Page 1

Instruction Manual

Form 5237

February 2009

Type 92W Liquid Regulator

Introduction

Scope of the Manual

This instruction manual provides installation, maintenance,

and parts ordering information for the Type 92W liquid

pressure-reducing regulator, which includes the Type 6492H

or 6492L pilot. Accessories used with this regulator, including

any pressure-loading device for a Type 6492H or 6492L

pilot with tapped spring case, are covered in other

manuals for those accessories.

Product Description

The Type 92W pressure-reducing regulator for liquid

service includes either a Type 6492H or a Type 6492L

pilot (Figure 1). Both pilots have a friction-reducing

bellows seal on the stem. They offer precise

pressure-setting adjustment plus high sensitivity to

downstream pressure changes.

Type 92W

W4086-3

NPS 1, NPT

STEEL MAIN VALVE WITH TYPE 6492H PILOT

These pilots are available in either a standard version

with a drilled spring case vent, or an optional version

with a tapped spring case vent and a sealed adjusting

screw for pressure-loading service. A Fisher® 67 or

1301 Series regulator or a 670 Series panel-mounted

regulator may be used to load the pilot of a version for

pressure-loading service.

Specications

Specications for the Type 92W regulator are found in

the Specications section.

Installation

WARNING

!

Personal injury, equipment damage,

or leakage due to escaping liquid

or bursting of pressure-containing

parts may result if this regulator is

W4088-1

NPS 3 (DN 80), FLANGED

CAST IRON MAIN VALVE WITH TYPE 6492L PILOT

Figure 1. Typical Connections

overpressured or is installed where

service conditions could exceed the limits

given in the Specications section and

on the appropriate nameplates, or where

conditions exceed any ratings of the

adjacent piping or piping connections.

www.emersonprocess.com/regulators

D101268X012

Page 2

Type 92W

Specications

Main Valve Body Sizes and End Connection Styles

BODY SIZE,

NPS (DN)

1, 1-1/2, and 2 NPT NPT

1, 1-1/2, 2, 2-1/2,

3, and 4

(25, 40, 50, 65,

80, and 100)

END CONNECTION STYLE AND RATING

Cast Iron Body Steel Body

Flat-faced CL125B

or raised-faced

CL250B anged

Raised-faced CL150,

CL300, or CL600 anged

Maximum Inlet and Pilot Supply Pressure

(1)

(1)

Cast Iron Main Valve and Pilot: 250 psig

(17,2 bar) or body rating limit, whichever is lower

Steel Main Valve and Pilot: 300 psig (20,7 bar)

or body rating limit, whichever is lower

Maximum Differential Pressure

(1)

150 psig (10,3 bar) or body rating limit, whichever

is lower

Minumum Differential Pressure

(1)

20 psig (1,4 bar)

Outlet (Control) Pressure Ranges

See Table 1

Maximum Outlet Pressures

(1)

See Table 2

Maximum Allowable Loading Pressure for Pilot with

Tapped Spring Case

(1)

Combination of pilot control spring setting and spring

case loading pressure must not exceed 150 psig

(10,3 bar) for Type 6492H pilot or 25 psig (1,7 bar)

for Type 6492L pilot

Main Valve Port Diameters and Flow Coefcients

BODY SIZE,

NPS (DN)

1 (25)

1-1/2 (40)

2 (50)

2-1/2 (65)

3 (80)

4 (100)

Maximum Material Temperature Capabilities

PORT DIAMETER

Inches mm

7/8

1-1/8

1-29/64

1-5/8

2-1/16

2-3/8

22,2

28,6

36,9

41,3

52,4

60,3

REGULATING

CAPACITIES

10

20

35

48

66

78

(1)

Cast Iron Construction: 406°F (208°C)

Steel Construction: 500°F (260°C)

Pressure Registration

External through downstream control line

Downstream Control Line Connection

NPS 1, 1-1/2, or 2 (DN 25, 40, or 50) Body Size:

1/4 NPT female in main valve cylinder spacer

NPS 2-1/2, 3, or 4 (DN 65, 80, or 100) Body Size:

1/4 NPT female in pilot body

Pilot Spring Case Vent

1/8-inch (3,18 mm) drilled hole (standard pilot) or

1/4 NPT female tapping for pressure loading service

(optional pilot)

Approximate Weights

BODY SIZE,

NPS (DN)

1 (25)

1-1/2 (40)

2 (50)

2-1/2 (65)

3 (80)

4 (100)

END CONNECTION

NPT or anged

NPT or anged

NPT

Flanged

Flanged

Flanged

Flanged

APPROXIMATE WEIGHTS

Pounds kg

32

44

55

67

90

115

165

14

20

25

30

41

52

75

K

0.62

0.62

0.62

0.71

0.71

0.71

m

1. The pressure/temperature limits in this Instruction Manual, or any applicable code or standard limitations, must not be exceeded.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions from

exceeding those limits.

Liquid pressure control systems should

be designed using good engineering

practices to eliminate quick starting or

Additionally, the pilot could be broken

off the main valve by physical damage,

stopping of the ow stream, which can

produce water hammer. .

causing personal injury and property

damage due to escaping liquid. To avoid

such injury and damage, install the

regulator in a safe location where it is

protected from physical damage.

1. Only personnel qualied through training and

experience should install, operate, and maintain

a Type 92W regulator. Before installation, make

sure that there is no damage to, or debris in, the

regulator. Also make sure that all tubing and piping

are clean and unobstructed.

