Page 1

OEM Integration Manual

P/N 100-88002

Rev B, February 2009

Page 2

Change History

Rev A Initial Release Jan 2009

Rev B Style and formatting update Feb 2009

Added USB Watch dog

Added several internal code pages.

Page ii 100-88002 Rev B

Page 3

Federal Communications Commission Radio Frequency

Interference Statement

The

Epic 880TM

accordance with the specifications in Part 15 of FCC rules. These regulations are

designed to minimize radio frequency interference during installation; however, there

is no guarantee that radio or television interference will not occur during any particular

installation. Interference can be determined by turning the equipment off and on while

the radio or television is on. If the printer causes interference to radio or television

reception, try to correct the interference by one or more of the following measures:

1. Reorient the radio or television receiving antenna

2. Relocate the printer with respect to the receiver

3. Plug the printer and receiver into different circuits

If necessary, the user should consult their dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet

prepared by the Federal Communications Commission helpful:

Resolve Radio/TV Interference Problems

Government Printing Office, Washington, DC 20402. Ask for stock number 004-00000345-4.

Printer complies with the limits for a Class A computing device in

How to Identify and

. This booklet is available from the US

Canadian Department of Communications Radio

Interference Statement

The

Epic 880TM

digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communications.

Printer does not exceed Class A limits for radio noise emissions from

Regulatory Compliance

FCC Class B

CE Mark

EN 60950-1

UL 60950-1

CAN/CSA-C22.2 NO. 60950-1

EN55022

EN55024

ROHS

100-88002 Rev B Page iii

Page 4

Disclaimer

NOTICE TO ALL PERSONS RECEIVING THIS DOCUMENT:

The information in this document is subject to change without notice. No part of this

document may be reproduced, stored or transmitted in any form or by any means,

electronic or mechanical, for any purpose, without the express written permission of

TransAct Technologies, Inc. ("TransAct"). This document is the property of and

contains information that is both confidential and proprietary to TransAct. Recipient

shall not disclose any portion of this document to any third party.

TRANSACT DOES NOT ASSUME ANY LIABILITY FOR DAMAGES INCURRED,

DIRECTLY OR INDIRECTLY, FROM ANY ERRORS, OMISSIONS OR

DISCREPANCIES IN THE INFORMATION CONTAINED IN THIS DOCUMENT.

TransAct cannot guarantee that changes in software and equipment made by other

manufacturers, and referred to in this publication, do not affect the applicability of

information in this publication.

Copyright

© 2008, 2009 TransAct Technologies, Inc. All rights reserved.

Revision Level B

February 2009

Printed in USA

Trademarks

Some of the product names mentioned herein are used for identification purposes

only and may be trademarks and/or registered trademarks of their respective

companies.

BANKjet, 50Plus, Insta-Load, Ithaca, “Made to Order. Built to Last”, Magnetec, PcOS,

POSjet, PowerPocket and TransAct are registered trademarks and Epic 880

Zone, Import, ithaColor, iTherm, KITCHENjet, Momentum, QDT and TicketBurst are

trademarks of TransAct Technologies, Inc.

TM

, Flex-

Page iv 100-88002 Rev B

Page 5

Table of Contents

Change History ............................................................................................................. ii

Federal Communications Commission Radio Frequency Interference Statement ...... iii

Canadian Department of Communications Radio Interference Statement .................. iii

Regulatory Compliance ............................................................................................... iii

Disclaimer .................................................................................................................... iv

Copyright ..................................................................................................................... iv

Trademarks ................................................................................................................. iv

Table of Contents ......................................................................................................... v

Figures.......................................................................................................................... x

Tables ........................................................................................................................... x

Introducing your Epic 880TM Printer .............. 1

About your TransAct

Who Should Read This Guide? .................................................................................... 4

What Is Included in This Guide? ................................................................................... 4

Technical and Sales Support ........................................................................................ 5

On-line Technical Support ....................................................................................... 5

Telephone Technical Support .................................................................................. 5

Return Materials Authorization and Return Policies ................................................ 6

Service Programs .................................................................................................... 6

Sales Support .......................................................................................................... 6

Contact Information ................................................................................................. 7

®

Epic 880TM Printer ..................................................................... 3

Epic 880TM Specifications and Requirements . 9

Epic 880

Standard Features ...................................................................................................... 11

Optional Features ....................................................................................................... 12

General Specifications................................................................................................ 13

Printing Specifications ................................................................................................ 18

Paper Roll Specifications............................................................................................ 18

Auto Cutter Position .................................................................................................... 18

Paper Out ................................................................................................................... 18

Communications Interface .......................................................................................... 19

TM

Specifications and Requirements ............................................................. 11

Printer Dimensions ................................................................................................ 13

Weight .................................................................................................................... 13

Interface Type ........................................................................................................ 14

Printer Type ........................................................................................................... 14

Printer Environmental Conditions .......................................................................... 14

Reliability ............................................................................................................... 14

AC Power Requirements ....................................................................................... 15

DC Power Requirements ....................................................................................... 15

Power connector .................................................................................................... 17

Test Standards ...................................................................................................... 17

Accoustic Noise: .................................................................................................... 17

RS232 Serial Communications Interface ............................................................... 19

USB Interface ........................................................................................................ 20

Operational Procedures .............................. 23

Operational Procedures .............................................................................................. 25

How to Operate the Epic 880

Indicator Lights (LED) ................................................................................................. 25

100-88002 Rev B Page v

TM

Printer ....................................................................... 25

Page 6

The FEED button ........................................................................................................ 25

The Diagnostics/Config button ................................................................................... 27

Using Self-Test ...................................................................................................... 28

Level 0 Diagnostics ................................................................................................ 30

Boot Loader Mode ................................................................................................. 30

Printer Status LED’s............................................................................................... 31

Auto Error Recovery .............................................................................................. 32

Loading Paper ............................................................................................................ 34

Cleaning the Print Head ............................................................................................. 34

Configuring Your Epic 880TM Printer ............ 37

Configuration Mode Overview .................................................................................... 39

Most Frequent Configuration Incompatibilities ....................................................... 39

How to Change Configuration Settings ...................................................................... 39

Entering into Configuration Mode .......................................................................... 39

Setting up for Color Paper .......................................................................................... 40

Custom Color ......................................................................................................... 40

Remote Configuration ................................................................................................. 40

Remote Boot Load ...................................................................................................... 40

Field Configuration Feature ........................................................................................ 41

Mounting Requirements .............................. 43

Mounting Requirements ............................................................................................. 45

Bezel Mounting Specifications ............................................................................... 46

Spindle Mounting Options .......................................................................................... 47

45˚ Up Spindle Mounting ....................................................................................... 47

Straight Back Spindle Mounting ............................................................................. 48

45˚Down Spindle Mounting .................................................................................... 48

Straight Down Center Spindle Mounting ................................................................ 49

Straight Down Rear Spindle Mounting ................................................................... 50

Control Panel Side Spindle Mounting .................................................................... 50

Retract Opening ......................................................................................................... 51

Printer Sensors ........................................... 53

Printer Sensors ........................................................................................................... 55

Paper Out Sensor .................................................................................................. 55

Cover-Open Switch ................................................................................................ 55

Top-of-Form Sensor .............................................................................................. 55

Paper Low Sensor ................................................................................................. 56

Anti-Jam Sensor .................................................................................................... 56

Transport Ticket Taken Sensor .............................................................................. 56

Transport Ticket Retract Sensor ............................................................................ 57

Electrical Connections ................................. 59

Communications Interface .......................................................................................... 61

