Page 1

Instruction Manual

Form 1056

November 2008

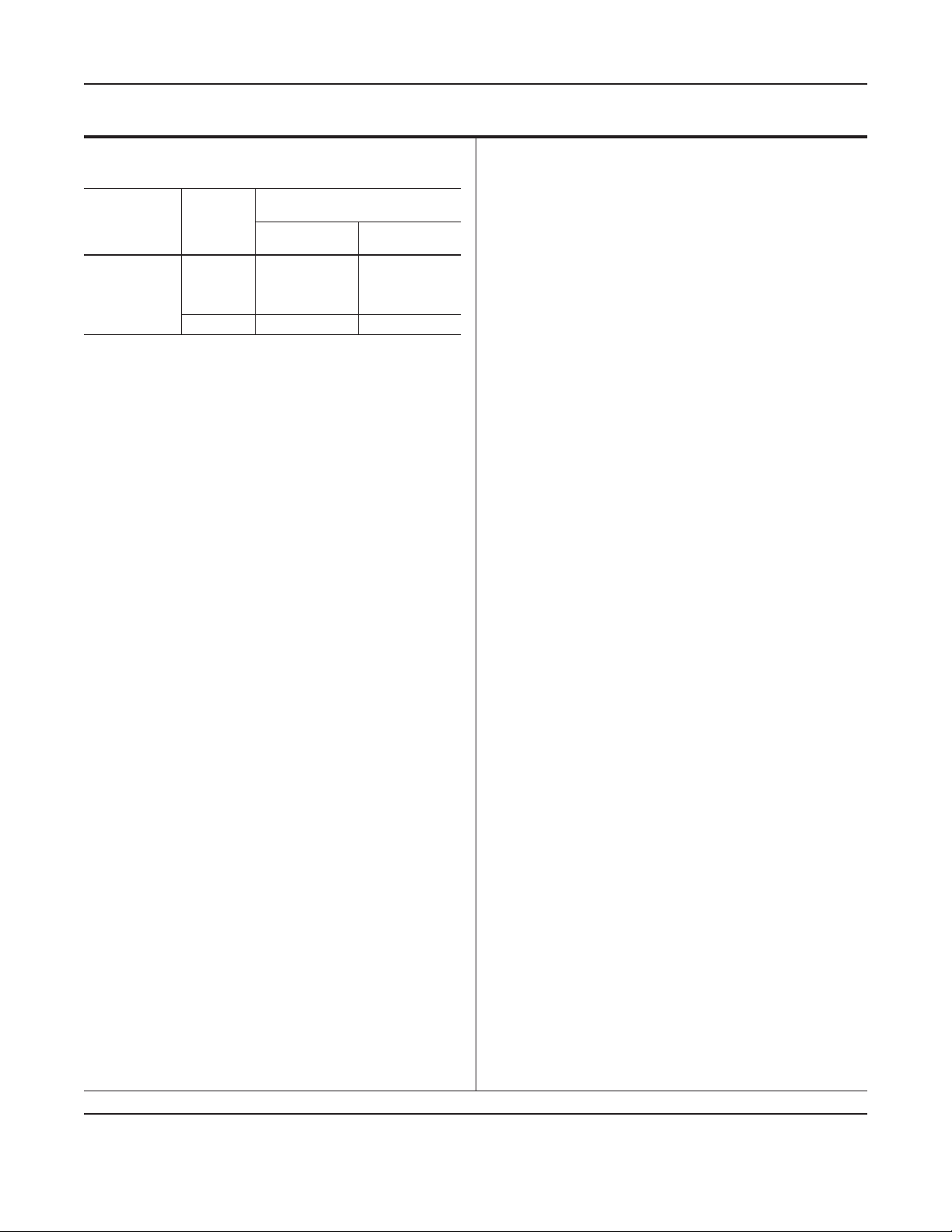

Types 66, 66Z, and 66ZZ

Types 66, 66Z, and 66ZZ Pressure

Reducing Regulators

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage and

personal injury or death.

Fisher® regulators must be installed,

operated, and maintained in accordance

with federal, state, and local codes, rules

and regulations, and Fisher instructions.

If the regulator vents gas or a leak

develops in the system, service to

the unit may be required. Failure

to correct trouble could result in a

hazardous condition.

W1935-1

Figure 1. Type 66 Self-Operated Pressure

Reducing Regulator

Call a gas service person to service

the unit. Only a qualied person must

install or service the regulator.

Introduction

Scope of the Manual

This instruction manual provides instructions for

the installation, adjustment, and maintenance

of the Types 66, 66Z, and 66ZZ pressure

reducing regulators. Parts ordering information

is also provided. Other 66 Series regulators and

accessories are covered in other manuals.

Description

The Type 66 self-operated regulator (Figure 1)

maintains a reduced outlet pressure while satisfying

the downstream ow demands. The Types 66Z and

66ZZ self-operated regulators (Figures 8 and 9) also

control a reduced outlet pressure; however, both have

springs sensitive to negative pressures and can be

used for vacuum regulation. Each regulator type has

a balancing diaphragm which increases accurate and

sensitive response to pressure changes by reducing

the unbalanced forces acting on the valve plug. This

regulator and its installation should be checked for

compliance with all applicable codes.

Specications

The Specications table lists the specications for

the Types 66, 66Z, and 66ZZ self-operated pressure

reducing regulators. Some of the specications for a

given regulator as it comes from the factory appear on

the regulator nameplate.

