Page 1

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

Paper roll printers

EPSON

EPSON

TM-U200B/D

TM-T88II

TM-L60II

Features

& Technical

Information

Commands listed by function

Commands listed in alphanumeric order

Character code tables

Usable application programs and tips

Definitions

TM-U300A/B

CONFID

CONFID

CONFIDENTIAL

Page 2

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

TM-T88II

Features

Specifications

Self test

Hex dump

Supported commands

EPSON

EPSON

CONFID

CONFID

CONFIDENTIAL

Page 3

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

TM-L60II

Features

Specifications

Self test

Hex dump

Supported commands

EPSON

EPSON

CONFID

CONFID

CONFIDENTIAL

Page 4

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

TM-U200B/D

Features

Specifications

Self test

Hex dump

Supported commands

EPSON

EPSON

CONFID

CONFID

CONFIDENTIAL

Page 5

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

ESC/POS

TM-U300A/B

Features

Specifications

Self test

Supported commands

EPSON

EPSON

CONFID

CONFID

CONFIDENTIAL

Page 6

CONFIDENTIAL

Usable application programs and tips

■ ■ ■

■ ■ ■

more

more

USABLE APPLICATION PROGRAMS AND TIPS

System Processing

This example illustrates ESC/POS command functions and printing results. It shows a receipt issue processing

and its procedure using the TM-U200B.

Print Sample

E P S O N

Thank you

January 14, 1998 15:00

TM-U200B

TM-U200D

PS-170

$20.00

$21.00

$17.00

Stamp

←

Item A

Date and Time

TOTAL

PAID

CHANGE

$58.00

$60.00

$2.00

←

Paper roll Usable application programs and tips

Item B

Cutting Position

Ver. 4.0

p. 943

Page 7

CONFIDENTIAL

more

System Processing Procedure

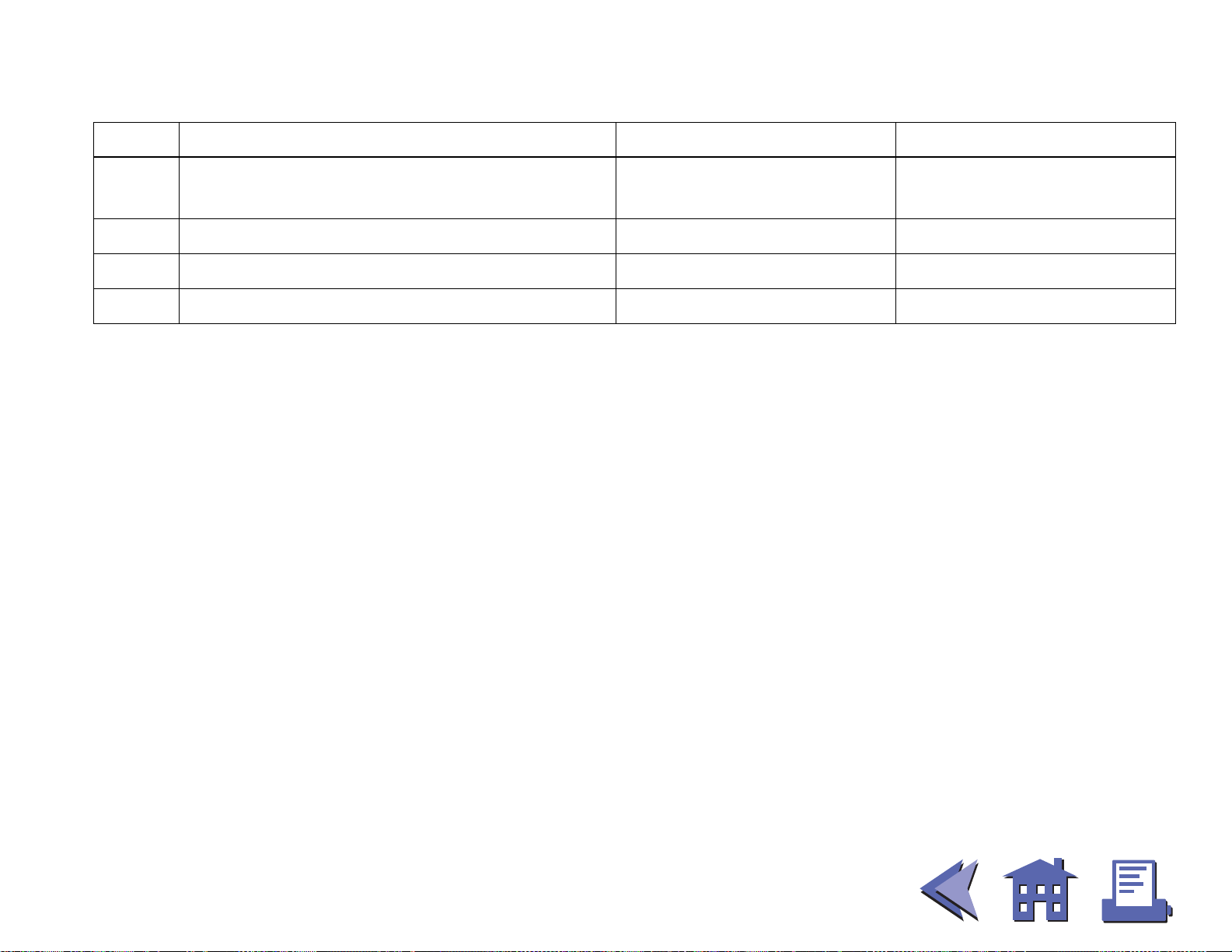

Procedure Commands used Description

1. Stamp printing

2. Print date and

time

3. Print Item A

4. Print Item B

5. Cut paper

ESC 3, ESC a, ESC !,

ESC U, ESC 2, LF, CR

ESC a, ESC d

ESC t, ESC !, LF

ESC !, ESC U, LF

GS V

Specifies a print position to the center by using the

command. Prints a stamp data in the center of the paper roll in

the unidirection. Adjusts line spacing for a line data being

continuous.

Specifies a print position to the left by using the

command after printing the date and time in the center of the

paper roll.

Selects the 7 x 9 font by using the

the Item A.

Specifies double-height by using the

prints “TOTAL” in the unidirection. Cancels the double-height

and prints in the bidirectional mode for other lines.

Feeds the paper to the cutting position and executes cutting.

ESC !

ESC !

■ ■ ■

■ ■ ■

ESC a

command and prints

command, and

more

ESC a

Paper roll Usable application programs and tips

Ver. 4.0

p. 944

Page 8

CONFIDENTIAL

more

Programming Example

PRINT #1, CHR$(&H1B);"@"; ← Initializes the printer

GOSUB stamp

PRINT #1, CHR$(&H1B);"a";CHR$(1);

PRINT #1, CHR$(&H1B);"!";CHR$(0);

PRINT #1, CHR$(&H1B);"J";CHR$(4);

PRINT #1, “January 14, 1998 15:00”;

PRINT #1, CHR$(&H1B);"d";CHR$(3);

PRINT #1, CHR$(&H1B);"a";CHR$(0);

PRINT #1, CHR$(&H1B);"!";CHR$(1);

PRINT #1, "TM-U200B $20.00";CHR$(&HA);

PRINT #1, "TM-U200D $21.00";CHR$(&HA);

PRINT #1, "PS-170 $17.00";CHR$(&HA);

PRINT #1, CHR$(&HA);

PRINT #1, CHR$(&H1B);”!”;CHR$(17);

PRINT #1, CHR$(&H1B);”U”;CHR$(1);

PRINT #1, "TOTAL $58.00";CHR$(&HA);

PRINT #1, CHR$(&H1B);"U";CHR$(0);

PRINT #1, CHR$(&H1B);”!”;CHR$(0);

PRINT #1, "------------------------------";CHR$(&HA);

Prints stamp

←

Specifies a centered printing position

←

Specifies 9 x 9 font

←

Adjusts line spacing

←

Selects the left print position

←

Selects 7 x 9 font

←

Selects double-height mode

←

Selects uni-directional printing

←

Cancels uni-directional printing

←

Cancels double-height mode

←

Prints date

and time

Item A

Item B

■ ■ ■

■ ■ ■

more

PRINT #1, "PAID $60.00";CHR$(&HA);

PRINT #1, "CHANGE $ 2.00";CHR$(&HA);

PRINT #1, CHR$(&H1D);"V";CHR$(66);CHR$(0);

END

Feeds paper to the cutting position

←

and cuts paper

Paper roll Usable application programs and tips

Ver. 4.0

p. 945

Page 9

CONFIDENTIAL

more

Programming Example (continued)

Stamp:

PRINT #1, CHR$(&H1B);"3";CHR$(18);

PRINT #1, CHR$(&H1B);"U";CHR$(1);

PRINT #1, CHR$(&H1B);"a";CHR$(1);

PRINT #1, CHR$(&H1B);"!";CHR$(48);

For I = 1 T0 14*2

READ d$: PRINT #1, CHR$(VAL (“&H”+d$));

NEXT I

PRINT #1, CHR$(&H1B);”!”;CHR$(0);

PRINT #1, ”Thank you”;CHR$(&HD);

←

Sets line spacing

←

Selects uni-directional printing

←

Selects center print position

←

Selects double-height and double-width modes

←

Cancels double-height and double-width modes

←

Printing with CR

Prints stamp

■ ■ ■

■ ■ ■

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 946

Page 10

CONFIDENTIAL

more

Programming Example (continued)

PRINT #1, CHR$ (&H1B);”!”;CHR$(32); ← Selects double-height mode

FOR I =1 TO 14

READ d$: PRINT #1, CHR$(VAL(“&H”+d$));

NEXT I

PRINT #1, CHR$ (&H1B);”!”;CHR$(48);

FOR I =1 TO 14

READ d$: PRINT #1, CHR$(VAL(“&H”+d$));

NEXT I

PRINT #1,CHR$(&H1B);”U”;CHR$(0);

PRINT #1,CHR$(&HB);”2”;

RETURN

DATA C9, CD, CD, CD, CD, CD, CD, CD, CD, CD, CD, CD, BB, 0A

DATA BA, 20, 20, 20, 45, 50, 53, 4F, 4E, 20, 20, 20, BA, 0A

DATA BA, 20, 20, 20, 20, 20, 20, 20, 20, 20, 20, 20, BA, 0A

DATA C8, CD, CD, CD, CD, CD, CD, CD, CD, CD, CD, CD, BC, 0A

←

Cancels uni-directional printing

←

Selects double-height and double-width modes

Prints stamp

Stamp data

■ ■ ■

■ ■ ■

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 947

Page 11

CONFIDENTIAL

more

Tips (Print commands)

■ ■ ■

■ ■ ■

more

These are the print commands. All the commands have the same printing result but an operation after

printing differs depending on the command. Using the appropriate command enables you to easily make an

effective program for issuing a receipt.

<LF: Print and line feed>

The command is used to print and feed one line.

<CR: Print and carriage return>

With a serial interface or a parallel interface with auto line feed disabled, if the printer has a serial dot

head, printing on the same line is enabled. The program example shows a procedure for overwriting the

previous line.

