Operating Guide

1000 Series Dispensers

1000XL 1000D

•

A NORDSON COMPANY

®

In the US: 800-556-3484 In the UK: 0800 585733 In Mexico: 001-800-556-3484

Introduction

The 1000 Series dispensers provide years of trouble-free, productive service. This Operating Guide will help you maximize the

usefulness of your new dispenser.

Please spend a few minutes to become familiar with the controls and

features of your new dispenser. Follow our recommended testing

procedures. Review the helpful information we have included based

on over 30 years of industrial dispensing experience.

Most questions you will have are answered in this Guide. However,

if you need assistance, please do not hesitate to contact EFD or your

authorized EFD distributor.

☎

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

The EFD Pledge

We pledge that you will be completely satisfied with our products.

We endeavor to ensure that every EFD product is produced to our

no-compromise quality standards.

If you feel that you are not receiving all the support you require,

or if you have any questions or comments, I invite you to write or call

me personally.

Our goal is to build not only the finest equipment and components,

but also to build long-term customer relationships founded on

superb quality, service, value and trust. John Carter, President

Contents

Getting Started ............................................................................. 4

Specifications

First Steps .................................................................................... 5

Unpacking the Dispenser and Activating your Ten Year No-fault Warranty

1000XL - Hookup ...................................................................... 6-7

1000XL - Setup for Testing ....................................................... 8-9

1000D - Hookup .................................................................... 10-11

1000D - Setup for Testing ..................................................... 12-13

Testing the 1000 Series Dispensers ..................................... 14-15

Making Timed Deposits

Changing Deposit Size

Drawing Stripes

ULTRA Dispensing System................................................... 16-17

How to Use the Vacuum Control........................................... 18-19

1000XL only

Loading the Barrel Reservoirs............................................... 20-21

Now, Test Your Fluid.................................................................. 22

This manual is for the express and sole use of EFD

dispenser purchasers and users, and no portion of this

manual may be reproduced in any form.

EFD, ULTRA System, LV Barrier, SmoothFlow,

ZeroDraft, SafetyLok, SnapLok and DispenStand are

trademarks of EFD Inc. ©2004 EFD Inc.

Troubleshooting ......................................................................... 23

1000XL and 1000D Schematic & Parts...................................... 24

1000 Series Programmable Timer ............................................. 25

Suggestions & Reminders.......................................................... 26

Components Reorder................................................................. 27

Ten Year No-fault Warranty ....................................................... 28

Meets applicable CSA and CE requirements.

Reference CSA LR File Number 84105

Getting Started

We have organized this Guide to provide setup and testing procedures for the 1000XL and 1000D dispensers.

If you have the 1000XL, first review pages 6 - 9 which illustrate how

to hook up the dispenser and what the controls do.

For the 1000D, review pages 10 - 13.

Next, pages 14 - 15 show how to dispense the thick, paste-like test

material included in the Test Kit. These instructions are common to

both 1000 Series dispensers.

Finally, pages 18 - 19 illustrate how to dispense low-viscosity liquid

using the vacuum control provided on the 1000XL.

The rest of the information in this Guide applies to both of the 1000

Series dispensers.

1000 Series Specifications

Input voltage: Selectable

100/120/220 VAC

50/60 Hz 16/13 VA

Internal voltage: 24 VDC

Foot-pedal voltage: 9 VDC

Air input: 80 to 100 psi

(5.5 to 6.9 bar)

Air output: 0 to 100 psi

(0 to 6.9 bar)

Cycle rate: > 600/minute

Time repeat: ±0.1%

Initiation: maintained or momentary

Time Range: programmable (seconds)

0.005 to 0.04 sec.

0.01 to 1.0 sec.

0.1 to 10 sec.

0.2 to 20 sec.

0.3 to 31 sec.

1000XL

10⅜ x 8½ x 2⅝ 5 lb 12 oz

26.4 x 21.6 x 6.7 cm 2.63 kg

1000D

8⅝ x 8½ x 2⅝ 4 lb 12 oz

21.9 x 21.6 x 6.7 cm 2.18 kg

First Steps

First: Unpack and use the checklist enclosed with the Dispenser Kit

to identify all items. If there is any discrepancy, please call us

immediately.

Second: Power and compressed plant air should be available where

the dispenser is to be set up. Air pressure should be between 80 and

100 psi (5.5 to 6.9 bar). (Bottled nitrogen can be used.) If you are

not using an EFD five-micron filter regulator #2000F755, be certain

your plant air is properly filtered and dry.

Check voltage label to be certain it agrees with the available power.

Third: Now is a good time to ACTIVATE your extended Ten Year

No-fault Warranty. Please fill in and return the postage-paid

Warranty card. Or, if you prefer, call the appropriate toll-free number

listed below, provide the serial number of your dispenser and

respond to a few short questions.

☎

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

Power

cord

❸

Plant air, 125 psi maximum to

regulator. Output from regulator

should be a minimum of 80 psi,

maximum of 100 psi.