Principle of Operation

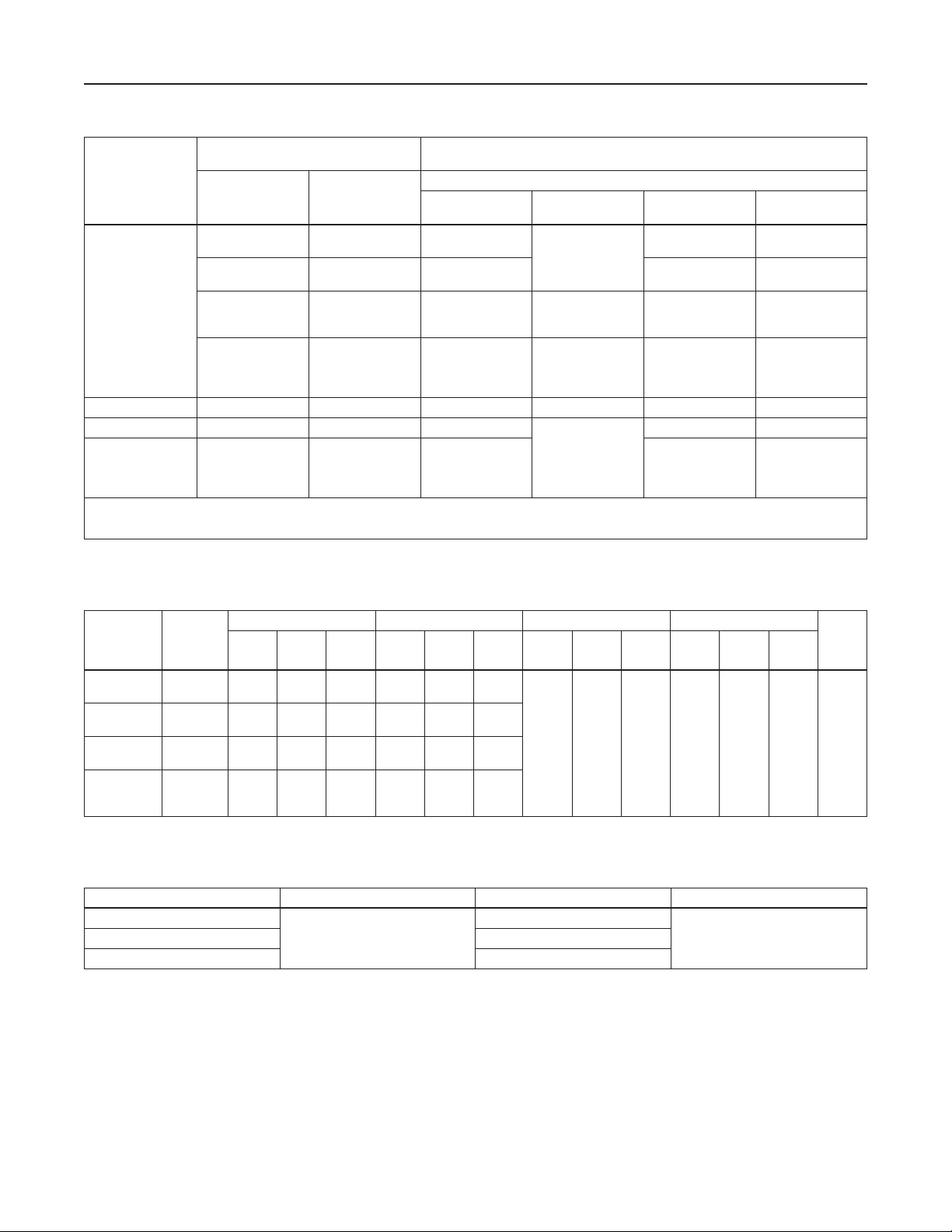

The cast iron Type 66 regulator uses a pitot tube to

sense outlet pressure while the steel Type 66 regulator

uses an external control line to sense outlet pressure

as shown in Figure 6. Both pressure-sensing methods

register the outlet pressure under the main diaphragm.

When increased downstream demand lowers the outlet

pressure, the lower pressure under the main diaphragm

causes the regulator main spring and valve plug and

stem assembly to open the regulator seat ring and to

supply more gas to the downstream system.

www.emersonprocess.com/regulators

D100247X012

Page 2

Types 66, 66Z, and 66ZZ

Specications

Body Sizes and End Connection Styles

END CONNECTION STYLES

AND RATINGS

Standard Cast

Iron Body

CONSTRUCTION

Type 66, 66Z,

66ZZ, or 66

vacuum

regulators

or breakers

NOMINAL

BODY SIZE,

INCH (DN)

2 (50) NPT or CL125 FF

3, 4 (80, 100) CL125 FF CL150 RF

Maximum Allowable Inlet Pressures

(1)

(1)

Optional Steel

Body

NPT (all types),

CL150 RF (all

types), CL150 FF,

CL300 RF

(1)

Emergency Inlet Pressure:

Type 66, 66Z, 66ZZ, or 66 Series Vacuum

Breakers: 25 psig (1,72 bar) positive pressure

66 Series Vacuum Regulators: 8 psig or

16.3-inches of mercury (0,55 bar

differential) vacuum

Maximum Safe Pressure to Avoid Internal

Parts Damage:

Type 66: 10 psig (0,69 bar)

Type 66Z: 5 psig (0,34 bar)

Type 66ZZ: 2 psig (0,14 bar)

66 Series Vacuum Regulators or Breakers:

No more than 1 psig (0,07 bar differential) change

from spring setting

Maximum Operating Inlet Pressure

Recommended for Good Performance:

Type 66, 66Z, or 66 Series Vacuum Breakers:

5 psig (0,34 bar) positive pressure

Type 66ZZ: 2 psig (0,14 bar)

66 Series Vacuum Regulator: 6-inches w.c. or

0.4-inch of mercury (15 mbar differential) vacuum

Maximum Allowable Outlet Pressures

(1)

Emergency Outlet (Casing) Pressure:

Type 66, 66Z, or 66ZZ: 8 psig (0,55 bar)

positive pressure

66 Series Vacuum Regulator: 14.7 psi or

29.9-inches of mercury (1,01 bar

differential) vacuum

66 Series Vacuum Breakers: 8 psi or 16.3-inches

of mercury (0,55 bar differential) vacuum

Maximum Safe Pressure to Avoid Internal

Parts Damage:

Type 66, 66Z, or 66ZZ: 1 psig (0,07 bar

differential) above outlet pressure setting

66 Series Vacuum Regulator: No more

than 1 psig (0,07 bar differential) change from

spring setting

Maximum Operating Pressure Recommended

for Good Performance (66 Series Vacuum

Regulators or Breakers Only):

Vacuum Regulators: 10 psig or 20.4-inches of

mercury (0,69 bar differential) vacuum

Vacuum Breakers: 6-inches w.c. or 0.4-inch of

mercury (15 mbar differential) vacuum

Elastomer Temperature Capabilities

Nitrile (NBR) Standard Elastomers:

-40°to 180°F (-40°to 82°C)

Fluorocarbon (FKM) Elastomers:

0°to 350°F (-18°to 177°C)

Ethylenepropylene (EPDM) Elastomers:

-40°to 275°F (-40° to 135°C)

Pressure Registration

Type 66, 66Z, or 66ZZ

Cast Iron Body: Internal (standard) or external

Steel Body: External (standard) or internal

66 Series Vacuum Regulators or

Breakers: External

Control Line when Used: 3/4-inch NPT standard

Bottom Flange Line when Used: 1/4-inch NPT

standard with removable plug

Spring Case Vent: 3/4-inch NPT standard with

removable Type Y602-10 vent assembly

Outlet (Control) Pressure Ranges

See Tables 1A through 1C

Control Line Connection

3/4-inch NPT

Flow and Sizing Coefcients

See Tables 2 and 3

Approximate Weights

2-inch (DN 50) Body

NPT: 50 pounds (22,7 kg)

Flanged: 55 pounds (25,0 kg)

3-Inch (DN 80) Flanged Body:

100 pounds (45,4 kg)

4-Inch (DN 100) Flanged Body:

155 pounds (70,3 kg)

1. The pressure/temperature limits in this Instruction Manual and any applicable standard or code limitation for valve should not be exceeded.

2

Page 3

Table 1A. Outlet (Control) Pressure Ranges, 2-inch (DN 50) Body

Types 66, 66Z, and 66ZZ

CONSTRUCTION

Type 66

OUTLET (CONTROL)

PRESSURE RANGE

Inches w.c. Unless

Otherwise

Designated

(1)

4 to 11

(1)

8 to 28

2 to 5

4 to 8

7 to 12

10 to 17

14 to 28

0.75 to 1.5 psig

1 to 2 psig

1.5 to 3 psig

3 to 5 psig

mbar

(1)

10 to 27

(1)

20 to 70

5 to 12

10 to 20

17 to 30

25 to 42

35 to 70

0,05 to 0,10 bar

0,07 to 0,14 bar

0,10 to 0,21 bar

0,21 to 0,34 bar

Part Number Color Code

0B019727052

1E611427022

1D892527022

1D892627022

1D892727012

1D892827032

1D892927032

1D765727032

1D765827032

1D962627032

1N506427142

(2)

(2)

(2)

(3)

CONTROL SPRING INFORMATION

2-inch (DN 50) Body

Free Length,

Inches (mm)

Purple

None

Brown

Red

Black

Orange stripe

Unpainted

6.00 (152)

6.00 (152)

6.12 (155)

7.53 (191)

7.88 (200)

7.75 (197)

7.53 (191)

6.09 (155)

Unpainted

6.00 (152)

6.25 (159)

6.31 (160)

Type 66Z -1 to 2 -2 to 5 1D892527022 Brown 6.12 (155) 0.109 (2,77)

Type 66ZZ -0.25 to 0.25 -0,62 to 0,62 1E991427012

66 Series

vacuum regulators

or breakers

1. 1 psig (0,07 bar) minimum differential pressure required with this range.

