Emko ESM-3720 User manual

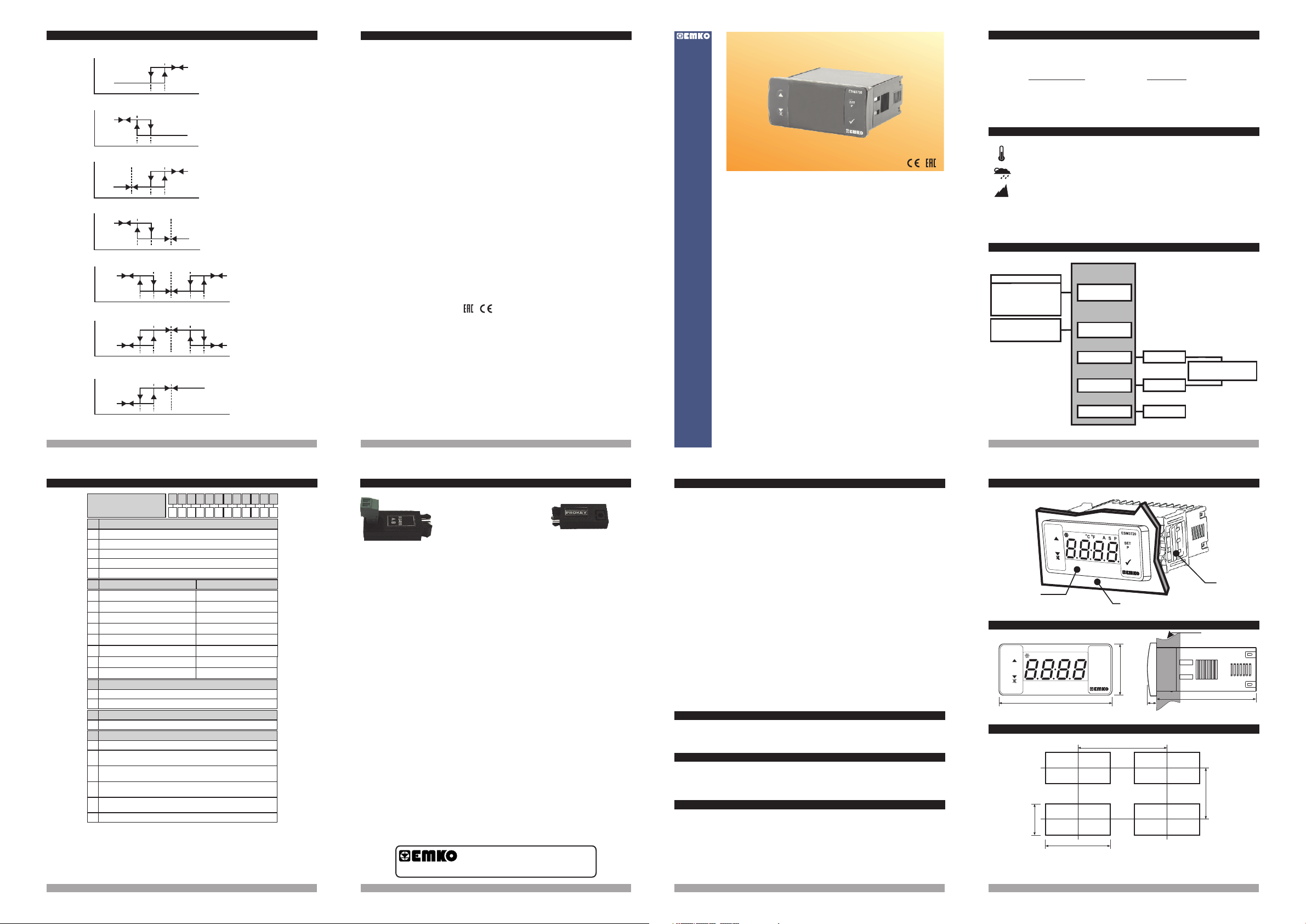

6.5 Alarm Types

Alarm

Output

Process High

Alarm

Alarm

Output

Process Low

Alarm

Alarm

Output

Deviation High

Alarm

Alarm

Output

Deviation Low

Alarm

Alarm

Output

Deviation Band

Alarm

Alarm

Output

Deviation Range

Alarm

Alarm

Output

Deviation Range

High Alarm

7. Specifications

Device Type : Temperature Controller

Alarm

Hysteresis

Alarm

Set

Alarm

Hysteresis

Process

( + )

Hysteresis

Alarm

Set

Alarm

Hysteresis

Process

Alarm

( - )

Set

Set

Alarm

Hysteresis

Process

Alarm

( - )

Set

Set

Alarm

Hysteresis

Process

Alarm

( - )

Set

Set

Alarm

Hysteresis

Set

Alarm

Alarm

Set

Set

Alarm

Process

Set

Process

Set

Process

Set

Process

Alarm

( + )

Set

Set

Alarm

Hysteresis

Process

Alarm

( + )

Set

Set

Alarm

Hysteresis

Process Value

Process Value

Process Value

Process Value

Process Value

Process Value

Process Value

ON

OFF

ON

OFF

Process

Set

ON

OFF

Process

( - )

Set

ON

OFF

ON

OFF

ON

OFF

ON

OFF

13 14

Housing & Mounting : 76mm x 34.5mm x 71mm plastic housing for panel

Protection Class : NEMA 4X (Ip65 at front, Ip20 at rear).

