Rosemount® 8700M

Magnetic Flowmeter Platform

with HART® Protocol

Reference Manual

00809-0100-4444, Rev AD

August 2015

Reference Manual

00809-0100-4444, Rev AD

Rosemount® 8700M

Magnetic Flowmeter Platform

Read this manual before working with the product. For personal and system safety, and for

optimum product performance, make sure you thoroughly understand the contents before

installing, using, or maintaining this product.

Failure to follow these installation guidelines could result in death or serious injury.

Installation and servicing instructions are for use by qualified personnel only. Do not

perform any servicing other than that contained in the operating instructions, unless

qualified.

Verify the installation is done safely and is consistent with the operating environment.

If installed in explosive atmospheres [hazardous areas, classified areas, or an “Ex”

environment], it must be assured that the device certification and installation

techniques are suitable for that particular environment.

Explosion hazard. Do not disconnect equipment when a flammable or combustible

atmosphere is present.

To prevent ignition of flammable or combustible atmospheres, disconnect power

before servicing circuits.

Do not connect a Rosemount 8732EM Transmitter to a non-Rosemount sensor that is

located in an explosive atmosphere.

Substitution of components may impair Intrinsic Safety.

Follow national, local, and plant standards to properly earth ground the transmitter and

sensor. The earth ground must be separate from the process reference ground.

Rosemount Magnetic Flowmeters ordered with non-standard paint options or

non-metallic labels may be subject to electrostatic discharge. To avoid electrostatic

charge build-up, do not rub the flowmeter with a dry cloth or clean with solvents.

The electronics may store energy after power is removed. Allow ten minutes for charge to

dissipate prior to removing electronics compartment cover.

Explosions could result in death or serious injury.

Verify the operating atmosphere of the sensor and transmitter is consistent with the

appropriate hazardous locations certifications.

Do not remove the transmitter cover in explosive atmospheres when the circuit is live.

Before connecting a HART-based communicator in an explosive atmosphere, make

sure the instruments in the loop are installed in accordance with intrinsically safe or

non-incendive field wiring practices.

Both transmitter covers must be fully engaged to meet explosion-proof requirements.

iii

Reference Manual

00809-0100-4444, Rev AD

Failure to follow safe installation and servicing guidelines could result in death or serious

injury.

Installation should be performed by qualified personnel only.

Do not perform any service other than those contained in this manual.

Process leaks may result in death or serious injury.

The electrode compartment may contain line pressure; it must be depressurized before

the cover is removed.

High voltage that may be present on leads could cause electrical shock.

Avoid contact with leads and terminals.

Failure to follow these maintenance guidelines could result in death or serious injury.

Installation and servicing instructions should be performed by qualified personnel only.

Do not perform any servicing other than that contained in the operating instructions.

Verify that the operating environment of the sensor and transmitter is consistent with

the appropriate hazardous area approval.

Do not connect a Rosemount 8732EM to a non-Rosemount sensor that is located in an

explosive atmosphere.

Mishandling products exposed to a hazardous substance may result in death or serious

injury.

If the product being returned was exposed to a hazardous substance as defined by

OSHA, a copy of the required Material Safety Data Sheet (MSDS) for each hazardous

substance identified must be included with the returned goods.

Failure to follow these troubleshooting guidelines could result in death or serious injury.

Installation and servicing instructions should be performed by qualified personnel only.

Do not perform any servicing other than that contained in the operating instructions.

Verify that the operating environment of the sensor and transmitter is consistent with

the appropriate hazardous area approval.

Do not connect a Rosemount 8732EM to a non-Rosemount sensor that is located in an

explosive atmosphere.

Mishandling products exposed to a hazardous substance may result in death or serious

injury.

If the product being returned was exposed to a hazardous substance as defined by

OSHA, a copy of the required Material Safety Data Sheet (MSDS) for each hazardous

substance identified must be included with the returned goods.

The Rosemount 8732EM Transmitter has not been evaluated for use with other

manufacturers' magnetic flowmeter sensors in hazardous (Ex or Classified) areas.

Special care should be taken by the end-user and installer to ensure the 8732EM

transmitter meets the safety and performance requirements of the other

manufacturer’s equipment.

iv

Reference Manual

00809-0100-4444, Rev AD

Do not connect mains or line power to the magnetic flowtube sensor or to the transmitter coil

excitation circuit.

The products described in this document are NOT designed for nuclear-qualified applications.

Using non-nuclear qualified products in applications that require nuclear-qualified hardware or

products may cause inaccurate readings.

For information on Rosemount nuclear-qualified products, contact your local Emerson Process

Management Sales Representative.

v

Reference Manual

00809-0100-4444, Rev AD

vi

Reference Manual

00809-0100-4444, Rev AD

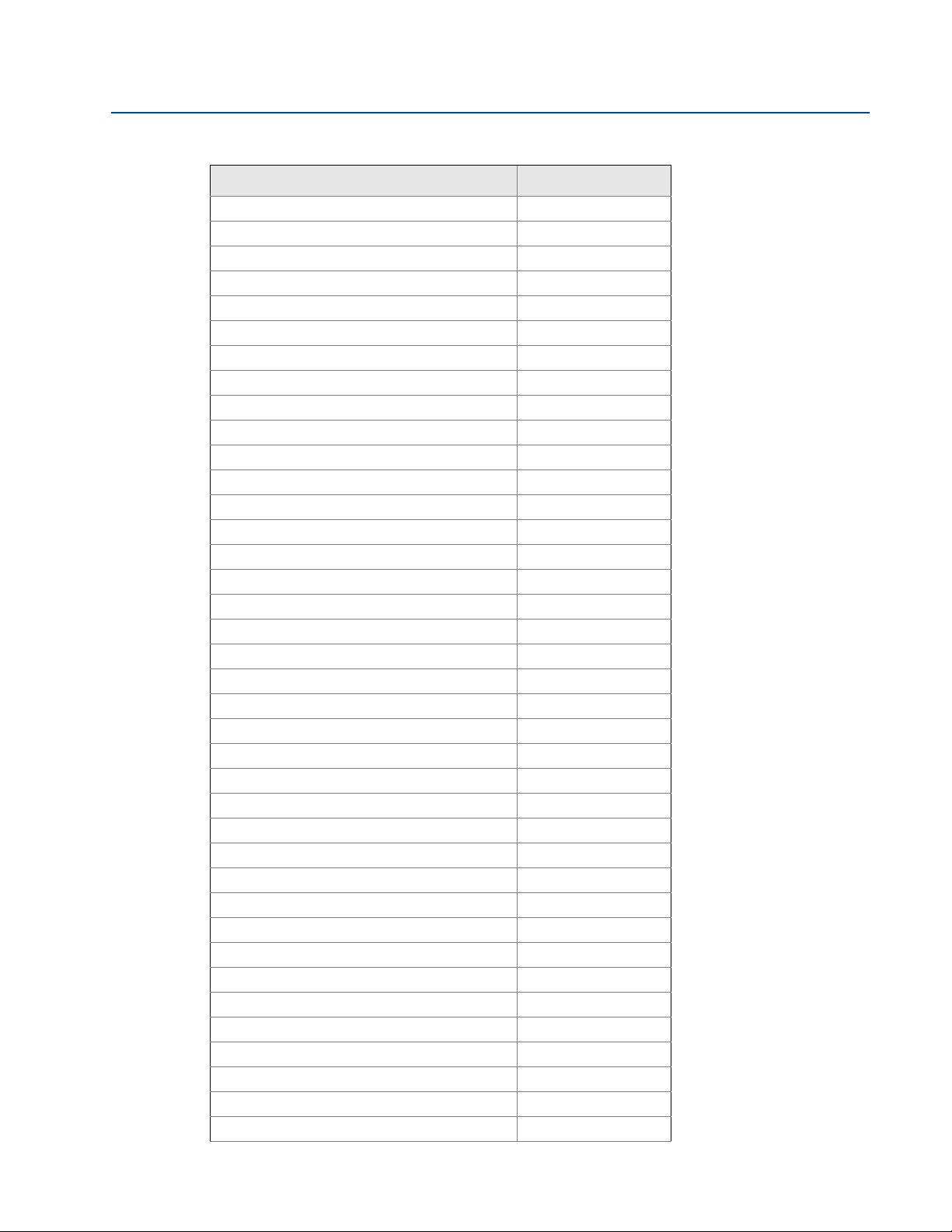

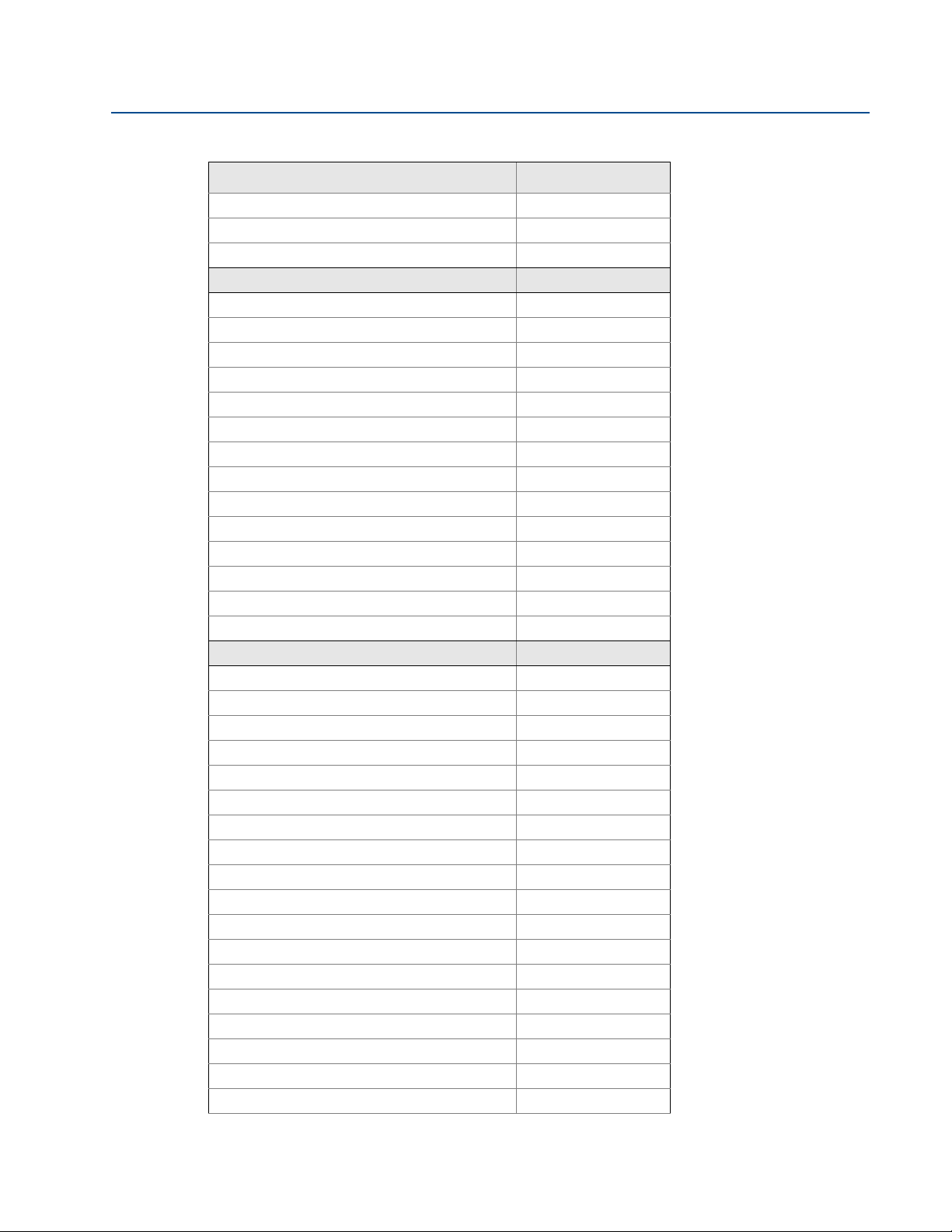

Contents

1Section 1: Introduction

2Section 2: Installation

Table of Contents

August 2015

1.1 System description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Product recycling/disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.2 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

2.3 Transmitter symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2.4 Pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.5 Installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.1 Transmitter installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.2 Identify options and configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.5.3 Mechanical considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2.5.4 Electrical considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.5 Environmental considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.6 Handling and lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

2.7 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.7.1 Upstream/downstream piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.7.2 Flow direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.8 Sensor location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.8.1 Electrode orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.9 Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.9.1 Flanged sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.9.2 Flange bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2.10 Wafer sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.10.1 Gaskets. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

2.10.2 Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

2.10.3 Flange bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.11 Process reference connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

2.12 Wiring the transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.12.1 Conduit entries and connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

2.12.2 Conduit requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Tabl e o f Con tent s

2.12.3 Connecting sensor to transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

vii

Table of Contents

August 2015

Reference Manual

00809-0100-4444, Rev AD

2.12.4 8732EM terminal block connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

2.12.5 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

2.12.6 Powering the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

2.13 Cover jam screw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2.14 Basic configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

2.14.1 Basic setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3Section 3: Advanced Installation Details

3.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.2 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.3 Hardware switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.3.1 Alarm mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

3.3.2 Transmitter security. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.3.3 Internal/external analog power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.3.4 Internal/external pulse power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.3.5 Changing hardware switch settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.4 Additional loops . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.4.1 Connect pulse output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

3.4.2 Connect discrete output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3.4.3 Connect discrete input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

3.5 Process reference connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

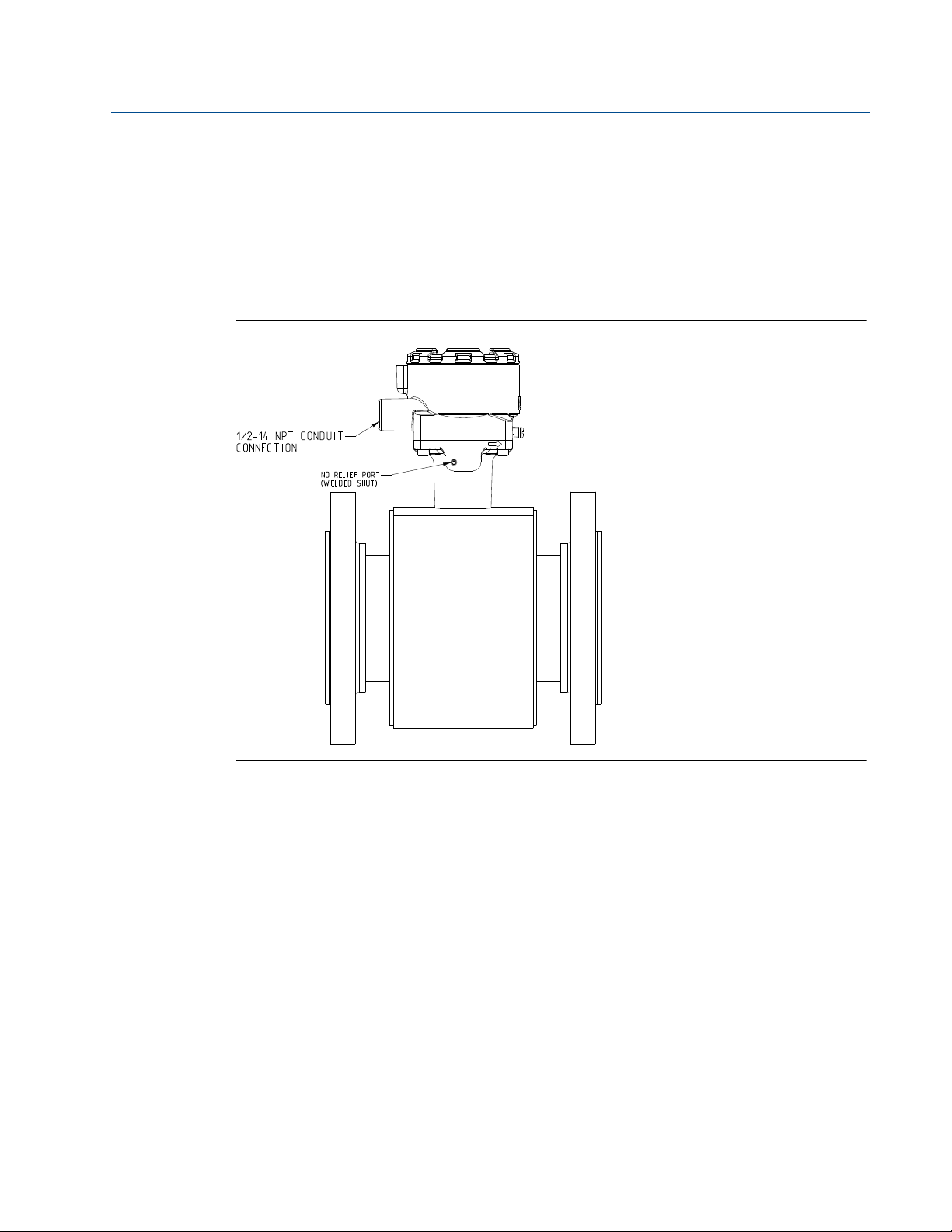

3.6 Coil housing configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3.6.1 Standard coil housing configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

