Page 1

SERVICE MANUAL

Color Inkjet Printer

EPSON Stylus Photo R800

SEIJ03012

Page 2

PRECAUTIONS

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in performing

procedures preceded by DANGER Headings.

WARNING Signals a precaution which, if ignored, could result in damage to equipment.

The precautionary measures itemized below should always be observed when performing repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY MAINTENANCE OR REPAIR

PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED FOR ALL

ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL INSTRUCTED TO

DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON POWER SUPPLY AND OTHER

ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/RATING PLATE. IF THE

EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR REPLACING

PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS ANTI-STATIC WRIST

STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF SECOND-SOURCE

ICs OR OTHER NON-APPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE EPSON WARRANTY.

Page 3

About This Manual

This manual describes basic functions, theory of electrical and mechanical operations, maintenance and repair procedures of the printer. The instructions and

procedures included herein are intended for the experienced repair technicians, and attention should be given to the precautions on the preceding page.

Manual Configuration

This manual consists of six chapters and Appendix.

CHAPTER 1.PRODUCT DESCRIPTIONS

Provides a general overview and specifications of the product.

CHAPTER 2.OPERATING PRINCIPLES

Describes the theory of electrical and mechanical operations of

the product.

CHAPTER 3.TROUBLESHOOTING

Describes the step-by-step procedures for the troubleshooting.

CHAPTER 4.DISASSEMBLY / ASSEMBLY

Describes the step-by-step procedures for disassembling and

assembling the product.

CHAPTER 5.ADJUSTMENT

Provides Epson-approved methods for adjustment.

CHAPTER 6.MAINTENANCE

Provides preventive maintenance procedures and the lists of

Epson-approved lubricants and adhesives required for servicing

the product.

APPENDIX Provides the following additional information for reference:

• Connector pin assignments

• Exploded diagram & Parts List

• Electric circuit boards components layout

• Electrical circuit boards schematics

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide ad ditional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Be aware of all symbols when they are used, and

always read NOTE, CAUTION, or WARNING messages.

Indicates an operating or maintenance procedure, practice or

condition that is necessary to keep the product’s quality.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in damage to,

or destruction of, equipment.

May indicate an operating or maintenance procedure, prac tice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in injury or loss

of life.

Indicates that a parti cu la r ta sk mu st be ca rr i ed o ut ac co rd ing to a

certain standard after disassembly and before re-assembly,

otherwise the quality of the components in question may be

adversely affected.

Page 4

Revision Status

Revision Date of Issue Description

A December 16, 2003 First Release

B May 27, 2004 Correction of the misspellings

Page 5

CONTENTS

Chapter 1 PRODUCT DESCRIPTION

1.1 Overview.......................... ... ... .......................................... .... ... ... ... ........... 9

1.2 PG Setting ....................................... .......................................... ... ......... 10

1.3 Functions ........ ... ... .... ... ... ... ... .... ... .......................................... ... ... .... ... .. 11

1.3.1 Control Panel ............. ... .... ... ... ... .... ... .......................................... .. 11

1.3.2 Switches ............................ ... ... ... .......................................... .... ..... 11

1.3.3 Indicators ........................................................... ... ......................... 11

1.3.4 Switch Functions ............................................................... ... .... ... .. 11

1.3.5 Indicator Display in Normal Mode ................................................. 12

1.3.6 Error Status ....... ... ... ... ... .......................................... .... ... ... ... .... ... .. 13

1.4 Casing Specifications .................................... .... ... ... ... ... .... ... ... ... .... ... .. 14

1.5 Accessories .............. ............................................................................ 14

Chapter 2 OPERATING PRINCIPLES

2.1 Overview.......................... ... ... .......................................... .... ... ... ... ......... 16

2.2 Printer Mechanism ............... .......................................... .... ... ............... 16

2.2.1 Carriage Mechanism .. ... .... ... ... ... .... .......................................... ... .. 17

2.2.2 Printhead Specifications ....................... ... .... ... ... ... ... .... ... ... ... ......... 20

2.2.3 Paper Feeding Mechanism ........................................................... 20

2.2.4 Paper Loading Mechanism ........................................................... 24

2.2.5 Ink System Mechanism ................................................................. 26

2.2.6 Ink Sequence .......................................... .... ... ... ... ... .... ... ... ............ 28

2.2.7 Paper Cutter Mechanism .............................................................. 30

2.2.8 Power-On Sequence ..................................................................... 32

2.3 Electrical Circuitry Operating Principles................................ ....... ... .. 33

2.3.1 Power Supply Circuit Operating Principle ..................................... 33

2.3.2 C550 MAIN Circuit Operating Principle .................................... ... .. 34

3.1 Overview ............................................................................................... 38

3.1.1 Troubleshooting according to panel messages ............................ 38

3.1.2 Superficial Phenomenon-Based Troubleshooting ......................... 62

Chapter 4 DISASSEMBLY & ASSEMBLY

4.1 Overview ............................................................................................... 73

4.1.1 Precautions ................................................................................... 73

4.1.2 Tools to Be Used ............... .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... . 74

4.1.3 Screw List ..................................................................................... 75

4.1.4 Pre-Shipment Checks ................................................................... 76

4.2 Disassembly ......................................................................................... 77

4.2.1 Removing the Housings ................................................................ 78

4.2.2 Stacker Assy. ................................................................................ 82

4.2.3 Waste Ink Pads ............................................................................. 84

4.2.4 ASF Assy. ..................................................................................... 86

4.2.5 Removing the Boards ................................................................... 90

4.2.6 Disassembling the Printer Mechanism .......................................... 96

4.2.7 Removing the Motors .................................................................. 130

4.2.8 Removing the Sensors ................................................................ 133

Chapter 5 ADJUSTMENT

5.1 Adjustment Items and Overview....................................................... 140

5.1.1 Servicing Adjustment Item List .................................................... 140

5.1.2 Replacement Part-Based Adjustment Priorities .......................... 143

5.1.3 Required Adjustment Jigs, Tools and Like .................................. 145

5.2 Adjustments........................................................................................ 145

5.2.1 PF Belt Tension Adjustment ....................................................... 145

5.2.2 PG Adjustment ............................................................................ 147

Chapter 3 TROUBLESHOOTING

Chapter 6 MAINTENANCE

Page 6

6.1 Overview.......................... ... ... .... ... .......................................... ... ... .... ... 153

6.1.1 ROM Replacement ..................... .... ... ... ... .... ... ... ... ... .... ... ... .......... 153

6.1.2 Cleaning .. ... ... .... .......................................... ... ... ... ... .................... 153

6.1.3 Service Maintenance ................................................................... 154

6.1.4 Lubrication ......................... ... ... .......................................... ... .... ... 155

Chapter 7 APPENDIX

7.1 Connector Summary .......................................................................... 162

7.1.1 Connectors and Pin Layouts ....................................................... 162

7.2 Exploded Diagram........................................................................... ... 163

7.3 Parts List for EPSON Stylus Photo R800 ......................................... 170

7.4 Component Layout............................................................................. 172

7.5 Circuit Diagram............................... .......................................... ... .... ... 174

Page 7

PRODUCT DESCRIPTION

CHAPTER

1

Page 8

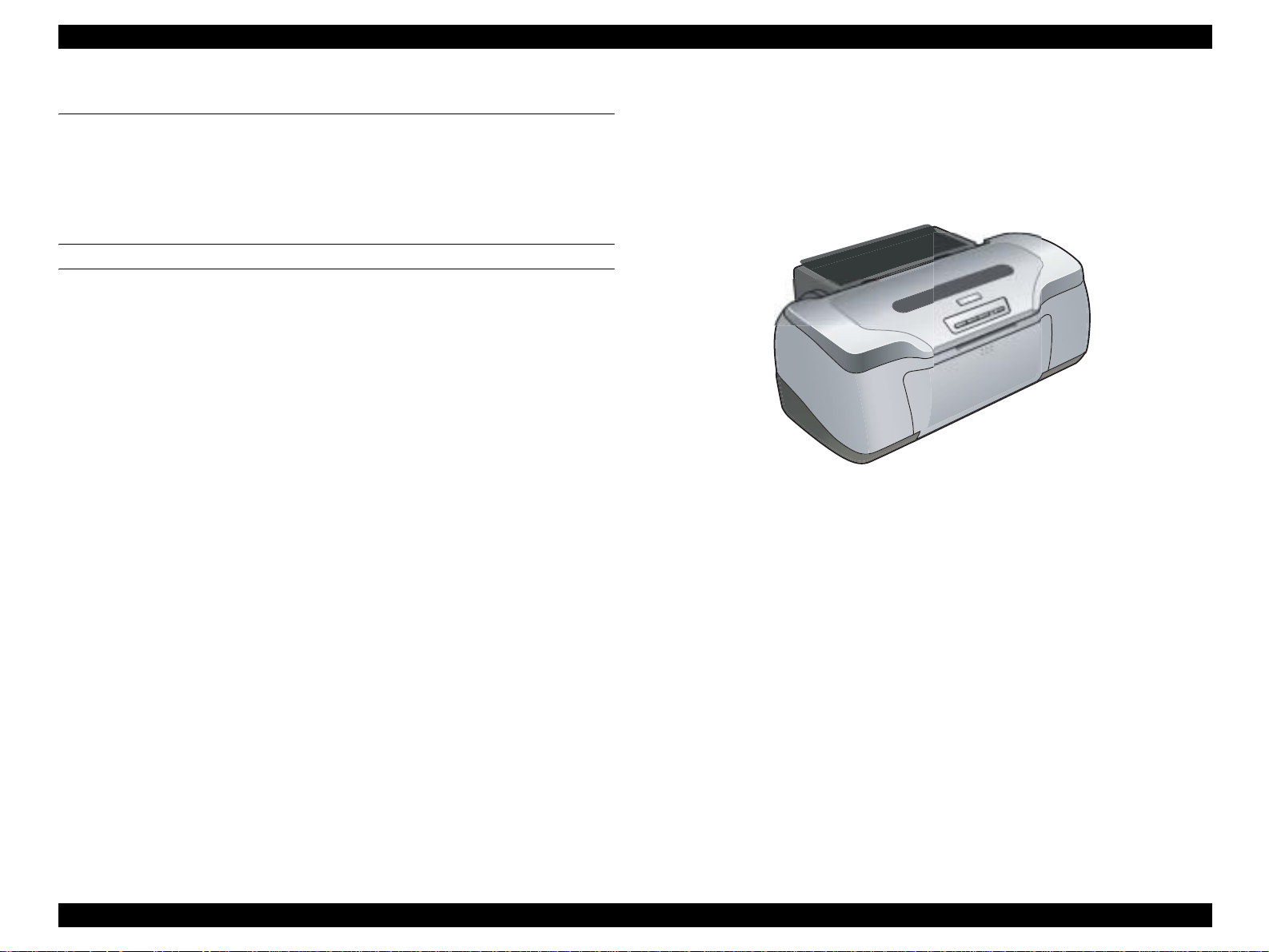

EPSON Stylus Photo R800 Revision A

1.1 Overview

The Stylus Photo R800 is a photo printer designed for a wide range of users

from individual users to commercial users. As a successor to the Stylus Photo

950/960, this consumer middle high model is capable of CD-R/DVD-R printing

and roll paper cutter functions.

This product has the following features.

FEATURES

High Color Print Quality

High photo quality thanks to Photo Mach technology

Achievement of higher quality using microweaves and super

microweaves

High resolution printing of 5760 x 1440dpi, world's minimum dot 1.5pl

MSDT

High-speed printing

Two Different Interfaces Supported

USB 2.0 (HS compatibility)

IEEE-1394

Compact, space saving

Windows/Macintosh Exclusive

Multi-size Capable ASF

ASF equipped as standard supports forms ranging from business cards to

A4.

CSIC-compatible Independent Ink Cartridge

Roll paper compatibility

Note"*1": When user performs the "Auto nozzle check and cleaning", Prints

nozzle check pattern and automatically checks print head nozzles. If they are

clogged, performs head cleaning. If they are not recovered, and perfor ms head

cleaning and detection up to tree times.

Figure 1-1. Product Appearance

Fast, 4-side borderless printing compatibility

Two-sided printing compatibility

Prevention of platen printing by optical sensor

CD-R/DVD-R printing compatibility by front loading

Business card, card photo printing compatibility

Auto Nozzle Check and Cleaning*1

PRODUCT DESCRIPTION Overview 9

Page 9

EPSON Stylus Photo R800 Revision A

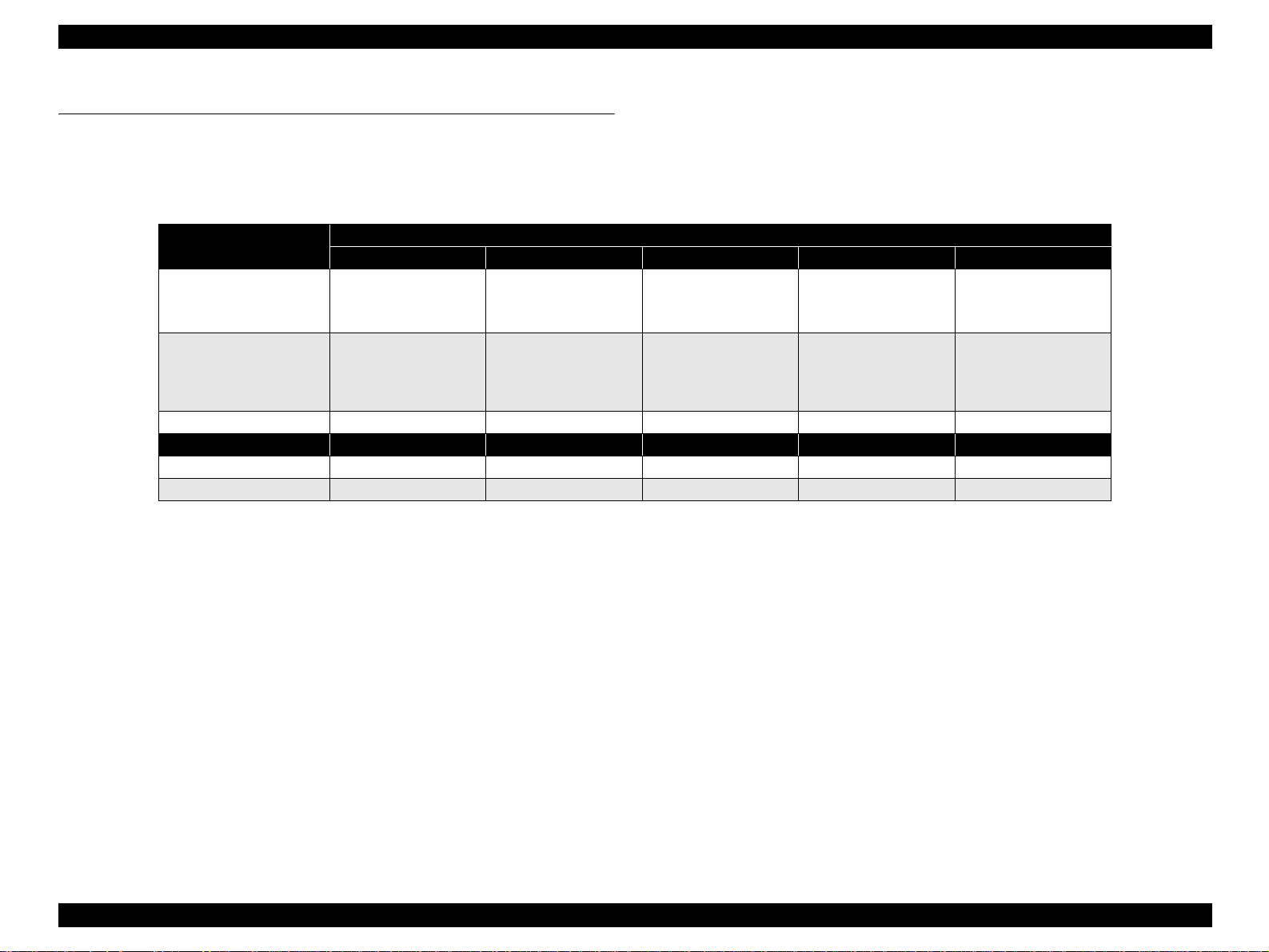

1.2 PG Setting

As this printer uses an Auto PG (APG), an appropriate PG position is set according to the used paper type.

