Page 1

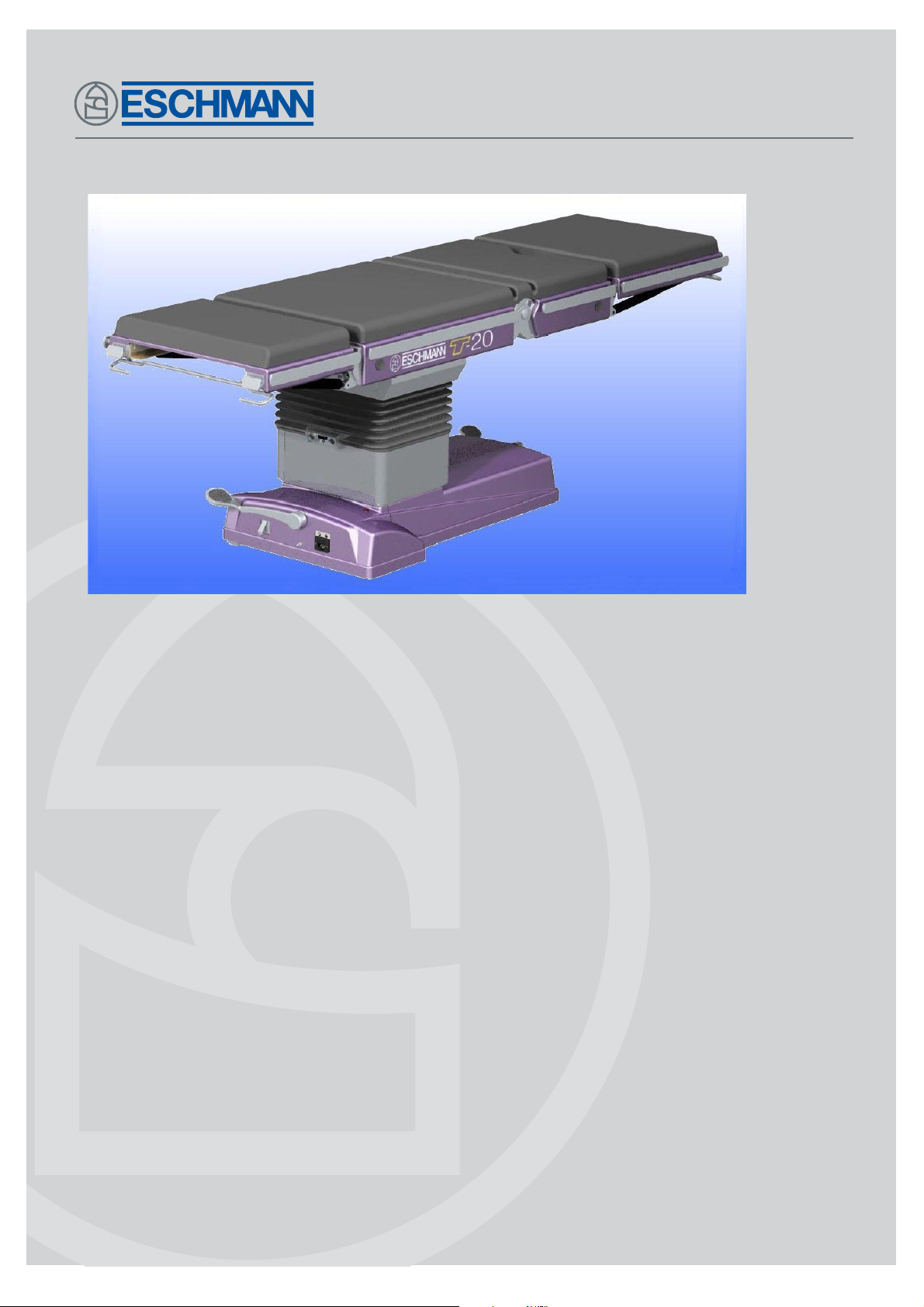

T20-a

OPERATION TABLE

Service manual

111707

T-SM47j

Page 2

Preliminary

Information

Technical data

Technical

description

Read these Instructions before use

Keep these ‘Instructions’ in a safe convenient place for future reference. Read in conjunction

with the Publications detailed in Section 1.1.

Eschmann After Sales Service Department

Safety notes

Maintenance

Part removal

adjustment

replacement

The Eschmann After Sales Service Department is staffed and equipped to provide advice and

assistance during normal office hours. To avoid delays when making enquiries, please quote the

Model and Serial Number of your Operation T able which is shown on the Serial Number plate, the

location of which is shown below. Please ensure you include all alpha and numeric digits of the

Serial Number.

The Serial Number

plate is located here

For further information visit www.eschmann.co.uk

All correspondence relating to the after sales service of Eschmann Equipment to be addressed to :

UK Customers

Eschmann Equipment, Peter Road, Lancing, West Sussex BN15 8TJ, England.

T el: +44 (0) 1903 765040. Fax: +44 (0) 1903 875711.

Overseas Customers

Contact your local distributor. In case of doubt contact Eschmann Equipment.

Patents and Trade marks

The ESCHMANN name and logo are registered trade marks of Eschmann Holdings Limit ed.

“Eschmann Equipment” is a trading name of Eschmann Holdings Limit ed.

“T20-a” is a trade mark of Eschmann Holdings Limited .

Patents : Worldwide Patents Pending.

Copyright © 2005 Eschmann Holdings Limited

All rights reserved. This booklet is protected by copyright. No part of it may be reproduced, stored in a

retrieval system or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording or otherwise without written permission from Eschmann Holdings Lim ited.

The information in this publication was correct at the time of going to print. The Company, however,

reserves the right to modify or improve the equipment referred to.

The CE marking affixed to the product certifies that it complies with the

European Medical Devices Directive 93/42/EEC and related legislation.

T-SM47j July 2005

Service manual

Page 3

T20-a

OPERATION TABLE

CONTENTS

1.0 Preliminary information

1.0 Preliminary information . . . . . . . . . . . . . . . . . . . 5

2.0 Technical data

2.1 Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Movements . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4 Table loading . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Classification and symbology . . . . . . . . . . . . . . 9

2.7 Use in conjunction with other equipment . . . . . . 9

2.8 Standards compliance . . . . . . . . . . . . . . . . . . . . 9

2.9 Environmental conditions . . . . . . . . . . . . . . . . . . 9

3.0 Technical description

3.1 Power supply assembly . . . . . . . . . . . . . . . . . . 13

3.2 Control electronics . . . . . . . . . . . . . . . . . . . . . . 13

3.2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2.2 Handset overview . . . . . . . . . . . . . . . . . . . . 14

4.0 Safety warnings

4.1 ‘Service position’ . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 M10 trunk screw removal . . . . . . . . . . . . . . . . 16

4.4 Trend and tilt actuator removal . . . . . . . . . . . . . 16

4.5 Working with mains voltage . . . . . . . . . . . . . . . 16

4.6 Gas springs . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.7 Hot parts on PCAs . . . . . . . . . . . . . . . . . . . . . 16

4.8 Biological contamination . . . . . . . . . . . . . . . . . 16

4.9 Connection of leads . . . . . . . . . . . . . . . . . . . . . 16

4.10 Leaking batteries . . . . . . . . . . . . . . . . . . . . . . . 16

5.0 Maintenance

5.1 Power supply assembly . . . . . . . . . . . . . . . . . . 17

5.2 Table fault finding . . . . . . . . . . . . . . . . . . . . . . . 17

5.2.4 Break motion control . . . . . . . . . . . . . . . . . 17

5.2.5 Trunk section connector blocks . . . . . . . . . 17

5.3 Fuse location . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.4 Service schedule and safety check . . . . . . . . . 18

6.0 Part removal/adjustment/

replacement

6.1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2 Table base and column covers . . . . . . . . . . . . 20

6.2.2 Base covers . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2.1 Removal of base covers . . . . . . . . . . 20

6.2.2.2 Replacing base covers . . . . . . . . . . . 21

6.2.3 Access to column . . . . . . . . . . . . . . . . . . . . 21

6.2.3.2 Lower column access . . . . . . . . . . . . 21

6.2.3.3 Lower-mid column access . . . . . . . . 21

6.2.3.4 Upper-mid column access . . . . . . . . 21

6.2.3.5 T op of column access . . . . . . . . . . . . 23

6.2.4 Telescopic covers . . . . . . . . . . . . . . . . . . . . 23

6.2.4.1 Removal of telescopic covers . . . . . . 23

6.2.4.2 Refitting the telescopic covers . . . . . 23

6.2.5 Bellows . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.2.5.1 Removal of the bellows . . . . . . . . . . . 23

6.2.5.2 Replacing the bellows . . . . . . . . . . . . 24

6.3 Table base components . . . . . . . . . . . . . . . . . . 24

6.3.2 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.3.3 Pedal dampers . . . . . . . . . . . . . . . . . . . . . . 24

6.3.4 Front wheels . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.5 Castors . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.5.1 Castor assembly . . . . . . . . . . . . . . . . 25

6.3.5.2 Castor wheels . . . . . . . . . . . . . . . . . . 25

6.3.6 Brake pads . . . . . . . . . . . . . . . . . . . . . . . . 25

6.3.7 Castor pillar bushes . . . . . . . . . . . . . . . . . 29

6.3.8 Pedal spindle bushes . . . . . . . . . . . . . . . . 29

6.3.9 Lifting roller assembly.. . . . . . . . . . . . . . . . 29

6.3.10 Pedal catch block . . . . . . . . . . . . . . . . . . . 29

6.3.11 Pedal anti-skid pads . . . . . . . . . . . . . . . . . 29

6.3.12 Pedal catch pawl and spring . . . . . . . . . . . 29

6.4 Table column components . . . . . . . . . . . . . . . . 30

6.4.2 Trendelenburg actuator . . . . . . . . . . . . . . . . 30

6.4.3 Tilt actuator . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.4 Telescopic column assembly . . . . . . . . . . . . 30

6.4.5 Tilt & Trendelenburg motor . . . . . . . . . . . . . . 32

6.4.6 Tilt bush . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.7 Trendelenburg bush . . . . . . . . . . . . . . . . . . . 32

6.4.8 Bearing pads . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Table sections . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5.1 Head and leg section . . . . . . . . . . . . . . . . . 33

