Page 1

IMPORTANT

Read Before Using

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

IMPORTANT

Lire avant usage

IMPORTANTE

Leer antes de usar

DIGILAB

LC40 Laser Cutter

P.O. Box 081126 Racine, WI 53408-1126

Call Toll Free for Consumer Information & Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente, appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio

1-844-4DRML3D (1-844-437-6533) www.dremel.com

For English Version

See page 2

Version française

Voir page ??

Versión en español

Ver la página ??

Page 2

Safety Symbols

!

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7

Safety Symbols . . . . . . . . . . . . . . . . . . .2

General Safety Warnings . . . . . . . . . .3-4

Laser Cutter Safety Warnings . . . . . . .4-5

Additional Safety Warnings . . . . . . . . . .5

Symbols . . . . . . . . . . . . . . . . . . . . . . . . .6

FCC and IC Compliance . . . . . . . . . . . . . .7

Information on Intellectual Property . . . . .7

Specifications . . . . . . . . . . . . . . . . . . . . .8-9

Material Usage . . . . . . . . . . . . . . . . . . . . .10

Resources . . . . . . . . . . . . . . . . . . . . . . . .11

Glossary of Terms . . . . . . . . . . . . . . .11-13

Introduction . . . . . . . . . . . . . . . . . . . . . .13

Tools & Supplies Needed for Setup . . . .13

Unpacking . . . . . . . . . . . . . . . . . . . . . . . .13

Kit Contents . . . . . . . . . . . . . . . . . . . . . .14

Getting to Know Your Laser Cutter . .16-18

LCD Touch Screen . . . . . . . . . . . . . . .19-38

Laser Control Software . . . . . . . . . . .39-44

Setup . . . . . . . . . . . . . . . . . . . . . . . . .45-60

Locate & Cut Zip Ties . . . . . . . . . . . . .45

Install Honeycomb Sheet . . . . . . . . . . .46

Remove Camera Lens Cap . . . . . . . . . .46

Attach Water Tubes . . . . . . . . . . . . . . .47

Attach Air Tube . . . . . . . . . . . . . . . . . .48

Attach Hex Box™ Cord . . . . . . . . . . . . .49

Attach Exhaust Shroud . . . . . . . . . . . .49

Exhaust Connection . . . . . . . . . . . .50-55

Attach Power Cord . . . . . . . . . . . . . . .56

Test GFCI Unit . . . . . . . . . . . . . . . . . . .56

Turn On the Laser Cutter . . . . . . . . . .57

Get Started . . . . . . . . . . . . . . . . . . . . .57

Fill Hex Box™ with Distilled Water . . . .58

Connect a Computer to the

Laser Cutter . . . . . . . . . . . . . . . . . . . .59

Network Setups . . . . . . . . . . . . . . .60-61

Tests & Alignments . . . . . . . . . . . . . . .62-69

Mirror Alignment Overview . . . . . . . . .62

Tools & Supplies Needed for

Tests & Alignments . . . . . . . . . . . . . . .62

4 Corner Mirror Alignment Test . . .63-64

Mirror Alignment Procedure . . . . . .65-69

Tube Guard Removal . . . . . . . . . . . . . . . .70

Operating the Laser Cutter . . . . . . . .71-81

Prohibited Uses & Restrictions . . . . . .71

Create a Project . . . . . . . . . . . . . . . . .72

Maintenance . . . . . . . . . . . . . . . . . . . .82-84

Shipping & Storage . . . . . . . . . . . . . . . . .85

Serviceable Parts . . . . . . . . . . . . . . . . . .86

Firmware and Open Source Software . . .87

Dremel Limited Warranty . . . . . . . . . . . .88

2

Page 3

GENERAL SAFETY WARNINGS

Read all safety warnings, instructions, illustrations and specifications

below may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE

Keep work area clean and well lit. Cluttered

or dark areas invite accidents.

Do not operate laser cutter in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Laser

beam may ignite the dust or fumes.

Set up and operate the laser cutter in a wellventilated area. Place laser cutter on flat

nonflamm able surface and away from

flammable material. Provide at least 8 inches

of unobstructed spacing around laser cutter

to allow ventilation. Laser cutters may create

fumes that irritate eyes and airways. Obstructing

airflow into or out of laser cutter may result in

serious personal injury.

Always use a properly configured, installed,

maintained, and operating fume/smoke

exhaust system as recommended by the

manufacturer when operating the laser

cutter. Caustic fumes and smoke from the

cutting and en gra ving process mus t be

extracted from the laser system and exhausted

outside or properly filtered to reduce the risk of

personal injury.

Always keep a properly maintained and

inspected fire extinguisher in the area.

Typically, Carbon Dioxide (CO2) chemical fire

extinguishers should be used.

Laser cutters must be operated only by

persons familiar with their operation and

manufacturer’s instructions. Operation of

laser cutters by persons unfamiliar with their

operation and manufacturer’s instructions can

result in electric shock, fire and/or serious injury.

Do not allow unsupervised children and

bystanders to interact with the laser cutter

while it is operating. Persons unfamiliar with

the operation of the laser cutter may change its

setup, which may increase the risk of electric

shock, fire and/or serious injury.

Laser cutter plugs must match the outlet.

Never modify the plug in any way. Do not

use an y adapte r pl ugs w ith earthed

(grounded) laser cutters. Unmodified plugs

provided with this laser cutter. Failure to follow all instructions listed

READ ALL INSTRUCTIONS

Work Area Safety

and matching outlets will reduce risk of electric

shock.

While operating the laser cutter, avoid body

contact with earthed or grounded surfaces,

such as pipe s, ra diators , ran ges and

refrigerators. There is an increased risk of

electric shock if y our body is eart hed or

grounded.

Do not expose laser cutters to rain or wet

conditions. Water entering a laser cutter may

increase the risk of electric shock.

Before every operation of a water-cooled

laser cutter, make sure that the coolant

connections and laser tube are leak-free.

Water leaks may increase the risk of electric

shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the laser

cutter. Keep cord away from heat, oil, sharp

edges or movi ng parts . Damaged o r

entangled cords increase the risk of electric

shock.

Do not opera te laser cutter s in damp

location s. U se of lase r cutters in damp

locations may increase the risk of electric shock.

Personal Safety

Stay alert, watch what you are doing and

use common sense when operating a laser

cutter. Do not use a laser cutter while you

are tired or under the influence of drugs,

alcohol or me dication. A mome nt of

inattention while operating laser cutters may

result in serious personal injury.

Use personal protective equipment. Always

wear eye protection appropriate for class of

laser engraver. Protective equipment such as

heat and cut resistant gloves used when work

pieces are hot or have sharp edges will reduce

personal injuries.

Dress properly. Do not wear loose clothing

Electrical Safety

or jewelry. Keep your hair, clothing and

gloves away from moving pa rts. Loose

clothes, jewellery or long hair can be caught in

moving parts.

Be careful removing work pieces from the

laser cutter. Cutting with a laser increases

3

Page 4

GENERAL SAFETY WARNINGS

the temperature of the work piece and the

temperature of the work piece may remain

high after laser cutter stops operating.

Touching hot work pieces before they cool down

may result in burns.

Do not let familiarity gained from frequent

use of laser cutters allow you to become

complacent and ignore laser cutter safety

principles. A careless action can cause severe

injury within a fraction of a second.

Laser Cutter Use and Care

Prevent idle laser cutter from being used by

children and do not allow persons unfamiliar

with the laser cutter or these instructions to

operate the laser cutter. Laser cutters can be

dangerous in the hands of untrained users.

Maintain l aser c utt ers. C hec k for

misalignment or binding of moving parts,

LASER CUTTER SAFETY WARNINGS

Never expose yourself

to the laser beam since

it ma y ca u se physica l bu r ns a n d ca n

cause severe eye damage. Proper use and

care of this laser cutter system are essential

to safe operation.

Neve r o per ate the lase r cut ter syst em

without constant super v i s i o n of th e

cutting and engraving process. Exposure

to the laser beam may c ause ignit ion of

combustible materials and start a fire.

Never use PVC or other nonconductive

duct materials for the exhaust system.

Static charges may build up and may cause

a risk of fire or explosion.

Alway s use fire r ate d rigid or flex ible

metal or metalized ducting in the exhaust

system. Non-fire rated exhaust ducting may

increase the risk of fire.

Always inspect the exhaust fan and duct

work for obstructions and ensure proper

air flow exists before each use .

Unobstructe d and properly maintained

exhaust fan and duct work will reduce the

risk o f fire and effecti vely extract caustic

fumes and smoke.

breakage of parts and any other condition

that may affect the laser cutter’s operation. If

damaged, have the laser cutter repaired

before use. A poorly maintained laser engraver

may result in a risk of shock, fire and/or serious

injury.

Use the laser engraver in accordance with

these instructions, taking into account the

working conditions and the work to be

performed. Use of the laser engraver for

operations different from those intended could

result in a hazardous situation.

Service

Have yo ur laser cutter serviced by a

qualified repair person using only identical

replacement parts. This will ensure that the

safety of the laser cutter is maintained.

Never engrave or cut any unknow n

material. Only e n g r av e mat e r i a l s

recommended by the manufacturer. The

vaporization/melting of many materials,

in c l uding b u t no t li m i ted to PV C an d

polycarbonates, can give off hazardous

fu mes. Alwa ys refer to the Sa fety Data

Sheet (SDS) from the material manufacturer

to deter m i n e the r e s p o nse of any w o r k

material to extreme heat (burning/fire hazard)

to prevent hazards.

Always use th e air assist as

recommended b y t h e m a n u f ac t u r e r,

especially wh i l e c u t t i n g . C u tt i n g

movements are relatively slow and apply

an extremely large amount of heat to the

work piece. Avoid the build-up of heat in

order to reduce the risk of fire.

Keep the i n t e r i o r of t h e laser c u t t e r,

including the table tray, clean and free of

debris. Clean the laser. A build-up of cutting

and engra v i n g r e s i du e a nd d e br i s is

dangerous and may increase the risk of fire.

Never look into the beam of the alignment

laser. Eye injury can result.

4

Page 5

LASER CUTTER SAFETY WARNINGS

Never operate the alignment laser without

he focus lens or other optical elements of

t

laser cutter in place. The unfocused beam

may b e refl ect ed o ut of the c hassis and

increase the risk of eye injury.

Do not operate the laser machine with any

of the panels removed. Remember that

the laser beam is invisible! Exposure of the

laser beam will greatly increase the risk of

injury and/or fire.

Before using the laser machine, test the

grou nd fault circ uit inte rru pte r ( GFC I)

provided with the supply cord to insure it

is operating correctly. A properly operating

GFCI reduces the risk of electrical shock.

Do not attempt to modify or defeat the

safety interlock system for any reason.

This could result in exposure to hazardous

laser radiation.

Do not use laser cutter with extension

cords. The GFCI on the machine power cord

will not prevent electrical shock from the

extension cords.

Always use provided work piece support

structure. Fabrication without honeycomb

support may lead to fire or release of stray

radiation.

Do not use irregularly shaped work piece.

Risk of stray radiation or fire.

Do not stack work pieces. Stacking work

ieces increases the risk of fire.

p

Us e onl y reco m m e n ded ac c essories.

Follow i n s t ru c t i o n s that a c c o m p a ny

accessories. Use of improper accessories

may cause hazards

Ensure tools and parts such as spacer

puck, wrench, debris, etc. are removed

from the honeycomb plate before starting

a laser job. Objects or debris may interfere

with th e laser he ad and le a d to st r a y

radiation or risk of fire.

Do Not Block exhaust fan. VOCs created

by the l a s e r en g r a v e r pro c e s s must be

properly vented to help prevent personal

injury.

This product is provided with a ground

fault circuit interrupter (GFCI) built into

the power cord plug. If replacement of the

plug or cord is needed, use only identical

replacement parts.

Do not try to clean exhaust ducting. The

high co nc e n t ra t i on of partic l e s may

become airborne and create inhalation

exposure.

Do not spill water on the Hex Box™ unit.

Damage to electronics may occur.

ADDITIONAL SAFETY WARNINGS

Use of controls or

adjustm e n t s or

pe r f o rmance of pro c e dures o t h er th an

those s p e c i f i e d h e r ei n may re s u l t i n

hazardous radiation exposure.

Do not tap o r scra t c h

LCD scre en with sha rp

objects. T h e LCD sc r e e n may be c o m e

damaged.

Do not m ove th e laser

head b y h a n d wh e n

locked. Moving a locked laser head by hand

may result in damage to the gantry system.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE.

Use care when removing

the tube guard. The LED

lights may be damaged by contact with tube

guard edges.

Never remove the

mirrors for cle a n i n g !

Take extra caut i o n t o n o t m o v e t h e

orientation of the mirrors as this will affect

laser beam alignment and would require

time intensive laser beam realignment.

