Page 1

User’s Manual

400665709

Page 2

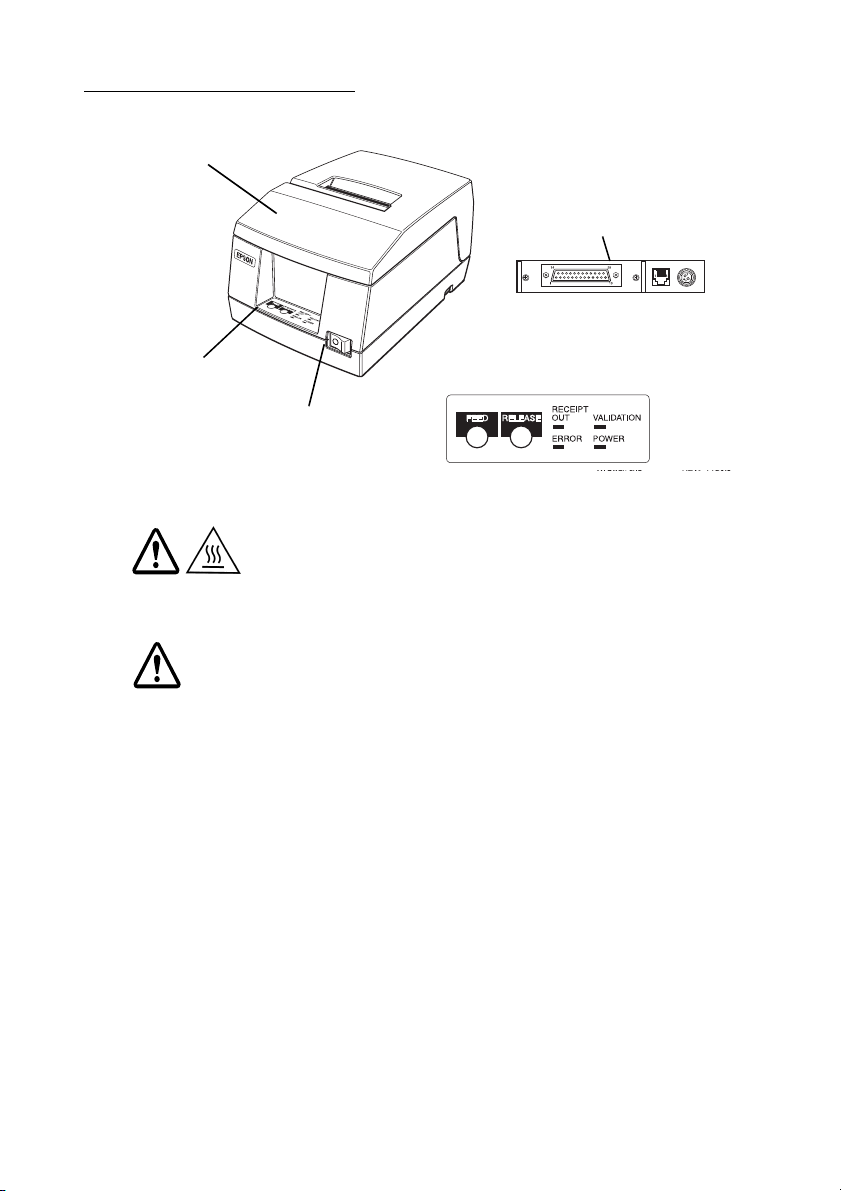

Printer Parts and Labels

Control panel

Printer cover

On/Off switch

Control panel

Serial interface connector

Labels

CAUTION:

Print head cover and print head are hot.

CAUTION:

Caution label for drawer kick-out connector.

Page 3

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise,

without the prior written permission of Seiko Epson Corporation. The contents of this manual are

subject to change without notice. While every precaution has been taken in the preparation of this

manual, Seiko Epson Corporation assumes no responsibility for errors or omissions. Neither is any

liability assumed for damages resulting from the use of the information contained herein.

Neither Seiko Epson Corporation nor its affiliates shall be liable to the purchaser of this product or third

parties for damages, losses, costs, or expenses incurred by purchaser or third parties as a result of:

accident, misuse, or abuse of this product or unauthorized modifications, repairs, or alterations to this

product, or (excluding the U.S.) failure to strictly comply with Seiko Epson Corporation’s operating and

maintenance instructions.

Seiko Epson Corporation shall not be liable for any damages or problems arising from the use of any

options or any consumable products other than those designated as Original Epson Products or Epson

Approved Products by Seiko Epson Corporation.

EPSON is a registered trademark of Seiko Epson Corporation. Exceed Your Vision is a registered

trademark or trademark of Seiko Epson Corporation. All other trademarks are the property of their

respective owners and used for identification purpose only. Product information is subject to change

without due notice.

© Seiko Epson Corporation 1996-2016. All rights reserved.

i

Page 4

About This Manual

Setting Up and Using

❏ Chapter 1 contains information on setting up the printer.

❏ Chapter 2 contains information on using the printer.

❏ Chapter 3 contains troubleshooting information.

Reference

Chapter 4 contains specifications and character code tables.

Warnings, Cautions, and Notes

WARNING:

Warnings must be followed carefully to avoid serious bodily injury.

CAUTION:

Cautions must be observed to avoid minor injury to yourself or damage to

your equipment.

Note:

Notes have important information and useful tips on the operation of your

printer.

Downloading Drivers, Utilities, and Manuals

The latest versions of drivers, utilities, and manuals can be downloaded

from the following URL:

http://www.epson.com/support/

ii

Page 5

Introduction

Features

The TM-U325D is a high-quality POS printer that can print a multiple-line validation and on

receipt paper (roll paper). The printer has the following features:

❏ Excellent reliability (long life) and good operability (drop-in paper loading).

❏ Multiple-line validation printing (possible to print a maximum of 9 lines).

❏ Compact and light in weight.

❏ High-speed printing through logic-seeking control.

❏ Excellent reliability and long life due to adoption of stepping motor, both for moving the

carriage and for paper feeding.

❏ Flexible line space setting permits printing in accordance with any user-defined format.

❏ Conforms with ESC/POS; excellent universality of control.

❏ Built-in drawer kick-out interface provides capability to drive two drawers.

❏ Selectable character fonts (7 × 9 and 9 × 9).

❏ Semi-automatic paper loading capability.

❏ AC adapter provides compact power supply.

❏ Automatic status back (ASB) function that automatically transmits changes in printer

status.

Accessories

❏ AC adapter

❏ Epson ribbon cassette, ERC-38

Options

Printer fastening tape (Model No. DF-10)

Restriction of Use

When this product is used for applications requiring high reliability/safety, such as

transportation devices related to aviation, rail, marine, automotive, etc.; disaster prevention

devices; various safety devices, etc.; or functional/precision devices, etc.; you should use this

product only after giving consideration to including fail-safes and redundancies into your

design to maintain safety and total system reliability. Because this product was not intended

for use in applications requiring extremely high reliability/safety, such as aerospace

equipment, main communication equipment, nuclear power control equipment, or medical

equipment related to direct medical care, etc., please make your own judgment on this

product’s suitability after a full evaluation.

iii

Page 6

Chapter 1

Setting Up the Printer

Selecting a Location

Place the printer on a surface that is as horizontal as possible. Make sure

that the printer does not tilt more than 15 degrees.

The printer should be installed so that it does not move or vibrate during

paper cutting or the drawer kick-out operation.

Fastening tape is available as an option.

Adjusting the Roll Paper Near-End Sensor

Notes:

Use rolls of paper with an inner core diameter of 10.5 to 12.5 mm so

that the sensor detects the remaining paper correctly.

When the last portion of a roll paper bears red markings, the marking

is sometimes an adhesive that pulls the entire roll paper up. In this

case, the sensor may not detect the remaining paper correctly.

If the roll paper easily becomes loose because of the quality of the

paper or other factors, incorrect detection of the paper end may result.

