Page 1

3D45 Unclog Extruder

Read the Dremel 3D45 manual and

these instructions before unclogged

the extruder in your Dremel 3D45. Failure to comply with

he warnings and instructions may result in fire, equip-

t

ment damage, property damage, or personal injury.

Always unplug Dremel 3D45 from its power before performing any service procedures. Failure to do so may re-

sult in personal injury and equipment damage.

Use only Dremel approved materials and components.

Use of object materials, or 3D objects other than Dremel

approved object materials and genuine Dremel components

may void warranty.

Repairs on the Dremel 3D45 may require the use of special

tools (pulling devices and bearing press). Authorized repair

centers have trained repair technicians and equipment

necessary to perform these repairs.

PRE-SERVICE PREPARATION

This document will outline the steps necessary to clear a

clog in the heatsink tube assembly caused by the filament

bulging up inside the tube. If the filament becomes clogged,

neither loading nor unloading will be possible. Tube clogging

can occur by either using an old filament that’s kept in the

open for a longer duration or from 3rd party filaments with

lower transition temperatures.

Tools Required:

• Unclog tool

• Brush

• Scissors

• Pliers

• 2mm Hex bit or Hex wrench (Allen key)

• 2.5mm Hex bit or Hex wrench (Allen key)

• T10 Torx bit or screwdriver (no longer than 4 inches).

For the location of the repair center near you, please call

1-844-4DRML3D (1-844-437-6533) Monday thru Friday,

8AM to 6PM CST. Or, look on our web site at

ww.Dremel3D.com and follow the link for ‘Support’.

w

CONTINENTAL UNITED STATES CANADA

Dremel Service Center

4915 21st Street

Racine, WI 53406

Phone: 1-844-4DRML3D

Giles Tool Agency

47 Granger Ave,

Scarborough, ON

M1K 3K9, Canada

Phone:1-416-287-3000

West Coast Tool

4008 Myrtle Street

Burnaby, B.C. V5C 4G2

Phone: 1-604-873-5394

Preventative Measures:

In order to help avoid clogging please follow the recommendations below.

1. Only use Dremel filament.

2. Always unload the filament from the printer when not in

use.

3. Always wait for the extruder to cool down see thermometer icon on screen empty.

4. Store your filament in a dry environment with a desiccant

bag and clip the free end of the filament to the two holes

in the spool to prevent filament getting tangled or brittleness.

Please call Dremel service center for help in unclogging

your extruder.

