SES LS3

A UTOCLAVE

Instructions for use

490346

ST-IM29h

Introduction

Warnings and

information

Preparation

and loading

Sterilizing

and drying

Cleaning and care

Maintenance

Technical data

Read these Instructions before use

Keep these ‘Instructions for use’ in a safe convenient place for future reference.

Eschmann After Sales Service Department

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquires, please quote the

Model and Serial Number of your Autoclave (NOTE: For location of the Serial Number Plate

see Fig.1. Item 19).

For Customers on the Mainland of England, Scotland and Wales, or on the Isle of Wight :When you receive your Little Sister 3 Autoclave ensure that you complete your Service Guarantee

and Registration Card, and then FREEPOST it to Eschmann Equipment. Failure to return this

card means you will not benefit from our FREE installation service, which will ensure your Autoclave

is correctly installed, plus two FREE service visits during the following 12 months.

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

T el: +44 (0) 1903 765040. Fax: +44 (0) 1903 762006.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limited .

“Eschmann Equipment” is a trading name of Eschmann Holdings Limit ed.

“Little Sister”, “SES”, and “LS3” are trade marks of Eschmann Holdings Limited.

Patents : Patents Pending plus - Pat. US5090033 and Pat. GB2238407

Copyright © 2002

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Limited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

If the CE mark is affixed to the product, it indicates compliance with Council Directive

93/42/EEC of 14 June 1993 concerning medical devices.

Instructions for use

ST-IM29h October 2003

SES LS3

AUTOCLAVE

CONTENTS

INTRODUCTION

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Water quality caution . . . . . . . . . . . . . . . . . . . . . . . 3

WARNINGS

Hazards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

User notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

INFORMATION

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Declaration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conditions of safe use . . . . . . . . . . . . . . . . . . . . . 5

Warning markings. . . . . . . . . . . . . . . . . . . . . . . . . 5

INITIAL PREPARATION FOR USE

Initial preparation for use . . . . . . . . . . . . . . . . . . . . 6

LOADING THE AUTOCLAVE

Loading the autoclave . . . . . . . . . . . . . . . . . . . . . . 6

STERILIZING AND DRYING

Sterilizing and drying . . . . . . . . . . . . . . . . . . . . . . . 6

CLEANING AND CARE

Cleaning and care . . . . . . . . . . . . . . . . . . . . . . . . . 7

SAFETY CHECKS

Weekly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Annually . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

UK Guidance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

MAINTENANCE

Fuse renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Preventative Maintenance Agreement . . . . . . . . . 7

Error Correction . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Overheating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Cleaning Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TABLE 1

Fault finding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATING INSTRUCTIONS FOR PRINTER

Printer output . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Front Panel Controls. . . . . . . . . . . . . . . . . . . . . . 10

Paper Roll Renewal . . . . . . . . . . . . . . . . . . . . . . 10

Ribbon Cartridge Renewal . . . . . . . . . . . . . . . . . 10

Spares pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Setting Time and Date . . . . . . . . . . . . . . . . . . . . . 11

Illustrations for Printer. . . . . . . . . . . . . . . . . . . . . . 11

TECHNICAL DATA

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

INTRODUCTION

There are four versions of the Little Sister 3 Autoclave,

Short and Long chamber both with and without printer. For

instructions on how to use the printer (if fitted) see the

special section towards the end of this booklet.

These instructions apply to the following Autoclaves:SES LITTLE SISTER 3 STANDARD

(from Serial Number LCB8B0000, or LSK8B0000 for non-CE).

without printer : 87-020-05 87-022-01

87-022-17

with printer : 87-020-13 87-022-09

87-022-25

SES LITTLE SISTER 3 LONG

(from Serial Number LLCB8B0000, or LLSB8B0000 for non-CE).

without printer : 87-020-21 87-022-49

87-022-66

with printer : 87-020-29 87-022-58

87-022-74

The Accessories listed below are available:-

Tray . . . . . . . . . . . . . . . . . . . . . . . . REF 87-040-07

Tray lifter . . . . . . . . . . . . . . . . . . . . . REF 87-040-90

Chiropody tray . . . . . . . . . . . . . . . . . REF 87-041-12

Tray - Long . . . . . . . . . . . . . . . . . . . . REF 87-040-19

Cassette (tray with lid) . . . . . . . . . . . REF 87-040-87

Printer spares pack . . . . . . . . . . . . . REF 87-034-05

Service Manual

A Service Manual containing technical description,

complete maintenance procedures and an illustrated list

of spare parts is available on request from the Eschmann

After Sales Service Department.

Reservoir Water Quality Caution

a. Eschmann recommend filling the reservoir with ‘Sterile

Water for Irrigation’. This is low in dissolved solids and

has a low microbial count. In the U.K. the Department

of Health recommend that ‘Sterile Water for Irrigation’

is used in bench-top Autoclaves (NHS Estates

document HTM2031).

b. If ‘Sterile Water for Irrigation’ is not being used then

Eschmann strongly recommend the use of either

distilled water, deionized water, purified water or

water treated by the reverse osmosis process. These

types of water are low in dissolved solids and can help

reduce the effects of tap water detailed below.

c. DO NOT USE TAP WATER, this is high in dissolved

solids and can deposit lime scale, block filters and

cause damage to the pressure vessel.

d. Eschmann also recommend changing the water in the

reservoir on a weekly basis, with the type of water

detailed in ‘a’ (or ‘b’) above. This will reduce the build-up

of contaminants in the water that may cause blocked

filters and/or damage to the pressure vessel. Your local

Health Authority may suggest that you change the

reservoir water more frequently. Eschmann advise you

to follow your local Health Authority’s recommendations.

ST-IM29h P3/12

WARNING

READ NOTES (1-5) BEFORE USE

The use of this autoclave should be under the

control of a responsible Person with sterilization

training. The user remains responsible for ensuring

that the load is suitable for the process adopted.

Note 1.

regarding the maximum temperature the instrument

can withstand. This is necessary as the sterilizing

temperature for 121ºC cycles may be exceeded

(typically to peaks of 130°C) during the drying phase

under certain conditions such as small loads.

g. The Autoclave will discharge steam during and at the

end of some cycles. Ensure the autoclave is not

positioned close to heat or smoke detectors as these

may be activated by the release of steam.