The program example illustrates printing with CR shown in lines 100, 120, and 140 and if you do not

have any corrections, then you feed paper with LF shown in lines 110, and 150. When you have a

correction, transmitting [character data + LF] to perform printing on the same line shown in line 130.

Sending bit image data instead of character data enables execution of mesh printing.

Program Example Print Sample

100 PRINT #1, “TM-U200B $20.00”;CHR$(&HD); ← Print using CR

110 PRINT #1, CHR$(&HA);

120 PRINT #1, “TM-U200D $24.00”;CHR$(&HD);

130 PRINT #1, “

140 PRINT #1, “TM-U200D $21.00”;CHR$(&HD);

150 PRINT #1, CHR$(&HA);

Line feed using LF

←

Line feed using LF

←

Print using CR

←

”;CHR$(&HA); ← Print and line feed using LF

Print using CR

←

TM-U200B $20.00

TM-U200D $24.00

TM-U200D $21.00

Ver. 4.0

Paper roll Usable application programs and tips

p. 948

Page 12

CONFIDENTIAL

more

ESC d

<

The command is used to feed paper continuously. The printing result is the same as when

transmitting LF n times continuously. Using

feed time, since LF is used for repeating one line paper feed n times. However,

for n lines.

ESC J

<

: Print and feed n lines>

: Print and feed paper>

ESC d

enables you to feed paper smoothly and to shorten paper

ESC d

■ ■ ■

■ ■ ■

is used to feed paper

more

This command is used to adjust line spacing.

after setting line spacing with

the next line. If you use

without resetting the line spacing.

<Other print commands>

Special print commands are shown below: Some printers support the commands.

■

■

■

ESC K

FF

or

FF

or

ESC e

or

ESC FF

GS FF

is used to feed paper in the reverse direction.

is used to print page mode data.

is used to print a label.

ESC J

ESC 3

, the current line spacing is not changed and it is possible to print the next line

. If you use [

ESC J

ESC 3

n has the same printing result as when transmitting LF

+ LF], you need to reset line spacing when printing

Paper roll Usable application programs and tips

Ver. 4.0

p. 949

Page 13

CONFIDENTIAL

more

System Processing

■ ■ ■

■ ■ ■

more

This example illustrates ESC/POS command functions and printing results. It shows a receipt issue processing

with a bar code and its procedure using the TM-T88II.

Set DIP switch 2-1 of the TM-T88 to On (customer display connected), insert the plug of the DM-D102 firmly

into the customer display connector (DM-D) which is on the bottom of the printer, and then turn on the

printer power.

Refer to

GS k

for a bar code printing in detail.

Print Sample

YOUR RECEIPT

Thank you

December 10, 1997 15:00

Stamp

TM-T88

PS-170 $17.00

TOTAL

PAID

CHANGE

<< Bonus points : 21 >>

✻

0 0 0 2 1

$88.00

$105.00

$110.00

$5.00

✻

←

Paper roll Usable application programs and tips

Item

Bar code

Paper cutting

Ver. 4.0

p. 950

Page 14

CONFIDENTIAL

more

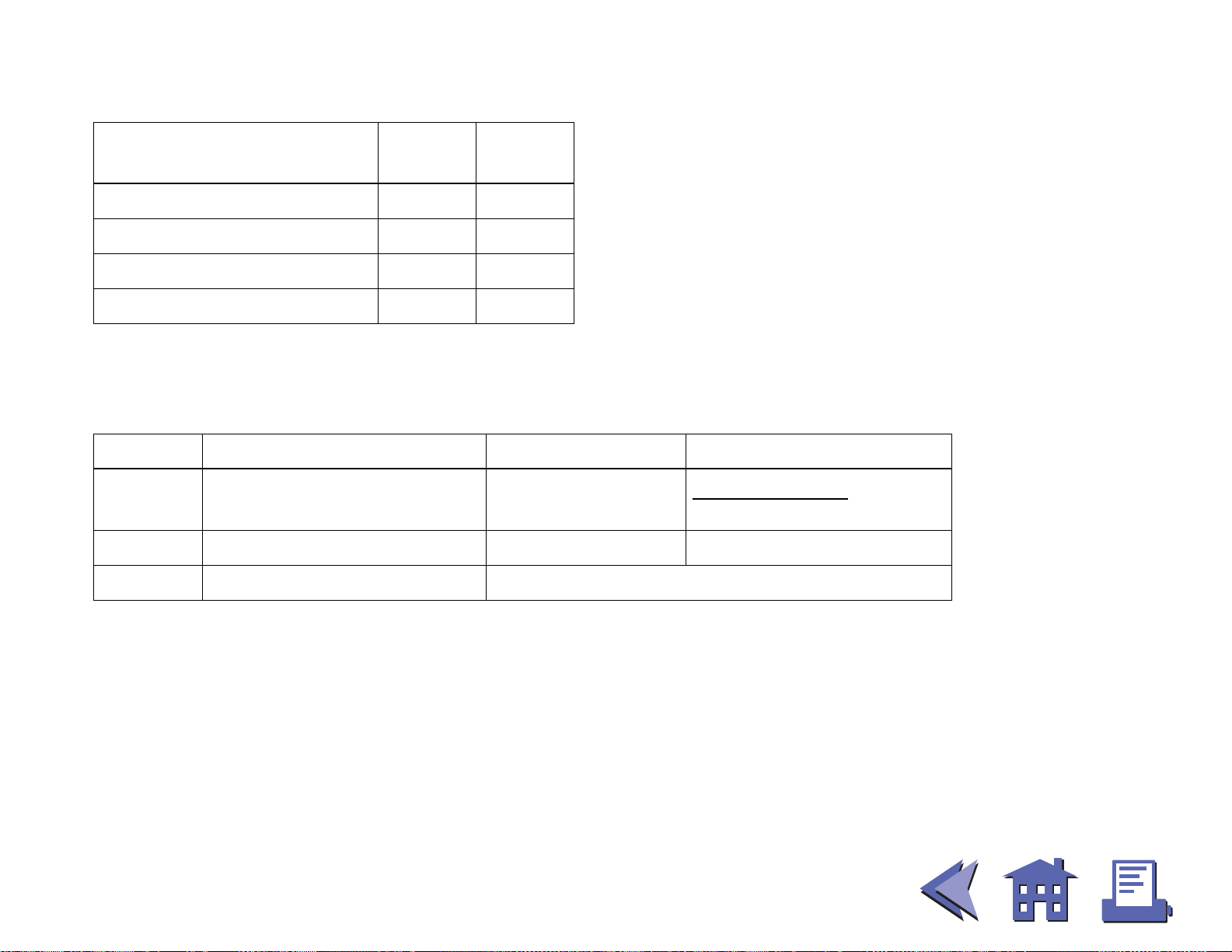

System Processing Procedure

Procedure Commands used Description

1. Set a default

2. Define stamp data

3. Stamp

4. Print an item

5. Print a bar code

6. Paper cut

ESC @, ESC D, GS P

GS

✻

ESC a, GS /, ESC J,

LF, ESC d

ESC a, HT, LF, GS !,

ESC d

ESC a, ESC J, GS h,

GS H, GS f, GS k

GS V

Set a horizontal tab position and horizontal and vertical motion

units.

Define a downloaded bit image for a stamp.

After selecting the center justification for the printing position

with

time.

After selecting the left justification for the printing position

with

Print a message “Bonus point” and a bar code. The example

uses CODE39 bar code.

Execute cutting.

ESC a

ESC a

■ ■ ■

■ ■ ■

, print the stamp (downloaded bit image), date, and

, print an item. Align the character columns with HT.

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 951

Page 15

CONFIDENTIAL

more

Set a default

Print an item

Stamp

Define a

downloaded bit

image

Print a bar code

Programming Example

PRINT #1, CHR$(&H1B);"@"; ← Initialize the printer

PRINT #1, CHR$(&H1B);"D";CHR$(34);CHR$(0)

PRINT #1, CHR$(&H1B);"P";CHR$(180);CHR$(180)

PRINT #1, CHR$(&H1D);"*";CHR$(30);CHR$(5);

FOR i=1 TO 1200

READ a$

PRINT #1, CHR$(VAL(“&H”+a$));

NEXT i

PRINT #1, CHR$(&H1B);"a";CHR$(1);

PRINT #1, CHR$(&H1D);"/";CHR$(2);

PRINT #1, CHR$(&H1B);"J";CHR$(8);

PRINT #1, “Thank you”; CHR$(&HA);

PRINT #1, “December 10, 1997 15:00”;

PRINT #1, CHR$(&H1B);"d";CHR$(3);

PRINT #1, CHR$(&H1B);"a";CHR$(0);

PRINT #1, “TM-T88”;CHR$(&H9);" $88.00";CHR$(&HA);

PRINT #1, “PS-170”;CHR$(&H9);" $17.00";CHR$(&HA);CHR$(&HA);

PRINT #1, CHR$(&H1D);"!";CHR$(1);

PRINT #1, “TOTAL”;CHR$(&H9);"$105.00";CHR$(&HA);

PRINT #1, CHR$(&H1D);"!";CHR$(0);

PRINT #1, “-------------------------------------";CHR$(&HA);

PRINT #1, “PAID”;CHR$(&H9);"$110.00";CHR$(&HA);

PRINT #1, “CHANGE”;CHR$(&H9);" $5.00";

PRINT #1, CHR$(&H1B);"d";CHR$(3);

Set horizontal tab position

←

Set horizontal and vertical motion units

←

Justification (center)

←

Print the downloaded bit image

←

Paper feed

←

Print and 3-line paper feed

←

Justification (left)

←

Select font size (double-height)

←

Select font size (standard)

←

Print and 3-line paper feed

←

■ ■ ■

■ ■ ■

more

PRINT #1, CHR$(&H1B);"a";CHR$(1);

PRINT #1, “<<Bonus points : 21>>";

PRINT #1, CHR$(&H1B);”J”;CHR$(35);

PRINT #1, CHR$(&H1D);"h";CHR$(50);

PRINT #1, CHR$(&H1D);"H";CHR$(2);

PRINT #1, CHR$(&H1D);"f";CHR$(1);

PRINT #1, CHR$(&H1D);"k";CHR$(4);

PRINT #1, CHR$(&H1D);"V";CHR$(66);CHR$(30);

END

Justification (center)

←

Print and paper feed

←

Set bar code height

←

Select printing position of HRI characters

←

Select font for HRI characters

←

Print bar code

←

Paper cut

←

Paper roll Usable application programs and tips

Ver. 4.0

p. 952

Page 16

CONFIDENTIAL

more

Programming Example (continued)

