Emko ESM-9920, ESM-9420, ESM-7720, ESM-4920, ESM-4420 User manual

PID TEMPERATURE CONTROL UNITS

ESM-9920, ESM-9420, ESM-7720, ESM-4920, ESM-4420

PID Temperature Control Units

- 4 digit process (PV) and 4 digit set (SV) display

- Process input (TC, RTD)

- Programmable ON/OFF, P, PI, PD and PID control forms

- Adaptation of PID Coefficients to the system with Self-Tune

operation (Step Response Tuning)

-

Programmable Heating or Cooling Functions for Control

Output

PID Temperature Controller ESM-XX20

- Selectable Alarm Functions for Alarm Output

ESM series temperature controllers are designed for measuring and

controlling a process value. They can be used in many applications with their

TC and RTD temperature measurement input, multi-function control outputs,

selectable alarm functions.

They are mainly used in glass, plastic, petro-chemistry, textile, automotive

and machine production industries. Accurate and advanced controlling is

performed with selectable ON-OFF, P, PI, PD, PID and Self Tune PID

functions.

ENGLISH

ESM-XX20

Introduction Brochure. ENG ESM-XX20 01 V13 08/15

Specifications

Process Input: TC, RTD

Thermocouple (TC): J, K, R, S and T (IEC584.1)(ITS90) Thermoresistance (RTD): PT-100

(IEC751)(ITS90)

Measurement Range : Please refer to Table-1 for selection of input type and scale.

Accuracy : ± 0.25% of scale for thermocouple and thermoresistance

Cold Junction Compensation : Automatically ±0.1°C/1°C

Line Compensation : Maximum 10 Ohm

Sensor Break Protection : Upscale

Sampling Cycle : 3 samples per second

Input Filter : 1.0 second.

Control Form : ON/OFF, P, PI, PD or PID (Control form can be programmed by the user.)

Output

Process Output : Relay (5A@250VVat resistive load) or SSR

Driver Output (Maximum 24mA, Max. 12V Z )

Alarm Output : Relay(5A@250VV at resistive load) or SSR Driver

Output(Alarm Output - 2) (Maximum 24mA, Max. 12V Z )

Supply Voltage

24V V ( ±15% ) 50/60 Hz - 3VA or 24VZ (±%15) -3W

230V V ( ±15% ) 50/60 Hz - 3VA

115V V ( ±15% ) 50/60 Hz - 3VA

24V V ( ±15% ) 50/60 Hz - 3VA

(It must be determined in order)

Display

Process Display :

ESM-4420 : 10.1 mm Red 4 digit LED Display

ESM-4920 : 13.2 mm Red 4 digit LED Display

ESM-7720 : 13.2 mm Red 4 digit LED Display

ESM-9420 : 10.1 mm Red 4 digit LED Display

ESM-9920 : 19 mm Red 4 digit LED Display

Set Value Display :

ESM-4420 : 8 mm Gr een 4 digits LED Display

ESM-4920 : 8 mm Gr een 4 digits LED Display

ESM-7720 : 9.1 mm Green 4 di gits LED Display

ESM-9420 : 8 mm Gr een 4 digits LED Display

ESM 9920 : 10.8 mm G reen 4 digits LED Display

Leds : PS (Process Set Value), PO (Process Output Status Led) ,

AS1, AS2 (Alarm Set Values), AO1, AO2 (Alarm Output S tatus

Environmental Ratings and Physical Specifications

Operating Temperature : 0...50°C

Humidity : 0-90%RH (none c ondensing)

Protection Class : IP65 at front, I P20 at rear

Weight : ESM-4420 : 220 gr. , ESM-4920 : 240 gr.

ESM-7720 : 270 gr. , ESM-9420 : 230 gr.

ESM-9920 : 340 gr.

ENGLISH

2

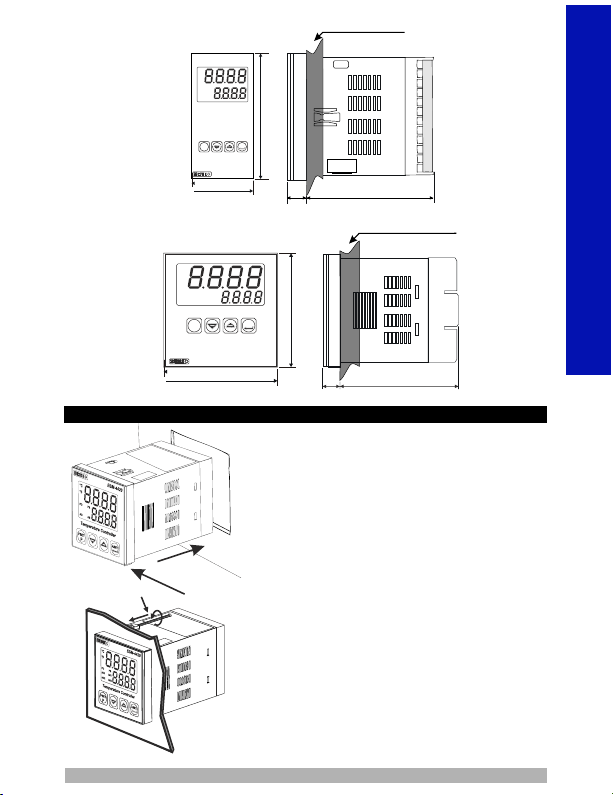

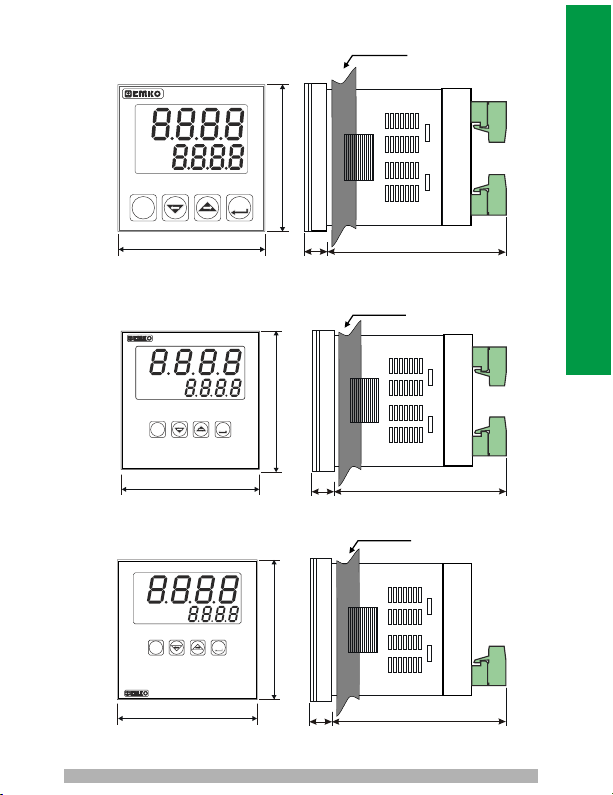

Dimension :

