Page 1

IF YOU SHOULD EXPERIENCE A PROBLEM WITH YOUR DEWALT PURCHASE,

CALL 1-800-4 DEWALT

IN MOST CASES, A DEWALT REPRESENTATIVE CAN RESOLVE

YOUR PROBLEM OVER THE PHONE.

IF YOU HAVE A SUGGESTION OR COMMENT, GIVE US A CALL.

YOUR FEEDBACK IS VITAL TO THE SUCCESS OF DEWALT'S

QUALITY IMPROVEMENT PROGRAM.

Questions? See us on the World Wide Web at www.dewalt.com

INSTRUCTION MANUAL

GUIDE D'UTILISATION

MANUAL DE INSTRUCCIONES

DW734

12-1/2" (318 mm) Heavy-Duty Portable Thickness Planer

INSTRUCTIVO DE OPERACION, CENTROS DE SERVIClO Y POLIZA

DE GARANTiA. ADVERTENCIA: LEASE ESTE INSTRUCTIVO

ANTES DE USAR EL PRODUCTO.

®

Raboteuse portative de service intensif de 318 mm (12-1/2 po)

Cepillo port&til de 318 mm (12-1/2") para trabajo pesado

Page 2

/I Definitions: Safety Guidelines

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

i_, DANGER: Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

J& WARNING: Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

,& CAUTION: Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE: indicates a practice not related to personal injury which, if not avoided, may

result in property damage.

J

IF YOU HAVE ANY QUESTIONS OR COMMENTS ABOUT THIS OR ANY DEWALT TOOL,

CALL US TOLL FREE AT: 1-800-4-DEWALT (1-800-433-9258}

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS FOR ALL TOOLS

i}, WARNING: For your own safety, read the instruction manual before operating the planer.

Failure to heed these warnings may result in personal injury and serious damage to the

planer. When servicing this tool, use only identical replacement parts. Have damaged cords

replaced by an authorized service center.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding provides apath of least resistance for

electric current to reduce the risk of electric shock. This tool is equipped with an electric cord

having an equipment-grounding conductor and grounding plug. The plug must be plugged

into a matching outlet that is properly installed and grounded in accordance with all local

codes and ordinances. Do not modify plug provided -- if it will not fit the outlet, have the

proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric

shock. The conductor with insulation having an outer surface that is green with or without

yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric

cord or plug is necessary, do not connect the equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles

that accept the tool's plug.

REPAIR OR REPLACE DAMAGED OR WORN CORDS IMMEDIATELY.

This tool is intended for use on a circuit that A GROUNDED B C

has an outlet that looks like the one illustrated OUTLET GROUNDING

in Figure A. The tool has a grounding plug MEANS

that looks like the plug illustrated in Figure A.

A temporary adapter, which looks like the

adapter illustrated in Figures B and C, may

be used to connect this plug to a 2-pole GROUNDING PIN

receptacle as shown in Figure B if a properly

grounded outlet is not available. The

temporary adapter should be used only until aproperly grounded outlet can be installed by a

qualified electrician. The green-colored rigid ear, lug, and the like, extending from the adapter

must be connected to a permanent ground such as a properly grounded outlet box.

The adapter (C) is not for use in Canada.

ADAPTER

_J,WARNING: When using electric tools, basic safety precautions should always be followed

to reduce the risk of fire, electric shock, and personal injury, including the following:

General Safety Instructions

• KEEP GUARDS IN PLACE and in working order.

• REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys

and adjusting wrenches are removed from tool before turning it on.

• KEEP WORK AREA CLEAN. Cluttered areas and benches invite injuries.

• DON'T USE IN DANGEROUS ENVIRONMENT. Don't use power tools in damp or wet

locations, or expose them to rain. Keep work area well lighted. Always operate tool in a

well-ventilated area free of combustible materials, gasoline or solvent vapors. If sparks

come in contact with flammable vapors, they may ignite, causing fire or explosion.

• KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area.

• MAKE WORKSHOP KID PROOF with padlocks, master switches, or by removing starter

keys.

• DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don't force tool or attachment to do a job for which it was not

designed.

• USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition.

When using and extension cord, be sure to use one heavy enough to carry the current

your product will draw. An undersized cord will cause a drop in line voltage resulting in

overheating and loss of power. The following table shows the correct size to use depending

on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord. When operating a power tool outside, use

an outdoor extension cord marked "W-A" or "W." These cords are rated for outdoor use

and reduce the risk of electric shock.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating 120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

Not More

Than

0

6

10

12

WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings, bracelets,

or other jewelry which may get caught in moving parts. Nonslip footwear is recommended.

Wear protective hair covering to contain long hair. Air vents often cover moving parts and

should also be avoided.

ALWAYS USE SAFETY GLASSES. Also use face or dust mask it cutting operation is

dusty. Everyday eyeglasses only have impact resistant lenses, they are not safety glasses.

ACTUATING TOOL MAY RESULT IN FLYING DEBRIS, COLLATION MATERIAL, OR

DUST WHICH COULD HARM OPERATOR'S EYES. The operator and all those persons

in the general area should wear safety glasses with permanently attached side shields.

Approved safety glasses are imprinted with the characters "Z87.1". It is the employer's

responsibility to enforce the use of eye protection equipment by the tool operator and other

people in the work area.

SECURE WORK. Use of clamps or a vise to hold work when practical It's safer than using

your hands and it frees both hands to operate tool.

DON'T OVERREACH. Keep proper footing and balance at all times.

MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing accessories.

Than

6

10

12

16

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Not Recommended

AWGMore

Page 3

• DISCONNECT TOOLS before servicing; when changing

accessories, such as blades, bits, cutters, and the like.

• REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure switch is in off position before plugging in.

• USE RECOMMENDED ACCESSORIES. Consult the

instruction manual for recommended accessories. The

use of improper accessories may cause risk of injury to

persons.

• NEVER STAND ON TOOL. Serious injury could occur if

the tool is tipped or if the cutting tool is unintentionally

contacted.

• CHECK DAMAGED PARTS. Before further use of the

tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly

and perform its intended function-check for alignment of

moving parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect its

operation. A guard or other part that is damaged should

be properly repaired or replaced.

• NEVER LEAVE TOOL RUNNING UN ATTENDED.

TURN POWER OFF. Don't leave tool until it comes to a

complete stop.

Additional Specific Safety Rules for

Planers

• To reduce the riskofinjury, usermustreadandunderstand

instruction manual before operating planer.

• Always wear eye protection and dust mask if necessary.

• Keep hands away from the underside of the cutter head

carriage.

• Direction of feed. Feed work into planer according to

direction of feed arrows on top of the unit.

• Never clear clogs, make cutter knife replacement, or any

other repairs/adjustments with unit plugged in.

• Make certain that the switch is in the OFFposition before

connecting plug to a power source.

• Be sure that the cutter knives are mounted as described

in the instruction manual and check that all bolts are firmly

tightened before connecting unit to power source.

• To avoid injury, never rotate the cutter block directly with

your hands.

• Keep guards in place and in good working order.

• Stay alert - never operate the unit when tired or under the

influence of drugs, alcohol, or medication.

• Do not use in dangerous environments. Do not use near

flammable substances, in damp or wet locations, or

expose to rain.

• Neverplane material which is shorterthan 12" (304.8 ram)

in length.

• Exhaust chute: remove shavings with brush or vacuum

after power has been shut off and cutter head has

stopped rotating.

• Always secure planer to stable work surface using

mounting holes in the base. Refer to Bench Mounting

paragraph.

• ALWAYSLOCATEPLANERWITHPROPERCLEARANCE

ON THE OUTFEED SIDE of the unit to prevent pinching

or binding of the workpiece against any obstacle.

• Clean out your tool often, especially after heavy use.

Dust and grit containing metal particles often accumulate

on interior surfaces and could create a risk of serious

injury, electric shock or electrocution. ALWAYS WEAR

SAFETY GLASSES.

