Page 1

SERVICE MANUAL

Color Inkjet Printer

L800/L801

Confidential

SEMF10-008

Page 2

Notice:

All rights reserved. No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying,

recording, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would greatly appreciate being

informed of them.

The contents of this manual are subject to change without notice.

The above not withstanding SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences thereof.

EPSON is a registered trademark of SEIKO EPSON CORPORATION.

Note :Other product names used herein are for identification purpose only and may be trademarks or registered trademarks of their respective owners. EPSON dis-

claims any and all rights in those marks.

Copyright 2011 SEIKO EPSON CORPORATION

I&I CS Quality Assurance Department

Confidential

Page 3

Safety Precautions

All safety procedures described here shall be strictly adhered to by all parties servicing and maintaining this product.

DANGER

Strictly observe the following cautions. Failure to comply could result in

serious bodily injury or loss of life.

1. Always disconnect the product from the power source and peripheral

devices when servicing the product or performing maintenance.

2. When performing works described in this manual, do not connect to a

power source until instructed to do so. Connecting to a power source

causes high voltage in the power supply unit and some electronic

components even if the product power switch is off. If you need to perform

the work with the power cable connected to a power source, use extreme

caution to avoid electrical shock.

WARNING

Strictly observe the following cautions. Failure to comply may lead to personal

injury or loss of life.

1. Always wear protective goggles for disassembly and reassembly to protect

your eyes from ink in working. If any ink gets in your eyes, wash your eyes

with clean water and consult a doctor immediately.

2. When using compressed air products; such as air duster, for cleaning

during repair and maintenance, the use of such products containing

flammable gas is prohibited.

Confidential

Page 4

PRECAUTIONS

Strictly observe the following cautions. Failure to comply may lead to personal injury or damage of the product.

1. Repairs on Epson product should be performed only by an Epson certified

repair technician.

2. No work should be performed on this product by persons unfamiliar with

basic safety knowledge required for electrician.

3. The power rating of this product is indicated on the serial number/rating

plate. Never connect this product to the power source whose voltages is

different from the rated voltage.

4. Replace malfunctioning components only with those components provided

or approved by Epson; introduction of second-source ICs or other nonapproved components may damage the product and void any applicable

Epson warranty.

5. In order to protect sensitive microprocessors and circuitry, use static

discharge equipment, such as anti-static wrist straps, when accessing

internal components.

6. Do not tilt this product immediately after initial ink charge, especially after

performing the ink charge several times. Doing so may cause ink to leak

from the product because it may take some time for the waste ink pads to

completely absorb ink wasted due to the ink charge.

7. Never touch the ink or wasted ink with bare hands. If ink comes into

contact with your skin, wash it off with soap and water immediately. If you

have a skin irritation, consult a doctor immediately.

8. When disassembling or assembling this product, make sure to wear gloves

to avoid injuries from metal parts with sharp edges.

9. Use only recommended tools for disassembling, assembling or adjusting

the printer.

10. Observe the specified torque when tightening screws.

11. Be extremely careful not to scratch or contaminate the following parts.

Nozzle plate of the printhead

CR Scale

PF Scale

Coated surface of the PF Roller

Gears

Rollers

Exterior parts

12. Never use oil or grease other than those specified in this manual. Use of

different types of oil or grease may damage the component or give bad

influence on the printer function.

13. Apply the specified amount of grease described in this manual.

14. Make the specified adjustments when you disassemble the printer.

15. When cleaning this product, follow the procedure described in this manual.

16. When transporting this product after filling the ink in the printhead, pack

the printer without removing the ink cartridges in order to prevent the

printhead from drying out.

17. Make sure to install antivirus software in the computers used for the

service support activities.

18. Keep the virus pattern file of antivirus software up-to-date.

Confidential

Page 5

About This Manual

This manual, consists of the following chapters, is intended for repair service personnel and includes information necessary for properly performing maintenance

and servicing the product.

Manual Configuration

CHAPTER 1. DISASSEMBLY / REASSEMBLY

Describes the disassembly/reassembly procedures for main parts/units of

the product, and provides the standard operation time for servicing the

product.

CHAPTER 2. ADJUSTMENT

Describes the required adjustments for servicing the product.

CHAPTER 3. MAINTENANCE

Describes maintenance items and procedures for servicing the product.

CHAPTER 4. APPENDIX

Provides the following additional information for reference:

• Power-On Sequence

• Standard Operation Time for servicing the product

• Troubleshooting

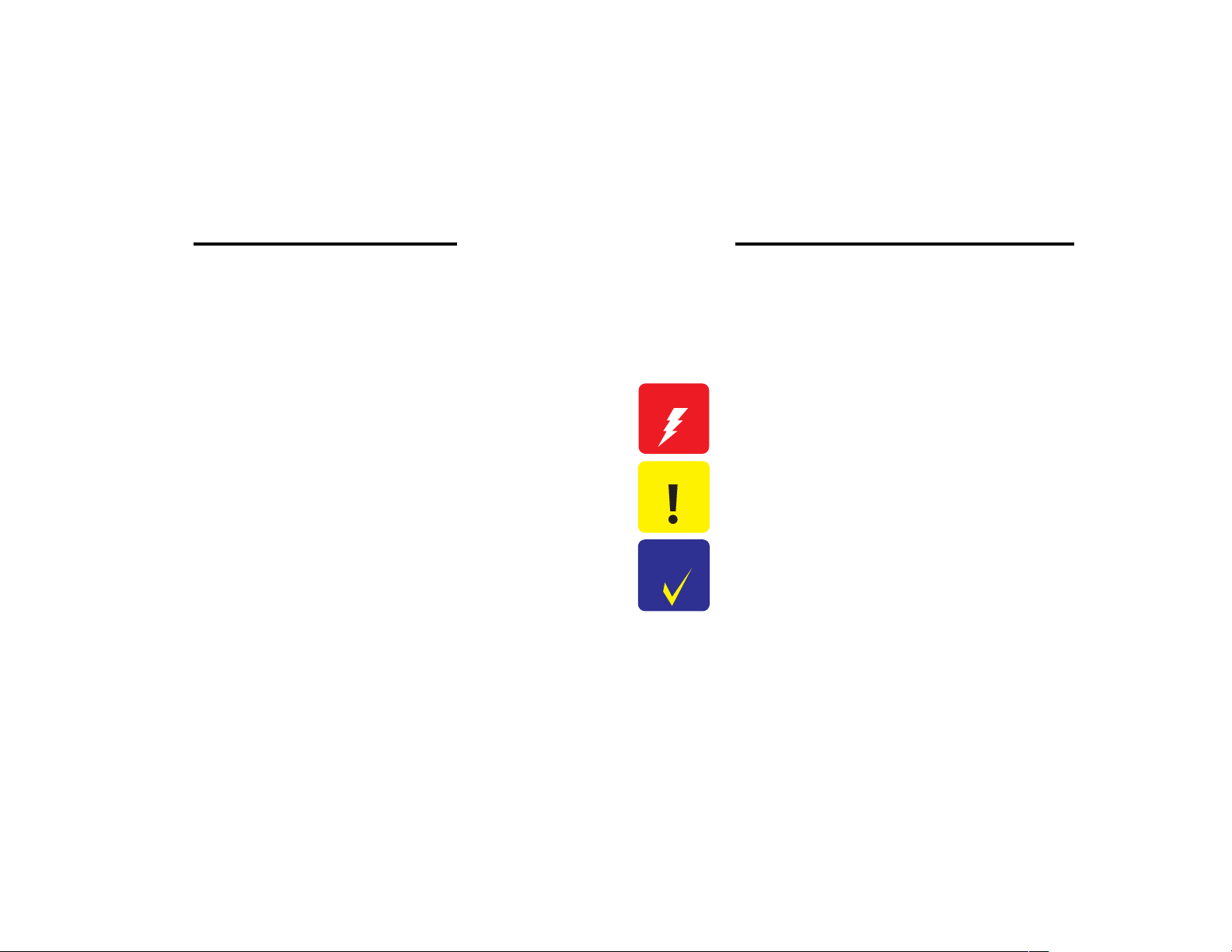

Symbols Used in this Manual

Various symbols are used throughout this manual either to provide additional

information on a specific topic or to warn of possible danger present during a

procedure or an action. Pay attention to all symbols when they are used, and

always read explanation thoroughly and follow the instructions.

W A R N I N G

C A U T I O N

C H E C K

P O I N T

Indicates an operating or maintenance procedure, practice or

condition that, if not strictly observed, could result in serious

injury or loss of life.

Indicates an operating or maintenance procedure, practice, or

condition that, if not strictly observed, could result in bodily

injury, damage or malfunction of equipment.

May indicate an operating or maintenance procedure, practice or

condition that is necessary to accomplish a task efficiently. It may

also provide additional information that is related to a specific

subject, or comment on the results achieved through a previous

action.

For Chapter 1 “Disassembly/Reassembly”, symbols other than indicated above

are used to show additional information for disassembly/reassembly. For the

details on those symbols, see “ 1.2 Disassembly/Reassembly Procedures

(p17)”.

Confidential

Page 6

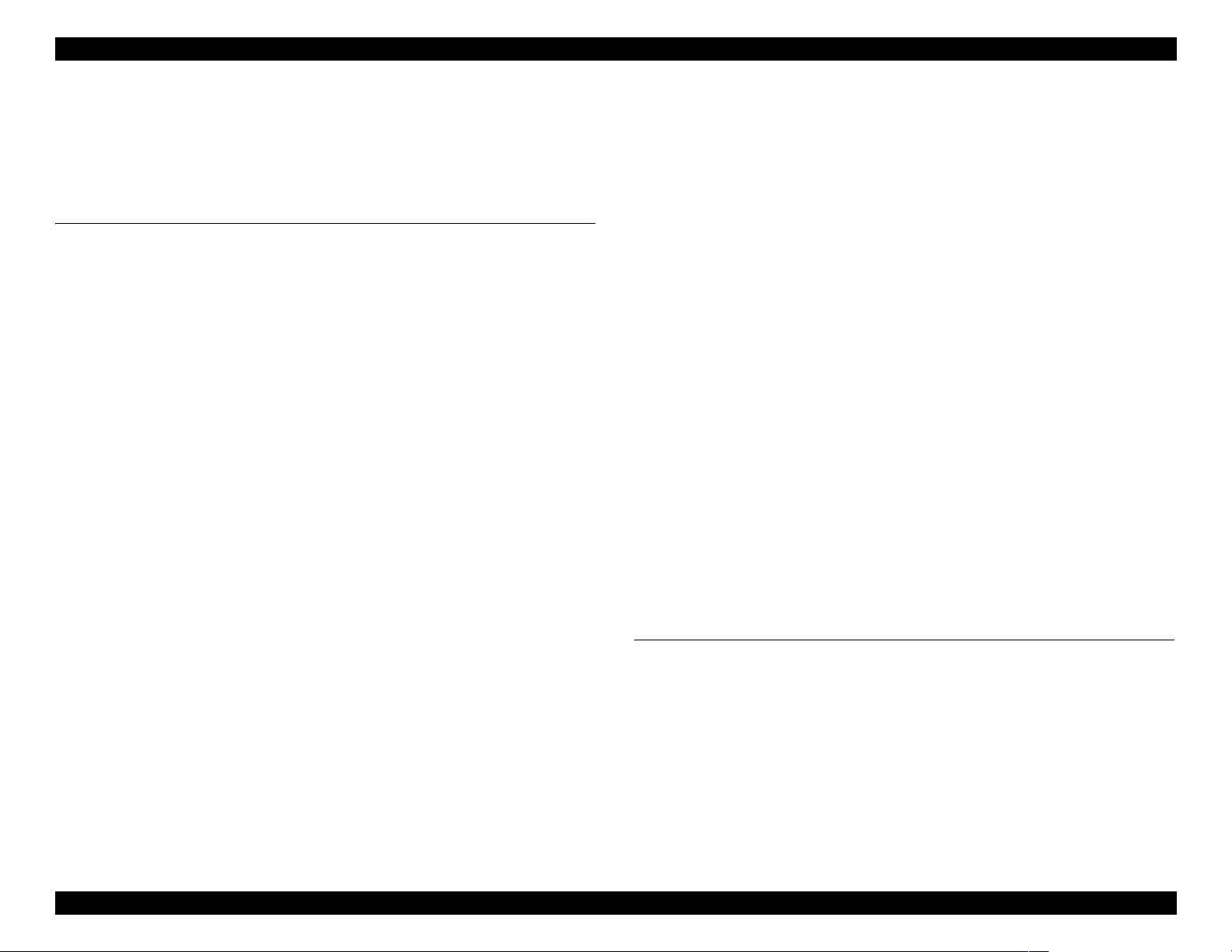

Revision Status

Revision Date of Issue Description

A April 6, 2011 First Release

Confidential

Page 7

L800/L801 Revision A

CONTENTS

Chapter 1 Disassembly/Reassembly

1.1 Overview ............................................................................................................ 10

1.1.1 Tools ........................................................................................................ 10

1.1.2 Checks and Precautions before Disassembling ....................................... 10

1.1.3 Protection for Transportation .................................................................. 14

1.1.4 Making a Special Tool for Holder Contact ............................................. 15

1.1.5 Orientation Definition ............................................................................. 16

1.1.6 How to Unlock the Carriage .................................................................... 16

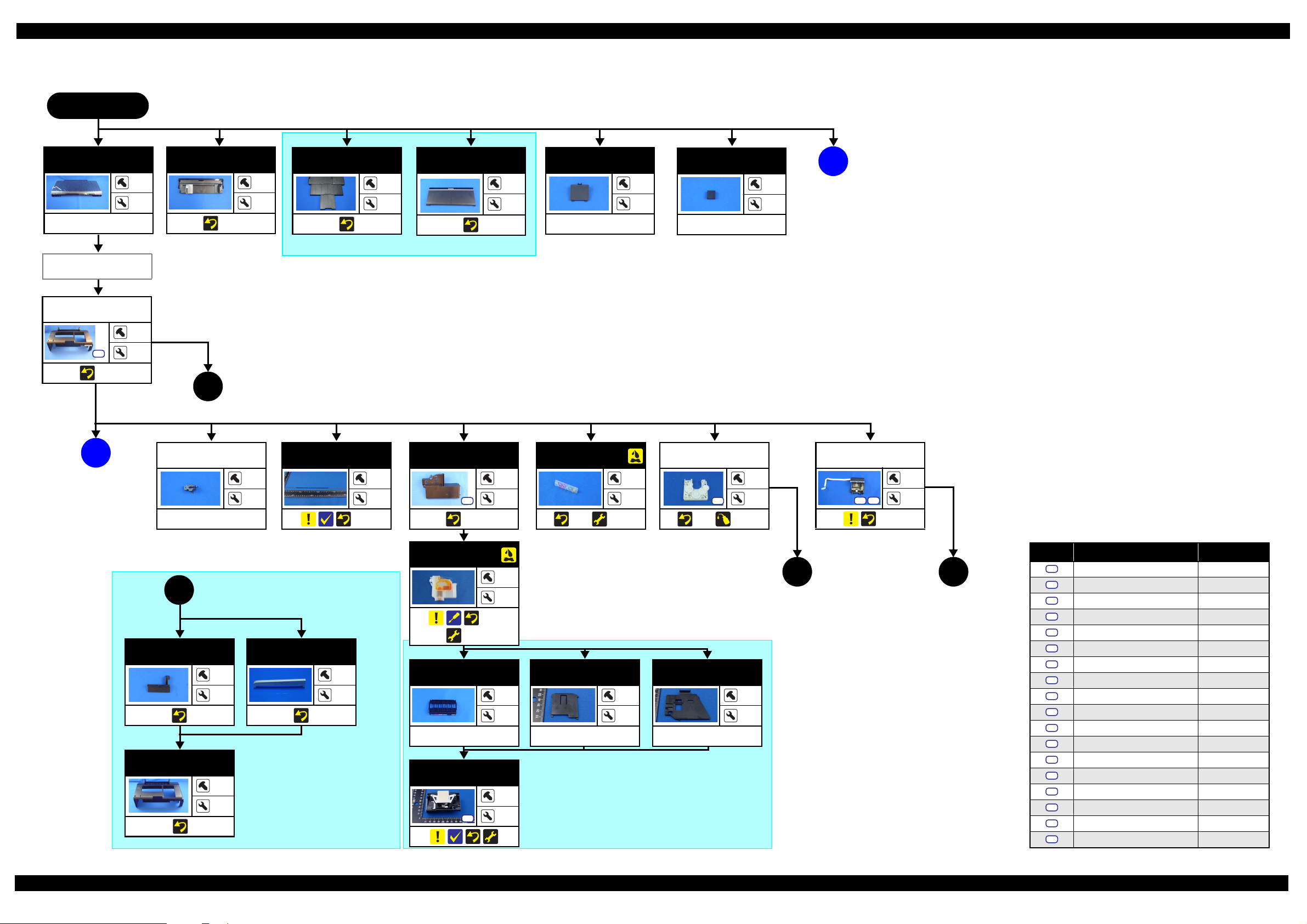

1.2 Disassembly/Reassembly Procedures ................................................................ 17

1.2.1 Overview ................................................................................................. 17

1.2.2 Disassembly Flowchart ........................................................................... 18

1.3 Removing Exterior Parts/Components ............................................................... 24

1.3.1 Printer Cover ........................................................................................... 24

1.3.2 Paper Support Assy ................................................................................. 24

1.3.3 Stacker Assy / Stacker Cover .................................................................. 25

1.3.4 Housing Upper Assy................................................................................ 25

1.4 Removing Control Boards.................................................................................. 27

1.4.1 Main Board Unit...................................................................................... 27

1.4.2 Panel Assy/ Cover Open Sensor.............................................................. 30

1.4.3 P/S Assy................................................................................................... 34

1.5 Disassembling the Printer Mechanism ............................................................... 35

1.5.1 Removing the Printer Mechanism ........................................................... 35

1.5.2 Printhead .................................................................................................. 37

1.5.3 CR Scale .................................................................................................. 40

1.5.4 APG Unit ................................................................................................. 41

1.5.5 Waste Ink Tray ........................................................................................ 42

1.5.6 Waste Ink Pad Lower / Waste Ink Pad Cap Lower ................................. 43

1.5.7 Left & Right Guide Stackers / CDR Guide Sensor ................................. 44

1.5.8 Ink System ............................................................................................... 45

1.5.9 EJ Frame Assy ......................................................................................... 46

1.5.10 PF Encoder / PF Scale ........................................................................... 49

1.5.11 PF Motor................................................................................................ 49

1.5.12 CR Motor ............................................................................................... 50

1.5.13 CR Unit.................................................................................................. 52

1.5.14 ASF Unit................................................................................................ 54

1.5.15 Upper Paper Guide ................................................................................ 56

1.5.16 APG Sensor Assy .................................................................................. 57

1.5.17 Front Paper Guide Assy ........................................................................ 57

1.5.18 CDR Tray Sensor .................................................................................. 60

1.6 Disassembling the CISS section......................................................................... 61

1.6.1 Refilling Ink Label / Valve Position Label ............................................. 61

1.6.2 Top Cover................................................................................................ 61

1.6.3 Tube Valve Holder Front / Rear.............................................................. 62

1.6.4 Valve Lever ............................................................................................. 62

1.6.5 Bottom Cover / Left Cover / Right Cover / Cover Joint ......................... 63

1.6.6 Ink Supply Tank Assy ............................................................................. 64

1.6.7 Ink Supply Tank Tube Assy .................................................................... 64

1.6.8 Joint ......................................................................................................... 65

1.6.9 Cover Case .............................................................................................. 65

1.6.10 PF Scale Cover / PF Scale Sheet........................................................... 66

1.6.11 Tube Guide Sheet / Tube Guide Sheet Sub........................................... 66

1.6.12 Ink Supply Tube Assy ........................................................................... 67

1.6.13 Adapter Cover ....................................................................................... 68

1.6.14 Adapter .................................................................................................. 68

Chapter 2 Adjustment

2.1 Adjustment Items and Overview........................................................................ 70

2.1.1 Servicing Adjustment Item List .............................................................. 70

2.1.2 Required Adjustments ............................................................................. 74

2.2 Using the Adjustment Program .......................................................................... 77

2.2.1 Top Margin Adjustment .......................................................................... 77

2.2.2 Head Angular Adjustment....................................................................... 77

2.2.3 Bi-D Adjustment ..................................................................................... 78

2.2.4 PW Adjustment/First Dot Position Adjustment ...................................... 79

2.2.5 PF Adjustment......................................................................................... 80

2.2.6 PG Adjustment ........................................................................................ 81

7

Confidential

Page 8

L800/L801 Revision A

2.3 Banding Reduction System (BRS) Adjustment / Paper Feed Amount Profile (PFP)

Correction............................................................................................................ 83

2.3.1 Overview ................................................................................................. 83

2.3.2 Adjustment Procedure ............................................................................. 85

Chapter 3 Maintenance

3.1 Overview ............................................................................................................ 89

3.1.1 Cleaning ................................................................................................... 89

3.1.2 Service Maintenance ............................................................................... 89

3.1.3 Lubrication .............................................................................................. 90

Chapter 4 Appendix

4.1 Power-On Sequence ........................................................................................... 97

4.2 Standard Operation Time for servicing the product ........................................... 99

4.3 Troubleshooting................................................................................................ 102

4.3.1 Troubleshooting Workflow ................................................................... 102

4.3.2 Fatal Error Code .................................................................................... 104

8

Confidential

Page 9

DISASSEMBLY/REASSEMBLY

CHAPTER

1

Confidential

Page 10

L800/L801 Revision A

1.1 Overview

C H E C K

P O I N T

This chapter describes procedures for disassembling the main parts/units of

L800/L801. Unless otherwise specified, disassembled parts/units can be

reassembled by reversing the disassembly procedure. See the cautions or tips

for disassembly/reassembly described in “ 1.2 Disassembly/Reassembly

Procedures (p17)”.