DATA 15,55,55,55,50,2A,AA,AA,AA,A8,55,55,55,55,54,A0,00,00,00,0A,40,00,00,00,04

DATA 80,00,00,00,02,40,00,00,00,04,80,00,00,00,02,48,00,00,00,04,85,00,00,00,02

DATA 4A,A0,00,00,04,85,54,00,00,02,4A,AA,80,00,04,85,55,50,00,02,40,AA,A8,00,04

DATA 80,15,54,00,02,40,02,AA,AA,A4,80,00,55,55,42,40,00,0A,AA,A4,80,00,55,55,42

DATA 40,02,AA,AA,A4,80,15,54,00,02,40,AA,A8,00,04,85,55,50,00,02,4A,AA,80,00,04

DATA 85,54,00,00,02,4A,A0,00,00,04,85,00,00,00,02,48,00,00,00,04,80,00,00,00,02

DATA 40,2A,AA,A8,04,80,55,55,54,02,40,AA,AA,AA,04,81,55,55,55,02,42,Aa,AA,AA,84

DATA 85,40,00,05,42,4A,80,00,02,A4,85,00,00,01,42,4A,80,00,02,A4,85,00,00,01,42

DATA 4A,80,00,02,A4,85,00,00,01,42,4A,80,00,02,A4,85,00,00,01,42,4A,80,00,02,A4

DATA 85,40,00,05,42,42,AA,AA,AA,84,81,55,55,55,02,40,AA,AA,AA,04,80,55,55,54,02

DATA 40,2A,AA,A8,04,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02,4A,AA,AA,A8,04

DATA 85,55,55,54,02,4A,AA,AA,AA,04,85,55,55,55,02,4A,AA,AA,AA,84,80,00,00,05,42

DATA 40,00,00,02,A4,80,00,00,01,42,40,00,00,02,A4,80,00,00,01,42,40,00,00,02,A4

DATA 80,00,00,01,42,40,00,00,02,A4,80,00,00,01,42,40,00,00,02,A4,80,00,00,05,42

DATA 4A,AA,AA,AA,84,85,55,55,55,02,4A,AA,AA,AA,04,85,55,55,54,02,4A,AA,AA,A8,04

DATA 80,00,00,00,02,40,00,00,00,04,80,00,00,00,02,4A,AA,AA,AA,A4,85,55,55,55,42

DATA 4A,AA,AA,AA,A4,85,55,55,55,42,4A,AA,AA,AA,A4,85,00,14,00,02,4A,80,2A,00,04

DATA 85,00,14,00,02,4A,80,2A,00,04,85,00,15,00,02,4A,80,2A,80,04,85,00,15,40,02

DATA 4A,80,2A,AA,A4,85,55,55,55,42,42,AA,A8,AA,A4,81,55,50,55,42,40,AA,A0,2A,A4

DATA 80,55,40,00,02,40,00,00,00,04,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02

DATA 40,00,00,00,04,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02,4A,AA,AA,AA,A4

DATA 85,55,55,55,42,4A,AA,AA,AA,A4,85,55,55,55,42,4A,AA,AA,AA,A4,85,00,14,00,02

DATA 4A,80,2A,00,04,85,00,14,00,02,4A,80,2A,00,04,85,00,15,00,02,4A,80,2A,80,04

DATA 85,00,15,40,02,4A,80,2A,AA,A4,85,55,55,55,42,42,AA,A8,Aa,A4,81,55,50,55,42

DATA 40,AA,A0,2A,A4,80,55,40,00,02,40,00,00,00,04,80,00,00,00,02,40,00,00,00,04

DATA 8A,AA,AA,AA,A2,45,55,55,55,44,8A,AA,AA,AA,A2,45,55,55,55,44,8A,AA,AA,AA,A2

DATA 45,00,50,01,44,8A,80,A8,02,A2,45,00,50,01,44,8A,80,A8,02,A2,45,00,50,01,44

DATA 8A,80,A8,02,A2,45,00,50,01,44,8A,80,A8,02,A2,45,00,00,01,44,8A,80,00,02,A2

DATA 40,00,00,00,04,80,00,00,00,02,40,00,00,00,04,80,15,55,50,02,40,2A,AA,A8,04

DATA 80,55,55,54,02,40,AA,AA,AA,04,81,55,55,55,02,42,A0,00,0A,84,85,40,00,05,42

DATA 4A,80,00,02,A4,85,00,00,01,42,4A,80,00,02,A4,85,00,00,01,42,4A,80,00,02,A4

DATA 85,00,00,01,42,4A,80,00,02,A4,85,00,00,01,42,4A,80,00,02,A4,80,00,00,00,02

DATA 40,00,00,00,04,80,00,00,00,02,4A,AA,AA,AA,A4,85,55,55,55,42,4A,AA,AA,AA,A4

DATA 85,55,55,55,42,4A, AA, AA, AA, A4,85,00,50,01,42,4A, 80, A8,02, A4,85,00,50,01,42

DATA 4A, 80, A8,02, A4,85,00, 50,01,42,4A, 80, A8,02, A4,85,00,50,01,42,4A, 80, A8,02, A4

DATA 85,00,00,01,42,4A, 80, 00,02, A4,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02

Stamp data

(downloaded

bit image)

■ ■ ■

■ ■ ■

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 953

Page 17

CONFIDENTIAL

more

Programming Example (continued)

DATA 85,55,55,55,42,4A,AA,AA,AA,A4,85,00,50,01,42,4A,80,A8,02,A4,85,00,50,01,42

DATA 4A,80,A8,02,A4,85,00,50,01,42,4A,80,A8,02,A4,85,00,50,01,42,4A,80,A8,02,A4

DATA 85,00,00,01,42,4A,80,00,02,A4,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02

DATA 40,00,00,00,04,8A,AA,AA,AA,A2,45,55,55,55,44,8A,AA,AA,AA,A2,45,55,55,55,44

DATA 8A,AA,AA,AA,A2,40,00,00,00,04,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02

DATA 4A,AA,AA,AA,A4,85,55,55,55,42,4A,AA,AA,AA,A4,85,55,55,55,42,4A,AA,AA,AA,A4

DATA 85,00,14,00,02,4A,80,2A,00,04,85,00,14,00,02,4A,80,2A,00,04,85,00,14,00,02

DATA 4A,80,2A,00,04,85,00,14,00,02,4A,80,2A,00,04,85,55,54,00,02,42,AA,A8,00,04

DATA 81,55,50,00,02,40,AA,A0,00,04,80,55,40,00,02,40,00,00,00,04,80,00,00,00,02

DATA 4A,80,00,00,04,85,00,00,00,02,4A,80,00,00,04,85,00,00,00,02,4A,80,00,00,04

DATA 85,00,00,00,02,4A,80,00,00,04,85,00,00,00,02,4A,AA,AA,AA,A4,85,55,55,55,42

DATA 4A,AA,AA,AA,A4,85,55,55,55,42,4A,AA,AA,AA,A4,85,00,00,00,02,4A,80,00,00,04

DATA 85,00,00,00,02,4A,80,00,00,04,85,00,00,00,02,4A,80,00,00,04,85,00,00,00,02

DATA 4A,80,00,00,04,80,00,00,00,02,40,00,00,00,04,80,00,00,00,02,40,00,00,00,04

DATA A0,00,00,00,0A,55,55,55,55,54,2A,AA,AA,AA,A8,15,55,55,55,50,00,00,00,00,00

Stamp data

(downloaded

bit image)

■ ■ ■

■ ■ ■

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 954

Page 18

CONFIDENTIAL

more

Tips (bar code printing)

Some printers such as the TM-T88II and TM-L60II support bar code printing. ESC/POS supports UPC-A, UPC-E,

JAN13(EAN13), JAN8(EAN8), CODE39, ITF (interleaved 2 of 5), CODABAR(NW7), CODE93, and CODE128.

When the standard mode is selected, a bar code and a character cannot be printed on the same printing line

and a ladder bar code cannot be printed. Page mode, which has a flexible layout for printing a character, a

bit image, and a bar code, should be selected when printing a bar code and a character on the same line or

printing a ladder code. When page mode is selected, a character and a bar code can be overlapped but the

bar code cannot be read. Be sure to check data layout so that a bar code can be read.

Basic processing for bar code printing (example):

Procedures:

1. Select a bar code height with

2. Select a bar code width with

3. Select the printing position for HRI characters with

GS h

GS w

. The height of a HRI character cannot be selected by

.

GS H

.

■ ■ ■

■ ■ ■

GS h

more

.

4. Select a font for HRI characters with

5. Print a bar code with

Procedures 1 to 4 can be omitted. If there is no specified value, a default value is used. The settings from 1

to 4 are effective until the printer is initialized (

both functions “storing a bar code data in the print buffer” and “printing.” Therefore, no print command is

needed.

Paper roll Usable application programs and tips

GS k

.

GS f

. The setting affects only the HRI characters.

ESC @

), reset, or is turned off.

Ver. 4.0

p. 955

GS k

in procedure 5 supports

Page 19

CONFIDENTIAL

more

Causes for not printing a bar code:

1. The bar code width set by

printing area.

2. There are so many bar code data set by

3. There is character data which cannot be printed with a bar code set by

4. The number of bar code data is few when selecting UPC-A, UPC-E, JAN13(EAN13), or JAN8(EAN8) with

GS k

5. When selecting ITF bar code with

6. When selecting CODE128 with

be character data which is not included in the specified code set.

7. When processing

8. When processing

.

GS k

GS k

GS w

in standard mode, there is already print data in the print buffer.

in page mode, the printing position is already outside of the printing area.

is so large that not all data will fit in the current

GS k

GS k

GS k

, bar code data is odd number.

, the first data is none of CODE A, CODE B, and CODE C. There might

that not all data will fit in the current printing area.

GS k

.

■ ■ ■

■ ■ ■

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 956

Page 20

CONFIDENTIAL

more

Page Mode Printing

This example illustrates ESC/POS command functions and printing results. The example shows a coupon issue

processing and its procedure using page mode function with the TM-T88II. You can use the page mode to

rotate data so that you can print characters, bar codes, and bit images that would not fit in the printable

area in the standard mode.

■ ■ ■

■ ■ ■

more

Print Sample

Paper roll Usable application programs and tips

Paper feed direction

Ver. 4.0

p. 957

Page 21

CONFIDENTIAL

more

System Processing Procedure

Procedure Commands used Description

1. Select page mode

2. Transmit edge data

3. Transmit a

message

4. Transmit data for

symbols A and B

5. Transmit bar code

data

ESC L, GS P

ESC W, ESC T,

ESC

ESC W, ESC T, GS !,

LF, ESC J

ESC W, ESC T,

ESC 3, ESC

ESC W, ESC T, GS H

GS f, GS h, GS w,

GS $, GS k

✻

✻

Select page mode.

Change horizontal and vertical motion units to set normal dot

units.

Select the printing area for edge data with

printing direction with

Transmit the edge data as bit image.

Select the printing area for message data with

printing direction with

Select a character size with

Select the printing area for symbol data with

printing direction with

Transmit data for symbols A and B as bit image.

Select the printing area for a bar code with

printing direction with

After setting bit images with

for CODE 39 bar code to the printing position set by

ESC T

ESC T

GS !

ESC T

ESC T

■ ■ ■

■ ■ ■

ESC W

.

.

and transmit message data.

ESC W

.

ESC W

.

GS H

and

GS f

, etc., transmit data

and the

ESC W

and the

and the

GS $

more

and the

.

6. Printing all data

7. Return to standard

mode

When printing multiple coupons, transmits

Paper roll Usable application programs and tips

ESC FF, GS V

ESC S

Print all data collectively in page mode and cut paper.

Return to standard mode. All data in page mode are cleared.

ESC FF

and

GS V

times you want to print in procedure 6.

