Page 1

Installation Manual

P/N 20003402, Rev. C

January 2007

Micro Motion

®

Model 2400S Transmitters

Installation Manual

Page 2

©2007, Micro Motion, Inc. All rights reserved. ELITE, ProLink, and the Micro Motion logo are registered trademarks of Micro

Motion, Inc., Boulder, Colorado. MVD and MVD Direct Connect are trademarks of Micro Motion, Inc., Boulder, Colorado. The

Emerson logo is a trademark of Emerson Electric Co. All other trademarks are property of their respective owners.

Page 3

Contents

Chapter 1 Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.3 Flowmeter components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Transmitter installation overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.5 Flowmeter documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Chapter 2 Transmitter Orientation and Power Supply . . . . . . . . . . . . . . . . . . . . 5

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Moisture protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Rotating the transmitter on the sensor (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Rotating the user interface module on the transmitter (optional) . . . . . . . . . . . . . . . . 6

2.5 Power supply requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5.1 DC power requirements for Model 2400S Analog and

PROFIBUS-DP transmitters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6 Wiring the power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 3 I/O Wiring – Model 2400S Analog Transmitters. . . . . . . . . . . . . . . . 11

3.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 Moisture protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.3 I/O options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.4 Wiring the outputs (Zone 1 Exe and Zone 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.4.1 mA output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.4.2 Frequency output wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.4.3 Discrete output wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.4.4 Discrete input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.5 Wiring the outputs (Zone 1 Exi). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.1 Hazardous area safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.5.2 Hazardous area mA wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5.3 Hazardous area frequency/discrete output wiring . . . . . . . . . . . . . . . . . . 23

3.5.4 Hazardous area discrete input wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Chapter 4 I/O Wiring – Model 2400S PROFIBUS-DP and

DeviceNet Transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.2 Moisture protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

4.3 I/O wiring for Model 2400S PROFIBUS-DP transmitters . . . . . . . . . . . . . . . . . . . . . 28

4.3.1 Enabling the internal termination resistor . . . . . . . . . . . . . . . . . . . . . . . . 29

4.4 I/O wiring for Model 2400S DeviceNet transmitters . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation Manual iii

Page 4

Contents

Appendix A Dimensions and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 31

A.1 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

A.2 Physical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

A.3 Power supply – Models 2400S Analog and PROFIBUS-DP. . . . . . . . . . . . . . . . . . . 32

A.4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

A.5 User interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

A.6 Input/output signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

A.7 Digital communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

A.8 Host interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

A.9 Environmental limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A.10 Environmental effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

A.11 Hazardous area classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Appendix B Return Policy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

B.1 New and unused equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

B.2 Used equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

iv Micro Motion® Model 2400S Transmitters

Page 5

Chapter 1

Before You Begin

1.1 Overview

This chapter provides an orientation to the use of this manual. This manual describes the procedures

required to install the following transmitters:

• Model 2400S transmitter with analog outputs

• Model 2400S transmitter with PROFIBUS-DP

• Model 2400S transmitter with DeviceNet

The 2400S Analog transmitter can be approved for Exe or Exi installation in Zone 1, or for

installation in Zone 2. If you are installing your transmitter in a hazardous area, be sure the transmitter

is approved for that area.

1.2 Safety

Safety messages are provided throughout this manual to protect personnel and equipment. Read each

safety message carefully before proceeding to the next step.

™

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

WARNING

Improper installation in a hazardous area can cause an explosion.

For information about hazardous applications, refer to Micro Motion hazardous

area installation instructions, shipped with the transmitter or available from the

Micro Motion web site.

WARNING

Hazardous voltage can cause severe injury or death.

Make sure power is disconnected before installing transmitter.

CAUTION

Improper installation could cause measurement error or flowmeter failure.

Follow all instructions to ensure transmitter will operate correctly.

Installation Manual 1

Page 6

Before You Begin

1.3 Flowmeter components

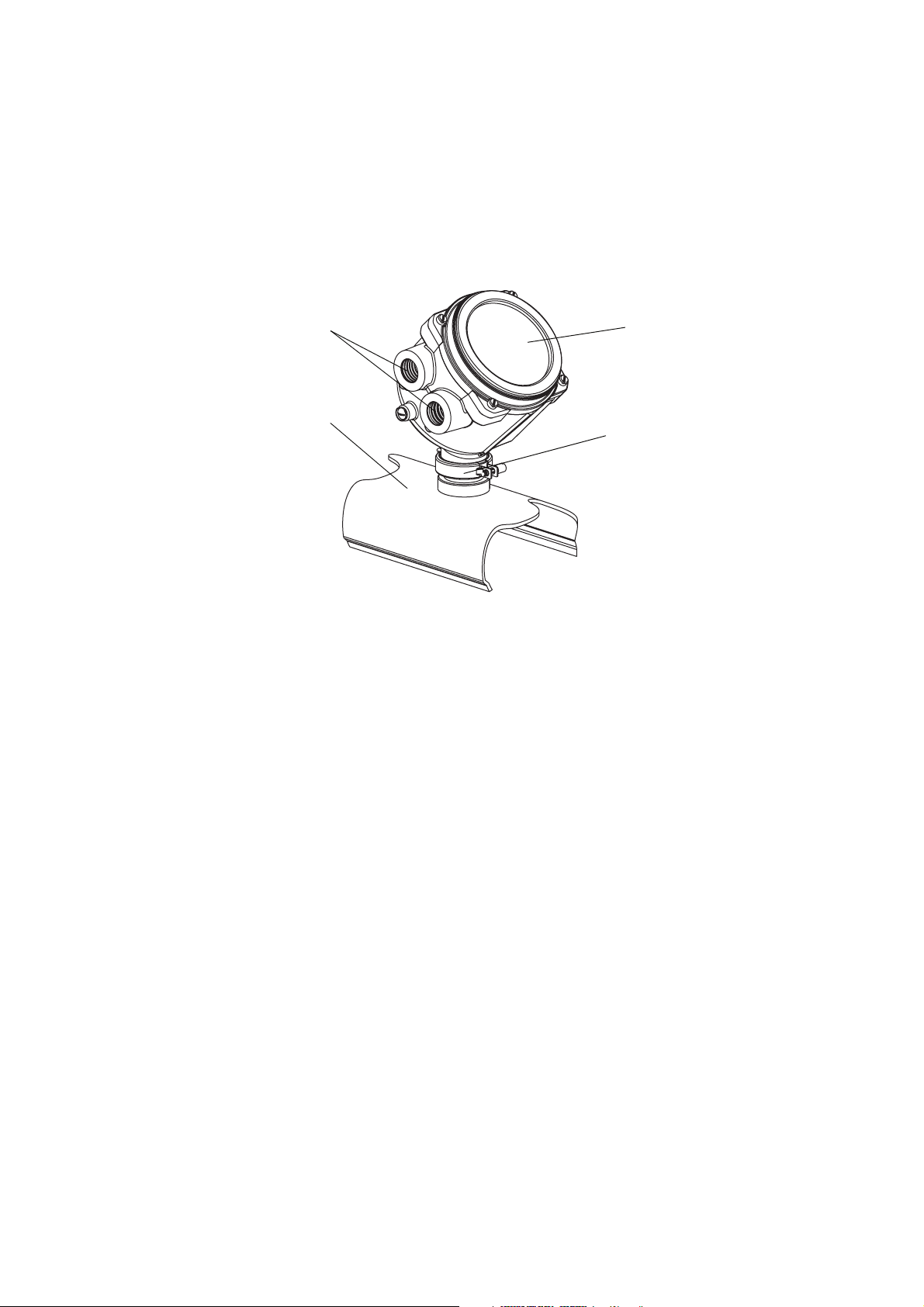

The Model 2400S transmitter is mounted on a Micro Motion sensor. The transmitter and sensor

together comprise the Micro Motion flowmeter.