Weight : Approximately 0.20 Kg.

Environmental Ratings : Standard, indoor at an altitude of less than 2000 meters

Storage / Operating Temperature : -30 C to +80 C / -20 C to +70 C

Storage / Operating Humidity : 90 % max. (None condensing)

Installation : Fixed installation

Overvoltage Category : II.

Pollution Degree : II, office or workplace, none conductive pollution

Operating Conditions : Continuous

Supply Voltage and Power :

:10 - 30

Temperature Sensor Input : NTC, PTC, TC, RTD

NTC input type : NTC (10 kW @25 °C )

PTC input type : PTC (1000 W @25 °C )

Thermocouple input type : J, K (IEC584.1) (ITS 90)

Thermoresistance input type : PT-100, PT-1000 (IEC751) (ITS 90)

Accuracy : ± 1 % of full scale for thermoresistance

Cold Junction Compensation : Automatically ± 0.1°C / ± 1°C

Sensor Break Protection : Upscale

Sampling Cycle : 3 samples per second

Control Form : PID or ON / OFF

Relay Output : 16(8) A@250 V V for Resistive load ( Output)

(Electrical life : 100.000 switching at full load)

: 5 A@250 V V for Resistive load (Alarm Output)

Optional SSR Drive Output : Maximum 20mA, Maximum V

Display : 14 mm Red 4 digits LED Display

LED : S (Green), P (Green), C (Yellow), F(Yellow),

Compressor Output (Red), Heating Output (Red)

Internal Buzzer : ³83dB

Approvals :

: 115

: 24

: 24

Mounting. Panel cut-out is 71x29mm.

with none condensing humidity.

o o o o

230V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

W ±

VZ 1.5W

15 Z

o o

,

Compressor

ESM-3720 77 x 35 DIN Size

Digital Temperature Controller

- 4 Digits Display

- NTC Input or

PTC Input or

J Type thermocouple Input or,

K Type thermocouple Input or,

2-Wire PT-100 Input or,

2-Wire PT-1000 Input

- Adjustable temperature offset

ON/OFF temperature control

- PID or

- Selectable heating or cooling function

- Selection of operation with hysteresis

- Adjustable temperature offset

- Set value low limit and set value high limit boundaries

- Operation selection of compressor operates continuously,

stops or operates periodically in case of sensor defect

- Compressor protection delays

- Alarm parameters

- Adjustable internal buzzer according to sensor defect status.

- Password protection for programming section

- Installing parameters using Prokey

ESM-3720 77x35 DIN Size Temperature Controller

- Remote access, data collecting and controlling with Modbus RTU

- Having CE mark according to European Norms

(Must be determined in order.)

Instruction Manual. ENG ESM-3720 01 V05 03/18

1.Preface

ESM-3720 series temperature controllers are designed for measuring and controlling

temperature. They can be used in many applications with their On / Off control form, heating

and cooling control form and easy-use properties. Some application fields which they are

used are below:

Application Fields Applications

Glass Heating

Food Baking Ovens

Plastic Incubators

Petro-Chemistry Storages

Textile, Automative Air Conditioning

Machine Production Industries Etc... Etc...

1.1 Environmental Ratings

Operating Temperature : -20 to 70 °C

Max. Operating Humidity : 90% Rh (non-condensing)

Altitude : Up to 2000 m.

Forbidden Conditions:

Corrosive atmosphere

c

Explosive atmosphere

Home applications (The unit is only for industrial applications)

1.2 General Specifications

Standard

230V ( %15) 50/60HzV ±

Optional Supply Voltage

V

115 V (±%15) 50/60Hz,

V

24 V (±%15) 50/60Hz,

W

24 V (±%15) 50/60Hz,

10

- 30 V Z

NTC, PTC,

J or K Type TC

2-Wire PT-100

2-Wire PT-1000

ESM-3720

Power Supply

Input

Temperature Sensor

Input

Standard

Output-1

(Relay Output)

Optional

Output-1

(SSR Drive Output)

Output-2

(Relay Output)

Control Output

Control Output

Alarm Output

Heating or Cooling

Function

PID or ON/OFF Operation

2

8.Ordering Information

ESM-3720

(77x35 DIN Sizes)