WARNING: For your own safety, it is recommended that

two people carry this machine or serious injury could result.

WARNING: Wear appropriate personal hearing

protection during use. Under some conditions and duration

of use, noise from this product may contribute to hearing

loss.

WARNING: Some dust created by power sanding,

sawing, grinding, drilfing, and other construction activities

contains chemicals known to cause cancer, birth defects

or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints.

• crystalfine sifica from bricks and cement and other

masonry products.

• arsenic and chromium from chemically-treated lumber

(CCA).

Your risk from these exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work

with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power

sanding, sawing, grinding, drilling, and other

construction activities. Wear protective clothing and

wash exposed areas with soap and water. Allowing

dust to get into your mouth, eyes, or lay on the skin may

promote absorption of harmful chemicals.

WARNING: A dust mask or respirator should be worn

by all persons entering the work area. The filter should

be replaced daily or whenever the wearer has difficulty

breathing. See your local hardware store for the proper

NIOSH/OSHA approved dust mask.

• The label on your tool may include the following symbols.

The symbols and their definitions are as follows:

V......... volts

Hz....... hertz

min .....minutes

---... direct current

(_)....... Class I Construction

(grounded)

[] ....... Class II Construction _ ......... earthing terminal

(double insulated) A ........ safety alert symbol

.../min per minute BPM .... beats per minute

RPM... revolutions per minute

A .......... amperes

W......... watts

"_ ....... alternating current

....... alternating or direct

current

no ........ no load speed

Specifications

Input ............................ 120V AC, 15 Amp

No-load speed ............ 10,000 RPM

Feed speed ................. 26' (7.9 m) per minute

Planing height ............. Maximum 6" (152.4 mm),

Minimum 1/8" (3.2 mm)

Planing width .............. Maximum 12-1/2" (317.5 mm)

Planing depth .............. Maximum 1/8" (3.2 mm)

(for boards 6" (152.4 mm) wide

or less)

Electrical Connection

Be sure your power supply agrees with the nameplate

marking. Volts, 50/60 Hz or "AC only" means your planer

must be operated only with alternating current and never

with direct current. Voltage decrease of more than 10% will

cause loss of power and overheating. All DEWALT tools are

factory tested, if this tool does not operate, check the power

supply.