Panel CutOut :

ESM-4420 : (48 x 48mm, Depth : 95mm)

ESM-4920 : (96 x 48mm, Depth : 94.5mm)

ESM-7720 : (72 x 72mm, Depth : 95.5mm)

ESM-9420 : (48 x 96mm, Depth : 94.5mm)

ESM-9920 : (96 x 96mm, Depth : 96mm)

ESM-4420 : (46 x 46mm)

ESM-4920 : (92 x 46mm)

ESM-7720 : (69 x 69mm)

ESM-9420 : (46 x 92mm)

ESM-9920 : (92 x 92mm)

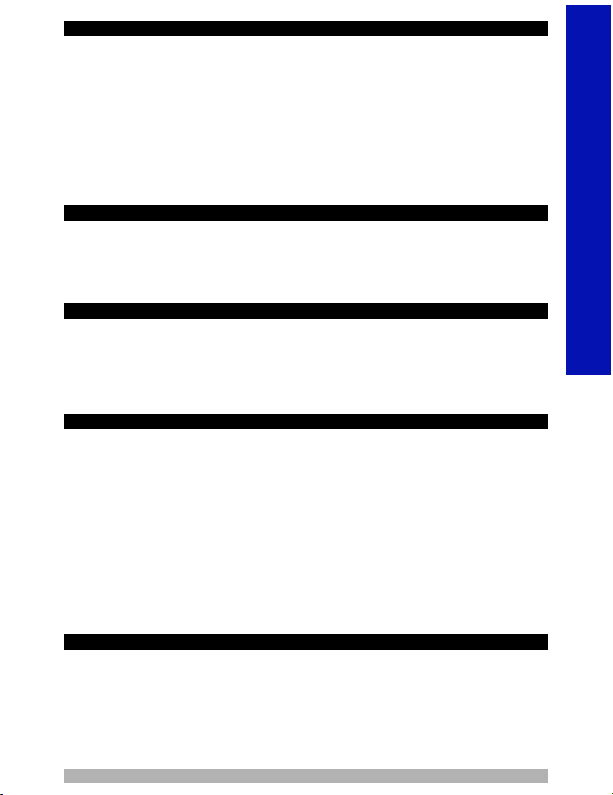

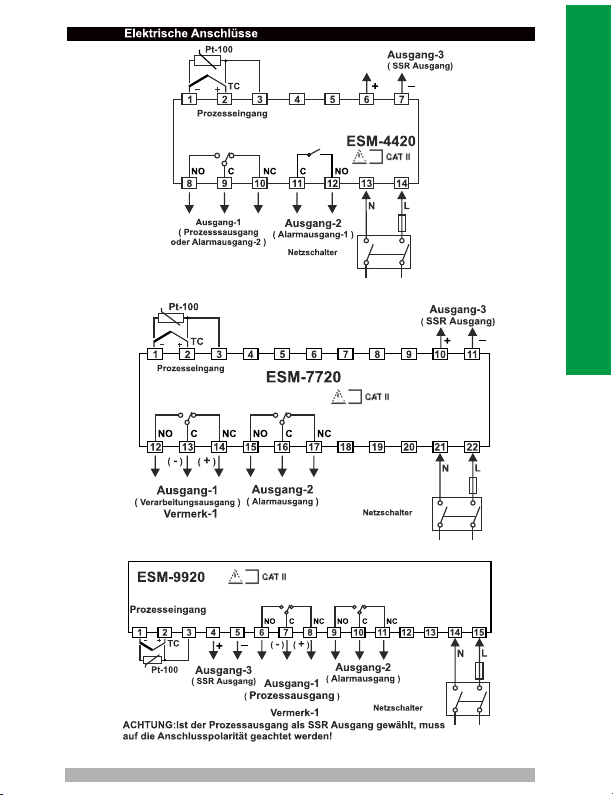

Electrical Wirings

ESM-4420

ESM-4920

1.5 Maintenance

Process Input

Max. 24 mA, 12V

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

1.6 Manufacturer Company

TC

Pt-100

Pt-100

TC

192

Process Input

5A@250VV

8

( - )

( + )

Output-1

( Process Output or

Alarm Output-2 )

Note-1

Y

c

_

+

Output

( Process Output or

(SSR )-3Output

Alarm Output-2 )

3

NCNO C

10

( Alarm Output-1 )

CAT II

5A@250VV

( - )

Output

Note-1

4

5A@250VV

C NO

11

Output

NCNO C

( + )

-1

Output-3

( SSR Output )

+

5 6

Max. 24 mA, 12V

c

Y

12 13

N

-2

Supply

Switch

230 VV

50/60 Hz

5A@250VV

Output

( Alarm )-2Output-1

CAT II

NCNO C

7

14

_

L

1A V T

Fuse

Supply

Switch

1A V T

Fuse

N

230 VV

50/60 Hz

ENGLISH

L

3

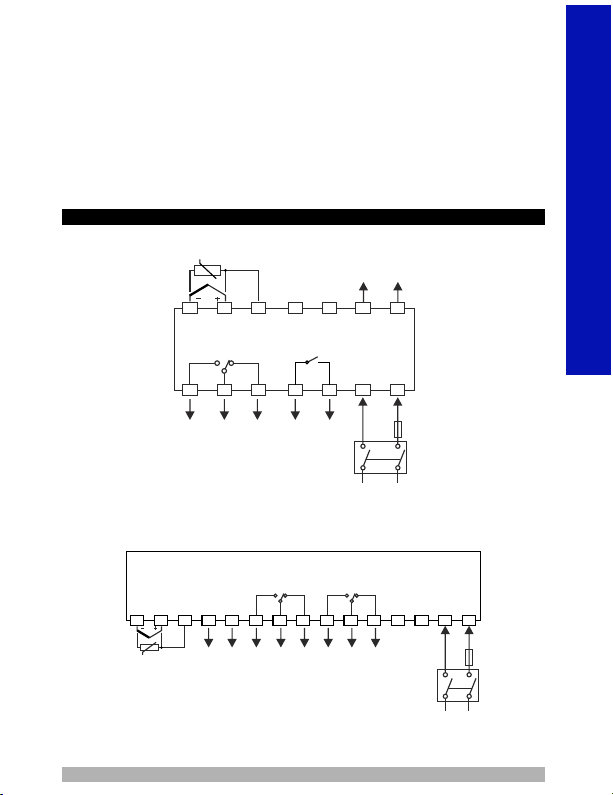

ESM-7720

Pt-100

TC

1 2

Process Input

5A@250VV

( - )