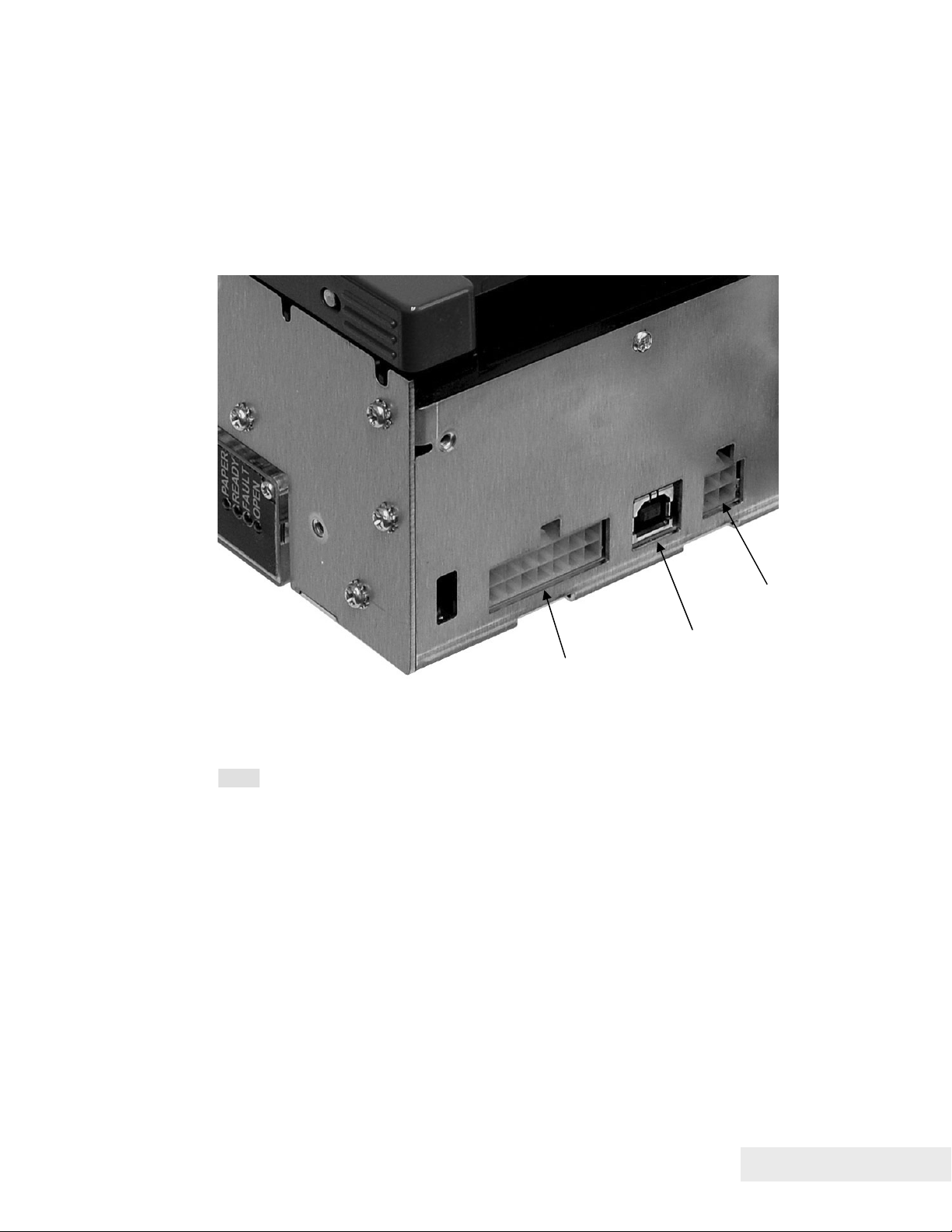

Cable connection locations ......................................................................................... 62

Printer Block Diagram ................................................................................................. 63

Control Codes .............................................. 65

Control Codes Overview ............................................................................................. 67

Nomenclature ............................................................................................................. 67

Standard Emulation ............................................................................................... 68

IPCL Codes ........................................................................................................... 68

Other Emulations ................................................................................................... 68

Page vi 100-88002 Rev B

Page 7

Application Development ............................................................................................ 68

TransAct Control Codes and Commands ................................................................... 68

PcOS Printer Control Codes .................................................................................. 68

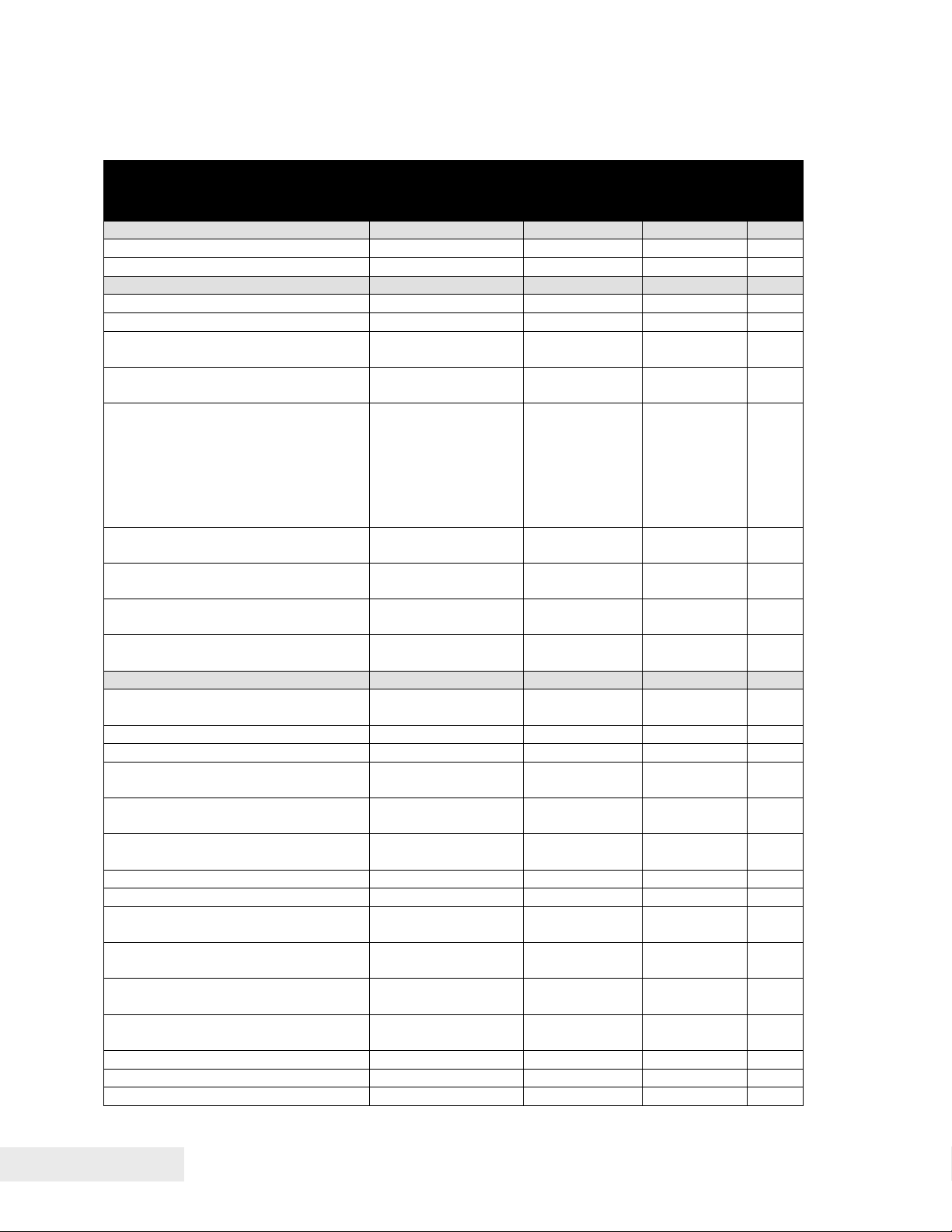

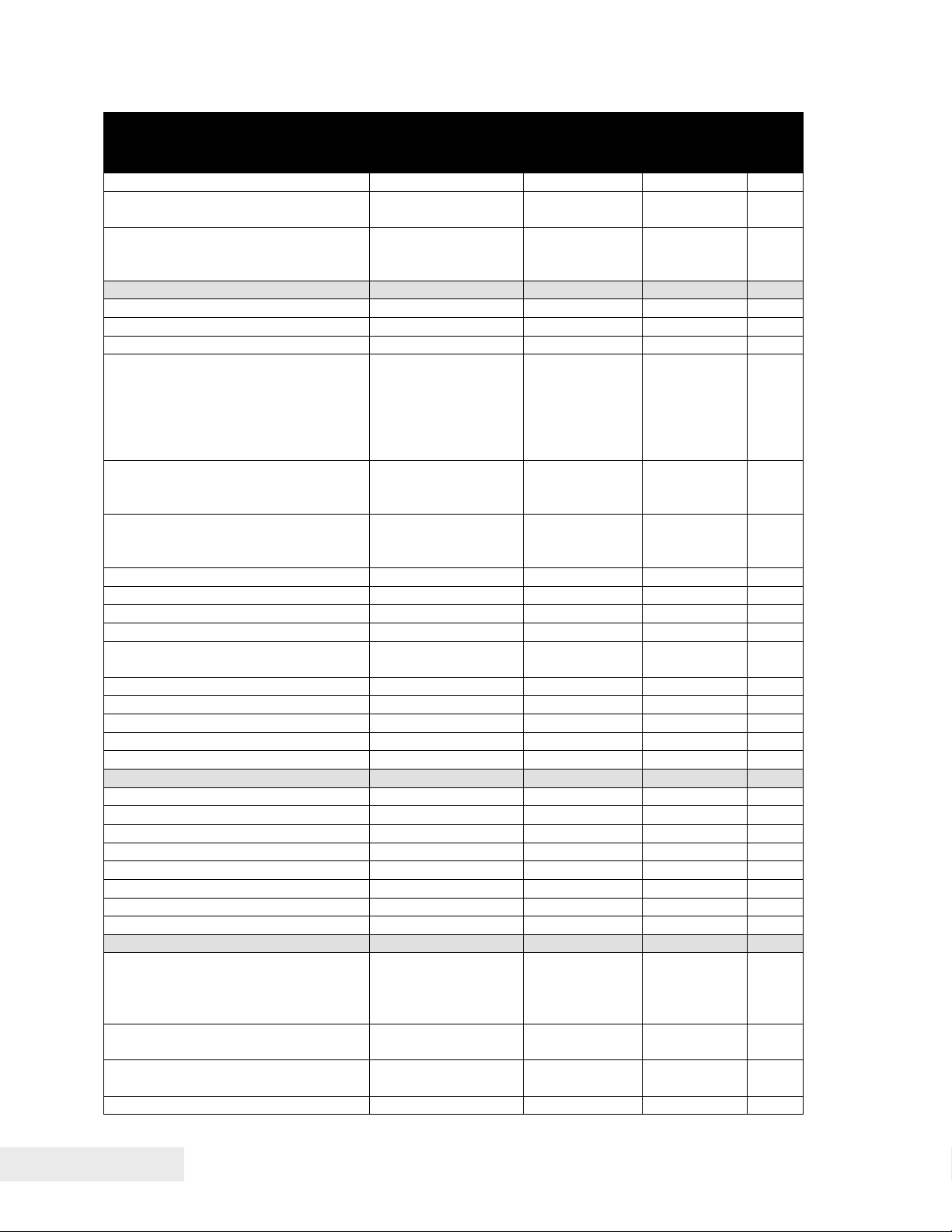

Quick PcOS Reference Chart ................................................................................ 70