Read the following before disassembling and reassembling.

“ Safety Precautions (p3)”

“ 1.1.2 Checks and Precautions before Disassembling (p10)”

When you have to remove units or parts that are not described in this chapter,

see the exploded diagrams of SPI (Service Parts Information).

1.1.1 Tools

Use only specified tools to avoid damaging the printer.

Some pictures in this manual are for Epson Stylus Photo R280/

R285/R290; therefore, the shapes of the parts are different from

those of L800/L801, but the differences does not affect the

disassembly/reassembly procedures.

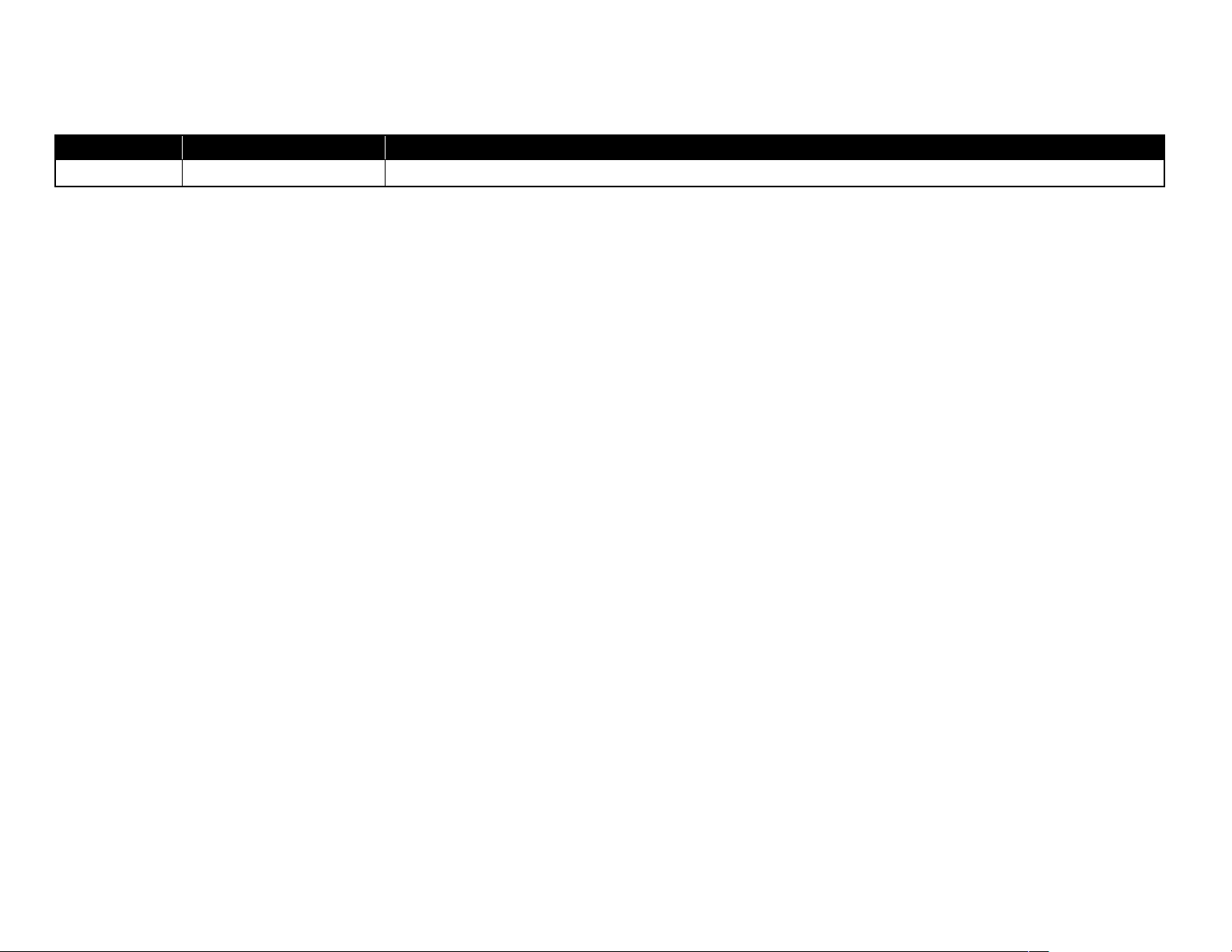

Table 1-1. List of Tools

1.1.2 Checks and Precautions before Disassembling

1.1.2.1 Factors which Affect the Print Quality

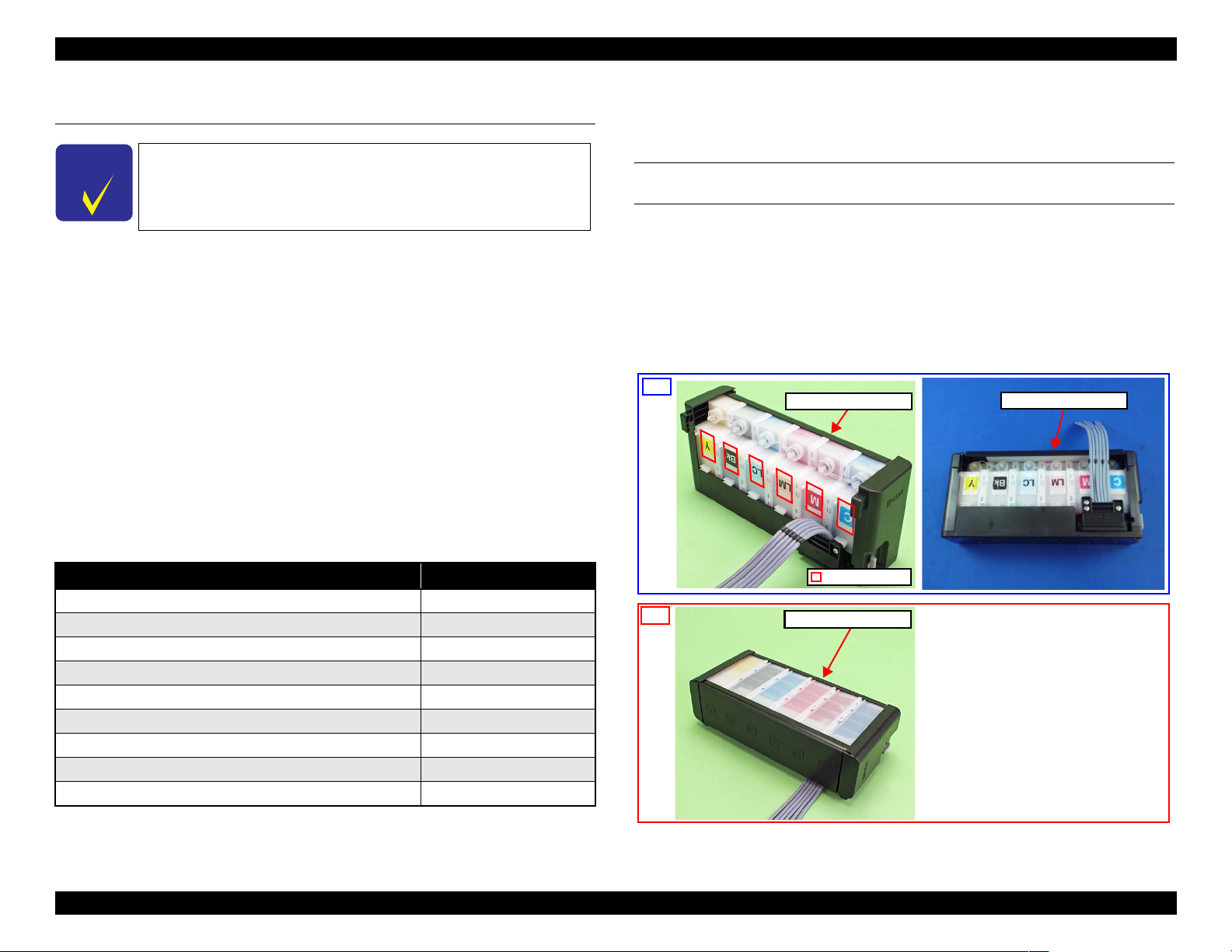

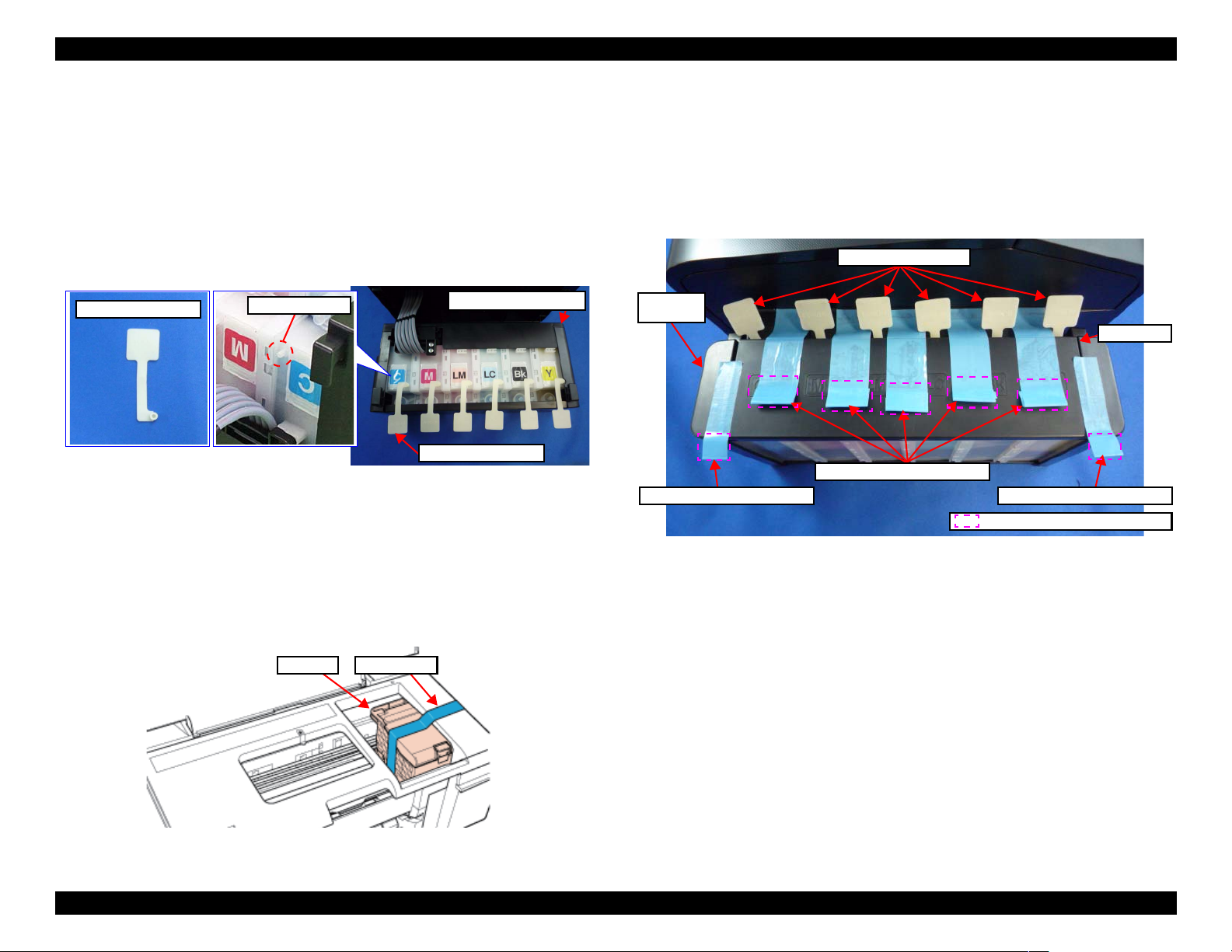

HOW TO PLACE THE INK TANK ASSY WHEN DISASSEMBLING/

REASSEMBLING

The film under sealing film attached on the Ink Supply Tank Assy of this

printer is ventilation film. The ink in the ink tanks is vented to atmosphere

through this film to keep ink supply to the Printhead stable. If the film gets wet

with ink, the ink in the tanks is not properly vented and printing may not be

capable.

In order to prevent this from occurring, make sure to place the Ink Supply Tank

Assy as shown below after removing it.

OK

Ink Supply Tank Assy

Ink Supply Tank Assy

Tool Part No.

Phillips Screwdriver (No.1) 1080530

Phillips Screwdriver (No.2) ---

Flathead Screwdriver ---

Precision Screwdriver #1 (flathead) ---

Tweezers ---

Long-nose pliers ---

Acetate tape 1003963

2 pins (thinner than Ø2 mm) ---

Strong tape 1032813

Note : All of the tools listed above are commercially available. EPSON provides the tools

listed with EPSON tool code.

NG

Figure 1-1. How to Place the Ink Tank Assy

Ventilation film

Ink Supply Tank Assy

Do not place the Ink Supply Tank Assy with

its film side down. Otherwise, ink in the Ink

Supply Tank Assy may reach and cover the

ventilation film, and the printing failure may

occur.

Disassembly/Reassembly Overview 10

Confidential

Page 11

L800/L801 Revision A

1.1.2.2 Factors which Affect the Safety of Service Personnel such as

Ink Leakage during Operation

Ink may spill when removing the following parts from L800/L801.

This section describes the parts that may cause ink spill and the means to

minimize the ink spill when removing the parts.

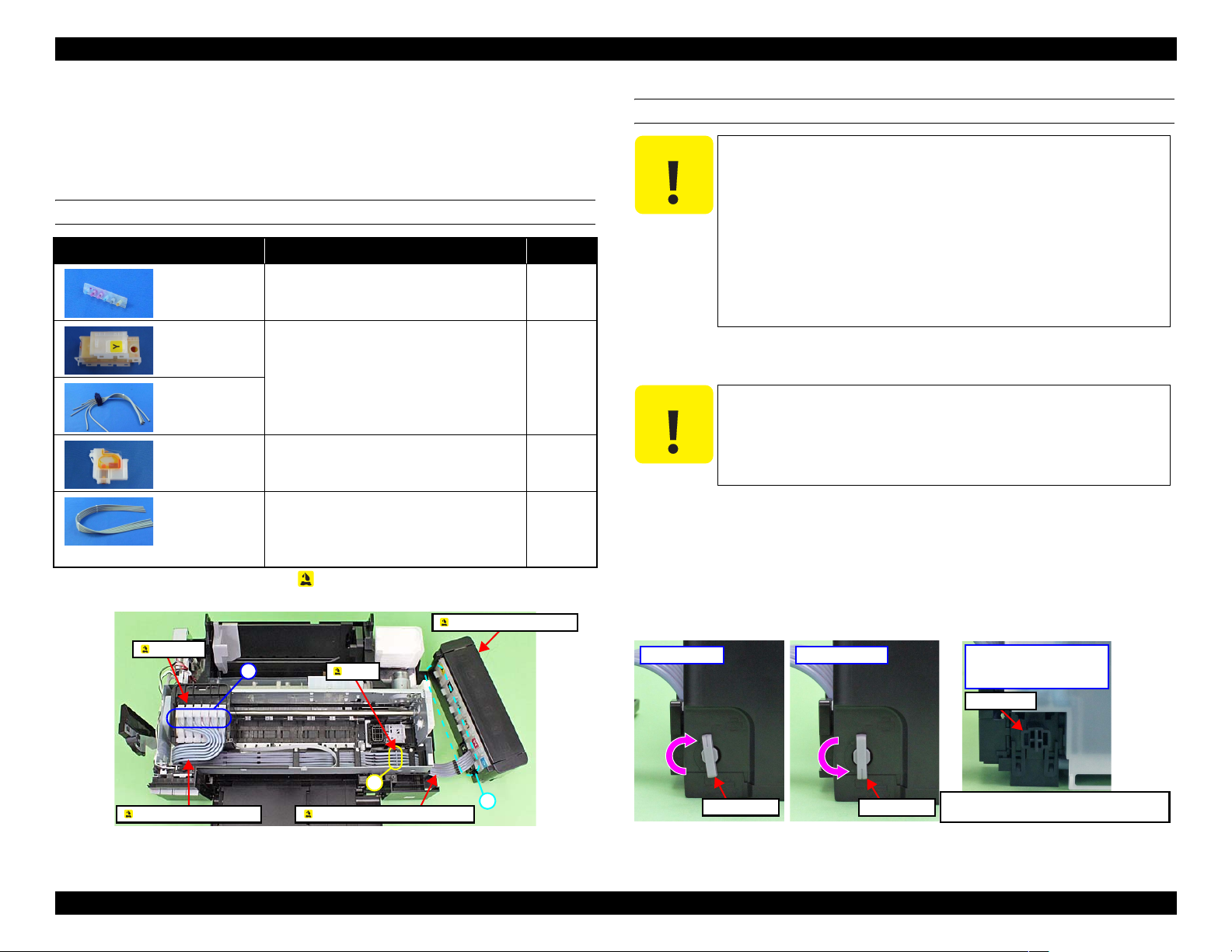

THE PARTS THAT MAY CAUSE INK SPILL WHEN REMOVING

Parts When ink may spill Location

Joint Removing the Ink Supply Tank Tube Assy

/ Ink Supply Tube Assy from the Joint

Ink Supply

Tank Assy

Ink Supply

Tank Tube Assy

(w/Valve Assy)

Adapter Removing the Ink Supply Tube Assy from

Ink Supply

Tube Assy

Note : These parts are indicated with the icon in disassembly/reassembly flowchart. (See

“ 1.2 Disassembly/Reassembly Procedures (p17)”.)

Removing the tubes of the Ink Supply

Tank Tube Assy from the Joint

Removing the tubes of the Ink Supply

Tank Tube Assy from the Ink Supply

Tank Assy

the Adapter

Removing the Ink Supply Tank Tube Assy

/ Ink Supply Tube Assy from the Joint

Removing the Ink Supply Tube Assy

from the Adapter

Ink Supply Tank Assy

A

A, B

C

A, C

MEANS DO TO MINIMIZE THE INK SPILL

C A U T I O N

Even observing the points described in this section, ink may

spill in the following situations. Therefore, be careful not to

contaminate the inside of the printer or its surroundings by

preparing the container to receive the leaked ink, or the like.

When removing the Ink Supply Tank Tube Assy (w/

Valve Assy), some ink will spill from both ends of the

tube even the Valve Lever is closed.