5

Page 6

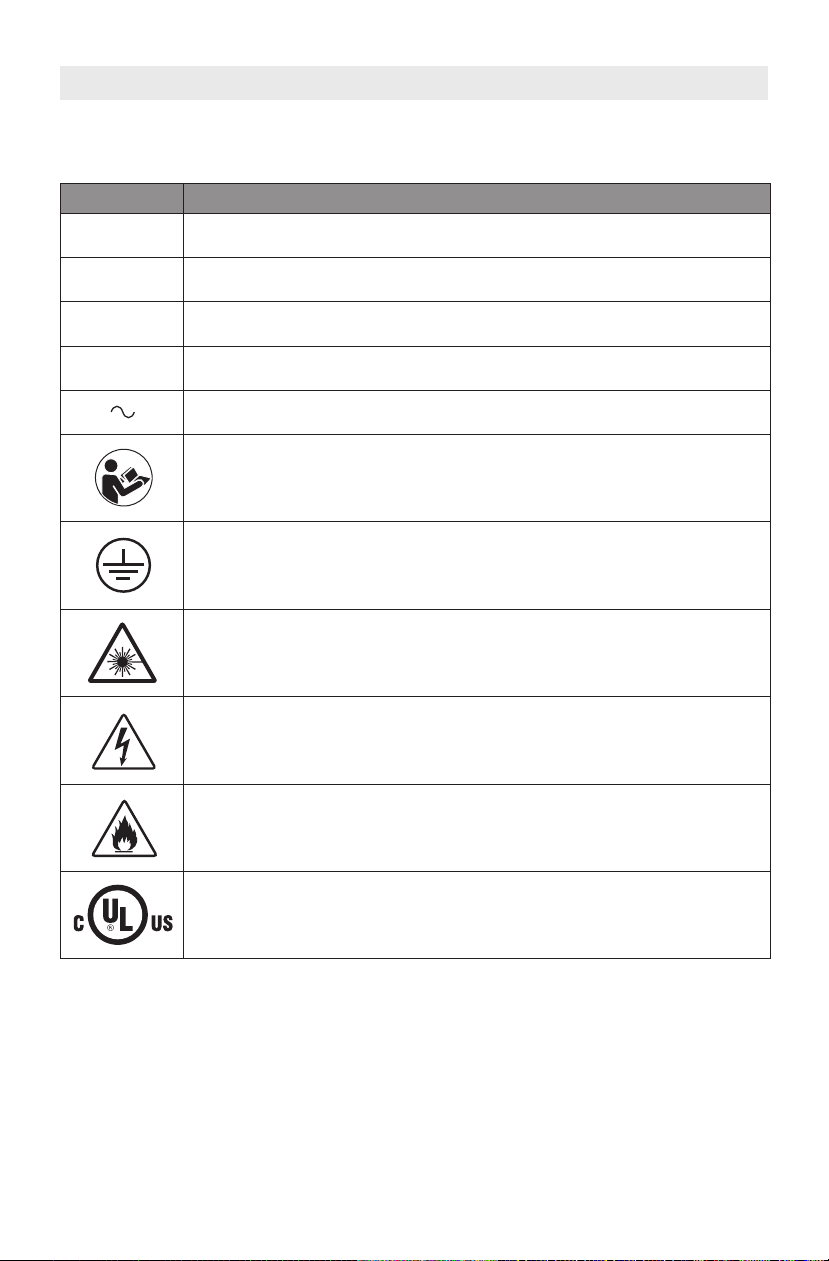

SYMBOLS

IMPORTANT: Some of the following symbols may be used on your LC40. Please study

them and learn their meaning. Proper interpretation of these symbols will allow you to

perate the tool better and safer.

o

Symbol Designation / Explanation

Hz

ø

V

A

Volts (voltage)

Amperes (current)

Hertz (frequency, cycles per second)

Diameter

Alternating current (type or a characteristic of current)

Alerts user to read manual

Earthing terminal (grounding terminal)

Warns of laser radiation. Avoid direct eye exposure. Class 3R laser

product.

Warns of high voltage. Contact with high voltage can cause death or

serious injury.

This fire warning icon calls attention to fire risks that are present while

operating the laser.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

6

Page 7

FCC AND IC COMPLIANCE

FCC COMPLIANCE

NOTE: This equipment has been tested and

found to comply with the limits for a Class

B digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to

pr o v i d e rea s o n a b l e protecti o n agains t

harmful i n t e rf e r e nc e in a r e s id e n t ia l

in stal lati o n. Thi s equip ment ge nera t es,

us e s , and c a n radiat e radio f r e q u e n c y

ener gy and, if not inst alled and used in

ac c o r d ance w i t h th e ins t r u c tions, may

cause h a rm f u l inte r f e r e n c e to r ad i o

co m m u n ication s . How e v e r , th e r e is no

guarantee that interference will not occur in

a particular installation. If this equipment

does cause harmful interference to radio or

televis i o n r e c e pt i o n, w hi c h ca n b e

determined by turning the equipment off

and on, the user is encouraged to try to

correct the interference by one or more of

the following measures:

• R e o r i e n t o r re lo c a te t he r ec e i v in g

antenna.

• Incr e ase the se p arat i on b e twee n th e

equipment and receiver.

• Connect the equipment into an outlet on

INFORMATION ON INTELLECTUAL PROPERTY

a circuit different from that to which the

receiver is connected.

• Con sul t t he deale r o r an e xpe rie nce d

radio/TV technician for help.

Changes and Modifications not expressly

approved by the manufacturer or registrant

of this equipment can void your authority to

op e r a t e this e q u i p m e n t under Federal

Communications Commission’s rules.

INDUSTRY CANADA (IC)

This device complies with Industry Canada’s

licence-exempt RSSs. Operation is subject

to the following two conditions:

(1) This device may not cause interference;

and

(2) T h i s dev i c e must accept any

interference, including interference that

may cause undesired operation of the

device.

The device meets the exemption from the

routine evaluation limits in section 2.5 of

RSS 102 and compliance with RSS-102 RF

exposur e , us er s can ob t a i n Can a d i a n

informa t i o n on RF e xp o s u re and

compliance.

Th e Dr e m el LC 40 is in t ended for las e r

cutting / e n g r a v i ng material s to cr ea t e

objects using digital files and digital designs

that you create or own, or have the right to

use when you operate the Dremel LC40.

When cutting/engraving materials to create

objects using the Dremel LC40, it is your

responsibi lity to e nsure that you do not

infringe any third party intellectual property

right s or v iola te a ny applic abl e laws or

regulat i o n s , s u c h a s U . S . o r f o r ei g n

intellectual property laws.

The Dremel LC40 may not be used to create

objects using digital files or digital designs

protected by intellectual property rights

owned by third parties without such third

parties’ permission to use such digital files

or digital designs for the creation of such

objects. Using the Dremel LC40 to do any of

the following, which are provided to you as

examples and must not be viewe d as an

exhaustive list, may require the permission

of third parties: to create a duplicate or

facsimile (in whole or in part) of any digital

de sign not ow n ed b y yo u, t o cr eate an

object from a digital file you do not own, or

to make an object from a scan of a physical

object that you did not create. It is your

responsibility to obtain such permission. In

some cases, you may not be able to obtain

such permission. Where such permission

cannot be obtained, you must not create

such objects. You must not modify, reverse

engineer, decompile, or disassemble the

Dremel LC40, except as pe r m it t e d by

applicable law.

If you use the Dremel LC40 in any way other

than as rec omm ended and describ ed in

these Operating/Safety Instructions, you do

so at your own risk. Using the Dremel LC40

to m a k e obj e c t s that i nf r i n ge any

intellectual property rights owned by third

pa r ties cou l d result in civ il o r cr i mina l

prosecution and penalties, and you could be

liable f o r m o n ey d am a g e s, f in e s , o r

imprisonment.

7

Page 8

SPECIFICATIONS

LASER SYSTEM

Laser Type: Sealed CO2 Laser Tube

Laser Power: 40W

Laser Classification: IEC 60825-1 Class 3R

Beam Size: 6.5 mm diameter @ 1.2 m

Working Current: 20mA

Wavelength: 10.6 μm

LASER CUTTER WEIGHT & DIMENSIONS

Dimensions: 32” x 20” x 8.25”

(812.5 mm x 508 mm x 209.55 mm)

Weight: 63.3 lbs (28.7 kg) (without Hex

Box™ or accessories)

Shipping Weight: 100 lbs (45 kg)

HEX BOX™ WEIGHT & DIMENSIONS

Dimensions: 7.25” x 11” x 7.25”

(184 mm x 279 mm x 184 mm)

Weight: 10 lbs (4.5 kg)

Total Water Capacity: 35 oz (1 liter)

ELECTRICAL REQUIREMENTS

LC40 input rating: 120V, 60Hz, 6 A

Hex Box™ rating: 12V DC, 4.7 A

SUPPORTED OPERATING SYSTEM AND

SYSTEM SPECIFICATIONS

Compatibility: Mac & PC

•Apple® Mac® OS® X v10.9 or later

(Mavericks)

•Microsoft® Windows® 10

•Microsoft® Windows® 8.1

•Microsoft® Windows® 7 SP1

Browser Compatibility: Chrome, Safari,

Firefox, & IE

Min Screen Resolution: 1024 x 768 Pixels

Ability to Connect Through Network

(Ethernet or Wireless) without Internet

Connection

Wireless connection frequency: 2.4 GHz

OPERATING CAPACITIES

Engraving Area: 18.4” x 12”

(467 mm x 304.8 mm)

Cutting Area: 20” x 12”

(508 mm x 304.8 mm)

Max Engraving Height: 1.25” (32 mm)

Max Cutting Height: ¼” Wood and

Acrylic (6 mm)

OPERATING ENVIRONMENT

Recommended Environmental

Temperature: 60-85F (16-29C)

Sturdy, flat, and level workspace that

holds weight of the Laser, material,

and Hex Box™.

For indoor use only.

8

Page 9

10” (254mm) Min.

8”

(203mm)

Min.

8”

(203mm)

Min.

WALL

30”

(762mm)

Laser Cutter

8”

(203mm)

Min.

8”

(203mm)

Min.

Hex Box™

SPECIFICATIONS

LASER CUTTER & HEX BOX™ CLEARANCE REQUIREMENTS

9

Page 10

MATERIAL USAGE

Table 1

Acrylic

†

LC40 Commonly Used Materials

Aluminum, anodized

Plywood*

†

Cork

Cardboard

Cotton fabric

* Must be California 93120 Phase 2 & TSCA Title VI compliant for formaldehyde

Table 2

ABS

Beryllium oxide

Carbon

Chlorinated plastics

Coated carbon fiber

Coated materials

Epoxy based or phenolic resins

Fiberglass

Fluorine based plastics:

PTFE (Teflon)

Fluorinated ethylene propylene (FEP)

Galvanized metal

HDPE (High Density Poly Ethylene)

Leather, Artificial or Treated

Materials containing:

• Astanine

• Bromine

• Chlorine

• Fluorine

• Formaldehyde (including wood)

• Flame-retardants

• Halogens

• Iodine

Mirrored surfaces

†

Birch Plywood and Acrylic are available from Dremel.

LC40 Prohibited Materials

Denim fabric

Felt (wool)

Glass

Leather, unstained

Maple, solid

Mat board

Nylon

Painted material,

varnished materials

Particleboard, paneling

Polycarbonate

Polychloroprene (CR or

chloroprene rubber, marketed

under the brand name of Neoprene)

Polypropylene foam,

Polypropylene sheet

Polystyrene foam

Polyurethane,

Polyurethane foam

Polyvinyl chloride (PVC) Found in

many common products such as

but not limited to; flooring, siding,

piping, roofing membranes,

credit cards, toys, flexible tubing.

POM Delrin/acetyl.

Rubber

Styrofoam

Wood that has been:

• Coated

• Fumigated

• Pressure treated

• Stained

Oak, solid

Paper

Rubber, laser grade

Walnut, solid

While the LC40 can cut and etch a variety of materials, some materials such as most metals,

cannot be marked and will give less than desirable results. Other materials may not have

acceptable finish quality.

10

Page 11

RESOURCES

Resource Description Location

Quick Start

Guide

Provides an illustrated walkthrough of

how to un-box the laser cutter and start

a job.

Printed version is located in

the box with the laser

cutter. It is also available on

digilab.dremel.com/support/

laser-support

Laser Cutter

LCD

Interface

Dremel LC40

Control

Software

Dremel

Website

DigiLab

Website

Dremel

Customer

Support

Term Definition

Air Assist

Provides step-by-step instructions for

setting up the laser cutter. Also allows

control of the laser head, run recent

jobs, and adjust machine settings.

Provides the interface for setting up,

saving, and sending cutting and

engraving jobs to the laser cutter.

Access project inspiration and

downloads, Dremel product

information, and customer support.

Access information about Dremel

DigiLab products, education projects,

and more.

Contact Dremel for product support,

maintenance, and service.

Air delivery system that helps to control flareups. Air is supplied by the Hex

Box™.

On the laser cutter machine

Enter the IP address of

the laser cutter into the

browser.

dremel.com

digilab.dremel.com

1-844-437-6533

dremel.com/digilab-support

GLOSSARY OF TERMS

Alignment Laser

Auto Array

.bin File

Cut

Design Software

An additional laser diode whose beam results in a red dot that is used to

help align the mirrors.

A software function that creates a grid of the desired size by repeating the

selected image.

A binary file format used to save and load workspace projects to and from a

computer.

Also called "vector", used for cutting through work piece. This function

requires a vector, or line file to execute.

Graphics editing software used to create and manipulate images for laser

cutting and engraving.

11

Page 12

GLOSSARY OF TERMS

Engrave/Etch

Exhaust Hose

Exhaust Shroud

Exhaust Port

Firmware

Greyscale

Hex Box™

Honeycomb Plate

Job A project that is sent to the laser for fabrication.

Laser Head

LC40 Control

Software

Function, also called "raster", used to darken or remove the surface of a

material, rather than cut through it. This function requires an image file to

execute.

