Page 1

BA00251R/09/EN/14.13

71209223

Device software

02.00

Products Solutions Services

Operating instructions

iTEMP® TMT85

Temperature head transmitter

with FOUNDATION Fieldbus™ - protocol

9

Page 2

Brief overview

For quick and easy commissioning:

Safety instructions → Page 4

Æ

Installation instructions → Page 8

Æ

Wiring → Page 13

Æ

Display and operating elements → Page 22

Information on configuration and operating programs from other

manufacturers.

Information about setting the hardware write protection, device

address, etc. for FOUNDATION Fieldbus communication

Æ

Commissioning → Page 27

Commissioning via the FOUNDATION Fieldbus interface - quick start

for device configuration for standard operation

Customer-specific configuration → Page 52

Complex measurement tasks require additional functions to be

configured that the user can individually select, set and adapt to his

process conditions by setting the appropriate parameters.

A detailed description of all the functions and device parameters.

Endress+Hauser

Page 3

TMT85

Table of contents

1 Safety instructions . . . . . . . . . . . . . . . . . . 4

1.1 Designated use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Installation, commissioning, operation . . . . . . . . . 4

1.3 Operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Notes on safety conventions and icons . . . . . . . . . 5

2 Identification . . . . . . . . . . . . . . . . . . . . . . 6

2.1 Device designation . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Certificates and approvals . . . . . . . . . . . . . . . . . . . . 6

2.4 Registered trademarks . . . . . . . . . . . . . . . . . . . . . . . 7

3 Installation instructions . . . . . . . . . . . . . 8

3.1 Incoming acceptance, transport, storage . . . . . . . . 8

3.2 Installation conditions . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Installation instructions . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Post-installation check . . . . . . . . . . . . . . . . . . . . . 12

4 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Quick wiring guide . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Connecting the sensor cables . . . . . . . . . . . . . . . 14

4.3 FOUNDATION Fieldbus™ cable specification . . 15

4.4 Connecting the measuring unit . . . . . . . . . . . . . . 18

4.5 Post-connection check . . . . . . . . . . . . . . . . . . . . . 20

10 Technical Data. . . . . . . . . . . . . . . . . . . . 43

11 Operation via FOUNDATION Fieldbus™ .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

5 Operation. . . . . . . . . . . . . . . . . . . . . . . . . 21

5.1 Quick operation guide . . . . . . . . . . . . . . . . . . . . . 21

5.2 Display and operating elements . . . . . . . . . . . . . 22

5.3 FOUNDATION Fieldbus™ technology . . . . . . . . . 22

5.4 Configuration of the transmitter and FF functions

26

5.5 Hardware settings (optional) . . . . . . . . . . . . . . . . 26

6 Commissioning. . . . . . . . . . . . . . . . . . . . 27

6.1 Function check . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Switching on the measuring device . . . . . . . . . . 27

6.3 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

7 Maintenance. . . . . . . . . . . . . . . . . . . . . . 33

8 Accessories . . . . . . . . . . . . . . . . . . . . . . . 33

9 Troubleshooting. . . . . . . . . . . . . . . . . . .34

9.1 Troubleshooting instructions . . . . . . . . . . . . . . . . 34

9.2 Status messages . . . . . . . . . . . . . . . . . . . . . . . . . . 36

9.3 Application errors without messages . . . . . . . . . 40

9.4 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.5 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.7 Software history and overview of compatibility 42

Endress+Hauser 3

Page 4

Safety instructions TMT85

NOTICE

1 Safety instructions

1.1 Designated use

• The device is a universal and configurable temperature head transmitter for resistance

thermometers (RTD), thermocouples (TC) and resistance and voltage transmitters. The

device is designed for installation in a connection head form B according to DIN EN50446.

• The manufacturer cannot be held responsible for damage caused by misuse of the unit.

1.2 Installation, commissioning, operation

Please note the following:

• The device may only be installed, connected, commissioned and maintained by properly

qualified and authorized staff (e.g. electrical technicians) in strict compliance with these

Operating Instructions, applicable standards, legal regulations and certificates (depending

on the application).

• The specialist staff must have read and understood these Operating Instructions and must

follow the instructions they contain.

• The installer must ensure that the measuring system is correctly connected in accordance

with the electrical wiring diagrams.

• Damaged devices which could constitute a source of danger must not be put into operation

and must be clearly indicated as defective.

• Invariably, local regulations governing the opening and repair of electrical devices apply.

1.3 Operational safety

Please pay particular attention to the technical data on the nameplate! The nameplate is

located on the side of the transmitter housing.

Hazardous area

When using in hazardous areas, the national safety requirements must be met. Separate Ex

documentation is contained in these Operating Instructions for measurement systems that

are to mounted in hazardous areas. Strict compliance with the installation instructions,

ratings and safety instructions as listed in this supplementary documentation is mandatory.

The documentation number of that document (XA...) is also indicated on the nameplate.

Electromagnetic compatibility

The measuring device meets the general safety requirements of EN 61010 and the EMC

requirements of IEC/EN 61326 as well as NAMUR recommendations NE 21 and NE 89.

Power supply

‣ Power must be fed to the device from an 9 to 32 VDC power supply in accordance with

NEC Class 02 (low voltage/current) with short-circuit power limit to 8 A/150 VA.

4 Endress+Hauser

Page 5

TMT85 Safety instructions

1.4 Notes on safety conventions and icons

Always refer to the safety instructions in these Operating Instructions labeled with the

following symbols:

Symbol Meaning

WARNING!

A0011190-EN

A0011191-EN

A0011192-EN

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in serious or fatal injury.

CAUTION!

This symbol alerts you to a dangerous situation. Failure to avoid this situation

can result in minor or medium injury.

NOTICE!

This symbol contains information on procedures and other facts which do not

result in personal injury.

ESD - Electrostatic discharge

Protect the terminals against electrostatic discharge. Failure to comply with

this instruction can result in the destruction of parts or malffunction of the

electronics.

Indicates additional information, Tip

A0011193

Endress+Hauser 5

Page 6

Identification TMT85

2 Identification

2.1 Device designation

2.1.1 Nameplate

The right device?

Compare the nameplate on the device with the following graphic:

A0008278

Fig. 1: Nameplate of the head transmitter (example)

1 Device identification number (Device_ID)

2 Power supply and extended order code

3 Serial number and FW release

4 Approvals with symbols

52D barcode

6Tag name (TAG)

7 Approval in hazardous area with number of the relevant Ex documentation (XA...)

8Order code

2.2 Scope of delivery

The scope of delivery of the device comprises:

• Temperature head transmitter

•Securing material

• Multi-language hard copy of Brief Operating Instructions

• Operating Instructions and additional documentation on CD-ROM

• Additional documentation for devices that are suitable for use in hazardous areas (

2 1

), such as Safety Instructions (XA...), Control or Installation Drawings (ZD...).

0

2.3 Certificates and approvals

The device is designed in accordance with good engineering practice to meet state-of-theart safety requirements, has been tested and left the factory in a condition in which it is safe

to operate. The device complies with the standards EN 61 010-1 "Protection Measures for

Electrical Equipment for Measurement, Control, Regulation and Laboratory Procedures" and

with the EMC requirements of IEC/EN 61326.

2.3.1 CE mark, declaration of conformity

The device described in these Operating Instructions is therefore in conformity with the

statutory requirements of the EU Directives. The manufacturer confirms a positive

completion of all tests by fitting the unit with a CE mark.

6 Endress+Hauser

Page 7

TMT85 Identification

2.3.2 Certification Foundation Fieldbus™

The temperature transmitter has successfully passed all the tests and is certified and

registered by the Fieldbus Foundation. The device meets all the requirements of the

following specifications:

• Certified in accordance with FOUNDATION Fieldbus™ specification

• FOUNDATION Fieldbus™ H1

• Interoperability Test Kit (ITK), (device certification number available on request): the

device may also be operated using certified devices from other manufacturers

• Physical Layer Conformance Test of the Fieldbus FOUNDATION™

An overview of additional approvals and certifications can be found on → ä 50.

2.4 Registered trademarks

FOUNDATION Fieldbus

Registered trademark of the Fieldbus Foundation Austin, Texas, USA

TM

Endress+Hauser 7

Page 8

Installation instructions TMT85

NOTICE

3 Installation instructions

3.1 Incoming acceptance, transport, storage

3.1.1 Incoming acceptance

On receipt of the goods, check the following points:

• Are the contents or the packaging damaged?

• Is the delivery complete and is anything missing? Check the scope of delivery against you

order.

3.1.2 Transport and storage

Note the following points:

• Pack the device in such a way as to protect it reliably against impact for storage (and

transportation). The original packaging provides optimum protection.

• The permitted storage temperature is -40 to +100 °C (-40 to 212 °F).

3.2 Installation conditions

3.2.1 Dimensions

The dimensions of the device can be found in chapter 10 ''Technical data''.

3.2.2 Installation point

• In the terminal head, flat face, as per DIN EN50446, direct mounting on insert with cable

entry (middle hole 7 mm)

• In the field housing, separate from the process (see Section 8 'Accessories')

• Mounting on a DIN rail as per EN 60715 is also possible with the DIN rail clip accessory,

see Section 8 'Accessories'.

Information on installation conditions, such as ambient temperature, protection

classification, climatic class etc., can be found in chapter 10 "Technical data".

When using in the hazardous area, the limit values of the certificates and approvals must be

observed (see Safety Instructions XA or CD).

3.3 Installation instructions

A screwdriver is needed to mount the head transmitter.

Damage of the head transmitter

‣ Do not overtighten the mounting screws as this could damage the head transmitter.

Maximum torque = 1 Nm (¾ pound-feet).

8 Endress+Hauser

Page 9

TMT85 Installation instructions

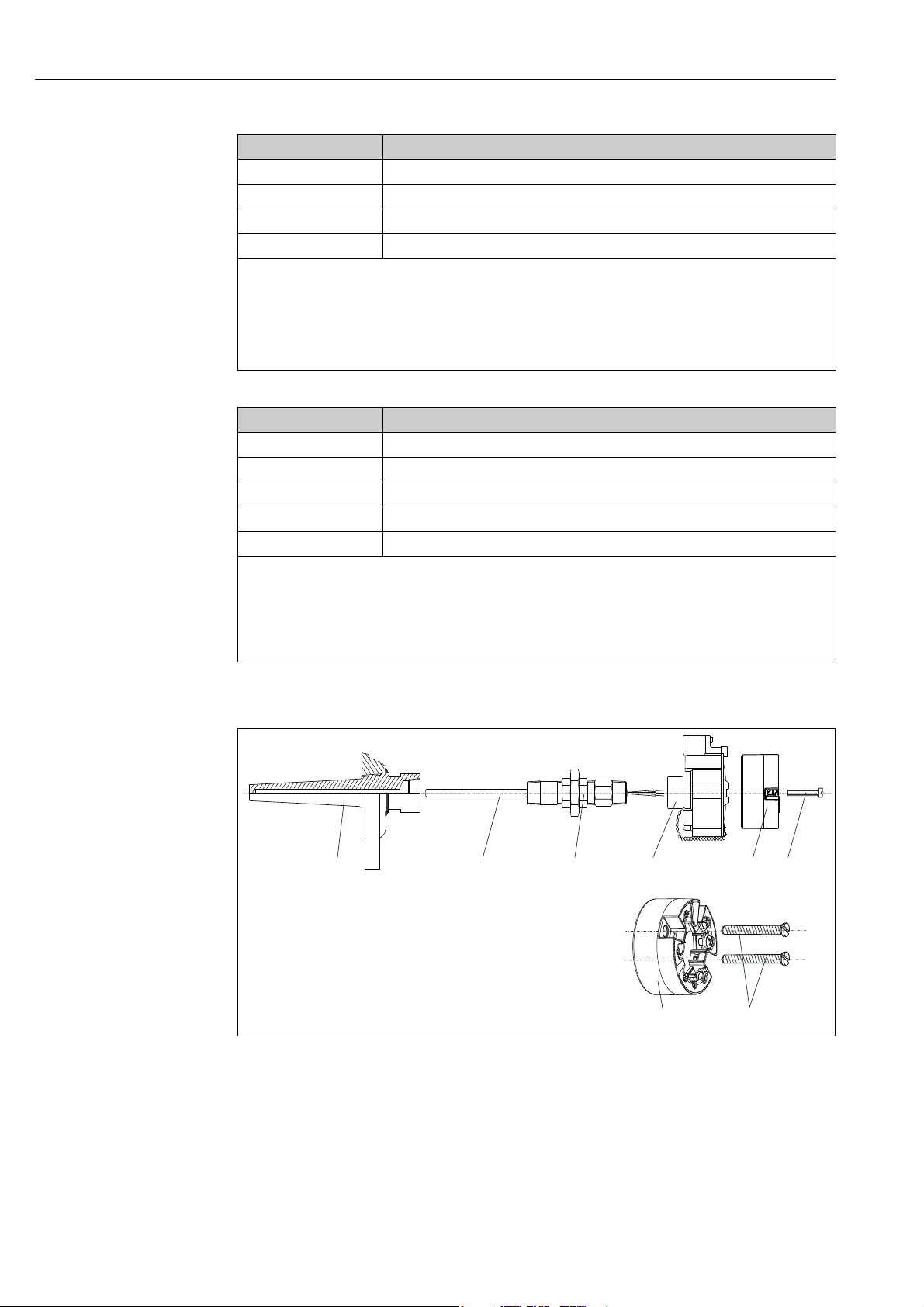

3.3.1 Mounting typical of Europe

A0008281-EN

Fig. 2: Head transmitter mounting (three versions)

