Page 1

8. Repair Information Unit, Electronics Module, Climatic Sensor

Table of Contents

8.1Unit................................................................................................................................2

8.1.0Table of Contents...................................................................................................2

8.1.1Information on Unit 2M 20 276 / 2M 20 615 (of Inc. 8000 SC/IC/NC)....................3

8.1.2PCB Unit and Fuses...............................................................................................3

8.1.3Air Heating with Thermal Release..........................................................................6

8.1.4Boiler with Water heating and Thermostatic Switch...............................................6

8.1.5Fan Motor...............................................................................................................8

8.1.6 Mains Transformer...............................................................................................10

8.1.7Semiconductor Relay...........................................................................................10

8.1.8Test of Heating Unit (Complete)...........................................................................11

8.1.9Voltage Selection.................................................................................................26

8.1.10Replacement of Unit in the event of Repair..........................................................27

8.1.11Repair Information and Change Status................................................................27

8.2Electronics module......................................................................................................28

8.2.0Table of Contents.................................................................................................28

8.2.1Keyboards............................................................................................................30

8.2.2PCB Display Air Temperature..............................................................................36

8.2.3PCB Display (of options), PCB Display Skin (as of SW 11 and 21).....................39

8.2.4PCB Display Humidity (only Inc. 8000 SC/NC)....................................................42

8.2.5PCB CPU..............................................................................................................44

8.2.6PCB Analog with PCB Filter.................................................................................56

8.2.7PCB Power Pack..................................................................................................74

8.2.8PCB Motherboard and PCB Fan..........................................................................80

8.2.9PCB Switch...........................................................................................................84

8.2.10N/A.......................................................................................................................84

8.2.11PCB Controller (RS232) 82 90 581......................................................................85

8.3Climatic sensor............................................................................................................90

8.3.0Table of Contents.................................................................................................90

8.3.1Information on Climatic Sensors..........................................................................90

8.3.2Climatic Sensor 82 90 380 and 2M 21 688..........................................................91

8.3.3Testing and Adjustment........................................................................................92

8.3.4Replacement and Repair......................................................................................95

8.3.5Repair Information and Change Status................................................................96

6141.22x Incubator 8000 SC/IC/NC Repair Information 11.99 Page 1 of 96

Page 2

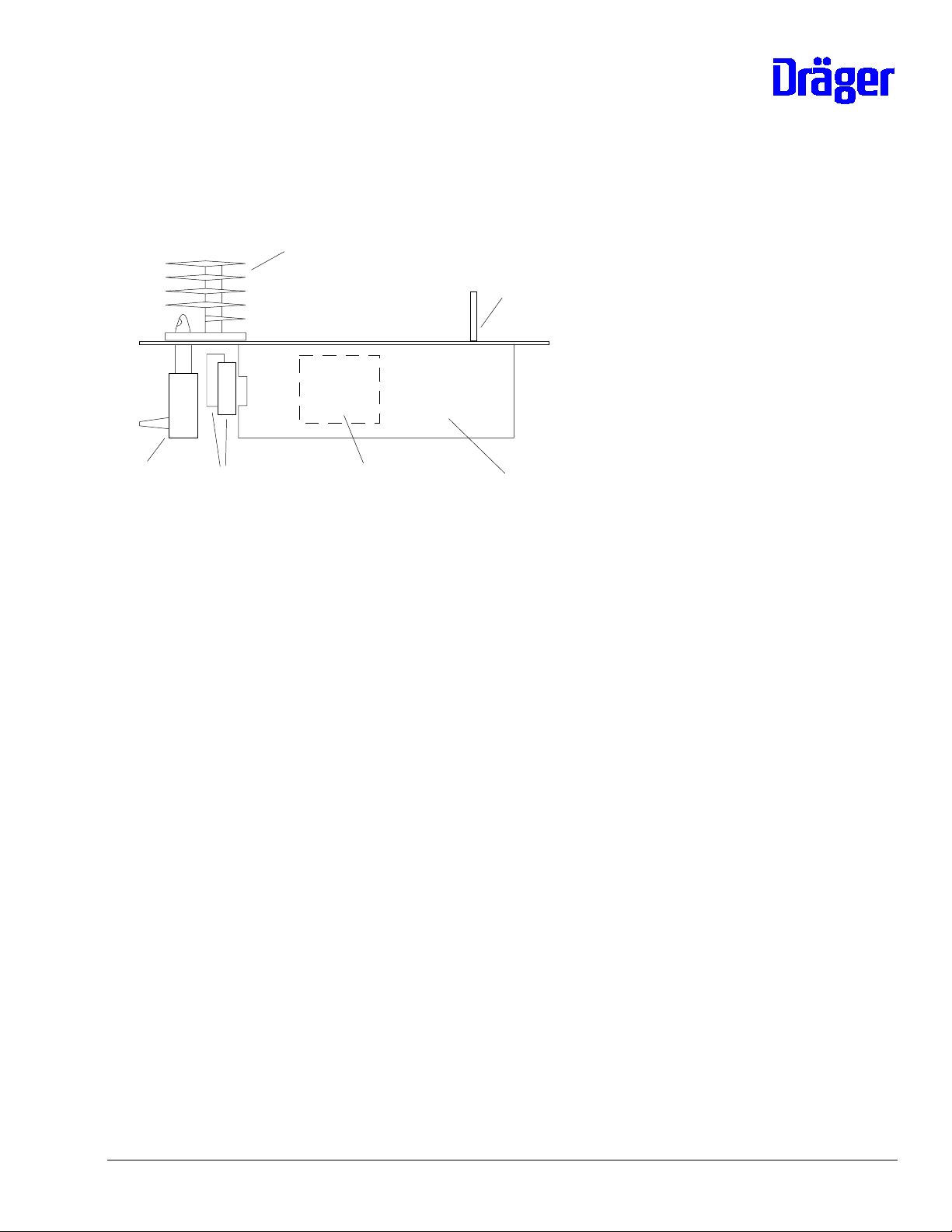

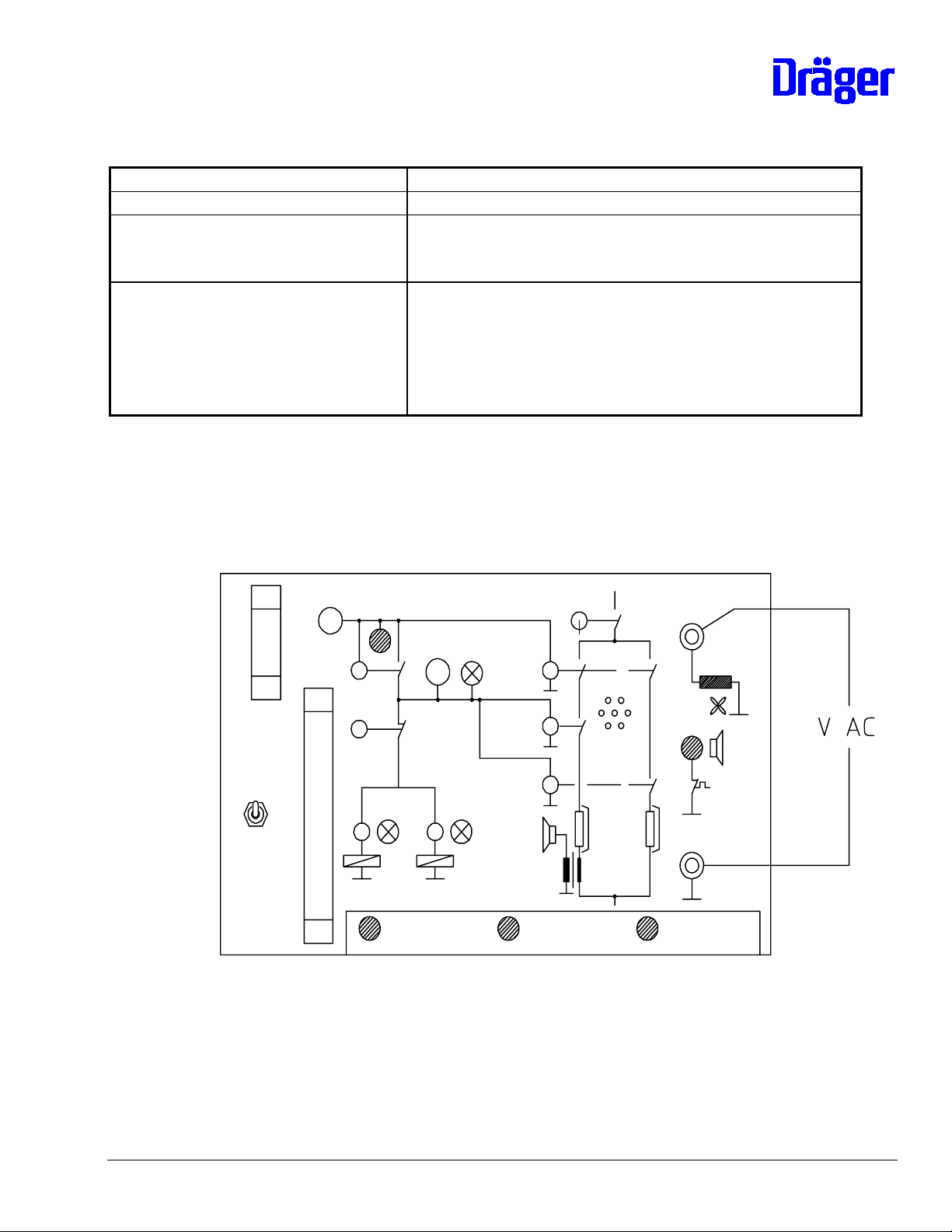

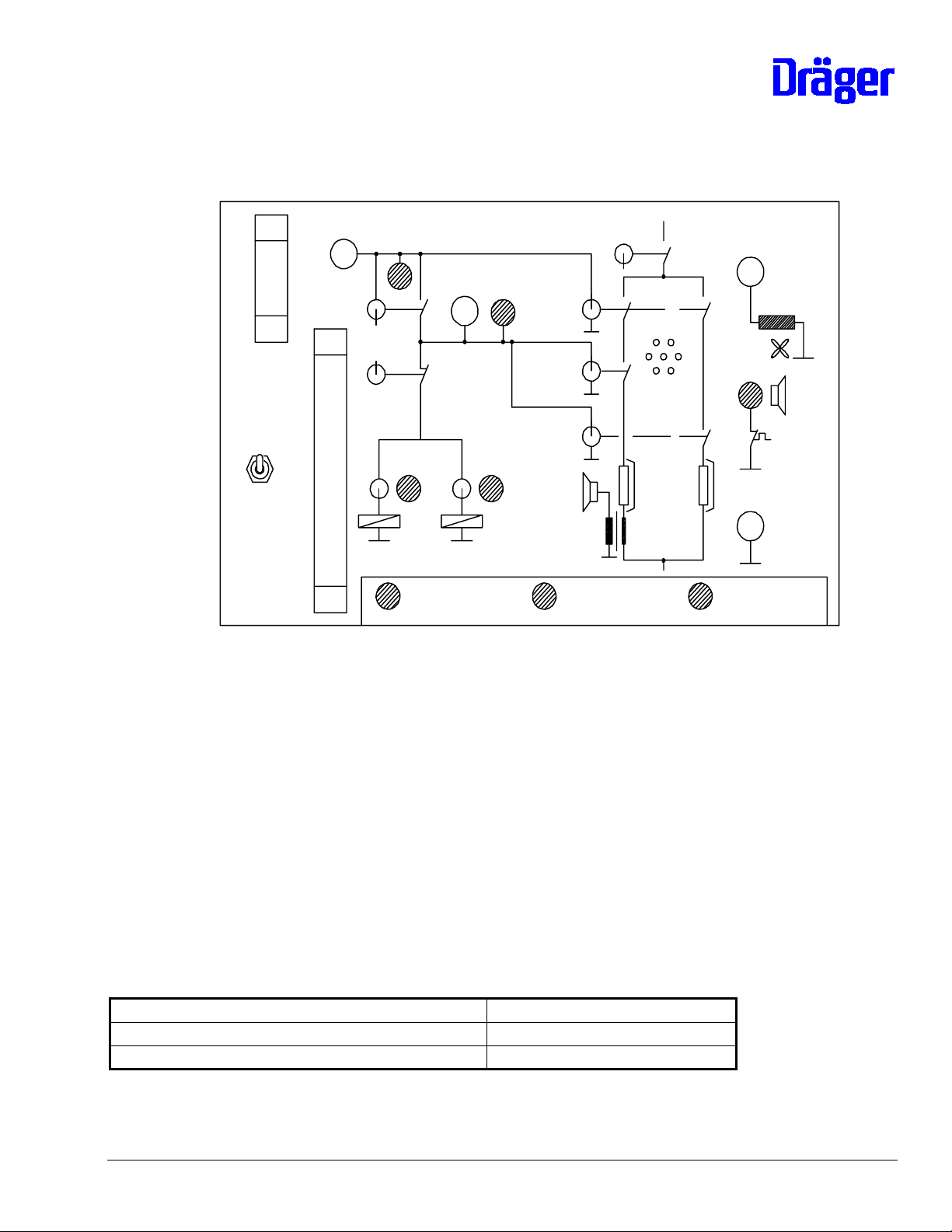

8.1 Unit

8.1.0 Table of Contents

8.1.3

H2O

Air

8.1.5

8.1.4

8.1.7

8.1.6

8.1.2

8.1.1 Information on Units Used

8.1.2 PCB Unit and Fuses

8.1.3 Air Heating with Thermal Release

8.1.4 Boiler with W ater Heating and Thermostatic Switch

8.1.5 Fan Motor

8.1.6 Mains Transformer

8.1.7 Semiconductor Relay

8.1.8 Testing of Unit (Complete)

8.1.9 Voltage Selection

8.1.10 Replacement of Unit in the event of Repair

8.1.11 Repair Information and Change Status

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 2 of 96

Page 3

8.1.1 Information on Unit 2M 20 276 / 2M 20 615 (of Inc. 8000 SC/IC/NC)

Characteristics:

-

PCB Unit 82 90 511

- All connections to printed circuit board plugged-in

- Heating cartridges for one mains voltage only (100 V, 120 V / 127 V or 230 V / 240 V)

- Boiler (complete) plugged-in. In the Inc. 8000 SC/IC/NC it can be removed through a

service opening without dismounting the Unit

Since both Units are identical as far as their function is concerned it is possible to use the Unit

2M 20 615 in the Inc. 8000, refer to 8.1.9 "Replacing in the event of Repair".