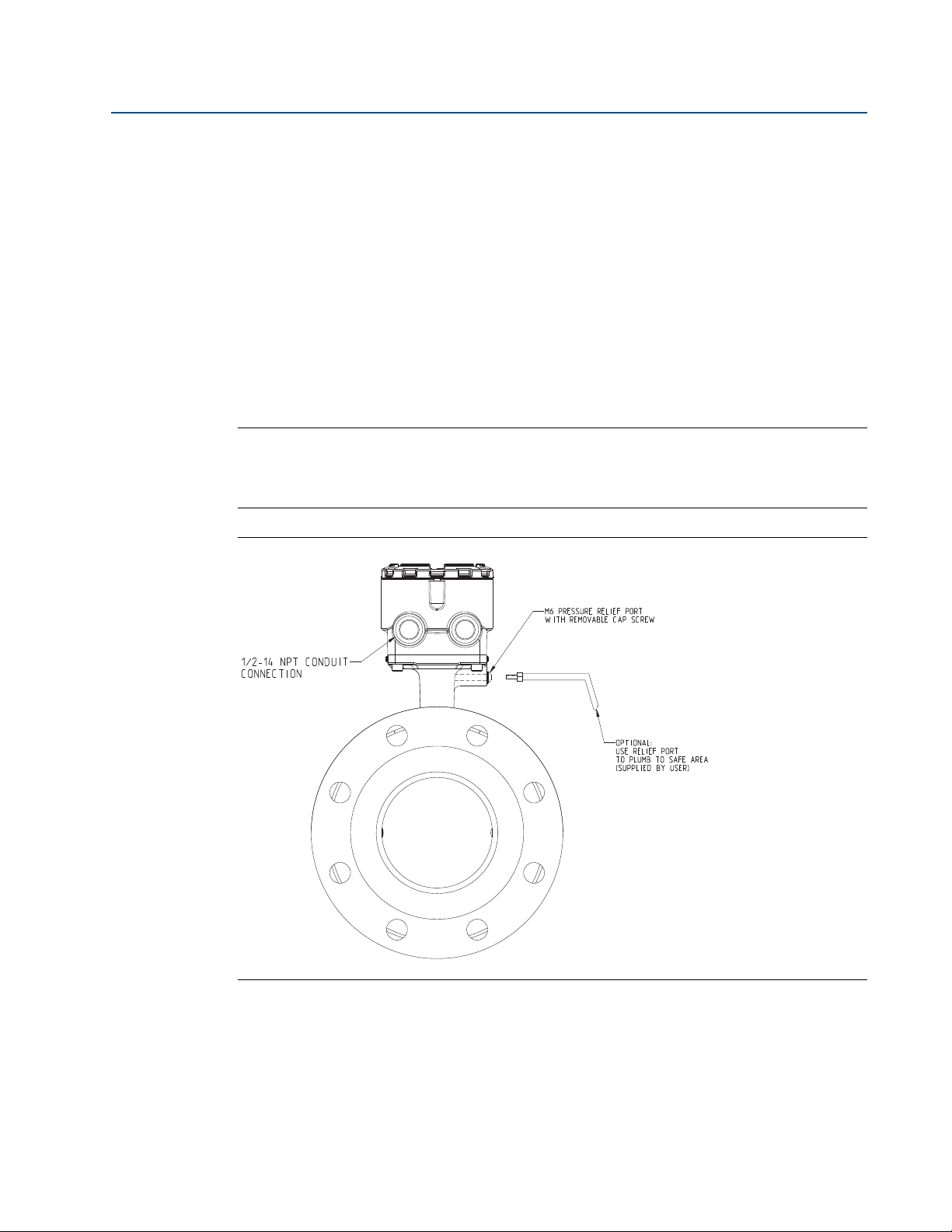

3.6.2 Process leak protection (option M1). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

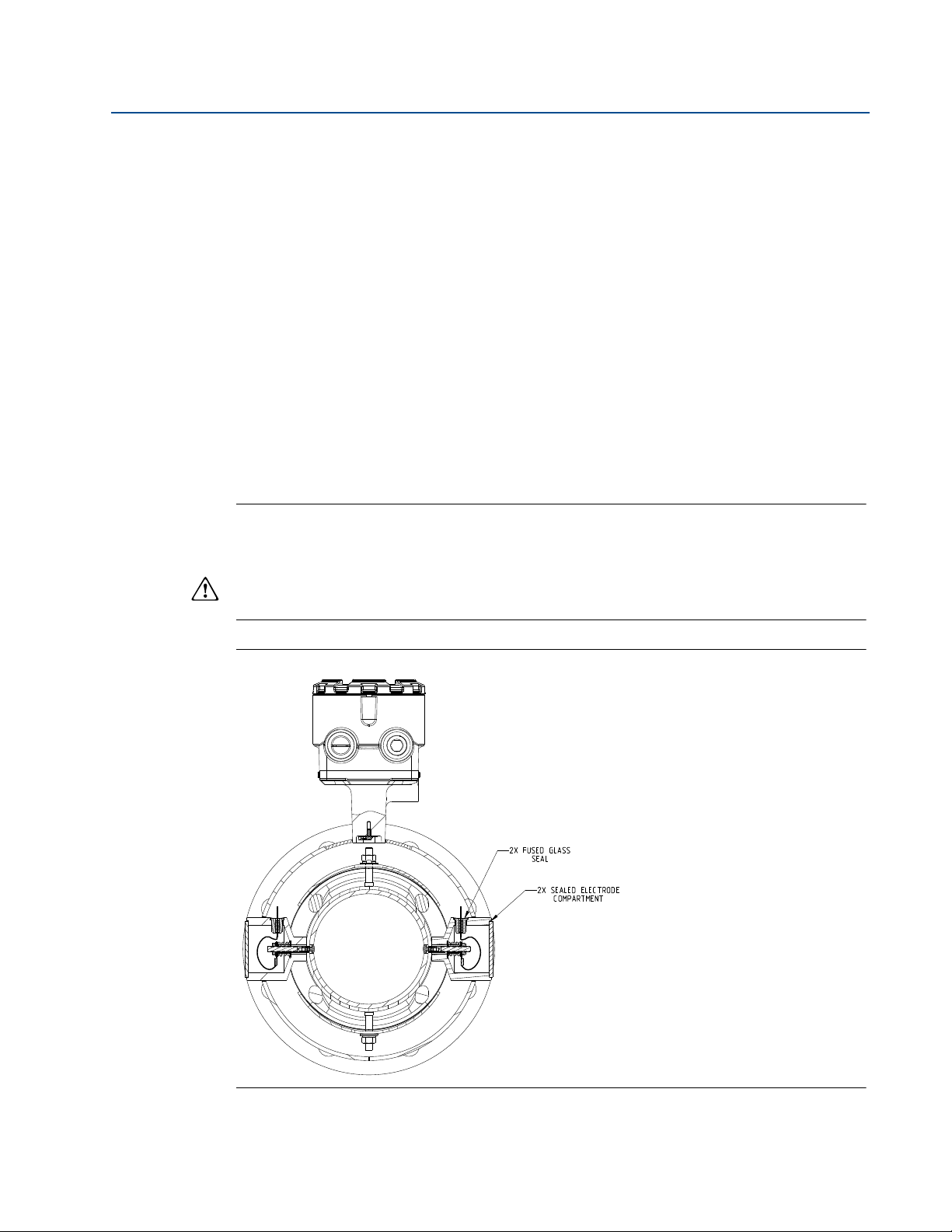

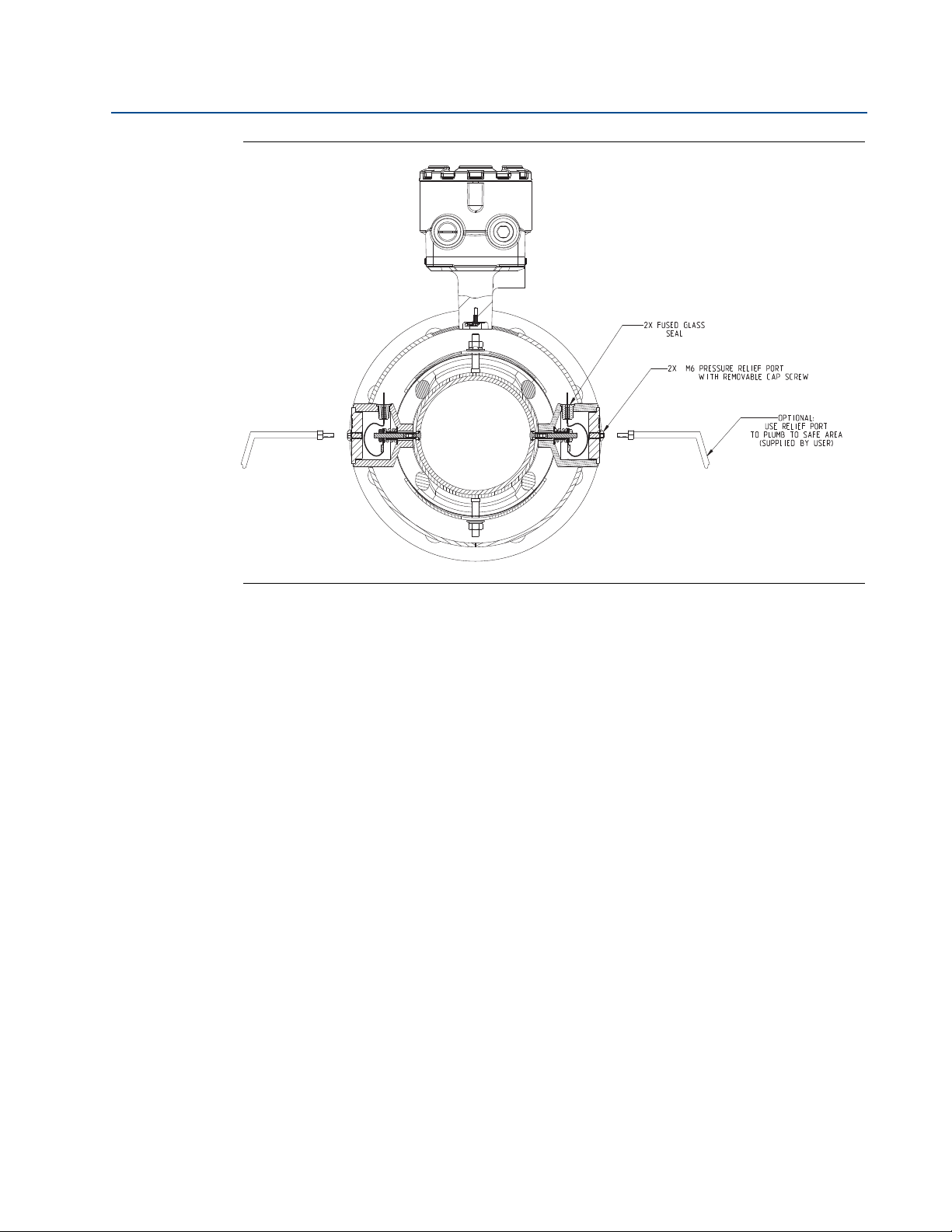

3.6.3 Process leak containment (Option M2 or M4). . . . . . . . . . . . . . . . . . . . . . .53

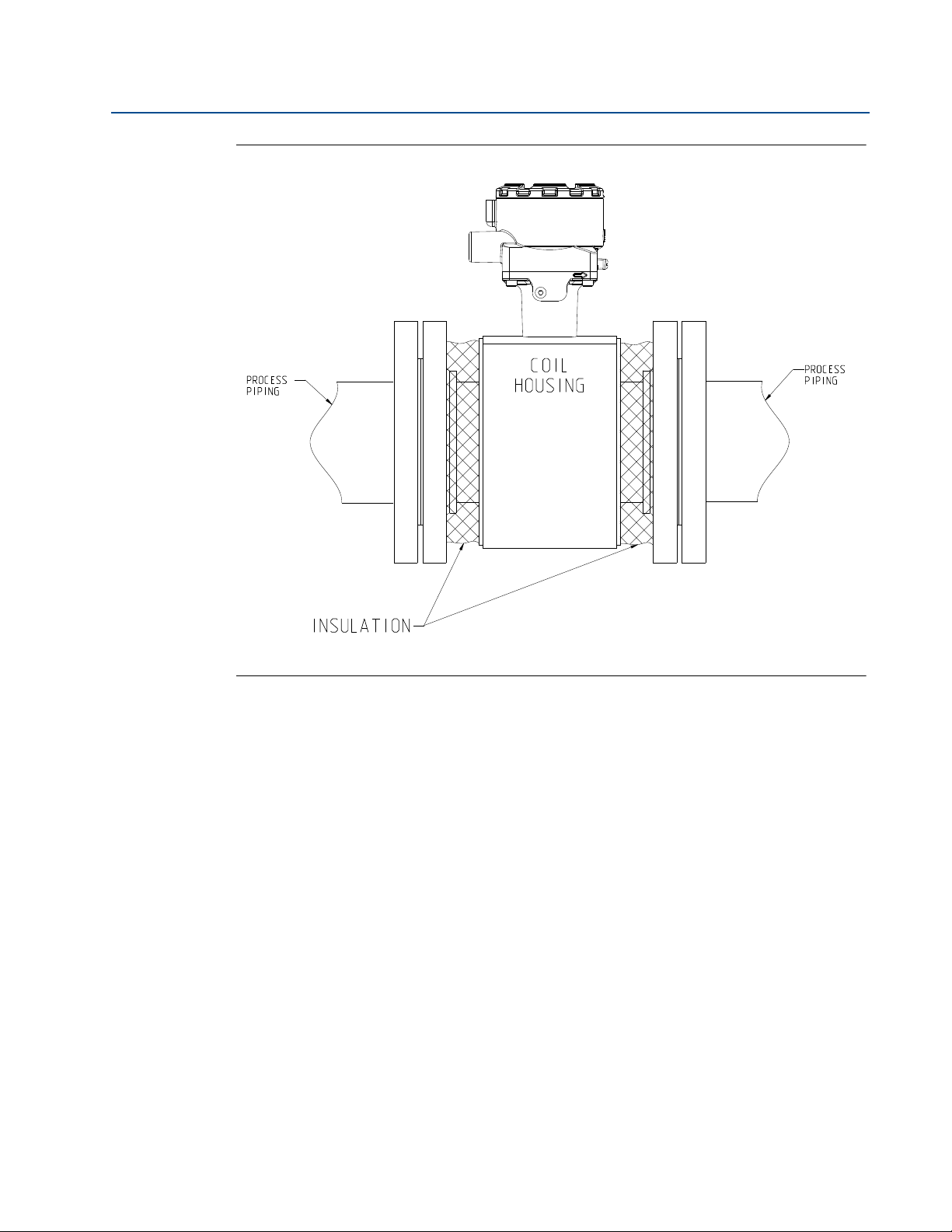

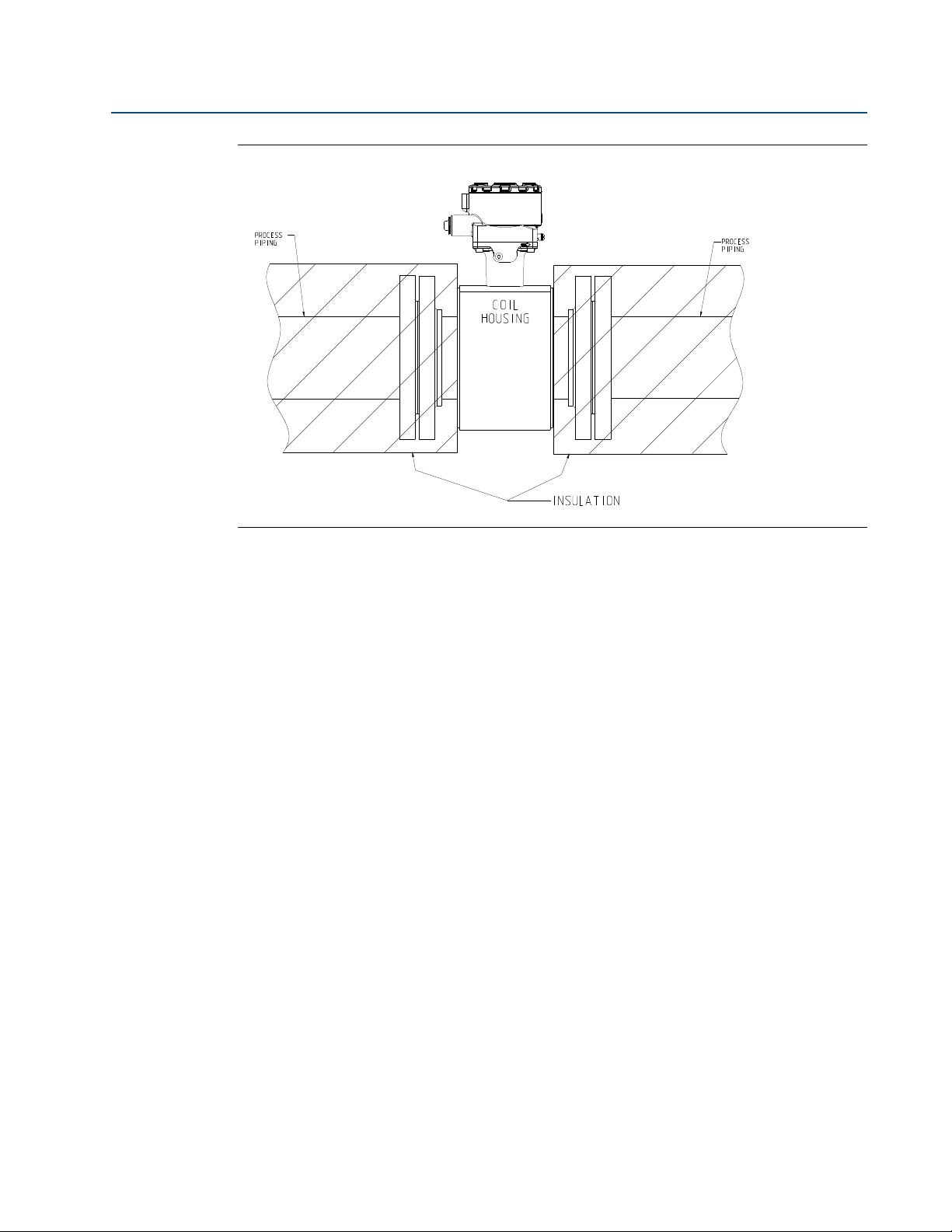

3.6.4 Higher temperature applications and sensor insulation best practices .54

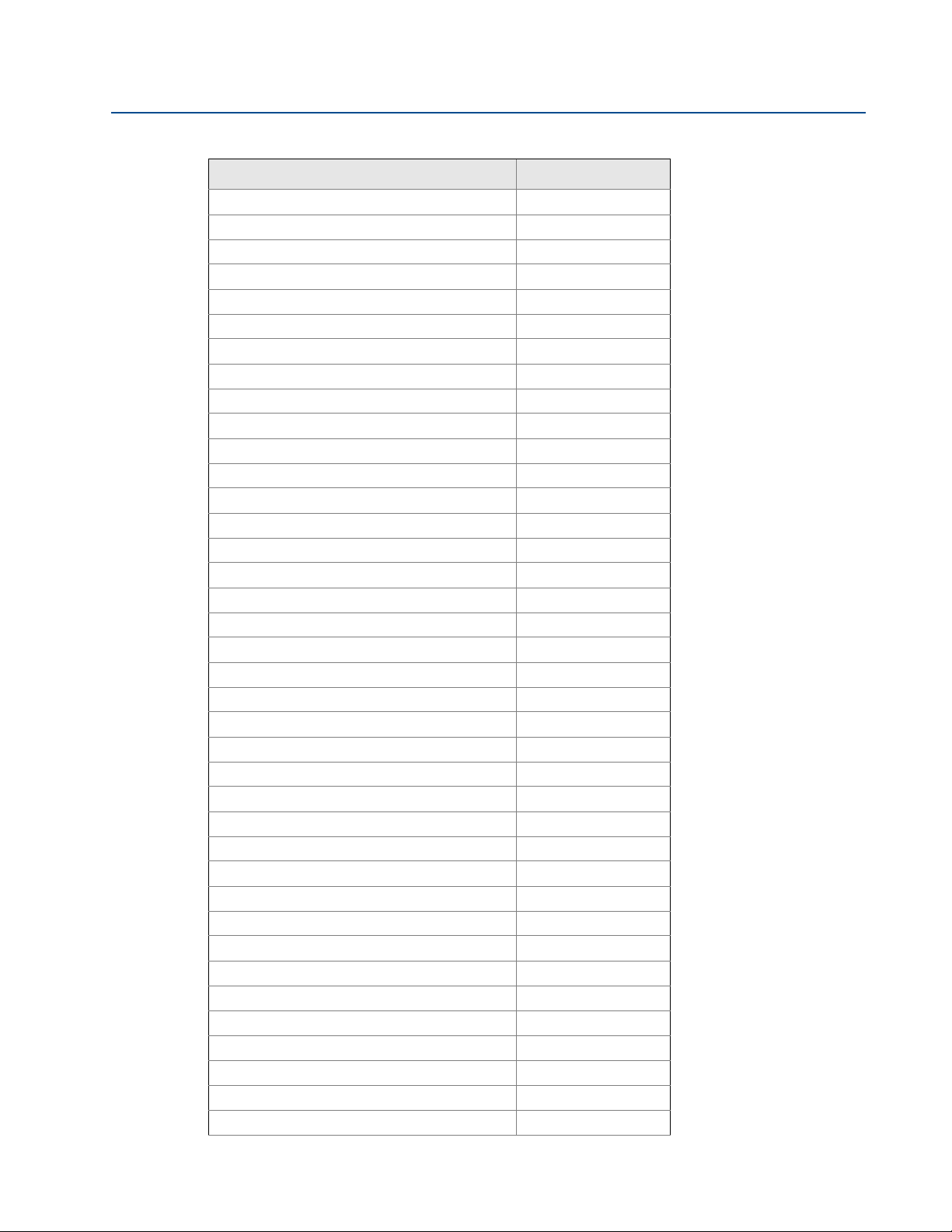

4Section 4: Operation

4.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

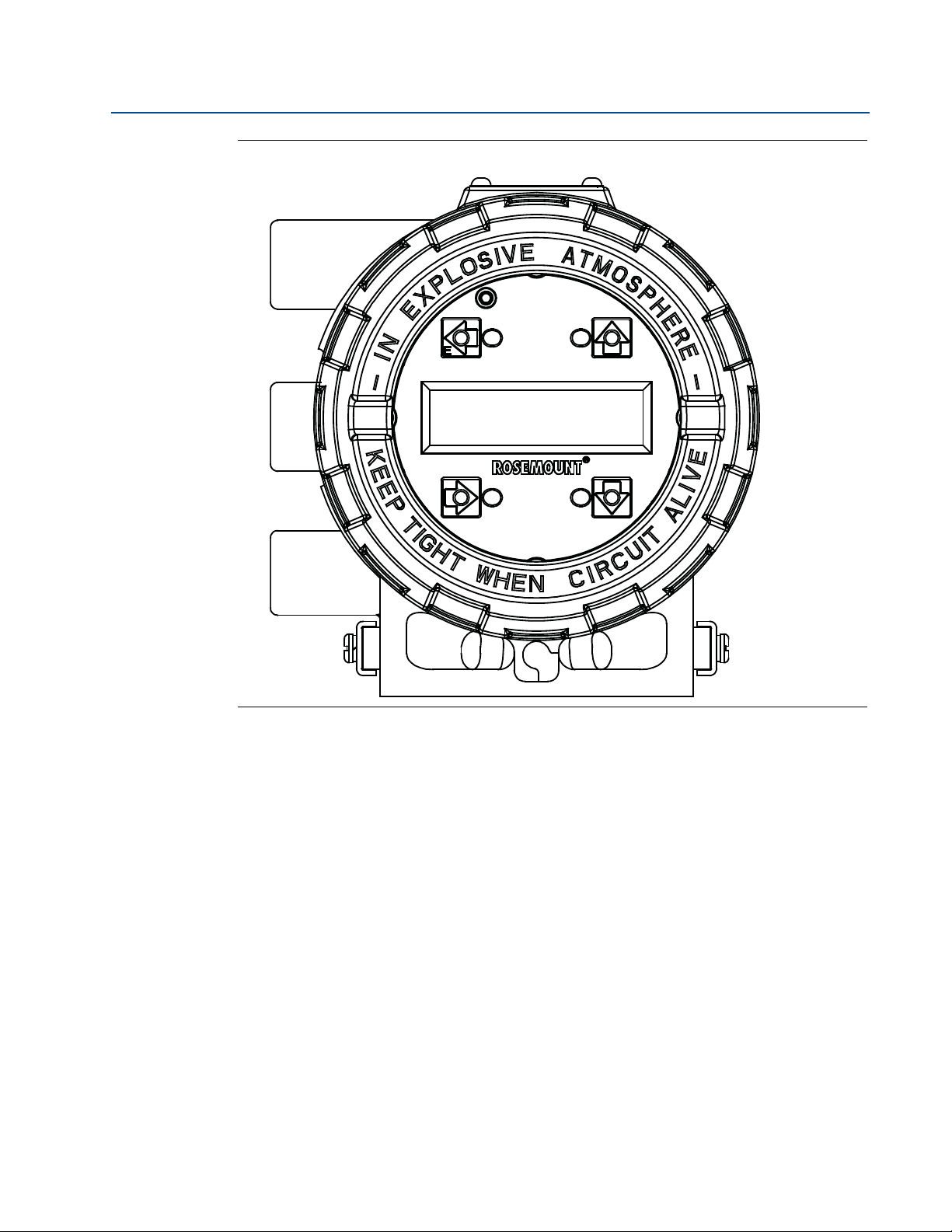

4.2 Local operator interface (LOI). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.2.1 Basic features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4.2.2 Data entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