THE USER SHOULD BE A WARE OF THE FOLLOWING

POSSIBLE HAZARDS

a. Burns to the user caused by hot accessible surfaces

of the load, burns to the user caused by high

temperature internal surfaces of the chamber, scalds

to the user caused by hot water and/or steam from the

reservoir, scalds to the user caused by hot water from

the chamber on opening the door, scalds to the user

caused by hot water and/or steam from overfilling the

reservoir.

b. The hazard of scalds and burns from contact with hot

surfaces are greater during validation with the cover

removed which also exposes the risk of electric

shock. Validation should therefore only be carried out

by a qualified engineer.

c. Infection, caused by contact with water in the reservoir

if the reservoir is not drained, left to dry and recharged

at regular intervals as described in these instructions

for use (see paragraph 22) to prevent possible

contamination.

d. The autoclave indicates a successful cycle, but the

load remains non-sterile because the load is not

suitable for the steam sterilization cycle. All loads and

loading conditions must be validated. It is

recommended that the user consults the instructions

for use of the items to be autoclaved and if in doubt

consult a qualified microbiologist or Authorized Person.

Note 3.

THE USER SHOULD FOLLOW THESE ELECTRICAL

SAFETY MEASURES

a. This equipment must be earthed.

b. Switch ‘off’ unit and disconnect from mains power

supply before renewing fuses.

c. Switch ‘off’ unit and disconnect from mains power

supply before checking and cleaning the autoclave.

d. Do not attempt to service this equipment internally.

Note 4.

THE USER SHOULD FOLLOW THESE GENERAL

SAFETY MEASURES

a. Do not fill the reservoir during a sterilizing cycle.

b. Do not cover the ventilation louvres.

c. Do not use abrasive powders, chemicals, or solutions

containing chlorine to clean the autoclave.

d. Always allow unit to cool before attempting to open

the chamber door.

e. If an error display appears during a cycle, do not

switch-off power until discharge of hot water or steam

into the reservoir has stopped. Do not attempt to open

chamber door until unit has cooled and internal

pressure has fallen sufficiently to release pressure

safety bolt. Also see ‘Safety Checks’ page 7.

Note 2.

THE USER SHOULD BE A WARE OF THE FOLLOWING

LIMITATIONS DURING USE

a. Never use trays or cassettes without perforations as

this will result in a non-sterile load.

b. Do not process wrapped, sealed or porous goods or

fluids in this autoclave.

c. Not to be used in zones of risk associated with

flammable anaesthetics.

d. The Little Sister 3 is designed to sterilize instruments,

NOT TO WASH THEM. If instruments are not cleaned

this may compromise the efficiency of the sterilization

process.

e. These Autoclaves are not suitable for instruments or

items with narrow lumens.

f. When sterilising instruments not of solid metal

construction, the manufacturer of the instrument must

be consulted about its suitability for autoclaving,

P4/12 ST-IM29h

Note 5.

GENERAL POINTS TO REMEMBER DURING USE

a. Close the chamber door properly before selecting the

required programme.

b. Always leave the chamber door slightly open after

use.

c. Never use tap water see section 6 and ‘Reservoir

Water Quality Caution’ on page 3.

d. Ensure instruments are free from debris before placing

them in sterilizer chamber.

e. Use the ‘tray lifter’ to remove the sterilized load.

f. Keep chamber trays and chamber face clean.

g. Clean door seal and chamber face with a lint-free

cloth at weekly intervals.

h. Regular maintenance (every three months is

recommended) is required to ensure continued safety

and reliability

SES LS3

AUTOCLAVE

GENERAL INFORMATION NOTES

IMPORTANT

The design of the autoclave pressure vessel is

approved by a third party to PD5500 Cat.3. The

pressure vessel is constructed and tested to BS3970

Parts 1 and 4. In order to ensure safety and to

comply with UK regulations, the vessel and fittings

should be inspected by a ‘competent person’ at

intervals of no more than 14 months. This can be

carried out by an Eschmann trained engineer.

The Little Sister 3 Autoclave (Standard and Long) is designed

for the sterilization of unwrapped instruments, utensils and

other items. It operates automatically at the touch of a single

programme selector touch button, and has four programmes

134°C and 121°C, both with and without drying (see Important

Note below right). The Autoclave is capable of 4 cycles per

hour when the ‘134°C Without drying’ programme is selected.

For sterilization cycle times, refer to the ‘TECHNICAL DA T A ’

section on page 12.

Little Sister 3 Autoclave, safety features:-

a. Pressure Door Lock. The door is mechanically locked

at pressures above 0.14 bar.

b. Door Interlock Switch. This prevents programme

starting if door is not properly closed.

c. Electrical Door Lock. This prevents the door being

opened inadvertently by the operator once the cycle

has started and holds the door closed until the end of

the cycle. It will also keep the door closed under all

fault conditions.

d. Pressure Relief Valve (safety valve). This valve safely

releases excess pressure (i.e. above 2.6 bar).

e. Microcomputer. The microcomputer constantly

monitors all key functions. If an error arises, it

immediately stops the cycle, discharges pressure,

and causes the appropriate message to be displayed

(See Error Correction para. 27).

f. Overheat Control. The microcomputer operates in

conjunction with an independent manual reset

thermostat to protect the heating element from

overheating. The autoclave is also fitted with a fusible

link which, should overheating occur, will cut all power

to the heating element and microcomputer and operate

the manual reset thermostat, leaving only the red

overheat warning lamp illuminated on the front panel.

Declaration

The design of the autoclave pressure vessel is approved

by a third party to PD5500 Cat.3. The pressure vessel is

constructed and tested to BS3970 Parts 1 and 4.

Conditions of Safe Use:-

a. Indoor Use.

b. Altitude up to 2000 metres.

c. Temperature 5°C to 40°C.

d. Maximum relative humidity 80% for temperatures up

to 31°C, decreasing linearly to 50% relative humidity

at 40°C.

e. Mains supply voltage fluctuations not to exceed ±10%

of the normal voltage.

f. No other voltage fluctuations specified by the

manufacturer.

Note: If it is required to operate this Autoclave outside of

these conditions, contact Eschmann Equipment at the

address given in these instructions.

IMPORT ANT NOTE:

UK Customers should arrange for this equipment

to be installed by an Eschmann Trained Engineer

before use. (For free installation and service details

see page 2). Also see ‘Safety Checks’ page 7.

The preset sterilizing temperature for your Little Sister 3

Autoclave is displayed on a temporary label affixed to the

front of the unit. All programmes can be deactivated or

reactivated by an Eschmann Trained Engineer , on request.