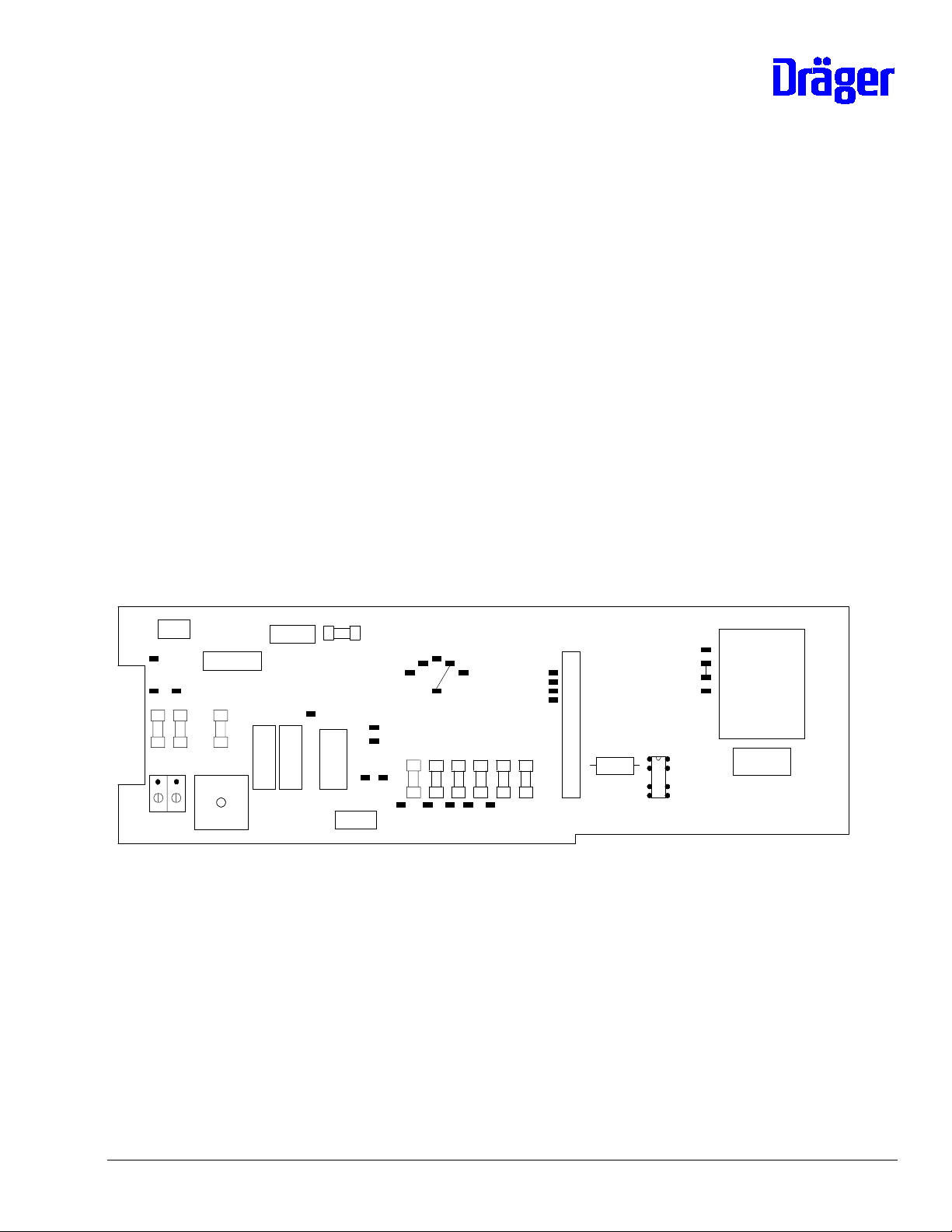

8.1.2 PCB Unit and Fuses

Layout Component Mounting Side:

T58

F4

T57

100

110

127

230

T60

240

T3

T4

T2

T5

X1

T41

T42

T43

T44

T54

T56

T59

F1 F2

X12

T61

X10

X11

F3

K4

K3

X3 X4

T53

K1

K5

K2

X2

F5 F6 F7 F8 F9 F10

T55

T1

T6

T7 T10 T9 T8 T63

C2 +

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 3 of 96

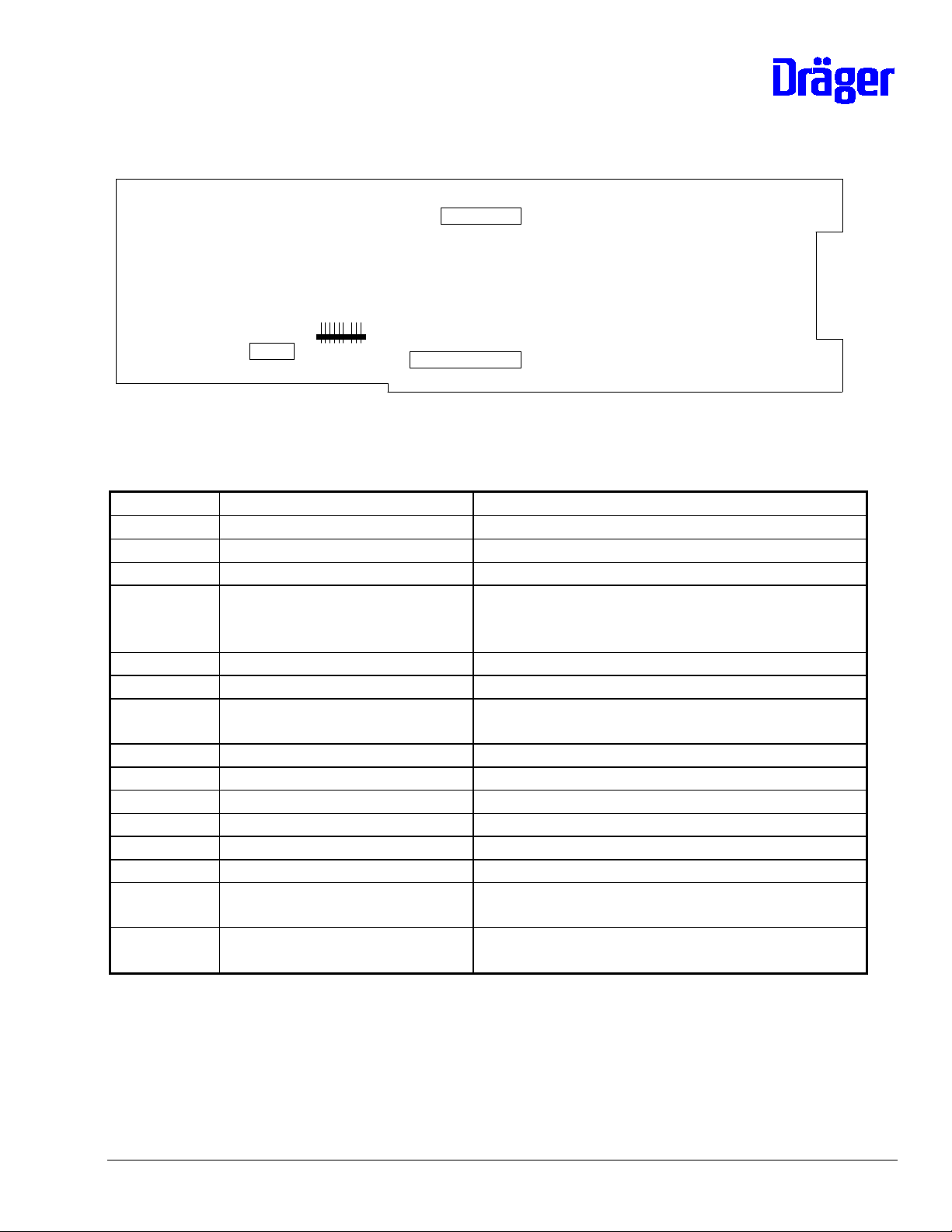

Page 4

Layout Rear:

X7

X5

X13

X6

Component Mounting without Fuses:

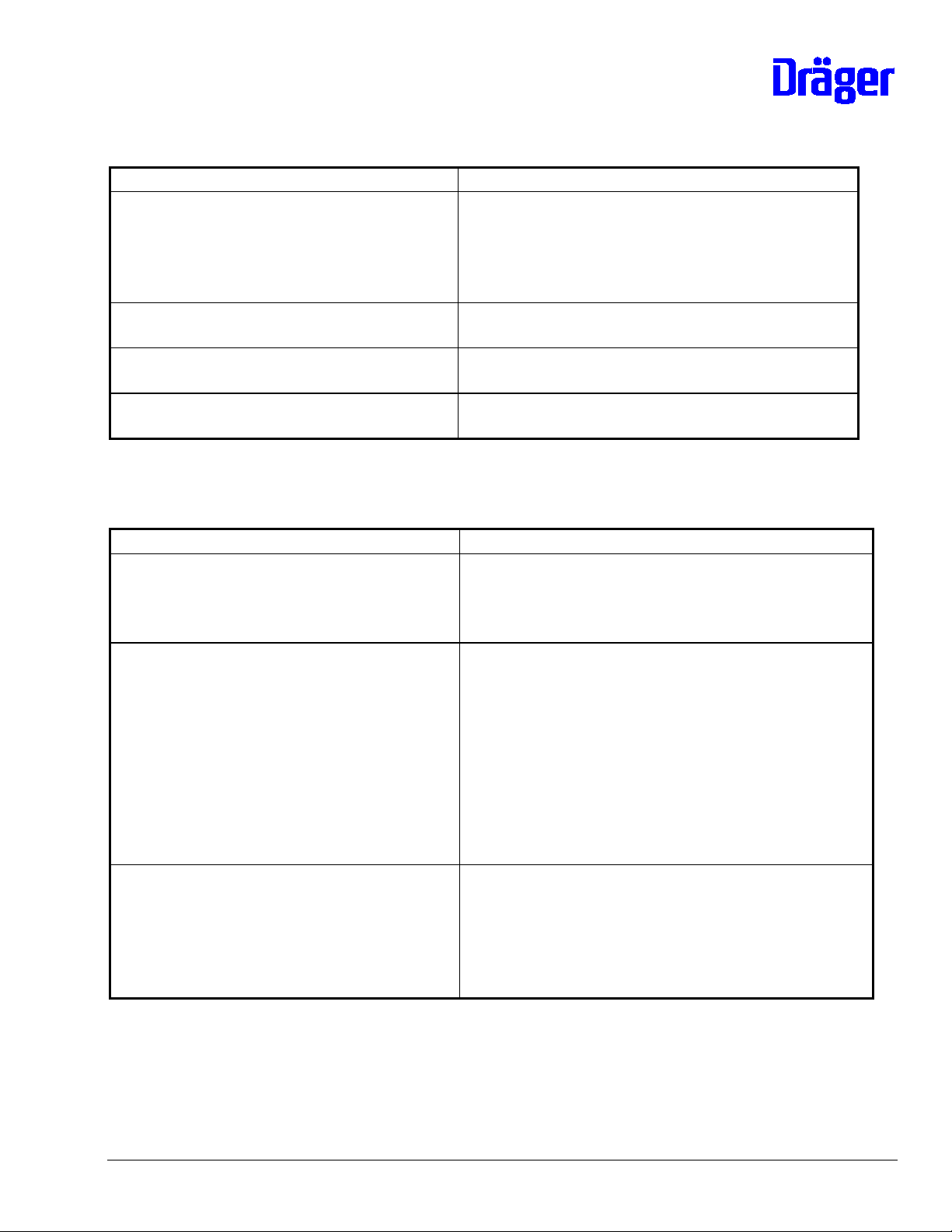

Position Component Function

X1 Connector 18 13 641 Cable connection to electronics module

X2 Connector 18 13 544 Cable connection to valve(s)

X3, X4 Terminal 68 04 759 Mains connection

X5 Connector 18 10 669 Connection for coil of fan watchdog,

Thermostatic switch water shortage and

control of semiconductor relay

X6 Connector 18 28 592 Connection mains voltage for transformer

X7 Connector 18 28 576 Return transformer voltages

X10 Connector 18 28 533 Connection heating cartridge for water

heating

X11 Connector 18 28 541 Connection semiconductor relay supply side

X12 Connector 18 28 525 Connection heating cartridge of air heating

X13 Connector 18 28 533 Connection fan motor

K1, K5 Relay 18 30 732 Mains closing relay

K2 Relay 18 21 474 Safety relay for heating

K3 Relay 18 21 474 Safety relay for valve(s)

K4 Relay 83 01 198 Safety relay for disconnection Semiconductor

relay of heating valve(s)

T54 Transformer 18 13 927 Auxiliary transformer for mains closing relays

K1 and K5

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 4 of 96

Page 5

Fuses:

Position 100 V to 127 V 220 V to 240 V

F1, F2 T 6,3 A 18 15 172 T 3,15 A 18 15 148

F 3 T 80 mA 18 14 974 T 40 mA 18 14 931

F4 T 1A 18 15 083 T 500 mA 18 15 059

F5 T 200 mA 18 15 016 T 200 mA 18 15 016

F6 T 500 mA 18 15 059 T 500 mA 18 15 059

F7 T 2,5 A 18 15 121 T 2,5 A 18 15 121

F8 T 1,6 A 18 15 105 T 1,6 A 18 15 105

F9, F10 T 160 mA 18 15 008 T 160 mA 18 15 008

Testing:

Refer to 8.1.8 "Testing Unit (complete)"

Replacement in the event of repair:

In the event of repair the PCB Unit 82 90 511 (complete) can be replaced or

components can be renewed. All relays are available for this purpose, refer to

component mounting list.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 5 of 96

Page 6

8.1.3 Air Heating with Thermal Release

Three different heating cartridges are uses i n this Unit:

- 220 V to 240 V (132 Ohm) 2M 20 329

- 120 V / 127 V (33 Ohm) 2M 20 331

- 100 V (25 Ohm) 2M 20 669

Prolonged heating cartridges are in use since 1992. When installing these heating cartridges

lock them using an M4-screw.

M4

8.1.3.3 Thermostatic Switch

A safety thermostat which has been tripped must be replaced, no soldering permitted. Prior to

replacement, determine cause for tripping, for example:

- wrong heating cartridges

- device assembled incorrectly

The resistance of the thermostat can be checked at its contacts.

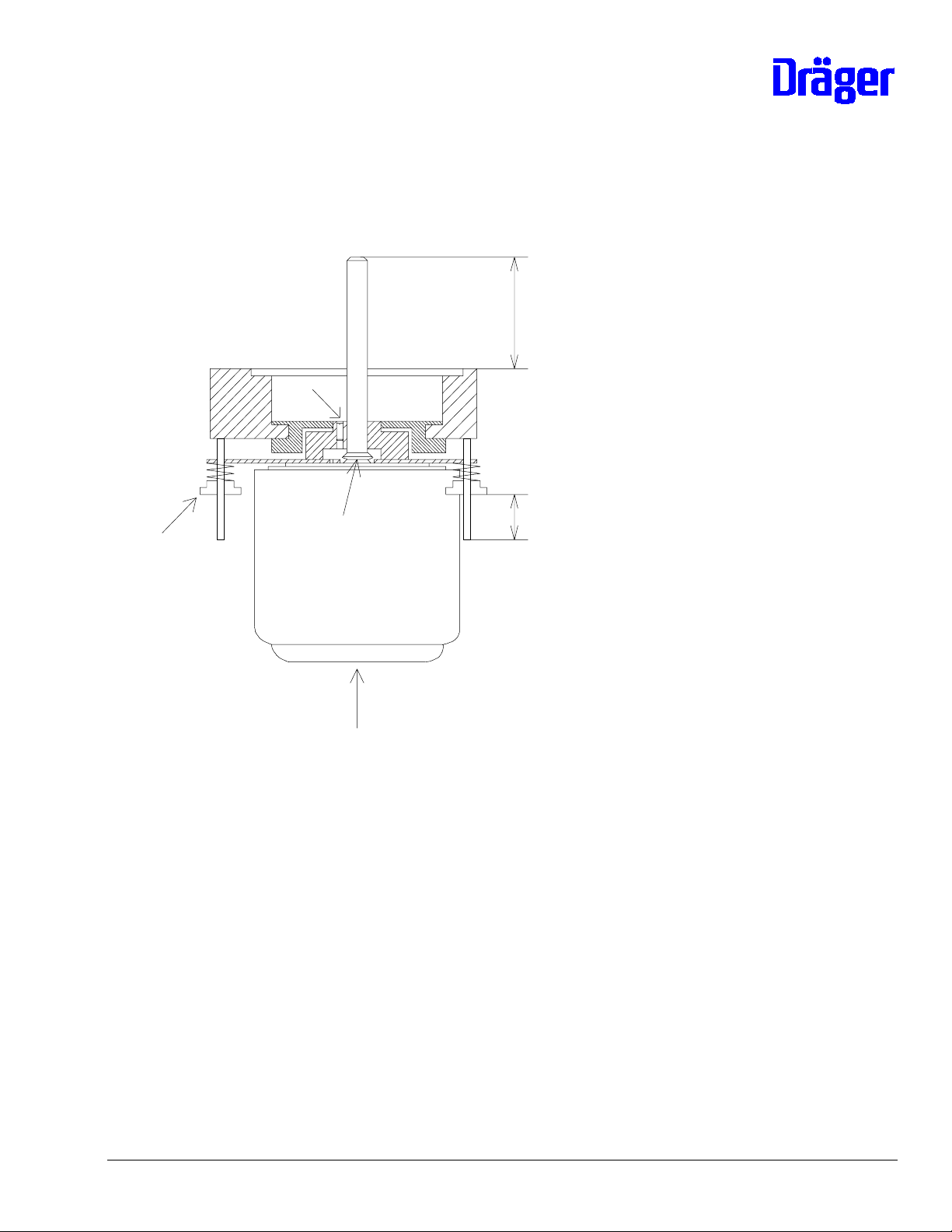

8.1.4 Boiler with Water heating and Thermostatic Switch

The boiler system is a plug-in unit consisting of:

- Aluminum housing 2M 20 291

- Heating cartridge for 230 V, 120 V / 127 V or 100 V

- Cap for vaporizer 2M 20 292

- O-ring cap 2M 08 777

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 6 of 96

Page 7

- Thermostatic switch water shortage alarm 115 °C 2M 20 381

- Safety thermostat 140 °C 2M 20 382

- Plug-in connector

All components can be replaced in the event of repair. If the safety thermostat has been

tripped both thermostatic switches must be replaced.

