Page 1

INSTRUCTION

MANUAL

GEBRAUCHSANWEISUNG----

MANUEL

D'INSTRUCTION

MODO

DUSO-

---

101,/

300

....

3

00

-

-

--

-

-

/-

-

Page 2

IMPORTANT

SAFETY

INSTRUCTIONS

-

Do

not

unplug

by

pulling

on

cord

To

unplug,

grasp

the

plug,

not the

cord.

-

Keep

fingers

away

from

all

moving

parts.

Special

care

is

required

around

the

sewing

needle

When

using

an

electrical

appliance,

basic

safety

precautions

should

always

be

followed,

including

the

following:

-

Always

use the

proper

needle

plate

The

wrong

plate

can

cause

the

needle

to

break.

Read

all

instruction

before

using

this

household

sewing

machine.

-

Do

not

use

bent

needles

-

Do

nor

pull

or

push

fabric

while

stitching.

It

may

deflect

the

needle

causing

it

to

break.

DA

NCGER

-

to

reduce

the

risk

of

electrk•

shock:

-

Switch

the

sewing

machine

off

when

making

any

adjustment

in

the

needle

area,

such

as

This

household

sewing machine

should

never

be

left

unattended

when

plugged

in.

Always

threading

needle,

changing

needle,

threading

bobbin,

or

changing

presser

foot,

and

the like

unplug

it

from

the

electric

outlet

immediately

after

using

and

before

cleaning.

Always

unplug

-

Always

unplug

the

sewing

machine

from

the

electrical

outlet

when

making

any

user

servicing

before

relamping

Replace

bulb

with

same

type

and

rating,

15

W

max

(Model

3003)or

mentioned

in

the

instruction

manual

3 W (Mdedls

3005+3007)

-

Use

only

identical

replacement

parts.

WARN

ING

-

To

reduce

the

risk

of

burns,

fire,

electric

shock,

or

injury

to

persons:

-

Do

not

allow

to

be

used

as

a

toy.

Close

attention

is

necessary

when

this

appliance

is

used

by

"SAVE

THESE

INSTRUCTIONS"

or

near

children,

-

Use

this

sewing

machine

only

for

its

intended

use

as

described

in

this

manual.

Use

only

attachments

recommended

by

the

manufacturer

as

contained

in

this

manual.

Warning

-

Never

operate

this

sewing

machine

if

it

has

a

damaged

cord

or

plug,

if

it

is

not

working

prop

When

workng

close

to

the

needle,

be

very

careful

not

to

prick

your

fingers

erly,

if

it

has

been

dropped

or

damaged,

or

dropped

into

water

Return

the

sewing

machine

to

the

nearest

authorized

dealer

or

service

center

for

examination,

repair,

electrical

or

me-

chanicol

adjustment

-

This

machine

is

equipped

with

a

special

connexion

cord

which,

if

damaged,

mustI

be

replaced

by

an

identical

cord

This

can

be

obtained

from

the

dealer.

Never

operate

the

sewing

machine

with

any

air

opening

blocked.

Keep

ventilation

openings

of

the

sewing

machine

and

foot

controller

free

from

the

accumulation

of

lint,

dust

and cloth

Never

drop

or

insert

any

object

into

any

opening

-

Do

not

use

outdoors

-

Do

not

operate

where

aerosol

(spray)

products

are

being

used

or

where

oxygen

is

being

administered

To

disconnect,

turn

all

controls

to

the

off

position,

then

remove

plug

from

outlet

ao

Page 3

TABLE

OF

CONTENTS

Sewing

an

Angle...........

....

A-16

Straight

Stitching

on

Heavy

Fabrics

...

A-16

1

MAIN

PARTS

Zigzag

Stitch

A

17

Designation of

Parts

....

A

3.4

Foot

Storage

Compartment

..

A-5

IV

UTILITY

STITCHES

Extension

Table (Accessory

BOX)-~

A-5

Quick Overcasting

. .... -

111',.....

A

17

Assembling

Stretch

Fabrics

(Model

3007)

-..........

..

A-

17

11

GETTING

READY

TO

SEW

Overedge

Stitch

...

A.17

Connecting

the

Machine

to

the

Power

Supply

....-....

A-6

Double

Overcasting

A-

I8

Needle

Up/Down

(Model

3007)

~..

.-...

A-6

Elastic Stitch.

-..........

A-18

Foot

Control

..... ...

.....

........

.....

A-6

Triple

Seam

..

......

. .........

A

19

Speed Reducer

....................

.......................

A-6

Interlock

Shell

Stitching

.......

A-19

S e w

in g L

ig

ht

...........

.........

...........

...........

........

.......

...........

. . . .... .A -6

Sew

ing o n B

utto

ns

..........

......

A

-2

0

F

o o

t P

re

ssu

re

..............

..............

................

...... ....

..........

..

.....

..

..... A -7 A uto m a

tic B utto

nho

le

..

............

2..............

....................

.. ..

... A

-2 0 , 2 1

D

ropp

ing

the Feed D og

........................

.. .

........

. .

........

......... ... ...

....... A -7 M a

nual

Buttonho

le

....

2...........................-

....

2............... A 2 2

To

Snap

Off

and

On

the

Presser

Foot,....

.... ......

A-7

Corded

Buttonhole

.A23

To

Rem

ove

and

Attach

the

Foot

Holder

............................

.....

....

A-8

Zipper

Insertion

.....

...................

............

A-23,

24

S e w ing

in R e

ve rse

........

I.........

....

........

.... ..

.............

.....

....................

A

-8 N a

rrow

H e m ....

...............

...

.............

.... .........

..............

A 2 5

S e a m G u

id e ........

...............

............................ .... . . . . . . . .

. . . . . . . . . . . . . ........... A

-8

B

lin d S

titc h ......

. . . . . . . . ..

. . . . . . . . .

.......

I.. ''.........................

......... .. .. A -2

6

C h a n g

in g the N e e d le

.

A

-........

S.......................................................

.................

.... A -8

Fabrics,

Threads

and

Needles

.......................

.................

........

...

A-9

V

D

ECO

RATIVE

SEW

IN

G

Placing

the Thread S pool

.............. .............

..............

........

........

...... A -9

Decorative

Sa

tin

Stitch

............................

....................................

D

ec...o.rat...

A 2 7

A

dditional

Spool

Pin

.A.. ....

.................................

.

.......

A

-9

Stretch

Stitch

Patterns

...................

................

..... A 27

R e m

oving

the

B

ob b in

.................

.......

...... .................

.........................

.. ...... A -9 A d

justing

Stretch

Stitch

Ba

la

nce

.........

..

...........

............................

.... . . . . ..

. . . . .A -2

7

W

ind ing

the B o

b b

in

(M o d e l

3003

) -. ... .... ..

............

.........

.......

...................

. .... A -10

Sm

ocking

.....

..........

...............

.................... ......

.. .. . . . . .. . . ............... A -2

8

Inserting

the

Bobbin

(ModelA uting

Stretch

Stitch.........

.. .. .Balance..... A... 2n.......................

A-28

W

inding

the

Bobbin

(M

odel

3005+3007)

.....................

A-11

Pin-Tucking

.............

.....................................

A-29

Inserting

the

Bobbin

(Model

3005+3007)

.....

............... . ...

A-11

Shell

Tuck

...................

A

29

Threading

the M achine

.................................

.. .

..... ........

A-12

Fagoting

(M

odel

3007)

............................

................ A 29

Automatic Needle

Threader

(Model

3005+3007)

A-13

Applications

..............

...........................................

A-30

Drawing Up the

Bobbin

Thread

..........

A-14

Assembling

Edge-to-Edge

.....................................

A-30

B

alancing

the

Thread

Tension

....... ....

............

......

.............................

...... A -14

Pattern

Selection

..- .... ......................

A-15

VI

MAINTENANCE

Stitch W idth

....... ............

A

-..................

......

.........

. ..

C leaning

the

Bobbin

C

ase

...................................

A

-31

S

tiict

L

e n ghe ..

..... .....

....

.....

....

.....

.....

....

.....

....

.....

.....

....

.....

.....

....

.....

....

.....

.H

oo1kCle-in

g h e.Ho

k ..

.....

....

.....

.....

....

.....

....

.....

.....

....

.....

....

..... .....

....

..... A .3

Decentering

the

Needle

..........................................

.................

.....

.

A-15

Refitting

the

Bobbin

C

ase

..........

A-3l1

III

BA SIC

SEW

IN

G

M

inor

Disorders

............................................

..............

..

A-32,

33

Straight

Stitch

...........

........

