Page 1

EPSON TERM

EPL-3000

NAL PR NTER

ActionLaser

1300

SERVICE MANUAL

EPSON

Page 2

NOTICE

All rights reserved. Reproduction of any part of this manual in any form whatsoever without

SEIKO EPSON’s express written permission is forbidden.

The contents of this manual are subjects to change without notice.

All efforts have been made to ensure the accuracy of the contents of this manual. However, should

any errors be detected, SEIKO EPSON would greatly appreciate being informed of them.

The above notwithstanding SEIKO EPSON can assume no responsibility for any errors in this

manual or the consequence thereof.

Epson is registered trademark of Seiko Epson Corporation.

General Notice: Other product names used herein are for identication purposes only and maybe

trademarks of their respective campanies.

Copyright @ 1994 by SEIKO EPSON CORPORATION Nagano, Japan

t

!

G’ i

-i-

Page 3

SAFETY INFORMATION

This printer is a page printer which operates by means of a laser. There is no possibility of danger from

the laser, provided the printer is operated according to the instructions in this manual provided.

Since radiation emitted by the laser is completely confined within protective housings, the laser beam

cannot escape from the machine during any phase of user operation.

For United States Users;

[Laser Safety]

This printer is certified as a Class 1 Laser product under the U.S. Department of Health

and Human Services

tion Control for Health and Safety Act of 1968. This means that the printer does not

produce hazardous laser radiation.

[CDRH Regulations]

(DHHS)

Radiation Performance Standard according to the Radia-

The Center for Devices and Radiological Health

Administration implemented regulations for laser products on August 2,1976. Compliance is mandatory for products marketed in the United States. The label shown below

indicates compliance with the

marketed in the United States.

WARNING: Use of controls, adjustments or performance of procedures other

thanthosespecified in this manual may result in hazardous radiation

[Internal Laser Radiation]

Maximum Radiation Power:

Wave Length:

This is a Class

unit is NOT A FIELD SERVICE ITEM. Therefore, the print head unit should not be

opened under any circumstances.

For Other Countries Users;

WARNING: Use of controls, adjustments or performance of procedures other

than those specified in this manual may result in hazardous radiation exposure.

(CDRH)

CDRH

regulations and must be attached to laser products

1OA

3.025 X

*20

780

IIIb Laser Diode Assay that has an invisible laser beam. The print head

(W)

nm

of the U.S. Food and Drug

exposurel

For Denmark

This is a semiconductor laser. The maximum power of the laser diode is 3.025

4

W and the wavelen

x 10

gth is 780

f

20 nm.

Usem;

ADVARSEL

Usynlig

Undgi?i

Klasse

laserstr~ling

udszttelse for

1

laser produkt der opfy

ved

iibning, ni%

strtiling.

lder

. . .

- Ill -

sikkerhedsafbrydere er ude af

IEC825

sikkerheds kravene.

funktion.

I

Page 4

SAFETY INFORMATION

This printer is a page printer which operates by means of a laser. There is no possibility of danger from

the laser, provided the printer is operated according to the instructions in this manual provided.

Since radiation emitted by the laser is completely confined within protective housings, the laser beam

cannot escape from the machine during any phase of user operation.

For United Slates

[Laser Safety]

This printer is certified as a Class 1 Laser

and Human Services (DHHS) Radiation Perfo

tion Control for Health and Safety Act of 1968. This means that the printer does not

produce hazardous

[CDRH Regulations]

The Center for Devices and Radiological Health

Administration implemented regulations for laser products on August 2,1976. Compliance is mandatory for products marketed in the United States. The

indicates compliance with the

marketed in the United States.

I

[Internal Laser Radiation]

Maximum Radiation Power:

Wave Length:

Users;

prcduct under the U.S. Department of Health

rmance Standard according to the Radia-

laser radiation.

CDRH

WARNING: Use of controls, adjustments or

thanthosesoecified in this manual mav result

regulations and must be attached tolaserproducts

4

3.025X 10

780 + 20nm

(w)

(CDRH)

performan

inhaardous

of the U.S. Food and Drug

label

shown below

ceof procedures othe

radiation exDosure

1

This is a Class

unit is NOT A FIELD SERVICE ITEM. Therefore, the print head unit should not be

opened under any circumstances.

For Other Coun&ks

WARNING: Use of controls, adjustments or

thanthosespeci

This is a semiconductor laser.

x 10

For Denmark

Usem;

ADVARSEL

Usynlig laserstdling ved

Undgi% udszettelse

Klasse 1 laser produkt der opfylder

IIIb

Laser Diode

Users;

“fied in this manual may result in hazardous radiationexposurel

4

Wand the wavelength

for

&say

&mins &r

str?ding.

that has. an invisible laser beam. The print head

perforrnance of procedures other

The

maximum power of the laser diode is 3.(X#

is 780 f 20 nm.

sikkerhedsafbrydere er ude af

IEC825

sikkerheds kravene.

funktion.

.- ,.

.. ,.,

”

~)

I

-

Ill -

. . .

Page 5

For Finland, Sweden Users;

VAROITUS

Laitteen

taa altistaa kayttajan turvallisuusluokan 1 ylittavalle nakymattomalle

lasersateiylle.

VARNING

Om

kan

for laser klass 1.

kiiyttaminen muulla

apparaten

anviindaren

anviinds pa

utsattas for osynlig

For Finland, Sweden Service People

VAROITUS

Avattaessa ja

sateilylle.

VARNING

Osynlig laserstrNning

Betrakta ej

suojalukitus ohitettaessa olet

Ala katso sateeseen.

stri?den.

kuin

tiissii lciiyttoohjeessa mainitulla tavalla saat-

annat satt an i denna bruksanvisning specificerats,

laserstriNnin&

niir

denna del ar oppnad och sparren ar

som overskrider

alttiina nakymattorrkille laser-

urkopplad.

gransen

For Norway Users;

ADVARSEL

Dersom

visning, kan brukeren utsettes for unsynlig

grensen for laser klasse 1.

Dette er en

og bolgelengde er 780 * 20 nm.

apparatet brukes

halvleder laser. Maksimal effeckt

pii

annen

rni%e

em spesifisert i denne

laserstr~ling

til

laserdiode er 3.025 x 10

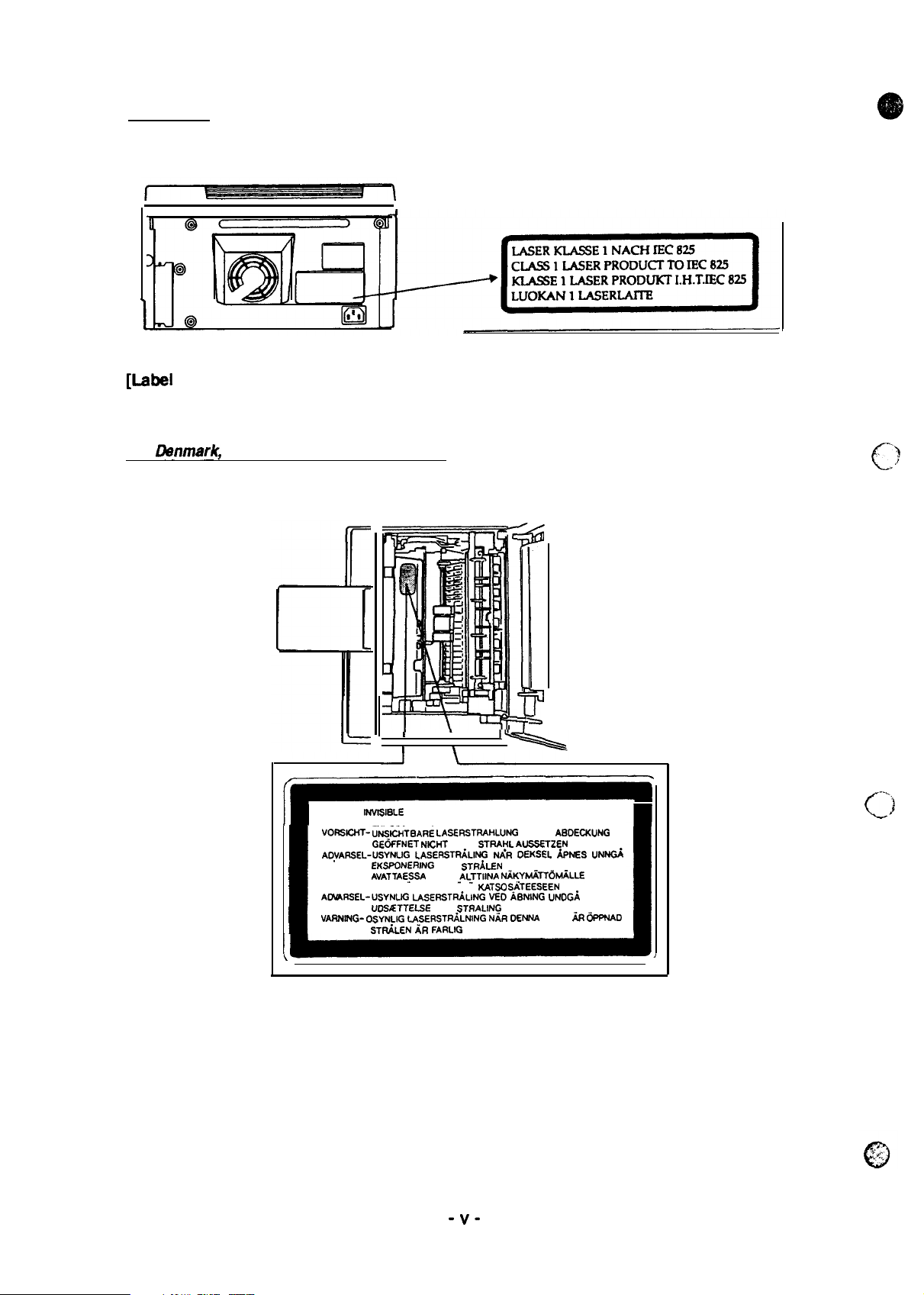

Laser Safety Labels

[Label on rear printer case]

A laser safety labels is attached on the outside of the printer shown below.

For United State

This laser product conferms to the

applicable requirement of 21

Chapter 1, subchapter J.

SEIKO EPSON CORP.

Hirooka Office

80

Hirooka, Shiojiri-shi,

JAPAN

MANUFACTURED:

bruksan-

som overskrider

-4

W

CFR

Nagano-ken,

-

iv -

Page 6

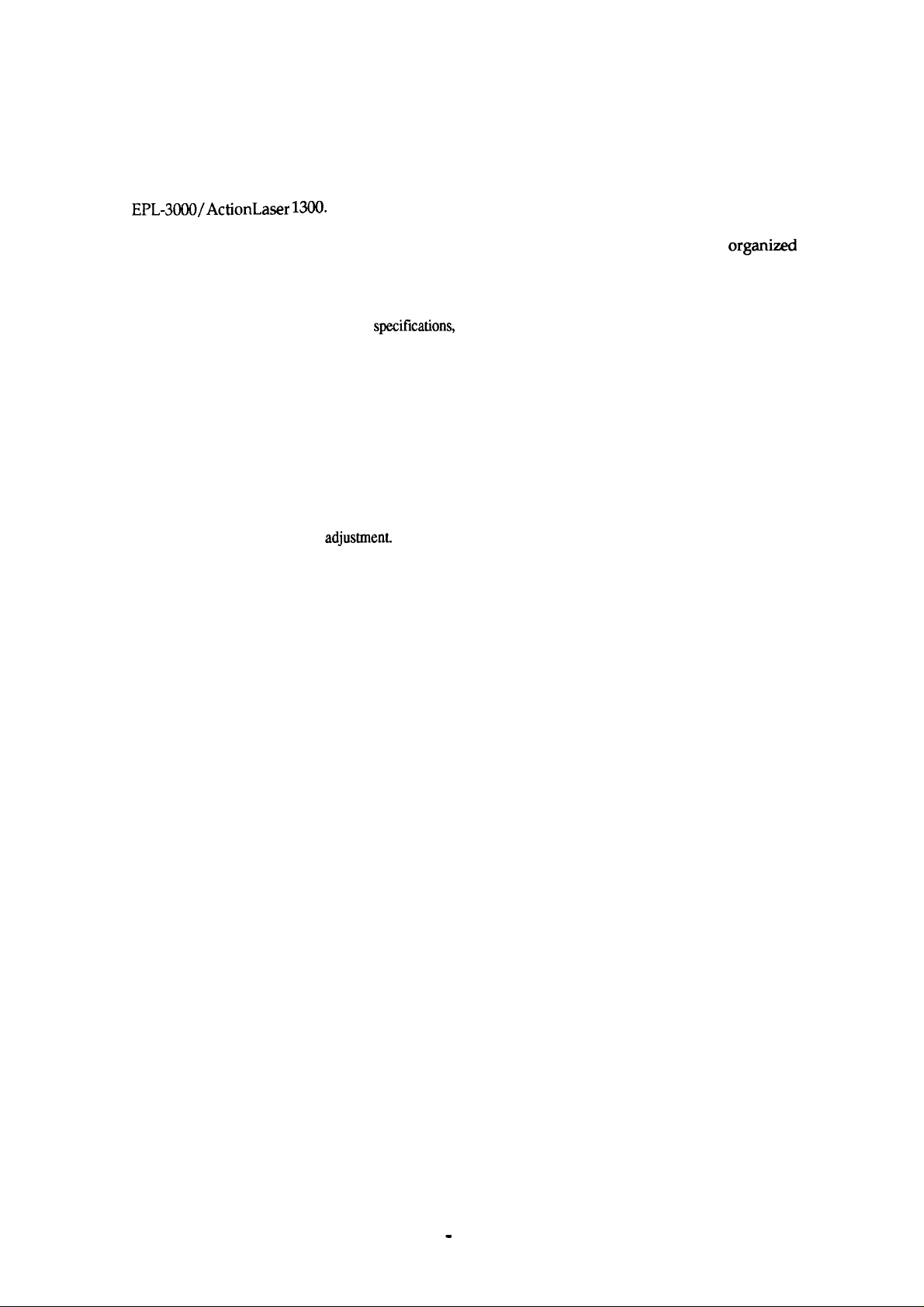

For Europa

[Lsbel

inside printer]

The following laser safety label will be attached inside the printer as shown below.

