Page 1

Incubator 8000 NC

Instructions for Use

– Software 11.n –

D

1-151-94

Page 2

Contents

Contents

Page

For Your Safety and that of Your Patients................. 3

Intended Use.............................................................. 4

Preparation.................................................................5

Before using for the first time....................................... 5

Doors, ports and bed...................................................5

Connecting air temperature sensor.............................. 8

Fitting accessories ......................................................8

Preparing oxygen therapy accessories........................12

Routing cables and hoses.......................................... 13

Checking Readiness for Operation.......................... 14

Before using for the first time..................................... 14

Before each use.........................................................14

Page

Maintenance Intervals...............................................42

Disposal of NiCd batteries..........................................42

What's What..............................................................43

Technical Data..........................................................47

Description............................................................... 49

Design....................................................................... 49

Alarm hierarchy.......................................................... 50

Order List..................................................................51

Index......................................................................... 53

Operation..................................................................17

Precautions................................................................17

Controlling air temperature.........................................20

Using skin temperature control .................................. 23

ThermoMonitoring......................................................28

Using humidity control ...............................................29

Supplying oxygen.......................................................31

Using electronic baby scales...................................... 32

Using vacuum mattress.............................................. 32

Using phototherapy unit..............................................33

Using "BabyLink Incubator" interface......................... 33

Care.......................................................................... 34

Stripping down...........................................................34

Cleaning/disinfecting/sterilizing.................................. 35

Before re-using.......................................................... 37

Fault, Cause, Remedy...............................................38

2

Page 3

For Your Safety and that of Your

Patients

For Your Safety and that of Your Patients

For correct and effective use of the apparatus and to

avoid hazards it is essential to read the following recommendations and to act accordingly1):

Strictly follow the Instructions for Use

Any use of the apparatus requires full understanding and

strict observation of these instructions. The apparatus is

only to be used for purposes specified here.

Maintenance

The apparatus must be inspected2) and serviced2) regularly by trained service personnel at six monthly intervals

(and a record kept).

Repair2) and general overhaul of the apparatus may only

be carried out by trained service personnel.

We recommend that a service contract be obtained with

DrägerService and that all repairs also be carried out by

them. Only authentic Dräger spare parts may be used for

maintenance2).

Observe chapter "Maintenance Intervals".

Liability for proper function or damage

The liability for the proper function of the apparatus is

irrevocably transferred to the owner or operator to the

extent that the apparatus is serviced or repaired by

personnel not employed or authorized by DrägerService

or if the apparatus is used in a manner not conforming to

its intended use.

Drägerwerk Aktiengesellschaft cannot be held

responsible for damage caused by non-compliance with

the recommendations given above. The warranty and

liability provisions of the terms of sale and delivery of

Drägerwerk Aktiengesellschaft are likewise not modified

by the recommendations given above.

Drägerwerk Aktiengesellschaft

Power connection

The apparatus is to be used only in rooms with mains

power supply installations complying with national safety

standards (such as in F. R. of Germany: VDE 0107).

The requirements laid down in IEC 601-1 "Safety of

Medical Electrical Equipment" are applicable for

electrically powered equipment.

Not for use in areas of explosion hazard

This apparatus is neither approved nor certified for use in

areas where combustible or explosive gas mixtures are

likely to occur.

Safe connection with other electrical equipment

Electrical connections to equipment which is not listed in

these Instructions for Use should only be made following

consultations with the respective manufacturers or an

expert.

1)

Insofar as reference is made to laws, regulations or standards, these

are based on the legal system of the Federal Republic of Germany.

2)

Definitions according to DIN 31 051:

Inspection = examination of actual condition

Service = measures to maintain specified condition

Repair = measures to restore specified condition

Maintenance = inspection, service, repair

3

Page 4

Intended Use

Intended Use

Heat therapy for premature babies and sick neonates;

with control of air temperature and humidity; and also

skin temperature as an option.

The incubator must only be used by properly trained

staff under the supervision of qualified medical staff

who have up-to-date knowledge of the risks and

benefits of the use of incubators.

Do not use the skin temperature control on babies

who are in shock or who have high temperatures.

The air in the incubator should only be enriched with

oxygen when prescribed by a doctor. It is absolutely

essential that such oxygen enrichment is controlled

on the basis of the arterially-measured oxygen partial

pressure in the patient's blood. If this is not done

there is a risk of hyperoxaemia (damage to the eyes)

and hypoxaemia (damage to the brain).

Do not nebulize any medicaments or similar

substances in the patient's room. If nebulized

substances fall onto the incubator this may impair its

functioning.

Mobile telephones must not be used within 10 metres

of the incubator.

Mobile telephones may interfere with the functioning of

electro-medical equipment.

Maximum load must not exceed 25 kg.

Only connect incubator to a mains power socket.

Do not use a mains distribution board.

If there is a circuit breaker in the supply to the distribution

board the permitted limit for leakage currents might be

exceeded. There could then be an electrical risk for

patient and staff.

4

Page 5

Preparation

The incubator is supplied fully assembled.

Before using for the first time

● Check that all packaging material has been removed.

Doors, ports and bed

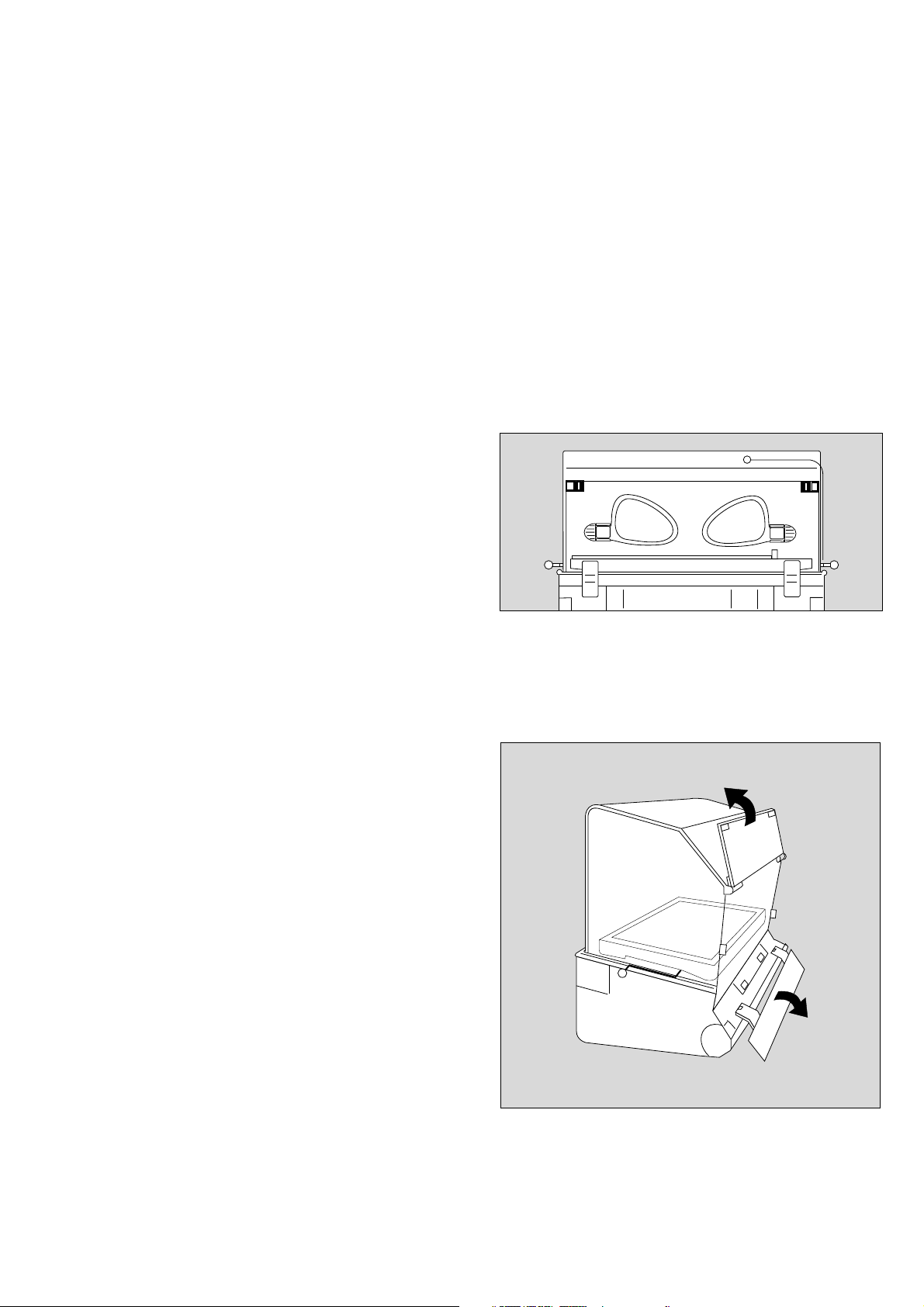

Front door

To open front door:

Preparation

Before using for the first time

Doors, ports and bed

1 Squeeze catches together with thumb and index

finger and at the same time lower front door until it

rests on housing.

To close front door:

● Lift up front door.

1 Squeeze catches together on both sides, push front

door forward and release catches. Push firmly on

front door to ensure that catches fully engage. Red

mark on catches should no longer be visible.

Divided front door, optional

To open front door:

● Squeeze catches on both sides together, and at

the same time fold upper section back until it rests on

sloping surface of canopy. It is then possible to attend

to the patient.

If necessary:

● Pull lower section down, pulling gently against pivots

to do so, and lower until it rests on housing.

1 1

To close front door:

● First lift up lower section and push back into place –

until it engages.

● Then fold upper section down and, while squeezing

catches on both sides together, push door back into

place – until it engages.

Red mark on catch should not be visible any more.

