Page 1

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:27 AM Page 1

IMPORTANT: IMPORTANT : IMPORTANTE:

Read Before Using Lire avant usage Leer antes de usar

Operating/Safety Instructions

Consignes de fonctionnement/sécurité

Instrucciones de funcionamiento y seguridad

MM40

Call Toll Free for

Consumer Information

& Service Locations

Pour obtenir des informations

et les adresses de nos centres

de service après-vente,

appelez ce numéro gratuit

Llame gratis para

obtener información

para el consumidor y

ubicaciones de servicio

1-800-4-DREMEL (1-800-437-3635) http://www.dremel.com

For English Version Version française Versión en español

See page 2 Voir page 19 Ver la página 36

Page 2

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:27 AM Page 2

General Power Tool Safety Warnings

WARNING

!

Read all safety warnings and all instructions. Failure to follow the warnings

and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

Electrical safety

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

us e a ny adapter pl ug s with earthe d

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of electric

shock.

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk

of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet

conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors,

use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

If operating a power tool in a damp location

is unavoidable, use a Ground Fault Circuit

Interrupter (GFCI) protected supply. Use of

an GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and

us e co mmon sense w hen opera ting a

power tool. Do not use a power tool while

you are tired or under the influence of drugs,

alcohol or medication. A moment of inattention

while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always

wear eye protection. Protective equipment

such as dust mask, non-skid safety shoes, hard

hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the

sw itch is in th e o ff-po sitio n b efore

connecting to power source and / or battery

pa ck, picki ng up or carrying the t ool.

Carrying power tools with your finger on the

switch or energizing power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before

turning the power tool on. A wrench or a

key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing and

balance at all times. This enables better

co ntrol of the power to ol in unexpe ct ed

situations.

Dress properly. Do not wear loose clothing

or jewelry. Keep your hair, clothing and

gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in

moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of dust collection can reduce dust-

related hazards.

Power tool use and care

Do not forc e the power to ol. Use the

correct power tool for your application. The

correct power tool will do the job better and

safer at the rate for which it was designed.

Do not use the power tool if the switch does

not turn it on and off. Any power tool that

ca nn ot be co nt ro ll ed wi th th e swi tc h is

dangerous and must be repaired.

-2-

Page 3

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:27 AM Page 3

Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment

or binding of moving parts, breakage of

parts and any other condition that may

affect the power tool’s operation. If damaged,

have the power tool repaired before use.

Ma ny acci de nt s ar e ca us ed by poorly

maintained power tools.

Safety Rules for Oscillating Tools

Hold power tool by insulated gripping

surfaces, when performing an operation

where the cutting tool may contact hidden

wiring o r i ts ow n cord. C ut ti ng tool

contacting a "live" wire may make exposed

metal parts of the power tool "live" and could

give the operator an electric shock.

Use clamps or another practical way to

secure and support the workpiece to a

stable platform. Holding the work by hand or

against your body leaves it unstable and may

lead to loss of control.

Do not drill, fasten or break into existing

walls or other blind areas where electrical

wi ring may exist. If th is s ituatio n i s

unavoidable, disconnect all fuses or circuit

breakers feeding this worksite.

Use a metal detector to determine if there

are gas or water pipes hidden in the work

area or call the local utility company for

assistance before beginning the operation.

Striking or cutting into a gas line will result in

explosion. Water entering an electrical device

may cause electrocution.

Always hold the tool firmly with both hands

for maximum control. Keep proper footing

and balance at all times. This enables better

co ntrol of the power tool i n unex pected

situations.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

Use the power tool, accessories and tool

bits etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from those

intended could result in a hazardous situation.

Service

Have your power tool serviced by a qualified

re pa ir person u sing on ly identical

replacement parts. This will ensure that the

safety of the power tool is maintained.

Keep hands away from cutting area. Do

not reach under the material being cut. The

proximity of the blade to your hand is hidden

from your sight.

Do not use dull or damaged blades. Bent

blade can break easily or cause kickback.

Exercise extreme caution when handling

the accessories. The accessories are very

sharp.

Wear protective gloves when changing

cutting accessories. Accessories become

hot after prolonged usage.

Use thick cushioned gloves and limit the

exposure time by taking fr equ ent rest

periods. Vibration caused by the tool may be

harmful to the hands and arms.

Before scraping, check workpiece for nails.

If there are nails, either remove them or set

them well below intended finished surface.

Striking a nail with accessory edge could

cause the tool to jump.

Do not wet sand with this tool. Liquids

entering the motor housing is an electrical

shock hazard.

Never work in area which is soaked with a

li quid, such as a solv ent or wat er, or

da mpened su ch as ne wly appl ied

wallpape r. Th ere is an ele ctr ical shock

-3-

Page 4

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:27 AM Page 4

hazard when working in such conditions with a

power tool and heating of the liquid caused by

scraping action may cause harmful vapors to

be emitted from workpiece.

Always wear eye protection and a dust

mask for dusty applications and when

sanding overhead. Sanding particles can be

absorbed by your eyes and inhaled easily

and may cause health complications.

Use special precautions when sanding

chemically pressure treated lumber, paint

th at may be lea d base d, or a ny oth er

materials that may contain carcinogens. A

suitable breathing respirator and protective

Additional Safety Warnings

GFCI and personal protection devices like

electrician’s rubber gloves and footwear will

further enhance your personal safety.

Do not use AC only rated tools with a DC

power supply. While the tool may appear to

work, the electrical components of the AC

rated tool are likely to fail and create a hazard

to the operator.

Keep handles dry, clean and free from oil

and grease. Slippery hands cannot safely

control the power tool.

Develop a periodic maintenance schedule

for your tool. When cleaning a tool be

careful not to disassemble any portion of

th e tool sinc e interna l wires may be

misplaced or pinched or safety guard return

sp rings may be improperly moun ted.

Certain cleaning agents such as gasoline,

carbon tetrachloride, ammonia, et c. may

damage plastic parts.

clothing must be worn by all persons entering

the work area. Work area should be sealed by

plastic sheeting and persons not protected

should be kept out until work area is thoroughly

cleaned.

Do not use sandpaper intended for larger

sanding pads. Larger sandpaper will extend

beyond the sanding pad causing snagging,

tearing of the paper or kick-back. Extra paper

extending beyond the sanding pad can also

cause serious lacerations.

Risk of injury to user. The power cord must only

be serviced by a Dremel Service Facility.

WARNING

!

drilling, and other construction activities

contains chemicals known to cause cancer,

birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead from lead-based paints,

• Crystalline silica from bricks and cement and

other masonry products, and

• Arsenic and chromiu m from chemicallytreated lumber.

Yo ur ri sk from these expo su re s var ie s,

depending on how often you do this type of

work. To reduce your exposure to these

chemicals: work in a well ventilated area, and

work with approved safety equipment, such as

those dust masks that are specially designed

to filter out microscopic particles.

Some dust created by power

sanding, sawing, grinding,

-4-

Page 5

0

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:27 AM Page 5

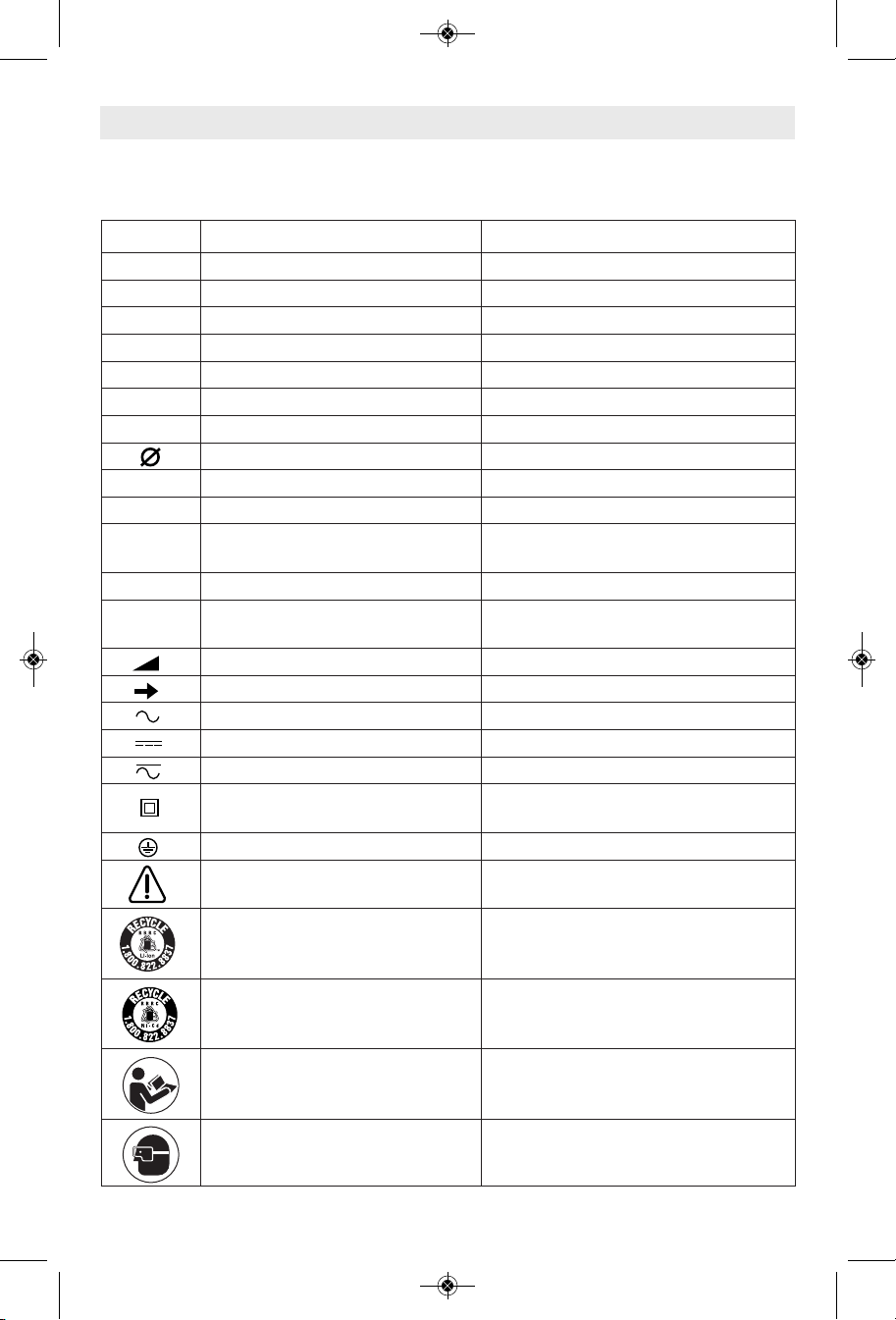

Symbols

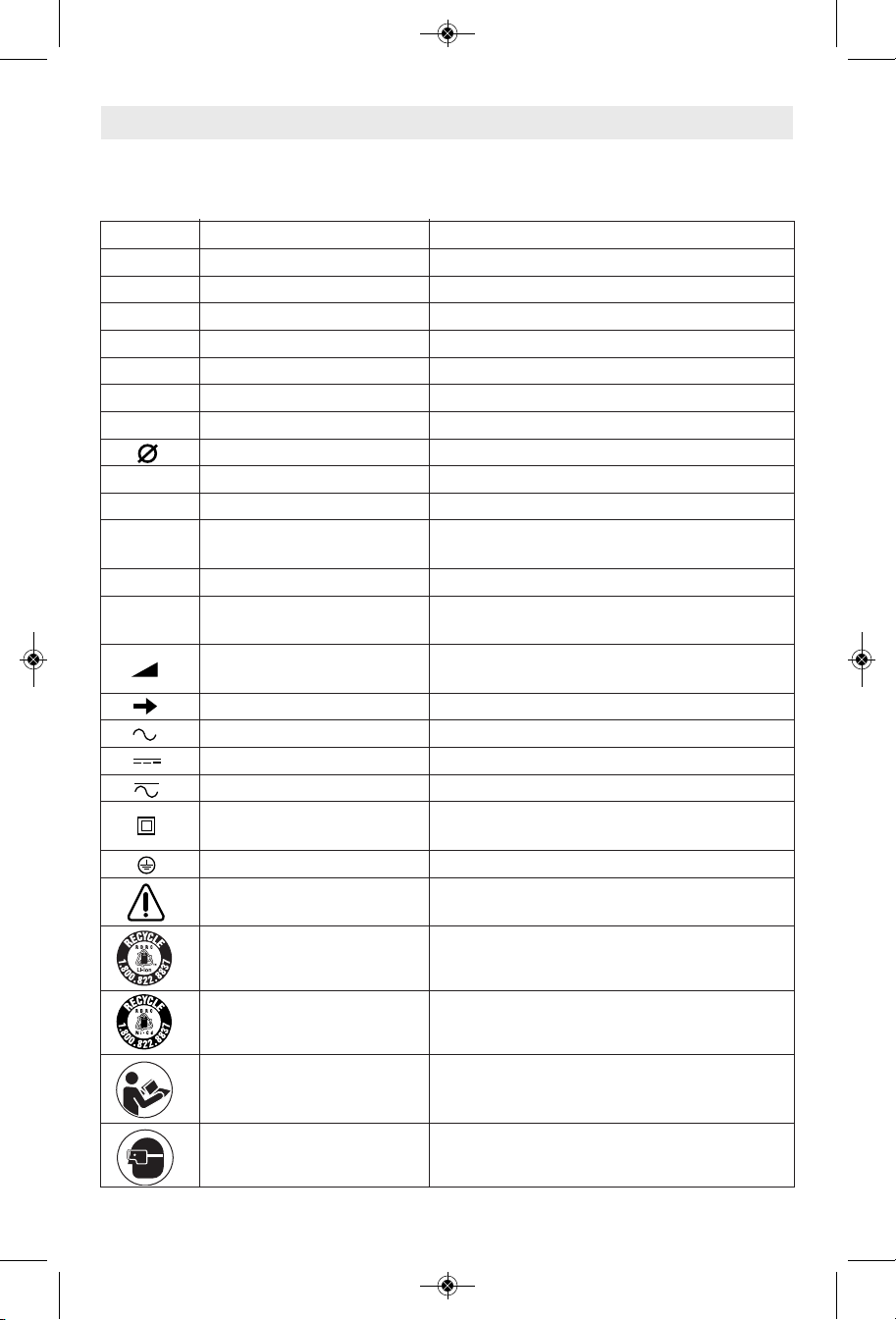

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Diameter Size of drill bits, grinding wheels, etc.

n

0

n Rated speed Maximum attainable speed

.../min Revolutions or reciprocation Revolutions, strokes, surface speed,

0 Off position Zero speed, zero torque...

1, 2, 3, ... Selector settings Speed, torque or position settings.

I, II, III, Higher number means greater speed

No load speed Rotational speed, at no load

per minute orbits etc. per minute

Infinitely variable selector with off Speed is increasing from 0 setting

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction Designates Double Insulated

Construction tools.

Earthing terminal Grounding terminal

Warning symbol Alerts user to warning messages

Li-ion RBRC seal Designates Li-ion battery recycling

program

Ni-Cad RBRC seal Designates Ni-Cad battery recycling

program

Read manual symbol Alerts user to read manual

Wear eye protection symbol Alerts user to wear eye protection

-5-

Page 6

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:27 AM Page 6

Symbols (continued)

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and safer.

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters Laboratories.

This symbol designates that this tool is listed by Underwriters Laboratories,

to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian Standards

Association.

This symbol designates that this tool is listed by the Canadian Standards

Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican Standards.