6.5.1.1 Guide pins . . . . . . . . . . . . . . . . . . . . 33

6.5.1.2 Gas springs . . . . . . . . . . . . . . . . . . . 33

6.5.1.3 Top cover . . . . . . . . . . . . . . . . . . . . . 33

6.5.1.4 Gas spring release head/pin . . . . . . . 33

6.5.1.5 Gas spring release handle . . . . . . . . 35

6.5.1.6 X-ray translucent top . . . . . . . . . . . . 35

6.5.2 Trunk sections . . . . . . . . . . . . . . . . . . . . . . . 35

6.5.2.1 Traverse motor . . . . . . . . . . . . . . . . . 35

6.5.2.2 Traverse drive belt . . . . . . . . . . . . . . 36

6.5.2.3 Break motor . . . . . . . . . . . . . . . . . . . 36

6.5.2.4 Break gearbox . . . . . . . . . . . . . . . . . 36

6.5.2.5 Side rails . . . . . . . . . . . . . . . . . . . . . 39

6.5.2.6 Top covers . . . . . . . . . . . . . . . . . . . . 39

6.5.2.7 Push button components . . . . . . . . . 39

6.5.2.8 Traverse rod bearing . . . . . . . . . . . . . 39

6.5.2.9 Drive belt guide bearing . . . . . . . . . . 41

6.5.2.10 Attachment blocks . . . . . . . . . . . . . . 41

6.5.2.11 Black tops . . . . . . . . . . . . . . . . . . . . 41

6.6 Electrical components . . . . . . . . . . . . . . . . . . . 41

6.6.2 Three actuator PCA . . . . . . . . . . . . . . . . 42

6.6.3 Four actuator PCA . . . . . . . . . . . . . . . . . 42

6.6.4 Infrared receiver PCA . . . . . . . . . . . . . . 42

6.6.5 Power supply assembly . . . . . . . . . . . . . 43

6.6.6 Traverse motor . . . . . . . . . . . . . . . . . . . . 43

(continued over page)

T -SM47j P3/54

Page 4

6.6.7 Break motor . . . . . . . . . . . . . . . . . . . . . . 43

6.6.8 Tilt and Trendelenburg motors . . . . . . . . 43

6.6.9 Telescopic column assembly . . . . . . . . . 43

6.6.10 Break potentiometer loom . . . . . . . . . . . 43

6.6.11 Tilt potentiometer loom . . . . . . . . . . . . . 43

6.6.12 Trendelenburg potentiometer . . . . . . . . . 43

6.6.13 Height potentiometer loom . . . . . . . . . . . 43

6.6.14 Traverse motor loom & m’switches . . . . . 45

6.6.15 Connector blocks & looms . . . . . . . . . . . 45

6.6.16 Switch & accessory panel looms . . . . . . 45

6.6.17 Column energy chain and loom . . . . . . . 45

6.6.18 Break gearbox loom . . . . . . . . . . . . . . . . 46

6.6.19 Batteries, table & handset . . . . . . . . . . . 46

6.6.20 Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.6.21 Table infrared code change . . . . . . . . . . 46

6.6.22 Infrared handset code change . . . . . . . . 46

6.6.23 Handset service . . . . . . . . . . . . . . . . . . . 47

6.6.24 Processor PCA . . . . . . . . . . . . . . . . . . . 47

6.6.25 Standby panel and loom . . . . . . . . . . . . 47

6.6.26 Battery management reconditioning . . . . 47

6.7 Function tests . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.1 Batteries . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.2 Battery charger . . . . . . . . . . . . . . . . . . . 47

