Emko EZM-4950 User manual

Programmable Timer & Counter

EZM-4950 96x48 1/8 DIN

EZM-4950 96 x 48 1/8 DIN

Universal Input Programmable Timer &

Counter with Output Module System

- 6 digits Process (PV) and 6 digits Set (SV) Value Display

- Operation with 2 Set Value

- Reset , Pause and ChA-ChB Counting Inputs

- Configurable Counter / “Totalizer Counter”, Batch Counter ,

Timer, Chronometer , Frequencymeter and Tachometer Functions

- Programmable Time Bases for Timer and Chronometer (Second ,

Minute , Hour )

- Operation with Automatic and Manual Reset

- Output Module System

- NPN/PNP Type Operation

-INC,DEC,INC/INC,INC/DEC,UP/DOWN,x1/x2/x4

Counting with Phase Shifting Property in Counter Function

- Multiplication Coefficient and Decimal Point Position

- Different Alarm Alternatives in Frequencymeter and Cycle

Measuring Functions

- Absolute or Offset Operation in Counter Function

- RS-232 (standard) or RS-485 (optional) Serial Communication

with Modbus ASCII or RTU Protocol

Instruction Manual. ENG EZM-4950 02 V02 12/07

ABOUT INSTRUCTION MANUAL

Instruction manual of EZM-4950 Programmable Timer&Counter consists of two main

sections. Explanation of these sections are below. Also, there are other sections which include

order information and technical specifications of the device. All titles and page numbers in

instruction manualare in“ ” section.User canreach to anytitle withsection number.

Installation:

In this section, physical dimensions of the device, panel mounting, electrical wiring,

module mountingin the device, physical andelectrical installation of the deviceto the systemare

explained.

Operation andParameters:

In this section, user interface of the device, how to access to the parameters, description

of parametersare explained.

Also in these sections, there are warnings to prevent serious injury while doing the

physical andelectrical mounting or using thedevice.

Explanation ofthe symbolswhich are usedin thesesections are givenbelow.

c

CONTENTS

This symbol is used for safety warnings. User must pay attention to these

warnings.

This symbolis used todetermine the dangeroussituations as aresult of anelectric

shock. Usermust payattention to thesewarnings definitely.

a

This symbolis used todetermine the importantnotes about functionsand usage of

i

the device.

2

CONTENTS

1.PREFACE..................................................................................................................

1.1 GENERAL SPECIFICATIONS

1.2 ORDERING INFORMATION

1.3 WARRANTY

1.4 MAINTENANCE

2.INSTALLATION.........................................................................................................

2.1 GENERAL DESCRIPTION

2.2 DIMENSIONS

2.3 PANEL CUT-OUT

2.4 ENVIRONMENTAL RATINGS

2.5 PANEL MOUNTING

2.6 INSTALLATION FIXING CLAMP

2.7 REMOVING FROM THE PANEL

2.8 SELECTION OF OPERATION FUNCTION AND INPUT TYPE WITH DIP

SWITCH

3.ELECTRICAL WIRINGS...........................................................................................

3.1 TERMINAL LAYOUT AND CONNECTION INSTRUCTION

3.2 ELECTRICAL WIRING DIAGRAM

3.3 CONNECTION OF DEVICE SUPPLY VOLTAGE INPUT

3.4 COUNTING INPUT CONNECTION

3.4.1 PROXIMITY & SWITCH CONNECTION

3.4.2 INCREMENTAL ENCODER & SWITCH CONNECTION

3.4.3 SWITCH CONNECTION

3.5 GALVANIC ISOLATION TEST VALUES OF EZM-4950 PROGRAMMABLE

TIMER&COUNTER AND OUTPUT MODULES

4.DEFINITIONS AND SPECIFICATIONS OF OUTPUT MODULES...........................

4.1 EMO-400 RELAY OUTPUT MODULE

4.2 EMO-410 SSR DRIVER MODULE

4.3 EMO-420 DIGITAL (TRANSISTOR) OUTPUT MODULE

4.4 INSTALLING AND PULLING OUT OUTPUT MODULES

4.5 TO STICK OUTPUT MODULES’ LABELS TO THE DEVICE

5.CONNECTION TERMINALS OF OUTPUT MODULES AND CONNECTION

WIRING.....................................................................................................................

5.1 EMO-400 RELAY OUTPUT MODULE CONNECTION

5.2 EMO-410 SSR DRIVER MODULE CONNECTION

5.3 EMO-420 DIGITAL (TRANSISTOR) OUTPUT MODULE CONNECTION

6.CONNECTIONS FOR RS-232 / RS-485 SERIAL COMMUNICATION.....................

6.1 CABLE CONNECTION BETWEEN RS-232 TERMINAL OF THE DEVICE

AND PC

6.2 CONNECTION FOR RS-485 SERIAL COMMUNICATION

6.3 INSTALLING RS-232 / RS-485 SERIAL COMMUNICATION MODULES TO

THE DEVICE

7.DEFINITION OF FRONT PANEL AND ACCESSING TO THE PARAMETERS.......

7.1 DEFINITION OF FRONT PANEL

7.2 POWER ON OBSERVATION OF EZM - 4950 PROGRAMMABLE TIMER &

COUNTER AND SOFTWARE REVISION ON THE DISPLAY

Page 6

Page 9

Page 15

Page 22

Page 27

Page 29

Page 32

3

7.3 ADJUSTMENT OF SET1 AND SET2 VALUES

7.4 RESETTING COUNT VALUE AND OBSERVING TOTAL COUNT VALUE IN

COUNTER / “TOTALIZER COUNTER” FUNCTION

7.5 COUNTER / “TOTALIZER COUNTER” PARAMETERS

7.5.1 COUNTER / “TOTALIZER COUNTER” APPLICATIONS EXAMPLES

7.6 BATCH COUNTER PARAMETERS

7.6.1 BATCH COUNTER APPLICATIONS EXAMPLES

7.7 TIMER PARAMETERS

7.7.1 TIMER APPLICATIONS EXAMPLES

7.8 FREQUENCYMETER / TACHOMETER PARAMETERS

7.8.1 FREQUENCYMETER / TACHOMETER APPLICATIONS EXAMPLES

7.9 CHRONOMETER PARAMETERS

7.9.1 CHRONOMETER APPLICATIONS EXAMPLES

7.10 ACCESSING TO THE PROGRAM PARAMETERS

8.PROGRAM PARAMETERS.....................................................................................

9.FAILURE MESSAGES IN EZM-4950 PROGRAMMABLE TIMER & COUNTER ..

10.SPECIFICATIONS.................................................................................................

Page 67

Page 100

Page 102

4

EU DECLARATION OF CONFORMITY

Manufacturer Company Name : Emko Elektronik A.S.

Manufacturer Company Address: DOSAB, Karanfil Sokak, No:6, 16369 Bursa, Turkiye

The manufacturer hereby declares that the product conforms to the following

standards and conditions.

Product Name : Programmable Timer & Counter

Model Number : EZM-4950

Type Number : EZM-4950

Product Category : Electrical equipment for measurement, control and

laboratory use

Conforms to the following directives :

73 / 23 / EEC The Low Voltage Directive as amended by 93 / 68 / EEC

89 / 336 / EEC The Electromagnetic Compatibility Directive

Has been designed and manufactured according to the following specifications

EN 61000-6-4:2001 EMC Generic Emission Standard for the Industrial Environment

EN 61000-6-2:2001 EMC Generic Immunity Standard for the Industrial Environment

EN 61010-1:2001 Safety Requirements for electrical equipment for measurement,

control and laboratory use

5

1.Preface

EZM Series Programmable Timer & Counter can be used in package machines,

production andquality control rollers,in cutting andprocessing machine ofglass, plastic, marble,

sheet, iron, fabric all measuring and controlling of dimension, count, total c unt, speed, cycle,

productivity, time and can be adapted easily to all mechanical construction and automation

system. They can be used in many application with their control outputs, serial communication

unit andoutput modules.