2

CAUTION

Page 3

Table 1. Outlet (Control) Pressure Ranges

OUTLET (CONTROL) PRESSURE RANGES

Psig bar

Type 6492L Pilot Type 6492H Pilot Type 6492L Pilot Type 6492H Pilot

2 to 6

5 to 15

13 to 25

CONSTRUCTION

With Type 6492H pilot

With Type 6492L pilot

10 to 30

25 to 75

70 to 150

Table 2. Maximum Outlet Pressures

MAXIMUM OPERATING

OUTLET PRESSURE

150 psig

(10,3 bar)

25 psig

(1,7 bar)

0,14 to 0,41

0,34 to 1,0

0,90 to 1,7

MAXIMUM EMERGENCY OUTLET PRESSURE

(IF EXCEEDED, PRESSURE VESSEL INTEGRITY MAY NOT

BE RETAINED AND PERSONAL INJURY OR PROPERTY

Cast Iron Main Valve

and Pilot Body

250 psig (17,2 bar) or main valve

body rating limit, whichever is lower

50 psig (3,4 bar) 125 psig (8,6 bar)

0,69 to 2,1

1,7 to 5,2

4,8 to 10,3

DAMAGE COULD RESULT)

Type 92W

PILOT CONTROL SPRING

COLOR CODE (SEE PARTS

LIST FOR PART NUMBER)

Yellow

Green

Red

Steel Main Valve

and Pilot Body

300 psig (20,7 bar) or main valve

body rating limit, whichever is lower

2. A Type 92W regulator may be installed in any

orientation, as long as ow through the regulator

matches the direction of the arrow on the main

valve body.

3. Apply liquid-compatible pipe compound to the male

pipeline threads for an NPT body, or use suitable

line gaskets for a anged body. Use acceptable piping

procedures when installing the regulator. .

4. If continuous operation of the system is required during

inspection and maintenance, install a three-valve

bypass around the regulator. If the owing medium

contains solids, install a properly sized strainer

upstream of the regulator.

Note

A regulator that has the Type 6492H or

6492L pilot with a 1/8-inch (3,2 mm) drilled

hole in the spring case may function

improperly if this spring case vent hole

becomes clogged. Install and maintain

such regulator so that the spring case vent

hole stays clear.

5. As shown in Figure 2, connect a control line as

large as possible but no smaller than 3/8-inch

(9,5 mm) diameter bushed down to the 1/4 NPT

connection in the cylinder spacer (NPS 1, 1-1/2,

or 2 body size) (DN 25, 40, or 50) or the pilot body

(NPS 2-1/2, 3, or 4 body size) (DN 65, 80, or 100).

With the NPS 2-1/2, 3, or 4 (DN 65, 80, or 100

body size, the pilot may be mounted as shown in

Figure 6 so that the control line connection faces

either upstream or downstream.

6. Locate the control line connection at least 10 pipe

diameters away from the regulator or swage and in a

section of straight pipe. .

7. Do not locate the control line connection in a gate,

plug, or check valve; or in an elbow, swage, or

other area of the pipeline where turbulence or

abnormal velocities may occur; or in a large-volume

vessel that can cause noticeable control lag.

8. Install a shutoff valve (not a needle valve) in the control

line to isolate the pilot during maintenance.

9. Install a pressure gauge in the control line, or near the

regulator, to aid in setting the outlet pressure.

10. With a pressure-loaded or on-off pilot, connect

the pressure-loading or on-off piping or tubing to

the 1/4 NPT connection in the tapped pilot

spring case.

11. The pressure setting of the regulator is determined by:

• The pilot control spring adjustment on a standard

pilot, or .

• The pressure-loading device in conjunction with the

control spring adjustment on a pressure-loaded

pilot. In both cases, check these settings to make

sure they are correct for the application.

Startup and Adjustment

Note

The maximum inlet pressure for a specic

construction is stamped on the main

valve nameplate. Use pressure gauges

to monitor upstream and downstream

pressures during startup. .

3

Page 4

Type 92W

STRAINER

CONTROL LINE

CONNECTION

CONTROL LINE

SHUTOFF VALVE

AIR

LOADING

REGULATOR

STRAINER

NEEDLE

VALVE

BLEED RESTRICTION (REQUIRED ONLY

IF THE LOADING REGULATOR DOES

NOT HAVE INTERNAL RELIEF)

CONTROL LINE

CONNECTION

CONTROL LINE

SHUT OFF VALVE

BLOCK

VALVE

BYPASS LINE

16A7958-B

A2607-1

BLOCK

VALVES

WITH STANDARD PILOT WITH PRESSURE-LOADED PILOT

VENT VALVE

Figure 2. Typical Installations

Adjustment

On a regulator with a standard or pressure-loaded

Type 6492H or 6492L pilot, loosen the hex nut

(key 16, Figure 4). Turn the adjusting screw (key 15,

Figure 4) into the spring case to increase the downstream

pressure. Turn the adjusting screw out of the spring

case to decrease the downstream pressure. When

the required downstream pressure is maintained

for several minutes, tighten the hex nut to lock the

adjusting screw in position.

O

n a regulator with a pressure-loaded Type 6492H

or 6492L pilot, also refer to the instruction manual of

the pressure-loading device for downstream pressure

adjustment procedures. Make sure that the combined pilot

control spring setting pressure and spring case loading

pressure does not exceed 150 psig (10,3 bar) for the

Type 6492H pilot or 25 psig (1,7 bar) for the Type 6492L

pilot. For example, combining a 5 psig (0,34 bar) spring

setting pressure and a 10 psig (0,69 bar) spring case loading

pressure results in a regulator pressure of 15 psig (1,0 bar).

Startup with New Regulator Installation

1. Remove all pilot control spring compression by turning

the adjusting screw out of the spring case according to

the adjustment procedure.

2. Slowly open the upstream block valve.

3. Open the downstream block valve.

4. Open the control line shutoff valve.

5. If a bypass is used, slowly close the bypass line

block valve. .

6. Perform the adjustment procedure until the downstream

pressure reaches the desired setting.

BLOCK

VALV E

BYPASS LINE

16A7958-B

16A1547-A

A3334

BLOCK

VALVES

VENT VALVE

Startup with Existing Regulator

Installation After Normal Shutdown

1. Open the upstream and downstream block valves and

let the regulator take over control at the existing pilot

control spring setting. .

2. If a bypass line is used, slowly control the bypass line

block valve. .

Shutdown

1. If a bypass line is used, slowly open the bypass line

block valve while monitoring the downstream pressure.

2. Close the control line shutoff valve.

3. Close the downstream block valve.

4. Close the upstream block valve.

5. If a pressure-loaded or on-off pilot is used, close the

needle valve to the pilot. .

6. Vent the regulator and control line to release any

trapped pressure.

Principle of Operation

Pilot supply pressure is piped from the main valve inlet

(Figure 3) to the pilot inlet connection. Downstream

pressure registers on the main valve pistons through the

downstream control line and then on the pilot diaphragm.