6.7.3 Corded handset . . . . . . . . . . . . . . . . . . . 47

6.7.4 Infrared handset . . . . . . . . . . . . . . . . . . . 47

6.7.5 Footswitch control . . . . . . . . . . . . . . . . . 47

6.7.6 Standby control panel . . . . . . . . . . . . . . 47

6.7.7 Sections (head and leg) . . . . . . . . . . . . . 47

6.7.8 Base pedals . . . . . . . . . . . . . . . . . . . . . . 48

6.7.9 Cycle of movements . . . . . . . . . . . . . . . 48

6.8 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Figures

1.0 Identification of main parts . . . . . . . . . . . . . . . . . 6

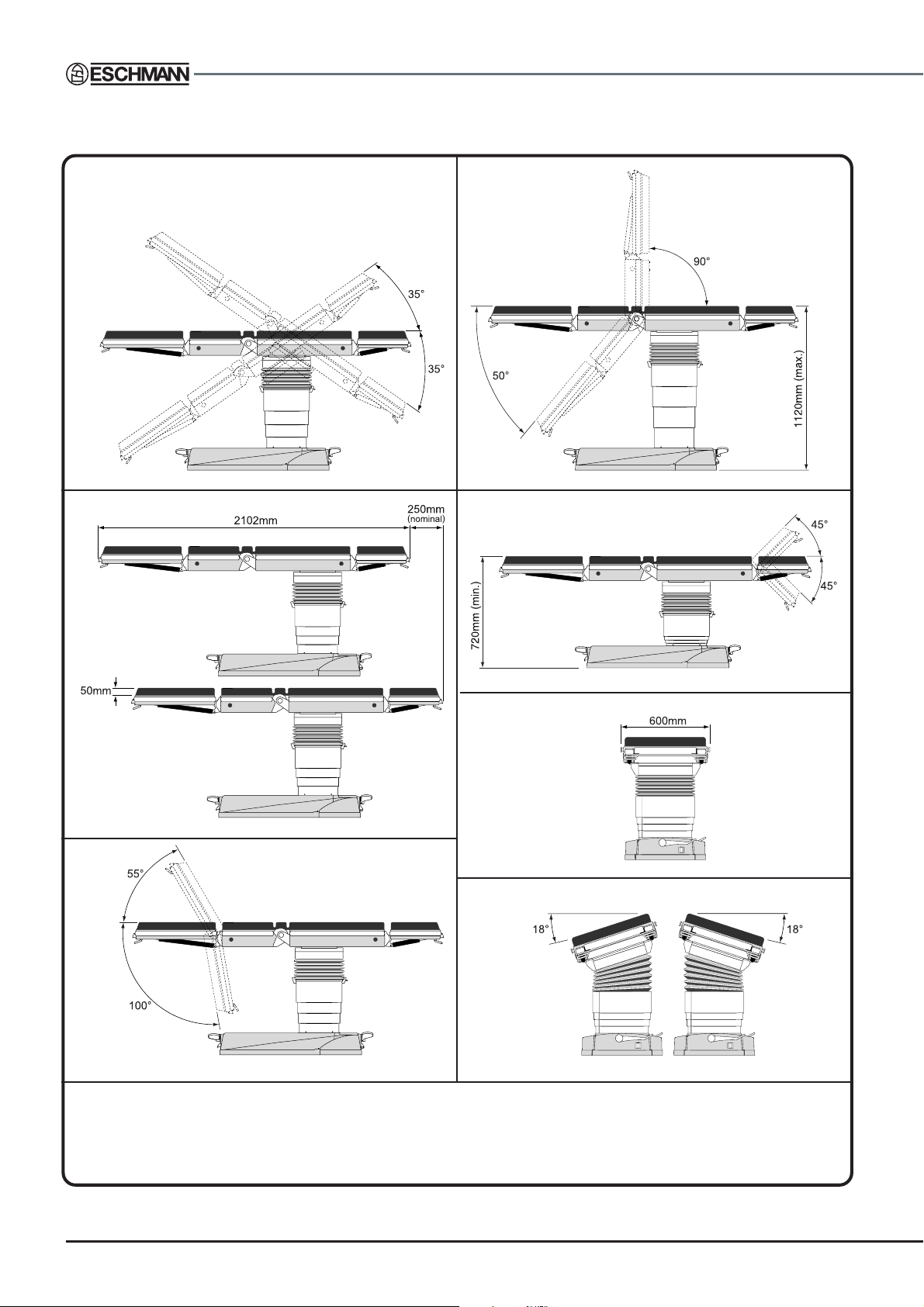

2.1 Major dimensions and movements . . . . . . . . . . 10

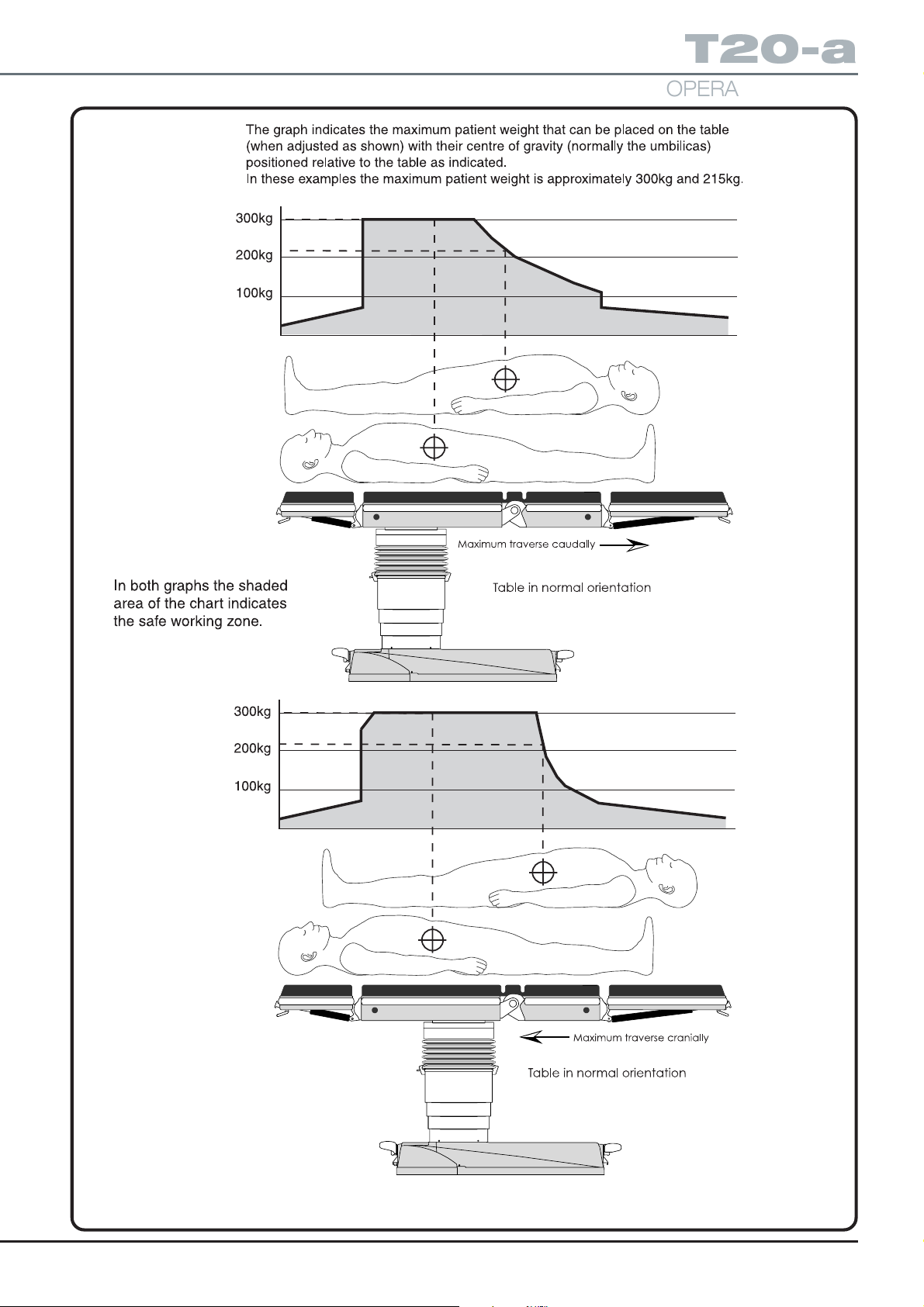

2.2 Maximum patient weights . . . . . . . . . . . . . . . . 11

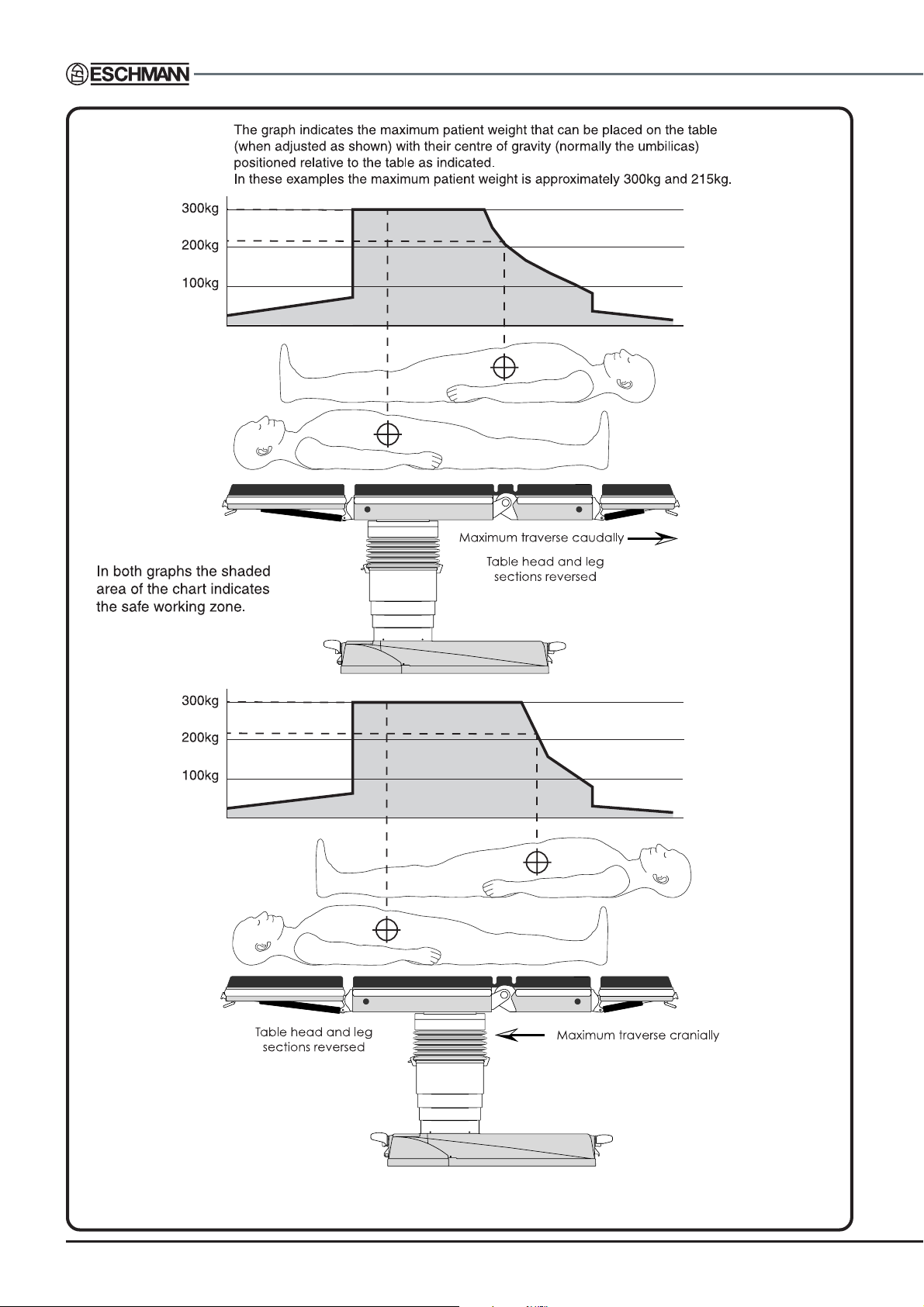

2.3 Maximum patient weights . . . . . . . . . . . . . . . . 12

3.1 Schematic diagrams . . . . . . . . . . . . . . . . . . . . 15

6.1 Table covers general arrangement . . . . . . . . . . 22

6.2a T able base general arrangement (ext’l catch) . . 26

6.2b T able base general arrangement (int’l catch) . . . 27

6.2c T able base general arrangement (int’l catch

and increased height) . . . . . . . . . . . . . . . . . . . . 28

6.3 Table column general arrangement . . . . . . . . . . 31

6.4 General arrangement, head & leg section. . . . . 34

6.5 Table long trunk general arrangement . . . . . . . . 37

6.6 Table short trunk general arrangement . . . . . . . 38

6.7 Table traverse general arrangement . . . . . . . . . 40

6.8 Table base main electrical components . . . . . . 42

6.9 Handset button functions and serial labels . . . . 4 4

6.10 Old and new infrared Handset buttons . . . . . . . 44

A1 T20-a Schematic diagram - Base Section . . . . 51

A2 T20-a Schematic diagram - Pedestal Section . . 52

A3 T20-a Schematic diagram - Trunk Section . . . . 53

Appendix 1

Torque conversions . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix 2

Application software guide . . . . . . . . . . . . . . . . . . . . . 50

Appendix 3

T20-a Table schematics . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix 4

Electrical safety checks . . . . . . . . . . . . . . . . . . . . . . . 54

P4/54 T-SM47j

Page 5

T20-a

OPERATION TABLE

1.0 PRELIMINARY INFORMATION

WARNING

Before servicing this operation table the

engineer should be familiar with all the

warnings and cautions contained within the

‘Instructions for use’ detailed in section 1.1.

This service manual does not provide details

of how to operate the table nor does it provide

information on the symbols and warning signs

provided on the table. All this information is in

the ‘Instructions for use’ supplied with the table.

Additional copies of the ‘Instructions for use’

can be obtained from Eschmann Equipment.

Only qualified and trained engineers should

service or maintain this operation table to

ensure that all the built-in safety features are

not compromised.

1.1 This Service Manual should be referred to for details

of the T20-a Powered Operation Table, Serial Number (SN)

T2AA3A0000 or above:

REF T20-223-2301* & T20-108-2301*

REF T20-221-2301 & T20-106-2301

REF T20-221-2101 & T20-106-2101

* These models have Denyer style accessory side rails.

The related publications listed below provide additional

information.

T-IM102 (1 11701) - Instructions for use

T-IPL35 (111706) - Illustrated parts list

T-IM94 (11 1012) - ‘T’ Series Application software manual

T-IM56 (698907) - General accessory leaflet

The number in brackets above, is the part number for that

publication.

1.2 ‘Instructions for use’ and ‘Service manuals’ should

be readily accessible for reference prior to and when

operating, cleaning, servicing, or, maintaining the operation

table.

1.3 The table and all accessories are not supplied sterile

therefore the table and all accessories should be cleaned

and disinfected in line with hospital practice and the

information supplied in the ‘Instructions for Use’ before use.

1.4 The manuals listed above and the Application

software, are available to order from Eschmann Equipment,

see inside front cover for address details.

1.5 Make sure that routine servicing is carried out as

detailed in the service schedule, section 5.4, by Eschmann

trained or accredited engineers.

1.6 The service schedule provided in this manual details

a program of maintenance work to be carried out at six

monthly intervals, refer to the applicable section of this

manual for details of how to perform these various functions.

Any special adjustments required for components are

detailed in the part replacement (section 6.0) for that item

to save duplication. As routine the Service Schedule should

be followed in the event of an additional service due to a

fault developing with any aspect of the table, this will ensure

that all aspects of the table are covered.

WARNING

Ensure that the correct screw torque settings

are used as detailed within this manual to

ensure safety and that parts are not damaged.

1.7 Throughout this manual there are recommended

torque settings for many of the screws. In the main, these

are only provided on the illustrations. Ensure that these

are checked and the correct torque settings are used where

specified. These are provided to ensure safety (i.e. screws

are tightened correctly) and that components are not

damaged by excessively high torques.

1.8 Fig. 1.0 identifies the main parts of the T20-a

operation table.

1.9 The table can be placed into a ‘Service Position’ that

provides easy access to components within the ‘top of

column’ area (ensure table is switched ‘off’ before opening

top). To achieve this position first note the safety warning

in section 4.1. Remove as much as possible from the table

top (e.g. leg and head sections, accessories and

mattresses etc.). Remove the top of column steel covers

(items 13 and 14 of Fig. 6.1). Remove the four M10 screws

(each side) that secure the trunk sections to the pedestal

(not the M6 cap head screws that can be seen passing

through the oilite bushes on each side) and allow the trunk

section to pivot (short trunk down) about the oilite bush

pivots (item 16, Fig. 6.3). Extreme care should be taken at

all times with the table in this position, especially during

transition into and out of the ‘Service Position’. Use tool

number T2203 to maintain contact between the connector

blocks if required when the table is in the ‘Service Position’.

When returning the table out of the ‘Service Position’ ensure

the eight M10 screws are tightened to the correct torque

and that the covers are replaced.

1.10 The ‘Instructions for use’ (provided with the table)

contain all the cleaning, disinfection and care instructions,

consult this for these aspects as they are not duplicated in

this manual.

CAUTION

Continued use of the table batteries when

‘critically low’ can damage the batteries. Charge

batteries regularly to maintain peak

performance. Do not remove the table from

charge until both charging LED’s are ‘green’ to

avoid false battery level indication on the

handset.

T -SM47j P5/54

Page 6

NOTE: The table illustrated has external pedal locking catches. Some

tables have internal locking catches, see section 6.2 and 6.3 for details.

