Emerson Copeland EazyCool OMQ-56-Nxx-TWD, Copeland EazyCool OMTQ-60-Nxx-TFD, Copeland EazyCool OLQ-33V-Nxx-TWD, Copeland EazyCool OMTQ-60D-Nxx-TFD, Copeland EazyCool OMTQ-76-Nxx-TFD Application Manuallines

...

TM

Copeland EazyCool

outdoor condensing units

for refrigeration networks

Application Guidelines

Condensing Unit For Refrigeration Networks

AApppplliiccaattiioonn GGuuiiddeelliinnee

1 SAFETY INSTRUCTIONS...........................................................................................2

1.1 ICON EXPLANATION.................................................................................................. 2

1.2 SAFETY STATEMENTS ..............................................................................................2

1.3 GENERAL INSTRUCTIONS .........................................................................................3

1.4 ABOUT THIS GUIDELINE:........................................................................................... 3

2 PRODUCT DESCRIPTION..........................................................................................4

2.1 COPELAND EAZYCOOL™ CONDENSING UNITS FOR REFRIGERATION NETWORKS ......... 4

2.2 NETWORK CONFIGURATIONS .................................................................................... 4

2.3 PRODUCT NAMEPLATE .............................................................................................4

2.4 NOMENCLATURE ..................................................................................................... 5

2.5 APPLICATION RANGE ............................................................................................... 5

2.6 MAIN COMPONENT DESCRIPTION ..............................................................................6

3 INSTALLATION.........................................................................................................13

3.1 CONDENSING UNIT HANDLING................................................................................. 13

3.2 CONNECTION ACCESS ........................................................................................... 15

3.3 ELECTRICAL BOX ACCESS ......................................................................................15

3.4 ELECTRICAL CONNECTION...................................................................................... 16

3.5 REFRIGERATION CONNECTIONS.............................................................................. 18

3.6 2 UNIT NETWORK : INSTALLATION ..........................................................................20

3.7 3 & 4 UNIT NETWORK ...........................................................................................23

3.8 ELECTRONIC CONTROLLER EC2-551..................................................................... 29

4 STARTING UP & OPERATION.................................................................................31

4.1 CHARGING PROCEDURE ........................................................................................31

4.2 SOUND .................................................................................................................31

4.3 ROTATION DIRECTION OF SCROLL COMPRESSORS ...................................................31

4.4 MAXIMUM COMPRESSOR CYCLE ............................................................................. 32

4.5 CHECKS BEFORE STARTING & DURING OPERATION .................................................. 32

5 MAINTENANCE & REPAIR: REPLACING A COMPRESSOR................................32

6 CERTIFICATION AND APPROVAL .........................................................................32

7 DISMANTLING AND DISPOSAL..............................................................................32

C6.1.4/0305/E 1 Part no: 3136433

Condensing Unit For Refrigeration Networks

1 Safety instructions

The Copeland EazyCool™ condensing units are manufactured according to the latest

and valid industrial standards.

Particular emphasis has been placed on the user safety.

These condensing units are intended for installation in machines and systems according

to the EC Machines directive. They may be put to service only, if they have been installed

in these machines according to the existing instruction and as a whole agree with the

corresponding provisions of legislation (standards to apply: refer to Manufacturers

declaration).

Manufacturer declaration and declarations of conformity are available on request.

Retain these operating instructions during the entire lifetime of the compressor as well as

the condensing unit.

We strongly advise to follow these safety instructions.

1.1 Icon explanation

WARNING

This Icon indicates instructions to avoid heavy personnel injuries and heavy material

damage.

High Voltage

This icon indicates operations with a danger of an electric shock.

Danger of burning or frostbite

This icon indicates operations with a danger of burning or frostbite.

Explosion Hazard

This Icon indicates operations with a danger of explosion.

CAUTION

This Icon indicates instructions to avoid property damage without or with low personnel

injuries.

IMPORTANT

This icon indicates instructions to avoid malfunction of the compressor.

NOTE this word indicates a recommendation for easier operations.

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

1.2 Safety statements

Refrigerant compressors must be employed only for the use they are made for.

Only qualified and authorised refrigeration personnel are allowed to do the

installation, commissioning and maintenance.

Qualified electrical personnel must connect the condensing unit and its

accessories.

All valid standards for connecting electrical and refrigeration equipment must be

observed.