For

Danmark,

Finland, Swadan, and Norway

I

\

I

CAUTION-

NVISISLE

IB

VORSICHT- U”iJSICNTBARE LASERSTRAHLUNG

AOYARSEL-USYNLIG

VARO !

AOVARSEL-USYNIJG

VARNING- OSYNLIG

I

LASER RADIATION WHEN OPEN AVOID

EXPOSURE TO BEAM

GE6FFNET NICNT

EKSPONERING

AVATTAESSA

LASERSATEILYLLE ALA

uD.9ETTELSE

LASERSTRiLNING

STF&LEN AR FARLIG

I

DEM

LASERSTRiLlffi

FOR

OLET

LASERSTtiLING

FOR

1%

WENN

STRA~L AUSSSTZEN

NAR OEKSEL hJES U*

STRdLEN

-A~TTllNA

N~KYMiTT6M~LLE

KATSO S.ATEESEEN

VED ABNING

STf7ALlNG

NAR OENNA

“)

C..

.

I

-..,

(J

ABOECKUNG

UNDG/i

OEL h I%WAD

-v-

Page 7

PREFACE

This manual describes functions, theory of electrical and mechanical operations, maintenance, and repair

of EPL-3000/ActionLaser

The instructions and procedures included herein are intended for the experience repair technician, and

attention should be given to the precautions on the preceding page. The chapters are

follows:

CHAPTER 1. GENERAL DESCRIPTION

Provides a general product overview, lists

CHAPTER 2. OPERATING PRINCIPLES

Describes the theory of printer operation.

CHAPTER 3. DISASSEMBLY AND ASSEMBLY

Includes a step-by-step guide for product disassembly and assembly.

CHAPTER 4. ADJUSTMENT

Includes a step-by-step guide for

CHAPTER 5. TROUBLESHOOTING

Provides Epson-approved techniques for adjustment.

1300.

adjustmen~

speeitications,

and illustrates the

main components

of the printer.

organizd

as

CHAPTER 6. MAINTENANCE

Describes preventive maintenance techniques and lists lubricants and adhesives required to service the equipment.

APPENDIX

Describes connector pin assignments, circuit diagrams, circuit board component layout and exploded diagram.

The contents of this manual are subject to change without notice.

- vi -

Page 8

REVISION SHEET

t

Revision

Rev.

A

laeue

Date

July 22,1994

Revision Page

let

iesue

T

- vii -

5.

..

.

‘i

C“

Page 9

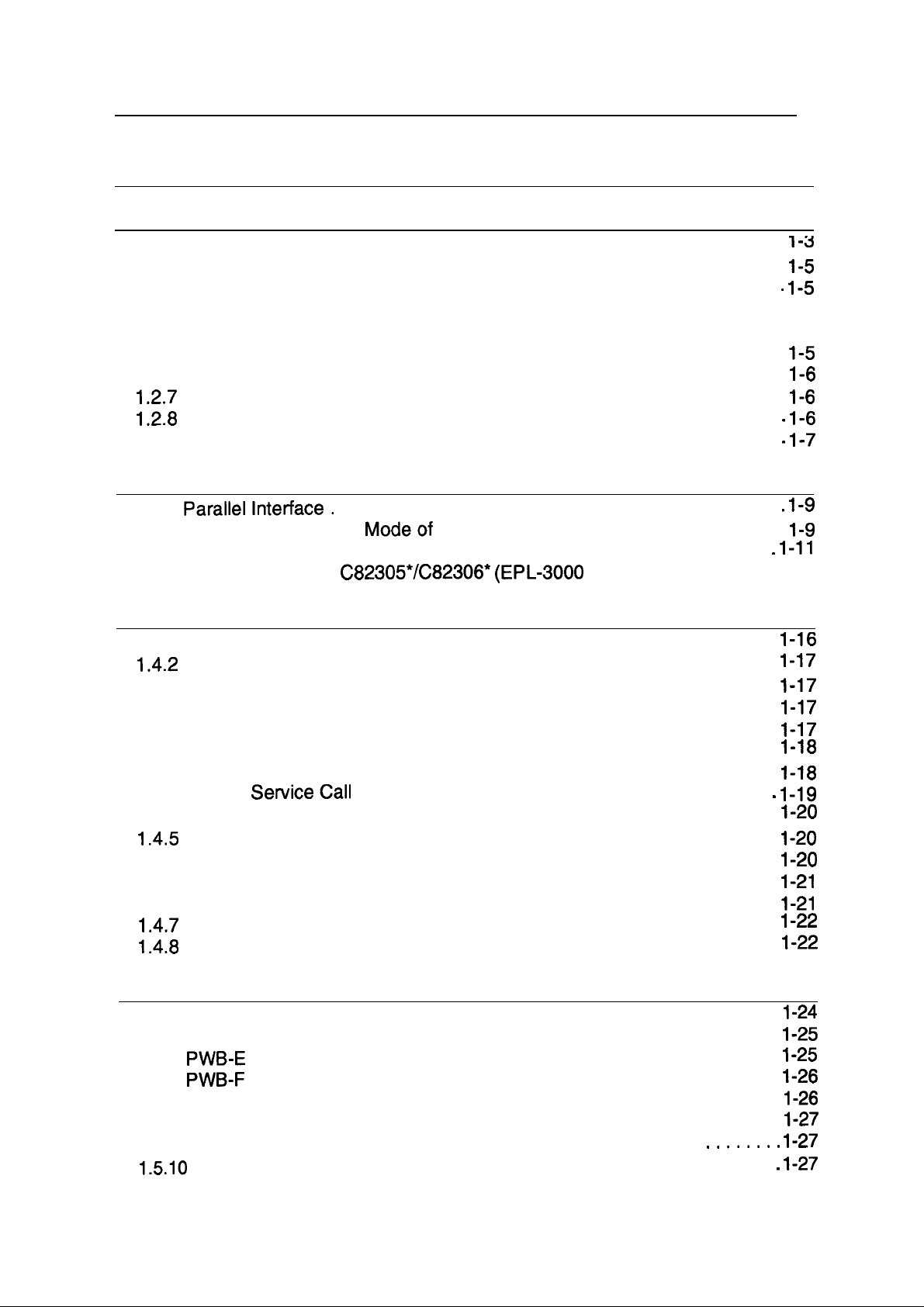

TABLE OF CONTENTS

CHAPTER 1.

CHAPTER 2.

CHAPTER 3.

CHAPTER 4.

CHAPTER 5.

CHAPTER 6.

APPENDIX

GENERAL DESCRIPTION

OPERATING PRINCIPLES

DISASSEMBLY AND ASSEMBLY

ADJUSTMENT

TROUBLESHOOTING

MAINTENANCE

-

. . .

Vlll

-

Page 10

Chapter 1

General Description

Table of Contents

1.1

FEATURES

1.2 SPECIFICATIONS

1.2.1

1.2.2

1.2.3

1.2.4

1.2.5

1.2.6

1.2.7

1.2.8

1.2.9

1.3 INTERFACE SPECIFICATIONS

1.3.1

1.3.2 Optional Interface C82305*/C82306* (EPL-3000 only) . . . . . . . . . . . . . 1-15

Basic Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reliability Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Conditions for Operation (Including Imaging Cartridge). . 1-5

Environmental Conditions for Storage and Transportation

(Excluding Image Cartridge) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applicable Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Consumable (Imaging Cartridge) Specifications . . . . . . . . . . . . . . . . . . .

Physical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parailellnterface.

1.3.1.1 Compatibility lvlodeof Parallel Interface. . . . . . . . . . . . . . . . . . .

1.3.1.2 Reverse Mode... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 OPERATING INSTRUCTIONS

1.4.1

1.4.2

1.4.3

1.4.4

1.4.5

1.4.6

1.4.7

1.4.8

Control Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.1 Hexadecimal Dump Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.2 Factory Service Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.3 EEPROM Format Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Message Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.1 Status and Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.3.2

Printer Sharing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Emulation Mode Switch Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.1 Emulation Switch by SPL . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4.5.2 Intelligent Emulation Switch . . . . . . . . . . . . . . . . . . . . . . . . . . .

Resolution Improvement Technology . . . . . . . . . . . . . . . . . . . . . . . . . .

Toner Save Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Optional Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SewiceCall

Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-1

1-3

.-

l-~

1-5

1-5

1-5

1-6

1-6

1-6

1-7

1-9

1-9

1-9

1-11

1-16

1-16

1-17

1-17

1-17

1-17

1-18

1-18

1-19

1-20

1-20

1-20

1-21

1-21

1-22

1-22

1.5 MAIN COMPONENTS

1.5.1 C144 MAIN Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.2 ROM SIMM Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.3

1.5.4

PWB-E

PWB-F

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.5 Optical Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.8 Fusing Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.9 Drive Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5.10

Imaging Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

........

1-23

1-24

1-25

1-25

1-26

1-26

1-27

1-27

. 1-27

Page 11

EPL-3000

1.1

The EPSON@ EPL-3000

semi-conductor laser with

feature high-speed, high-resolution printing. Maintenance is very easy because of various built-in

diagnostic functions. The main features are:

c1

Ct

cl

c1

c1

Q

c1

D

a

c1

c1

c1

Q

c1

c1

c1

c1

c1

/ActionLaser 1300

Sewice

Manual

FEATURES

and the ActionLaser

electro-photographic technology. These printers are small and light, and

No

ozone

Printing speed — 4 ppm (pages per minute)

Resolution — 300 dpi (dots per inch)

Light weight — about 7 kg (15 lb.)

Small footprint

Easy maintenance

@

LaserJet@

HP

22 built-in scalable fonts (8

Resolution Improvement Technology

edges from images and characters.

levels

Two

Optional

Optional WPS (Windows Printing System) SIMM module

1 MB standard RAM and up to 5 MB RAM with the addition of optional SIMM

Bidirectional parallel interface

High-speed parallel communication rate of approximately 125 KB/second

A multi-user, multi-emulation mode

IES (Intelligent Emulation Switch) allows switching between EPSONScript mode and

emulation mode.

SPL (Shared Printer Language) enables switching of the printer mode by command.

4L emulation mode

Agfa@

and 14 TrueType fonts)

(35~o

less

and

50~0

less) for Toner

EPSONScript Level 2 (PostScript@ compatible) SIMM module

TM

(PCL@5e

(RITech)

(EPL-3000)

1300 are non-impact page printers that combine a

emulation)

refines the print quality by eliminating jagged

Save

Mode

General Description

PCL5e

Figure 1-1 shows an exterior view of the

Paper support

(Paper

suppoti\extenSiOn)

cover

\

-

, ,-. . . .

.

Ac

mleT

i-usel

EPL-3000

and ActionLaser 1300.

. Latch

J“---+!n!?!

-B%&R1

.

Power

Switchl

\w//

Parallel

interface

/ cover

~

l\

%

\

,

Control

panel

Rev.

Imaging

cartridge

T

Figure 1-1. Exterior View of the

and

ActionLaser

1300

paper guides

EPL-3000

A

\

Front cover

1-1

Page 12

General

Description

EPL~(M/ActionLaser 13W

Service

Umue!

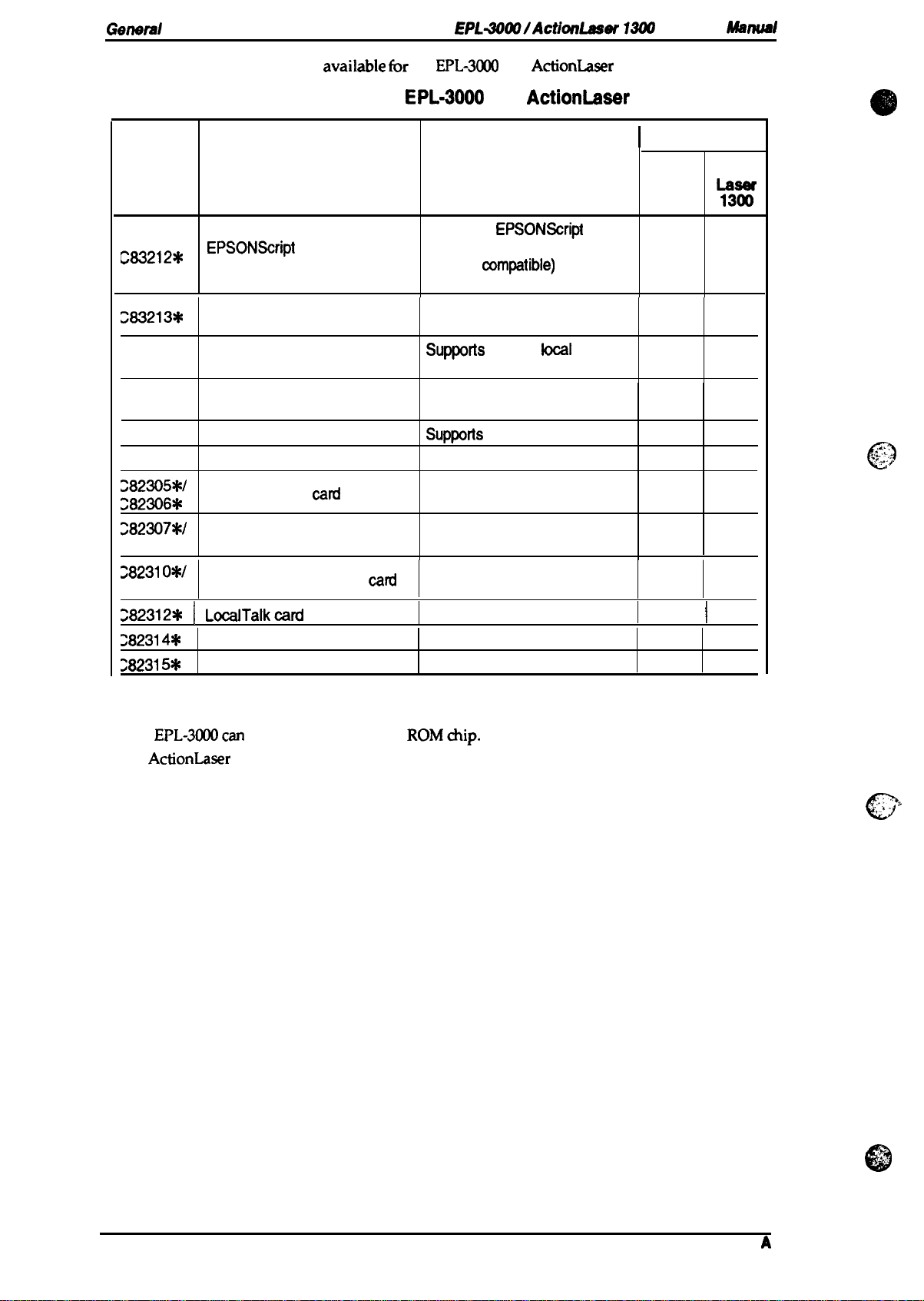

Table 1-1 lists the optional units avaiiable tbr the

Cat. No.

