PROCESS INDICATOR UNITS

ESM-XX00

ESM-4400, ESM-7700, ESM-9900, ESM-4900

Universal Input Smart output module system Process

display units

- 4 digit process (PV) display

- Universal process input (TC, RTD, mV Z, V Z, mA Z)

- Dual or multi point calibration for Zvoltage &Zcurrent

inputs

- Smart output module system

- Programmable Alarm functions

ESM-XX00 Process Indicator Units

- Process control or re-transmission with 0/4...20 mA Z

Current output module

- RS-232 (standart) or RS-485(Optional) serial

communication with Modbus RTU protocol

ENGLISH

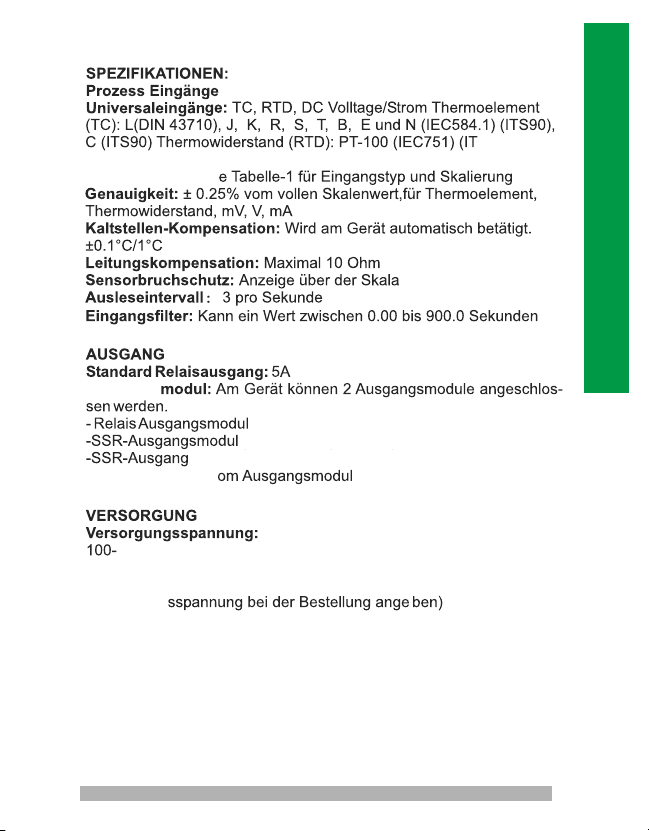

SPECIFICATIONS

PROCESS INPUT

Universal Input: TC, RTD, Z Voltage/Current

Thermocouple (TC): L(DIN 43710) ,J , K , R , S , T , B , E and N

(IEC584.1)(ITS90) ,C (ITS90)

Thermoresistance (RTD): PT-100 (IEC751)(ITS90)

Z Input: mV, V, mA

Measurement Range : Please refer to Table-1 for selection of input

type and scale

Accuracy:± 0.25% of full scale for thermocouple, thermoresistance,

mV, V and mA input.

Cold Junction Compensation:Automatically ±0.1°C/1°C

Line Compensation: Maximum 10 Ohm

Sensor break protection:Upscale

Sampling Cycle:3 samples per second

Input Filter: 0.0 to 900.0 seconds

OUTPUT

Standart Relay Output: 5A@250VV (on resistive load)

Output Modules: User can insert 2 output module to the device.

-Relay Output Module

-SSR Output Module (Max. 26mA , Max. 22V Z)

-Digital (Transistor) Output Module (Max.40 mA @18V Z)

-0/4...20 mA Z Current Output Module

POWER SUPPLY

Power Supply Voltage :

100-240V V 50/60 Hz (-%15;+%10) -6VA

24V V 50/60 Hz (-%15 ; +%10) -6VA

24V Z (-%15 ; +%10) -6W

(It must be determined in order.)

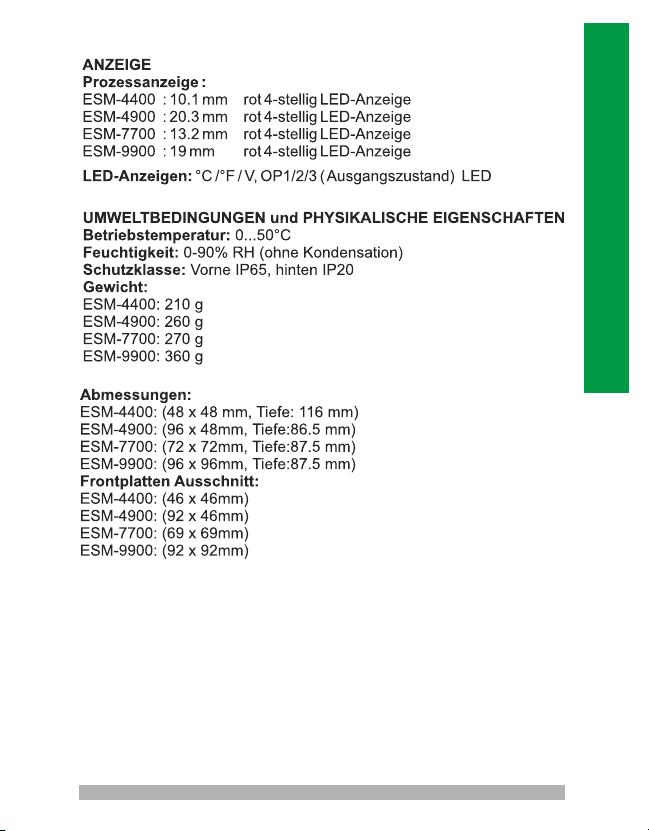

DISPLAY

Process Display :

ESM-4400 : 10.1 mm Red 4 digit LED Display

ESM-4900 : 20.3 mm Red 4 digit LED Display

ESM-7700 : 13.2 mm Red 4 digit LED Display

ESM-9900 : 19 mm Red 4 digit LED Display

ENGLISH

LED Göstergeler : °C /°F / V, OP1/2/3 (Output Status) LED.

2

ENVIRONMENTAL RATINGS and PHYSICAL SPECIFICATIONS

Operating Temperature : 0...50°C

Humidity : 0-90%RH (non condensing)

Protection Class : IP65 at front, IP20 at rear

Mounting : Type-1 Enclosure Mounting

Installation : Fixed installation Category II

Over Voltage Category : II

Pollution Degree : II, office or workplace, none conductive pollution

Weight:

ESM-4400: 210 gr.

ESM-4900: 260 gr.

ESM-7700: 270 gr.

ESM-9900: 360 gr.

Dimensions / Panel Cut-Out:

ESM-4400 : (48 x 48mm, Depth:116 mm) / (46 x 46mm)

ESM-4900 : (96 x 48mm, Depth:86.5 mm) / (92 x 46mm)

ESM-7700 : (72 x 72mm, Depth:87.5 mm) / (69 x 69mm)

ESM-9900 : (96 x 96mm, Depth:87.5 mm) / (92 x 92mm)

Minimum Distance Between Panel Cut-Out Centers:

ESM-4400 : X=65mm, Y=65mm

ESM-4900 : X=129mm, Y=65mm

ESM-7700 : X=97mm, Y=97mm

ESM-9900 : X=129mm, Y=129mm

This symbol is used for safety warnings. User must pay

c

a

attention to these warnings.

This symbol is used to determine the dangerous

situations as a result of an electric shock. User must

pay attention to these warnings definitely.

This symbol is used to determine the important notes

about functions and usage of the device

i

ENGLISH

3

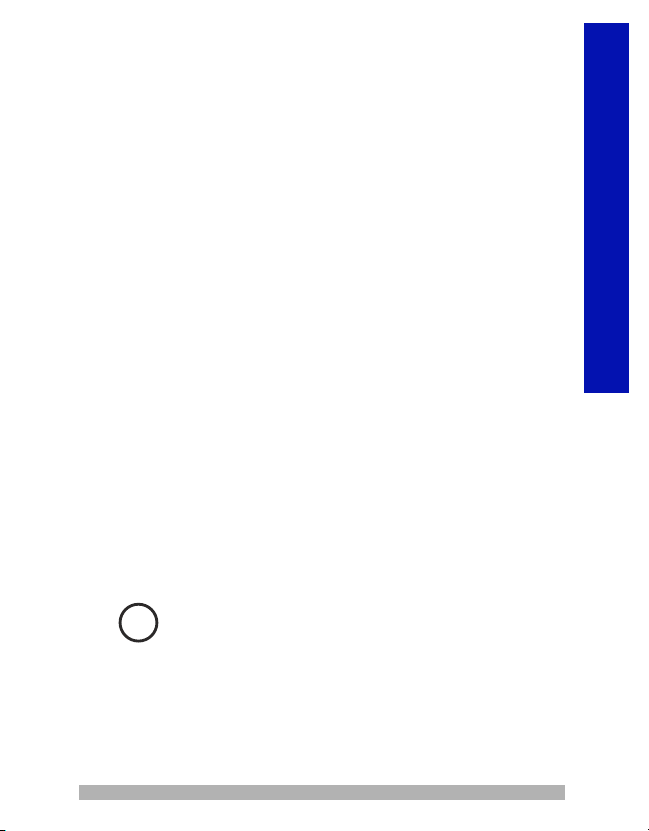

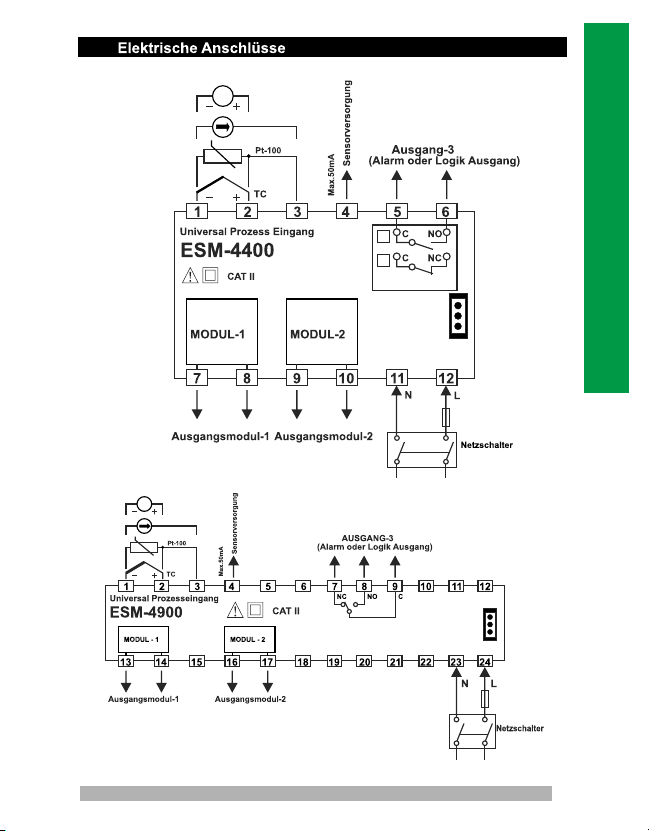

Electrical Wirings

1

Universal Process Input

ESM-4400

Y

c

2

CAT II

0 to 50 mV Z

0 to 10 V Z

0 to 20 mA Z

Pt-100

TC

OUTPUT-3

(Alarm or Logic Output)

Sensor

Supply

Max.50mA

24 V Z

5A@250VV

6

NO

NCCC

ENGLISH

MODULE-1

7

Output

Module-1

0 to 50 mV Z

0 to 10 V Z

0 to 20 mA Z

Pt-100

24 V Z

Max.50mA

TC

Universal Process Input

ESM-4900

MODULE - 1

1311421531641751861972082192210231124

Output Module-1 Output Module-2

c

Y

MODULE - 2

Sensor

Supply

CAT II

MODULE-2

8

9310411512

Output

Module-2

(Alarm or Logic Output)

NC

OUTPUT-3

NO C

5A@250VV

Fuse

a

(-)

N

Note-3

100...240 VV

50/60 Hz

Note-3

Note-1

(+)

L

External

Note-2

Fuse

Power

Supply

Switch

12

Fuse

a

(-) (+)

N L

External

100...240 VV

50/60 Hz

Note-1

Fuse

Note-2

Power

Supply

Switch

4

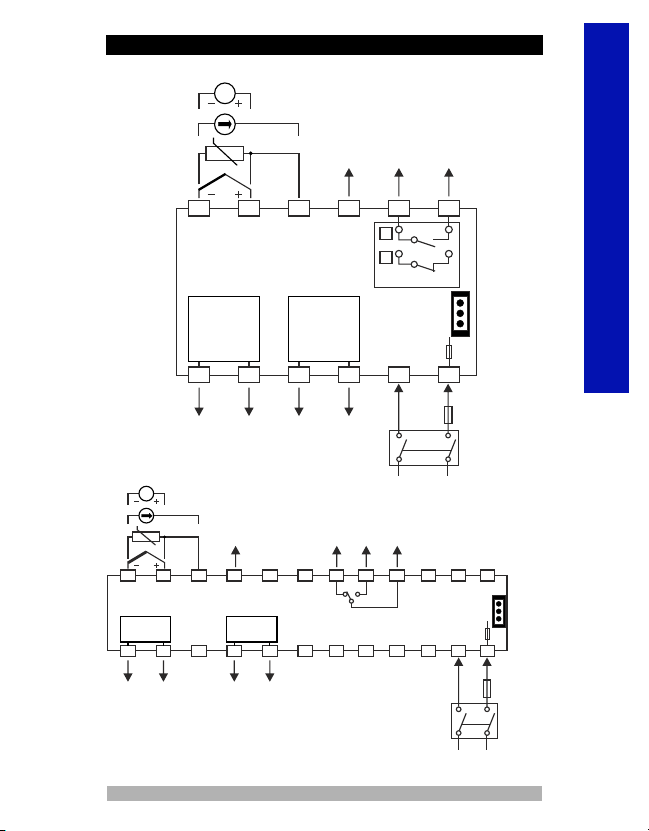

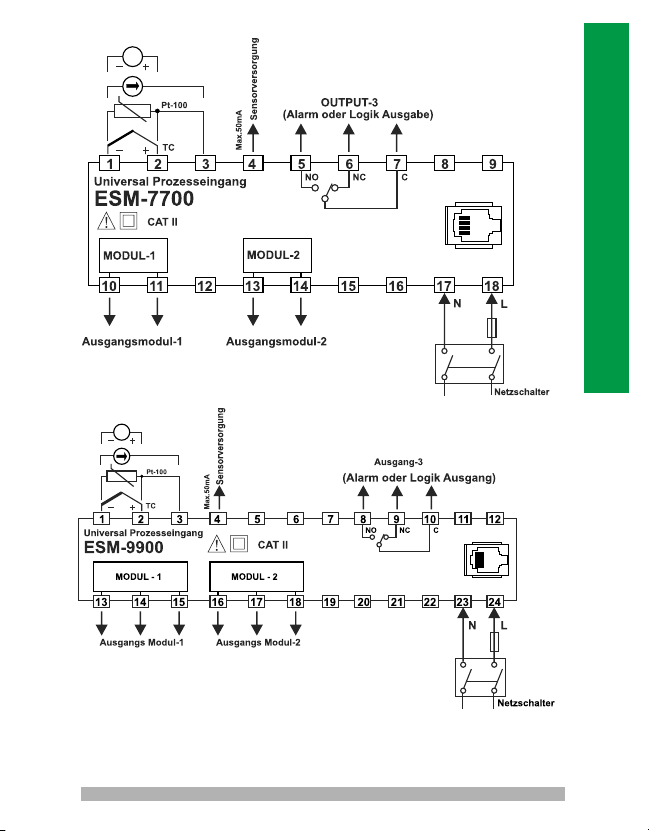

0 to 50 mV Z

0 to 10 V Z

0 to 20 mA Z

Pt-100

TC

Universal Process Input

3134145156167178189

ESM-7700

CAT II

Y

c

MODULE-1

Sensor

24 V Z

Max.50mA

MODULE-2

OUTPUT-3

(Alarm or Logic Output)

Supply

NCNO C

5A@250VV

10111212

Output

Module-1

0 to 50 mV Z

0 to 10 V Z

0 to 20 mA Z

Pt-100

TC

Universal Process Input

ESM-9900

MODULE - 1 MODULE - 2

c

1311421531641751861972082192210231124

Output Module-1 Output Module-2

Note-1 :There is an internal fusible flameproof resistor.