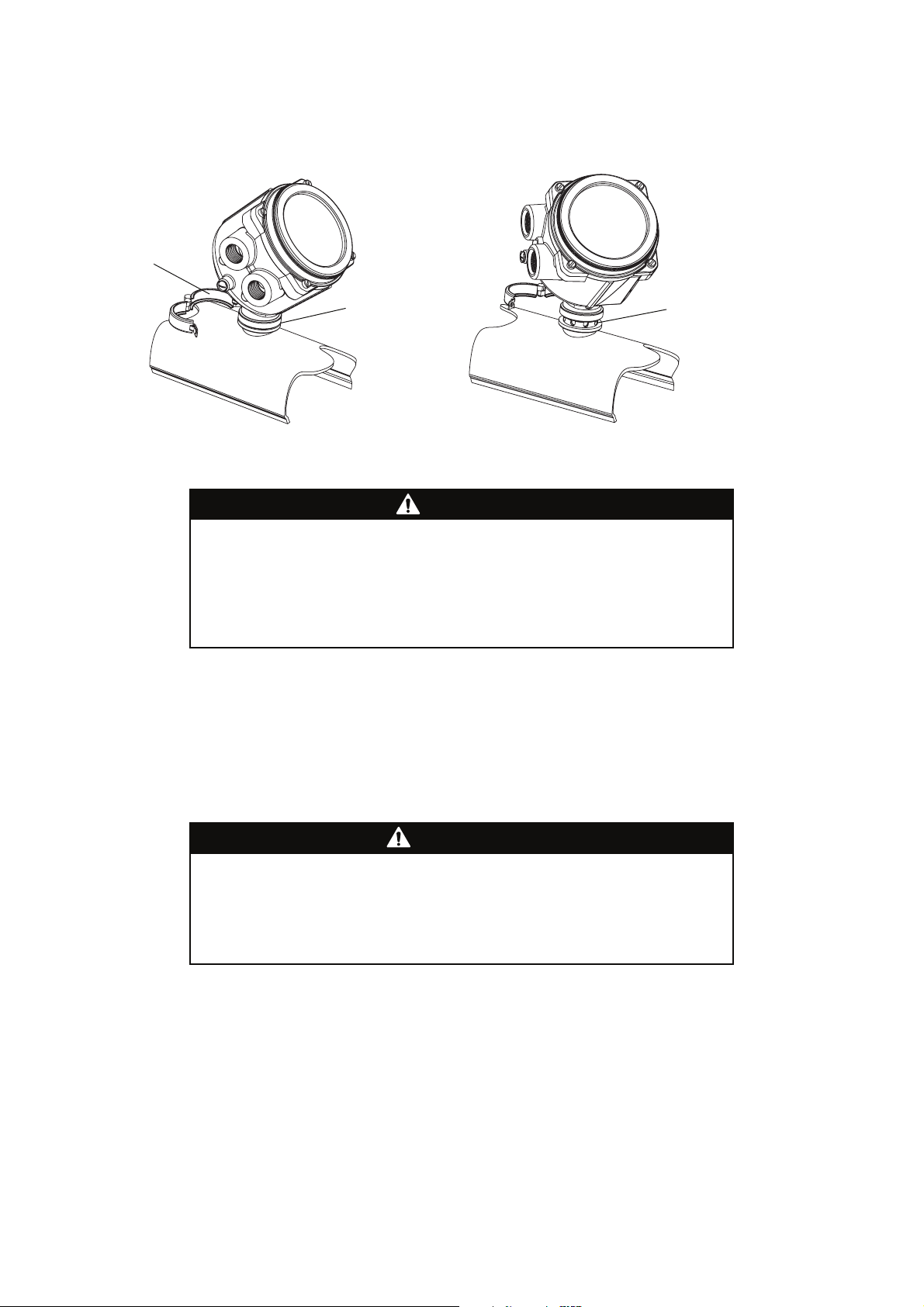

Figure 1-1 provides a view of the Model 2400S transmitter mounted on a sensor.

Figure 1-1 Model 2400S transmitter

Conduit openings

Sensor case

1.4 Transmitter installation overview

The Model 2400S transmitter component is mounted integrally with the sensor and grounded via the

sensor. To install and ground the sensor, see the sensor documentation.

Additional transmitter installation steps are documented in this manual:

• Rotate the transmitter on the sensor (optional) – see Chapter 2

• Rotate the user interface module on the transmitter (optional) – see Chapter 2

• Wire and ground the transmitter’s power supply – see Chapter 2

Transmitter housing cover

Clamping ring

• Wire the transmitter I/O:

- For the Model 2400S Analog transmitter, see Chapter 3

- For the Model 2400S PROFIBUS-DP and DeviceNet transmitters, see Chapter 4

2 Micro Motion® Model 2400S Transmitters

Page 7

Before You Begin

1.5 Flowmeter documentation

Table 1-1 lists documentation sources for other required information.

Tabl e 1-1 Flowmeter documentation resources

Topic Document

Sensor installation Sensor documentation shipped with sensor

Hazardous area installation See the approval documentation shipped with the

Transmitter configuration

Transmitter startup and use

Transmitter troubleshooting

transmitter, or download the appropriate

documentation from the Micro Motion web site

(www.micromotion.com)

• Micro Motion® Model 2400S Transmitters with

Analog Outputs: Configuration and Use Manual

• Micro Motion® Model 2400S Transmitters with

PROFIBUS-DP: Configuration and Use Manual

• Micro Motion® Model 2400S Transmitters with

DeviceNet

™

: Configuration and Use Manual

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

Installation Manual 3

Page 8

4 Micro Motion® Model 2400S Transmitters

Page 9

Chapter 2

Transmitter Orientation and Power Supply

2.1 Overview

This chapter describes:

• Rotating the transmitter on the sensor (optional)

• Rotating the user interface module on the transmitter (optional)

• Power supply requirements and wiring

2.2 Moisture protection

When rotating or wiring the transmitter, guard against condensation or excessive moisture inside the

transmitter housing. Be sure that the conduit openings are completely sealed after all installation and

wiring procedures have been performed.

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

CAUTION

Condensation or excessive moisture entering the transmitter could damage

the transmitter and result in measurement error or flowmeter failure.

To reduce the risk of measurement error or flowmeter failure:

• Do not mount the sensor so that the conduit openings on the transmitter point

upward.

• Ensure the integrity of gaskets and O-rings.

• Grease the O-rings every time the transmitter housing is opened and closed.

• Install drip legs on conduit or cable.

• Seal the conduit openings.

• Fully tighten all covers.

2.3 Rotating the transmitter on the sensor (optional)

For easier access to the user interface or the wiring terminals, the transmitter can be rotated on the

sensor in 45° increments, for eight different orientations.

To rotate the transmitter on the sensor:

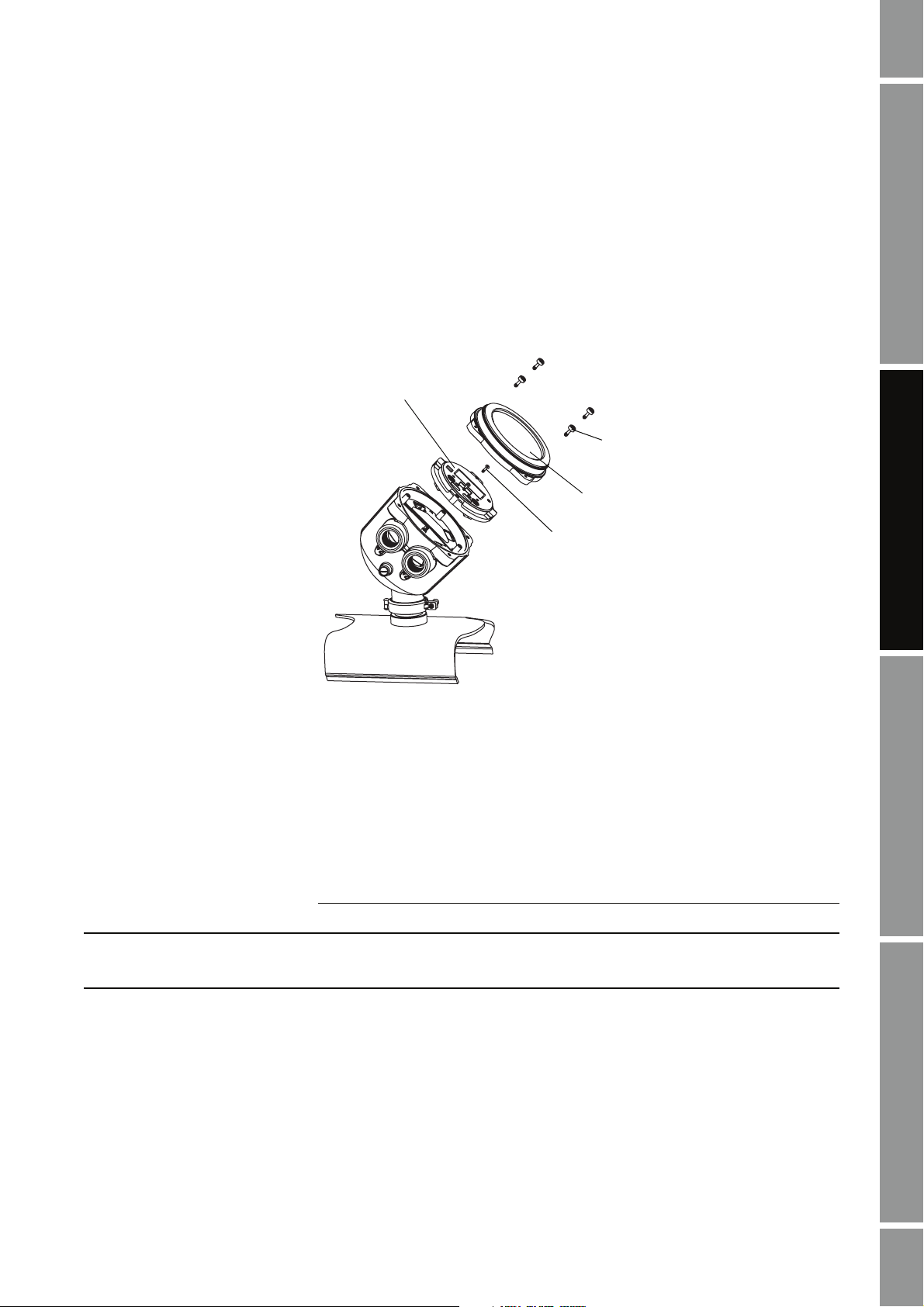

1. Referring to Figure 2-1, unscrew the clamp that holds the transmitter to the feedthrough.

2. Gently lift the transmitter on the feedthrough until it disengages from the notches on the

feedthrough. You will not be able to remove the transmitter completely.

3. Rotate the transmitter to the desired position.

4. Lower the transmitter, sliding it onto the notches on the feedthrough.

5. Replace the clamp and tighten the screw.

Installation Manual 5

Page 10

Transmitter Orientation and Power Supply

Figure 2-1 Rotating the transmitter on the sensor

Clamping ring

Feedthrough

CAUTION

Excessive rotation of the housing on the feedthrough can cause wiring

damage and result in measurement error or flowmeter failure.

To reduce the risk of damaging internal wiring, do not rotate the housing more than

°. You can rotate the transmitter either clockwise or counter-clockwise to reach

360

the desired position.

2.4 Rotating the user interface module on the transmitter (optional)

For easier access, the user interface module (whether or not the transmitter has an LCD display) can

be rotated on the transmitter up to 360° in 90° increments.

To rotate the user interface module on the transmitter:

Feedthrough notches

1. Remove power from the unit.

WARNING

Removing the transmitter housing cover in a hazardous area while the

transmitter is powered up can cause an explosion.

To avoid the risk of an explosion, remove power from the transmitter before

removing the transmitter housing cover.

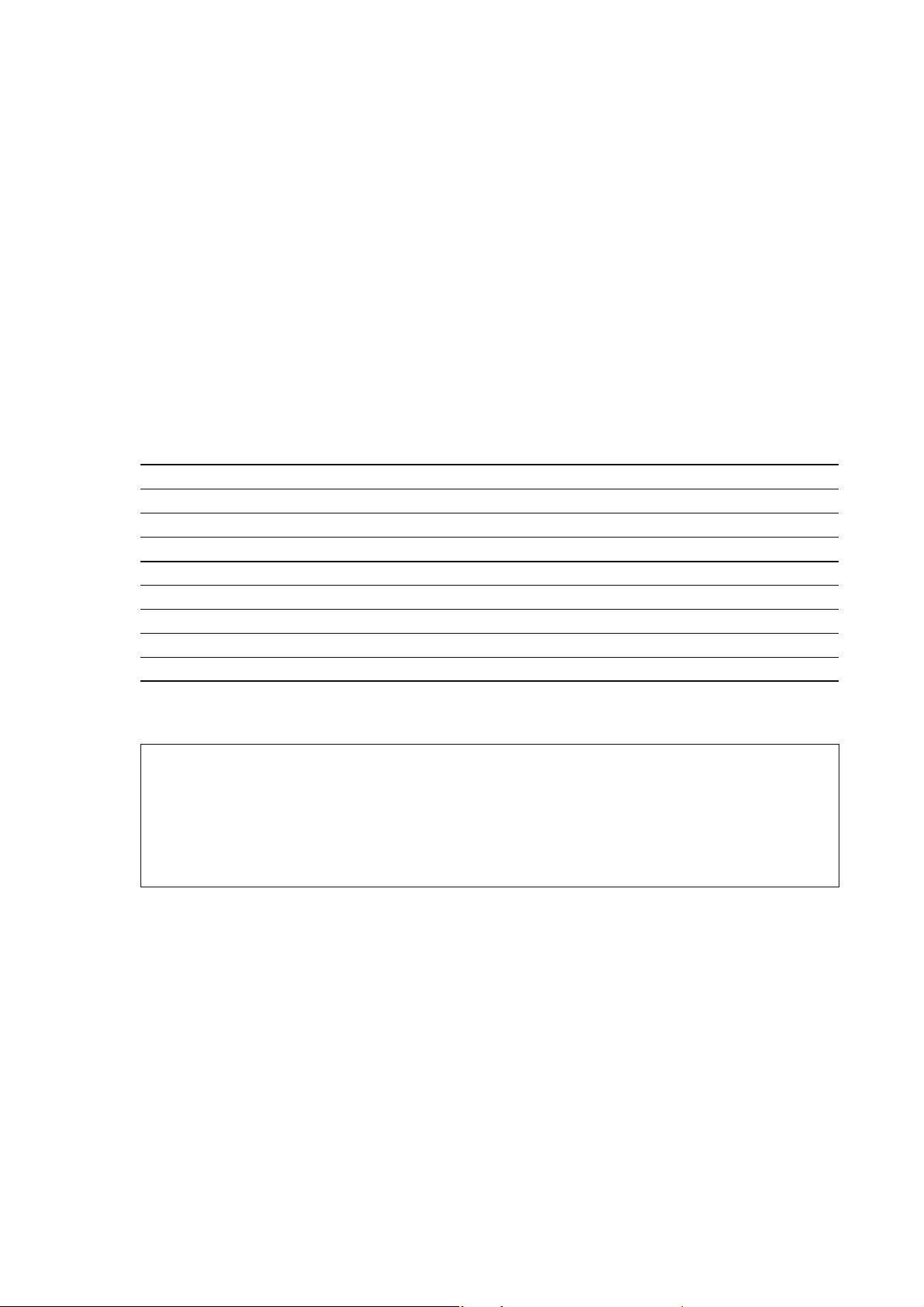

2. Referring to Figure 2-2, remove the transmitter housing cover and user interface module:

a. Loosen the four transmitter housing cover screws.

b. Remove the transmitter housing cover.

c. Loosen the two user interface screws.

d. Gently lift the user interface module, disengaging it from the user interface connector on

the transmitter.

6 Micro Motion® Model 2400S Transmitters

Page 11

Transmitter Orientation and Power Supply

3. On the back of the user interface module, four user interface connectors are provided. Rotate

the user interface module to the desired position and plug it into the user interface connector

on the transmitter. (See Figure 2-3 for another view of the user interface connector on the

transmitter.)

4. Tighten the user interface screws.

5. Replace the transmitter housing cover and tighten the transmitter housing cover screws.

6. Restore power to the transmitter if required.

Figure 2-2 Rotating the user interface module on the transmitter

User interface module

4 × Transmitter housing cover

screws (captive)

Transmitter housing cover

2 × User interface screws

(captive)

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

2.5 Power supply requirements

Model 2400S Analog and Model 2400S PROFIBUS-DP transmitters can accept either AC or DC

power. The transmitter automatically recognizes the source voltage. Power supply requirements for

these transmitter models are listed in Table 2-1.

Tabl e 2 -1 Power supply requirements

Power type

Transmitter

Model 2400S Analog

Model 2400S PROFIBUS-DP

(1) These requirements assume a single transmitter per cable. Connecting multiple transmitters to a single cable should generally be

avoided.

AC DC

• 85–265 VAC

•50/60 Hz

• 4 watts typical, 7 watts maximum

(1)

• 18–100 VDC

• 4 watts typical, 7 watts maximum

The Model 2400S DeviceNet transmitter is powered from the DeviceNet network per the DeviceNet

specification. There is no need to connect separate power-supply wiring for the Model 2400S

DeviceNet transmitter. Skip to Chapter 4.