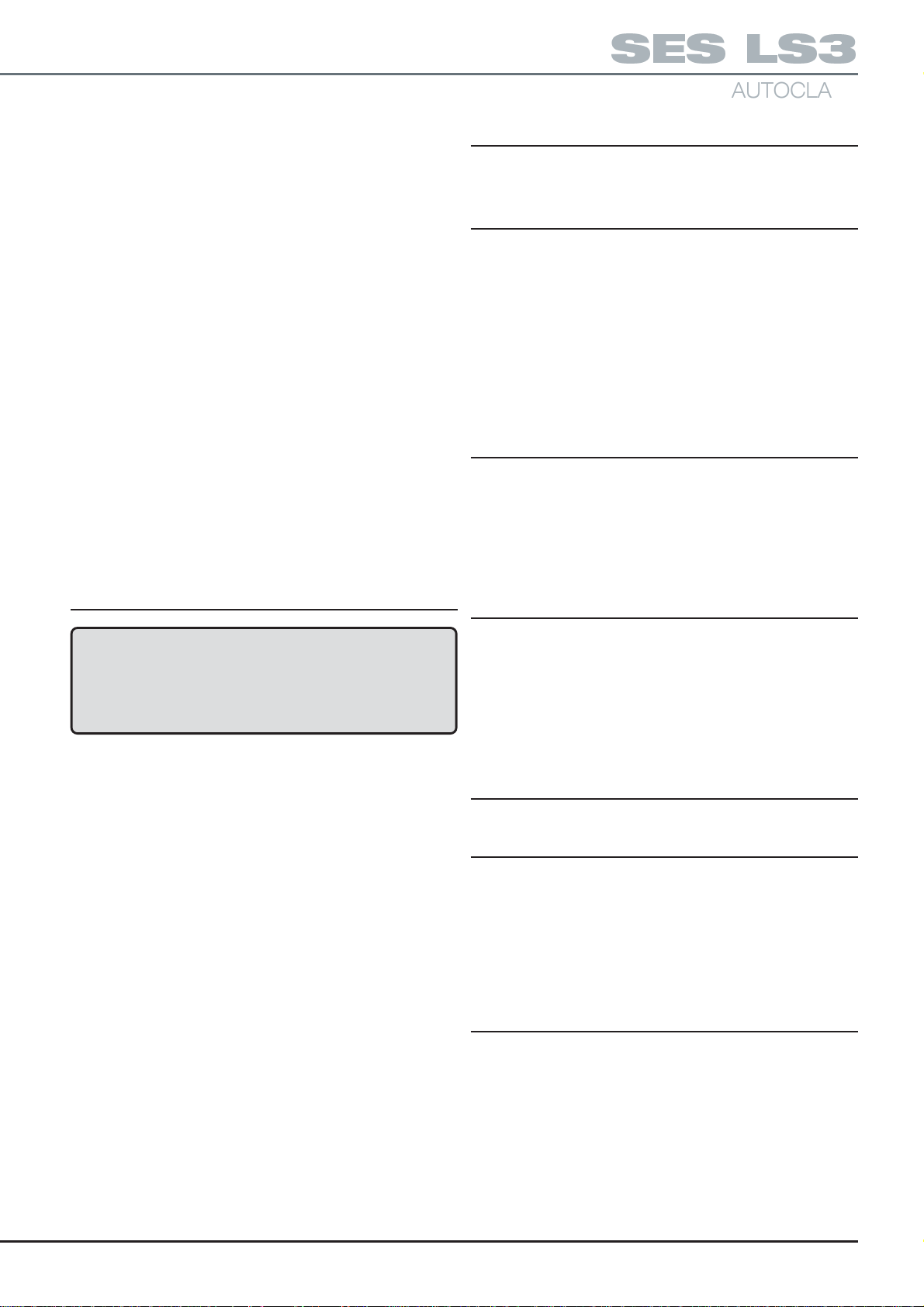

WARNING MARKINGS

The warning markings on this equipment have the

following meanings

Caution; refer to accompanying documents

(i.e. these Instructions for Use).

This symbol, adjacent to the door knob, warns

the user of the possible escape of steam and

hot water when the door is opened.

Caution; refer to accompanying documents

(i.e. these Instructions for Use).

This symbol, adjacent to the overheat light at

the bottom of the control panel, warns the user

of overheating of the sterilizing chamber.

Caution; hot surface.

This symbol warns the user of high surface

temperatures on the outside of the equipment.

Caution; refer to accompanying documents

(i.e. these Instructions for Use).

This symbol on the serial number label (rating

plate), and on the lid of the unit, warns the user

that it is necessary to read the Instructions for

Use before using the equipment.

Note: This equipment is defined as:

Installation Category 2 (Overvoltage Category 2)

Pollution Degree 2 (in accordance with IEC664).