Low Level Paper Motion Control ............................................................................ 76

Horizontal Motion Control ...................................................................................... 77

Vertical Motion Control .......................................................................................... 79

Feed to Black Dot .................................................................................................. 86

Character Pitch ...................................................................................................... 88

Character Font ....................................................................................................... 93

Character Sets and Code Pages ........................................................................... 94

Double-Byte and Multi-Byte Code Page Description Files ..................................... 96

Code Page Selection ............................................................................................. 96

Page Mode .......................................................................................................... 106

Graphic Mode ...................................................................................................... 115

Graphics Compression ........................................................................................ 120

Simple Raster Graphics ....................................................................................... 121

User Store (Graphic Save and Macros) ............................................................... 122

Legacy User Macros ............................................................................................ 129

Bar Codes ............................................................................................................ 131

Electronic Journal ................................................................................................ 141

Transport Control ................................................................................................. 152

Miscellaneous Control ......................................................................................... 154

Remote Power Control......................................................................................... 160

Documented Extended Control commands ......................................................... 161

Printer Status ....................................................................................................... 162

Inquire Commands .............................................................................................. 163

Double Level Loader ................................................................................................ 177

Entering Field Boot Load Mode. .......................................................................... 177

Epic 880TM Color Graphics ......................... 179

Printing Graphics ...................................................................................................... 181

Character Graphics .............................................................................................. 181

APA Graphics ...................................................................................................... 182

Epic 880

Bitmapped File Graphic Support .............................................................................. 189

Epic 880

TM

Universal Color Graphics ....................................................................... 183

Print File Graphics ............................................................................................... 184

Store Graphics in the printer: ............................................................................... 184

How universal color graphics is done .................................................................. 185

How to use IPCL commands in text strings ......................................................... 186

Cautions ............................................................................................................... 186

Universal Graphics Command Descriptions ........................................................ 187

TM

Coupon-Cut-Logo Feature ..................................................................... 190

Unicode and Fonts .................................... 191

Fonts ......................................................................................................................... 193

Character Generation .......................................................................................... 193

Internal Fonts ....................................................................................................... 196

Custom Fonts ...................................................................................................... 196

Stacked or Linked fonts ....................................................................................... 197

Font Storage ........................................................................................................ 197

Bitmap Fonts ........................................................................................................ 199

100-88002 Rev B Page vii

Page 8

Unicode .................................................................................................................... 202

Unicode Encoding ................................................................................................ 202

File system and the POR.INI file .............................................................................. 204

Font Size and Spacing ............................................................................................. 210

Font Size and Spacing command interactions ..................................................... 211

Legacy Printer Features that Have Changed ........................................................... 217

User Defined Characters ..................................................................................... 217

Dynamic Code Page Definition ............................................................................ 217

File System ............................................... 219

File System Interface ................................................................................................ 221

File System Commands ....................................................................................... 221

Epic 880TM Extended Printer Control ......... 227

Remote Printer Reset ............................................................................................... 232

Reset in Serial Mode............................................................................................ 232

Miscellaneous Communication Features .................................................................. 233

Power-cycle Recovery ......................................................................................... 233

Off-line Control ..................................................................................................... 233

Remote Boot Load Mode ..................................................................................... 234

USB Recovery Watch Dog ................................................................................... 235

Recovery from Mechanical Errors ............................................................................ 237

Epic 880TM Programmers Notes ................. 239

General Notes .......................................................................................................... 241

What Drivers Are Needed ......................................................................................... 241

Definitions ............................................................................................................ 241

Do you want to use the standard USB printing device interface? ........................ 241

Do you want to use USB and simulate a communication port? ........................... 242

Are you using OPOS (UnifiedPOS/UPOS)? ........................................................ 242

Do you want to print from a Windows application? .............................................. 242

Windows Printer Driver ........................................................................................ 243

PC Hardware ............................................................................................................ 243

GDI ........................................................................................................................... 243

OPOS driver ........................................................................................................ 244

PC Hardware ............................................................................................................ 244

USB driver: .......................................................................................................... 245

POSPrinter Activex Control (POSPrinter OCX): .................................................. 246

PC Hardware ............................................................................................................ 246

Appendix A: Unicode Character Addresses 247

Appendix B: WGL4.0 Character Addresses 249

Appendix C: GB18030 Character Addresses

................................................................. 254

Appendix D: Typical Code Page Definition . 261

Appendix E: Internal Code Pages .............. 263

Appendix F: ASCII Code Table ................... 265

Appendix G: Ordering Supplies ................. 266

Index .......................................................... 267

Page viii 100-88002 Rev B

Page 9

100-88002 Rev B Page ix

Page 10

Figures

Figure 1. Epic 880

Figure 2. Epic 880

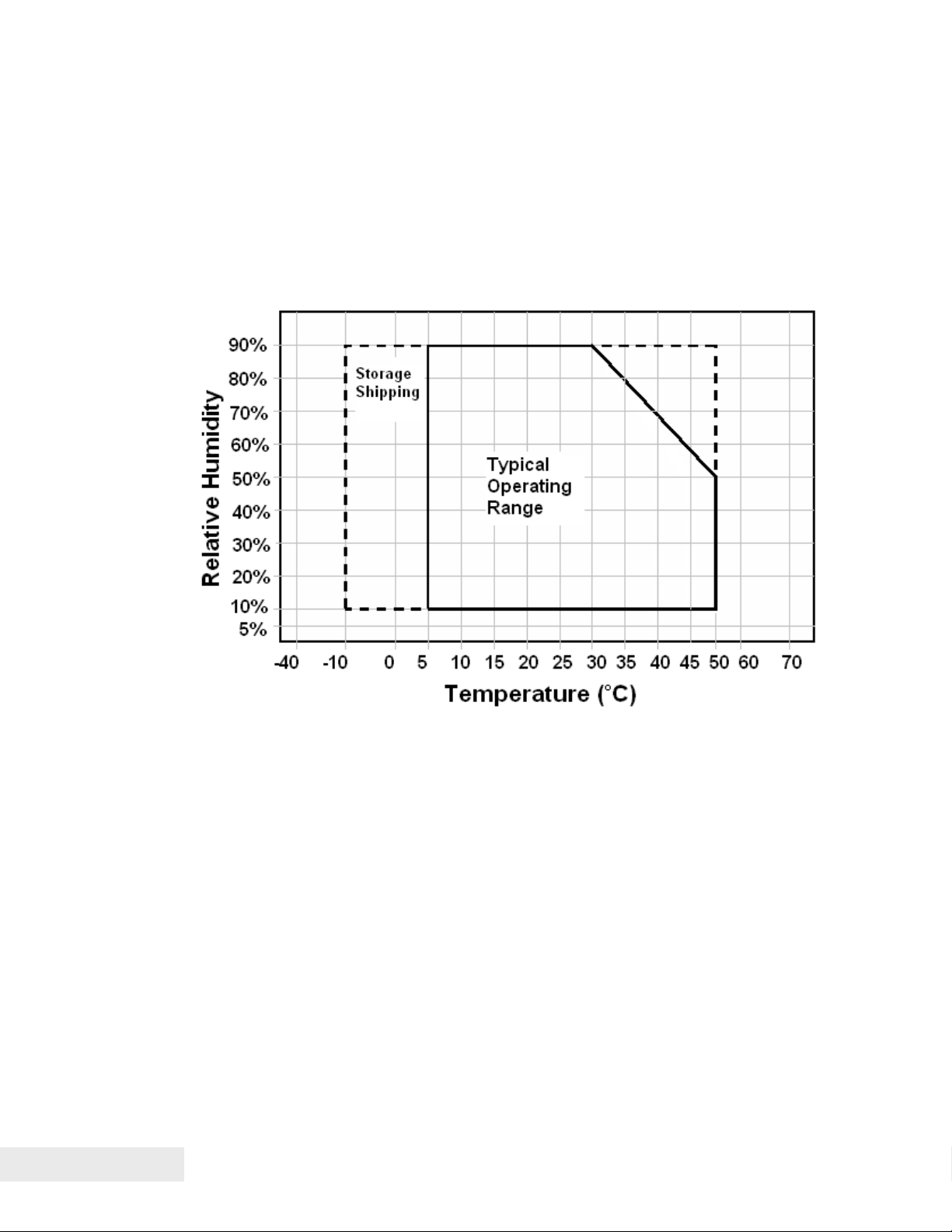

Figure 3. Temperature and Humidity Ranges. ............................................................ 14

Figure 4. Control panel with FEED and Diagnostics/CONFIG buttons and indicator

lights. ................................................................................................................... 25

Figure 5. Location of Diagnostics/Config Button. ....................................................... 27

Figure 6. Auto-feeding a Paper Roll. .......................................................................... 34

Figure 7. Startup message in Field Configuration mode. ........................................... 41

Figure 8. Sample pre-loaded configuration. ............................................................... 42

