Page 1

Installation Guide

English – May 2002

Type 92W

Introduction

This installation guide provides instructions for installation,

startup, and adjustment. To receive a copy of the instruction

manual, contact your local Fisher Sales

Office or Sales Representative or view a copy at

www.FISHERregulators.com. For further information refer to:

Type 92W Instruction Manual, form 5237, D101268X012.

P.E.D. Categories

This product may be used as a safety accessory with

pressure equipment in the following Pressure Equipment

Directive 97/23/EC categories. It may also be used outside of the Pressure Equipment Directive using sound

engineering practice (SEP) per table below.

EZISTCUDORPSEIROGETACEPYTDIULF

)hcni-1(52NDPES

001x051,001,08,56,05,04ND

)hcni-4x6dna,4,3,2/1-2,2,2/1-1,1(

II,I

1

Specifications

Main Valve Body Sizes and End Connection Styles

See table 1

Maximum Inlet and Pilot Supply Pressure

Cast Iron Main Valve and Pilot: 17 bar (250 psig)

or body rating limit, whichever is lower

Steel Main Valve and Pilot: 21 bar (300 psig) or

body rating limit, whichever is lower

Minimum and Maximum Differential Pressures

See table 2

Maximum Outlet Pressures

(1)

See table 3

Outlet (Control) Pressure Ranges

See table 4

Maximum Allowable Loading Pressure for Pilot

with Tapped Spring Case

Combination of pilot control spring setting and

spring case loading pressure must not exceed

10 bar (150 psig) for Type 6492H pilot or 1,7 bar

(25 psig ) for Type 6492L pilot

(1)

Proof Test Pressure

All Pressure Retaining Components have been proof

tested per Directive 97/23/EC - Annex 1, Section 7.4

1. The pressure/temperature limits in this installation guide and any applicable

standard or code limitation should not be exceeded.

(1)

(1)

1)

Maximum Material Temperature Capabilities

(1)

Cast Iron Construction: 208°C (406°F)

Steel Construction: 260°C (500°F)

Installation

Only qualified personnel should install or service

a regulator. Regulators should be installed,

operated, and maintained in accordance with

international and applicable codes and

regulations, and Fisher instructions.

If the regulator vents fluid or a leak develops in

the system, it indicates that service is required.

Failure to take the regulator out of service

immediately may create a hazardous condition.

Personal injury, equipment damage, or leakage due

to escaping fluid or bursting of pressure-containing

parts may result if this regulator is overpressured

or is installed where service conditions could exceed

the limits given in the Specifications section, or

where conditions exceed any ratings of the adjacent

piping or piping connections.

To avoid such injury or damage, provide pressurerelieving or pressure-limiting devices (as required

by the appropriate code, regulation, or standard) to

prevent service conditions from exceeding limits.

Additionally, physical damage to the regulator could

result in personal injury and property damage due

to escaping fluid. To avoid such injury and damage,

install the regulator in a safe location.

Clean out all pipelines before installation of the regulator

and check to be sure the regulator has not been damaged or

has collected foreign material during shipping. For NPT

bodies, apply pipe compound to the male pipe threads. For

flanged bodies, use suitable line gaskets and approved

piping and bolting practices. Install the regulator in any

position desired, unless otherwise specified, but be sure

flow through the body is in the direction indicated by the arrow

on the body.

