Emko EZM-3735 User manual

EZM-3735 77 x 35 DIN Size

Digital Timer Controller

- 4 Digits Display

- Operation with One Set value

- Single Contact Output for Timing control ( )

- External Start and Pause Input

- Start and Stop Possibility by front Panel

- Pause possibility by front Panel

et value high limit boundaries

- S

- Display can be adjusted to show Second, Minute and Hour

Programmable Time Bases (Second, Minute, Hour)

-

- Adjustable internal buzzer according to Timer Stop status.

- Password protection for programming section

- Having CE mark according to European Norms

EZM-3735 77x35 DIN Size Digital Timer Controller

Instruction Manual. ENG EZM-3735 01 V04 07/17

ENGLISH

ON /OFF

1.Preface

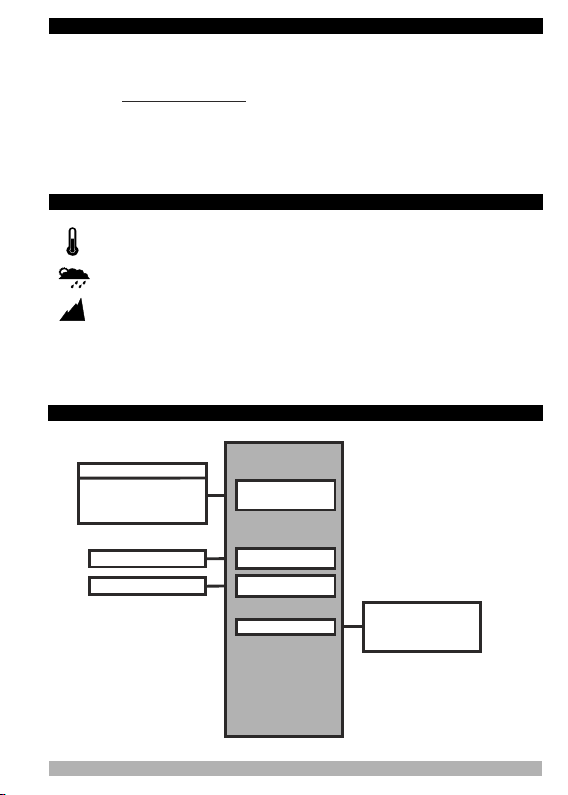

EZM-3735 Programmable Timer can be used in package machines, production and quality

control rollers, and can be adapted easily to all mechanical construction and automation

system. Some application fields which they are used are below:

Production bands

1.1 Environmental Ratings

Application Fields

Package machines,

Quality Control rollers,

Filling Systems,

Tool Benchs,

Building Automation.

Operating Temperature : 0 to 50 °C

Max. Operating Humidity : 90% Rh (non-condensing)

Altitude : Up to 2000 m.

Forbidden Conditions:

Corrosive atmosphere

c

Explosive atmosphere

Home applications (The unit is only for industrial applications)

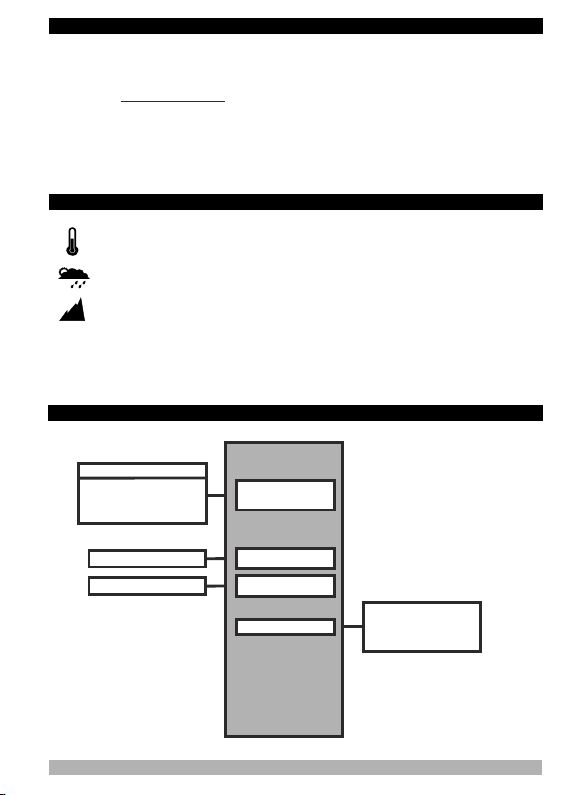

1.2 General Specifications

Standard

230V ( %15) 50/60HzV ±

Optional Supply Voltage

V

115 V (±%15) 50/60Hz,

V

24 V (±%15) 50/60Hz,

10

- 30 V Z

Start Input

Pause Input

EZM-3735

Power Supply

Input

Digital Input

Digital Input

Output

Output Relay

ON/OFF Operation

2

1.3 Installation

A visual inspection of this product for possible damage occurred during shipment is

recommended before installation. It is your responsibility to ensure that qualified mechanical

and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power off the

system and separate the electrical connection of the device from the system.

The unit is normally supplied without a power supply switch or a fuse. Use power switch and fuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to prevent

failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble with the

unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may results in

malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During putting equipment in hole on the metal panel while mechanical installation some metal

burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the montage

of the device with inappropriate fixing clamp. Be sure that device will not fall while doing the

montage.

It is your responsibility if this equipment is used in a manner not specified in this instruction

manual.

1.4 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts

from the delivery date. This warranty is in force if duty and responsibilities which are determined

in warranty document and instruction manual performs by the customer completely.

1.5 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the

device before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in

ethyl alcohol or water to clean the external plastic case.