1. Make sure that the power supply is disconnected from the printer.

1–1 Setting Up the Printer

Page 7

2. Two spacers are included. See the illustration below and decide whether

Distance A

Spacers

Roll paper

near-end sensor

or not you want to use them. Use them if you want the near-end sensor to

be triggered when distance A is 3 to 4 mm; otherwise it will be triggered

when distance A is approximately 6 mm.

3. Secure the roll paper near-end sensor (and spacers) with two screws.

When you insert the spacers, be sure you set the spacers in the direction

shown in the illustration.

4. Check to be sure that the detecting lever moves freely.

Setting Up the Printer 1–2

Page 8

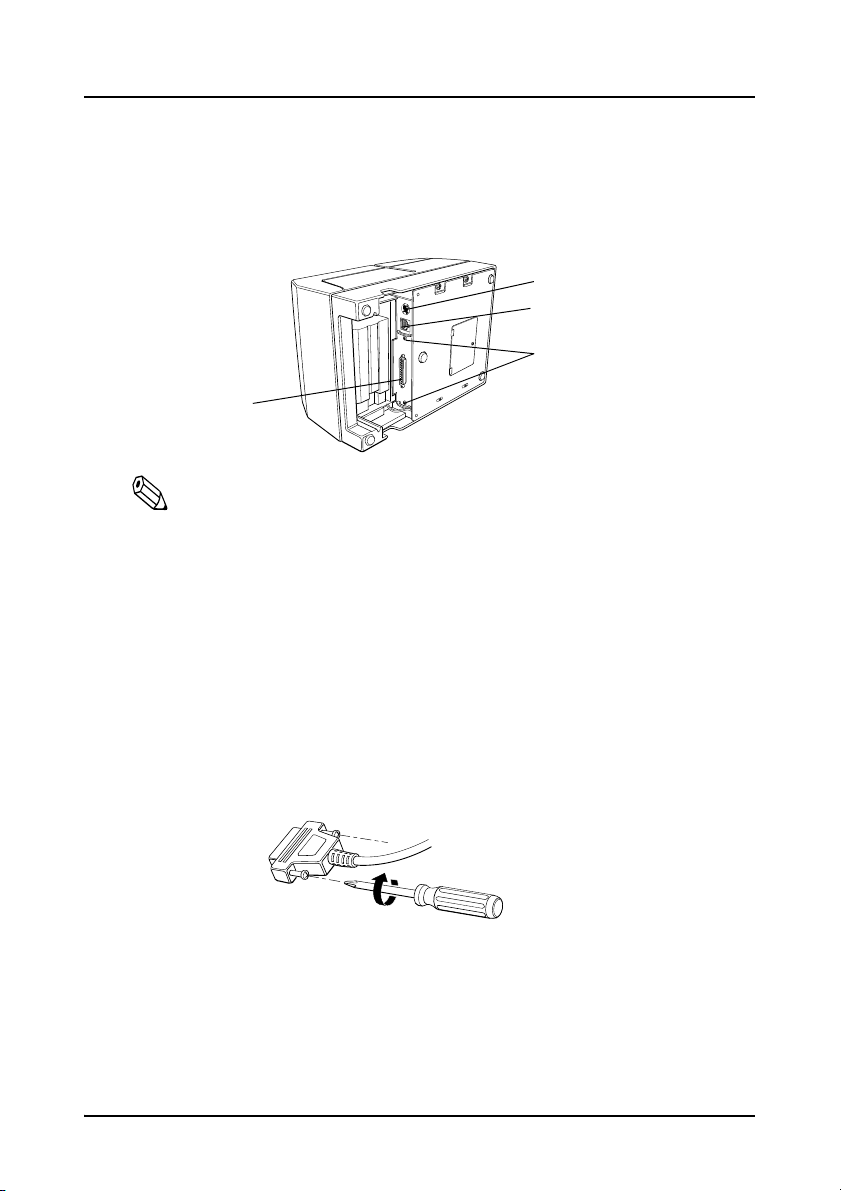

Connecting the Cables and Grounding the Printer

Power supply

Drawer kick-out

Interface

Grounding screws

You can connect up to three cables and a grounding wire to the printer.

They all connect to the connector panel on the bottom of the printer,

which is shown below:

Notes:

There is a caution label beside the drawer kick-out connector.

Depending on the interface installed, the interface connector on your

printer may look different from the one illustrated.

Before connecting any of the cables, make sure that both the printer and

the computer are turned off.

Connecting the Computer

1. Plug the cable into the connector on the printer and tighten the screws

on both sides of the cable connector, as shown.

2. Connect the other end of the cable to the connector on your computer.

1–3 Setting Up the Printer

Page 9

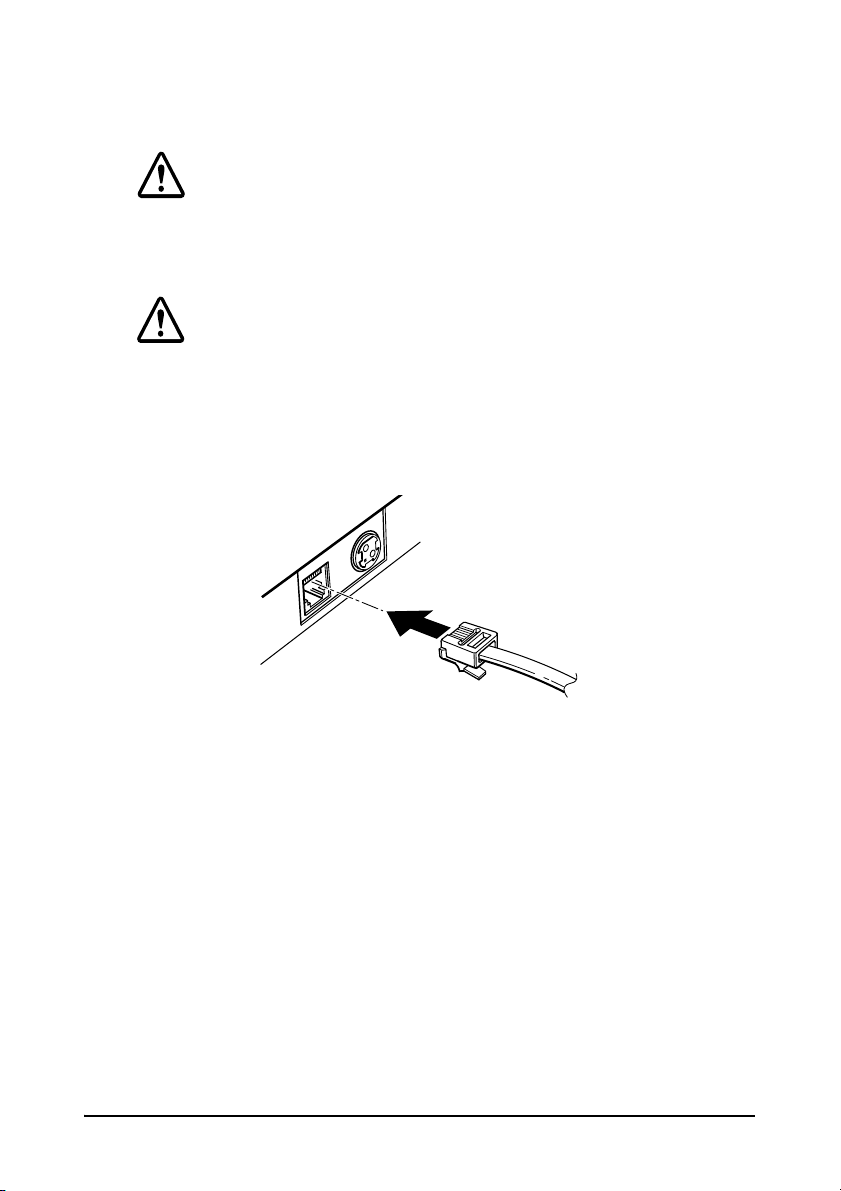

Connecting the Drawer

WARNING:

Use a drawer that matches the printer specification. Using an improper

drawer may damage the drawer as well as the printer.

