Page 1

SERVICE MANUAL

Scanner•Printer•Copier

EPSON

Stylus PHOTO RX 560/580/590

SEMF06003

Page 2

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing procedures preceded by

DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL ELECTRONICS

TECHNICIANS IN THEIR LINE OF WORK

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO. WHEN

THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS

4. WHEN DISASSEMBLING OR ASSEMBLING A PRODUCT, MAKE SURE TO WEAR GLOVES TO AVOID INJURIES FROM METAL PARTS WITH SHARP EDGES.

5. WHEN USING COMPRESSED AIR PRODUCTS; SUCH AS AIR DUSTER, FOR CLEANING DURING REPAIR AND MAINTENANCE, THE USE OF SUCH PRODUCTS

CONTAINING FLAMMABLE GAS IS PROHIBITED.

.

.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE EPSON

PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING PRINTED CIRCUIT

BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST STRAPS, WHEN

ACCESSING INTERNAL COMPONENTS.

5. DO NOT REPLACE IMPERFECTLY FUNCTIONING COMPONENTS WITH COMPONENTS WHICH ARE NOT MANUFACTURED BY EPSON. IF SECOND SOURCE IC OR

OTHER COMPONENTS WHICH HAVE NOT BEEN APPROVED ARE USED, THEY COULD CAUSE DAMAGE TO THE EPSON PRODUCT, OR COULD VOID THE

WARRANTY OFFERED BY EPSON.

Page 3

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the pri nt e r . The i n str uc t i o n s and proce d u r es included

herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for servicing

the product.

APPENDIX Provides the following additional information for reference:

• Connection with Connectors

• Circuit Boards Component Layout

• Exploded diagram & Parts List

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

A D J U S T M E N T

R E Q U I R E D

C A U T I O N

C H E C K

P O I N T

W A R N I N G

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to, or

destruction of, equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Page 4

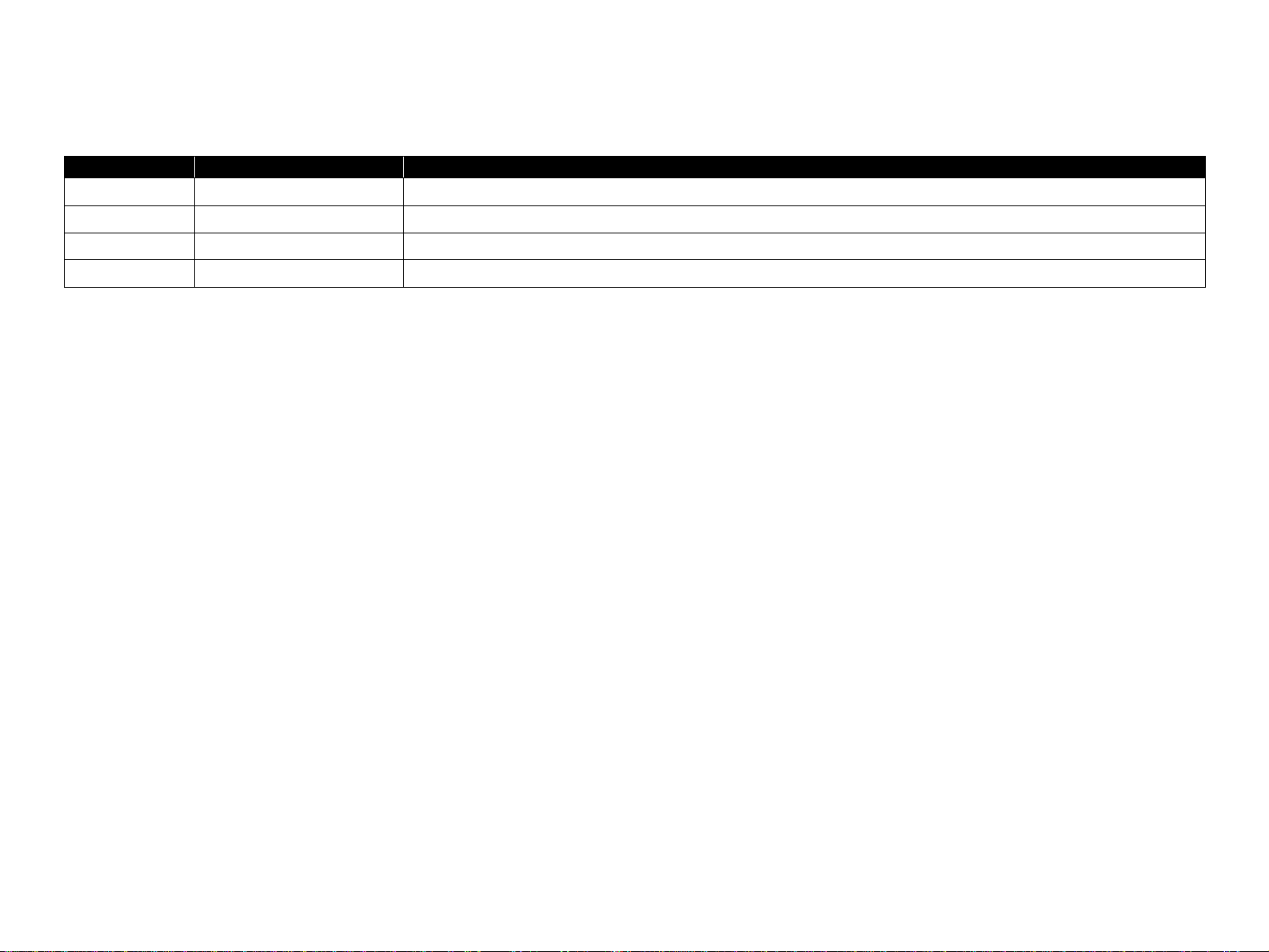

Revision Status

Revision Date of Issue Description

A September 1, 2006 First Release

Page 5

EPSON Stylus PHOTO RX560/580/590 Revision A

CONTENTS

Chapter 1 Product Description

1.1 Overview . ............................................................................................................. 9

1.2 Basic Specifications . ......................................................................................... 10

1.2.1 Printer and PC Printing . ............................................................................ 10

1.2.2 Scanner . .................................................................................................... 10

1.2.3 Interfaces . .................................................................................................. 11

1.2.3.1 USB Interface . ................................................................................... 11

1.2.3.2 Infrared Communication Printing Function ...................................... 11

1.2.3.3 Memory Card Slots ........................................................................... 12

1.3 Consumables and Options . .............................................................................. 13

1.3.1 Ink Cartridges . .......................................................................................... 13

1.4 Common Specifications . ................................................................................... 13

1.4.1 Electrical Specifications . .......................................................................... 13

1.4.2 Safety Standards/EMC . ............................................................................. 14

1.4.3 Environment Resistance . .......................................................................... 14

1.4.4 Lifetime . .................................................................................................... 14

1.4.5 Noise .......................................................................................................... 14

1.4.6 Weight / Physical Specifications . ............................................................. 14

1.4.7 Special Operations . ................................................................................... 14

Chapter 2 Operating Principles

2.1 Overview ............................................................................................................. 16

2.1.1 Mechanical Components .......................................................................... 16

2.1.2 Motors and Sensors . .................................................................................. 17

2.2 Operating Principles of Electric Circuitry ..................................................... 18

2.2.1 Overview . .................................................................................................. 18

2.2.2 Features . .................................................................................................... 18

2.2.3 Circuit Board Constitution . ....................................................................... 18

2.3 Banding Reduction System (BRS)/ Paper Feed Profile Correction (PFP) .. 19

Chapter 3 Troubleshooting

3.1 Overview ............................................................................................................. 21

3.1.1 Specified Tools . ........................................................................................ 21

3.1.2 Preliminary Checks . .................................................................................. 21

3.1.3 Procedure for Troubleshooting . ................................................................ 21

3.2 Troubleshooting When There is Error Display . ............................................ 22

3.2.1 Error List .................................................................................................... 22

3.2.2 Warning List . ............................................................................................ 23

3.2.3 FATAL Error ......................................................................................... 27

3.3 Troubleshooting When There is No Error Display . ...................................... 30

3.3.1 Troubleshooting for Printer . ..................................................................... 30

3.3.2 Power Supply Related Troubleshooting . .................................................. 34

3.3.3 Ink Supply Related Troubleshooting . ....................................................... 34

3.3.4 I/F Related Troubleshooting . .................................................................... 36

3.3.5 Troubleshooting for Scanner . ................................................................... 37

3.3.6 Troubleshooting for Motors and Sensors ....................................... 38

Chapter 4 Disassembly and Assembly

4.1 Overview ............................................................................................................. 40

4.1.1 Precautions ................................................................................................. 40

4.1.2 Tools .......................................................................................................... 40

4.1.3 Preparation before Disassembly . .............................................................. 40

4.1.4 Disassembly and Reassembly Procedure ................................................. 41

4.2 Removal of Exterior Parts . .............................................................................. 42

4.2.1 Panel Assy ................................................................................................. 42

4.2.2 Disassembly of Panel Assy . ...................................................................... 43

4.2.3 Scanner Unit . ............................................................................................ 44

4.2.4 Main Board ................................................................................................ 45

6

Page 6

EPSON Stylus PHOTO RX560/580/590 Revision A

4.2.5 Middle Housing . ....................................................................................... 48

4.2.6 Waste Ink Tray Assy ................................................................................ 51

4.2.7 Printhead . .................................................................................................. 52

4.2.8 Linear Scale . ............................................................................................. 54

4.2.9 Printer Mechanism . ................................................................................... 55

4.3 Disassembly of Housing Lower Assy .............................................................. 56

4.3.1 Waste Ink Pads . ........................................................................................ 56

4.3.2 Power Supply Board . ................................................................................ 56

4.3.3 Stacker Assy . ............................................................................................ 57

4.4 Disassembly of Scanner Unit . .......................................................................... 59

4.4.1 Scanner Housing . ...................................................................................... 59

4.4.2 CIS Unit ..................................................................................................... 60

4.4.3 CR Motor Unit . ......................................................................................... 61

4.5 Disassembly and Assembly of Major Parts of Printer .................................. 62

4.5.1 PF Motor, PF Encoder and PF Scale . ....................................................... 62

4.5.2 I/S Assy . .................................................................................................... 63

4.5.3 ASF Assy . ................................................................................................. 64

4.5.4 APG Assy .................................................................................................. 65

4.5.5 CR Motor . ................................................................................................. 66

4.5.6 Carriage Assy . ........................................................................................... 67

4.5.7 Eject Frame Assy . ..................................................................................... 69

4.5.8 Upper Paper Guides . ................................................................................. 70

4.5.9 Paper Guide Front Assy . ........................................................................... 71

Chapter 6 Maintenance

6.1 Overview ............................................................................................................. 88

6.1.1 Maintenance Error . ................................................................................... 88

6.1.2 Cleaning ..................................................................................................... 88

6.1.3 Lubrication ................................................................................................. 89

Chapter 7 Appendix

7.1 Connectors ......................................................................................................... 95

7.2 Component Layout ............................................................................................ 98

7.3 Electric Circuit Diagrams . ............................................................................... 99

7.4 Exploded Diagrams & ASP Reference List . ................................................ 107

Chapter 5 Adjustment

5.1 Overview ............................................................................................................. 73

5.1.1 Adjustment by Use of Adjustment Program ............................................. 74

5.2 PG Adjustment . ................................................................................................ 75

5.3 Banding Reduction System (BRS) Adjustment / Paper Feed Profile Correction

(PFP) ......................................................................................................................... 77

5.3.1 Overview . .................................................................................................. 77

5.3.2 Adjustment Procedure .............................................................................. 79

5.3.2.1 BRS adjustment . ................................................................................ 79

5.3.2.2 PFP adjustment . ................................................................................. 81

5.4 Scanner Home Position Adjustment . .............................................................. 84

5.4.1 Preparations for Use of the Adjustment Program ..................................... 84

5.4.2 Home Position Adjustment Procedure . ..................................................... 85

5.4.3 Home Position Confirmation Procedure ................................................... 86

7

Page 7

PRODUCT DESCRIPTION

CHAPTER

1

Page 8

EPSON Stylus PHOTO RX560/580/590 Revision A

1.1 Overview

Realizing 4-in-1 functionality (computer-connected printer or scanner, stand-alone

copy machine, and stand-alone memory card printing), this unit is targeted for both

home/personal use and small office and home office (SOHO) use. Its main functions

are described below.

Printer Functions

As a printer, this unit realizes high-quality printing at a high speed on plain paper,

excellent light-, water-, and gas-resistance and rub fastness using new dye-based inks,

and features the following:

Maximum print resolution: 5760 (H) x 1440 (V) dpi

Six colors available with separate respective ink cartridges

Borderless printing available using EPSON special media paper.

Reduced noise level

CD-R Printing

ESC/P-R Level-1 commands supported, and printing of RGB data transmitted

from the host computer available

Scanner Functions

High-quality scanning available with the newly employed 1200-dpi CIS sensor. In

addition, the scanner features the following:

Maximum optical resolution 1200 x 2400 dpi

Scan pixel depth (for each color of RGB): Input 16 bits / Output 1 bit or 8 bits

Scanning to Memory Card function available (in stand-alone mode)

Stand-alone copy functions

“3 mm bottom margin” printing function

Memory card print functions

The printer is equipped with a memory card reader function and has a stand-

alone memory card printing function.

Index Sheet printing supported (Images can be selected simply by marking the

desired images on the Index Sheet and scanning the sheet.)

In addition to photo selection methods, such as “View and Print”, “Print All

Photos” and “Print by Date”, which permit setting the number of copies of the

selected photos, photo editing functions, such as “Cropping and enlarging a

photo” is also available.

The P.I.F. print mode provided (Print Image Framer Ver.2 or 3 supported)

Scan functions

The “Scan to Memory Card” function facilitates the conversion of a reflective

document to digital form.

Specialty print functions

“Photo Greeting Card” (Only EAI) provided, which is helpful in printing

greeting cards or 4 x 6-inch photos with handwritten text superimposed.

Expanded from the functions existing in Stylus Photo RX700 are “Watermark

printing” - a function to facilitate alignment by printing a faint photo image on

the handwritten area - and character decoration.

“Reprint/Restore Photos” provided, which helps to reprint three 4 x 6-inch

photos or one 5 x 7-inch photo.

“CD/DVD Print (EAI/Euro/Asia)” provided, by which the image of the

favorite is printed on CD/DVD.

Simultaneous use of functions

Printer functions and scanner functions, which are independent of each other, can be

operated simultaneously from a computer. However, note that printing by ESC/P-R

commands cannot be operated simultaneously with scanner functions.

“Borderless copying”

Printing on CD/DVD labels and jackets

Repeated copying to provide various types of copying

“2-up copying” helpful in minimizing paper waste

“Wallet Photo Copy” to enable printing on Wallet Photo size (Only EAI)

Product Description Overview 9

2.5-inch TFT LCD (240 x 480 dots)

Page 9

EPSON Stylus PHOTO RX560/580/590 Revision A

1.2 Basic Specifications

1.2.1 Printer and PC Printing

Basic Specifications

Table 1-1. Printer Basic Specifications

Items Specifications

Print method On-demand ink jet

Black ink: 90 nozzles

Print heads

Print direction Bi-directional minimum distance printing (with logic seeking)

Print resolution 5760 x 1140 dpi (max)

Input buffer size 256K Bytes

Paper Feed Specifications

Items Specifications

Paper feed method Friction feed using an ASF (Auto Sheet Feeder)

Paper path Top feed, front out

Paper feed rates

CR interval Programmable in 0.0176 mm (1/1440 inch) steps

Platen print prevention

Color ink: 90 nozzles x 5 colors

(cyan, magenta, yellow, light cyan, and light magenta)

Table 1-2. Paper Feed Specifications

584.2 mm/sec (23 inches/sec) (when 25.4-mm paper feeds)

296.64 mm/sec (11.6 inches/sec) (when paper feeds in high-speed

continuous mode)

Printing using a borderless layout:

Top detection and PW detection implemented for platen print

prevention.

Printing using a layout with borders:

platen print prevention with the paper width of 1st page or 1st job

Economy printing mode:

no platen print prevention.