Note-2 : External fuse is recommended.

100...

1AVT for power supply 240 VV or 24VV

1AZT for power supply 24V Z

Note-3 : “L” is ( + ) ,” N” is ( - ) for 24V Z supply voltage

24 V Z

Max.50mA

Y

Sensor

Supply

CAT II

Output

Module-2

Power

Supply

Switch

OUTPUT-3

( Alarm or Logic Output)

NC

NO C

5A@250VV

Note-3

a

(-)

N

Note-3

100...240 VV

50/60 Hz

a

(-)

N

100...240 VV

50/60 Hz

Fuse

12

L

Note-1

(+)

L

External

Fuse

Note-2

Fuse

Note-1

(+)

External

Fuse

Note-2

Power

Supply

Switch

ENGLISH

5

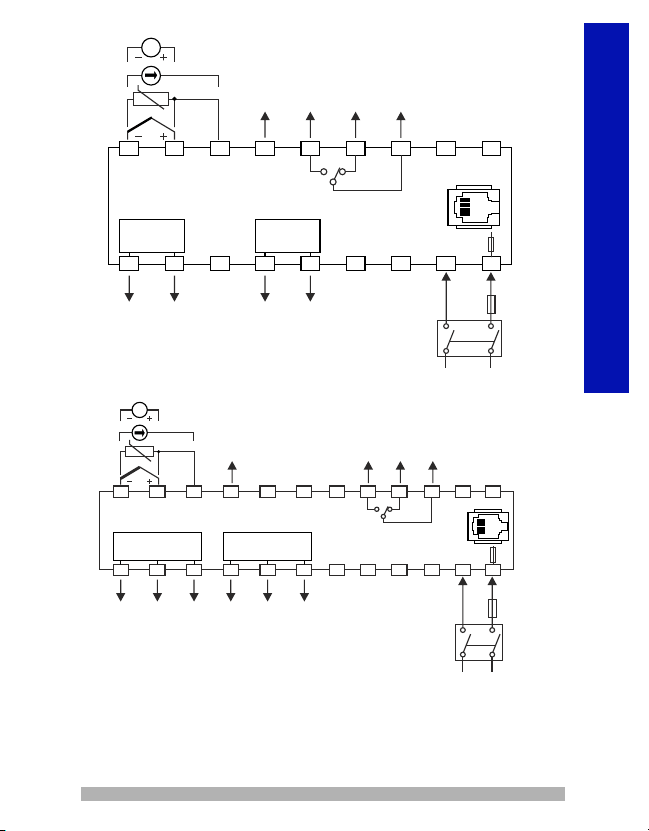

DIMENSIONS

ESM-4400

°C

°F

V

OP1

OP2

OP3

Process Indicator

SET

48mm / 1.89 inch

Maximum 5mm / 0.2 inch

48 mm / 1.89 inch

11.5 ± 1 mm /0.45 inch

104.5 mm/ 4.11 inch

Maximum 15mm / 0.59 inch

Process Indicator ESM - 4900

°C

°F

V

SET

P

96mm / 3.78 inch

Process Indicator

72mm / 2.83 inch

OP1

OP2

OP3

Process Indicator

ESM-7700

SET

SET

ESM-9900

°C

°F

V

OP1

OP2

OP3

°C

°F

V

96mm / 3.78 inch

O1

O2

O3

48mm/ 1.89 inch

10.5 ± 1 mm /0.41 inch

Maximum 15mm / 0.59 inch

72mm / 2.83 inch

11.5 ± 1 mm /0.45 inch

Maximum 15mm / 0.59 inch

96mm / 3.78 inch

ENGLISH

76mm / 2.99 inch

76mm / 2.99 inch

76mm / 2.99 inch11.5 ± 1 mm /0.45 inch

6

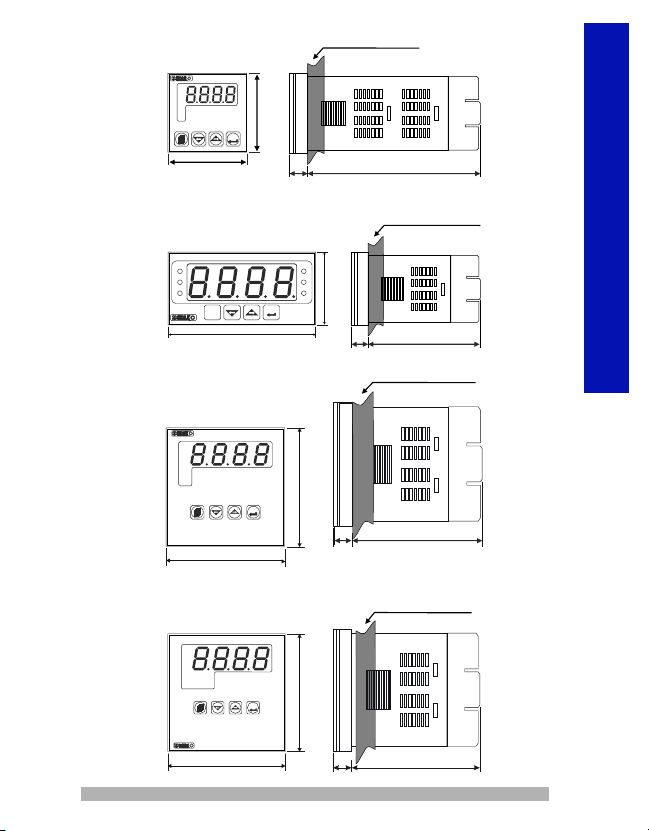

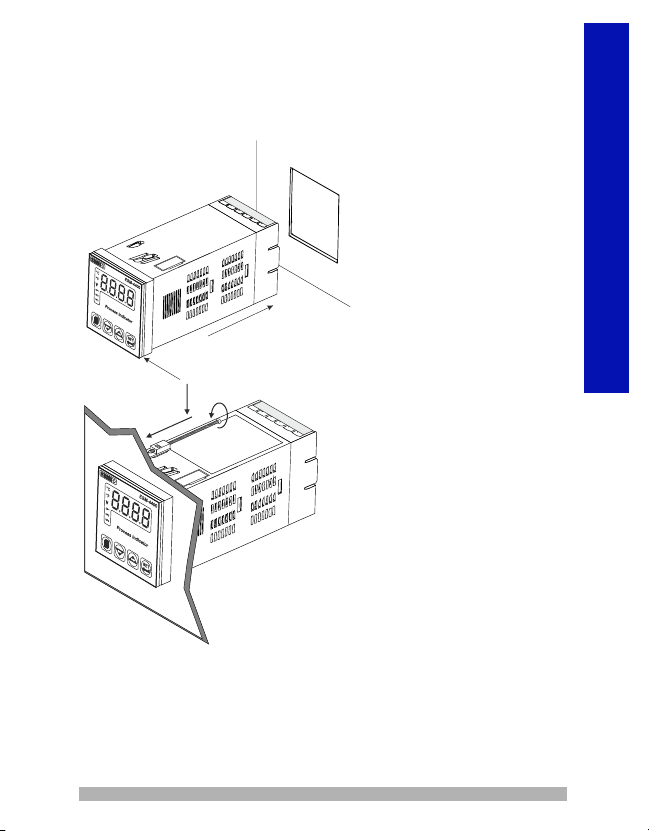

PANEL MOUNTING

2

2

5

4

1-Before mounting the device

in your panel, make sure that

1

1

the cut-out is of the right size.

2-Check front panel gasket

position.

3-Insert the device through the

cut-out. If the mounting clamps

are on the unit, put out them

before inserting the unit to the

3

3

panel.

4-Insert the unit in the panel

cut-out from the front side.

5- Insert the mounting clamps

to the holes that located top

and bottom sides of device

and screw up the fixing

screws until the unit

completely immobile within

the panel

ENGLISH

7

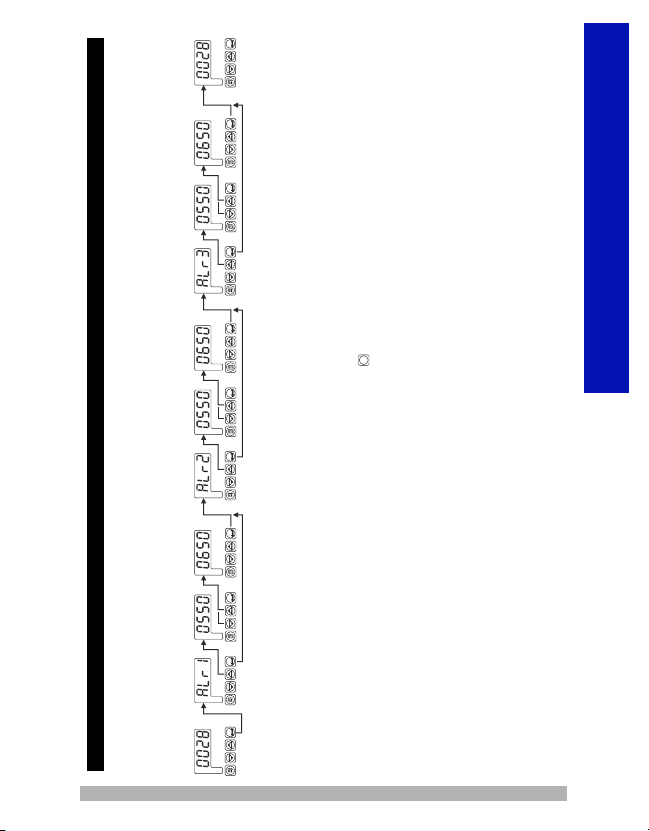

SET

V

°C

°F

OP1

OP2

OP3

Main Screen

SET

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Alarm-3 Set Screen

SET

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Alarm-2 Set Screen

SET

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

SET

Press SET

button to

save the

Alarm-3 Set

value.

Press increment

or decrement

button to change

the Alarm-3 Set

Value.

Press

Increment

button to

enter Alarm-3

set value.

Press SET

button to

save the

Alarm-2 Set

value.

Value.

Press increment

or decrement

button to change

the Alarm-2 Set

set value.

Press

Increment

button to

enter Alarm-2

Press SET

button to

save the

Alarm-1 Set

value.

ENGLISH

P

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

SET

Access and change Set values

V

°C

°F

OP1

OP2

OP3

Main Screen Alarm-1 Set Screen

Value.

Press increment

or decrement

button to change

the Alarm-1 Set

Press

Increment

button to

enter Alarm-1

set value.

Press SET

Button

Note: User can exit from Set Value section without saving the values by pressing button.

If no operation for 120 seconds, device automatically exits from Set Value section .

8

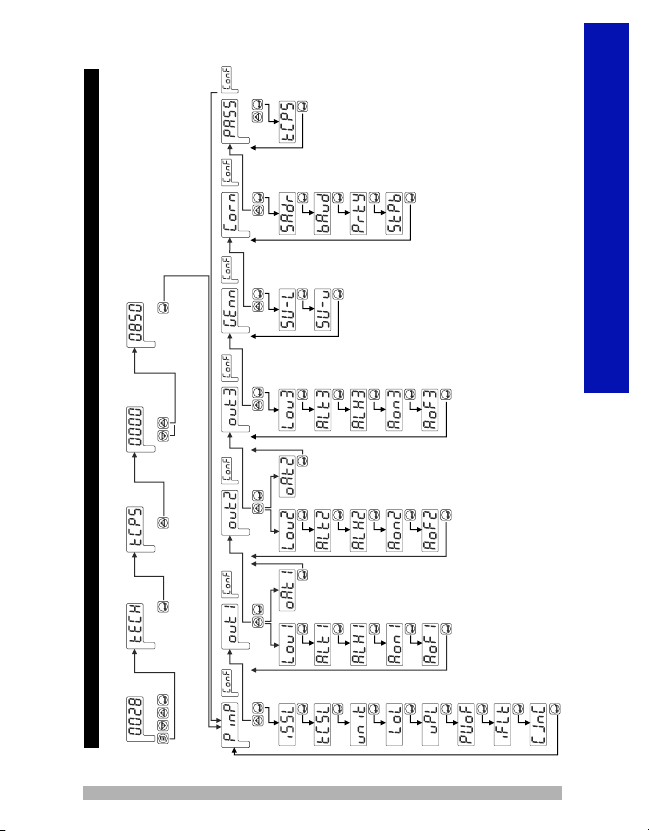

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Note: For detailed information look PASS ConF

section.

