Page 1

Register your instrument!

www.eppendorf.com/myeppendorf

Top Buret

Operating manual

™

Page 2

Copyright

©

2013 Eppendorf AG, Hamburg. No part of this publication may be

reproduced without the prior permission of the copyright owner.

Eppendorf and the Eppendorf logo are a registered trademark of Eppendorf AG.

®

Trademarks are not marked in all cases with ™ or

in this manual.

4965 900.018-03/032013

Page 3

Table of contents

Top Bu ret

English (EN)

Operating manual Top Buret™seeon p.Fig.Tab.p.

English (EN)Operating manual

Table of contents

1 Operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Using this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Danger symbols and danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.1 Danger symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2.2 Danger levels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Symbols used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4 Abbreviations used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 Main illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2.2 Delivery package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.4 Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3.2 User profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3.3 Warnings for intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.4 Information on product liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

™

3

4 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.1 Mounting the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

4.2 Inserting the batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.3 Mounting the telescopic aspirating tube . . . . . . . . . . . . . . . . . . . . . 18

4.3.1 Extending the telescopic aspirating tube . . . . . . . . . . . . . . 18

4.3.2 Shortening the telescopic aspirating tube . . . . . . . . . . . . . 18

4.3.3 Mounting the telescopic aspirating tube . . . . . . . . . . . . . .19

4.4 Mounting the Top Buret on the bottle . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Connecting the drying tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.1 Dispensing settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.2 Deairing the Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

5.3 Titrating liquid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

5.4 Changing the supply bottles during titration . . . . . . . . . . . . . . . . . .25

5.5 Removing the bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

5.6 Emptying the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Page 4

Table of contents

4

Top Buret

English (EN)

™

6 Calibration and adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

6.1 Calibrating the Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.1 Measuring the testing volume . . . . . . . . . . . . . . . . . . . . . . 27

6.1.2 Calculating the error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1.3 Evaluating the calibration . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.2 Adjusting the Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

6.2.1 Adjustment to distilled water . . . . . . . . . . . . . . . . . . . . . . .29

6.2.2 Adjustment to a liquid with a different density. . . . . . . . . . 29

6.3 Resetting the Top Buret to the factory settings . . . . . . . . . . . . . . . .30

7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

8 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.1 Cleaning the Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.1.1 Standard cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8.1.2 Intensive cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

8.2 Disassembling the Top Buret . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

8.3 Replacing the batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

9 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.1 Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.2 Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

9.3 Parameters for titratable media . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.4 Conditions for calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

10 Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.1 Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

10.2 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

10.3 Threaded adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

11 Transport, storage and disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

11.1 Transport. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

11.2 Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

11.3 Disposal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

12 Measurement report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Page 5

Operating instructions

Top Bu ret

English (EN)

1 Operating instructions

1.1 Using this manual

Read this operating manual completely before using the device for the first

time. Please also note the operating instructions for the accessories, if

applicable.

This operating manual is part of the product. Thus, it must always be easily

accessible.

Enclose this operating manual when transferring the device to third parties.

1.2 Danger symbols and danger levels

The safety instructions in this manual appear with the following danger symbols

and danger levels:

1.2.1 Danger symbols

Biohazard Explosion

Tox ic subst ances Hazard point

™

5

Material damage

1.2.2 Danger levels

DANGER Will lead to severe injuries or death.

WARN ING May lead to severe injuries or death.

CAUTION May lead to light to moderate injuries.

NOTICE May lead to material damage.

Page 6

Operating instructions

6

Top Buret

English (EN)

™

1.3 Symbols used

Symbol Meaning

Handling

1.

Actions in the specified order

2.