ST-IM29h P5/12

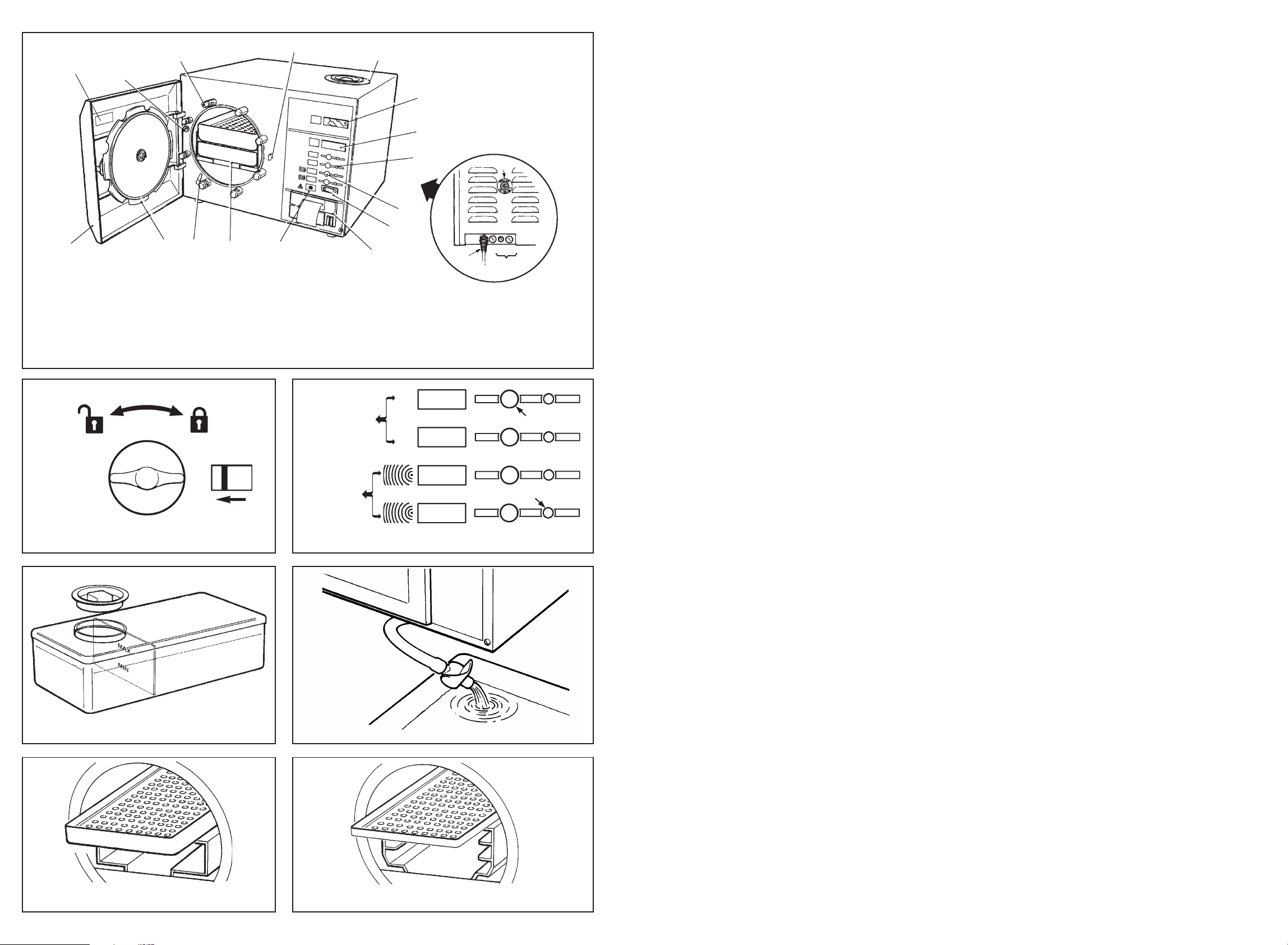

INITIAL PREPARATION FOR USE

1. When lifting or moving the Little Sister 3 Autoclave

(preferably with two people), place the hands under

the base at each side of the unit. Place the autoclave

on a flat, level surface and ensure there is a working

clearance of 150 mm all round for adequate ventilation.

Do not cover the ventilation louvres. Also see Note 2

part ‘g’ on page 4.

2. Check that the plug fuse is appropriate for the voltage

of the equipment (see rating plate on back of cabinet).

3. Connect unit to mains power supply (Warning this

equipment must be earthed) and switch on by

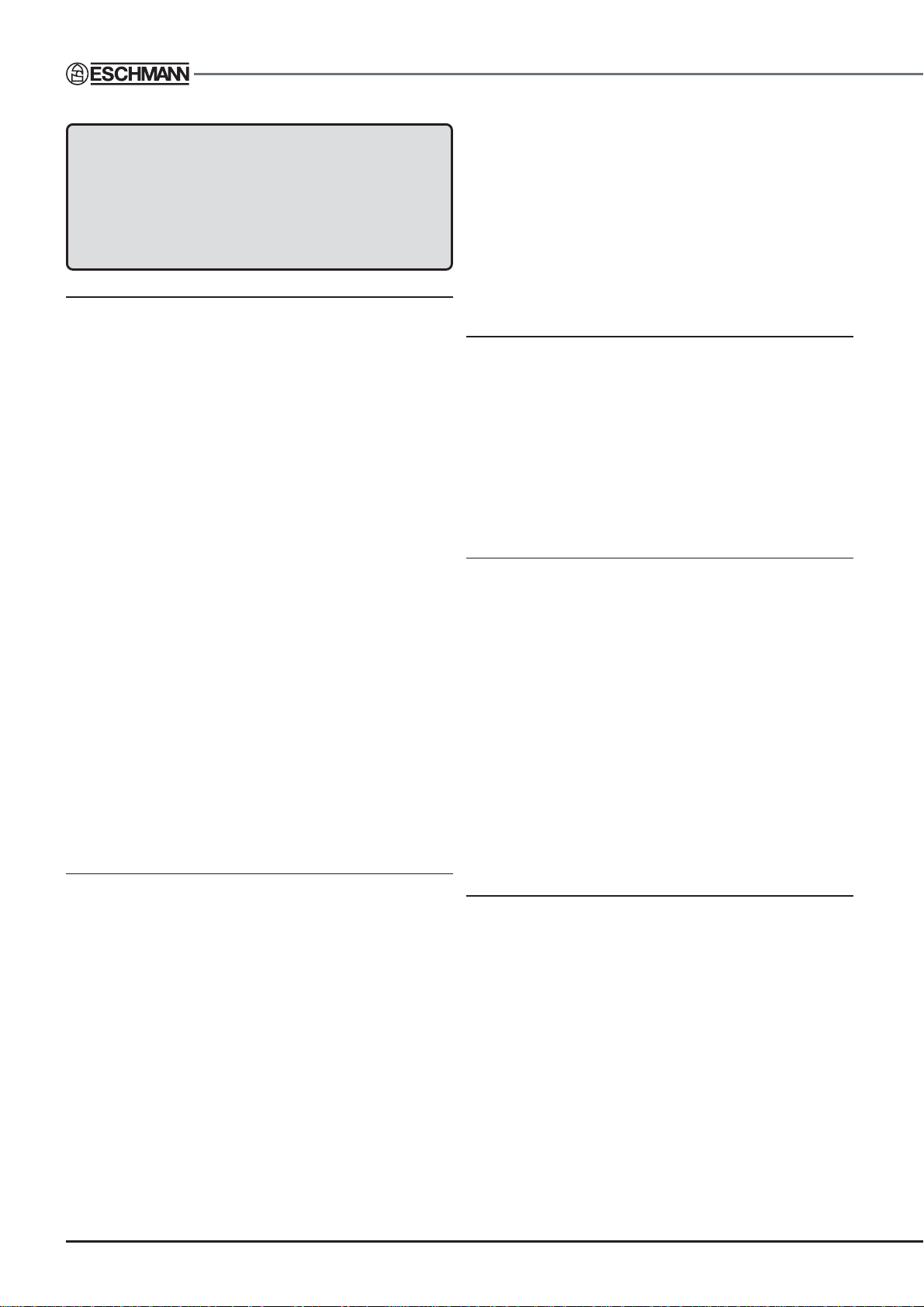

selecting unit power switch ‘0-I’ to ‘I’ (Fig. 1). Display

will go to ‘LS3’ followed by cycle count then door/test.

