Emko ESM-3712-HCN User manual

ESM-3712-HCN 77 x 35 DIN Size

Digital ON / OFF Temperature

Controller (ALARM+SET)

- 4 Digits Display

- NTC Input or

PTC Input or

J Type thermocouple Input or,

K Type thermocouple Input or,

2-Wire PT-100 Input or,

2-Wire PT-1000 Input

ON/OFF temperature control

-

2 output for compressor and alarm controls

-

- Selectable heating or cooling function

- Selection of operation with hysteresis

- Adjustable temperature offset

- Process Set value and Alarm Set value low limit and set value

high limit boundaries

- Operation selection of compressor operates continuously,

stops or operates periodically in case of sensor defect

- Compressor protection delays

- Alarm parameters

- Adjustable Alarm Set Value from front panel

Adjustable internal buzzer according to Sensor prob defect and

-

Alarm status

- Password protection for programming section

- Installing parameters using Prokey

- Remote access, data collecting and controlling with Modbus RTU

- Having CE mark according to European Norms

(Must be determined in order.)

ESM-3712-HCN 77x35 DIN Size Temperature Controller

Instruction Manual. ENG ESM-3712-HCN 01 V03 10/19

ENGLISH

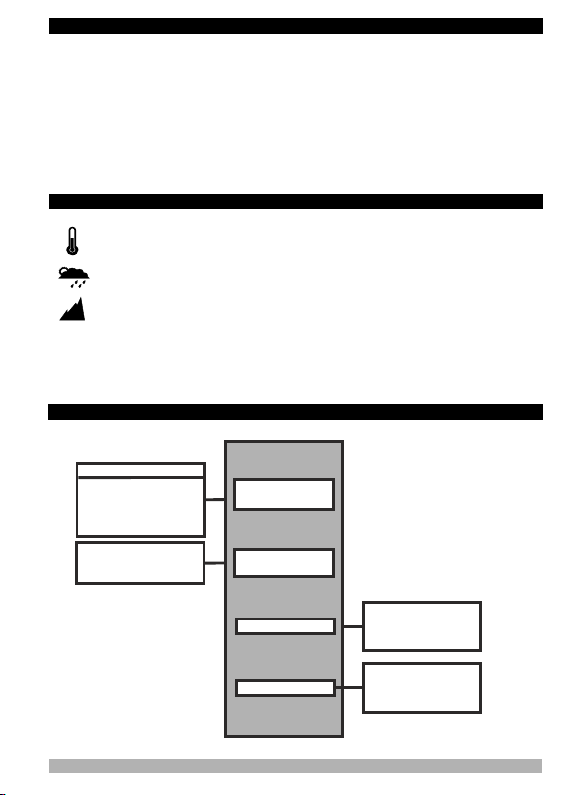

1.Preface

ESM-3712HCN series temperature controllers are designed for measuring and controlling

temperature. They can be used in many applications with their On / Off control form, heating

and cooling control form and easy-use properties. Some application fields which they are

used are below:

Application Fields Applications

Glass Heating

Food Baking Ovens

Plastic Incubators

Petro-Chemistry Storages

Textile, Automative Air Conditioning

Machine Production Industries Etc... Etc...

1.1 Environmental Ratings

Operating Temperature : 0 to 50 °C

Max. Operating Humidity : 90% Rh (non-condensing)

Altitude : Up to 2000 m.

Forbidden Conditions:

Corrosive atmosphere

c

Explosive atmosphere

Home applications (The unit is only for industrial applications)

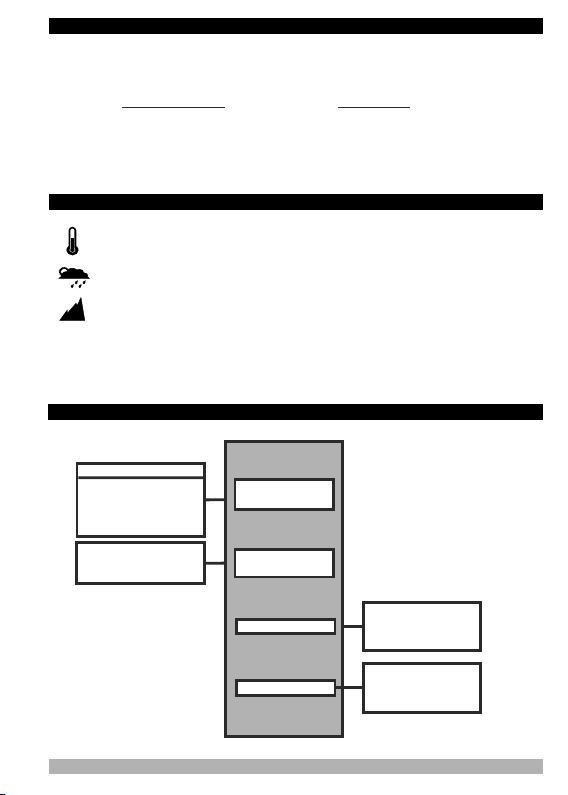

1.2 General Specifications

Standard

230V ( %15) 50/60HzV ±

Optional Supply Voltage

V

115 V (±%15) 50/60Hz,

V

24 V (±%15) 50/60Hz,

W

24 V (±%15) 50/60Hz,

10

- 30 V Z

NTC, PTC,

J or K Type TC

2-Wire PT-100

2-Wire PT-1000

ESM-3712-HCN

Power Supply

Input

Temperature Sensor

Input

Compressor Output

Alarm Output

Heating or Cooling

Function

ON/OFF Operation

Alarm Control Output

ON/OFF Operation

2

1.3 Installation

A visual inspection of this product for possible damage occurred during shipment is

recommended before installation. It is your responsibility to ensure that qualified mechanical

and electrical technicians install this product.

If there is danger of serious accident resulting from a failure or defect in this unit, power off the

system and separate the electrical connection of the device from the system.

The unit is normally supplied without a power supply switch or a fuse. Use power switch and fuse

as required.

Be sure to use the rated power supply voltage to protect the unit against damage and to prevent

failure.

Keep the power off until all of the wiring is completed so that electric shock and trouble with the

unit can be prevented.

Never attempt to disassemble, modify or repair this unit. Tampering with the unit may results in

malfunction, electric shock or fire.

Do not use the unit in combustible or explosive gaseous atmospheres.

During putting equipment in hole on the metal panel while mechanical installation some metal

burrs can cause injury on hands, you must be careful.

Montage of the product on a system must be done with it’s fixing clamps. Do not do the montage

of the device with inappropriate fixing clamp. Be sure that device will not fall while doing the

montage.

It is your responsibility if this equipment is used in a manner not specified in this instruction

manual.

1.4 Warranty

EMKO Elektronik warrants that the equipment delivered is free from defects in material and

workmanship. This warranty is provided for a period of two years. The warranty period starts

from the delivery date. This warranty is in force if duty and responsibilities which are determined

in warranty document and instruction manual performs by the customer completely.

1.5 Maintenance

Repairs should only be performed by trained and specialized personnel. Cut power to the

device before accessing internal parts.

Do not clean the case with hydrocarbon-based solvents (Petrol, Trichlorethylene etc.). Use of

these solvents can reduce the mechanical reliability of the device. Use a cloth dampened in

ethyl alcohol or water to clean the external plastic case.