A BC D E FG HI /

0 1 0 0

/

Supply VoltageA

2

24VW ( %15) 50/60Hz - 1.5VA ±

3

24V ( %15) 50/60Hz - 1.5VAV ±

4

115V ( %15) 50/60Hz - 1.5VAV ±

5

230V ( %15) 50/60Hz - 1.5VAV ±

8

10 - 30 V Z

Input Type

BC

J ,Fe CuNi IEC584.1(ITS90)

05

K ,NiCr Ni IEC584.1(ITS90)

10

PT 100, IEC751(ITS90)

11

PT 100, IEC751(ITS90

09

PT 1000, IEC751(ITS90)

14

PT 1000, IEC751(ITS90

13

PTC (Not-1)

12

NTC (Not-1)

18

Control Output

E

Relay Output (16(8) A@250 V V,at resistive Load, 1 NO )

1

SSR Driver Output (Maximum 20m, Maximum 17VZ )

2

Alarm Output

FG

01

Relay Output (5 A@250 V V,at resistive Load, 1 NO )

Temp. Sensor which is given with ESM-3720

V

0

None

PTC-M6L40.K1.5 (PTC Air Probe 1.5 mt Silicon Cable)

1

PTCS-M6L30.K1.5.1/8” (PTC Liquid Probe 1.5 mt Silicon Cable)

2

NTC-M5L20.K1.5 (NTC Sensor, thermoplastic moulded with 1.5 m cable

3

for cooling application)

NTC-M6L50.K1.5 (NTC Sensor, stainless steel housing with 1.5 m cable

4

for cooling application)

Customer

9

All order information of ESM-3720 Temperature Controller are given on the table at above. User may

form appropriate device configuration from information and codes that at the table and convert it to the

ordering codes.Firstly, supply voltage then other specifications must be determined. Please fill the order

code blanks according to your needs.

Please contact us, if your needs are out of the standards.

Note-1:If input type is selected PTC or NTC (BC= 12, 18), Temperature sensor is given with the

device.For this reason, if input type is selected as PTC,sensor type (V = 0,1 or 2) or if input type is

selected as NTC, sensor type (V = 0,3 or 4) must be declared in ordering information.

Scale(°C)