-6-

Page 7

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 7

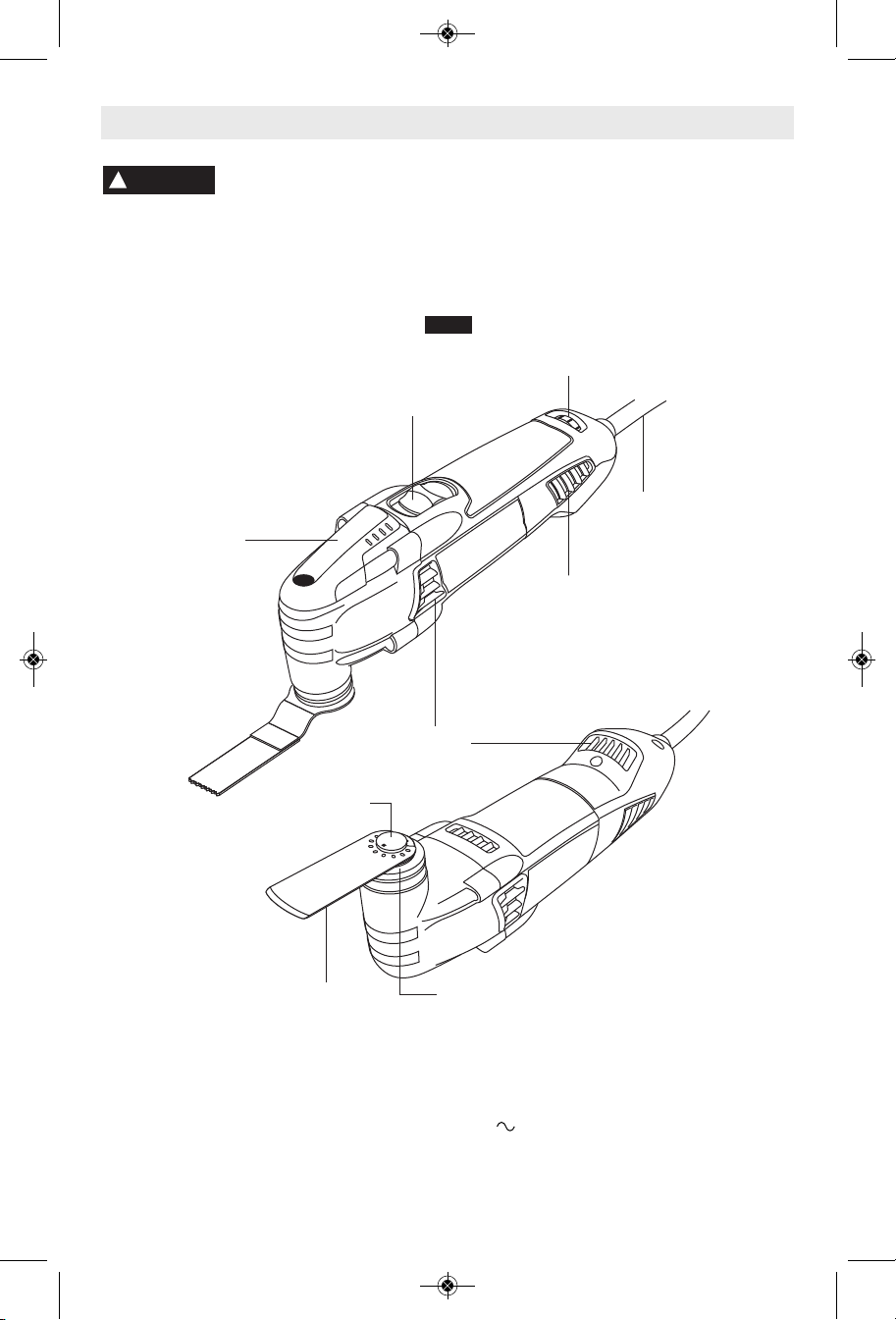

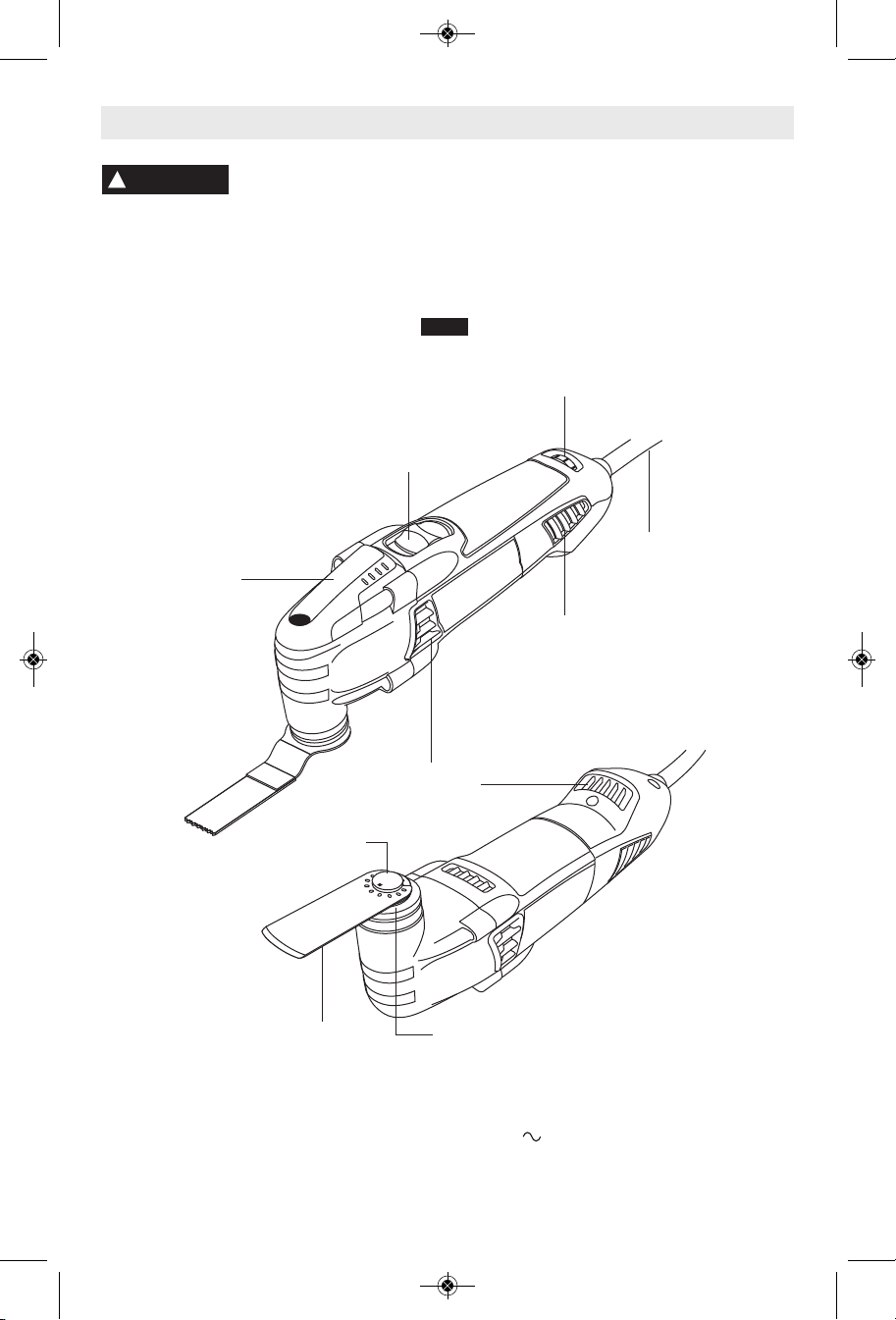

Functional Description and Specifications

WARNING

!

Di sc onnect the plug fro m the pow er source bef ore maki ng any

assembly, adjustments or changing accessories. Such preventive safety

measures reduce the risk of starting the tool accidentally.

Model MM40 Multi-Max™ Oscillating Power Tool

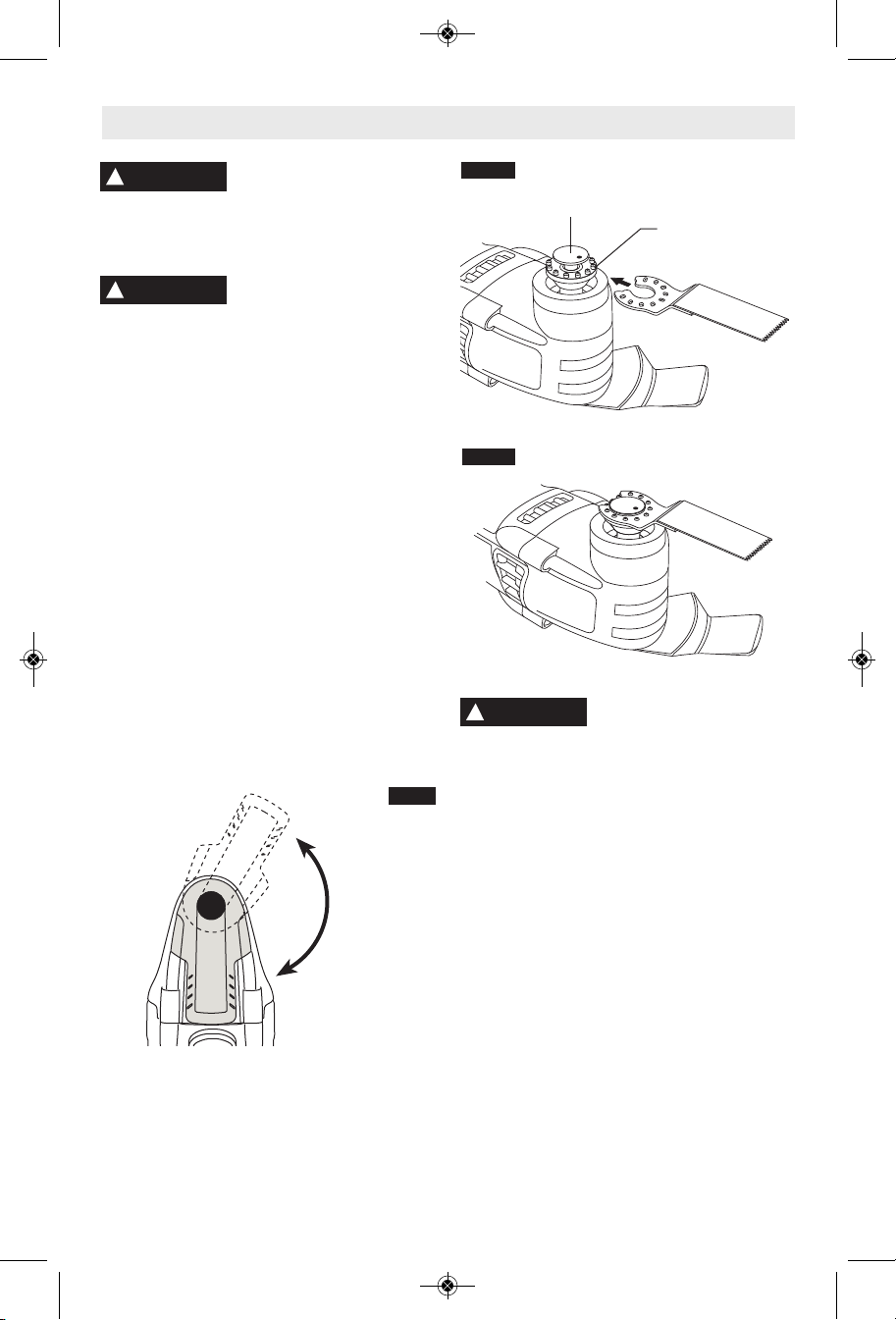

FIG. 1

ON/OFF

SWITCH

QUICK LOCK

™

LEVER

VENTILATION

OPENINGS

VARIABLE SPEED

CONTROL DIAL

POWER

CORD

VENTILATION

OPENINGS

CLAMPING

FLANGE

ACCESSORY

ACCESSORY HOLDER

Model number MM40

No load speed n

10,000-21,000/min

0

Voltage rating 120 V 60 Hz

NOTE: For tool specifications refer to the nameplate on your tool.

-7-

Page 8

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 8

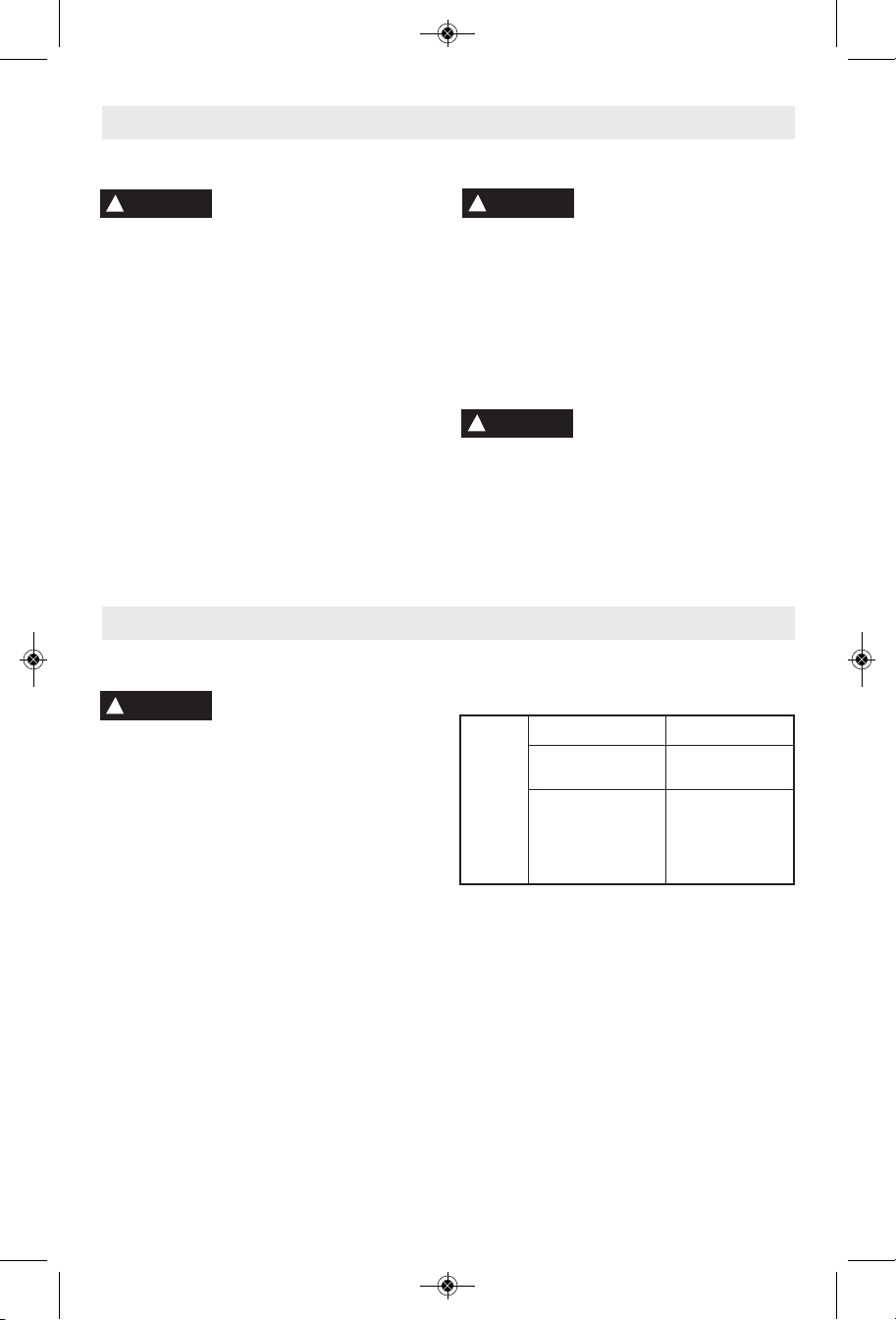

Assembly

WARNING

!

making any assemb ly, adjustmen ts or

changing accessories. Such preventive

safety measures reduce the risk of starting the

tool accidentally.

WARNING

!

alway s wear protectiv e glo ves. Such

preventive safety measures reduce the risk of

injury from sharp edges of the accessories.

Application tools can become very hot while

working. Danger of burns!

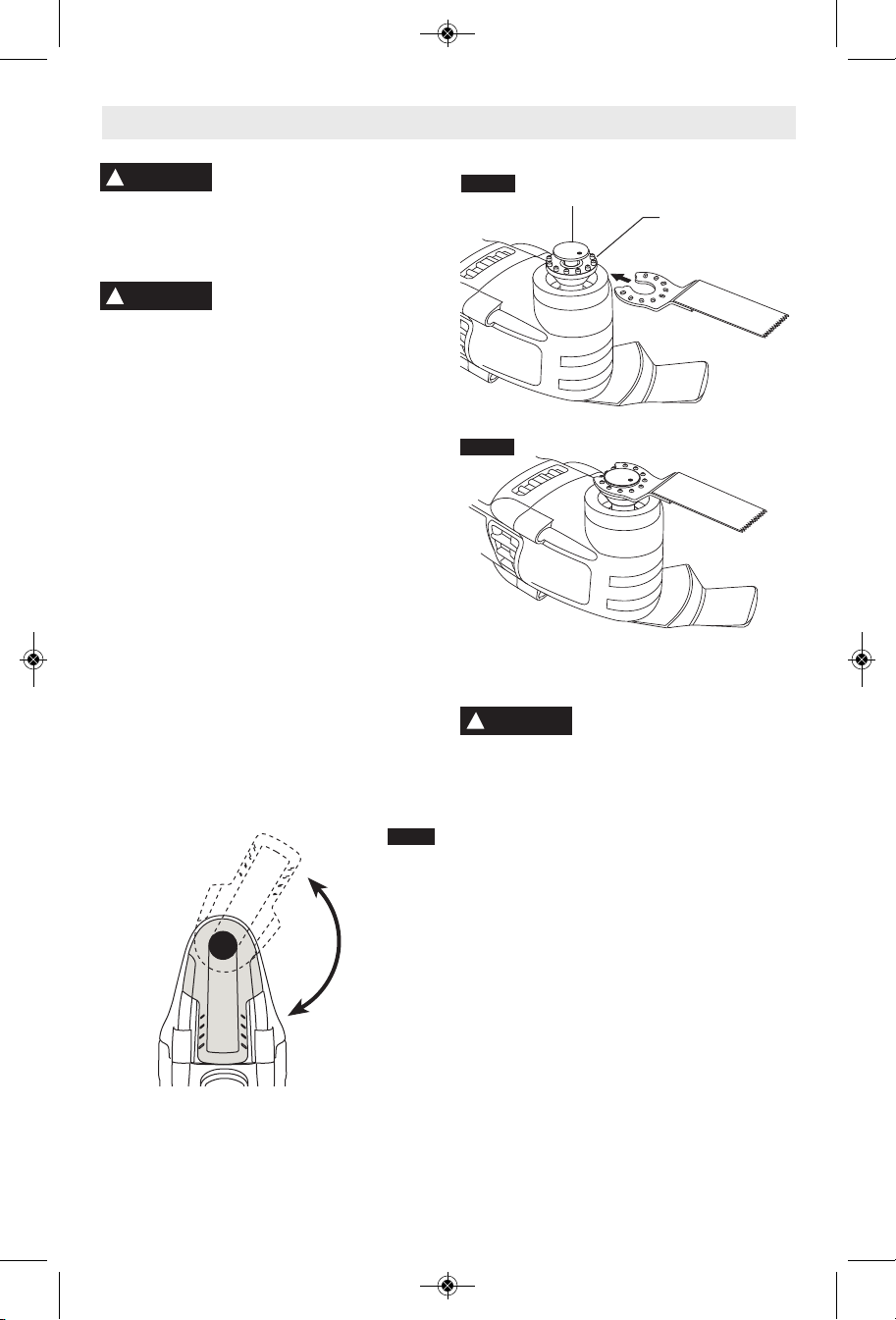

INSTALLING AND REMOVING

ACCESSORIES WITH QUICK LOCK™

The Dremel Multi-Max™ MM40 includes an

integrated accessory change mechanism. The

Quick Lock™ accessory interface allows you to

install and remove accessories without the need

of a wrench or hex key. You will also no longer

need to worry about losing a clamping screw &

washer as these parts are no longer used in the

MM40 version of the Multi-Max™.