Some applicationfields whichthey are usedare below:

Application Fields

Glass

Plastic

Marble

Sheet iron

Automative

Machine production industries

o

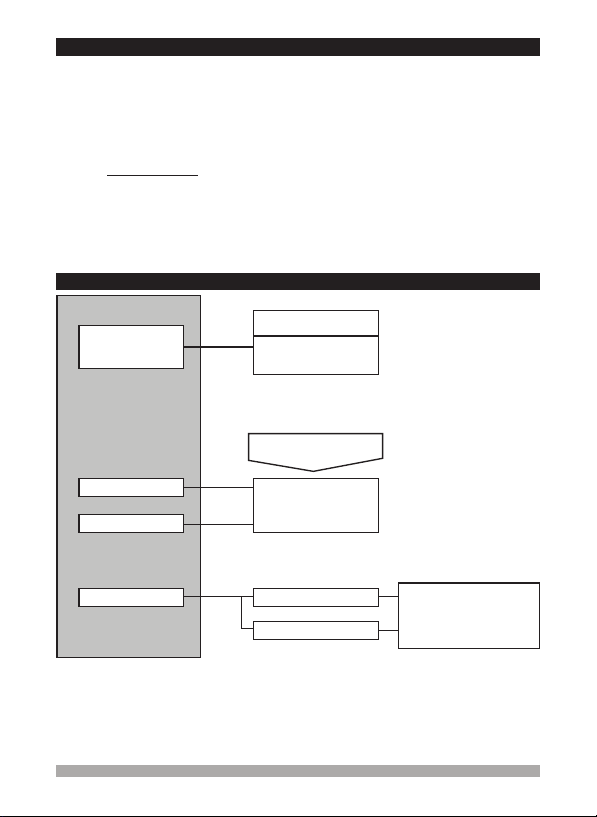

1.1 General Specifications

E M-4950Z

Supply Voltage

Input

Optional

Output Module-1

Optional

Output Module-2

Standard

Universal Supply Input

100-240 V , 50/60HzV

Low Voltage (optional)

Supply Input

24V 50/60Hz ,24VVZ

Relay, SSR Driver ,Digital

(Transistor) Output

Module

Control Output

Alarm Output

Serial Communication RS-232

Standard

Optional

RS-485

Baud Rate from 1200

to 19200

Modbus ASCII or RTU

Protocol

6

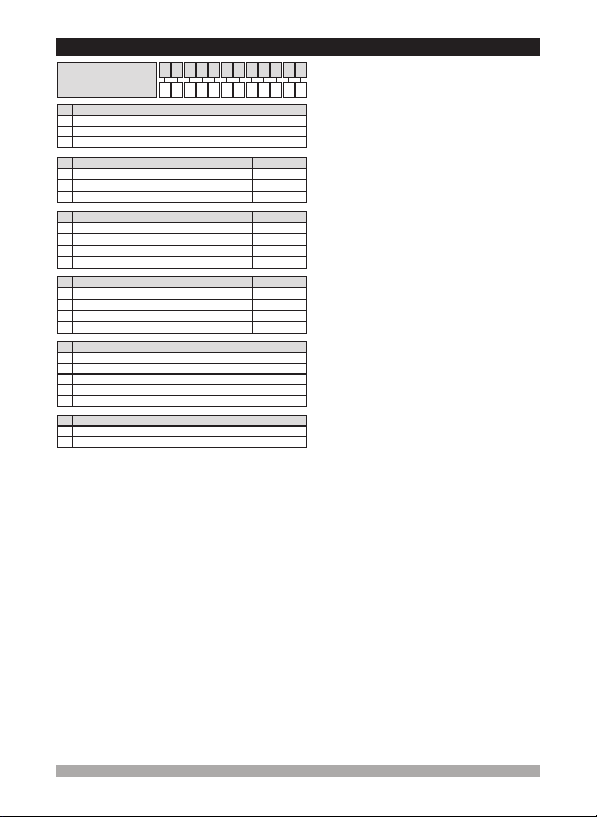

1.2 Ordering Information

A

E M-4950z ( 96x48 1/8 DIN)

Supply Voltage

A

100-240V (- ) 50/60HzV 15%;+10%

1

24 V (- 50/60Hz 24V (-VZ15%;+10%) 15%;+10%)

2

Customer (Maximum 240V (- ))50/60HzV 15%;+10%

9

Serial CommunicationD

0

None

1

RS-232

2

RS-485

Module-1FG

00

None -

01

Relay Output Module(3A@250V Resistive Load)V EMO-400

02

SSR Driver Output Module EMO-410

03

Digital(Transistor) Output Module EMO-420

Module-2HI

None -

00

Relay Output Module(3A@250V Resistive Load)V EMO-400

01

SSR Driver Output Module EMO-410

02

Digital(Transistor) Output Module EMO-420

03

Function of DeviceU

Counter / “TotalizerCounter”

0

1

Batch Counter

2

Timer

3

Frequencymeter and Tachometer

4 Chronometer

Input TypeV

0

NPN

1

PNP

BC D E FG HI //UVWZ/

/

0

00 0 0

Product Code

EMC-400

EMC-410

Product Code

Product Code

All order information of EZM-4950

Programmable Timer&Counter are given on

the table at left. User may form appropriate

device configuration from information and

codes that at the table and convert it to the

ordering codes.

Firstly, supply voltage then output

modules and other specifications must be

determined. Please fill theorder code blanks

according toyour needs.

Please contact us, if your needs are

out ofthe standards.

V

Symbol meansVac,

Z

c

Symbol meansVdc

W

Symbol meansVac and Vdc

7

1.3 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warrantyis provided fora period oftwo years. The warrantyperiod starts from

the delivery date. This warranty is in force if duty and responsibilities which are determined in

warranty documentand instructionmanual performs bythe customercompletely.

1.4 Maintenance

Repairs should only be performed bytrained and specialized personnel. Cut power to the device

before accessinginternal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solventscan reduce the mechanical reliability of thedevice. Use a cloth dampened in ethyl

alcohol orwater toclean the externalplastic case.

8

2.Installation

Before beginning installation of this product, please read the instruction

manual andwarnings belowcarefully.

c

In package,

- Onepiece unit

- Two pieces mounting clamps

- Onepiece instructionmanual

A visual inspection of this product for possible damage occured during shipment is

recommended before installation. It is your responsibility to ensure that qualified

mechanical andelectrical techniciansinstall this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power

off thesystem and the electricalconnection ofthe device fromthe system.

The unitis normally suppliedwithout a powerswitch or a fuse. Usepower switch andfuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble

with theunit canbe prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may

results inmalfunction, electricshock or fire.

Do notuse theunit in combustibleor explosivegaseous atmospheres.

During the equipment is putted in hole on the metal panel while mechanical installation

some metalburrs cancause injury onhands, youmust be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the

montage of the device with inappropriate fixing clamp. Be sure that device will not fall

while doingthe montage.

It is your responsibility if this equipment is used in a manner not specified in this

instruction manual.