Output

Note-1

( + )

14

-1

12 13

( Process Output or

Alarm Output-2 )

3

4

NCNO C

15

( Alarm )

5

5A@250VV

16

Output

-2

Output-1

7

6

17

8 9

Y

c

CAT II

NCNO C

18

19 20

ESM-9420

CAT II

Y

c

5A@250VV

Process Input

Max. 24 mA, 12V

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

TC

Pt-100

+

Output

(SSR )

Output

_

( - )

Output

-3

( Process Output or

Alarm Output-2 )

Note-1

( + )

-1

5A@250VV

NCNO C

Output

( Alarm )

-2

Output-1

NCNO C

ESM-9920

CAT II

Y

c

5A@250VV

Process Input

Max. 24 mA, 12V

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

TC

Pt-100

Note-1: If process output is SSR driver output, pay attention to the

(+) and (-) pins while doing the connection of the device

+

Output

Output

(SSR )

_

( - )

-3

Output

( Process Output or

Alarm Output-2 )

Note-1

( + )

-1

5A@250VV

NCNO C

Output

( Alarm )

-2

Output-1

NCNO C

( SSR Output )

Max. 24 mA, 12V

1A V T

Fuse

Supply

Switch

1A V T

Supply

Switch

1A V T

Supply

Switch

Output-3

+

10

21

N

230 VV

50/60 Hz

Fuse

Fuse

11

22

L

N

230 VV

50/60 Hz

N

230 VV

50/60 Hz

_

ENGLISH

L

L

4

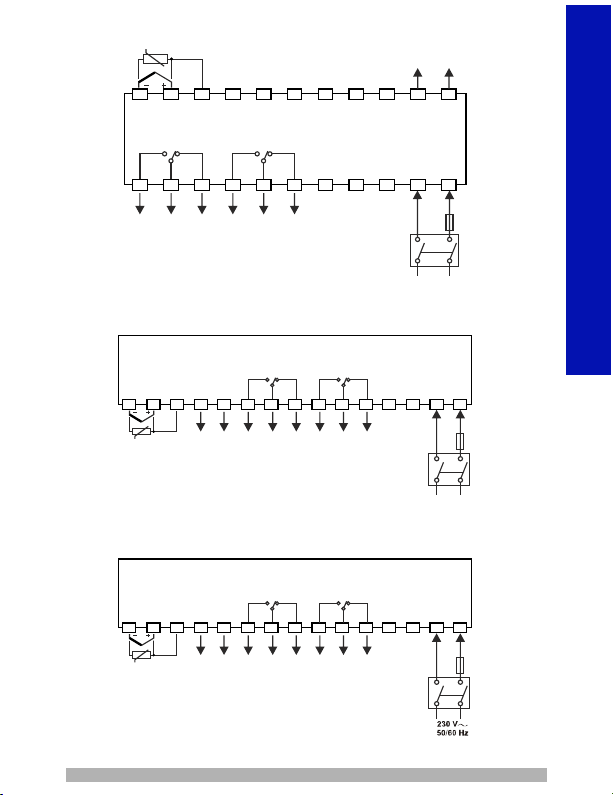

Dimension

ESM-4420

ESM-4920

ESM-7720

°C

°F

PO

AO1

AO2

Temperature Controller

PSET

P

ESM-4420

PS

AS1

AS2

ASET

48 mm/ 1.89 inch

Temperature Controller ESM - 4920

°C

°F

PS

PO

AS1

AO1

AS2

AO2

PSET ASET

P

96mm / 3.78 inch

PS

AS1

AS2

PSET

P

Temperature Controller

ESM-7720

ASET

°C

°F

PO

AO1

AO2

72mm / 2.83 inch

Maximum 5mm / 0.2 inch

48 mm/ 1.89 inch

11 ± 1 mm /0.43 inch

48mm/ 1.89 inch

Maximum 15mm / 0.59 inch

72mm / 2.83 inch

11.5 ± 1 mm /0.45 inch

ENGLISH