2. Heavy head construction required.

3. Extra heavy head construction required.

0 to -2

-0.2 to -0.8

-2 to -6

0 to -5

-0,74 to -2

-5 to -15

1J196527012

1H387327012

1N152427012

Unpainted

5.62 (143) 0.085 (2,16)

5.62 (143)

5.62 (143)

5.62 (143)

Table 1B. Outlet (Control) Pressure Ranges, 3-inch (DN 80) Body

Wire Diameter,

Inches (mm)

0.148 (3,76)

0.200 (5,08)

0.109 (2,77)

0.112 (2,85)

0.130 (3,30)

0.148 (3,76)

0.162 (4,12)

0.207 (5,26)

0.225 (5,72)

0.262 (6,66)

0.283 (7,19)

0.102 (2,59)

0.095 (2,41)

0.112 (2,85)

OUTLET (CONTROL)

PRESSURE RANGE

CONSTRUCTION

Type 66

Inches w.c. Unless

Otherwise

Designated

(1)

4 to 11

(1)

8 to 28

2 to 5

4 to 8

7 to 12

10 to 17

14 to 28

0.75 to 1.5 psig

1 to 2 psig

1.5 to 3 psig

3 to 5 psig

mbar

(1)

10 to 27

(1)

20 to 70

5 to 12

10 to 20

17 to 30

25 to 42

35 to 70

0,05 to 0,10 bar

0,07 to 0,14 bar

0,10 to 0,21 bar

0,21 to 0,34 bar

Part Number Color Code

1D479927032

1D527327022

1D893027022

1D893127012

1D892827032

1D893227032

1D893327032

1D765827032

1D962627032

1E204427032

1N506527142

(2)

(2)

(2)

(3)

Type 66Z -1 to 2 -2 to 5 1D893027022 6.12 (155) 0.112 (2,85)

CONTROL SPRING INFORMATION

3-inch (DN 80) Body

Free Length,

Inches (mm)

6.00 (152)

Unpainted

6.00 (152)

6.12 (155)

7.12 (181)

Orange Stripes

Gray with White Stripe

Green

7.75 (197)

7.50 (191)

7.25 (184)

6.00 (152)

6.25 (159)

6.38 (162)

6.38 (162)

Unpainted

Wire Diameter,

Inches (mm)

Type 66ZZ -0.25 to 0.25 -0,62 to 0,62 1E991527012 8.62 (219) 0.100 (2,54)

66 Series

vacuum regulators

or breakers

1. 1 psig (0,07 bar) minimum differential pressure required with this range.

2. Heavy head construction required.

3. Extra heavy head construction required.

0 to -2

-2 to -6

0 to -5

-5 to -15

1J196627012

1K384427012

5.62 (143)

5.62 (143)

0.162 (4,12)

0.207 (5,26)

0.112 (2,85)

0.125 (3,18)

0.148 (3,76)

0.156 (3,96)

0.182 (4,62)

0.225 (5,72)

0.262 (6,66)

0.306 (7,77)

0.362 (9,20)

0.114 (2,90)

0.120 (3,05)

3

Page 4

Types 66, 66Z, and 66ZZ

Table 1C. Outlet (Control) Pressure Ranges, 4-inch (DN 100) Body

CONSTRUCTION

Type 66

OUTLET (CONTROL)

PRESSURE RANGE

Inches w.c. Unless

Otherwise

Designated

(1)

4 to 11

(1)

8 to 28

2 to 5

4 to 8

7 to 12

10 to 17

14 to 28

0.75 to 1.5 psig

1 to 2 psig

1.5 to 3 psig

3 to 5 psig

mbar

(1)

10 to 27

(1)

20 to 70

5 to 12

10 to 20

17 to 30

25 to 42

35 to 70

0,05 to 0,10 bar

0,07 to 0,14 bar

0,10 to 0,21 bar

0,21 to 0,34 bar

Part Number Color Code

1D527527022

1D527627032

1D892627022

1D893427022

1D893227032

1D893527032

1D893627032

1D771227032

1D771327032

1E204527032

(2)

(2)

(3)

- - - -

CONTROL SPRING INFORMATION

4-inch (DN 100) Body

Free Length,

Inches (mm)

7.75 (197)

Unpainted

7.75 (197)

7.53 (191)

7.75 (197)

Gray

Unpainted

Unpainted

Unpainted

Unpainted

Unpainted

- - - -

7.50 (191)

7.75 (197)

7.81 (198)

7.75 (197)

7.75 (197)

7.53 (191)

- - - -

Type 66Z -1 to 2 -2 to 5 1D892627022 Red 7.53 (191) 0.112 (2,85)

Type 66ZZ -0.25 to 0.25 -0,62 to 0,62 1E937227012

66 Series

vacuum

regulators

or breakers

1. 1 psig (0,07 bar) minimum differential pressure required with this range.

2. Heavy head construction required.

3. Extra heavy head construction required.

0 to -2

-0.2 to -0.8

-2 to -6

0 to 1.5

0 to -5

-0,74 to -2

-5 to -15

0 to 4

1J196727012

1E937227012

1K418127012

1J823827012

Unpainted

11.06 (281) 0.112 (2,85)

11.06 (281)

11.06 (281)

11.50 (292)

11.56 (294)

Table 2. Flow Coefcients

Wire Diameter,

Inches (mm)

0.170 (4,32)

0.225 (5,72)

0.112 (2,85)

0.135 (3,43)

0.156 (3,96)

0.170 (4,32)

0.207 (5,26)

0.262 (6,66)

0.283 (7,19)

0.331 (8,41)

- - - -

0.154 (3,91)

0.112 (2,85)

0.162 (4,12)

0.135 (3,43)

OUTLET

PRESSURE

RANGE,

PSIG (bar)

0.75 to 1.5

(0,05 to 0,10)

1 to 2

(0,07 to 0,14)

1.5 to 3

(0,10 to 0,21)

3 to 5

(0,21 to 0,34)

DROOP,

PSIG (bar)

0.2 (0,01)

0.3 (0,02)

0.3 (0,02)

0.4 (0,03)

0.4 (0,03)

0.6 (0,04)

0.6 (0,04)

0.8 (0,06)

1.0 (0,07)

REGULATING C

2-inch

(DN 50)

765

1150

825

1100

665

1000

540

720

900

3-inch

(DN 80)

Table 3. IEC Sizing Coefcients

BODY SIZE, INCH (DN) X

2 (50)

4 (100) 0.30

1865

2800

1650

2200

1165

1750

725

970

1210

g

4-inch

(DN 100)

2-inch

(DN 50)

3330

5000

3150

4200

2500

37501928.6

- - - -

T

0.775

REGULATING C

3-inch

(DN 80)

21.9

53.38095.1

32.9

23.6

31.4

47.1

62.990120

33.35071.4

15.4

20.6

25.7

20.7

27.7

34.6

v

4-inch

(DN 100)

143

107

- - - -

WIDE-OPEN C

2-inch

(DN 50)

3-inch

(DN 80)

g

4-inch

(DN 100)

WIDE-OPEN C

2-inch

(DN 50)

3-inch

(DN 80)

v

4-inch

(DN 100)

1260 3400 5250 36 97.1 150 35

F

D

F

L

0.35

0.893 (80) 0.34

C

1

4

Page 5

Types 66, 66Z, and 66ZZ

REMOTE VENT

SWAGE NIPPLE

AD6808

A2495-1

BYPASS

LINE

VENT

BLOCK

VALVE OR

PLUG COCK

12 DIAMETER OF REGULATOR

SIZE PIPE BEFORE SWAGE

BLOCK VALVES OR

PLUG COCKS

Figure 2. Type 66 Regulator in Pressure-Reducing Application

When decreased downstream demand raises the

outlet pressure, the higher pressure under the

main diaphragm opposes the regulator main spring

causing the valve plug and stem assembly to close

the regulator seat ring and to supply less gas to the

downstream system.