Adapter

assembly

Foot pedal

assembly

❺

Blue

test fluid

Check voltage label

on dispenser

1000XL

❹

Air input

hose

❷

❼

❻

Male quick-connect,

insert and twist to lock

❶

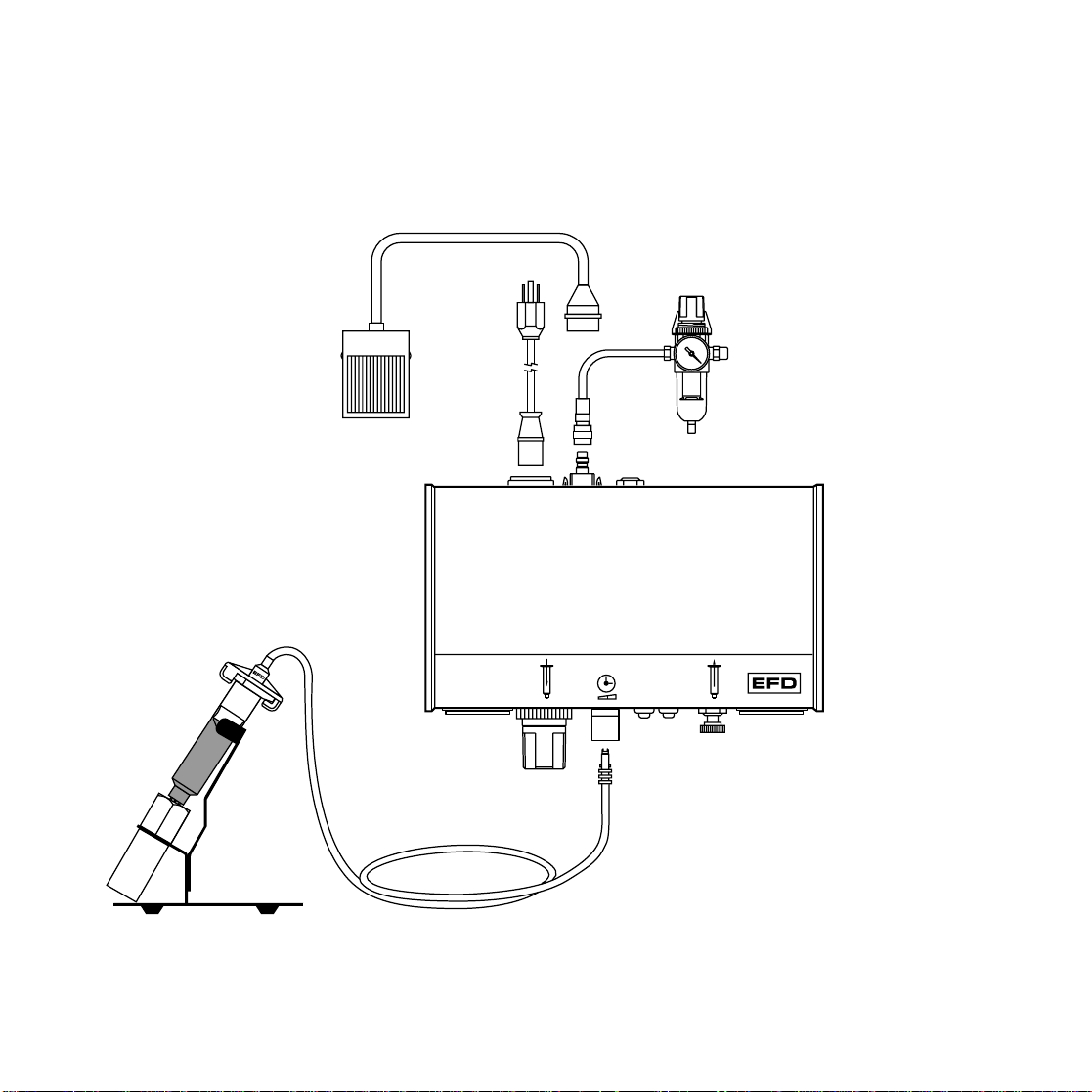

1000XL -- Hookup

❶ Connect the air input hose to a plant air source. Set plant air supply

within 80 to 100 psi (5.5 to 6.9 bar). Where required, use an EFD

five-micron filter regulator #2000F755 (see Warranty).

❷ Attach the air input hose coupling to the dispenser. Pull back metal

ring to attach to dispenser.

❸ Plug in the polarized foot pedal connector.

1000XL

❹ Check the voltage label on the input voltage selector cartridge. To

change the voltage, remove the voltage selector from the cartridge, rotate it and position the correct voltage to show through the

cartridge window. Replace the cartridge into the power cord

receptacle and insure that both sides snap securely into position.

Install the power cord.

❺ Attach the 10cc barrel pre-filled with blue, nontoxic test fluid

(included with the dispenser) to the 10cc adapter head.

❻ Take the 10cc adapter assembly (#5150 on the adapter head) and

insert the black, male quick-connect into the air output fitting on the

front panel and turn clockwise to lock. Place the barrel in the barrel

stand.

❼ During the initial testing, you will not use the vacuum control. Keep

this control shut off (turned completely clockwise—do not force).

Spare fuse

220

120

100

Cartridge window

(check voltage indicated)

