Page 1

Centrifuge 5702 / Centrifuge 5702 R /

Centrifuge 5702 RH

Page 2

1

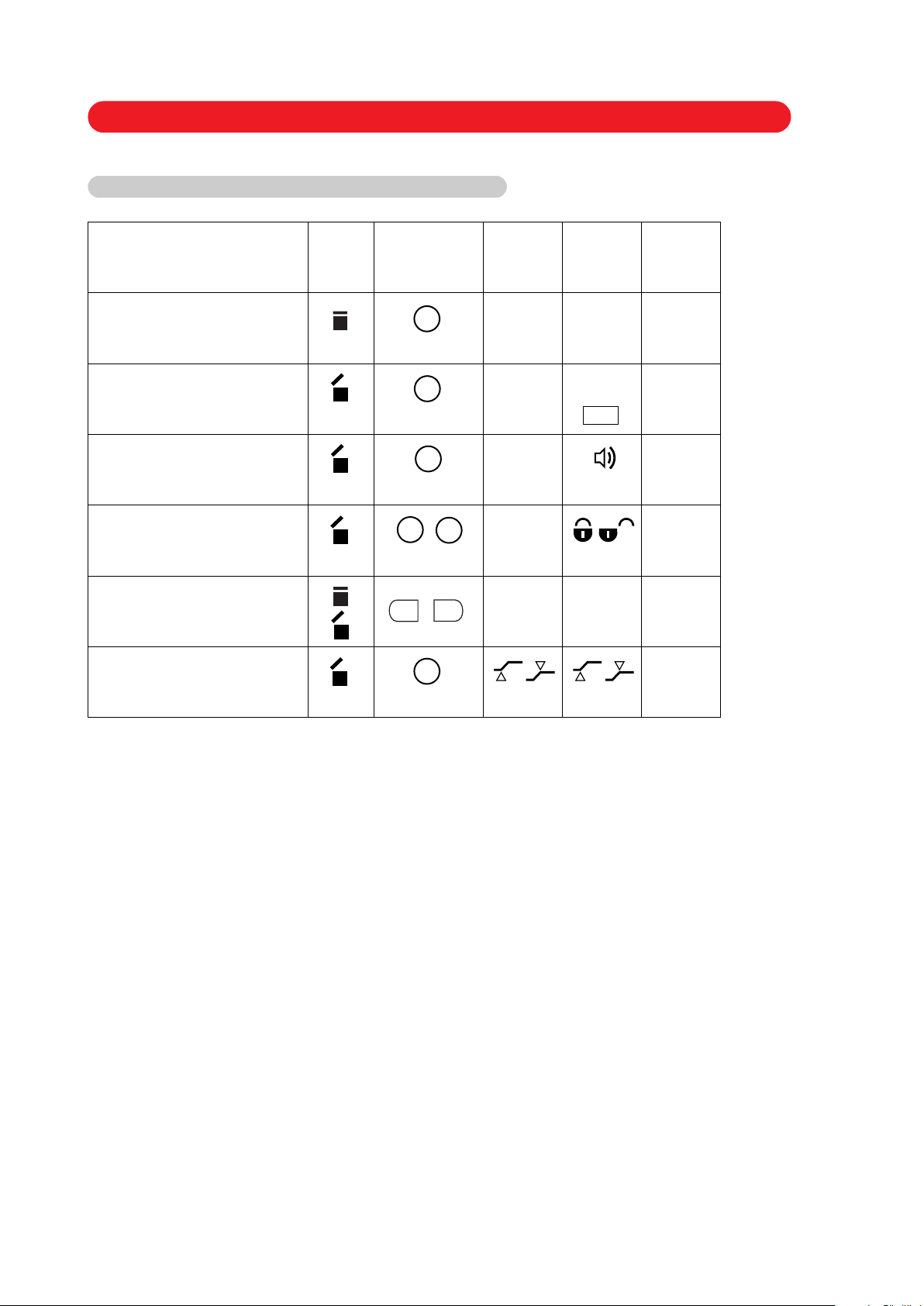

Centrifuge 5702 / 5702 R / 5702 RH

Tastenkürzel / Shortcuts

Task Lid Press

Parameter change

during centrifugation

closed

Brake

ON / OFF

open

Signal

ON / OFF

open

Parameter lock

ON / OFF

open

Program

(only Centrifuge 5702 R / RH) –

short

> 2 sec

short

> 5 sec

open

> 2 sec

short

+

open

> 2 sec

. set parameter

or

1

2

Display

5702

Display

flashes

5 sec

br on

br OF

b on

b OF

Lo on

Lo OF

> 2 sec

At set rpm

open

time

> 2 sec

Display

5702 R /

5702 RH

Display

flashes

5 sec

br on

br OF

soft

prog 1

prog 2

Instruction

manual

3.8

3.12

3.14

3.15

3.16

3.13

No part of this publication may be reproduced without the prior permission of the copyright owner.