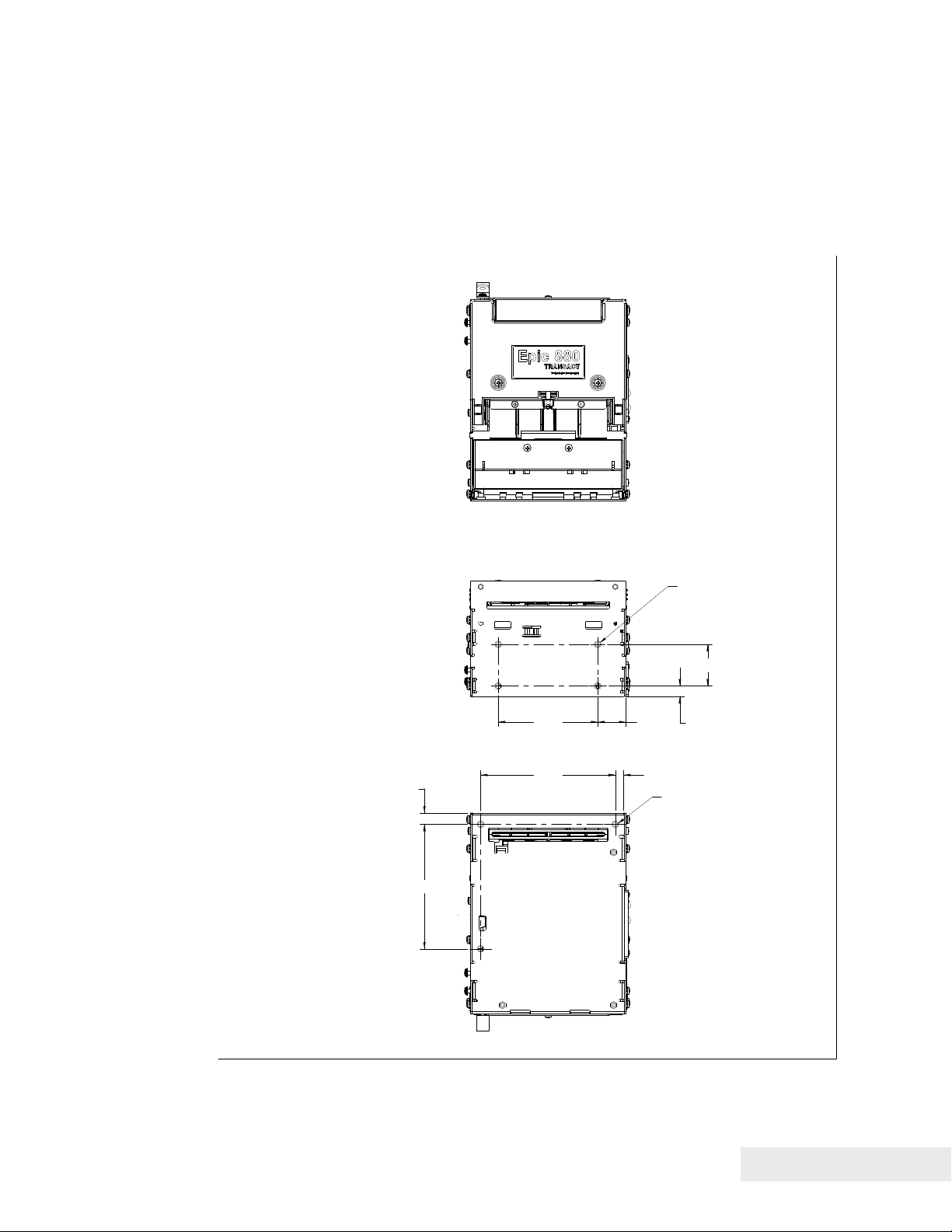

Figure 9. Epic 880

Figure 10. Bezel Mounting and Hardware Requirements ........................................... 46

Figure 11. 45˚ Up Spindle Location ............................................................................ 47

Figure 12. Straight Back Spindle Location ................................................................. 48

Figure 13. Angle Down Spindle Location ................................................................... 48

Figure 14. Straight Down Center Spindle Location ..................................................... 49

Figure 15. Straight Down Rear Spindle Location ........................................................ 50

Figure 16. Retract Opening. ....................................................................................... 51

Figure 17. Dimensions for Retract Opening. .............................................................. 52

Figure 18. Sensor Breakdown and Locations. ............................................................ 55

Figure 19. Transport Ticket Taken Sensor. ................................................................ 56

Figure 20. Transport Ticket Retract Sensor. ............................................................... 57

Figure 21. Communication PCB Location and Connector Info. .................................. 61

Figure 22 Power and RS232 Left hand Exit ............................................................... 62

Figure 23 Power and USB Left hand Exit ................................................................... 62

Figure 24 Page Mode Entry Orientations ................................................................. 106

Figure 25 Page mode set printable area .................................................................. 110

Figure 26 Default Page mode printed area ............................................................... 110

Figure 27 Defined Page mode printed area .............................................................. 111

Figure 28 Code 39 Full 128 Character Encoding ..................................................... 133

Figure 29 Expanded Function Coding ...................................................................... 134

Figure 30 Code 128 Encoding Values ...................................................................... 136

Figure 31 Example of Character Graphics ............................................................... 181

Figure 32 Windows Driver ........................................................................................ 243

Figure 33 OPOS (UPOS) Driver ............................................................................... 244

Figure 34 USB Driver ............................................................................................... 245

Figure 35 POSPrinter OCX ...................................................................................... 246

TM

Printer. ....................................................................................... 11

TM

Dimensions. .............................................................................. 13

TM

Mounting Locations ................................................................... 45

Tables

Table 1. Input Power Requirements ........................................................................... 16

Table 2 Serial Interface Pin-outs ................................................................................ 19

Table 3 Character Pitch .............................................................................................. 91

Table 4 Inter-character Spacing ................................................................................. 92

Table 5 Language Table ID’s ..................................................................................... 97

Table 6 Euro Character Substitution Matrix ................................................................ 98

Table 7 Paper Sensor Commands ........................................................................... 156

Table 8 Paper Sensor Commands ........................................................................... 157

Page x 100-88002 Rev B

Page 11

Table 9. Possible Character Pitches ........................................................................ 195

Table 10 Requested CPI and Resulting CPI ............................................................ 196

Table 11 Character Pitch .......................................................................................... 217

100-88002 Rev B Page xi

Page 12

Page 13

Chapter 1

Introducing your Epic 880TM Printer

100-88002 Rev B Page 1

Page 14

This page intentionally left blank

Page 2 100-88002 Rev B

Page 15

Introducing Your Epic 880

About your TransAct® Epic 880TM Printer

The TransAct

for thermal receipt printing, specifically designed for the needs of gaming and

kiosk applications. It builds upon the architecture of TransAct’s proven thermal

printers, together with a host of features specifically designed to improve the

performance of your receipt printing applications, including:

• Integrated printer mechanism/main controller PCB architecture

• Paper roll bracket/spindle allowing paper roll to be mounted behind or

below printer mechanism

• High-speed (6 inches per second) thermal receipt printing

• Barcode printing capabilities.

• Up to six (6) inch (152 mm) diameter paper roll

• Long-life ticket cutter

• Standard variable length presenter capable of handling from 63.5 to 254

mm. (2.5 -10 inches) length tickets

• Stroke-based fonts capable of supporting Asian and Latin characters

• Standard ticket retract feature

• Standard illuminated bezel assembly (Translucent blue)

These features and more let you quickly and easily integrate reliable ticket

printing in your gaming and kiosk applications, while giving you the quality,

durability and uptime you have come to expect from TransAct

®

Epic 880TM printer represents the very latest technology for use

®

printers.

TM

Printer

100-88002 Rev B Page 3

Page 16

Introducing Your Epic 880TM Printer

Who Should Read This Guide?

This document provides information useful to original equipment

manufacturers (OEM) who will integrate the Epic 880

products.

What Is Included in This Guide?

This Integration Manual includes information on the mechanical, electrical and

command language requirements of the Epic 880

following information to support your integration efforts:

• Warranty and technical support information.

• Specifications and functionality description.

• Mounting requirements and mounting locations.

• Power and interface connections.

• Operational procedures.

• Programming information, including documentation of low-level and high-

level command interfaces, as well as sample scripts to guide your own

implementation efforts.

We want you to have a trouble-free implementation with your TransAct

printer. For any issues not covered in this guide, quality technical support is

available on-line at www.transact-tech.com

the following pages for more details about our support services.

TM

printer into their

TM

printer. It provides the

®

, or by telephone or fax – consult

Page 4 100-88002 Rev B

Page 17

Introducing Your Epic 880

Technical and Sales Support

Your printer is backed by the resources of TransAct Technologies, a global

technology firm with dedicated technical support and sales assistance. Here is

how we can help you:

On-line Technical Support

Our web site at www.transact-tech.com is your on-line portal to obtaining

technical assistance with your TransAct

Support link to find support information for your printer. Our on-line support

site also includes a convenient e-mail assistance request form, where you can

submit support requests 24 hours a day, and receive a return contact from a

TransAct support technician during regular business hours.

Telephone Technical Support

Live telephone support is available Monday through Friday from 8 AM to 5 PM

local time, excluding holidays. We can provide general information about

programming for your Epic 880

assistance in sending a printer for service. To obtain telephone support,

contact the number below for your region and ask for Technical Support.

United States: 1.877.7ITHACA (1.877.748.4222), Fax: 607.257.3911

Europe, Middle East and Africa (EMEA): 011-44-170-977-2500, Fax: 011-44170-977-2505

To help us serve you faster, please have the following information ready when

you call:

• The Model Number and Serial Number of the printer.

• A list of any other peripheral devices attached to the same port as the

printer.

• What application software, operating system, and network (if any) you are

using.

