Page 1

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 1

XRP MultiSaw

Owner’s Manual

(For use with Dremel 400 Series XPR)

Parlez-vous français? Voir page 9

(MS400)

Safety – 2 - 4

Getting to Know Your Saw – 5

Assembly – 5

Operation – 6 - 7

Cleaning – 8

Service Parts & Diagram – 8

Warranty – 8

¿Habla español? Ver página 17

SAVE THESE INSTRUCTIONS

4915 21ST

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Form No. 2610923865 Printed 10/04

STREET

Page 2

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 2

POWER TOOL SAFETY RULES

WARNING

!

Keep your work area clean and well lit.

Cluttered benches and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases, or dust.

tools create sparks which may ignite the dust

or fumes.

Keep bystanders, children, and visitors

away while operating a power tool.

Distractions can cause you to lose control.

Double Insulated tools are equipped with

a polarized plug (one blade is wider than

the other.) This plug will fit in a polarized

outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician to install a polarized outlet. Do not

change the plug in any way.

Insulation eliminates the need for the three

wire grounded power cord and grounded

power supply system. Before plugging in the

tool, be certain the outlet voltage supplied is

within the voltage marked on the nameplate.

Do not use “AC only” rated tools with a DC

power supply.

Avoid body contact with grounded surfaces such as pipes, radiators, ranges

and refrigerators.

of electric shock if your body is grounded. If

operating the power tool in damp locations is

unavoidable, a Ground Fault Circuit

Interrupter must be used to supply the power

to your tool. Electrician’s rubber gloves and

footwear will further enhance your personal

safety.

Don't expose power tools to rain or wet

conditions.

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

to carry the tools or pull the plug from an

outlet. Keep cord away from heat, oil,

sharp edges or moving parts.

damaged cords immediately. Damaged

cords increase the risk of electric shock.

When operating a power tool outside, use

an outdoor extension cord marked "W-A"

or "W."

use and reduce the risk of electric shock.

Read and understand all instructions. Failure to follow all instructions listed below, and those included in the Rotary Tool Owner’s Manual, may result

in electric shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

WORK AREA

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use tool while tired or

under the influence of drugs, alcohol, or

medication.

Power

Electrical Safety

Double

There is an increased risk

Water entering a power tool will

Replace

These cords are rated for outdoor

operating power tools may result in serious

personal injury.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep

your hair, clothing, and gloves away from

moving parts.

long hair can be caught in moving parts.

Keep handles dry, clean and free from oil and

grease.

Avoid accidental starting. Be sure switch

is “OFF” before plugging in.

with your finger on the switch or plugging in

tools that have the switch “ON” invites accidents.

Remove adjusting keys or wrenches

before turning the tool ON.

key that is left attached to a rotating part of

the tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times.

balance enables better control of the tool in

unexpected situations.

Use safety equipment. Always

wear eye protection.

non-skid safety shoes, hard hat, or

hearing protection must be used for appropriate conditions.

Use clamps or other practical way to

secure and support the workpiece to a

stable platform.

or against your body is unstable and may

lead to loss of control.

Do not force tool. Use the correct tool for

your application.

job better and safer at the rate for which it is

designed.

Do not use tool if switch does not turn it

ON or OFF.

trolled with the switch is dangerous and must

be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories, or storing the tool.

Personal Safety

A moment of inattention while

Loose clothes, jewelry, or

Carrying tools

A wrench or a

Proper footing and

Dust mask,

Tool Use and Care

Holding the work by hand

The correct tool will do the

Any tool that cannot be con-

2

Page 3

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 3

Such preventive safety measures reduce the

risk of starting the tool accidentally.

Store idle tools out of reach of children

and other untrained persons.

dangerous in the hands of untrained users.

Maintain tools with care. Keep cutting

tools sharp and clean.

tained tools, with sharp cutting edges are

less likely to bind and are easier to control.

Any alteration or modification is a misuse

and may result in a dangerous condition.

Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using.

Tools are

Properly main-

Many accidents

SAFETY RULES FOR RECIPROCATING SAWS

Hold tool by insulated gripping surfaces

when performing an operation where the

cutting tool may contact hidden wiring or

its own cord.

make exposed metal parts of the tool “live”

and shock the operator.

break into existing walls or other blind areas

where electrical wiring may exist. If this situation is unavoidable, disconnect all fuses or

circuit breakers feeding this worksite.

Never leave the trigger locked “ON”.

Before plugging the tool in, check that the

trigger lock is “OFF”.

could cause injury.

Keep hands away from cutting area. Do

not reach under the material being cut.

The proximity of the blade to your hand is

hidden from your sight.

Keep hands from between the gear housing and saw blade holder.

ing blade holder can pinch your fingers.

Do not use dull or damaged blades. Bent

blade can break easily or cause kickback.

Before starting to cut, turn tool “ON” and

allow the blade to come to full speed.

can chatter or vibrate if blade speed is too

slow at beginning of cut and possibly kickback.

Always wear safety goggles or eye protection when using this tool. Use a dust

mask or respirator for applications which

generate dust.

Contact with a “live” wire will

Do not drill, fasten or

Accidental start-up

The reciprocat-

Tool

are caused by poorly maintained tools.

Develop a periodic maintenance schedule

for your tool.

Use only accessories that are recommended by the manufacturer for your

model.

Accessories that may be suitable for

one tool, may become hazardous when

used on another tool.

Service

Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified personnel could result in a risk of injury. For

example: internal wires may be misplaced

or pinched, safety guard return springs may

be improperly mounted.

Secure material before cutting. never hold

it in your hand or across legs.

material may flex or vibrate with the blade,

causing loss of control.

Make certain the blade holder is tight

before making a cut.

cause the tool or blade to slip and loss of

control may result.

When removing the blade from the tool,

avoid contact with skin and use proper

protective gloves when grasping the

blade or accessory.

hot after prolonged use.

WARNING

!

and other construction activities contains

chemicals known to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

• Lead from lead-based paint.

• Crystalline silica from bricks and cement

and other masonry products, and

• Arsenic and chromium from chemically

treated lumber

our risk from these exposures varies,

Y

depending on how often you do this type of

work. to reduce your exposure to these

chemicals, work in a well ventilated area, and

work with approved safety equipment, such

as those dust masks that are specially

designed to filter out microscopic particles.

Accessories may be

Some dust created by

sawing, grinding, drilling,

.

Small or thin

A loose holder can

3

Page 4

0

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 4

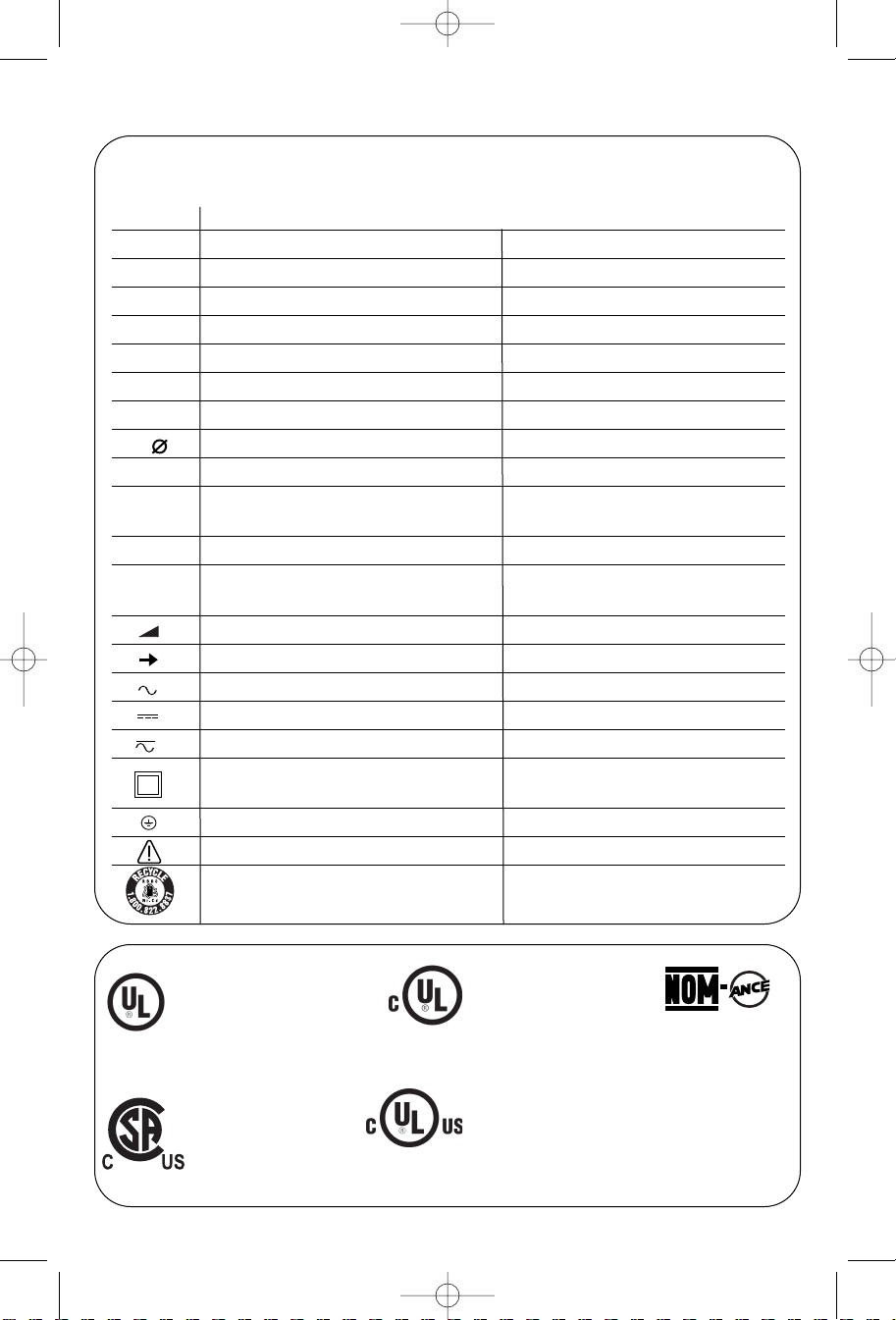

SYMBOLS

IMPORTANT! Some of the following symbols may be used on your tool. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you to

operate the tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels,etc.

n

0

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

per minute orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

This symbol designates

that this tool is listed by

Underwriters Laboratories.

This symbol designates that this tool is

listed by the

Canadian Standards

Association, and is

listed to US

This symbol designates

that this tool is listed to

Canadian Standards by

Underwriters

Laboratories.