When increased downstream demand lowers the

downstream pressure to a value below the setting of the

pilot control spring, this spring forces the pilot valve plug

open to increase the loading pressure on the main valve

4

Page 5

Type 92W

Type 92S

Type 92S

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

A6552 A6553

NPS 1 THROUGH 2 (DN 25 THROUGH 50) MAIN VALVE

TYPE 92W WITH TYPE 6492L PILOT

Figure 3. Operational Schematics

pistons. At the same time, the increased demand lowers

the downstream pressure on the main valve piston(s).

This opens the main valve plug, increasing ow to the

downstream system to satisfy the increased demand and

to restore downstream pressure to the setting of the pilot

control spring.

Decreased downstream demand increases the downstream

pressure registered on the pilot diaphragm. The increased

pressure overcomes the force of the pilot control spring

and allows the pilot valve plug spring to close the pilot

valve plug. As the pilot valve plug closes, excess loading

pressure bleeds to the downstream system through the pilot

bleed restriction. At the same time, decreased downstream

demand increases the downstream pressure registered

on the main valve piston(s). This allows the main valve

spring to close the main valve plug, reducing ow to the

downstream system in response to the decreased demand.

With a pressure-loaded or on-off pilot, the operation is the

same as for a standard pilot except that the pilot control

spring force on the pilot valve plug is aided by pneumatic

Types 6492H and 6492L Pilots

These procedures are to be performed if inspecting,

cleaning, or replacing any pilot parts, or if cycling, erratic

control, or too high or too low an outlet (control) pressure

is noted. Perform only those procedures in this section

required to correct the problem. Key numbers refer to

Figure 4 unless otherwise noted.

pressure from the loading device or solenoid valve.

Maintenance

Regulator parts are subject to normal wear and must be

inspected periodically and replaced as necessary. The

frequency of inspection and replacement depends upon

the severity of service conditions and upon applicable

codes and government regulations.

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

LOADING PRESSURE

NPS 2-1/2 THROUGH 6 X 4 (DN 65 THROUGH 150 X 100) MAIN VALVE

TYPE 92W WITH TYPE 6492H PILOT

WARNING

!

Avoid personal injury or damage to

property from sudden release of pressure

or uncontrolled process uid. Before

starting to disassemble:

• Isolate the regulator from the process,

• Release process pressure, and .

• Vent the pilot supply and main valve

loading pressures. .

Note

Before performing any maintenance,

loosen the hex nut (key 16), if used,

and turn the adjusting screw (key 15)

counterclockwise until all compression is

removed from the control spring (key 12).

Remove the pilot from the pipe nipple and

connectors (keys 82 and 83, Figure 6). .

5

Page 6

Type 92W

1. Unscrew the plug guide (key 2). Remove the screen

(key 77), plug (key 4), plug spring (key 3), and stem

(key 7). Unscrew the seat ring (key 5). Examine the

seat ring and plug seating surfaces for damage.

2. Clean and replace parts as necessary. Apply Led-Plate

Number 250

(1)

sealant or equivalent to the seat ring

threads. Thread the seat ring into place and tighten it

to between 19 and 25 foot-pounds (26 and 34 N•m)

of torque.

3. Handle the parts carefully, and place the plug spring

(key 3) in the plug guide (key 2). Slide the plug (key 4)

over the spring and into the plug guide. Place the

screen (key 77) onto the plug guide. Place the stem

(key 7) in the center hole of the plug guide. Apply

Led-Plate Number 250 sealant or equivalent to the plug

guide threads, and screw the guide plus attached parts

into the body (key 1).

4. Remove the pipe plug and bleed restriction (keys 74 and

76). Clean or replace the restriction as necessary.

5. Sparingly apply Led-Plate Number 250 sealant or

equivalent to the threads of the restriction, and thread

the restriction into place.

6. Apply Led-Plate Number 250 sealant or equivalent to the

threads of the pipe plug. Thread the pipe plug into place

and tighten it to between 5 and 15 foot-pounds (7,0 and

20 N•m) of torque.

7. Remove the cap screws (key 17), spring case (key 14),

control spring (key 12), and upper spring seat (key 13)

from the body.

8. Remove the lower spring seat (key 11, Type 6492H

pilot only) or diaphragm assembly (key 24, Type 6492L

pilot only), diaphragms (key 10), and diaphragm gasket

(key 18) from the body. Inspect and clean the

diaphragm gasket, and replace it if necessary.

9. Unscrew the bellows retainer (key 8) and remove the

bellows (key 9). Replace worn parts as necessary, and

install the bellows and bellows retainer. Tighten the

bellows retainer to between 19 and 25 foot-pounds (26

and 34 N•m).

10. Install the diaphragm gasket. Install both diaphragms

with their raised preformed centers facing toward the

spring case.

11. Lubricate the upper spring seat and the exposed

threads of the adjusting screw with Never-Seez

(2)

lubricant or equivalent. Install the lower spring seat

(key 11, Type 6492H pilot only) or diaphragm assembly

(key 24, Type 6492L pilot only), control spring

(key 12), upper spring seat (key 13), and spring case

(key 14). Insert and tighten the cap screws (key 17)

to between 12 and 18 foot-pounds (16,0 and

24,00 N•m) of torque, using a crisscross bolting pattern.

1. Trademark of Armite Laboratories.

2. Trademark of Never-Seez Corp.

12. When pilot maintenance is complete, refer to the

startup and adjustment procedure to put the regulator

back in operation and adjust the pressure setting.

Type 92W Main Valve

Perform these procedures if replacing the piston(s),

cylinder(s), stem(s), seals, valve plug, or seat ring. All

key numbers are referenced in Figure 5 except where

otherwise indicated. Instructions are given for complete

disassembly and assembly. Disassemble the main

valve only as far as necessary to complete the required

maintenance. Then, begin the assembly procedure at the

appropriate step. .

Note

The regulator may remain in the pipeline

during maintenance procedures unless the

main valve body is replaced or removed

for repairs. .

Whenever a gasket seal is disturbed by

removing or shifting gasketed parts, a

new gasket should be installed upon

reassembly. This is necessary to ensure a

good gasket seal. .

Disassembly

1. Disconnect all tubing and remove the pilot from the

main valve. .