Copyright

©

2012 Eppendorf AG, Hamburg

Page 3

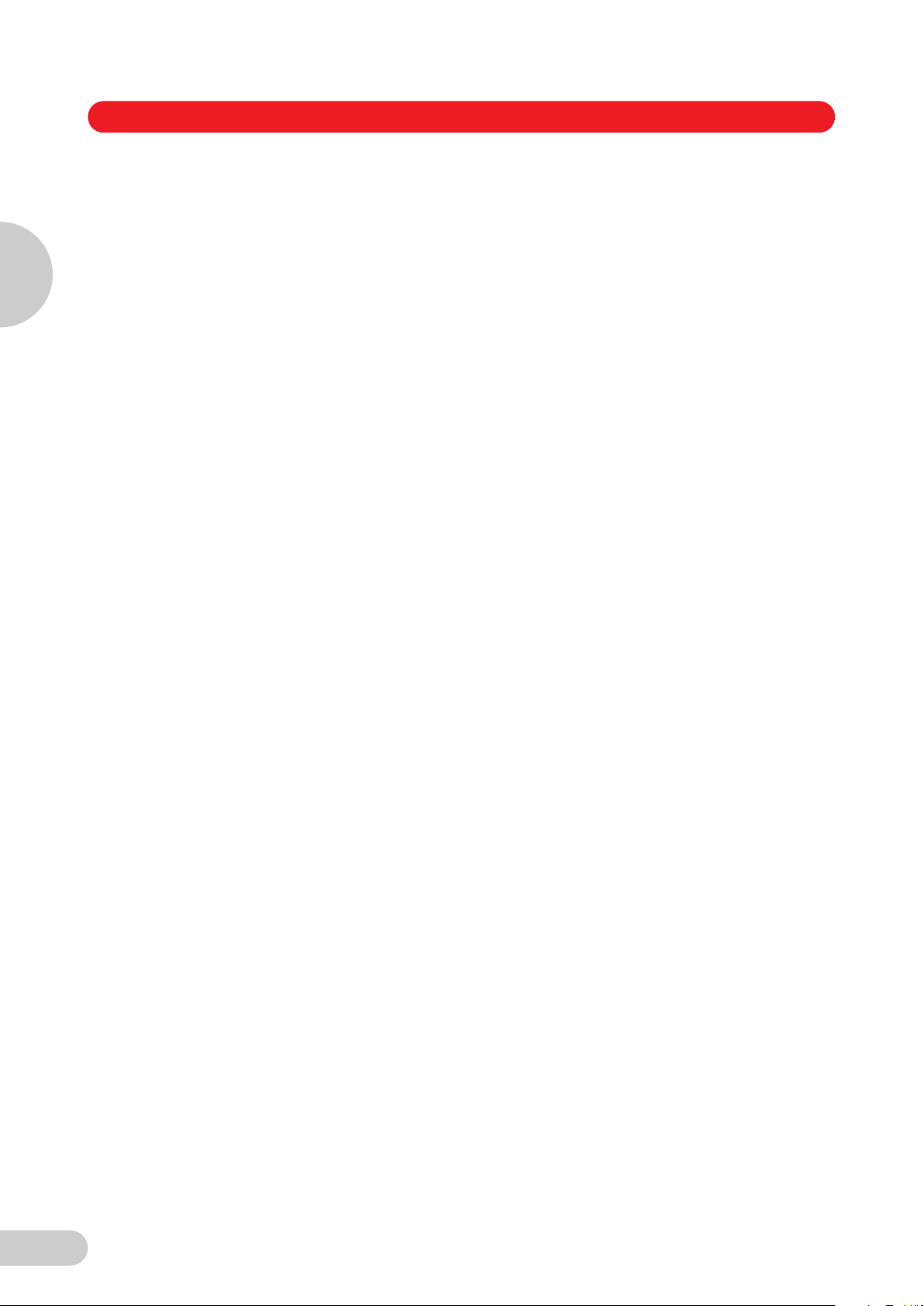

Centrifuge 5702

Abb. 1 / Fig. 1

Abbildung 1 / Figure 1

1

2

3

time

short

open

1 Netzschalter und -stecker 1 Mains switch and plug

2 Rotormutter 2 Rotor nut

3Rotor 3Rotor

E Notentriegelung E Emergency lid release

speed

stand-by

E

Page 4

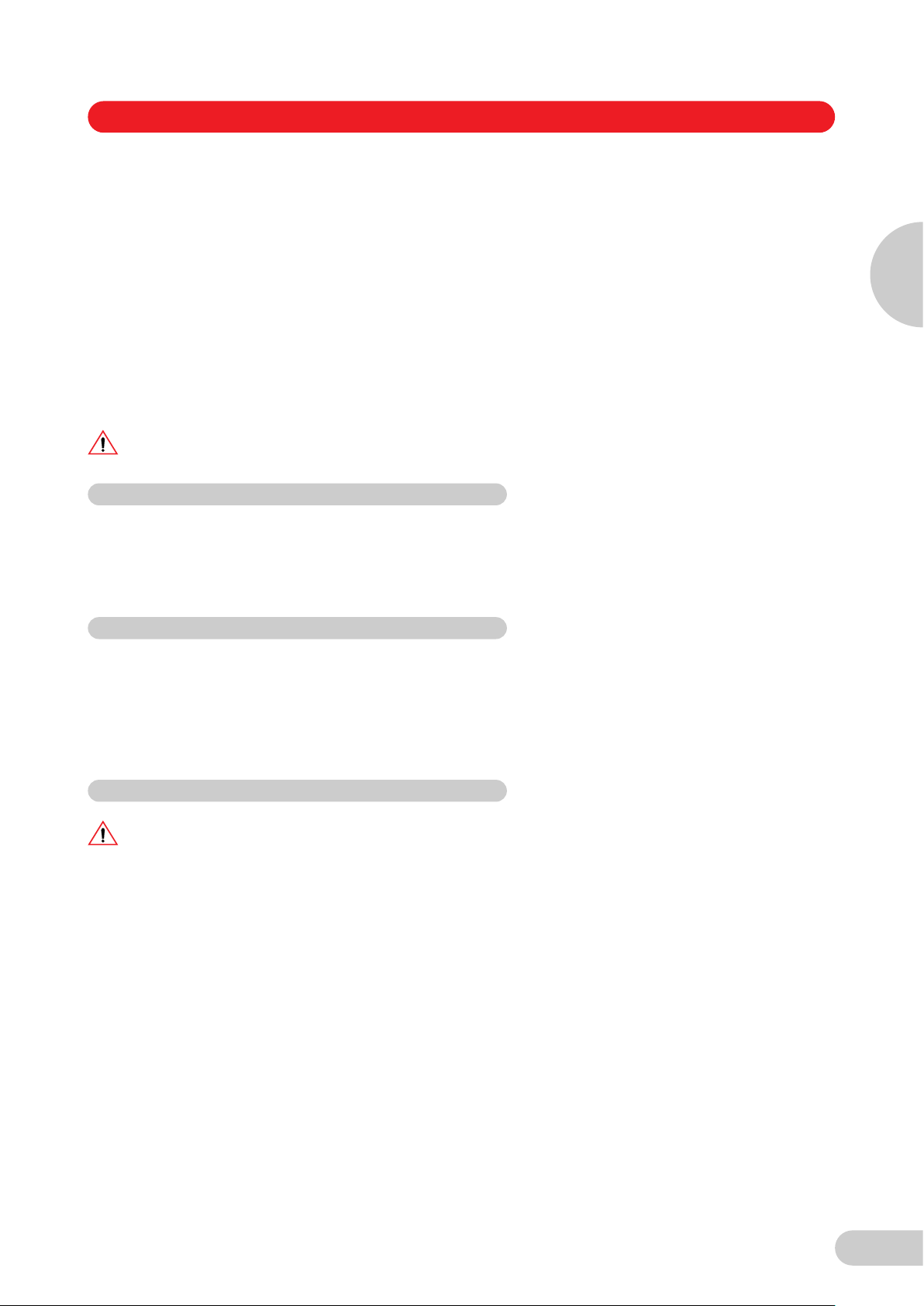

Centrifuge 5702 R

Abb. 2 / Fig. 2

Abbildung 2 / Figure 2

1

2

3

prog 1 /2

temp

time

short

C

open

fast temp

speed

stand-by

E

1 Netzschalter und -stecker 1 Mains switch and plug

2 Rotormutter 2 Rotor nut

3 Rotor 3 Rotor

E Notentriegelung E Emergency lid release

C Kondenswasserschale (nur 5702 R) C Condensation water tray (only 5702 R)

Front Centrifuge 5702 RH baugleich mit Centrifuge 5702 R.

Front of the Centrifuge 5702 RH is structurally identical to that of the 5702 R.

Page 5

Contents

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.2 Delivery package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

1.3 Installing the device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

2 Safety precautions and applicational limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.1 Functional and operator control elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.2 Fitting and removing the rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.3 Loading the rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.4 Fixed-angle rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

3.5 Swing-bucket rotors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6 Operation of round bucket with aerosol-tight caps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.7 Centrifugation with timer setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.8 Changing the centrifugation parameters during the run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.9 Short centrifugation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

3.10 Continuous running . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.11 Rcf display and calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.12 Adjusting the acceleration and braking ramps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.13 At set rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.14 Activating and deactivating the signal tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.15 Parameter lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.16 Programming (for 5702 R / 5702 RH only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.17 Program selection (for 5702 R / 5702 RH only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.18 Refrigeration (for 5702 R only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.19 Heating and refrigeration (only for 5702 RH). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.20 Opening the centrifuge in case of power failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

3.21 Device fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

4 Maintenance and cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.1 Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.2 Rotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.3 Refrigerated centrifuges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4.4 Glass breakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

4.5 Returning devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5 Troubleshooting guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

7 Ordering information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

24

Page 6

1 Introduction

Centrifuge 5702 is non-refrigerated, Centrifuge 5702 R is refrigerated and Centrifuge 5702 RH is a refrigerated and

heatable bench-top centrifuge. For these centrifuges following rotors are available:

Fixed-angle rotor F-35-30-17 with a capacity of 30 x 15 ml centrifuge tubes.

Fixed-angle rotor F-45-24-11 with a max. capacity of 24 x 1.5 / 2.0 ml in micro test tubes.

Fixed-angle rotor F-45-18-17-Cryo with a max. capacity of 18 x cryotubes (max. 17 mm).

Swing-bucket rotor A-4-38 with a max. capacity of 4 x 85 ml in round buckets and 4 x 90 ml in

rectangular buckets.

Swing-bucket rotor A-8-17 with a max. capacity of 8 x 15 ml.

Before using the centrifuge 5702 / 5702 R / 5702 RH for the first time, please read the operating manual.

The latest version of the manual and the safety instructions in your language can be found on the Internet at

www.eppendorf.com.

You will see this symbol on your centrifuge and at a number of points throughout this manual. The texts it

highlights are relevant to safety. Use the centrifuge only after having read the safety notices.

1.1 Intended use

The Centrifuge 5702 / 5702 R / 5702 RH is intended exclusively for indoor use and for separating aqueous solutions and

suspensions of various densities in approved test tubes.

This device may only be operated by trained specialist staff. They must have carefully read the operating manual and be

familiar with the function of the device.

1.2 Delivery package

1 Centrifuge 5702 non-refrigerated or 1 Centrifuge 5702 R refrigerated with condensation water tray or

1 Centrifuge 5702 RH refrigerated and heatable, each without rotor

1 power cable

1 operating manual

1 rotor key

1 set of fuse

1

Introduction

1.3 Installing the device

– The device is heavy. Lifting and carrying the device can lead to back injuries.

► The device may only be transported in its original packaging.

► The device must be transported by least two people.

► Use a transport aid (e.g., dolly) to transport the device longer distances.

– For 5702 R / RH only: In order to prevent damage to the compressor following improper transport, the device

may not be switched on until four hours after setting up.

– For 5702 only: Please remove the transport safety device and keep it for possible use if the device is

subsequently moved again.

– Place the centrifuge on a solid, flat, non-resonant lab bench. For the Centrifuge 5702 R / RH , the condensation

water tray should be inserted from the side (see cover flap).

– The surrounding area must be well ventilated and protected against direct sunlight.

To ensure that the ventilation of the device is not impaired, a fundamental clearance of 30 cm to the side and a

min. of 15 cm to the back wall must be maintained. This is especially important for the refrigeration capacity of

the 5702 R / RH.

– During centrifugation, according to the recommendations set out in EN 61010-2-020 a safety clearance of 30 cm

must be maintained around the centrifuge within which there are no objects which may be destroyed and so

cause further damage.

– Only connect the device to power supplies which correspond with the electrical requirements on the name plate.

Only use sockets with a protective earth (PE) conductor and suitable power cable.

– Now connect the centrifuge to the power supply and switch it on at the main power switch (on the rear side,

see cover flap). The centrifuge is now ready for operation. The Stand-by button lights up green and the display is

active.

– Before starting, check that the rotor is firmly seated.

25

Page 7

2

2 Safety precautions and applicational limitations

For your personal safety, please be sure to comply with the following regulations unconditionally:

– The centrifuge 5702 / 5702 R / 5702 RH must only be use for the specified applications (see Introduction). It must not

be operated in explosive atmospheres. Explosive or highly reactive substances must not be centrifuged.

– When being moved from the cool room to a normal lab environment, the centrifuge must either warm up for half an

hour in the cool room first or it must warm up for at least 3 hours in the lab before being connected to the supply

system, in order to prevent damage by condensation.

– The centrifuge must not be moved or knocked while in operation.

– Improperly installed or serviced centrifuges must not be operated. Repairs may only be carried out by Service

personnel authorized by Eppendorf. Use only original Eppendorf spare parts and rotors.

– When handling toxic, radioactive liquids or pathogenic microorganisms of risk group II (see World Health

Organization: Laboratory Biosafety Manual) comply with the relevant national regulations. Bioseals are a part of

biological safety systems, which are not able to guarantee the safety of people and the environment on their own

when handling pathogenic microorganisms. When working with pathogenic organisms of a higher risk group, more

than one aerosol-tight bioseal must be provided for. If the named liquids are spilled in the rotor or rotor chamber, the

centrifuge must be thoroughly and professionally cleaned. Before using any cleaning or decontamination method

other than that set out in section 4, "Maintenance and cleaning", please consult Eppendorf to ensure the intended

method will not damage the device.

– Rotors must always be properly secured. The centrifuge may only be operated with the rotor firmly tightened.

For mechanical stability, all the places on the rotor must be fitted with identical buckets.

– The rotor may only be loaded symmetrically. Opposing tubes should be of the same type and be filled equally. On the

rotor you will find information concerning the weight that a completely filled bucket may not exceed.

– Prior to centrifugation, the tubes should in any case be visually inspected for material damage. Damaged tubes may

not be centrifuged. This is because broken tubes can, in addition to sample loss, result in further damage to the

centrifuge and accessories.

– Rotors showing clear signs of corrosion or mechanical damage must not be used. Check the accessories regularly.

Safety precautions and applicational limitations

– Rotors are high-grade components which have to withstand extreme stresses and strains. Aluminum rotors are

largely protected from corrosion by the most common laboratory chemicals by means of an anodized coating, though

the protection is not unlimited. Protect the rotors from mechanical damage. Even minor scratches or cracks can

result in serious internal material damage. Avoid damaging the rotors by the use of aggressive chemicals, such as:

strong and weak alkalis, strong acids, solutions of mercury, copper and other heavy metal ions, chlorinated

hydrocarbons, concentrated salt solutions and phenol. If the rotor is contaminated by aggressive substances, clean it

immediately

– The material being centrifuged may not exceed a density of 1.2 g/ml at maximum rotation speed. If the rotor is run for

a lengthy period of time, or more often with short centrifugation runs the sample tubes will become hot. Keep within

the limits specified by the tube manufacturers.