CAUTION:

Do not connect a telephone line to the drawer kick-out connector;

otherwise the printer and the telephone line may be damaged.

Plug the drawer cable into the drawer kick-out connector on the bottom of

the printer next to the power supply connector.

Grounding the Printer

You need a ground wire to ground your printer. Make sure that the wire

meets the specifications below.

Thickness of wire: AWG 18 or equivalent

Diameter of terminal to be attached: 3.2

1. Make sure that the printer is turned off.

Setting Up the Printer 1–4

Page 10

2. Connect the ground wire to the printer using the FG screw on the bottom

of the printer, as shown.

Connecting the Power Supply

WARNING:

Be sure to use the specified AC adapter. Connection to an improper power

source may cause fire.

CAUTION:

When connecting or disconnecting the power supply from the printer,

make sure that the power supply is not plugged into an electrical outlet;

otherwise you may damage the power supply or the printer.

If the power supply’s rated voltage and your outlet’s voltage do not match,

contact your dealer for assistance. Do not plug in the AC cable. Otherwise

you may damage the power supply or the printer.

1. Make sure that the printer’s power switch is turned off, and the power

supply’s AC cable is unplugged from the electrical outlet.

1–5 Setting Up the Printer

Page 11

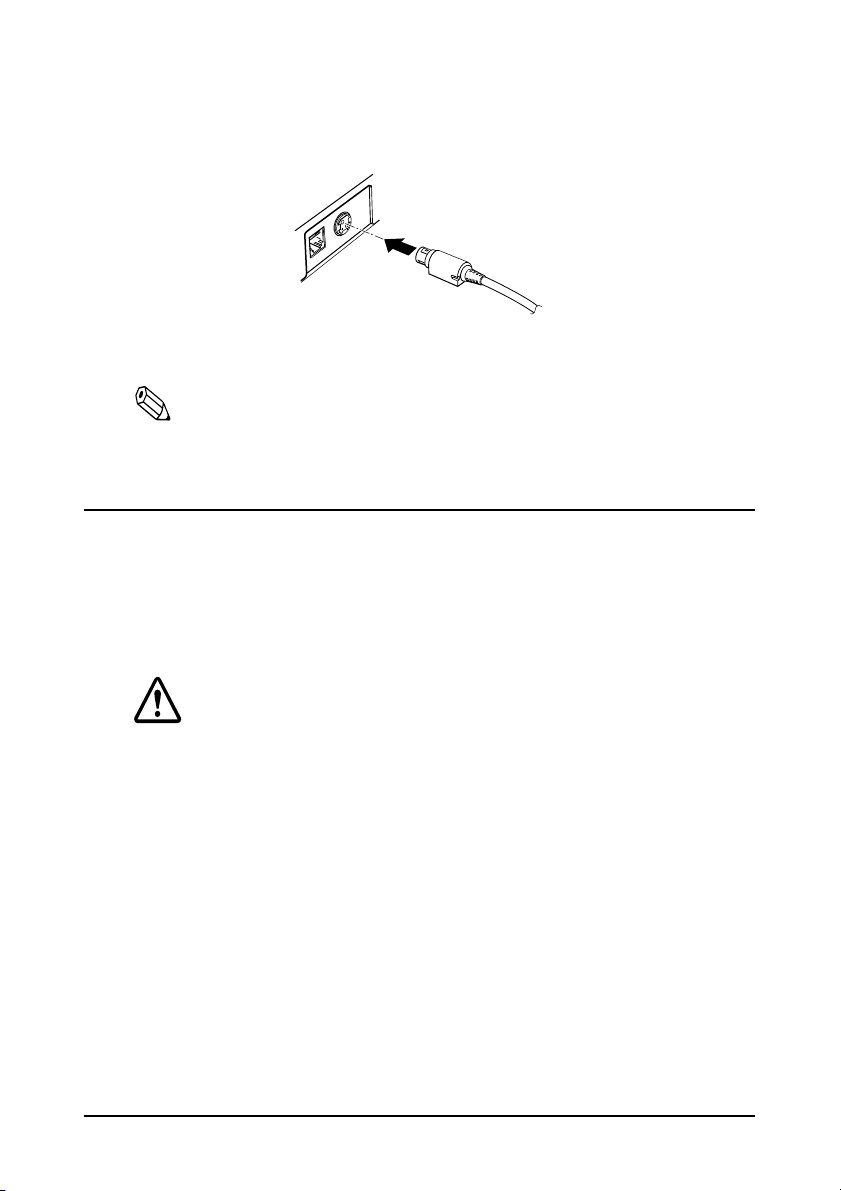

2. Plug in the power supply’s cord as shown below. Notice that the flat side

of the connector faces down.

3. Plug the power supply’s AC cable into an outlet.

Note:

If you ever need to remove the cable, unplug the power supply’s AC

cable from the outlet and then grasp the connector firmly at the arrow

mark and pull it straight out.

Installing the Ribbon Cassette

Use the Epson ERC-38 ribbon cassette for your printer.

Note the label inside the printer cover that can assist you in installing the

ribbon.

CAUTION:

Never turn the ribbon cassette’s feed knob in the opposite direction of the

arrow marked on the cassette; otherwise the ribbon cassette may be

damaged.

1. Be sure the printer is not receiving data when you replace a ribbon

cassette; otherwise data may be lost.