• List

Text Name of fields in the software

Useful information

1.4 Abbreviations used

ETFE

Ethylene-tetrafluoroethylene copolymer

FEP

Tetrafluoroethylene-perfluoropropylene copolymer

FKM

Fluororubber

PFA

Perfluoroalkoxy copolymer

PP

Polypropylene

PTFE

Polytetrafluorethylene

PVDF

Polyvinylidene fluoride

Page 7

2 Product description

Start

Pause

ml

Calibrate

Reset

Top Buret M

1

5

4

3

2

8

7

6

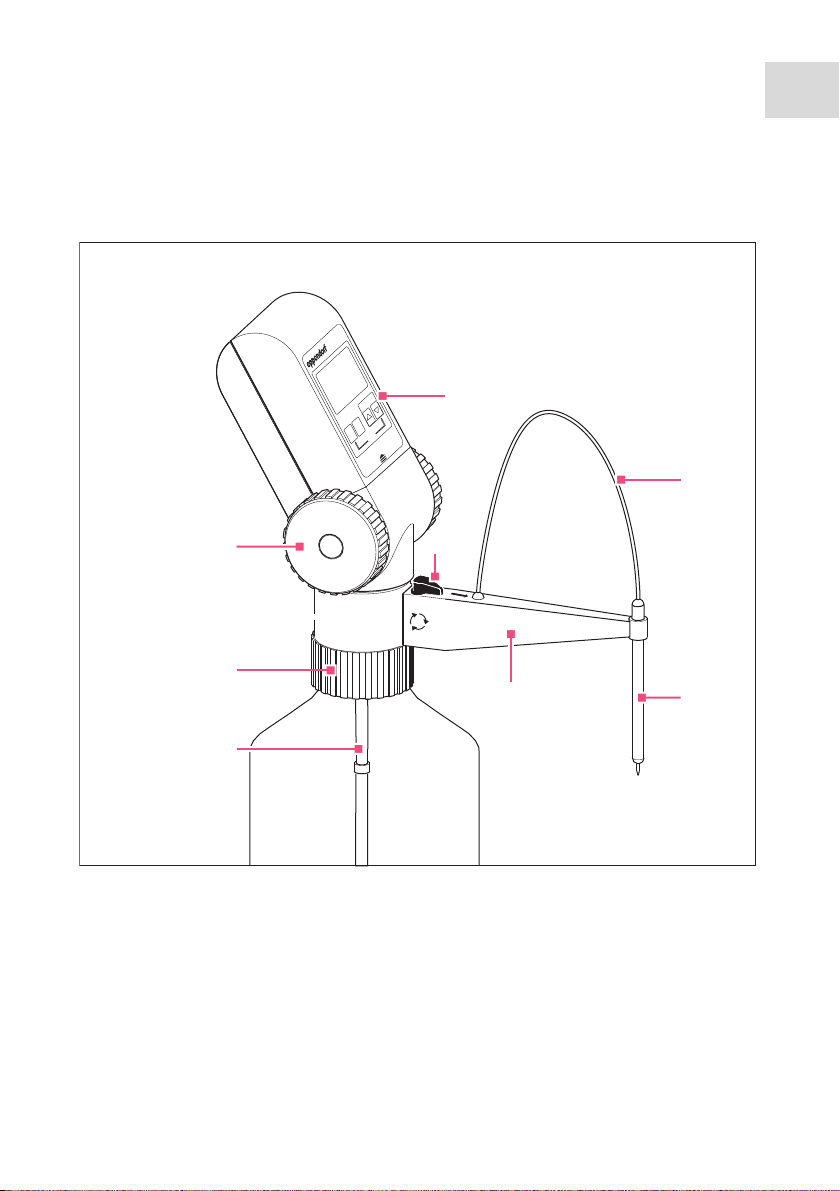

2.1 Main illustration

Abb. 2-1: Top Buret M/H

Product description

Top Bu ret

English (EN)

™

7

Fig. 2-1: Top Buret M/H

1 Control panel

2 Discharge tube

3 Canula holder

4 Canula arm

5 Discharge valve toggle

6 Telescopic aspirating tube

7 Bottle thread

8 Dispensing wheels

Page 8

Product description

Top Buret H

1

2

3

7

8

9

6

5

4

8

Top Buret

English (EN)

Abb. 2-2: Operating controls

™

Fig. 2-2: Operating controls

1Calibration mode

2Volume display

3Arrow keys

4 Opening symbol

5Start key

6Pause key

7 Battery flat symbol

8 Titration mode symbol

9 Pause symbol

Page 9

2.2 Delivery package

Number Description

1 Eppendorf Top Buret M 25 mL

or Eppendorf Top Buret H 50 mL

1 Canula arm

1 Discharge tube with knurled nut

1 Canula holder

1 Telescopic aspirating tube

1 Bottle thread adapter

From GL 45 to S 40 (buttress thread), PP

From GL 45 to GL 38, PP

From GL 38 to GL 32, PP

1 Battery

LR03/AAA, 1.5 V, set of 2

1 Eppendorf Top Buret M/H operating manual

2.3 Features

Product description

Top Bu ret

English (EN)

™

9

The Top Buret is a bottle-top buret which features a continuous, pulse-free

dispensing technique. The Top Buret can dispense volumes between 10 μL and

999.9 mL at a maximum concentration of 1 mol/L.

When the dispensing wheels are fully rotated, the following volumes are

dispensed:

• Top Buret M: 2.5 mL

• Top Buret H: 5.0 mL

The Top Buret has two dispensing settings. The dispensing settings are set with

the toggle on the canula arm.

• Titration

Titrate liquid from the bottle to a destination vessel.

• Deairing

Rinse liquid through the discharge valve into the bottle, e.g., to remove air

bubbles.

Page 10

Product description

10

Top Buret

English (EN)

™

2.4 Materials

NOTICE! Aggressive substances may damage the Top Buret and

accessories.

Check the chemical resistance before using organic solvents or

aggressive chemicals.

Follow the cleaning instructions.

The assembly parts of the Top Buret consist of the following materials:

Assembly parts that come into

contact with liquid

• Borosilicate glass 3.3 (Boro 3.3)

• Ethylene-tetrafluoroethylene

copolymer (ETFE)

• Perfluoroalkoxy copolymer (PFA)

• Tetrafluoroethylene-

perfluoropropylene copolymer (FEP)

• Platinum iridium (Pt-Ir)

• Polytetraflourethylene (PTFE)

Assembly parts that do not come into

contact with liquid

• Stainless steel

• Fluororubber (FKM)

•Polyester

•Polypropylene (PP)

• Polyvinylidene fluoride (PVDF)

• Polyamide (PA)

• Polyoxymethylene (POM)

• Polyphenylene sulfide (PPS)

Page 11

Safety

Top Bu ret

English (EN)

3 Safety

3.1 Intended use

The Top Buret is a laboratory device for dispensing aqueous solutions in a

volume range between 10 μL and 999.9 mL. Applications in or on the human

body (in vivo applications) are not permitted.

