Page 1

Bulletin 62.3:670

February 2015

670 Series Panel-Mounted Loading Regulators

P1127_670

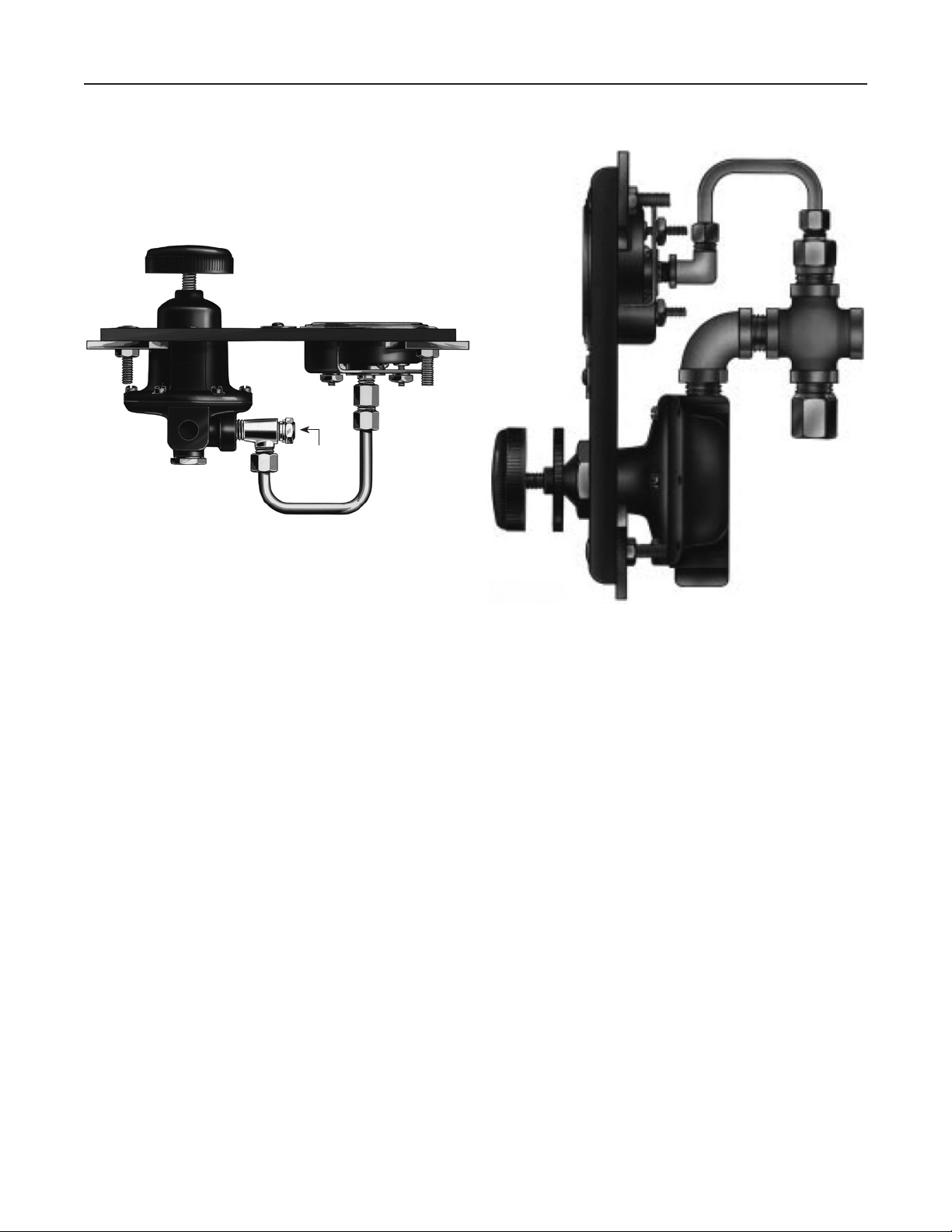

1-GAUGE PANEL

(671 AND 670 SERIES)

Figure 1. Typical Panel Layouts

P1128_670G-3

2-GAUGE PANEL

(670 SERIES)

Introduction

The Types 670, 671, 674 and 675 panel-mounted

loading regulators (Figures 1, 2, 3 and 6) are compact,

rugged units used primarily for manually loading

pressure-balanced gas regulators and providing

manual control for diaphragm actuator control valves.

