Page 1

Centrifuge 5424

Page 2

Centrifuge 5424

Inhaltsverzeichnis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Instruction Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Notice abrégée . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Istruzioni in breve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Instrucciones breves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .67

Table of contents

Beknopte handleiding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Kort vejledning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Kort handledning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Pikaohje. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Manual abreviado . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Συνοπτικές οδηγίες

No part of this publication may be reproduced without the prior permission of

the copyright owner.

©

Copyright

2

2005 Eppendorf AG, Hamburg

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Page 3

Centrifuge 5424

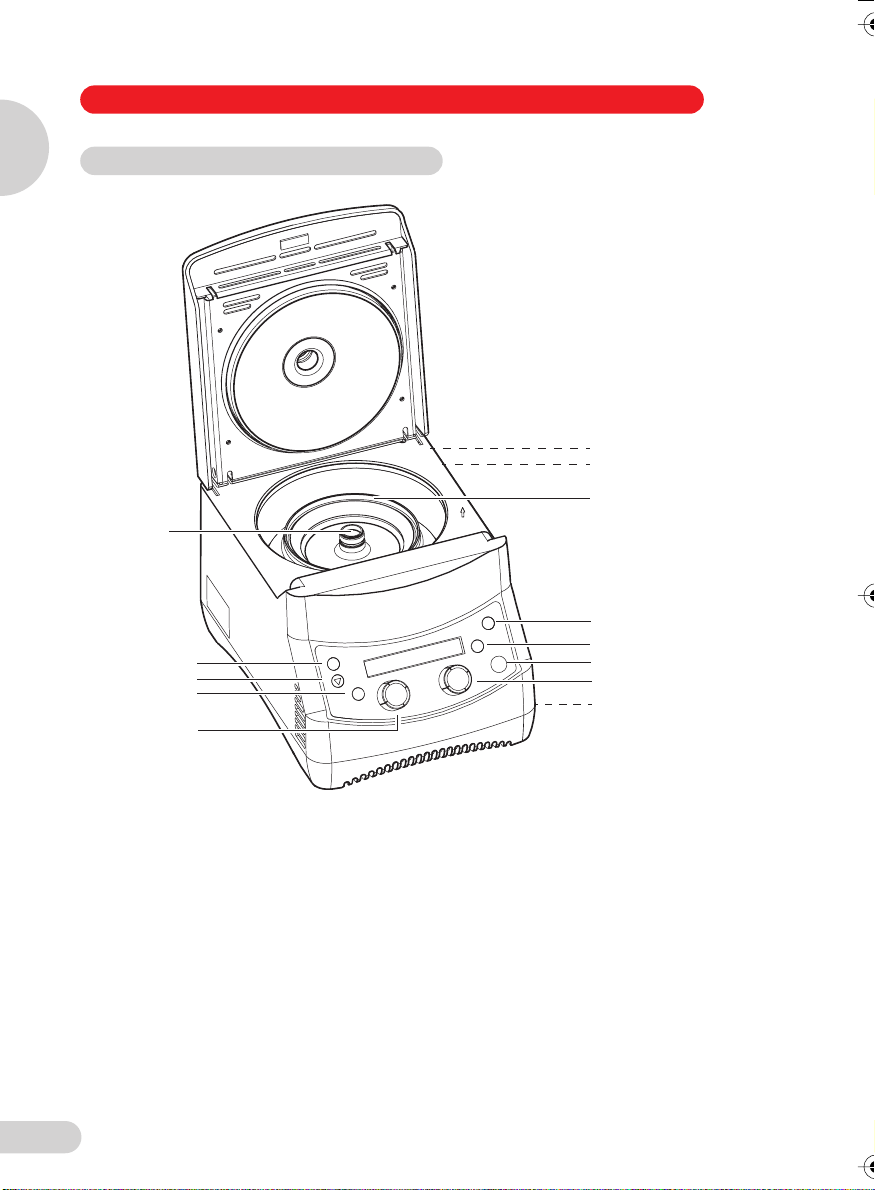

Figure 1 / Abbildung 1

Figure 1 / Abbildung 1

3

menu/enter

Arrow button

rpm/rcf

time

1

2

4

open

short

start/stop

speed

E

menu/enter

Arrow button

rpm/rcf

time

speed

open

short

start/stop

1

2

3

4

E

3

menu/enter button menu/enter-Taste

Arrow button Pfeiltaste

rpm/rcf button rpm/rcf-Taste

Time arrow buttons Zeitwahl-Pfeiltasten

Speed arrow buttons Geschwindigkeits-Pfeiltasten

Lid release button Deckelentriegelungs-Taste

Short run button Kurzzeitlauf-Taste

Start/stop button Start/Stop-Taste

Power plug Netzstecker

Power switch Netzschalter

Rotor nut Rotormutter

Rotor Rotor

Emergency lid release Notentriegelung

Page 4

Centrifuge 5424

Figure 2 / Abbildung 2

Figure 2 / Abbildung 2

3

menu/enter

Arrow button

rpm/rcf

time

1

2

4

open

short

start/stop

speed

E

menu/enter

Arrow button

rpm/rcf

time

speed

open

short

start/stop

1

2

3

4

E

4

menu/enter button menu/enter-Taste

Arrow button Pfeiltaste

rpm/rcf button rpm/rcf-Taste

Time knob Zeitwahl-Drehknopf

Speed selector knob Geschwindigkeits-Drehknopf

Lid release button Deckelentriegelungs-Taste

Short run button Kurzzeitlauf-Taste

Start/stop button Start/Stop-Taste

Power plug Netzstecker

Power switch Netzschalter

Rotor nut Rotormutter

Rotor Rotor

Emergency lid release Notentriegelung

Page 5

Table of contents

1 Introduction................................................................................................................28

1.1 Delivery package .........................................................................................................28

1.2 Installing the device .....................................................................................................28

2 Safety precautions and applicational limitations....................................................30

3 Operation....................................................................................................................33

3.1 Functional and operator control elements...................................................................33

3.2 Menu structure.............................................................................................................34

3.3 Fitting and removing the rotors ...................................................................................34

3.4 Loading the rotors .......................................................................................................34

3.5 Rotors ..........................................................................................................................34

3.6 Centrifugation with timer setting..................................................................................35