1.6 Manufacturer Company

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and maintenance service information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA /TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

3

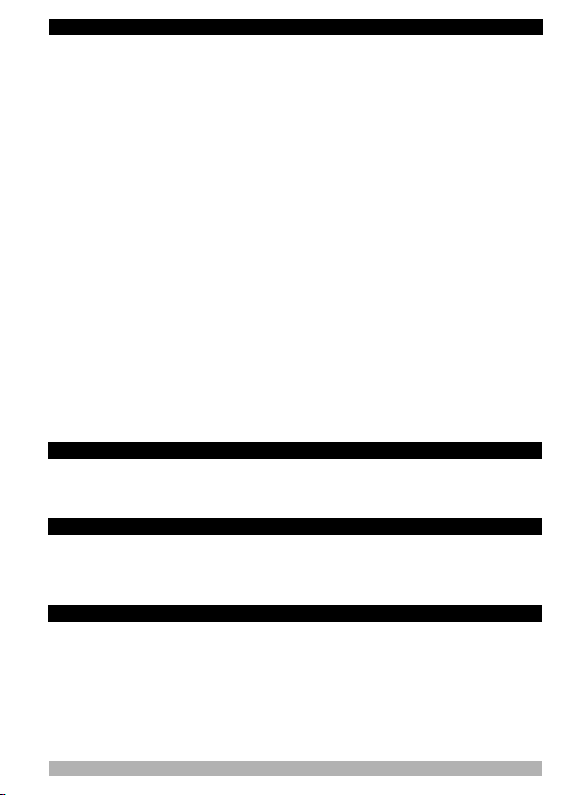

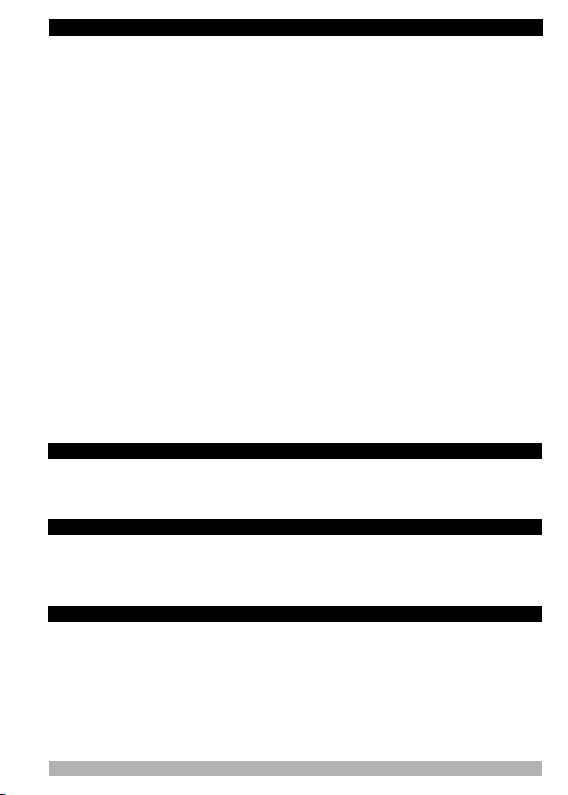

2. General Description

Front Panel

IP65 protection

NEMA 4X

Panel Surface

(maximum thickness 15 mm / 0.59 inch)

2.1 Front View and Dimensions of EZM-3735 Digital Timer

S

START

STOP

hsm

76 mm / 3 inch

P

PAUSE

ü

34,5 mm / 1.36 inch

6 mm / 0.24 inch

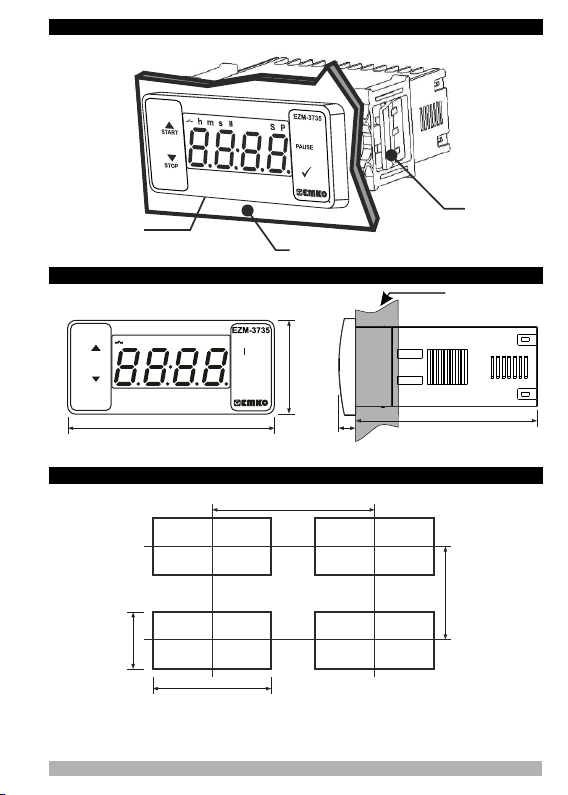

2.2 Panel Cut-Out

110 mm / 4.33 inch (min)

29 mm / 1.14 inch

71 mm / 2.79 inch

Mounting Clamp

Maximum 15 mm / 0.59 inch

65 mm / 2.56 inch

50 mm / 1.97 inch (min)

4

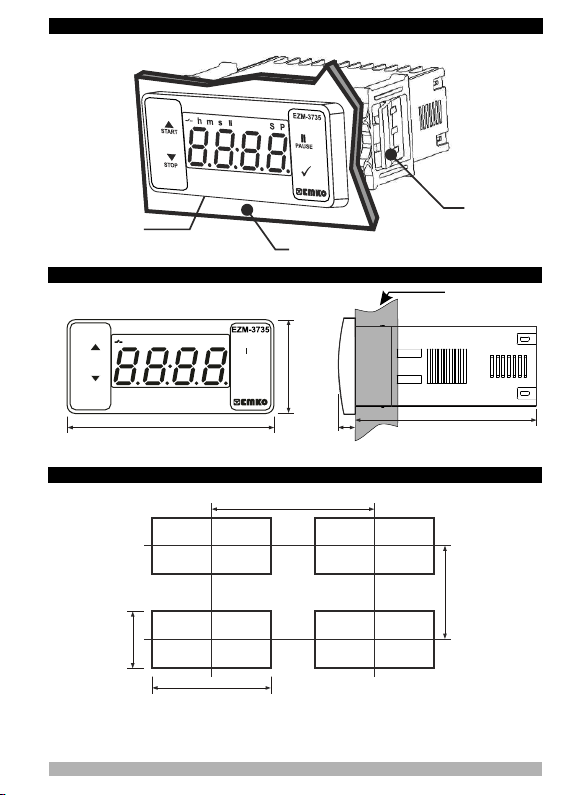

2.3 Panel Mounting

1

2

1-Before mounting the device in your panel,

make sure that the cut-out is of the right size.

