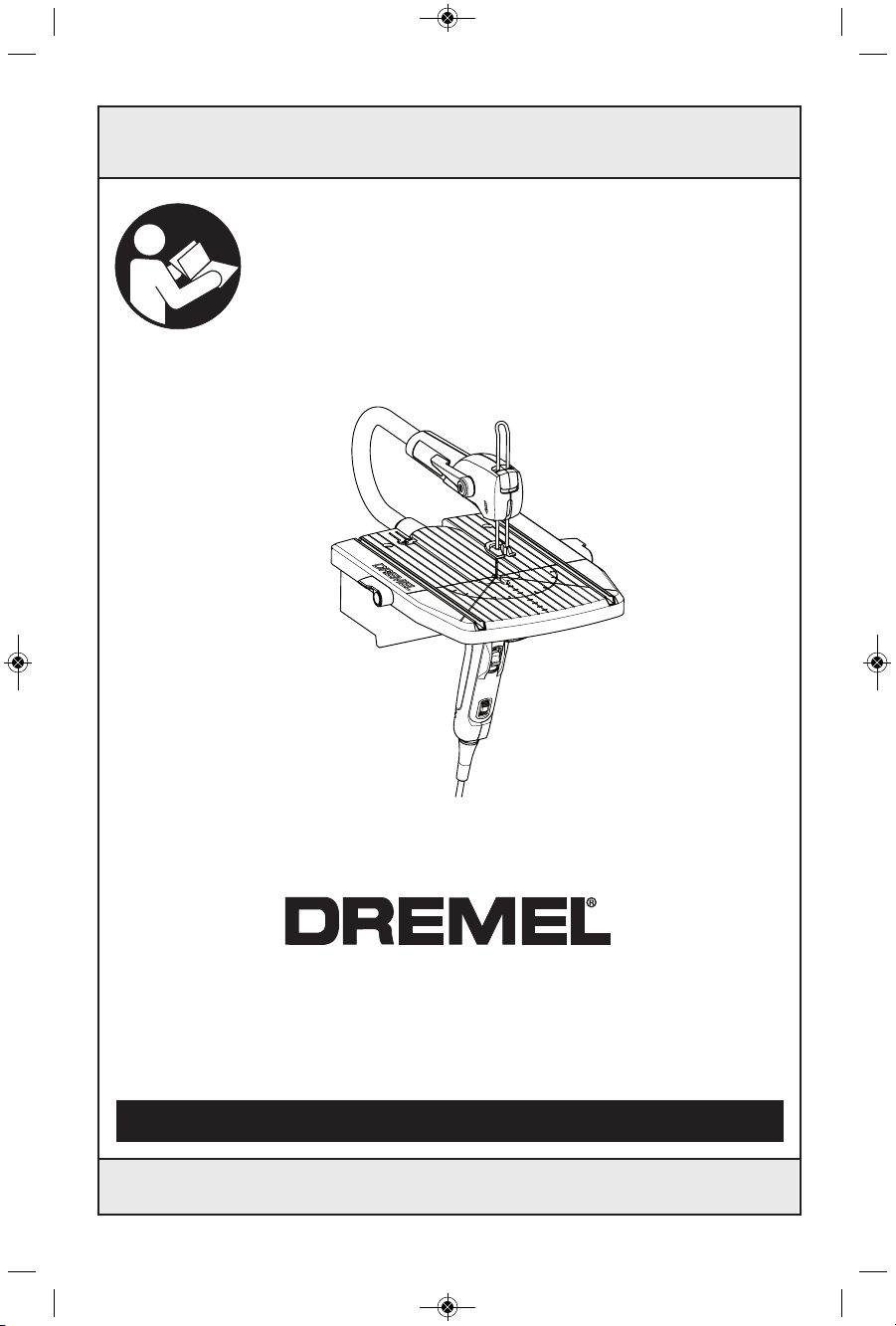

Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

For English Version Version française Versión en español

See page 2 Voir page 20 Ver la página 38

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

1-800-4-DREMEL (1-800-437-3635) www.dremel.com

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

P.O. Box 081126 Racine, WI 53408-1126

MS20

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 1

Page 2

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapter pl ug s w ith earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating the power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

a GFCI reduce the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e co mmon s ense when opera ting a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in the off- posit ion befo re

connecting to power source and / or battery

pa ck, picking up or carryi ng t he t ool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a key

left attached to a rotating part of the power

tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co ntrol of the power to ol in unexpe ct ed

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not force the power tool. Use the correct

power tool for your application. The correct

power tool will do the job better and safer at

the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca nn ot be co nt ro lled with the swi tc h is

dangerous and must be repaired.

2

Read all safety warnings and instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

!

WARNING

General Power Tool Safety Warnings

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 2

Page 3

3

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma ny acci de nt s a re ca us ed by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

re pa ir person using o nl y id en ti cal

replacement parts. This will ensure that the

safety of the power tool is maintained.

Safety Rules for Coping Saw

Hold po wer tool by insulated gripp ing

surfaces, when performing an operation

where the cutting accessory may contact

hidden wiring or i ts own cord. C utt ing

accessory contacting a "live" wire may make

exposed metal parts of the power tool "live"

and could give the operator an electric shock.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand

or against your body leaves it unstable and

may lead to loss of control.

Never leave the switch in "ON" position.

Before plugging the tool in, check that the

switches are "OFF". Accidental start-ups

could cause injury.

Keep hands away from cutting area. Do

not reach under the material being cut.

The proximity of the blade to your hand may

be hidden from your sight.

Keep hands away from the space between

the gear housing and saw blade holder.

The reciprocating blade holder can pinch

your fingers.

Use only Dremel Moto-Saw blades. Use

the right blade size, style and cutting

speed for the material and the type of cut.

Using the proper blade minimizes the risk of

breakage.

Do not use dull or damaged blades. Dull

blades can bend and break easily potentially

striking the operator.

Before starting to cut, turn tool "ON" and

allow the blade to come to full speed. Tool

can chatter or vibrate if blade speed is too

slow at beginning of cut and may cause a

loss of control.

Make certain all adjusting screws and the

blade holder are tight before making a

cut. Loose adjusting screws and holders can

cause the tool or blade to slip and loss of

control may result.

When removing the blade from the tool

avoid contact with skin and use proper

pr ot ec ti ve gloves when graspin g the

blade or accessory. Accessories may be

hot after prolonged use and present a burn

hazard.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 3

Page 4

4

Safety Rules for the Saw Station

Never leave tool running unattended. Turn

power off. Don't leave tool until it comes to a

complete stop.

Never leave the switch in "ON" position.

Before plugging the tool in, check that the

switches are "OFF". Accidental start-ups

may cause injury.

Av oi d awk wa rd op er at io ns an d h an d

positions and always make sure you have

good balance. A sudden slip could cause

your hand to move into the blade.

Firmly clamp or bolt your saw station to a

stable, level workbench or table. The most

comfortable table height is approximately

waist height.

Never stand on tool. Injury may occur if the

tool is tipped or if the blade is unintentionally

contacted.

Before m aking a cut, be s ur e all

adjustments are secure. Loose table or

guards could shift in use and cause you to

lose control of the workpiece.

Always adjust drop foot to just clear the

workpiece. Proper adjustment of the drop

foot will stabilize the workpiece, help protect

your fingers, and minimize blade breakage.

Always support large workpieces while

cutting to minimize risk of blade pinching

and loss of control. A heavy workpiece may

cause the table to slip, walk or slide while

cutting.

Be sure the blade path is free of nails.

Inspect for and remove nails from lumber or

workpiece before cutting or sanding.

Keep hands away from cutting area. Do

not hand-hold pieces so small that your

fingers go under the drop foot. Do not

reach underneath work or in blade cutting

path with your hands and fingers for any

reason. Close hand proximity to the blade

may result in blade contact and injury.

Never start the tool when the blade is in

contact with the wor kpi ece. Al low the

motor to come up to full speed before

starting a cut. Having the blade in contact

with the workpiece on start up may cause

loss of control.

Observe and follow correct direction of

feed and do not feed the mat erial too

quickly. Hold the work firmly against the

table. Feed work into a blade against the

teeth of t he b lade. Feedin g ma terial too

forcefully may cause blade to break.

Use caution when cutting materials with

an irregular cross-section or rounds like

dowel rods. If possible lay the material on

its "flat" side when cutting. For r ound

stock use a "Vee" block to support the

material. Wavy material like mo lding will

tend to rock and may bind whi le cutt ing .

Rounds will tend to roll while being cut and

the blade may "bite" and grab it from your

control.

Do not remove jammed cutoff pieces until

blade has stopped. Never touch blade or

other moving parts during use. Contacting

the blade or other moving mechanism may

cause injury.

Use base only with the Dremel Moto-Saw.

Other tools may not fit and c au se a

hazardous condition.

Position vacuum hoses such that you do

no t bl ock th e po wer sw itch. You must

maintain clear access to the ON/OFF switch

for full control.

When connecting tool to dust collection

and extraction systems, be sure these are

connected and used according to tool and

vacuum instructions. Proper use of dust

collection systems maximizes effectiveness.

When using tool with dust collection and

extract io n sys te ms , empty the dust

contain er before b eg inning w or k,

frequently during work, after completion

of work, and before storing the tool. Use

care when disposing dust, materials in fine

particle form may be explosive.

Do not throw dust on an open fire. Fine

dust particles may burn explosively.

Do not use dust extraction for operations

that i nc lude b ur ni ng, s mo king o r

smolder in g i te ms like hot ashe s o r

sparks. Fire inside the vacuum bag/tank may

occur. Dust may smolder and set vacuum on

fire long after work is completed.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 4

Page 5

5

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleani ng a tool be

careful not to disassemble any portion of

th e tool since inter nal wires may be

misplaced or pinched or safety guard return

sp rings ma y be impro perly mo unted .

Certain cleaning agents such as gasoline,

carbon tetrachloride, a mmo nia, etc. ma y

damage plastic parts.

The product must only be serviced by a

Bosch Factory Service Center or Authorized

Bosch Service Station. This product does not

contain user serviceable parts other than those

addressed in this manual.

Some du st created by

power sandin g, sawing,

grinding, drilling, and other construction

activities contains chemicals known to

ca use can cer, b ir th defec ts or other

reproductive harm. Some examples of

these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chro mium fro m chemic ally-

treated lumber.

You r ris k from these exposu re s varies,

depending on how often you do this type of

work. To reduce your expos ure to t hese

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Additional Safety Warnings

!

WARNING

Do not use dust extraction with explosive

dusts, varnish, polyurethane coatings,

cleaners, or oil-based paints. The electrical

vacuum and tool components may create

sparks which may ignite dust or fumes.