When removing the Ink Supply Tube Assy, all the ink in

the tube will spill.

Before disassembling, confirm that the printer is in the following condition.

Choke Valve is closed

C A U T I O N

Do not turn the Valve Lever too much when closing the

Choke Valve, otherwise, the Valve Lever and/or Valve Assy

may get damaged.

Before disassembling:

Turn the Valve Lever and be sure to close the Choke Valve.

After reassembling is complete:

Open the Choke Valve to perform the print inspection.

Before returning the printer to the user after repairing:

Make sure to turn the Valve Lever up to the choke position to close the Choke

Valve before packing the printer.

Adapter

C

Joint

A

Ink Supply Tank Tube Assy Ink Supply Tube Assy

Figure 1-2. Location

Open position

Open position

B

Valve Lever

Valve Lever

Choke position

Valve Lever

Figure 1-3. Opening/closing the Choke Valve

Choke position

(When checking with the

Valve Lever removed.)

Valve shaft

Choke Valve shaft is secured more tightly

in Choke position than in Open position.

Disassembly/Reassembly Overview 11

Confidential

Page 12

L800/L801 Revision A

Adapter is removed

Before disconnecting the joint parts of the ink path, make sure that the Adapter

is removed from the Carriage.

Adapter

Carriage

Ink path

Ink valve

Figure 1-4. Adapter

C H E C K

P O I N T

The Adapter has an ink valve which cuts off the ink path

when removing the Adapter from the Carriage.

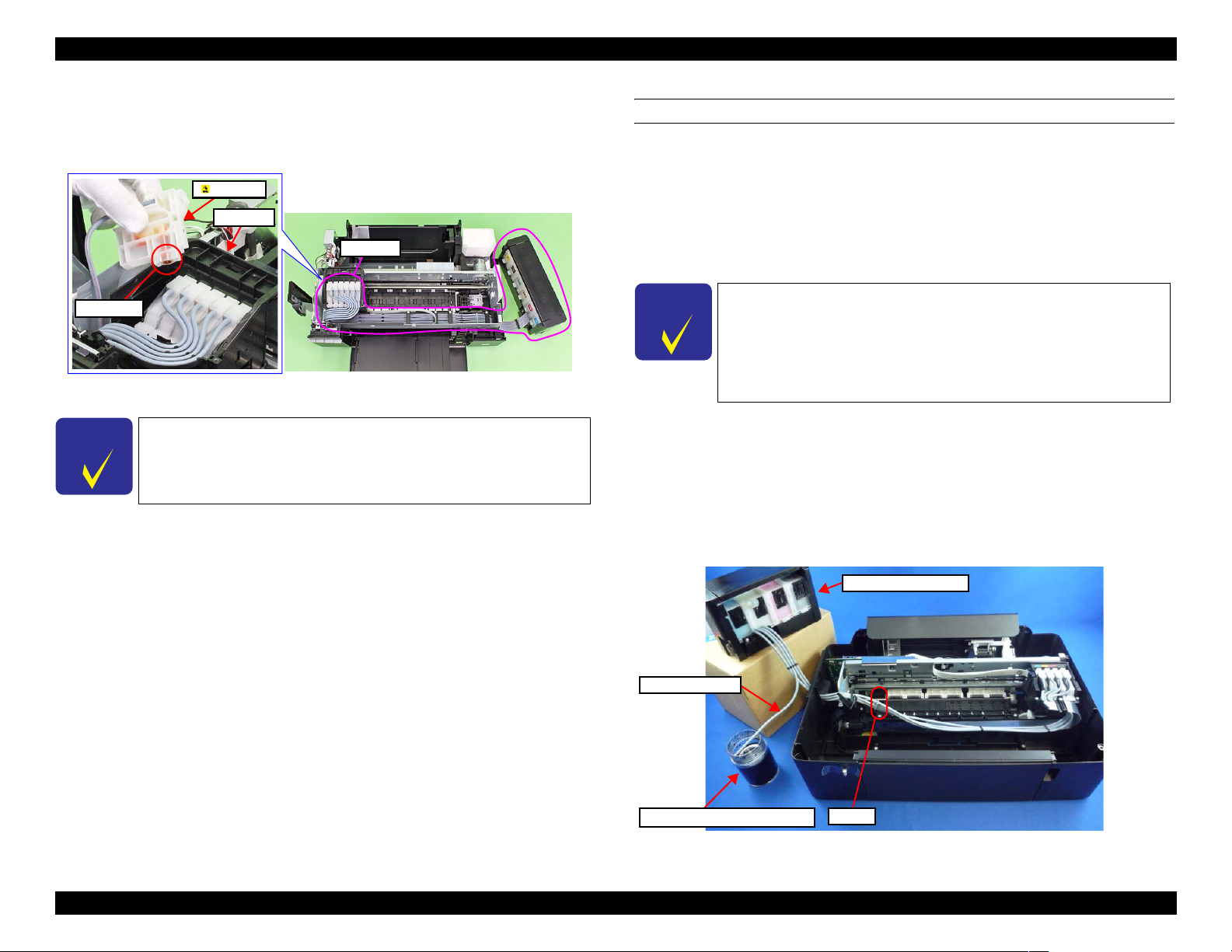

DISCHRGING INK FROM THE INK SUPPLY TANK

Discharging ink is recommended only when disconnecting the Ink Supply Tank

Tube Assy from the Ink Supply Tank. Before performing the above

disconnection, discharge ink from the Ink Supply Tank as follows.

Necessary tools

• Containers (x 6) for each discharged ink

• Injector (with a tip of φ3.2 mm)

• Tube (capable to be connected to the joint)

C H E C K

P O I N T

Discharging procedure

The photos in the following procedure are for L200/L201, but

the procedure for L800/L801 is the same; the numbers of the

tube and the location of the Ink Supply Tank Assy in the

photos are different from those of L800/L801, though.

Prior to the following steps, connect the injector with the tube,

and then discharge ink according to the procedure.

1. Remove the Housing Upper Assy. (p. 25)

2. With the choke value closed (p.11), place the Ink Supply Tank Assy on a

place where its bottom is higher than the top of the Printhead.

3. Prepare a container for ink to discharge, then disconnect the Ink Supply

Tube from the joint and put its tip into the container for the ink.

4. Open the choke valve to discharge the ink in the Ink Supply Tank Assy to

the container.

Ink Supply Tank Assy

Ink Supply Tube

Container for discharged ink

Joint

Figure 1-5. Discharging Ink (1)

Disassembly/Reassembly Overview 12

Confidential

Page 13

L800/L801 Revision A

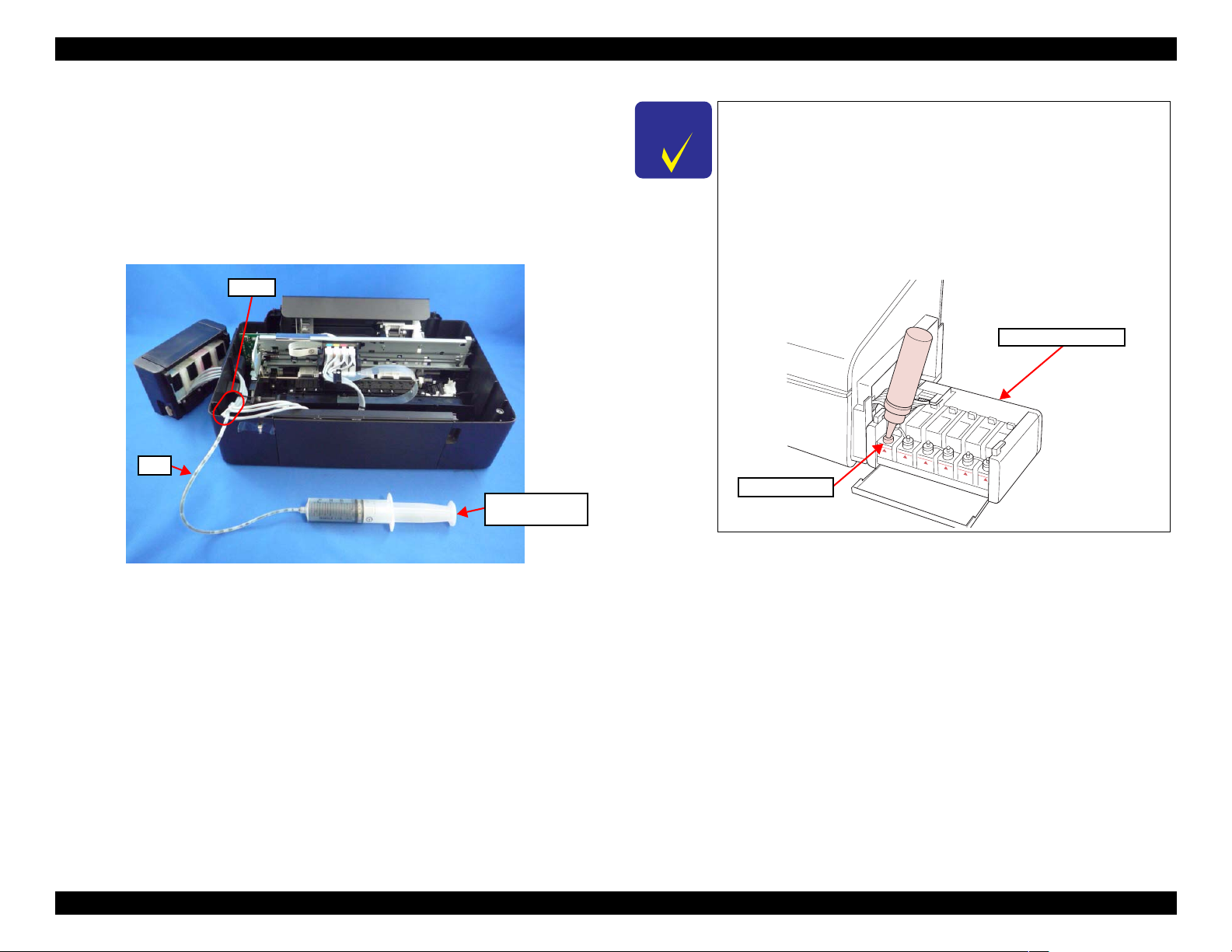

5. When the ink stops flowing from the tube, close the choke valve, and

then connect the Ink Supply Tube back to the joint.

6. Disconnect the Ink Supply Tube of the same color connected to the

opposite side of the joint.

7. Connect the tube from the injector.

8. Open the choke valve again, and suck up the remaining ink in the Ink

Supply Tank into the injector.

9. Disconnect the tube from the injector, and connect the Ink Supply Tube

of the same color back to the joint.

Joint

Tube

Injector

(tip of

φ 3.2 mm)

C H E C K

P O I N T

It is recommended that the ink in the Ink Supply Tank should

be discharged completely before proceeding to disassembling/

reassembling.

After all the reassembling work is complete, the discharged ink

of each color should be refilled back to the Ink Supply Tank

before performing the adjustment. Confirm the colors

indicated on the film of the Ink Supply Tank so as not to

mistake them, and make sure to refill each ink back to the

correct tank from the corresponding ink supply hole.

Ink Supply Tank Assy

Ink supply hole

Figure 1-6. Discharging Ink (2)

10. Repeat Step 3 to Step 10 for all ink tanks to discharge all ink in the Ink

Supply Tank.

Disassembly/Reassembly Overview 13

Confidential

Page 14

L800/L801 Revision A

1.1.3 Protection for Transportation

Before packing the printer for returning it to the user, secure it at the specified

points with strong tape to avoid damaging the printer or ink leakage during

transport, and make sure to check the points as follows.

Attaching the Air Release Hole Caps

To prevent the ventilation film from getting wet, attach the Air Release

Hole Caps (part number: 1556135) to the air release holes of the Ink Supply

Tank Assy.

Air Release Hole Cap

Air release hole

Figure 1-7. Attaching the Air Release Hole Caps

Securing each parts

Secure the following parts with strong tape (width: 22 mm).

Securing the CR Unit

1. Confirm that the CR Unit is locked in the home position.

2. Attach the unfolded end of strong tape (fold the other end back 10 mm)

on the bottom left of the Adapter Cover.

3. Pull the tape to the right side of the housing and attach it tightly.

Ink Supply Tank Assy

Air Release Hole Cap

Securing the Ink Tank

• Secure both sides of the Top Cover with strong tape (x2).

• Align the unfolded end of strong tape (x5) with the edge of the

Housing Upper, and attach the tape along the shape of the Housing

Upper/Ink Supply Tank Assy through the openings between the Air

Release Hole Caps.

Ink Supply

Tank Assy

Strong tape (60 mm x 22 mm)

Figure 1-9. Securing the Ink Supply Tank Assy

Air Release Hole Cap

Top Cover

Strong tape (80 mm x 22 mm)

Strong tape (60 mm x 22 mm)

Fold over the tape edge by 10 mm

Strong tapeCR Unit

Figure 1-8. Securing the CR Unit

Disassembly/Reassembly Overview 14

Confidential

Page 15

L800/L801 Revision A

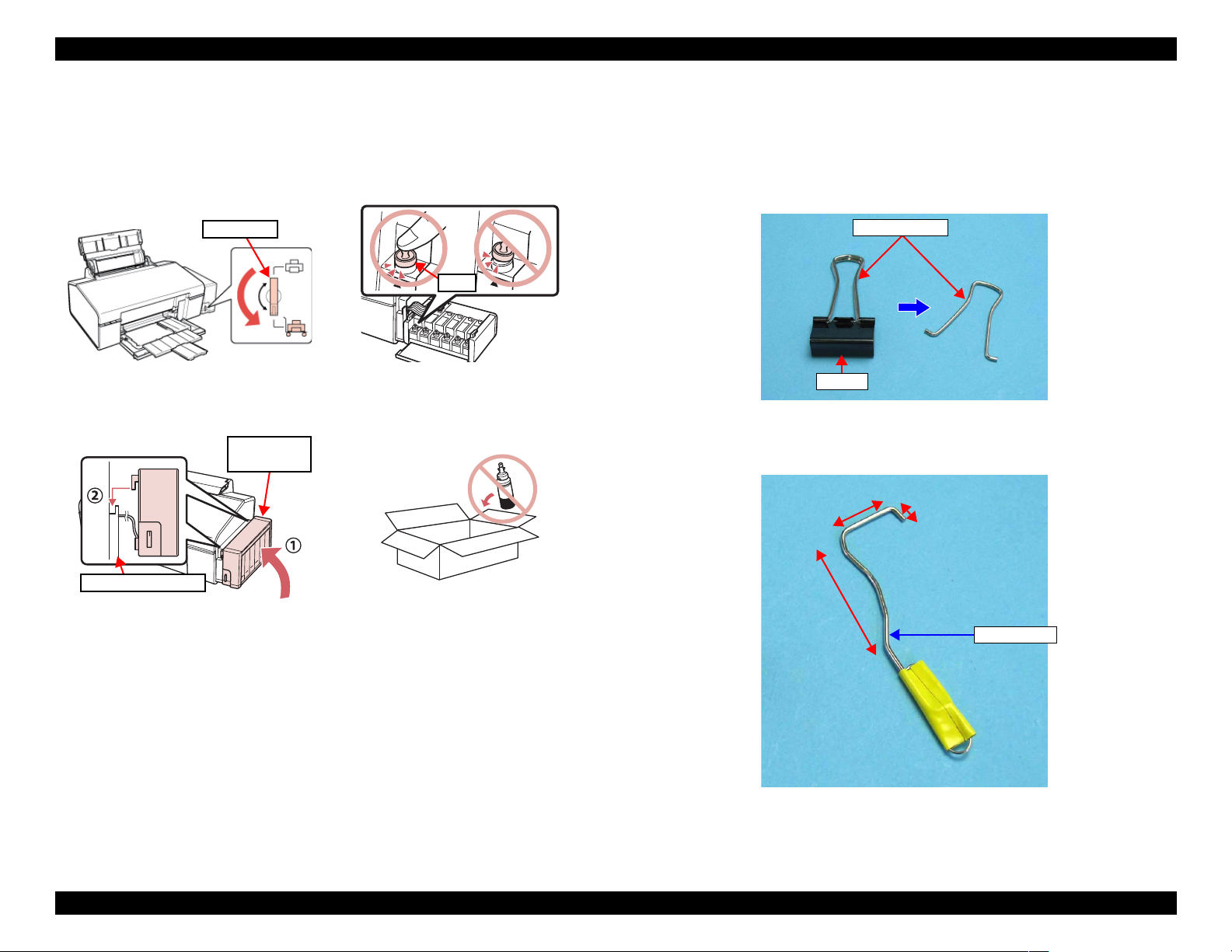

Points to be checked before packing the printer

The Valve Lever is on the position

shown below (the Choke Valve is

All the caps of the Ink Supply Tank

Assy are securely closed.

closed). (See Figure 1-3.)

Valve Lever

The hooks (x2) of the Ink Supply

Tank Assy are securely engaged

The opened ink bottle is not

included in the box.

with the Housing Upper Assy.

Ink Supply

Tank Assy

Cap

1.1.4 Making a Special Tool for Holder Contact

The Holder Contact (refer to p.38) can be easily removed by using a special

tool. The method for making the tool is described below.

1. Prepare a handle part of a clip, or a similar metal wire piece.

Handle part

Clip

Figure 1-10. Making Special Tool for Holder Contact (1)

2. Bend the metal wire as shown below.

25mm

7mm

Housing Upper Assy

50mm

Special Tool

Figure 1-11. Making Special Tool for Holder Contact (2)

Disassembly/Reassembly Overview 15

Confidential

Page 16

L800/L801 Revision A

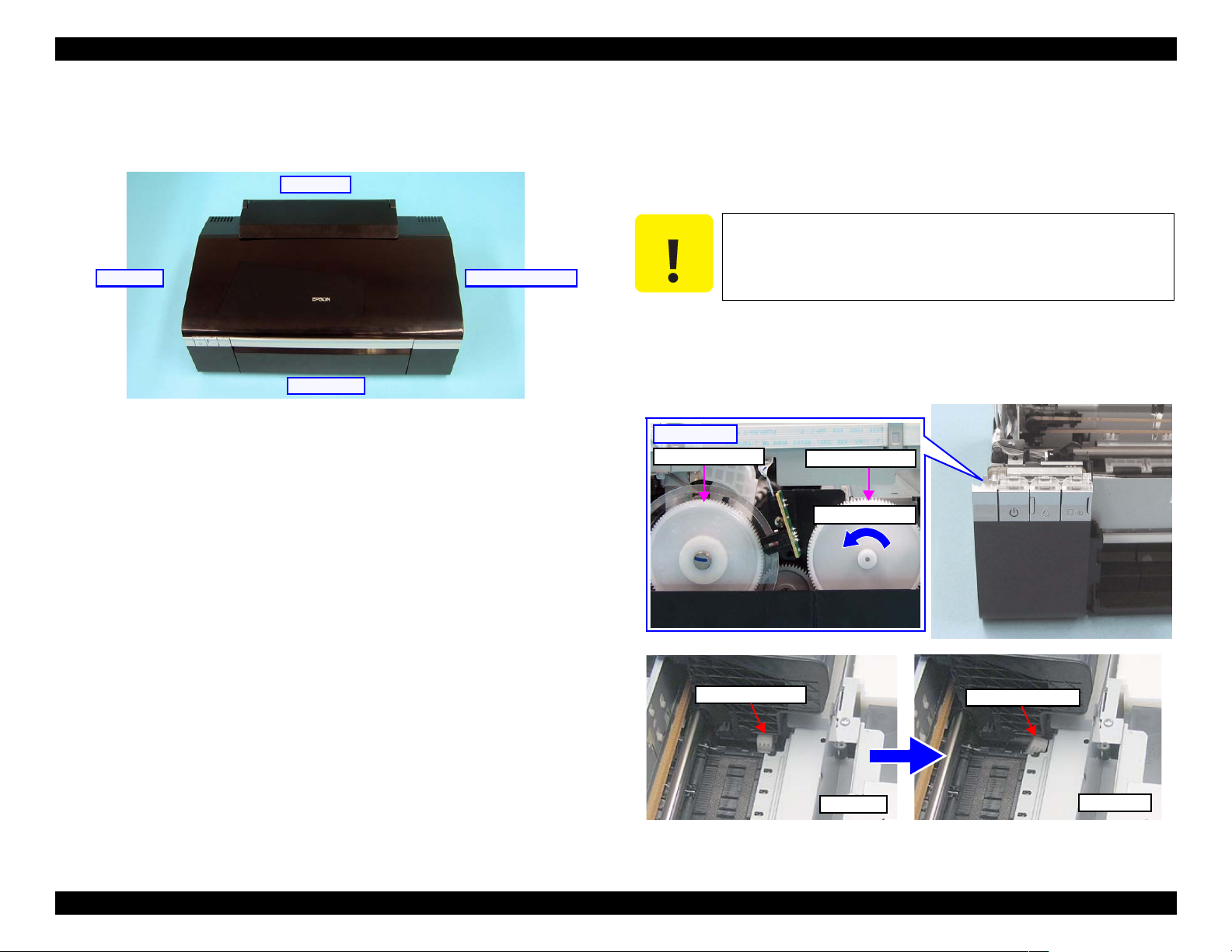

1.1.5 Orientation Definition

Orientation descriptions used in the disassembly/reassembly procedures are as

follows.