2-Insert the device through the cut-out. If the

mounting clamps are on the unit, put out them

before inserting the unit to the panel.

2.4 Removing from the Panel

1

3

3

3- Insert the mounting clamps to the fixing sockets

that located left and right sides of device and make

the unit completely immobile within the panel

1-Pull mounting clamps from left and right fixing

sockets.

2-Pull the unit through the front side of the panel

2

3

Before starting to remove the unit from

panel, power off the unit and the related

system.

c

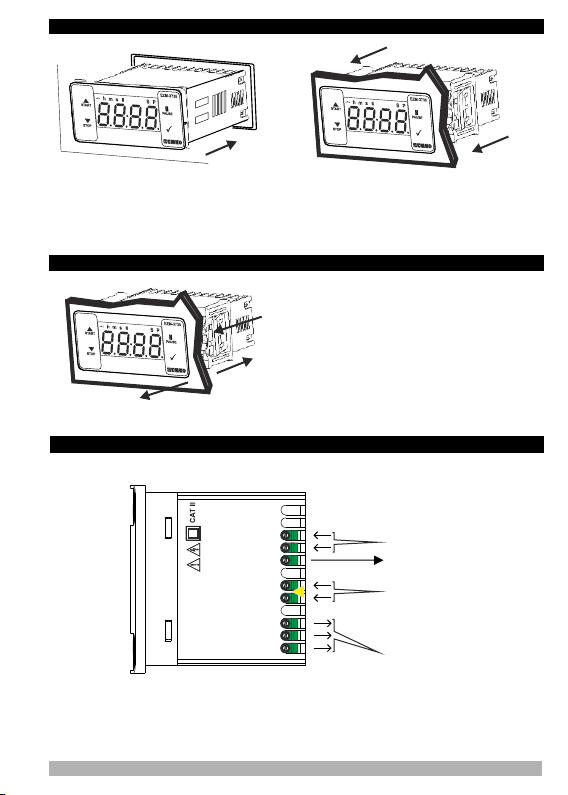

4. Electrical Wiring Diagram

Digital Input

Pause

N

a

L

3 6

P/N : EZM-3735

Note-1 : For 230VV , 115VV or 24VV power supply; 4 is “L”, input 5 is “N”, for

10...30VZ power supply; input 4 is “-”, input 5 is “+”.

21 4 5 7 8

input

Supply Voltage Input

V ±

230V ( %15) 50/60Hz

V ±

115V ( %15) 50/60Hz

V ±

24V ( %15) 50/60Hz

10..30 V

Z

Must be determined in order.

Relay Output

5

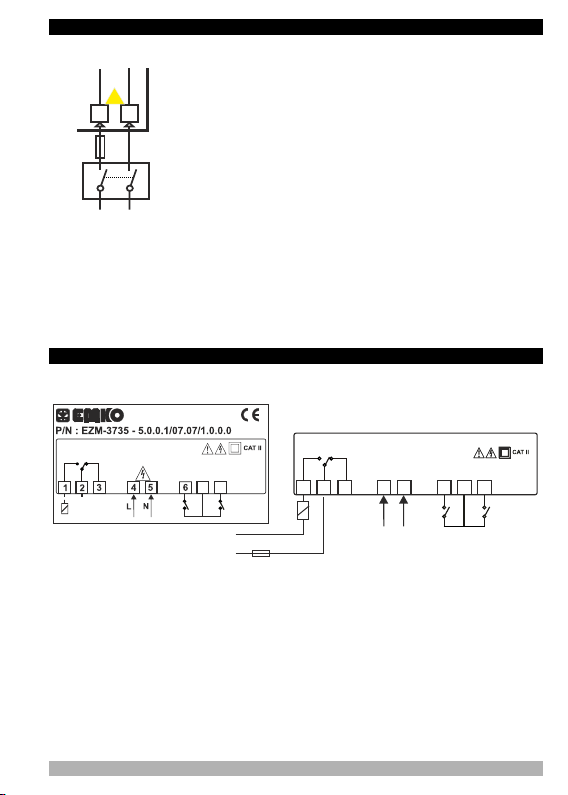

4.1 Supply Voltage Input Connection of the Device

Power Supply Connection

L

N

a

4

5

EXTERNAL

FUSE

Note-1

(1A T)

Supply

Switch

c

Supply Voltage

230V ( %15) 50/60Hz ,

V ±

115 V ( % 15) 5 0/6 0Hz,

V ±

24V ( %15) 50/60Hz ,

V ±

Z

10...30 V 1.5 W

Must be determined in order.

Note-1 : External fuse is recommended.

Note-2 : For 230VV , 115VV or 24VV power supply; input 4 is “L”, input 5 is “N”, for 10...30VZ

power supply; input 4 is “-”, input 5 is “+”.

Make sure that the power supply voltage is the same

indicated on the instrument.

c

Switch on the power supply only after that all the electrical

connections have been completed.

Supply voltage range must be determined in order. While

installing the unit, supply voltage range must be controlled

and appropriate supply voltage must be applied to the unit.

There is no power supply switch on the device. So a power

supply switch must be added to the supply voltage input.

c

Power switch must be two poled for seperating phase and

neutral, On/Off condition of power supply switch is very

important in electrical connection.

External fuse that on Vpower supply inputs must be on

phase connection.

External fuse that on Zpower supply inputs must be on (+)

connection.