The device must not be exposed to an aggressive atmosphere, e.g., HCI vapors.

The device must not be autoclaved.

The device is intended for dispensing liquids with the following properties:

• Maximum concentration: 1 mol/L

• Maximum density: 2.2 g/cm

• Maximum vapor pressure: 50 kPa

The following reagents must not be titrated with the device:

• Liquids which attack PFA, ETFE, PTFE, Boro 3.3 or FEP

• Solutions containing hydrofluoric acid, since they attack borosilicate glass

• Unstable substances because they react catalytically with platiniridium, e.g.,

hydrogen peroxide

• Solutions prone to crystallization

• Suspensions containing solid particles

• Fuming acids or highly concentrated alkaline solutions

• Solutions which decompose and form solid particles, e.g., Biuret reagent

• Carbon disulfide, as it is highly flammable

3

™

11

The Top Buret is suitable for dispensing the following titration solutions up

to a concentration of 1 mol/L:

• Ammonium iron(II) sulfate solution

• Ammonium thiocyanate solution

• Barium chloride solution

• Bromid bromate solution

• Cerium(IV) sulfate solution

• EDTA solution

• Iron(II) sulfate solution

• Acetic acid

Page 12

Safety

12

Top Buret

English (EN)

™

• Iodine solution

• Caustic potash solution

• Potassium bromate solution

• Potassium bromide bromate solution

• Potassium dichromate solution

• Potassium iodate solution

• Potassium permanganate solution

• Potassium thiocyanate solution

• Sodium arsenite solution

• Sodium carbonate solution

• Sodium chloride solution

• Sodium nitrite solution

• Sodium thiosulfate solution

• Caustic soda

•Oxalic acid

•Perchloric acid

• Nitric acid

•Hydrochloric acid

•Sulfuric acid

•Silver nitrate solution

• Tetra-n-butylammonium hydroxide solution

• Zinc sulfate solution

Refer to the information provided by the reagent manufacturers. If you have any

questions, contact Eppendorf Service.

3.2 User profile

The device and accessories may only be operated by trained and skilled

personnel.

Before using the device, read the operating manual carefully and familiarize

yourself with the device's mode of operation.

Page 13

3.3 Warnings for intended use

DANGER! Risk of explosion.

Do not operate the device in areas where work is completed with

explosive substances.

Do not use this device to process any explosive or highly reactive

substances.

Do not use this device for processing any substances which could

generate an explosive atmosphere.

WARNING! Damages to health due to infectious liquids and

pathogenic germs.

When handling infectious liquids and pathogenic germs, observe the

national regulations, the biological security level of your laboratory,

the material safety data sheets, and the manufacturer's application

notes.

Wear personal protective equipment.

Consult the "Laboratory Biosafety Manual" (Source: World Health

Organization, Laboratory Biosafety Manual, as amended) for

comprehensive regulations on the handling of risk group II germs or

biological materials).

Safety

Top Bu ret

English (EN)

™

13

WARNING! Damage to health due to toxic, radioactive or aggressive

chemicals.

Wear personal protective equipment.

Observe the national regulations for handling these substances.

Observe the material safety data sheets and manufacturer's

application notes.

Page 14

Safety

14

Top Buret

English (EN)

™

CAUTION! Contamination from biological or chemical substances.

Only initiate dispensing if it is safe to do so.

Do not place people in danger during dispensing.

Turn the dispensing wheels slowly and evenly to prevent spraying.

Never point the opening of the discharge tube toward people.

CAUTION! Poor safety due to incorrect accessories and spare parts.

The use of accessories and spare parts other than those recommended

by Eppendorf may impair the safety, functioning and precision of the

device. Eppendorf cannot be held liable or accept any liability for

damage resulting from the use of incorrect or non-recommended

accessories and spare parts, or from the improper use of such

equipment.

Only use accessories and original spare parts recommended by

Eppendorf.

NOTICE! Damage to the device due to autoclaving.

Do not autoclave the device.

3.4 Information on product liability

In the following cases, the designated protection of the device may be

compromised. Liability for any resulting property damage or personal injury is

then transferred to the operator:

• The device is not used in accordance with the operating manual.

• The device is used outside of its intended use.

• The device is used with accessories or consumables which are not

recommended by Eppendorf.

• The device is maintained or repaired by people not authorized by Eppendorf.

• The user makes unauthorized changes to the device.

Page 15

4 Installation

Top Buret H

2

1

14

13

10

11

12

8

9

7

5

6

3

4

4.1 Mounting the device

Abb. 4-1: Top Buret

Installation

Top Bu ret

English (EN)

™

15

Fig. 4-1: Top Buret

1 Control panel

2 Discharge tube

3 Canula holder

4 Canula arm

5 Knurled nut

6 Discharge valve toggle

7Discharge valve

8 Recirculation tube

9 Telescopic aspirating tube

10 connection opening

11 Bottle thread

12 Valve head

13 Air vent cover

14 Dispensing wheels

Page 16

Installation

16

Top Buret

English (EN)

™

To assemble the device, proceed as follows:

1. Rotate the discharge valve toggle to

the deairing position. Remove the

toggle upwards.