Item A Mounting in a terminal head (terminal head as per DIN EN50446, flat face)

1Terminal head

2 Circlips

3Insert

4 Connection wires

5 Head transmitter

6 Mounting springs

7Mounting screws

8 Terminal head cover

9Cable entry

Procedure:

1. Open the terminal head cover (8).

2. Guide the connection wires (4) of the insert (3) through the middle hole in the head transmitter (5).

3. Fit the mounting springs (6) onto the mounting screws (7).

4. Guide the mounting screws (7) through the lateral bores of the head transmitter and the insert (3). Then fix

both mounting screws in position with the circlips (2).

5. Then screw down the head transmitter (5) to the insert (3) in the terminal head.

6. After wiring (see section 4), close the terminal head cover (8) back on tight.

Endress+Hauser 9

Page 10

Installation instructions TMT85

1

234 5

6

5

6

Item B Mounting in a field housing

1 Field housing cover

2 Mounting screws with springs

3 Head transmitter

4 Field housing

Procedure:

1. Open the cover (1) of the field housing (4).

2. Guide the mounting screws (2) through the lateral bores of the head transmitter (3).

3. Screw the head transmitter to the field housing.

4. When wiring is complete (see section 4), screw the field housing cover (1) back on.

Item C Mounting on DIN rail as per IEC 60715

1 Mounting screws with springs

2 Head transmitter

3 Circlips

4DIN rail clip

5DIN rail

Procedure:

1. Press the DIN rail clip (4) onto the DIN rail (5) until it engages.

2. Fit the mounting springs onto the mounting screws (1) and guide them through the lateral bores of the head

transmitter (2). Then fix both mounting screws in position with the circlips (3).

3. Screw the head transmitter (2) to the DIN rail clip (4).

3.3.2 Mounting typical of North America

A0008520

Fig. 3: Head transmitter mounting

1: Thermowell

2: Insert

3: Adapter, threaded joint

4: Terminal head

5: Head transmitter

6: Mounting screws

10 Endress+Hauser

Page 11

TMT85 Installation instructions

NOTICE

Thermometer design with thermocouples or RTD sensors and head transmitter

→ å 3)

(

• Fit the thermowell (item 1) on the process pipe or the container wall. Secure the

thermowell according to the instructions before the process pressure is applied.

• Fit the necessary neck tube nipples and adapter (item 3) on the thermowell.

• Make sure sealing rings are installed if such rings are needed for harsh environmental

conditions or special regulations.

• Guide the mounting screws (item 6) through the lateral bores of the head transmitter

(item 7).

• Position the head transmitter (item 5) in the terminal head (item 4) in such a way that the

bus cable (terminals 1 and 2) point to the cable entry.

• Using a screwdriver, screw down the head transmitter (item 5) in the terminal head (item

4).

• Guide the connection wires of the insert (item 3) through the lower cable entry of the

terminal head (item 4) and through the middle hole in the head transmitter (item 5). Wire

the connection wires and transmitter (see Section 4) with one another.

• Screw the terminal head (item 4), with the integrated and wired head transmitter, onto

the ready-mounted nipple and adapter (item 3).

Requirements for explosion protection

‣ Once the wiring is completed, screw the terminal head cover back on. The terminal head

cover must be secured properly.

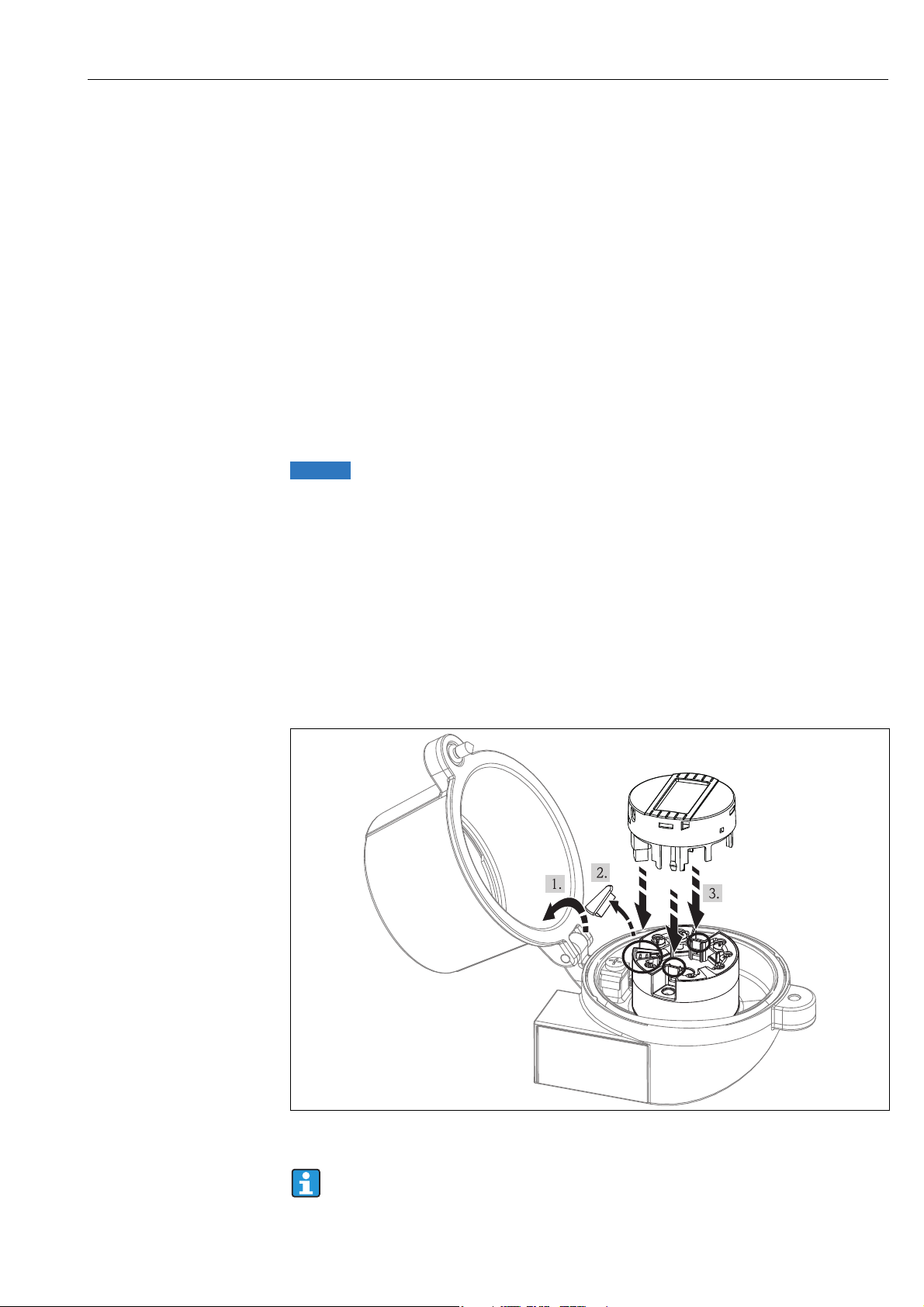

3.3.3 Mounting the display

1. Remove the screw from the terminal head. Open the terminal head cap (1).

2. Remove the cover of the display connection (2). Plug the display module onto the

mounted and wired head transmitter. The mounting pins (3) must snap securely into

the head transmitter.

3. After mounting the display, close the terminal head cap and refit the screw.

A0009852

Fig. 4: Mounting the display

The display can only used with the suitable Endress+Hauser terminal heads TA30

and caps with display window.

Endress+Hauser 11

Page 12

Installation instructions TMT85

3.4 Post-installation check

After installing the device, always run the following final checks:

Device condition and specifications Notes

Is the device visibly damaged (visual check)? -

Does the device comply to the measurement point specifications, such as

ambient temperature, measurement range etc.?

See chapter 10 "Technical data"

12 Endress+Hauser

Page 13

TMT85 Wiring

NOTICE

-

+

+

1

-

2

7

6

5

4

3

1

2

7

6

5

4

3

Sensor input 2

Sensor input 1

Bus connection

and supply voltage

Display connection/

service interface

TC, mV

RTD, 4-, 3- and 2-wire:Ω

RTD, 3- and 2-wire:Ω

TC, mV

white

red

red

white

white

red

red

(black)

(yellow)

(black)