3.7 Adjusting centrifuging parameters during centrifugation ............................................35

3.8 Short spin centrifugation .............................................................................................36

3.9 Continuous operation ..................................................................................................36

3.10 rcf display and calculation...........................................................................................37

3.11 Setting startup and braking ramp................................................................................38

3.12 Run start ......................................................................................................................38

3.13 Permanent setting of parameters ................................................................................39

3.14 Activating and deactivating the loudspeaker ..............................................................39

3.15 Volume control.............................................................................................................40

3.16 Standby mode .............................................................................................................40

3.17 Opening the centrifuge in case of power failure..........................................................41

3.18 Fuses ...........................................................................................................................41

4 Maintenance and cleaning........................................................................................42

4.1 Device ..........................................................................................................................42

4.2 Rotors ..........................................................................................................................42

4.3 Glass breakage............................................................................................................43

4.4 Returning devices ........................................................................................................43

5 Troubleshooting ........................................................................................................44

6 Technical data............................................................................................................45

7 Ordering information .................................................................................................46

Table of contents

27

Page 6

The Centrifuge 5424 is a non-refrigerated bench-top centrifuge. It is intended for sample

preparation within the sphere of clinical diagnostics and in the routine, training and research

laboratory in hospitals, science and industry. The devices may only be operated by trained

specialist staff.

1

The various fixed-angle rotors and adapters enable a large number of tubes like micro test

tubes, PCR strips, Microtainers® and Spin Columns to be used. In the context of in vitro

diagnostics, the Centrifuge 5424 is designed among other things for chromosome analysis of

human cells by the FISH technique (Kievits et al. 1990).

Before using the centrifuge 5424 for the first time, please read the manual. The latest

version of the manual and the safety instructions in your language can be found on the

Internet at www.eppendorf.com.

Introduction

1 Centrifuge 5424

1 Rotor FA-45-24-11 incl. rotor lid (only for order no. 5424 000.410, 5424 000.010,

1 power cable

1 manual

1 rotor key

1 Captain Eppi rotor key holder

1 set of fuses

1 Introduction

You will see this symbol on your centrifuge and at a number of points throughout this

manual. The texts it highlights are relevant to safety. Use the centrifuge only when you

have read these safety instructions.

1.1 Delivery package

5424 000.428, 5424 000.029, 022620428, 022620461, 022620401 and 022620444)

1.2 Installing the device

– To disconnect the power supply of the centrifuge from the power supply in the

event of a fault, an emergency switch must be provided away from the centrifuge,

preferably outside the room in which the centrifuge is located or next to the exit

from this room.

– Remove the transport safety device and keep it together with the centrifuge pack-

aging for possible use if the device is subsequently moved.

– Place the centrifuge on a solid, flat, non-resonant lab bench. Check beforehand

whether the lab bench is specified for the weight of the centrifuge.

– The surrounding area must be well-ventilated and protected against direct sunlight.

To ensure that ventilation of the device is not impaired, a minimum fundamental

clearance of at least 30 cm to the side and at least 15 cm to the back wall must be

maintained.

– During centrifugation, according to the recommendations set out in EN 61010-2-020,

a safety clearance of 30 cm must be maintained around the centrifuge within which

there are no objects which may be destroyed and so cause further damage.

– Please ascertain that the power supply and the power frequency are compatible

28

with the information given on the device ID plate.

Page 7

1 Introduction

– Now connect the centrifuge to the power supply and switch it on at the main power

switch (see inside cover page). The centrifuge is now ready for operation and the

display is active.

– Before starting for the first time, check whether the rotor and the rotor lid are

tightened in accordance with specification. To tighten the rotor, place the rotor

key supplied on the rotor nut and turn it clockwise until the rotor nut is firmly tightened up. The rotor lid is then tightened up.

1

Introduction

29

Page 8

2 Safety precautions and applicational limitations

For your personal safety, please be sure to comply with the following regulations

unconditionally.

– The centrifuge 5424 must only be used for the specified applications (see Section 1,

“Introduction”). It must not be operated in explosive atmospheres. Explosive, radioactive

2

Safety precautions and applicational limitations

or highly reactive substances must not be centrifuged.

– When being moved from the cool room to a normal lab environment, the centrifuge must

either run for half an hour in the cool room first to warm up, or it must warm up for at least

3 hours in the lab before being connected to the power supply system, in order to prevent

damage from condensation.

– The centrifuge must not be moved or knocked while in operation.

– Centrifuges which have not been properly installed or repaired may not be operated.

Repairs may only be carried out by Service personnel authorized by Eppendorf. Use only

original Eppendorf spare parts and rotors.

– When handling toxic liquids or pathogenic microorganisms of risk group II (see World Health

Organization: Laboratory Biosafety Manual) comply with the relevant national regulations.

Bioseals are a component of biosafety systems which are not capable, in isolation, of

ensuring that people and the environment are protected when pathogenic microorganisms

are being handled. When working with pathogenic microorganisms of a higher risk group,

more than one aerosol-tight bioseal must be provided for. If the named liquids are spilled in

the rotor or rotor chamber, the centrifuge must be thoroughly and professionally cleaned.

Before using any cleaning or decontamination method other than that set out in Section 4,

"Maintenance and cleaning", please consult Eppendorf to ensure the intended method will

not damage the device.

– Rotors and rotor lids must always be properly secured. The centrifuge may only be

operated with the rotor and rotor lid firmly tightened. To do this, before centrifugation,

place the rotor key supplied for tightening up the rotor on the rotor nut and turn it

clockwise until the rotor nut is firmly tightened up. The rotor lid is then screwed on

tightly (see Section 3.5 "Rotors" with regard to exceptions for rotors FA-45-24-11 and

FA-45-24-11-Special for centrifuging micro test tubes with closed tube lids).

If unusual noises occur when the centrifuge starts, the rotor or the rotor lid are not properly

secure. In this case, stop centrifugation immediately using start/stop.

– The rotor may only be loaded symmetrically. Opposing vessels should be of the same type

and be filled equally. On each rotor you will find information about maximum load (adapter,

tube and contents) per bore - this limit may not be exceeded.

– Rotors showing clear signs of corrosion or mechanical damage must not be used. Check

the accessories regularly.