Do not use dust extraction when working

on metal. Particles from sanding, grinding or

cutting metal m ay be hot and may spark

which may melt plastic adaptors, vacuum

ho se s, and may caus e a fire ins id e the

vacuum bag/tank.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 5

Page 6

6

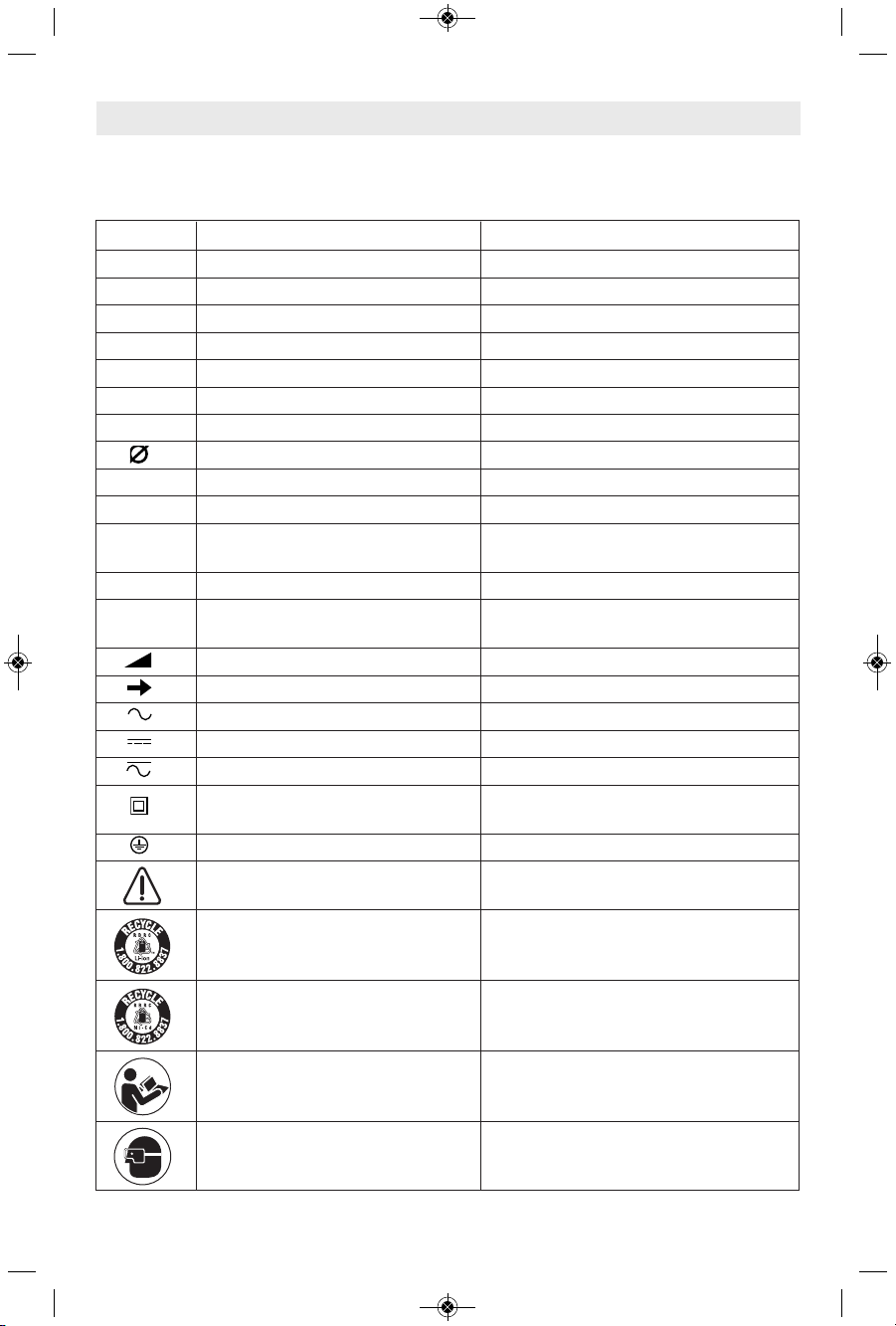

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

No load speed Rotational speed, at no load

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

per minute orbits etc. per minute

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

Symbols

0

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 6

Page 7

7

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this component is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 7

Page 8

8

Di sc onnect the plug fro m the pow er source bef ore maki ng any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

!

WARNING

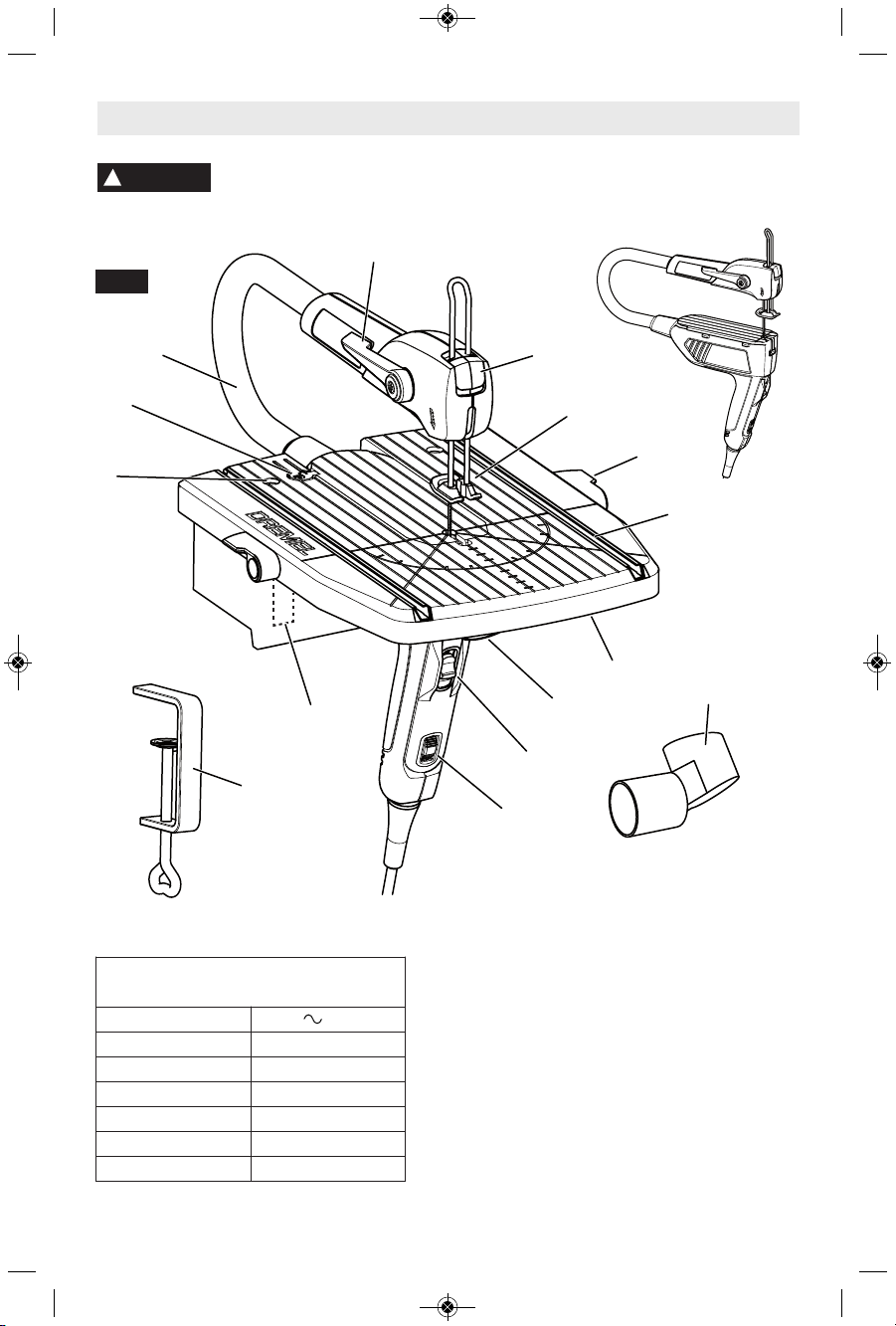

Functional Description and Specifications

A. Hold-Down Foot Release Button

B. Hold-Down Foot

C. Fence Lock Lever

D. Guide Rail

E. Base

F. Vacuum-Cleaner Connection

G. On/Off Switch

H. Speed Dial Switch

I. Securing Clamps

J. Clamp Slot

K. Permanent Fixing Hole

L. Quick Release Button

M. Moto-Saw

N. Accessory Quick Change Lever

O. Vacuum Dust Adapter

A

B

C

E

F

G

I

H

N

L

K

M

D

J

O

FIG. 1

Dremel Moto-Saw 2-in-1

Compact Scroll Saw MS20

Voltage Rating 120V 60Hz

Amps 0.6A

No load speed 1500 - 2250

Throat Depth 9.84 inches

Stroke Length .31 inches

Weight 2.4 pounds

Blade Length 3.8 inches

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 8

Page 9

Disconnect the plug from

the pow er source before

making any assembly, adjustments or

changi ng accessories . Such preventive

safety measures reduce the risk of starting

the tool accidentally.

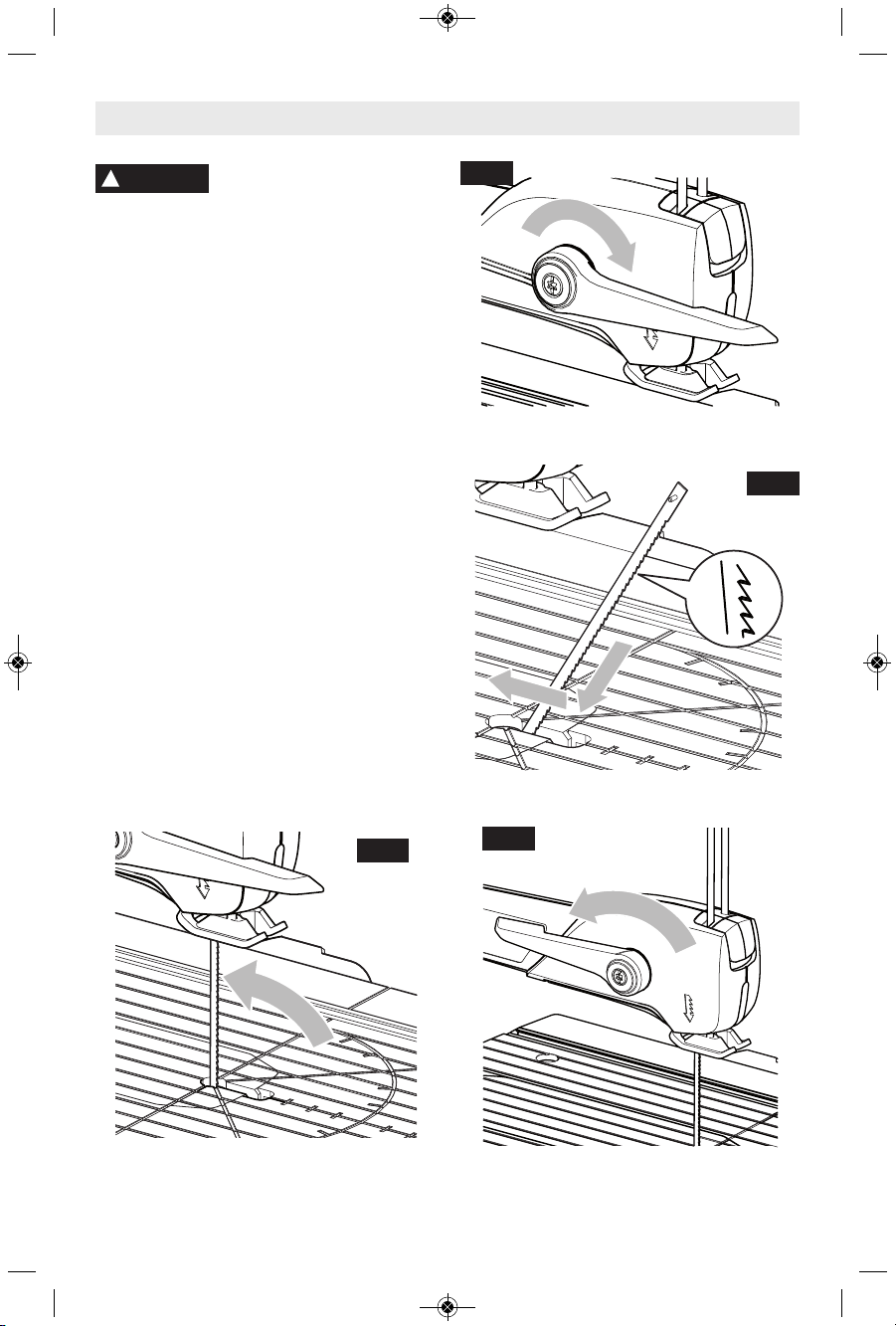

Attaching Blade onto Moto-Saw

1. When fa cing f ro nt of too l, pull q ui ck

ch an ge le ve r towards yo ur se lf to th e

loosened position, Fig. 2.