1.6 Manufacturer Company

Manufacturer Information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Repair and maintenance service information:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA /TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

3

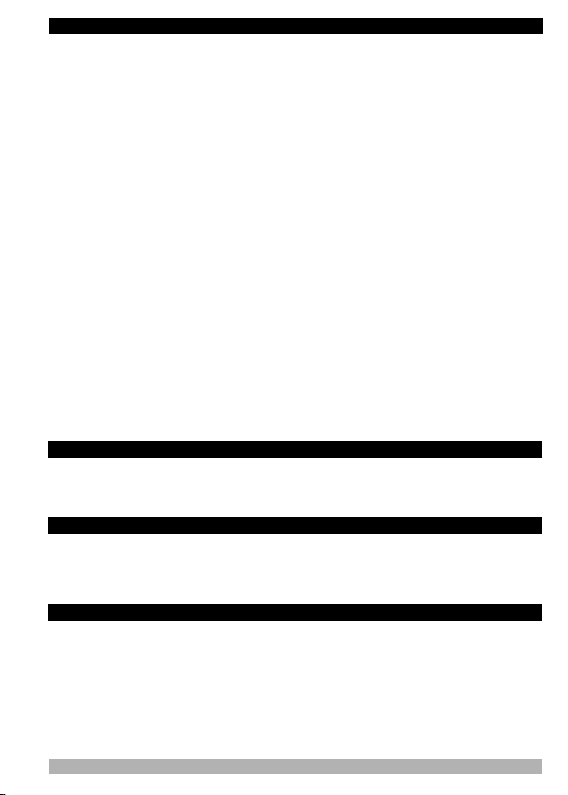

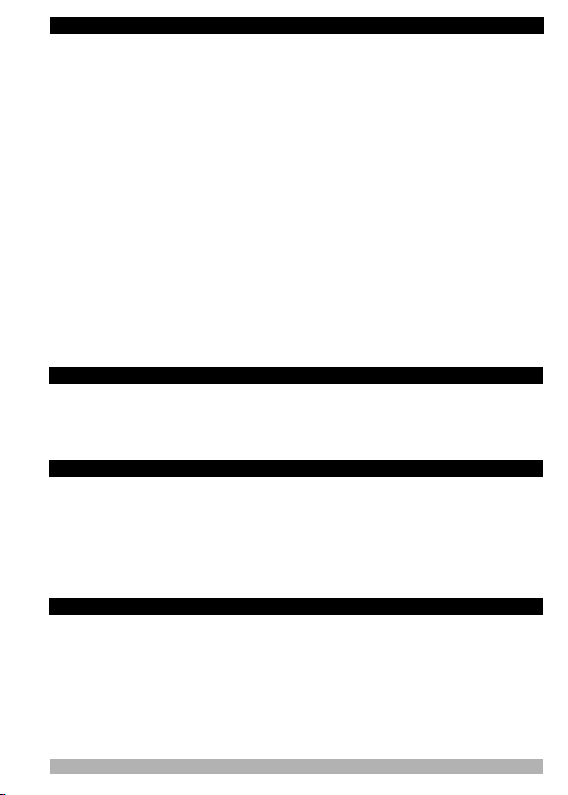

2. General Description

Front Panel

IP65 protection

NEMA 4X

Panel Surface

(maximum thickness 15 mm / 0.59 inch)

Mounting Clamp

2.1 Front View and Dimensions of ESM-3712-HCN Temperature Controller

Maximum 15 mm / 0.59 inch

34,5 mm / 1.36 inch

76 mm / 3 inch

6 mm / 0.24 inch

65 mm / 2.56 inch

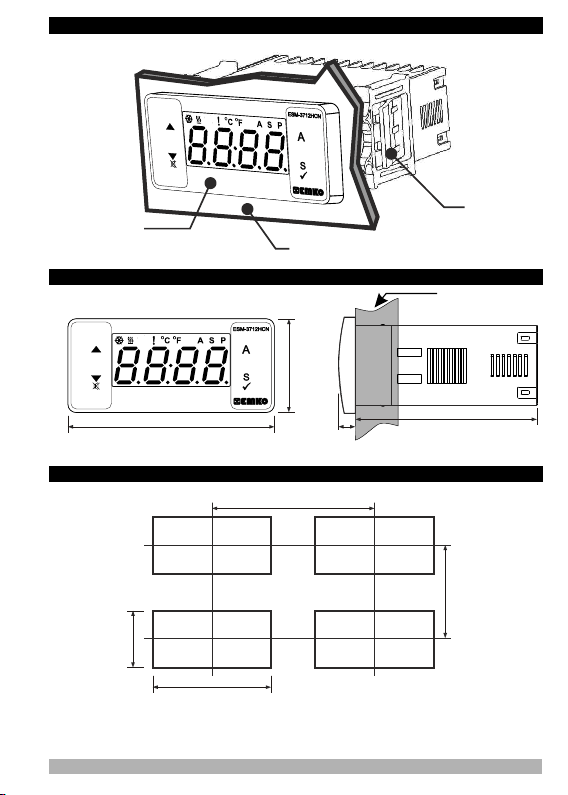

2.2 Panel Cut-Out

110 mm / 4.33 inch (min)

50 mm / 1.97 inch (min)

29 mm / 1.14 inch

71 mm / 2.79 inch

4

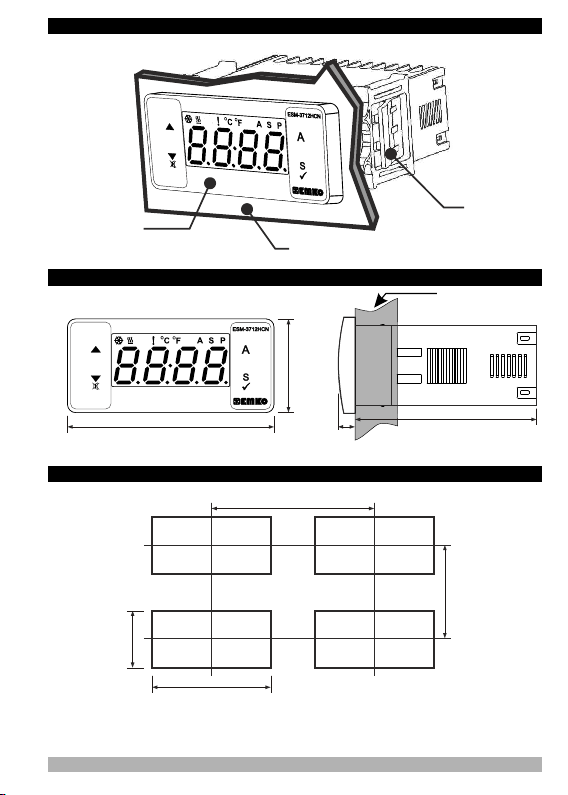

2.3 Panel Mounting

1

3

2

1-Before mounting the device in your panel,

make sure that the cut-out is of the right size.

2-Insert the device through the cut-out. If the

mounting clamps are on the unit, put out them

before inserting the unit to the panel.

3- Insert the mounting clamps to the fixing sockets

that located left and right sides of device and make

the unit completely immobile within the panel

3

2.4 Removing from the Panel

1-Pull mounting clamps from left and right fixing

sockets.

2-Pull the unit through the front side of the panel

1

2

Before starting to remove the unit from

panel, power off the unit and the related

system.