Note: If the door knob is turned to the fully closed

position the chamber door cannot be opened until

power is switched on.

4. Open chamber door (Fig. 2). Remove tissue paper

from the door; autoclaving trays, tray lifter; reservoir

lid, drip tray and feet adjustment pack. Discard all

packing pieces.

5. Fit reservoir cover and place plastic drip tray at front

of unit, below door. Fit feet adjustment pack

components as follows:

a. Plastic cups to protect work surface from rubber

feet marks.

b. If work surface is not level, place spacers, as

required, inside cup(s).

11. Do not overload trays, and avoid ‘bunching’ items

together.

12. Do not use trays or cassettes without holes and

ensure that the load does not block the holes in the

perforated trays and cassettes.

13. Load trays and place them in the sterilizing chamber

(Fig. 4 and 4a). All items must be positioned so that

they drain freely and do not trap rising air bubbles.

14. Close the chamber door by first ensuring the door

handle is turned fully open (counter-clockwise) before

shutting the door and locking by turning the handle

180° clockwise (Fig. 2).

STERILIZING & DRYING THE LOAD

15. Select required programme by pressing the

appropriate button on control panel (Fig. 5). The

indicator lamp for the selected programme remains

illuminated. The sterilizing cycle will now proceed

automatically and the printer (if fitted) will commence

printing. As the cycle progresses various displays will

appear in the display window (Fig. 1 item 3) to indicate

programme status.

Note: Select only from the programmes at the preset

sterilizing temperature (see Important Note, page 5).

16. The display sequence during the sterilizing cycle is:

Display Interpretation

6. Remove reservoir lid (Fig. 1) and fill reservoir up to

‘MAX’ mark (Fig. 3) with ‘Sterile Water for Irrigation’.

DO NOT USE TAP WATER, see ‘Reservoir Water

Quality Caution’ on page 3. Refit the reservoir lid.

LOADING THE AUTOCLAVE

7. Check you have read the limitations on use page 4

and technical Specification page 12.

8. Check that water level in reservoir is between ‘MAX’

and ‘MIN’ marks (Fig. 3). DO NOT FILL DURING

CYCLE.

9. With chamber door open (para. 3, Note), select mains

‘on/off’ switch to ‘I’ (on) (Fig. 1). This will initiate a single

audible signal followed by the display ‘LS3’, then the

number of cycles, the time of day (see note below) and

the flashing green indicators for the preset cycles.

Note: For units without a printer ‘rEAdy’ is displayed

not the time of day.

10. Before loading instruments into trays or cassettes

they should be pre-washed, preferably in an ultrasonic

cleaner to remove amalgam, debris, etc., then rinsed

to remove all traces of proprietary cleaners, chemicals

or disinfectants, before being placed in the sterilizer

chamber. Residue from these products could result in

a blockage of the water recycling system.

door/tESt Test door interlock switch (para. 14)

(Flashing

alternately)

door Sterilizing chamber door open

time of day Programme can now be selected

(e.g. 1 1-45) Note: for units without a printer

‘rEAdy’ is displayed.

FiLL Chamber being filled

HEAt Heater temperature below 92°C

92 to 136 Heating to sterilizing stage

S135.5 ‘S’ flashing, indicates sterilizing begun

and timing started

cond Steam being discharged and

condensed

dry Load being dried

End Cycle complete

Ser Service set to display at 1500 cycles.

This will not inhibit the use of the

autoclave, but, do arrange a service.

P6/12 ST-IM29h

SES LS3

AUTOCLAVE

17. If a cycle “With Drying” is selected then commencement

of the drying phase is indicated by the display ‘dry’

accompanied by a rapid intermittent audible signal.

When this signal is heard, maximum drying will be

achieved if the chamber door is opened halfway and

then closed until it touches the metal catch on the front

fascia panel, leaving a small gap (approx. 1cm) for

ventilation. Instruments can be taken out any time

during the drying phase, but best results will be

achieved by waiting until the automatic cycle is

complete.

18. On completion of a sterilizing cycle ‘without drying’,

the display ‘End’ will appear, accompanied by a brief

audible signal. When the door is opened to remove

load the display will change to ‘door’.

19. On completion of a sterilizing cycle ‘with drying’ (where

chamber door is opened slightly during the drying

phase), the display ‘End’ will appear briefly

accompanied by an audible signal and followed, after

a few seconds by ‘door’.

20. Open door fully and remove load USING THE TRAY

LIFTER and leave the door open slightly when not in

use.

AUTOCLAVE CLEANING & CARE

SAFETY CHECKS

24. Users should ensure that the following periodic safety

checks are carried out at the stated intervals:-

Weekly

¬ Check that the door opens and closes easily

¬ Check the door seal for any signs of damage

¬ Check that the secondary door catch latches

effectively

¬ Check for any obvious escape of steam or water

during a cycle (i.e. other than is normal from the top

of the reservoir)

CAUTION

Annual inspections should only be

undertaken by a Competent Person.

Annually

¬ Check the pressure relief valve operates freely

and at the set pressure

¬ Inspect the Pressure System for integrity

¬ Check Door micro-switches and interlocks

¬ Check Door locking mechanism for integrity

¬ Check Pressure indicators for correct operation

¬ Check overheat devices for function

UK Guidance

WARNING

Chlorine, even in the concentrations found in tap

water, can cause stainless steel to crack and could

damage the chamber. Disconnect from the mains

electrical supply before cleaning the Autoclave.

21. Keep chamber trays, door seal and chamber face

clean. These should only be cleaned with a lint-free

cloth. Clean the outside of the autoclave by wiping

down with a cloth dampened with a 70% solution of

industrial methylated spirit (IMS) and water. Allow to

dry by evaporation.

Note: Do not use abrasive powders, chemicals, or

solutions containing chlorine to clean the autoclave.