4.2 Device Label and Connection Diagram

230VV CONNECTION DIAGRAM

16A

16A T Fuse

LOAD

@250VV1HP

OUTPUT

NO NCC

2

1

a

4

3

N

L

7

6

5

PAUSE

250VV1HP

NO NCC

LOAD

16A @

OUTPUT

LINE

230 VV ± 15%

50/60Hz - 1.5VA

7

8

START

PAUSE

N

L

8

START

6

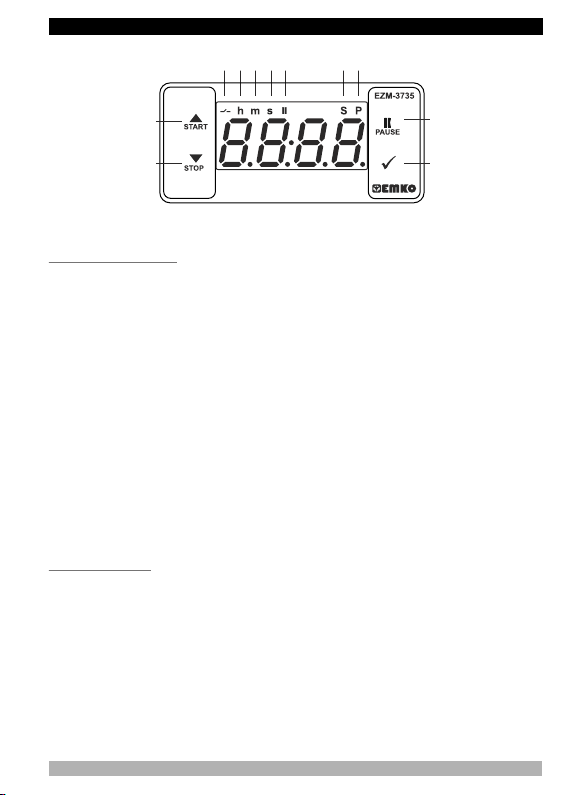

5.Front Panel Definition and Accessing to the Menus

567

6 7

8

10

9

11

7

1

2

BUTTON DEFINITIONS

1. Increment Button and Start Button :

** It is used to increase the value in the Set screen and Programming mode.

** It is used for Start the Timer in the Main Screen.

2. Decrement, Silencing Buzzer and Stop Button :

** It is used to decrease the value in the Set screen and Programming mode.

** It is used to silence the buzzer.

** It is used for Stop the Timer in the Main Screen.

3. Pause Button :

** While digital timer is running if Pause button is pressed or external pause input is activated,

timer stops running.After that if the pause button is pressed again or external pause input is

deactivated, timer starts running again.

4. Enter Button:

** In the main operation screen; if this button pressed, set value will be displayed. Value can be

changed using increment and decrement buttons. When Set button pressed again, value is

saved and returns back to main operating screen.

** To access the programming screen; in the main operation screen, press this button for 5

seconds.

** It is used to saving value in the Set screen and programming screen.

LED DEFINITIONS

5. Output led :

** This led indicates that Output is active.

6.Hour led :

** Indicates that device is in Hour mode.

7.Minute led :

** Indicates that device is in Minute mode.

8.Second led :

** Indicates that device is in Second mode.

9.Pause led :

** This led indicates that Pause is active.

10.Set led :

** Indicates that device is in Set value changing mode.

11.Program led :

**Blinks in programming mode .

3

3

4

7

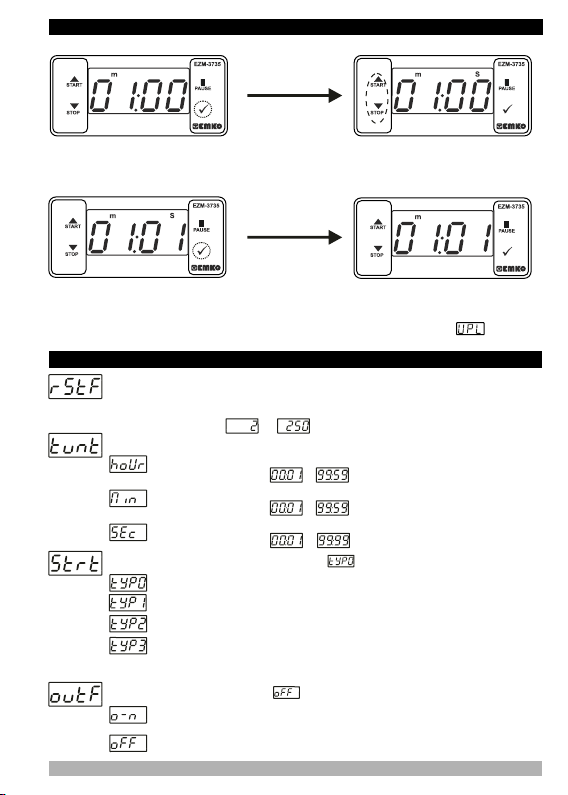

6. Changing and Saving Timing Set Value

Main Operation Screen

SET Value Screen

When Enter button pressed ‘’S’’ led will

be active and temperature set value will

Timer set value parameter (Default=01:00)

Timer set value, can be programmed between minimum Timer set value 00:01 and maximum

set limit.

be displayed.

When Enter button pressed Timing set

value can be saved.

Timer set value can be

changed with increment and

decrement buttons.

Main Operation Screen

‘’S’’ will be inactive and goes back to

main operation screen.

6.1 Programming Mode Parameter List

Filter Time of Digital Inputs( Default = 100 )

It is used for protection against the electrical contact debounce or the signal that is less than

the determined pulse time.

It can be adjusted from to msec .

Time Unit and Scale Selection ( Default = 1 ) Parameter

Hour / Minute

It can be adjusted from to .

Minute /Second

It can be adjusted from to .

Second /10 Milisecond

It can be adjusted from to .

Start Type Selection Parameter ( Default = )

Start / Stop buttons can be used to run or stop the timer.

Start / Stop buttons can be used to run or stop the timer.

External Start Input can be used to run or stop the timer.

External Start Input can only be used to run the timer. In order to stop the timer

the Stop button must be used.

For detailed information refer to graphics.

Output Functions (Default = )

if ON is selected timer runs by start and relay contact is closed. When time is

over, relay contact opens.

if OFF is selected timer runs by start. When time is over, relay contact is closed.