1.2.2 Scanner

Basic Specifications

Table 1-3. Basic Specifications

Items Specifications

Product type Flatbed color image scanner

Scanning method Fixed document and carriage movement

Sensor CIS

Document sizes A4, US Letter

Max. effective pixels 10,200 x 14,040 pixels (1200 dpi)

Resolution

Scanning resolution 50 to 4800 dpi (selectable in 1-dpi steps), 7200 dpi, 9600 dpi

Pixel depth 16-bit input and 1.8-bit output for each element of each color

Light source LED

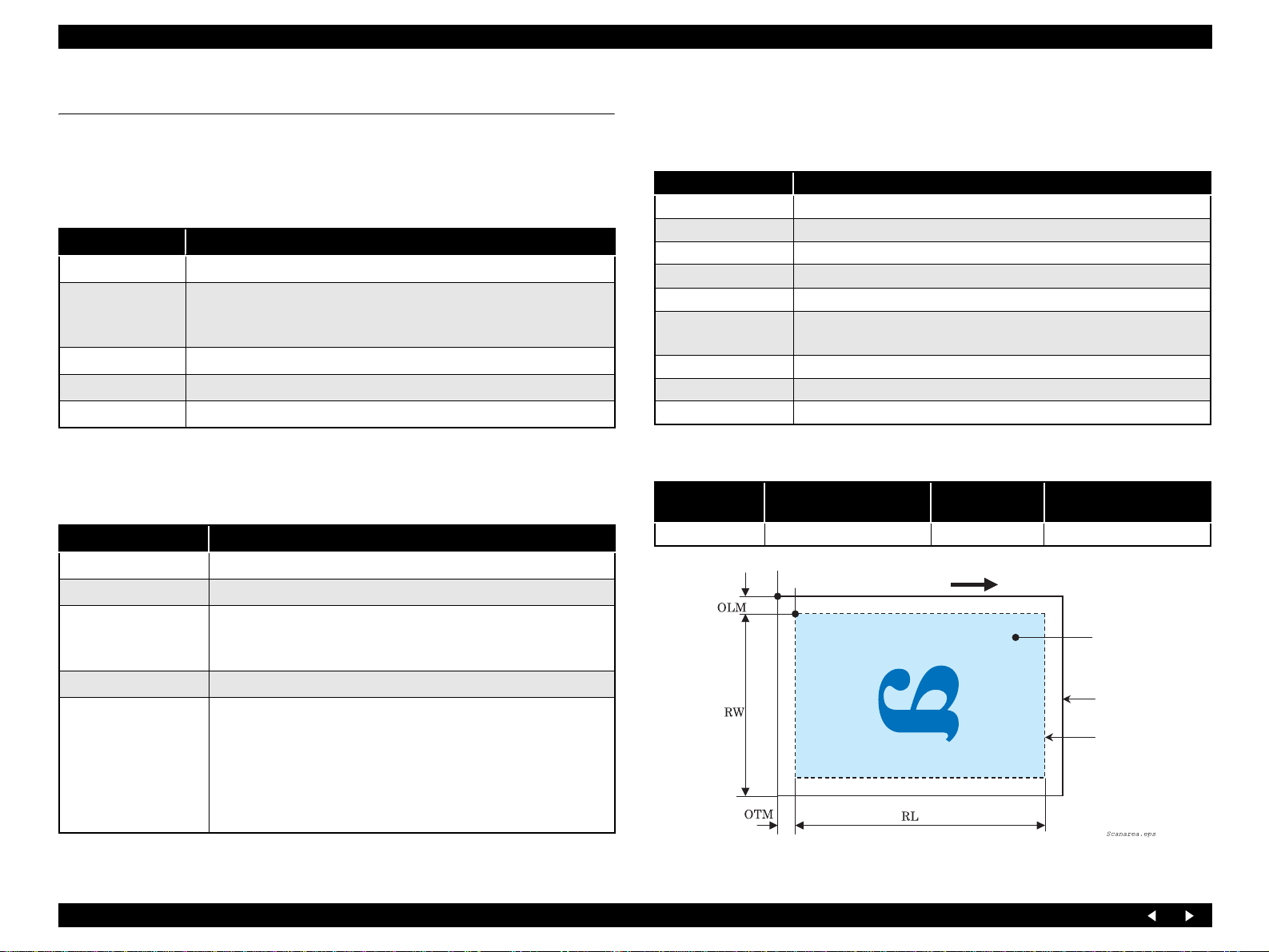

Scanning Area

RW

(readable width)

216 mm (8.5”) 1.5 mm ± 1 mm 297 mm (11.7”) 1.5 mm ± 1 mm

Main scan: 1200 dpi

Sub scan: 2400 dpi

OLM

(out-of-range left margin)RL(readable length)

Original’s top left alignment

1st Pixel

Control panel side

Scan direction

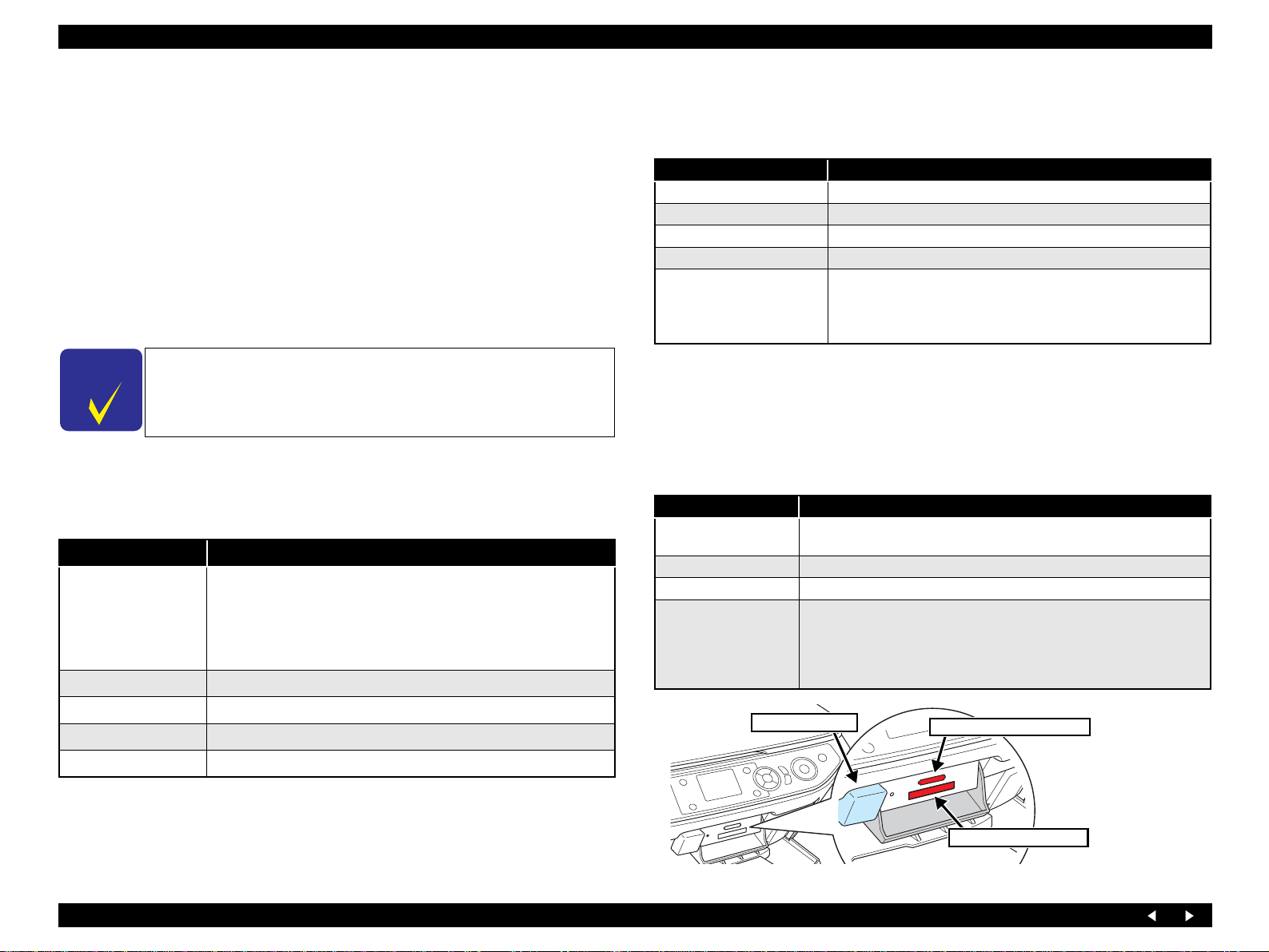

Figure 1-1. Image Scanning Area

OTM

(out-of-range top margin)

Original

(Face down)

Scan bed

Scan area

Product Description Basic Specifications 10

Page 10

EPSON Stylus PHOTO RX560/580/590 Revision A

1.2.3 Interfaces

The interfaces this unit is equipped with are as follows:

USB I/F

Mounted on the printer (for connection to a PC)

For printing of data from a USB storage (printing of data from an external

storage device, such as a DSC or CD-R disk or wireless printing by use of the

optional Bluetooth adapter)

Memory card slot (multi-slot)

IrDA (infrared communication with a mobile phone or the like)

C H E C K

P O I N T

1.2.3.1 USB Interface

Main specifications

Standards

Transfer rate 480Mbps (High Speed Device)

Data format NRZI

Compatible connector USB Series B

Maximum cable length Less than 2 m

Detailed information on above-mentioned external storage

devices, Bluetooth adapter and devices compatible with IrDA

(infrared data association) is available on EPSON web site.

Table 1-4. Main Specifications

Items Specifications

“Universal Serial Bus Specifications Revision 2.0”

Printer: “Universal Serial Bus Device Class Definition for Printing

Devices Version 1.1”

Storage:“Universal Serial Bus Mass Storage Class Bulk-Only

Transport Revision 1.0”

Wireless printing is available by installing the optional Bluetooth adapter in the

External Storage Device Connection Port.

Table 1-5. Bluetooth Communication Basic Specifications

Items Specifications

Communication method Bluetooth standard specification Ver. 2.0 + EDR

Output Bluetooth standard specification Power Class 2

Communication distance Approx. 10 m (line-of-sight)

Frequency band used 2.4 GHz band (2.4 GHz to 2.4835 GHz)

Basic Printing Profile (BPP)

Supported profiles

Note : Subject to conditions such as obstructions between communication devices, radio wave condition,

magnetic field, static electricity, locations where interferences occur, software or OS used, receiver

sensitivity of communication devices, and antenna performance.

Basic Imaging Profile (BIP)

Object Push Profile (OPP)

Hardcopy Cable Replacement Profile (HCRP)

1.2.3.2 Infrared Communication Printing Function

Stylus PHOTO RX560/580/590 incorporates an infrared communication port on the

Main Board.

Items Specifications

Standards

Communication speed 9.6 kbits/s-115.2 kbits/s, 0.576 Mbits/s, 1.152 Mbits/s, 4.0 Mbits/s

Communication distance 0-20 cm (without obstruction), Infrared range is as shown below.

Object data

Compliant with the infrared data communication standards (IrDA Ver.1.3

[Low Power option], etc.)

• JPEG file

• vNote file (including support for NTT Docomo image transfer format)

• vCard file

• vCalendar file

• vMessage file

Infrared receiver

SD/MMC/MS/xD Slot

External Storage Device Connection Ports

Recommended cable length: 2 m

CF Slot

Product Description Basic Specifications 11

Page 11

EPSON Stylus PHOTO RX560/580/590 Revision A

1.2.3.3 Memory Card Slots

Priority Slots Support Memory Card Standards Remarks

xD-Picture card xD-Picture card (Type-M/H) xD-Picture Card Specification Version 1.20 compliant Type M/H supported

Memory Stick MemoryStick Standard Version 1.42-00 compliant Max: 128 MB, including versions with memory select function

MagicGate Memory Stick Max: 128 MB, copy protection function is not supported

Memory Stick

1

SD/MMC

2 CF Type II

Note 1: For both PC connection and Directing printing, only one type of media is accessible at the same time.

Priority is assigned to each slot, so that if multiple media are inserted into multiple slots at the same time, an accessible slot is determined in the order of priority.

2: In order to select the medium inserted into an invalid slot, the medium in the valid slot needs to be removed.

•For direct printing: Only the image files in a valid slot are determined to be valid and assigned photo numbers. The number of images does not change even if media are inserted into unselected slots.

•For PC connection (Windows): Only one “removable disk” drive is displayed; and only the medium in a valid slot can be accessed from the “removable disk.” Media inserted in unselected slots are not accessible.

•For PC connection (Macintosh): Only the medium in a valid slot is mounted onto the desktop. Media inserted in unselected slots can not be mounted onto the desktop.

3: Selecting a slot when power is turned on: If media are inserted into multiple slots when power is turned on, an accessible slot is determined in accordance with the above order of priority.

4: Selecting a slot after power is turned on: When the medium is removed from the valid slot, the slot of the second highest priority becomes valid (if a medium is inserted there). It is not necessary to reinsert the

C H E C K

P O I N T

Stylus PHOTO RX560/580/590 does not support SmartMedia.

(No slot for SmartMedia)

Memory Stick PRO MemoryStick Standard Memory Stick PRO Format Specifications Version 1.02-00 compliant Copy protection function is not supported

Memory Stick Duo Requires Memory Stick Duo adapter

Memory Stick Pro Duo Requires Memory Stick Duo adapter

SD SD Memory Card Specifications / PART1. Physical Layer Specification Version 2.0 compliant

miniSD Requires SD adapter

microSD Requires SD adapter

SDHC Speed class is not supported

miniSDHC Requires SD adapter. Speed class is not supported

microSDHC Requires SD adapter. Speed class is not supported

MMC MultiMediaCard System Specifications Version 4.1 compliant

Compact Flash CF+ and CompactFlash Specification ReVision 3.0 compliant Only Memory card that supports True-IDE Mode

Microdrive

medium before it is accessed.

Table 1-6. Maximum Capacity of the Media

Media

Maximum Capacity

Specified in the Standard

CompactFlash Unknown 4GB

Memory Stick 128MB 128MB

Memory Stick PRO 32GB 4GB

SD Memory Card 2GB 2GB

SDHC Memory Card 32GB 4GB

MultiMediaCard 4GB (Presumed) 64MB

xD-Picture Card 2GB 1GB

Operation-confirmed

Maximum Capacity

Product Description Basic Specifications 12

Page 12

EPSON Stylus PHOTO RX560/580/590 Revision A

1.3 Consumables and Options

1.3.1 Ink Cartridges

Table 1-7. Ink Cartridges

Items Specifications

Type Each-color separate ink cartridge

Colors Black, Cyan, Magenta, Yellow, Light Cyan, Light Magenta

The term of

validity

Storage

temperature

Dimensions 12.7 mm (W) x 68.0 mm (D) x 47.0 mm (H)

Note : Ink cartridges cannot be refilled. They are provided as consumable items.

C H E C K

P O I N T

2 years (Total period of packed state and unpacked state)

6 months after unpacking

Installed : -20°C ~ 40°C (Within 1 month at 40°C)

Packing storage : -30°C ~ 40°C (Within 1 month at 40°C)

Ink cartridges whose validity has expired should not be used.

The ink in cartridges freezes if left at a temperature of -16°C or

below. To restore frozen ink to a usable condition, it takes

approximately 3 hours, for example, if it is moved from an

environment at -20°C to an environment at 25°C.

The ink cartridges for Stylus PHOTO RX560/580/590, which

are of a newly developed type, are not interchangeable with

those for Stylus PHOTO RX640/650.

1.4 Common Specifications

1.4.1 Electrical Specifications

Primary power input

Table 1-8. Primary Power Input

100-120 V model 220-240 V model

Rated power supply voltage AC100 - 120 V AC220 - 240 V

Input voltage range AC90 - 132 V AC198 - 264 V

Rated current 0.6 A 0.3 A

Maximum rated current 1.2 A 0.6 A

Rated frequency 50 - 60 Hz

Input frequency range 49.5 - 60.5 Hz

Approx. 16 W (Standalone copying,

ISO10561 Letter Patter, Plain Paper - A4 Text)

Power consumption

Note 1: This product conforms to “Energy Star”.

2: If inactive condition of the printer continues for more than 3 minutes, the status shifts to

the standby status to reduce holding current to motor.

3: If inactive condition of the scanner continues for more than 3 minutes, power supply to

the scan lamp is stopped.