• What happened and what you were doing when the problem occurred.

• How you tried to solve the problem.

TM

printer, technical support, documentation, or

®

printer. Click on the Technical

TM

Printer

100-88002 Rev B Page 5

Page 18

Introducing Your Epic 880TM Printer

Return Materials Authorization and Return Policies

If a support technician determines that the printer should be serviced at a

TransAct facility, and you want to return the printer for repair, we will issue you

the Returned Materials Authorization (RMA) number that is required before

returning the printer. Repairs are warranted for 90 days from the date of repair

or for the balance of the original warranty period, whichever is greater. Please

prepare the printer being returned for repair as follows:

• Pack the printer to be returned in the original packing material.

• Packing material may be purchased from TransAct's Ithaca Facility.

• Do not return any accessories unless asked to do so by a support

technician.

• Write the RMA number clearly on the outside of the box.

Service Programs

TransAct Technologies Incorporated has a full service organization to meet

your printer service and repair requirements. If your printer needs service,

please contact your service provider first. If any problems still persist, you can

directly contact the Technical Support department at the numbers listed above

for a return authorization. Customers outside the United States and United

Kingdom should contact your distributor for services. TransAct offers the

following service programs to meet your needs.

• Extended Warranty.

• Depot Repair.

• Maintenance Contract.

• Internet Support.

Sales Support

To order supplies, receive information about other Ithaca products, or obtain

information about your warranty, contact our Sales Department at the contact

telephone or fax numbers listed below. To receive information on International

distribution, visit our web site at www.transact-tech.com.

Page 6 100-88002 Rev B

Page 19

Introducing Your Epic 880

Contact Information

TransAct Technologies Incorporated

Ithaca Facility

20 Bomax Drive

Ithaca, NY 14850 USA

TransAct Technologies

World Gaming Headquarters

& Western Regional Repair Center

6700 Paradise Road

Suite D

Las Vegas, NV 89119 USA

Telephone 877.7ithaca or 607.257.8901

Main fax 607.257.8922

Sales fax 607.257.3868

Technical Support fax 607.257.3911

Web site www.transact-tech.com

Western United States: 877.822.8923, Fax: 702.254.7796

United Kingdom: 011-44-170-977-2500, Fax: 011-44-170-977-2505

TM

Printer

100-88002 Rev B Page 7

Page 20

Page 21

Chapter 2

Epic 880TM Specifications and Requirements

100-88002 Rev B Page 9

Page 22

This page intentionally left blank

Page 10 100-88002 Rev B

Page 23

Epic 880TM Specifications and Requirements

Epic 880TM Specifications and Requirements

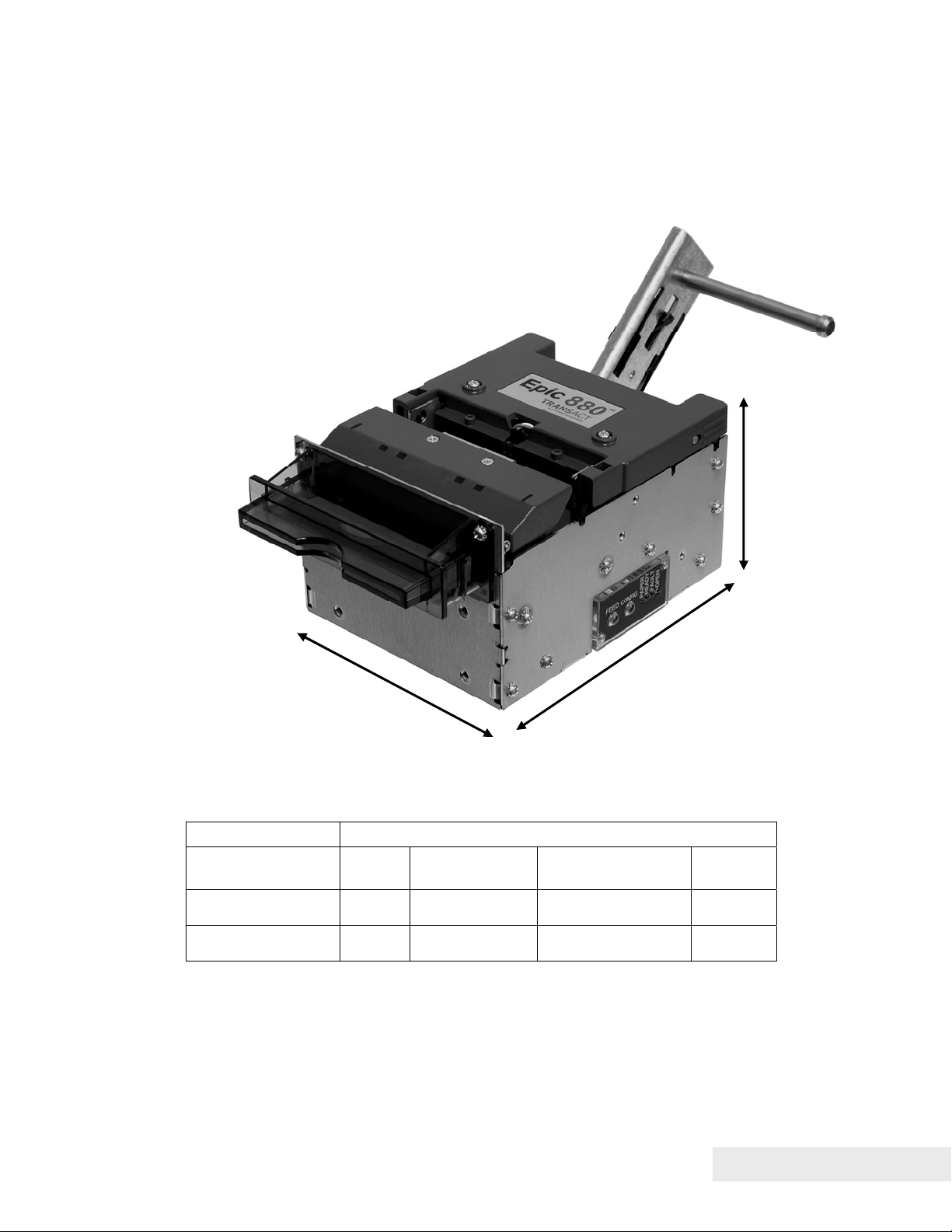

Figure 1. Epic 880TM Printer.

Standard Features

The following features are standard for Epic 880

• Integrated printer mechanism/main controller PCB architecture

• Variable length presenter, capable of handling from 63.5 to 254 mm. (2.5 -10

inches) length tickets

• Full-cut auto-cutter module as part of printer mechanism

• Minimum 150 mm (6.0”)/second print speed (monochrome black text)

• 203 dpi print resolution (8 dots/mm.)

• Special print scalable to 8x with reverse, underscore, italic, and bold print

• 44/57 characters per line for 80 mm paper width

• Face-up print orientation

• ASCII and Unicode character encoding

• Ladder and fence barcode printing supporting UPC-A, UPC-E, EAN13, EAN8,

Code39, ITF, CODABAR, Code93, Code 128, Code31, and Interleaved 2 of 5

• Serial RS232C and USB interfaces built into main controller PCB

• Selectable baud rates

TM

printers:

100-88002 Rev B Page 11

Page 24

Epic 880TM Specifications and Requirements

• Drivers for Windows XP and XPe

• 4 MB minimum flash memory and 8 MB RAM

• Ithaca command set emulation

• Power: 24 VDC

• Power Connector: 4 pin Molex

• Paper Out, Paper Cover-Open, Paper Low, Top-Of-Form, Jam Detection,

Transport Ticket Taken, Head Temperature, and Ticket Retract sensors

• Ticket retract feature

• Power and error LED(s)

• Paper feed button

• Easy paper loading

• Portrait or landscape printing under Windows

• Internal counters to track number of hours on, cuts completed, lines fed, and error

conditions

• Capable of handling a 152 mm. (6.0 inch) diameter, 82.5mm. wide paper roll

• Compliant with RoHS (Restriction on Hazardous Substances)

• Bezel assembly with LEDs (translucent blue)

Optional Features

The following options are available:

• 80mm paper guide

• Lower paper guide

• Additional or custom fonts or character sets.

• Custom emulations (Epson, Custom)

• Universal power supply (100-240 VAC, 47-63 Hz)

Page 12 100-88002 Rev B

Page 25

Epic 880TM Specifications and Requirements

)

(

)

General Specifications

4.70” (119.28mm)

Figure 2. Epic 880TM Dimensions.

Printer Dimensions

Max Dimensions

W D (w/out paper)

Dimensions in

inches

Dimensions in

millimeters

(fully assembled as single unit)

4.77 6.05 7.02 3.48

121.2 153.7 178.2 88.4

6.04” (153.62 mm

D (with paper guide

and w/out paper)

H

3.39”

86.13mm

Weight

Approximate weight 4 lb 1.8 Kg

100-88002 Rev B Page 13

Page 26

Epic 880TM Specifications and Requirements

Interface Type

Bi-directional serial RS-232 or USB

Printer Type

Fixed 80 mm linear thermal head.

Figure 3. Temperature and Humidity Ranges.

Printer Environmental Conditions

Operating Temperature Range: 5º - 50ºC (41ºF - 122ºF)

Shipping/Storage Temperature Range: –10º - 50ºC (14ºF - 122ºF)

Operating Humidity Range: 10% - 90% non-condensing

Shipping/Storage Humidity Range: 10% - 90% non-condensing (excluding

paper)

Reliability

Printer Life: 10,000,000 print lines

Print Head Life: 100Km. min.