Use personnel safety equipment. This is important to avoid

injuries from the refrigerant.

C6.1.4/0305/E 2 Part no: 3136433

Dismantling &

Disposal

Condensing Unit For Refrigeration Networks

1.3 General instructions

WARNING

System breakdown! Personnel injuries! Never install a system in the field and leave it

unattended when it has no charge, a holding charge, or with the service valves closed

without electrically locking out the system.

System breakdown! Personnel injuries! Only approved refrigerant and refrigerating oils

must be used.

High Shell Temperature! Burning! Do not touch the compressor until it has cooled

down. Ensure that other materials in the area of the compressor do not get in touch with

it. Lock and mark accessible sections.

CAUTION

Overheating! Bearing damage! Do not operate compressors without refrigerant charge or

without being connected to the system.

IMPORTANT

Transit damage! Compressor malfunction! Use original packaging. Avoid collisions and

tilting.

Only qualified personnel should install and intervene on COPELAND condensing units.

The contractor, responsible for the installation of the unit, should ensure sufficient liquid

sub-cooling in the line to the expansion valve(s) to avoid “flash-gas” in the liquid line.

It is of vital importance that the discharge stop valve has been fully opened before the

compressor is started. If the discharge stop valve is closed or partly closed an

unacceptable pressure with accordingly high temperatures may develop in the cylinder

head. When operating with air the so-called diesel effect may occur, i.e. the air sucked in

is mixed with oil gas and can explode due to the high temperature in the cylinder head,

and thereby destroy the compressor.

Safety

Instructions

Product

Description

Installation Electrical

Connection

1.4 About this guideline:

These guidelines ensure the safe installation, starting, operation and maintenance of

Copeland EazyCool™ condensing units.

In case of a failure, important topics are mentioned in the chapter causes of failure.

These guidelines are not meant to replace the system expertise available from system

manufacturers.

For additional information, please refer to the “Product Catalogue“ or to the “Copeland

Selection Software” accessible from the Copeland website at www.ecopeland.com

.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 3 Part no: 3136433

Condensing Unit For Refrigeration Networks

2 Product Description

2.1 About Copeland EazyCool™ condensing units for refrigeration

networks

Copeland has developed a special version of Copeland EazyCool condensing units that

can be used to create medium and larger size refrigeration network systems. The range

consists of Copeland EazyCool condensing units for medium and low temperature

applications and covers units from 7.5 to 15 hp. It includes units with two compressors,

allowing modulation in two steps as well as Copeland EazyCool Digital Scroll™

Condensing Units, which feature continuous modulation from 10 to 100%.

The concept of a condensing unit refrigeration network is based on connecting up to four

condensing units mechanically (tubing) and electronically (control system). The control

and oil distribution system is a Master/Slave configuration in which the Master unit takes

care of:

Compressor staging based on suction pressure

Oil distribution (oil reservoir in master unit)

Communication for remote monitoring

The Slave unit takes care of:

Fan speed control

And emergency control in case of communication line disruption between the unit

(master/slave)

Each Network should have only one master unit.

2.2 Network configurations

Safety

Instructions

Product

Description

Installation Electrical

Connection

Basically there are three different configurations possible: two-unit network, three-unit

network and four-unit network. The three and four condensing unit network requires an

external receiver. Copeland offers a LRU (Liquid Receiver Unit) which contains a 90 l

receiver. If a larger receiver is required, this should be obtained from a third party. The

two-unit network consists of units with internal receivers, which allow faster installation.

2 Unit Network 3 Unit Network with LRU 4 Unit Network with LRU

LRU: Liquid Receiver Unit

2.3 Product nameplate

The condensing unit nameplate shows model designation and serial number.

The compressor has its own nameplate with all electrical characteristics.

The medium temperature range features ZB Scroll compressors, some models include a

Digital Scroll™ compressor.