– Seal the tube lid down tight before centrifuging. The lids of unclosed tubes may rip off during centrifugation and

damage the centrifuge.

– When using organic solvents (e.g. phenol, chloroform) the durability of plastic tubes may be impaired.

– When closing the centrifuge lid do not place your fingers between the lid and the centrifuge, otherwise they may be

trapped.

with a mild cleaning agent.

26

Page 8

2 Safety precautions and applicational limitations

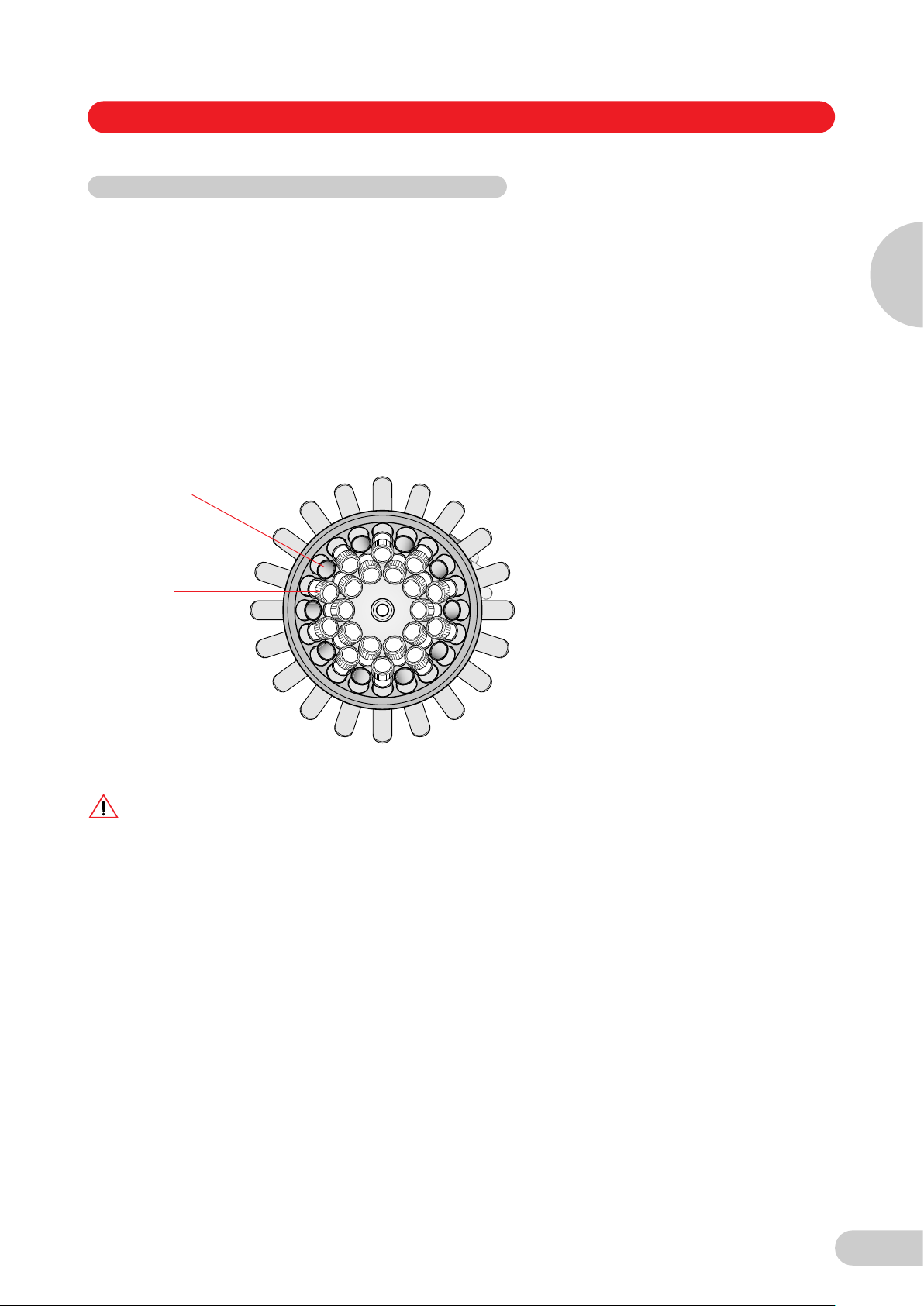

The following rotors and accessory buckets have a maximum service life of 7 years:

A-4-38 5702 720.003 and 5702 740.004

A-8-17 5702 700.002

The date of manufacture is engraved on them in the format 10/01 (October 2001).

Transparent aerosol-tight caps made of polycarbonate have a maximum service life of 3 years.

The date of manufacture is embossed on them in the form of a clock .

12

1

11

2

10

3

1

9

4

8

0

5

7

6

Aerosol tight caps may lose their sealing strength when exposed to organic solvents (e.g. phenol, chloroform).

Check the aerosol-tight caps regularly for changes or cracking. Aerosol-tight caps showing cracks or other changes must

be replaced immediately.

Rotors, caps or buckets which have been damaged by chemical or mechanical factors or which have passed

their maximum service life may no longer be used

!

– Transfer

If the device is passed on to someone else, please include the instruction manual.

– Disposal

In case the product is to be disposed of, the relevant legal regulations are to be observed.

– Information on the disposal of electrical and electronic devices in the European Community

The disposal of electrical devices is regulated within the European Community by national regulations based on EU

Directive 2002/96/EC on waste electrical and electronic equipment (WEEE).

According to these regulations, any devices supplied after 13.08.05 in the business-to-business sphere, to which this

product is assigned, may no longer be disposed of in municipal or domestic waste. They are marked with the

following symbol to indicate this.

As disposal regulations within the EU may vary from country to country, please contact your supplier if

necessary.

– Declaration concerning the ATEX directive (94/9/EC)

The present design and ambient conditions inside Eppendorf centrifuges mean that they are not suitable for use in a

potentially explosive atmosphere. The centrifuges must therefore only be used in a safe environment such as the open

environment of a ventilated laboratory or a fully-extracted fume hood. The use of substances which may contribute to a

potentially explosive atmosphere is not permitted. The final decision on the risks in connection with the use of such

substances is the responsibility of the user of the centrifuge.

2

Safety precautions and applicational limitations

27

Page 9

3

Operation

3 Operation

3.1 Functional and operator control elements

Refer to the frontal view on the first inside cover page of this manual.

Fig. 1: Front view of the Centrifuge 5702.

Fig. 2: Front view of the Centrifuge 5702 R. Front of the Centrifuge 5702 RH is structurally identical to that of the 5702 R

time

short – Short run button

speed

open

1

E

For the Centrifuge 5702 R / 5702 RH only:

temp

fast temp

prog 1

prog 2

C

–

Time dial and Start/Stop button

–

Speed selector dial and rpm/rcf button

–

Stand-by button

–

Lid release

–

Line socket with fuse set and main power switch,

device identification plate with power supply ratings

(rear).

–

Emergency lid release on underside with pull cord

–

Temperature selection buttons

–

Controlled temperature button

–

Program button 1

–

Program button 2

–

Condensation water tray

3.2 Fitting and removing the rotors

When fitting the rotor, follow the marking triangles on each side of the rotor nut . They indicate the direction of the

groove on the underside of the rotor, and are needed to position the rotor safely.

To insert the rotor rotate the driver pin of the motor shift longitudinally.

Fit the rotor onto the motor shaft so the marking triangles point in the same direction as the motor shaft driver pin. Tighten

the rotor nut by turning them clockwise using the rotor key supplied. If the rotor nut does not tighten easily, check whether

the rotor has caught on the motor shaft driver pin.

To release the rotor turn the rotor nut anticlockwise using the rotor key.

3.3 Loading the rotors

The rotors and buckets (round and rectangular) must be loaded symmetrically. The adapters must be loaded only with the

specified tubes. Minimize the difference in weight between the filled sample tubes. This will reduce wear on the drive and

cut running noise. The centrifuges 5702 / 5702 R / 5702 RH have an automatic imbalance detector, which shuts down the

centrifuge if the weight differences are excessive. This is indicated by the error message "Inb" in the display.

The maximum weight for a fully loaded bucket is indicated on each rotor.

28

Page 10

3 Operation

3.4 Fixed-angle rotor

The fixed-angle rotor F-35-30-17 can be loaded with 15 ml Falcons® and 15 ml round bottom centrifuge tubes. It is

available in the 10 and 30 position versions. Please use only swing-bucket rotor A-4-38 with round buckets and the

appropriate adapters for centrifuging blood sampling systems.

®

Before centrifuging the Falcons

being destroyed. For the centrifugation of round bottom tubes made of Duran® glass, round rubber pads are required to

prevent the tubes from cracking. Make sure a rubber pad is placed under each glass tube before centrifuging.

In order to avoid breakage of the tubes when using centrifuge tubes of glass, polystyrene or similar materials, please

observe the limiting data with reference to endurance specified by the manufacturer.

The maximum load capacity for Falcons

be loaded with a combination of 15 ml Falcons® and 15 ml round bottom centrifuge tubes. The maximum capacity is then

20 x 15 ml Falcons® and 10 x 15 ml round bottom centrifuge tubes.

15 ml

round bottom

centrifuge tube

, place their plastic adapters in the tube holders. The adapters prevent the Falcons® from

®

is 20 x 15 ml; for 15 ml round bottom centrifuge tubes 30 x 15 ml. The rotor can

3

Operation

15 ml Falcon

Fig.3: Loading of rotor F-35-30-17 with 15 ml Falcons® and 15 ml round bottom centrifuge tubes

A maximum of 24 1.5/2.0 ml test tubes can be centrifuged in rotor F-45-24-11. If the appropriate adapters are used, it is

also possible to load it with 0.2 ml PCR tubes, 0.4 ml test tubes, 0.5 ml test tubes and 0.6 ml Microtainers

Fixed-angle rotor F-45-18-17-Cryo can be equipped with cryotubes (max. diameter 17 mm or 13 mm with adapters) and

sealable centrifuge tubes (max. diameter 16.5 mm or 12.2 mm with adapters). In each of these cases, max. tube length is

50 mm.