[Rear Side]

[Left Side] [Right (home) Side]

[Front Side]

Figure 1-12. Orientation Definition

1.1.6 How to Unlock the Carriage

Unlocking the carriage is required for disassembly of some parts or

components. Carry out any of the following operations to unlock the carriage

and move the carriage to other than its home position.

C A U T I O N

Power the printer and turn it off forcedly by disconnecting the power cable

Turn the EJ Roller gear on the left side of the printer in the direction of the

[Left side]

PF Roller Gear

Be extremely careful not to damage the EJ Roller gear. Extra care

must be taken to avoid injury from sharp metal edges.

when the CR Unit is unlocked and moved away from the home position.

arrow until the carriage is unlocked.

EJ Roller Gear

Turn this gear

Carriage Lock

Locked

Carriage Lock

Unlocked

Figure 1-13. How to Unlock the Carriage

Disassembly/Reassembly Overview 16

Confidential

Page 17

L800/L801 Revision A

1.2 Disassembly/Reassembly Procedures

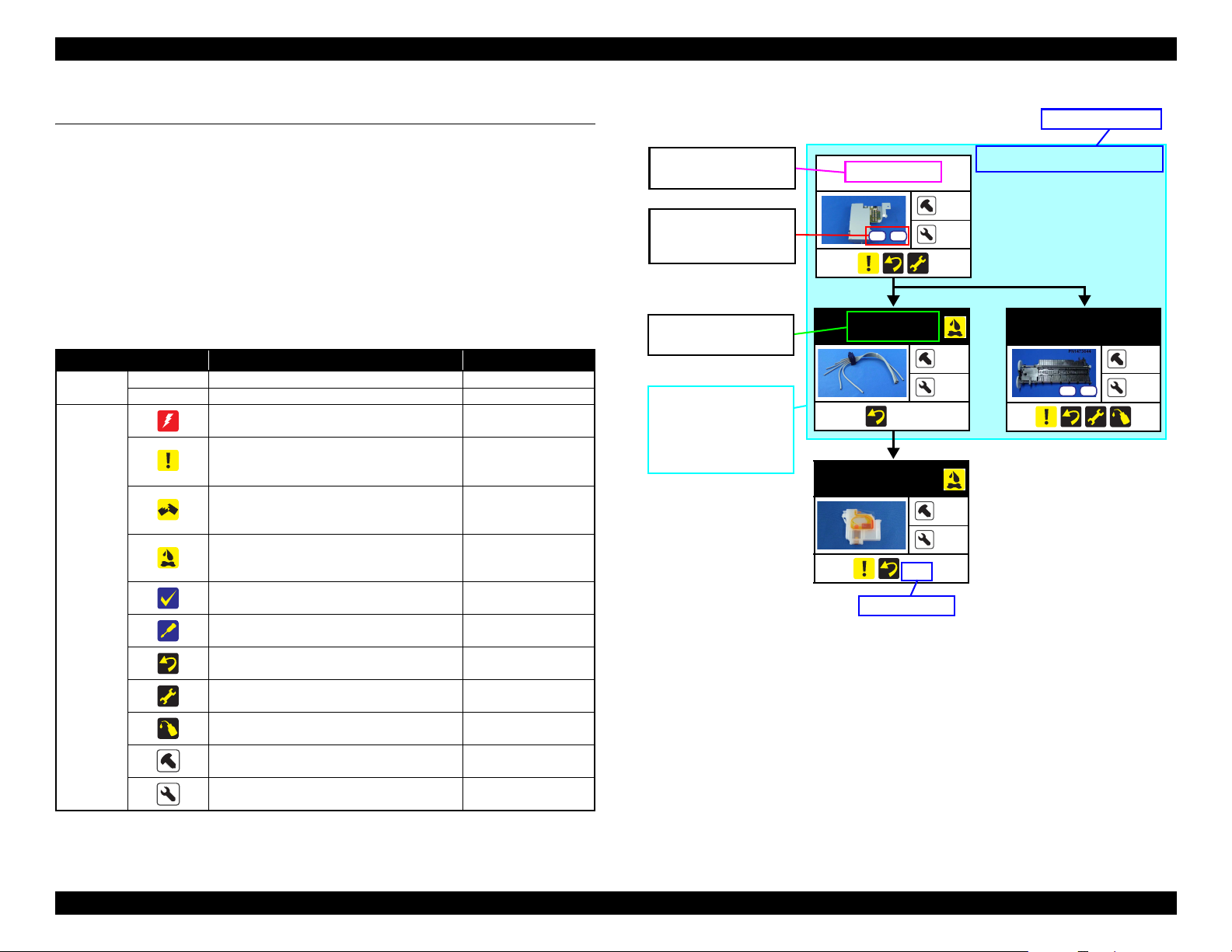

1.2.1 Overview

This section describes procedures for disassembling the parts/units in a

flowchart format. For some parts/units, detailed procedures or precautions are

provided (accordingly indicated by icons and cell's color). Refer to the

explanations in the example chart below and perform an appropriate

disassembling and reassembling procedure. (See“ 1.3 Removing Exterior

Parts/Components (p24)”.)

The example below shows how to see the charts on the following pages.

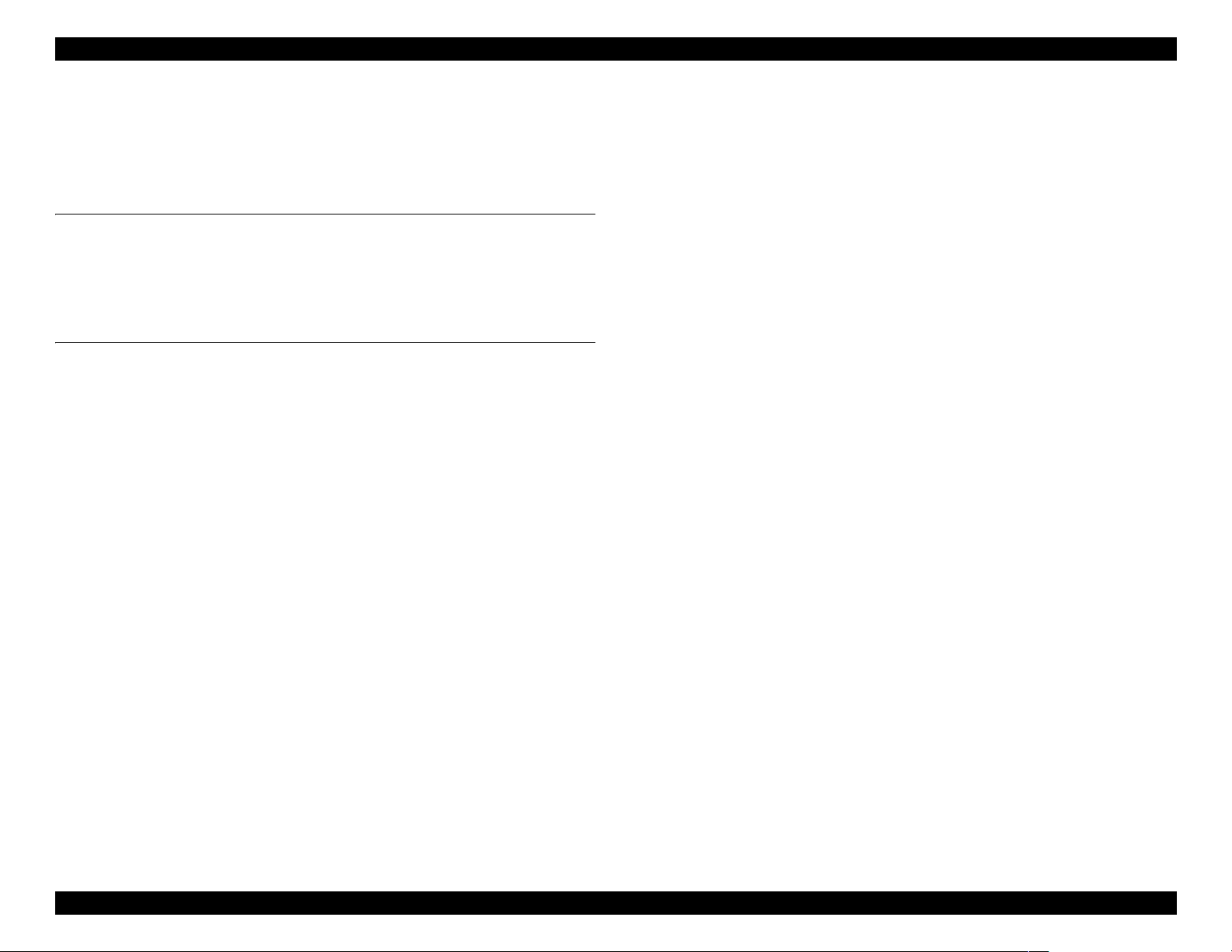

Table 1-2. Explanatory Note

Item Description Reference

Parts/unit

name

Icon

White-letter Parts/units supplied as an ASP --Black-letter Parts/units not supplied as an ASP ---

Indicates a practice or condition that could result

in injury or loss of life if not strictly observed.

Indicates a practice or condition that could result

in damage to, or destruction of equipment if not

strictly observed.

Indicates the parts that are inevitably broken in

the disassembling procedure, and should be

replaced with a new one for reassembly.

Indicates the parts that may cause the ink spill

when they are removed.

Indicates necessary check items in the

disassembling/reassembling procedure.

Indicates supplementary explanation for

disassembly is given.

Indicates particular tasks to keep quality of the

units are required.

Indicates particular adjustment(s) is/are required.

Indicates lubrication is required.

Indicates the number of screws securing the

parts/units.

Indicates the points secured with other than a

screw such as a hook, rib, dowel or the like.

Indicates the reference

page in blue-letter

Indicates the reference

page in blue-letter

“ 1.1.2 Checks and

Precautions before

Disassembling (p10)”

Indicates the reference

page in blue-letter

Indicates the reference

page in blue-letter

Indicates the reference

page in blue-letter

Chapter 2 “ Adjustment

(p69)”

Chapter 3 “

Maintenance (p88)”

---

---

---

Black letters indicate a

part/unit not supplied as

an ASP.

Shows the screw types

and the specified torque

in the “Screw type/torque

list”.

White letters indicate a

part/unit supplied as an

ASP.

Indicates that the

disassembly procedure of

boxed parts is explained

all together and step by

step in the section shown

as reference page (A).

Main Board Unit

3

S7

S15

Ink Supply Tank

Tube Assy

(p 20)

Adapter

(p 18)

Reference page

---

---

---

---

1

Figure 1-14. Example Chart

Reference page (A)

“ 1.5.8 Ink System (p45)”

Front Paper

Guide Assy

S15

S9

2

1

Disassembly/Reassembly Disassembly/Reassembly Procedures 17

Confidential

Page 18

L800/L801 Revision A

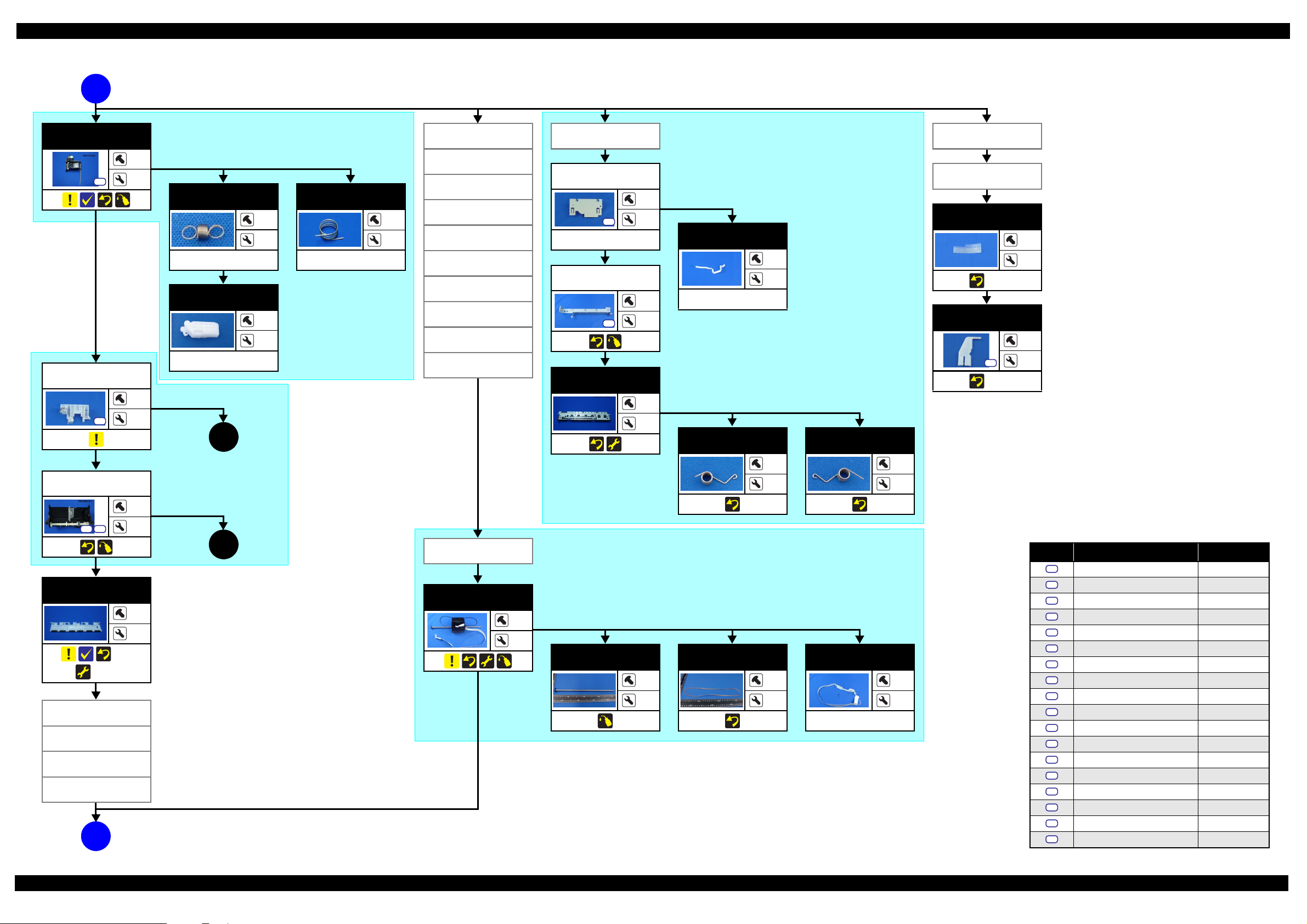

1.2.2 Disassembly Flowchart

START

Printer Cover

(p 24)

Paper Support

Assy

Housing Upper

Assy

S4

(p 25)

(p 20)

B

---

---

4

Paper Support

Assy

---

2

(p 24)

2

Stacker Assy

---

Stacker Cover

---

2

2

Cover Ink Tube

(p 35)

Foot

---

1

---

---

---

A

(p 19)

“ 1.3.3 Stacker Assy / Stacker Cover (p25) ”

(p 18)

1

Cover Open

Sensor

CR Scale

Adapter Cover

Joint

APG Unit

Panel Assy

(p 18)

1

Housing Right

Housing Upper

---

2

(p 30)

(p 40)

“ 1.3.4 Housing Upper Assy (p25)”

Decoration Belt

Right

---

2

---

---

---

1

2

S6

(p 68)

3

(p 65) (p 69)

---

2

2

S15

(p 41) (p 88)

---

S4

S14

(p 30)

2

1

Screw type/torque list

Adapter

---

(p 19)

2

(p 19)

3

1

(p 68)

(p 69)

---

2

Holder Contact

---

2

---

Cover FFC Inner

---

Cover FFC

---

1

---

---

1

Printhead

3

S2

---

“ 1.5.2 Printhead (p37)”