Fig. 1.0 Identification of main parts

P6/54 T-SM47j

Page 7

T20-a

OPERATION TABLE

Key to Fig. 1.0

1 Head section

2 Long trunk section

3 Short trunk section

4 Leg section

5 Leg section gas spring

6 Short trunk section release button

7 Long trunk section release button

8 Battery fuses

9 Wheel foot pedal

10 Head section release bar

11 Head section gas spring

12 Standby control panel

13 Base

14 Pedestal

15 Castor foot pedal

16 Leg section release bar

17 Mains fuses

18 Connection socket for mains (ONLY use Eschmann mains cord, Part No. 391177)

19 Main battery charging state LED:

Red = Mains ‘on’, batteries in ‘bulk’ charge

Amber = Mains ‘on’, batteries in ‘top-up’ charge (duration 2 hours)

Green = Mains ‘on’, batteries in ‘trickle’ charge (i.e. fully charged)

20 Standby battery charging state LED (colour code as main battery above)

21 Main table ‘On/Off’ switch ( = Of f, = On)

22 Connection socket for Eschmann footswitch (ONLY)

23 Table ‘On’ LED (green)

Bright = Table in use, micro-controllers active

Dim = T able ready for instant use but in battery save (sleep) mode

24 Connection socket for Eschmann handset (ONLY)

25 Head and leg section end blocks (use to stow UK handset)

26 Accessory side rails (can also be used to stow handset*)

27 Standby battery switch

* Clip on handset must match side rail type, see ‘Instructions for Use’.

Note: For location of the Serial Number plate see inside front cover.

T -SM47j P7/54

Page 8

2.0 TECHNICAL DATA

2.1 Weights

2.4 Table loading

See maximum patient weight distribution charts in Fig. 2.2

and 2.3 for various table positions and orientations.

The nominal weights of the standard table components

are listed below (for 50mm mattresses):

Leg section (without mattress) .. .. 11.50kg

Leg section mattress .. .. .. .. 2.75kg

Head section (without mattress) .. .. 7.75kg

Head section mattress .. .. .. 2.00kg

T able (base and column only) .. 192.00kg

Long and short trunk assembly* .. 55.75kg

Long and short trunk mattress .. .. 7.25kg

T otal weight standard table .. .. .. 279kg

Lightweight leg section.. .. .. .. 4.50kg

Footrest (incl. mattress) .. .. .. 7.00kg

Width extender (incl. mattress) .. .. 6.00kg

Perineal instrument tray .. .. .. 3.00kg

* (without mattress)

2.2 Dimensions

The following are the nominal major dimensions of the

standard table (with head and leg sections fitted) and

include the 50mm mattress and side rails if applicable (see

Fig. 2.1 for illustration, the number in brackets after the

item details which part):

Overall length (2) .. .. .. 2102mm

Maximum height (4) .. .. .. 1120mm*

Minimum height (5) .. .. .. 720mm*

Maximum top traverse (2) .. .. 250mm

Overall width (6) .. .. .. 600mm

Sidebars (Denyer) .. .. .. 37.8 x 5.5mm

* 5mm less for Serial Numbers prefixed T2AA or T2AB

2.3 Movements

Maximum section loading is stated on each item and is

detailed below for reference:

Leg section .. .. 44kg

Head section .. .. 22kg

For accessories the maximum loading is stated on each

item and detailed in the User Handbook supplied with them.

For specific notes on the obese patient see the ‘Instructions

for Use’.

2.5 Electrical

2.5.1 Antistatic requirements

The table has an antistatic pathway from the table top,

through an internal resistor, to the castors.

CAUTION

To complete and maintain the antistatic

pathway the table must be used on an

electrically conductive or antistatic floor and

with mattresses supplied by Eschmann

Equipment.

2.5.2 Batteries

T able base:

Main batteries**:

Two, 12V 10.0Ah, sealed lead acid

Backup batteries**:

Two, 12V 1.2Ah, sealed lead acid

(see battery disposal caution in the ‘Instructions for Use’)

Infrared handset:

Two, 1.5V size AA Alkaline (Note: Must only be

changed in accordance with the notes in the section

6.6.19.2 to ensure the IP rating is not compromised).

The following table movements are maximums and cannot

be assumed to be available in all combinations of table

positioning (see Fig. 2.1 for illustration, the number in

brackets after the item details which part). For example,

with the table in its normal configuration and at minimum

height the maximum Trendelenburg and leg section

movements cannot be achieved due to the proximity of

the floor. Similarly with a large amount of tilt set, maximum

Trendelenburg cannot be achieved.

Max. Trendelenburg (1) .. .. .. 35°

Max. reverse Trendelenburg (1) .. .. 35°

Max. extension (4) .. .. .. .. 230°

Max. flexion (4) .. .. .. .. .. 90°

Head section (5) .. .. .. .. ±45°

Leg section (3) .. .. .. .. -100° +55°

Max. lateral tilt (7) .. .. .. .. ±18°

2.5.3 Internal battery charger**

Input

100-240V a.c. 2.4A (max) 50-60Hz

Output

29.2V d.c. 2A (max.) when charge state LED

red or orange, 27.6V d.c. when charge state

LED green

2.5.4 Fuses

2.5.4.1

Mains input fuses (item 17, Fig. 1.0)

Battery fuses (item 8, Fig. 1.0)

External fuses

2 x T4A (5 x 20mm) 250V

2 x T20A (6.35 x 32mm) 500V

P8/54 T-SM47j

Page 9

T20-a

OPERATION TABLE

Note: The right hand fuse is linked to the main batteries

and the left hand fuse (i.e. nearest to the backup battery

switch) is linked to the backup batteries.

Mains plug fuse

.. .. 10A (type is dependent on plug

which may have been changed from that originally

supplied)

2.5.4.2

Battery fuses** (joining each battery pair)

Internal fuses**

2 x 30A blade type* (1 per battery pair)

(only accessible by engineer)

2.5.5 Duty cycle

This symbol is used to indicate the table’s duty cycle

which, in the worst case, is ‘60s : 600s’, the ratio of the

operating time to the sum of the operating time and the

ensuing interval (see note below). Each motor drive has

its own duty cycle and this is dependent on loading and

table position as detailed below.

Trendelenburg 1 : 4 (60s : 240s) at a maximum torque of

417Nm (e.g. 135kg load offset 31cm from the

fulcrum, or a 300kg load offset 14cm from the

fulcrum. Where this load is the patient and

accessories weight and the offset is how far the loads

centre of gravity is, from the centre of the column).

Traverse 1 : 4 (60s : 240s) when the table is

horizontal and at the maximum load of 300kg, or at

17.5° with a patient weight of 225kg, or at 35° with a

patient weight of 150kg.

Break 1 : 10 (60s : 600s) at maximum patient

weight of 300kg.

Height 1 : 4 (60s : 240s) at maximum patient

weight of 300kg (not offset).

Tilt 1 : 4 (60s : 240s) at maximum patient

weight of 300kg.

Note: The duty cycles above are all for the worst case (i.e.

maximum loads). For reduced loading the above duty

cycles can be increased.

2.7 Use in conjunction with other

equipment

2.7.1 Electrosurgical equipment (h.f.)

The T20-a operation table has been designed to minimise

the possibility of accidental electrosurgery burns and can

be used in conjunction with electrosurgical equipment.

However, contact with any metal surfaces (e.g. table side

bars, or other equipment etc.) can cause burns during

electrosurgery and must be avoided.

2.7.2 Defibrillation equipment

With the mains cord attached the equipment has

defibrillator proof applied parts with type BF protection

against electric shock.

2.7.3 Other

When the T20-a is used in conjunction with other infrared

controlled devices, their controllers should be checked to

ensure that no interference between them and the T20-a is

possible, prior to surgical intervention. Also see the

‘Instructions for Use’.

2.8 Standards compliance

The table has been designed and built to comply with the

following international standards:

BS EN 60601-1: 1990 (issue 2, October 1997)

BS EN 60601-1-2: 1993

BS EN 60601-2-46: 1998

BS EN 60601-1-4: 1997

2.9 Environmental conditions

2.9.1 Operating environment

The table has been designed to operate in the following

environment:

Temperature range .. .. 10°C to +40°C

Pressure range .. .. .. 69KPa to 106KPa.

Humidity range .. .. .. 30% to 75% RH

non-condensing.

2.6 Classification and symbology

All the symbols used on this table are shown and explained

in the ‘Instructions for Use’. These detail the safety category

and class of this table as marked on the table or section by

the use of these symbols.

2.9.2 Transport & storage environment

The table can be transported and stored safely, in the

following environment:

Temperature range .. .. -30°C to +50°C

Pressure range .. .. .. 69KPa to 106KPa

Humidity range .. .. .. 30% to 90% RH

non-condensing.

** NOTE: Items marked ** are to be changed with caution. During change or

replacement they must only be disconnected for a maximum of 60 seconds. If

battery power is removed from the table for longer than this then reconditioning

of the battery management system must be carried out, see section 6.6.26.

T -SM47j P9/54

Page 10

1

4

(see section 2.2)

2

5

(see section 2.2)

6

3

7

These are maximum movements for each aspect, they may not be available in certain combinations (e.g. maximum

tilt and maximum Trendelenburg). Movements that could cause damage cannot be catered for (e.g. position of the

leg section).