Approx. 5.5 W (Low-power Mode)

Approx. 2.5 W (Sleep Mode)

Approx. 0.2 W (Power Off Mode)

Dielectric strength

AC 1000 Vrms, 1 minute or AC 1200 Vrms, 1 second

Product Description Consumables and Options 13

Page 13

EPSON Stylus PHOTO RX560/580/590 Revision A

1.4.2 Safety Standards/EMC

100-120 V version 220-240 V version

Safety standards UL60950

CSA C22.2 No.60950

EMI FCC part15 subpart B class B

CAN/CSA-CEI/IEC CISPR

22 Class B

Safety standards EN 60950

EMC EN 55022 (CISPR Pub.22)

class B

EN61000-3-2

EN61000-3-3

EN55024

AS/NZS CISPR22 class B

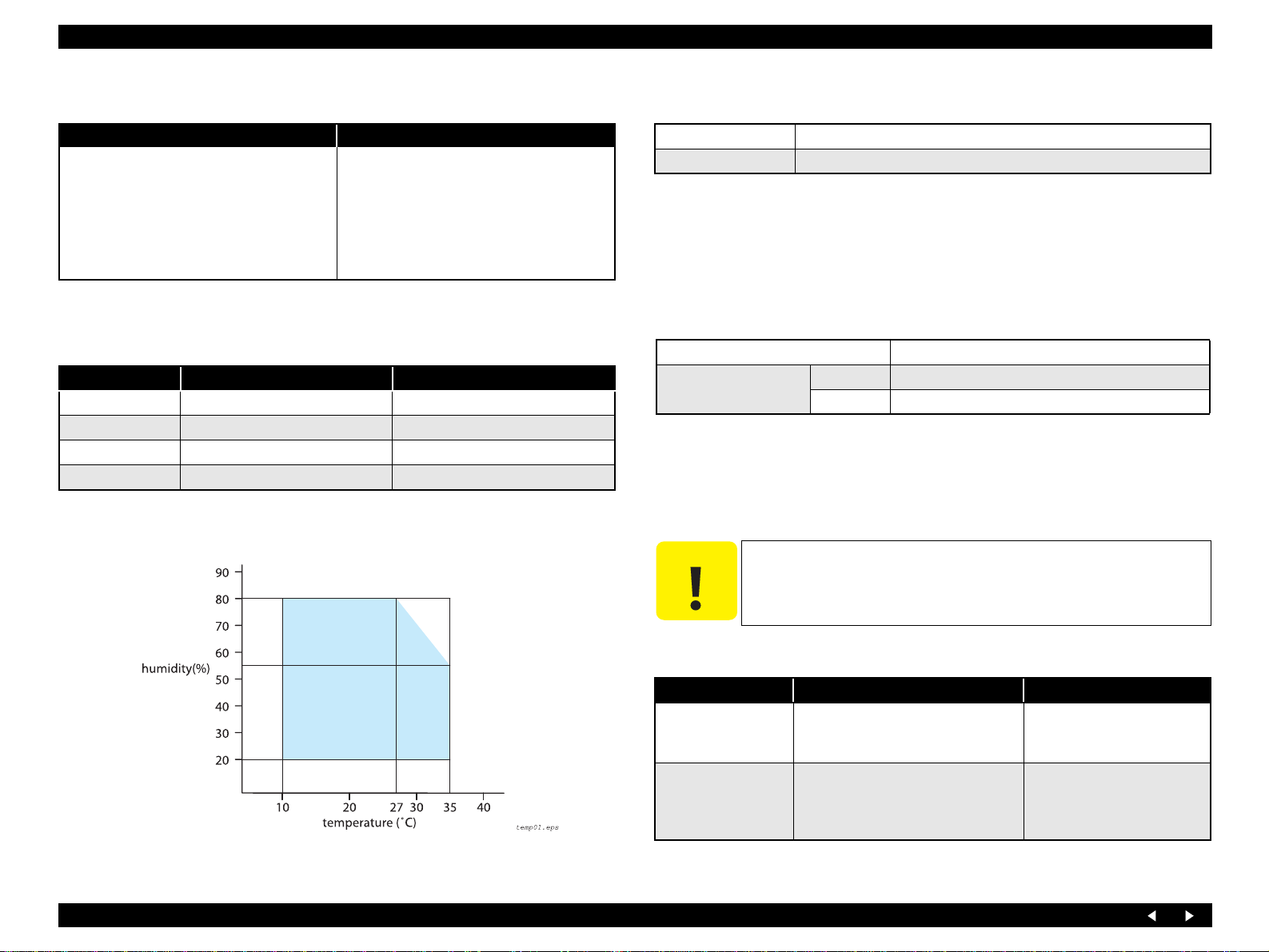

1.4.3 Environment Resistance

Table 1-9. Environment Resistance

Operating Not operating

Temperature 10~35 °C *2 -20~40 °C (1 month when at 40 °C)

Humidity 20~80% *1,*2 5~85% *1

Impact 1 G, 1x10-3 seconds 2 G, 2x10-3 seconds*

Vibration 0.15G 10~55Hz 0.50G 10~55Hz *1

Note*1: No condensation

*2: Under the following conditions

1

1.4.4 Lifetime

Total print volume 16,000 pages (A4/Letter) or 5 years, whichever comes first

Print head lifetime 6 billion shots (per nozzle) or 5 years, whichever comes first

1.4.5 Noise

Noise level : Max T.B.D. dB (During copy, ISO7779)

1.4.6 Weight / Physical Specifications

Weight 8.3 kg (Excluding the ink cartridges and power cable)

External Dimensions

(Width x Depth x Height)

when closed 450 mm x 414 mm x 210 mm

in operation 450 mm x 534 mm x 281 mm

1.4.7 Special Operations

With Stylus PHOTO RX560/580/590, the special operation modes described below are

available by pressing the specified buttons.

C A U T I O N

The functions described below, intended for use by service

personnel, must not be opened to users.

Table 1-10. Special Operations

Switches Function

Operation for Forced

Power Off

Displaying the fatal

error code

[Power] + [Stop]

(Press Power SW first, and press both

switches for more than seven seconds)

[Stop] + [Print Setting] + [Display]

Turning the power off forcibly

(processing equivalent to

power down)

Displaying error type on the

LCD by pressing the buttons

specified at left together when

a printer error has occurred

Figure 1-2. Environmental Conditions

Product Description Common Specifications 14

Page 14

OPERATING PRINCIPLES

CHAPTER

2

Page 15

EPSON Stylus PHOTO RX560/580/590 Revision A

2.1 Overview

This Chapter describes the operating principles of the mechanism and electric circuits

of Stylus PHOTO RX560/580/590.

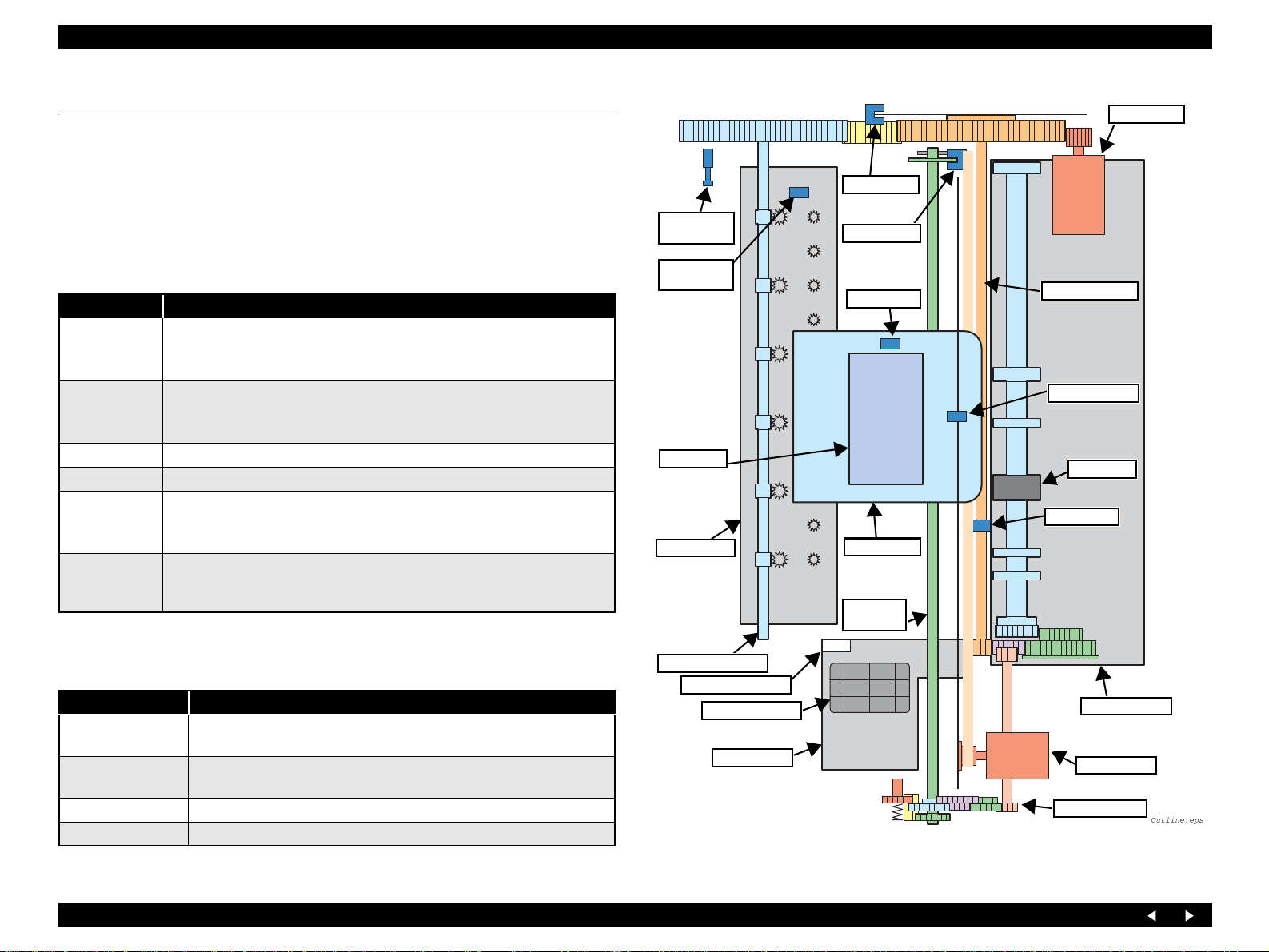

2.1.1 Mechanical Components

The printer of Stylus PHOTO RX560/580/590 consists of the following major

mechanisms:

Table 2-1. Mechanical Components 1

Mechanism Function/Description

Moves on the CR Guide Shaft right and left and performs printing on paper.

CR Assy

APG Assy

PF Assy Driven by the PF Motor to turn the PF Roller Shaft for feeding paper.

ASF Assy Driven by the PF Motor to load paper into the Printer Mechanism.

Eject Assy

I/S Assy

The units and circuit boards constituting Stylus PHOTO RX560/580/590 are as

follows:

Unit /Circuit Board Function/Description

Main Board

Power Supply Board

Panel Board Consists of two pieces located on the Middle Housing.

Scanner Unit CIS consisting of 1200 dpi CCD for reflection (light source: LED)

The Carriage Assy incorporates the Printhead, PW Sensor, and CR Encoder.

The drive source is the CR Motor.

Controls the platen gap in four stages.

Detects the current height of the carriage with the APG Sensor, and moves

the carriage up and down, driven by the PF Motor.

Driven by the PF Motor to eject the paper (CD-R Tray).

As the Stacker is moved up and down (by manual operation), the paper eject

frame moves up and down so that its height can be adjusted to the media.

Located in the right end of the mechanism, performs capping the Printhead,

while it is not used, and sucking waste ink. The waste ink is sent to the Waste

Ink Tray via the Waste Ink Tube.

Table 2-2. Mechanical Components 2

Located on the Middle Housing, incorporating the USB I/F (x2), card

reader, and infrared communication function.

Located on the Lower Housing. The power cable can be plugged in and

unplugged.

CD-R Guide

Sensor

CD-R Tray

Sensor

Printhead

Eject Frame

Eject Roller Shaft

CR Lock Lever

Cap Assy

I/S Assy

PF Encoder

APG Sensor

PW Sensor

CR Assy

CR Guide

Shaft

PF Roller Shaft

CR Encoder

PE Sensor

Figure 2-1. Schematic Printer Mechanism

PF Motor

LD Roller

ASF Assy

CR Motor

APG Assy

Operating Principles Overview 16

Page 16

EPSON Stylus PHOTO RX560/580/590 Revision A

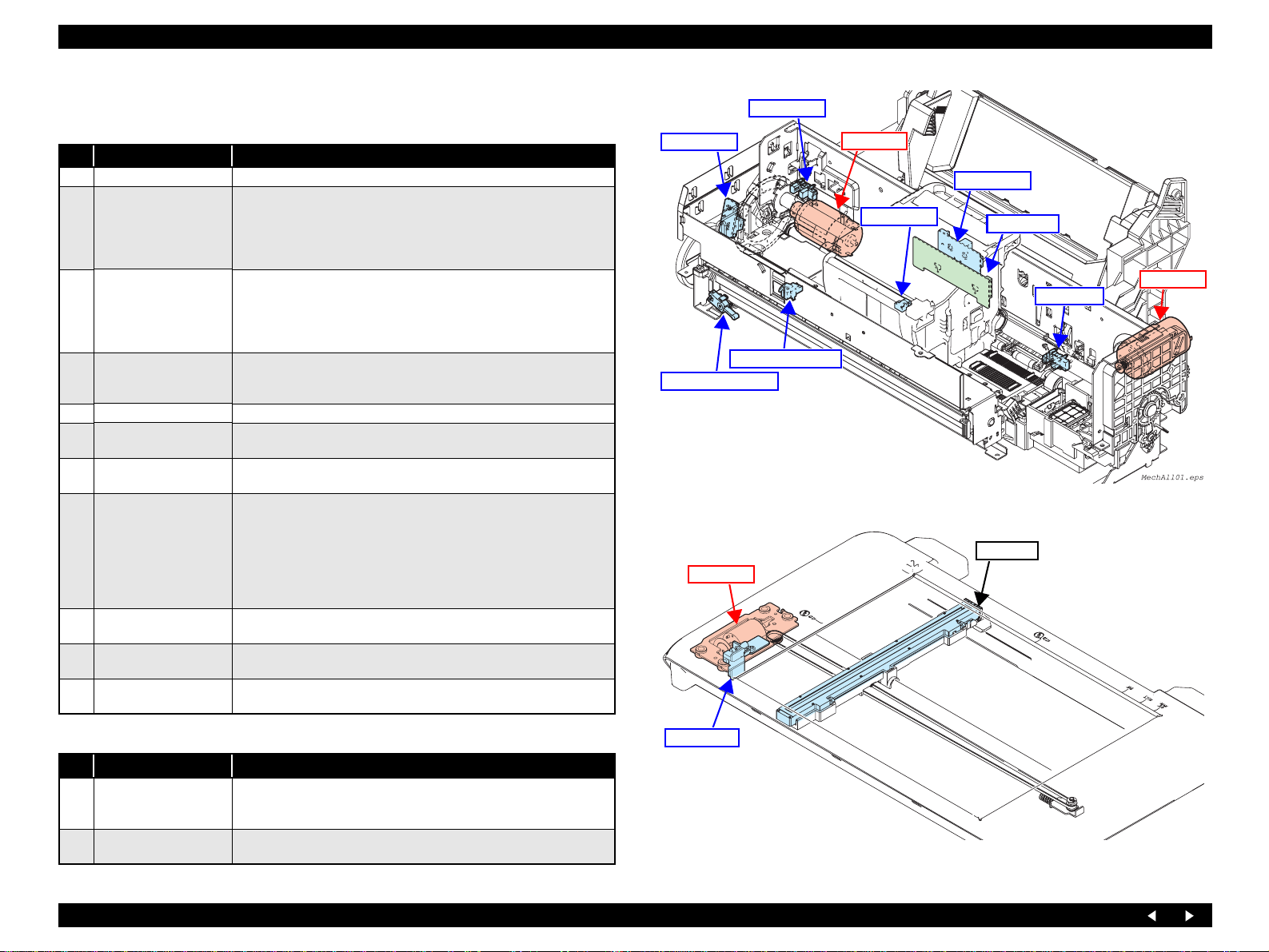

2.1.2 Motors and Sensors

Table 2-3. Motors and Sensors (Printer Mechanism)

No. Name Function

1 Printhead F3-MACH head (6 colors x 90 nozzles)

Type: DC motor

Voltage: 42V DC ± 5% (voltage applied to the driver)

2 CR Motor

3 PF Motor

4 PE detector

5 Ink Cartridge detector CSIC board

6 PTS detector (CR)

7 PTS detector (PF)

8 PW detector

9 APG detector

10 CD-R Guide detector

11 CD-R Tray detector

Characteristics: Armature resistance : 22.7 Ω ± 10%

Inductance : 17.5 mH ± 25%

Drive system: PWM system, constant-current chopping system

Type: DC motor

Voltage: 42V DC ± 5% (voltage applied to the driver)

Characteristics: Armature resistance : 21.2 Ω ± 10%

Inductance : 17.2 mH (1kHz)

Drive system: PWM system

Function: Detection of the paper tail end, Paper leading edge

positioning control

Detection method:Transmissive-type photo-interrupter

Type: Linear encoder

Resolution: 180 pulse/inch

Type: Linear encoder

Resolution: 180 pulse/inch

Function • Paper left and right edge

(before and during printing)

• Paper top edge (before printing)

• Paper bottom edge (during printing)

• CD-R top, bottom, right and left edges

(before printing)