Maximum load (adapter, tube and contents) per bore is 3.75 g on rotor F-45-24-11 and 8.7 g on rotor F-45-18-17-Cryo.

When loading the rotors, please make sure that the tubes are inserted in the bores of the rotor opposite one another in

pairs.

To ensure that the rotor is loaded symmetrically, the tubes opposite one another need to contain approximately the same

filling quantity.

®

The specified max. weight of 56 g imprinted on the rotor is the gross weight rating including the tube holder,

adapter, tubes and contents. Always weigh the tube holder and the load together.

®

.

Fixed-angle rotors are operated without a rotor lid.

29

Page 11

3

Operation

3 Operation

3.5 Swing-bucket rotors

The swing-bucket rotor A-4-38 can be equipped with round or rectangular buckets. Round buckets and the associated

adapters (see ordering information) are conceived for the centrifugation of Falcons®, blood withdrawal systems and other

centrifuging tubes with round bottoms. Rectangular buckets and associated adapters (see ordering information) are

conceived for the centrifugation of glass centrifugation tubes.

Use only the rotor / bucket (round or rectangular) / adapter combinations approved by Eppendorf. Check that all

buckets are fully attached, lubricated lightly and can swing out freely. If you use overlength tubes, it is essential to

carry out a manual swing test with empty tubes! When the rectangular buckets are not completely filled, insert the

adapters so that the bolts of the rotor A-4-38 are symmetrically loaded. Avoid unbalanced loading of the inner

adapter bores, pointing to the rotor nut, since this could cause overshooting of the rectangular buckets.

For mechanical stability, all the places must be fitted with identical buckets. The buckets are sorted by weight. The weight

class is embossed on the side of the bucket: e.g. 90 (the last 2 digits in grams). Opposing buckets must be

of the same weight class. When reordering, please quote the weight class required.

Before inserting the buckets in the grooves, make sure the grooves are clean. Dirty grooves or pegs will prevent the

buckets from swinging out evenly.

Fig. 4:

Rotor and buckets symmetrically

loaded.

The specified max. weight of 400 g imprinted on the rotor is the gross weight rating of a bucket (including adapter, tubes

and contents).

The maximum load (adapter, tubes and contents) of the round bucket is 190 g. The maximum load (adapter, tubes and

contents) of the rectangular bucket is 240 g.

®

A maximum of 8 x 15 ml Falcons

centrifugation of 15 ml Falcons®, please insert the provided plastic adapter into the rotor. Prior to the centrifugation of

tubes of Duran® glass, please insert the round rubber plate into the rotor. Please make certain prior to centrifugation that

such a rubber plate is found under every glass tube. In order to avoid breakage of the tubes when using centrifuge tubes

of glass, polystyrene or similar materials, please observe the limiting data with reference to endurance specified by the

manufacturer.

Only load the rotor symmetrically, so that the rotor and the pivots are evenly loaded during centrifugation. The maximum

load (adapter, tubes and contents) of the rotor A-8-17 is 8 x 38 g. The maximum permissible tube length is 120 mm.

or 8 x 15 ml tubes of Duran® glass can be centrifuged in the rotor A-8-17. Prior to the

Fig. 5:

Rotor and buckets asymmetrically

loaded. Not permitted, because the

pegs of the buckets are subject to

differing loads.

Fig. 6:

Adapter loaded asymmetrically.

Not permitted, because the

pegs of the bucket are not

uniformly loaded and the

loading of the adapter bores

pointing to the rotor nut could

cause overshooting of the

rectangular buckets.

30

Page 12

3 Operation

3.6 Operation of round bucket with aerosol-tight caps

The inner part of the aerosol-tight cap is also equipped with a silicone sealing ring. Never remove this sealing ring from

the cap. Whenever using the cap, make sure that the sealing ring is undamaged and sits uniformly in the groove.

Silicone sealing ring

The round bucket and the aerosol-tight cap are autoclavable (121 °C, 20 minutes). The aerosol-tight cap, including the

silicone sealing ring, is subject to natural wear and must be replaced when visual inspection reveals wear.

When handling the aerosol-tight cap, remember that polycarbonate has limited chemical resistance to phenol.

3.7 Centrifugation with timer setting

Switch on the centrifuge, with the mains power switch if necessary, and then with the switch. The nominal values of

the last run are displayed. Load the rotor symmetrically and close down the centrifuge lid.

–

time

speed

start

Alters the running time.

–

Alters the speed in increments of 100 1/min or rcf.

–

Starts the run. The symbol flashes while the rotor is running.

3

Operation

stop

stand-by

open

temp

While the centrifuge is running the remaining time is displayed. The last minute is counted down in seconds. When the

preset time elapses the centrifuge stops automatically and emits a signal tone to indicate the centrifugation is finished.

The lid of the non-refrigerated Centrifuge 5702 opens automatically following centrifugation. The lid of the refrigerated

Centrifuge 5702 R / 5702 RH remains closed to maintain the sample temperature and can be opened with the OPEN

button.

When you switch off the centrifuge 5702 / 5702 R / 5702 RH at the main power switch the display goes blank after a few

seconds' delay.

3.8 Changing the centrifugation parameters during the run

The timer setting, the rotation speed and the temperature (only 5702 R / 5702 RH) can be changed during the run by

briefly pressing the SHORT button. The display begins flashing. You can then set the new centrifugation parameters with

the TIME and SPEED and the TEMP dial adjustors. The new centrifugation parameters are programmed after 5 seconds.

3.9 Short centrifugation

–

Stops the centrifuge. The symbol appears briefly as soon as the rotor comes to a

standstill.

–

Centrifuge switched to stand-by mode.

–

Releases the lid latch.

–

Changes the nominal temperature value (for 5702 R / 5702 RH only)

short

–

Press this button with the lid closed to start a short run at maximum speed.

The centrifuge stops when you release the SHORT button again.

31

Page 13

3

3 Operation

3.10 Continuous running

–

time

stop

3.11 Rcf display and calculation

SPEED – Press the dial to toggle the display between 1/min (rpm) and (rcf) and vice versa.

The continuous run function is set by turning the TIME dial to either above

99 minutes or below 0.5 minutes. The timer displays "oo" to indicate that continuous

running is active. The time is counted upward in minutes.

–

Ends continuous running

Operation

Note that the rcf (g-force) indicated when the display is switched is standardized to 15 ml Falcon® tubes in the

rotor A-4-38. At 4,400 1/min you can achieve the following maximum rcf with the various adapters.

Rotor Adapter Max. centrifuging

radius (cm) r

A-4-38

Round bucket

A-4-38

Rectangular bucket

A-8-17 15 ml Falcon

F-35-30-17

Outer ring

F-35-30-17

Inner Ring

F-45-24-11 0.2 ml 6.6 1,430

F-45-18-17-Cryo without adapter 9.1 1,970

1.5/2.0 ml 13.4 2,900

1.1 – 1.4 ml 13.2 2,850

2 – 7 ml 13.2 2,850

2.6 – 7 ml 13.2 2,850

4 – 10 ml 13.2 2,850

9 – 15 ml 13.0 2,800

15 ml Falcon

25 ml 13.5 2,900

50 ml Falcon

85 ml 13.5 2,900

5 – 7 ml 12.7 2,750

9 ml 12.7 2,750

15 ml 12.7 2,750

20 ml 12.7 2,750

25 ml 12.7 2,750

15 ml DIN-tube 12.8 2,770

15 ml 12.7 2,750

15 ml Falcon

15 ml 10.7 2,300

15 ml Falcon

0.4 ml 8.2 1,770

0.5/0.6 ml 7.4 1,600

1.5/2.0 ml 8.2 1,770

with adapter 8.9 1,930

®

®

®

®

®

max

13.7 3,000

13.5 2,900

12.8 2,770

12.7 2,750

10.7 2,300

Max. rcf (g-force),

rounded

To ascertain the maximum rcf for a specific adapter you can apply the following formula as per DIN 58 970:

–5

rcf = 1,118 · 10

n: rotational speed in 1/min

r

: max. centrifuging radius in cm

max

Example: The 85 ml adapter has a maximum radius of 13.5 cm. At 4,000 rpm a maximum rcf of 2,415 x g is reached.

32

· n2 · r

max

Page 14

3 Operation

3.12 Adjusting the acceleration and braking ramps

When working with Ficoll® density gradients or other sensitive applications (e.g. certain types of blood and urine

centrifugations) slower acceleration and braking ramps can be switched on for the Centrifuge 5702 / 5702 R / 5702 RH.

This makes the centrifuge accelerate and decelerate gently. This guarantees optimal centrifugation results.

Press the SHORT key for longer than 5 seconds while the centrifuge lid is open. On the Centrifuge 5702, the text in the

display changes from "br on" (brake on) to "br OF" (brake off). The symbol appears in the display of Centrifuges

5702 R / RH. The slower acceleration and braking ramps are now activated. The current status will be displayed when the

SHORT button is pressed for less than 5 seconds while the centrifuge lid is open.

To switch faster acceleration and braking back on, press the short key for longer than 5 seconds again while the centrifuge

lid is open. The "br on" message appearing briefly in the display signals the reactivation of the faster acceleration and

braking ramps.

3.13 At set rpm

For centrifugation, time can be counted either immediately from the start or not until attainment of the preset speed.

Pressing the START / STOP button for longer than 2 seconds with the centrifuge lid open switches the "at set rpm" mode,

symbolized by the pictogram .

To exit the "at set rpm" mode again and begin counting down the centrifugation time immediately after starting the

centrifuge, press the START / STOP button again for longer than 2 seconds with the centrifuge lid open until the pictogram

is displayed.

soft

3

Operation

3.14 Activating and deactivating the signal tone

Press and hold down the OPEN button for longer than 2 seconds with the centrifuge lid open to toggle between "b on"

(signal tone on) and "b OF" (signal tone off). Press the OPEN button for less than 2 seconds with the centrifuge lid open to

display the current status. With the Centrifuge 5702 R / 5702 RH the selected signal tone is symbolized by the pictogram

.

The current status is shown when the OPEN button is pressed for less than 2 seconds while the centrifuge lid is open

(Centrifuge 5702).