84 mm / 3.31 inch

Maksimum 15mm / 0.59 inch

84mm / 3.31 inch10.5 ± 1 mm /0.43 inch

84 mm / 3.31 inch

5

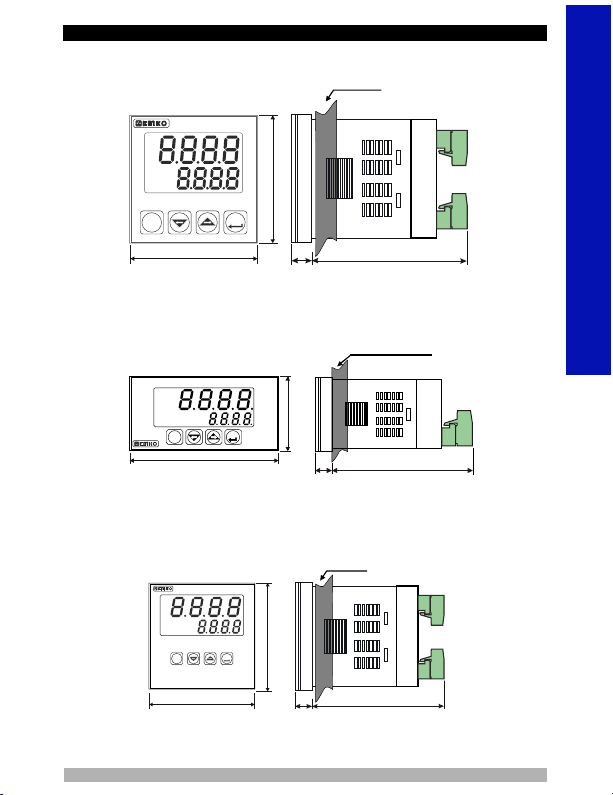

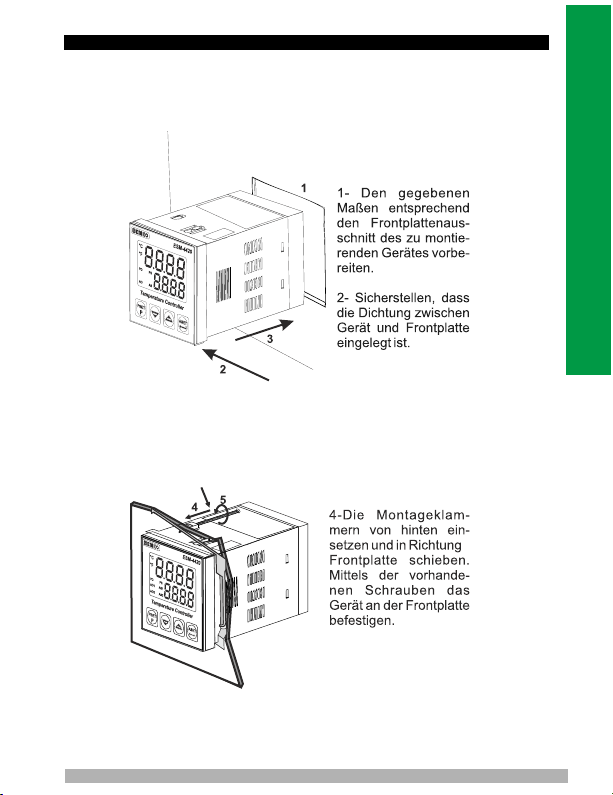

Panel Mounting

4

2

5

ESM-9420

°C

°F

PO

AO 1

AO 2

48mm / 1.89 inch

ESM-9920

°C

°F

PO

AO 1

AO 2

PSET

P

Temperature Controller

96mm / 3.78 inch

3

Maximum 15mm / 0.59 inch

PS

AS 1

AS 2

Temperature

Controller

96mm / 3.78 inch

ASET

PSET

P

ESM-9420

PO

AO

84 mm / 3.31 inch10.5 ± 1 mm /0.41 inch

Maximum 15 mm / 0.59 inch

PS

AS 1

AS 2

ASET

96mm / 3.78 inch

ESM-9920

84 mm / 3.31 inch12 ± 1 mm /0.47 inch

1

1-Before mounting the device in your panel, make sure

that the cutout is of the right size.

2-Check front panel gasket position

3-Insert the device through the cutout.If the mounting

clamps are on

the unit, put out them before inserting the unit to the panel.

4-Insert the unit in the panel cut-out from the front side.

5- Insert the mounting clamps to the holes that located

top and bottom sides of device and screw up the fixing

screws until the unit completely immobile within the

panel.

ENGLISH

6

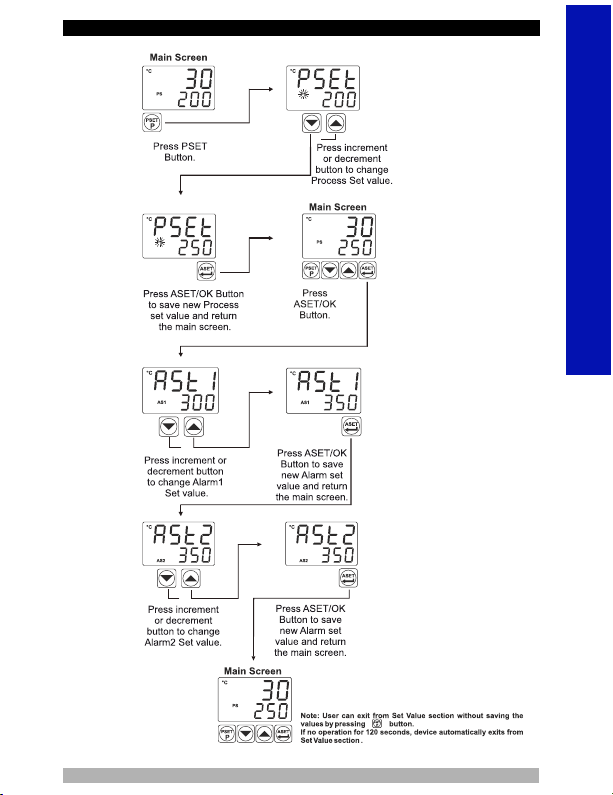

Access and Change S et Values

ENGLISH

7

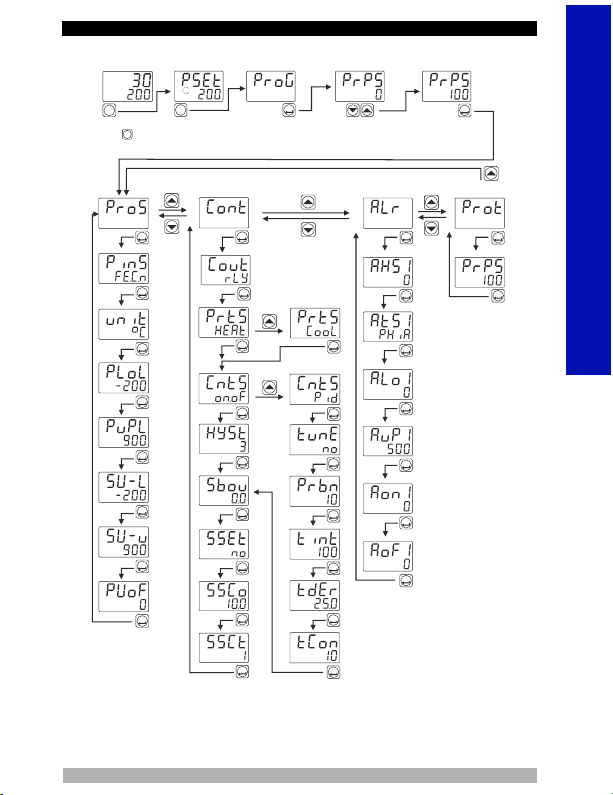

Easy Access Diagram For Program Parameters

After 5 sec.

°C

°F

PS

PO

AS

AO

PSET

P

To enter Program menu

press button for 5

seconds.

°C

°F

POAOPS

AS

PSET

P

PSET

P

°C

°F

PS

PO

AS

AO

Press ASET/OK

Button to access

Password Screen.

ASET

Password ScreenMain Screen

°C

°F

PO

AOPSAS

Enter Password with

increment or

decrement buttons.

°C

°F

PS

PO

AS

AO

ASET

Approve

password with

ASET/OK Button.