Ver. 4.0

p. 958

Page 22

CONFIDENTIAL

more

Program Example

PRINT #1, CHR$(&H1B);"@"; ←

PRINT #1, CHR$(&H1B);"L";←

PRINT #1, CHR$(&H1D);"P";CHR$(180);CHR&(180);←

PRINT #1, CHR$(&H1B);"W";CHR$(6);CHR $(0);CHR$(0);CHR$(0);CHR$(244);CHR$(1);CHR$(238);CHR$(2);

PRINT #1, CHR$($H1B);"T";CHR$(0);

n=10: GOSUB Edge

PRINT #1, CHR$(&H1B);"T";CHR$(1);

n=15: GOSUB Edge

PRINT #1, CHR$(&H1B);"T";CHR$(2);

n=10: GOSUB Edge

PRINT #1, CHR$(&H1B);"T";CHR$(3);

n=15: GOSUB Edge

PRINT #1, CHR$(&H1B);"W";CHR$(140);CHR$(0);CHR$(118);CHR$(0);CHR$(104);CHR$(1);CHR$(16);CHR$(2);

PRINT #1, CHR$(&H1B);"T";CHR$(1);

PRINT #1, CHR$(&H1D);"!";CHR$(17);

PRINT #1, CHR$(&HA);" Merry Christmas !!";CHR$(&HA);CHR$(&HA);

PRINT #1, CHR$(&H1D);"!";CHR$(16);

PRINT #1, " 10% OFF COUPON";CHR$(&H1B);"J":CHR$(200);

PRINT #1, "EPSON DEPARTMENT STORE";

Select page mode

Initialize the printer

Set horizontal and vertical motion units

←

Select printing direction (left to right)

←

Select printing direction (bottom to up)

←

Select printing direction (right to left)

←

Select printing direction (up to bottom)

←

Select printing direction (bottom to up)

Transmit

edge data

Transmit a

message

■ ■ ■

■ ■ ■

more

PRINT #1, CHR$(&H1B);"W";CHR$(50);CHR $(0);CHR$(76);CHR$(2);CHR$(72);CHR$(0);CHR$(68);CHR$(0);

PRINT #1, CHR$(&H1B);"T";CHR$(1);

PRINT #1, CHR$(&H1B);"3";CHR$(24);

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(34);CHR$(0)

FOR c=1 to 34 READ a$: PRINT #1, CHR$(VAL("&H"+a$));:NEXT c

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(34);CHR$(0)

FOR c=1 to 34 READ a$: PRINT #1, CHR$(VAL("&H"+a$));:NEXT c

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(34);CHR$(0)

FOR c=1 to 34 READ a$: PRINT #1, CHR$(VAL("&H"+a$));:NEXT c

(Continued on next page)

←

Select printing direction (bottom to up)

Paper roll Usable application programs and tips

Transmit data

for symbol A

Ver. 4.0

p. 959

Page 23

CONFIDENTIAL

more

Program Example (continued)

PRINT #1, CHR$(&H1B);"W";CHR$(58);CHR $(1);CHR$(102);CHR$(0);CHR$(72);CHR$(0);CHR$(96);CHR$(0);

PRINT #1, CHR$(&H1B);"T";CHR$(1);

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(48);CHR$(0)

FOR c=1 to 48 READ a$: PRINT #1, CHR$(VAL("&H"+a$));:NEXT c

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(48);CHR$(0)

FOR c=1 to 48 READ a$: PRINT #1, CHR$(VAL("&H"+a$));:NEXT c

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(48);CHR$(0)

FOR c=1 to 48 READ a$: PRINT #1, CHR$(VAL("&H"+a$));:NEXT c

PRINT #1, CHR$(&H1B);"W";CHR$(20);CHR $(1);CHR$(226);CHR$(0);CHR$(70);CHR$(0);CHR$(56);CHR$(1);

PRINT #1, CHR$(&H1B);"T";CHR$(1);

PRINT #1, CHR$(&H1D);"H";CHR$(2);←

PRINT #1, CHR$(&H1D);"f";CHR$(1);←

PRINT #1, CHR$(&H1D);"h";CHR$(40);←

PRINT #1, CHR$(&H1D);"w";CHR$(2);←

PRINT #1, CHR$(&H1D);"$";CHR$(40);CHR$(0);←

PRINT #1, CHR$(&H1D);"k";CHR$(4);"*10% OFF*";CHR$(0);

PRINT #1, CHR$(&H1B);CHR$(&HC); ←

PRINT #1, CHR$(&H1D);"V";CHR$(66);CHR$(80); ←

PRINT #1, CHR$(&H1B);"S"; ←

END

←

Select printing direction (bottom to up)

←

Select printing direction (bottom to up)

Select printing position of HRI characters (bottom)

Select font for HRI characters (font B)

Set bar code height

Set bar code width

Print data collectively

Return to standard mode

Set absolute vertical print position

Cut paper

Transmit data

for symbol B

Transmit

bar code

■ ■ ■

■ ■ ■

more

Edge

FOR i=1 To n

PRINT #1, CHR$(&H1B);"*";CHR$(0);CHR$(25);CHR$(0);

PRINT #1, CHR$(128);CHR$(128);CHR$(128);CHR$(96);CHR$(128);

PRINT #1, CHR$(128);CHR$(128);CHR$(166);CHR$(165);CHR$(81);

PRINT #1, CHR$(78);CHR$(32);CHR$(26);CHR$(32);CHR$(78);

PRINT #1, CHR$(81);CHR$(165);CHR$(166);CHR$(128);CHR$(128);

NEXT i

RETURN

(Continued on next page)

Paper roll Usable application programs and tips

Subroutine for

transmitting the

edge data

Ver. 4.0

p. 960

Page 24

CONFIDENTIAL

more

Program Example (continued)

DATA 00,00,00,00,00,00,01,01,03,03,05,05,28,28,38,38

DATA F0,F0,38,38,28,28,05,05,03,03,01,01,00,00,00,00,00,00

DATA 00,00,08,08,19,19,2A,2A,4C,4C,82,82,47,47,E2,E2

DATA 40,40,11,11,3B,3B,91,91,4C,4C,2A,2A,19,19,08,08,00,00

DATA 40,40,C0,C0,40,40,5C,5C,57,57,55,55,55,55,75,75

DATA 55,55,75,75,D5,D5,55,55,57,57,5C,5C,40,40,C0,C0,40,40

DATA 00,00,00,00,00,00,00,00,07,07,09,09,7D,7D,10,10,16,16,78,F8,FC,7C,3E,3E

DATA 3E,3E,7C,FC,F8,78,16,16,10,10,7D,7D,09,09,07,07,00,00,00,00,00,00,00,00

DATA 1F,1F,24,24,41,41,42,42,F1,F1,29,29,49,49,AC,AC,94,94,AC,AC,C4,C4,AC,AC

DATA 94,94,AC,AC,C4,C4,AC,AC,94,94,69,69,49,49,F1,F1,42,42,41,41,24,24,1F,1F

DATA F0,F0,48,48,24,24,64,64,12,12,52,52,52,52,89,89,A9,A9,89,89,99,99,C9,C9

DATA 89,89,99,99,C9,C9,A9,A9,89,89,12,12,52,52,12,12,24,24,A4,A4,C8,C8,F0,F0

Data for

symbol A

Data for

symbol B

■ ■ ■

■ ■ ■

more

Paper roll Usable application programs and tips

Ver. 4.0

p. 961

Page 25

CONFIDENTIAL

more

Tips (standard mode/page mode)

Some of the TM printers, such as the TM-T88II and the TM-L60II, support two different print modes:

standard mode and page mode.

The standard mode is supported by all printers and in this mode, the printers print data in the print buffer

by executing the print commands (such as LF, CR, and

The standard mode is the print mode which prints data one line at a time.

The page mode executes batch printing with FF or

page mode is selected with

ESC J

or

to standard mode. The page mode is the print mode which prints data one page at a time.

, only move the printing position and do not execute actual printing. Executing

ESC L

. In this mode, the print commands other than FF or

Standard mode

ESC S, FF

ESC J

ESC FF

ESC L

) or when the buffer is full.

for all data in the print buffer stored after the

ESC FF

Page mode

■ ■ ■

■ ■ ■

, such as LF, CR,

ESC S

or FF returns

more

Basic processing procedure for the page mode:

9. Select the page mode with

10.Set the position and size for the printing area with

11.Select the starting position and the direction for data development with

12.Store print data (such as characters or bit images) in the print buffer.

13.Print all data in the print buffer collectively with

14.Return to standard mode with

(You can skip procedure 6 if you use FF instead of

Paper roll Usable application programs and tips

ESC L

ESC S

(standard mode is changed to page mode).

ESC W

ESC FF

.

ESC FF

.

.

in procedure 5.)

ESC T

Ver. 4.0

p. 962

.

Page 26

CONFIDENTIAL

more

Characteristics of the page mode

The flexible layout enables you to execute printing which you cannot accomplish in the standard mode.

■

Downloaded bit images or bar codes can be printed on the same line with characters at the same time.

■

Ladder bar code printing is possible.

■

Characters and bit images can be rotated (90° clockwise, 180° clockwise (upside down), or 90°

■

counterclockwise).

Data can be processed only in normal dot units.

■

Data cannot be processed in half dot units in the page mode.

■

Copy printing is possible.

■

Because printing with

■

results in the same printing. It is also possible to print repeated data with changes in some parts.

ESC FF

enables storing of data in the print buffer, executing

■ ■ ■

■ ■ ■

ESC FF

more

repeatedly

Paper roll Usable application programs and tips

Ver. 4.0

p. 963

Page 27

CONFIDENTIAL

more

System Processing

■ ■ ■

■ ■ ■

more

This example illustrates ESC/POS command functions and printing results. The example shows how to issue a

label containing bar codes.

Print Sample

EPSON Rental Video

*00001*

NAME

Jan. 10, 1998

EPSON Rental Video

*00002*

NAME

Jan. 10, 1998

Paper roll Usable application programs and tips

Ver. 4.0

p. 964

Page 28

CONFIDENTIAL

more

Bar Codes Label Issuing

Procedure Commands used Description

1. Print label title

ESC a, ESC !, LF, GS !,

ESC E

GS H, GS f, GS h, GS

2. Print bar code

k, ESC J

3. Print NAME ESC -, ESC J Prints “NAME” using

4. Print date ESC a, ESC ! , GS FF

Sets the print position to the center with

label title with LF.

Prints bar code after selecting the height of the bar code with

GS h

the font with

Sets the print position to the right using

(9 x 24) with

*The paper LED blinks when the label is fed forward to the

position where the label can be peeled off. Press the PAPER

FEED button and peel off the label. The next label feeds to the

starting position.

, the printing position of the HRI characters with

GS f

ESC !

.

, and prints the date with

ESC J

■ ■ ■

■ ■ ■

ESC a

. Adds an underline to “NAME.”