Symbol Screw type Torque

S1

C.B.P. 2.6X8 3.5-4.5kgf.cm

S2

C.B.P. 2.6X8 3-5kgf.cm

S3

C.B.P. 3X10 3-5kgf.cm

S4

C.B.P. 3X10 5-7kgf.cm

S5

C.B.P. 3X6 3-5kgf.cm

S6

C.B.P. 3X8 5-7kgf.cm

S7

C.B.P.(P2) 3X8 5-7kgf.cm

S8

C.B.S 3X6 5-7kgf.cm

S9

C.B.S. (P2) 3X8 6-8kgf.cm

S10

C.B.S. (P4) 3X6 7-9kgf.cm

S11

C.B.S. (P4) 3X6 9-11kgf.cm

S12

C.B.S. 3X10 4-6kgf.cm

S13

C.B.S. 3X6 4-6kgf.cm

S14

C.B.S. 3X6 5-7kgf.cm

S15

C.B.S. 3X6 7-9kgf.cm

S16

C.P. 3X4 3-5kgf.cm

S17

C.P. 3X6 3-5kgf.cm

S18

C.P. 3X6 4-6kgf.cm

Disassembly/Reassembly Disassembling/Reassembling Flowchart 18

Confidential

Page 19

L800/L801 Revision A

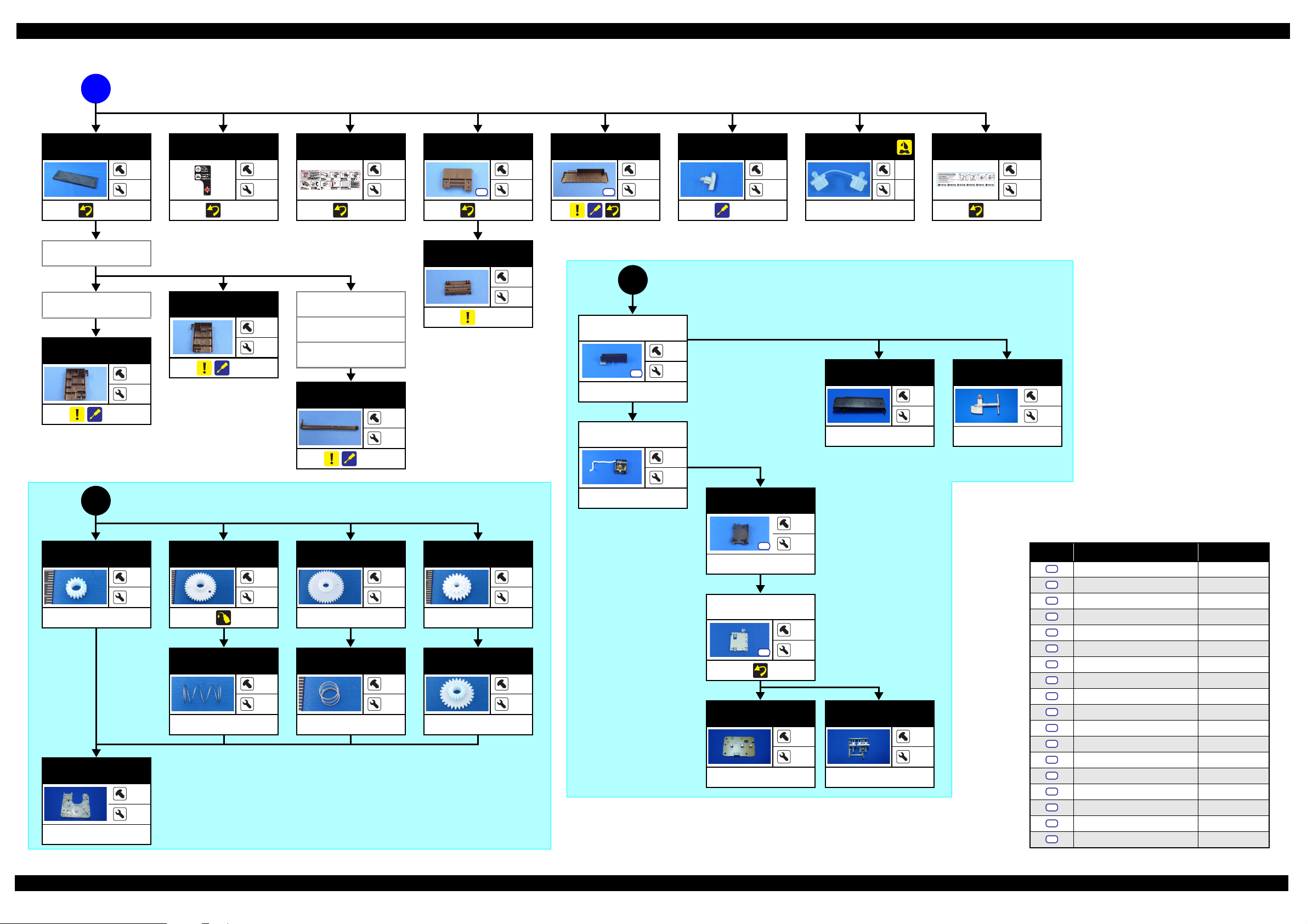

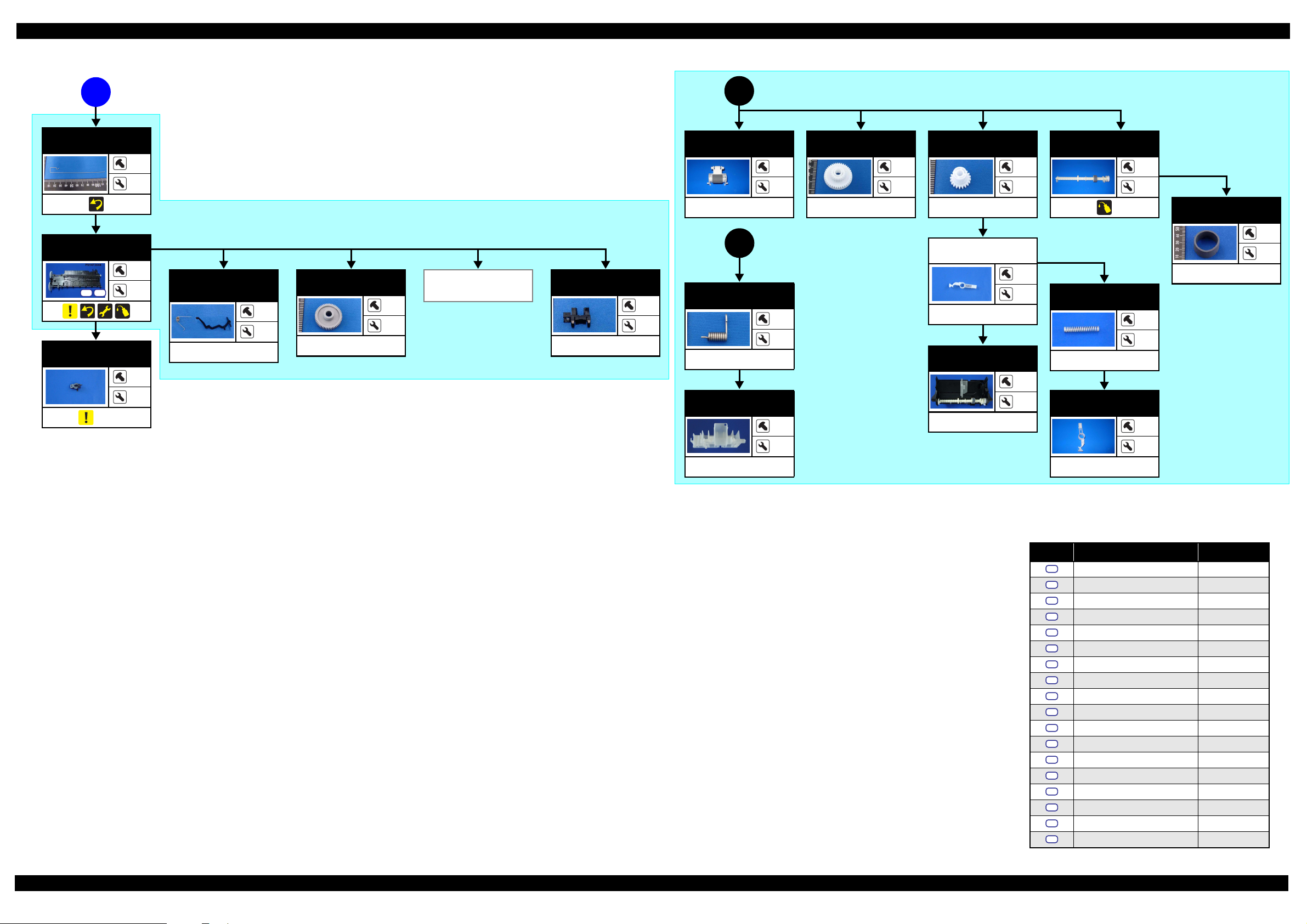

(p 18)

A

Top Cover

(p 61)

Bottom Cover

Valve Leve r

Right Cover

(p 63)

2

(p 18)

Valve Posi t i o n

Label

---

2

(p 61)

---

---

Refilling Ink

Label

(p 61)

---

---

Tube Valve

Holder Rear

S5

(p 62)

Bottom Cover

3

6

S5

(p 63)

8

---

Valve Leve r

---

2

(p 62)

Cap

---

---

---

Top Cover Label

---

---

(p 61)

Tube Valve

Holder Front

---

Left Cover

---

7

---

(p 63)

7

Left Cover

(p 62)

Valve Le v e r

Right Cover

Cover Joint

---

Panel Cover

3

Assy

---

(p 18)

2

S3

---

---

2

(p 63)

Panel Unit

---

“ 1.4.2 Panel Assy/ Cover Open Sensor (p30)”

Panel Cover

---

---

---

Decoration Belt

Left

---

---

---

---

“ 1.5.4 APG Unit (p41)”

---

Open Sensor

Holder

Spur Gear 12.8

---

APG Holder

---

1

Spur Gear 28.8

---

---

---

---

Spur Gear 33.6

---

---

---

Combination

Gear 14.22

---

---

---

S3

---

Panel Shield

Plate

4

2

Compression

Spring 2.25

---

---

---

Compression

Spring 0.97

---

Combination

S3

Gear 12.8.27

---

---

---

---

---

Panel Board

---

---

Housing Panel

Assy

---

1

---

---

---

---

---

Screw type/torque list

Symbol Screw type Torque

S1

C.B.P. 2.6X8 3.5-4.5kgf.cm

S2

C.B.P. 2.6X8 3-5kgf.cm

S3

C.B.P. 3X10 3-5kgf.cm

S4

C.B.P. 3X10 5-7kgf.cm

S5

C.B.P. 3X6 3-5kgf.cm

S6

C.B.P. 3X8 5-7kgf.cm

S7

C.B.P.(P2) 3X8 5-7kgf.cm

S8

C.B.S 3X6 5-7kgf.cm

S9

C.B.S. (P2) 3X8 6-8kgf.cm

S10

C.B.S. (P4) 3X6 7-9kgf.cm

S11

C.B.S. (P4) 3X6 9-11kgf.cm

S12

C.B.S. 3X10 4-6kgf.cm

S13

C.B.S. 3X6 4-6kgf.cm

S14

C.B.S. 3X6 5-7kgf.cm

S15

C.B.S. 3X6 7-9kgf.cm

S16

C.P. 3X4 3-5kgf.cm

S17

C.P. 3X6 3-5kgf.cm

S18

C.P. 3X6 4-6kgf.cm

Disassembly/Reassembly Disassembling/Reassembling Flowchart 19

Confidential

Page 20

L800/L801 Revision A

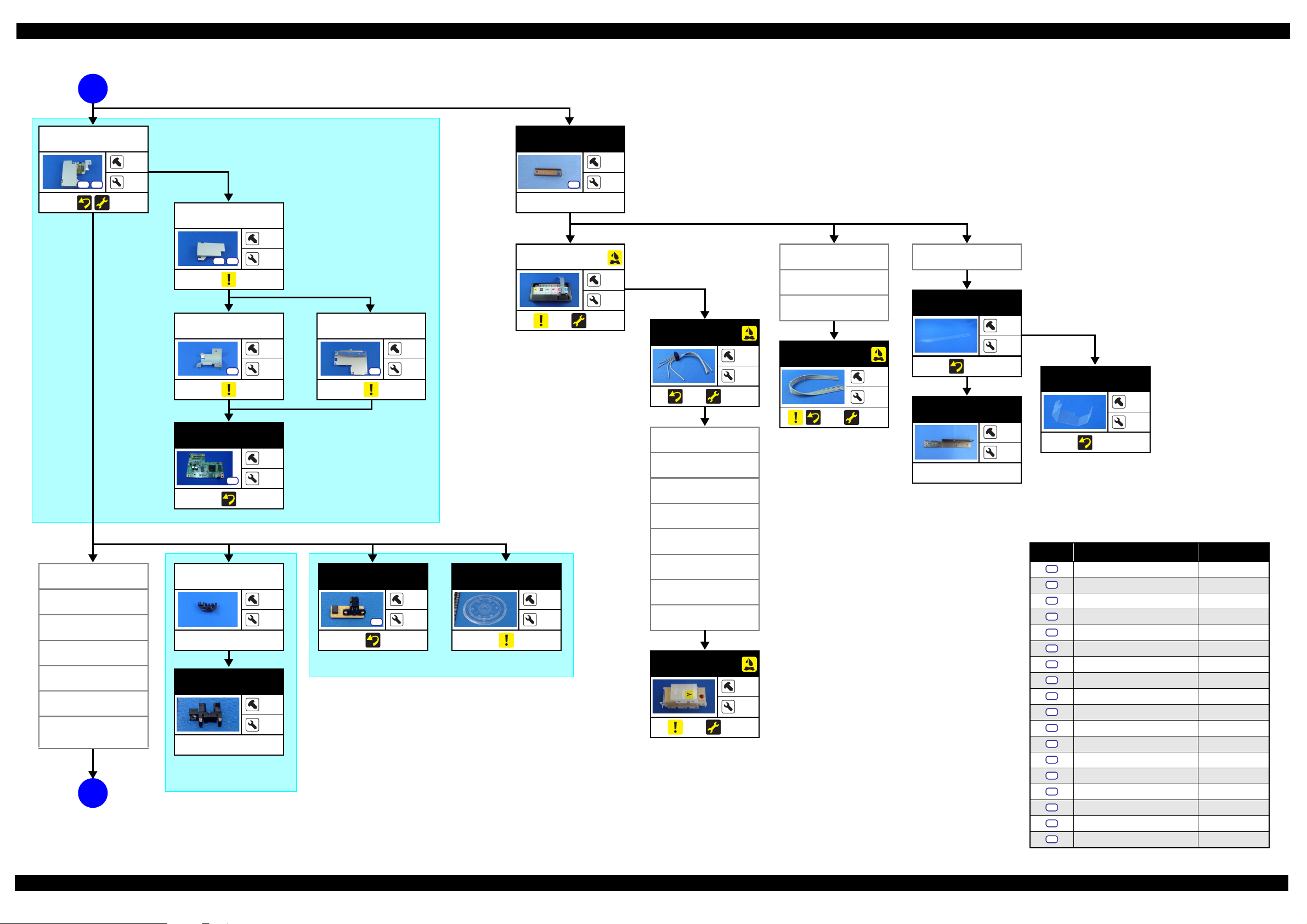

(p 18)

B

Main Board Unit

S7

S15

“ 1.4.1 Main Board Unit (p27) ”

Tube H o l d e r*

*: There are four Tube Holders installed in this printer. Depending on the target parts or units, the number of

Tube Holders you should remove differs.

3

---

Upper Shield

Plate M/B

S6

---

7

S14 S18

Shield Plate M/B

Sub

S13

---

Lower Shield

Plate M/B

2

---

S13

2

---

Ink Supply Tank

Assy

(p 64) (p 69)

Main Board

1

S12

---

1

1

When removing the Ink Supply Tank Assy: The Tube Holder on the home position side (on the Cover Case)

When removing the Printer Mechanism: All Tube Holders

Adapter CoverAdapter Cover

---

---

Ink Supply Tank

Tube Assy

---

---

(p 64) (p 69)

Top Cover

Adapter

Joint

Ink Supply Tube

Assy (W/Clamp)

(p 67) (p 69)

Tube Guide

Sheet

---

3

---

(p 66)

---

Tube Guide

Tube Guide

Sheet Sub

---

1

---

4

(p 66)

Bottom Cover

---

Valve Le v e r

Cover Ink Tube

Panel Assy

Tube Holder

Ink Supply Tank

Assy

Adapter Cover

Adapter

Tube Guide

Sheet/Tube

Guide Sheet Sub

(p 21)

C

APG Sensor

Assy

---

2

---

Photo Interrupter

---

2

---

“ 1.5.16 APG Sensor Assy

(p57)”

PF Encoder

S1

PF Scale

1

---

---

---

“ 1.5.10 PF Encoder / PF Scale (p49)”

Right Cover

Left Cover

Cover Joint

Tube Valve

Holder Rear

Tube Valve

Holder Front

Ink Supply Tank

(p 64) (p 69)

Screw type/torque list

Symbol Screw type Torque

S1

C.B.P. 2.6X8 3.5-4.5kgf.cm

S2

C.B.P. 2.6X8 3-5kgf.cm

S3

C.B.P. 3X10 3-5kgf.cm

S4

C.B.P. 3X10 5-7kgf.cm

S5

C.B.P. 3X6 3-5kgf.cm

S6

C.B.P. 3X8 5-7kgf.cm

S7

C.B.P.(P2) 3X8 5-7kgf.cm

S8

---

---

C.B.S 3X6 5-7kgf.cm

S9

C.B.S. (P2) 3X8 6-8kgf.cm

S10

C.B.S. (P4) 3X6 7-9kgf.cm

S11

C.B.S. (P4) 3X6 9-11kgf.cm

S12

C.B.S. 3X10 4-6kgf.cm

S13

C.B.S. 3X6 4-6kgf.cm

S14

C.B.S. 3X6 5-7kgf.cm

S15

C.B.S. 3X6 7-9kgf.cm

S16

C.P. 3X4 3-5kgf.cm

S17

C.P. 3X6 3-5kgf.cm

S18

C.P. 3X6 4-6kgf.cm

Disassembly/Reassembly Disassembling/Reassembling Flowchart 20

Confidential

Page 21

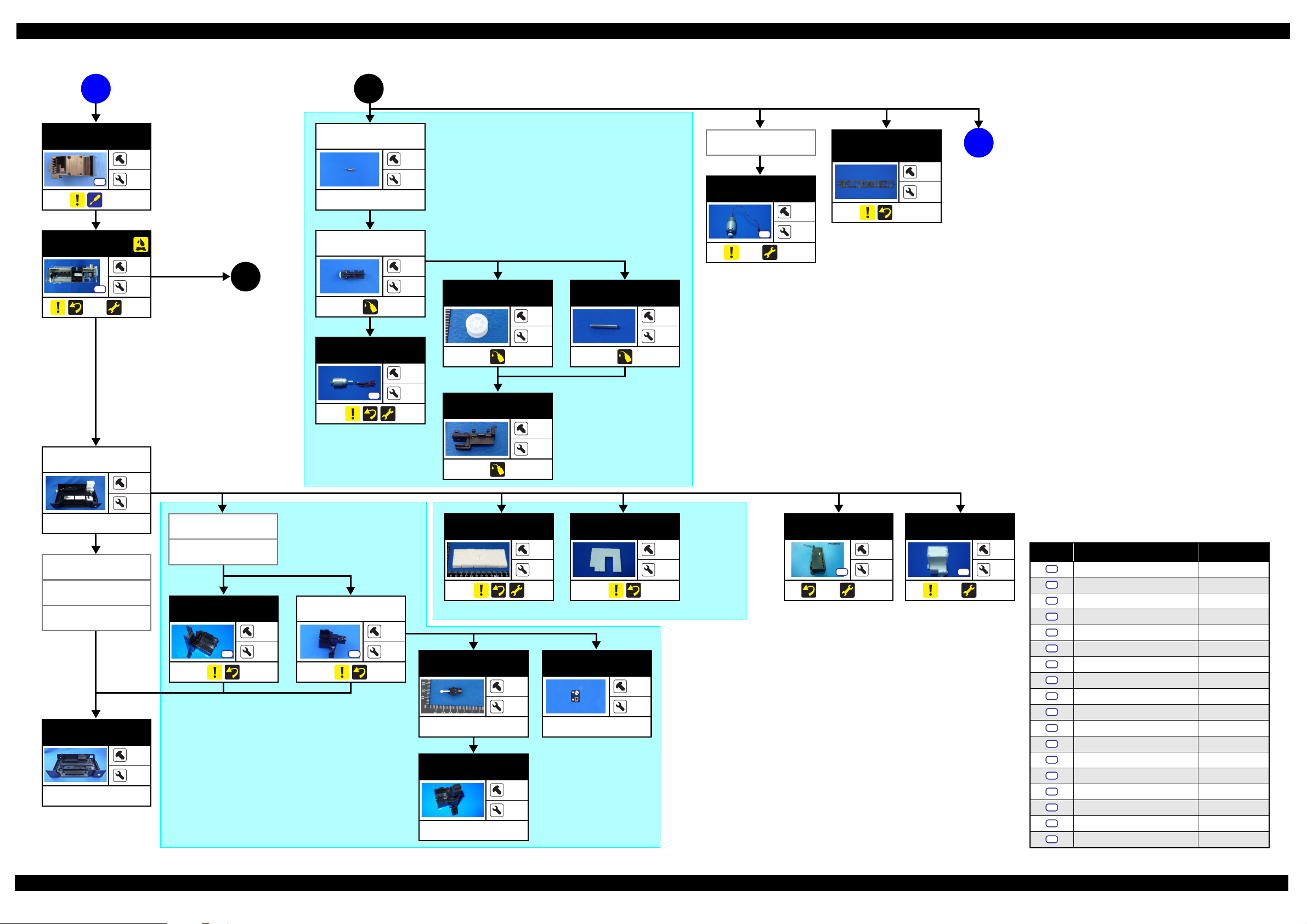

L800/L801 Revision A

(p 20) (p 21)

C

Cover Case

S6

(p 65)

Printer

Mechanism

S6

(p 35) (p 69)

4

Extension Spring

1

---

---

Driven Pulley

Assy

5

(p 21)

4

4

---

2

---

---

Driven Pulley

CR Motor

2

S16

---

Driven Pulley

Holder

“ 1.5.12 CR Motor (p50) ”

Driven Pulley

Shaft

---

---

---

PF Encoder/

PF Scale

Porous Pad

Paper Guide

Front

D

(p 22)

---

PF Motor

S17

(p 49) (p 69)

---

2

(p 57)

---

---

---

Housing Lower

Assy

---

Waste Ink Pad

Lower

Waste Ink Pad

Cap

P/S Assy

Housing Lower

(W/Foot)

---

---

---

---

“ 1.5.7 Left & Right Guide

Stacker Assy

Stackers / CDR Guide Sensor

(p44)”