Fig. 2.1 Major dimensions and movements

P10/54 T -SM47j

Page 11

T20-a

OPERATION TABLE

Fig. 2.2 Maximum patient weight v table position graphs

T -SM47j P11/54

Page 12

Fig. 2.3 Maximum patient weight v table position graphs

P12/54 T -SM47j

Page 13

T20-a

OPERATION TABLE

3.0 TECHNICAL DESCRIPTION

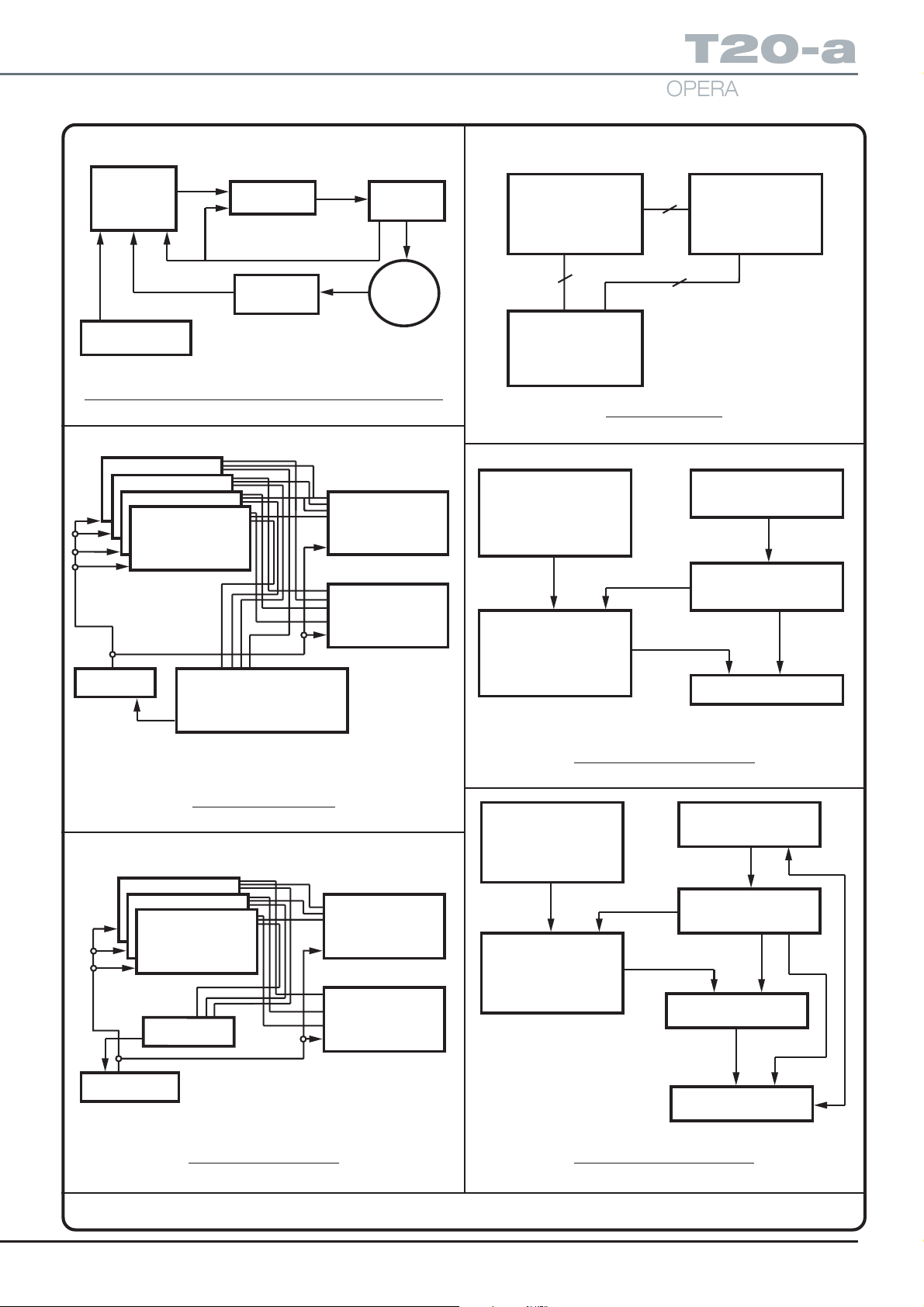

See Fig. 3.1 and Appendix 3 for schematic diagrams.

3.1 Power supply assembly

This assembly (Part number 111765) which is located in

the table base, has no user serviceable parts and must be

changed as a complete unit. The assembly includes, a

Battery charger loom, a Battery charger module, a Battery

management PCA, a Battery connector loom, a Chassis

plate, two Battery support brackets, a Switch, two Fuses

(32 x 6.35mm 20A ‘T’ type), two Fuse holders, two battery

pairs and all connections, cable ties and screws etc.

3.2 Control electronics

3.2.1 Overview

The control electronics for the T20-a is distributed between

two PCA ’s (the ‘4 actuator PCA ’ and the ‘3 actuator PCA ’).

These two PCA’s contain three distinct microprocessor

daughter PCAs (two on the ‘4 actuator PCA’ and one on

the ‘3 actuator PCA ’).

The ‘4 actuator PCA’ (111524) is located on the column

and includes the ‘main controller’ and the ‘4 actuator

controller’. Each of these ‘controllers’ consists of a

‘microprocessor daughter PCA ’ (1 11526) which have their

control electronics on the ‘4 actuator PCA ’.

The ‘Three actuator PCA’ (111525) is located in the long

trunk section of the table and contains the ‘3 actuator

controller’, another ‘microprocessor daughter PCA’

(1 1 1526) with its control electronics on the ‘Three actuator

PCA’.

3.2.1.1 Microprocessor daughter PCAs

The daughter PCAs consist of a Motorola MC68HC912B32

micro controller, a watchdog circuit, an RS232 line driver

and an SPI UART and RS485 line driver. All the micro

controllers on the T20-a require these components. The

RS232 communications can be used to provide a telemetry

link to custom software running on a PC. Once fitted to

their respective controller boards the micro controllers are

programmed with the appropriate software application.

There is a ‘main controller application’ (110442) and an

‘actuator controller application’ (110443). Both the 4actuator and 3-actuator are programmed with the same

‘actuator controller application’ (110443). A configuration

file is then downloaded to each micro controller that

specifies which controllers are present on which board. It

is possible to configure any actuator to any board, however

the configuration of the electronics is specific to each

actuator.

3.2.1.2 The ‘main controller’

The ‘main controller’ provides the control and supervisory

functions for the table. This consists of the interface to the

infrared handset, corded handset (via RS232), footswitch

and standby panel. It also controls the table power LED.

The main controller communicates with the two actuator

controllers (one of which is co-located on the 4 actuator

PCA) by means of an RS485 multi-drop bus. This system

enables multiple slave controllers to be attached at any

time. The main controller issues a health check poll

message to each of the actuators (up to four of which can

be controlled by the single PCA) to ensure that they are

functioning correctly .

When a command is received from any of the user-input

devices the main controller issues the appropriate

movement commands to the required actuator (or actuator

groups in the case of combined movements).

3.2.1.3 The ‘4 actuator PCA’

The ‘4 actuator PCA ’ is responsible for movement of four

actuators on or within the table’s column. These are the

‘top and bottom height actuators’ inside the column

assembly , the ‘Trendelenburg actuator’ and the ‘Tilt actuator’

mounted on the column. A number of signals control the

movement of each actuator.

A PWM signal is used to set the speed of the motor; digital

signals control direction (forward/reverse), a digital signal

enables the drive circuit and another digital signal effects

a brake on the motor by shorting the windings together.

The electronics provide a digital fault signal to indicate when

there is a problem with the control circuit, or an over current

situation has occurred. An analogue signal is also provided

on all but the ‘bottom height actuator’. The analogue signal

on the top height actuator is the output from a potentiometer

that indicates the combined position of the height actuators.

Although the column contains two motors, there is only a

single potentiometer to indicate the height of the column.

This analogue signal is fed to the ‘top height actuator’; the’

bottom height actuator’ is effectively slaved to the top.

3.2.1.4 The ‘Three actuator PCA’

The ‘Three actuator PCA ’ is responsible for movement of

the three actuators within the tables long and short trunk

sections. These are the ‘left break actuator’, ‘right break

actuator’ and the ‘traverse actuator’. These actuators are

controlled by the same signals as on the ‘4 actuator PCA ’.

In terms of feedback, both the ‘left and right break actuators’

have potentiometers and the ‘traverse actuator’ has limit

switches which open when the long trunk reaches either

end of its movement. The ‘left and right break actuators’

are independently controlled to move at a set speed and

to maintain a minimum deviation between them.

T -SM47j P13/54

Page 14

3.2.2 Handset overview

There are two versions of handset, a cordless type (infrared

handset) with an infrared emitter powered by 2 AA cells

and a corded version (corded handset) with an RS232 link

to the main processor on the ‘4 actuator PCA’. The latter

version derives its power from the T20-a.

3.2.2.1 Infrared handset

The 4 x 5 matrix keyboard is decoded using a proprietary

keyboard decoder. This device is powered down and

remains dormant until a key is pressed causing its clock

oscillator to be initialised. The key is decoded and the 38kHz

modulated signal is fed to the infrared LED via a FET . The

whole system is powered via 2 AA batteries

3.2.2.2 Corded handset

The 4 x 5 matrix keyboard is decoded using a proprietary

keyboard decoder. This device is powered down and

remains dormant until a key is pressed causing its clock

oscillator to be initialised. The key is decoded and the 38kHz

modulated signal is fed to a PIC processor. The processor

decodes the output from the keyboard decoder into RS232.

This output is fed to an RS232 line driver. The corded

handset’s power is supplied directly from the T20-a, 5V

power supply . The handset contains a DC-DC converter to

supply 3.3V for the keyboard decoder. There are indicator

LED’s to show the charge status of the table batteries (main

and standby).

P14/54 T -SM47j

Page 15

T20-a

OPERATION TABLE

PROCESSOR

CONTROL

CONTROL FROM

HOST MICRO

FET DRIVERS

POSITIONAL

FEEDBACK

OVER

CURRENT

MANAGER

MOTOR

Basic control and feedback - all actuator drivers

AXIS TILT

AXIS TREND

AXIS HEIGHT 1

AXIS HEIGHT 2

POSITION ENCODERS AND

ANCILLARIES

OVER CURRENT MANAGERS

PROCESSOR COMMUNICATIONS

44

CONNECTOR 64 WAY

INTERFACE

12

4

Processor PCA

BatteryKeyboard

Power Management

Keyboard Encoder

POWER

MANAGEMENT

AXIS BREAK RIGHT

AXIS BREAK RIGHT

AXIS TRAVERSE

POWER

MANAGEMENT

CONNECTORS

INC:

CONNECTORS & INTERFACES

MICRO CONNECTORS

Four Actuator PCA

CONNECTORS

POSITION

MONITORS

OVER CURRENT

MANAGERS

Infrared Driver / Emitter

Handset remote version

Connector/LeadKeyboard

Power Management

Keyboard Encoder

Processor

RS232 Decoder/Driver

Three actuator PCA

Handset corded version

Fig. 3.1 Schematic diagrams

T -SM47j P15/54

Page 16

4.0 SAFETY WARNINGS

4.1 ‘Service position’

When the four M10 screws (each side) that secure the

trunk sections to the pedestal are removed, to place the

table in the ‘Service position’ as detailed in section 1.9,

always take extreme care (and ensure table is switched

‘off’ before tilting top into or out off the ‘Service position’).

When the M10 screws are removed the table trunk sections

may tilt dramatically unless the sections are fully supported

during screw removal. Always lower the trunk sections into

(and out of) the ‘Service position’ slowly and always return

the table trunk sections to the ‘normal’ position (taking care

not to trap fingers) as soon as possible, replacing the eight

M10 screws securely. Also remove the following before

placing the table into the ‘Service position’:

Head section Leg section

Trunk mattress All accessories

When powering the table in the ‘Service position’ using

tool T2203 (to connect the table top connector blocks)

extreme care should be taken and powering the table in

this position should be limited to essential testing only . It is

preferable to return the table out of the ‘Service position’

before powering the table.