Applications include remote control of gas pressure to

burners in reneries, power plants and various process

furnaces. The Types 670 and 675 units use the

Type 67CR or 67CFR pressure regulator, the Type 671

unit uses the Type 912 pressure regulator and the

Type 674 unit uses the Type 1301F pressure regulator.

Three basic panels are available within the product

line as shown in Figures 1 and 6, each having one

pressure regulator connected to one or two gauges

P1130_670GV

2-GAUGE PANEL WITH

CHANGEOVER VALVE

(670 SERIES)

or two gauges and a changeover valve. A single

gauge typically shows loading pressure to the control

valve. With two gauges, one gauge shows the loading

pressure and the other gauge can be connected to

show downstream control pressure or any other

pressure up to 300 psig / 20.7 bar. Manual backup

of pneumatic controllers can be handled with those

670 Series units having a changeover valve. With it

the operator selects either the automatic controller

output (displayed on one gauge) or the manual

loader output (displayed on the other gauge and

adjusted by the handwheel) as the signal to the

control valve actuator.

www.fisherregulators.com

D200027X012

Page 2

Bulletin 62.3:670

Specications

This section lists the specications for the 670 Series panel-mounted loading regulators. Factory specications

are stamped on the nameplate fastened on the regulator at the factory.

Available Congurations

See Table 1

End Connections

Inlet: 1/4 NPT internal

Outlet: Types 670 and 675—1/4 NPT internal;

Type 671—3/8 NPT internal;

Type 674—1/4 NPT internal

Maximum Allowable Inlet Pressure

Without Changeover Valve: 250 psig / 17.2 bar

With Changeover Valve: 50 psig / 3.4 bar

Maximum Outlet Pressure

See Table 1

Maximum Emergency Outlet Pressure

See Table 1

Outlet Pressure Ranges

Types 670 and 675

(1)

: 3 to 18 psig / 0.21 to 1.2 bar

5 to 30 psig / 0.34 to 2.1 bar; 30 to 50 psig / 2.1 to

3.4 bar; and 35 to 80 psig / 2.4 to 5.5 bar except

35 to 50 psig / 2.4 to 3.4 bar with change over valve

Type 671: 0 to 1 psig / 0 to 0.07 bar; 0 to 5 psig /

0 to 0.34 bar

Type 674: 10 to 75 psig / 0.69 to 5.2 bar;

50 to 150 psig / 3.4 to 10.3 bar;

100 to 225 psig / 6.9 to 15.5 bar

Pressure Registration

Internal

Construction Materials

Panel Tubing: Copper, PVC-coated copper,

aluminum or 316 (316 Stainless steel)

Regulator Body

Types 670 and 675: Die-cast aluminum

Type 671: Die-cast zinc

Type 674: Brass

Regulator Spring Case

Types 670 and 675: Die-cast zinc/Stainless steel

Type 671: Die-cast zinc

Type 674: Forged brass or steel

Panel

Types 670, 670F and 671: Zinc

Types 670FG, 670G, 670FGV and 670GV: Steel

Handwheel: Die-cast aluminum

Construction Materials (continued)

Other Regulator Parts

Diaphragm: Nitrile (NBR)

Valve Disk: Nitrile (NBR)

Diaphragm Plate: Plated steel

Spring: Plated steel

Filter Cartridge (Type 67CFR Regulator Only):

Cellulose (standard) or Stainless steel or Brass

Temperature Capabilities

-20 to 180°F / -29 to 82°C

Pressure Gauges

Connection: 1/8 NPT external tting on back

of case

Ranges: Standard ranges shown in Table 2 with

other ranges available upon request

Face Colors: White with black numerals

Case Color: Black

Gauge Identication: White engraving on black

laminated plastic plate below gauge indicates units

and function. Up to 16 characters per line, 3 lines,

are available.

Regulator Port Diameters

Types 670 and 675: 0.125 in. / 3.2 mm

Type 671: 0.073 in. / 1.9 mm (standard);

0.094 in. / 2.4 mm (optional)

