Page 1

Instruction Manual

Form 965

February 2015

670 Series Panel-Mounted Loading

Regulator Assemblies

WARNING

!

Fisher® regulators should be installed,

operated and maintained in accordance

with federal, state and local codes, rules

and regulations and Emerson Process

Management Regulator Technologies,

Inc. instructions.

If a leak develops in the system, it indicates

that service is required. Failure to take the

regulator out of service immediately may

create a hazardous condition.

Call a gas service person in case of trouble.

Only a qualied person must install or

service the regulator.

670 Series

Introduction

The 670 Series panel-mounted loading regulator assemblies

are used primarily for manually controlling pressure to

diaphragm control valves or as remote pressure loaders for

pressure-balance gas regulators. They are also widely used

for remote control of gas pressure to burners in renery tube

stills, power plants and similar process furnaces.

Principle of Operation

The 670 Series regulators are set manually to control supply

pressure to diaphragm control valves or gas regulators.

Instrument and manual loading pressures are read from the

pressure gauges of the regulator. If pressure to the valve

needs to be adjusted, the regulator handwheel is turned

clockwise to increase the supply pressure or counterclockwise

to decrease the supply pressure.

Installation

Inspect the panel after it is removed from its packing.

Connect a 1/4 in. / 6.4 mm pipe line from the operating

supply pressure to the connection marked “IN” on the

pressure regulator.