Duct that is connected to the laser cutter unit to vent byproducts outside or

into a filtration unit or to outside ventilation.

A metal tubing connection that is screwed onto the rear of the laser cutter

unit over the exhaust vent fan.

An opening on the rear of the laser unit that allows the vent fan to draw air

out of the workspace.

Software that is embedded on the computer hardware of the laser cutter and

controls its operation. Updates to the firmware will be provided by Dremel

and applied to the laser cutter directly over the internet.

Also called "dither", takes a black and white image and assigns different

densities of dots to visually create a number of different shades of grey. Darker

areas of the image will have more dots, while lighter areas will have less dots.

A separate and interconnected part of the laser cutter system that integrates

the water circulation and air assist functions of the laser cutter.

An aluminum tray that rests on the bed and supports the work piece as it is

cut and engraved.

An assembly of components, including a mirror, lens, and cone, which the

laser passes through before making contact with the material.

The laser control software that is provided on the machine and accessed by

a computer through the network connection.

Laser Tube A glass tube located at the rear of the laser unit that generates the laser beam.

Lens

Material The substance of which the work piece or work is composed.

Material Library

Mirrors

Project

Raster Digital art composed of horizontal and vertical rows of pixels.

Score

Spacer Puck

12

A glass lens in the laser head that focuses the beam of the laser for optimal

cutting and engraving.

A listing of materials for which suggested laser settings are predefined in the

Dremel LC40 Control Software.

A set of mirrors that direct the laser beam of the laser from the tube to the

work piece.

A planned piece of work created in the Dremel LC40 Control Software which

can be sent to the laser engraver as a job.

Function used to make a mark on the surface of the material when you want

to emphasize the outline of text or an object

A small cylinder that is placed between the work piece and laser head to

assist in focusing the laser.

Page 13

GLOSSARY OF TERMS

Touch Screen Touch activated full color display.

Vector Art

Vent Fan A fan located in the exhaust port that helps draw air out of the workspace.

Work piece

Workspace

X-Axis Guide Rails

Y-Axis Guide Rails

Art created using vector illustration software programs, such as Adobe

Illustrator

Also called "work" or "material". It is the object to be cut or engraved with the

laser.

a) The area inside of the laser unit that is open for work piece placement

and the movement of the laser head.

b) A screen in the Dremel LC40 Control Software where a job is created. It

provides a graphical representation of the intended job and its position

relative to the general boundaries of the laser working area.

A set of rails at the rear of the laser bed that allow movement of the laser

head to the left or right side of the workspace.

A set of rails on either side of the laser bed that allow movement of the laser

head to the front or rear of the workspace.

®

or Corel Draw®.

INTRODUCTION

Welcome to the world of Dremel Digilab.

Our mission is to mentor you through the

digital fabrication process and share best

practices for bringing your ideas to life.

Lase r c ut ti ng and e n gr a vi ng are

proc e s s e s that wi l l invok e

expe r i m e nt at io n a n d pe r s i s te nc e.

Thankfully, the Dremel experts are here

to make your job easier with online tips,

documentatio n, and live support. T he

Drem e l L a s e r C u t te r b r i ng s ro b u st

func t i o n al it y such as n e t w or k

connectivity, recommended settings for

co mmon ly used materi als, and mul tisensor checks. To get started with the

La s e r Cutter fol l o w the in i tial se t u p

routine on the touch screen to guide you

through the hardware and software setup

of the machine.

You can register your Laser Cutter and

crea t e a user profi l e by goi n g to

dremel.com/support/product-registration.

Your profile gives you access to a variety

of laser projects and support. Once setup

and regi stratio n is complete , you are

ready to start making.

TOOLS & SUPPLIES NEEDED FOR SETUP

Distilled Water Funnel Scissors Screwdriver

13

Page 14

UNPACKING

Box 2

Tote Bag

& Box 1

LC40

1 2

3 4

Box 3

Straps

Two pers o n l i f t

laser cutter alone may result in personal

requ i r e d .

injury.

Lifting the

Crea te a wor kst ation. Prep are a fl at,

sturd y tab l e or work b e n c h t h a t c a n

support the weight of the Laser and Hex

Box™. The workstation should be close to

an e le c tr ic a l ou t l e t an d allo w for

necessary ventilation described in the

SETUP sectio n "Exhaust Connec tions"

page xx.

Open the top of the box.

1. R e mo ve Re u s a bl e T o t e B a g f r o m

packaging and pull out box 1. Open lid

to reveal the project sample material

and the Honeycomb Plate.

2. Remove Instructional Manual, Water

Hoses, Air Tube, Screws, Hex Box™

Cap, Hex Key W rench, S pacer Puck

from box 2.

3. R e mo ve f oa m t o rev e a l t he La s e r

Cutter. Use two people to lift Laser

Cutter out of box by straps and place

on workstation. After the Laser Cutter

has been taken out of the box, hook

straps to the Reusable Tote Bag. DO

NOT CUT STRAPS.

4. Open the lid of the Laser Cutter to

reveal box 3 with Hex Box™, Exhaust

Duct, and Exhaust Shroud.

Note: Sav e the D remel Digi Lab Las er

Cutter packaging for future transport and

storage.

14

Page 15

KIT CONTENTS

DIGILAB

LC40 Laser Cutter

For English Version

See page 2

Version française

Voir page 37

Versión en español

Ver la página 73

IMPORTANT

Read Before Using

IMPORTANT

Lire avant usage

IMPORTANTE

Leer antes de usar

1-844-4DRML3D (1-844-437-6533) www.dremel.com

P.O. Box 081126 Racine, WI 53408-1126

Operating/Safety Instructions

Consignes d’utilisation/de sécurité

Instrucciones de funcionamiento y seguridad

Call Toll Free for Consumer Information & Service Locations

Pour obtenir des informations et les adresses de nos centres de service après-vente, appelez ce numéro gratuit

Llame gratis para obtener información para el consumidor y ubicaciones de servicio

A

l

c

o

h

o

l

P

r

e

p

P

a

d

A

l

c

o

h

o

l

P

r

e

p

P

a

d

The LC40 laser cutter is shipped with the following included parts and accessories:

Reusable Tote Bag Project Sample

Material

Operating/Safety

Instructions

Ethernet

Cable

(2) Hose Clamps Hex Box™

Connector Cord

Honeycomb Plate Quick Start Guide

Water Hose

(1 blue & 1 clear)

Hex Box™

Air Tube

(black)

Hex Keys

Water Tank Cap

Lens Cleaning Wipes Spacer Puck Alignment Paper Laser Cutter

Hex Box™ Exhaust Hose Exhaust Shroud

15

Page 16

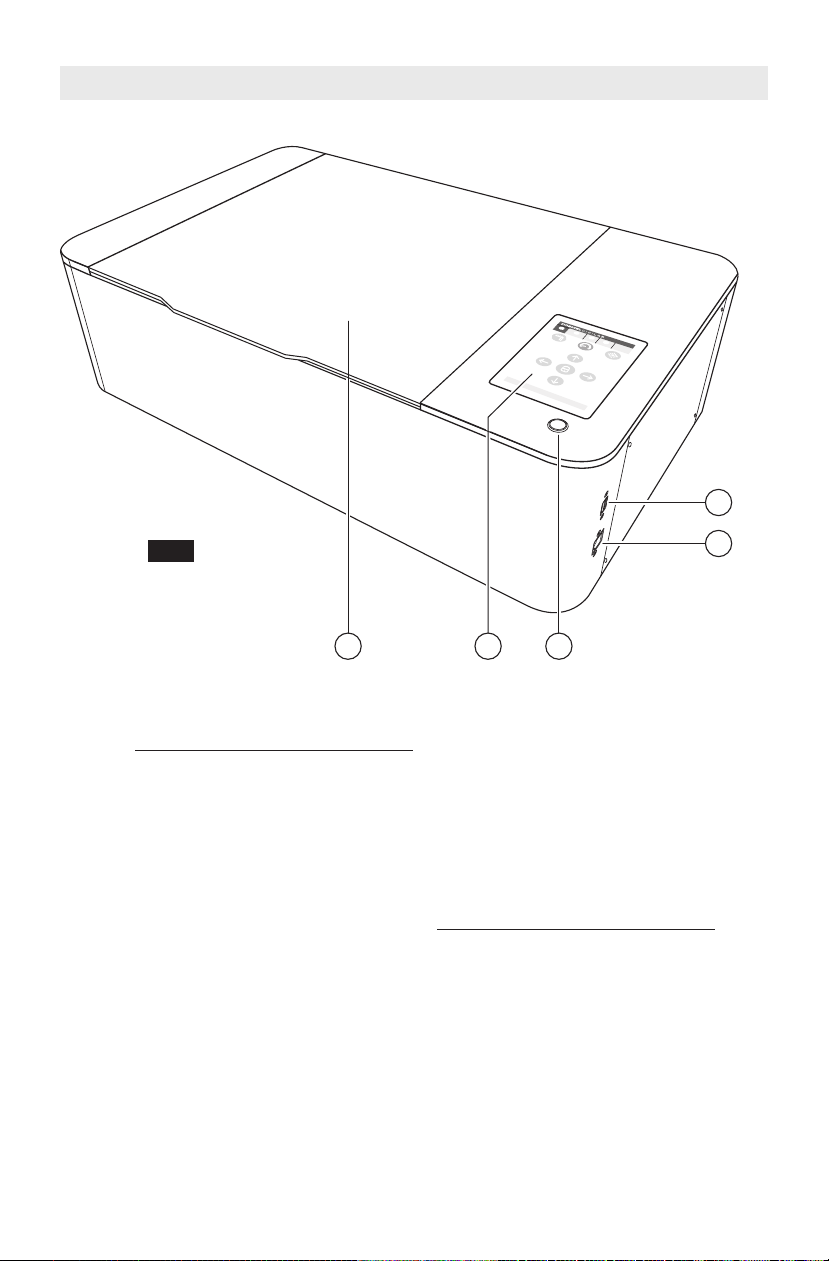

GETTING TO KNOW YOUR LASER CUTTER

21 3

5

4

Fig. 1

LC40 Laser Cutter

1. Lid

2. Touchscreen

3. Start Button

4. USB Port (for service only)

5. Ethernet Port

6. LED Lights

7. Laser Tube Shroud

8. Honeycomb Plate

9. Gantry

10. Mirror 1

11. Beam Combiner Lens

12. Mirror 2

13. Laser Head

a. Mirror 3

b. Focus Lens

c. Air Nozzle

d. Laserhead Knob

e. Wide Angle Camera

16

14. Power Switch

15. Power Cord

16. Hex Box™ Power Outlet

17. Air Inlet

18. Exhaust Shroud

19. Water Outlet

20. Water Inlet

Hex Box™

21. Water Tank Cap

22. Water Tank

23. Power Inlet

24. Air Outlet

25. Water Outlet

26. Water Inlet

Page 17

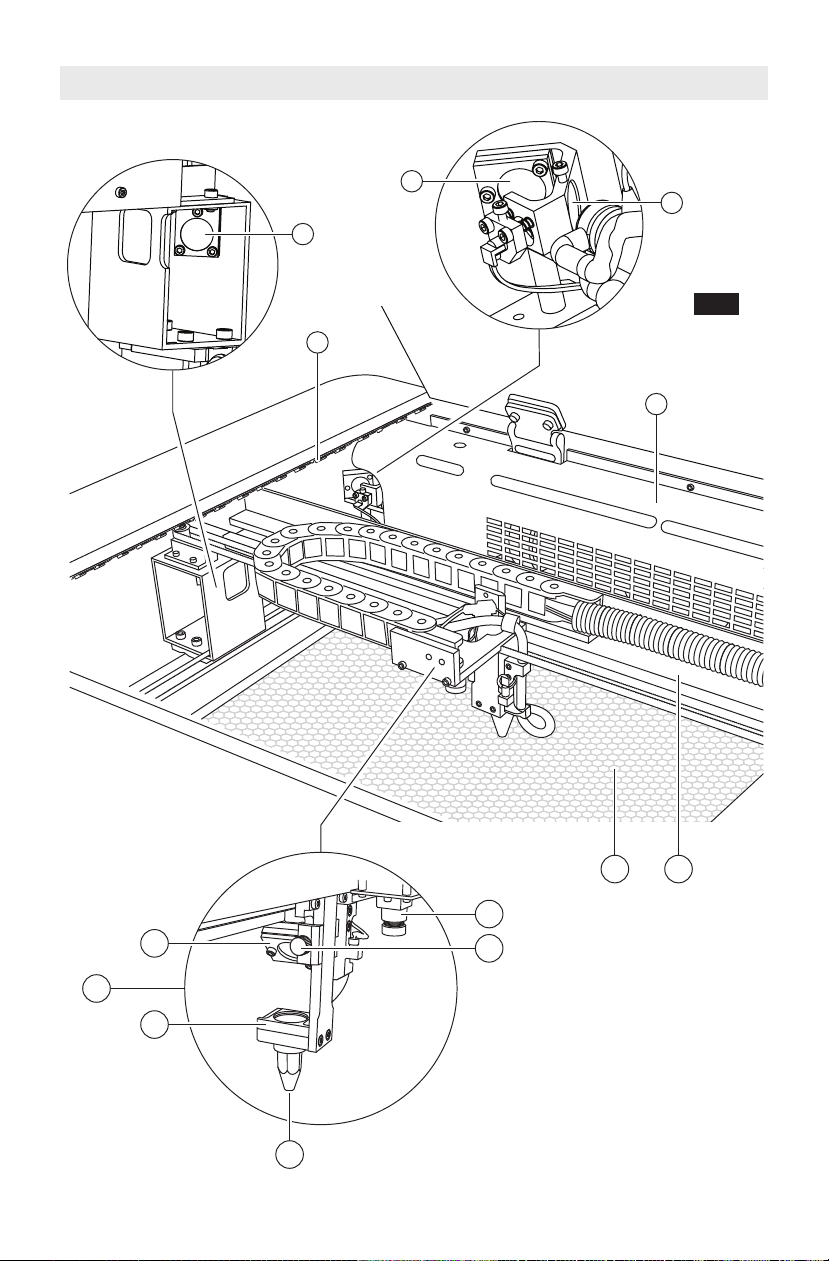

GETTING TO KNOW YOUR LASER CUTTER

c

e

d

b

a

2

.

