Page 1

Quick Installation Guide

Step 1: Mount the Transmitter

Step 2: Consider Housing Rotation

Step 3: Set Switches and Jumpers

Step 4: Connect Wiring and Power Up

Step 5: Verify Configuration

Step 6: Trim the Transmitter

Safety Instrumented Systems

Product Certifications

Start

End

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

Rosemount 3051S Series Pressure

Transmitter with HART® Protocol

Rosemount 3051SF Series Flowmeter

Transmitter with HART

© 2008 Rosemount Inc. All rights reserved. All marks property of owner. Rosemount and the

Rosemount logotype are registered trademarks of Rosemount Inc.

HART®

¢00825-0100-4801J¤

®

Protocol

www.rosemount.com

Page 2

Rosemount 3051S

IMPORTANT NOTICE

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount Inc.

8200 Market Boulevard

Chanhassen, MN USA 55317

T (US) (800) 999-9307

T (Intnl) (952) 906-8888

F (952) 949-7001

Emerson Process Management

Asia Pacific Private Limited

1 Pandan Crescent

Singapore 128461

T (65) 6777 8211

F (65) 6777 0947/65 6777 0743

Emerson Process Management

GmbH & Co. OHG

Argelsrieder Feld 3

82234 Wessling

Germany

T 49 (8153) 9390, F49 (8153) 939172

Beijing Rosemount Far East Instrument

Co., Limited

No. 6 North Street, Hepingli, Dong Cheng District

Beijing 100013, China

T (86) (10) 6428 2233

F (86) (10) 6422 8586

This installation guide provides basic guidelines for Rosemount 3051S

transmitters (reference manual document number 00809-0100-4801). It

also provides the basic electronics guidelines for the 3051SFA

(reference manual document number 00809-0100-4809), 3051SFC

(reference manual document number 00809-0100-4810), and 3051SFP

(reference manual document number 00809-0100-4686). It does not

provide instructions for diagnostics, maintenance, service, or

troubleshooting. This document is also available electronically on

www.rosemount.com.

2

Page 3

Quick Installation Guide

WARNING

00825-0100-4801, Rev HA

February 2008

Explosions could result in death or serious injury:

Installation of this transmitter in an explosive environment must be in

accordance with the appropriate local, national, and international

standards, codes, and practices. Please review the approvals section of

the 3051S reference manual for any restrictions associated with a safe

installation.

• Before connecting a HART communicator in an explosive

atmosphere, ensure the instruments in the loop are installed in

accordance with intrinsically safe or non-incendive field wiring

practices.

• In an Explosion-Proof/Flame-Proof installation, do not remove the

transmitter covers when power is applied to the unit.

Process leaks may cause harm or result in death.

• Install and tighten process connectors before applying pressure.

Electrical shock can result in death or serious injury.

• Avoid contact with the leads and terminals. High voltage that may be

present on leads can cause electrical shock.

Rosemount 3051S

3

Page 4

Rosemount 3051S

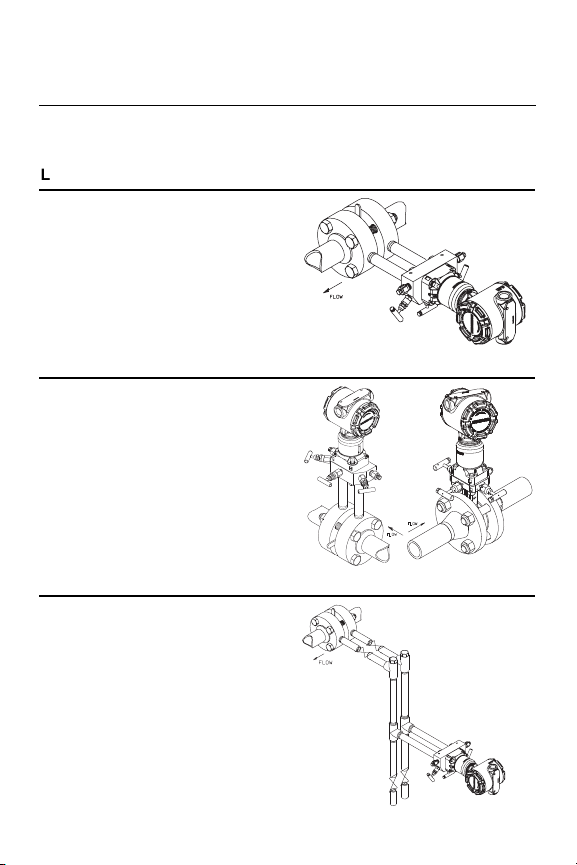

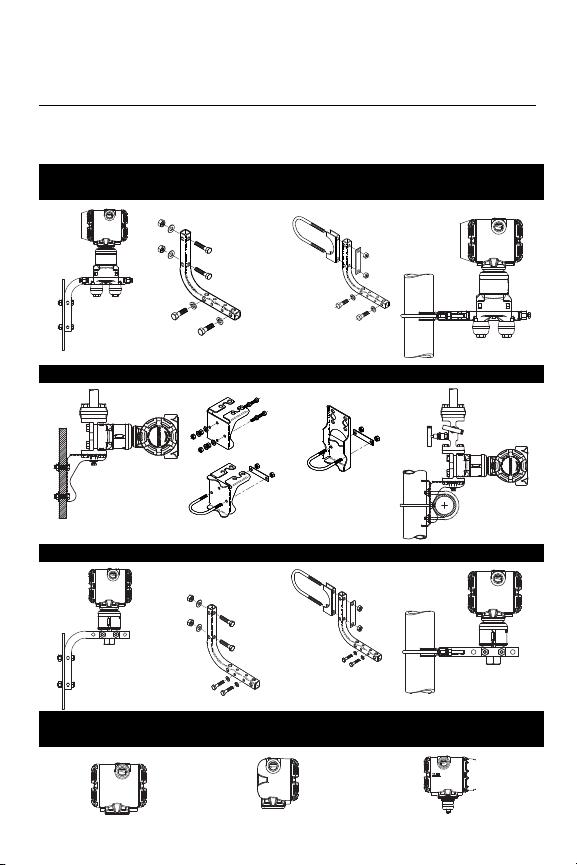

STEP 1: MOUNT THE TRANSMITTER

Liquid Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Mount the transmitter so that the

drain/vent valves are oriented

upward.