Note

It is important that the regulator be installed so that

the vent hole in the spring case is unobstructed at all

times. For outdoor installations, the regulator should

be located away from vehicular traffic and positioned

so that water, ice, and other foreign materials cannot

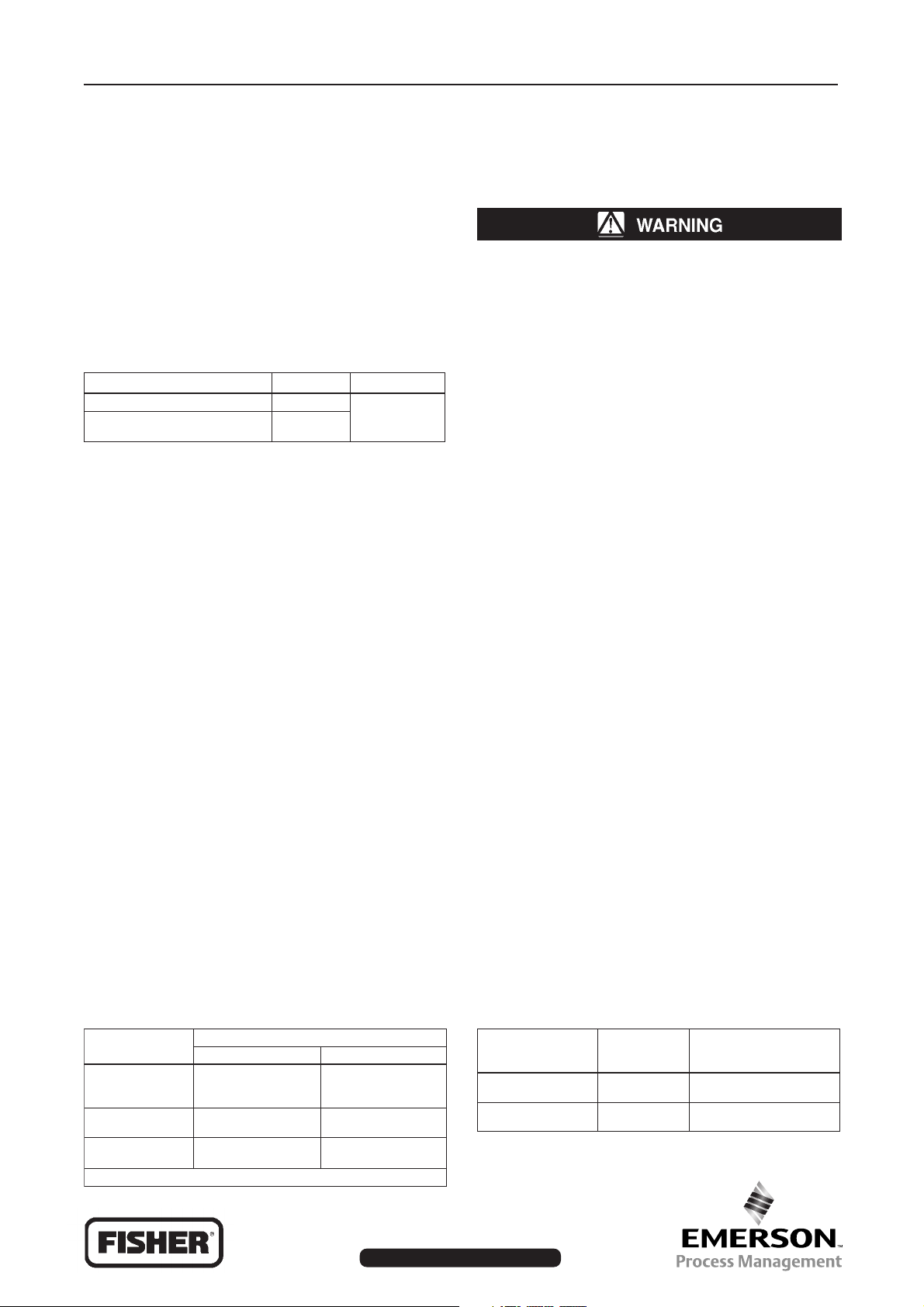

Table 1. Main Valve Body Sizes and End Connection Styles

,EZISYDOB

)SEHCNI(ND

05,04,52

)2,2/1-1,1(

001,08,56

)4dna,3,2/1-2(

001x051

)1(

)4x6(

ydoBnorItsaCydoBleetS

ro,FF521ssalC;TPN

degnalfFR052

roFF521ssalC

degnalfFR052

elbaliavAtoN

GNITARDNAELYTSNOITCENNOCDNE

ro,FR003

degnalfFR006

degnalfFR006

roFR003ssalC

degnalfFR006

.ezismirtybezisnoitcennocdnesetacidninoitangisedrebmun-owtehT.1

www.FISHERregulators.com

Table 2. Minimum and Maximum Differential Pressures

,EZISYDOB

,FR051ssalC;TPN

ro,FR003,FR051ssalC

)SEHCNI(ND

05,04,52

)2,2/1-1,1(

002x051,001,08,56

)4x6,4,3,2/1-2(

MUMINIM

LAITNEREFFID

ERUSSERP

)isp51(rab0,1

)isp02(rab4,1