Voltage value

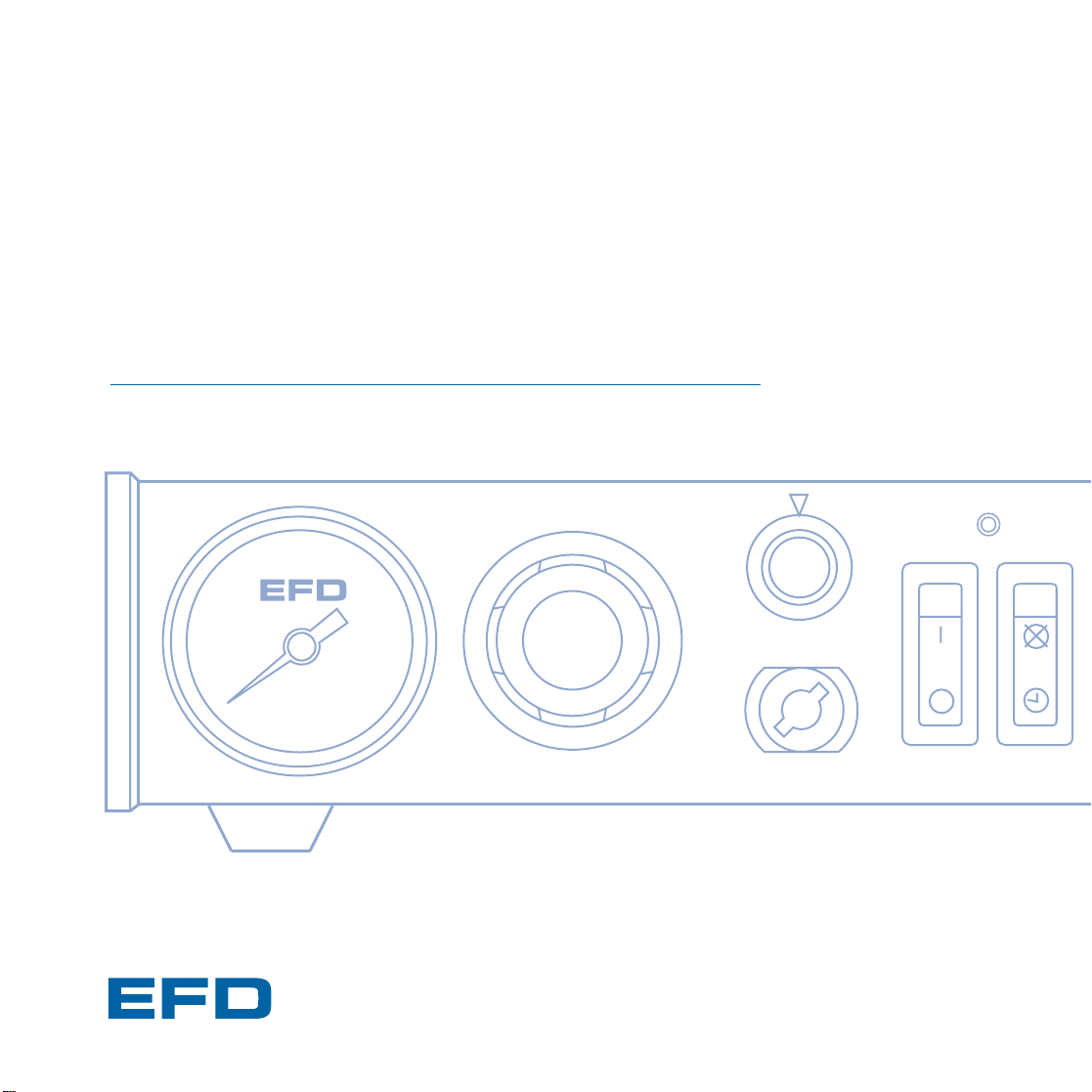

CONTROLS and CONNECTIONS

2

Cover screw

Air pressure

regulator

1

Air output

quick-connect

controlAir gauge

Time

3

6

Power

switch

vacuum control

Barrel

Cycle LED

7

Timer

bypass

Vacuum gauge

4

Voltage selector and

fuse cartridge

220

5

Vacuum transducer

air exhaust port

Air input

Power input

receptacle

1000XL -- Setup for Testing

Power switch 6 should be off.

The amount of material dispensed each cycle depends on the

combination of air pressure, time of air pulse, viscosity of material

and dispensing tip size.

The first step is to remove the tip cap from the pre-filled barrel of blue

test material (twist and pull). Replace it with an 18 gage (green)

tapered dispensing tip. Press the tip on and twist clockwise to lock.

Pull out air pressure regulator knob 1 until it "clicks" into the unlocked

position. Turn clockwise to adjust the air pressure to 30 psi (2.1 bar)

for the initial tests.

Always set the pressure desired by turning the air regulator knob 1

clockwise. To reduce the pressure, turn the knob counterclockwise

until the air gauge 2 reads a lower pressure than desired. Then

increase and stop at desired pressure. Push knob in to lock.

Set the time control 3 to #7. Dispense cycle time increases from

0.01 second minimum to 1.0 second as knob is turned clockwise.

Be sure vacuum control 4 is shut off. In the initial tests, the vacuum

pressure gauge 5 will indicate zero pressure. You may notice the

needle on this gauge (when turned off) will jump slightly after each

cycle. This is normal.

Press power switch 6 to turn on the dispenser. It will light green.

Press timer bypass switch 7. It will light yellow. In this operation

mode, the timer will be bypassed to fill the dispensing tip before you

begin testing. A continuous flow of material will occur as long as the

foot pedal is pressed.

1000XL

Please continue to page 14 for test procedures.

Power

cord

❸

Plant air, 125 psi maximum to

regulator. Output from regulator

should be a minimum of 80 psi,

maximum of 100 psi.

Adapter

assembly

Foot pedal

assembly

❺

Blue

test fluid

Check voltage label

on dispenser

1000D

❹

Air input

hose

❷

❻

Male quick-connect,

insert and twist to lock

❶

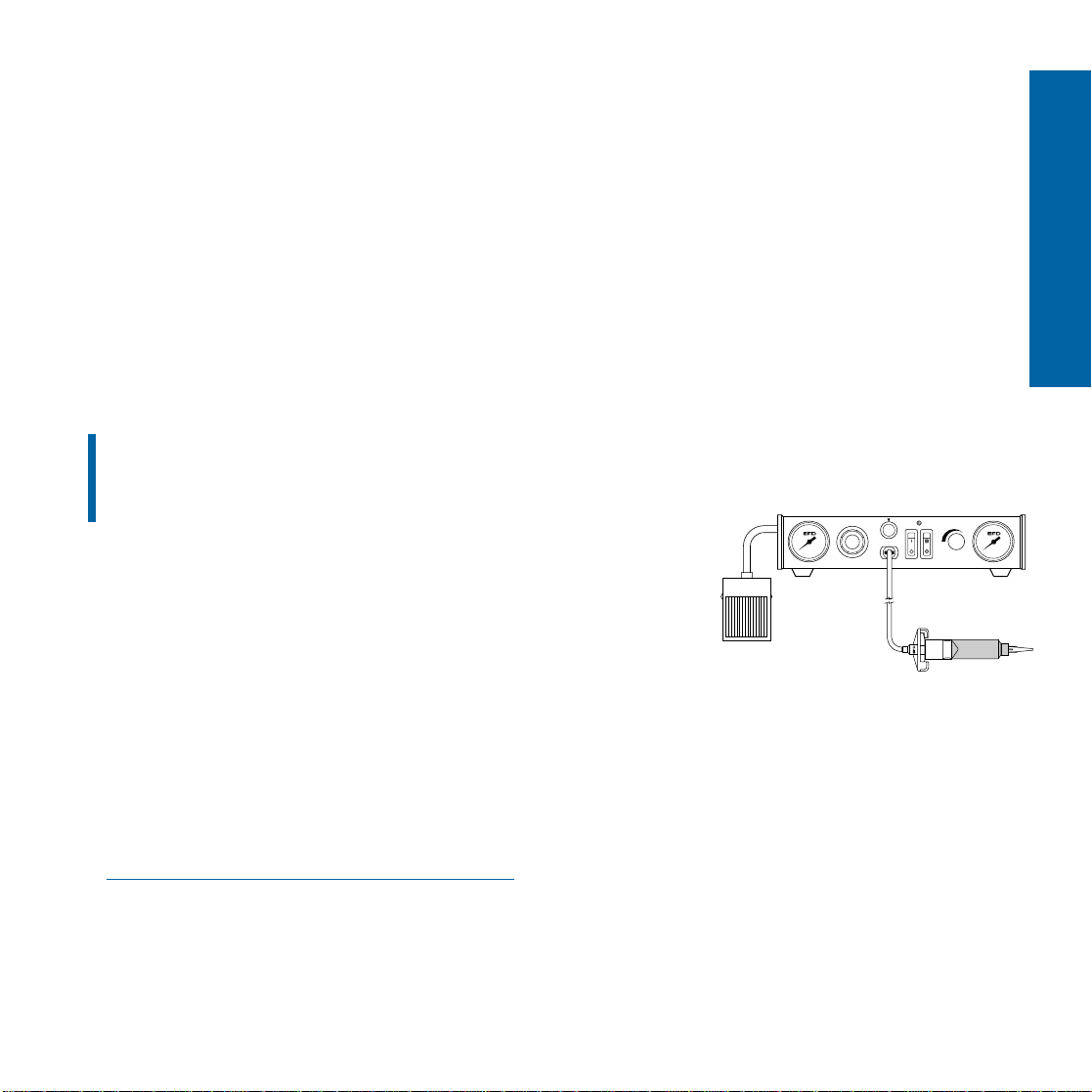

1000D -- Hookup

❶ Connect the air input hose to a plant air source. Set plant air supply

within 80 to 100 psi (5.5 to 6.9 bar). Where required, use an EFD

five-micron filter regulator #2000F755 (see Warranty).

