Ducati 998 '02, 748 '02 User Manual

1

E

DUCATI998/748

Owner’s manual

2

E

3

E

Hearty welcome among Ducati fans! Please accept our

best compliments for choosing a Ducati motorcycle. We

think you will ride your Ducati motorcycle for long

journeys as well as short daily trips. Ducati Motor Holding

s.p.a wishes you smooth and enjoyable riding.

We are steadily doing our best to improve our “Technical

Assistance” service. For this reason, we recommend you

to strictly follow the indications given in this manual,

especially for motorcycle running-in. In this way, your

Ducati motorbike will surely give you unforgettable

emotions.

For any servicing or suggestions you might need, please

contact our authorized service centres.

Enjoy your ride!

Ducati Motor Holding S.p.A. declines any liability

whatsoever for any mistakes incurred in drawing up this

manual. The information contained herein is valid at the

time of going to print. Ducati Motor Holding S.p.A.

reserves the right to make any changes required by the

future development of the above-mentioned products.

For your safety, as well as to preserve the warranty,

reliability and worth of your motorcycle, use original

Ducati spare parts only.

Warning

This manual forms an integral part of the

motorcycle and - if a transfer of title occurs - must always

be handed over to the new owner.

4

E

TABLE OF CONTENTS

General 6

Warranty 6

Symbols 6

Useful information for safe riding 7

Carrying the max load allowed 8

Identification data 9

Controls 10

Position of motorcycle controls 10

Instrument panel 11

Keys 12

Ignition switch and steering lock 12

Left switch 13

Clutch lever 14

Cold start button 15

Starter lever 15

Right switch 16

Throttle twistgrip 16

Front brake lever 16

Rear brake pedal 17

Gear change pedal 17

Setting the gear change and rear brake pedals 18

Main components and devices 19

Location 19

Tank filler plug 20

Seat catch and helmet hook 21

Side stand 23

Steering damper 24

Front fork adjusters 748/748S/998 24

Shock absorber adjusters (748/748S) 26

Shock absorber adjusters (998) 27

Changing motorcycle track alignement 28

Directions for use 29

Running-in recommendations 29

Pre-ride checks 31

Starting the engine 32

Moving off 34

Braking 34

Stopping the motorcycle 35

Parking 35

Refueling 35

Tool kit and accessories 36

Main maintenance operations 37

Removing the fairing 37

Cleaning and changing air filters 39

Checking the coolant level 40

Checking brake and clutch fluid level 41

Checking brake pads for wear 42

Lubricating cables and joints 43

Throttle cable adjustment 43

Charging the battery 44

5

E

Adjusting headstock angle 45

Chain tension inspection 46

Chain lubrication 46

Replacing bulbs 47

Beam setting 50

Rear view mirror adjustment 51

Tubeless tyres 51

Checking engine oil level 53

Cleaning and replacing the spark plugs 54

Cleaning the motorcycle 55

Storing the bike away 56

Important notes 56

Technical data 57

Overall dimensions 57

Weights 57

Top-ups 58

Engine (748/748S) 59

Timing system (748/748S) 59

Engine (998) 60

Timing system (998) 60

Performance data 61

Spark plugs 61

Brakes 61

Transmission 62

Frame 63

Wheels 64

Tyres 64

Suspensions 65

Available colours 65

Electric system 66

For United States of America version only 73

Routine maintenance record 82

6

E

GENERAL

Warranty

In your own interest, and in order to guarantee product

reliability, you are strongly advised to refer to a Ducati

Dealer or Authorized Workshop for any servicing

requiring particular technical expertise. Our highly skilled

staff have access to the implements required to perform

any servicing job at best, using Ducati original spare parts

only as the best guarantee for full interchangeability,

smooth running and long life.

All Ducati motorcycles come with a “Warranty Card”.

However, warranty does not apply to the motorcycles

used in competitions. No motorcycle part may be

tampered with, altered, or replaced with parts other than

original Ducati spare parts during the warranty period, or

the warranty will be automatically invalidated.

Symbols

Ducati Motor Holding S.p.A. advises you to read this

manual carefully so as to become familiar with your

motorcycle. In case of any doubts, please call a Ducati

Dealer or Authorized Workshop. The information

contained herein will prove useful on your trips - and

Ducati Motor Holding S.p.A. wishes you smooth,

enjoyable riding - and will help you keep the performance

of your motorcycle unchanged for a long time.

Warning

Failure to comply with these instructions may put

you at risk and lead to severe injury or death.

Important

Possibility of damaging the motorcycle and/or its

components.

Note

Additional information concerning the job being

carried out.

The terms right and left are referred to the motorcycle

viewed from the riding position.

7

E

Useful information for safe riding

Warning

Read this section before riding your motorcycle.

Accidents are frequently due to inexperience. Always

make sure you have your licence with you when riding;

you need a valid licence to be entitled to ride your

motorcycle.

Do not lend your motorcycle to inexperienced riders or

who do not hold a valid licence.

Both rider and pillion passenger must always wear a

safety helmet.

Wear proper clothing, with no loose items or accessories

that may become tangled in the controls or limit your

zone of vision.

Never start or run the engine indoors. Exhaust gases are

poisonous and may lead to loss of consciousness or even

death within a short time.

Both rider and pillion passenger should keep their feet on

the footpegs when the motorcycle is in motion.

Always hold the handlebars firmly with both hands so

you will be ready for sudden changes of direction or in

the road surface. The pillion passenger should always

hold on to the suitable belt on the rear seat with both

hands.

Ride within the law and observe national and local rules.

Always respect speed limits where these are posted.

However, always adjust your speed to the visibility, road

and traffic conditions you are riding in.

Always signal your intention to turn or pull to the next

lane in good time using the suitable turn indicators.

Be sure you are clearly visible and do not ride within the

blind spot of vehicles ahead.

Be very careful when tackling road junctions, or when

riding in the areas near exits from private grounds, car

parks or on slip roads to access motorways.

Always turn off the engine when refueling.

Be extremely careful not to spill gasoline on the engine

or on the exhaust pipe when refueling.

Do not smoke when refueling.

While refueling, you may inhale noxious gasoline vapors.

Should any gasoline drops be spilled on your skin or

clothing, immediately wash with soap and water and

change your clothing.

Always remove the key when you leave your motorcycle

unattended.

The engine, exhaust pipes, and mufflers stay hot for a

long time.

Park your motorcycle where no one is likely to hit it and

use the side stand.

Never park on uneven or soft ground or your motorcycle

may fall over.

8

E

Carrying the maximum load allowed

Your motorcycle is designed for long-distance riding,

carrying the maximum load allowed in full safety.

Even weight distribution is critical to preserving safety

features and avoiding trouble when performing sudden

manoeuvres or riding on bumpy roads.

Information about carrying capacity

The total weight of the motorcycle in running order

including rider, pillion passenger, luggage and additional

accessories should not exceed 375 Kg.

Arrange your luggage or heavy accessories in the lowest

possible position and close to motorcycle centre.

Be sure to secure the luggage to the supports provided

on the motorcycle as firmly as possible. Improperly

secured luggage may affect stability.

Never fix bulky or heavy objects to the handlebar or to

the front mud guard as this would affect stability and

cause danger.

Do not insert any objects you may need to carry into the

gaps of the frame as these may foul moving parts.