This symbol designates that

this tool is listed by

Underwriters Laboratories,

and listed to Canadian

Standards by Underwriters

Laboratories.

This symbol

designates

that

this tool com

plies

to NOM

Mexican

Standards.

-

Standards by CSA.

4

Page 5

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 5

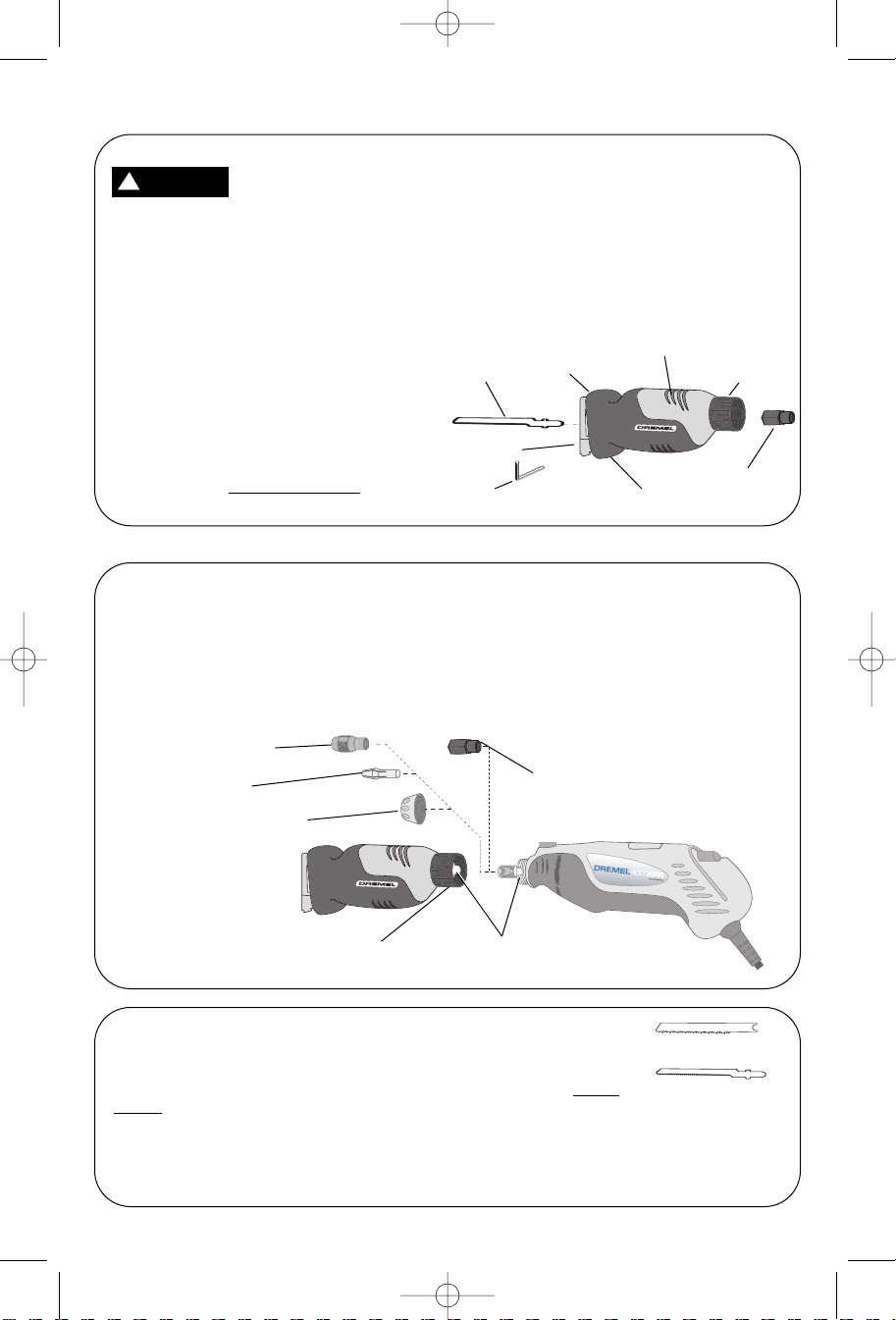

GETTING TO KNOW YOUR XPR MULTISAW

Unpacking & Checking Contents

WARNING

!

making any assembly, adjustments or

changing accessories.

safety measures reduce the risk of starting

the tool accidentally.

Separate all loose parts from packing materials and check each item with the contents

listed on the carton to make sure all items are

accounted for before discarding any packing

material.

IMPORTANT! If any parts are missing, or if

you require any assistance with these

instructions, please contact Dremel™

Consumer Service at:

Disconnect the plug from

the power source before

Such preventative

1-800-437-3635

or at www.Dremel.com.

ASSEMBLY

Installing Saw to Rotary Tool

1. Remove the collet nut, collet and housing cap from rotary tool.

NOTE: Housing cap must be re-installed on

rotary tool when XPR MultiSaw is removed.

2. Install driver nut onto rotary tool shaft.

Collet Nut

Description

The XPR MultiSaw attachment is for use with

Dremel™ 400 Series XPR Rotary tool only.

The Dremel XPR MultiSaw turns your rotary

tool into a multipurpose saw that will allow

you to make straight and curved cuts in a

variety of materials. Scroll cutting patterns is

now fast and easy. Using standard jigsaw

blades, you can cut soft & hard wood, plywood, metal, PVC, plastic, and much more!

Saw Blade

Footplate

Allen Wrench (2.5 mm)

(for blade installation)

Housing

3. Thread the saw onto the rotary tool

housing and tighten overthrow nut

securely. Saw should be positioned so

Dremel markings on tool and saw are

facing same side.

NOTE: Be sure to align keys on tool with keyways in overthrow nut.

Air Vents

Overthrow Nut

Driver Nut

Rubberized Grip

Collet

Housing Cap

Overthrow Nut

Be sure to align keys on tool

with keyways in overthrow nut.

Driver Nut

Blade Selection

Dremel recommends the use of Dremel XPR saw blades.

The XPR MultiSaw

comes with a saw blade for straight and curved cuts in wood and soft materi

als up to 1-7/16" thick.

The Dremel XPR MultiSaw accepts all standard

jigsaw

blades, both “T” or “U” shank.

No one blade can be efficient for all cutting jobs. Different materials require different blades.

Since your saw can cut so many materials, be sure to use the proper blade for the job to

ensure proper cutting performance.

NOTE: Refer to blade packaging for information on recommended materials and blade usage.

5

5

“U” Shank Blade

-

“T” Shank Blade

Page 6

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 6

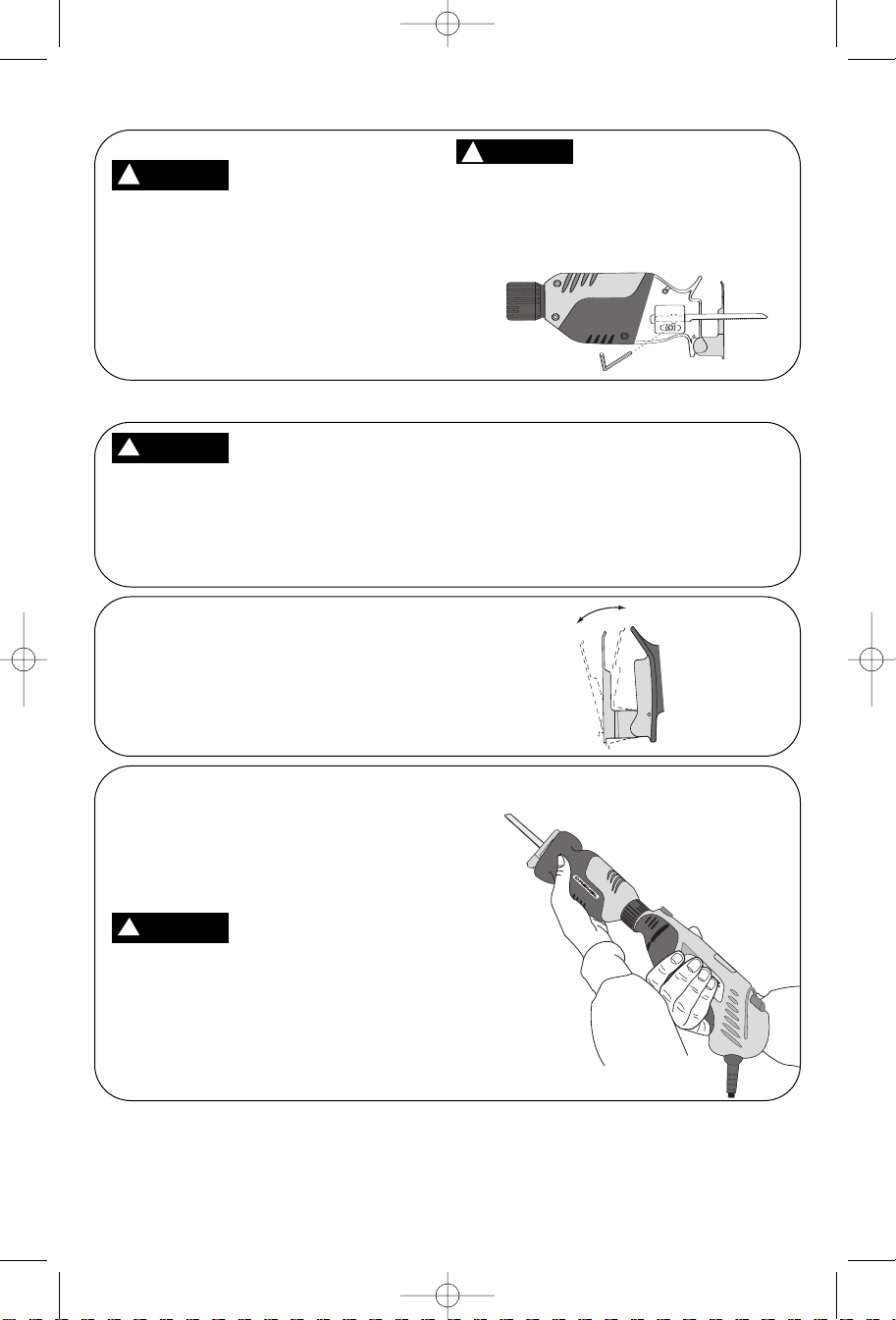

ASSEMBLY (CONTINUED)

Installing Blade

WARNING

!

blade or making any adjustments.

1. Insert the blade fully into the saw opening until it bottoms in the tool.

2. Secure the blade in the saw using the

Allen wrench to tighten the setscrew.

NOTE: Blade can be mounted with teeth facing either direction.

Unplug tool from power

source before changing

OPERATION

WARNING

!

your hand. Blocking the air vents could

cause the motor to overheat.

