Page 1

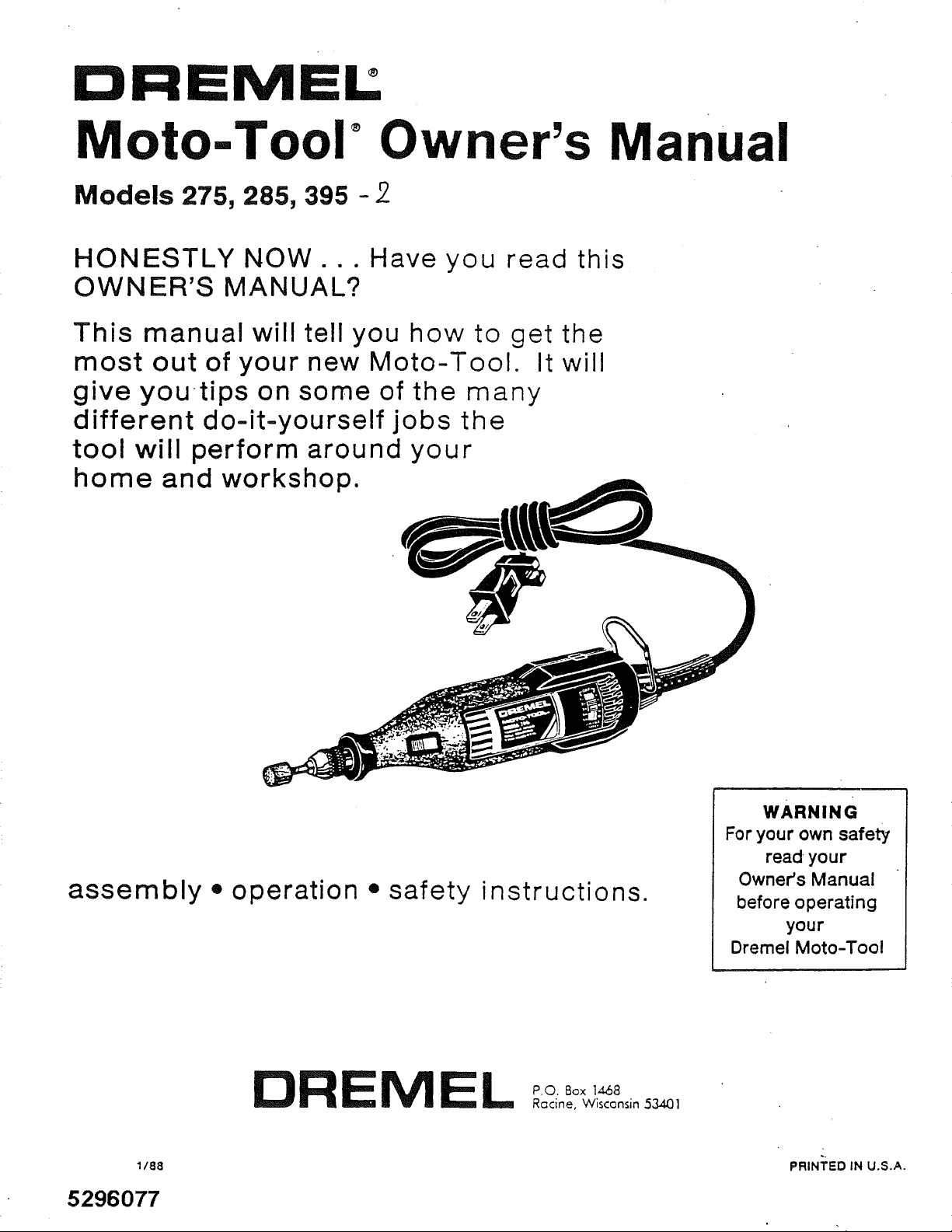

DREMEi o

Moto-Tool ° Owner's Manual

Models 275, 285, 395 -2

HONESTLY NOW... Have you read this

OWNER'S MANUAL?

This manual will tell you how to get the

most out of your new Moto-Tool. It will

give youtips on some of the many

different do-it-yourself jobs the

tool will perform around your

home and workshop.

assembly • operation • safety instructions.

OREMEL _.o.,o__

1/88

5296077

Racine, Wisconsin 53401

WARNING

For your own safety

read your

Owner's Manual

before operating

your

Dremel Moto-Tool

PRINTED IN U.S.A.

Page 2

For Your Safety...

READ AND SAVE ALL THE FOLLOWING INSTRUCTIONS:

When using electric tools, basic safety precautions

electric shock, and personal injury, including the following:

should always be followed to reduce the risk of fire,

1. Keep work area clean -- Cluttered areas

and benches invite injuries.

2. Avoid dangerous environment -- Don't

expose tools to rain. Don't use power tools in

damporwetlocations. Don't use power tools

in the presence of flammable liquids or gases.

Avoid chemical or corrosive environments

Keep work area welt lit.

3. Guard against electric shock -- Prevent

body contact with grounded surfaces. For

example: pipes, radiators, refrigerator

enclosures.

4. Keep children away -- Do not let visitors

contact tool or extension cord. All visitors

should be kept away from work areas.