3.15 Parameter lock

To secure the centrifuge parameters against unintentional adjustment, the Centrifuge 5702 and the Centrifuge 5702 R /

5702 RH allows you to lock in the parameters you need.

Press and hold down OPEN- and SHORT-button simultaneously for at least 5 seconds with the centrifuge lid open.

After 5 seconds the dial adjuster is disabled and the centrifugation parameters are locked against unintentional

adjustment. "Lo on" appears in the display of the Centrifuge 5702. In the display of the Centrifuge 5702 R / 5702 RH the

locked parameters are symbolized by an additional pictogram . The preset parameters can then no longer be altered,

whether the centrifuge is running or not. The START/STOP button can still be used to start and stop the centrifuge

however. It is also still possible to switch the signal tone and rcf switch on and off.

With the Centrifuge 5702 R / 5702 RH it is also possible to additionally lock a program called up against unintentional

resetting. A program already written is called up through the program buttons and then – as described above – the

program buttons and dial adjustor setting deactivated.

To enable the dial adjuster again, press and hold down OPEN- and SHORT-button simultaneously for 5 seconds with the

centrifuge lid open. The display shows "Lo OF" or (5702 R / 5702 RH ). The current status ("Lo on") can be displayed

on the Centrifuge 5702 by briefly pressing the SHORT and OPEN buttons while the lid is open.

33

Page 15

3

3 Operation

3.16 Programming (for 5702 R / 5702 RH only)

With the Centrifuge 5702 R / 5702 RH it is possible to store up to two permanent programs (only during standstill):

First set the required program data with the TIME and SPEED dial adjustors. The function "at set rpm" and the switchedoff braking function can also be stored if necessary in the permanent program.

–

PROG 1 or 2

3.17 Program selection (for 5702 R only)

Hold down for 2 seconds until the program button is no longer flashing and lights up

continuously. A brief signal will sound. The program is now stored.

Program selection is only possible during stillstand

Operation

PROG 1 or 2

If dial adjustors or buttons are required for the program setting, the program remains unchanged.

The text "Pr 1" (Program 1) or "Pr 2" (Program 2) appears in the centrifuge display.

Exit the program by again pressing the program button. The blue lighting of the button extinguishes and the centrifugation

parameters can be set freely again.

temp

fast temp

Stand-by refrigeration

–

Pressing once calls up the required program. The button for the program activated

lights up in blue.

3.18 Refrigeration (for 5702 R only)

–

The nominal temperature value can be set with the arrow keys from

– 9 °C to + 40 °C. During stillstand, the nominal temperature setting and the current

temperature in the rotor chamber are displayed alternately. With the centrifuge

running, only the current temperature in the rotor chamber is displayed.

A deviation of more than ± 3 °C from the temperature set is signalled during the run.

–

starts a controlled temperature run with a centrifuge-specific rotation speed, in

order to quickly reach the selected temperature in the rotor. During the FAST TEMP

run, "FA" appears in the display, as well as the present temperature and the fixed

optimal rotational speed. The run ends automatically or by pressing the STOP

button. A signal tone sounds periodically.

–

With closed centrifuge lid the rotor chamber is refrigerated before and after a run to

the selected nominal temperature if this is less than the ambient temperature. Since

there is no rotation of the rotor, the temperature adaptation takes place slowly. If the

centrifuge was in standby refrigeration over a longer time or at low temperatures,

start a brief FAST TEMP run before inserting the samples in order to prevent the

samples from freezing.

.

If the centrifuge is not used for more than 8 hours or the lid is not opened, the refrigeration switches off to protect the

device.

Remark: In cases of higher ambient temperature, temporary air noises may occur until the desired temperature is

attained. These are a sign of high refrigeration capacity. Block the ventilation slots under no circumstances!

For ambient temperatures below 18 °C a warming-up time of 1 hour is required before operating.

34

Page 16

3 Operation

3.19 Heating and refrigeration (5702 RH)

In the case of the Centrifuge 5702 RH, we are dealing with a benchtop centrifuge with a regulated heating and cooling

system. The Centrifuge 5702 RH can be refrigerated or heated precisely within a temperature range from – 9 °C to

+ 42 °C. By way of preprogrammed temperature profiles, it is possible to set optimized temperature arcs for the available

swing-bucket and fixed angle rotors. This enables exact temperature control even for sensitive samples.

Setting the preprogrammed temperature profiles:

Pressing the Fast Temp key while the centrifuge lid is open results in the display of the set rotor with the corresponding

temperature profile. Using the arrow keys it is possible to select other temperature profiles. The displays appearing stand

respectively for the following rotors:

Display Rotor

ro F 35 Fixed-angle rotor F-35-30-17

ro F 24 Fixed-angle rotor F-45-24-11

ro F 18 Fixed-angle rotor F-45-18-17-Cryo

ro A4 rE Swing-bucket rotor A-4-38 with rectangular buckets

ro A4 ro Swing-bucket rotor A-4-38 with round buckets

ro A8 Swing-bucket rotor A-8-17

ro AL L General temperature profile for all rotors

After 5 seconds a selected temperature profile will be automatically adopted and the display will return to the

operating status.

3

Operation

–

temp

fast temp

Stand-by

Heating and

refrigeration

3.20 Opening the centrifuge in case of power failure

Pull the power plug and wait for the rotor to come to a stop (this may take as long as 5 minutes!). Emergency lid release

on underside of device by pull cord: In front of the front right suction foot there is a small white plastic cap in the base

plate (see "E" in figures 1 and 2, cover flap). Remove the cap and draw the cord out straight downward.

The temperature nominal value can be set using the arrow keys. During the rest

period of the centrifuge, the current temperature and the temperature nominal value

are displayed alternately (current temperature short, temperature nominal value

long). Only the current temperature is displayed during the run. A deviation of the set

temperature nominal value of more than ± 3 °C is signalled during the run by a

blinking temperature display

–

Starts a temperature control run in order to reach the preselected temperature as

quickly as possible. During the temperature control run, "FA" appears in the display,

as well as the current temperature and the optimum rotational speed. Refrigeration

runs at less than room temperature are automatically carried out with a rotorspecific, low rotational speed, while heating runs are carried out initially with a

maximum and then with a nominal rotational speed. For runs with precisely

controlled temperatures, we recommend starting a short Fast Temp run immediately

prior to centrifugation. This prevents an overshooting of the temperature in the rotor

chamber, such as can sometimes occur after longer standby periods.

–

The rotor chamber is heated or cooled to the selected nominal temperature both

before and after a run with the lid closed. Because the rotor does not thereby rotate,

the temperature adjustment occurs slowly. The current temperature in the rotor

chamber is displayed. For runs with precise temperature control following longer

standby periods, we recommend starting a brief Fast Temp run immediately prior to

centrifugation. This prevents potential overshooting of the temperature in the rotor

chamber.

Please be sure to later make certain that the cord is pushed back completely into the housing before closing the lid.

Press the plastic button into the baseplate again.

3.21 Device fuses

The fuse box is located under the main power plug. The fuse box can be removed from the rear. The two fuses can be

replaced (see Ordering information).

35

Page 17

4 Maintenance and cleaning

4.1 Device

The outer surfaces of the centrifuge and the rotor chamber should be cleaned regularly with a mild cleaning agent. This is

for hygiene purposes and to prevent adhering impurities causing corrosion.

4

If material hazardous to health or aggressive material contaminate the device, the owner is responsible for appropriate

cleaning and decontamination.

Before cleaning, unplug the power plug with the lid open, unscrew the rotor using the rotor key supplied and clean it

separately. Use a mild cleaning agent for cleaning the accessible surfaces of the device. Choose disinfection methods that

correspond to the current legal regulations and guidelines for your area of application. Use, for example, alcohol (ethanol,

isopropanol) or alcohol-based disinfectants.

Do not allow any liquid to get into the gap at the motor shaft outlet. For this reason, the rotor chamber should be cleaned

only with a damp cloth.

You should also consult your laboratory safety officer with regard to a suitable method of cleaning and disinfecting. Before

any cleaning or disinfecting method other than that recommended by the manufacturer is used, please check with

Eppendorf that the intended method will not damage the device or its accessories. In order to ensure long-term, reliable

work with your centrifuge, please note that aggressive chemicals may damage the rotor and the chamber. Check your

device once a month for corrosion and damage.

The rubber seals in the rotor chamber should be rinsed off thoroughly with water and lubricated with glycerin or talc after

every clean to prevent them becoming brittle.

Maintenance and cleaning

4.2 Rotors

The rotors, buckets, tube holders and adapters should be cleaned once a month or when necessary with a neutral

cleaning agent to prevent residues of the material being centrifuged from changing the properties of the centrifuge and its

accessories. The rotor must be taken off for this.

Never place components in disinfectants or cleaning agents which contain sodium hypochlorite/chlorine or are oxidants.

This will cause the material to change. Disinfection with glutaraldehyde solution is possible. We recommend Cidex

activated glutaraldehyde solution. The plastic adapters and rubber plates are dishwasher safe.

®

Check the tube holders and buckets for residues and corrosion. For thorough cleaning, remove the rubber plates from tube

holders and buckets and clean all parts separately.

Then refit the rotor and bolt it into place with the supplied rotor key. Check the rotor, tube holders and buckets once a

month for mechanical damage.

All rotors, buckets, adapters, caps and tube holders can be autoclaved (121 °C, 20 min).

The aerosol-tight cap, including silicon sealing ring, rubber mats and rectangular bucket adapters are subject to normal

wear and must be replaced when a visual inspection reveals wear.

Do not unbolt the rectangular bucket adapters from each other.

On the swing-bucket rotor make sure, in particular, that the pegs and grooves of the buckets are free of dirt. They should

be lightly lubricated with pivot grease (provided with each swing-bucket rotor) so the buckets can swing freely.

The aerosol-tight buckets must not be stored with their caps sealed!

4.3 Refrigerated centrifuges

Clean condensation water and ice buildup regularly from the rotor chamber (by defrosting), using a soft, absorbent towel.

Regularly empty and clean the condensation water collector. Remove this from the left. Please clean the condensation

water drain regularly.