5

Page 6

Preparation

Doors, ports and bed

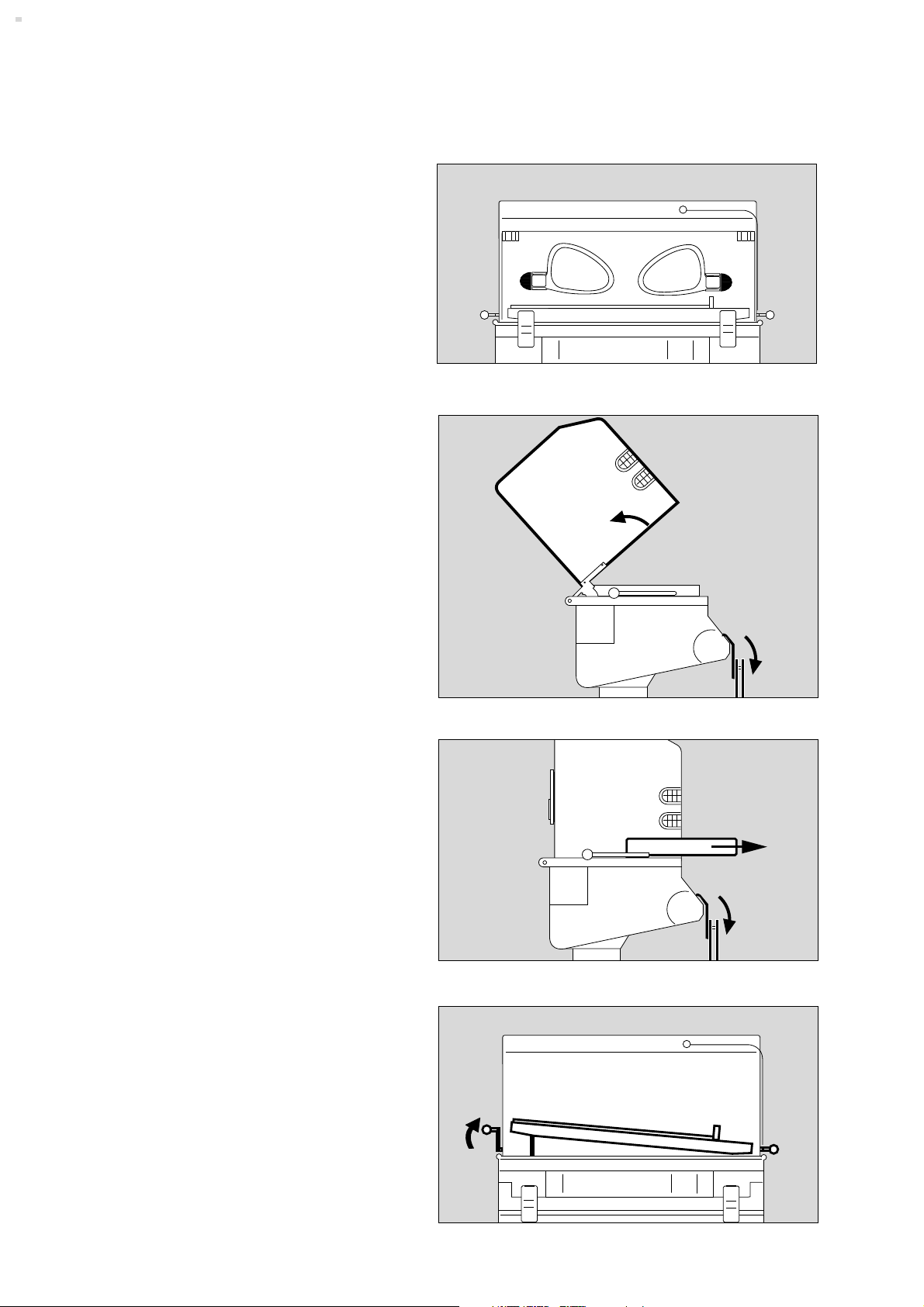

To open hand ports:

1 Press catch on serrated area to open hand port.

To close hand ports:

● Push hand ports back into place until catch is safely

engaged.

Canopy

To lift up canopy:

11

● Open front door.

● Tip canopy back as far as it goes.

Taking out the bed

● Open front door.

● Pull bed out forwards until it stops.

● After completing care procedure, push bed back as

far as it will go and close front door.

Tilting the bed

● Raise left lever until it engages to lift left end of bed.

● Raise right lever until it engages to lift right end of

bed.

● Lift bed end as required.

6

D

Incubator 8000 NC

Page 7

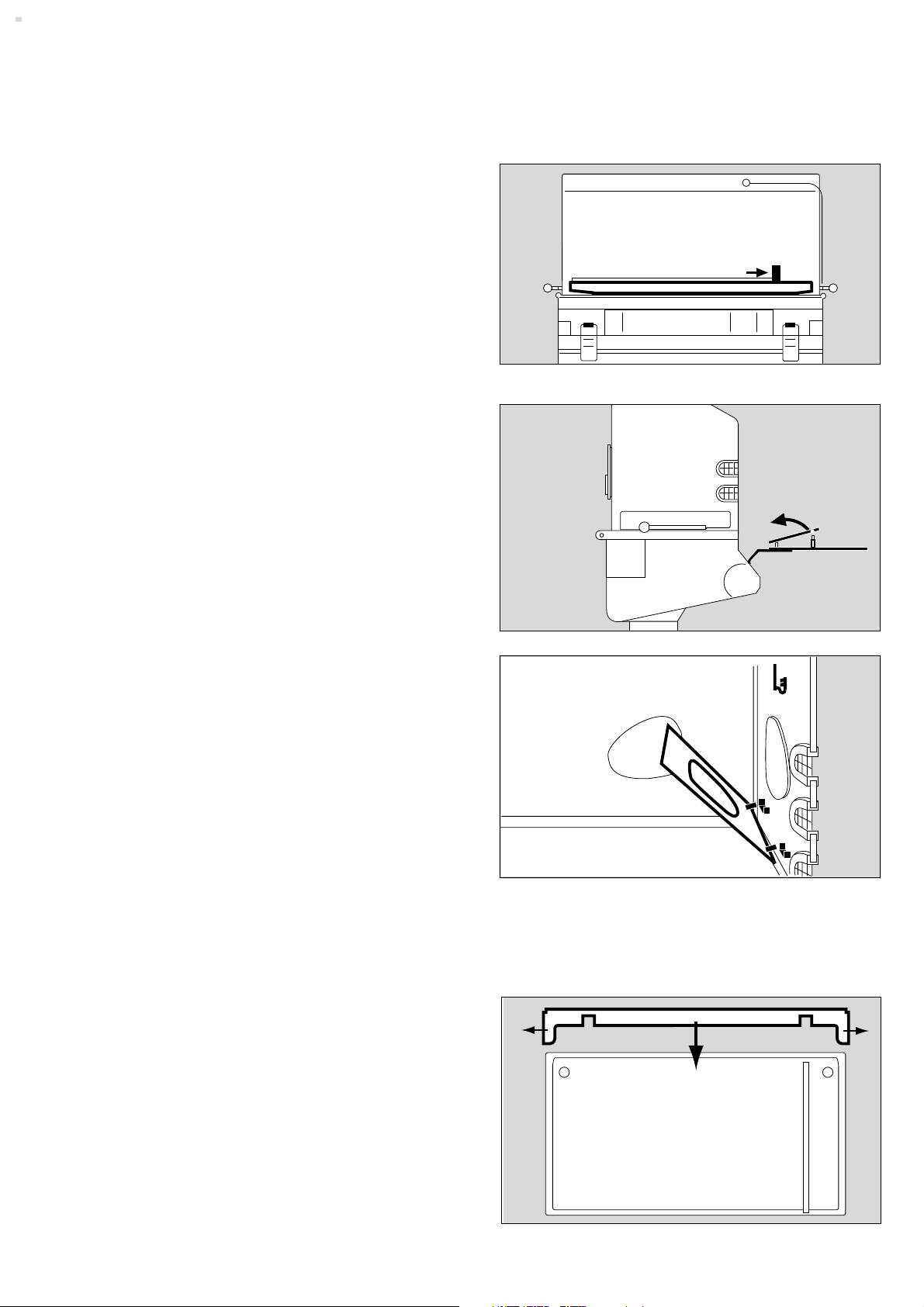

Re-positioning bed end

Can be used at right or left end of bed, as required.

● Open front door.

Preparation

Doors, ports and bed

1 Push middle of bed end outwards until it is released

from the groove and

● re-position at other end of bed.

● Close front door.

Double wall on front door

e. g. when cleaning the incubator

● Open front door.

2 Disengage double wall from upper bracket and

remove.

● After cleaning refit the double wall by gently pushing

back until it engages again; close the front door.

Removable double walls, optional

When older children are being treated, heat production is

greater and the temperature in the incubator may become

too high – the double walls should then be removed.

D

1

Incubator 8000 NC

2

To remove:

● Disengage double wall from upper bracket and

remove.

To put back:

● Open front door.

● Fit double wall to clips provided, raise and

● engage in upper bracket.

● Close front door.

Bed extension

Required when the rear double wall is not being used

to reduce risk of patient being trapped.

● Open front door and pull out bed.

3 Push both ends of bed extension out slightly and

4 click on the rear side of the bed.

Make sure that the bed extension is securely atteched.

● Replace bed in incubator.

3

4

3

Do not use bed extension when the rear double wall is in

place as the incubator temperature may be affected.