5o Store idle tools -- When not in use, tools

should be stored in dry, and high or locked-

up place - out of reach of children.

6. Don't force t,:ol -- It will do the job better

and safer at the rate for which it was intended.

7. Use right tool - Don't force small tool or

attachment to do the job of a heavy-duty tool.

Don't use tool for purpose not intended - for

example - don't use circular saw for cutting

tree limbs or logs.

8, Dress properly _ Do not wear loose cloth-

ing or jewetry. They can becaught in moving

parts. Rubber gloves and non-skid footwear

are recommended when worR.ing out-

doors. Wear protective hair coyering to con-

tain long hair.

9. Use safety glasses -- Also use face or dust

mask if cutting operation is dusty.

10. Don't abuse cord -- Never carry tool by

cord or yank it to disconnect from recep-

tacle. Keep cord from t_eat, oil, and sharp

edges.

11. Secure work -- Use clamps or vise to

hold work. It's safer than using your hand and

it frees both hands to operate tool.

12. Don't over-reach _ Keep proper footing

and balance at all times,

13. Maintain tools with care -- Keep tools

sharp and clean for be_er and safer perfor-

mance. Follow instructions for lubricating

and changing accessories. Inspect tool cords

periodically and if damaged, have repaired,

by authorized service facility. Inspect exten-

sion cords periodically and replace if damaged.

Keep handles dry, clean, and free from oil

and grease.

14. Disconnect tools -- Wh en not in use, before

servicing, and when ohanging accessories,

such as blades, bit, cutters.

15. Remove adjusting keys and wrenches--

Form habit of checking to see that keys and

adjusting wrenches are removed from tool

before turning it on.

16. Avoid unintentional starting -- Don't

carry plugged-in tool with finger on switch.

Be sure switch is off when plugged in.

17. Outdoor use extension cords -- When

tool is used outdoors, use only extension

cords intended for use outdoors and so

marked.

18. Stay alert -- Watch what you are doing.

Use common sense. Do not operate tool

when you are tired. Don't use power tools

after taking drugs, alcohol or medications.

19, Do not alter or misuse tool -- These tools

are precision built. Any alteration or mod-

ification not specified is misuse and may

result in a dangerous condition.

20. Avoid gaseous areas -- Do not operate

portable electric tools ingaseous or explosive

atmospheres, Motors inthese tools normally

spark, and the sparks might ignite fumes.

21 Check for damaged parts-- before further

use of the toot, check for damaged parts.

Check for alignment of moving parts, binding

of moving parts, breakage of parts, mount-

ing, and any other conditions that may affect

its operation. A part that is damaged should

be properly repaired or replaced by authorized

service center before further use of the tool.

Have defective switches replaced by authorized

service center. Do not use tool if switch does

not turn it on and off.

22. Your tool is double insulated -- And no

grounding is necessary. The tool is equipped

with atwo wire cord and two prong plug which

can be used instandard 120 volt A.C° curriers.

Use only identical replacement part= when

service is required.

23. EXTENSION CORDS - An undersize

cord will cause a drop in line voltage, result-

ing in toss of power and over-heating. Use 18

gauge or heavier cord. NOTE: The smaller

the gauge number, the heavier the cord.

(Extension cords are available.)

24. WARNING: Use of damaged cords can

shock, burn or electrocute.

READ AND SAVE ALL THE PRECEDING INSTRUCTIONS

Dremel Limited Warranty

Your Dremet product is warranted against defective material or

workmanship for a period of one year from date of purchase. In

the event of a failure of a product to conform to this written

warranty you should return the product, along with proof of

purchase date and a written statement about the nature of the

problem, to:

Dremel Service Center

4915 Twenty-first Street

Racine, Wisconsin 53406

or

Oreme! Service Center

4631 E. Sunny Dunes

Palm Spring, California 92264

No employee, agent, dealer or other person is authorized to give

any warranties on behalf ofDremel. IfOremelinsoeclionshows

that the problem was caused by defective material or work-

manship within the limitations of the warranty, Dremel will repair

or replace the product free of charge and return product pre-

paid. Repairs made necessary by normal wear or abuse, or

repair for product outside the warranty period, if they can be

made, will be charged at regular factory prices.

OREMEL MAKES NO OTHER WARRANTY OF ANY KIND

WHATEVER, EXPRESSED OR IMPLIED, AND ALL IMPLIED

WARRANTIES OF MERCHANTASILITY AND FITNESS FOR A

PARTICULAR PURPOSE WHICH EXCEED THE ABOVE

MENTIONED OBLIGATION ARE HEREBY DISCLAIMED BY

DREMEL AND EXCLUDED FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also

have Diner rights which vary from state to state. The obligation of

the warrantor is soley to repair or replace the product. The

warrantor is not liable for any incidental or consequential

damages due to such defect. Some states do not allow the exclu-

sion or limitations of incidental or consequential damages, so the

above limitations or exclusion may not apply to you.