2. Remove the cap screws (key 3, not shown) from a cast

iron body, or stud nuts (key 4) from a steel body, and lift

off the body ange.

3. For the NPS 1, 1-1/2, and 2 sizes (DN 25, 40, and 50),

remove the top cylinder (key 17), and pull out the top

piston with attached stem and other parts. Remove

the hex nut (key 41), lock washer (key 40), top ring

retainer (key 26), and top piston ring (key 25) from the

top piston (key 24).

4. For the NPS 1, 1-1/2, and 2 sizes (DN 25, 40, and 50),

lift off the cylinder spacer (key 21), and remove the

stem seal retainer (key 23) and stem seal (key 22) from

the spacer.

5. Remove the cylinder (key 17), piston (key 24) with

attached parts, and spiral wound gasket (key 8).

6. Remove the cotter pin (key 16, NPS 1, 1-1/2, and 2

sizes only) (DN 25, 40, and 50), stem nut (key 15),

bottom stem (key 9) with hex head, valve plug (key 6),

piston ring retainer (key 26), piston ring (key 25), bottom

piston ring retainer (key 26, NPS 1, 1-1/2, and 2

sizes only) (DN 25, 40, and 50), piston (key 24), spring

(key 12), piston spacer (key 11), cage (key 5), and seat

ring (key 7).

6

Page 7

Type 92W

7. Either remove the retaining ring (key 14), or, if it is

necessary to remove the bafe (key 13), remove the

spring seat, washer, and O-ring (keys 32, 34, and 38).

With an NPS 2-1/2 through 4 (DN 65 through 100) sizes

only, also remove the plug spacer (key 33).

Assembly

1. Inspect and replace parts as necessary, making

sure that the hollow passage in the top stem (NPS 1,

1-1/2, and 2 sizes only) (DN 25, 40, and 50) is free

from debris.

2. Install a spiral wound gasket (key 8) into the

body (key 1).

3. If installing a new valve plug and/or a new seat ring,

lap the seating surfaces together outside the body. Use

a commercial lapping compound or a mixture of

solidied vegetable oil and 600-grit or ner silicon

carbide or aluminum oxide.

4. Install the bafe (key 13), plug spacer (key 33) if used,

and either the retaining ring (key 14) or the O-ring,

washer, and spring seat (keys 38, 34, and 32), and then

install the seat ring (key 7), valve plug (key 6), and stem

(key 9) into the cage (key 5). Then, install the piston

spacer (key 11) down through the bafe until it contacts

the valve plug. Install the spring (key 12), and secure

with the piston (key 24), piston ring (key 25) with its open

end pointing out, piston ring retainer (key 26), and stem

nut (key 15).

For the NPS 1, 1-1/2, and 2 sizes (DN 25, 40, and 50),

lock the stem nut in place with a cotter pin (key 16), but

do not fold the pin ends up on top of the stem since this

can interfere with loading pressure registration through

the top stem passage.

5. Install the main piston cage assembly with attached

parts into the body. Coat one of the serrated edges

of the main cylinder (key 17) with Led-Plate Number 250

sealant or equivalent, install a new cylinder gasket

(key 18) onto this edge, and install the cylinder gasket side-up on the cage.

6. Install a new body gasket (key 19) onto the appropriate

edge of the body.

7. For NPS 1, 1-1/2, and 2 sizes (DN 25, 40, and 50),

install the stem seal (key 22) onto the cylinder spacer

(key 21) in the orientation shown in Figure 5, and secure

with the stem seal retainer (key 23). Coat the serrated

edge of the spacer with Led-Plate Number 250 sealant

or equivalent, and install the spacer edge-side-down

over the bottom cylinder.

8. For NPS 1, 1-1/2, and 2 sizes (DN 25, 40, and 50),

install the top piston ring (key 25) with its open end

pointing out, ring retainer (key 26), and stem (key 20) on

the top piston. Secure these parts with the lock washer

and hex nut (keys 40 and 41). Install the top piston plus

attached parts stem-rst through the stem seal until the

top stem contacts the bottom stem. .

9. For NPS 1, 1-1/2, and 2 sizes (DN 25, 40, and 50), coat

both serrated edges of the top cylinder (key 17) with

Led-Plate Number 250 sealant or equivalent, install

new cylinder gaskets (key 18) on these edges, and

install the cylinder down over the top piston into the

cylinder spacer.

10. Install the body ange (key 2) on the body, and secure

with the cap screws (key 3, not shown) for a cast iron

body or with the stud nuts (key 4) for a steel body.

11. Install the pilot and connect all tubing as shown

in Figure 6. .

12. When all maintenance is complete, refer to the startup

and adjustment procedure to put the regulator back into

operation and adjust the pressure setting.

Parts Ordering

When corresponding with a local Sales Ofce about

this equipment, always reference the equipment serial

number as found on the regulator nameplates.

When ordering replacement parts, reference the

complete 11-character part number of each needed part

as found in the following parts list.