The low temperature range features ZF Scroll compressors with vapour injection using a

pre-installed sub-cooler.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 4 Part no: 3136433

Condensing Unit For Refrigeration Networks

2.4 Nomenclature

The model designation contains the following technical information about the condensing

unit:

OM T Q 90 D

1 2 3 4 5

N L O

6 7 8

TFD

9

Specific for Network

models

1 - Condensing unit family:

OM = Medium temperature Copeland EazyCool™ unit

OL = Low temperature Copeland EazyCool™ unit

2 - Number of compressor: “blank” = single compressor, “T” = two compressors

3 - Quiet version

4 - Compressor size: 90 = 1 x ZBD45KCE (digital), 1 x ZB45KCE

5 - D = Copeland Digital Scroll™

- V = Low temperature:Copeland Scroll™ with vapour injection (EVI)

6 - N = Unit suitable for creation of a refrigeration network

7 - L = Liquid receiver included (only for 2 unit network)

8 - O = Oil reservoir included (always Master)

9 - Motor version: TFD or TWD: 380-420V/3Ph/50H

Safety

Instructions

Product

Description

Installation Electrical

Connection

2.5 Application range

2.5.1 Qualified refrigerants and oils

OMQ-56-Nxx

~

OMQ-110-Nxx

R404A/R507

Qualified refrigerant

Qualified Servicing Oil

Table 1: Qualified refrigerants and oils

2.5.2 Application limits

For Application envelope, please refer to the Compressor application envelope available

in Copeland Selection Software version 6.

Medium temperature range

Evaporating Temperature: from –30°C up to 12.5°C

Low temperature range

Evaporating Temperature: from –40°C up to 7°C

R134a,R407C

R22

OMTQ-60(D)-Nxx

OMTQ-76-Nxx

OMTQ-90(D)-Nxx

R404A/R507

R22

ICI Emkarate RL 32 CF

Mobil EAL Artic 22 CC

OLQ-24V-Nxx ~ OLQ-48V-Nxx

OLTQ-26V-Nxx & OLTQ-36V-Nxx

R404A/R507

R22

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 5 Part no: 3136433

Condensing Unit For Refrigeration Networks

2.6 Main component description

2.6.1 Compressor

Low TemperatureMedium Temperature

Unit Model Compressor Model Unit Model Compressor Model

Single compressor unit

OMQ-56-Nxx-TW D ZB56KCE-TWD-551 OLQ-24V-Nxx-TW D ZF24KVE-TWD-551

OMQ-75-Nxx-TW D ZB75KCE-TWD-551 OLQ-33V-Nxx-TW D ZF33KVE-TWD-551

OMQ-92-Nxx-TW D ZB92KCE-TWD-551 OLQ-40V-Nxx-TW D ZF40KVE-TWD-551

OMQ-110-Nxx-TWD ZB11MCE-TWD-551 OLQ-48V-Nxx-TWD ZF48KVE-TWD-551

Two compressor unit

OMTQ-60-Nxx-TFD 2 x ZB30KCE-TFD-551 OLTQ-26V-Nxx-TFD 2 x ZF13KVE-TFD-556

1 X ZBD30KCE-TFD-250

OMTQ-60D-Nxx-TFD

OMTQ-76-Nxx-TFD 2 x ZB38KCE-TFD-551

OMTQ-90-Nxx-TFD 2 x ZB45KCE-TFD-551 OLTQ-36V-Nxx-TFD 2 x ZF18KVE-TFD-556

OMTQ-90D-Nxx-TFD

(*)

Digital ScrollTM available in Master version only (NLO & NO)

Table 2: Compressor type used in Copeland EazyCool™ condensing units for

refrigeration networks

2.6.2 Sound Blanket

(*)

1 x ZB30KCE-TFD-551

1 X ZBD45KCE-TFD-250

(*)

1 x ZB45KCE-TFD-551

Safety

Instructions

Product

Description

Installation Electrical

Connection

The OM(T)Q and OL(T)Q units include one or two compressors, equipped with a sound

jacket.

The sound jacket developed by Copeland has no impact on the performance of the

compressor.

The design consists of a top cap cover and compressor shell cover with adjustable Velcro

system.

It has good characteristics in case of fire and is resistant to:

Mineral and Polyolester oil

Refrigerants R22/R404A

Temperature up to 150°C

Water

2.6.3 Condenser Fan(s)

The condensers of the OM (T) Q & OL (T) Q units for refrigeration networks are equipped

with single-phase fans, with low speed (910 rpm) 6 pole single-phase motor.