C83212*

283213*

—

—

—

3051020

:::::$

Table 1-1. Options for

Description

EPSONScript

Module

AWPS SIMM Module

Bitmap Local Language Font

ROM Chip

Scalable Local Language Font Supports scalable local

ROM Chip

Thai Font ROM Chip

Imaging cartridge

Serial interface

Level 2 SIMM

card

EPL-3000

EPL-3000

Supports

Level 2 mode (PostScript

Level 2

commands

Supports AtWork Printing

System

SUWRS

language fonts

language fonts

Suppotis

Toner cartridge Yes

—

and ActionLaser 1300.

and

ActionLaser

Note

EPSONScript

mmpatible)

bitmap

Thai fonts

fonts and

local

1300

I

MachineType

EPL3000

Yes

Yes Yes

Yes

Yes

Yes

Yes

Action

y6&

Yes

No

No

No

Yea

No

&

.. . . . ;

c?

>82307W

282308X

28231 OW

28231 1X

282312X I LocalTalkcard

28231 4X

28231 5*

Notes:

1. These printers can use only one optional ROM SIMM module.

2. The

3. The

EPL-3M10can

ActionLaser 1300 has not optional Type-B interface card slot.

32 KB serial interface card

32 KB parallel interface

COAX interface card

TWINAX interface card

useonlyoneoptional ROMchip.

cad

—

—

—

—

—

Yes

Yes

Yes I No

Yes

Yes

No

No

No

No

.’. : --

-,.,.

0

$

1-2

Rev.

,,

@

A

Page 13

EPL-3000/ActionLaser

1300 Service Manual

1.2 SPECIFICATIONS

This section provides statistical data for the EPL-3000 and ActionLaser 1300.

1.2.1 Basic Specifications

Printing method:

Resolution:

Printing speed:

First printing time (A4/LT): Less than30 seconds

Warm-up time:

Paper supply:

Laser beam scanning and dry electro-photography

300 dpi

4 ppm

Less than 40 seconds

(at rated current and 23‘C (73

See Table 1-2.

(letter/A4)

0

F) temperature)

Table 1-2. Paper Feed Methods

General Description

Paper Supply

Standard built-in

paper tray

Auto feed

Manual feed

Capacity

(20 lb. (70

paper

150

5 to

10

1

/m2)

Y

Paper Size

A5, B5, A4, LT,

GLT,

EXE, LG,

GLG, F4, HLT

Monarch,

DL, C5, C6,

Commercial-10

Any size feedable 16 to 42 lb.

(Note 2)

Usage Thickness

(Ream Weight)

16 to 24 lb.

(60 to 90

Envelopes made

IB5

of 16 to 24 lb. (60

to 90

(60 to 157

g/m2)

g/m2)

paper

g/m2)

Notes:

1. The weight inpounds (lb.) is determined by how much 500 sheets cut to 17 x 22 inches would

weigh;

2. Paper size range: width

Paper types:

l-g/mz= 0.2659763 lb.

length

See Table 1-3.

3.0 to 8.5 inches (76.2 to 216 mm)

5.0 to 14.0 inches

(127 to 356 mm)

Table 1-3. Paper Types

Xerox@

Standard paper

Normal paper

Special paper

20 lb. (75

4024 DP paper

g/m2)

Regular photocopier paper

Bond paper

Recycled paper

16 to 24 lb. (60 to 90

Card stock (90 to 157

g/m2)

g/m2)

Envelopes

Labels

Letterhead

Transparency

(OHP)

sheets

Colored paper

Rev. A

1-3

Page 14

General Description

EPL4000/ActionLaser 1300 Service

h#imual

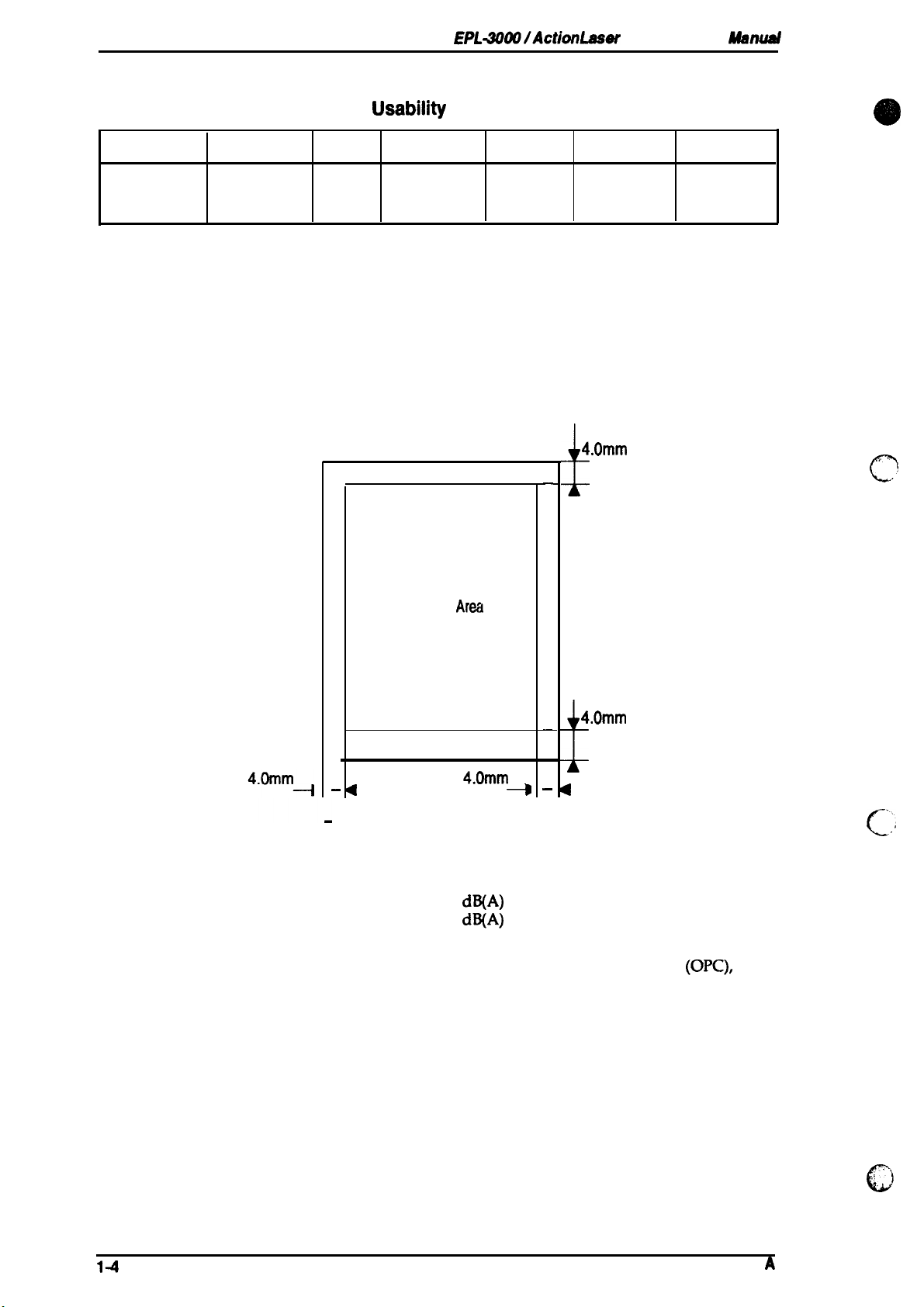

Usability of special paper:

Table 1-4.

Input

Standard

built-in paper Face down

tray

R: Reliable feeding and good

P: Possible, but better avoided.

N: Not supported.

Paper feed alignment and direction:

Paper ejection:

Output tray capacity:

Printable area (standard paper):

output

OHP Envelopes

image quality.

See Table 1-4.

Uaability

P

Center alignment for all sizes

Face down

50 sheets (standard paper)

See Figure 1-2.

of Special Paper

P

Labels

P P

—

i

Card Stock

4.Omm

Letterhead

R

0

Note:

Noise:

Ozone density:

Toxicity:

The

—

Printable

I

Areii

4.Omm

Figure 1-2. Printable Area

actual printable area depends on the printer mode.

dB(A)

dB(A)

(standby)

(operating)

Less than 30

Less than 47

Less than 0.01 ppm

No toxicity exists in organic photo conductor

or plastic materials

—

—

4.Omm

i

4

(OPC),

c’

toner,

1-4

Rev.

,.

.!

0

A

Page 15

EPL-3000 /ActionLaser

1300 Service Manual

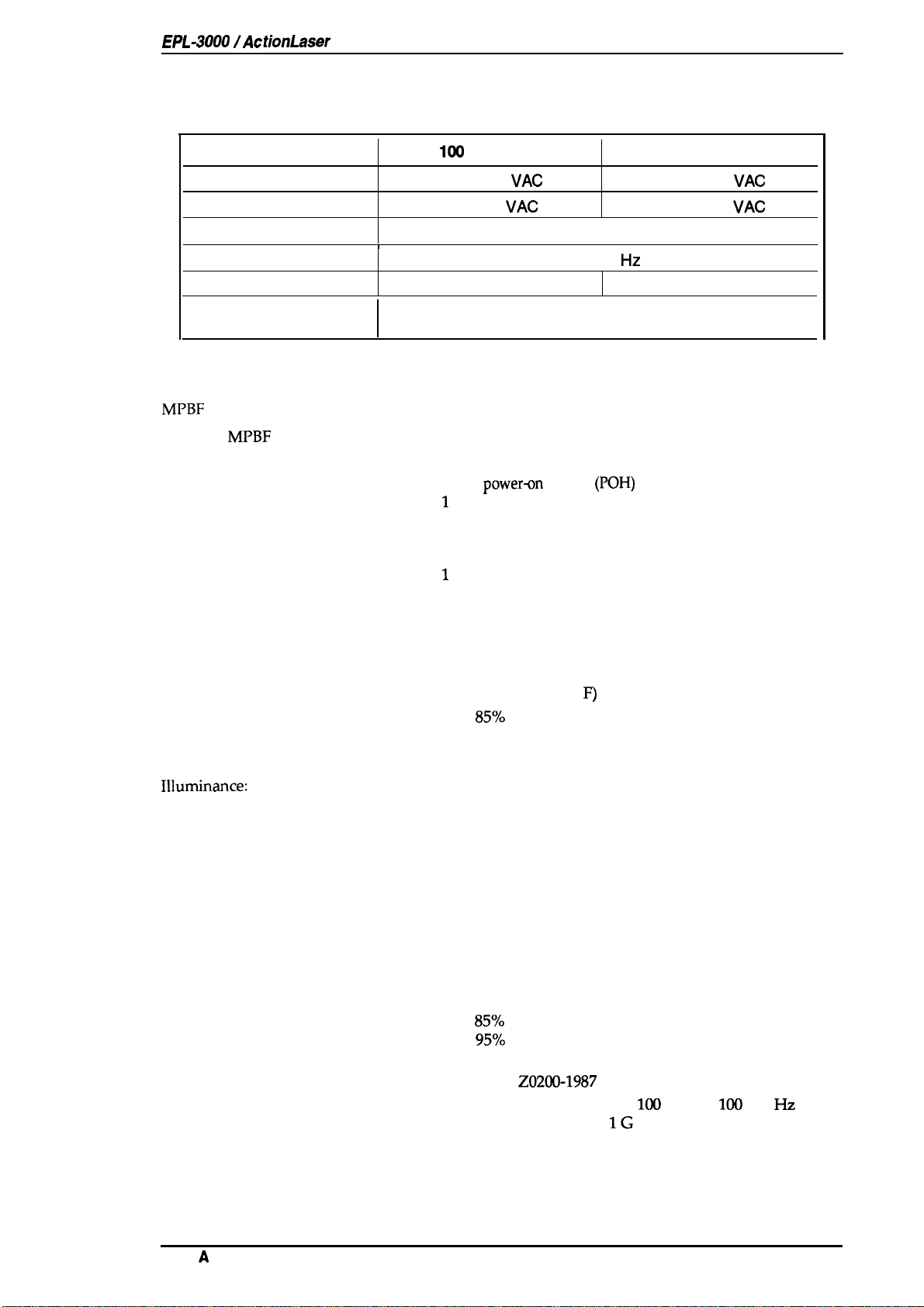

1.2.2 Electrical Specifications

Table 1-5. Electrical Specifications

Description

lMl

V Version

General Description

200 V Version

Rated

Input voltage range

Rated frequency range

Input frequency range

Power consumption

Power consumption while

in standby mode

voltage

100-120

90-132

I

Less than 350 W

1.2.3 Reliability Specifications

MPBF

(Mean Prints Between Failures): Over 17,000 sheets

Note:

MTBF (Mean Time Between Failures):

Jam rate:

Feed failure:

Multiple paper feeds:

Paper curl height:

Leading edge bending (1 cm or more):

MTTR (Mean Time To Repair):

Durability:

MPBF indicates the average number of pages printed before the occurrence of a problem

requiring replacement or service.