8

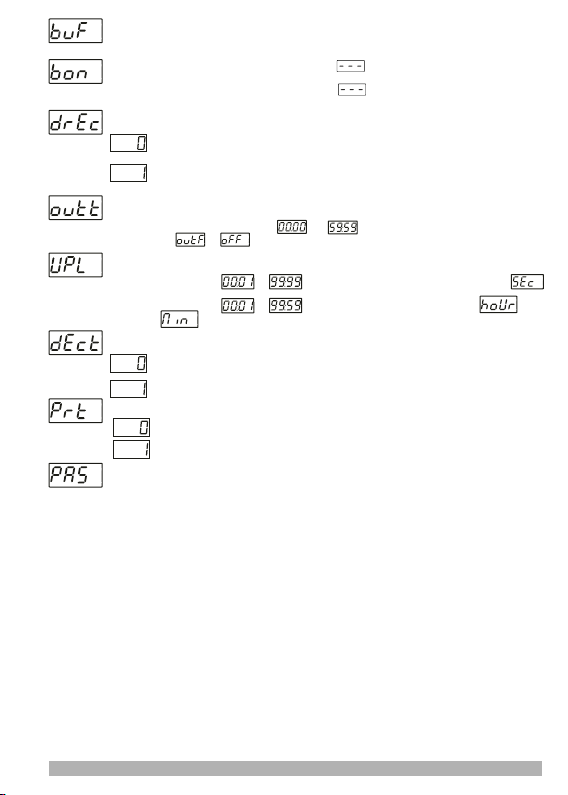

Buzzer Function Selection Parameter ( Default = 0 )

if this parameter is selected 0, Buzzer is inactive. Adjustable 16 different buzzer sounds.

It can be adjusted from 0 to16.

Buzzer is active during this time ( Default = )

Buzzer stays active during this time. It can be adjusted from 1 to 99 seconds When this

parameter is 1, if decrement button is pressed, is observed. In this condition

buzzer is active till buzzer Stop button is pressed.

Data Record ( Default = 1 )

Timer count value is saved to memory when power is disconnected and restored

on power up.

Timer count value is not saved to memory when power is disconnected. When

power up, Set value is shown on the screen.

Output Relay On Delay Time ( Default = 0 )

It determines how long output relay will be active. If it is 0000 second, then it operates

indefinitely.

It can be adjusted from to minute/second. This parameter is

active only if

Maximum Set Value Parameter ( Default = 01:00)

Maximum set value for set time value.

It can be adjusted from to .

It can be adjusted from to .

Minutes. )

Timer Counting Direction ( Default = 1 )

Button Protection Parameter 0( Default = )

Programming Section Access Password . ( Default = 0 )

It is used for accessing to the programming section. It can be adjusted from 0 to 9999. If it is

selected 0, password will not be asked

= .

( If time value is monitored in miliseconds. )

( If time value is monitored in Hours or

Timer upcount. 0 to Set value.

Timer Downcount. Set value to 0.

Button protection is not active.

Buttom protection is active for Timer set value.

9

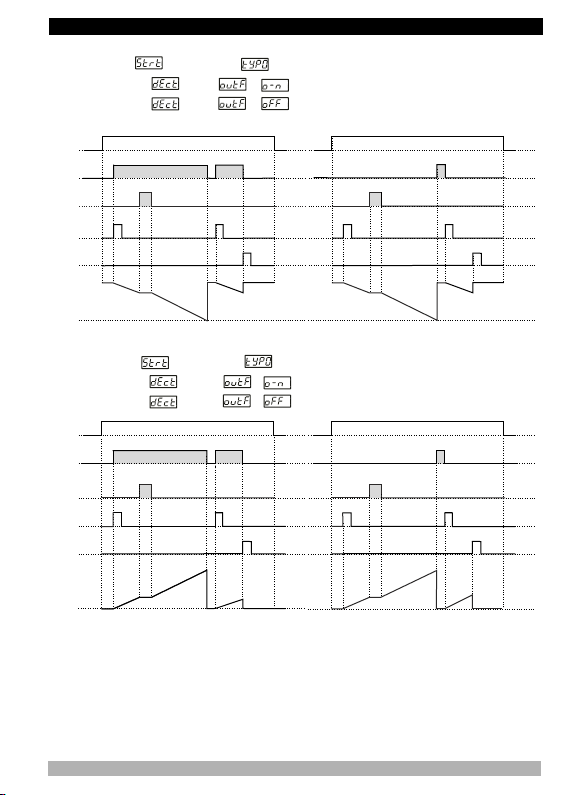

6.3 Operation Graphics of ESM-3735 Digital Timer

1.Control diagram using Start / Stop buttons.

1.1 If Start type is selected as .

1.1.1 If downcount =1 and is the control diagram is shown in Figure 1.1

1.1.2 If downcount =1 and is the control diagram is shown in Figure 1.2

Power

Output

Power

Output

Pause PausePause Pause

Start

Button

Stop

Button

Set

Screen

Figure 1.1

1.2 If Start type is selected as .

1.2.1 If Upcount =0 and is the control diagram is shown in Figure 1.3

1.2.2 If Upcount =0 and is the control diagram is shown in Figure 1.4

Power

Output

Pause

Start

Button

Stop

Button

Set

Screen

Figure 1.3

Start

Button

Stop

Button

Set

Screen

Power

Output

Pause

Start

Button

Stop

Button

Set

Screen

Figure 1.2

Figure 1.4

10

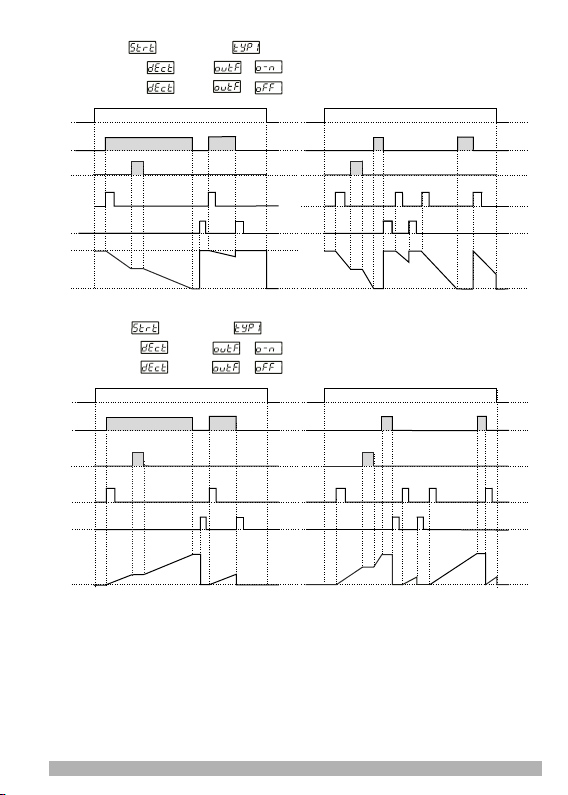

2.Control diagram using Start / Stop buttons.