22. The reservoir must be drained weekly and be allowed

to dry (Fig. 6). When refilling see section 6 and

‘Reservoir Water Quality Caution’ on page 3, DO

NOT USE TAP WATER. Regular cleaning of the

reservoir will reduce the effects of excessive handpiece

lubricant which could be detrimental to the function of

the autoclave.

23. Attention to the following will increase the life of the

your Little Sister 3 Autoclave:

a. After use leave chamber door slightly open.

b. At weekly intervals, lightly clean door seal and

chamber face with a lint-free cloth.

Inspections can be arranged by contacting the Eschmann

After Sales Service Department, see inside cover for contact

details. Eschmann can also provide comprehensive service

contracts, which cover preventive maintenance to ensure

trouble free operation of your autoclave as well as an annual

inspection of the pressure system to satisfy the requirements

of the Pressure Systems Safety Regulations 2000.

MAINTENANCE

(Ensure you have read pages 3-5)

Fuse Renewal

25. Fuses are fitted at the back of the autoclave (Fig. 1,

detail). For fuse ratings refer to ‘TECHNICAL DATA’.

To extract a fuse switch ‘off’ the unit and disconnect

from the mains power supply, insert a screwdriver or

small coin in the slot of the fuse holder and twist it

counter-clockwise. After inspecting or renewing a fuse,

reverse the above procedure to re-secure fuse holder.

Preventive Maintenance Agreement

26. We would strongly recommend that a ‘P.M.A.’ is taken

out on your Little Sister 3 Autoclave. Although the

autoclave requires minimal maintenance, it is important

to have the autoclave checked and calibrated at

regular intervals. This ensures that the exacting

conditions necessary for sterilization are maintained

throughout the unit’s working life.

ST-IM29h P7/12

Error Correction

27. If, after switching ‘on’ power there is no visual display,

or audible tone, first check power supply connections.

Also check all 3 fuses at rear of unit (see Fuse Renewal).

If any error occurs during a cycle (i.e. any time after

selecting a programme), the cycle will abort and provided

power supply to the unit is maintained, the error will be

indicated by one of the visual displays shown in Table 1.

If power fails during a cycle, check supply conditions,

fuses, and connections as indicated in this paragraph.

Overheating

28. In the unlikely event of overheating, the red overheat

warning lamp (Fig. 1) will illuminate. If this happens,

first allow approximately 10 to 15 minutes for the

autoclave to cool, then check the water level in

reservoir. When the water level is correct, press the

button marked ‘PRESS TO RESET’ at the rear of the

cabinet (Fig.1, detail) and re-start the cycle in the

normal way. If the fault persists, switch off the unit and

call an Eschmann trained engineer.

Note: Should the ‘press to reset’ thermostat operate

in a nil water condition, the chamber temperature is

below 138°C. The maximum chamber temperature

on overheat, to melt the thermal fuse is 250°C.

Cleaning the Filter

29. The Little Sister 3 Autoclave is fitted with a filter which

will require cleaning by a qualified service engineer.

This should be carried out at least annually.

P8/12 ST-IM29h

SES LS3

AUTOCLAVE

Table 1 Fault Finding

WARNING

If an error display appears during a cycle, do not switch-off power until discharge of hot water or steam

into reservoir has stopped. Do not attempt to open the chamber door until the unit has cooled and internal

pressure has fallen sufficiently to release the pressure safety bolt. Loads whose cycles are aborted by one

of these error displays should be treated as non-sterile.

DISPLAY CAUSE REMEDY

a. Check local supply conditions

b. Check supply plug wiring and power cable for possible breaks.

c. Because there can be no guarantee that the load has been sterilised,

‘ELECt’ will continue to be displayed after power has been restored.

ELECt Temporary failure in T o re-start cycle:

(+ audible the mains supply to i. Wait until discharge of water or steam into reservoir has stopped.

signal) unit. ii. Switch ‘of f’ power and wait approximately 10 seconds.

iii. Push and hold-in any one of the four programme selection

buttons and, at the same time, switch ‘on’ power .

iv . Release programme selection button as soon as ‘LS3’ appears.

v . Select required programme to re-start cycle.

ERR2 Door switch faulty a. T o re-start cycle see remedy for ELECt.

(+ audible or maladjusted. b. If ‘ERR2’ persists call an Eschmann trained engineer .

signal)

WARNING: Do Not Open Door

a. For safety reasons, switch ‘off’ power.

LoH2O Insufficient water b. Check water level in reservoir is above ‘MIN’ mark.

(+ audible in reservoir If water is above the ‘MIN’ mark, do not fill to ‘MAX’ mark

signal) during a cycle.

c. To re-start cycle see remedy for ELECt.

d. If ‘LoH2O’ persists call an Eschmann trained engineer .

WARNING: Do Not Open Door

ERR3 Water failed to a. Allow unit to cool, there may be hot water in the chamber.

enter chamber To re-start cycle see remedy for ELECt.

from reservoir b. If these errors persist call an Eschmann trained engineer.

Water level in a. Wait for any discharge of water or steam into reservoir to cease.

ERR4 chamber has b. Switch ‘off’ power and carry out water level check, as for ‘LoH2O’.

(+ audible dropped slightly . c. To re-start cycle see remedy for ELECt.

signal) d.If ‘H2O’ persists call an Eschmann trained engineer .

ERR5 Heater not working a. Check RESET button (see para 28).

(+ audible b. If ‘ERR5’ persists call an Eschmann trained engineer .

signal)

ERR6,7,8,9 Temperatures outside a. Allow unit to cool. To re-start cycle see remedy for ELECt.

ERR8 pre-programmed b. If these errors persist call an Eschmann trained engineer.

ERR9 limits for sterilization

(+ audible

signal)

door/tESt Door closed with

Flashing power on. a. Leave door open slightly when not in use before removing power.

alternately

ST-IM29h P9/12

OPERATING INSTRUCTIONS

FOR PRINTER

Printer Output

The printer output gives the following information:

¬ Manufacturer’s name Eschmann Equipment

¬ Machine type SES Little Sister 3

¬ Serial number Alpha numeric code

¬ Cycle type e.g. 134°C no drying

¬ Time and date started hh:mm:ss on dd:mm:yy

¬ Counter reading Fiv e di gits wit h leading zeros

¬ Time/temp information Time every 22 secs

(approx.) + temp. + graph

of temperature.

¬ Cycle ended message The ‘cycle end’ is defined

as the end of the

sterilizing phase.