A-16

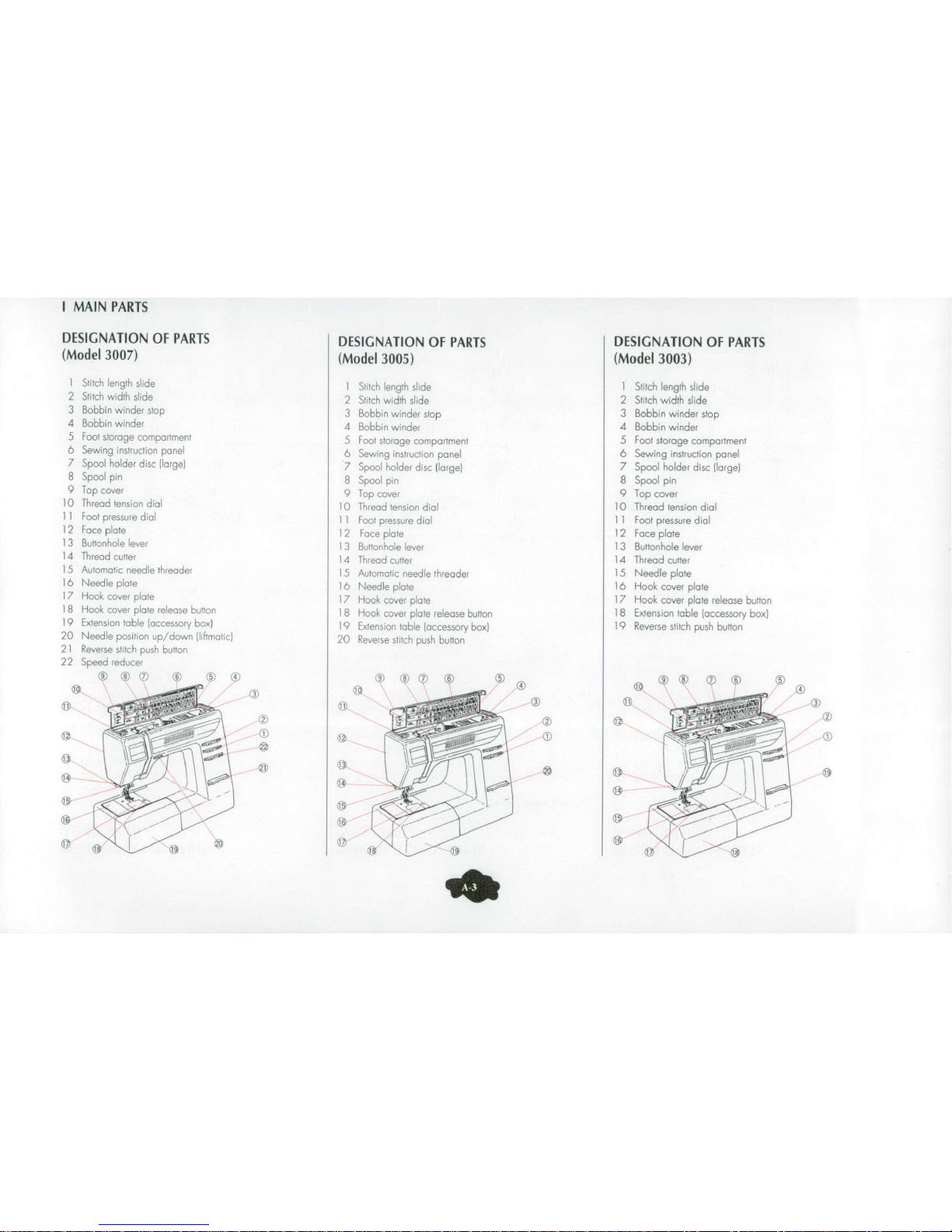

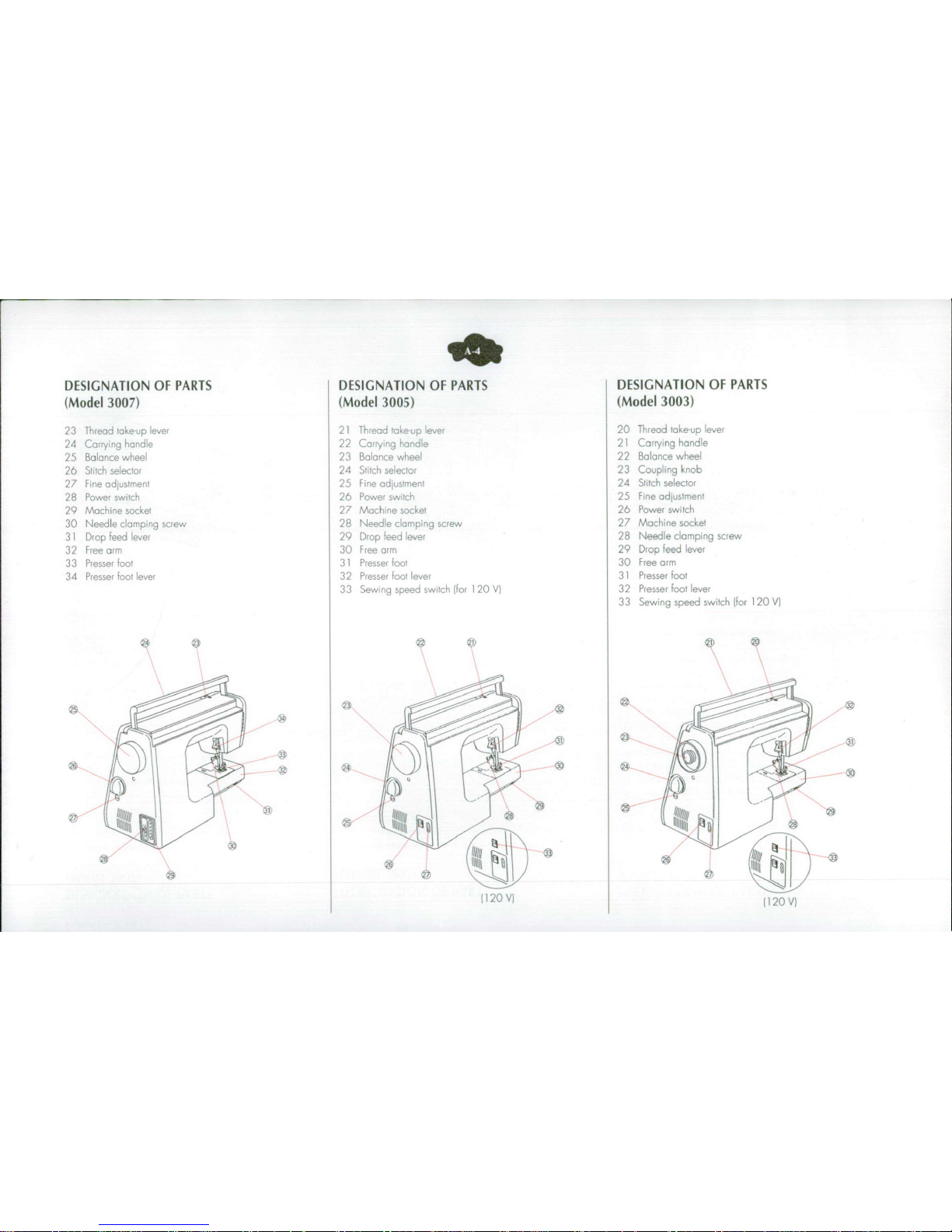

Page 4

I

MAIN

PARTS

DESIGNATION

OF

PARTS

DESIGNATION

OF

PARTS

DESIGNATION

OF

PARTS

(Model

3007)

(Model

3005)

(Model

3003)

1

Stitch

length

slide

I

Stitch

length

slide

I

Stitch

length

slide

2

Stitch

width

slide

2

Stitch

width

slide

2

Stitch

width

slide

3

Bobbin

winder

stop

3

Bobbin

winder

stop

3

Bobbin

winder

stop

4

Bobbin

winder

4

Bobbin

winder

4

Bobbin

winder

5

Foot

storage

compartment

5

Foot

storage

compartment

5

Foot

storage

comportment

6

Sewing

instruction

panel

6

Sewing

instruction

panel

6

Sewing

instruction

panel

7

Spool

holder

disc

(large)

7

Spool

holder

disc

(large)

7

Spool

holder

disc

(large)

8

Spool

pin

8

Spool

pin

8

Spool

pin

9

Top

cover

9

Top

cover

9

Top

cover

I0

Thread

tension

dial

10

Thread

tension

dial

10

Thread

tension

dial

1 I

Foot

pressure

dial

1

I

Foot

pressure

dial

1 I

Foot

pressure

dial

12

Face

plate

12

Face

plate

12

Face

plate

13

Buttonhole

lever

1 3

Buttonhole

lever

1 3

Buttonhole

lever

14

Thread

cutter

14

Thread

cutter

14

Thread

cutter

I5

Automatic

needle

threader

15

Automatic

needle

threader

15

Needle

plate

16

Needle

plate

16

Needle

plate

16

Hook

cover

plate

17

Hook

cover

plate

17

Hook

cover

plate

17

Hook

cover

plate

release

button

18

Hook

cover

plate

release

burton

I8

Hook

cover

plate

release

button

18

Extension

table

(accessory

box)

19

Extension

table

laccessory

box)

19

Extension

table

(accessory

box)

19

Reverse

stitch

push

button

20

Needle

position

up/down

(/iltmoaic)

20

Reverse

stitch

push

button

21

Reverse

stitch

push

button

22

Speed

reduce

@.

"

Q,

y....

>@

t

@

,'---Ž<

14

"d(t

Nte

14

2*4

Page 5

DESIGNATION

OF

PARTS

DESIGNATION

OF

PARTS

DESIGNATION

OF

PARTS

(Model

3007)

(Model

3005)

(Model

3003)

23

Thread

take

up

lever

21

Ti-ead

ua

e

ap

lve,

20

Thread

take-co

lever

24

Carr/ing

handie

22

Caryng

randle

21

Carrving

handle

25

Balance wheel

23

Balance

wheel

22

Balance

wheel

26

Stitch

selector

24

Stitch

selector

23

Coupling

knob

27

Firre

adjustrmenr

25

Fine

adrstmenr

24

Sltlch

selector

28

Power

switcfh

26

Power

swtch

25

Fine

adjustment

29

Machine

socket

27

Machine

socket

26

Power

switch

30

Needle

clamping

screw

28

Needle

clamping

screw

27

Machine

socket

31

Drop

feed

lever

29

Drop feed

lever

28

Needle

clamping

screw

32

Free

arm

30

Free

arm

29

Drop

feed lever

33

Presser

foor

31

Presse

[oor

30

Free

arm

34

Presser

foot

lever

32

Presser

foot

lever

31

Presser

foot

33

Sewing

speed

switch

ifor

120

V)

32

Presser

foot

lever

33

Sewing

speed

switch

(for

120

V)

'34

ý

S.

r)

-A

2 VII

12V

l120OV)

(120

V)