❷ Attach the air input hose coupling to the dispenser. Pull back metal

ring to attach to dispenser.

❸ Plug in the polarized foot pedal connector.

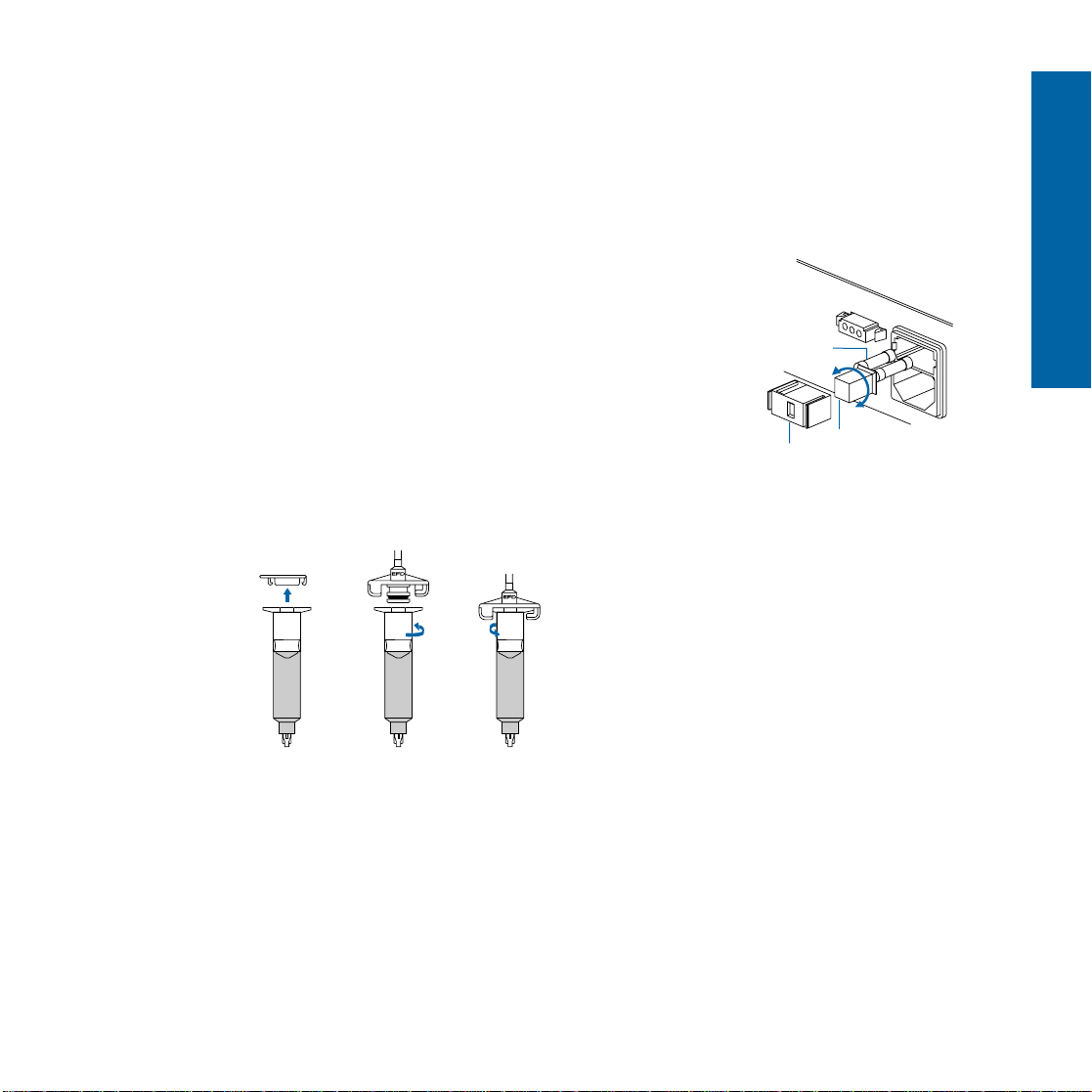

❹ Check the voltage label on the input voltage selector cartridge. To

change the voltage, remove the voltage selector from the cartridge, rotate it and position the correct voltage to show through the

cartridge window. Replace the cartridge into the power cord

receptacle and insure that both sides snap securely into position.

Install the power cord.

❺ Attach the 10cc barrel pre-filled with blue, nontoxic test fluid

(included with the dispenser) to the 10cc adapter head.

Spare fuse

220

120

100

Cartridge window

(check voltage indicated)

Voltage value

1000D

❻ Take the 10cc adapter assembly (#5150 on the adapter head) and

insert the black, male quick-connect into the air output fitting on the

front panel and turn clockwise to lock. Place the barrel in the barrel

stand.