The following table indicates the PG positions, the main applications of each position, and the relationships between the two sensors used with the APG.

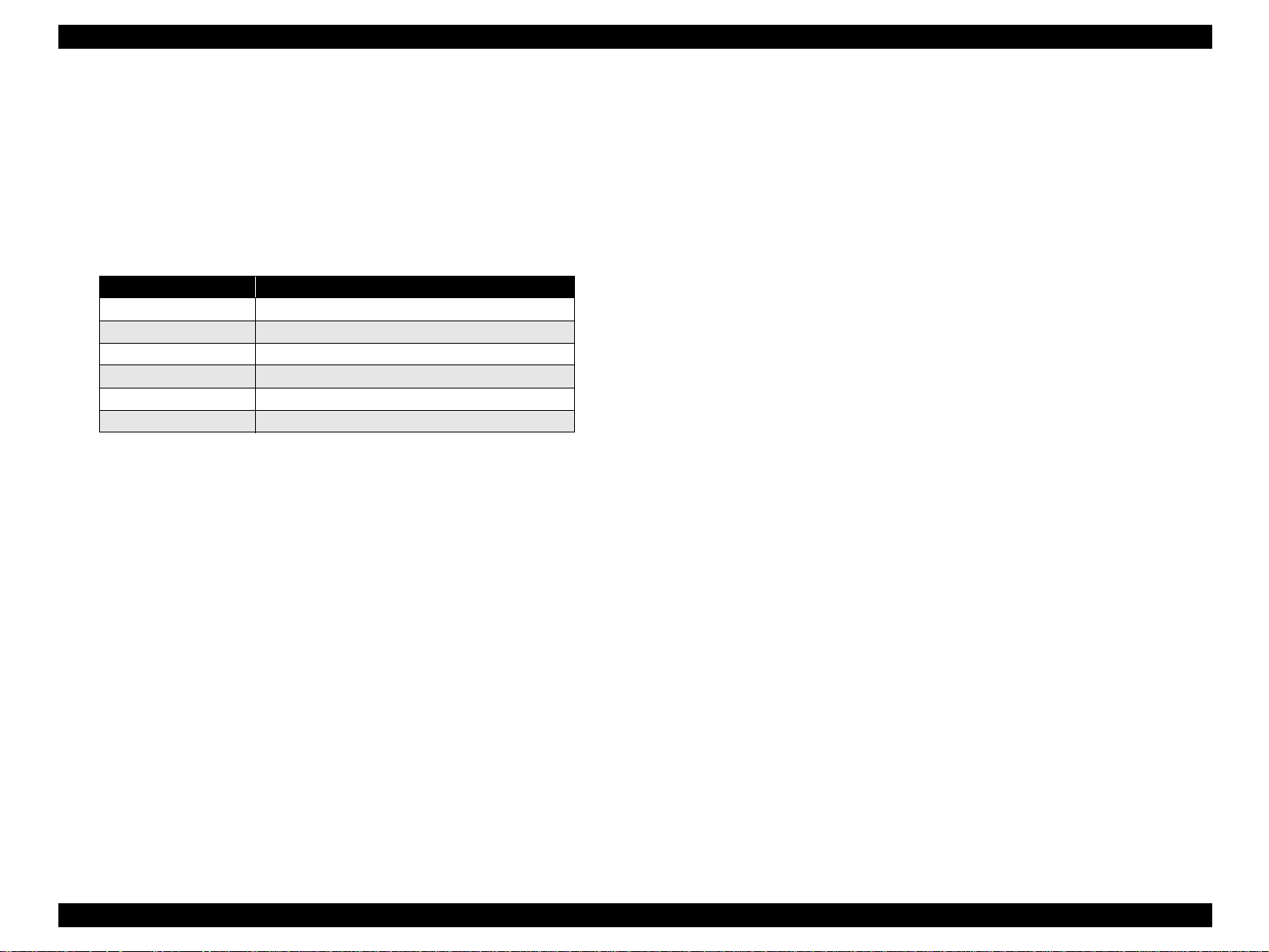

Table 1-1.

Application

Printing • Special thick paper • Plain paper

Non-printing

PG value 1.2mm 1.7mm 2.1mm 4.5mm –

Sensor PG (-) PG (Typ.) PG (+) PG (++) Release

APG Sensor 1 OFF OFF OFF OFF OFF

APG Sensor 2 ON ON ON OFF OFF

PG (-) PG (0) PG (+) PG (++) Release

• Special thin paper

• PG(-) rub avoidance

• Standby position

–

after power-on (For

bottom stacker)

PG Position

• Envelope

• PG(0) rub avoidance

–

• CD-R/Board paper

• Initialization at

power-on

• Cleaning (wiping)

–

• Waiting for CD-R/

Board paper to be

fed

• Paper jam removal

PRODUCT DESCRIPTION PG Setting 10

Page 10

EPSON Stylus Photo R800 Revision A

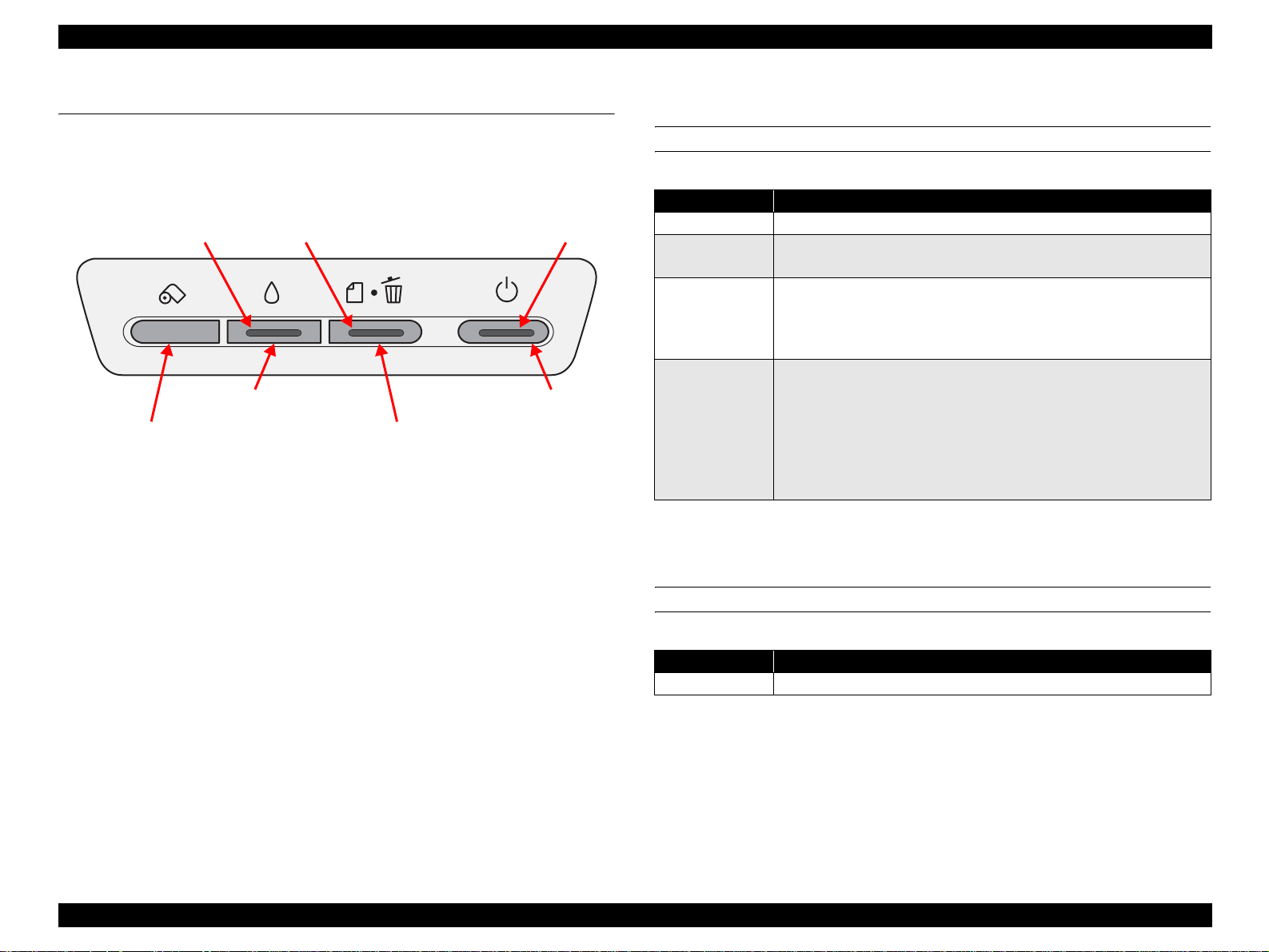

1.3 Functions

1.3.1 Control Panel

The appearance of the control panel is shown below.

Ink LED Paper LED

Ink switch

Roll paper switch

Figure 1-2. Control Panel Appearance

1.3.2 Switches

Paper switch

Power LED

Power switch

1.3.4 Switch Functions

FUNCTIONS IN NORMAL STATUS

Table 1-2. Normal-status Functions

Switch Function

Power switch • Power On/Off

Paper switch

Ink switch

Roll paper

switch

Note : When the prin ter has frozen, hold down the Power switch and Ink switch for 7

seconds to forcibly switch power off.

• Loads or Ejects the Paper.

• In the condition of printing, cancel the print job.

• Starts the Cleaning of head with 3 second pushing.

• Moves the Carriage to ink cartridge change position.

• When Carriage is on the ink cartridge change position, return

carriage from ink cartridge change position.

• Loads the Roll paper.

• Back out the roll paper with 3 second pushing.

• Move to tear off position / Return from tear off position.

• When the cutter is set, cuts the paper.

• When the photo album is used, ejects the paper forwards only.

(At this mode, the printer can't move the cutter and can't move

backwards.)

Power switch

Paper switch

FUNCTION AT POWER-ON

Ink switch

Roll paper switch

1.3.3 Indicators

Power LED : Green

Switch Function

Paper switch Starts status printings.*

Note "*1 ": Status printings prints firmware version, ink counter and nozzle check

patterns.

Table 1-3. Power-on Function

1

Paper LED : Red

Ink LED : Red

PRODUCT DESCRIPTION Functions 11

Page 11

EPSON Stylus Photo R800 Revision A

1.3.5 Indicator Display in Normal Mode

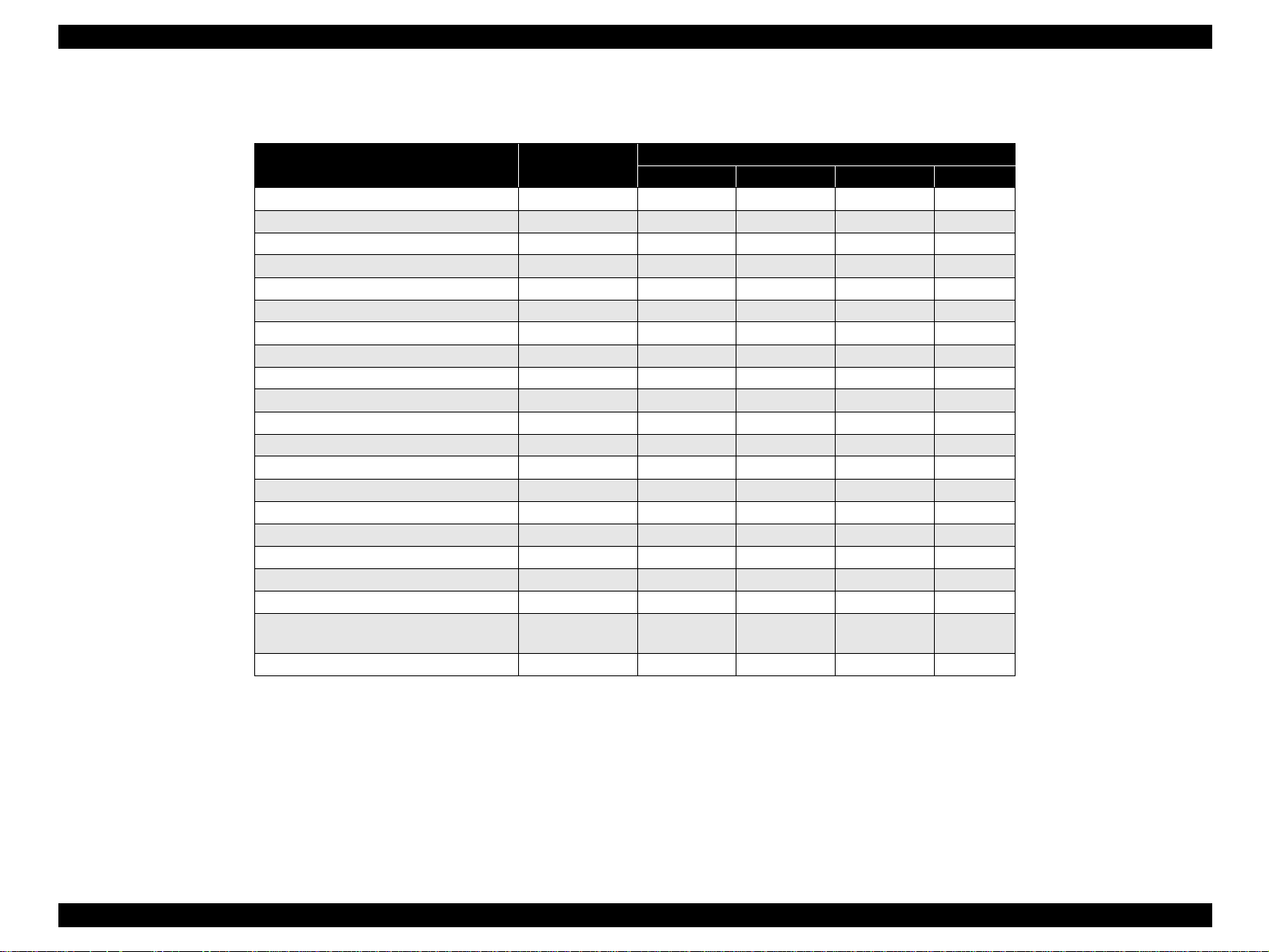

Table 1-4. Printer Condition and LED Status

Printer status Error status

Idle – On – – 20

Data Processing – Blink – – 19

Pause *

Ink Sequence Processing – Blink – – 17

Ink Cartridge Change Mode – Blink – – 16

PG Release Processing – Blink Blink Blink 15

Ink Low (warning) – – – Blink 14

Tear Off Status 11h – – – 13

Paper Mismatch Error 0Ch Fast Blink – 12

Paper Out 06h – On – 11

Ink Out 05h – – On 10

No Ink Cartridge or Ink Cartridge Error 05h – – On 9

Paper Jam Error 04h – Blink – 8

Card Loading Error 2Ah – Fast Blink – 7

Cutter Jam Error 1Dh –| Blink 2 – 6

Cover Open Error 02h – Blink 2 Fast Blink 5

Reset Input – On On On Å|

Fatal Error 00h Off Fast Blink Fast Blink 4

Cutter Position Error 1Ch Off Blink 2 Blink 2 3

Maintenance Request

Power Off – Fast Blink Off Off 1

1

Note: • "–" : Don't care

• Blink : 0.5sec on + 0.5sec off repetition

• Blink 2 : 0.2sec on + 0.2sec + 0.2sec on + 0.4sec off repetition

• Fast Blink : 0.1sec on + 0.1sec off repetition

• Blink alternately 1 : 0.5sec on + 0.5sec off repetition

• Blink alternately 2 : 0.5sec off + 0.5sec on repetition

Status 05h – – – 18

10h Off

Power Paper Ink Priority

Indicators

Blink

Alternately 1

Blink

Alternately 2

2

Note"*1": When the Photo album paper is end, the printer goes to this status.