Stacker Cover

Guide Stacker

Left

1

S6

---

---

---

Guide Stacker

Right Assy

S6

“ 1.5.6 Waste Ink Pad Lower / Waste Ink Pad Cap Lower (p43)”

1

---

Waste Ink Pad

Lower

CDR Guide

Sensor

---

Guide Stacker

Right

---

Waste Ink Pad

Cap Lower

---

---

---

---

P/S Assy

S4

(p 34) (p 69)

1

---

Label CDR

---

2

---

---

---

---

---

Waste Ink Tray

S4

(p 42) (p 69)

Screw type/torque list

2

1

Symbol Screw type Torque

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

C.B.P. 2.6X8 3.5-4.5kgf.cm

C.B.P. 2.6X8 3-5kgf.cm

C.B.P. 3X10 3-5kgf.cm

C.B.P. 3X10 5-7kgf.cm

C.B.P. 3X6 3-5kgf.cm

C.B.P. 3X8 5-7kgf.cm

C.B.P.(P2) 3X8 5-7kgf.cm

C.B.S 3X6 5-7kgf.cm

C.B.S. (P2) 3X8 6-8kgf.cm

C.B.S. (P4) 3X6 7-9kgf.cm

C.B.S. (P4) 3X6 9-11kgf.cm

C.B.S. 3X10 4-6kgf.cm

C.B.S. 3X6 4-6kgf.cm

C.B.S. 3X6 5-7kgf.cm

C.B.S. 3X6 7-9kgf.cm

C.P. 3X4 3-5kgf.cm

C.P. 3X6 3-5kgf.cm

C.P. 3X6 4-6kgf.cm

Disassembly/Reassembly Disassembling/Reassembling Flowchart 21

Confidential

Page 22

L800/L801 Revision A

(p 21)

D

Ink System

S15

LD Roller

Guide Assy

S10

2

---

Extension Spring

CR Lock

“ 1.5.14 ASF Unit (p54)”

1

5

0.8

---

---

5

---

---

---

(p 23)

“ 1.5.8 Ink System (p45)”

Compression

Spring 0.98

2

---

APG Unit

Tube Guide

“ 1.5.9 EJ Frame Assy (p46)”

Tube G u i d e

Extension Spring

Driven Pulley

Assy

Cable Holder

Frame

Cable Holder

Frame

2

---

---

CR Scale

Adapter Cover

S15

---

Adapter

Front Frame

2

PF Encoder FFC

---

---

Cover FFC

---

Cover FFC Inner

Holder Contact

S15

2

---

Printhead

EJ Frame Assy

PF Scale Sheet

(p 66)

PF Scale Cover

S6

(p 66)

---

---

1

1

---

---

EJ Frame

Torsion Spring L

---

EJ Frame

Torsion Spring R

---

ASF Unit

S10 S11

Upper Paper

Guide

(p 56)

(p 69)

Tube G u i d e

Cable Holder

Frame

Front Frame

EJ Frame Assy

E

(p 23)

---

---

2

2

(p 23)

6

Cable Holder

Frame

“ 1.5.13 CR Unit (p52)”

CR Unit

---

---

---

2

CR Guide Shaft

---

---

Timing Belt

---

---

Head FFC

---

---

---

Screw type/torque list

Symbol Screw type Torque

S1

C.B.P. 2.6X8 3.5-4.5kgf.cm

S2

C.B.P. 2.6X8 3-5kgf.cm

S3

C.B.P. 3X10 3-5kgf.cm

S4

C.B.P. 3X10 5-7kgf.cm

S5

C.B.P. 3X6 3-5kgf.cm

S6

C.B.P. 3X8 5-7kgf.cm

S7

C.B.P.(P2) 3X8 5-7kgf.cm

S8

C.B.S 3X6 5-7kgf.cm

S9

C.B.S. (P2) 3X8 6-8kgf.cm

S10

C.B.S. (P4) 3X6 7-9kgf.cm

S11

C.B.S. (P4) 3X6 9-11kgf.cm

S12

C.B.S. 3X10 4-6kgf.cm

S13

C.B.S. 3X6 4-6kgf.cm

S14

C.B.S. 3X6 5-7kgf.cm

S15

C.B.S. 3X6 7-9kgf.cm

S16

C.P. 3X4 3-5kgf.cm

S17

C.P. 3X6 3-5kgf.cm

S18

C.P. 3X6 4-6kgf.cm

Disassembly/Reassembly Disassembling/Reassembling Flowchart 22

Confidential

Page 23

L800/L801 Revision A

E

EJ Ground

Spring

Front Paper

Guide Assy

S9

S15

CDR Tray

Sensor

(p 60)

(p 22)

(p 22)

6

Retard Roller

Holder Assy

---

3

“ 1.5.17 Front Paper Guide Assy (p57)”

---

---

2

Combination

Gear 168.32.8

---

Spur Gear 16

---

1

---

---

---

LD Roller

Shaft Assy

“ 1.5.14 ASF Unit (p54)”

---

2

LD Roller

---

(p 22)

5

2

1

PE Lever/

PE Lever

Torsion Spring

---

---

Spur Gear 26.5

---

2

---

1

---

2

Porous Pad

Paper Guide

Front

Photo Interrupter

(PE Sensor)

---

---

Torsion Spring

137.7

4

---

---

---

LD Roller Guide

---

Change Lever

Assy

---

ASF Assy

---

---

---

---

Compression

Spring 2.36

---

---

---

---

---

---

Change Lever

---

---

---

---

1

Screw type/torque list

Symbol Screw type Torque

S1

C.B.P. 2.6X8 3.5-4.5kgf.cm

S2

C.B.P. 2.6X8 3-5kgf.cm

S3

C.B.P. 3X10 3-5kgf.cm

S4

C.B.P. 3X10 5-7kgf.cm

S5

C.B.P. 3X6 3-5kgf.cm

S6

C.B.P. 3X8 5-7kgf.cm

S7

C.B.P.(P2) 3X8 5-7kgf.cm

S8

C.B.S 3X6 5-7kgf.cm

S9

C.B.S. (P2) 3X8 6-8kgf.cm

S10

C.B.S. (P4) 3X6 7-9kgf.cm

S11

C.B.S. (P4) 3X6 9-11kgf.cm

S12

C.B.S. 3X10 4-6kgf.cm

S13

C.B.S. 3X6 4-6kgf.cm

S14

C.B.S. 3X6 5-7kgf.cm

S15

C.B.S. 3X6 7-9kgf.cm

S16

C.P. 3X4 3-5kgf.cm

S17

C.P. 3X6 3-5kgf.cm

S18

C.P. 3X6 4-6kgf.cm

Disassembly/Reassembly Disassembling/Reassembling Flowchart 23

Confidential

Page 24

L800/L801 Revision A

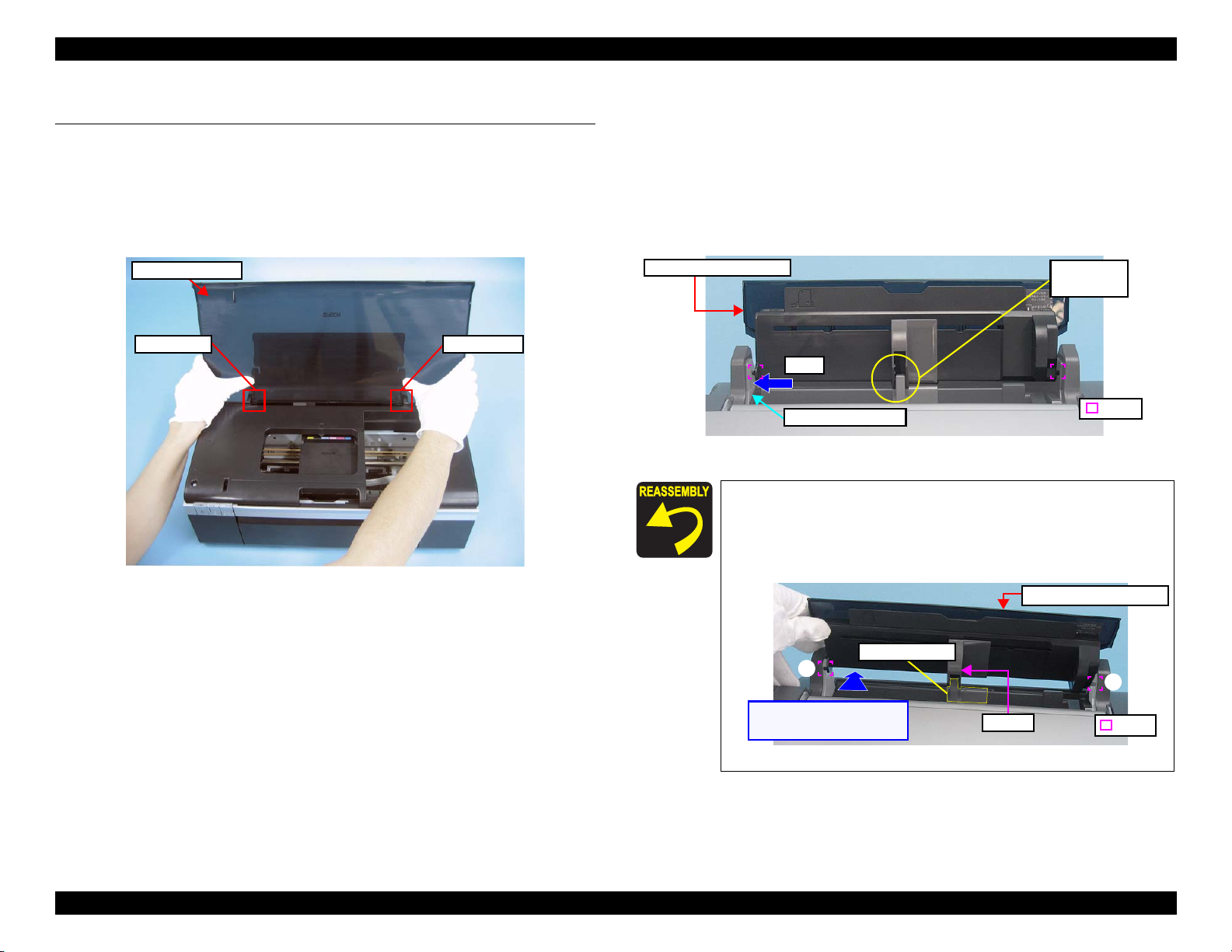

1.3 Removing Exterior Parts/Components

1.3.1 Printer Cover

Removal procedure

1. Pull out the left shaft and right shaft of the Printer Cover, and remove the

Printer Cover.

Printer Cover

Shaft (left)

Figure 1-15. Removing the Printer Cover

Shaft (right)

1.3.2 Paper Support Assy

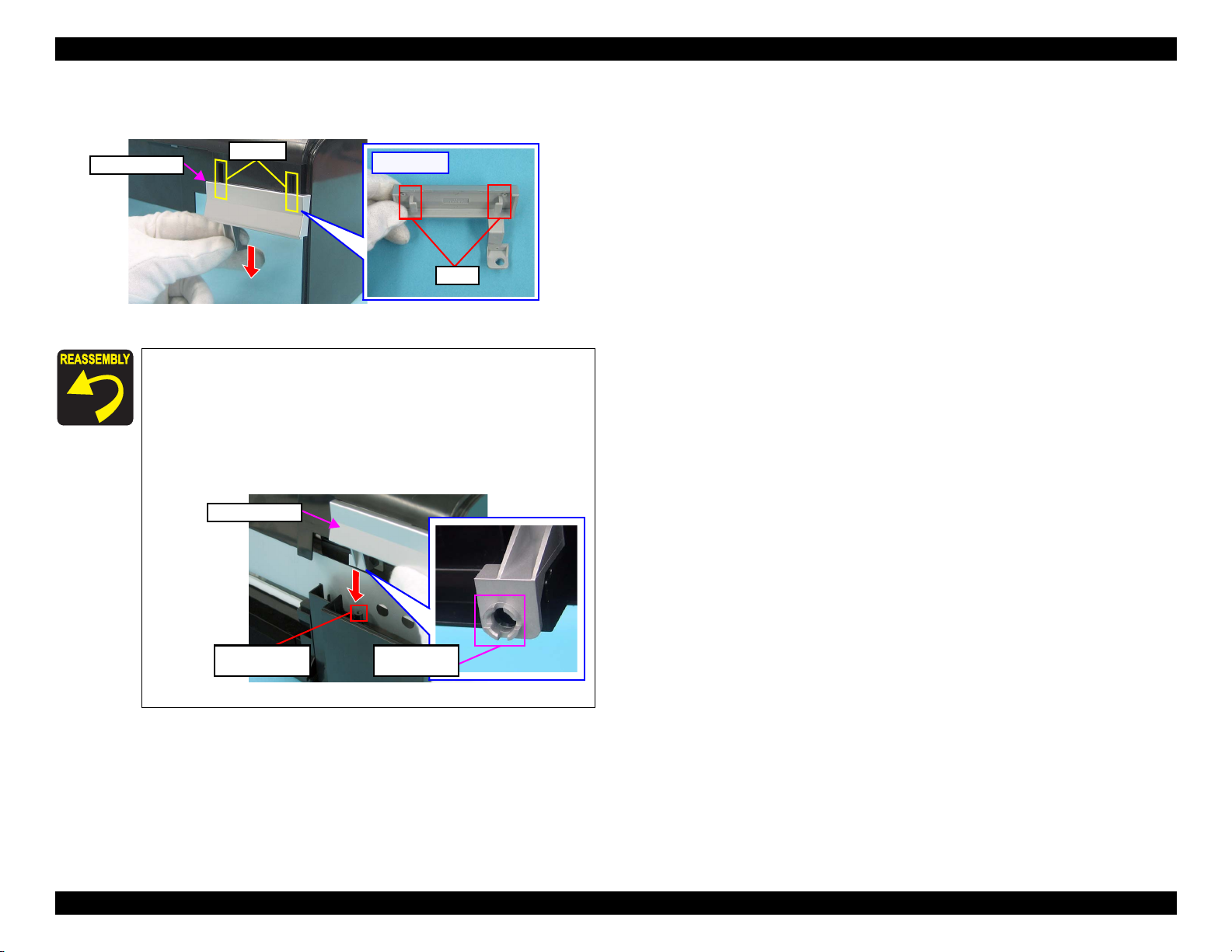

Removal procedure

1. Open the Paper Support Assy.

2. Disengage the right shaft of the Paper Support Assy from the bushing of the

ASF Unit by pushing the bushing outward. Then remove the Paper Support

Assy, disengaging the left shaft preventing the Edge Guide projection from

hitting against the other parts.

Paper Support Assy

Push

Bushing of the ASF

Figure 1-16. Removing the Paper Support Assy

When reinstalling the Paper Support Assy, match the projection

and hole of the Edge Guide, then attach the right shaft and the left

shaft in that order. (Put the shafts at the front side in the bushing

and then push them rearward.) After reinstalling, check that the

Paper Support Assy moves smoothly.

Edge Guide

Projection

Paper Support Assy

:Shaft

Convex Portion

2

1

Mounting Direction

(from front side to rear side)

Hole

: Shaft

Figure 1-17. Reinstalling the Paper Support Assy

Disassembly/Reassembly Printer Cover 24

Confidential

Page 25

L800/L801 Revision A

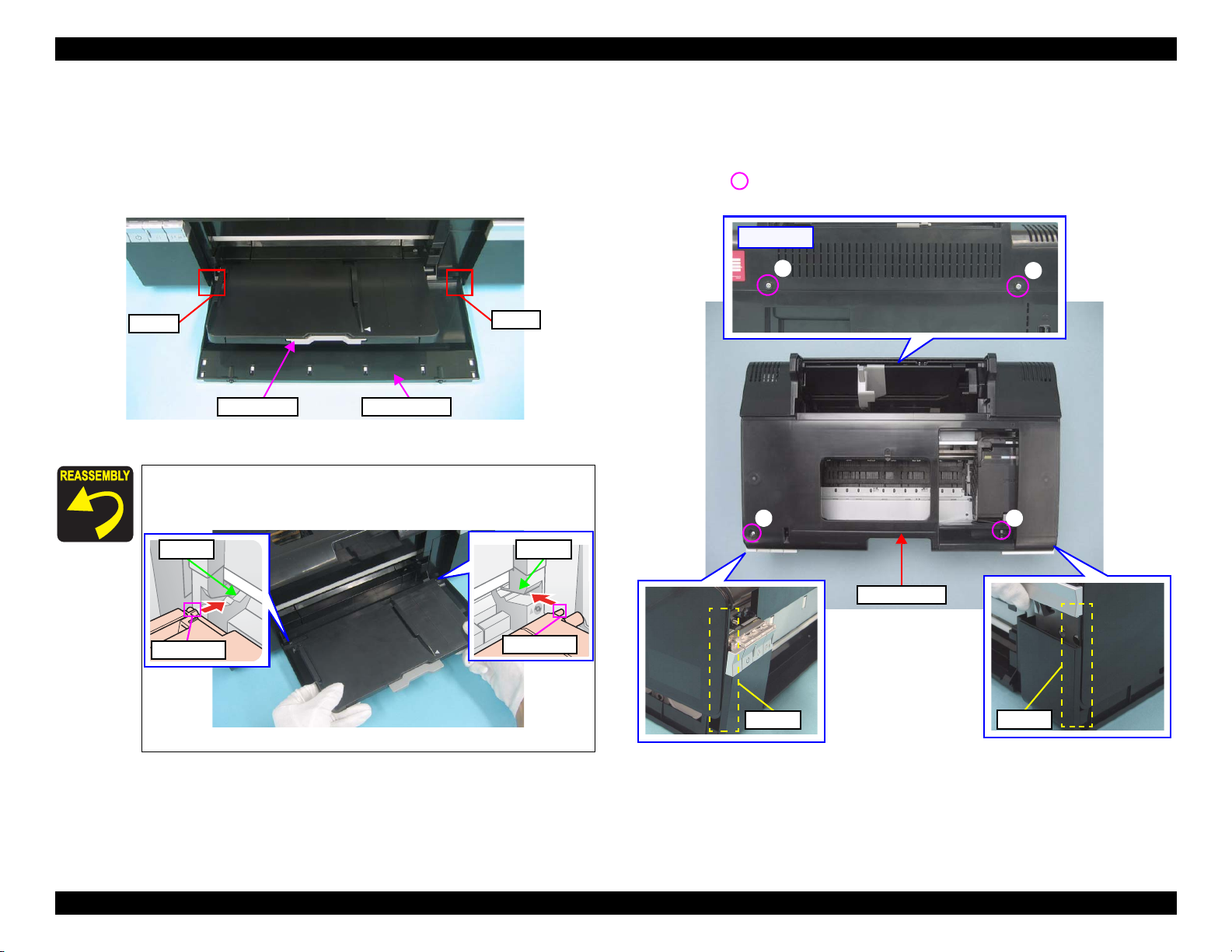

1.3.3 Stacker Assy / Stacker Cover

Removal procedure

1. Open the Stacker Cover.

2. Remove the Stacker Assy.

3. Release the Stacker Cover from the two shafts and remove the Stacker Cover.

Shaft

Stacker Assy Stacker Cover

Figure 1-18. Removing the Stacker Assy / Stacker Cover

When installing the Stacker Assy, insert the guide pins of the

Stacker Assy into the lower grooves of the Guide Stacker Assy.

(The upper grooves are used when CDR is printed.)

Groove

Shaft

Groove

1.3.4 Housing Upper Assy

Removal procedure

1. Remove the four screws and remove the Upper Housing upward.

•

Screw : C.B.P. M3x10 (tightening torque: 5-7 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

[Rear Side]

4

1 2

3

Upper Housing

Guide Pin

Guide Pin

Groove

Groove

Figure 1-19. Installing the Stacker Assy

Figure 1-20. Removing the Upper Housing

Disassembly/Reassembly Stacker Assy / Stacker Cover 25

Confidential

Page 26

L800/L801 Revision A

2. Slide the Front Housing in the direction of the arrow and remove the Front

Housing from the Upper Housing.

Front Housing

Grooves

[Rear Side]

Ribs

Figure 1-21. Removing the Front Housing

When installing the Upper Housing, be careful of the following:

Do not pinch the cables.