1. To install an accessory using the Quick

Lock™ feature, hold tool upside down to

preve nt th e blade from fal ling off the

acces sory holder when instal ling an d

removing accessories.

2. Turn the Quick Lock™ lever on the top on the

tool counter-clockwise to unlock the clamping

mechanism (Fig. 2). The lever needs to be

fully engage d to unlock the clamping

mechanism.

3. Clean accessory holder, accessory and the

clamping flange with a clean cloth.

4. Place the accessory onto the accessory

holder making sure the accessory engages

all pins in the holder and the accessory is

Disconnect the plug from

the pow er source before

For all work or when

chang ing acces sories

ACCESSORY CHANGE

FIG. 2

OPEN

CLOSE

FIG. 3a

FIG. 3b

!

fastening accessory. Avoid placing hands

or fingers between lever and tool body.

5. Turn the Quick Lock™ lever on the top of the

tool in a clockwise motion, to the closed

position, to securely lock the accessory in

place (Fig. 2).

6. To remove an accessory, simply unlock the

clamping mechanism by turning the Quick

Lock™ lever counter-clockwise as described

above (Fig. 2).

7. Lift up on the accessory bracket to take it off

the pins. (Note: be careful, blade may be

hot.)

NOTE: Some accessories, such as scrapers

or blades, may be mounted either straight

on the tool, o r at an angle to i ncr eas e

usability (Fig. 4). In order to do this with the

Quick Lock™ interface, place the accessory

onto the accessory holder making sure the

accessory engages all pins in the holder and

the accessory is flush against the accessory

holder. Securely lock the accessory in place

as described previously (Fig. 2).

CLAMPING

FLANGE

flush against the accessory holder (Fig. 3a &

Fig 3b).

WARNING

To avoid pinching, firmly

hold Quick Lock lever when

ACCESSORY

HOLDER

-8-

Page 9

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 9

INSTALLING AND REMOVING

SANDING SHEETS

Your backing pad uses hook-and-loop backed

sandpaper, which firmly grips the backing pad

when applied with moderate pressure.

1. Align the sanding sheet and press it onto

the sanding plate by hand.

2. Firm ly press th e pow er tool with the

sanding sheet against a flat surface and

briefly switch the power tool on. This will

pr omote good adhesion and helps to

prevent premature wear.

3. To change, merely peel off the old sanding

sheet, remove dust from the backing pad if

necessary, and press the new sanding

sheet in place.

After considerable service the backing pad

surface will become worn, and the backing pad

must be replaced when it no longer offers a

firm grip. If you are experiencing premature

Introduction

Thank you for purchasing the Dremel MultiMax™.

This tool was designed to tackle home repair,

remodeling and restoration projects. The

Dremel Multi-Max™ tackles tasks that are

tedious, time consuming or simply next to

impossible to achieve with any other tool.

The ergonomic housing is designed for you

to hold and control in a comfortable manner

during operation.

It comes with an assortment of accessories

that are specifically designed for remodeling

work where you need precision and control.

Your Dreme l Multi- Ma x™ ha s a ro bust

electric motor, is comfortable in the hand,

and is m ade to acce pt a lar ge variety of

ac ce ss or ie s including fl us h cut bl ad es ,

wear out of the backing pad facing, decrease

the amount of pressure you are applying

during operation of the tool.

For maximum use of abrasive, rotate pad 120

degrees when tip of abrasive becomes worn.

FIG. 4

scraper blades, grout removal wheels and

sanding pads.

Accessories come in a variety of shapes and

permit you to do a number of different jobs.

As you become familiar with the range of

accessories and their uses, you will learn just

how versatile your Dremel Multi-Max™ is.

Visit www.dremel.com to learn more about

what you can do with your Dremel MultiMax™.

INTENDED USE

This Dremel Multi-Max™ Tool is intended for

dry san ding of surface s, corners, edges,

sc rapin g, saw ing soft m etals , wood and

plastic components, and grout removal using

the app li cable t oo ls and a cc es sorie s

recommended by Dremel.

Operating Instructions

LEARNING TO USE THE TOOL

Getting the most out of your oscillating tool is a

matter of learning how to let the speed and the

feel of the tool in your hands work for you.

The first step in learning to use the tool is to

get the “feel” of it. Hold it in your hand and feel

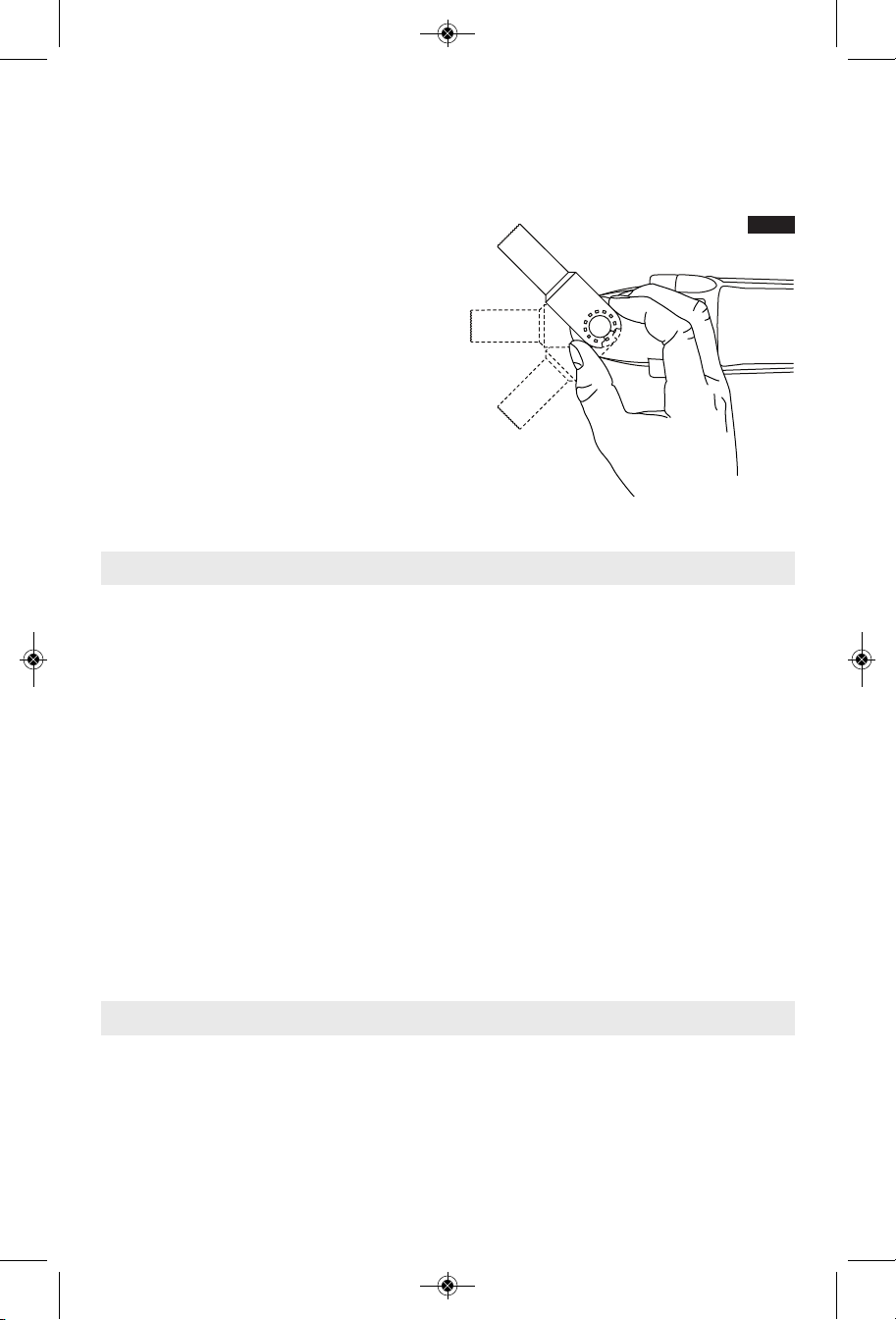

its weight and balance (Fig. 5). Depending on

the application, you will need to adjust your

hand position to achieve optimum comfort and

control. The unique comfort grip on the body of

the tool allows for added comfort and control

during use.

-9-

Page 10

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 10

FIG. 5

When holding tool, do not cover the air vents

with your hand. Blocking the air vents could

cause the motor to overheat.

IMPORTANT! Practice on scrap material first

to see how the to ol’s h igh-s pe ed a ction

performs. Keep in mind that your tool will

perform best by allowing the speed, along with

the correct accessory, do the work for you. Be

careful not to apply too much pressure.

Instead, lower the oscillating accessory lightly

to the work surface and allow it to touch the

point at which you want to begin. Concentrate

on guiding the tool over the work using very

little pressure from your hand. Allow the

accessory to do the work.

Usually it is better to make a series of passes

with the tool rather than to do the entire job

with one pass. To make a cut, for example,

pass the tool back and forth over the work. Cut

a little material on each pass until you reach

the desired depth.

SLIDE "ON/OFF" SWITCH

The tool is switched "ON" by the slide switch

located on the topside of the motor housing.

TO TURN THE TOOL "ON", slide the switch

button forward.

TO TURN THE TOOL "OFF", slide the switch

button backward.

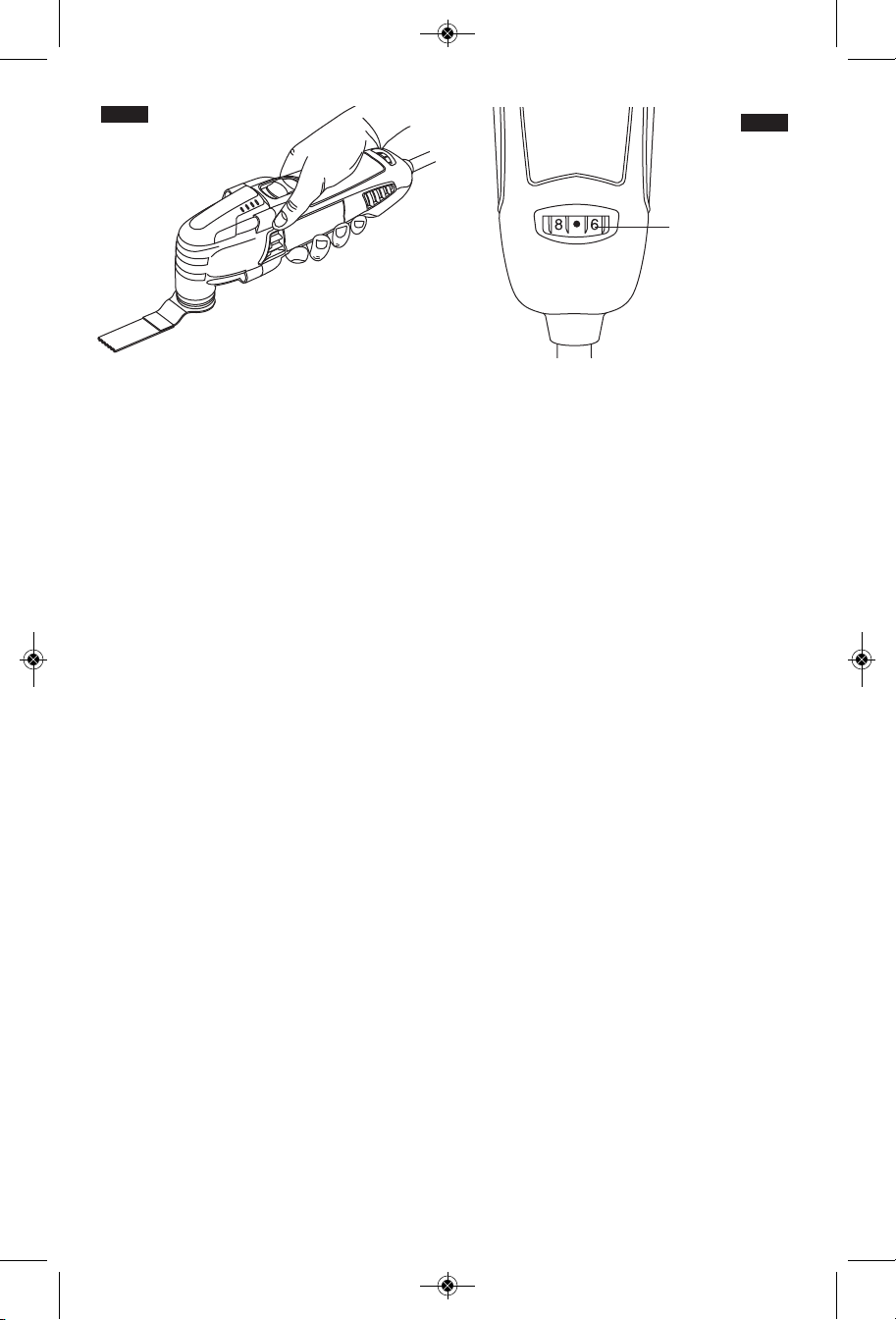

VARIABLE SPEED CONTROL DIAL

This tool is equipped with a variable speed

co ntrol di al (Fi g. 6). The spee d may b e

controlled during operation by presetting the

dial in any one of ten positions.

OPERATING SPEEDS

The Dremel Multi-Max™ consists of an AC

universal motor and oscillating mechanism to

perform applications such as cutting, grout

removal, scraping, sanding and more.

FIG. 6

VARIABLE SPEED

CONTROL DIAL

The Dre me l M ul ti-Max™ h as a h ig h

oscillating motion of 10,000 - 21,000 /min

(OPM). The high speed motion allows the

Dremel Multi-Max™ to achieve with excellent

results. The oscillating motion allows the dust

to fall to the surface ra ther than slinging

particles into the air.

To achieve the best results when working

with d ifferent materials, set the var iable

speed control to suit the job (See Speed

Chart on Page 12 & 13 for guidance) . To

select the right speed for the accessory in

use, practice with scrap material first.

NOTE: S peed is af fecte d by volta ge s

changes. A reduced incoming voltage will

slow the OPM of the tool, especially at the

lowest setting. If your tool appears t o be

running slowly, increase the speed setting

accordingly. The tool may not start at the

lowest switch setting in areas where outlet

voltage is less than 120 volts. Simply move

the speed setting to a hig her pos iti on to

begin operation.

Th e variab le speed contr ol setti ng s are

marked on the sp ee d c ontrol d ia l. Th e

settings for approximate /min (OPM) are:

Switch Setting Speed Range

/min (OPM)

2 10,000-11,000

4 11,000-13,000

6 13,000-16,000

8 16,000-19,000

10 19,000-21,000

You can refer to the charts on the following

pages to determine the proper speed, based

on the material and accessory being used.

These charts enable you to select both the

correct accessory and the optimum speed at a

glance.