PRODUCT DESCRIPTION Functions 12

Page 12

EPSON Stylus Photo R800 Revision A

1.3.6 Error Status

If any of the following states is detected, this printer is put in an error status a nd

turns the interface signal -ERROR "Low" and BUSY "High" to inhibit data input.

At this time, the printer is automatically disabled from printing. However, when

communication is being made using the IEEE1284.4 protocol, communication

with the printer is enabled.

General error

After the cause of this type of error is removed, the printer can resume its

operation from where it stopped due to the error

Table 1-5. General error

Error Status Occurring Condition Resuming Condition

Paper Mismatch

Error

Paper Out When printer fails to load a sheet, it

Ink Out When the printer runs out the most

No Ink Cartridge/

CSIC Error

Paper Jam Error • Failure of ejecting a sheet

Card Loading

Error

If the paper path specified by the

print data is different from the

printer's real paper path, the printer

goes to this error.

goes Paper Out Error.

part of the ink of any one color, it

warns Ink Low and keeps printing.

When the printer runs out the whole

ink of any one color, it stops printing

and indicates Ink Out Error. User is

requested to install a new InkCartridge in this state.

When printer detects that Ink

Cartridge comes off, it goes this error

mode.

• Failure of loading a sheet to the

loading position

When the card was loaded to the

wrong position, the printer goes this

error.

Change the printer's

paper path to the one

specified by the data.

Set the paper to the ASF

and push the Paper

switch.

Install the new Ink

Cartridge.

Install the new Ink

Cartridge.

Remove the jammed

paper.

Set an A4 paper to the

ASF, and press the

Paper switch. If the card

couldn't eject at your first

try, repeat again the

same method.

Table 1-5. General error

Error Status Occurring Condition Resuming Condition

Cutter Jam Error When Cutter can't cut the paper, it

goes Cutter Jam Error.

Cover Open Error When the cover is opened at

Economy printing mode, the printer

goes this error.

Switch power off and

recheck the cutter state.

When a paper jam has

occurred, clear the

paper.

Close the cover.

Fatal error

After the cause of this type of error is removed, the printer cannot return to

normal unless it is powered off and then on again

Table 1-6. Fatal error

Error Status Occurring Condition Resuming Condition

Fatal Error When detecting a Fatal Error such as

a carriage control error, the printer is

placed in an error status.

Cutter Position

Error

Maintenance

Request

When Cutter can't return to cutter

home position, it goes Cutter Position

Error.

When the total quantity of ink wasted

through the cleaning and flushing is

reaches to the limit, printer indicates

this error and stops.

Turn off and turn on.

Switch power off and

recheck the cutter state.

When a paper jam has

occurred, clear the

paper.

Replace the Waste Ink

Pads in the printer

enclosure by a service

person.

PRODUCT DESCRIPTION Functions 13

Page 13

EPSON Stylus Photo R800 Revision A

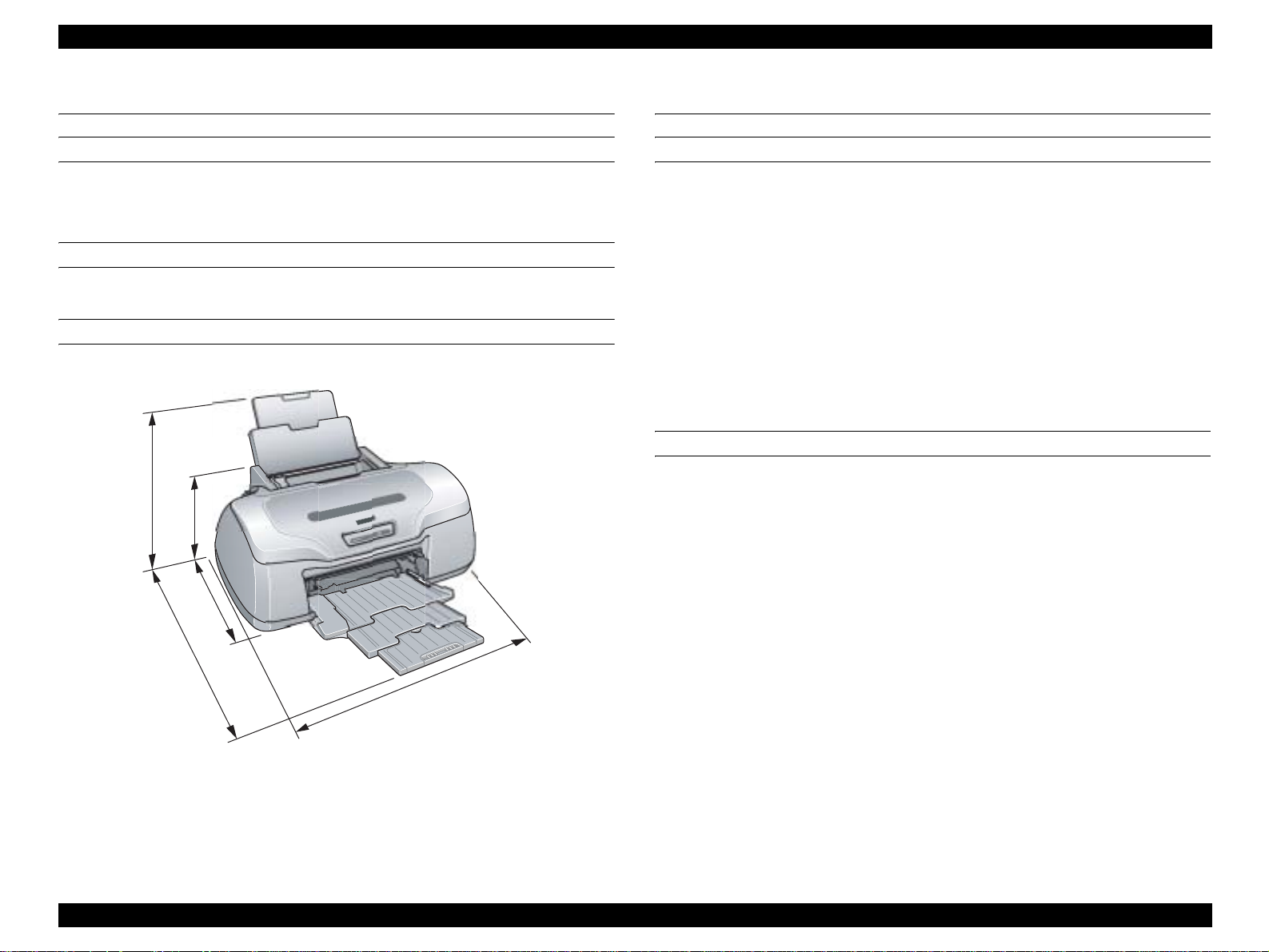

1.4 Casing Specifications

EXTERNAL DIMENSIONS

When tucked : 495 (width) x 305 (depth) x 193 mm (height)

When used : 495 (width) x 644 (depth) x 322 mm (height)

WEIGHT

7.0kg

EXTERNAL DIMENSION DIAGRAM

322

193

305

644

495

1.5 Accessories

STANDARD ACCESSORIES

Setup guide : 1 set

Ink Cartridge (one for each of 8 colors) : 1 set

CD-ROM (Printer driver utility) : 1 set

CD/DVD tray : 1 set

CD/DVD print position check sheet : 1 set

8cm CD/DVD attachment : 1 set

Roll paper holder : 1 set

Power cord : 1 set

CONSUMABLES AND OPTIONS

Ink cartridges

Gloss Optimizer: T0540

Black : T0541

Cy an : T0542

Magenta : T0543

Yellow : T0544

Red : T0547

Matte Black : T0548

Blue : T0549

Roll paper auto cutter

(Cutter, paper support basket, instruction manual) : PMA4RAC3

USB cable : USBCB2

Figure 1-3. External Dimension Diagram

PRODUCT DESCRIPTION Casing Specifications 14

Page 14

OPERATING PRINCIPLES

CHAPTER

2

Page 15

EPSON Stylus Photo R800 Revision A

2.1 Overview

This chapter explains the operating princ i ple s of th e mech an ica l sect ion s an d

electrical circuits in this product. The main components of this product are as

follows.

Control circuit board : C550 MAIN

Power supply circuit board : C550 PSB/PSE

Control panel board : C550 PNL

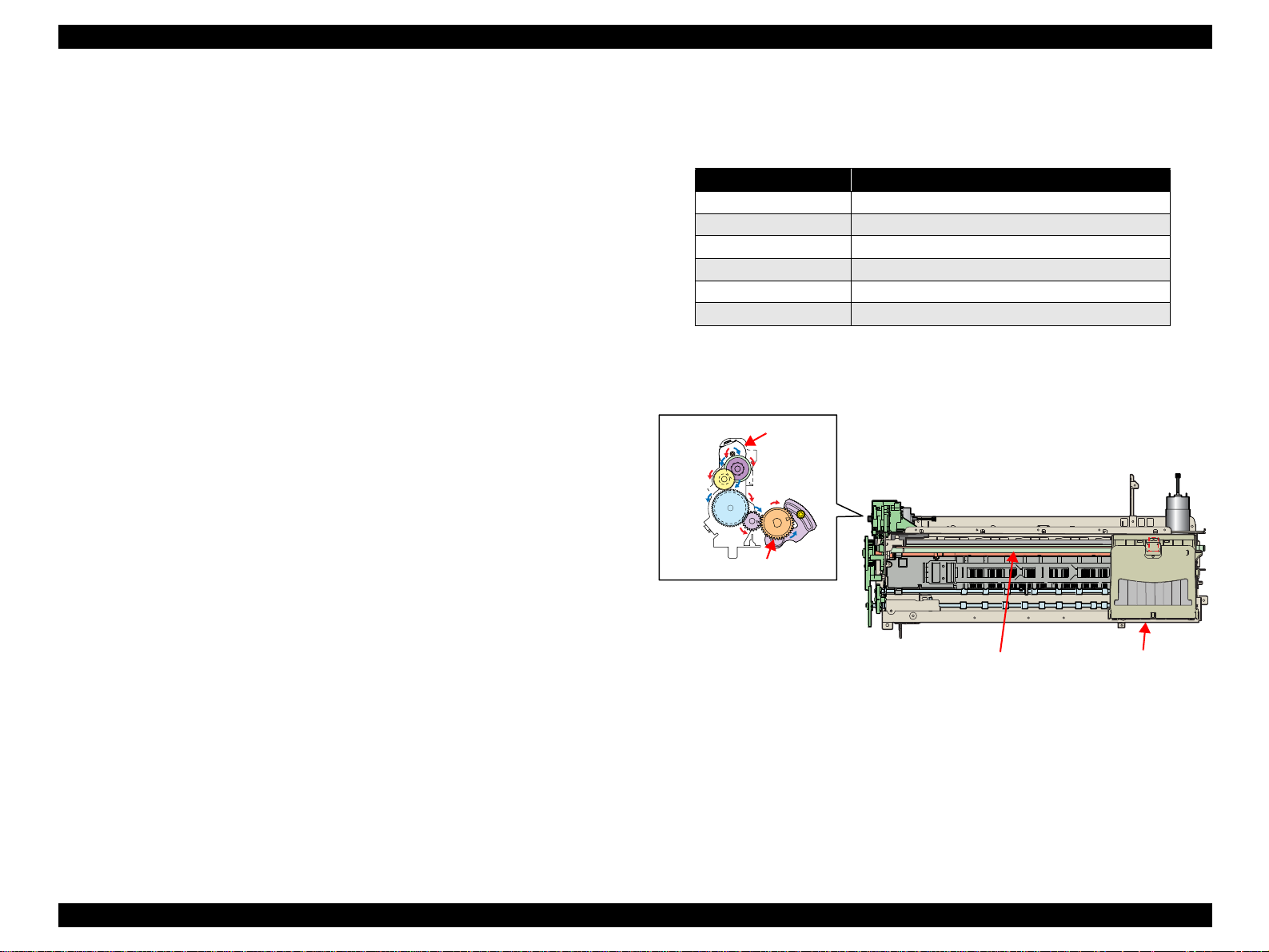

2.2 Printer Mechanism

Like the conventional model, this product uses DC motors as power sources.

The following table describes the motor types and their applications.

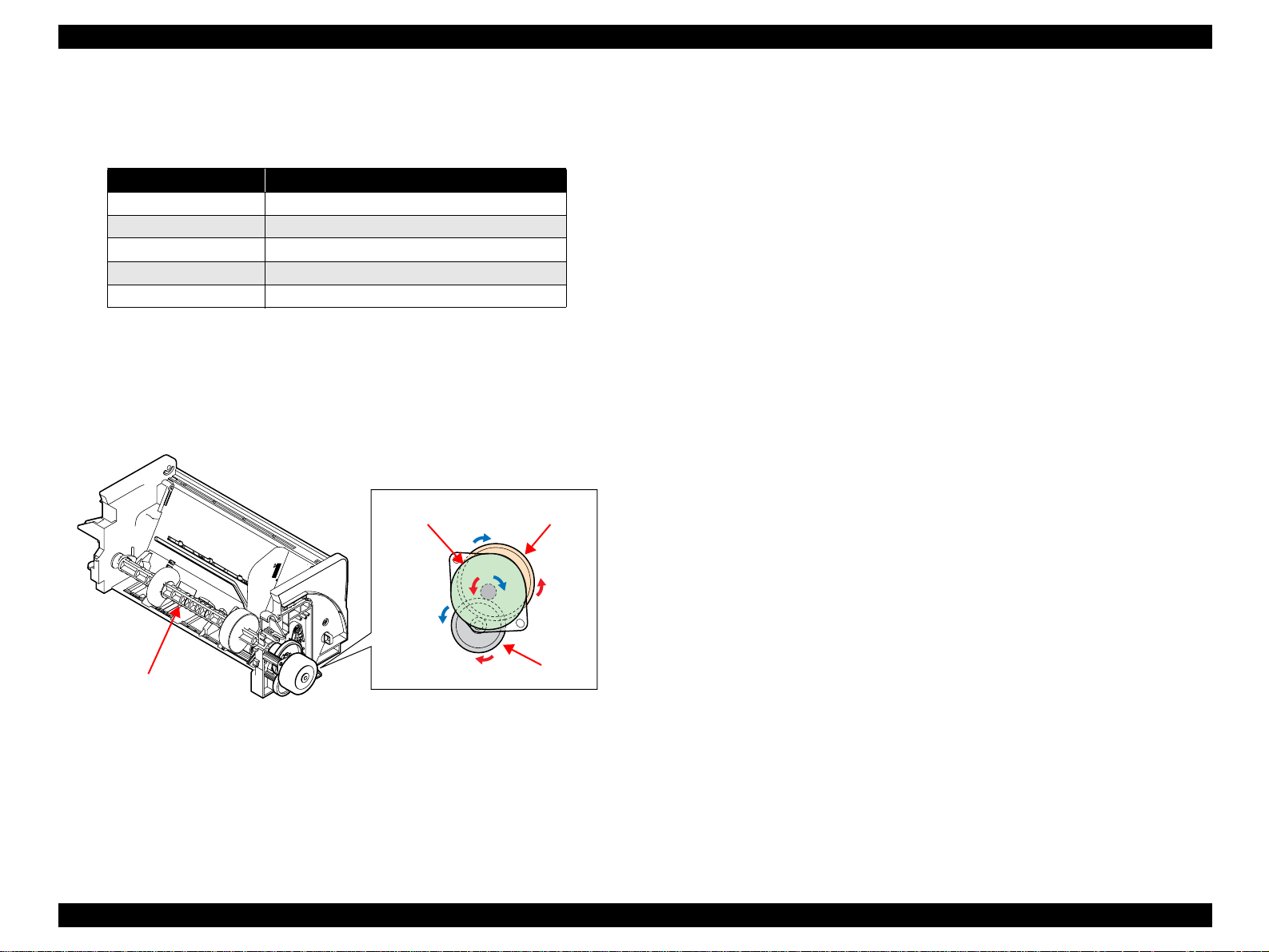

Table 2-1. Various Motors

Motor Name Type Applications/Functions

Used for carriage driving. Makes little noise

during driving. The CR linear scale and CR

encoder sensor are used to control the motor.