30

Page 9

2 Safety precautions and applicational limitations

– Rotors are high-grade components which have to withstand extreme stresses and strains.

Aluminum rotors are surface-treated to provide them with a high level of protection from

corrosion by the most common laboratory chemicals, though this protection is not unlimited. Avoid damage from the use of aggressive chemicals such as strong and weak alkalis,

strong acids, solutions of mercury, copper and other heavy metal ions, chlorinated hydrocarbons, concentrated salt solutions and phenol. If the rotor is contaminated by aggressive

substances, clean it immediately with a neutral agent (e.g. Extran® neutral, RBS® neutral or

Teepol® 610 S). This applies to the rotor bores in particular.

Rotors labeled "coated" are particularly resistant to chemicals. However, even on these

rotors, this does not replace regular cleaning as described in Section 4 "Maintenance and

cleaning".

Protect the rotors from mechanical damage. Even minor scratches or cracks can result in

serious internal material damage.

– The material being centrifuged may not exceed a density of 1.2 g/ml at maximum speed.

– If the rotor is run for a lengthy period or more often with short centrifugation runs, the sam-

ple tubes will become hot.

– Keep within the load limits specified for the tubes by the tube manufacturer. Tubes may only

be centrifuged at the preselected g-force (rcf) if they are approved for this application by the

manufacturer.

– Before centrifugation, all the tubes should be subjected to a visual inspection for material

damage. Damaged tubes must not be centrifuged, as if tubes break, there may be further

damage to the centrifuge and its accessories in addition to loss of the sample.

– Tube lids must be sealed down tight before centrifuging. The lids of tubes which are not

sealed may rip off during centrifugation and damage the rotor lid and the centrifuge.

– When using organic solvents (e.g. phenol, chloroform), the durability of plastic tubes may be

impaired with the result that tubes may break during centrifugation.

– When closing the centrifuge lid, do not place your fingers between the lid and the centri-

fuge, otherwise they may be trapped.

– The transparent rotor covers made from polypropylene have a maximum useful life of 3

years. The date of manufacture is impressed on them in the form of a watch .

Rotors and rotor covers which have been damaged chemically or mechanically or

which have passed their maximum useful life must no longer be used.

12

1

11

2

10

3

1

9

4

8

0

5

7

6

2

Safety precautions and applicational limitations

Declaration concerning the ATEX directive (94/9/EC)

The present design and ambient conditions inside Eppendorf centrifuges mean that they are not

suitable for use in a potentially explosive atmosphere. The centrifuges must therefore only be

used in a safe environment such as the open environment of a ventilated laboratory or a fullyextracted fume hood. The use of substances which may contribute to a potentially explosive

atmosphere is not permitted. The final decision on the risks in connection with the use of such

substances is the responsibility of the user of the centrifuge.

31

Page 10

2 Safety precautions and applicational limitations

Transfer

If the device is passed on to someone else, please include the instruction manual.

Disposal

2

In case the product is to be disposed of, the relevant legal regulations are to be observed.

Information on the disposal of electrical and electronic devices in the European

Community

The disposal of electrical devices is regulated within the European Community by national

regulations based on EU Directive 2002/96/EC on waste electrical and electronic equipment

(WEEE).

According to these regulations, any devices supplied after 13.08.05 in the business-to-business

sphere, to which this product is assigned, may no longer be disposed of in municipal or

domestic waste. They are marked with the following symbol to indicate this.

As disposal regulations within the EU may vary from country to country, please contact

your supplier if necessary.

Safety precautions and applicational limitations

32

Page 11

3 Operation

3.1 Functional and operator control elements

See the frontal view (Figure 1 / 2) on the first inside cover page of this manual.

menu/enter Menu/enter button see Section 3.8

Arrow button see Section 3.8

rpm/rcf rpm/rcf button see Section 3.10

time Time knob/arrow buttons see Sections 3.6, 3.7 and 3.9

speed Speed selector knob/arrow

buttons

open Lid release button see Section 3.6

short Short run button see Section 3.8

start/stop Start/stop button see Section 3.6

1 Power plug see Section 3.6

2 Power switch see Section 3.6

3 Rotor nut see Section 3.3

4 Rotor see Sections 3.3 to 3.5

E Emergency lid release see Section 3.17

3.2 Menu structure

In the menu you can

– adjust the startup and braking ramp,

– activate and deactivate the loudspeaker,

– adjust run start,

– vary the speed of short run centrifugation,

– switch standby mode on and off,

– control volume and

– set permanent centrifugation parameters.

menu/enter activates the menu and confirms a selected menu item or adjusted setting.

the arrow button selects a menu item

The menu consists of two levels, M1 and M2. In the first menu level, you can select between the

various menu items. The symbols for the functions light up. In addition, the symbol for each

menu item selected flashes in the activated setting. In the second menu level, the setting for the

selected function can be amended. The relevant symbol always appears when the settings are

selected.

The last inside cover page shows the menu structure with reference to the relevant sections of

this manual.

see Sections 3.6 and 3.7

3

Operation

33

Page 12

3 Operation

3.3 Fitting and removing the rotors

Fit the rotor onto the motor shaft and tighten the rotor nut firmly by turning it clockwise

using the appropriate rotor key provided. Before each start, check that the rotor is firmly

3

tightened.

To release the rotor, turn the rotor nut anticlockwise using the rotor key.

Under no circumstances centrifuge with rotors which already have obvious traces of

corrosion or mechanical damage (see Section 2 "Safety precautions and applicational

limitations").

Operation

3.4 Loading the rotors

The rotors must only be loaded symmetrically. The adapters must be loaded only with

the specified tubes. Minimize differences in weight between the filled sample tubes taring with a scale is recommended. This will reduce wear on the drive and cut running

noise.

The maximum load per bore is indicated on each rotor.

3.5 Rotors

A maximum of 24 x 1.5/2.0 ml micro test tubes can be centrifuged in rotors FA-45-24-11 and

FA-45-24-11-Special. With the appropriate adapters, it is also possible to load it with 0.2 ml

PCR tubes, 0.4 ml micro test tubes, 0.5 ml micro test tubes and 0.6 ml Microtainers

possible to load the rotor with 24 Spin Columns. However, the rotor F-45-18-11-Kit is recommended for centrifuging Spin Columns. The maximum speed of rotors FA-45-24-11 and

FA-45-24-11-Special is 14,680 rpm (120 V: 15,000 rpm) and the maximum g-force (rcf)

20,238 x g (120 V: 21,130 x g). The maximum load (adapter, tube and contents) per bore for the

rotors is 3.75 g.