Type 674: 0.078 in. / 2.0 mm

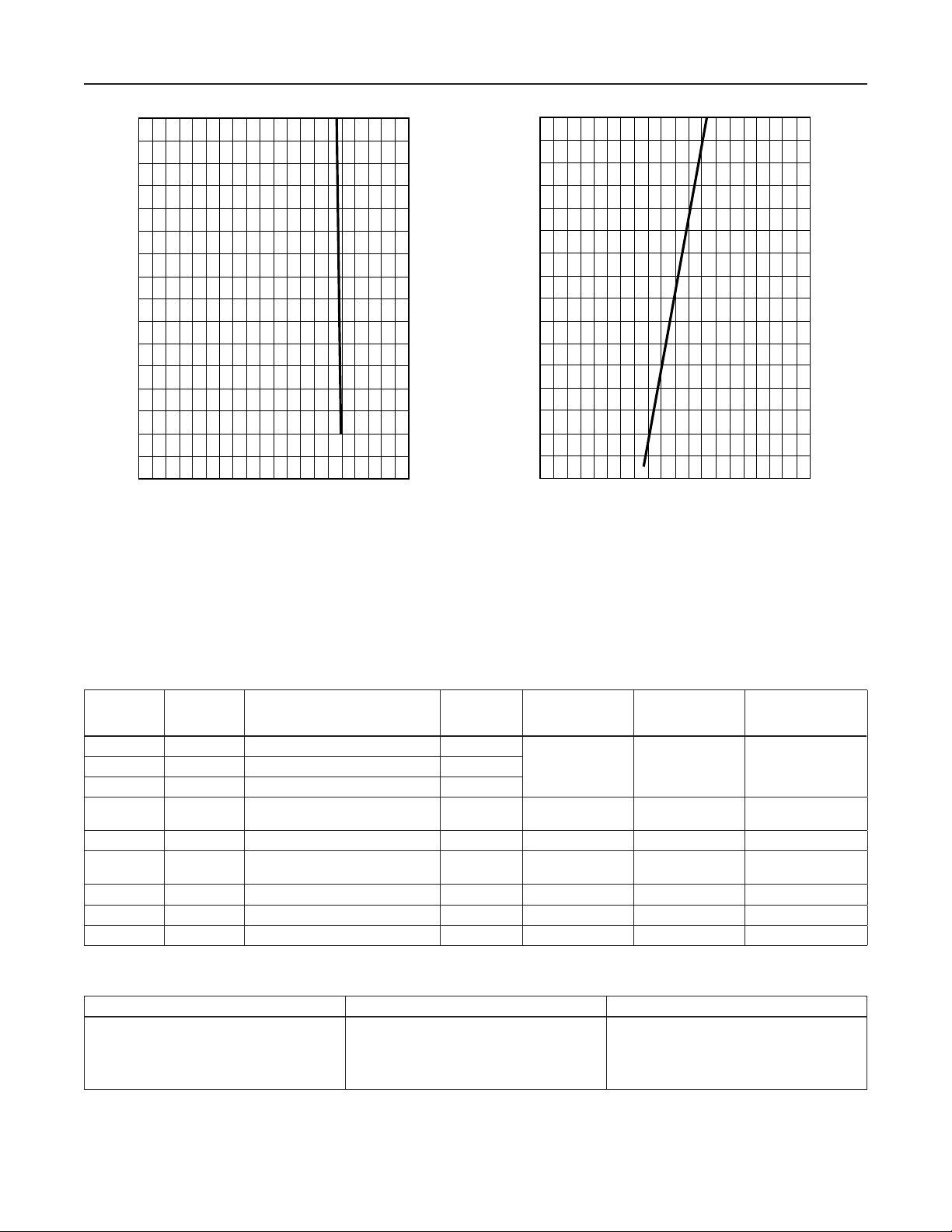

Operating Inuences

670 Series: As shown in Figure 4, output pressure

(2)

changes less than 5 psig / 0.34 bar when the input

pressure changes between 20 to 140 psig / 1.4 to

9.7 bar

Type 671: As shown in Figure 5, output pressure

changes less than 1 in. w.c. / 2 mbar when the

input pressure changes between 20 to 140 psig /

1.4 and 9.7 bar

Regulator Flow Capacity

See appropriate pressure regulator bulletin

Internal Relief for Pressure Regulators

Adequate for relieving only minor build-up

situations. Refer to the appropriate pressure

regulator bulletin to determine if external relief

is required.

1. These pressure ranges are recommended, but all springs used in the Type 67CR or 67CFR regulators can be adjusted down to 0 psig / 0 bar.

2. Dened in ISA Standard S51.1-1979.

2

Page 3

SCREENED

BLEED

ORIFICE

Bulletin 62.3:670

W0532

Figure 2. Type 670 Panel Loader

Features

• Control Flexibility—With a changeover valve, the

operator can deliver pressure to the control valve

from the manual loader, a controller or bypass the

panel completely.