The Types 66Z and 66ZZ regulators are identical

to the Type 66 regulator in operation but different

in construction. The Type 66Z regulator (Figure 8)

has a counter spring under the valve plug and disk

assembly which counters the main spring force to

allow settings below atmospheric pressures. The

Type 66ZZ regulator (Figure 9) has a longer spring

case where the main spring, a low rate tension spring,

is stretched between the adjusting screw and the

valve plug stem, also providing below atmospheric

settings and more sensitive pressure regulation than

the Types 66 and 66Z regulators.

Installation

WARNING

!

Exposure of the regulator to physical

damage and to corrosive material can

cause improper operation or release of

pressure. Either condition may result

in equipment damage or personal

injury. Properly install the regulator in

a safe location.

CAUTION

AIR CONTROL VALVE

FAN

OPTIONAL PRESSURELOADING LINE

BLOCK

VALVE

MIXER

GAS

15A9913-A

A2496-1

BLOCK

VALVE

Figure 3. Type 66Z Regulator in Gas-Mixing Application

VACUUM REGULATOR SET TO OPEN

AT 1.0-INCH W.C. (2,50 mbar) VACUUM

TYPE 66ZZ REGULATOR SET TO OPEN

AT 0.25-INCH W.C. (0,62 mbar) VACUUM

CONTROL LINES

FILTERS

0 TO 5 PSIG

(0 to 0,34 bar)

AIR OR INERT

GAS SUPPLY

PRESSURE

BJ9005-B

A2494-2

GLOVE

PORT

HOOD PRESSURE TO BE KEPT AT

0.23-INCH W.C. (0,57 mbar) VACUUM

GLOVE

PORT

Figure 4. Type 66ZZ Regulator Installation in Hood

Control System

Regulator operation within Specications

limits and applicable codes does not

eliminate the possibility of damage from

external sources or from debris in the line.

The regulator should be inspected for

damage regularly and after any condition

exceeding Specications limits.

Complete downstream protection is

needed with a Type 66, 66Z, or 66ZZ

regulator if the actual inlet pressure can

exceed the regulator outlet pressure rating

or the pressure ratings of any downstream

equipment. Provide adequate

overpressure protection for the regulator

and any downstream equipment.

FURNACE

TO EXHAUST

HEADER AT

9-INCHES W.C.

(22 mbar)

VACUUM

Use of this regulator where service

conditions can exceed Specications

limits may cause equipment damage

or injury to personnel. Be sure the

regulator service conditions do not

exceed Specications limits.

Make sure that there is no damage to or foreign

material in the regulator and that all tubing and piping

is clean and unobstructed. Install the regulator so

that ow through it matches the arrow marked on

the regulator body. Some typical 66 Series regulator

installations are shown in Figures 2, 3, and 4.

5

Page 6

Types 66, 66Z, and 66ZZ

VALVE STEM

CONTROL SPRING

DIAPHRAGM

VALVE SKIRT

A6550

INLET PRESSURE

OUTLET PRESSURE

ATMOSPHERIC PRESSURE

Figure 5. Standard Steel Body Operational Schematic

Install the Types 66, 66Z, and 66ZZ regulators

horizontally with the spring case vertically above the

valve body. Other orientations change the regulator

set point and controlled pressure range due to the

weight of the internal parts.

If threaded connections are used, apply a good grade

of pipe compound to only the male pipeline threads.

If anged connections are used, use good bolting

practices and suitable gaskets.

If continuous operation of the system is required

during inspection and maintenance, install a threevalve bypass around the regulator. If an upstream

strainer is not provided for the entire unit, an optional

lter may be installed on the optional external control

line to help protect the pressure sensing parts.

EXTERNAL

CONTROL LINE

SEAT RING

WARNING

!

The Type 66, 66Z, or 66ZZ regulator

upper diaphragm casing vent must

remain clear and unobstructed. A

clogged vent may cause equipment

damage or personal injury due to

improper regulator functioning. Install

and maintain the regulator so that

dust, insects, and weather conditions

do not clog or obstruct the vent.

The vented gas must not be allowed

to accumulate where it can cause

a hazardous condition. In pit,

underground, or indoor installations,

6

Page 7

Types 66, 66Z, and 66ZZ

vented gas can become an explosion,

re, or toxic hazard. Provide piping

to remotely vent the gas to a safe

area away from buildings, air intakes,

or any hazardous location. The line

or stack opening must be protected

against condensation, freezing, or any

clogging substance.

If a remote vent is needed, remove the upper

diaphragm casing vent and connect 3/4-inch threaded

NPT piping to the upper diaphragm casing. The piping

should be as short as possible, have as few bends

as possible, must vent the gas to a safe location, and

should have a screened vent on the exhaust end.

With steel bodies, an external control line is required.

Connect 3/4-inch threaded NPT control line to the lower

diaphragm casing connection from the point where the

downstream pressure is to be sensed. A needle valve

should be installed in the control line for isolating the

regulator and for damping out control line pulses.

The regulator set pressure is adjusted at the factory

for the reduced pressure specied on the order. If

no pressure is specied, the regulator is set for a

pressure approximately in the middle of the main

spring pressure range. Check the spring setting to

make sure it is correct for the application.

checking outlet pressure setting. Remove the

closing cap (key 27, Figures 6, 7, 8, and 9) and turn

the adjusting screw (key 25, Figures 6, 7, 8, and 9)

clockwise, or toward, the spring case to increase the

downstream reduced pressure. Turn the adjusting

screw counterclockwise, or away from, the spring

case to decrease the downstream reduced pressure.

For vacuum service, turning the adjusting screw

toward the spring case decreases the vacuum

downstream. Turning the adjusting screw away from

the spring case increases the vacuum downstream.

Shutdown

To remove the Type 66, 66Z, or 66ZZ regulator from

positive pressure service, rst close the upstream and

then the downstream block valve. Close the needle

valve in the external control line, if one is used, and

vent the regulator body and lower diaphragm casing to

release any trapped pressure.

To remove the Types 66Z and 66ZZ regulators from

negative pressure service, close the upstream and

downstream block valves. If a control line is used,

close the control line needle valve. Vent the regulator

body and lower diaphragm casing.

Maintenance

Startup

CAUTION

If the regulator is in a system already

pressurized (either positive or negative

pressure), use care when placing

the Type 66, 66Z, or 66ZZ regulator

in service. Use pressure gauges to

monitor upstream, control line, if one is

used, and downstream pressure. If the

limits in Specications are exceeded

during start-up, damage to the regulator

may result.

With proper installation completed and downstream

equipment properly adjusted, slowly open the

upstream and downstream block valves while using

pressure gauges to monitor pressure. Regulator outlet

pressure may be monitored on a gauge installed at

some point downstream from the regulator.

If outlet pressure adjustment is necessary for

Types 66, 66Z, 66ZZ regulators, monitor the outlet

pressure with a gauge during adjustment. Make

sure there is ow through the regulator when

Regulator parts are subject to normal wear and must

be inspected and replaced as necessary. Inspection

and maintenance frequency depends upon the

severity of service conditions.

WARNING

!

To avoid personal injury or equipment

damage from the sudden release of

pressure, isolate the reducing regulator

from the pressure system and release

all pressure from the regulator before

performing maintenance operations.

Maintenance steps are in two general sections.

Replacing the Valve Plug O-Ring or the Metal-Seated

Valve Plug is the rst section. Replacing the Main

Spring, the Main and Balancing Diaphragms, and

the Seat Ring is the second section. Complete the

necessary maintenance steps in the appropriate

section, inspecting and replacing parts as required.