¬ Time and date ended hh:mm:ss on dd:mm:yy

If an error occurs during the cycle, it is recorded with date

and time on the printout and the message ‘CYCLE FAILED’.

Errors are designated by error codes as follows:

ERR1 -Faulty temperature sensor/channel

detected (‘ELECt’ on display)

ERR2 -Door open during cycle

ERR3 -Chamber did not fill with water

ERR4 -Water loss early in cycle

ERR5 -No heat

ERR6 -Control temperature low

ERR7 -Control temperature high

ERR8 -Monitor temperature low

ERR9 -Monitor temperature high

These error codes will generally require investigation by

an Eschmann trained engineer.

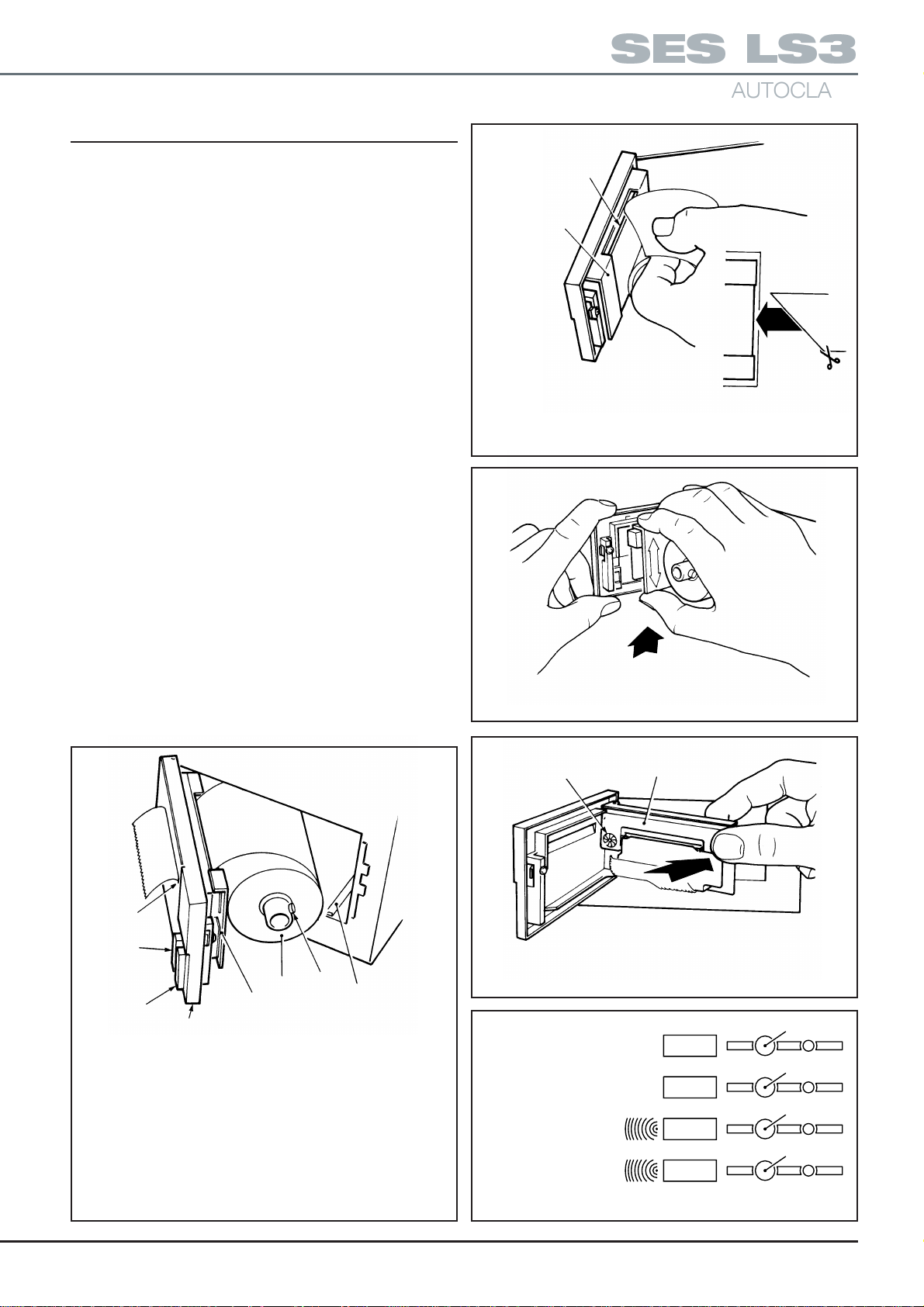

Front Panel Controls

All controls for the printer are on the front of the panel.

a. Door Latch Button - To open door (Fig. 7,1) push the

door latch (Fig. 7, 2) sideways, in the direction of

arrow, and pull the door open to expose paper roll

(Fig. 7,4).

b. Paper Feed Button - Ensure the sterilizer mains ‘on/

off’ switch is in the ‘I’ (on) position. Press lower part of

paper feed button (Fig. 7,3) to activate paper feed,

which will continue for as long as the button is

depressed.

Paper Roll Renewal

Renew paper roll as follows:

a. Open autoclave chamber door to provide more access.

b. Push door latch button (Fig. 7,2) sideways, in direction of

arrow and pull door open to expose paper roll (Fig. 7,4).

c. If any paper remains in the printer, tear end off against

paper tear bar (Fig. 7,8) and carefully withdraw the

remaining paper backwards from the rear of printer

mechanism (Fig. 7,5).

d. Compress paper roll spring-loaded retainer button

(Fig. 7,6) and withdraw empty paper spool from spindle.

e. Take new roll of paper, separate paper end from the roll.

Remove any damaged or gummed part of the paper.

f. Compress paper roll spring-loaded retainer button

(Fig. 7,6) and locate new paper roll on spindle with

paper unrolling counter-clockwise as seen from open

end of spindle (Fig 7).

g. Using scissors, trim end of paper roll at an angle of

approximately 30° (Fig. 8) and insert this end of the

paper into the paper insert slot (Fig. 8,1). Press paper

feed actuator arm (Fig. 7,7) until mechanism grips

paper and pulls it through to front of printer door.

h. Turn paper roll by hand to take up any slack paper

i. Close the printer door. Check paper feed by pressing

paper feed button (Fig. 7,3) until the end of the

trimmed paper is clear of the tear bar. Ensure that the

paper feeds freely from the printer.