4.2 Lifting

During some of the procedures detailed in this manual it is

necessary to lift heavy assemblies. These are the long and

short trunk assembly, the wrapround assembly and the

telescopic assembly. These all require two people to lift

safely and any procedure that requires these to be removed

from the table should not be attempted if two people are

not available. Other components although not heavy

enough to require two people, should be handled using

the correct lifting techniques to minimise personnel injury .

It is advised that suitable protective footwear is worn when

handling heavy parts.

4.3 M10 trunk screw removal

When removing the four M10 (hexagonal head) screws

that secure the trunk sections to the column, always ensure

that precautions similar to those detailed in 4.1 above are

taken. Remove all accessories, sections and trunk mattress

and support the trunk sections during screw removal.

4.4 Trend and tilt actuator removal

When the Trend and /or tilt actuators are removed the trunk

sections will not be stable. Before removal follow similar

precautions to those detailed in section 4.1. Remove all

accessories, sections and trunk mattress and support the

trunk sections during actuator removal. Replace the

actuator as soon as possible.

4.5 Working with mains voltage

The only time that it may be required to work with mains

voltage applied to the table is whilst testing the battery

charger. During this procedure ensure that normal safe

working procedures are employed for an activity that entails

working with mains voltage, such as:

i Reduce the amount of live work to the minimum

possible.

ii Use common sense and stop working if

approached, distractions can kill.

iii Ensure the area is clear of all unnecessary

personnel or warn people in the area to stay

clear during live work. Also ensure that you are

not entirely alone and that someone could come

to your assistance if you should suffer an electric

shock.

iv Only use the correct equipment, probes and

cables for the work in hand.

v Mains power should be supplied via an RCD

(residual current device).

vi Turn of f the mains power whenever possible to

reduce risks.

4.6 Gas springs

When removing or servicing the table head and leg sections

gas springs refer to the warning in section 6.5.1.2. They

do not require lubrication and do not attempt to open them.

Also note the disposal notes provided in 6.5.1.2 (vii).

4.7 Hot parts on PCAs

During service and when covers are removed note that

parts of the PCAs can become hot enough to cause burns.

Beware that touching these assemblies when hot could

result in unexpected body movements.

4.8 Biological contamination

During servicing of the table it is advised that protective

gloves should be warn to avoid biological contamination. It

is preferable that the table be cleaned and disinfected

before service.

4.9 Connection of leads

When connecting test leads to the table during service

ensure that these do not constitute a tripping hazard.

4.10 Leaking batteries

In the unlikely event of a battery leaking in the table base

avoid spreading the contamination (sulphuric acid) and:

i Wear suitable personnel protection (goggles, gloves

etc.) do not smoke and avoid sparks.

ii Use a bonding agent such as sand, or sodium

carbonate to absorb and neutralise the bulk of the

electrolyte. Wash (and rinse well) the contaminated

area with water, taking care not to splash electronics

or any other table base components.

iii Do not flush electrolyte into the sewer system but

dispose of the used bonding agent and all cleaning

materials in accordance with local waste regulations.

In the case of skin contact wash and rinse immediately

with water. If splashed into eyes rinse well with water and

seek medical advice. If acid mist is inhaled, inhale fresh

air and seek medical advice.

P16/54 T -SM47j

Page 17

T20-a

OPERATION TABLE

5.0 MAINTENANCE

5.1 Power supply assembly

This assembly (Part number 111765) which is located in

the table base, has no user serviceable parts and must be

changed as a complete unit (also see section 3.1).

5.2 T able fault finding

5.2.1 The ‘Instructions for use’ contains a basic fault finding

table that can be used to solve any minor problems. This

covers the main user errors (i.e. there is no fault) that can

occur when the user has not read and understood the

‘Instructions for use’. It also contains the first line of fault

finding (i.e. check external fuses, try another handset, try

another mains lead). The following section (5.2.2) provides

a test sequence to help determine the fault (for the majority

of faults that may occur) that could stop the table responding

to an input via a control device. Mechanical faults are

normally self evident in that a part is worn, damaged or

broken. In this case refer to the appropriate section of this

manual for part replacement information. Appendix 3

provides the schematic diagrammes that can also be used

in fault finding.

5.2.2 Follow the sequence below to identify most major

faults that result in a lack of response to a control command:

1 When the table is initially switched ‘on’ is the table

‘on’ LED (item 23 of Fig. 1.0) bright, dull or ‘off’ for

the first few seconds.

If dull turn the table ‘off’ wait at least 10 seconds

and then turn back on. If the LED is still dull or

‘off’ this indicates an electronics fault see 5.2.3.

If bright move to 2 below.

If it is flashing this also indicates an electronics

fault see 5.2.3.

2 Try the ‘standby control panel’ (any motion except

Trendelenburg), if this fails try the ‘standby control

panel’ with the backup battery switch depressed.

If the table works from the ‘standby control panel’

this indicates a fault with the control device or

its connection to the table.

If the table works from the ‘standby control panel’

only when the backup battery switch is pressed

this indicates a fault with the main batteries

(replace the whole Power supply unit).

Now try Trendelenburg from the ‘standby control

panel’, if this and only this motion works it indicates

a problem with the main control PCA.

3 If one of the motor groups ‘only’ has failed then this

indicates a problem with its associated PCA as follows:

Break and traverse - Three actuator PCA

Tilt, T rend and Height - 4 Actuator PCA

This distinction may help in reducing the amount of

diagnostics and cover removal.

4 Remove covers and check battery fuses (see

section 5.3.1 and 6.6.26). Also look to see if the

PCA indicator lights are flashing ‘on’ for 1 second

and ‘off’ for 1 second. If they are ‘off’ or flashing

faster, this indicates an electronics fault see 5.2.3.

5 If the fault is only apparent for one motion this could

indicate a failed motor or failed sensor for that motion,

or, an electronics fault. If the motion starts and then

stops immediately this could indicate a failed sensor

or an over current situation. Test motor (as detailed

in section 6.6), if the motor works and no small

movement is observed following a demand for that

motion, it indicates an electronics fault, see 5.2.3.

5.2.3 Electronic faults can only be determined with the

table connected to a PC with the ‘T20 Application Software’

installed. Consult the Application Software Manual (as

detailed in section 1.1) which provides guidance on fault

diagnosis. Also note that when correcting electronic faults

(and following some parts replacement) the table will require

reprogramming, reconfiguring or recalibration. These aspects

are also fully covered in the Application Software Manual.

5.2.4 Break motion control

5.2.4.1 The two break arms are independently controlled

and are synchronised to operate within a programmed limit

of each other. This control system can result in small

variances that appear as a slight misalignment, this is

acceptable and a part of the normal table control software

routine. In the unlikely event that this deviation goes outside

of the programmed limit the table break motion (only) will

stop working. This can sometimes be corrected as below .

5.2.4.2 Whilst observing the two break arms press (for

approximately 0.5 seconds only) a break control button on

the handset (B7 or B8 of Fig. 6.9) once or twice. If this

makes the deviation worse press the other break control

button as above once or twice. If the break motion still

does not work correctly after this there could be a fault in

one of the following:

Break motor

Break potentiometer

Wiring to any of the above

Significant uneven table loading*

*This problem will only be evident during use and if

investigated at service it will be difficult to reproduce.

5.2.5 Trunk section connector blocks

5.2.5.1 If all the top table functions stop working (e.g. break

and traverse) the connector blocks (item 5, Fig. 6.7 and item

14, Fig 6.3) could be failing to connect correctly due to

contamination etc. Check that a good contact is being made

between the column and trunks connector blocks.

5.3 Fuse location

5.3.1 All fuse locations are identified in section 2.5.4 and

Fig. 1.0. DO NOT REMOVE OR CHANGE INLINE BA TTERY

FUSES UNLESS YOU HA VE READ SECTION 6.6.26.

T -SM47j P17/54

Page 18

5.4 Service schedule and safety check

This should be performed every 6 months to ensure the

continued safe operation of the table.

NOTES:

1. The numbers in brackets in this schedule details the

section of this manual that should be referred to when

performing or checking the activity detailed.

2. Prior to service operate all table functions (6.7) to

ensure correct operation, note any problems for

investigation during the service.

3. Remove base covers as required (6.2.2.1). Access

can be gained to the lower, lower-mid, upper-mid and

top of the column (6.2.3.2 to 6.2.3.5). If necessary the

telescopic covers can be removed (6.2.4.1).

4. Prior to changing a motor check it has failed and that

the fault is not in the control electronics (6.6.6 - 6.6.9).

5. In the sections below where the word ‘check’ is used

it is inferred that if the check reveals a fault then this

should be corrected.

6. Tilt tabletop into service position as required (1.9) but

note safety warning, section 4.1.

7. The right-hand column should be used to tick off each

item of the schedule on completion and to note parts

replaced (or wearing that will soon need replacing).

8. This schedule should be photocopied and completed,

copies to be retained by the engineer conducting the

service and the person responsible for the table.

Base and column:

1. Check pedal dampers for wear or leaking (6.3.3).

2. Disassemble, clean and lubricate the two fixed wheel assemblies and the four

castor assemblies (6.3.4, 6.3.5). Test resistor assembly as 6.3.5.1 (viii).

3. Check brake pads for wear, damage, or hard and brittle (6.3.6).

4. Check the castor pillar and pedal spindle bushes for wear (6.3.7 and 6.3.8).

5. Check and lubricate both lifting roller assemblies (6.3.9).

6. Check for wear of both pedal catch mechanisms (6.3.12) and renew the antislip pad on both pedals (6.3.11).

7. Check security of all fixing screws, nuts and retaining clips within the base area

and check the pedal operation works smoothly and correctly .

8. Check main and standby battery voltage (standby and load) as 6.3.2.(iia). Check

security , connectors and loom routing of PSU.

9. Check the Trendelenburg, tilt and telescopic column actuator assemblies for

excessive wear or failure (6.4.2, 6.4.3, 6.4.4 and 6.4.5) and grease worm and

wheel on Trendelenburg and tilt motor assemblies.

10. Check the security and positioning of all wiring looms and connections. Add

cable ties, reposition or replace as necessary .

11. Check switch and fuse panels for operation and signs of damage (6.6.16).

12. Check for wear or damage to the tilt and Trendelenburg bushes in the trend

and tilt frame (6.4.6 and 6.4.7). Check all fixing screws within the inner and

outer (tilt and Trend) gimbal assemblies.