7

Page 8

Preparation

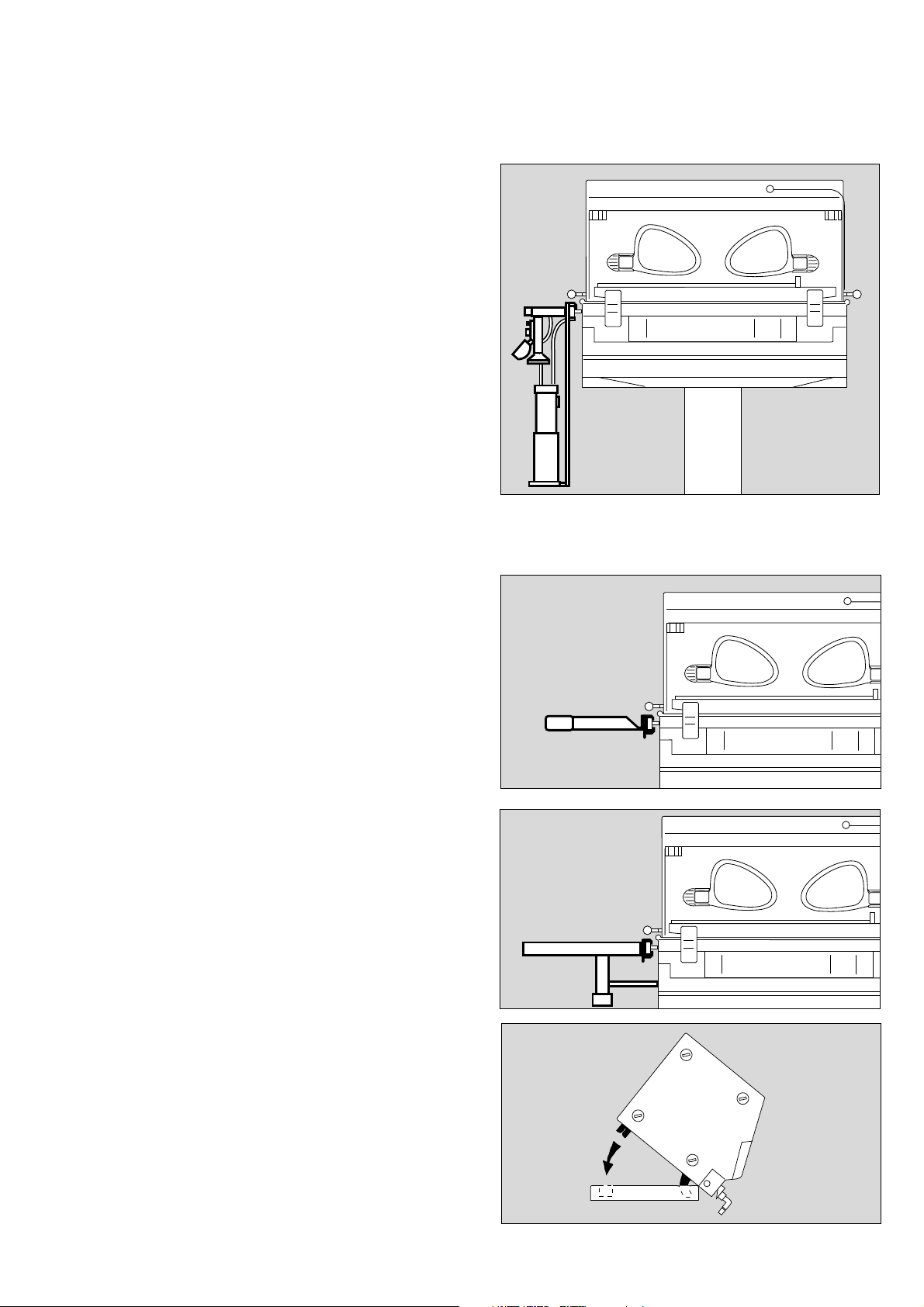

Connecting air-temperature sensor

Accessories

Connecting air temperature sensor

● Push air temperature sensor plug through slot in the

incubator housing, from below and

1 push into socket until it engages.

2 Route sensor cable through cable clips.

Fitting accessories

Support for ventilation hoses

● Fold down front door.

● Raise bed and lift out of incubator.

● Push mattress to one side a little.

Push hose support into appropriate hole, right or left.

● Screw knurled screws on from below and tighten.

2

2

1

● Replace bed in the incubator and close front door.

Fitting rail

Rail is used to hold

Bronchial suction equipment

Instrument tray

Mounting plate for ancillary equipment

Infusion stand

Oxygen therapy equipment

● Screw rail to left or right side of housing with Allen

screws.

Maximum load must not exceed 25 kg.

8

Page 9

Bronchial suction equipment

See also relevant Instructions for Use.

To mount on incubator

● Attach holder to one of the rails using rail clamp.

● Hang cylinder holder on it.

● Attach ejector to rail with rail clamp.

Preparation

Accessories

● Connect hose.

Instrument tray

(for small items)

● Attach tray to rail and tighten clamp. Maximum load

must not exceed 2 kg.

D

Incubator 8000 NC

D

Incubator 8000 NC

Mounting plate

For monitor and ventilator with latching system for

standard Dräger housings 1/2 B, e. g.

Dräger Babylog 8000.

Maximum load must not exceed 20 kg.

● Attach plate to rail and tighten clamp.

Fixing equipment to mounting plate

Example: Dräger Babylog 8000

● Remove foot strips from Babylog.

● Tilt Babylog forward by about 45°.

1 Insert front latches into slots in mounting plate.

2 Lower Babylog, insert the rear latches into slots in

mounting plate and secure at back with knurled

screws.

D

Incubator 8000 NC

2

1

9

Page 10

Preparation

Accessories

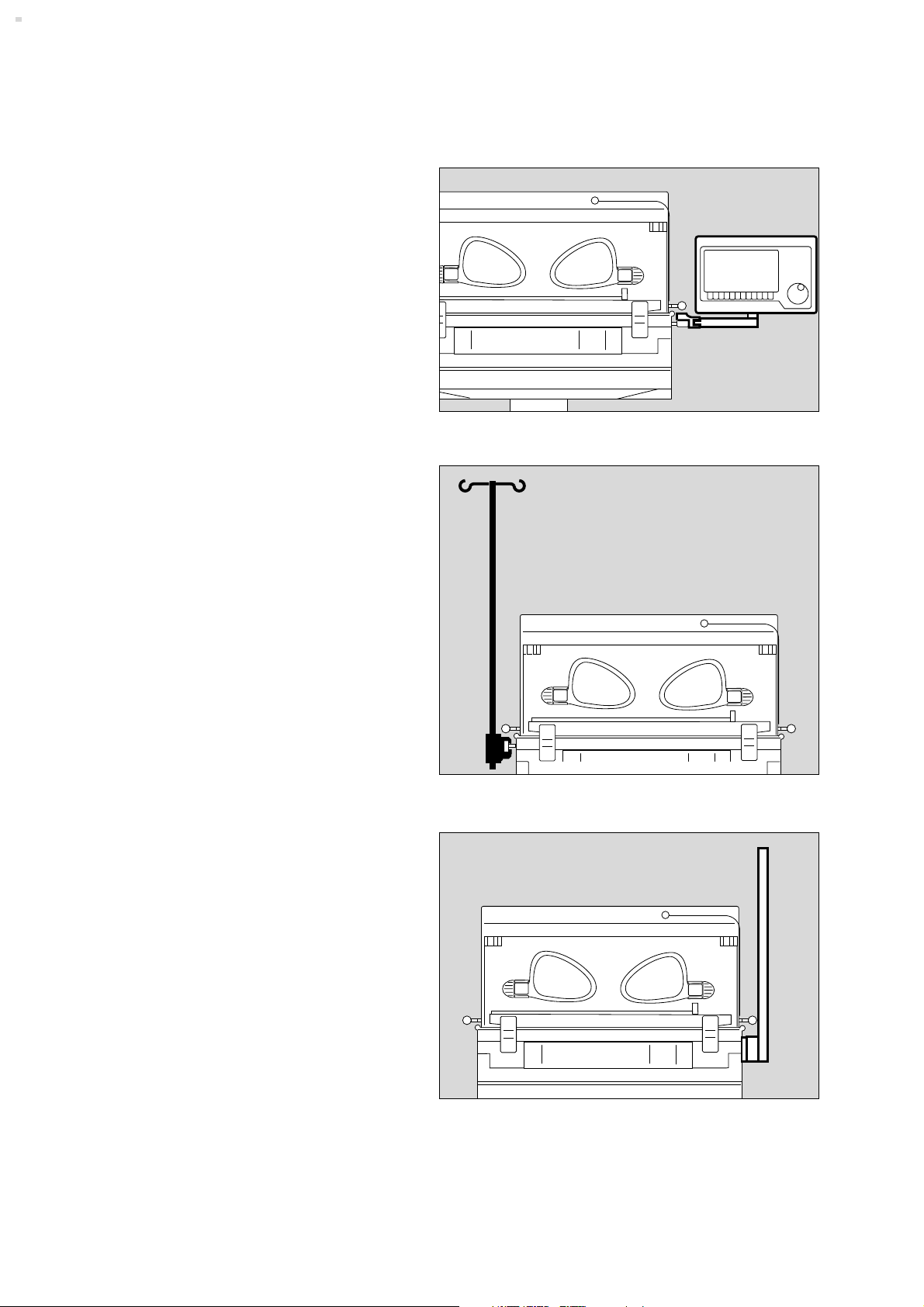

BabyScreen

Optional for ThermoMonitoring

● Attach holder to rail.

● Engage BabyScreen in holder.

● Follow relevant assembly instructions.

D

Infusion stand

● Attach stand to rail with rail clamp and tighten.

D

Incubator 8000 NC

Fitting pillar

● Screw pillar to left or right of housing, as required.

● Secure pillar with allen screw.

10

D

Incubator 8000 NC

Page 11

Attaching infusion bottle holder to pillar

● Attach clamp for infusion bottle holder to pillar and

tighten using tommy screw.

Preparation

Accessories

Swivel table

For small items, maximum load = 3 kg

● Attach clamp on swivel table to pillar and tighten

screw. Make sure that swivelling area is clear.

Swivel cupboard, optional

To fit a swivel cupboard:

D

D

Incubator 8000 NC

Incubator 8000 NC

● Push Allen screw up through unit from below and

screw firmly to unit mounting.

● Insert extra drawers.

● Store whatever is needed in them.

The maximum load on the incubator must not

exceed 25 kg.

D

Incubator 8000 NC

11

Page 12

Preparation

Preparing oxygen therapy accessories

Preparing oxygen therapy accessories

– for oxygen enrichment of incubator air

– for oxygen enrichment using a head box

● Follow Instructions for Use of equipment used.