Rotors FA-45-24-11 and FA-45-24-11-Special can be operated both with and without

a rotor lid. Without a rotor lid, the rotors are not aerosol-tight and are slightly noisier.

Particular attention should be paid to the fact that tube lids are closed in accordance

with specification before centrifugation. Aerosol-tight centrifugation can only be carried

out with the rotor lid in place. Spin Columns must always be centrifuged with the

rotor lid. The rotor lid is not required during standard operation.

With the rotor F-45-18-11-Kit, up to 18 Spin Columns can be centrifuged at a maximum of

14,680 rpm (120 V: 15,000 rpm) or 17,347 x g (120 V: 18,111 x g). This rotor is characterized by

a particularly high edge so that all standard Spin Columns fit under the rotor lid. But it is also

possible to load the rotor with 1.5/2.0 ml micro test tubes, and using the appropriate adapters,

with 0.2 ml PCR tubes, 0.4 ml micro test tubes, 0.5 ml micro test tubes and 0.6 ml Microtainers®. The maximum load (adapter, tube and contents) per bore for this rotor is 3.75 g.

Rotor F-45-18-11-Kit may only be centrifuged with the rotor lid tightened in

accordance with specification.

®

. It is also

34

Page 13

3 Operation

With rotor F-45-32-5-PCR, up to 32 PCR tubes (0.2 ml) or four 5x or 8x rows of 0.2 ml PCR

tubes can be centrifuged at maximum 14,680 rpm (120 V: 15,000 rpm) or 17,829 x g (120 V:

18,615 x g). Maximum load (tubes and contents) per 8x row with this rotor is 3.5 g.

Rotor F-45-32-5-PCR may only be centrifuged with the rotor lid tightened in

accordance with specification.

When loading rotors, make sure that the micro test tubes are inserted in the rotor bores

opposite one another in pairs. To ensure that the rotor is symmetrically loaded,

opposing tubes must contain the same filling volume.

3.6 Centrifugation with timer setting

Switch on the centrifuge with the power switch if necessary and open the lid using the open

button. The specified values of the last run are displayed. Load the rotor symmetrically, fit the

rotor lid and close the centrifuge lid.

time adjusts the run time up to 10 min. in 0.5 min. increments, then in 1 min.

increments up to 09:59 h.

speed adjusts the speed in increments of 50 rpm or the g-force (rcf) in increments of

50 x g.

start/stop starts centrifugation. The symbol ■ flashes while the rotor is running.

During centrifugation, the remaining run time is displayed in minutes. The last minute is counted

down in seconds. In addition, the speed of the rotor/relevant g-force (rcf) is displayed. The timer

setting, speed and rpm/rcf display can be adjusted during centrifugation. The menu, the open

and the short buttons are blocked during centrifugation.

start/stop if the button is pressed again, centrifugation is stopped before expiry of the set

run time.

After expiry of the set run time, the centrifuge will otherwise stop automatically. During braking,

the timer flashes and shows the spin time which has elapsed. When the rotor has come to a

standstill, a signal tone is heard and the centrifuge lid opens automatically. The display then

shows the symbol .

3

Operation

3.7 Adjusting centrifuging parameters during centrifugation

The timer setting and rotation speed can be changed during centrifugation using the two knobs

or the arrow buttons. If these parameters are adjusted, the display begins flashing. The new

centrifuging parameters are accepted after a short time.

The time which has elapsed up to this point is offset against the new actual value. In order that

centrifugation cannot be stopped by changing the timer setting, the shortest time which can be

set is the time which has already elapsed plus 2 minutes. Parameters cannot be adjusted during

the braking process.

35

Page 14

3

Operation

3 Operation

3.8 Short spin centrifugation

Switch on the centrifuge with the power switch if necessary and open the lid using the open

button. The specified values of the last run are displayed. Load the rotor symmetrically, fit the

rotor lid and close the centrifuge lid.

short starts a short run at the specified speed. The short button must be kept

depressed throughout the entire short run. The symbol ■ flashes while the rotor is

running. Time is counted upwards in seconds. Centrifugation is stopped by

releasing the short button during the braking process, centrifugation can be restarted twice by pressing the short button again.

The timer flashes and shows the spin time which has elapsed during braking. When the rotor

has come to a standstill, the centrifuge lid opens automatically. The display then shows the

symbol .

During a short run, all other buttons and knobs are blocked.

Specified speed is set via the menu:

menu/enter activates the menu.

select the item SHORT and confirm with

menu/enter.

in the second menu level, select the item MAX in order to centrifuge at maximum

speed/g-force. To perform short-run centrifugation at the currently-set speed/

g-force, select the item SET with the arrow button.

menu/enter confirms the set speed and you automatically return to the item BACK in the first

menu level. Press the key again to exit the menu.

If the specified speed is not to be changed after all, it is possible to exit the second menu level

by selecting the BACK menu item and then confirming with the menu/enter button.

3.9 Continuous operation

Switch on the centrifuge with the power switch if necessary and open the lid using the open

button. The specified values of the last run are displayed. Load the rotor symmetrically, fit the

rotor lid and close the centrifuge lid.

time the continuous function is set using the time selection knob/arrow buttons to

above 09:59 h or below 30 sec. The timer shows "oo" to indicate continuous running. Time is counted upwards in 30-second increments.

speed adjusts the speed in increments of 50 rpm or the g-force (rcf) in increments of

50 x g.

start/stop starts centrifugation. The symbol ■ flashes while the rotor is running.

start/stop if the button is pressed again, centrifugation will stop.

During braking, the timer flashes and shows the spin time which has elapsed. When the rotor

has come to a standstill, a signal tone is heard and the centrifuge lid opens automatically. The

display then shows the symbol .

36

Page 15

3 Operation

3.10 rcf display and calculation

rpm/rcf Pressing the button toggles the display from rpm (1/min) to rcf and vice versa.