viii

Tabl e of Co nten ts

Reference Manual

00809-0100-4444, Rev AD

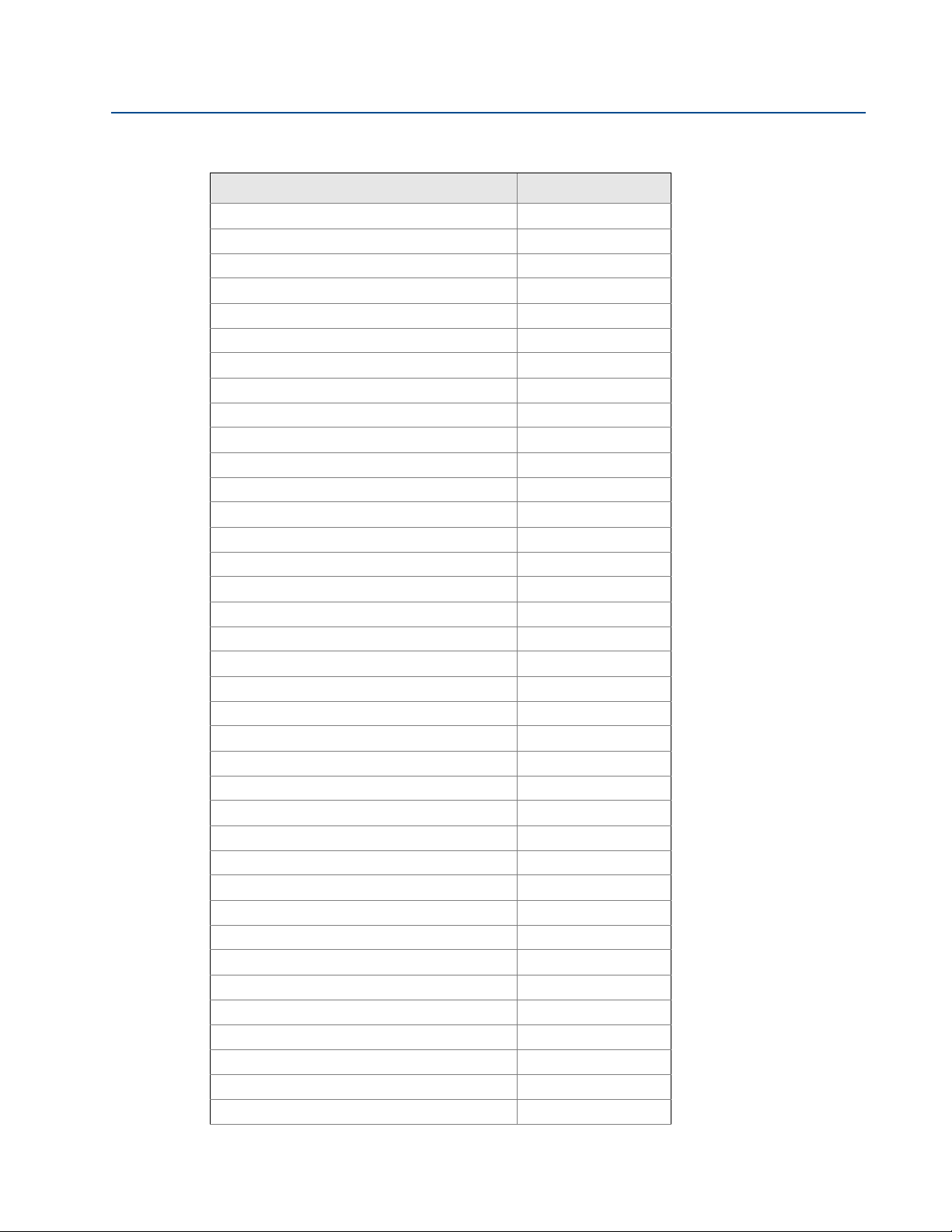

5Section 5: Advanced Configuration Functionality

Table of Contents

August 2015

4.2.3 Data entry examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4.2.4 Totalizer functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4.2.5 Display lock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

4.2.6 Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

4.2.7 Display symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

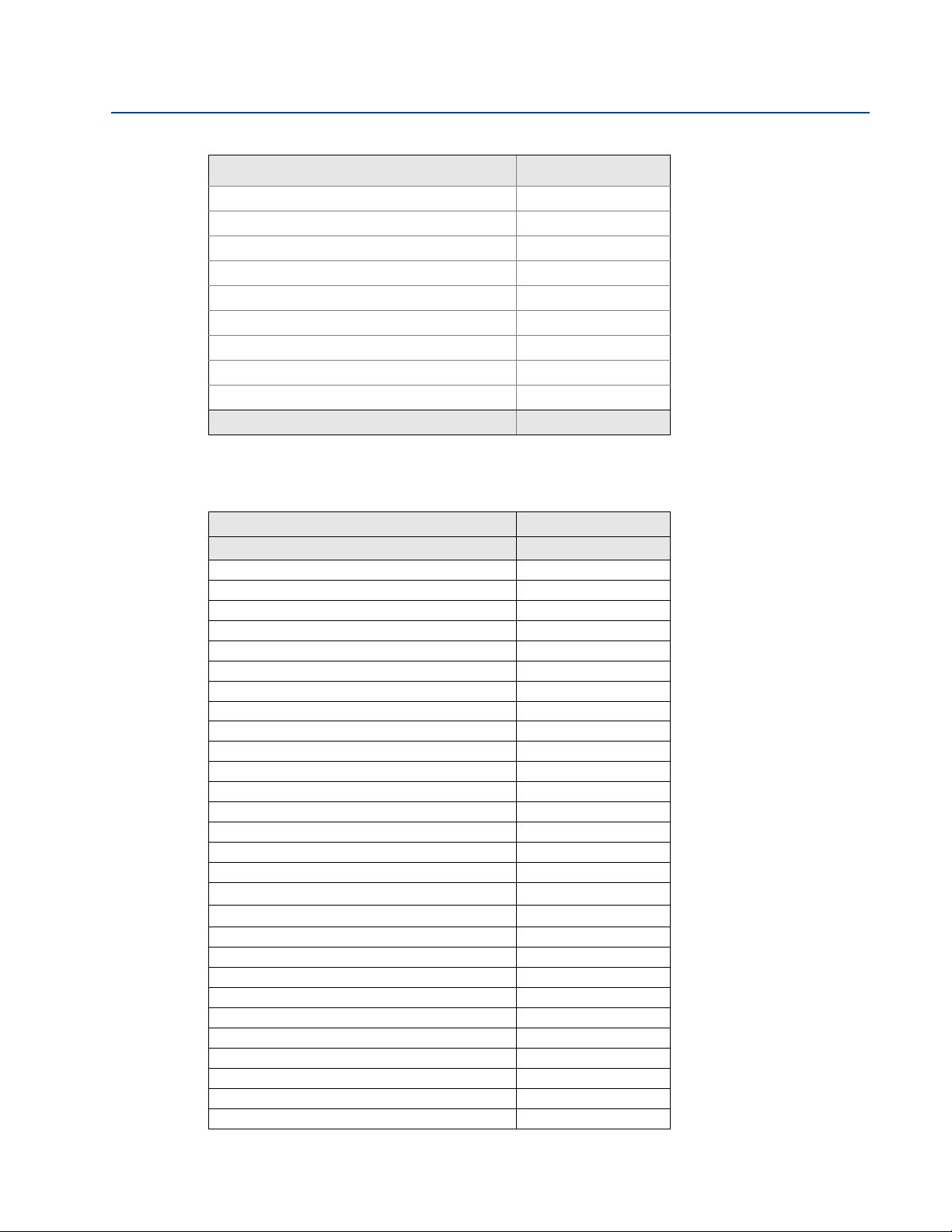

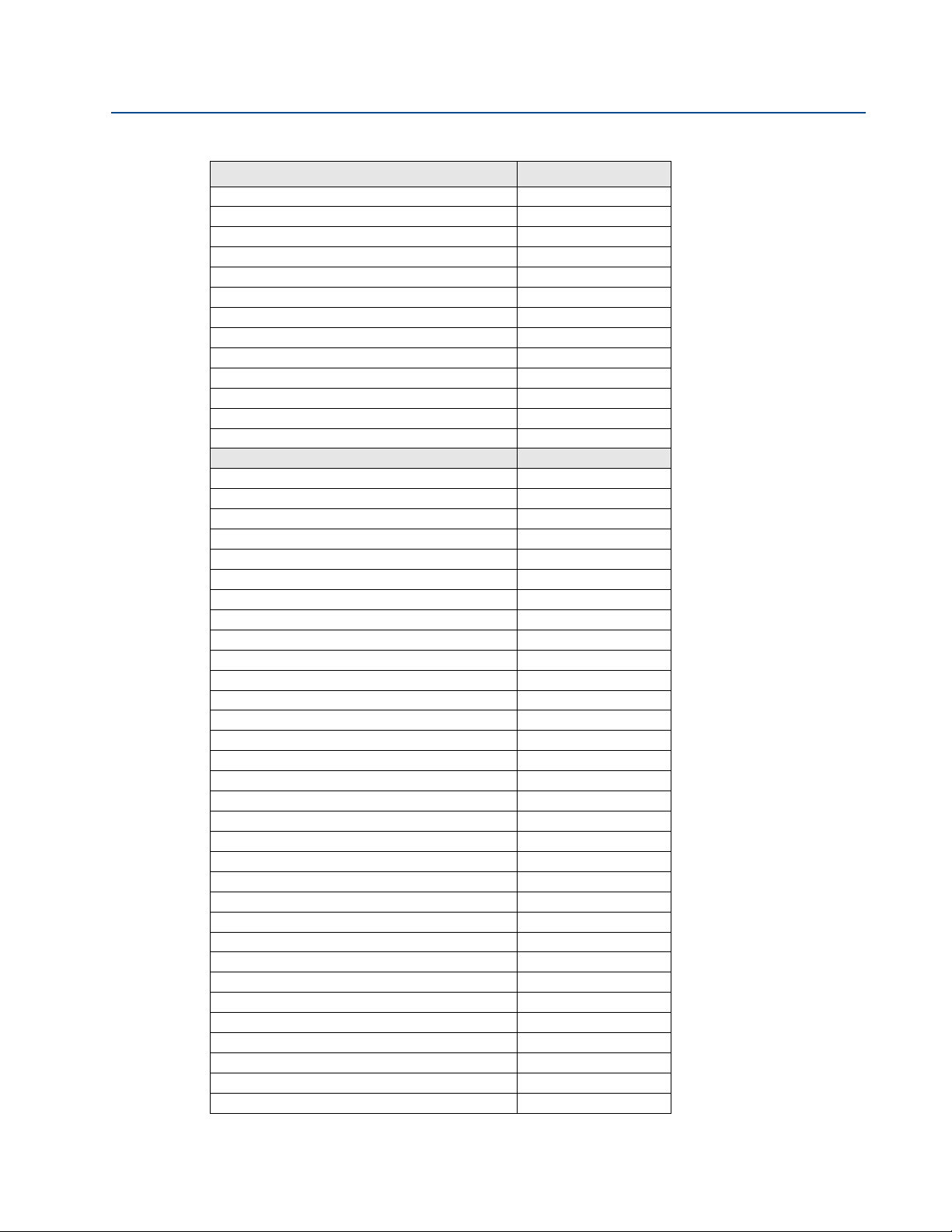

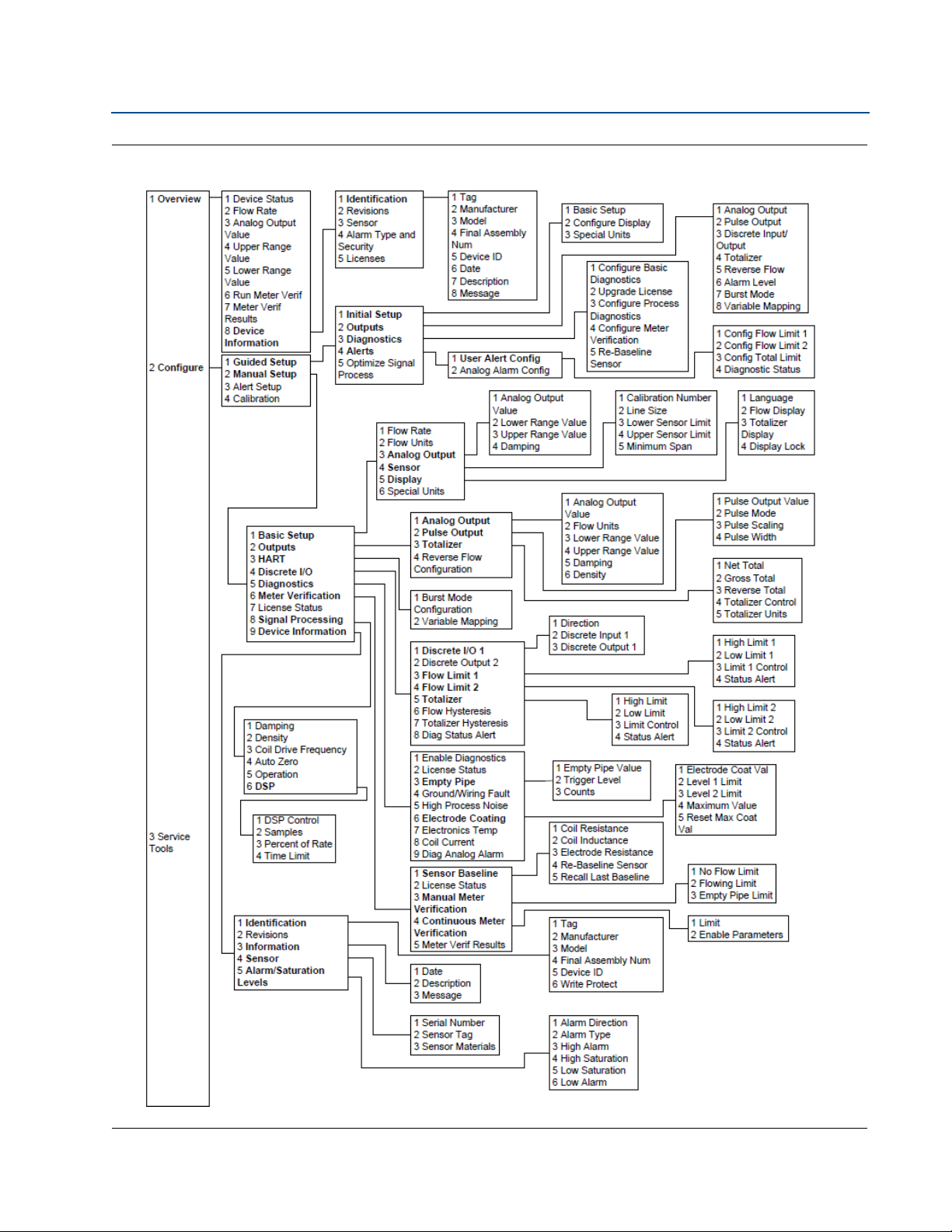

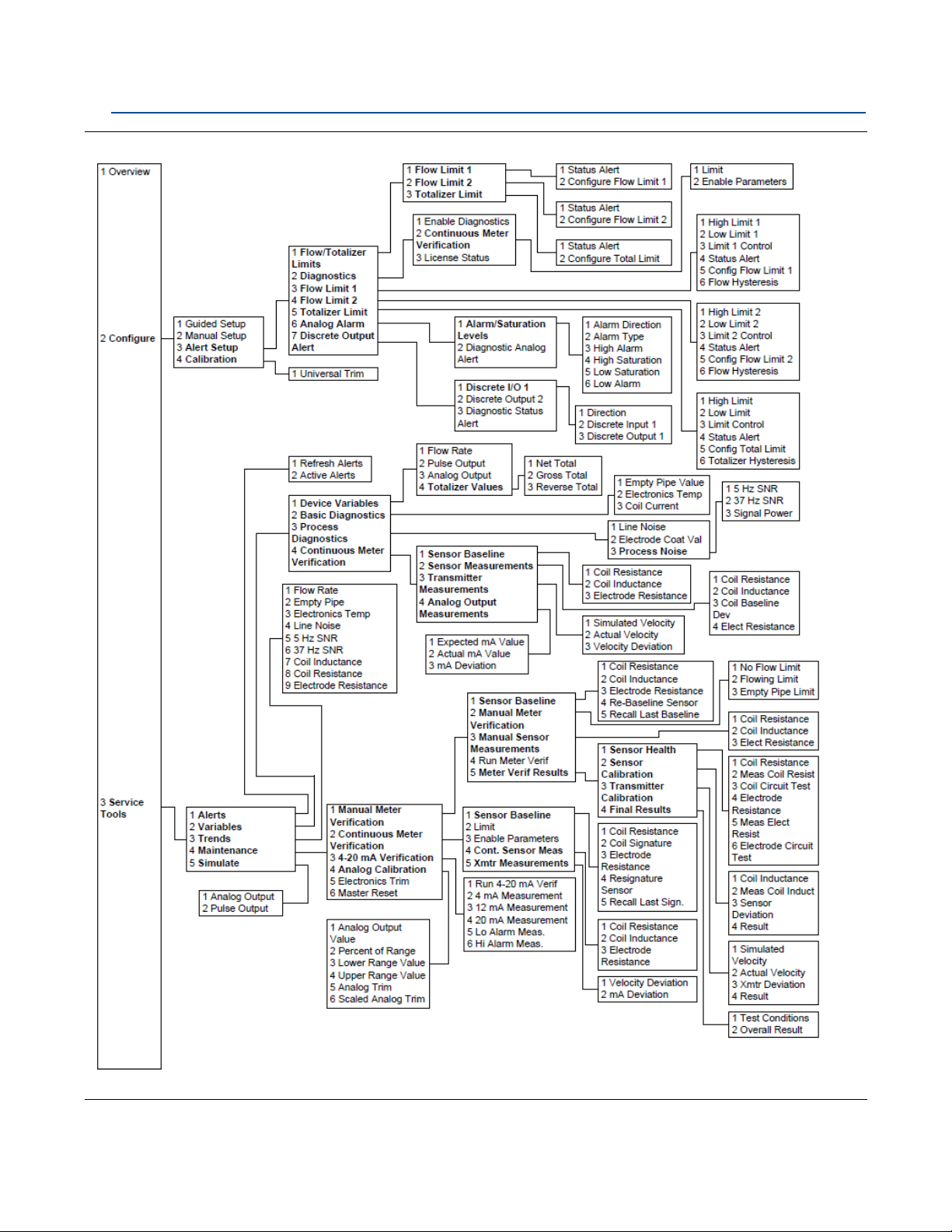

4.3 Field Communicator interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4.3.1 Field Communicator user interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4.4 Process variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4.4.1 PV - Primary variable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4.4.2 PV - Percent of range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

4.4.3 PV - Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

4.4.4 Pulse output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

5.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.2 Configure outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.2.1 Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

5.2.2 Pulse output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

5.2.3 Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

5.2.4 Discrete input/output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

5.3 Configure HART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5.3.1 Variable mapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

5.3.2 Poll address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

5.3.3 Burst mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

5.3.4 Configure LOI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

5.4 Additional parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.4.1 Coil drive frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.4.2 Process density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.4.3 Reverse flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

5.4.4 Low flow cutoff . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.4.5 PV damping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.4.6 Signal processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