Cutter Life: 1,000,000 cuts (POS Grade)

750,000 cuts (Lottery grade)

Page 14 100-88002 Rev B

Page 27

Epic 880TM Specifications and Requirements

AC Power Requirements

90-264 VAC at 47-63 Hz.

DC Power Requirements

Thermal printers require high peak currents based on how many print elements are

being used and how often. High density printing requires much more current than low

density printing. High density printing in the horizontal axis will put extreme peak

loads on the power supply. These high peak currents can cause power supplies to

sag, roll back or even shut down. A power supply with an average rating sufficient to

meet the average printer requirements many not be sufficient to meet the peak

requirements. The power supply selection is critical to proper printer operation.

Typical power supplies are designed to provide a continuous well regulated voltage at

an average current that does not fluctuate too much and will typically have a wattage

rating based on that average current. A power supply suitable for the Epic 880

could have a wattage rating of 48 watts but unless it can provide peak currents of 8

amps (192 watts) and maintain 24VDC output, it will not function properly.

Some power supplies are designed to provide multiple voltages. These power

supplies typically provide a logic supply voltage that requires close regulation. The

other voltages are not as well regulated or have post regulation. In this case when

the 24 volt output is required to provide high peak currents, the circuitry within the

power supply must maintain the logic voltage and the 24 volt supply will sag. In some

cased the high peak load will actually shut down the complete supply.

Thermal printing has specific power requirements to develop the thermal paper. The

Epic 880

requirements if the voltage is low. The printer will adjust the print element burn time

and that will resulting in increased average current requirements. Input voltage

ranges from about 20 to 27 volts can be accommodated by the Epic 880

input voltage is outside the acceptable range, the printer will issue a fault and will not

function.

A suitable power supply for a thermal printer will provide a constant voltage over a

wide range of loads with a low average current requirement.

Consider the following when selecting or designing a power supply for the Epic 880.

1) It must be able to provide quick response to step loads

2) Current will range widely with peaks at least 4 times the average

3) Load requirements for the power supply are as shown in the table below.

4) Consider a dedicated power supply for the printer.

5) If the printer is expected to print dense graphics, increase the average and

6) Use power cables that are as short as possible and use adequate wire size based

7) Make sure the power supply uses a low ESR capacitor of at least 2200uF and

TM

printer monitors the incoming voltage and will increase its current

TM

continuous current requirements by at least 25%.

on the cable length. Typically AWG 18 is the minimum wire size provided the

length is less than 3 ft (1 m).

preferably larger in the output circuit.

TM

. If the

100-88002 Rev B Page 15

Page 28

Epic 880TM Specifications and Requirements

8) When the printer prepares to print, it will activate the print head power and charge

a bulk capacitor attached to the print head. This current spike can be up to 15

amps for up to 200uS depending on the charge state of the capacitor.

9) Make sure the power supply specification includes any bezel current

requirements.

10) Consider that the frame ground and the 24V return are connected together in the

printer.

11) Use connectors in the power interconnect that are rated for the maximum average

current.

Voltage

Under all line, load and

environmental

conditions

Load Current 0A min

Max. Ripple 240mv p-p

Over voltage Protection < 30V

Over current Protection Output equipped with auto restart short circuit protection

24VDC ±8.5%

1.87A continuous

3.5A continuous - 1 minute maximum.

8A peak load 23.38% duty cycle 2ms period .1A/us slew rate

200 ms maximum

NOTE: This load current does not include the optional Bezel

drive requirement.

< 7amps when t

Table 1. Input Power Requirements

short >10ms

Page 16 100-88002 Rev B

Page 29

Epic 880TM Specifications and Requirements

Power connector

Note: Power may be applied through the 14 pin connector. See the Communications

Interface section for more information.

Note: The 24V RTN and FRAME pins are connected inside the printer.

Test Standards

CE MARK (1998)

FCC CLASS B

EN 60950-1

IEC 60950 (1991) Second Edition with Amendments 1,2,3,4

ROHH/WEEE

Accoustic Noise:

58 dbA average (sound pressure level) while printing a rolling ASCII format.

Microphone positions are at 10 different positions spaced around the printer as

defined in ISO 779.

100-88002 Rev B Page 17

Page 30

Epic 880TM Specifications and Requirements

Printing Specifications

Printing method: Thermal Sensitive Line Dot System

Vertical/Horizontal dot pitch: 0.125 mm.

Resolution: 8 dots per mm (203 DPI)

Line feed pitch: 3.2 mm. (.125 inches)

Print zone (typical) 80 mm (3.15 inches)

Print speed (monochrome): 6 inches per second

Number of print elements: 640 dots in-line

Paper Roll Specifications

Paper Type: One ply thermal paper

Paper Width: 79.5 +/- .05 mm (3.13 +/- .02 inches)

or 82.0 +/- 0.5 mm. (3.23 +/- .02 inches)

Paper Thickness 0.076 mm to 0.09 mm (.0022 to .0035 in.) thick

Roll Diameter: 152 mm (6.0 in.)

Roll Core Inside Diameter: .445 to .635 inches

Roll Core Outside Diameter: .730 to .860 inches

Paper Grades : POS and Lottery grades

Paper Usage Precautions:

Use only specified thermal paper. If other paper is used, print quality, head life, and

cutter life may deteriorate. Contact TransAct customer service for approved papers.

Auto Cutter Position

A full cut auto-cutter is a standard feature with all TransAct® Epic 880TM printers.

Cutter type Guillotine

Media width 82.5 mm. (3.25 inches)

Media thickness range 0.0022 to 0.0035 inch

Cut to line of print 0.38 inch

Cutter life 1,000,000 cuts (POS grade)

750,000 cuts (Lottery grade)

Cut time: Less than 750 milliseconds

Paper Out

A receipt paper out sensor is provided as a standard feature, which senses when

approximately .5 inches length of paper is left on the paper roll.

Page 18 100-88002 Rev B

Page 31

Epic 880TM Specifications and Requirements

Communications Interface

RS232 Serial Communications Interface

The RS232 Serial interface connector is a 14 position Molex Minifit Jr®., part number

39-30-1140, which mates with Molex part number 39-01-2140 or equivalent.

1 2 3 4 5 6 7

8 9 10 11 12 13 14

14-pin Direction Description

Pin 1 - No connect

Pin 2 IN Data Set Ready

Pin 3 - No connect

Pin 4 IN Clear to Send

Pin 5 - Signal Ground

Pin 6 - +24V

Pin 7 - Signal Ground

Pin 8 - +24V

Pin 9 - No connect

Pin 10 - Frame Ground

Pin 11 IN Receive Data

Pin 12 OUT Transmit Data

Pin 13 OUT Data Terminal Ready

Pin 14 OUT Request to Send

Table 2 Serial Interface Pin-outs

Signal Voltage and Current levels

The serial interface meets EIA RS232 interface specifications:

Voltage Levels Max +-15 Volts

Min +- 3 Volts

Mark = Off = -3 to –15 Volts

Space = On = +3 to +15 Volts

Note: Power may be applied through this connector or the 4 pin power connector.

See the DC Power Requirements section for 24 volt power requirements.

Note: GND is the 24V return.

Note: FGND and GND are connected in the printer.

100-88002 Rev B Page 19

Page 32

Epic 880TM Specifications and Requirements

USB Interface

The USB interface supports USB Version 2.0 High speed or full speed. The standard

USB interface is implemented through a standard Series “B” receptacle as defined in

the USB Specification. The printer is self-powered and does not draw power from the

standard type B USB interface cable.

The Standard USB Type B connector has the following pin functions:

Pin Signal

1 Vbus (+5 V dc1) (This is used to select between Interfaces)

2 Minus data

3 Plus data

4 Ground

Note: The standard USB interface does not have enough power to run the printer. It

is not possible to power the printer with the USB cable alone.

USB Configuration

To allow the application to use a virtual serial port or a USB printer port to interact with

the printer, the EPIC 880

Virtual COM port or a USB Printer device. The USB section of the configuration

allows USB Mode, USB Enumeration, and whether the printer will perform a normal

Windows plug and play operation to be configured. The default is printer port, use

description, with Windows PnP on.

You should configure these options based on how you want the printer to perform in

your system. Typically only the Virtual COM or USB printer driver is required: to load

the Transact Virtual COM port driver, disable the USB printer port. Typically you can

use the description as the enumeration ID, representing how the printer is uniquely

identified to the host. If you select a description, all Epic 880’s will be the same, and

you can interchange printers without affecting the port location, subject to the

limitation that no more than one Epic 880 can be connected to the same host. If that

is a requirement, select ID by serial number or allow the ID number to be assigned by

windows based on the connection.

You can also disable the Windows PnP sequence. This will prevent the Windows

system from receiving the printer driver selection sequence. This will allow you to

manually assign a driver to the USB printer connection and not have Windows keep

asking for a printer driver.

The adapter will support a high speed USB interface if the host also supports high

speed. If the host does not support high speed the printer will revert to full speed. It

is possible to disable high speed operation by setting a configuration option. The

printer does not support the USB low speed protocol.

TM

supports both ports, and can be configured to support a

1

The Vbus signal is used to disable the serial port. If the USB is connected the RS232 serial

port is not active.