Tighten the screws in the order given in Fig.1-20 (p.25).

Match the ribs of the Upper Housing shown in Fig.1-20 (p.25)

with the grooves of the Housing Lower.

As shown in Fig.1-22, match the A part of the Front Housing

with the screw box of the Housing Lower.

Front Housing

Screw box of

Housing Lower

A part of Front

Housing

Figure 1-22. Installing Upper Housing

Disassembly/Reassembly Housing Upper Assy 26

Confidential

Page 27

L800/L801 Revision A

1.4 Removing Control Boards

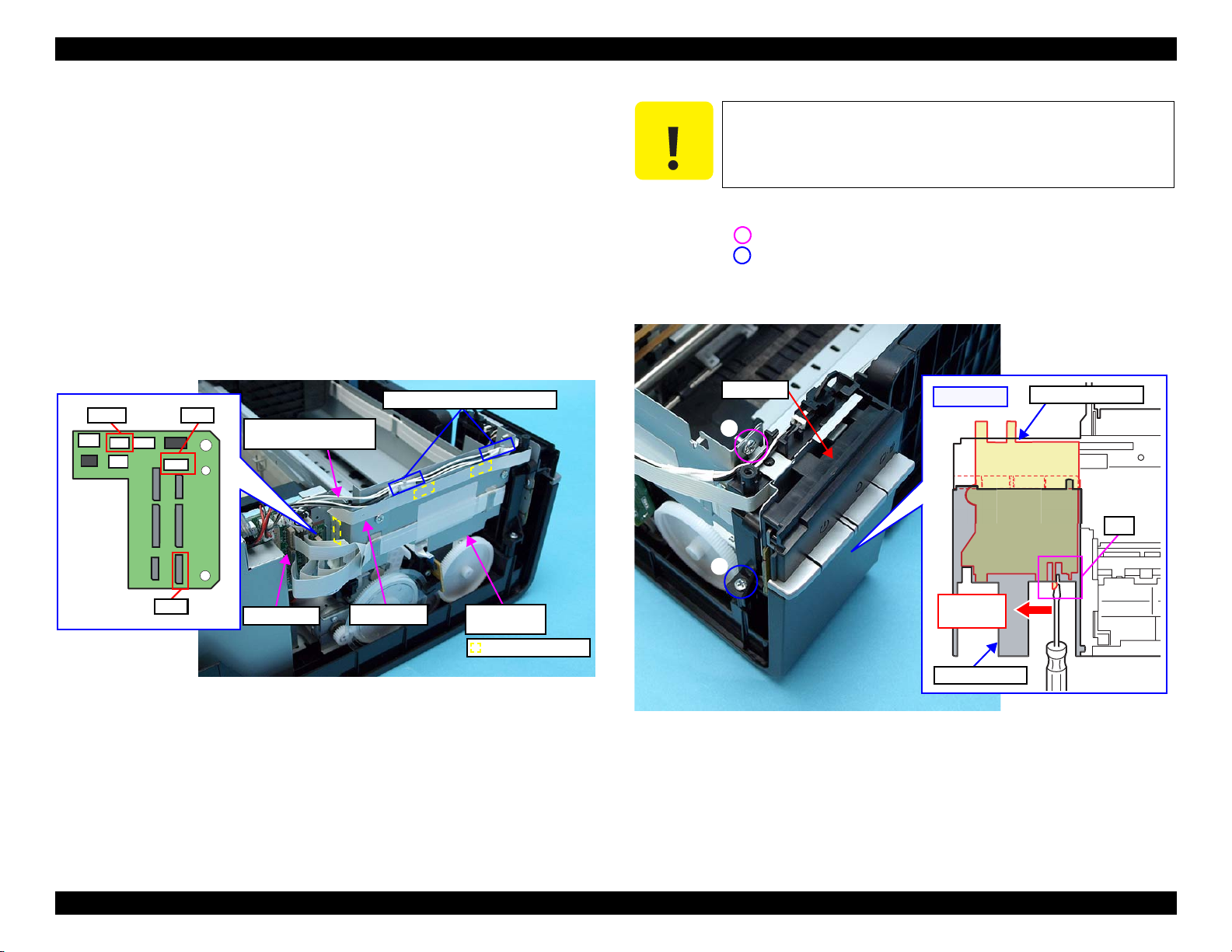

1.4.1 Main Board Unit

Removal procedure

Main Board Unit removal

1. Disconnect all connectors on the Main Board Unit.

2. Peel off the double-sided tape that secures the Panel FFC to the Holder Frame

and release the Panel FFC. (Fig.1-29 (p.30))

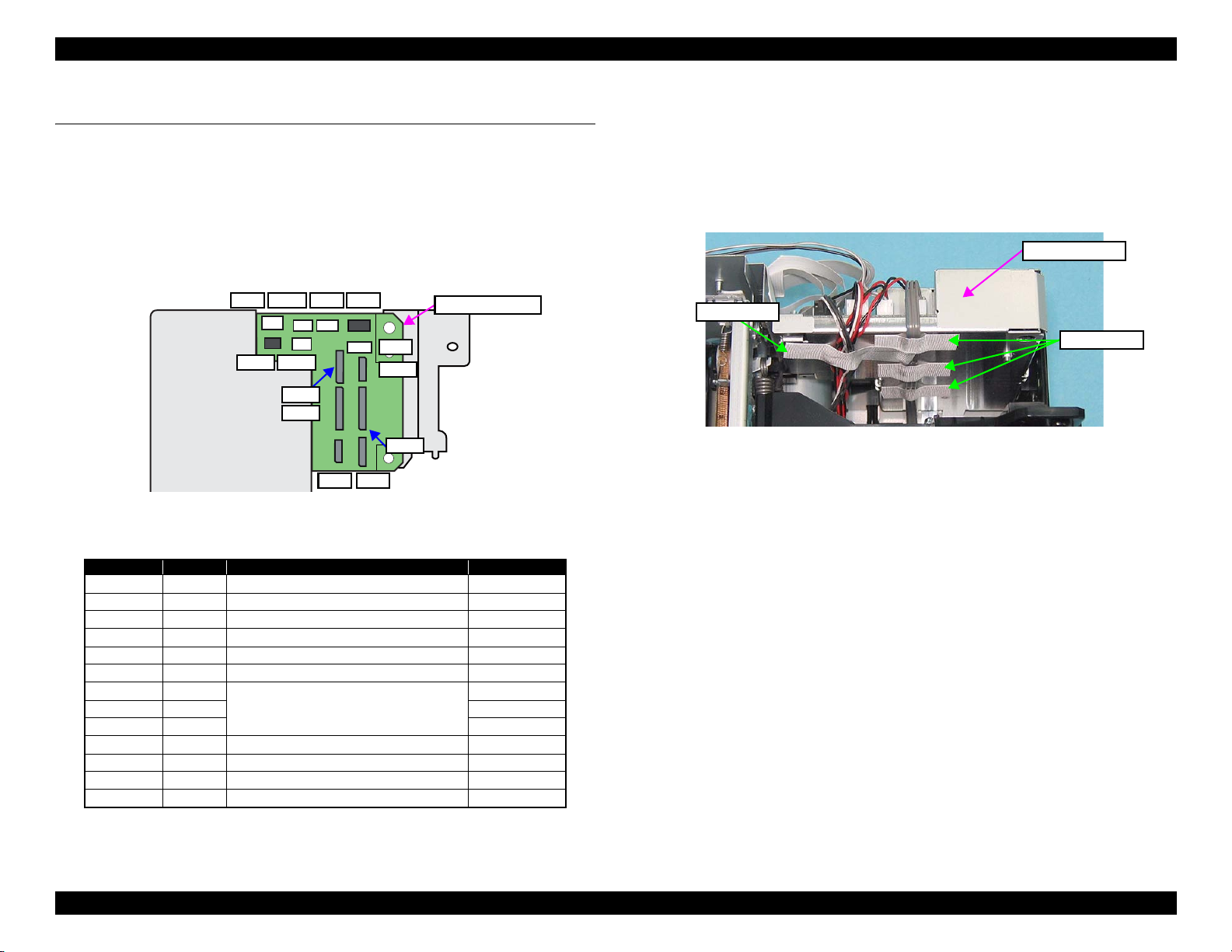

CN6 CN7CN3

CN17

CN4

CN13

CN14

CN12

CN11

CN16

CN10

CN5CN8

Figure 1-23. Connector layout of the Main Board

Table 1-3. List of Connectors and their Destinations

CN No.@ Color Destination Number of pins

CN3 White

CN4 White

CN5 FFC

CN6 White

CN7 Black

CN8 FFC

CN10 FFC

CN11 FFC 13pin

CN12 FFC 9pin

CN13 Black

CN14 White

CN16 FFC

CN17 White

P/S Assy

CDR Guide Sensor / CDR Tray Sensor

Panel Board

PE Sensor

APG Sensor

PF Encoder

Head FFC

PF Motor

CR Motor

PW Sensor / CR Encoder Sensor

Cover Open Sensor

Main Board Unit

3pin

4pin

8pin

3pin

3pin

5pin

13pin

2pin

2pin

6pin

2pin

3. Peel off the four acetate tapes that secures the following cables on the back of

the Main Board Unit.

•

Power Supply Cable

•

CR Motor Cable

•

PF Motor Cable

•

PE Motor Cable

•

APG Sensor Cable

Main Board Unit

Acetate Tape

Acetate Tape

Figure 1-24. Removing the Main Board Unit (1)

Disassembly/Reassembly Main Board Unit 27

Confidential

Page 28

L800/L801 Revision A

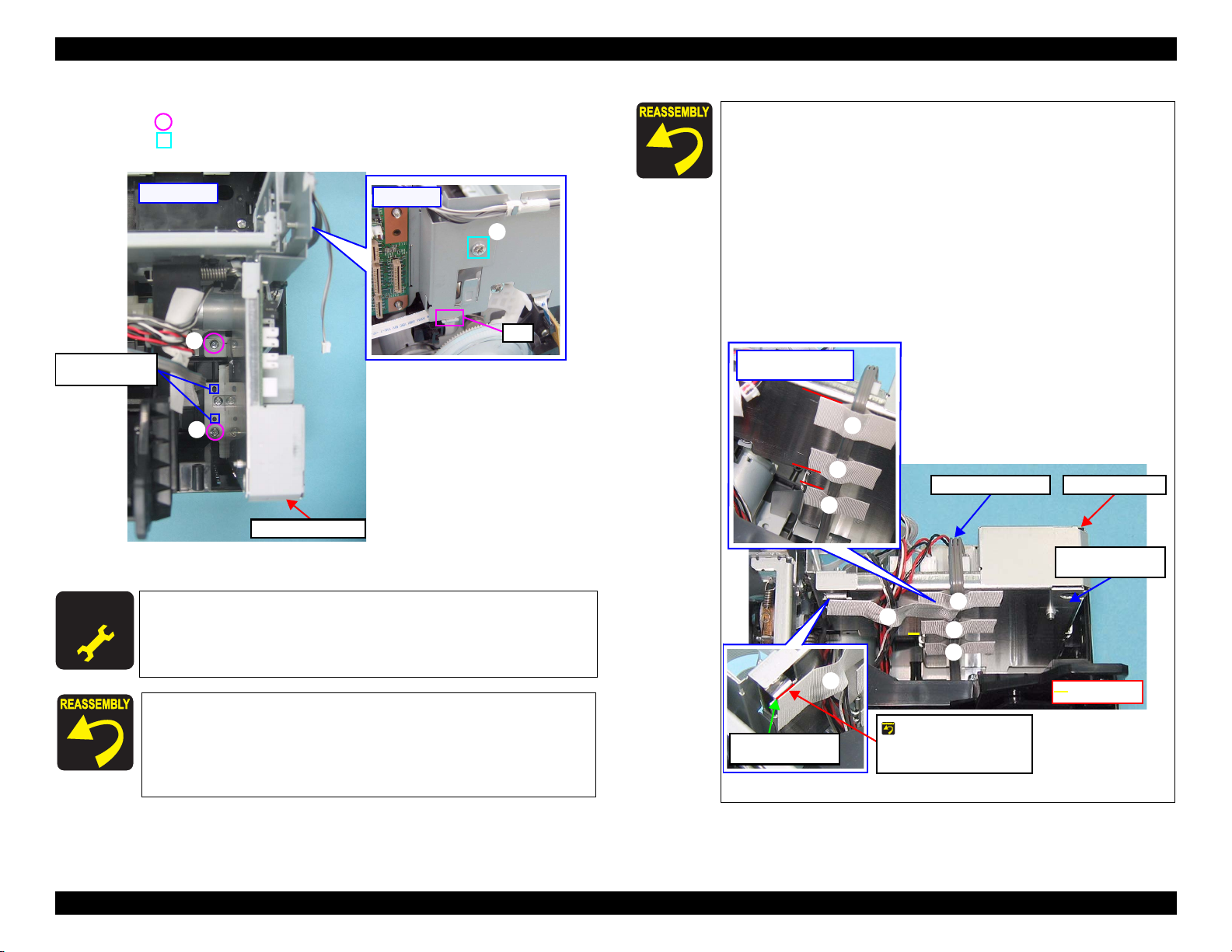

4. Remove the three screws and remove the Main Board Unit.

• Screw (2 pcs.): C.B.P.(P2) M3x8 (tightening torque: 5-7 kgf.cm)

• Screw (1 pc.): C.B.S. M3x6 (tightening torque: 7-9 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

[Upper Side]

[Left Side]

2

Positioning Holes

and Guide Pins

1

Main Board Unit

Figure 1-25. Removing the Main Board Unit (2)

After connecting the cables, secure them with acetate tape

following the procedures below.

1. Route the Power Supply Cable closely along the Lower Shield

Plate M/B, and secure the cable with acetate tapes at the

positions A, B, and C (30 mm each) as shown in Fig.1-26.

2. Avoiding the sharp edge shown in Fig.1-26, secure the

3

Rib

following cables with the acetate tape D (50 mm).

•

Power Supply Cable

•

CR Motor Cable

•

PF Motor Cable

•

PE Motor Cable

•

APG Sensor Cable

Positions of Acetate

tape A, B, C

A

B

Power Supply Cable

Main Board Unit

C

Lower Shield Plate

M/B

A D J U S T M E N T

R E Q U I R E D

Whenever the Main Board Unit is replaced, the required adjustment

must be carried out.

• Refer to "2.1.2 Required Adjustments" (p.74)

D

A

B

C

D

Sharp edge

When installing the Main Board Unit, be careful of the following:

Match the positioning holes with guide pins shown in Fig.1-25.

Insert the rib of the Main Board Unit into the positioning hole

of the Cable Holder Frame as shown in Fig.1-25.

Tighten the screws in the order given in Fig.1-25.

Edge of Lower

Shield Plate M/B

Figure 1-26. Routing the Cables

Align the upper left end

of acetate tape D with

the edge of the Lower

Shield Plate M/B.

Disassembly/Reassembly Main Board Unit 28

Confidential

Page 29

L800/L801 Revision A

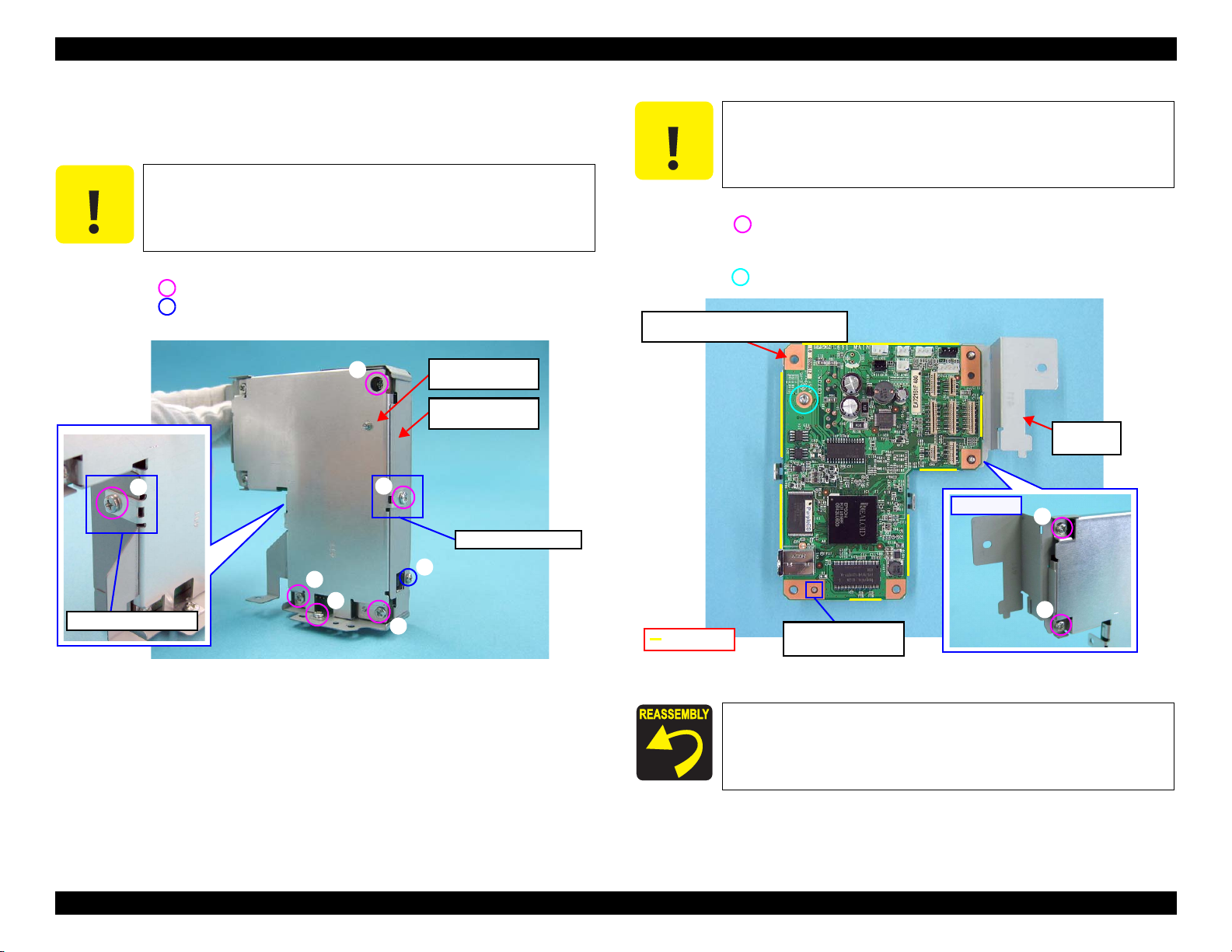

Disassembling the Main Board Unit

1. Remove the Main Board Unit (p. 27).

C A U T I O N

Do not apply unnecessary force on the screw receiving parts of

the Lower Shield Plate M/B, as they are easy to deform.

When assembling or disassembling the Upper Shield Plate M/B,

be careful of its sharp edges.

2. Remove the seven screws and remove the Upper Shield Plate M/B.

• Screw (6 pcs.): C.B.S. M3x6 (tightening torque: 5-7 kgf.cm)

• Screw (1 pc.): C.P. M3x6 (tightening torque: 4-6 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

5

3

2

Lower Shield Plate

M/B

Upper Shield Plate

M/B

Screw Receiving Part

C A U T I O N

Be careful of the sharp edges shown in the figure below when

assembling or reassembling.

3. Remove the two screws and remove the Shield Plate M/B Sub.

• Screw (2 pcs.): C.B.S. M3x6 (tightening torque: 4-6 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

4. Remove the screw and remove the Main Board Unit.

• Screw C.B.S. M3x10 (tightening torque: 4-6 kgf.cm)

Upper Side: Main Board

Lower Side: Lower Shield Plate M/B

[Rear Side]

Shield Plate

M/B Sub

1

7

4

Screw Receiving Part

Figure 1-27. Removing the Upper Shield Plate M/B

1

2

6

Sharp edge

Positioning Hole and

Guide Pin

Figure 1-28. Removing the Main Board

When installing the Main Board, match the positioning hole

with the guide pin shown in Fig.1-28.