For prices and warranty fulfillment in Ihe continental United States,

contact your local Dremel distributor,

Page 2

Page 3

introduction

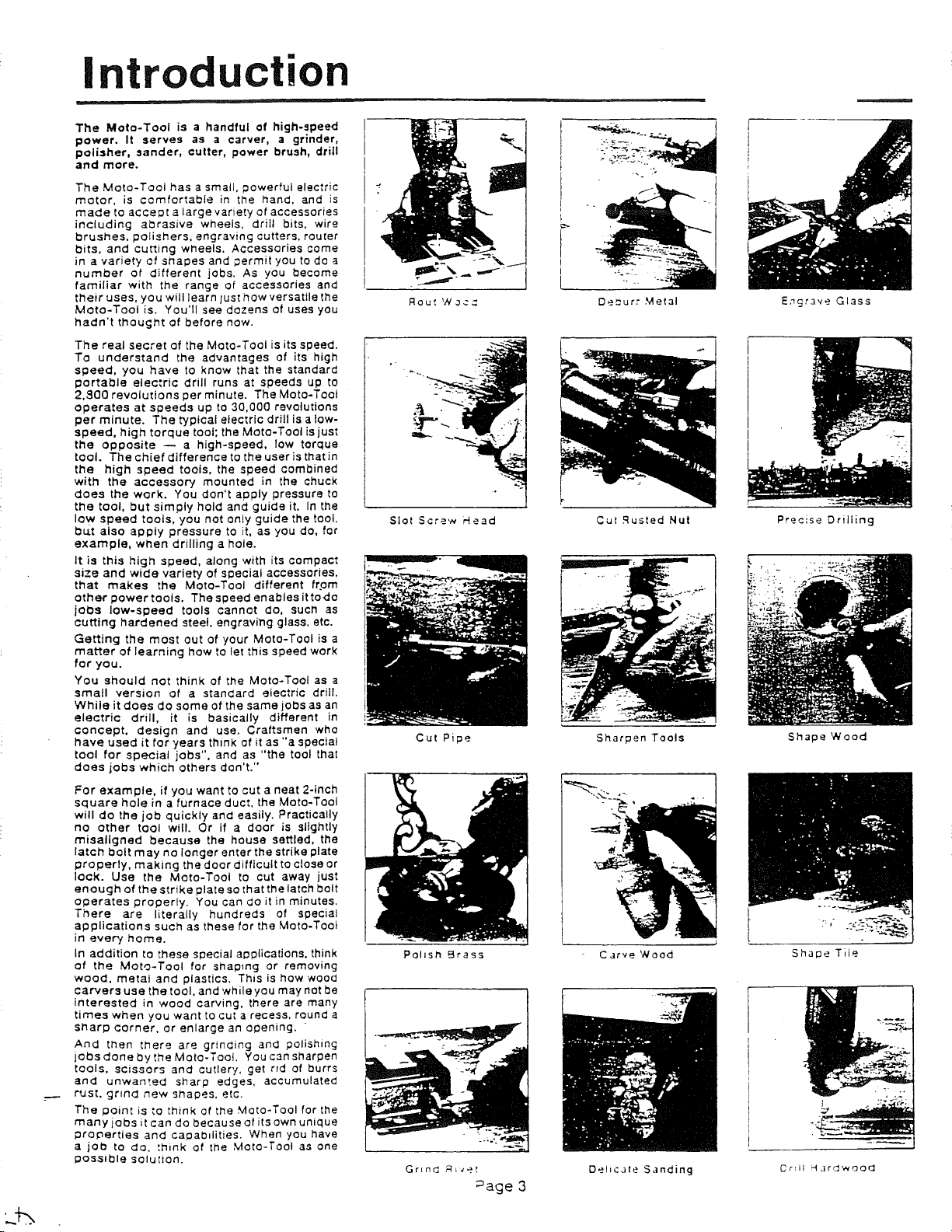

The Moto-Tool is a handful of high-speed

power. It serves as a carver, a grinder,

polisher, sander, cutter, power brush, drill

and more.

The Mote-Tool has a small, powerful electric

motor, is comfortable in the hand. and is

made to accept a large variety of accessories

including abrasive wheels, drill bits, wire

brushes, polishers, engraving cutters, router

bits, and cutting wheels. Accessories come

in a variety of shapes and permit you to do a

number of different jobs. As you become

familiar with the range of accessories and

their uses, you will learn just how versatile the

Moto-Toolis. You'll see dozens of uses you

hadn't thought of before now.

The real secret of the Mote-Tool is its speed.

To understand the advantages of its high

speed, you have to know that the standard

portable electric drill runs at speeds up to

2,800 revolutions per minute. The Mote-Tool

operates at speeds up to 30,000 revolutions

per minute. The typical electric drill is a low-

speed, high torque tool; the Mote-Tool is just

the opposite -- a high-speed, low torque

tool. The chief difference to the user is that in

the high speed tools, the speed combined

with the accessory mounted in the chuck

does the work. You don't apply pressure to

the tool, but simply hold and guide it. In the

low speed tools, you not only guide the tool,

bu.t also apply pressure to it, as you do, for

example, when drilling a hole.

It is this high speed, along with its compact

size and wide variety of special accessories,

that makes the Mote-Tool different from

other power tools. The speed enables ittodo

jobs low-speed tools cannot do, such as

cutting hardened steel, engraving glass, etc.