separate

9

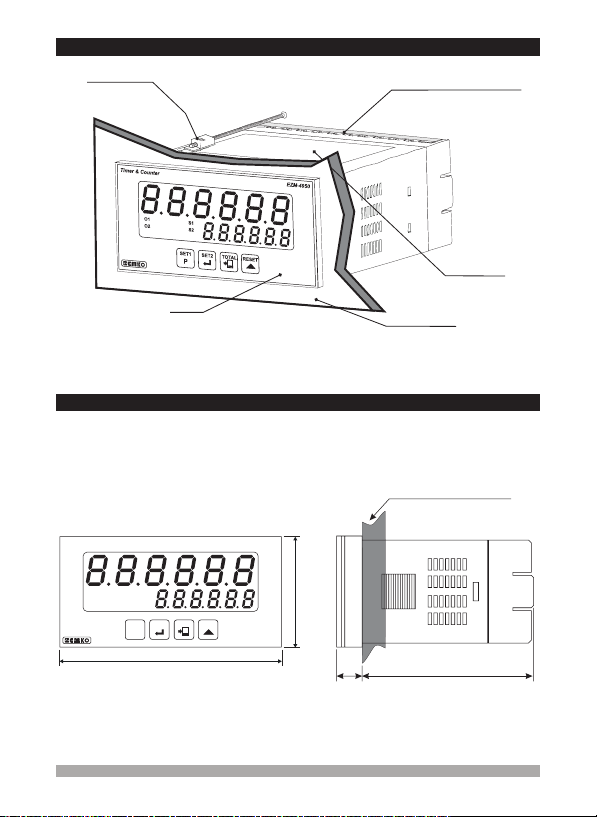

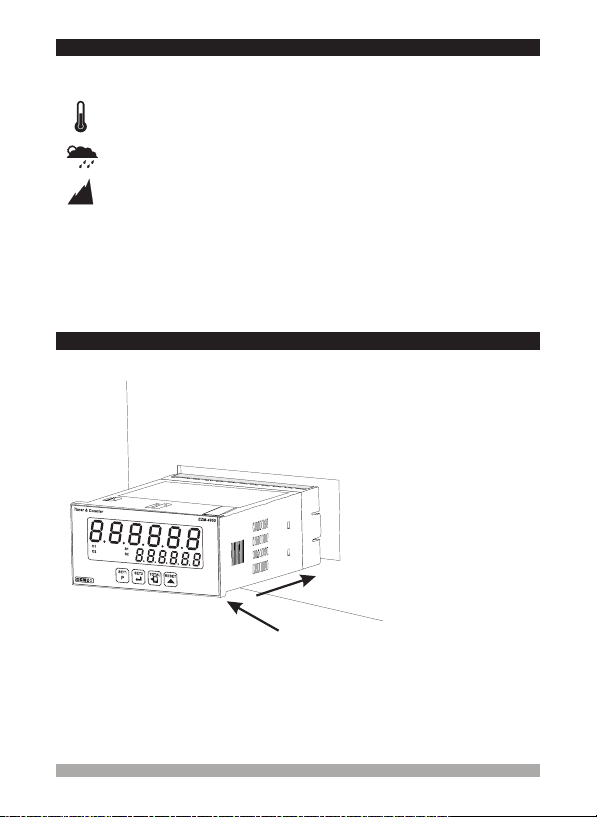

2.1 General Description

Mounting Clamp

Terminal protection cover

Product Label

2.2 Dimensions

Timer & Counter

O1

O2

96 mm / 3.78 inch

Front Panel

IP65 protection

NEMA 4X

S1

S2

TOTAL

SET2

SET1

P

RESET

EZM-4950

ESM-4430

Panel surface

(maximum thickness 15 mm / 0.59 inch)

Maximum 15 0.59 inchmm /

48 mm/ 1.89 inch

76 mm / 2.99 inch10.5±1mm/0.41 inch

10

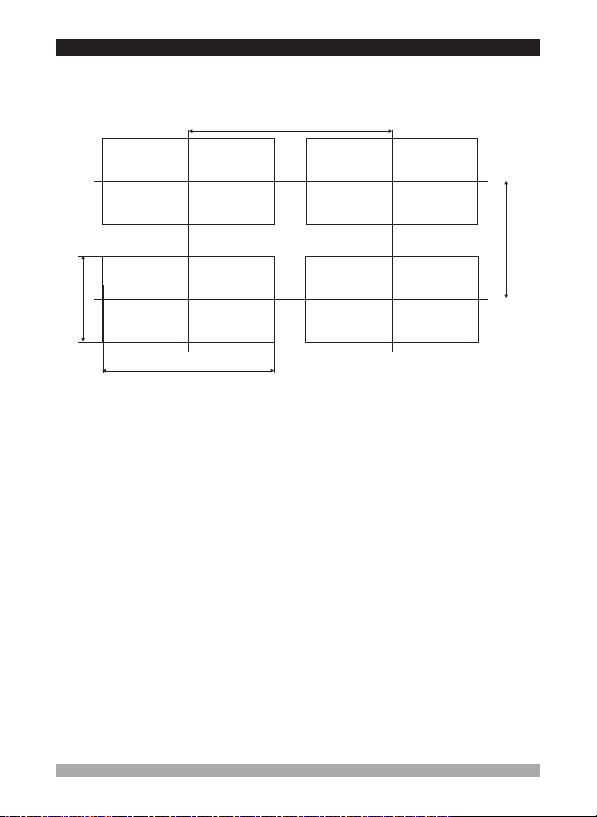

2.3 Panel Cut-Out

129 mm / 5.08 inch (min)

65 mm / 2.56 inch (min)

46 mm / 1.81 inch (min)

92 mm / 3.62 inch

11

2.4 Environmental Ratings

Operating Conditions

Operating Temperature :

Max. Operating Humidity :

Altitude :

Forbidden Conditions:

Corrosive atmosphere

Explosive atmosphere

c

Home applications(The unitis only forindustrial applications)

2.5 Panel Mounting

During installation into a metal panel, care should be taken to avoid injury from

metal burrs which might be present. The equipment can loosen from vibration

and become dislodged if installation parts are not properly tightened. These

c

precautions forthe safetyof the personwho doesthe panel mounting.

0to50°C

90 Rh (non-condensing)

%

Up to 2000m.

1

3

2

1-Before mounting the device in

your panel, make sure that the

cut-out isthe rightsize.

2-Check front panel gasket

position

3-Insert the device through the

cut-out. If the mounting clamps

are on the unit, put out them

before inserting the unit to the

panel.

12

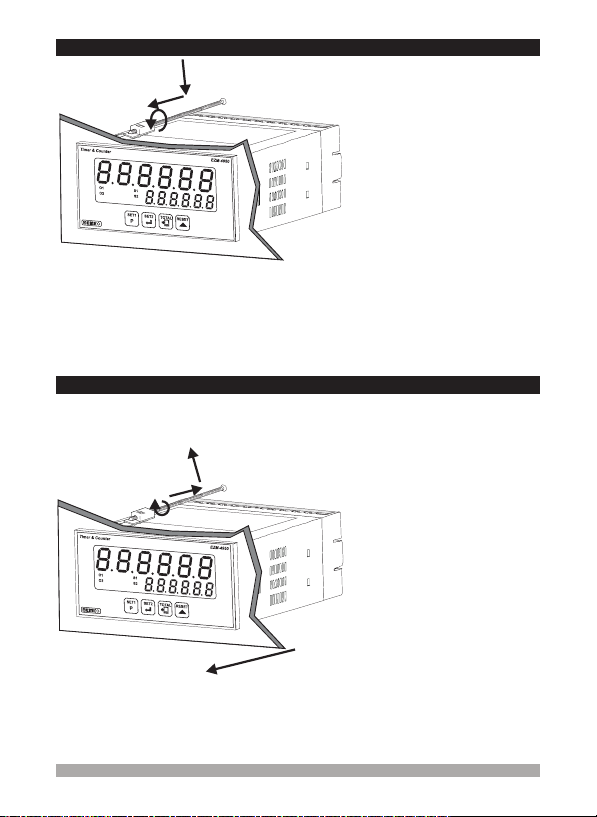

2.6 Installation Fixing Clamp

1

2

Montage ofthe unit to a systemmust be done withit’s ownfixing clamps. Do not

do the montage of the device with inappropriate fixing clamps. Be sure that

device willnot fallwhile doing themontage.

c

2.7 Removing from the Panel

Before starting to removethe unit from panel, power off theunit and the related

system.

c

2

1

1

The unit is designed for panel

mounting.

1-Insert the unit in the panel cut-out

from thefront side.

2- Insert the mounting clamps to the

holes that located top and bottom

sides of device and screw up the

fixing screws until the unit

completely immobile within the

panel

1-Loosen thescrews.

2-Pull mounting clamps from top

and bottomfixing sockets.

3-Pull the unit through the front

side ofthe panel

3

13

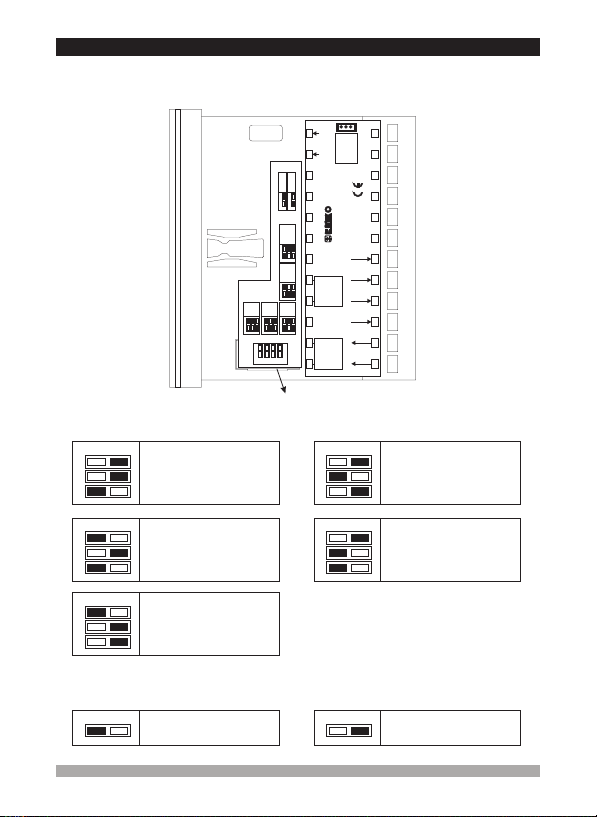

2.8 Selection of Operation Function and Input Type with DIP Switch

Operation function and input type ( NPN / PNP ) can be changed by DIP switch

on thedevice.