5.5 Configure special units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

5.5.1 Base volume unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Tabl e o f Con tent s

5.5.2 Conversion factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

ix

Table of Contents

August 2015

Reference Manual

00809-0100-4444, Rev AD

5.5.3 Base time unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

5.5.4 Special volume unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

5.5.5 Special flow rate unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .110

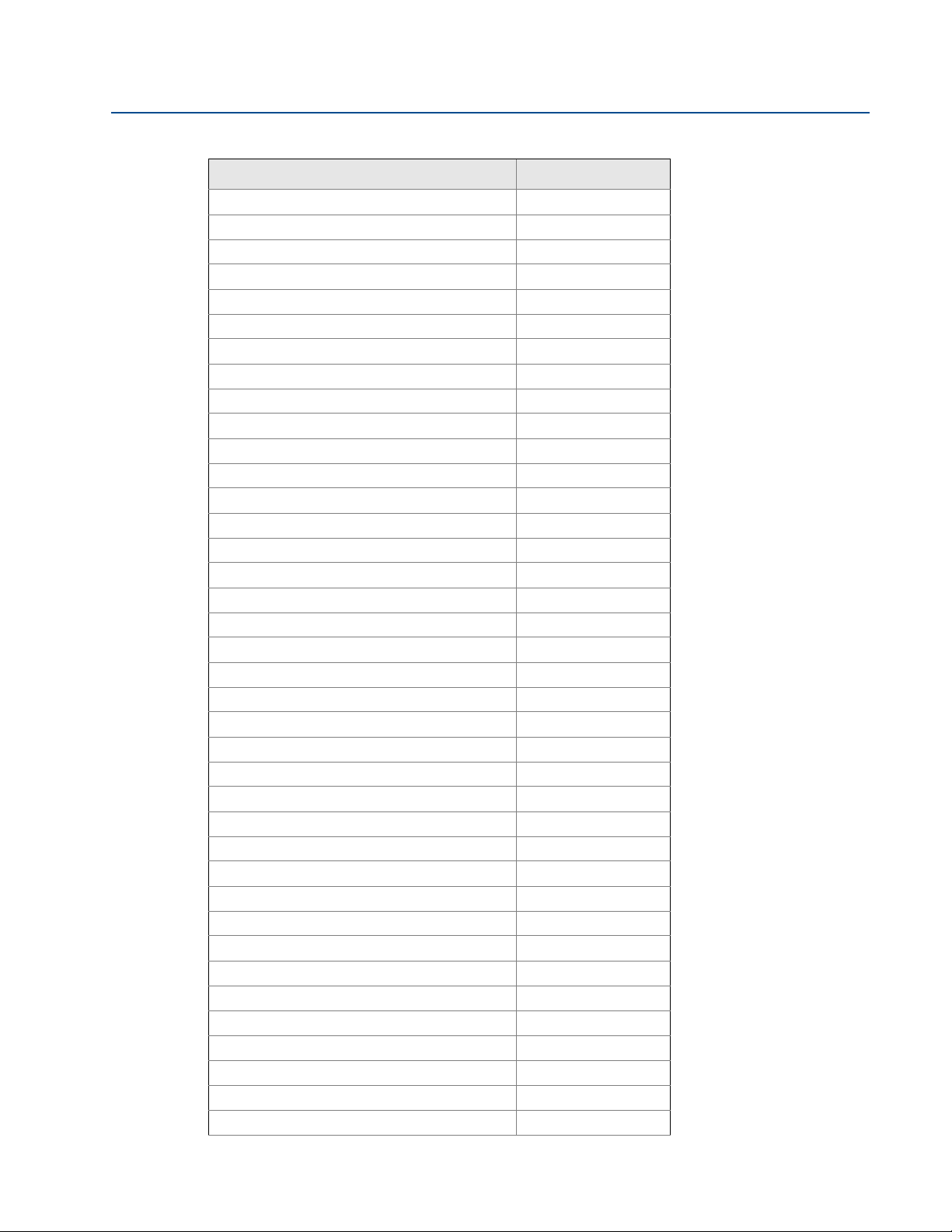

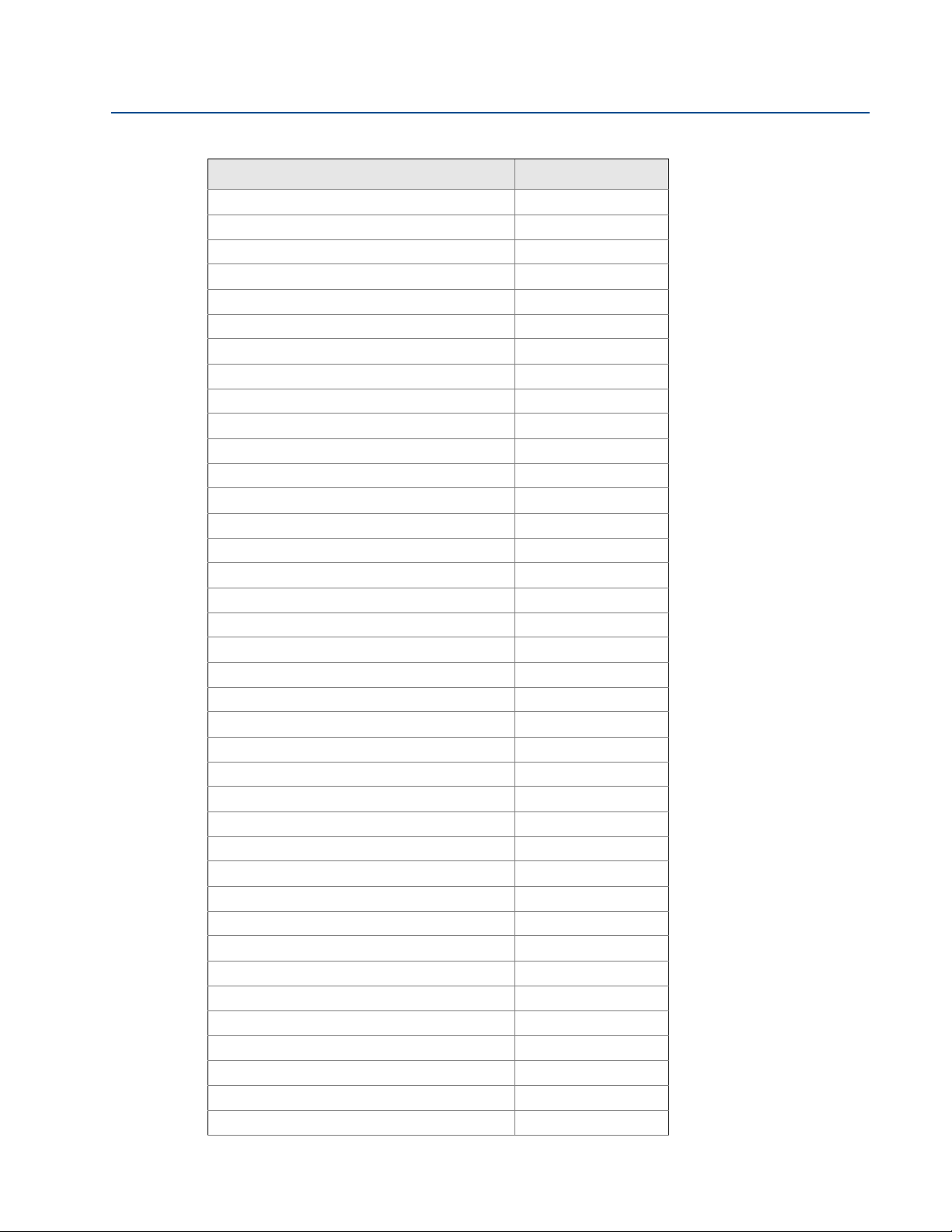

6Section 6: Advanced Diagnostics Configuration

6.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

6.2 Licensing and enabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.2.1 Licensing the 8732EM diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6.3 Tunable empty pipe detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.3.1 Tunable empty pipe parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

6.3.2 Optimizing tunable empty pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

6.4 Electronics temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.4.1 Turning electronics temperature on/off . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6.4.2 Electronics temperature parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

6.5 Ground/wiring fault detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

6.5.1 Turning ground/wiring fault on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

6.5.2 Ground/wiring fault parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

6.6 High process noise detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

6.6.1 Turning high process noise on/off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

6.6.2 High process noise parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

6.7 Coated electrode detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

6.7.1 Turning coated electrode detection on/off. . . . . . . . . . . . . . . . . . . . . . . .118

6.7.2 Coated electrode parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

6.8 4-20 mA loop verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

6.8.1 Initiating 4-20 mA loop verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

6.8.2 4-20 mA loop verification parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

6.9 SMART

™

Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6.9.1 Sensor baseline (signature) parameters . . . . . . . . . . . . . . . . . . . . . . . . . .121

6.9.2 Establishing the sensor baseline (signature). . . . . . . . . . . . . . . . . . . . . . . 122

6.9.3 SMART Meter Verification test criteria. . . . . . . . . . . . . . . . . . . . . . . . . . . .122

6.10 Run manual SMART Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .123

6.10.1 Test conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

6.10.2 Test scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .124

6.11 Continuous SMART Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

6.11.1 Test scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .125

6.12 SMART Meter Verification test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .126

6.13 SMART Meter Verification measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .127

6.14 Optimizing the SMART Meter Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .130

x

Tabl e of Co nten ts

Reference Manual

00809-0100-4444, Rev AD

7Section 7: Digital Signal Processing

8Section 8: Maintenance

Table of Contents

August 2015

6.14.1 Optimizing continuous SMART Meter Verification. . . . . . . . . . . . . . . . . 131

7.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.2 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

7.3 Process noise profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7.4 High process noise diagnostic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7.5 Optimizing flow reading in noisy applications . . . . . . . . . . . . . . . . . . . . . . . . . . 134

7.5.1 Coil drive frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.5.2 Auto zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

7.5.3 Digital signal processing (DSP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

7.6 Explanation of signal processing algorithm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

8.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

8.3 Installing a Local Operator Interface (LOI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

8.4 Replacing 8732EM revision 4 electronics stack. . . . . . . . . . . . . . . . . . . . . . . . . . 143

8.5 Replacing socket module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8.5.1 Integral mount socket module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

8.5.2 Replacing terminal block socket module. . . . . . . . . . . . . . . . . . . . . . . . . 147

8.6 Trims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8.6.1 D/A trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

8.6.2 Scaled D/A trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.6.3 Digital trim. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

8.6.4 Universal trim . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

8.7 Review . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

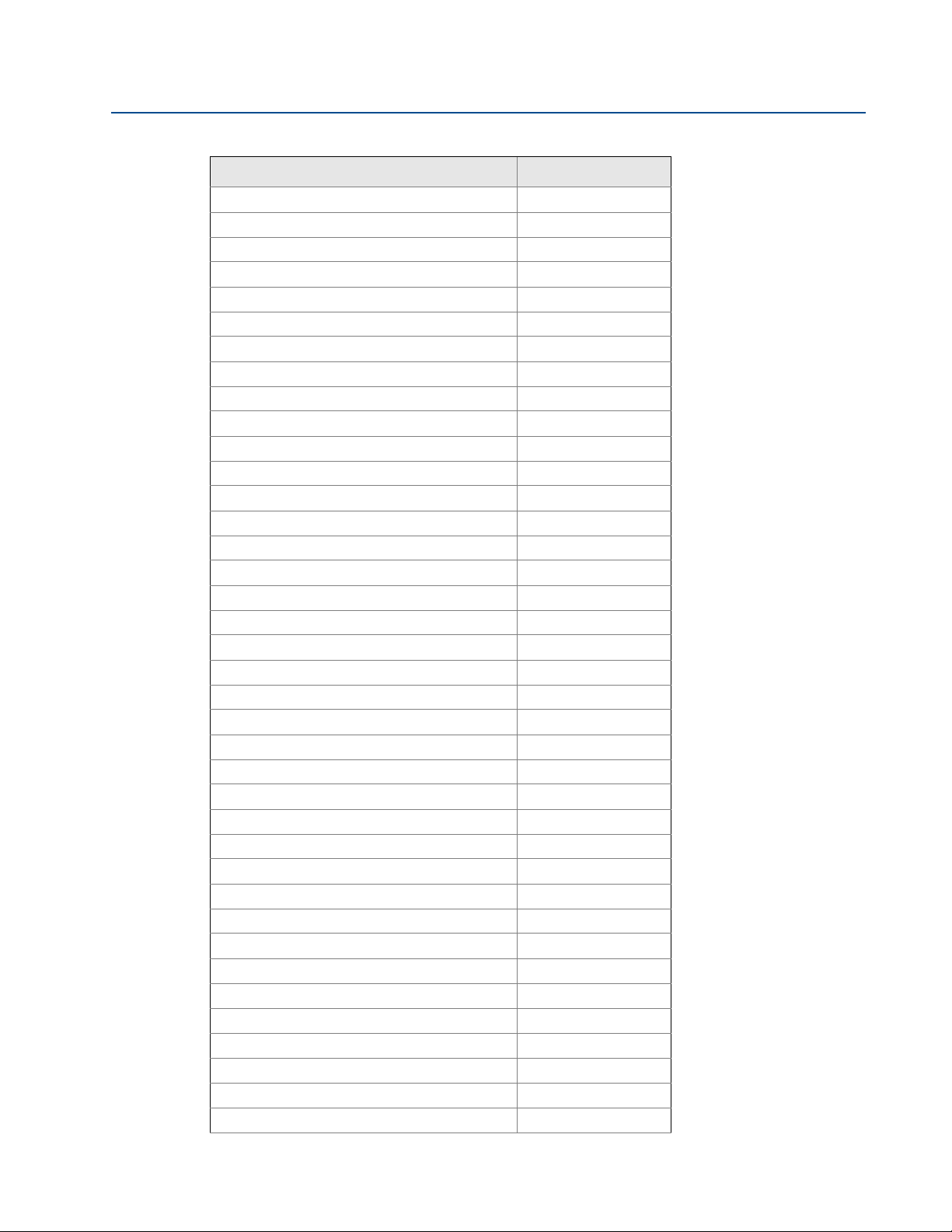

9Section 9: Troubleshooting

9.1 Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

9.2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.3 Installation check and guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.3.1 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

9.3.2 Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Tabl e o f Con tent s

9.3.3 Remote wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.3.4 Process fluid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

9.4 Diagnostic messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

9.4.1 Troubleshooting empty pipe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

xi

Table of Contents

August 2015

Reference Manual

00809-0100-4444, Rev AD

9.4.2 Troubleshooting ground/wiring fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

9.4.3 Troubleshooting high process noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

9.4.4 Troubleshooting coated electrode detection . . . . . . . . . . . . . . . . . . . . . 164

9.4.5 Troubleshooting 4-20 mA loop verification. . . . . . . . . . . . . . . . . . . . . . . 164

9.4.6 Troubleshooting the SMART Meter Verification test . . . . . . . . . . . . . . . 165

9.5 Basic troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

9.6 Sensor troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

9.6.1 Sensor adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

9.6.2 Socket module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

9.6.3 Installed sensor tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

9.6.4 Uninstalled sensor tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

9.7 Technical support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

9.8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

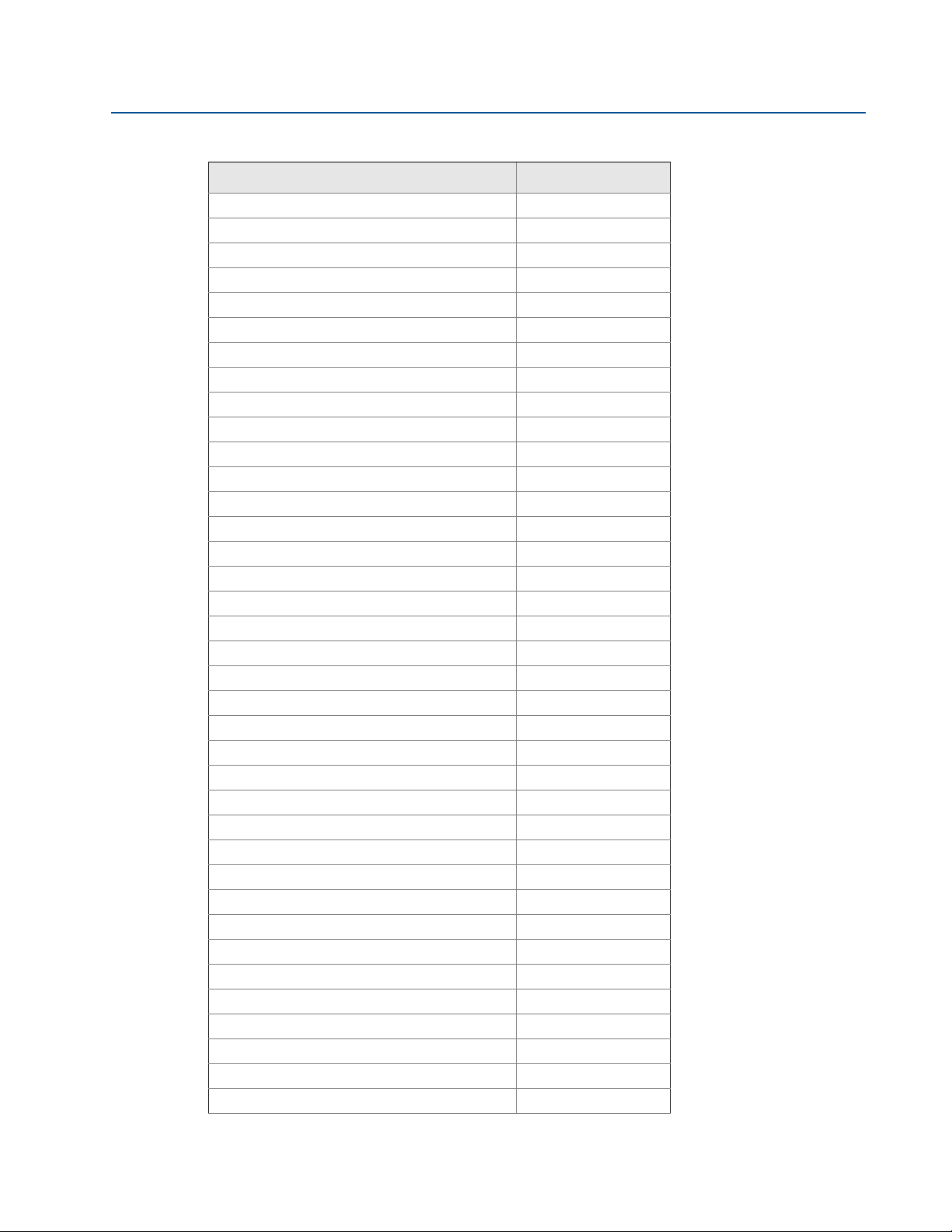

AAppendix A: Specifications and Reference Data

A.1 Rosemount 8732EM Transmitter specifications. . . . . . . . . . . . . . . . . . . . . . . . . 177

A.1.1 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

A.1.2 Advanced diagnostics capabilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

A.1.3 Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

A.1.4 Sensor compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

A.1.5 Performance specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

A.1.6 Analog output effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

A.1.7 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

A.1.8 F0875 Low Power Software Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

A.2 Rosemount 8705-M Flanged Sensor specifications . . . . . . . . . . . . . . . . . . . . . . 188

A.2.1 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

A.2.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

A.3 Rosemount 8711-M/L Wafer Sensor specifications . . . . . . . . . . . . . . . . . . . . . . 194

A.3.1 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

A.3.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

A.4 Rosemount 8721 Hygienic (Sanitary) Sensor specifications . . . . . . . . . . . . . . 198

A.4.1 Functional specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

A.4.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

xii

BAppendix B: Product Certifications

B.1 Product certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

B.2 FM hazardous locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

B.3 ATEX/IECEx hazardous locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Tabl e of Co nten ts

Reference Manual

00809-0100-4444, Rev AD

CAppendix C: Wiring Diagrams

DAppendix D: Implementing a Universal Transmitter

Table of Contents

August 2015

B.4 EC Declaration of Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

C.1 8732EM wiring diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

C.2 775 Smart Wireless THUM

™

Adapter wiring diagrams . . . . . . . . . . . . . . . . . . . 233

C.3 475 Field Communicator wiring diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

D.1 Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

D.2 Universal capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

D.2.1 Implementation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

D.3 Rosemount sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

D.3.1 8705/8707/8711/8721 sensors to 8732 Transmitter . . . . . . . . . . . . . . 240

D.3.2 8701 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

D.3.3 Connecting sensors of other manufacturers. . . . . . . . . . . . . . . . . . . . . . 242

D.4 Brooks sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

D.4.1 Model 5000 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 243

D.4.2 Model 7400 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 244

D.5 Endress and Hauser sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

D.5.1 Endress and Hauser sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . 245

D.6 Fischer and Porter sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

D.6.1 Model 10D1418 sensor to 8732 transmitter. . . . . . . . . . . . . . . . . . . . . . 246

D.6.2 Model 10D1419 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . 247

D.6.3 Model 10D1430 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . 248

D.6.4 Model 10D1430 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . 249

D.6.5 Model 10D1465/10D1475 sensors to 8732 Transmitter . . . . . . . . . . . 250

D.6.6 Fischer and Porter sensor to 8732 Transmitter. . . . . . . . . . . . . . . . . . . . 251

D.7 Foxboro sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

D.7.1 Series 1800 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 252

D.7.2 Series 1800 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 253

D.7.3 Series 2800 Sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 254

D.7.4 Foxboro Sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

D.8 Kent Veriflux VTC sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

D.8.1 Veriflux VTC sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 256

Tabl e o f Con tent s

D.9 Kent sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

D.9.1 Kent sensor to 8732 Transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

D.10 Krohne sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

D.10.1 Krohne sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

xiii

Table of Contents

August 2015

Reference Manual

00809-0100-4444, Rev AD

D.11 Taylor sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

D.11.1 Series 1100 sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . 259

D.11.2 Taylor sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

D.12 Yamatake Honeywell sensors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

D.12.1 Yamatake Honeywell sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . 261

D.13 Yokogawa sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

D.13.1 Yokogawa sensor to 8732 Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . 262

D.14 Generic manufacturer sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

D.14.1 Generic manufacturer sensor to 8732 Transmitter . . . . . . . . . . . . . . . . 263

D.14.2 Identify the terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

D.14.3 Wiring connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

xiv

Tabl e of Co nten ts

Reference Manual

00809-0100-4444, Rev AD

Section 1 Introduction

1.1 System description

The 8700M Magnetic Flowmeter Platform consists of a sensor and a transmitter. The sensor is

installed in-line with the process piping; the transmitter can be remotely mounted or integrally

mounted to the sensor.

Figure 1-1. Field Mount Transmitters

Integral Remote

Section 1: Introduction

August 2015

There are three Rosemount® flow sensors available.

Figure 1-2. Flow Sensors

8705 8711 8721

(1)

See Figure 1-2.

Introduction

1. Also available for use with 8707 High Signal sensor with dual calibration (option code D2).

1

Section 1: Introduction

August 2015

Figure 1-3. 8705 Cross Section

Reference Manual

00809-0100-4444, Rev AD

The flow sensor contains two magnetic coils located on opposite sides of the sensor. Two

electrodes, located perpendicular to the coils and opposite each other, make contact with the

liquid. The transmitter energizes the coils and creates a magnetic field. A conductive liquid

moving through the magnetic field generates an induced voltage at the electrodes. This voltage

is proportional to the flow velocity. The transmitter converts the voltage detected by the

electrodes into a flow reading.