2. Open the printer cover.

Setting Up the Printer 1–6

Page 12

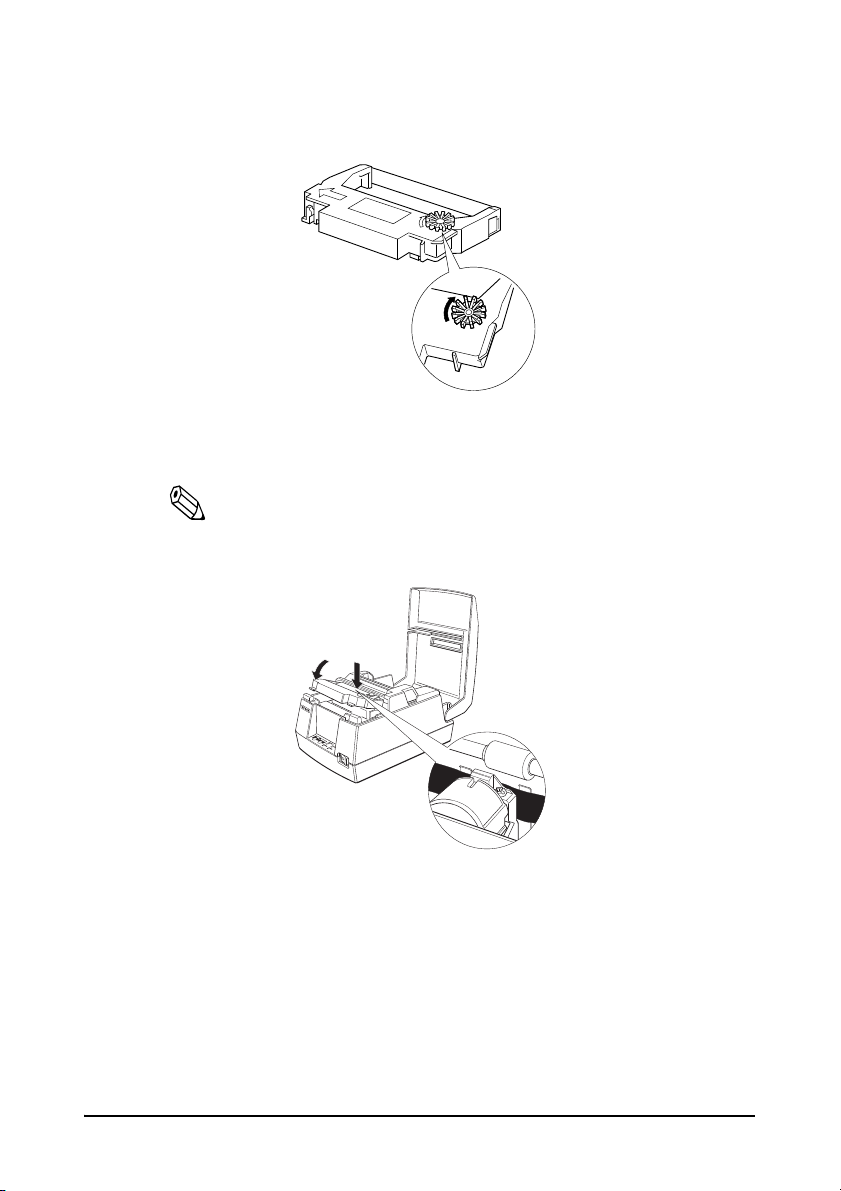

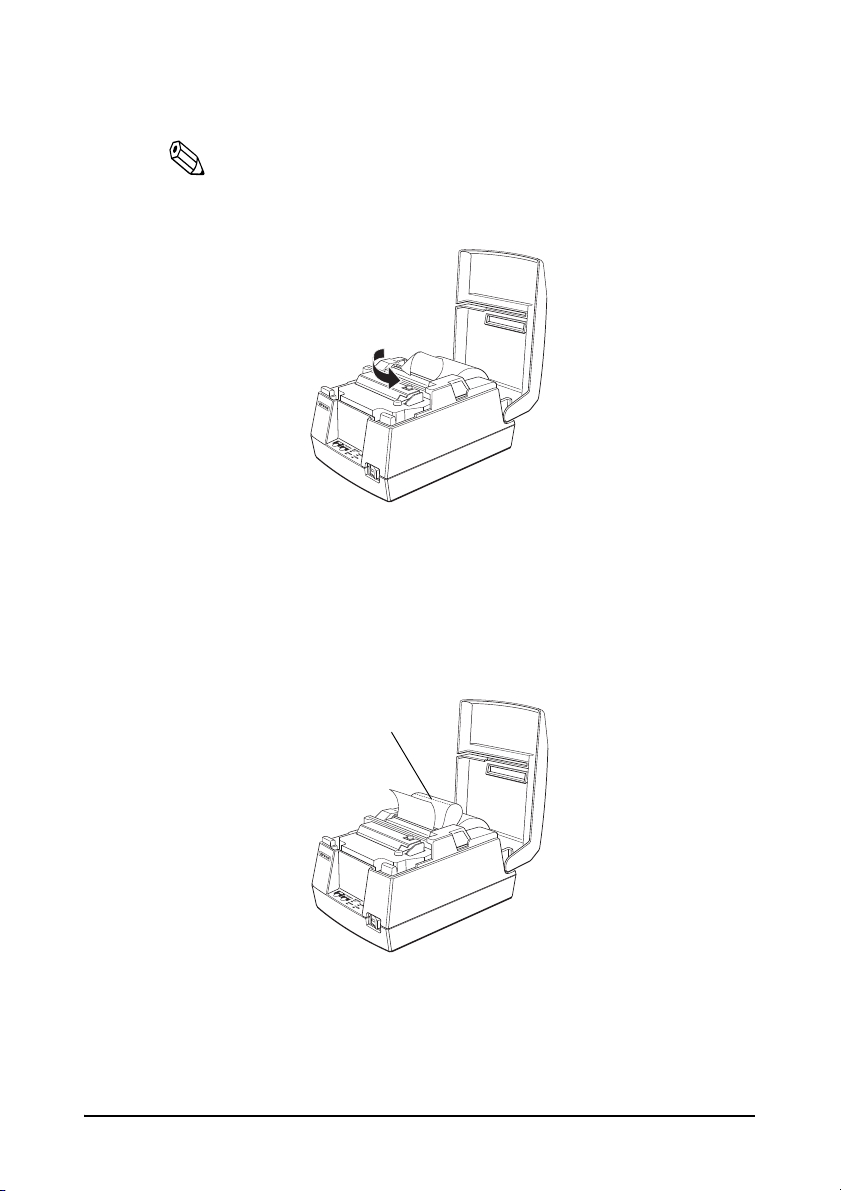

3. Turn the ribbon cassette’s knob in the direction of the arrow, to take up

any slack in the ribbon.

4. Insert the ribbon in the position shown in the illustration below and push

the ribbon cassette until it clicks.

Note:

Make sure that the ribbon is installed between the print head and

the platen without wrinkles or creases.

1–7 Setting Up the Printer

Page 13

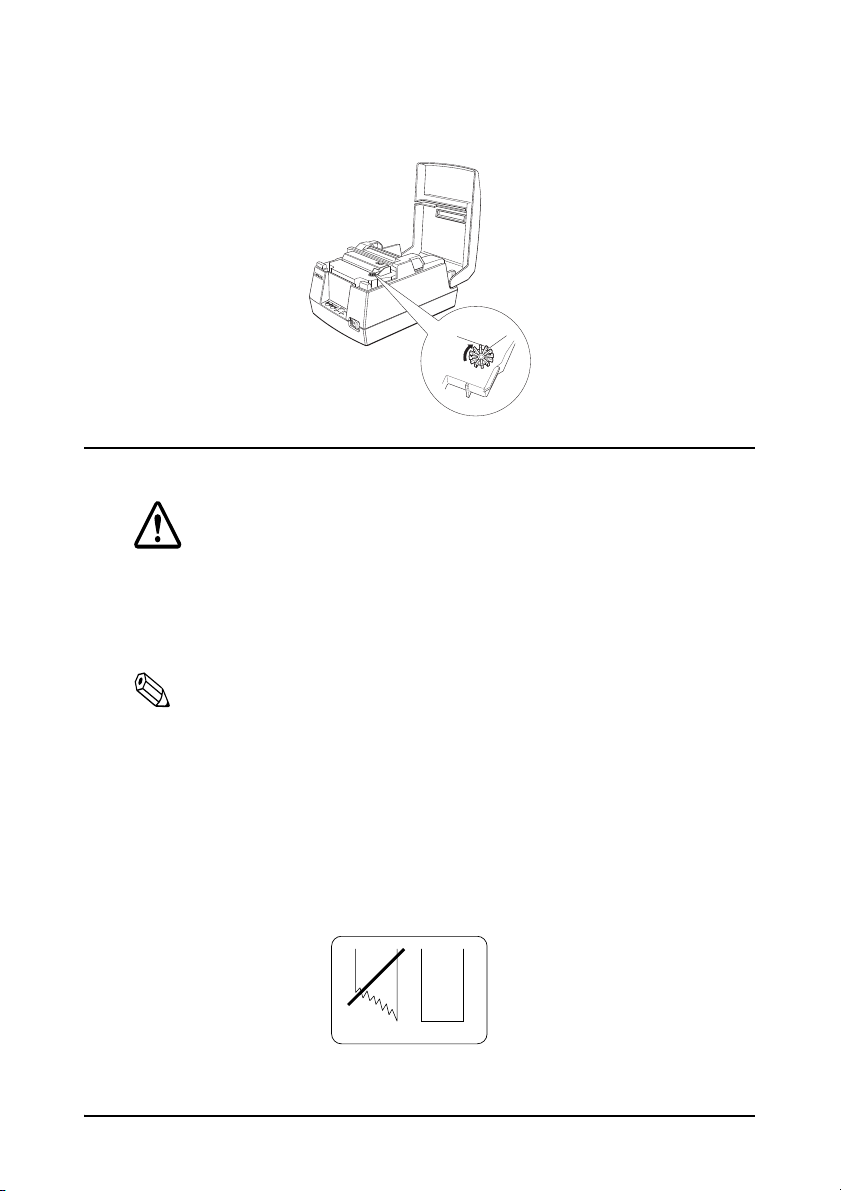

5. Turn the ribbon cassette’s knob 5 or 6 times in the direction of the arrow

again, to take up any slack in the ribbon.