SET

V

°C

°F

OP1

OP2

OP3

V

°C

°F

OP1

OP2

OP3

Technician password

entering screen

V

°C

°F

OP1

OP2

OP3

Technician password

entering screen

SET

V

°C

°F

OP1

OP2

OP3

Technician menu

entering screen

SET

Easy Access diagram of Program Parameters

V

°C

°F

OP1

OP2

OP3

Main Screen

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Press Set/OK Button

to approve password.

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Enter password with

using Increment or

decrement buttons.

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Press Increment button

to access password

entering screen

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

Press Set/OK Button

Press Menu

OP3

to enter password

entering screen.

V

°C

°F

OP1

OP2

OP3

Button.

V

°C

°F

OP1

OP2

OP3

SET

NOTE4

NOTE3

NOTE1 NOTE2

SET

SET

SET

SET

SET

If there is EMO-X30 module in MODULE-2

If there is EMO-X00, EMO-X10, EMO-X20

NOTE1: If there is EMO-X00, EMO-X10, EMO-X20

output module in MODULE-1 socket, these

parameters are shown.

NOTE3: If there is EMO-X30 module in MODULE-1

socket, this parameter is shown.

NOTE4:

NOTE2:

output module in MODULE-2 socket, these

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

parameters are shown.

SET

SET

SET

ENGLISH

socket, this parameter is shown.

9

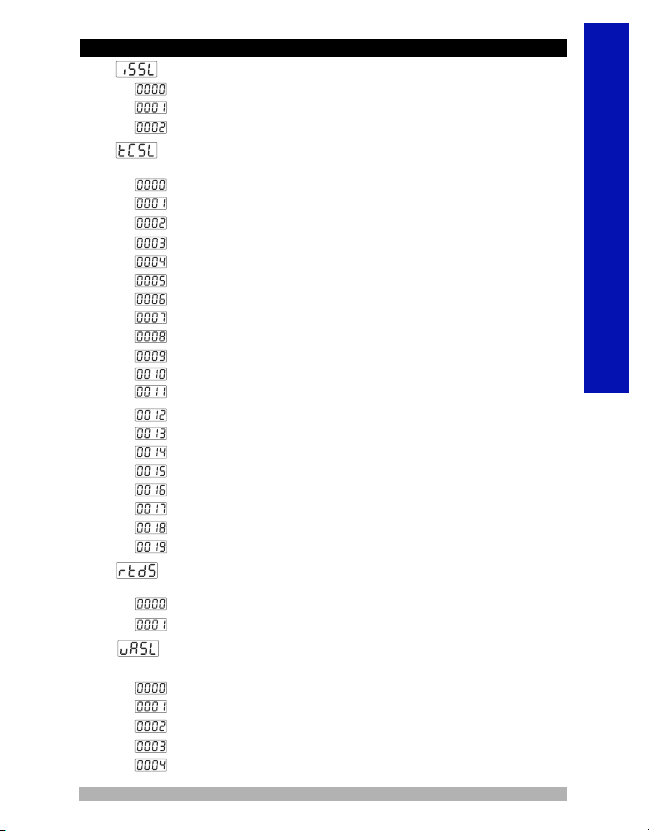

PınP ConF: Process Input Type and Relevant Parameters

Process Input Type

TC input type selection

RTD input type selection

ZVoltage / Current input type selection.

TC Input Selection

This parameter is active if TC input type is selected.

L (-100°C;850°C) or (-148°F;1562°F)

L (-100.0°C;850.0°C) or (-148.0°F;999.9°F)

J (-200°C;900°C) or (-328°F;1652°F)

J (-199.9°C;900.0°C) or (-199.9°F;999.9°F)

K (-200°C;1300°C) or (-328°F;2372°F)

K (-199.9°C;999.9°C) or (-199.9°F;999.9°F)

R (0°C;1700°C) or (32°F;3092°F)

R (0.0°C;999.9°C) or (32.0°F;999.9°F)

S (0°C;1700°C) or (32°F;3092°F)

S (0.0°C;999.9°C) or (32.0°F;999.9°F)

T (-200°C;400°C) or (-328°F;752°F)

T (-199.9°C;400.0°C) or (-199.9°F;752.0°F)

B (44°C;1800°C) or (111°F;3272°F)

B (44.0°C;999.9°C) or (111.0°F ; 999.9°F)

E (-150°C;700°C) or (-238°F;1292°F)

E (-150.0°C;700.0°C) or (-199.9°F;999.9°F)

N (-200°C;1300°C) or (-328°F;2372°F)

N (-199.9°C;999.9°C) or (-199.9°F;999.9°F)

C (0°C;2300°C) or (32°F;3261°F)

C (0.0°C;999.9°C) or (32.0°F;999.9°F)

RTD Input Selection

This parameter is active if RTD input is selected.

PT-100 ( -200°C ; 650°C ) or ( -328°F ; 1202°F)

PT-100 ( -199.9°C ; 650.0°C ) or ( -199.9°F ;999.9°F)

Zvoltage / Current Input Selection

This parameter is active if ZVoltage / Current is selected.

0...50mV Z ( -1999 ; 9999 )

0...5V Z ( -1999 ; 9999 )

0...10V Z ( -1999 ; 9999 )

0...20mA Z ( -1999 ; 9999 )

4...20mA Z ( -1999 ; 9999 )

ENGLISH

10

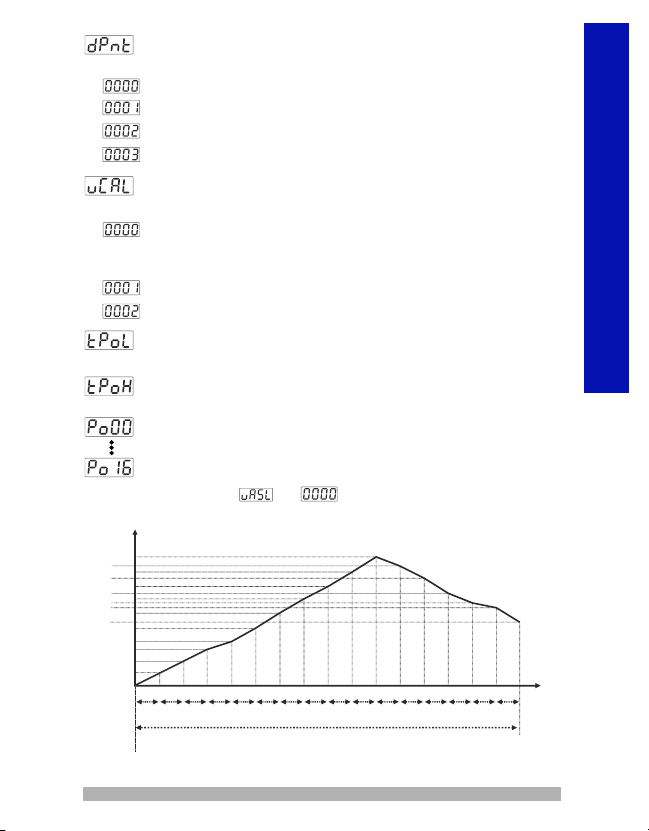

Display Point Position

This parameter is active if oltage/Current input is selected.ZV

No point

Between first and second digits “0.0”

Between second and third digits “0.00”

Between third and fourth digits “0.000”

Display Value Adjustment Type

This parameter is active if oltage/Current input is selected.ZV

Fixed dual point display adjustment. Display adjustment low

point value is fixed to -1999, display adjustment high point

value is fixed to 9999.

User can do dual point display adjustment with tPoL and tPoH.

User can do defined 16 display adjustment points.

Low Point Display adjustment (-1999, 9999)Unit

This parameter is active if oltage/Current input is selected.ZV

High Point Display adjustment (-1999, 9999)Unit

This parameter is active if oltage/Current input is selected.ZV

Display adjustment points (-1999, 9999)Unit

This parameter is active if oltage/Current input is selected.

In multi point display adjustment operation, defined scale is

divided into 16 adjustment points.

For example : is (0-50 mV ) .ZVZ

Process

Set value

Po10

Po11

Po09

Po12

Po08

Po13

Po07

Po14

Po15

Po06

Po16

Po05

Po04

Po03

Po02

Po01

Po00 = 0

3.125 6.25 9.375 12.5 15.625 18.75 21.825 25 28.125 31.25 34.375 37.5 40.625 43.75 46.875

3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125

0-50 mVZ range are divided into 16 egual parts. Every “Poxx” SET value is defined

50 / 16 = 3.125 mVZ range.

50

mV Z

ENGLISH

11

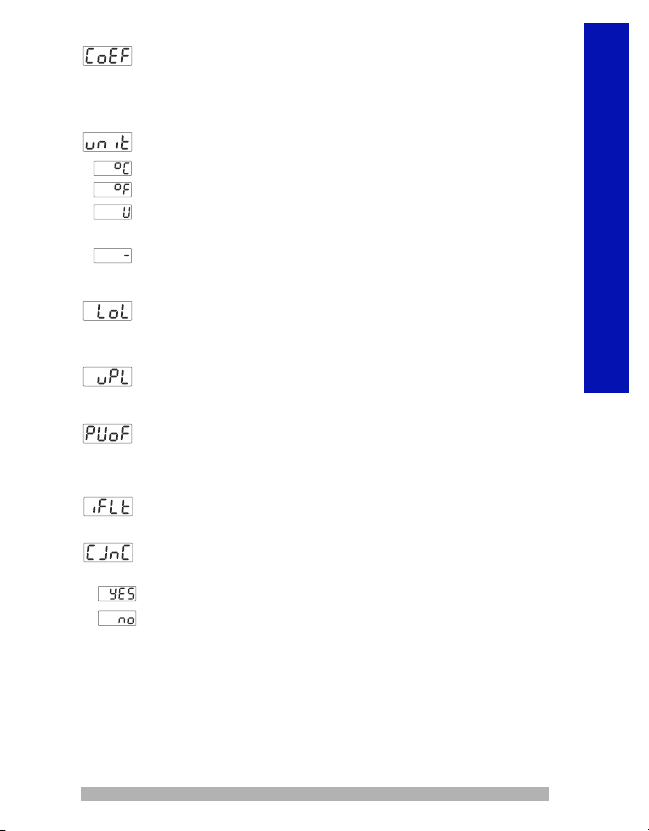

Coefficient value (1.000, 9.999)

Process value is multiplied with this value.

Unit selection

Unit is °C

Unit is °F

Unit is Voltage. This selection is active if ZVoltage/Current

input is selected

No unit. This selection is active if oltage / current input is

selected

Operating Scale Minimum Value

(Scale Low Point, Scale High Point)Unit

Used for Proportional band calculation and display blink.

Operating Scale Maximum Value

(Scale Low Point, Scale High Point)Unit

Used for Proportional band calculation and display blink.

Display offset for process value (Scale -10%, Scale

+10%)Unit

This parameter value is added to the process value.

Filter Time (0.0, 900.0)Second

Defines filter time for display value.

Cold Junction Compensation

This parameter is active if process input is selected TC input.

Cold junction compensation is active.

Cold junction compensation is not active.

Scale: The difference, between high point and low point of the process

input type. Example: If tCSL = 2 (low point is -200, high point is 900),

then scale is 1100. If input type is Voltage/Current, then the scale is

difference between tPoH and tPoL parameters.

ZVThis parameter is active if oltage/Current input is selected.

ZV

ENGLISH

12

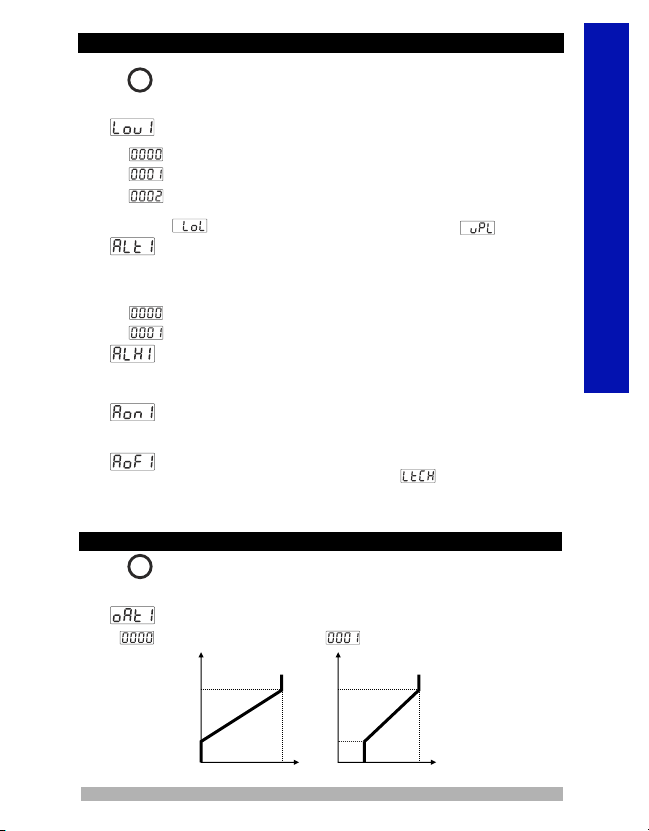

out1 ConF: MODULE-1 parameters

If there is EMO-X00 (Relay Output) , EMO-X10 (SSR driver)

i

and EMO-X20 (Digital Output) module in MODULE-1

socket, then the following parameters is active.

MODULE-1 output module Logic output function

Alarm output

Sensor break alarm output

Output is active when the process value is out of the band

which is defined with minimum value of operating scale

and maximum value of operating scale

Alarm-1 Type

MODULE-1 alarm type. This parameter is active, if the Logic1 output function is Alarm output.

Process high alarm

Process low alarm

Alarm-1 hysteresis value (0% of scale, 50% of scale)Unit

This parameter is active, if the Logic-1 output function is

Alarm output.

Alarm-1 On delay time (0, 9999)Second

This parameter is active, if the Logic-1 output function is

Alarm output.