Parts List

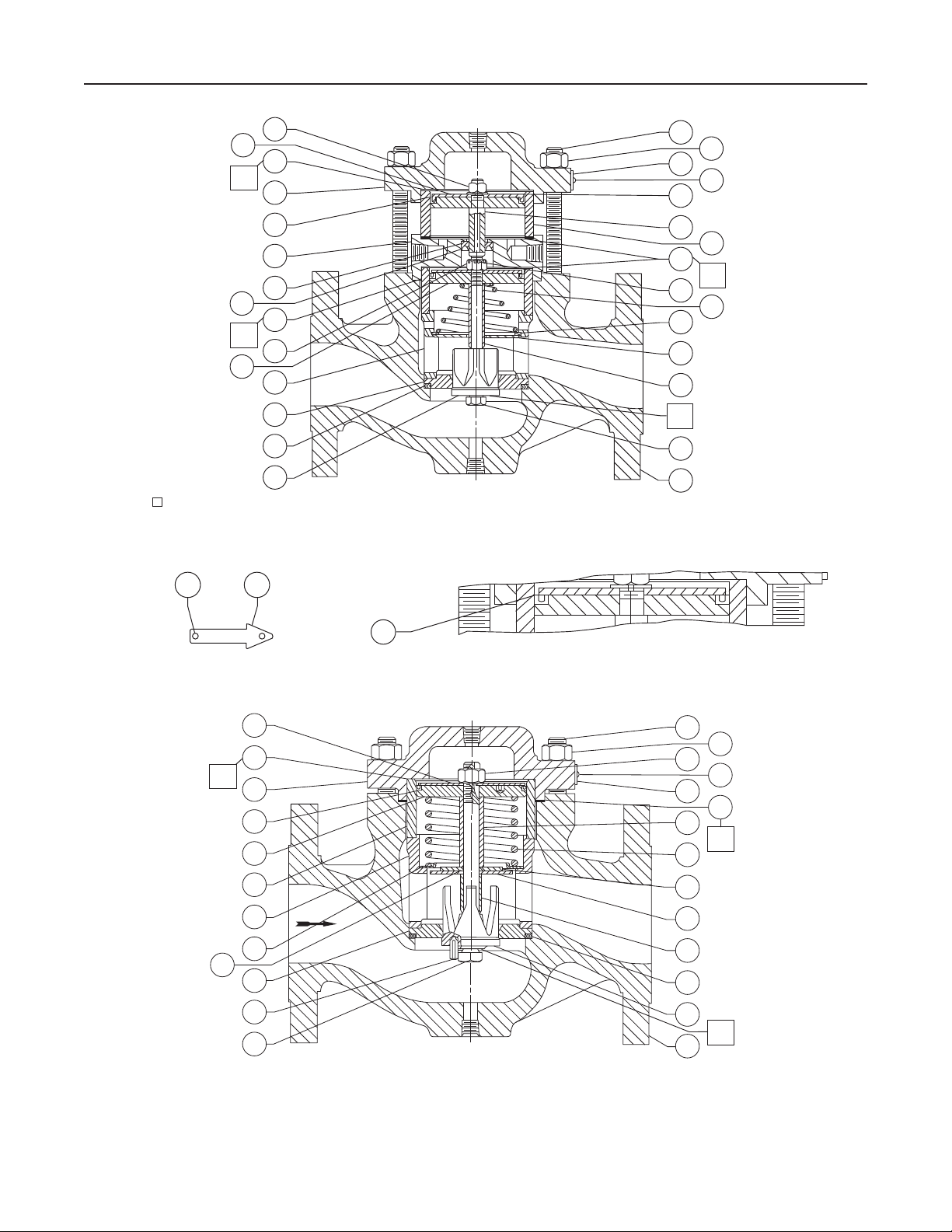

Types 6492L and 6492H Pilots (Figure 4)

Key Description Part Number

Repair Kits (included are keys 4, 5, 7

8, 9, 10, and 18)

Type 6492L pilot R6492LX0012

Type 6492H pilot R6492HX0012

1 Body

Cast Iron

Type 6492L pilot 32A0404X012

Type 6492H pilot 22A0403X012

Steel

Type 6492L pilot 32A0404X052

Type 6492H pilot 22A0403X052

2 Plug Guide, Stainless steel 1E391835132

3 Plug Spring, 302 Stainless steel 1E392437022

4* Plug, 302 Stainless steel 1F967446172

5* Seat Ring, 416 Stainless steel 1H564446172

7* Stem, 416 Stainless steel 1F967835132

8* Bellows Retainer, Brass 1F971214012

9* Bellows, Brass 1F971318992

10* Diaphragm, 302 Stainless steel (2 required)

Type 6492L pilot 1E396936012

Type 6492H pilot 1E395836012

*Recommended spare part.

7

Page 8

Type 92W

Key Description Part Number Key Description Part Number

11 Lower Spring Seat, Aluminum

(Type 6492H pilot only) 1E395408012

12 Control Spring, Steel, Cadmium Plate

(see Table 1 for outlet pressure ranges)

Yellow color code 1E395627022

Green color code 1D745527142

Red color code 1E395727192

13 Upper Spring Seat Steel, Cadmium Plate 1D667125072

14 Spring Case

Standard cast iron

Type 6492L pilot 3J496319012

Type 6492H pilot 2J496219012

Tapped cast iron

Type 6492L pilot 3L442119012

Type 6492H pilot 2L441919012

Standard steel

Type 6492L pilot 3L416122012

Type 6492H pilot 2L416322012

Tapped steel

Type 6492L pilot 3L442222012

Type 6492H pilot 2L442022012

15 Adjusting Screw (standard spring

case only) steel, Cadmium Plate 1D995448702

16 Hex Nut (standard spring case only),

steel, Cadmium Plate 1A353724122

17 Cap Screw, steel, plate (10 required for

Type 6492L pilot and 8 required for

Type 6492H pilot) 1A381624052

18* Diaphragm Gasket, Encapsulated

Fiber Asbestos

Type 6492L pilot 1E397004022

Type 6492H pilot 1E396104022

19 Drive Screw, SST (2 required) 1A368228982

20 Nameplate, Aluminum 19A3510X0A2

24 Diaphragm Plate Assembly,

Aluminum/Steel/Stainless steel

(Type 6492L pilot only) 1E3967X0012

74 Pipe Plug, Steel 0Z020128992

76 Bleed Restriction, 304 Stainless steel 19A2612X012

77 Screen, 304 Stainless steel 16A1512X012

78 Reducing Bushing, Carbon steel 1C379026232

79 Never-Seez Lubricant, 1 gallon (3,8 L)

can (not furnished) 1M523906992

80 Led-Plate No. 250 Sealant, 5 pounds

(2 kg) can (not furnished) 1M524006992

87 Sealing Washer, Carbon steel

(tapped spring case only) 1V205699012

Type 92W Main Valve (Figure 5)

Repair Kits (included are keys 8, 16,

18, 19, 25, and 38)

NPS 1 (DN 25) body R92SX000052

NPS 1-1/2 (DN 40) body R92SX000062

NPS 2 (DN 50) body R92SX000072

NPS 2-1/2 (DN 65) body R92EX0000B2

NPS 3 (DN 80) body R92EX000032

NPS 4 (DN 100) body R92EX000042

1 Body See following Table

2 Body Flange

Cast iron

NPS 1 (DN 25) body 26A7837X012

NPS 1-1/2 (DN 40) body 26A7900X012

NPS 2 (DN 50) body 26A7869X012

NPS 2-1/2 (DN 65) body 27A1548X012

NPS 3 (DN 80) body 27A1576X012

NPS 4 (DN 100) body 27A1600X012

WCC steel

NPS 1 (DN 25) body 26A7838X012

NPS 1-1/2 (DN 40) body 26A7901X012

*Recommended spare part.