Installation Manual 7

Page 12

Transmitter Orientation and Power Supply

2.5.1 DC power requirements for Model 2400S Analog and PROFIBUS-DP transmitters

If you are using DC power with a Model 2400S Analog or PROFIBUS-DP transmitter, the following

requirements apply:

• At startup, the transmitter power source must provide a minimum of 1 A of short-term current

per transmitter.

• Length and conductor diameter of the power cable must be sized to provide 18 VDC minimum

at the power terminals, at a load current of 0.5 A. To size the cable, refer to Table 2-2 and use

the following formula as a guideline:

MinimumSupplyVoltage 18V CableResistance CableLength× 0.5A×()+=

Tabl e 2 -2 Typical power cable resistances at 68 °F (20 °C)

Gauge Resistance

14 AWG 0.0050 Ω/foot

16 AWG 0.0080 Ω/foot

18 AWG 0.0128 Ω/foot

20 AWG 0.0204 Ω/foot

2

2,5 mm

2

1,5 mm

2

1 mm

0,75 mm

0,5 mm

(1) These values include the resistance of both high and low conductors in a cable.

Example

2

2

The transmitter is mounted 350 feet from a DC power supply. If you want to use

0,0136 Ω/meter

0,0228 Ω/meter

0,0340 Ω/meter

0,0460 Ω/meter

0,0680 Ω/meter

(1)

16 AWG cable, calculate the required voltage at the DC power supply as follows:

MinimumSupplyVoltage 18V CableResistance CableLength× 0.5A×()+=

MinimumSupplyVoltage 18V 0.0080 Ohms/ft 350 ft× 0.5A×()+=

MinimumSupplyVoltage 19.4V=

2.6 Wiring the power supply

Note: This procedure is required only for Model 2400S Analog and PROFIBUS-DP transmitters.

To wire the power supply:

1. Remove the transmitter housing cover and user interface module as described in Section 2.4.

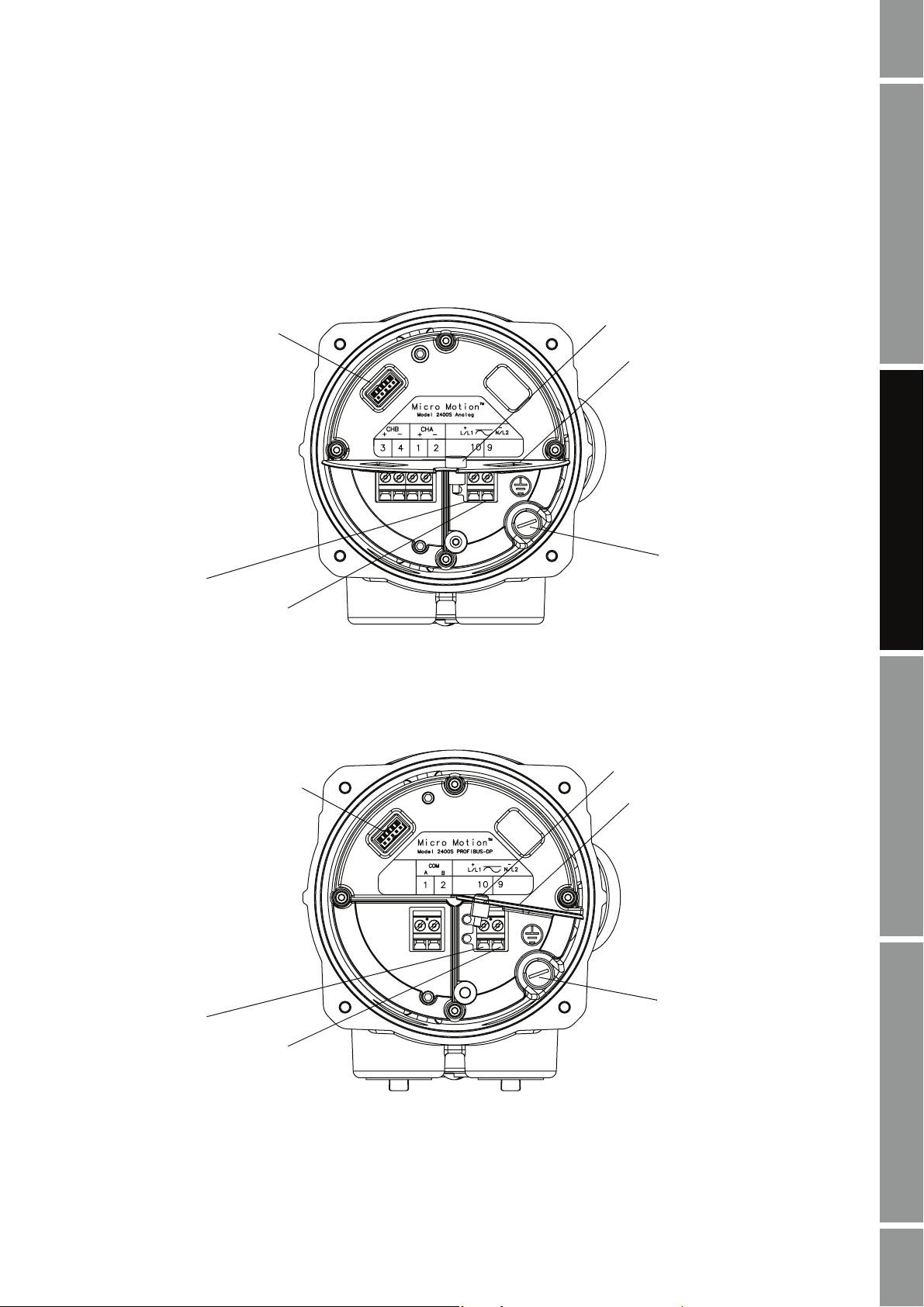

2. Unscrew the warning flap screw and raise the warning flap. Figure 2-3 shows the warning flap

in the open position.

3. Connect the power supply wires to terminals 9 and 10, as shown in Figure 2-3.

4. Ground the power supply to the transmitter’s internal grounding screw, shown in Figure 2-3.

5. Lower the warning flap and tighten the warning flap screw.

8 Micro Motion® Model 2400S Transmitters

Page 13

Transmitter Orientation and Power Supply

A user-supplied switch may be installed in the power supply line. For compliance with low-voltage

directive 73/23/EEC (European installations), a switch in close proximity to the transmitter is

required.

Figure 2-3 Wiring the transmitter power supply

Model 2400S Analog transmitter

User interface connector

+ (L)

– (N)

User interface connector

Warning flap screw

Warning flap

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

Transmitter internal

grounding screw

Model 2400S PROFIBUS-DP transmitter

Warning flap screw

Warning flap

Transmitter internal

+ (L)

– (N)

Installation Manual 9

grounding screw

Page 14

10 Micro Motion® Model 2400S Transmitters

Page 15

Chapter 3

I/O Wiring – Model 2400S Analog Transmitters

3.1 Overview

This chapter describes how to wire I/O for Model 2400S Analog transmitters.

Note: To wire I/O for Model 2400S PROFIBUS-DP and DeviceNet transmitters, see Chapter 4.

The 2400S Analog transmitter can be approved for Exe or Exi installation in Zone 1, or for

installation in Zone 2. If you are installing your transmitter in a hazardous area, be sure the transmitter

is approved for that area. It is the user’s responsibility to verify that the specific installation meets the

local and national safety requirements and electrical codes.

3.2 Moisture protection

When rotating or wiring the transmitter, guard against condensation or excessive moisture inside the

transmitter housing. Be sure that the conduit openings are completely sealed after all installation and

wiring procedures have been performed.

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

3.3 I/O options

Table 3-1 lists the options for the transmitter’s two I/O channels. Before wiring Channel B, ensure

that you know how it will be configured. For information on configuring Channel B for function and

power, see the manual entitled Micro Motion

Configuration and Use Manual.

CAUTION

Condensation or excessive moisture entering the transmitter could damage

the transmitter and result in measurement error or flowmeter failure.

To reduce the risk of measurement error or flowmeter failure:

• Do not mount the sensor so that the conduit openings on the transmitter point

upward.

• Ensure the integrity of gaskets and O-rings.

• Grease the O-rings every time the transmitter housing is opened and closed.

• Install drip legs on conduit or cable.

• Seal the conduit openings.

• Fully tighten all covers.