-10-

Page 11

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 11

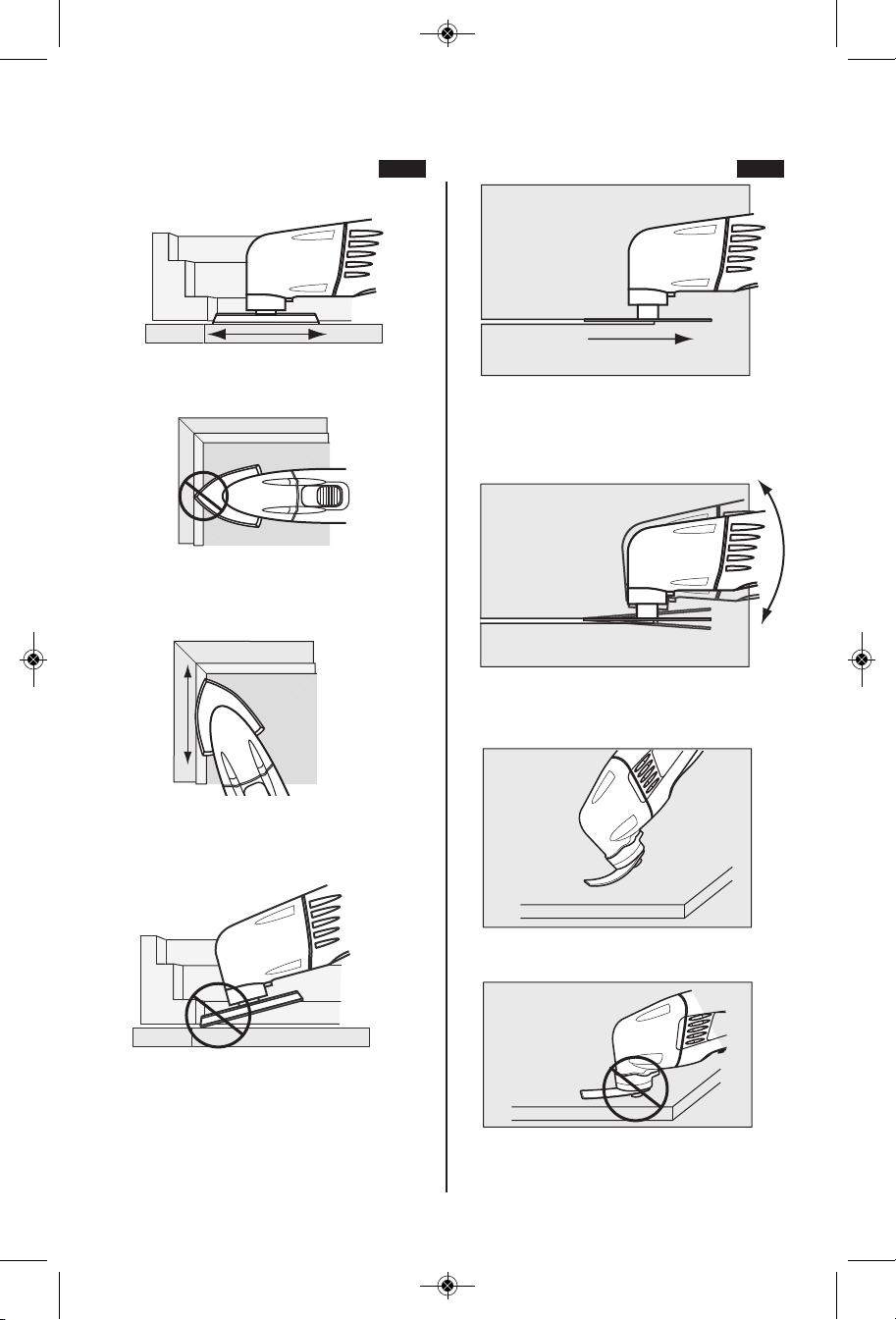

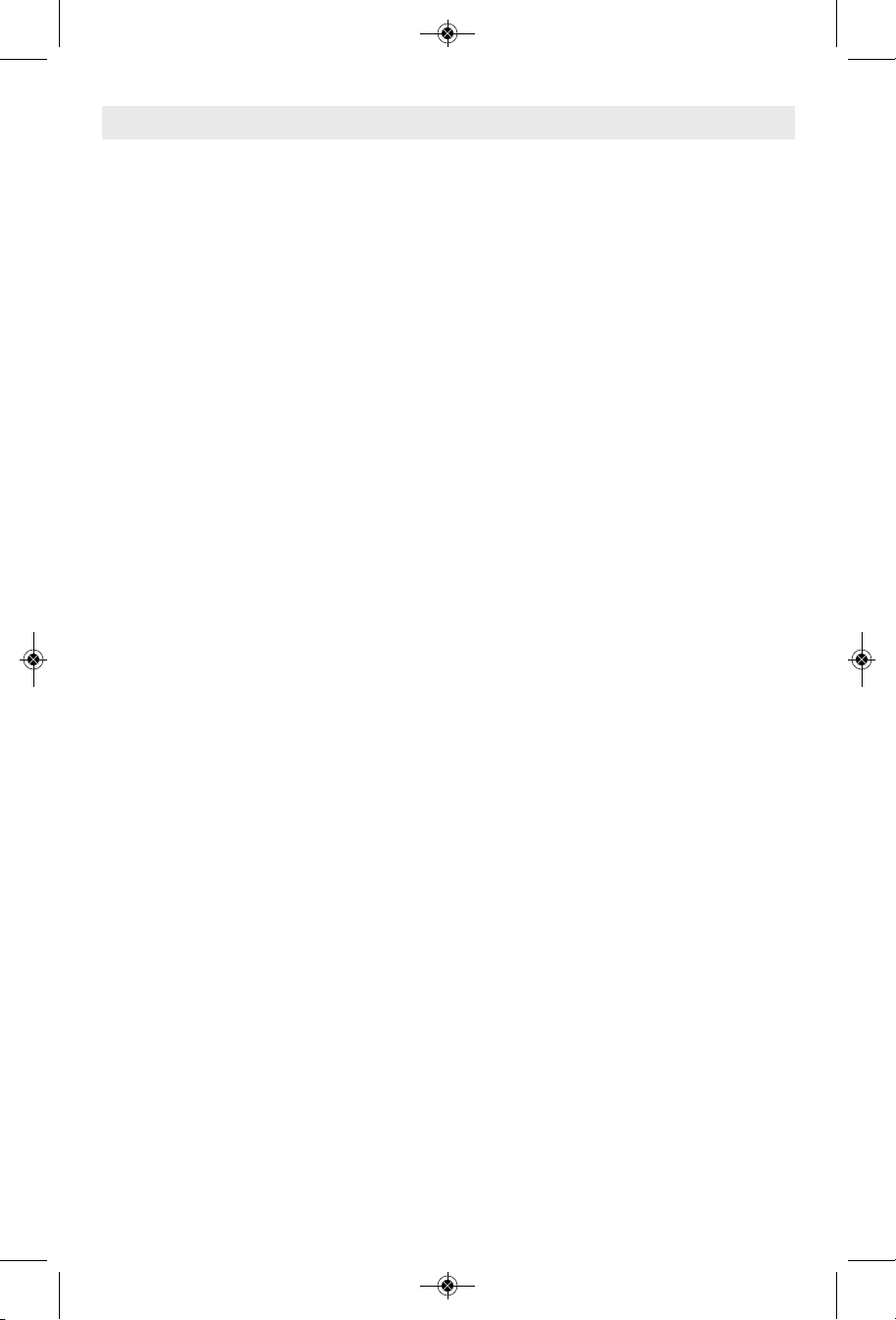

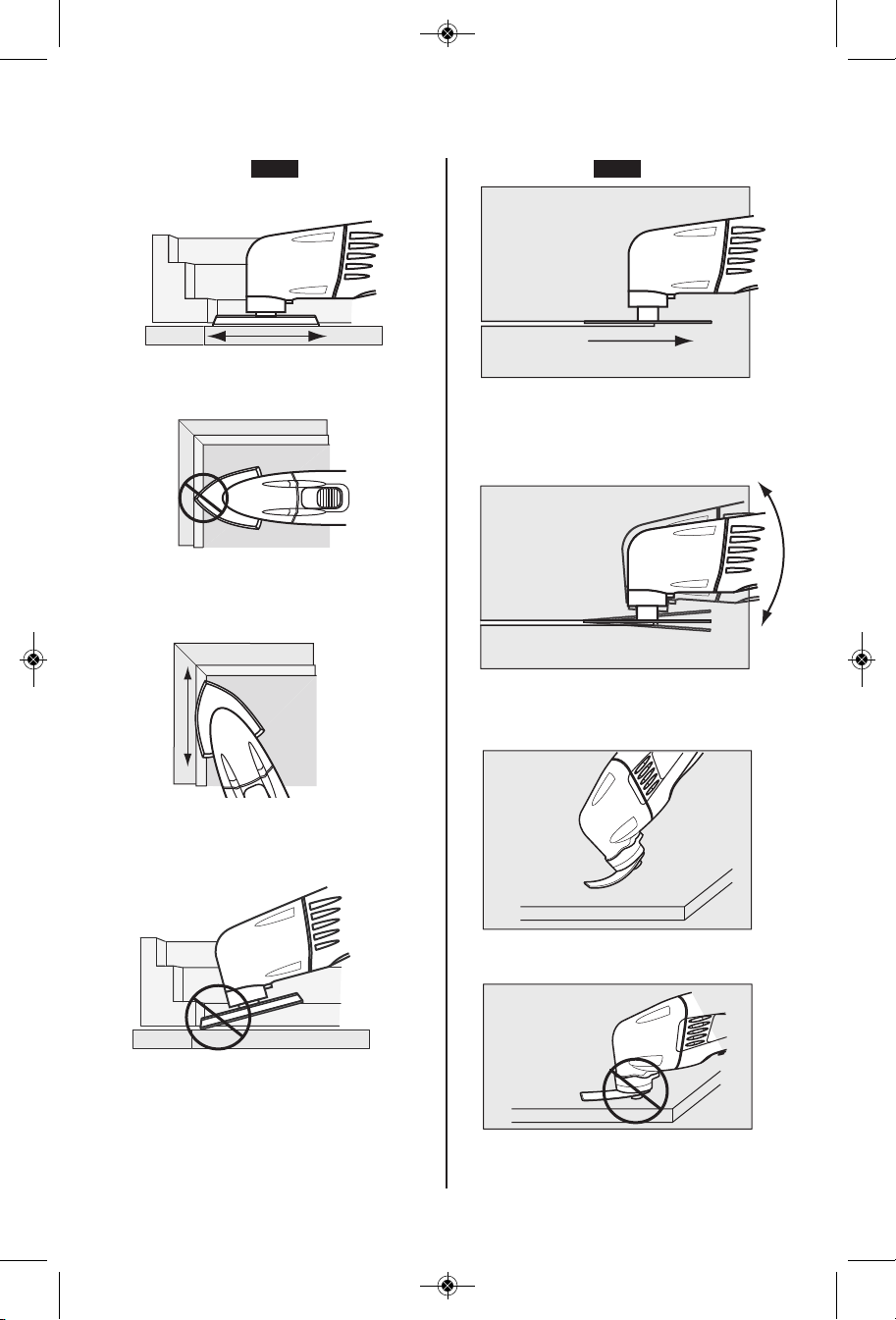

Please refer to figures 7 and 8 for further instruction on how to use your Dremel Multi-Max™.

Following these instructions will allow you to get the highest performance out of your oscilating tool.

CORRECT: Sand with a smooth

back and forth motion, allowing the

weight of the tool to do the work.

CORRECT: Always cut with a

smooth back and forth motion.

Never force the blade. Apply light

pressure to guide the tool.

INCORRECT: Avoid sanding with

only the tip of the pad. Keep as

much sand paper in touch with the

work surface as possible.

FIG. 8FIG. 7

CORRECT: Always sand with the

pad and sandpaper flat against the

work surface. Work smoothly in a

back and forth motion.

INCORRECT: Avoid tipping the

pad. Always sand flat.

INCORRECT: Do not twist the tool

while cutting.This can cause the

blade to bind.

CORRECT: Make sure flexible

scraper blade flexes enough

INCORRECT: Avoid screw head

touching surface with flexible

scraper blade.