ø

420

500

420

Voltage

V/ph/Hz

220-240

1~50

Power

input (W)

145

290

145

Current

input (A)

0.67

1.4

0.67

Winding

resistance

Ohm (Ω)

Condensing unit

Medium Temp Low Temp

OMQ-56-Nxx OLQ-24V-Nxx

OMQ-75-Nxx OLQ-33V-Nxx

OMQ-92-Nxx OLQ-40V-Nxx

OMQ-110-Nxx OLQ-48V-Nxx

OMTQ-60(D)-Nxx OLTQ-26V-Nxx

OMTQ-76-Nxx

OMTQ-90(D)-Nxx OLTQ-36V-Nxx 2 301 8µF-400V 500 290 1.4 25

Electrical data @ 50 Hz

N° of

Fan

2

2

2

Fan

Model

145

301

145

Run Capacitor

Capacity

4µF-400V

8µF-400V

4µF-400V

Diameter

(mm)

Table 3: Condenser fan: technical data

70

25

70

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 6 Part no: 3136433

Condensing Unit For Refrigeration Networks

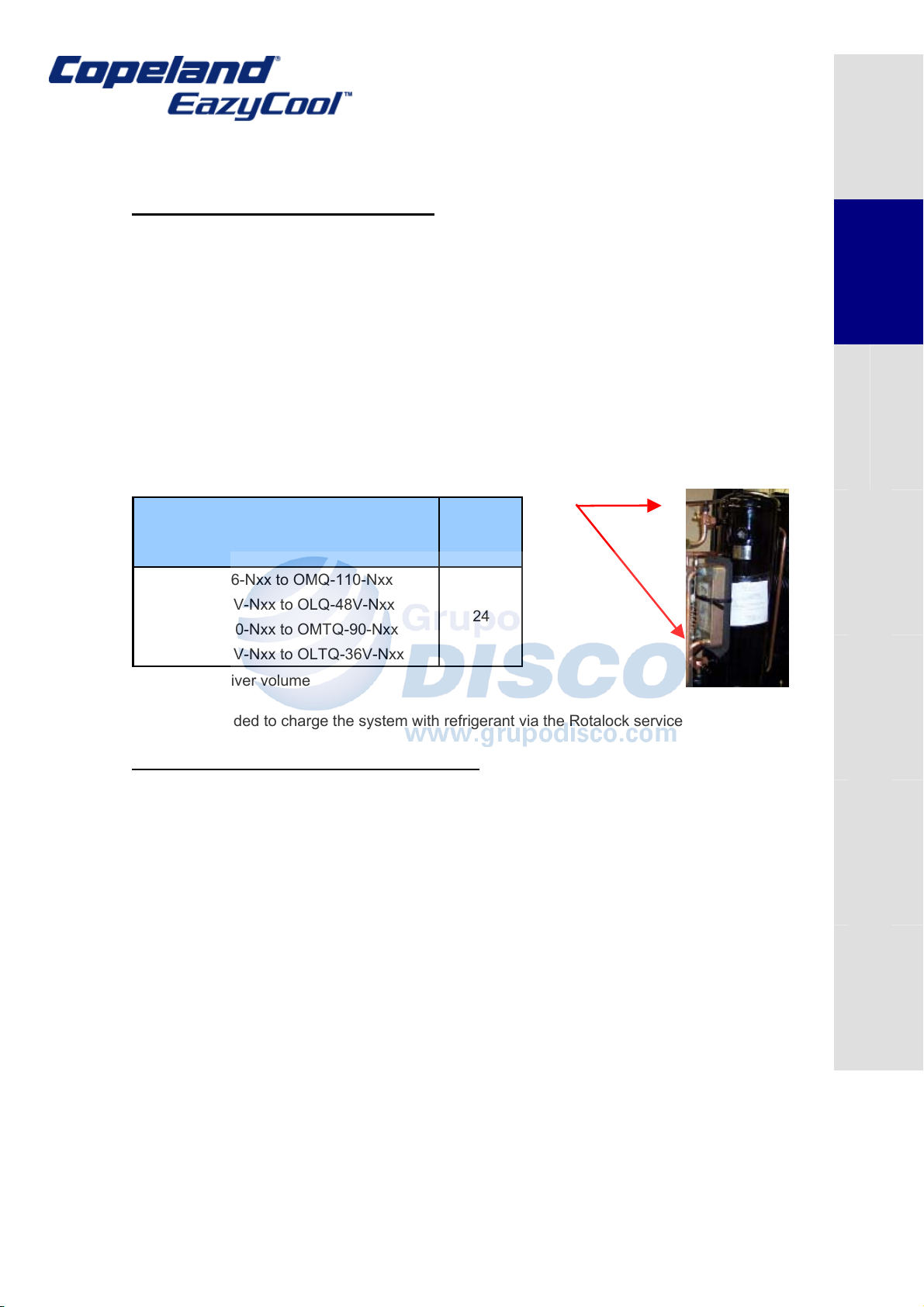

2.6.4 Liquid receiver

Liquid receiver for 2 unit network system

Master and Slave units for 2-unit network configuration are equipped with a liquid

receiver.