c

L

24

23

22

PNP

NPN

ON

ON

21

OFF

OFF

4

4

20

19

Chronometer

ON

OFF

1

2

3

18

Tachometer

17

ON

OFF

1

2

3

16

&

Timer

Batch

Counter

Counter

Totalizer

ON

ON

ON

OFF

1

15

OFF

OFF

2

3

2

3

1

1

2

3

14

ON

OFF

1

2

3

4

13

12

N

11

50/60 Hz - 6VA

100 to 240 VV

10

9

Y

8

a

7

c

m

P/N : Z4E M- 950

RESET

6

PAUSE

5

ChB

MODULE- 2

4

ChA

3

0V

Z

2

Max.50mA

12V

Z

1

MODULE- 1

DIP Switch is under cover and cover is on top side of the device

Function Selection

ONOFF

1

2

3

1

2

Counter / “Totalizer

Counter”

ONOFF

Timer

3

ONOFF

1

2

Chronometer

3

ONOFF

1

2

Batch Counter

3

ONOFF

1

2

Frequencymeter and

Tachometer

3

Input Type Selection

ONOFF

4

NPN PNP

ONOFF

4

14

3.Electrical Wirings

You must ensure that the device is correctly configured for your application.

Incorrect configurationcould result indamage to the process beingcontrolled,

and/or personal injury. It is your responsibility, as the installer, to ensure that

c

the configurationis correct.

Parameters ofthe device has factory defaultvalues. These parametersmust be

set accordingto thesystem’s needs.

Only qualified personnel and technicians should work on this equipment. This

equipment contains internal circuits with voltage dangerous to human life.

There issevere dangerfor human lifein thecase of unauthorizedintervention.

c

Be sure to use the rated power supply voltage to protect the unit against

damage andto preventfailure.

c

Keep thepower off until all ofthe wiring is completed sothat electric shockand

trouble withthe unitcan be prevented.

c

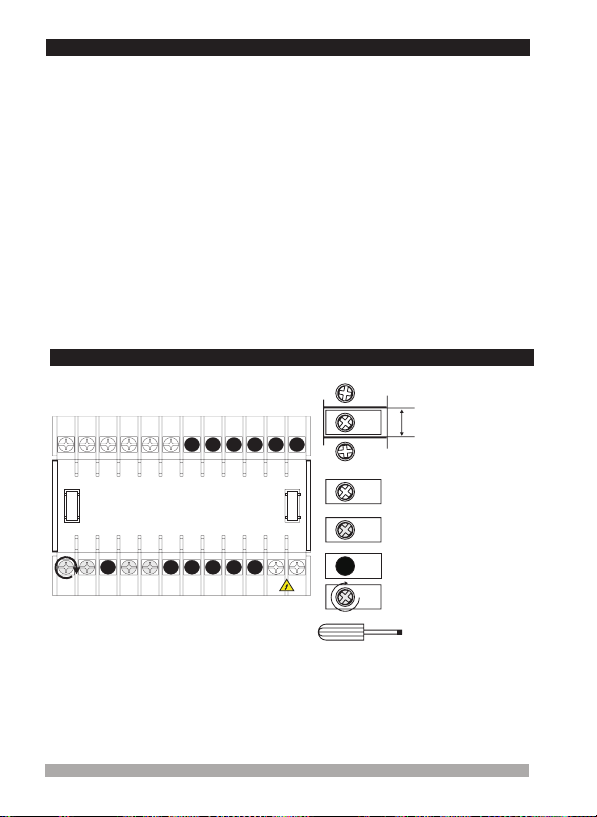

3.1 Terminal Layout and Connection Instructions

1

13214315416517618719820921102211231224

0.5 Nm

6 mm/ 0.236inch

Wire Size:

18 AWG/ 1 mm²

Solid /Stranded

24 screws terminal

M3

Optional

Connections

Empty terminals

Torque0.5 Nm

Screw driver

0.8x3mm

15

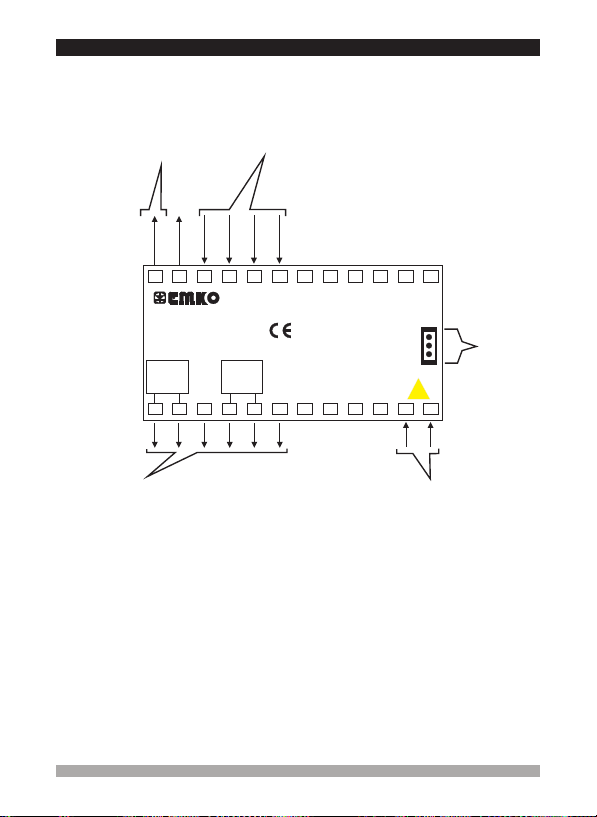

3.2 Electrical Wiring Diagram

Electrical wiring of the device must be the same as ‘Electrical Wiring Diagram’

below toprevent damageto the processbeing controlledand personnel injury.

c

Sensor

Supply Voltage

12 V Z

Max 50mA

123456

P/N : Z 4E M- 950

c

MODULE-1

13 14 15 16 17 18

Optional Output Module Terminals

Relay Output Module

SSR Driver Module

Digital (Transistor) Output Module

0VZ

Y

Counting Inputs

Ch A

Ch B

m

MODULE-2

PAUSE

RESET

7

89

10 11 12

Communication

19

20 21

100-240V (- ) 50/60Hz - 6VA

24 V (- 50/60Hz - 6VA

(It must be determined in order)

a

22 23 24

Supply Voltage Input

V

15%;+10%

V

15%;+10%)

24V (-

Z

15%;+10%) - 6W

Socket

16

3.3 Connection of Device Supply Voltage Input

Connection of Universal

Supply Voltage Input

Y

Note-1

Fuse

NL

a

23

24

External

Fuse

Note-3

(1 A T)V

Power

Supply

Switch

Connection of Low Voltage

24 V Supply Voltage InputW

Y

Note-1

Fuse

a

N

23L24

Note-2

(24V : 1 A T)VV

Note-3

(24V : 1 A T)ZZ

Power

Supply

Switch

cc

Supply Voltage

100 - 240 V (-15%;+10%)

V

Note-1 :

There isinternal 33R fusible flameproof resistor in100-240 V 50/60Hz

There isinternal 4R7 fusible flameproof resistor in 24V 50/60Hz and 24V

Note-2 :

“L” is“+”, “N”is “-” for24V supply voltage

Note-3 :

External fuseis recommended.

c

c

c

50/60Hz

W

W

Make sure that the power supply voltage is the same indicated on the

instrument.

Switch on the power supply only after that all the electrical connections have

been completed.

Supply voltage range must be determined in order. While installing the unit,

supply voltage range must be controlled and appropriate supply voltage must

be applied to the unit. Controlling prevents damages in unit and system and

possible accidentsas aresult of incorrectsupply voltage.

There is no power supplyswitch on the device. So a power supply switch must

be addedto the supplyvoltage input. In accordancewith the safetyregulations,

the power supply switch shall bring the identification of the relevant

instrument.Power supplyswitch shallbe easily accessibleby theuser.