The speed of your saw is variable from 550 3900 SPM (strokes per minute).

The footplate tilts in order to keep as much of

the surface in contact with the work surface.

Keep the saw footplate firmly against the

work to minimize counterforce (jumping) and

vibration.

When holding tool, do not

cover the air vents with

Operating Speeds

Footplate

WARNING

!

footplate for the entire stroke length. Do

not use specialty blades that are very

short or those with a significant cant.

Blade must not contact footplate. A blade

which is too short or canted, could jam

inside the footplate and snap.

Higher speed settings are generally used for

fast cutting, or when cutting softer materials

such as wood, composite materials, and

plastics. Slower speed settings are generally

used when precision is required, or when cutting harder materials.

NOTE: If the tool is “chewing” rather than cutting the material, use a higher speed setting.

Make sure front end of

blade extends through the

Using the Saw

1. Securely clamp the work.

2. Mark the line of cut and grasp the tool

with one hand on the rotary tool, and the

other hand firmly grasping the insulated

rubber housing on the saw.

WARNING

!

front housing. If you saw into a blind area

where live wiring exists, you may be

shocked or electrocuted.

3. Turn the rotary tool on and let the saw

reach full speed before starting the cut.

Guide the saw so the blade will move

along the marked line.

Always hold the saw by

the insulated grip on the

6

66

Page 7

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 7

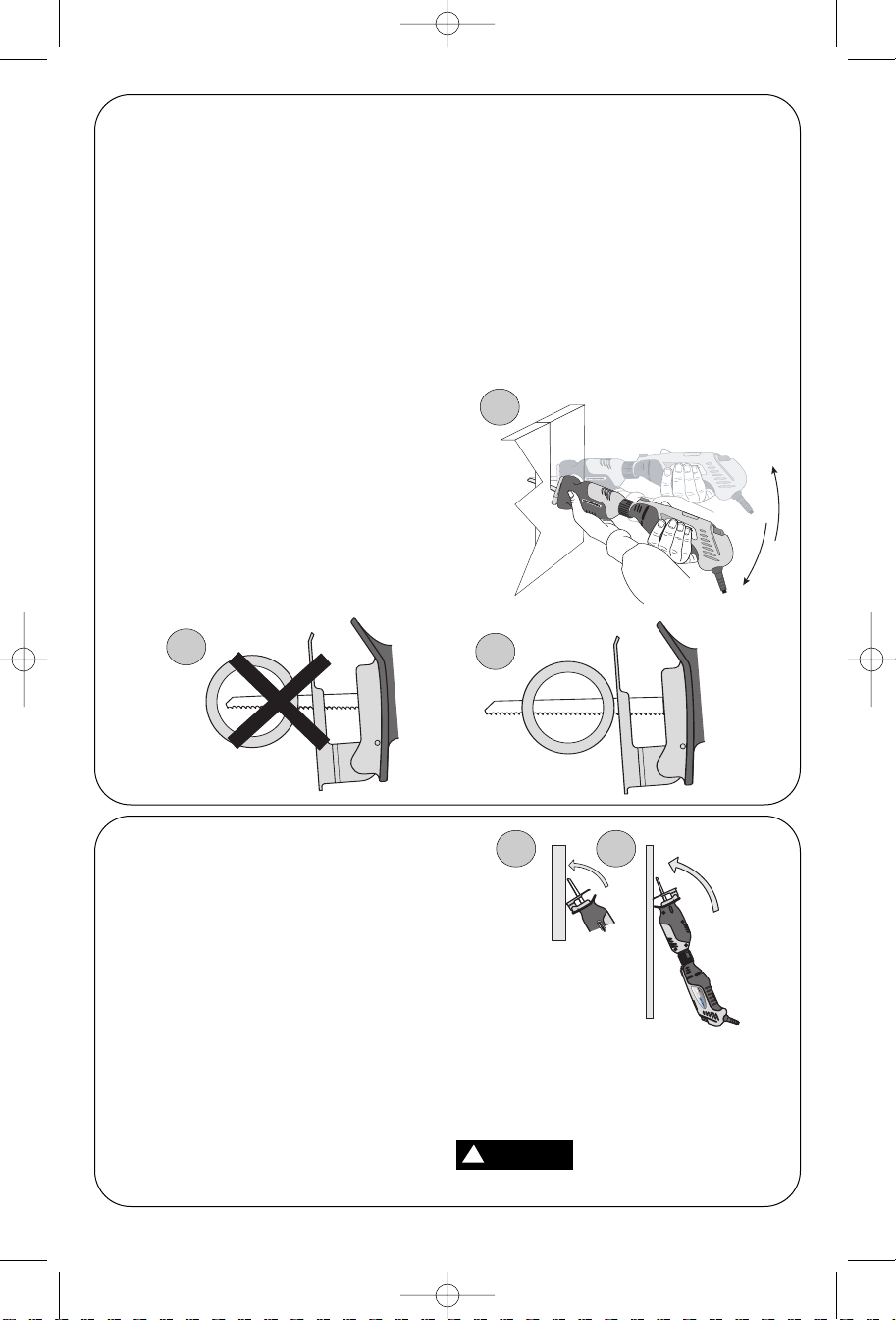

Sawing Tips

Following a few simple tips will reduce the wear

on the workpiece, the tool and the operator.

• For faster cutting, especially in thicker

material, rock the saw up and down to aid

in the chip removal (Figure A).

• Blades cut on the draw or back stroke.

On fine work, such as paneling, fiberglass, etc., place the good side of the

workpiece facing down.

• Use the correct saw blade for the material being cut and keep extra blades on

hand to use when others become dull.

Replace cracked or bent blades immediately.

• To reduce the risk of injury, be sure the

blade always extends beyond the footplate and workpiece throughout the

stroke (Figures B and C). Blades may

shatter if the front of the blade hits the

work and/or footplate.

• When cutting metal:

- Apply lubricant to blade for easier,

smoother, faster cutting and longer

blade life.

B

- For non-ferrous metals, aluminum,

bronze or brass, use a stick wax on the

blade.

- For ferrous metals, iron and steel, use

machine cutting oil along the surface to

be cut.

• When cutting thin metal, “sandwich” the

material between two pieces of scrap

wood. Clamp or put in a bench vise. One

piece of lumber on top of the metal can

be used with adequate clamping. Place

your cut lines or design on the wood.

• Don’t force the cutting. Let the saw and

blade do the work.

A

C

Pocket / Plunge Cuts

The saw can be used to make plunge cuts

into softer material (soft wood or light building

materials for walls) without starting a hole.

1. Mark the line to be cut clearly on the

work surface.

Set the tool with one edge of the foot

2.

plate firmly against the material (Figure

A).

3.

Place the tip of the blade (not running)

on the line to be cut.

ilt the saw so the blade clears the work.

T

4.

5. Turn the rotary tool on and carefully

engage the moving saw blade into the

material.

6. After the blade penetrates through the

work, continue sawing along the marked

line.

A

-

NOTE: To make plunge cutting easier, use

a heavy gauge blade. Install the blade with

the teeth facing upward, and hold the saw

upside down as shown (Figure B).

Do not plunge cut in metal surfaces.

WARNING

!

this manual may create a hazard.

777

B

The use of any accessories not specified in

Page 8

DM 2610922740 8-04 E.qxd 8/10/04 8:20 AM Page 8

CLEANING

V

WARNING

!

To avoid accidents, always

disconnect the tool from

the power supply before cleaning or performing any maintenance.

The tool may be cleaned most effectively

with compressed dry air. Always wear safety goggles when cleaning tools with compressed air.

entilation openings and switch levers must be

kept clean and free of foreign matter. Do not

attempt to clean by inserting pointed objects

through openings.

WARNING

!

tic parts. Some of these are gasoline, carbon tetrachloride, chlorinated cleaning solvents, ammonia and household detergents

containing ammonia.

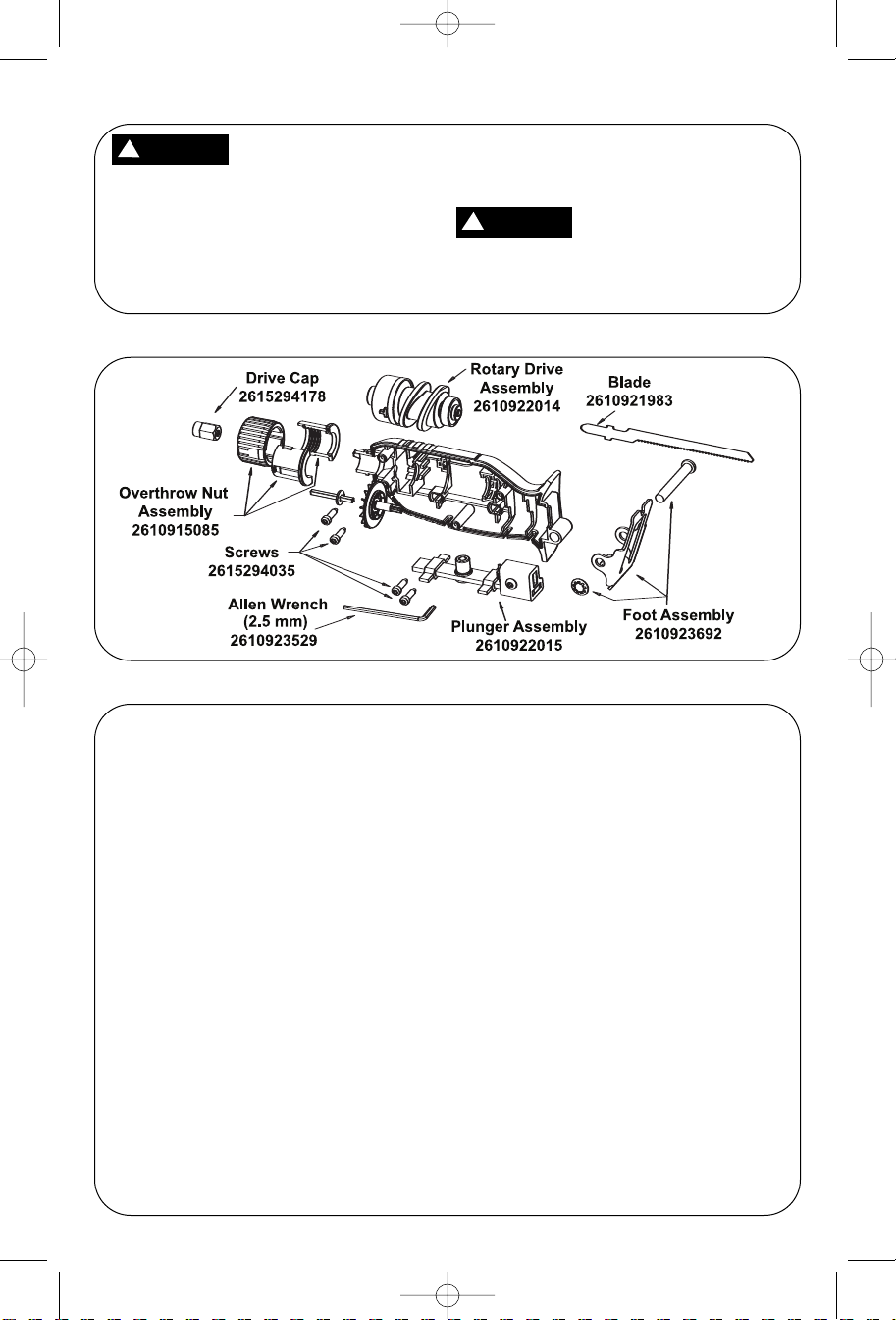

SERVICE PARTS & DIAGRAM

Certain cleaning agents

and solvents damage plas-

DREMEL™ LIMITED WARRANTY

Your Dremel™ product is warranted against defective material or workmanship for a period of one year from date of purchase. In

the event of a failure of a product to conform to this written warranty, please take the following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

e recommend that the package be insured against loss or in transit damage for which we cannot be responsible.