-50°C/-58°F ; 400°C/752°F

-19.9°C/-4°F ; 99.9°C/212°F

-50°C/-58°F ; 400°C/752°F

-19.9°C/-4°F ; 99.9°C/212°F

-50°C/-58°F ; 150°C/302°F

-50°C/-58°F ; 100°C/212°F

U

V W Z/

/

01 00

0°C/32°F ; 800°C/1472°F

0°C/32°F ; 999°C/1830°F

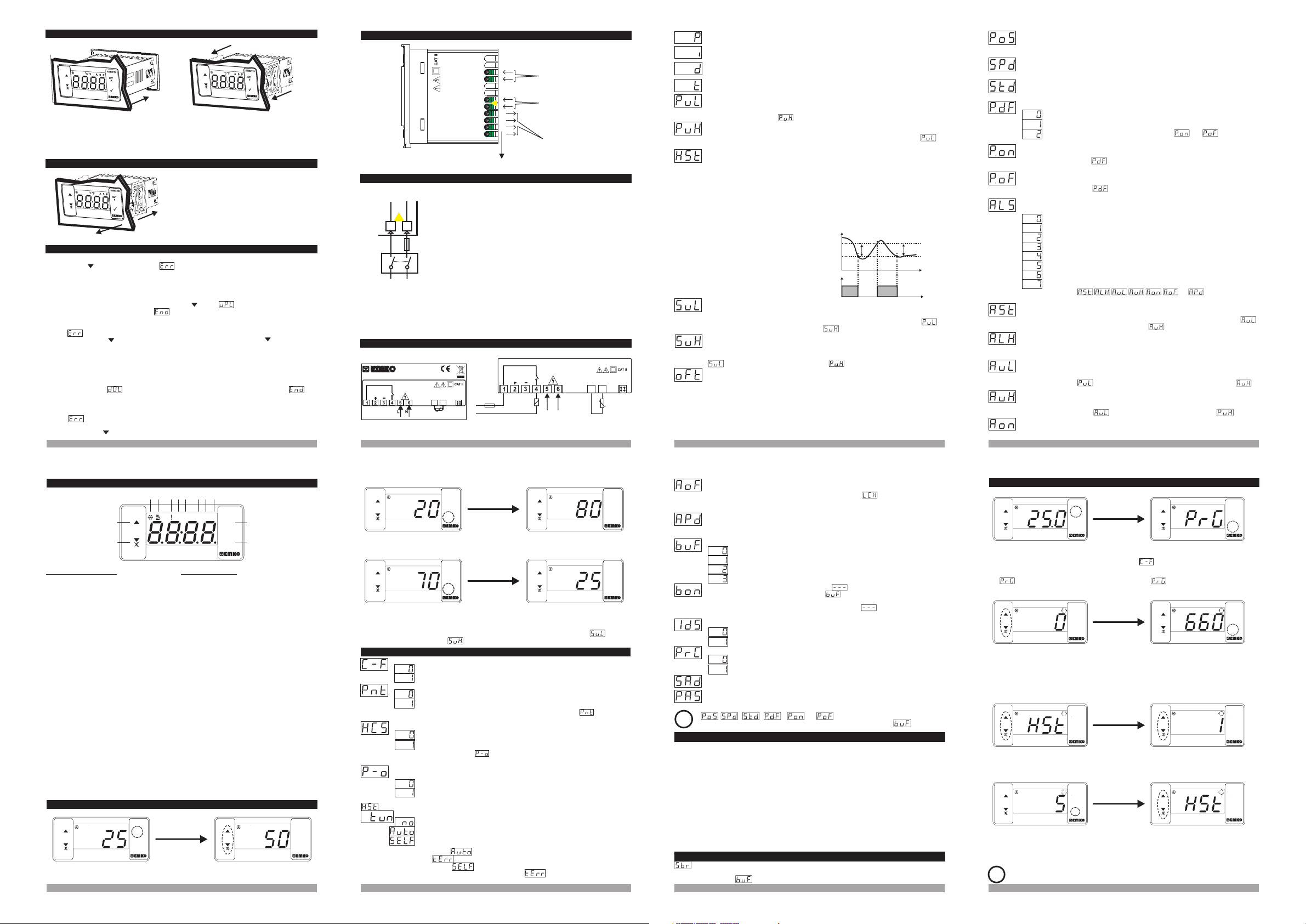

9.Optional Accessories

1.RS-485 Module 2.PROKEY Programming Module

RS-485 Communication

Interface

Your Technology Partner

V Þ Vac,

Z Þ Vdc

c

Þ Vdc or Vac can be appliedW

Thank you very much for your preference to

use Emko Elektronik products, please visit our

web page to download detailed user manual.

The device is programmed(Upload or

Download) by using The parameters.

www.emkoelektronik.com.tr

1.3 Installation

A visual inspection of this product for possible damage occurred during shipment is

recommended before installation. It is your responsibility to ensure that qualified mechanical

and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power off the

system and separate the electrical connection of the device from the system.

The unit is normally supplied without a power supply switch or a fuse. Use power switch and fuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to prevent

failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble with the

unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may results in

malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During putting equipment in hole on the metal panel while mechanical installation some metal

burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the montage

of the device with inappropriate fixing clamp. Be sure that device will not fall while doing the

montage.

It is your responsibility if this equipment is used in a manner not specified in this instruction

manual.

1.4 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts

from the delivery date. This warranty is in force if duty and responsibilities which are determined

in warranty document and instruction manual performs by the customer completely.

1.5 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the

device before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in

ethyl alcohol or water to clean the external plastic case.

1.6 Manufacturer Company

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and maintenance service information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA /TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

2. General Description

Front Panel

IP65 protection

NEMA 4X

Panel Surface

(maximum thickness 15 mm / 0.59 inch)

Mounting Clamp

2.1 Front View and Dimensions of ESM-3720Temperature Controller

Maximum 15 mm / 0.59 inch

O

O

C

ESM3720

S

P

F

A

SET

P

ü

34,5 mm / 1.36 inch

76 mm / 3 inch

6 mm / 0.24 inch

2.2 Panel Cut-Out

110 mm / 4.33 inch (min)

29 mm / 1.14 inch

71 mm / 2.79 inch

3 41615

65 mm / 2.56 inch

50 mm / 1.97 inch (min)

2.3 Panel Mounting

1

2

1-Before mounting the device in your panel,

make sure that the cut-out is of the right size.

2-Insert the device through the cut-out. If the

mounting clamps are on the unit, put out them

before inserting the unit to the panel.

3- Insert the mounting clamps to the fixing sockets

that located left and right sides of device and make

the unit completely immobile within the panel

3

3

2.4 Removing from the Panel

1-Pull mounting clamps from left and right fixing

sockets.

2-Pull the unit through the front side of the panel

1

Before starting to remove the unit from

panel, power off the unit and the related

system.

2

c

3. Using Prokey

TO USE PROKEY, VALUE OF THE PrC PARAMETER MUST BE ‘0’.

IF PrC=1 AND BUTTON IS PRESSED MESSAGE WILL BE SHOWN. 10s. LATER

DEVICE TURNS BACK TO THE MAIN OPERATION SCREEN OR YOU CAN PRESS SET

BUTTON TO TURN BACK TO MAIN OPERATION SCREEN.