• Gauge Identication—Big, clear, white-on-black

labels (see Figure 1) show gauge function and

units at a glance.

• Convenient Fingertip Control—Turn the panel-

mounted handwheel clockwise to increase or

counterclockwise to decrease pressure to the

control valve while watching the high visibility

black-on-white gauges.

W6110-1/IL

Figure 3. Side View of Type 671 Panel Loader Using

Type 912 Regulator

• Easy Connections—Unit comes with all the

hardware necessary to connect the loading

pressure gauge to the pressure regulator.

• Versatility—Pressure regulators are suitable for

a variety of gaseous uids including natural gas,

propane and air.

• Compact Size—The slim proles of the regulators

are ideal for installations where space behind the

panel is limited.

3

Page 4

Bulletin 62.3:670

A2554/IL

160

140

120

100

80

60

INLET PRESSURE, psig

40

20

5 /

0.34

10 /

0.69

15 /

1.0

OUTLET PRESSURE, psig / bar

NOTE:

TEST CONDUCTED USING A CONSTANT FLOW RATE OF

50 STANDARD CUBIC FEET PER HOUR AT 60°F AND

14.7 psia (1.3 NORMAL CUBIC METERS PER HOUR AT 0°C

AND 1.01325 bar, ABSOLUTE)

20 /

1.4

25 /

1.7

11.0

9.7

8.3

6.9

5.5

4.1

2.8

1.4

INLET PRESSURE, bar

160

140

120

100

80

60

INLET PRESSURE, psig

40

20

0

A2553/IL

9 /

22

10 /

25

11 /

28

OUTLET PRESSURE, IN. W.C. / mbar

NOTE:

TEST CONDUCTED USING A CONSTANT FLOW RATE OF

50 STANDARD CUBIC FEET PER HOUR AT 60°F AND

14.7 psia (1.3 NORMAL CUBIC METERS PER HOUR AT 0°C

AND 1.01325 bar, ABSOLUTE)

12 /

30

13 /

32

11.0

9.7

8.3

6.9

5.5

4.1

2.8

1.4

INLET PRESSURE, bar

Figure 4. Pressure Variation of Type 67CR Regulator

Figure 5. Pressure Variation of Type 912 Regulator

Table 1. Available Congurations

TYPE

NUMBER

NUMBER OF

GAUGE

DESCRIPTION

REGULATOR

TYPE

NUMBER

670 1 Basic 1-gauge panel 67CR

670FG 2 2-gauge panel; regulator has lter 67CFR

670FGV 2

2-gauge panel with 3-way

changeover valve; regulator has lter

67CFR 50 psig / 3.4 bar 50 psig / 3.4 bar 55 psig / 3.8 bar

670G 2 Basic 2-gauge panel 67CR 250 psig / 17.2 bar 100 psig / 6.9 bar 110 psig / 7.6 bar

670GV 2

2-gauge panel with 3-way or 4-way

changeover valve

67CR 50 psig / 3.4 bar 50 psig / 3.4 bar 55 psig / 3.8 bar

671 1 Basic 1-gauge panel 912N 250 psig / 17.2 bar 5 psig / 0.34 bar 10 psig / 0.69 bar

674G 2 Basic 2-gauge panel 1301F 6000 psig / 414 bar 225 psig / 15.5 bar 250 psig / 17.2 bar

675G 2 Basic 2-gauge panel 67CR 250 psig / 17.2 bar 100 psig / 6.9 bar 110 psig / 7.6 bar

MAXIMUM

INLET

PRESSURE

250 psig / 17.2 bar 100 psig / 6.9 bar 110 psig / 7.6 bar670F 1 1-gauge panel; regulator has lter 67CFR