0

”

1

2

6

7

8 9

11

1

0

13

Fig. 2

17

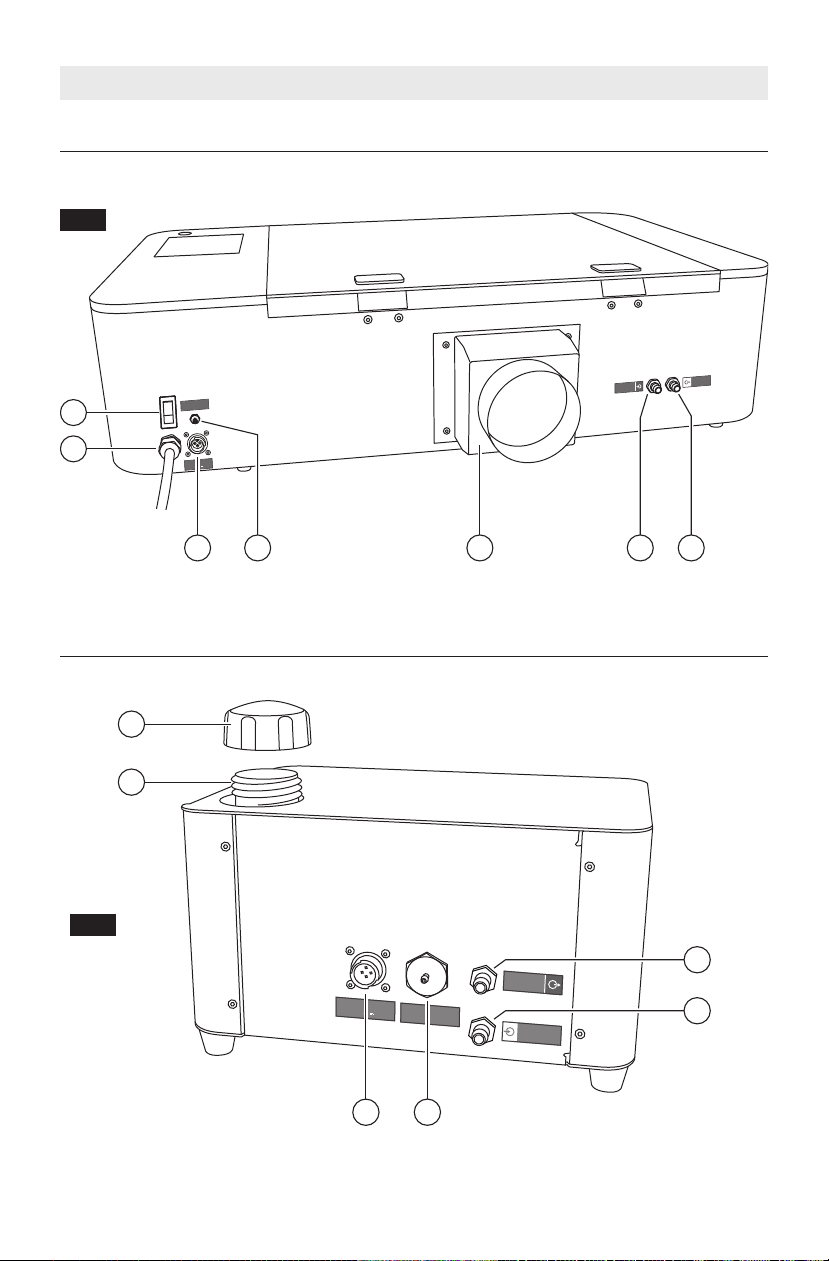

Page 18

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

W

A

T

E

R

O

U

T

S

O

R

T

I

E

D

’

E

A

U

S

A

L

I

D

A

D

E

A

G

U

A

W

A

T

E

R

I

N

E

N

T

R

É

E

D

’E

A

U

E

N

T

R

A

D

A

D

E

A

G

U

A

H

e

x

B

o

x

1

2

V

23

24

25

22

21

26

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

H

e

x

B

o

x

1

2

V

18 19 2017

14

16

15

W

A

T

E

R

O

U

T

S

O

R

T

I

E

D

’

E

A

U

S

A

L

I

D

A

D

E

A

G

U

A

W

A

T

E

R

I

N

E

N

T

R

É

E

D

’

E

A

U

E

N

T

R

A

D

A

D

E

A

G

U

A

Fig. 3

GETTING TO KNOW YOUR LASER CUTTER

REAR VIEW OF LASER CUTTER

REAR VIEW OF HEX BOX™

18

Fig. 4

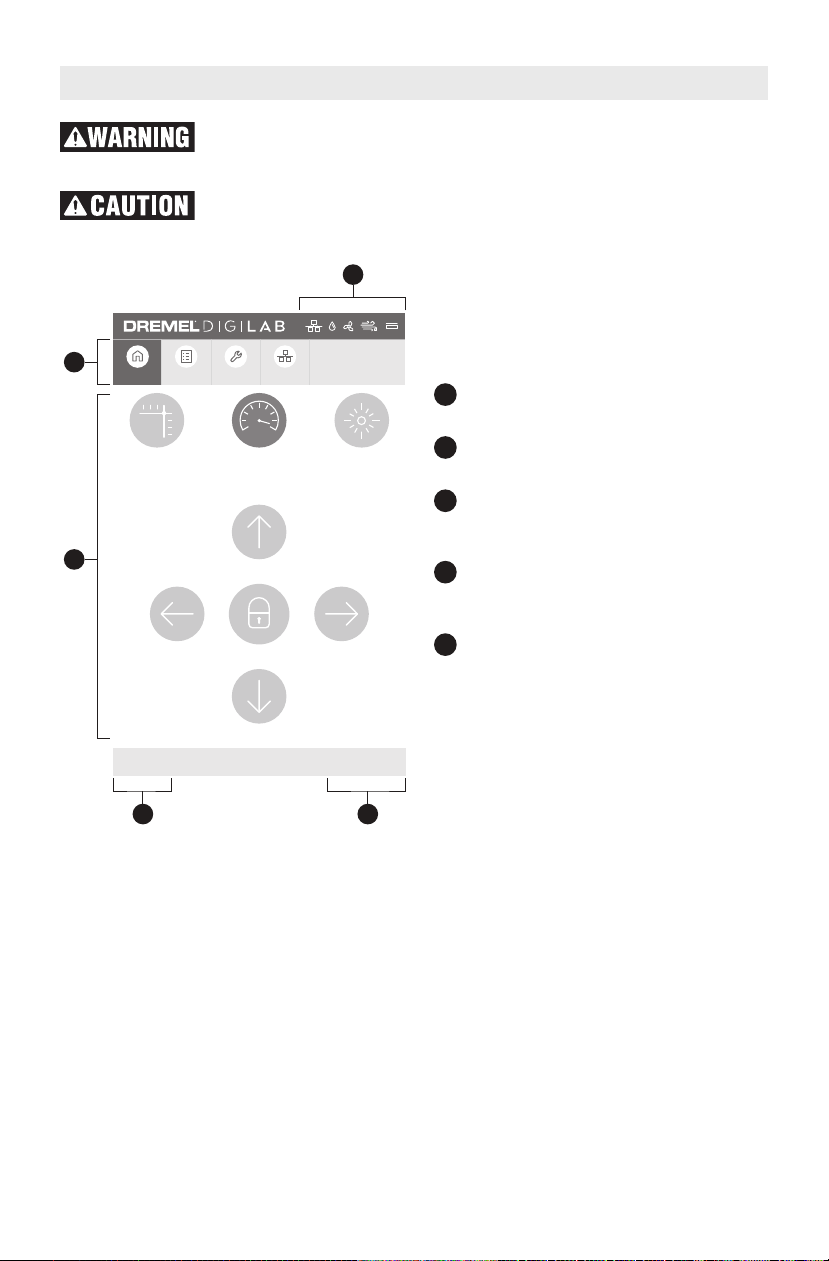

Page 19

LCD TOUCH SCREEN

1

2

3

45

192.168.1.115 v1.0.0

LASER

HOME

JOG SPEED

FAST

TEST FIRE

H

OME JOB HISTORY TOOLS NETWORK

1

2

3

4

5

Observe all provided warnings and safety instructions when using

the Dremel LC40. Failure to do so may result in fire, equipment

damage, property damage or personal injury.

Do not tap or scratch LCD screen with sharp objects. The LCD

screen may become damaged.

The LC40 touch screen allows control of

the basic functions of the laser without

the need to connect to a computer.

St a t u s Ba r — D i s p l a ys in f o rmation

about selected conditions of the LC40.

Menu Bar — D ispla ys the icon s a nd

names of the Touch Screen menus.

Co ntr o l I n ter face — Inform atio n or

additional action pertaining to selected

menu item.

IP Address — A unique number used to

connect t h e L a s er C u tt e r over a

network to a web browser.

Firmwar e Ve r s i o n — Di sp l a ys th e

currently installed firmware version.

19

Page 20

2

HOME JOB HISTORY TOOLS NETWORK

LCD TOUCH SCREEN

1

Status Bar

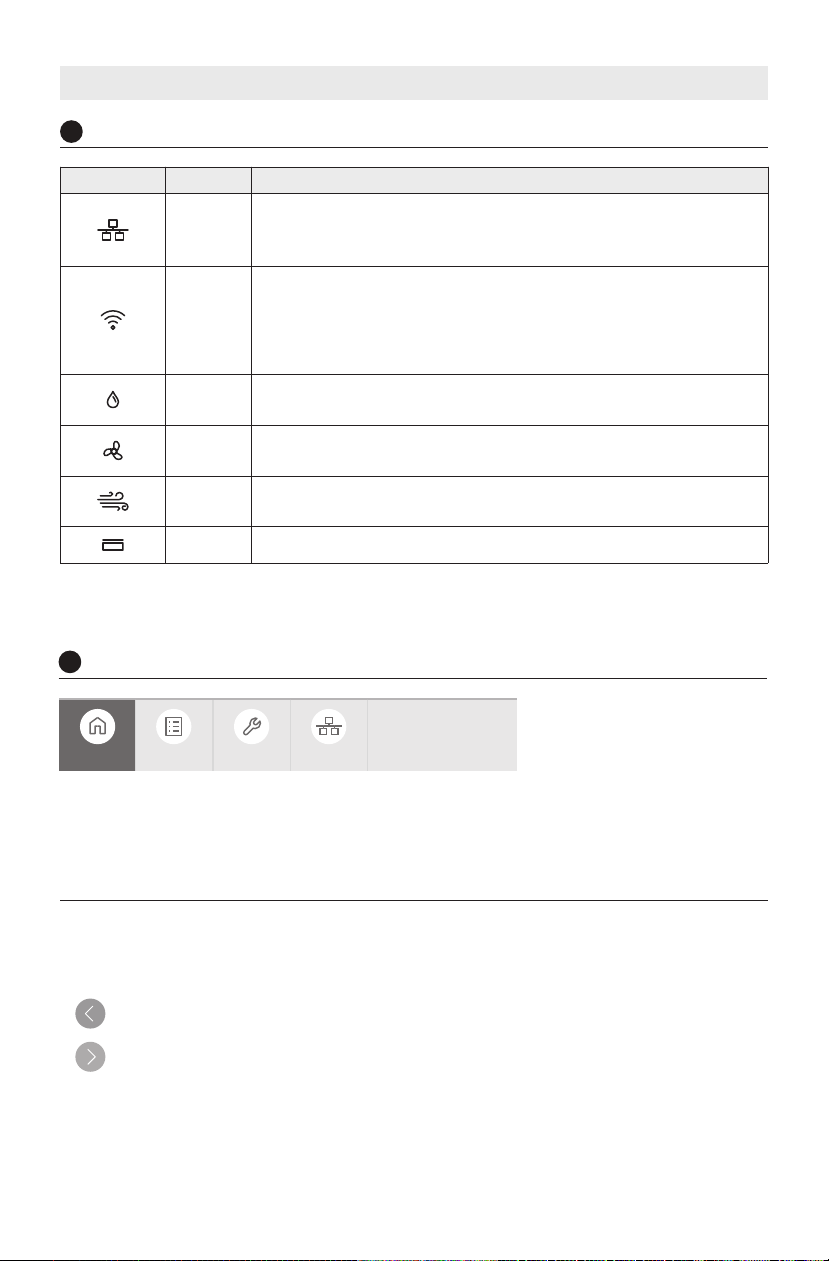

Status Icon Name What it means

Ethernet

Wireless

Water

Cooling

Vent

Fan

Air

Assist

Lid WHITE: Lid is closed. RED: Lid is open.