2. Place bottom pin end of saw blade into

bottom corner of lower accessory holding

area. The blade teeth must be pointing

down, Fig. 3.

3. Place top pin end of saw blade into top

accessory holding area of tool by pivoting

it forward into top holding area of tool,

Fig. 4.

4. Push quick change lever away from you to

tighten ed pos it io n to s ec ure blade,

Fig. 5.

To remove the accessory, reverse the above

steps.

9

Assembly

!

WARNING

7

FIG. 2

FIG. 3

FIG. 4

FIG. 5

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 9

Page 10

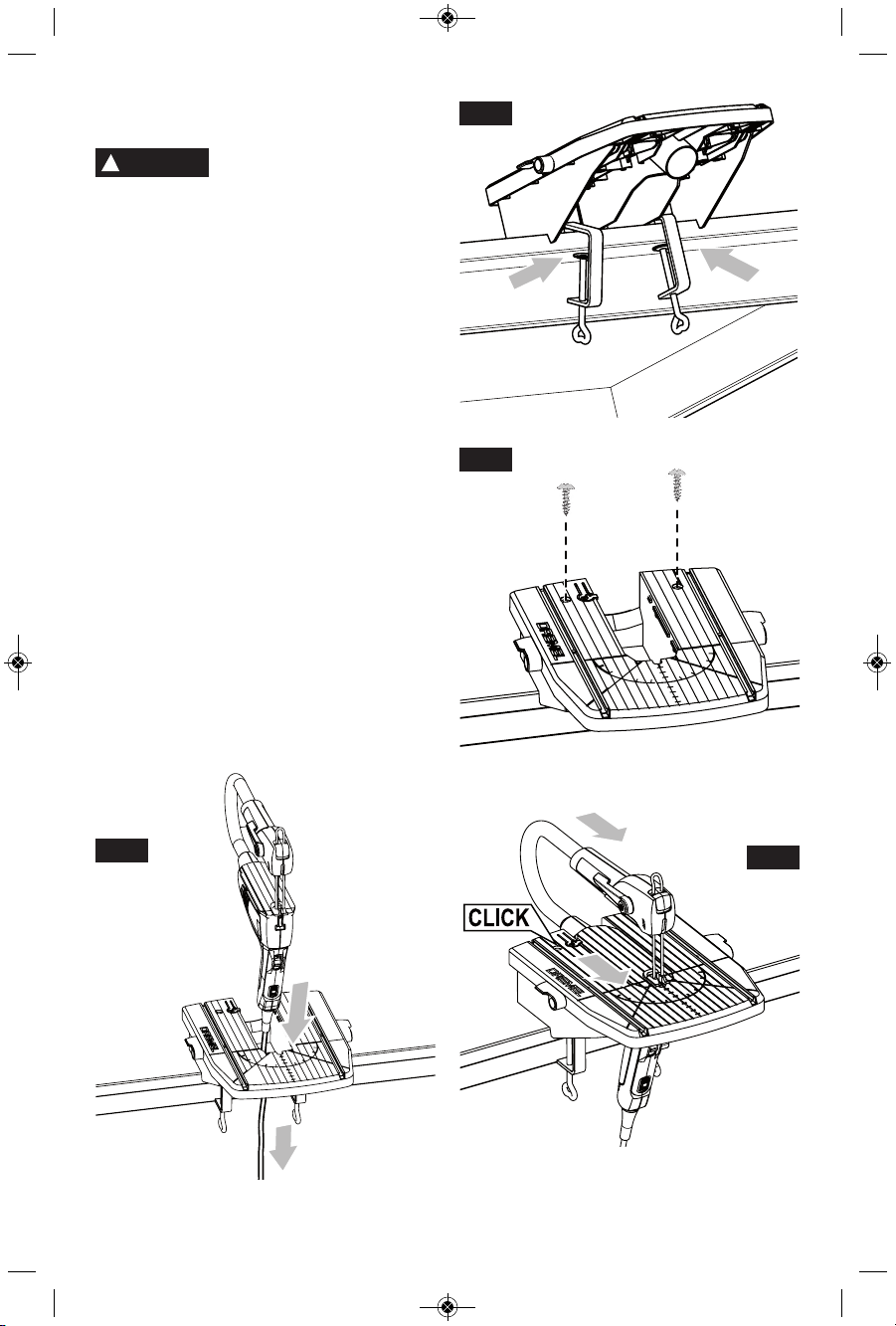

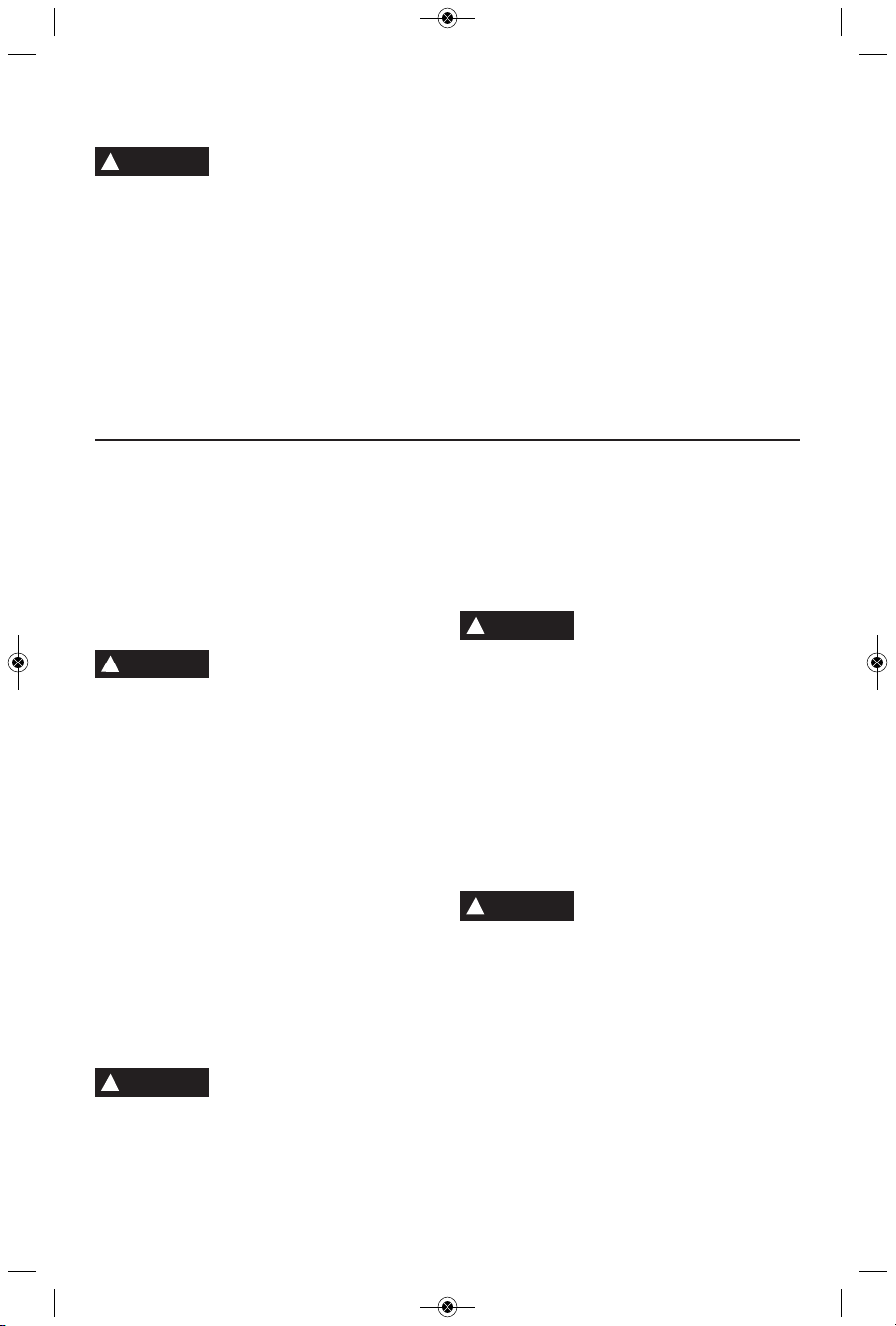

Assembling Base Station for

Stationary Use

Disconnect the plug from

the pow er source before

making any assembly, adjustments or

changi ng accessories . Such preventive

safety measures reduce the risk of starting

the tool accidentally.

Mount the Base Station to a flat working

surface of a comfortable height. Insure that

the working surface is of a thickness that can

accept the clamps and/or mounting screws.

Mounting the Base Station to an unstable

surface can invite an accident.

1. Position the saw station at the front edge

of the flat work surface the saw station will

be clamped to.

2. Unthread the provided clamps to ensure

they will be a ble to c lamp to the work

surface. Slide the flat edge of the clamp

in to the slot in the botto m of th e saw

station and tighten the clamp to prevent

the saw station from shifting during use,

Fig. 6.

The base can be permanently secured to a

work bench with regular screws through

the two holes located on the top of the

base, Fig. 7.

3. Feed the Moto-Saw cord through the hole

in the center of the base, Fig. 8.

4. Lower the Moto-Saw to the saw station

surface then push forward until it clicks

into the locked position, Fig. 9.

10

FIG. 6

FIG. 8

FIG. 9

FIG. 7

!