MAXIMUM

OUTLET

PRESSURE

MAXIMUM

EMERGENCY

OUTLET PRESSURE

Table 2. Pressure Gauge Ranges - Triple Scale

psig Pa bar

0 to 10

0 to 30

0 to 60

0 to 160

0 to 300

0 to 0.6 K

0 to 0.2 M

0 to 0.4 M

0 to 1.1 M

0 to 2 M

0 to 0.69

0 to 2.1

0 to 4.1

0 to 11.0

0 to 20.7

4

Page 5

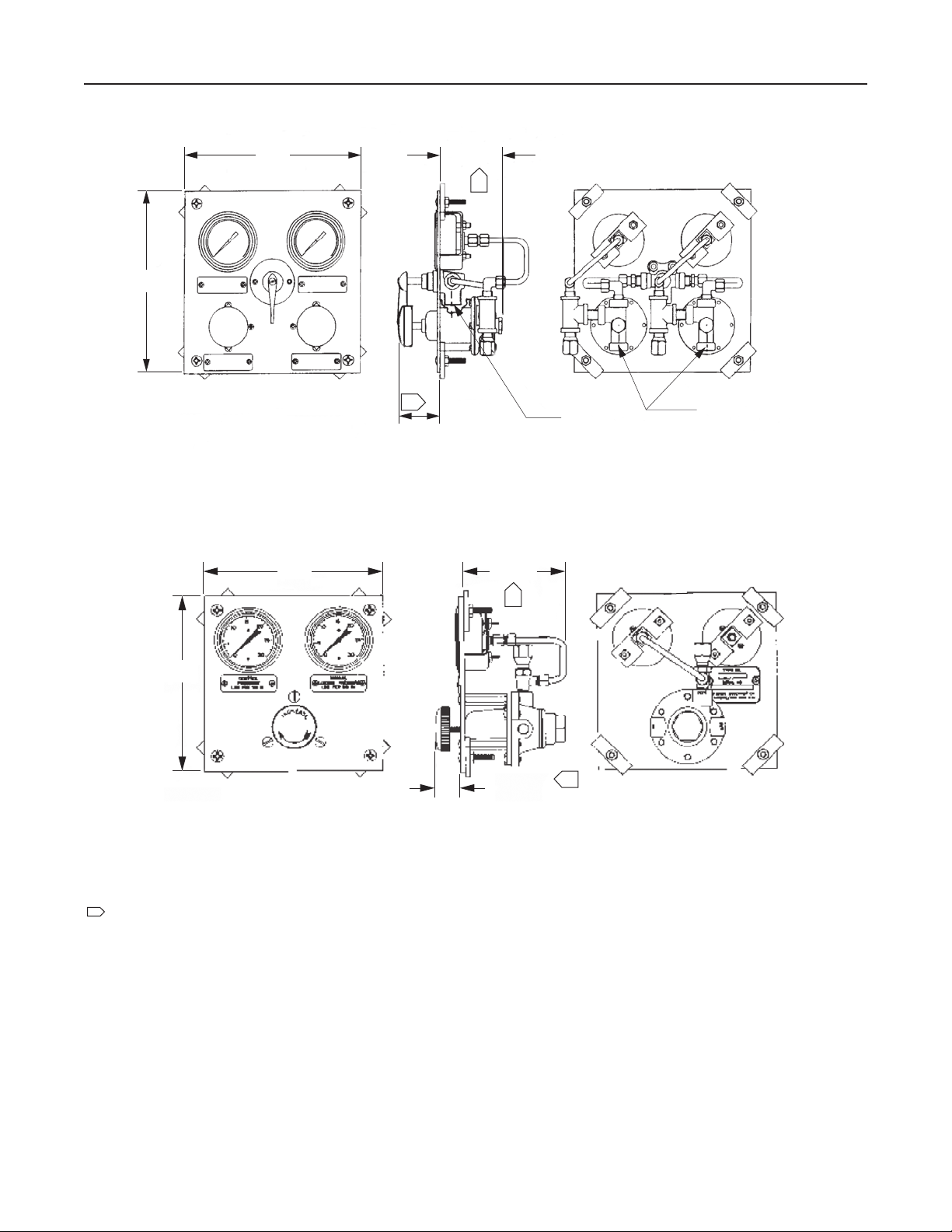

Bulletin 62.3:670

IN

B

MANUAL

LOADING PRESSURE

PSIG/BAR/MPa

A

6.80 /

173

GE03276

8.00 /

203

TYPE 670

8.00 /

203

6.80 /

GE13900

173

C

(MAXIMUM)

B

A

INTRUMENT

LOADING PRESSURE

LBS PER SQ IN.

MANUAL

AUTOMATIC

IN

D

F

OFF

B

GE02157

MANUAL

LOADING PRESSURE

LBS PER SQ IN.

INCREASE

6.80 /

173

IN

C

F

8.00 /

203

ED

TYPE NO.

SERIAL NO.