Gas Flow Applications

1. Place taps in the top or side of

the line.

2. Mount beside or above the taps.

Steam Flow Applications

1. Place taps to the side of the line.

2. Mount beside or below the taps.

3. Fill impulse lines with water.

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

4

Page 5

Quick Installation Guide

STEP 1 CONTINUED...

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

Panel Mount Pipe Mount

PlantWeb™ Junction Box Remote Mount Display

Coplanar™ Flange

Traditional Flange

In-line

Housings

5

Page 6

Rosemount 3051S

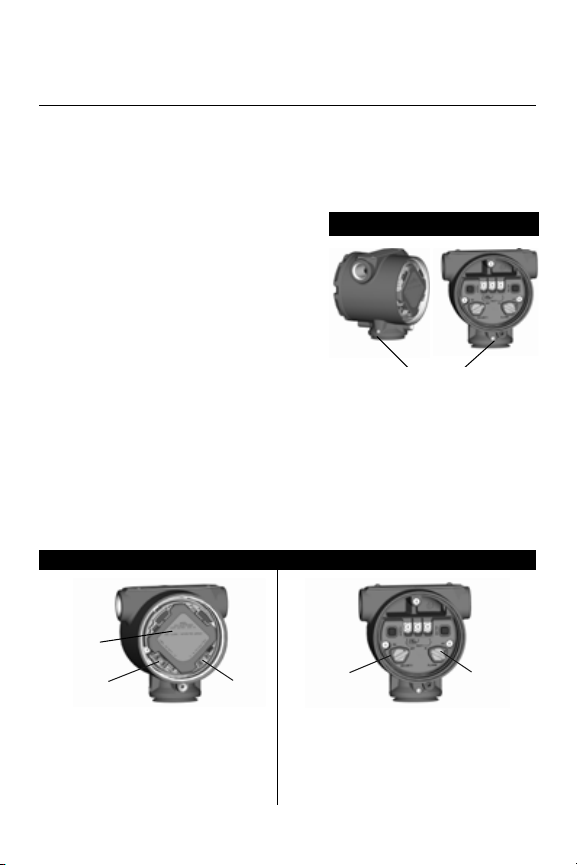

STEP 2: CONSIDER HOUSING ROTATION

STEP 3: SET SWITCHES AND JUMPERS

Housing Rotation Set

Screw (3/32-inch)

Alarm

Security

Meter/

Adjustment

Module

Security

Alarm

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

To improve field access to wiring or to

better view the optional LCD display:

1. Loosen the housing rotation set

Figure 1. Transmitter Housing

Set Screw

PlantWeb Junction Box

screw.

2. First rotate the housing clockwise

to the desired location. If the

desired location cannot be

achieved due to thread limit,

rotate the housing counter

clockwise to the desired location

(up to 360° from thread limit).

3. Retighten the housing rotation set

screw.

If alarm and security adjustment option is not installed, the transmitter

will operate normally with the default alarm condition alarm high and

the security off.

Figure 2. Transmitter Switch and Jumper Configuration

PlantWeb Junction Box

Slide the security and alarm

switches into the preferred position

by using a small screwdriver.

(A LCD display or an adjustment

module must be in place to activate

the switches.)

6

Pull the jumpers out and rotate 90°

into desired position to set the security

and alarm.

Page 7

Quick Installation Guide

STEP 4: CONNECT WIRING AND POWER UP

RL ≥ 250 Ω

Power

Supply

Power

Supply

RL ≥ 250 Ω

00825-0100-4801, Rev HA

February 2008

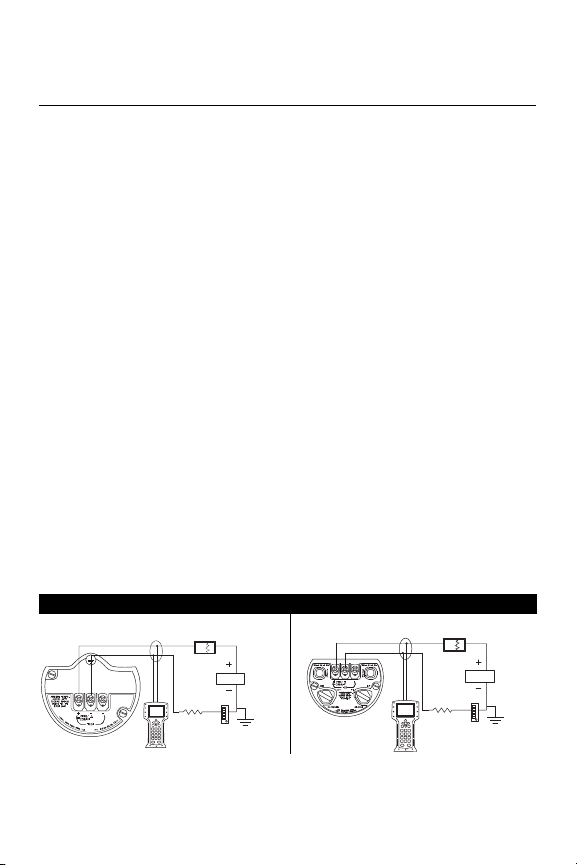

Use the following steps to wire the transmitter:

1. Remove the housing cover labeled “Field Terminals.”

2. Connect the positive lead to the “+” terminal, and the negative lead

to the “–” terminal.