Service:

The condition of the boiler housing must be checked every six months. If the vaporizer

chamber is soiled it can be scraped out.

Heating cartridges:

- 220 V to 240 V (530 Ohm)2M 20 327

- 120 V / 127 V (132 Ohm) 2M 20 328

- 100 V (100 Ohm) 2M 20 668

Prolonged heating cartridges are in use since 1992. As before, the end of the heating

cartridge must be flush with the boiler housing.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 7 of 96

Page 8

8.1.5 Fan Motor

Fan motor (simplifi ed representation):

A

43,5 +/- 0,5

D

Service required:

The fan motor must be lubricated every six months with oil 2M 07 839. Procedure:

Remove screw A located next to the motor shaft and apply approx. 10 drops of oil into

the bore hole.

Bearing play:

C

E

B

The bearing play can be adjusted using screw B. The screw must be adjusted such to

allow a motor shaft play of approx. 0.2 mm. The screw must be sealed with locking

compound.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 8 of 96

Page 9

Replacing the Fan Motor

Procedure:

- Interrupt mains connection to Incubator and remove Unit

- Unscrew coil of the fan watchdog from aluminum block of the motor mount

- Disconnect cable connection from motor to printed circuit board

- Unscrew fixing bracket underneath the motor

- Measure and write down dimension E of the 4 retaining screws

- Remove 4 retaining screws

D

D

- Using oil 2M 07 839 lubricate later bearing surface of V-ring C of the new motor

- Plug new motor with springs onto threaded pins and screw 4 retaini ng screw D onto

dimension

E

- Precision adjustment:

While the Unit is in its working position the motor shaft must protrude by

43.5 +/- 0.5 mm from the top edge of the aluminum block and must be positioned

perpendicularly to the block. The motor must be suspended freely on the springs.

- Seal the 4 retaining screws D with Loctite 221.

- Lubricate the motor

- The remaining steps of the installation are performed in the reverse order

- When connecting the grounding rings make sure that they do not protrude from the

edge of the resilient motor retaining plate. The fl at head screws of the motor retaining

clip must be sealed with locking compound.

After installation into the Incubator make sure that the fan wheel does not rub against

-

the tank and that it can move freely on the spring-loaded bearing.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 9 of 96

Page 10

8.1.6 Mains Transformer

- Transformer with Efen sensor 82 90 426

The test procedure is described under 8.1.8.3

8.1.7 Semiconductor Relay

The test procedure is described under 8.1.8

The following spare parts can be used in the event of repair:

- Semiconductor relay (electromagnetic or crydom 18 31 399

partial interference suppression)

- Semiconductor relay 18 21 148

Note: The semiconductor relays 18 31 399 have a better switching behavior.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 10 of 96

Page 11

8.1.8 Test of Heating Unit (Complete).

8.1.8.0 Contents

8.1.8.1 Test equipment required

8.1.8.2 Preparation of test

8.1.8.3 Test of power-up relay and supply voltages

8.1.8.4 Test of fan monitoring

8.1.8.5 Test of relay K4

8.1.8.6 Test of relay K3

8.1.8.7 Test of relay K2, air heating and feedback air heating

8.1.8.8 Test of relay K2, water heating and thermo-switch

8.1.8.9 Test of heating unit inside incubator

8.1.8.1 Test equipment required

- Tester heating unit Inc. 8000 79 01 764

- Multimeter 79 01 021

- Measuring line, red 1 m 79 01 022

- Measuring line, black, 1m 79 01 023

- Mains line (only if heating unit is disassembled for test)

- 40-pole ribbon cable use the one of incubator or

"test board uni 40" 79 00 610

- 10-pole ribbon cable included in tester "heati ng unit"

Inc. 8000" 79 01 764 or use the one of

"test board uni 40" 79 00 610

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 11 of 96

Page 12

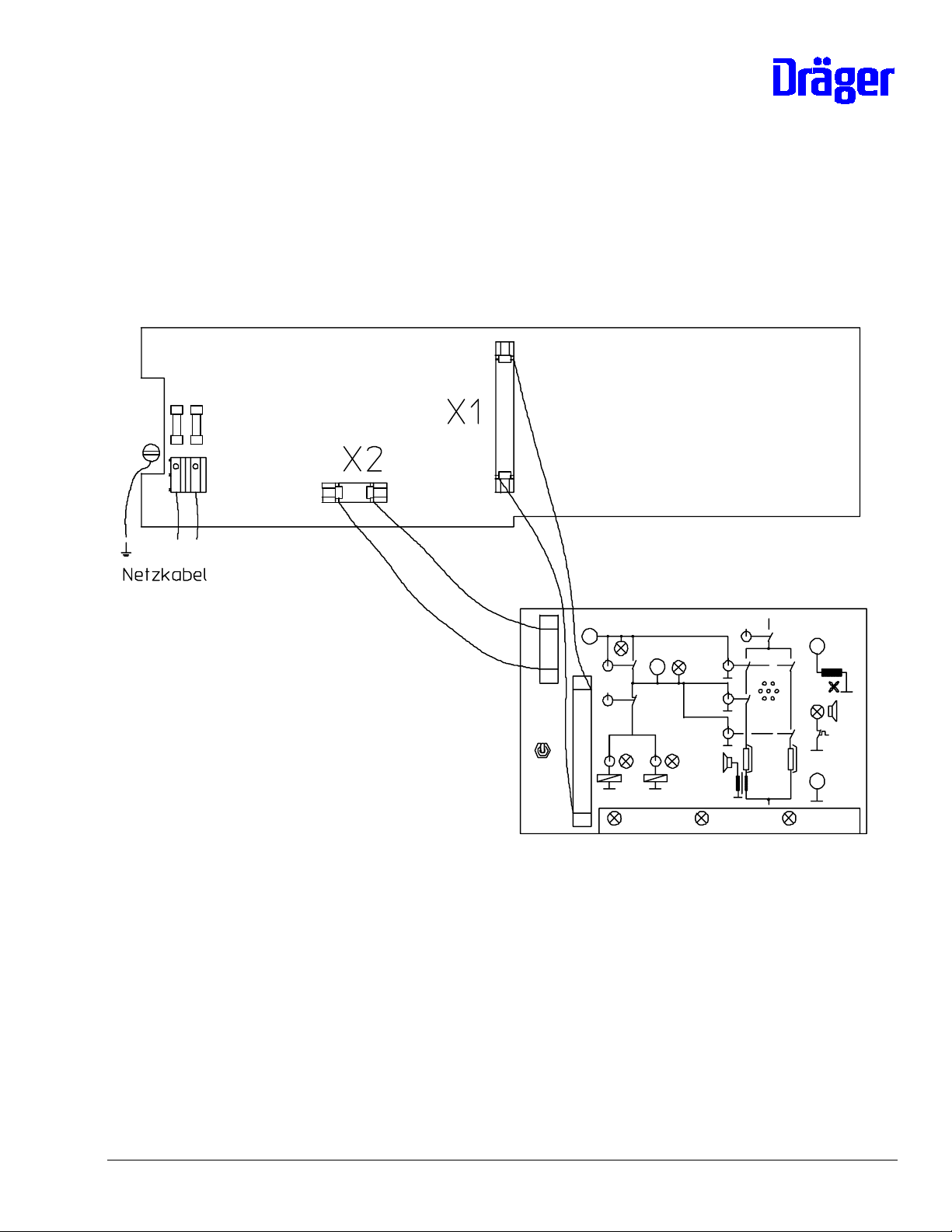

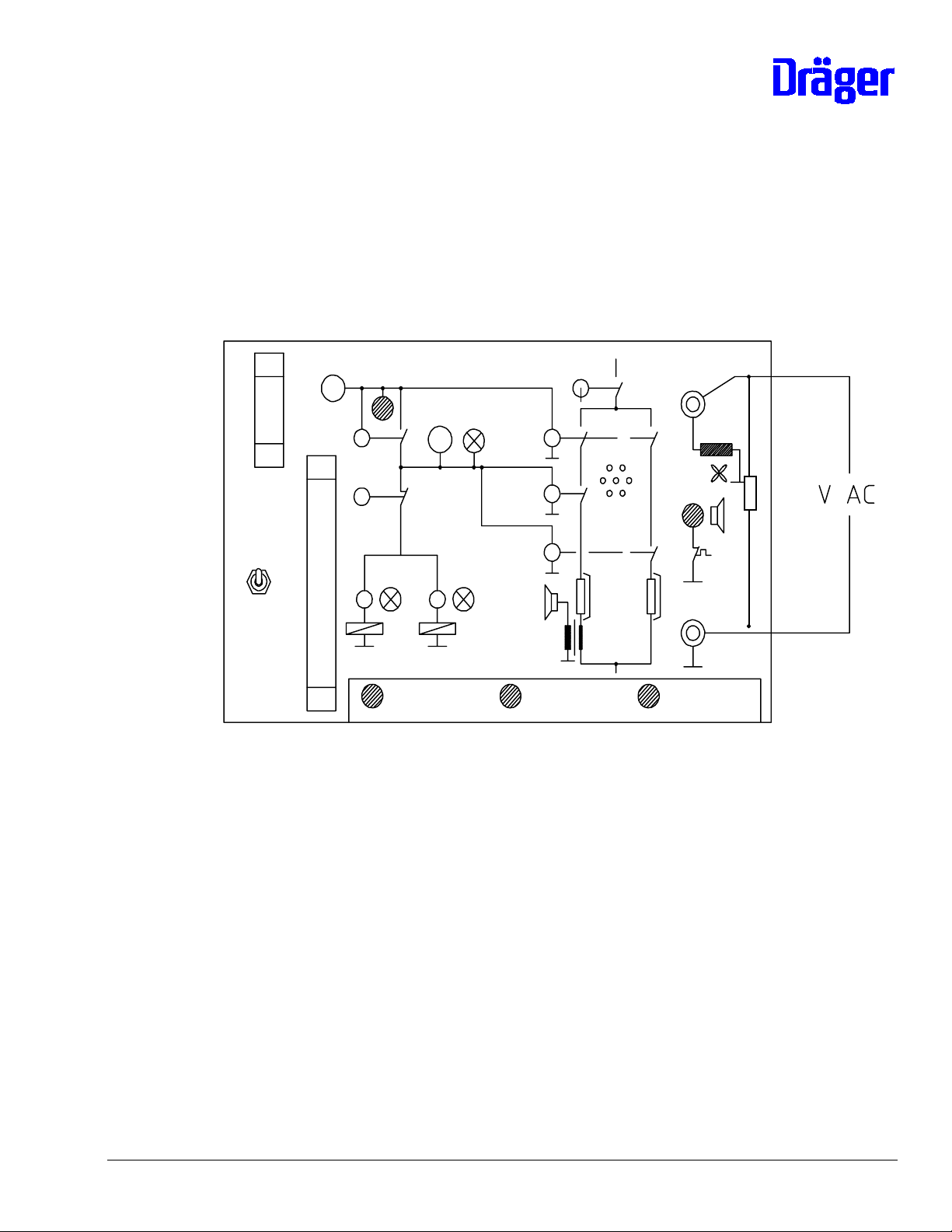

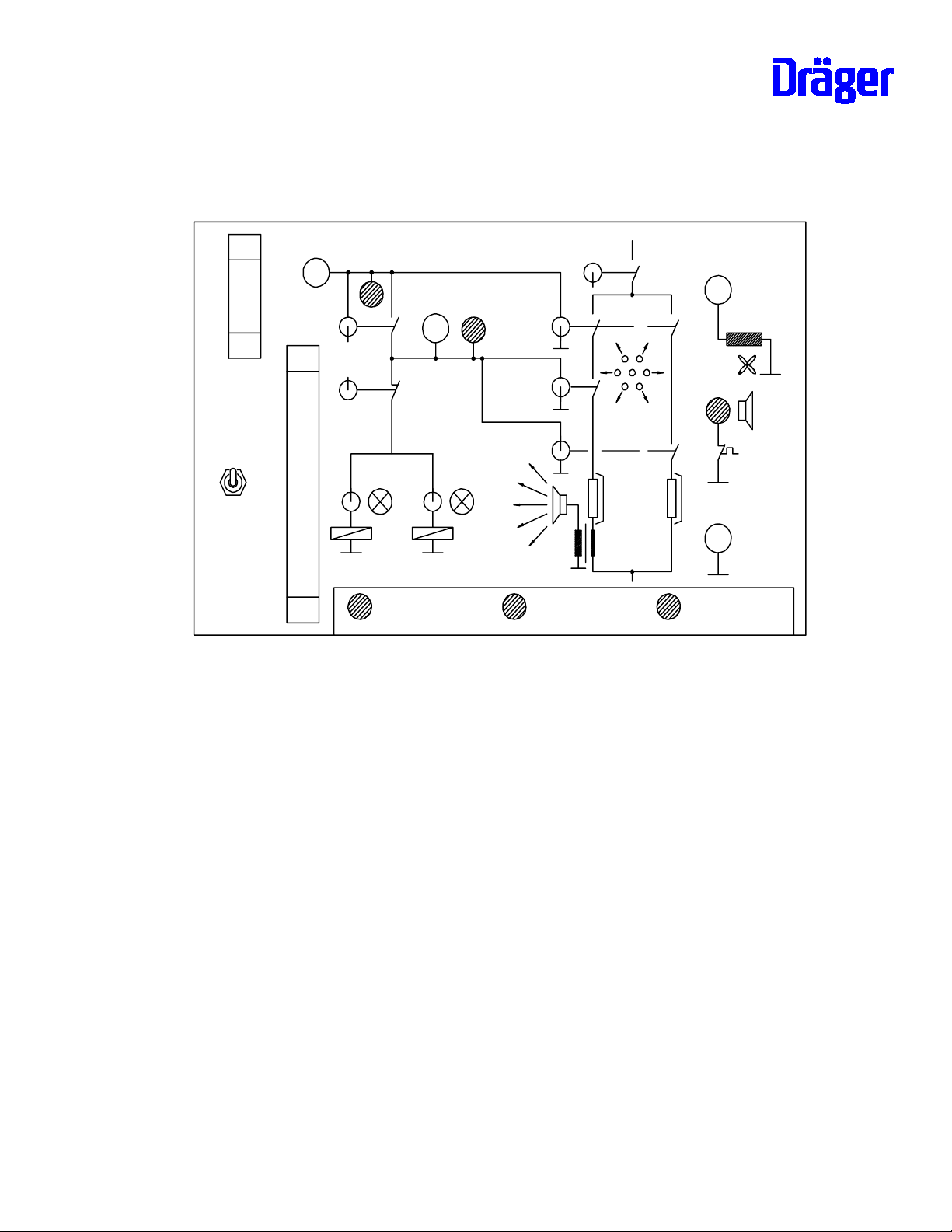

8.1.8.2 Preparation of test

The heating unit of Incubators 8000 SC/ICNC can be tested while assembled or

disassembled.

Note: If the unit is disassembled an isolating transformer must be used.