Alarm-1 Off Delay Time (0, 9998)

When the value is greater than 9998, is seen on the

screen. It means alarm latching output is selected.

parameter is active

Output is alarm output.

out1 ConF: MODULE-1 parameters

If there is EMO-X30 ( )

i

module in MODULE-1 socket, then the following

parameter is active.

if logic-1 output function of Alarm-1

0/4...20 mA Z Current output

Second

MODULE-1 analogue output module configuration

0...20mAZ output

Scale

Re-transmission

UPL

Scale

Re-transmission

UPL

4...20mAZ output

ENGLISH

This

LOL

0 20

LOL

mA

0 20

4

mA

13

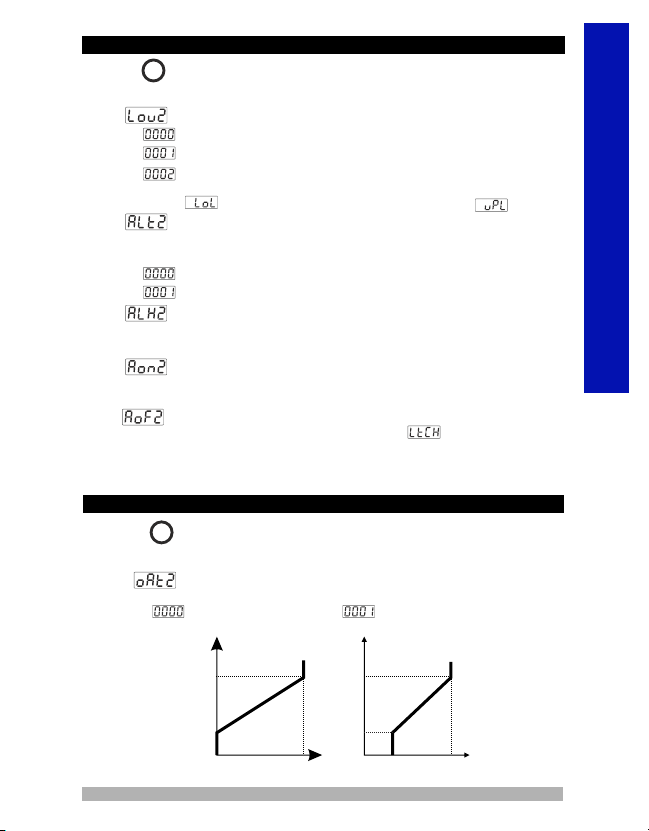

out2 ConF: MODULE-2 parameters

If there is EMO-X00 (Relay Output) , EMO-X10 (SSR driver)

i

and EMO-X20 (Digital Output) module in MODULE-2

socket, then the following parameters is active.

MODULE-2 output module Logic output function

Alarm output

Sensor break alarm output

Output is active when the process value is out of the band

which is defined with minimum value of operating scale

and maximum value of operating scale

Alarm-2 Type

MODULE-2 alarm type. This parameter is active, if the Logic2 output function is Alarm output.

Process high alarm

Process low alarm

Alarm-2 hysteresis value (0% of scale, 50% of scale)Unit

This parameter is active, if the Logic-2 output function is

Alarm output.

Alarm-2 On delay time (0, 9999)Second

This parameter is active, if the Logic-2 output function is

Alarm output.

Alarm-2 Off Delay Time (0, 9998)

When the value is greater than 9998, is seen on the

screen. It means alarm latching output is selected. This

parameter is active if logic-2 output function of Alarm-2

Output is alarm output.

Second

out2 ConF: MODULE-2 parameters

If there is EMO-X30 ( )

i

module in MODULE-2 socket, then the following

parameter is active.

0/4...20 mA Z Current output

MODULE-2 analogue output module configuration

0...20mAZ output

Scale

Re-transmission

UPL

4...20mAZ output

Scale

Re-transmission

UPL

ENGLISH

LOL

0 20

LOL

mA

0 20

4

mA

14

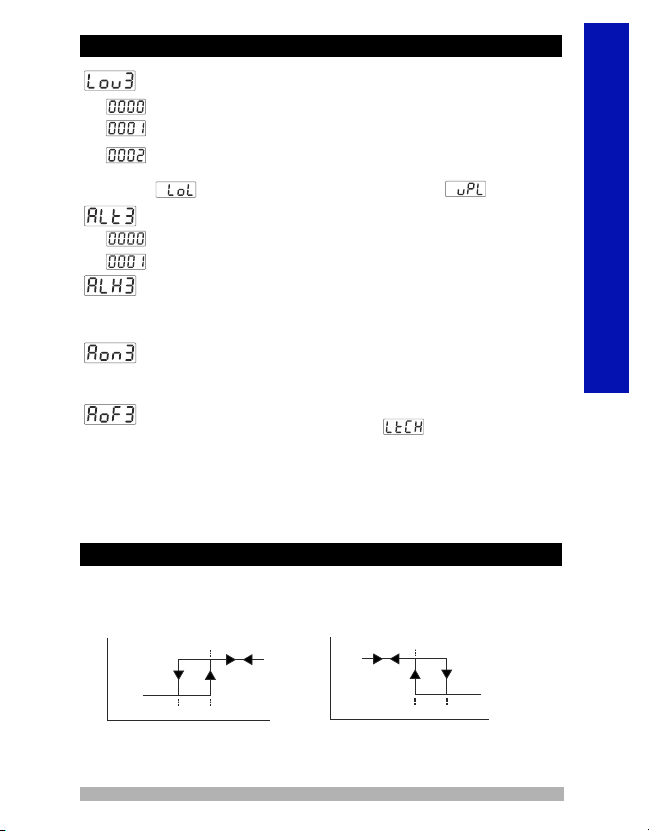

out3 ConF: MODULE-3 parameters

Output-3 Logic output function

Alarm output

Sensor break alarm output

Output is active when the process value is out of the band

which is defined with minimum value of operating scale

and maximum value of operating scale

Alarm-3 Type

Process high alarm

Process low alarm

Alarm-3 hysteresis value (0% of scale, 50% of scale)Unit

This parameter is active, if the Logic-3 output function is

Alarm output.

Alarm-3 On delay time (0, 9999)Second

This parameter is active, if the Logic-3 output function is

Alarm output.

Alarm-3 Off Delay Time (0, 9998)

When the value is greater than 9998, is seen on the

screen. It means alarm latching output is selected. This

parameter is active if logic-3 output function of Alarm-3

Output is alarm output.

Alarm Types

ENGLISH

Second

Process High Alarm

Alarm

Output

ON

OFF

Alarm

HYS

Set

Process Value

Process Low Alarm

Alarm

Output

ON

OFF

Alarm

Set

HYS

Process Value

15

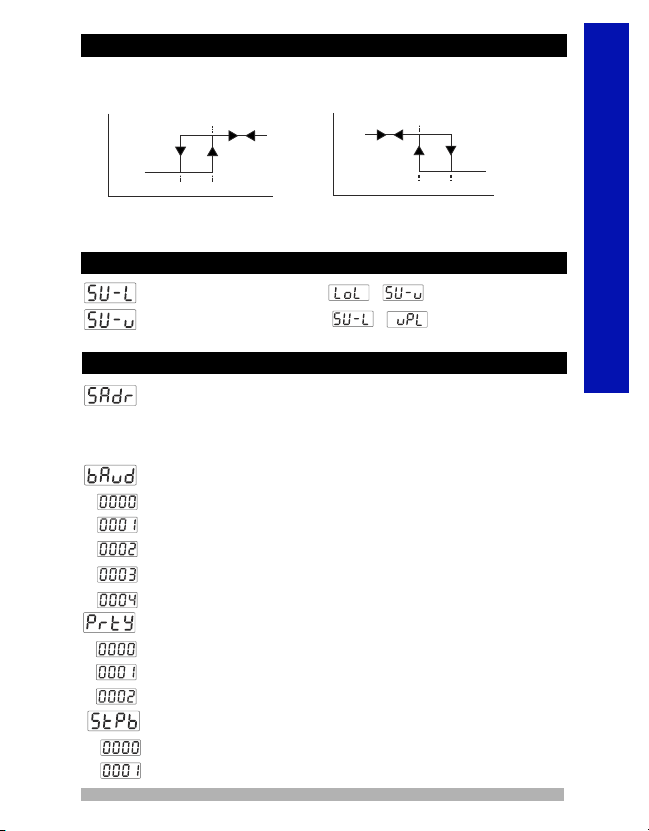

Alarm Types

Process High Alarm

Alarm

Output

ON

Alarm

Set

Process Low Alarm

Alarm

Output

ON

Alarm

Set

OFF

HYS

Process Value

OFF

HYS

Process Value

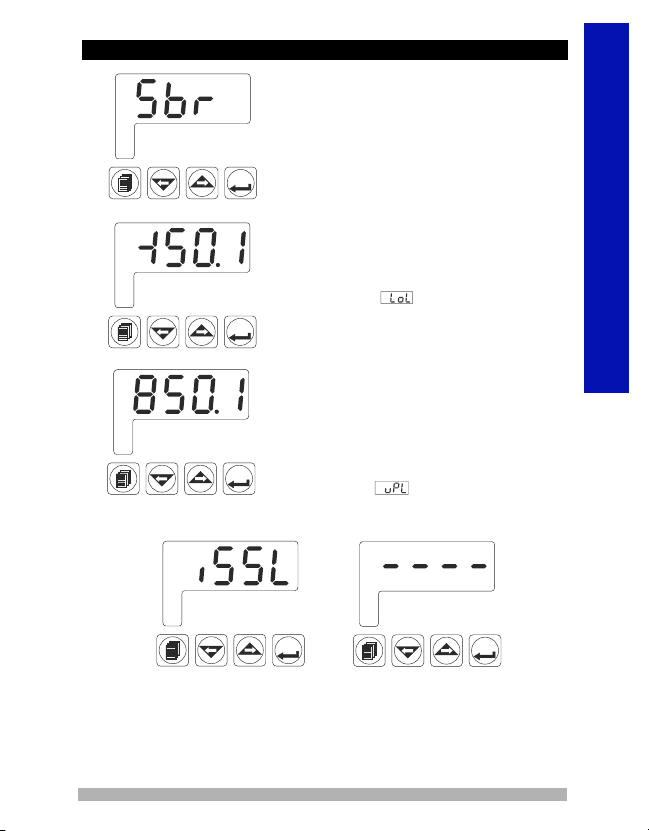

Gen ConF: General Parameters

Alarm Set value Low limit ( , )Unit

Alarm Set ( , )Unitvalue High limit

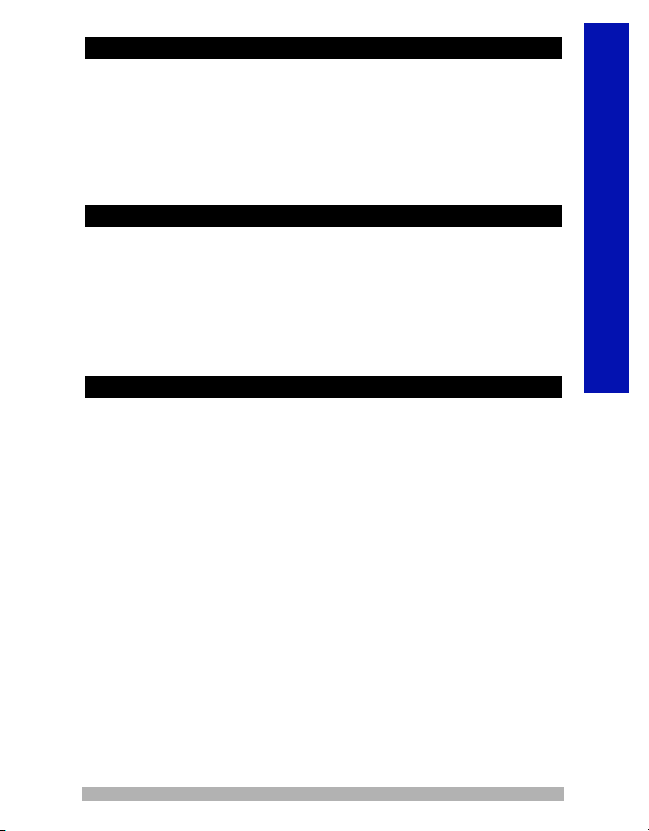

Com ConF: Serial Communication Configuration Parameters

Communication Accessing Address (1,247)

Communication accessing address of device.

Communication accessing address can be adjusted from 1

to 247.

Communication Baud Rate

1200 Baud Rate.

2400 Baud Rate .

4800 Baud Rate

9600 Baud Rate

19200 Baud Rate

Parity Selection for Communication

No parity.

Odd parity.

Even parity.

Stop Bit Selection for Communication

1 stop bit

2 stop bit

16

ENGLISH

ENGLISH

ESM-XX00 Process Control Unit Error Messages

°C

°F

V

OP1

OP2

OP3

°C

°F

V

OP1

OP2

OP3

°C

°F

V

OP1

OP2

OP3

1 - Sensor failure in analogue inputs.

Sensor connection is wrong or there is no

sensor connection.

SET

2- If top display blinks : If analogue input

value is less than minimum value of

operating scale top display starts to

blink.

SET

3- If top display blinks : If analogue input

value is greater than maximum value of

SET

operating scale top display starts to

blink.

ENGLISH

ENGLISH

°C

°F

V

OP1

OP2

OP3

SET

4- If technician password is different from “0” and user accesses

to the parameter by Set button without entering the technician

password and wants to change a parameter, the warning

message is shown on the display as shown on the right.

Device does not allow to do any changes without entering the

password correctly.

°C

°F

V

OP1

OP2

OP3

SET

17

Installation

Before beginning installation of this product, please

c

In package ,

- One piece unit

- Two pieces mounting clamp

- One piece instruction manual

A visual inspection of this product for possible damage occured during

shipment is recommended before installation. It is your responsibility

to ensure that qualified mechanical and electrical technicians install

this product.

If there is danger of serious accident resulting from a failure or defect in

this unit, power off the system and separate the electrical connection

of the device from the system.

The unit is normally supplied without a power switch or a fuse. Use

power switch and fuse as required.

Be sure to use the rated power supply voltage to protect the unit

against damage and to prevent failure.

Keep the power off until all of the wiring is completed so that electric

shock and trouble with the unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering

with the unit may results in malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During the equipment is putted in hole on the metal panel while

mechanical installation some metal burrs can cause injury on hands,

you must be careful.

Montage of the product on a system must be done with it’s mounting

clamp. Do not do the montage of the device with inappropriate

mounting clamp. Be sure that device will not fall while doing the

montage.

It is your responsibility if this equipment is used in a manner not

specified in this instruction manual.

read the instruction manual and warnings below

carefully.