One and two-gauge panels: Connect a line to the diaphragm

casing of the main valve or regulator and run it to the

connection marked “OUT” on the panel regulator. When

installing a two-gauge panel, connect a line from the control

pressure line to the upper diaphragm casing and to the

W0554

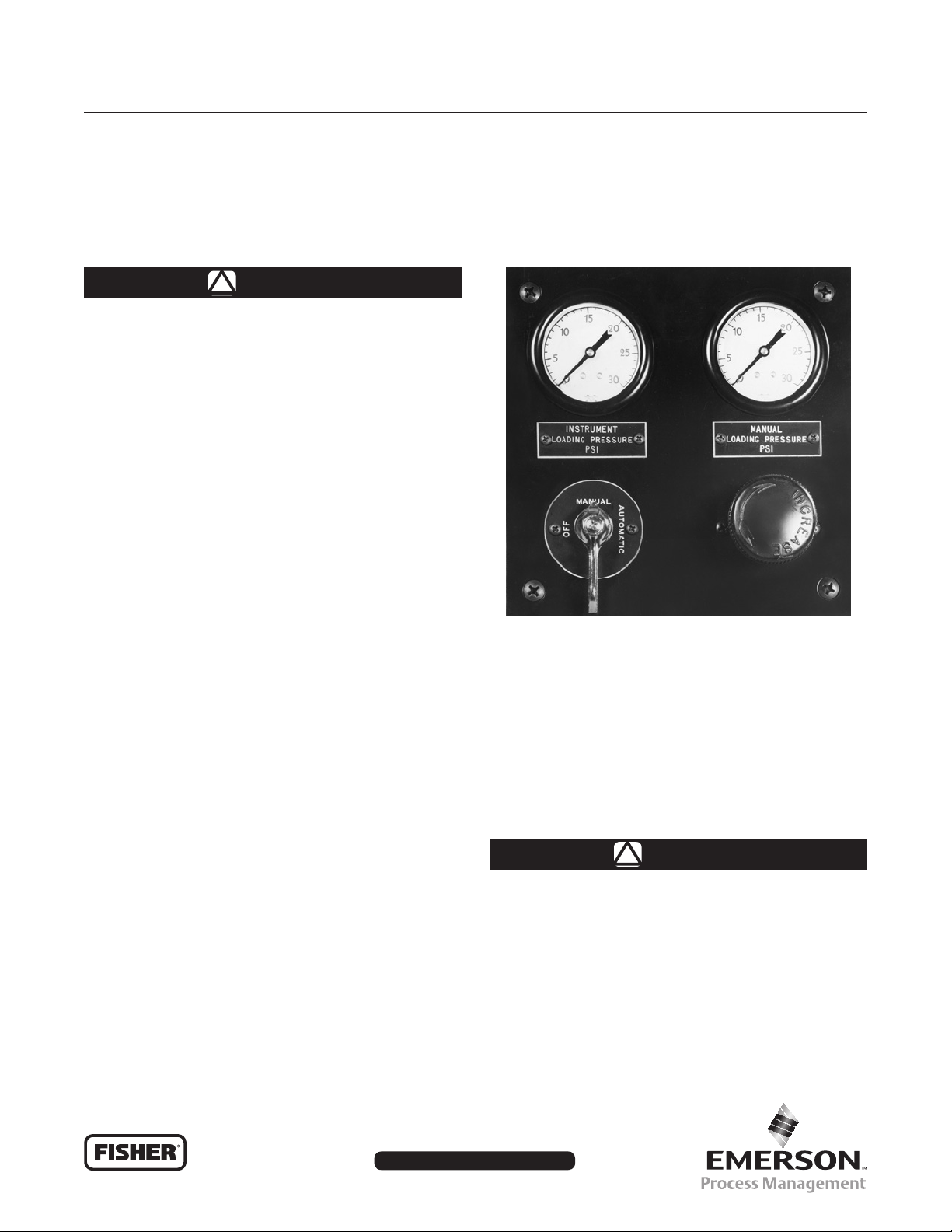

Figure 1. Typical 670 Series Regulators: Two-Gauge Panel with

Three-Way Changeover Valve

control pressure gauge (instrument loading pressure) in the

back of the panel (see Figure 2).

Two-gauge panel with a three-way changeover valve:

Connect the air supply, diaphragm connection and

instrument loading pressure line to the panel regulator as

shown in Figure 4.

Overpressure Protection

WARNING

!

Overpressuring any portion of this equipment

may cause damage to regulator parts, leaks

in the regulators or personal injury due to

bursting of pressure-containing parts or

explosion of accumulated gas.

To avoid overpressure, provide appropriate

overpressure protection to ensure that none of

the pressure limits will be exceeded.

The regulator assembly should be inspected for

damage after any overpressure condition.

