Page 1

®

EPSON EPL-N1600 Option

500 Sheets Feeder

Page 2

Notice

g

g

g

g

g

g

g

EPSON is a re

General Notice: Other product names used herein are for identification purpose only and may be trademarks or registered trademar ks of their

Copyright © 1998 SEIKO EPSON CORPORATION. Printed in Japan.

hts reserved. No part of t his manual may be r eprod uced, st ored in a r etri eval sy ste m, or t ransmit ted in any for m or by an y means el ectroni c,

All ri

mechanical, photocopyin

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The contents of this manual are subject to chan

All effort have been made to ensure the accuracy of the contents of this manual. However, should any errors be detected, SEIKO EPSON would

reatly appreciate being informed of them.

The above not withstandin

thereof.

istered trademark of SEIKO EPSON CORPORATION.

respective owners. EPSON disclaims any and all rights in those marks.

, or otherwise, without the prior written permission of SEIKO EPSON CORPORATION.

e without notice.

SEIKO EPSON CORPORATION can assume no responsibility for any errors in this manual or the consequences

Page 3

PRECAUTIONS

g

g

Precautionary notations throughout the text are categorized relative to 1)Personal injury and 2) damage to equipment.

DANGER

WARNING

The precautionary measures itemized below should always be observed when performin

Signals a precaution which, if ignored, could result in serious or fatal personal injury. Great caution should be exercised in

performin

Signals a precaution which, if ignored, could result in damage to equipment.

procedures preceded by DANGER Headings.

repair/maintenance procedures.

DANGER

1. ALWAYS DISCONNECT THE PRODUCT FROM THE POWER SOURCE AND PERIPHERAL DEVICES PERFORMING ANY

MAINTENANCE OR REPAIR PROCEDURES.

2. NO WORK SHOULD BE PERFORMED ON THE UNIT BY PERSONS UNFAMILIAR WITH BASIC SAFETY MEASURES AS DICTATED

FOR ALL ELECTRONICS TECHNICIANS IN THEIR LINE OF WORK.

3. WHEN PERFORMING TESTING AS DICTATED WITHIN THIS MANUAL, DO NOT CONNECT THE UNIT TO A POWER SOURCE UNTIL

INSTRUCTED TO DO SO. WHEN THE POWER SUPPLY CABLE MUST BE CONNECTED, USE EXTREME CAUTION IN WORKING ON

POWER SUPPLY AND OTHER ELECTRONIC COMPONENTS.

WARNING

1. REPAIRS ON EPSON PRODUCT SHOULD BE PERFORMED ONLY BY AN EPSON CERTIFIED REPAIR TECHNICIAN.

2. MAKE CERTAIN THAT THE SOURCE VOLTAGES IS THE SAME AS THE RATED VOLTAGE, LISTED ON THE SERIAL NUMBER/

RATING PLATE. IF THE EPSON PRODUCT HAS A PRIMARY AC RATING DIFFERENT FROM AVAILABLE POWER SOURCE, DO NOT

CONNECT IT TO THE POWER SOURCE.

3. ALWAYS VERIFY THAT THE EPSON PRODUCT HAS BEEN DISCONNECTED FROM THE POWER SOURCE BEFORE REMOVING OR

REPLACING PRINTED CIRCUIT BOARDS AND/OR INDIVIDUAL CHIPS.

4. IN ORDER TO PROTECT SENSITIVE MICROPROCESSORS AND CIRCUITRY, USE STATIC DISCHARGE EQUIPMENT, SUCH AS

ANTI-STATIC WRIST STRAPS, WHEN ACCESSING INTERNAL COMPONENTS.

5. REPLACE MALFUNCTIONING COMPONENTS ONLY WITH THOSE COMPONENTS BY THE MANUFACTURE; INTRODUCTION OF

SECOND-SOURCE ICs OR OTHER NONAPPROVED COMPONENTS MAY DAMAGE THE PRODUCT AND VOID ANY APPLICABLE

1. EPSON WARRANTY.

Page 4

About This Manual

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

g

This manual describes bas ic funct ions, the ory of elect rical a nd mecha nic al operati ons, mai ntenance and repa ir pr ocedur es of th e 500 Sheet s Feeder

for the EPL-N1600. The instructions and procedures included herein are intended for the experienced repair technicians, and attention should be

iven to the precautions on the preceding page.

Contents

This manual consists of six chapters and Appendix.

