool. (Position is indicated

by a label on the left-hand side of the unit).

Cycling thermostat, Fig.4 item 3. (Non-vacuum only) This

is used to control the temperature of the chamber

heating element, in conjunction with the

microprocessor, during drying.

Band heater overheat cutout, Fig.3 item 29. (Vacuum units

only). The band heater cutout is fitted on the band

heater and is connected in series with the band heater.

It contains a bimetallic disc thermostat which operates

if the temperature of the heater surface exceeds 250°C.

The cutout will remake electrically if the reset button is

pressed when the heater has cooled.

Mains fuses, Fig. 2 item 8. Two fuses are on the front panel

of the unit rated as shown in TECHNICAL DATA,

connected in the ‘mains supply’ to the unit.

Transformer, Fig.3 item 27. The transformer converts the

mains voltage to 20V a.c. It is rated at 75VA.

Water fill solenoid valve, Fig.3 item 11. The water fill solenoid

valve controls the entry of water into the chamber. It is

electrically operated from the 24V d.c. supply generated

and signalled from the power board.

Water discharge solenoid valve, Fig.3 item 16. The water

discharge solenoid valve is used at the end of the

sterilizing cycle to allow water and steam vapour from

the chamber to pass back into the reservoir. The valve

is electrically operated from a 24V d.c. supply

generated and signalled from the power board.

Steam bleed solenoid valve, Fig.3 item 2. The steam bleed

solenoid valve is used at the beginning of the heating

phase to allow air and steam vapour to pass back into

the reservoir, and at the start of discharge to remove

P8/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

pressure before the discharge valve opens. The valve

is electrically operated from a 24V d.c. supply

generated and signalled from the power board.

Safety valve, Fig.3 item 24. The safety valve is factory set

[pressure rating 2.85Bar (Gauge)] to release excess

elevated pressure from within the chamber. It is a

primary safety device and must not be readjusted. It

should operate between 2.72 and 3.13Bar (Gauge).

Air admit solenoid valve, Fig.3 item 1. (Vacuum units only)

The air admit solenoid valve controls the admission of

air (filtered by the Bacterial Filter, Fig.2 item 1) into the

chamber during the drying phase.

Vacuum solenoid valve, Fig.3 item 3. (Vacuum units only)

When open, this valve allows the vacuum pump to

suck air and steam from the chamber. The valve is

electrically operated from a 24V d.c. supply generated

and signalled from the power board.

Vacuum pump, Fig.3 item 9. (Vacuum units only) The

vacuum pump is a two stage diaphragm pump and

used to suck air and steam from the chamber. The

pump is electrically operated from the mains supply

and signalled from the power board.

Bacterial Filter, Fig.2 item 1. (Vacuum units only) The

bacterial filter filters the air entering the chamber

during the drying phase.

Chamber temperature sensors, Fig.3 item 23. These are

used to sense the chamber temperature. Two are

provided within the single sensor unit to provide

controller accuracy.

Band heater temperature sensor, Fig.3 item 28. (Vacuum

units only) The band heater temperature sensor is

used to control the band temperature during the

drying phase.

Thermocouple entry port, Fig.3 item 22. Marked TT on the

chamber door. This is used to insert a thermocouple

into the chamber to allow the operating temperature

to be measured and, if necessary, adjusted.

Pressure test port, Fig.3 item 15#. Marked PT on the

chamber door. The pressure test port is for inserting

a pressure probe to monitor chamber pressure.

Spare test port, Fig.3 item 20#. Spare temperature or

pressure test port for use as required during test

procedures.

Membrane key pad, Fig.2 item 3 & Fig.1a & 1b. Incorporates

programme selector buttons, digital display windows

and programme indicator LEDs. It is connected to the

display board via an 11-way ribbon cable.

Pressure transducer (on the power board). The pressure

transducer monitors the pressure in the chamber and

generates chamber pressure signals for cycle

monitoring, control, and display.

Printer, Fig.2 item 5. The printer, if fitted, starts automatically

when a cycle is selected and will print out hardcopy of

the sterilization cycle. Details of printer output is given

in the ‘Instruction for Use’.

Water pump, Fig.4 item 2. (Non-vacuum units only) Used

to pump water into the chamber from the reservoir.

The pump is operated from a 24V d.c. supply generated

and signalled from the power board.

Fan, Fig.3 item 10. The fan draws air over the chamber for

rapid cooling between cycles. The fan is electrically

operated from the 24V supply and signalled from the

power board.

Band heater, Fig.3 item 4. (Vacuum units only) The band

heater heats the chamber during the drying cycle. The

heating element is controlled by a solid state relay on

the Power PCA and protected from overheating by a

manual reset thermostat (Fig.3, item 25). Refer to

TECHNICAL DATA for heater element loading.

Chamber water level sensors, Fig. 2 items 10 and 11 and

Fig.3 items 14 and 17. These signal the power board

when the minimum and maximum water levels have

been achieved in the chamber during filling. They are

connected to the power board.

Thermal fuse, not illustrated, strapped on the outside of the

chamber behind neck ring (Non vacuum units only).

The thermal fuse is connected in series with the

chamber heater element, providing protection if the

temperature of the thermal fuse exceeds 184°C

(chamber will be above 250°C). It cannot be reset and

must be replaced if it trips.

RS232 serial connection port (9-way D type), Fig.2 item 4.

This connection port can be used to link the autoclave

to a P.C. for calibration, customization, software

upgrades, fault diagnosis etc. providing the correct

equipment is available (e.g. software).

Magnetic door latch, Fig.3 item 7. (Vacuum units only)

Used to hold the primary door lock (Fig.3 item 12) in

place during the vacuum cycle.

Pressure door lock, Fig. 3 item 34. This lock stops the door

opening when the pressure inside the chamber is

above 0.2Bar (Gauge). Note: Not fitted on early units.

5 Operation cycle

5.1 A detailed knowledge of the operation of the

autoclave is not necessary to be able to repair it effectively;

however, a basic understanding of the various processes

of autoclave operation which occur during a cycle is given

in the following paragraphs.

CAUTION

Ensure that the Autoclave is switched off

before filling the reservoir.

# Note: Items 15 and 20 are shown with ‘twinlocks’ fitted, the autoclave is supplied with a blanking plug only

ST-SM33l P9/51

TABLE 1 - KEY TO DISPLAY A2

Phase 1 LED 1 Cycle started.