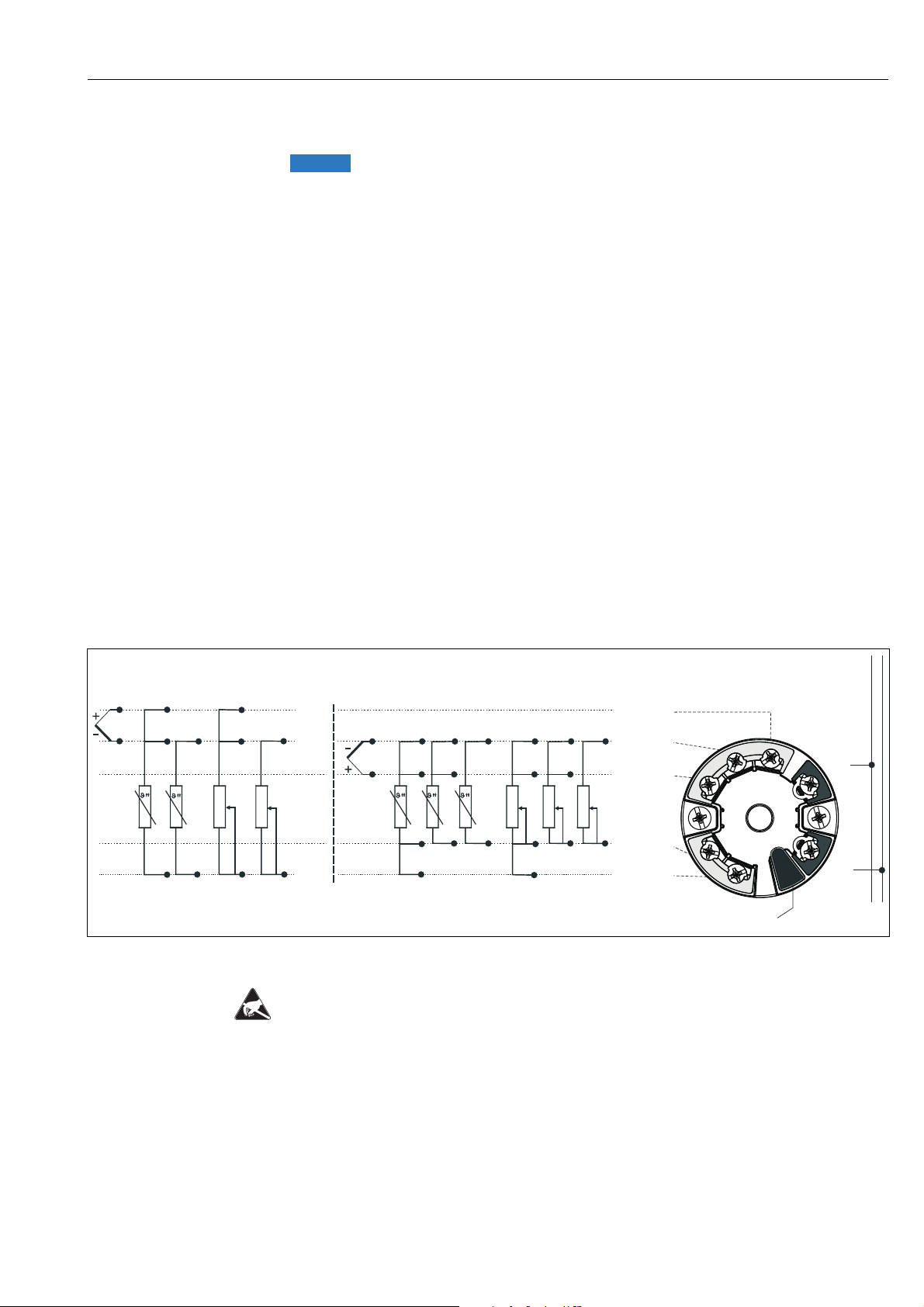

4 Wiring

Electronic parts may be damaged

‣ Switch off power supply before installing or connecting the device. Failure to observe this

may result in destruction of parts of the electronics.

‣ When installing Ex-approved devices in a hazardous area please take special note of the

instructions and connection schematics in the respective Ex documentation added to

these Operating Instructions. The local E+H representative is available for assistance if

required.

‣ The 4-pin post connector is only designed for connecting the associated display.

Connecting other devices can destroy parts of the electronics.

For wiring a mounted head transmitter, proceed as follows:

1. Open the cable gland and the housing cover on the terminal head or the field housing.

2. Feed the cables through the opening in the cable gland.

3. Connect the cables as shown in → å 5. If the head transmitter is fitted with spring

terminals, please pay particular attention to → Chap. 4.2.1.

4. Retighten the cable gland and close the housing cover.

5. In order to avoid connection errors always take note of the hints given in the section

connection check!

4.1 Quick wiring guide

Terminal assignment

Fig. 5: Wiring the head transmitter

ESD - electrostatic discharge

Protect the terminals from electrostatic discharge. Failure to observe this may result in

Endress+Hauser 13

destruction or malfunction of parts of the electronics.

A0007285-EN

Page 14

Wiring TMT85

ABCD

4.2 Connecting the sensor cables

When connecting 2 sensors ensure that there is no galvanic connection between the

sensors (e.g. caused by sensor elements that are not isolated from the thermowell).

The resulting equalizing currents distort the measurements considerably. In this

situation, the sensors have to be galvanically isolated from one another by connecting each sensor separately to a transmitter. The device provides sufficient galvanic

isolation (> 2 kV AC) between the input and output.

Please refer to → å 5 for the terminal assignment of the sensor connections.

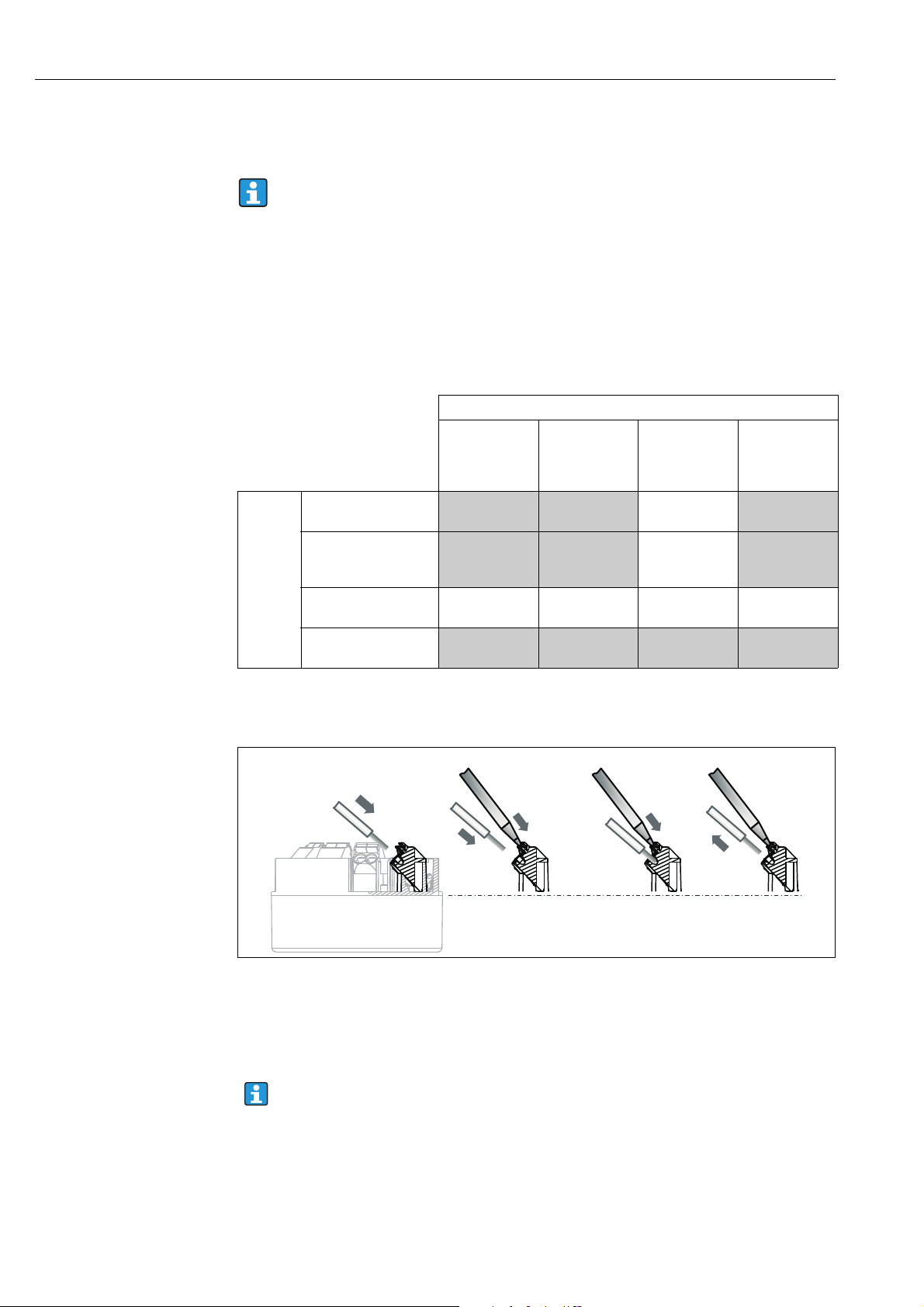

The following connection combinations are possible when both sensor inputs are assigned:

Sensor input 1

Sensor

input 2

RTD or resistance

transmitter, two-wire

RTD or resistance

transmitter, threewire

RTD or resistance

transmitter, four-wire

Thermocouple (TC),

voltage transmitter

RTD or

resistance

transmitter,

two-wire

- Â

- Â

----

Â

RTD or

resistance

transmitter,

three-wire

RTD or

resistance

transmitter,

four-wire

Thermocouple

(TC), voltage

transmitter

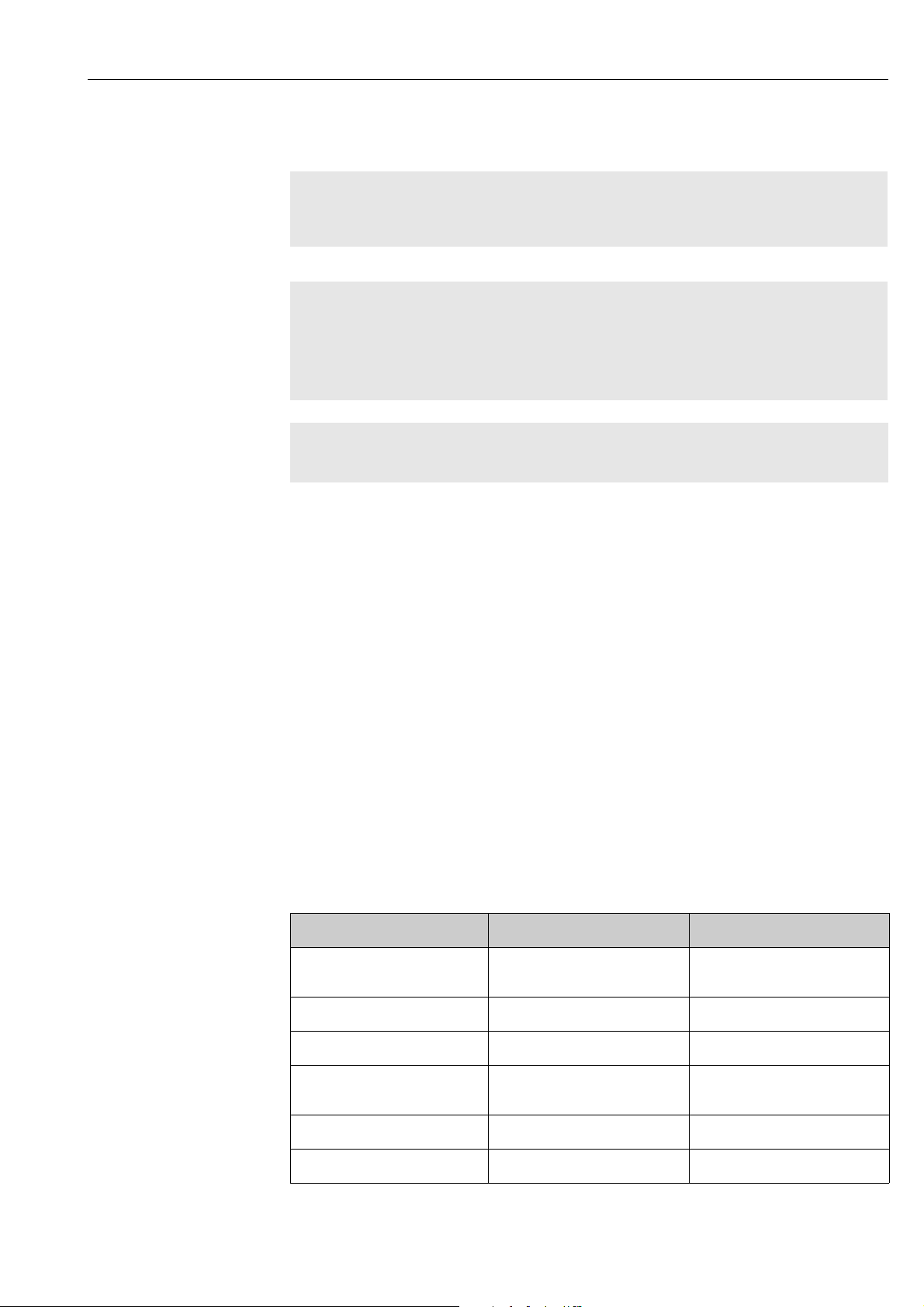

4.2.1 Connecting to spring terminals

Fig. 6: Spring terminal connection

A Insert wire end (solid wire or wire with ferrule)

B Insert wire end (fine-strand wire without ferrule)

C Release wire end with tool

D Remove wire end

When connecting flexible cables and spring terminals, it is not recommended to use ferrules.