Power switch must be two poled for seperating phase and neutral. On/Off

condition of power switch is very important in electrical connection. On/Off

condition ofpower switchmust be signedfor preventingthe wrong connection.

If anexternal fuseis used, itmust beon phase connectionin supply input.V

If anexternal fuseis used, itmust beon (+) lineconnection in supplyinput.Z

The instrument is protected with an internal fuse (Please refer to Note1 for

information). In case of failure it is suggested to return the instrument to the

manufacturer forrepair.

Z

Supply Voltage

24V (-15%;+10%) 50/60Hz

V

or 24V (-15%;+10%)

Z

V

VZ

External

Fuse

17

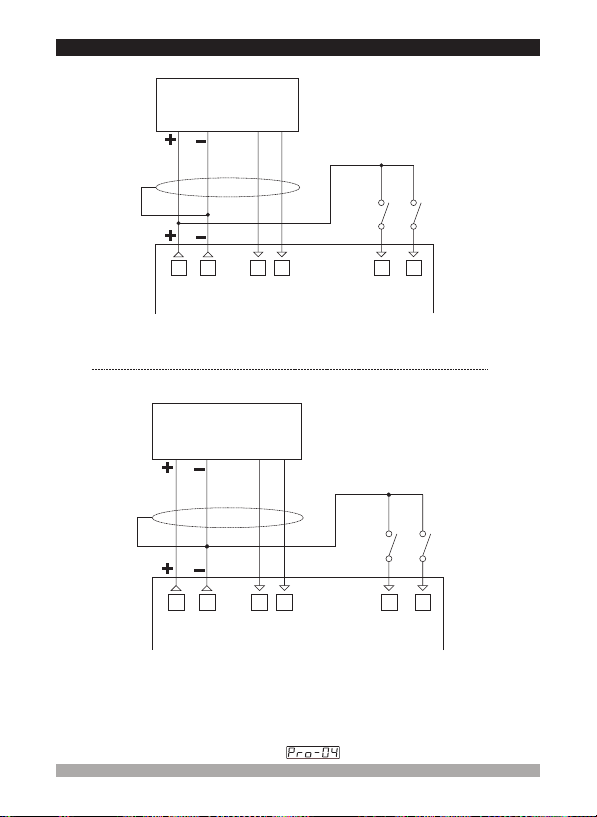

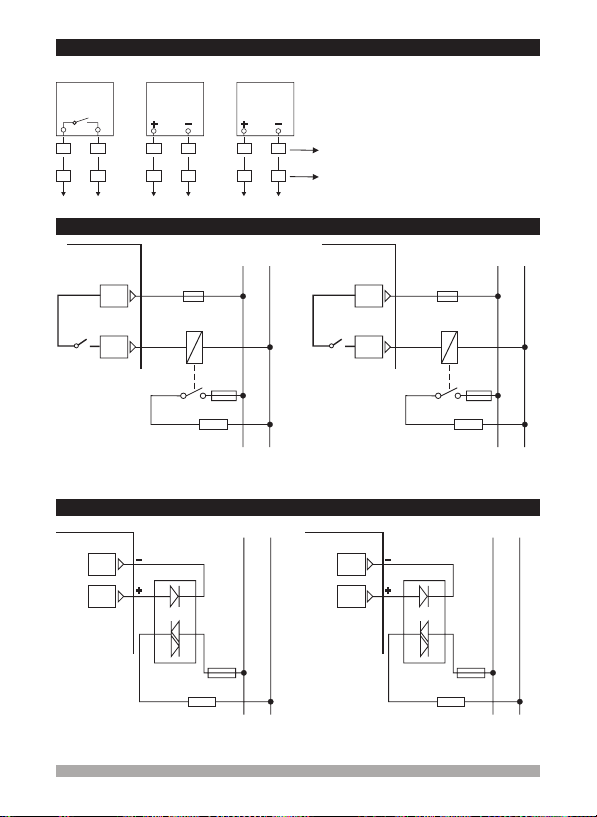

3.4 Counting Input Connection

3.4.1 Proximity & Switch Connection

DIP SWITCH ADJUSTMENT : PNP

PROX. PROX.

PNP PNP

142536

0VZ

Z

12 V

Max. 50mA

NOTE-1

DIP SWITCH ADJUSTMENT : NPN

PROX. PROX.

NPN NPN

142536

ChA

ChB

Switch

PAUSE

NOTE-2

Switch

Switch

RESET

Switch

PAUSE

ChA

Z

12 V

NOTE-1

NOTE-1 :Auxiliary powersupply for external transmitter

12V ± 10%, 50 mAmaximum with short circuitprotectionZ

NOTE-2 : Reset and Pause inputs have protection time against electrical contact

debounce. Protectiontime canbe set with parameter. (2-250msec.)

0VZ

Max. 50mA

ChB

NOTE-2

RESET

18

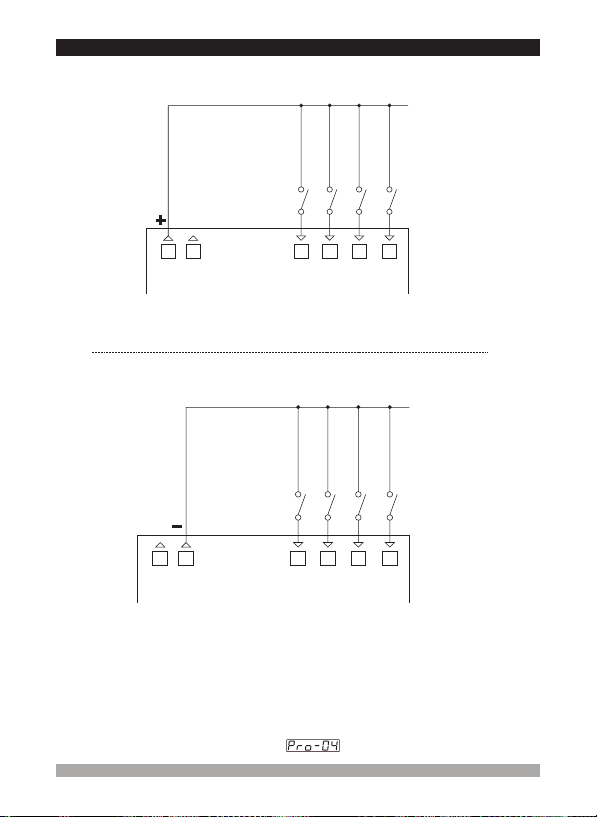

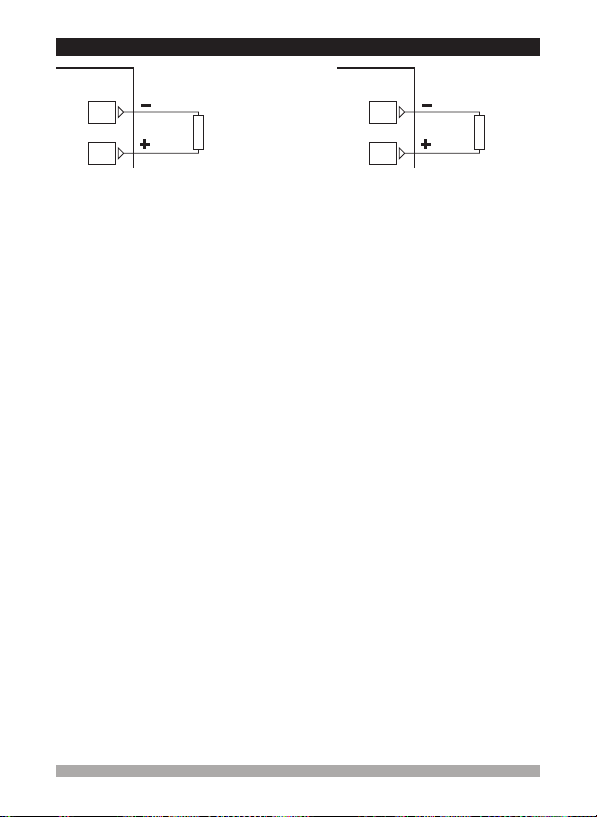

3.4.2 Incremental Encoder & Switch Connection

DIP SWITCH ADJUSTMENT : PNP

INCREMENTAL ENCODER

10 to 30VZ

142536

Switch

Switch

Z

12 V

NOTE-1

Max. 50mA

ChA

0VZ

ChB

PAUSE

NOTE-2

RESET

DIP SWITCH ADJUSTMENT : NPN

INCREMENTAL ENCODER

10 to 30VZ

Switch

Switch

142536

ChA

Z

0VZ

12 V

Max. 50mA

NOTE-1

NOTE-1 :Auxiliary powersupply for external transmitter

12V ± 10%,50 mAmaximum short circuit protectionZ

NOTE-2 : Reset and Pause inputs have protection time against electrical contact

debounce. Protectiontime canbe set with parameter. (2-250msec.)