Make sure the tyres are inflated to the proper pressure

indicated at page 51 and that they are in good condition.

9

E

Identification data

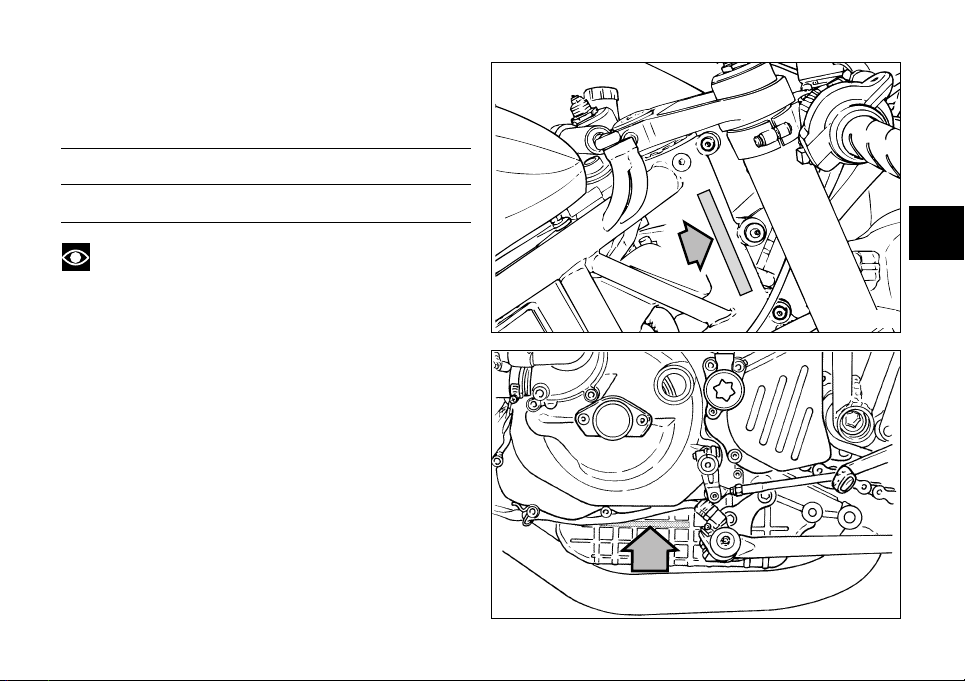

All Ducati motorcycles have two identification numbers,

for frame (fig. 1.1) and engine (fig. 1.2).

Frame number

Engine number

Note

These numbers identify the motorcycle model and

are required when ordering spare parts.

fig. 1.2

fig. 1.1

10

E

CONTROLS

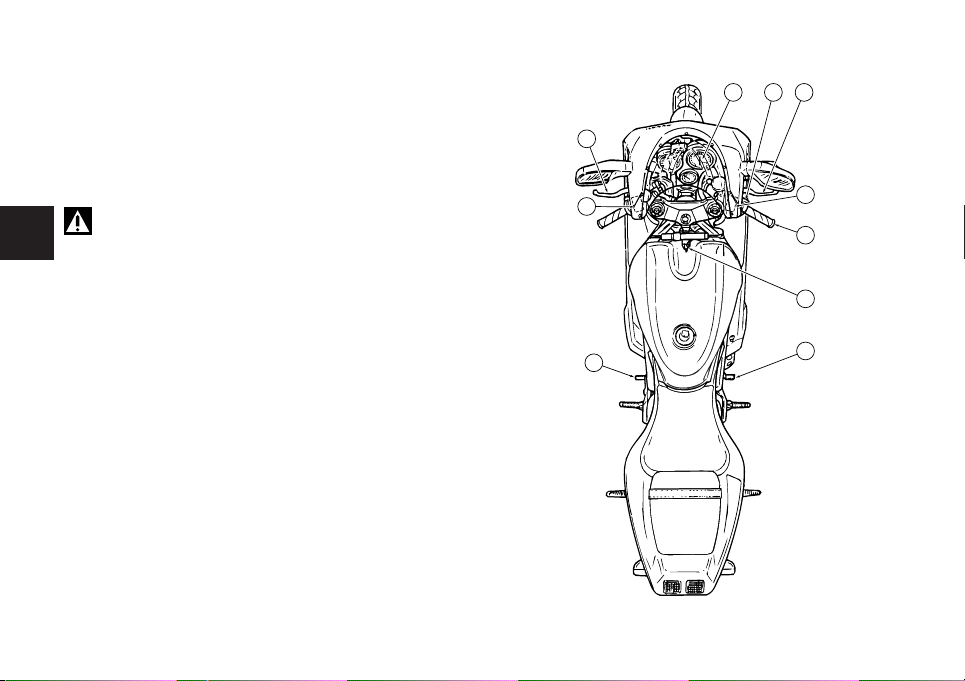

Warning

This section details the position and function of all

the controls you need to drive your motorcycle. Be sure

to read this information carefully before you use the

controls.