Getting the most out of your Mote-Tool is a

matter of learning how to let this speed work

for you.

You should not think of the Mote-Tool as a

small version of a standard electric drill.

While it does do some of the same jobs as an

electric drill, it is basically different in

concept, design and use. Craftsmen who

have used it for years think of it as "a special

tool for special jobs", and as "the tool that

does jobs which others don't."

For example, if you want to cut a neat 2-inch

square hole in a furnace duct, the Mote-Toot

will do the job quickly and easily, Practically

no other tool will. Or if a door is slightly

misallgned because the house settled, the

latch bolt may no longer enter the strike plate

properly, making the door difficult to close or

lock. Use the Mote-Tool to cut away just

enough of the strike plate so that the latch bolt

operates properly. You can do it in minutes.

There are literally hundreds of special

applications such as these for the Mote-Toot

in every home.

In addition to these special applications, think

of the Mote-Tool for shaping or removing

wood, metal and plastics. This is how wood

carvers use the tool, and while you may not be

interested in wood carving, there are many

times when you want to cut a recess, round a

slnarp corner, or enlarge an opening. "

And then there are grinding and polishing

jobs done by theMoto-Toot. You can sharpen

tools, scissors and cutlery, get nd of burrs

and unwanted sharp edges, accumulated

rust. grind new shapes, etc.

The point is to think of the Mote-Tool for the

many jobs it can do because of its own unique

properties and capabdities. When you have

a job to do, think of the Mote-Toot as one

possible solution,

Slot Screw Head

Cut Pipe

Polzsn Brass

Grlnd R_ ,_et

_age 3

DeCur; Metal

Cut Rusted Nut

Sharpen Tools

Carve Wood

Delicate Sanding

Engrave Glass

Precise Drilling

Shape Wood

1

.

J

Shape Tile

Crlil Hjrdwood

:.%

Page 4

Operation Guidelines

Read the next sections carefully. They will

help you use your MolD-TOOl correctly and

help you select the correct accessory for

your job.

Using the Moto-Tool

The first step in learning to use the Moto-Tool

is to get the "feel" of it. Hold it in your hand

and feel its weight and balance. Feel the

taper of the housing. This taper permits the

Moto-Tool to be grasped much like a pen or

pencil. If you nave a variable speed model,

turn iron by sliding the switch speed indicator

to each of the speed settings (1 Ihru 5), allowing

the toot to maintain full speed at each

setting. If you have a two-speed model, turn

it on by sliding the switch indicator to the LOW

speed setting. You will notice a detent at this

setting. Then slide the switch indicatortothe

HIGH speed setting. You will also notice a

detent at this setting. If you have a single

speed model, turn it on by sliding the switch

indicator to the on position, you will also

notice a detent at this setting.

When you turn on the tool for the first time,

hold it away from your face. Accessories can

be damaged during handling, and can fly

apart as they come up to speed. This is not

common, but it does happen.

Practice on scrap materials first to see how

the Moto-Tool cuts. Keep in mind that the

work']s done by the speed of the tool and by

the accessory in the chuck. You should not

lean on or push the tool into the work.

Instead, lower the spinning accessory lightly

to the work and allow it to touch the point at.

which you want cutting (or sanding or etch-"

ing, etc.) to begin. Concentrate'on guiding

the tool over the work using very little pros-

sure from your hand. Allow the accessory to

do the work.

Usually, it is best to make a series of passes

with the tool rather than attempt to do all the

work in one pass. To make a cut. for example,

pass the tool bacX and forth over the work,

much as you would a small paint brush.

Cut a little material on each pass until you

reach the desired depth. For most work, the

deft, gentle touch is best. With it, you have

me best control, are less likely to make

errors, and will get the most efficient work out

of the accessory.

The pencil grip we described is one way to

hold the Moto-Tool. A second way to grip the

tool much as you would the handgrip on a

bicycle, with your hand wrapped around the

housing and the chuck extending just beyond

your thumb and forefinger. This grip must be

used for cutoff wheels and saws for maximum

control and is often used with polishing,

brushing, and grinding accessories.

When using the steel saws

wheels (Nos. 409, 420, 426) always have the

work securely clamped. Never attempt to

hold the work with one hand while using

either of these accessories. The reason is

that these wheels will grab if they become

slightly canted in the groove, and can kick-

back causing loss of control resulting in

serious injury. Your second hand should be

used to steady and guide the hand holding

the tool. When a cutoff wheel grabs, the

wheel itself usually breaks. When the steel

saw wheel grabs, it may jump from the

groove and you could lose control of the

tool.

(No.s. 400, 406) or cutoff

f,'

For best control in close work, grip the Moto-

Tool like a pencil between your thumb and

forefinger.

This isthe "handgrip" method of holding the

tool used for operations such as grinding a

flat surface.

The operation of any power tool can result in foreign objects being thrown into the eyes. ,which can

result in severe eye damage. Always wear safety glasses or eye shields before commencing oo,,ver tool

operation. We recommended Wide Vlsion Safety Mask for use over spectac!es or standard

safety glasses.