Test set-up (Netzkabel = power cord):

PCB Unit (part of the heating unit)

- Interrupt mains connection

- Connect tester to X1 PCB Unit using cable

- Connect tester to X2 PCB Unit, the cable connection to the valve(s) must be interrupted

before

- Set all switches at tester to "0" (off)

- Interrupt water supply to boiler of the heating unit

- Attach fan wheel

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 12 of 96

Page 13

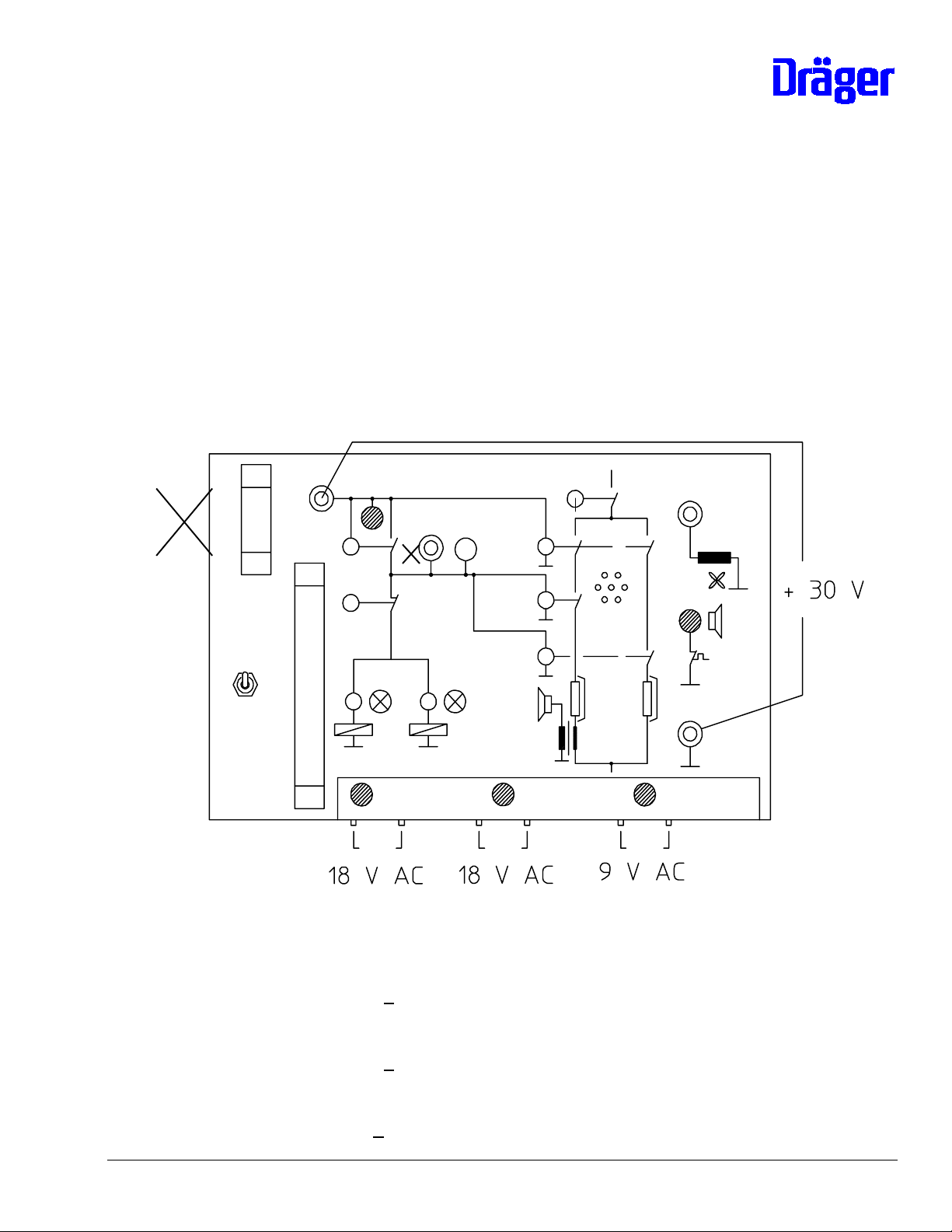

- Establish mains connection to incubator (heating unit installed) respective to heating

unit (not installed)

Set switch K1 at tester to "1" (on).

- Action inside the heating unit

o Mains power-up relays K1/K5 (heating unit 82 90 511) on

o Fan wheel turns

- Test of tester displays:

o LED + 30 V lights up

o LED 18 V ∼ F5 lights up

o LED 18 V ∼ F6 lights up

o LED 9 V ∼ F7 lights up

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 13 of 96

Page 14

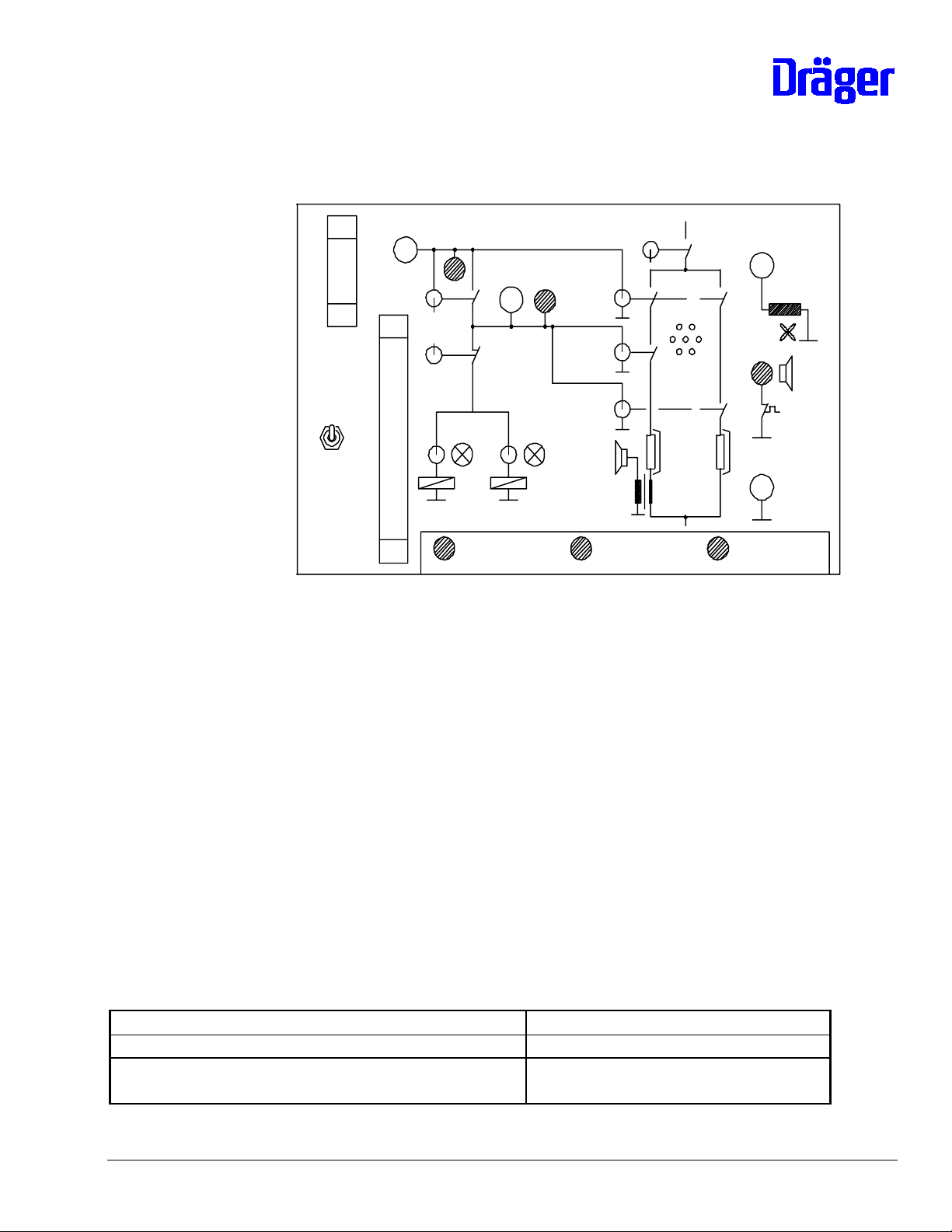

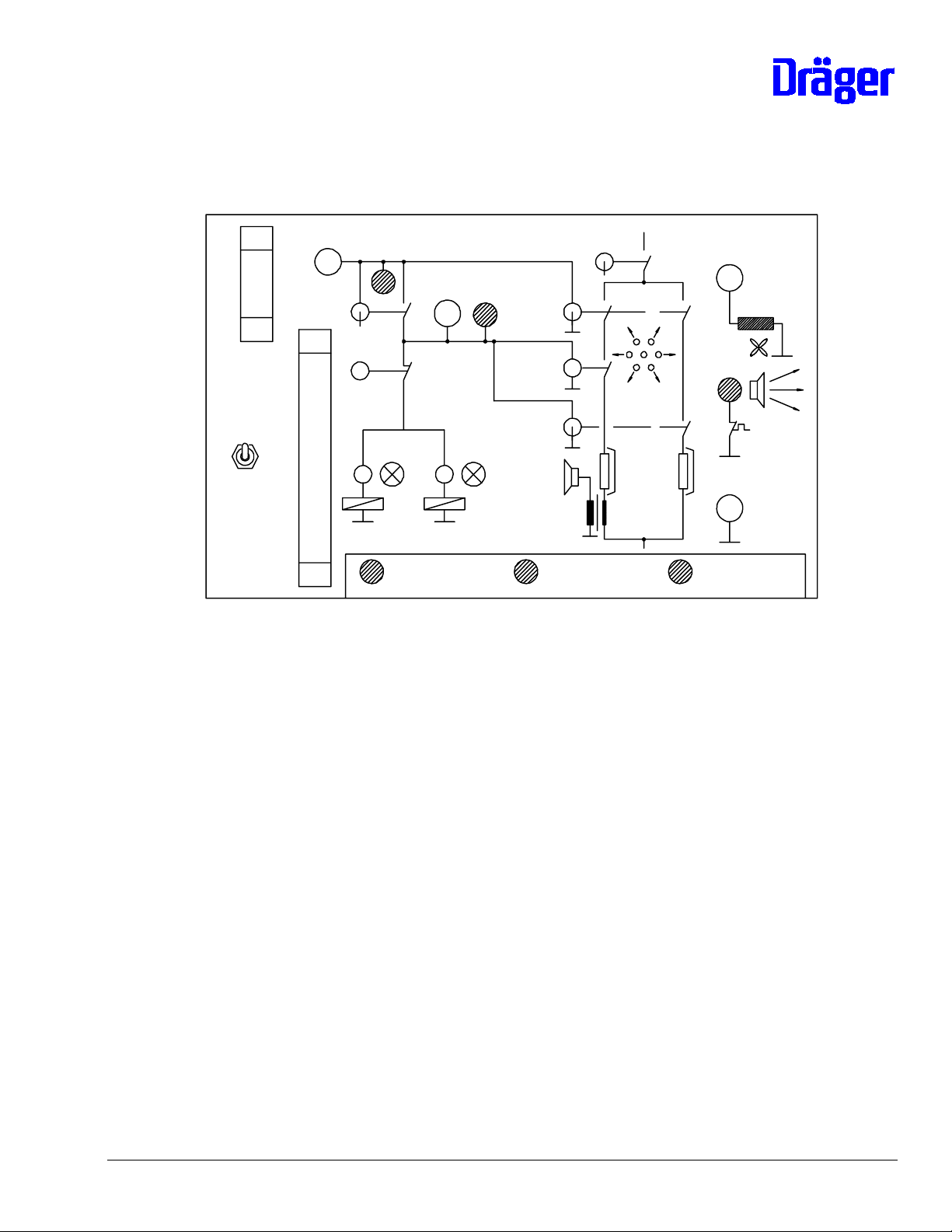

8.1.8.3 Test Set-up for testing a Unit in the Field

It is possible to use the fol lowing test-up for testing the power unit in the field:

open up the unit

•

disconnect the electronic module

•

connect the power unit and the test box with the 40 pin cable

•

carry out the test procedures as given in the following pages (i.e. item 8.1.8.3 and

•

onwards)

Note: The 3 LEDs marked in the drawing below are not active in this test-setup.

Do not connect

40 pin conn.

- Measurement of supply voltages at tester

o alternating voltage 18 V ∼ F5

test value: U= 18 V + 15 %

o alternating voltage 18 V ∼ F6

test value U = 18 V + 15 %

o alternating voltage 9 V ∼ F7

test value U = 9 V + 15 %

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 14 of 96

Page 15

o direct voltage + 30 V

test value U = 30 V + 4 V

Possible errors:

Error Possible cause

no reaction after switching of K1 - mains input fuses F1/F2 defective

- fuse F3, F9 or F10 of auxiliary mains

transformer defective (F9 and F10 only on

PCB 82 90 511)

- mains power-up relay K1 or. K1/K5

defective

- fuse F4 for mains transformer

defective

- mains auxiliary transformer or rectifier

behind mains auxiliary transformer on PCB

defective

- Efen sensor of transformer defective

LED 18 V ∼ F5 off or voltage

outside the tolerance

- fuse F5 defective

- transformer defective

- voltage changeover to PCB O.K.?

LED 18 V ∼ F6 off or voltage

outside the tolerance

- fuse F6 defective

- transformer defective

- voltage changeover to PCB O.K.?

LED 9 V ∼ F7 off or voltage

outside the tolerance

- fuse F7 defective

- transformer defective

- voltage changeover to PCB O.K.?

LED + 30 V off, fan wheel stops - fuse F8 defective

- transformer defective

LED + 30 V off, fan wheel turns - rectifier for + 30 V on PCB defective,

alternating voltage exists, because fan wheel

turns

LED + 30 V lights up, fan wheel

stops

- fan motor defective

- starting capacitor for fan motor defective

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 15 of 96

Page 16

Troubleshooting:

component to be tested test

fuses resistance measurement with disassembled fuses

mains auxiliary transformer and

rectifier behind mains auxiliary

transformer

Efen sensor transformer If after switch on the voltage on the PCB exists in

voltage measurement on the PCB via capacitor C2,

test value approx. 12 V

front of the transformer, and no LED lights up on the

tester, the transformer must be replaced. The voltage

(mains voltage) is measured on the PCB between the

soldering joint for mains voltage adjustment and fuse

F4.

8.1.8.4 Test of fan monitoring

Prepare test as described in 8.1.8.2, test 8.1.8.3 passed.

Switch K1 at tester set to "1" (on), the fan wheel turns.

Measurement of alternating voltage at tester at socket "feedback fan" and GND.

Test value:

Measurement using an oscilloscope VSS > 2,8 V Peak to Peak

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 16 of 96

Page 17

in this respect only the negative half-wave is important

or (very inaccurate)

Measurement using multimeter: V > 0,6 V

∼

In the case where a high ohm multimeter is used, measure over a 10-20 KOhm resistor as

follows:

10-20 K

Note: Observe service information No. 29 in case of

electronics module Incubator 8000 with PCB Motherboard 82 00 850,

otherwise an excess output voltage might result in INOP error 9.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 17 of 96

Page 18

Possible errors:

Error possible cause

Voltage cannot be measured - fan wheel properly attached?

- cable connection of PCB to coil of fan

monitoring interrupted

fan monitoring interrupted

- coil of fan monitoring defective

(measure voltage directly at the coil

with the heating unit disassembled)

voltage too low observe service information No. 1 (Inc.

8000SC/IC) and service information No. 31 (Inc.

8000), with Inc. 8000 observe service

information No. 29!

voltage ok, but continuous fan

PCB Motherboard in electronics module

failure alarm at the assembled

incubator

INOP-error 9 with assembled

Incubator 8000

voltage too high, observe service i nformation

No. 29 for Incubator 8000. In Incubator 8000

SC/IC this means there is a failure on the PCB

Motherboard.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 18 of 96

Page 19

8.1.8.5 Test of relay K4

Prepare test as described in 8.1.8.2, test 8.1.8.3 passed.

Switch K1 at tester set to "1" (on), LED "+ 30 V" at tester lights up.

Test:

LED at tester behind switch K4 off

Switch K4 at tester set to "1" (on)

Test:

LED at tester behind switch K4 lights up

Switch K4 at tester set to "0" (off)

Note: The voltage behind the switching contacts of relay K4 can be

measured at the socket behind switch K4 at the tester.

Possible errors:

Error possible cause

LED always off or no voltage relay K4 defective

LED continuously lights up or vol tage exists

continuously

relay K4 defective

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 19 of 96

Page 20

8.1.8.6 Test of relay K3

Prepare test as described in 8.1.8.2, tests 8.1.8.3 and 8.1.8.5 passed.

Switch K1 and K4 at tester set to "1" (on), LED "+ 30 V" lights up.

Switch V1 and V2 set to "1" (on)

Test: LED V1 and V2 at tester light up.

Switch K3 at tester set to "1" (on)

Test: LED V1 and V2 off

Switch K3 at tester set to "0" (off)

Possible errors:

Error possible cause

LED V1 or V2 continuously light up relay K3 defective

LED V1 or V2 continuously off relay K3 defective

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 20 of 96

Page 21

8.1.8.7 Test of relay K2, air heating and feedback air heating

Prepare test as described under 8.1.8.2, tests 8.1.8.3 and 8.1.8.5 passed.