c

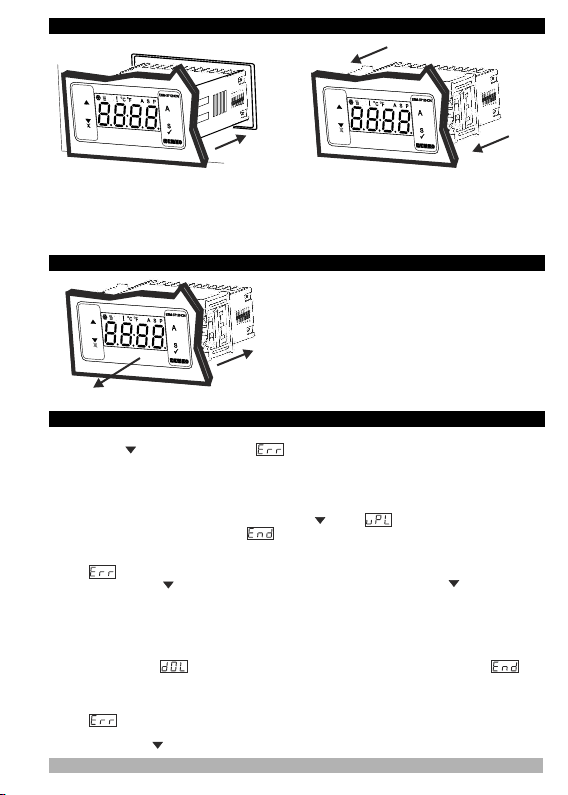

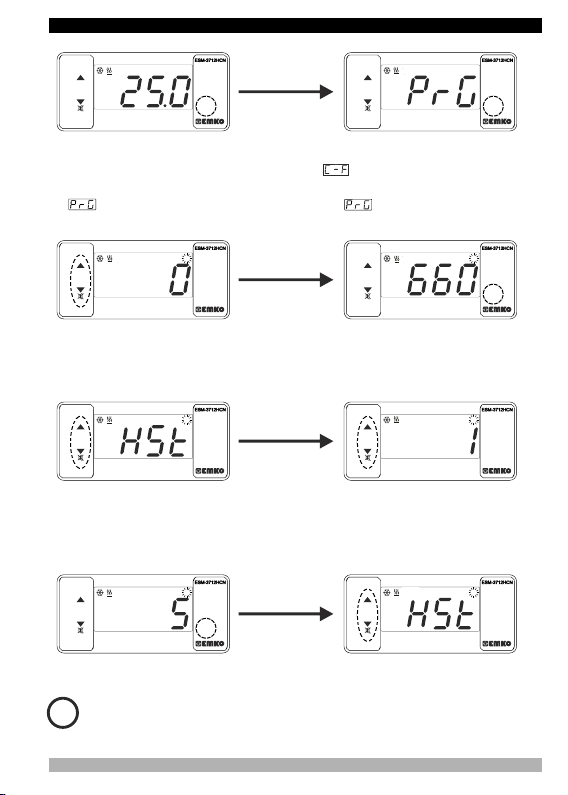

3. Using Prokey

TO USE PROKEY, VALUE OF THE PrC PARAMETER MUST BE ‘0’.

IF PrC=1 AND BUTTON IS PRESSED MESSAGE WILL BE SHOWN. 10s. LATER

DEVICE TURNS BACK TO THE MAIN OPERATION SCREEN OR YOU CAN PRESS SET

BUTTON TO TURN BACK TO MAIN OPERATION SCREEN.

DOWNLOADING FROM DEVICE TO PROKEY

1.The device is programmed by using the parameters.

2.Energize the device then put in PROKEY and press button. Message is shown on the

display. When the loading has finished, message is shown.

3.Press any button to turn back to main operation screen.

4.Remove the PROKEY.

NOTE: message is shown when an error occurs while programming. If you want to reload, put

in PROKEY and press button. If you want to quit, remove PROKEY and press button. The

device will turn back to main operation screen.

DOWNLOADING FROM PROKEY TO DEVICE

1.Switch off the device.

2.Put in PROKEY then energize the device.

3.When the device is energized, the parameter values in PROKEY, start downloading to the device

automatically. At first, message is shown on the display, when loading has finished,

message is shown.

4.After 10 seconds device starts to operate with new parameter values.

5.Remove the PROKEY.

NOTE: message is shown when an error occurs while programming. If you want to reload,

switch off the device and put in PROKEY then energize the device. If you want to quit remove

PROKEY and press button. The device will turn back to main operation screen.

5

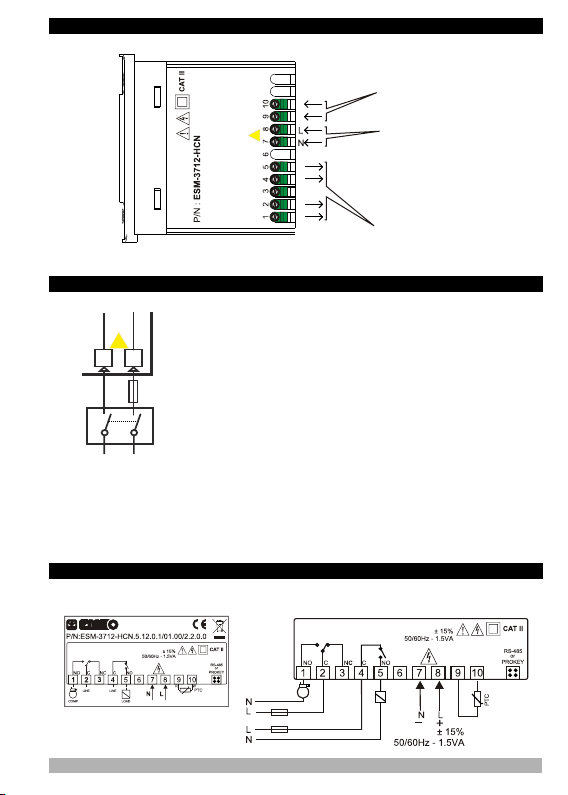

4. Electrical Wiring Diagram

a

4.1 Supply Voltage Input Connection of the Device

Power Supply Connection

L

N

a

(+)(-)

7

8

EXTERNAL

FUSE

(1A T)

Note-1

Supply

Switch

c

Supply Voltage

V ±

230V ( %15) 50/60Hz ,

V ±

115V ( %15) 50/60Hz,

V ±

24V ( %15) 50/60Hz ,

W ±

24V ( %15) 50/60Hz ,

10..30 V - 1.5 W

Z

Must be determined in order.

Note-1 : External fuse is recommended.

Make sure that the power supply voltage is the same

indicated on the instrument.

c

Switch on the power supply only after that all the electrical

connections have been completed.

Supply voltage range must be determined in order. While

installing the unit, supply voltage range must be controlled

and appropriate supply voltage must be applied to the unit.

There is no power supply switch on the device. So a power

supply switch must be added to the supply voltage input.

c

Power switch must be two poled for seperating phase and

neutral, On/Off condition of power supply switch is very

important in electrical connection.

External fuse that on Vpower supply inputs must be on

phase connection.

External fuse that on Zpower supply inputs must be on (+)

connection.

4.2 Device Label and Connection Diagram

230VV CONNECTION DIAGRAM

16(8)A@250VV

16(8)A@250VV

1HP COMP.

5A@250VV

ALARM

230VV

1HP COMP.

Temperature Sensor

TC, NTC, PTC, PT-100

or PT-1000

Supply Voltage Input

V ±

230V ( %15) 50/60Hz

V ±

115V ( %15) 50/60Hz

V ±

24V ( %15) 50/60Hz

W ±

24V ( %15) 50/60Hz

10...30 V

Z

Must be determined in order.

Process and Alarm

Relay Outputs

5A@250VV

230VV

ALARM

Input

INPUT SCALE

(-50°C, 150°C; -58°F,302°F)

16A T Fuse

5A T Fuse

230VV

6

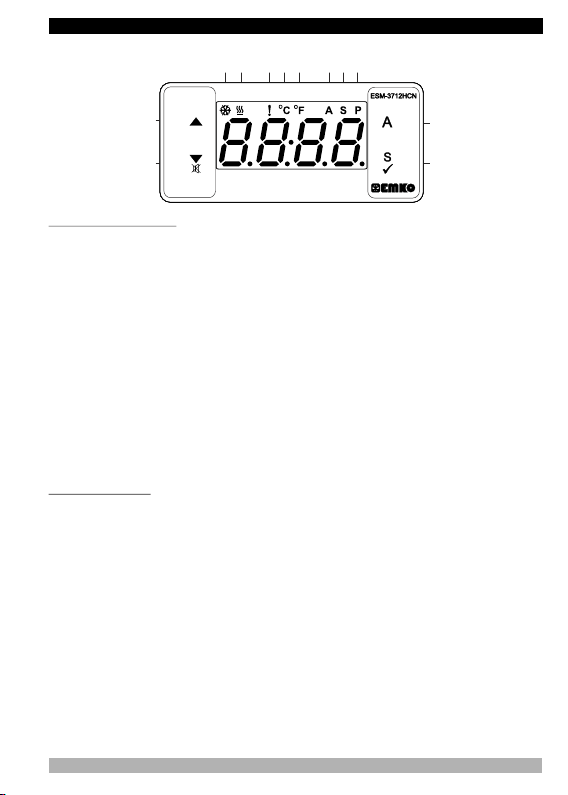

5.Front Panel Definition and Accessing to the Menus

5

8

11

967 10

12

1

2

BUTTON DEFINITIONS

1. Increment Button :

** It is used to increase the value in the Set screen and Programming mode.

**In the main operation screen: After pressing this button for 5 seconds, alarm output will be

Active manually during pressing button. Alarm output will be passive after release the button.