Please note that the g-force (rcf) shown when toggling the display is standardized to rotor

FA-45-24-11/ FA-45-24-11-Special without adapter. At the maximum speed in each case you

can achieve the following maximum g-force (rcf) in the various rotors with the different adapters:

Rotor Adapter

FA-45-24-11,

FA-45-24-11Special

F-45-18-11-Kit without adapter 7,2 17.347 18.111

F-45-32-5-PCR 7,4 17.829 18.615

To calculate the g-force (rcf) for a specific adapter you can apply the following formula according to DIN 58 970:

rcf = 1.118 • 10-5 • n2 • r

n: speed in rpm

r

: max. centrifugal radius in cm

max

Example: in rotor FA-45-24-11, the 0.5 ml adapter has a maximum radius of 7.3 cm.

At 7,000 rpm, a maximum g-force (rcf) of 4,000 x g is achieved.

without adapter 8,4 20.238 21.130

0.2 ml 6,3 15.179 15.848

0.4 ml 8,4 20.238 21.130

0.5 ml 7,3 17.588 18.363

0.6 ml 8,4 20.238 21.130

0.2 ml 5,1 12.288 12.829

0.4 ml 7,2 17.347 18.111

0.5 ml 6,1 14.697 15.345

0.6 ml 7,2 17.347 18.111

max

Max. centrifugal

radius r

max

Max. g-force (rcf)

[cm]

(230 V / 100 V)

Max. g-force (rcf)

(120V)

3

Operation

37

Page 16

3

Operation

3 Operation

3.11 Setting startup and braking ramp

When setting the startup and braking ramp, you can select between two levels. Selection is

made using the menu:

menu/enter activates the menu.

select the item SOFT and confirm with

menu/enter.

in the second menu level, select the item ON for the rotor to start up and brake

more slowly and the item OFF for it to start up and brake more quickly.

menu/enter confirms the amended startup and braking ramp and you automatically return to

the item BACK in the first menu level. Press the key again to exit the menu.

If the startup and braking ramp is not to be changed after all, it is possible to exit the second

menu level by selecting the BACK menu item and then confirming with the menu/enter button.

If the slower startup and braking ramp is switched on, the symbol appears in the display.

3.12 Run start

For centrifugation, time can be counted either immediately from the start or not until attainment

of the preset speed or g-force (rcf). This is specified via the menu:

menu/enter activates the menu.

select the item ATSET and confirm with

menu/enter.

In the second menu level select the item ON for time to the counted only once the

set speed/g-force (rcf) has been reached. Select the item OFF if time is to be

counted from the start of centrifugation.

menu/enter confirms the selected run start and you automatically return to the item BACK in

the first menu level. Press the key again to exit the menu.

If the setting for run start is not to be changed after all, it is possible to exit the second menu

level by selecting the BACK menu item and then confirming with the menu/enter button.

The selected setting is shown in the display. If time is counted from the start, the symbol

appears. If time is only counted from when the specified speed/g-force (rcf) is reached, this is

symbolized by .

soft

38

Page 17

3 Operation

3.13 Permanent setting of parameters

The selected centrifugation parameters can be permanently set via the menu so that neither

time or rotation speed/g-force (rcf) can be altered using the relevant knobs/arrow buttons:

menu/enter activates the menu.

select the item LOCK and confirm with

menu/enter.

In the second menu level, select the item ON if centrifugation parameters are to be

made permanent. To enable centrifugation parameters to be set freely, select the

item OFF using the arrow button.

menu/enter confirms the permanent setting of parameters and you automatically return to the

item BACK in the first menu level. Press the key again to exit the menu.

If the permanent setting of parameters is not to be changed after all, it is possible to exit the

second menu level by selecting the BACK menu item and then confirming with the menu/enter

button.

The selected setting is shown in the display. Once the centrifugation parameters are locked, the

display shows the symbol of a . If the set parameters can be adjusted, this is symbolized by

an .

If the parameters have been permanently set and these are to be changed using the knobs/

arrow buttons, SAFE appears in the display.

3.14 Activating and deactivating the loudspeaker

3

Operation

The loudspeaker is activated and deactivated via the menu:

menu/enter activates the menu.

select the item ALARM and confirm with

menu/enter.

In the second menu level, select the item ON to activate the loudspeaker.

The loudspeaker can be deactivated via the OFF item.

menu/enter confirms that the loudspeaker has been activated/deactivated and you automati-

cally return to the item BACK in the first menu level. Press the key again to exit the

menu.

If the setting for the loudspeaker is not to be changed after all, it is possible to exit the second

menu level by selecting the BACK menu item and then confirming with the menu/enter button.

When the loudspeaker is activated, the symbol appears in the display.

39

Page 18

3

Operation

3 Operation

3.15 Volume control

The volume of the loudspeaker is controlled in the menu. The loudspeaker needs to be activated for you to hear the change in volume (see Section 3.14 "Activating and deactivating the

loudspeaker"):

menu/enter activates the menu.

select the item VOL and confirm with

menu/enter.

In the second menu level, select the item VOL1. A bleep is heard. To increase the

volume of this sound further, use the arrow button to select the other items VOL2

to VOL5. For every change, a signal at the new volume is heard, becoming louder

each time.

menu/enter confirms the selected volume of the loudspeaker and you automatically return to

the item BACK in the first menu level. Press the key again to exit the menu.

If the volume is not to be changed after all, it is possible to exit the second menu level by selecting the BACK menu item and then confirming with the menu/enter button.

3.16 Standby mode

If the centrifuge has not been used for 15 min., it switches to standby mode. The “EP” logo then

appears in the display. When a button (or knob) is used or the centrifuge lid is closed, the centrifuge is reactivated and ready for operation.

Standby mode can be switched on and off via the menu:

menu/enter activates the menu.

select the item SLEEP and confirm with

menu/enter.

In the second menu level, select the item ON to switch on Standby mode.

Standby mode can be switched off via the OFF item.

menu/enter confirms that Standby mode has been switched on/off and you automatically

return to the item BACK in the first menu level. Press the key again to exit the

menu.

If standby mode is not to be changed after all, it is possible to exit the second menu level by

selecting the BACK menu item and then confirming with the menu/enter button.

40

Page 19

3 Operation

3.17 Opening the centrifuge in case of power failure

If the lid release does not function following a power failure, the emergency lid release

can be operated by hand.