1.2 Product recycling/disposal

Recycling of equipment and packaging should be taken into consideration and disposed of in

accordance with local and national legislation/regulations.

2

Introduction

Reference Manual

00809-0100-4444, Rev AD

Section 2 Installation

Safety messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3

Transmitter symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

Pre-installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Installation procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Handling and lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 9

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 10

Sensor location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 11

Sensor installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 12

Wafer sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 17

Process reference connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 19

Wiring the transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 23

Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 34

Section 2: Installation

August 2015

2.1 Introduction

This section covers the steps required to physically install the magnetic flowmeter. Instructions

and procedures in this section may require special precautions to ensure the safety of the

personnel performing the operations. Refer to the following safety messages before performing

any operation in this section.

2.2 Safety messages

Note

This section provides basic installation guidelines for the Rosemount

Flowmeter Platform with HART

configuration, diagnostics, maintenance, service, installation, or troubleshooting refer to the

appropriate sections in this manual. The quick start guide—as well as this manual—are available

online at www.rosemount.com.

®

®

protocol. For comprehensive instructions for detailed

8700M Magnetic

Installation

3

Section 2: Installation

August 2015

Reference Manual

00809-0100-4444, Rev AD

Failure to follow these installation guidelines could result in death or serious injury.

Installation and servicing instructions are for use by qualified personnel only. Do not

perform any servicing other than that contained in the operating instructions, unless

qualified.

Verify the installation is done safely and is consistent with the operating environment.

If installed in explosive atmospheres [hazardous areas, classified areas, or an “Ex”

environment], it must be assured that the device certification and installation

techniques are suitable for that particular environment.

Explosion hazard. Do not disconnect equipment when a flammable or combustible

atmosphere is present.

To prevent ignition of flammable or combustible atmospheres, disconnect power

before servicing circuits.

Do not connect a Rosemount 8732EM Transmitter to a non-Rosemount sensor that is

located in an explosive atmosphere.

Substitution of components may impair Intrinsic Safety.

Follow national, local, and plant standards to properly earth ground the transmitter

and sensor. The earth ground must be separate from the process reference ground.

Rosemount Magnetic Flowmeters ordered with non-standard paint options or

non-metallic labels may be subject to electrostatic discharge. To avoid electrostatic

charge build-up, do not rub the flowmeter with a dry cloth or clean with solvents.

NOTICE

The sensor liner is vulnerable to handling damage. Never place anything through the

sensor for the purpose of lifting or gaining leverage. Liner damage may render the sensor

inoperable.

Metallic or spiral-wound gaskets should not be used as they will damage the liner face of

the sensor. If spiral wound or metallic gaskets are required for the application, lining

protectors must be used. If frequent removal is anticipated, take precautions to protect

the liner ends. Short spool pieces attached to the sensor ends are often used for

protection.

Correct flange bolt tightening is crucial for proper sensor operation and life. All bolts must

be tightened in the proper sequence to the specified torque specifications. Failure to

observe these instructions could result in severe damage to the sensor lining and possible

sensor replacement.

In cases where high voltage/high current are present near the meter installation, ensure

proper protection methods are followed to prevent stray voltage / current from passing

through the meter. Failure to adequately protect the meter could result in damage to the

transmitter and lead to meter failure.

Completely remove all electrical connections from both sensor and transmitter prior to

welding on the pipe. For maximum protection of the sensor, consider removing it from the

pipeline.

2.3 Transmitter symbols

Caution symbol — check product documentation for details

Protective conductor (grounding) terminal

4

Installation

Reference Manual

00809-0100-4444, Rev AD

2.4 Pre-installation

Before installing the Rosemount 8732EM Magnetic Flowmeter Transmitter, there are several

pre-installation steps that should be completed to make the installation process easier:

Identify the options and configurations that apply to your application

Set the hardware switches if necessary

Consider mechanical, electrical, and environmental requirements

2.5 Installation procedures

2.5.1 Transmitter installation

Installation of the Rosemount Magnetic flowmeter includes both detailed mechanical and

electrical installation procedures.

2.5.2 Identify options and configurations

Section 2: Installation

August 2015

The typical installation of the 8732EM includes a device power connection, a 4–20mA output

connection, and sensor coil and electrode connections. Other applications may require one or

more of the following configurations or options:

Pulse output

Discrete input/discrete output

HART multidrop configuration

Hardware switches

The 8732EM electronics stack is equipped with user-selectable hardware switches. These

switches set the alarm mode, internal/external analog power, internal/external pulse power, and

transmitter security. The standard configuration for these switches when shipped from the

factory are as follows:

Table 2-1. Standard Switch Configuration

Alarm Mode High

(1)

Internal/External Analog Power

Internal/External Pulse Power

Transmitter Security

1. For electronics with intrinsically safe analog and pulse outputs, the power

must be provided externally. In this configuration, these two hardware

switches are not provided.

Internal

(1)

External

Off

Installation

In most cases, it will not be necessary to change the setting of the hardware switches. If the

switch settings need to be changed, follow the steps outlined in “Changing hardware switch

settings” on page 40).

Note

To prevent switch damage, use a non-metallic tool to move switch positions.

5

Section 2: Installation

August 2015

Identify any additional options and configurations that apply to the installation. Keep a list of

these options for consideration during the installation and configuration procedures.

2.5.3 Mechanical considerations

The mounting site for the 8732EM Transmitter should provide enough room for secure

mounting, easy access to conduit entries, full opening of the transmitter covers, and easy

readability of the Local Operator Interface (LOI) screen (if equipped).

For remote mount transmitter (8732EMRxxx) installations, a mounting bracket is provided for

use on a 2-in. pipe or a flat surface (see Figure 2-1).

Note

If the 8732EM is mounted separately from the sensor, it may not be subject to limitations that

might apply to the sensor.

Rotate integral mount transmitter housing

The transmitter housing can be rotated on the sensor in 90-degree increments by removing the

four mounting screws on the bottom of the housing. Do not rotate the housing more than

180 degrees in any one direction. Prior to tightening, be sure the mating surfaces are clean, the

O-ring is seated in the groove, and there is no gap between the housing and the sensor.

Reference Manual

00809-0100-4444, Rev AD

6

Installation

Reference Manual

>@

00809-0100-4444, Rev AD

Figure 2-1. Rosemount 8732EM Dimensional Drawing

Section 2: Installation

August 2015

Note

Default conduit entries for FM approvals are

thread adapters will be supplied.

2.5.4 Electrical considerations

Before making any electrical connections to the 8732EM, consider national, local and plant

electrical installation requirements. Be sure to have the proper power supply, conduit, and other

accessories necessary to comply with these standards.

Both remotely and integrally mounted 8732EM Transmitters require external power so there

must be access to a suitable power source.

Installation

1

/2-in. NPT. If M20 thread connections are required,

7

Section 2: Installation

August 2015

Table 2-2. Electrical Data

Rosemount 8732EM Flow Transmitter

Power input 90–250VAC, 0.45A, 40VA

Pulsed circuit Internally powered (Active): Outputs up to 12VDC, 12.1mA, 73mW

Reference Manual

00809-0100-4444, Rev AD

12–42VDC, 1.2A, 15W

Externally powered (Passive): Input up to 28VDC, 100mA, 1W

4-20mA output

circuit

Internally Powered (Active): Outputs up to 25mA, 24VDC, 600mW

Externally Powered (Passive): Input up to 25mA, 30VDC, 750mW

Um 250V

Coil excitation

500mA, 40V max, 9W max

output

Rosemount 8705-M and 8711-M/L Sensor

Coil excitation

500mA, 40V max, 20W max

(1)

input

Electrode circuit 5V, 200uA, 1mW

1. Provided by the transmitter.

2.5.5 Environmental considerations

To ensure maximum transmitter life, avoid extreme temperatures and excessive vibration.

Typical problem areas include the following:

High-vibration lines with integrally mounted transmitters

Tropical/desert installations in direct sunlight

Outdoor installations in arctic climates

Remote mounted transmitters may be installed in the control room to protect the electronics

from the harsh environment and to provide easy access for configuration or service.

8

Installation

Reference Manual

AB

00809-0100-4444, Rev AD

2.6 Handling and lifting

Handle all parts carefully to prevent damage. Whenever possible, transport the system

to the installation site in the original shipping container.

PTFE-lined sensors are shipped with end covers that protect it from both mechanical

damage and normal unrestrained distortion. Remove the end covers just before

installation.

Keep the shipping plugs in the conduit connections until you are ready to connect and

seal them.

The sensor should be supported by the pipeline. Pipe supports are recommended on

both the inlet and outlet sides of the sensor pipeline. There should be no additional

support attached to the sensor.

Additional safety recommendations for mechanical handling:

- Use proper PPE (Personal Protection Equipment) including safety glasses and

steel toed shoes).

- Do not drop the device from any height.

Do not lift the meter by holding the electronics housing or junction box.The sensor liner

is vulnerable to handling damage. Never place anything through the sensor for the

purpose of lifting or gaining leverage. Liner damage can render the sensor useless.

If provided, use the lifting lugs on each flange to handle the Magnetic Flowmeter when

it is transported and lowered into place at the installation site. If lifting lugs are not

provided, the Magnetic Flowmeter must be supported with a lifting sling on each side

of the housing.

Section 2: Installation

August 2015

- Standard Pressure 3-in. through 36-in. Flanged Magnetic Flowmeters come with

lifting lugs.

- High Pressure (above 600#) 1-in. through 24-in. Flanged Magnetic Flowmeters

come with lifting lugs.

- Wafers and Sanitary Magnetic Flowmeters do not come with lifting lugs.

Figure 2-2. Rosemount 8705 Sensor Support for Handling and Lifting

A. Without lifting lugs

B. With lifting lugs

Installation

9

Section 2: Installation

2 Pipe Diameters

Flow

5 Pipe Diameters

August 2015

2.7 Mounting

2.7.1 Upstream/downstream piping

To ensure specified accuracy over widely varying process conditions, install the sensor with a

minimum of five straight pipe diameters upstream and two pipe diameters downstream from the

electrode plane (see

Figure 2-3. Upstream and Downstream Straight Run

Figure 2-3).

Reference Manual

00809-0100-4444, Rev AD

Installations with reduced upstream and downstream straight runs are possible. In reduced straight

run installations, the meter may not meet absolute accuracy specifications. Reported flow rates will

still be highly repeatable.

2.7.2 Flow direction

The sensor should be mounted so that the arrow points in the direction of flow. See Figure 2-4.

Figure 2-4. Flow Direction Arrow

10

Installation

Reference Manual

FLOW

FLOW

CORRECT INCORRECT

00809-0100-4444, Rev AD

2.8 Sensor location

The sensor should be installed in a location that ensures it remains full during operation. Vertical

installation with upward process fluid flow keeps the cross-sectional area full, regardless of flow

rate. Horizontal installation should be restricted to low piping sections that are normally full.

Figure 2-5. Sensor Orientation

Section 2: Installation

August 2015

2.8.1 Electrode orientation

The electrodes in the sensor are properly oriented when the two measurement electrodes are in

the 3 and 9 o’clock positions or within 45 degrees from the horizontal, as shown on the left in

Figure 2-6. Avoid any mounting orientation that positions the top of the sensor at 90 degrees

from the vertical position as shown on the right in Figure 2-6.

Figure 2-6. Mounting Position

For hazardous location installations, refer to Appendix B for Installation Drawings 08732-2060

and 08732-2062 for sensor orientation pertaining to specific T-code compliance.

Installation

11

Section 2: Installation

August 2015

2.9 Sensor installation

2.9.1 Flanged sensors

Gaskets

The sensor requires a gasket at each process connection. The gasket material must be compatible with

the process fluid and operating conditions. Gaskets are required on each side of a grounding ring

(see

Figure 2-7). All other applications (including sensors with lining protectors or a grounding

electrode) require only one gasket on each process connection.

Note

Metallic or spiral-wound gaskets should not be used as they will damage the liner face of the

sensor. If spiral wound or metallic gaskets are required for the application, lining protectors

must be used.

Figure 2-7. Flanged Gasket Placement

Reference Manual

00809-0100-4444, Rev AD

A. Grounding ring and gasket (optional)

B. Customer-supplied gasket

B

A

FLOW

12

Installation

Reference Manual

00809-0100-4444, Rev AD

2.9.2 Flange bolts

Note

Do not bolt one side at a time. Tighten both sides simultaneously. Example:

1. Snug upstream

2. Snug downstream

3. Tighten upstream

4. Tighten downstream

Do not snug and tighten the upstream side and then snug and tighten the downstream side.

Failure to alternate between the upstream and downstream flanges when tightening bolts may

result in liner damage.

Suggested torque values by sensor line size and liner type are listed in Ta b le 2 - 4 for ASME B16.5

flanges and Tab l e 2 - 5 for EN flanges. Consult the factory if the flange rating of the sensor is not

listed. Tighten flange bolts on the upstream side of the sensor in the incremental sequence

shown in

downstream side of the sensor. For sensors with greater or fewer flange bolts, tighten the bolts

in a similar crosswise sequence. Repeat this entire tightening sequence at 40%, 60%, 80%, and

100% of the suggested torque values.

Figure 2-8 to 20% of the suggested torque values. Repeat the process on the

Section 2: Installation

August 2015

If leakage occurs at the suggested torque values, the bolts can be tightened in additional 10%

increments until the joint stops leaking, or until the measured torque value reaches the

maximum torque value of the bolts. Practical consideration for the integrity of the liner often

leads the user to distinct torque values to stop leakage due to the unique combinations of

flanges, bolts, gaskets, and sensor liner material.

Check for leaks at the flanges after tightening the bolts. Failure to use the correct tightening

methods can result in severe damage. While under pressure, sensor materials may deform over

time and require a second tightening 24 hours after the initial installation.

Figure 2-8. Flange Bolt Torquing Sequence

Installation

13

Section 2: Installation

August 2015

Prior to installation, identify the lining material of the flow sensor to ensure the suggested

torque values are applied.

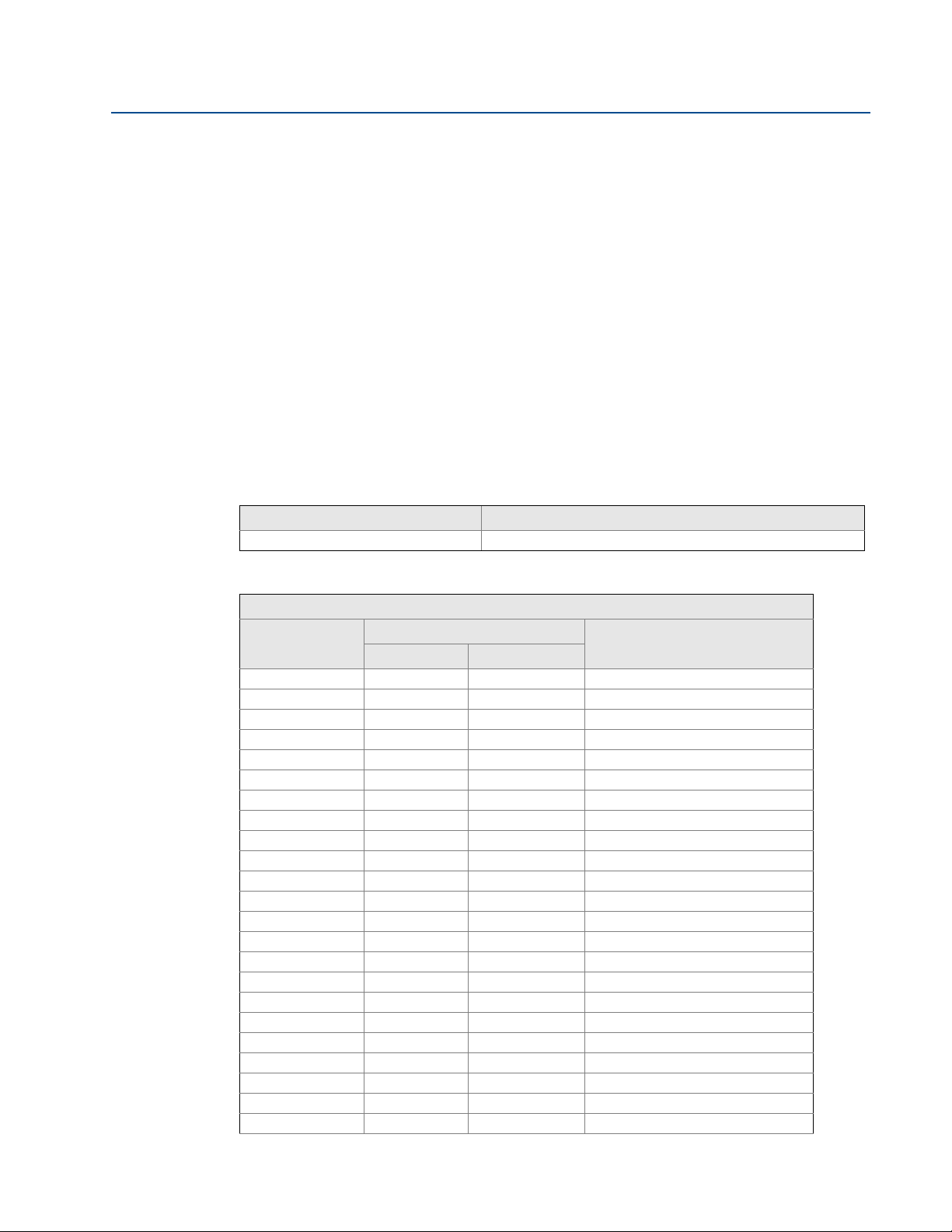

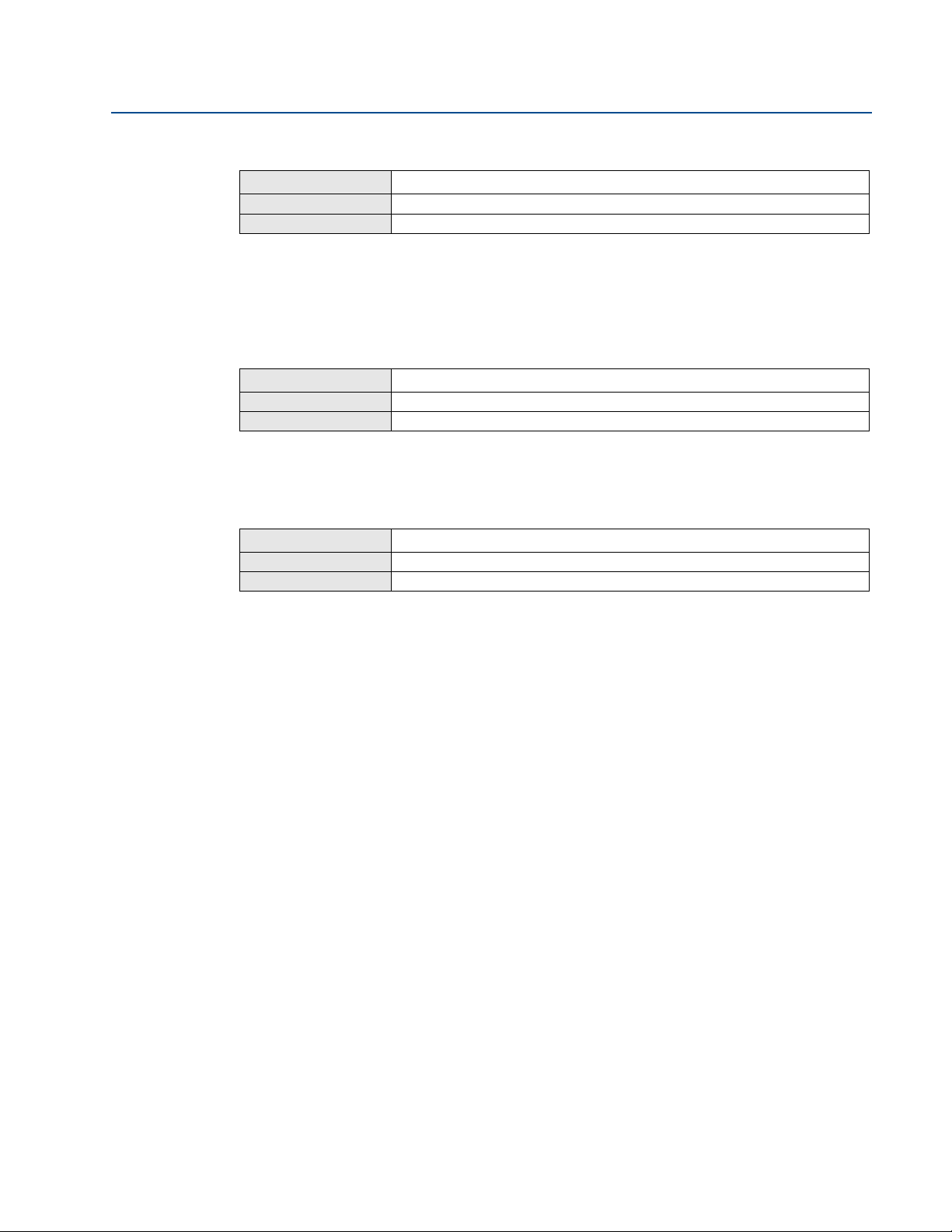

Table 2-3. Lining Material

Fluoropolymer liners Other liners

Table 2-4. Suggested Flange Bolt Torque Values for Rosemount 8705 (ASME)