2. Decrement, Silencing Buzzer and Downloading to Prokey Button :

** It is used to decrease the value in the Set screen and Programming mode.

** It is used to silence the buzzer.

** If Prc =0, it is used to download from device to prokey.

3. Set Button :

** In the main operation screen; if this button pressed, set value will be displayed. Value can be

changed using increment and decrement buttons. When Set button pressed again, value is

saved and returns back to main operating screen.

** To access the programming screen; in the main operation screen, press this button for 5

seconds.

** It is used to saving value in the Set screen and programming screen.

4. Alarm Set Button :

** In the main operation screen; if this button is pressed, Alarm set value will be displayed. Value

can be changed using increment and decrement buttons. When Set button is pressed again,

value is saved and returns back to main operating screen.

LED DEFINITIONS

5. Cooling led :

** This led indicates that cooling control is selected and process output relay is active. If any of

compressor protection time active, this led blinks.

6.Heating led :

** This led indicates that heating control is selected and process output relay is active.

7.Alarm led :

** It is active in all alarm status.

8.Celcius led :

** Indicates that device is in C mode.

9.Fahrenheit led :

** Indicates that device is in F mode.

10.Alarm Set led :

** It is active when alarm statuses.

11.Set led :

** Indicates that device is in Set value changing mode.

12.Program led :

**Blinks in programming mode .

o

o

4

3

7

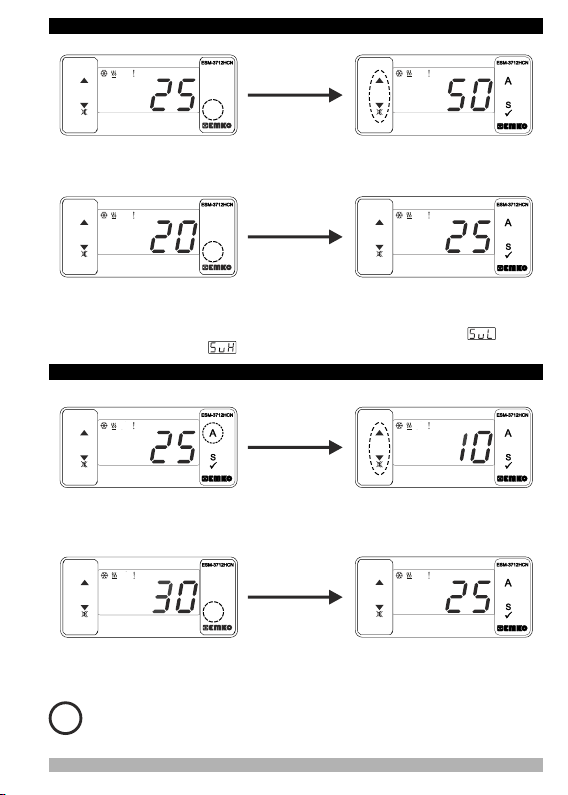

6. Changing and Saving Temperature Set Value

Main Operation Screen

O

O

S

P

C

F

A

S

ü

When SET button pressed ‘’S’’ led will

be active and temperature set value will

be displayed.

SET Value Screen

O

O

S

P

C

F

A

S

ü

When SET button pressed

temperature set value can be saved.

Temperature set value parameter (Default=30) MODBUS ADDRESS:40001

Temperature set value, can be programmed between minimum temperature set value and

maximum temperature set value .

SET Value Screen

O

O

S

P

C

F

Temperature set value can

be changed with increment

and decrement buttons.

Main Operation Screen

O

O

S

P

C

F

‘’S’’ will be inactive and goes back to

main operation screen.

6.1 Changing and Saving Alarm Set Value

Alarm Set ScreenMain Operation Screen

O

O

SA

P

C

F

O

O

SA

P

C

F

When ALARM SET button pressed ‘’A’’

led will be active and temperature set

value will be displayed.

Alarm set value can be

changed with increment and

decrement buttons.

Main Operation ScreenAlarm Set Screen

O

O

O

SA

P

C

F

A

S

ü

When SET button pressed

Alarm set value can be

saved.

If no operation is performed in Alarm set value changing mode and process set value changing

i

mode for 20 seconds, device turns to main operation screen automatically.

’A’ will be inactive and goes back to

O

C

F

Alarm set Value saved,

main operation screen.

S

P

8

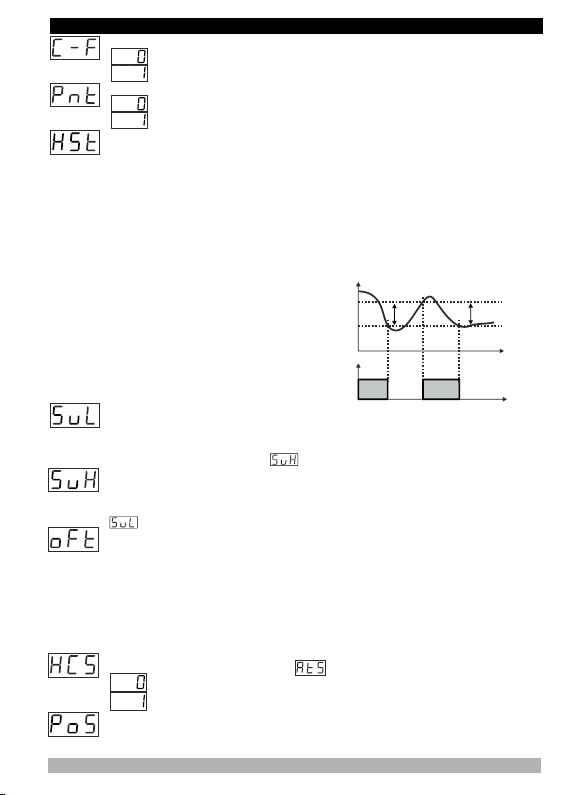

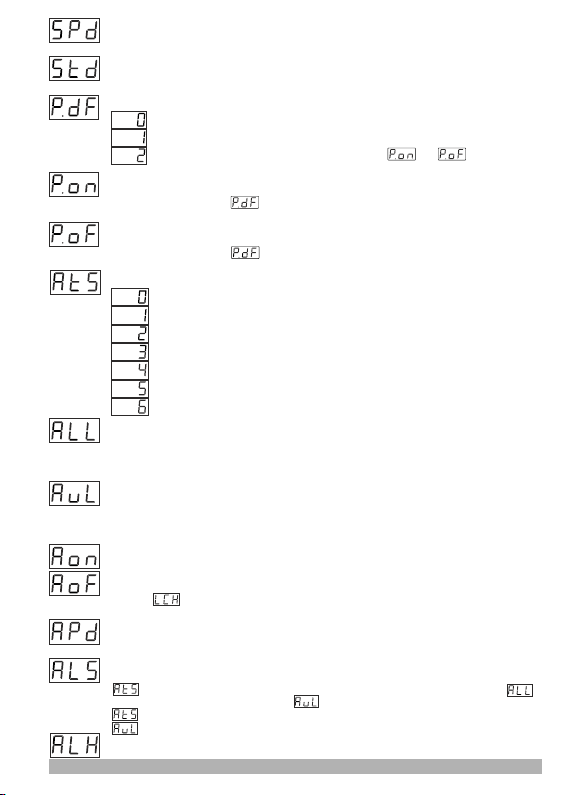

6.2 Programming Mode Parameter List

Temperature Unit Selection Parameter ( Default = 0 ) MODBUS ADDRESS : 40002

°C selected.