WARNING

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 10

Page 11

11

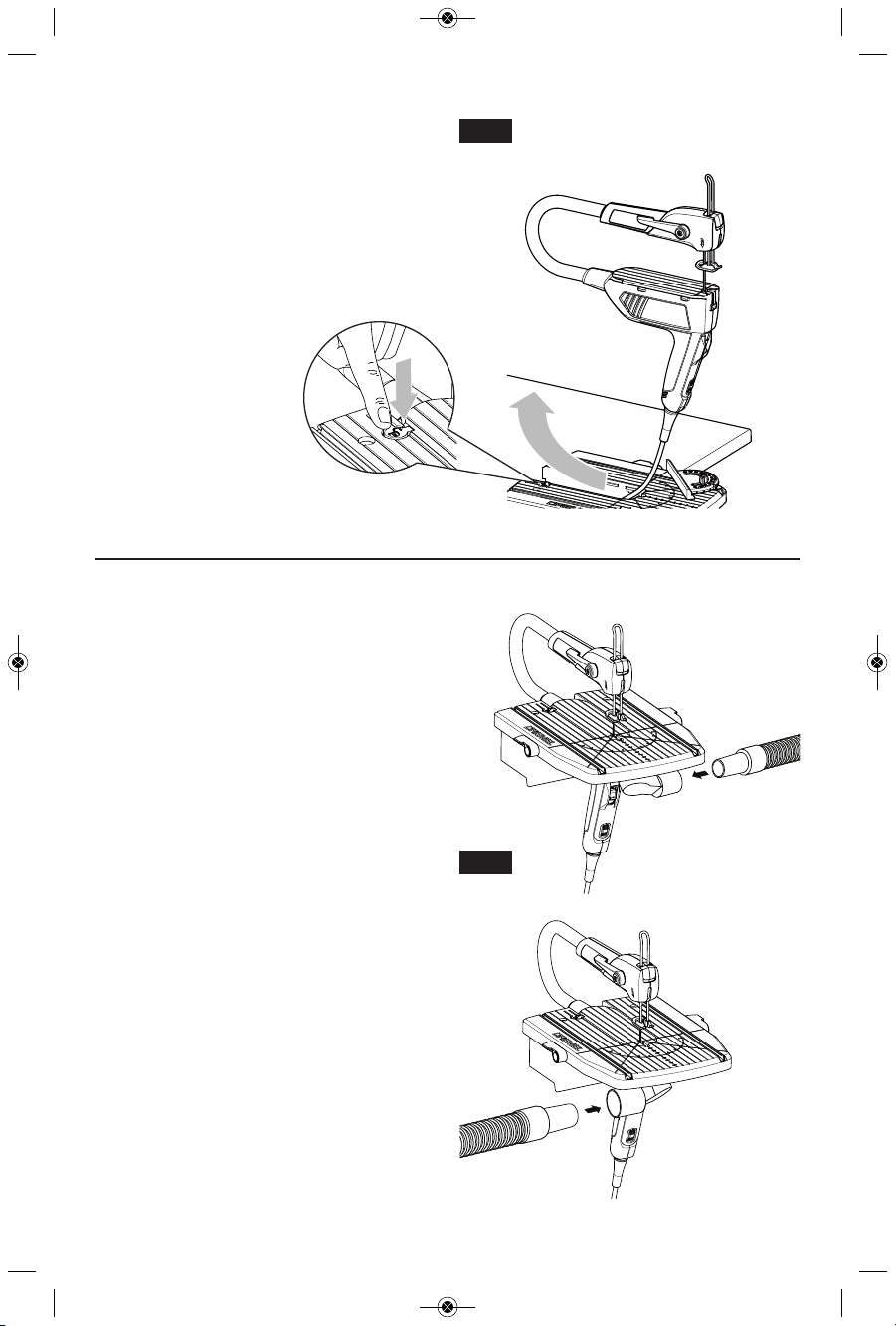

To remove the Moto-Saw for

hand held use

1. Unplug the Moto-Saw.

2. Press the release lock release button at

the rear of the saw station work surface.

3. Slide the Moto-Saw back to release from

the lock mechanism.

4. Pull the Moto-Saw up from the saw station

and pull the cord through the saw station.

Installing Dust Extraction

When connecting tool to dust collection and

extract io n sy st ems, be su re the se are

connected and used according to tool and

vacuu m in structions. Pro per use of dust

collection systems maximizes effectiveness.

Do not use dust extraction when working on

metal. Particles from sanding, grinding or

cutting metal m ay be hot and may spark

which may melt plastic adaptors, vacuum

ho se s, and may caus e a fire ins id e the

vacuum bag/tank.

Position vacuum hoses such that you do not

block the power switch. You must maintain

clear access to the ON/OFF switch for full

control.

Your Moto-Sa w incl udes a vacuu m dust

adapter. The adaptor can be used to connect

the vacuum hose to either the left or the right

side of the tool, Fig. 11.

The outside of the adaptor can be used to

connect 1 5/ 8 in. and the in side of th e

adapter can be used to connect 1 3/8 in.

1. Attach dust extraction adaptor onto saw

station.

2. Attach vacuum hose to vacuum adaptor.

To remove, reverse instructions.

FIG. 10

FIG. 11

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 11

Page 12

12

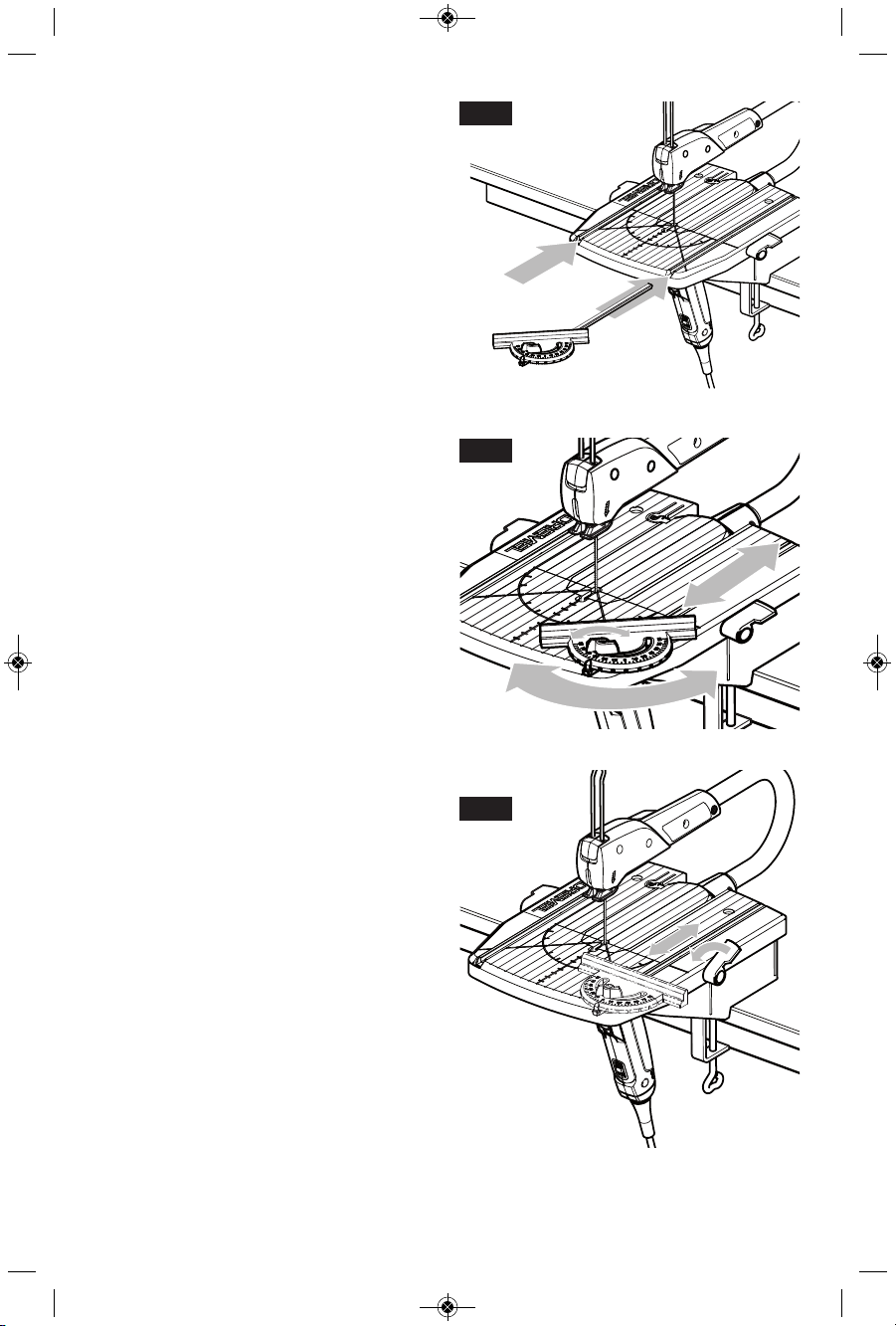

Installing Fence / Miter Gauge

(Optional Accessory)

Your Moto-Saw can use a combination fence

and miter gauge.

For use as a miter gauge:

1. To use the miter gauge slide the metal T

section into the track in the surface of the

saw station, Fig. 12.

2. Twist t he knob o n the miter ga ug e to

adjust the angle of the miter gauge and

tighten at the desired angle, Fig. 13.

For use as a fence:

1. Inst al l the m it er gauge as de sc ribed

above.

2. Adjust the miter angle to 90° then slide the

miter gauge to the desired fence position,

Fig. 14.

3. Rotate the blue lever on the side of the

saw station forward to lock.

To remove, reverse procedure.

FIG. 12

FIG. 13

FIG. 14

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 12

Page 13

13

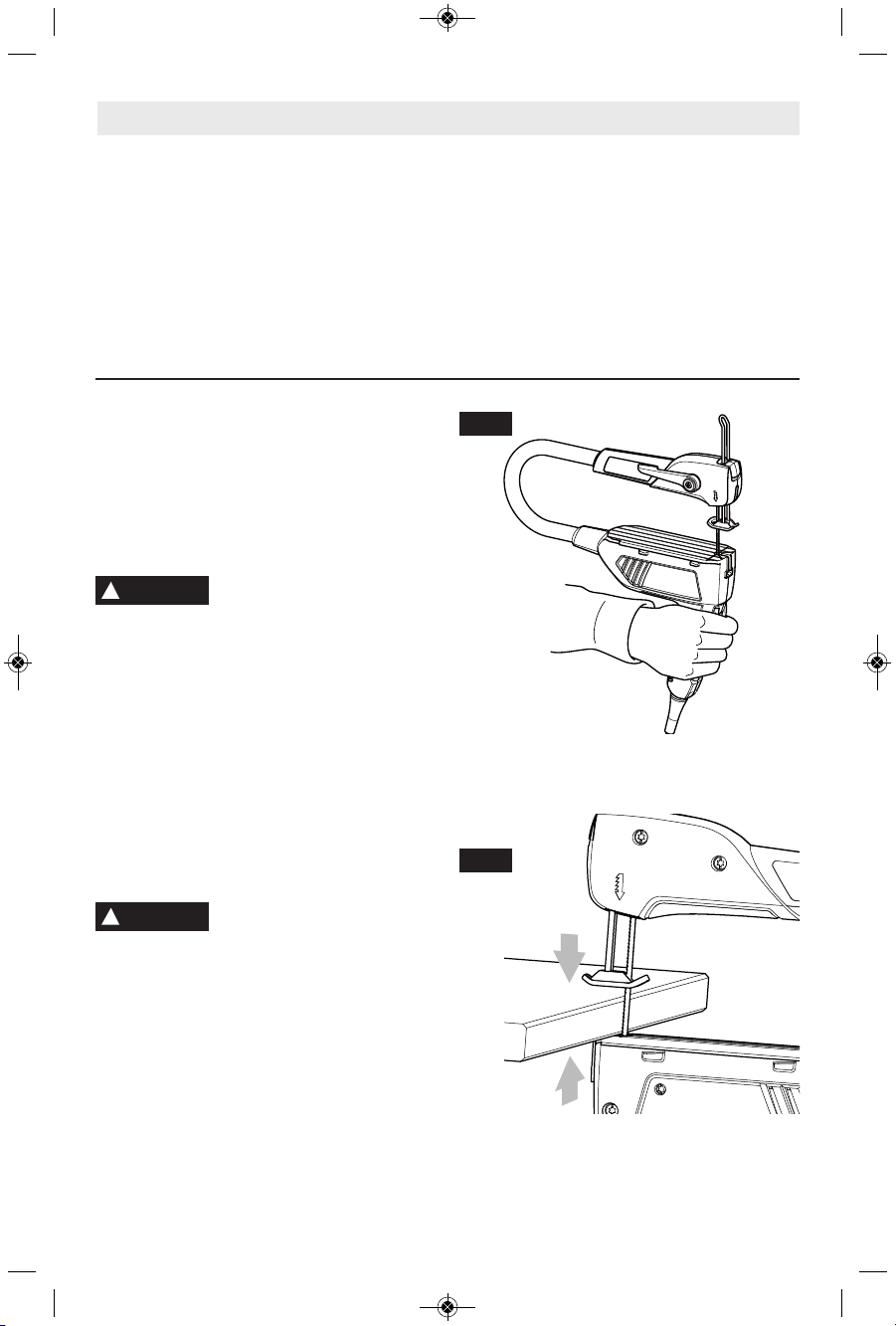

Operation - Hand-Held Mode

Using the Moto-Saw in hand-held mode is

advised when the work piece is too big or

fixed and therefore cannot be put onto and

maneuvered about the base. Typical handheld operation includes coping or shaping

large wood workpieces. Do not cut materials

other than wood in hand held mode.