Page 6

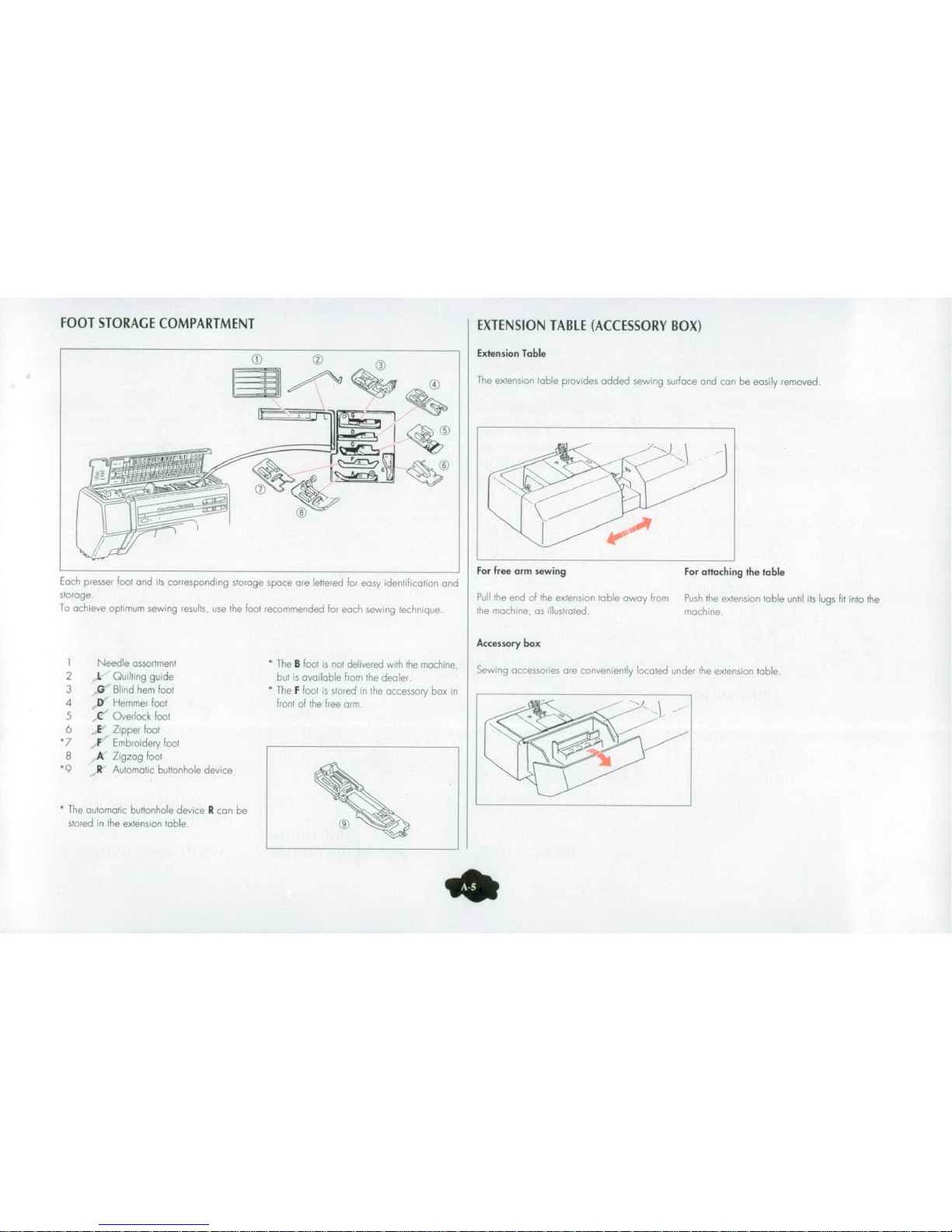

FOOT

STORAGE

COMPARTMENT

EXTENSION

TABLE

(ACCESSORY

BOX)

J)

C.3

Extension

Table

4ý"

ý

The

extension

table

provides

added

sewing

surface

and

can

be

easily

removed,

P--

-

For

free

arm

sewing

For

attaching

the

table

Each

presser

foot and

its

corresponding

storage

space

are

lettered

for

easy

idenlification

and

storage,

Pull

the

end

of

the

ex-ension

table

away

from

Push

the

extension

table

until

its

lugs

fit

into

the

To

achieve

optimum

sewing

results,

use

the

foot

recommended

for

each

sewng

technique

the

mochine,

as

llusirated

machine

Accessory

box

I

Needle

assortment

*

The

B

foot

is

nor

delivered

with

the

machine,

Sewo

accessories

ore

conveniently

located

under

the

extension

table.

2

L

Quilting

guide

but

is

available

from

the

dealer

S

3

G

Blind

hem

foot

*

The

F

foot

is

stored

in

the

accessory

box

in

4

D

Hemmer

fool

front

of the

free

arm.

5

.C'

Overlock

foot

6

.1

Zipper

foot

'7

j

Embroidery

foot

l_-__

_"

a

A

Zigzag

foot

'9

lit,

Automattc

buttonhole

device

I

the

automatic

buttonhole

device

R

can

be

stored

in

the

extension

table.

ak

Page 7

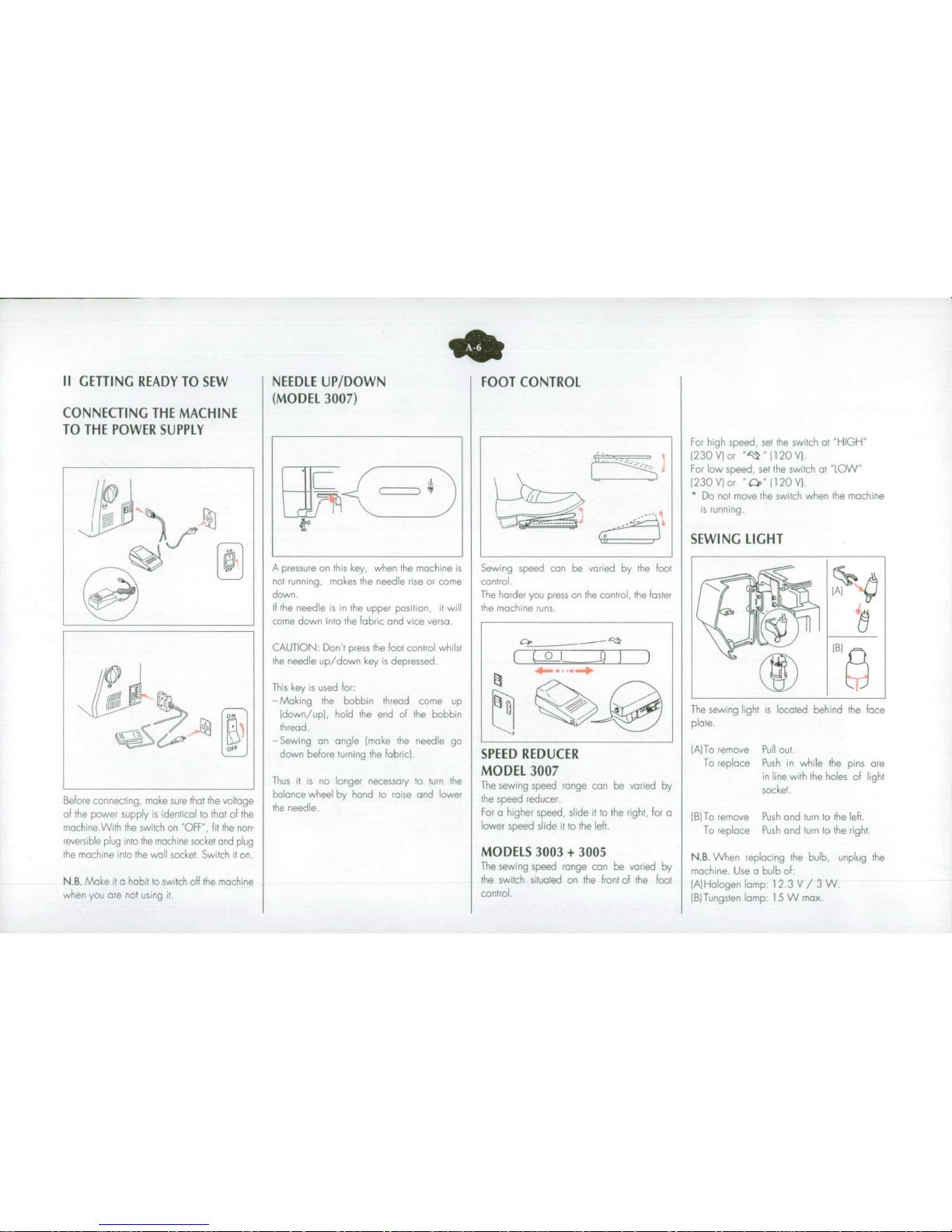

II

GETTING

READY

TO

SEW

NEEDLE

UP/DOWN

FOOT

CONTROL

(MODEL

3007)

CONNECTING

THE

MACHINE

TO

THE

POWER

SUPPLY

for

high

speed,

set

the

switch

at

'HIGH"

-

.

(230V)

or

""

(120V),

For

low

speed,

set

the

switch

at

"LOW"

I~\(230

VI

of

'Cp

10V

*

Do

not

move

the

switch

when

the

machine

..-

"'s

running.

41J

.SEWING

LIGHT

•

-A

pressure

on

this

key,

when

the

machine

is

Sewing

speed can

be

varied

by

the

foot

not

running,

makes

the

needle

rise

or

come

control.

down

The

harde

you

press

on

the

control,

the

faster

-

If

;he

needle

is in

the

upper

position,

it

will

the

machine

runs

come

down

into

the

fabric

and

vice

versa

CAUTION:

Don't

press

the

foot

control

whilst

(B)

the

needle

up/down

key

is

depressed.

40

This

key

is

used

for,

l-'•lJ•

•

•Making

the

bobbin

thread

come

up

Maki•on/upg

hod

d

the

bobbin•• tThe

sewing

lght

is

located

behind

the

face

(down/up),

hold

the

end

of

thCobbi

thread.

plate.