NOTE

Do not connect the power across the test terminals. Power could

damage the test diode in the test connection. Twisted pairs yield best

results. For single compartment housing (Junction Box housing),

shielded signal wiring should be used in high EMI/RFI environments.

Use 24 AWG to 14 AWG wire and do not exceed 5,000 feet

(1500 meters).

3. Plug and seal the unused conduit connection.

4. If applicable, install wiring with a drip loop. Arrange the drip loop

so the bottom is lower than the conduit connections and the

transmitter housing.

5. Replace the housing cover.

The figures below show the wiring connections necessary to power a

3051S and enable communications with a hand-held HART

communicator.

Figure 3. Transmitter Wiring

PlantWeb Housing Wiring Junction Box Housing Wiring

Rosemount 3051S

NOTE

Installation of the transient protection terminal block does not

provide transient protection unless the 3051S case is properly

grounded.

7

Page 8

Quick Installation Guide

STEP 4 CONTINUED...

Rosemount 3051S

00825-0100-4801, Rev HA

February 2008

Remote Display Wiring and Power Up

The Remote Mount Display and Interface system consists of a local

transmitter and a remote mount LCD display assembly. The local

3051S transmitter assembly includes a Junction Box housing with a

three position terminal block integrally mounted to a SuperModule.

The remote mount LCD display assembly consists of a dual

compartment PlantWeb housing with a seven position terminal block.

See Figure 4 on page 9 for complete wiring instructions. The following

is a list of necessary information specific to the Remote Mount Display

system:

• Each terminal block is unique for the remote display system.

• A 316 SST housing adapter is permanently secured to the remote

mount LCD display PlantWeb housing providing an external

ground and a means for field mounting with the provided mounting

bracket.

• A cable is required for wiring between the transmitter and remote

mount LCD display. The cable length is limited to 100 ft.

• 50 ft. (option M8) or 100 ft. (option M9) cable is provided for wiring

between the transmitter and remote mount LCD display. Option

M7 does not include cable; see recommended specifications

below:

Cable type: Recommend Belden 3084A DeviceNet cable or Belden

123084A Armored DeviceNet cable. Other comparable cable may be

used as long as it has independent dual twisted shielded pair wires

with an outer shield. The Power wires must be 22 AWG minimum and

the CAN communication wires must be 24 AWG minimum.

Cable length: Up to 100 feet depending upon cable capacitance.

Cable capacitance: The capacitance from the CAN communications

line to the CAN return line as wired must be less than 5000 picofarads

total. This allows up to 50 picofarads per foot for a 100 foot cable.

8

Page 9

Quick Installation Guide

STEP 4 CONTINUED...

4-20 mA

(white) 24 AWG

(blue) 24 AWG

(black) 22 AWG

(red) 22 AWG

00825-0100-4801, Rev HA

February 2008

Intrinsic Safety Consideration: The transmitter assembly with

remote display has been approved with Belden 3084A DeviceNet

cable. Alternate cable may be used as long as the transmitter with

remote display and cable is configured according to the installation

control drawing or certificate. Refer to appropriate approval certificate

or control drawing in Appendix B of the 3051S reference manual for

remote cable IS requirements.

IMPORTANT

Do not apply power to the remote communications terminal. Follow

wiring instructions carefully to prevent damage to system components.

Figure 4. Remote Mount Display wiring diagram

Junction Box Housing Remote Mount Display

Rosemount 3051S

9

Page 10

Quick Installation Guide

STEP 4 CONTINUED...

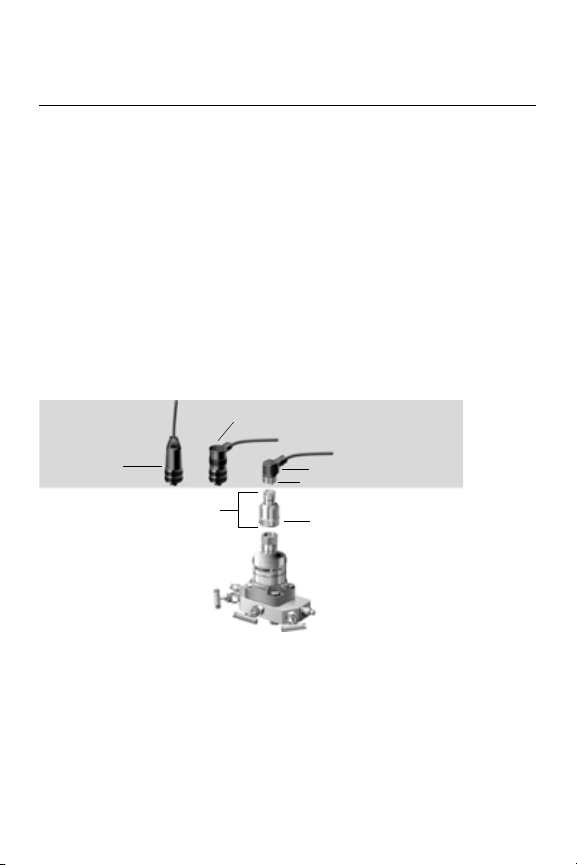

Straight Field

Wireable

Connector

(1)(3)

Right Angle Field Wireable

Connector

(2)(3)

Coupling Nut

Cordset

(4)

Quick Connect

Housing

Quick Connect Coupling Nut

(1) Order part number

03151-9063-0001.