These maintenance procedures refer to all three

regulator types unless otherwise indicated.

All key numbers refer to Figures 6, 7, 8, and 9 unless

otherwise indicated.

7

Page 8

Types 66, 66Z, and 66ZZ

Replacing Plug O-Ring or Metal Seated

Valve Plug

1. Remove hex screws (key 20) from the bottom

ange (key 7).

2. Remove the bottom ange and bottom ange

gasket (key 19). With the Type 66Z regulator, the

counter spring (key 38) will fall out when the

bottom ange is removed.

3. Remove the pipe plug from the side of the valve

body. To keep the valve stem (key 13) from

rotating, insert a 5/16-inch (7,94 mm) or smaller

rod into the pipe plug hole and through the hole

in the valve stem.

4. For all regulators with a valve plug O-ring,

remove the stop nut (key 23), the disk retainer

(key 9), the plug skirt (key 10), the sealing washer

(key 37), and the plug O-ring (key 8). For the

Type 66Z regulator, also remove the lower spring

seat (key 17).

For a Type 66 metal-seated regulator, remove

the stop nut (key 23) and the plug skirt (key 10).

5. For all regulators with a valve plug O-ring,

place the sealing washer, the plug skirt, the

O-ring, and the disk retainer on the plug stem in

the order shown in Figures 6, 7, 8 and 9. For the

Type 66Z regulator, also place the counter spring

seat on the plug stem.

For a Type 66 metal-seated regulator, place the

plug skirt (key 10) on the plug stem (key 13).

6. Secure the stop nut (key 23) to the plug stem.

7. For the Type 66Z regulator, place the counter

spring (key 38) against the lower spring seat

(key 17).

Remove all compression in the spring (key 6) by

turning the adjusting screw (key 25) out of the

spring case.

For the Types 66 and 66Z regulators, remove

the adjusting screw (key 25), the upper spring

seat (key 24), and the spring (key 6).

For the Type 66ZZ regulator (Figure 9), tip the

adjusting screw (key 25) to one side so that it can

be grasped and pull it, the spring retainer (key 43),

and the ten ball bearings (key 54) out of the

spring case. Unhook the spring (key 6) and

leave the spring retainer (key 43) and the ten ball

bearings (key 54) in the adjusting screw (key 25).

Note

If a spring change is the only

maintenance required for the Type 66

or 66Z regulator, proceed to steps 16

through 19 in the Assembly section. For

further disassembly, proceed to step 2.

2. Unscrew the diaphragm casing hex nuts (key 22)

and remove the cap screws (key 21).

3. If a special spring case orientation is required

for remote venting, mark the side of the

diaphragm casing anges to aid in assembly.

Remove the upper diaphragm casing (key 2).

For the Type 66ZZ regulator, unhook the spring

(key 6) from the plug stem (key 13).

Note

If the spring change is the only

maintenance required for the Type 66ZZ

regulator, proceed to steps 16 through

19 in the Assembly section. For further

disassembly, proceed to step 4.

8. Install the bottom ange gasket (key 19) and the

bottom ange (key 7) on the valve body. Secure

the ange with the cap screws (key 20).

9. Remove the 5/16-inch (7,94 mm) or smaller rod

rod and replace the pipe plug (key 31) in the

valve body.

Replacing Main Spring, Main and

Balancing Diaphragms, and Seat Ring

Disassembly

1. For all regulators, remove the closing cap

(key 27) and closing cap gasket (key 26).

8

4. Remove the valve body pipe plug from the side of

the body. To keep the valve plug from twisting,

insert a 5/16-inch (7,94 mm) or smaller rod

through the pipe plug hole and the hold in the

plug stem (key 13).

5. Remove the upper stop nut (key 23), washer

(key 36, except for the Type 66ZZ regulator),

the lower spring seat (key 17, except for the

Type 66ZZ regulator), and the upper diaphragm

plate (key 4).

6. Remove and inspect the main diaphragm (key 5).

If no further maintenance is needed, refer to

steps 13 through 19 in the Assembly section for

Page 9

Types 66, 66Z, and 66ZZ

instructions. Continue to step 7 if further

disassembly is required.

7. Remove the lower diaphragm plate (key 4), the

top stem gasket (key 18), the diaphragm spacer

(key 16), the middle stem gasket (key 18), and

the upper balancing diaphragm plate (key 15).

8. To aid in assembly, record the position of the

lower diaphragm casing with respect to the valve

body. Unscrew and remove the cap screws

(key 20) and washers (key 34) that hold the lower

diaphragm casing to the valve body (key 1).

Remove the lower diaphragm casing (key 3).

9. Remove and inspect the balancing diaphragm

(key 14) and the gasket (key 35).

If no further maintenance is required, proceed

to steps 5 through 19 in the Assembly section.

For further disassembly, proceed with step 10.

10. Remove the lower balancing diaphragm plate

(key 15) and the lower stem gasket (key 18).

11. Remove the 5/16-inch (7,94 mm) or smaller rod

from the valve body pipe plug hole so that the

valve plug and stem assembly can be moved.

Slide a seat ring puller, T-wrench, or other

suitable tool over the valve plug stem. Engage

the tool with the seat ring lugs. If a suitable

tool will not t over the valve plug stem, remove

the valve body bottom ange (key 7) using

steps 1 and 2 of the Replacing Plug O-Ring

or Metal Seated Valve Plug section and remove

the valve plug and stem assembly. Unscrew

the seat ring (key 11).

Assembly

1. Apply a good grade of piping compound to the

seat ring (key 11) threads. Thread in the seat ring

using the seat ring puller or a similar device. Wipe

off any excess piping compound.

2. If the valve plug and stem assembly was not

removed, proceed to step 3.

If the valve plug and stem assembly was

removed, place the assembly in the valve body

and insert the 5/16-inch (7,94 mm) or smaller

rod through the pipe plug and valve stem holes.

Use steps 5 through 7 of the Replacing Plug

O-Ring or Metal Seated Valve Plug section to

secure the bottom ange (key 7).

3. Place the lower stem gasket (key 18) on the

valve plug stem (key 13).

4. Place one balancing diaphragm plate (key 15) on

the valve plug stem (key 13) with “cupped” side

facing the valve plug.

5. Align the gasket (key 35) holes with the valve body

pitot tube and cap screw holes and place the

gasket on the valve body.

6. Align the balancing diaphragm (key 14), pitot tube

(key 12), and cap screw holes with the holes in the

valve body and place the balancing diaphragm on

top of the gasket (key 35).

7. Align the lower diaphragm casing (key 3) using the

position recorded in the Disassembly section

step 8 so that the pitot tube (key 12) will be open.

Secure the casing (key 3) with the washers

(key 34) and cap screws (key 20), tightening

the cap screws using an even, crisscross pattern.

8. Place the balancing diaphragm plate (key 15) on

the balancing diaphragm so that the “cupped” side

of the plate faces the main diaphragm (key 5).

9. Place the middle stem gasket (key 18) on top of

the balancing diaphragm plate.

10. Slide the diaphragm spacer (key 16) onto the

valve plug stem.

11. Place the upper stem gasket (key 18) on the

valve plug stem.

12. Position a diaphragm plate (key 4) so that its

“cupped” side faces the balancing diaphragm.

13. Align the main diaphragm cap screw holes with

the diaphragm casing cap screw holes and place

the diaphragm (key 5) on the diaphragm plate

(key 4).

14. Place another diaphragm plate (key 4) on the main

diaphragm (key 5) so that the plate “cupped” side

faces the main spring (key 6).

15. For the Types 66 and 66Z regulators, place

the lower spring seat (key 17) and the washer

(key 36) on the valve plug stem. Secure these

parts with the stop nut (key 23).