2.1 If Start type is selected as .

2.1.1 If Downcount =1 and is the control diagram is shown in Figure 2.1

2.2.2 If Downcount =1 and is the control diagram is shown in Figure 2.2

Power

Output

Power

Output

Pause Pause

Start

Button

Stop

Button

Set

Screen

1.4 If Start type is selected as .

1.4.1 If Upcount =0 and is the control diagram is shown in Figure 2.3

1.4.2 If Upcount =0 and is the control diagram is shown in Figure 2.4

Figure 2.1 Figure 2.2

Power

Output

Start

Button

Stop

Button

Set

Screen

Power

Output

Pause Pause

Start

Button

Stop

Button

Set

Screen

Start

Button

Stop

Button

Set

Screen

Figure 2.3 Figure 2.4

11

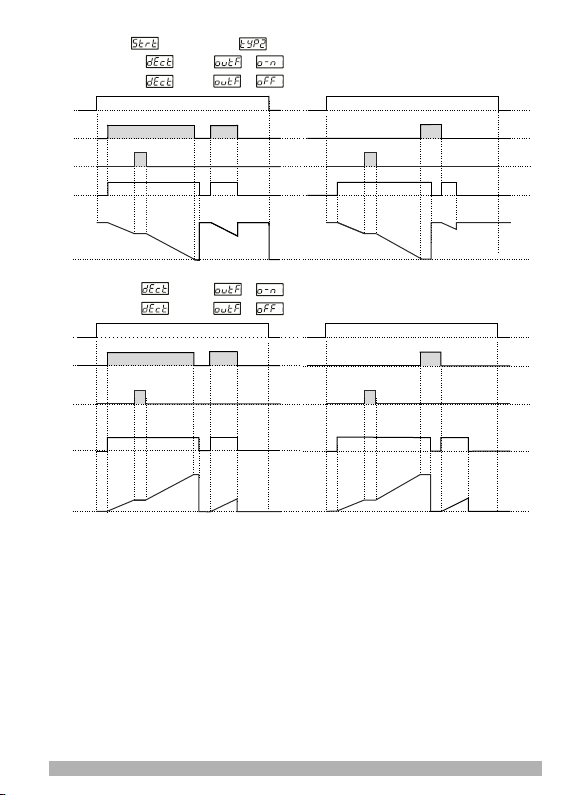

3.Control diagram using External Digital Start Input.

3.1 If Start type is selected as .

3.1.1 If Downcount =1 and is the control diagram is shown in Figure 3.1

3.1.2 If Downcount =1 and is the control diagram is shown in Figure 3.2

Power

Output

Power

Output

Pause Pause

Start

Input

Start

Input

Set

Screen

3.2.1 If Upcount =0 and is the control diagram is shown in Figure 3.3

3.2.2 If Upcount =0 and is the control diagram is shown in Figure 3.4

Figure 3.1 Figure 3.2

Power

Output

Set

Screen

Power

Output

Pause Pause

Start

Input

Set

Screen

Figure 3.3 Figure 3.4

Start

Input

Set

Screen

12

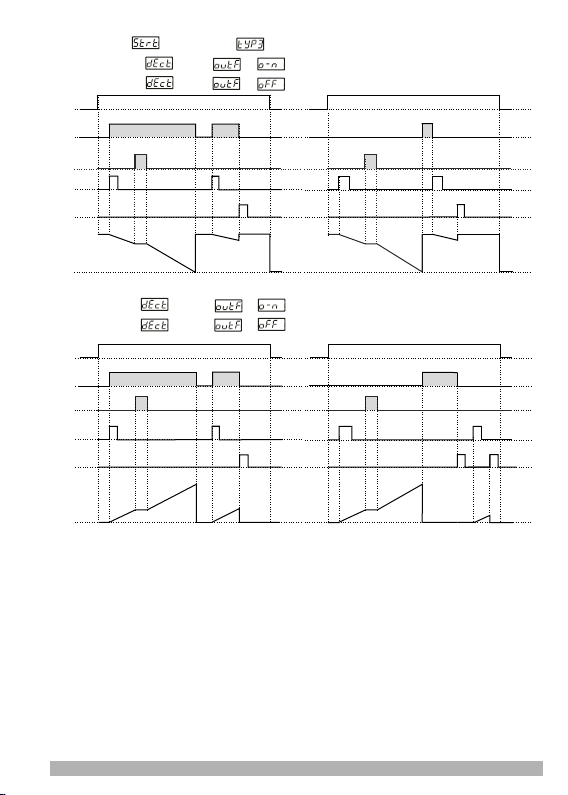

4.Control diagram using External Digital Start Input.