LED 2 Chamber minimum fill achieved.

LED 3 Chamber filled with water.

Phase 2 LED 1 Heater on.

LED 2 Approximately 90°C reached.

LED 3 Final heating phase started.

Phase 3 LED 1 Sterilization phase started.

LED 2-7 One sixth of the sterilization time

completed for each LED illuminated.

Phase 4 LED 1 Condensing stage started

LED 2 Water removed from chamber.

LED 3 Pressure approaching ambient.

Note: Eschmann recommend the use of ‘Sterile Water

for Irrigation’ alternatively clean distilled or deionized water ,

or water treated by reverse osmosis may be used.

5.2 Power is switched on by selecting the power switch

(O-I) to I (Fig.2 item 9).

NOTE: If the door was locked closed when switching

‘on’ indicator A4 will flash and button B7 should be

pressed to unlock the door, the secondary catch can

then be released to open the door fully.

5.3 After loading the chamber close the door and hold it

firmly shut until the automatic door lock operates. This is

shown by indicator A3 switching off and indicator A4

switching on.

NOTE: A cycle cannot be selected (as detailed in the

‘Instruction for Use’) with the door open.

5.4 When the door is closed, with the power switched

on, this is sensed by the power board via the door closed

microswitch. Indicator A4 will not illuminate until the

automatic lock has operated and the door locked

microswitch has been actuated by the primary lock. After

cycle selection (as detailed in the ‘Instruction for Use’) the

cycle is started by pressing B6. If the autoclave has a printer

it will start printing automatically .

5.5 As the cycle progresses indicator A2 will show the

cycle stage reached (see Table 1) and the digital displays

D2 and D3 will display the actual chamber temperature

and pressure respectively .

5.6 Control of the cycle is fully automatic with

temperature information being monitored by temperature

sensors and displayed on the front panel. Timing is

controlled by the power board and cycle times cannot be

adjusted. By comparing measured values with known time/

temperature relationships, the power board is able to detect

faults such as lack of water at the fill stage, or loss of water

and steam during the process, and it will indicate such

problems by displaying errors codes (e.g. 'Err03') which

will be accompanied by an audible warning signal (see

Table 4 for details on clearing errors and error codes).

Phase 5 LED 1 Start of drying phase.

LED 2 Drying phase 50% completed.

LED 3 Cycle completed (audible bleep).

5.7 The autoclave operates at temperatures slightly

above the usual recommended minimums. The operating

temperature for the 121°C cycle is set to 122.5°C, and the

134°C cycle is set for 135.5°C.

5.8 Operating information relating to the printer is given

in the ‘Instructions for Use’.

5.9 The overall time for the cycle is not fixed and

depends on many factors such as the supply voltage, the

load, and the ambient temperature. However, the power

board will ensure a satisfactory sterilization cycle even

when these factors vary over wide ranges. T ypical cycles

details are explained in section 6.

6 Cycle details

6.1 A typical vacuum cycle (e.g. 134° Wrapped extended

cycle) progresses through several stages. The following

information provides details of the controls actuated and

the resultant functions performed by the autoclave during

selection and running of a typical vacuum sterilization cycle.

Note: The water reservoir must be above minimum and

the door must be closed.

Select temperature 134° with B2 button. (121° light

extinguished, 134° light illuminated or vice versa for

each press of button B2).

Push B8 button. (Wrapped LED illuminated, all other

cycle LED’s extinguished).

Push B5 button. (Extend LED illuminates, gives

sterilization time of 18 minutes at 134°C).

Push B6 button. (First LED on progress indicator

illuminates. If fitted, the printer records time and cycle

data. Mains relay is on. V acuum pump is on.

V acuum inlet valve open. All other valves closed).

Wait for pressure to drop to 32kPa. (Vacuum inlet valve

closed. V acuum pump off. If fitted, the printer outputs

‘TPV’ followed by the time and temperature and

pressure values).

P10/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

Programmed pause. (If chamber pressure does not rise

by more than 0.9kPa in the last minute, water fill

valve opens).

Wait for water to reach minimum level. (Second LED on

progress indicator illuminates).

Wait for water to reach maximum level. (W ater fill valve

closes. Third LED on progress indicator illuminates).

Immersion heater on. (Fourth LED on progress indicator

illuminates. T emperature rises).

Wait for the pressure to rise to 50kPa above atmospheric.

(Fifth LED on progress indicator illuminates. Steam

bleed valve opens. If fitted, the printer outputs ‘TPP’

followed by the time and temperature and pressure

values).

Programmed pause. (Steam bleed valve closes.

Sixth LED on progress indicator illuminates. Heater

off. If pressure above 115kPa, fan on until 115kPa

achieved. Fan off, vacuum inlet valve opens and

pump starts).

Wait for pressure to fall 20kPa below atmospheric. (Pump

off, vacuum valve closes, heater comes on).

Wait for temperature to reach 135.0°. (Seventh LED on

progress indicator illuminates. If fitted, the printer

outputs ‘TSS’ followed by current time, temperature

and pressure values, D1 indicates remaining

sterilization time in minutes, initially 18 mins).

Eighth to thirteenth LED’s on progress indicator illuminate

at regular intervals. (T emperature should not deviate

from 135.5° by more than ±1.5° during sterilisation

plateau. If fitted, the printer outputs the temperature

and pressure values every 20 seconds. Immersion

heater duty drops to approximately 20%).

Programmed pause. (Immersion heater disabled. Beep

sounds. If fitted, the printer outputs ‘TSE’ followed

by the temperature and pressure values. Fan on.

Fourteenth LED on progress indicator illuminates.

Steam bleed valve pulses to exhaust steam).

Wait for 20 seconds. (Air admit valve opens).

(Note: Above two steps repeat until end of drying time)

Wait for half of specified drying time. (Eighteenth LED

on progress indicator illuminates).

Wait until five minutes before the end of the specified

drying time. (Band heater disabled. Fan on).

Wait until the end of specified drying time. (Nineteenth

LED on progress indicator illuminates. Mains relay

off. Three beeps sound. If fitted, the printer outputs

‘TDE’ followed by the temperature and pressure

values, ‘Cycle Complete’ followed by the time. D1

displays time).