3000 power-n hours

1

out of 2,000 sheets or less (excluding multiple-sheet feeding)

1 out of 2,000 sheets or less (excluding multiple-sheet feeding)

1 out of 500 sheets or less

30 mm (1.2 inches) or less

1

out of 1,000 sheets

30

minutes or less

5 years or 100,0000 sheets

VAC

VAC

Less than 15 W

50-60 Hz

47-63

tiz

(POH)

220-240

198-264

Less than 450 W

VAC

VAC

1.2.4 Environmental Conditions for Operation (Including Imaging Cartridge)

Temperature:

Humidity:

Altitude:

Horizontal placement:

Illuminance:

Surrounding space:

10 to 35° c (50 to 95°

8570

15 to

2,500 m (8,200 feet) or lower

The printer should be installed on a level plane.

3,000 IUX or less (must not be exposed to direct sunlight)

The printer should have at least 100 mm of clearance on its

sides and rear.

RH

F)

1.2.5 Environmental Conditions for Storage and Transportation

(Excluding Imaging Cartridge)

Temperature:

Humidity: 30 to

Drop test:

Vibration:

Resistance to atmospheric pressure:

Storage term:

O to 35° C (32 to 95° F) over full storage term

-20 to 55° C (-4 to 131° F) under extreme conditions

(Extremes are allowable for up to 1/30 of full storage term)

Temperature variation must be 10” C (18° F)/hour or less

857. RH over full storage term

%~.

10 to

(Extremes are allowable for up to 1/30 of full storage term)

Clear to JIS Z0200-1987 Level 1

Vibration frequency

Acceleration

Acceleration direction 3 direction

More than 613 hPa

24 months (following date of manufacture)

RH under extreme conditions

5 to

100

Hz and

IG

100

to 5

Hz

Rev.

A

1-5

Page 16

General Description

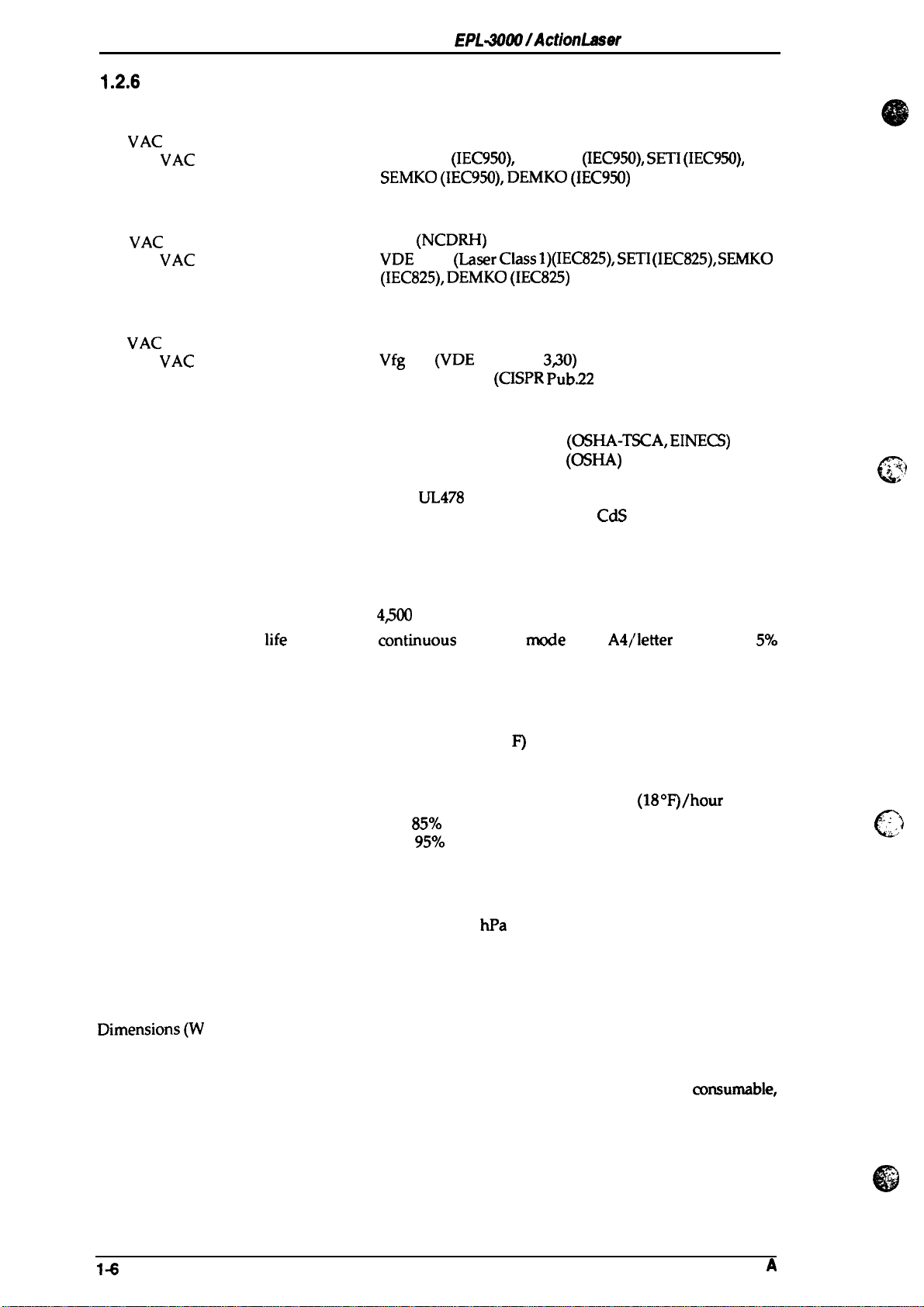

1.2.6

Applicable Standards

EPL+OtUllActionLaser 1300 Service Manual

Safety

120

220/240

Standards

VAC

model:

VAC

model:

UL 1950, CSA 22.2 No.950 Deviation 3

EN 60950

SEMKO

Safety Regulations (Laser radiation)

120

VAC

220/240

model:

VAC model:

FDA (NCDRH) Class 1

VDE 0837 (Laser Class

(IEC825),

EMI

120

VAC

220/240

model:

VAC

model:

FCC Part 15 Subpart B Class B

Vfg 243 (VDE 0878 Part

EN55022 class B (CISPR

Others

Toner:

OPC:

Ozone:

Materials:

No effect on human health

No effect on human health

Less than 0.01 mmp

other

SWISS Environmental Law (No

(IEC950),

DEMKO

UL478

(IEC950),

(5th edition)

NEMKO

DEMKO

(IEC825)

(IEC950),

(IEC950)

1)(IEC825), SETI (IEC825), SEMKO

3s0)

Pub.22

class B)

(OSHA-TSCA,

(OSHA)

SETI

(IEC950),

EINECS)

CdS must be contained)

“’$”::,

.

c

“)

1.2.7 Consumable (Imaging Cartridge) Specifications

Life:

Note:

Consumable

image ratio (black/white ratio). The life varies, depending on the printing mode

(continuous or intermittent) and/or the image ratio.

life

is based on

Environmental Conditions for Storage and Transportation

Temperature:

Humidity:

Drop test:

Vibration:

Resistance to atmospheric pressure:

Storage term:

3,000 pages (unit included with printer)

4300

pages (optional consumable)

COXItinUOtM

Oto300 C (32to860

–20 to40‘C (-4 to 104 “F) under extreme conditions

(Extremes are allowable for up to 1/.30 of full storage term)

Temperature variations must be10“C

30 to

10 to

(Extremes are allowable for up to 1/30 of full storage term)

Height 76 cm (30.4 inches)

Same as printer

More than 740

18 months (following date of manufacture)

printing mode with A4/letter paper at a

F’)

over full storage term

85Y0

RH over full storage term

%~o

RH under extreme conditions

hpa

1.2.8 Physical Specifications

(18 OF)/hour

5’%.

or less.

. .

. .

.

)

:..

..,

c

Dimensions(W x D x H):

Weight:

14

376 x 311 x 216 mm (14.8

376 x 444 x 218 mm (14.8 x 17.5x 8.9 inches) (paper

tray set)

Approximately 7 Kg (15.5 lb.) (including

excluding all options)

x 12.3x 8.5 inches)

cmsumable,

Rev.

,.

@

A

Page 17

EPL-3000

/ActionLaser 1300

Service

1.2.9 Software Specifications

Built-in modes:

Optional modes:

Auxiliary software:

Built-in fonts:

HP LaserJet 4L emulation

EPSONScript Level 2 (PostScript Level 2 emulation) mode

AWPS (AtWork Printing System) mode

Hex dump

Status sheet

Font sample

Fact sheet

RITech test sheet

See Table 1-6

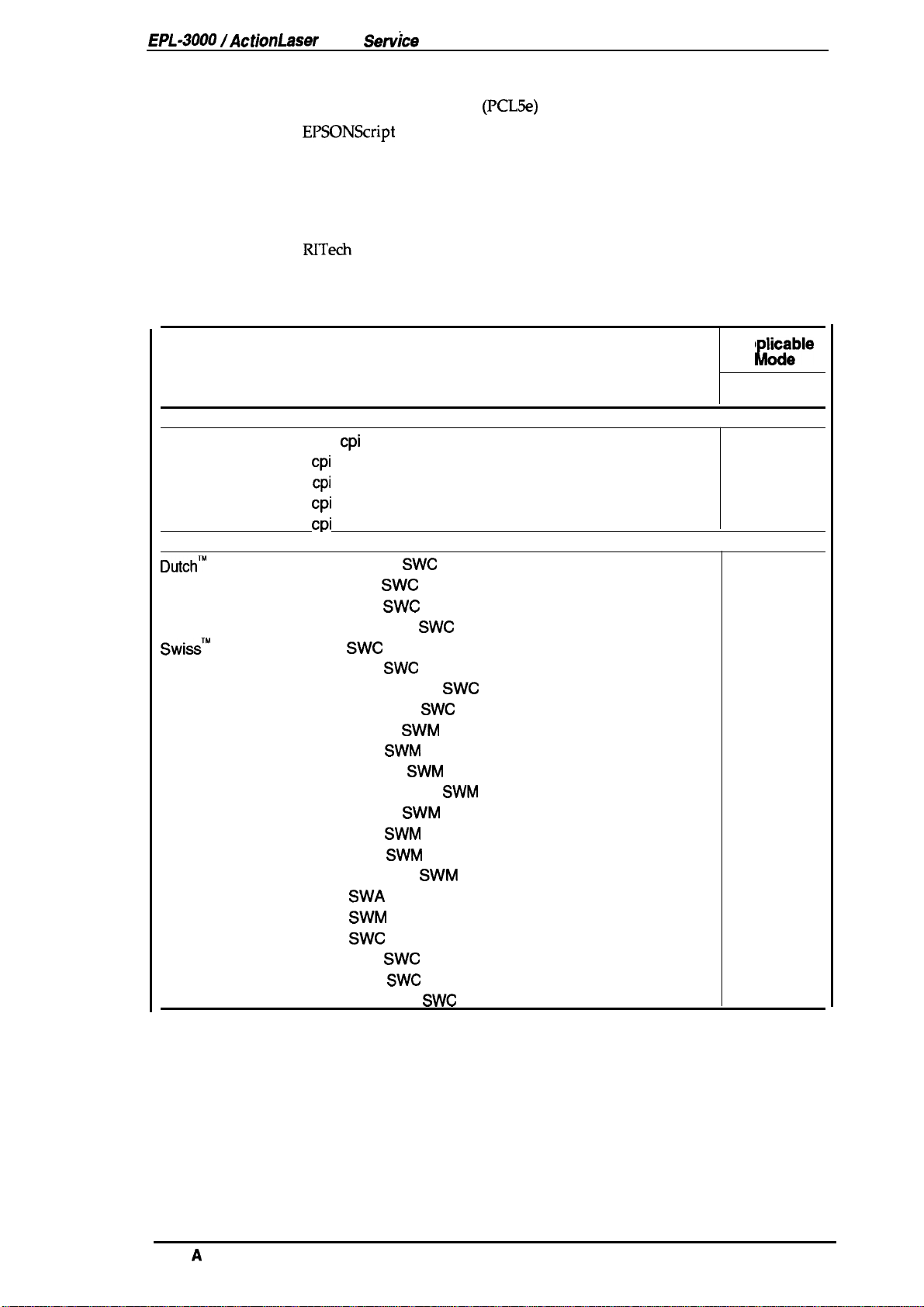

Table 1-6. Built-in Fonts

Resident Fonts

Bitmap fonts

Line Printer

Courier

Courier Bold

Courier

Courier Bold

Scalable fonts

Dutch’”

801

Dutch 801

Dutch 801

Dutch 801

Swiss’” 742

Swiss 742

Swiss 742

Swiss 742

Swiss

721

Swiss

721

Swiss 721

Swiss 721

Dutch 801

Dutch 801

Dutch 801

Dutch 801

Symbol Set

More WingBats

Courier

Courier

Courier

Courier

16.66

10

10

12

12

cpi

(Portrait)

cpi

cpi

cpi

cpi

Roman

Bold

Italic

Bold Italic

Swc

Bold

Medium Italic

Bold Italic

Roman

Bold

Oblique

Bold Oblique

Roman

Bold

Italic

Bold Italic

SWA

SWM

Swc

Bold

Italic

Bold Italic

(Portrait)

(Portrait)

(Portrait)

(Portrait)

SWC

SWC

SWC

SWM

SWM

SWM

SWC

SWC

Manual

SWC

SWC

SWC

SWM

SWM

SWM

SWM

SWC

SWC

SWM

(PCL5e)

General Description

Ap

gciible

L

HP LJ4L

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

s

S: Supported, NS: Not Supported

Note:

Rev.