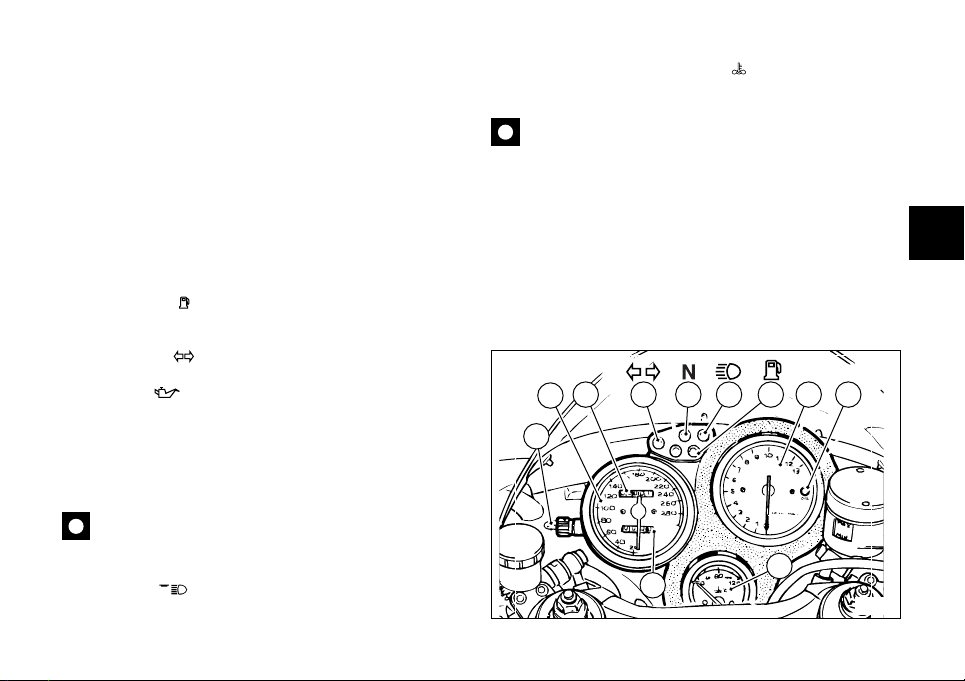

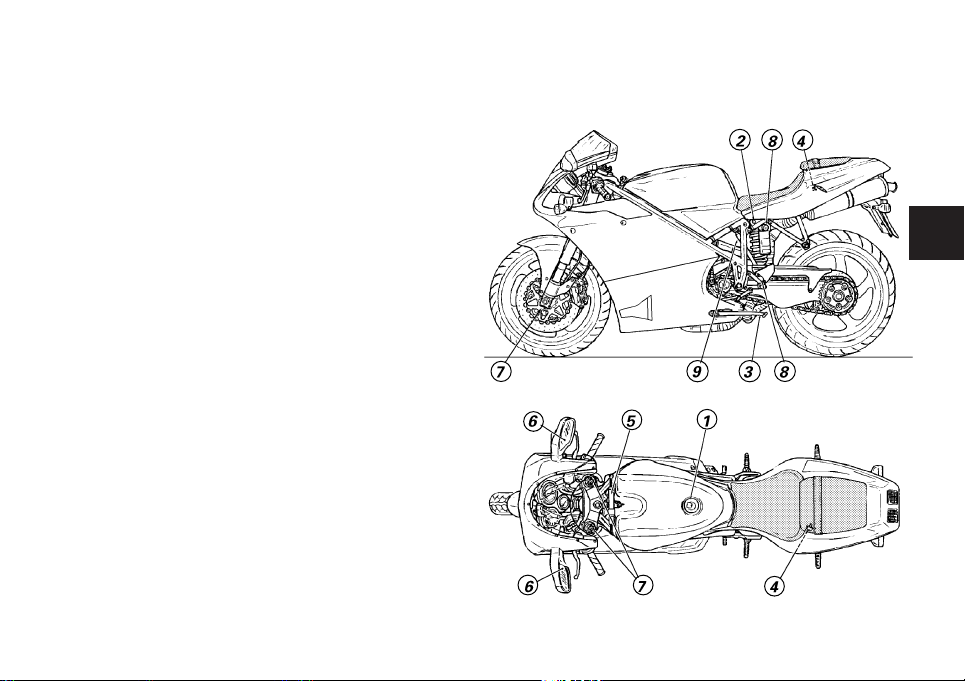

Position of motorcycle controls (fig. 2)

1) Instrument panel.

2) Key-operated ignition switch and steering lock.

3) Left switch.

4) Clutch lever.

5) Cold start button.

6) Right switch.

7) Throttle twistgrip.

8) Front brake lever.

9) Gear change pedal.

10) Rear brake pedal.

fig. 2

9

3

4

1 5 8

6

7

2

10

5a

1

c

b

8

3 7 4 2 6

D

U

C

A

T

I

C

O

R

S

E

11

E

Instrument panel (fig. 3)

1) Speedometer (km/h or mph).

Gives road speed.

a) Odometer (km or miles).

Gives total distance covered.

b) Trip meter (km or miles).

Gives distance covered since last resetting.

c) Trip meter resetting knob.

Turn to reset trip meter to “0000”.

2) Engine revolution meter (rpm)

Indicates engine rpm.

3) Green light N.

Comes on when gearbox is in neutral.

4) Yellow light .

Comes on when there are about 4 liters fuel left in the

tank.

5) Green light .

Comes on and flashes when a turn indicator is on.

6) Red light .

Comes on when engine oil pressure is too low. It comes

on when the ignition is switched to ON and normally

goes out a few seconds after engine starts.

It may shortly come on when the engine is hot, however,

it should go out as the engine revs up.

Important

If this light (6) stays on, stop the engine or it may

suffer severe damage.

7) Blue light .

Comes on when right high beam is on.

fig. 3

8) Water temperature indicator .

Indicates engine coolant temperature.

Important

Stop riding if the temperature reaches the max.

value, otherwise the engine might damage.

When parking light is on, the instrument panel is lighted.

12

E

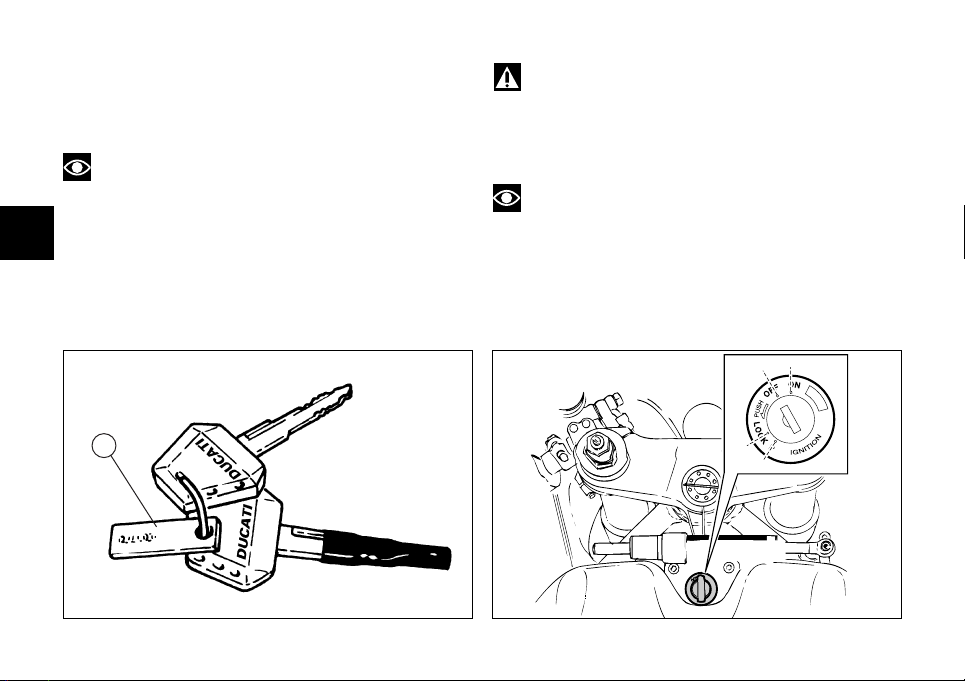

Keys (fig. 4)

Your Ducati was delivered with two universal keys for

ignition, steering lock and seat catch and a key

identification plate (1).

Note

Separate the two keys and keep the identification

plate (1) in a safe place.

Ignition switch and steering lock (fig. 5)

It is located in front of the fuel tank and has four

positions:

A) ON: lights and engine enabled;

B) OFF: lights and engine disabled;

C) LOCK: steering locked;

D) P: parking light and steering lock.

Warning

The 998 model is equipped with an energy-saving

CPU. If the key stays ON for a long period but the ignition

button is not pressed within 15 seconds, the CPU will

stop operating to avoid current absorption. Move the key

to OFF and then to ON again.

Note

To move the key to the last two positions, press it

down before turning it. Switching to (B), (C) and (D), you

will be able to take the key out.