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

POAOPS

AS

ASET

°C

°F

PS

PO

AS

AO

ASET

Note:If user does not do anything for 120 seconds while device is on programming

section, device turns to operation screen.

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

°C

°F

POAOPS

AS

°C

°F

PS

PO

AS

AO

°C

°F

PS

PO

AS

AO

°C

°F

PO

AOPSAS

°C

°F

PS

PO

AS

AO

°C

°F

PS

PO

AS

AO

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

°C

°F

POAOPS

AS

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

ASET

AS

AO

ASET

ASET

°C

°F

PS

PO

AS

AO

ASET

°C

°F

PS

PO

AS

AO

ASET

ASET

ASET

ASET

ASET

ASET

ASET

ASET

ENGLISH

8

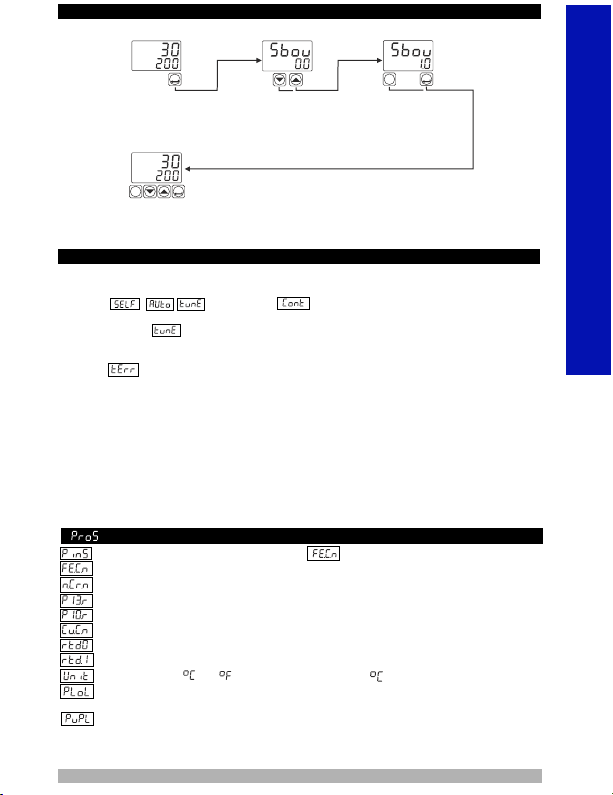

Easy Access Diagr am For Sensor Break Output Value

Main Screen

°C

°F

PO

AS

AO

ASET

To enter the Sensor

Break Output Value,

press ASET/OK

button for 5 seconds.

°C

°F

PO

AS

AO

ASET

PSET

Note:If user does not do anything for 120 seconds while device is on this section, device turns

to operation screen.

Note-2: Sensor Break Output Value can be adjusted on programming section too.

P

°C

°F

PO

AS

AO

Change the Sensor

Break Output Value

with increment and

decrement buttons.

Press ASET/OK button to exit and save.

°C

°F

PO

AS

AO

ASET

PSET

P

Press PSET button to exit

without saving the value.

Tune Operation

Starting the Tune operation

1-Enter to the programming section

2- Select , , parameter in menu. Press ASET/OK button for saving the

parameter and turn to the main operation screen.

3- Observe that “ ” blinks in set display.

Note- For starting the Tune operation,

Heating Tune Operation:Process value must be lower than process set value at least 5% of

full scale

Cooling Tune Operation :Process value must be greater than process set value at least

5%of the full scale . If this condition is not okay, Blinks on the screen for 10 seconds.

Canceling Self Tune operation :

1- If sensor breaks ;

2- If Self Tune operation can not be completed in 8 hours ;

3- While heating Self Tune is running, if process value becomes greater than Process Set

value

4- While cooling Self Tune is running, if process value becomes less than Process Set value;

5- While Self Tune operation is running, if user changes the process set value;

Then Self Tune operation is canceled,

without changing PID parameters.

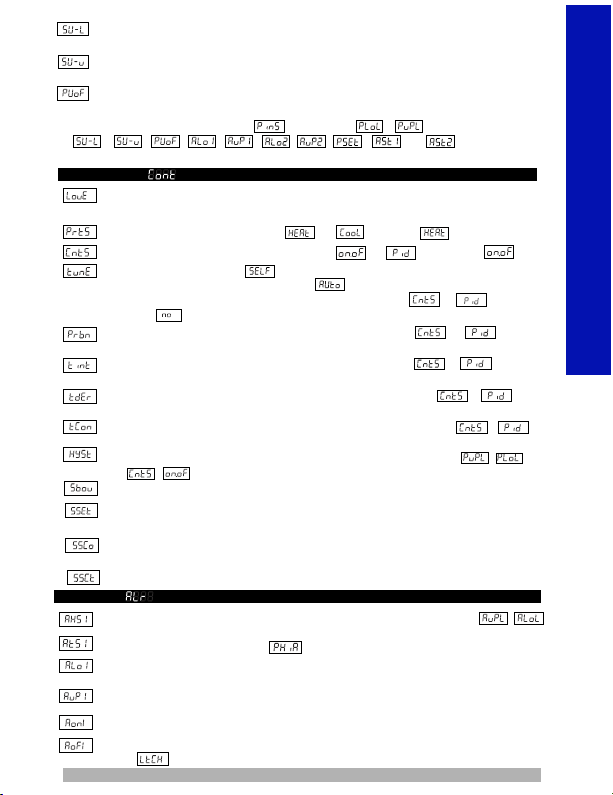

: Process Menu Parameters

: Process input type selection ; (Default: )

: J type (Fe,Cu,Ni) Thermocouple , ; -200°C,900°C -328°F,1652°F

: K type (Ni,Cr,Ni) Thermocouple , -200°C,1300°C ; -328°F,2372°F

: R type (Pt13%RhPt) Thermocouple , 0°C,1700°C ; 32°F,3092°F

: S type (Pt10%RhPt) Thermocouple , 0°C,1700°C ; 32°F,3092°F

: T type (Cu,Cu,Ni) Thermocouple , -200°C,400°C ; -328°F,752°F

: Pt - 100 , -200°C,650°C ; -328°F,1202°F

: Pt - 100 , -199.9°C,650.0°C ; -199.9°F,999.9°F

: Unit Selection. or can be chosen. (Default: )

: Operation Scale minimum (Low . It changes according to the

process input type and scale. (Default: -200)

Operation Scale It changes according to the

: maximum (High Limit) value.

process input type and scale. (Default: 900)

device continues to run with former PID parameters

Limit) value

ENGLISH

9

: Process Set value Low Limit. Minimum set value is defined with this parameter. It

changes according to the process input type and scale. (Default: -200)

: Process Set value High Limit. Maximum set value is defined with this parameter.