Switch K1 and K4 at tester set to "1" (on)

Switch K2 and HLR1 at tester set to "1" (on)

Test:

Horn (high frequency) in tester on, air heating gets warm (do not allow to become too

hot, at 350 °C the thermostatic switch operates)

Switch K2 set to "0" (off), the relay interrupts the power supply to the air heating

Test: Horn in tester off

Switch K2 set to "1" (on)

Test: Horn in tester on

Switch HLR1 set to "0" (off), the semiconductor relay of the ai r heating is switched off

Test: Horn in tester off

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 21 of 96

Page 22

Possible errors:

Error possible cause

horn continuously off - relay K2 defective

- HLR1 of air heating defective

- air heating defective (hi ghly ohmic)

- thermostatic switch of air heating operates

- feedback defective

(line interrupt)

horn cannot be switched off with K2 relay K2 defective

horn cannot be switched off with HLR1 semiconductor relay HLR1of air heating

defective

Troubleshooting:

Component to be tested Test

Thermostatic switch air heating Resistance measurement approx. 0 Ohm, defective

switches must be replaced

Air heating Resistance measurement, different types of

heating cartridges may be used:

- 132 Ohm (230 V / 240 V)

- 33 Ohm (120V / 127 V)

- 25 Ohm (100V)

- 2 x 60 Ohm (230/115 V)

Semiconductor relay HLR1 for air

heating

For this bridge contacts of relay K2 on the PCB via

the test points:

- PCB 82 90 511 and PCB 82 00 600 ≥ 4:

bridge test points T55 and T57

- PCB 82 00 600 - 3:

bridge between fuse holder F2 and

solder tag T6 (connection air heati ng)

Switch on heating via tester (as described in the

test above); however, heating cannot be switched

off via K2.

Relay K2 For this bridge HLR1 of air heating at the mains

side directly at HLR at connections 1 and 2. The

front relay is the HLR for the air heating.

Switch on heating via tester (as described in the

test above), however, the heating cannot be

switched off via K2

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 22 of 96

Page 23

8.1.8.8 Test of relay K2, water heating and thermostatic switch

Prepare test as described under 8.1.8.2, tests 8.1.8.3 and 8.1.8.5 passed.

Switch K1 and K4 at tester set to "1" (on)

Test: LED "H2O-shortage" shows green light

Switch K2 and HLR2 set to "1" (on)

Test: Boiler gets warm, after approx. 5 to 15 minutes horn on and LED "H2O-shortage" shows

red light

Switch HLR2 at tester set to "0" (off)

Test: After 5 minutes max. horn off, LED "H2O-shortage" at tester shows green light again

Repeat all test steps

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 23 of 96

Page 24

Possible errors:

Error possible cause

Boiler does not heat up, LED "H2Oshortage" continuously shows green

light

- excess temperature switch at heating

switched off

- heating cartridge defective (hi ghly ohmic)

- relay K2 defective

- HLR2 of water heating defective

Boiler heats up, LED "H2O-shortage"

continuously shows green light

LED "H2O-shortage" continuously shows

red light

Boiler cannot be switched off by means

thermostatic switch water shortage defective

(always closed)

thermostatic switch water shortage defective

(always open)

HLR2 defective

of switch "HLR2"

Troubleshooting:

component to be tested test

excess temperature switch resistance test at resettable thermostatic switch

at boiler (approx. 0 Ohm).

If switch has operated both thermostatic

switches at the boiler must be replaced.

Semiconductor relay HLR2 of water

heating

For this, bridge contacts of relay K2 on the PCB

via the test points:

- PCB 82 90 511 and PCB 82 00 600 ≥ 4:

Bridge test points T55 and T58

- PCB 82 00 600 -3:

bridge between fuse holder F2 and

solder tag T11 (connection water heating)

Switch on heating via tester (as described in the

test above), however the heating cannot be

switched off via K2

Relay K2 For this, bridge HLR2 on the mains side directly

at HLR at connection 1 and 2. The HLR of the

water heating is the back relay. It must be

possible to switch on the heating via the tester,

however, it cannot be switched off by means of

switch "HLR2", but only with switch K2.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 24 of 96

Page 25

8.1.8.9 Test of heating unit in the incubator

Assemble incubator in operable condition and switch it on.

Test: No INOP or error alarm after switch-on test

Perform O2 calibration (not Inc. 8000 SC/NC) and increase O2-desired value by at least 5 %

by vol. compared to actual value

Test: No error-alarm in O2-module

Set humidity desired value to maximum:

Test with water supply:

The humidity measured value rises after a few minutes

Test without water supply:

Water-shortage alarm after a few minutes. The heating is switched off by the control,

the boiler cools down and the warning is switched off.

Repeat test several times.

Measurement of power consumption of water heating

Measure power consumption of unit. After self-test briefly withdraw and insert the

environmental sensor, thus air heating is suppressed for 90 seconds and with switched-

on humidity module and at max. desired value now a pulsating current of approx. 0,5 A

(230 V to 240 V-units) or of approx. 1 A (100 V to 127 V-units) can be measured.

Note: By pressing the two desired value buttons in the humidity module switched on for

approx. 3 seconds, a "heating LED" can be called up in the humidity module. Thus the

control and the pulsating current can be compared.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 25 of 96

Page 26

8.1.8.10 Testing of valves

As a special function the valve of Inc. 8000 IC can be triggered with the tester "heating unit

Inc. 8000".

Prepare test set up as described in 8.1.8.2, but connect valve(s) to X2 on the PCB Unit, the

previous cable connection to the tester is no longer used. The LEDs at the tester for "V1", "V2"

and the LED behind K4 do not have any function now.

For switch-on set the following switches at the tester to "1" (on): K1, K4 and V1 or V2

8.1.9 Voltage Selection

Caution: The electrical height adjustment is only intended for a voltage range of (100 V

to 127 V or 220 V to 240 V)! In Incubator 8000 SC/IC/NC also observe mains input fuses!

The following circuit must be modified on the PCB 82 90 511:

- Solder jumper on printed circuit board into desired mains voltage position, refer to

8.1.2 Layout. There are several versions avail able, therefore the marking for the mains

voltages on the printed circuit board shall apply!

- In addition, the following soldering jumpers for the auxiliary transformer need to be

soldered:

220 V to 240 V: soldering jumper T42 ↔ T43

100 V to 127 V: soldering jumpers T41 ↔ T42 and T43 ↔ T44

- Modify fuses on the printed circuit board, refer to 8.1.2.2

The heating cartridge of the air heati ng must be replaced:

- 220 V to 240 V 2M 20 329

- 120 V /127 V 2M 20 331

- 100 V 2M 20 669

The heating cartridge of the water heating must be replaced:

- 220 V to 240 V 2M 20 327

- 120 V / 127 V 2M 20 328

- 100 V 2M 20 668

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 26 of 96

Page 27

8.1.10 Replacement of Unit in the event of Repair

In the event of repair the Units for the Incubators 8000 and 8000 SC/IC/NC can be replaced by

the Unit 2M 20 615.

This order number includes heating cartridges, boil er and fuses for 120 V / 127 V. The Unit 2M

20 276 was only intended for one specific mains voltage and is no longer available.

8.1.11 Repair Information and Change Status

8.1.11.1 Boiler for Inc. 8000 SC/IC in Unit 2M 19 940 for Inc. 8000

The boiler system for Inc. 8000 is considerably easier to service. The boiler housing can be

replaced at considerably less cost. For servicing purposes it is still necessary to remove the

Unit because the housing of Incubator 8000 has no servicing flap.

The following parts are required for modification:

- Boiler modification kit 2M 20 680

- Boiler (complete) 230 V / 240 V 2M 20 618 or

- Boiler (complete) 120 V / 127 V 2M 20 619

The modification kit will be available as of approx. September 1993.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 27 of 96