W

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING FROM TAMPERING,

ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS, UNAPPROVED ATTACHMENTS OR

OTHER CAUSES UNRELA

RANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel. If Dremel inspection shows

that the problem was caused by problems with material or workmanship within the limitations of the warranty, Dremel will repair

or replace the product free of charge and return product prepaid. Repairs made necessary by normal wear or abuse, or repair

for product outside the warranty period, if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED WARRANTIES OF MERCHANT

OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to state.

warrantor is solely to repair or replace the product. The warrantor is not liable for any incidental or consequential damages due to any

such alleged defect. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

UNITED STATES

Dremel Service Center Dremel Service Center

4915 21st Street OR 4631 E. Sunny Dune

Racine, WI 53406 Palm Springs, CA 92264

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

6520 Lawrence Av. East See your local distributor or write to

Scarborough, Ont Dremel, 4915 21st Street

Canada M1C 4A7 Racine, WI 53406

TO PROBLEMS WITH MATERIAL OR WORKMANSHIP ARE NOT COVERED BY THIS WAR-

TED

AND FITNESS FOR

ABILITY

A PARTICULAR PURPOSE WHICH EXCEED THE ABOVE MENTIONED

8

88

The obligation of the

Page 9

DM 2610922740 8-04 F 8/10/04 8:21 AM Page 9

(À utiliser avec la série Dremel 400 XPR)

Pièces détachées et diagramme – 16

XPR MultiSaw

(MS400)

Manuel d'utilisation

Sécurité – 10 - 11

Généralités sur votre scie – 13

Assemblage – 13

Utilisation – 14 - 15

Nettoyage – 16

Garantie – 16

Parlez-vous français? Voir page 9

¿Habla español? Ver página 17

CONSERVEZ CES INSTRUCTIONS

4915 21ST STREET

Racine, WI 53406

1-800-437-3635

http://www.dremel.com

Page 10

DM 2610922740 8-04 F 8/10/04 8:21 AM Page 10

POWER TOOL SAFETY RULES

AVERTISSEMENT

!

Vous devez lire et comprendre toutes les instructions. Lenonrespect, même partiel, des instructions ci-après entraîne un

risque de choc életrique, d'incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

Veillez à ce que l'aire de travail soit propre et bien éclairée.

Le désordre et le manque de lumière favorisent les accidents.

N'utilisez pas d'outils électriques dans une atmosphère

explosive, par exemple enprésence de liquides, de gaz ou

de poussières inflammables.

des étincelles qui pourraient enflammer les poussières ou les

vapeurs.

Tenez à distance les curieux, les enfants et les visiteurs

pendant que vous travaillezavec un outil électrique.

pourraient vous distraire et vous faire faire une fausse

manoeuvre.

Les outils électriques créent

Sécurité électrique

Aire de travail

Les outils à double isolation sont équipés d'une fiche

polarisée (une des lames est pluslarge que l'autre), qui ne

peut se brancher que d'une seule façon dans une prise

polarisée. Si la fiche n'entre pas parfaitement dans la prise,

inversez sa position ; si elle n'entre toujours pasbien,

demandez à un électricien qualifié d'installer une prise de

courant polarisée. Ne modifiez pas la fiche de l'outil.

double isolation élimine le besoin d'un cordon d'alimentationà

trois fils avec mise à la terre ainsi que d'une prise de courant mise

à la terre. Avant de brancher l'outil, assurez-vous que la tension de

la prise correspond, à celle indiquée sur la plaque signalétique.

N'utilisez pas d'outils prévus pour courant alternatif seulement avec

une source de courant continu.

Évitez tout contact corporel avec des surfaces mises à la

terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs,

Le risque de choc électrique est plus grand si votre corps

etc.).

est encontact avec la terre.Si l'utilisation de l'outil électrique

dans un endroit humide est inévitable, un disjoncteur de fuite à

la terre doit être utilisé pour alimenter votre outil. Des

chaussures et des gants en caoutchouc d'électricien

contribueront à accroître davantage votre sécurité personnelle.

N'exposez pas les outils électriques à la pluie ou à l'eau. La

présence d'eau dans un outil électrique augmente le risque de

choc électrique.

Ne maltraitez pas le cordon. Ne transportez pas l'outil par

son cordon et ne débranchez pas la fiche en tirant sur le

cordon. N'exposez pas le cordon à la chaleur, à des huiles,

à des arêtes vives ou à des pièces en mouvement.

Remplacez immédiatement un cordon endommagé.

cordon endommagé augmente le risque de choc électrique.

Lorsque vous utilisez un outil électrique à l'extérieur,

employez un prolongateur pour l'extérieur marqué « W-A »

Ces cordons sont faits pour être utilisés à l'extérieur

ou « W ».

et réduisent le risque de choc électrique. Reportez-vous aux «

Dimensions recommandées des cordons de rallonge

section Accessoires de ce manuel.

» dans la

Sécurité des personnes

Restez alerte, concentrez-vous sur votre travail et faites

preuve de jugement. N'utilisez pas un outil électrique si

vous êtes fatigué ou sous l'influence de drogues, d'alcool

ou de médicaments.

entraîner des blessures graves.

Un instant d'inattention suf

fit pour

Habillez-vous convenablement. Ne portez ni vêtements

flottants ni bijoux. Confinez les cheveux longs.

N'approchez jamais les cheveux, les vêtements ou les

gants des pièces en mouvement.

des bijoux ou des cheveux longs risquent d'être happés par

des pièces en mouvement. Gardez les poignées sèches,

propres et exemptes d'huile et de graisse.

Méfiez-vous d'un démarrage accidentel.

l'outil, assurez-vous que son interrupteur est sur ARRÈT.

Le fait de transporter un outil avec le doigt sur la détente ou de

Ils

brancher un outil dont l'interrupteur est en position MARCHE

peut mener tout droit à un accident.

Enlevez les clés de réglage ou de serrage avant de

démarrer l'outil.

l'outil peut provoquer des blessures.

Ne vous penchez pas trop en avant. Maintenez un bon

appui et restez en équilibre entout temps.

vous permet de mieux réagir à une situation inattendue.

La

des bottes de sécurité antidérapantes, un casque

protecteur et/ou un appareil antibruit.

Une clé laissée dans une pièce tournante de

Utilisez des accessoires de sécurité. Portez

toujours des lunettes ou une visière.

conditions, portez aussi un masque antipoussière,

Utilisation et entretien des outils

Immobilisez le matériau sur une surface stable au moyen

de brides ou de toute autre façon adéquate.

la pièce avec la main ou contre votre corps offre une stabilité

insuffisante et peut amener un dérapage de l'outil.

Ne forcez pas l'outil. Utilisez l'outil approprié à la tâche.

L'outil correct fonctionne mieux et de façon plus sécuritaire.

Respectez aussi la vitesse de travail qui lui est propre.

N'utilisez pas un outil si son interrupteur est bloqué. Un

outil que vous ne pouvez pas commander par son interrupteur

est dangereux et doit être réparé.

Débranchez la fiche de l'outil avant d'effectuer un réglage,

de changer d'accessoire oude ranger l'outil.

mesures préventives de sécurité réduisent le risque de

démarrage accidentel de l'outil.

Rangez les outils hors de la portée des enfants et d'autres

personnes inexpérimentées.

les mains d'utilisateurs novices.

Un

Prenez soin de bien entretenir les outils. Les outils de

coupe doivent être toujours bien affûtés et propres.

outils bien entretenus, dont les arêtes sont bien tranchantes,

sont moins susceptibles de coincer et plus faciles à

diriger.Toute altération ou modification constitue un usage

erroné et peut causer un danger

Soyez attentif à tout désalignement ou coincement des

pièces en mouvement, à tout bris ou à toute autre

condition préjudiciable au bon fonctionnement de l'outil.

Si vous constatez qu'un outil est endommagé, faites-le

réparer avant de vous en servir

causés par des outils en mauvais état. Élaborez un calendrier

d'entretien périodique de votre outil.

Des vêtements flottants,

Avant de brancher

Un bonne stabilité

Selon les

Le fait de tenir

De telles

Les outils sont dangereux dans

Des

.

De nombreux accidents sont

.

10

Page 11

DM 2610922740 8-04 F 8/10/04 8:21 AM Page 11

N'utilisez que des accessoires que le fabricant

recommande pour votre modèle d'outil.

accessoires peuvent convenir à un outil, mais être dangereux

avec un autre.

Certains

Réparation

La réparation des outils électriques doit être confiée à un

réparateur qualifié.

électrique par un amateur peut avoir des conséquences

graves. Ainsi, des fils internes peuvent être mal placés ou

pincés, des ressorts de rappel de protecteur peuvent être

montés erronément.

L'entretien ou la réparation d'un outil

CONSIGNES DE SÉCURITÉ POUR SCIES ALTERNATIVES

Tenez l'outil au niveau de ses poignées isolées

lorsque vous effectuez une opération où l'outil de

coupe risque de toucher des conducteurs cachés

ou son propre cordon.

teur sous tension mettra les parties métalliques

exposées de l'outil sous tension et enverra une

décharge électrique à l'opérateur. Ne percez, fixez ou

cassez pas des murs existants ou d'autres surfaces

pouvant masquer des conducteurs électriques. Si cette

situation est inévitable, débranchez tous les fusibles ou

disjoncteurs qui alimentent le site.