The built-in fonts for this printer are not same as the fonts for the HP LaserJet 4L.

A

1-7

Page 18

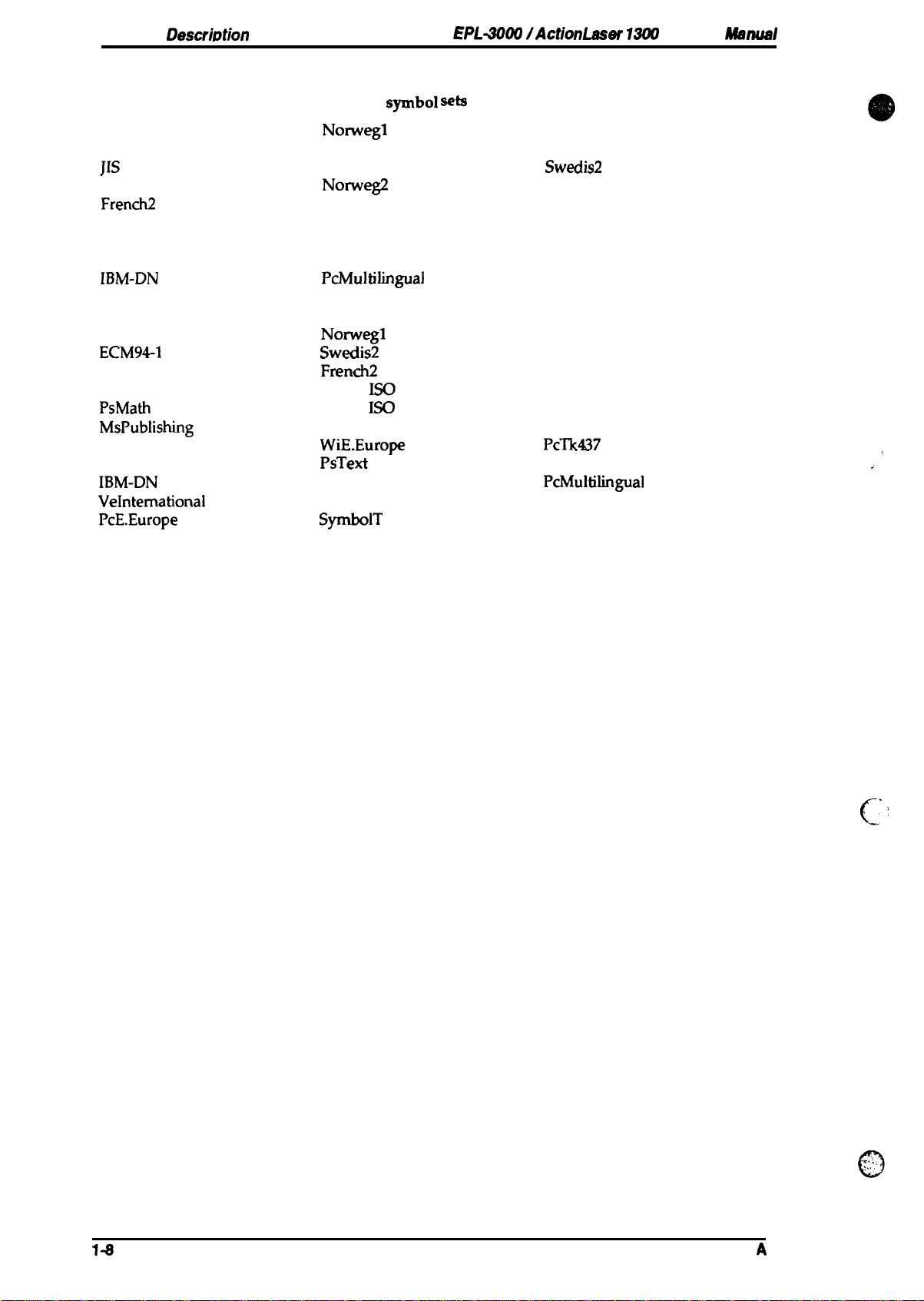

General

Font Symbol Sets

HP LaserJet 4L Mode (bitmap fonts): 26 symbol sets

DescriMion

EPL4009

IActionLsser 13tM

Service Msnud

Roman-8

French

JIS ASCII

ANSI ASCII

French2

Legal

IRV

IBM@ Portuguese

IBM-DN

HP LaserJet 4L Mode (scalable fonts): 34 symbol sets

Roman-8

ECM94-1

UK

Legal

PsMath

MsPublishing

Math-8

Windows

IBM-DN

VeIntemational

PcE.Europe

Wingdings

Norwegl

HP German

ECM941

Norweg2

German

Chinese

Swedish

IBM Spanish

PcMultilingual

Norwegl

Swedis2

French2

8859-2

8859-9

VeMath

WiE.Europe

PsText

McText T

VeUS

SyrnbolT

1S0

1S0

Roman Extension

Italian

Swedis2

UK

HP Spanish

Spanish

Portuguese

IBM- US

Italian

ANSI ASCII

German

Spanish

WiTurkish

DeskTop

PcTk437

IBM-US

PcMultilingual

PiFont

WiAnsi

,

:

.

.

,.

c?

c’

Rev.

I*

A

Page 19

EPL-3000/ActjonLaser 1300

Sendce

Manual

1.3 INTERFACE SPECIFICATIONS

The EPL-3000 is equipped with the following external interfaces:

■ Parallel interface

■ Optional Type-B interface

The ActionLaser 1300 is equipped with the following external interface:

I

Parallel interface

1.3.1 Parallel Interface

The parallel interface has two modes as follows:

■ Compatibility mode (same as parallel interface of Epson’s current page printer)

■ Reverse mode

1.3.1.1 Compatibility Mode of Parallel Interface

General

Descrjptjon

System:

Handshaking:

Connector type:

Applicable plug:

Transfer speed:

Signal timing:

Signal description:

DATA 1-8

STROBE

ACKNLG

STROBE synchronization, 8-bit parallel data transfer

BUSY and ACKNLG signals

P90-25027-1

57-30360 (Amphenol or equivalent)

Approximately 125,(XN bytes/second (maximum)

See Figure 1-3.

See Table 1-7.

o.5ps

(minimum) (minimum)

0.5ps

(maximum)

BUSY

(Amphenol) receptacle

o.5ps

V

LID

)

:4

\

1

0s

*

/

~

VALID

Rev.

1

or

IOps

(typical)

Figure 1-3. Compatibility Mode Signal Timing

A

1-9

Page 20

General Description

Table

EPL40~lActlonLaser 131M

1-7. Parallel Interface Pin Assignment

Service

Manual

Pin ~.

1

2-9 DATA 1-8

10

11

12

13

14

15

16

17

18

19”30

31

32

33

34

35

36

I

Signal Name

STROBE

ACKNLG

BUSY

PE

SLCT

AUTO-FEED

NC

GND

CHASSIS

NC

GND

m

ERROR

GND

NC

+5

SLCT

IN

GND

Uo

STROBE is

computer. The pulse width must be more than 0.5

IN

Normally it is HIGH, and data is latched at the trailing edge of

this signal.

DATA 1 to 8 are parallel data bits. When the signal is HIGH,

the data bit is 1, and when it is LOW, the data bit is O.

The most significant bit

IN

must be maintained for 0.5 @cc. on either side of the

STROBE signal active edge.

ACKNLG

of 1 or 10P. This signal goes

OUT

OUT

OUT

OUT

OUT . in paper jam state

reception is completed, which indicates that the printer can

accept new data. Timing with the BUSY signal is

through

The BUSY signal informs the host computer of the printer

state. When the signal is HIGH, the printer cannot accept

The PE signal indicates paper empty for the standard tray

selected through

paper cassette. Paper empty is indicated by HIGH.

Use in reverse mode.

Not used.

IN

.

Not used.

Logic ground level.

Connected to the printer chassis. The printer chassis

-

and the signal

.

Not connected.

.

Ground level for the

IN

The STROBE signal is ignored when this signal is LOW.

This level goes LOW when the printer is:

. out of paper

. in

enor

●

off

line

.

Same as for pins19 to 30.

.

Not used.

Pulled up to

.

Use the reverse mode.

a strobe pulse used to read data from the host

is an acknowledge pulse with an approximate width

SelecType.

SelecTyps

GND

are connected to each other.

twisted pair return signal.

state

+5V

through 1.0 KQ resistance.

Description

(MSB)

is

DATA8.

LOW when the data

or command,

p.sec.

The signal state

speci%d

data,

or for the optional

GND

1

1-1o

Rev.

,...

L

A

Page 21

EPL-3000/ActionLaser

1300 Service Manual

General Description

1.3.1.2

The reverse mode for the EPL-3000/ActionLaser 1300 supports

reverse mode. This section describes the nibble mode. This

which the printer can inform the computer of its status by EJL

System:

Connector type:

Applicable plug:

Signal description:

Reverse Mode

IEEE-P1284

P90-25027-1

57-30360 (Amphenol or equivalent)

See Table 1-8.

nibble mode

(Amphenol) receptacle

Table 1-8. Parallel Interface Pin Assignment

Pin No.

1

Signal Name

STROBE

2-9 DATA 1-8

10

11

ACKNLG

BUSY

12 PE

13

14

15

16

17

18

19-30

31

32

33

34

SLCT

AUTO-FEED

NC

GND

CHASSIS

NC

GND

INIT

ERROR

GND

NC

35 +5

36

SLCT

IN

GND

I/o

HostClk:

IN

request values from the host computer during negotiation.

This signal is a strobe pulse used to read extension

The signals are data bits of extension request values during

negotiation. This printer supports the following values:

IN

0000 0100: Request Device ID (by nibble mode transmission)

0000 0000: Request nibble mode

OUT

OUT

PtrClk:

Printer data sending clock.

PtrBusy:

Printer sending data bits 3 and 7 during data transfer

to host computer.

OUT AckDataReq: Printer sending data bits 2 and 6 during data

transfer to host computer.

OUT

Xflag:

Printer sending data bits 2 and 6 during data transfer to

host computer.

HostBusy: This signal informs the printer of the host computer

IN

state. When the signal is HIGH, the host computer cannot

accept data.

Not

USed.

Logic ground level.

Connected to the printer chassis. The printer chassis

-

and the signal

GND

Not connected.

Ground level for the twisted pair return signal.

nlnit:

IN

OUT

High level fixed

nDataAvail:

Printer sending data bits O and 4 during data

transfer to host computer.

Same as for pins19 to 30.

Not

USed.

Pulled up to

1264Active:

IN

P1264

+5V

through 1.0 KQ resistance.

If this signal is set to HIGH, this printer active

(reverse mode).

Description

are connected to each other.

IEEE-P1284

printer can run in reverse mode, in

~nd

PJL commands.

nibble mode and WPS

GND

Rev.

A

1-11

Page 22

General Description

Figure 1-4 shows the parallel interface state switch diagram.

EPL401X1/ActionLaser

131#

Service Manual

[

Forvvard

Data

Transfer

o

I

Compatibility Mode —-----l

. STROBE

ACK and

ERR=HIGH

No data sent

BU:Y

SLCT

IN=HIGH

r

Failed

Negotiation

J

ERR= LOW

Sending data

ERR= LOW

SLCT

N= LOW

AUTO

FEED= LOW

AUTO

FEED=HIGI

A

Reverse

Idle

(

Figure 1-4. Parallel Interface State Switch Diagram

)

ERR= LOW

‘\ Host

I

Q

1-12

Rev.

A

Page 23

EPL-3000 /ActionLaser 1300 Service Manual

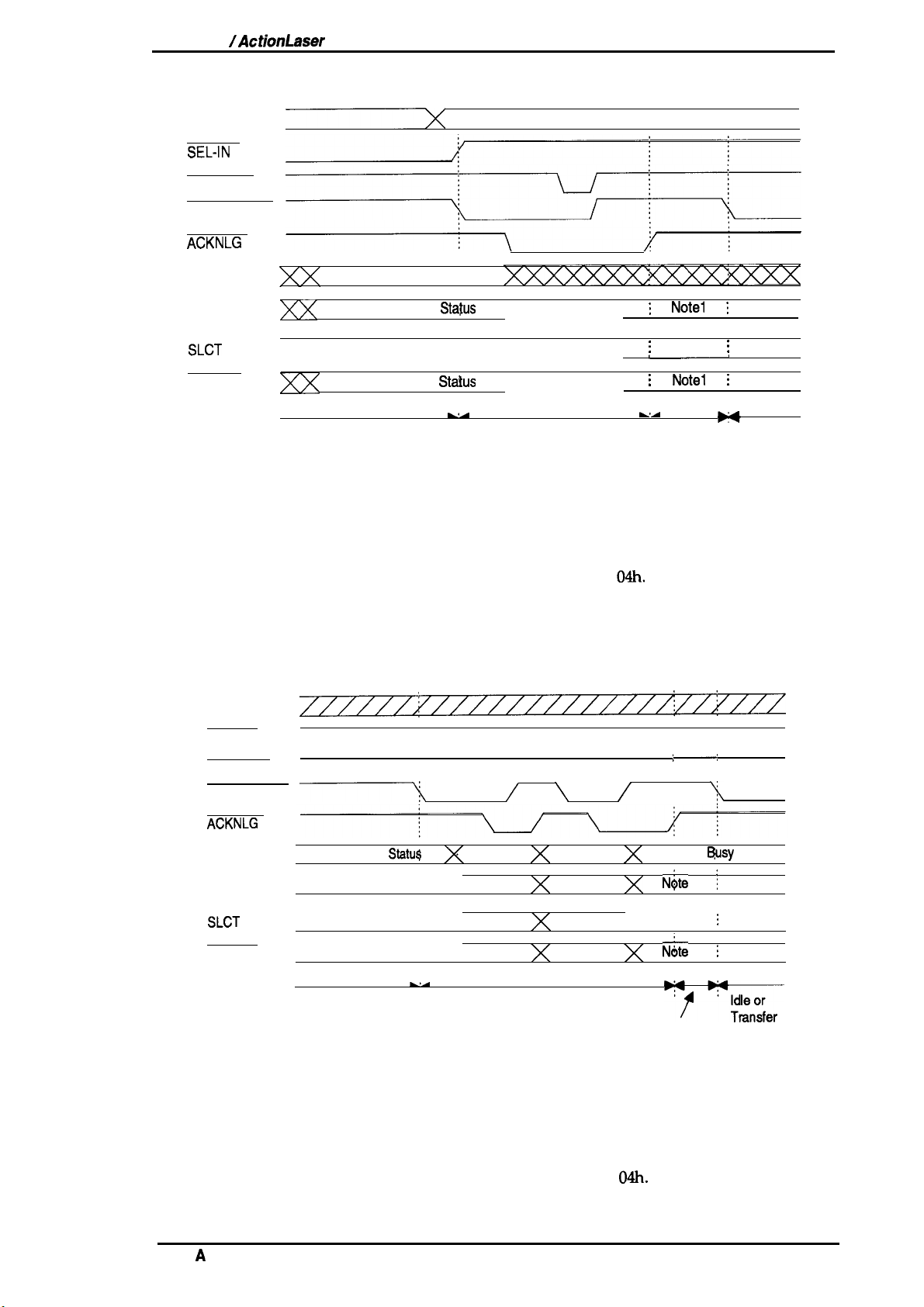

Figure 1-5 shows the negotiation timing chart.