www.fisherregulators.com

D200109X012

Page 2

670 Series

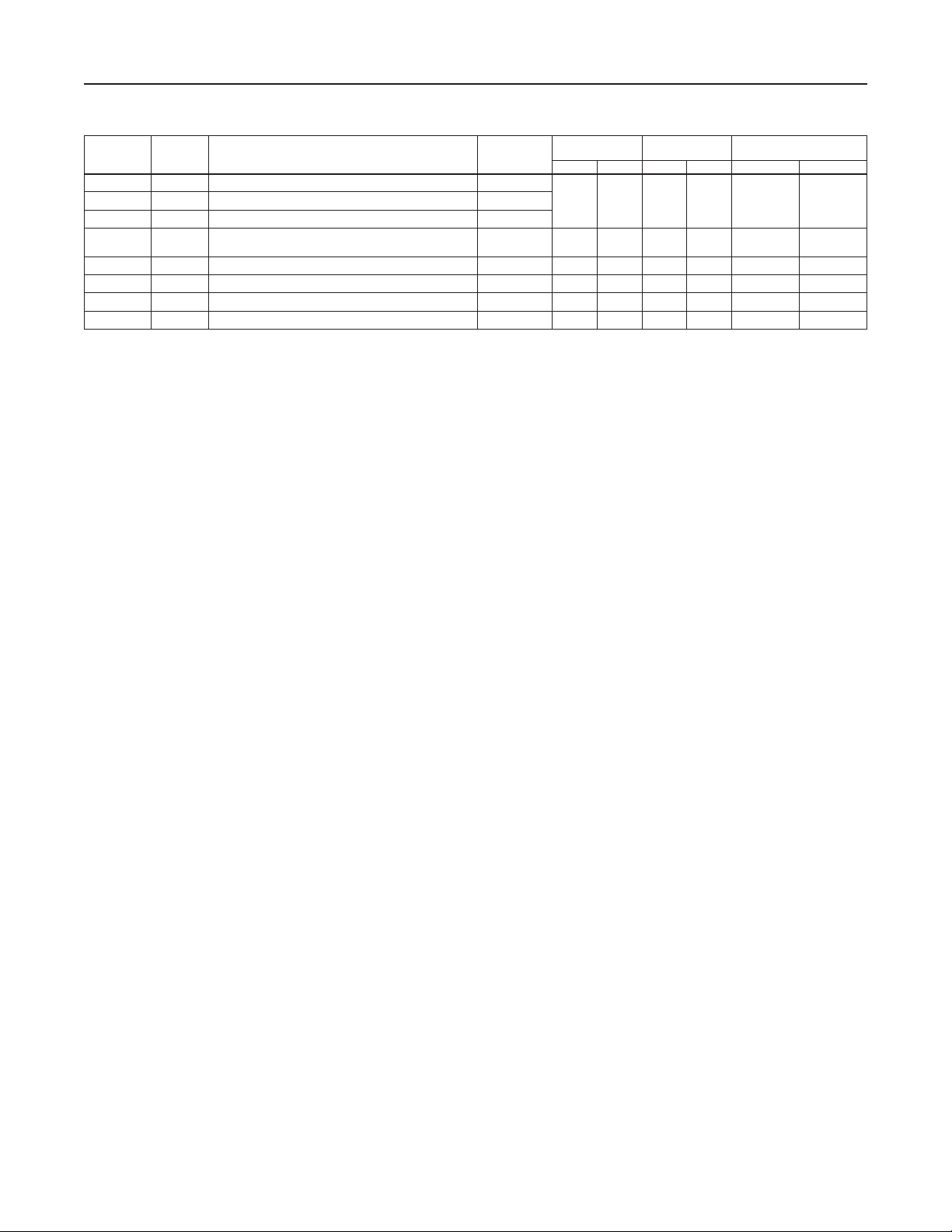

Table 1. Type Number Description

TYPE

670 1 Basic 1-gauge panel 67CR

670FG 2 2-gauge panel; regulator has lter 67CFR

670FGV 2

670G 2 Basic 2-gauge panel 67CR 250 17.2 100 6.9 11 0 7.6

670GV 2 2-gauge panel with 3-way or 4-way changeover valve 67CR 50 3.5 50 3.5 55 3.8

671 1 Basic 1-gauge panel 912N 250 17.2 5 0.35 10 0.69

675 2 Basic 2-gauge panel 67CR 250 17.2 100 6.9 11 0 7.6

NUMBER

OF GAUGE

DESCRIPTION

2-gauge panel with 3-way changeover valve;

regulator has lter

REGULATOR

TYPE NUMBER

67CFR 50 3.5 50 3.5 55 3.8

MAXIMUM INLET

PRESSURE

psig bar psig bar psig bar

250 17.2 100 6.9 110 7.6 670F 1 1-gauge panel; regulator has lter 67CFR

MAXIMUM OUTLET

PRESSURE

MAXIMUM EMERGENCY

OUTLET PRESSURE

As is the case with most regulators, regulators in the

670 Series have outlet pressure ratings which are lower than

the inlet pressure ratings. Overpressure protection is needed if

the actual inlet pressure can exceed the outlet pressure rating.

A common method of overpressure protection is a relief valve.

Maximum emergency outlet pressure ratings are shown in

Table 1 for each loading regulator.

Startup

Open the air supply line. Check all connections for leaks. The

manual loading pressure gauge indicates the loading pressure

on the diaphragm of the main valve. To increase the loading

pressure, turn the handwheel clockwise. To decrease the

loading pressure, turn the handwheel counterclockwise.

Units with a three-way changeover valve may be placed

under manual operation. When changing from manual

to automatic or from automatic to manual control, set the

manual control pressure gauge to read the same as the

instrument pressure in order to prevent bumping.

Maintenance

The regulator can be removed from the panel to be nut

disassembled. Take out the set screws or loosen the hex to

remove the regulators from the panel. Refer to the appropriate

instruction manual for further maintenance on the regulator.

Parts Ordering

When corresponding with your local Sales Ofce about

this equipment, be sure to include the serial number that is

stamped on the nameplate on the back of the panel. Include

the complete eleven-character part numbers from the following

Parts List when ordering new parts.