Page 20 100-88002 Rev B

Page 33

Epic 880TM Specifications and Requirements

The most reliable USB interface is as a USB printing device. The Virtual COM driver

is an added layer of code that allows legacy software to believe it is interacting with a

serial port. Note that a limitation of serial communications port virtualization is that

each version of windows is slightly different, and not all RS232 features are

supported: only features such as receive, transmit and ready/busy are supported,

while other features such as on hook, off hook, ring, and break are not supported.

100-88002 Rev B Page 21

Page 34

Page 35

Chapter 3

Operational Procedures

100-88002 Rev B Page 23

Page 36

This page intentionally left blank

Page 24 100-88002 Rev B

Page 37

Operational Procedures

Operational Procedures

How to Operate the Epic 880TM Printer

Your Epic 880

indicator lights: Paper, Ready, Fault, and Open. These are located on a panel on the

right-hand side of the printer.

TM

printer contains two buttons (FEED and CONFIG) and four (LED)

Figure 4. Control panel with FEED and Diagnostics/CONFIG buttons and indicator lights.

Indicator Lights (LED)

The four Epic 880

• Paper LED Indicates paper status (paper low or out)

• Ready LED Indicates printer activity and non-recoverable errors

• Fault LED Indicates problems and probability of recovery

• Open LED Indicates the cover is open

TM

indicator lights are:

The FEED button

The FEED button will provide various functions, depending upon how long it is

pressed.

Pressing this button will provide one of three functions. The function is timedependent, and the display indicators will change to indicate the next mode, as

follows:

100-88002 Rev B Page 25

Page 38

Operational Procedures

• The feed button is a multifunction button. By pressing and releasing the Feed

button, the printer will feed about 5 inches of paper while printing the printer

firmware version. This is intended to clear the printer and align the next ticket for

print.

• By pressing and holding the feed button for a longer time, two additional features

may be activated. Pressing and holding the button for about two seconds will

enter journal maintenance mode.

• Holding the button for about 4 seconds will enter configuration mode.

To aid in selecting the correct mode, the Fault LED will illuminate as soon as the

button is pressed and indicates that FEED is selected. After about 2 seconds the

Fault LED will go out and the PAPER indicator will illuminate. This indicates that

Journal mode is selected. After about 4 seconds, the Cover LED will illuminate

indicating configuration mode is selected

Page 26 100-88002 Rev B

Page 39

Operational Procedures

The Diagnostics/Config button

The printer has a configuration and diagnostics button on the right side of the printer,

labeled CONFIG.

FEED Button

Diagnostics/Config Button

Figure 5. Location of Diagnostics/Config Button.

The Diagnostics/Config button is a multifunction button. By pressing and releasing

the Diagnostics/Config button, the printer will enter self test mode. This is intended to

verify the printer’s operation.

By pressing and holding the Diagnostics/Config button for a longer time, two

additional features may be activated. Pressing and holding the button for about two

seconds will enter hex dump mode. Holding the button for about 4 seconds will enter

configuration mode.

To aid in selecting the correct mode, the Fault LED will illuminate as soon as the

button is pressed and indicates that self test is selected. After about 2 seconds the

Fault LED will go out and the PAPER indicator will illuminate. This indicates that hexdump mode is selected. After about 4 seconds, the Cover LED will illuminate

indicating configuration mode is selected

100-88002 Rev B Page 27

Page 40

Operational Procedures

Using Self-Test

Self-Test Mode allows you to perform a series of tests to show if the printer is

functioning correctly.

To enter self test, momentarily press

printer.

The Epic 880

performing on-site print evaluations. Others are designed for factory setup by

TransAct.

Once in test mode, the FEED button is used to select the test to be run.

Testing the printer

Use the first three TEST options when verifying basic printer operation. The last three

options are for factory test.

Operation –Ticket Print

The receipt test is the primary test option to use when determining if the printer is

functioning correctly.

The ticket test is mostly used during the early stages of troubleshooting, to eliminate

the possibility that the problem is occurring with the printer. If the printer experiences

a failure, and the error indicator light is activated, call TransAct’s Technical Support

department.

Operation – Head Test

This test performs a test pattern that will print all the head print elements and verify

that the drive roll is free from defects or debris. The print head has two heating

elements per dot position. A print element is not considered bad unless both

elements are missing. If the head test shows that there is an inconsistency in the

print there may be debris on the drive roll. If debris is indicated, cleaning the drive roll

should correct the problem. If this does not correct the problem, contact TransAct’s

Technical Support department.

Operation – Marker Calibration

The printer is equipped with several sensors in the paper path, which are adjustable

and will handle a wide range of paper under normal operation. However, if there

appear to be problems associated with any sensor’s operation, the Marker Calibration

test will attempt to adjust the sensors for optional operation with the paper installed.

The Top-of-Form, Paper Out and Jam sensors will be recalibrated. To run this test,

2

the Diagnostics/Config button on the side of the

TM

has several Self-Test options. Some are designed to be useful when

2

The Diagnostics/Config button is a multifunction button. By pressing and releasing the

Diagnostics/Config button, the printer will enter self test. By pressing and holding the

Diagnostics/Config button for a longer time, two additional features may be activated: pressing

and holding the button for about two seconds will enter hex dump mode, and holding the

button for about 4 seconds will enter configuration mode. To aid in selecting the correct mode,

the Error LED will illuminate as soon as the button is pressed and indicate that self test is

selected. After about 2 seconds the Error LED will go out and the PAPER indicator will

illuminate, indicating that hex dump is selected. After about 4 seconds, the Cover LED will

illuminate, indicating that configuration mode is selected.

Page 28 100-88002 Rev B

Page 41

Operational Procedures

simply select it. The printer will automatically position the paper and adjust the

sensors. If the paper installed does not have black dot markings, the Top-of-Form

sensor will be adjusted based on the white level of the paper only.

Factory Test

The printer is equipped with several factory test modes. These test options are only

used for factory burn-in and testing.

Operation – Continuous

Operation – Burn-in

Operation – Rolling ASCII

100-88002 Rev B Page 29

Page 42

Operational Procedures

Level 0 Diagnostics

Level 0 diagnostics are only run at power up, e.g. when power is first applied. These

diagnostics perform the following tasks:

Power On

1. Basic System Integrity

2. Vector Integrity

3. RAM Test

4. Flash Boot Loader Integrity

5. Flash Firmware Integrity (NOTE: If the firmware is corrupted, the printer will remain in boot load.)

6. USB Controller Diagnostics and verify.

7. Start Normal Firmware

8. Verify Configuration Integrity

9. Interface Configuration

10. File System Integrity

11. Start Kernel, Verify Multitasking, Start Tasks

Once the kernel is running, the following tests must pass to allow operation. However, if any

test fails (except the knife home test), the remaining tests will generate recoverable faults and

normal operation will start as soon as the fault is cleared. These tests are also run when

operation is resumed from OFF.

12. Cover Closed Check

13. Knife Home

14. Paper Present

15. Clear Paper Path.

16. Place Printer On-line, Start Normal Operation

The first phase of testing consists of step 1-5, and determines that the boot loader is

accurate and the printer firmware is correct. Tests 1 through 4 produce nonrecoverable errors if they fail, in which case the power must be removed from the

printer and the printer returned for service. If the boot loader is intact, but the main

firmware is corrupted, the printer automatically enters boot loader mode, where the

firmware can then be reloaded into the printer.

Boot Loader Mode

The boot loader may be entered during normal operation through special commands.

Normal boot load operation is by manually starting boot load mode. Boot loader mode

can be entered in one of three ways: (1) when Level 0 Diagnostics finds that the

firmware check (also known as a cyclical redundancy check, or CRC) is bad, (2)

manually, or (3) through the use of a special boot load command.

To manually enter the boot loader, hold the Diagnostics button in the side of the

printer while the power is applied. The FAULT Indicator comes on, and the READY

indicator blinks. At this time, the firmware boot program is operating and the boot

load file may be sent to the printer. When the printer receives the boot load file, the

printer will automatically restart if the firmware load was successful. If the load fails,

the printer will remain in boot load mode. If the load fails, reset the printer by removing

the power and restarting it, and then try again.

Note: In this download mode, the printer will only accept data on the serial port. A

second level loader, described in more detail in the command section of the

TM

880

OEM Integration Manual

Page 30 100-88002 Rev B

, supports the USB interface.

Epic

Page 43

Operational Procedures

Note: In rare cases, it may be required to load the firmware twice. The Epic 880TM

contains a flash file system. The complete flash image is sometimes distributed as

part of a firmware update. If the file system image is not compatible with the previous

firmware configuration, the new firmware may need to reformat the file system. If this

occurs, the firmware will have to be reloaded after the flash is reformatted. The

indications that this is happening will be an excessively long startup after a firmware

update after which the printer will not print: tickets are presented, however only

graphics are printed, and fonts will be missing. In this case it is important that the

reformat be allowed to complete, as it can take up to 30 seconds to reformat the

entire flash system.

Printer Status LED’s

The Epic 880TM printer has four indicator lights to indicate various operating states of

the printer. In general these are Fault, Cover Open, Paper Status, and Ready.

The printer may be in normal operation, self test or in one of two boot load modes.

The Ready and Fault indicators will indicate which mode by a unique blink pattern:

TransAct Boot Load Mode

In TransAct Boot Load Mode, the power LED will blink slowly with a 50% duty cycle.

It will repeat this cycle about every 2 seconds (1 Sec on, 1 Sec off). There will be a

red indication on the Error LED indicator until the down load is started.

Self Test Mode

When the printer is in Self Test Mode, the power indicator will blink slowly with a 50%

duty cycle at a 2 second rate. This is very similar to TransAct Boot Load Mode,

however, the red error indicator will not be present.