ChB

PAUSE

NOTE-2

RESET

19

3.4.3 Switch Connection

DIP SWITCH ADJUSTMENT : PNP

Switch

Switch

Switch

Switch

142536

ChA

ChB

PAUSE

Z

12 V

NOTE-1

0VZ

Max. 50mA

RESET

NOTE-2

DIP SWITCH ADJUSTMENT : NPN

Switch

Switch

Switch

Switch

142536

ChA

ChB

PAUSE

0VZ

Z

12 V

Max. 50mA

NOTE-1

NOTE-1 :Auxiliary powersupply for external transmitter

12V ± 10%, 50mA maximumshort circuit protectionZ

NOTE-2 : Reset and Pause inputs have protection time against electrical contact

debounce. Protectiontime canbe set with parameter. (2-250msec.)

NOTE-2

RESET

20

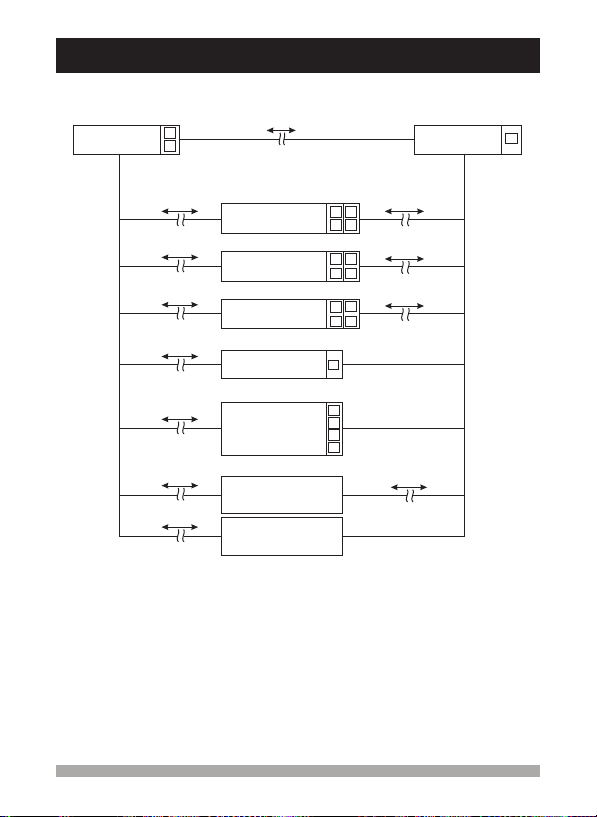

3.5 Galvanic Isolation Test Values of EZM-4950 Programmable Timer & Counter and

Output Modules

2000 E M-4950 1 )

V ( For Z . ...V

5

00V ( For EZM-4950.2...)V

Supply Input

24

23

0VZ

2

2000V V

2000V V

2000V V

2000V V

2000V V

2000V V

2000V V

EMO-400

Relay Output Module

EMO- 104

SSR Driver Module

EMO- 204

Digital Output Module

12V Sensor

Z

Supply Voltage

Counter Inputs

EMC-410

RS-485 Serial

Communication Module

EMC-400

RS-232 Serial

Communication Module

13

141617

13

141617

13

141617

1

3

4

5

6

2000V V

500V V

500V V

500V V

21

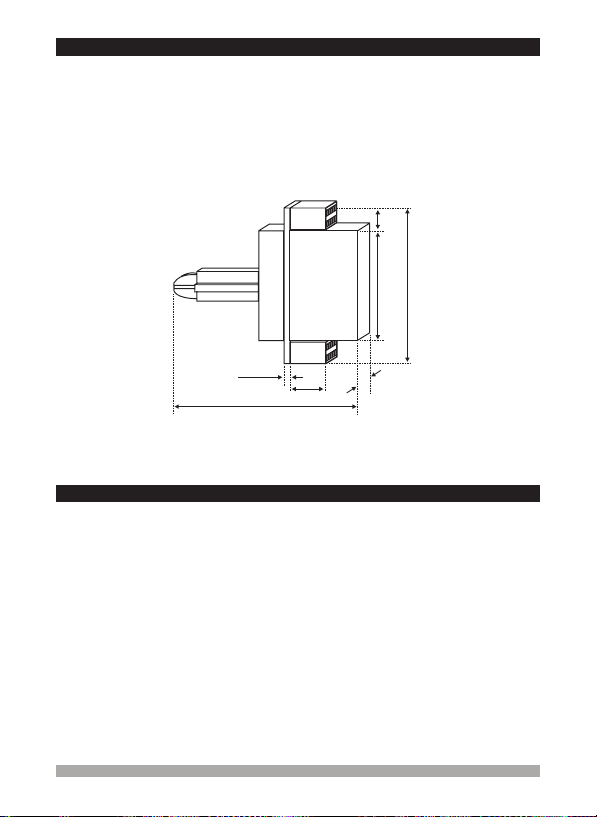

4. Definitions and Specifications of Output Modules

EZM-4950 programmable Timer &Counter is a modular product which is designed to

operate withadditional outputunits which usermay need.

Two output modulescan be plugged in theequipment by the user. User the

product for different applications according to the system requirements with the output modules

which aredescribed inthis section.

Dimensions of Output Modules

may configure

5mm

20.3mm

30.7mm

1.5mm

8.5mm

41.4mm

4.1 EMO-400 Relay Output Module

EMO-400 Relay output module can be plugged in Module-1 or Module-2 socket to be used in

applications thatrelay outputis necessary

Specifications of EMO-400 Relay Output Module

Output

Dimensions

Electrical Life

Applications ofEMO-400 RelayOutput Module

It canbe usedfor programmable different alarmfunctions ascontrol or alarmoutput.

: 3A @ 250V , Single Open Contact

: 14x30.7x41.4mm

: 100.000operation (FullLoad)

V

14mm

22

4.2 EMO-410 SSR Driver Module

EMO-410 SSR Driver Module can be plugged in Module-1 or Module-2 socket to be used in

applications thatSSR driveroutput is necessary

Specification of EMO-410 SSR Driver Module

Output :

Dimensions :

Applications ofEMO-410 SSRDriver Module

It canbe usedfor programmable different alarmfunctions ascontrol or alarmoutput.

Note 1:

short outputperiod b

4.3 EMO-420 Digital (Transistor) Output Module

EMO-420 Digital (Transistor) Output Module can be plugged in Module-1 or Module-2 socket to

be usedin applicationsthat digital outputis necessary

Specifications of EMO-420 Digital (Transistor) Output Module

Output :

Dimensions :

Applications ofEMO-420 Digital(Transistor) OutputModule

It canbe usedfor programmable different alarmfunctions ascontrol or alarmoutput.

Maximum 20 mA, 15-18V ±10%, isolated

14x30.7x41.4mm

SSR Driver Module must be preferred instead of relay output module in applications with

ecause oflimited lifeof their relaycontact (numberof open/close events).

Maximum 40 mA, 15-18V ±10%, isolated

14x30.7x41.4mm

Z

Z

23

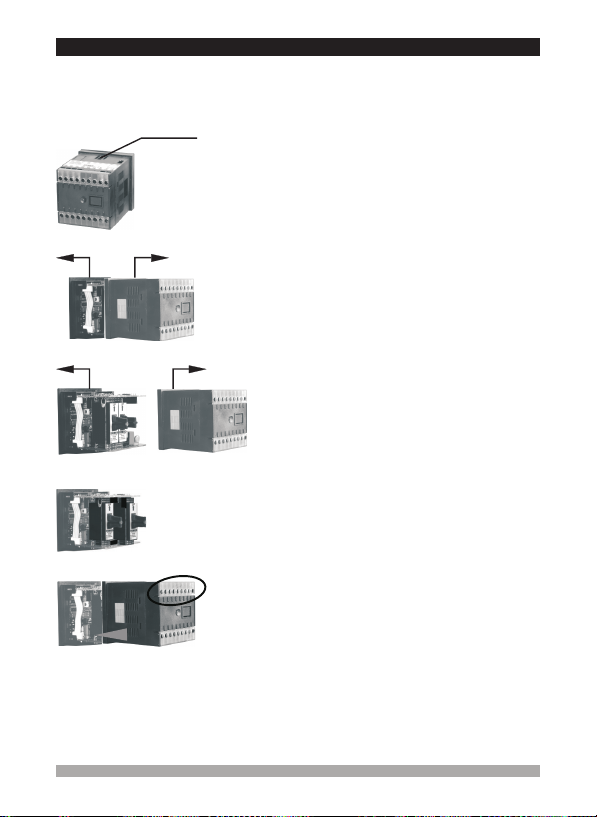

4.4 Installing and Pulling Out Output Modules

First, detach all cable connections from the device and uninstall it from the

panel.

c

Suppress tothe lockpins where topand bottomof the device

Pull the cover case with your other hand from front panel to rear

side.