● Monitor O2 concentration

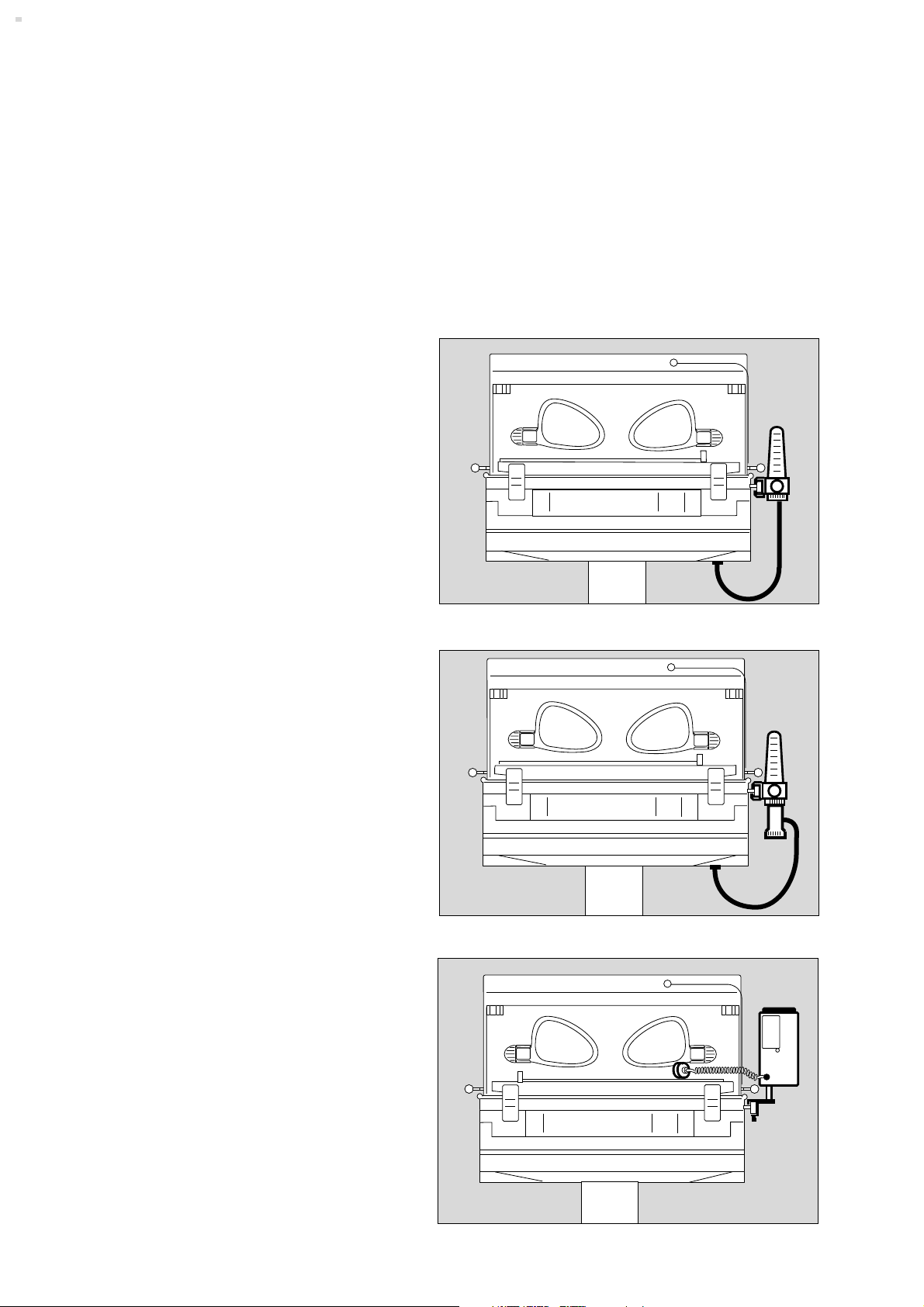

O2 flowmeter

● Attach O2 flowmeter to rail.

● Fit hose to connector on O2 flowmeter and

● to O2 connection underneath incubator.

● Push probe on O2 connecting hose into terminal unit,

only as far as "parking position" initially.

Oxygen limiter

If an oxygen limiter is going to be used:

● Unscrew connector on O2 flowmeter and screw

oxygen limiter on.

● Connect hose.

O2 meter

D

D

Incubator 8000 NC

Incubator 8000 NC

Monitor O2 concentration with O2 meter which has alarm

limits, e. g. Dräger Oxydig:

● Attach O2 Oxydig meter to rail with meter bracket.

● Place sensor capsule in incubator.

● Route sensor cable through one of the flexible hose

seals. Push sensor plug into socket on Oxydig until it

clicks into place.

12

D

Incubator 8000 NC

Page 13

Oxygen distributor

● Attach oxygen distributor, order no. 2M 18 810, to

rail.

Preparation

Oxygen therapy accessories

Cables and hoses

Routing cables and hoses

● Route hoses and cables through the flexible hose

seals.

D

Incubator 8000 NC

● Push ventilation hoses and cables into clip at end of

hose support.

13

Page 14

Checking Readiness for Operation

Before using for the first time

Before each use

Checking Readiness for Operation

Before using for the first time

● Check that the mains voltage corresponds to the

specification on the rating plate.

Before each use

● Check that the equipment has been disinfected.

● Check that the calibration seals on the front of the

equipment and on the skin temperature sensor are still

valid (only required in Germany).

● Check that an adequate gas supply is available for the

equipment to be used.

● Check that the accessories and therapy equipment

required are to hand and in perfect condition.

Check readiness for operation in accordance with

relevant Instructions for Use.

● Check that the incubator canopy has no cracks or

sharp, chipped edges.

● Check that the hinges and pivots on the canopy are in

proper working order.

● Check that the cables and hoses are routed correctly

and safely.

● If the rear double wall has been removed: Check that

the bed extension is provided. See page 7.

● Connect to mains power supply.

Do not use a mains distribution board.

[

If there is a protective circuit breaker in the supply

to the mains distribution board, the permitted limit

value for leakage currents might be exceeded.

There could then be an electrical risk for patient

and staff.

14

Page 15

Checking that hand ports will stay closed

● Open each hand port and then close carefully until

catch engages.

Checking Readiness for Operation

Before each use

1 Grip rim of closed hand port and pull outwards – it

should not open.

If the hand port does not remain engaged:

● Call DrägerService.

Checking that front door will stay closed

● Open front door.

● Lift up front door again.

2 Squeeze catches together on both sides, push front

door forward and release catches. Push firmly on

front door to ensure that catches fully engage. Red

mark on catches should no longer be visible.

If the front door does not engage:

● Call DrägerService.

Checking air filter

3 Open filter cover plate downwards.

If a filter is fitted:

● Remove filter and check fitting date; label is on edge

of filter.

1

22

If filter is more than 2 months old:

● Replace with a new filter.

● Write fitting date on new filter label and stick to edge

of filter.

● Press filter firmly into the seal.

Make sure that the direction of flow through filter is

correct. Arrow on filter has to point into incubator.

● Close cover plate.

Testing tilting mechanism for bed

4 Raise left end of bed to maximum height.

5 Push down on raised bed with hand – bed must not

drop down.

If bed does drop down:

● Call DrägerService.

● Check tilting mechanism at right end of bed in the

same way.

3

5

4

3

4

D

Incubator 8000 NC

15

Page 16

Checking Readiness for Operation

Before each use

Activating incubator self-test

1 Push on/off switch in – until it engages = on.

Functioning of incubator is self-tested.

2 Green LED is lit.

3 Display of actual values shows dashes.

If Err is displayed = error, see p. 39 to 41.

Checking mains power failure alarm and NiCd batteries

● Disconnect from mains.

4 Red N LED is lit. Continuous sound commences.

The volume should remain constant for at least

30 seconds.

If the volume decreases too soon:

● Leave incubator connected to mains and switched on

for 24 hours for the NiCd battery to be charged.

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

15.22

87.06

Control

°C

3

±1,5 °C

Sensor

°C

Reset

°C

± 0,5 °C

Sensor

3

°C

Check

36 °C

±0,1

°C LUFT/AIR

°C

>37 °C

Control

Reset

Control

>37 °C

>37 °C

Control

Check

Inop.Control

2

Check

1

4

● Repeat check.

If volume decreases too soon again:

● Call DrägerService.

Checking LEDs, displays and alarm sound

5 Press k key:

For about 2 seconds – all LEDs are lit (except the

mains power failure LED), the digital displays show

88.8 and alarm sound commences.

Thereafter, displays and LEDs go dark and alarm

sound ceases. After approximately another 2 seconds

the original displays for measured and set values reappear.

This check may also be carried out during operation.

● Check at least once daily.

If there is a fault:

Call DrägerService.

°C LUFT/AIR

°C

Reset

>37 °C

Control

Check

5

The incubator is ready for operation when all

checks have been carried out successfully.

16

Page 17

Operation

Precautions

Operation

Precautions

Warming-up time

Allow adequate time for warming-up before placing the

baby in the incubator (about 35 minutes).

Recommendation: operate incubator in standby,

see p. 19.

Do not cover air stream channels in base plate:

Danger of burning or cooling patient.

Controlling temperature of incubator

– Temperature may be increased very rapidly when

required because of high heating power.

– Temperature drops slowly because of good thermal

insulation.

Additional external heat sources, such as sunlight, heat

lamps, spotlamps, electric cushions should be avoided.

These increase the air temperature inside the incubator in

an uncontrolled manner.

Setting air temperature of incubator

The baby experiences minimal heat loss

– by convection because of low air speed across bed

– by conduction through the mattress

– by evaporation because of high humidity setting in

incubator.

Therefore,

compared with other incubators, such as the Incubator

6000 or 7000, a lower incubator air temperature can be

set.

The baby's core temperature must be monitored

continually, particularly during the first few hours of

incubator care.

17

Page 18

Operation

Precautions

Reducing the internal temperature of the incubator

The cooling time is dependent on the design and can be

accelerated by:

– reducing the outside temperature (when possible)

– reducing the air-humidity setting.

The rate of cooling is not accelerated by:

– setting the air temperature to a lower value than is

actually required.

In urgent cases: open front door or hand ports. When

front door is opened, there must be continuous

supervision to make sure that the baby does not fall out.

Fire risk from oxygen

– No naked lights or smoking. Textiles, oil and plastics

can very easily catch fire and burn rapidly in an

oxygen-enriched atmosphere.

– Keep all fittings and seals in contact with oxygen free

of oil and grease.

– Open valves on O2 cylinders slowly.

– Do not use an incubator where there are flammable

anaesthetic gases or disinfection agents.

Risk of explosion.

Phototherapy in the incubator

Absorption of light through the baby's skin will supply

heat which may increase the baby's core temperature.

Therefore,

● Decrease temperature setting for incubator air by

about 2 °C 15 minutes before phototherapy.

● Decrease the set value for humidity.

● Reduce the room temperature to at least 3 °C below

the air temperature of the incubator.

This value applies for Dräger 800/8000/4000

phototherapy units.

Other phototherapy units, particularly those without a

built-in fan, may cause even greater heating of the

incubator.

The core temperature of the baby must be monitored

with particular care during phototherapy.

The supply of fluids to the baby must be increased

e.g. by parenteral infusion, in order to compensate for

increased loss of water during phototherapy.

The phototherapy lamp and incubator canopy must

not be covered with cloths, aluminium foil, or other

materials, to boost the photo-therapeutic effect.

Risk of heat build-up. The incubator could not then be

adequately cooled with ambient air.

Danger of overheating the patient.

– Do not use or keep flammable liquids, such as

alcohol, ether and acetone in the incubator.

– Do not use any electrical equipment inside the

incubator, except, that is, for equipment expressly

designed for use in areas where there is a risk of

explosion.

Physiological risks from oxygen

The air in the incubator should only be enriched with

oxygen when prescribed by a doctor. It is absolutely

essential that such oxygen enrichment is controlled

on the basis of the arterially-measured oxygen partial

pressure in the blood of the patient. This is the only

way of avoiding both hyperoxaemia (damage to the

eyes) and hypoxaemia (damage to the brain).

Temperature of breathing gas

During ventilation the breathing-gas hoses may become

too warm from the heated air circulating in the incubator.

The temperature of the breathing gas must be monitored.