A0008322

14 Endress+Hauser

Page 15

TMT85 Wiring

Procedure:

Item A, solid wire: 1. Strip wire end. Minimum stripping length = 10 mm (0.39 in)

2. Insert the wire end into the terminal (A).

3. Check the connection by pulling on the wire lightly. Repeat from

step 1 if necessary.

Item B, fine-strand wire without ferrule:1. Strip wire end. Minimum stripping length = 10 mm (0.39 in)

2. Operate lever opener with tool (B).

3. Insert the wire end into the terminal (B).

4. Release lever opener.

5. Check the connection by pulling on the wire lightly. Repeat from

step 1 if necessary.

Item C and D, releasing the connection: 1. Operate lever opener with tool (C).

2. Remove wire from terminal (D).

3. Release lever opener.

4.3 FOUNDATION Fieldbus™ cable specification

4.3.1 Cable type

Twin-core cables are required for connecting the device to the FOUNDATION Fieldbus™ H1.

Following IEC 61158-2 (MBP), four different cable types (A, B, C, D) can be used with the

FOUNDATION Fieldbus™, only two of which (cable types A and B) are shielded.

• Cable types A or B are particularly preferable for new installations. Only these types have

cable shielding that guarantees adequate protection from electromagnetic interference

and thus the most reliable data transfer. In the case of cable type B, several field buses

(same degree of protection) may be operated in one cable. No other circuits are permissible

in the same cable.

• Practical experience has shown that cable types C and D should not be used due to the lack

of shielding, since the freedom from interference generally does not meet the

requirements described in the standard.

The electrical data of the fieldbus cable have not been specified but determine important

characteristics of the design of the fieldbus, such as distances bridged, number of users,

electromagnetic compatibility, etc.

Type A Type B

Cable structure Twisted pair, shielded One or more twisted pairs, fully

shielded

Wire size 0.8 mm

Loop-resistance (direct current) 44 Ω/km 112 Ω/km

Characteristic impedance at

31.25 kHz

Attenuation constant at 39 kHz 3 dB/km 5 dB/km

Capacitive asymmetry 2 nF/km 2 nF/km

2

(AWG 18) 0.32 mm2 (AWG 22)

100 Ω ± 20% 100 Ω ± 30%

Endress+Hauser 15

Page 16

Wiring TMT85

Type A Type B

Envelope delay distortion (7.9 to

39 kHz)

Shield coverage 90% *

Max. cable length (incl. spurs >1 m)1900 m (6233 ft) 1200 m (3937 ft)

* Not specified

1.7 ms/km *

Suitable fieldbus cables (type A) from various manufacturers for non-hazardous areas are

listed below:

• Siemens: 6XV1 830-5BH10

• Belden: 3076F

• Kerpen: CeL-PE/OSCR/PVC/FRLA FB-02YS(ST)YFL

4.3.2 Maximum overall cable length

The maximum network expansion depends on the type of protection and the cable

specifications. The overall cable length combines the length of the main cable and the length

of all spurs (>1 m/3.28 ft). Note the following points:

• The maximum permissible overall cable length depends on the cable type used.

• If repeaters are used, the maximum permissible cable length is doubled. A maximum of

three repeaters are permitted between user and master.

4.3.3 Maximum spur length

The line between the distribution box and field device is described as a spur.

In the case of non-Ex applications, the max. length of a spur depends on the number of spurs

(>1 m/3.28 ft):

Number of spurs 1 to 12 13 to 14 15 to 18 19 to 24 25 to 32

Max. length per spur 120 m (393

ft)

90 m (295

ft)

60 m (196

ft)

30 m (98 ft) 1 m (3.28 ft)

4.3.4 Number of field devices

In accordance with IEC 61158-2 (MBP), a maximum of 32 field devices can be connected per

fieldbus segment. However, this number is restricted under certain conditions (explosion

protection, bus power option, field device current consumption). A maximum of four field

devices can be connected to a spur.

4.3.5 Shielding and grounding

Optimum electromagnetic compatibility (EMC) of the fieldbus system can only be

guaranteed if the system components and, in particular, the lines are shielded and the shield

forms as complete a cover as possible. A shield coverage of 90% is ideal.

• To ensure an EMC protective effect, connect the shield as often as possible to the reference

ground.

• For reasons of explosion protection, you should refrain from grounding however.

16 Endress+Hauser

Page 17

TMT85 Wiring

NOTICE

To comply with both requirements, the FOUNDATION Fieldbus™ basically allows three

different types of shielding:

• Shielding at both ends

• Shielding at one end on the feed side with capacitance connection to the field device

• Shielding at one end on the feed side

Experience shows that the best results with regard to EMC are achieved in most cases in

installations with one-sided shielding. Appropriate measures with regard to input wiring

must be taken to allow unrestricted operation when EMC interference is present. These

measures have been taken into account for this device. Operation in the event of disturbance

variables as per NAMUR NE21 is possible with one-sided shielding.

Where applicable, national installation regulations and guidelines must be observed during

the installation!

Where there are large differences in potential between the individual grounding points, only

one point of the shielding is connected directly with the reference ground. In systems

without potential equalization, therefore, cable shielding of fieldbus systems should only be

grounded on one side, for example at the fieldbus supply unit or at safety barriers, → å 7

A0008770

Fig. 7: Shielding and one-sided grounding of the fieldbus cable shielding

1 Supply unit

2 Distribution box (T-box)

3Bus terminator

4 Grounding point for fieldbus cable shielding

5 Optional grounding of the field device, isolated from cable shielding.

If the shielding of the cable is grounded at more than one point in systems without

potential matching, power supply frequency equalizing currents can occur that damage

the bus cable or shielding or have serious effect on signal transmission.

‣ In such cases the shielding of the fieldbus cable is to be grounded on only one side, i.e. it

must not be connected to the ground terminal of the housing (terminal head, field

housing). The shield that is not connected should be insulated!

4.3.6 Bus termination

The start and end of each fieldbus segment are always to be terminated with a bus

terminator. With various junction boxes (non-Ex), the bus termination can be activated via

a switch. If this is not the case, a separate bus terminator must be installed. Note the

following points in addition:

• In the case of a branched bus segment, the device furthest from the segment coupler

represents the end of the bus.

• If the fieldbus is extended with a repeater, then the extension must also be terminated at

both ends.

Endress+Hauser 17

Page 18

Wiring TMT85

NOTICE

4.3.7 Further information

General information and further pointers on wiring can be found on www.fieldbus.org, the

Web site of the Fieldbus Foundation or in the Operating Instructions "FOUNDATION

Fieldbus™ Overview" which can also be found on the CD-ROM. (Additional sources: →

www.endress.de → Download).

4.4 Connecting the measuring unit

Devices can be connected to the FOUNDATION Fieldbus™ in two ways:

• Connection via conventional cable gland → Chap. 4.4.1

• Connection via fieldbus connector (optional, can be purchased as an accessory)

→ Chap. 4.4.2

Risk of damaging

‣ Switch off power supply before installing or connecting the head transmitter. Failure to

observe this may result in destruction of parts of the electronics.

‣ Grounding via one of the grounding screws (terminal head, field housing) is

recommended.

‣ If the shielding of the fieldbus cable is grounded at more than one point in systems

without additional potential matching, power supply frequency equalizing currents can

occur that damage the cable or the shielding. In such cases the shielding of the fieldbus

cable is to be grounded on only one side, i.e. it must not be connected to the ground

terminal of the housing (terminal head, field housing). The shield that is not connected

should be insulated!

‣ We recommend that the fieldbus not be looped using conventional cable glands. If you

later replace even just one measuring device, the bus communication will have to be

interrupted.

4.4.1 Cable glands or entries

Please also observe the general procedure on → ä 13.

A0008284

Fig. 8: Connection to the FOUNDATION Fieldbus™ fieldbus cable - installed in the field housing on the left, and in the terminal

1 FF terminals - fieldbus communication and power supply

2 Inner ground terminal

3Outer ground terminal

4 Shielded fieldbus cable (FOUNDATION Fieldbus™)

head on the right

• The terminals for the fieldbus connection (1+ and 2-) are not polarity sensitive.

• Conductor cross-section:

2

max. 2.5 mm

max. 1.5 mm

for screw terminals

2

for spring terminals

• A shielded cable must be used for the connection.

18 Endress+Hauser

Page 19

TMT85 Wiring

190 mm (7.48 in)

26.5 mm

(1.040 in)

M20x1.5 /

NPT 1/2”

7/8-16 UNC

A

B

4

1

2

C

3

5

6

4.4.2 Fieldbus connector

Optionally, a fieldbus connector can be screwed into the terminal head or field housing

instead of a cable gland. Fieldbus connectors can be ordered from Endress+Hauser as an

accessory (see Section 8 'Accessories').

The connection technology of FOUNDATION Fieldbus™ allows measuring devices to be

connected to the fieldbus via uniform mechanical connections such as T-boxes, junction

boxes, etc.

This connection technology using prefabricated distribution modules and plug-in connectors

offers substantial advantages over conventional wiring:

• Field devices can be removed, replaced or added at any time during normal operation.

Communication is not interrupted.

• Installation and maintenance are significantly easier.

• Existing cable infrastructures can be used and expanded instantly, e.g. when constructing

new star distributors using 4-channel or 8-channel distribution modules.

A0008283

Fig. 9: Connectors for connecting to the FOUNDATION Fieldbus™

A Fieldbus connector (pin assignment/color codes)

– 1 Blue wire: FF– (terminal 2)

– 2 Brown wire: FF+ (terminal 1)

– 3 Gray wire: shielding

– 4 Green/yellow wire: ground

– 5 Positioning tappet

– 6 7/8" UNC thread

B Terminal head thermometer

C Connector at the housing (male)

Connector technical data:

Wire cross-section 4 x 0.8 mm2

Connection thread M20 x 1.5 / NPT ½"

Degree of protection IP 67 as per DIN 40 050 IEC 529

Contact surface CuZn, gold-plated

Housing material 1.4401 (316)

Flammability V - 2 as per UL - 94

Ambient temperature –40 to +105 °C (–40 to +221 °F)