Power source to drive the Paper loading rollers

at the time of fixed-value paper loading or paper

feed/eject operation. To grasp the paper feed

pitch, the precision gear surface is fitted with the

PF scale and the PF encoder sensor is used to

control the motor.

Power source to drive the Carriage Unit at the

time of PG setting. The two APG Sensors and

Carriage Shaft are driven vertically to control the

motor.

Performs the paper feed operation of the ASF.

Because of a stepping motor, this motor does

not require a scale, photo sensor and like to be

fitted to grasp the driving conditions.

Drives the pump, wiper, etc. of the Ink System.

Because of a stepping motor, this motor does

not require a scale, photo sensor and like to be

fitted to grasp the driving conditions.

CR Motor

PF Motor

APG Motor

ASF Motor

Pump Motor

DC motor with

brushes

DC motor with

brushes

DC motor with

brushes

4-phase, 48-pole

PM type

stepping motor

4-phase, 48-pole

PM type

stepping motor

The basic structure of the mechanism has the following features.

The se nsor dedicated to Auto Bi-D adjustment and auto nozzle check is

installed.

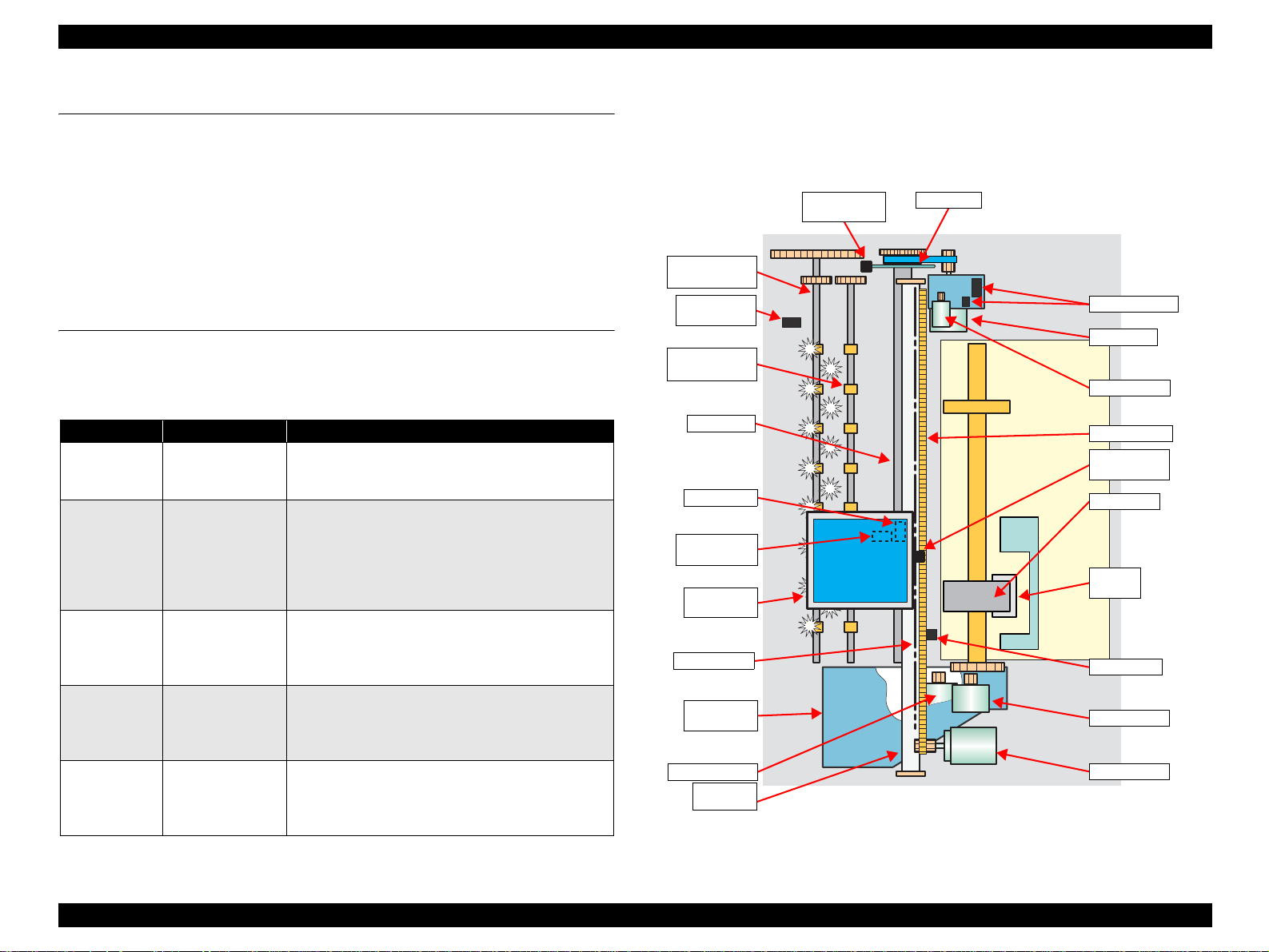

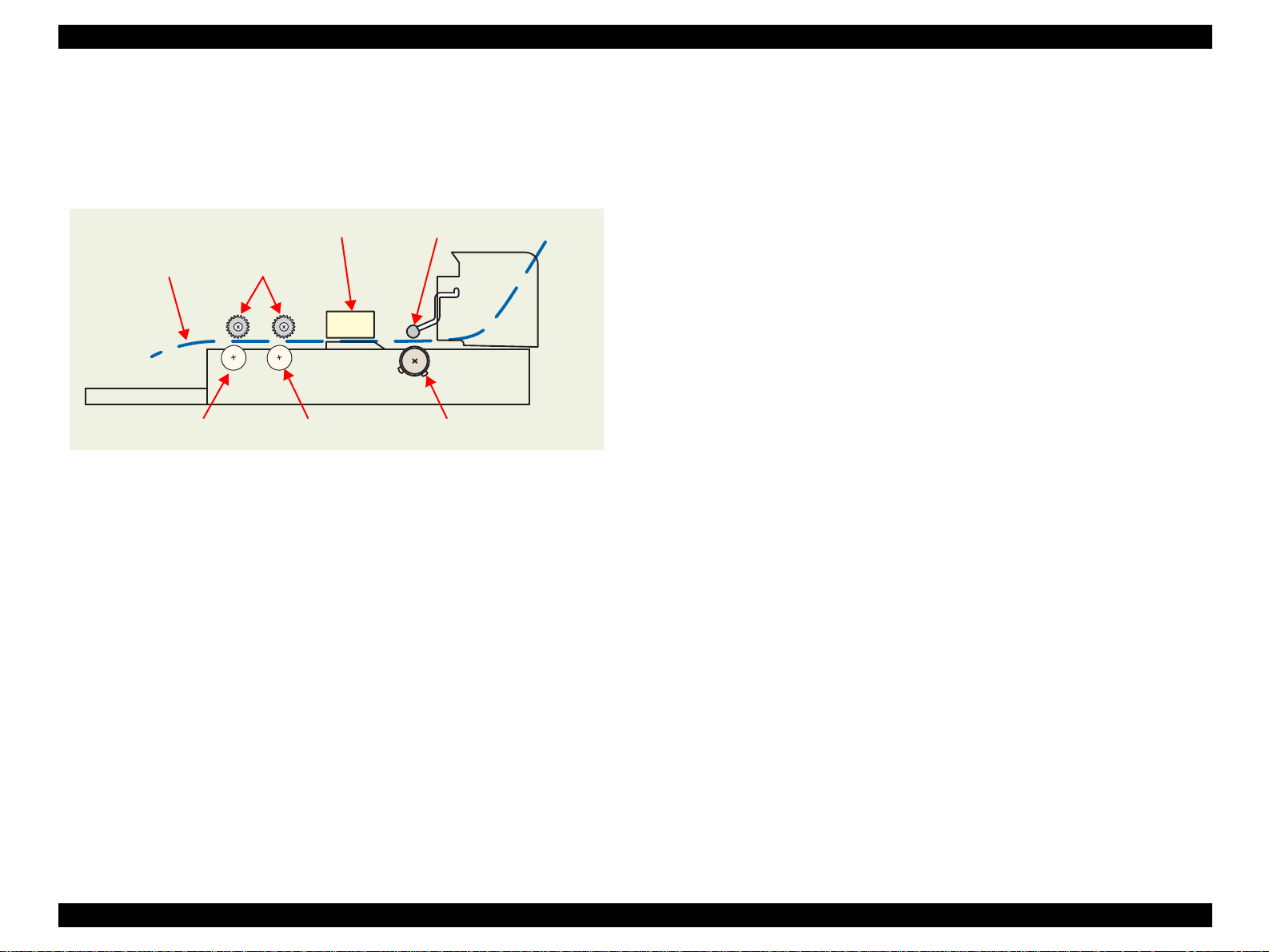

The following shows the outline of the printer mechanism.

PF Encoder

Sensor

Paper Eject

Roller (front)

PG Release

Sensor

Paper Eject

Roller (rear)

PF Roller

PW Sensor

Ink Mark

Sensor

Carriage

Unit

CR Scale

Ink System

Unit

Pump Motor

Carriage

Shaft

PF Scale

APG Sensors

PF Motor

APG Motor

Timing Belt

CR Encoder

Sensor

LD Roller

Retard

Roller

PE Sensor

ASF Motor

CR Motor

Figure 2-1. Printer Mechanism Outline

OPERATING PRINCIPLES Overview 16

Page 16

EPSON Stylus Photo R800 Revision A

2.2.1 Carriage Mechanism

The Carriage mechanism consists of the Carriage Motor (CR Motor), Carriage

Shafts, Platen Gap Adjustment Mechanism, Carriage Lock Mechanism, and

others.

2.2.1.1 Carriage Mechanism

The following indicates the Carriage driving DC motor specifications.

Table 2-2. CR Motor Specifications

Item Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Winding resistance 24.4Ω ± 15%

Inductance 17.5mH ± 25%

Drive method PWM, constant-current chopping

Drive IC A6615

Closed loop control based on the CR Motor (DC Motor) and CR Encoder

Sensor has advantages in stabilized print quality and silent operation.

Heat generation control

Using low-cost DC motors, this product grasps the variations of the torque

constants, coil resistances and power supply board output voltages of the

individual DC motors adequately to carry out heat generation control

according to individual differences.

CR variation measurement sequence

The variations of the torque constant, coil resistance and power supply

board output voltage of the motor are measured in a CR variation

measurement sequence when the CR mechanical load is in the initial

status and saved into the EEPROM (A6<H>). According to the variations

(individual differences) measured in this sequence, the voltage is corrected

to make the drive current value constant (without an individual difference)

according to the variations (individual differences) measured in this

sequence.

CR measurement sequence

To set the appropriate drive current value according to the variation of the

CR mechanical load, the mechanical load is measured in a CR

measurement sequence and saved into the EEPROM A4<H>, A5<H> in a

power-on or IC change sequence. However, if 46 is saved at the EEPROM

A4<H> and 05 at A5<H>, Fatal error will occur since too large load is

applied to the CR drive system.

The above control and sequences correct the drive current value of the CR

Motor according to not only the mechanical load but also the variations of the

motor and like. In addition, the resultant CR drive current value is used to

calculate a heating value, and when the specified heating value is reached,

wait time is provided per CR path for printing.

OPERATING PRINCIPLES Printer Mechanism 17

Page 17

EPSON Stylus Photo R800 Revision A

2.2.1.2 Carriage Home Position Detection

As in the conventional model, the Carriage Home Position is detected using the

drive current of the CR Motor and the speed/position signal of the CR Linear

Encoder.

The basic home position detection sequence is as described below.

1. The CR linear encoder pulse counter in the CPU is reset by the

initialization operation performed at power-on.

2. When the CR Motor rotates counterclockwise, the Carriage Unit moves

from left to right. When the following conditions are satisfied, the CPU

assumes that the Carriage Unit made contact with the right frame.

The ASIC detects 862/1500 counts or more in the PWM output under

CR Motor load positioning control.

P1 (number of output pulses from when power is switched on until the

Carriage Unit makes contact with the right frame) is 12 steps or less.

3. When the CR Motor rotates clockwise, the Carriage Unit moves from right

to left. When the following conditions are satisfied, the CPU assumes that

the Carriage Unit reached the CR lock confirmation position.

The ASIC detects 483/1500 counts or more in the PWM output under

CR Motor load positioning control.

A difference between P1 and P2 (number of output pulses from when

the Carriage Unit made contact with the right frame until it reaches the

Carriage lock confirmation position) is 12 steps or less.

4. When the CR Motor rotates counterclockwise to move the Carriage from

left to right and the CPU detects 862/1500 counts or more in the PWM

output under CR Motor load positioning control, the printer judges it as

contact with the frame.

5. When a difference between P1 and P3 (number of output pulses from

when the Carriage Unit reached the Carriage lock confirmation position

until it makes contact with the right frame) is 4 steps or less, the printer

judges that the Carriage Unit is in the home position.

The IC14 (ASIC) sets the drive current value adequate for the Carriage Unit

motion and outputs it to the motor driver.

Based on the signal output from the IC14 (ASIC), the IC5 (Motor Driver)

outputs the CR Motor drive current to the CR Motor.

2.2.1.3 Sequence Used for PW Detection

The PW (paper width detection) Sensor installed on the Carria ge Unit bottom is

used to control the printer according to various sequences.

The following briefly describes the PW Sensor operating principle.

A dark voltage is measured by the PW Sensor in three places on the right end

plane (area without the absorber) of the Front Paper Guide every time power is

switched on, and the measurement values are saved into the EEPROM as

threshold values.

Threshold value > detection voltage: Paper present

Threshold value < detection voltage: Paper absent

The following sequences are performed .

Off-paper printing prevention control

Before start of printing (immediately after the end of paper locating), or

during printing, whether paper is present or not is detected to prevent offpaper printing on the Paper Guide by borderless printing used in a wrong

way. (This applies to only the left or right end of the paper.)

This control applies to only the four-side borderless mode.

CD-R center detection control

When printing is not being performed, the PW detector is used to detect

the center of CD-R. Refer to "2.2.3.4 CD-R Printing Mechanism (p.23)" for

details.

Board paper/roll paper leading edge detection control

Control exercised to detect the user-preset board paper leading edge, or

control carried out to detect the roll paper edge. Therefore, the PW sensor

does not detect a paper leading edge at the time of ASF cut sheet feeding.

OPERATING PRINCIPLES Printer Mechanism 18

Page 18

EPSON Stylus Photo R800 Revision A

Off-range restriction control

At the time of frameless printing, a paper leading edge is detected using

the PW Sensor to restrict the frameless off-range am o un t.

Complete frameless mode

Control is performed to print the print data 3mm larger at top, 5mm

larger at bottom, and 2.5mm lager at left and right than the detected

paper size.

Roll paper mode

In the left and right frameless mode, control is performed to print the

print data 2.5mm lager at left and right than the detected paper size.

PW sensor dark voltage (VH) measurement

PW sensor dark voltage (VH) measurement is performed at the following

timings and locations and used to calculate the threshold value of whether

paper is present or not.

Cut sheets, Roll paper

The dark voltage is measured and updated at every power-on, and th e

threshold value (VS) is calculated and saved in the EPROM area as a

PW detection level.

• Threshold value > detection voltage: Paper present

• Threshold value < detection voltage: Paper absent

CD-R Tray

When a CD-R is used, the dark voltage is measured on the CD-R tray,

and the threshold value (VS) is then calculated and saved in the

EPROM area as a PW detection level.