Page 2

SERVICE

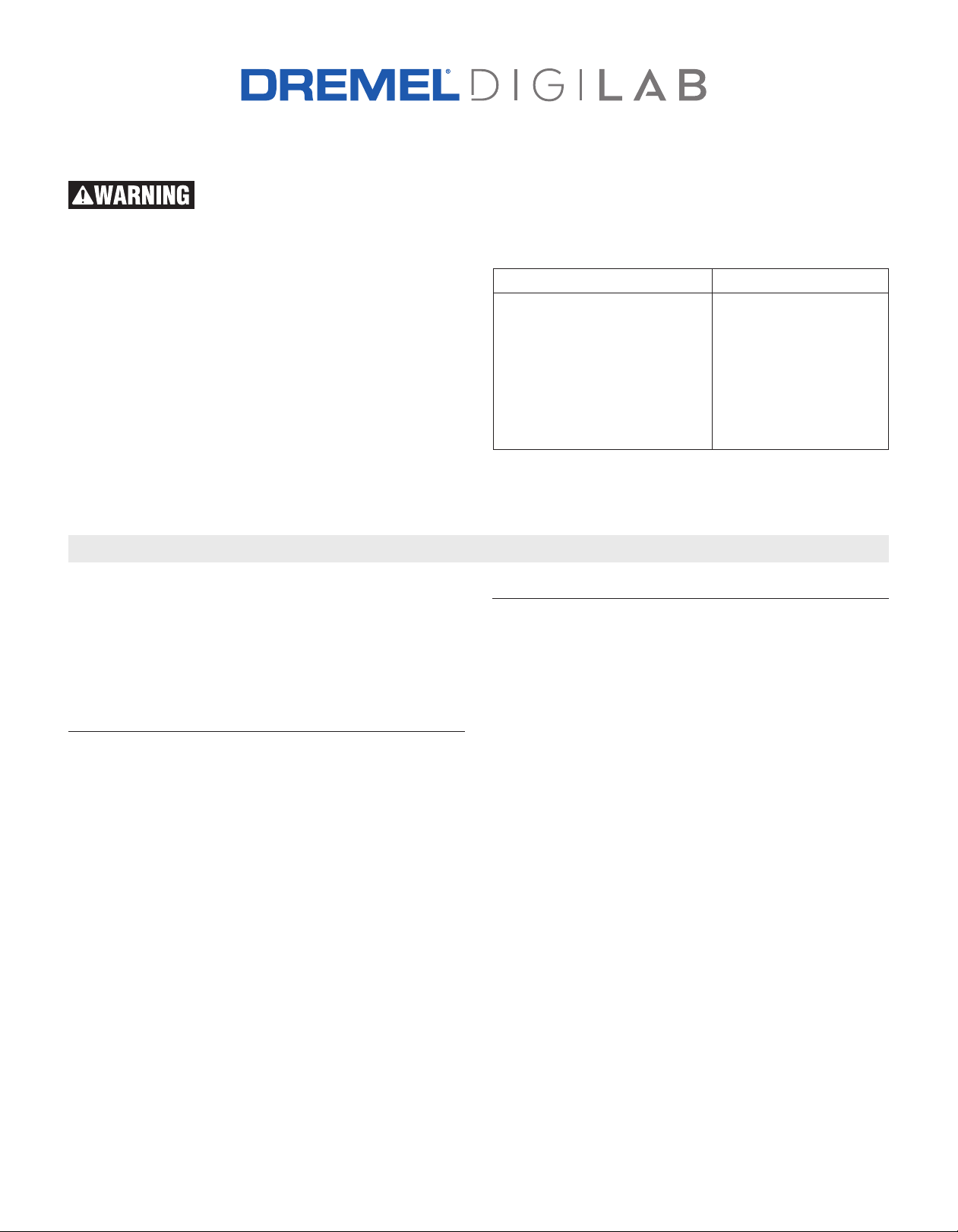

A) Purge Filament:

1. Pre-heat the extruder, go to Tools/Pre-heat. Wait until the

extruder reaches the recommended temperature for your

filament then click on purge when the icons turns green.

Check for filament extruding. If there is no filament coming

out your nozzle, please go to the next step.

2. Go to filament, select edit/view settings and increase the

temperature of the extruder by 10°C go back to preheat

and purge. Check for filament extruding. If there is no

filament coming out your nozzle, please go to step B.

Tip: A good way to speed up the pre-heat process of the

extruder is to click the pause icon on the screen for the

platform temperature, this will allow your 3D printer nozzle

to heat up faster.

B) Pull Filament:

1. Pre-heat the extruder, go to Tools/Pre-heat. Wait until the

extruder temperature reaches the recommended temperature for your filament.