6.2 A typical non-vacuum cycle (e.g. 134° unwrapped

with drying extended cycle) progresses through several

stages. The following information provides details of the

controls actuated and the resultant functions performed

by the autoclave during selection and running of a typical

non-vacuum sterilization cycle. Note: The water reservoir

must be above minimum and the door must be closed.

Select temperature 134° with B2 button. (121° light

extinguished, 134° light illuminated or vice versa for

each press of button B2).

Push B3 button. (With drying LED illuminated, all other

cycle LED’s extinguished).

Push the button B5. (Extend LED illuminated, gives

sterilization time of 18 minutes at 134°C).

Push the button B6. (First LED on progress indicator

illuminates. If fitted, the printer records time and cycle

data. Water pump is on. Water fill valve opens.

Steam bleed valve opens. All other valves are

closed).

Wait for water to reach minimum level. (Second LED on

progress indicator illuminates).

Wait for water to reach maximum level. (W ater fill valve

closes. Water pump is off. Third LED on progress

indicator illuminates).

Wait for temperature to drop to 120°C. (W ater discharge

valve opens. Band heater enabled.

Wait for the water in the chamber to drain. (Fifteenth

LED on progress indicator illuminates).

Wait for rate of pressure drop below 40kPa/minute.

(Sixteenth LED on progress indicator illuminates.

Seventeenth LED on progress indicator illuminates.

If fitted, the printer outputs ‘TDS’ followed by the

temperature and pressure values. Vacuum pump

on. Vacuum inlet valve opens at 115kPa. Beep

sounds. D1 displays drying time left).

Wait for chamber pressure to fall 5kPa below

atmospheric. (Air admit valve opens).

Wait for pressure to return to atmospheric. (Air admit

valve closes).

Mains relay on. (Immersion heater on. Fourth LED on

progress indicator illuminates. Temperature rises).

Wait for the temperature to be above 90° and to rise at

over 1.8°/minute. (Fifth LED on progress indicator

illuminates).

Programmed pause and condition check. (Steam bleed

valve closed. Sixth LED on progress indicator

illuminates).

Wait for temperature to reach 135.0°. (Seventh LED on

progress indicator illuminates. If fitted, the printer

outputs ‘TSS’ followed by the current time and the

temperature and pressure values. Immersion heater

duty drops. Temperature should not deviate from

135.5° by more than ±1.5° during sterilisation

plateau. Eighth to thirteenth LED’s on progress

ST-SM33l P11/51

indicator illuminate at regular intervals. If fitted, the

printer outputs the temperature and pressure values

every 20 seconds. D1 indicates remaining

sterilization time, initially 18 mins).

Programmed pause. (Immersion heater disabled. Beep

sounds. If fitted, the printer outputs ‘TSE’ followed

by the temperature and pressure values, and

maximum and minimum sterilization temperatures).

Fan on. (Fourteenth LED on progress indicator

illuminates. Steam bleed valve pulses to exhaust

steam).

Wait for temperature to drop to 120°C. (W ater discharge

valve opens).

Wait for the water in the chamber to drain. (Chamber

minimum indicator off. Fifteenth LED on progress

indicator illuminates).

Wait for rate of pressure drop to go below 60kPa/minute.

(Sixteenth LED on progress indicator illuminates.

Seventeenth LED on progress indicator illuminates.

Fan off at 1 15kPa. Door catch releases and door is

opened by residual pressure. Beep sounds. D1

displays remaining drying time).

display D1 will show F0, each time the ‘P’ button B5 is

pressed, this will increase from F0 up to F8* (F4, F5, F6

vacuum autoclave only), and then back to F0 again, until

either the start button B6 is pressed to select that function,

or, the autoclave is switched ‘off’ or B7 is pressed (with

the door open) to cancel special function selection. To

access F0 the autoclave PIN number (password) is

required. If this is known the protected functions are

available and are detailed in T able 3 - protected functions.

* Door must be shut before access to F4, F5, F6 and F7 is

permitted.

7.2 Protected functions.

Protected functions are accessed through special function

F0 (see above) using the autoclave PIN number (password).

If this is known the protected functions are available as

detailed in Table 3 - protected functions. When access to

the protected functions has been made all displays and

indicators are blank except D1 which shows P0. For each

press of B5 the “P” number will increase by 1 and then back

to P0. Cycle to the number required and press button B6 to

perform that function as detailed in Table 3.

7.3 Errors and faults.

Immersion heater duty to 4%. (Steam bleed valve opens.

If fitted, the printer outputs ‘TDS’ followed by the

temperature and pressure values. D1 displays

drying time left).

Wait for half of specified drying time. (Eighteenth LED

on progress indicator illuminates).

Wait for second half of specified drying time. (Nineteenth

LED on progress indicator illuminates. Immersion

heater disabled. Mains relay off. Fan on. Three

beeps sound. If fitted, the printer outputs ‘TDE’

followed by the temperature and pressure values,

‘Cycle Complete’ followed by the time. D1 displays

time).

7 Maintenance

For easy reference to the buttons, display and indicator

numbers (B1, D1, A1, etc.) used within the following

sections note that Figs. 1a and 1b are repeated on a fold

out page at the back of this manual. Open out this page to

provide a quick reference guide.

7.1 Special functions.

Switch ‘off’ the mains switch (item 9, Fig.2). Press and

hold in the ‘P’ button B5 whilst switching the mains switch

back ‘on’ (display D1 will show F0) to make available

several special functions as detailed in Table 2 - Special

functions. When the autoclave is switched on in this way

display D1 only will be illuminated (with other displays as

required depending on which function is selected). Initially

7.3.1 Power failure

If, after switching ‘on’ power there is no visual display , first

check power supply connections, both fuses at the front of

the unit (see Fuse Renewal) and the fuse in the mains

plug (if it is a fused plug). If power fails during a cycle,

check supply conditions and fuses at the front of the unit

and in the mains plug if fused, also check the mains lead

is correctly connected at both ends. Once power is restored

the display D1 will show the error number (D2 and D3 will

be blank) until cleared by switching the autoclave ‘off’ and

then ‘on’ whilst depressing the start button B6.

7.3.2 Aborted cycles and errors

If an error occurs during a cycle (i.e. any time after pressing

the start button B6), the cycle will abort and provided power

supply to the unit is maintained, the error number will be

indicated by the visual display D1 (displays D2 and D3 will

continue to show actual temperature and pressure). To

display the last error number in display D1 press B1 and

B5 together at any time. Errors are detailed in Table 4 Fault diagnosis with error number details.