For the Type 66ZZ regulator, screw on a stop nut

(key 23) to secure the diaphragm plates (key 4).

9

Page 10

Types 66, 66Z, and 66ZZ

16. For the Types 66 and 66Z regulators, align

the upper diaphragm casing (key 2) using the

marks made in the Disassembly section step 3.

Place the upper diaphragm casing (key 2) on

the diaphragm, fasten the cap screws and hex

nuts (keys 21 and 22), tightening the cap

screws using an even, crisscross pattern and

put the spring (key 6) on the spring seat in the

spring case.

For the Type 66ZZ regulator, hook the spring

(key 6) to the valve stem (key 13). Align the

upper diaphragm casing (key 2) using the marks

made in the Disassembly section step 3, put

the spring (key 6) in the spring case while placing

the upper diaphragm casing (key 2) on the

diaphragm. Fasten the cap screws and hex nuts

(keys 21 and 22) together tightening them using

an even, crisscross pattern.

17. For the Types 66 and 66Z regulators, place the

upper spring seat (key 24) on the spring (key 6).

For the Type 66ZZ regulator, apply an

appropriate lubricant to the ball bearings, pull

the spring out of the spring case using a stiff wire

hook or similar tool. Holding the adjusting screw

(key 25), spring retainer (key 43), and ten ball

bearings (key 54) together, hook the spring

(key 6) into the spring retainer (key 43).

18. Thread the adjusting screw (key 25) into the

spring case. Apply a good grade of piping

compound to the adjusting screw threads,

remove the rod and thread the pipe plug (key 31)

into the body, and adjust the regulator following

the steps in the Start-Up section.

19. Thread the closing cap (key 27) onto the

spring case.

Parts Ordering

Parts List

Key Description Part Number

Note

In this parts list, parts marked NACE are

intended for corrosion-resistant service

as detailed in the NACE International

standards MR0175/ISO 15156

and/or MR0103.

Parts Kits

Included are keys 5, 8, 14, 18, 19, 26, and 35

2-inch (DN 50) body R66X0000022

3-inch (DN 80) body R66X0000032

4-inch (DN 100) body R66X0000042

1 Valve Body

2-inch (DN 50) body

NPT connection

Cast iron 2D474119012

Steel 2K928522012

NACE, Steel 2K9285X0012

CL125 FF anged

Cast iron 3E713919012

CL150 RF anged

Steel 2J838322012

NACE, Steel 2J8383X0042

CL150 FF anged

Steel 24A4617X012

NACE, Steel 24A4617X022

CL300 RF anged

Steel 2K655122012

3-inch (DN 80) body

CL125 FF anged

Cast iron 3D474319012

CL150 RF anged

Steel 2L291322012

NACE, Steel 2L2913X0062

4-inch (DN 100) body

CL125 FF anged

Cast iron 2D474519012

CL150 RF, anged

Steel 2L291422012

NACE, Steel 2L2914X0032

2 Upper Diaphragm Casing (standard and NACE)

2-inch (DN 50) body 1D4792000A2

3-inch (DN 80) body 1D5391000A2

4-inch (DN 100) body 1D5395000A2

The Types 66, 66Z, and 66ZZ regulators have a serial

number stamped on a nameplate attached to the upper

diaphragm casing. When corresponding with your local

Sales Ofce, always refer to this serial number of each

needed part as found in the following parts list.

10

3 Lower Diaphragm Casing

Standard

2-inch (DN 50) body 3D478728992

3-inch (DN 80) body 3D478928992

4-inch (DN 100) body 3D479128992

With external control line

2-inch (DN 50) body 1F4421000A2

2-inch (DN 50) body (NACE) 1F4421X0022

3-inch (DN 80) body 1F4419000A2

3-inch (DN 80) body (NACE) 1F4419X0022

4-inch (DN 100) body 1F1319000A2

4-inch (DN 100) body (NACE) 1F1319X0012

Page 11

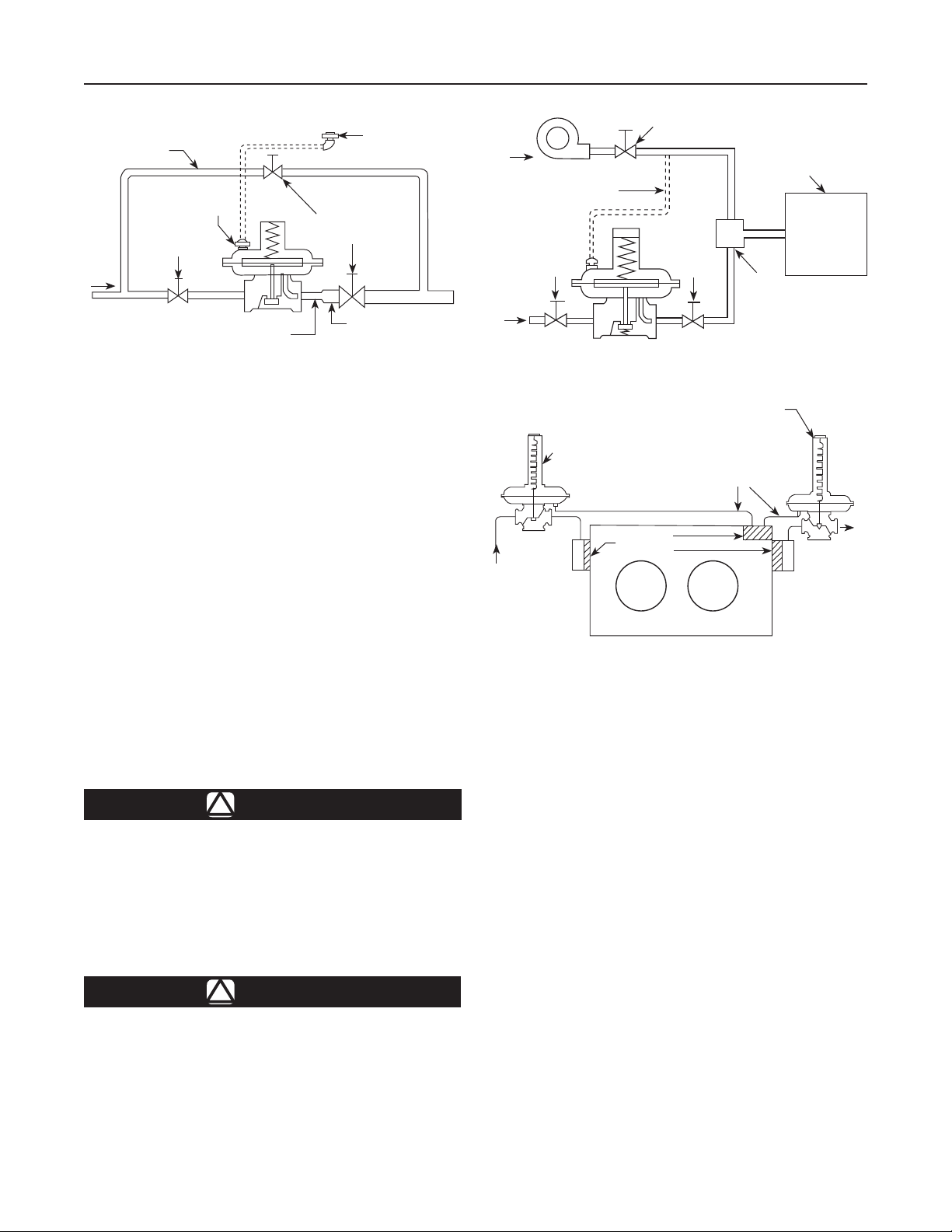

Types 66, 66Z, and 66ZZ

31

APPLY LUB

NOT SHOWN

CJ8392-F

CK4805-D

A2502-1

13

30

29

28

21

3

11

OPTIONAL

METAL SEAT

34

14

35

15

11

10

7

69

37

23

8

68

27

26

25

33

2

17

36

20

23

37

4

5

32

22

16

51

18

13

9

1

19

29

28

Figure 6. Soft-Seated Type 66 Regulator

(with external control line)