Reference Manual

00809-0100-4444, Rev AD

T - PTFE P - Polyurethane

F - ETFE N - Neoprene

A - PFA L - Linatex (Natural Rubber)

K - PFA+ D - Adiprene

Fluoropolymer liners Other liners

Size

code

005 0.5-in. (15 mm) 8 8 N/A N/A

010 1-in. (25 mm) 8 12 N/A N/A

015 1.5-in. (40 mm) 13 25 7 18

020 2-in. (50 mm) 19 17 14 11

025 2.5-in. (65 mm) 22 24 17 16

030 3-in. (80 mm) 34 35 23 23

040 4-in. (100 mm) 26 50 17 32

050 5-in. (125 mm) 36 60 25 35

060 6-in. (150 mm) 45 50 30 37

080 8-in. (200 mm) 60 82 42 55

100 10-in. (250 mm) 55 80 40 70

120 12-in. (300 mm) 65 125 55 105

140 14-in. (350 mm) 85 110 70 95

160 16-in. (400 mm) 85 160 65 140

180 18-in. (450 mm) 120 170 95 150

200 20-in. (500 mm) 110 175 90 150

Line size

Class 150

(pound-feet)

Class 300

(pound-feet)

Class 150

(pound-feet)

Class 300

(pound-feet)

14

240 24-in. (600 mm) 165 280 140 250

(1)

300

360

1. Torque values are valid for ASME and AWWA flanges.

30-in. (750 mm) 195 415 165 375

(1)

36-in. (900 mm) 280 575 245 525

Installation

Reference Manual

00809-0100-4444, Rev AD

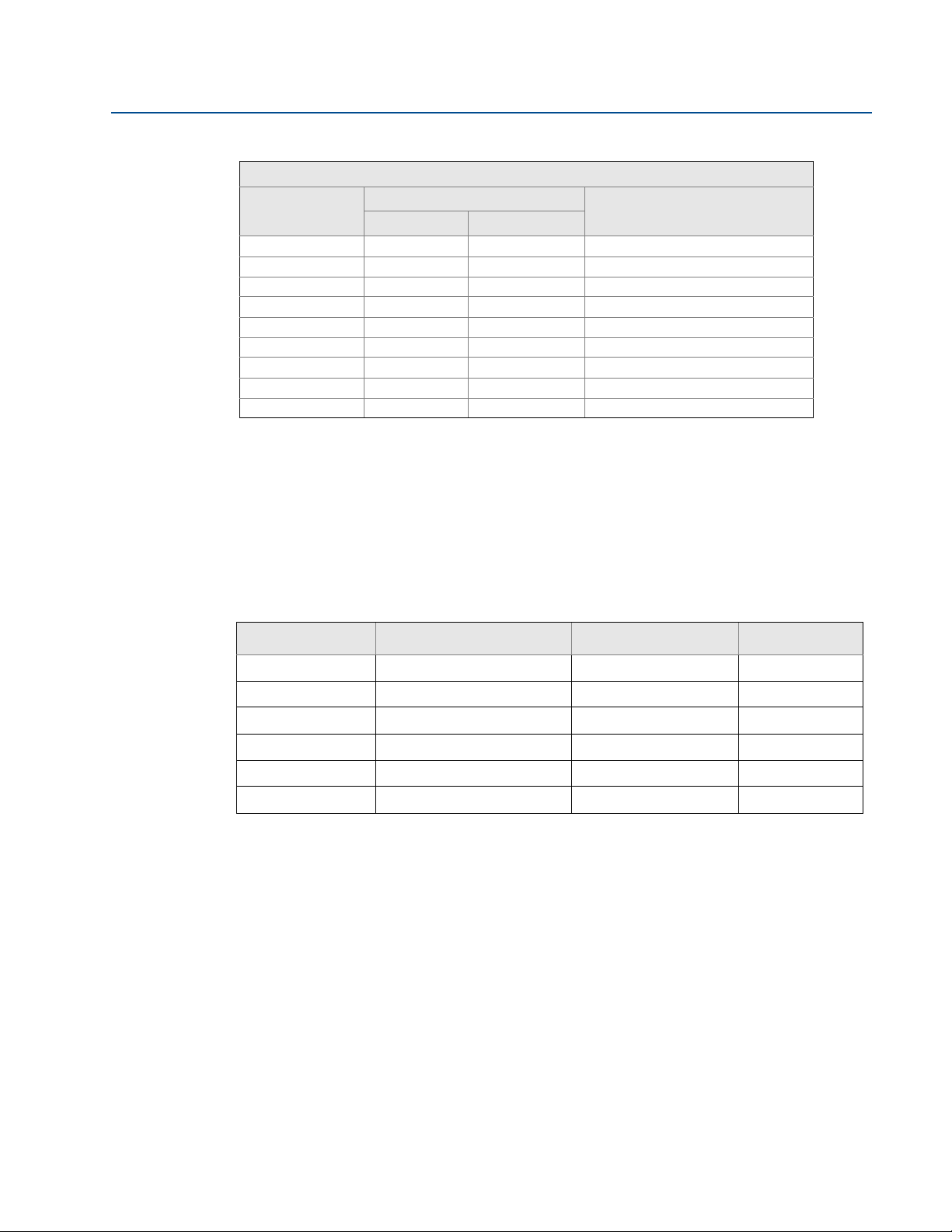

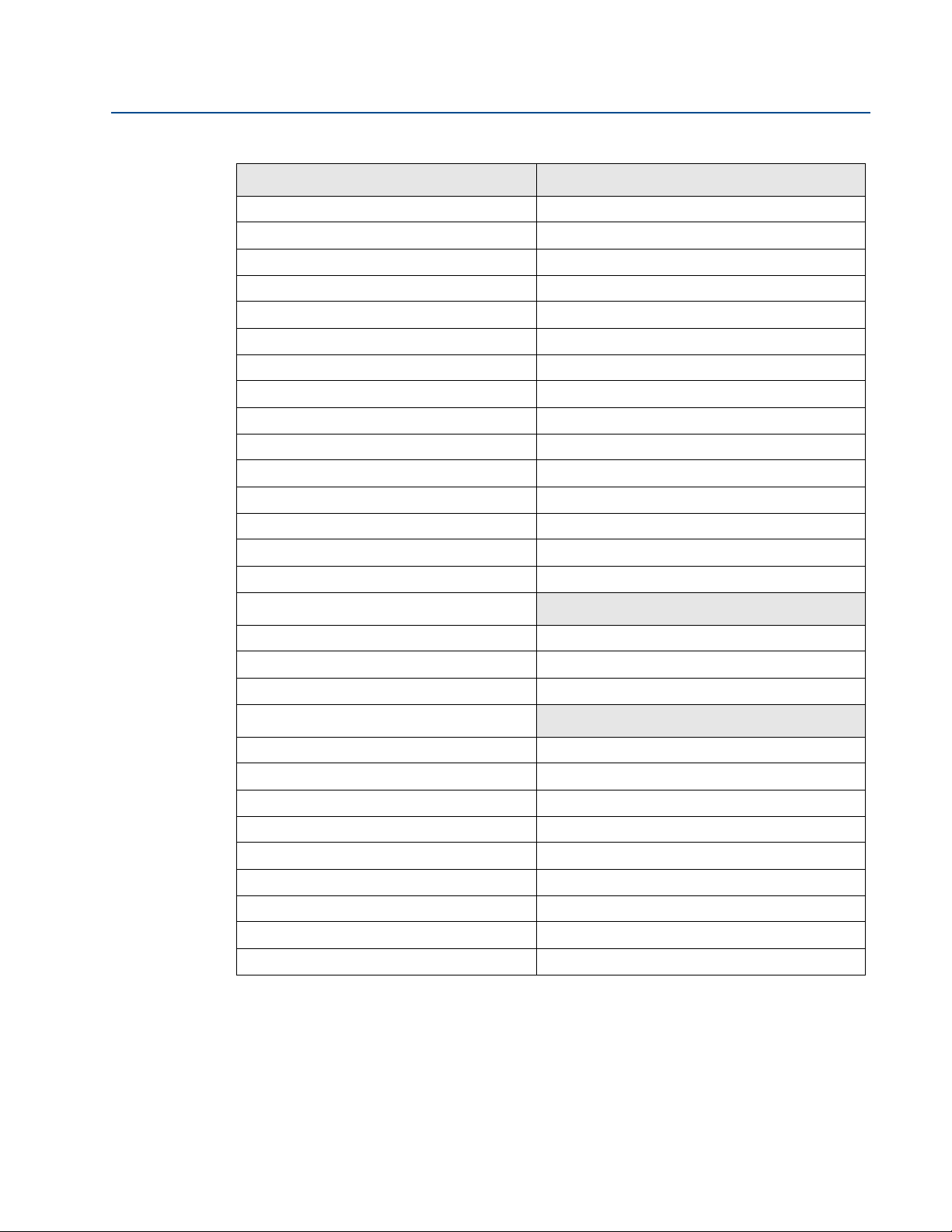

Table 2-5. Flange Bolt Torque and Load Specifications for 8705 (EN 1092-1)

Section 2: Installation

August 2015

Size

code

005

010

015

020

025

030

040

050

060

080

100

120

140

160

180

200

240

Line size

0.5-in. (15 mm)

1-in. (25 mm)

1.5-in. (40 mm)

2-in. (50 mm)

2.5-in. (65 mm)

3-in. (80 mm)

4-in. (100 mm)

5.0-in. (125 mm)

6-in. (150 mm)

8-in. (200 mm)

10-in. (250 mm)

12-in. (300 mm)

14-in. (350 mm)

16-in. (400 mm)

18-in. (450 mm)

20-in. (500 mm)

24-in. (600 mm)

Fluoropolymer liners (in Newton-meters)

PN10 PN 16 PN 25 PN 40

N/A N/A N/A 10

N/A N/A N/A 20

N/A N/A N/A 50

N/A N/A N/A 60

N/A N/A N/A 50

N/A N/A N/A 50

N/A 50 N/A 70

N/A 70 N/A 100

N/A 90 N/A 130

130 90 130 170

100 130 190 250

120 170 190 270

160 220 320 410

220 280 410 610

190 340 330 420

230 380 440 520

290 570 590 850

Installation

15

Section 2: Installation

August 2015

Table 2-6. Flange Bolt Torque and Load Specifications for 8705 (EN 1092-1)

Reference Manual

00809-0100-4444, Rev AD

Size

code

010 1-in. (25 mm) N/A N/A N/A 20

015 1.5-in. (40 mm) N/A N/A N/A 30

020 2-in. (50 mm) N/A N/A N/A 40

025 2.5-in. (65 mm) N/A N/A N/A 35

030 3-in. (80 mm) N/A N/A N/A 30

040 4-in. (100 mm) N/A 40 N/A 50

050 5.0-in. (125 mm) N/A 50 N/A 70

060 6-in. (150 mm) N/A 60 N/A 90

080 8-in. (200 mm) 90 60 90 110

100 10-in. (250 mm) 70 80 130 170

120 12-in. (300 mm) 80 110 130 180

140 14-in. (350 mm) 110 150 210 280

160 16-in. (400 mm) 150 190 280 410

Line size

Other liners (in Newton-meters)

PN 10 PN 16 PN 25 PN 40

180 18-in. (450 mm) 130 230 220 280

200 20-in. (500 mm) 150 260 300 350

240 24-in. (600 mm)

200 380 390

560

16

Installation

Reference Manual

00809-0100-4444, Rev AD

2.10 Wafer sensors

2.10.1 Gaskets

The sensor requires a gasket at each process connection. The gasket material selec ted must be

compatible with the process fluid and operating conditions. Gaskets are required on each side of

a grounding ring. See Figure 2-9 below.

Note

Metallic or spiral-wound gaskets should not be used as they will damage the liner face of the

sensor.

Figure 2-9. Wafer Gasket Placement

Section 2: Installation

August 2015

Installation

17

Section 2: Installation

August 2015

2.10.2 Alignment

On 1.5-in. through 8-in. (40 through 200 mm) line sizes, Rosemount requires installing the

alignment spacers to ensure proper centering of the wafer sensor between the process flanges.

1. Insert studs for the bottom side of the sensor between the pipe flanges and center the

alignment spacer in the middle of the stud. See Figure 2-9 for the bolt hole locations

recommended for the spacers provided. Stud specifications are listed in Tab le 2-7.

2. Place the sensor between the flanges. Make sure the alignment spacers are properly

centered on the studs. For vertical flow installations slide the O-ring over the stud to

keep the spacer in place. See Figure 2-9. Ensure the spacers match the flange size and

class rating for the process flanges. See Table 2-8.

3. Insert the remaining studs, washers, and nuts.

4. Tighten to the torque specifications shown in Table 2-9. Do not over-tighten the bolts

or the liner may be damaged.

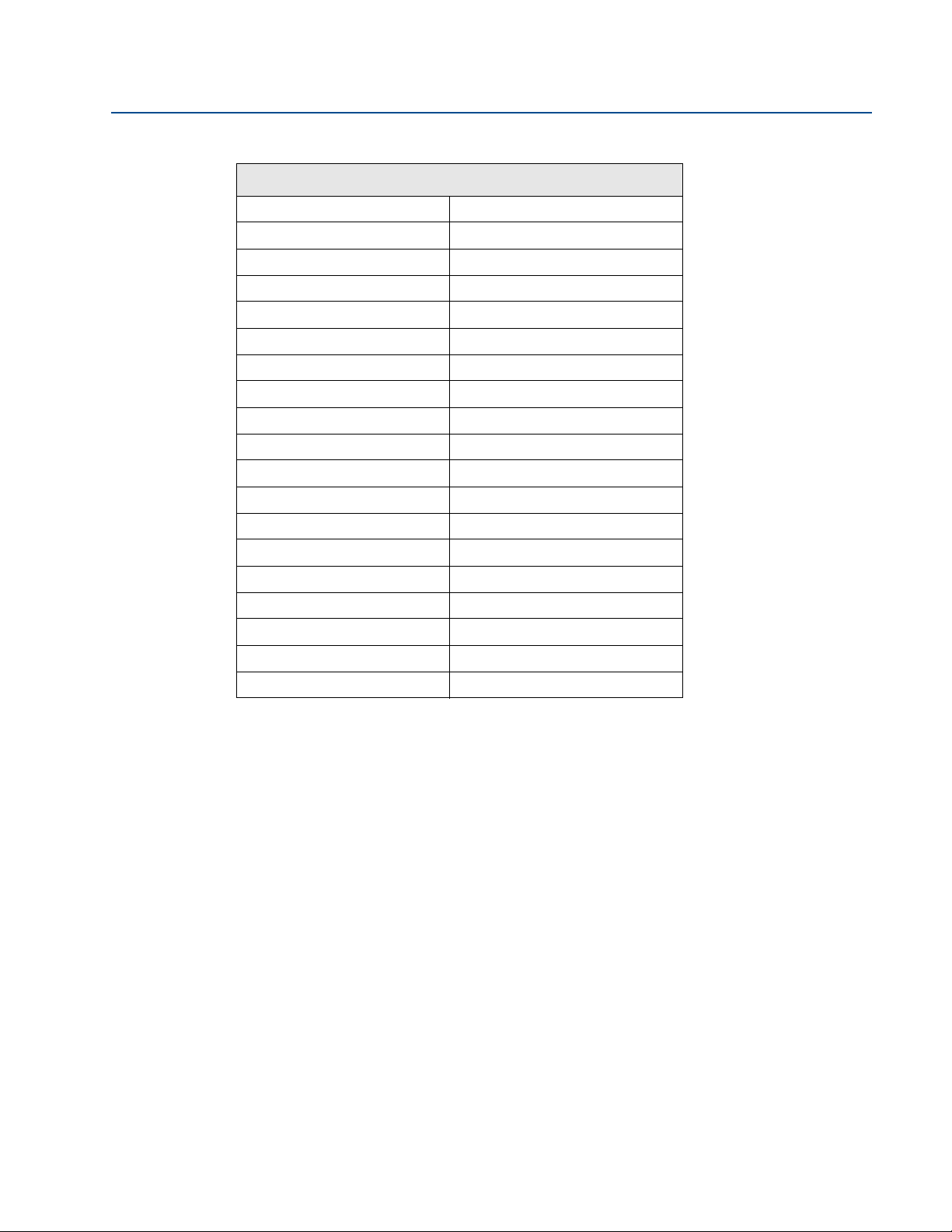

Table 2-7. Stud Specifications

Reference Manual

00809-0100-4444, Rev AD

Nominal sensor size Stud specifications

1.5 through 8-in. (40 through 200 mm) CS, ASTM A193, Grade B7, threaded mounting studs

Table 2-8. Rosemount Alignment Spacer Table

Rosemount alignment spacer table

Dash no.

(-xxxx)

0A15 1.5 40 JIS 10K-20K

0A20 2 50 JIS 10K-20K

0A30 3 80 JIS 10K

0B15 1.5 40 JIS 40K

AA15 1.5 40 ASME- 150#

AA20 2 50 ASME - 150#

AA30 3 80 ASME - 150#

AA40 4 100 ASME - 150#

AA60 6 150 ASME - 150#

AA80 8 200 ASME - 150#

AB15 1.5 40 ASME - 300#

AB20 2 50 ASME - 300#

AB30 3 80 ASME - 300#

AB40 4 100 ASME - 300#

AB60 6 150 ASME - 300#

AB80 8 200 ASME - 300#

DB40 4 100 EN 1092-1 - PN10/16

DB60 6 150 EN 1092-1 - PN10/16

DB80 8 200 EN 1092-1 - PN10/16

DC80 8 200 EN 1092-1 - PN25

DD15 1.5 40 EN 1092-1 - PN10/16/25/40

DD20 2 50 EN 1092-1 - PN10/16/25/40

DD30 3 80 EN 1092-1 - PN10/16/25/40

Line size

Flange rating(in) (mm)

18

Installation

Reference Manual

00809-0100-4444, Rev AD

Table 2-8. Rosemount Alignment Spacer Table (continued)

Dash no.

(-xxxx)

DD40 4 100 EN 1092-1 - PN25/40

DD60 6 150 EN 1092-1 - PN25/40

DD80 8 200 EN 1092-1 - PN40

RA80 8 200 AS40871-PN16

RC20 2 50 AS40871-PN21/35

RC30 3 80 AS40871-PN21/35

RC40 4 100 AS40871-PN21/35

RC60 6 150 AS40871-PN21/35

RC80 8 200 AS40871-PN21/35

To order an Alignment Spacer Kit (qty 3 spacers) use p/n 08711-3211-xxxx along with the Dash

no. above.

2.10.3 Flange bolts

Section 2: Installation

August 2015

Rosemount alignment spacer table

Line size

Flange rating(in) (mm)

Wafer sensors require threaded studs. See Figure 2-8 on page 13 for torque sequence. Always

check for leaks at the flanges after tightening the flange bolts. All sensors require a second

tightening 24 hours after initial flange bolt tightening.

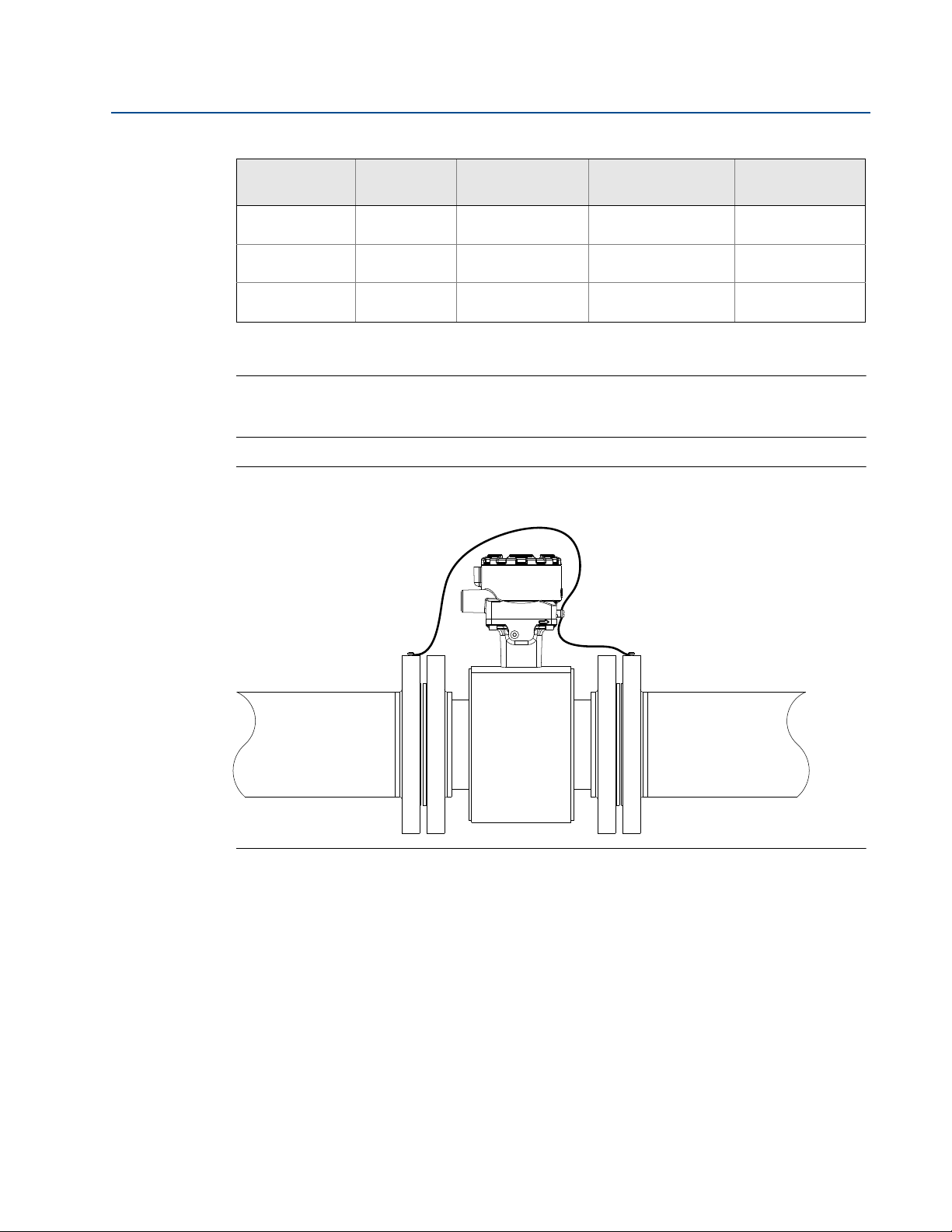

Table 2-9. Rosemount 8711 Torque Specifications

Size code Line size Pound-feet Newton-meter

015 1.5-in. (40 mm) 15 20

020 2-in. (50 mm) 25 34

030 3-in. (80 mm) 40 54

040 4-in. (100 mm) 30 41

060 6-in. (150 mm) 50 68

080 8-in. (200 mm) 70 95

2.11 Process reference connection

Figure 2-10 through Figure 2-13 illustrate process reference connections only. Earth safety

ground is also required as part of the installation but is not shown in the figures. Follow national,

local, and plant electrical codes for safety ground.