-Sewing

an

angle

(make

the

needle

go

down before

turning

the

fabric).

SPEED

REDUCER

)A)To

remove

Pull

out

MODEL

3007

To

replace

Push

in

while

the

pins

are

MODEL

3007in

line

with

the

holes

of

light

Thus

it

is

no

longer

necessary

to

turn

the

The

sewing

speed

range

can

be

varied

by

inliet

balance

wheel

by

hand

to

raise

and

lower

the

speed

reducer

Bef~or

connecting,

make

sure

tha I the

voltage

the

needle.

tesedrdcr

of

the

power

supply

is

identical

to

that

of

the

For a higher

speed,

slide

it

to

the

right,

for

0

FB)

To

remove

Push

and

turn

to

the

left.

machine

With

the

switch

on

"OFF",

fit

the

non

lower

speed

slide

it

to

the

left.

To

replace

Push

and

turn

to

the

right.

reversible

plug

into

the

machine

socket

and

plug

the

machine

into

the

wail

socket

Switch

it

on

MODELS

3003

+

3005

N.B.

When

replacing

the

bulb,

unplug

the

The

sewing

speed

range

can

be

varied

by

machine

Use

a

bulb

of:

NB.

Make

ita

habit

to

switch

off

the

machine

the

switch

situated

on

the

front

of

the

foot

[A)Halogen

lamp

123V/3W

when

you are not

using

it

control.

(B}Tungsten

lamp:

15

W

max,

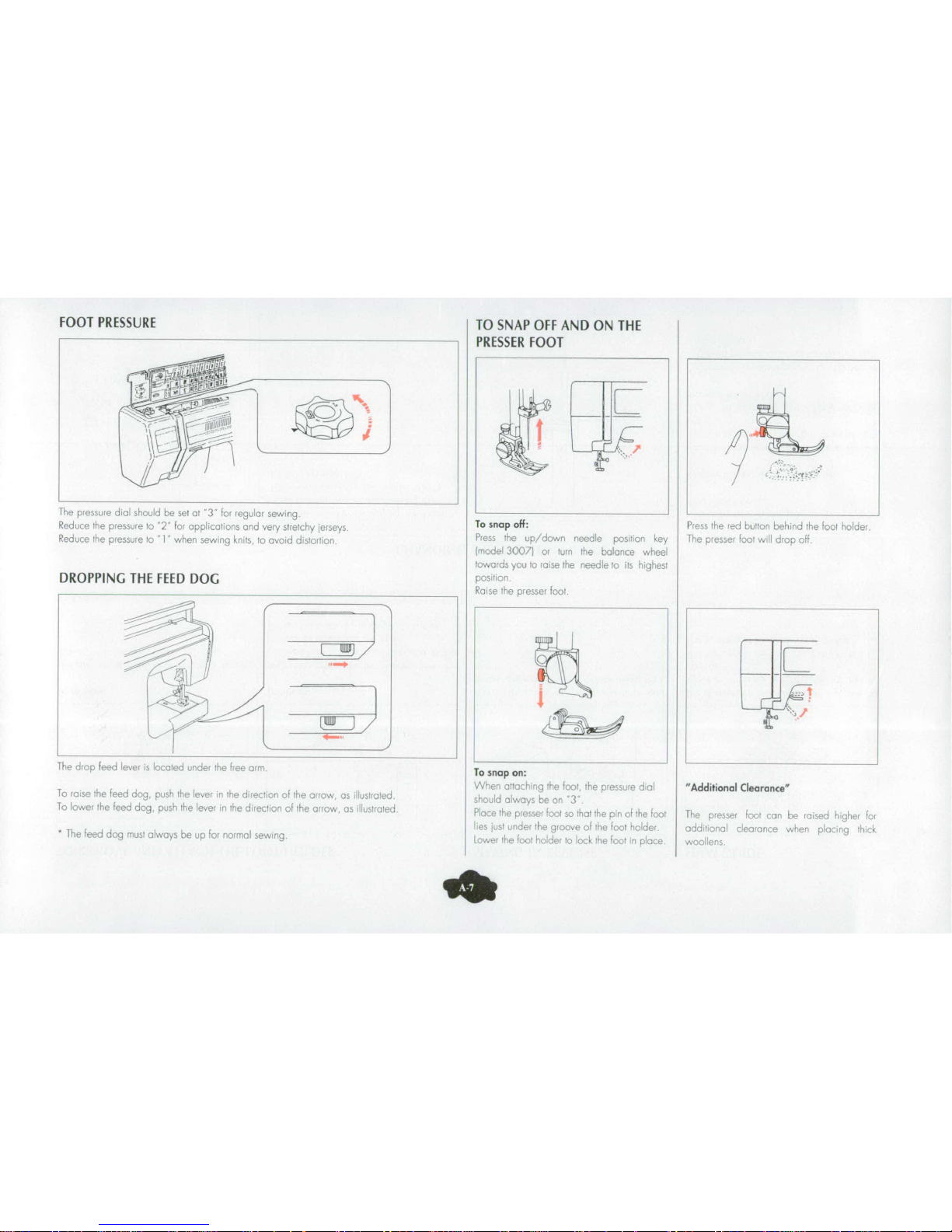

Page 8

FOOT

PRESSURE

TO

SNAP

OFF

AND

ON

THE

PRESSER

FOOT

The

pressure

dial

should

be

set

at

'3"

for

regular

sewing.

..... ...............

Reduce

the

pressure

to

"2"

for

applications

and

very

stretchy

jerseys,

To

snap

off:

Press

the

red

button

behind

the

foot

hlcder

Reduce

the

pressure

to

"'

when

sewing

knits,

to

avoid

distottion

Press

the

up/down

needle

position

key

Ithe

Presser

root

wil

drop

off

!model

3007/

or

turn

the

balance

wheel

oowards

you

to

raise

the

needle

to

its

hkghesi

DROPPING

THE

FEED

DOG

poston

.....

_

-_

-_------Raise

the

presser

foot

.

•~

~~~~~~

~~~~~~

.........................

.........

x" I

•

L

-------

-

L

The

daop

feed

lever

is

lo

aed

u

der

the

free

arm

To

snap

on:

*,rn

!'&ýg

Irfotrheprssreda9

"Additional

Clearoncew

to

raise

the

feed

dog

push

the

lever

in

the

directon

of

the

arrow

as

rusvtred

should

always

be

on

"3'

To

lower

the

feed

dog,

push

'he

lever

in

the

drrecton

of

the

arrow,

as

ilusirated

Place

the

oresser

foot

so

that

the

pit

of

the

ootr

The

presser

foot

(an

be

raised

higher

lor

os

iust

under'

the

groove

of

the

foot

holder

aatid

ioral

clearance

when

placing

•,c;k

*

The

heed

dog

must

always

be

up

nor

normal

sewing

lower

the

foot

holder

to

ock

the

foot

in

oace

wooOners

ao

Page 9

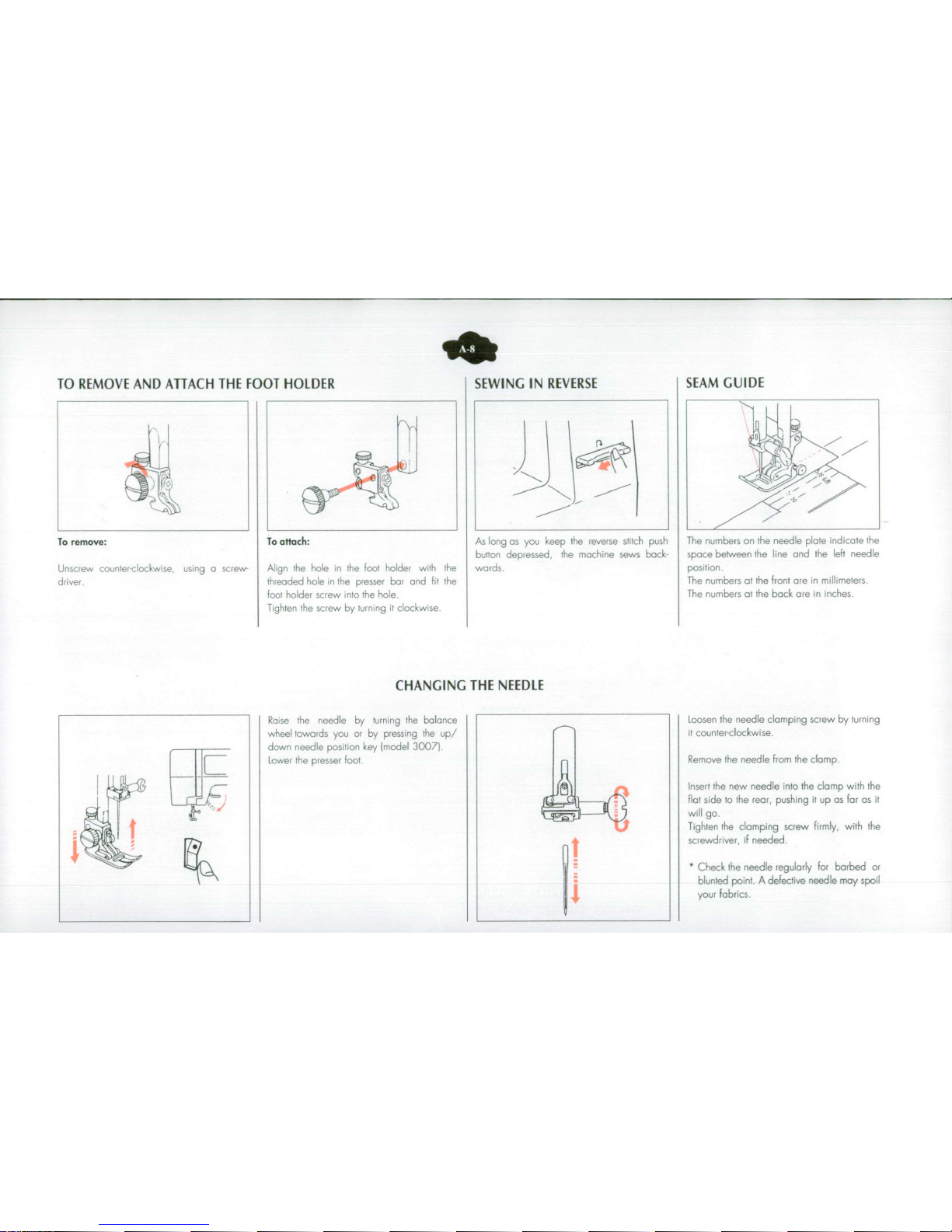

TO

REMOVE

AND

ATTACH

THE

FOOT

HOLDER

SEWING

IN

REVERSE

SEAM

GUIDE

To

remove:

To

attach:

As

long

as

you

keep

the

reverse

stitch

push The

numbers

on

the

needle

plate

indicate

the

button

depressed,

the

machine

sews

back- space

between

the

line

and

the

left

needle

Unscrew

counterclockwise

using a screw

Align

the

hole

in

the

foot

holder

with

the

wards

position.

driver,

threaded

hole

in

the

presser

bar

and

fit

the

The

numbers

at

the

front

are

in

millimeters.

foot

holder screw

into

the

hole.