13. Check the wraparound aligning bearing pads, adjust as required to remove play

or replace (6.4.8).

14. Check height potentiometer is secure to the wrapround and that the cable is in

good condition and secure to the base (6.6.13).

15. Check the security and the routing of the 4 actuator PCA, connectors, energy

chains and all looms within the column. Cable-tie if necessary

16. Remove and replace bellows if split/damaged (6.2.5).

17. Check the security and the routing of the Three actuator PCA, connectors,

energy chains and traverse and break motor looms within the traverse housing.

Cable-tie if necessary .

18. Check that traverse motor and traverse belt tensioners are secure to the support

plate and lubricate tensioner bearings between screw and bearing only . Check

traverse motor (6.5.2.1) and adjustment of the traverse belt tensioners’ (6.5.2.2).

19. Check the condition and lubricate if necessary the drive belt guide needle

bearings between screw and bearing only (6.5.2.9).

P18/54 T -SM47j

Page 19

Trunk sections and covers.

20. Check condition (excessive wear/breakage) of traverse rod bearings (6.5.2.8).

21. Check operation and adjustment of the traverse limit switch assemblies’ (6.6.14).

NOTE: Check that the traverse movement stops when the traverse limit switch

pin is depressed from both ends and from both sides of the table.

22. Check that the set screws that retain the traverse leadscrews are tight (20Nm)

and lubricate the lead screw and traverse rod.

23. Clean the male and female pins on the 4-way communication connector block

to ensure a good contact, check for cracks or damage (6.6.15).

24. Remove long / short trunk push button assemblies, clean and check condition

of catch blade (6.5.2.7), do not lubricate.

25. Check guide pin holes (in the attachment blocks) for excessive wear (6.5.2.10)

26. Checks for equal and even movement of the two break motors (i.e. check both

break arms in the short trunk move up and down together). If required, replace,

adjust or recalibrate (6.5.2.3 and 6.5.2.4).

27. Service infrared handset (6.6.23). Check function and condition of corded handset.

28. Check that all side rail fixing screws are tight in the long and short trunk sections

(21Nm) and the head and leg sections (15Nm).

29. Check the condition of the trunk section covers (6.5.2.6 and 6.5.1.3).

30. Ensure tabletop is not in the service position and the locking screws are replaced

to lock the trunk sections out of the service position.

31. Ensure free movement of the telescopic covers. Check condition and function

of Standby control panel, replace if adhesion to column cover shows any sign

of failure (6.6.25).

32. Ensure the base covers are refitted (6.2.2.2).

33. Conduct the function tests (6.7) correct any faults and conduct the function

tests again until all functions are working correctly .

T20-a

OPERATION TABLE

Head and leg sections.

34. Check all guide pins for wear or damage (6.5.1.1).

35. Check gas springs for leaks or poor performance (6.5.1.2).

36. Check gas spring pivot pins and shoulder screws for security and wear (6.5.1.4)

36. Check the condition of the head and leg section covers (6.5.2.6 and 6.5.1.3).

Ensure the ‘Electrical safety checks’ have been carried out (see Appendix 4 of the ‘Service Manual’).

Leave table clean and in a fully functioning condition with batteries on charge and table switched off.

Service / T able details

Service Engineer

Engineers Name (Eschmann / Hospital*)....................................................................Contact T el. No. ...........................................

Person responsible for table

Name....................................................... Position ...............................................Dept. ............................................

Hospital ................................................... Health Authority ..................................Tel.No...........................................

T able details

T able SN.................................................. Location ..............................................Account No. (If appl.) .............................

Service detail

Date......................................................... Time completed ..................................2nd visit reqd. YES /NO*

(* Delete as required)

T -SM47j P19/54

Page 20

6.0 PART REMOVAL/ADJUSTMENT/

REPLACEMENT

6.1 GENERAL

6.1.1 This section has been split into the following sections

for easy reference, note safety warnings in section 4.0:

6.2 Table base and column covers

6.3 Table base components

6.4 Table column components

6.5 Table sections

6.6 Electrical components

6.7 Function tests after maintenance

6.8 Accessories

6.1.2 Within the text detailing a part replacement any

specific setting or adjustment is fully detailed. Each section

also provides specific details of any required lubrication

during assembly, the use of threadlock fluids and any

specific torque settings that should be adhered to.

Note: Conversion chart and conversion data for Torque

values in Appendix 1.

6.1.3 All replacement parts must be supplied by

Eschmann and note that this also includes all the nuts,

screws, roll pins, pivot pins etc. that are specified in the

‘Illustrated parts list’. Some of these are provided to a

specific standard (e.g. high tensile) and the use of ‘similar’

items could compromise the strength and therefore the

safety of the table.

6.1.4 All electrical components are non-repairable and

must be replaced with new Eschmann parts only, to

maintain the safety of the system. Replacement is usually

a self-evident procedure but ensure :

i Good wiring practice is observed and static

discharge procedures are adopted as applicable

when handling PCAs (printed circuit assemblies).

ii All wiring is replaced as found and secured away

from any moving parts using adequate quantities of

cable clips and restraints.

iii All fixings are replaced as found and no substitutes

are used.

iv The function checks detailed in this manual (section

6.7) are carried out on completion of any part

replacement.

6.1.5 After all procedures the table should be left clean

and in full working order (run function test detailed in 6.7)

to ensure safety and ensure the (Electrical safety checks)

in Appendix 4.

6.1.6 Before any part removal/replacement procedure

ensure the table is not connected to the mains. If mains

power is required at any time during diagnostic checks

ensure that appropriate safe working procedures for live

working are adopted (see section 4.5).

6.1.7 T o avoid duplication of common procedures a cross

reference to the required part of the manual detailing the

procedure is provided where required. Note these sections

also contain assembly notes that must be followed.

6.1.8 All part numbers can be found in the Illustrated parts

list (Publication number T -IPL35 available from Eschmann

Equipment at the address on the inside of the front cover).

This Illustrated parts list should be available for reference

during part removal or replacement.

6.1.9 The locking catch for foot pedals can be external or

internal. Please check which type is fitted to the table and

follow the appropriate notes in the sections that follow. The

external catch is shown in Fig. 6.2a, item 20 and the internal

catch is shown in Fig. 6.2b, item 6.

5.1.9 Tables with a Serial Number prefix T2AC or later

have been increased in height by 5mm. Check that the

correct parts are fitted by referring to the Illustrated parts

list. Fig. 6.2b and Fig. 6.2c shown both configurations.

6.2 TABLE BASE & COLUMN COVERS

6.2.1 The removal, replacement and method of gaining

access behind the table covers, has been split into the

following sections for easy reference:

6.2.2 Base covers.

6.2.3 Access to column.

6.2.4 T elescopic covers.

6.2.5 Bellows.

For reference Fig. 6.1 shows the general arrangement of

all the cover components.

6.2.2 Base covers

CAUTION

Ensure the cable to both of the infrared PCA’s

are released before sliding the base covers

away from the base, see ‘v’ below.

6.2.2.1 Removal of base covers.

i Raise the height of the tabletop sufficiently to expose

the screws at the lower edge of the lowest telescopic

section where it joins the base covers.

ii Remove both foot pedals by releasing their retaining

screws, taking care not to loose the return spring

(spring only fitted if the pedal has an external catch).

iii Remove the button head screw from the end of the

long base cover and the countersunk screw from both

sides of the covers where they join at their lower edge.

iv Remove the two screws from the lower edge of each

side of the lowest telescopic cover (not the end face

screws).

Note: These screws differ in length and must be put

back as found (short 12mm to short trunk end, long

15mm to long trunk end).

P20/54 T-SM47j

Page 21

T20-a

OPERATION TABLE

v Raise the telescopic covers sufficiently to clear the

base covers and slide the base covers away from

the pedestal column taking care to release the cable

connected to the infrared receiver PCA fitted below

each base cover section. The cable plug is released

by pressing the moulded release catch.

vi Continue to slide the base covers away from the

table until clear and place them safe until replaced.

6.2.2.2 Replacing base covers.

i Slide the base covers into a suitable position to enable

the two infrared receiver leads to be reconnected to

the PCA fitted to each cover section, ensuring the

plug snaps into place correctly. Check both the

receivers are working by covering each in turn and

send a control command via an infrared handset.

ii Raise the telescopic cover sufficiently to enable the

covers to be correctly positioned and aligned.

iii Replace all the fixing screws (without threadlock)

and the earth equalization pin using threadlock (part

number 670650).

iv Replace and secure the foot pedals (see note below)

ensuring they are placed at their correct ends (long

pedal at head end) with the internal return spring in

place (spring only fitted if the pedal has an external

catch). Use threadlock (part number 670650) on

both screws.

Note: When replacing the foot pedal shoulder screw

(on pedals with internal spring return) initially tighten

with fingers to ensure that the shoulder of the screw

has correctly located into the hole in the shaft.

v T est table base functions.

6.2.3 Access to column.

6.2.3.1 Access can be gained behind the column covers

in four ways. Either, release the bottom of the telescopic

covers and lift them to gain access to the lower column

(see section 6.2.3.2), or release the top of the telescopic

covers and lower them to gain access to the lower-mid

column (see section 6.2.3.3), or release the bottom of the

bellows and raise them to gain access to the upper-mid

column (see section 6.2.3.4), or release the top of the

bellows and lower them to gain access to the top of the

column (see section 6.2.3.5).

6.2.3.2 Lower column access

i Raise the height of the tabletop as far as possible,

this will ensure maximum access and expose the

screws at the lower edge of the lowest telescopic

section where it joins the base covers.

ii Remove the two screws from the lower edge of each

side of the lowest telescopic cover (not the end face

screws).

Note: These screws differ in length and must be put

back as found (short 12mm to short trunk end, long

15mm to long trunk end).

iii Raise the telescopic covers to gain access to the

lower part of the column.

iv On completion of work on the lower column replace

the four lower retaining screws to secure the

telescopic covers to the base.

v T est that the telescopic covers function correctly by

powering the table between maximum and minimum

height several times.