-11-

Page 12

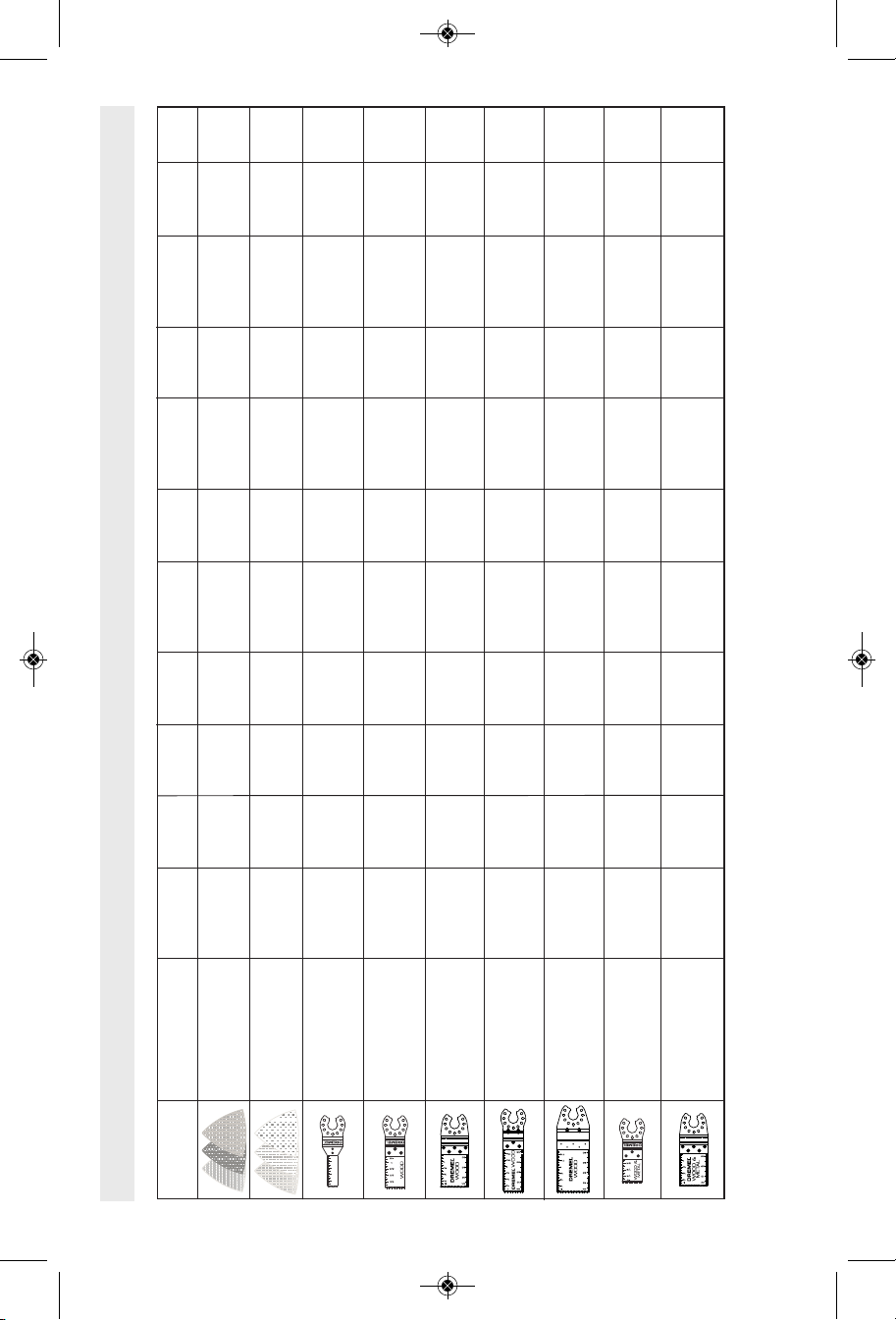

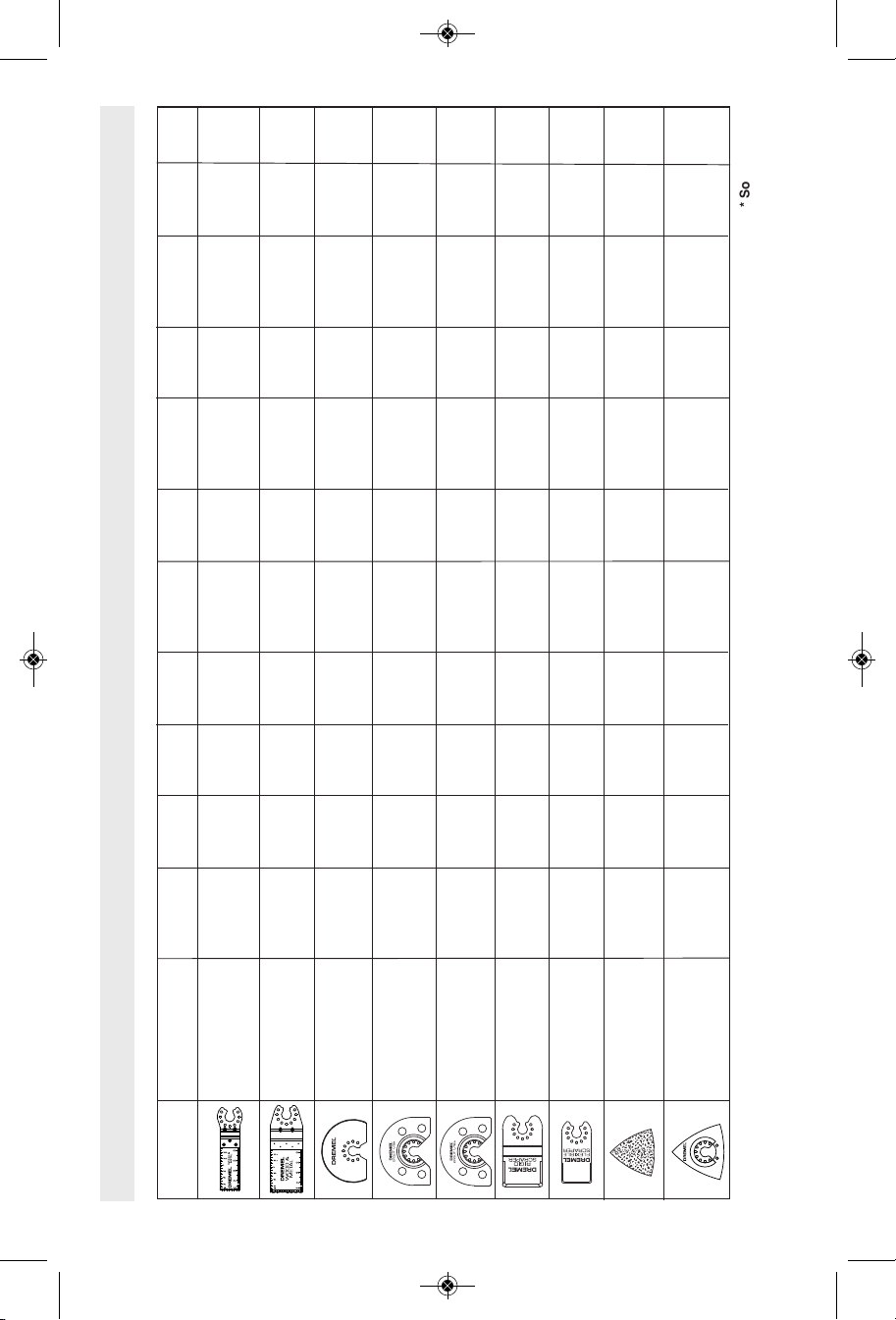

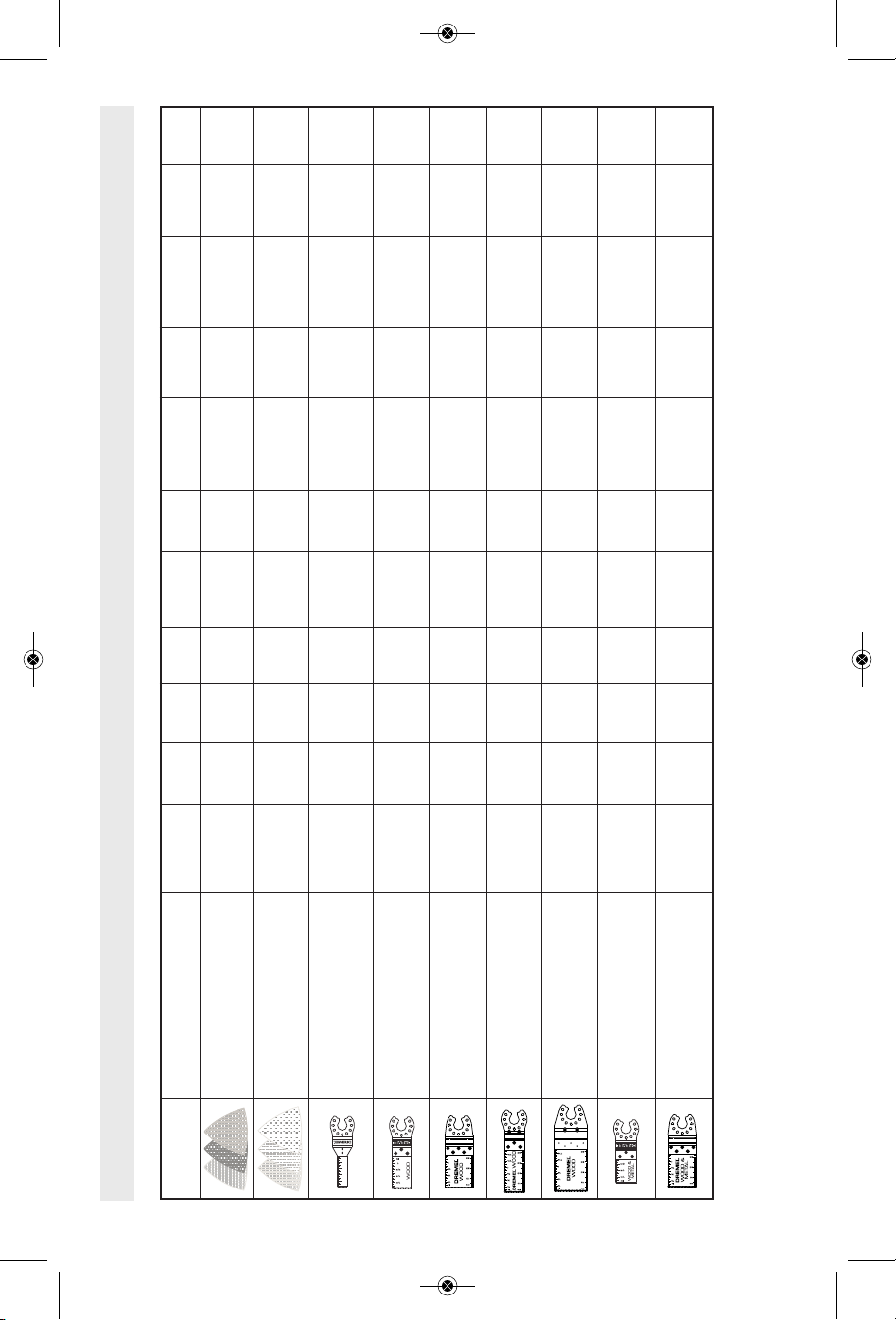

60, 120 and 240 Grit

Paper - Bare Wood

60, 120 and 240 Grit

Paper - Paint

HCS Wood Flush

Cut Blade

1-1/4" x 3/8"

HCS Wood Flush

Cut Blade

1-1/4" x 3/4"

HCS Wood Flush

Cut Blade

1-1/4" x 1-1/8"

HCS Wood Flush

Cut Blade

1-5/8" x 3/4"

HCS Wood Flush

Cut Blade

1-1/4" x 1-11/16"

BiM Wood/Metal

Flush Cut Blade

1" x 3/4"

BiM Wood/Metal

Blade

1-1/4" x 1-1/8"

2 - 10

2 - 10

8 - 10

8 - 10

8 - 10

8 - 10

8 - 10

8 - 10

8 - 10

2 - 10

2 - 10

6 - 10

6 - 10

6 - 10

6 - 10

6 - 10

6 - 10

6 - 10

2 - 10

-

-

-

-

-

-

-

2 - 6

2 - 6

2 - 6

2 - 6

2 - 6

2 - 6

2 - 6

2 - 6

2 - 6

8 - 10

8 - 10

-

-

-

-

8 - 10*

8 - 10*

8 - 10

8 - 10

-

-

-

-

8 - 10

8 - 10

"

-

-

-

-

-

-

-

-

-

!

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

MM70W

MM70P

MM411

MM440

MM460

MM470

MM480

MM422

MM462

WOOD

1/4

IN

3/4

1

1/2

"

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 12

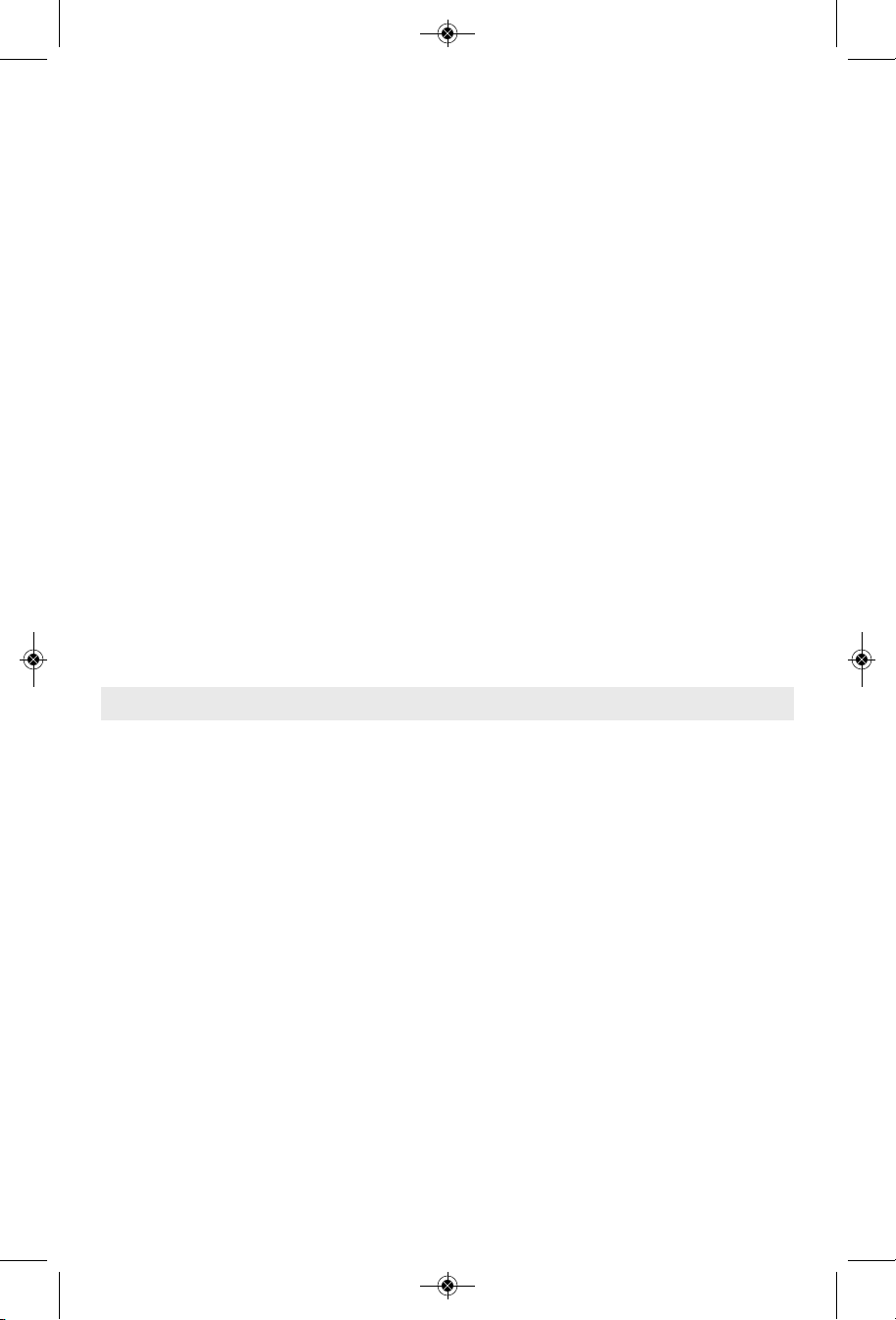

Use only Dremel, high-performance accessories.

Multi-Max™ Accessory Speed Settings

-12-

Page 13

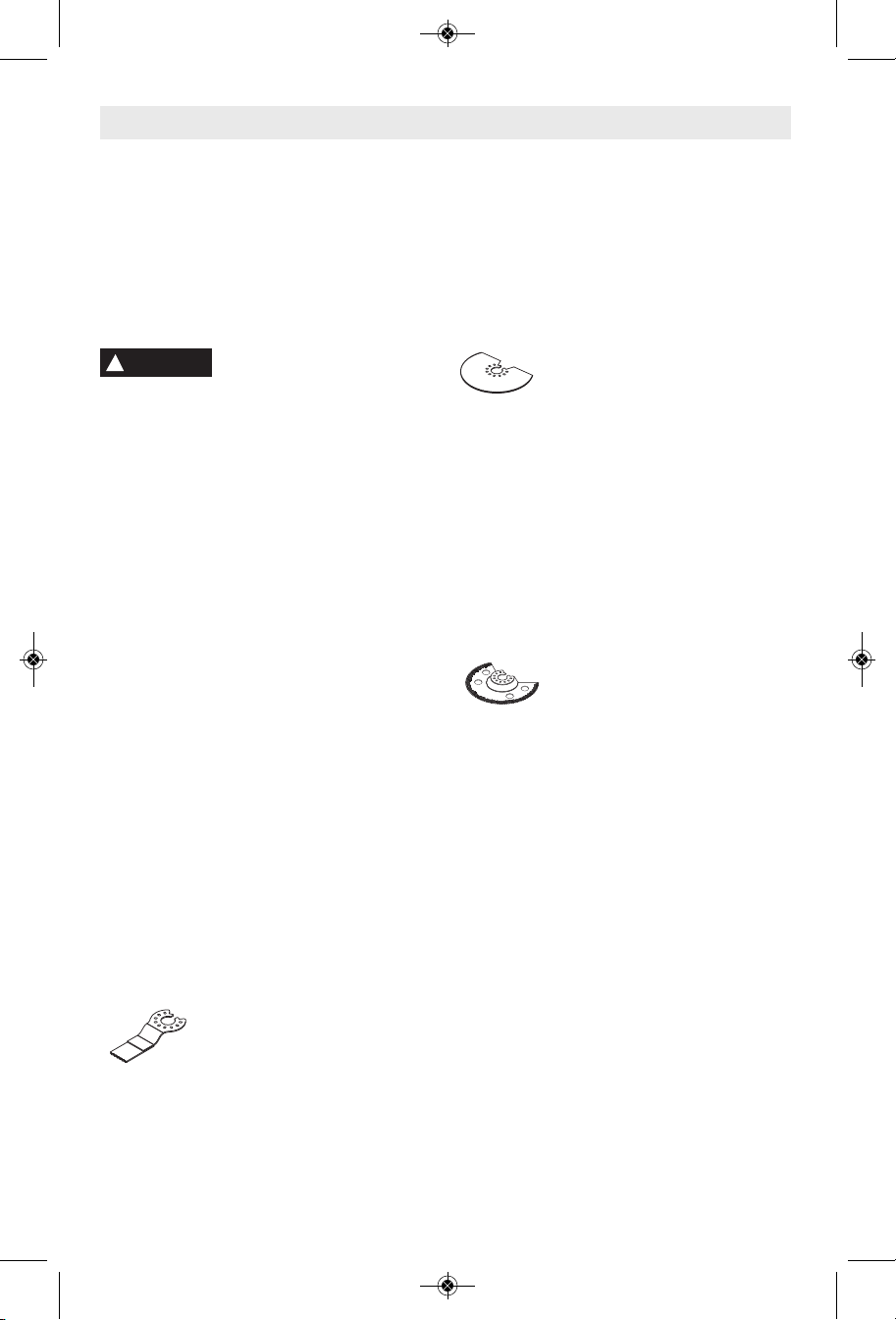

BiM Wood/Metal

Blade

1-5/8" x 3/4"

BiM Wood/Metal

Blade

1-1/4" x 1-11/16"

3" Flat

Saw Blade

1/8" Grout Removal

Blade

1/16" Grout Removal

Blade

Rigid Scraper Blade

Flexible Scraper

Blade

60 Grit Diamond

Paper

24 Grit Carbide

Rasp

8 - 10

8 - 10

8 - 10

-

-

-

6 - 10

6 - 10

6 - 10

6 - 10

-

-

-

-

6 - 10

-

-

-

-

2 - 4

2 - 4

6 - 10

2 - 6

2 - 6

2 - 6

-

-

-

-

-

-

8 - 10*

8 - 10*

-

-

-

-

-

-

-

8 - 10

8 - 10

-

-

-

-

-

-

-

"

-

-

-

-

2 - 8

-

-

-

!

-

-

-

-

2 - 6

2 - 6

-

-

-

-

-

-

-

-

6 - 10

6 - 10

-

-

6 - 10

6 - 10

-

6 - 10

6 - 10

MM472

MM482

MM450

MM500

MM501

MM600

MM610

MM900

MM920

WOOD

a

a

a

MM920

"

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 13

Use only Dremel, high-performance accessories.

Multi-Max™ Accessory Speed Settings

-13-

Page 14

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 14

Operating Applications

Your Dremel Multi-Max™ Tool is intended for

sanding and cutting wooden materials, plastic,

plaster and non-ferrous metals. It is especially

suitable for working close to edges, in tight

spaces, and for flush cutting. This tool must be

used only with Dremel accessories .

Below are some typical uses for your Dremel

Multi-Max™ Tool.

WARNING

!

from the body. Never position hand near or

directly in front of working area. Always hold

the tool with both hands and wear protective

gloves.

Flush Cutting

Remove excess wood from door jamb, window

sill and/or toekick. Removing excess copper or

PVC pipe.

Removal work

e.g. carpets & backing, old tile adhesives,

ca ulking on masonry, wood and ot he r

surfaces.

Removal of excess materials

e.g. plaster, mortar splatters, concrete on tiles,

sills.

Preparation of surfaces

e.g. for new floors and tiles.

Detail sanding

e.g. for sanding in extre mely ti ght are as

otherwise difficult to reach and require hand

sanding

Saw blades are ideal for making precise cuts

in tight areas, close to edges or flush to a

surface.