Page 28

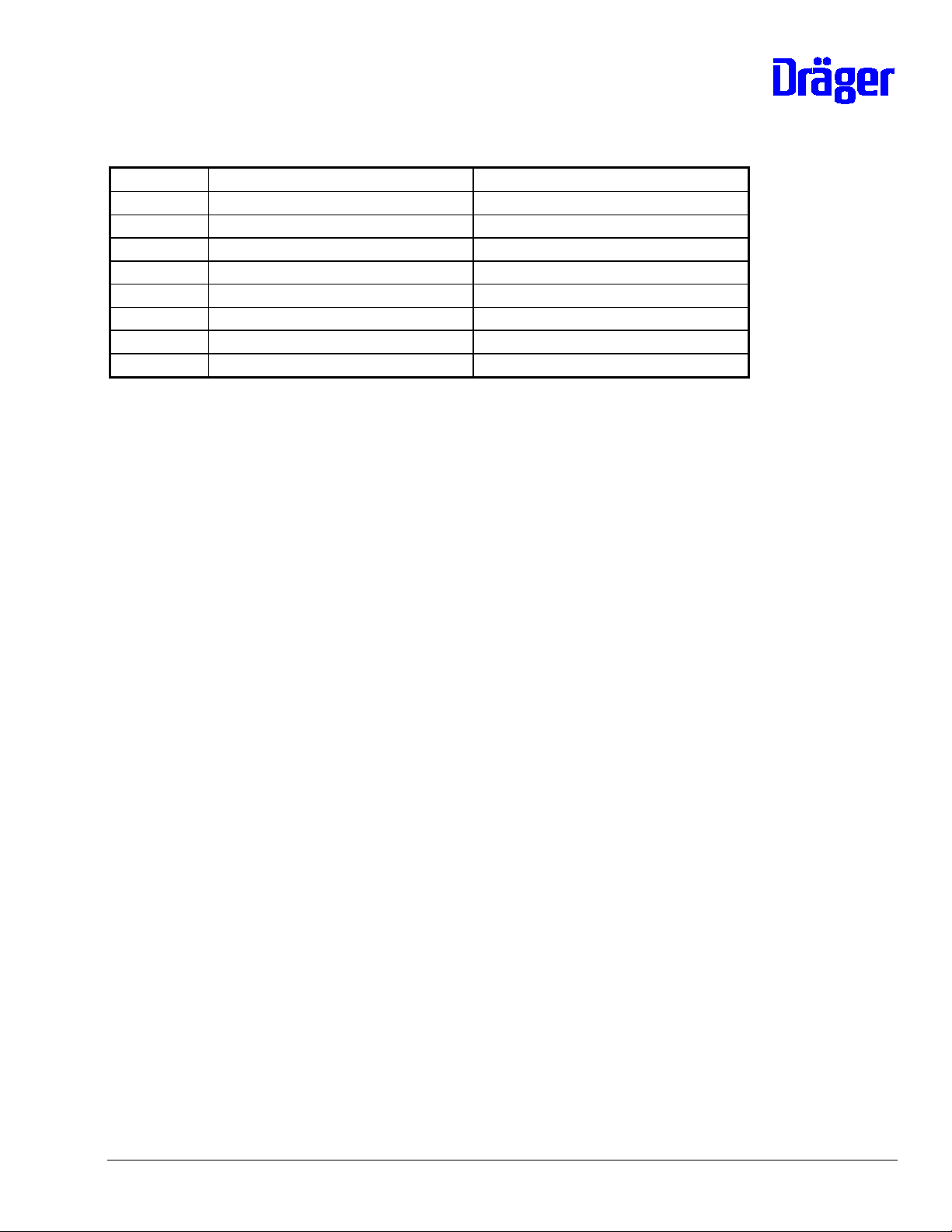

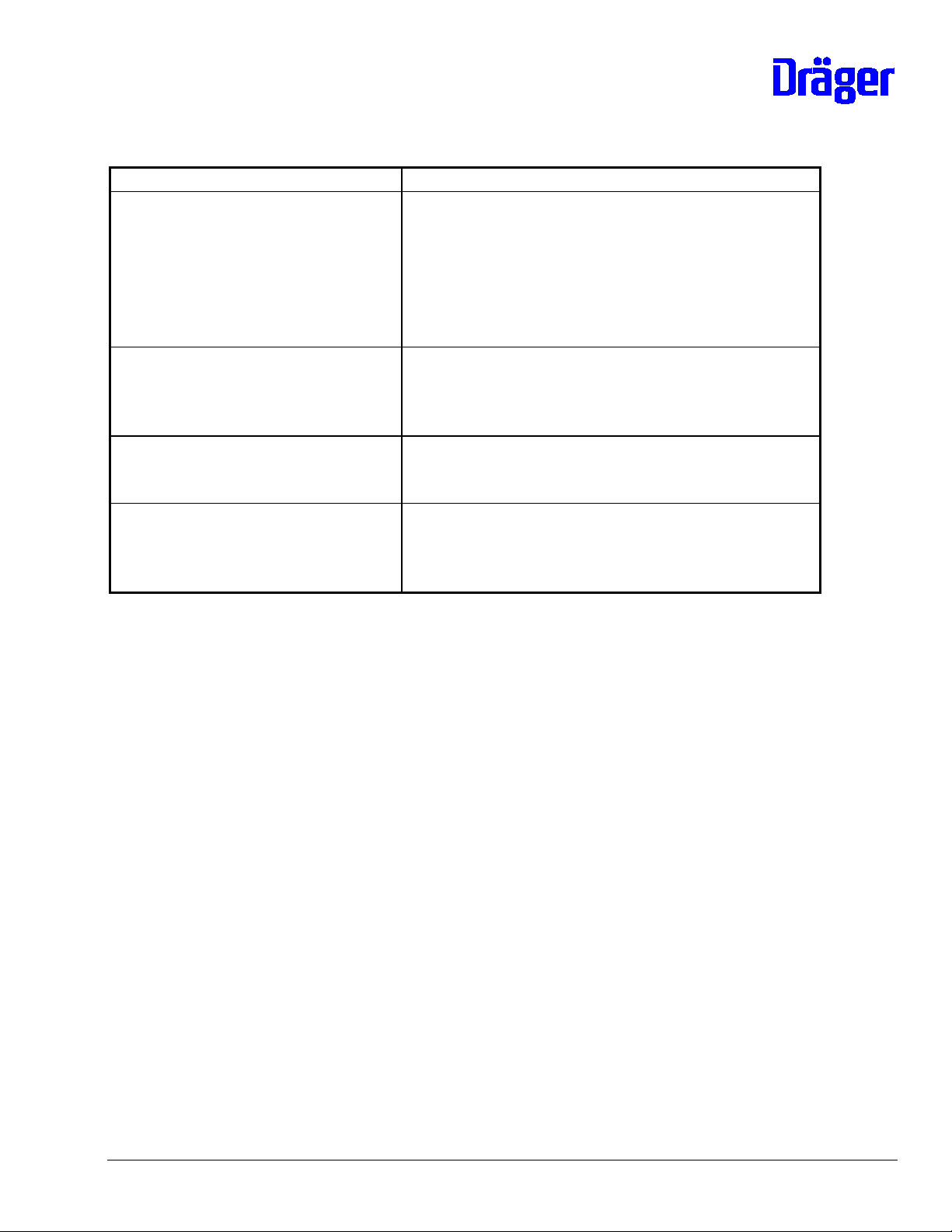

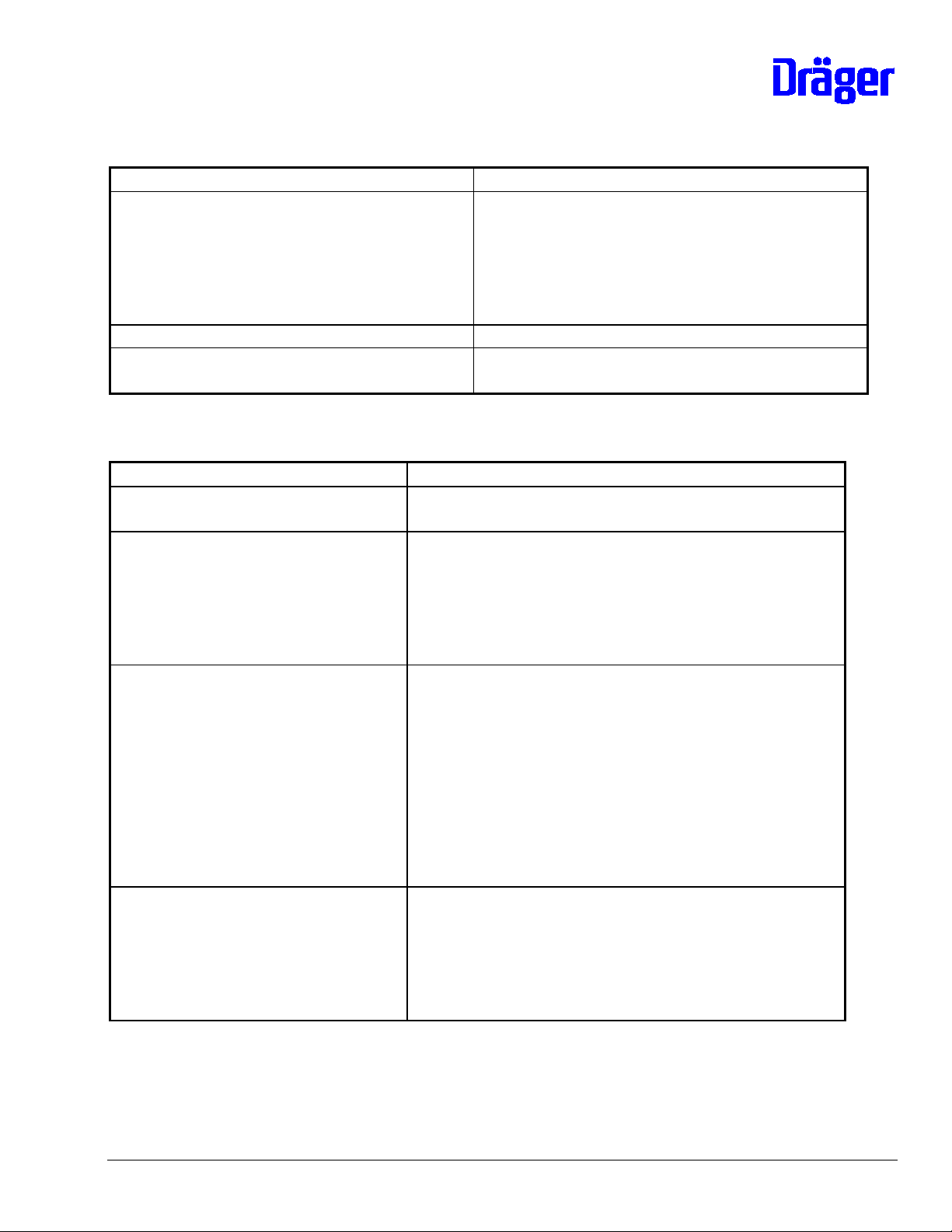

8.2 Electronics module

8.2.0 Table of Contents

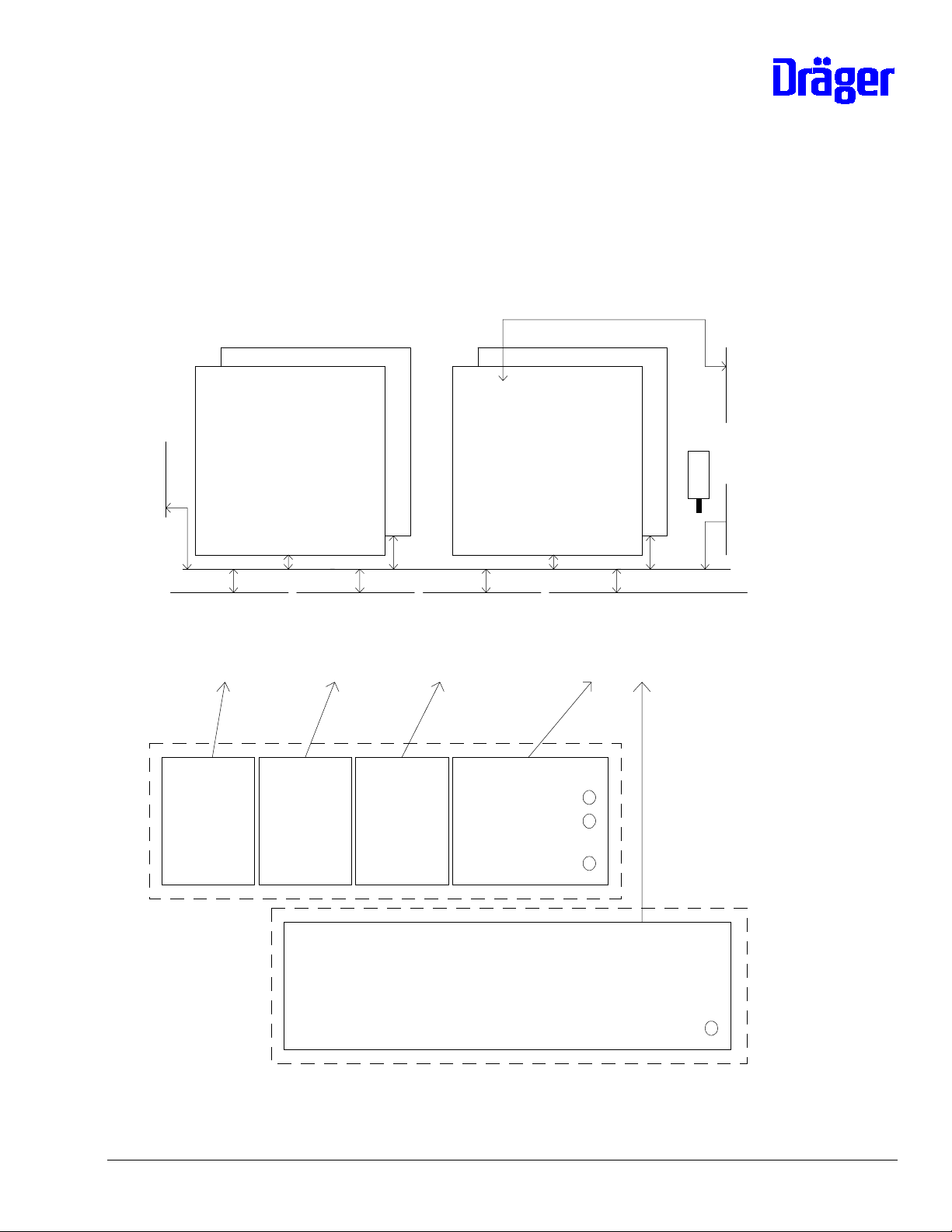

Position of the sub-assemblies in the electronics module:

8.2.8

8.2.8

8.2.11

8.2.11

8.2.11

8.2.5

8.2.7

8.2.6

8.2.6

8.2.10

8.2.9

8.2.28.2.38.2.38.2.3 / 8.2.4

8.2.1 (Ink. 8000)

8.2.1 (Inc.8000 SC/IC)

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 28 of 96

Page 29

8.2.1 Keyboards, Inc. 8000 NC/SC/IC

8.2.2 PCB Display Air Temperature

8.2.3 PCB Display (of options), PCB Display Skin

8.2.4 PCB Display Humidity (only Inc. 8000 SC/NC)

8.2.5 PCB CPU and Software-Information

8.2.6 PCB Analog and PCB Filter

8.2.7 PCB Power Pack and Voltage Controller

8.2.8 PCB Motherboard and PCB Fan

8.2.9 PCB Switch

8.2.10 Push Buttons for Height Adjustment (only Inc. 8000)

8.2.11 PCB Controller (RS232)

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 29 of 96

Page 30

8.2.1 Keyboards

8.2.1.0 Table of Contents

8.2.1.1 Information about keyboards used

8.2.1.2 N/A

8.2.1.3 Keyboards Incubator 8000 SC/IC/NC

8.2.1.4 Test

8.2.1.5 Exchange in case of repair

8.2.1.6 Repair information and change status

8.2.1.1 Information about keyboards used

Different keyboards are used in the Incubators:

Incubator 8000 SC/IC/NC:

- Inc. 8000 IC with skin temperature control

- Inc. 8000 IC without skin temperature control

- Inc. 8000 SC/NC with skin temperature control

- Inc. 8000 SC/NC without skin temperature control

The keyboard is connected to the PCB Display Air Temperature and is read out

therefrom. The keyboard is structured like 4 or 3 individual keyboards of Inc. 8000, but

with one cable connection only.

8.2.1.2 N/A

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 30 of 96

Page 31

8.2.1.3 Keyboards of Incubator 8000 SC/IC/NC

The keyboard is to be seen like 3 or 4 individual keyboards.

Pin assignment:

111

Field for air temperature control:

1246

35 7

1

8

7

6

5

4

3

2

S7

S6

S5

S4

S3

S2

S1

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 31 of 96

Page 32

Field for humidity, oxygen and skin temperature:

4

5

6

7

4

21

8

5

3

X

Note: "Foot symbol" key (where fitted) is S4.

Module X = Pin terminal

Skin temperature Pin 9

Oxygen Pin 10

Humidity Pin 11

The keyboard switches can be tested ohmically.

S5

S4

S3

S2

S1

8.1.1.4 Test

All keyboards can be tested ohmically, please refer to 8.1.1.3. In assembled condition the

following tests can be performed:

If a key is identifi ed as being pressed for more than 30 seconds an error storage

(potential INOP or Err-message) is performed.

8.2.1.5 Exchange in case of repair

The keyboards cannot be repaired and must be replaced in case of an error. The following

spare parts are available:

Keyboards of Incubator 8000 IC:

Software version For units Keyboard

20.nn (old) w/o skin-temperature meas. 82 90 470

20.nn (old) with skin-temperature meas.

(1 measurement channel)

Currently 2 possibilities:

- 82 90 467 (discontinued type)

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 32 of 96

Page 33

- 2M 21 681

Important for use of 2M 21 681 in units

which used to have a different keypad:

- Use strip supplied to deactivate

key for second skin-temperature

channel.

- On display PCB (82 90 431) for

skin, remove third LED from top,

as there is no hole for this in the

new keyboard.

21.nn (new) w/o skin-temperature meas. 82 90 470

21.nn (new) with skin-temperature meas.,

1 measurement channel

2M 21 681

Important: Use strip supplied to

deactivate key for second skintemperature channel. Please order the

sticker 2M 21 921 always in addition to

the spare parts keypad or electronics

module for US units with

ThermoMonitoring.

21.nn (new) with skin-temperature meas.,

2 measurement channels

(ThermoView)

2M 21 681

Important: Use strip supplied to

activate key for second skintemperature channel. Please order the

sticker 2M 21 921 always in addition to

the spare parts keypad or electronics

module for US units with

ThermoMonitoring.

Keyboards of Incubator 8000 SC/NC:

Software version For units Keyboard

10.nn (old) w/o skin-temperature meas. For SC and NC with central alarm

LED:

- 2M 21 182

or only for SC (discontinued type) w/o

central alarm LED labeled

„Incubator 8000 SC“:

- 82 90 419

Note: The central alarm LED is not

served by SW 10.nn and is also not

described in operating instructions.

10.nn (old) with skin-temperature meas.

(1 measurement channel)

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 33 of 96

Currently several possibilities:

For SC and NC without central alarm

Page 34

LED:

- 2M 21 180 (discontinued type)

or only for SC (discontinued type) w/o

central alarm LED labeled

„Incubator 8000 SC“:

- 82 90 415

In future for all SC and NC with central

alarm LED:

- 2M 21 691

Important for use of 2M 21 691 in units

which used to have a different

keyboard:

- Use strip supplied to deactivate

key for second skin-temperature

channel.

- On display PCB (82 00 650 or

82 90 431) for skin, remove

third LED from top, as there is

no hole for this in the new keyboard.

Note: The central alarm LED is not

served by SW 10.nn and is also not

described in operating instructions.

11.nn (new) w/o skin-temperature meas. For SC and NC with central alarm

LED:

- 2M 21 182

11.nn (new) with skin-temperature meas.,

1 measurement channel

2M 21 691

Important: Use strip supplied to

deactivate key for second skintemperature channel.

11.nn (new) with skin-temperature meas.,

2 measurement channels

(Thermomonitoring)

2M 21 691

Important: Use strip supplied to

activate key for second skintemperature channel.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 34 of 96

Page 35

8.2.1.6 Repair information and change status

Re: Change of skin temperature deviation alarm from 0.5 to 1.0 ºC for

all US versions of Incubator 8000 IC with ThermoMonitoring

Reason: All US versions Incubator 8000 IC with ThermoMonitoring for the USA

and Canada will be delivered with a skin temperature deviation alarm

limit of 1.0 ºC according the US version of the Operating Instructions of

the Incubator 8000 IC Software Version 21.n.

Solution: For this change the following modification is necessary:

1. Place a sticker " ± 1 ºC " with the order no. 2M 21 921 on the

keypad of the skin temperature control module directly over the

" ± 0.5 ºC " label.

2. Change the jumper configuration X5 on the Analog PCB 82 90 680

from:

1 1

0.5 ºC to 1.0 ºC

8 8

Devices affected: All Incubators 8000 IC as of software version 21.n in the USA and

Canada.

Additional info: Please order the sticker 2M 21 921 " ± 1 ºC " always in addition to the

spare parts keypad or electronics module.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 35 of 96

Page 36

8.2.2 PCB Display Air Temperature

8.2.2.0 Table of Contents

8.2.2.1 Information about PCB Display Air Temperature used

8.2.2.2 N/A

8.2.2.3 PCB Display Air Temperature 82 90 411 (Inc. 8000 SC/IC/NC)

8.2.2.4 Test

8.2.2.5 Exchange in case of repair

8.2.2.6 Repair information and change status

8.2.2.1 Information About PCB Display Air Temperature Used

PCB Display Air Temperature 82 90 411 (of Inc. 8000 SC/IC/NC)

With this PCB

In case of repair this PCB can be installed in all Incubators 8000 and 8000 SC/IC/NC,

please refer to 8.2.3.5 "Exchange in case of repair".

8.2.2.2 N/A

all

keyboards of Incubator 8000 and 8000 SC/IC/NC can be connected.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 36 of 96

Page 37

8.2.2.3 PCB Display Air Temperature 82 90 411

Layout connection side for keyboard:

82 90 411

X2

111

Layout component mounting side:

82 90 411

D1

X1

Configuration:

Position Component

X1 Connection to motherboard

X2 Connection to keyboard

D1 Keyboard and display driver 18 20 877

8.2.2.4 Test

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 37 of 96

Page 38

Displays:

All displays, except for the mains failure LED can tested with the air temperature

module by pressing the "Check" key. The LED mains failure only lights up in case of

mains failure and the operational LED li ghts up as soon as the unit is switched on. In

the case of an error in the keyboard and display driver an INOP message is given.

Keyboard evaluation:

The keys can be simulated by short-circuiting of connecti ons (keys) at connector X2,

please also refer to 8.2.1.2 and 8.1.2.3. When short-circuiting the keys or in the event

of a short-circuit on the PCB for more than 30 seconds an error is stored (does not

apply to SW 0.4 of Inc. 8000).

8.2.2.5 Exchange in case of repair

- PCB Display Air Temperature 82 90 411

8.2.2.6 Repair information and change status

1. Manufacturing fault in the PCB Display Air Temperature 82 90 411 08.94

Description: Contact problems between this board and the PCB Motherboard due to

soldering agent vapors at the plug-in connector X1. The fault is visible at

the plug-in connector:

OK = contacts are gleaming gold

Not OK= contacts are silver gray

Devices

affected: Incubators 8000 SC/IC manufactured between June '92 and end '93.

Measures: No preventive check required since this fault has reportedly occurred only

once so far (August 94). Should this type or fault occur, then replace the

board.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 38 of 96

Page 39

8.2.3 PCB Display (of options), PCB Display Skin (as of SW 11 and 21)

8.2.3.0 Table of Contents

8.2.3.1 Information about PCBs Display used

8.2.3.2 PCB Display 82 00 431 / 82 90 650 / 82 90 691

8.2.3.3 Functional adjustment for humidity, oxygen and skin temperature

8.2.3.4 Exchange in case of repair

8.2.3.5 Test

8.2.3.6 Repair instructions and change status

8.2.3.1 Information about PCBs Display used

Incubator 8000 SC/IC/NC:

- PCB Display 82 90 431

- PCB Display Skin 82 90 691

(with SW 11.nn and 21.nn)

PCB Display Skin 82 90 691 is only intended for skin temperature. It is required with SW 11.nn

and 21.nn.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 39 of 96

Page 40

8.2.3.2 PCB Display 82 90 431

Layout connection side keyboard:

82 00 650 / 82 90 431

X2

16

Layout configuration side:

82 00 650 / 82 90 431

D1

S7 S8 S9

X1

S1 - S6

Configuration:

Position Component

X1 Connection to motherboard

X2 Connection to keyboard of Inc. 8000, unassigned in Inc.

8000 SC/IC/NC

D1 Keyboard and display driver

S1 to S9 Option switch or soldering bridges, refer to 8.2.3.3

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 40 of 96

Page 41

8.2.3.3 Functional adjustment for humidity, oxygen and skin temperature

Before installing the PCB Displays, it is necessary to adjust the function of the board using the

switches or the soldering bridges S1 to S9. The soldering bridges are located at the same

point as the switches.