ENGLISH

18

Warranty

Warranty

EMKO Elektronik warrants that the equipment delivered is free from

defects in material and workmanship. This warranty is provided for a

period of two years. The warranty period starts from the delivery date.

This warranty is in force if duty and responsibilities which are

determined in warranty document and instruction manual performs by

the customer completely.

Maintenance

Warranty

Maintenance

Repairs should only be performed by trained and specialized

personnel. Cut power to the device before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol,

Trichlorethylene etc.). Use of these solvents can reduce the

mechanical reliability of the device. Use a cloth dampened in ethyl

alcohol or water to clean the external plastic case.

Maintenance

Warranty

Other Informations

Other Informations

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA /TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and Maintenance Service Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA /TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

ENGLISH

19

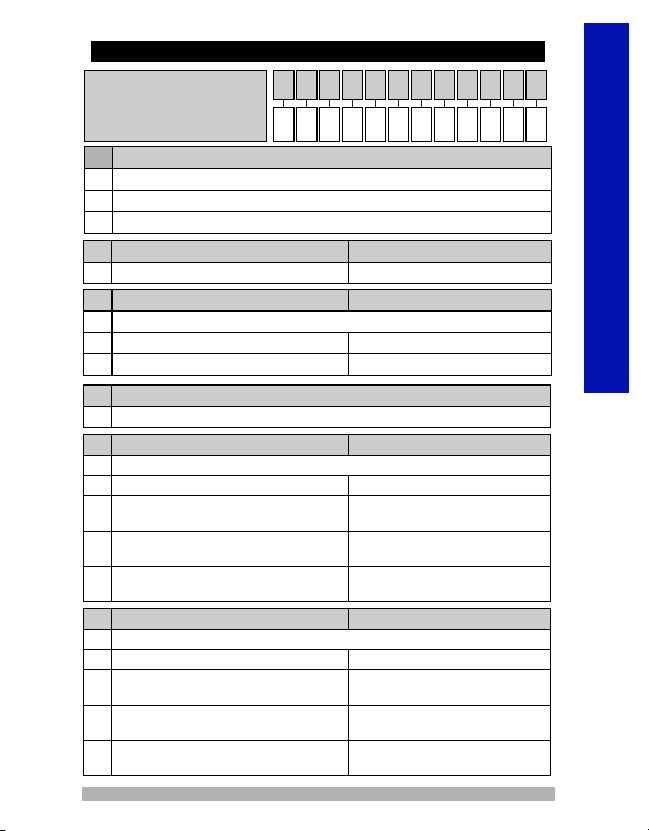

Ordering Information

ESM-4400 (48x48 DIN 1/16)

ESM-4900 (96x48 DIN 1/8)

ESM-7700 (72x72 DIN Size)

ESM-9900 (96x96 DIN 1/4)

Supply Voltage

A

100-240V V (-%15;+%10) 50/60Hz

1

2

24V V (-%15;+%10) 50/60Hz 24V Z (-%15;+%10)

Customer (Maximum 240V V (-%15;+%10))50/60Hz

9

Input type ScaleBC

A

BC D E FG HI //U V W Z/

/

1

20 Configurable(Table-1) Table-1

Serial CommunicationD

0

None

1

RS-232

2

RS-485

Output-3

E

Relay Output(5A@250VV on resistive Load)

1

Module-1

FG

None

00

Relay Output Module

01

SSR driver Output Module

02

(Maximum 26mA, 22V Z)

Digital (Transistor) Output Module

03

(Maximum 40mA@18V Z)

Current Output Module

04

(0/4...20 mA Z veya 0...10V Z)

Module-2

HI

None

00

Relay Output Module

01

SSR driver Output Module

02

(Maximum 26mA, 22V Z)

Digital (Transistor) Output Module

03

(Maximum 40mA@18V Z)

Current Output Module

04

(0/4...20 mA Z veya 0...10V Z)

Product Code

EMC-400,EMC-700,EMC-900

EMC-410,EMC-710,EMC-910

Module Codes

EMO-400,EMO-700,EMO-900

EMO-410,EMO-710,EMO-910

EMO-420,EMO-720,EMO-920

EMO-430,EMO-730,EMO-930

Module Codes

EMO-400,EMO-700,EMO-900

EMO-410,EMO-710,EMO-910

EMO-420,EMO-720,EMO-920

EMO-430,EMO-730,EMO-930

0 0 0 0

ENGLISH

20

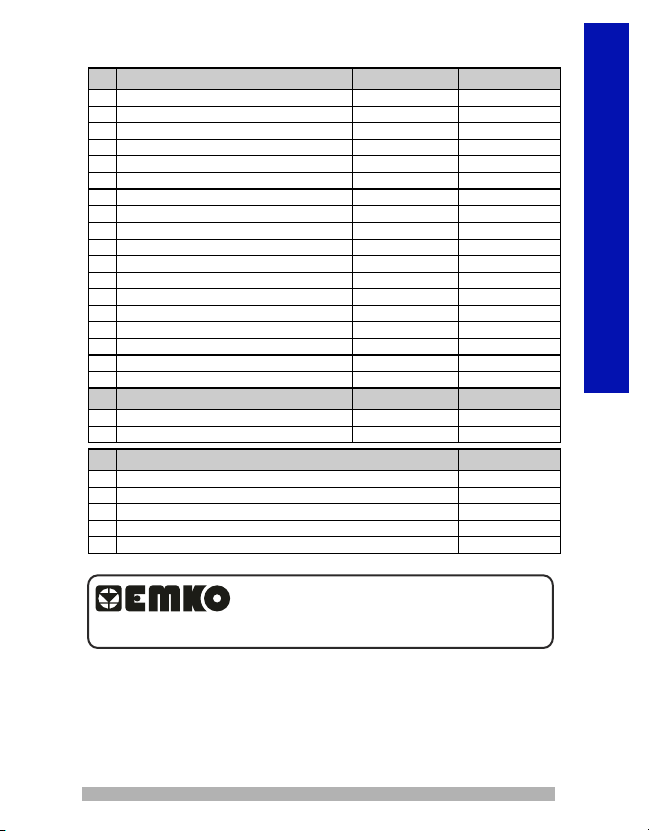

Table-1

Input Type(TC)

BC

21

L ,Fe Const DIN43710

22

L ,Fe Const DIN43710

23

J ,Fe CuNi IEC584.1(ITS90)

24

J ,Fe CuNi IEC584.1(ITS90)

25

K ,NiCr Ni IEC584.1(ITS90)

26

K ,NiCr Ni IEC584.1(ITS90)

27

R ,Pt13%Rh Pt IEC584.1(ITS90)

S ,Pt10%Rh Pt IEC584.1(ITS90)

28

29

T ,Cu CuNi IEC584.1(ITS90)

30

T ,Cu CuNi IEC584.1(ITS90)

31

B ,Pt30%Rh Pt6%Rh IEC584.1(ITS90)

32

B ,Pt30%Rh Pt6%Rh IEC584.1(ITS90)

33

E ,NiCr CuNi IEC584.1(ITS90)

34

E ,NiCr CuNi IEC584.1(ITS90)

35

N ,Nicrosil Nisil IEC584.1(ITS90)

36

N ,Nicrosil Nisil IEC584.1(ITS90)

37

C , (ITS90)

38

C , (ITS90)

Input Type(RTD)

BC

39

PT 100 , IEC751(ITS90)

40

PT 100 , IEC751(ITS90)

Input Type( Z Voltage and Current)

BC

41

0...50 mV Z

42

0...5 V Z

43

0...10 V Z

44

0...20 mA Z

45

4...20 mA Z

Thank you very much for your preference to

use Emko Elektronik products, please visit our

Your Technology Partner

web page to download detailed user manual.

Scale(°C)

-100°C,850°C

-100.0°C,850.0°C

-200°C,900°C

-199.9°C,900.0°C

-200°C,1300°C

-199.9°C,999.9°C

0°C,1700°C

0°C,1700°C

-200°C,400°C

-199.9°C,400.0°C

44°C,1800°C

44.0°C,999.9°C

-150°C,700°C

-150.0°C,700.0°C

-200°C,1300°C

-199.9°C,999.9°C

0°C,2300°C

0.0°C,999.9°C

Scale(°C)

-200°C,650°C

-199.9°C,650.0°C

Scale(°F)

-148°F ,1562°F

-148.0°F,999.9°F

-328°F,1652°F

-199.9°F,999.9°F

-328°F,2372°F

-199.9°F,999.9°F

32°F,3092°F

32°F,3092°F

-328°F,752°F

-199.9°F,752.0°F

111°F,3272°F

111.0°F,999.9°F

-238°F,1292°F

-199.9°F,999.9°F

-328°F,2372°F

-199.9°F,999.9°F

32°F,3261°F

32.0°F,999.9°F

Scale(°F)

-328°F,1202°F

-199.9°F,999.9°F

Scale

-1999,9999

-1999,9999

-1999,9999

-1999,9999

-1999,9999

www.emkoelektronik.com.tr

ENGLISH

21

ESM-4400,ESM-7700,ESM-9900,ESM-4900

Prozessanzeige mit Universal Eingang und Smart Ausgangs

Modulsystem

-4-stellige Prozess(PV) Anzeige

-Universal Prozesseingä

Duale oder Multipunkt Kalibrierun

-Smart Ausgangs Modulsystem

ESM-XX00 Prozessanzeige

-Programmierbare Alarmfunktionen

-Prozesssteuerung oder ‘re-transmission (erneute Übertragung)

(mit 0/4...20 mA

-RS-232 (Standard) oder RS-485 (optional) Kommunikation mit

Modbus RTU Protokoll

DC Strom Ausgangsmodul

(TC, RTD, mV Z, V Z, mA Z)

nge

g für DCV/ Strom Eingänge

DEUTCH

Eingang: mV, V, mA

Messbereich: Sieh

S90) Z

DEUTCH

Ausgangs

(Max. 26mA, Max 22V Z)

-0/4...20 mA Z Str

240V V 50/60Hz (-15% ;+10%)-6VA

24V V 50/60Hz (-15%

24V Z (-%15 ; +%10) -6W

(Versorgung

smodul (Max. 40mA @18V Z)

; +10%) -6A

@250V V (Ohmsche Last)

2

DEUTCH

3

0...50 m V Z

0...10 V Z

0...20 mA Z

24 V Z

0...50 mV Z

0...10 V Z

0...20 mA Z

24 V Z

5A@ 250 V V

5A@250VV

100...240V V

50/60 Hz

1AV T

Sicherung

DEUTCH

100...240V V

50/60 Hz

1AV T

Sicherung

4

0...50 mV Z

0...10 V Z

0...20 mA Z

0...50 m V Z

0...10 V Z

0...20 mA Z

24 V Z

5A@250VV

DEUTCH

1AV T

Sicherung

100...240VV

50/60 Hz

24 V Z

5A@ 250 V V

100...240V V

50/60 Hz

1AV T

Sicherung

5

DEUTCH

6

DEUTCH

7

DEUTCH

8

DEUTCH

9

DEUTCH

Spannung / Strom

Ist Z Spannung/ Stro

Parameter

0...50mV Z (-1999; 9999)

0...5V Z (-1999; 9999)

0...10V Z (-1999; 9999)

0...20mA Z (-1999; 9999)

4...20mA Z (-1999; 9999)

m Eingang gewählt, wird dieser

10

Dezimalpunkt Position für die Anzeige

Wenn Z Vollta

Anzeigewert Einstellung

Wenn Z Spannung/ Str

DEUTCH

Wenn Z Spannung/ Strom Eingang gewählt ist, wird dieser

Parameter is aktiv.

heiten

9) Einheiten

Wenn Z Spannung/ Strom Eingang gewählt ist, wird dieser

Parameter is aktiv.

Wenn Z Spannung/ Strom Eingang gewählt ist, wird dieser

Parameter is aktiv.

Bei der Mehr

teilt.

Beispiel : = (0-50 mV Z)

0-50mV Z Bereich wird in 16 gleiche Teile geteilt.Je

im 3.125 mV Z Abstand definiert.

der ‘‘Poxx’’ SET-Wert 50/16 = wird

Z

11

Wenn Z

beitungswert wird mit diesem Wert multipliziert.

Spannung/ Strom Eingang gewählt is, wir

DEUTCH

12

Wenn im MODUL-1 Gehäuse ein EMO-X30 (0/4...20 mA Z

Strom

0...20mA ZAusgang

4...20mA ZAusgang

13

DEUTCH

Wenn im MODUL-2 Gehäuse ein EMO-X30 (0/4...20 mA Z

Stro

0...20mA ZAusgang

4...20mA ZAusgang

DEUTCH

14

DEUTCH

15

DEUTCH

16

DEUTCH

17

DEUTCH

18

Herstellerangaben:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA/ TURKIYE

Tel : +90 224 261 1900

Fax : +90 224 261 1912

DEUTCH

19

)

(

ESM-7700

72x72

100-240V V (-%15;+%10) 50/60Hz

24V V (-15%;+%10) 50/60Hz 24V Z (-%15;+%10)

Kundenspezifisch (maximal 240 VV

Relaisausgang (5A@250V V ohmsche Last)

(Max. 26mA, Max 22V Z)

(Maximal 40mA@18V Z)

(Strom Ausgangsmodul (0/4...20mA Z)

(oder 0...10V Z)

(Maximal 20mA@18V Z)

DEUTCH

(Maximal 40mA@18V Z)

(Strom Ausgangsmodul (0/4 20mA Z)

(oder 0...10V Z)

20

Eingangs Typ(Z Spannung und Strom)

0...50 mV Z

0...5 V Z

0...10 V Z

0...20 mA Z

4...20 mA Z

DEUTCH

21

INDICATEURS DE PROCESS

ESM-XX00

ESM-4400, ESM-7700, ESM-9900, ESM-4900

Écrans du processus du système de module de sortie intelligente

de l'entrée universelle

- Afficheur de process (PV) 4 chiffres

- Entrées de processus universelles

(TC, RTD, mVZ, VZ, mA Z)

- étalonnage en deux ou plusieurs points pour les entrées de

tension Z et d'intensité Z

- Système de module de sortie intelligent

- Fonctions d'alarme programmables

ESM-XX00 Indıcateurs De Process

- Contrôle ou retransmission de process avec module de sortie

de courant 0/4...20 mA Z

- Communication série avec protocole MODBUS RTU RS-232

(standard) ou RS-485 (en option)

FRANCE

CARACTÉRISTIQUES

ENTRÉE DU PROCESS

Entrée universelle : Tension/courant TC, RTD, Z

Thermocouple (TC) : L(DIN 43710), J, K, R, S, T, B, E et N

(IEC584.1)(ITS90), C (ITS90)

Thermo resistance (RTD) : PT-100 (IEC751)(ITS90)

Entrée Z : mV, V, mA

Plage de mesure : Veuillez vous reporter au tableau 1 pour la

sélection du type et de l'échelle d'entrée

Précision : ± 0,25% de la pleine échelle pour l'entrée du

thermocouple, de la thermorésistance, mV, V et mA.

