Emerson 289 Instruction Manual

Instruction Manual

Form 1724

October 2014

289 Series Relief Valves

WARNING

!

Failure to follow these instructions or

to properly install and maintain this

equipment could result in an explosion

and/or re causing property damage and

personal injury or death.

Fisher® relief valves must be installed,

operated and maintained in accordance

with federal, state and local codes,

rules and regulations and

manufacturer’s instructions.

If a leak develops or if the outlet

continually vents gas, service to the

unit may be required. Failure to correct

trouble could result in a hazardous

condition. Only a quali ed person must

install or service the unit.

Call a gas service person to service the

unit. Only a quali ed person must install

or service the regulator.

289 Series

18702

2 NPT TYPE 289H

Introduction

Scope of the Manual

This manual provides instructions for installation,

maintenance and parts ordering information for

the 289 Series relief valves. Instructions for other

equipment used with these relief valves can be

found in separate instruction manuals.

Description

The 289 Series pressure relief valves (see Figure 1)

are throttling relief valves used downstream of

pressure regulators to protect the downstream system

from overpressure. These relief valves can be used for

natural gas, air, propane or other noncorrosive, gas-

ow service.

W18701

1 NPT TYPE 289H

Figure 1. Type 289H Relief Valves

D100280X012

www.fisherregulators.com

289 Series

Specications

Available Congurations

See Table 1

Body Sizes and Inlet Connections

Type 289L: 3/4 or 1 NPT

Types 289A and 289U: 1/4 NPT

Type 289H: 1 or 2 NPT

Type 289HH: 1 NPT

Maximum Allowable Relief (Inlet) Pressure

Maximum Relief Set Pressure

See Table 1

Material Temperature Capabilities

Nitrile (NBR) and Neoprene (CR):

-20 to 150°F / -29 to 66°C

Fluorocarbon (FKM)

20 to 300°F / -7 to 149°C

Available with Types 289H and 289HH only

1. The pressure/temperature limits in this Instruction Manual and any applicable standard limitation should not be exceeded.

2. Bubble-tight shutoff cannot be attained at settings below 5 psig / 0.34 bar with Fluorocarbon (FKM) O-ring seat.

(2)

:

(1)

(1)

and

Pressure Setting Adjustment

Adjusting screw

Pressure Registration

Internal

Approximate Shipping Weights

Types 289A and 289U: 0.75 lbs / 0.3 kg

Type 289H:

1 NPT Size: 4 lbs / 2.0 kg

2 NPT Size: 15 lbs / 7.0 kg

Type 289HH: 4 lbs / 2.0 kg

Type 289L: 15 lbs / 7.0 kg

Additional Specications

For construction materials, see Parts List

Principle of Operation

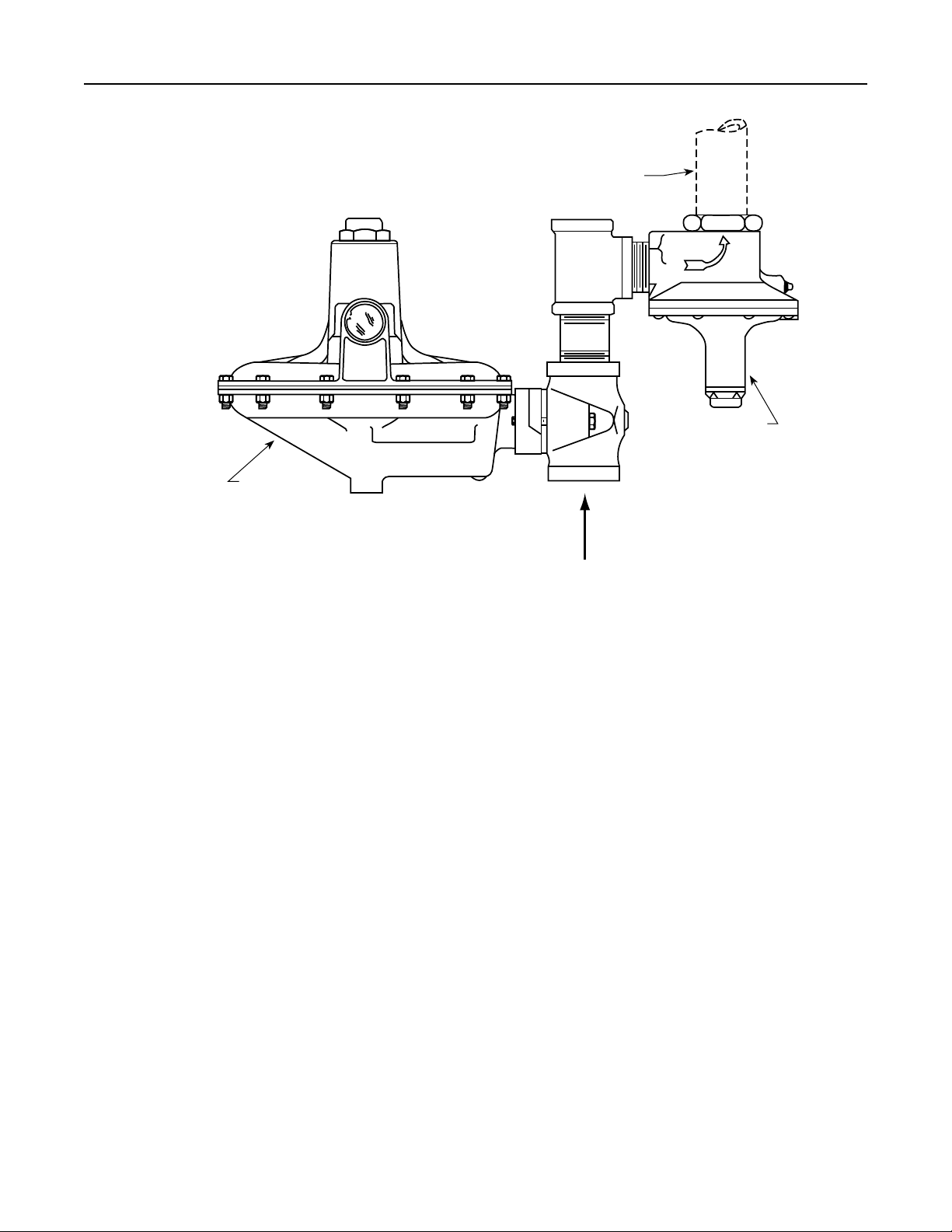

Refer to Figures 2 and 4. The 289 Series Relief valves

are to be installed (between large service regulators

such as S202G or S302G Series) so the outlet is

piped downstream to relieve excess pressure to the

atmosphere. As inlet pressure increases, the spring

is compressed by the diaphragm, moving the disk

away from the seat. When the valve is opening, high

gas velocity through the orice creates an area of

relatively low pressure near the end of the pitot tube.

This pitot tube effect forms a partial vacuum above the

diaphragm (spring case area) which helps to open the

valve further.

Installation

WARNING

!

Installing a 289 Series relief valve where

its capabilities can be exceeded or where

proper operation might be impaired

may cause personal injury, property

damage or leakage due to bursting of

pressure-containing parts or explosion

of accumulated gas. To avoid such

conditions, install a 289 Series relief

valve where:

• Service conditions are within the

unit capabilities specied in the

Specications section and

• The relief valve is protected from

exposure to physical damage and/or

corrosive substances.

1. When installing a 289 Series relief valve, make sure

that the installation of the system complies with

applicable local, state or federal codes or regulations.

2. Use qualied personnel when installing, operating

and maintaining a 289 Series relief valve. Before

installation, make sure there is no damage to

or foreign material in the relief valve and that all

piping is clean and unobstructed.

3. For installation of Types 289H, 289HH and 289L

relief valves, the vent in the spring case must

remain plugged or undrilled in order for the pitot

tube to function properly.