°F selected.

Decimal Seperator Enabling Parameter ( Default = 0 ) MODBUS ADDRESS:40003

Disable.

Enable.

Hysteresis Parameter for Compressor Output (Default = 1)

MODBUS ADDRESS:40004

From 1 to 20°C for NTC (-50°C, 100°C), PTC (-50°C, 150°C), J Type TC ( 0°C, 800°C ),

K Type TC ( 0°C, 1000°C), PT-100 Type ( -50°C,400°C ), PT-1000 Type ( -50°C,400°C )

PT-100 Type ( -20°C,100°C ),

From 1 to 36°F for NTC (-58°F, 212°F),PTC (-58°F, 302°F), J Type TC (32°F,1472°F)

K Type TC (32°F,1830°F), PT-100 Type (-58°F,752°F),PT-1000 Type (-58°F,752°F),

PT-100 Type (-4°F,212°F)

From 0.1 to 10.0°C for NTC (-50.0°C,100.0°C), PTC (-50.0°C,150.0°C),

PT-100 (-19.9°C,99.9°C),

From 0.1 to 18.0°F for NTC (-58.0°F,212.0°F), PTC (-58.0°F,302.0°F),

PT-100 (-4.0°F,212.0°F),

In ON/OFF control algorithm, temperature

value is tried to keep equal to set value by

opening or closing the last control element.

ON/OFF controlled system, tem perature

value oscillates continuously. Temperature

value’s oscillation period or amplitude around

set value changes according to controlled

system. For reducing oscillation period of

temperature value, a threshold zone is formed

below or around set value and this zone is

named hysteresis.

Minimum Temperature Set Value Parameter (Default = Minimum Value of Device

Scale ) MODBUS ADDRESS:40005

Temperature set value can not be lower than this value.

This parameter value can be adjusted from minimum value of device scale to maximum

temperature set value parameter

Maximum Temperature Set Value Parameter (Default = Maximum Value of Device

Scale )MODBUS ADDRESS:40006

Temperature set value can not be bigger than this value.

This parameter value can be adjusted from minimum temperature set value parameter

to maximum value of the device scale

Sensor Offset Parameter ( Default = 0 ) MODBUS ADDRESS:40007

From -20 to 20 °C for NTC (-50°C, 100°C), PTC (-50°C, 150°C), J Type TC (0°C,800°C),

KType TC (0°C,1000°C), PT-100 (-50°C, 400°C), PT-1000 (-50°C, 150°C),

PT-100(-20°C, 100°C),

From -36 to 36 °F for NTC (-58°F, 212°F), PTC (-58°F, 302°F), J Type TC (32°F,1472°F),

K Type TC (32°F,1830°F), PT-100 (-58°F, 752°F), PT-1000 (-58°F, 752°F), PT-100 (-4°F, 212°F)

From -10.0 to 10.0°C for NTC (-50.0°C,100.0°C), PTC (-50.0°C,150.0°C),

PT-100 (-19.9°C,99.9°C)

From -18.0 to 18.0°F for NTC (-58.0°F,212.0°F), PTC(-58.0°F,302.0°F),

PT-100 (-4.0°F, 212.0°F)

Operating Type Parameter ( Default = 0) MODBUS ADDRESS:40008

If parameter value is ‘0’ device skips to parameter

Heating

Cooling

Compressor Start Delay at Power On Parameter ( Default = 0)

MODBUS ADDRESS:40009

When power is first applied to the device, compressor is on when this time delay is expired.

It can be adjusted from 0 to 20 minutes.

Temperature

Set

Control

Output

ON

OFF

HSt

HSt

Time

Time

9

Compressor Stop-Start Delay Parameter ( Default = 0) MODBUS ADRES:40010

When compressor is inactive, this time delay must be expired for activation of the

compressor. It can be adjusted from 0 to 20 minutes.

Compressor Start-Start Delay Parameter ( Default = 0) MODBUS ADRES:40011

This time delay must be expired between two activation of the compressor. It can be

adjusted from 0 to 20 minutes.

Sensor Defect Parameter ( Default = 0 ) MODBUS ADDRESS:40012

Compressor is OFF in case of sensor defect.

Compressor is ON in case of sensor defect.

Compressor operates periodically according to and Time periods in

case of sensor defect.

Compressor is active during this time period in case of probe defect (Default = 0)

MODBUS ADDRESS:40013

If probe defect parameter is 2, then this parameter is observed. It can be adjusted from

0 to 99 minutes.

Compressor is inactive during this time period in case of probe defect

( Default = 0 ) MODBUS ADDRESS:40014

If probe defect parameter is 2, then this parameter is observed. It can be adjusted from

0 to 99 minutes.

Alarm Type Selection Parameter ( Default = 2 ) MODBUS ADRESS:40015

Sensor Break Alarm

Process High Alarm

Process Low Alarm

Deviation High Alarm

Deviation Low Alarm

Deviation Band Alarm

Deviation Range Alarm

Alarm Set Value Low Limit Parameter ( Default = Minimum Value of Device Scale)

MODBUS ADDRESS:40016

Alarm set value can not be lower than this value.This parameter value can be adjusted

from minimum process set value parameter to alarm set value high limit parameter

value.

Alarm Set Value High Limit Parameter ( Default = Maximum Value of Device Scale)

MODBUS ADDRESS:40017

Alarm set value can not be greather than this value.This parameter value can be

adjusted from alarm set value low limit parameter value to maximum process set value

parameter.

Alarm On Delay Time Parameter( Default = 0 ) MODBUS ADDRESS:40018

It can be adjusted from 0 to 999 minutes.

Alarm Off Delay Time Parameter( Default = 0 ) MODBUS ADDRESS:40019

It can be adjusted from 0 to 99 minutes.When this parameter is 99, if increment button is

pressed, is observed and alarm latching output is selected. To make the alarm latching

output passive,decrement button must be pressed in main operation screen.

Alarm Delay Parameter After Power On

This parameter defines the delay for the alarm is being active after power on.It can be

adjusted from 0 to 99 minutes.

Alarm Set Value Parameter ( Default = 20 ) MODBUS ADDRESS:40021

Alarm output is controlled according to this value.For alarm type selection paramater

=1 or 2,this parameter value is can be adjusted from alarm set value low limit

parameter to alarm set value high limit parameter,for alarm type selection parameter

=3,4,5 or 6 this parameter value is can be adjusted from 0 to alarm set value high limit

parameter.

Alarm Hysteresis Parameter

Alarm hysteresis value.

This parameter is can be adjusted 0 to %50 of the device scale.