Compensation soudure froide : Automatiquement ±0,1°C/1°C

Compensation de ligne : Maximum 10 Ohm

Protection contre la rupture du capteur : Haut de gamme

Fréquence de scrutation : 3 échantillons par seconde

Filtre d'entrée : 0,0 à 900,0 secondes

SORTIE

Sortie relais standard : 5 A @ 250 VV (sur charge résistive)

Modules de sortie : L'utilisateur peut raccorder 2 modules de sortie à

l'appareil.

-Module de sortie relais

-Module de sortie SSR (Max. 26 mA, Max. 22 V Z)

-Module de sortie (transistor) numérique (Max. 40 mA @ 18 VZ)

-Module de sortie courant 0/4...20 mA Z

ALIMENTATION

Tension d'alimentation :

100-240 V V 50/60 Hz (-%15;+%10) -6 VA

24 V V 50/60 Hz (-%15 ; +%10) -6 VA

24 V Z (-%15 ; +%10) -6 W

(elle doit être déterminée dans l'ordre.)

AFFICHAGE

Affichage de process :

ESM-4400 : Afficheur DEL rouge 4 chiffres 10,1 mm

ESM-4900 : Afficheur DEL rouge 4 chiffres 20,3 mm

ESM-7700 : Afficheur DEL rouge 4 chiffres 13,2 mm

ESM-9900 : Afficheur DEL rouge 4 chiffres 19 mm

FRANCE

ENGLISH

L’indicateurs DEL : DEL (état de sortie) °C /°F / V, OP1/2/3.

2

ÉVALUATION ENVIRONNEMENTALE ET CARACTÉRISTIQUES

PHYSIQUES

Température de fonctionnement : 0...50°C

Humidité : 0-90%RH (sans condensation)

Classe de protection : IP65 à l'avant, IP20 à l'arrière.

Montage : Boîtier de type 1

Catégorie de surtension : II

Degré de pollution : II, bureau ou lieu de travail,

pollution non-conductrice

Poids :

ESM-4400 : 210 g

ESM-4900 : 260 g

ESM-7700 : 270 g

ESM-9900 : 360 g

Dimensions/Découpe du panneau :

ESM-4400 : (48 x 48 mm, profondeur : 116 mm)/(46 x 46 mm)

ESM-4900 : (96 x 48 mm, profondeur : 86,5 mm)/(92 x 46 mm)

ESM-7700 : (72 x 72 mm, profondeur : 87,5 mm)/(69 x 69 mm)

ESM-9900 : (96 x 96 mm, profondeur : 87,5 mm)/(92 x 92 mm)

Distance minimale entre les centres de découpe du panneau :

ESM-4400 : X = 65 mm, Y = 65 mm

ESM-4900 : X = 129 mm, Y = 65 mm

ESM-7700 : X = 97 mm, Y = 97 mm

ESM-9900 : X = 129 mm, Y = 129 mm

Installation : Installation fixe de catégorie II

Ce symbole est utilisé pour les avertissements de

c

a

sécurité. L'utilisateur doit prêter attention à ces

avertissements.

Ce symbole est utilisé pour déterminer les situations

dangereuses à la suite d'un choc électrique.

L'utilisateur doit absolument prêter attention à ces

avertissements.

Ce symbole est utilisé pour déterminer les remarques

importantes concernant les fonctions et l'utilisation de

i

l'appareil.

FRANCE

ENGLISH

3

Câblages électriques

1

Entrée process universelle

ESM-4400

CAT II

Y

c

0 à 50 mV Z

0 à 10 V Z

0 à 20 mA Z

Pt-100

TC

2

SORTIE-3

(sortie alarme ou logique)

Alimentation

du capteur

Max. 50 mA

24 V Z

5 A @ 250 VV

6

NO

NCCC

ENGLISH

FRANCE

MODULE-1

7

Sortie

Module-1

0 à 50 mV Z

0 à 10 V Z

0 à 20 mA Z

Pt-100

TC

Entrée process universelle

ESM-4900

MODULE - 1

1311421531641751861972082192210231124

Sortie Module-1

24 V Z

Y

c

Sortie Module-2

Alimentation

Max. 50 mA

CAT II

MODULE - 2

MODULE-2

8

9310411512

Sortie

Module-2

du capteur

(sortie alarme ou logique)

SORTIE-3

NO C

NC

5 A @ 250 VV

a

(-)

N

Remarque-3

100...240 VV

50/60 Hz

Remarque-3

Fusible

100...240 VV

50/60 Hz

Remarque-1

(+)

L

Fusible

externe

Interrupteur

d'alimentation

12

a

(-) (+)

N L

Fusible

externe

Remarque-2

-1

Fusible

Remarque

Remarque-2

Interrupteur

d'alimentation

4

0 à 50 mV Z

0 à 10 V Z

0 à 20 mA Z

Pt-100

TC

Entrée process universelle

Alimentation

24 V Z

Max. 50 mA

3134145156167178189

ESM-7700

CAT II

Y

c

24 V Z

Max. 50 mA

Y

MODULE-2

Alimentation

du capteur

CAT II

Module-2

MODULE-1

10111212

Sortie

Module-1

0 à 50 mV Z

0 à 10 V Z

0 à 20 mA Z

Pt-100

TC

Entrée process universelle

ESM-9900

MODULE - 1 MODULE - 2

1311421531641751861972082192210231124

Sortie Module-1 Sortie Module-2

Remarque-1 : Il existe une résistance interne fusible antidéflagrante.

Remarque-2 : Un fusible externe est recommandé.

1 AZT pour alimentation 24 V Z

Remarque-3 : « L » est ( + ) , « N » est ( - ) pour la tension d'alimentation de 24 V Z

c

1 AVT pour l'alimentation 100...240 VV ou 24 VV

SORTIE-3

(sortie alarme ou logique)

du capteur

NCNO C

5 A @ 250 VV

Sortie

(sortie alarme ou logique)

Interrupteur

d'alimentation

SORTIE-3

NC

NO C

5 A @ 250 VV

Remarque-3

a

(-)

N

Remarque-3

100...240 VV

50/60 Hz

a

(-)

N

100...240 VV

50/60 Hz

Fusible

12

L

Fusible

externe

Fusible

(+)

-1

Remarque

(+)

L

Remarque-2

-1

Remarque

Fusible

externe

Remarque-2

Interrupteur

d'alimentation

FRANCE

ENGLISH

5

DIMENSIONS

ESM-4400

°C

°F

V

OP1

OP2

OP3

Indicateur de process

SET

48 mm / 1,89 pouces

Maximum 5 mm / 0,2 pouce

48 mm / 1,89 pouces

11,5 ± 1 mm / 0,45 pouce

104,5 mm / 4,11 pouces

Maximum 15mm / 0,59 pouce

Indicateur de process ESM - 4900

°C

°F

V

SET

P

96 mm / 3,78 pouces

Indicateur de process

OP1

OP2

OP3

Indicateur de process

ESM-7700

SET

SET

ESM-9900

°C

°F

V

OP1

OP2

OP3

72 mm / 2,83 pouces

°C

°F

V

96 mm / 3,78 pouces

O1

O2

O3

48 mm / 1,89 pouces

10,5 ± 1 mm / 0,41 pouce

Maximum 15 mm / 0,59 pouce

72 mm / 2,83 pouces

11,5 ± 1 mm / 0,45 pouces

Maximum 15 mm / 0,59 pouce

96 mm / 3,78 pouces

11,5 ± 1 mm /0,45 pouces

76 mm / 2,99 pouces

76 mm / 2,99 pouces

76mm / 2,99 pouces

6

FRANCE

FRANCE

MONTAGE SUR PANNEAU

3

3

2

2

5

4

1- Avant d'installer l'appareil

dans votre panneau, assurez-

1

1

vous que la découpe a la taille

appropriée.

2- Vérifiez la position du joint

du panneau avant.

3- Insérez le produit à travers la

découpe. Si les pinces de

fixation sont sur l'appareil,

enlevez-les avant d'insérer

l'appareil dans le panneau.

4- Insérez l'appareil dans la

découpe du panneau de la

face avant.

5- Insérez les brides de

fixation dans les trous situés

sur les faces supérieure et

inférieure du produit et serrez

les vis de fixation jusqu'à ce

que l'appareil soit

complètement immobilisé

dans le panneau.

ENGLISH

FRANCE

7

SET

V

°C

°F

OP1

OP2

OP3

Écran principal

SET

Appuyez sur la

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

Écran consigne alarme-3

°C

°F

°C

°F

°C

°F

Écran consigne alarme-2

°C

°F

°C

°F

°C

°F

Écran consigne alarme-1

V

V

V

V

V

V

OP1

OP2

OP1

OP2

OP1

OP2

OP1

OP2

OP1

OP2

OP1

OP2

SET

OP3

SET

OP3

SET

OP3

SET

OP3

SET

OP3

SET

OP3

SET

Appuyez sur la touche

Appuyez sur la

Appuyez sur la

Appuyez sur la touche

Appuyez sur la

Appuyez sur la

Appuyez sur la touche

touche SET

pour enregistrer

la valeur de

consigne de

l'alarme-3.

d'incrémentation ou

de décrémentation

pour modifier la valeur

de consigne de

l'alarme-3.

touche

d'incrémentation

pour saisir la

valeur de

consigne de

l'alarme-3.

pour enregistrer

la valeur de

consigne de

l'alarme-2.

touche SET

d'incrémentation ou

de décrémentation

pour modifier la valeur

de consigne de

l'alarme-2.

touche

d'incrémentation

pour saisir la

valeur de

consigne de

l'alarme-2.

touche SET

pour enregistrer

la valeur de

consigne de

l'alarme-1.

d'incrémentation ou

de décrémentation

pour modifier la valeur

de consigne de

l'alarme-1.

P

FRANCE

V

°C

°F

OP1

OP2

OP3

Appuyez sur

la touche

d'incrémentation

pour saisir la

valeur de consigne

la touche

Appuyez sur

de consigne.

de l'alarme-1.

SET

Accès et modifications des valeurs de consignes

V

°C

°F

OP1

OP2

OP3

Écran principal

Remarque : L'utilisateur peut quitter la Section valeur de consigne sans enregistrer les valeurs en appuyant sur la touche .

Si aucune opération n'est effectuée pendant 120 secondes, l'appareil quitte automatiquement la Section valeur de consigne.

8

V

°C

°F

OP1

OP2

OP3

SET

SET

V

°C

°F

OP1

OP2

OP3

V

°C

°F

OP1

OP2

OP3

V

°C

°F

Remarque : Pour plus d'informations, consultez

la section PASS ConF.

V

°C

°F

OP1

OP2

OP3

SET

V

°C

°F

OP1

OP2

OP3

V

°C

°F

OP1

OP2

OP3

Écran de saisie du mot

de passe technicien

V

°C

°F

OP1

OP2

OP3

Écran de saisie du mot

de passe technicien

SET

V

°C

°F

OP1

OP2

OP3

Écran d'accès au

menu technicien

SET

Schéma d'accès facile aux paramètres de programmation

V

°C

°F

OP1

OP2

OP3

Écran principal

V

°C

°F

Appuyez sur la touche

Set/OK pour valider le mot

de passe.

V

°C

°F

OP1

OP2

OP3

V

°C

°F

Saisissez le mot de passe

avec l'aide des touches

d'incrémentation ou de

décrémentation.

V

°C

°F

OP1

OP2

OP3

V

°C

°F

Appuyez sur la touche

d'incrémentation pour

accéder à l'écran de saisie de

mot de passe.

V

°C

°F

OP1

OP2

OP3

V

°C

°F

Appuyez sur la touche

Set/OK pour accéder à

l'écran de saisie de mot

de passe.

V

°C

°F

OP1

OP2

OP3

Appuyez sur la

touche Menu.

V

°C

°F

SET

SET

OP1

OP2

OP3

SET

OP1

OP2

OP3

SET

OP1

OP2

OP3

REMARQUE 4

SET

OP1

OP2

OP3

REMARQUE 3

SET

OP1

OP2

OP3

REMARQUE 1 REMARQUE 2

SET

OP1

OP2

OP3

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

EMO-X00, EMO-X10, EMO-X20 dans la prise du

MODULE-1, ces paramètres s'affichent.

dans la prise du MODULE-2, ce paramètre

s'affiche.

EMO-X00, EMO-X10, EMO-X20 dans la prise du

MODULE-2, ces paramètres s'affichent.

REMARQUE 1 : S'il existe un module de sortie

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

SET

REMARQUE 3 : S'il existe un module EMO-X30

REMARQUE 2 : S'il existe un module de sortie

SET

SET

SET

FRANCE

9

PınP ConF : Type d'entrée de process et paramètres pertinents

Type d'entrée de process

Sélection du type d'entrée TC

Sélection du type d'entrée RTD

Sélection du type d'entrée de tension/courant Z

Sélection d'entrée TC

Ce paramètre est actif si le type d'entrée TC est sélectionné.

L (-100°C ; 850°C) ou (-148°F ; 1562°F)

L (-100,0°C ; 850,0°C) ou (-148,0°F ; 999,9°F)

J (-200°C ; 900°C) ou (-328°F ; 1652°F)

J (-199,9°C;900,0°C) ou (-199,9°F ; 999,9°F)

K (-200°C ; 1300°C) ou (-328°F ; 2372°F)

K (-199,9°C ; 999,9°C) ou (-199,9°F ; 999,9°F)

R (0°C ; 1700°C) ou (32°F ; 3092°F)

R (0,0°C ; 999,9°C) ou (32,0°F ; 999,9°F)

S (0°C ; 1700°C) ou (32°F ; 3092°F)

S (0,0°C ; 999,9°C) ou (32,0°F;999,9°F)

T (-200°C ; 400°C) ou (-328°F ; 752°F)

T (-199,9°C ; 400,0°C) ou (-199,9°F ; 752,0°F)

B (44°C ; 1800°C) ou (111°F ; 3272°F)

B (44,0°C ; 999,9°C) ou (111,0°F ; 999,9°F)

E (-150°C ; 700°C) ou (-238°F ; 1292°F)

E (-150,0°C ; 700,0°C) ou (-199,9°F ; 999,9°F)

N (-200°C ; 1300°C) ou (-328°F ; 2372°F)

N (-199,9°C ; 999,9°C) ou (-199,9°F ; 999,9°F)

C (0°C ; 2300°C) ou (32°F; 3261°F)

C (0,0°C ; 999,9°C) ou (32,0°F; 999,9°F)

Sélection d'entrée RTD

Ce paramètre est actif si l'entrée RTD est sélectionnée.