(2) Order part number

03151-9063-0002.

(3) Field wiring supplied by customer.

(4) Supplied by cordset vendor.

Rosemount 3051S

NOTE

Wire colors provided on page 9 are per Belden 3084A DeviceNet

cable. Wire color may vary depending on cable selected.

Belden 3084A DeviceNet cable includes a ground shield. This shield

must be connected to earth ground at either the SuperModule or the

Remote Display, but not both.

00825-0100-4801, Rev HA

February 2008

Quick Connect Wiring

As standard, the 3051S Quick Connect arrives properly assembled to

the SuperModule and is ready for installation. Cordsets and Field

Wireable Connectors (in shaded area) are sold separately.

Figure 5. Rosemount 3051S Quick Connect Exploded View

IMPORTANT

If Quick Connect is ordered as a 300S spare housing or is removed

from the SuperModule, follow the instructions below for proper

assembly prior to field wiring.

1. Place the Quick Connect onto the SuperModule. To ensure proper

pin alignment, remove coupling nut prior to installing quick connect

onto SuperModule.

10

Page 11

Quick Installation Guide

STEP 4 CONTINUED...

“+”

“–”

Ground

No Connection

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

2. Place coupling nut over quick connect and wrench tighten to a

maximum of 300 in-lb. (34 N-m).

3. Tighten the set screw using a

3

/32-in hex wrench.

4. Install Cordset/ Field Wireable Connectors onto the Quick Connect.

Do not over tighten.

Figure 6. Quick Connect Housing Pin-Out

For other wiring

details, refer to pin-out

drawing and the

cordset

manufacturer’s

installation

instructions.

Conduit Electrical Connector Wiring (Option GE or GM)

For 3051S transmitters with conduit electrical connectors GE or GM,

refer to the cordset manufacturer’s installation instructions for wiring

details. For FM Intrinsically Safe, non-incendive or FM FISCO

Intrinsically Safe hazardous locations, install in accordance with

Rosemount drawing 03151-1009 to maintain outdoor rating (NEMA 4X

and IP66.) See Appendix B of the 3051S reference manual.

11

Page 12

Quick Installation Guide

STEP 4 CONTINUED...

Voltage (V dc)

Load (Ohms)

Operating

Region

1387

1000

500

0

10.5 20 30

42.4

Voltage (V dc)

Load (Ohms)

Operating

Region

1322

1000

500

0

12.0 20 30

42.4

Rosemount 3051S

00825-0100-4801, Rev HA

February 2008

Power Supply

The dc power supply should provide power with less than two percent

ripple. The total resistance load is the sum of the resistance of the

signal leads and the load resistance of the controller, indicator, and

related pieces. Note that the resistance of intrinsic safety barriers, if

used, must be included.

Figure 7. Load Limitation

Standard Transmitter

Maximum Loop Resistance =

43.5 * (Power Supply Voltage – 10.5)

The HART communicator requires a minimum loop

resistance of 250Ω for communication.

HART Diagnostics Transmitter

(option code DA1)

Maximum Loop Resistance =

43.5 * (Power Supply Voltage – 12.0)

12

Page 13

Quick Installation Guide

STEP 5: VERIFY CONFIGURATION

00825-0100-4801, Rev HA

February 2008

Use any HART-compliant master to communicate with and verify

configuration of the 3051S. For the HART Diagnostics transmitter

(option code DA1), DD revision 3051S HDT Dev. 1 Rev. 1 is required.

A check (⻫) indicates the basic configuration parameters. At a

minimum, these parameters should be verified as part of the

configuration and startup procedure.

Table 1. HART Fast Key Sequence

Function Fast Key Sequence

Alarm Level Configuration 1, 4, 2, 7, 7

Alarm and Saturation Levels 1, 4, 2, 7

Analog Output Alarm Direction 1, 4, 2, 7, 6

Analog Output Trim 1, 2, 3, 2

Burst Mode On/Off 1, 4, 3, 3, 3

Burst Options 1, 4, 3, 3, 4

⻫ Damping 1, 3, 6

Date 1, 3, 4, 1

Descriptor 1, 3, 4, 2

Digital To Analog Trim (4-20 mA

Output)

Field Device Information 1, 4, 4, 1

LCD Display Configuration 1, 3, 7

Loop Test 1, 2, 2

Lower Sensor Trim 1, 2, 3, 3, 2

Message 1, 3, 4, 3

Number of Requested Preambles 1, 4, 3, 3, 2

Pressure Alert Configuration 1, 4, 3, 5, 3

Poll Address 1, 4, 3, 3, 1

Poll a Multidropped Transmitter Left Arrow, 3, 1, 1

Remapping 1, 4, 3, 6

Rerange- Keypad Input 1, 2, 3, 1, 1

Continued on Next Page

Rosemount 3051S

1, 2, 3, 2, 1

13

Page 14

Quick Installation Guide

STEP 5 CONTINUED...