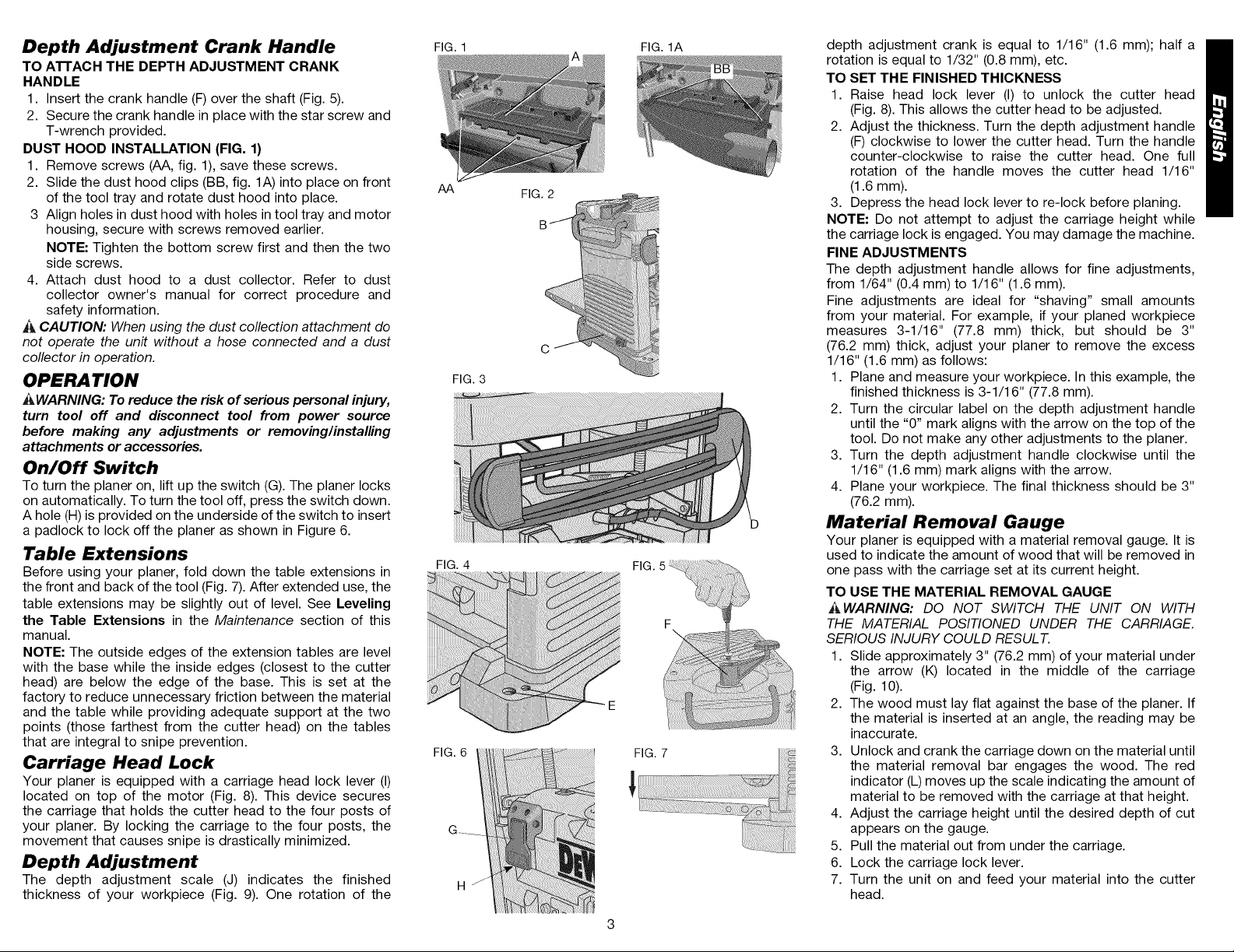

Transporting the Planer

WARNING: For your own safety, it is recommended that

two people carry this machine or serious injury could result.

When moving your planer, hold it by the side carrying

handles (B) or by the hand indentation (C) at the base of the

planer. (Fig. 2).

When transporting or storing the planer, use the cord wrap

(D) located in the back of the tool (Fig. 3) to keep the cord

in place.

Bench Mounting

To facilitate bench mounting, two different sized holes (E)

are provided on the four corners of your planer as shown

in Figure 4. If mounting the planer with bolts, use the larger

holes. If mounting the planer with nails or screws, use the

smaller holes. It is not necessary to use both sets of holes.

Always mount your planer firmly to a secure surface to

prevent movement. To enhance the tool's portability, it can

be mounted to a piece of 1/2" (12.7 mm) or thicker plywood

which can then be clamped to your work support or moved

to other work areas and reclamped.

NOTE: If you elect to mount your planer to a piece

of plywood, make sure that the mounting screws don't

protrude from the bottom of the wood. The plywood must

sit flush on the work support.

_JLCAUTION: The mounting surface should not be warped

or otherwise uneven.

ASSEMBL Y

_WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source

before making any adjustments or removing/installing

attachments or accessories.

Page 4

Depth Adjustment Crank Handle

TO A'n'ACH THE DEPTH ADJUSTMENT CRANK

HANDLE

1. Insert the crank handle (F) over the shaft (Fig. 5).

2. Secure the crank handle in place with the star screw and

T-wrench provided.

DUST HOOD INSTALLATION (FIG. 1)

1. Remove screws (AA, fig. 1), save these screws.

2. Slide the dust hood clips (BB, fig. 1A) into place on front

of the tool tray and rotate dust hood into place.

3 Align holes in dust hood with holes in tool tray and motor

housing, secure with screws removed earlier.

NOTE: Tighten the bottom screw first and then the two

side screws.