To do so, first unplug the power plug. Before activating the emergency release, also

ensure that the rotor has come to a standstill. Check by looking through the window in

the centrifuge lid. It can take up to 6 minutes for the rotor to come to a standstill.

The emergency release is located on the right-hand side of the centrifuge (see “E” in

Figure 1 / 2, first inside cover page).

After a visual check that the rotor has come to a standstill, first remove the plastic cap.

The rotor key supplied then has to be inserted in the nut underneath the cap and turned

anticlockwise. This releases the lid and allows it to be opened.

The rotor key must then be removed immediately and the plastic cap put back on.

3.18 Device fuses

The fuse box is located under the power plug. To replace the fuses, unplug the power plug and

pull the fuse box out towards the rear. The two fuses can then be replaced (see Ordering

information).

3

Operation

41

Page 20

4 Maintenance and cleaning

4.1 Device

The outer surfaces of the centrifuge and the rotor chamber should be cleaned regularly with a

neutral agent (e.g. Extran

4

poses and to prevent adhering impurities causing corrosion.

If material hazardous to health or aggressive material contaminate the device, the owner is

responsible for appropriate cleaning and decontamination.

Before cleaning, unplug the power plug with the lid open, unscrew the rotor using the rotor key

supplied and clean it separately. Use only neutral agents for cleaning (e.g. Extran

®

RBS

neutral, Teepol® 610 S). Bacillol® AF, Meliseptol® und Perform® are recommended for

cleaning and disinfecting the outer surface of the centrifuge and the rotor chamber. Do not allow

any liquid to get into the gap at the motor shaft outlet. For this reason, the rotor chamber should

be cleaned only with a damp cloth.

The outer surface of the centrifuge and the rotor chamber have been tested for resistance to the

cleaning agents and disinfectants mentioned. However, this does not guarantee that the device

is disinfected following application of one of the methods mentioned. You should also consult

your laboratory safety officer with regard to a suitable method of cleaning and disinfecting.

Before any cleaning or disinfecting method other than that recommended by the manufacturer

Maintenance and cleaning

is used, please check with Eppendorf that the intended method will not damage the device or

its accessories. In order to ensure long-term, reliable work with your centrifuge, please note that

aggressive chemicals may damage the rotor and the chamber. Check your device once a month

for corrosion and damage.

The rubber seals in the rotor chamber should be rinsed off thoroughly with water and lubricated

with glycerin or talc after every clean to prevent them becoming brittle.

4.2 Rotors

Rotors need cleaning regularly to prevent residues of the material being centrifuged from

changing their properties. Check the rotors for residues and corrosion at least once a month.

This applies to the rotor bores in particular. Please look after your rotor regularly; this will protect

it and increase its service life.

For thorough cleaning, the rotor is unscrewed using the rotor key supplied and cleaned using a

neutral agent (e.g. Extran

®

Perform

rotor bores are also brushed out with a bottle brush. The rotor and bores are then rinsed out

thoroughly and placed on a cloth with the bores facing downwards to dry. The rotor is then put

back in and the rotor nut tightened up.

The rotors have been tested for resistance to the cleaning agents and disinfectants mentioned.

However, this does not guarantee that the device is disinfected following application of one of

the methods mentioned. You should also consult your laboratory safety officer with regard to a

suitable method of cleaning and disinfecting. However, before any cleaning or disinfecting

method other than that recommended by the manufacturer is used, please check with Eppendorf that the intended method will not damage the rotors or their accessories. In order to ensure

long-term, reliable work with your centrifuge, please note that aggressive chemicals may damage the rotor.

are recommended for cleaning and disinfecting the rotor and the rotor bores. The

®

neutral, RBS® neutral or Teepol® 610 S). This is for hygiene pur-

®

neutral,

®

neutral, RBS® neutral, Teepol® 610 S). Bacillol® AF, Meliseptol® und

42

Page 21

4 Maintenance and cleaning

All the rotors, rotor lids and adapters can be autoclaved (121 ˚C, 20 min.). The lids of aerosoltight rotors FA-45-24-11 and FA-45-24-11-Special should be replaced after no more than

50 autoclaving operations.

On the aerosol-tight rotors, the rotor lids should be replaced if the sealing rings on the lid thread

and in the lid groove become worn. Regular care of the sealing rings is required to protect the

rotors. Check that the seals are undamaged before use.

Aerosol-tight rotors may not be stored with lids done up tightly!

4.3 Glass breakage

When centrifuging glass tubes, be aware that as speed/rcf increases, so does the risk of glass

breaking. Please observe manufacturers’ information about maximum loading of centrifuge

tubes.

In case of glass breakage, carefully remove all splinters and all ground glass from the rotor, the

adapters and the rotor chamber. You may need to replace adapters in order to prevent further

damage.

Otherwise fine glass splinters will scratch the surface of the rotors, reducing their resistance to

chemicals. Air vortices will result in very fine black abraded metal in the rotor chamber; in addition to damaging the rotor chamber, rotor and adapters, this material will also cause samples to

become contaminated.

Check the rotor bores regularly for residues or damage.

4.4 Returning devices

4

Maintenance and cleaning

When returning centrifuges, ensure that these devices are fully decontaminated and do not

present any kind of health risk to our service staff.

For further information and a blank of the decontamination confirmation, please visit

www.eppendorf.com. Do also consult your laboratory safety officer about a suitable decontamination method.

Please fill in the decontamination confirmation and enclose it with the device if it is to be

returned to Eppendorf.

43

Page 22

5 Troubleshooting guide

If the suggested rectification measures repeatedly fail, contact Eppendorf.