Never leave the switch in

"ON" pos it io n. Before

pluggin g th e to ol i n, check that the

switches are "OFF". Accidental start-ups

may cause injury.

1. Grasp the Moto-Saw as shown in Fig. 15.

2. Adjust the variable speed dial based on

the blade and material you are going to

cut. You can refer to the chart on page 18

to determine the proper speed. This chart

en ab le you to select bot h the correct

accessory and the optimum speed at a

glance.

3. With the work securely clamped take the

tool the work and adjust the hold down foot

so that it rests on the workpiece, Fig. 16.

Never start the tool when

the blade is in contact with

the workpiece. Allow the motor to come

up to fu ll speed be for e starting a cut.

Having th e blade in c ontact wi th t he

workpiece o n start up may cause loss of

control.

4. Turn the tool ON and let the tool come up

to speed before contacting the work piece.

The too l is switched "ON" by the slide

sw itch loca ted on the front of pri mary

handle.

TO TURN THE TOOL "ON", sli de the

switch button up.

!

WARNING

!

WARNING

FIG. 15

FIG. 16

Operating Instructions

The Moto-Saw is a compact and very easy to

use 2-in-1 scroll saw. It can be used either in

stationary mode, when the tool is docked in

its base or in hand-held mode. This tool is

intended to pe rfo rm precise str aig ht and

curved cuts in different materials including

soft wood, hard wood, composite boards,

laminate, PVC or soft sheet metal using the

applicable ac ces sor ies recommended by

Dremel.

The teeth of this tool only cut on the down

stroke. The work must be fed into the saw

blade very slowly becau se the teeth are

small and can remove only small amounts of

material on each stroke. Trying to cut too

fast will bend or break the blade.

To get most accurate cuts, compensate for

the blades tendency to follow the wood grain

as you are cutting.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 13

Page 14

14

Stationary Mode

Using the Moto-Saw in stationary mode gives

yo u the freedom to cut w ith bo th han ds

holding your work piece. In this mode you

can co mp lete differ en t ho bb y or woo d

working projects by precisely cutting wood,

plast ic a nd t hin metal workpi eces easily

when using the correct blade.

Never leave the switch in

"ON" pos it io n. Before

pluggin g th e to ol i n, check that the

switches are "OFF". Accidental start-ups

could cause injury.

1. Make sure the base is securely attached to

a flat work surface with the help of the

clamps provided or secured with screws.

2. Adjust the variable speed dial based on

the blade and material you are going to

cut. You can refer to the chart on page 18

to determine the proper speed. This chart

en ab le you to select bot h the correct

accessory and the optimum speed at a

glance. In order to reduce vibrations when

cutting pla stics and sheet metal, place

your workpi ec e on top of a piece of

cardboard as a dampener. Cut through

both materials for a cleaner, more accurate

cut.

3. Take the work piece to the tool.

Keep ha nds awa y from

cutting area. Do not handhold pieces so small that your fingers go

under the drop foot. D o not re ac h

underneath work or in blade cutting path

with your han ds an d fingers for an y

reason. Close hand proximity to the blade

may result in blade contact and injury.

4. Press down the hold down foot onto your

work piece to prevent it from bouncing.

Never start the tool when

the blade is in contact with

the workpiece. Allow the motor to come

up to fu ll speed be for e starting a cut.

Having th e blade in c ontact wi th t he

workpiece o n start up may cause loss of

control.

5. Turn the tool ON and let the tool come up

to speed before contacting the work piece.

The too l is switched "ON" by the slide

sw itch loca ted on the front of pri mary

handle.

TO TURN THE TOOL "ON", sli de the

switch button up.

Do not force the saw into

and through the

workpie ce . Cut accura cy ma y b e

compromised and the blade may break from

excessive force.

6. When th e cut i s complete , move th e

trailing edge of the workpiece beyond the

hold down foot and turn the switch to OFF.

TO TURN THE TOOL "OFF", s lide the

switch button down.

!

WARNING

!

WARNING

!

WARNING

!

WARNING

5. Slowly feed the workpiece into the blade

while guiding the cut.

Do not force the saw into

and thr ou gh the

workpie ce . Cut accura cy ma y b e

compromised and the blade may break from

excessive force.

6. When the cut is complete, move the tool

and blade clear of the workpiece and turn

the switch to OFF.

TO TURN THE TOOL "OFF", s lide the

switch button down.

!

WARNING

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 14

Page 15

15

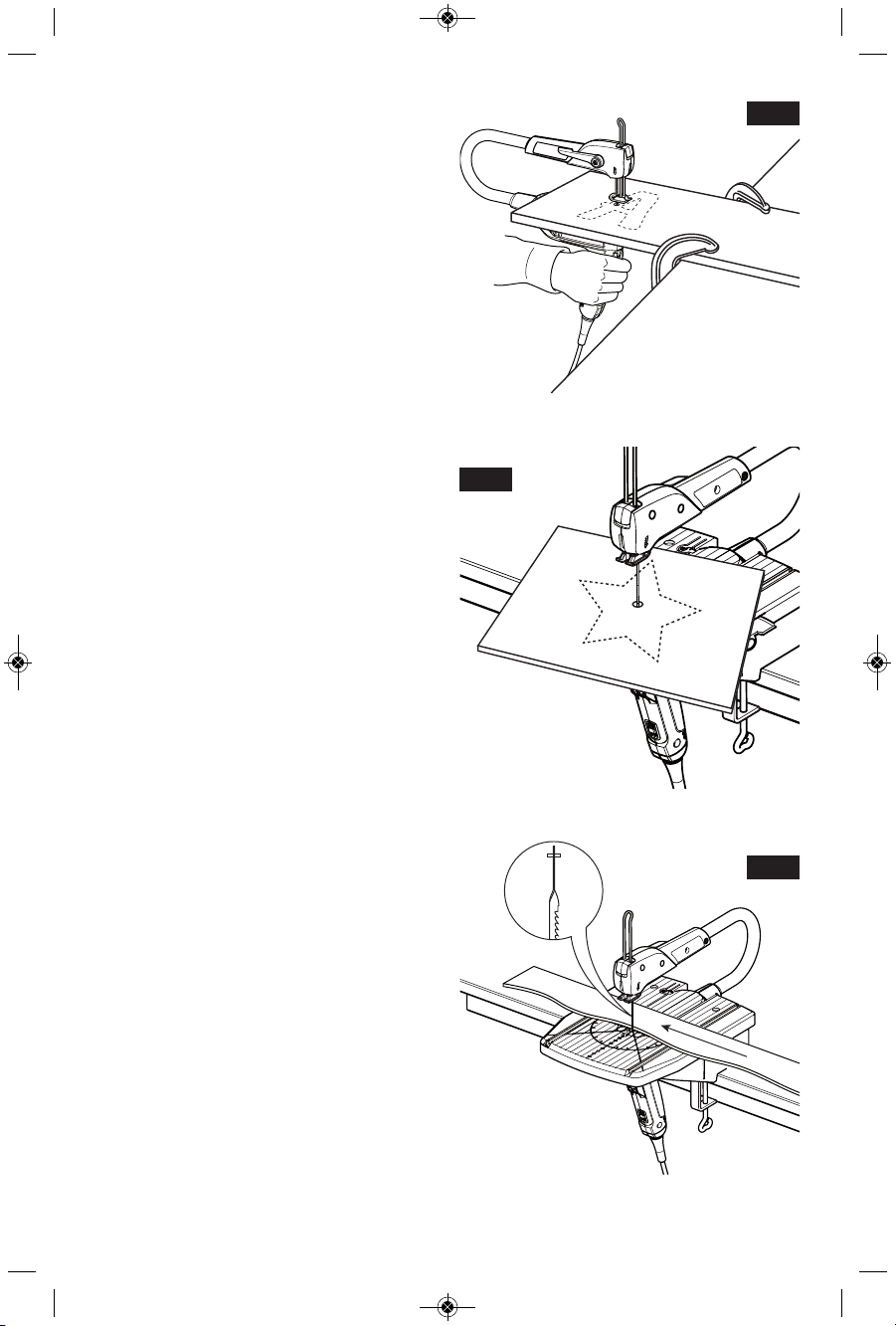

Interior Cutting – Hand-Held Mode

1. Lay-out the design of the workpiece. Drill a

¼“ hole into the workpiece.

2. Remove the blade from the saw. Refer to

the section “Attaching Blade onto MotoSaw.”

3. Refer to the section “Attaching Blade onto

Moto-Saw” and reinstall the blade through

the hole in the workpiece.

4. Foll ow steps three through five i n

“Operation – Hand-Held Mode.”

5. When cutting is co mplete, refer to t he

section ““Attaching Blade onto Moto-Saw”

to remov e the saw bla de to free the

workpiece.

Interior Cutting – Stationary Mode

1. Lay-out the design of the workpiece. Drill a

¼“ hole into the workpiece.

2. Remove the blade from the saw. Refer to

the section “Attaching Blade onto MotoSaw.”

3. Place the workpiece on the saw table with

the hole in the workpiece over the access

hole in the table.

4. Refer to the section “Attaching Blade onto

Moto-Saw” and reinstall the blade through

the hole in the workpiece.

5. Follow the steps in “Operation – Stationary

Mode.”

6. When cutting is co mplete, refer to t he

section “Attaching Blade onto Moto-Saw”

to remov e the saw bla de to free the

workpiece.

Side Cutting

Using the Moto-Saw with a side cutting blade

allows you to make cuts from left to right or

right to l ef t a cross the tool. In t hi s

configuration you have the ability to work with

longer pieces of wood and plastic materials

that may be too large for cutting in a front-toback direction as material will not strike the

back of the tool. Do not side cut metal.

1. Refer to the section “Attaching Blade onto

Mo to -S aw” and i ns ta ll the MS 50 side

cutting blade to the Moto-Saw.

2. Follow the steps in “Operation – Hand

Held Mod e” fo r side cu tt in g wood or

“Operation – Stationary Mode” for side

cutting wood and plastic.