Preventing high noise levels

Noise levels that are too high for the patient may be

caused by:

– using head boxes to deliver pressurised gas,

– wear on the bearings of the fan motor,

– placing objects on the incubator canopy.

● Observe maintenance intervals, p. 42.

● Do not place anything on the incubator canopy.

Electrical safety

Use only electro-medical ancillary equipment which

complies with the IEC 601-1, EN 60601-1 or DIN

VDE 0750, part 1, regulations.

18

Page 19

Wait for warming-up time.

Wait for about 35 minutes before use.

● Heat incubator in "air temperature control" operating

mode.

If incubator has to be used urgently:

● Operate incubator in standby mode:

Set air temperature to 32 °C to 36 °C,

see p. 20, and set humidity control to 0, see p. 30.

Just before placing the baby in the incubator:

Fill water container

Operation

● If required use protective gloves.

1 Take cover of water container off and

2 fill container to mark with clean, distilled or

demineralised water (hospital dispensary).

Do not use any additives.

Take care not to overfill.

● Put cover of water container back.

● Then disinfect hands.

If water bottles are used:

Fill water bottles

● If required use protective gloves.

1 Open back panel and fold down.

2 Disconnect empty water bottles and refill with 500 mL

clean, distilled or demineralised water (hospital

dispensary). Do not use any additives.

● Refit filled water bottles and close back panel

again.

● Then disinfect hands.

1

2

1

2

Placing baby in the incubator

● Open front door and pull out bed.

● Put the baby on the bed and slide the bed back in

position.

● Close the front door and check that the catches are

properly engaged.

● Adjust the bed as required.

19

Page 20

Operation

Controlling air temperature

Controlling air temperature

Measure the patient's core temperature at regular

intervals.

1 Push on/off switch in – until it engages = on.

2 Green LED is lit.

● Wait for self-test to finish, then incubator will switch to

"air temperature control" mode.

3 The display alternates regularly between measured

value for air temperature and the word, SEt.

4 Default value for flashing display of air temperature set

value is 33.0 °C.

°C LUFT/AIR

3

°C

4

Reset

>37 °C

Control

Check

1

2

5 Press P or p key briefly to select this set value.

The display will remain continuously lit.

Setting values in 28 °C to 37 °C range

The set value can be changed in 0.1 °C steps.

6 Press p key – the set value is decreased,

7 Press P key – the set value is increased.

°C LUFT/AIR

5

°C LUFT/AIR

°C

5

Reset

>37 °C

Control

Check

8

● Press P or p key until the set value required is

reached.

8 While green R LED flashes – incubator is in heating-

up phase.

20

°C

6

7

Reset

>37 °C

Control

Check

Page 21

Extending range of set values from 37 °C to 39 °C

Only do this if prescribed by a doctor.

The patient's core temperature must be monitored

very carefully.

1 Press unlocking key 7,

2 yellow >37 °C control LED is lit.

Operation

Controlling air temperature

The alarm limit for high temperature will be increased

from 38 °C to 40 °C.

3 Keep P or p key pressed until the value required is

displayed.

● Set a value between 37 °C and 39 °C within

1 minute.

Otherwise:

– >37 °C control LED will go out.

The lock against setting a higher range of values will

be in force again.

The alarm limit for high temperature will return to

38 °C again.

If a value below 37 °C is set after the range of values has

been extended:

– the extension is automatically cancelled.

If the actual temperature remains above 38 °C, the high

temperature alarm is triggered.

°C LUFT/AIR

3

2

°C

3

Reset

>37 °C

Control

1

Check

Recommendation to prevent an high temperature alarm:

● Set value to 37.1 °C and wait until incubator has

cooled to 37.9 °C,

● then set value below 37 °C, as required.

21

Page 22

Operation

Controlling air temperature

Alarms

Alarms

Central alarm

1 Red Alarm LED flashes, and an appropriate alarm

sound commences.

Alarms with intermittent tone may be suppressed for

10 minutes:

2 Press G key,

3 yellow

LED and

g

1 red Alarm LED are lit.

If there is a deviation of more than ±1.5 °C between set

value for air temperature and measured value:

● Red Alarm LED and

4 red ±1.5 °C LED flashes,

5 display flashes and intermittent tone commences. The

intermittent tone may be suppressed for 10 minutes:

°C LUFT/AIR

°C LUFT/AIR

5

1

3

2

°C

°C

Reset

>37 °C

Control

>37 °C

Check

2

3

When measured value is again within ±1.5 °C of

temperature set,

● ±1.5 °C LED and Alarm LED go out.

The intermittent tone ceases.

When the incubator is switched on the alarm sound is

automatically suppressed for 30 minutes during the

warming-up phase:

4 red ±1.5 °C LED and

● yellow

LED and red Alarm LED are lit.

g

If the air temperature is above 38 °C, or above 40 °C

for extended range of values,

● red Alarm LED and

6 red T LED flash.

7 Display flashes and intermittent tone commences. The

alarm sound may be suppressed for 10 minutes.

When the air temperature has fallen below the alarm limit

again:

8 Press ƒ key, the alarm is cancelled.

For other alarms, see "Fault, Cause, Remedy",

p. 38 and 39.

4

7

°C LUFT/AIR

6

Reset

Control

°C

Reset

>37 °C

Control

Check

Check

8

22

Page 23

When there is a "skin temperature control" module installed

and it is in operation, the "air temperature control" mode

can be switched on again:

1 Press ç key,

2 green Control LED is lit.

°C LUFT/AIR

Operation

Using skin temperature control

2

The "air temperature control" mode is re-activated.

The set value for air temperature will be the last value

determined by the system.

Using skin temperature control

When the skin temperature control option is installed.

Do not use on babies in shock as their skin temperature

is well below normal. Using skin temperature control

would increase the temperature of the incubator too

much.

To control air temperature, see p. 20.

Core temperature must be measured regularly.

°C

Reset

>37 °C

Control

Check

1

23

Page 24

Operation

Using skin temperature control

Connecting skin temperature sensor

1 Insert yellow sensor plug into the yellow socket on left

side of housing.

2 Route sensor cable through one of the flexible hose

seals in the canopy.

3 Remove protective foil from adhesive pad and place

skin temperature sensor on pad.

● Using the adhesive pad, attach sensor tip to the

infant's skin where the temperature is to be

measured.

● Keep sensor cable in place with adhesive plaster.

Placing sensor

2

3

1

If the baby is lying on its back:

● Attach sensor to the abdomen in the region of the

liver.

If the baby is lying on its stomach:

● Attach the sensor to the back in the region of the

kidneys.

The sensor must never be attached under the baby

since it would then be measuring and controlling core

temperature and not skin temperature.

● Check regularly that the skin temperature sensor

is properly fixed to the baby's skin.

A skin temperature sensor which has fallen off would

be measuring air temperature so that the baby could

become overheated (though the temperature of the air

in the incubator would not exceed 39 °C).

● Do not use skin temperature sensors to measure

rectal temperature.

When a skin temperature sensor is attached but the "air

temperature control" mode is in operation, the measured

skin temperature is displayed.

Skin temperature is not then being controlled.

24

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C °C

Check

Control

36 °C

±0,1

Reset

>37 °C

Control

Page 25

When the temperature falls outside the 30 °C to 42 °C

measuring range:

Operation

Using skin temperature control

– 3 dashes in the bottom of the display =

temperature below 30 °C

– 3 dashes in the top of the display =

temperature above 42 °C

● see "Fault, Cause, Remedy" section, p. 40.

Activating skin temperature control

Allow at least 5 minutes for the skin temperature

sensor to reach the baby's temperature.

When value displayed remains constant,

1 Press ç key,

2 green Control LED is lit,

skin temperature control is in operation.

3 The display alternates between measured value of

skin temperature and the word SEt.

4 Flashing display of set value for skin temperature.

5 The measured value for air temperature continues to

be displayed.

°C

°C

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

2

3

°C °C

4

Check

36 °C

±0,1

5

1

Reset

>37 °C

Control

The incubator offers an appropriate value, depending on

the situation.

Situation Set value

Set value for air temperature not confirmed; 36.3 °C

Faulty or disconnected sensor

Actual skin temperature below 35 °C when 35 °C

switching over

Actual skin temperature between 35 °C actual skin

and 37 °C when switching over temperature

selected

Actual skin temperature above 37 °C

37 °C when switching over

Confirming set value:

6 Press P or p key briefly, the display remains

continuously lit.

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C °C

>37 °C

6 6

Check

36 °C

±0,1

Control

Reset

Control

25

Page 26

Operation

Using skin temperature control

Setting values in 35 °C to 37 °C range

1 Press P or p key until the set value required is

displayed.

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

Time needed for control to be effective

Differences between the set value and the actual value

for skin temperature are corrected by the temperature of

the air in the incubator which is between a minimum of

28 °C and a maximum of 39 °C.

When the skin temperature required is higher than the

actual temperature (skin too cold), air temperature in the

incubator is increased.

When the skin temperature required is lower than the

actual temperature (skin too warm), the air temperature in

the incubator is decreased.

The length of time during which there is a difference

between the set value and actual value of skin

temperature also has an influence on the control of air

temperature inside the incubator.

°C °C

1 1

Check

36 °C

±0,1

Control

skin temperature air temperature

set value

actual value

controls

skin temperature air temperature

actual value

set value

controls

Reset

>37 °C

Control

The patient's skin temperature can change suddenly, as

a result of feeding or being handled, for instance, so that

deviations of a few tenths of a degree are quite normal.

Therefore:

The value set for skin temperature should not be

changed unless the core temperature needs to be

corrected.

Check functioning during operation:

2 Press 6 key – the simulated temperature value

should be 36 ±0.1 °C.

Check daily.

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C °C

Check

Control

36 °C

2

±0,1

Reset

>37 °C

Control

26

Page 27

Alarms

For deviations greater than ±0.5 °C between set value

and actual value of skin temperature:

1 Red Alarm LED and

2 Red ±0.5 °C LED flash,

Using skin temperature control

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

Operation

Alarms

1

3 display flashes and intermittent tone commences.

The intermittent tone can be suppressed for 10 minutes:

4 Press G key.

5 Yellow g LED and red Alarm LED are lit.

When measured value is within ±0.5 °C of the set value

again,

2 ±0.5 °C LED and

1 red Alarm LED go out.

intermittent tone ceases.

5 Yellow g LED goes out.

If the sensor plug is disconnected or sensor is faulty:

6 Display of 3 dashes in centre of display.

After 15 seconds:

● Intermittent tone commences.