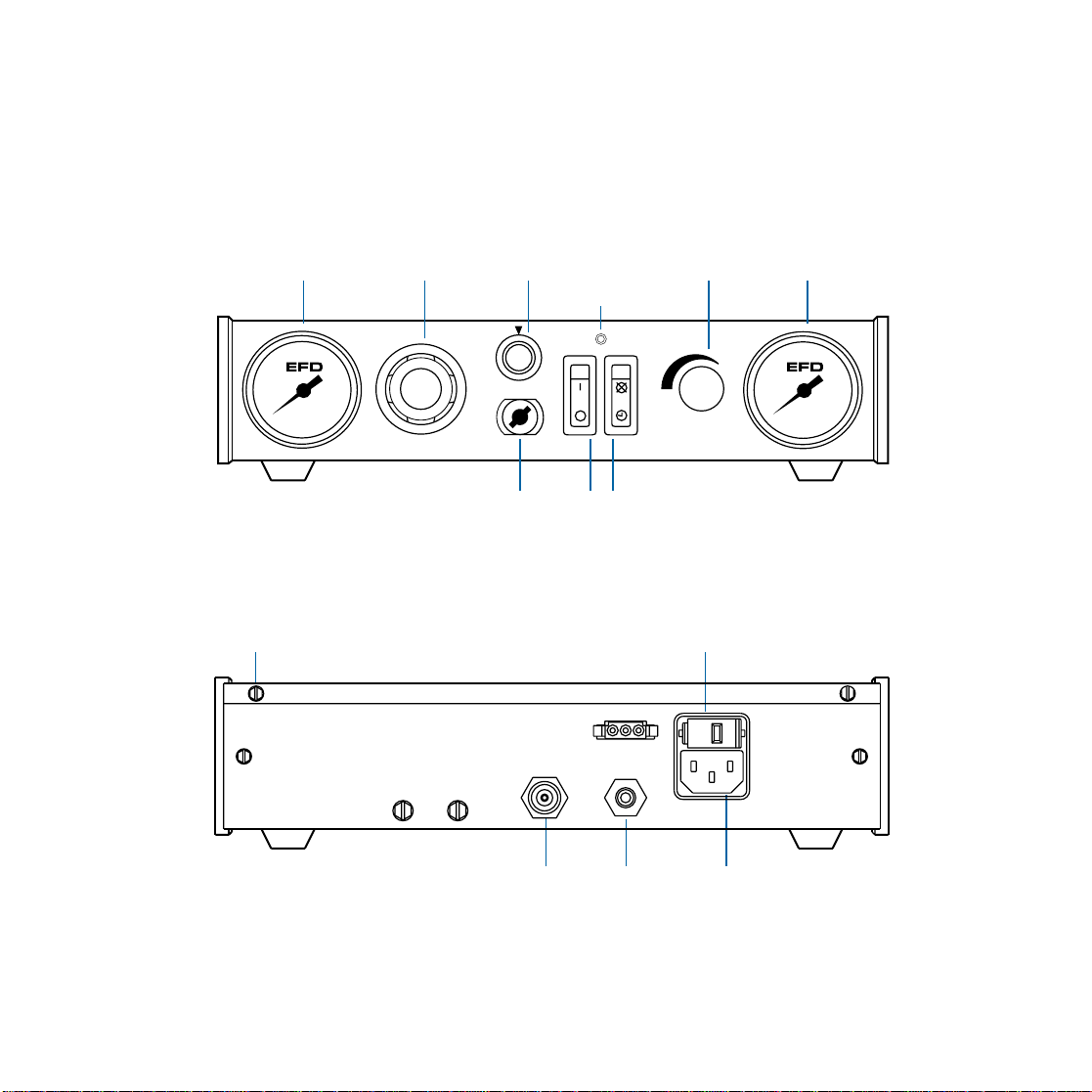

CONTROLS and CONNECTIONS

2

Cover screw

Air pressure

regulator

1

Time

controlAir gauge

Air output

quick-connect

Foot pedal

receptacle

Cycle

LED

3

4

Power

switch

5

Timer bypass

Voltage selector

and fuse cartridge

220

Solenoid Power input

Air input

receptacle

1000D -- Setup for Testing

Power switch 4 should be off.

The amount of material dispensed each cycle depends on the

combination of air pressure, time of air pulse, viscosity of material

and dispensing tip size.

The first step is to remove the tip cap from the pre-filled barrel of blue

test material (twist and pull). Replace it with the 18 gage (green)

tapered dispensing tip. Press the tip on and twist to lock.

Pull out air pressure regulator knob 1 until it "clicks" into the unlocked

position. Turn clockwise to adjust the air pressure to 30 psi (2.1 bar)

for the initial tests.

Always set the pressure desired by turning the air regulator knob 1

clockwise. To reduce the pressure, turn the knob counterclockwise

until the air gauge 2 reads a lower pressure than desired. Then

increase and stop at desired pressure. Push knob in to lock.

Set the time control 3 to #7. Dispense cycle time increases from 0.01

second minimum to 1.0 second as knob is turned clockwise.

Press power switch 4 to turn on the dispenser. It will light green.

Press timer bypass switch 5. It will light yellow. In this operation

mode, the timer will be bypassed to fill the dispensing tip before you

begin testing. A continuous flow of material will occur as long as the

foot pedal is pressed.

1000D

Please continue to page 14 for test procedures.

Testing the 1000 Series Dispensers

45°

80°

Making Timed Deposits

You are now ready to test the pre-filled, nontoxic, blue test fluid. This

material is representative of thick, non-leveling fluids like sealants,

pastes or greases.

Check your initial settings:

A) Air gauge reads 30 psi

Pressure

30

2

Timer

8

7

6

B) Timer is set at #7

C) Green tapered tip is on the test barrel

D) Power and timer bypass switches are on.

Holding the barrel as shown, rest the tip on a piece of paper. Press

the foot pedal until the tip fills and some fluid is pushed out onto the

paper. Repeat this whenever you change to a new tip.

With the tip filled, turn the timer bypass switch off (yellow light out).

Use the Dot Test sheet supplied, and press the foot pedal to activate

the timer. Check the dot size. Press the foot pedal again and note

the size consistency.

Remember—When the yellow timer bypass switch is on, a continuous flow of material will occur as long as the foot pedal is pressed.

The yellow light must be off to make timed deposits.

Try different pressure settings. Continue to experiment by replacing

the green tip with the blue (22 gage) tapered tip included in the Dot

Test Kit. Note the effects of air pressure and tip size on the deposit.

Correct angle for consistent deposits.

Remember - always bring the tip in

contact with the work surface at

the illustrated angle. After the tip

is in position, press the foot pedal.

Release pedal and remove tip by

lifting straight up.

Changing Deposit Size, Drawing Stripes

The dot size is determined by the tip diameter, the air pressure

output setting and the pulse time. For large dots, use a large tip,

higher pressure and more time. Normally, you want to use as short

a time pulse as possible. To increase the dot size, slightly increase

the air pressure output, or increase the tip size, or both.

Green Tip Settings

Test Pressure Time Dot Size

A 30 psi #7

B 20 psi #7

C 20 psi #3

D 15 psi #3

E 10 psi #3

Blue Tip Settings

Test Pressure Time Dot Size

F 30 psi #6

G 20 psi #6

H 20 psi #3

I 15 psi #3

J 10 psi #3

Use the convenient Dot Test sheet included.

Dot Test with Green Tapered Tip

First, follow the settings illustrated on the left, and you will get dots

about the sizes shown. Try other times and pressures to see how

easy it is to get just the dot size you want.

Dot Test with Blue Tapered Tip

These tests show the effect of using a smaller diameter tip.

Replace the green tip with the blue (22 gage) tapered tip. Now, turn

on the timer bypass switch and press the foot pedal to fill the tip.

Then, turn off the timer bypass switch (yellow light out) and press the

foot pedal.