• Threshold value > detection voltage: CD-R present

(tray home position detected)

The measurement voltage in the presence of the CD-R is saved into

the EEPROM as a white level. The white level value is used to check

the sensor deterioration condition during servicing or like.

• If the measurement value of the white level is close to that of the PW

detection level, it means that the sensor is dirty or deteriorated.

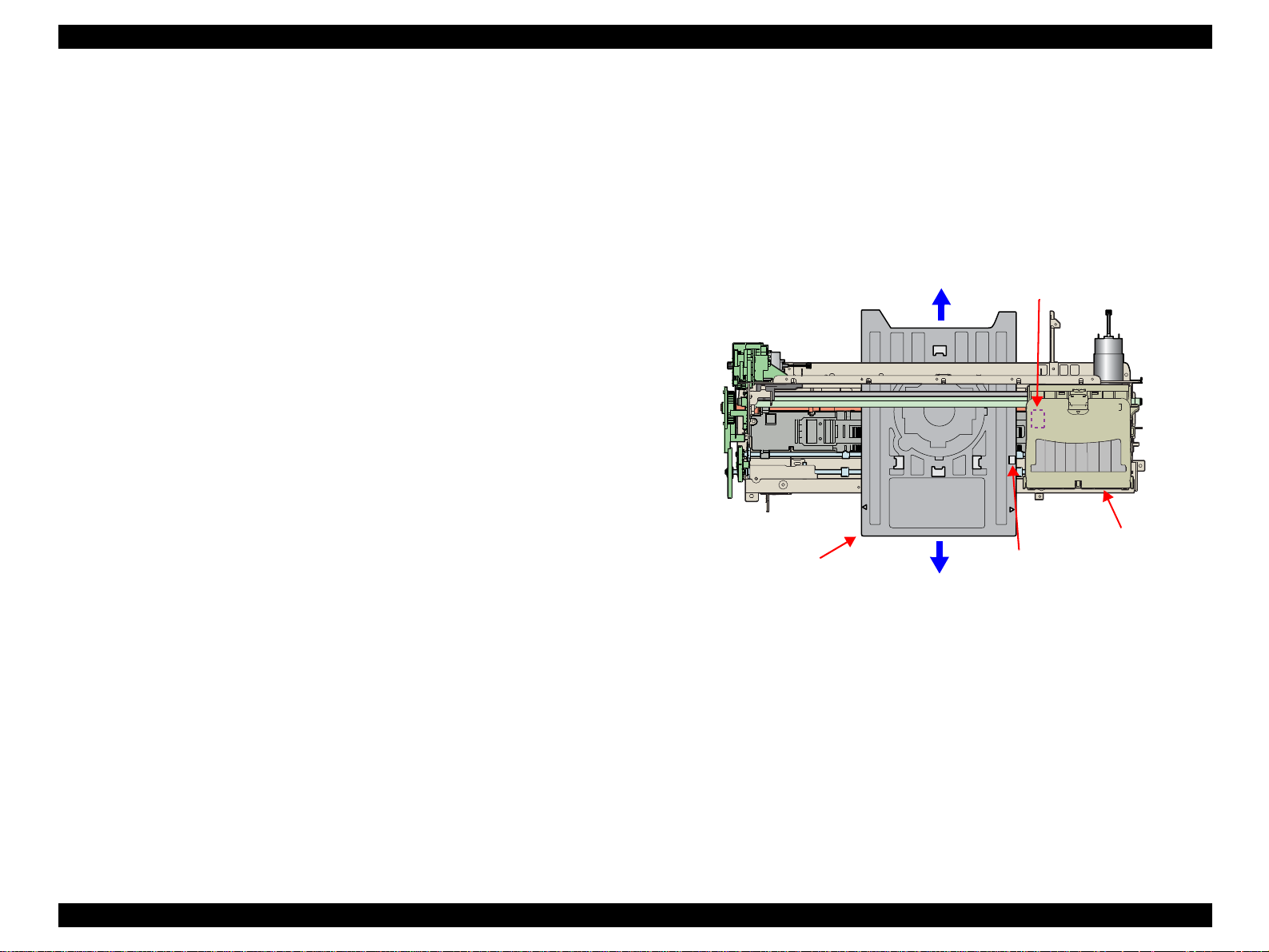

2.2.1.4 APG (Auto PG) Mechanism

The following indicates the APG DC motor specifications.

Table 2-3. APG Motor Specifications

Item Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Winding resistance 64.7Ω ± 15%

Inductance 37.6mH ± 25%

Drive method PWM, constant-current chopping

Drive IC A6615

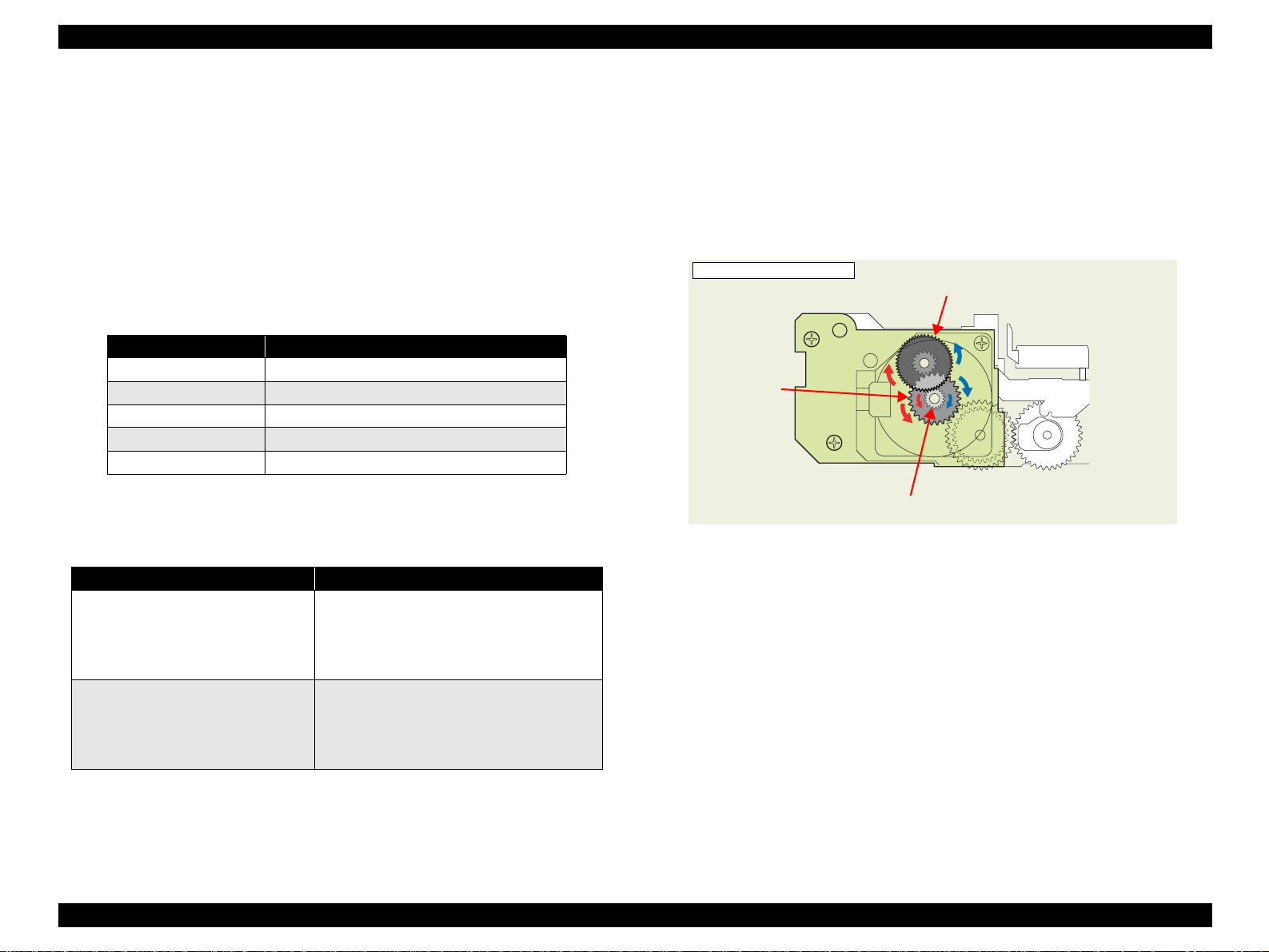

The APG Motor (DC Motor) and two APG Sensors automatically adjust the PG

amount according to the paper.

APG Motor

PG Cam

Carriage Shaft

Figure 2-2. APG Mechanism

Carriage Unit

OPERATING PRINCIPLES Printer Mechanism 19

Page 19

EPSON Stylus Photo R800 Revision A

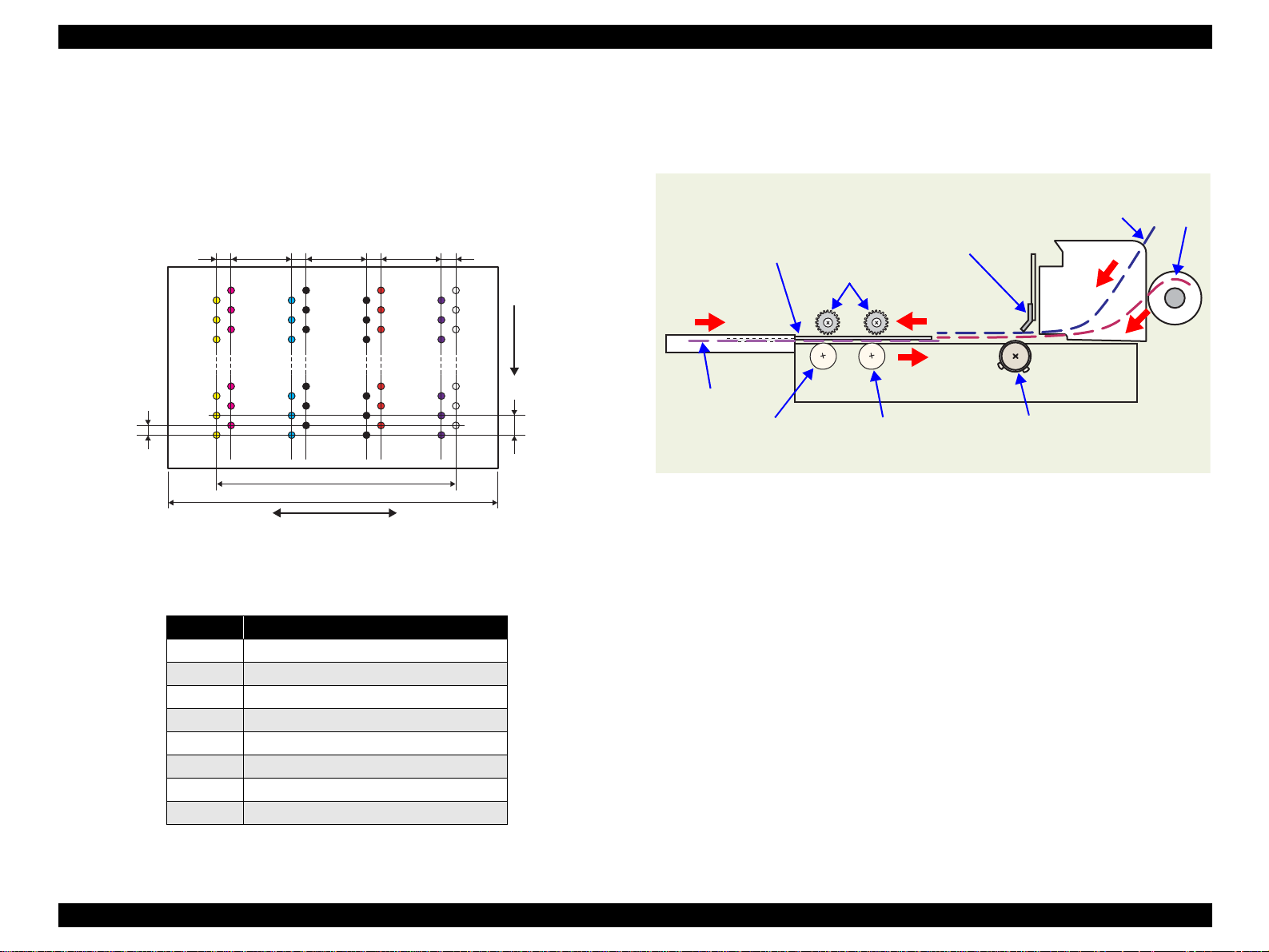

2.2.2 Printhead Specifications

The Printhead of this product is a F-Mach head.

The following shows the arrangement of the nozzles and the color

arrangement of each nozzle line when they are viewed from behind.

0.071mm

(1/360inch)

7.620mm

(216/720inch)

2.258mm

(64/720inch)

Line A

Figure 2-3. Nozzle Rear View

7.620mm

(216/720inch)

2.258mm

(64/720inch)

Line C

Line B

Carriage moving direction

(64/720inch)

Line E

Line D

31.89mm

41.66mm

(216/720inch)

2.258mm

Line F

7.620mm

2.258mm

(64/720inch)

Paper feeding

Line G

Line H

direction

0.141mm

(1/180inch)

2.2.3 Paper Feeding Mechanism

The paper feeding mechanism indicates the me ch a nism tha t feed s pa pe r or

CD-R Tray to the PF Roller Shaft.

CD-R Tray

PE Sensor

Star Wheel Rollers

Board Paper

Paper eject roller (front) Paper eject roller (rear)

Figure 2-4. Paper Feeding Mechanism

Cut sheet

PF Roller

Roll paper

Table 2-4. Relationships between Nozzle Lines and Color Arrangement

Line Ink

AYellow

B Magenta

C Cyan

D Matte-black

EPhoto-black

F Red

GBlue

H

Gloss Optimizer

OPERATING PRINCIPLES Printer Mechanism 20

Page 20

EPSON Stylus Photo R800 Revision A

2.2.3.1 ASF Paper Feeding Mechanism

The following indicates the ASF Assy. driving stepping motor specifications.

Table 2-5. ASF Motor Specifications

Item Specifications

Type 4-phase, 48-pole PM type stepping motor

Drive voltage Bipolar drive/constant-current drive

Winding resistance +42 V ± 5% (voltage applied to driver)

Inductance 7.4Ω ± 10% (per phase at 25°C)

Drive method 12.0mH ± 20% (1kH, 1Vrms)

The drive of the ASF Motor is transmitted to the LD Roller in the following path.

LD Roller Drive Transmission Path

ASF Motor Pinion Gear

⇒ Combination Gear 29, 11 ⇒ Paper Back Cam

⇒ LD Roller

ASF Motor

Paper Back Cam

Driven by the ASF Motor, the ASF Assy. performs the following feeding

operation.

1. When a paper feeding command is issued from the PC or the Paper Switch

of the panel is pressed after power-on, the driving force of the ASF Motor

begins to be transmitted to the LD Roller.

2. The flag of the Paper Back Cam moves away from the home position of the

ASF Sensor and the LD Roller rotates.

3. When the LD Roller rotates one turn and the flag of the Paper Back Cam

returns to the home position of the ASF Sensor again, the LD Roller stop s

rotating.

2.2.3.2 Manual Paper Feeding Mechanism (Board Paper)

To enable direct printing onto thick paper and CD-R label, this product has the

mechanism to feed paper from the printer front manually.

1. When the Stacker is lifted, the close signal of the PG Release Sensor is

transmitted to the APG Assy. in the following order.

PG Release Sensor

⇒ Main Board ⇒ Relay Board ⇒ APG Motor

⇒ APG Assy.

2. Driven by the APG Motor, the APG Assy. sets the PG position to PG

release to release the Upper Paper Guide (Driven Roller).

3. Along the Paper Feed Guide of the Stacker, match the leading edge (front

side) of the board paper to the marking position of the Stacker.