LAITNEREFFIDMUMIXAM

ERUSSERP

gnitarydobro)isp002(rab41

rewolsirevehcihw,timil

gnitarydobro)isp571(rab21

rewolsirevehcihw,timil

D101268XENG

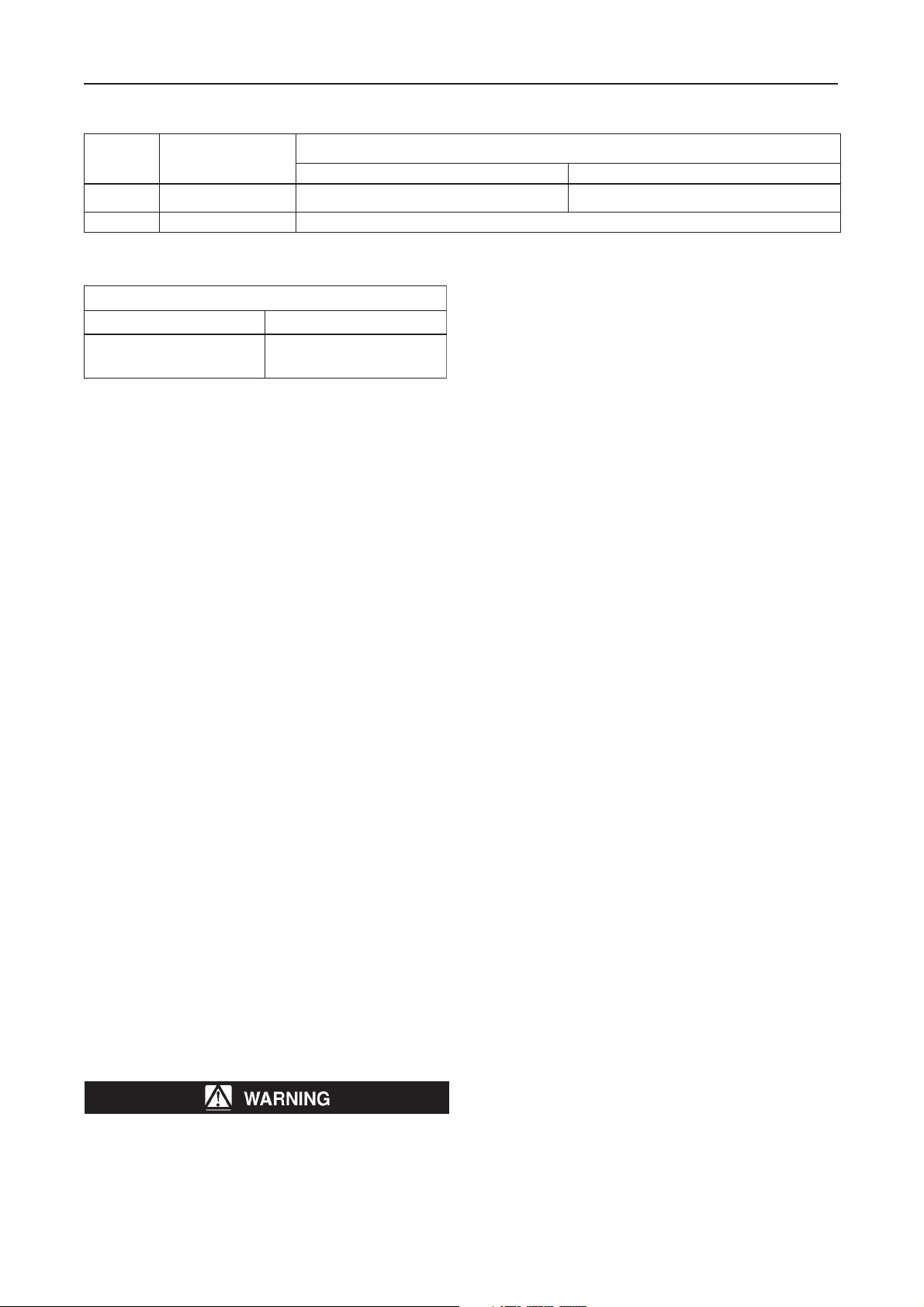

Page 2

Type 92W

Table 3. Maximum Outlet Pressures

EPYTTOLIP

rab)GISP(

H2946)051(01

L2946)52(7,1 )001(9,6

GNITAREPOMUMIXAM

,ERUSSERPTELTUO

ydoBtoliPdnaevlaVniaMnorItsaC ydoBtoliPdnaevlaVniaMleetS

ydobevlavniamro)052(71

rewolsirevehcihw,timilgnitar

YTIRGETNILESSEVERUSSERP,DEDEECXEFI(ERUSSERPTELTUOYCNEGREMEMUMIXAM

)TLUSERDLUOCEGAMADYTREPORPROYRUJNILANOSREPDNADENIATEREBTONYAM

ydobevlavniamro)003(12

rewolsirevehcihw,timilgnitar

Table 4. Outlet (Control) Pressure Ranges

,EGNARERUSSERP)LORTNOC(TELTUOrab)GISP(

toliPL2946epyTtoliPH2946epyT

14,0ot41,0

(6ot2)

0,1ot43,0

(51ot5)

7,1ot09,0

(52ot31)

1,2ot96,0

(03ot01)

2,5ot7,1

(57ot52)

01ot8,4

(051ot07)

enter the spring case through the vent. Avoid placing

the regulator beneath eaves or downspouts, and be

sure it is above the probable snow level.