CHAPTER 1. PRODUCT DESCRIPTIONS

Provides a

product.

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of electrical and mechanical

operations of the product.

CHAPTER 3. TROUBLESHOOTING

Provides the step-by-step procedures for

troubleshootin

CHAPTER 4. DISASSEMBLY AND ASSEMBLY

Describes the step-by-step procedures for

disassemblin

CHAPTER 5. ADJUSTMENTS

Provides Epson-approved methods for adjustment.

CHAPTER 6. MAINTENANCE

Provides preventive maintenance procedures and the

lists of Epson-approved lubricants and adhesives

required for servicin

APPENDIX

Provides the followin

reference:

• Connector pin assi

• Electric circuit boards components layout

• Exploded dia

• Electrical circuit boards schematics

eneral overview and specifications of the

.

and assembling the product.

the product.

additional information for

nments

ram

Symbols Used in This Manual

Various symbols are used throughout this manual either to provide

additional information on a specif ic topic or to warn of possible dan

present durin

they are used, and always read WARNING, CAUTION or NOTE

CHECK

PO IN T

es.

messa

W ARNING

CAUTION

a procedure or an action. Be aware of all symbols when

Indicates an operatin

or condition that, if not strictly observed, could result in

injury or loss of life.

Indicates an operatin

or condition that, if not strictly observed, could result in

dama

May indicate an operatin

practice or condition that is necessary to accomplish a task

efficiently. It may also provide additional information that is

related to a specific subject, or comment on the resul ts

achieved throu

e to, or destruction of, equipment.

h a previous action.