After the above operation, press the Paper Switch. When the PE Sensor

detects that the paper is present, it detects the leading edge of the paper, and

LD Roller Shaft

Figure 2-5. LD Roller Drive Transmission Path

Combination Gear 29, 11

the printer performs paper locating and then enters the standby status.

OPERATING PRINCIPLES Printer Mechanism 21

Page 21

EPSON Stylus Photo R800 Revision A

2.2.3.3 Roll Paper Feeding

Since panel operation in the roll paper mode differs from the above operation,

the differences of panel operation after roll paper feeding will be described.

1. When roll paper is fed, the PE Sensor detects the paper, and after 3

seconds have elapsed, the paper is fed.

2. The PW Sensor check for the leading edge of the paper, and if it detects

the paper, the printer operates in the Cutter Self-Cleaning Mode.

3. The printer back-feeds the paper to the paper print starting position.

At this time, panel Switch operation is invalid, and the definitions of the panel

operation and Paper Switch differ between cut sheets and roll paper.

The following describes a difference between Panel Switch operations

performed when roll paper is fed and performed when roll p aper printing data is

received from the PC.

When roll paper is fed

Pressing the Roll Paper Switch for more than 3 seconds back-feeds the

leading edge of the roll paper to the PE Sensor (the Paper LED blinks). In

this state, draw the roll paper and press the Paper Switch to return to the

panel operation that enables paper feeding from the ASF.

When roll paper printing data is received (when cutter is fitted)

When data is "No auto cut"

1. After end of printing, press the Roll Paper Switch. This feeds the

separation position in the print data to the roll paper cut position.

2. After the paper is cut, the leading edge of the paper retu rn s to th e

print starting position.

When data is "Standard 1 cut" or "Specific 2 cuts"

When roll paper printing data is received (when cutter is not fitted)

1. After end of printing, press the Roll Paper Switch.

2. A tear-off line is printed, and the roll paper is fed to the roll paper

cut position.

3. After cutting the roll paper with a pair of scissors or like, Press the

Roll Paper Switch. This returns the leading edge of the paper to

the print starting position.

1. The roll paper is cut automatically at every separation of the print

data.

2. After the paper is cut, the leading edge of the paper retu rn s to th e

print starting position.

OPERATING PRINCIPLES Printer Mechanism 22

Page 22

EPSON Stylus Photo R800 Revision A

2.2.3.4 CD-R Printing Mechanism

CD-R tray home position detection sequence

Lift the Stacker (PG Release Sensor: Close), insert the CD-R Tray into the

specified position, and press the Paper Switch. This starts the following

operation.

When the close signal of the PG Release Sensor is detected, no paper is

fed from the ASF if the Paper Switch is pressed. In this case, the Paper

Switch executes a CD-R Tray home position detection sequence.

1. When the APG Assy. is driven, the PG position is set to "++" and

the Driven Roller of the Upper Paper Guide presses the CD-R

Tray.

2. When the Carriage Unit moves leftward and the PW Sensor

detects the CD-R, the Carriage Unit returns to the carriage home

position (HP).

3. After waiting for about 5 seconds at the carriage HP, the Carriage

Unit moves to the CD-R Tray HP detectable position (right end of

the CD-R Tray).

4. The CD-R Tray is pulled in the ASF direction, the PW Sensor

detects the CD-R Tray HP, and then the Carriage Unit moves to

the center of the CD-R Tray.

5. When the PW Sensor detects the white marking in the center of

the CD-R Tray, the CD-R Tray is fed in the paper ejection

direction.

6. The Carriage Unit moves leftward, the PW Sensor detects the left

side white marking, then the Carriage Unit moves rightward, and

the PW Sensor detects the right side white marking.

7. The Carriage Unit moves to the center of the CD-R Tray, and the

PW Sensor starts detection in the back-and-forth direction of the

CD-R. After the leading edge of the CD-R is detected, the CD-R

Tray is fed in the paper ejection direction, and the trailing edge of

the CD-R is detected. After that, the CD-R Tray is fed to the center

of the CD-R in the paper ejection direction.

8. The Carriage Unit moves leftward, and the PW Sensor starts

detection in the horizontal direction of the CD-R. After the left end

of the CD-R is detected, the Carriage Unit moves rightward, and

the right end of the CD-R is detected.

9. The Carriage Unit moves to the CD-R Tray HP detectable position

and stops there, and then the CD-R Tray is fed in the ASF

direction.

10. When the CD-R Tray stops operating, the Carriage Unit moves to

the carriage HP and stands by.

If the CD-R Tray HP, white marking or CD-R cannot be detected in any

specified step operation in the CD-R Tray HP detection sequence, the CD-R

Tray is ejected and Paper Out Error is displayed.

PW Sensor

Carriage Unit

CD-R Tray

CD-R home position

Figure 2-6. CD-R Printing Mechanism

OPERATING PRINCIPLES Printer Mechanism 23

Page 23

EPSON Stylus Photo R800 Revision A

2.2.4 Paper Loading Mechanism

The Paper Loading Mechanism is designed to transfer the paper fed from the

ASF, Roll Paper Guide or Board Paper Guide or the CD-R fed from the CD-R

Tray according to the print data.

2.2.4.1 Paper Loading Mechanism

The following indicates the paper loading driving DC motor specifications.

Table 2-6. PF Motor Specifications

Item Specifications

Type DC motor with brushes

Drive voltage +42V ± 5% (voltage applied to driver)

Winding resistance 22.3Ω ± 25%

Inductance 17.3mH ± 25%

Drive method PWM

Drive IC A6615

Like the CR Motor, a DC motor is used as the PF Motor in this product.

Closed loop control based on the DC Motor and Rotary Encoder has the

following advantages.

Improved paper feed accuracy

Paper feed amount control

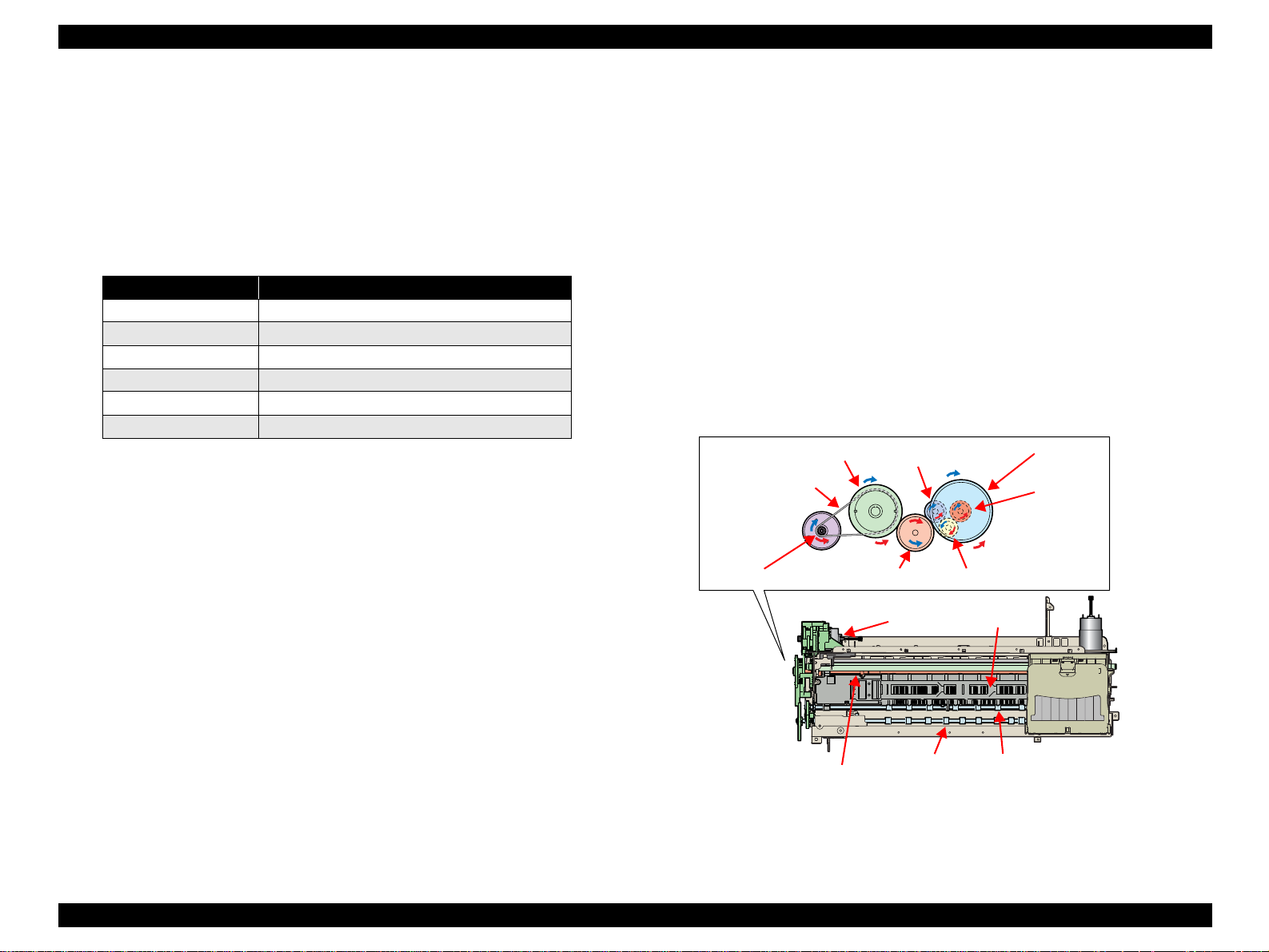

The driving force of the PF Motor is transmitted to the PF Roller and Paper

Eject Roller in the following path.

PF Roller Drive Transmission Path

PF Motor Pinion Gear

⇒ PF Timing Belt ⇒

Combination Gear 36.294, 45.5 ⇒ PF Roller Shaft

Paper Eject Roller (front) Drive Transmission Path

PF Motor Pinion Gear

⇒ PF Timing Belt ⇒

Combination Gear 36.294, 45.5 ⇒ Spur 31.5 ⇒ Spur 54 ⇒

Paper Eject Roller (front)

Paper Eject Roller (re ar) Drive Transmission Path

PF Motor Pinion Gear

⇒ PF Timing Belt ⇒

Combination Gear 36.294, 45.5 ⇒ Spur 31.5 ⇒ Spur 54 ⇒ Spur 18 ⇒

Spur 15.5

⇒ Spur 18 ⇒ Paper Eject Roller (rear)

The following shows the part names and outline of the drive transmission path.

Paper is transferred in the above driving force transmission path.

Combination Gear

36.294, 45.5

PF Timing Belt

Pinion Gear

Spur 18

Spur 31.5

PF Motor

Spur 15.5

Front Paper

Guide

Spur 54

Spur 18

PF Roller

Paper Eject

Roller (front)

Paper Eject

Roller (rear)

Figure 2-7. Paper Loading Mechanism 1

OPERATING PRINCIPLES Printer Mechanism 24

Page 24

EPSON Stylus Photo R800 Revision A

The fed paper is detected by the PE Sensor, and its leading edge is then

transferred to the front of the Front Paper Guide.

To eliminate the deflection of the paper, the paper is then returned toward the

ASF Assy. by the specified number of steps according to the paper feed mode.

The paper is transferred again to the specified paper locating position of the

Front Paper Guide.

Print Head

Paper

Paper eject roller (front) Paper eject roller (rear)

Star Wheel Rollers

Driven Roller

PF Roller

Figure 2-8. Paper Loading Mechanism 2

2.2.4.2 PF Measurement Sequence

The mechan ical load in the pap er loading path is measured in the following

cases to perform control so that an adequate current value is set according

to the mechanical load.

When power is switched on

When the Ink Cartridge is replaced

When the removal or fitting of the cutter is recognized in the paper feed

sequence

When the mech anical load in the paper loa ding p ath reaches the specified

value, Fatal Error is displayed. (When the cutter is not fitted)

When the cutter is fitted, the mechanical load when the cutter is fitted is

measured and reflected on the control since the mechanical load of the

cutter must be taken into consideration to set the adequate current value.

OPERATING PRINCIPLES Printer Mechanism 25

Page 25

EPSON Stylus Photo R800 Revision A

2.2.5 Ink System Mechanism

The Ink System Mechanism consists of the following mechanisms.

Pump Unit (including the CR Lock Lever)

Cap Unit

2.2.5.1 Pump Unit

The Pump Unit is designed to suck ink from the Print Head or Cap Unit. The

Cap Unit has a built-in Head Cleaning Wiper.

The following indicates the Pump Unit driving stepping motor specifications.

Table 2-7. Pump Motor Specifications

Item Specifications

Type 4-phase, 48-pole PM type stepping motor

Drive voltage Bipolar drive/constant-current drive

Winding resistance +42 V ± 5% (voltage applied to driver)

Inductance 10.3Ω ± 10% (per phase at 25°C)

Drive method 13.4mH ± 20% (1kH, 1Vrms)

The following operations are performed when the drive of the Pump Motor is

transmitted to the Pump Unit.

Table 2-8. Pump Motor Rotation Directions and Functions

Pump Motor Rotation Direction* Functions

• Cap closing

CW direction

CCW direction

• Ink suction

• Wiper resetting

• CR Lock setting

• Cap opening

• Pump release

• Wiper setting

• CR Lock resetting

2.2.5.2 Drive Transmission Path to Pump Unit

The drive of the Pump Motor is transmitted to the Pump Unit in the following

path.

Moto r Pinion Gear

⇒ Combination Gear 10.2, 21.2 IS

⇒ Spur Gear 20.4 IS ⇒ Pump Unit

The following shows the internal part names and operation outline of the Pump

Unit.

<Pump Unit inside>

Combination Gear 10.2, 21.2 IS

Spur Gear

20.4 IS

Motor Pinion Gear

Figure 2-9. Outline of Pump Unit Inside

Note: As the rotation directions of the motor, CW indicates a clockwise

direction, and CCW indicates a counterclockwise direction, as seen

from the output shaft side of the motor mounting plate.