69

68

6

27

26

25

66

DETAIL A

SCALE 2:1

30

3321736

21

A

3

5

4

1435

15

13

32

22

16

34

18

1

12

9

31

APPLY LUB

NOT SHOWN

CD5300

10

11 8 37 23 20 7

Figure 7. Type 66 Regulator Assembly (with pitot tube)

19

11

Page 12

Types 66, 66Z, and 66ZZ

69

68

36

2

18

31

APPLY LUB

NOT SHOWN

29

28

30A4436-D

A2501-1

30

3

14

35

15

13

8

19

7

27

26

25

6

17

4

16

32

33

21

22

34

10

11

12

37

9

23

38

1

20

5

30A6347-D

33

32

20

Figure 8. Type 66Z Regulator

69

68

26

25

53

52

34

4

16 13

18

3

21

22

1

10

37

9

19

Figure 9. Type 66ZZ Regulator

5 2

27

57

54

43

6

30

15

14

35

12

11

8

23

7

12

Page 13

Types 66, 66Z, and 66ZZ

Key Description Part Number

4 Diaphragm Plate, Plated steel (2 required)

2-inch (DN 50) body 1D255625072

3-inch (DN 80) body 1D477328992

4-inch (DN 100) body 1D477425062

5* Diaphragm

Nitrile (NBR)/Nylon (PA)

2-inch (DN 50) body 1D477002072

3-inch (DN 80) body 1D477102072

4-inch (DN 100) body 1D477202072

Fluorocarbon (FKM)

2-inch (DN 50) body 1D477002332

3-inch (DN 80) body 1D477102332

4-inch (DN 100) body 1D477202332

6 Spring See Tables 1A to 1C

7 Bottom Flange, Zinc plated steel

Standard

2-inch (DN 50) body 1D477825062

3-inch (DN 80) body

Type 66 17A9250X012

Types 66Z and 66ZZ 17A9250X012

4-inch (DN 100) body 1D478025062

Type 66 with external control line and

adjustable travel stops

2-inch (DN 50) body 1N9449000A2

4-inch (DN 100) body 1V1716X0012

8* O-Ring

Nitrile (NBR)

2-inch (DN 50) body 1D785306992

3-inch (DN 80) body 1D785406992

4-inch (DN 100) body 1D785506992

4-inch (DN 100) body (NACE) 1D785506992

Fluorocarbon (FKM)

2-inch (DN 50) body 1N115606382

3-inch (DN 80) body 1N115706382

4-inch (DN 100) body 1D2658X0022

9 Disk Retainer

Brass

2-inch (DN 50) body 1D475814012

3-inch (DN 80) body 1D475914012

4-inch (DN 100) body 1D476014012

Stainless steel (also NACE)

2-inch (DN 50) body 1D475835072

3-inch (DN 80) body 1D475935072

4-inch (DN 100) body 1D476035072

10 Valve Plug Skirt

With soft seats

Brass

2-inch (DN 50) body 1D476112012

3-inch (DN 80) body 1D476212012

4-inch (DN 100) body 1D476312012

Stainless steel (also NACE)

2-inch (DN 50) body 1D476133092

3-inch (DN 80) body 1D476233092

4-inch (DN 100) body 1D476333092

Metal-to-Metal Seats

Brass

2-inch (DN 50) body 1E322712012

3-inch (DN 80) body 1E121512012

4-inch (DN 100) body 1J423612012

Stainless steel

2-inch (DN 50) body 1D783012022

3-inch (DN 80) body 1D783112022

4-inch (DN 100) body 1D783212022

Key Description Part Number

11 Seat Ring

Standard

Brass

2-inch (DN 50) body 1D783012022

3-inch (DN 80) body 1D783112022

4-inch (DN 100) body 1D783212022

Stainless steel (also NACE)

2-inch (DN 50) body 1D783033092

3-inch (DN 80) body 1D783133092

4-inch (DN 100) body 1D783233092

Metal-to-Metal Seats

Brass

2-inch (DN 50) body 1E323512022

3-inch (DN 80) body 1E121412022

4-inch (DN 100) body 1J423812022

Stainless steel

2-inch (DN 50) body 1E323533092

3-inch (DN 80) body 1E121433092

4-inch (DN 100) body 1J423833092

12 Pitot Tube

2-inch (DN 50) body

With NPT connection and

brass trim, Copper 1D475117012

With NPT connection and stainless

steel trim, 304 Stainless steel 1D475138072

With anged connection and

brass trim, Copper 1E737917012

With anged connection and stainless

steel trim, 304 Stainless steel 1E737938072

3-inch (DN 80) body

With brass trim,

Copper 1D475217012

With stainless steel trim,

304 Stainless steel 1D475238072

4-inch (DN 100) body

With brass trim,

Copper 1D475317012

With stainless steel trim,

304 Stainless steel 1D475338072

13 Valve Plug Stem

For Types 66 and 66Z standard and with

external control line

2-inch (DN 50) body

Brass 1D475414012

Stainless steel (also NACE) 1D475435072

3-inch (DN 80) body

Cast iron bodies only

Brass 1D475514012

Stainless steel 1D475535072

3-inch (DN 80) body,

Steel bodies only

Brass 1N445614012

Stainless steel (also NACE) 1N445635072

4-inch (DN 100) body

Brass 1D475614012

Stainless steel (also NACE) 1D475635072

For Type 66 with metal-to-metal seating

2-inch (DN 50) body

Brass 1E322814012

Stainless steel 1E322835072

3-inch (DN 80) body

Brass 1E121314012

Stainless steel 1E121335072

4-inch (DN 100) body

Brass 1J423714012

Stainless steel 1J423735072

*Recommended Spare Parts

13

Page 14

Types 66, 66Z, and 66ZZ

Key Description Part Number

13 Valve Plug Stem (continued)

For Type 66ZZ

2-inch (DN 50) body

Brass 1E991614012

3-inch (DN 80) body

Brass 1E991714012

4-inch (DN 100) body

Brass 1E868914012

14* Balancing Diaphragm

Types 66 and 66Z

Nitrile (NBR)

2-inch (DN 50) body 1D476702042

3-inch (DN 80) body 1D476802042

4-inch (DN 100) body 1D476902042

Fluorocarbon (FKM)

2-inch (DN 50) body 1H7370X0012

3-inch (DN 80) body 1J1981X0012

4-inch (DN 100) body 1H7275X0012

Type 66ZZ

Nitrile (NBR)

2-inch (DN 50) body 1D476702042

3-inch (DN 80) body 1D476802042

4-inch (DN 100) body 1D476902042

15 Sealing Diaphragm Plate,

Zinc-plated steel (2 required)