2 Body Flange

WCC steel (continued)

NPS 2 (DN 50) body 26A7870X012

NPS 2-1/2 (DN 65) body 27A1549X012

NPS 3 (DN 80) body 27A1577X012

NPS 4 (DN 100) body 27A1601X012

3 Cap Screw (not shown), Plate steel

(for cast iron body)

NPS 1 (DN 25) body (4 required) 16A7839X012

NPS 1-1/2 or 2 (DN 40 or 50)

body (8 required) 1U625631192

NPS 2-1/2 (DN 65) body (8 required) 1R281124052

NPS 3 (DN 80) body (8 required) 1A454124052

NPS 4 (DN 100) body (8 required) 1A440224052

3 Stud Bolt, B7 Steel (for steel body)

NPS 1 (DN 25) body (4 required) 1V5426X0012

NPS 1-1/2 or 2 body (DN 40 or 50)

(8 required) 16A7902X012

NPS 2-1/2 (DN 65) body (8 required) 1R284831012

NPS 3 (DN 80) body (8 required) 1A378131012

NPS 4 (DN 100) body (8 required) 1R369031012

4 Stud Nut, Steel (for steel body)

NPS 1 (DN 25) body (4 required) 1C330624072

NPS 1-1/2 or 2 (DN 40 or 50) body

(8 required) 1A377224072

NPS 2-1/2 (DN 65) body (8 required) 1C330624072

NPS 3 (DN 80) body (8 required) 1A376024072

NPS 4 (DN 100) body (8 required) 1A352024072

5 Cage, Cast Iron

NPS 1 (DN 25) body 29A1379X012

NPS 1-1/2 (DN 40) body 26A7903X012

NPS 2 (DN 50) body 26A7872X012

NPS 2-1/2 (DN 65) body 27A1550X012

NPS 3 (DN 80) body 27A1578X012

NPS 4 (DN 100) body 27A1602X012

6 Valve Plug, 17-4PH Stainless steel

NPS 1 (DN 25) body 16A7842X012

NPS 1-1/2 (DN 40) body 16A7904X012

NPS 2 (DN 50) body 16A7873X012

NPS 2-1/2 (DN 65) body 27A1552X012

NPS 3 (DN 80) body 27A1580X012

NPS 4 (DN 100) body 27A1604X012

7 Seat Ring, 416 Stainless steel

NPS 1 (DN 25) body 16A7844X012

NPS 1-1/2 (DN 40) body 16A7906X012

NPS 2 (DN 50) body 16A7875X012

NPS 2-1/2 (DN 65) body 27A1553X012

NPS 3 (DN 80) body 27A1581X012

NPS 4 (DN 100) body 27A1605X012

8* Spiral Wound Gasket,

316L Stainless steel and Graphite

NPS 1 (DN 25) body 16A7845X012

NPS 1-1/2 (DN 40) body 16A7907X012

NPS 2 (DN 50) body 16A7876X012

NPS 2-1/2 (DN 65) body 17A1554X012

NPS 3 (DN 80) body 17A1582X012

NPS 4 (DN 100) body 17A1606X012

9 Bottom Stem, Plate steel

NPS 1 (DN 25) body 16A7846X012

NPS 1-1/2 (DN 40) body 16A7908X012

NPS 2 (DN 50) body 16A7877X012

NPS 2-1/2 (DN 65) body 17A1556X012

NPS 3 (DN 80) body 17A1584X012

NPS 4 (DN 100) body 17A1608X012

11 Piston Spacer, Steel

NPS 1 (DN 25) body 16A7848X012

NPS 1-1/2 (DN 40) body 16A7910X012

NPS 2 (DN 50) body 16A7879X012

NPS 2-1/2 (DN 65) body 17A1558X012

NPS 3 (DN 80) body 17A1585X012

NPS 4 (DN 100) body 17A1610X012

8

Page 9

Key 1 Body

BODY

MATERIAL

Cast iron

WCC steel

END

CONNECTION

STYLE

NPT

CL125 FF

CL250 RF

NPT

CL150 RF

CL300 RF

CL600 RF

Type 92W

BODY SIZE, NPS (DN)

1 (25) 1-1/2 (40) 2 (50) 2-1/2 (65) 3 (80) 4 (100)