OPERATING PRINCIPLES Printer Mechanism 26

Page 26

EPSON Stylus Photo R800 Revision A

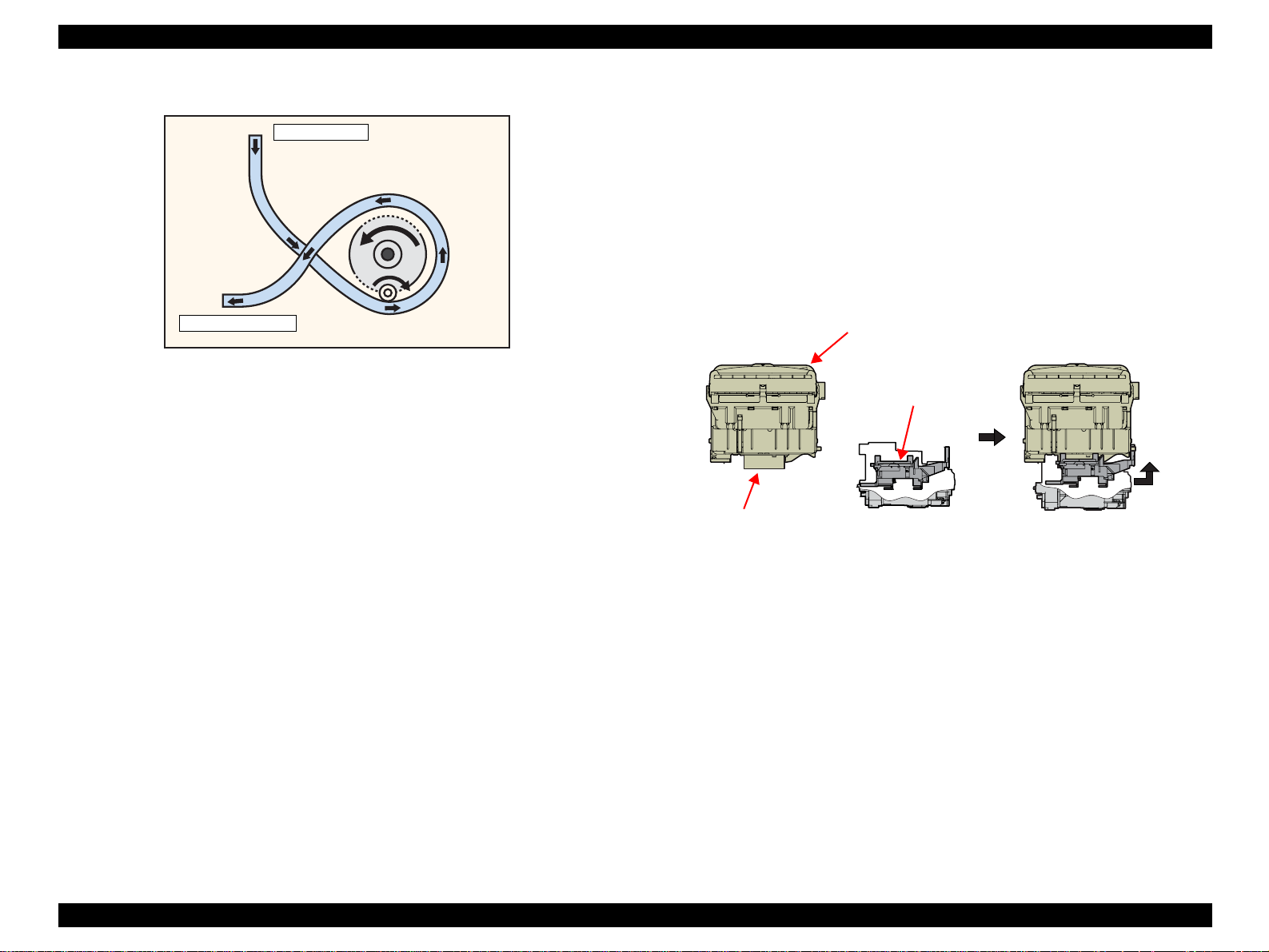

The following shows the Pump Unit operating principle.

Cap Unit Side

To Waste ink pad

Figure 2-10. Pump Unit Operating Principle

Ink suction

1. The Pinion Gear of the Pump Motor rotates in the CW direction.

2. The Roller turns and simultaneously presses the tube.

3. Ink is fed from the Cap Unit toward the Waste Ink Pad.

Pump release

1. The Pinion Gear of the Pump Motor rotates in the CCW direction.

2. The Roller moves away from the tube and releases the tube.

3. Ink is not sucked.

2.2.5.3 Cap Unit

The Cap Unit is designed to bring the Cap into close contact with the Print

Head surface and suck ink by the driving force of the Pump Unit to secure air

tightness in the Cap.

When the printer is in a standby status or its power is OFF, the Cap Unit

prevents the ink from thickening.

Ink is fed to the Waste Ink Pad in the following path.

Ink Cartridge

The following diagram shows the outline of Cap Unit operation.

Print Head

⇒ Head Cavity ⇒ Cap ⇒ Waste Ink Pad

Carriage Unit

Cap

Slider cap rises to perform

capping.

Figure 2-11. Capping Mechanism

OPERATING PRINCIPLES Printer Mechanism 27

Page 27

EPSON Stylus Photo R800 Revision A

2.2.6 Ink Sequence

The following ink sequence is executed according to various timer, counter,

flag and other information saved on the EEPROM.

CSIC-related sequence

The ink type code stored in the CSIC Memory Chip is identical regardless

of the Japanese domestic or overseas cartridges, and is saved at the Main

Board EEPROM.

At power-on, data is read from each color CSIC and the CSIC data status

is made valid. If the data read from each CSIC has any problem, Ink

cartridge error or Ink end error is displayed.

After CSIC operation is checked, the ink consumption of the I/C currently

installed per color is compared with the ink consumption saved in the

printer EEPROM, and control is performed under the following conditions.

When current I/C consumption differs (from ink consumption in

EEPROM)

1. On the assumption that the I/C has been changed at power-off, the

first I/C flag is reset.

2. The installation count in the printer EEPROM is updated for the

CSIC. In the CSIC information replacement sequence, the CSIC

side ink consumption data is updated to the ink consumption data

in the printer EEPROM.

3. The used model name data on the I/C side is rewritten.

Note: Reason why the used model name data is rewritten from the

printer to the I/C: To grasp which printer used the I/C removed.

4. The change flag 2 (flag that indicates change CL) is set and CL is

executed.

When current I/C consumption is the same (as ink consumption in

EEPROM)

1. When the initial filling flag is set and the CSIC side ink

consumption is 0, the printer judges that initial filling is not yet

performed.

(The printer before initial filling judges that the I/C is fitted in a

power-off status.)

2. Installation count updating, CSIC information replacement, and

initial filling are executed in this order.

3. If the initial filling flag is not set, the printer judges that I/C change

was not made at power-off and regards the CSIC data as valid.

Data is written to the CSIC at the following timings.

At powe r- of f

In the power saving mode

At the tim e of Ink C artr i dg e re pla ce m en t

At the time of cleaning

1. Data is read from the CSIC and developed in the RAM on the Main

Board.

2. The data is compared with the ink consumption in the printer

EEPROM. If the data are the same, the data is written to the CSIC.

If they are different, only the consumed difference is added and

written to the CSIC. When cleaning is performed, the CL count is

also written, and when the I/C is changed, the installation count is

also written.

OPERATING PRINCIPLES Printer Mechanism 28

Page 28

EPSON Stylus Photo R800 Revision A

Initial ink filling

When the printer is powered on for the first time after the purchase of the

product, the printer executes the initial ink filling operation to fill the ink

cavities of the Head with ink. When the initial ink filling operation is

performed properly, the printer clears the flag in the EEPROM so that initi al

ink filling operation will not be performed when it is powered on next. The

Stylus Photo R800 requires about 150 seconds to perform the initial ink

filling operation and consumes about 1/ 7 of the new ink cartridge.

If the sequence does not end normally during initial filling, the initial filling

flag is not cleared and the CL operating flag is set. Because of these flags,

when powered on next time, the printer assumes that it was powered off for

some reason during initial filling and executes CL3 instead of the initial

filling sequence. (On the conventional mode, initial filling was executed

again. However, when this operation was performed, ink was wasted and

therefore CL3 is executed to cover the ink filling performance.)

When the initial filling flag is set and the CL operating flag is not set, the

printer assumes that the initial filling was not executed at all (power was

switched on but the cartridges were not set), and when the printer is

powered on next time, it executes initial filling.

Change cleaning

Change CL1 is executed when Ink Cartridge change is made.

Change CL1: 3.4g (0.425g per color)

Manual cleaning

This product provides three different manual cleanings to remove ink

coagulated by air bubbles, viscous material or foreign matter. Perform the

following manual CL operations by operating the panel or using the utility

included in the printer driver.

Independently of the printing path after the previous CL, perform manual

CL from CL1 to CL3 in order if the cumulative printing timer counter is less

than 7min. Only when the cumulative printing timer counter is more than

7min, execute only CL1.

CL1: 1.704g (0.213g per color)

CL2: 4.488g (0.561g per color)

CL3: 7.120g (0.890g per color)

Wiper operation

Clean the nozzle surface with the right-half rubber part of the wiper.

Flushing operation

Prevent color mixture. Stabilize the ink surface inside the nozzles.

If the remaining ink amount of the I/C is short or the I/C is in an Ink Low/Out

status, all manual cleanings are disabled and STM3 shows the condition.

OPERATING PRINCIPLES Printer Mechanism 29

Page 29

EPSON Stylus Photo R800 Revision A

Timer cleaning

Ink is consumed depending on the combination of the cumulative printing

timer, cumulative cleaning count and cleaning timer.

Flushing

Two different flushing operations are executed for the following reasons.

Periodic flushing

This is done to prevent ink viscosity in the Print Head nozzles from

increasing during continuous printing. A specific small amount of ink is

discharged into the Cap according to the Periodic flushing timer.

Periodic large-amount flushing

This is done to prevent ink viscosity in the Print Head nozzles from

increasing during continuous printing. A large amount of ink is

discharged into the Cap according to the Periodic large-amount

flushing timer.

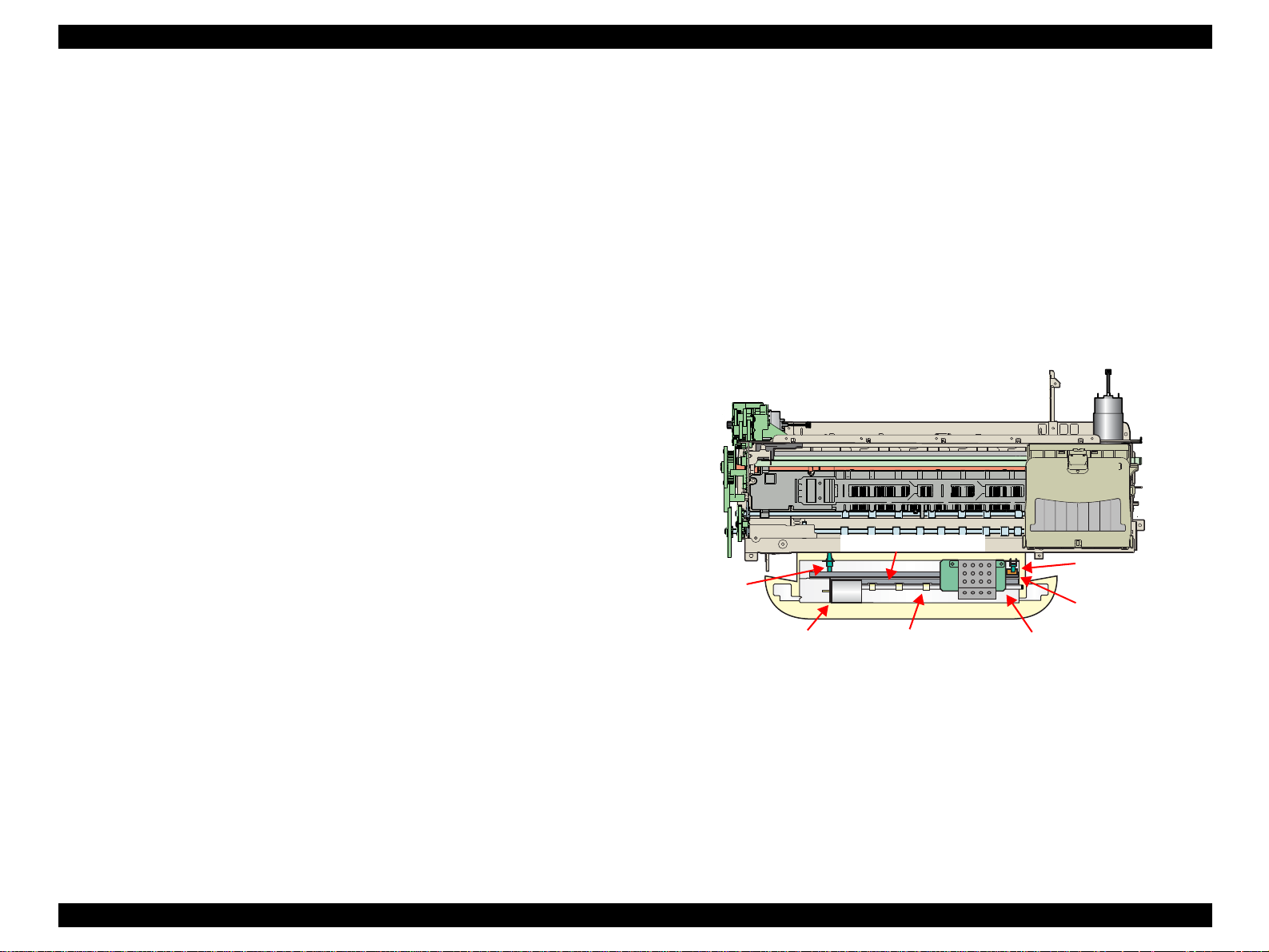

2.2.7 Paper Cutter Mechanism

The Paper cutter mechanism consists of such main parts as the Cutter Motor,

left and right HP Sensors (2 pcs. in all), Relay Board, Paper Eject Roller and

Paper Holddown Flap in the Cutter unit.

Operation during printing

When the Cutter Blade starts cutting, the Paper Hold-down Flap rises.

The paper is held and simultaneously cut.

The HP Sensors installed on both ends of the Cutter operating area

detect the Cutter Blade position.

The HP Sensors detect whether the Cutter Blade operates properly,

and Cutter Position Error or Cutter Jam Error is displayed according to

the operating condition.

Paper Holddown Flap

Left HP

Sensor

Right HP Sensor

Cutter Blade

Cutter Motor

Paper Eject Roller

Relay Board

Figure 2-12. Paper Cutter Mechanism

OPERATING PRINCIPLES Printer Mechanism 30

Page 30

EPSON Stylus Photo R800 Revision A

2.2.7.1 Cutter Initialization Sequence

When the Cutter is fitted, the Cutter initialization sequence is executed if the

printer has confirmed that the Cutter has been fitted (the Power Switch blinks

about 5 seconds).

Cutter Initialization Sequence

The initialization sequence is performed to securely put the Cutter Blade in

a standby position detected by the right HP Sensor if the Cutter Blade is

not detected by the right HP Sensor.

The initialization operation is not performed if the Cutter Blade is in the

right HP Sensor position when the Cutter is fitted.

During Cutter operation, Cutter Position Erro r or Cutter Jam Erro r ma y oc cur .

These errors are explained below.

If the Cutter Blade cannot reach the left or right HP Sensor, the Cutter

Blade is returned to the HP Sensor located in the motion starting position

(right HP Sensor).

Cutte r Ja m Err or

Indicates that the Cutter Blade can return to the HP Sensor position in

the motion starting position within 3 seconds.

Cutter Position Error

Indicates that the Cutter Blade cannot return to the HP Sensor p osition

located in the motion starting position within 3 seconds.

Paper cutting by the Cutter consists of the basic cutting sequences 1 and 2.

Basic cutting sequences 1

Means movement from the right HP Sensor to the left HP Sensor. At this

time, as soon as the Cutter Blade starts moving from the right HP Sensor,

the Timer starts. If the left HP Sensor does not detect the Cutter Blade

within 3 seconds, the Cutter initialization sequence is executed and then

Cutter Jam Error or Cutter Position Error occurs.

Basic cutting sequences 2

Means movement from the left HP Sensor to the right HP Sensor. At this

time, if the Cutter Blade cannot move from the left HP Sensor to the right

HP Sensor within 3 seconds, Cutter Position Error occurs.

2.2.7.2 Cutter Self-cleaning

This sequence indicates the operation performed to hold down and remo ve the

ink, which may stick to the Plate above the Paper Hold-down Fl ap (Plate where

the paper print surface comes into contact), with the leading edge of the fed roll

paper.

The Cutter Blade must be operated left-to-right to operate the Paper Holddown Flap. At this time, the Cutter Blade generates operating noise during

Cutter self-cleaning when the roll paper is fed.

2.2.7.3 Cutter Cleaning (Driver Side)

This sequence is executed on the driver side. By cutting the roll paper three

times at intervals of 7cm, the ink that may stick to the Cutter Blade is removed

to clean the Cutter Blade.

OPERATING PRINCIPLES Printer Mechanism 31

Page 31

EPSON Stylus Photo R800 Revision A

2.2.8 Power-On Sequence

The following explains the operation to be performed when the Carriage Unit is

inside or outside the HP with the printer powered on.

CARRIAGE UNIT INSIDE HP (CR LOCKED)

1. After power-on, the drive of the APG Motor is transmitted to the Carriage

Shaft, and the PG position changes from PG Typ. to PG++.

2. The drive of the CR Motor is transmitted to the Carriage Unit, and the

Carriage Unit performs HP detection operation in the following path.