DOWNLOADING FROM DEVICE TO PROKEY

1.The device is programmed by using the parameters.

2.Energize the device then put in PROKEY and press button. Message is shown on the

display. When the loading has finished, message is shown.

3.Press any button to turn back to main operation screen.

4.Remove the PROKEY.

NOTE: message is shown when an error occurs while programming. If you want to reload, put

in PROKEY and press button. If you want to quit, remove PROKEY and press button. The

device will turn back to main operation screen.

DOWNLOADING FROM PROKEY TO DEVICE

1.Switch off the device.

2.Put in PROKEY then energize the device.

3.When the device is energized, the parameter values in PROKEY, start downloading to the device

automatically. At first, message is shown on the display, when loading has finished,

message is shown.

4.After 10 seconds device starts to operate with new parameter values.

5.Remove the PROKEY.

NOTE: message is shown when an error occurs while programming. If you want to reload,

switch off the device and put in PROKEY then energize the device. If you want to quit remove

PROKEY and press button. The device will turn back to main operation screen.

4. Electrical Wiring Diagram

Temperature Sensor Input

TC,NTC,PTC,PT-100

or PT-1000

Supply Voltage Input

V ±

N

aa

L

4

3

(-)(-)

21 5 6 7 8

P/N : ESM-3720

(+)(+)

230V ( %15) 50/60Hz

V ±

115V ( %15) 50/60Hz

V ±

24V ( %15) 50/60Hz

10...30 V

Z

Must be determined in

Relay or SSR Output

For SSR Output

4.1 Supply Voltage Input Connection of the Device

Power Supply Connection

L

N

a

(+)(+)(-)(-)

5

6

EXTERNAL

FUSE

(1A T)

Note-1

Supply

Switch

c

Supply Voltage

V ±

230V ( %15) 50/60Hz ,

V ±

115V ( %15) 50/60Hz,

V ±

24V ( %15) 50/60Hz ,

W ±

24V ( %15) 50/60Hz ,

10..30 V - 1.5 W

Z

Must be determined in order.

Note-1 : External fuse is recommended.

Make sure that the power supply voltage is the same

indicated on the instrument.

c

Switch on the power supply only after that all the electrical

connections have been completed.

Supply voltage range must be determined in order. While

installing the unit, supply voltage range must be controlled

and appropriate supply voltage must be applied to the unit.

There is no power supply switch on the device. So a power

supply switch must be added to the supply voltage input.

c

Power switch must be two poled for seperating phase and

neutral, On/Off condition of power supply switch is very

important in electrical connection.

External fuse that on Vpower supply inputs must be on

phase connection.

External fuse that on Zpower supply inputs must be on (+)

connection.

4.2 Device Label and Connection Diagram

230VV CONNECTION DIAGRAM

P/N: ESM-3720 - 5.09.0.2/01.00/1.0.0.0

5A@ 250V V

230 VV ± 15%

HEAT

ALARM

50/60Hz - 1.5VA

SSR Driver Out

Max.

15V@30mA

NOC

7

8

PT-100

INPUT SCALE

(-19.9 ,99.9 ; °C °C °F °F-4 ,212 )

RS-485

PROKEY

or

L

N

5A SIGORTA

5A@ 250V V

HEAT

SSR Driver Out

Max.

15V@30mA

LOAD

ALARM

NOC

L

N

RS-485

or

PROKEY

7

8

0

10

Pt

5 6 9 10

PID - Proportional Control Parameter ( Default = 10.0 ) MODBUS ADRES:40007

This parameter can be adjusted from %1.0 to %100.0

PID-Integral Parameter( Default = 100 ) MODBUS ADRES:40008

This parameter value can be adjusted from 0 to 3600.

PID-Derivativel Parameter ( Default = 25.0 ) MODBUS ADRES:40009

This parameter value can be adjusted from 0.0 to 999.9

PID-Period parameter( Default = 10 ) MODBUS ADRES:40010

This parameter value can be adjust from 0 to 150 second.

Operation Scale Minimum Parameter (Default = Minimum Value of Device Scale )

MODBUS ADDRESS:40011

This parameter value can be adjusted from minimum value of device scale to operation

scale maximum parameter

Operation Scale Maximum Parameter (Default = Maximum Value of Device Scale )

MODBUS ADDRESS:40012

This parameter value can be adjusted from operation scale minimum parameter to

maximum value of the device scale.