Ne laissez jamais la détente bloquée sur position "

Marche ". Avant de brancher l'outil, assurez-vous

que le verrou de la détente n'est pas enclenché.

démarrage intempestif de l'outil risque de causer des

blessures.

Tenez les mains à l'écart de la zone de coupe. Ne

passez pas la main sous le matériau en train d'être

coupé. La proximité de la lame par rapport à vos mains

est masquée de votre vue.

Gardez les mains en dehors de la zone comprise

entre la boîte de vitesses et le porte-lame de la

scie.

Le porte-lame de la scie alternative peut vous

pincer les doigts.

N'utilisez pas de lames émoussées ou endommagées.

Une lame déformée peut se casser facile-

ment ou causer un effet de recul.

Avant de commencer à couper, démarrez l'outil et

laissez la lame arriver à plein régime.

ou les vibrations de l'outil sont possibles si la vitesse de

la lame est insuffisante au début de la coupe, avec

effet de recul possible.

Portez toujours des lunettes de sécurité ou une

protection oculaire lorsque vous utilisez cet outil.

Utilisez un masque antipoussières pour les applications qui dégagent de la poussière.

Un contact avec un conduc-

Le broutage

Pour la réparation d'un outil, n'employez que des pièces

de rechange d'origine. Suivez les directives données à la

section « Réparation » de ce manuel.

autorisées ou le non-respect des instructions d'entretien peut

créer un risque de choc électrique ou de blessures. Certains

agents nettoyants tels qu'essence, tétrachlorure de carbone,

ammoniac, etc., peuvent abîmer les pièces en plastique.avant

l’entretien ; avant de changer les lames, les mèches, les

couteaux, etc.

L'emploi de pièces non

Fixez le matériau avant de le couper. Ne le tenez

jamais dans la main et ne le calez pas non plus sur

vos genoux.

Un matériau de petite taille ou fin risque

de se courber ou de vibrer avec la lame, entraînant une

perte de contrôle.

Assurez-vous que le porte-lame est bien fixé avant

de couper.

Un porte-lame mal fixé risque d'entraîner le

glissement de l'outil ou de la lame, entraînant une

éventuelle perte de contrôle.

Lorsque vous retirez la lame de l'outil, évitez tout

contact avec la peau et utilisez des gants de protection adaptés pour saisir la lame ou l'accessoire.

Il est possible que les accessoires soient chauds après

Le

une utilisation prolongée.

!

AVERTISSEMENT

Certaines poussières

créées par un sciage,

meulage, perçage et d'autres activités de construction contiennent des produits chimiques connus

pour causer des cancers, des déformations congénitales ou d'autres troubles de la reproduction.

Citons notamment:

• plomb issu de peintures à base de plomb,

• silice cristalline issue des briques et du ciment et

d'autres produits de maçonnerie, et

• arsenic et chrome issus du bois d'œuvre traité aux

produits chimiques.

Les risques associés à ces expositions varient selon la

fréquence de ce type de travaux. Pour réduire votre

exposition à ces produits chimiques, travaillez dans

une zone bien ventilée et utilisez un équipement de

sécurité agréé, notamment des masques antipoussières spécialement conçus pour filtrer les particules

microscopiques.

11

Page 12

0

DM 2610922740 8-04 F 8/10/04 8:21 AM Page 12

SYMBOLES

Important : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre leur

signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus efficace et

plus sûre.

Symbol Name Designation/Explanation

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules,

n

0

Vitesse à vide Vitesse de rotation, à vide

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de

l, ll, lll, ... position. Un nombre plus élevé signifie

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif Type ou caractéristique du courant

ou continu

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

Sceau Ni-Cad RBRCmc Désigne le programme de recyclage des piles

etc.

une vitesse plus grande.

d'avertissement.

que

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories.

Ce symbole signifie que cet

outil est approuvé par

l'Association canadienne de

normalisation.

Ce symbole

cet outil est approuvé conformément aux normes canadiennes par Underwriters

Laboratories.

Ce symbole signifie que cet outil

est approuvé par Underwriters

Laboratories et qu’il a été homologué selon les normes canadi

ennes par Underwriters

signifie

Ce symbole signifie que

cet outil se con

forme aux

normes mexi

caines NOM.

-

-

-

Laboratories.

12

Page 13

DM 2610922740 8-04 F 8/10/04 8:21 AM Page 13

GÉNÉRALITÉS SUR VOTRE SCIE

Déballage et contrôle du contenu

!

AVERTISSEMENT

avant tout assemblage, réglage ou

changement d'accessoire. Ces mesures

de sécurité préventives réduisent le

risque de démarrage intempestif de

l'outil.

Séparez toutes les pièces non fixées des

matériaux d'emballage et pour chaque article, pointez sur la liste de colisage qui figure

sur le carton pour vous assurer que rien ne

manque avant de jeter les matériaux d'emballage.

IMPORTANT! S'il manque la moindre pièce

ou si vous comprenez mal ces instructions,

contactez le service clientèle Dremel™ au :

Débranchez le cordon d'alimentation

1-800-437-3635

ou à www.Dremel.com.

ASSEMBLAGE

Installation de la scie sur l'outil rotatif

1. Retirez l'écrou de la bague, la bague et

le capuchon du boîtier de l'outil rotatif.

REMARQUE : Le capuchon du boîtier doit

être réinstallé sur l'outil rotatif une fois la

scie XPR MultiSaw retirée.

2. Installez l'écrou d'entraînement sur l'arbre de l'outil rotatif.

Écrou du collet

Bague de serrage

Capuchon du boîtier

Description

L'accessoire XPR MultiSaw s'utilise uniquement avec l'outil rotatif Dremel™ 400 série

XPR. La scie Dremel XPR MultiSaw transforme votre outil rotatif en une scie polyvalente qui vous permettra de pratiquer des

coupes droites et incurvées dans une variété

de matériaux. Les motifs de coupe en C sont

désormais rapides et faciles. Avec des lames

de scie sauteuse standard, vous pouvez

couper bois mou et bois dur, contreplaqué,

métal, PVC, plastique et bien plus encore !

Lame de scie

Crapaud

Clé Allen, 2.5mm (pour

l'installation de la lame)

Boîtier

3. Vissez la scie sur le boîtier de l'outil

rotatif et serrez bien l'écrou de renversement. La scie doit être positionnée de

sorte que les repères Dremel sur l'outil

et la scie soient tournés du même côté.

REMARQUE : Veillez à aligner les clavettes

de l'outil sur les rainures de clavette de

l'écrou de renversement.

Écrou d'entraînement

Bouches d'aération

Écrou d'entraînement

Écrou de renversement

Poignée caoutchoutée

Écrou de renversement

Veillez à aligner les clavettes de l'outil sur les rainures de clavette de l'écrou de renversement.

Sélection de la lame

Dremel recommande l'utilisation de lames de scie Dremel XPR. La scie XPR

MultiSaw est fournie avec une lame pour coupes droites et incurvées dans le

bois et les matériaux mous jusqu'à 36,5 mm d'épaisseur

MultiSaw accepte toutes les lames de scie sauteuse standard, à tige en

. La scie Dremel XPR

T

en U.

Une lame unique ne peut pas être efficace pour tous les travaux de coupe. Chaque matériau exige une lame différente. Comme votre scie peut couper de nombreux matériaux, veillez

à utiliser la lame adaptée au travail pour garantir une performance de coupe correcte.

REMARQUE : Pour des informations sur les matériaux recommandés et les lames compatibles, reportez-vous à l'emballage de la lame.

13

13

ou

Lame à tige en U

Lame à tige en T

Page 14

DM 2610922740 8-04 F 8/10/04 8:22 AM Page 14

Installation de la lame

!

AVERTISSEMENT

de changer de lame ou d'effectuer des

réglages.

1.

Insérez la lame à fond dans l'ouverture

de la scie jusqu'à ce qu'elle bute.

2. Fixez la lame dans la scie avec la clé

Allen pour serrer la vis.

REMARQUE : La lame peut être montée

avec les dents tournées dans n'importe

quelle direction.

Débranchez l'outil de

l'alimentation avant

UTILISATION

!

AVERTISSEMENT

pas les bouches d'aération avec votre

main. L'obturation des bouches d'aération entraînera la surchauffe du moteur.

Régimes d'exploitation

Le régime de votre scie est variable (de 550

à 3 900 coups par minute).

Le crapaud s'incline pour maintenir le maximum de surface en contact avec la surface

de travail.

Plaquez fermement le crapaud contre l'ouvrage pour minimiser l'effet de contre-force

(saut) et les vibrations.

Lorsque vous tenez

l'outil, ne couvrez

Crapaud

!

AVERTISSEMENT

dépasse du crapaud sur toute la longueur

de la course. N'utilisez pas de lames spéciales très courtes ou sensiblement

biseautées. La lame ne doit pas toucher le

crapaud. Une lame trop courte ou

biseautée risque de se coincer à l'intérieur du crapaud et de se casser

Les hauts régimes s'utilisent pour les coupes

rapides ou pour couper les matériaux plus

mous comme le bois, les matériaux composites et les plastiques. Les bas régimes sont

généralement utilisés pour la coupe de précision ou la coupe de matériaux plus durs.

REMARQUE: Si l'outil ronge le matériau au

lieu de le couper, augmentez le régime d'exploitation.

Assurez-vous que

l'avant de la lame

.

Mode d'emploi de la scie

1. Fixez solidement l'ouvrage.

2. Marquez la ligne de coupe et saisissez

l'outil en plaçant une main l'outil rotatif,

la seconde tenant fermement le boîtier

isolé en caoutchouc de la scie.

!

AVERTISSEMENT

isolée sur l'avant du boîtier. Si vous sciez

dans une zone pouvant masquer des conducteurs électriques sous tension, vous

risquez une électrocution.

3. Mettez l'outil rotatif sous tension et

attendez que la lame atteigne son plein

régime avant de commencer à couper.

Guidez la scie pour que la lame bouge

le long de la ligne tracée.

Tenez toujours la

scie par la poignée

14

1414

Page 15

DM 2610922740 8-04 F 8/10/04 8:22 AM Page 15

Conseils de sciage

Suivez ces quelques conseils pour réduire

l'usure de la pièce à travailler et de l'outil, et la

fatigue de l'opérateur.

• Pour une coupe plus rapide, surtout dans

un matériau plus épais, basculez la scie

vers le haut et vers le bas pour faciliter

l'évacuation des copeaux (figure A).

