Page 1

Complete Clean Pressure Regulation Solution

Offering a full line of sanitary and clean regulators.

Uncompromising.

Engineered for Optimum Performance.

From pharmaceutical, biotechnology, and health care

industries to food, dairy, beverage, and consumer product

manufacturing plants Fisher® regulators provide reliable and

accurate pressure control for a broad range of ow media for

clean and sterile service. Time-tested and globally trusted,

Fisher regulators are a dependable solution for your process

needs.

Fisher pressure reducing and backpressure regulators are used

to control pressure in the following applications:

• Batching tanks

• Bioreactor agitator seal pressure control

• Bioreactors

• Chromatography

• Clean-in-place (CIP) systems

• Cookers, dryers, and autoclaves

• Fermenters

• Homogenizers

• Lyophilization (freeze-drying)

• Parenteral lling

• Sanitize-in-place (SIP) systems

• Separators

• Sterile process

• Tank blanketing

95 SERIES

TYPE SR5

67C SERIES

Product Advantages:

• Construction materials are compliant with sanitary or NACE

standards offering superior performance

• Wide variety of body sizes, construction materials, and control

ranges available

• Highly versatile and accurate ow control

• Compact rugged construction

• Robust design and easy maintenance

Media Include:

• Acid

• Alcohol

• Blanketing gas

• Biologics

• Buffer solution

• Caustic solution

• Clean ltered air

• Clean steam

• Food and beverage product

• Pharmaceutical product

• Process gas

• Solvent

• Sparge gas

• Water-for-injection (WFI)

Oxygen Cleaning

Available

www.sherregulators.com

Page 2

Complete Clean Pressure Regulation Solution

Fisher® regulators operate in a variety of process and clean utility applications in the pharmaceutical, biotechnology, health

care, dairy, food and beverage, cosmetic and consumer product industries.