( Default = 0 ) MODBUS ADDRESS:40020

( Default = 0 ) MODBUS ADDRESS:40022

10

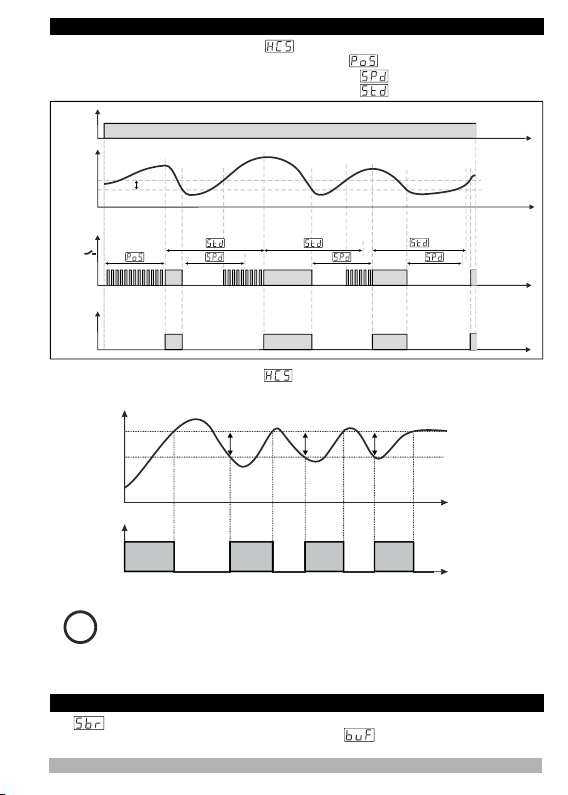

Buzzer Function Selection Parameter ( Default = 0 ) MODBUS ADDRESS:40023

Buzzer is inactive.

Buzzer is active if an alarm occurs.

Buzzer is active during sensor failures.

Buzzer is active during alarm or sensor failures.

Buzzer is active during this time

If buzzer function selection parameter value =0, this parameter can not be

observed. Buzzer stays active during this time. It can be adjusted from 1 to 99 minutes

When this parameter is 1, if decrement button is pressed, is observed. In this

condition buzzer is active till buzzer silence button is pressed.

Communication Mode Selection Parameter 25( Default = 0 ) MODBUS ADDRESS:400

PROKEY communication selected.

RS 485 communication selected.

Slave ID Parameter 26( Default = 1 ) MODBUS ADDRESS=400

Device communication address parameter (1 to 247).

Manual Alarm Output Active Parameters (Default=0) MODBUS ADDRESS=40027

Manual Alarm output passive

Manual Alarm output active

Programming Section Accessing Password 28

It is used for accessing to the programming section. It can be adjusted from 0 to 9999. If it is

selected 0, password will not be asked

, , , , and Parameters are observed if Operation type

i

is selected “Cooling”. If operation type is selected “Heating ” ,skip to the parameter.

( Default = ) MODBUS ADDRESS:40024

( Default = 0 ) MODBUS ADDRESS:400

.

6.3 Modbus Adresses of Device Status Parameters (Read Input Register)

MODBUS ADRES:30001 Temperature Value

MODBUS ADRES:30002 Led Status : 0.bit C Led,6.bit Compressor Led,

7.bit Alarm Led, 13.bit Program Led,

14.bit Set Led

MODBUS ADRES:30003 Device Status : 0.bit Alarm Status

A

2.bit Buzzer Status

3.bit Sensor Break Status

MODBUS ADRES:30004 Output Status 0.Bit Compressor Output,1.bit Alarm Output

MODBUS ADRES:30005 Device Type and Device Version

o

11

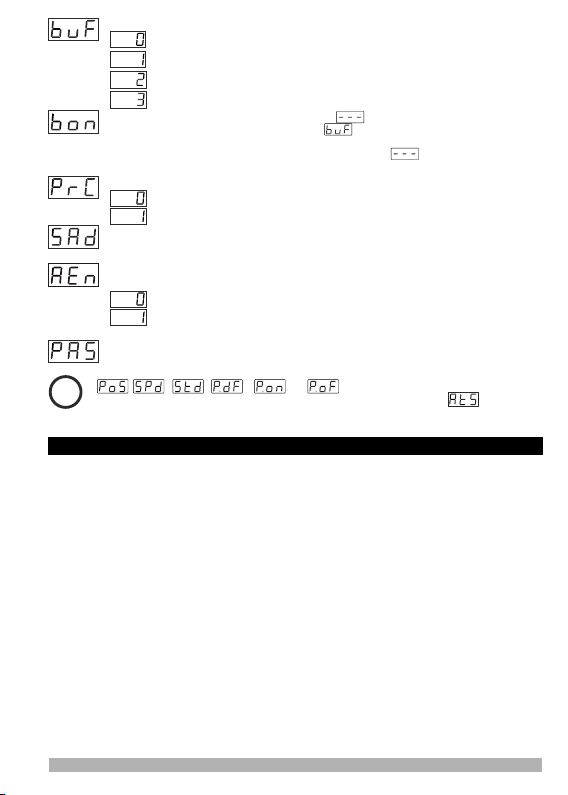

6.4 Operation Graphics of Alarm Output and Alarm Types

Power

Alarm

Status

Alarm

Output

Active

Led

Alarm

Output

°C

Time

Time

Time

Time

Power

Alarm

Status

Alarm

Output

Active

Alarm

Output

6.4 Operation Graphics of Alarm Output and Alarm Types

Process High Alarm

Alarm

Output

ON

OFF

Deviation High Alarm

Alarm

Output

ON

OFF

= Alarm Set Value

i

( + )

= Process Set Value

Process

Value

Process

Value

Alarm

Output

( Alarm Latching Output is Selected )

=

°C

Led

Process Low Alarm

ON

OFF

Deviation Low Alarm

Alarm

Output

ON

OFF

( - )

Time

Time

Decrement

Button must

be pressed

to make alarm

output is

passive.

Time

Time

Process

Value

Process

Value

Deviation Band Alarm

Alarm

Output

ON

OFF

( - )

( + )

Deviation Range Alarm

Alarm

Output

ON

OFF

Process

Value

( - ) ( + )

Process

Value

12

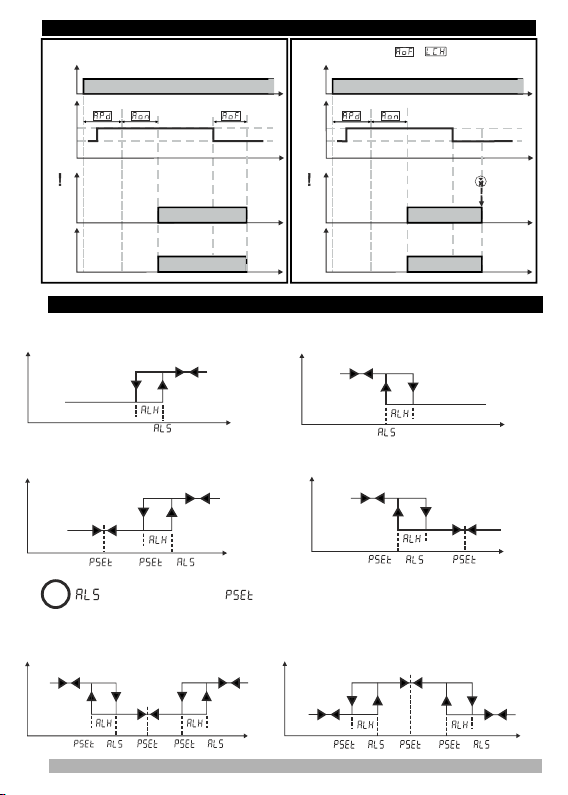

6.5 Operation Graphics of ESM-3712-HCN ControllerTemperature

1-If Operating Type Parameter Value = 1 (Cooling),

Switch On Delay After Power On Parameter Value ³ 1 ,

Compressor Stop/Start Time Delay Parameter Value ³ 1 and

Compressor Start/Start Time Delay Parameter Value ³ 1;

Power

°C

SET

Output

Led

Output

2-If Operating Type Parameter Value = 0 (Heating),

i

Hst

Temperature

Value

SET

ON

OFF

to set value by opening or closing the last control element. ON/OFF controlled

system, temperature value oscillates continuously. Temperature value’s oscillation

period or amplitude around set value changes according to controlled system. For

reducing oscillation period of temperature value, a threshold zone is formed below or

around set value and this zone is named hysteresis. Action of control output is

described with figures above.