4.1 If Start type is selected as .

4.1.1 If Downcount =1 and is the control diagram is shown in Figure 4.1

4.1.2 If Downcount =1 and is the control diagram is shown in Figure 4.2

Power

Output

Power

Output

Pause Pause

Start

Input

Stop

Button

Set

Screen

4.2.1 If Upcount =0 and is the control diagram is shown in Figure 4.3

4.2.2 If Upcount =0 and is the control diagram is shown in Figure 4.4

Figure 4.1 Figure 4.2

Power

Output

Start

Input

Stop

Button

Set

Screen

Power

Output

Pause Pause

Start

Input

Stop

Button

Set

Screen

Figure 4.3 Figure 4.4

Start

Input

Stop

Button

Set

Screen

13

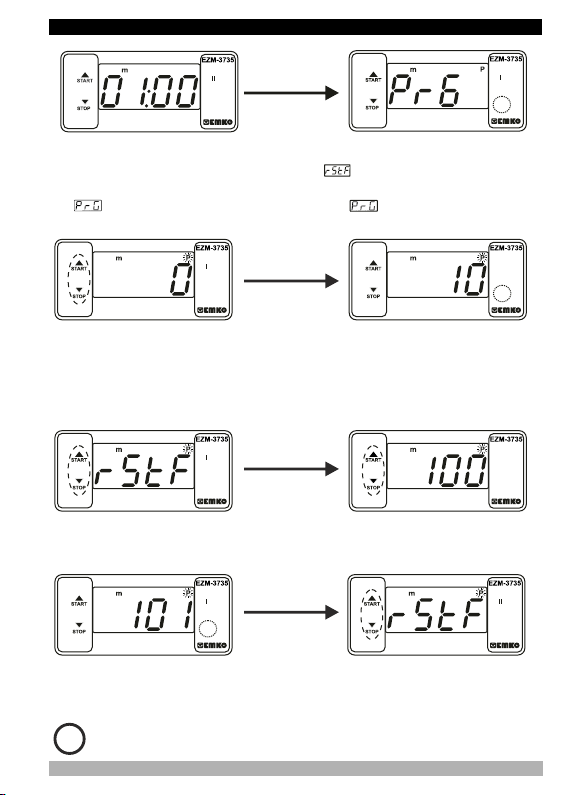

6.5 Entering To The Programming Mode, Changing and Saving Parameter

Main Operation Screen

PAUSE

ü

When Enter button is pressed for 5

seconds, “P” led starts to blink. If

programming mode entering

password is different from 0,

programming mode entering screen

will be observed.

Note1: If programming

mode accessing

password is 0,

Temperature Unit screen

is observed instead of

programming screen

PAUSE

Programming Mode

Entering Screen

Press Enter button for

accessing to the

password entering

screen.

ü

Password Entering Screen

Enter programming mode accessing password

with increment and decrement buttons.

Note2: If programming mode accessing password is 0, only three parameters

are accessible, and the parameter values can be changed.

Programming Screen

PAUSE

Password Entering Screen

Press OK button for entering

the password.

ü

Press Enter button for accessing to the parameter

value. Press increment button for accessing to the

next parameter, press decrement button for

accessing to the previous parameter.

PAUSE

Filter Time of Start Input

Change the value with increment

and decrement buttons.

ü

Filter Time of Start Input

Press OK button for saving

the parameter.

If no operation is performed in programming mode for 20 seconds, device turns to main

i

operation screen automatically..

Press increment button for accessing to the

next parameter, press decrement button for

accessing to the previous parameter

Filter Time of Start Input

PAUSE

ü

PAUSE

ü

PAUSE

ü

PAUSE

ü

14

7. Specifications

Device Type : Digital Timer

Housing&Mounting : 76mm x 34.5mm x 71mm plastic housing for panel

Protection Class : Ip65 at front, Ip20 at rear.

Weight : Approximately 0.20 Kg.

Environmental Ratings : Standard, indoor at an altitude of less than 2000 meters

Storage / Operating Temperature : -40 C to +80 C / -30 C to +80 C

Storage / Operating Humidity : 90 % max. (None condensing)

Installation : Fixed installation

Overvoltage Category : II.

Pollution Degree : II, office or workplace, none conductive pollution

Operating Conditions : Continuous

Supply Voltage and Power :

Time Accuracy : within

Digital Start and Pause Inputs : Mechanical contact

Control Form : ON / OFF

Relay Output : 16(8) A@250 V V for Resistive load (Output Relay)

(Electrical life : 100.000 switching at full load)

Display : 14 mm Red 4 digits LED Display

LED : S (Green), P (Green), h (Red), m(Red),s (Red),

Output (Red)

Internal Buzzer : ³83dB

Approvals : ,

: 115

: 24

Mounting. Panel cut-out is 71x29mm.

with none condensing humidity.

o o o o

V ±

230V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

±%1 error

15

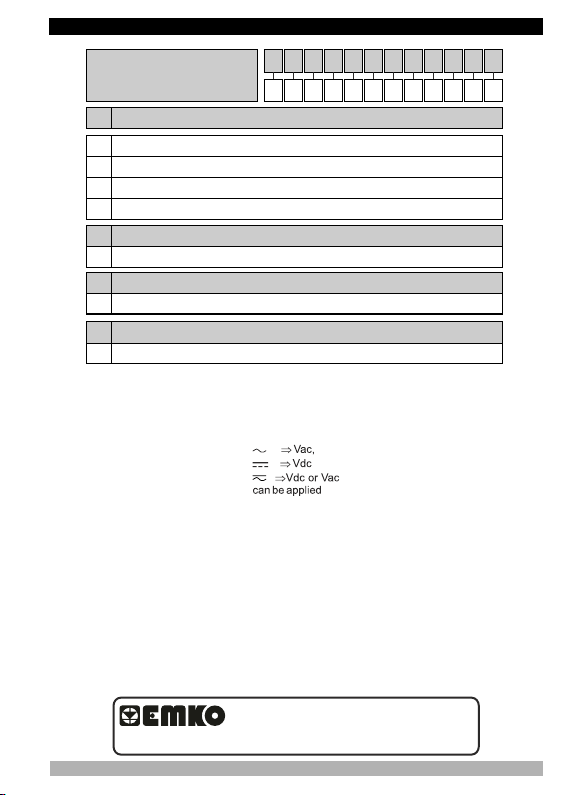

8.Ordering Information

EZM-3735

(77x35 DIN Sizes)

A BC D E FG HI /

0 0 0

0 1 01

/

07 07

U

V W Z/

/

Supply VoltageA

3

24V ( %15) 50/60Hz - 1.5VAV ±

4

115V ( %15) 50/60Hz - 1.5VAV ±

5

230V ( %15) 50/60Hz - 1.5VAV ±

8

10 - 30 V Z

Output

E

Relay Output (16(8) A@250 V V,at resistive Load, 1 NO+NC )

1

Input

FG

Digital Input

07

Input

HI

Digital Input

07

All order information of EZM-3735 Digital Timer are given on the table at above. User may form

appropriate device configuration from information and codes that at the table and convert it to the

ordering codes. Firstly, supply voltage then other specifications must be determined. Please fill the order

code blanks according to your needs.

Please contact us, if your needs are out of the standards.

Your Technology Partner

Thank you very much for your preference to

use Emko Elektronik products, please visit our

web page to download detailed user manual.

www.emkoelektronik.com.tr

16

EZM-3735 77 x 35 DIN-Größe

Digitaltimer-Steuerung

- 4-stellige Anzeige

- Betrieb mit einem Sollwert

- Einzelkontaktausgang für Zeitsteuerung (EIN/AUS)

- Externe Start- und Pauseneingabe

- Start- und Stoppmöglichkeit über Bedienfeld

- Pausenfunktion über Bedienfeld

- Obere Sollwertbegrenzung

- Anzeige kann eingestellt werden, damit Sekunden,

Minuten und Stunden angezeigt werden

- Programmierbare Zeitbasen (Sekunde, Minute, Stunde)

- Einstellbarer interner Summer gemäß Timer-Stopp-Status.