Use Ta b l e 2- 1 0 to determine which process reference option to follow for proper installation.

Installation

19

Section 2: Installation

August 2015

Table 2-10. Process Reference Installation Options

Non-Conductive

1. Grounding ring, reference electrode, and lining protectors are not required for process reference. Grounding straps per Figure 2-10

Note

For line sizes 10-in. and larger, the ground strap may come attached to the sensor body near the

flange. See Figure 2-14.

Figure 2-10. Grounding Straps in Conductive Unlined Pipe or Reference Electrode in Lined

Pipe

Type of pipe

Conductive

Unlined Pipe

Conductive

Lined Pipe

Pipe

are sufficient.

Grounding

straps

See Figure 2-10 See Figure 2-11

Insufficient

Grounding

Insufficient

Grounding

Grounding rings

See Figure 2-11

See Figure 2-12

(1)

See Figure 2-13

See Figure 2-10

Not Recommended

Reference

electrode

Reference Manual

00809-0100-4444, Rev AD

Lining

protectors

(1)

See Figure 2-13

See Figure 2-11

See Figure 2-12

(1)

20

Installation

Reference Manual

00809-0100-4444, Rev AD

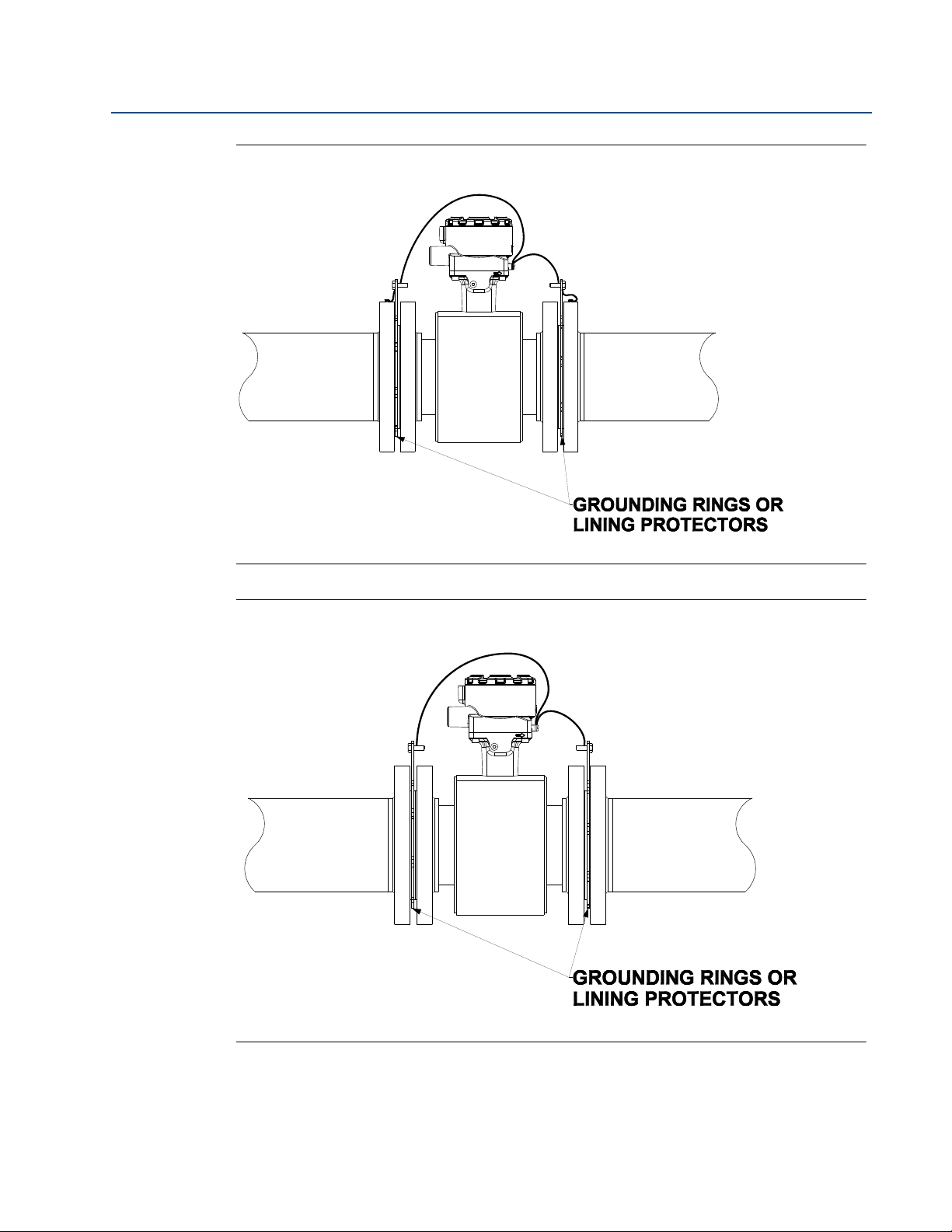

Figure 2-11. Grounding with Grounding Rings or Lining Protectors in Conductive Pipe

Section 2: Installation

August 2015

Figure 2-12. Grounding with Grounding Rings or Lining Protectors in Non-conductive Pipe

Installation

21

Section 2: Installation

August 2015

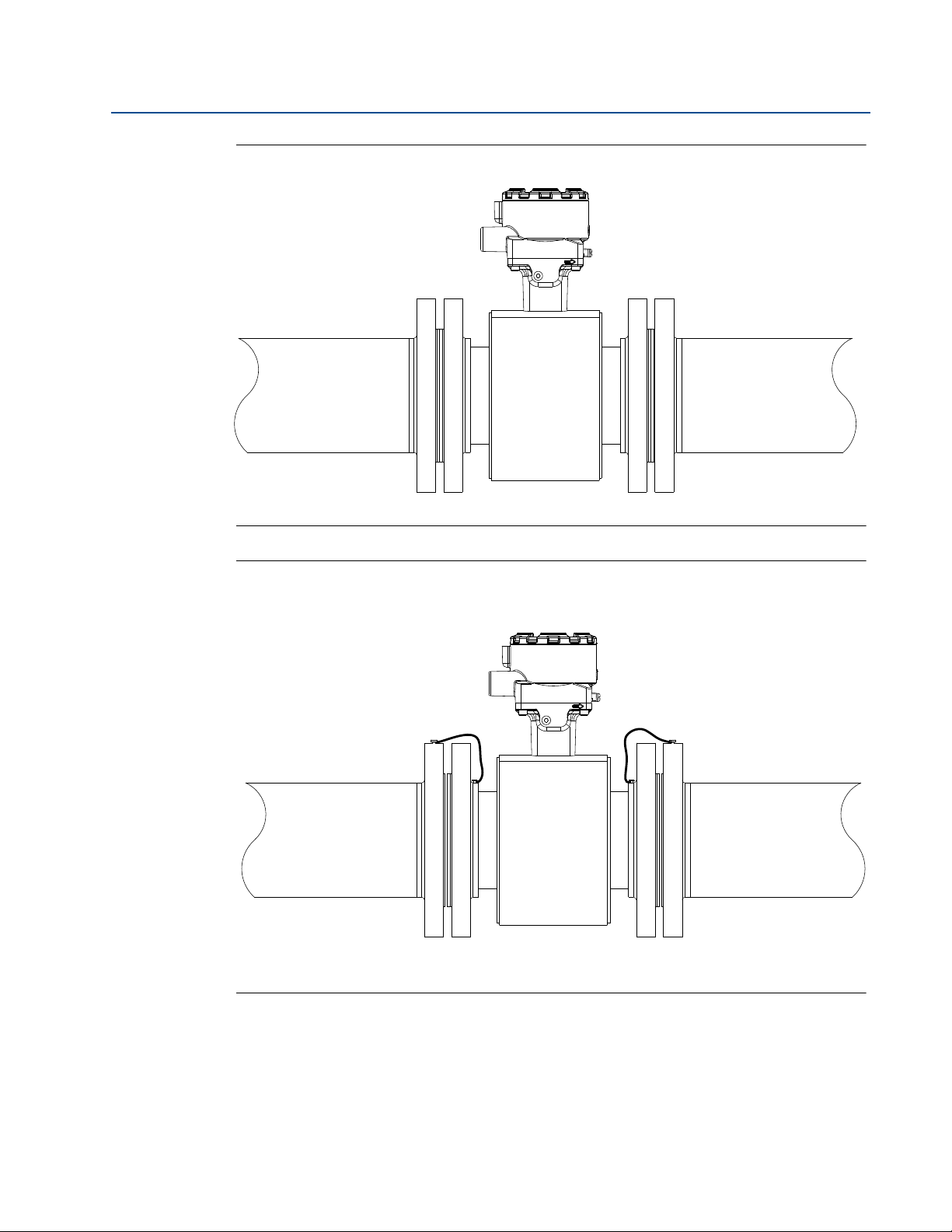

Figure 2-13. Grounding with Reference Electrode in Conductive Unlined Pipe

Reference Manual

00809-0100-4444, Rev AD

Figure 2-14. Grounding for Line Sizes 10-in. and Larger

22

Installation

Reference Manual

00809-0100-4444, Rev AD

2.12 Wiring the transmitter

This wiring section covers the wiring between the transmitter and sensor, the 4-20mA output,

and supplying power to the transmitter. Follow the conduit, cable, and electrical disconnect

requirements in the sections below.

For sensor wiring diagrams, reference Electrical Drawing 08732-1504 in Appendix C Wiring

Diagrams.

For hazardous locations, reference Installation Drawings 08732-2060 and 08732-2062 in

AppendixB .

For information on connecting to another manufacturer’s sensor, refer to Appendix D

Implementing a Universal Transmitter.

2.12.1 Conduit entries and connections

The standard conduit entries for the transmitter and sensor are 1/2 -in. NPT. Thread adapters are

provided for units ordered with M20 conduit entries. Conduit connections should be made in

accordance with national, local, and plant electrical codes. Unused conduit entries should be

sealed with the appropriate certified plugs. The flow sensor is rated IP68 to a depth of 33 feet

(10 meters) for 48 hours. For sensor installations requiring IP68 protection, the cable grands,

conduit, and conduit plugs must be rated for IP68. The plastic shipping plugs do not provide

ingress protection.

Section 2: Installation

August 2015

2.12.2 Conduit requirements

For installations with an intrinsically safe electrode circuit, a separate conduit for the

coil cable and the electrode cable may be required. Refer to the Installation Drawings in

AppendixB.

For installations with non-intrinsically safe electrode circuit, or when using the

combination cable, a single dedicated conduit run for the coil drive and electrode cable

between the sensor and the remote transmitter may be acceptable. Bundled cables

from other equipment in a single conduit are likely to create interference and noise in

the system. See Figure 2-15.

Electrode cables should not be run together and should not be in the same cable tray

with power cables.

Output cables should not be run together with power cables.

Select conduit size appropriate to feed cables through to the flowmeter.

Installation

23

Section 2: Installation

A

B

B

C

D

August 2015

Figure 2-15. Best Practice Conduit Preparation

A. Power

B. Output

C. Coil

D. Elec trode

Reference Manual

00809-0100-4444, Rev AD

2.12.3 Connecting sensor to transmitter

Integral mount transmitters

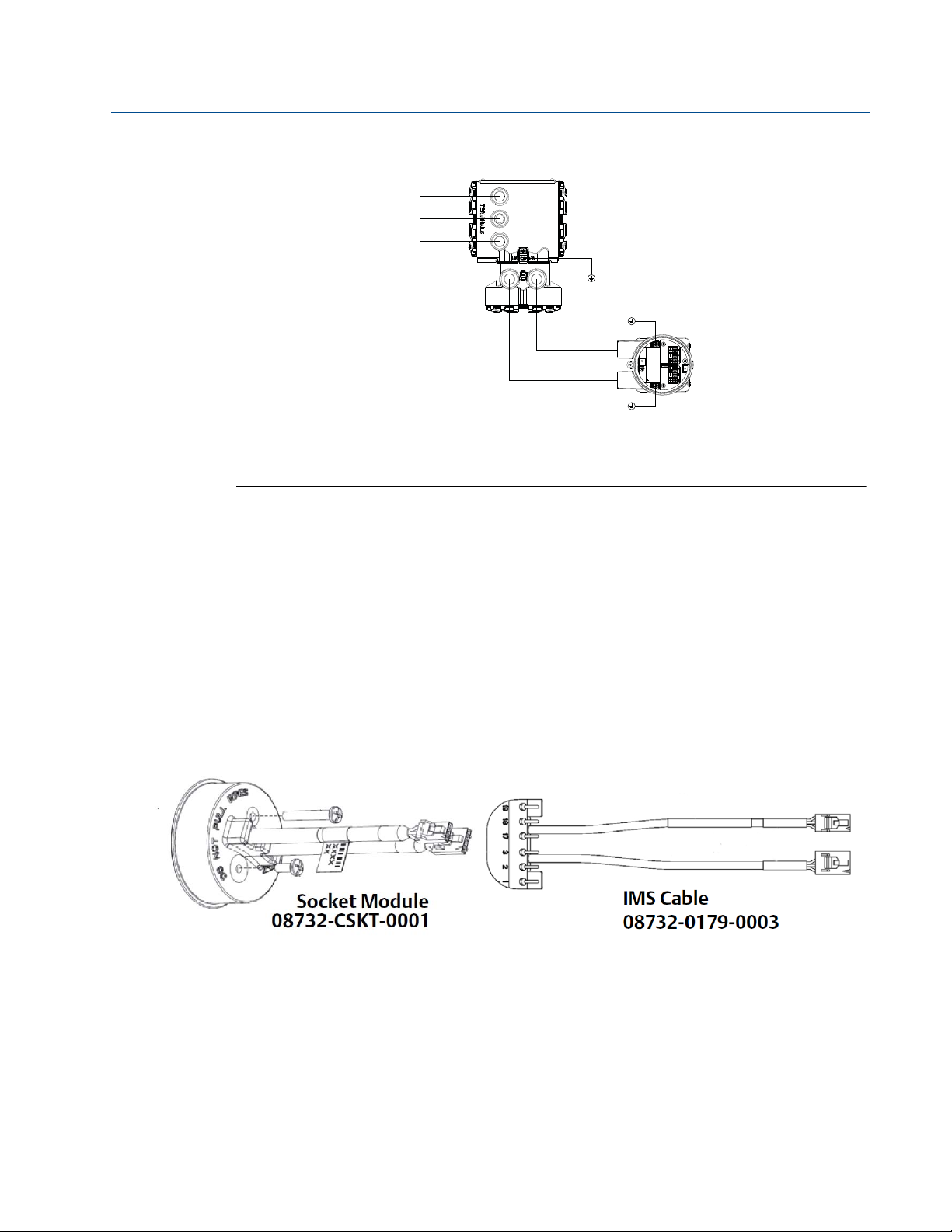

Integral mount transmitters ordered with a sensor will be shipped assembled and wired at the

factory using an interconnecting cable (see Figure 2-16). Use only the socket module or IMS

cable provided by Emerson

For replacement transmitters use the existing interconnecting cable from the original assembly.

Replacement cables are available.

Figure 2-16. Interconnecting Cables

™

Process Management.

Remote mount transmitters

24

Cables kits are available as individual component cables or as a combination coil/electrode

cable. Remote cables can be ordered direct from Emerson Process Management using the kit

numbers shown in Tab l e 2 - 11 . Equivalent Alpha cable part numbers are also provided as an

alternative. To order cable, specify length as quantity desired. Equal length of component

cables is required.

Example: 25 feet = Qty (25) 08732-0065-0001

Installation

Reference Manual

00809-0100-4444, Rev AD

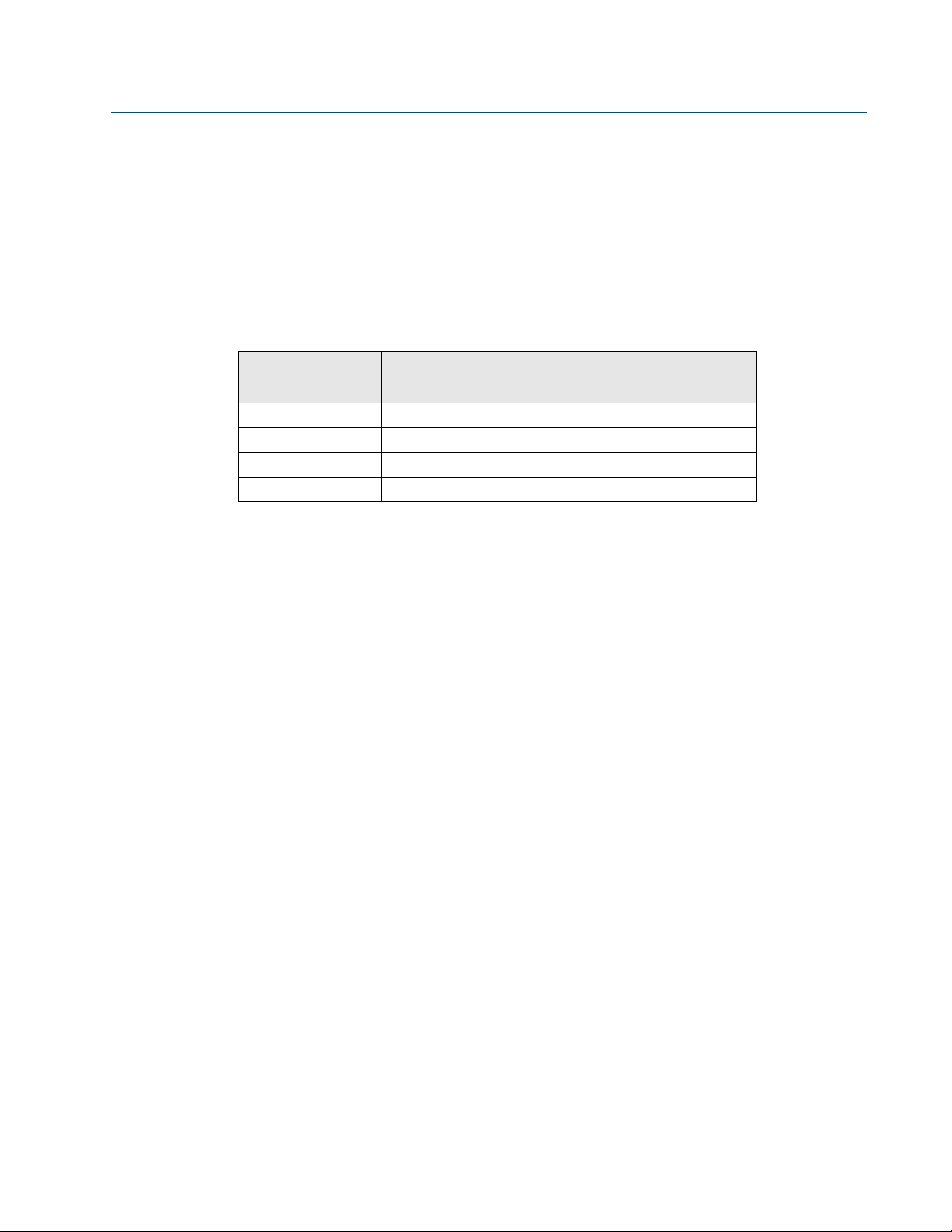

Table 2-11. Component Cable Kits

Section 2: Installation

August 2015

Standard temperature (-20 °C to 75 °C)

Cable kit # Description Individual cables Alpha

08732-0065-0001

(feet)

08732-0065-0002

(meters)

08732-0065-0003

(feet)

08732-0065-0004

(meters)

Kit, Component Cables, Std Temp

(includes Coil and Electrode)

Kit, Component Cables, Std Temp

(includes Coil and Electrode)

Kit, Component Cables, Std Temp

(includes Coil and I.S.Electrode)

Kit, Component Cables, Std Temp

(includes Coil and I.S.Electrode)

Coil

Electrode

Coil

Electrode

Coil

Intrinsically Safe Blue Electrode

Coil

Intrinsically Safe Blue Electrode

p/n

518243

518245

518243

518245

518243

518244

518243

518244

Extended temperature (-50 °C to 125 °C)

Cable kit # Description Individual cables Alpha

08732-0065-1001

(feet)

08732-0065-1002

(meters)

08732-0065-1003

(feet)

08732-0065-1004

(meters)

Kit, Component Cables, Ext Temp.