General Description

DATA

SEL4N

STROBE

AUTO-FEED

ACKNLG

BUSY

PE

Peripheral Busy Status

~

Current Peripheral

Stafus

OOh or 04 h

/

SLCT

ERROR

Current Peripheral

Compatibility

Stalus

k,-

/

Negotiation

~

Figure 1-5. Negotiation Timing Chart

Note 1: The signal is set to HIGH when not sending data.

The signal is set to LOW when sending data.

Note 2: The signal is set to HIGH if the extension request value is

Note 3: HB DA: Host Busy Data Available

HB DNA: Host Busy Data Not Available

x

! Notel ;

\

;

Note 2

\

I Notel !

\

L-A

:

HB DA or : Idle or

HB DNA

(Note 3)

04h.

;

H

Transfer

Figure 1-6 shows the data transfer timing chart.

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

BUSY

Peripheral Busy

Statu$

PE

SLCT

ERROR

-

HB DA

Figure 1-6. Data Transfer Timing Chart

/

Bit 3 Bit

\ /

7

Bit 2 Bit 6

Bit 1

Bit O

Negotiation

Bit 5

Bit 4

X

Peripheral

N4te

N&e 2

N;te

HB DAor

HB DNA

(Note

;—:

3)

1

1

‘$

8usy

j

;

;

Status

Note 1: The signal is set to HIGH when not sending data.

The signal is set to LOW when sending data.

Note2: The signal is set to HIGH if the extension request value is

Note3: HB DA: Host Busy Data Available

HB DNA: Host Busy Data Not Available

Rev.

A

04h.

1-13

Page 24

General Description

Figure 1-7 shows the termination timing chart.

DATA

SEL-IN

STROBE

AUTO-FEED

ACKNLG

EPLiXNM/ActionLasar

131M Servke Mimual

BUSY

PE

SLCT

ERROR

Peripheral

HB DNA, Idle, ‘

Busy

Statu$

Note

Note 2

Note 1

1 ;

\

;

H

Termination

or HB DA

Figure 1-7. Termination Timing Chart

Note 1: The signal is HIGH when HB DNA.

HB

The signal is LOW when

Note 2: The signal is set to HIGH if the extension request value is

Note3: Idle= LOW

Figure 1-8 shows the interrupt timing chart.

DATA

DA.

\ Peripheral Busy Status

:

Current Peripheral Status

:

Current Peripheral Status

Compatibility

04h.

3EL-IN

STROBE

AUTO-FEED

ACKNLG

BUSY

~

PE

SLCT

ERROR

Note 1

Reverse Idle

Figure

Note 1: The signal is set to HIGH if

Peripheral Busy Status

- : -

Interrupt

;

-,

1-8. Interrupt Timing Chart

theextmsion

request value is

04h.

HB DA

.,

/

C

:

,*

..’;

?

.,

‘

c1

1-14

Rev.

A

Page 25

EPL-3000 /ActionLaser

1300 Service Manual

General Description

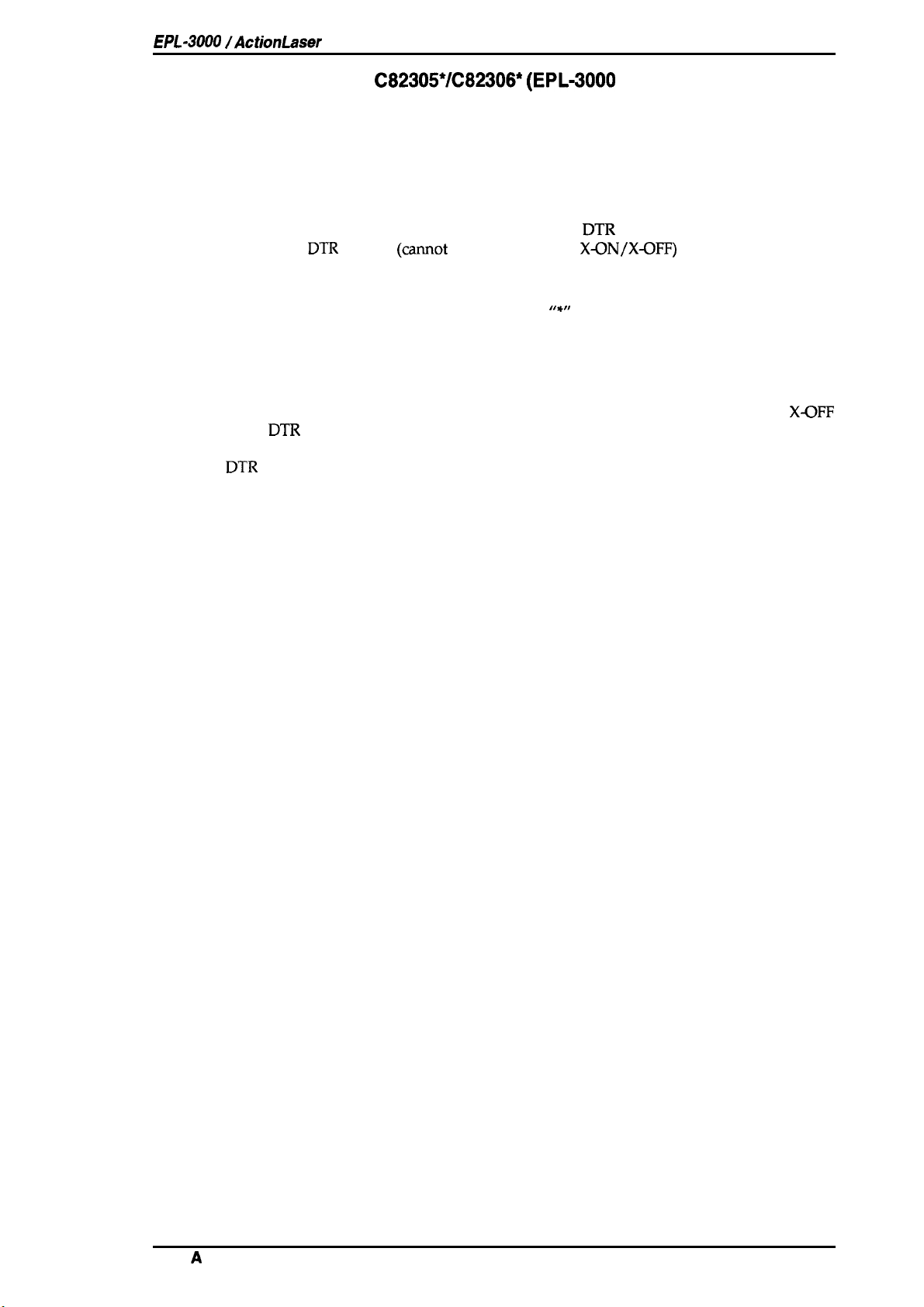

1.3.2 Optional Interface

Type:

Synchronization:

Protocol:

Transfer

Error handling: Overrun error:

speed:

RS-232C or current loop

Asynchronous start-stop system

Start bit:

Stop bit:

Data length: 7 or 8 bits

Parity:

X-ON/X-OFF (cannot be combined with

DTR

300,600,1200,1800,2400, 4800,9600, or 19200 bps

Parity error:

Framing error:

Breaking character: Ignored

C82305*/C82306* (EPL-3000

1

bit

1 bit

Odd,

even, or

control (camot be combined

Processed as missing data and replaced by “*”

Replaced by

Replaced by “*”

none

DTR

with

X~N/X-OFF)

““”

only)

control)

Handshaking

When the vacant area for data in the input buffer drops to 256 bytes, the printer outputs an

code or sets the DTR signal level to LOW, indicating that the printer cannot receive more data.

Once the vacant area for data in the buffer recovers to 512 bytes, the printer outputs an X-ON code

or sets the

DTR signal level to HIGH, indicating that the printer is again ready to receive data.

X~FF

Rev.

A

1-15

Page 26

General Description

EPL40~lActbnLaser 131M Sewke

Manual

1.4 OPERATING INSTRUCTIONS

This section describes the functions performed through the control panel, such as test print,

hexadecimal dump, and panel setting functions.

Control Panel

1.4.1

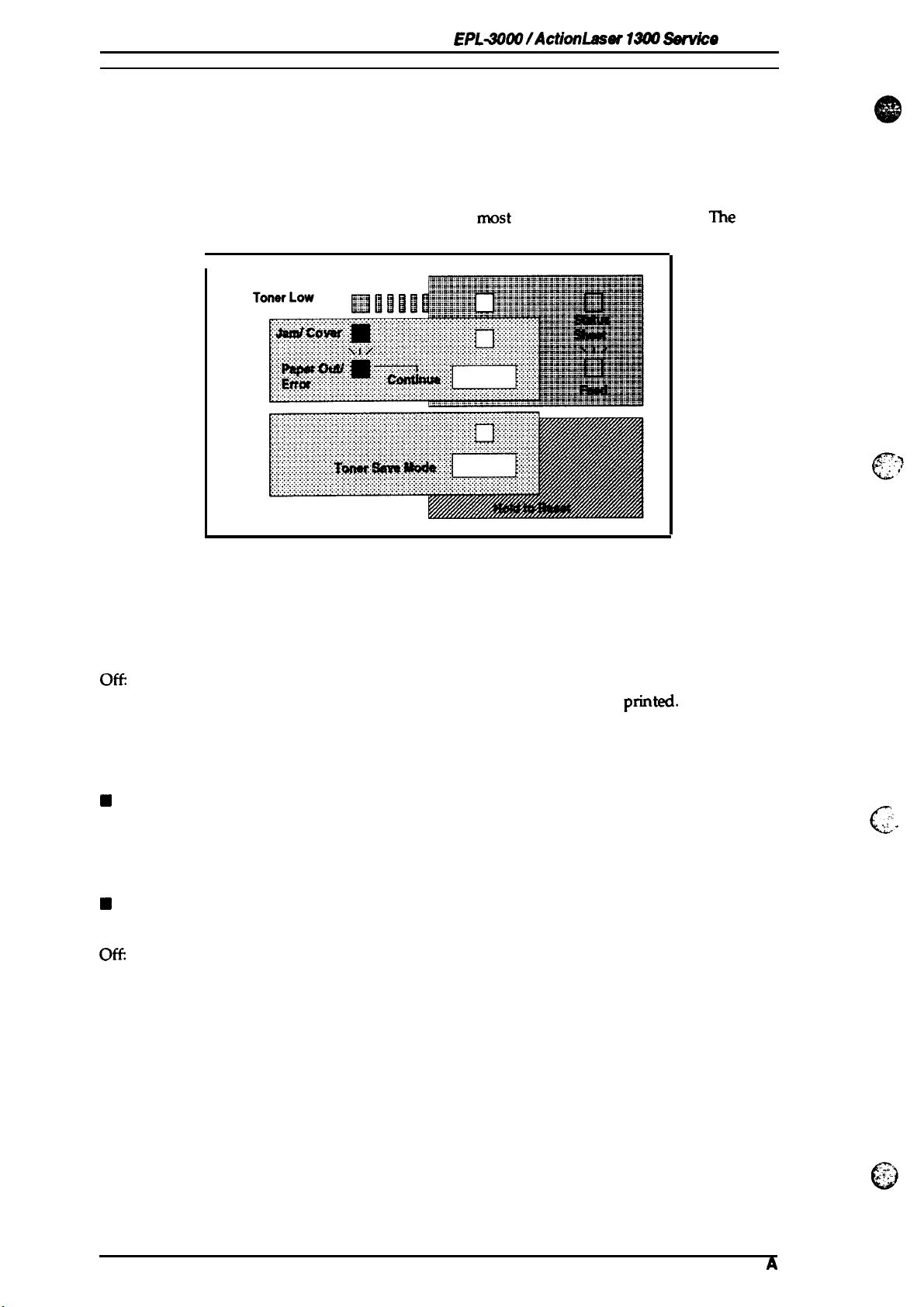

printer control panel gives you easy control over

The

consists

of indicator lights and buttons.

I

Figure 1-9. Control Panel

Indicator lights

■ Data

rrmst

common printer operations. The panel

off

Slow flashing:

Quick flashing:

on:

Orange color:

H

Jam/Cover

on:

Slow flashing:

Quick flashing:

H

Toner Save Mode

on:

Ot%

Flashing

Power off

Received data is stored in the printer but has not been

The printer is receiving or processing data.

There is no printable data remaining in the printer.