Whenever you hold the tool, be careful not to

cover the air vents with your hand. This

blocks the air flow and causes the motor to

overheat.

ALWAYS UNPLUG MOTO-TOOL BEFORE

CHANGING ACCESSORIES, CHANGING

COLLETS OR SF--=_VlCING YOUR MOTO TOOL

LOCK 77._IB)_ f_,l

BUT'tON

WRENCH o

COLLET _

COLLET -- Consists of a collet nut and toilet.

To loosen, first slide shaft lock forward and

rotate the shaft by hand until the lock engages

the shaft preventing further rotation.

(NOTE: Do not engage lock while the Moto-

Tool is running.) With the lock engaged use

the collet wrench to loosen the collet nut.

Change accessories inserting the new one

Into the collet as far as possible to minimize

runout and unbalance. With the lock engaged,

tighten the collet nut with the wrench until the

accessory shank is gripped by the poller.

Avoid excessive tightening of Ihe oollet nut.

This means of securing accessories is best

when using the same bit for extended periods

or during heavy material removal applications.

l \ COLLET

TO LOOSEN COLLET NUT

COLLETS -- Four different size toilets (see

illustration), to accommodate different shank

SELF-ADJUSTING

KEYLESS

AVAILABLE AS ACCESSORY)

CHUCK

/

482 1116"

COLLET

483 1132"

COLLET

sizes, are available for your Moto-Tool. To

install a different toilet, remove the cotlet nut

and remove the old collet. Insert the unslotted

end of the cotlet in the hole in the end of the

tool shaft. Replace collet nut on the shaft.

Always use the collet which matches the

shank size of the accessory you plan to use.

Never force a larger diameter shank into a

collet.

KEYLESS CHUCK--Can be threaded on the

end of the shaft by engaging the shaft lock

button, you need only use hand tightening to

secure an accessory. Use the keyless chuck

when there is a need to change bits frequently,

for light duty jobs.

Page 4

BALANCING ACCESSORIES -- For precision

work, it is important that all accessories be in

good balance (much the same as the tires on

your automobile). To true up or balance an

accessory, slightly loosen collet nut and give

the accessory or collet a I/4" turn. Retighten

toilet nut and run the Moto-Toot. You should

be able to tell by the sound and feel if your

accessory is running in balance. Continue

adjusting in this fashion until best balance is

achieved. To maintain balance on abrasive

wheel points, before each use, with the wheel

point secured in me toilet, turn on the Moto-

Tool and run the 415 Dressing Stone lightly

against the revolving wheel point. This

removes high soots and trues up the wheel

point for good balance.

WHEEL DIAMETER -- Other than the No. 426

cutoff wheel, do not use grinding wheels over

1" in diameter, Mote-Tool's high speed can

cause larger wheels to fly apart and could

cause injury.

SAFETY -- Protect your ey_es when grinding

or routing with the Moto-Tool... always wear

an approved type of safety glasses.

Remember. your new Dremel Moto-Tool is

the finest power tool of its kind. But its

performance is only as good as the

accessories with wmct_ it is used. "_'e

recommend onb/ Oreme{ accessories to be

used," "Use of any other accessories may

create a hazard." We hope you'll enjoy many

years of trouble free pleasure from your

Oremel Moto-Tool.

Page 5

Operating Speeds & Accessories

Set the speed indicator to fit the job - To

achieve the best job results when working

with different materials, the speed of the

Moto-Tool should be regulated. Only a full

wave output speed control such as the

Dremel Models 217 and 219 should be used

with the Model 275. Model 285 and 395

Moto-Tool has an integral speed control and

an external speed control should never be

used with these tools.

To select the right speed for each job, use a

practice piece of material. Vary speed to

find the best speed for the accessory you are

using and the job to be done.

There are three basic types of Moto-Tools:

single speed, :wo-soeed and variable speed

models. On the single speed model, thereis

an ON-OFFswitcn. When the switch is on, the

tool runs at 28,000 F_PM. On the two-speed

model, there is a LO and HI switch. When the

switch indicator is on the low setting, the tool

runs at about 15,000 RPM. When the switch

indicator is on the high setting the tool runs

about 28,000 RPM. On the variable speed

model, there is a switch indicator; with a white

line on it. Slide to the number on the housing

to select the operating speed needed

from 5,000-- 30,000 R.P.M, You can referto

the charts on page 6 to determine the

proper speed, based on the material being

worked and the type of cutter or other

accessory being used. These charts enable

you tO select both the correct accessory and

the optimum speed at a glance.

If you have a single speed or two-speed

model, you wil be able to use many acces.-.

sories to do a wide assortment of jobs. For.

the majority of applications, all models of the

Moto-Tool should be used at top'speed.

Needs for Slower Speeds

However certam materials (some plastics,

for example) require a relatively slow speed

because at mgh speed me frtotion of the tool

generates neat and causes ti'le plastic to melt.

Most work is done at top spe_:l on all Moto-Tooi

models. Lower speeds are needed only for

certain tasks.