It changes according to the process input type and scale. (Default: 900)

: Display offset for process value. It can be adjusted from -10% of scale to 10%

of scale. It is added to the process display value. (Default: 0)

Note: If process input type s election( ) is changed, , ,

, , , , , , , , and

parameters may need to be updated according to th e input type

: Process Type Selection. It can be or .(Default: )

: Process Control Type Selection. It can be or .(Default: )

: If tune parameter is set to , device start to Self Tune to calculate PID parameters

automatically. If tune parameter is set to , device start to Auto Tune to calculate

PID parameters automatically. This parameter is shown if = .

(Default: )

: Proportional band . It can be adjusted from %1 to %100.If

this parameter can be observed. (Default: 10.0)

: Integral Time. 0 to 3600 second.If

this parameter can be observed. (Default: 100)

: Derivative Time. 0.0 to 999.9 second.If

this parameter can be observed. (Default: 25.0)

: Output Control Period. 1 to 150 second

then this parameter can be observed. (Default: 10)

: Hysteresis value. of the Scale

If = , then this parameter can be observed (Default: 3)

: Sensor Break Output Value. %0 to %100. It can be adjusted from (Default: 0.0)

: Soft Start Set value. Device operates in Soft Start mode, until the temperature reaches

Soft Start set value. (Default: no)

: Soft Start Control Output. This parameter determines soft start mode control output

percentage. (Default: 10.0)

: Soft Start Control time. . This parameter determines soft start mode control time (Default:1)

: Control Menu Parameters

: This parameter determines, which output will be Process control output. If rLY is

chosen, process output is relay output, if SSr is chosen, process output is SSR output.

(Default: Ssr)

It can be adjusted from = , then

It can be adjusted from = ,then

It can be adjusted from If = ,

It can be adjusted from %0 ile %50 ( - )

selection.

= , then

: Alarm Menu Parameters

: Alarm Hysteresis value. .

(Default: 0)

: Alarm Type selection. (Default: )

:

Alarm Set Low Limit parameter. It can be adjusted from Operation Scale minimum to

Alarm Set High Limit. (Default: 0)

Alarm Set High Limit parameter. It can be adjusted from Alarm Set Low Limit to

:

Operation Scale maximum. (Default: 500)

: Alarm on Delay Time. It can be adjusted from 0 to 9999 seconds. (Default: 0)

Alarm off Delay Time. It can be adjusted from 0 to 9998 seconds. If it is higher than

:

9998, , is seen on the screen and Alarm Latching Output is selected. (Default: 0)

It can be adjusted from %0 ile %50 of the Scale( - )

10

ENGLISH

: Alarm Hysteresis value. It can be adjusted from %0 ile %50 of the Scale

( - ). (Default: 0)

: Alarm Type selection. (Default: )

Alarm Set Low Limit parameter. It can be adjusted from Operation Scale minimum

:

to Alarm Set High Limit. (Default: 0)

: Alarm Set High Limit parameter. It can be adjusted from Alarm Set Low Limit to

Operation Scale maximum. (Default: 500)

: Alarm on Delay Time. It can be adjusted from 0 to 9999 seconds. (Default: 0)

: Alarm off Delay Time. It can be adjusted from 0 to 9998 seconds. If it is higher than

9998, is seen on the screen and Alarm Latching Output is selected. (Default: 0)

NOTE: Alarm-2 parameters(AHS2 , AtS2 , Alo2 ,AuP2 , Aon2 , AoF2 )

are active,if Cout parameter is set as SSR.

: Protection Menu Parameter

:

Password for accessing to the programming section. It can be adjusted from 0 to

9999. If is 0, password screen is not observed. If is different from 0 and user

enters to the menu pages without entering the password, all the menus can be observed

except protection menu . But device does not allow to do any changes in

parameters. (Default value is 0)