ESC a

and prints a

, selects font B

GS FF

.

more

GS H

and

Paper roll Usable application programs and tips

Ver. 4.0

p. 965

Page 29

CONFIDENTIAL

more

Programming Example

PRINT #1, CHR$(&H1B);"@"; ← Initializes the printer

NO$="00001" : GOSUB start

NO$="00002" : GOSUB start

END

start:

PRINT #1, CHR$(&H1B);"a";CHR$(1);

PRINT #1, CHR$(&H1B);"!";CHR$(40);

PRINT #1, "EPSON";

PRINT #1, CHR$(&H1B);"!";CHR$(8);

PRINT #1, "Rental Video"; CHR$(&HA);

PRINT #1, CHR$(&H1B);"!";CHR$(0);

PRINT #1, CHR$(&H1D);"H";CHR$(2);

PRINT #1, CHR$(&H1D);"f";CHR$(1);

PRINT #1, CHR$(&H1D);"h";CHR$(35);

PRINT #1, CHR$(&H1D);"k";CHR$(4);"*";NO$;"*";CHR$(0);

PRINT #1, CHR$(&H1B);"J";CHR$(5);

Selects center print position

←

Selects character print mode

←

(emphasized + double-height + double-width)

Cancels double-width

←

Cancels emphasized

←

Selects printing position for HRI characters

←

Selects HRI characters

←

Sets bar code height

←

■ ■ ■

■ ■ ■

Prints a

label title

Prints bar code

more

PRINT #1, CHR$(&H1B);"-";CHR$(2);

PRINT #1, "NAME ";

PRINT #1, CHR$(&H1B);"J";CHR$(70);

PRINT #1, CHR$(&H1B);"-";CHR$(0);

PRINT #1, CHR$(&H1B);"a";CHR$(2);

PRINT #1, CHR$(&H1B);"!";CHR$(1);

PRINT #1, "Jan. 10, 1998";

PRINT #1, CHR$(&H1D);CHR$(HC);

W$=INPUT$(1)

RETURN

Ready to input (waiting to input)

←

Sets underline width to 2 dots

←

Cancels previous character print mode

←

Selects right print position

←

Selects font B (9 x 24)

←

Prints and feeds the label to the print starting

←

position

Paper roll Usable application programs and tips

Prints “NAME”

Prints the date

and feeds the

label to the

print starting

position

Ver. 4.0

p. 966

Page 30

CONFIDENTIAL

more

Tips (label printer)

Some TM printers, such as the TM-L60II, can print on labels. ESC/POS has label commands for the mechanism

control function type, such as ejecting a label or feeding paper to the print starting position and has

commands such as a serial number counter that apply to the label printers.

Printing on one label

If you want to repeat the flow of the operation of printing on a label, peeling it off, and pasting it, use

GS FF

1. Executes printing the last line on the label.

2. Ejects the label to the position where it can be peeled off.

3. Blinks the paper LED.

4. Waits for the paper feed button to be pressed.

5. After the paper feed button is pressed, it feeds the label to the print starting position using reverse paper

Be sure to press the paper feed button after peeling the label off as shown in procedure 4. If you use

for the last print command line in your program. The printer executes the following:

feed.

■ ■ ■

■ ■ ■

more

GS FF

,

you will not waste labels.

Continuous printing on labels

When printing on labels continuously, FF is used for the last print command line for one label, which

enables the printer to feed the next label to the print starting position. When printing on the last label,

GS FF

Paper roll Usable application programs and tips

is used for not wasting a label.

Ver. 4.0

p. 967

Page 31

CONFIDENTIAL

Serial number counter

Features for the serial number counter function:

1. Operation is possible in the range of the counter values from 1 to 65535.

2. There are two counter modes, count-up and count-down.

3. Printing styles such as the number of print columns and print position of the counter value can be set by

a command.

4. Incrementing or decrementing of the counter value, such as step amount or the number or repetition,

can be set by the command.

5. Various settings for the serial counter number can be set by using a number or a character string.

GS C 1

■

GS C ;

■

6. Character data, bit image data, and serial counter can be printed on the same printing line.

Example for using the serial counter (when making labels with a different number for each)

Procedures:

GS C 0

1.

GS C 1

2.

decrement, and the repetition number of the same counter.

GS C 2

3.

GS c

4.

GS FF

5.

GS c

as described in procedure 5 for printing the counter value. In procedure 4, transmitting character data

enables you to make a label combining character data and serial counter.

is used for setting using a character string.

sets print columns, print position, and print style for the serial counter.

sets the minimum value, maximum value, and the number of the step amount for increment and

sets the counter value.

sets the serial counter value in the print buffer and increments or decrements the counter value.

prints the data, ejects a label, and feeds the next label to the print starting position.

in procedure 4 is the only command which cannot print the counter value. A print command is needed

and

GS C 2

are used for setting using a number.

Paper roll Usable application programs and tips

Ver. 4.0

p. 968

Page 32

CONFIDENTIAL

more

Character code tables

CHARACTER CODE TABLES

SP in a table represents space. See Using the character code tables for information on how to read these

tables.

Page 0 (PC437: U.S.A., Standard Europe) (International character set: U.S.A)

■ ■ ■

■ ■ ■

more

FS

Paper roll Character code tables

Ver. 4.0

p. 969

Page 33

CONFIDENTIAL

more

Page 1 (Katakana)

■ ■ ■

■ ■ ■

more

Paper roll Character code tables

Ver. 4.0

p. 970

Page 34

CONFIDENTIAL

more

Page 2 (PC850: Multilingual)

■ ■ ■

■ ■ ■

more

Paper roll Character code tables

Ver. 4.0

p. 971

Page 35

CONFIDENTIAL

more

Page 3 (PC860: Portuguese)

■ ■ ■

■ ■ ■

more

Paper roll Character code tables

Ver. 4.0

p. 972

Page 36

CONFIDENTIAL

more

Page 4 (PC863: Canadian-French)

■ ■ ■

■ ■ ■

more

Paper roll Character code tables

Ver. 4.0

p. 973

Page 37

CONFIDENTIAL

more

Page 5 (PC865: Nordic)

■ ■ ■

■ ■ ■

more

Paper roll Character code tables

Ver. 4.0

p. 974

Page 38

CONFIDENTIAL

Using the character code tables

USING THE CHARACTER CODE TABLES

The example below uses Page 0 (PC437) to illustrate the use of the character code tables.

You can find the character "A" in Page 0 as follows:

The decimal value for the character "A" is 65.

Follow its column straight up to find the digits.

Hexadecimal. . . . . . . . . . 4

Binary . . . . . . . . . . . . . . . 0100

These numbers are the most significant bits of the ASCII code.

Follow its row to the left to find the digits.

Hexadecimal. . . . . . . . . . 1

Binary . . . . . . . . . . . . . . . 0001

These numbers are the least significant bits of the ASCII code.

The combination of the numbers above is the ASCII code for character "A".

Decimal. . . . . . . . . . . . . . 65

Hexadecimal. . . . . . . . . . 41

Binary . . . . . . . . . . . . . . . 01000001

Paper roll Using the character code tables

Ver. 4.0

p. 975

Page 39

CONFIDENTIAL

Features for the TM-T88II

FEATURES FOR THE TM-T88II

The TM-T88II and TM-T88IIP are high-quality POS printers that can print on a paper roll. The printers have

the following features:

High speed printing: approximately 28.4 lines/second (1/6 inch feed).

■

Low-noise thermal printing.

■

High reliability due to a stable mechanism.

■

Command protocol based on the ESC/POS standard.

■

Various layouts are possible by using page mode.

■

Characters can be scaled up to 64 times as large as the standard size. Smoothing is also possible.

■

Bar code printing is possible by using a bar code command. Bar codes can be printed both in the vertical

■

direction (fence bar code) and in the horizontal direction (ladder bar code).

Repeated operation and copy printing are possible by using macro definitions.

■

Character font size (12 × 24 font or 9 × 17 font) can be selected using a command.

■

Easy paper roll setting.

■

Equipped with an autocutter.

■

The printer allows easy maintenance for tasks such as head cleaning.

■

Selectable receive buffer size (4K bytes or 45 bytes).

■

Four different print densities can be selected by DIP switches.

■

The built-in interface provides control capability for two drawers.

■

Non-volatile 256 KB bit image buffer size available.

■

User NV (non-volaile) memory size 1 KB available.

■

Paper roll Features for the TM-T88II

Ver. 4.0

p. 976

Page 40

CONFIDENTIAL

more

Specifications f or the TM-T88II

SPECIFICATIONS FOR THE TM-T88II

Printing specifications

■

Printing method: Thermal line printing

Printing speed: High speed mode:

28.4 lines/second maximum (1/6 inch feed) (at 24V, 20

120 mm/second maximum (4.72 inches/second maximum)

Speeds are switched automatically depending on the applied voltage to the

printer and head temperature conditions.

Lower power consumption mode:

Approximately 16.5 lines/second (1/6 inch feed)

Approximately 70mm/second (approximately 2.76 inches/second)

When a ladder bar code is printed:

Approximately 42 mm/second (approximately 1.7 inches/second)

Dot density: 180 dpi (W) × 180 dpi (H) (the number of dots per 25.4 mm)

Printing width: 72 mm (512 dot positions)

■ ■ ■

■ ■ ■

°

C, Density level 2)

more

Character specifications

■

Character fonts: Font A (12 × 24) / Font B (9 × 17)

Characters per line: 42 / 56

Character size: 1.41 mm (W) × 3.39 mm (H) / 0.99 mm (W) × 3.39 mm (H)

Character sets: ASCII: 95 characters

International: 32 characters

Extended graphics: 128 characters × 6 pages

Paper specifications

■

Paper type: Specified thermal roll paper, NTP080-80

Paper size: 79 to 80 mm (W) × 83 mm diameter

Paper roll Specifications for the TM-T88II

Ver. 4.0

p. 977

Page 41

CONFIDENTIAL

Panel button: FEED: Feed paper roll (this button also can be used for the self test, hexadecimal

■

Panel LEDs: POWER (green):

■

Interface: RS-232 (TM-T88II: serial interface)

■

dump printing, and macro printing).

Off when the printer is off.

On when the printer is on.

ERROR (red):

Off when the printer is in normal operation.

On when the printer is off-line (except during paper feed using the FEED

button, self test printing, and the error state).

Blinks when an error occurs.

PAPER OUT (red):

Off when the paper roll is adequate.

On when paper roll is near-end.

Blinks when the printer is waiting for the button to be pressed.