Slow speeds ( 15,000 R PM or less) usually are

best for polishing o_erations employing the

felt polisning accessories. They may also be

best for working on delicate projects as

"eggery" work, delic:_te wood cawing, and

fragile model parts. You should always do

polishing with wire brush accessories at slower

speeds and never higher than 15,000 RPM.

Higher speeds are better for cawing, cutting,

routing, shaping, cutting dadoes or rabbets

in wood.

Hardwoods, metals, and glass require high

speed operation, and drilling should also be

done at high speeds.

The speed of model 395 is controlled by setting

this indicator on the housing.

The Settings for Approximate Revolutions

Per Minute Moto-Tool Variable Speed Model

395.

Switch Setting Speed Range

1 4,500- 8,000 RPM

2 9,000-11,000 RPM

3 12.000-17,000 RPM

4 18,000-24,000 RPM

5 25,000-30,000 RPM

NOTE: Speed is affected by voltage changes°

A reduced incoming voltage will slow the

R.P.M. of the tool, especially at the lowest

setting. If your tool appears to be running

slow increase the speed setting accordingly.

If you choose, dial the speed you need on the

single speed model 275 with this table-top

control accessory.

Dial Settings for Approximate Revolutions

Per Minute, using the No. 219 Manually

Operated Speed Control with single

speed Moto-Tools.

Dial Setting Speed Range

1 500 RPM

2 4,000 RPM

3 12,000 RPM

4 22,000 RPM

5 28,000 RPM

(Note: You can dial intermediate settings.

For example, a dial setting of 2-1/2 would

produce a motor speed of approximately

8,000 RPM.)

I

If you need it. single-speed models also can

have speed control by the addition of a foot

control unit.

The point to remember is this: You can do the

great malonty of work wtth the single speed at

its regular speed of 28,000 RPM. But for

certain materials and t'/pes of work, you need

slower speeds -which _sthe reason the variable

speed models and t_e speed control units

were de,,'e_c #e_.

To aid you in determining the optimum

ooera[_onalaoeed for gifferent materials and

different accessories. 'we have constructed a

series of to[ales tl_at acapear on page 6. By

referring to _nese tables, you can discover the

recommended speeds for each type of

accessory Looktheseta_lesoverandbecome

faro,liar w!tn [hem.

Page 5

Ultimately, the best way to determine the correct

speed for work on any material is to practice

for a few minutes on a piece of scrap, even

after referring to _he chart. You can quickly

learn that a slowe? or faster speed is more

effective just by observing what happens as

you make a pass or two at different speeds.

When working with plastic, for example, start

at a slow rate of speed and increase the speed

until you observe that the plastic is melting at

the point of contact. Then back the speed off

sligntly to get the optimum working speed.

Some rules of thumb in regard to speed:

1. Plastic and materials that melt at low

temperatures should be cut at low speeds.

2.

:olishing, buffing and cleaning with awire

brush should be done at speeds below

15,000 RPM Io prevent damage to the

brush.

3. Soft wood should be cut at high speed.

4. Iron or steel should be cut at top speed if

using atungsten carbide accessory, but at

slower speeds if using high speed steel

cutters. If a high speed steel cutter starts

to chatter - this normally means it is

running too slow.

5. Aluminum, coplber alloys, lead alloys, zinc

alloys, and tin may be cut at any speed,

depending on the type of cutting being

done• Use paraffin or omer suitable

lubricant on the cutter to prevent the cut

material from adhering to the cutter teeth.

Increasing the pressure on me tool is not the

answer when it is not cutting as you think it

should. Pernaps you should be using a

different cutter, and perhaps an adjustment

in speed would solve the problem. But lean-

ing on the tool seldoms helps.

Page 6

Speed Settings

" Speed for light cuts, caution burning on deep grooves.

t"Depending on cutting direction relative to grain.

CATALOG

NUMBER

100. 121.131.141

114.124,134.144

189.190

118.191.193

192,194

118,117,125,196

115,178

197

198

199

105.108

108, 109

107,110

111

112

113

Ace Set 201

Acc Set 202

425.427

400

406

409,420,428

610

612, 813,814,832.840

650,652

654

7103.7105,7117.

7120.7122,7123,

7134.7144

915, 923,924,

945.997.8153

913. 914,943.953,954,

963, 964,974.992

8160,8162,8163

904.922.932

941,952,984

8173,8174,8175

911,921,962

973,8184

903.971,8193

981,8200,8202

8215

83322.83642.

83702.86442

83142.84382

84922

85422

85562

85342.85602

85622

9901.9902,

9903,9904.