The

numbers

at

the

back

are

in

,nches.

Tighten

the

screw

by

turning

it

clockwise

CHANGING

THE

NEEDLE

Raise

the

needle

by

turning

the

balance

Loosen

the

needle

clamping

screw

by

turning

wheel

towards

you

or

by

pressing

the

up/

it

counter-clockwise.

down

needle

position

key

(model

30071

L

I

Lower

the

presser

foot

Remove the

needle

from

the

clamp.

Insert

the

new

needle

into

the

clamp

with

the

flat

side

to

the

rear, pushing

it

up

as

far

as

it

will

go.

Tighten

the

clamping

screw

firmly,

with

the

screwdriver,

if

needed.

*Check

the

needle

regularly

for

barbed

or

blunted

point.

A

defeclive

needle

may

spoil

your

fabrics.

Page 10

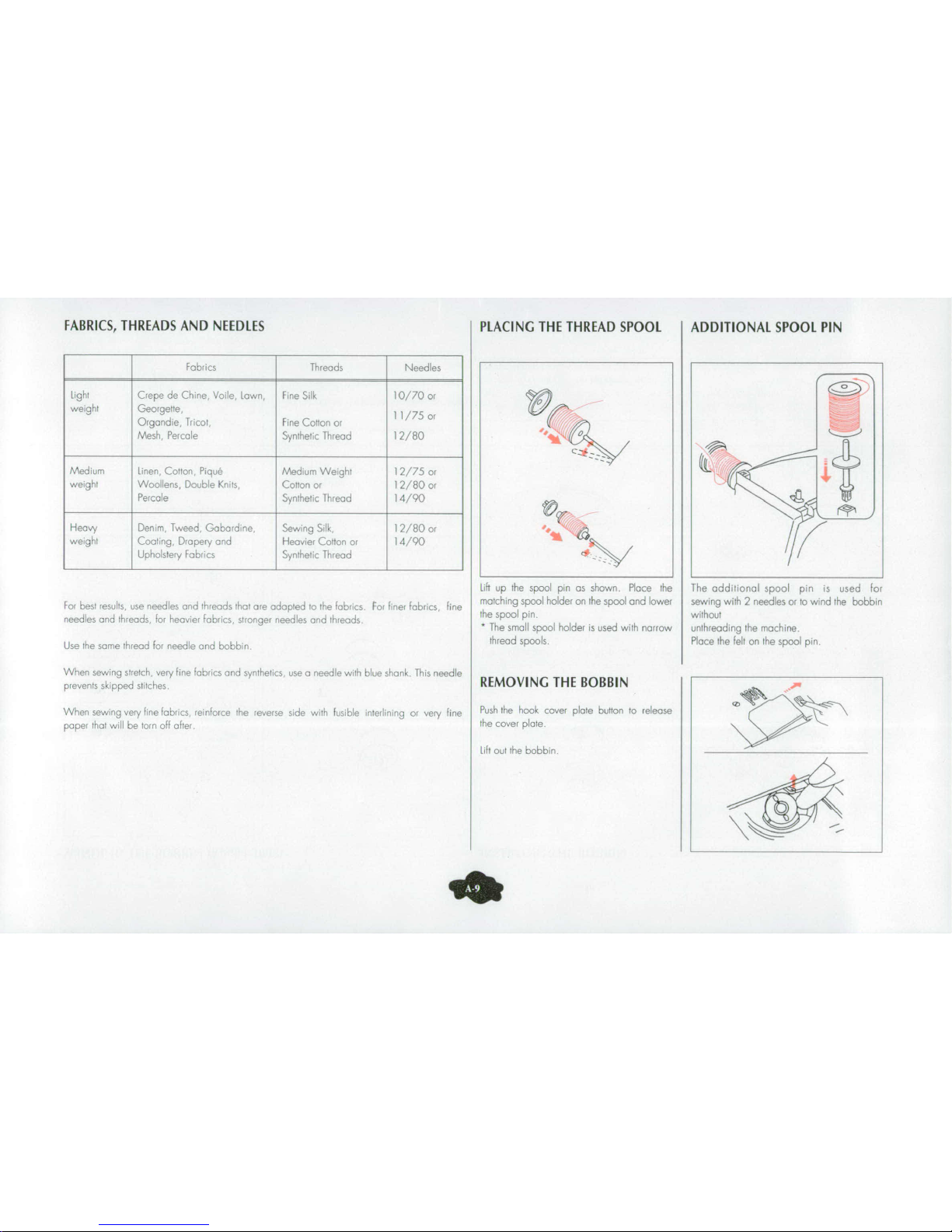

FABRICS,

THREADS

AND

NEEDLES

PLACING

THE

THREAD

SPOOL

ADDITIONAL

SPOOL

PIN

Fabics

Threads

Needles

Light

Crepe

de

Chine,

Voile,

lawn,

fine

Silk

10/70

or

,7

weight

Georgette,

11/75

or

Orgondie,

Trico,

fine Cotton

or

Mesh,

Percale

Synthetic

Thread

12/80

Medium

Linen,

Cotton

Piqu6

Medium

Weight

12/75

or

,-

weight

Woollens,

Double

Knits

Cotton

or

12/80

or

Percale

Synthetic Thread

14/90

Hear/

Denin,

Tweed,

Gabardine,

Sewing

Silk,

12/80

or

#

weight

Coatng,

Drapery

and

Heavier

Cotton

or

14/90

Upholstery

Fabrics

Synthetic

Thread

Lift

up

the

spool

pin

as

shown.

Place

the

The

additional

spool

pin

is

used

for

For

best

results,

use

needles

and

threads

that

are

adapted

to

the

fabrics.

For

finer

fabrics,

fine

matching

spool

holder

on

the

spool

and

lower

sewing with

2

needles

or

to

wind

the

bobbin

needles

and

threads,

for

heavier

fabrics,

stronger

needles

and

threads

the

spool pin

without

*

The

small

spool

holder

is

used

with

narrow

unthreading

the

machine.

Use

the

same

thread

For

needle

and

bobbin

thread

spools.

Place

the felt

on

the

spool

pin

When

sewing

stretch,

very

fine

fabrics and

synthelics,

use

a

needle

with

blue

shank.

This

needle

prevents

skipped

stitches.

REMOVING

THE

BOBBIN

When

sewing

very fine

fabrics,

reinforce

the

reverse

side

with fusible

intledining

or

very

fine

Push

the

hook

cover

plate

button to

release

paper

that

will

be

torn

off

afler

the

cover

plate.

tift

out

the

bobbin.

Page 11

Ca

3

4,

thP0"Rc-e

thre

LoLL>

+rt

bor>;

os

wtrh

te

Keep

s'owfy

puihng

th-e

thread

unr::i

it

ie

2

[>0w,

the

thread!

ifarn

tht

sar,.

trec

'nlea

rring~

ca

rio

the

notch

'13,

4Gui

eth~e

thread

around

the

LoLL n wir

LB

[ &

er

thrFead

guii"t7

/

Hoik

the

end

ofý

the

threaýd

and

depress

t4

e n fo

tru(c l

fat a (cu

i-Pe

oF

turns

5Passý

the

thread

thtrioghthe

hale

in:

thie

babbitt

C

t4

e

thren

Da ii

ens

the,

fear

cor

tra!

ak

neuban

wrill

stop

automaricatioly

when

i

6

Place-

t~h'

LbcbLer

on,

the

abobin

win)der

')A

and

rujsih

1

tot

the

rýr ht

3 $ rLL'>winder

Lack

-c

the,

el,

the

tx-rhr)F,

& r

co u the

t~hreag.

9

r

a>

V n he

balaince

K

nIth

oulig

Guide

the

thtreaoiro

the

notch

'A'

on

the

Puff

out

aout

15c-m

6"of

th-reard

and

roth'

4

e

r

ont,

Har!d

the

LoLbin

with

yorr

right

h~and

the

hook

cover

pi.Ote

i

~and

pukl

the

tread

to

the

left

arrd

througth

the

tenston

spring

blades.