Detection method:Reflective photosensor

Function: APG position detection

Detection method:Transmissive-type photo-interrupter

Function: CD-R Guide up/down detection

Detection method:Mechanical contact detector

Function: CD-R Tray presence detection

Detection method:Mechanical contact detector

APG Sensor

PF Encoder

CD-R Tray Sensor

CD-R Guide Sensor

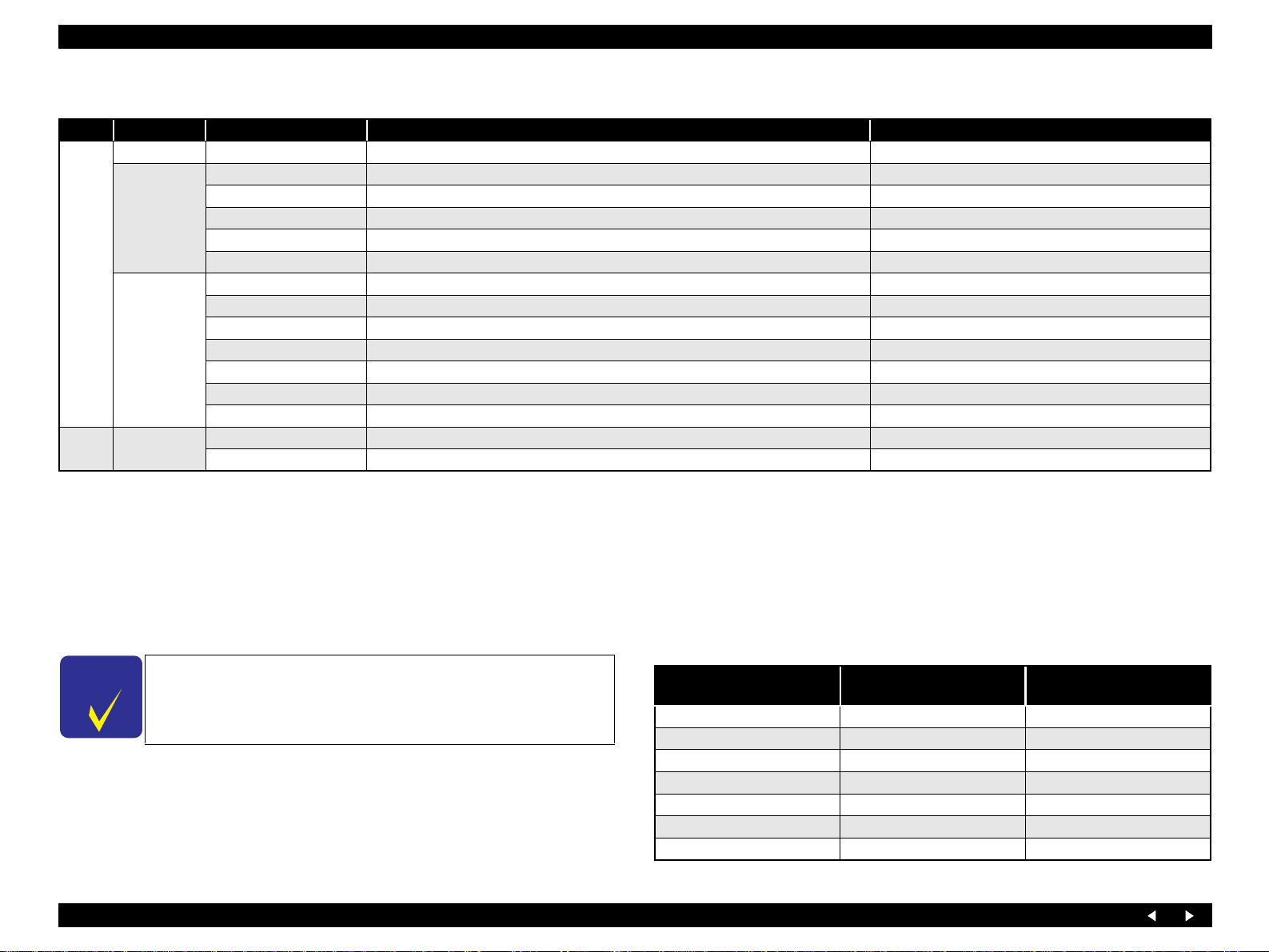

Figure 2-2. Motors and Sensors (Front Side of Mechanism)

CR Motor

PF Motor

PW Sensor

CR Encoder

CSIC board

CR Motor

PE Sensor

CIS Unit

Table 2-4. Motors and Sensors (Scanner Unit)

CR Encoder

No. Name Function

Type: DC motor

1 CR Motor

2 Encoder sensor

Voltage: 42V DC ± 5% (voltage applied to the driver)

Drive system: VrefPWM input constant-current chopping system

Type: Linear encoder

Resolution 180 pulse/inch

Figure 2-3. Motors and Sensors (Scanner Unit)

Operating Principles Overview 17

Page 17

EPSON Stylus PHOTO RX560/580/590 Revision A

2.2 Operating Principles of Electric Circuitry

2.2.1 Overview

The major circuit boards of Stylus PHOTO RX560/580/590 are as follows:

Main Board: C663MAIN

Power Supply Board: C653PSB

Panel Board: C663PNL + C663PNL-B

2.2.2 Features

Control by one V850E2 core CPU.

Throughput improved by newly employed SOC, E01A73B*

Reduced cost of power supply for the core of SOC and of motor drive by a newly

employed motor driver with a built-in power supply

Realized circuit compatible with multi-common system

Reduced cost by employment of newly developed E09A7218A as the HEAD

DAC IC

Improved processing speed of memory card interface by newly developed

memory card control ASIC (USX2007-NW-**)

Equipped with a color LCD (2.5-inch alpha TFT LCD) as a standard feature

Power consumption reduced by executing the following actions at transition to the

power save mode

System control: Stopping part of clock inside the ASIC

Motor drivers entering sleep mode

Head DAC IC entering standby mode

Turning off power to the LCD

Printer control: Releasing the printer motor short brake

Cutting off the photo-electric current of the photo sensor

Scanner control: Stopping scanner motor chopping

Cutting off CIS & CIS LED current

Others: SDRAM entering self-refresh mode (automatic entering by ASIC

setting)

2.2.3 Circuit Board Constitution

Table 2-5. Circuit Board Constitution

Circuit Board Description

Oscillation circuit (48MHz ± 100 ppm)

SSCG setting circuit

ASIC incorporating CPU core (E01A73B*)

• Package: 352-pin PBGA

• Power voltage: Internal 1.0 V ± 0.1V External 3.3V ± 0.3V

• CPU core: V850E2

• Operation frequency: Inside of CPU core: F288MHz (SSCG)

SD-RAM controller: F96MHz (SSCG)

PT/ scanner section: F48MHz (SSCG)

System

section

Main

Board

Power Supply

section

Printer

section

Card I/F

section

Scanner

section

Panel Board

Power Supply section

LCD Board

Hardware JPEG decompression, AFP: F96MHz (SSCG)

Printer drive timer base clock: F48MHz (No SSCG)

• Built-in command RAM: 40 kByte (iLB-RAM)

• Built-in data RAM: 16 kByte (dLB-RAM)

Memory (FLASH ROM (64 Mbits), local SDRAM (256 Mbits), CPU

SDRAM (128 Mbits)

RTC (RTC/ power supply monitoring / FLASH ROM) circuit

USB interface (HOST = High-Speed, DEVICE = High-Speed)

Panel interface

Color LCD interface

SERIAL FLASH ROM for banding reduction system

IrDA circuit

Power supply control circuit (PSC/ESAVE)

DC-DC converter circuit

Overvoltage protection circuit

Power-saving controller

Head drive circuit

CSIC interface

CR Motor control/driving circuit

PF Motor control/driving circuit

Sensor circuit

Memory card control ASIC (USX2007-NW-**)

Memory card connector (CF connector, 4 in 1 connector)

Power supply control circuit for CF

Scanner motor control/driving circuit

Scanner interface circuit

Sensor circuits

LED lighting circuit

Switch reading circuit

42 V generation circuit (flyback converter)

Module made by SEID (2.5-inch alpha TFT)

Printer section: F48MHz (No SSCG)

Operating Principles Operating Principles of Electric Circuitry 18

Page 18

EPSON Stylus PHOTO RX560/580/590 Revision A

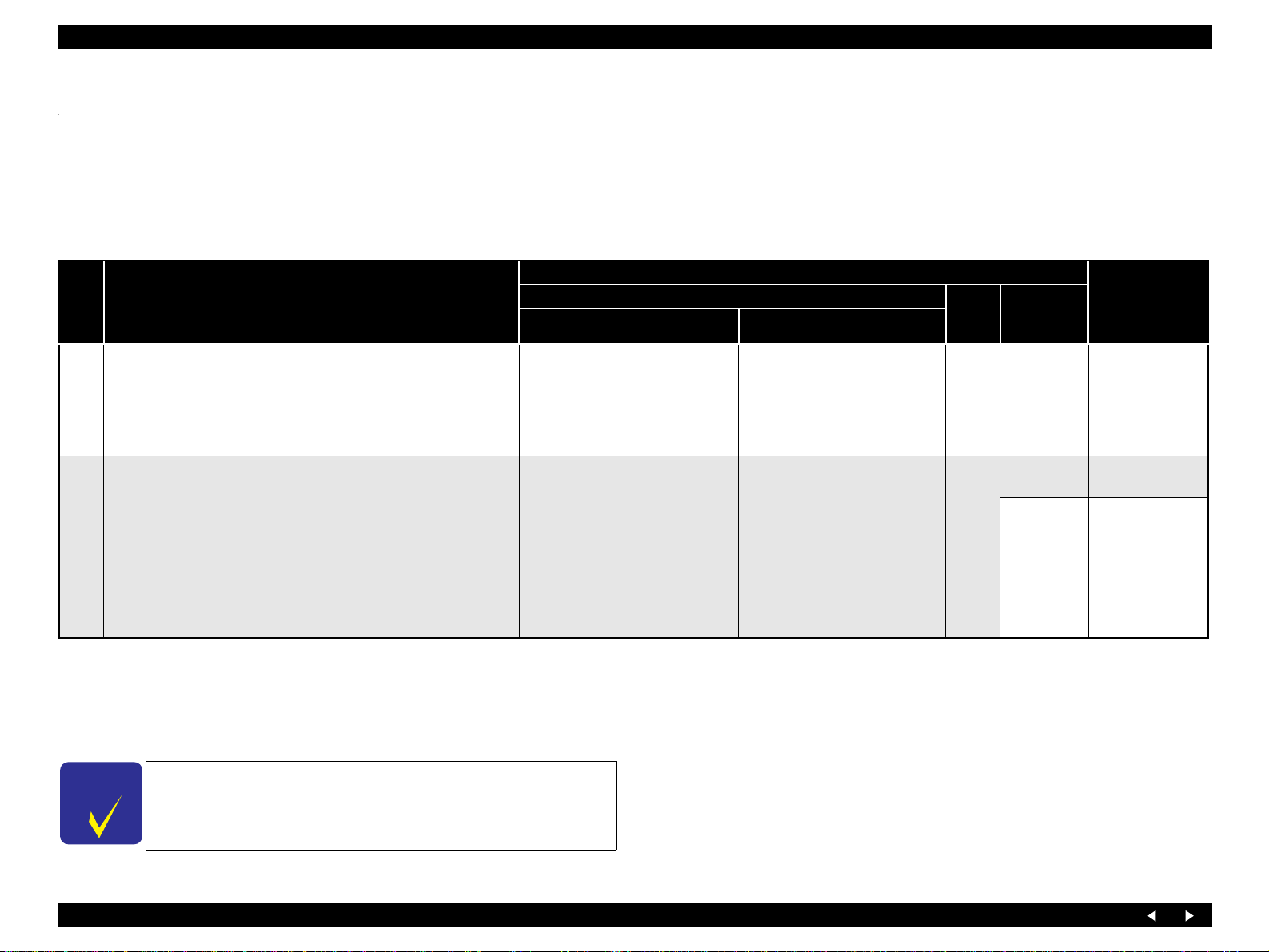

2.3 Banding Reduction System (BRS)/ Paper Feed Profile Correction (PFP)

Overview

To ensure high-speed printing and high print quality, this printer is provided with the Banding Reduction System (BRS) and Paper Feed Profile Correction (PFP) function, which are

outlined below:

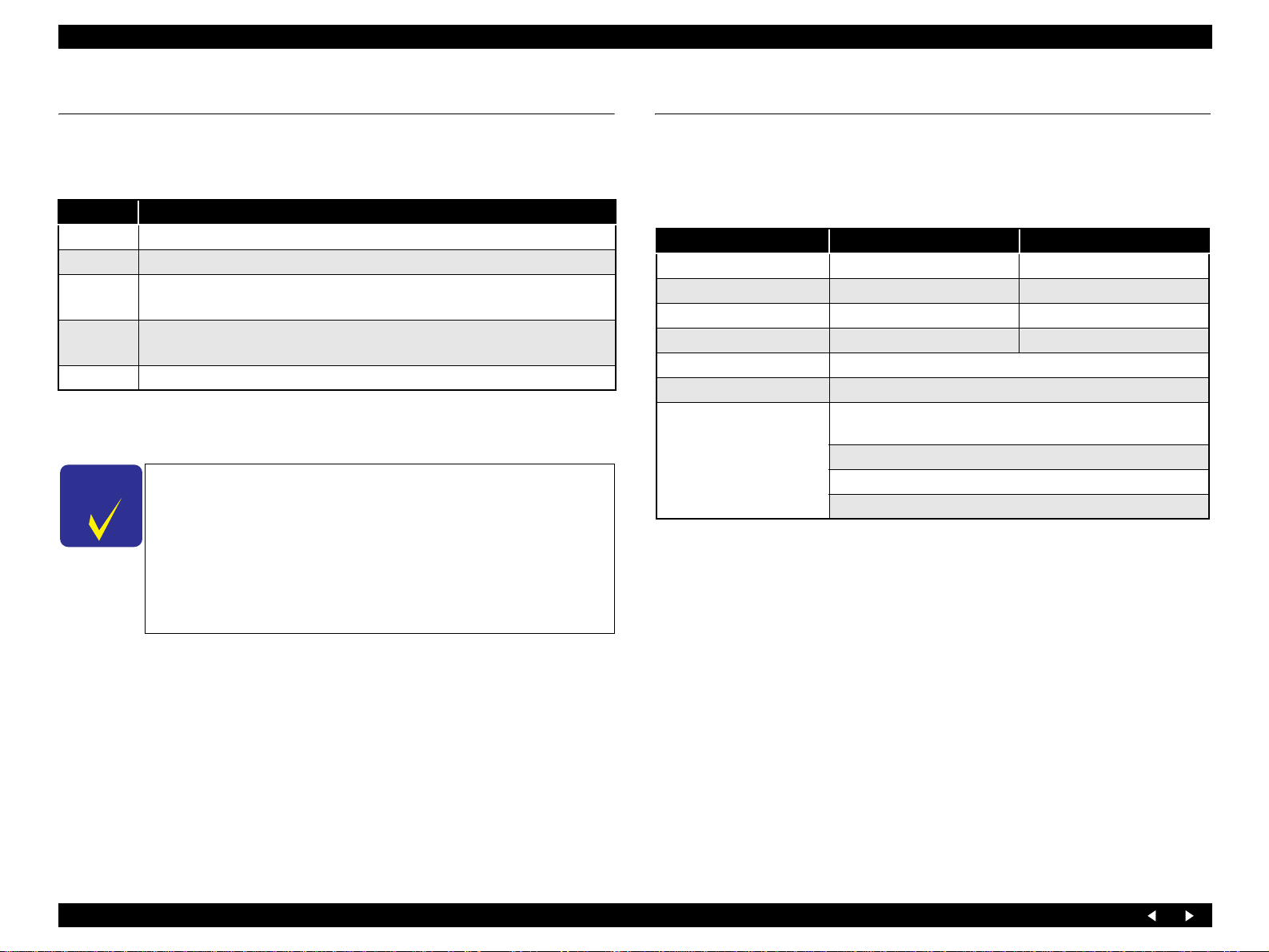

Table 2-6. Outline of Banding Reduction System and Paper Feed Profile Correction Function

Supported Printing Mode

Outline

Conventional models perform overlapping printing (two-pass or fourpass printing) to reduce banding for ensuring high print quality.

However, the printer provided with the Banding Reduction System

BRS

corrects the dot generation rate (amount of settled ink) for each raster,

and performs one-pass printing. This function ensures both high print

quality (reduction of banding) and high-speed printing.

The conventional paper feed adjustment method is such that the

correction value calculated fr o m the data based on a specific part of the

sheet is reflected to almost all over the sheet. Therefore, the

conventional method cannot cope with the fluctuating error in the paper

feed rate during paper feeding. However, the Paper Feed Profile

PFP

Correction function measures the error in the paper feed rate at each of

minutely distributed measuring points on the sheet and provides a

correction value for each point. Thus with this function, the printer

realizes high print quality and high-speed printing on a supported paper

type and in a supported printing resolution.

Paper Type

EAI Other than EAI

Ultra Premium Photo Paper Glossy

Premium Photo Paper Glossy

Photo Paper Glossy

Premium Photo Paper Semi-Gloss

Ultra Premium Photo Paper Glossy

Premium Photo Paper Glossy

Photo Paper Glossy

Premium Photo Paper Semi-Gloss

Ultra Glossy Photo Paper

Premium Glossy Photo Paper

Glossy Photo Paper

Premium Semigloss Photo Paper

Ultra Glossy Photo Paper

Premium Glossy Photo Paper

Glossy Photo Paper

Premium Semigloss Photo Paper

Paper

Size

4x6 720x720 –

4x6

Printing

Resolution

(dpi)

720x720

720x360

Remarks

Borderless printing

with BRS

Borderless printing

without BRS

How to prepare correction data

For each of BRS and PFP, print the relevant pattern for correction data preparation and read the printed pattern through the scanner. Then calculate the correction data and store the data

in the serial flash ROM on the Main Board. The correction data are applied to printing in the supported printing mode.

C H E C K

P O I N T

Refer to Chapter 5 “ADJUSTMENT” for details of correction

data preparation for BRS and PFP.

Operating Principles Banding Reduction System (BRS)/ Paper Feed Profile Correction (PFP) 19

Page 19

TROUBLESHOOTING

CHAPTER

3

Page 20

EPSON Stylus PHOTO RX560/580/590 Revision A

3.1 Overview

With Stylus PHOTO RX560/580/590, almost all troubles can be coped with by

following the instructions given on “EPSON Status Monitor 3” (when connected to the

PC) or on the LCD.