2. The canula holder has gripping nubs

on the inside for the canula at one

end. Insert the canula holder into

the canula arm mount ensuring that

the gripping nubs are below.

3. Guide the free end of the discharge

tube through the hole in the canula

arm from below.

4. Insert the free end of the discharge

tube into the canula holder from

above until it protrudes slightly at

the bottom.

5. Screw the discharge tube with the

knurled nut onto the discharge

valve.

Page 17

Installation

Top Bu ret

English (EN)

6. Slide the canula arm over the

discharge valve from above up to the

stop.

7. Attach the discharge valve toggle.

™

17

4.2 Inserting the batteries

NOTICE! Damage to the battery compartment due to inserting the

batteries incorrectly.

Observe the correct polarity of the batteries.

Do not use force.

The display automatically switches on when the batteries are inserted. If

the device is not used, the display will switch off after about 5 minutes.

Page 18

Installation

18

Top Buret

™

English (EN)

Proceed as follows:

Abb. 4-2: Removing the control panel

1. Press and hold the opening symbol.

2. Slide the control panel upwards and

remove it.

ml

Calibrate

Pause

Start

Reset

Top Buret M

3. Remove the battery compartment lid

at the back of the control panel.

4. Insert the batteries.

5. Replace the battery compartment

lid.

6. Attach the control panel and slide it

downwards until it engages.

Fig. 4-2: Removing the control panel

To remove the batteries, proceed in the reverse order.

4.3 Mounting the telescopic aspirating tube

The Top Buret conveys the liquid through the telescopic aspirating tube from the

supply bottle. Adjust the length of the telescopic aspirating tube to the bottle

height to empty the bottle completely.

4.3.1 Extending the telescopic aspirating tube

Prerequisites

• The device has been mounted (see p. 15)

• The bottle is larger than the collapsed telescopic aspirating tube

Proceed as follows:

Push the inner tube out of the outer tube until the tube length corresponds to

the length of the bottle.

4.3.2 Shortening the telescopic aspirating tube

Prerequisites

• The device has been mounted (see p. 15)

• The bottle is smaller than the collapsed telescopic aspirating tube

Page 19

Proceed as follows:

1. Push the inner tube completely out of the outer tube.

2. Shorten both tubes to the required length using a pair of scissors.

3. Insert the inner tube into the outer tube.

4.3.3 Mounting the telescopic aspirating tube

Installation

Top Bu ret

English (EN)

™

19

Abb. 4-3: Sliding the telescopic aspirating tube onto the connection opening

1. Slide the inner tube onto the

connection opening up to the stop.

2. Pull out the outer tube so that it

stops short of the bottom of the

bottle.

3. Cut the lower end of the outer tube

off at an angle.

Fig. 4-3: Sliding the telescopic

aspirating tube onto the

connection opening

4.4 Mounting the Top Buret on the bottle

CAUTION! Personal injury due to incorrect transportation of buret.

If the mounted buret is not transported properly, reagents may be

released. Contact with reagents may be harmful to eyes or skin.

To transport the mounted buret, grasp the buret with one hand and

the bottle with the other hand.

Do not hold the buret by the housing.

Page 20

Installation

20

Top Buret

English (EN)

™

CAUTION! Personal injury due to contact with reagents.

Contact with reagents may be harmful to eyes or skin.

Wear personal protective equipment.

Make sure that no reagents are leaking from the buret.

The Top Buret can be directly screwed onto bottles with a GL 45 thread. The

adapters from the delivery package (see p. 9) and the accessories available for

ordering (see p. 37) allow the use on bottles with other threads.

Prerequisites

• The device has been mounted (see p. 15)

• The telescopic aspirating tube has been attached (see p. 18)

• The length of the telescopic aspirating tube has been adjusted to the length of

the bottle.

Proceed as follows:

Abb. 4-4: Screwing the Top Buret onto the bottle

Fig. 4-4: Screwing the Top Buret

onto the bottle

1. If the bottle has a different thread to

the Top Buret, use the appropriate

adapter.

2. Rotate the discharge valve toggle to

deairing.

3. Attach the Top Buret onto the bottle

from above.

4. If necessary, correct the length of

the telescopic aspirating tube.

5. Screw the Top Buret onto the bottle.

Page 21

Installation

Top Bu ret

English (EN)

4.5 Connecting the drying tube

For the titration of hygroscopic liquids you need a drying tube. The drying tube

must be filled with suitable liquid absorbers.

The drying tube is not included in the delivery package. You can order the

drying tube as an accessory.

Suitable liquid absorbers:

• Silica gel with a particle size of 1 mm – 3 mm

•CaCO

• NaOH pills (5 mm ø, for the absorption of CO2)

Prerequisites

• The batteries have been inserted (see p. 17)

• The device has been mounted (see p. 15)

• The telescopic aspirating tube has been mounted (see p. 18)

• The device has been screwed onto a bottle (see p. 19)

Proceed as follows:

2

™

21

Abb. 4-5: Removing the air vent cover

Fig. 4-5: Removing the air vent cover

1. Remove the air vent cover.

2. Insert the drying tube into the

opening.