Note: Water Cooling. Vent Fan and Air Assist icons will only update in real time. (When the Hex Box

is activated by the LC40).

Menu Bar

LC40 is connected to a computer or a network router via

Ethernet Port.

The icon will disappear when there is no Ethernet connection.

LC40 is connected to a computer or network router via wireless.

The icon will disappear either when there is no wireless

connection or when the Ethernet icon is active. When LC40 is

connected with both Ethernet and Wireless, only the Ethernet

icon will display.

WHITE: Cooling system functioning normally.

RED: Cooling system needs attention.

WHITE: Vent fan functioning normally.

RED: Vent fan needs attention.

WHITE: Air assist functioning normally.

RED: Air assist needs attention.

HO M E — Acc e ss to la ser h e a d po sitio n

controls and to test fire the laser.

JOB HISTORY — Lists previously run jobs

and provides option to re-run them.

When necessary, the LCD touch screens will offer options to return to the previous screen

or advance to the next screen.

Tap to return to previous screen.

Tap to proceed to the next screen.

20

TOOLS — Information about the unit and

settings.

NETWO RK — Inf orma tio n and acces s to

network connection settings.

Page 21

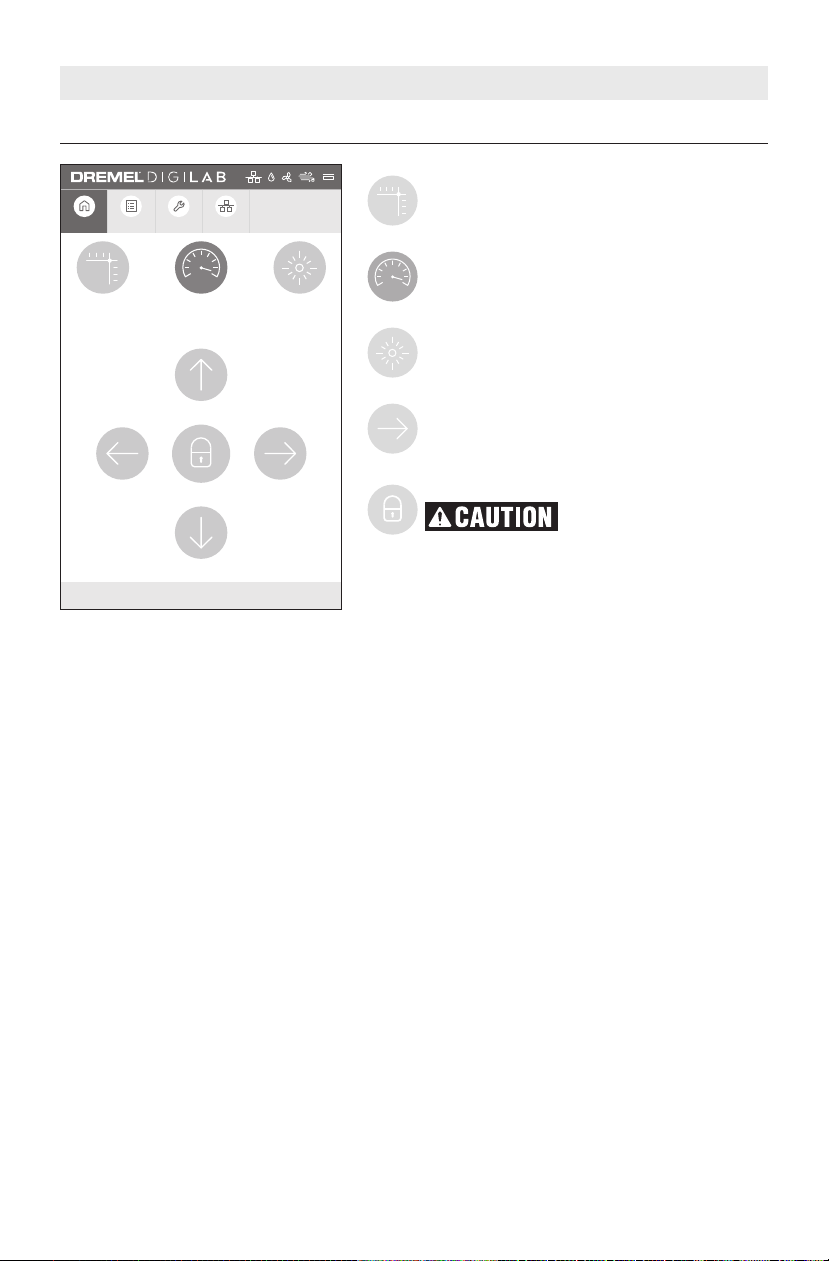

HOME > UNLOCKED

192.168.1.115 v1.0.0

LASER

HOME

JOG SPEED

FAST

TEST FIRE

HOME JOB HISTORY TOOLS NETWORK

LCD TOUCH SCREEN

LASER HOME – Moves the laser head

back to its origin location. Button will

flash when homing is necessary.

JOG SPEED – Toggles between fast and

slow laser head movement speed. Fast is

default speed.

TEST FIRE – Enable the laser to fire for a

sh o r t period to identi f y its lo c a t i o n

relative to the material.

Directional Arrows

Moves the la ser hea d in di rect ion of

arrow.

Laser Head Locked (default)

Do not move the laser

head b y hand w h e n

locked. Moving a locked laser head by

hand may result in damage to the gantry

system.

A cl osed lock icon indicat es that the

lase r head is loc ked and c an only be

move d us in g th e di re ct io n al ar r o w

buttons.

Pres s i n g the l o ck butt o n toggl e s

between locked or unlocked laser head

setting.

21

Page 22

192.168.1.115 v1.0.0

L

ASER

H

OME

J

OG SPEED

F

AST

T

EST FIRE

HOME JOB HISTORY TOOLS NETWORK

HOME > LOCKED

LCD TOUCH SCREEN

Laser Head Unlocked

An open lock icon indicates th at the

laser head can be moved by hand.

Note: When Laser Head is unlocked the

Dire cti onal Arrows and Speed v irtual

buttons are nonfunctional.

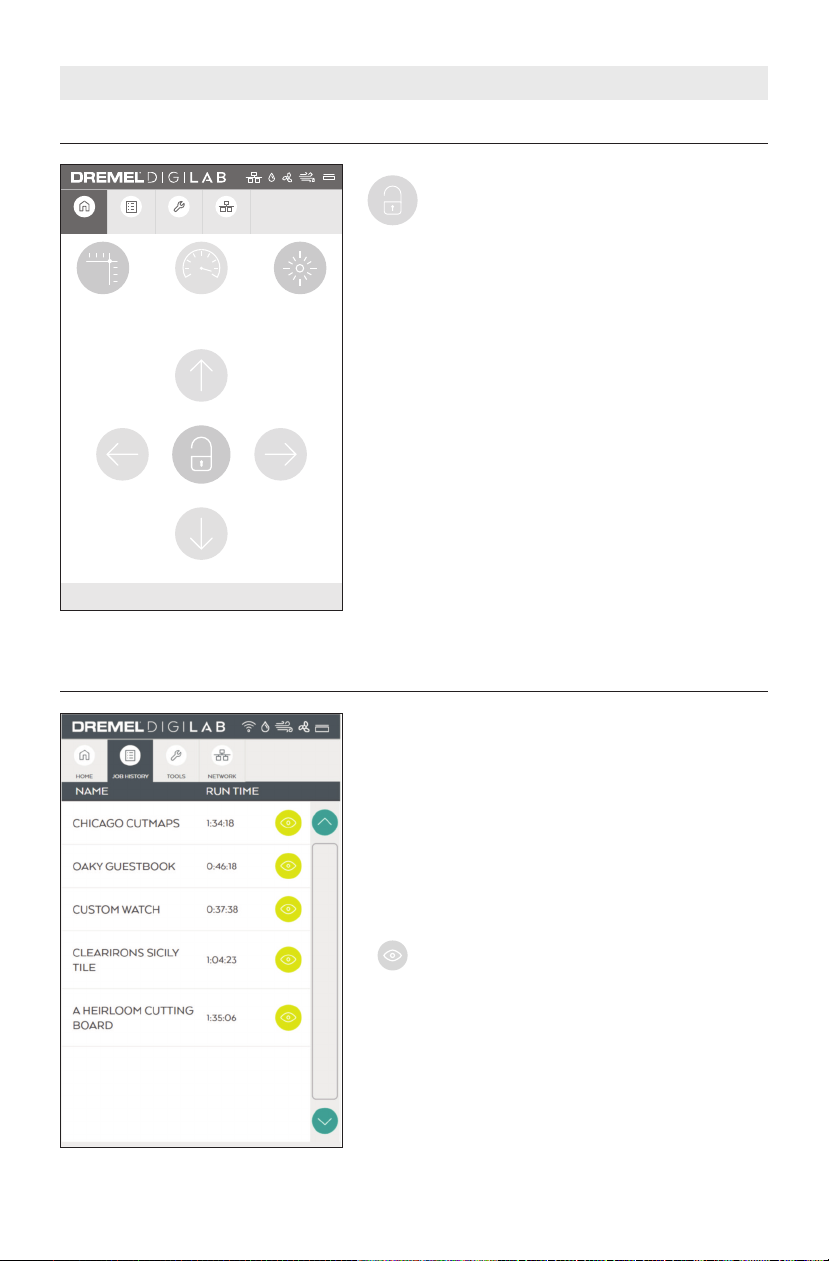

JOB HISTORY

22

This tab displays jobs received by the laser cutter.

As received from the factory, this list is empty. The

Factory Reset opt io n will clear J ob His to ry . Job

creation is explained in the Software Section.

Once a job is sent from the software to the laser, it

will appear in the job history tab.

NAME — the name of project job(s) within the Job

History list.

RUN TIME — required time to complete project.

Tap to preview the job and open the submenu for the job.

Page 23

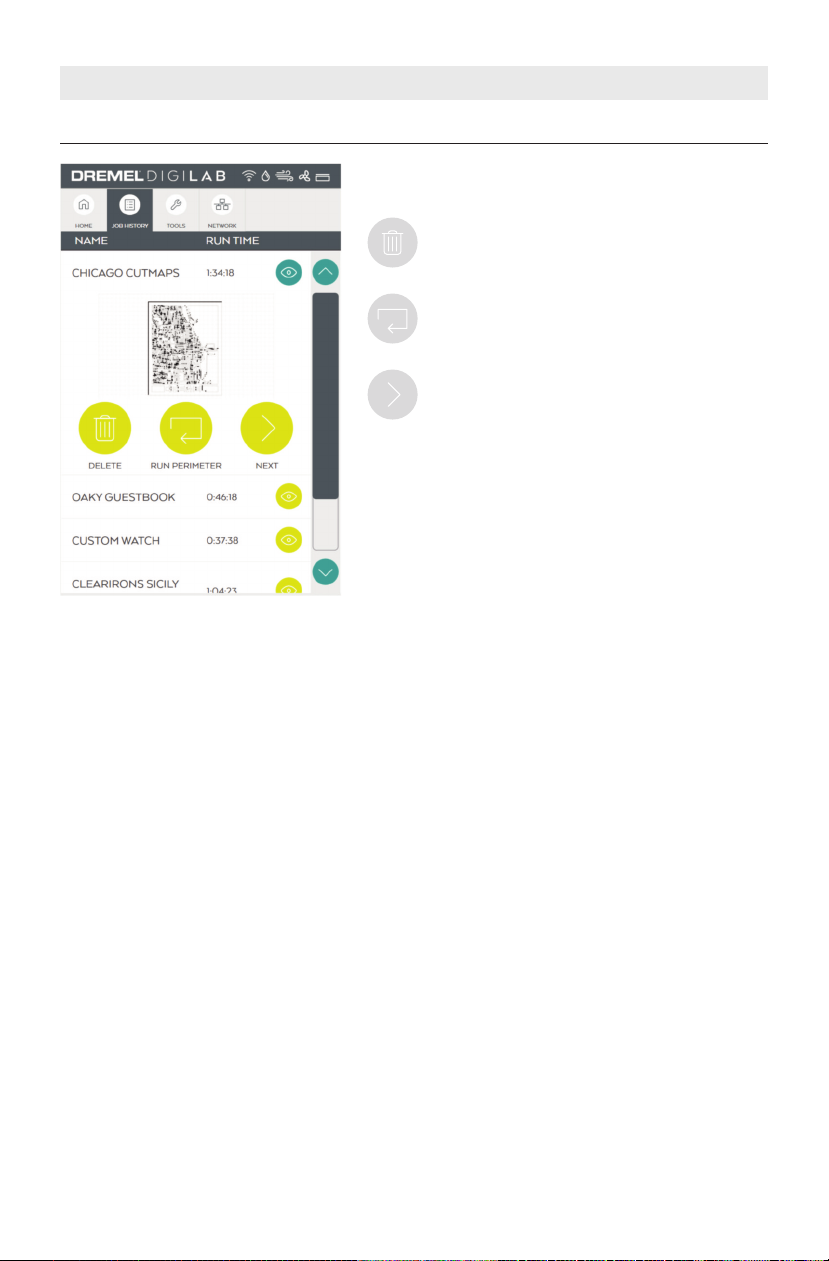

JOB HISTORY

LCD TOUCH SCREEN

This screen displays options for the Job selected

from the list.

DELETE – Delete files from the Job History

list.

RUN PERIMET E R – Exec u t e s t h e r u n

perimeter.