Parts List

Key Description Part Number

1 Regulator—Part numbers for the regulators

used in the 670 Series are shown in the

regulator instruction manuals

Key Description Part Number

2 Gauge

0 to 5 psig / 0 to 0.35 bar 23A8325X012

0 to 15 psig / 0 to 1.0 bar 2C2332000B2

0 to 30 psig / 0 to 2.1 bar 2C2332000C2

0 to 60 psig / 0 to 4.1 bar 2C2332000D2

0 to 100 psig / 0 to 6.9 bar 2C2332000E2

0 to 160 psig / 0 to 11.0 bar 2C2332X0022

0 to 200 psig / 0 to 13.8 bar 2C2332000F2

0 to 300 psig / 0 to 20.7 bar 2C2332X00A2

0 to 400 psig / 0 to 27.6 bar 2C2332X0032

0 to 600 psig / 0 to 41.3 bar 2C2332X0042

0 to 60 psig / 0 to 4.1 bar and 0 to 4 kg/cm2 1R766299012

0 to 60 to 200 psig / 0 to 4.1 to 13.8 bar

and 0 to 4 to 14 kg/cm2 1R766399012

3 Panel

Types 670 and 670F, Zinc 1C233344012

Type 670FG, Steel 3E660725132

Type 670G, Steel 3J846025132

Types 670GV and 670FGV (3-way valve),

Steel 3E660825132

Type 671, Zinc 1C233744012

Type 675G, Steel 3H184325132

4 Clamp bar, Cadmium Plate steel (4 required) 1C233824162

5 Hex Nut, Cadmium Plate Steel

Types 670, 670F, 670FG, 670FGV, 671

and 675G (4 required) 1E985324142

Types 670G and 670GV

(6 required) 1E985324142

6 Machine Screw, Steel (4 required) 1C233928992

7 Tubing, Copper

Type 670 19A1553X012

Type 670F 19A1562X012

Type 670FG 19A1564X012

Type 670FGV 19A1565X012

Type 670G 19A1569X012

Type 670GV 19A1556X012

Type 671 19A1511X012

Type 675G 19A1573X012

8 Fitting, Brass

Types 670, 670F and 671 15A6002X272

All other types 15A6002X262

9 Fitting, Brass

Types 670 and 670F 1C619718992

Type 670FG 15A6002X172

Types 670FGV and 670GV (3 required) 15A6002X172

Type 670G 15A6002X212

Type 671 15A6002XA92

Type 675G (2 required) 1C619718992

2

Page 3

AF5052-C

TYPE 670G LOADING REGULATOR

CONTROL PRESSURE

LOADING PRESSURE

OPERATING MEDIUM

200 FT / 61 m

OR LESS

TYPE 796EK MAIN VALVE

Figure 2. Typical Installation of a Type 670 Regulator

670 Series

30A6617

5

4

3

2

7

6

8

9

27

28

15

19

10

1

11

24

Figure 3. Type 671 Regulator Assembly Drawing

26

25

DC2668-D

A1728-1

AIR

SUPPLY

18

13 19

CONNECTION TO

MAIN DIAPHRAGM

INSTRUMENT

OUTPUT

Figure 4. Type 670GV Regulator Assembly Drawing

3

Page 4

670 Series

Key Description Part Number

10 Nipple

Types 670, 670F and 670G, Brass 1B678218992

Types 670FGV, 670GV and 675G, Brass

(2 required) 1B678218992

Type 671, Steel 1H392926012

11 Fitting, Brass

Type 670 15A6002X212

Type 670F 15A6002X382

Type 670FG 1L472018992

Types 670FGV, 670G and 670GV

(2 required) 1C619718992

Type 671 1D501621992

Type 675G (2 required) 15A6002X212

12 Tubing, Copper

Type 670GV 19A1560X012

Type 675G 19A1574X012

13 Changeover Valve

Types 670FGV and 670GV 1C269518992

15 Gauge Service Marking

(1)

Types 670, 670F and 671 1C538606092

Type 670FG (one of each) 1C538606092

1C538706092

Type 670FGV (one of each) 1L335506092

1L335606092

Types 670G and 670GV (one of each) 1C538606092

14A2561X012

Type 675G (2 required) 1C538606092

16 Machine Screw, Plate steel

Types 670FGV and 670GV (2 required) 1C270328992

Key Description Part Number

17 Fitting, Brass

Type 670G 1C269818992

Types 670GV and 670FGV (2 required) 1C269818992

18 Valve Dial, Plastic

Type 670FGV (3-way valve) 1L351106992

Type 670GV (2-way valve) 1D6367X0021

Type 670GV (3-way valve) 1C269606092

19 Machine Screw, Steel

Types 670, 670F and 671 (2 required) 1C270428992

Types 670FG, 670G and 675G (4 required) 1C270428992

Types 670FGV and 670GV (6 required) 1C270428992

20 Tubing, Copper

Types 670FGV and 670GV (2 required) 19A1558X012

23 Support Post, Brass

Types 670FGV and 670GV (2 required)

(Not shown) 1C269714012

24 Bleed Orice and Screen Assembly, Brass/Monel

Types 670, 670F, 670FG, 670FGV and 670GV 1K8845X0012

Type 671 1D5015X0012

Type 675G (2 required) 1K8843X0012

25 Serial Plate, Aluminum 1C584011992

26 Hex Nut, Plate steel

Type 670FG (4 required) 1A330328982

All other types (2 required) 1A330328982

27 Fitting

Type 671, Malleable Iron 1D501721992

Types 670FGV and 670GV, Brass 15A6002X212

28 Fitting, Brass

Types 670FGV, 670G and 670GV 15A6002X272

33 Mounting Post, Steel (3 required)

(not shown) 1F2449X0012

1. A plate may be engraved with any service marking or terminology. Letter height is 1/8 in. / 3.2 mm. There is space for 3 lines with up to 16 letters per line.

Monel® is a mark owned by Special Metals Corporation.

®

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9000

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75070 USA

Tel: +1 800 558 5853

Outside U.S. +1 972 548 3574

Asia-Pacic

Singapore 128461, Singapore

Tel: +65 6770 8337

Europe

Bologna 40013, Italy

Tel: +39 051 419 0611

Chartres 28008, France

Tel: +33 2 37 33 47 00

Middle East and Africa

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445, USA

Tels: +1 763 241 3238

+1 800 447 1250

Europe

Selmsdorf 23923, Germany

Tel: +49 38823 31 287

Asia-Pacic

Shanghai 201206, China

Tel: +86 21 2892 9499

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.fisherregulators.com

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls International LLC,

a business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management Regulator Technologies, Inc. does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and

maintenance of any Emerson Process Management Regulator Technologies, Inc. product remains solely with the purchaser.

©Emerson Process Management Regulator Technologies, Inc., 1987, 2015; All Rights Reserved

Loading...

Loading...