7.3.3 Reset thermostat (overheat)

Some solutions to an error number will indicate that the

manual reset thermostat may have tripped and caused

the error. Should the heating element manual reset

thermostat operate this can be reset by pressing the ‘reset

button’ on the underside of the autoclave (approximately

11cm in on the left hand side underneath the unit as

indicated on the left hand side of the unit).

P12/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

7.4 Calibration.

The autoclave can be calibrated by running the calibration

cycles (Protected functions P3, P4 and P5 consecutively)

This will require the positioning of probes (from calibrated

instruments or chart recorders) into the autoclave chamber

through the test ports. The three available test ports are

positioned in the autoclave door, one marked TT (a twinlock)

for the chamber test probe, one marked PT (a blank plug)

for the chamber pressure probe and a spare blank plug for

probes that could be positioned in the load should this be

required. To insert a probe remove the port cover and

carefully insert ROUNDED tipped probes into the chamber

through the seal built into the port, take care not to damage

the port seals and replace the cover after use. During

calibration of the band heater a temperature probe should

be placed under the spring clip provided on the heater, this

will require the top cover to be removed to gain access. It is

important that the top cover is replaced for accurate

calibration.

Running protected function P5 will enable chamber

temperature and pressure calibration, band heater

calibration and a pressure relief valve test. The latter can

be avoided if this test is not required during calibration.

7.5 LED Function test.

Annually

i Check that the pressure relief valve operates

correctly at the set pressure.

ii Inspect the pressure system for integrity.

iii Check door microswitches and interlocks.

iv Check door locking mechanism for integrity

v Check pressure indicators for correct operation.

NOTE:

Annual inspections should only be undertaken by a

‘Competent Person’. Eschmann can provide

comprehensive service contracts which cover preventive

maintenance to ensure trouble free operation of your

autoclave as well as six monthly and annual inspections

of the pressure system to satisfy the requirements of the

Pressure Systems Safety Regulations 2000.

To test the function of all LEDs (i.e. to check that they are

capable of illumination) press and hold buttons B6 and B7

together with the door open. All LEDs will be illuminated

while the buttons are held depressed together.

7.6 Connections, air, water and electrical.

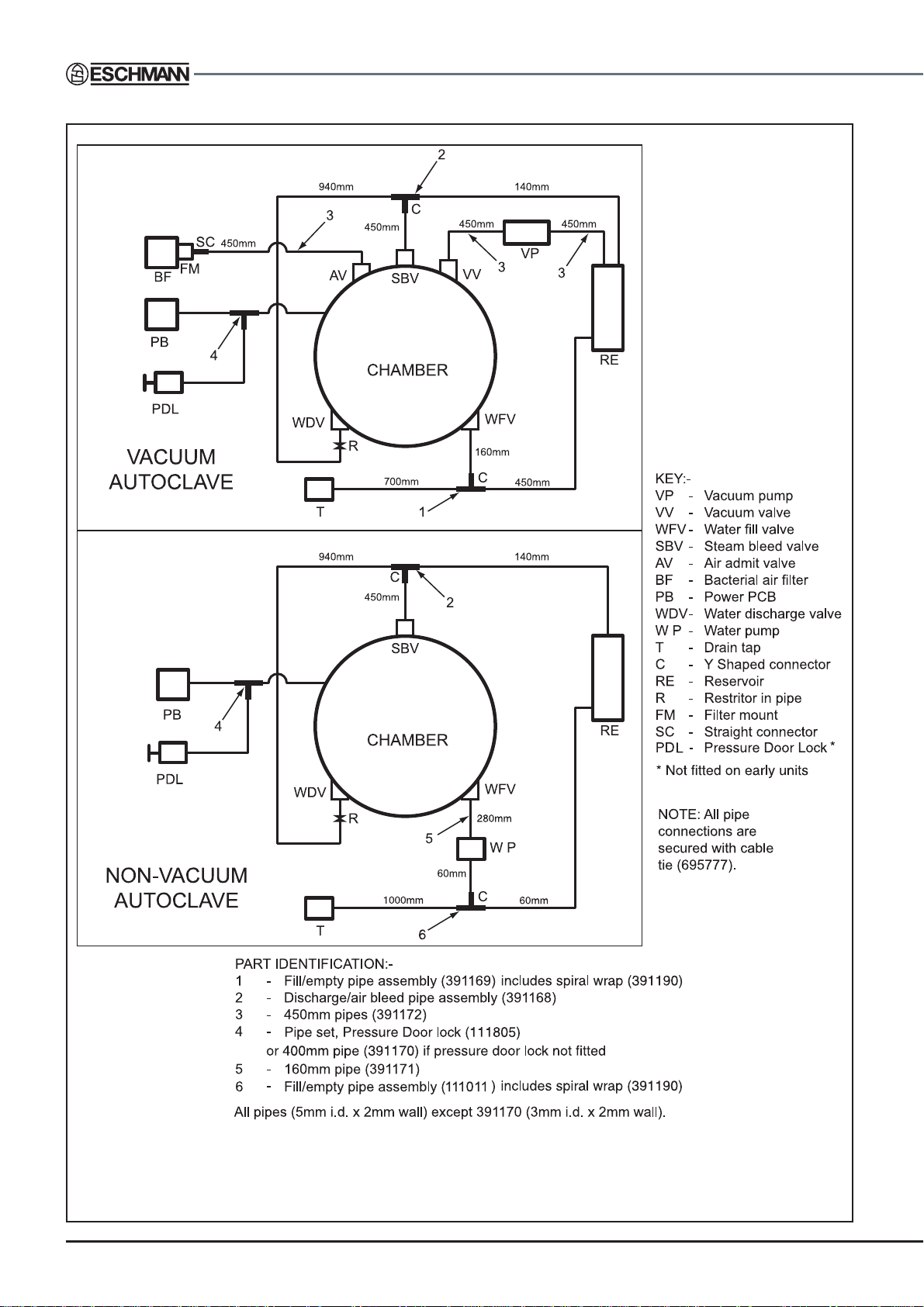

During maintenance refer to Figs. 5, 10 and 1 1 for details

on all autoclave connections. Fig. 5 shows all the air and

water connections whilst Figs. 10 and 1 1 show the electrical

connections for the non-vacuum and vacuum units

respectively. (Note: Figs. 10 and 11 open out at the back

of this manual). When refitting tie wraps to pipes, use ‘Tie

wrap tool 5401’ set at tension 2.