®

Model 2400S Transmitters with Analog Outputs:

Installation Manual 11

Page 16

I/O Wiring – Model 2400S Analog Transmitters

Tabl e 3 -1 Terminal configuration options

Channel Terminals Function Power

A 1 & 2 mA Internal

B 3 & 4 Frequency

mA Internal or external None

Discrete output Internal or external None

Discrete input Internal or external None

(1) For transmitters with Zone 1 Exi approval, I/O power is external only.

(2) Factory default.

(2)

Internal

3.4 Wiring the outputs (Zone 1 Exe and Zone 2)

Note: For wiring instructions for Zone 1 Exi transmitters, see Section 3.5.

WARNING

Hazardous voltage can cause severe injury or death.

To avoid the risk of hazardous voltage, shut off the power before wiring the

transmitter outputs.

(1)

(2)

or external

(2)

or external None

Comm

HART/Bell 202

WARNING

A transmitter that has been improperly wired or installed in a hazardous area

could cause an explosion.

To avoid the risk of an explosion:

• Make sure the transmitter is wired to meet or exceed local code requirements.

• Install the transmitter in an environment that complies with the classification tag

on the transmitter. See Appendix A.

To wi re the outp u ts:

1. Remove the transmitter housing cover and user interface module. See Section 2.4 for

instructions.

2. Wire the outputs according to the appropriate wiring diagram:

• For mA output wiring diagrams, see Section 3.4.1.

• For frequency output wiring diagrams, see Section 3.4.2.

• For discrete output wiring diagrams, see Section 3.4.3.

• For a discrete input wiring diagram, see Section 3.4.4.

3. Replace the user interface module and transmitter housing cover.

12 Micro Motion® Model 2400S Transmitters

Page 17

I/O Wiring – Model 2400S Analog Transmitters

3.4.1 mA output wiring

The wiring diagrams in this section are examples of proper wiring for the Model 2400S mA output.

The following options are shown:

• Internal power:

- Basic mA output wiring – Figure 3-1

- HART/analog single-loop wiring – Figure 3-2

• External power:

- Basic mA output wiring – Figure 3-3

- HART/analog single-loop wiring – Figure 3-4

• HART multidrop wiring, internal or external power – Figure 3-6

Note: If you plan to configure the transmitter to poll an external temperature or pressure device, you

must wire the mA output to support HART communications. You may use either HART/analog

single-loop wiring or HART multidrop wiring.

Figure 3-1 Basic mA output wiring – Internal power

–

820 Ohm maximum

loop resistance

+

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

Note: Channel B (terminals 3 and 4) can also

be configured this way.

Installation Manual 13

Page 18

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-2 HART/analog single-loop wiring – Internal power

–

For analog communications:

• 820 Ohm maximum loop

resistance

For HART communications:

• 600 Ohm maximum loop

resistance

• 250 Ohm minimum loop

resistance

HART-compatible

host or controller

+

Figure 3-3 Basic mA output wiring – External power

VDC

R

load

–

+

Note: See Figure 3-5 for voltage and

resistance values.

Note: Channel B (terminals 3 and 4)

can also be configured this way.

Excessive current will damage the transmitter.

Do not exceed 36 VDC input. Terminal current must be less than 500 mA.

–

+

CAUTION

14 Micro Motion® Model 2400S Transmitters

Page 19

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-4 HART/analog single-loop wiring – External power

–

R

(250–600 Ohm

resistance)

load

VDC

–

+

HART-

compatible host

or controller

+

Note: See Figure 3-5 for voltage and resistance values.

Figure 3-5 Required external voltage versus mA load resistance

If communicating with HART, a minimum of 250 Ohms is required.

36

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

32

28

OPERATING REGION

24

20

16

12

8

4

Minimum required external voltage (Volts)

0

0 200 400 600 800 1000 1200 1400

Total mA load resistance (Ohms)

Installation Manual 15

Page 20

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-6 HART multidrop wiring – Internal or external power

HART-compatible

host or controller

600 Ohm maximum resistance

250 Ohm minimum resistance

Model 2400S

Internal power

Note: For optimum HART communication, make sure the output loop

is single-point-grounded to an instrument-grade ground.

HART-compatible

transmitter

Model 2400S

External power

SMART FAMILY

transmitter

24 VDC loop power

™

supply required for

HART 4–20 mA

passive transmitters

3.4.2 Frequency output wiring

Frequency output wiring depends on whether you will use internal or external power. The following

diagrams are examples of proper wiring for these configurations:

• Internal power – Figure 3-7

• External power – Figure 3-8

Figure 3-7 Frequency output wiring – Internal power

–

000042

+

Counter

Output voltage level is +24 VDC ±3%

with high resistance load.

Note: See Figure 3-11 for output

voltage versus load resistance.

16 Micro Motion® Model 2400S Transmitters

Page 21

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-8 Frequency output wiring – External power

–

3–36 VDC

–

+

000042

+

Counter

Pull-up resistor

Note: See Figure 3-12 for recommended

resistor versus supply voltage.

CAUTION

Excessive current will damage the transmitter.

Do not exceed 36 VDC input. Terminal current must be less than 500 mA.

3.4.3 Discrete output wiring

Discrete output wiring depends on whether you will use internal or external power. The following

diagrams are examples of proper wiring for these configurations:

• Internal power – Figure 3-9

• External power – Figure 3-10

Figure 3-9 Discrete output wiring – Internal power

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

–

Total load

+

Note: See Figure 3-11 for output

voltage versus load information.

Installation Manual 17

Page 22

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-10 Discrete output wiring – External power

3–36 VDC

–

+

Pull-up resistor or

DC Relay

Maximum sink current: 500 mA

Note: Refer to Figure 3-12 for recommended

resistor versus supply voltage.

CAUTION

–

+

Excessive current will damage the transmitter.

Do not exceed 36 VDC input. Terminal current must be less than 500 mA.

Figure 3-11 Output voltage vs. load resistance – Internal power

24

22

20

18

16

14

12

10

8

6

4

High level output voltage (Volts)

2

0

0 20000 40000 60000 80000 100000

Open circuit output

voltage = 24 VDC ±3%

OPERATING REGION

Load resistance (Ohms)

18 Micro Motion® Model 2400S Transmitters

Page 23

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-12 Recommended pull-up resistor versus supply voltage – External power

5200

4800

4400

4000

3600

3200

2800

2400

2000

1600

Recommended

resistor value range

External pull-up resistor range (Ohms)

1200

800

400

6

12 18 24 30 36

Supply voltage (Volts)

Note: When using a discrete output to drive a relay, choose external pull-up to limit current to

less than 500 mA.

3.4.4 Discrete input wiring

Discrete input wiring depends on whether you will use internal or external power. The following

diagrams are examples of proper wiring for these configurations:

• Internal power – Figure 3-13

• External power – Figure 3-14

If external power is configured, power may be supplied by a PLC or other device, or by direct DC

input. See Table 3-2 for input voltage ranges.

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

Tabl e 3 -2 Input voltage ranges for external power

VDC Range

3–36 High level

0–0.8 Low level

0.8–3 Undefined

Installation Manual 19

Page 24

Figure 3-13 Discrete input wiring – Internal power

Figure 3-14 Discrete input wiring – External power

PLC or

other device

–

+

–

+

–

+

Direct DC input

(see Table 3-2)

(see Table 3-2

ORVDC

)

3.5 Wiring the outputs (Zone 1 Exi)

The following notes and diagrams are intended to be used as a guide for installing the 2400S Analog

transmitter with Zone 1 Exi approval.

Hazardous voltage can cause severe injury or death.

To avoid the risk of hazardous voltage, shut off the power before wiring the

transmitter outputs.

WARNING

20 Micro Motion® Model 2400S Transmitters

Page 25

I/O Wiring – Model 2400S Analog Transmitters

A transmitter that has been improperly wired or installed in a hazardous area

could cause an explosion.

To avoid the risk of an explosion:

• Make sure the transmitter is wired to meet or exceed local code requirements.

• Install the transmitter in an environment that complies with the classification tag

on the transmitter. See Appendix A.

3.5.1 Hazardous area safety

The proper barrier selection will depend on what output is desired, which approval is applicable, and

many installation-specific parameters. The information that is provided about IS barrier selection is

intended as an overview. Refer to barrier manufacturers for more detailed information regarding the

use of their products. Application-specific questions should be addressed to the barrier manufacturer

or to Micro Motion.