9905.9906.9912

9907,9908,

9909.9910,9911

WOOD WOOD PLJ_STIC BRASS, ETO, STONE

I

5. 5 3 t 2 4

5 3 2 t 1-2 2

5 5 2 4 5

5 5 2 3 5

5 5 2 3 5

5 3 2 2 2

5 5 2 1-2 1-2

4 2 2 1 3

4 2 2 2 3

4 2 1-2 2 2

SMALL ENGRAVING CUTTERS

5 5 4 4 3

5 5 3 4 3

5 5 3 4 2

5" 5" 4" 4 3

5" 5" 3" 4 3

5" 5" 3" 4 2

RUBBER POLISHING POINT

CUTTING ACCESSORIES -- SEE WARNING PAGE 7

5" 5

5 5

HIGH SPEED ROUTER BITS

3 3

3 21"

5 5t

5 21"

ALUMINUM OXIDE GRINDING STONES

SILICON CARBIDE GRINDING STONES_

TUNGSTEN CARBIDE CUTTERS

4 4 1 2 3

5 5 1 2 3

HIGH SPEED CUTTERS

2 1 1

2 1

5

DIAMOND WHEEL POINTS

I I I I

1 3 1/3

1 1-2 1/1

1 1-2 1/1

1 1 1/1

1

1 1/1

1 I/I

2 1

2 1

1-2

1 1

2 1

2 1

2 1

Page 6

t

CERAMIC

1

I

!

2

2

2

2

2

2

2

1-2

1 .

1

1

1

Page 7

Moto-Tool Accessories

The number and variety of accessories for the

Moto-Tool are almost limitless. There is a

category suited to almost any job you might

have to do--and a variety of sizes and shapes

within each category which enables you to get

the perfect accessory for ever,,, need.

Refer to the DREMEL BITS OF INFORMATION

ACCESSORY ORDER FORM for illustratiorts of

ttte acces_orie-J available. These accessories

may be found at your local hardware, hobby

or home center dealers.

Collets (_=====__

If you expect to use a variety of accessories,

we recommend that in the beginning you

purchase a corn plate set of four cotlets. Store

these so that you will have the proper size of

toilet for any accessory or drill bit you want to

use. Currently, the 1/8" and 3/32 n collet_

accommodate all of the available Dremel

accessories.

Mandrels

A mand rei is a shank with a threaded or screw

head, and mandrels are required when you

use polishing accessories, cutting wheels,

sanding discs, and polishing points. The

reason mandrels are used is that sanding

disc.s, cutting wheels and similar accessories

must be replaced frequently. The mandrel is

a permanent shank, allowing you to replace

only the worm head when necessary, thus

saving the expense of replacing the shaft

each time.

Screw Mandrel No. 401

This is a screw mandrel used with the felt;

polishing tip and felt polishing wheels

Small Screw Mandrel No. 402

This is a mandrel with a small screw at its tilS,

and is used with emery cutting wheels, sanding

discs, and polishing wheels.

Threaded Tip Mandrel No. 424

This is a mandrel with threaded tip which

threads into the polishing point accessory

No. 427.

High Speed Cutters

Available in 24 shapes, high speed cutters

are used in carving, cutting, and slotting in

wood, plastics, and soft metals such as

aluminum, copper, and brass. These arethe

accessories to use for freehand routing or

carving in wood or plastic, and for precision

cutting.

Tungsten Carbiae Cutters

These are tough, long-lived cutters for use on

hardened steel, fired ceramics, and other very

hard materials. They can be used for engraving

on tools and garden equipment.

hard materials but are excellent on wood,

plastic, and soft metals. Needs 3/32"toilet.

Structured Tooth

Tungsten Carbide Cutters

Fast cutting, needle-sharp teeth for greater

material removal, minimum loading. Use on

fiberglass, wood, plastic, epoxy and rubber.

Aluminum Oxide Grinding Stones

Round, pointed, flat -- you name the shape

and there is one available in this category.

These are made of aluminum oxide and cover

virtually every possible kind of grinding

application. Use them for sharpening lawn

mowers blades, screwdriver tips, knives,

scissors, chisets and other cutting tools. Use

to remove flash from metal castings, debur-

ring any metal after cutting, smoothing

welded joints, grinding off rivets and removing

rust. In macnineshops, high soeed drtllsand

cutters normally are ground with aluminum

oxide wheels.

Silcon Carbide Grinding Stones

Tougher than aluminum oxide points, these

are made especially for use on hard materials

such as glass and ceramics. Typical uses

might be the removal of stilt marks and

excess glaze on ceramics and engraving on

glass.

Diamond Wheel Points

Excellent for fine detail work on wood. jade,

ceramic, glass and other hard material. Bits

are covered with diamond particles. 3/32 °

shanks.

Polishing Accessories

These include an impregnated polishing point

and an impregnated polishing wheel for

bringing metal surfaces to smooth finish; a

felt polishing tip and felt polishing wheel, and

cloth polishing wheel, all used for polishing

plastics, metals, jewelry small parts. Also

included in this group is a polishing compound

(No. 421) for use with the felt and cloth

polishers.

Polishing points make a very smooth surface,

but a high luster is obtained using felt or cloth

wheels and polishing compound.

No polishing compound is needed when

using the 425 Polishing Wheel, 427' Polishing

point.

O

Sanding Accessories

Sanding discs in fine, medium, and coarse

grades are made to fit mandrel No. 402. They

can be used for nearly any small sanding job

you might have, from model making to fine

furniture finishing. In addition, there is the

drum sander, a tiny drum which fits into the

Moto-Tool and makes it possible to shape

wood, smooth fiberglass, sand inside curves

and other difficult places, and other sanding

jobs. You replace the sanding bands on the

drum as they become worn and lose their

grit. Bands come in fine and coarse grades.