26A7830X012

26A7831X012

26A7832X012

26A7833X012

26A7834X012

26A7835X012

26A7836X012

26A7893X012

26A7894X012

26A7895X012

26A7896X012

26A7897X012

26A7898X012

26A7899X012

26A7862X012

26A7863X012

26A7864X012

26A7865X012

26A7866X012

26A7867X012

26A7868X012

- - - 37A1543X012

37A1544X012

- - - 37A1545X012

37A1546X012

37A1547X012

- - - 37A1571X012

37A1572X012

- - - 37A1573X012

37A1574X012

37A1575X012

37A1595X012

37A1596X012

37A1597X012

37A1598X012

37A1599X012

- - - -

- - - -

Key Description Part Number

12 Spring, Spring Wire

NPS 1 (DN 25) body 16A7849X012

NPS 1-1/2 (DN 40) body 16A7911X012

NPS 2 (DN 50) body 16A7880X012

NPS 2-1/2 (DN 65) body 17A1559X012

NPS 3 (DN 80) body 17A1586X012

NPS 4 (DN 100) body 17A1611X012

13 Bafe, Stainless steel

NPS 1 (DN 25) body 19A1378X012

NPS 1-1/2 (DN 40) body 16A7912X012

NPS 2 (DN 50) body 16A7881X012

NPS 2-1/2 (DN 65) body 17A1560X012

NPS 3 (DN 80) body 17A1587X012

NPS 4 (DN 100) body 17A1612X012

14 Retaining Ring, Steel

NPS 1 (DN 25) body 16A7851X012

NPS 1-1/2 (DN 40) body 16A7913X012

NPS 2 (DN 50) body 16A7882X012

15 Stem Nut, Steel

NPS 1 (DN 25) body 16A7852X012

NPS 1-1/2 or 2 (DN 40 or 50) body 16A7914X012

NPS 2-1/2 or 3 (DN 65 or 80) body 1A413224122

NPS 4 (DN 100) body 1A420124122

16 Cotter Pin, Stainless steel

NPS 1 (DN 25) body 16A7930X012

NPS 1-1/2 or 2 (DN 40 or 50) body 17A5574X012

17 Cylinder, 416 Stainless steel

NPS 1 (DN 25) body (2 required) 16A7853X012

NPS 1-1/2 body (DN 40) (2 required) 16A7915X012

NPS 2 (DN 50) body (2 required) 16A7884X012

NPS 2-1/2 (DN 65) body (1 required) 17A1561X012

NPS 3 (DN 80) body (1 required) 17A1588X012

NPS 4 (DN 100) body (1 required) 17A1613X012

18* Cylinder Gasket, Copper

NPS 1 (DN 25) body (3 required) 16A7854X012

NPS 1-1/2 (DN 40) body (3 required) 16A7916X012

NPS 2 (DN 50) body (3 required) 16A7885X012

NPS 2-1/2 (DN 65) body (1 required) 14A5685X022

NPS 3 (DN 80) body (1 required) 17A1589X012

NPS 4 (DN 100) body (1 required) 17A1614X012

19* Body Gasket, Copper

NPS 1 (DN 25) body 14A6785X022

NPS 1-1/2 (DN 40) body 14A3384X022

NPS 2 (DN 50) body 14A5685X022

NPS 2-1/2 (DN 65) body 17A1563X012

NPS 3 (DN 80) body 13A0354X022

NPS 4 (DN 100) body 14A5650X022

20 Top Stem, Stainless steel

NPS 1 (DN 25) body 16A7855X012

NPS 1-1/2 or 2 (DN 40 or 50) body 16A7886X012

21 Cylinder Spacer, Steel

NPS 1 (DN 25) body 26A7856X012

NPS 1-1/2 (DN 40) body 26A7918X012

NPS 2 (DN 50) body 26A7887X012

22 Stem Seal, Polytetrauoroethylene (PTFE)/glass

NPS 1 (DN 25) body 16A7962X012

NPS 1-1/2 or 2 (DN 40 or 50) body 16A7963X012

Key Description Part Number

23 Stem Seal Retainer, Stainless steel

NPS 1 (DN 25) body 16A7857X012

NPS 1-1/2 or 2 (DN 40 or 50) body 16A7888X012

24 Piston, 416 Stainless steel

NPS 1 (DN 25) body (2 required) 19A6005X012

NPS 1-1/2 (DN 40) body (2 required) 19A6006X012

NPS 2 (DN 50) body (2 required) 19A6007X012

NPS 2-1/2 (DN 65) body (1 required) 17A1564X012

NPS 3 (DN 80) body (1 required) 17A1590X012

NPS 4 (DN 100) body (1 required) 17A1615X012

25 Piston Ring, PTFE

NPS 1 (DN 25) body (2 required) 19A6010X012

NPS 1-1/2 (DN 40) body (2 required) 19A6011X012

NPS 2 (DN 50) body (2 required) 19A6012X012

NPS 2-1/2 (DN 65) body (1 required) 17A1565X012

NPS 3 (DN 80) body (1 required) 17A1591X012

NPS 4 (DN 100) body (1 required) 17A1616X012

26 Ring Retainer, 302 Stainless steel

NPS 1 (DN 25) body (2 required) 16A7860X012

NPS 1-1/2 (DN 40) body (2 required) 16A7922X012

NPS 2 (DN 50) body (2 required) 16A7891X012

NPS 2-1/2 (DN 65) body (1 required) 17A1566X012

NPS 3 (DN 80) body (1 required) 17A1592X012

NPS 4 (DN 100) body (1 required) 17A1617X012

28 Nameplate, Stainless steel 16A7917X0A2

29 Flow Arrow, Stainless steel

NPS 1 (DN 25) body 1V105938982

NPS 1-1/2, 2, 2-1/2, 3, or 4

(DN 40, 50, 65, 80, or 100) body 1V106038982

30 Drive Screw, Stainless steel (4 required) 1A368228982

31 Led-Plate Number 250 Sealant,

5 pounds (2 kg) can (not furnished

with regulator) 1M524006992

32 Spring Seat, Carbon steel

NPS 2-1/2 (DN 65) body 17A1567X012

NPS 3 (DN 80) body 17A1593X012

NPS 4 (DN 100) body 17A1618X012

33 Plug Spacer, steel

NPS 2-1/2 (DN 65) body 17A1568X012

NPS 3 (DN 80) body 17A1594X012

NPS 4 (DN 100) body 17A1619X012

34 Washer, Carbon steel

NPS 2-1/2 or 3 (DN 65 or 80) body 17A1569X012

NPS 4 (DN 100) body 17A1620X012

35 Groove Pin, Stainless steel

NPS 2-1/2 (DN 65) or larger body 1C8989X0012

38* O-Ring, PTFE

NPS 2-1/2 or 3 (DN 65 or 80) body 17A7396X012

NPS 4 (DN 100) body 17A7397X012

40 Lockwasher, Stainless steel

NPS 1 (DN 25) body 1F128035022

NPS 1-1/2 or 2 (DN 40 or 50) body 1A505638992

41 Hex Nut

NPS 1 (DN 25) body, 316 Stainless steel 1A391535252

NPS 1-1/2 or 2 (DN 40 or 50) body,

Zinc-plated steel 1A346524122

*Recommended spare part.