Home position ⇒ Right frame ⇒ CR Lock confirmation position

⇒ Right frame ⇒ Home position

3. The drive of the Pump Motor is transmitted to the Cap Unit, the Cap opens

(lowers), and the CR Lock is released.

4. After the Carriage Unit has moved leftward by the specified number of

steps, the Wiper is driven by the Pump Motor to perform the following

operation, and during that period, ink is sucked for about 4 seconds.

Wiper setting ⇒ Wiper resetting

5. The Carriage Unit returns to the home position, and the PG position

returns from PG++ to PG Typ.

6. The drive of the PF Motor is transmitted to the PF Roller and Paper Eject

Rollers (front and rear), which then rotate for about 2 seconds.

7. After moving between the left and right frames twice, the Carriage Unit

moves to the right end of the Front Paper Guide.

8. The PF Roller and Paper Eject Rollers (front and rear) rotate.

Rotation for about 4 seconds (slow speed) ⇒ Rotation for about 2

seconds

9. The Carriage Unit returns to the home position and is fixed by the CR Lock.

CARRIAGE UNIT OUTSIDE HP

1. When the PG position is other than PG++ after power-on, the drive of the

APG Motor is transmitted to the Carriage Shaft, and the PG position

changes to PG++.

2. The drive of the CR Motor is transmitted to the Carriage Unit, and the

Carriage Unit returns to the home position at slow speed.

3. The drive of the PF Motor is transmitted to the PF Roller and Paper Eject

Rollers (front and rear), which then rotate for about 2 seconds.

4. After the Carriage Unit has moved leftward by the specified number of

steps, the Wiper is set, driven by the Pump.

5. After the Carriage Unit has returned to the home position, it moves leftward

again by the specified number of steps. And, driven by the Pump Motor, ink

is sucked for about 4 seconds and then the Wiper is set, and the CR Lock

is placed.

6. The Carriage Unit performs HP detection operation in the following path.

Home position ⇒ Right frame ⇒ CR Lock confirmation position

⇒ Right frame ⇒ Home position

7. The drive of the Pump Motor is transmitted to the Cap Unit, the Cap o pens

(lowers), and the CR Lock is released.

8. The Carriage Unit returns to the home position, and the PG position

returns from PG++ to PG Type.

9. The drive of the PF Motor is transmitted to the PF Roller and Paper Eject

Rollers (front and rear), which then rotate and stop as described below.

Rotation for about 3 seconds ⇒ Stop for about 0.5 seconds ⇒

Rotation for about 2 seconds

10. As soon as the operation in step 9 starts, the drive of the ASF Motor is

transmitted to the LD Roller, and the LD Roller rotates one turn.

11. The operations in Steps 7 to 9 of "Carriage Unit inside HP (CR locked)

(p32)" are performed, and the Carriage Unit is locked.

OPERATING PRINCIPLES Printer Mechanism 32

Page 32

EPSON Stylus Photo R800 Revision A

2.3 Electrical Circuitry Operating Principles

The electrical circuitry of Stylus Photo R800 consists of the following circuits.

Control circuit board : C550 MAIN

Power supply circuit board : C550 PSB/PSE

Control panel board : C550 PNL

The following shows how the three circuit boards are connected.

PNL Board

MAIN Board

CR Motor

PF Motor

APG Motor

ASF Motor

Pump Motor

Head drive circuit

Printer

Mechanism

2.3.1 Power Supply Circuit Operating Principle

The power supply circuit board of this product is the C550 PSB/PSE.

Basic circuit structure

RCC switching regulator system

+42VDC and +3.3VDC are supplied to the Printer Mechanism and

Control Board

The following indicates the applications of the voltages generated in this power

supply circuit.

Table 2-9. Supplied Power

Voltage Applications

+42VDC

Rated output current: 0.45A

+3.3VDC

Rated output current: 0.5A

• CR Motor

•PF Motor

•PG Motor

•ASF Motor

•Pump Motor

• Head drive voltage

• Logic sensor circuit

• Sensor circuit

• Nozzle selection circuit (above Print Head)

• Interface control circuit

Sensors

Power OFF +3.3VDC +42VDC

PSB/PSE

Power Supply

Board

Figure 2-13. Electrical Circuitry Block Diagram

OPERATING PRINCIPLES Electrical Circuitry Operating Principles 33

Page 33

EPSON Stylus Photo R800 Revision A

The following is the block diagram of the power supply circuit.

2.3.2 C550 MAIN Circuit Operating Principle

The C550 MAIN Board consists of the following circuits and sensors.

Logic Circuits (CPU-ASIC 2 in 1, PROM, SDRAM)

Motor control/Drive circuits

(CR Motor, PF Motor, APG Motor, ASF Motor, Pump Motor)

Head control/Drive circuit

Interface Circuits

USB 2.0, IEEE1394

Sensor circuits

Reset circuits

EEPROM circuit

D/A converter circuit

Figure 2-14. Power Supply Circuit Block Diagram

OPERATING PRINCIPLES Electrical Circuitry Operating Principles 34

Page 34

EPSON Stylus Photo R800 Revision A

The following indicates differences between the control circuits of this product

and conventional model.

Adoption of 1.5V drive logic circuit components

The 1.5V voltage is generated by the Regulator IC installed on the C550

MAIN Board that reduces +3.3VDC generated by the C550 PSB/PSE

Board, and is used to drive multiple components.

This is done to reduce the power of the logic circuit.

The following table indicates the 3.3V drive components and 1.5V drive

components.

Table 2-10. 3.3V and 1.5V Drive Components

3.3V 1.5V

• Nozzle selection circuit

(above Print Head)

• CR Encoder Sensor

• PE Sensor

• PG Release Sensor

•CSIC

• CPU-ASIC 2 in 1

•PROM

• SDRAM

• Motor circuit

• Panel LED

• Interface circuit

• USB 2.0

• Sensors

(other than CR Encoder Sensor, PE

Sensor, PG Release Sensor)

OPERATING PRINCIPLES Electrical Circuitry Operating Principles 35

Page 35

EPSON Stylus Photo R800 Revision A

The following is the block diagram of the C550 MAIN control board.

CR Motor

IEEE 1394

CN3

IEEE 1394

(IC1)

PROM

(IC4, IC15)

SDRAM

(IC12)

USB

CN2

Reset

(IC13)

Data

Address

CPU-ASIC

2 in 1

(IC14)

CN5

DAC

(IC2)

Motor

Driver

(IC5)

Motor

Driver

(IC6)

Relay Board

CN4

PF Motor

APG Motor

ASF Motor

Pump Motor

PF Encoder Sensor

CR Encoder Sensor

Ink Mark Sensor

PW Sensor

C550 PSB/PSE Board

C550 Panel Board

CSIC Board

Cutter Unit

Reset

(IC16)

CN4

CN7

CN8

CN10

CN6

EEPROM

(IC3)

Head

Driver

(IC7)

CN11

CN12

Q13, Q14

CN13

CN14

PE Sensor

PG Release Sensor

ASF Sensor

APG Sensor 1

APG Sensor 2

Print Head

Figure 2-15. C550 MAIN Control Board Block Diagram

OPERATING PRINCIPLES Electrical Circuitry Operating Principles 36

Page 36

TROUBLESHOOTING

CHAPTER

3

Page 37

EPSON Stylus Photo R800 Revision A

3.1 Overview

This chapter describes unit-level troublesh oo tin g.

3.1.1 Troubleshooting according to panel messages

After checking the printer LED and EPW3 error indications, you can grasp the fault location using the check list in this section. When you have found the fault

location, refer to Chapter 4 "Disassembly and Reassembly" and change the corresponding part and/or unit. The following table indicates the check point reference

tables corresponding to the error states (LED and EPW3).

Table 3-1. Reference Tables of Error States

Error State Reference Table

Communication Error Refer to Table 3-2 "Phenomenon-Based Communication Error Check Points" on page 39

Model Difference Refer to Table 3-2 "Phenomenon-Based Communication Error Check Points" on page 39

Cover Open Error Refer to Table 3-3 "Phenomenon-Based Cover Open Error Check Points" on page 42

Paper Out Error Refer to Table 3-4 "Phenomenon-Based Pap er Out Error Check Points" on page 43

Paper Jam Error Refer to Table 3-5 "Phen omenon-Based Paper Jam Error Check Points" on page 48

Card Loading Error Refer to Table 3-6 "Phenomenon-Based Card Loading Error Check Points" on page 49

Paper Mismatch Error Refer to Table 3-7 "Phenomenon-Based Paper Mismatch Error Check Points" on page 50

Ink Low Refer to Table 3-8 "Phenomenon-Based Ink Low Check Points" on page 50

Ink Out Error Refer to Table 3-9 "Phenomenon-Based Ink Out Error Check Points" on page 50

No Ink Cartridge/CSIC Error Refer to Table 3-10 "Phenomenon-Based No Ink Cartridge/Ink Cartridge Error Check Points" on page 51

Cutter Jam Error Refer to Table 3-11 "Phenomenon-Based Cutter Jam Error Check Points" on page 53

Cutter Position Error Refer to Table 3-12 "Phenomenon-Based Cutter Position Error Check Points" on page 54

Maintenance Request Refer to Table 3-13 "Phenomenon-Based Maintenance Request Check Points" on page 55

Fatal Error Refer to Tabl e 3-14 "Phenomenon-Based Fatal Error Check Points" on page 56

TROUBLESHOOTING Overview 38

Page 38

EPSON Stylus Photo R800 Revision A

Table 3-2. Phenomenon-Based Communication Error Check Points

Occurrence

Timing

Phenomenon Detail

At power-on The printer does not operate

at all.

Faulty Part/

Part Name

Panel FFC 1. Check that the Panel FFC is securely connected to the

Panel Board connector and Main Board connector (CN8).

Panel FFC

Main Board

connector

Check Point Remedy

1. Connect the Panel FFC to the Panel

Board and Main Board connectors.

Panel FFC

Panel Board

connector

2. Check the Panel FFC for damage. 2. Change the Panel FFC for a new one.

Panel Board 1. Check the Panel Board for damage. 1. Change the Panel Board for a new one.

Power Supply

Board

1. Check that the Connector cable of the Power Supply

Board is securely connected to the Main Board (CN7).

Blue line

Connector cable

of the Power

Supply Board

1Pin side

1. Connect the Connector cable of the

Power Supply Board.

2. Check that the blue line side pin of the Power Supply

Board Connector cable is inserted into the 1 Pin. (Refer to

the above photo.)

2. Match and connect the blue line of the

Power Supply Board Connector cable

into the 1 Pin.

TROUBLESHOOTING Overview 39

Page 39

EPSON Stylus Photo R800 Revision A

Table 3-2. Phenomenon-Based Communication Error Check Points

Occurrence

Timing

At power-on The printer does not operate

Phenomenon Detail

at all.

After the power-on sequence

has started, the LED turns off

and the printer does not

operate.

Faulty Part/

Part Name

Power Supply

Board

Main Board 1. Check that the Relay connector of the ASF Motor and the

3. Check that the Fuse (F1) on the Power Supply Board is not

blown.

4. Check the devices on the Power Supply Board for

damage.

Relay connector of the Pump Motor are not connected to

cause a short circuit.

Relay Connector

of the ASF Motor

Check Point Remedy

Fuse (F1)

3. Change the Power Supply Board for a

new one.

4. Change the Power Supply Board for a

new one.

1. Change the Main Board for a new one.

Relay Connector

of the Pump Motor

TROUBLESHOOTING Overview 40

Page 40

EPSON Stylus Photo R800 Revision A

Table 3-2. Phenomenon-Based Communication Error Check Points

Occurrence

Timing

At operation Operation at power-on is

Phenomenon Detail

normal, but the error appears

when the print jog is sent to

the printer.

Faulty Part/

Part Name

Interface cable 1. Check that the Interface cable is connected between the

PC and printer.

2. Check the Interface cable for wire break. 2. Change the Interface cable for a new

EPSON

USB driver

USB 1. Check that the PC and printer are connected via the USB

IEEE1394 1. Check that the same code as the IEEE1394 QR label code

Printer driver 1. Check that the Stylus Photo R800 printer driver has been

Main Board 1. Check that a wrong model name has not been input to the

1. When USB is used, check that the EPSON USB driver has

been installed in the PC.

hub.

is saved at BA<H> to BE<H> of the EEPROM.

installed.

2. Check that the connected printer is the Stylus Photo R800. 2. Connect the Stylus Photo R800 printer.

EEPROM address (E0<H>) on the Main Board.

Check Point Remedy

1. Connect the Interface cable to the PC

and printer.

one.

1. Install the EPSON USB driver.

1. Enter the USB serial No. indicated on the

product nameplate.

(Refer to Chapter 5 "ADJUSTMENT".)

1. Input the code given as the IEEE1394

QR label code.

(Refer to Chapter 5 "ADJUSTMENT".)

1. Install the Stylus Photo R800 printer

driver.

1. Using the Adjustment Program, enter the

correct model name (save 02 into

E0<H>).

(Refer to Chapter 5 "ADJUSTMENT".)

TROUBLESHOOTING Overview 41

Page 41

EPSON Stylus Photo R800 Revision A

Table 3-3. Phenomenon-Based Cover Open Error Check Points

Occurrence

Timing

During printing Cover Open Error is

Phenomenon Detail

displayed during printing in

the "Economy" mode.

The Printer Cover is in a

closed state but Cover Open

Error is displayed.

Faulty Part/

Part Name

Printer Cover 1. Che ck that the Printer Cover is not open. 1. Close the Printer Cover.

Cover Open

Sensor

1. Check that the Connector cable of the Cover Open Sensor

is securely connected to the connectors of the Cover Open

Sensor and Panel Board.

Panel Board

2. Check the Cover Open Sensor for damage. 2. Change the Cover Open Sensor for a

Check Point Remedy

1. Connect the Connector cable of the

Cover Open Sensor to the connectors of

the Cover Open Sensor and Panel

Board.

Cover Open Sensor

new one.

TROUBLESHOOTING Overview 42

Page 42

EPSON Stylus Photo R800 Revision A

Table 3-4. Phenomenon-Based Paper Out Error Check Points

Occurrence

Timing

Phenomenon Detail

At operation When the Paper Switch was

pressed, the LD Roller

attempt to feed paper but the

paper is not fed.

Faulty Part/

Part Name

Check Point Remedy

ASF Assy. 1. Check the LD Roller or Retard Roller of the ASF Assy. for

paper dust and foreign matter.

1. Using a cleaning sheet, clean the LD

Roller and Retard Roller. The procedure

is as follows.

(1) Place the cleaning sheet upside

down and put it into the ASF Assy.

(2) Press the Paper Switch to start

paper feed.

(3) Repeat the above steps several

times.

* To remove persistent contamination,

staple an alcohol-dampened cloth to a

postcard and clean the rollers in the

following method.

Cleaning sheet Postcard used

Non-adhesive part

Adhesive part

This side down

as mount

Stapling

Cloth damped

with alcohol

(1) Place the alcohol-dampened cloth

toward the LD Roller surface of the

ASF Assy.

(2) Hold the mount top end securely

and press the Paper Switch.

(3) Repeat the paper feed sequence

several times to clean the LD Roller

surface of the ASF Assy.

TROUBLESHOOTING Overview 43

Page 43

EPSON Stylus Photo R800 Revision A

Table 3-4. Phenomenon-Based Paper Out Error Check Points

Occurrence

Timing

At operation Paper is not fed. ASF Motor 1. Check that the Connector cable of the ASF Motor is

Phenomenon Detail

Faulty Part/

Part Name

Check Point Remedy

connected to the Relay Connector.

ASF Motor

Relay Connector

2. Using a tester, check the resistance value of the ASF

Motor.

Resistance value: 7.4Ω ± 10%

3. Check the ASF Motor connector cable for damage. 3. Change the ASF Motor for a new one.

1. Connect the Connector cable of the ASF

Motor to the Relay Connector.

2. If the resistance value is abnormal,

change the ASF Motor for a new one.

TROUBLESHOOTING Overview 44