NEXT – Changes the text to LOADING. The

Job will prepare to start.

Note: If a job is rerun, the system safety checklist

will appear (see page XX Operation Screens).

23

Page 24

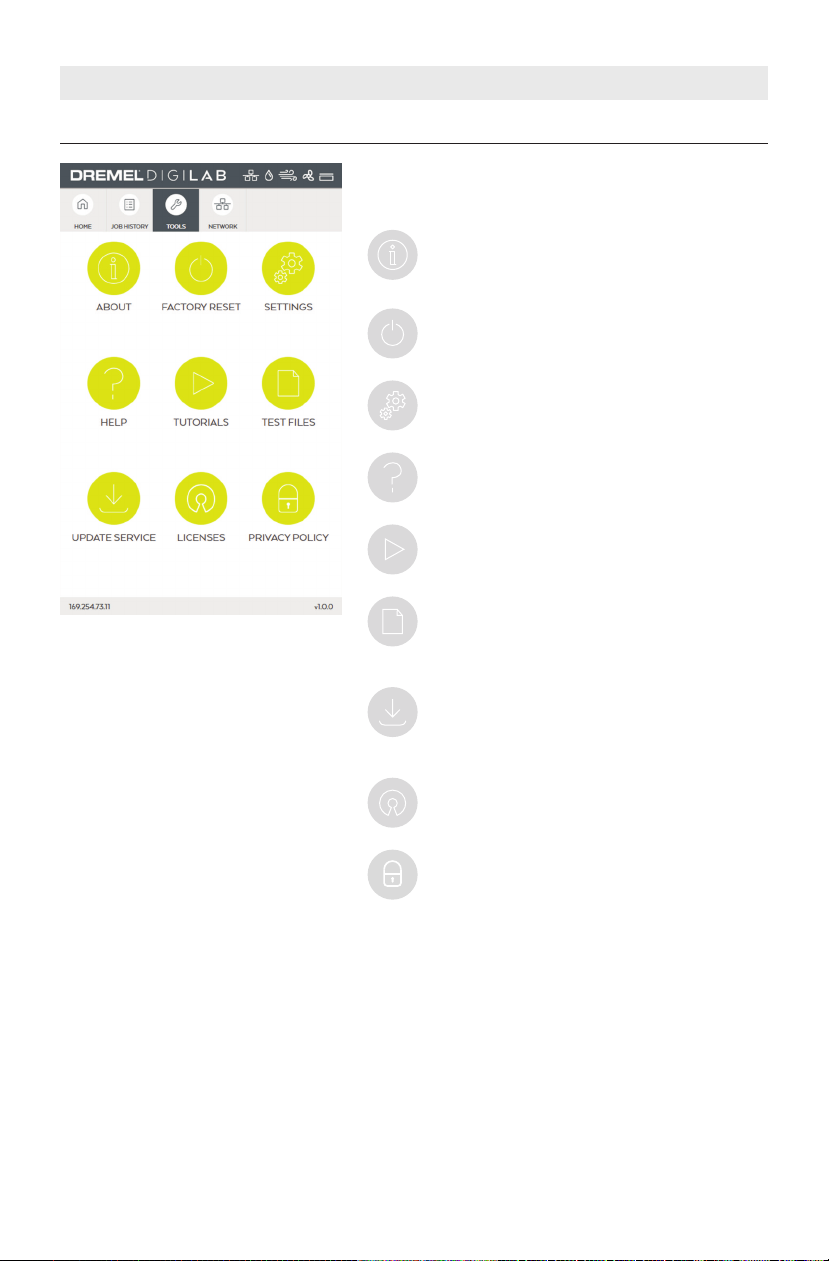

TOOLS > MENU SCREEN

LCD TOUCH SCREEN

This screen displays available tools for mangement

of the laser cutter.

ABOUT — Displays laser cutter information

su c h as m o d e l nu m b e r , se r i a l nu m b e r ,

firmwar e versio n , usag e , and ne tw o r k

information.

FACTORY RESET – Remove all information

stored o n L C40 and r etu rn it to fact ory

defaults.

SETTINGS – Shows language and display

settings.

HELP - Displays service menu with customer

service contact information.

TUTORIALS – Displays short tutorials on

operation of the laser.

TEST FILES – Displays and allows execution

of test files to verify proper operation of the

laser.

UP D A T E SER V I C E – D i s p l ays av a i lable

service updates from Dremel. Updates are

pushed to t h e unit a n d cann o t be

re q u e s t e d . The u s e r has t h e option to

accept or ignore the update.

LI CEN S ES – Displ ays the lists of OP EN

SOURCE software licenses associated with

the unit.

PR I V ACY P O LICY – Di s plays a w e bsite

address for further detail s on Dremel

privacy policy.

24

Page 25

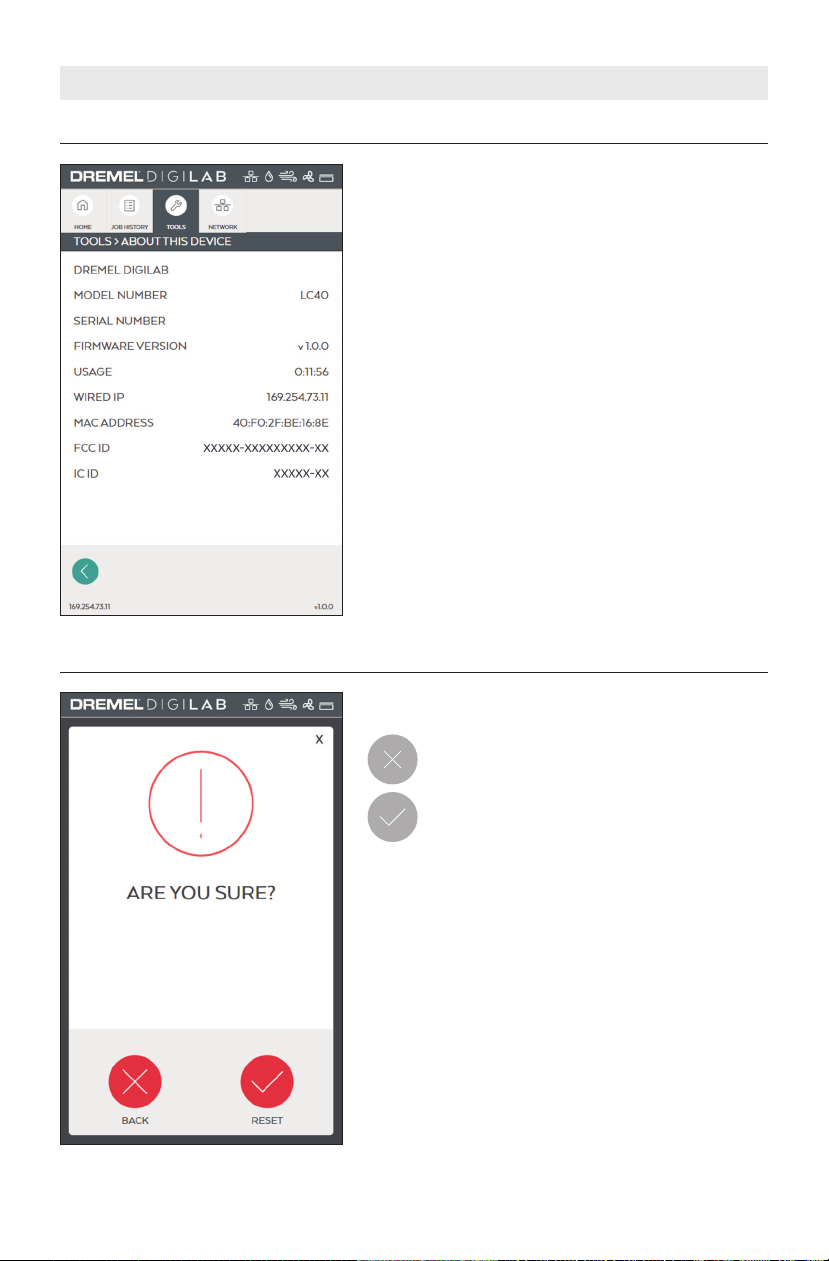

LCD TOUCH SCREEN

TOOLS > ABOUT THIS DEVICE

TOOLS > FACTORY RESET

This sc ree n disp lay s l aser cutt er hardw are and

software information.

MODEL NUMBER — Displays unit model number.

SERIAL NUMBER — Displays unit serial number.

FIRMWAR E NUMBE R — Dis p l a y s th e curre n t l y

installed firmware version.

USAGE — Displays total hours of time that jobs have

been run.

WIRED IP — Displa y s Et h e rn e t IP ad d r e s s , if

connected.

WIRELESS I P — D is plays IP address assigned b y

wireless router.

MAC ADDRESS — Displays unique identifier assigned

to a network interface controller.

FCC ID — Displays FCC ID

IC ID — Displays IC ID

This screen allows for verification of factory reset

selection.

BACK – Tap to can cel factory rese t a nd

return to Tools > Menu Screen.

RESET – Tap to perform factory reset.

NO TE - T he fol lo win g act ions o ccu r when F act or y Re se t i s

performed:

• EULA screen will appe ar on next power up and needs to be

accepted.

• Country and Language selection will appear on next power cycle.

• Job history on the LCD software Interface will be cleared.

• Default material settings will be restored for the Laser browser

interface software.

• User custom material settings will be cleared.

• Network configuration will be restored to default with all custom

settings cleared.

• Saved wireless network and password will be cleared.

• Ve ntilati on setting will re vert back to default of EX TERNAL

FILTRATION/VENTILATION SYSTEM.

25

Page 26

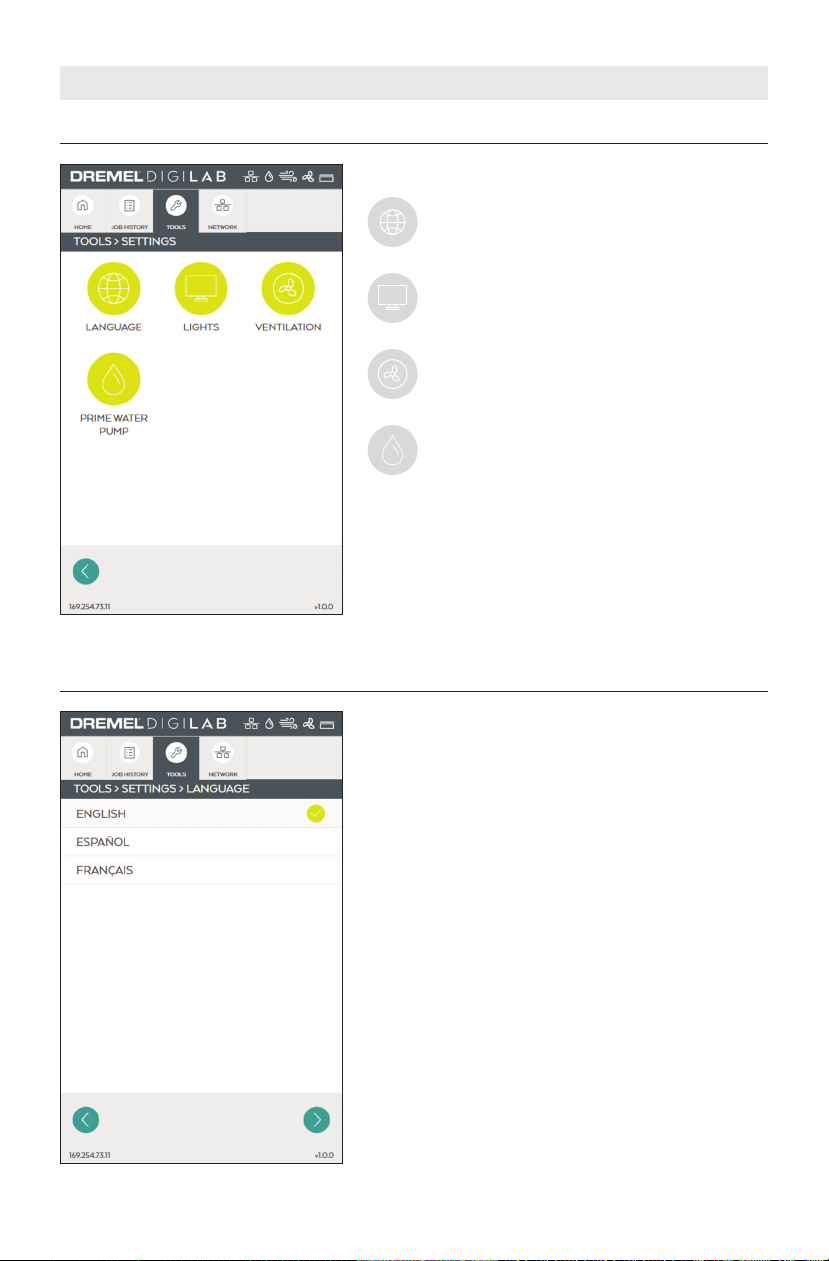

TOOLS > SETTINGS

LCD TOUCH SCREEN

This screen displays available settings

LANGUAGE – Displays a sub-menu where

LCD me n u w a r n in g s la nu a g e c a n b e

selected.

LIGHTS – Disp l a y s a sub-me n u whe r e

cabinet LED lights can be turned “ON” and

“OFF”.

VENTILATION – Displays a sub-menu screen

where ventilation type can be selected.

PRIM E WATER P UMP – Disp lay s a submenu with water pump controls.