Once an error occurs, the “EPSON Status Monitor 3” will appear as a pop-up window

on the screen of the host PC. It will show details of how to cope with the trouble. In

almost all cases, the user can recover the unit from the error, provided that the user

follows the instructions indicated on the pop-up window.

In addition, the User’s Manual for EPSON Stylus PHOTO RX560/580/590 describes

detailed steps to be taken for recovery from typical errors.

3.1.1 Specified Tools

Stylus PHOTO RX560/580/590 does not require any specified tools for

troubleshooting.

3.1.2 Preliminary Checks

Before starting troubleshooting, be sure to verify that the following conditions are all

met:

The power supply voltage must be within the specification limits. (Measure

the voltage at the wall outlet.)

The POWER CORD must be free from damage, short circuit or breakage, or

miswiring in the POWER CORD.

The Unit must be grounded properly.

The Unit should not be located in a place where it can be exposed to too high

or low temperature, too high or low humidity, or abrupt temperature change.

The Unit should not be located near waterworks, near humidifiers, near

heaters or near flames, in a dusty atmosphere or in a place where the Unit can

be exposed to blast from an air conditioner.

The Unit should not be located in a place where volatile or inflammable gases

are produced.

The Unit should not be located in a place where it can be exposed to direct

rays of the sun.

The Unit must be placed on a strong and steady level table (without an

inclination larger than 5 degrees).

There must be no vibration generating source placed in contact with this Unit.

The paper used must conform to the specification.

There must be no error in handling of the Unit.

Check the inside of the Unit, and remove foreign matters, if any, such as paper

clips, staples, bits of paper, paper dust or toner.

Clean the inside of the Unit and the rubber rolls.

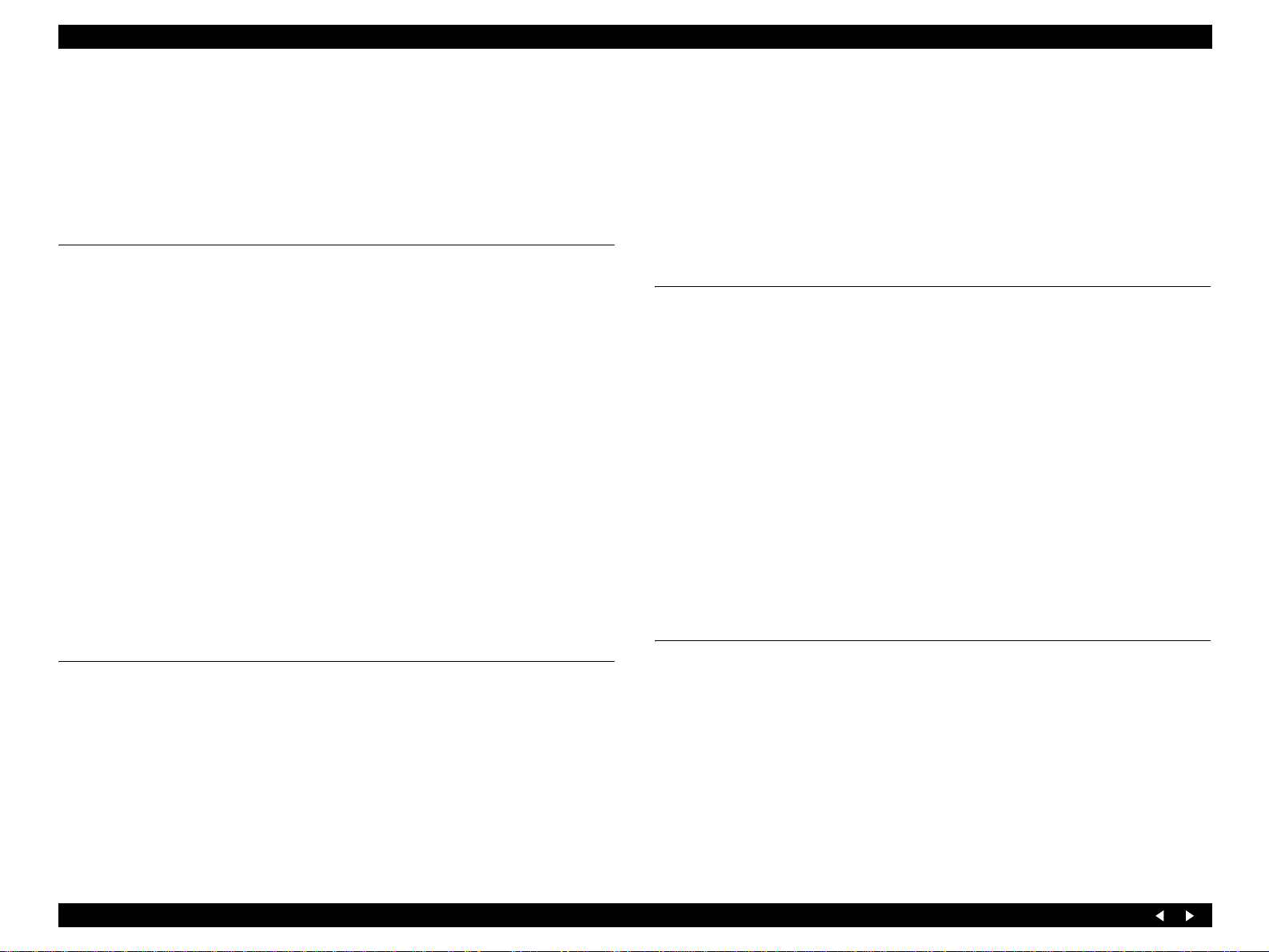

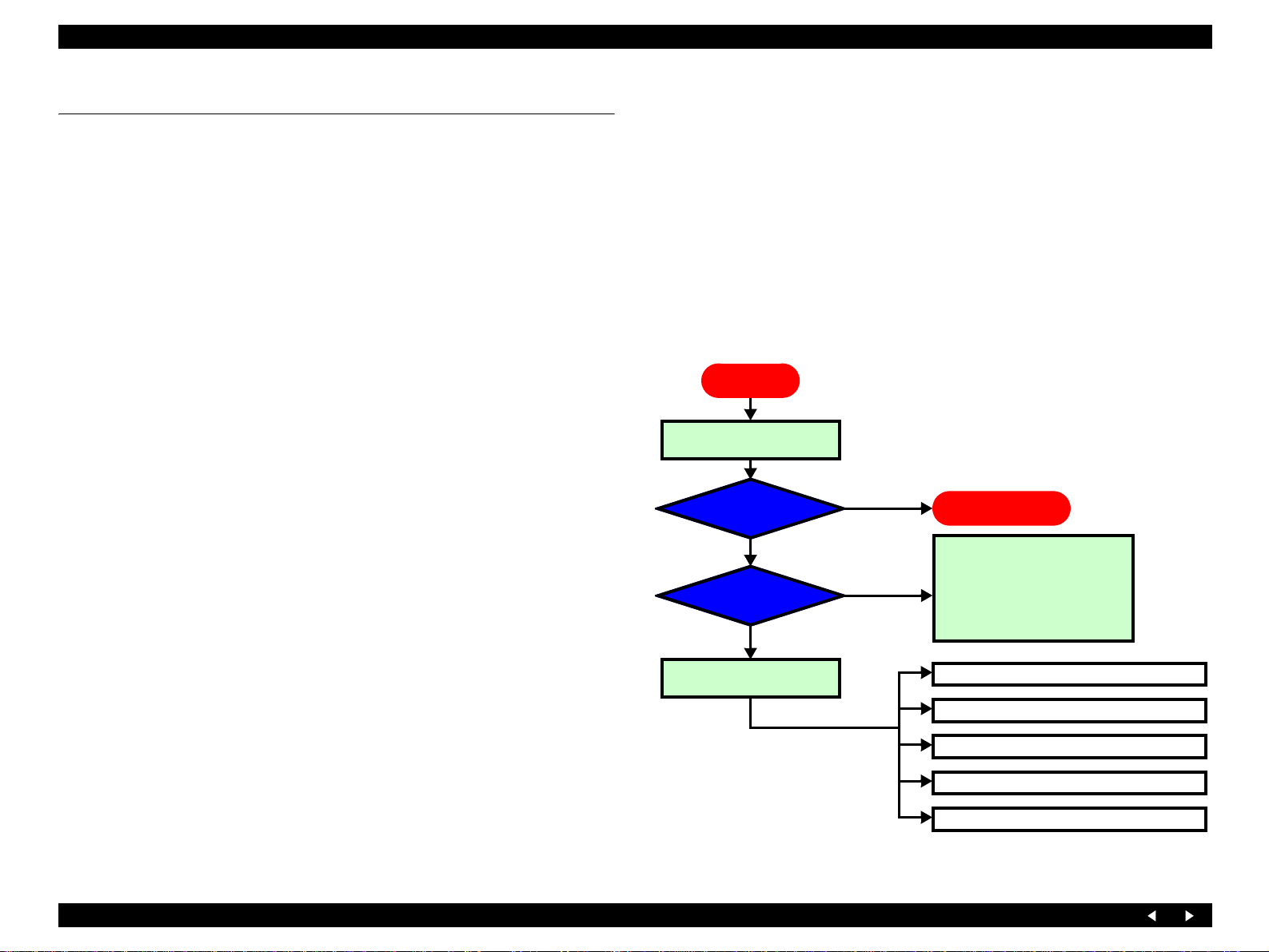

3.1.3 Procedure for Troubleshooting

Perform troubleshooting according to the flowchart shown below.

START

Perform“ 3.1.2 Preliminary

Checks (p.21) ”.

Does the error recur?

Yes

Is there any error

display?

No

To Troubleshooting for

Individual Units

No

Yes

Problem solved

By referring to “3.2

Troubleshooting When There is

Error Display (p.22)”, identify

the error and repair it.

(Also refer to “Solving Problems”

in User's Guide)

Troubleshooting for Printer (p.30)

Power Supply Related Troubleshooting (p.34)

Ink Supply Related Troubleshooting (p.34)

I/F Related Troubleshooting (p.36)

Troubleshooting for Scanner (p.37)