The liquid receivers are equipped with:

Rotalock service valves for connection of a liquid level equalisation line as well as

a gas pressure equalisation line between the receivers to ensure equal liquid

levels in both receivers. Both lines are partly pre-installed and protrude at the rear

of the units.

Rotalock service valve on top of the receiver for liquid outlet line.

3/8’’–14 NPTF connection for relief valve. Maximum allowable working pressure -

MAWP 33 Bar

Fitting a pressure relief device according to standard EN378-2 is the responsibility of the

installer.

Rotalock service valve

Model Type

OMQ-56-Nxx to OMQ-110-Nxx

OLQ-24V-Nxx to OLQ-48V-Nxx

OMTQ-60-Nxx to OMTQ-90-Nxx

OLTQ-26V-Nxx to OLTQ-36V-Nxx

Receiver

volume

l

24

Safety

Instructions

Product

Description

Installation Electrical

Connection

Table 4: Receiver volume

It is recommended to charge the system with refrigerant via the Rotalock service valves.

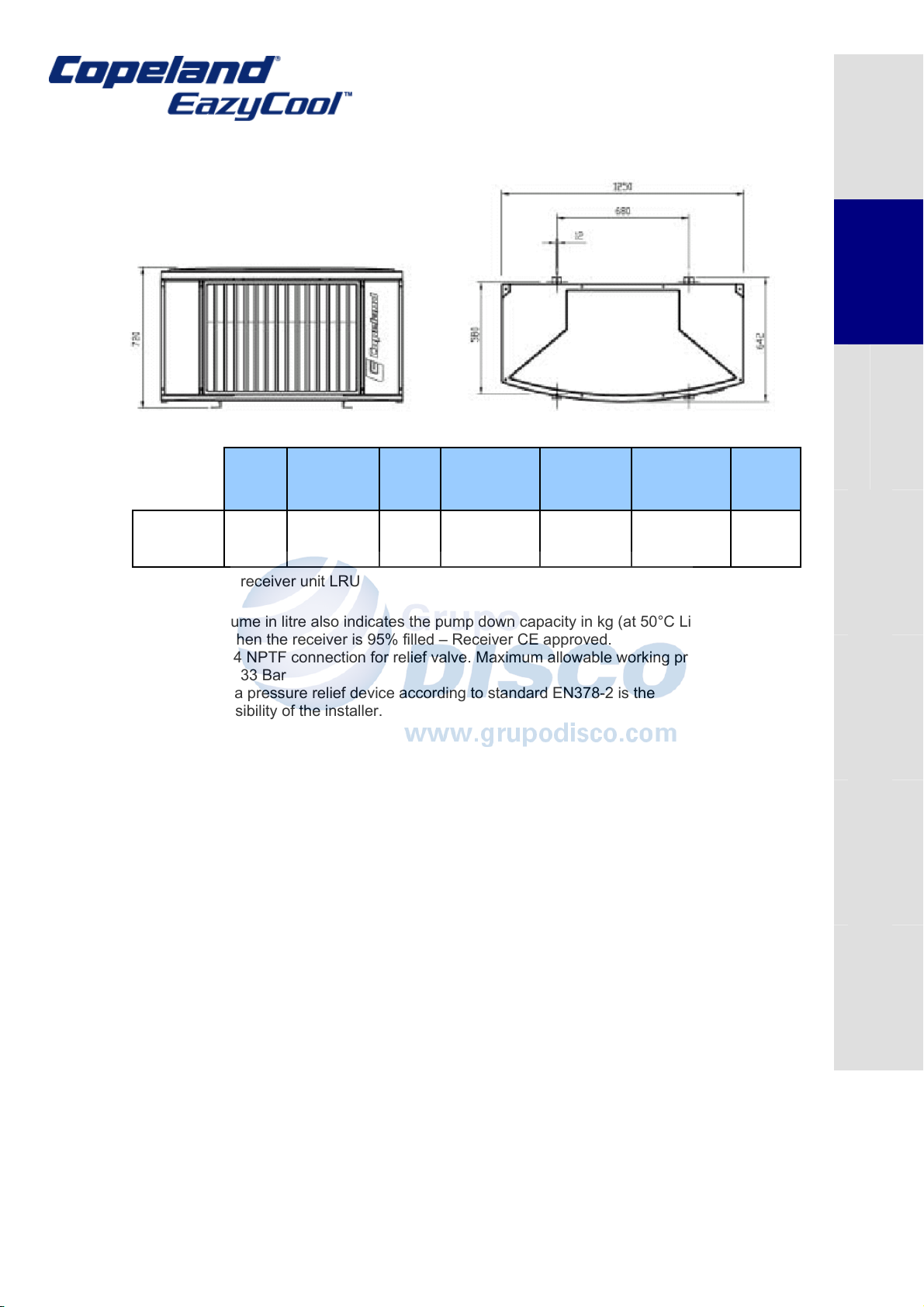

Liquid receiver for 3 and 4 unit network system

With larger systems (refrigeration systems requiring 3 or 4 units in a network) a remote

liquid receiver should be used. The condensing unit models for systems with remote

receivers are provided without liquid receiver. The condenser liquid outlet line protrudes

from the rear of the unit to allow an easy connection to a remote liquid receiver.

Copeland offers a LRU (Liquid Receiver Unit), which contains a 90 litres liquid receiver

for remote use with filter drier, sight glass with moisture indicator and ball valves for liquid

inlet and outlet. If a larger receiver is required, this should be obtained from a third party.

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 7 Part no: 3136433

Condensing Unit For Refrigeration Networks

The LRU collects liquid refrigerant from each condenser in a network. It has a single

liquid inlet and outlet line.

Safety

Instructions

Product

Description

Receiver Depth / Width Height Dimensions Liquid Liquid Weight

Capacity T/B H (holes) Inlet diameter Outlet diameter Net/Gross

1)

l

Liquid

Receiver

Unit