Skin temperature Oxygen Humidity

S7 S8 S9

S7 S8 S9

S7 S8 S9

X1

S1 - S6

X1

S1 - S6

X1

S1 - S6

S1, S4 and S7 closed S2, S5 and S8 closed S3, S6 and S9 closed

8.2.3.4 Exchange in case of repair

- PCB Display 82 90 431

- PCB Display Skin 82 90 691

The new PCB Display Skin 82 90 691 is required if the Incubator features the PCB

Analog 82 90 680 with SW 11.nn or 21.nn. The difference with respect to the old PCB

Display 82 90 431 is that there is a differently positioned LED for the additional key for

readout of the second skin-temperature channel. This new PCB Display Skin 82 90 691

can be used on all units IC/SC/NC for skin temperature.

8.2.3.5 Test

The display is tested as described in 8.2.2.4 "Test of PCB Display Air Temperature". Note:

The keyboards for the options of Incubator 8000 are connected to this PCB, but evaluations

takes place on the PCB Display Air Temperature.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 41 of 96

Page 42

8.2.3.6 Repair instructions and change status

1. Manufacturing fault in the PCB Display 82 90 431 08.94

Description: Display flickers or INOP with display error has occurred.

Cause: Contact problems between this board and the PCB Motherboard due to

soldering agent vapors at the plug-in connector X1. The fault is visible at

the plug-in connector:

OK = contacts are gleaming gold

Not OK = contacts are silver gray

Devices

affected: Incubators 8000 SC/IC manufactured between June '92 and end '93.

Measures: No preventive check required since this fault has reportedly occurred only

once so far (August 94) on the PCB Display Air Temperature 82 90 411.

Should this type or fault occur, then replace the board.

2. Soldering switches replace DIL switches 08.94

As of end 94, the option switches S1 to S9 will be replaced with soldering switches,

refer to 8.2.3.5.

8.2.4 PCB Display Humidity (only Inc. 8000 SC/NC)

8.2.4.0 Table of Contents

8.2.4.1 Description PCB Display Humidity 82 90 451

8.2.4.2 Exchange in case of repair

8.2.4.3 Repair information and change status

8.2.4.1 Description of PCB Display Humidity

The PCB Display Humidity is almost identical with the PCB Display 82 90 431, but the LEDs,

switches and 7-segment displays for Inc. 8000 SC not used are not fitted. Test and layout plan

are identical with PCB Display, refer to 8.2.3. The switch or the soldering bridge S9 must be

adjusted or bridged as described in 8.2.3.3. The switches S1 to S8 (if available) remain open.

8.2.4.2 Exchange in case of repair

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 42 of 96

Page 43

For repair of the PCB Display Humidity the following spare part may be used:

- PCB Display Humidity 82 90 431

8.2.4.3 Repair information and change status

1. Manufacturing fault in the PCB Display Humidity 82 90 431 08.94

Description: Display flickers or INOP with display error has occurred.

Cause: Contact problems between this board and the PCB Motherboard due to

soldering agent vapors at the plug-in connector X1. The fault is visible at

the plug-in connector:

OK = contacts are gleaming gold

Not OK = contacts are silver gray

Devices

affected: Incubators 8000 SC/IC manufactured between June '92 and end '93.

Measures: No preventive check required since this fault has reportedly occurred only

once so far (August 94) on the PCB Display Air Temperature 82 90 411.

Should this type or fault occur, then replace the board.

2. Soldering switches replace DIL switches 08.94

As of end 94, the option switch S9 will be replaced with a soldering switch, refer to

8.2.3.3. This connection must be closed, S1 to S8 must remain open.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 43 of 96

Page 44

8.2.5 PCB CPU

8.2.5.0 Contents

8.2.5.1 Information about PCB CPUs used

8.2.5.2 PCB CPU Standard 2

8.2.5.3 PCB CPU Incubator

8.2.5.4 Test

8.2.5.5 Exchange of PCB CPU in the case of repair

8.2.5.6 Repair information software

8.2.5.7 Repair information and modification states

8.2.5.1 Information about PCB CPUs used

Two different PCB CPUs can be used in Incubator 8000 SC/IC/NC.

PCB CPU Standard 2 (83 05 141)

A Standard-CPU, which is used in several Dräger-devices, e.g. in Incubator 8000 series

and EVITA. In the incubator many functions of this PCB are not used..

PCB CPU Incubator 8000 (82 90 571)

A modified version of the PCB CPU Standard 2, in which components which are not

used are not fitted, e.g. the battery for retention of data. This PCB can only be used in

Incubator 8000 and Incubator 8000 SC/IC/NC.

Note:

replaced by a modification status "≥ 01", see IDM no. 15 or TSB no. 12.

In the event of repairs both versions can be used. The different fittings are described in in

8.2.5.2 and 8.2.5.3, also refer to 8.2.5.5 "Exchange of PCB CPU in the case of repair.

The PCB CPU Incubator 82 90 571 with the modification status "00" is being

6141.22x Incubator 8000 SC/IC/NC Repair Information 11.99 Page 44 of 96

Page 45

8.2.5.2 PCB CPU Standard 2 (83 05 141)

Layout plan (Drawing shows configuration with software 1x.xx or 2x.xx.):

T2

(GND)

B1

CPU Standard 2

T1

(5V)

X7

D14

D13

X6

D6

X5

X4 X3 X2

D1

D12

D11 D10 D9

X1

Configuration of jumper fields with jumper 18 14 508:

R1

LED V11

D8

X8

SW 0.4

Position SW 1.xx, 1x.xx or 2x.xx

X2 not fitted

X3 not fitted

X4 not fitted

X5 1-2, 3-4 (like drawing)

X6 1-18, 4-15, 8-11 (like drawing)

X7 not fitted

X8 3-4 (like drawing)

Configuration of components:

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 45 of 96

Page 46

Component

and Position

D1 Microprocessor 18 09 156

D6 Address decoder 83 04 920

D8 Time-Keeper-RAM 18 28 142

D9 not fitted

D10 not fitted

D11 not fitted

D12 EPROM, see 8.2.5.5

D13 Timer 18 13 900

D14 not fitted

B1 not fitted

Calibration of voltage comparator:

The voltage comparator on the PCB CPU Standard 2 is not required for

Incubator 8000 SC/IC/SC, potentiometer R1 must be turned right until it stops

(clockwise).

SW 1x.xx or 2x.xx

(Pin 1 of component into Pin 3 of

base)

Note: If after use of this PCB in the incubator it shall be used in a

different device (e.g. Evita) the voltage comparator must be

calibrated to the value of the respective unit before.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 46 of 96

Page 47

Function of LED V11

LED Cause Remedy

off or glows slightly normal condition

off or glows slightly,

but unit shows

sporadic INOP-errors

without storage of

INOP error numbers

LED lights up, device

indicates INOP

- +5V-supply defective

(unstable)

- Voltage comparator incorrectly

adjusted

- Watchdog-error

- Voltage comparator incorrectly

adjusted

- +5V-supply too low

- Test of +5V-voltage on the

PCB CPU between T1 and T2:

test value V = 4,8 to 5,2V

- Check voltage comparator on

PCB CPU

Replace PCB CPU

-

- Check voltage comparator on

PCB CPU

- Check of +5V-voltage

on PCB CPU between T1

and T2,

Test value V = 4,8 to 5,2V

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 47 of 96

Page 48

8.2.5.3 PCB CPU Incubator 8000 (82 90 571)

Note:

by a modification status "≥ 01", see IDM no. 15 or TSB no. 12.

Layout plan:

The PCB CPU Incubator 82 90 571 with the modification status "00" is being replaced

X20

T2

(GND)

CPU Incubator 8000

X19

D13

X6

D6

X5

T1

(5V)

LED V11

D1

D12

X1

Configuration of jumper fields with jumper 18 14 608:

Position Software 1.xx, 1x.xx or 2x.xx

X5 1-2, 3-4 (like drawing)

X6 1-18, 4-15, 8-11 (like drawing)

X8 3-4 (like drawing)

X19 1-2 (like drawing)

X20 1-2 (like drawing)

D8

X8

6141.22x Incubator 8000 SC/IC/NC Repair Information 11.99 Page 48 of 96

Page 49

Component configuration:

Component and Position Software 1.xx, 1x.xx, 2x.xx

D1 Microprocessor 18 09 156

D6 Address decoder 83 04 920

D8 Time-Keeper-RAM 18 28 142 (Pin 1 of component in

Pin 3 of base)

D12 EPROM, see 8.2.5.6

D13 Timer 18 13 900

B1 (not shown) Battery not provided, SW 0.4 not possible

Calibration:

Not required.

Function of LED V11:

LED Cause Remedy

LED off or glows slightly normal condition

LED lights up, incubator

switches to INOP

- Power-On-Reset on

PCB CPU (N22) defective

Replace PCB CPU

-

immediately after switch-on

- Jumper X19 missing

LED lights up, Incubator O.K. - Voltage comparator N22

- Check jumper

Replace PCB CPU

-

defective

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 49 of 96

Page 50

8.2.5.4 Test

The test is performed by the operation software, the errors are listed in the error list, if

technically possible and can be read out.

The following error description indicates a CPU error:

- Device goes to INOP immediately after switch-on. In this case first of all check all

operating voltages, please refer to 6, troubleshooting.

- LED on the PCB CPU lights up, see function of LED in 8.2.5.2 and 8.2.5.3.

8.2.5.5 Exchange of PCB CPU in case of repair

Note:

by a modification status "≥ 01", see IDM no. 15 or TSB no. 12.

PCB CPU Standard 2 (less useful)

The PCB CPU Incubator 82 90 571 with the modification status "00" is being replaced

The following components are required for repair:

- PCB CPU Standard 2 83 05 141

- Timer 18 13 900

- RAM (only for SW 0.4) 18 17 426

- Time-Keeper-RAM 18 28 142

(for SW 1.xx, 1x.xx or 2x.xx)

- Address-Decoder 83 04 920

- Jumper 18 14 508

(to be taken from the defective PCB CPU)

- EPROM see 8.2.5.6 or spare parts list

Note: With SW version 1.xx, 1x.xx or 2x.xx battery B1 must be unsoldered.

6141.22x Incubator 8000 SC/IC/NC Repair Information 11.99 Page 50 of 96

Page 51

PCB CPU Incubator (useful)

The following components are required for exchange:

- PCB CPU Incubator 82 90 571

- Time-Keeper-RAM 18 28 142

- EPROM see 8.2.5.6 or spare parts list

- Jumper 18 14 508

(are to be taken from defective PCB CPU)

Note:

replaced by a modification status "≥ 01", see IDM no. 15 or TSB no. 12.

The PCB CPU Incubator 82 90 571 with the modification status "00" is bei ng

8.2.5.6 Repair information software

Important: When performing repairs, software version is not to be upgraded from 10.nn

to 11.nn or from 20.nn to 21.nn. Exception: Retrofitting with ThermoMonitoring set.

These units have different operating instructions. Please note: SW 11.n is not available

for US versions!

Comparison of new software versions 11.nn (SC/NC) and 21.nn (IC) with old software versions

10.nn and 20.nn

Incubator 8000 IC with skin-temperature measurement

Assembly SW 21.nn (new) SW 20.nn (old)

Analog PCB Order no. 82 90 680

Connection of 1 or 2 skintemperature sensors is by way of

wiring harness on left of basic

housing. Recognition of 1 or 2

sensors is via the wiring harness

which has its own connector

separate from the other sensor

connections.

Range: 30 to 42 °C

Climate sensor 2M 21 688

without skin temperature connection

Order no. 82 00 920

Connection of skin-temperature

sensor on IC is to climate sensor.

Range: 33 to 38 °C.

82 90 380 with skin temperature

connection

Keyboard New keyboard 2M 21 681 with

additional key for readout of second

skin-temperature channel. If key is

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 51 of 96

Use can be made of either the old or

the new keyboard

Page 52

not needed due to absence of

thermomonitoring option, the key

position is covered with a strip.

Skin display

PCB

New skin display PCB 82 90 691

with LED at different position for

Use can be made of old or new

Display PCB

additional key requi red for readout

of optional second skin-temperature

channel.

Incubator 8000 IC without skin-temperature measurement

Assembly SW 21.nn (new) SW 20.nn (old)

Climate sensor 2M 21 688 without skin temperature

connection

82 90 380 with skin temperature

connection

Incubator 8000 SC/NC with skin-temperature measurement

Assembly SW 11.nn (new) SW 10.nn (old)

Analog PCB Order no. 82 90 680

Connection of 1 or 2 skintemperature sensors is by way of

wiring harness on left of basic

Order no. 82 00 920

Skin-temperature sensor is

connected on back of unit.

Range: 33 to 38 °C.

housing. Recognition of 1 or 2

sensors is via the wiring harness.

Keyboard New keyboard 2M 21 691 with

additional key for readout of second

skin-temperature channel. If key is

not needed due to absence of

Use can be made of either the old or

the new keyboard. An alarm LED

(central alarm) is not actuated even

if it is fitted.

ThermoMonitoring option, key

position is covered with a strip.

Additional feature: Alarm LED

(central alarm).

Skin display

PCB

New skin display PCB 82 90 691

with LED at different position for

Use can be made of old or new

Display PCB.

additional key needed for readout of

optional second skin-temperature

channel.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 52 of 96

Page 53

Incubator 8000 SC/NC without skin-temperature measurement

No fundamental changes in terms of function between SW 10.nn and 11.nn, however

different operating instructions.

Assembly SW 11.nn (new) SW 10.nn (old)

Keyboard with central alarm no central alarm

The following software versions apply to the units:

Incubator 8000 IC with software 20.nn:

- SW 20.00 allowed, but no longer available

Is replaced by SW 20.01 (errors must be identified three times consecutively to lead to

an Err- or INOP error). Principle exchange is not intended, but useful should errors

occur sporadically.

- SW 20.01 allowed, but no longer available

- SW 20.02 allowed, but no longer available

Are replaced by SW 20.03: Service mode "A" has been included (vol tage A/D test

channel), skin-temp. mode up to 39 °C (previously 37 °C), additional alarm delay of 90 s

for O2-measurement after swiveling climate sensor in, 2nd skin temp. channel provided

by software (hardware is being prepared).

- SW 20.03 allowed, but no longer available

- SW 20.04 2M 22 327

Incubator 8000 SC/NC with SW 10.nn:

- SW 10.00 not released

- SW 10.01 / 10.02 all owed, but no longer available

Are replaced by SW 10.03 (errors must be identified three times consecutively to lead

to an Err- or INOP error). A principle exchange is not intended, but useful should errors

occur sporadically.

- SW 10.03 allowed, but no longer available

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 53 of 96

Page 54

Is replaced by SW 10.04: Service mode "A" has been included (voltage A/D test

channel), skin-temp. mode up to 39 °C air temperature (previously 37 °C).

- SW 10.04 allowed, but no longer available

- SW 10.05 2M 22 326

Incubator 8000 IC with software 21.nn:

- SW 21.02 2M 22 331

Incubator 8000 SC/NC with SW 11.nn (not available for US versions):

- SW 11.02 2M 22 332

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 54 of 96

Page 55

8.2.5.7 Repair information and modification states

1. New PCB CPU Incubator 01.93

From the beginning of 1993 all Incubators 8000 SC/IC/NC will include the new PCB

CPU Incubator 83 05 141. This PCB CPU replaces the current PCB CPU Standard 2. In

case of repair both versions can be used, since the PCB CPU Incubator is a simplified

version of PCB CPU Standard on which unused components are not fitted. Also refer to

8.2.5.5 "Exchange of PCB CPU in case of repair".

Note:

replaced by a modification status "≥ 01", see IDM no. 15 or TSB no. 12.

The PCB CPU Incubator 82 90 571 with the modification status "00" is being

6141.22x Incubator 8000 SC/IC/NC Repair Information 11.99 Page 55 of 96

Page 56

8.2.6 PCB Analog with PCB Filter

8.2.6.0 Table of Contents

8.2.6.1 Information about PCBs used

8.2.6.2 PCB Analog 82 00 770 / 82 00 920 with PCB Filter 83 02 526

(layout up to mid 95)

8.2.6.3 PCB Analog 82 00 770 / 82 90 920 / 82 90 680

(layout as of mid 95)

8.2.6.4 Test and Calibration PCB Analog 82 00 770 / 82 00 920 / 82 90 680

8.2.6.5 N/A

8.2.6.6 Exchange of PCB Analog in case of repair

8.2.6.7 Repair information and change status

8.2.6.1 Information about PCBs used

3 different PCBs are currently in use in Incubator 8000 and 8000 SC/IC/NC.