IEEE 1284 (TM-T88IIP: parallel interface)

RS-485 (dealer option)

Receive buffer: 4K or 45 bytes (selectable by DIP switch)

■

NV (non-volatile) bit image buffer: 256 KB

User NV (non-volatile) memory: 1 K byte

User-defined buffer (both for user-defined characters and

user-defined bit images): 12K bytes

Macro buffer: 2K bytes

Paper roll Specifications for the TM-T88II

Ver. 4.0

p. 978

Page 42

CONFIDENTIAL

more

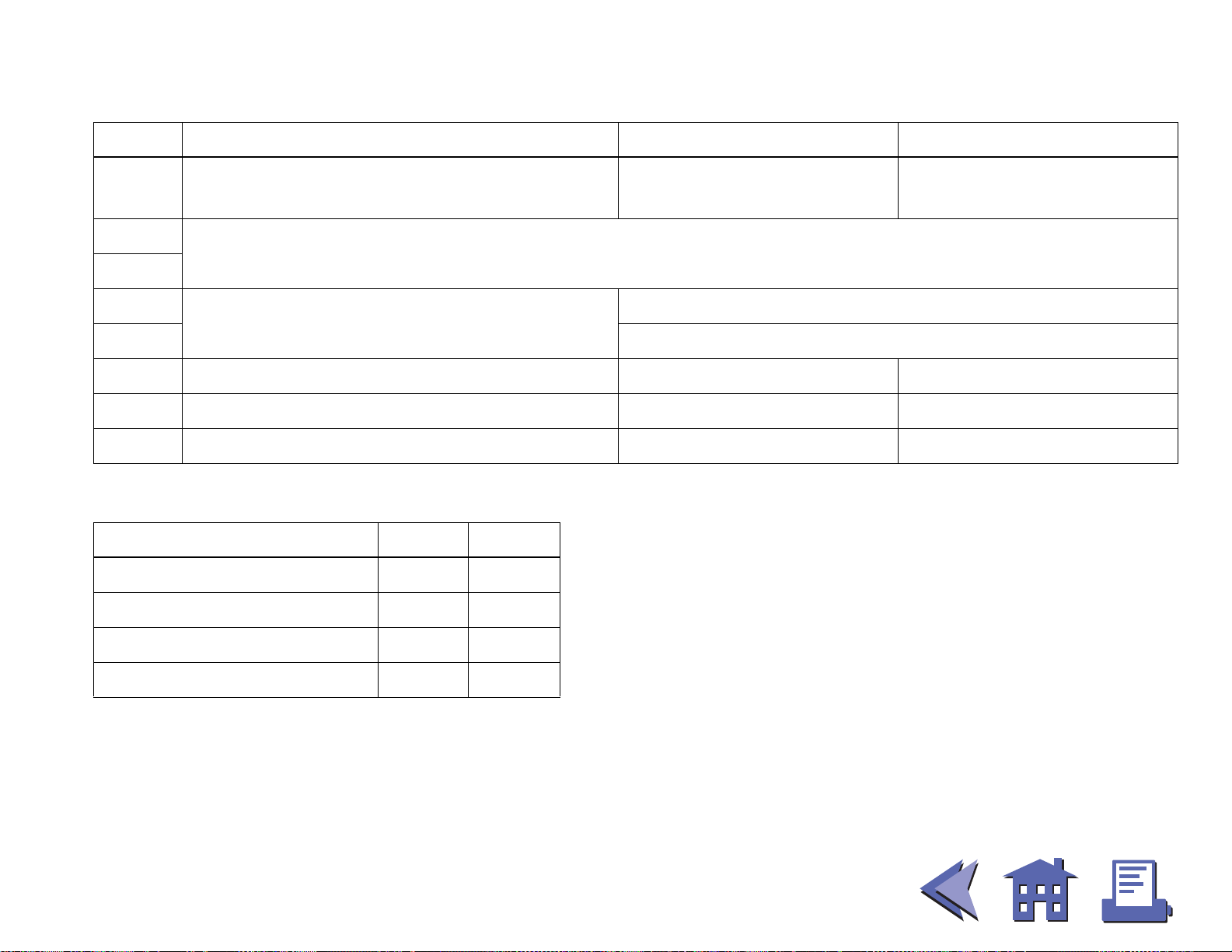

DIP switch functions for the TM-T88II

DIP SWITCH FUNCTIONS FOR THE TM-T88II

Serial Interface (TM-T88II)

DIP switch 1

SW Function ON OFF

1-1 Data receive error Ignored Convert data to “?”

1-2 Receive buffer capacity 45 bytes 4K bytes

1-3 Handshaking XON/XOFF DTR/DSR

1-4 Data word length 7 bits 8 bits

1-5 Parity check Enabled Disabled

1-6 Parity selection Even Odd

1-7

Transmission speed

1-8

■ ■ ■

■ ■ ■

more

Transmission speed

Transmission speed

bits per second (BPS) SW 1-7 SW 1-8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OFF

Paper roll DIP switch functions for the TM-T88II

Ver. 4.0

p. 979

Page 43

CONFIDENTIAL

more

DIP switch 2

SW Function ON OFF

2-1 BUSY condition Receive buffer full Off line or receive buffer full

2-2 Reserved (Do not change settings) Fixed to Off

2-3

Selects print density/Low power consumption mode

2-4

2-5 Reserved (Do not change settings) Fixed to Off

2-6 Reserved (Do not change settings) Fixed to Off

2-7 I/F pin 6 reset signal Enabled Disabled

2-8 I/F pin 25 reset signal Enabled Disabled

■ ■ ■

■ ■ ■

more

Print density

Print density SW 2-3 SW 2-4

Low power consumption mode ON ON

1 Print density (Normal) OFF OFF

2

3 Print density (Dark) OFF ON

Paper roll DIP switch functions for the TM-T88II

ON OFF

Ver. 4.0

p. 980

Page 44

CONFIDENTIAL

more

Parallel Interface (TM-T88IIP)

DIP switch 1

SW Function ON OFF

1-1 Auto line feed Always enabled Always disabled

1-2 Receive buffer capacity 45 bytes 4K bytes

1-3 ~1-8 Undefined — —

DIP switch 2

SW Function ON OFF

Receive buffer full or

2-1 BUSY condition

reading data

2-2 Reserved (Do not change settings) Fixed to Off

2-3

Selects print density/Low power consumption mode

2-4

■ ■ ■

■ ■ ■

Off line, receive buffer

full, or reading data

more

2-5 ~ 2-7 Reserved (Do not change settings) Fixed to Off

2-8

I/F pin 31 reset signal

(Do not change settings)

Paper roll DIP switch functions for the TM-T88II

Fixed to On

Ver. 4.0

p. 981

Page 45

CONFIDENTIAL

Print density

Print density SW 2-3 SW 2-4

Low power consumption mode ON ON

1 Print density (Normal) OFF OFF

2

3 Print density (Dark) OFF ON

ON OFF

Paper roll DIP switch functions for the TM-T88II

Ver. 4.0

p. 982

Page 46

CONFIDENTIAL

Errors for the TM-T88II

ERRORS FOR THE TM-T88II

Automatically recoverable errors:

■

Print head high temperature error

Cover open error during printing

Recoverable errors:

■

Auto cutter error

Unrecoverable errors:

■

R/W error in memory or gate array

High voltage error

Low voltage error

CPU execution error

Internal circuit connection error

Data receive errors:

■

If the following errors occur with a serial interface, the printer processes data

depending on the setting of DIP switch 1-1.

Parity error

Framing error

Overrun error

Paper roll Errors for the TM-T88II

Ver. 4.0

p. 983

Page 47

CONFIDENTIAL

Options for the TM-T88II

OPTIONS FOR THE TM-T88II

EPSON power supply unit, PS-170.

■

Affixing tapes (model: DF-10).

■

RS-485 interface board is a dealer option.

■

Paper roll Options for the TM-T88II

Ver. 4.0

p. 984

Page 48

CONFIDENTIAL

Self test for the TM-T88II

SELF TEST FOR THE TM-T88II

The self test lets you know if your printer is operating properly. It checks the control circuits, printer

mechanisms, print quality, ROM version, and DIP switch setting. This test is independent of any other

equipment or software.

Running the self test with a paper roll

1. Make sure the printer is turned off and the printer covers are closed properly.

2. While holding down the FEED button, turn on the printer using the power switch to begin the self test.

The self test prints the printer settings and then prints the following, cuts the paper, and pauses. (The

PAPER OUT light blinks.)

Self test printing.

Please press the Paper feed button.

3. Press the FEED button to continue printing. The printer prints a pattern using the resident

characters.

4. The self test automatically ends and cuts the paper after printing the following:

***completed***

The printer is ready to receive data as soon as it completes the self test.

Ver. 4.0

Paper roll Self test for the TM-T88II

p. 985

Page 49

CONFIDENTIAL

Hexadecimal dump for the TM-T88II

HEXADECIMAL DUMP FOR THE TM-T88II

This feature allows experienced users to see exactly what data has been received. This can be useful in

finding software problems. When you turn on the hexadecimal dump function, the printer prints all

commands and other data in hexadecimal format on paper roll to help you find specific commands.

To use the hexadecimal dump feature, follow these steps:

1. After you make sure that the printer is off, open the cover.

2. Hold down the FEED button while you turn on the printer.

3. Close the cover.

4. Run any software program that sends data to the printer. The printer prints “Hexadecimal Dump” and

then all the codes it receives in a two-column format. The first column contains the hexadecimal codes

and the second column gives the ASCII characters that correspond to the codes.

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 . ! . . & . @ @

1B 25 01 1B 63 34 00 1B . % . . c 4 . .

41 42 43 44 45 46 47 48 A B C D E F G H

A period (.) is printed for each code that has no ASCII equivalent.

■

During the hexadecimal dump all commands except

■

5. Press the FEED button so that the printer will print the last line.

6. Turn off the printer or reset it to turn off the hexadecimal dump mode.

Paper roll Hexadecimal dump for the TM-T88II

DLE EOT

and

DLE ENQ

Ver. 4.0

p. 986

do not function.