Tabl e 3 -3 Safety parameters

WARNING

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

Val ue

Parameter

Voltage (Ui) 36 V 36 V

Current (Ii) 500 mA 500 mA

Power (Pi) 1.5 W 1.5 W

Capacitance (C

Inductance (Li) 0.0 mH 0.0 mH

) 1.1 nF 1.1 nF

i

4–20 mA output Frequency/discrete output

Hazardous area voltage

The Model 2400S transmitter’s safety parameters require the selected barrier’s open-circuit voltage to

be limited to less than 36 VDC (V

= 36 VDC). This voltage is the combination of the maximum

max

safety barrier voltage (typically 28 VDC) plus an additional 2 VDC for HART communications when

communicating in the hazardous area.

Hazardous area current

The Model 2400S transmitter’s safety parameters require the selected barrier’s short-circuit currents

to sum to less than 500 mA (I

= 500 mA) for the milliamp outputs and 500 mA (I

max

= 500 mA) for

max

the frequency/discrete output.

Hazardous area capacitance

The capacitance (C

capacitance (C

) of the Model 2400S transmitter is 1.1 nF. This value added to the wire

i

) must be lower than the maximum allowable capacitance (Ca) specified by the IS

cable

barrier. Use the following equation to calculate the maximum length of the cable between the

transmitter and the barrier:

CiC

Installation Manual 21

≤+

cableCa

Page 26

I/O Wiring – Model 2400S Analog Transmitters

Hazardous area inductance

The inductance (Li) of the Model 2400S transmitter is 0.0 mH. This value plus the field wiring

inductance (Lcable) must be lower than the maximum allowable inductance (L

barrier. The following equation can then be used to calculate the maximum cable length between the

transmitter and the barrier:

) specified by the IS

a

3.5.2 Hazardous area mA wiring

Figure 3-15 illustrates the basic hazardous area wiring for the Model 2400S Analog transmitter’s mA

output.

Figure 3-15 Hazardous area mA output wiring

Hazardous area Safe area

L

iLcableLa

≤+

V

R

R

barrier

barrier

4–20 mA

out

R

load

Ground

V

in

Note: R

determine the proper V

barrier

and R

should be added together to

load

. Refer to Figure 3-16.

in

Note: Channel B (terminals 3 and 4) can also be

configured this way.

22 Micro Motion® Model 2400S Transmitters

Page 27

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-16 Safe area mA output load resistance values

R

= (Vsupply – 4)/0.022

max

Supply voltage VDC (Volts)

(Ohms)

barrier

+ R

load

External resistor R

If communicating with HART, a minimum of 250 Ohms and 17.5 V is required

1400

1200

1000

800

600

400

200

0

0 4 8 12 16 20 24 28 32 36

OPERATING REGION

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

3.5.3 Hazardous area frequency/discrete output wiring

The following frequency/discrete output wiring diagrams are examples of proper hazardous area

wiring for the transmitter’s frequency/discrete output:

• The diagram in Figure 3-17 utilizes a galvanic isolator that has an internal 1000 Ohm resistor

used for sensing current:

- ON > 2.1 mA

- OFF < 1.2 mA

• The diagram in Figure 3-18 utilizes a barrier with external load resistance.

Installation Manual 23

Page 28

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-17 Hazardous area frequency/discrete output wiring using galvanic isolator

Hazardous area Safe area

External power supply

V

R

out

load

COUNTER

Galvanic isolator

Figure 3-18 Hazardous area frequency/discrete output wiring using barrier with external load resistance

Hazardous area Safe area

V

R

barrier

R

load

COUNTER

out

R

barrier

V

in

Note: R

determine the proper V

barrier

and R

should be added together to

load

. Refer to Figure 3-19.

in

24 Micro Motion® Model 2400S Transmitters

Page 29

I/O Wiring – Model 2400S Analog Transmitters

Figure 3-19 Safe area frequency/discrete output load resistance values

Absolute minimum = 10 Ohms for supply voltage less than 5 Volts

200

190

180

170

160

150

140

130

minimum value (Ohms)

120

110

barrier

100

+ R

90

load

80

70

60

50

40

30

20

10

0

5 7 9 11131517192123252729313335

External pull-up resistor R

OPERATING REGION

Supply voltage VDC (Volts)

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

3.5.4 Hazardous area discrete input wiring

The following discrete input wiring diagram is an example of proper hazardous area wiring for the

transmitter’s discrete input.

Figure 3-20

Hazardous area Safe area

R

R

barrier

barrier

–

+

Direct DC input

(see Table 3-2

PLC or

other device

VDC

OR

)

(see Table 3-2

)

Installation Manual 25

Page 30

26 Micro Motion® Model 2400S Transmitters

Page 31

Chapter 4

I/O Wiring – Model 2400S PROFIBUS-DP and

DeviceNet Transmitters

4.1 Overview

This chapter describes how to wire I/O for Model 2400S PROFIBUS-DP and DeviceNet transmitters.

Note: To wire I/O for Model 2400S Analog transmitters, see Chapter 3.

It is the user’s responsibility to verify that the specific installation meets the local and national safety

requirements and electrical codes.

4.2 Moisture protection

When rotating or wiring the transmitter, guard against condensation or excessive moisture inside the

transmitter housing. Be sure that the conduit openings are completely sealed after all installation and

wiring procedures have been performed.

Condensation or excessive moisture entering the transmitter could damage

the transmitter and result in measurement error or flowmeter failure.

To reduce the risk of measurement error or flowmeter failure:

• Do not mount the sensor so that the conduit openings on the transmitter point

upward.

• Ensure the integrity of gaskets and O-rings.

• Grease the O-rings every time the transmitter housing is opened and closed.

• Install drip legs on conduit or cable.

• Seal the conduit openings.

• Fully tighten all covers.

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

CAUTION

Installation Manual 27

Page 32

I/O Wiring – Model 2400S PROFIBUS-DP and DeviceNet Transmitters

4.3 I/O wiring for Model 2400S PROFIBUS-DP transmitters

To connect the I/O wiring for a 2400S PROFIBUS-DP transmitter:

1. Remove the user interface cover and user interface module. See Section 2.4 for instructions.

2. Wire the transmitter to the PROFIBUS-DP segment according to the diagram in Figure 4-1.

Follow all local safety regulations.

3. Replace the user interface module and user interface cover.

Note: It is not necessary to open the power compartment to wire the outputs. Do not open the power

compartment unless you are also wiring the power supply.

Note: The PROFIBUS cable shield is required to be grounded at both ends. At the 2400S, ground the

cable shield in an appropriate cable gland. If an optional PROFIBUS-DP Eurofast M12 connector is

used, the cable shield is grounded via the threads of the connector.

WARNING

Hazardous voltage can cause severe injury or death.

To avoid the risk of hazardous voltage, shut off the power before wiring the

transmitter outputs.

WARNING

A transmitter that has been improperly wired or installed in a hazardous area

could cause an explosion.

To avoid the risk of an explosion:

• Make sure the transmitter is wired to meet or exceed local code requirements.

• Install the transmitter in an environment that complies with the classification tag

on the transmitter. See Appendix A.

28 Micro Motion® Model 2400S Transmitters

Page 33

I/O Wiring – Model 2400S PROFIBUS-DP and DeviceNet Transmitters

Figure 4-1 Model 2400S PROFIBUS-DP I/O wiring

Note: The Model 2400S

PROFIBUS-DP transmitter does

not have terminals for termination

wiring. An external terminator is

not required. The transmitter has

an internal terminator. There is a

switch on the user interface for

enabling internal termination. See

Section 4.3.1.

➯

Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin Power Supply I/O Wiring – DP and DNI/O Wiring – ANBefore You Begin

Spur to PROFIBUS-DP segment according to the

Installation Guideline for PROFIBUS-DP/FMS

available at www.profibus.org

COM A (green) COM B (red)

4.3.1 Enabling internal termination

Model 2400S PROFIBUS-DP transmitters have a switch on the user interface module to enable

internal termination impedance. Refer to Figure 4-2.

Figure 4-2 Model 2400S PROFIBUS-DP internal termination impedance switch

Switch to enable

internal termination

impedance

Installation Manual 29

Page 34

I/O Wiring – Model 2400S PROFIBUS-DP and DeviceNet Transmitters

4.4 I/O wiring for Model 2400S DeviceNet transmitters

Connect the transmitter to the DeviceNet segment according to the diagram in Figure 4-3. The

transmitter is shipped with a DeviceNet male sealed Micro Connector (Eurofast) that has been

preinstalled and wired according to the DeviceNet specification.

Follow all local safety regulations.

WARNING

A transmitter that has been improperly wired or installed in a hazardous area

could cause an explosion.

To avoid the risk of an explosion:

• Make sure the transmitter is wired to meet or exceed local code requirements.