Wire Brushes

Three different shapes of wire brushes are

available. For best results wire brushes

should be used at speeds not greater than

15,000 RPM. They remove rust from tools

and other metal surfaces, and clean and

burnish metal parts. Use for such jobs as

cleaning electrical connections to assure

good conduction.

Bristle Brushes

These are excellent cleaning tools on silverware,

jewelry and antiques. The three shapes make

it possible to get into tight corners and other

difficult places. Bristle brushes can be used

with polishing compound for faster cleaning

or polishing.

When using the steel saws

wheels (Nos, 409, 420, 426) always have the

work securely clamped. Never attempt to

hold the work with one hand while using

either of these accessories. The reason is

that these wheels will grab if they become

slightly canted in the groove, and can kick-

back causing loss of control resulting in

serious injury. Your second hand should be

used to steady and guide the hand holding

the tool. When a cutoff wheel grabs, the

wheel itself usually breaks. When the steel

saw wheel grabs, it may jump from the

groove and you could lose control of the

tool.

Cutting Wheels

These are thin discs of emery or fiberglass

used for slicing, cutting off and similar

operations. Use them for cutting off frozen

bolt heads and nuts, or to reslot a screw head

which has become so damaged that the

screwdriver won't work in it. Fine for cutting

BX cable, small rods, jubing, cable and

cutting rectangular holes_ln sheet metal.

(Nos. 400, 406) or cutoff

Small Engraving Cutters

This group has a wide variety of sizes and

shapes, and are made for intricate work on

ceramics (greenware), wood carvings, jewelry,

and scrimshaw. They often are used in making

complicated printed circuit boards. They

should not be used on steel and other very

Aluminum Oxide Abrasive Wheels

Use to remove paint, deburr metal, polish

stainless steel and other metals. Available in

fine and medium grits.

Page 7

Page 8

Maintenance Information

MAJNT'ENANCE OF REPLACEABLE BRUSHES

Models 275,285, & 395

The brushes should be inspected frequently

when tools are used continuously. If your

tool runs s_oradicatly, loses power, makes

unusual noises or runs at a reduced speed,

check the brushes. To continue using the

tool in this condition will permanently

damage your tool.

BRUSH & HOLDER

SPRING LOCK

HOLDER LOCK

IN DIRECTfON

OF ARROW TO OPEN

WARNING: Be aware that the brush

can fly out of tool toward eyes when

opening the brush holder lock.

"With the cord unplugged, use thumb

pressure or small screwdriver to depress the

brush holder lock and rotate the holder

(right-side down and left-side up;) slowly to

prevent the brush and spring from ejffcting

out of the holder• While rotating the holder

slowly, you will begin to see the brush. Place

BRUSH

SLIDE

a finger over the brush while rotating the

holder, remove your finger slowly to reduce

the spring tension.

CAUTION: Do no_ force the brush holder to

rotate once you feel _t stop. To do so will

damage the tool.

If the brush is less than 1/8" long and the end

surface of the brush that contacts the

commutator is rough and/or pitted, they

should be replaced. Check both brushes.

Usually the brushes will not wear out

simultaneously. If one brush is worn out

replace both brushes, insert the spring

portion of the brush spring assembly into the

brush holder opening first. Make sure the

brushes are ins:ailed as illustrated. The

curved surface of the brush must match the

curvature of the commutator.

After replacing brushes the _ool should be

run at no-load; place it on a clean surface and

run it freely for 5 minutes before loading (or

using) the tool. This will allow the brushes to

"seat" properly and will give you more hours

of life from each set of brushes. Thiswill also

extend the total life of your tool since the

commutator surface will "wear _ longer.

BEARINGS - Moto-Tool Nos. 275 and 285 are

equipped wi_ oil impregnated sleeve bearings.

Model No. 395 have double ball bearing

construction. Under normal use neither type

requires additional lubrication.

CAUTION:

Any servicing of this tool (Excluding brush

replacement for Models 275. 285 and 395)

shou_ be performed by an authorized

serve- _. representative.

IMPORTANT!

Use of any accessories or attachments other

than those supplied by Dremel may be

hazardous.

Dremel Service Centers, 4915 TwenW-first

St., Racine, W153406, or 4631 E. Sunny Dunes

Palm Springs, CA 92264.

Moto-Tool Attachments

i i

Add these Dremel attachments to your compact workshop and make your Moto-Tool more versatile.

Model 230 Router Attachment

ShaDes, edges, chamfers, cuts, rabbets,

dadoes, etc. Adjustable edges guide can be

easily removed for freehand routing. The

Model 230 can be used with Models 270, 280,

380 or 275, 285, & 395.

Allows finger-Tip control for tight corners and

hard-to-reach areas. 36" long cable attaches

to new Moto-Tools 395,285 and 275. Pencil-

like 1/2" diameter hand piece is cool-running,

ideal for light duty wood carving and other

uses.

Model 225 Flex-Shaft

Y

iii

For precision drilling, routing, grooving, 6°

Model 212 Drill Press

square work surface, 0° to 3" throat depth.

Table slotted for guides, hold downs. Holds

Moto-Tools 395, 285. 275 onlv,

Loading...

Loading...