Rosemount 3051S

00825-0100-4801, Rev HA

Function Fast Key Sequence

Saturation Level Configuration 1, 4, 2, 7, 8

Scaled D/A Trim (4–20 mA Output) 1, 2, 3, 2, 2

Scaled Variable Configuration 1, 4, 3, 4, 7

Self Test (Transmitter) 1, 2, 1, 1

Sensor Information 1, 4, 4, 2

Sensor Temperature 1, 1, 4

Sensor Trim 1, 2, 3, 3

Sensor Trim Points 1, 2, 3, 3, 5

Status 1, 2, 1, 2

⻫

Ta g 1, 3, 1

Temperature Alert Configuration 1, 4, 3, 5, 4

⻫

Transfer Function

(Setting Output Type)

Transmitter Security (Write Protect) 1, 3, 4, 5

⻫

Units (Process Variable) 1, 3, 2

Upper Sensor Trim 1, 2, 3, 3, 3

Zero Trim 1, 2, 3, 3, 1

February 2008

1, 3, 5

14

Page 15

Quick Installation Guide

STEP 6: TRIM THE TRANSMITTER

00825-0100-4801, Rev HA

February 2008

Transmitters are shipped fully calibrated per request or by the factory

default of full scale (lower range value = zero, upper range value =

upper range limit).

Rosemount 3051S

Zero Trim

A zero trim is a single-point adjustment used for compensating

mounting position and line pressure effects. When performing a zero

trim, ensure that the equalizing valve is open and all wet legs are filled

to the correct level.

If zero offset is less than 3% of true zero, follow the “Using the HART

Communicator” instructions below to perform a zero trim. If zero offset

is greater than 3% of true zero, follow the “Using the Transmitter Zero

Adjustment Button” instructions below to rerange. If hardware

adjustments are not available, see the 3051S Reference Manual

(document number 00809-0100-4801) to perform a rerange using the

HART Communicator.

Using the HART Communicator

HART Fast Keys Steps

1, 2, 3, 3, 1 1. Equalize or vent the transmitter and connect HART

communicator.

2. At the menu, input the HART Fast Key sequence.

3. Follow the commands to perform a zero trim.

15

Page 16

Quick Installation Guide

Span

Zero

Span

Zero

Rosemount 3051S

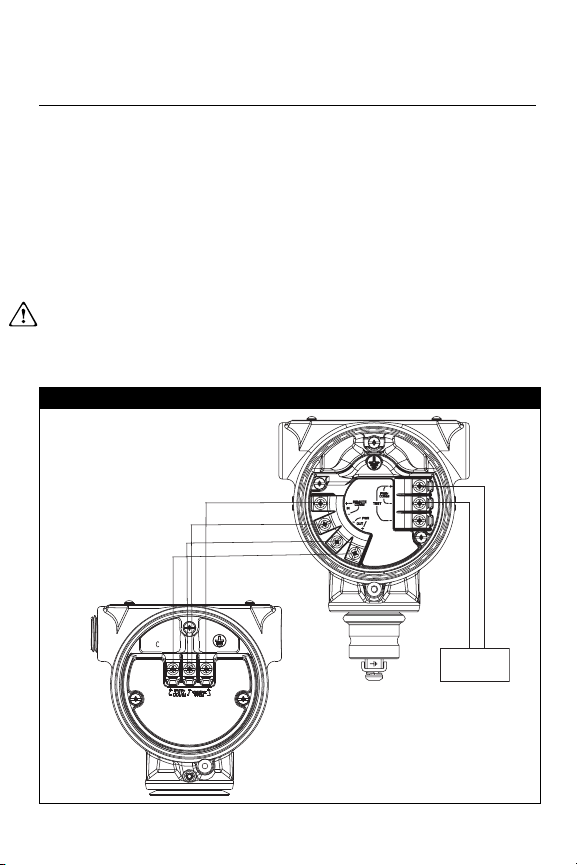

Using the Transmitter Zero Adjustment Button

Push and hold the zero adjustment button for at least two seconds but

no longer than ten seconds.

Figure 8. Transmitter Adjustment Buttons

PlantWeb Junction Box

00825-0100-4801, Rev HA

February 2008

16

Page 17

Quick Installation Guide

SAFETY INSTRUMENTED SYSTEMS

Revision #’s

Fld Dev Rev 7

Software Rev 7

Hardware Rev 16

00825-0100-4801, Rev HA

February 2008

Additional Safety Instrumented Systems information is available in the

Rosemount 3051S reference manual (document number

00809-0100-4801). The manual is available electronically on

www.rosemount.com or by contacting an Emerson Process

Management representative.

Rosemount 3051S

3051S Safety-Certified Identification

All 3051S transmitters must be identified as safety-certified before

installing into SIS systems.

NOTE

There are two versions of safety-certified 3051S pressure transmitters.

For transmitters with a yellow SIS circuit board installed and output

code B in the model number, please refer to Manual Supplement

00809-0700-4801.

To identify a safety-certified 3051S:

1. Connect a HART host to the transmitter.

2. Check the software to verify that the software revision is 7 or

higher.

Fast Key Sequence - 1, 5

3. Verify that option code QT is included in the transmitter model

code.

17

Page 18

Quick Installation Guide

Rosemount 3051S

00825-0100-4801, Rev HA

February 2008

Installation

No special installation is required in addition to the standard

installation practices outlined in this document. Always ensure a

proper seal by installing the electronics housing covers so that metal

contacts metal.

The loop should be designed so the terminal voltage does not drop

below 10.5 Vdc when the transmitter output is 23.0 mA.

If hardware security switches are installed, the security switch should

be in the “ON” position during normal operation. See Figure 2 on

page 6. If hardware security switches are not installed, security should

be “ON” in the software to prevent accidental or deliberate change of

configuration data during normal operation.