4. Attach dust hood to a dust collector. Refer to dust

collector owner's manual for correct procedure and

safety information.

_j, CAUTION: When using the dust collection attachment do

not operate the unff without a hose connected and a dust

collector in operation.

OPERA TION

AWARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source

before making any adjustments or removing/installing

attachments or accessories.

On/Off Switch

To turn the planer on, lift up the switch (G). The planer locks

on automatically. To turn the tool off, press the switch down.

A hole (H) is provided on the underside of the switch to insert

a padlock to lock off the planer as shown in Figure 6.

Table Extensions

Before using your planer, fold down the table extensions in

the front and back of the tool (Fig. 7). After extended use, the

table extensions may be slightly out of level. See Leveling

the Table Extensions in the Maintenance section of this

manual.

NOTE: The outside edges of the extension tables are level

with the base while the inside edges (closest to the cutter

head) are below the edge of the base. This is set at the

factory to reduce unnecessary friction between the material

and the table while providing adequate support at the two

points (those farthest from the cutter head) on the tables

that are integral to snipe prevention.

Carriage Head Lock

Your planer is equipped with a carriage head lock lever (I)

located on top of the motor (Fig. 8). This device secures

the carriage that holds the cutter head to the four posts of

your planer. By locking the carriage to the four posts, the

movement that causes snipe is drastically minimized.

Depth Adjustment

The depth adjustment scale (J) indicates the finished

thickness of your workpiece (Fig. 9). One rotation of the

FIG. 1

AA

FIG. 3

FIG. 4

FIG. 6

FIG. 2

FIG. 1A

FIG.

depth adjustment crank is equal to 1/16" (1.6 mm); half a

rotation is equal to 1/32" (0.8 mm), etc.

TO SET THE FINISHED THICKNESS

1. Raise head lock lever (I) to unlock the cutter head

(Fig. 8). This allows the cutter head to be adjusted.

2. Adjust the thickness. Turn the depth adjustment handle

(F) clockwise to lower the cutter head. Turn the handle

counter-clockwise to raise the cutter head. One full

rotation of the handle moves the cutter head 1/16"

(1.6 mm).

3. Depress the head lock lever to re-lock before planing.

NOTE: Do not attempt to adjust the carriage height while

the carriage lock is engaged. You may damage the machine.

FINE ADJUSTMENTS

The depth adjustment handle allows for fine adjustments,

from 1/64" (0.4 mm)to 1/16" (1.6 mm).

Fine adjustments are ideal for "shaving" small amounts

from your material. For example, if your planed workpiece

measures 3-1/16" (77.8 mm) thick, but should be 3"

(76.2 mm) thick, adjust your planer to remove the excess

1/16" (1.6 mm) as follows:

1. Plane and measure your workpiece. In this example, the

finished thickness is 3-1/16" (77.8 mm).

2. Turn the circular label on the depth adjustment handle

until the "0" mark aligns with the arrow on the top of the

tool. Do not make any other adjustments to the planer.

3. Turn the depth adjustment handle clockwise until the

1/16" (1.6 mm) mark aligns with the arrow.

4. Plane your workpiece. The final thickness should be 3"

(76.2 mm).