Page 50

CONFIDENTIAL

more

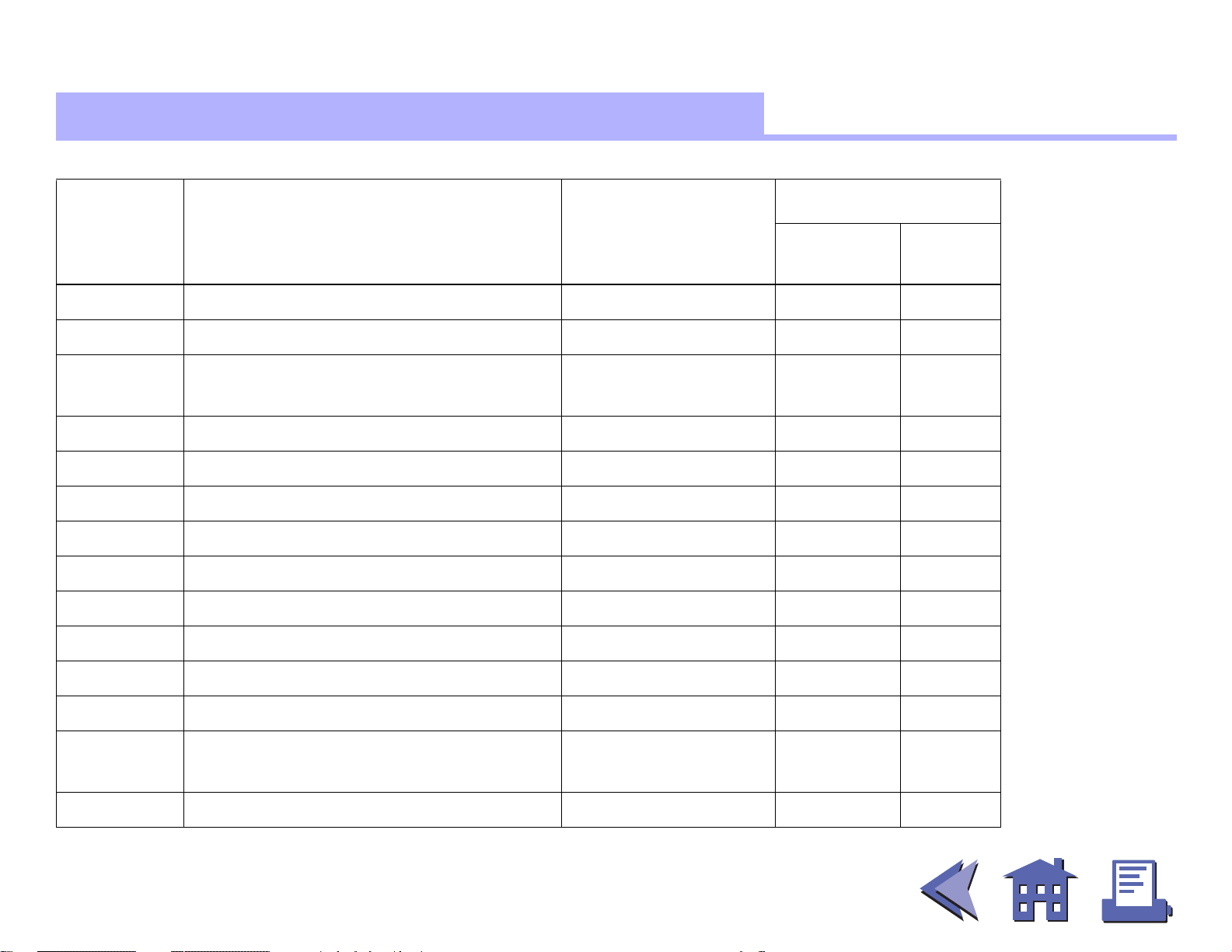

TM-T88II supporte d commands

TM-T88II SUPPORTED COMMANDS

Command Name Function Type

HT

LF

FF

CR

CAN

DLE EOT

DLE ENQ

DLE DC4

ESC FF

ESC SP

Horizontal tab Print position O

Print and line feed Print O

Print and return to standard mode

Print O

(in page mode)

Print and carriage return Print O

Cancel print data in page mode Character O

Real-time status transmission Status O

Real-time request to printer Miscellaneous O

Generate pulse at real-time Miscellaneous O

Print data in page mode Print O

Set right-side character spacing Character O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

ESC !

ESC $

ESC %

ESC &

Paper roll TM-T88II supported commands

Select print mode(s) Character O

Set absolute print position Print position O

Select/cancel user-defined character

Character O

set

Define user-defined characters Character O

Ver. 4.0

p. 987

Page 51

CONFIDENTIAL

more

Command Name Function Type

ESC

ESC –

ESC 2

ESC 3

ESC =

ESC ?

ESC @

ESC D

ESC E

ESC G

✻

Select bit-image mode Bit-image O

Turn underline mode on/off Character O

Select default line spacing Line spacing O

Set line spacing Line spacing O

Select peripheral device Miscellaneous O

Cancel user-defined characters Character O

Initialize printer Miscellaneous O O

Set horizontal tab positions Print position O

Turn emphasized mode on/off Character O

Turn double-strike mode on/off Character O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

ESC J

ESC L

ESC M

ESC R

ESC S

ESC T

ESC V

Paper roll TM-T88II supported commands

Print and feed paper Print O

Select page mode Miscellaneous O

Select character font Character O

Select an international character set Character O

Select standard mode Miscellaneous O

Select print direction in page mode Print position O

Turn 90° clockwise rotation mode

Character O

on/off

Ver. 4.0

p. 988

Page 52

CONFIDENTIAL

more

Command Name Function Type

ESC W

ESC \

ESC a

ESC c 3

ESC c 4

ESC c 5

ESC d

ESC p

ESC t

Set printing area in page mode Print position O

Set relative print position Print position O

Select justification Print position O

Select paper sensor(s) to output

Paper sensor O

paper-end signals

Select paper sensor(s) to stop

Paper sensor O

printing

Enable/disable panel buttons Panel button O

Print and feed n lines Print O

Generate pulse Miscellaneous O

Select character code table Character O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

ESC {

FS g 1

FS g 2

FS p

FS q

GS !

Paper roll TM-T88II supported commands

Turn upside-down printing mode

Character O

on/off

Write to user NV memory Miscellaneous O

Read from user NV memory Miscellaneous O

Print NV bit image Bit-image O

Define NV bit image Bit-image O

Select character size Character O

Ver. 4.0

p. 989

Page 53

CONFIDENTIAL

more

Command Name Function Type

GS $

GS ✻

GS ( A

GS /

GS :

GS B

GS H

GS I

Set absolute vertical print position

Print position O

in page mode

Define downloaded bit image Bit-image O

Execute test print Miscellaneous O

Print downloaded bit image Bit-image O

Start/end macro definition Macro function O O

Turn white/black reverse printing

Character O

mode on/off

Select printing position of HRI

Bar code O

characters

Transmit printer ID Miscellaneous O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

GS L

GS P

GS V

GS W

GS \

GS ^

Paper roll TM-T88II supported commands

Set left margin Print position O

Set horizontal and vertical motion

Miscellaneous O

units

Select cut mode and cut paper Mechanism control O

Set printing area width Print position O

Set relative vertical print position in

Print position O

page mode

Execute macro Macro function O

Ver. 4.0

p. 990

Page 54

CONFIDENTIAL

more

Command Name Function Type

GS a

GS b

GS f

GS h

GS k

GS r

GS v 0

GS w

Enable/disable Automatic Status

Status O O

Back (ASB)

Turn smoothing mode on/off Character O

Select font for HRI characters Bar code O

Set bar code height Bar code O

Print bar code Bar code O

Transmit status Status O

Print raster bit image Bit-image O

Set bar code width Bar code O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

Paper roll TM-T88II supported commands

Ver. 4.0

p. 991

Page 55

CONFIDENTIAL

more

Features for the TM-L60II

■ ■ ■

■ ■ ■

FEATURES FOR THE TM-L60II

The TM-L60II and TM-L60IIP are line thermal printers that can print on roll paper and thermal labels. The

printers have the following features:

Light weight and ultra-compact size.

■

High-speed printing: 12 lines per second.

■

Low-noise thermal printing.

■

High reliability due to a stable mechanism.

■

Easy maintenance for tasks such as head cleaning.

■

Easy paper insertion with semi-auto loading for both roll paper and labels.

■

Label ejection commands prevent extraneous label feeding.

■

Serial numbers can be printed on labels.

■

Command protocol based on the ESC/POS standard.

■

more

Various layouts possible using page mode.

■

Font selection (font A (12 × 24) or font B (9 × 17)) possible using a command.

■

Character extension (up to 64 times the standard size) and character smoothing.

■

Four different print densities selectable via DIP switch settings.

■

Four-way routing of the interface, drawer control, and power cables: on either side, underneath, or from

■

the back of the case.

Water-resistant operation panel.

■

Bar code printing possible both in the vertical direction (fence bar code) and horizontal direction (ladder

■

bar code in page mode) using a command.

Repeated operation and copy printing possible using macro definitions.

■

Paper roll Features for the TM-L60II

Ver. 4.0

p. 992

Page 56

CONFIDENTIAL

Control capability for two drawers via the built-in interface.

■

The power switch is on the front panel of the printer, allowing easy operation.

■

Bidirectional parallel interface based on the IEEE 1284 Nibble/Byte Modes standard.

■

Thermal paper or thermal label can be selected via DIP switch settings.

■

Paper roll Features for the TM-L60II

Ver. 4.0

p. 993

Page 57

CONFIDENTIAL

more

Specifications f or the TM-L60II

SPECIFICATIONS FOR THE TM-L60II

Printing specifications

■

Printing method: Thermal line printing

Printing speed: Approximately 12 LPS (1/6-inch feed)

Dot density: 180 dpi × 180 dpi

Printing width: Thermal paper: 54.19 mm (2.13”), 384 dot positions

Thermal label: 51.93 mm (2.04”), 368 dot positions

Character specifications

■

Character fonts: Font A (12 × 24) / Font B (9 × 17)

Characters per line: Thermal paper: 32 / 42

Thermal label: 30/40

Character size: 1.41 mm (W) × 3.39 mm (H) / .99 mm (W) × 3.39 mm (H)

Character sets: ASCII: 95 characters

International: 32 characters

Extended graphics: 128 characters × 6 pages

■ ■ ■

■ ■ ■

more

Paper specifications

■

Paper type: Paper roll:Specified thermal paper: Nakagawa Seisakujo, NTP080-80

Thermal label:Specified thermal paper (1-inch long (25.4 mm) label):

Nakagawa Seisakujo, NTL 060-80)

Paper size: Paper roll: 59.0 to 60.0 mm (W) × 83.0 mm diameter

Thermal label:59.5 to 60.2 mm (W) × 83.0 mm diameter

Panel button PAPER FEED:

■

Feed paper (this button also can be used for the self test, hexadecimal dump

printing, macro printing, and GS FF execution standby mode).

Paper roll Specifications for the TM-L60II

Ver. 4.0

p. 994

Page 58

CONFIDENTIAL

Panel LEDs: POWER (green):

■

Off when the printer is turned off.

On when the printer is turned on.

PAPER (red):

Off when the paper roll is adequate.

On when the paper roll is near-end or at end.

Blinks when the printer is waiting for the PAPER FEED button to be pressed in

the following:

Self test standby state

GS ^ execution standby state

GS FF execution standby state

ERROR (red):

Off when the printer is in normal operation.

On when the printer is off-line (except during paper feed using the

PAPER FEED button and during the self test).

Blinks when an error occurs.

Interface: RS-232 (TM-L60II: serial interface)

■

IEEE-1284 (TM-L60IIP: parallel interface)

Receive buffer: 4K or 45 bytes (selectable by DIP switch)

■

Paper roll Specifications for the TM-L60II

Ver. 4.0

p. 995

Page 59

CONFIDENTIAL

more

DIP switch functions for the TM-L60II

DIP SWITCH FUNCTIONS FOR THE TM-L60II

Serial Interface (TM-L60II)

DIP switch 1

SW Function ON OFF

1-1 Data receive error Ignored Convert data to “?”