• Les lames coupent sur la course avant et

la course arrière. Sur les matériaux fragiles, comme les lambris, la fibre de verre,

etc., orientez la face de la pièce qui sera

visible vers le bas.

• Utilisez la lame de scie adaptée au

matériau coupé et prévoyez des lames

de réserve pour remplacer les lames

émoussées. Remplacez immédiatement

les lames fendues ou déformées.

• Pour réduire le risque de blessure, veillez

à ce que la lame dépasse toujours le crapaud et la pièce à travailler tout au long

de la course (figures B et C). Les lames

peuvent se casser si l'avant de la lame

frappe la pièce à travailler et/ou le crapaud.

• Lorsque vous coupez du métal:

• Appliquez un lubrifiant sur la lame pour

B

une coupe plus facile, rapide et sans àcoups et prolonger la durée de vie de la

lame.

- Pour les métaux non ferreux, l'aluminium,

le bronze ou le laiton, passez un bâton de

cire sur la lame.

- Pour les métaux ferreux, le fer et l'acier,

utilisez de l'huile de coupe le long de la

surface à couper.

• Lorsque vous coupez du métal fin, placez

le métal en sandwich entre deux chutes

de bois. Serrez dans un étau d'établi. Un

morceau de bois de coupe sur le dessus

du métal peut être utilisé avec une fixation adéquate. Tracez vos lignes ou votre

dessin de coupe sur le bois.

• Ne forcez pas durant la coupe. Laissez la

scie et la lame faire le travail.

A

C

Coupe en plongée / découpe de poches

La scie peut servir à effectuer des coupes en

plongée dans des matériaux plus mous (bois

mou ou matériaux de construction léger pour

murs) sans faire de trou de départ.

1. Marquez clairement la ligne à couper

sur la surface de la pièce à travailler.

2. Placez l'outil en plaquant fermement un

bord du crapaud contre le matériau (figure A).

Placez l'extrémité de la lame (à l'arrêt)

3.

sur la ligne de coupe.

4. Inclinez la scie pour que la lame dégage

l'ouvrage.

5. Mettez l'outil rotatif sous tension et

engagez avec précaution la lame de la

scie dans le matériau.

6. Une fois que la lame pénètre dans le

matériau, continuez à scier le long de la

ligne tracée.

A

REMARQUE: Pour faciliter la coupe en

plongée, utilisez une lame épaisse. Installez

la lame les dents vers le haut et tenez la

scie à l'envers, comme illustré (figure B).

Ne pratiquez pas de coupe en plongée dans

les surfaces métalliques.

!

VERTISSEMENT

A

cifié dans ce manuel risque de présenter

un danger.

151515

B

L'utilisation d'un

accessoire non spé-

Page 16

Capuchon d'entraînement

Entraînement rotatif

Lame

Pied

Piston-plongeur

Vis

Écrou de renversement

Clé Allen

DM 2610922740 8-04 F 8/10/04 8:22 AM Page 16

NETTOYAGE

!

AVERTISSEMENT

Pour éviter les acci-

dents, débranchez

toujours le cordon d'alimentation de l'outil

avant de le nettoyer ou d'effectuer une

maintenance.

L'outil se nettoie au mieux à l'air comprimé.

Portez toujours des lunettes de sécurité

lorsque vous nettoyez des outils à l'air comprimé..

Les bouches d'aération et les leviers de commutateur doivent être maintenus propres.

N'essayez pas de les nettoyer en insérant un

objet pointu dans les ouvertures.

!

AVERTISSEMENT

mageront les composants en plastique,

comme l'essence, le tétrachlorure de carbone, les solvants de nettoyage chlorés,

l'ammoniaque et les détergents ménagers

ammoniacaux.

PIÈCES DÉTACHÉES ET DIAGRAMME

Certains nettoyants et

solvants endom

-

Votre produit Dremel est garanti contre les vices de matière et de main d'œuvre pour une période de deux ans à partir

de la date d'achat. Au cas ou un produit n'est pas conforme à cette garantie écrite, il convient d'agir comme suit:

1. NE rapportez PAS votre produit là où vous l'avez acheté.

2. Emballez le produit seul avec soin, sans rien d'autre, et renvoyez-le en port payé accompagné des docu-

ments suivants:

A. Une copie de votre preuve d'achat datée (veuillez conserver une copie pour vous-même).

B. Une description écrite du problème.

C. Nom, adresse et numéro de téléphone à l'attention de :

ÉTATS-UNIS

Dremel Service Center

4915 21st Street Racine, WI 53406 4631 E. Sunny Dune, Palm Springs, CA 92264

CANADA EN DEHORS DES ÉTATS

Giles Tool Agency AMÉRICAINS CONTINENTAUX

6520 Lawrence Av. East Contactez votre distributeur local ou écrivez à

Scarborough, Ont., Canada M1C 4A7 Dremel, 4915 21st Street, Racine, WI 53406

Nous vous recommandons d'assurer votre envoi contre la perte ou les dégâts de transport, lesquels ne peuvent

en aucun cas engager notre responsabilité.

Cette garantie ne s'applique qu'à l'acheteur inscrit d'origine. LES DÉGÂTS AU PRODUIT RÉSULTANT DE

MODIFICATIONS, D'ACCIDENT, D'UN MAUVAIS TRAITEMENT, D'UNE NÉGLIGENCE, DE RÉPARATIONS

NON AUTORISÉES, DE L'UTILISATION D'ACCESSOIRES NON HOMOLOGUÉS OU D'AUTRES CAUSES

NON LIÉES À DES VICES DE MATIÈRE OU DE MAIN D'OEUVRE NE SONT PAS COUVERTS PAR CETTE

GARANTIE.

Aucun employé, agent ou distributeur ni qui que ce soit d'autre n'est autorisé à donner aucune garantie de la

part de Dremel. Si l'inspection par Dremel démontre que le problème a été causé par un vice de matière ou de

main d'œuvre dans les limites de la garantie, Dremel réparera ou remplacera le produit sans frais et le renver

ra en port payé. Les réparations nécessitées par l'usure normale ou un mauvais traitement et les réparations

du produit en dehors de la période de garantie, si elles sont possibles, seront effectuées au coût usine normal.

DREMEL

LES GARANTIES IMPLICITES QUE LE PRODUIT

USAGE PARTICULIER SAUF COMME EXPRESSÉMENT MENTIONNÉ CI-DESSUS SONT EXPRESSÉMENT

DÉCLINÉES ET EXCLUES DE CETTE GARANTIE LIMITÉE.

Cette garantie vous donne des droits spécifiques et il se peut que vous ayez d'autres recours légaux qui varient d'état à état. Le devoir du garant se limite à la réparation ou au remplacement du produit. Le garant ne saurait être

tenu pour responsable des dommages directs ou indirects causés par le vice supposé. Certains états n'admettent

pas l'exclusion ou la limitation des dommages directs ou indirects. Les limitations ou exclusions mentionnées cidessus ne s'appliquent donc pas forcément à vous.

Pour vous renseigner sur les prix ou l'exécution de la garantie dans les états américains continentaux, contactez

votre distributeur Dremel.

NE F

AIT

GARANTIE LIMITÉE DREMEL™

Dremel Service Center

AUCUNE

AUTRE GARANTIE D'AUCUNE SOR

EST COMMERCIALISABLE ET QU'IL CONVIENT À UN

16

1616

-

TE, EXPLICITE OU IMPLICITE, ET TOUTES

Page 17

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 17

XPR MultiSaw

(MS400)

Manual del propietario

(para usarse con la herramienta rotatoria Series 400 XPR de Dremel)

Seguridad – 18 - 19

Familiarícese con su sierra – 20

Montaje – 22

Operación – 22 - 23

Limpieza – 24

Piezas de servicio y diagra – 24

Garantía – 24

Parlez-vous français? Voir page 9

¿Habla español? Ver página 17

GUARDE ESTAS INSTRUCCIONES

4915 21ST STREET

Racine, WI 53406

1-800-437-3635

http://www

.dremel.com

Page 18

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 18

NORMAS DE SEGURIDAD PARA HERRAMIENTAS MECÁNICAS

ADVERTENCIA

!

Mantenga el área de trabajo limpia y bien iluminada.

Las mesas desordenadas y las áreas oscuras invitan a que

se produzcan accidentes.

No utilice herramientas mecánicas en atmósferas

explosivas, tales como las existentes en presencia de

líquidos, gases o polvos inflamables. Las herramientas

mecánicas generan chispas y éstas pueden dar lugar a la

ignición del polvo o los vapores.

Mantenga a las personas que se encuentren

presentes, a los niños y a los visitantes alejados al

utilizar una herramienta mecánica. Las distracciones

pueden hacer que usted pierda el control.

Las herramientas con aislamiento doble están

equipadas con un enchufe polarizado (un terminal es

más ancho que el otro). Este enchufe entrará en un

tomacorriente polarizado solamente de una manera. Si

el enchufe no entra por completo en el tomacorriente,

déle la vuelta. Si sigue sin entrar, póngase en contacto

con un electricista competente para instalar un

tomacorriente polarizado. No haga ningún tipo de

cambio en el enchufe. El aislamiento doble elimina la

necesidad del sistema de cordón de energía de tres hilos

conectado a tierra y la fuente de energía conectada a

tierra. Antes de enchufar la herramienta, asegúrese de que

la tensión del tomacorriente suministrada se encuentre

dentro del margen de la tensión especificada en la placa

del fabricante. No utilice herramientas con capacidad

nominal "AC solamente" ("AC only") con una fuente de

energía DC.

Evite el contacto del cuerpo con las superficies

conectadas a tierra tales como tuberías, radiadores,

estufas de cocina y refrigeradores. Hay mayor riesgo de

que se produzcan sacudidas eléctricas si su cuerpo está

conectado a tierra. Si la utilización de la herramienta

mecánica en lugares húmedos es inevitable, se debe usar

un interruptor de circuito para fallos a tierra para

suministrar la energía a la herramienta. Los guantes de

goma para electricista y el calzado antideslizante

aumentarán más la seguridad personal.

No exponga las herramientas mecánicas a la lluvia ni a

situaciones húmedas. La entrada de agua en una

herramienta mecánica aumentará el riesgo de que se

produzcan sacudidas eléctricas.

No abuse del cordón. Nunca use el cordón para llevar las

herramientas ni para sacar el enchufe de un tomacorriente.

Mantenga el cordón alejado del calor, el aceite, los bordes

afilados o las piezas móviles. Cambie los cordones

dañados inmediatamente. Los cordones dañados

aumentan el riesgo de que se produzcan sacudidas

eléctricas.