1

fig. 4

fig. 5

A

B

C

D

13

E

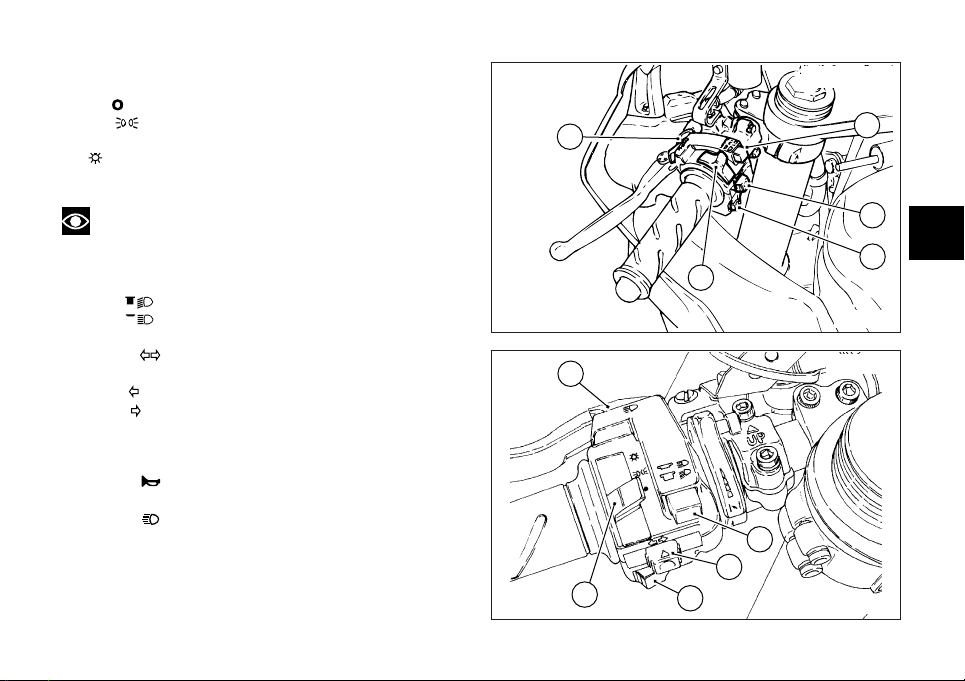

Left switch

1) Switch, light switch, 3 positions:

Down = light off;

Centre = front and rear parking light, number plate

light and panel lights on;

Up = headlamp, front and rear parking light, number

plate light and panel lights on.

Note

This device is not fitted on the Australia and Japan

versions.

2) Dip switch, light dip switch, two positions:

position = low beam on;

position = high beam on.

3) Switch = 3-position turn indicator:

centre position = off;

position = left turn;

position = right turn.

To cancel turn indicators, return switch to central position

and push in.

4) Button = warning horn.

5) Button = high-beam flasher.

4

2

3

1

5

fig. 6

4

2

3

1

5

fig. 6.1

748/748S

998

14

E

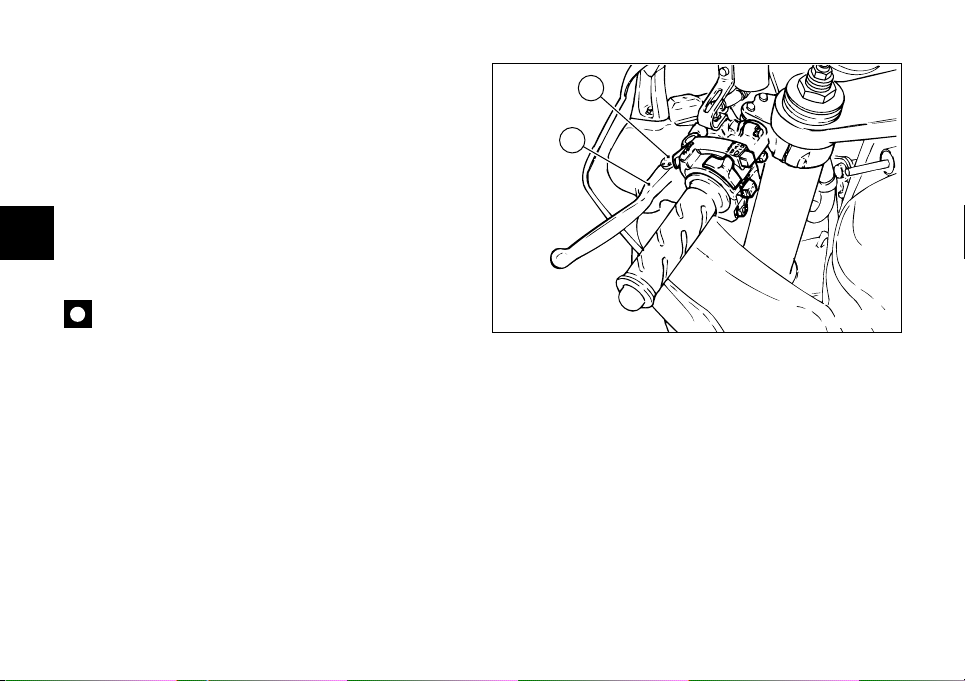

Clutch lever (fig. 7)

Lever (1) disengages the clutch. It features a dial adjuster

(2) for lever distance from the twistgrip on handlebar.

To set lever distance from twistgrip, push lever (1) fully

forward and turn the dial adjuster (2) to one of its four

positions. Remember that position no. 1 gives maximum

distance between lever and twistgrip, whereas lever and

twistgrip are closest when adjuster is set to position no. 4.

When you pull in the lever (1), you will disengage the

engine from the gearbox and therefore from the driving

wheel. Using the clutch properly is essential to smooth

riding, especially when moving off.

Important

Using the clutch properly will avoid damage to

transmission parts and spare the engine.

1

2

fig. 7

Cold start button (fig. 8)

This device is on throttle control. Push the button (3) to

enable control. In this way, the throttle control (4) will

lightly turn, thus increasing the engine rotation speed.

Use this device to start the engine from cold (page 32).

Important

Move the button (3) back to rest position once the

engine is warm. Turn the throttle twistgrip (4) clockwise

(slow down). Never use this device when the engine is

warm.

Starter lever (fig. 8.1)

The starter lever (1) is used to start the engine from cold

and to increase the engine idle rotation speed after

starting. Control positions:

A - (vertical) Control not activated

B - Control fully activated

The lever may also be placed on intermediate positions

to match the progressive engine warming up (see page

32).

Important

Never use this device when the engine is warm.

Do not run with the starter control on.

15

E

1

A

B

fig. 8.1

4

3

fig. 8

748/748S

998

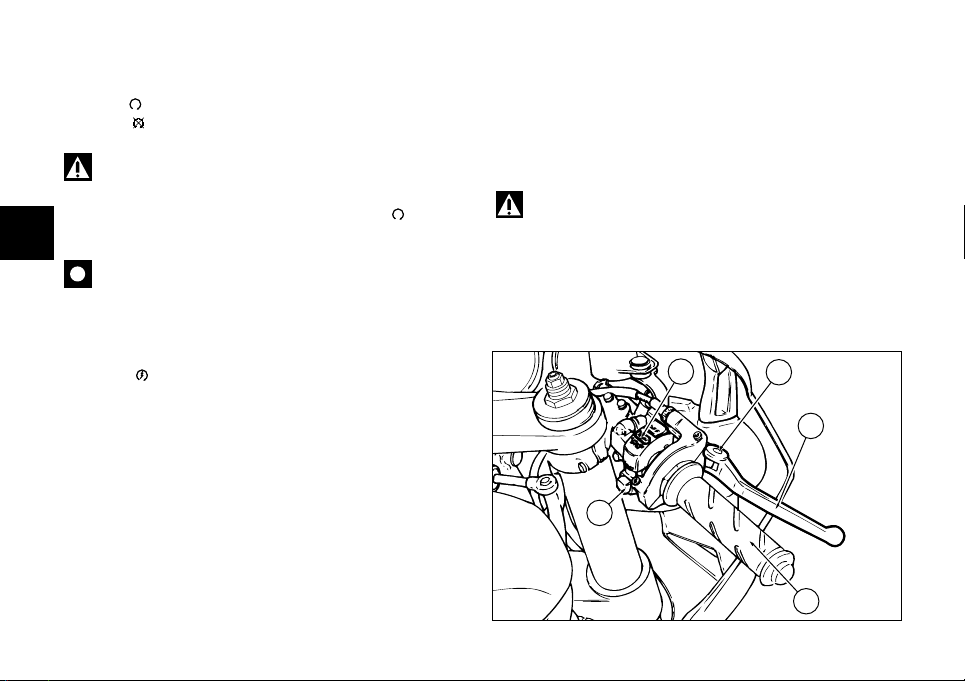

Right switch (fig. 9)

1) Switch for ENGINE STOP, two positions:

position (RUN) = run.

position (OFF) = stop.