1-2 Receive buffer capacity 45 bytes 4K bytes

1-3 Handshaking XON/XOFF DTR/DSR

1-4 Data word length 7 bits 8 bits

1-5 Parity check Enabled Disabled

1-6 Parity selection Even Odd

1-7

Transmission speed

1-8

■ ■ ■

■ ■ ■

more

Transmission speed

Transmission speed

bits per second (BPS) SW 1-7 SW 1-8

2400 ON ON

4800 OFF ON

9600 ON OFF

19200 OFF OFF

Paper roll DIP switch functions for the TM-L60II

Ver. 4.0

p. 996

Page 60

CONFIDENTIAL

more

DIP switch 2

SW Function ON OFF

2-1 Handshaking operation Receive buffer full

2-2

Selects print density

2-3

2-4

2-5 Fixed to On

2-6 Paper selection Thermal label Thermal paper

2-7 I/F pin 6 reset signal Enabled Disabled

2-8 I/F pin 25 reset signal Enabled Disabled

Reserved

(Setting must not be changed)

Fixed to Off

Off line or receive buffer

full

■ ■ ■

■ ■ ■

Print density

Print density SW 2-2 SW 2-3

more

1 (Light) ON ON

2 OFF OFF

3ONOFF

4 (Dark) OFF ON

Paper roll DIP switch functions for the TM-L60II

Ver. 4.0

p. 997

Page 61

CONFIDENTIAL

Parallel Interface (TM-L60IIP)

DIP switch 1

SW Function ON OFF

1-1 Auto line feed Always enabled Always disabled

1-2 Receive buffer capacity 45 bytes 4K bytes

1-3 Handshaking (BUSY condition)

1-4

Select print density

1-5

Reserved

1-6

(Setting must not be changed)

1-7 Paper selection Thermal label Thermal paper

1-8 Undefined — —

Receive buffer full or

reading data

Fixed to On

Off line, receive buffer

full, or reading data

Print density

Print density SW 1-2 SW 1-3

1 (Light) ON ON

2 OFF OFF

3ONOFF

4 (Dark) OFF ON

Paper roll DIP switch functions for the TM-L60II

Ver. 4.0

p. 998

Page 62

CONFIDENTIAL

Errors for the TM-L60II

ERRORS FOR THE TM-L60II

Automatically recoverable errors:

■

Print head high temperature error

Recoverable errors:

■

Label detection error

Unrecoverable errors:

■

R/W error in memory or gate array

High voltage error

Low voltage error

CPU execution error

Thermistor error

Data receive errors:

■

If the following errors occur with a serial interface, the printer processes data

depending on the setting of DIP switch 1-1.

Parity error

Framing error

Overrun error

Paper roll Errors for the TM-L60II

Ver. 4.0

p. 999

Page 63

CONFIDENTIAL

Options for the TM-L60II

OPTIONS FOR THE TM-L60II

EPSON power supply unit, PS-150.

■

Paper roll Options for the TM-L60II

Ver. 4.0

p. 1000

Page 64

CONFIDENTIAL

Self test for the TM-L60II

SELF TEST FOR THE TM-L60II

The self test lets you know if your printer is operating properly. It checks the control circuits, printer

mechanisms, print quality, ROM version, and DIP switch setting. This test is independent of any other

equipment or software.

Running the self test with a paper roll

1. Make sure the printer is turned off and the printer covers are closed properly.

2. While holding down the PAPER FEED button, turn on the printer using the power switch to begin the self

test. The self test prints the printer settings and then prints the following and pauses. (The PAPER light

blinks.)

Self test printing.

Please press the Paper feed button.

3. Press the PAPER FEED button to continue printing. The printer prints a pattern using the resident

characters.

4. The self test automatically ends and feeds the paper to a manual cutting position after printing the following:

***completed***

The printer is ready to receive data as soon as it completes the self test.

Paper roll Self test for the TM-L60II

Ver. 4.0

p. 1001

Page 65

CONFIDENTIAL

Hexadecimal dump for the TM-L60II

HEXADECIMAL DUMP FOR THE TM-L60II

This feature allows experienced users to see exactly what data has been received. This can be useful in

finding software problems. When you turn on the hexadecimal dump function, the printer prints all

commands and other data in hexadecimal format on paper roll to help you find specific commands.

To use the hexadecimal dump feature, follow these steps:

1. After you make sure that the printer is off, open the cover.

2. Hold down the PAPER FEED button while you turn on the printer.

3. Close the cover.

4. Run any software program that sends data to the printer. The printer prints “Hexadecimal Dump” and

then all the codes it receives in a two-column format. The first column contains the hexadecimal codes

and the second column gives the ASCII characters that correspond to the codes.

Hexadecimal Dump

1B 21 00 1B 26 02 40 40 . ! . . & . @ @

1B 25 01 1B 63 34 00 1B . % . . c 4 . .

41 42 43 44 45 46 47 48 A B C D E F G H

A period (.) is printed for each code that has no ASCII equivalent.

■

During the hexadecimal dump all commands except

■

5. Press the PAPER FEED button so that the printer will print the last line.

6. Turn off the printer or reset it to turn off the hexadecimal dump mode.

Paper roll Hexadecimal dump for the TM-L60II

DLE EOT

do not function.

Ver. 4.0

p. 1002

Page 66

CONFIDENTIAL

more

TM-L60II supported commands

TM-L60II SUPPORTED COMMANDS

Command Name Function Type

HT

LF

FF

CR

CAN

DLE EOT

ESC FF

ESC SP

Horizontal tab Print position O

Print and line feed Print O

(1) Print and return to standard

mode (in page mode)

Print O

(2) Print and feed label to print

starting position (on label)

Print and carriage return Print O

Cancel print data in page mode Character O

Real-time status transmission Status O

Print data in page mode Print O

Set right-side character spacing Character O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

ESC !

ESC $

ESC %

ESC &

Paper roll TM-L60II supported commands

Select print mode(s) Character O

Set absolute print position Print position O

Select/cancel user-defined character

Character O

set

Define user-defined characters Character O

Ver. 4.0

p. 1003

Page 67

CONFIDENTIAL

more

Command Name Function Type

ESC

ESC –

ESC 2

ESC 3

ESC =

ESC ?

ESC @

ESC D

ESC E

ESC G

✻

Select bit-image mode Bit-image O

Turn underline mode on/off Character O

Select default line spacing Line spacing O

Set line spacing Line spacing O

Select peripheral device Miscellaneous O

Cancel user-defined characters Character O

Initialize printer Miscellaneous O O

Set horizontal tab positions Print position O

Turn emphasized mode on/off Character O

Turn double-strike mode on/off Character O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

ESC J

ESC L

ESC R

ESC S

ESC T

ESC V

ESC W

Paper roll TM-L60II supported commands

Print and feed paper Print O

Select page mode Miscellaneous O

Select an international character set Character O

Select standard mode Miscellaneous O

Select print direction in page mode Print position O

Turn 90° clockwise rotation mode

Character O

on/off

Set printing area in page mode Print position O

Ver. 4.0

p. 1004

Page 68

CONFIDENTIAL

more

Command Name Function Type

ESC \

ESC a

ESC c 3

ESC c 4

ESC c 5

ESC d

ESC p

ESC t

ESC u

Set relative print position Print position O

Select justification Print position O

Select paper sensor(s) to output

Paper sensor O

paper-end signals

Select paper sensor(s) to stop

Paper sensor O

printing

Enable/disable panel buttons Panel button O

Print and feed n lines Print O

Generate pulse Miscellaneous O

Select character code table Character O

Transmit peripheral device status Status O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

ESC v

ESC {

GS FF

GS !

GS $

GS ✻

Paper roll TM-L60II supported commands

Transmit paper sensor status Status O

Turn upside-down printing mode

Character O

on/off

Print and eject label Print O

Select character size Character O

Set absolute vertical print position in

Print position O

page mode

Define downloaded bit image Bit-image O

Ver. 4.0

p. 1005

Page 69

CONFIDENTIAL

more

Command Name Function Type

GS /

GS :

GS <

GS A

GS B

GS C 0

GS C 1

GS C 2

GS C ;

GS H

Print downloaded bit image Bit-image O

Start/end macro definition Macro function O O

Initialize printer mechanism Miscellaneous O

Adjust label print starting position Miscellaneous O O

Turn white/black reverse printing

Character O

mode on/off

Select counter print mode Miscellaneous O

Select count mode (A) Miscellaneous O

Select counter print mode Miscellaneous O

Select counter mode (B) Miscellaneous O

Select printing position of HRI

Bar code O

characters

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

GS I

GS L

GS P

GS W

GS \

Paper roll TM-L60II supported commands

Transmit printer ID Miscellaneous O

Set left margin Print position O

Set horizontal and vertical motion

Miscellaneous O

units

Set printing area width Print position O

Set relative vertical print position in

Print position O

page mode

Ver. 4.0

p. 1006

Page 70

CONFIDENTIAL

more

Command Name Function Type

GS ^

GS a

GS b

GS c

GS f

GS h

GS k

GS r

GS w

Execute macro Macro function O

Enable/disable Automatic Status

Status O O

Back (ASB)

Turn smoothing mode on/off Character O

Print counter Miscellaneous O

Select font for HRI characters Bar code O

Set bar code height Bar code O

Print bar code Bar code O

Transmit status Status O

Set bar code width Bar code O

Classification

Executing

Cmds

Setting

Cmds

■ ■ ■

■ ■ ■

more

Paper roll TM-L60II supported commands

Ver. 4.0

p. 1007

Page 71

CONFIDENTIAL

Features for the TM-U200

FEATURES FOR THE TM-U200

The TM-U200B, TM-U200PB, TM-U200D, and TM-U200PD are high-quality POS printers that can print on a

paper roll. The printer has the following features:

Compact and lightweight.

■

High-speed printing through logical seeking control.

■

Excellent reliability and long life due to adoption of stepping motor, both for moving the carriage and

■

for paper feeding.

Flexible paper feed pitch setting permits printing in accordance with any user-defined format.

■

Command protocol based on the ESC/POS standard.

■

Built-in drawer-kick interface provides capability to drive two drawers.

■

Selectable character fonts (7×9, 9×9).

■

Semi-automatic paper loading capability.

■

AC adapter provides compact power supply.

■

Automatic status back (ASB) function that automatically transmits changes in printer status.

■

Two-color printing (black and red) (two-color version only).

■

Autocutter is equipped (TM-U200B only).

■

Paper roll Features for the TM-U200

Ver. 4.0

p. 1008

Page 72

CONFIDENTIAL

more

Specifications for the TM-U200

SPECIFICATIONS FOR THE TM-U200

Printing specifications

■

Printing method: 9-pin, serial impact dot matrix

Printing speed: Approximately 3.5 LPS (40 columns, 16 cpi)

Approximately 6.4 LPS (16 columns, 16 cpi)

Character specifications

■

Character fonts: 7 × 9 font / 9 × 9 font

Characters per line: 40 / 33 (with 3 half dots), 42 / 35 (with 2 half dots)

Character pitch: 16 / 13.3 (with 3 half dots) CPI, 17.8 / 14.5 (with 2 half dots) CPI

Character size: ANK: 1.2 mm (W) × 3.1 mm (H) / 1.6 mm (W) × 3.1 mm (H)

Graphics:1.7 mm (W) × 3.1 mm (H) / 2.0 mm (W) × 3.1 mm (H)

(with 3 half dots spacing)

1.6 mm (W) × 3.1 mm (H) / 1.9 mm (W) × 3.1 mm (H)

(with 0 dots spacing)

Character sets: ASCII: 95 characters

■ ■ ■

■ ■ ■

more

International: 32 characters

Extended graphics: 128 characters × 6 pages

Paper specifications

■

Paper type: Paper roll:

Normal paper

➀

Pressure-sensitive paper:

➁

Number of copies: Original 1 sheet + one copy sheet (U200B)

Original 1 sheet + up to two copy sheets (U200D)

Paper size: Paper roll: 75.5 – 76.5 mm (W) × 83.0 mm diameter