36

Page 18

4 Maintenance and cleaning

4.4 Glass breakage

When centrifuging glass tubes, please observe that high speeds/rcf’s increase the risk of glass breakage. Please follow

the manufacturer’s instructions concerning the maximum speed/rcf of centrifuge tubes. In the event of glass breakage,

carefully remove all splinters and all ground glass from the rotor, the buckets, the adapters and the rotor chamber. You

may need to replace the rubber mats and adapters to prevent further damage.

Fine splinters of glass may otherwise scratch the surface of the rotors and buckets, reducing their resistance to

chemicals. The air turbulences within the rotor chamber produce a very fine black powder of abraded metal. In addition

to causing damage to the rotor chamber, rotor, buckets and adapters, the powder also contaminates the samples.

Check the rotor bores regularly for residues and damage.

4.5 Returning devices

When returning centrifuges, please ensure that these devices are fully decontaminated so that they do not present a

health risk to our service staff.

You will find additional information and a blank of the decontamination confirmation at www.eppendorf.com.

Do also consult your laboratory safety officer about a suitable decontamination method.

Please fill out the decontamination confirmation and place it together with the device when it is to be sent back to

Eppendorf.

4

Maintenance and cleaning

37

Page 19

5 Troubleshooting

Error Cause Remedy

Stand-by button lit red. Centrifuge not ready. Press STANDBY button.

No display. No power. Plug power cable in on both ends.

5

Lid will not open. Power failure. Emergency lid release (see section 3.20).

Centrifuge shakes

when starting up.

Centrifuge will not start. Lid not closed. Press lid down or press OPEN button.

Display: LID Lid not released. Press lid down tight, press Start/Stop or emergency lid

Troubleshooting

Power failure. Check power fusing of lab / device.

Rotor still running. Wait for rotor to stop.

Rotor unevenly loaded. Stop centrifuge and load evenly.

release.

Lid not locked. Close lid again.

Lo on

(only 5702)

P 1

P 2

FA Display indicates a FAST TEMP

Inb Rotor unevenly

Int Power failure during run. Check power plug. Wait for rotor to come to a stop.

Er 2 Unbalanced rotor switch

Er 3 Error in speed system. Leave device switched on until error message

Er 5 Lid switch. Close lid, restart.

Centrifugation parameters

locked against adjustment.

Program 1 or 2 is called up. Press illuminated program button to exit the program

run.

loaded.

defective.

With open centrifuge lid simultaneously press SHORT

and OPEN for 5 seconds (see 3.15) if parameters

should be readjusted.

level (if required).

The run can be interrupted with the START / STOP

button if required.

Check loading and repeat run.

Repeat run.

Inform Service.

disappears (up to 5 min).

Er 6 Drive error. Repeat run.

Er 7 Overspeed. Error in drive or speed measurement system.

Er 8 Drive error. Repeat run.

Er 9 – 25 Electronics error. Repeat run.

Er 18 Temperature deviation

> 5 °C fr. nominal value.

Er 19 Refrigeration unit overheated. Make sure that the air circulation through the cooling

Er 23

(only 5702)

Er 24 Fault in the refrigeration unit. At start of operation: contact Service. After longer

If the suggested remedy repeatedly fails, please contact Service.

38

Motor overheating. Allow motor to cool.

Nominal value setting too low or refrigeration defective.

slots is not impaired.

running time: allow centrifuge to cool down.

Page 20

6 Technical data

Line connection: Centrifuge 5702

230 V / 50 – 60 Hz

120 V / 50 – 60 Hz

100 V / 50 – 60 Hz

Power output: 200 W 380 W

Max. speed: 4 400 rpm 4 400 rpm

Max. centrifugal acceleration: 3 000 rcf 3 000 rcf

Max. load: 4 x 90 ml 4 x 90 ml

Max. kinetic energy: 2 280 Nm 2 280 Nm

Permissible density of material

being centrifuged:

Ambient temperature: 2 – 40 °C 10 – 40 °C

Max. rel. air humidity: 75 % 75 %

Positioning height: max. 2000 m above NSL max. 2000 m above NSL

Dimensions: Height: 241 mm

Weight excluding rotor: 20 kg 36 kg

1,2 g/ml 1,2 g/ml

Depth: 395 mm

Width: 320 mm

Centrifuge 5702 R / 5702 RH

230 V / 50 – 60 Hz

120 V / 50 – 60 Hz

100 V / 50 – 60 Hz

Height: 265 mm

Depth: 580 mm

Width: 380 mm

6

Technical data

Startup time (230 V): < 25 sec < 25 sec

Deceleration time: < 25 sec < app. 25 sec

Startup time (100 V / 120 V): < 25 sec < 25 sec

Deceleration time: < 25 sec < app. 25 sec

Fuses: 2.5 A time-lag 230 V

5.0 A time-lag 120 V / 100 V

Noise level: < 58 dB (A) < 54 dB (A),

Overvoltage category: II II

Degree of contamination: 2 2

Technical specifications subject to change!

2.5 A time-lag 230 V

5.0 A time-lag 120 V

6.0 A time-lag 100 V

steady state at 4ºC;

23ºC ambient temperature,

empty rotor

39

Page 21

7 Ordering information

Centrifuge 5702

230 V / 50 – 60 Hz, without rotor 5702 000.019

Centrifuge 5702 R

230 V / 50 – 60 Hz, without rotor 5703 000.012

7

Ordering information

Centrifuge 5702 RH

230 V / 50 – 60 Hz, without rotor 5704 000.016

Fixed-angle rotor and accessories

Fixed-angle rotor F-35-30-17

Aluminum, 30 places, angle 35°,

for mounting of 15 ml Falcons

15 ml round bottom centrifuge tubes,

complete with stainless steel tube holders for

30 places 5702 704.008

10 places 5702 705.004

Tube holders (stainless steel), for rotor F-35-30-17,

for mounting of 15 ml Falcons

15 ml round bottom centrifuge tubes, set of 10 5702 707.007

Adapter, conical, to support 15 ml Falcons®,

for rotor F-35-30-17, set of 10 5702 706.000

Rubber mat for 15 ml round bottom centrifuge tubes, set of 10 5702 708.003

Fixed-angle rotor F-45-24-11

Aluminum, angle 45°, 24 places, max. 11 mm

for mounting of 1.5/2.0 ml micro test tubes 5702 746.002

Adapter for 0.2 ml PCR tubes,

for rotor F-45-24-11, set of 6 5425 715.005

Adapter for 0.4 ml micro test tubes,

for rotor F-45-24-11, set of 6 5425 717.008

®

or

®

or

Adapter for 0,5 ml micro test tubes and

0.6 ml Microtainer

Fixed-angle rotor F-45-18-17-Cryo

Aluminum, angle 45°, 18 places, max. 17 mm

for mounting of cryotubes (max. 17 mm) and

centrifuge tubes which can be sealed (max. 16.5 mm),

max. length in mm: 50 5702 747.009

Adapter for cryotubes (max. 13 mm) and

centrifuge tubes which can be sealed (max. 12.2 mm),

max. length in mm: 50 5702 752.002

Swing-bucket rotors and accessories

Swing-bucket rotor 4 x 85 ml, type A-4-38,

aluminum, incl. 4 round buckets 5702 720.003

Swing-bucket rotor 4 x 85 ml, type A-4-38,

aluminum, excluding round buckets 5702 740.004

Round bucket 85 ml for A-4-38, set of 4 5702 722.006

Round bucket 85 ml for A-4-38, set of 2 5702 761.001

Caps, aerosol tight, for round bucket 85 ml, set of 2 5702 721.000

®

, for rotor F-45-24-11, set of 6 5425 716.001

40

Page 22

7 Ordering information

Adapter for standard tubes and blood sampling systems for round bucket 85 ml

2 adapters 4 x 1.5 – 2.0 ml micro test tubes 5702 745.006

2 adapters 5 x 1.1 – 1.4 ml (ø adapter bore x max. vessel length in mm: 8.5 x 100) 5702 736.007

2 adapters 5 x 2 – 7 ml (12.5 x 100) 5702 737.003

2 adapters 4 x 2.6 – 7 ml (13.5 x 100) 5702 719.005

4 adapters 4 x 4 – 10 ml (16 x 100) 5702 735.000

9 adapters 4 x 9 – 15 ml (17.5 x 100) 5702 724.009

2 adapters 1 x 15 ml Falcon

2 adapters 2 x 15 ml Falcon® * (17.2 x 121) 5702 723.002

2 adapters 1 x 25 ml (25 x 100) 5702 717.002

2 adapters 1 x 50 ml Falcon

2 adapters 1 x 85 ml (38 x 106) 5702 718.009

Rectangular bucket 90 ml for A-4-38, set of 4 5702 709.000

Rectangular bucket 90 ml for A-4-38, set of 2 5702 762.008

Do not use with aerosol tight caps.

*

Adapter for standard tubes for rectangular buckets

2 adapters 10 x 5 – 7 ml 5702 710.008

2 adapters 8 x 9 ml 5702 711.004

2 adapters 6 x 15 ml 5702 712.000

2 adapters 4 x 20 ml 5702 713.007

2 adapters 2 x 25 ml 5702 716.006

®

(17.2 x 121) 5702 732.001

®

(30 x 115) 5702 734.004

7

Ordering information

Swing-bucket rotor type A-8-17 5702 700.002

®

Adapter, conical, to support 15 ml Falcons

,

for rotor A-8-17, set of 8 5702 702.005

Rubber pad for 15 ml round bottom centrifuge tubes, set of 8 5702 701.009

Set of fuses

for 5702 / 5702 R 230 V (2 x 2.5 A time-lag) 5425 351.003

for 5702 / 5702 R 120 V (2 x 5 A time-lag) 5425 353.006

Important note:

Please use the original accessories recommended by Eppendorf. Using spare parts or disposables which we have not

recommended can reduce the precision, accuracy and life of the centrifuges. We do not honor any warranty or accept

any responsibility for damage resulting from such action.