Making Stripes

Keep the settings at Test G (shown to the left) and turn on the timer

bypass switch (yellow light on). With the tip in contact with the test

sheet, press and hold down the foot pedal while drawing a line for

beading or striping.

Advanced Dispensing System

TM

If you dispense thick fluids, several problems may

occur. First, the repetitive air cycles can bore

tunnels through non-leveling fluids, causing

spitting and inconsistent deposits. Second, thick

fluids contain trapped air that leads to drooling

and oozing.

These problems are eliminated by using the

SmoothFlow™ piston. That's because the white

pistons prevent tunneling by providing a barrier to

the pulsed-air cycles, and prevent oozing by

responding to the pressure of trapped air with a

slight suck-back movement after the dispense

cycle.

The white piston is used for most fluids.

However, if you are applying RTV silicone and

find that the piston bounces and causes stringing,

switch to the orange, flat wall piston.

The SmoothFlow™ pistons make barrel filling

easier, too. As you load the fluid in, air is trapped

in the bottom and throughout the fluid. Simply

insert a SmoothFlow™ piston and gently press

down on the fluid as far as possible. This action

forces out most of the air and results in consistent

deposits.

For Thick Fluids

Air Pressure

ON

Air Pressure

OFF

No drip

or ooze.

If you use low to medium viscosity fluids, the white

SmoothFlow™ piston has several advantages.

First, vacuum adjustment is much less sensitive.

Second, the piston prevents fumes from the fluid

being exhausted into the work environment. Third,

the piston prevents fluid backflow into the dispenser if the barrel is inadvertently turned upside

down. Fourth, using the piston makes it easy and

safe to change tips without dripping.

Note: If you use watery-thin fluids such as solvents,

cyanoacrylates and anaerobics, specify the ULTRA

System™ with the blue LV Barrier™. Available only

in 10cc size.

For Watery-thin Fluids

Blue LV Barrier™ for

improved control of

very low viscosity

fluids.

For Thin Fluids

SmoothFlow™ piston

prevents fluid backflow.

Fumes

cannot

escape.

Note: If you choose not to use the piston,

please refer to page 19 for instructions.

How to Use the Vacuum Control (1000XL only)

The vacuum control allows low viscosity fluids, even water, to be

consistently dispensed without dripping between cycles. The vacuum

exerts a negative pressure on the fluid in the barrel and prevents

dripping.

For these tests, you will use the test barrel with the clear fluid.

1. While holding the barrel upright in one hand, remove the orange

end cap and insert the white SmoothFlow™ piston. Carefully

press the piston down to contact the liquid.

Be sure to push it far enough to remove all air, but not into the

fluid, since this will force the fluid up along the sides of the piston.

2. Attach the barrel to the 10cc adapter. Snap the safety clip tightly

closed to prevent any dripping or bubbling. Remove the tip cap

and attach the 25 gage (red) tip.

3. Set air pressure at 5 psi and timer to #5, then turn on timer bypass.

4. With the barrel pointing downward over a container, press the

foot pedal to fill the tip.

5. Turn off the timer bypass switch (yellow light out).

6. If a drop begins to form at the end of the tip, slowly turn the

vacuum control knob counterclockwise to stop the drop from

growing. Wipe the tip and slowly adjust vacuum. Normally, only

1 to 2 psi of vacuum pressure is necessary.

Remove

orange

end cap.

Remove

tip cap.

Insert

SmoothFlow

piston.

™

7. Take the barrel and place the tip on the test sheet. Press the foot

pedal and release. Check the deposit. Increase or decrease by

adjusting pressure or time.

Three things to remember

If you do not use the piston when

dispensing thin fluids:

Do not tip the barrel upside down

or lay flat. This will cause the

liquid to run into the dispenser.

Open

When changing tips

or attaching a tip cap,

snap the safety clip

completely closed to

prevent any dripping

Closed

Use an EFD filter trap (#1000FLT-Y).

This filter trap will impede the flow

should the low viscosity liquid be

sucked back towards the dispenser.

or bubbling.

If you choose not to use the piston, please follow these instructions carefully:

1. While holding the barrel upright in one hand, twist on an

orange tip cap. Using the small funnel supplied, fill about

2/3 full with your liquid.

2. Open the safety clip and attach the barrel to the 10cc adapter.

3. Close the safety clip as tight as possible.

4. Increase vacuum by turning vacuum control knob counterclockwise and set to 1.5 on the vacuum pressure gauge.

5. Then, without tipping the barrel upside down, remove the tip

cap and attach the 25 gage (red) tip.

6. Open the safety clip. Your material may begin to bubble.

Reduce vacuum by turning vacuum control knob clockwise.

7. If a drop begins to form at the end of the tip, slowly turn the

vacuum control knob counterclockwise to stop the drop from

growing. Wipe the tip and adjust vacuum as necessary.

Now the fluid is in proper balance. It does not bubble or drip.

Repeat tests as before, keeping the air pressure low and adjust-

ing the time for different deposit sizes. Contact EFD if you have

any questions.

☎

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

Loading the Barrel Reservoirs

Caution: Do not completely fill barrels. The optimum fill is a maximum

2/3 of the barrel capacity and 1/2 of the barrel capacity when using

the LV Barrier™.

If the fluid you are dispensing is pourable, take the barrel, twist on a

tip cap and pour your fluid in. If appropriate, insert the SmoothFlow

piston (see page 13). Carefully press the piston down until it contacts

the fluid. The barrel is now ready for use.

If you are dispensing solvents, cyanoacrylates or anaerobics, use

the LV Barrier™. Place barrier in the top of the barrel reservoir. Allow

air between barrier and fluid. Do not contact the barrier to the fluid.

If your fluid is thick or non-leveling, you can spoon it into the barrel

with a spatula. Or, if the fluid comes packed in a 1/10 gallon cartridge,

try loading the barrel with a caulking gun. Then, press in the

SmoothFlow™ piston to move the fluid to the bottom of the barrel and

to remove trapped air.

Fill procedure with

caulking gun.

™

Fill procedure for

pourable fluids.

LV Barrier

Air

™

2/3

Maximum

Fill

White

SmoothFlow

piston.

™

Fill procedure for

watery-thin fluids.

1/2 maximum fill

Filling the cartridge

for the barrel loader.

EFD offers productive alternatives to traditional barrel-loading methods. Here are a few suggestions that can help keep your work area

clean, save time and reduce the chance of entrapped air in the fluid.

1. You could use the EFD #920BL barrel loader. Pack the fluid into

the 12 ounce cartridge as shown. Then place the pre-filled

cartridge into the barrel loader. Using air pressure, the barrel

loader fills the barrel (with piston) from the bottom up.