Installing Roll Paper

CAUTION:

Take care not to injure your fingers on the manual cutter

• When you remove printed paper

• When you perform other operations such as loading/replacing roll

paper

Notes:

Be sure to use roll paper that meets the specifications.

Do not use rolls of paper that have the paper glued to the core because

the printer cannot detect the paper end correctly. However, if you will

stop the printing using the roll paper near-end sensor, you can use

glued roll paper.

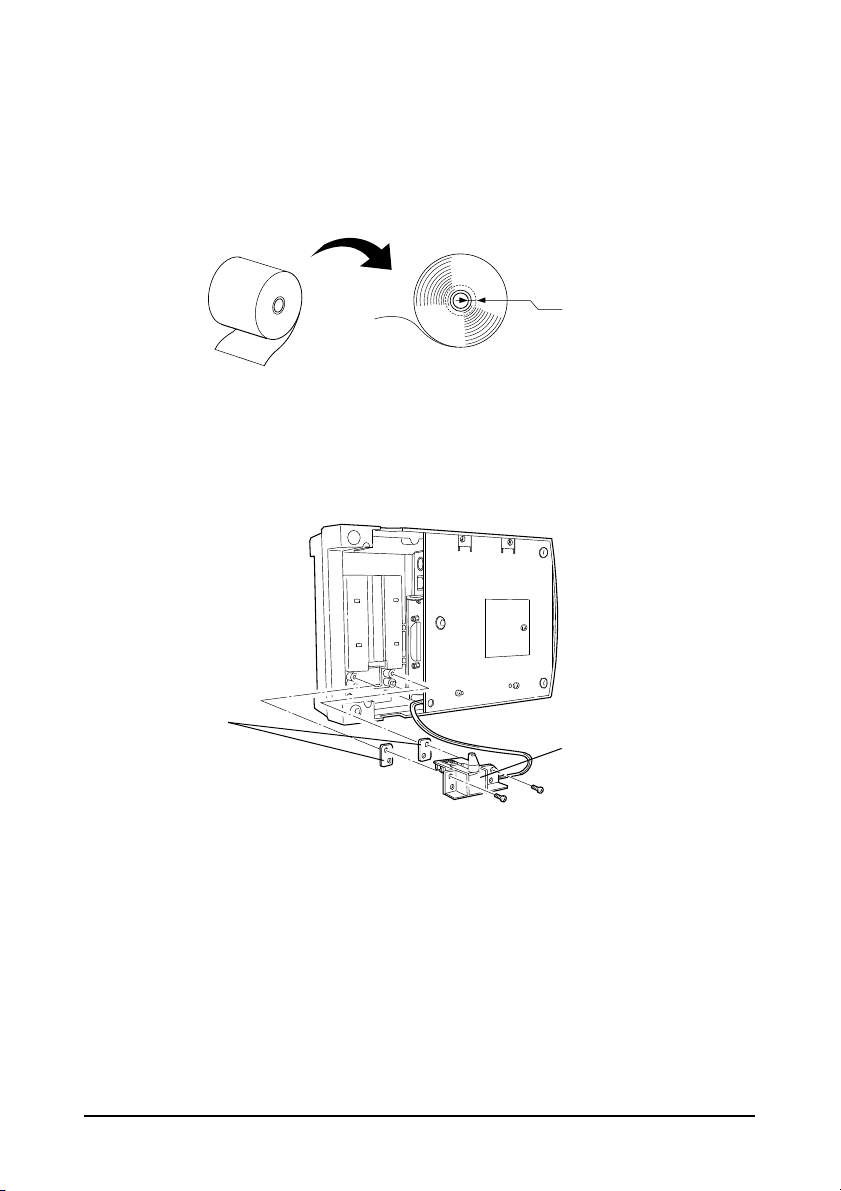

1. Using scissors, cut the leading edge of the roll paper as shown below.

Setting Up the Printer 1–8

Page 14

2. Turn on the printer and open the printer cover.

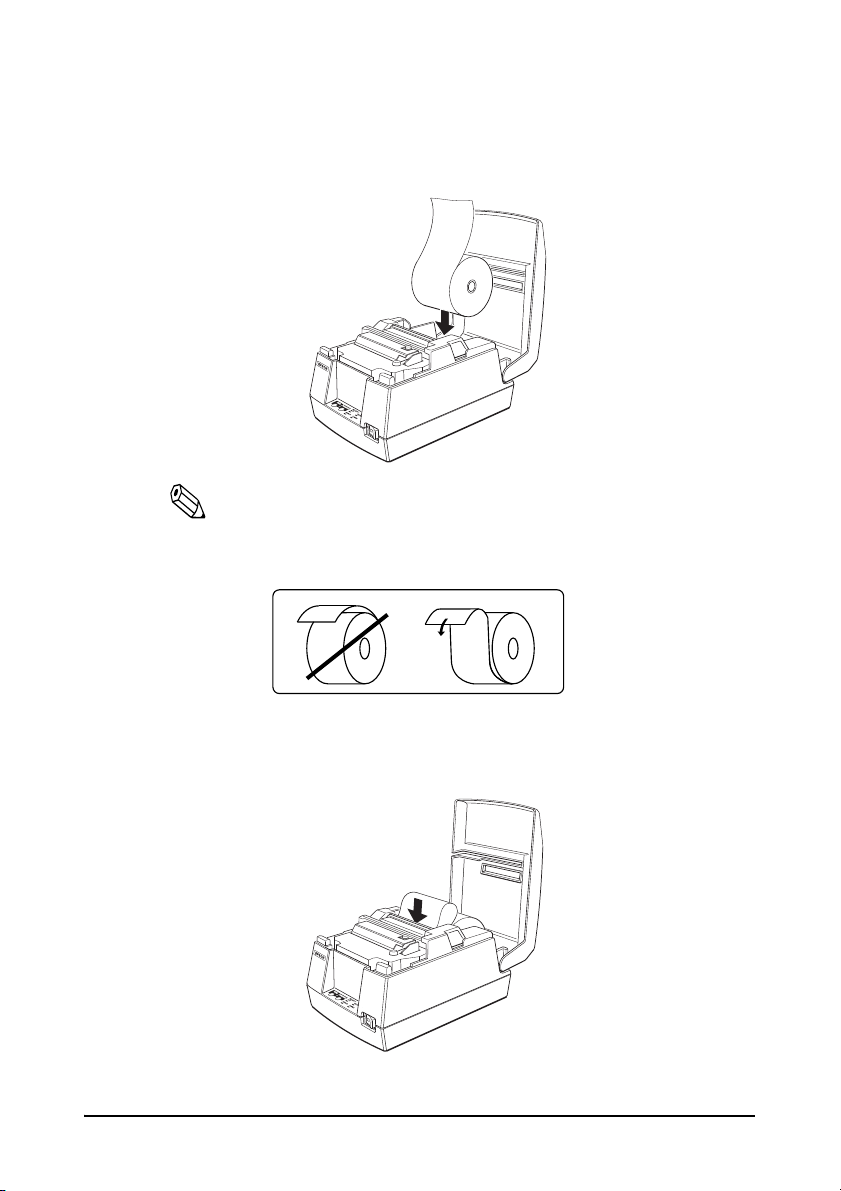

3. Insert the roll paper.

Note:

Be sure to note the correct direction that the paper comes off the

roll as shown below.

4. Hold both edges of the paper and insert it straight into the paper slot. The

printer feeds the paper automatically.

1–9 Setting Up the Printer

Page 15

5. Tear off the paper; then close the cover.

Cut here

Note:

Before closing the cover, make sure that the roll paper has no

slack.

To remove the roll of paper, follow the steps below.