7.7 Safety Checks

The following safety checks, detailed in the ‘Instructions

for Use’, are repeated here as they are important.

Operators should ensure that the following safety checks

are carried out.

Weekly

i Check that the door opens and closes easily .

ii Check the door seal for any signs of damage.

iii Check the secondary door catch latches effectively.

iv Check for any obvious escape of steam or water

during a cycle (apart from the normal escape via

reservoir vents).

Any of the above defects should be attended to by a

‘Competent Person’ immediately and the autoclave should

not be used until repair has been effected (see note below).

ST-SM33l P13/51

Fig. 5 Pipe connections and identification

P14/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

TABLE 2 - SPECIAL FUNCTIONS (See section 7.1 which provides instructions for

accessing these special functions and Fig. 1a & 1b foldout, at the back of this manual)

DISPLAY FUNCTION METHOD OF USE

F0 Protected functions To use protected P functions requires knowledge of the PIN code (code is in HEX

format). With display D1 showing F0 press the start button B6, display D1 shows 0.

Use B2 and B3 to adjust D1 to show the first digit of the PIN number, then press B4

to confirm it. D1 will show a 0 in the next position of the PIN number, use B2, B3

and B4 to adjust and confirm the second digit. Continue until all digits have been

entered, D1 will show P0. Press button B5 to cycle through the protected functions

P0-P9. Use the information in T able 3 - Protected Functions to carry out the selected

P function and return the autoclave to normal operation mode.

F1 Printer test (Note: The printer should be loaded with paper before entering this special

functions mode). With display D1 showing F1 press the start button B6 to start

the printer test, a character set printout, display D1 shows F11. To stop the test

press button B7, the printer will stop at the end of the test cycle, display D1

shows F0. T o resume normal use switch ‘off’ the mains switch (item 9, Fig. 2) and

then switch back ‘on’, or press B7 with the door open.

F2 Cycle history With display D1 showing F2 press the start button B6 to start printing a summary

of the last five cycles completed by the unit (cycle temperature, cycle type, cycle

count, date and time at start of cycle, date and time at end of cycle and the cycle

result). Display D1 returns to F0. To resume normal use switch ‘off’ the mains

switch (item 9, Fig. 2) and then switch back ‘on’, or press B7 with the door open.

F3 Set delayed start With display D1 showing F3 press the start button B6 to enter the delayed start

time setting mode and delayed start initiation, display D1 will show .

If the start hour displayed in D2 is correct (as set last time) and the minutes can

be assumed correct (as set last time) press the start button B6 to programme the

autoclave to start automatically at this set time. The display D1 will change to F0

when B6 is pressed. Press B7 with the door open to exit the setting mode.

If the start time is not correct when entering function F3 (display D1 showing

, display D2 showing the hour set in 24 hour clock mode) press B2 to

increase the hour (or B3 to reduce it). Press B4 to confirm the hour when it is

correct. Display D1 will show , to increase the minutes (shown in D2)

press B2, or B3 to reduce them. Press B6 to confirm the minutes. The display D1

will show F0. Press B7 with the door open to exit the setting mode.

The autoclave should be left switched ‘on’ with the required load in place, the

door shut and the required cycle selected as follows. When the door is shut a ‘ ’

flashes ‘on and off’ after the time in display D1. This continues while the program

selection and any adjustments to it are made (see ‘Instructions for Use’ if ‘ ’

appears in display D2). When cycle selection has been completed and B6 is

pressed to confirm them, the ‘ ’ stops flashing. The cycle selected will be run

automatically , starting at the time set, a ‘ ’ will be displayed in D1 after the time to

show that a delayed start time has been set.

On completion of the cycle the autoclave is ready for the load to be removed and

normal use resumed without the need to exit from the special functions mode.

Note: If the same delayed start time is required each day the setting can be

entered quickly once display D1 shows F3, by pressing (B6 B6 B7).

F4 Leak Test With display D1 showing F0 close the autoclave door (if open), press B5 until

(Vacuum Autoclave ONLY)

Note. To conduct this test the

chamber temperature must be

below 50°C to avoid an Error 38,

and the door closed before

selecting F4.

display D1 shows F4, press B6. Indicator A4 will flash, press B7 to open the door,

indicator A3 will illuminate. Close the door, A4 will illuminate, press B6 this starts

an automatic leak test which checks to see if the autoclave system is still pressure

tight. Display D3 will show the chamber pressure, after a few minutes display D2

will show the pressure rise to the nearest 0.1kPa. After a further 10 minutes if the

pressure has not risen by more than 1.3kPa display D2 will show indicating

the autoclave has passed the test (or to indicate the autoclave has failed the

test) and an audible sound will be heard. (continues on page 16)

ST-SM33l P15/51

TABLE 2 (continued) - SPECIAL FUNCTIONS

DISPLAY FUNCTION METHOD OF USE

F4 (continued from page 15) Press button B5 and wait until display D2 and D3 go blank. To resume normal

use switch ‘off’ the mains switch (item 10, Fig. 2) and then switch back ‘on’, or

press B7 with the door open.

F5 Air Detection Test With display D1 showing F0 close the autoclave door (if open), press B5 until

(Vacuum Autoclave ONL Y)

Note. To conduct this test the

chamber temperature must be

below 50°C to avoid an Error 38,

and the door closed before

selecting F5. Connect a needle

valve (calibrated to provide a

leak of between 1.0 and 1.3kPa

per minute) via a short length of

6mm hose to the antibacterial

filter before pressing B6.

F6 Steam penetration test. With display D1 showing F0 close the autoclave door (if open), press B5 until

(Vacuum Autoclave ONLY)

Note. To conduct this test the

door must be closed before

selecting F6.

display D1 shows F5, press B6. Indicator A4 will flash, press B7 to open the door ,

indicator A3 will illuminate. Close the door , A4 will illuminate, press start button B6.