Pull outthe covercase from thedevice

Slide outputmodules intosocket.

Pull outthe module from it’s socket,instead of thismodule install the new one

or othermodule userwants to use.

Replace the cover case by taking care of the terminal numbers

should beat right .position

After addingor changing modules tothe unit, these changesmust be takeninto

consideration whilemounting of the unitto the system. If mountingis incorrect,

it can cause accidents to harm system, operator or person who does the

c

mounting. Responsibilityof thesekind of harmfulevents belongsto the user.

24

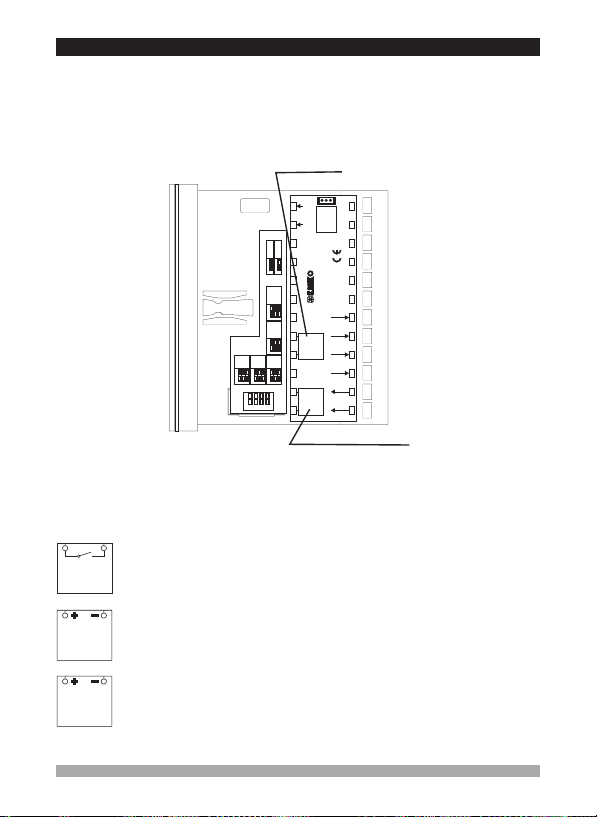

4.5 To Stick Output Modules’ Labels to the Equipment

Every module which is plugged in Module-1 or Module-2 socket has labels’ for showing

the relation between connection terminal and the device. These labels are attached to empty

attachment places which are d for Module-1 and Module-2 on the device. Labels for all

modules andattachment placesare shown below.

Label which is plugged in Module-2 socket, describes module

Label which is plugged in Module-1 socket, describes module

separate

termination connection is attached to this area.

L

12

24

N

11

23

50/60Hz - 6VA

100to 240 VV

10

22

PNP

NPN

ON

ON

OFF

OFF

4

4

Chronometer

ON

OFF

1

2

3

Tachometer

ON

OFF

1

2

3

&

Timer

Batch

Counter

Counter

Totalizer

ON

ON

ON

OFF

OFF

OFF

1

2

3

1

2

3

1

2

3

ON

OFF

1

2

3

4

9

21

Y

8

20

a

7

19

c

m

P/N : Z4E M- 950

RESET

6

18

PAUSE

5

17

ChB

MODULE- 2

4

16

ChA

3

15

0VZ

2

14

Max.50mA

12VZ

1

MODULE- 1

13

termination connection is attached to this area.

LABELS FOR OUTPUT MODULES

NOC

Label for EMO-400 Relay Output Module

3A@250VV

EMO-400

Relay Output

Module

Label for EMO-410 SSR Driver Module

Max.

20mA@18VZ

EMO-410

SSR Driver

ModuleOutput

Label for EMO-420 Digital (Transistor) Output Module

Max.

40mA@18VZ

EMO-420

Digital

Output

Module

25

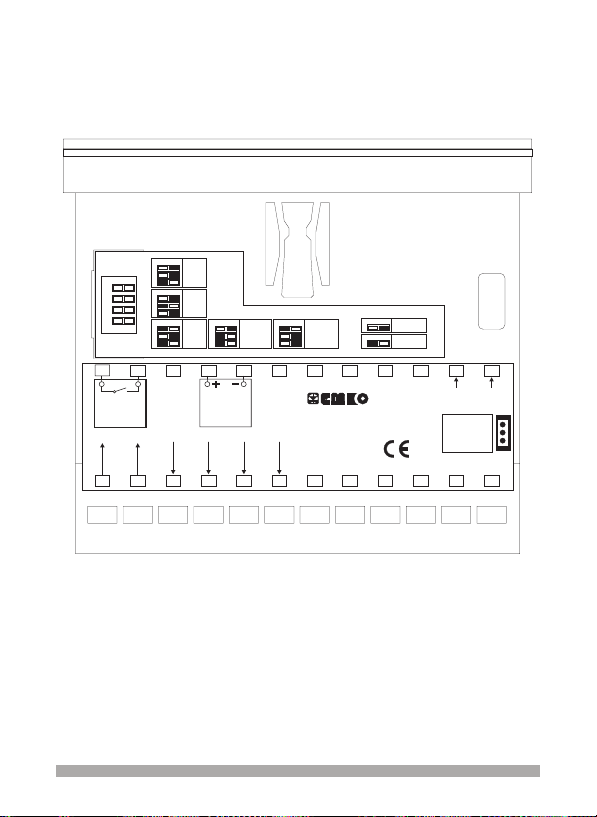

Example : If user installs EMO-400 Relay Output Module to Module-1 socket, EMO-410 SSR

Output Module to Module-2 socket and attach the appropriate labels on the device view will be

like below:

OFF

ON

Counter

1

&

2

OFF

1

2

3

4

13

NOC

3A@250VV

EMO-400

Relay Output

Module

MODULE - 1 MODULE - 2

Z

12 V

Max.50mA

11421531641751861972082192210

Totalizer

ON

3

ON

OFF

1

Batch

Counter

2

3

ON ON ON

OFF OFF OFF

11 1

Timer Tachometer Chronometer

22 2

33 3

Max.

20mA@18VZ

EMO-410

SSR Driver

ModuleOutput

Z

ChA

ChB

0V

PAUSE

P/N : Z 4E M- 950

c

m

RESET

a

Y

ON

OFF

PNP

4

ON

OFF

NPN

4

24

23

L

N

100 to 240 VV

50/60 Hz - 6VA

12

11

26

5.Connection Terminals of Output Modules and Connection Wirings

Module-1 / Module-2 Optional Output Modules

EMO-400

Relay Output

Module

3A@250V V

NOC

131614

17

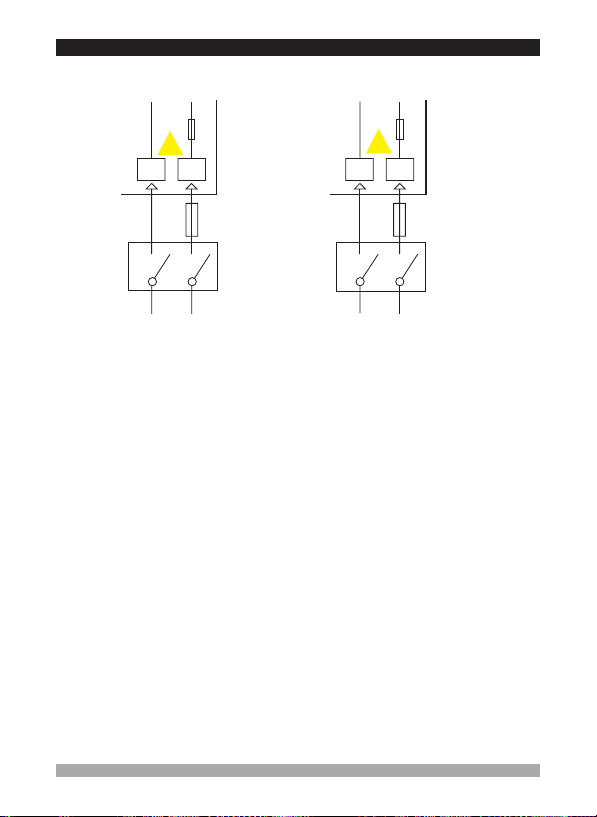

5.1 EMO-400 Relay Output Module Connection

Module-1

C

13

NO

EMO-410

SSR Driver

Output Module

Max.