FIG. 18

FIG. 19

FIG. 17

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 15

Page 16

16

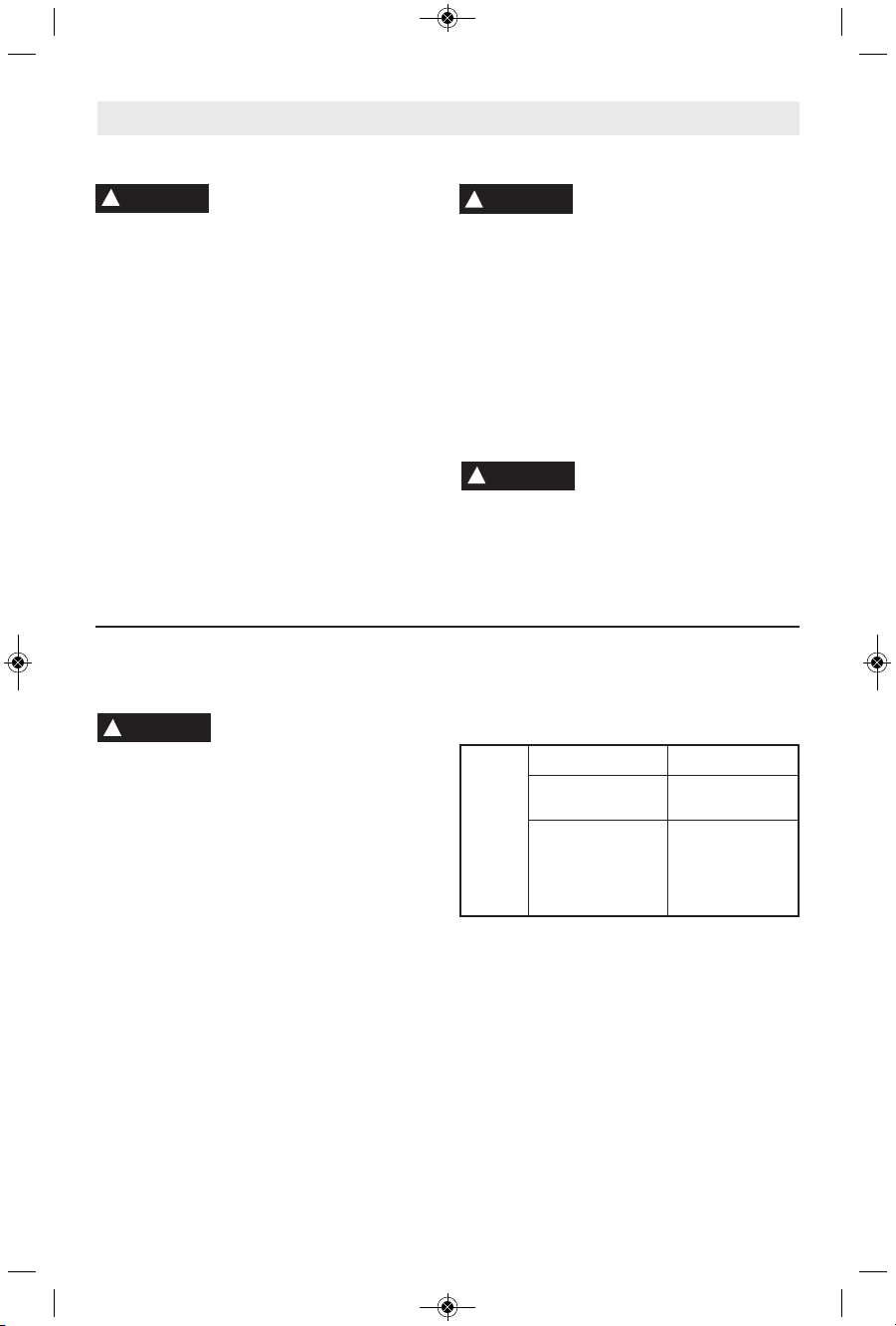

Extension Cords

If an exten si on cord is

ne ce ss ary, a cord with

adequate size conductors that is capable

of carrying the current necessary for your

to ol mu st be used. This will pr ev en t

excess ive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

heav i er the cord.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

Cord Size in A.W.G.

Wire Sizes in mm

2

2-6

6-8

8-10

10-12

12-16

18 16 16 14 0.75 0.75 1.5 2.5

18 16 14 12 0.75 1.0 2.5 4.0

18 16 14 12 0.75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 —— ————

25 50 100 150 15 30 60 120

Cord Length in Feet Cord Length in Meters

Maintenance Information

Service

Disconnect the plug from

the power source and/or

the battery pack from the power tool before

ma king an y adju st ments, changi ng

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

The product must only be serviced by a

Dr emel Factory Se rvice Center. This

product does not contain user serviceable

parts other than t hos e addre ssed in this

manual.

Cleaning

Disconnect the plug from

the power source and/or the

battery pack from the power tool before

ma king an y adjust ments, changi ng

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

The tool may be cleaned most effectively with

compressed dry air. Always wear safety

go ggles when cleani ng tool s with

compressed air. Ventilation openings and

switch levers must be kept clean and free of

foreign matter. Do not attempt to clean by

inserting pointed objects through openings.

Ce rtain clean ing ag ents

an d sol ve nts da ma ge

plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning

solvents, ammonia and house hold detergents

that contain ammonia.

WARNING

!

!

WARNING

CAUTION

!

!

WARNING

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 16

Page 17

17

Moto-Saw Accessories

Use only Dremel Moto-Saw blades. Use the right blade size, style and

cutting speed for the material and the type of cut. Using the proper blade

minimizes the risk of breakage.

!

WARNING

Teeth on Mo to-Saw b lades wear out and

must be replaced frequently for best cutting

results.

Moto-Saw blades are intended to stay sharp

for ½ hour to 2 hours of cutting.

Blade life depends on the material being cut,

thickness, blade type and the user.

Users can shorten the life of the blade by

pushing too hard when cutting.

Moto-Saw Blades

MS51 General Wood & Plastic Blade

In tended f or makin g straig ht and la rger

diameter curved cuts in materials such as

soft wood, laminate and plastics.

MS52 Fine Wood Cutting Blade

Inten ded for mak ng s traight and smaller

diameter intricate curved cuts in materials

such as soft wood, laminate and plastics.

MS53 Metal Cutting Blade

Intended for making straight and curved cuts

in soft sheet metal.

MS50 Side Cutting Blade

Intended for making long straight and curved

cuts in larger pieces of soft wood and plastic

materials.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 17

Page 18

18

Scroll Saw/Moto-Saw Tips

• Three things will have great effect on the

cut when using a scroll type saw:

1. The material being cut.

2. Blade speed (strokes per minute blade).

3. C uttin g sp eed (how f ast mater ial is

pushed into blade).

• There is not ONE blade that is the best for

every given job.

• A coarse blade should be used for thicker

ma te rial and a finer bla de for thin ne r

materia l. T he t hi nn er the bl ad e, the

sharper the turn it can execute.

• There should always be 3 to 4 teeth in

contact with the work at all times.

• C ut ting h ar d ma te ri al like metal and

material th at can melt, like acrylic, will

generally require slower speed on the tool

and a lower feed rate.

• The best starting point on any cut is at a

point or corner because you can control

the intersection of the cut and make it as

smooth as it needs to be.

• Certain actions will require practice – like

cutting a corner or a 180° turn.

• Saws that scroll can present a challenge

when attempting a straight cut. With some

practic e, i t’s ea sy to do. P ractice

compensating for the grain by turning the

material slightly to stay on a straight line.

Once the degree of comp en sa ti on is

determined for any material, being able to

then cut a straight line will only be a matter

of blade selection, speed, and feed rate.

• If a blade seems to be cutting slowly or

se em s to wander wi th little mea ns of

control, chances are the blade is becoming

dull. The re’s no sub stitute for a sha rp

blade. Wood and metal will both dull a

blade quickly. If a lot of cutting is being

completed, change your blade as often as

necessary.

Material

Tool

Speed

Recommended

Thickness

MS51 Wood

& Plastic

Blade

MS52 Fine

Wood

Blade

MS53

Metal

Blade

MS50 Side

Cutting

Blade

Wood

Plywood 6 .75” x x x

Pine 6 .75” x x x

Poplar 6 .75” x x x

Balsa 6 1.75” x x x

Laminate Flooring 6 .5” x x x

Metal

HVAC 6 20-ga. x

TIN 6 20-ga. x

AL sheet 6 20-ga. x

Gal. Sheet Metal 6 20-ga. x

Plastic

Plexiglass 4 .2” x x x

PVC Pipe 4 .75” x x x

Speed Settings

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 18

Page 19

19

Your Dremel product is warranted against defective material or workmanship for a period of two years from

date of purchase. In the event of a failure of a product to conform to this written warranty, please take the

following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES CANADA

Dremel Service Center Giles Tool Agency

4915 21st Street OR 47 Granger Av.

Racine, WI 53406 Canada M1K 3K9 1-416-287-3000

OUTSIDE CONTINENTAL UNITED STATES CONTINENTAL UNITED STATES

See your local distributor or write to Dremel, 4915 21st Street Racine, WI 53406

We recommend that the package be insured against loss or in transit damage for which we cannot be

responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING

FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS,

UNAPPROVED ATTACHMENTS OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR

WORKMANSHIP ARE NOT COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel. If

Dremel inspection shows that the problem was caused by problems with material or workman ship within the

limitations of the warranty, Dremel will repair or replace the product free of charge and return product

prepaid. Repairs made necessary by normal wear or abuse, or repair for product outside the warranty period,

if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH

EXCEED THE ABOVE MENTIONED OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED

FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to

state. The obligation of the warrantor is solely to repair or replace the product. The warrantor is not liable for

any incidental or consequential damages due to any such alleged defect. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not

apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

Exportado por:

© Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado a México por: Robert Bosch, S. de R.L. de C.V.

Calle Robert Bosch No. 405 - 50071 Toluca, Edo. de Méx. - México

Tel. 052 (722) 279 2300 ext 1160 / Fax. 052 (722) 216-6656

Dremel®Limited Warranty

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 19

Page 20

20

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si l'on

n'observe pas ces avertissements et ces consignes de sécurité, il existe un risque de

choc électrique, d'incendie et/ou de blessures corporelles graves.

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil branché sur le secteur (avec fil) ou

à votre outil alimenté par piles (sans fil).

Avertissements généraux concernant la sécurité des outils électroportatifs

AVERTISSEMENT

!

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on

travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple en

présence de gaz, de poussières ou de liquides

inflammables. Les outils électroportatifs produisent

des étincelles qui risquent d’enflammer les poussières

ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument jamais

modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil

électroportatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés

augmentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez une

alimentation protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur GFCI réduit

les risques de choc électrique.

Sécurité personnelle

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de

médicaments. Quand on utilise des outils

électroportatifs, il suffit d’un moment d’inattention pour

causer des blessures corporelles graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d'équipements de sécurité tels que des masques

antipoussières, des chaussures de sécurité

antidérapantes, des casques de chantier et des

protecteurs d'oreilles dans des conditions appropriées

réduira le risque de blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l'interrupteur est dans la position arrêt (Off) avant de

brancher l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le transporter. Le

transport d'un outil électroportatif avec le doigt sur la

gâchette ou le branchement de cet outil quand

l'interrupteur est en position de marche (ON) est une

invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés correctement.

L'utilisation d'un dépoussiéreur peut réduire les

dangers associés à l'accumulation de poussière.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 20

Page 21

21

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas

être commandé par son interrupteur est dangereux et

doit être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage,

changement d’accessoires ou avant de ranger l’outil

électroportatif. De telles mesures de sécurité

préventive réduisent le risque de démarrage intempestif

de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil électroportatif.

Si l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les accessoires et les

embouts d'outil, etc. conformément à ces

instructions, en tenant compte des conditions de

travail et des travaux à réaliser. L'emploi d’outils

électroportatifs pour des tâches différentes de celles

pour lesquelles ils ont été prévus peut résulter en une

situation dangereuse.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

l’outil électroportatif est préservée.

Consignes de sécurité pour l’utilisation des scies à chantourner

Tenez l’outil électrique par ses zones de préhension

isolées lorsque vous effectuez une opération lors de

laquelle l’accessoire de coupe peut entrer en contact

avec un fil électrique caché ou avec son propre

cordon d’alimentation. Le contact entre un accessoire

de coupe et un fil électrique sous tension peut

provoquer un transfert du courant vers les parties en

métal exposées de l’outil électrique et causer un choc

électrique pour l’opérateur.

Utilisez des brides de fixation ou un autre moyen

pratique de sécuriser et de supporter l’ouvrage sur

une plate-forme stable. Si vous tenez l’ouvrage à la

main ou contre vos corps, il sera instable et pourrait par

conséquent causer une perte du contrôle.