6.2.3.3 Lower-mid column access

CAUTION

Ensure the cable to the standby control panel

and the earth wire is released before lowering

the telescopic covers, see ‘iii’ and ‘iv’ below.

i Remove fourteen plastic rivets (see inset of Fig. 6.1

for details) around the lower edge of the bellows.

ii Lift the bellows to the left and right of the accessory

and switch panels (items 8 and 9 of Fig. 6.1) and

remove the four screws securing the top edge of

the upper telescopic cover to the telescopic cover

support brackets (item 6 of Fig. 6.1).

iii Lower the telescopic covers slowly until sufficient

access has been gained behind them to allow

disconnection of the ribbon cable from the standby

control panel where it connects onto the column PCA.

iv Continue to lower the telescopic covers and if

required (i.e. if table is near maximum height)

disconnect the earth wire from the middle telescopic

cover where it is connected to the wrap round.

v On completion of work on the lower-mid column,

replace the column covers in the reverse of the

sequence above, check the electrical connections

have been made correctly during assembly. Use

threadlock (part number 670650) on all screws.

vi Test the telescopic covers and standby panel

function correctly by powering table between

maximum and minimum height several times and

testing other standby buttons.

6.2.3.4 Upper-mid column access

i Remove fourteen plastic rivets (see inset of Fig. 6.1

for details) around the lower edge of the bellows.

ii Lift the bellows to the left and right of the accessory

and switch panels (items 8 and 9 of Fig. 6.1) and

remove the two screws securing each switch panel

retainer (item 7 of Fig. 6.1) to the telescopic cover

support brackets (item 6 of Fig. 6.1).

iii The bellows can now be raised but take care not to

lift then too far without disconnecting the loom

connections from the switch panels where they

connect to the column PCA.

iv On completion of work on the upper-mid column,

replace the column covers in the reverse of above

sequence, check that the electrical connections have

been remade correctly during assembly. Use

threadlock (part number 670650) on all screws.

T-SM47j P21/54

Page 22

AB C

Bellows rivet removal/replacement detail

To remove rivets :

a) Pull up plunger head (see B), do not damage rivet head.

b) Pull rivet out of cover (see A).

To replace rivets :

a) Align holes in cover sections (see A).

b) Place rivet in hole so that shoulder of rivet shaft is flush

with outer cover face (see B).

c) Press rivet plunger head until flush (see C).

Fig. 6.1 Table covers general arrangement

P22/54 T-SM47j

Page 23

T20-a

OPERATION TABLE

v T est that the bellows work correctly by moving table

through several complete sequences of extreme tilt

and Trendelenburg (use handset not standby panel).

6.2.3.5 Top of column access

i Remove the steel covers (items 12, 13 and 14 of

Fig. 6.1) surrounding the top of the bellows (two

screws per side cover, three screws per end cover).

ii Remove twelve screws holding the four top bellow

clamping strips (item 10 of Fig. 6.1) in place. This

will release the top of the bellows allowing them to

be lowered gaining access to the top of the column.

iii On completion of work on the top of the column,

replacing the bellows and steel covers in the reverse

of the sequence above, checking that the bellows

have been correctly positioned in their top and

bottom clamps. Use threadlock (part number

670650) on all screws.

vii T est that the bellows work correctly by moving table

through several complete sequences of extreme tilt

and Trendelenburg movements (use handset not

standby panel).

vii Remove the four screws (two per join) holding the

top telescopic section together and remove the

section. Continue removing the top telescopic

section (disconnecting the earth link as required)

until all sections have been removed. Note

orientation of parts for later assembly .

6.2.4.2 Refitting the telescopic covers

i Ensure the plastic scratch and noise reducers are

in place on the lower and upper edges of each

telescopic section before starting to refit them.

ii Refit the covers by reversing the removal sequence

detailed above, checking that the earth connections

and the standby control panel are reconnected. Use

threadlock (part number 670650) on all screws.

iii On completion, test that the telescopic covers move

correctly, by powering tabletop (use handset not

standby panel) up and down from minimum to

maximum several times. Check bellows work

correctly by moving table through several complete

sequences of extreme tilt and Trendelenburg

movements. Then check all the functions of the

standby panel

6.2.4 Telescopic covers

6.2.4.1 Removal of telescopic covers

CAUTION

Ensure the ribbon cable from the standby

control panel and the earth wire are released

during removal of covers, see ‘v and vii’ below .

To remove the telescopic covers completely from the

column proceed as follows, but note that access to the

column can be gained by releasing the telescopic covers

not removing them (see sections 6.2.3.2 and 6.2.3.3):

i Raise the height of the tabletop sufficiently to expose

the screws at the lower edge of the lowest telescopic

section where it joins the base covers.

ii Remove the two screws from lower edge of each

side of the lowest telescopic cover (not the end face

screws). See note in 6.2.3.2 (ii).

iii Remove fourteen plastic rivets (see inset of Fig. 6.1

for details) around the lower edge of the bellows.

iv Lift the bellows to the left and right of the accessory

and switch panels (items 8 and 9 of Fig. 6.1) and

remove the four screws securing the top edge of

the upper telescopic cover to the telescopic cover

support brackets (item 6 of Fig. 6.1).

v Lower the telescopic covers slowly until sufficient

access has been gained behind them to allow

disconnection of the standby control panel ribbon

cable from its connection on the column PCA.

vi Continue to lower the telescopic covers and

disconnect the earth wire from the middle telescopic

cover where it is connected to the wrap round.

6.2.5 Bellows

WARNING

Removal and replacement of the bellows entails

removal of the trunk sections, which are heavy

and require two people to lift safely.

6.2.5.1 Removal of the bellows

T o remove the bellows completely proceed as follows, but

note that access to the column can be gained by releasing

the telescopic covers and bellows without removing them

(as detailed in section 6.2.3):

i Remove as much as possible from the tabletop

including all sections fitted to the two trunk sections

and the mattress.

ii Release the top of the bellows as detailed in section

6.2.3.5, points ‘i-ii’.

iii Release the bottom of the bellows as detailed in

section 6.2.3.4, points ‘i-ii’.

iv Reach inside the bellows and remove the four

screws (two per panel) securing the switch panel

retainers (item 7 of Fig. 6.1) to the accessory panel

and the switch panel (items 8 and 9 of Fig. 6.1). The

switch panel retainers can now be removed.

v Remove the trunk sections (see note below) together

with the traversing and break mechanisms by

removing the four screws that secure this assembly

to the top of the pedestal (two M10 hexagonal head

screws underneath each side). Carefully place the

trunk sections to one side, leaving them in a stable

position not resting on any fragile components.

T-SM47j P23/54

Page 24

Note: The trunk sections may become unstable

when the M10 screws are removed and extreme

care should be taken. Ensure trunks sections are

supported during removal of these screws.

vi Remove the two top location angles (item 15 of Fig.

6.3) and carefully remove the bellows by lifting them

up and off the top of the column.

6.2.5.2 Replacing the bellows

Replace the bellows by reversing the removal sequence

ensuring that the trunk sections are replaced in the correct

orientation (short trunk section at leg end). Note that the

four M10 fixings screws should be tightened to a torque

setting of 48Nm. Also ensure that the sprung electrical

contact pins on the underside of the long trunk section are

not damaged, use threadlock (part number 670650) on all

screws (except those securing the switch panel and the

accessory panel). Check that the bellows have been

correctly positioned in their top and bottom retainers and

that they work correctly by moving table (use handset not

standby panel) through several complete sequences of

extreme tilt and Trendelenburg movements. Test that the

telescopic covers move correctly, by powering the tabletop

up and down from minimum to maximum several times.

6.3 TABLE BASE COMPONENTS

6.3.1 The following parts on the table base may need

replacement in the event of wear, damage, or malfunction,

(see notes in each section) for the Power supply assembly

see section 6.6.5. The procedures for these are detailed

in the following sections:

6.3.2 Batteries

6.3.3 Pedal dampers

6.3.4 Front wheels

6.3.5 Castors

6.3.6 Brake pads

6.3.7 Castor pillar bushes

6.3.8 Pedal spindle bushes

6.3.9 Lifting roller assembly

6.3.10 Pedal catch block

6.3.11 Pedal anti-skid pads

6.3.12 Pedal catch pawl and spring

Fig. 6.2a shows the general arrangement for a table with

external pedal catches and Fig. 6.2b and Fig. 6.2c show

the general arrangement for a table with internal pedal

catches (Fig. 6.2c shows the new base arrangement for

tables having a Serial number prefix of T2AC or later).

These figures identify the main parts of the table base

assembly, refer to them as required. Ensure you refer to

the correct instructions according to the type of pedal catch

fitted to the table (also see section 6.1.9) and base

arragemnet according to table height. Always ensure the

correct parts are used during part replacement, refer to

the illustrated Parts list.

6.3.2 Batteries

IMPORT ANT NOTE:

See section 6.6.26 (battery management system

reconditioning) before changing the batteries.

i Check fuses in the event of power failure before

replacing batteries (before removing or replacing

either battery inline fuse see section 6.6.26).

ii Ensure the table is switched ‘off’ at the main column

switch. If batteries are suspect do not change a them

unless they are obviously faulty using the following

notes as a guide.

a) The fully charged (single) battery voltage should

be at least 12.5V (or a series voltage of 25-27.5V

per pair) and a series voltage of between 23.5V

and 25.5V when powering the tilt motor (table

not loaded). To test the standby batteries press

and hold the standby battery switch whilst

operating the tilt motor via a handset.

b) Each battery within a pair should be at the same

voltage (i.e. within 0.5V of each other).

c) If the voltage of one battery is significantly lower

than the other (> 2V) change the Power supply

assembly .

iii When changing batteries always change them as a

pair (main or standby). Disconnect them at the inline

connector on the top of each battery .

iv Replace covers, if required recondition the battery

management system (see section 6.6.26) and check

table functions.

6.3.3 Pedal dampers.

To replace a pedal damper if operation of the associated

pedal shows sign of unit failure (pedal operation not

damped), or oil is visible during inspection of the base

during maintenance, refer to Fig. 6.2a or 6.2b as

appropriate and proceed as follows.

i Ensure both pedals are in the raised position.

ii Remove the appropriate base cover as detailed in

section 6.2.2.1.

iii To gain easier access for this procedure remove

the damper angle bracket from the table base plate

by removing its two retaining screws. This will enable

the damper to be swung out and up clear of its low

position making removal of the pivot pins easier.

iv Note the orientation of the spring clip on the piston

pivot pins, this is critical and must be copied when

replacing them (the limb of the clip should rest

against the pedal anchor block to stop any lateral

movement of the pedal assembly). Remove both

the pivot pins and the faulty damper.

v Replace the damper with a new unit (piston end to

the pedal anchor block end not the damper angle

bracket end). When replacing pivot pins apply grease

(part number 110477) and ensure the piston spring

clip is in the correct orientation as noted in ‘iv’ above.

P24/54 T-SM47j

Page 25

T20-a

OPERATION TABLE

vi Compress or extend the damper length manually to

enable the damper angle bracket to be secured back