• Install the transmitter in an environment that complies with the classification tag

on the transmitter. See Appendix A.

Figure 4-3 Model 2400S DeviceNet I/O wiring

➯

Attach a 5-pin female

Eurofast connector here

30 Micro Motion® Model 2400S Transmitters

Page 35

Appendix A

Dimensions and Specifications

A.1 Dimensions

Figure A-1 shows the dimensions of the Model 2400S transmitter. For sensor dimensions, see the

sensor data sheet.

Figure A-1 Transmitter dimensions

Dimensions in

inches

(mm)

4.545

(115,4)

3.140

(79,7)

Return Policy IndexSpecifications

4.689

(119,1)

3.140

(79,7)

4.344

(110,3)

.800

(20,3)

6.256

(158,9)

1.600

(40,6)

3.649

(92,7)

Cover dimensions for stainless

steel housing

Installation Manual 31

Page 36

Dimensions and Specifications

A.2 Physical specifications

Housing Polyurethane-painted aluminum

Optional: 304L stainless steel with surface finish of 32 RA

Weight Transmitter is mounted integrally with sensor. For weight of flowmeter, see product

data sheet for sensor.

Mounting and cabling Model 2400S transmitters are mounted integrally with sensor. The transmitter can

be rotated on the sensor up to 360° in 45° increments.

A.3 Power supply – Models 2400S Analog and PROFIBUS-DP

Self-switching AC/DC input, automatically recognizes supply voltage.

Complies with low voltage directive 73/23/EEC per IEC 61010-1.

Installation (Overvoltage) Category II, Pollution Degree 2.

AC • 85–265 VAC

•50/60 Hz

• 4 watts typical, 7 watts maximum

DC • 18–100 VDC

• 4 watts typical, 7 watts maximum

Fuse IEC 127-1.25 fuse, slow blow

32 Micro Motion® Model 2400S Transmitters

Page 37

Dimensions and Specifications

A.4 Electrical connections

Model 2400S Analog

Input and output connections Two pairs of wiring terminals for transmitter inputs/outputs. Screw terminals accept

solid or stranded conductors, 26 to 14 AWG (0,14 to 2,5 mm

Power connections One pair of wiring terminals accepts AC or DC power. One internal ground lug for

power supply ground wiring.

Digital comm maintenance

connections

Screw terminals accept solid or stranded conductors, 26 to 14 AWG

(0,14to2,5mm

Two clips for temporary connection to the service port.

Two clips for temporary connection to HART/Bell 202 terminals.

2

).

Model 2400S PROFIBUS-DP

PROFIBUS-DP segment One pair of wiring terminals for connection to PROFIBUS-DP segment. Connection

type:

• Screw terminals accept solid or stranded conductors, 26 to 14 AWG

(0,14to2,5mm

2

).

• Five-pin PROFIBUS-DP M12 (Eurofast) female connector (optional).

Power connections One pair of wiring terminals accepts AC or DC power. One internal ground lug for

power supply ground wiring.

Digital comm maintenance

Screw terminals accept solid or stranded conductors, 26 to 14 AWG

(0,14to2,5mm

Two clips for temporary connection to the service port.

2

).

connections

Model 2400S DeviceNet

DeviceNet segment One pre-installed male 5-pin Eurofast connector for I/O and power supply wiring

Digital comm maintenance

Two clips for temporary connection to the service port.

connections

2

).

Return Policy IndexSpecifications

Installation Manual 33

Page 38

Dimensions and Specifications

A.5 User interface

Model 2400S Analog

Model 2400S PROFIBUS-DP

With display Without display

With display Without display

Model 2400S DeviceNet

34 Micro Motion® Model 2400S Transmitters

With display Without display

Page 39

Dimensions and Specifications

Interface functions

All models with or without display • Suitable for hazardous area installation.

• User interface module can rotate 360° on the transmitter in 90° increments.

• Three-color status LED on user interface module indicates flowmeter condition at

a glance, using a solid green, yellow, or red light. Zero in progress is indicated by

a flashing yellow light.

• Two clips for service port connections (requires removing transmitter housing

cover).

Model 2400S Analog with or

without display

Model 2400S DeviceNet, with or

without display

Model 2400S PROFIBUS-DP, with

or without display

All models with display • Depending on purchase option, transmitter housing cover has glass or

All models without display • Transmitter housing cover is all metal (no lens).

• Two clips for HART/Bell 202 connections (requires removing transmitter

housing cover).

• HART security switch (requires removing transmitter housing cover).

• Three rotary switches for selecting network address and baud rate (network

address and baud rate are also software selectable).

• Module and network LEDs to indicate DeviceNet status.

• Three rotary switches for selecting network address (network address is also

software selectable).

• DIP switch for enabling internal termination resistor.

• Address and network LEDs that indicate PROFIBUS-DP status.

plastic lens.

• User interface module includes LCD panel. LCD line 1 displays process variable;

line 2 displays engineering unit of measure.

• Display update rate is user-configurable: 1 to 10 seconds at 1-second increments.

• Display backlighting may be adjusted or turned off.

• Operator access to transmitter menus is provided via optical switches that are

operated through the lens. LED indicators show when a “button” has been

pressed.

• Infrared port allows access to service port from IrDA device (e.g., PDA running

Pocket ProLink) without removing transmitter housing cover.

• Access to user interface requires removing transmitter housing cover.

• Zero button allows flowmeter zero from field (requires removing transmitter

housing cover).

•No IrDA.

Return Policy IndexSpecifications

Installation Manual 35

Page 40

Dimensions and Specifications

A.6 Input/output signals

Model 2400S Analog (Zone 1 Exe or Zone 2)

Channel A One active or passive 4–20 mA output

• Not intrinsically safe

• Isolated to ±50 VDC from all other outputs and earth ground

• Maximum load limit: 820 ohms

• Can report mass flow, volume flow, density, temperature, or drive gain

• Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (June 1994)

Channel B (configurable) One active or passive 4–20 mA output

• Not intrinsically safe

• Isolated to ±50 VDC from all other outputs and earth ground

• Maximum load limit: 820 ohms

• Can report mass flow, volume flow, density, temperature, or drive gain

• Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (June 1994)

One active or passive frequency/pulse output

• Not intrinsically safe

• Can report mass flow or volume flow, which can be used to indicate flow rate or

total

• Scalable to 10,000 Hz

•Power:

- Internal (active): +24 VDC ±3% with a 2.2 kohm internal pull-up resistor

- External (passive): +36 VDC maximum, +24 VDC typical

• Output is linear with flow rate to 12,500 Hz

One active or passive discrete output

• Not intrinsically safe

• Can report five discrete events, flow switch, forward/reverse flow, calibration in

progress, or fault

•Power:

- Internal (active): +24 VDC ±3% with a 2.2 kohm internal pull-up resistor

- External (passive): +36 VDC maximum, +24 VDC typical

• Maximum sink capability: 500 mA

One active or passive discrete input

• Not intrinsically safe

•Power:

- Internal (active): +24 VDC, 10 mA maximum source current

- External (passive): +3 to 36 VDC maximum

• Can reset all totals, reset mass total, reset volume total, or start sensor zero

36 Micro Motion® Model 2400S Transmitters

Page 41

Dimensions and Specifications

Model 2400S Analog (Zone 1 Exi)

Channel A One passive 4–20 mA output

• Intrinsically safe

• Isolated to ±50 VDC from all other outputs and earth ground

• Maximum load limit: 820 ohms

• Can report mass flow, volume flow, density, temperature, or drive gain

• Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (June 1994)

Channel B (configurable) One passive 4–20 mA output

• Intrinsically safe

• Isolated to ±50 VDC from all other outputs and earth ground

• Maximum load limit: 820 ohms

• Can report mass flow, volume flow, density, temperature, or drive gain

• Output is linear with process from 3.8 to 20.5 mA, per NAMUR NE43 (June 1994)

One passive frequency/pulse output

• Intrinsically safe

• Can report mass flow or volume flow, which can be used to indicate flow rate or

total

• Scalable to 10,000 Hz

• Power: External (passive): +36 VDC maximum, +24 VDC typical

• Output is linear with flow rate to 12,500 Hz

One passive discrete output

• Intrinsically safe

• Can report five discrete events, flow switch, forward/reverse flow, calibration in

progress, or fault

• Power: External (passive): +36 VDC maximum, +24 VDC typical

• Maximum sink capability: 500 mA

One passive discrete input

• Intrinsically safe

• Power: External (passive): +3 to 36 VDC maximum

• Can reset all totals, reset mass total, reset volume total, or start sensor zero

Entity parameters

Parameter

Voltage (U

Current (I

Power (Pi) 1.5 W 1.5 W

Capacitance (Ci) 1.1 nF 1.1 nF

Inductance (L

) 36 V 36 V

i

) 500 mA 500 mA

i

) 0.0 mH 0.0 mH

i

4–20 mA output

Return Policy IndexSpecifications

Value

Frequency/

discrete output

Model 2400S PROFIBUS-DP Digital 2-way PROFIBUS-DP signal.