20mA@18V Z

131314 14

16 16

3A T FuseV

Last Control Element

(Contactor)

14

EMO-420

Digital Output

Module

Max.

40mA@18V Z

Module-1 Connection Terminals

c

Fuse

17

LN

Module-2 Connection Terminals

Module-2

16

17

3A T FuseV

Last Control Element

C

NO

17

(Contactor)

c

Fuse

LN

Load

Fuses mustbe selectedaccording to theapplications.

c

5.2 EMO-410 SSR Driver Module Connection

Module-1

14

Last Control

Element

(SSR)

LN

13

c

Fuse

15-18 V

Z

Max.20mA

Fuses mustbe selectedaccording to theapplications.

c

Load

Module-2

17

16

15-18 V

Z

Max.20mA

Last Control

Element

(SSR)

Load

Load

c

Fuse

LN

27

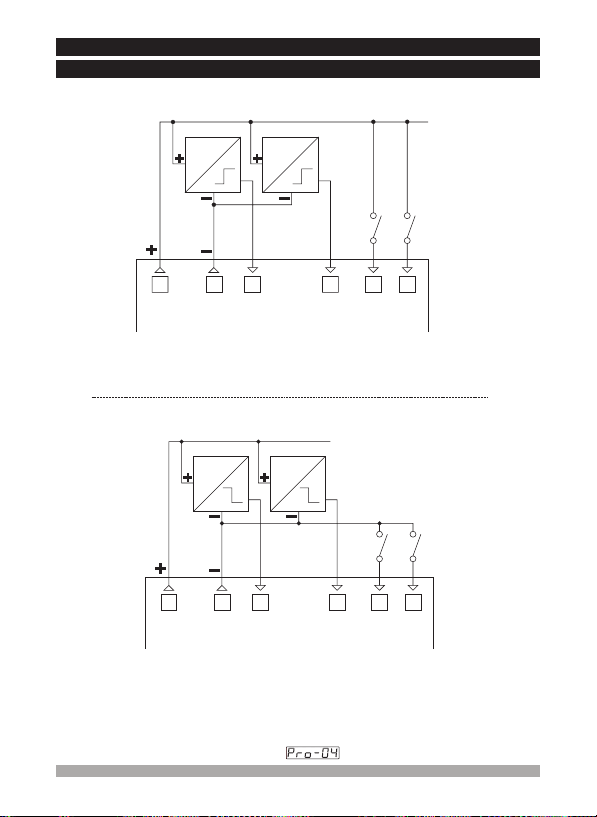

5.3 EMO-420 Digital (Transistor) Output Module Connection

Module-1

14

13

15-18 V

Z

Max.40mA

Load

Module-2

17

16

15-18 V

Z

Max.40mA

Load

28

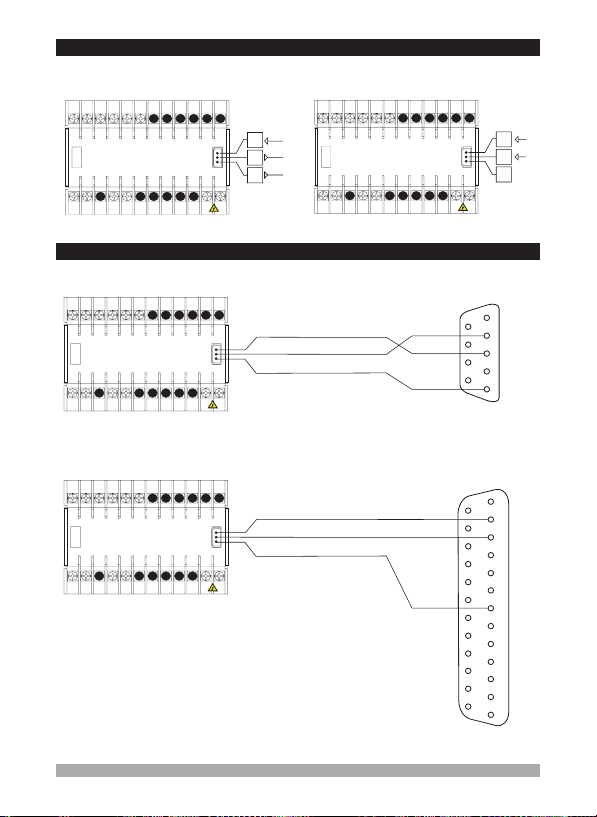

6.Connection for RS-232 / RS-485 Serial Communication

RS-232 Terminal Definitions RS-485 Terminal Definitions

1

13214315416517618719820921102211231224

1

2

3

1

RX

TX

GND

13214315416517618719820921102211231224

6.1 Cable Connection Between RS-232 Terminal of the Device and the PC

EM- 0Z 495

1

13214315416517618719820921102211231224

EM-Z 4950

1

13214315416517618719820921102211231224

Cable Lenght must

be max. 12 meters

for 9600 baud rate

RX RX

TX TX

GND

Cable Lenght must

be max. 12 meters

for 9600 baud rate

RX

TX

GND

PC (Personal Computer)

9 Pin DCON connection

GND

PC (Personal Computer)

25 Pin DCON connection

TX

RX

GND

9

8

7

6

25

24

23

22

21

20

19

18

17

16

15

14

1

2D+

3

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

D-

29

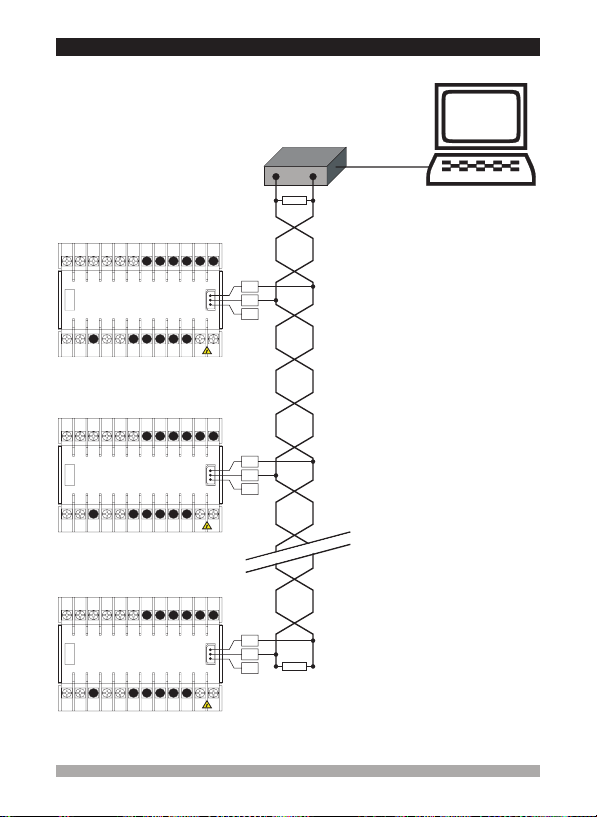

6.2 Connection for RS-485 Serial Communication

RS-232 RS-485

Þ

Convertor

PC(PersonalComputer)

SLAVE-1

1

13214315416517618719820921102211231224

SLAVE-2

1

13214315416517618719820921102211231224

SLAVE-N

1

13214315416517618719820921102211231224

D+

Rt

DD+

DD+

DD+

Rt

RS-232

D-

Connection

Cable

32 terminal can be connected in RS485 line

Rt resistor = 120

For communication connection

Twisted Pair cable must be used

Cable lenght can be maximum 1000

meters in 9600 baud rate.

When baud rate increases, cable

lenght must decrease.

MASTER

W

30

Loading...

Loading...