Hysteresis Parameter for Compressor Output ( Default = 3 )

MODBUS ADDRESS:40013

from 1 to 20°C for NTC (-50°C, 100°C) or PTC (-50°C, 130°C) or J Type TC ( 0°C, 800°C ) or

K Type TC ( 0°C, 1000°C or PT-100 Type ( -50°C,400°C ) or PT-1000 Type ( -50°C,400°C )

or PT-100 Type ( -20°C,100°C ),

from 1 to 36°F for NTC (-58°F, 212°F) or PTC (-58°F, 266°F) or J Type TC (32°F,1472°F)or

K Type TC (32°F,1830°F) or PT-100 Type (-58°F,752°F) or PT-1000 Type (-58°F,752°F)

or PT-100 Type (-4°F,212°F)

from 0.1 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC (-50.0°C,130.0°C)

or PT-100 (-19.9°C,99.9°C),

from 0.1 to 18.0°F for NTC (-58.0°F,212.0°F) or PTC (-58.0°F,266.0°F) or

PT-100 (-4.0°F,212.0°F),

In ON/OFF control algorithm, temperature

value is tried to keep equal to set value by

opening or closing the last control element.

ON/OFF controlled system, temperature

value oscillates continuously. Temperature

value’s oscillation period or amplitude around

set value changes according to controlled

system. For reducing oscillation period of

temperature value, a threshold zone is formed

below or around set value and this zone is

named hysteresis.

Minimum Temperature Set Value Parameter (Default = Minimum Value of Device

Scale ) MODBUS ADDRESS:40014

Temperature set value can not be lower than this value.

This parameter value can be adjusted from operation scale minimum parameter to

maximum temperature set value parameter

Maximum Temperature Set Value Parameter (Default = Maximum Value of Device

Scale ) MODBUS ADDRESS:40015

Temperature set value can not be bigger than this value.

This parameter value can be adjusted from minimum temperature set value parameter

to operation scale maximum parameter

Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40016

from -20 to 20 °C for NTC(-50°C, 100°C) or PTC(-50°C, 130°C) or J Type TC (0°C,800°C)

or J Type TC (0°C,1000°C) or PT-100(-50°C, 400°C)or PT-1000 (-50°C, 150°C) or

PT-100 (-20°C, 100°C),

from -36 to 36 °F for NTC(-58°F, 212°F) or PTC(-58°F, 266°F) or J Type TC (32°F,1472°F)

or K Type TC (32°F,1830°F) or PT-100(-58°F, 752°F) or PT-1000(-58°F, 752°F) or

PT-100(-4°F, 212°F),

from -10.0 to 10.0°C for NTC(-50.0°C,100.0°C) or PTC(-50.0°C,130.0°C) or

PT-100 (-19.9°C,99.9°C),

from -18.0 to 18.0°F for NTC(-58.0°F,212.0°F) or PTC(-58.0°F,266.0°F) or

PT-100 (-4.0°F,212.0°F),

Temperature

Set

Control

Output

ON

OFF

HSt

HSt

Time

Time

Note: If this parameter is select 0, , , , , , and parameters

will be not observed

Compressor Start Delay at Power On Parameter ( Default = 0)

MODBUS ADDRESS:40017

When power is first applied to the device, compressor is on when this time delay is expired.

It can be adjusted from 0 to 20 minutes.

Compressor Stop-Start Delay Parameter ( Default = 0) MODBUS ADRES:40018

When compressor is inactive, this time delay must be expired for activation of the

compressor. It can be adjusted from 0 to 20 minutes.

Compressor Start-Start Delay Parameter ( Default = 0) MODBUS ADRES:40019

This time delay must be expired between two activation of the compressor. It can be

adjusted from 0 to 20 minutes.

Sensor Defect Parameter ( Default = 0 ) MODBUS ADRES:40020

Compressor is OFF in case of sensor defect.

Compressor is ON in case of sensor defect.

Compressor operates periodically according to and Time periods in

case of sensor defect.

Compressor is active during this time period in case of probe defect (Default = 0)

MODBUS ADRES:40021

If probe defect parameter is 2, then this parameter is observed. It can be adjusted

from 0 to 99 minutes.

Compressor is inactive during this time period in case of probe defect

( Default = 0 )MODBUS ADRES:40022

If probe defect parameter is 2, then this parameter is observed. It can be adjusted

from 0 to 99 minutes.

Temperature Alarm Function Selection Parameter ( Default =1 )

MODBUS ADRES:40023

Alarm function is inactive.

Process High alarm selected.

Process Low alarm selected.

Deviation High alarm selected.

Deviation Low alarm selected.

Deviation Band alarm selected.

Deviation Range alarm selected.

Deviation Range High alarm selected.

Temperature Alarm Parameter

MODBUS ADRES:40024

This parameter value can be programmed between temperature minimum alarm set

parameter and temperature alarm set maximum parameter.

Temperature Alarm Parameter

MODBUS ADRES:40025

This parameter value can be adjusted form 0.1 to %50 of the device scale if Pnt parameter is

1, 1 to %50 of the device scale if Pnt parameter is 0.