or maintenance procedure, practice

or maintenance procedure, practi ce,

or maintenance procedure,

er

Page 5

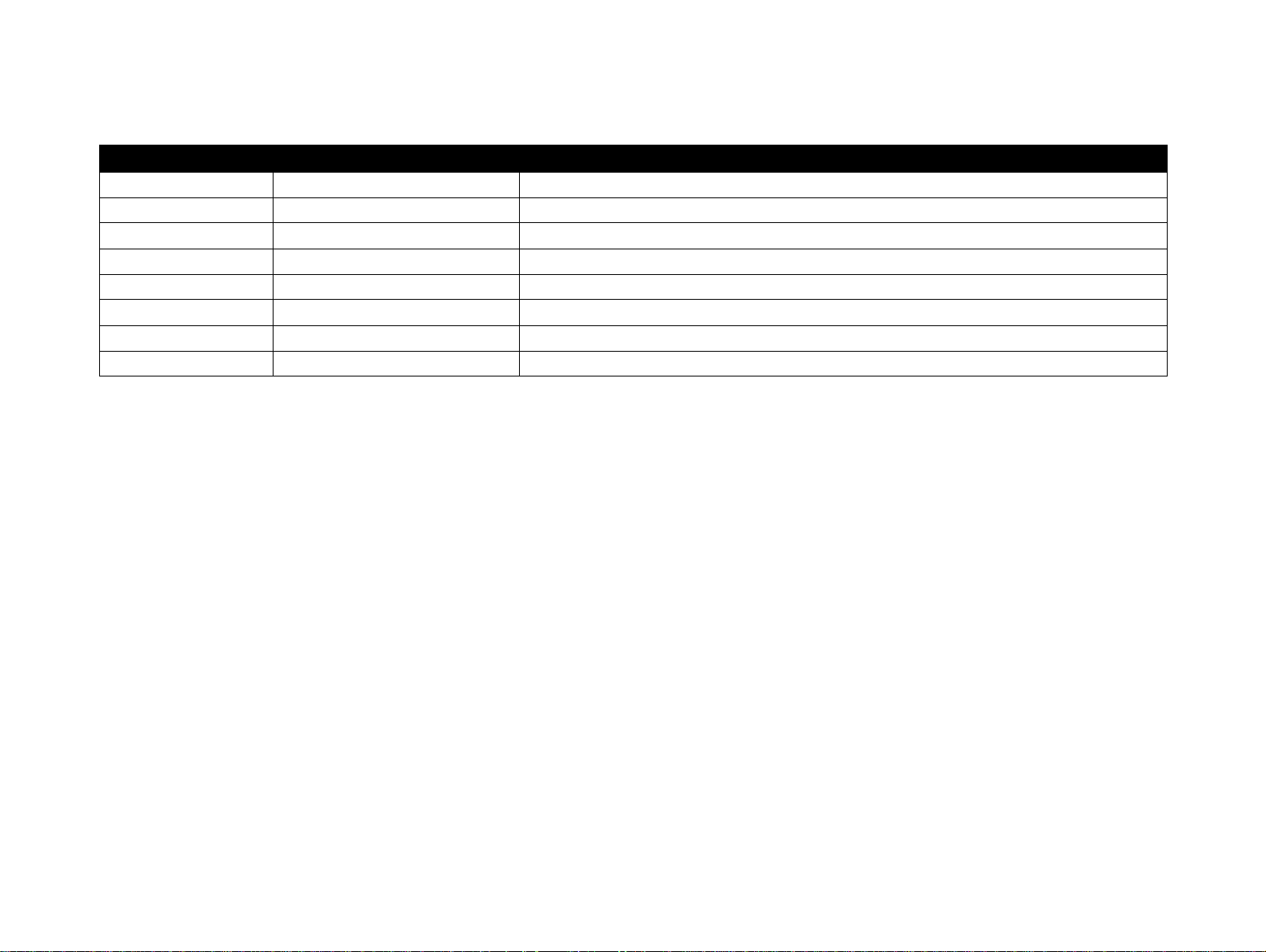

Revision Status

Revision Issued Date Description

Rev. 0 August 17, 1998 Prelimina ry release. (intended for service training purpose only)

Rev. A October 30, 1998 First release.

Page 6

EPSON EPL-N1600

g

g

g

g

Table of Contents

Product descriptions

OVERVIEW ..................................... ...... ....... ...... ....... ...... ............................... 8

Basic specificatio n ........................ ...... ....................................... ..... 8

Paper specification.......................................................................... 8

Reliability/Durability/s ervicea bil it y ................................. ....... ...... ..... 8

demension and wei

ht..................................... ....... ........................ 8

Operating Principles

OVERVIEW .................................................................................................. 10

Paper Transportation............................................................................... 10

Drive Power Transmission ...................................................................... 12

Function of Major Components............................................................... 13

Paper Jam Detection............................................................................... 14

Troubleshooting

Disassembly and Assembly

OVERVIEW .................................................................................................. 18

Precautions ............................................................................................. 18

Tools........................................................................................................ 18

Removin

Frame 500 Removal................... ...... ....... ...... ....... ...... ....... ...................... 20

Solenoid Pick-Up Removal...................................................................... 21

Cover-L 500............................................................................................. 22

PWB Assembly Size 500 Removal ......................................................... 23

Feeder Assembly 500 ............................................................ 19

Adjustment

Maintenance

Appendix

Connector Location ...................................................................................... 30

Master Wirin

Exploded Dia

Diagram................................................................................. 31

ram........................................................................................ 32

500 SHEET FEEDER (Optional)................................................... 32

Rev. 0 6

Page 7

PRODUCT DESCRIPTIONS

Page 8

EPSON EPL-N1600/500 Sheets Feeder Chapter 1 Product descriptions

g

g

g

g

g

g

g

g

g

g

1.1 OVERVIEW

This section describes the specification of the 500 Sheets feeder.

BASIC SPECIFICATION

Paper Separation: By paper separation claw

Drive Source: Driven by the base printer

Speed: <With sin

A4 = 15.2PPM / Letter = 16.0PPM

<With duplex printin

A4 = 7.8PPM / Letter = 8.0PPM

Paper Feed Ori

PAPER SPECIFICATION

Paper Type: <Standard Paper>

Paper Size: A4 (210 x 297mm)

in: Left edge of sheet

Xerox 4024DP 20 lb. (75

<Normal Paper>

60 - 105

- PPC Paper

- Bond paper

- Recycled paper

Letter (8.5 x 11 inch)

G-Le

al (8.5 x 14 inch)

Le

le side printing>

>

/m2) paper

/m2 (16 - 28 lbs.)

al (8.5 x 13 inch)

RELIABILITY/DURABILITY/SERVICEABILITY

MPBF: 120,000 sheets or more

MTBF: 3,000 hours or more

Life: 300,000 sheets or 5 years

(whichever comes first)

Paper Feed Reliability *1:<Jam rate>

1/3000 sheets or less

(1/2000 or less : Duplex printin

<Misfeed>

1/3000 sheets or less

(1/2000 or less: Duplex printin

<Multiple sheet feed>

1/800 sheets or less

<Folded coners>

1C or more at 1/1000 sheets or less

(1C or less is not included)

)

NOTE:

*1:With recommended paper and normal conditions

MTTR: 30 minutes or less

DEMENSION AND WEIGHT

Dimension: 396 x 389 x 114 mm (W x D X H)

Wei

ht: 4.6 Kg (Feeder + Cassette)

)

Rev. 0 8

Page 9

OPERATING PRINCIPLES

Page 10

EPSON EPL-N1600/500 Sheets Feeder Chapter 2 OPERATING PRINCIPLES

g

2.1 OVERVIEW

This section describes the operating principles of the 500 Sheets feeder

unit.