Warning

This switch is mainly intended for use in emergency

cases when you need to stop the engine quickly. After

stopping the engine, return the switch to the position

to enable starting.

Important

Stopping the engine using switch (1) after riding

with the lights on and leaving the ignition key in the ON

position, may run the battery flat as the lights will remain

on.

2) Button = engine start

Throttle twistgrip (fig. 9)

The twistgrip (3) on the right handlebar opens the

throttles. When released, it will spring back to the initial

position (idling speed).

16

E

4

3

1

2

5

fig. 9

Front brake lev

er (fig. 9)

Pull in the lever (4) towards the twistgrip to operate the

front brake. The system is hydraulically operated and you

just need to pull the lever gently.

The brake lever is provided with a dial adjuster (5) for

lever distance adjustment from twistgrip on handlebar.

Warning

Please read the instructions on page 34 before

using these controls.

17

E

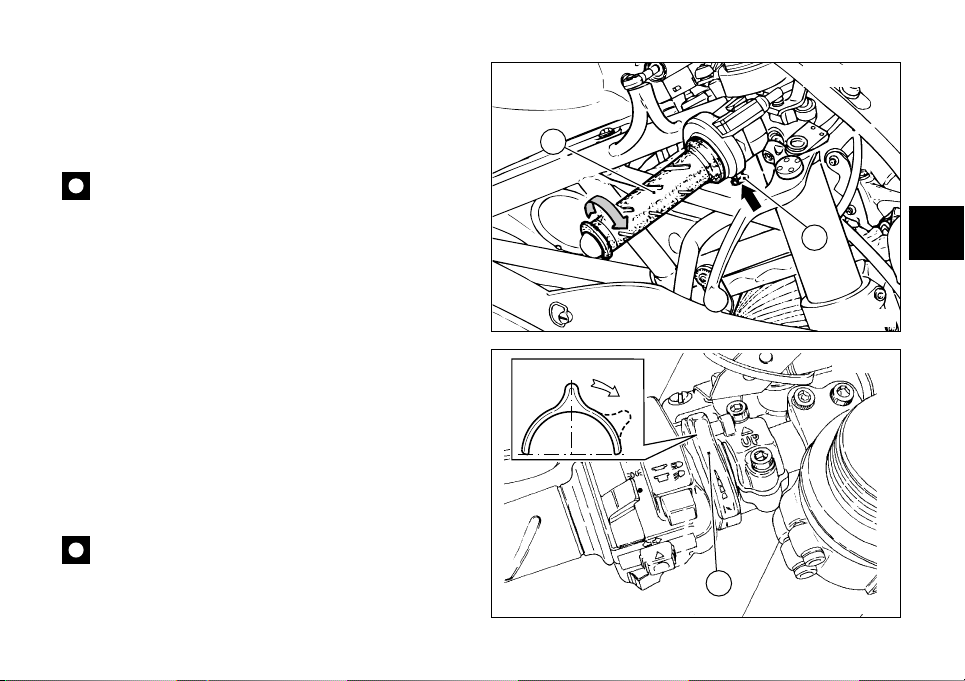

Rear brake pedal (fig. 10)

Push down on the pedal (1) with your foot to operate the

rear brake.

The system is hydraulically operated.

1

fig. 10

1

N

2

3

4

5

6

Gear change pedal (fig. 11)

The gear change pedal is at rest when in the central

position N, is moved up and down to change gears and

then returns to the central position.

down = push down on the pedal to engage 1stgear and

to shift down. The N light will go out.

up = lift the pedal to engage the 2ndgear and then the 3rd,

4th, 5thand 6thgear. Each time you move the pedal you will

engage the next gear.