Configuration

Use any HART-compliant master to communicate with and verify

configuration of the 3051S Safety-Certified Pressure Transmitter (see

Table 1 on page 13 and 14 to verify configuration).

User-selected damping will affect the transmitters ability to respond to

changes in the applied process. The damping value + response time

should not exceed the loop requirements.

18

Page 19

Quick Installation Guide

Normal Operation

4 mA

20 mA

20.8 mA

high saturation

21.75

(2)

3.9 mA

low saturation

3.75 mA

(1)

Normal Operation

4 mA

20 mA

20.5 mA

high saturation

22.5

(2)

3.8 mA

low saturation

3.6 mA

(1)

Normal Operation

4 mA

20 mA

20.1 - 20.5 mA

high saturation

20.2 - 23.0

(2)

3.7 - 3.9 mA

low saturation

3.6 - 3.8 mA

(1)

00825-0100-4801, Rev HA

February 2008

NOTES

1. Transmitter output is not safety-rated during the following:

configuration changes, multidrop, loop test. Alternative means should

be used to ensure process safety during transmitter configuration and

maintenance activities.

2. DCS or safety logic solver should be configured to match transmitter

configuration. Figure 9 identifies the three alarm levels available and

their operation values.

Rosemount 3051S

Figure 9. Alarm Levels

Rosemount Alarm Level

Namur Alarm Level

Custom Alarm Level

(1) Transmitter Failure, hardware or software alarm in LO position.

(2) Transmitter Failure, hardware or software alarm in HI position.

(3) High alarm must be at least 0.1 mA higher than the high saturation value.

(4) Low alarm must be at least 0.1 mA lower than the low saturation value.

(3)(4)

19

Page 20

Quick Installation Guide

Rosemount 3051S

Setting the alarm values and direction is dependent on whether or not

the hardware switch option is installed. You can use a HART master or

communicator to set the Alarm and Saturation values.

Switches installed

1. If using a communicator, use the following fast key sequence to set

the Alarm and Saturation values.

Alarm Levels - Fast Key; 1, 4, 2, 7, 7

Saturation Levels - Fast Key; 1, 4, 2, 7, 8

2. Manually set the direction for the Alarm to HI or LO using the

ALARM switch as shown in Figure 2 on page 6.

Switches not installed

If using a communicator, use the following fast key sequence to set the

Alarm and Saturation values and the Alarm Direction:

Alarm Levels - Fast Key; 1, 4, 2, 7, 7

Saturation Levels - Fast Key; 1, 4, 2, 7, 8

Alarm Direction Fast Key; 1, 4, 2, 7, 6

00825-0100-4801, Rev HA

February 2008

20

Page 21

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

Operation and Maintenance

Proof Test and Inspection

The following proof tests are recommended. Proof test results

and corrective actions taken must be documented at

www.emersonprocess.com/rosemount/safety/certtechdocumentation.

htm in the event that an error is found in the safety functionality.

Use "Table 1: HART Fast Key Sequence" to perform a Loop Test,

Analog Output Trim, or Sensor Trim. See the 3051S reference manual

for additional information.

Proof Test 1

Conducting an analog output Loop Test satisfies the proof test

requirements and will detect more than 52% of DU failures not

detected by the 3051S_C or 3051S_L automatic diagnostics, and

more than 62% of DU failures not detected by the 3051S_T automatic

diagnostics.

Required tools: HART host/communicator and mA meter.

1. On HART host/communicator enter the Fast Key Sequence 1, 2, 2.

2. Select “4 Other.”

3. Enter the milliampere value representing a high alarm state.

4. Check the reference meter to verify the mA output corresponds to

the entered value.

5. Enter the milliampere value representing a low alarm state.

6. Check the reference meter to verify the mA output corresponds to

the entered value.

7. Document the test results per your requirements.

21

Page 22

Quick Installation Guide

Rosemount 3051S

Proof Test 2

This proof test, when combined with the Proof Test 1, will detect over

92% of DU failures not detected by the 3051S_C or 3051S_L

automatic diagnostics, and over 95% of DU failures not detected by

the 3051S_T automatic diagnostics.

Required tools: HART host/communicator and pressure calibration

equipment.

1. Perform a minimum two point sensor calibration check using the

4-20mA range points as the calibration points.

2. Check the reference mA meter to verify the mA output corresponds

to the pressure input value.

3. If necessary, use one of the “Trim” procedures available in the

3051S reference manual to calibrate.

4. Document the test results per your requirements.

NOTE

The user determines the proof-test requirements for impulse piping.

Visual Inspection

Not required.

Special Tools

Not required.

Product Repair

All failures detected by the transmitter diagnostics or by the proof-test

must be reported. Feedback can be submitted electronically at

www.emersonprocess.com/rosemount/safety/certtechdocumentation.

htm.

The 3051S is repairable by major component replacement. Follow the

instructions in the 3051S reference manual (document number

00809-0100-4801) for additional information.

00825-0100-4801, Rev HA

February 2008

22

Page 23

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

Reference

Certification

The 3051S Safety-Certified Pressure Transmitter was designed,

developed, and audited to be compliant to IEC 61508 safety-certified

SIL 2 Claim Limit.

Specifications

The 3051S Safety-Certified Pressure Transmitter must be operated in

accordance to the functional and performance specifications provided

in the 3051S reference manual.

Failure Rate Data

The FMEDA report includes failure rates and common cause Beta

factor estimates. This report is available at

www.emersonprocess.com/rosemount/safety/certtechdocumentation.

htm.