TOOLS > SETTINGS > LANGUAGE

This screen displays and allows selection of different

languages.

Note: Choosing the language on this screen does not

set the software language on the computer, only the

LCD warning screens are affected.

26

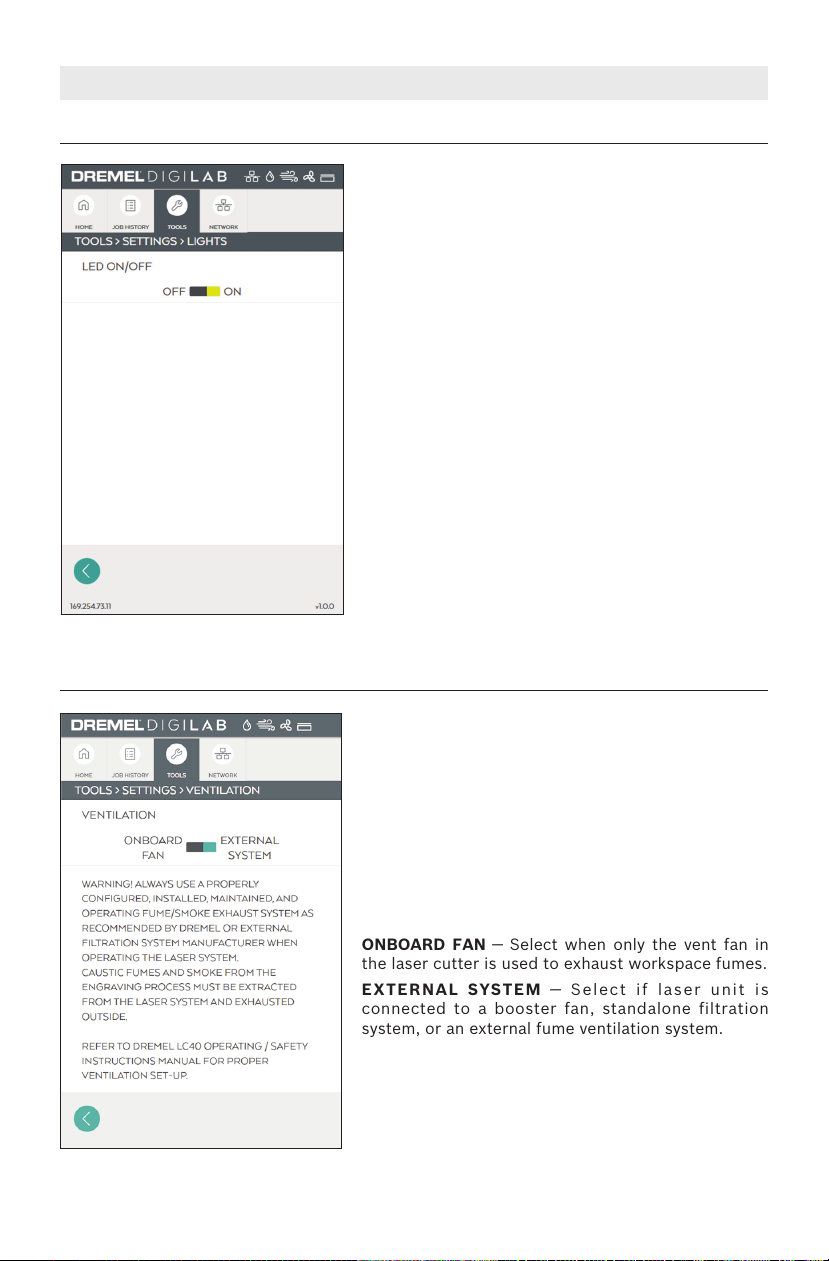

Page 27

LCD TOUCH SCREEN

TOOLS > SETTINGS > LIGHTS

This screen displays the option to turn ON or OFF

the LED lights that illuminate the workspace.

LED ON/OFF — Turns “ON” and “OFF” LED lights.

LED lights are “ON” by default. If the main power

switch is cycled, the light setting will return to the

default.

TOOLS > SETTINGS > VENTILATION

This screen provides an option to select between

the internal vent fan and external ventilation systems

such as a booster fan, a standalone filtration system,

or an external fume ventilation system.

To assure proper removal of fumes produced during

operati o n o f Dremel L C 4 0 laser c u t t e r , th e

ventilation selection must match the actual fume

extrac tion set up. Dremel LC40 must be set up

according to instructions provided in the Exhaust

Connections chapter of the Setup section on page

XYZ to assure proper ventilation.

ONBOARD FAN — Select when only the vent fan in

the laser cutter is used to exhaust workspace fumes.

EXTERNA L SY ST E M — Se l e c t if la s e r uni t is

connected to a booster fan, standalone filtration

system, or an external fume ventilation system.

27

Page 28

LCD TOUCH SCREEN

TOOLS > SETTINGS > PRIME WATER PUMP

This screen provides control to start the water pump

during priming of the laser cooling system.

START – Starts the coolant pump.

This screen provides control to stop the water pump

during priming of the laser cooling system.

STOP – Stops the pump.

28

Page 29

TOOLS > HELP

LCD TOUCH SCREEN

Th i s screen dis p lays cus t omer ser vice con tact

information.

TOOLS > TUTORIALS

This screen provides access to available tutorial.

FO CUS LA SER HEAD – Instr ucti ons fo r

adjusting the laser head to focus the laser

beam on the work piece surface.

MACHI NE SETUP – In str ucti ons for t he

initial setup of Dremel LC40.

OTHER – Instructions for cleaning of the

mirrors and lens.

29

Page 30

TOOLS > TUTORIALS

LCD TOUCH SCREEN

Sequence of screens stepping through JOB PREP.

Sequence of screens stepping through HOOK UP.

30

Page 31

TOOLS > TEST FILES

LCD TOUCH SCREEN

This screen displays available test files and allows

their execution.

Tes t files are used to verify proper operation of

select functions and features of Dremel LC40 laser

cutter.

• Test Files "CUT TEST - BOX 1" thru "CUT TEST BOX 12" are used to identify optimized cut and

score settings.

• Test Files "ENGRAVE TEST" are used to identify

optimized engrave settings.

• Recommended material size for tests: 12”x20

Preview the test file.

This sample screen illustrates how the option to run

a test file can be selected.

NEXT — To start running the job.

31

Page 32

LCD TOUCH SCREEN

TOOLS > UPDATE SERVICE

Th is scr een pr ovid es n etwo rk c onne ctiv ity and

status of update service from Dremel.

LOCAL NETWORK – Shows whether ethernet or

wireless is connected to the local network.

UPDATE SERVICE – Indicates if the unit is able to

comm uni cat e with the up dat e s erv ice (Internet

connection is required).

UPDATE STATUS – Provides information regarding

any new software updates.

LAST CONNECTION TIME – Shows how long ago

the last update service connection was made. If unit

is actively connected to update service, then the

LAST CONNECTION TIME will not be shown.

If an u pdate is available, an UPDATE AVAILABLE

screen and UPDATE PENDING screen will be shown.

The update prompt, which appears on the Home

menu screen, allows allows a user the option of

accepting the update or deferring for another time.

TOOLS > LICENSES

32

Displays information regarding open source software

licenses.

Page 33

LCD TOUCH SCREEN

000.000.000

TOOLS > PRIVACY POLICY

Provides the web address where the current and

complete privacy policy can be reviewed.

NETWORK > MENU SCREEN

This screen displays the Network connection menu.

Available options allow connection or disconnection

from the wireless network and set up a static IP

address.

WIRELESS – Setup or modify a wireless

local a r ea network co n n ec t i o n for t he

Dremel laser cutter to connect to.

STATIC IP – Setup the Dremel laser cutter

to use a Static IP address or default to a

DHCP (Dynamic Host Configuration Protocol

address) IP address.

33

Page 34

NETWORK > WIRELESS

TOUCH SCREEN

This screens displays wireless networks detected by

Dremel LC40.

Selecti n g an availa b l e netw o r k will sta r t the

connection process.

Wireless network signal strength indicator.

This scre en display s t he pass word p rompt that

ap p e a r s when a p a s s w o r d pr o t e c t e d wi r e l e s s

network is selected.

34

Page 35

NETWORK > WIRELESS

UNA BLE TO CONNECT

ACCEPT

RETRY

TOUCH SCREEN

This scree n dis plays a not ification that a ppears

when a successful wireless network connection is

made.

DONE – Return to Network menu screen.

This scree n dis plays a not ification that a ppears

when co n n e c t i o n to the wi r e l e s s ne tw o r k is

unsuccessful.

RETRY – Allows adjustment of the network

information and an attempt to connecting

again.

ACCEPT – Return to Network screen.

35

Page 36

NETWORK > STATIC IP

TOUCH SCREEN

This screen displays network set up options.

WIRELES S IP – A l l o w s s e t u p a n d

con f i g u r a t i o n of t h e Wireless Network

Connection.

WIRED IP – Allows setup and configuration

of the Wired Ethernet Network Connection.

This screen displays options for setting a static IP

address for a wireless or a wired (LAN) network.

STATIC IP – Allows selection of Static IP adress.

DHCP – A l l ow s select i o n of Dynam i c H os t

Configuration Protocol address IP address. Values

displayed on IP Address, Netmask, and Gateway are

ignored but saved for future use.

AUTO DNS – Allows the Dremel Laser Cutter to use

the domain name system server as determined by

the network router.

MANUAL – Allo ws for i nputting a specific DNS

server IP address.

Edit settings

SAVE – Save Static IP settings.

CANCEL – Cancel Static IP setup.

36

Page 37

TOUCH SCREEN

OPERATION SCREENS

These screens appear during operation.

CHECKLIST SCREEN

Th is s cree n di spla ys s y stem ch ecks pe r form ed

automatically by Dremel LC40 and operator inputs

that must be completed before a job can be started.

CHECKLIST SCREEN — ERRORS DETECTED

Displays errors detected in systems of the Dremel

LC40 while it is preparing to start a job. The status

bar will also display red icons for system or systems

where errors were found.

Link to a trouble shooting tutorial related to

the system where an error was found.

37

Page 38

OPERATION SCREENS

TOUCH SCREEN

If all icons at the top are white, then items in the

checklist should be green.

Manual checks that can be completed after

the work piece is placed in the workspace

and laser head adjusted using the spacer

puck.

To start the job the lid must be closed and the Start

Button rapidly pressed twice.

JOB IN PROGRESS

This scre e n di s p l a y s th e jo b fi l e na m e , ti m e

remaining to complet e the job, and two control

buttons.

PAUSE - Temporarily pause the job, which

can be resumed from the same place.

STOP – Cancel the current job.

38

Page 39

0

1

2

3

4

5

6

7

8

9

1

0

1

1

0

1

2

3

4

5

6

7

8

9

1

0

11

0 181716151413121110 9 8 7 6 5 4 3 2 1 19

0 181716151413121110 9 8 7 6 5 4 3 2 1 19

IMPORT REDOUNDO A UTO ARRAY MATERIAL OPTIONSTIME: 00:00:00 RUN PERIMETER

S

TART

F

ILE EDIT HELP PROJECT NAME: JOB 1

LASER CUTTER

Workspace Saved

1

2

5

6

7

4

3

8

DREMEL LC40 CONTROL SOFTWARE

1

2

3

4

5

6

7

8

This section introduces the major interface features of the Laser Control Software. The Laser

Control Software is a combination of print driver and control software that communicates

with, downloads jobs to, and controls the laser system. There is no download required. The

software will link a web browser with the LC40 using the IP address (found at the bottom of

the LCD home screen) on the local connection (Wireless or Ethernet).

Menu Bar — includes the following

menu options: File, Edit (shown when

a project is opened), and Help.

Tool Bar — inc lude s the followin g

tool s : Impo r t , U n d o, R e do , A u to

Array, Material, Time, Options, Run

Perimeter, and Start.

Workspace — On-screen area where a

job is created. Provides a graphical

representation of the intended job

and it s p o s i ti on re l a ti ve to t h e

gene r a l bou n d a ri e s of th e l a s e r

working area.

Project Name — displays the name of

the current project.

Zoom In — enlarges workspace screen

detail.

Zoom Out — reduc e s wo r k sp ac e

screen detail.

Return to Default Size — auto size to

fit window.

Stat u s — di s p l ay s st a t us o f t h e

current project.

39

Page 40

DREMEL LC40 CONTROL SOFTWARE

FILE EDIT HELP PROJECT NAME: JOB 1

LASER CUTTER

A B C

Menu Bar

A. FILE

OPEN — select to open a file.

IMPORT — import a file or use the camera capture feature to create a file or place a picture

of your laser bed in the background of your workspace.

B. EDIT

REDO — to redo most recent action/change.

UNDO — to undo most recent action/change

COPY — select to copy the object that is highlighted.

DUPLICATE — select to duplicate the object that is highlighted.

PASTE —

FLIP HORIZONTAL — select to flip horizontal the object that is highlighted.

FLIP VERTICAL — select to flip vertical the object that is highlighted.

ROTATE RIGHT — select to rotate right the object that is highlighted.

ROTATE LEFT — select to rotate left the object that is highlighted.

SELECT ALL — select to select all.

DESELECT ALL — select to deselect all.

select to paste the object that is highlighted.

C. HELP

ABOUT YOUR LASER — select to see more details about your laser cutter.

MANUAL — select to access the laser manual.

TUTORIALS — select to see tutorials for your laser.

FAQS — select to see a list of frequently asked questions with answers.