Flowchart 3-1. Procedure for Troubleshooting

Troubleshooting Overview 21

Page 21

EPSON Stylus PHOTO RX560/580/590 Revision A

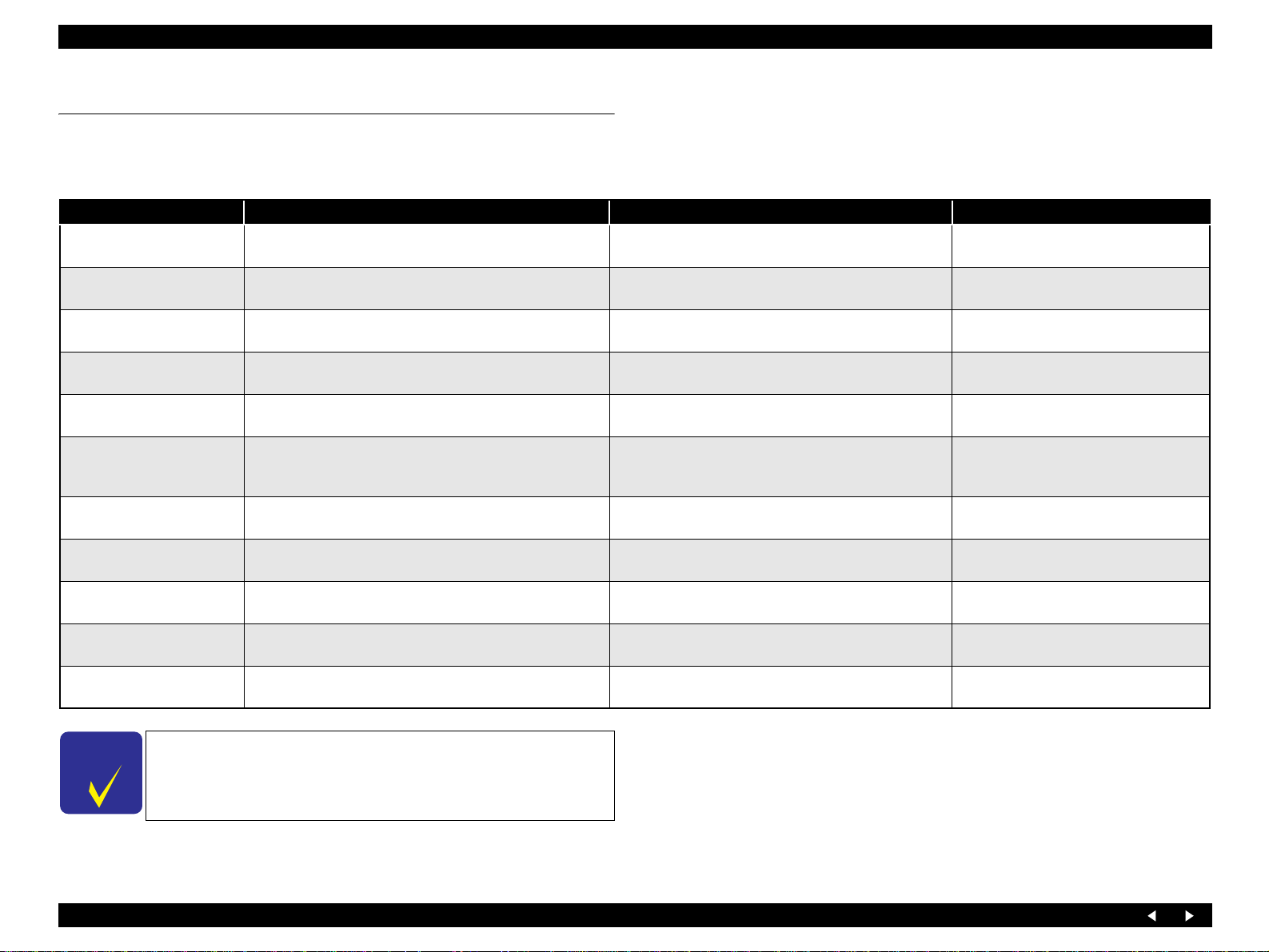

3.2 Troubleshooting When There is Error Display

3.2.1 Error List

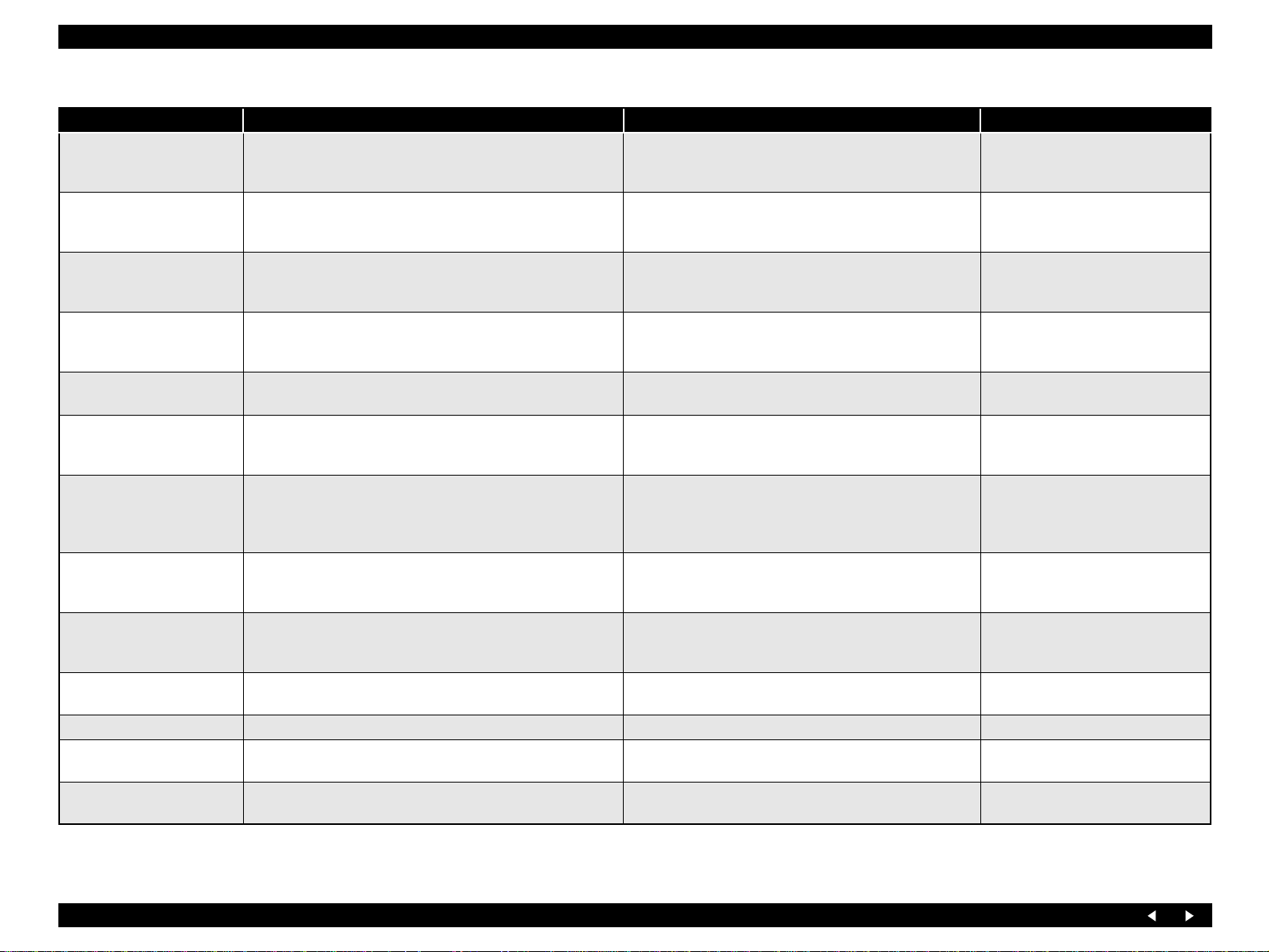

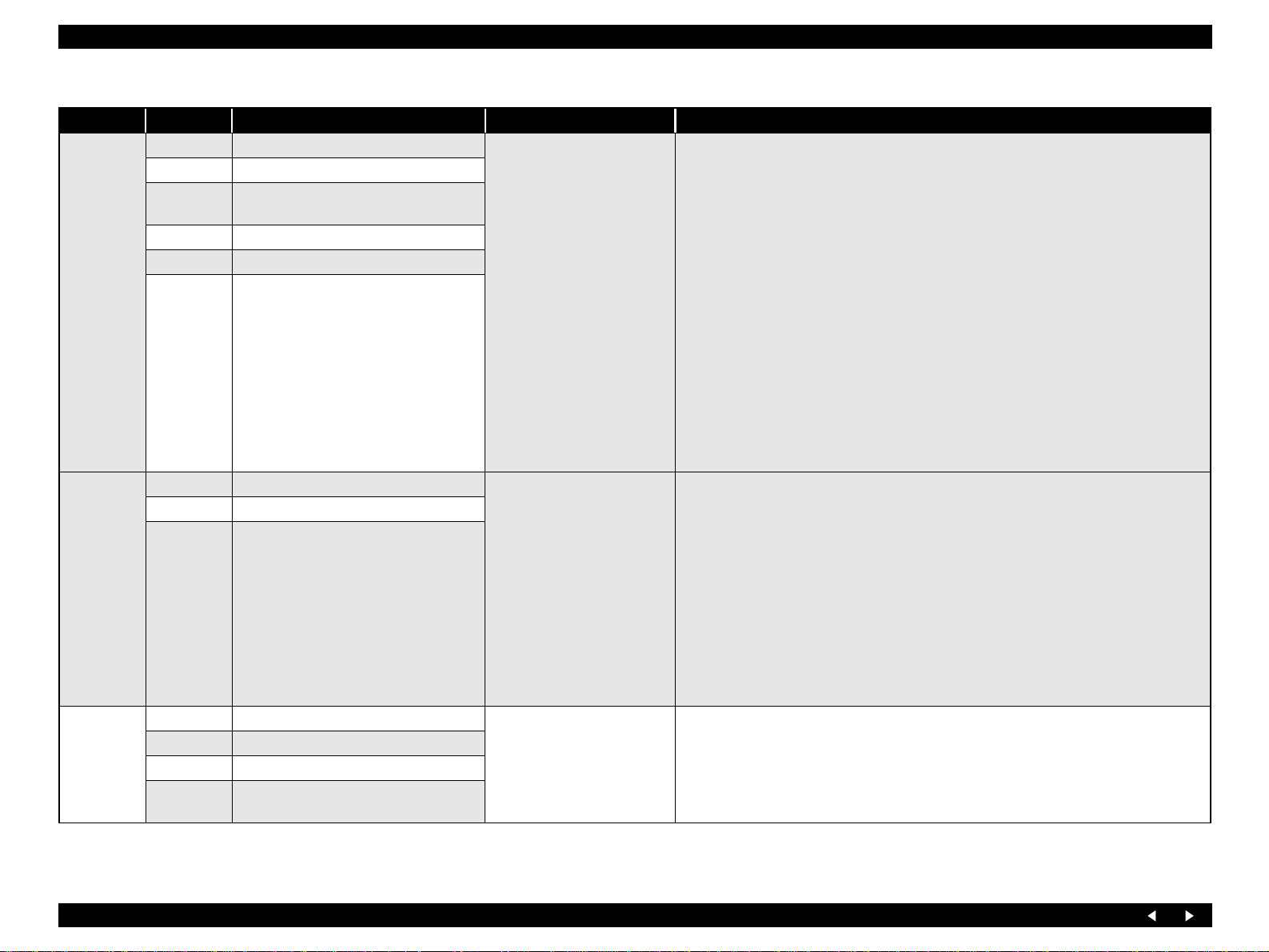

Table 3-1. Error List

Error Name Displayed Message Occurrence Condition Recovery Procedure

Maintenance Error

Printer FATAL Error A printer error has occurred. Please see your manual. An irrecoverable error has occurred.

Scanner Error A scanner error has occurred. Please see your manual.

Message related to Ink (1)

Message related to Ink (2)

Paper Detect Error

Paper Jam Error

Message related to Ink (3) Cannot recognize ink cartridges.

Message related to Ink (4) Press the OK button to replace ink cartridges. Ink end

Paper Empty Error Paper out. Load paper and press the Start button. There is no paper in the sheet feeder.

Multi-page Feed Error

Waste ink pad in the printer is saturated. Contact your dealer

to replace it.

Cannot recognize ink cartridges. Make sure the ink cartridges

are installed correctly.

Ink cartridge cover is open. Open the scanner unit and close

the ink cartridge cover.

Paper jam. Load paper and press Start. If the error does not

clear, repeat the procedure.

Paper or CD/DVD jam or feed error. Press Start. If the error

does not clear, remove the media by hand.

Multi-page feed error. Remove and reload the paper, then

press the Start button.

The printer requires maintenance due to waste liquid

overflow or elastomer tube replacement time, etc.

The error that was not able to be recovered with the

scanner occurred.

The ink cartridges have not been inserted or defective ink

cartridges have been inserted.

Ink cartridges were replaced with new ones with the ink

cartridge fixation cover open.

A sheet was loaded in a wrong orientation and caused a

jam.

The paper jam has occurred. Turn power off, and remove the paper.

The ink cartridge had not been inserted at an initial filling

or the ink cartridge error occurred

Multi-page feed error has occurred.

Replace the waste ink pads.

See “6.1.1 Maintenance Error” (p.88)

Turn off the power

See “3.2.3 FATAL Error” (p.27)

Turn off the power

See “6.1.1 Maintenance Error” (p.88)

Install the normal ink cartridges correctly

and press the OK button.

Close the ink cartridge fixation cover and

press the OK button

Follow the displayed message until the

sheet loaded in a wrong orientation is

ejected.

Install the normal ink cartridges filled with

ink correctly and press the OK button.

Install the normal ink cartridges filled with

ink correctly and press the OK button.

Press the start button to feed paper

correctly.

Re-set paper and press the start button to

feed paper correctly.

C H E C K

P O I N T

The messages displayed on the LCD that are listed in the “Error

List” above and “Warning List (p.23)“ on the next page and

subsequent pages are given only for information. In other words,

they are not exactly the same as the messages actually displayed.

Troubleshooting Troubleshooting When There is Error Display 22

Page 22

EPSON Stylus PHOTO RX560/580/590 Revision A

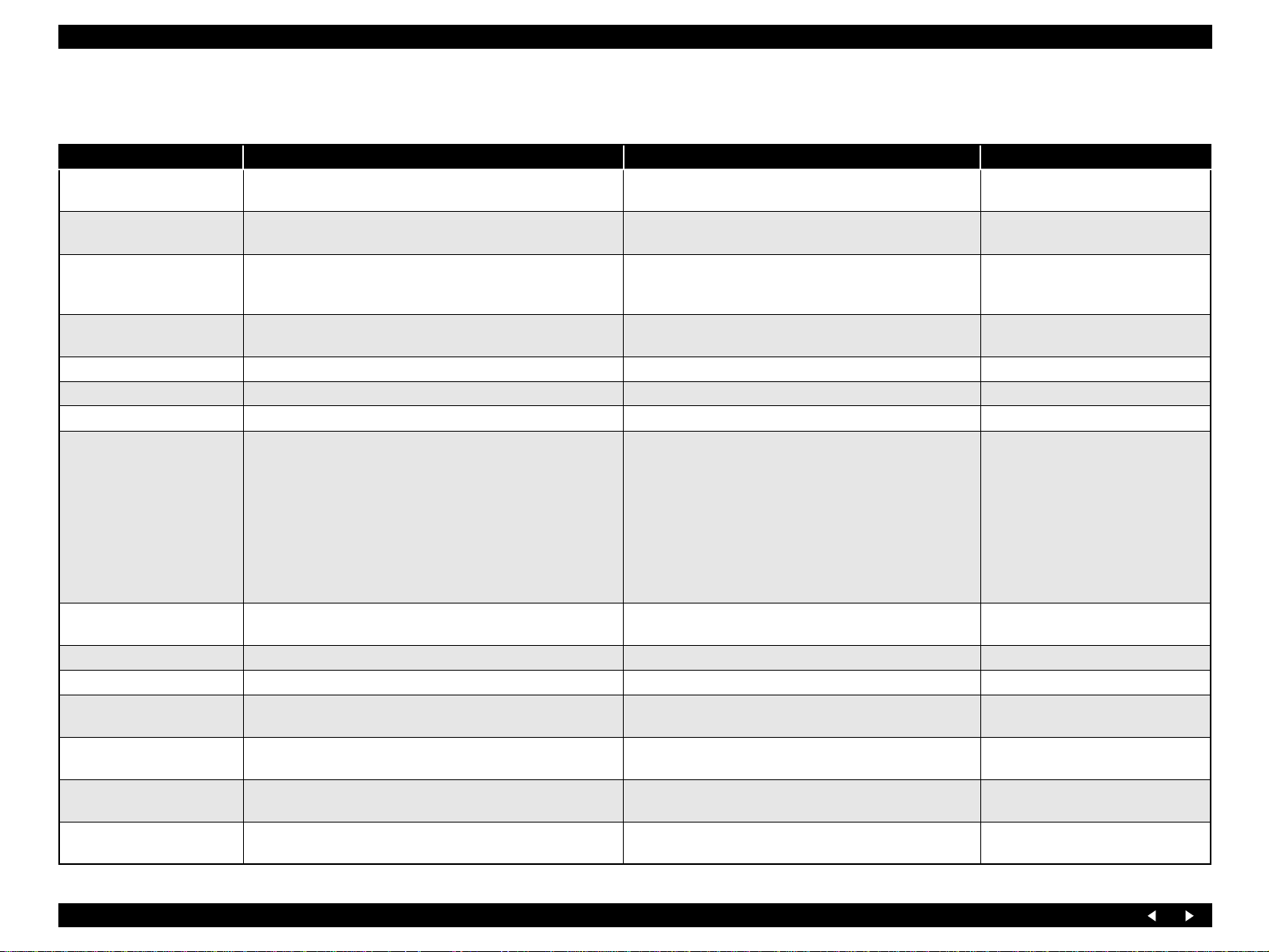

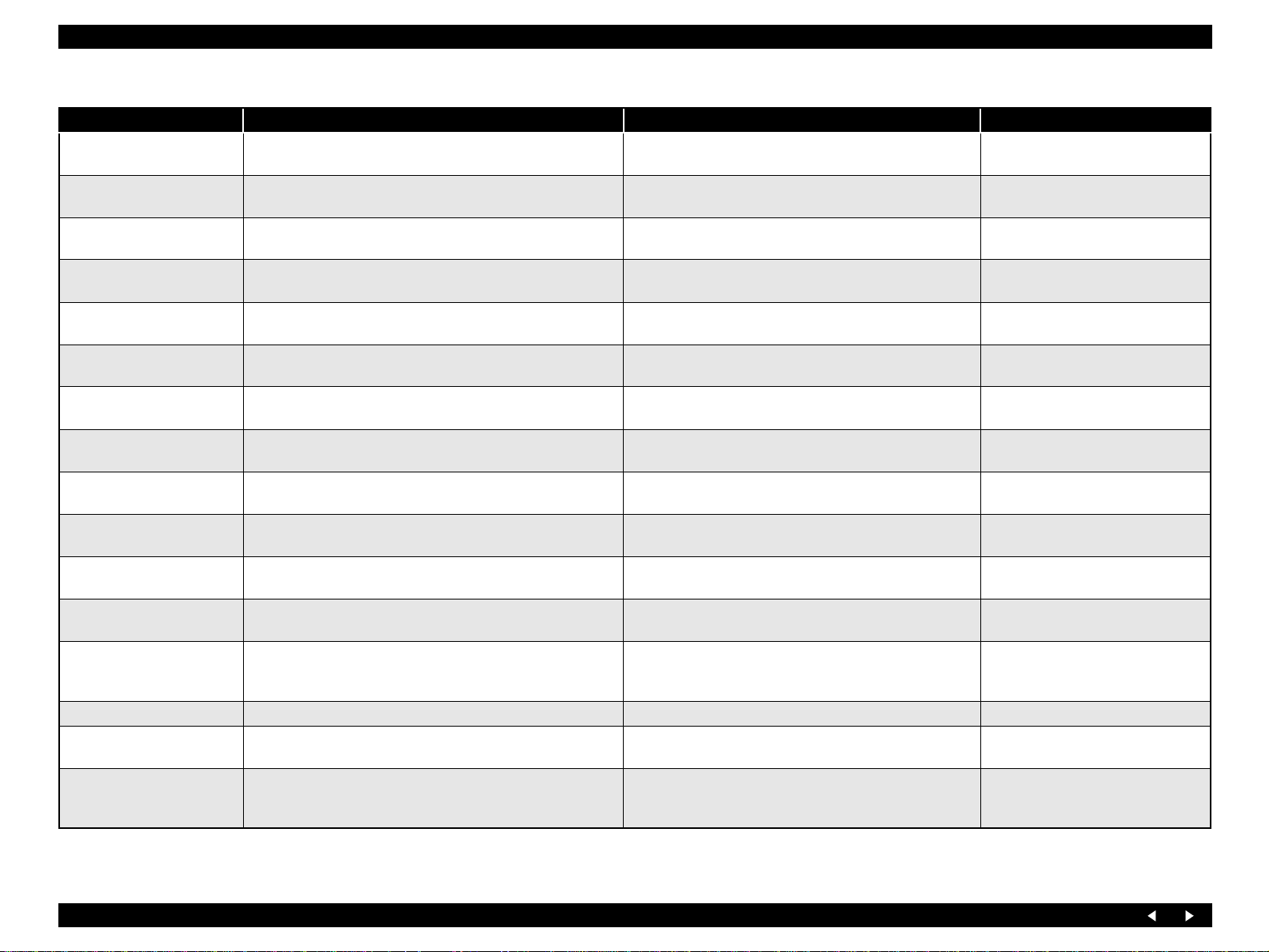

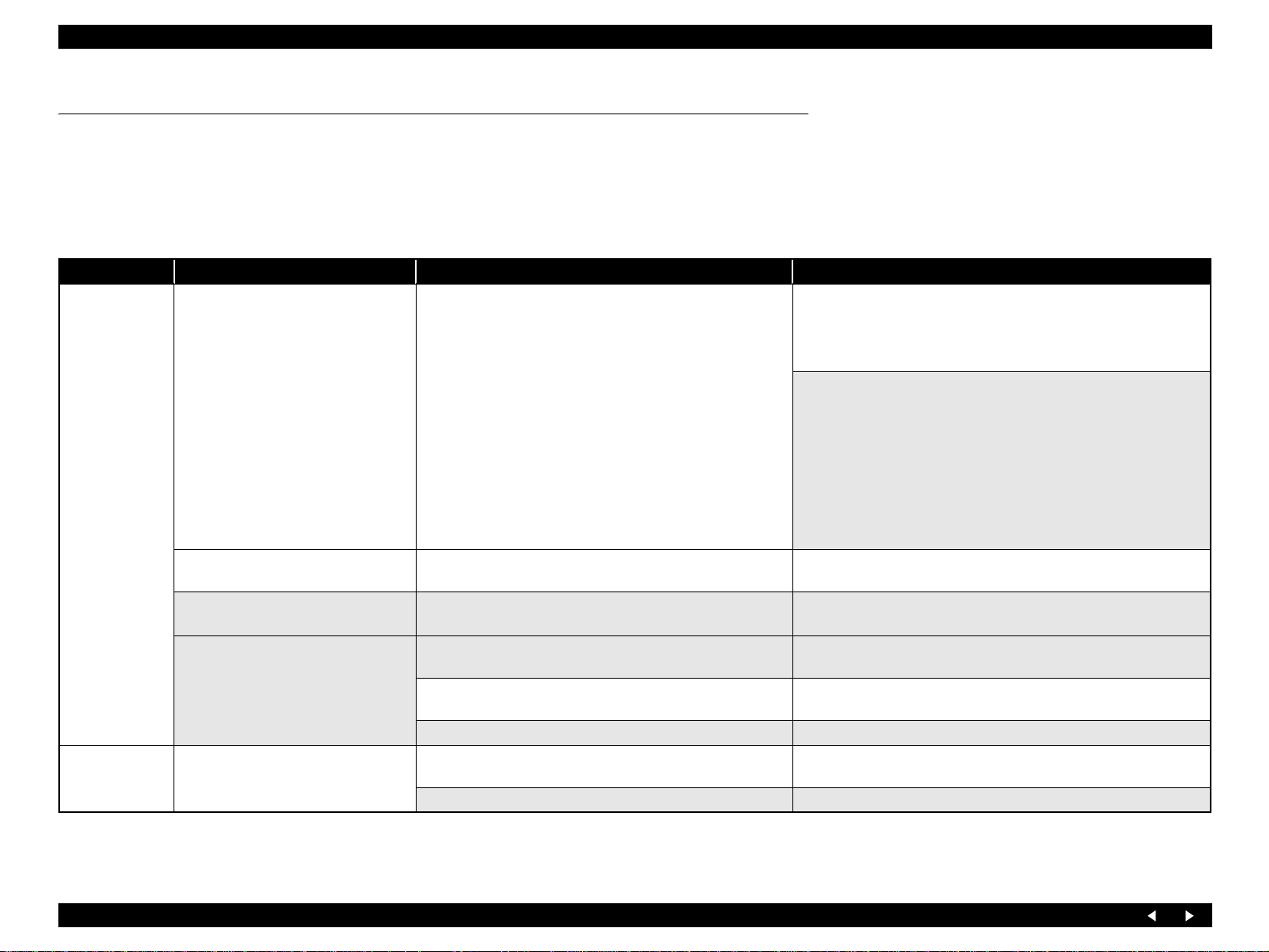

3.2.2 Warning List

Table 3-2. Warning List

Warning Name Displayed Message Occurrence Condition Recovery Procedure

Waste fluid is near end

Set the CD-R/DVD tray

(Set correctly)

CD/DVD guide warning

(Open error)

CD/DVD guide warning

(Close error)

BT File size error The document is too large to print with Bluetooth. Data size is too big. Change or check the transmitted data.