fig. 11

18

E

fig. 11.2

fig. 11.3

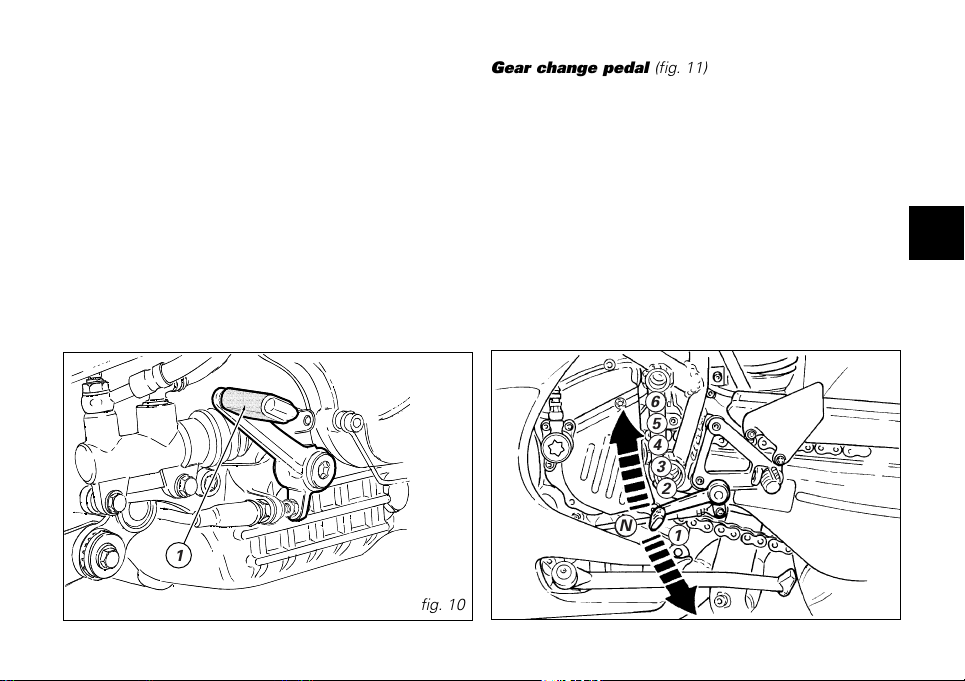

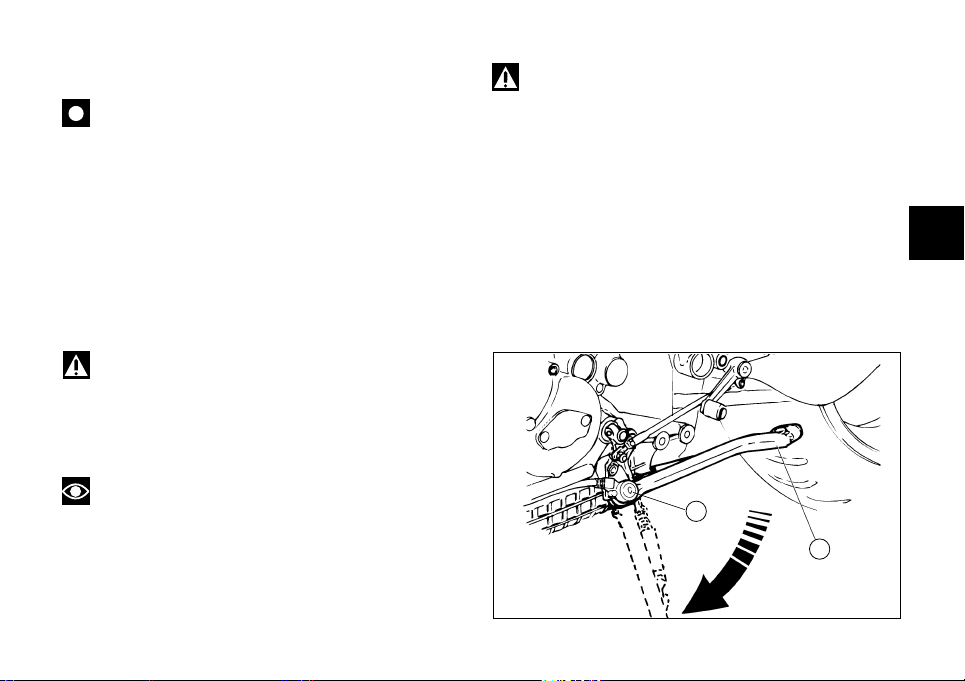

Setting the gear change and rear brake pedals

(fig. 11.2 and 11.3)

The gear change and rear brake pedals can be adjusted

to suit the preferred riding position of each rider.

To set the gear change pedal, lock linkage (1) and loosen

the check nuts (2) and (3).

Note

Nut (2) has a left-hand thread.

Fit an open-end wrench to the hexagon portion of linkage

(1). Rotate linkage until setting pedal in the desired

position.

Tighten both check nuts onto linkage.

To set the rear brake pedal,

loosen check nut (4).

Turn pedal travel adjusting screw (5) until pedal is in the

desired position.

Tighten check nut (4).

Work pedal by hand to make sure it has 1.5 - 2 mm free

play before brake begins to bite.

If not so, set the length of cylinder linkage as follows.

Loosen the check nut (6) on cylinder linkage.

Tighten linkage into fork (7) to increase play, or unscrew

linkage to reduce it.

Tighten check nut (6) and check pedal free play again.

19

E

MAIN COMPONENTS AND DEVICES

Location (fig. 12)

1) Tank filler plug.

2) Seat catch.

3) Side stand.

4) Hook for helmet fastening cable.

5) Steering damper.

6) Rear view mirrors.

7) Front fork adjusters.

8) Rear shock absorber adjusters.

9) Motorcycle track alignment linkage.

fig. 12

20

E

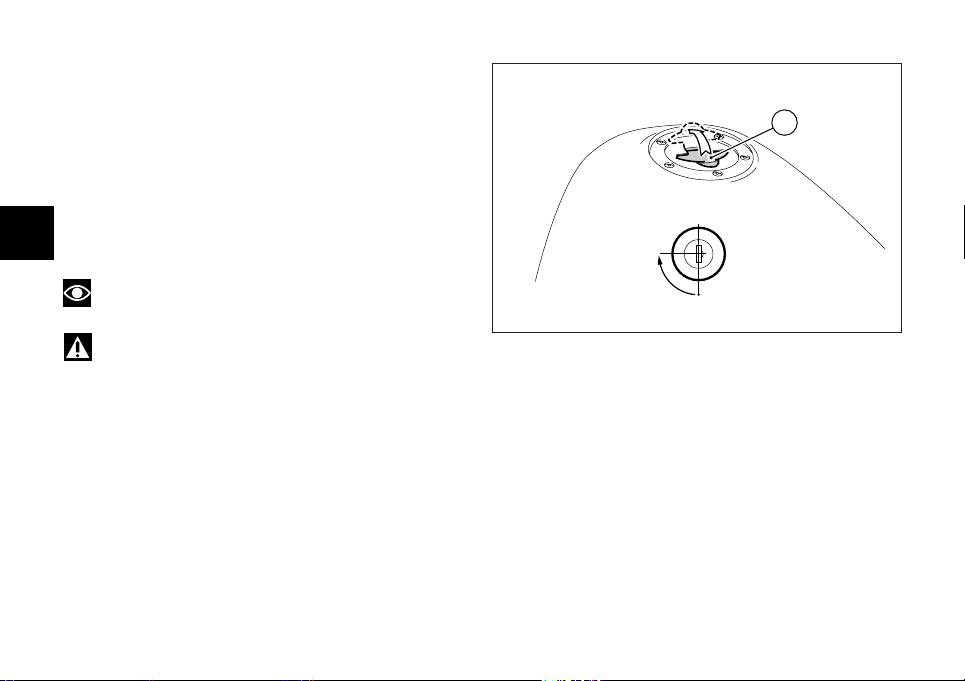

Tank filler plug (fig. 13)

Opening

Lift the protection lid (1) and fit the ignition key into the

lock. Turn the key clockwise 1/4 turn to unlock.

Lift the plug.

Closing

Refit the plug with the key in it and push it down into its

seat. Turn the key anticlockwise to its initial position and

take it out. Close the lock protection lid (1).

Note

The plug can only be closed with the key in.

Warning

Always make sure you have properly refitted (see

page 35) and closed the plug after each refueling.

1/4

0

OPEN

1

fig. 13

21

E

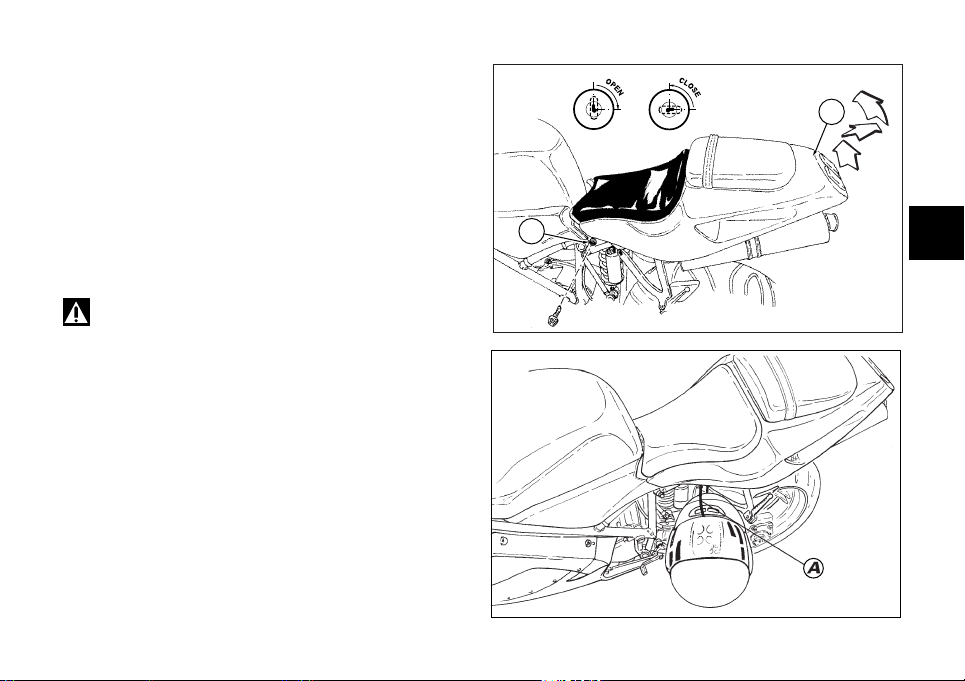

Seat catch and helmet hook

Opening (fig. 14.1 and fig. 14.3)

Fit the ignition key into the lock (1) and turn the key

clockwise.