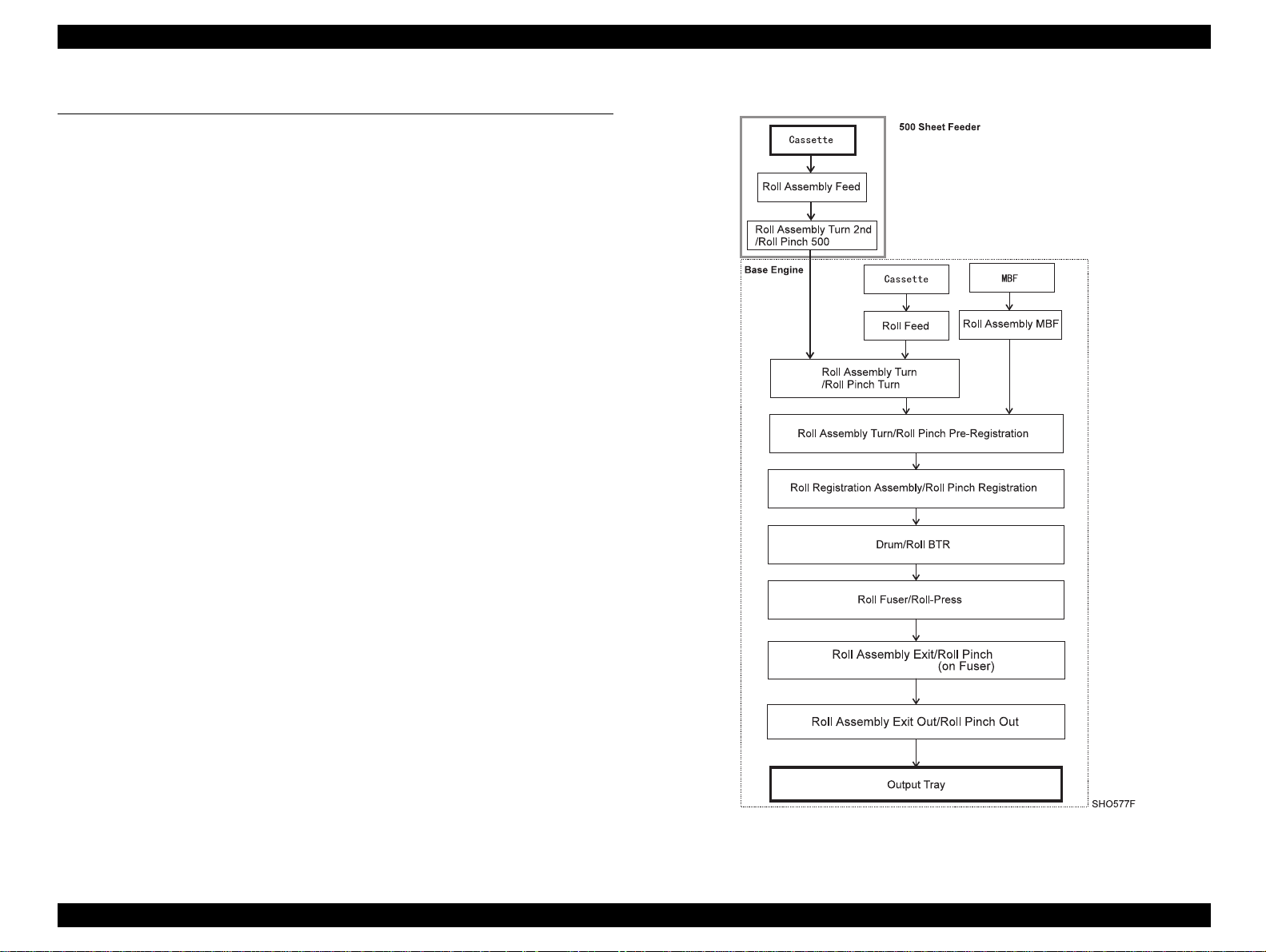

2.1.1 Paper Transportation

Paper that is fed from the 500 Sheet Feeder is transported through the

printer alon

the paper path shown in the Figure right.