BT Designation error The document is too complex to print with Bluetooth. Data quantity exceeded the range where it can be processed. Change or check the transmitted data.

BT structure error Data error. The document cannot be printed. There is an error in the contents of data. Change or check the transmitted data.

A part of the reference object

is broken (BT-MIME)

BT communications error

External device installment Cannot recognize the device. An unsupported device has been installed. Remove the device.

Card insertion Cannot recognize the memory card or disk. Memory card recognition failed. Remove the memory card

Memory card print A memory card was inserted. No photos found. No image is contained in the memory card.

Memory card is not inserted No memory card or disk inserted.

Screen translation and print

executions connecting DSC

Index sheet scan error

(no index sheet)

Waste ink pad in the printer is saturated. Contact your dealer to

replace it.

The CD/DVD tray is set incorrectly. Set the CD/DVD tray

correctly, then press the Start button.

The front tray is in the CD/DVD position. Raise the tray lever to

set the front tray to the paper position.

The front tray is in the wrong position. Push down the tray lever

to set the front tray to the CD/DVD position.

Data error. The document may not be printed correctly.

Bluetooth print adapter not recognized. Please remove and

reinstall the adapter.

A camera is connected. Disconnect the camera and try again.

There is no index sheet or it is not positioned correctly. Check it

and try again.

The waste ink pads have already absorbed waste ink nearly

to its full capacity.

At start of printing, the printer has not recognized the CD-R/

DVD tray correctly.

When printing data is not for printing on CD/DVD, the tray

is in the CD/DVD printing position. Or the tray is in the CD/

DVD printing position when the printer is started.

When printing data is for printing on a CD/DVD, the CD-R/

DVD tray is not recognized correctly. .

While XHTML-Print data could be decoded, a part or all of

the reference object had a MIME encode error and could not

be obtained. The following two problems are considered

depending on the type of the un-obtained reference object.

• For an image, an area where that image is to be printed

becomes blank.

• For a CSS (style sheet) file, the background color, basic

character size or the like cannot be the same as specified

by the send side.

An error has occurred in communication with the BT

adapter.

Memory card Mode has been selected with no memory card

inserted.

Entering a menu screen for use of memory cards or starting

to print was attempted with a DSC connected.

An index sheet was not set.

Replace the waste ink pads.

See “6.1.1 Maintenance Error” (p.88)

Set the CD-R/DVD tray correctly, and

press the Start button.

Raise the lever to change the printing

position to the lower position.

Lower the lever to change the print

position to the upper position.

Change or check the transmitted data.

Remove the BT adapter. Press the OK

button to clear the message.

Remove the memory card, and check

the image file.

Insert the memory card.

Disconnect the camera

Set the index sheet and press the OK

button.

Troubleshooting Troubleshooting When There is Error Display 23

Page 23

EPSON Stylus PHOTO RX560/580/590 Revision A

Table 3-2. Warning List (continued)

Warning Name Displayed Message Occurrence Condition Recovery Procedure

Index sheet scan error

(incorrect image selection

marking)

Index sheet scan error

(incorrect paper selection

marking)

Index sheet scan error

(Discrepancy between index

sheet and card)

Combo print error 1 (Euro)

Photo Greeting card error 1

(EAI)

Combo print error 2 (Euro)

Combo print error 3 (Euro)

Photo Greeting card error 3

(EAI)

Combo print error 4 (Euro)

Photo Greeting card error 4

(EAI)

Combo print error 5 (Euro)

Photo Greeting card error 5

(EAI)

Combo print error 6 (Euro)

Photo Greeting card error 6

(EAI)

Select photos in CD label

print.

Select the number of copy. Only 1 copy can be selected. More than one copy has been selected. Select only one copy.

Photo recognize Error

Scan to memory error

(no card)

Photos are not selected or the ovals are marked incorrectly.

Please correct and try again.

The paper type is not selected or ovals are marked incorrectly.

Please correct and try again.

The contents of the memory card have changed. Print a new

index sheet and try again.

Error reading the template. Make sure the template is placed

correctly on the glass and try again.

Selection of the text style is not correct. Select only one text

style and try again.

Error reading the template. Make sure the glass is clean and no

pen marks are outside the writing area.

The layout is not selected or ovals are not marked correctly.

Only one layout may be selected.

The contents of the memory card have changed. Print a new

template and try again.

The paper type is not selected or ovals are marked incorrectly.

Please correct and try again.

The selectable number of photos was exceeded.

No photos could be recognized. Make sure the photos are

positioned correctly. For details, see your manual.

No memory card or disk inserted. Save canceled.

The image selection marking on the index sheet is not

correct.

The paper selection marking on the index sheet is not

correct.

After index sheet printing, a different memory card was

inserted or images were added or deleted.

No recognition mark could be found on the template sheet. Set sheet and press the OK button

No mark is given for Paper Type or Text Style selection

area, or more than one mark is given.

Combo Area cannot be recognized.

No mark is given for compose layout, or more than one

mark is given.

After template printing, a different memory card was

inserted or images were added or deleted.

The paper selection marking on the template is not correct.

More than the specified number of photos have been

selected.

The photo could not be recognized. Set the photo and try again

Execution of scanning to a memory card function was

attempted with no memory card inserted.

Correct image selection. And press

the OK button.

Correct paper selection. And press the

OK button.

Restore the same memory card

condition as was when the index sheet

was printed or print a new index sheet.

Select a text style on the template and

press the OK button.

Print the sheet again and make entry

again.

Put a mark for compose layout or in

the case where there are two or more

marks, print the sheet again and put a

mark only for one layout.

Restore the same memory card

condition as was when the template

was printed or print a new template.

Select a paper on the template and

press the OK button.

Select not more than the specified

number of photos.

Insert a memory card.

Troubleshooting Troubleshooting When There is Error Display 24

Page 24

EPSON Stylus PHOTO RX560/580/590 Revision A

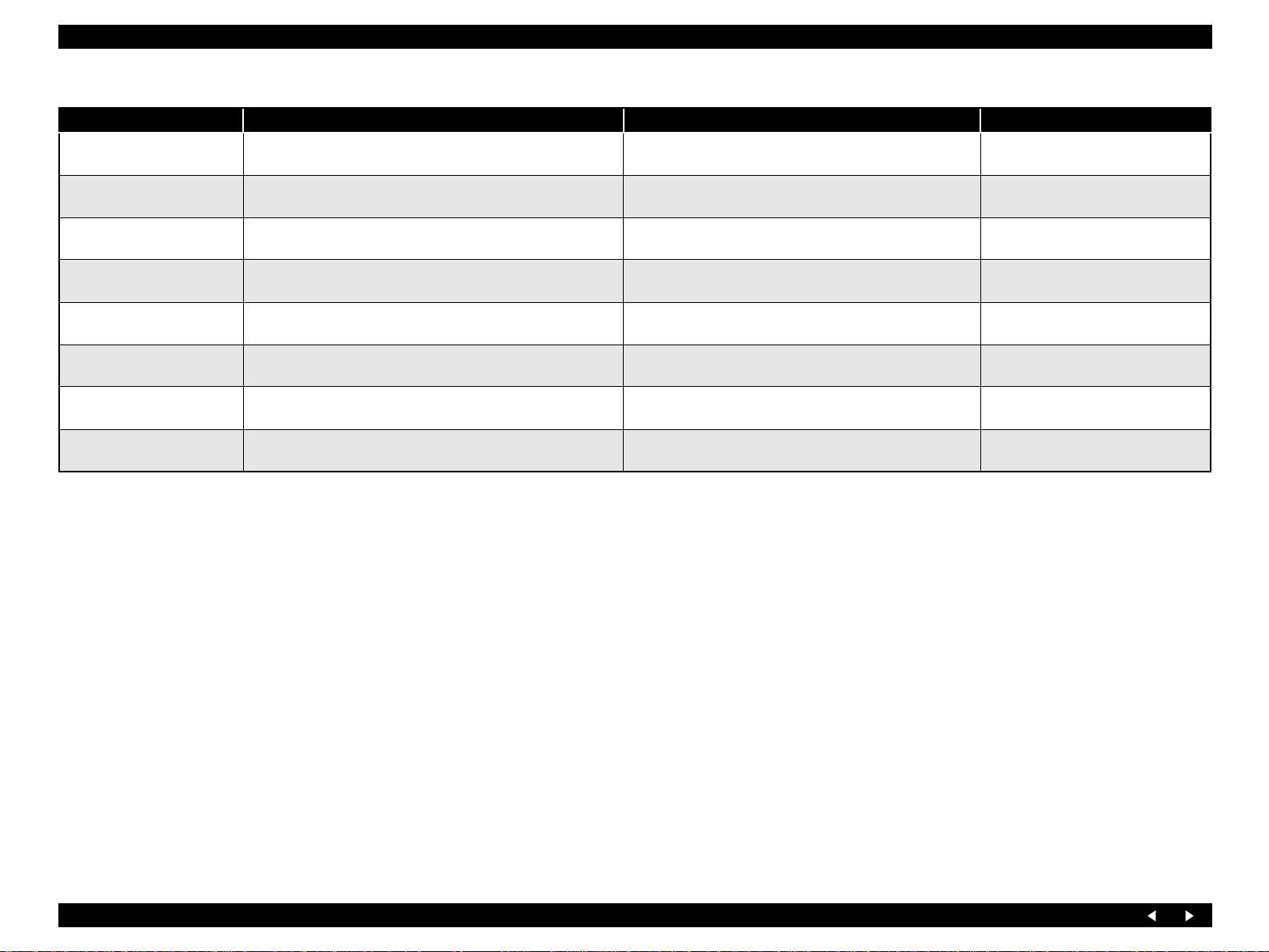

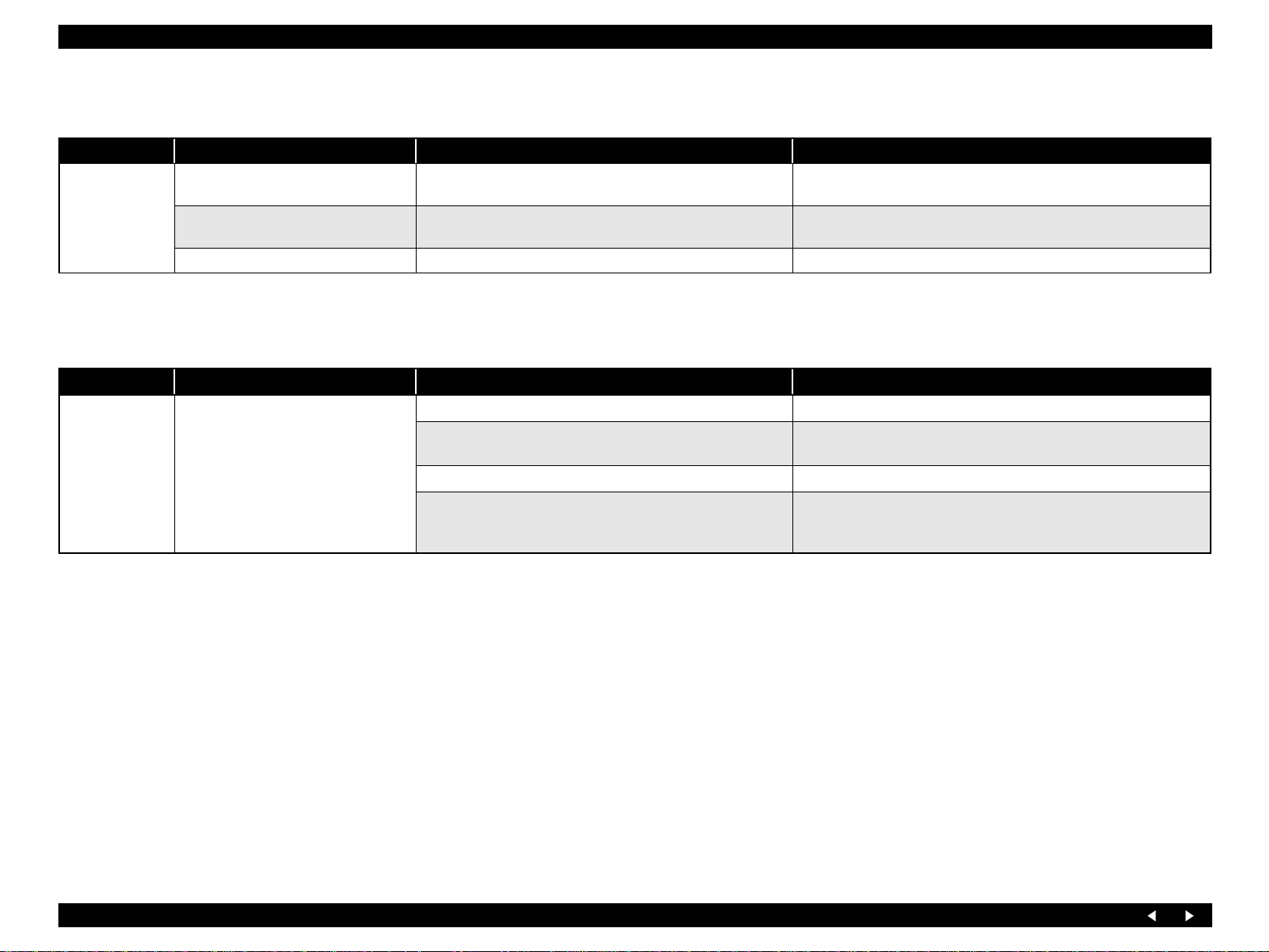

Table 3-2. Warning List (continued)

Warning Name Displayed Message Occurrence Condition Recovery Procedure

Scan to memory error

(insufficient card capacity)

Scan to memory error

(card write-protect)

Scan to memory error

(folder not created)

Scan to memory error

(card removed)

Scan to memory error

(save error)

Format check (scan)

Format Warning

(Format error) (scan)

Format Warning

(card write-protect) (scan)

Format Warning

(card removed) (scan)

No Image File Insert a memory card that contains photos.

Head Cleaning Replace ink cartridge before cleaning print head. Head cleaning was attempted in the Ink Low state.

Backup error

(no external connection)

Backup error

(insufficient external media

capacity)

Backup error (no card) No memory card in slot. Backup canceled. No backup source exists. Insert the memory card

Backup error

(connecting to PC)

Backup error

(File name and Folder levels

Error)

The capacity of the memory card or disk is insufficient.

Operation canceled.

The memory card or disk is write-protected. Operation canceled.

Cannot create a folder on the memory card or disk. Operation

canceled.

The memory card or disk was removed. Operation canceled.

An error occurred while saving. Save canceled. Data saving was not achieved for some reason. Check the source data or media.

Cannot recognize the memory card or disk. Do you want to

format it?

An error occurred during formatting. Formatting will be

discontinued.

The memory card or disk is write-protected. Operation canceled. As the memory card was write-protected, formatting failed.

The memory card or disk was removed. Format canceled. The media is removed when formatting is to be started. Insert media and try again

External device is not connected or media is not inserted.

Backup canceled.

Insufficient space on the backup device. Cannot back up files.

Disconnect from PC before backing up files. Backup was attempted with the PC left connected. Disconnect the PC

Backup canceled. File name is too long or there are too many

folder levels

The memory card capacity is insufficient.

As the memory card is write-protected, it is not possible to

save data.