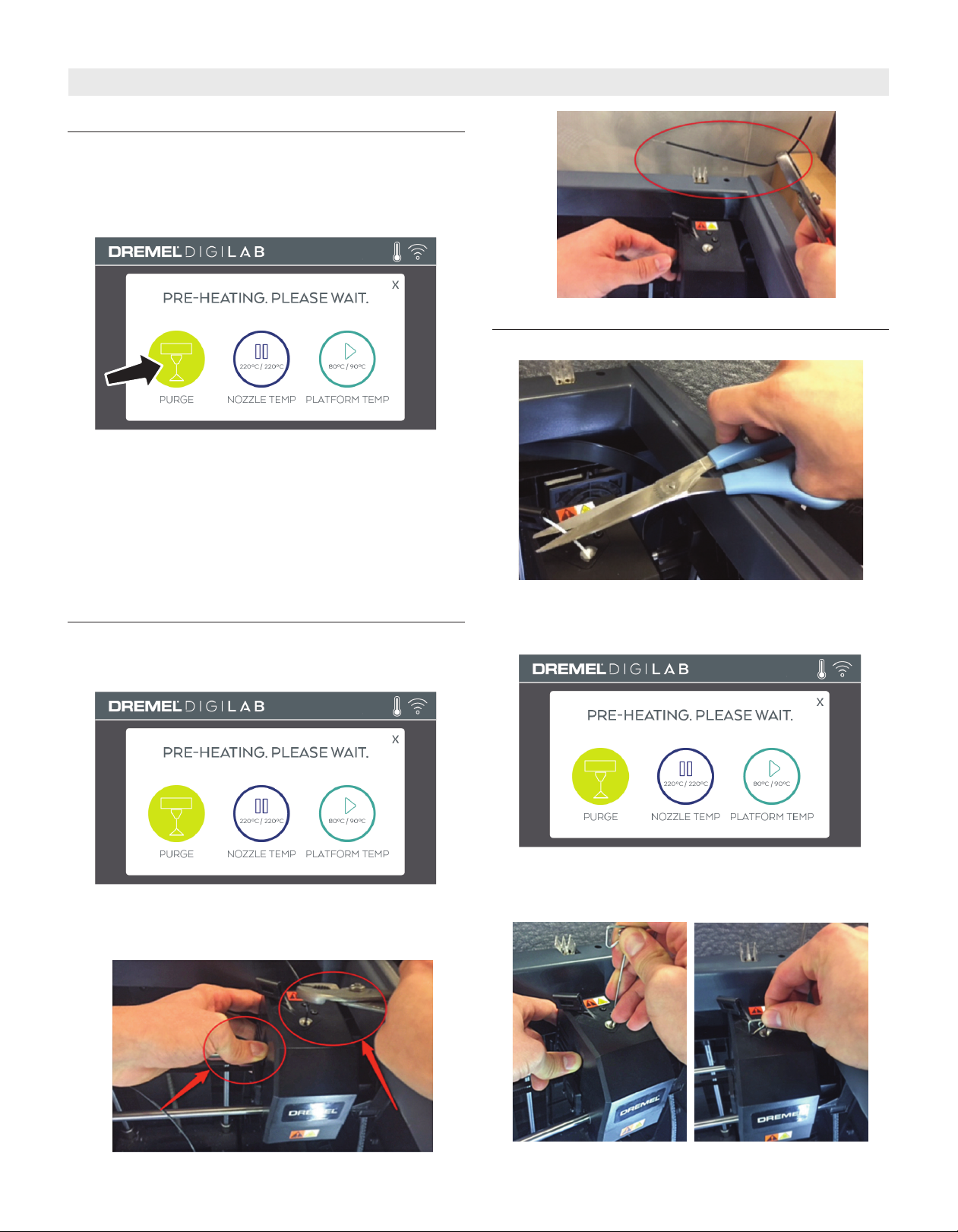

C) Push Filament:

1. Cut filament.

2. Pre-heat the extruder, go to Tools/Pre-heat. Wait until the

extruder temperature reaches the recommended temperature for your filament.

2. Grab the filament end that is available with the pliers, push

on the side lever in the extruder to release tension on the

filament and pull the filament at the same time with pliers.

3. Push down on the lever on the side of extruder to release

tension on the filament, and push the filament with a light

force using the unclog tool. Check for filament extruding.

2

Page 3

D) Check for Clogs in Stepper Motor:

se proper anti-static precautions

U

when performing this replacement.

Discharge static electricity before beginning. Work on a

static-free surface.

It is possible for filament to get stuck on the stepper motor,

or to have a buildup of filament on the stepper motor drive

gear (gear used to move filament through the extruder). To

lean up the stepper motor drive gear, it is required to disas-

c

semble the extruder.

Follow the instructions below to disassembly your extruder

and clean the stepper motor gear.

1. Bring Printer to Safe State for Service.

a. Turn on the printer, and verify that the temperature icon

reads cool (see thermometer icon empty), if it is not cool

(full thermometer), allow adequate time for the nozzle

and bed to cool.

b. Remove screw located on the right side of the hole

using the T10 Torx screwdriver. The first picture below

shows the location of the screw, the second picture a

ottom view of the area where the screw is located,

b

circled in red is the screw that needs to be removed.

c. Unscrew the two screws on the top of the filament guide

bracket using the 2.5mm bit or Hex wrench

Hot Cool

b. Turn off the printer

c. Unplug the printer

2. Remove Top Cover on the Extruder.

a. Cut the filament just before the intake on the top of the

extruder.

d. Remove the top cover.

e. Carefully unplug filament run out switch from the

extruder circuit board, ensuring to pull from the plastic

plug and not the wires; pulling the wires can damage

the connection to the extruder. Please see picture

below.

3

Page 4

3. Removing the Extruder Motor.

a. Disconnect the white extruder terminal block from the

xtruder connector as shown in the picture below.

e

Ensure to grab the block and avoid pinching the wires.

b. Unscrew the two motor screws below using the Torx

screwdriver, as shown in the picture below. Please

ensure that the screws once fully unscrewed, should

still be left inserted in the extruder chassis hole.

c. Pull the extruder motor assembly away from the printer

(vertically) as shown in the picture below.

4. Cleaning the stepper gear. There might be filament residue

in your stepper motor gear, use your brush to clean the

gear of the stepper motor.

5. Replace Extruder Motor.

a. Place the extruder motor on the chassis. Extruder motor

screw holes should line up with holes in the chassis.

b. Tighten the two hex screws with 2.5mm Hex wrench.

Refer picture under Step 3b.

c. Plug in the white terminal block on the extruder connec-

tor as shown in picture under Step 3a (encircled).

6. Replace Top Cover.

a. Attach the filament runout switch wires of the cover to

the extruder circuit board. Refer picture under Step 2d.

b. Place the new top cover over the extruder.

c. Replace the two 2mm screws onto the cover. Refer

picture under Step 2c.

7. Test the Machine.

a. Plug in and turn on the 3D45.

b. Navigate to “Filament” and follow the on screen instruc-

tions to load filament.

c. Build a file on the machine to ensure the 3D45 printer

is working correctly.

Congratulations!

You are now ready to build. Build On.

2610038113 05/2018

Loading...

Loading...