HSt

Temperature Control Output

HSt HSt

In ON/OFF control algorithm, temperature value is tried to keep equal

Time

Time

Time

Time

Time

Time

6.6 Failure Messages in ESM-3712-HCN Temperature Controller

Screen BlinkingSensor failure . Sensor connection is wrong or there is no sensor

connection. If buzzer function selection parameter is 2, internal buzzer starts to

operate.

13

6.7 Entering To The Programming Mode, Changing and Saving Parameter

Main Operation Screen

O

O

S

P

C

F

A

S

ü

Password Entering Screen

O

O

S

C

F

P

A

S

ü

When SET button is pressed for 5

seconds, “PR” led starts to blink. If

programming mode entering

password is different from 0,

programming mode entering screen

will be observed.

Note1: If programming

mode accessing

password is 0,

Temperature Unit screen

is observed instead of

programming screen

Password Entering Screen

O

O

S

P

C

F

A

S

ü

Enter programming mode accessing

password with increment and

decrement buttons.

Note2: If programming mode accessing password is 0, only three parameters are accessible, and the

parameter values can be changed.

Programming Screen

O

O

S

P

C

F

A

S

ü

Press SET button for accessing to the

paramete r v alue. Press increment

button for accessing to the ne xt

parameter, press decrement button for

accessing to the previous parameter.

Hysteresis Value for

Compressor Output

O

O

S

P

C

F

A

S

ü

Press set button for saving the

parameter.

If no operation is performed in programming mode for 20 seconds, device turns to main

i

operation screen automatically..

Press increment button for accessing to the

next parameter, press decrement button for

accessing to the previous parameter

Press SET button for

accessing to the

password entering

screen.

Password Entering Screen

O

O

S

P

C

F

A

S

ü

Press SET/OK button for

entering the password.

Hysteresis Value for

Compressor Output

O

O

S

P

C

F

A

S

ü

Change the value with increment

and decrement buttons.

Hysteresis Parameter for

Compressor Output

O

O

S

P

C

F

A

S

ü

14

7. Specifications

Device Type : Temperature Controller

Housing&Mounting : 76mm x 34.5mm x 71mm plastic housing for panel

Protection Class : NEMA 4X (Ip65 at front, Ip20 at rear).

Weight : Approximately 0.20 Kg.

Environmental Ratings : Standard, indoor at an altitude of less than 2000 meters

Storage / Operating Temperature : -40 C to +80 C / -30 C to +80 C

Storage / Operating Humidity : 90 % max. (None condensing)

Installation : Fixed installation

Overvoltage Category : II.

Pollution Degree : II, office or workplace, none conductive pollution

Operating Conditions : Continuous

Supply Voltage and Power :

:10 - 30

Temperature Sensor Input : NTC, PTC, TC, RTD

NTC input type : NTC (10 kW @25 °C )

PTC input type : PTC (1000 W @25 °C )

Thermocouple input type : J, K (IEC584.1) (ITS 90)

Thermoresistance input type : PT-100, PT-1000 (IEC751) (ITS 90)

Accuracy : ± 1 % of full scale for thermoresistance

Sensor Break Protection : Upscale

Sampling Cycle : 3 samples per second

Control Form : ON / OFF

Relay Outputs : 16(8) A@250 V V for Resistive load (Compressor output)

(Electrical life : 100.000 switching at full load)

: for Resistive load 5 A@250 V V (Alarm output)

Display : 14 mm Red 4 digits LED Display

LED : S (Green), P (Green), A(Green), C (Yellow), F(Yellow),

Compressor Output (Red),Alarm Output (Red)

Internal Buzzer : ³83dB

Approvals : ,

8.Optional Accessories

1.RS-485 Module 2.PROKEY Programming Module

: 115

: 24

: 24

Mounting. Panel cut-out is 71x29mm.

with none condensing humidity.

o o o o

230V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

V ±

V ( %15) 50/60Hz - 1.5VA

W ±

VZ 1.5W

o o

c

V Ş Vac,

RS-485 Communication Interface

Z Ş Vdc

Ş Vdc or Vac

W

can be applied

The device is programmed(Upload or

Download) by using the parameters.

15

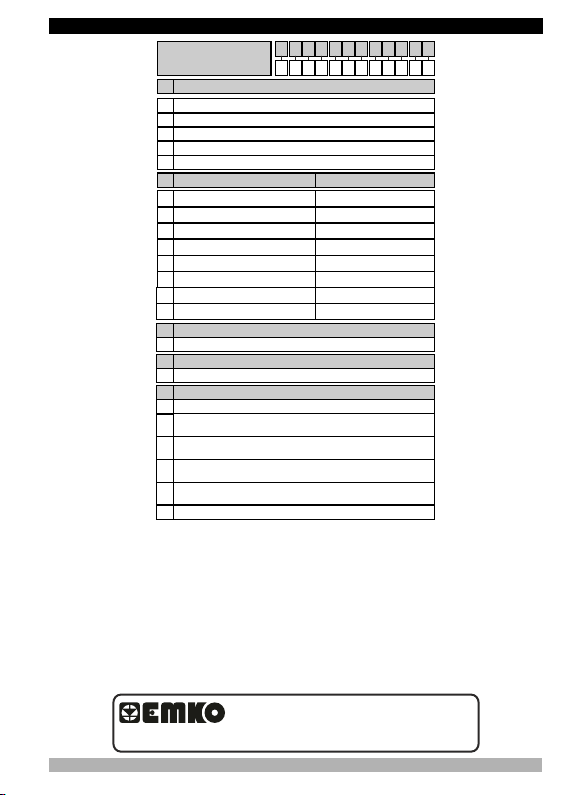

9.Ordering Information

ESM-3712HCN

(77x35 DIN Sizes)

Supply VoltageA

2

24VW ( %15) 50/60Hz - 1.5VA ±

3

24V ( %15) 50/60Hz - 1.5VAV ±

4

115V ( %15) 50/60Hz - 1.5VAV ±

5

230V ( %15) 50/60Hz - 1.5VAV ±

8

10 - 30 V Z

Input Type

BC

J ,Fe CuNi IEC584.1(ITS90)

05

K ,NiCr Ni IEC584.1(ITS90)

10

PT 100, IEC751(ITS90)

11

PT 100, IEC751(ITS90

09

PT 1000, IEC751(ITS90)

14

PT 1000, IEC751(ITS90

13

PTC (Not-1)

12

NTC (Not-1)

18

Compressor Output

E

Relay Output (16(8) A@250 V V,at resistive Load, 1NO + NC )

1

Alarm Output

FG

01

Relay Output (5 A@250 V V,at resistive Load, 1 NO )

Temp. Sensor which is given with ESM-3712HCN

V

0

None

PTC-M6L40.K1.5 (PTC Air Probe 1.5 mt Silicon Cable)

1

PTCS-M6L30.K1.5.1/8” (PTC Liquid Probe 1.5 mt Silicon Cable)

2

NTC-M5L20.K1.5 (NTC Sensor, thermoplastic moulded with 1.5 m cable

3

for cooling application)

NTC-M6L50.K1.5 (NTC Sensor, stainless steel housing with 1.5 m cable

4

for cooling application)

Customer

9

All order information of ESM-3712-HCN Temperature Controller are given on the table at above. User

may form appropriate device configuration from information and codes that at the table and convert it to

the ordering codes.Firstly, supply voltage then other specifications must be determined. Please fill the

order code blanks according to your needs.

Please contact us, if your needs are out of the standards.

Note-1:If input type is selected PTC or NTC (BC= 12, 18), Temperature sensor is given with the

device.For this reason, if input type is selected as PTC,sensor type (V = 0,1 or 2) or if input type is

selected as NTC, sensor type (V = 0,3 or 4) must be declared in ordering information.