Table 5: Liquid receiver unit LRU

1)

Receiver volume in litre also indicates the pump down capacity in kg (at 50°C Liquid

temperature) when the receiver is 95% filled – Receiver CE approved.

1/2’’–14 NPTF connection for relief valve. Maximum allowable working pressure -

MAWP 33 Bar

Fitting a pressure relief device according to standard EN378-2 is the

responsibility of the installer.

2.6.5 Electrical box: components

All electrical components are pre-wired into the panel.

This panel contains:

Compressor contactor(s)

Fuse

Terminal blocks

DIN rail mounted terminals

Electronic controller

Fan Speed controller

Alarm relays

90 630 / 1250 720 680 x 580 (12) 1 5/8 1 3/8 120 / 142

mm mm b x t,(ø mm) ø (inch) ø (inch) kg

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

2.6.6 Pressure switch

All single compressor Copeland EazyCool™ condensing units for refrigeration networks

are equipped with:

Single low pressure switch with automatic reset: ALCO PS1-W3A

Electronic Condensing Unit Controller with HP and LP pressure transmitters

All two-compressor Copeland EazyCool™ condensing units for Refrigeration Network are

equipped with:

Single low pressure switch with automatic reset: ALCO PS1-W3A

Two high pressure switches ALCO PS3-WF4-HNS

Electronic Condensing Unit Controller with HP and LP pressure transmitters

C6.1.4/0305/E 8 Part no: 3136433

Dismantling &

Disposal

+

+

Condensing Unit For Refrigeration Networks

1) PS2-W7A: Alco Controls® dual pressure switch with automatic reset (fo r single

compressor unit)

The switch is equipped with display scale and pointers to indicate the

approximate settings. The display scales are printed in relative pressure

units “bar” and “psi”.

For precise setting of the control, external gauges must be used.

The PS2-W7A has the following characteristics:

Automatic reset dual pressure controls

Combined pressure limiter for low pressure / high-pressure

protection.

On pressure rise above the upper setpoint, contacts 1-2 open and

contacts 1-4 close.

On decreasing pressure below lower setpoint contacts 1-4 open and

contacts 1-2 close.