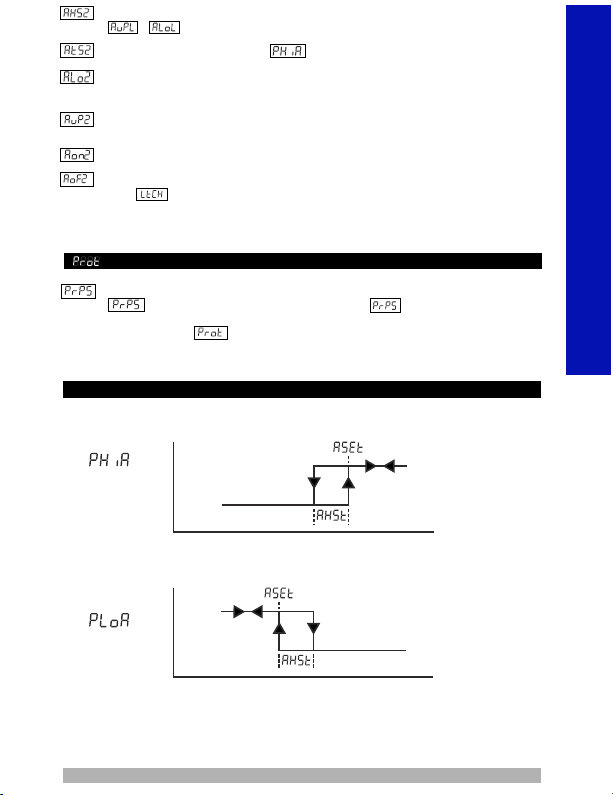

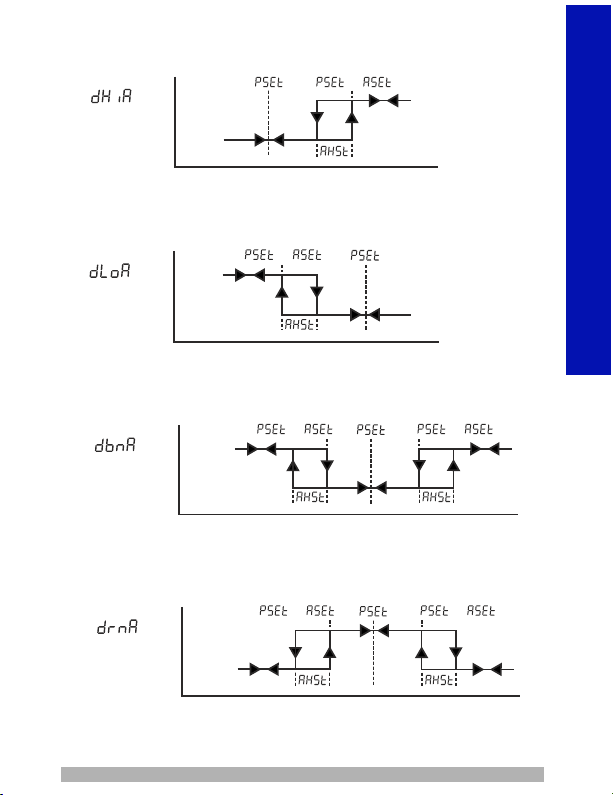

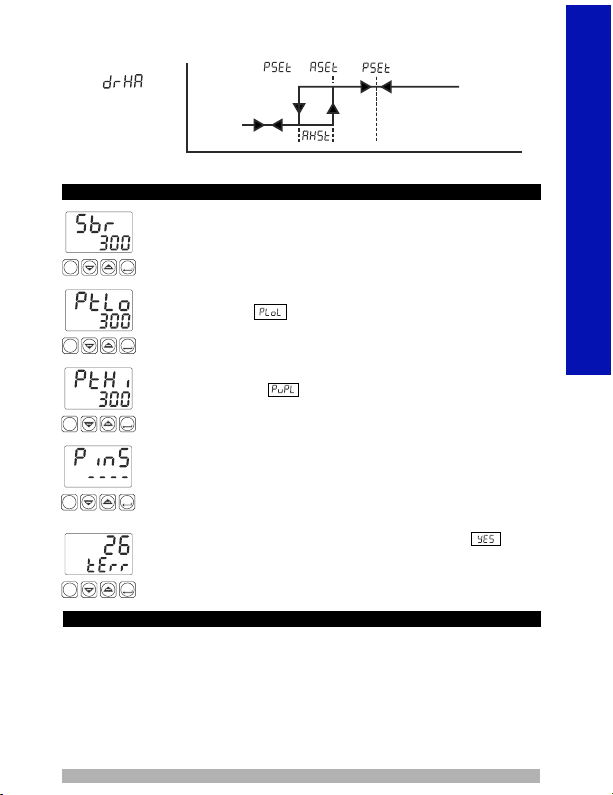

Alarm Types

Alarm

Output

Alarm

Output

ON

OFF

Process Value

ON

Process High

Alarm

ENGLISH

Process Low

Alarm

OFF

Process Value

11

Deviation High

Alarm

Alarm

Output

ON

OFF

( + )

Process Value

Deviation Low

Alarm

Alarm

Alarm

Band

Deviation

Deviation Range

Alarm

Output

Alarm

Output

Alarm

Output

( - )

ENGLISH

ON

OFF

Process Value

( + ) ( - )

ON

OFF

Process Value

( + ) ( - )

ON

OFF

Process Value

12

Alarm

Output

( - )

ON

Deviation Range

High Alarm

OFF

Error Messages

PSET

PSET

PSET

PSET

PSET

°C

°F

PO

AO

P

°C

°F

PO

AO

P

°C

°F

PO

AO

P

°C

°F

PO

AO

P

°C

°F

POAOPS

P

PS

AS

PS

AS

PS

AS

PS

AS

AS

1- Sensor failure in analog inputs. Sensor connection is wrong or there is

no sensor connection.

ASET

2- If value that is read from the analog input is lower than process set

low limit parameter , value on the top display starts to blink like on

the picture.

ASET

3- If value that is read from the analog input is higher than process set high

limit parameter value , value on the top display starts to blink like on

the picture.

ASET

4- If programming section entering password is different from “0” and user

accesses to the parameter by ASET/OK button without entering the

password and wants to change a parameter, the warning message is

shown on the bottom display as shown on the left. Device does not allow

ASET

to do any changes without entering the password correctly.

5- In programming section, when Tune operation is selected , if

warning which is shown on the left blinks in operation screen for 10

seconds, it means that start conditions is not okay for Tune operation.

ASET

Installation

Before beginning installation of this product, please

read the instruction manual and warnings below carefully.

c

In package ,

-One piece unit

-Two pieces mounting clamp

-One piece instruction manual

Process Value

ENGLISH

13

A visual inspection of this product for possible damage occured during shipment is

recommended before installation. It is your responsibility to ensure that qualified mechanical

and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power off the

system and the electrical connection of the device from the system.

The unit is normally supplied without a power switch or a fuse. Use power switch and fuse as

required.

Be sure to use the rated power supply voltage to protect the unit against damage and to

prevent failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble with

the unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may results

in malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres. During the equipment

is putted in hole on the metal panel while mechanical installation some metal burrs can cause

injury on hands, you must be careful.

Montage of the product on a system must be done with it’s mounting clamp. Do not do the

montage of the device with inappropriate mounting clamp. Be sure that device will not fall

while doing the montage.

It is your responsibility if this equipment is used in a manner not specified in this instruction

manual.

Garanti

Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts

from the delivery date.

This warranty is in force if duty and responsibilities which are determined in warranty

document and instruction manual performs by the customer completely.

Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the

device before accessing internal parts. Do not clean the case with hydrocarbon-based

solvents (Petrol, Trichlorethylene etc.). Use of these solvents can reduce the mechanical

reliability of the device. Use a cloth dampened in ethyl alcohol or water to clean the external

plastic case.