Page 12

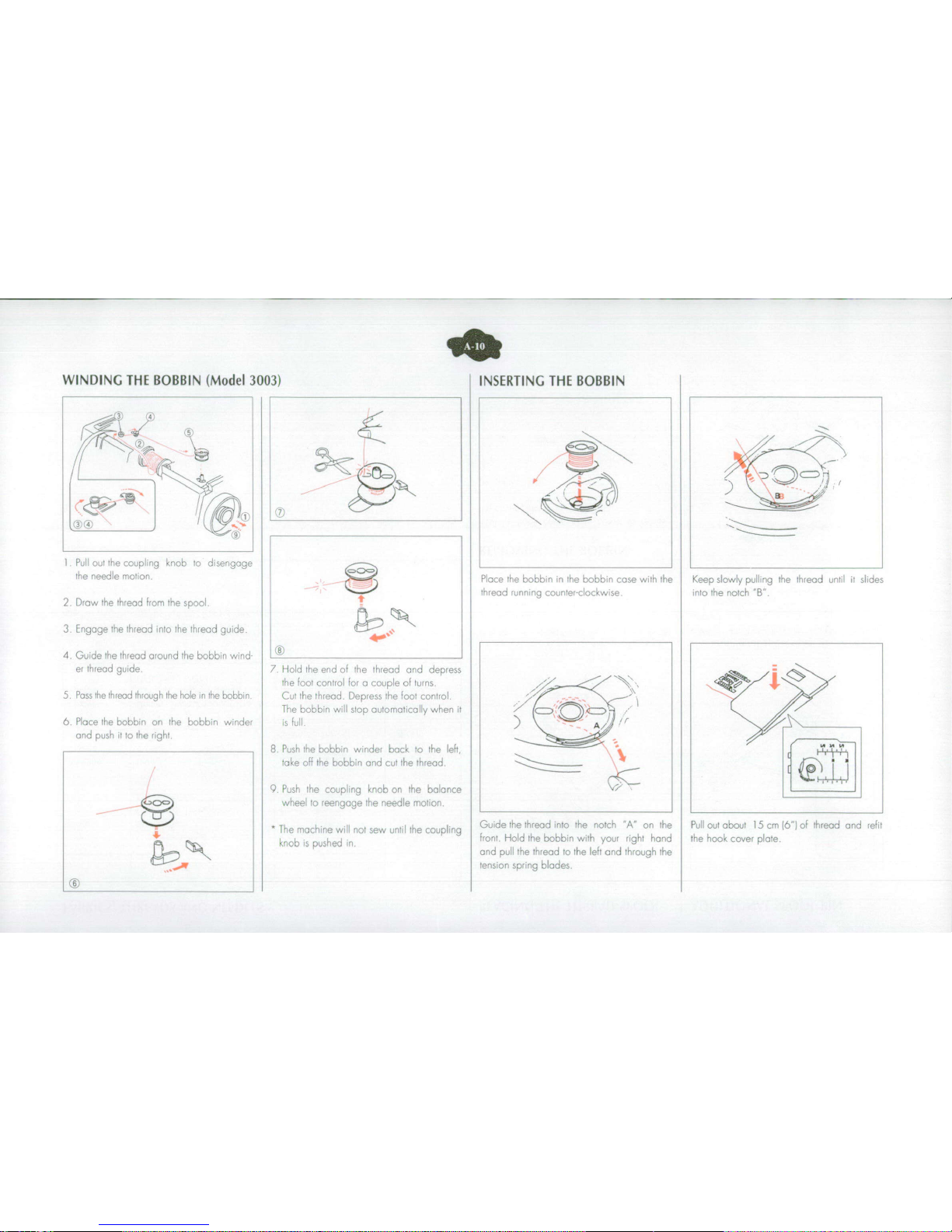

WINDING

THE

BOBBIN

(Models

3005

+

3007)

INSERTING

THE

BOBBIN

Draw

the

thread

from

the

spool,

Place

the

bobbin

in

the

bobbin

case

with

the

Keep

slowly

pulling

the

thread

unti

it

sides

read

running

counter-cl

ockwise.

into

the

notch

'B'.

2.

Engage

the

thread

into

the

thread

guide.

3.

Guide

the

thread

around

the

bobbir

wind

t

er

thread

guide.

4.

Pass

the

thread

through

the

hole

in

the

prýorbhin.

5.

Place

thre

bobbin

or

the

bobbion

wrrrder

6

Hoin

tihoendot

the

thriead

and

depress7

and

push

it

to

the

rghi

the

hoot

control

for a couole

of

turns.

Cut

"

the

thread

Depress

the

foot

control.

The

A

_

botbi

woi

stop

auiomatically

when

it

is

full.H

+

7.

Pus

the

brobbn

winder

back

to

the

le;7

take

art

the buobbin

and

cut

the

thread

6Guae

the

thread

into

the

notch

'A

on

the

Pul

out

about

1Scm(6")of

Thread

and

refit

front.

Hold

the

bobbin

with

your

right

hand

the

hook

cover

plate

~and

pull

the

thread

to

tire

left

and

thfough

the

tension

spring

blades.

S.)

al

Page 13

THREADING

THE

MACHINE

itLi

__ __ __C_)

05

Raose

rhe

oake p ovef

to

its

highest

2.

Pass

the

thread

around

the

thread

3

Frmly

draw

the

thread

from

right

4.

Slide

the

thread

to the

left

behind

(jc

,

position

by

turnin

thie

ba.'je

wheel

guide

and

up

again

in

the

left

to

left

into

the

take-up lever

the

thread

guide

on

the

needle

:wards

yeo

slot.

eyelet

bar.

or

P

Rise

the

pesser

fcot,

then

pass

the

/3

t-I-thoed

"i [le

,rdef

Foret

1

to

5

Model

3003

5.

Draw

about

15

cm

(6"1

of

-I)

Pas

the

hread

nro

he

thread

thread

through

needle

eye.

2'-

qguide

and

draw

it

down

along

4-

the

right

s5ot

Models

3005

+

3007:

/

5

Thread

the

needle

by

using

the

needle

threader

(see

page A 13)

Page 14

AUTOMATIC

NEEDLE

THREADER

(MODELS

3005 + 3007)

t

(Model

3005):

Turn

the

balance

Turn

the

knob

®) n

the

direction

of

Turn

the

knob ® in

the

direction

of

Raise

the

needle

threader

knob

(®)

Pass

the

end

of

the

thread

through

wheel

towards

you

to

raise

the

the

arrow

in

the

illustration,

then

the

arrow

in

the

llustrotior

then

slowly

to

draw

the

thread

loop

up,

the

needle

eye

by pulling

the

thread

needle

to

the

highest

position.

insert

the

hook

(B

into

the

needle

draw

the

thread

loop

to

the

back

of

loop

to

the

back,

Pull

15

cm

16') of

thread,

eye.

the

needle

Lead

the

thread

around

the

guide

The

needle

threader

can

be

used

(Model

3007):

By

pressing

the

©)

and

under

the

hook

®.

with

needles

No.

11/75,

up/down

needle

position

key,

raise

12/80,

14/90, 16/00oand

the

needle

to

its

highest

position

needles

with

blue

shank.

Pull

15

cm

(6")

of

thread.

Pull

the

automatic

needle

threader

down

as

far as

it

will

go.

Page 15

DRAWING

UP

THE

BOBBIN

THREAD

Raise

the

presser

foot

and

hold

the

needle

thread

Q007)

Press

the

up/down

needle

position

key

3003

+

3005):

Turn

the

balance

wheel

Pull

bath

threads

to

the

leh

and

lrghrly

w~th

your

left

hand.

'Wrce

towards

you

until

the

needle

has

risen

and

the

under

the

presser

foot,

leaving

take-up

lever

is

at

its

highest

position.

10

cm

(4")

Lightly

draw

up

the

needle thread

forming a loop

of

the

bobbin

thread

BALANCING

THE

THREAD

TENSION

In

straight

seams,

the

needle

thread

Turn

the

thread

tension

dial

until

the

Loosen

the

needle

thread

tension

by

Tighten

the

needle

thread

tension

Adjusting

the

Thread

Tension

for

and

the

bobbin

thread

should

inter-

desired

number

is

facing

the

setting

moving

the

dial

to

a

lower

number

by

turning

the

dial

to

a

higher

Z'ftgz

and Embroidery.

lock

in

the

center

of

the

two

layers

mark

number.

The

upper

thread

tension

should

be

of

fabric.

slightly

weaker

when

sewing

a

zig-

zag

or a pattern

based

on

the

satin

stitch.

The

upper

thread

should

appear

slightly

on

the

reverse

side

of

the

fabric.

Page 16

PATTERN

SELECTION

STITCH

WIDTH

STITCH LENGTH

DECENTERING

THE

NEEDLE

C3D

0-1-2-3-4-5-6-

o

=1

2

3

4

4

0"1*2 3 4-5 6 "

0

-~1 2 3 - 4

o

0

234-5

6. '

Select

a

pattern

by

turning

the

stitch

selector

The

higher

the

number,

the

wider

the

srich.

The

higher

the

number,

the

longer

the

stitch

The

straight

stitch

and

the

triple

seam

may

be

The

red

signal

confirms

the

chosen

pattern.

This

machine

can sew

stitches

of

a maximum

For a fine

fabric,

a

stitch

length

of

1,5

to

2,5

decenered

to

the

left

by

using

the

stitch

width

width

of

6.5

mm

(1/4)

is

preferable

slide

N.B.

The

needle

must

be

in

the

upper

position

For a thicker

fabric

a

stitch

ength

of 2 5

to

when

you

turn

the stitch

selector

*

For

adjusting

the

stitch

width,

the

needle

4 0 is

indicated

must

be

in

the

upper

position,

i.e

out

of

the

fabric

N.B

1he

stitch

length

is

automatc

and

cannot

be

modified

as

from

the

triple

seam

onward,

Page 17

III

BASIC

SEWING

STRAIGHT

STITCH

1.5

-

4

...

7

Rose

the

presser

foot

and place

the

fabric

To

secure

the

ends

of

the

seams,

press

the

The

thread

cutter

cuts

the

threads

to

the

next

to

the

guide

line

on the

needle

plate,

reverse

stitch

button

and

sew

a

few

stitches,

proper

length

for

starting

the

next

seam,

__mA

Smooth

the

threads

to

the

left

and

lower

the

Raise

the

presser

foot

and

eemove

the

fabric

presser

foot

Depress

the

foot

control

pulling

the

threads

to

the

rear,

Gently

guide

the

fabric

along

the

guide

line

The

needle

must

be

in

its

highest

position

when

removing

the

fabric.