This starts an automatic air detection test which checks if the autoclave system

detects a leak if present (it performs a leak test similar to F4 first, to ensure no leaks

are present, then admits air through the needle valve). Display D3 shows chamber

pressure, after a few minutes display D2 will show pressure rise to the nearest

0.1kPa. After a further 10 minutes if pressure has not risen by more than 1.3kPa

display . Display D2 will then show or according to result (test aborts on

). If first test is the air valve will open to conduct detection test. After one

minute if pressure <34kPa the leak rate is measured for one minute (if =>34kPa

test aborts), display D3 will show pressure. If the rate of pressure rise is more than

0.9kPa display D2 will show indicating the autoclave has passed the test, or

to indicate the autoclave has failed the test (i.e. pressure rise equal or less

than 0.9kPa). To resume normal use switch ‘off’ the mains switch (item 9, Fig. 2)

and then switch back ‘on’, or press B7 with the door open.

display D1 shows F6, press B6. Indicator A4 will flash, press B7 to open the

door, indicator A3 will illuminate. Place the Eschmann LS5 Vacuum T ype-S and

QuickV ac Steam Penetration T est Device in it’ s pouch (see test device instructions

for use) and into the chamber. Close the door, A4 will illuminate, press the start

button B6, this will start a special B8 cycle (no drying), D2 and D3 will show

temperature and pressure as normal during the cycle. At the end of the cycle the

normal audible sound will be heard. Press B7 to open the door, display D1 will

be showing F0. To resume normal use switch ‘off’ the mains switch (item 9, Fig.

2) and then switch back ‘on’, or press B7 with the door open. (NOTE: This

function can also be used to carry out HTM2010 Performance Qualification (PQ)

Tests in conjunction with the ‘Instructions for Testing’ manual ST -IM55).

F7 Disinfect function With display D1 showing F7 load the autoclave with the load to be disinfected

Note. To conduct this test the

door must be closed before

selecting F7.

F8 Adjust date and time With display D1 showing F8 press the start button B6 to enter the adjust date and

and close the door. Press the start button B6 to start the disinfect function (a 2.5

minute disinfect time at 1 10°C), D1 will continue to show F7 during the cycle and

D2 and D3 will show temperature and pressure. At the end of the cycle the normal

audible sound will be heard. Press B7 to open the door and remove the load,

display D1 will be showing F0 . T o resume normal use switch ‘off’ the mains switch

(item 9, Fig. 2) and then switch back ‘on’, or press B7 with the door open. (NOTE:

The ex-factory condition is for this function to be disabled.)

time function. Display D1 will show and D2 will show the year, to increase

the year press B2 (or B3 to reduce it) when correct press button B4 to confirm

the year. The display D1 will show and D2 will show the month in numerical

format, to increase the month press B2 (or B3 to reduce it) when correct press

button B4 to confirm. The display D1 will show and D2 will show the day in

numerical format, to increase the day press B2 (or B3 to reduce it) when correct

press button B4 to confirm. The display D1 will show and D2 will show the

hour , to increase the hour press B2 (or B3 to reduce it) when correct press button

B4 to confirm. The display D1 will show and D2 will show the minute, to

increase the minute press B2 (or B3 to reduce it) when correct press button B6,

display D1 shows F0 display D2 and D3 will be blank. The time and date are now

set (seconds were set to zero when B6 was pressed). Press B7 with the door

open to continue normal use.

P16/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

TABLE 3 - PROTECTED FUNCTIONS (See section 7.2 which provides instructions for

accessing these special functions and Fig. 1a & 1b foldout, at the back of this manual)

DISPLAY AND FUNCTION METHOD OF USE

P0 - Print last 5 failed cycles This protected function prints a summary of the last five failed cycles. Display

D1 shows P0. Press button B6. The printer prints a summary of the last five failed

cycles containing the following information for each cycle; Cycle temperature, Cycle

type, the word “Extended” if the cycle was extended, Cycle count, Date and time at start

of cycle, Date and time at end of cycle and the word “Error” followed by the error number.

Display shows F0. With the door open press B7 to exit back to normal mode, or B5 to

cycle through and gain access to other protected functions (by pressing B6 when the

correct P number is displayed).

P1 - Print last failed cycle This protected function prints a summary of the last failed cycle. Display D1

shows P1. Press the button B6. The printer prints a summary of the last failed cycle,

containing the following information; Cycle temperature, Cycle type, the word “Extended”

if the cycle was extended, Cycle count, Date and time at start of cycle, Date and time at

end of cycle, the word “Error” followed by the error number and up to nineteen lines

containing the time, temperature and pressure. Display shows P1. With the door open

press B7 to exit back to special function F0, or B5 to cycle through and gain access to

other protected functions (by pressing B6 when the correct P number is displayed).

P2 - Recall factory calibration This protected function recalls and copies the factory calibration to the field

calibration area. Display D1 shows P2. Press button B6, display D1 shows P21. Press

and hold B3 and B5 buttons together until a beep is heard. The factory calibration

information overwrites the current field calibration. Display D1 shows P2. With the door

open press B7 to exit back to special function F0, or B5 to cycle through and gain

access to other protected functions (by pressing B6 when the correct P number is

displayed). Always recalibrate after using this function, see section 7.4.

P3 - Room T emperature Calibration This protected function performs a room temperature calibration. Ensure

autoclave is at room temperature before starting to eliminate calibration errors. Insert

the required probes from the calibrated instruments and/or chart recorders (e.g. chamber

temperature probe, chamber pressure probe) as detailed in section 7.4. Replace the

autoclave cover during calibration. The door must be open and on the secondary

catch for this protected function. Display D1 shows P3, press button B6, display D1

shows “t” followed by the current temperature. Display D2 shows the current temperature,

display D3 shows the current pressure in kPa. Use buttons B2 and B3 to set the value

in display D1 to the current temperature indicated on the calibrated instrument. Press

button B6 until a beep is heard. Press button B1, display D1 shows “P” followed by the

current pressure in mBars. Use buttons B2 and B3 to set the value in display D1 to the

current pressure indicated on the calibrated instrument. (Note: The value in display D1

changes in steps of 2 mBars). Press button B6 until a beep is heard and the temperature

and pressure displays change to the values entered in the previous steps. Press button

B7, display D1 shows P3. With the door open press B7 to exit back to special function

F0, or B5 to cycle through and gain access to other protected functions (by pressing B6

when the correct P number is displayed).