A BC D E FG HI /

0 2 0 0

-19.9°C/-4°F ; 99.9°C/212°F

-19.9°C/-4°F ; 99.9°C/212°F

U

V W Z/

00

/

/

Scale(°C)

0°C/32°F ; 800°C/1472°F

0°C/32°F ; 999°C/1830°F

-50°C/-58°F ; 400°C/752°F

-50°C/-58°F ; 400°C/752°F

-50°C/-58°F ; 150°C/302°F

-50°C/-58°F ; 100°C/212°F

Your Technology Partner

Thank you very much for your preference to

use Emko Elektronik products, please visit our

web page to download detailed user manual.

www.emkoelektronik.com.tr

16

ESM-3712-HCN Digitaler EIN/AUS-

Temperaturregler DIN-Größe

77 x 35 (ALARM+SET)

– 4-stelliges Display

– NTC-Eingang oder PTC-Eingang (muss in der Bestellung

angegeben werden.)

– Auswählbare Heiz- oder Kühlfunktion

– Auswahl des Betriebs mit Hysterese

– Einstellbarer Temperatur-Offset

– Prozesssollwert Unter- und Obergrenzen

– Auswahl des Kompressorbetriebs: durchgängiger Betrieb, Stopp

oder intermittierender Betrieb bei einem Sensordefekt

– Kompressorschutzverzögerungen

– Alarmparameter

– Von der Vorderseite aus einstellbarer Alarmsollwert

Einstellbarer interner Summer abhängig vom Sensordefekt-Status

und Alarmstatus

– Passwortschutz für den Programmierabschnitt

– Installationsparameter unter Verwendung von Prokey

– Fernzugriff, Datenerfassung und Regelung mit Modbus RTU

– Mit CE-Zeichen gemäß europäischen Normen

EIN/AUS-Temperaturregelung 2 Ausgänge für Kompressor- und

Alarmsteuerelemente

ESM-3712-HCN Temperaturregler DIN-Größe 77x35

Bedienungshandbuch. DE ESM-3712-HCN 01 V03 10/19

DEUTCH

1. Vorwort

Temperaturregler der Baureihe ESM-3712-HCN sind auf die Temperaturmessung und regelung ausgelegt. Mit ihrer Ein/Aus-Regelungsfunktion, Heiz- und Kühlfunktionen und

benutzerfreundlichen Eigenschaften können sie in zahlreichen Anwendungen eingesetzt

werden. Nachfolgend sind einige Anwendungsbereiche aufgelistet, für die sie geeignet sind

Anwendungsbereiche Anwendungen

Glas Heizung

Lebensmittel Backöfen

Kunststoff Brutschränke

Petrochemie Lager

Textil, Automation Klimaanlagen

Maschinenproduktion Industrie Usw. Usw.

1.1 Umgebungssollwerte

Betriebstemperatur : 0 bis 50 °C

Max. Betriebsfeuchte : 90 % RF (nicht kondensierend)

Höhe : Bis zu 2000 m.

Unzulässige Bedingungen:

Korrosive Atmosphäre

c

Explosive Atmosphäre

Anwendungen im Wohnbereich (Das Gerät ist nur für industrielle

Anwendungen vorgesehen)

1.2 Allgemeine Spezifikationen

Standard

230V ( %15) 50/60HzV ±

Optionale

Versorgungsspannung

115 V (±%15) 50/60Hz,

V

24 V (±%15) 50/60Hz,

V

W

24 V (±%15) 50/60Hz,

- 30 V Z

10

NTC, PTC,

J oder K Typ TC

2-Wire PT-100

2-Wire PT-1000

ESM-3712-HCN

Stromversorgung

Eingang

NTC-, PTCSensoreingang

Kompressorausgang

Alarm Output

Heiz- oder Kühlfunktion

EIN/AUS-Betrieb

Alarmsteuerausgang

EIN/AUS-Betrieb

2

1.3 Installation

Vor der Installation dieses Produkts wird eine Sichtprüfung auf etwaige beim Transport

verursachte Schäden empfohlen. Sie müssen sicherstellen, dass dieses Produkt von

qualifizierten Elektrikern und Mechanikern installiert wird.

Falls bei einem Ausfall oder Defekt dieser Einheit die Gefahr eines ernsthaften Unfalls

besteht, schalten Sie das System aus und trennen den Stromanschluss des Geräts vom

System. Die Einheit wird normalerweise ohne Netzschalter und Sicherung ausgeliefert.

Verwenden Sie bei Bedarf einen Netzschalter und eine Sicherung.

Achten Sie darauf, die Auslegungsspannung für die Stromversorgung zu verwenden, um

das Gerät vor Schäden zu schützen und Ausfälle zu vermeiden.

Schalten Sie den Strom erst ein, wenn die gesamte Verdrahtung abgeschlossen ist, sodass

ein Stromschlag und Probleme mit dem Gerät vermieden werden können.

Versuchen Sie auf keinen Fall, dieses Gerät zu zerlegen, zu ändern oder zu reparieren. Eine

Manipulation des Geräts führt zu Fehlfunktion, Stromschlag oder Brand.

Setzen Sie das Gerät nicht in feuergefährlichen oder explosiven gasförmigen Atmosphären

ein.

Wenn Sie die Ausrüstung bei der mechanischen Installation in die Öffnung in der

Metallplatte einsetzen, können Metallgrate Verletzungen an den Händen verursachen. Sie

müssen vorsichtig sein.

Die Montage des Produkts an einem System muss unter Verwendung der zugehörigen

Befestigungsklammern erfolgen. Führen Sie die Montage des Geräts nicht mit ungeeigneten

Befestigungsklammern durch. Achten Sie darauf, dass das Gerät während der Montage

nicht zu Boden fällt.

Sie sind dafür verantwortlich, dass dieses Gerät nicht auf eine Weise verwendet wird, die

nicht in diesem Anweisungshandbuch angegeben ist.

1.4 Garantie

EMKO Elektronik garantiert, dass die Ausrüstung frei von Material- und

Herstellungsschäden ist. Diese Garantie gilt für einen Zeitraum von zwei Jahren. Der

Garantiezeitraum beginnt mit dem Lieferdatum. Diese Garantie gilt, solange der Kunde alle

im Garantiedokument und im Betriebshandbuch angegebenen Verpflichtungen und

Verantwortlichkeiten einhält.

1.5 Wartung

Reparaturen dürfen ausschließlich von geschultem und spezialisiertem Personal

durchgeführt werden. Trennen Sie die Stromversorgung zu dem Gerät, bevor Sie auf interne

Bauteile zugreifen.

Reinigen Sie das Gehäuse nicht mit auf Kohlenwasserstoff basierenden Lösungsmitteln

(Benzin, Trichloräthylen usw.). Durch den Einsatz dieser Lösungsmittel kann die

mechanische Zuverlässigkeit des Geräts beeinträchtigt werden. Verwenden Sie ein mit

Ethylalkohol oder Wasser befeuchtetes Tuch, um das äußere Kunststoffgehäuse zu

reinigen.

1.6 Herstellerunternehmen

Herstellerinformationen

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

Informationen zum Reparatur- und Wartungsservice:

Emko Elektronik Sanayi ve Ticaret A.Ş.

Demirtaş Organize Sanayi Bölgesi Karanfil Sk. No:6 16369 BURSA/TURKEY

Phone : +90 224 261 1900

Fax : +90 224 261 1912

3

2. Allgemeine Beschreibung

Frontplatte

IP65 Schutz

NEMA 4X

Schaltschrankoberfläche

(max. Dicke 15 mm / 0,59")

Montageklammer

2.1 Vorderansicht und Abmessungen des Temperaturreglers ESM-3712-HCN

Maximum 15 mm / 0.59 inch

34,5 mm / 1.36 inch

76 mm / 3 inch

6 mm / 0.24 inch

65 mm / 2.56 inch

2.2 Einbauausschnitt

110 mm / 4.33 inch (min)

50 mm / 1.97 inch (min)

29 mm / 1.14 inch

71 mm / 2.79 inch

4

Loading...

Loading...