1. Open the printer cover.

2. Pull up the paper and cut the paper at the dotted line shown in the

illustration below.

3. Remove the roll paper from the printer.

4. Press the FEED button to remove the remaining paper.

Setting Up the Printer 1–10

Page 16

Running a Self-test

Any time that you want to check the performance of your printer, you can

run a Self-test described below. This shows whether your printer is

working correctly. It is independent of any other equipment or software.

Note:

Be sure to install the ribbon cassette and the roll paper before you

run the Self-test.

1. To perform a Self-test, hold down the FEED button while you turn on

the printer with the power switch.

2. The printer prints the current printer settings and then the RECEIPT OUT

light flashes to indicate that the printer is in the test printing standby state.

3. Press the FEED button to start the second part of the test, in which the

printer prints a pattern using the built-in character set.

4. After the printer completes a certain number of lines, it prints the

following:

*** completed ***

Then it enters the normal mode.

Note:

If you want to pause the Self-test manually, press the FEED

button. Press the FEED button again to continue the Self-test.

Setting the DIP Switches

CAUTION:

Turn off the printer while removing the DIP switch cover to prevent an

electrical short, which can damage the printer.

If you have special requirements, you can change the DIP switch settings.

1. Make sure that the printer is off.

1–11 Setting Up the Printer

Page 17

2. Turn the printer over and remove the DIP switch access cover, as shown

below.

3. There are two sets of switches. Notice that ON is marked on each set of

switches. Use tweezers or another narrow tool to move the switches.

4. Use the following tables to set the DIP switches. Numbers starting with 1

are in the first set, and numbers starting with 2 are in the second.

DIP Switch Set 1

Switch Function ON OFF

1-1 Data reception error Ignored Prints”?”

1-2 Receive buffer capacity 45 bytes 4 KB

1-3 Handshaking XON/XOFF DTR/DSR

1-4 Word length 7 bits 8 bits

1-5 Parity check Yes No

1-6 Parity selection Even Odd

1-7, 1-8 Transmission speed (see table below)

Setting Up the Printer 1–12

Page 18

Transmission Speed

Transmission Speed (BPS)-bits per second 1-7 1-8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OFF

DIP Switch Set 2

Switch Function ON OFF

2-1 Handshaking (BUSY condition) Receive buffer full

2-2 Not defined — —

2-3

2-4, 2-5 Not defined — —

2-6 Internal use — Fixed to Off

2-7 Interface pin 6 reset signal Enabled Disabled

2-8 Interface pin 25 reset signal Enabled Disabled

Select number of characters per line

(CPL) 7 × 9 font/9 × 9 font

42CPL/35CPL 40CPL/33CPL

Off line or receive

buffer full

Notes:

DIP Switch 1, 2-7 and 2-8 are only available when using a serial

interface.

Changes in DIP switch settings (excluding switches 2-7 and 2-8) are

recognized only when the printer power is turned on or when the

printer is reset by using the interface. If the DIP switch setting is

changed after the printer power is turned on, the change does not take

effect until the printer is turned on again or is reset.

If DIP switch 2-7 or 2-8 is turned on while the printer is turned on, the

printer may be reset, depending on the signal state.

DIP switches should not be changed while the printer power is on.

1–13 Setting Up the Printer

Page 19

Using the Power Switch Cover

WARNING:

If an accident occurs when the power switch cover is attached, unplug the

power supply cord from the outlet immediately; otherwise the printer may

be damaged.

You can use the provided power switch cover to protect the power switch

from accidental or improper operation. Attach the cover as shown in the

illustration below.

You can turn the power on or off with the switch cover attached by

inserting a pointed object (like a ball point pen) through either of the two

small holes on the switch cover.

Affixing the Fastening Tape (Option)

Two sets of tape are included as an option to fasten your printer to a

countertop or other surface. Follow the steps below:

1. Clean the countertop or other surface where the printer will be

installed.

Setting Up the Printer 1–14

Page 20

2. Peel the green backing paper off of one side of each of the two sets of tapes

and affix them to the bottom of the printer, as shown below.

3. Peel the green backing paper off of the other side of the tapes.

4. Press the printer onto the countertop; it will be held firmly in place by the

fastening tape.

1–15 Setting Up the Printer

Page 21

Chapter 2

Using the Printer

Operating the Control Panel

You can feed or release paper with the buttons on the control panel. The

indicator lights help you monitor the printer’s status.

Switch

The power switch on the front of the printer turns the printer on and off.

Buttons

FEED

Press the FEED button once to advance the roll paper one line. You can

also hold down the FEED button to feed the paper continuously.

RELEASE

Press the RELEASE button to release the validation paper.

Notes:

These buttons can be disabled by the ESC c 5 command, but they work

whenever the printer cover is open, even if they have been disabled by

the ESC c 5 command.

The power switch and FEED button can also be used to start the Self-

test.

Using the Printer 2-1

Page 22

Indicator lights

Approximately 160 ms

The control panel lights provide information on printer conditions.

POWER (Green)

The POWER light is on when the printer power is on.

RECEIPT OUT (Red)

This light is on when the roll paper is at the end or near the end.

This light flashes in the following cases. When it flashes, press the FEED

button.

In the Self-test standby state

VALIDATION (Green)

The light is on when validation paper is inserted and the printer is ready to

print. The light flashes when the printer is in the validation insertion/

removal waiting state.

ERROR (Red)

This light is on when the printer is off line (except during paper feed using

the FEED button and during the Self-test). It flashes to indicate an error

condition.

The flashing pattern shown below indicates that the temperature of the

print head is too high. The printer recovers automatically and resumes

printing when the head cools.

2-2 Using the Printer

Page 23

If the printer stops working and the ERROR light is flashing, turn the

printer off, check for jammed paper, and remove the paper by following

the instructions on page 3-3, if necessary. Then turn the printer back on. If

the printer still does not work, unplug the power supply cord from the

outlet immediately, and contact a qualified service person.

CAUTION:

Take care not to injure your fingers on the manual cutter

• When you remove printed paper

• When you perform other operations such as loading/replacing roll

paper

The print head becomes very hot during printing. Allow it to cool before you

reach into the printer.

Do not use aerosol sprayers containing flammable gas inside or around

this product. Doing so may cause fire.

Using the Printer 2-3

Page 24

Validation Paper Handling

Notes:

Use only validation paper that matches the printer’s specifications. See

Paper Specifications in Chapter 4.

Be sure that roll paper is loaded before you use validation paper.

Be sure that the validation paper is flat, without curls, folds, or

wrinkles.

1. Send appropriate control commands from the computer to print on

validation paper.

2. When the VALIDATION light flashes, insert the validation paper into the

validation paper inlet using the right edge of the validation paper inlet as a

guide. (Follow steps ➀ and ➁ in the illustration.)

3. Make sure you insert the validation paper into the inlet as far as it will go.

4. When the validation paper is detected by the sensor, the VALIDATION

light is changed from flashing to on and the paper is automatically drawn

into the printer and printing begins.

5. When the VALIDATION light begins flashing after printing, remove the

validation.

2-4 Using the Printer

Page 25

Chapter 3

Troubleshooting

Troubleshooting

This chapter gives solutions to some of the more common printer

problems.

General Problems

The lights on the control panel do not come on.

Make sure that the power supply cords are correctly plugged into the

printer, the power unit, and to the power outlet.

Make sure that power is supplied to the power outlet. If the outlet is

controlled by a switch or timer, use another outlet.

Printing Problems

The ERROR light is flashing and the printer does not print.

First, turn off the printer and check for a paper jam. (See the paper jam

description on page 3-3.)

If there is no paper jam and the printer has been printing for quite a while,

the print head may be overheated. If the print head is overheated, the

printer will resume printing when the head has cooled (usually about 30

seconds).

If there is no paper jam and the print head is not overheated, turn off the

printer and turn it back on after about 10 seconds. If the printer still does

not work, unplug the power supply cord from the outlet immediately.