Figure 2-1. Paper Path

Rev. 0 10

Page 11

EPSON EPL-N1600/500 Sheets Feeder Chapter 2 OPERATING PRINCIPLES

The Figure below is a cut-away side view of the EPL-N1600 with the

optional 500 Sheet Feeder attached that shows the paper paths and the

major components directly related to the paper transportation.

Figure 2-2. 500 Sheet Feeder Paper Path

Rev. 0 11

Page 12

EPSON EPL-N1600/500 Sheets Feeder Chapter 2 OPERATING PRINCIPLES

g

g

2.1.2 Drive Power Transmission

The drive power to operate the 500 Sheet Feeder is supplied by the

Paper Handlin

Motor of the Base Engine through the Drive Assembly.

The fi

Feeder.

ure below shows the drive power transmission to 500 Sheet

Figure 2-3. 500 Sheet Feeder Drive Power Transmission

Figure 2-4. Drive Power Transmission

Rev. 0 12

Page 13

EPSON EPL-N1600/500 Sheets Feeder Chapter 2 OPERATING PRINCIPLES

g

g

g

g

g

g

g

g

g

g

g

g

g

gag

g

g

g

2.1.3 Function of Major Components

500 Sheet Universal CassetteUniversal paper cassette that holds 500

plain paper cut sheets of various re

sizes. You adjust the Cassette Guides to

accommodate different paper siz es. Adjustin

the Back Guide chan

Actuators that are located alon

of the cassette. When the cassette with paper

loaded is installed in the Feeder, the

Actuators press a

es the position of the

ainst the Size Spring.

ular

the left side

PWB Assembly Size 500 A Sprin

Switches, and the No-Paper Sensor are

mounted on the Size PWB.

Spring CST Act:

Actuators on the side of the Paper Cassette

press a

in turn press a

Paper Size Switches:

when the correspondin

ainst it, and Off when the corresponding

a

sprin

combination of On and Off Size Switches

represents the size o the paper that i s loaded

in the Cassette.

No Paper Senso

is empty, the Actuator No Paper 500 actuates

the No Paper Sensor.

Sprin

Solenoid Pick-Up Releases the Gear Feed to allow i t to en

Roll Assembly Feed Is a D-shaped roll that is driven to rotate one

CST Latch Secures the 500 Sheet Feeder in place in the

Feeder.

with the drive

actuated, and latches the Feed Gear after

one turn. This causes the Roll Assembly

Feed to rotate one turn.

turn each time the Solenoid Pick Up is

actuated.

CST Act, three Paper Size

has three pron

ainst individual prongs. Each prong

ainst a Paper Size Switch.

A Size Switch is On

spring prong presses

prong does not press against it. The

r: When the Paper Cassett e

ear and rotate one turn when

s. The

e

Envelope/Postcard CassetteHolds standard envelopes and postcards.

See Section 16 500 Sheet Feeder

Specification.

Roll Assembly Turn 2nd Transports, alon

located in the Cassette, paper out of the

Cassette into the Base En

with the Roll Pinch that is

ine paper path.

Rev. 0 13

Page 14

EPSON EPL-N1600/500 Sheets Feeder Chapter 2 OPERATING PRINCIPLES

g

g

g

2.1.4 Paper Jam Detection

A paper jam between the 500 Sheet Feeder and the Sensor Pre-

istration (Misfeed jam) is detec ted usi ng the E

re

is a time interval from Solenoid Pick-Up actuation to Sensor Pre-

istration actuation. If the paper fed fr om the 500 Sheet Feeder do not

re

actuate the Sensor Pre-re

istration within this time interval, the MCU

interprets that a Misfeed jam has occurred and displays Error (Feed

jam).

time. The E

2-1

2-1

time

The E

time for the 500 Sheet Feeder (cassette 2) is 2.036 seconds.

2-1

Rev. 0 14

Page 15

TROUBLESHOOTING

Page 16

EPSON EPL-N1600/500 Sheets Feeder Chapter 3 TROUBLESHOOTING

This chapter is not applicable to the 500 sheets Feeder.