P4 - Low pressure calibration This protected function performs a low-pressure calibration. This function

can only be run on a vacuum autoclave. The door must be closed for this protected

function. Insert a suitable pressure probe from a calibrated instrument and/or chart

recorder as detailed in section 7.4. Display D1 shows P4, press button B6. Display D1

shows P 200, display D3 shows the current pressure in kPa. (Note: D3 pressure is

always in kPa). Wait until the pressure drops to about 200 mBars on the calibrated

instrument then press button B5 (this closes the vacuum solenoid valve, but leaves the

pump running). Use buttons B2 and B3 to set the value in display D1 to the current

(Continued on page 18)

ST-SM33l P17/51

TABLE 3 (continued) - PROTECTED FUNCTIONS

DISPLAY AND FUNCTION METHOD OF USE

pressure indicated on the calibrated instrument. (Note: The pump is running during this

calibration and the vacuum solenoid valve can be toggled open and closed by pressing

B5, this enables chamber pressure to be adjusted if required). Press button B6 until a

beep is heard to save calibration data . Press button B7, wait for the pressure to return

to within 5 mBars of atmospheric. Display D1 shows P4. With the door open press B7

to exit back to special function F0, or B5 to cycle through and gain access to other

protected functions (by pressing B6 when the correct P number is displayed).

P5 - Low and high temperature calibration Insert the required probes from the calibrated instruments and/

or chart recorders (e.g. chamber temperature probe, chamber pressure probe and band

heater probe) as detailed in section 7.4. Replace the autoclave cover during

calibration. The door must be closed for this protected function. Display D1 shows

P5, press button B6.

For Non-Vacuum - A 121°C Naked without Drying cycle is started.

For Vacuum - A 121°C Naked with Drying cycle is started.

(Note: For both the above cycles the sterilisation time is extended to give adequate

time to achieve an accurate calibration).

Button B5 LED is illuminated and (if fitted) the printer records time and cycle data with

the words “Calibration Cycle” after the cycle type. Wait for the sterilisation plateau to be

reached, then press button B1. Display D1 shows “t” followed by the current temperature.

Use buttons B2 and B3 to set the value in display D1 to the current temperature indicated

on the calibrated instrument. Continue to adjust the temperature in D1 until a stable

condition is achieved. (Note: The sterilisation time can be extended if required by pressing

B5). Press button B4 until a beep is heard. Display D1 shows the new temperature

value. Press button B1, display D1 shows “P” followed by an estimated pressure value

based on the current temperature. Use buttons B2 and B3 to set the value in display D1

to the current pressure indicated on the calibrated instrument (the value in display D1

changes in steps of 2). Press button B4 until beep is heard. Display D3 shows the new

pressure value. Press and hold buttons B2 and B6 until beep is heard. The 121° LED is

extinguished and the 134° LED is illuminated, the temperature rises towards 135.5°C,

process display A2 returns to the seventh LED illuminated, display D1 shows P5. W ait

for the temperature to approach 135.5°C, then press button B1. Display D1 shows t

followed by the current temperature. Use buttons B2 and B3 buttons to set the value in

display D1 to the current temperature indicated on the calibrated instrument. Continue

to adjust the temperature in D1 until a stable condition is achieved. (Note: The sterilisation

time can be extended if required by pressing B5). Press button B4 until beep is heard.

Display D1 shows the new temperature value. Press button B1, display D1 shows “P”

followed by an estimated pressure value based on the current temperature. Use buttons

B2 and B3 to set the value in display D1 to the current pressure indicated on the calibrated

instrument. Press button B4 until beep is heard. Display D3 shows new pressure value.

If it is required to test the safety valve press and hold buttons B2 and B7 until beep is

heard, the 121° LED illuminates, the temperature rises towards 148°C (approx.), the

process display A2 returns to the seventh LED illuminated, display D1 shows P5. Wait

for the pressure to reach about 385kPa, the safety relief valve starts to release the

pressure from the chamber, note valve limits are 2.72 - 3.13Bar (Gauge.)

Press and hold buttons B5 and B7, the water discharge valve opens, process display

A2 advances to the fourteenth LED.

Non-Vacuum - The steriliser completes the cycle normally, display D1 shows P5 all

other displays are blank.

(Continued on page 19)

P18/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

TABLE 3 (CONTINUED) - PROTECTED FUNCTIONS

DISPLAY AND FUNCTION METHOD OF USE

Vacuum - The steriliser continues onto the drying phase, wait for band heater temperature

to reach about 158°C on the calibrated instrument, then press button B1. Display D1

shows “t” followed by current band heater temperature. Use buttons B2 and B3 to set

the value in display D1 to the current temperature indicated on the calibrated instrument.

Continue to adjust the temperature in D1 until a stable condition is achieved. Press

button B4, a beep is heard. Press and hold button B5 and B7, the autoclave completes

the cycle immediately . Display D1 shows P5, all other displays are blank. With the door

open press B7 to exit back to special function F0, or B5 to cycle through and gain

access to other protected functions (by pressing B6 when the correct P number is

displayed).

P6 - Cycle Enable/Disable This protected function enables or disables the sterilization cycles. Display D1 shows

P6, press button B6. The programme and temperature LEDs display the default

programme. All LEDs on the progress indicator A2 are illuminated to indicate this

programme is enabled. Button B4 can now be used to toggle all LEDs on the progress

indicator A2 “on” or “off” showing that the indicated programme is enabled or disabled

respectively.

Press button B2, the programme and temperature LEDs display the next programme.

Use B4 to toggle all LEDs in A2 “on” or “off” to enable or disable the indicated programme.

Repeat pressing B2 and enable or disable each programme as required (when indicated)

until all programmes have been set as required. (Note: When B2 is pressed and no

indicator lights are “on” display D2 will show either , to indicate the disinfect cycle, or

, to indicate the ‘Hollow Naked’ cycle. These can also be enabled or disabled by

pressing button B4. Autoclaves without button B9 will still display the option to enable or

disable the ‘Hollow Naked’ cycle even though the cycle cannot be run).

Note: Pressing button B3 will enable all programmes, it is not possible to disable all

programmes. When button B5 indicator illuminates this indicates an extended cycle.

Press button B6 until a beep is heard, all the programme enabling or disabling settings

made above are stored in memory , display D1 shows P6 all other displays or indicators

are “off”. To exit press B7 (with the door open) or B5 to cycle through and gain access

to another protected functions. When the correct P number is displayed by pressing B6.