3. Fill the drying tube with moisture

absorber.

Page 22

Operation

22

Top Buret

English (EN)

™

5 Operation

5.1 Dispensing settings

The Top Buret has two dispensing settings. The dispensing settings are set with

the toggle on the canula arm.

1. Titration

Symbol for the toggle setting:

Titrate liquid from the bottle to a

destination vessel.

2. Deairing

Symbol for the toggle setting:

Rinse liquid through the discharge

valve back into the bottle, e.g., to

remove air bubbles.

Page 23

Operation

Top Bu ret

English (EN)

5.2 Deairing the Top Buret

CAUTION! Personal injury due to contact with reagents.

Contact with reagents may be harmful to eyes or skin.

Wear personal protective equipment.

Do not point the discharge tube at people.

Air bubbles in the supply lines and in the feeding mechanics will distort the

measuring results.

Deair the Top Buret in the following situations:

• Prior to initial operation

• After intensive cleaning

• After changing the bottle

• After a long period of inactivity

Proceed as follows:

Prerequisites

• The device has been completely mounted.

™

23

Abb. 5-1: Deairing the int erior system

Fig. 5-1: Deairing the interior system

1. Rotate the discharge valve toggle to

deairing.

2. Remove the control panel.

3. Rotate the dispensing wheels slowly

and evenly forward until there is no

more air left in the system.

Page 24

Operation

24

Top Buret

English (EN)

™

Abb. 5-2: Deairing the discharge tube

Fig. 5-2: Deairing the discharge tube

5.3 Titrating liquid

If you rotate the dispensing wheels backwards, they do not engage. No

dispensing of liquid is performed and no volume is counted.

If the Top Buret is not used, the display will switch off after 5 minutes.

The titrated volume is stored until the next titration.

Proceed as follows:

Abb. 5-3: Titration by rotating the dispensing wheel

Fig. 5-3: Titration by rotating the

dispensing wheel

4. Rotate the discharge valve toggle to

titration.

5. Place a collection vessel below the

canula.

6. Rotate the dispensing wheels

forward until liquid emerges from

the opening of the discharge tube.

7. Attach the control panel.

8. Wipe any chemical residues from

the discharge tube.

1. To switch on the display, press the

Start key.

The display shows either 0.00 or the

volume of the last titration.

2. Press the Start key to set the volume

display to 0.00.

3. Pull out the canula arm to the

desired length.

4. Hold a collection vessel below the

discharge tube.

5. Rotate the discharge valve toggle to

titration.

Page 25

Operation

Top Bu ret

English (EN)

6. Press the Start key to set the volume display to 0.00.

7. Pull out the canula arm to the desired length.

8. Hold a collection vessel below the discharge tube.

9. Rotate the discharge valve toggle to titration.

10.Rotate the dispensing wheels forward to dispense liquid.

11.To end titration, rotate the discharge valve toggle to deairing.

12.To avoid the dispensing of liquid from the discharge tube, set the valve toggle

to recirculation.

5.4 Changing the supply bottles during titration

You can change the supply bottles during a titration sequence without changing

the displayed volume.

Proceed as follows:

1. Press the Pause key.

On the display, the Stop symbol appears. The titrated value is stored.

2. Remove the bottle (see p. 26).

3. Mount the new bottle (see p. 19).

4. Deair the device (see p. 23).

5. Press the Pause key again.

The display is enabled. The display shows the stored value and the titration

symbol .

6. Continue titration.

™

25

Page 26

Operation

26

Top Buret

English (EN)

™

5.5 Removing the bottle

Abb. 5-4: Emptying the telescopic aspirating tube

Fig. 5-4: Emptying the telescopic

aspirating tube

5.6 Emptying the device

1. Rotate the discharge valve toggle to

deairing.

2. Place the Top Buret with bottle into

a suitable collecting vessel.

3. Unscrew the device from the bottle

in a counterclockwise direction.

4. Lift the Top Buret until the

telescopic aspirating tube is no

longer immersed in the liquid.

5. Gently tap the telescopic aspirating

tube against the inside of the bottle.

The residual liquid from the

telescopic aspirating tube runs into

the bottle.

Before changing the liquid and before cleaning, the Top Buret must be emptied.

Proceed as follows:

Prerequisites

• The bottle has been unscrewed (see p. 26)

1. Mount the Top Buret onto an empty bottle.

2. Place a collection vessel below the canula.

3. Rotate the discharge valve toggle to titration.

4. Rotate the dispensing wheels forward until no more liquid runs out of the

discharge tube.

5. Rotate the discharge valve toggle to deairing.

6. Rotate the dispensing wheels forward until no more liquid runs out of the

recirculation tube.

To remove the reagents completely, clean the device.