6 Display of 3 flashing dashes in centre of display.

°C

3

°C

2

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C

Check

Control

36 °C

±0,1

6

°C

°C

°C

5

°C

Reset

>37 °C

Control

4

Check

7

°C

>37 °C

7 Red Alarm LED and

8 red Sensor alarm LED are lit.

Then:

● Connect sensor without delay or replace skin

temperature sensor.

The intermittent tone can be suppressed for 10 minutes:

● Press G key, yellow

LED and

g

red Alarm LED are lit.

Check

Control

36 °C

8

±0,1

Reset

Control

Check

27

Page 28

Operation

Using skin temperature control

ThermoMonitoring

ThermoMonitoring, optional

For a better diagnosis of the child's thermal condition, it

is recommended that the temperature is measured both

centrally and peripherally. Both temperature measurements

may be displayed graphically via a Windows-PC or a

Dräger BabyScreen to document both the progress of

therapy for the child and the therapy itself.

Incubator must have:

– Second socket for peripheral skin temperature

sensor.

– Operator panel with © key

– BabyLink interface and MediCable connecting cable

(optional).

ThermoMonitoring data may be displayed on:

– Babyguard 8000 patient monitor

– BabyScreen (optional)

– Windows PC with ThermoView programme (optional).

Follow relevant Assembly and Operating Instructions.

Connecting peripheral skin temperature sensor

1 Connect white peripheral skin temperature sensor to

white bottom socket on left wall of housing.

2 Route sensor cable through one of hose seals.

3 Remove protective foil from adhesive pad and place

skin temperature sensor on pad.

● Attach sensor to patient's extremeties, preferably on

foot, using adhesive pad.

● Fix sensor cable in place with adhesive plaster.

● Connect Windows-PC or BabyScreen to serial

BabyLink interface using MediCable.

Follow relevant Instructions for Use.

Displaying measured values from peripheral skin

temperature sensor

4 Press © key and keep pressed. Yellow LED in key is

lit.

5 Peripheral skin temperature is displayed.

4 Release © key,

5 skin temperature recorded close to core by first skin

temperature sensor is displayed again.

If 3 dashes appear in the display, see p. 25.

The measured value of the peripheral temperature does

not affect the control of the temperature in the incubator.

Both in air temperature and skin temperature mode the

peripheral skin temperature sensor can be disconnected.

No alarm will be given.

Both skin temperatures can be displayed and requested

when the incubator is operating in the air temperature

mode.

3

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C

5

°C

Check

Control

36 °C

±0,1

°C

4

2

1

°C

Reset

>37 °C

Control

Check

28

Page 29

Using humidity control

Air temperature and relative air humidity are

interdependent. If the air temperature in the incubator is

changed, the incubator adjusts the output of the

humidifier to suit the changed temperature conditions so

that the relative air humidity required remains constant.

Up to 85 % relative humidity can be achieved.

Line A

Typical ambient conditions found in neonatal intensive

care units.

(normal conditions: room temperature, 25 °C to 28 °C,

relative humidity, about 30 %)

Line B

During low air humidity or when dry oxygen is supplied

the linemoves down the light grey range, (e. g. relative

humidity 60 %, heat level 6 to 7)

Line C

When ambient air humidity is greater than 30 %, the line

moves down the dark grey range, (e. g. relative

humidity 60 %, heat level 1 to 3)

required

rel. humidity

in %

(max. 85%)

60

CAB

80

70

50

40

30

20

10

01 2345678910

humidifier

switched off

Operation

Controlling humidity

heat level

Recommended air humidity for neonates:

Gestation week Recommended relative humidity

up to 32nd week as high as possible

from 32nd week about 50 %

to end of therapy

Example:

60 % humidity required.

For normal conditions (line A),

1 Set heat level to »5«, see page 30.

Under normal conditions, if heat level 7 or above is set,

condensation may occur on the incubator walls.

Then:

● Decrease heat level by one level.

°C FEUCHTE/HUMID.

1

29

Page 30

Operation

Controlling humidity

When incubator is switched on:

1 »0« flashes is display – humidity control = off.

2 Press P or p key briefly – to confirm off,

»0« remains continuously lit in the display.

Changing set value for humidity:

3 Press P key – set value is increased in steps from

0 to 10.

4 Press p key – set value is decreased in steps from

10 to 0 (0 = OFF).

°C FEUCHTE/HUMID.

2

2

1

°C FEUCHTE/HUMID.

34

34

Alarm for water shortage:

5 Red Alarm LED flashes,

6 red H2O LED and

7 display flash.

Intermittent tone commences.

● Replenish water supply, see p. 19.

The intermittent tone can be suppressed for 10 minutes:

8 Press G key,

9 yellow LED is lit.

°C FEUCHTE/HUMID.

7

6

°C LUFT/AIR

5

Check

9

°C

Reset

>37 °C

Control

8

Check

30

Page 31

Supplying oxygen

Caution: physiological risks from oxygen

The air in the incubator should only be enriched with

oxygen if prescribed by a doctor. Oxygen enrichment

should be controlled on the basis of the arteriallymeasured oxygen partial pressure in the blood of the

patient. This is the only way in which both

hyperoxaemia (damage to the eyes) and hypoxaemia

(damage to the brain) can be prevented.

● Monitor O2 concentration in incubator.

Use O2 monitor, such as Dräger-Oxydig.

Preparation, p. 12.

● Supply oxygen from a medical gas pipeline system via

an O2 flowmeter – push probe in fully.

Operation

Supplying oxygen

● Preparation, p. 12.

● When concentration required is reached, switch off

O2 supply at flowmeter.

Recommended set values:

O2 concentration

Vol.% (approx.)

25 30 35 40 45 50 55 60

O2 flow

L/min

1.5 3.5 5.5 7.5 9 11 13 15

Using oxygen limiter

● Preparation, p. 12.

The handwheel of the O2 limiter has 2 settings.

Red setting: no limitation of O2 supply.

D

Incubator 8000 NC

White setting: O2 supply limited to 6 L/min =

O2 concentration about 40 vol.%,

with O2 flow valve fully open.

If a lower O2 concentration is required,

set O2 supply to less than 6 L/min.

● Set handwheel as required.

D

Incubator 8000 NC

31

Page 32

Operation

Baby scales

Vacuum mattress

Using electronic baby scales

Accessory

1 Set bed at maximum height with both levers.

● Open and then lower front door.

2 Slide the electronic scales under bed as far as

possible. Guide scales along ridges on base plate.

Rail carrying display unit passes through the lower

hose seal.

● Close front door again and lower bed to its lowest

setting.

● Weigh baby, following Instructions for Use for

Seca Inscale Baby Scales.

After weighing:

● Take scales out in reverse order

or

● Scales may remain in incubator.

Bed can be tilted, as before.

1

D

Incubator 8000 NC

1

2

D

Incubator 8000 NC

Using vacuum mattress

Accessory

The mattress can be formed into any shape, and will

keep this shape after the mattress has been evacuated.

In this way babies can be supported in extreme positions

for special treatment. The standard mattress may also

remain inside the incubator.

● Open and then lower front door.

● Place mattress inside and form it into approximately

the shape required.

● Place baby on mattress and "mould" mattress around

baby.

● Connect hose of suction unit to vacuum mattress.

Open valve and evacuate vacuum mattress.

● Close valve and remove hose.

● Close front door.

32

Page 33

Using phototherapy unit 800/8000/4000

Accessory

Follow relevant Instructions for Use.

● Push trolley carrying phototherapy unit under incu-

bator or in the case of Photo-Therapy 4000 can also

be placed directly on top of the canopy.

● Adjust height:

Minimum distance between bottom of phototherapy

unit and patient is:

0.4 m for Photo-Therapy 800/8000

0.3 m for Photo-Therapy 4000

If the height of the bed is changed later, make

sure that this minimum clearance is still

maintained.

Exampel: Photo-Therapy 4000

Fuse

7

Operation

Phototherapy

Interface

mindestens 0,3 m

minimum 0.3 m

● Follow safety advice, see p.18.

Using "BabyLink Incubator" interface

(optional)

The "Babylink Incubator" interface provides incubator

data (actual values, set values, alarms) via a serial

interface.

At present, measured values can be displayed as trends

on the Dräger Babyguard 8000 Paediatric Monitor.

Other possible connections are the Dräger BabyScreen

or any Windows-PC which can run the ThermoView

program.

The interface protocol is included in the BabyLink

modification set (82 90 607).

Follow Instructions for Use for interface.

33

Page 34

Care

Stripping down

Care

Clean and disinfect incubator thoroughly:

– after each change of patient

– at least once a week.

With septic patients:

– disinfect seals on hand ports daily.

Clean and disinfect the accessories, such as the suction

equipment, the flowmeter and the skin temperature

sensor in accordance with the relevant Instructions for

Use.

Stripping down

● Switch off incubator. Disconnect from mains and

disconnect the medical gas supply.

● Remove all accessories.

Emptying the water container/water bottles: Risk of

microbial contamination

Observing hospital hygiene regulations.

Water container:

● Remove cover from water container.

1 Remove container from holder by lifting it up. Drain

water, observing hospital hygiene regulations.

● Hold hose by cuff and detach from connector on

heater.

Water bottles:

● Fold down back panel.

● Allow water to flow back into bottles.

1 Remove bottles from holder and drain,

● Hold connecting hose by cuff and detach from

connector on heater.

● Unscrew bottle holder.

2 Open hand port, remove seals from hand port

openings and close hand port again.

1

1

2

When skin temperature control option has been used:

● Disconnect skin temperature sensor.

● Remove skin temperature sensor from inside

incubator.

3 Remove all hose seals.

4 Tilt canopy back as far as it goes.

34

3

4

Page 35

Care

Stripping down

Cleaning/disinfecting/sterilizing

1 Remove mattress from bed.

2 Lift off bed. Undo screw on ventilator hose support

and remove hose support. Remove bed extension.

3 Pull both support brackets up and out.

4 Remove base plate

Caution. Be careful not to burn yourself

The risk of burns from the heater is particularly great

when the incubator has been closed and this risk remains

for a long time after the unit has been switched off. (It

takes about one hour for the temperature to fall to 70 °C).

5 Remove fan.

6 Remove trough.

1

2

33

4

5

6

Cleaning/disinfecting/sterilizing

For users in the Federal Republic of Germany we recommend that only disinfectants on the current DGHM

(DGHM: German Society for Hygiene and Microbiology)

list of surface disinfectants are used.

For medical and hygienic reasons, disinfectants based on

quaternary compounds should be used.

Damage may occur to the material of the incubator, particularly to the sensetive covering parts (PMMA/plexiglass

and PC/polycarbonate), if preparations are used which

are based on

– chlorine-releasing compounds

– organic and inorganic acids

– alcohols.