4. The 289 Series relief valves may be installed in any

orientation. However, when installing the relief valve

at an outside location, adequate protection, such as

2

rain caps or elbow piping (see Figure 4), must be

attached to the outlet to keep the relief valve from

getting plugged or from collecting moisture, corrosive

chemicals or other foreign materials. If piping is to be

attached to the valve outlet, the following parts (if they

are connected to the valve outlet as shown in

Figures 6 through 10) must rst be removed: the

screen (key 9), the snap ring (key 13) and the gasket

(key 15). A typical installation of a 289 Series Relief

Valve is shown in Figure 4.

WARNING

!

If using a 289 Series relief valve on

hazardous or ammable gas service,

personal injury and property damage

could occur due to re or explosion of

vented gas that may have accumulated.

To prevent such injury or damage,

provide piping or tubing to vent the gas

to a safe, well-ventilated area. Also, when

venting a hazardous gas, the piping or

tubing should be located far enough

away from any buildings or windows so

to not create a further hazard and the

vent opening should be protected against

anything that could clog it.

289 Series

M1048

INLET PRESSURE

OUTLET PRESSURE

Figure 2. 2 NPT Type 289H Operational Schematic

5. Apply pipe compound to the male pipeline

threads only; do not apply pipe compound to

the internal body threads. Then install the

relief valve so that the ow through it will match

the direction arrow or marking cast on the

valve body.

When installing the molded diaphragm in the

289 Series Relief Valves, make sure the diaphragm

convolutions is installed in the down position as shown

in Figure 3.

Startup

Key numbers are shown in Figures 6 through 10.

With proper installation completed and system

equipment properly adjusted, close any vent valves

and slowly open the upstream shutoff valve while

using pressure gauges to monitor pressure.

Note

To ensure proper operation of the pitot

tube, if present, the spring case (key 2)

must be tightly sealed. It is recommended

that the gasket (key 15) be replaced

whenever the closing cap (key 14) is

Figure 3. Installation of Diaphragm

INSTALL

DIAPHRAGM

CONVOLUTION

DOWN

3

289 Series

SERVICE

REGULATOR

PROTECT VENT PIPE

WITH RAIN CAP

289 SERIES

RELIEF VALVE

AJ4698-C

A2404-1

Figure 4. Typical Installation

removed. Antiseizing sealant should be

applied to the adjusting screw (key 6)

threads on valves without closing caps.

If set pressure adjustment is necessary, monitor the

inlet pressure with a gauge during the adjustment

procedure. Remove the closing cap (key 14) or loosen

the hex nut (key 11) and turn the adjusting screw (key 6)

clockwise to increase or counterclockwise to decrease

the relief pressure setting.

For 2 NPT Type 289H relief valves, when changing from

one spring range to another, it is recommended that a

new spring case be used so that the travel stop drive

screw will be positioned correctly for the corresponding

spring range. Each spring range requires that the travel

stop drive screw be positioned appropriately in the

spring case to prevent setting the relief valve pressure

too high. The location of the travel stop drive screw for

each spring and spring range is shown in Figure 5.

Maintenance

Relief valve parts are subject to normal wear and

should be inspected periodically for maintenance.

The frequency of inspection and replacement of parts

depends upon the severity of service conditions.

This section contains information for inspection

and maintenance of 289 Series relief valves.

Maintenance procedures are presented for relief valve

congurations of similar construction. Refer to the

appropriate procedure and gure for the particular

relief valve conguration when changing the control

spring to one of a different range or when inspecting,

cleaning or replacing any other relief valve parts. The

screen (key 9, Figures 6 through 9) and vent piping, if

present, should be free of foreign material that might

impair relief ow.

Note

Shutdown

Close the upstream shutoff valve, and release all

pressure from the relief valve.

4

The relief valve body (key 1, Figures 6

through 10) may remain in the pipeline

during maintenance unless replacement

of the valve body is necessary.

Loading...

Loading...