Error / Display Cause Remedy

5

Troubleshooting guide

No display No power Check power connection

Lid cannot be opened Power failure See above, activate emergency lid

Centrifuge will not start Lid not closed Press lid shut

Centrifuge shakes when

starting up

Centrifuge brakes during a

short run although the

short button is still

depressed

LID ERROR Lid cannot be locked Close lid again and start

INT Power interruption

NO RPM Error in speed

Err 6 Drive error Repeat run, if error recurs => Service

Err 7 Overspeed or major

Err 8 Rotor loose, drive error Tighten up rotor, repeat run, if error

Err 11 Power interruption

Err 9, 10, 12 - 17 Electronics error Repeat run, if error recurs => Service

Power failure Check power fuses of device and

Rotor still running Wait for rotor to stop

Rotor unevenly loaded Stop centrifugation and load evenly

Button was released

briefly more than 2x

(drive protection

function)

Lid cannot be unlocked Switch device off and back on, press

Lid cannot be unlocked

during a run

during a run

measuring system

control deviation

during a run

laboratory

release

Do not release button during a short

run

the open button, if error recurs:

switch off device, activate emergency

lid release, if error recurs => Service

Wait for centrifuge to come to a

standstill, repeat run, if error recurs

=> Service

Check power plug

Leave device switched on until the

error message disappears (10 s or

6 min.), repeat run, if error recurs =>

Service

Check rotor properly tightened,

repeat run

recurs => Service

Check power plug, repeat run

44

Page 23

6 Technical data

Mains power connection: 230 V / 50 – 60 Hz

120 V / 50 - 60 Hz

100 V / 50 - 60 Hz

Power output 250 W

Max. speed 100 to 14,680 rpm (230 V / 100 V)

100 to 15,000 rpm (120 V)

Max. relative centrifugal force (rcf) 20,238 x g (230 V / 100 V)

21,130 x g (120 V)

Max. load 24 x 2.0 ml micro test tubes

Max. kinetic energy 7500 Nm

Permissible density of material to be centrifuged 1.2 g/ml

Ambient temperature 2 - 40 ˚C

Relative humidity 10 - 75 %

Setup height max. 2000 m above NSL

Dimensions Width: 236 mm

Depth: 320 mm

Height: 227 mm

Weight excluding rotor: 13.4 kg

Startup time (230 V) 15 s

Deceleration time (230 V) 16 s

Startup time (120 V) 15 s

Deceleration time (120 V) 18 s

Startup time (100 V) 20 s

Deceleration time (100 V) 16 s

Fuses 3.15 AT (230 V)

6.3 AT (120 V / 100 V)

Noise level < 56 dB (A)

Overvoltage category II

Degree of contamination: 2

6

Technical data

Technical specifications subject to change!

45

Page 24

7 Ordering information

Centrifuge 5424

7

with knobs, without rotor

230 V / 50 - 60 Hz 5424 000.614 022620436

Centrifuge 5424

with keypad, without rotor

230 V / 50 - 60 Hz 5424 000.215 022620452

Centrifuge 5424

with knobs, with rotor FA-45-24-11

incl. rotor lid, 230 V / 50 - 60 Hz 5424 000.410 022620428

Centrifuge 5424

with keypad, with rotor FA-45-24-11

incl. rotor lid, 230 V / 50 - 60 Hz 5424 000.010 022620461

Ordering information

Centrifuge 5424

with knobs, without rotor

120 V / 50 - 60 Hz 5424 000.622 022620487

Centrifuge 5424

with keypad, without rotor

120 V / 50 - 60 Hz 5424 000.223 022620498

Centrifuge 5424

with knobs, with rotor FA-45-24-11

incl. rotor lid, 120 V / 50 - 60 Hz 5424 000.428 022620401

Centrifuge 5424

with keypad, with rotor FA-45-24-11

incl. rotor lid, 120 V / 50 - 60 Hz 5424 000.029 022620444

Fixed-angle rotors and rotor lids

Fixed-angle rotor FA-45-24-11

with rotor lid, aluminum, aerosol-tight,

angle 45˚, 24 places, max. diameter 11 mm,

designed for 1.5/2.0 ml micro test tubes 5424 702.007 022653008

Spare lid (aluminum) for rotor FA-45-24-11,

aerosol-tight 5424 703.003 022653024

Fixed-angle rotor FA-45-24-11-Special

with rotor lid, aluminum, aerosol-tight, coated

angle 45˚, 24 places, max. diameter 11 mm,

designed for 1.5/2.0 ml micro test tubes 5424 700.004 022653041

Spare lid (aluminum) for rotor

FA-45-24-11-Special, aerosol-tight, coated 5424 701.000 022653067

Order no. Order no.

International North America

46

Page 25

7 Ordering information

Order no. Order no.

International North America

Fixed-angle rotor F-45-18-11-Kit

with rotor lid, aluminum,

angle 45˚, 18 places, max. diameter 11 mm,

designed for 1.5/2.0 ml micro test tubes 5424 706.002 022653083

Spare lid (polypropylene) for rotor F-45-18-11-Kit 5424 707.009 022653105

Fixed-angle rotor F-45-32-5-PCR

with rotor lid, aluminum,

angle 45˚, 32 places, max. diameter 5 mm,

designed for 0.2 ml PCR tubes 5424 704.000 022653121

Spare lid (aluminum) for rotor F-45-32-5-PCR 5424 708.005 022653148

Accessories

Adapter for 0.2 ml PCR tubes,

for FA-45-24-11, FA-45-24-11-Special

and F-45-24-11-Kit, per 6 pcs 5425 715.005 022636260

Adapter for 0.4 ml micro test tubes,

for FA-45-18-11, FA-45-18-11-Special

and F-45-24-11-Kit, per 6 pcs 5425 717.008 022636243

Adapter for 0.5 ml micro test tubes

and 0.6 ml Microtainers

for FA-45-18-11, FA-45-18-11-Special

and F-45-24-11-Kit, per 6 pcs 5425 716.001 022636227

Rotor key 5416 301.001 022634305

Captain Eppi, rotor key holder, 1 pc 5703 350.102 022639609

Set of fuses 2 x 3.15 AT (230 V) 5424 852.122 950004266

®

,

2 x 6.3 AT (120 V / 100 V) 5424 852.130 950004240

7

Ordering information

Rotor code

All Eppendorf rotors are designated according to a simple, logical system which describes the

technical specifications as a uniform series of numbers and letters e.g.:

Fixed-angle Angle of

rotor

adapter bore

Ø Tube/

Adapter Swing-bucket rotor

Ø tube/adapter

bore

F A 45 30 11 A 4 81

Aerosol-tight

version

Max. no. tubes/

adapters

Max. no tubes/

adapters

47

Page 26

7 Ordering information

Important

Use only the original accessories we recommend. The functioning and safety of centrifuges may

be impaired if you use spares or disposables other than those we recommend! Any warranty

and liability for losses thus caused shall be excluded.