PT-100 (-200°C ; 650°C) ou (-328°F ; 1202°F)

PT-100 (-199,9°C ; 650,0°C ) ou (-199,9°F ; 999,9°F)

Sélection d'entrée de tension/courant Z

Ce paramètre est actif si la tension/le courant Z est sélectionné.

0...50 mV Z (-1999 ; 9999)

0...5 V Z (-1999 ; 9999)

0...10 V Z (-1999 ; 9999)

0...20 mA Z (-1999 ; 9999)

4...20 mA Z (-1999 ; 9999)

ENGLISH

ENGLISH

10

FRANCE

Affichage position de point

Ce paramètre est actif si l'entrée de tension/courant Z est sélectionnée.

Pas de point

Entre le premier et deuxième chiffre « 0,0 »

Entre le deuxième et troisième chiffre « 0,00 »

Entre le troisième et quatrième chiffre « 0,000 »

Type de réglage de la valeur d'affichage

Ce paramètre est actif si l'entrée de tension/courant Z est sélectionnée.

Réglage fixe de l'affichage en deux points. La valeur du point bas

du réglage d'affichage est de -1999, tandis que la valeur du point

haut du réglage d'affichage est de 9999.

L'utilisateur peut effectuer un réglage d'affichage en deux

points avec tPoL et tPoH.

L'utilisateur peut effectuer les 16 points définis du

réglage d'affichage.

Réglage d'affichage du point bas (-1999, 9999) unité

Ce paramètre est actif si l'entrée de tension/courant Z est sélectionnée.

Réglage d'affichage du point haut (-1999, 9999) unité

Ce paramètre est actif si l'entrée de tension/courant Z est sélectionnée.

Points de réglage d'affichage (-1999, 9999) unité

Ce paramètre est actif si l'entrée de tension/courant Z est sélectionnée.

Dans un fonctionnement de réglage d'affichage multipoints,

l'échelle définie est divisée en 16 points de réglage.

Par exemple : est (0-50 mV ) .Z

Valeur de consigne

du process

Po10

Po11

Po09

Po12

Po08

Po13

Po07

Po14

Po15

Po06

Po16

Po05

Po04

Po03

Po02

Po01

Po00 = 0

3.125 6.25 9.375 12.5 15.625 18.75 21.825 25 28.125 31.25 34.375 37.5 40.625 43.75 46.875

3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125 3.125

La gamme 0-50 mVZ est divisée en 16 parties égales. Chaque valeur de consigne (SET)

« Poxx » SET est définie 50/16 = gamme 3,125 mVZ.

50

mV Z

FRANCE

11

Valeur de coefficient (1,000 - 9,999)

La valeur du process est multipliée par cette valeur.

Ce paramètre est actif si l'entrée de tension/courant Z est

sélectionnée.

Sélection de l'unité

L'unité est le °C

L'unité est le °F

L'unité est la tension. Cette sélection est active si l'entrée de

tension/courant Z est sélectionnée.

Aucune unité. Cette sélection est active si l'entrée de

tension/courant Z est sélectionnée.

Valeur minimum de l'échelle d'exploitation

(point bas échelle, point haut échelle) unité

Utilisé pour le calcul de la bande proportionnelle et l'affichage clignote.

Valeur maximum de l'échelle de fonctionnement

(point bas échelle, point haut échelle) unité

Utilisé pour le calcul de la bande proportionnelle et l'affichage clignote.

Décalage d'affichage de la valeur de process (échelle 10%, échelle +10%) unité

Cette valeur du paramètre est ajoutée à la valeur de process.

Temps de filtre (0,0 - 900,0) secondes

Définit le temps de filtre pour la valeur d'affichage.

Compensation de soudure froide

Ce paramètre est actif si l'entrée de process sélectionnée est TC.

La compensation de soudure froide est active.

La compensation de soudure froide n'est pas active.

Échelle : La différence entre le point haut et le point bas du type d'entrée

du process. Exemple : Si tCSL = 2 (point bas -200, point haut 900), alors

l'échelle est de 1100. Si le type d'entrée est tension/courant, alors

l'échelle est la différence entre les paramètres tPoH et tPoL.

FRANCE

ENGLISH

12

out1 ConF : Paramètres du MODULE-1

S'il existe un module EMO-X00 (sortie relais), EMO-X10

i

(entraîneur SSR) et EMO-X20 (sortie numérique) dans la

prise MODULE-1, alors les paramètres suivants sont actifs.

La fonction de sortie logique du module de sortie MODULE 1

Sortie d'alarme

Sortie de l'alarme de rupture du capteur

La sortie est active lorsque la valeur de process est hors de la

bande qui est définie avec la valeur minimum de l'échelle

d'exploitation et la valeur maximale de l'échelle

d'exploitation .

Type d'alarme-1

Type d'alarme du MODULE-1 Ce paramètre est actif, si la

fonction de sortie logique 1 est la sortie d'alarme.

Alarme haute de process

Alarme basse de process

Valeur d'hystérésis de l'alarme-1 (0% de l'échelle, 50% de

l'échelle) unité

Ce paramètre est actif, si la fonction de sortie logique 1 est la

sortie d'alarme.

Temps de délai d'activation de l'alarme-1 (0, 9999) secondes

Ce paramètre est actif, si la fonction de sortie logique 1 est la

sortie d'alarme.

Temps de délai de désactivation de l'alarme-1 (0, 9998) secondes

Lorsque la valeur est supérieure à 9998, apparaît à l'écran.

Cela signifie que la sortie d'enclenchement de l'alarme est

sélectionnée. Ce paramètre est actif si la fonction de sortie logique 1

de la sortie d'alarme 1 est la sortie d'alarme.

out1 ConF : Paramètres du MODULE-1

S'il existe un module EMO-X30 (sortie de courant 0/4...20

i

dans la prise du MODULE-1, alors le paramètre

suivant est actif.

Configuration du module de sortie analogique du MODULE-1

Sortie 0...20 mAZ

Échelle

Retransmission

UPL

Échelle

Sortie 4...20 mAZ

Retransmission

UPL

mA Z)

ENGLISH

FRANCE

LOL

0 20

LOL

mA

0 20

4

mA

13

out2 ConF : Paramètres du MODULE-2

S'il existe un module EMO-X00 (sortie relais), EMO-X10

i

(entraîneur SSR) et EMO-X20 (sortie numérique) dans la

prise MODULE-2, alors les paramètres suivants sont actifs.

fonction de sortie logique du module de sortie MODULE-2

Sortie d'alarme

Sortie de l'alarme de rupture du capteur

La sortie est active lorsque la valeur de process est hors de la

bande qui est définie avec la valeur minimum de l'échelle

d'exploitation et la valeur maximale de l'échelle

d'exploitation .

Type d'alarme-2

Type d'alarme du MODULE-2 Ce paramètre est actif, si la

fonction de sortie logique-2 est la sortie d'alarme.

Alarme haute de process

Alarme basse de process

Valeur d'hystérésis de l'alarme-2 (0% de l'échelle, 50% de

l'échelle) unité

Ce paramètre est actif, si la fonction de sortie logique-2 est la

sortie d'alarme.

Temps de délai d'activation de l'alarme-2 (0, 9999) secondes

Ce paramètre est actif, si la fonction de sortie logique-2 est la

sortie d'alarme.

Temps de délai de désactivation de l'alarme-2 (0, 9998) secondes

Lorsque la valeur est supérieure à 9998, apparaît à l'écran.

Cela signifie que la sortie d'enclenchement de l'alarme est

sélectionnée. Ce paramètre est actif si la fonction de sortie logique-2

de la sortie d'alarme-2 est la sortie d'alarme.

out2 ConF : Paramètres du MODULE-2

S'il existe un module EMO-X30 (sortie de courant

i

0/4...20 mA Z) dans la prise du MODULE-2, alors le

paramètre suivant est actif.

FRANCE

Sortie 0...20 mAZ

Échelle

Retransmission

UPL

LOL

0 20

Échelle

UPL

LOL

mA

0 20

Sortie 4...20 mAZ

Retransmission

4

mA

14

out3 ConF : Paramètres du MODULE-3

Fonction de sortie logique de Sortie-3

Sortie d'alarme

Sortie de l'alarme de rupture du capteur

La sortie est active lorsque la valeur de process est hors de la

bande qui est définie avec la valeur minimum de l'échelle

d'exploitation et la valeur maximale de l'échelle

d'exploitation .

Type d'alarme-3

Alarme haute de process

Alarme basse de process

Valeur d'hystérésis de l'alarme-3 (0% de l'échelle, 50% de

l'échelle) unité

Ce paramètre est actif, si la fonction de sortie logique-3 est

la sortie d'alarme.

Temps de délai d'activation de l'alarme-3 (0, 9999) secondes

Ce paramètre est actif, si la fonction de sortie logique-3 est

la sortie d'alarme.

Temps de délai de désactivation de l'alarme-3 (0, 9998) secondes

Lorsque la valeur est supérieure à 9998, apparaît à l'écran.

Cela signifie que la sortie d'enclenchement de l'alarme est

sélectionnée. Ce paramètre est actif si la fonction de sortie logique 3

de la sortie d'alarme 3 est la sortie d'alarme.

Types d'alarme

FRANCE

Alarme haute de process

Sortie

d'alarme

ON (Marche)

OFF (Arrêt)

Consigne

alarme

HYS

Valeur du process

Alarme basse de process

Sortie

d'alarme

ON (Marche)

OFF (Arrêt)

Consigne

alarme

HYS

Valeur du process

15

Gen ConF : Paramètres généraux

Limite basse de la valeur de consigne de l'alarme ( , ) unité

Limite haute de la valeur de consigne de l'alarme ( , ) unité

Com ConF : Paramètres de configuration de communication série

Adresse d'accès à la communication (1,247)

Adresse d'accès à la communication de l'appareil L'adresse

d'accès à la communication peut être définie de 1 à 247.

Débit en bauds de communication

Débit en bauds 1200

Débit en bauds 2400

Débit en bauds 4800

Débit en bauds 9600

Débit en bauds 19260

Sélection de la parité de communication

Pas de parité.

Parité impaire.

Parité paire.

Sélection du bit d'arrêt de communication

Bit d'arrêt 1

Bit d'arrêt 2

PASS ConF : Paramètre mot de passe

Mots de passe technicien (0,9999)

Le mot de passe est utilisé pour avoir accès aux

paramètres technicien. S'il est de , il n’y a pas de

protection par mot de passe pour accéder aux paramètres

technicien. S'il est différent de « 0 » et que l'utilisateur

souhaite accéder aux paramètres technicien ;

1-

Si l'utilisateur ne saisit pas le mot de passe

correctement : l'appareil passe à l'écran d'opération

sans accéder aux paramètres :

Lorsque dans l'écran supérieur et dans l'affichage

inférieur s'affichent, si l'utilisateur appuie sur le bouton SET

sans entrer le mot de passe (pour afficher les

paramètres) : L'utilisateur peut voir les menus et paramètres

utilisateur mais ne peut pas modifier les paramètres.

FRANCE

16

Messages d'erreur du régulateur de process ESM-XX00 Messages d'erreur du régulateur de process ESM-XX00

°C

°F

V

OP1

OP2

OP3

°C

°F

V

OP1

OP2

OP3

°C

°F

V

OP1

OP2

OP3

1 - Défaillance du capteur dans les entrées

analogiques. Le raccordement du capteur

est mauvais ou inexistant.

SET

2-

Si l'écran supérieur clignote : Si la valeur

d'entrée analogique est inférieure à la

valeur minimum de l'échelle d'exploitation

l'écran supérieur commence à

SET

clignoter.

Si l'écran supérieur clignote : Si la valeur

3-

d'entrée analogique est supérieure à la

SET

valeur maximum de l'échelle d'exploitation

l'écran supérieur commence à

clignoter.

FRANCE

°C

°F

V

OP1

OP2

OP3

SET

4- Si le mot de passe technicien est différent de « 0 » et que

l'utilisateur accède au paramètre en appuyant sur la touche Set

sans entrer le mot de passe technicien et veut modifier un

paramètre, le message d'avertissement est affiché sur l'écran,

comme indiqué à droite. L'appareil ne permet pas de faire des

modifications sans entrer correctement le mot de passe.

°C

°F

V

OP1

OP2

OP3

SET

17

Installation

Avant de commencer l'installation de ce produit,

veuillez lire attentivement le manuel d'utilisateur et les

c

Dans l'emballage,

- l'appareil (x1)

- Brides de fixation (x2 pièces)

- Manuel d'utilisateur (x1 copie)

Une inspection visuelle de ce produit pour détecter d'éventuels

dommages survenus durant la livraison est recommandée avant

l'installation. Il est de votre responsabilité de vous assurer que les

techniciens mécaniques et électriques qualifiés installent ce produit.

En cas de danger d'accident grave résultant d'une défaillance ou d'un

défaut dans l'appareil, mettez le système hors tension et déconnectez le

raccordement électrique de l'appareil du système.

L'appareil est normalement fourni sans interrupteur d'alimentation ni

fusible.

Veillez à utiliser la tension nominale d'alimentation pour protéger

l'appareil contre les dommages et pour éviter toute défaillance.

Gardez l'appareil hors tension jusqu'à ce que tout le câblage soit terminé

afin d'éviter tout choc électrique et tout problème dans l'appareil.

Ne tentez jamais de démonter, modifier ou réparer cet appareil. Toute

tentative d'ouverture de ce produit peut provoquer une panne, un choc

électrique, un incendie.

N'utilisez pas l'appareil dans les atmosphères gazeuses, inflammables

ou explosives.