Current carrying capacity 9 A

Rated voltage max. 600 V

Contact resistance ≤ 5 mΩ

Insulation resistance ≥ 109 Ω

Endress+Hauser 19

Page 20

Wiring TMT85

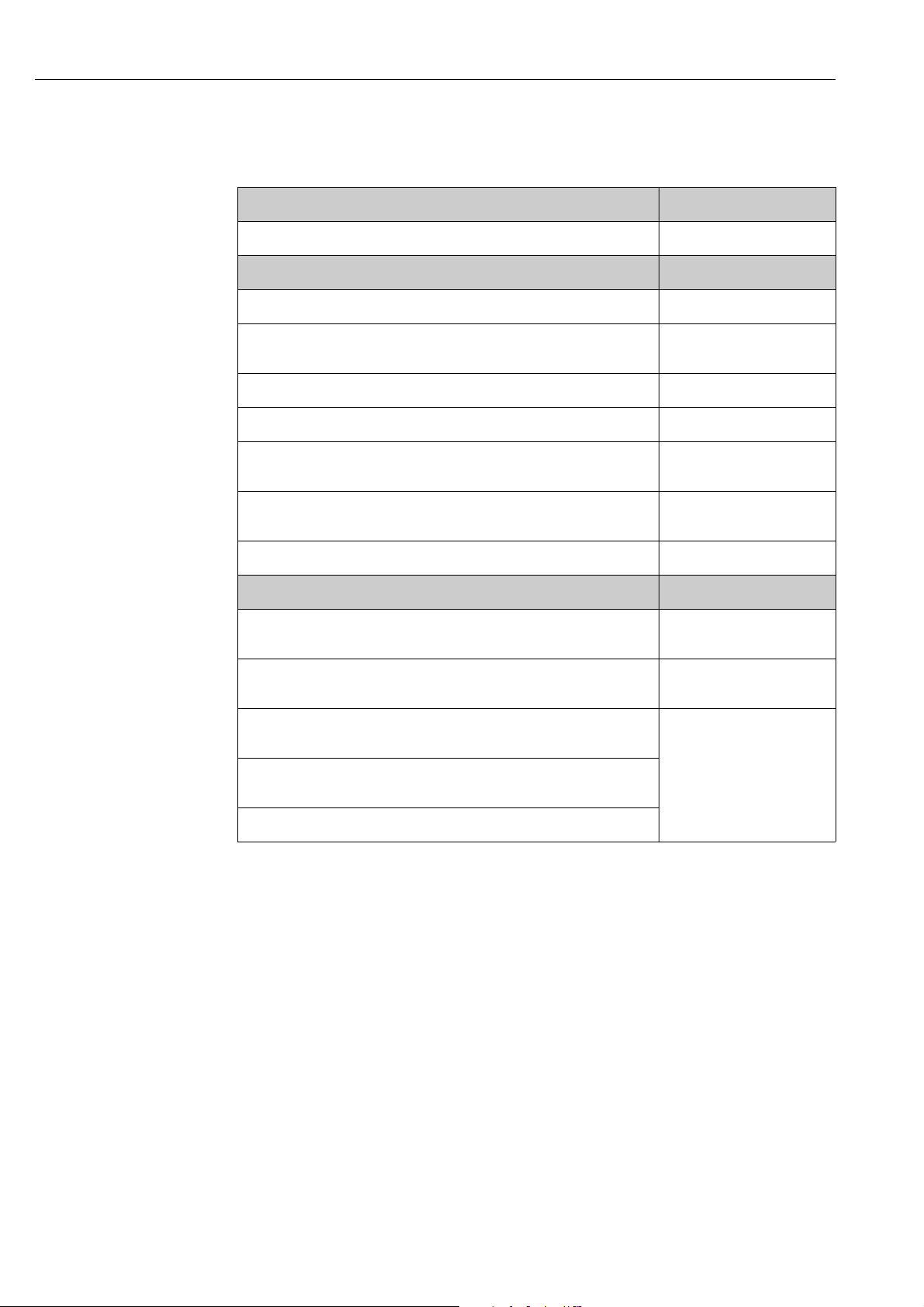

4.5 Post-connection check

After the electrical installation of the device, always perform the following final checks:

Device condition and specifications Notes

Are the measuring device or the cables damaged (visual check)? -

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate? 9 to 32 V DC

Do the cables used comply with the specifications? Fieldbus cable, → ä 15

Sensor cable, → ä 14

Do the cables have adequate strain relief? -

Are the power supply and signal cables correctly connected? → Chap. 4.1

Are all the screw terminals well tightened and have the connections of the

spring terminals been checked?

Are all the cable entries installed, tightened and sealed?

Cable run with "water trap"?

Are all the housing covers installed and tightened?

Electrical connection of FOUNDATION Fieldbus™ Notes

Are all the connecting components (T-boxes, junction boxes, connectors,

etc.) connected with each other correctly?

Has each fieldbus segment been terminated at both ends with a bus

terminator?

Has the max. length of the fieldbus cable been observed in accordance with

the FOUNDATION Fieldbus™ specifications?

FOUNDATION Fieldbus™ specifications?

Is the fieldbus cable fully shielded (90%) and correctly grounded?

→ ä 14

-

-

→ ä 15Has the max. length of the spurs been observed in accordance with the

20 Endress+Hauser

Page 21

TMT85 Operation

5Operation

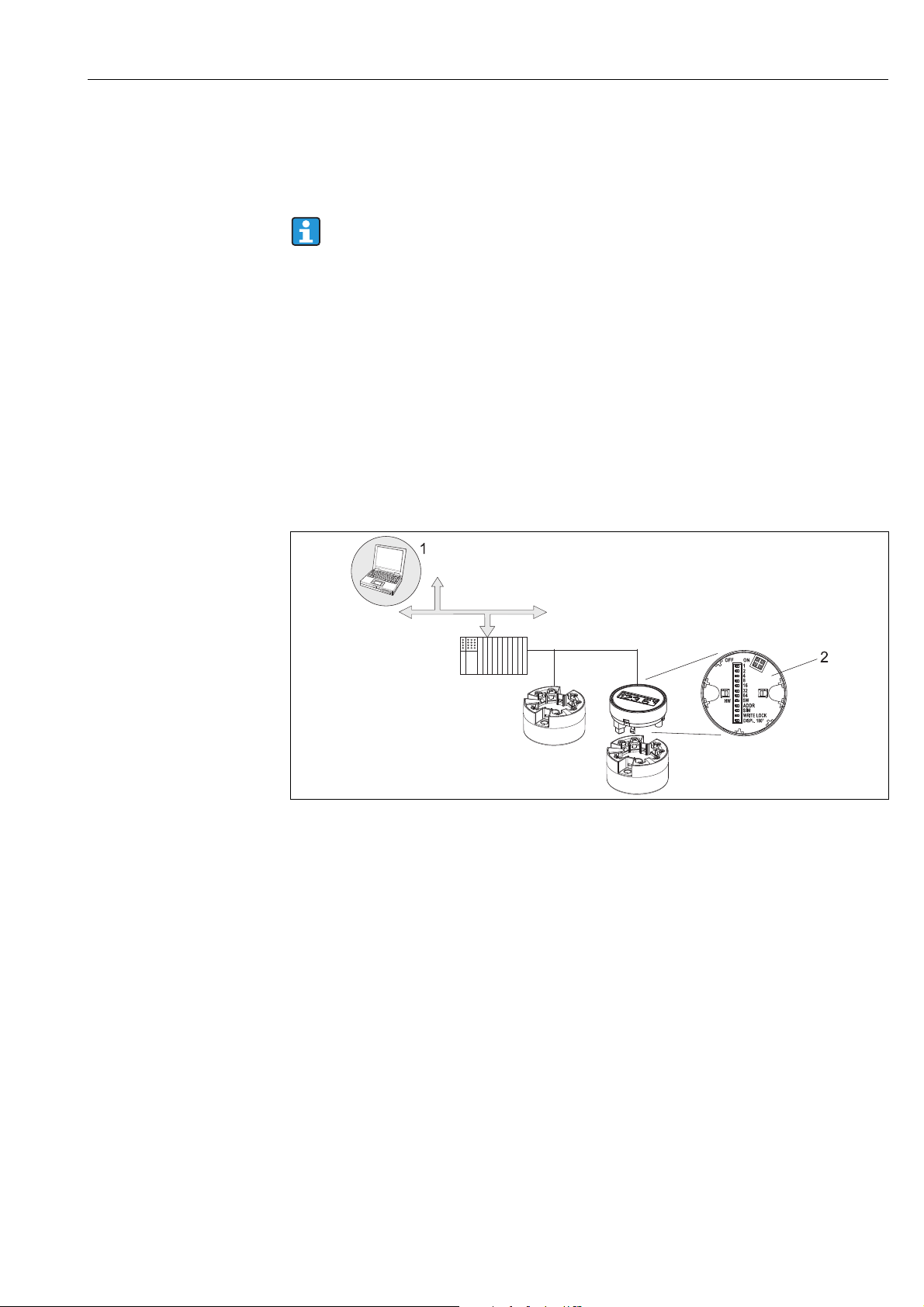

5.1 Quick operation guide

Display and operating elements are only available locally if the head transmitter was

ordered with a display unit!

You have a number of options for configuring and commissioning the device:

1. Configuration programs

The configuration of FF functions and device-specific parameters is done via the fieldbus

interface. You can obtain special configuration and operating programs from various

manufacturers for these purposes.→ ä 26

2. Miniature switches (DIP switches) for diverse hardware settings, optional

You can make the following hardware settings for the FOUNDATION Fieldbus™ interface

using miniature switches (DIP switches) on the rear of the optional display → ä 26:

• Enabling/disabling the simulation mode in the Analog Input function block

• Switching the hardware write protection on/off

• Switching (turning) the display 180 °

Fig. 10: Head transmitter operating options

1 Configuration/operating programs for operation via FOUNDATION Fieldbus™ (Foundation Fieldbus functions, device

parameter)

2 DIP switch for hardware settings is on the rear of the optional display (write protection, simulation mode)

A0008323

Endress+Hauser 21

Page 22

Operation TMT85

1

2

3

4

5

6

7

5.2 Display and operating elements

5.2.1 Display

A0008549

Fig. 11: Optional LC display of the head transmitter

5.2.2 Display symbols

Item

Function Description

No.

1 Displays the TAG TAG, 32 characters long.

2 'Communication' symbol The communication symbol appears when read and

3 Unit display Unit display for the measured value displayed.

4 Measured value display Displays the current measured value.

5 Channel display C1 or C2, P1, S1, RJ e.g. S1 for a measured value from sensor1.

6 'Configuration locked' symbol The 'configuration locked' symbol appears when

7 Warning or error message If a warning occurs, the display alternates between the

write-accessing via the FOUNDATION Fieldbus™

protocol.

configuration is locked via the hardware.

measured value and the warning code. If an error

occurs, the display alternates between the error code

and "- - - -" (no valid measured value available), (see

Section 9.2 'Status messages'.

5.2.3 Local operation

You can make hardware settings for the FOUNDATION Fieldbus™ interface using miniature

switches (DIP switches) on the rear of the optional display → ä 26:

5.3 FOUNDATION Fieldbus™ technology

The FOUNDATION Fieldbus™ (FF) is a purely digital, serial communication system that

connects fieldbus devices (sensors, actuators), automation and process control systems with

each other. As a local communications network (LAN) for field devices the FF was primarily

designed for the requirements of process technology. The FF thus forms the basic network

throughout the hierarchy of a communication system.

Please refer to Operating Instructions BA 013S/04/en “FOUNDATION Fieldbus Overview:

Installation and Commissioning Guidelines” for configuration information.