Pull gently the tail guard (2) outwards and lift it until it

rests onto the fuel tank.

On the rear end of the compartment underneath the

seat, there is the helmet fastening cable. Insert the cable

(A) into the helmet and insert the ends of the cable into

the hook. Leave the helmet hanging outside (fig. 14.2)

and refit the seat.

Warning

This system is intended to lock your helmet safely

when you park your motorcycle. Never leave the helmet

hanging from the hook when riding or it may get in the

way and make you lose control of the motorcycle.

Inserting the cable under the frame from the left side will

enable to lock the seat.

fig. 14.1

0

1

0

1

1

2

fig. 14.2

22

E

3

4

Closing (fig. 14.3)

Pull gently the tail guard outwards and lower it to its

horizontal position. Press on the passenger pillion to

allow the clips (3) – integral with the fairing - to catch the

pins (4) – integral with the frame, until you hear the catch

click.

Pull the tail guard gently up to make sure it is firmly

secured to the frame.

fig. 14.3

23

E

Side stand (fig. 15)

Important

Before lowering the side stand, make sure that the

bearing surface is hard and flat.

Do not park on soft or pebbled ground or on asphalt melt

by the sun heat and similar or the motorcycle may fall

over.

When parking in downhill road tracts, always park the

motorcycle with its rear wheel facing downhill.

To pull down the side stand, hold the motorcycle

handlebars with both hands and push down on the thrust

arm (1) with your foot until it is fully extended. Tilt the

motorcycle until the side stand is resting on the ground.

Important

Do not sit on the motorcycle when it is supported

on the side stand.

To move the side stand to its rest position (horizontal

position), tilt the motorcycle to the right and, at the same

time, lift the thrust arm (1) with your foot.

Note

Check for proper operation of the stand mechanism

(two springs, one into the other) and the safety sensor (2)

at regular intervals.

1

2

Warning

The motorcycle can be started only if the side stand

is in “rest” position as it is equipped with a safety device

preventing engine start if the stand is down.

fig. 15

24

E

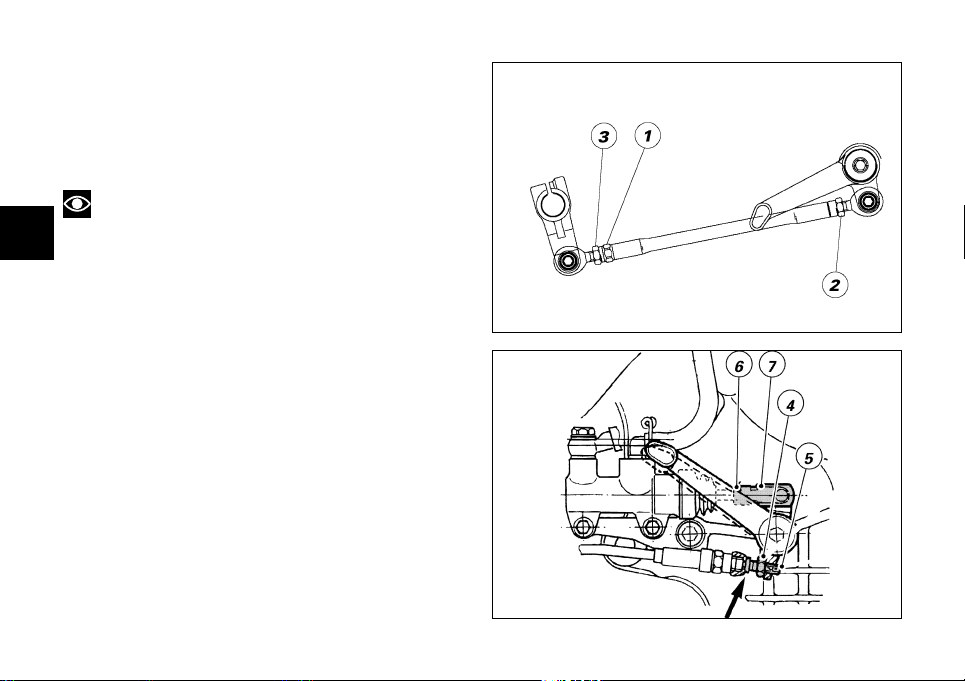

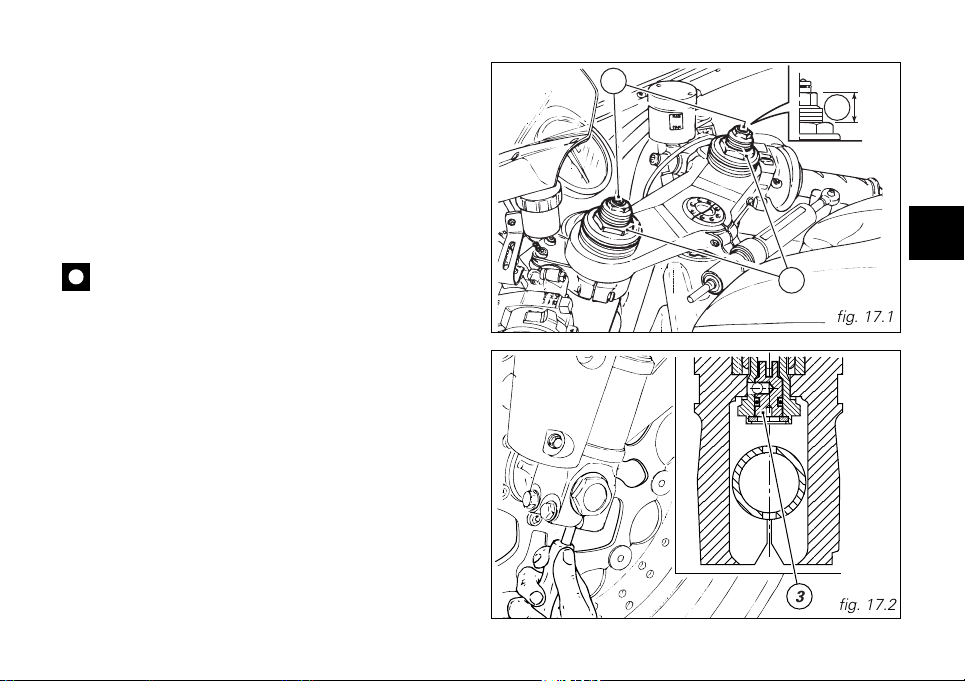

Front fork adjusters 748/748S/998

The front fork has rebound and compression damping

adjusters.