7

Bacillol® AF Registered trade mark of Bode Chemie GmbH & Co., Hamburg, Germany

®

Extran

neutral Registered trade mark of Merck KgaA, Darmstadt, Germany

Meliseptol

Microtainer

Perform

RBS

Teepol

Ordering information

®

®

®

®

neutral Registered trade mark of Carl Roth GmbH + Co. KG, Karlsruhe, Germany

®

610 S Registered trade mark of Sigma-Aldrich Corp., St. Louis, USA

Registered trade mark of B. Braun Melsungen AG, Melsungen, Germany

Registered trade mark of Becton Dickinson, Franklin Lakes, USA

Registered trade mark of Schülke & Mayr GmbH, Norderstedt, Germany

48

Page 27

Page 28

Page 29

Page 30

Menu structure / Menüstruktur

M1 M2

BACK

SOFT BACK

ON

OFF

ALARM BACK

ON

OFF

ATSET

SHORT

SLEEP

LOCK

VOL

BACK

ON

OFF

BACK

MAX

SHORT

BACK

ON

OFF

BACK

ON

OFF

BACK

VOL1

VOL2

VOL3

VOL4

VOL5

SOFT

see Section 3.11 /

siehe Kapitel 3.11

see Section 3.14 /

siehe Kapitel 3.14

see Section 3.12 /

siehe Kapitel 3.12

see Section 3.8 /

siehe Kapitel 3.8

see Section 3.16 /

siehe Kapitel 3.16

see Section 3.13 /

siehe Kapitel 3.13

see Section 3.15 /

siehe Kapitel 3.15

132

Page 31

Eppendorf Offices

SPAIN

SWITZERLAND

UNITED KINGDOM

USA

OTHER COUNTRIES

AUSTRALIA / NEW ZEALAND

Eppendorf South Pacific Pty. Ltd.

Tel. +61 2 98 89 50 00

Fax +61 2 98 89 51 11

E-Mail: Info@eppendorf.com.au

Internet: www.eppendorf.com.au

AUSTRIA

Eppendorf Austria

Tel. +43 1 2901756-0

Fax +43 1 2901756-20

E-Mail: office@eppendorf.at

Internet: www.eppendorf.at

BRAZIL

Eppendorf do Brasil Ltda.

Tel. +55 11 3095 9344

Fax +55 11 3095 9340

E-Mail:

eppendorf@eppendorf.com.br

Internet: www.eppendorf.com.br

CANADA

Eppendorf Canada Ltd.

Tel. +1 905 826 5525

Fax +1 905 826 5424

E-Mail: canada@eppendorf.com

Internet: www.eppendorfna.com

GERMANY

Eppendorf Vertrieb

Deutschland GmbH

Tel. +49 2232 418-0

Fax +49 2232 418-155

E-Mail: vertrieb@eppendorf.de

Internet: www.eppendorf.de

INDIA

Eppendorf India Limited

Tel. +91 44 42 11 13 14

Fax +91 44 42 18 74 05

E-Mail: info@eppendorf.co.in

Internet: www.eppendorf.co.in

ITALY

Eppendorf s.r.l.

Tel. +390 2 55 404 1

Fax +390 2 58 013 438

E-Mail: eppendorf@eppendorf.it

Internet: www.eppendorf.it

JAPAN

Eppendorf Co. Ltd.

Tel. +81 3 5825 2363

Fax +81 3 5825 2365

E-Mail: info@eppendorf.jp

Internet: www.eppendorf.jp

Eppendorf Ibérica S.L.U.

Tel. +34 91 651 76 94

Fax +34 91 651 81 44

E-Mail: iberica@eppendorf.es

Internet: www.eppendorf.es

Vaudaux-Eppendorf AG

Tel. +41 61 482 1414

Fax +41 61 482 1419

E-Mail: vaudaux@vaudaux.ch

Internet: www.eppendorf.ch

Eppendorf UK Limited

Tel. +44 1223 200 440

Fax +44 1223 200 441

E-Mail: sales@eppendorf.co.uk

Internet: www.eppendorf.co.uk

Eppendorf North America

Tel. +1 516 334 7500

Fax +1 516 334 7506

E-Mail: info@eppendorf.com

Internet: www.eppendorfna.com

CHINA

Eppendorf China Ltd.

Tel. +86 21 68760880

Fax +86 21 50815371

E-Mail: market.info@eppendorf.cn

Internet: www.eppendorf.cn

FRANCE

EPPENDORF FRANCE S.A.R.L.

Tel. +33 1 30 15 67 40

Fax +33 1 30 15 67 45

E-Mail: eppendorf@eppendorf.fr

Internet: www.eppendorf.fr

NORDIC

Eppendorf Nordic Aps

Tel. +45 70 22 29 70

Fax +45 45 76 73 70

E-Mail: nordic@eppendorf.dk

Internet: www.eppendorf.dk

SOUTH & SOUTHEAST ASIA

Eppendorf Asia Pacific Sdn. Bhd.

Tel. +60 3 8023 2769

Fax +60 3 8023 3720

E-Mail:

asiapacifichq@eppendorf.com.my

Internet: www.eppendorf.com.my

Internet:

www.eppendorf.com/worldwide

Page 32

is a registered trademark.

®

In touch with life

Your local distributor: www.eppendorf.com/worldwide

Eppendorf AG · 22331 Hamburg · Germany · Tel: +49 40 538 01-0 · Fax: +49 40 538 01-556

E-Mail: eppendorf@eppendorf.com

Eppendorf North America, Inc. · One Cantiague Road · P.O. Box 1019 · Westbury, N.Y. 11590-0207 · USA

Tel: +1 516 334 7500 · Toll free phone: +1 800 645 3050 · Fax: +1 516 334 7506 · E-Mail: info@eppendorf.com

Application Support

Europe, International: Tel: +49 1803 666 789 · E-Mail: support@eppendorf.com

North America: Tel: +1 800 645 3050 ext. 2258 · E-Mail: support_na@eppendorf.com

Asia, Pacific: Tel: +60 3 8023 6869 · E-Mail: support_asiapacific@eppendorf.com

eppendorf

B 5424 900.011-04/0408 · Printed in Germany

Loading...

Loading...