With regard to material compatibility we recommend the

following surface disinfectants:

Demykosan AF Messrs. Bayrol, Munich

Incidur Messrs. Henkel, Düsseldorf

Sekusept Powder Messrs. Henkel, Düsseldorf

Follow manufacturer's instructions.

A precondition for using non-recommended disinfectants

is that the manufacturer can prove material compatibility

with PMMA and PC.

D

Incubator 8000 NC

35

Page 36

Care

Cleaning/disinfecting/sterilizing

Canopy, inside and outside

Inner wall folded down

Mattress

Bed / Bed extension

Support brackets

Base plate

Trough

Incubator housing, inside and outside:

● Remove obvious soiling with disposable cloth and

detergent.

● Wipe-disinfect surfaces.

● Allow time for the disinfection process, then wipe the

surfaces again with a clean, damp cloth and dry.

Fan

Seals

Hose seals

Water hose

Water container/Bottle holder:

● Wash with detergent and rinse with clean water.

● Disinfect in bath. Allow time for the disinfection

process, then rinse with clear water and dry;

or

● sterilize at 120 °C (glove programme).

Use recommended cleaning and disinfecting agents only.

If other agents, such as alcohol for instance, are used

there is a risk of tension cracks in the Acrylic and

Makrolon.

Do not use UV-radiation on the incubator. This may cause

cracks in the acrylic parts.

36

Page 37

Before re-using with a patient

● Re-assemble equipment, see "Stripping down", p. 35.

Fitting seals in the hand port openings:

● Open hand port.

● Insert seal marked with an "L" on nose, into left

opening.

Care

Before re-using

● Insert seal marked with an "R" on nose, into right

opening.

● Position nose of seal on hinge.

Put sealing lip (thin edge of profile) to the outside.

● Close hand port.

● Testing Readiness for Operation, see p. 14.

Allow water heater to run dry:

– to disinfect heater

– to test that "water shortage" display is working

properly.

● Select humidity setting »5«, see p. 30.

● Allow heater to run until "water shortage" alarm is

triggered, see p. 30.

● Switch off humidity control = humidity setting »0«.

L

R

Do not refill water container until just before placing

baby in incubator.

If a bottle holder is used:

Do not put full bottles into bottle holder until just

before placing baby in incubator.

● Operate incubator in standby, p. 19

or

● switch off incubator, cover with dust cover and store

ready for use.

37

Page 38

Fault, Cause, Remedy

Main module

Fault, Cause, Remedy

Main module

Alarm

Inop.

Check

Fault Cause Remedy

Red Alarm LED is lit. Fault in module. Identify faulty module.

Alarm tone commences. See "Fault, Cause, Remedy"

of module.

Red Inop. LED is lit. Basic fault in electronics. Switch incubator off and on again.

Continuous tone commences. If Inop message not repeated:

press ƒ key and reset values.

If Inop message repeated,

incubator not working.

Call DrägerService.

Red Inop. LED is lit. Fault in specific module:

Continous tone commences,

also Err display in a module (except Skin temperature control module/ Switch off specific module. All

air temperature control module). humidity control module. other functions will remain

operational.

Call DrägerService.

Red N LED is lit. No mains supply. Check that mains plug is

Continuous tone commences. connected to power supply.

Check that power is being supplied.

Inform in-house technical staff.

Fault in incubator. Call DrägerService.

38

Page 39

Air temperature control module

Fault, Cause, Remedy

Air temperature control module

°C LUFT/AIR

°C

°C

±1,5 °C

Sensor

Reset

Control

>37 °C

>37 °C

Control

Fault Cause Remedy

Red ±1.5 °C LED flashes. Air temperature in incubator is Below set value:

Actual value display flashes. deviating from set value by more close openings in canopy and wait

intermittent tone commences. than ±1.5 °C. for incubator to warm up.

Above set value:

remove additional heat sources

(lamps, radiators, sunlight). Wait until

incubator has cooled down.

Red T LED flashes. Air temperature above 38 °C Remove additional heat sources

Actual value display flashes. (Range of values set up to 37 °C) (lamps, radiators, sunlight).

intermittent tone commences. Air temperature above 40 °C Wait for incubator to cool down.

(Range of values set up to 39 °C)

Press ƒ key when temperature has

dropped below the alarm limit for

temperature.

Red S LED flashes. Fan not fitted. Fit fan.

Actual value display flashes.

Continuous tone commences. Fan not rotating or rotating too Check that fan is connected to

slowly. drive shaft properly.

Call DrägerService.

Red Sensor LED flashes. Faulty air temperature sensor. Call DrägerService.

Three dashes flash in centre of

value display. Incubator temperature below 5 °C. Wait for incubator to warm up fully.

Continuous tone commences.

Temperature sensor disconnected. Connect temperature sensor.

39

Page 40

Fault, Cause, Remedy

Skin temperature control module

Skin temperature control module (optional)

°C HAUT/SKIN/PEAU/PIEL

°C

°C

± 0,5 °C

15.22

87.06

Sensor

Check

36 °C

±0,1

Control

Control

Fault Cause Remedy

Red ±0.5 °C LED flashes. Skin temperature deviating from Below set value:

Actual value display flashes. set value by more than ±0.5 °C. check that sensor is properly fitted

intermittent tone commences. to patient.

Above set value:

measure core temperature of patient

and inform doctor responsible for

patient immediately.

Red Sensor LED flashes. Skin temperature sensor not Check connection and put right, if

Three dashes flash in centre of properly connected. necessary.

actual value display.

Continuous tone commences. Faulty skin temperature sensor. Replace sensor.

Err flashes in actual value display. Fault in skin temperature control Switch to air temperature control.

Red Inop. LED is lit in main module. module while in operation. Call DrägerService.

Continuous tone commences.

Err is lit in actual value display. Fault in the skin temperature Other modules continue to operate

control module; skin temperature properly.

control switched off. Call DrägerService.

Reference temperature of 36 °C Temperature measuring unit not Call DrägerService.

is outside tolerance of ±0.1 °C operating correctly.

when 6 key is pressed.

Three dashes are lit at the top in Temperature measured above 42 °C. Cooling required.

actual value display. Inform doctor responsible for

patient immediately.

Three dashes are lit at bottom of Temperature measured below 30 °C. Check that sensor is properly fitted

actual value display. to patient.

40

Page 41

Humidity control module

°C FEUCHTE/HUMID.

H O

2

Fault, Cause, Remedy

Humidity control modul

Fault Cause Remedy

Red H2O LED flashes. Not enough water. Refill water container.

Set value display flashes.

intermittent tone commences

Err display flashes alternately Fault in humidifier. Switch off humidifier.

with set value. Humidity control in operation. Set value to »0«.

Continuous tone commences. Humidity control still activated. All other modules continue to

operate properly.

Call DrägerService.

Err is lit in display. Fault in humidifier. All other modules continue to

Humidity control switched off. operate properly.

Call DrägerService.

41

Page 42

Maintenance Intervals

Disposal of NiCd batteries

Maintenance Intervals

Clean and disinfect incubator and parts before

carrying out any maintenance* procedures, and before

returning for repair.

Air filter replace after two months, p. 15.

Dispose of as normal waste.

Seals of hand replace, when the material

port openings becomes brittle or tacky or

when a proper seal can no

longer be obtained.

Hose seals replace, when the material becomes

brittle or tacky and when the

lamination is torn.

Ventilator motor grease with 10 drops of

51524-HLP 32 oil every six months

by trained service personnel.

NiCd battery for replace once a year by

power failure trained service personnel.

Disposal, see below p. 42.

Inspection and every six months by trained service

service* personnel.

Disposal of NiCd batteries

– do not throw into fire; NiCd batteries may explode.

– do not open by force; risk of corrosion.

Batteries must be treated as special waste:

● in accordance with local waste disposal regulations.

Information can be obtained from local environmental and

public health authorities or from approved waste disposal

companies.

* According to DIN 31 051 the following definitions apply:

Inspection = determining actual condition

Service = measures to maintain required condition

Repair = measures to re-establish required condition

Maintenance = inspection, service and, when necessary, repair

42

Page 43

What's What

Front view

1 Canopy

2 Front door catch

3 Front door

4 Hand port

5 Hand port catch

6 Control panel

7 Air temperature sensor

8 Hose seals, 5 off

What's What

1

7

2

3

4

5

8

9

10

°C FEUCHTE/HUMID.

H O

6

D

2

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C

°C°C°C

>37 °C

Check

Reset

Check

36 °C

Control

Control

±0,1

Incubator 8000 NC

11

9 Bed with mattress, bed end and bed extension

10 Levers at left and right to tilt bed

11 Rail, left and right

12 Swivel cupboard, optional

13 Trolley with fixed pillar and four castors

(2 lockable)

Back view

14 Support for temperature sensor cable

15 Connector for air temperature sensor

16 Air filter

17 Optional RS 232 interface connector

18 Mains power cable

19

Water container with cover

On side of incubator

14

15

16

12

13

20

19

20

Sockets for skin temperature sensor (optional)

Top socket: yellow, skin temperature control

Bottom socket: white, ThermoMonitoring

18

17

43

Page 44

What's What

Control panel

4

°C FEUCHTE/HUMID.

H O

2

1 Main module with on/off switch and check key

2 Air temperature control module

3 Skin temperature control module

4 Humidity control module

3

°C HAUT/SKIN/PEAU/PIEL °C LUFT/AIR

°C

°C

± 0,5 °C

15.22

87.06

Sensor

Check

36 °C

±0,1

Control

Control

°C

±1,5 °C

Sensor

2

Control

>37 °C

°C

Reset

>37 °C

Control

1

Alarm

Inop.

Check

Main module

1.1 On/off switch for mains power

1.2 Green Control LED;

is lit when incubator is switched on.

1.3 Red Alarm LED;

is lit when there is a fault in a module.

1.4 Red Inop. LED;

is lit when there is a malfunction.

1.5 Red N LED;

is lit during mains power failure.

1.6 Yellow g LED;

is lit when intermittent tone has been suppressed.

1.7 Key to suppress intermittent tone for 10 minutes.

1.8 Key to test display function, LEDs and

alarm sound.

1.3

1.4

1.5

1.6

1.7

1.8

Alarm

Inop.

Check

1.2

1.1

44

Page 45

Air temperature control module

2.1 Key to switch on air temperature control (only when

skin temperature control module is fitted).

2.2 Unlocking key for setting a higher range of values.

2.3 Yellow >37 °C LED

is lit when a higher range of values has been set.

2.4 Green R LED

indicates heating-up phase.

2.5 Green Control LED

is lit when air temperature control is switched on

(only when skin temperature control module is

installed).