Page 27

Calibration and adjustment

V = 1/n Vi

∑

n

i = 1

Top Bu ret

English (EN)

6 Calibration and adjustment

6.1 Calibrating the Top Buret

The Top Buret has been calibrated with distilled or deionized water. You can

carry out a gravimetric test of the Top Buret error. The procedure is described in

detail in DIN EN ISO 8655.6.

You need the following auxiliary equipment:

• Distilled water

• Calibrated analytical balance

• Beaker

6.1.1 Measuring the testing volume

Prerequisites

• The device and auxiliary equipment must have the same temperature (20 °C –

25 °C, ±0.5 °C).

Proceed as follows:

1. Set up the calibrated analytical balance at a vibration and draft-free location.

2. Place a beaker on the balance.

3. With the Top Buret M, titrate 25 mL of distilled water into the beaker and

record the weight.

4. Repeat step 3 10 times.

5. With the Top Buret H, titrate 50 mL of distilled water into the beaker and

record the weight.

6. Repeat step 5 10 times.

™

27

6.1.2 Calculating the error

1. Calculate the volume of the water.

2. Calculate the average value of the volumes.

Density of water (ρ) at 16 °C – 21 °C = 0.998 g/mL

Density of water (ρ) at 22 °C – 25 °C = 0.997 g/mL

V =

m

ρ

Page 28

Calibration and adjustment

V

V

(Vi – V)

∑

n

i = 1

n – 1

sr =

V

100 × s

r

CV =

28

Top Buret

English (EN)

™

3. Calculate the inaccuracy (e

(Vs).

) using the nominal volume

s

V – V

es = × 100 %

s

V

s

• = actual volume (average value of the weighings)

= nominal volume (Top Buret M = 25 mL, Top Buret H

•V

s

= 50 mL)

4. Calculate the standard deviation (s

).

r

•sr = standard deviation

• n = number of dispensing steps

= measured value (weight of the sample)

•V

i

• = actual volume (average value of the weighings)

5. Calculate the imprecision (CV).

6.1.3 Evaluating the calibration

1. Compare the results for inaccuracy and imprecision with table (see p. 36).

2. If the errors are within the tolerance range specified in the table, no

adjustment is necessary.

3. If the errors are outside the tolerance range, adjust the device or contact a

service technician.

6.2 Adjusting the Top Buret

The Top Buret has been calibrated and adjusted before delivery. Adjust the Top

Buret in the following situations:

• The calibration error with distilled water is outside the tolerance range

• The density of the titrated liquid differs from the density of distilled water

Calibration is only possible with a testing volume between 10 mL – 90 mL.

Page 29

Calibration and adjustment

Top Bu ret

English (EN)

™

29

If the testing volume is < 10 mL,

the display shows:

If the testing volume is > 90 mL, the display

shows:

To display the set adjustment value, either press the or arrow key

in titration mode. After you release the key, the display automatically

returns to the last volume display.

6.2.1 Adjustment to distilled water

Proceed as follows:

1. Carry out the measurement of the testing volumes and calculate the average

value of the volumes (see Calibrating the Top Buret on p. 27).

2. Use the average value of the volumes that you have obtained from the

calibration.

3. Press the Pause key.

The volume is saved.

4. Press and hold the and arrow keys at the same time for 3 seconds.

The display shows CAL at the top right

5. Set the calculated average value of the volumes using the and arrow

keys.

6. Press the Start key.

• The set value is accepted

• The display is reset to zero

• The adjustment is ended

• The display shows C at the top right. The display indicates that the factory

settings have been changed.

6.2.2 Adjustment to a liquid with a different density

1. Set up the calibrated analytical balance at a vibration and draft-free location.

2. Place a beaker on the balance.

Page 30

Calibration and adjustment

V =

ρ

m

V = 1/n Vi

∑

n

i = 1

30

Top Buret

English (EN)

™

3. With the Top Buret M, titrate 25 mL of the test liquid into the beaker and

record the weight.

4. Repeat step 3 10 times.

5. With the Top Buret H, titrate 50 mL of the test liquid into the beaker and

record the weight.

6. Repeat step 5 10 times.

7. Calculate the volume of the standard solution.

8. Calculate the average value of the volumes.

9. Press the Pause key.

The volume is saved.

10.Press and hold the and arrow keys at the same time for 3 seconds.

The display shows CAL at the top right

11.Set the calculated average value of the volumes using the and arrow

keys.

12.Press the Start key.

• The set value is accepted

• The display is reset to zero

• The adjustment is ended

• The display shows C at the top right. The display indicates that the factory

settings have been changed.

6.3 Resetting the Top Buret to the factory settings

The reset function is used to restore the factory settings. If you have adjusted the

device, the display will show a C. When you restore the factory settings again,

the C will disappear.

1. Press the Start key to switch on the Top Buret.

2. Press and hold the Start and keys at the same time for 3 seconds to activate

•The display C disappears.

• The factory settings have been restored.

the reset function.

Page 31

7 Troubleshooting

7.1 Troubleshooting

Symptom/message Cause Remedy

• Air is aspirated.

•The titrated liquid

contains air bubbles.

Liquid is not aspirated. • The connection

The titration volume is

too small.

The display shows the

symbol.

• The device was not

sufficiently deaired.

•The telescopic

aspirating tube has

not been mounted

completely.