Temperature Minimum Alarm Parameter (Default =Minimum Value of Device Scale)

MODBUS ADRES:40026

If temperature alarm is active, this parameter value can be adjusted from operation scale

minimum parameter to temperature alarm set maximum parameter value .

Temperature Alarm Maximum Parameter ( Default = Maximum Value of Device Scale)

MODBUS ADRES:40027

If temperature alarm is active, this parameter value can be adjusted from temperature

alarm set value parameter to operation scale maximum parameter

Temperature Alarm On Delay Time Parameter(Default = 0)MODBUS ADDRESS:40028

Temperature alarm on delay time can be defined with this parameter.

It can be adjusted from 0 to 99 minutes.

Set ( Default =80 )

Hysteresis ( Default =3 )

5.Front Panel Definition and Accessing to the Menus

5 6 7 87

6

1

2

BUTTON DEFINITIONS

1. Increment Button :

** It is used to increase the value in the Set

screen and Programming mode.

2. Decrement, Silencing Buzzer and

Downloading to Prokey Button :

** It is used to decrease the value in the Set

screen and Programming mode.

** It is used to silence the buzzer.

** If Prc =0, it is used to download from

device to prokey.

3. Set Button :

** In the main operation screen; if this button

pressed, temperature set value will be

displayed. Value can be changed using

increment and decrement buttons. When

Enter button pressed, value is saved and

alarm set value is displayed. Value can be

changed using increment and decrement

buttons. When Enter button pressed, alarm

set value is saved and returns back to main

operating screen.

** To access the programming screen; in the

main operation screen, press this button for 5

seconds.

4. Enter Button :

** It is used to saving value in the Set screen

and programming screen.

**In the main operation screen; press ENTER

button for 3 seconds to start Auto Tune

operation.,

6. Changing and Saving Temperature Set Value And alarm Set Value

Main Operation Screen

O

C

ESM3720

O

S

P

F

SET

P

1110

12

9

C

F A

LED DEFINITIONS

5. Cooling led :

** This led indicates that cooling control is

selected and process output relay is active. If

any of compressor protection time active, this

led blinks.

6.Heating led :

** This led indicates that heating control is

selected and process output relay is active.

7.Alarm led :

** This led indicates that alarm output relay is

active.

8.Celcius led :

** Indicates that device is in C mode.

9.Fahrenheit led :

** Indicates that device is in F mode.

10.Auto Tune / Self Tune led :

** Indicates that device is operating Auto Tune

or Self Tune.

11.Set led :

** Indicates that device is in Set value changing

mode.

12.Program led :

**Blinks in programming mode .

ESM3720

S

P

SET

3

3

P

4

ü

SET Value Screen

ü

When SET button pressed ‘’S’’ led will

be active and temperature set value will

be displayed.

Temperature set value can be changed

with increment and decrement buttons.

O

C

When ENTER button pressed

temperature set value can be saved.

O

C

When ENTER button pressed alarm

set value can be saved.

Temperature set value parameter (Default=50) MODBUS ADDRESS:40001

Temperature set value, can be programmed between minimum temperature set value and

maximum temperature set value .

ESM3720

O

S

P

F

SET

P

ü

ü

ESM3720

O

S

P

F

SET

P

ü

ü

Alarm Set Value Screen

O

C

Alarm set value can be changed with

increment and decrement buttons.

Main Operation Screen

O

C

‘’S’’ will be inactive and goes back to

main operation screen.

ESM3720

O

S

P

F

SET

P

ü

ü

ESM3720

O

S

P

F

SET

P

ü

ü

6.1 Programming Mode Parameter List

o

o

Note: If sensor input type is selected J, K, PT-100 or PT-1000 (BC =05,10,11 or 14) parameter is

skipped.

Note: If operating type is selected cooling parameter and PID parameters are Device

operates with On-Off control.

Note: If this parameter is select 0, PID parameters will be not observed.If this parameter select 1,

Parameter will be not observed.

O

C

ESM3720

O

S

P

F

SET

P

ü

Note-1: If this parameter is select the temperature must be lower than temperature set value.

If this condition is not okey

Note-2: must be greater than temperature set

value at least 5% of the full scale. If this condition is not okey is seen on the main screen for

10 seconds.

Temperature Unit Selection Parameter ( Default = 0 ) MODBUS ADDRESS:40002

°C selected.

°F selected.

Decimal Seperator Enabling Parameter ( Default = 0 ) MODBUS ADDRESS:40003

Disable.

Enable.

Operating Type Parameter ( Default = 0) MODBUS ADDRESS:40004

Heating

Cooling

skipped.

Temperature Control Selection Parameter On/Off or PID (Default = 0 )

MODBUS ADRES:40005

On - Off selected.

PID selected

Tune Selection Parameter ( Default = no ) MODBUS ADRES:40006

Device does not do Tune operation.