Overpressure Protection

The recommended pressure limitations are stamped on

the regulator nameplate. Some type of overpressure

protection is needed if the actual inlet pressure exceeds the

maximum operating outlet pressure rating. Overpressure

protection should also be provided if the regulator inlet

pressure is greater than the safe working pressure of the

downstream equipment.

Regulator operation below the maximum pressure limitations

does not preclude the possibility of damage from external

sources or debris in the line. The regulator should be inspected

for damage after any overpressure condition.

Startup

The regulator is factory set at approximately the midpoint of

the spring range or the pressure requested, so an initial

adjustment may be required to give the desired results. With

proper installation completed and relief valves properly

adjusted, slowly open the upstream and downstream shutoff

valves.

Adjustment

To change the outlet pressure, remove the closing cap or

loosen the locknut and turn the adjusting screw clockwise

to increase outlet pressure or counterclockwise to decrease

pressure. Monitor the outlet pressure with a test gauge

during the adjustment. Replace the closing cap or tighten

the locknut to maintain the desired setting.

Taking Out of Service (Shutdown)

To avoid personal injury resulting from sudden

release of pressure, isolate the regulator from all

pressure before attempting disassembly.

Type 92W Main Valve Parts List

Key Description

1 Body

2 Body Flange

3 Stud Bolt

5 Cage

6 Valve Plug

7 Seat Ring

8 Spiral Wound Gasket

9 Bottom Stem

11 Piston Spacer

12 Spring

13 Baffle

14 Retaining Ring

15 Stem Nut

16 Cotter Pin

17 Cylinder

18 Cylinder Gasket

19 Body Gasket

20 Top Stem

21 Cylinder Spacer

22 Stem Seal

23 Stem Seal Retainer

24 Piston

25 Piston Ring

26 Ring Retainer

28 Nameplate

29 Flow Arrow

30 Drive Screw

32 Spring Seat

33 Plug Spacer

34 Washer

35 Groove Pin

38 O-Ring

40 Lockwasher

41 Hex Nut

Type 6492L and 6492H Pilots Parts List

Key Description

1 Body

2 Plug Guide

3 Plug Spring

4 Plug

5 Seat Ring

7 Stem

8 Bellows Retainer

9 Bellows

10 Diaphragm

11 Lower Spring Seat

12 Control Spring

13 Upper Spring Seat

14 Spring Case

15 Adjusting Screw

16 Hex Nut

17 Cap Screw

18 Diaphragm Gasket

19 Drive Screw

20 Nameplate

24 Diaphragm Plate Assembly

74 Pipe Plug

76 Bleed Restriction

77 Screen

78 Reducing Bushing

87 Sealing Washer

2

Page 3

Type 92W

37A6565-B

DETAIL OF WHISPER TRIM

NOISE ATTENUATOR

36A7960-D

DN 25, 40, OR 50 (1, 1-1/2, OR 2-INCH) BODY SIZE

37A1622-D

DN 65, 80, 100, 150 x 100 (2-1/2, 3, 4, OR 6 x 4-INCH) BODY SIZE

Figure 1. Type 92W Main Valve Assemblies

3

Page 4

Type 92W

39A3514-B

COMPLETE TYPE 6492H PILOT

32A4712-A

A3505-1

DETAIL OF TAPPED

SPRING CASE WITH

SEALED ADJUSTING

SCREW

39A3515-B

COMPLETE TYPE 6492L PILOT

Figure 2. Pilot Assemblies

©Fis her C ontro ls Inte rnati onal, I nc., 2002; All R ights Rese rved

Fisher and Fisher Regulators are marks owned by Fisher Controls International, Inc. The Emerson logo is a trade mark and service mark of Emerson Electric Co.

All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or guarantees, express

or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

For information, contact Fisher Controls, International:

Within USA (800) 588-5853 – Outside USA (972) 542-0132

Italy – (39) 051-4190-606

Singapore – (65) 770-8320

Mexico – (52) 57-28-0888

Printed in U.S.A.

www.FISHERregulators.com

Loading...

Loading...