•The telescopic

aspirating tube is

damaged.

•The telescopic

aspirating tube does

not immerse into the

liquid.

•The connection

opening is damaged.

opening is clogged.

•The telescopic

aspirating tube has

not been mounted

completely.

•The telescopic

aspirating tube is

damaged.

• The device is

incorrectly adjusted.

•The connection

opening is damaged.

• The batteries are flat.

Deair the device

(see p. 23).

Slide the telescopic

aspirating tube firmly onto

the connection opening

(see p. 18).

Shorten the telescopic

aspirating tube or replace

it.(see p. 18).

Lengthen the telescopic

aspirating tube until it is

immersed in the liquid

(see p. 18).

Send in the device for repair.

Clean the device

(see p. 32).

Slide the telescopic

aspirating tube firmly onto

the connection opening (see

p. 18).

Shorten the telescopic

aspirating tube or replace it

(see p. 18).

Set the device to the factory

adjustment (see p. 30).

Send in the device for repair.

Replace the batteries.

Troubleshooting

Top Bu ret

English (EN)

™

31

Page 32

Maintenance

32

Top Buret

English (EN)

™

8 Maintenance

8.1 Cleaning the Top Buret

CAUTION! Personal injury due to contact with reagents during

cleaning.

The feeding mechanics, valves, telescopic aspirating tube and discharge

tube are filled with reagents. Reagents enter the bottle with the cleaning

solution.

Wear personal protective equipment.

Discard the cleaning solution after cleaning.

The feeding mechanics consists of tubing and the valves inside the

housing. These parts may become heavily contaminated. These parts

may only be cleaned by authorized personnel. If the feeding mechanics

need to be cleaned, contact Eppendorf Service.

Replace the discharge tube when it is heavily contaminated or damaged.

To disinfect the Top Buret, clean the buret with a suitable disinfectant,

e.g., 70% ethanol.

Clean the Top Buret in the following situations:

• Prior to changing the reagent

• Prior to storage

• Prior to maintenance and repair work

• Daily after use with solutions prone to crystallization or highly concentrated

alkaline solutions

• The dispensing wheels are hard to turn

• The device is heavily contaminated.

Page 33

Maintenance

Top Bu ret

English (EN)

8.1.1 Standard cleaning

Prerequisites

• The Top Buret has been emptied (see p. 26).

Proceed as follows:

1. Mount the Top Buret onto a bottle filled with a neutral cleaning solution.

2. Place a collection vessel below the discharge tube.

3. Switch the toggle to titration.

4. Rotate the dispensing wheels at least 10 times slowly and evenly forward.

5. Switch the toggle to deairing.

6. Rotate the dispensing wheels at least 10 times slowly and evenly forward.

7. Remove the device from the bottle.

8. To evacuate the Top Buret, rotate the dispensing wheels.

9. Screw the Top Buret onto a bottle filled with distilled water.

10.Repeat steps 2 to 6.

11.Remove the Top Buret from the bottle.

12.Rotate the dispensing wheels until the Top Buret is completely emptied.

8.1.2 Intensive cleaning

™

33

We recommend performing intensive cleaning in the following situations:

• The device is heavily contaminated.

• The dispensing wheels are hard to turn.

• After titration of highly crystalline liquid.

Prerequisites

• The device has been cleaned according to the standard procedure (see p. 33).

• The device has been disassembled (see p. 34).

Proceed as follows:

1. Clean the telescopic aspirating tube with a soft bottle brush.

2. Clean all parts with a soft brush and a mild cleaning agent.

3. Wipe the housing without the control panel with a damp cloth and a mild

cleaning agent.

4. Rinse all parts with distilled water.

Page 34

Maintenance

34

Top Buret

English (EN)

™

5. Allow all assembly parts to dry.

6. Reassemble the Top Buret.

Carry out assembly in the reverse order to disassembly (see p. 34).

7. Using distilled water, check that the device is not leaking and that the device

is functioning correctly.

8. Calibrate the Top Buret. (see p. 27).

8.2 Disassembling the Top Buret

When disassembling the canula arm, be careful not to bend the

discharge tube.

Prerequisites

• The Top Buret has been cleaned according to the standard procedure (see

p. 33).

Proceed as follows:

Abb. 8-1: Removing the recirculation tube from the valve head

1. Unscrew the Top Buret from the

bottle in a counterclockwise

direction.

2. Remove the telescopic aspirating

tube from the connection opening.

3. Remove the recirculation tube from

the front hole in the valve head.

4. Rotate the discharge valve toggle to

deairing and remove it upwards.

5. Remove the canula arm from the

grooves of the discharge valve from

above.

6. Unscrew the discharge tube knurled

Fig. 8-1: Removing the recirculation

tube from the valve head

nut from the discharge valve thread.

7. Remove the discharge tube from the

discharge valve.

8. Remove the discharge tube from the canula holder and canula arm.

9. Remove the canula holder from the canula arm.

10.Pull the discharge valve out of the valve head.

Page 35

Maintenance

Top Bu ret

English (EN)

8.3 Replacing the batteries

If the batteries are flat, the display will show the symbol .

Replace the batteries (see p. 17).