Device does Auto-Tune operation

Device does Self-Tune operation

If this parameter is select the temperature

is seen on the main screen for 10 seconds.

6.2 Modbus Adresses of Device Status Parameters (Read Input Register)

MODBUS ADDRESS:30001 Temperature Value

MODBUS ADDRESS:30002 Empty

MODBUS ADDRESS:30003 Led Status : 0.bit C Led,

1.bit F Led,

3.bit Auto Tune Led,

5.bit Heating Led,

6.bit Compressor Led,

7.bit Alarm Led,

13.bit Program Led,

14.bit Set Led

MODBUS ADDRESS:30004 Device Status : 0.bit Alarm Status

MODBUS ADDRESS:30005 Output Status: 0.bit Control Output

A

MODBUS ADDRESS:30006 Device Type and Device Version

Screen Blinking

Sensor failure . Sensor connection is wrong or there is no sensor connection. If buzzer function

selection parameter is 1, internal buzzer starts to operate.

Temperature Alarm Off Delay Time Parameter(Default = 0)MODBUS ADDRESS:40029

Temperature alarm off delay time can be defined with this parameter.

It can be adjusted from 0 to 99 minutes. If it is higher than 99 is seen on the screen and

alarm latching output is selected. In alarm latching output mode, in order to make passive

alarm output, press DECREMENT button at main screen.

Temperature Alarm Delay After Power On Parameter

MODBUS ADRES:40030

When power is first applied to the device, this time delay must be expired for activation of

temperature alarm. It can be adjusted from 0 to 99 minutes.

Buzzer Function Selection Parameter ( Default = 0 ) MODBUS ADDRESS:40031

Buzzer is inactive.

( Default = 0 )

Buzzer is active during sensor failures.

Buzzer is active if an alarm occurs.

Buzzer is active if an alarm occurs or sensor failures.

Buzzer is active during this time

If buzzer function selection parameter value =0, this parameter can not be

observed. Buzzer stays active during this time. It can be adjusted from 1 to 99 minutes

When this parameter is 1, if decrement button is pressed, is observed. In this

condition buzzer is active till buzzer silence button is pressed.

Increment/Decrement Mode ( Default = 0 ) MODBUS:40033 Selection Parameter

( Default = ) MODBUS ADDRESS:40032

Mode-1

Mode-2

Communication Mode Selection Parameter ( Default = 0 ) MODBUS ADDRESS:40034

PROKEY communication selected.

Rs485 communication selected.

Slave ID Parameter ( Default = 1 ) MODBUS ADDRESS=40035

Device communication address parameter (1 to 247).

Programming Section Accessing Password . ( Default = 0 ) MODBUS ADDRESS:40036

It is used for accessing to the programming section. It can be adjusted from 0 to 9999. If it is

selected 0, password will not be asked

, , , , and Parameters are observed if Operation type

i

is selected “Cooling”. If operation type is selected “Heating ” ,skip to the parameter.

o

o

o

1.bit Buzzer Status

2.bit Sensor

Break Status

1.bit Alarm Output

6.3 Failure Messages in ESM-3720 Temperature Controller

6.4 Entering To The Programming Mode, Changing and Saving Parameter

Main Operation Screen

O

ESM3720

O

S

P

C

F

SET

P

O

C

ü

When SET button is pressed for 5

seconds, “P” led starts to blink. If

programming mode entering

password is different from 0,

programming mode entering screen

will be observed.

O

O

S

P

C

F

Note1: If programming

mode accessing

password is 0,

Temperature Unit screen

is observed instead of

programming screen

ESM3720

SET

P

Programming Mode

Entering Screen

Press OK button for

accessing to the

password entering

screen.

O

C

ü

Password Entering Screen

Enter programming mode accessing password

with increment and decrement buttons.

Note2: If programming mode accessing password is 0, only three parameters

are accessible, and the parameter values can be changed.

Password Entering Screen

Press OK button for entering

the password.

ESM3720

O

S

P

F

SET

P

ü

ESM3720

O

S

P

F

SET

P

ü

Programming Screen

O

ESM3720

O

S

P

C

F

SET

P

O

C

ü

Press SET button for accessing to the parameter

value. Press increment button for accessing to the

next parameter, press decrement button for

accessing to the previous parameter.

O

ESM3720

O

S

P

C

F

SET

P

Hysteresis Value for

Compressor Output

Change the value with increment

and decrement buttons.

O

C

ü

Hysteresis Value for

Compressor Output

Press OK button for saving the

parameter.

If no operation is performed in programming mode for 20 seconds, device turns to main

i

operation screen automatically..

Press increment button for accessing to the

next parameter, press decrement button for

accessing to the previous parameter

Hysteresis Parameter

for Compressor

ESM3720

O

S

P

F

SET

P

ü

ESM3720

O

S

P

F

SET

P

ü

121187

Loading...

Loading...