Ne laissez jamais l’interrupteur dans la position de

marche (ON). Assurez-vous que les interrupteurs sont

dans la position d’arrêt (OFF). Une mise en marche

accidentelle pourrait causer des blessures.

Gardez les mains à bonne distance de la zone de

coupe. Ne tentez PAS de mettre la main sous le

matériau qui est en train d’être coupé. Vous risqueriez

de ne pas voir la proximité de la lame par rapport à

votre main

Gardez les mains à bonne distance de l’espace

compris entre le boîtier des engrenages et le portescie à chantourner. Le porte-lame à va et vient

risquerait de vous pincer les doigts.

Utilisez seulement des lames Dremel Moto-Saw.

Utilisez une lame de la taille, du style et de la vitesse

de coupe appropriés pour le matériau et le type de

coupe. L’emploi d’une lame de taille appropriée réduit le

risque de cassure.

N’utilisez pas de lames émoussées ou

endommagées. Les lames émoussées risquent de se

courber et de se casser, et elles pourraient ainsi frapper

l’opérateur.

Avant de commencer à couper, mettez l’outil en

marche (ON) et laissez la lame tourner à sa vitesse de

croisière. L’outil risquerait de trembler ou de vibrer si la

vitesse de la lame était trop lente au début de l’opération

de coupe, et ceci risquerait de causer une perte de

contrôle.

Assurez-vous que toutes les vis de réglage et le portelame sont bien serrés avant de réaliser une coupe.

Des vis de réglage et un porte-lame desserrés

pourraient causer un glissement de l’outil ou de la lame,

et ceci risquerait de causer une perte de contrôle.

Lorsque vous retirez la lame de l’outil, évitez tout

contact avec la peau et utilisez des gants de

protection appropriés quand vous saisissez la lame

ou l’accessoire. Les accessoires peuvent être très

chauds après un emploi prolongé, et vous risqueriez de

vous brûler.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 21

Page 22

22

Ne laissez jamais un outil fonctionner sans

surveillance. Mettez hors tension. Ne laissez pas l’outil

sans surveillance avant qu’il ne se soit complètement

arrêté de tourner.

Ne laissez jamais l’interrupteur dans la position de

marche (ON). Avant de brancher l’outil, assurez-vous

que les interrupteurs sont en position d’arrêt (OFF).

Une mise en marche accidentelle risquerait de causer

des blessures.

Évitez les opérations mettant vos mains et votre corps

dans des positions maladroites, et assurez-vous

toujours que vous êtes bien en équilibre. Un

glissement soudain pourrait mettre votre main dans la

trajectoire de la lame.

Fixez ou boulonnez fermement votre poste de sciage

sur une table ou un établi stable et de niveau. La

hauteur de table la plus confortable est à peu près la

hauteur de la taille.

Ne montez jamais sur l’outil. Vous risqueriez de vous

blesser si l’outil basculait ou si vous entriez

accidentellement en contact avec la lame.

Avant de réaliser une coupe, assurez-vous que tous

les réglages sont sécurisés. Si la table ou des

dispositifs de protection ne sont pas bien assujettis, ils

pourraient bouger pendant l’emploi et vous faire perdre

le contrôle de l’ouvrage.

Ajustez toujours le pied articulé de façon à ce qu’il ne

cause pas d’interférence avec l’ouvrage. Un

ajustement correct du pied articulé stabilisera l’ouvrage,

aidera à protéger vos doigts et réduira le risque de

cassure de la lame.

Supportez toujours les ouvrages de grandes

dimensions pendant les opérations de coupe afin de

réduire le risque de pincement par la lame et de perte

de contrôle pouvant en résulter. Un ouvrage lourd

pourrait causer le glissement ou un autre mouvement

de la table pendant la coupe.

Assurez-vous qu’il n’y a pas clous sur la trajectoire de

coupe. Inspectez la surface à couper et retirez les clous

du bois ou de l’ouvrage le cas échéant avant de couper

ou de poncer.

Gardez les mains à bonne distance de la zone de

coupe. Ne tenez pas à la main des pièces tellement

petites que vos doigts risqueraient d’aller en dessous

du pied articulé. N’étendez pas votre bras en dessous

de l’ouvrage et ne mettez pas vos doigts sur la

trajectoire de coupe de la lame pour quelque raison

que ce soit. Si votre main est positionnée très près de

la lame, elle risquerait d’entrer en contact avec celle-ci et

vous risqueriez alors de vous blesser.

Ne mettez jamais l’outil en marche lorsque la lame

est en contact avec l’outil. Laissez le moteur atteindre

sa vitesse de croisière avant de commencer une

coupe. Si la lame est en contact avec l’ouvrage au

moment du démarrage, vous risquez de perdre le

contrôle de l’outil.

Observez et suivez le sens correct de l’alimentation,

et ne faites pas avancer le matériau trop rapidement.

Maintenez l’ouvrage fermement contre la table. Faites

avancer l’ouvrage vers la lame contre les dents de la

lame. Si vous faites avancer le matériau avec trop de

force, vous risquez de causer la rupture de la lame.

Faites très attention lorsque vous coupez des

matériaux ayant une section irrégulière ou des

matériaux ronds tels que des pièces de bois rondes

allongées. Si possible, posez le matériau sur son côté

« plat » lorsque vous coupez. Pour les matériaux

ronds, utilisez un bloc en forme de V pour supporter

le matériau. Des matériaux ondulés, tels que des

moulures, auront tendance à se balancer et risqueraient

de se coincer dans la scie pendant les opérations de

coupe. Les matériaux ronds ont tendance à rouler

pendant les opérations de coupe, et la lame risquerait de

les « mordre » et de vous faire perdre le contrôle.

Ne retirez jamais des pièces tronçonnées coincées

avant que la lame ait cessé de tourner. Ne touchez

jamais la lame ou d’autres pièces mobiles pendant

l’emploi. Tout contact avec la lame ou un autre

mécanisme mobile pourrait causer une blessure.

N’utilisez l’embase qu’avec l’outil Dremel Moto-Saw.

D’autres outils risqueraient de ne pas bien tenir et de

causer une situation dangereuse.

Positionnez les tuyaux flexibles d’inspiration de telle

façon qu’ils ne bloquent pas l’interrupteur. Vous devez

veiller à ce que l’accès à l’interrupteur marche/arrêt

(ON/OFF) soit toujours bien dégagé afin d’assurer un

contrôle adéquat.

Lorsque vous connectez l’outil à des systèmes de

ramassage et d’extraction de la poussière, assurezvous que ces derniers sont raccordés et utilisés

conformément aux instructions de l’outil et du

système d’aspiration. Une utilisation correcte des

systèmes de dépoussiérage augmente la productivité du

travail.

Lorsque vous utilisez un outil pourvu d’un système de

ramassage ou d’extraction de la poussière, videz le

réservoir à poussière avant de commencer le travail,

fréquemment pendant le travail, après avoir fini le

travail et avant de ranger l’outil. Faites très attention

lorsque vous jetez la poussière accumulée, car des

matériaux sous forme de particules fines pourraient être

explosifs.

Consignes de sécurité pour l’utilisation du poste de sciage

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 22

Page 23

Maintenez les poignées sèches et exemptes d’huile et

de graisse. On ne pas maîtriser un outil électroportatif

en toute sécurité quand on a les mains glissantes.

Créez un agenda d’entretien périodique pour votre

outil. Quand vous nettoyez un outil, faites attention

de n’en démonter aucune pièce car il est toujours

possible de mal remonter ou de pincer les fils

internes ou de remonter incorrectement les ressorts

de rappel des capots de protection. Certains agents

de nettoyage tels que l’essence, le tétrachlorure de

carbone, l’ammoniaque, etc. risquent d’abîmer les

plastiques.

Le produit ne doit être réparé que par un centre de

service après-vente usine Bosch ou un centre de

service agréé par Bosch. Ce produit ne contient pas de

pièces pouvant être réparées par l’utilisateur en dehors

de celles qui sont mentionnées par ailleurs dans ce

mode d’emploi.

Les travaux à la machine

tel que ponçage, sciage,

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

23

Ne jetez pas de poussière sur des flammes vives. Les

particules de poussières fines risquent de brûler de

façon explosive.

N’utilisez pas de système d’extraction de la poussière

pour des opérations qui incluent des matériaux

brûlants, fumants ou dans un état de combustion

couvante, tels que des cendres chaudes ou des

étincelles. Ceci risquerait de déclencher un incendie à

l’intérieur du sac ou du réservoir de l’aspirateur. La

poussière chaude peut continuer à se consumer

lentement et mettre le feu à l’aspirateur longtemps après

la fin de votre travail.

N’utilisez pas de système de dépoussiérage en

présence de poussières explosives, de vernis,

d’enduits en polyuréthane, de produits de nettoyage

ou de peintures à l’huile. Les composants électriques

de l’aspirateur et de l’outil risqueraient de produire des

étincelles qui pourraient mettre le feu à des poussières

ou fumées.

N’utilisez pas de système de dépoussiérage lorsque

vous travaillez sur du métal. Des particules générées

par des opérations de ponçage, rectification ou coupe

de métal peuvent être très chaudes et produire des

étincelles pouvant causer la fusion d’adaptateurs en

plastique et de tuyaux d’aspiration flexibles, et elles

pourraient également causer un incendie à l’intérieur du

sac/réservoir de l’aspirateur.

Avertissements supplémentaires concernant la sécurité

AVERTISSEMENT

!

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 23

Page 24

24

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules, etc.

n

0

Vitesse à vide Vitesse de rotation, à vide

n Vitesse nominale Vitesse maximum pouvant être atteinte

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

minute etc., par minute

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de position. Un

l, ll, lll, ... nombre plus élevé signifie une vitesse plus grande

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif ou continu Type ou caractéristique du courant

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre Borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Li-ion RBRC Désigne le programme de recyclage

des piles Li-ion.

Sceau Ni-Cad RBRC Désigne le programme de recyclage

des piles Ni-Cad.

Symbole de lecture du mode Alerte l’utilisateur pour lire le mode

d’emploi d’emploi

Symbole de port de lunettes Alerte l’utilisateur pour porter des lunettes

de sécurité de sécurité

Symboles

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 24

Page 25

25

Ce symbole signifie que cet outil est approuvé par Underwriters Laboratories.

Ce symbole signifie que cet outil est approuvé par l'Association canadienne

de normalisation.

Ce symbole signifie que cet outil est approuvé par l'Association canadienne de normalisation

selon les normes des États-Unis et du Canada.

Ce symbole signifie que cet outil se conforme aux normes mexicaines NOM.

Ce symbole signifie que cet outil est approuvé par Intertek Testing Services selon

les normes des États-Unis et du Canada

Symboles (suite)

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Ce symbole indique que ce composant est reconnu par Underwriters Laboratories.

Ce symbole signifie que cet outil est approuvé par Underwriters Laboratories selon les

normes des États-Unis et du Canada.

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 25

Page 26

26

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

AVERTISSEMENT

!