P7 - I/O T est This test verifies all the inputs and outputs to the Microcontroller. When familiar with the

use of this protected function, see T able 5 for a quick reference chart which details how to

use P7 to check individual components, rather than progressing through each one, as

detailed below. Before using Table 5 ensure you know how to activate and leave this

protected function. The water reservoir should be empty (if not, the 8th LED of the progress

indicator A2 will be “on” throughout this test and it will not be possible to test the reservoir

sensor). Display D1 shows P7, press button B6. Display D1 shows the raw ADC value for

the first pressure transducer, display D2 shows P1, display D3 shows 1, the fourth and

sixth LEDs on the progress indicator A2 are illuminated if the door is open. Press button

B1, display D1 shows the raw ADC value for the second pressure transducer , display D2

shows P2. Press button B1, display D1 shows the raw ADC value for the first chamber

temperature transducer, display D2 shows t1. Press button B1, display D1 shows the raw

ADC value for the second chamber temperature transducer, display D2 shows t2. Press

button B1, display D1 shows the raw ADC value for the Band Heater temperature

transducer, display D2 shows t3. Press button B1, display D1 shows the raw ADC value

for the first pressure transducer, display D2 shows P1, display D3 shows 1.

Press button B4, B4 LED illuminates, and the water discharge valve opens. Press

button B4, B4 LED goes “off” and the water discharge valve closes.

(Continued on page 20)

ST-SM33l P19/51

TABLE 3 (CONTINUED) - PROTECTED FUNCTIONS

DISPLAY AND FUNCTION METHOD OF USE

P7 - I/O T est (cont’d) Press button B2, display D3 shows 2. Press button B4, B4 LED illuminates, and the

water fill valve opens. Press button B4, B4 LED goes “off” and the water fill valve closes.

Press button B2, display D3 shows 3. Press button B4, B4 LED illuminates, and the air

admit valve opens. Press button B4, B4 LED goes “off” and the air admit valve closes.

(Only on vacuum autoclaves).

Press button B2, display D3 shows 4. Press button B4, B4 LED illuminates, and the fan

runs. Press button B4, B4 LED goes “off” and the fan stops.

Press button B2, display D3 shows 5. Press button B4, B4 LED illuminates, and the

steam bleed valve opens. Press button B4, B4 LED goes “off” and the steam bleed

valve closes.

Press button B2, display D3 shows 6. Press button B4, B4 LED illuminates, and the

vacuum inlet valve opens. Press button B4, B4 LED goes “off” and the vacuum inlet

valve closes. (Only on vacuum autoclaves).

Press button B2, display D3 shows 7. Press button B4, B4 LED illuminates, and the

door open solenoid operates. Press button B4, B4 LED goes “off” and the door open

solenoid operates.

Press button B2, display D3 shows 8. Press button B4, B4 LED illuminates, and the

door close solenoid operates. Press button B4, B4 LED goes “off” and the door close

solenoid operates.

Press button B2, display D3 shows 9. Press button B4, B4 LED illuminates, and the

mains relay is “on”. Press button B4, B4 LED goes “off” and the mains relay is “off”.

Press button B4, to turn the mains relay “on” and leave it “on” to enable other tests (e.g.

heaters) that follow.

Press button B2, display D3 shows 10. Press button B4, B4 LED illuminates, and the

water pump operates. Press button B4, B4 LED goes “off” and the water pump stops.

(Only on non-vacuum autoclaves).

Press button B2, display D3 shows 11*. Press button B4, B4 LED illuminates, and the

vacuum pump operates. Press button B4, B4 LED goes “off” and the vacuum pump

stops. (Only on vacuum autoclaves).

Press button B2, display D3 shows 12*. Press button B4, B4 LED illuminates, and the

band heater is “on”. Press button B4, B4 LED goes “off” and the band heater is “off”.

(Only on vacuum autoclaves).

Press button B2, display D3 shows 13*. Press button B4, B4 LED illuminates, and the

immersion heater is “on”. Press button B4, B4 LED goes “off” and the immersion heater

is “off”.

Press button B2, display D3 shows 14. Press button B4, B4 LED illuminates, and the

beeper is “on”. Press button B4, B4 LED goes “off” and the beeper is “off”.

Press button B2, display D3 shows 1. Press button B4, B4 LED illuminates, and the

water discharge valve opens. Press button B3, B4 LED goes “off” and the water discharge

valve closes.

Short the chamber minimum water level sensor to the door, the second LED on progress

indicator A2 illuminates.

(Continued on page 21)

* Ensure mains relay was left “on” (when D3 shows 9 above) to perform this test.

P20/51 ST-SM33l

LS5/SES2555 & QuickVac

VACUUM & NON- VACUUM AUTOCLAVES

TABLE 3 (CONTINUED) - PROTECTED FUNCTIONS (See section 7.2)

DISPLAY AND FUNCTION METHOD OF USE

P7 - I/O T est (cont’d) Short the chamber maximum water level sensor to the door, the third LED on progress

indicator A2 illuminates.

Operate the door closed microswitch, the fourth LED on progress indicator A2 is

extinguished and the fifth LED on progress indicator A2 is illuminated.

Operate the door locked microswitch, the sixth LED on progress indicator A2 is

extinguished and the seventh LED on progress indicator A2 is illuminated.

Short the two reservoir water level sensors together, the eighth LED on progress indicator

A2 illuminates.

Press button B7, display D1 shows P7, all other displays are blank.

T o exit press B7 (with the door open) or B5 to cycle through and gain access to another

protected functions. When the correct P number is displayed by pressing B6.

P8 - Service completion When service is carried out in response to a service request from the autoclave, it is

necessary to reset the service request flag in the EEPROM. This occurs automatically

if the unit is re-calibrated. It can also be done through the protected function P8. Display

D1 shows P8. Press button B6. The autoclave beeps. The service request is set for 1 1

months later and will print ‘Service and Certification due’. Display D1 shows P8.

T o exit press B7 (with the door open) or B5 to cycle through and gain access to another

protected functions. When the correct P number is displayed by pressing B6.

P9 - Enable/disable This function changes the configuration file to disable, or to enable, the facility which

adjustable drying

and sterilization

times

allows the user to alter the preset sterilization and drying times when selecting a cycle.

Display D1 shows P9. Press button B6. D2 displays either if the function is disabled

or if it is enabled. Press button B2 to enable it, or press button B3 to disable it. Press

button B6 to confirm the setting. The autoclave beeps to acknowledge. Display D1