If the fluid comes packed in a 1/10 gallon (300 ml.) caulking type

cartridge, use the EFD #930BL barrel loader.

2. If you receive frozen epoxies or other fluids in medical type

syringes with a manual plunger, request our luer-to-luer fitting

#2160 to transfer the material.

Please call an EFD Product Specialist for additional assistance.

2/3

Maximum

Fill

EFD #920BL Barrel Loader

(Specify #930BL for pre-filled 1/10 gallon caulking tubes)

#2160 Luer-to-luer fitting

Barrel Rack

#905BR for 3cc and 5cc barrels

#910BR for 10cc, 30cc and 55cc barrels

Now, test your fluid.

Made

U.S.A.

Barrel Reservoir Selection

Remember, each barrel must use the proper size adapter head. Five

sizes of barrels and four sizes of adapter heads (30cc and 55cc

barrels use the same size adapter head) are provided with this

dispenser—3cc, 5cc, 10cc, 30cc and 55cc.

The most comfortable size barrel is the 10cc. But if you plan to make

very small dots, we recommend the 5cc or even the 3cc size. For

large dots or encapsulating work, use the 30cc or 55cc size.

If you find you need more reservoir capacity than 55cc, consider the

2 1/2, 6 or 12 ounce cartridges. Contact EFD for assistance and

specific recommendations based on your application.

Tip Selection

The EFD 5100 Component Kit included with the dispenser contains

a complete selection of disposable tips.

The appropriate tip for your application will increase assembly

production. Refer to the enclosed booklet with the Component Kit for

helpful recommendations.

I

F

T

I

E

R

D

E

C

F

ade

M

O

R

I

N

All components are quality produced

in a silicone-free environment by

EFD in the USA.

E

in

S

.A.

U.S

U

L

A

I

D

R

U

T

S

Time and Pressure Settings

When establishing settings for your material, keep the time as short

as possible, the tip as large as possible and air pressure as needed

to produce the dot size you require.

Rule of Thumb: Start with a short pulse time. Use the dispensing tip

size appropriate for the size dot required. Vary air pressure. For

more output, gradually increase pressure.

Caution: Use of high air pressure with low viscosity material and a

small gage tip can expel the material some distance.

Troubleshooting

NO POWER

POWER, BUT NO LIGHT

POWER, LIGHT, BUT

MACHINE DOES NOT OPERATE

INCONSISTENT DOTS

TIMER SEEMS INOPERATIVE

MATERIAL SUCK-BACK

1. Check voltage at wall outlet.

2. Check fuse. Replace #7111E.

3. Unplug from wall, remove top cover, visually inspect for any loose

or shorted connections.

1. Switch module must be replaced.

1. Unplug input power cord.

2. Check foot pedal connection, foot pedal and internal switch.

1. Check dispensing tip, barrel and material for possible clogging.

2. Check air gauge to be sure air pressure is not varying.

3. Check to see if there are air bubbles in the material being

dispensed.

1. Check to be sure timer bypass switch is off (yellow light out).

2. Check DIP switch positions (see page 25).

Note: The EFD timer is very reliable. Most questions about the timer

are resolved by simply turning the timer bypass switch off (yellow

light out).

1. Use SmoothFlow™ pistons or LV Barriers™ to prevent this. (See

pages 16-17.)

2. If it occurs, attach an empty barrel, put timer bypass switch on, put

barrel in a cup and press the pedal to expel the sucked-back fluid.

3. If problem cannot be corrected, contact an EFD Product Specialist

for assistance. Dispensers can be returned to EFD for repair.

☎

If you have any problems, we will correct them immediately. Please

do not hesitate to contact EFD or your authorized EFD distributor.

In the US, call 800-556-3484.

In Mexico, call 001-800-556-3484.

In the UK, ring free 0800 585733.

Schematic and Parts

2

5

7

Model 1000XL

2

5

7

Model 1000D

18

19

29

27

18

19

8

3

17

3

17

26

30

9

12

9

6

33

1

4

16

10

11

8

6

4

16

13

10

11

29

1413

31

35

9

12

1

14

9

34

9

15

15

32

28

Input Air

Regulated Air

Vacuum

1000D and 1000XL

Replacement Parts List

1. 2024-160 1/4" OD x .160" ID tubing

2. 2-2031-1000 Transformer assembly multi input

3. 2-2017A-24XL Foot pedal receptacle

4. 2169 Fitting 1/8 NPT x 1/8 NPT elbow brass

5. 2088 Fitting 1/8 NPT x 1/4 barb brass

6. 2-2006-24PR Programmable timer

7. 2001C 0 to 100 psi (0 to 7.0 bar) gauge

8. 2081A Male mini air-coupler panel mount

9. 2087 Fitting 1/8 NPT x 1/4 barb elbow brass

10. 2-2007-XL Potentiometer assembly

11. 2008A Time control knob

12. 2-2003-1000 24 VDC solenoid assembly

13. 2010-A24 Power switch 115 VAC

14. 2-2011-24 1000XL timer bypass switch assembly

15. 2019 Dispenser end panel

16. 2-2004B Quick-connect assembly

17. 2089 Fitting 1/8 NPT x 1/4 barb tee brass

18. 7111E Fuse .160A

19. 2014XL Input power receptacle

20. 2002SCR Replacement screen for regulator*

21. 2009-A24 Power cord American*

22. 2009-E24 Power cord European*

23. 2015A Foot pedal assembly*

24. 2033 Dispense indicator LED*

25. 1000INP-AKIT Air input hose*

26. 2-2002 1000D regulator assembly 0 to 100 psi

(0 to 7.0 bar)

27. 2-2002-XL 1000XL regulator assembly 0 to 100 psi

(0 to 7.0 bar)

28. 2001B 0 to 15 psi (0 to1.0 bar) gauge

29. 2178 Fitting 1/8 NPT x 1/4 barb elbow brass

30. 2-2170LV Vacuum transducer assembly

31. 2-2176-XL Barrel vacuum control assembly

32. 2036 Fitting 1/8 NPT x 1/4 barb brass

33. 2083 Gauge restrictor

34. 2084 Air restrictor

35. 7108 1000D muffler

* Not Shown

Programmable Timer

The heart of each 1000 Series dispenser is the EFD advanced solidstate, digital timer with programmable time ranges and choice of

Momentary (press the foot pedal once) or Maintained (hold foot

pedal down during time cycle) initiation modes.

This unique timer is located inside the dispenser. To access, remove

the two cover screws and slide the cover off the dispenser.

Caution: Always disconnect the power cord before removing the

cover.