Select a medium to high speed for making

initial plunge, start off at medium speed for

increased control. After making your initial cut,

you can increase speed for faster cutting

ability.

it is important not to force the tool during the

plunge cut. If you experience a strong vibration

in you r hand dur ing the pl unge cut, this

indicates that you are applying too much

pressure. Back the tool out and let the speed

of the tool do the work. While keeping the teeth

APPLICATION

For all accessories, work

with the accessory away

CUTTING

Fl ush cutting b lades are

intended to make precise cuts to

allow for installation of flooring or

wall material. When flush cutting

of the blade in the work surface, move the

back of the tool in a slow sideways motion.

This motion will help expedite the cut.

When making a flush cut it is always a good

idea to have a piece of scrap material (tile or

wood) supporting the blade. If you need to rest

the flush cutting blade on a delicate surface,

you should protect the surface with cardboard

or masking tape.

Th e fl at s aw blade i s id eal for

ma king pr ecise cut s in wo od ,

plaster, drywall material.

Applications include cutting openings in flooring

for venting, repairing damaged flooring, cutting

openings for electrical boxes. The blade works

best on softer woods such as pine. For harder

woods, the blade life will be limited.

Select a medium to high speed.

The flat saw blad e can also be used for

window restoration making glazing easy to

remove. The saw blade can be placed directly

against the edge of the window frame, guiding

the blade through the glazing.

GROUT REMOVAL

Grout removal blades are ideal

fo r r emoving dama ged or

cr acked grout. Grou t blad es

come in different widths (1/16" and 1/8") to

tackl e diffe rent gr out lin e width s. Befo re

selecting a grout blade measure the grout line

width to pick the appropriate blade.

Select a medium to high speed.

To remove the grout, use a back and forth

motion, making several passes along the grout

line. The hardness of the grout will dictate how

many passes are needed. Try and keep the

grout blade aligned with the grout line and be

careful not to apply too much side pressure on

the grout blade during the process. To control

plunge depth use the carbide grit line on the

blade as an indicator. Be careful not to plunge

beyond the carbide grit line to avoid damage to

the backer board material.

The grout blades can handle both sanded and

un sanded grout. If you n otice the blade

clogging during the grout removal process, you

can use a brass brush to clean the grit, thus

exposing the grit again.

The grout blade geometry is designed so that

the blade can remove all grou t up to the

su rface of a w all or cor ner. This can be

-14-

Page 15

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 15

accomplished by ensuring that the segmented

portion of the blade is facing the wall or corner.

SCRAPING

Scrapers are suitable for removing old coats of

va rnish or adhes iv es, re mo ving b on ded

carpe ting, e .g. on stairs/ steps a nd othe r

small/medium size surfaces.

Select low to medium speed.

Rigid scrapers are for large area

removal, and harder materials

such as vinyl flooring, carpeting

an d ti le adhesive s. When

removing strong, tacky adhesives, grease the

scraper blade surface with (petroleum jelly

or silicone grease) to reduce gumming up.

The carpet/vinyl flooring removes easier if

it is scored prior to removal so the scraper

blade can move underneath the flooring

material.

Flexible scrapers are used for

hard to reach areas and softer

material such as caulk.

Mount the scraper blade with the logo side

facing up. With the flexible scraper, make sure

that the screw head does not make contact

with surface during the scraping process (a 30

- 45 degree pitch is recommend). This can be

accomplished by making sure that the tool is at

an angle to the blade. You should be able to

see the blade flex during the scraping process.

If you are removing caulk from a delicate

surface such as a bath tub or tile back splash,

we recomme nd tapin g or protecti ng the

surface that the blade will rest on. Use rubbing

alcohol to clean the surface after the caulk

and/or adhesive is removed.

Turn the tool on and place desired accessory

on the area where material is to be removed.

Begin with light pressur e. The oscillating

mo tion of ac cessory only occurs when

pressure is ap plied to the mat eri al to be

removed.

Excessive pressure can gouge or damage the

background surfaces (e.g,. wood, plaster).

SANDING

Sanding accessories are suitable

for dry sanding of wood, metal,

surfaces, corners and edges and

hard to reach areas.

Work with the complete surface of the sanding

pad, not only with the tip.

Corners may be finished using the tip or edge

of the s elected acce ssory, which should

occasionally be rotated during use to distribute

the wear on the accessory and backing pad

surface.

Sand with a continuous motion and light

pressure. DO NOT apply excessive pressure let the tool do the work. Excessive pressure

will result in poor handling, vibration, and

unwanted sanding marks and premature wear

on the sanding sheet.

Always be certain that smaller workpieces are

securely fastened to a bench or other support.

Larger panels may be held in place by hand on

a bench or sawhorses.

Open-coat aluminum oxide sanding sheets are

recommended for most wood or metal sanding

applications, as this synthetic material cuts

quickly and wears well. Some applications,

such as metal finishing or cleaning, require

special abrasive pads which are available from

your dealer. For best results, use Dremel

sanding accessories which are of superior

quality and are carefully selected to produce

professional quality results with your oscillating

tool.

The following suggestions may be used as a

general guide for abrasive selection, but the

best results will be obtained by sanding a test

sample of the workpiece first.

Grit Application

Coarse For rough wood or metal

sanding, and rust or old

finish removal.

Medium For general wood or metal

sanding

Fine For final finishing of wood,

metal, plaster and other

surfaces.

With the workpiece firmly secured, turn tool on

as described above. Contact the work with the

tool after the tool has reached its full speed,

and remove it from the work before switching

the tool off. Operating your oscillating tool in

this manner will prolong switch and motor life,

and greatly increase the quality of your work.

Move the oscillating tool in long steady strokes

parallel to the grain using some lateral motion

to overlap the strokes by as much as 75%.

DO NOT apply excessive pressure - let the

tool do the work. Excessive pressure will result

in poor handling, vibration, and unwanted

sanding marks.

-15-

Page 16

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 16

GRINDING

Th e d iamond p ap er acces so ry

allows for the Multi-Max™ to be

used for grin ding away cement ,

plaster or thin set. Preparing the surface for tile

replacement is a common application for this

accessory.

The diamond paper needs to be mounted to

the backing pad prior to use.

Select a low to high speed depending on the

material removal rate desired.

The carbide rasp accessory also

allows the Mul ti-Max™ to grind

aw ay cement , thinse t mortar ,

plaster, and also wood. This accessory is

commonly used to prepare for tile replacement

or ras ping w ood to smo oth a surf ace or

remove material.

The speed should be set at high speed for

aggressive material removal or at low speed

for a more detailed removal of material.

Do not apply excessive pressure on the tool-let

it do the work.

Corners may be finished using the tip or edge

of the s elected acce ssory, which should

occasionally be rotated during use to distribute

the wear on the accessory and backing pad

surface.

Grind with a continu ous motion and light

pressure. DO NOT apply excessive pressure let the tool do the work. Excessive pressure

will result in poor handling, vibration, and

premature wear on the diamond paper sheet.

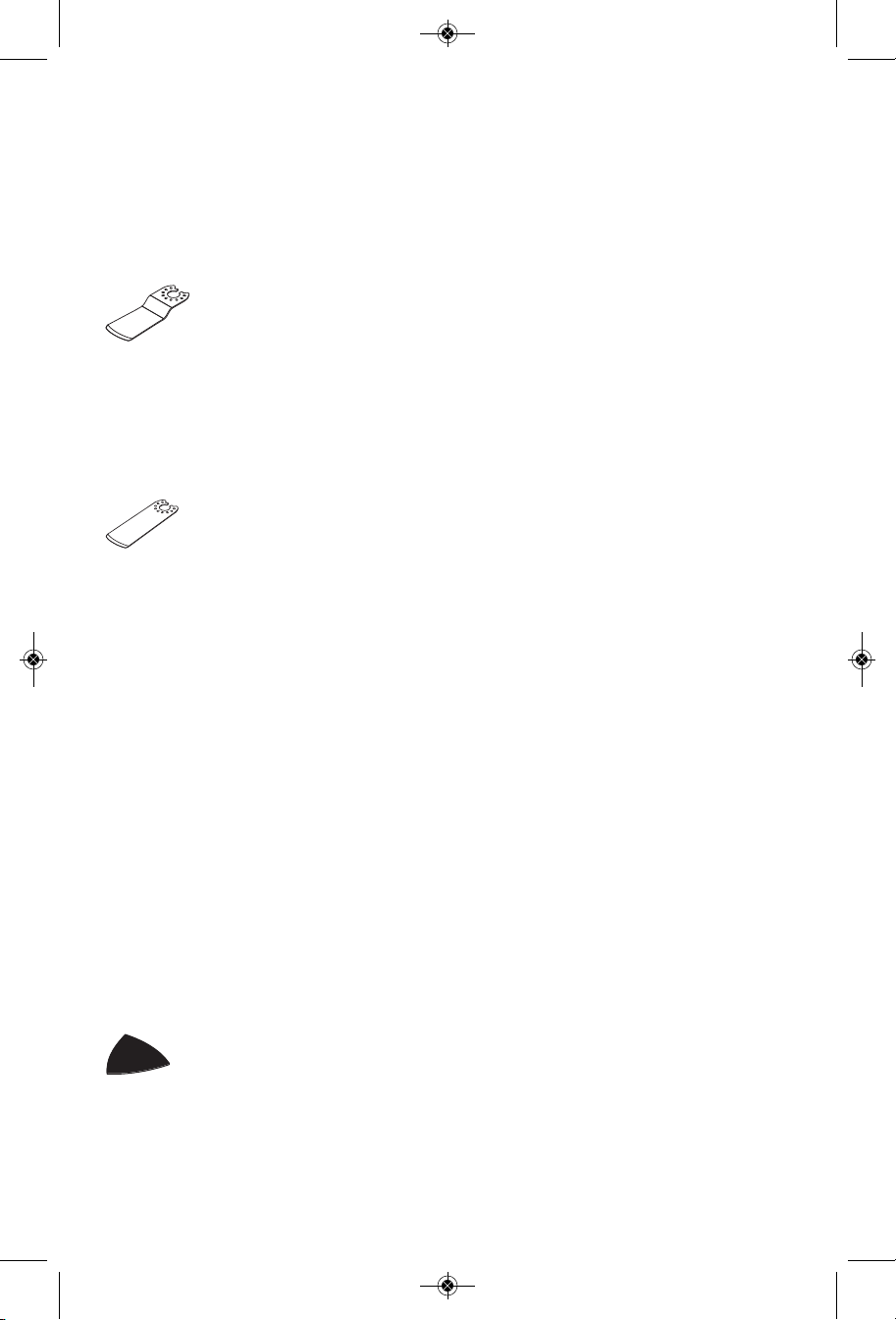

Selecting Sanding/Grinding Sheets

Material Application Grit Size

All wooden materials (e.g.,

hardwood, softwood, chipboard,

building board) Metal materials–

For coarse-sanding, e.g. of

rough, unplanned beams and

boards

Coarse

60

Metal materials, fiberglass

and plastics

Sand Paper (Dark)

Paint, varnish, filling compound

and filler

Sand Paper (White)

Masonry, stone, cement

and thin set

Diamond Paper

For face sanding and planing

small irregularities

For finish and fine sanding of

wood

For sanding off paint

For sanding primer (e.g., for

removing brush dashes, drops

of paint and paint run)

For final sanding of primers

before coating

For smoothing, shaping and

braking edges

-16-

Medium

Fine

Coarse

Medium

Fine

Coarse

120

240

80

120

240

60

Page 17

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 17

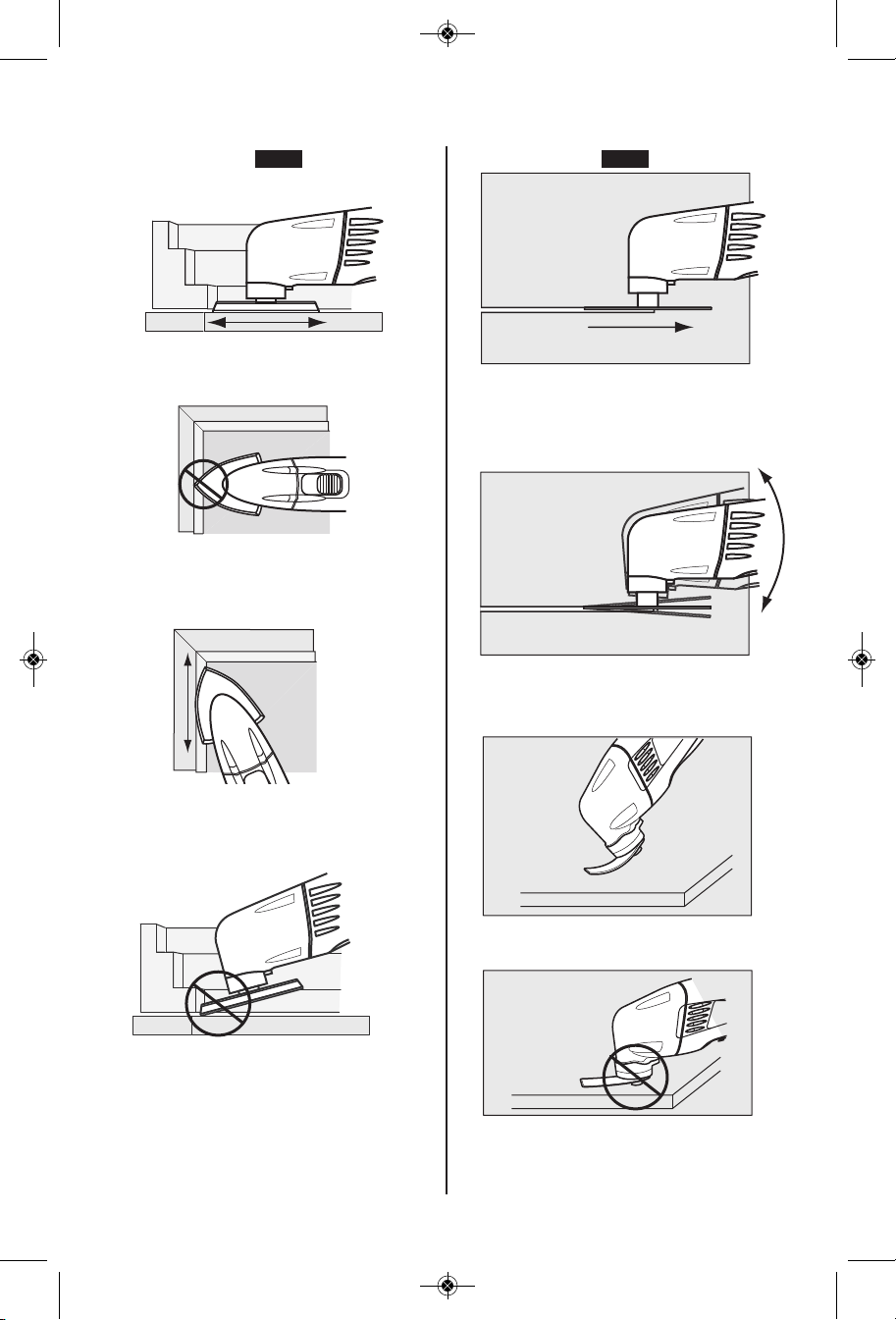

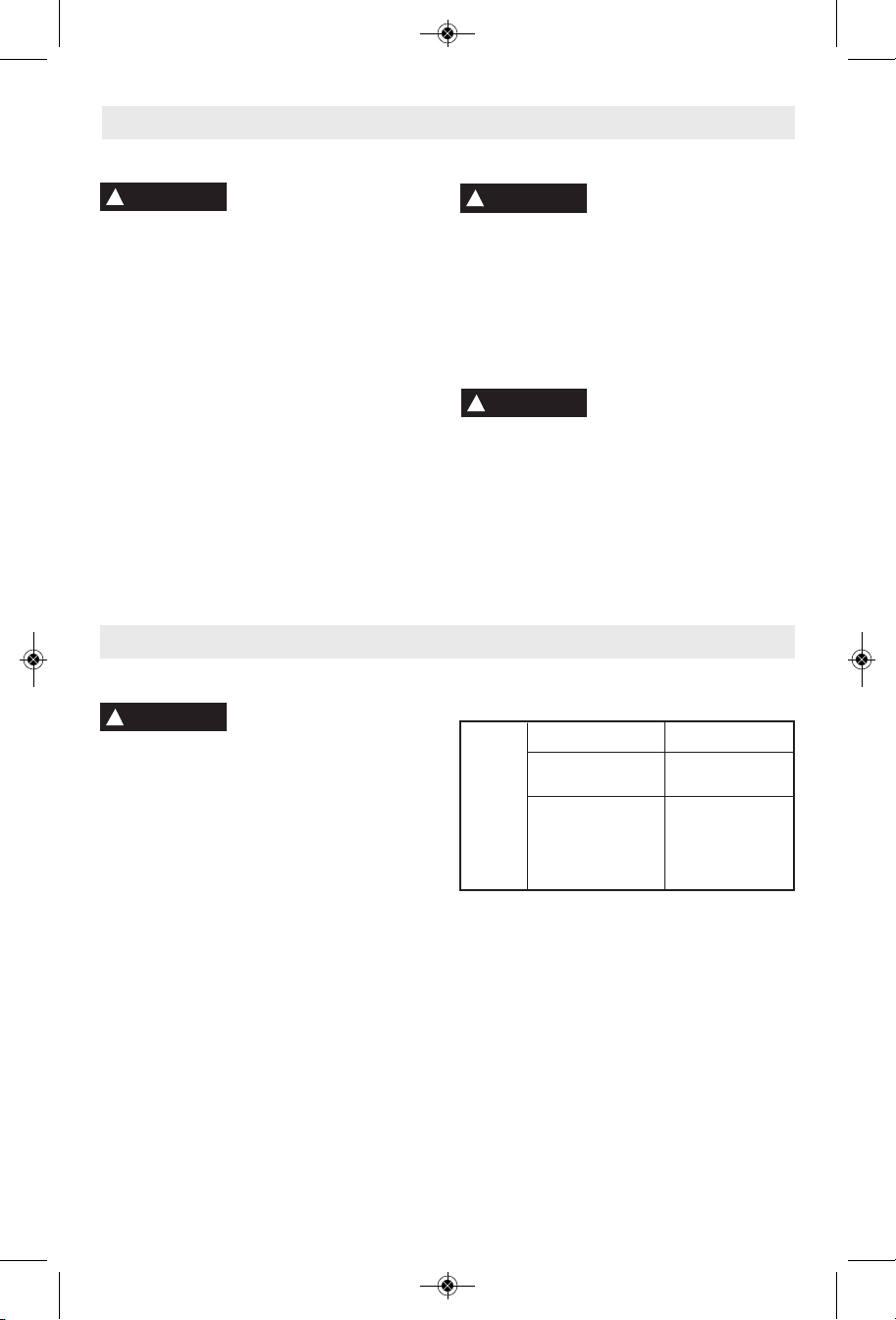

Maintenance Information

Service

!