Pendant l'installation mécanique, prenez les précautions nécessaires

pour ne pas vous blesser sur les bords irréguliers de l'orifice dans le

panneau métallique.

Le montage du produit sur un système doit être fait avec ses pinces de

fixation. N'effectuez pas le montage de l'appareil avec la pince de fixation

inappropriée. Assurez-vous que le produit ne tombera pas pendant le

montage.

Il vous incombe de vérifier que ce produit est toujours installé et utilisé

conformément à son manuel d'utilisation.

mises en garde ci-dessous.

FRANCE

18

Warranty

Garantie

EMKO Elektronik garantit que le matériel livré est exempt de défauts

de matériaux et de fabrication. Cette garantie est valide pendant deux

ans. La période de garantie commence à partir de la date de livraison.

Cette garantie reste valide si les conditions et les responsabilités

stipulées dans la garantie et le manuel d'utilisation sont intégralement

respectées par le client.

Maintenance

Warranty

Maintenance

Les opérations de maintenance et de réparation doivent uniquement

être confiées à un technicien spécialisé. Coupez l'alimentation de

l'appareil avant d'accéder aux composants. Ne nettoyez pas le boîtier

avec des solvants à base d'hydrocarbures (essence, trichloréthylène,

etc.). L'utilisation de ces solvants peut réduire la fiabilité mécanique du

produit. Utilisez un chiffon imbibé d'alcool éthylique ou d'eau pour

nettoyer le boîtier en plastique.

Maintenance

Warranty

Société du fabricant

Other Informations

Informations sur le fabricant :

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA /TURQUIE

Téléphone : +90 224 261 1900

Fax : +90 224 261 1912

Informations sur le service de réparation et de maintenance :

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369

BURSA /TURQUIE

Téléphone:

Fax

: +90 224 261 1900

: +90 224 261 1912

FRANCE

19

Informations de commande

ESM-4400 (48x48 DIN 1/16)

ESM-4900 (96x48 DIN 1/8)

ESM-7700 (Taille DIN 72x72)

ESM-9900 (96x96 DIN 1/4)

Tension d'alimentation

A

100-240 V V (-%15;+%10) 50/60 Hz

1

2

24 V V (-%15;+%10) 50/60 Hz 24 V Z (-%15;+%10)

Client (Maximum 240 V V (-%15;+%10)) 50/60 Hz

9

A

BC D E FG HI //U V W Z/

/

1

Type d'entrée ÉchelleBC

20 Configurable (Tableau-1)

Communication sérieD

0

Aucun

1

RS-232

2

RS-485

Sortie-3

E

1

Sortie relais (5 A @ de 250 VV sur charge résistive)

Module-1

FG

Aucun

00

Module de sortie relais

01

Module de sortie à entraîneur SSR

02

(Maximum 26 mA, 22 V Z)

Module de sortie (résistance) numérique

03

(Maximum 40 mA @ 18 V Z)

Module de sortie courant

04

(0/4...20 mA Z ou 0...10 V Z)

Module-2

HI

Aucun

00

Module de sortie relais

01

Module de sortie à entraîneur SSR

02

(Maximum 26 mA, 22 V Z)

Module de sortie (résistance) numérique

03

(Maximum 40 mA @ 18 V Z)

Module de sortie courant

04

(0/4...20 mA Z ou 0...10 V Z)

Tableau-1

Code produit

EMC-400, EMC-700, EMC-900

EMC-410, EMC-710, EMC-910

Codes de modules

EMO-400, EMO-700, EMO-900

EMO-410, EMO-710, EMO-910

EMO-420, EMO-720, EMO-920

EMO-430, EMO-730, EMO-930

Codes de modules

EMO-400, EMO-700, EMO-900

EMO-410, EMO-710, EMO-910

EMO-420, EMO-720, EMO-920

EMO-430, EMO-730, EMO-930

0 0 0 0

FRANCE

20

Tableau-1

Type d'entrée (TC)

BC

21

L, Fe Const DIN43710

22

L, Fe Const DIN43710

23

J, Fe CuNi IEC584.1(ITS90)

24

J, Fe CuNi IEC584.1(ITS90)

25

K, NiCr Ni IEC584.1(ITS90)

26

K, NiCr Ni IEC584.1(ITS90)

27

R, Pt13%Rh Pt IEC584.1(ITS90)

S, Pt10%Rh Pt IEC584.1(ITS90)

28

29

T, Cu CuNi IEC584.1(ITS90)

30

T, Cu CuNi IEC584.1(ITS90)

31

B, Pt30%Rh Pt6%Rh IEC584.1(ITS90)

32

B, Pt30%Rh Pt6%Rh IEC584.1(ITS90)

33

E, NiCr CuNi IEC584.1(ITS90)

34

E, NiCr CuNi IEC584.1(ITS90)

35

N, Nicrosil Nisil IEC584.1(ITS90)

36

N, Nicrosil Nisil IEC584.1(ITS90)

37

C, (ITS90)

38

C, (ITS90)

Type d'entrée (RTD)

BC

39

PT 100, IEC751(ITS90)

40

PT 100, IEC751(ITS90)

Type d'entrée (tension et courant Z)

BC

41

0...50 mV Z

42

0...5 V Z

43

0...10 V Z

44

0...20 mA Z

45

4...20 mA Z

Nous vous remercions d'avoir choisi les produits Emko

Elektronik. Vous pouvez télécharger le manuel d'utilisation détaillé

Votre partenaire technologique

sur notre site internet.

Échelle (°C)

-100°C, 850°C

-100,0°C, 850,0°C

-200°C, 900°C

-199,9°C, 900,0°C

-200°C, 1300°C

-199,9°C, 999,9°C

0°C, 1700°C

0°C, 1700°C

-200°C, 400°C

-199,9°C, 400,0°C

44°C, 1800°C

44,0°C, 999,9°C

-150°C, 700°C

-150,0°C, 700,0°C

-200°C, 1300°C

-199,9°C, 999,9°C

0°C, 2300°C

0,0°C, 999,9°C

Échelle (°C)

-200°C, 650°C

-199,9°C, 650,0°C

Échelle (°F)

-148°F,1562°F

-148,0°F, 999,9°F

-328°F, 1652°F

-199,9°F, 999,9°F

-328°F, 2372°F

-199,9°F, 999,9°F

32°F, 3092°F

32°F, 3092°F

-328°F, 752°F

-199,9°F, 752,0°F

111°F, 3272°F

111,0°F, 999,9°F

-238°F, 1292°F

-199,9°F, 999,9°F

-328°F, 2372°F

-199,9°F, 999,9°F

32°F, 3261°F

32,0°F, 999,9°F

Échelle (°F)

-328°F, 1202°F

-199,9°F, 999,9°F

Échelle

-1999,9999

-1999,9999

-1999,9999

-1999,9999

-1999,9999

www.emkoelektronik.com.tr

FRANCE

21

UNIDADES DEL INDICADOR DE PROCESO

ESM-XX00

ESM-4400, ESM-7700, ESM-9900, ESM-4900

Unidades de la pantalla de proceso del sistema del módulo de

salida inteligente de entrada universal

- Pantalla de 4 dígitos para el valor de proceso (PV)

- Entrada de proceso universal (TC, RTD, mV , V , mA )Z Z Z

- Calibración de dos puntos o multipunto para entradas de voltaje

y de corriente

- Sistema de módulo de salida inteligente

- Funciones de alarma programables

- Retransmisión o control de proceso con módulo de salida de

corriente de 0/4...20 mA

- Comunicación de serie de RS-232 (estándar) o RS-485

(opcional) con el protocolo Modbus RTU

ESM-XX00 Unidades Del Indıcador De Proceso

ESPA OLÑ

ESPECIFICACIONES

ENTRADA DE PROCESO

Entrada universal: TC, RTD, Tensión/Corriente

Termopar(TC): L(DIN 43710), J, K, R, S, T, B, E y N (IEC584.1)

(ITS90), C (ITS90)

Termorresistencia (RTD): PT-100 (IEC751)(ITS90)

Z Entrada: mV, V, mA

Intervalo de medición: Consulte en la Tabla-1 la selección del tipo

de entrada y la escala.

Precisión: ± 0,25% de escala completa para el termopar,

termorresistencia, entrada de mV, V y mA.

Compensación de junta fría: automáticamente ±0,1°C/1°C

Compensación de línea: 10 Ohm como máximo

Protección contra roturas del sensor: Mejorada

Ciclo de muestreo: 3 muestras por segundo

Filtro de entrada: de 0,0 a 900,0 segundos

SALIDA

Salida de relé estándar: 5 A @ 250 V (en la carga resistiva)

Módulos de salida: el usuario puede introducir 2 módulos de salida en

el dispositivo.

-Módulo de salida del relé

-Módulo de salida de SSR (Máx. 26 mA , Máx. 22 V)

-Módulo de salida digital (Transistor) (Máx. 40 mA @ 18 VZ)

-Módulo de salida de corriente de 0/4 a 20 mA

FUENTE DE ALIMENTACIÓN

Tensión de alimentación:

100-240 V V 50/60 Hz (-%15;+%10) -6 VA

24 V V 50/60 Hz (-%15; +%10) -6 VA

24 V Z (-%15; +%10) -6 W

(Se debe determinar en el pedido).

PANTALLA

Pantalla de proceso:

ESM-4400: Pantalla LED 10,1 mm roja de 4 dígitos

ESM-4900: Pantalla LED 20,3 mm roja de 4 dígitos

ESM-7700: Pantalla LED 13,2 mm roja de 4 dígitos

ESM-9900: Pantalla LED de 19 mm roja de 4 dígitos

LED Göstergeler: LED de °C /°F / V, OP1/2/3 (Estado de salida).

ESPA OLÑ

2

CALIFICACIONES AMBIENTALES y ESPECIFICACIONES FÍSICAS

Temperatura de funcionamiento : De 0 a 50 °C

Humedad: 0-90 % de humedad relativa (sin condensación)

Clase de Protección: IP65 en la parte delantera, IP20 en la parte

trasera

Montaje: Montaje del recinto de tipo-1

Instalación: Instalación fija Categoría II

Categoría de sobretensión: II

Grado de contaminación: II, oficina o lugar de trabajo, sin

contaminación conductiva

Peso:

ESM-4400: 210 g

ESM-4900: 260 g

ESM-7700: 270 g

ESM-9900: 360 g

Dimensiones / encastre del panel:

ESM-4400: (48 x 48 mm, Profundidad: 116 mm) / (46 x 46 mm)

ESM-4900: (96 x 48 mm, Profundidad: 86,5 mm) / (92 x 46 mm)

ESM-7700: (72 x 72 mm, Profundidad: 87,5 mm) / (69 x 69 mm)

ESM-9900: (96 x 96 mm, Profundidad: 87,5 mm) / (92 x 92 mm)

Distancia mínima entre los centros de encastre del panel:

ESM-4400: X = 65 mm, Y = 65 mm

ESM-4900: X = 129 mm, Y = 65 mm

ESM-7700: X = 97 mm, Y = 97 mm

ESM-9900: X = 129 mm, Y = 129 mm

Este símbolo se utiliza para las advertencias de

c

a

seguridad. El usuario debe prestar atención a estas

advertencias.

Este símbolo se utiliza para determinar las situaciones

peligrosas como resultado de una descarga eléctrica.

El usuario debe prestar atención a estas advertencias

indudablemente.

Este símbolo se utiliza para determinar las notas

importantes acerca de las funciones y el uso del

i

dispositivo.

ESPA OLÑ

3

Cableados eléctricos

1

Entrada de proceso universal

ESM-4400

CAT II

Y

c

de 0 a 50 mV Z

de 0 a 10 V Z

de 0 a 20 mA Z

Pt-100

TC

2

SALIDA-3

(Salida lógica o de la alarma)

Alimentación

del sensor

Máx. 50 mA

24 V Z

NO

C

NC

C

5 A @250 VV

6

ESPA OLÑ

MÓDULO-1

7

Módulo-1

de salida

de 0 a 50 mV Z

de 0 a 10 V Z

de 0 a 20 mA Z

Pt-100

TC

Entrada de proceso universal

ESM-4900

MÓDULO - 1

c

Y

24 V Z

Máx. 50 mA

8

Alimentación

del sensor

CAT II

MÓDULO - 2

MÓDULO-2

100...240 VV

50/60 Hz

NO C

5 A @ 250 VV

a

(-)

N

Nota-3

9310411512

Módulo-2

de salida

SALIDA-3

(Salida lógica o de la alarma)

NC

Fusible

1311421531641751861972082192210231124

Módulo-1 de salida Módulo-2 de salida

Nota-3

-1

a

Not

(+)

L

Fusible

externo

Conmutador

de fuente

de alimentación

12

a

Fusible

(-) (+)

N L

100...240 VV

50/60 Hz

Nota-2

Nota-1

Fusible

externo

Nota-2

Conmutador

de fuente

de alimentación

4

de 0 a 50 mV Z

de 0 a 10 V Z

de 0 a 20 mA Z

Pt-100

TC

Entrada de proceso universal

Alimentación

24 V Z

Máx. 50 mA

3134145156167178189

ESM-7700

CAT II

Y

c

24 V Z

Y

Alimentación

Máx. 50 mA

CAT II

MÓDULO-2

Módulo-2

de salida

del sensor

MÓDULO-1

10111212

Módulo-1

de salida

de 0 a 50 mV Z

de 0 a 10 V Z

de 0 a 20 mA Z

Pt-100

TC

Entrada de proceso universal

ESM-9900

MÓDULO - 1 MÓDULO - 2

1311421531641751861972082192210231124

Módulo-1 de salida Módulo-2 de salida

Nota-1 : hay una resistencia ignífuga en el fusible interno.

Nota-2 : se recomienda el fusible externo.

1 A T para la fuente de alimentación de 100...240 V o 24 V

c

SALIDA-3

(Salida lógica o de la alarma)

del sensor

NCNO C

5 A @ 250 VV

Conmutador

de fuente

de alimentación

SALIDA-3

(Salida lógica o de la alarma)

NO C

5 A @ 250 VV

NC

a

(-)

N

Nota-3

100...240 VV

50/60 Hz

(-)

N

Nota-3

100...240 VV

50/60 Hz

a

Fusible

12

Fusible

L

-1

a

Not

(+)

L

Fusible

externo

Nota-2

a-1

Not

(+)

Fusible

externo

Nota-2

Conmutador

de fuente