Al utilizar una herramienta mecánica a la intemperie,

utilice un cordón de extensión para intemperie

marcado "W-A" o "W".

nominal para uso a la intemperie y reducen el riesgo de

que se produzcan sacudidas eléctricas. Consulte

"Tamaños recomendados de los cordones de extensión"

en la sección Accesorios de este manual.

Lea y entienda todas las instrucciones. El incumplimiento de todas las instrucciones indicadas a continuación puede dar lugar a sacudidas eléctricas, incendios y/o lesiones personales

graves.

Area de trabajo

Seguridad eléctrica

Estos cordones tienen capacidad

CONSERVE ESTAS INSTRUCCIONES

Manténgase alerta, fíjese en lo que está haciendo y use

el sentido común cuando utilice una herramienta

mecánica. No use la herramienta cuando esté cansado

o se encuentre bajo la influencia de drogas, alcohol o

medicamentos. Un momento de distracción al utilizar

herramientas mecánicas puede dar lugar a lesiones

personales graves.

Vístase adecuadamente. No se ponga ropa holgada ni

joyas. Sujétese el pelo. Mantenga el pelo, la ropa y los

guantes alejados de las piezas móviles. La ropa

holgada, las joyas o el pelo largo pueden quedar atrapados

en las piezas móviles. Mantenga los mangos secos,

limpios y libres de aceite y grasa.

Evite el arranque accidental. Asegúrese de que el

interruptor esté en la posición "OFF" (apagado) antes

de enchufar la herramienta. El llevar las herramientas

con el dedo en el interruptor o el enchufar herramientas

que tengan el interruptor en la posición "ON" (encendido)

invita a que se produzcan accidentes.

Quite las llaves de ajuste o de tuerca antes de

encender la herramienta. Una llave de ajuste o de tuerca

que se deje puesta en una pieza giratoria de la herramienta

puede ocasionar lesiones personales.

No intente alcanzar demasiado lejos. Mantenga un

apoyo de los pies y un equilibrio adecuados en todo

momento. El apoyo de los pies y el equilibrio adecuados

permiten un mejor control de la herramienta en situaciones

inesperadas.

según lo requieran las condiciones.

Utilización y cuidado de las herramientas

Utilice abrazaderas u otro modo práctico de fijar y

soportar la pieza de trabajo a una plataforma estable.

La sujeción de la pieza de trabajo con la mano o contra el

cuerpo resulta inestable y puede ocasionar pérdida de

control.

No fuerce la herramienta. Use la herramienta correcta

para la aplicación que desea. La herramienta correcta

hará el trabajo mejor y con más seguridad a la capacidad

nominal para la que está diseñada.

No utilice la herramienta si el interruptor no la

enciende o apaga. Toda herramienta que no se pueda

controlar con el interruptor es peligrosa y debe ser

reparada.

Desconecte el enchufe de la fuente de energía antes de

hacer cualquier ajuste, cambiar accesorios o guardar

la herramienta.

reducen el riesgo de arrancar la herramienta

accidentalmente.

Guarde las herramientas que no esté usando fuera del

alcance de los niños y otras personas no capacitadas.

Las herramientas son peligrosas en las manos de los

usuarios no capacitados.

Mantenga las herramientas con cuidado. Conserve las

herramientas de corte afiladas y limpias.

herramientas mantenidas adecuadamente, con bordes de

18

Seguridad personal

Utilice equipo de seguridad. Use siempre

protección de los ojos. Se debe utilizar una

máscara antipolvo, zapatos de seguridad

antideslizantes, casco o protección de los oídos

Estas medidas de seguridad preventivas

Las

Page 19

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 19

corte afilados, tienen menos probabilidades de atascarse y

son más fáciles de controlar. Toda alteración o modificación

constituye un uso incorrecto y puede tener como resultado

una situación peligrosa.

Compruebe la desalineación o el atasco de las piezas

móviles, la ruptura de piezas y cualquier otra situación

que pueda afectar el funcionamiento de las

herramientas. Si la herramienta está dañada, haga que

realicen un servicio de ajustes y reparaciones a la

herramienta antes de usarla. Muchos accidentes son

causados por herramientas mantenidas deficientemente.

Establezca un programa de mantenimiento periódico para

la herramienta.

Utilice únicamente accesorios que estén

recomendados por el fabricante de su modelo. Los

accesorios que pueden ser adecuados para una

herramienta pueden volverse peligrosos cuando se utilizan

en otra herramienta.

El servicio de ajustes y reparaciones de una

herramienta debe ser realizado únicamente por

personal de reparaciones competente. El servicio o

mantenimiento realizado por personal no competente

podría ocasionar un peligro de que se produzcan lesiones.

Por ejemplo: Los cables internos pueden colocarse mal o

pellizcarse, los resortes de retorno de los protectores de

seguridad pueden montarse inadecuadamente.

Al realizar servicio de ajustes y reparaciones de una

herramienta, utilice únicamente piezas de repuesto

idénticas. Siga las instrucciones que aparecen en la

sección Mantenimiento de este manual. El uso de

piezas no autorizadas o el incumplimiento de las

instrucciones de Mantenimiento puede ocasionar un

peligro de que se produzcan sacudidas eléctricas o

lesiones. Ciertos agentes de limpieza, tales como gasolina,

tetracloruro de carbono, amoníaco, etc., pueden dañar las

piezas de plástico.

Servicio

REGLAS DE SEGURIDAD PARA LAS SIERRAS ALTERNATIVAS

Sujete la herramienta por las superficies de

agarre aisladas cuando realice una

operación en la cual la herramienta de corte

pueda entrar en contacto con cableado

oculto o con su propio cable. El contacto con

un alambre energizado energizará las piezas

metálicas expuestas de la herramienta y darán

una descarga eléctrica al operador. No perfore

con taladro, sujete ni corte a través de paredes

existentes o de otras áreas ciegas en las que

pueda existir cableado eléctrico. Si no puede

evitar hacerlo, desconecte todos los fusibles o

disyuntores que alimentan el área de trabajo.

Nunca deje el gatillo trabado en la posición

"ON" (ENCENDIDO). Antes de enchufar la

herramienta, revise que la traba del gatillo

se encuentre en "OFF" (APAGADO). El

arranque accidental podría causar lesiones.

Mantenga las manos alejadas del área de

No se extienda debajo del material que

corte.

está cortando. La proximidad de la hoja con su

mano queda fuera de su vista.

Mantenga las manos alejadas del espacio

que se encuentra entre el casco del equipo

y el portahojas de la sierra. El portahojas de

la sierra alternativa puede prensarle los dedos.

No use hojas sin filo o dañadas. Una hoja

doblada puede romperse fácilmente o causar

un contragolpe.

Antes de comenzar a cortar, "ENCIENDA" la

herramienta y permita que la hoja se

encuentre a toda velocidad.

puede rechinar o vibrar si la velocidad de la hoja

es demasiado lenta al inicio del corte, y posible

mente causar un contragolpe.

Siempre use gafas de seguridad o protección para los ojos cuando use esta herramienta. Use una mascarilla contra el polvo o

un respirador para aquellas aplicaciones que

generen polvo.

La herramienta

Fije el material antes de cortarlo. Nunca lo

sujete en sus manos ni a través de sus piernas.

Los materiales pequeños o delgados se

pueden doblar o vibrar con la hoja, y causar la

pérdida del control.

Asegúrese de que el portahojas esté firmemente ajustado antes de hacer un corte. Un

portahojas suelto puede causar que la herramienta o la hoja se deslice y esto puede dar

como resultado la pérdida del control.

Cuando quite la hoja de la herramienta, evite

el contacto con la piel, y cuando agarre la

hoja o el accesorio use guantes protectores

adecuados. Los accesorios pueden estar

calientes después de su uso prolongado.

ADVERTENCIA

!

esmerilar, taladrar y en otras actividades de

construcción contienen sustancias químicas que se sabe que provocan cáncer,

defectos congénitos y otros daños al sistema reproductor. Algunos ejemplos de

estas sustancias químicas son:

• Plomo de las pinturas a base de plomo.

• Sílice cristalino de tabiques y cemento y de

otros productos de albañilería, y

• Arsénico y cromo de madera químicamente

tratada.

Su riesgo de estar expuesto a estos productos

varía dependiendo de la frecuencia con la que

realice este tipo de trabajo. Para reducir su

exposición a estas sustancias químicas, trabaje

en un área bien ventilada, y con el equipo de

seguridad aprobado, tales como las mascarillas

contra polvo que están especialmente diseñadas para filtrar partículas microscópicas.

Algunos tipos de polvo

que se generan al aserrar,

19

Page 20

0

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 20

SYMBOLS

Importante: Es posible que algunos de los símbolos siguientes se usen en su herramienta. Por favor, estúdielos y

aprenda su significado. La interpretación adecuada de estos símbolos le permitirá utilizar la herramienta mejor y con

más seguridad.

Símbolo Nombre Designación/explicación

V Volt Tensión (potencial)

A Ampere Corriente

Hz Hertz Frecuencia (ciclos por segundo)

W Watt Potencia

kg Kilogramo Peso

min Minuto Tiempo

s Segundo Tiempo

Diámetro Tamaño de las brocas taladradoras,

muelas, etc.,

n

0

.../min Revoluciones o alternación por minuto Revoluciones, golpes, velocidad de

0 Posición "off" (apagado) Velocidad cero, par motor cero...

1, 2, 3, ... Graduaciones del selector Graduaciones de velocidad, par motor o

I, II, III, posición. Un número más alto significa

Velocidad sin carga Velocidad rotacional sin carga

superficie, órbitas, etc., por minuto

mayor velocidadselector settings

Selector infinitamente variable con La velocidad aumenta desde la

apagado graduación de 0

Flecha Acción en la dirección de la flecha

Corriente alterna Tipo o una característica de corriente

Corriente continua Tipo o una característica de corriente

Corriente alterna o continua Tipo o una característica de corriente

Construcción de clase II Designa las herramientas de construcción

con aislamiento doble.

Terminal de toma de tierra Terminal de conexión a tierra

Símbolo de advertencia Alerta al usuario sobre mensajes de

advertencia

Sello RBRCTM de Ni-Cd Designa el programa de reciclaje de baterías

de Ni-Cd

que

Este símbolo indica que esta her

ramienta está catalogada por

Underwriters

Laboratories.

Este símbolo indica que esta

herramienta está catalogada

por la Canadian Standards

Association.

-

Este símbolo

Underwriters Laboratories ha

catalogado esta herramienta

indicando que cumple las normas canadienses.

Este símbolo indica que esta herramienta está catalogada por

Underwriters Laboratories y que

Underwriters Laboratories la ha

catalogado según las normas

indica

Este símbolo

indica que esta

herramienta

cumple con la

norma mexicana

oficial (NOM).

canadienses.