(includes Coil and Electrode)

Kit, Component Cables, Ext Temp.

(includes Coil and Electrode)

Kit, Component Cables, Ext Temp.

(includes Coil and I.S.Electrode)

Kit, Component Cables, Ext Temp.

(includes Coil and I.S.Electrode)

Coil

Electrode

Coil

Electrode

Coil

Intrinsically Safe Blue Electrode

Coil

Intrinsically Safe Blue Electrode

p/n

840310

518189

840310

518189

840310

840309

840310

840309

Table 2-12. Combination Cable kits

Coil/electrode cable (-20 °C to 80 °C)

Cable kit # Description

08732-0065-2001

(feet)

08732-0065-2002

(meters)

08732-0065-3001

(feet)

08732-0065-3002

(meters)

Kit, Combination Cable,

Standard

Kit, Combination Cable,

Submersible

(80°C dry/60°C Wet)

(33ft continuous)

Installation

25

Section 2: Installation

August 2015

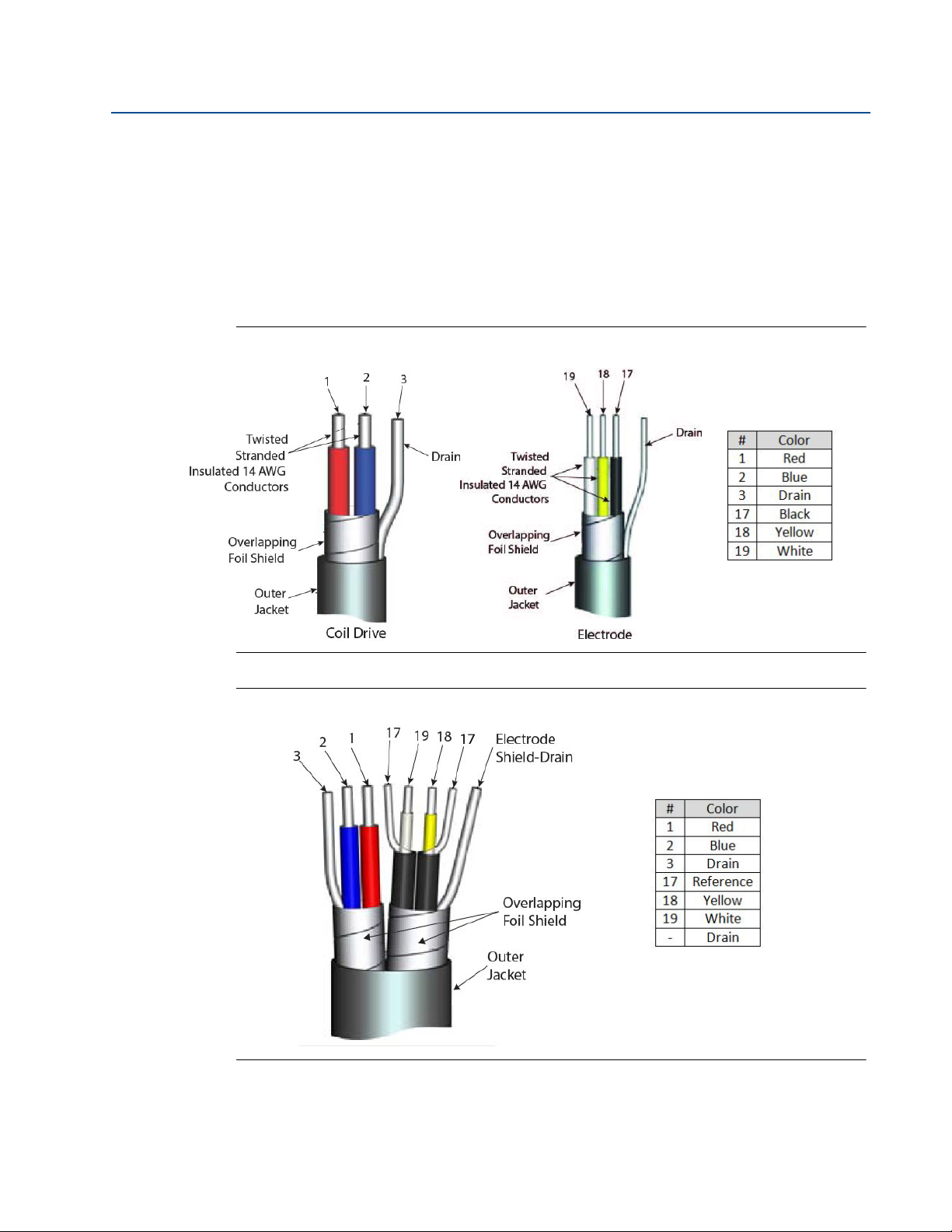

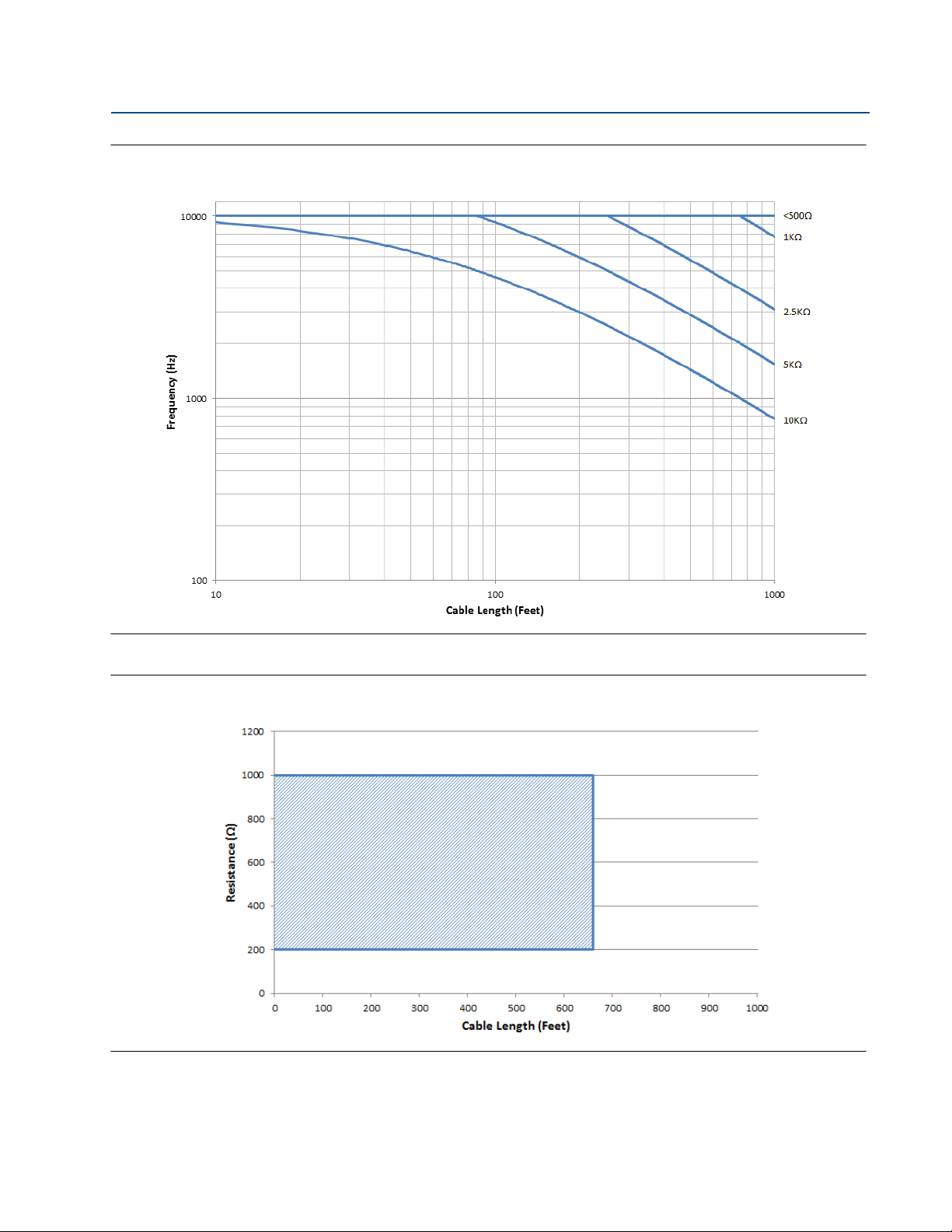

Cable requirements

Shielded twisted pairs or triads must be used. For installations using the individual coil drive and

electrode cable, see Figure 2-17. Cable lengths should be limited to less than 500 feet (152 m).

Consult factory for length between 500–1000 feet (152–304 m). Equal length cable is required

for each.

For installations using the combination coil drive/electrode cable, see Figure 2-18. Combination

cable lengths should be limited to less than 330 feet (100 m).

Figure 2-17. Individual Component Cables

Reference Manual

00809-0100-4444, Rev AD

Figure 2-18. Combination Coil / Electrode Cable

26

Installation

Reference Manual

00809-0100-4444, Rev AD

Cable preparation

When preparing all wire connections, remove only the insulation required to fit the wire

completely under the terminal connection. Prepare the ends of the coil drive and electrode

cables as shown in Figure 2-19. Limit the unshielded wire length to less than one inch on both

the coil drive and electrode cables. Any length of unsheathed conductor should be insulated.

Excessive removal of insulation may result in an unwanted electrical short to the transmitter

housing or other wire connections. Excessive unshielded lead length, or failure to connect cable

shields properly, may expose the unit to electrical noise, resulting in an unstable meter reading.

Figure 2-19. Cable Ends

Section 2: Installation

August 2015

Installation

Shock Hazard

Potential shock hazard across remote junction box terminals 1 & 2 (40V).

Explosion Hazard

Electrodes exposed to process. Use only compatible transmitter and approved installation

practices.

For process temperatures greater than 284 °F (140 °C), use a wire rated for 257 °F (125 °C).

27

Section 2: Installation

Sensor Tra ns mit er

August 2015

Figure 2-20. Remote Junction Box Views

Wire Ter mi na l Wire Te rm in al

RED 1 RED 1

BLUE 2 BLUE 2

BLACK 17 Shield 3

YELLOW 18 BLACK 17

WHITE 19 YELLOW 18

Reference Manual

00809-0100-4444, Rev AD

WHITE 19

For sensor wiring diagrams, reference the installation drawings in Appendix C Wiring Diagrams.

For hazardous locations, reference the drawings in Appendix B Product Certifications.

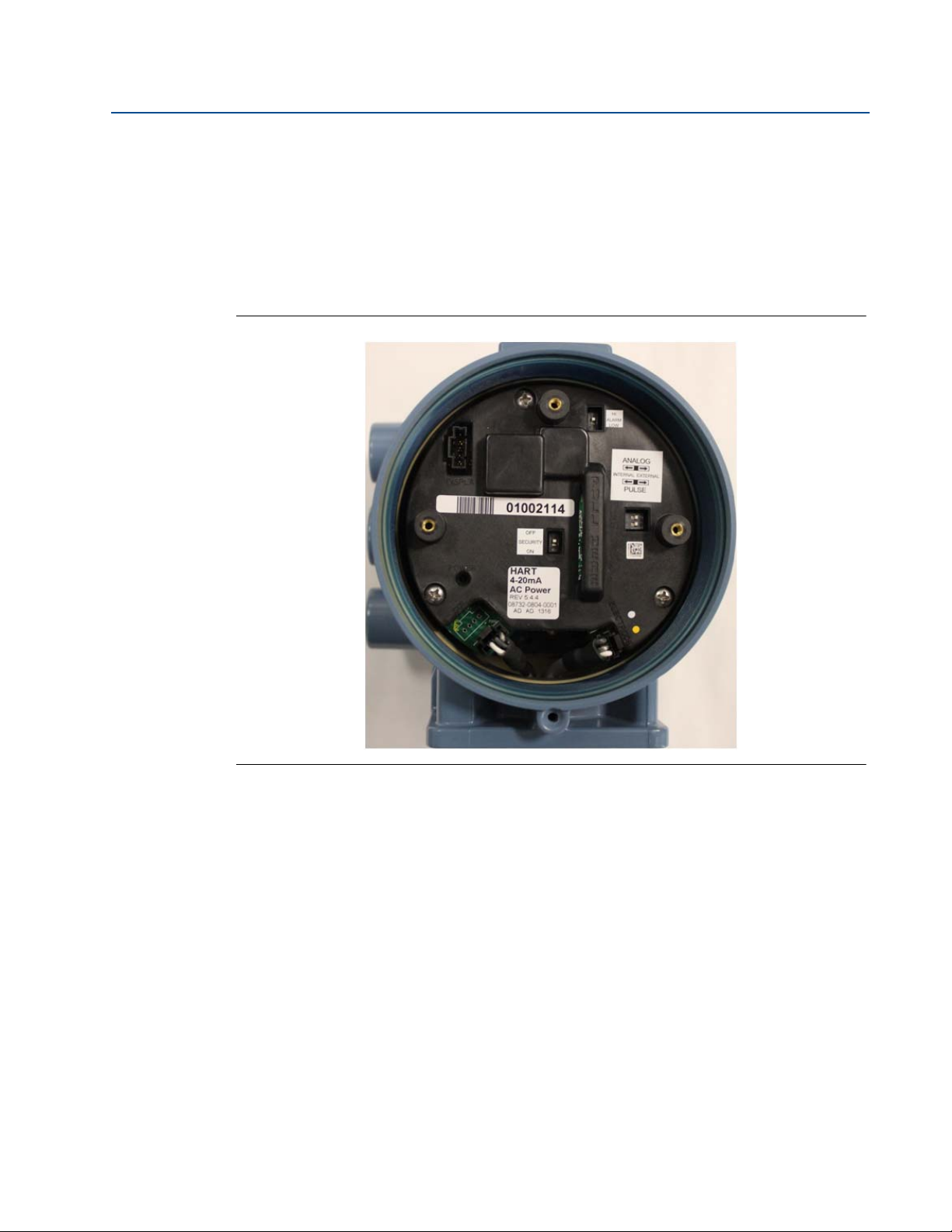

2.12.4 8732EM terminal block connections

Remove the back cover of the transmitter to access the terminal block. See Figure 2-21 for

terminal identification. To connect pulse output and/or discrete input/output, reference

Appendix C Wiring Diagrams. For installations with intrinsically safe outputs, reference the

hazardous location installation drawings in Appendix B Product Certifications.

Figure 2-21. Terminal Block Connections

28

Installation

Reference Manual

- 4-20mA

+ 4-20mA

00809-0100-4444, Rev AD

2.12.5 Analog output

The analog output signal is a 4-20mA current loop. The loop can be powered internally or

externally via a hardware switch located on the front of the electronics stack. The switch is set to

internal power when shipped from the factory. For units with a display, the LOI must be removed

to change switch position.

Intrinsically safe analog output requires a shielded twisted pair cable.

For HART communication a minimum loop resistance of 250 ohms is required. It is

recommended to use individually shielded twisted pair cable. The minimum conductor size is

0.51 mm diameter (#24 AWG) for cable runs less than 5,000 feet (1,500m) and 0.81 mm

diameter (#20 AWG) for longer distances.

Internal power

The 4-20mA analog signal is a 24VDC active output.

Maximum allowable loop resistance is 500 ohms.

Section 2: Installation

August 2015

Wire terminal 1 (+) and terminal 2 (-). See Figure 2-22.

Figure 2-22. Analog Wiring—Internal Power

Note

Terminal polarity for the analog output is reversed between internally and externally powered.

Installation

29

Section 2: Installation

+ POWER

- SUPPLY

Power Supply (Volts)

Load (Ohms)

Operating

Regio n

600

0

10.8 30

August 2015

External power

The 4-20mA analog signal is passive and must be powered from an external power source.

Power at the transmitter terminals must be 10.8 - 30VDC.

Wire terminal 1 (-) and terminal 2 (+). See Figure 2-23.

Figure 2-23. Analog Wiring—External Power

Reference Manual

00809-0100-4444, Rev AD

30

Analog loop load limitations

Maximum loop resistance is determined by the voltage level of the external power supply, as

described in Figure 2-24.

Figure 2-24. Analog Loop Load Limitations

R

= 31.25 (Vps – 10.8)

max

V

= Power Supply Voltage (Volts)

ps

R

= Maximum Loop Resistance (Ohms)

max

Installation

Reference Manual

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

1.1

1.2

12 16 20 24 28 32 36 40

Supply Current (DC Amps)

Power Supply (DC Volts)

0.12

0.14

0.16

0.18

0.20

0.22

0.24

90 110 130 150 170 190 210 230 250

Supply Current (Amps)

Power Supply (VAC)

AC Supply Characteristics

00809-0100-4444, Rev AD

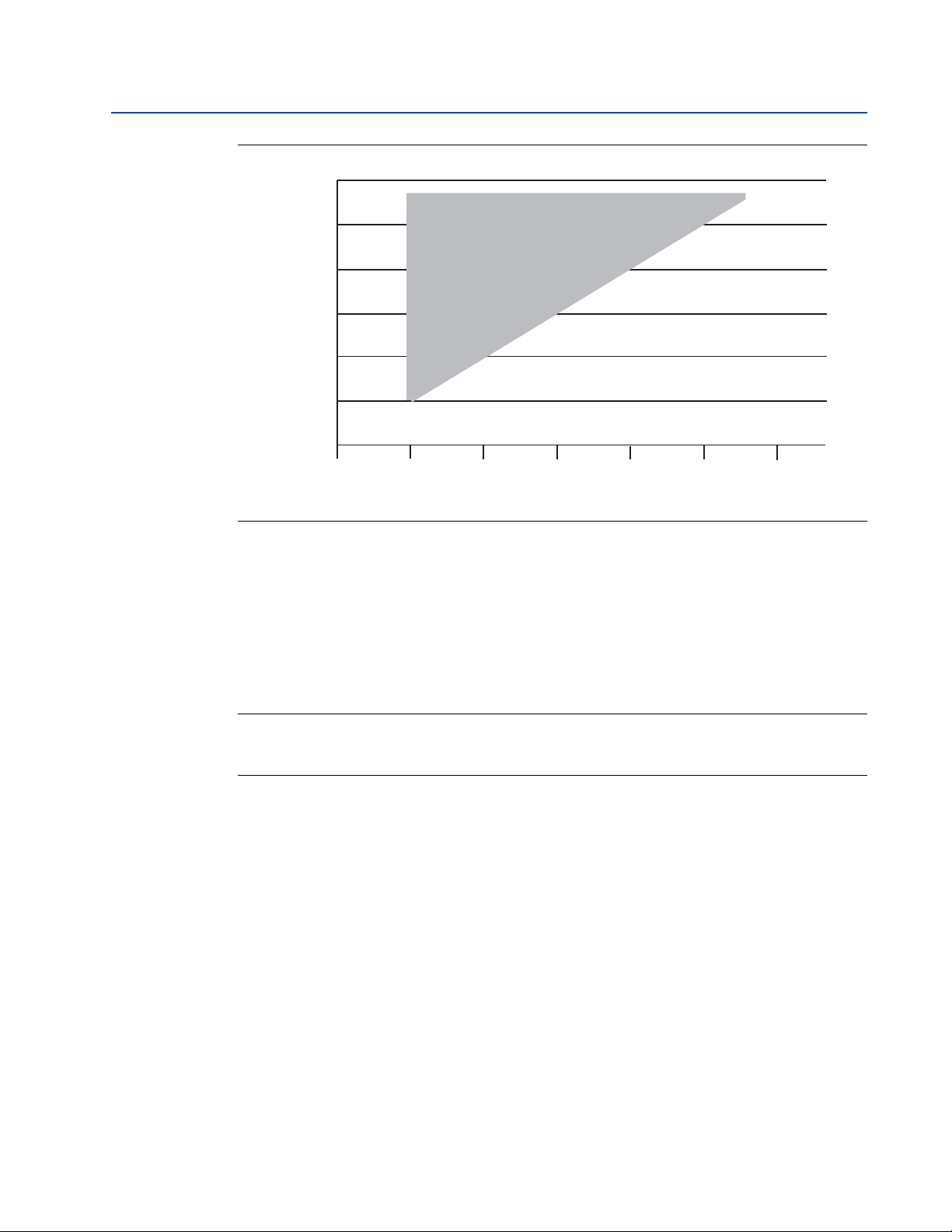

2.12.6 Powering the transmitter

The 8732EM transmitter is available in two models. The AC powered transmitter is designed to

be powered by 90–250VAC (50/60Hz). The DC powered transmitter is designed to be powered

by 12–42VDC. Before connecting power to the 8732EM, be sure to have the proper power

supply, conduit, and other accessories. Wire the transmitter according to national, local, and

plant electrical requirements for the supply voltage. See

Figure 2-25. DC Power Requirements

Section 2: Installation

August 2015

Figure 2-25 or Figure 2-26.

Peak inrush is 42A at 42VDC supply, lasting approximately 1ms.

Inrush for other supply voltages can be estimated with:

Inrush (Amps) = Supply (Volts) / 1.0

Figure 2-26. AC Power Requirements