PROJECT INSPIRATION — select to browse project inspiration.

CUSTOMER SERVICE — select to see customer service contact info.

40

Page 41

Tool Bar

I

MPORT

R

EDO

U

NDO

A

UTO AR RAYMATE RIA L

O

PTIONSTIME: 00:00:00

R

UN PERIMETER

START

A B C D E F G H I

A

B

C

D

DREMEL LC40 CONTROL SOFTWARE

IMPORT

Click to impor t a fil e or use the camera

capture feature to create a file or place a

picture of the laser bed in the background

of the workspace. Alternatively, the file can

be dragged and dropped directly into the

workspace.

FILE – Use import/file to bring in a file as

typically done in other software programs.

For PDF files the options are to bring in only

cut files, only engrave files, or both. Select

the option from the drop down menu. All

other file types will default to either engrave

or cut based on their optimal application.

UNDO

Click to undo most recent action/change.

REDO

Click to redo most recent action/change.

AUTO ARRAY

Choose the object to duplicate. Then click

and high l i g h t th e nu m b e r of ti m e s to

duplicate the object.

CAPT URE – Use impo rt/ captu re to take

advantage of the camera capture feature.

This can be used to either place a picture of

the material that’s on the honeycomb plate,

into the bac k g r o u n d o f t h e so f t w a re

worksp ace Thi s f eatur e can be use d f or

placing a file on top of an oddly shaped

material, or to take a picture of a sketch,

and transform that sketch into a file that

can be engraved or cut.

41

Page 42

DREMEL LC40 CONTROL SOFTWARE

E

F

G

MATERIALS

Observe a l l p r o v i d e d

warning s and safe t y

instructions when using the Dremel LC40.

Failure t o d o s o m a y r e s u l t i n f i r e,

equipmen t dam age, property damage or

personal injury.

Never engrave or cut any

unknown material. Only

engrave material s recommended by the

manufacturer. The vaporization/melting of

many materials, including but not limited

to PVC and polycarbonates, can give off

hazardous fumes. Always refer to the Safety

Data S h e e t (SD S ) from t h e mat e r i a l

manufacturer to determine the response of

any w o r k m a t er i a l t o e x tr e m e h ea t

(burning/fire hazard) to prevent hazards.

Click to select a material from the list of

Dremel provided defaults, or choose “more”

to a dd / d e le t e /e d i t t h e list of f av o r i te

materials. Use the star to denote a default

material that will be saved and used for all

jobs, until changed. The settings that are

populated when a material is selected will

be applied to all files brought in, unless

edited in the print settings box, or changed

in the materials list.

TIME

Click to calculate a rough estimate of how

long the job will take to complete.

OPTIONS

Display s mo r e ad v a nc e d settings an d

defaults.

42

Page 43

DREMEL LC40 CONTROL SOFTWARE

H

I

RUN PERIMETER

Laser head will mov e along the exte rior

perimeter of the job. Click again to stop this

motion, otherwise it will continue running.

PAUSE – Appears once a job starts and will

pause the job.

START

This button will send the job to the laser.

STOP – Appears once the job starts and will

cancel the job.

PRINT SETTINGS

A print s e t t i n g s bo x will pop u p when

clicking on an imported file. There are two

ta b opt i o n s at th e top (Cu t / S core a n d

Engrave ) , an d only th e on es that ar e

applica b l e f o r t h a t f i l e t y p e w i l l b e

highlig h t e d . T h i s b o x c a n b e m o v ed

anywhere on the screen simply by dragging

it . The jog i n the t o p right c o r n e r wil l

expand “ad v a n c e d ” se t t in g s fo r mo r e

control. The “X” will minimize the box and

can be reopened by clicking on the pencil

that appears.

CUT

This function is used when cutting through

a work piece. This function is also called

“vector” since a vector, or line file is needed

in o rder to exe cute. The laser h ead will

follow the lines of the file. The software will

detect up to 21 different colors in a line file

and allow adjustment of the print settings

based on those colors. The order that the

different colors are cut can be adjusted in

the p rint previ ew s cre en o nce re ady to

send.

HEAT – A djus t how quick ly t he l ase r is

firing, or how much heat is generated on the

surface of the work piece. Turning up the

heat will cause charring for materials like

wood or paper, but will create a glossy edge

for a material like acrylic.

SPEED – Adjust how quickly the laser head

moves. Slowing the laser head down allows

it to cut deeper into the work piece, while

turning the speed up prevents the cut from

going as deep.

DEPTH – adjust to control how deep the

laser will go into the work piece. Turning up

the depth will increase the likelihood that

th e wor k pie c e will be c u t all the w a y

through.

# OF PASSES – adjust to control how many

times the lase r trac e s ove r the lines .

Increasing the number of passes means the

laser will execute that job, then immediately

execute it in the exact same loca t i o n

however many times entered. Increasing the

number of passes can be an effective way to

ensure the work piece is cut all the way

through, especially as the thickness of the

material goes up.

SCORE

A function when it is preferred not to cut all

the wa y t h r o u g h the wo rk piec e . This

function requires a vector, or line type file

and is most useful when emphasizing the

outline of text or an object. It is very similar

to “cut,” but the software will default to

less pow erful settings , in an atte mpt t o

mark the work piece, but not cut all the way

through it.

Print Settings box (Cut)

Print Settings box (Score)

43

Page 44

DREMEL LC40 CONTROL SOFTWARE

ENGRAVE

This fu nc t i on dark e n s or re m o ve s th e

su r f ace o f the wor k pi e c e , ra t her t h a n

cutting th rou gh it. T his funct ion is also

known as “raster” and will require an image

file to execute. The laser head will move

side to side like an inkjet printer.

Print Settings box (Engrave)

BLACK/WHITE THRESHOLD – Use this to

adjust the amount of black that is included

in the image. The furthest left setting will

include a larger amount of black from the

file, whil e the furthe st righ t s etting will

include less black, or a larger amount of

white.

GREYS CALE – Ta kes a black an d whit e

image and assign s differen t densi ties of

dots to visually create a number of different

shades of grey. Darker areas of the image

will have more dots, while lighter areas will

have less dots. This is useful for images that

ha ve a lot of di f fere n t colors , an d it is

desired that the finished product appear

more realistic. This setting can be toggled

on or off.

INVERT – This setting will transform the

im a g e so tha t the whi t e ar e a s be c ome

black, and the black areas become white.

DEPTH – Adjust to control how deep the

laser will go into the work piece. Turning up

the depth will remove more material, so

that a noticeable void is felt when touching

the work piece, creating almost a 3D effect.

Turning d o w n the d e p t h will k e e p the

surface of the work piece relatively flat or

even.

SPEED – Adjust how quickly the laser head

moves. Slowing the laser head down will

ge ner ally ma ke the engr a vin g darke r o r

deeper, while turning the speed up typically

results in a lighter finish.

RESOLUT I O N – 3 differe n t resolu t i o n

options are available: low, medium, high.

This setting adjusts the DPI (dots per inch)

in the image, the low setting will be faster

and lig ht er tha n the high set ti ng . In l ow

setting th e resolu t i o n is p ix e l a t ed , or

individual dots are easy to see. The high

setting will result in a less pixelated final

result.

JOB PREVIEW

After pressing “start” the PREVIEW screen

allows re v i ew of al l the se t t in g s and

placement of the files before sending the

job to the laser. Changes can be made to

th e orde r the f iles ex ecu te. By de fau l t,

engraving is completed first then cutting. If

other settings need to be adjusted, exit out

of th i s box before sendin g the job. If

everything l ooks correct, t he job can be

sent to the laser. The physical start button

on the laser must be pressed twice before

the job will begin.

Job Preview Screen

44

Page 45

SETUP

Observe all provided warnings and safety instructions when using

the Dremel LC40. Failure to do so may result in fire, equipment

damage, property damage or personal injury.

Disconnect the plug from the power source before making any

assembly, adjustments or changing accessories. Such preventive

safety measures reduce the risk of starting the Laser Cutter accidentally.

Cut and Remove Zip Ties

On ce all i nteri or packa ging has bee n

removed from the laser, locate both zip

ties securing the laser head and gantry.

One zip tie can be found at each end of

the gantry.

Fig. 5

Using a small pair of scissors or diagonal

cutting pliers, carefully cut and remove

both zip ties. DO NOT cut any other cord

or wire. Be aware that the laser tube is

ex t r e m e ly fr a g i l e . Be c a r e f ul NO T to

damage any part of the machine during

this process.

45

Page 46

SETUP

Install Honeycomb Plate

Place the honeycomb plate inside the

laser on the laser bed. Be careful not to

damage any part of the machine during

this process. The head can be moved out

of the way by hand if necessary.

Th e ho n eycomb plat e si t s fl a t at the

bottom of the laser. There is a slight

rece s s in the bed to h e l p al i g n th e

honeycomb plate (Fig. 7).

Fig. 7

Recess

in Laser

Bed

Recess in

Laser Bed

Remove Camera Lens Cap

Remove the cap from the camera lens on

the laser head.

46

Camera

Fig. 8

Lens

Cap

Page 47

Attach Water Hoses

W

A

T

E

R

I

N

E

N

T

R

É

E

D

’

E

A

U

E

N

T

R

A

D

A

D

E

A

G

U

A

W

A

T

E

R

O

U

T

S

O

R

T

I

E

D

’

E

A

U

S

A

L

I

D

A

D

E

A

G

U

A

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

H

e

x

B

o

x

1

2

V

W

A

T

E

R

O

U

T

S

O

R

T

I

E

D

’

E

A

U

S

A

L

I

D

A

D

E

A

G

U

A

W

A

T

E

R

I

N

E

N

T

R

É

E

D

’

E

A

U

E

N

T

R

A

D

A

D

E

A

G

U

A

SETUP

1. Place the Hex Box™ in the workspace.

The maximum distance the Hex Box™

can be placed from the laser cutter is

5 feet.

2. R e mo ve t h e s h o rt s i li c on e tubi n g

capping the water inlet and outlet on

the back of both the laser cutter and

the Hex Box™.

Water Hose

Fittings

Clear

Water

Blue

Hose

Water

Hose

Fig. 9 — Rear of Laser Cutter

3. Match the blue and clear water tubes

to the appropri ate inl et and out let

fittings on the laser cutter and the Hex

Bo x™, Fig. 9 & 10. The fit tings are

labeled with colors to help identify the

appropriate tubes.

Water Hose

Fittings

Blue

Clear

Water

Water

Hose

Hose

Fig. 10 — Rear of Hex Box™

Push the ends of the tubing onto the

fittings until they are snug.

Correct Incorrect

47

Page 48

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

W

A

T

E

R

I

N

E

N

T

R

É

E

D

’

E

A

U

E

N

T

R

A

D

A

D

E

A

G

U

A

W

A

T

E

R

O

U

T

S

O

R

T

I

E

D

’

E

A

U

S

A

L

I

D

A

D

E

A

G

U

A

H

e

x

B

o

x

1

2

V

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

H

e

x

B

o

x

1

2

V

SETUP

Attach Air Tube

Connect the Air Tube to the fittings on

the laser cutter and the Hex Box™. There

are labels on the laser cutter and the Hex

Box™ to help identify the correct fittings.

Fig. 11 & 12.

Air Tube

Fitting

Air Tube

Fitting

Air Tube

Fig. 11 — Rear of Laser Cutter

Push the ends of the tubing onto the

fittings until they are snug.

Correct Incorrect

Air Tube

Fig. 12 — Rear of Hex Box™

48

Page 49

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

W

A

T

E

R

I

N

E

N

T

R

É

E

D

’

E

A

U

E

N

T

R

A

D

A

D

E

A

G

W

A

T

E

R

O

U

T

S

O

R

T

I

E

D

’

E

A

U

S

A

L

I

D

A

D

E

A

G

U

A

H

e

x

B

o

x

1

2

V

A

I

R

T

U

B

E

T

U

Y

A

U

À

A

I

R

T

U

B

O

D

E

A

I

R

E

H

e

x

B

o

x

1

2

V

SETUP

Connect Hex Box™ Connector Cord

Connect the Hex Box™ connector cord to

the laser cutter and the Hex Box™. Fig. 13

& 14.

Connector

Fitting

Connector

Fitting

Connector

Cord

Fig. 13 — Rear of Laser Cutter

Attach Exhaust Shroud

Using a screwdriver, attach the exhaust

shroud to the back of the laser cutter,

Fig. 15. Ensure that the shroud is flush

ag ains t the back sur face of the las er

cutter.

Attachment of the exhaust tubing to the

shro u d is exp l a i ne d in the Ex h au s t

Connections section.

Connector

Cord

Fig. 14 — Rear of Hex Box™

Fig. 15

49

Page 50

4 ft Max.

Outside

Window

Clamp

Clamp

Ex

ha

us

t C

onne

tions

c

SETUP

Venting/Exhaust

Ob serve all prov i ded

warn i n g s an d sa f e ty

in s truct i ons when using the Dre m el

LC40. Failure to do so may result in fire,

equipment damage, property damage or

personal injury.

Al w ays u s e th e las e r

cutter with a properly

functioning exhaust and/or a filtration

system. Emissions from some materials

and the long-term effects to exposure are

unknown, which may lead to personal

injury.

It is important to properly vent the laser

exhaust system. The laser melts and/or

burns material as it moves along its axis

and depending on the type of material

can ge ne ra te s m o k e . Th e smo k e is

compo sed of partic ulates, fu mes and