Then contact a qualified service person.

Troubleshooting 3-1

Page 26

The ERROR light is off, but nothing is printed.

Try to run the Self-test to check that the printer works properly. See the

Self-test instructions in Chapter 1 to run the Self-test. If the Self-test does

not work, contact your dealer or a qualified service person.

If the Self-test works properly, check the following:

1. Check the connection at both ends of the interface cable between the

printer and the computer. Also make sure that this cable meets the

specifications for both the printer and the computer.

2. The data transmission settings may be different between the printer and

computer. Make sure that the printer’s DIP switch settings for data

transmission are the same as the computer’s. You can print the printer’s

interface settings using the Self-test.

If the printer still does not print, contact your dealer or a qualified service

person.

The printer sounds like it is printing, but nothing is printed.

The ribbon cassette may not be installed properly. See the instructions in

Chapter 1.

The ribbon may be worn out. Replace the ribbon cassette as described in

Chapter 1.

The printout is faint.

The ribbon may be worn out. Replace the ribbon cassette as described in

Chapter 1.

A line of dots is missing in the printout.

The print head may be damaged. Stop printing and contact your dealer or

a qualified service person.

3-2 Troubleshooting

Page 27

Removing Jammed Paper

Cut here

Follow these steps to clear a paper jam:

CAUTION:

The print head becomes very hot during printing. Allow it to cool before you

reach into the printer.

1. Open the printer cover.

2. Pull up the paper and cut the paper at the dotted line shown in the

illustration below.

3. Remove the roll paper from the printer.

4. Remove the ribbon cassette.

Troubleshooting 3-3

Page 28

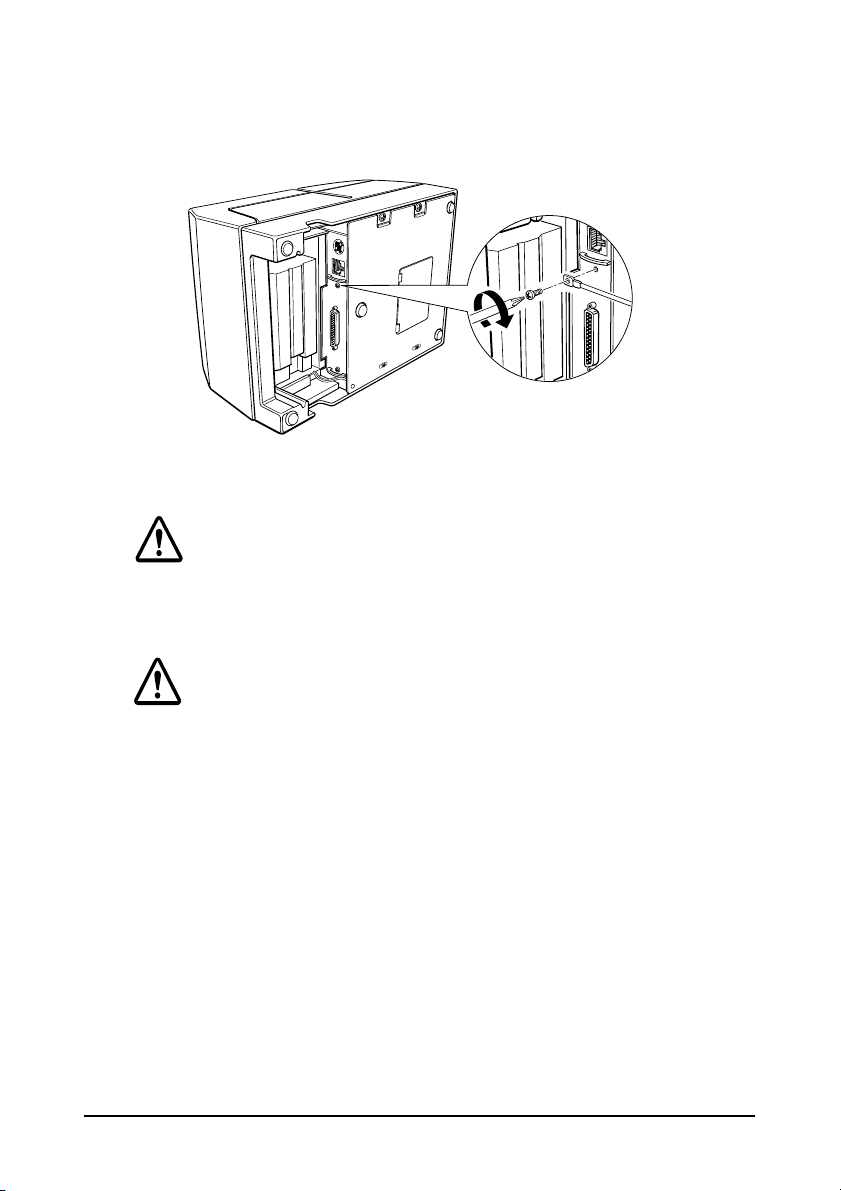

5. Loosen the screw on the print head cover as shown below.

6. Lift up the print head cover.

7. Remove all the jammed paper.

Note:

Do not pull the jammed paper in the opposite direction of paper

feeding.

8. Replace the print head cover and secure it with the screw.

9. Replace the ribbon cassette and roll paper; then close the printer cover.

3-4 Troubleshooting

Page 29

Hexadecimal Dump

This feature allows experienced users to see exactly what data is coming to

the printer. This can be useful in finding software problems. When you

turn on the hex dump function, the printer prints all commands and other

data in hexadecimal format along with a guide section to help you find

specific commands.

To use the hexadecimal dump feature, follow these steps:

1. Turn on the printer while you hold down the FEED button; then close

the cover.

2. When the printer enters the hexadecimal dump mode, it prints

“Hexadecimal Dump.”

3. Run any software program that sends data to the printer. The printer

prints all the codes it receives in a two-column format. The first column

contains the hexadecimal codes and the second column gives the ASCII

characters that correspond to the codes.

Hexadecimal Dump

1B 40 1B 21 30 41 42 43 . @ . ! 0 A B C

44 45 46 47 0A DE F G.

❏ A period (.) is printed for each code that has no ASCII equivalent.

❏ During the hexadecimal dump, all commands except DLE EOT

and DLE ENQ are disabled.

4. When the printing finishes, turn off the printer or reset it to turn off the

hexadecimal dump mode.

Note:

Insufficient print data to fill the last line can be printed by setting the

printer off-line.

Troubleshooting 3-5

Page 30

Chapter 4

Reference Information

Printing Specifications

Printing Method: Serial impact dot-matrix

Head wire

configuration:

Printing Direction: Bi-directional, logic-seeking

Characters/line

(default):

Character spacing

(default)

Fonts A and B:

Printing speed: Approx. 3.5 lines/second (40 columns, 16 cpi)

[cpi: characters per 25.4 mm (characters per inch)]

Note:

When printing exceeds the allowable print duty cycle, the printer automatically stops printing.

In this case, the printing speed described above is not guaranteed.

9-pin serial configuration

See table on page 4-2.

See table on page 4-2.

Approx. 6.4 lines/second (16 columns, 16 cpi)

(excluding data transmission time and

processing time)

4-1 Reference Information

Page 31

Character Specifications

Number of characters Alphanumeric characters: 95

Extended graphics: 128 × 8 pages,

International characters: 32

Character structure: 7 × 9 (the total number of dots for each

horizontal line: 400 in half dot units)

9 × 9 (the total number of dots for each

horizontal line: 400 in half dot units)

Character size: See table below.