A

TYPE 670GV

1/4 NPT

CONTROL PRESSURE

MONITORING

8.61 /

219

1/4 NPT

ACTUATOR CONNECTION

C

TYPE 670G

IN

D

F

1.38 /

E E

8.61 /

1/4 NPT

SUPPLY CONNECTION

35

3.25 /

83

219

1.38 /

35

0.12 to 0.75 /

3.0 to 19

PANEL

2.62 /

1

DC3352-B

NOTE:

ENVELOPE DIMENSIONS ± 0.25 IN. / ± 6.4 mm

1

NOTE:

A0879-2

67

MAXIMUM

1.62 /

41

2.12 /

54

4.75 /

121

TYPE 671 DIMENSIONS

Figure 6. Dimensions

Table 3. Dimension Table

TYPE NUMBER

670

670F

670G

670FG

670GV

670FGV

671

1. Dimension F refers to the depth to which those regulators with lters extend behind the panel.

A B C D E F

In. mm In. mm In. mm In. mm In. mm In. mm In. mm

4.00

102

4.00

8.00

8.00

8.00

8.00

4.00

102

203

203

203

203

102

2.80

2.80

6.80

6.80

6.80

6.80

2.80

71

71

173

173

173

173

71

2.55

2.70

2.01

2.40

2.01

2.40

2.60

65

69

51

61

51

61

66

2.15

2.00

2.69

2.40

2.69

2.40

2.10

3/8-18 NPT

1/4-18 NPT

DIMENSION

55

51

68

61

68

61

53

0.72

- - - -

2.72

- - - -

0.72

- - - -

- - - -

4.00 /

102

2.00 /

51

18

- - - 69

- - - 18

- - - -

- - - -

3.66

6.00

5.73

7.10

4.20

7.10

- - - -

IN. /

mm

(1)

93

152

146

180

107

180

- - - -

Panel Count

3.25 x 7.25

3.25 x 7.25

7.25 x 7.25

7.25 x 7.25

7.25 x 7.25

7.25 x 7.25

3.25 x 7.25

83 x 184

83 x 184

184 x 184

184 x 184

184 x 184

184 x 184

83 x 184

5

Page 6

Bulletin 62.3:670

9.00 /

229

11B4602-A

9.00 /

229

8.00 /

203

4.88 /

124

1

2.38 /

1

60

MAXIMUM

TYPE 675G DIMENSIONS

5.50 /

140

ACTUATOR

DIAPHRAGM

CONNECTION

1

SUPPLY CONNECTION

8.00 /

203

4DA6615-B

NOTE:

1

ENVELOPE DIMENSIONS ± 0.25 IN. / ± 6.4 mm

B2405/IL

Figure 6. Dimensions (continued)

1.50 / 38

MAXIMUM

TYPE 674G DIMENSIONS

1

IN. /

mm

6

Page 7

Bulletin 62.3:670

Installation

Dimensions for installation clearances are shown in

Figure 6.

Ordering Guide

Type (See Table 1 for Construction details)

(Select One)

670

670F

670FG

670FGV

670G

670GV

671

674G

675G

Outlet Pressure Range (Select One)

Types 670 and 675

3 to 18 psig / 0.21 to 1.2 bar

5 to 30 psig / 0.34 to 2.1 bar

30 to 50 psig / 2.1 to 3.4 bar

35 to 80 psig / 2.4 to 5.5 bar except 35 to

50 psig / 2.4 to 3.4 bar with change over valve

Type 671

0 to 1 psig / 0 to 0.07 bar

0 to 5 psig / 0 to 0.34 bar

Type 674

10 to 75 psig / 0.69 to 5.2 bar

50 to 150 psig / 3.4 to 10.3 bar

100 to 225 psig / 6.9 to 15.5 bar

Ordering Information

When ordering, complete the ordering guide on this

page. Refer to the Specications section on page 2.

Review the description to the right of each specication

and the information in each referenced table or gure.

Specify your choice whenever a selection is offered.

Pressure Gauge Ranges

0 to 10 psig / 0 to 0.6 kPa / 0 to 0.69 bar

0 to 30 psig / 0 to 0.2 MPa / 0 to 2.1 bar

0 to 60 psig / 0 to 0.4 MPa / 0 to 4.1 bar

0 to 160 psig / 0 to 1.1 MPa / 0 to 11.0 bar

0 to 300 psig / 0 to 2 MPa / 0 to 20.7 bar

Changeover Valve

Yes

No

(1)

(Select One)

1. Other ranges available upon request.

7

Page 8

Bulletin 62.3:670

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28008, France

Tel: +33 2 37 33 47 00

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

©Emerson Process Management Regulator Technologies, Inc., 1992, 2015; All Rights Reserved

Loading...

Loading...