Falcon®: Registered trademark of Becton Dickinson

Cidex®: Registered trademark of Johnson & Johnson

Duran®: Registered trademark of Schott

Ficoll®: Registered trademark of Pharmacia Biotech AB

Microtainer®: Registered trademark of Becton Dickinson

Rotor code

All Eppendorf rotors are designated

according to a simple, logical system

which describes the technical specifications as a uniform series of numbers

and letters e.g.:

Fixed-angle Angle of

rotor

adapter bore

F A 45 30 11 A 4 81

version

Aerosol-tight

Max. no. tubes/

adapters

∅ Tube/

Adapter Swing-bucket rotor

Max. no tubes/

adapters

∅ tube/adapter

bore

41

Page 23

Istruzioni in breve

La centrifuga 5702 è una centrifuga da banco non refrigerata, la centrifuga 5702 R è una versione da banco refrigerata e

la centrifuga 5702 RH è una versione da banco refrigerata e riscaldata

Prima di mettere in funzione le centrifughe 5702 / 5702 R / 5702 RH per la prima volta, siete pregati di leggere le

istruzioni per l'uso. La versione più aggiornata delle istruzioni per l'uso e delle avvertenze di sicurezza è

disponibile in diverse lingue sul sito internet www.eppendorf.com. Consigliamo inoltre, per avere una visione

generale dell'utilizzo, di leggere anche la versione più completa in inglese (da pagina 24 a pagina 40) o in tedesco

(da pagina 5 a pagina 23).

Questo simbolo è riportato sulla centrifuga ed in diversi punti delle presenti istruzioni. I testi contrassegnati da tale

simbolo sono avvertenze importanti per la sicurezza vostra e dell'impianto. Utilizzate la centrifuga soltanto dopo

aver letto queste avvertenze di sicurezza.

Uso conforme

La Centrifuge 5702 / 5702 R / 5702 RH è concepita esclusivamente per l'uso in luoghi chiusi e serve a separare le

soluzioni acquose e le sospensioni di diversa densità nelle apposite provette.

L'apparecchio può essere utilizzato esclusivamente da personale specializzato e appositamente addestrato. È necessario

aver letto accuratamente le istruzioni per l'uso e conoscere bene il funzionamento dell'apparecchio.

Collocazione dell'apparecchio

– L'apparecchio è pesante. Sollevare e trasportare l'apparecchio può causare lesioni dorsali.

► Trasportare l'apparecchio solo nella confezione originale.

► Trasportare l'apparecchio con l'aiuto di una seconda persona.

► Se il trasferimento richiede un certo tempo avvalersi di un ausilio per il trasporto (ad es. il carrello portapacchi).

Istruzioni in breve

– Ponete la centrifuga su un banco da laboratorio stabile, orizzontale e privo di risonanze. L'ambiente circostante

deve essere ben ventilato e protetto dalla luce solare diretta. Per non compromettere la corretta ventilazione

dell'apparecchio è necessario mantenere una distanza di 15 cm su entrambi i lati rivolti verso altre

apparecchiature adiacenti e sul retro. Questa distanza deve essere osservata soprattutto per il corretto

raffreddamento della 5702 R / 5702 RH. Prima di collegare la centrifuga alla corrente di rete per la prima volta,

lasciatela spenta per tre ore affinché possa raggiungere la temperatura ambiente del laboratorio. In questo modo

eviterete danni alla centrifuga.

– Rimuovete tutti i dispositivi di sicurezza che sono stati applicati per il trasporto.

– Durante la centrifugazione, intorno alla centrifuga deve essere garantito uno spazio libero di 30 centimetri.

– Collegare l'apparecchio solo a fonti di alimentazione che corrispondano ai requisiti elettrici indicati sulla targhetta

del prodotto.

Utilizzare esclusivamente le prese dotate di messa a terra e un cavo di rete adeguato.

–Prima della prima messa in esercizio occorre controllare che il rotore sia saldamente fisso in sede.

Avvertenze di sicurezza e limitazioni di utilizzo

Per la vostra sicurezza personale, vi preghiamo di osservare scrupolosamente le seguenti disposizioni:

– La centrifuga 5702 / 5702 R / 5702 RH può essere utilizzata esclusivamente per le applicazioni indicate, non può

funzionare in locali esposti al pericolo di esplosione e non deve essere utilizzata con sostanze esplosive o con reazioni

chimiche violente.

– Quando si passa da un locale refrigerato al normale ambiente del laboratorio, la centrifuga deve essere lasciata

funzionare per almeno mezzora nel locale refrigerato oppure deve riscaldarsi almeno tre ore nel laboratorio senza

essere collegata alla rete per evitare che si formi condensa.

– Durante il funzionamento, la centrifuga non deve essere né spostata né urtata.

– Le centrifughe non installate o sottoposte a manutenzione da personale specializzato non devono essere utilizzate. Le

riparazioni possono essere effettuate unicamente dal personale di assistenza tecnica autorizzato dalla ditta Eppendorf

e si possono installare soltanto parti di ricambio e rotori originali Eppendorf.

– Per la centrifugazione di liquidi tossici e radioattivi oppure di germi patogeni del gruppo di rischio II (vedi

Organizzazione Mondiale per la Sanità: Manuale di sicurezza nel laboratorio biologico) si dovranno osservare le

disposizioni nazionali vigenti in materia. In presenza di germi patogeni appartenenti ad un gruppo di rischio più alto è

necessario prevedere più di una guarnizione biologica a tenuta di aerosol. Qualora si rovesciassero involontariamente

detti liquidi nel rotore o nel vano del rotore, occorrerà procedere ad un’accurata pulizia della centrifuga.

47

Page 24

Istruzioni in breve

– I rotori devono essere sempre fissati secondo le istruzioni. Si può centrifugare soltanto se il rotore è saldamente

serrato. Il rotore può essere caricato soltanto simmetricamente, le provette contrapposte l’una all’altra devono essere

dello stesso tipo e con lo stesso livello di riempimento.

– Prima della centrifugazione controllate sempre visivamente le provette per verificare l’eventuale presenza di danni del

materiale. Le provette danneggiate non devono essere centrifugate, in quanto l’eventuale rottura delle provette

potrebbe causare non solo la perdita dei campioni ma anche altri danni alla centrifuga e agli accessori.

– I rotori che presentano evidenti tracce di corrosione o danni meccanici non devono essere utilizzati. Controllate

mensilmente gli accessori ed, inoltre, evitate un eventuale indebolimento con sostanze chimiche aggressive, tra le

quali alcali forti e deboli, acidi forti, soluzioni con ioni di mercurio, rame ed altri metalli pesanti, idrocarburi clorurati,

soluzioni saline concentrate e fenolo. In caso di contaminazione con sostanze aggressive, pulire accuratamente il

rotore con un detergente blando.

– La densità della sostanza centrifugata non deve superare i 1,2 g/ml alla massima velocità di centrifugazione. In caso di

funzionamento prolungato, le provette si riscaldano.

– Chiudete il coperchio della provetta prima della centrifugazione. Durante la centrifugazione, i coperchi ancora aperti

potrebbero staccarsi danneggiando gravemente la centrifuga. Inoltre, si dovranno osservare i valori limite specificati

dal produttore delle provette riguardanti il carico ammissibile per le provette in plastica. Se si utilizzano solventi organici

(ad esempio fenolo, cloroformio) si potrebbe ridurre la stabilità e la capacità di portata delle provette in plastica.

– Chiudendo il coperchio della centrifuga occorre prestare attenzione a non lasciare le dita sotto il coperchio, poiché vi è

il pericolo di schiacciamento.

I seguenti rotori e relative sospensioni hanno una durata utile massima di 7 anni. La data di costruzione è incisa sotto

forma di cifre 10/01 = Ottobre 2001:

A-4-38 5702 720.003

A-8-17 5702 700.002

I coperchi ermetici in policarbonato trasparente hanno una durata utile massima di 3 anni. La data di costruzione è incisa

sotto forma di sigillo .

Se attaccati dall’azione di solventi organici (ad esempio fenolo, cloroformio), i coperchi a tenuta di aerosol potrebbero

perdere la loro stabilità. Pertanto, occorrerà assicurarsi ad intervalli regolari che non siano deformati e non presentino

Istruzioni in breve

fessurazioni. I coperchi ermetici danneggiati dovranno essere immediatamente sostituiti.

I rotori, i coperchi o le sospensioni danneggiati da azioni chimiche o meccaniche oppure che hanno

superato la propria durata utile massima non devono più essere utilizzati!

– Cessione

In caso di cessione del prodotto vogliate allegare le presenti istruzioni d’uso.

– Smaltimento

In case the product is to be disposed of, the relevant legal regulations are to be observed.

– Informazioni sullo smaltimento degli apparecchi elettrici ed elettronici nella Comunità Europea

Per lo smaltimento del prodotto attenersi alle disposizioni giuridiche in materia. All’interno della Comunità Europea lo

smaltimento è regolamentato da disposizioni nazionali basate sulla Direttiva UE 2002/96/CE sui rifiuti di apparecchia-

ture elettriche ed elettroniche (WEEE).

In base a tale disposizione tutti gli apparecchi forniti dopo il 13.08.2005 nel settore Business-to-Business, di cui fa

parte il presente prodotto, non possono più essere smaltiti con i rifiuti comunali o domestici. A scopo identificativo sono

contrassegnati con i seguenti simboli.

Poiché la normativa in materia di smaltimento in ambito UE può cambiare a seconda del Paese, vogliate

contattare i Vostri fornitori in caso di necessità.

12

1

11

2

10

3

1

9

4

8

0

5

7

6

Impiego

Accendete la centrifuga con l’interruttore di rete e premete il tasto di stand-by . A questo punto verranno visualizzati i

valori nominali dell'ultima centrifugazione. Per l'installazione del rotore occorre osservare i triangoli di contrassegno posti

su entrambi i lati del dado del rotore [Fig. triangoli] che indicano la direzione della scanalatura sul lato inferiore del rotore e

sono necessari per posizionare con sicurezza il rotore.

Per utilizzare il rotore occorre girare la spina di trascinamento dell'albero motore in direzione longitudinale, dopodiché si

dovrà innestare il rotore sull'albero motore in modo tale che i triangoli di contrassegno siano rivolti nella stessa direzione

della spina di trascinamento dell'albero motore stesso. A questo punto, stringete a fondo il dado del rotore girandolo in

senso orario con la chiave fornita in dotazione. In caso di problemi, assicuratevi che il rotore abbia ingranato con la spina

48

Page 25

Istruzioni in breve

di trascinamento dell'albero motore.