22 Endress+Hauser

Page 23

TMT85 Operation

0 - 10 bar

0 - 10 bar

Visualisation and monitoring

e. g. P View, FieldCare

and diagnostic software

High speed Ethernet

(HSE) 100 Mbit/s

32 devices per segment

Field controller

linking

device

ENDRESS+HAUSER

ENDRESS+HAUSER

linking

device

linking

device

H1

31.25 kbit/s

H1 IEC 61158-2

H1 FISCO

Measuring point with

installed TMT85

Measuring point with

installed TMT85

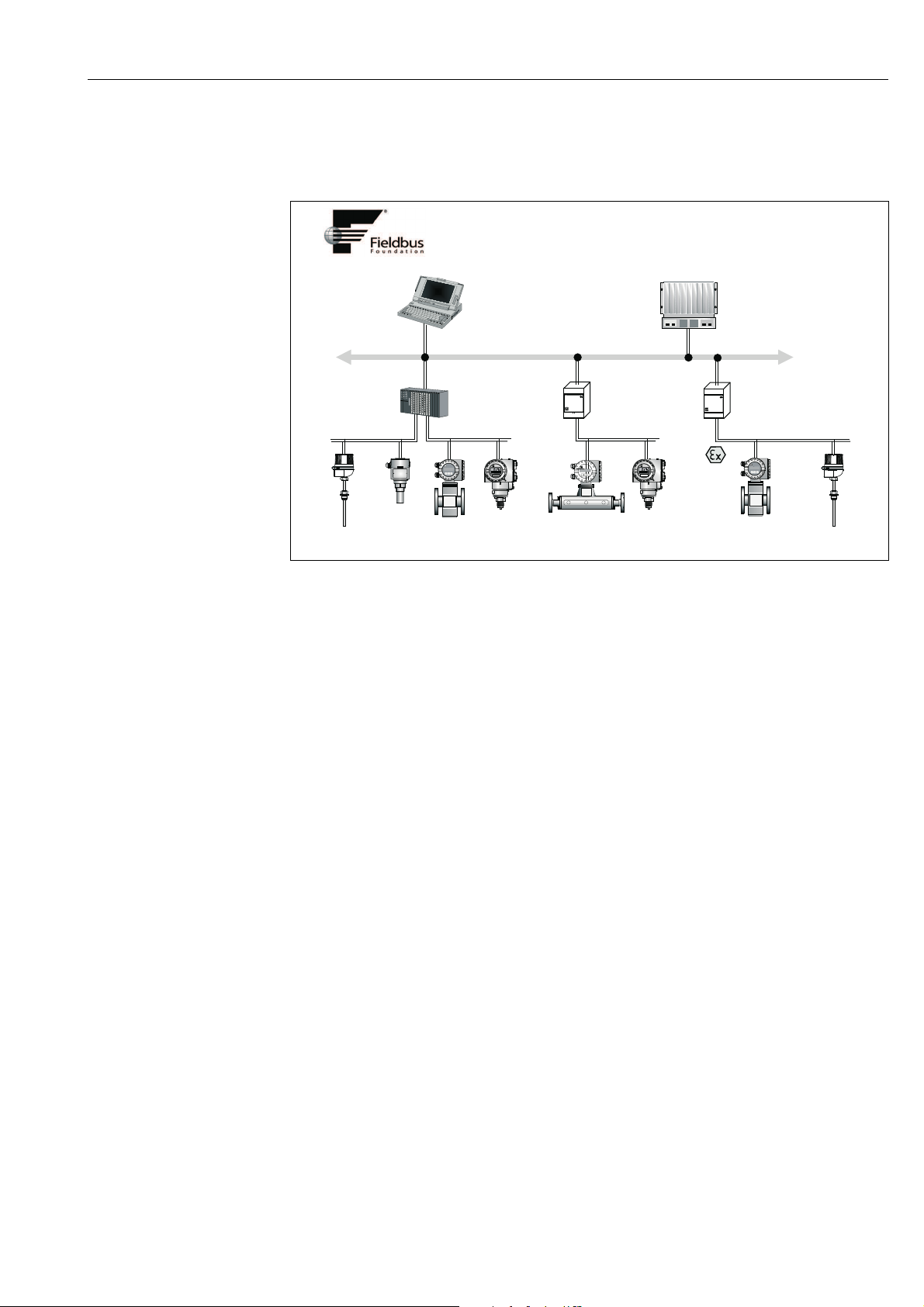

5.3.1 System architecture

The following figure shows an example of a FOUNDATION Fieldbus™ network with the

associated components.

Fig. 12: System integration via FOUNDATION Fieldbus™

HSE = High Speed Ethernet, H1 = FOUNDATION Fieldbus-H1

The following system connection options are possible:

– A linking device can be used to connect to higher ranking fieldbus protocols (e.g. to the High Speed

– A H1 card is required for direct connection to a process control system.

– System inputs are available directly for H1 (HSE).

The system architecture of the FOUNDATION Fieldbus™ can be divided into two

subnetworks:

H1 bus system:

In the field, fieldbus devices are connected only via the slower H1 bus system that is specified

following IEC 61158-2. The H1 bus system allows simultaneous feed to the field devices and

data transfer on the two-wire line.

The following points describe some important characteristics of the H1 bus system:

• All fieldbus devices are powered via the H1 bus. Like the fieldbus devices, the power supply

• One of the most common network structures is the line structure. Star, tree or mixed

• The bus connection to the individual fieldbus devices is achieved by means of a T-

• The number of connected fieldbus devices depends on various factors, such as use in

• If using fieldbus devices in a hazardous area, the H1 bus must be equipped with an

• A bus terminator is required at each end of the bus segment.

A0007668-EN

Ethernet - HSE) (Control Net)

is connected in parallel to the bus line. Devices requiring external power must use a

separate power supply.

network structures are also possible using connecting components (junction boxes).

connector or via a spur. This has the advantage that individual fieldbus devices can be

connected or disconnected without interrupting the bus or the bus communication.

hazardous areas, length of spur, cable types, current consumption of field devices etc. (see

→ ä 15).

intrinsically safe barrier before the transition to the hazardous area.

Endress+Hauser 23

High Speed Ethernet (HSE):

The superior bus system is realized via the High Speed Ethernet (HSE) with a transmission

rate of max. 100 MBit/s. This serves as the 'backbone' (basic network) between various local

sub-networks and/or where there is a large number of network users.

Page 24

Operation TMT85

5.3.2 Link Active Scheduler (LAS)

The FOUNDATION Fieldbus™ works according to the 'producer-consumer' relationship.

This provides various advantages.

Data can be directly exchanged between field devices, e.g. a sensor and an actuating valve.

Each bus user ’publishes’ its data on the bus and all the bus users configured accordingly

obtain this data. Publication of this data is carried out by a ’bus administrator’ known as the

’Link Active Scheduler’, which controls the sequence of bus communication centrally. The

LAS organizes all the bus activities and sends appropriate commands to the individual field

devices.

Other tasks of the LAS are:

• Recognition and reporting of newly connected devices.

• Reporting the removal of devices no longer communicating with the fieldbus.

• Keeping the ’Live List’. This list, in which all the fieldbus users are recorded, is checked by

the LAS regularly. If devices are logged on or logged off, the "Live List" is updated and sent

immediately to all the devices.

• Requesting process data from the field devices in accordance with a fixed schedule.

• Allocation of send rights (tokens) to devices between the untimed data transfer.

The LAS can be run redundantly, i.e. it exists both in the process control system and in the

field device. If one LAS fails, the other LAS can accurately take over communication. Through

precise timing of the bus communication via the LAS, the FF can run exact processes at

regular intervals.

Fi eld bus devi ces , suc h as thi s he ad t ran smi tte r, wh ich can tak e ov er t he L AS fu nct ion

in the event of failure of the primary master, are called 'Link Masters'. In contrast,

'Basic Devices' can only receive signals and send them to the central process control

system. The LAS function is deactivated in this head transmitter when the unit is

delivered.

5.3.3 Data transfer

We distinguish between two types of data transfer:

• Scheduled data transfer (cyclic): all time-critical process data (i.e. continuous

measurement or actuating signals) are transferred and processed in accordance with a

fixed schedule.

• Unscheduled data transfer (acyclic): device parameters that are not time-critical for the

process and diagnosis information are only transferred to the fieldbus when needed. This

data transfer is always carried out in the intervals between timed

communication.

5.3.4 Device ID, addressing

Within the FF network, each fieldbus device is identified by a unique device ID (DEVICE_ID).

The fieldbus host system (LAS) automatically gives the network address for this to the field

device. The network address is the address that the fieldbus currently uses.

The FOUNDATION Fieldbus™ uses addresses between 0 and 255:

• Groups/DLL: 0 to 15

• Devices in operation: 20 to 35

• Reserve devices: 232 to 247

• Offline/substitute devices: 248 to 251

The field device tag name (PD_TAG) is given to the device in question during commissioning

(see → ä 29). It remains stored in the device even during a supply voltage failure.

24 Endress+Hauser

Page 25

TMT85 Operation

5.3.5 Function blocks

The FOUNDATION Fieldbus™ uses predefined function blocks to describe the functions of a

device and to specify uniform data access. The function blocks implemented in each fieldbus

device provide information on the tasks which a device can accept in the whole of the

automation strategy.

In the case of sensors these are typically the following blocks:

• ’Analog Input’ or

• ’Discrete Input’ (digital input)

Actuating valves normally have the function blocks:

• ’Analog Output’ or

• ’Discrete Output’ (digital output)

For control tasks there are the blocks:

• PD controller or

•PID controller

More information on this can be found from Section 11 onwards.

5.3.6 Fieldbus based process control

With the FOUNDATION Fieldbus™ field devices can carry out simple process control

functions themselves, thereby relieving pressure on the superior process control system.

Here the Link Active Scheduler (LAS) coordinates data exchange between the sensor and

controller and makes sure that two field devices cannot access the bus at the same time. To

do this, configuration software such as the NI-FBUS Configurator from National Instruments

is used to connect the various function blocks to the desired control strategy – generally

graphically (→ ä 29).

5.3.7 Device description

For commissioning, diagnosis and configuration, make sure that process control systems or

superior configuration systems can access all device data and that the operating structure is

uniform.

The device-specific information required for this is stored as so-called device description

data in special files (the ’Device Description’- DD). This enables the device data to be

interpreted and shown via the configuration program. The DD is thus a kind of ’device

driver’.

On the other hand, a CFF file (CFF = Common File Format) is required for the network

configuration in the OFF-line mode.

These files can be acquired as follows:

– Free of charge via the Internet: www.endress.com

– Via the Fieldbus Foundation Organization: www.fieldbus.org

Endress+Hauser 25

Page 26

Operation TMT85

5.4 Configuration of the transmitter and FF functions

The FF communication system will only function properly if correctly configured. You can

obtain special configuration and operating programs from various manufacturers for the

configuration.

These can be used for configuring both the FF functions and all of the device-specific

parameters. The predefined function blocks allow uniform access to all the network and

fieldbus device data.

A detailed step-by-step description of the procedure for commissioning the FF functions is

given on → ä 29 together with information on configuring device-specific parameters.

System files

You require the following files for commissioning and configuring the network:

• Commissioning → device description (DD: *.sym, *.ffo, *.sy5, *.ff5)

•Network configuration → CFF file (Common File Format)

5.5 Hardware settings (optional)

DIP switches on the rear of the display are used to enable and disable hardware write

protection and the simulation mode (for the Analog Input Block), and to switch (turn) the

display 180°. When write protection is active, parameters cannot be modified. The current

write protection status is displayed in the WRITE_LOCK parameter (Resource Block, see

Section 11).

The simulation mode via the hardware setting must be changed before the software setting.

The display can optionally be ordered with the transmitter, or as an accessory for subsequent

mounting (see Section 8).

ESD - electrostatic discharge

Protect the terminals from electrostatic discharge. Failure to observe this may result in

destruction or malfunction of parts of the electronics.

To set the DIP switches, proceed as follows:

1. Open the cover of the terminal head or field housing.

2. Remove the attached display from the head transmitter.

3. Configure the DIP switch on the rear of the display accordingly. Switch to ON = function

enabled, switch to OFF = function disabled.

4. Fit the display onto the head transmitter in the correct position. The head transmitter

accepts the settings within one second.

5. Secure the cover back onto the terminal head or field housing.

The DIP switch settings are no longer valid as soon as the display is removed from

the head transmitter.

A0008326

Fig. 13: Hardware settings via DIP switches

1 Connection to head transmitter

2 DIP switch (1 - 7, SW/HW and ADDR ACTIVE), no function

3 DIP switch (SIM = simulation mode; WRITE LOCK = write protection; DISPL. 180° = switch (turn) the display 180°)

26 Endress+Hauser

Page 27

TMT85 Commissioning

6 Commissioning

6.1 Function check

Before commissioning the measurement point make sure that all final checks have been

carried out:

• Checklist “Post-installation check”→ ä 12

• Checklist “Post-connection check”→ ä 20

The FOUNDATION Fieldbus interface's technical data must be maintained in

accordance with IEC 61158-2 (MBP).

The bus voltage of 9 to 32 V and the current consumption of approx. 11 mA at the

measuring device can be checked using a normal multimeter.

6.2 Switching on the measuring device

Once the final checks have been successfully completed, it is time to switch on the supply

voltage. The head transmitter performs a number of internal test functions after power-up.