Ribbon Cartridge Renewal

Renew ribbon cartridge as follows:

a. Remove paper roll.

b. Support door with left hand and press upwards with

right hand on bottom of printer mechanism chassis

(Fig. 9) and separate chassis from door.

CAUTION:

Do not pull printer mechanism chassis from

door until catch has been released.

c. Leaving printer door fully open, expose printer

mechanism and ribbon cartridge (Fig. 10,1).

d. Pinch the end of ribbon cartridge marked ‘PUSH’

(Fig. 10,1) and remove cartridge.

e. Install new cartridge, checking that left hand side of

cartridge is correctly located on drive shaft, and

CAREFULLY press cartridge into place.

f. Ensure ribbon is taut. If necessary tighten ribbon by

turning faceted disc (Fig. 10,2) on cartridge, clockwise,

using finger or fingernail.

g. Fit paper roll as described above.

Spares Pack

CAUTION:

DO NOT USE ALTERNATIVE PAPER ROLLS

The quality and size of paper rolls used in the printer,

can only be supplied by Eschmann Equipment.

A spares pack is available comprising:

¬ Five paper rolls

¬ Two ribbon cartridges

The spares pack is available from Eschmann Equipment

under catalogue number 87-034-05.

P10/12 ST-IM29h

Setting Date and Time

SES LS3

AUTOCLAVE

1. To change the clock setting (e.g. from GMT to BST or

the reverse) proceed as follows:

a. Select mains ‘on/off switch to ‘0’ (off).

b. Refer to Fig. 11, push and hold down buttons

SW1 and SW4 simultaneously then select ‘on/

off’ switch to ‘I’ (on).

c. The display will read ‘01’.

d. Then proceed as described in paragraph 2 (a)

to (g).

2. To set the date and time proceed as

a. If closed, open chamber door.

b. Display reads ‘01’. Push and hold down button

SW1 (Fig.1 1). Observe that number changes to

02,03 etc. through to 12. Also note that pushing

and holding SW2 makes the number decrease.

Use SW1 and SW2 to set the number corresponding to the month (01=January etc.). Push

SW3 to retain selection.

c. Display reads ‘dy01’. Again use SW1 and/or

SW2 to display the day of the month (push SW3

to retain the day).

Note: The computer will prevent entry of dates

such as 31st November.

d. Display reads ‘yr00’. Use SW1/SW2 to set any year

from 00 to 99 e.g. 97. Then push SW3 to retain it.

e. Display reads ‘hr00’. Use SW1/SW2 to set the

hour - the system utilises a 24 hour clock. Push

SW3 to retain.

f. Display reads ‘in00’ (minutes). Use SWI/SW2 to

show current minutes and push SW3 to retain it.

g. The clock is now set.

1

2

1. Paper Insert Slot

2. Printer Mechanism Chassis

Fig. 8. Paper Feed

Fig. 9. Ribbon Cartridge

8

3

2

1. Printer Door

2. Door Latch

3. Paper Feed Button

4. Paper Roll

5. Printer Mechanism

6. Spring-Loaded Retainer Button

7. Paper Feed Actuator Arm

8. Paper T ear Bar

Fig. 7. Printer

2

1. Ribbon Cartridge

2. Faceted Disc

6

4

5

1

7

Fig. 10. Ribbon Cartridge in Position

Programmes

without drying

Programmes

with drying

Fig. 11. Setting Date and time

{

{

1

SW1

134°C

SW2

121°C

SW3

134°C

SW4

121°C

ST-IM29h P11/12

TECHNICAL DATA

ELECTRICAL

Supply

220V/230V,

50/60 Hz a.c.

For use with alternating current

Loading

Volts Standard Long

220V 1.9kW 2.4kW

230V 2.0kW 2.6kW

Fuses

Standard 220V - 13A (Pt.No.380002) (x2)

230V - 10A (Pt.No.380003) (x2)

Long 230V - 15A (Pt.No.301871) (x2)

220V - 15A (Pt.No.301871) (x2)

All versions F400mA (Pt.No.696181) (x1)

SAFETY STANDARDS

IEC 1010-1 (1990) - Standard version only

IEC 601-1 (1977) BS5724:Part 1 (1979)

ESCHLE (Second Edition 1986)

EN 61010-1 (1993) inc. Amendment 2 (1995)

EN 61010-2-041 (1996)

STERILIZING

Time

At 134/137°C - 3min 20sec

At 121/124°C - 15min

Typical overall cycle times without drying at 2kW

134°C - 13min

121°C - 24min

Drying time when selected

up to 17 minutes after sterilizing cycle

Operating pressure

137°C - 2.32 bar

134°C - 2.03 bar

124°C - 1.25 bar

121°C - 1.03 bar

Maximum Load per Tray

1.5kg Standard 3.5kg Long

WATER RESERVOIR

Capacity 2.0 litre

WEIGHT (approx.)

Net 27.5kg Standard 35.5kg Long

Shipping 32.0kg Standard 40.0kg Long

P12/12 ST-IM29h

OPEN THIS PAGE OUT FROM

THE OTHER SIDE TO GAIN

EASY ACCESS TO THE

ILLUSTRATIONS WHILST

READING THE TEXT.

ST-IM29h

OPEN HERE

TO GAIN

ACCESS TO

ILLUSTRATIONS

19

13

14

15

1

2

3

4

16

5

6

10

1112

1. Reservoir lid 6. Mains on/off Switch 12. Chamber Door

2. Analog Pressure Gauge 7. Printer (if fitted) 13. Electric Door Bolt

3. Display Window 8. Overheat Warning Lamp 14. Pressure Door Bolt 18. Fuses

4. Programme Indicator 9. Sterilising Trays (4 on 1 5 . Door Safety Catch 1 9. Serial Number Plate

Lamps Standard, 2 on Long) 16. Overheat Reset Button

5. Programme Selection 10. Door Interlock Switch 17. Power Supply Cable

Touch Buttons 11. Door Seal

9

8

7

17

18

Fig. 1. Little Sister 3 Autoclave

(Long Version + Printer)

Unlocked Locked

Programmes

without drying

134°C

Programme Selection Touch Buttons

121°C

Programmes

with drying

To Open

134°C

Programme Indicator Lamps

121°C

Fig. 2. Door Controls

Fig. 3. Water Reservoir

Fig. 5. Control Panel

Fig. 6. Drain T ap

Fig. 4. Sterilising Chamber Long

Fig. 4a. Sterilising Chamber Standard

Loading...

Loading...