A folder could not be created on the memory card. Check the data on the memory card.

Data saving was not executed, since the memory card had

been removed.

The memory card cannot be recognized. Execute or cancel formatting.

An error has occurred in formatting the card. Or you pulled

out the media while formatting it.

No image is contained in the memory card or no memory

card has been inserted.

The external device was not connected when backup was

started.

The capacity of the media on which the backup data is to be

saved is insufficient.

The file name is too long, or the file is positioned in too deep

a level in the holder hierarchy.

Insert a memory card that has a

sufficient capacity.

Insert a memory card with WriteProtect canceled.

Insert a memory card.

Press the OK button and check the

media.

Insert a memory card with WriteProtect canceled and try again.

Insert a memory card containing

image files.

Cancel the head cleaning, or replace

the ink cartridges.

Connect the external device.

Insert media that has sufficient free

space.

Check the file name and folder level.

Troubleshooting Troubleshooting When There is Error Display 25

Page 25

EPSON Stylus PHOTO RX560/580/590 Revision A

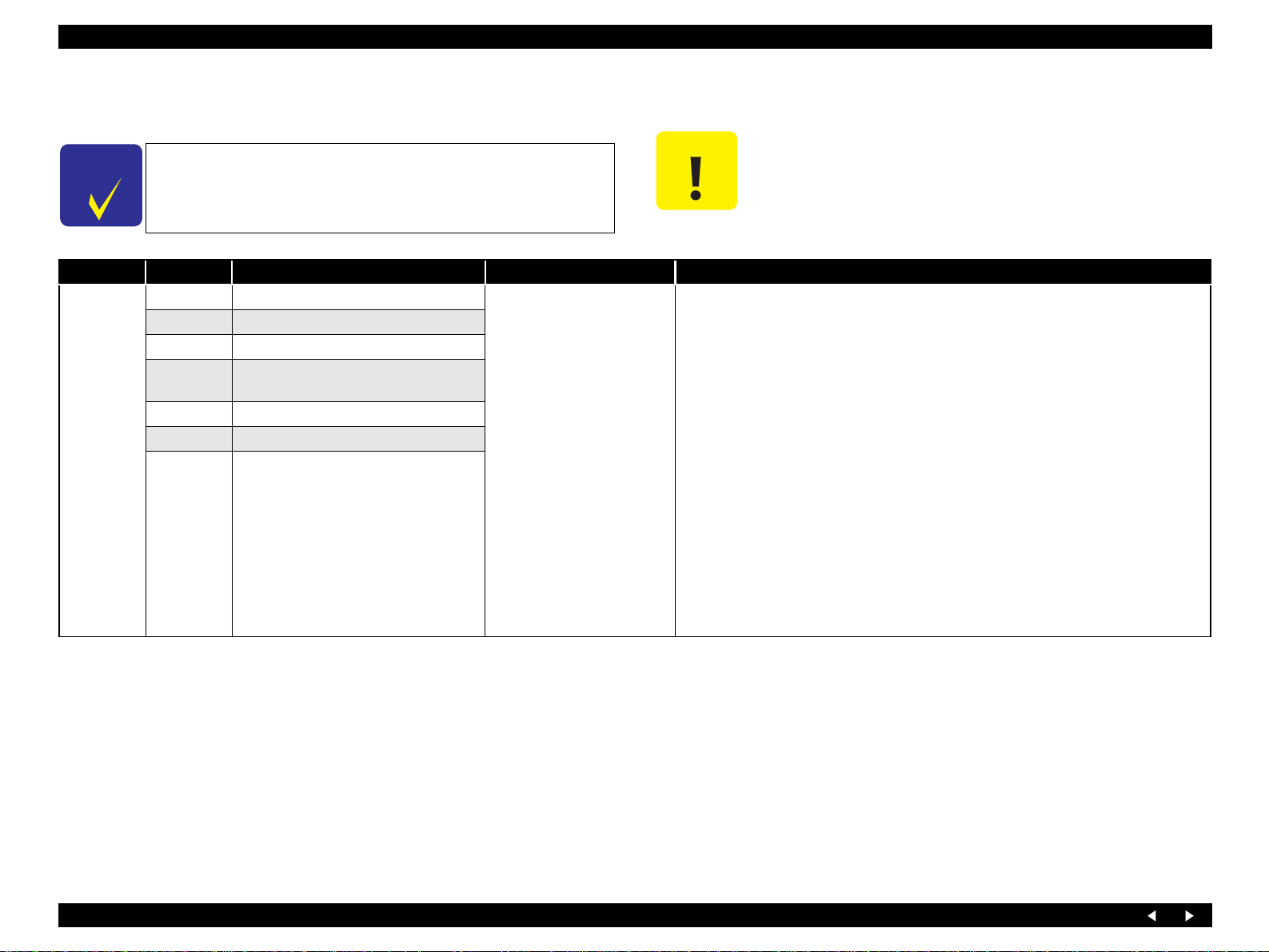

Table 3-2. Warning List (continued)

Warning Name Displayed Message Occurrence Condition Recovery Procedure

File clearness

(error has occurred)

File clearness

(memory card has removed)

File clearness

(write-protected)

File clearness

(no memory card)

In adjustment of borderless

expansion value

Zoom

Position of CD/DVD guide

(Re-set)

CD/DVD guide close error

An error occurred while deleting files. Operation canceled. An error occurred during file deletion. –

The memory card or disk was removed. Operation canceled. The memory card was removed during file deletion. –

The memory card or disk is write-protected. Operation canceled.

No memory card in slot. Operation canceled.

You can change the amount of image expansion, but a white

border may appear around your photo.

If you change the paper size, the crop area may change. Do you

want to continue?

The CD/DVD guide is in the CD/DVD position. Close the CD/

DVD guide.

The CD/DVD guide is closed. Open the CD/DVD guide, then

press the Start button.

Because the memory card is write-protected, it is not

possible to delete the file.

Because the memory card was not inserted, it was not

possible to delete the file.

This message is always displayed during adjustment of the

Borderless Expansion Value.

Warning for changing the paper size. Continue or cancel

The CD-R Guide is in the extended position.

CD/DVD tray is not set correctly. Set CD/DVD tray correctly.

Cancel Write-Protect.

Insert the memory card.

Accept it.

Return the CD-R Guide into the

withdrawn position.

Troubleshooting Troubleshooting When There is Error Display 26

Page 26

EPSON Stylus PHOTO RX560/580/590 Revision A

3.2.3 FATAL Error

C H E C K

P O I N T

The EEPROM stores the error code of the latest fatal error.

The latest fatal error can be identified using the adjustment

program.

C A U T I O N

As the printer motor drivers and the scanner motor driver are

built in one drive IC, the fatal error cord is stored as PF motor

error even if the scanner motor or scanner home sensor has

defective but the PF motor does not have any defective.

Table 3-3. Fatal Errors

Category Error Code Error Cause Remedy

DC error

(CR motor)

01H CR PID speed over error

02H CR load positioning lock error

08H CR PID reverse rotation detection error

0AH

0BH CR load positioning speed over error

0CH CR PID lock error

0DH CR PID aveTi max error

CR load positioning accumulation moving

distance error

An error occurred in the CR

motor operating sequence

Checking the operation of the Carriage Assy;

Move the Carriage Assy by hand, and check to see if it moves smoothly.

Making the following adjustments

♦Bi-D

♦Paper feed length with PF Assy

♦Paper feed length with Eject Assy

♦PW adjustment

Checking the following parts and replacing the defective one

♦Checking the head FFC (CN10/11/12) for disconnection or breakage

♦Checking the lead wires of the CR Motor (CN14) for disconnection or breakage

♦Checking the CR Encoder FFC (CN1) for disconnection or breakage

♦Checking the printer frame for adhesion of dirt or insufficient lubrication (p.90)

♦Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication (p.59)

♦Checking the Linear Scale for adhesion of dirt or damage (p.54)

♦Checking the CR Encoder for adhesion of dirt or damage (p.68)

♦Checking the PW Sensor for adhesion of dirt or damage (p.68)

♦Checking the CR Belt for damage or improper tension (p.66)

♦Checking the CR Motor and replacing it if necessary (p.66)

♦Main Board (p.45)

♦Power Supply Board (p.56)

Troubleshooting Troubleshooting When There is Error Display 27

Page 27

EPSON Stylus PHOTO RX560/580/590 Revision A

Table 3-3. Fatal Errors (continued)

Category Error Code Error Cause Remedy

DC error

(PF motor)

APG motor

Motor drive

time error

FBH PF acceleration lock error

FEH PF speed over error

FAH

Measurement value error in PF Duty

limiting control

EFH Position error in PF BS control

F0H DTY_max error in PF BS control

F3H PF BS drive time-out judgment error

70H APG error (normal drive error)

71H APG home seek error

72H Error in APG drive by factory command

D1H CR (PID) drive time-out

D2H CR (load positioning) drive time-out

D3H PF (PID) drive time-out

D4H PF (BS) drive time-out

An error occurred in the PF

motor operating sequence

An error occurred in the APG

operating sequence

The motor kept operating for

more than the specified time.

Checking the PF mechanism by visual inspection:

Check the PF mechanism for paper jam or adhesion of foreign matters by visual

inspection.

Checking the operation of the PF mechanism:

Operate the PF mechanism by hand, and check to see if it operates smoothly.

Making the following adjustments:

♦Bi-D

♦Paper feed length with PF Assy

♦Paper feed length with Eject Assy

♦PW adjustment

Checking the following parts and replace the defective one:

♦Checking the PF Encoder FFC (CN8) for disconnection or breakage

♦Checking the lead wires of the PF Motor (CN13) for disconnection or breakage

♦Checking the PF scale for adhesion of dirt or damage (p.62)

♦Checking the PF encoder for adhesion of dirt or damage (p.62)

♦Checking the Upper Paper Guides for improper installation (p.70)

♦Checking the PF Motor and replacing it if necessary (p.62)

♦Main Board (p.45)

♦Power Supply Board (p.56)

Checking the installation of the APG Sensor:

position of the sensor and connection of the connector (CN7)

Checking the drive of the APG Assy

♦Installation of the composite gear of the ASF Assy ~APG Assy

♦Standalone operation of the APG Assy

♦Reinstallation of the APG Assy (phase)

Checking the following parts and replace the defective one:

♦APG Assy (p.65)

♦ASF Assy (p.64)

♦APG Sensor

♦PG Left Cam (p.68)

♦Main Board (p.45)

♦Power Supply Board (p.56)

Checking the mechanism and operation:

Check the mechanism and operation of the motor in question.

Checking the connection of the connectors and routing of the lead wires

Checking the motor in question and the following parts and replacing the defective part:

♦Main Board (p.45)

♦Power Supply Board (p.56)

Troubleshooting Troubleshooting When There is Error Display 28

Page 28

EPSON Stylus PHOTO RX560/580/590 Revision A

Table 3-3. Fatal Errors (continued)

Category Error Code Error Cause Remedy

Factory

command

error

Head system

error

Sequence

error

Sensor error

Maintenance

error

30H Error by EEPROM verify command

40H Transistor ambient temperature abnormal

41H Error in X-Hot detection before printing

42H Error in X-Hot detection after flushing

43H Head ambient temperature abnormal

50H Home seek error

51H CR unlocking error

52H CR locking error

53H

Paper detect error before initial charge

completion

60H PW detection error (Hi check error)

61H PW detection error (Low check error)

62H Tray detection (CDR detector 2) error

63H Paper detection error

A0H Waste ink overflow

The thermistor on the

printhead detected abnormal

temperature.

An error occurred in the

carriage operating sequence.

PW detector trouble

Sensor trouble

Life expiration of maintenance

parts

Checking the following parts and replace the defective one:

♦Main Board (p.45)

♦Power Supply Board (p.56)

Checking the following parts and replace the defective one:

♦Printhead (p.52)

♦Main Board (p.45)

♦Power Supply Board (p.56)

♦Replace the Head FFC

See Remedy for DC error (CR motor)

Checking the PW Sensor (p.68)

♦Checking the PW Sensor for adhesion of dirt and dust

♦Checking the connection of the FFC

Making the following adjustments:

♦PW adjustment

Checking the following parts and replace the defective one:

♦Head FFC

♦Carriage Assy (p.67)

♦Main Board (p.45)

♦Power Supply Board (p.56)

Checking the operation of the actuator and the connection of the connector.

Checking the following parts and replace the defective one:

♦Sensor

♦Main Board (p.45)

♦Power Supply Board (p.56)

Replace all the maintenance parts, and clear the maintenance counter.

♦ Refer to “6.1.1 Maintenance Error” (p.88)

Troubleshooting Troubleshooting When There is Error Display 29

Page 29

EPSON Stylus PHOTO RX560/580/590 Revision A

3.3 Troubleshooting When There is No Error Display

3.3.1 Troubleshooting for Printer

This section describes repair/service of the Printer Mechanism. Listed below are various problems which may occur, observations of such problems, check point and remedies.

Faulty paper loading

Table 3-4. Diagnostics when feeder is abnormal

Condition Cause Check Point Remedy

Clean the rollers using a cleaning sheet.

1. Set a cleaning sheet upside down in the ASF Assy.

2. Start paper feed with the panel button.

3. Repeat steps above several times.

To remove oils from rollers, staple a cloth dampened with alcohol

to a postcard and follow the steps below.

1. Set the postcard in the tray with the alcohol dampened cloth side

facing the LD Roller (or Retard Roller).

2. Start paper feed while firmly holding the upper edge of the card.

3. Repeat the paper feed operation several times to clean the surface of

the LD Roller (or Retard Roller).

If these steps do not correct the problem, replace both the LD Roller

and Retard Roller.

Wipe the rollers with a cloth dampened with alcohol.

Adjust the phase of the paper loading mechanism.

Remove the dust and dirt, if any.

Connect the PE Sensor connectors to the sensor and Main Board CN6

properly.

Install the Torsion Spring on the PE Lever properly.

Install the tension spring properly.

Paper is not

loaded.

Several sheets of

paper are fed at

the same time

LD Roller and Retard Roller dirty or

worn

Pick Up Roller and Idle Roller dirty or

worn

Operation of paper loading mechanism

is abnormal

PE Sensor/PE Lever not operating

properly

Retard Roller operation is abnormal

Check to see if no Micro Pearl or oily substance is adhering to

the paper loading roller.

Check to see if no Micro Pearl or oily substance is adhering to

the rollers.

Check to see if there is no abnormality in the paper loading

mechanism.

Check to see if the PE Sensor connector has not been

disconnected from the sensor or Main Board.

Check to see if the Torsion Spring has been set on the PE Lever

properly.

Check for damaged PE Sensor. Replace the PE Sensor.

Check to see if the tension spring on the Retard Roller is

disengaged.

Check to see if the Retard Roller is out of position. Install the Retard Roller properly.

Troubleshooting Troubleshooting When There is No Error Display 30

Page 30

EPSON Stylus PHOTO RX560/580/590 Revision A

Faulty paper ejection

Table 3-5. Diagnostics when paper ejection is abnormal

Condition Cause Check Point Remedy

Faulty PF-related operation

Paper is jammed

on the way of

paper ejection.

PF degradation compensation counter

Faulty operation of Paper Eject Roller Check to see if Paper Eject Roller rotates correctly. Properly engage the gears driving the Paper Eject Roller.

Faulty carriage operation

Condition Cause Check Point Remedy

Abnormal

carriage operation

during printing

Carriage does not move smoothly.

Turn the PF Roller, and check to see if the paper is transferred

to the Paper Eject Rollers properly.

Check the PF degradation compensation counter and the

number of printed sheets using the adjustment program.

Engage the PF-related gears properly.

Initialize the PF degradation compensation counter and write the

maximum value.

Table 3-6. Diagnostics when carriage action is abnormal

Check to see if there is an obstacle in carriage route. Remove the obstacle.

Operate the carriage by hand and check to see if carriage moves

smoothly.

Check tension of timing belt. Replace the Compression Spring of the Driven Pulley Holder.

Move the carriage to the right end and left end fully and check

to see if the length of the Head FFC is proper and the carriage

moves smoothly.

Clean the CR guide shaft and lubricate.

Remove the Head FFC once and reinstall it properly.

Troubleshooting Troubleshooting When There is No Error Display 31

Page 31

EPSON Stylus PHOTO RX560/580/590 Revision A

Printer stops during initialization

Table 3-7. Diagnostics when printer stops during format

Condition Cause Check Point Remedy

Paper Eject Frame not installed properly

CR Motor not operating properly

PF Motor not operating properly

Linear Scale not operating properly

CR Encoder not operating properly

Printer error is

indicated.

Rotary Scale not operating properly

PF Encoder not operating properly

Head FFC not operating properly

Head Hot Error generated Check to see if ink is emitted from all nozzles. If condition does not improve after cleaning, replace the Printhead.

Check to see if the hook securing the Paper Eject Frame has

been engaged.

Check for disconnected CR Motor connector. Check the connector (CN14) of the CR Motor.

Check to see if CR Motor coil resistance is as specified. Replace the CR Motor.

Check for disconnected PF Motor connector. Check the connector (CN13) of the PF Motor.

Check to see if PF Motor coil resistance is as specified. Replace the PF Motor.

Check to see if the Linear Scale is traveling through the CR