Toner low

Paper jam or cover open

Paper out or feed jam

Warning (Refer to “Message Display” section)

Toner Save Mode selected

Toner Save Mode not selected

The panel is being reset

pMted.

,,:

’.,

. .

.

,.

c

1-16

Rev.

A

Page 27

EPL-3000 /ActionLaser

Buttons

■ Status Sheet

Warning Measures

Feed

Continue

Status Sheet Printing

H

Toner Save Mode

1300 Service Manual

When the Jam/Cover light is quickly flashing, press this button to

clear a warning.

When the Data light is slowly flashing, press this button to print out

data in the printer’s memory.

When the Jam/Cover light is slowly flashing, press this button to

starts printing.

When the Data light is on, press and hold this button until the Data

light begins quickly flashing. A status sheet will them print.

General Description

Toner Save Mode

Reset

■ Toner Counter Reset (Toner Save Mode+ Status Sheet)

Toner Counter Reset

Press this button to turn the Toner Save Mode light on (Toner Save

Mode selected) or off (Toner Save Mode not selected), or to reset

Toner Save Mode.

Press and hold down this button until the Toner Save Mode light

begins flashing.

To reset the toner counter, press and hold down the Toner Save

Mode and Status Sheet buttons until the Data light turns green and

then flashes orange.

1.4.2 Service Mode

This printer has three service mcdes as follows:

■ Hexadecimal Dump

■ Factory Reset

EEPROM Format (EEPROM reset)

■

1.4.2.1 Hexadecimal Dump Mode

The hexadecimal dump mode is a useful

m~e,

hexadecimal dump

until Data light comes on.

turn on the printer while holding down the Toner Save Mode button

tool for troubleshooting data control problems. To enter

1.4.2.2 Factory Reset Mode

This mode resets all settings except the printer name and total printing counter. To enter factory

reset mode, turn on the printer while holding down the Toner Save Mode button until only the

Toner Save Mode light is on.

1.4.2.3 EEPROM Format Mode

EEPROM format operations are required only when the main controller board or EEPROM is

replaced. These operations are specified in the documentation accompanying these components.

EEPROM format functions (printer name, default paper size

printing counter, and other settings) are all stored in memory.

Defaults for the

Turn on the printer while holding down the Status Sheet and Toner Save Mode buttons until only

the Data light is flashing.

Note:

EEPROM format functions can be written to EEPROM as follows:

The printer name

selected by jumper J3 for the main controller board when this operation is performed.

(EPL-3000

or ActionLaser 1300) and default paper size

(A4

or letter), toner counter, total

(A4

or letter) are

Rev.

A

1-17

Page 28

General Description

EPL40(M/ActionLaser

13tX7

Service

Manuai

1.4.3 Message Display

This printer displays two types of messages on the indicator lights: status and error, and service

call error.

1.4.3.1

Status and Error Messages

If any of the following status and errors conditions occur, they will be displayed on the indicator

lights. The error must be cleared immediately using the measures shown in the following table.

Table 1-9. Status and

Indicator Light Display

T&on~r

Mode

F.

—

—

Data

—

—

—

Jam/

Cover

—

ON

Q.F.

Enor

Messages

Status

Resetting

Paper jam or cover open

Warning

An error follows.

Insufficient Memory

There is not enough memory to

print or download data.

Print Overrun

Engine speed faster than print

image processing.

If the printer has unused

memory, it automatically

recovers.

Measures

—

If paper jams, open the cover

and remove the jammed paper.

Then close the cover.

Press the Status Sheet

If

you

need an error statement,

print a status sheet. The status

sheet is the printed error

statement.

Erase

downloaded data or add

optional memory.

If the printer cannot

automsticslty

the PAGE PROTECT setting by

with the PJL

software).

recover, change

mmmand

button.

(utility

1-18

—

S.F.

—

Image Optimum

The printer

quality.

Paper Size Mismatch

The printing paper size is

different from the paper size

chosen.

EEPROM

The

EEPROM

the new settings.

Soft Error/CPU Error

Controller error

Paper empty or feed jam

uses a lower print

Error

cannot memorize

Erase downloaded data or add

optional memory.

Change the paper and print

again.

Try again

Sentice

Insed

then press the Status Sheet

button.

call

or clear the paper

ad

Rev.

A

Page 29

EPL-i?OOO/ActionLaser

1300 Service Manual

Table 1-9. Status and Error Messages (Continued)

Indicator Light Display

General Description

Data

OR

Q.F.

S.F.

ON

— —

—

OFF

F.: Flashing,

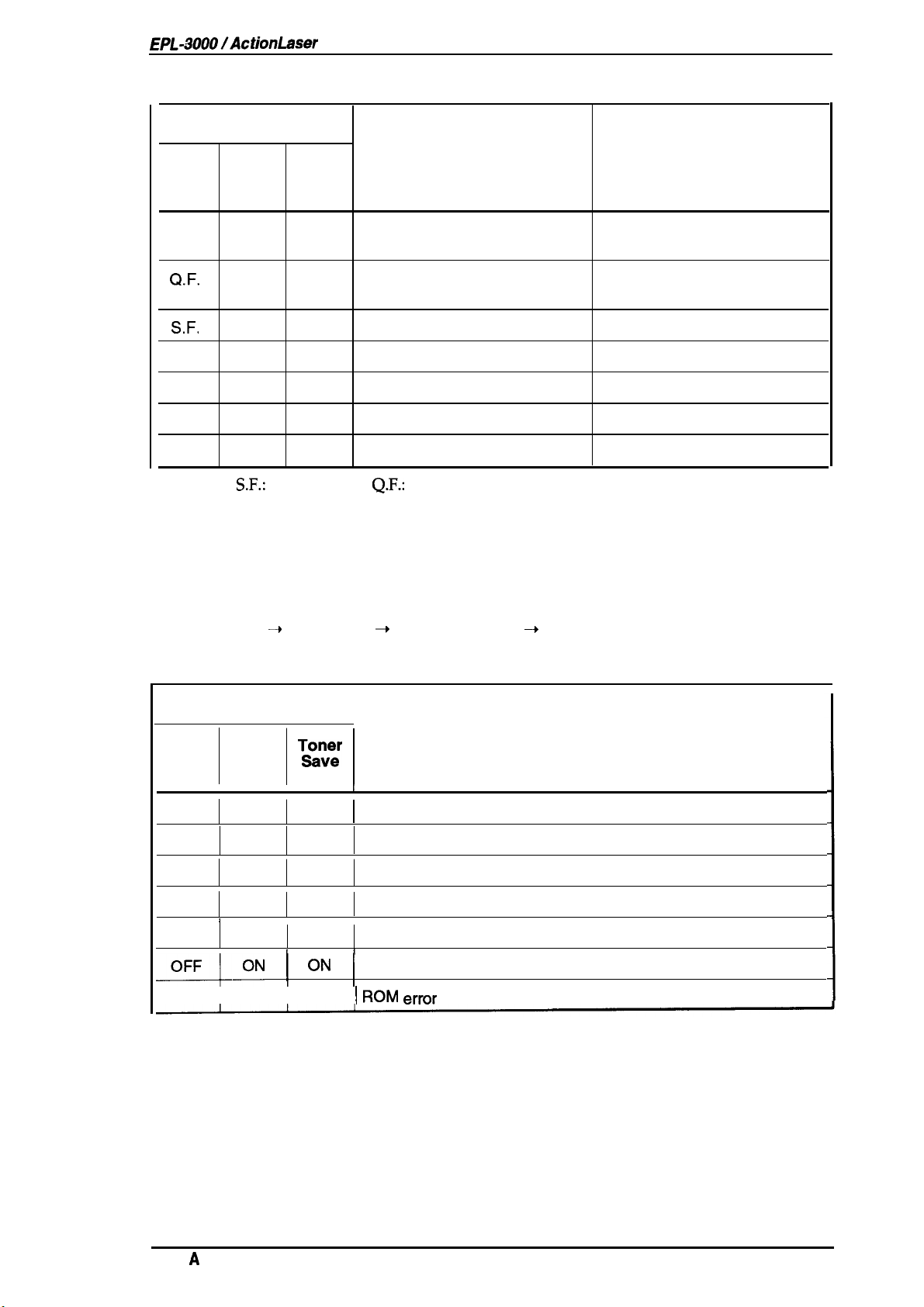

1.4.3.2 Service Call Error

This printer automatically checks the operating conditions of each component. If any abnormality

is detected, the printer displays an error message on the control panel.

While the printer detects a service call error, it continuously repeats the following display:

Jam/

Cover

—

OFF

—

—

—

OFF OFF

S.F.:

Toner

Save

Mode

—

—

—

—

ON

OFF

Slow Flashing,

Toner low

Data received or data

processing

Data held

Data not held

Toner Save Mode

No Toner Save Mode

No

power

Q.F.:

Status Measures

Prepare the new imaging

cartridge

—

—

—

—

—

—

Quick Flashing, OR.: Orange light

~

All lights on

Indicator Light Display

Data

ON

OFF

OFF

ON

ON

Cover

I

I

1

=-Q-oN 1

OFF I OFF I OFF

All lights off ~ Error code display ~ All lights off

Jam/

OFF

ON

OFF

ON

OFF

T&~~r

Mode

I

OFF

OFF

ON

r

OFF

I I

ON

[

‘N

Table 1-10. Service Call Error

I

I

I

Fusing unit error

Laser light error

Scanner motor error

1

Fan motor error

EEPROM format error

1

RAM error

1

I ROM

error

Error

Rev.

A

1-19

Page 30

General Description

1.4.4

Printer Sharing

l%is section describes printer sharing- It is possible to allocate each mode to parallel and optional

interfaces. The entire

receives the data first will print first.

User 1

memory

Mode Assignment

Parallel

*

Mode Assignment

will

be allocated to

HP mode

AWPS mode

EpsonScript

mode

L—

EPL+30W/ActionLaaer 19(M Servke Menuel

tie channels

that are used. The interface that

t-

Input buffer

Memory

User 2

Input

Bt#ter

The input buffer size is automatically adjustable from a minimum of 1/1000 of all memory to a

maximum of 1/5 of

all

1/1000 of

When the user

buffer size for the interface not processing data is a maximum

Note: While EPSONScript Level 2 is used, this printer sets the input buffer.

memory per one step.

AUX

Figure 1-10. Auto

all

memory. If the input buffer is

comects

the host computers

parallel

J

!

Sense Mode

full,

this printer expands the input buffer by

interface and optional interface, the input

~f

1/100 of all memory.

I

I

1.4.5 Emulation Mode Switch Function

This section describes the emulation mode switch function.

1.4.5.1 Emulation Switch by

The two types of emulation switch functions described below are available on this printer.

Together they are referred to as

SPL

SPL

(Shared Printer Language).

. .

c’

,,

EJL:

EPSON Job

This is EPSON’s original language system. It is able to

in Figure 1-11.

PJL:

Printer Job

This is HP’s original language, which is available with the LaserJet III Si printer.

It is able to skip among various destinations, as shown in Figure 1-11. The precise specifications for

this language are based on the HP LaserJet III Si.

The figure below shows three types of mode switching.

EJL

Neither

or

PJL.

nor

Then they enter another mode.

Unguage

Langua@

PJL

switches the mode directly. They first exit

1

PCL5e

4+

EJL

Figure 1-11. Emulation Switch by

sldp

among various destinations, as shown

tlw

current mode and return to

Am

I

SPL

EJL

,.

c“

1-20

Rev.

A

Page 31

EPL-3000 /ActionLaser 1300 Service Manual

1.4.5.2 Intelligent Emulation Switch

General Description

The Intelligent Emulation Switch

depending on the data sent from the host computer through one of the interface channels. It is able

to switch between EPSONScript and other modes as shown in the figure below.

PCL5e

(IES)

automatically switches the emulation switch mode,

EPSONScript

Figure 1-12. Intelligent Emulation Switch

1.4.6

Resolution Improvement Technology

The EPL-3000/ActionLaser 1300 printers have RITech (Resolution Improvement Technology),

which is designed to improve print quality at 300 dpi. With this method, the dot-map data

extracted from the image data is reassembled to improve the print data.

The main improvement from this technique is in eliminating

effective when the dot-map data fits the development characteristics of the printer mechanism. It is

PJL

therefore necessary to set appropriate values in

commands.

“jaggies”

4

123

in diagonal lines. It is most

1 inch

●

300

n

1 inch

/

R

300-

Figure 1-13. Effect of

Note:

The following settings are available in

OFF. When the toner density of area A is almost the same as that of area B (as shown in the figure

below), the

difficult to distinguish the shape of area A from that of area

RITech is not effective for printing a screen pattern or gray scale. In such cases,

must be set to OFF. (The default setting is MEDIUM.) Since the RITech effect depends on

the toner condition, it should be adjusted

the imaging cartridge is used for a long time.

PJL

commands for

RITech setting is optimum. In other words, the optimum setting is achieved when it is

when the imaging cartridge is replaced or after

RITech

RITech:

B.

RITech

DARK, MEDIUM, LIGHT, and

Rev.

A

1-21

Page 32

General Description

EPL40tM/ActionLaser

A

1

13(W

Service

#Amual

Figure 1-14.

1.4.7 Toner Save Mode

The Toner Save Mode uses about

substituting a gray shade for the

printed in full black.

black

Figure

1.4.8 Optional Memory

RITech

50Y0

less toner than normal. The printer saves toner by

inside of characters. The outlines of the characters are still

1-15.

Toner Save Mode

Adjustment

Upper Edge

If you have difficulty printing complex, graphics-intensive pages or if you regularly use

downloaded fonts, you may need to install the

board. The printer’s controller board comes with 1.0 MB of RAM installed.

By installing additional SWIMS, you can increase the printer’s memory to a total of 5 MB, including

the resident memory.

Epson supplies several types of SIMM memory options. Other

vendors. Be sure that the SIMM meets the requirements listed below.