Dispose of the old batteries in an environmentally friendly manner (Tab. on

p. 39).

™

35

Page 36

Technical data

36

Top Buret

English (EN)

™

9 Technical data

9.1 Ambient conditions

Ambience Only for use in indoors.

Ambient temperature 15 °C – 40°C

Relative humidity 0 % – 90 %, non-condensing.

Atmospheric pressure Use up to a height of 2000 m

above sea level.

9.2 Errors

Model Testing volume Inaccuracy Imprecision

Top Buret M 25 mL ±0.2% ≤ 0.1 %

Top Buret H 50 mL ±0.2% ≤ 0.1 %

9.3 Parameters for titratable media

Medium temperature 15 °C – 40°C

Maximum density

Maximum vapor pressure 50 kPa

2.2 g/cm

3

9.4 Conditions for calibration

Test conditions and test evaluation in accordance with ISO 8655, part 6. Test

with analytical balance with evaporation protection, approved by the board of

weights and measures.

The errors were determined under the following conditions:

Liquid Water according to ISO 3696

Number of determinations 10

Ambient temperature 20 °C – 25°C ± 0.5 °C

Dispensing liquid Dispensing on the tube inner wall

Page 37

Ordering Information

10 Ordering Information

10.1 Devices

Order no. (International) Description

4965 000.017 Eppendorf Top Buret M 25 mL

4965 000.025 Eppendorf Top Buret H 50 mL

10.2 Spare parts

Order no. (International) Description

4965 612.004 Discharge tube with knurled nut

4965 611.008 Cannula holder

4965 616.000 Discharge valve with toggle

4960 805.009 Telescopic aspirating tube

4960 851.000 Drying tube without drying agent

4965 620.007 Air vent cover/filter connection

4965 625.009 Battery LR03/AAA, 1.5 V, 2 pieces

Top Bu ret

English (EN)

™

37

10.3 Threaded adapter

Order no. (International) Description

Bottle thread adapter

4960 800.040

4960 800.139

4960 800.058

4960 800.163

4960 800.155

4960 800.147

4960 800.082

4960 800.090

4960 800.104

4960 832.006

From GL 32 to GL 25, PP

From GL 32 to GL 27, PP

From GL 32 to GL 28, PP

From GL 38 to GL 32, PP

From GL 45 to GL 38, PP

From GL 45 to S 40 (Buttress thread), PP

From GL 32 to NS 19/26, PP

From GL 32 to NS 24/29, PP

From GL 32 to NS 29/32, PP

Thread adapter

for 5 L-jerrycan from 45 mm to 17/8" thread

Page 38

Transport, storage and disposal

38

Top Buret

English (EN)

™

11 Transport, storage and disposal

11.1 Transport

Decontamination before shipment

If you are shipping the device to the authorized Technical Service for repairs or

to your authorized dealer for disposal please note the following:

WARNING! Risk to health from contaminated device

Observe the notes on the decontamination certificate. You find it as a

PDF file on our website (www.eppendorf.com/decontamination

Decontaminate all the parts you would like to dispatch.

Include the fully completed decontamination certificate in the

package.

NOTICE! Damage as a result of incorrect packing.

Eppendorf AG is not liable for damage caused by improper packing.

The device may only be stored and transported in its original

packaging.

).

Tab. 11-1: Transport conditions

Air temperature Relative humidity Atmospheric pressure

General

transport

Air freight -20°C – 50°C 0 % – 90 %,

15 °C – 40°C 0 % – 90 %,

non-condensing.

non-condensing.

11.2 Storage

Air temperature Relative humidity Atmospheric pressure

Storage 15 °C – 40°C 0 % – 90 %,

non-condensing.

Up to a height of 2000 m

above sea level.

Up to a height of 12200 m

above sea level.

Up to a height of 2000 m

above sea level.

Page 39

Transport, storage and disposal

Top Bu ret

English (EN)

11.3 Disposal

In case the product is to be disposed of, the relevant legal regulations are to be

observed.

Information on the disposal of electrical and electronic devices in the

European Community:

Within the European Community, the disposal of electrical devices is regulated

by national regulations based on EU Directive 2002/96/EC pertaining to waste

electrical and electronic equipment (WEEE).

According to these regulations, any devices supplied after August 13, 2005, in

the business-to-business sphere, to which this product is assigned, may no

longer be disposed of in municipal or domestic waste. They are marked with the

following symbol to indicate this:

As disposal regulations may differ from country to country

within the EU, please contact your supplier if necessary.

™

39

WARNING! Risk of explosion and fire due to overheated

accumulators and batteries.

Do not heat accumulators and batteries to over 80 °C and do not

throw them into fires.

Disposing of accumulators and batteries

Do not dispose of accumulators and batteries as household

waste. Dispose of accumulators and batteries according to the

locally applicable legal regulations.

Page 40

Measurement report

40

Top Buret

English (EN)

™

12 Measurement report

Page 41

Page 42

Evaluate your manual

Give us your feedback.

www.eppendorf.com/manualfeedback

Your local distributor: www.eppendorf.com/worldwide

Eppendorf AG · Hamburg · Germany · Phone: +49 40 538 01-0

www.eppendorf.com

Loading...

Loading...