WARNING

maintenance performed by un au thorized

personnel may result in misplacing of

inter nal wires and compon ents which

co uld cause serio us h az ar d. We

recommend that all tool service be performed

by a Dremel Service Facility.

The brushes and commutator in your tool have

be en engineer ed for many h ours of

de pendable s ervice.To m aintain pe ak

efficiency of the motor, we recommend every

50 - 60 hours the brush es be serviced by a

Dremel Service Facility.

NO USER SERVICEABLE

PARTS INSIDE. Preventive

CARBON BRUSHES

Extension Cords

Extension Cords

!

WARNING

adequate size conductors that is capable

of carrying the current necessary for your

to ol mu st be us ed . T hi s w il l p re vent

excessive voltage drop, loss of power or

overheating. Grounded tools must use 3-wire

extension cords that have 3-prong plugs and

receptacles.

NOTE: The smaller the gauge number, the

heav i er the cord.

If an extension cord is

ne ce ss ar y, a co rd with

Cleaning

!

WARNING

th e power supply be fo re cl ea ni ng or

performing any main tenance. The tool may

be cleaned most effectively with compressed

dry air. Always wear safety gog gles when

cleaning tools with compressed air.

Ventilation openings and switch levers must

be kept clean and free of foreign matter. Do

not at tempt to clean by inserting pointed

objects through openings.

!

CAUTION

plastic parts. Some of these are: gasoline,

carbon tetrachlo ride, chlo rinated cleaning

solvent s, a mmonia and hou se hold

detergents that contain ammonia.

RECOMMENDED SIZES OF EXTENSION CORDS

120 VOLT ALTERNATING CURRENT TOOLS

Tool’s

Ampere

Rating

3-6

6-8

8-10

10-12

12-16

To avoid accidents always

dis connect the tool from

Ce rtain clean ing ag ents

and sol vents d amage

Cord Size in A.W.G.

Cord Length in Feet Cord Length in Meters

25 50 100 150 15 30 60 120

18 16 16 14 0.75 0.75 1.5 2.5

18 16 14 12 0.75 1.0 2.5 4.0

18 16 14 12 0.75 1.0 2.5 4.0

16 16 14 12 1.0 2.5 4.0 —

14 12 —— ————

Wire Sizes in mm

2

-17-

Page 18

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 18

Dremel®Limited Warranty

Your Dremel product is warranted against defective material or workmanship for a period of two years from

date of purchase. In the event of a failure of a product to conform to this written warranty, please take the

following action:

1. DO NOT return your product to the place of purchase.

2. Carefully package the product by itself, with no other items, and return it, freight prepaid, along with:

A. A copy of your dated proof of purchase (please keep a copy for yourself).

B. A written statement about the nature of the problem.

C. Your name, address and phone number to:

UNITED STATES

Dremel Service Center Dremel Service Center

4915 21st Street OR 4631 E. Sunny Dunes Road

Racine, WI 53406 Palm Springs, CA 92264

1-800-4-Dremel

CANADA OUTSIDE

Giles Tool Agency CONTINENTAL UNITED STATES

47 Granger Av. See your local distributor or write to

Scarborough, Ont Dremel, 4915 21st Street

Canada M1K 3K9 Racine, WI 53406

1-416-287-3000

We recommend that the package be insured against loss or in transit damage for which we cannot be

responsible.

This warranty applies only to the original registered purchaser. DAMAGE TO THE PRODUCT RESULTING

FROM TAMPERING, ACCIDENT, ABUSE, NEGLIGENCE, UNAUTHORIZED REPAIRS OR ALTERATIONS,

UNAPPROVED ATTACHMENTS OR OTHER CAUSES UNRELATED TO PROBLEMS WITH MATERIAL OR

WORKMANSHIP ARE NOT COVERED BY THIS WARRANTY.

No employee, agent, dealer or other person is authorized to give any warranties on behalf of Dremel. If

Dremel inspection shows that the problem was caused by problems with material or workman ship within the

limitations of the warranty, Dremel will repair or replace the product free of charge and return product

prepaid. Repairs made necessary by normal wear or abuse, or repair for product outside the warranty period,

if they can be made, will be charged at regular factory prices.

DREMEL MAKES NO OTHER WARRANTY OF ANY KIND WHATEVER, EXPRESSED OR IMPLIED, AND ALL

IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE WHICH

EXCEED THE ABOVE MENTIONED OBLIGATION ARE HEREBY DISCLAIMED BY DREMEL AND EXCLUDED

FROM THIS LIMITED WARRANTY.

This warranty gives you specific legal rights and you may also have other rights which vary from state to

state. The obligation of the warrantor is solely to repair or replace the product. The warrantor is not liable for

any incidental or consequential damages due to any such alleged defect. Some states do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitations or exclusion may not

apply to you.

For prices and warranty fulfillment in the continental United States, contact your local Dremel distributor.

© Robert Bosch Tool Corporation 1800 W. Central Road Mt. Prospect, IL 60056-2230

Exportado por: Robert Bosch Tool Corporation Mt. Prospect, IL 60056 -2230, E.U.A.

Importado a México por: Robert Bosch, S. de R.L. de C.V.

Calle Robert Bosch No. 405 - 50071 Toluca, Edo. de Méx. - México

Tel. 052 (722) 279 2300 ext 1160 / Fax. 052 (722) 216-6656

-18-

Page 19

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 19

Avertissements généraux concernant la sécurité des outils électroportatifs

!

AVERTISSEMENT

choc électrique, d'incendie et/ou de blessures corporelles graves.

Veuillez lire tous les avertissements et toutes les consignes de sécurité. Si l'on

n'observe pas ces avertissements et ces consignes de sécurité, il existe un risque de

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES LES CONSIGNES

DE SÉCURITÉ POUR RÉFÉRENCE FUTURE.

Dans les avertissements, le terme « outil électroportatif » se rapporte à votre outil branché sur le secteur (avec fil) ou

à votre outil alimenté par piles (sans fil).

Sécurité du lieu de travail

Maintenez le lieu de travail propre et bien éclairé.

Les risques d’accident sont plus élevés quand on

travaille dans un endroit encombré ou sombre.

N’utilisez pas d’outils électroportatifs dans des

atmosphères explosives, comme par exemple en

présence de gaz, de poussières ou de liquides

inflammables. Les outils électroportatifs produisent

des étincelles qui risquent d’enflammer les poussières

ou les vapeurs.

Éloignez les enfants et les visiteurs quand vous vous

servez d’un outil électroportatif. Vous risquez une

perte de contrôle si on vous distrait.

Sécurité électrique

Les fiches des outils électroportatifs doivent

correspondre à la prise. Il ne faut absolument jamais

modifier la fiche. N’utilisez pas d’adaptateur de prise

avec des outils électroportatifs munis d’une fiche de

terre. Le risque de choc électrique est moindre si on

utilise une fiche non modifiée sur une prise qui lui

correspond.

Évitez tout contact du corps avec des surfaces reliées

à la terre tels que tuyaux, radiateurs, gazinières ou

réfrigérateurs. Le risque de choc électrique augmente

si votre corps est relié à la terre.

N’exposez pas les outils électroportatifs à la pluie ou

à l’humidité. Si de l’eau pénètre dans un outil

électroportatif, le risque de choc électrique augmente.

Ne maltraitez pas le cordon. Ne vous en servez

jamais pour transporter l’outil électroportatif, pour le

tirer ou pour le débrancher. Éloignez le cordon de la

chaleur, des huiles, des arêtes coupantes ou des

pièces mobiles. Les cordons abîmés ou emmêlés

augmentent les risques de choc électrique.

Si vous utilisez un outil électroportatif à l’extérieur,

employez une rallonge conçue pour l’extérieur. Ces

rallonges sont faites pour l’extérieur et réduisent le

risque de choc électrique.

S'il est absolument nécessaire d'utiliser l'outil

électroportatif dans un endroit humide, utilisez une

alimentation protégée par un disjoncteur de fuite de

terre (GFCI). L'utilisation d'un disjoncteur GFCI réduit

les risques de choc électrique.

Restez concentré, faites attention à ce que vous

faites, et servez-vous de votre bon sens lorsque vous

utilisez un outil électroportatif. N'employez pas

d’outils électroportatifs quand vous êtes fatigué ou

sous l’emprise de drogues, d’alcool ou de

médicaments. Quand on utilise des outils

électroportatifs, il suffit d’un moment d’inattention pour

causer des blessures corporelles graves.

Utilisez des équipements de sécurité personnelle.

Portez toujours une protection oculaire. Le port

d'équipements de sécurité tels que des masques

antipoussières, des chaussures de sécurité

antidérapantes, des casques de chantier et des

protecteurs d'oreilles dans des conditions appropriées

réduira le risque de blessure corporelle.

Évitez les démarrages intempestifs. Assurez-vous que

l'interrupteur est dans la position arrêt (Off) avant de

brancher l'outil dans une prise de courant et/ou un

bloc-piles, de le ramasser ou de le transporter. Le

transport d'un outil électroportatif avec le doigt sur la

gâchette ou le branchement de cet outil quand

l'interrupteur est en position de marche (ON) est une

invite aux accidents.

Enlevez toutes les clés de réglage avant de mettre

l’outil électroportatif en marche. Si on laisse une clé

sur une pièce tournante de l’outil électroportatif, il y a

risque de blessure corporelle.

Ne vous penchez pas. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Habillez-vous de manière appropriée. Ne portez pas

de vêtements amples ou de bijoux. Attachez les

cheveux longs. N’approchez pas les cheveux, les

vêtements ou les gants des pièces en mouvement.

Les vêtements amples, les bijoux ou les cheveux longs

risquent d’être happés par les pièces en mouvement.

Si l’outil est muni de dispositifs permettant le

raccordement d’un système d’aspiration et de

collecte des poussières, assurez-vous que ces

dispositifs sont raccordés et utilisés correctement.

L'utilisation d'un dépoussiéreur peut réduire les

dangers associés à l'accumulation de poussière.

Sécurité personnelle

-19-

Page 20

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 20

Utilisation et entretien des outils

électroportatifs

Ne forcez pas sur l’outil électroportatif. Utilisez l’outil

électroportatif qui convient à la tâche à effectuer.

L’outil qui convient à la tâche fait un meilleur travail et

est plus sûr à la vitesse pour lequel il a été conçu.

Ne vous servez pas de l’outil électroportatif si son

interrupteur ne parvient pas à le mettre en marche ou

à l’arrêter. Tout outil électroportatif qui ne peut pas

être commandé par son interrupteur est dangereux et

doit être réparé.

Débranchez la fiche de la prise ou enlevez le bloc-pile

de l’outil électroportatif avant tout réglage,

changement d’accessoires ou avant de ranger l’outil

électroportatif. De telles mesures de sécurité

préventive réduisent le risque de démarrage intempestif

de l’outil électroportatif.

Rangez les outils électroportatifs dont vous ne vous

servez pas hors de portée des enfants et ne permettez

pas à des personnes qui ne connaissent pas l’outil

électroportatif ou qui ignorent ces consignes de s’en

servir. Les outils électroportatifs sont dangereux dans

les mains d’utilisateurs inexpérimentés.

Entretenez les outils électroportatifs. Vérifiez que les

pièces mobiles sont alignées correctement et ne

coincent pas. Vérifiez qu’il n’y a pas de pièces

cassées ou d’autre circonstance qui risquent

d’affecter le fonctionnement de l’outil électroportatif.

Si l’outil est abîmé, faites-le réparer avant de

l’utiliser. De nombreux accidents sont causés par des

outils électroportatifs mal entretenus.

Maintenez les outils coupants affûtés et propres. Les

outils coupants entretenus correctement et dotés de

bords tranchants affûtés sont moins susceptibles de

coincer et sont plus faciles à maîtriser.

Utilisez l'outil électroportatif, les accessoires et les

embouts d'outil, etc. conformément à ces

instructions, en tenant compte des conditions de

travail et des travaux à réaliser. L'emploi d’outils

électroportatifs pour des tâches différentes de celles

pour lesquelles ils ont été prévus peut résulter en une

situation dangereuse.

Entretien

Faites réparer votre outil électroportatif par un agent

de service qualifié n’utilisant que des pièces de

rechange identiques. Ceci assure que la sécurité de

Consignes de sécurité pour les outils oscillants

Tenez l’outil électroportatif par ses surfaces de

préhension isolées lorsque vous effectuez une

opération à l’occasion de laquelle l'outil de coupe

risque d’entrer en contact avec un fil caché ou avec

son propre cordon d’alimentation. Tout contact de

l'outil de coupe avec un fil sous tension risque de

mettre aussi sous tension les parties métalliques

exposées de l’outil électroportatif, ce qui pourrait

causer un choc électrique pour l’opérateur.

Utilisez des brides ou d’autres moyens pratiques de

brider ou de supporter la pièce sur une plate-forme

stable. Tenir la pièce à la main ou contre le corps est

instable et risque de résulter en une perte de contrôle.

Ne percez, fixez et ne rentrez pas dans des murs

existants ou autres endroits aveugles pouvant abriter

des fils électriques. Si cette situation est inévitable,

débranchez tous les fusibles ou les disjoncteurs

alimentant ce site.

Utilisez un détecteur de métaux afin d’établir s’il y a

des tuyaux d’eau ou à gaz dissimulés dans l’aire de

travail ou appelez la compagnie de service public

locale pour assistance avant de commencer

l’opération. Le fait de frapper une conduite de gaz ou

de couper dans celle-ci provoquera une explosion.

L’eau pénétrant dans un appareil électrique peut

entraîner une électrocution.

Tenez toujours l’outil fermement à deux mains pour

mieux le maîtriser. Conservez toujours une bonne

assise et un bon équilibre. Ceci vous permettra de

mieux maîtriser l’outil électroportatif dans des situations

inattendues.

Tenez les mains à l'écart de l'aire de coupe. Ne

tendez pas la main sous la lame de scie ou à

proximité de celle-ci. La proximité de la lame par

rapport à votre main peut vous être dissimulée.

N' utilisez pas de lames émouss ées ou

endommagées. Les lames pliées peuvent aisément

se fracturer ou causer un rebond.

Fa ites extrêm ement attention lorsque vous

manipulez des accessoires. Les accessoires sont

très tranchants.

Po rtez des gants de protection lorsq ue vous

changez des accessoires de coupe. Les accessoires

de viennent très chauds après une utilisation

prolongée.

-20-

Page 21

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 21

Utilisez des gants épais et rembourrés, et limitez la

durée d'exposition en faisant des pauses fréquentes.

Les vibrations causées par l'outil pourraient être

nuisibles aux mains et aux bras.

Avant de racler, vérifiez l'ouvrage pour y relever

des clous. Si vous relevez des clous, enlevez-les ou

enfoncez-les bien en dessous de la surface finie

recherchée. Le contact du bord de l'accessoire avec

un clou pourrait faire sauter l'outil.

Ne poncez pas par voie humide à l'aide de cette

outil. La pénétration de liquides dans le carter du

moteur constitue un risque de secousses électriques.

Ne travaillez jamais dans un endroit qui est imbibé

de liquide, tel que solvant ou eau, ou humecté tel

qu'un papier peint nouvellement appliqué. Il existe

un danger de secousses électriques en travaillant

dans ces conditions avec un outil électrique, et le

chauffage du liquide causé par le raclage peut faire

dégager des vapeurs nocives du matériau.

Portez toujours des lunettes de protection et un

masque anti-poussières pour les applications

poussiéreuses et lors du ponçage au-dessus de la

Avertissements supplémentaires concernant la sécurité

tê te. D es particules de ponça ge peuvent être

absorbées par vos yeux et inhalées facilement et

peuvent causer des problèmes de santé.