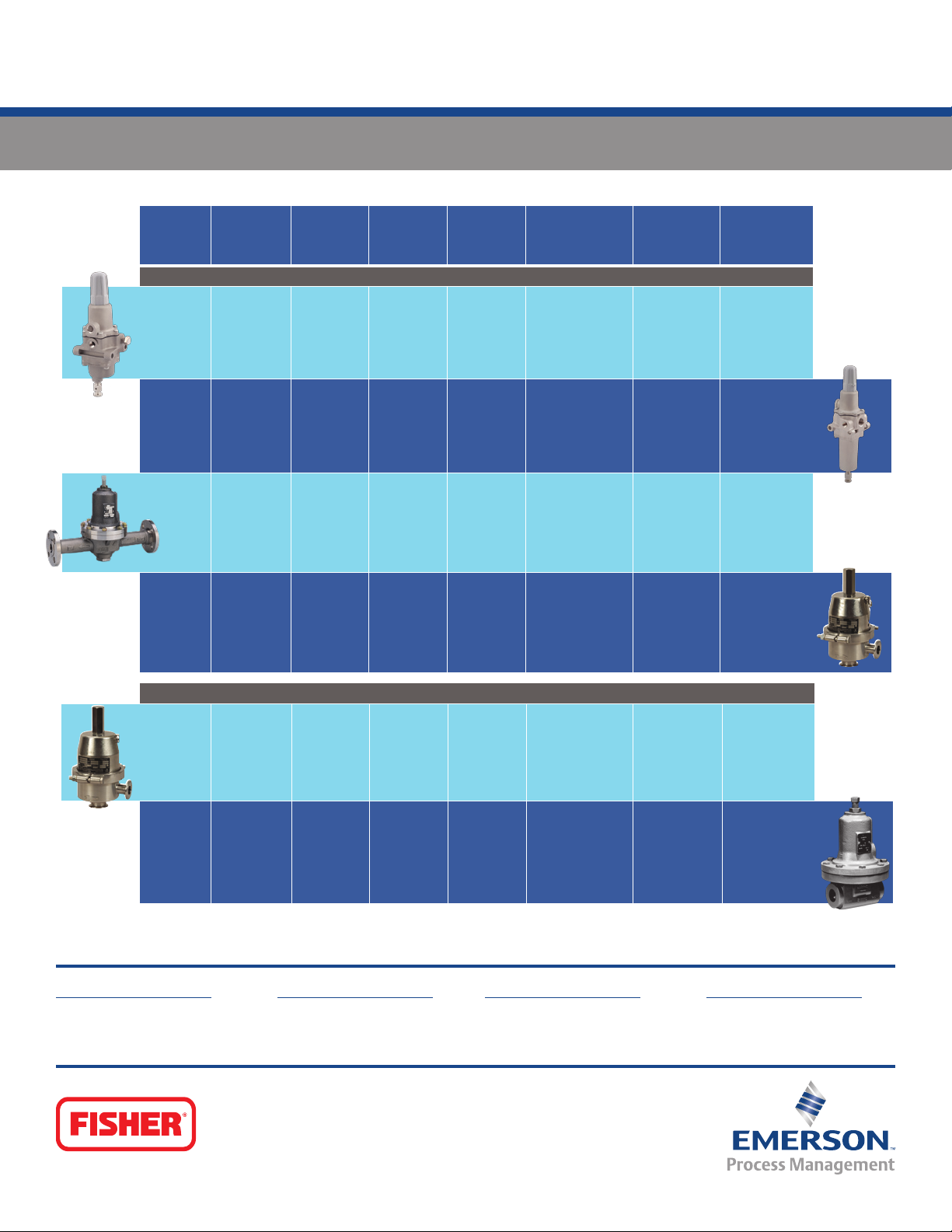

Type 67CFS

95 Series

BODY SIZES

INCHES

1/4 NPT

1/2 NPT

1/4, 1/2,

3/4, 1,

1-1/2,

and 2

1/2, 3/4, 1,

1-1/2 x1,

1-1/2, 2,

and 3

END

CONNECTION

STYLE

NPS

NPS

SET

PRESSURE

RANGE,

PSIG (bar)

0 to 150

(0 to 10,3)

0 to 150

(0 to 10,3)

2 to 400

(0,14 to 27,6)

2 to 135

(0,14 to 9,3)

MAXIMUM

INLET

PRESSURE,

PSIG (bar)

Pressure Reducing Regulators

250

(17,2)

250

(17,2)

600

(41,4)

210

(14,5)

OPERATION

METHOD

Direct-

Operated

Direct-

Operated

Direct-

Operated

Direct-

Operated

BODY

MATERIAL

Stainless Steel D102656X012

Stainless Steel D103152X012

Cast Iron,

Steel,

Stainless Steel,

Hastelloy® C, and

316L Stainless Steel,

20 μin (0,5 μm) Ra

Monel

®

BULLETIN PART

NUMBER

D100117X012

D103105X012

FEATURES AND

OPTIONS

• Cleaning/

Degreasing

Available

• Cleaning/

Degreasing

Available

Type 67DFS

• Cleaning/

Degreasing

Available

• CIP and SIP

Capable

• 3-A®, FDA, and

USP Class VI

Certications

Available

Backpressure Regulators

1/2, 3/4, 1,

1-1/2 x1,

1-1/2, 2,

and 3

Type SR8

1/4, 1/2,

3/4, 1,

1-1/2, and 2

USA - Headquarters Asia Pacific Europe Middle East and Africa

McKinney, Texas 75069-1872, USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

NPS

NPS

2 to 125

(0,14 to 8,6)

2 to 375

(0,14 to 25,9)

Shanghai 201206, China

Tel: +86 21 2892 9000

210

(14,5)

400

(27,6)

Direct-

Operated

Direct-

Operated

Bologna 40013, Italy

Tel: +39 051 419 0611

Stainless Steel

with

Electropolish

Cast Iron,

Stainless Steel,

Steel,

Hastelloy® C,

and Monel

®

D103106X012

D100153X012

• CIP and SIP

Capable

• 3-A®, FDA, and

USP Class VI

Certications

Available

• Cleaning/

Degreasing

Available

Dubai, United Arab Emirates

Tel: +971 4811 8100

Type SR5

98 Series

D351885X012 © 2010 Emerson Process Management Regulator Technologies, Inc.; All Rights Reserved.

Printed in the U.S.A. 12/10. Fisher, Emerson Process Management, and the Emerson Process Management

design are marks of one of the Emerson Process Management group of companies. All other marks are the

property of their respective owners.

Loading...

Loading...