Rev. 0 16

Page 17

DISASSEMBLY AND ASSEMBLY

Page 18

EPSON EPL-N1600/500 Sheets Feeder Chapter 4 DISASSEMBLY AND ASSEMBLY

ging

4.1 OVERVIEW

This section contains the removal and replacement procedures of major

parts or subsystems within optional Feeder Assembly 500 of the EPLN1600.

4.1.1 Precautions

Be sure to carry out all work in accordance with the precautions

provided below to avoid dama

assembly.

CAUTION

Names of parts that appear in this chapter may not be

exactly the same as the name appears in Parts List.

For example, Roll Assembly Exit on the Parts List

may appear as Roll Exit or Exit Roll in the RRPs, so

far as it does not cause confusion. This is because of

readability or conventions.

Always use correct type and size screws. Using a

wrong screw can damage a tapped hole. Do not overtighten screws.

Do not use excessive force to either remove or instal l

a part.

the unit during disassembly and

4.1.2 Tools

The following table lists the tools you need to disassemble and

reassemble the printer.

Table 4-1. Required Tools

Market

Tool

Phillips screwdriver Yes B743800200

Tweezers Yes B641000100

Round nose pliers Yes B740400100

Availability

Code

Rev. 0 18

Page 19

EPSON EPL-N1600/500 Sheets Feeder Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

g

g

g

4.1.3 Removing Feeder Assembly 500

1. Disconnect the AC power cord to the rear of the printer.

2. Disconnect all interface Cables to the rear of the printer.

3. Remove the Paper Cassette from the Feeder Assembly 500.

4. Remove the 250 Sheet Paper Cassette (2). Remove the Duplex

Chute Cover Assembly (2), if optional Duplex Unit is instal led.

5. Press the Joint Feeder cli ps to

Feeder clips securin

Duplex Unit (1).

6. Press the Joint Feeder clips to

Feeder clips securin

Duplex Unit (3).

7. Lift the base en

Duplex Unit is installed, first lift the base en

Unit, then lift the Duplex Unit off of the Feeder Assembly 500.

the Feeder Assembly 500 to the printer or t he

the Feeder Assembly 500 to the printer or t he

ine off of the Feeder Assembly 500. If the optional

ether and remove the two rear Joint

ether and remove the two front Joint

ine off of the Duplex

Figure 4-1. Removing Feeder Assembly 500

Rev. 0 19

Page 20

EPSON EPL-N1600/500 Sheets Feeder Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.1.4 Frame 500 Removal

1. Remove the Feeder Assembly 500.

2. Remove the four screws that are securin

500 to the Frame 500.

3. Push up on the Actuator No Paper 500 and raise the Subassembly

off of the Frame 500.

4. Unhook the Solenoid Pick-Up wire harness fr om the harness clip.

5. Disconnect J322 on the Solenoid Pick-Up wire harness from the

PWB Assembly Size 500.

6. Remove the Frame Subassembly.

the Frame Subassembly

Figure 4-2. Frame 500 Removal

Rev. 0 20

Page 21

EPSON EPL-N1600/500 Sheets Feeder Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.1.5 Solenoid Pick-Up Removal

1. Remove the Feeder Assembly 500.

2. Remove the Frame 500.

3. Remove the one screw that is securin

Frame Subassembly 500.

4. Remove the Solenoid Pick-Up.

the Solenoid Pick-Up to the

Figure 4-3. Solenoid Pick-Up Removal

Rev. 0 21

Page 22

EPSON EPL-N1600/500 Sheets Feeder Chapter 4 DISASSEMBLY AND ASSEMBLY

g

g

g

4.1.6 Cover-L 500

1. Remove the Feeder Assembly 500.

2. Set the Feeder Assembly 500 on the ri

side).

3. Remove the two machine screws ( screws with a flan

the bottom of the Feeder, that secure Cover-L 500 to the Frame

500.

4. Remove the three self-tappin

Feeder, that secure Cover-L 500 to the Frame 500.

5. If the Paper Cassette is installed, remove it from the Feeder

Assembly 500.

6. Pull Cover-L 500 away from the Frame 500.

screws, located on the top of the

ht side (the Cover R 500

e), located on

Figure 4-4. Cover-L 500 Removal

Rev. 0 22

Page 23

EPSON EPL-N1600/500 Sheets Feeder Chapter 4 DISASSEMBLY AND ASSEMBLY

g

4.1.7 PWB Assembly Size 500 Removal

1. Remove the Feeder Assembly 500.

2. Remove the Cover-L 500.

3. Disconnect J302 from J292. Remove the two screws that secure the

connector J292 bracket to the Fra me 500, and cut the wire harness

(1).