DIP Switch Settings

1234

O

N

1234

O

N

③ ON

0.01-1.0 second

Momentary

② ON

0.1-10 seconds

Momentary

The DIP switch that controls the timer has been set at the factory for

a time range of 0.01 to 1.0 second, with the initiation set to

MOMENTARY contact. (See top diagram.)

Experience shows this is the most often used initiation mode and

time range.

For larger deposits that require longer time, it may be advantageous

to set the initiation to MAINTAINED contact. The operator must then

keep the foot pedal pressed throughout the time cycle.

Four time ranges are provided so that you can have fine-time

adjustment in the range you select.

For extremely small dots of low viscosity, watery fluids, you may want

to select the 0.005 to 0.04 second range. For slow filling, a longer

time range will provide the time that's needed for flow control.

1234

O

N

1234

O

N

1234

O

N

1234

O

N

① ON

0.2-20 seconds

Momentary

① ② ③ ON

0.3-31 seconds

Momentary

① ② ③ OFF

0.005-0.04 second

Momentary

② ④ ON

0.1-10 seconds

Maintained

④ ON = Maintained pedal contact

④ OFF = Momentary pedal contact

Suggestions & Reminders

1. Always use an EFD SmoothFlow™ piston or LV Barrier™ to make

barrel loading, dispensing and handling cleaner, safer and more

accurate.

Caution (1000XL only): If you dispense pourable fluids and choose

not to use SmoothFlow™ pistons, do not increase vacuum pressure

rapidly and do not tip the barrel. Vacuum may pull liquid into the air

hose; or when tipped, liquid may flow back into the dispenser.

2. Always use new barrels and tips. Carefully dispose of after use.

This procedure ensures maximum cleanliness, prevents contamination and provides proper safety.

3. Do not completely fill the barrel. The optimum fill is a maximum

2/3 of the barrel capacity with the SmoothFlow™ piston and 1/2 of

the barrel capacity when using the LV Barrier™.

4. Properly filtered, clean, dry plant air should be available where

the dispenser is to be set up. (Bottled nitrogen can be used.) Use

an EFD five-micron filter regulator #2000F755 where required.

5. Use the EFD DispenStand™ #DS1400 to help organize bench

space. Adapter hose support keeps air hose off the work area.

6. Depending on the type of work you are doing, it may be easier to

bring the work to the barrel. Mount the barrel on the EFD stand

#7300A.

7. To ensure smooth fluid flow and consistent deposits, always

have the tip at a 45° angle to the work surface.

80°

#DS1400

DispenStand

45°

#2000F755

Five-micron filter

regulator

™

#7300A

Barrel stand

Tip should be at

a 45° angle to

work surface.

ULTRA System™ Dispensing Components

For complete selection and technical details, please refer to EFD Catalog and price list.

Barrel adapter assemblies

Molded one-piece, yellow, SnapLok™ adapter

head with Buna N O-ring, flexible 5/32" OD

hose, male quick-connect and safety clip.

size with 3-ft hose with 6-ft hose

3cc 1000Y5148 1000Y5148-6

5cc 1000Y5149 1000Y5149-6

10cc 1000Y5150 1000Y5150-6

30cc/55cc 1000Y5152 1000Y5152-6

ULTRA System™ barrels/pistons

Industrial-grade ZeroDraft™ barrels and white

SmoothFlow

by EFD. Each box contains the same quantity

of ZeroDraft™ barrels and white SmoothFlow

pistons.

size clear amber black box

3cc 5109CP-B 5109AP-B 5109UP-B 50

5cc 5110CP-B 5110AP-B 5110UP-B 40

10cc 5111CP-B 5111AP-B 5111UP-B 30

30cc 5112CP-B 5112AP-B 5112UP-B 20

55cc 5113CP-B 5113AP-B n/a 15

™

pistons are molded silicone-free

UV-block light-block sets/

LV Barrier™ ULTRA System

Designed specifically for dispensing low viscosity fluids including solvents, cyanoacrylates

and anaerobics.

quantity of ZeroDraft™ barrels and blue LV

Barriers

™

Each box contains the same

.

Smooth-flow tapered tips

Molded polyethylene with UV block. Packaged

(50) tips per see-through box with covers for easy

part identification.

gage ID tapered color

14 .063" 5114TT-B olive

16 .047" 5116TT-B grey

18 .033" 5118TT-B green

20 .023" 5120TT-B pink

22 .016" 5122TT-B blue

25 .010" 5125TT-B red

General-purpose precision tips

All EFD dispensing tips incorporate the unique

™

SafetyLok™ color-coded polypropylene hubs.

Packaged (50) tips per see-through box for easy

part identification.

gage ID 1/2" length hub color

14 .061" 5114-B olive

15 .054" 5115-B amber

18 .033" 5118-B green

20 .024" 5120-B pink

21 .020" 5121-B purple

22 .016" 5122-B blue

23 .013" 5123-B orange

25 .010" 5125-B red

27 .008" 5127-B clear

30 .006" 5130-B lavender

size clear sets/box

10cc 5111LV-B 3 0

r

EFD Ten Year No-fault Warranty

All components of EFD dispensers are warranted to the original end user for ten years

from date of purchase.

Within the period of this warranty, EFD will repair or replace free of charge any

defective component, regardless of fault, on return of the part, or the complete

dispenser, prepaid to the factory.

In no event shall any liability or obligation of EFD arising from this warranty exceed

the purchase price of the equipment. Before using, user shall determine the suitability

of the product for his intended use, and user assumes all risk and liability whatsoever

in connection therewith. This warranty is valid only when clean, dry, filtered air is used.

EFD makes no warranty whatsoever of merchantability or fitness for a particular purpose. In no event shall EFD be liable for incidental or consequential

damages.

®

A NORDSON COMPANY

Sales and service of EFD dispensers and

dispensing components is available through

EFD authorized distributors in over 30 countries. Please contact EFD U.S.A. for specific

names and addresses.

Printed on

recycled pape

©2004 EFD Inc. 1000-MAN

Headquarters: 977 Waterman Avenue, East Providence, RI 02914-1378 USA

Toll free: 800-556-3484 Mexico: 001-800-556-3484

Telephone: +1-401-434-1680 Fax: +1-401-431-0237

e-mail: technical@efd-inc.com www.efd-inc.com

Unit 14, Apex Business Centre, Boscombe Road

Dunstable, Bedfordshire LU5 4SB UK

Telephone: (0) 1582 666334 Fax: (0) 1582 664227

Freephone: 0800 585733 From Ireland: 00800 8272 9444

e-mail: uk@efd-inc.com

Loading...

Loading...