20

Page 21

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 21

FAMILIARÍCESE CON SU SIERRA XPR MULTISAW

Unpacking & Checking Contents

ADVERTENCIA

!

antes de cualquier montaje o ajuste, o

antes de cambiar los accesorios. Tales

medidas preventivas de seguridad

reducen el riesgo de arrancar accidentalmente la herramienta.

Separe todas las piezas sueltas de los materiales de empaque y verifique cada artículo

con la lista de piezas que se encuentra en la

caja, para asegurarse de que tenga todas las

piezas antes de desechar el material de

empaque.

¡IMPORTANTE! Si le falta alguna pieza, o si

requiere asistencia con estas instrucciones,

por favor comuníquese con el Departamento

de Servicio al Consumidor de Dremel™ al

teléfono:

o visite www

Desconecte el enchufe

de la fuente de energía

1-800-437-3635

.Dremel.com.

MONTAJE

Instalación de la sierra en la herramienta rotatoria

1.Quite la tuerca del collarín, el collarín y el

anillo tapa del casco de la herramienta

rotatoria.

NOTA: El anillo tapa del casco se debe

volver a instalar en la herramienta rotatoria

cuando se quite el accesorio XPR

MultiSaw..

2.Instale la tuerca impulsora en el eje de la

herramienta rotatoria.

Tuerca impulsora de

Collarín

Descripción

El accesorio XPR MultiSaw está diseñado

para usarse solamente con la herramienta

rotatoria Dremel™ 400 Series XPR. El accesorio Dremel XPR MultiSaw convierte su her

ramienta rotatoria en una sierra de múltiples

usos que le permitirá hacer cortes rectos y

curvos en una variedad de materiales. Los

patrones de corte espirales ahora se hacen

rápida y fácilmente. Con las hojas de la sierra alternativa vertical puede cortar madera

blanda y dura, madera contrachapada,

metal, PVC, plástico, ¡y mucho más!

Casco

Hoja de la sierra

Placa de soporte

Llave Allen, 2.5 mm (para la

instalación de la hoja)

Ventilas

3. Enrosque la sierra en el casco de la herramienta rotatoria y apriete firmemente

la tuerca de vuelco. La sierra debe estar

colocada de manera que las marcas

Dremel en la herramienta y en la sierra

queden del mismo lado.

NOTA: Asegúrese de alinear las llaves de la

herramienta con las bocallaves de la tuerca

de vuelco.

La tuerca del collarín

uerca de vuelco

T

Tuerca impulsora

Área de agarre

cauchotada

-

Anillo tapa del casco

Tuerca de vuelco

Asegúrese de alinear las llaves de la herramienta con las bocallaves de la tuerca de vuelco.

Selección de la hoja

Dremel recoDremel recomienda el uso de hojas para sierra Dremel XPR. El accesorio

XPR MultiSaw viene con una hoja de sierra para cortes rectos y curvos en madera y

materiales suaves con un espesor de hasta 1-7/16". El accesorio Dremel XPR MultiSaw

acepta todas las hojas de sierra alternativa estándar

, de espiga "T" o de espiga "U".

Ninguna hoja puede ser eficiente para todos los trabajos de corte. Los materiales diferentes

requieren hojas diferentes. Como su sierra puede cortar tantos materiales, asegúrese de

usar la hoja adecuada para el trabajo a fin de asegurar el desempeño adecuado en el corte.

NOTA: En el empaque de la hoja encontrará información sobre el uso recomendado de la

hoja y los materiales.

21

21

Hoja de espiga en "U"

Hoja de espiga en "T"

Page 22

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 22

FAMILIARÍCESE CON SU SIERRA XPR MULTISAW

Instalación de la hoja

ADVERTENCIA

!

energía antes de cambiar la hoja o hacer

ajustes.

1. Introduzca completamente la hoja en la

abertura de la sierra hasta que toque el

fondo de la herramienta.

2. Asegure la hoja en la sierra usando la

llave Allen para apretar el tornillo de

fijación.

NOTA: La hoja se puede montar con los

dientes orientados hacia cualquier dirección.

Desenchufe la herramienta de la fuente de

OPERACIÓN

ADVERTENCIA

!

salidas de aire con la mano. El bloqueo de

las salidas de aire podría causar el calentamiento excesivo del motor..

Velocidades de operación

La velocidad de su sierra es variable de 550

a 3900 SPM (carreras por minuto).

La placa de soporte se inclina a fin de mantener la mayor parte de la superficie en contacto con la superficie de trabajo.

Mantenga la placa de soporte firmemente

colocada contra la pieza de trabajo para minimizar la contrafuerza (saltos) y la vibración.

Cuando sujete la herramienta no cubra las

Placa de soporte

ADVERTENCIA

!

hoja se extienda a través de la placa de

soporte toda la longitud de la carrera. No

use hojas especializadas que sean muy

cortas o aquellas con oblicuidad. La hoja

no debe entrar en contacto con la placa

de soporte. Una hoja demasiado corta u

oblicua podría atascarse en el interior de

la placa de soporte y romperse.

Generalmente los ajustes de mayor velocidad se usan para el corte rápido, o cuando

se cortan materiales más suaves como

madera, materiales compuestos y plásticos.

Los ajustes de velocidad más lentos generalmente se usan cuando se requiere precisión,

o cuando se cortan materiales más duros.

NOTA: Si la herramienta está "masticando"

en lugar de cortar el material, use un ajuste

de velocidad más alto.

Asegúrese de que el

extremo frontal de la

Uso de la sierra

1. Fije firmemente la pieza de trabajo.

2. Marque la línea de corte y sujete la herramienta con una mano en la herramienta rotatoria y la otra mano sujetando firmemente el casco de caucho

aislante de la sierra.

ADVERTENCIA

!

aislada del casco frontal. Si su sierra se

encuentra en un área ciega en donde

exista cableado energizado, puede recibir

una descarga eléctrica o ser electrocutado.

3. Gire la herramienta rotatoria y permita

que la sierra se encuentre a toda velocidad antes de comenzar el corte. Guíe la

sierra para que la hoja se mueva a lo

largo de la línea marcada.

Siempre sujete la sierra

por el área de agarre

22

2222

Page 23

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 23

Sugerencias de corte con la sierra

Unas sugerencias simples reducirán el desgaste de la pieza de trabajo, la herramienta y

el operador.

• Para un corte más rápido, especialmente

en materiales gruesos, haga oscilar la

sierra hacia arriba y hacia abajo para

auxiliar en la remoción de astillas (Figura

A).

• Las hojas cortan durante la extracción o

durante la carrera de reversa. En trabajo

fino tal como empanelado, fibra de vidrio,

etc., coloque el lado bueno de la pieza de

trabajo hacia abajo.

• Use la hoja correcta para el material que

se está cortando y mantenga a la mano

hojas adicionales para que las use cuando las otras pierdan su filo. Reemplace

inmediatamente las hojas fracturadas o

dobladas.

• Para reducir el riesgo de lesiones, siempre asegúrese de que la hoja se extienda

más allá de la placa de soporte y de la

pieza de trabajo a lo largo de toda la carrera (Figuras B y C). Las hojas se

podrían romper si su extremo frontal golpea la pieza de trabajo y/o la placa de

soporte.

B

• Al cortar metal:

- Aplique un lubricante a la hoja para un

corte más fácil, suave y rápido y para

prolongar la vida útil de la hoja.

- Para metales no ferrosos, aluminio,

bronce o latón, use una barra de cera en

la hoja.

- Para materiales ferrosos, hierro y acero,

aplique aceite de corte de máquina a lo

largo de la superficie que va a cortar.

• Cuando corte metal delgado, coloque el

material entre dos trozos de madera

residual. Sujételo con una pinza o con un

tornillo de banco. Se puede usar un trozo

de madera sujetado adecuadamente en

la parte superior del metal. Coloque sus

líneas de corte o diseño en la madera.

• No aplique fuerza en el corte. Deje que la

sierra y la hoja hagan el trabajo.

A

C

Cortes de penetración

La sierra se puede usar para hacer cortes de

penetración en material más suave (madera

suave o materiales de construcción ligeros

para las paredes) sin hacer un orificio de inicio.

1. Marque claramente la línea a cortar en

la superficie de trabajo.

Coloque la herramienta con un borde de

2.

la placa de soporte firmemente coloca

do contra el material (Figura

3.

Coloque la punta de la hoja (sin que

esté funcionando) en la línea a cortar

4. Incline la sierra para que la hoja se sep

are de la pieza de trabajo.

5. Encienda la herramienta rotatoria y con

cuidado ponga en contacto la hoja de la

sierra en movimiento con el material.

A).

.

A

6. Después de que la hoja penetre en la

pieza de trabajo, continúe aserrando a

lo largo de la línea marcada.

A: Para facilitar el corte de penetración

NOT

utilice una hoja de mayor calibre. Instale la

hoja con los dientes orientados hacia arri

-

ba, sujete la hoja con la parte de arriba

hacia abajo, como se muestra (Figura B).

Do not plunge cut in metal surfaces.

No corte por penetración

las superficies de metal.

232323

WARNING

!

B

-

Page 24

Tap a impulsora

Conjunto accionador rotatorio

Lame

Conjunto de la

placa de soporte

Conjunto del accesorio

de penetración

Tor nillos

Conjunto de la

tuerca de vuelco

Llave Allen

DM 2610922740 8-04 S 8/10/04 8:29 AM Page 24

LIMPIEZA

ADVERTENCIA

!

Para evitar accidentes,

siempre desconecte la

herramienta del suministro de energía

antes de limpiarla o darle mantenimiento.

La herramienta se puede limpiar más eficaz

mente con aire comprimido. Siempre use

gafas de seguridad cuando limpie herramientas con aire comprimido.

Las aberturas de ventilación y las palancas del

conmutador se deben mantener limpias y libres

de materiales extraños. No intente limpiarlas

introduciendo objetos puntiagudos a través de

las aberturas.

-

ADVERTENCIA

!

de plástico, por ejemplo, gasolina, tetracloruro de

carbono, agentes de limpieza clorados, amoníaco

y detergentes domésticos que contienen amoníaco.

PIEZAS DE SERVICIO Y DIAGRAMA

Ciertos agentes limpiadores

y solventes dañan las partes

GARANTÍA LIMITADA DE DREMEL™

Su producto Dremel está garantizado contra material defectuoso o fabricación defectuosa durante un período de dos años a partir

de la fecha de compra. En el caso de que un producto no se ajuste a esta garantía escrita, por favor, tome las medidas siguientes:

1. NO devuelva el producto al lugar de compra.