4. Remove the two screws that secur e t he PWB Assemb ly Siz e 500 t o

the Frame 500.

5. Slide the PWBA Size out of the retainin

6. Remove the PWBA Size.

7. Disconnect J285 from the PWBA Size.

clips.

Figure 4-5. PWB Assembly Size 500 Removal

Rev. 0 23

Page 24

ADJUSTMENT

Page 25

EPSON EPL-N1600/500 Sheets Feeder Chapter 5 Adjustment

There is no specific adjustment required for 500 sheets feeder.

Rev. 0 26

Page 26

MAINTENANCE

Page 27

EPSON EPL-N1600/500 Sheets Feeder Chapter 6 Maintenance

No specific maintenance is required on the 500 Sheets Feeder.

Rev. 0 28

Page 28

APPENDIX

Page 29

EPSON EPL-N1600/500 Sheet Feeder Chapter 7 Appendix

y

y

y

y

y

7.1 Connector Location

Connector Location Harness

J292 E2

J302 E3

P/J322 E1

*1:"@" mark at the beginning of a harness name indicates that the subject harness is a

part of the component from where the harness extends.

Connects the 500 Sheet Feeder to the

PWB Assembl

Assembl

Connects the 500 Sheet Feeder to the

PWB Assembl

Assembl

Connects the Solenoid Pick-Up to the

PWB Assembl

-Size 1 or PWBA

Duplex.

-Size 1 or PWBA

Duplex.

Size 500.

Figure 7-1. Connector Location Diagram

Rev. 0 30

Page 30

EPSON EPL-N1600/500 Sheet Feeder Chapter 7 Appendix

g

g

g

7.2 Master Wiring Diagram

Signal names for the Base Engine or Duplex Unit ↔ PWB

Assembly Size 500 ↔ Solenoid Pick Up path

Signal Name Description

/SIZE2 Signal for indicating the detected size of paper in the Cassette in

Feeder 2. (Analo

NO PAPER Signal for monitoring paper in Feeder 2 (High when paper is

present and Low when paper is not present)

/FEED2 Si

nal for actuating the Solenoid feeding paper in Feeder 2.

value)

Pin numbers and voltage levels for the Base Engine or Duplex Unit

↔

PWB Assembly Size 500 ↔ Solenoid Pick-Up path

P242

or

P312

P282 Signal Name

6 9 SIZE2 M

510 NO PAPER2 M → S Level TTL TTL

1 14 /FEED2 M → S Level 24 V 0 V

Signal Direction

M: PWBA MMCU

S: PWBA Size 500 Trigger

←

S-**

High

Level

Low

Level

Relationship between paper sizes, pattern of actuated Paper

SizeSwitches, and voltage of the SIZE signal for 500 Sheet Feeder

Signal

Voltage

Paper Size SW1 SW2 SW3

Cassette not in place 0 0 0 0.45

Letter SEF 0 0 1 2.19

A4 SEF 0 1 1 2.82

Legal 13" 1 1 0 2.40

Le

al 14" 1 1 1 3.08

(VDC)

Figure 7-2. Wiring Diagram - 500 Sheets Feeder

Rev. 0 31

Page 31

EPSON EPL-N1600/500 Sheet Feeder Chapter 7 Appendix

g

g

g

g

g

7.3 Exploded Diagram

500 SHEET FEEDER (OPTIONAL)

1. Feeder Assembly 500 (with 2-19) $

2. Cover R 500

3. Frame 500

4. Sprin

5. Sprin

6. Cover-L 500

7. PWB Assembly Size 500 $

8. Sprin

9. Tie Bar 500

10. Actuator No Paper 500

CST Latch

CST Act

-Earth Feeder

18. Roll Assembly Turn 2nd

19. Connector

20. Envelope/Postcard Cassette

21. 500 Sheet Universal Cassette

22. Joint Feeder (PL10.1.8) $

11. Guide

12. Frame Subassembly 500 (with 13-18) $

13. Solenoid Pick-Up (PL3.1.14) $

14. Sprin

15. Support Sprin

16. Roll Assembly Feed

17. Plate N/P

Feed 500

Feed

Rev. 0 32

Page 32

Loading...

Loading...