SEWING

AN

ANGLE

STRAIGHT

STITCHING

ON

Slop

the

machine.,

HEAVY

FABRICS

13003 + 3005)

Turn

the

balance

wheele

owertheneedleintothefabricatthestarting,

towards

you

to

bring

the

needle

down

into

the

-

point

Press

the

small

black

button

on

foot

A

fabric,

with

your

left

hand

thus

giving

extra

weight

to

(3007):

Lower

the

needle

into

the

fabric

by

t

the

presser

foot,

pressing

the

needle

up/down

key

lower

the

presser

foot

with

your

right

hand,

Raise

the

presser

foot.

maintaining

the

pressure

on

the

black

button

Pivot

the

fabric

around

the

needle

To

change

,with

your

left

hand.

Release

the

block

button

the

sewing

direction

Lower

the

presser

foot

and

start

sewing.

and

continue

sewing

Page 18

ZIGZAG

STITCH

IV

UTILITY

STITCHES

QUICK

OVERCASTING

1

-65

5

1 25

2~

3-7

Simple

zigzag

stitching

is

used

For

overcast~

The

C

fool

prevents

the

fabric

from

rolling,

A

inmg

and

sew

ng on

bunions

Cwhen

overcasting.

NB.

For

a

decorative

satn

stitch,

use

trans-

Place

the

fabric

next

to the

black

guide

an

the

parent

fool

F,

reduce

stitch

length

between

right Minimum

stitch

width

5.

0.3

and

0.5

and

thread

tension

beween

2

and

3

ASSEMBLING

STRETCH

FABRICS

(MODEL

3007)

OVEREDGE

STITCH

5

"- 3-65

05

1 5

3-7

7

3

-6

For

light

jersey the

C

foot

keeps

the

fabric

This

stitch

is

useful

to

prevent

raw

edges

from

Pat

Place

the

edge

of

te

fabric

next

to

the

fraying

C

black

guide

on

the

right

A

Place

the

fabric

under

the

presser

fool,

so

that

- -

-

-----------

05Use

the

F

foot

for

sewing

inside

the

fabric

the

right

edge

runs

along

the

brim

of

the

For

assembling

and

overcasting slretch

fabics

N.B.

To

prevent

distortion

in

lerseys

reduce

transparent

par.

and

jerseys

in

one

opeiaion

.he

foot

pressure

see

pagle

A.7

ao

Page 19

DOUBLE

OVERCASTING

ELASTIC

STITCH

"

4,:

3

-3

6

5

05-.1

4-.

. -'

4-5

Eja

ýTl

s

a>c

ute~Fij

'o;

fcbr~cs

wihrch

tend

to

C

roy

Pace

the

edge

of

the

faricr

next

to

the

black

guide

on

the

right

-

_

Choose

this

stitch

to

attach

elastic

to

garments.

I

Mark

the

elastic

into

quarters

and

match

these

to

the

center

front,

center

back

and

side

seams.

2.

Place

the

middle

of

the

elastic

under

the

center

of

the presser

foot

and

sltitch

into

place,

making

sure

the

eiastic

is

eveny

distributed.

Page 20

TRIPLE

SEAM

INTERLOCK

SHELL

STITCHING

HI

K(CD)2-4

1-2

For

shell

stitching

on blouses

and

lingerie.

This

stitch

can

also

be

used

as a single

over

24

lock

stitch.

AA

A

A

This

reinforced

and

extensible

seam

is

recom

This stitch

is

sewn

with

2

stitches

forward

and

mended

for

armholes,

working

garments

and

I

stitch

backward,

forming

a

very

solid

seam,

sports

wear

Garments

should

be

basted

and

tried

before

inal

sewing

Page 21

SEWING

ON

BUTTONS

F

-__l

.

-]-

------

-

---

3-37

Push

the

lever

to

the

right

to

drop

the

feed

Make

sure

that

the

needle

stitches

well

into

the

of

the

holes,

wind

it

round

the

shank

and

knot

dog

right

hole

If

necessary,

adIust

the

width,

it

safely

on

the

wrong

side

PLce

the

button

on

the

fabric

and lower

the

Sew

a

few

stitches

When

sewing

on

buttons

N.B.

Bring

the

feed

dog

back

to

its

original

needle

into

the

left

hole

by

turning

the

with

a

shank,

place

a

pin

over

the

foot.

To

position

by

pushing

the

lever

to

the

left,

The

ba

once

wheel

reinforce

the

shank,

cut

the

threads

leaving

a

feed

dog

will

raise

automatically

when

turn-

Lower the

foot.

20cm

181

tail.

Draw

the

thread

through

one

ing

the

balance

wheel

AUTOMATIC

BUTTONHOLE

*

The

size

of the

buttonhole

its

automatically

set

to the

size

of

the

button

when

the

latter

4

-65

is

placed

into

the

buttonhole

device

R

U

0

I

*

The

button

holder

of

the

device

rakes

a

but-

'on

up

to

a 2

5

cm

(I "

size

on

its

rear

*

Make

a

test

buttonhole

on

a

sample

of

your

fabric

lined

with

interfacing

3003

+

3005):

Turn

balance

wheel

towards

you

or

(3007)

depress

the

needle

up/down

key

to

raise

the

needle

to

its

highest

position

1

5

tMark

he

starting

point

of

the

buttonhole Raise the

presser

foot,

*

Use

nerfacing

fr

stretchable

and

fine

th

sero

"H",

Turn

stitch

selector

t B'

U*

If

the

indicator

light

is

already

on

"BH"

reset

the

machine

according

to

the

instructions

on

abrc

page

A-2

I.

R

Attach

the

automatic

buttonhole

device

R

NOTE:

There

should

be

no

gap

between

the

presser

foot

and

the

front

of

the

device,

see

illustration.

Page 22

Pull

the

button

holder

to

the

back

and

place

the

button

Pass

the

needle

thread

under

the

presser

foot.

Models

3003 + 3005:

Push

the

button

holder

firmly

back

to

secure

the

button

Sew

slowly

and

stop

the

machine

at

the

starting

point

when

a

Pull

down

the

buttonhole

lever

as

far

as

it

will

go.

Place

the

fabric

under

the

presser foot.

buttonhole

is

completed

Turn

the

balance

wheel

towards

you,

until

the

needle descends

exactly

at

the

starting

point

of

the

buttonhole.

Model

3007:

Lower

the

presser

foot.

Depress

the

foot control

until

the

machine

stops

by

itself

*

When

the

buttonhole

is

completed,

the

3BHW

indicator

light

*

The

buttonhole

starts

with

the

barrack

The

left

row

is

sewn

will

flash

backwards.

272

Cut

threads at

10cm(14").

Pass

the

needle

thread

to

the

To

repeat a buttonhole:

When

buttonhole

sewing

is

firished,

raise

the

buttonhole lever

wrong

side

of

the

fabric

by

pulling

the

bobbin

thread

Knot

the

After

the

buttonhole

is

sewn,

select

stitch

I"

and

return

to

to

its

initial

position.

threads.

"RH"

to

be

at

the

starting point

of

the

buttonhole

Insert

a

pin

into

one of

the

bartacks

and

cut

open

carefully

with

the

buttonhole

knife

ao

Page 23

MANUAL

BUTTONHOLE

1'-5

*Butnoe

eo

utn

with

a

diameter

of

more than

2.5

cm

(3003

+

3005).

Turn

the

balance

wheel

towards

you

or

Pull

down

the

buttonhole

lever

completely.

]Ihvtobe

swn

manually.

13007)

depress

the

needle

up/down

key

to

raise

the

needle

to

tower

the

needle

into

the

fabric

at

the

starting

point

of

the

its

highest

position.

Raise

the

presser

foot.

buttonhole

and

lower

the

foot,

Turn

the

selector

dial

to

"BH"

for

the

buttonhole.

*If

the

indicator

light

is

already

on

"BH"

reset

the

machine

according

to

the

instructions

on

page

A-21.

Attach

the

F

foot.

Sew

the

first

oarlock

and

the

left

row

to

the

desired

length.

Pull

the

buttonhole

lever

towards

you.

Sew

the

second

bartack

and

the

right

raw.

Stop

when

you

reach

the

first

bartack.

*To

open

the

buttonhole

and

start

the

next

one,

refer

to the

_________________________________________

instructions

on

page

A-2

1

Page 24

CORDED

BUTTONHOLE

With

the

buttonhole

foot

raised,

hook

the

Sew

the

buttonhole

according

the

the

instruc

Pull

the

left

end of

the

piping

cord

to

make

cord

on

the

cord

spur

at

the

back

of

the

foot

tions

given

on

pages

A-20

and

A-2

I

disappear

the

loop

at

the

tear

Lead the

two

ends

of

the

cord

towards

you

Remove

the

garment

from

the

machine

and

Cut

flush

the

cord

ends.

R

and

under

the

foot,

with

the

tails

showing

in

secure

the

threads.

front.

"

Adjust

the

stitch

width

to

the

thickness

of

the

Pass

the

ends

into

the

forks

at

the

front

of

the

cord

used.

foot

and

hold

them

tightly.

"

To

open

the

buttonhole

and

start

the

next

Lower

the

needle

into

the

fabric

at

the

starling

one,

refer

to

the

instructions

on

page

A2

1.

point,

then

lower

the

foot.

ZIPPER

INSERTION

15-4

A

3 -6

The

zipper

foot E can

be

attached

either

on

Preparing

the

fabric:

Baste

the

opening

and

iron

Remove

the

bast

the

left

or

on

the

right,

depending

on

the

way

Prepare

an

open

searm

and

sew

both

fabrics

ing

threads.

the

zipper

is

fixed

on

the

garment

together,

right

side

against

right

side

to

the

height

oF

the

opening.