Certified by PNO.

Model 2400S DeviceNet Digital 2-way DeviceNet signal.

Certified by ODVA.

Installation Manual 37

Page 42

Dimensions and Specifications

A.7 Digital communications

All versions

Service port One service port for temporary connections (requires removing transmitter

Wireless If transmitter has display, service port can be accessed with IrDA device (for

Model 2400S Analog

HART/Bell 202 HART signal is superimposed on the primary milliamp output (Channel A), and is

Model 2400S PROFIBUS-DP

PROFIBUS-DP Digital 2-way communication protocol

Model 2400S DeviceNet

DeviceNet Digital 2-way communication protocol

housing cover)

Uses RS-485 Modbus signal, 38.4 kBaud, one stop bit, no parity

Address: 111 (not configurable)

example, a PDA running Pocket ProLink) without removing transmitter housing

cover. If transmitter has no display, access to service port requires removing

transmitter housing cover.

available for host system interface:

• Frequency: 1.2 and 2.2 kHz

• Amplitude: to 1.0 mA

• 1200 baud, one stop bit, odd parity

• Address: 0 (default), configurable

• Requires 250 to 600 Ω resistance

• Automatically recognizes network baud rate

• Address selectable by 3 rotary switches, or software selectable

• Address and baud rate selectable by 3 rotary switches (2 to select address, 1 to

select baud rate), or software selectable

A.8 Host interface

®

Model 2400S Analog ProLink

HART DD file supports all functionality.

Model 2400S PROFIBUS-DP ProLink II v2.5 from Micro Motion supports full device configuration.

• GSD file conforming to the PROFIBUS-DP specification:

• DD file conforming to Profibus EDDL specification

Model 2400S DeviceNet ProLink II v2.5 from Micro Motion supports full device configuration.

• EDS file conforming to the DeviceNet specification:

II v2.5 from Micro Motion supports full device configuration.

- Provides Profibus Class 1 Master functions

- Enables reading and controlling all process data

- Provides Profibus Class 2 Master functions

- Enables device configuration

- Supports Siemens Simatic PDM

- Enables device configuration

38 Micro Motion® Model 2400S Transmitters

Page 43

Dimensions and Specifications

A.9 Environmental limits

Ambient temperature limits Operating and storage: –40 to +140 °F (–40 to +60 °C)

Below –4 °F (–20 °C), LCD responsiveness decreases and LCD may become

difficult to read. Above 131 °F (55 °C), some darkening of the LCD panel might

occur.

ATEX requires limiting ambient temperature to below 131 °F (55 °C).

Humidity limits 5 to 95% relative humidity, non-condensing at 140 °F (60 °C)

Vibration limits Meets IEC68.2.6, endurance sweep, 5 to 2000 Hz, 50 sweep cycles at 1.0 g

A.10 Environmental effects

All models

EMI effects Meets EMC directive 89/336/EEC per EN 61326 Industrial

Conforms to NAMUR NE21 Version: 10.02.2004

Model 2400S Analog only

Ambient temperature effect On mA output: ±0.005% of span per °C

Return Policy IndexSpecifications

A.11 Hazardous area classifications

All models

(1)

C-US

CSA

AT E X

(2)

Zone 1 Analog II 2GD EEx mb e ib IIC T4

Zone 2 Analog or

PROFIBUS-DP

Zone 2 DeviceNet II 3G Ex nA II T5

(1) CSA is a Canadian approvals agency that provides approvals accepted both in the U.S.A. and in Canada.

(2) ATEX is a European directive.

Class I Division 2 Groups A, B, C, D

Class II Division 2 Groups F and G

II 3G EEx n A C II T5

II 3D IP66/IP67 T70°C

II 3D IP66/IP67 T70°C

Installation Manual 39

Page 44

40 Micro Motion

®

Model 2400S Transmitters

Page 45

Appendix B

Return Policy

Micro Motion procedures must be followed when returning equipment. These procedures ensure legal

compliance with government transportation agencies and help provide a safe working environment for

Micro Motion employees. Failure to follow Micro Motion procedures will result in your equipment

being refused delivery.

Information on return procedures and forms is available on our web support system at

www.micromotion.com, or by phoning the Micro Motion Customer Service department.

B.1 New and unused equipment

Only equipment that has not been removed from the original shipping package will be considered new

and unused. New and unused equipment requires a completed Return Materials Authorization form.

Return Policy IndexSpecifications

B.2 Used equipment

All equipment that is not classified as new and unused is considered used. This equipment must be

completely decontaminated and cleaned before being returned.

Used equipment must be accompanied by a completed Return Materials Authorization form and a

Decontamination Statement for all process fluids that have been in contact with the equipment. If a

Decontamination Statement cannot be completed (e.g., for food-grade process fluids), you must

include a statement certifying decontamination and documenting all foreign substances that have

come in contact with the equipment.

Installation Manual 41

Page 46

42 Micro Motion® Model 2400S Transmitters

Page 47

Index

C

Channels

configuration options

D

DeviceNet

Dimensions

Discrete input wiring

Discrete output wiring

Documentation

F

Flowmeter

Frequency output wiring

I

I/O

Impedance switch

Installation

M

mA output wiring

Moisture protection

27, 30

31

external power

internal power

17

3

components

documentation

external power

internal power

analog wiring

configuration options

DeviceNet wiring

PROFIBUS-DP wiring

2

16

11

29

I/O wiring

moisture protection

overview

power supply requirements

rotating transmitter on sensor

rotating user interface module on transmitter

transmitter dimensions

11, 27, 30

2

13

external power

HART multidrop

HART single-loop

external power

internal power

internal power

13

11, 28, 30

19

17

18

3

16

17

11, 28, 30

27, 30

27, 28

5

7

5

31

14

16

15

14

5, 11, 27

6

P

Power supply

requirements

wiring

PROFIBUS-DP

impedance switch

R

Return policy

S

Safety messages

2

Sensor

Specifications

T

Transmitter

dimensions

documentation

I/O options

I/O wiring

installation overview

orientation

rotating on sensor

rotating user interface module

specifications

U

User interface module

rotating

W

Wiring

11, 27

analog

DeviceNet

discrete input

discrete output

external power

internal power

frequency output

external power

internal power

I/O options

7

8

27, 28

29

41

1

31

2

31

3

1, 11, 28, 30

11, 27

5

5

31

6

11

30

19

17

18

17

16

17

16

1, 11, 30

Return Policy IndexSpecifications

2

6

Installation Manual 43

Page 48

Index

mA output 13

external power

HART multidrop

HART single-loop, external power

HART single-loop, internal power

internal power

moisture protection

power supply wiring

PROFIBUS-DP

14

16

15

14

13

11, 27

8

28

44 Micro Motion® Model 2400S Transmitters

Page 49

Page 50

©2007, Micro Motion, Inc. All rights reserved. P/N 20003402, Rev. C

*20003402*

For the latest Micro Motion product specifications, view the

PRODUCTS section of our web site at www.micromotion.com

Micro Motion Inc. USA

Worldwide Headquarters

7070 Winchester Circle

Boulder, Colorado 80301

T +1 303-527-5200

+1 800-522-6277

F +1 303-530-8459

Micro Motion Europe

Emerson Process Management

Neonstraat 1

6718 WX Ede

The Netherlands

T +31 (0) 318 495 670

F +31 (0) 318 495 689

Micro Motion United Kingdom

Emerson Process Management Limited

Horsfield Way

Bredbury Industrial Estate

Stockport SK6 2SU U.K.

T +44 0870 240 1978

F +44 0800 966 181

Micro Motion Asia

Emerson Process Management

1 Pandan Crescent

Singapore 128461

Republic of Singapore

T +65 6777-8211

F +65 6770-8003

Micro Motion Japan

Emerson Process Management

1-2-5, Higashi Shinagawa

Shinagawa-ku

Tokyo 140-0002 Japan

T +81 3 5769-6803

F +81 3 5769-6844

Loading...

Loading...