This adjustment is done using the outer adjusters:

1) (fig. 17.1) to adjust rebound damping;

2) (fig. 17.1) to adjust inner springs preload;

3) (fig. 17.2) to adjust compression damping.

Put and secure the motorcycle in vertical position.

Turn the adjuster (1) on fork leg top with a flat

screwdriver to adjust rebound damping.

To reach the adjuster (3), insert a screwdriver into the

passing hole on the wheel spindle at fork leg axis.

As you turn the adjusting screws (1 and 3), you will hear

them click. Each click identifies a setting.Turn the screw

all the way in to set the hardest damping (position 0).

This will be your starting point. Now turn the screw

anticlockwise and listen for the clicks that identify setting

positions no. “1”, “2” and so on.

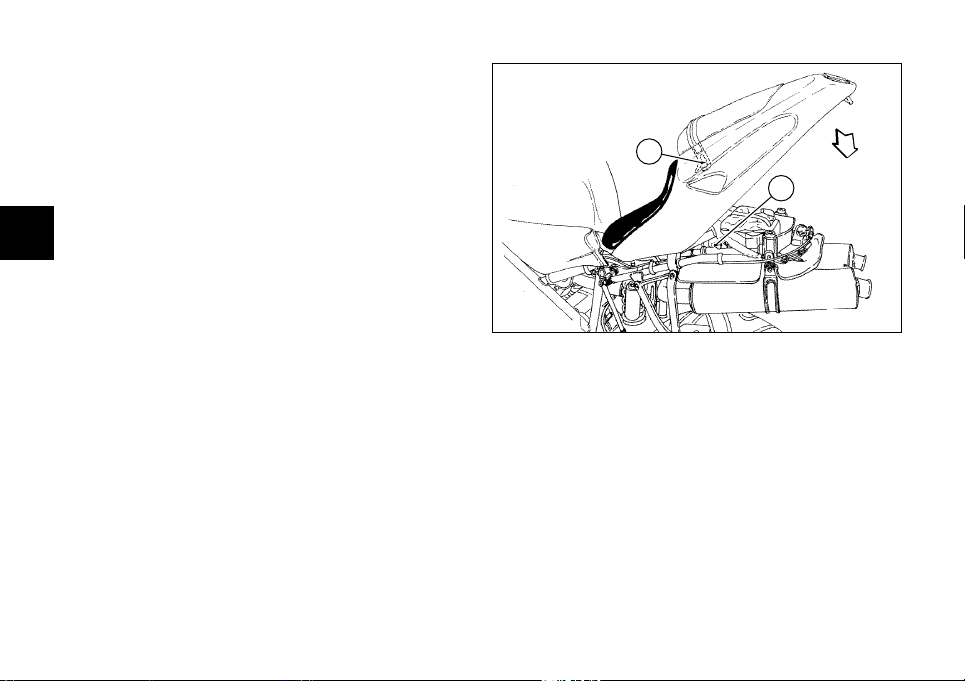

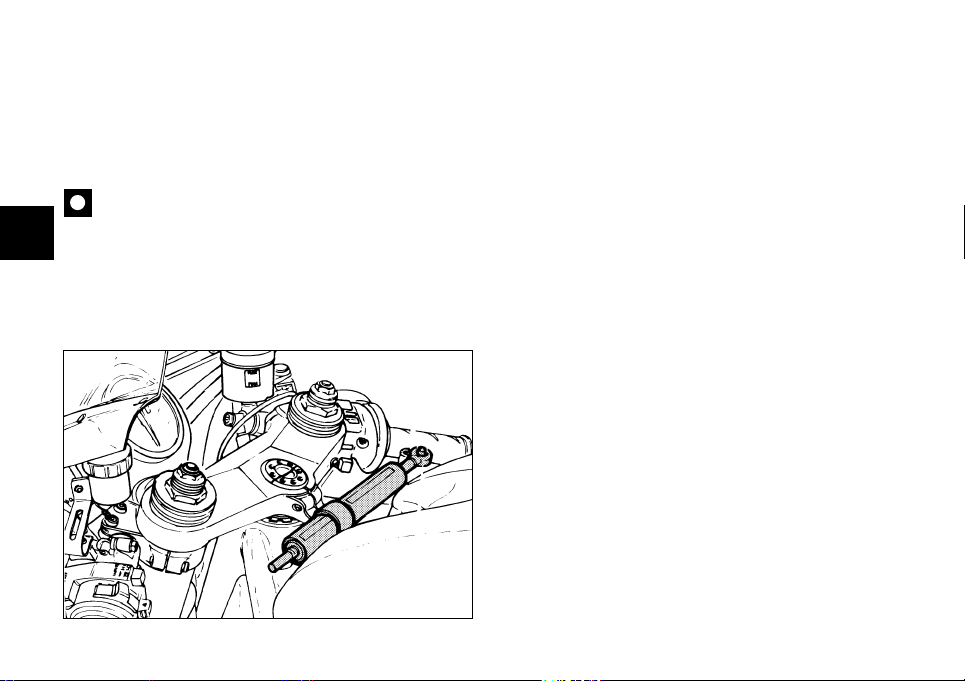

Steering damper (fig. 16)

The steering damper is before the tank and is secured to

the frame and the steering head.

It gives improved steering accuracy and stability, thus

also improving motorcycle road behavior under any riding

conditions.

Important

In case the steering damper position is changed,

the steering damper must be adjusted (see page 45).

fig. 16

25

E

STANDARD factory setting is as follows:

compression: 12 clicks;

rebound: 11 clicks.

Max. setting range for softest damping adjustment is 14

clicks (both for rebound and compression).

To change the preload of the spring inside each fork leg,

turn the hex. adjusting nut (2) with a 22-mm hexagon

wrench.

Preload setting range (A, fig. 17.1) is from 25 to 10 mm.

Factory setting is 20 mm.

Important

Adjust both fork legs to same settings.

1

2

A

;;@@ÀÀ;;@@ÀÀ;;

yy

;;;

;;;

;;;

;;;

@@@

@@@

@@@

@@@

ÀÀÀ

ÀÀÀ

ÀÀÀ

ÀÀÀ

;;;

;;;

;;;

;;;

@@@

@@@

@@@

@@@

ÀÀÀ

ÀÀÀ

ÀÀÀ

ÀÀÀ

;;;

;;;

;;;

;;;

yyy

yyy

yyy

yyy

;;@@ÀÀ;;@@ÀÀ;;

yy

;;;;

;;;;

;;;;

@@@@

@@@@

@@@@

ÀÀÀÀ

ÀÀÀÀ

ÀÀÀÀ

;;;;

;;;;

;;;;

@@@@

@@@@

@@@@

ÀÀÀÀ

ÀÀÀÀ

ÀÀÀÀ

;;;;

;;;;

;;;;

yyyy

yyyy

yyyy

;;@@ÀÀ;;@@ÀÀ;;

yy

;;;

;;;

;;;

;;;

@@@

@@@

@@@

@@@

ÀÀÀ

ÀÀÀ

ÀÀÀ

ÀÀÀ

;;;

;;;

;;;

;;;

@@@

@@@

@@@

@@@

ÀÀÀ

ÀÀÀ

ÀÀÀ

ÀÀÀ

;;;

;;;

;;;

;;;

yyy

yyy

yyy

yyy

fig. 17.1

fig. 17.2

3

Loading...

Loading...