Character Sizes, Character Spacing, Character Columns

Character structure

W x H (mm) Character

7 x 9

9 x 9

7 x 9

9 x 9

ANK 1.2 x 3.1 3 half dots 40 16

Graphics 1.7 x 3.1 0 40 16

ANK 1.6 x 3.1 3 half dots 33 13.3

Graphics 2.0 x 3.1 0 33 13.3

ANK 1.2 x 3.1 2 half dots 42 17.8

Graphics 1.6 x 3.1 0 42 17.8

ANK 1.6 x 3.1 2 half dots 35 14.5

Graphics 1.9 x 3.1 0 35 14.5

Character size

W x H (mm)

Character

spacing

Dot space

CPL

CPI

[cpl: characters per line]

[cpi: characters per 25.4 mm (characters per inch)]

Notes:

•The default is

• 2-dot spacing in half dot units and 3-dot spacing in half dot units depend on the DIP

switch setting.

7 x 9.

Reference Information 4-2

Page 32

Paper Specifications

Paper feed method: Friction feed

Paper feed pitch: Default 4.23 mm {1/6 inch}

Can be set in units of 0.176 mm {1/144

inch} by commands.

Paper feed speed: Approx. 105.9 mm {4.17 inches}/second (25

lines/second) (continuous feeding)

Paper size and weight:

Roll paper: Normal paper (single-ply)

Size: Width 76 mm ± 0.5 mm

{3.0" ± 0.02"}

4-3 Reference Information

Maximum

83 mm {3.27"}

outside dia:

Thickness: 0.06 to 0.085 mm {0.0024 to

0.0033"}

2

Mass: 52.3 to 64.0 g/m

{13.9 to 17

lbs} (45 to 55 Kg {20.41 to

24.94 lbs}/1000 sheets/1091

mm × 788 mm {43.00" ×

31.02"}

Page 33

Pressure sensitive paper

Maximum 1 original + 2 copies

Size: Width 76 mm ± 0.5 mm

{3.0" ± 0.02"}

Maximum

83 mm {3.27"}

outside dia:

Thickness: 0.05 to 0.08 mm {0.0020 to

0.0031"}

(Total thickness should be

0.2 mm or less and each

sheet should be 0.05 to 0.08

mm.)

Recommended

paper:

MITSUBISHI PAPER

MILLS, LTD.

Non-carbon paper

(blue color)

Top and middle sheets: N40

(thickness: 0.06 mm, mass:

2

47.2 g/m

)

Bottom sheet: N60

(thickness: 0.08 mm, mass:

2

68.0 g/m

Note:

When using original + 2 copies (the total is 3), the edges of the paper might fold

when the temperature is 34°C and the humidity is 90%.

)

Validation paper: Normal, pressure sensitive, and carbon

copy paper

Reference Information 4-4

Page 34

Paper size

(W × L):

135 mm × 70 mm (minimum) to 182 mm ×

182 mm (maximum)

{5.31” × 2.76” to 7.17” × 7.17”}

(maximum 9 lines at 4.23 mm {.17”} pitch)

Single-ply paper

thickness

(without copy

paper):

Copy paper

thickness:

Example: Original + 2-ply copy

0.09 mm to 0.12 mm {.0035” to .0047”}

Backing

paper:

Copy and

original paper:

Carbon

copy paper:

Total

thickness:

Original paper: 0.04 mm {.0016”}

Carbon copy paper: 0.07 mm {.0028”}

(0.035 mm {.0138”} × 2 sheets)

Copy paper: 0.04 mm {.0016”}

Backing paper: 0.07 mm {.0028”}

Roll paper: 0.08 mm {.0031”}

Total thickness: 0.30 mm {.0118”}

0.07 mm to 0.12 mm {.0028”

to .0047”}

0.04 mm to 0.07 mm {.0016”

to .0028”}

Approximately 0.035 mm

{.00138”}

0.09 mm to 0.31 mm {.0035”

to .012”}

Copy capability

4-5 Reference Information

Page 35

Roll paper and

validation paper:

Copy capability is greatly influenced by the

ambient temperature, so printing must be

performed under the conditions described

in the table below.

Relationship between ambient temperature and number of copies

Roll paper and validation paper:

Number of copies Ambient temperature

Original + 2 copies 10° to 40°C {50° to 104°F}

Original + 1 copy 5° to 50°C {41° to 122°F}

Notes on validation paper

❏ For correct validation printing, be sure that roll paper is loaded before

you use validation paper. Also be aware that the printing on validation

paper may also be visible on the roll paper if the roll paper is pressuresensitive paper.

❏ Use validation paper that is flat, without curls, folds, warps, or

wrinkles, especially at the paper edge. Otherwise, the paper may

become ink stained or the ribbon may get caught in the printer

mechanism.

❏ Choose validation paper carefully when glue is on the edge, since

paper feeding and insertion are affected by gluing conditions (e.g.,

glue quality, method, and length) and glue location.

❏ Using a multi-ply copy paper with a thick middle sheet may decrease

copying capability.

❏ Printing noise may change depending on paper thickness. Noise may

increase when thick single-ply paper is used.

Reference Information 4-6

Page 36

❏ Validation paper with holes (e.g., sprocket holes) within the areas

Inserting direction

11 mm (.43”)

: Holes are prohibited

in this area.

7 mm (.28”)

shown below must not be used. Otherwise, the paper cannot be

detected by the paper sensor. Translucent paper must not be used.

4-7 Reference Information

Page 37

Reliability

Life: 20,000,000 lines

End of Life is defined as the point at which

the printer reaches the beginning of the

Wearout Period.

MTBF: 180,000 hours

Failure is defined as Random Failure

occurring at the time of the Random

Failure Period.

MCBF: 49,000,000 lines

This is an average failure interval based on

failures relating to wearout and random

failures up to the life of 20 million lines.

Print head life: 150 million characters (when printing an

average of 2 dots/wire per character)

Validation switching

operation life:

500,000 transactions

Reference Information 4-8

Page 38

Environmental Conditions

0

10

20

40

60

80

90

0

20

10

30

40

50

34 ° C, 90%

40 ° C, 65%

50 ° C, 35%

Relative humidity

Environment temperature [ ° C]

Operating environment range

Temperature

Operating

Storage

Humidity

Operating

Storage

0 to 50° C {32 to 122° F}

(when the temperature is 30 ° C or more,

there is a limitation for the humidity. Refer to

the figure below.)

–10 to 50° C {14 to 122°F}

(except for paper, and a ribbon)

10 to 90% RH

10 to 90% RH

(except for paper and a ribbon)

4-9 Reference Information

Page 39

Character Code Tables

FS

SP in a table represents space.

Page 0 (PC437: U.S.A., Standard Europe) (International character set:

U.S.A)

Reference Information 4-10

Page 40

Page 1 (Katakana)

4-11 Reference Information

Page 41

Page 2 (PC850: Multilingual)

Reference Information 4-12

Page 42

Page 3 (PC860: Portuguese)

4-13 Reference Information

Page 43

Page 4 (PC863: Canadian-French)

Reference Information 4-14

Page 44

Page 5 (PC865: Nordic)

4-15 Reference Information

Page 45

Page 254 (Space Page)

Reference Information 4-16

Page 46

Page 255 (Space Page)

4-17 Reference Information

Page 47

International character set

ASCII code (hexadecimal)

Country

U.S.A.

France

Germany

U.K.

Denmark I

Sweden

Italy

Spain

Japan

Norway

Denmark II

Hex 2324405B5C5D5E607B7C7D 7E

Dec 3536649192939496123124125126

# $ @ [ \ ] ^ ` { ¦ }

# $ à ° ç § ^ ` é ù è ¨

# $ § Ä Ö Ü ^ ` ä ö ü ß

£

# $ @ Æ Ø Å ^ ` æ ø å

# ¤ É Ä Ö Å Ü é ä ö å ü

# $ @ ° \ é ^ ù à ò è ì

P t $ @ ¡ Ñ ¿ ^ ` ¨ ñ }

# $@[¥]^`{¦}

# ¤ É Æ Ø Å Ü é æ ø å ü

# $ É Æ Ø Å Ü é æ ø å ü

$@

~

[

]

\

^`

{ ¦ }

~

~

~

~

Reference Information 4-18

Loading...

Loading...