9

Page 10

Type 92W

2

16

15

87

78

74

76

77

5

1

18

10

24

15

13

12

9

8

7

4

3

2

17

19

20

14

16

15

11

10

18

5

77

2

3

4

74 78

1

76

17

19

20

14

16

7

8

9

12

13

74 78

1

76

17

19

20

14

16

39A3514-B

APPLY LUB/SEALANT

39A3514-B

APPLY LUB/SEALANT

COMPLETE TYPE 6492H PILOT

32A4712-A

A3505

DETAIL OF TAPPED

SPRING CASE WITH SEALED

ADJUSTING SCREW

39A3515-B

APPLY LUB/SEALANT

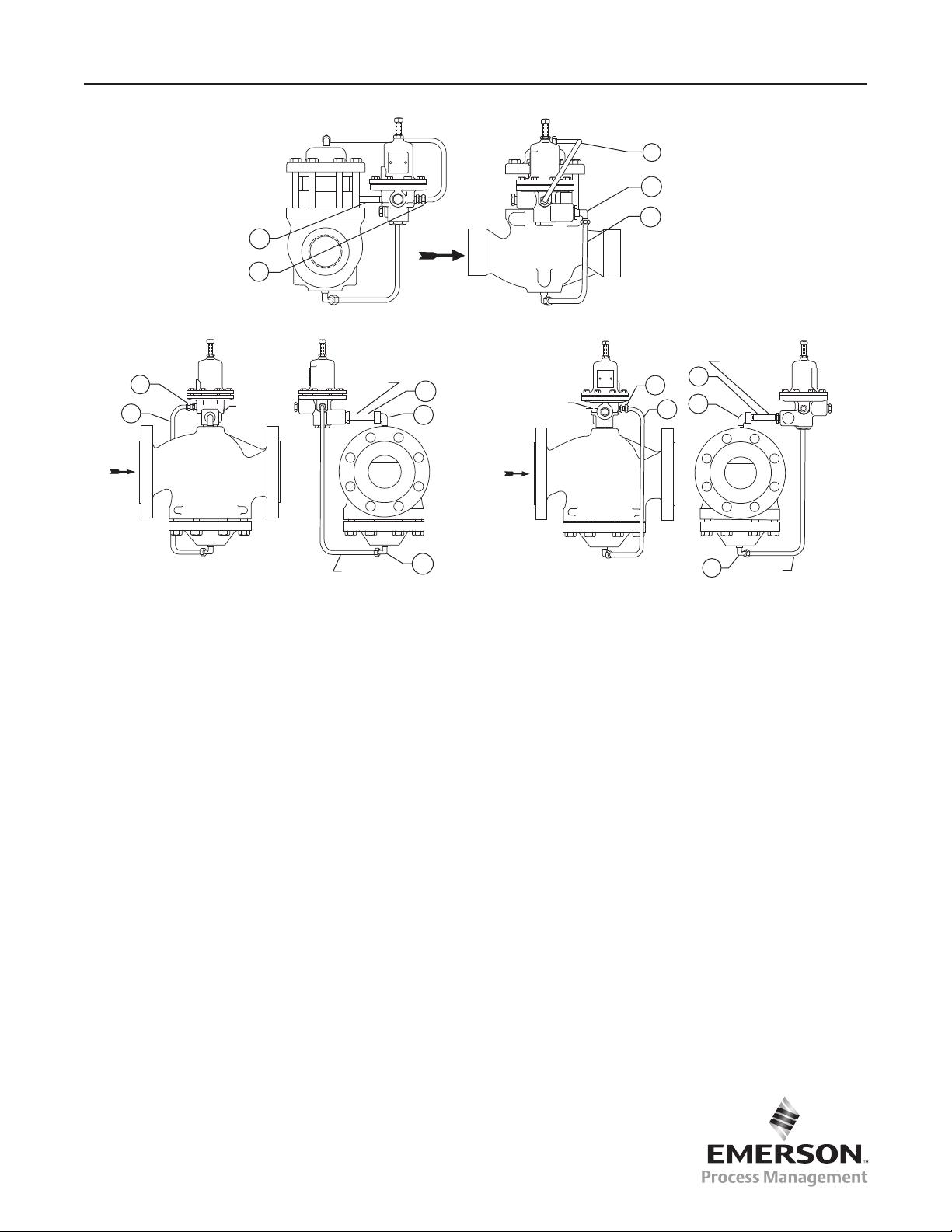

Pilot Mounting Parts (Figure 6)

Key Description Part Number

81 Loading Tubing, Copper 0500201701W

82 Pipe Nipple, Steel 1U264426232

83 Connector, Brass 15A6002X202

84 Elbow, brass (3 required for NPS 1, 1-1/2,

or 2 body size and 1 required for larger

sizes) (DN 25, 40, or 50) 15A6002X162

10

COMPLETE TYPE 6492L PILOT

Figure 4. Pilot Assemblies

Key Description Part Number

85 Inlet Tubing, copper (NPS 1, 1-1/2, or

2 body only) (DN 25, 40, or 50) 0500201701W

86 Elbow, carbon steel (NPS 2-1/2 through 4 body

only) (DN 65 thru 100) 1B8608X0012

Page 11

26

18

2

25

24

17

5

32

7

35

9

38

1

6

8

33

13

34

12

11

28

15

3

4

30

19

26

41

18

2

25

21

22

19

15

24

23

5

7

8

6

3

28

4

30

40

20

18

16

17

12

14

13

11

9

1

APPLY SEALANT

30 29

26

41

18

2

3

28

4

30

40

Type 92W

31

31

31

31

NPS 1, 1-1/2, OR 2 (DN 25, 40, OR 50) BODY SIZE

36A7960-D

31

37A1622-D

25

CORRECT ORIENTATION OF PISTON RING (KEY 25)

NPS 2-1/2, 3, OR 4 (DN 65, 80, OR 100) BODY SIZE

Figure 5. Type 92W Main Valve Assemblies

31

31

11

Page 12

Type 92W

29A3518-B

83

81

82

83

CONTROL

NPS 1, 1-1/2, OR 2 (DN 25, 40, OR 50) BODY SIZE

SUPPLY

82

CONTROL

86

84

85

81

83

81

SUPPLY

81

86

39A3519-C

WITH PILOT MOUNTED IN STANDARD POSITION SO CONTROL

LINE CONNECTION FACES DOWNSTREAM

LOADING

NPS 2-1/2, 3, OR 4 (DN 65, 80, OR 100) BODY SIZE

84

30B3840-A

WITH PILOT MOUNTED IN OPTIONAL POSITION SO CONTROL

LINE CONNECTION FACES UPSTREAM

84

LOADING

Figure 6. Pilot Mounting Parts

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 2004, 2009; All Rights Reserved

Loading...

Loading...