Page 25

Start

on

the

visible

side

of

the

zipper.

The

foot

is

on

the

right

Close

the

zipper

and

pin

the

other

side

of

the

fabric

onto

the

Finish

by

opening

the

zipper

as

indicated

before.

side,

fastener

taking

care

that

it is

well

covered.

It

is

preferable

to

If

the

zipper

is

covered

from

the

other

side,

attach

the

Foot

on

Place

?he

closed

zipper,

right

side

against

right

side

of

the

baste

first

the

left.

fabric,

so

that

the

zipper

teeth

run

along

the

fold

of

the

fabric.

Start

sewing

from

the

lower

end,

with

the

zipper

closed.

Pin

and

baste.

Start

sewing

from

the

lower

end,

using

the

tape

as

a

guide

for

the

edge

of

the

foot,

the

zipper

remains

closed.

Before

stopping

to

sew,

lower

the

needle

into

the

fabric,

lift

the

presser

foot

and

open

the

zipper

by

pulling

the

slide

Lower

the

presser

foot

to

finish

the

seam.

Page 26

NARROW

HEM

15

4

Make

a

double

fold

of

2.5

mm

1

/8"1

over

a

Lower

the

needle

into

the

fabric

at

the

starting

Lower

the

needle

into

the

fabric,

lift

the

D

length

of about

8

cm

(3).

point,

then

lower

the

hemmer

Foot

D.

presser

foot

and

insert

the

folded

portion

into

Sew 2 or

3

stitches

while

holding

both

the

spiral

of

the

foot.

threads.

Lower

the

Foot,

then

sew,

carefully

guiding

the

Trim

about

7

mm

(1/4")

from

the

corners,

as

fabric

so

that

it

remains

in

the

spiral.

illustrated, to

reduce

bulk.

Page 27

BLIND

STITCH

12 3 -3,

1-3

tron

+,

nem

at

the

equired

height

Place

the

fabric

so

that

the

needle

just

pierces

Adjust

the

guide

by

turning

the

nut.

Sew

by

the

folded

part

of

the

fabric

when

it

comes

to

guiding

the

folded edge

along

the

guide

G

•the

left

Lower

the

presser

foot.

On

light

fabrics,

the

raw

edge

can

be

turned

under

and

pressed

On

heavy

fabrics

that

tend

to

fray,

the

row

edge

should

be overcast

first

Page 28

V

DECORATIVE

SEWING

ADJUSTING

STRETCH

STITCH

BALANCE

DECORATIVE

SATIN

STITCH

4

-65

I

*

If

the

patterns

are

compressed,

the

stitch

is

too

short.

Correct

by

turning

the

screw

to

//-,

Sew

a

row

of

stitches

and

adjust

the

tension,

_

__-,..

_

+

_

so

that

the

needle

thread

will

slightly

appear

aon

the

reverse

side

of

the

fabric.

F

Test the stitch

on a piece

of

the

actual

fabric

for

the

best

result.

,,

,

If

the

patterns

are

not

neat,

it is

possible

to

adjust

them

with

the

feed

balance

screw,

STRETCH

STITCH

PATTERNS

After

sewing

with

the

modified

feed

balance,

I

If

the

patterns

are

too

distorted,

the

stitch

is

return

to

the

standard

adjustment

'o"

too

long.

Correct

by turning

the

screw

to

3-65

4

-

5

The

stitch

lengths

of

the

automatic

patterns

are

A F

,

preset.

No

adjustment

is

needed

for

the

stitch

length,

Page 29

SMOCKING

-•

46

o

cm(3/8"}

~O

F

VWith

the

stitch

length

on

4,

sew

straight

stith

lines

at

a

di

tance of

10

mm

13/8')

over

the

whole

area

to

be

smocked

Knot the

threads

on

one

side,

Pull

the

bobbin

1hreads

and

dis

tribute

the

gathers

evenly

Knot the

threads

on

the

other

side,

N.

Gatherin

is

easier

with

a

weaker

upper

ension

Sew

the

decorative

stitch

in

the

middle

between

the stitch

rows.

Remove the

gathering

threads.

QUILTING

•~

3-6

/•Atlach

the

quilting

guide

L. it

will

help

you

to

keep

on

ever,

Sew

and

let

the

guide

follow

the

previous

stitch

row

LA

distance

between

the

stitch

rows

L

Page 30

PIN-TUCKING

SHELL

TUCK

5-6,5

0I'554Se

1.5

-3

15-3

Place

the

fabric

under

the presser

foot

Lower

Hold

the

fabric

against

the

guide

when

the

needle

into

the

fabric

according

to the

sewing.

G

desired

depth

of

the

tucks.

Press

the

tucks

to

one side

F

Lower

the

presser

foot

Adjust

the

guide

by

Fold

the

fabric

left

side

against

left

side,

turning

the

thumb

nut

FAGOTING

(MODEL

3007)

5-6.5

----

~~Ol

I

§

Fold

under

each

fabric edge

1.5

cm

(1

/2")

Place

the

folded

fabric on

the

edge

of

the

3

~5

and

press

transparent

part

on

the

right,

Pin

the

two

edges

to

paoer

or

tear-away

The

needle

should

stitch

just

outside

on

the

backing 2 to 3 mm

(1

/81

apart

rght

and

form a fod

F

Sew

slowly,

guiding

the

fobr.c

so

rhat

the

needle

catches

the

folded

edge

on each

side

a&

Page 31

APP

ICATIONS

ASSEMBLING

EDGE-TO-EDGE

5-6,5

3-5

m

05-

1

Baste,

or

press,

using

self-adhesive

lining,

the

4

-

5

Fold

each

fabric

edge

to

the

wrong

side

and

2

4

application

onto

the

fabric.

,

press.

Present

the

folded

edges

facing

one

Sew

around

the

entire

application,

making

against

the

other

under

the

middle

of

the

pres

sure

the

needle

always

goes

down

outside

ser

foot.

the

application

when

at

the

right.

A

F

When

sewing

curbs,

stitch

the

needle

into

the

fabric,

raise

the

presser

fool

and

swing

round

the

fabric

in

the

direction

of

the

design.

*

When

the

application

is

finished,

reset

the

foot

pressure

on

Page 32

VI

MAINTENANCE

CLEANING

THE

BOBBIN

CASE

Remove the

plug

from

the

outlet

socket.

This

machine

does

not

need

oiling

However,

(

the

area

around

the

bobbin

and

hook

must

be

ý,)

cleaned

each

time

the

machine

has

been

used

extensively.

The

casing

may

be

cleaned

--

)

with

a

soft

cloth

and

pure

soap.

Remove

the

needle

before

cleaning

the

machine.

To

remove

the

hook

cover

push

the

button

on

Take

out

the

bobbin.

Insert

the

bobbin

the

side

to

the

right

Clean

the

whole

area

with

the

lint

brush.

Refit

the

hook

cover.

CLEANING

THE

HOOK

REFITTING

THE

BOBBIN

CASE

Remove

the

plug

from

the outlet

socket.

Remove

the

bobbin

and

the

bobbin

case

Clean

the

feed

dog,

the

hook

and

the

bobbin

When

refitring

the

bobbin

case, make

sure

Raise

the

needle

to

its

highest

position,

case

with

the lint

brush

that

the

front

notch

holds

the

bobbin

case

well

Remove

the

presser

foot

and

the

needle.

With

in

place

to

prevent

it

from turning

the

screwdriver,

remove

the

screw

at the

left

of

the

needle

plate.

Remove

the

needle plate

ao

Page 33

MINOR

DISORDERS

Problem

Cause

See

page

The

machine

is

noisy

and

does

not

I

Threads

have

been

caught

ithe

hoo

mechanism

A

run

smoothly

2.

The

feed

dog

is

packed

with

lint

A31

The

needle

thread

breaks

1.

The

needle

is

not

threaded

properly

AS8

2.

The

upper

tension

is

too

tight

A- 14

3.

The

needle

is

bent

or

blunt

A-8

4,

The

needle

is

not

inserted

correctly

A-8

5.

TheŽ

fabric

cannot

be

removed

to

the

rear

after

sewing

A-

16

6.

The

thread

is

either

too

heavy

or

too

fine

for

the

needle

A-9

The

bobbin

thread

breaks

1I

The

bobbin

thread

is

not

threaded

correctly

in

the

bobbin

case

A-10,

11

2.

Lint

has

collected

in

the

bobbin

case

A-3

1

3.

The

bobbin

is

damaged

and

does

not

turn

smoothly

Change

the

bobbin

The

needle

breaks

1.,

The

needle

is

badly

secured

A-8

2.

The

needle

is

bent

or

blunt

A-8

3,

The

needle

clamp

screw

is

loose

A-8

4,

The

upper

tension

is

too

tight

A-

14

5.

The

fabric

cannot

be

removed

to

the

rear

after

sewing

A-

16

6

The

needle

is

too

fine

for

the

fabric

being

sewn

A-9

7,

The

pattern

selector

dial

has

been

turned

while

the

needle

was

in

the

fabric

A-1

5

Skipped

stitches

1.

The

needle

is

not

inserted

correctly

A-S

2.

The

needle

is

bent

or

blunt

A-8

3

The

needle

and/or

the

threads

are

unsuitable

for the

work

A-9

4

No

needle

with

blue

shank

is

being

used

for

sewing

stretch,

very

fine

and

synthetic

fabrics

A-9

5

The

needle

thread

is

not

threaded

properly

A-i

2

Page 34

Problem

Cause

See

page

The

seam

puckers

1 ,

The

upper

tension

is

too

tight

A-14

2.

The

machine

is

not

threaded

correctly

A-]

2

3.

The

needle

is

too

heavy

for

the

fabric