Description fonctionnelle et spécifications

A. Bouton de relâchement du pied de

maintien

B. Pied de maintien

C. Levier de verrouillage du guide

D. Rail du guide

E. Embase

F. Point de raccordement de l’aspirateur

G. Interrupteur marche/arrêt (ON/OFF)

H. Sélecteur de vitesse à cadran

I. Brides de fixation

J. Fente pour la fixation

K. Orifice pour fixation permanente

L. Bouton de relâchement rapide

M. Moto-Saw

N. Levier de changement rapide pour les

accessoires

O. Adaptateur pour le tuyau flexible de

l’aspirateur

A

B

C

E

F

G

I

H

N

L

K

M

D

J

O

FIG. 1

Dremel Moto-Saw 2 en 1

Scie à découper compacte MS20

Tension nominale 120V 60Hz

Ampères 0,6 A

Vitesse à vide 1 500 - 2 250

Profondeur de la gorge 9,84 po

Longueur de la course 0,31 po

Poids 2,4 lbs

Longueur de la lame 3,8 po

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 26

Page 27

27

Assemblage

Déconnectez la fiche de la

prise de courant avant de

procéder à de quelconques montages, réglages ou

changements d’accessoires. De telles mesures de

sécurité préventives réduisent le risque de démarrage

accidentel de l’outil.

Fixation de la lame sur l’outil Moto-Saw

1. Depuis le devant de l’outil, tirez le levier de

changement rapide vers vous pour le mettre en

position desserrée, Fig. 2.

2. Placez l’extrémité de la lame de scie comportant la

broche du bas dans le coin inférieur de la zone

inférieure de fixation d’un accessoire. Les dents de

la lame doivent être orientées vers le bas, Fig. 3.

3. Placez l’extrémité de la scie comportant la broche

du haut dans la zone supérieure de l’outil prévue

pour la fixation d’un accessoire en la faisant pivoter

vers l’avant en direction de la zone de fixation

supérieure de l’outil, Fig. 4.

4. Appuyez sur le levier de changement rapide pour le

pousser dans le sens opposé à vous afin de le

mettre en position serrée pour fixer la lame en

place, Fig. 5.

Pour retirer l’accessoire, suivez la procédure inverse.

7

FIG. 2

FIG. 3

FIG. 4

FIG. 5

AVERTISSEMENT

!

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 27

Page 28

28

Assemblage de l’embase en vue d’un emploi en

position fixe

Déconnectez la fiche de la

prise de courant avant de

procéder à de quelconques montages, réglages ou

changements d’accessoires. De telles mesures de

sécurité préventives réduisent le risque de démarrage

accidentel de l’outil.

Montez l’embase sur une surface de travail plate à une

hauteur confortable. Assurez-vous que la surface de

travail a une surface de travail telle qu’elle puisse

accepter les brides de fixation et/ou les vis de

montage. Le montage de l’embase sur une surface

instable pourrait causer un accident.

1. Positionnez le poste de sciage sur le bord avant de

la surface de travail place à laquelle le poste de

sciage sera assujetti.

2. Éliminez le filet des brides de fixation fournies pour

assurer qu’elles pourront se fixer sur la surface de

travail. Faites glisser le bord plat de la bride de

fixation dans la fente qui se trouve au bas du poste

de sciage et serrez la bride de fixation pour

empêcher le poste de sciage de bouger pendant

l’emploi, Fig. 6.

L’embase peut être assujettie de façon permanente

à un établi au moyen de vis ordinaires qui peuvent

être insérées à travers les deux orifices situées en

haut de l’embase, Fig. 7.

3. Enfilez le cordon d’alimentation de l’outil Moto-Saw

dans le trou du centre de l’embase, Fig. 8.

4. Abaissez l’outil Moto-Saw sur la surface du poste

de sciage, puis poussez-le vers l’avant jusqu’à ce

que vous entendiez un déclic indiquant qu’il est

dans sa position verrouillée, Fig. 9.

FIG. 6

FIG. 8

FIG. 9

FIG. 7

AVERTISSEMENT

!

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 28

Page 29

29

Retrait de l’outil Moto-Saw afin de pouvoir l’utiliser

à la main

1. Débranchez l’outil Moto-Saw.

2. Appuyez sur le bouton de déverrouillage à l’arrière

de la surface de travail du poste de sciage.

3. Faites glisser l’outil Moto-Saw vers l’arrière à

no uveau pour le libérer du mécan isme de

verrouillage.

4. Soulevez l’outil Moto-Saw pour le faire sortir du

poste de sciage et tirez le cordon d’alimentation à

travers le poste de sciage.

Installation du système d’extraction de la poussière

Lors de toute connexion de l’outil à un système de

ramassage ou d’extraction de la poussière, assurezvous que ce système est bien raccordé et utilisé

conformément aux instructions du mode d’emploi de

l’outil et de l’aspirateur. Une utilisation appropriée des

systèmes de ramassage de la poussière permet

d’augmenter la productivité au maximum.

N’utilisez pas de système d’extraction de la poussière

lorsque vous travaillez sur du métal. Les particules

générées par une opération de ponçage, rectification

ou coupe du métal peuvent être très chaudes et

produire des étincelles qui pourraient causer la fusion

d’adaptateurs en plastique ou de tuyaux d’aspiration

flexibles, et elles pourraient également causer un

incendie à l’intérieur du sac/réservoir de l’aspirateur.

Positionnez les tuyaux flexibles d’inspiration de telle

façon qu’ils ne bloquent pas l’interrupteur. Vous devez

veiller à ce que l’accès à l’interrupteur marche/arrêt

(ON/OFF) soit toujours bien dégagé afin d’assurer un

contrôle adéquat.

Votre outil Moto-Saw inclut un adaptateur pour

co nnecter le tuyau flexib le d’un a spirateur.

L’adaptateur peut être utilisé pour connecter le tuyau

flexible d’un aspirateur au côté droit ou gauche de

l’outil, Fig. 11.

L’extérieur de l’adaptateur peut être utilisé pour

connecter des tuyaux de 1 po et l’intérieur de

l’adaptateur peut être utilisé pour connecter des

tuyaux de 1 po.

1. Attachez l’adaptateur du système d’extraction de la

poussière sur le poste de sciage.

2. Attachez le tuyau de l’aspirateur à l’adaptateur

prévu à cet effet.

Pour retirer l’adaptateur, inversez les instructions cidessus.

FIG. 10

FIG. 11

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 29

Page 30

30

Installation du guide/de la jauge à onglets

(accessoire optionnel)

Votre outil Moto-Saw peut utiliser à la fois un guide et

une jauge à onglets.

Pour utilisation de l’outil avec une jauge à onglets :

1. Pour utiliser la jauge à onglets, faites glisser la

section en métal en forme de T sur la piste de la

surface du poste de sciage, Fig. 12.

2. Tournez le bouton de la jauge à onglets afin

d’ajuster l’angle de celle-ci, et serrez une fois que

vous avez atteint l’angle désiré, Fig. 13.

Pour utilisation de l’outil avec un guide :

1. Installez la jauge à onglets tel que décrit ci-dessus.

2. Ajustez l’angle d’onglet à 90° puis faites glisser la

jauge à onglets jusqu’à la position désirée pour le

guide, Fig. 14.

3. Faites tourner le levier bleu sur le côté du poste de

sciage vers l’avant afin de verrouiller.

Pour retirer le guide ou la jauge à onglets, inversez la

procédure ci-dessus.

FIG. 12

FIG. 13

FIG. 14

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 30

Page 31

31

Utilisation – Mode manuel

L’utilisation de l’outil Moto-Saw en mode manuel est

conseillée lorsque l’ouvrage est excessivement

volumineux ou en position fixe, et qu’il n’est donc pas

po ssible de le m anœuvrer sur l’embas e. Un

fonctionnement en mode manuel inclut fréquemment

des opérations consistant à chantourner ou former de

grands ouvrages en bois. Ne coupez pas de matériaux

autres que du bois lorsque vous travaillez en mode

manuel.

Ne la issez jamais

l’interrupteur en position

de marche (ON). Assurez-vous que les interrupteurs

sont en position arrêt (OFF) avant de brancher

l’outil. Des démarrages accidentels pourraient causer

des blessures.

1. Saisissez l’outil Moto-Saw tel que décrit à la Fig. 15.

2. Ajustez le cadran de vitesses variables en fonction

de la lame et du matériau que vous voulez couper.

Vous pouvez vous référer au tableau de la page 18

pour déterminer la vitesse qu’il convient d’utiliser

en fonction de votre ouvrage. Ce tableau vous

aidera à savoir comment choisir à la fois le bon

accessoire et la vitesse idéale en un clin d’oeil.

3. Après vous êtes assuré au préalable que l’ouvrage

est solidement fixé, prenez l’outil et ajustez le pied

de maintien de façon qu’il repose sur l’ouvrage,

Fig. 16.

Ne mettez jamais l’outil en

ma rche pendant que la

lame est en contact avec l’ouvrage. Laissez le

moteur tourner jusqu’à ce qu’il atteigne sa vitesse

de croisière avant de commencer à couper. Vous

risqueriez de perdre le contrôle de l’outil si la lame

était en conta ct ave c l’ouvrage au moment du

démarrage.

4. Mettez l’outil en marche (ON) et laissez-le atteindre

sa vitesse de croisière avant de mettre la lame en

contact avec l’ouvrage. Pour mettre l’outil en

FIG. 15

FIG. 16

L’outil Moto-Saw est une scie à découper 2 en 1

compacte et très facile à utiliser. Il peut être utilisé

soit en mode fixe, lorsque l’outil est fixé sur son

embase, soit en mode manuel. Cet outil est conçu

pour effectuer des coupes droites et incurvées avec

précision dans différents matériaux, y compris dans le

bois tendre, le bois dur, les panneaux composites, les

matériaux stratifiés, le PVC ou la tôle souple à l’aide

des accessoires applicables recommandés par

Dremel.

Les dents de cet outil coupent uniquement lorsque la

course est descendante. Il faut faire avancer l’ouvrage

très lentement en direction de la lame de la scie car

les dents sont petites et elles ne peuvent retirer que

de petits morceaux de matériau à la fois. Si vous

essayez de couper trop rapidement, vous risquez de

tordre ou de casser la lame.

Pour couper avec une précision optimale, essayez de

compenser la tendance des lames à suivre le grain du

bois pendant que vous coupez.

Consignes de fonctionnement

AVERTISSEMENT

!

AVERTISSEMENT

!

DM 2610Z03287 05-13_DM 2610Z03287 05-13.qxp 5/24/13 8:09 AM Page 31

Page 32

32

Mode fixe

L’utilisation de l’outil Moto-Saw en mode fixe vous

donne la liberté de pouvoir couper en tenant votre

ouvrage des deux mains. Dans ce mode, vous pouvez

réaliser divers projets de travail du bois dans le cadre

de vos activités professionnelles ou de vos loisirs en

coupant facilement et de façon précise des ouvrages

en bois, en plastique ou en métal mince lorsque vous

utilisez la lame correcte.

Ne la issez jamais

l’interrupteur en position

de marche (ON). Assurez-vous que les interrupteurs

sont en position arrêt (OFF) avant de brancher

l’outil. Des démarrages accidentels pourraient causer

des blessures.

1. Assurez-vous que l’embase est solidement attachée

à une surface de travail plate à l’aide des brides de

fixation fournies ou qu’elle est assujettie par des

vis.

2. Ajustez le cadran de vitesses variables en fonction

de la lame et du matériau que vous voulez couper.

Vous pouvez vous référer au tableau de la page 18

pour déterminer la vitesse qu’il convient d’utiliser

en fonction de votre ouvrage. Ce tableau vous

aidera à savoir comment choisir à la fois le bon

accessoire et la vitesse idéale en un clin d’oeil.

Lorsque vous coupez du plastique ou de la tôle,

placez votre ouvrage sur un morceau de carton

pour réduire les vibrations. Coupez les deux

matériaux pour produire une coupe plus précise et

plus nette.

3. Faites avancer l’ouvrage en direction de la lame de

l’outil.

Gardez les mains à bonne

di stance de la zone de

coupe. Ne tenez pas à la main des pièces tellement