Incubators without skin temperature control:

- PCB Analog 82 00 770

Note: partly fitted PCB Analog 82 00 920 without skin temperature amplifier.

Incubators with skin temperature control:

- PCB Analog 82 00 920

Note: Until end of 1992 the units including PCB Analog 82 00 920 were equipped with a

PCB Filter Circuit 83 02 526. During repair thi s PCB Filter Circuit may be removed and

replaced by two jumpers on the PCB Analog 82 00 920, please refer to 8.2.6.2.

Only for SW 11.nn or 21.nn:

- PCB Analog 82 90 680

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 56 of 96

Page 57

8.2.6.2 PCB Analog 82 00 770 / 82 00 920 with PCB Filter 83 02 526 (layout

up to mid 95)

Layout: (the figure below shows PCB Analog 82 00 920 fully equipped):

(X3)

K1

X5

N19 N18

R24

R81

25

26

1

1

2

R7

X4

X2

R15R69R67

R4

R19R12

R55

R83

D1

R60R31

R75

R71

D2

K2

82 00 770 / 82 00 920

X1

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 57 of 96

Page 58

Configuration:

Position Component or function

X1 Connection to PCB Motherboard

X2 Connection to climatic sensor (Inc. 8000 and Inc. 8000

IC) or to air temperature sensor

(Inc. 8000 SC/NC)

X3 not used

X4 26 test points

X5 Connection to PCB Filter Circuit with PCB Analog 82

00 920. If no PCB Filter Circuit is i nstalled, jumpers

from X5/1 to X5/4 and from X5/2 to X5/5 must be

soldered on the back.

D1 Multiplexer 18 23 345

D2 A/D-converter 18 23 256

K1, K2 (K1 not with 82 00 770) Relay 18 13 714

N18 Voltage controller +5 V 18 21 458

N19 Voltage controller -5 V 18 23 337

Potentiometer R4 Calibration of air temperature amplifier

Potentiometer R7 Calibration of air temperature amplifier

Potentiometer R12 Calibration of overtemperature amplifier

Potentiometer R15 Calibration of overtemperature amplifier

Potentiometer R19 Calibration of overtemperature comparator 40°C

R24 Calibration of skin temperature amplifier

R31 Calibration of skin temperature amplifier

R60 no function

Potentiometer R67 no function

Potentiometer R69 no function

R71 Calibration of A/D converter

Potentiometer R75 Calibration of A/D converter

Potentiometer R81 no function

R55 / R83 Voltage divider A/D test channel

Calibration:

see 8.2.6.4

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 58 of 96

Page 59

Repair information:

1 . Repair information error 19 and 65

Whenever the PCB Analog 82 00 770 / 82 00 920 or the voltage regulator for + 15 V or

- 15 V or the PCB Power Pack 82 90 461 is replaced the A/D test channel must be

checked and calibrated, if necessary, please refer to 8.2.6.4.

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 59 of 96

Page 60

8.2.6.3 PCB Analog 82 00 770 / 82 90 920 / 82 90 680 (layout as of mid

95)

Layout: (the figure below shows PCB Analog 82 00 920 / 82 90 680 fully equipped):

R31

X6

R125

V40V39

X5

R24

1

1

8

25

26

1

2

R7

X4

X2

R15

R4

R19R12

R83

R55

D1

R75

R71

D2

T3 T1 T2

82 00 770 / 82 00 920 / 82 90 680

X1

Important:

- LED V40 lights if - 5 V for AD converter is available. This voltage is stepped down from

the - 15 V.

- LED V39 lights if + 5 V for AD converter is available. This voltage is stepped down from

the + 15 V.

Calibration: see 8.2.6.4

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 60 of 96

Page 61

Important: Repair information, errors 19 and 65

On replacing PCB Analog 82 00 770 / 82 00 920 / 82 90 680 or voltage regulator for + 15 V or

- 15 V or PCB Power Pack 82 90 461 A/D test channel must always be checked and if

necessary calibrated, see 8.2.6.4.

Wiring harness, skin temperature (82 90 680 only):

This is the side connection for skin-temperature sensors with cable link to PCB Analog

82 90 680. Important: With this PCB, skin-temperature sensor(s) is/are attached to

connector X6.

X6 X6

1

Sensor 1 Sensor 1

1

Sensor 2

*

*

7

1

X5

1

8

25

26

X6

X4

1 skin-temperature connection:

- Wiring harness, complete (with socket) 2M 21 738

2 skin-temperature connections:

X2

7

1

2

R7

- Wiring harness, complete (with socket) 2M 21 738

extended with

- (*) Thermomonitoring option (with 2nd socket) 2M 21 733

(incl. ThermoView PC program 2M 21 888)

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 61 of 96

Page 62

Important:

Al l US versions Incubator 8000 IC with ThermoMonitoring for the USA and

Canada will be delivered with a skin temperature deviation alarm limit of 1.0

ºC according the US version of the Operating Instructions of the Incubator

8000 IC Software Version 21.n.

For this change the following modification i s necessary:

1. Place a sticker " ± 1 ºC " with the order no. 2M 21 921 on the keypad of

the skin temperature control module directly over the " ± 0.5 ºC " label.

2. Change the jumper configuration X5 on the Analog PCB 82 90 680 from:

1 1

8 8

0.5 ºC to 1.0 ºC

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 62 of 96

Page 63

8.2.6.4 Test and Calibration of PCB Analog

Table of Contents

a Test equipment required

b Test of operating voltages

c Calibration of A/D test channel

d Calibration of air temperature amplifier

e Calibrati on of excess-temperature amplifier and excess-temperature comparator

f Calibration of skin temperature amplifier

g Test of O2-inputs and O2 comparators

h Calibration of A/D converter

:

a Test equipment required

- Multimeter 79 01 021

- Measuring adapter Incubator 8000 79 01 471 or

- Testboard uni 40 79 00 610

- Sensor simulator Incubator 8000 (for d, e , g, and e) 79 01 240

- Skin temperature sensor simulator (for f) 79 01 236

- 2 decade resistors (for f and e) 79 01 146

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 63 of 96

Page 64

b Test of operating voltages

Unit is open, but ready for operation. Switch on Incubator. To facilitate measurement the

measuring adapter 79 01 471 can be connected to terminal strip X4.

Measurement of voltages at terminal strip X4:

TP 25 (+ 5 V, of PCB Power Pack) ⇒ TP 26 (GNDD): V = + 5,0 ± 0,2 V

TP 18 (+ 15 V, of PCB Power Pack) ⇒ TP 26 (GNDD): V = + 15,0 V ± 0,6 V

TP 22 (- 15 V, of PCB Power Pack) ⇒ TP 26 (GNDD): V = - 15,0 V ± 0,6 V

TP 20 (+ 5 V, generated on PCB Analog) ⇒ TP 21 (GNDA): V = + 5,0 V ± 0,4 V

TP 24 (- 5 V, generated on PCB Analog) ⇒ TP 21 (GNDA): V = - 5,0 V ± 0,4 V

c Calibration of A/D test channel

Important: As of SW 10.04 (Inc. 8000 SC/NC) and SW 20.03 (Inc. 8000 IC) it is possible to

read out this voltage directl y in mV in service mode "A", see 6.2.2.11.

Unit is open, but ready for operation. Switch on unit and wait for self-test.

Read out voltage of A/D test channel:

- In service mode "A"

or

- Measure the A/D test channel voltage at the multiplexer D1 between Pin 2 (test voltage)

and Pin 12 (GNDA) using a quick multimeter (79 01 021, Soar or BBC).

R19R12

R83

R55

R75

R71

D2

K2

D1

V

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 64 of 96

Page 65

Measurement is performed after the self-test (approx. 35 seconds), but the device must not be

in INOP condition. In the event of an INOP error 65 or 19 follow the calibration instructions.

Test value: The A/D test channel test voltage is the lower voltage with the multiplexer

switched through.

V = 4.4 ± 0.3 V

Calibration instructions:

In the event of deviations from the test value the voltage divider R55 / R83 must be modified:

Important: The new layout as of approx. mid 95 features soldering terminals for calibration of

the AD converter test voltage:

T1 (AD test) and T2 (+15 V) are in parallel with R55

T1 (AD test) and T3 (-15 V) are in parallel with R83

- Voltage too low or error 65:

Increase voltage by means of additional resistor in series with R83 and repeat test,

recommendation: approx. 2kohm.

- Voltage too high or error 19:

Reduce voltage by means of additional resistor in series with R55 and repeat test,

recommendation approx. 1kohm.

d Calibration of air temperature amplifier

- Connect sensor simulator Incubator 8000 (79 01 240) to X2.

- The sensor simulator must have the following basic setting:

o Temperature = 35 °C

o Humidity = 70 %

o Sensor = 1

- Switch on incubator and wait for 35 second self-test.

- Measure voltage between X4/3 and X4/21 (GNDA)

- Set voltage to V = 625 mV ± 0,5 mV using potentiometer R7

- Measure voltage between X4/4 and X4/21 (GNDA)

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 65 of 96

Page 66

- Use potentiometer R4 to set the voltage to V = 2,917 V ± 0,005 V

- Indication on actual value display air temperature = 35,0 °C ± 0,1 °C

- Set sensor simulator to 25,0 °C

- Indication on actual value display air temperature = 25,0 °C ± 0,2 °C

- Set sensor simulator to 45,0 °C

- Indication on actual value display air temperature = 45,0 °C ± 0,2 °C

e Calibration of excess temperature amplifier and excess temperature

comparator

- Connect sensor simulator Incubator 8000 (79 01 240) to X2

- The sensor simulator must have the following basic setting:

o Temperature = 35 °C

o Humidity = 70 %

o Sensor = 1

- Switch incubator on and wait for 35 seconds self-test

- Call up service mode 5, please refer to 6.3 service mode

- Measure voltage between X4/6 and X4/ 21 (GNDA)

- Use potentiometer R15 to set the voltage to 625 mV ± 0,5 mV

- Measure voltage between X4/8 and X4/21 (GNDA)

- Use potentiometer R12 to set the voltage to 3,500 V ± 0,005 V

- Indication on actual value display air temperature = 35,0 °C ± 0,1 °C

- Set sensor simulator to 25 °C

- Indication on actual value display air temperature = 25,0 ± 0,2 °C

- Set sensor simulator to 45 °C

- Indication on actual value display air temperature = 45,0 °C ± 0,2 °C

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 66 of 96

Page 67

- Set sensor simulator to 40 °C

- Measure voltage between X4/7 and X4/21 (GNDA)

- Use potentiometer R19 to set the voltage such that it changes from negative value to

positive value

- Set sensor simulator to 39,7 °C (or 39,5 °C)

- Negative voltage (- 12 V to - 15,6 V)

- Set sensor simulator to 40,2 °C (or 40,5 °C)

- Positive voltage (+ 12 V to + 15,6 V)

f Calibration of skin temperature amplifier

- Connect sensor simulator Incubator 8000 (79 01 240) to X2

- Connect skin temperature sensor simulator (79 01 236) to sensor simulator

Incubator 8000

The sensor simulator Incubator 8000 must have the following basic setting:

o Temperature = 35 °C

o Humidity = 70 %

o Sensor = 1

The skin temperature sensor simulator must have the following basic setting:

o Temperature = 36.0 °C

o Sensor connected/not connected (82 90 680 only)

- Only for 82 90 680:

Connect pin X1/29c to GND. GND is e.g. X1/32a or X1/32b.

- Switch incubator on and wait for 35 second self-test

- Measure voltage between X4/17 and X4/21 (GNDA)

- Connect a decade resistor (initial value for 82 00 920 approx. 40 K ohm, for 82 90 680

approx. 5 K ohm) to the soldering tags of R24 and adjust such that the voltage is:

308.6 mV ± 0.5 mV for 82 00 920 or

385.5 mV ± 0.5 mV for 82 90 680

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 67 of 96

Page 68

- Solder the set resistance value to exactly 10 Ohm to the soldering tags of R24 (i f

applicable, 2 resi stors connected in series or in parallel)

- Check calibration

- Measure voltage between X4/11 and X4/21 (GNDA)

- Connect a decade resistor (initial value for 82 00 920 approx. 5 K ohm, for 82 90 680

approx. 150 K ohm) to the soldering tags of R31 (82 00 920) or R125 (82 90 680) and

adjust such that the voltage is:

2.857 V ± 0.010 V for 82 00 920 or

2.500 V ± 0.010 V for 82 90 680

- Solder the set resistance value to exactly 10 Ohm to the soldering tags of R31 (i f

applicable, 2 resi stors connected in series or in parallel)

- Check calibration

- Indication on actual value display skin temperature. = 36,0 °C ± 0,1 °C

- Set skin temperature sensor simulator to 33,2 °C

- Indication on actual value display skin temperature = 33,2 °C ± 0,2 °C

- Set skin temperature sensor simulator to 37,8 °C

- Indication on actual value display skin temperature = 37,8 °C ± 0,2 °C

- Press key "Check 36,0 °C" in skin temperature module

- Indication on actual value display air temperature = 36,0 °C ± 0,1 °C

- Only for 82 90 680:

Remove connection between pin X1/29c and GND.

g Test of O2 inputs and O2 comparators

- Connect sensor simulator Incubator 8000 (79 01 240) to X2

- The sensor simulator must have the following basic setting:

o Temperature = 35 °C

o Humidity = 70 %

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 68 of 96

Page 69

o Sensor = 1

- Switch on incubator and wait for 35 second self-test

- A potential excess-temperature warning can be switched off by pressing the "Reset

Excess-temperature" key

- Set O2-voltages at sensor simulator to 50 mV ± 1 mV each using the two

potentiometers. The voltages can be measured at the sensor simulator below the

potentiometers.

- Measure voltage between X4/1 and X4/21 (GNDA),

Test value = 1,97 V ± 0,05 V

- Measure voltage between X4/5 and X4/21 (GNDA),

Test value = 0,72 V ± 0,02 V

- Set both O2-voltages at sensor simulator to 10 mV ± 0,5 mV

- Measure voltage between X4/12 and X4/21 (GNDA),

Test value ≤ 0,1 V

- Reduce O2-voltage A to 1 mV

- Test value ≥ 11 V

- Set O2-voltage A to 10 mV ± 0,5 mV

- Test value ≤ 0,1 V

- Set O2-voltage B to 1 mV

- Test value ≥ 11V

- Set O2-voltage B to 10 mV ± 0,5 mV

- Test value ≤ 0,1 V

h Calibration of A/D-converter

- Connect sensor simulator Incubator 8000 (79 01 240) to X2

- The sensor simulator must have the following basic setting:

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 69 of 96

Page 70

o Temperature = R ext.

o Humidity = 70 %

o Sensor = 1

- Connect a decade resistor for "R ext. Excess-.temperature" at the sensor simulator.

- Switch incubator on and wait for 35 second self-test.

- Call service mode 5, please refer to 6.3 Service-Mode

- Measure voltage between X4/8 and X4/21 (GNDA)

- Set the voltage to 0 mV + 1 mV by means of the decade resistor.

- Use potentiometer R75 to set the zero point of the A/D-converter such that the actual

value display just changes from 0,0 °C to 0,1 °C

- Set voltage to 5,000 V ± 0,001 V by means of the decade resistor.

- Connect another decade resistor to the soldering tags of R71 and adjust such that the

actual value display just changes from 49,9 °C to 50,0 °C.

- Solder the set resistance to soldering tags of R71 (if applicable, 2 resistors connected

in series or parall el)

Check calibration at:

o 5,00 V = 50,0 °C ± 0,1 °C

o 4,00 V = 40,0 °C ± 0,1 °C

o 3,00 V = 30,0 °C ± 0,1 °C

o 2,00 V = 20,0 °C ± 0,1 °C

o 0,00 V = 0,0 °C ± 0,1 °C

8.2.6.5 N/A

6141.22x Incubator 8000 SC/ IC/NC Repair Information 11.99 Page 70 of 96

Page 71

8.2.6.6 Exchange of PCB Analog in case of repair

Important: When replacing PCB Analog, A/D test channel must be checked and if necessary

calibrated, see 8.2.6.4.

Important: In the case of PCBs with the new layout, the PCB Filter for the skin-temperature

sensor cannot be connected and is also not necessary.

In case of repair the following spare parts may be used:

Incubators with skin temperature control:

- Only for SW 10.nn / 20.nn:

° PCB Analog 82 00 920