As this procedure progresses, the following sequence of messages appears on the display:

Step Display

1 Display and firmware version (FW)

2Company logo

3 Device name as well as the firmware, hardware version and device revision of the

head transmitter

4 Displays sensor configuration

5 Current measured value or

Current status message

If the switch-on procedure fails, the appropriate status message is displayed,

depending on the cause. A detailed list of the status messages, as well as the

measures for troubleshooting, can be found in section 9, 'Troubleshooting'.

The device is operational after approx. 8 seconds and the attached display after approx. 16

seconds. Normal measuring mode commences as soon as the switch-on procedure is

completed. Various measured values and/or status values appear on the display.

6.3 Commissioning

Note the following points:

• The files required for commissioning and network configuration can be obtained as

described on → ä 25.

• In the case of the FOUNDATION Fieldbus™, the device is identified in the host or

configuration system by means of the device ID (DEVICE_ID). The DEVICE_ID is a

combination of the manufacturer ID, device type and device serial number. It is unique and

can never be assigned twice. The DEVICE_ID of the device is composed as follows:

DEVICE_ID = 452B4810CE-XXXXXXXXXXX

452B48 = Endress+Hauser

10CE = TMT85

XXXXXXXXXXX = device serial number (11-digit)

• For quick and reliable head transmitter configuration, a wide range of configuration

wizards are available to guide the user through the configuration of the most important

parameters of the Transducer Blocks. Please refer to the Operating Instructions of your

operating and configuration software.

Endress+Hauser 27

Page 28

Commissioning TMT85

The following wizards are available:

Configuration wizards

Name Block Description

Quick setup Sensor Transducer Configuration of the sensor input with sensor-relevant data.

Quick setup Display Transducer Menu-guided configuration of the display unit.

Set to OOS mode Resource, Sensor

Set to auto mode Resource, Sensor

Restart Resource Device restart with various options as to which parameters are

Sensor drift monitoring

configuration

Calc.- wizard for 2-wire

compensation value

Set all TRD to OOS mode All transducer

Set all TRD to auto mode All transducer

Show recommended

action

Calibration wizards

User sensor trim

configuration

Factory trim settings Sensor Transducer Reset scaling to the "Factory Standard Trim" (see section 11).

RTD-Platin configuration

Call.-Van Dusen

RTD-Copper

configuration

RTD-Nickel configuration Sensor Transducer Entry of coefficients for polynom nickel.

Transducer,

Display

Transducer,

AdvDiagnostic

Transducer, AI, PID

and ISEL

Transducer,

Display

Transducer,

AdvDiagnostic

Transducer, AI, PID

and ISEL

AdvDiagnostic

Transducer

Sensor Transducer Calculation of the conductor resistance for two-wire

blocks

blocks

Resource Shows the recommended action for the currently active

Sensor Transducer Menu guidance for linear scaling (offset + slope) to adapt the

Sensor Transducer Entry of Callendar-Van-Dusen coefficients.

Sensor Transducer Entry of coefficients for polynom copper.

Setup of the single block to mode "Out Of Service"

Setup of the single block to mode "Auto"

to be reset to default values.

Settings for drift or differential monitoring with 2 connected

sensors.

compensation.

Sets all transducer blocks to mode "Out Of Service" at the same

time

Sets all transducer blocks to mode "Auto" at the same time

condition

measuring point to the process (see section 11).

28 Endress+Hauser

Page 29

TMT85 Commissioning

6.3.1 Initial commissioning

The following description takes you step-by-step through commissioning the device and all

the necessary configurations for the FOUNDATION Fieldbus™:

1. Open the configuration program.

2. Load the device description files or the CFF file into the host system or the configuration

program. Make sure you are using the right system files (see Section 5.4).

3. Note the DEVICE_ID on the device nameplate for identification in the process control

system (see Section 2 'Identification').

4. Switch the device on.→ ä 27

The first time you establish a connection, the device reacts as follows in the

configuration system:

– EH_TMT85_xxxxxxxxxxx (tag name PD-TAG)

– 452B4810CE-xxxxxxxxxxx (DEVICE_ID)

– Block structure:

Display text (xxx... = serial number) Base index Description

RS_xxxxxxxxxxx 400 Resource Block

TB_S1_xxxxxxxxxxx 500 Transducer Block temperature sensor 1

TB_S2_xxxxxxxxxxx 600 Transducer Block temperature sensor 2

TB_DISP_xxxxxxxxxxx 700 Transducer Block “Display”

TB_ADVDIAG_xxxxxxxxxxx 800 Transducer Block “Advanced Diagnostic”

AI_1_ xxxxxxxxxxx 900 Analog Input function block 1

AI_2_ xxxxxxxxxxx 1000 Analog Input function block 2

AI_3_ xxxxxxxxxxx 1100 Analog Input function block 3

PID_ xxxxxxxxxxx 1200 PID function block

ISEL_xxxxxxxxxxx 1300 Input Selector function block

The device is delivered from the factory with the bus address “247” and is thus in the address range between 232 and 247 reserved for readdressing field devices. A lower bus address should be assigned to the

device for commissioning.

5. Using the DEVICE_ID noted, identify the field device and assign the desired tag name

(PD_TAG) to the fieldbus device in question.

Factory setting: EH_TMT85_xxxxxxxxxxx (xxx... = serial number).

Endress+Hauser 29

Page 30

Commissioning TMT85

A0019666

Fig. 14: Screen display in the configuration program “NI-FBUS Configurator” (National Instruments) after the connection has

1 Device designation in the Configurator (EH_TMT85_xxxxxxxxxxx = factory setting for tag name PD_TAG)

2 Block structure

been established

Configuring the "Resource Block" (base index 400)

6. Open the Resource Block.

7. When the device is delivered, the hardware write protection is disabled so the write

parameters can be accessed via the FF. Check the status via the WRITE_LOCK

parameter:

– Write protection enabled = LOCKED

– Write protection disabled = NOT LOCKED

Disable the write protection if necessary, → ä 26.

8. Enter the desired name for the block (optional).

Factory setting: RS_xxxxxxxxxxx

Set the operating mode in the MODE_BLK parameter group (TARGET parameter) to

AUTO.

Configuring the "Transducer Blocks"

The individual Transducer Blocks comprise various parameter groups arranged by devicespecific functions:

Temperature sensor 1 → Transducer Block “TB_S1_xxxxxxxxxxx” (base index:

500)

Temperature sensor 2 → Transducer Block “TB_S2_xxxxxxxxxxx” (base index:

600)

Onsite display functions → Transducer Block “TB_DISP_xxxxxxxxxxx” (base index: 700)

Advanced diagnostics → Transducer Block “TB_ADVDIAG_xxxxxxxxxx”

(base index: 800)

9. Enter the desired name for the block (optional). For factory settings, see the table

above. Set the operating mode in the MODE_BLK parameter group (TARGET

parameter) to AUTO.

30 Endress+Hauser

Page 31

TMT85 Commissioning

NOTICE

NOTICE

Configuring the "Analog Input function blocks"

The device has 2 x three Analog Input function blocks which can be assigned to the different

process variables as desired. The following section describes an example for the Analog

Input function block 1 (base index 900).

10. Enter the required name for the Analog Input function block (optional).

Factory setting: AI_1_ xxxxxxxxxxx

11. Open Analog Input function block 1.

12. Set the operating mode in the MODE_BLK parameter group (TARGET parameter) to

OOS, i.e. the block is out of service.

13. Use the CHANNEL parameter to select the process variable which should be used as the

input value for the function block algorithm (scaling and limit value monitoring

functions). The following settings are possible:

CHANNEL → Uninitialized

Primary Value 1

Primary Value 2

Sensor Value 1

Sensor Value 2

Device temperature

14. In the XD_SCALE parameter group, select the desired engineering unit as well as the

block input range for the process variable in question.

Faulty parameterization

‣Make sure that the engineering unit selected suits the measured variable of the

process variable chosen. Otherwise, the BLOCK_ERROR parameter displays the “Block

Configuration Error” error message and the operating mode of the block cannot be set to

AUTO.

15. In the L_TYPE parameter, select the type of linearization for the input variable (direct,

indirect, indirect sq. root), see Section 11.

Please note that if the “Direct” linearization type is selected, the settings in the

OUT_SCALE parameter group are not taken into account. The engineering units

selected in the XD_SCALE parameter group are decisive.

16. Use the following parameters to define the limit values for the alarm and warning

messages:

– HI_HI_LIM → Limit value for the upper alarm

–HI_LIM→ Limit value for the upper warning

–LO_LIM → Limit value for the lower warning

–LO_LO_LIM → Limit value for the lower alarm

The limit values entered must be within the value range specified in the OUT_SCALE

parameter group.

17. In addition to the actual limit values, the behavior in the event of limit value overshoot

must be specified by “alarm priorities” (HI_HI_PRI, HI_PRI, LO_PRI, LO_LO_PRI

parameters), see Section 11. Reporting to the fieldbus host system only occurs if the

alarm priority is greater than 2.

In addition to settings for the alarm priorities, digital outputs can also be defined for

limit value monitoring. Here, these outputs (HIHI_ALM_OUT_D, HI_ALM_OUT_D,

LOLO_ALM_OUT_D, LO_ALM_OUT_D parameters) are set from 0 to 1 when the limit

value in question is overshot. The general alarm output (ALM_OUT_D parameter),

where various alarms can be grouped together, has to be configured accordingly via the

ALM_OUT_D_MODE parameter. The behavior of the output in the event of an error

must be configured using the Fail Safe Type parameter (FSAFE_TYPE) and, depending

on the option selected (FSAFE_TYPE = "Fail Safe Value"), the value to be output must be

specified in the Fail Safe Value parameter (FSAFE_VALUE).

Endress+Hauser 31

Page 32

Commissioning TMT85

Alarm limit

value:

PV ≥ HI_HI_LIM 1

PV < HI_HI_LIM 0

PV ≥ HI_LIM

PV < HI_LIM

PV > LO_LIM

PV ≤ LO_LIM

PV >

LO_LO_LIM

PV ≤

LO_LO_LIM

HIHI_ALM_OUT_D HI_ALM_OUT_D LOLO_ALM_OUT_D LO_ALM_OUT_D

x x x

x x x

x1x x

x0x x

x x0x

x x1x

x x x0

x x x1

System configuration / connecting function blocks (→ å 15):

18. A final “overall system configuration” is necessary so that the operating mode of the

Analog Input function block can be set to AUTO and the field device is integrated in the

system application.

For this purpose, configuration software, e.g. NI-FBUS Configurator from National

Instruments, is used to connect the function blocks to the desired control strategy

(mostly using graphic display) and then the time for processing the individual process

control functions is specified.

A0008238

Fig. 15: Connecting function blocks with the aid of the “NI-FBUS Configurator” Example: Averaging

(output OUT in the Input Selector Block) of two temperature inputs (OUT in the Analog Input Blocks 1 and 2).

19. Once you have specified the active LAS (→ ä 24) download all the data and parameters

to the field device.

20. Set the operating mode in the MODE_BLK parameter group (TARGET parameter) to

AUTO. This is only possible, however, under two conditions:

– The function blocks are correctly connected to one another.

– The Resource Block is in the AUTO operating mode.

32 Endress+Hauser

Page 33

TMT85 Maintenance

7Maintenance

In general, no specific maintenance is required for this device.

8 Accessories

Various accessories, which can be ordered separately from your supplier, are available for

the device. Detailed information on the order code in question can be obtained from your

service organization. When ordering accessories, please specify the serial number of the

device!