Normal Operation

During Normal operation, the Power LED will remain on unless an error is being

indicated. There are two classes of errors, soft errors and hard errors. Soft errors are

recoverable without power cycling the printer; conversely, recovering from hard errors

requires removing the power from the printer, correcting the problem, and then

reapplying power.

Status LED response

Power On, Printer Ready Ready LED on (Not Blinking)

Paper Low Paper LED Blinking

Soft Errors

Soft errors may be recovered by the host, or by opening and closing the printer cover.

Each of these errors is indicated by a 5 second repeating blink pattern on the Power

LED with the red Fault LED continuously on.

Out of Paper 2 Blinks Paper LED will also be on.

Cover Open

3

4 Blinks

3

The printer may be configured to beep if the cover is open.

100-88002 Rev B Page 31

Page 44

Operational Procedures

Jam Detected 5 Blinks

Missed Top of Form 6 Blinks Paper LED will blink fast.

Illegal or Bad Command 7 Blinks Paper LED will blink fast.

Printer Over Temp 8 Blinks Fault LED will blink slow.

Bad Power 8 Blinks Fault LED will blink fast.

Hard Errors

Hard errors have a similar blink pattern to soft errors, except that they are slower and

repeat every 10 seconds. In general, these errors occur during level 0 diagnostics

and are not recoverable. In these cases, the Error and Power LEDs will blink at the

same time.

EEPROM read fault 2 Blinks

EEPROM write fault 3 Blinks

Error Vector Taken 4 Blinks

Knife Error 5 Blinks

User Store Format Error 7 Blinks

User Data Store Error 8 Blinks

Flash Read/Write Error 9 Blinks

Memory Error 12 Blinks

Com Adapter 14 Blinks

Kernel Fault 15 Blinks

File system Fault 16 Blinks

Auto Error Recovery

The Epic 880TM printer has the ability to auto recover from some internal errors.

Flash Format Errors

The internal flash that is used to store graphic images is formatted to assure data

integrity. If this format is corrupted, the printer will automatically delete and reformat

the flash. The host can then reload the images.

Input Power Fault

The printer monitors the power input to the printer. If it is found to be greater than 26

volts or less than 20, the printer will stop and wait for the power to return to

specification.

Head Temperature Fault

The printer monitors the head temperature. If the head temperature is greater than

60º C, the printer will start to slow down. If the head exceeds 65º C, the printer will

stop. The printer will heat the head to maintain a head temperature of 25º C. If the

printer cannot maintain a head temperature of 0º C, the printer will stop. In all cases,

the printer will automatically recover when the head temperature is within range.

Configuration Fault Recovery

The printer maintains an operating configuration in EEPROM. Information such as the

printer’s serial number, operating configuration, and running totals are stored in this

memory. Each section of this memory maintains a check character to signal that the

data is valid. If this memory is found to be corrupted, the printer will restore it based

on a backup copy saved in flash. This flash copy is generated when the printer was

Page 32 100-88002 Rev B

Page 45

Operational Procedures

electronically configured using the TransAct® configuration tool. Any configuration

parameters altered during normal operation will not be saved in the flash copy. The

EEPROM will be restored to the value set by the configuration program.

100-88002 Rev B Page 33

Page 46

Operational Procedures

Loading Paper

The Epic 880 printer uses a continuous roll of POS or Lottery grade thermal paper,

with specifications outlined in the chapter

Requirements

Epic 880TM Specifications and

.

Figure 6. Auto-feeding a Paper Roll.

Instructions for auto-feeding the paper are as follows:

1. Place a roll of new paper on the spindle, with the end of the paper unloading from

the back to the front of the printer, as shown in the figure.

2. Thread the free end of the paper under the top cover as shown.

3. Push the end of the paper forward until it engages the Paper Out sensor, located

under the center of the top cover.

4. Paper will feed automatically, and then print and eject a test ticket.

Cleaning the Print Head

Once the unit is opened, the paper path is accessible for cleaning or clearing paper.

Use a soft brush to clean the paper dust from inside the printer. The paper dust

should also be removed from the sensor optics. If streaking on the printed ticket is

evident, the thermal print head may need to be cleaned. This can be with a cotton

swab moistened with an alcohol solvent (ethanol, methanol, IPA).

Page 34 100-88002 Rev B

Page 47

Operational Procedures

Warning: After printing, the print head can be very hot. Be

careful not to touch it and let it cool down before you clean it.

Do not damage the print head by touching it with your fingers or

any hard object.

100-88002 Rev B Page 35

Page 48

Page 49

Chapter 4

Configuring Your Epic 880TM Printer

100-88002 Rev B Page 37

Page 50

This page intentionally left blank

Page 38 100-88002 Rev B

Page 51

Configuring Your Epic 880TM Printer

Configuration Mode Overview

There are two ways to configure the Epic 880TM printer: the first is to use the manual

configuration sequence by using the CONFIG and FEED key, and the second is to

use TransAct’s remote configuration software. TransAct Technologies offers the use

of a remote CONFIG program as a fast, easy way for system integrators to configure

or reconfigure your Epic 880

TM

printer. To obtain more information, or the latest

version of the CONFIG program, call TransAct’s Sales Department or Technical

Support.

Most Frequent Configuration Incompatibilities

• Emulation

• RS-232 Serial Interface (baud rate)

How to Change Configuration Settings

Entering into Configuration Mode

1) Press the CONFIG

2) Select configuration mode.

3) Follow the printed instructions.

• Press and hold the FEED button for the next option.

• Press and Release the FEED button to change the option.

• Power cycle to exit without changing.

• Press CONFIG to save and Exit

After you enter Configuration Mode, the printer will print the current configuration, the

current totals and the error logs, if any. Save this printout as a guide to changing the

configuration. It’s also useful in case you wish to return the printer to the previous

configuration.

Each emulation may have different configurable features. If you are changing the

emulation, note that the printout that was printed at the beginning of the configuration

process may be incorrect for the new emulation, and the configurable features may be

different. If you are using this printout as a configuration guide, and you are changing

the emulation, you may wish to save the new emulation and then re-enter

Configuration Mode to change other options. This will print all the available features

for the new emulation.

4

button for approximately 4 seconds.

4 The CONFIG button is a multifunction button. By pressing and releasing the CONFIG

button, the printer will enter self test. By pressing and holding the CONFIG button for a longer

time, two additional features may be activated: pressing and holding the button for about two

seconds will enter hex dump mode, and holding the button for about 4 seconds will enter

configuration mode. To aid in selecting the correct mode, the Error LED will illuminate as soon

as the button is pressed and indicate that self test is selected. After about 2 seconds the Error

LED will go out and the PAPER indicator will illuminate, indicating that hex dump is selected.

After about 4 seconds, the Cover LED will illuminate, indicating that configuration mode is

selected.

100-88002 Rev B Page 39

Page 52

Configuring Your Epic 880

gy

Setting up for Color Paper

The Epic 880

quality, the printer should be configured to print the paper being used. If the paper you

are using is included in the list of papers displayed during printer configuration, that

configuration should be used. If not, the printer should be set to Generic Color. If this

does not produce acceptable print quality, you may select Custom Color.

Custom Color

When using Custom Color, start with a read setting of about 0.12 mJ/sq.mm and a

black energy of 0.24 mJ/sq.mm. First, adjust the black level to produce acceptable

black print.

TM

Printer

TM

may be configured to print two color thermal paper. For good print

DO NOT EXCEED 0.40 mJ/sq.mm, or the paper may start to

stick to the print head and cause paper jams. Setting the Black

energy too high will also slow the printer down. All color papers

tested by TransAct will operate with black levels less than 0.35

mJ/sq.mm. When the Black energy is set, adjust the Color

value.

NEVER exceed the Black ener

with the Color energy.

The color level can be very critical. Do not attempt to

make the color darker by increasing the energy to the

point where black starts to appear, the print quality will

not be consistent.

Remote Configuration

Remote configuration is provided for all printers, and is accessed through a series of

extended diagnostic and configuration commands. The TransAct

®

universal

configuration program will allow the configuration to be read, edited, and written back

to the printer. It will also allow the configuration of one printer to be recorded and

replicated over a number of printers. The program is available from TransAct

Technical Support or by downloading it from the Internet – consult the section On-line

Technical Support for further details.

Remote Boot Load

The Epic 880

field updates of the printer’s firmware. This loader is started by command and then a

TransAct

successfully received by the remote boot loader, the printer will automatically reset

and operate with the updated code. If the firmware update fails for any reason, the

printer will remain in Remote Boot load mode until a successful load is accomplished.

TM

printer is equipped with a special boot loader feature that will allow

®

firmware load image is sent to the printer. When the load image is

Page 40 100-88002 Rev B

Page 53

Configuring Your Epic 880TM Printer

Field Configuration Feature

A field configuration feature allows easy setup and configuration of your Epic 880

printer. This feature provides a one-time prompt, on initial power-up, that lets you

select from a number of configurations that are pre-loaded for you at the factory.

This feature is an option, and must be set up and activated by TransAct. It stores a

specified number of complete, commonly-used configurations in the printer, together

with a text description and configuration summary.

Using Field Configuration

When the FEED button is pressed for over 6 seconds, the printer will either enter field

configuration mode or comprehensive configuration mode, depending on whether the

field configuration feature is present.

The initial print out will be as shown in Figure 7:

There are x

stored configurations

to select from.

Press and release FEED