Utilisez des précautions spéciales en ponçant le

bois d'oeuvre traité chimiquement par pression, la

peinture pouvant contenir du plomb, ou tout autre

ma tériau qui peut contenir des a gents

cancérigènes. Toutes les personnes pénétrant dans

la zone de travail doivent porter un respirateur et des

vêtements protecteurs adéquats. L'aire de travail doit

être scellée par des feuilles en plastique, et les

personnes non protégées doivent être maintenues à

l'extérieur jusqu'à ce que l'aire de travail soit dûment

nettoyée.

N'utilisez pas du papier de verre destiné à des blocs

de ponçage plus gros. Le papier de verre de

dimensions plus grandes fera saillie au-delà du bloc

de ponçage entr aînant ainsi des accrocs, un

déchirement du papier ou un rebond. Le papier

supplémentaire faisant saillie au-delà du bloc de

ponçage peut également causer des lacérations

graves.

L’emploi d’un GFCI et de dispositifs de protection

personnelle tels que gants et chaussures d’électricien en

caoutchouc améliorent votre sécurité personnelle.

N’utilisez pas un outil conçu uniquement pour le C.A.

sur une alimentation en C.C. Même si l’outil semble

fonctionner, les composants électriques d’un outil prévu

pour le C.A. tomberont probablement en panne et

risquent de créer un danger pour l’utilisateur.

Maintenez les poignées sèches et exemptes d’huile et

de graisse. On ne pas maîtriser un outil électroportatif

en toute sécurité quand on a les mains glissantes.

Créez un agenda d’entretien périodique pour votre

outil. Quand vous nettoyez un outil, faites attention

de n’en démonter aucune pièce car il est toujours

possible de mal remonter ou de pincer les fils

internes ou de remonter incorrectement les ressorts

de rappel des capots de protection. Certains agents

de nettoyage tels que l’essence, le tétrachlorure de

carbone, l’ammoniaque, etc. risquent d’abîmer les

plastiques.

Risque de blessure pour l'utilisateur. Le cordon

d'alimentation électrique ne doit être réparé que par un

Centre de service usine de Dremel ou à un centre de

service après-vente Dremel agréé.

!

AVERTISSEMENT

meulage, perçage et autres travaux du bâtiment

peuvent créer des poussières contenant des produits

chimiques qui sont des causes reconnues de cancer,

de malformation congénitale ou d’autres problèmes

reproductifs. Ces produits chimiques sont, par

exemple :

• Le plomb provenant des peintures à base de plomb,

• Les cristaux de silices provenant des briques et du

ciment et d’autres produits de maçonnerie, et

• L’arsenic et le chrome provenant des bois traités

chimiquement.

Le niveau de risque dû à cette exposition varie avec la

fréquence de ces types de travaux. Pour réduire

l’exposition à ces produits chimiques, il faut travailler

dans un lieu bien ventilé et porter un équipement de

sécurité approprié tel que certains masques à poussière

conçus spécialement pour filtrer les particules

microscopiques.

Les travaux à la machine

tel que ponçage, sciage,

-21-

Page 22

A

0

A

A

0

A

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 22

Symboles

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Symbole Nom Désignation/Explication

V Volts Tension (potentielle)

A Ampères Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Temps

s Secondes Temps

Diamètre Taille des mèches de perceuse, meules, etc.

n

0

n Vitesse nominale Vitesse maximum pouvant être atteinte

.../min Tours ou mouvement alternatif par Tours, coups, vitesse en surface, orbites,

0 Position d'arrêt Vitesse zéro, couple zéro ...

1, 2, 3, ... Réglages du sélecteur Réglages de vitesse, de couple ou de position. Un

l, ll, lll, ... nombre plus élevé signifie une vitesse plus grande

Vitesse à vide Vitesse de rotation, à vide

minute etc., par minute

Sélecteur variable à l'infini avec arrêt La vitesse augmente depuis le réglage 0

Flèche Action dans la direction de la flèche

Courant alternatif Type ou caractéristique du courant

Courant continu Type ou caractéristique du courant

Courant alternatif ou continu Type ou caractéristique du courant

Construction classe II Désigne des outils construits avec double

isolation

Borne de terre Borne de mise à la terre

Symbole d'avertissement Alerte l'utilisateur aux messages

d'avertissement.

Sceau Li-ion RBRC Désigne le programme de recyclage

des piles Li-ion.

Sceau Ni-Cad RBRC Désigne le programme de recyclage

des piles Ni-Cad.

Symbole de lecture du mode Alerte l’utilisateur pour lire le mode

d’emploi d’emploi

Symbole de port de lunettes Alerte l’utilisateur pour porter des lunettes

de sécurité de sécurité

-22-

Page 23

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 23

Symboles (suite)

IMPORTANT : Certains des symboles suivants peuvent être utilisés sur votre outil. Veuillez les étudier et apprendre

leur signification. Une interprétation appropriée de ces symboles vous permettra d'utiliser l'outil de façon plus

efficace et plus sûre.

Ce symbole signifie que cet outil est approuvé par Underwriters Laboratories.

Ce symbole indique que cet outil est reconnu par Underwriters Laboratories.

Ce symbole signifie que cet outil est approuvé par Underwriters Laboratories selon les

normes des États-Unis et du Canada.

Ce symbole signifie que cet outil est approuvé par l'Association canadienne

de normalisation.

Ce symbole signifie que cet outil est approuvé par l'Association canadienne de normalisation

selon les normes des États-Unis et du Canada.

Ce symbole signifie que cet outil est approuvé par Intertek Testing Services selon

les normes des États-Unis et du Canada

Ce symbole signifie que cet outil se conforme aux normes mexicaines NOM.

-23-

Page 24

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 24

Description fonctionnelle et spécifications

!

AVERTISSEMENT

préventive réduisent le risque d'une mise en marche accidentelle de l'outil.

Débranchez la fiche de la prise de courant avant d'effectuer quelque assemblage

ou réglage que ce soit ou de changer les accessoires. Ces mesures de sécurité

Outil électrique oscillant Multi-Max™ modèle MM40

FIG. 1

INTERRUPTEUR

MARCHE/ARRÊT

LEVIER QUICK

LOCK™

CADRAN DE

COMMANDE DE

VITESSE VARIABLE

OUVERTURES DE

VENTILATION

CORDON

D'ALIMENTATION

ÉLECTRIQUE

OUVERTURES DE

VENTILATION

BRIDE DE

FIXATION

ACCESSOIRE

Numéro de modèle MM40

Régime à vide n010,000-21,000/min

Tension nominale 120 V 60Hz

PORTE-ACCESSOIRE

-24-

Page 25

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 25

Assemblage

!

AVERTISSEMENT

d'effectuer quelque assemblage ou réglage que ce

soit ou de changer les accessoires. Ces mesures de

sécurité préventive réduisent le risque d'une mise en

marche accidentelle de l'outil.

!

AVERTISSEMENT

les opérations et pour changer les accessoires. De

telles mesures de sécurité à titre préventif réduisent le

risque de blessures causées par les bords tranchants

des accessoires. De plus, les outils d'applications

peuvent devenir très chauds après un emploi prolongé.

Risque de brûlures !

INSTALLATION ET RETRAIT DES ACCESSOIRES

AVEC LE SYSTÈME DE CHANGEMENT

L’outil Dremel Multi-Max™ MM40 comprend un

mécanisme de changement d’accessoires intégré.

L’interface pour les accessoires Quick Lock™ vous

permet d’installer et de retirer des accessoires sans

avoir besoin de vous servir d’une clé hexagonale ou

d’une clé à ouverture fixe. Et vous n’aurez plus besoin

de craindre de perdre une vis de serrage ou une

rondelle étant donné que ces pièces ne sont plus

utilisées dans la version MM40 de l’outil Multi-Max™.

1. Po ur ins taller un access oire en utilis ant la

2. Faites tourner le levier Quick Lock™ en haut de

3. Nettoyez le porte-accessoire, l'accessoire et la bride

4. Placez l'accessoire sur le porte-accessoire ; assurez-

D’ACCESSOIRES QUICK LOCK™

fonctionnalité de Quick Lock™, tenez l’outil sens

dessus dessous pour empêcher la lame de tomber

du porte-accessoire lorsque vous installez et retirez

des accessoires.

l’outil dans le sens contraire des aiguilles d’une

montre de façon à déverrouiller le mécanisme de

fixation (Fig. 2). Il faut que le levier soit totalement

engagé pour déverrouiller le mécanisme de fixation.

de fixation avec un tissu propre.

vous que l'accessoire s'engage dans toutes les

Débranchez la fiche de la

pr ise de courant avant

Portez toujours des gants

de protection pour toutes

FIG. 2

OUVRIR

FERMER

FIG. 3a

FIG. 3b

broches du porte-accessoire et qu'il est ajusté au ras

du porte-accessoire (Fig. 3a et Fig. 3b).

!

Quick Lock lorsque vous assujettissez l’accessoire.

Évitez de mettre les mains ou les doigts entre le

levier et le corps de l’outil.

5. Faites tourner le levier Quick Lock™ en haut de l’outil

dans le sens des aiguilles d’une montre, jusqu’à la

position fermée, afin de verrouiller solidement

l’accessoire en place (Fig. 2).

6. Pour enlever un accessoire, déverrouillez

simplement le mécanisme de fixation en faisant

tourner le levier Quick Lock™ dans le sens contraire

des aiguilles d’une montre, comme cela est décrit

plus haut (Fig. 2).

7. Soulevez le support de l’accessoire afin de le retirer

des goujons. (Remarque : faites très attention car il

se peut que la lame soit très chaude.)

REMARQUE : Certains accessoires, tels que des

racloirs et des lames, peuvent être montés soit droits

sur l’outil, soit à un certain angle afin de les rendre

plus faciles à utiliser (Fig. 4). Afin de pouvoir faire

ceci avec l’interface Quick Lock™, placez l'accessoire

sur le porte-accessoire ; assurez-vous que

l'accessoire s'engage dans toutes les broches du

porte-accessoire et qu'il est ajusté au ras du porteaccessoire. Verrouillez solidement l’accessoire en

place comme cela a été décrit précédemment (Fig. 2).

BRIDE DE

FIXATION

AVERTISSEMENT

PORTE-

ACCESSOIRE

Pour éviter de vous pincer,

tenez fermement le levier

-25-

Page 26

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 26

INSTALLATION ET RETRAIT DES FEUILLES

DE PAPIER ABRASIF

Votre plaque de support utilise des accessoires à fixation

par bandes velcro qui s'attachent solidement à la plaque

de support quand une pression modérée et appliquée.

1. Alignez la feuille de papier abrasif et appuyez-la à la

main sur la plaque à poncer.

2. Appuyez fermement sur l'outil électrique avec la

feuille de papier abrasif contre une surface plate et

mettez l'outil en marche pendant quelques

secondes. Ceci assurera une adhésion adéquate et

contribuera à éviter une usure prématurée.

3. Pour remplacer la feuille de papier abrasif, pelez

simplement l'ancienne feuille, enlevez la poussière

de la plaque de support si besoin est, et appuyez

sur la nouvelle feuille de papier abrasif pour la

mettre en place.

Après une période de service considérable, la surface de la

plaque de support commencera à s'user. La plaque de

support devra être remplacée quand elle ne permettra plus

d'accrocher adéquatement les feuilles de papier abrasif. Si

Introduction

Nous vous remercions pour votre achat de l'outil

Multi-Max™ de Dremel.

Cet outil a été conçu pour les projets de réparation, de

remaniement et de restauration dans un cadre

résidentiel. L'outil Multi-Max™ de Dremel permet de

réaliser des tâches qui sont laborieuses, qui prennent

beaucoup de temps ou qui sont même pratiquement

impossibles à réaliser avec n'importe quel autre outil.

Le bâti ergonomique est conçu pour vous permettre

de tenir et de contrôler l'outil de façon confortable

pendant son utilisation.

Cet outil est fourni avec un assortiment d'accessoires

qui sont conçus spécifiquement pour les travaux de

remaniement pour lesquels vous avez besoin de

précision et de contrôle.

Votre outil Multi-Max™ de Dremel a un moteur

électrique robuste, est confortable dans la main et a

été conçu de façon à pouvoir accepter un grand

nombre d'accessoires différents, dont des lames pour

vous constatez une usure prématurée de la surface de la

plaque de support, réduisez la force de pression que vous

utilisez pendant le fonctionnement de l'outil.

Pour utiliser le papier abrasif au maximum, faites

tourner la plaque de 120 degrés lorsque les pointes des

grains abrasifs sont usées.

FIG. 4

co upes à ras, des la mes à racler, des meules

d'enlèvement de coulis et des feuilles de papier

abrasif.

Les accessoires sont fournis avec des formes variées

qui vous permettent d'effectuer diverses opérations.

Au fur et à mesure que vous vous familiariserez avec

les divers accessoires et la façon de les employer,

vous apprendrez à apprécier la versatilité de votre

outil Multi-Max™ de Dremel.

Vi sitez www.dr emel.com pour en ap prendre

davantage sur tout ce que vous pouvez faire avec

votre outil Multi-Max™ de Dremel.

UTILISATIONS PRÉVUES

Cet outil Multi-Max™ de Dremel est conçu pour le

ponçage à sec de surfaces, coins et bords, pour

racler, pour scier des métaux doux, du bois et des

composants en plastique, et pour enlever le coulis en

ut ilisant les outils et accessoires applicabl es

recommandés par Dremel.

Instructions d'utilisation

APPRENEZ À VOUS SERVIR DE CET OUTIL

Vous tirerez le maximum de votre outil oscillant si vous

apprenez comment utiliser la vitesse et contrôler

manuellement l'outil de façon appropriée.

La première chose à apprendre pour utiliser cet outil est

de maîtriser son contrôle avec la main. Tenez-le dans la

main et habituez-vous à l'équilibrer en tenant compte de

son centre de gravité (Fig. 5). Selon l'application, vous

devrez ajuster la position de votre main afin d'assurer le

maximum de confort et de contrôle. La zone de

préhension confortable unique sur le corps de l'outil

offre un confort et un contrôle additionnels pendant

l'emploi.

-26-

Page 27

DM 2610016364 09-11:DM 2610016364 09-11.qxp 9/7/11 9:28 AM Page 27

FIG. 5

Lorsque vous tenez l'outil dans la main, faites attention

de ne pas bloquer les évents de ventilation. Si les évents

sont bloqués par votre main, le moteur de l'outil

risquerait de surchauffer.

IMPORTANT ! Pratiquez d'abord sur des résidus de

matériaux pour déterminer la performance de l'outil à

vitesse élevée. N'oubliez pas que votre outil produira les

meilleurs résultats possibles si vous laissez la vitesse et

l'accessoire approprié faire le travail pour vous. Faites

attention de ne pas appliquer une pression excessive.

Au lieu de cela, abaissez délicatement l'accessoire

oscillant sur la surface de travail et permettez-lui

d'entrer en contact avec le point précis où vous voulez

commencer le travail. Concentrez-vous sur le guidage

de l'outil sur la surface de travail en appliquant

seulement une faible pression avec votre main. Laissez

l'accessoire faire le travail pour vous.

Il est généralement préférable de faire une série de

passes avec l'outil plutôt que de faire tout le travail en

une seule passe. Par exemple, pour faire une coupe,

faites repasser l'outil sur l'ouvrage un certain nombre

de fois. Coupez un peu de matériau lors de chaque

passe jusqu'à ce que vous ayez atteint la profondeur

désirée.

INTERRUPTEUR « MARCHE/ARRÊT » COULISSANT

L'outil est mis en marche en faisant glisser

l'interrupteur coulissant, qui est situé sur le dessus du

bâti du moteur, en position de marche.

POUR METTRE L'OUTIL EN MARCHE, faites glisser le

bouton de l'interrupteur vers l'avant.

POUR ÉTEINDRE L'OUTIL, faites glisser le bouton de

l'interrupteur vers l'arrière.

CADRAN DE COMMANDE DE VITESSE VARIABLE

Cet outil est pourvu d'une cadran de commande de

vitesse variable (Fig. 6). La vitesse peut être contrôlée

pendant le fonctionnement en réglant le cadran sur l'une

quelconque des dix positions.

VITESSES DE FONCTIONNEMENT

L'outil Multi-Max™ de Dremel consiste en un moteur

c. a. universel et un mécanis me oscillant qu i

permettent de réaliser des applications telles que la

coupe, l'enlèvement de coulis, le raclage, le ponçage

et bien d'autres opérations.

FIG. 6

CADRAN DE

COMMANDE DE

VITESSE

VARIABLE

L'outil Multi-Max™ de Dremel a une plage étendue de

vitesses de fonctionnement oscillant comprise entre

10 000 et 21 000 /min (OPM). Le fonctionnement à

grande vitesse permet à l'outil Multi-Max™ de Dremel

d'obtenir d'excellents résultats. Le mouvement

oscillant permet à la poussière de tomber sur la

surface plutôt que de projeter des particules dans l'air.

Pour obtenir les meilleurs résultats possibles lorsque

vous travaillez avec des matériaux variés, réglez la

commande de vitesse variable sur la vitesse la plus

appropriée en fonction de l'opération désirée (voir le