Tighten the screws in the order given in Fig.1-27 (p.29),

Fig.1-28.

Disassembly/Reassembly Main Board Unit 29

Confidential

Page 30

L800/L801 Revision A

1.4.2 Panel Assy/ Cover Open Sensor

Removal procedure

Panel Assy removal

1. Disconnect the Panel FFC from the connector (CN5) on the Main Board and

peel the Panel FFC off the Cable Holder Frame.

2. Disconnect the CDR Sensor Cable and Cover Open Sensor Cable from the

connectors (CN4, CN17) on the Main Board.

3. Release the CDR Sensor Cable and Cover Open Sensor Cable from the two

hooks of the Cable Holder Frame.

4. Peel off the acetate tape A, B to separate the CDR Sensor Cable from the

Cover Open Sensor Cable.

Hooks and Acetate Tape A, B

CN4CN17

Cover Open Sensor and

CDR Sensor Cable

C A U T I O N

When removing the screw (2) shown in Fig.1-30, be careful not to

damage the Cover Open Sensor Cable and CDR Sensor Cable.

5. Remove the two screws.

• Screw (3 pcs.): C.B.P. M3x6 (tightening torque: 5-7 kgf.cm)

• Screw (3 pcs.): C.B.P. M3x10 (tightening torque: 5-7 kgf.cm)

6. From the bottom of the Printer, insert a flathead screwdriver into the hole to

disengage the tab, and remove the Panel Assy.

Panel Assy

[Front side]

Open Sensor Holder

2

Tab

1

CN5

Main Board

Panel FFC

Figure 1-29. Removing the Panel Assy (1)

Cable Holder

Frame

Double sided Tape

Figure 1-30. Removing the Panel Assy (2)

Disengage

direction

Housing Lower

Disassembly/Reassembly Panel Assy/ Cover Open Sensor 30

Confidential

Page 31

L800/L801 Revision A

When Installing the Panel Assy, be careful of the following:

Tighten the screws in the order given in Fig.1-30.

When routing the FFCs and cables, follow the procedures

below referring to Fig.1-31.

1. Route the Panel FFC aligning its upper edge with the

reference line marked on the Cable Holder Frame, and

secure the FFC with double-sided tape.

2. Attach the acetate tape C along with the edge of the Cable

Holder Frame to secure the Panel FFC and Head FFC.

3. Tie the two cables together using two pieces of acetate tape

(20 mm each) so that the two tape positions come to the two

hooks of the Cable Holder Frame respectively. The cables

orientation must be as follows;

CDR cable: faces its black side upward

Cover Open Sensor cable: faces its gray side upward

4. Route the cables through the two hooks of the Cable Holder

Frame aligning the center of the tapes with the hooks.

Fold the Panel FFC along the

corner of the Upper Shield

Plate M/B.

Upper Side : CDR Sensor Cable

Panel FFC

Lower Side : Cover Open Sensor Cable

A

B

As shown in Fig.1-32, route the CDR Sensor Cable and Cover

Open Sensor Cable through the gap between the two ribs of

the Open Sensor Holder.

Cover Open Sensor Cable

CDR Sensor Cable

Ribs

Figure 1-32. Installing the Panel Assy (1)

As shown in Fig.1-30 (p.30) and Fig.1-33, match the

positioning holes of the Open Sensor Holder with the guide

pins of the Housing Lower, and secure the Open Sensor Holder

with the tab.

Open Sensor Holder

Do not route the

Panel FFC over

the screw of the

Cable Holder

Frame.

Figure 1-31. Routing the Cables

Hook

Ref. Line

Housing Lower

Positioning Hole

and Guide Pin

Figure 1-33. Installing the Panel Assy (2)

Disassembly/Reassembly Panel Assy/ Cover Open Sensor 31

Confidential

Page 32

L800/L801 Revision A

Panel Board / Buttons Removal

1. Remove the Panel Assy. (p.30)

2. Remove the two screws on the back of the Panel Assy, and remove the Panel

Cover.

• Screw : C.B.P. M3x10 (tightening torque: 3-5 kgf.cm)

3. Remove the screw on the front of the Panel Unit, and remove the Panel Unit

from the Open Sensor Holder by sliding it in the upper right direction.

• Screw : C.B.P. M3x10 (tightening torque: 3-5 kgf.cm)

[Front side]

Panel Cover

Panel Unit

[Back Side]

Hook of the Panel

Shield Plate

Open Sensor Holder

Figure 1-34. Removing the Panel Board / Buttons (1)

4. Disconnect the connector (CN1) on the Panel Board, peel the Panel FFC off

the back of the Panel Shield Plate, and remove the Panel FFC.

5. Remove the two screws and remove the Panel Shield Plate from the Panel

Unit.

• Screw : C.B.P. M3x10 (tightening torque: 3-5 kgf.cm)

Panel Unit[Front side]

Panel Shield Plate

[Back Side]

6. Disengage the hook on the back of the Panel Board and remove the Panel

Board.

[Back Side]

Positioning Hole

Hook

and Guide Pin

Panel Board

Figure 1-36. Removing the Panel Board / Buttons (3)

7. Release the three hooks and remove the PS button, the Ink button, and the

Paper button from the Housing Panel B.

8. Slide the Lens of the PS button, the Ink button, and the Paper button in the

direction of the arrow to remove it.

[Front side]

[Back Side]

Housing Panel B

Housing Panel B

Hook

CN1

Panel FFC

Reference Line

Double-sided Tape

PS Button

Ink Button

Paper Button

Lens

Step 8

Lens

Figure 1-35. Removing the Panel Board / Buttons (2)

Figure 1-37. Removing the Panel Board / Buttons (4)

Disassembly/Reassembly Panel Assy/ Cover Open Sensor 32

Confidential

Page 33

L800/L801 Revision A

When installing the Panel Unit, be careful of the following:

When installing the Panel Shield Plate to the Open Sensor

Holder, match the hook and guide pins with the positioning

holes shown in Fig.1-38 and insert the Panel Shield Plate into

the groove of the Open Sensor Holder to secure the Panel

Shield Plate.

[Upper Side]

Panel Shield Plate

Guide Pin and Positioning Hole

Open Sensor Holder

Hook and Positioning Hole

Groove

Figure 1-38. Installing the Panel Unit

Cover Open Sensor Removal

1. Remove the Panel Assy. (p.30)

2. From the back of the Open Sensor Holder, disengage the hook of the Cover

Open Sensor, and remove the Cover Open Sensor pulling its rib out of the

hole by rotating the sensor in the direction of the arrow.

3. Disconnect the connector from the Cover Open Sensor to remove the Cover

Open Sensor.

Cover Open Sensor

Connector

Hook

Rib

[Back Side]

Open Sensor Holder

Figure 1-39. Removing the Cover Open Sensor

When installing the Cover Open Sensor, insert the rib shown in

Fig.1-39 into the hole of the Open Sensor Holder, and secure the

Cover Open Sensor with the hook.

Attach the Panel FFC with double-sided tape along with the

reference line shown in Fig.1-35 (p.32).

When installing the Panel Board, match the guide pin with the

positioning hole shown in Fig.1-36.

Install the PS button, Ink button, and Paper button as shown

in Fig.1-37.

Disassembly/Reassembly Panel Assy/ Cover Open Sensor 33

Confidential

Page 34

L800/L801 Revision A

1.4.3 P/S Assy

Removal procedure

1. Peel off the acetate tape and remove the ferrite core from the groove of the

Housing Lower.

2. Remove the screw that secures the P/S Assy, and remove the P/S Assy from

the Housing Lower.

• Screw : C.B.P M3x10 (tightening torque: 5-7 kgf.cm)

Housing Lower P/S Assy

Acetate Tape

Figure 1-40. Removing the P/S Assy

When installing the P/S Assy, put the ferrite core into the groove of

the Housing Lower and secure it with acetate tape as shown in

Fig.1-40.

A D J U S T M E N T

R E Q U I R E D

Whenever the P/S Assy is replaced, the required adjustment must be

carried out.

• Refer to "2.1.2 Required Adjustments" (p.74)

Disassembly/Reassembly P/S Assy 34

Confidential

Page 35

L800/L801 Revision A

1.5 Disassembling the Printer Mechanism

C A U T I O N

1.5.1 Removing the Printer Mechanism

Removal procedure

Do not touch the PF Scale with bare hands or damage it.

If the Printer Mechanism is tilted leftward about 15°, the PF

Scale hits against the desk surface and can break. After

removing the Printer Mechanism, take extra care to protect

the PF Scale.

C A U T I O N

Be careful of the four sharp edges shown in the figure below

when assembling or reassembling.

Printer Mechanism Handling Precaution

When lifting the printer, hold parts shown in the figure

below to prevent the frame from deforming.

Sharp Edge

Figure 1-41. Printer Mechanism Handling Precaution (1)

Figure 1-42. Printer Mechanism Handling Precaution (2)

When removing the Waste Ink Tube, take care not to

contaminate the printer and surroundings with ink.

Extra care must be exercised not to scratch or damage the

Waste Ink Tube.

1. Pull out the Waste Ink Tube by hand.

m

s

i

n

a

h

c

e

M

r

e

t

n

i

r

P

Do not tilt more than 15

degrees, or drag it while tilting.

About

15°

Waste Ink Tube

Figure 1-43. Removing the Waste Ink Tube

Disassembly/Reassembly Removing the Printer Mechanism 35

Confidential

Page 36

L800/L801 Revision A

2. Release the Waste Ink Tube from the groove of the Waste Ink Tray.

3.

Release the CR Motor Cable from the two ribs of the Waste Ink Tray.

CR Motor Cable

Waste Ink Tube

Waste Ink Tube

Waste Ink Tray

Figure 1-44. Removing the Printer Mechanism (1)

4. Disconnect the connector of the CDR Guide Sensor.

CDR Guide Sensor

5. Remove the five screws and remove the Printer Mechanism.

Screw : C.B.P.(P2) M3x8 (tightening torque:5-7 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

5

2

1

4

3

Positioning Hole and

Guide Pin

Figure 1-46. Removing the Printer Mechanism (3)

CDR Guide Sensor Cable Opening

Figure 1-45. Removing the Printer Mechanism (2)

Disassembly/Reassembly Removing the Printer Mechanism 36

Confidential

Page 37

L800/L801 Revision A

When installing the Printer Mechanism, be careful of the

following:

Wipe off any ink on the joint portion of the Waste Ink Tube

before reconnecting the tube. Ink on the joint portion makes

the tube likely to get disconnected.

As shown in Fig.1-47, insert the Waste Ink Tube over the tube

of the Waste Ink Tray until the top end of the Waste Ink Tube

contacts with the rib.

Top end of Waste Ink Tube

Waste Ink Tray

Rib

Tube of Waste Ink Tray

Tube of Waste Ink Tray

Waste Ink Tube

Figure 1-47. Cautions of inserting the Waste Ink Tube

Match the positioning holes with guide pins (two pairs) shown

in Fig.1-46 (p.36).

Tighten the screws in the order given in Fig.1-46 (p.36).

Make sure the Waste Ink Tube or cables are not pinched

between the Printer Mechanism and the Housing Lower.

Route the CDR Guide Sensor Cable through the opening as

shown in Fig.1-45.

1.5.2 Printhead

C A U T I O N

Removal procedure

C H E C K

P O I N T

1. Move the CR Unit to the center, open the Cartridge Cover and remove all Ink

2. While disengaging the hook of the Head FFC Cover with a flathead

When removing the Head FFC Cover and the Head FFC

Cover Inner, do not use tools with sharp ends as the FFC may

get damaged.

Be careful not to damage the FFC and cables when

disengaging the hook of the Holder Contact.

See the section given below on how to unlock the carriage.

• “ 1.1.6 How to Unlock the Carriage ”

Cartridges.

screwdriver, slide the Head FFC Cover downward and remove it.

Head FFC Cover

Removal Direction

A D J U S T M E N T

R E Q U I R E D

Whenever the Printer Mechanism is replaced, the required

adjustments must be carried out.

• Refer to "2.1.2 Required Adjustments" (p.74)

Screwdriver

Hook

Figure 1-48. Removing the Head FFC Cover

Disassembly/Reassembly Printhead 37

Confidential

Page 38

L800/L801 Revision A

3. While disengaging the hook of the Head FFC Cover Inner with a flathead

screwdriver, slide the Head FFC Cover Inner upward and remove it.

Head FFC Cover Inner

Hook

Screwdriver

Removal Direction

Figure 1-49. Removing the Head FFC Cover Inner

4. Using the special tool (see p.15) disengage the hook A of the Holder Contact

on the left back of the Carriage Unit.

[Back Side]

Hook A

Holder Contact

Special Tool

5. Using the special tool (see p.15) disengage the hook B of the Holder Contact

on the right back of the Carriage Unit.

6. Slide the Holder Contact upward and remove the Holder Contact.

Removal Direction

[Back Side]

Holder Contact

Special Tool

Hook B

Figure 1-51. Removing the Holder Contact (2)

C A U T I O N

Take extra care not to spill ink and contaminate the surroundings.

Be extremely careful not to touch the nozzle surface, the ink supply

needles and the Head Cover, otherwise the nozzles may get

clogged.

Printhead

Head Cover

Nozzle surface

Figure 1-52. Handling of the Printhead

Figure 1-50. Removing the Holder Contact (1)

Disassembly/Reassembly Printhead 38

Confidential

Page 39

L800/L801 Revision A

7. Remove the three screws and remove the Printhead.

• Screw : C.B.P. M2.6x8 (tightening torque: 3-5 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

Tighten the screws in the order given in Fig.1-53.

3

2

Printhead

1

Figure 1-53. Removing the Printhead (1)

8. Remove the two Head FFCs from the connectors on the back, and remove the

Printhead.

Printhead

Head FFC

A D J U S T M E N T

R E Q U I R E D

Whenever the Printhead is removed/replaced, the required

adjustments must be carried out.

• Refer to "2.1.2 Required Adjustments" (p.74)

Connectors

Figure 1-54. Removing the Printhead (2)

Disassembly/Reassembly Printhead 39

Confidential

Page 40

L800/L801 Revision A

1.5.3 CR Scale

C A U T I O N

Removal procedure

C H E C K

P O I N T

1. Unlock the carriage and move the CR Unit to the center.

2. Remove the Torsion Spring from the hook ( ) on the left side of the Main

3. Remove the CR Scale from the hook ( ) on the right side of the Main

4. Pull out the CR Scale from the slit of the CR Unit.

5. Turn the CR Scale 90 degrees in the direction of the arrow, and remove the

During the disassembly/reassembly of the Printer Mechanism,

take extra care not to touch the CR Scale with bare hands, and not

to contaminate or scratch it.

See the section given below on how to unlock the carriage.

• “ 1.1.6 How to Unlock the Carriage ”

Frame.

Frame.

CR Scale from the hook.

Extension Spring

Install the CR Scale with its cut-corner facing upward. Hitch one end

of the Torsion Spring to the hole of the CR Scale from the back side of

the CR Scale.

Hitch from the back side

Cut-corner

Hook

Figure 1-56. Reinstalling the CR Scale

Slit

Hook

Turn 90°

CR Scale

Figure 1-55. Removing the CR Scale

Disassembly/Reassembly CR Scale 40

Confidential

Page 41

L800/L801 Revision A

1.5.4 APG Unit

Removal procedure

1. Remove the two screws taking care not to lose the gears, and remove the APG

Unit.

• Screw : C.B.S. M3x6 (tightening torque: 7-9 kgf.cm)

(The numbers shown in the figure indicate the order of tightening the screws.)

APG Unit

1

2

Figure 1-57. Removing the APG Unit

2. Remove the Combination Gear (10, 15.2).

Lubrication is required. See the page given below for the

lubrication information.

Lubrication of APG Unit (p.93)

Install the APG Unit following the procedure below.

1. Put a pin (thinner than Ø2mm) through the positioning

holes of the Main Frame and the right PG Cam on the CR

Shaft.

Positioning Hole

Pin (1)

Right PG Cam

Figure 1-59. Reinstalling the APG Unit (1)

2. Put the pin through the positioning holes of the Spur gear

28.8 and the APG Unit.

Front: Positioning Hole of Spur Gear 28.8

Back: Positioning Hole of APG Unit

Pin

Combination Gear (10,15.2)

Figure 1-58. Removing the Combination Gear (10, 15.2)

APG Unit

Spur Gear 28.8

Figure 1-60. Reinstalling the APG Unit (2)

Disassembly/Reassembly APG Unit 41

Confidential

Page 42

L800/L801 Revision A

3. Install the APG Unit to the Main Frame.

APG UnitPin

Figure 1-61. Reinstalling the APG Unit (3)

4. Check that the hooks ( ) are attached to the positioning

holes of the Main Frame, then screw the APG Unit.

Main Frame

1.5.5 Waste Ink Tray

Removal procedure

C A U T I O N

1. Remove the two screws, disengage the hook, and remove the Waste Ink Tray.

• Screw : C.B.P. M3x10 (tightening torque: 5-7 kgf.cm)

When removing the Waste Ink Tray, take extra care not to spill

ink and contaminate the printer and surroundings.

Waste Ink Tray

Hook

Figure 1-63. Removing the Waste Ink Tray

A D J U S T M E N T

R E Q U I R E D

Whenever the Waste Ink Tray is replaced, the required

adjustments must be carried out.

• Refer to "2.1.2 Required Adjustments" (p.74)

Figure 1-62. Reinstalling the APG Unit (4)

Tighten the screws in the order given in Fig.1-57 (p.41).

Disassembly/Reassembly Waste Ink Tray 42

Confidential

Page 43

L800/L801 Revision A

1.5.6 Waste Ink Pad Lower / Waste Ink Pad Cap Lower

Removal procedure

C A U T I O N

1. Remove the four Waste Ink Pad Lowers and Waste Ink Pad Cap Lower from

When removing the Waste Ink Pad Lower and Waste Ink Pad

Cap Lower, take extra care not to contaminate the printer and

surroundings with ink.

Be careful of the seven sharp edges shown in Fig.1-64 when

disassembling or reassembling.

the Housing Lower.

Waste Ink Pad Lower (x1)

Waste Ink Pad Cap Lower (x1)

Waste Ink Pad Lower (x3)

Figure 1-64. Removing the Waste Ink Pad

Insert the Waste Ink Pad Lowers into the Housing Lower inserting

the slits of the pads over the tabs on the Housing Lower. Make

sure to push the pads as far as they will go (until their top surface

locate lower than the top surface of the Housing Lower edges).

Sharp edge

A D J U S T M E N T

R E Q U I R E D

Whenever the Waste Ink Pad Lower is replaced, the required

adjustments must be carried out.

• Refer to "2.1.2 Required Adjustments" (p.74)

Tab

Slit

Figure 1-65. Installing the Waste Ink Pad Lower

Disassembly/Reassembly Waste Ink Pad Lower / Waste Ink Pad Cap Lower 43

Confidential

Page 44

L800/L801 Revision A

1.5.7 Left & Right Guide Stackers / CDR Guide Sensor

Removal procedure

C A U T I O N

Be careful of the seven sharp edges shown in

assembling or reassembling.

Left / Right Guide Stacker Removal

1. Remove the screw and remove the Left Guide Stacker.

• Screw : C.B.P. M3x8 (tightening torque: 5-7 kgf.cm)

2. Remove the screw and remove the Right Guide Stacker.

• Screw : C.B.P. M3x8 (tightening torque: 5-7 kgf.cm)

Left Guide Stacker

Left Guide Stacker

Fig.1-66

when

When installing the Left Guide Stacker, insert the rib indicated

with in

Fig.1-67

and match the positioning holes and guide

pins indicated with (two pairs).

When installing the Right Guide Stacker, match the

positioning holes and guide pins indicated with (two

pairs)

Left Guide

Stacker

in Fig.1-67

.

Right Guide

Stacker

Figure 1-67. Installing the Left / Right Guide Stacker

CDR Guide Sensor Removal

1. Disengage the two hooks on the back of the CDR Guide Sensor and remove

the CDR Guide Sensor.

Sharp edge

Right Guide Stacker