Types 66 and 66Z

2-inch (DN 50) body 1D475725062

2-inch (DN 50) body (NACE) 1D4757X0022

3-inch (DN 80) body 1D479325062

3-inch (DN 80) body (NACE) 1D479325062

4-inch (DN 100) body 1D479425062

4-inch (DN 100) body (NACE) 1D4794X0012

Type 66ZZ

2-inch (DN 50) body 1D475725062

3-inch (DN 80) body 1D479325062

4-inch (DN 100) body 1D479425062

16 Diaphragm Spacer

Zinc-plated steel

2 and 3-inch (DN 50 and 80) bodies 1D477626092

4-inch (DN 100) body 1D477726092

17 Lower Spring Seat, Types 66 and 66Z only

Aluminum 0X014744012

18* Stem Gasket, (3 required) Composition

2 and 3-inch (DN 50 and 80) bodies 1D255304022

4-inch (DN 100) body 1D478404022

19* Bottom Flange Gasket, Composition

2-inch (DN 50) body 1D476404022

3-inch (DN 80) body 1D476504022

4-inch (DN 100) body 1D476604022

20 Cap Screw, Zinc-plated steel

2-inch (DN 50) Cast iron

body (12 required) 1C631224052

2-inch (DN 50) Steel

body (12 required) 1C275224052

2-inch (DN 50) Steel

body (NACE 12 required) 1C2752X0032

3-inch (DN 80)

body (16 required) 1D529824052

3-inch (DN 80)

body (NACE 16 required) 1D5298X0012

Key Description Part Number

20 Cap Screw, Zinc-plated steel (continued)

4-inch (DN 100)

body (16 required) 1D530824052

4-inch (DN 100)

body (NACE 16 required) 1D5308X0022

21 Cap Screw, Zinc-plated steel

2-inch (DN 50)

body (16 required) 1D529624052

3-inch (DN 80)

body (20 required) 1D529624052

4-inch (DN 100)

body (24 required) 1D529624052

22 Hex Nut, Plated steel

2-inch (DN 50)

body (16 required) 1A309324122

3-inch (DN 80)

body (20 required) 1A309324122

4-inch (DN 100)

body (24 required) 1A309324122

23 Stop Nut (2 required)

Types 66 and 66Z

Brass

2 and 3-inch (DN 50 and 80) bodies 1D529718992

4-inch (DN 100) body 1D530918992

Stainless steel

2 and 3-inch (DN 50 and 80) bodies 1D5297X0022

2 and 3-inch (DN 50 and 80) bodies (NACE) 1D6496X0012

4-inch (DN 100) body 1D5309X0052

4-inch (DN 100) body (NACE) 1D5309X0042

Type 66ZZ

Brass

2 and 3-inch (DN 50 and 80) bodies 1D529718992

4-inch (DN 100) body 1D530918992

25 Adjusting Screw

For Types 66 and 66Z, Aluminum 1L928608012

For Type 66ZZ, Brass 1E869214012

26* Closing Cap Gasket

Neoprene (CR) 1N446206992

27 Closing Cap

For Type 66 with external control line

and adjustable travel stops 1N756414012

For all others, Zinc 1A589544022

28 Flapper Valve, Brass 1C901715072

29 Snap Ring, Bronze 1D178016012

30 Type Y602-10 Vent Assembly,

Stainless steel/Zinc 1D5295000A2

31 Pipe Plug, Steel (not shown) 1A369224492

34 Washer, Zinc-plated steel

2-inch (DN 50)

body (6 required) 1D793624152

3-inch (DN 80)

body (8 required) 1D716228982

4-inch (DN 100)

body (8 required) 1D716328982

*Recommended Spare Parts

14

Page 15

Types 66, 66Z, and 66ZZ

Key Description Part Number

35* Gasket, Neoprene (CR)

2-inch (DN 50) body 1D843604082

3-inch (DN 80) body 1D843704082

4-inch (DN 100) body 1D843804082

36 Washer, Types 66 and 66Z only

2 and 3-inch (DN 50 and 80)

Zinc-plated steel 1H723125072

37 Sealing Washer, Steel

2 and 3-inch (DN 50 and 80) bodies 1F990428982

4-inch (DN 100) body 1N720799012

38 Counter Spring, Type 66Z only

Zinc-plated steel

2-inch (DN 50) body 1D891527022

3-inch (DN 80) body 1D891627022

4-inch (DN 100) body 1D891727022

43 Spring Retainer, Type 66ZZ only

Brass 1E869414012

44 Set Screw, for Type 66 with external

control line and adjustable travel stops,

Steel (2 required) 1A279128982

45 Hex Nut, for Type 66 with external control

line and adjustable travel stops

Zinc-plated steel (2 required) 1A352424122

46 Adjusting Screw Cap, for Type 66 with

external control line and adjusting travel

stops, Brass (2 required) 1J944114012

Key Description Part Number

50 Lock Washer, for Type 66 with external

control line and adjusting travel stops,

Steel (2 required)

2-inch (DN 50) body 1A339828992

4-inch (DN 100) body 1A343628992

51 Plug

Types 66 and 66Z

Brass

2 and 3-inch (DN 50 and 80) bodies 1D781714012

4-inch (DN 100) body 1D782114012

Stainless steel

2 and 3-inch (DN 50 and 80) bodies 1D781735232

4-inch (DN 100) body 1D782135132

Type 66ZZ

Brass 1D781714012

52 Spring Case Coupling, Type 66ZZ only

Brass 1E869214012

53 Spring Case Extension, Type 66ZZ only

Steel

2-inch (DN 50) body 1E869026012

Cast iron

2-inch (DN 50) body 1E869026012

3-inch (DN 80) body 1N153126012

4-inch (DN 100) body 1E937326012

54 Ball, Type 66ZZ only (10 required)

Stainless steel 1B793546202

57 Retaining Ring, Type 66ZZ only

Steel 10A3074X012

47 Adjusting Cap Gasket, for Type 66 with

external control line and adjusting travel

stops, Composition (2 required) 1J944004022

48 Upper Travel Stop, for Type 66 with

external control line and adjusting travel

stops, Brass

2-inch (DN 50) body 1N930114012

4-inch (DN 100) body 1U965414012

49 Lower Travel Stop, for Type 66 with

external control line and adjusting travel

stops, Brass

2-inch (DN 50) body 1N930214012

4-inch (DN 100) body 1U965514012

*Recommended Spare Parts

66* Casing Gasket, Fluorocarbon (FKM)

2-inch (DN 50) body 1U6985X0012

3-inch (DN 80) body 1U6986X0012

4-inch (DN 100) body 1U6989X0012

68 Flow Arrow, 18-8 Stainless steel 1V105938982

69 Drive Screw, 18-8 Stainless steel (2 required) 1A368228982

70 Tag, NACE, Stainless steel 19A6034X012

71 Tag Wire, 304 Stainless steel 1U7581X0022

15

Page 16

Types 66, 66Z, and 66ZZ

Industrial Regulators

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Shanghai, China 201206

Tel: +86 21 2892 9000

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Middle East and Africa

Dubai, United Arab Emirates

Tel: +971 4811 8100

For further information visit www.emersonprocess.com/regulators

The Emerson logo is a trademark and service mark of Emerson Electric Co. All other marks are the property of their prospective owners. Fisher is a mark owned by Fisher Controls, Inc., a

business of Emerson Process Management.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed as warranties or

guarantees, express or implied, regarding the products or services described herein or their use or applicability. We reserve the right to modify or improve the designs or specications of such

products at any time without notice.

Emerson Process Management does not assume responsibility for the selection, use or maintenance of any product. Responsibility for proper selection, use and maintenance of any Emerson

Process Management product remains solely with the purchaser.

Natural Gas Technologies

Emerson Process Management

Regulator Technologies, Inc.

USA - Headquarters

McKinney, Texas 75069-1872 USA

Tel: 1-800-558-5853

Outside U.S. 1-972-548-3574

Asia-Pacic

Singapore, Singapore 128461

Tel: +65 6777 8211

Europe

Bologna, Italy 40013

Tel: +39 051 4190611

Gallardon, France 28320

Tel: +33 (0)2 37 33 47 00

TESCOM

Emerson Process Management

Tescom Corporation

USA - Headquarters

Elk River, Minnesota 55330-2445 USA

Tel: 1-763-241-3238

Europe

Selmsdorf, Germany 23923

Tel: +49 (0) 38823 31 0

©Emerson Process Management Regulator Technologies, Inc., 1952, 2008; All Rights Reserved

Loading...

Loading...