2.6 Display for actual value (measured value) of air

temperature.

2.6

2.7

2.8

2.9

°C LUFT/AIR

°C

±1,5 °C

Sensor

What's What

Control

>37 °C

°C

Reset

>37 °C

Control

2.5

2.4

2.3

2.2

2.1

2.122.112.10

2.7 Display for set value for air temperature;

left key: to decrease set value

right key: to increase set value

2.8 Red ±1.5 °C LED

flashes/is lit when the actual value of the air

temperature deviates from the set value by more

than 1.5 °C.

2.9 Red Sensor LED

flashes when air temperature sensor is faulty.

2.10 Red S LED

flashes for fan failure.

2.11 Red T LED for high temperature

is lit when air temperature is or was higher than

38 °C (40 °C for higher range of set values) and

after Inop-alarm.

2.12 Key to reset high temperature alarm.

45

Page 46

What's What

Skin temperature control module

3.1 On/off button for skin temperature control.

3.2 Calibration stamp (only in Germany).

3.3 Key to display peripheral skin temperature (only

when ThermoMonitoring option is installed).

Yellow LED in key is lit when peripheral

temperature is displayed.

3.4 Green Control LED

is lit when skin temperature control is switched on.

3.5 Display for actual value (measured value) of skin

temperature.

3.6 Display for set value for skin temperature

left key: to decrease set value

right key: to increase set value

3.7 Red ±0.5 °C LED

flashes/is lit when the actual value of skin

temperature deviates from the set value by more

than 0.5 °C.

3.8 Red Sensor LED

flashes/is lit when the skin temperature sensor is

faulty or disconnected.

3.9 Certification mark.

3.10 Key for checking measurement electronics

Display 36 ±0.1°C (reference).

3.5

3.6

3.7

°C HAUT/SKIN/PEAU/PIEL

°C

°C

± 0,5 °C

15.22

87.06

Sensor

3.9

3.8

Check

36 °C

±0,1

3.10

Control

Control

3.4

3.3

3.2

3.1

Humidity control module

4.1 Display for set value of heat level: 0 to 10

0 = humidity control off,

left key: to decrease set value

right key: to increase set value

4.2 Red H2O LED

flashes for water shortage.

4.1

4.2

°C FEUCHTE/HUMID.

H O

2

46

Page 47

Technical Data

Ambient conditions:

During operation

Temperature 20 °C to 30 °C

Atmospheric pressure 900 to 1100 hPa

Rel. humidity 15 to 95 %

During storage

Temperature 0 °C to 70 °C

Atmospheric pressure 900 to 1100 hPa

Rel. humidity 15 to 95 %

Operating data

Technical Data

Electrical power source 220/230 to 240 V AC (as per order)

50/60 Hz (as per order)

Heat output at 230 V

Air 400 W

Water heater 100 W

Current consumption at 230 V 2.5 A

Performance data

Warming-up time 35 minutes from 20 °C to 31 °C (with or without humidification)

Temperature drop (at room temperature of 25 °C

and temperature inside incubator of 36 °C)

Two hand ports opened <1 °C

Front door opened <5 °C

Humidification Evaporation of distilled or demineralised water

Air speed over the bed

Single wall <15 cm/second

Double wall <8 cm/second

Fresh air flow 30 L/min

CO2 flushing, according to IEC 601-2-19/105.1

maximum CO2 concentration inside incubator 0.2 %

Raising bed at right or left, 8° angle of tilt on both sides

Range of measured values

Air temperature 10 °C to 50 °C

Skin temperature 30 °C to 42 °C

Range of set values

Air temperature 28 °C to 39 °C

Skin temperature 35 °C to 37 °C

Humidity Depending on operating conditions, setting values from

1 to 10 gives a relative humidity inside the incubator from

about 30 to 85 %.

47

Page 48

Technical Data

Measuring principles of sensors

Air temperature senso NTC x 2

Skin temperature sensor NTC

Noise level inside the canopy <49 dB (A) at 50 Hz;

<56 dB (A) at 60 Hz

Air filter Particle class P 2, in accordance with DIN 3181, factor 2 %

Skin temperature control

Sensor Use only authentic Dräger sensors (see Order List, p. 52).

Certification marks* 15.22

Display component, 87.06

subject to calibration

Sensor** subject to calibration 15.14

(2M 20 737) 91.10

Certification document*

Display component, lB.13-78/87

subject to calibration

Sensor** subject to calibration lB.9.13-205/91

Calibration tolerances*

Display component, ±0.2 °C

subject to calibration

Sensor** subject to calibration ±0.1 °C

Total measuring system ±0.3 °C

Classification The incubator complies with DIN– VDE 0750, Part 1,

EN 60601-1, IEC 601-1 and IEC 601-2-19

Type B

m

Electromagnetic compability (EMC) according to EN 60601-1-2

"BabyLink Incubator"Interface (optional) serial interface for print-out interface (optional)

of incubator data (actual values, set values, alarms)

ThermoMonitoring (optional) 2nd skin temperature sensor to display peripheral

skin temperature.

Dimensions

Unit: height x width x depth in mm 1400 x 970 x 600

Bed: width x depth in mm 650 x 350

Weight 77 kg

* applies only in Germany

** or certified sensor with the same characteristic (400 Series, 2252 Ω @ 25 °C)

48

Page 49

Description

Design

The heated and humidified air flows over the entire front

face into the canopy. It is channelled over the front door,

along the roof of the canopy and then drawn down past

the back wall by means of an extraction system.

The baby lies in a still area with very little air flow. Heat

loss is minimal.

When the hand ports are open, there is still an effective

hot air curtain which minimises cooling inside the

incubator.

The mattress is made of soft foam plastic encased in film,

which gives a very low heat loss.

Description

Design

Humidity

The incubator air is humidified hygienically by the

evaporation of water from a water supply.

Humidity can be set manually according to a 1 to 10

scale. Humidity control off = 0.

Safety features

When it is switched on, the incubator carries out a selftest to check all memories in the microprocessor control

system and to establish that the various program

segments are running correctly.

Actuators, acknowledgement signals and displays are

switched on and then off to check that they are

functioning correctly. This test is also repeated every

10 minutes during operation. All modules installed in the

incubator are tested. An Error message may be given for

a faulty module, even if it is switched off.

The heating is switched off if operating conditions are

outside permitted limits.

An additional cooling fan provides effective cooling as

soon as the actual value of the air temperature exceeds

the set value.

49

Page 50

Description

Alarm hierarchy

Alarm hierarchy

The incubator has a hierarchical system of alarms.

Any faults which occur are signalled in order of

importance. If a non-essential function fails, the functions

which are of vital importance remain in operation.

Continuous tone

cannot be suppressed, for faults which entail the greatest

potential danger:

– Malfunction of incubator or module

– Mains failure

– "Air temperature sensor" alarm

– "Fan failure" alarm.

Intermittent tone

can be suppressed for 10 minutes, for faults which entail

a less serious potential danger:

– Deviations from set values

– Air temperature too high

– Water shortage.

– Faulty skin temperature sensor or sensor plug

disconnected

In addition, the relevant alarm LEDs flash.

Each different alarm is shown by the central alarm LED.

If another alarm occurs when the alarm sound has

already been suppressed, the sound is automatically

re-activated. Depending on what the fault is, this alarm

sound may also be suppressed. The period before the

first alarm tone is automatically switched on again is then

prolonged by the time of the interval between the two

alarms.

Ergonomics

The hand ports are oval in shape to allow optimum

freedom of movement with low cross-section.

The incubator has rotating castors so that it can be

moved around easily. Two of the castors can be locked in

position, if necessary.

Ancillary equipment can be attached to the side rails.

A swivel cupboard (optional) is provided for storage

purposes.

Hygiene

All parts of the incubator which come into contact with

the gas breathed by the baby can be removed from the

basic unit for disinfecting.

50

Page 51

Order List

Order List

Name and Description Order No.

Basic unit

Incubator 8000 NC FR 00 083

with control of air temperature and humidity

Optional

Skin temperature control*

Canopy with horizontally divided front door

Canopy with removable double walls

BabyLink incubator interface

ThermoMonitoring

ThermoView

Accessories

Swivel cupboard 2M 20 638

with storage drawer

Storage drawer for swivel cupboard 2M 20 642

Mounting set for cupboard, left 2M 21 362

Mounting set for cupboard, right 2M 21 363

Name and Description Order No.

Photo-Therapy 4000 2M 21 000

Trolley for phototherapy unit 2M 21 190

Bronchial suction:

A: Connection casing with rail clamp,

O2/Air 2M 85 006

B: Aspiration ejector; –0.5 bar M 26 981

C: Bacterial filter 767 St, 5 ea 67 23 976

D: Vacuum regulator, –1 bar, rail 2M 85 583

E: Jar set 2M 85 056

F: Set wall holder

(for mounting at trolley) 2M 85 010

G: Support for fitting on rail 2M 85 119

Combination

A + B + E + F 2M 85 045

A + D + E + F

A + B + C + E + G

O2/Air hose assembly, 1.5 m M 29 283

Pillar, ø 38 mm, to be mounted on

incubator housing 2M 21 380

Swivel table to be attached to pillar 2M 21 186

Infusion stand to be attached to pillar 2M 21 514

To be fitted to rail:

Infusion stand 2M 16 520

Instrument tray (20 x 30 cm),

maximum load 2 kg M 24 678

Mounting plate, maximum load 20 kg 2M 19 460

Vacuum mattress 2M 16 920

Electronic "Seca Inscale" baby scales 2M 22 150

BabyLink incubator modification set 82 90 607

Medi-Cable, required to connect

peripheral equipment 83 06 488

BabyScreen 2M 21 707

ThermoView 2M 21 888

O2/Air hose assembly, 3 m M 29 243

O2/Air hose assembly, 5 m M 29 263

Vacuum hose assembly, 1.5 m M 29 287

Vacuum hose assembly, 3 m M 29 247

Vacuum hose assembly, 5 m M 29 267

O2 flowmeter, 0-15 L/min with

connector and silicone hose 2M 19 510

O2 hose assembly, 1.5 m M 29 271

O2 hose assembly, 3 m M 29 231

O2 hose assembly, 5 m M 29 251

O2 limiter

(only used with 2M 19 510 flowmeter) 2M 16 010

O2 head box 2M 19 250

Support for ventilation hoses 84 11 075

Oxydig, O2 monitor, including

sensor capsule 83 04 411

* Only the calibrated version may be sold in Germany.

51

Page 52

Order List

Name and Description Order No.

O2 monitor holder for incubators 2M 17 770