Type Order number

®

Display TID10 for Endress+Hauser head transmitters iTEMP

pluggable

TID10 service cable for remote operation of the display for service work;

length 40 cm

Field housing TA30x for Endress+Hauser head transmitter TA30x-xx

Adapter for DIN rail mounting, DIN rail clip as per IEC 60715 (TH35) 51000856

Standard - DIN mounting set (2 screws + springs, 4 securing disks and 1

display connector cover)

US - M4 securing set (2 screws M4 and 1 display connector cover) 71044062

Fieldbus connector (FF):

•NPT1/2"

• M20

Stainless steel wall mounting bracket for field housing TA30x

Stainless steel pipe mounting bracket for field housing TA30x

È 7/8"

È 7/8"

TMT8x;

TID10-xx

71086650

71044061

71082009

71082008

71123339

71123342

Endress+Hauser 33

Page 34

Troubleshooting TMT85

NOTICE

9Troubleshooting

9.1 Troubleshooting instructions

Always start troubleshooting with the checklists below if faults occur after start up or during

operation. This takes you directly (via various queries) to the cause of the problem and the

appropriate remedial measures.

The device cannot be repaired due to its design.

‣ However, it is possible to send the device in for examination. Please refer to → Chap. 9.5

in this situation.

Check display (optional, attachable LC display)

No display visible 1. Check the supply voltage at the head transmitter → Terminals + and -

2. Check whether the retainers and the connection of the display module are

correctly seated on the head transmitter, → ä 26

3. If available, test the display module with other suitable E+H head

transmitters

4. Display module defective → Replace module

5. Head transmitter defective → Replace transmitter

Æ

Onsite error messages on the display

→ Chap. 9.2

Æ

Faulty connection to the fieldbus host system

No connection can be made between the fieldbus host system and the measuring device.

Check the following points:

Fieldbus connection Check the data cable

Fieldbus connector (optional) Check pin assignment / wiring, → ä 19

Fieldbus voltage Check that a min. bus voltage of 9 V DC is present at the +/- terminals.

Permitted range: 9 to 32 V DC

Network structure Check permissible fieldbus cable length and number of spurs, → ä 15

Basic current Is there a basic current of min. 11 mA?

Terminating resistors Has the FOUNDATION Fieldbus H1 been terminated correctly?

Each bus segment must always be terminated with a bus terminator at both

ends (start and finish). Otherwise there may be interference in data

transmission.

Current consumption

Permissible feed current

Error messages in the FF configuration system

→ Chap. 9.2

Problems when configuring function blocks

Check the current consumption of the bus segment:

The current consumption of the bus segment in question (= total of basic

currents of all bus users) must not exceed the max. permissible feed current of

the bus power supply unit.

Æ

34 Endress+Hauser

Page 35

TMT85 Troubleshooting

NOTICE

NOTICE

Transducer Blocks:

The operating mode cannot be

set to AUTO.

Analog Input function block:

The operating mode cannot be

set to AUTO.

Analog Input function block:

Although the operating mode is

set to AUTO, the status of the AI

output value OUT is “BAD” or

“UNCERTAIN”.

• Parameters cannot be

changed or

• No write access to

parameters.

Check whether the operating mode of the Resource Block is set to

AUTO → MODE_BLK parameter group / TARGET parameter.

Faulty parameterization

‣ Make sure that the unit selected suits the process variable chosen in the

SENSOR_TYPE parameter. Otherwise the BLOCK_ERROR parameter

displays the “Block Configuration Error” error message. In this state, the

operating mode cannot be set to AUTO.

There can be several reasons for this. Check the following points one after

another:

1. Check whether the operating mode of the Analog Input function block is

set to AUTO: MODE_BLK parameter group / TARGET parameter.

If not and the mode cannot be changed to AUTO, first check the following

points.

2. Make sure that the CHANNEL parameter (select process variable) has

already been configured in the Analog Input function block (→ ä 29).

The option CHANNEL = 0 (uninitialized) is not valid.

3. Make sure that the XD_SCALE parameter group (input range, unit) has

already been configured in the Analog Input function block.

4. Make sure that the L_TYPE parameter (linearization type) has already

been configured in the Analog Input function block (→ ä 29).

5. Check whether the operating mode of the Resource Block is set to AUTO.

MODE_BLK parameter group / TARGET parameter.

6. Make sure that the function blocks are correctly connected together and

that this system configuration has been sent to the fieldbus users,

→ ä 29.

Check whether an error is pending in the Transducer Block “Advanced

Diagnostic”: Transducer Block “Adv. Diagnostic”, “Actual Status Category” and

“Actual Status Number” parameters.→ ä 36

1. Parameters that only show values or settings cannot be changed!

2. Hardware write protection is enabled → Disable the write protection,

→ ä 26.

Write protection

‣You can check whether the hardware write protection is enabled or

disabled via the WRITE_LOCK parameter in the Resource Block: LOCKED

= write protection enabled UNLOCKED = write protection disabled.

3. The block operating mode is set to the wrong mode. Certain parameters

can only be changed in the OOS (out of service) mode or the MAN

(manual) mode → Set the operating mode of the block to the desired

mode → MODE_BLK parameter group.

4. The value entered is outside the specified input range for the parameter

in question: → Enter a suitable value → Increase input range if

necessary.

Transducer Blocks:

The manufacturer-specific

parameters are not visible.

Analog Input function block:

The output value OUT is not

updated despite a valid “GOOD”

status.

Other errors (application errors without messages)

The device description file (Device Description, DD) has not yet been loaded to

the host system or the configuration program? → Download the file to the

configuration system.

For information on where to obtain the DD, → ä 25

Make sure you are using the correct system files for integrating field devices

into the host system.

Simulation is active → Deactivate simulation by means of the SIMULATE

parameter group.

Æ

Endress+Hauser 35

Page 36

Troubleshooting TMT85

Some other error has occurred. Possible causes and remedial measures → Chap. 9.3

9.2 Status messages

The device displays warnings or alarms as status messages. If errors occur during

commissioning or measuring operation, these errors are displayed immediately. This takes

place in the configuration program by means of the parameter in the Adv. Diagnostic Block

or on the mounted display. A distinction is made here between the following 4 status

categories:

Status category Description Error category

F Fault detected ('Failure') ALARM

C Device is in the service mode ('Function check')

WARNINGS Specifications not observed ('Out of specification')

M Maintenance necessary ('Maintenance required')

WARNING error category:

With "M", "C" and "S" status messages, the device tries to continue measuring (uncertain

measurement!). If a display unit is attached, the display alternates between the main

measured value and the status in the form of the letter in question plus the defined error

number.

ALARM error category:

The device does not continue measuring when the status message is "F". If a display unit is

attached, the display alternates between the status message and "- - - -" (no valid measured

value available). Depending on the setting of the Fail Safe Type parameter (FSAFE_TYPE),

the last good measured value, the incorrect measured value or the value configured under

Fail Safe Value (FSAFE_VALUE) is transmitted via the fieldbus with the status "BAD" for the

measured value. The fault state is displayed in the form of the letter "F" plus a defined

number. The status message can also apply for just one channel (e.g. F041 - Sensor break).

The second channel is still fully functional.

In both instances, the system outputs the sensor that generates the status, e.g. "C1",

"C2". If no sensor name is displayed, the status message does not refer to a sensor

but refers to the device itself.

Abbreviations of the output variables:

• SV1 = Sensor value 1

• SV2 = Sensor value 2

•PV1 = Primary value 1

•PV2 = Primary value 2

• DT = Device temperature

36 Endress+Hauser

Page 37

TMT85 Troubleshooting

Defa

No. Status messages

ult

categ

ory

F- 041Device status message (FF):

M- 042Device status message (FF):

F- 043Device status message (FF):

M- 101Device status message (FF):

M- 102Device status message (FF):

M- 103Device status message (FF):

M- 104Device status message (FF):

F- 221Device status message (FF):

– ACTUAL_STATUS_NUM

BER in the 'Advanced

Diagnostics' Transducer

Block

–Local display

Sensor line break

F-041

Local display:

F-041

Sensor corrosion

M-042

Local display:

M-042 ↔ Measured value

Sensor shortcut

F-043

Local display:

F-043

Under-usage of sensor

range

M-101

Local display:

M-101 ↔ Measured value

Exceedence of sensor range

M-102

Local display:

M-102 ↔ Measured value

Sensor drift detected

M-103

Local display:

M-103 ↔ Measured value

Backup active

M-104

Local display:

M-104 ↔ Measured value

Reference measurement

F-221

Local display:

F-221

Error messages in the

Sensor Transducer Block in

question

BLOCK_ERR =

Other ⏐

Input Failure

Transducer_error =

Mechanical failure

BLOCK_ERR =

Other

Transducer_Error = No error SUBSTATUS =

BLOCK_ERR =

Other ⏐

Input Failure

Transducer_error =

Mechanical failure

BLOCK_ERR =

Other

Transducer_Error = No error SUBSTATUS =

BLOCK_ERR =

Other

Transducer_Error = No error SUBSTATUS =

BLOCK_ERR =

Other

Transducer_Error = No error SUBSTATUS =

BLOCK_ERR =

Other

Transducer_Error = No error SUBSTATUS =

BLOCK_ERR =

Other

Transducer_Error = General

error

Sensor

Transducer

Block measured

value status

(default)

QUALITY = BAD Cause of error:

SUBSTATUS =

Sensor failure

QUALITY =

UNCERTAIN

(configurable)

Sensor conversion

not accurate

QUALITY = BAD Cause of error:

SUBSTATUS =

Sensor failure

QUALITY =

UNCERTAIN

Sensor conversion

ot accurate

n

QUALITY =

UNCERTAIN

Sensor conversion

not accurate

QUALITY =

UNCERTAIN

(configurable)

Non-specific

QUALITY = GOOD

/ BAD

Non-specific

QUALITY = BAD Cause of error:

SUBSTATUS =

Device failure

Cause of error / remedy Output

variables

affected

SV1, SV2 also

1. Electr. interruption of sensor or

sensor wiring

2. Incorrect setting for type of

connection in the SENSOR_

CONNECTION parameter

Remedy:

Re 1.) Reestablish electr. connection or

replace sensor.

Re 2.) Configure correct type of

connection.

Cause of error:

Corrosion detected on the sensor

terminals.

Remedy:

Check wiring and replace if necessary.

Short circuit detected at the sensor

terminals.

Remedy:

Check sensor and sensor wiring.

Cause of error:

Physical measuring range undershot.

Remedy:

Select suitable sensor type.

Cause of error:

Physical measuring range overshot.

Remedy:

Select suitable sensor type.

Cause of error:

Sensor drift has been detected (in

accordance with the settings in the

Advanced Diagnostics Block).

Remedy:

Check the sensor, depending on the

application.

Cause of error:

Backup function activated and an error

was detected at one sensor.

Remedy:

Rectify sensor error.

Internal reference junction defective.

Remedy:

Device defective, replace

PV1, PV2

depending on

the

configuration

SV1, SV2 also

PV1, PV2

depending on

the

configuration

SV1, SV2 also

PV1, PV2

depending on

the

configuration

SV1, SV2 also

PV1, PV2

depending on

the

configuration

SV1, SV2 also

PV1, PV2

depending on

the

configuration

PV1, PV2

SV1, SV2

SV1, SV2 also

PV1, PV2

depending on

the

configuration

SV1, SV2,

PV1, PV2, DT

Endress+Hauser 37

Page 38

Troubleshooting TMT85

Defa

No. Status messages

ult

categ

ory

F- 261Device status message (FF):

F- 283Device status message (FF):

C- 402Device status message (FF):

F- 431Device status message (FF):

F- 437Device status message (FF):

C-

C- 501Device status message (FF):

S- 502Device status message (FF):

– ACTUAL_STATUS_NUM

BER in the 'Advanced

Diagnostics' Transducer

Block

–Local display

Electronic board defective

F-261

Local display:

F-261

Memory error

F-283

Local display:

F-283

Startup of device

C-402

Local display:

C-402 ↔ Measured value

No calibration

F-431

Local display:

F-431

Configuration error

F-437

Local display:

F-437

482Device status message (FF):

Simulation Mode Active

C-482

Local display:

C-482 ↔ Measured value

Device preset

C-501

Local display:

C-501 ↔ Measured value

Special Linearization

S-502