Adjustable dual pressure switch

Setpoint adjustment range: LP (left) = -0.5 to 7 bar and HP (right) = 6 to 31 bar.

Differential adjustment range: LP = 0,5 to 5 bar, HP = 4 bar.

Factory setting: LP = 3,5 / 4,5 bar, HP = 20 bar.

2) PS1-W3A: Alco Controls single low pressure switch with automatic

reset

The control is equipped with display scale and pointers to indicate the

approximate settings.

The display scales are printed in relative pressure units “bar” and “psi”.

For precise setting of the control, external gauges must be used.

The PS1-W3A has the following characteristics:

Automatic reset single pressure controls

Pressure limiter for low-pressure protection.

On decreasing pressure below lower set-point contacts 1-4 open and

contacts 1-2 close.

Adjustable single pressure switch

Setpoint adjustment range: = -0.5 to 7 bar.

Differential adjustment range: = 0,5 to 5 bar.

Factory setting: = 3,5 / 4,5 bar.

3) PS3-WF4-HNS: Alco Controls high pressure switch with an automatic reset

Automatic reset single pressure switch

Pressure limiter for high-pressure protection.

Switches from 1-2 to 1-4 on rising pressure and from 1-4 to 1-2 on falling

pressure.

Fixed switch point settings

Cut-out point: 22 bar

Cut-in point: 26.2 bar.

p

-

p

-

2 4

1

2 4

1

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

& Repair

Maintenance

Disposal

Dismantling &

C6.1.4/0305/E 9 Part no: 3136433

Condensing Unit For Refrigeration Networks

4) PT3 Pressure Transmitter (Alco Controls)

Two compressor-condensing units are equipped with HP and LP pressure transmitters

that are connected to the EC2 electronic controller.

The EC2 controller description and programming instructions are available in the

corresponding guideline (C6.1.5/E, Part no: 3136444) which is shipped with the units. It

is also available for download on www.eCopeland.com.

An Alco PT3-30A pressure transmitter is used at the high-pressure part of the system.

An Alco PT3-07A pressure controller is used at the low-pressure part of the system.

The PT3 pressure transmitter converts a pressure into a linear electrical 4-20 mA

current output signal. The heart of the transmitter is a piezo resistive chip enclosed in an

oil capsule.

Features:

Pressure sensitive piezo-based cell with strong primary output signal for precise

and sound-free operation

Vibration and pulsation resistant

2.6.7 Fan speed controller (FSP150) Alco Controls

An electronic speed control is fitted as standard in units

suitable for refrigeration networks. It controls the speed of the

fans based on condenser pressure. Fan speed is controlled by

the EC2-551 condensing unit controller in combination with a

FSP-150 fan speed controller.

Two fans are controlled at the same time.

The control operates with single-phase motors.

The electrical connection is made in the terminal box of the condensing

unit.

Using a fan speed controller offers the following benefits for your

application:

The head pressure can be kept high enough to ensure proper operation of the

expansion valve, and hence, sufficient mass flow through the expansion valve to

feed the evaporator. This maintains the required cooling capacity and avoids a

drop of evaporator temperature.

The sound level of fan motors can be kept at a minimum by avoiding the

permanent on/off cycling of the fan motor. The Alco Controls fan speed control

can be delivered with the Copeland units or as a separate accessory.

Safety

Instructions

Product

Description

Installation Electrical

Connection

Operation

Starting up &

2.6.8 Liquid line equipment (only for 2 unit network configuration)

a) Filter drier Alco Controls ADK-plus

ADK-plus liquid line filter-drier is for new installation or after service.

Optimum blend of molecular sieve and activated alumina

b) Liquid sight glass Alco Controls AMI 1SS*

The AMI series of moisture indicator is designed to monitor the moisture

content within the liquid line of a refrigeration system. When the line is empty

of liquid, circles may be seen in the glass. However, when the liquid refrigerant

touches the glass, the circles disappear indicating the system is fully charged.

2.6.9 Liquid line solenoid valve (for low temp. model only) Alco

Controls 200 RBT 5

This is used in low temperature with 2, 3 & 4 unit network systems

Compact size

Snap-on clip for attaching solenoid coils

∆p minimum = 0,05 bar

C6.1.4/0305/E 10 Part no: 3136433

Maintenance

Dismantling &

& Repair

Disposal

Loading...

Loading...