■ 72-pin type

● Capacity is

■ Access speed is less than 70

■ Size is within the following dimensions:

mm(l.42 in.)x 1(XI

36

oneofthefollowing: 1,2,4MB

m.

mm (4.25

in.)x

IOmm (.39in.) (Hx W x D)

optioml SIMM sets on this printer’s controller

SIMMS

can be purchased from other

1-22

Rev.

A

Page 33

EPL-3000

/ActionLaser

1300 Service Manual

1.5 MAIN COMPONENTS

General Description

To simplify maintenance and repair, the main components of the

been designed for easy removal and replacement. The main

Q C144

Cl

Q PWB-E

Cl PWB-F

Cl

U

Cl

Cl

Cl

MAIN Board

ROM SIMM board

Board

Board

Optical Unit

Fusing Unit

Drive Unit

Imaging Cartridge

Housing

Video controller circuit and engine controller circuit board

Optional ROM module

Power supply circuit board

High-voltage supply circuit board

PWB-F

EPL-3000 /ActionLaser

components are:

Fusing

(hit

.

1300 have

Figure 1-16”. Component Layout

PWB-E

Rev.

A

1-23

Page 34

General Description

EPL-30~/ActionLaaar 131M hvke

Manual

1.5.1

The

functions of the video controller circuit are receiving print data from the host, generating the print

image (video), and sending the print image to the engine controller

Motorola

and custom

■

Note:

C144

MAIN Board

C144

MAIN board is a video controller circuit and

68ECCX10,

Memory chips

Code ROM: two

Font ROM: one

Code and font ROM: one

4Mbit

DRAM (IC1O, 11)

16Kbit EEPROM (IC8)

This printer can select one included code and font

16-bit, 16.7 MHz CPU (location:

ICS

are assigned to the 16 MB memory space.

4Mbit EEPROM (IC17,

8Mbit

mask ROM

16Mbit

18) or one

(M80ATBD: IC8)

mask ROM

(IC8)

engine

IC6)

8Mbit

controller

is used, and the following memory chips

mask ROM

ROMora

arcuit

board. The primary

arcuit via the video interface. A

. .

(IC19)

separate type.

Table 1-11. ROM and Jumper Settings

Jumper Settings

J2

1-2

J4

1-2

I

IC17

4Mbit

EEPROM EEPROM

Code U Code L

4Mbit

ROM Locations

IC18

IC19

—

IC8

8Mbit

Mask

Font ROM

c’

—

.

scanning (the polygon mirror drive motor), image

(lC5)

(IC13)

1-2

2-3

C144

MAIN boards used as after-service parts. The following table shows

1-2

1-2

■

Custom

ASIC

ASIC E05B01 (IC9)

ASIC

PAL

The engine controller arcuit consists of an M37451M4 8-bit CPU (including a MASK ROM) and a

gate array. The circuit controls laser

synchronization, laser beam pulse width, and power.

There are two types of

differences between them.

ICS

E05A83

E05B04

E06A01 (IC22)

Table 1-12. Differences in Components for the

EPL4~

Optional

(CN5)

IC2,

Jumper

3

intefface

J3

connector

Connector used

IC

socket used

short

.

—

8Mbit

Mask

Code ROM

—

C144

MAIN Boards

ActionLaser 1300

None

None

8Mbit

Mask

Font ROM

16Mbit

Mask

Code & Font

ROM

-.

(..

Note:

The first release

1-24

C144

MAIN board also has a small board

(C144

SUB board).

Rev.

A

Page 35

EPL-3000 /ActionLaser 1300 Service Manual

7

General Description

E05B04

(IC23)

E05A83 (IC5)

\

CPU

,E05B01

, ROM

\

‘ROM

(IC6)

(IC9)

(IC8)

ROM (IC17)

(IC18)

Figure 1-17. C144 MAIN Board

1.5.2

This printer can use an optional ROM SIMM board. It is a code ROM for other software modes.

1.5.3

The

the AC line voltage into +12 V and +5 VDC voltages. There are two types of power supply board,

the 120V and 220/240V type. The difference between the two circuits is only in the input section.

ROM

SIMM Board

PWB-E

PWB-E

Board

is the power supply board, which consists of a switching regulator circuit. It converts

Do not touch VRIE on

PWB-E

board, as it is set at the

Figure 1-18.

PWB-E

factoy

Board

and should not be changed.

Rev.

A

1-25

Page 36

General Description

EPL40@ /ActionLaser

1300 Service

Manual

1.5.4

The

charge bias, and image transfer bias.

PWB-F

PWB-F

Do

not touch

Board

is the high-voltage supply circuit board. It converts the development bias,

VR2F

on

PWB-F

board, as it is set

D

Figure 1-19.

@

VR2F

PWB-F

at the

fhctory

Board

and

should not be

OPC

drum

changed.

1.

1.5.5 Optical Unit

The optical unit consists of the laser diode

which drives the polygon mirror

generated by the laser diode is conducted to the

as well as several mirrors and lenses, to create a latent

tbr

laser

(sernkonductor

scannin~

and several mirrors and lenses.

OPC

drum

elecbvphotographic

Figure 1-20. Optical Unit

laser), the mirror motor (

surfaa?

by way of the polygon mirror,

image on the drum.

scanner motor)

The

laser beam

1-26

Rev.

A

Page 37

EPL-3000 /ActionLaser 1300 Service Manual

General Description

1.5.6 Fusing Unit

The fusing unit fixes the toner to the paper using heat and pressure. This unit has a heater lamp,

thermistor, and thermal fuse. There are two types of

type. The only difference between them is the heater lamp:

fusing uNts,

the 120 V type and the 220/240 V

. .

1.5.7 Drive Unit

The drive unit consists of the main motor and a series of gears and clutches. It drives the paper

transport rollers, OPC drum, sleeve roller, fusing roller, and some other mechanisms.

Figure 1-22. Drive Unit

1.5.8 Imaging Cartridge

The core mechanisms of the printing process, such as charging, developing, and cleaning, are

integrated into this imaging cartridge.

Rev.

Figure 1-23. Imaging Cartridge

A

1-27

Page 38

Chapter 2 Operating Principles

Table of Contents

2.1 ENGINE OPERATION

2.1.1

Print Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.1

Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.1.1.2 Imaging Cartridge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.3

Drum Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.4 Laser Exposure.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.5 Development. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

2.1.1.6 Drum Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.7 Image Transfer.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.8 Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.1.9 Paper Exit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.I.2

Engine Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

2.1.2.1 Main

2.1.2.2

2.1.2.3 FuserControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

2.1.2.4 Polygon MotorControl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2.5 LaserDiode Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

2.1.2.6 BiasVoltages and LaserDriveTiming . . . . . . . . . . . . . . . . . . .

2.1.2.7 Fan Motor Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1.2.8 Power Supply Circuit Functions and Safety protection . . . . . . . 2-19

PaperTake-Up and paper Exit Sensors . . . . . . . . . . . . . . . . . .

MotorFunctions and Control . . . . . . . . . . . . . . . . . . . . . . . 2-9

2-1

“

. 2-2

.

2-4

.

2-5

.

2-5

.

2-6

.

2-6

.

2-7

.

2-7

2-11

2-14

2-16

.

2-18

2.2

VIDEO CONTROLLER OPERATION

2.2.1

C144MAlN

Board Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.1 Reset Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.2

BusControlCircuti

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

2.2.1.3 Interrupt Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2.1.4 DRAM Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

2.2.1.5 Parallel Interface Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2.2.1.6 Optional Type-B

lntefface.

2.2.1.7 Video Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-20

2-20

.

2-22

.

2-23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

.

2-24

Page 39

List of Figures

Figure 2-1. Main Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . ..........2-1

Figure2-2.

Figure 2-3. Paper Feeding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2-4. Imaging Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Figure 2-5. Drum Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Figure2-6.

Figure 2-7. Development. . . . . . . . . . . . . . . . . . . . . . . . . . . ...............2-6

Figure2-8.

Figure 2-9. Fusing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ...2-7

Figure2-10.

Figure 2-11.

Figure 2-12. P/C

Figure2-13.

Figure2-14.

Figure2-15.

Figure2-16.

Figure 2-17. Sensor On/Off Timing. . . . . . . . . . . . . . . . . .“. . . . . . . . . . .....2-11

Figure 2-18. Fuser Control

Figure 2-19. Temperature

Figure 2-20. Polygon Motor

Figure 2-21. Polygon Motor Driving Start Timing . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-22. Laser Diode Drive

Figure 2-23. Laser Emission Power Adjustment Timing . . . . . . . . . . . . .....2-16

Figure 2-24. High-Voltage

Figure 2-25. Print Process. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-17

Figure 2-26. Print Sequence (Staft). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-27. Print Sequence (End) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 2-28. Printing Multiple Pages. . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-18

Figure 2-29. Fan Motor Control Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .2-18

Figure2-30.

Figure 2-31.

Figure 2-32. Data

Figure 2-33. Reset Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-22

Figure 2-34. Bus Control

Figure 2-35. DRAM Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-23

Figure 2-36. Parallel

PrintProces sDiagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....2-2

LaserExposure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .......2-5

Image Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...2-6

Engine ControflerConn*ing Diagram . . . . . . . . . . ...........2-8

”GearPositions

Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .2-9

Developing Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......2-9

Feeding Drive... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ......2-9

Fusing Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. ....2-8

Main

Power

MotorDriveCircu~

SupplyCircuti

C144

MAIN Board

Flow

Intedace Cimuti

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ........2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuk.

Control.

Control

Circuti

Supply Block

Block Diagram. . . . . . . . . . . . . . . . . . . . . .

Block

Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuti

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagram. . . . . . . . . . . . . . . . . . . . . .2-16

Diagram . . . . . . . . . . . . . . . . . . . .....2-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-24

2-10

2-12

2-14

2-14

2-15

2-17

2-17

2-19

Z-21

e

~~

c

c

i

Table 2-1. Gears and

Table 2-2. Laser Diode

Table 2-3. Functions of

Rollers

Control Circuti

C144 MAIN Board

List of Tables

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .....2-10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Eiements . . . . . . . . . . . . . . . . . . .

2-15

2-20

. .

,, .

.

c)

Page 40

EPL-3000

/Action Laser 1300 Service Manual

2.1 ENGINE OPERATION

Operating Principles

This section describes the functions and operating principles of the

EPL-3000/ActionLaser

engine.

Figure 2-1 shows the locations and names of the main engine components.

1

2

3

4 56 789

1300

10

11

12

13

14

20

1. Paper exit tray

2. Optical unit

3. Imaging cartridge

4. Exit roller

5. Thermistor

(THl)

6. Upper fusing roller

7. Thermal fuse

(TFl)

8. Heater lamp (Hi)

9. Fusing separator

10. Paper exit sensor

(PC2)

19

18

17

16 15

11. Lower fusing roller

12. cooling fan

13. Image transfer roller

14. Main motor (Ml)

15. Paper Take-up sensor

16. Transport roller

17. Paper take-up roller

18. Polygon motor

19. Paper Guide

20. Paper tray

Figure 2-1. Main Components

(PC1)

(M2)

Rev.

A

2-1

Page 41

Operating Principles

2.1.1 Print Process

This section describes the print process from paper feeding to paper exit.

Figure 2-2 shows a dia~am of the print process.

EPL4UtM/Action

Laser 131M Service Wmnd

6.

/’ 3

\

Imaging Cartridge

“

‘L

--- —. —-—--

laser

Exposure

1.

./-

Paper

Feeding

+=-n

-,

9.

--

.“

.

Figure 2-2. Print Process Diagram

.

-.

I

.

c

:,..

Q“

2-2

Rev.

A

Page 42

EPL-3000

/Action Laser 1300 Service Manual

Operating Principles

2.1.1.1

On the multi-purpose tray (standard tray), various sizes of paper can be fed by fitting the paper

guide against the sides of the paper.

The depressing cam is fixed to the shaft of the paper take-up roller, but the transport rollers are

free. The transport rolls are rotated by the rotation of the transport roller. The depressing cam

presses the paper lifting-up plate.

When the paper take-up solenoid

depressing cam releases to feed the first sheet of paper.

The timing to align the leading edge of paper with the image is determined by the paper take-up

sensor

Both of the sensors are comprised of a photo interrupter and an actuator. When the paper turns the

actuator on, output from the paper take-up sensor

exit sensor

Paper Feeding

(PC1).

(PC2)

switches to “H”.

(SL1)

is actuated, the paper take-up roller rotates and the

(PC1)

switches to “L” and output from the paper

Paper

Roller

Pape

Plate

Figure 2-3. Paper Feeding

Rev.

A

2-3

Page 43

Operating

Prhcipks

EPL-3tXN)lActh Lasar 1300

Service

Afmua/

2.1.1.2

The imaging cartridge consists

cleaning unit, the toner bottle, and the used toner bottle, all

Imaging

Cartridge

of the drum

chargin&

developing and cleaning sections; the

combimxi

10 9

in a single unit.

8

11

@’&,

1

Figure 2-4. Imaging Cartridge

This

1. Toner Hopper

2. Toner Agitating Screw

3.

Toner Transport Rollers

4. Doctor Blade

5. Sleeve

6. Flexible Sleeve

7. PC Drum

8.

Cleaning

9.

Drum Charge Brush

10. Used Toner Box

11. PC Drum Protecting Cover This

Roller

BIade

contains the toner.

This mixes

transport rollers.

These

transport toner to the

This

sprea&

toner passes between the doctor blade and the flexible sleeve, it

becomes negatively charged though friction.

These are used to rotate the flexible

This transports toner to the surface of the PC drum and

developing.

‘l’he latent image is formed by laser beams

drum, and development is carried out by the flexible sleeve. The

developed image is then conveyed to the

After the image is transferred, toner left on the surface of the PC

drum (used toner) is wiped away by this blade.

This negatively

Used toner is

protects the surface of the PC drum when it is removed from

the printer unit.

2

3

the toner in the toner hopper and feeds it to the

a thin,

charges the PC

collected here.

4

ewm

coat of toner over the flexible sleeve. As

5

skeve

drum.

roller.

6

skeve.

on

surt%ce

7