3051S Safety-Certified Pressure Transmitter Failure Values

Safety accuracy: 2.0%

Safety response time: 1.5 seconds

Self-diagnostics Test Interval: At least once per hour

Product Life

50 years – based on worst case component wear-out mechanisms –

not based on wear-out process wetted materials.

(1)

(1) A 2% variation of the transmitter mA output is allowed before a safety trip. Trip

values in the DCS or safety logic solver should be derated by 2%.

23

Page 24

Quick Installation Guide

PRODUCT CERTIFICATIONS

Rosemount 3051S

00825-0100-4801, Rev HA

February 2008

Approved Manufacturing Locations

Rosemount Inc. — Chanhassen, Minnesota USA

Fisher-Rosemount GmbH & Co. — Wessling, Germany

Emerson Process Management Asia Pacific Private Limited — Singapore

Beijing Rosemount Far East Instrument Co., LTD — Beijing, China

Emerson Process Management LTDA — Sorocaba, Brazil

Emerson Process Management (India) Pvt. Ltd. — Daman, India

European Directive Information

The EC declaration of conformity can be found on page 32. The most

recent revision can be found at www.rosemount.com.

Ordinary Location Certification for FM Approvals

As standard, the transmitter has been examined and tested to determine

that the design meets basic electrical, mechanical, and fire protection

requirements by FM Approvals, a nationally recognized testing laboratory

(NRTL) as accredited by the Federal Occupational Safety and Health

Administration (OSHA).

24

Page 25

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

Hazardous Locations Certifications

North American Certifications

FM Approvals

E5 Explosion proof for Class I, Division 1, Groups B, C, and D;

dust-ignition proof for Class II and Class III, Division 1, Groups E,

F, and G; hazardous locations; enclosure Type 4X, conduit seal

not required when installed according to Rosemount drawing

03151-1003.

I5 Intrinsically Safe for use in Class I, Division 1, Groups A, B, C,

and D; Class II, Division 1, Groups E, F, and G; Class III, Division

1; Class I, Zone 0 AEx ia IIC when connected in accordance with

Rosemount drawing 03151-1006; Non-incendive for Class I,

Division 2, Groups A, B, C, and D, Enclosure Type 4X

For entity parameters see control drawing 03151-1006.

Canadian Standards Association (CSA)

E6 Explosion-Proof for Class I, Division 1, Groups B, C, and D;

Dust-Ignition-Proof for Class II and Class III, Division 1, Groups

E, F, and G; suitable for Class I, Division 2, Groups A, B, C, and

D, when installed per Rosemount drawing 03151-1013, CSA

Enclosure Type 4X; conduit seal not required.

I6 Intrinsically Safe for Class I, Division 1, Groups A, B, C, and D

when connected in accordance with Rosemount drawings

03151-1016;

For entity parameters see control drawing 03151-1016.

25

Page 26

Quick Installation Guide

Rosemount 3051S

00825-0100-4801, Rev HA

European Certifications

I1 ATEX Intrinsic Safety

Certificate No.: BAS01ATEX1303X II 1 G

EEx ia IIC T4 (T

-HART/Remote Display/Quick Connect/HART Diagnostics

1180

Table 2. Input Parameters

Loop / Power Groups

U

= 30V All

i

Ii = 300 mA All

P

= 1.0W All

i

Ci = 30nF SuperModule™/Quick Connect

C

= 11.4nF With PlantWeb or Junction Box Housing

i

Ci = 0 Remote Display

L

= 0 All Except Remote Display

i

Li = 60 µH Remote Display

Special Conditions for Safe Use (X)

1. The apparatus, excluding the Types 3051 S-T and 3051 S-C

(In-line and Coplanar SuperModule Platforms respectively), is

not capable of withstanding the 500V test as defined in Clause

6.4.12 of EN 50020. This must be considered during

installation.

2. The terminal pins of the Types 3051 S-T and 3051 S-C must

be protected to IP20 minimum.

N1 ATEX Type n

Certificate No.: BAS01ATEX3304X II 3 G

EEx nL IIC T4 (T

Ui = 45 Vdc max

IP66

= -60 °C to 70 °C)

a

= -40 °C TO 70 °C)

a

February 2008

26

Page 27

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Special Conditions for Safe Use (x)

The apparatus is not capable of withstanding the 500V insulation

test required by Clause 9.1 of EN 50021: 1999. This must be

taken into account when installing the apparatus.

ND ATEX Dust

Certificate No.: BAS01ATEX1374X II 1 D

T105°C (-20 °C ≤ T

= 42.4 volts max

V

max

A = 24 mA

IP66

1180

Special Conditions for safe use (x):

1. The user must ensure that the maximum rated voltage and

current (42.4 volts, 22 milliampere, DC) are not exceeded. All

connections to other apparatus or associated apparatus shall

have control over this voltage and current equivalent to a

category “ib” circuit according to EN 50020.

2. Cable entries must be used which maintain the ingress

protection of the enclosure to at least IP66.

3. Unused cable entries must be filled with suitable blanking plugs

which maintain the ingress protection of the enclosure to at

least IP66.

4. Cable entries and blanking plugs must be suitable for the

ambient range of the apparatus and capable of withstanding a

7J impact test.