- Passwortschutz für Programmierbereich

- CE-Kennzeichnung gemäß Europäischen Normen

EZM-3735 77x35 DIN-Größe Digitaltimer-Steuerung

Bedienungsanleitung. DE EZM-3735 01 V04 07/17

DEUTSCH

1. Einleitung

Der EZM-3735 Programmierbare Timer kann für Verpackungsmaschinen, Produktions- und

Qualitätskontrollrollen verwendet werden und ist leicht an alle mechanischen Konstruktionsund Automatisierungssysteme anzupassen.

Anwendungsbereiche

Verpackungsmaschinen,

Qualitätskontrollrollen,

Abfüllanlagen,

Werkbänke,

Gebäudeautomation,

Produktionsbänder.

1.1 Umgebungsbedingte Leistungsfähigkeit

Betriebstemperatur : 0 bis 50 °C

Max. Luftfeuchtigkeit bei Betrieb : 90% Rh (nicht kondensierend)

Höhe : Bis zu 2000 m.

Verbotene Bedingungen:

Korrosive Atmosphäre

c

Explosionsfähige Atmosphäre

Heimbereich (Das Gerät ist nur für industrielle Anwendungen)

1.2 Allgemeine Spezifikationen

Standard

230V ( %15) 50/60HzV ±

Optionale Versorgungsspannung

V

115 V (±%15) 50/60Hz,

V

24 V (±%15) 50/60Hz,

10

- 30 V Z

Starteingabe

Pauseneingabe

EZM-3735

Stromversorgungseingang

Digitaler Eingang

Digitaler Eingang

Ausgang

Ausgangsrelais

EIN/AUS Betrieb

2

1.3 Installation

Eine Sichtprüfung dieses Produkts auf mögliche Transportschäden wird vor der Installation

empfohlen. Es liegt in Ihrer Verantwortung dafür zu sorgen, dass qualifizierte Maschinenbauund Elektrotechniker dieses Produkt installieren.

Bei Gefahr eines schweren Unfalls durch Ausfall oder Defekt dieser Einheit, schalten Sie das

System aus und trennen Sie die elektrische Verbindung des Geräts vom System.

Die Einheit wird normalerweise ohne Stromschalter oder Sicherung geliefert. Verwenden Sie

Netzschalter und Sicherung nach Bedarf.

Stellen Sie sicher, dass Sie die Nennversorgungsspannung verwenden, um die Einheit vor

Schäden zu schützen und einen Ausfall zu verhindern.

Lassen Sie den Strom abgeschaltet, bis die gesamte Verkabelung abgeschlossen ist, damit

Stromschläge und Probleme mit dem Gerät verhindert werden können.

Versuchen Sie niemals die Einheit zu zerlegen, zu verändern oder zu reparieren.

Die Manipulierung des Geräts kann zu Fehlfunktion, Stromschlag oder Brand führen.

Verwenden Sie die Einheit nicht in brennbaren oder explosionsgefährdeten gashaltigen

Atmosphären.

Beim Einsetzen des Geräts in die Öffnung der Metallplatte während der mechanischen

Installation, können Metallgrate Verletzungen an den Händen verursachen. Seien Sie

vorsichtig.

Die Montage des Produkts in einem System muss mit dessen Befestigungsklammern erfolgen.

Führen Sie die Montage des Geräts nicht mit ungeeigneten Befestigungsklammern durch.

Achten Sie darauf, dass das Gerät während der Montage nicht herunterfällt.

Es liegt in Ihrer Verantwortung, wenn das Gerät auf eine nicht in dieser Bedienungsanleitung

vorgeschriebenen Art und Weise benutzt wird.

1.4 Garantie

EMKO Elektronik garantiert, dass das gelieferte Gerät keinerlei Material- oder Verarbeitungsmängel

aufweist. Diese Garantie beschränkt sich auf einen Zeitraum von zwei Jahren. Die Garantiezeitbeginnt

mit dem Lieferdatum. Diese Garantie ist gültig, wenn die im Garantieschein und in der

Bedienungsanleitung festgelegten Pflichten und Verantwortlichkeiten vollständig durch den Kunden

erfüllt werden.

1.5 Wartung

Reparaturen dürfen nur von geschultem Fachpersonal durchgeführt werden. Trennen Sie das Gerät

von der Stromversorgung, bevor Sie Innenteile manipulieren. Reinigen Sie das Gehäuse nicht mit

Kohl enwa sser stoff-Lö semi tteln (Benzin, Tr ichl orät hylen usw.). Die Verwendung dieser

Lösemittelkann die mechanische Zuverlässigkeit des Geräts beeinträchtigen. Verwenden Sie ein mit

Ethylalkohol oder Wasser angefeuchtetes Tuch, um das externe Kunststoffgehäuse zu reinigen.

1.6 Herstellerfirma

Herstellerangaben:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Telefon : +90 224 261 1900

Fax : +90 224 261 1912

Reparatur und Wartungsservice:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA /TURKEY

Telefon : +90 224 261 1900

Fax : +90 224 261 1912

3

2. Allgemeine Beschreibung

Bedienfeld

IP 65 Schutz

NEMA 4X

Tafeloberfläche

(maximale Dicke 15 mm / 0,59 Zoll)

Befestigungsklammer

2.1 Frontansicht und Abmessungen des EZM-3735 Digitaltimers

Maximum 15 mm / 0,59 Zoll

S

START

STOP

hsm

76 mm / 3 Zoll

P

PAUSE

ü

34,5 mm / 1.36 inch

6 mm / 0,24 Zoll

65 mm / 2,56 Zoll

2.2 Tafelausschnitt

110 mm / 4,33 Zoll (min)

29 mm / 1,14 Zoll

71 mm / 2,79 Zoll

50 mm / 1,97 Zoll (min)

4

Loading...

Loading...