Other Information:

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and Maintenance Service Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

ENGLISH

14

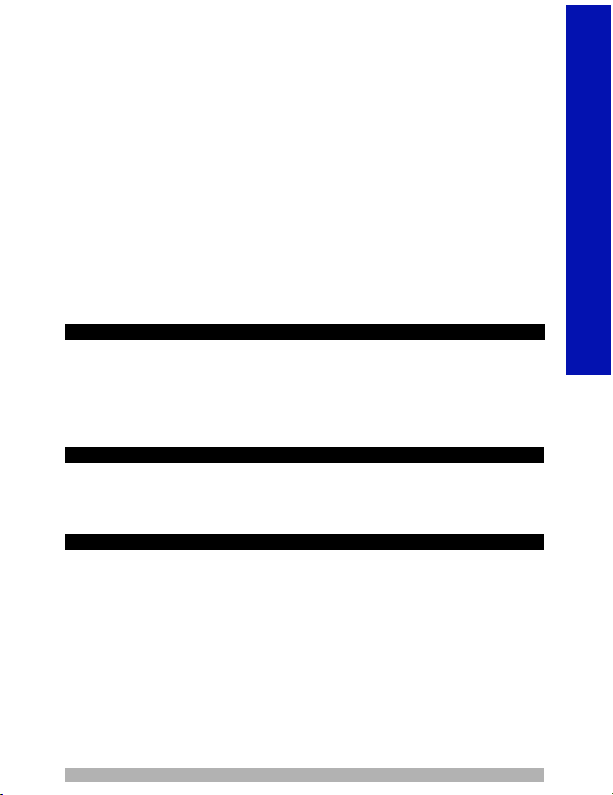

Ordering Information

ENGLISH

Su Socio Tecnológico

Muchas gracias por haber elegido productos

Emko Elektronik, visite nuestra página web

para descargar el manual de usuario

detallado.

www.emkoelektronik.com.tr

15

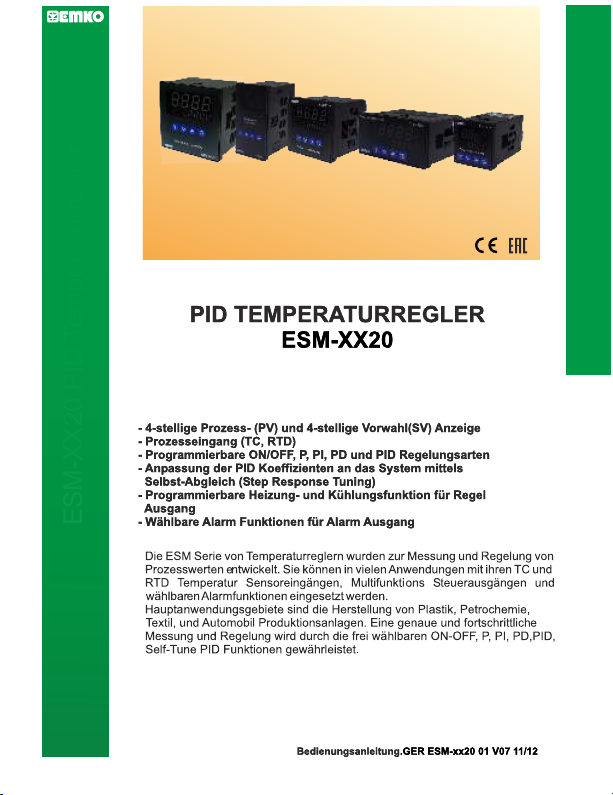

ESM-9920, ESM-9420, ESM-7720, ESM-4920, ESM-4420

PID Temperaturregler

ESM-XX20 PID Temperaturregler ESM-XX20 PID Temperaturregler

DEUTSCH

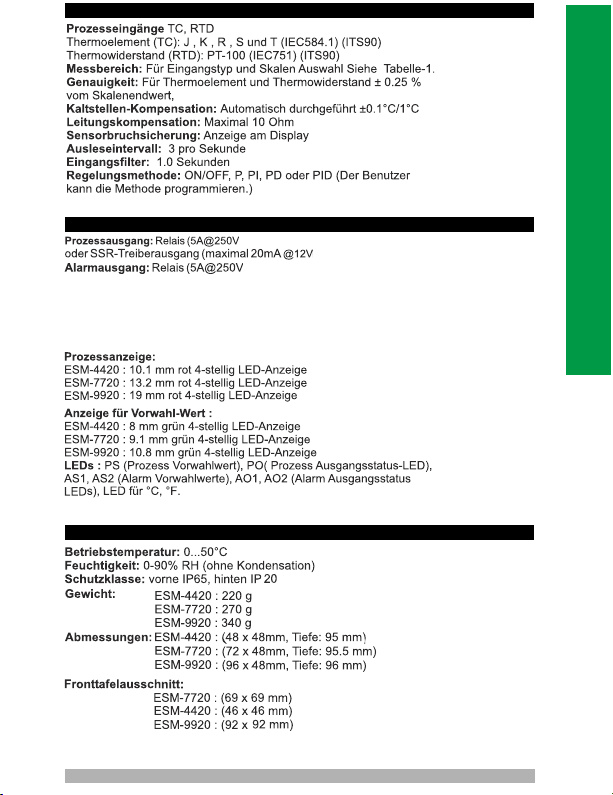

Spezifikationen

Ausgang

Versorgungsspannung:

230V V ( ±15% ) 50/60 Hz - 3VA

115V V ( ±15% ) 50/60 Hz - 3VA

24V V ( ±15% ) 50/60 Hz - 3VA

(Versorgungsspannung bei der Bestellung angeben)

Schutzklassen und Physikalische Eingenschaften

V ohmsche Last )

V ohmsche Last )

Z)

DEUTSCH

2

5A@250VV 5A@250VV

5A@250VV

Max.

24 mA, 12V Z

5A@250VV

5A@250VV 5A@250VV

Max.

24 mA, 12V Z

230 VV

50/60 Hz

1A V T

Sicherung

1A V T

Sicherung

Max.

24 mA, 12V Z

230 VV

50/60 Hz

1A V T

Sicherung

DEUTSCH

230 VV

50/60 Hz

3

ABMESSUNGEN

ESM-4420

Maximal 5 mm/ 0,2 zoll.

°C

°F

PS

PO

AS1

AO1

AS2

AO2

Temperaturregler

PSET

P

48 mm / 1,89 zoll

ABMESSUNGEN

ESM-7720

°C

°F

PS

PO

AS1

AO1

AS2

AO2

PSET

P

Temperaturregler

72 mm / 2,83 zoll

ESM-9920

°C

°F

PS

PO

AS1

AO1

AS2

AO2

PSET

P

Temperaturregler

ESM-4420

ASET

ESM-7720

ASET

ASET

ESM-9920

48 mm / 1,89 zoll

11 ± 1 mm /0,43 zoll

Maximal 5 mm/ 0,2 zoll

72 mm / 2,83 zoll

11,5 ± 1 mm / 0,45 zoll

96 mm / 3,78 zoll

DEUTSCH

84 mm / 3,31 zoll

84 mm / 3,31 zoll

Maximal 15 mm/ 0,59 zoll

96 mm / 3,78 zoll

12 ± 1 mm /0,47 zoll

84 mm / 3,31 zoll

4

Frontplattenmontage

DEUTSCH

5

Loading...

Loading...