5. The 3051S must be securely screwed in place to maintain the

ingress protection of the enclosure. (The 3051S SuperModule

must be properly assembled to the 3051S housing to maintain

ingress protection.)

amb

≤ 85 °C)

Rosemount 3051S

27

Page 28

Quick Installation Guide

Rosemount 3051S

E1 ATEX Flame-Proof

Certificate No.: KEMA00ATEX2143X II 1/2 G

EEx d IIC T6 (-50 °C ≤ T

EEx d IIC T5 (-50 °C ≤ T

= 42.4V

V

max

1180

Special conditions for safe use (x)

This device contains a thin wall diaphragm. Installation,

maintenance and use shall take into account the environmental

conditions to which the diaphragm will be subjected. The

manufacturer’s instructions for installation and maintenance

shall be followed in detail to assure safety during its expected

lifetime. The Model 3051S pressure transmitter must include a

Series 300S housing integrally mounted to a Series Model

3051S Sensor module as per Rosemount drawing 03151-1023.

Japanese Certifications

E4 TIIS Flame-Proof

Ex d IIC T6

Table 3. TIIS Certificates

Certificate Description

TC15682 Coplanar w/Junction Box Housing

TC15683 Coplanar w/PlantWeb Housing

TC15684 Coplanar w/PlantWeb Housing & LCD Display

TC15685 In-Line SST w/Junction Box Housing

TC15686 In-Line Hastelloy w/Junction Box Housing

TC15687 In-Line SST w/PlantWeb Housing

TC15688 In-Line Hastelloy w/Plantweb Housing

TC15689 In-Line SST w/Plantweb Housing & LCD Display

TC15690 In-Line Hastelloy w/PlantWeb Housing & LCD Display

TC17102 Remote Display

TC17099 3051SFA/C/P SST/Hastelloy w/ PlantWeb Housing & LCD Display

TC17100 3051SFA/C/P SST/Hastelloy w/ PlantWeb Housing & Remote Display

TC17101 3051SFA/C/P SST/Hastelloy w/ Junction Box Housing

amb

amb

≤ 65 °C)

≤ 80 °C)

00825-0100-4801, Rev HA

February 2008

28

Page 29

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Australian Certifications

E7 SAA Explosion-Proof and Dust Ignition-Proof

Certification No.: AUS Ex 3798X

Ex d IIC T6 (T

DIP A21 TA T6 (T

Conditions for safe use (X)

1. It is a condition of safe use that each housing shall be

connected to external circuits via suitable conduit of Standards

Australia certified cable glands. Where only one entry is used

for connection to external circuits, the unused entry shall be

closed by means of the blanking plug supplied by the

equipment manufacturer or by a suitable Standards Australia

certified blanking plug.

2. It is a condition of safe use that dielectric strength test shall be

applied whenever the terminal block is changed or replaced in

either the dual compartment or single compartment housings.

The breakdown current shall be less than 5 mA, when 500 V,

47 to 62 Hz, is applied for one minute. Note: if tested with an

optional T1 transient protector terminal block fitted, the

protection will operate and hence there will be no current

indicated.

3. It is a condition of safe use that each transmitter module shall

be used with a Model 300S housing, in order to comply with

Flame-Proof requirements.

4. It is a condition of safe use that each Model 300S housing

fitted with a transmitter module shall be marked with the same

certification marking code information. Should the housing be

replaced after initial supply to another Model 300S housing,

the replacement housing shall have the same certification

marking code information as the housing it replaces.

= 60°C) IP66

a

= 60°C) IP66

a

Rosemount 3051S

29

Page 30

Quick Installation Guide

Rosemount 3051S

I7 IECEx Intrinsic Safety

Certificate No.: IECExBAS04.0017X

Ex ia IIC T4 (T

-HART/Remote Display/Quick Connect/HART Diagnostics

IP66

Table 4. Input Parameters

Loop / Power Groups

U

= 30V All

i

Ii = 300 mA All

P

= 1.0W All

i

Ci = 30nF SuperModule™/Quick Connect

C

= 11.4nF With PlantWeb or Junction Box Housing

i

Ci = 0 Remote Display

L

= 0 All Except Remote Display

i

Li = 60 µH Remote Display

Conditions for safe use (X)

1. The 3051S HART 4-20mA, 3051S F

3051S Profibus and 3051S FISCO are not capable of

withstanding the 500V test as defined in clause 6.4.12 of IEC

60079-11. This must be taken into account during installation.

2. The terminal pins of the Types 3051S-T and 3051S-C must be

protected to IP20 minimum.

N7 IECEx Type n

Certificate No.: IECExBAS04.0018X

Ex nC IIC T4 (Ta = -40 °C to 70 °C)

Ui = 45 Vdc MAX

IP66

Conditions for safe use (X)

The apparatus is not capable of withstanding the 500 V

insulation test required by Clause 8 of IEC 79-15: 1987.

= -60 °C to 70 °C)

a

00825-0100-4801, Rev HA

February 2008

OUNDATION fieldbus,

30

Page 31

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

Combinations of Certifications

Stainless steel certification tag is provided when optional approval is

specified. Once a device labeled with multiple approval types is

installed, it should not be reinstalled using any other approval types.

Permanently mark the approval label to distinguish it from unused

approval types.

K1 Combination of E1, I1, N1, and ND

K5 Combination of E5 and I5

K6 Combination of E6 and I6

K7 Combination of E7, I7, and N7

KA Combination of E1, I1, E6, and I6

KB Combination of E5, I5, I6 and E6

KC Combination of E5, E1, I5 and I1

KD Combination of E5, I5, E6, I6, E1, and I1

31

Page 32

Rosemount 3051S

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

DOC

32

Page 33

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

33

Page 34

Rosemount 3051S

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

34

Page 35

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

Rosemount 3051S

35

Page 36

Rosemount 3051S

NOTES

Quick Installation Guide

00825-0100-4801, Rev HA

February 2008

36

Loading...

Loading...