Ora, caricate il rotore simmetricamente e chiudete il coperchio della centrifuga. Non caricate mai il rotore in modo

squilibrato. Al termine della centrifugazione, il coperchio della centrifuga 5702 si apre automaticamente, mentre il

coperchio della centrifuga refrigerata 5702 R / 5702 RH resta ancora chiuso per mantenere costante la temperatura delle

provette; per aprirlo basta premere il tasto OPEN.

–

time

speed

start

stop

stand-by

open

temp

fast temp

modifica la durata del ciclo.

La funzione di ciclo continuo può essere impostata con la manopola TIME in un arco di 99

minuti oppure meno di 0,5 minuti. Il display visualizza "oo” per indicare il ciclo continuo.

–

modifica la velocità a passi di 100 giri/min. oppure in ACR. La commutazione da giri/min. ad

ACR avviene premendo il tasto SPEED.

–

avvia il ciclo. Il simbolo lampeggia finché è in funzione il rotore.

–

interrompe il ciclo. Il simbolo compare non appena il rotore si ferma e si può aprire il

coperchio della centrifuga.

–

accende e spegne la centrifuga.

–

sblocca il dispositivo di chiusura del coperchio.

–

modifica il valore nominale di temperatura (solo per il modello 5702 R / 5702 RH). Il valore

nominale di temperatura può essere impostato con i tasti a freccia da – 9 °C a + 40 °C

(centrifuga 5702 RH: da – 9 °C a + 42 °C). Durante le fasi di inattività della centrifuga, il display

visualizza alternativamente il valore nominale di temperatura impostato e la temperatura

attualmente presente nella cassa del rotore. Durante il ciclo di centrifugazione viene

visualizzata unicamente la temperatura correntemente presente nella cassa del rotore.

_

savvia un ciclo di termostatizzazione a velocità di centrifugazione specifica, il display visualizza

"FA”. Il ciclo termina automaticamente oppure attivando il tasto STOP. Si inserisce un segnale

acustico periodico.

Istruzioni in breve

L'impostazione del tempo, della temperatura e della velocità può essere modificata anche durante il funzionamento della

centrifuga. A tale scopo, premete dapprima il tasto SHORT; il display del timer lampeggia. Dopo aver modificato i

parametri di centrifugazione avviene un’accelerazione alla nuova velocità nominale impostata.

Durante il ciclo viene visualizzata la durata residua. In caso di modifica della durata durante la centrifugazione viene

tenuto in considerazione il tempo già trascorso. Per l’ultimo minuto avviene un conto alla rovescia in secondi. Trascorsa la

durata impostata, la centrifuga si ferma automaticamente.

–

short

Programmazione

Con la centrifuga 5702 R / 5702 RH si possono memorizzare sino a due programmi fissi (soltanto a centrifuga ferma)

impostando come prima cosa i parametri desiderati. Quindi, tenete premuto PROG 1 oppure 2 finché il tasto dei

programmi non lampeggia più e resta sempre acceso. Il programma è memorizzato. Per richiamare il programma

desiderato basta premere brevemente il tasto dei programmi.

Disattivazione della funzione di frenatur

Per un avvio delicato senza freno basta tenere premuto il tasto SHORT per più di 5 secondi quando il coperchio della

centrifuga è ancora aperto. Il messaggio sul display cambia da "br on" (freno attivo) a "br OF" (freno disattivato) oppure

viene visualizzato (5702 R / 5702 RH); a questo punto, il freno della centrifuga è disattivato.

Impostazione di precisione dei parametri

Per evitare di modificare inavvertitamente i parametri impostati, premete contemporaneamente il tasto SHORT ed il tasto

OPEN per 5 secondi quando il coperchio della centrifuga è ancora aperto. In questo modo, i parametri o i programmi

impostati non potranno più essere modificati, sia durante il ciclo che a centrifuga ferma, tuttavia si può normalmente

avviare o concludere un ciclo di centrifugazione con il tasto START/STOP.

Premendo questo pulsante quando il coperchio è chiuso si attiva un ciclo breve alla velocità

massima. Il ciclo viene arrestato rilasciando il tasto SHORT.

soft

49

Page 26

Istruzioni in breve

Apertura della centrifuga in caso di interruzione di corrente

Staccate la spina ed attendete che il rotore si fermi (può durare anche 5 minuti!). Sbloccaggio di emergenza tirando la

corda posta sul fondo dell’apparecchio: a monte del piedino a ventosa anteriore destro è inserito un pernetto bianco di

plastica nella piastra base (vedi il punto "E” dell’illustrazione). Estraetelo e tirate la corda verticalmente verso il basso.

Assicuratevi che, al termine, la corda sia completamente rientrata nell'alloggiamento. Dopo l'apertura del coperchio,

premete nuovamente il pernetto di plastica nella piastra base.

Manutenzione e pulizia

Centrifuga

Le superfici esterne della centrifuga e della camera rotore devono essere pulite regolarmente con un detergente blando al

fine di assicurare l’igiene ed evitare la corrosione da impurità non rimosse.

Sta all’utilizzatore effettuare l’opportuna pulizia e decontaminazione in caso di impurità dovute a sostanze aggressive o

pericolose per la salute.

A coperchio aperto staccare la spina, allentare il rotore con l’apposita chiave in dotazione e pulire separatamente. Per

effettuare la pulizia delle superfici accessibili dell’apparecchio utilizzare un detergente blando. Scegliere metodi di

disinfezione che siano conformi alle disposizioni e alle direttive di legge vigenti per il proprio campo di applicazione.

Utilizzare ad esempio alcol (etanolo, isopropanolo) o disinfettanti contenenti alcol. Non deve penetrare alcun liquido nella

fenditura presso l’albero motore, pertanto la camera rotore deve essere pulita esclusivamente con un panno umido.

Rivolgersi al responsabile per la sicurezza del proprio laboratorio in merito ai metodi di disinfezione e di pulizia appropriati.

Prima di utilizzare una procedura di pulizia e disinfezione diversa da quella consigliata dal produttore, consultare

Eppendorf per assicurarsi che la procedura in questione non danneggi l’apparecchio e gli accessori. Per garantire un

utilizzo della centrifuga duraturo e sicuro, fare attenzione alle sostanze chimiche aggressive che possono danneggiare il

rotore e la caldaia. Controllare una volta al mese che il proprio apparecchio non presenti segni di corrosione e danni.

Le guarnizioni in gomma nella camera rotore devono essere ben risciacquate con acqua dopo ogni pulizia e strofinate con

glicerina o talco per evitare la formazione di screpolature.

Istruzioni in breve

Rotori

Il rotore, il bilancino ermetico e la sospensione devono essere puliti ogni mese con un detergente neutro. Assicuratevi che

nei fori del rotore non vi siano residui né tracce di corrosione. Tutti i rotori, i bilancini ermetici, gli adattatori e le sospensioni

possono essere sterilizzati in autoclave (a 121 °C per 20 minuti). I coperchi a tenuta di aerosol, incluse le guarnizioni in

gomma, sono soggetti alla normale usura e in caso di deterioramento devono essere sostituiti.

Per i rotori a bilancini occorre prestare particolare attenzione a che i perni e le scanalature del bilancino ermetico e le

sospensioni siano perfettamente puliti.

Questi componenti devono essere lubrificati con grasso per perni in modo che i bilancini possano oscillare

senza attrito!

Rottura della vetreria

Durante la centrifugazione dei recipienti in vetro, occorre prestare attenzione al maggiore rischio di rottura dovuto al

numero crescente di giri e/o all'accelerazione centrifuga relativa. Rispettate le indicazioni del produttore per il carico

massimo ammesso dei recipienti per la centrifuga.

In caso di rottura di un vetro rimuovete i frammenti e tutta la polvere di dal rotore, dai becher, dagli adattatori e dal vano

centrifuga.

Per escludere ulteriori danni, si devono eventualmente sostituire le piastre in gomma e gli adattatori.

Spedizione di ritorno di apparecchiature

In caso di ritorno di apparecchi siete pregati di verificare che tali apparecchi siano perfettamente decontaminati e che

quindi non costituiscano alcun rischio per la salute del nostro personale addetto all'assistenza tecnica.

Per ulteriori informazioni e un prestampato della certificazione di decontaminazione visitate il sito www.eppendorf.com.

Per quanto riguarda un metodo di decontaminazione adeguato rivolgetevi anche all’incaricato della sicurezza del vostro

laboratorio.

Compilate la certificazione di decontaminazione e, una volta compilata, allegatela all’apparecchiatura che deve essere

rispedita alla ditta Eppendorf.

50

Page 27

Istruzioni in breve

Tabella per la ricerca dei guasti

Anomalia Causa Rimedio

Nessuna visualizzazione. Manca il collegamento a rete. Collegare entrambe le estremità del cavo di rete.

Interruzione di corrente. Controllare il fusibile del laboratorio / dell’apparecchio.

Non è possibile aprire il

coperchio.

La centrifuga vibra

all’avviamento.

Non è possibile avviare la

centrifuga.

Messagio: LID Il coperchio non è sbloccato. Premere con forza il coperchio, avvio/stop oppure

Lo on

(solo 5702)

P 1

P 2

FA Indica un ciclo di

Inb Il rotore non è caricato

Int Interruzione di corrente durante il

Er 2 L'interruttore di sbilanciamento

Er 3 Errore nel sistema di velocità. Lasciare acceso l’apparecchio finché il messaggio di

Interruzione di corrente. Sbloccaggio di emergenza.

Il rotore non funziona. Attendere che il rotore si fermi.

Il rotore non è caricato

uniformemente.

Il coperchio non è chiuso. Premere il coperchio.

Il coperchio non è bloccato. Chiudere di nuovo il coperchio.

I parametri di centrifugazione sono

protetti da un'eventuale modifica.

È stato richiamato il

Programma 1 o 2.

termostatizzazione FAST TEMP.

uniformemente.

ciclo.

difettoso.

Fermare la centrifuga e caricare uniformemente.

sbloccaggio di emergenza.

Per modificare i parametri, premere contemporaneamente i pulsanti SHORT e OPEN per 5 secondi a

coperchio aperto.

Premere il tasto dei programmi acceso per uscire dal

livello di programma attuale (se desiderato).

Il ciclo può essere interrotto, se necessario, con il tasto

START / STOP.

Controllare il carico e ripetere il ciclo.