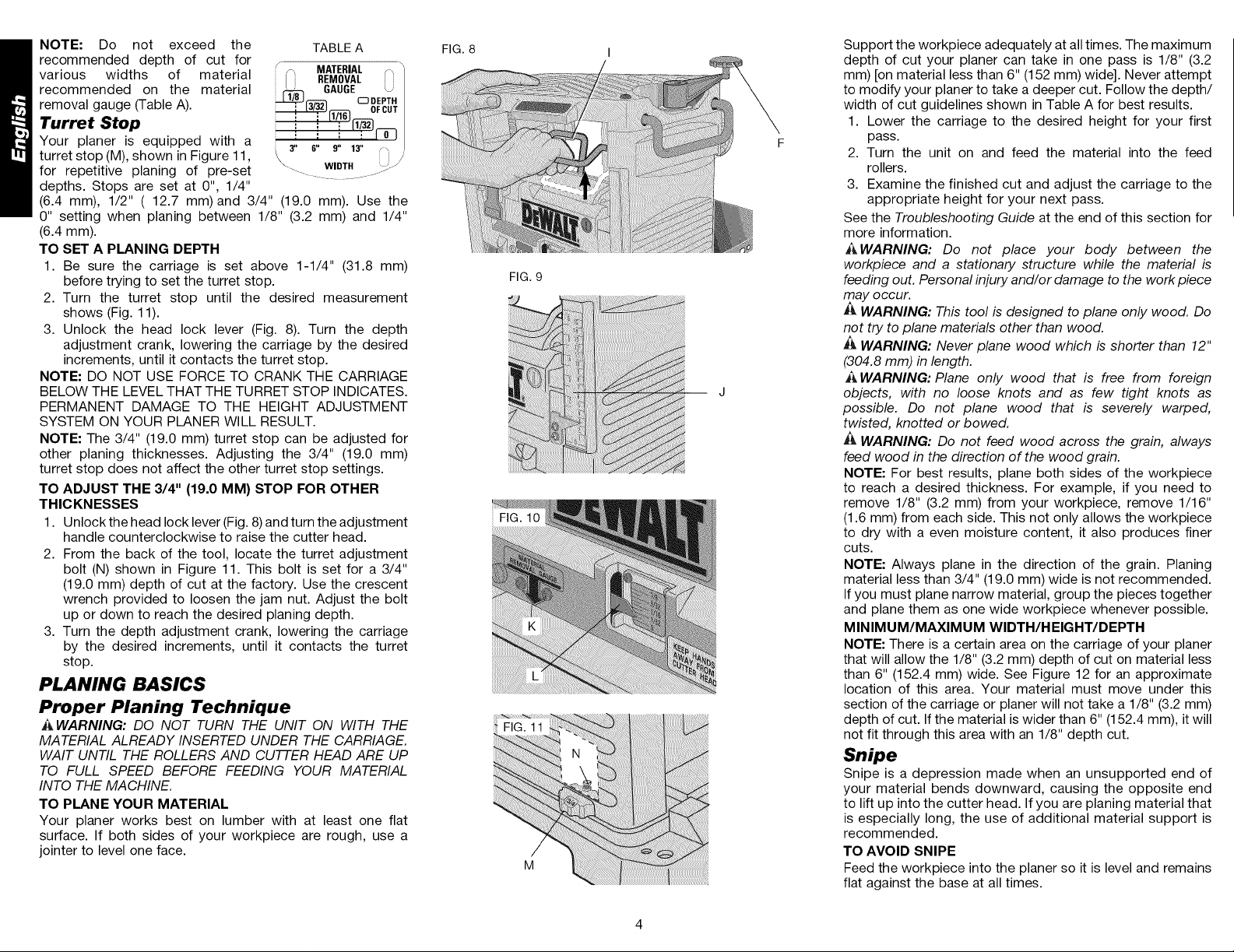

Material Removal Gauge

Your planer is equipped with a material removal gauge. It is

used to indicate the amount of wood that will be removed in

one pass with the carriage set at its current height.

TO USE THE MATERIAL REMOVAL GAUGE

A WARNING: DO NOT SWITCH THE UNIT ON WITH

THE MATERIAL POSITIONED UNDER THE CARRIAGE.

SERIOUS INJURY COULD RESULT.

1. Slide approximately 3" (76.2 mm) of your material under

the arrow (K) located in the middle of the carriage

(Fig. 10).

2. The wood must lay flat against the base of the planer. If

the material is inserted at an angle, the reading may be

inaccurate.

3. Unlock and crank the carriage down on the material until

the material removal bar engages the wood. The red

indicator (L) moves up the scale indicating the amount of

material to be removed with the carriage at that height.

4. Adjust the carriage height until the desired depth of cut

appears on the gauge.

5. Pull the material out from under the carriage.

6. Lock the carriage lock lever.

7. Turn the unit on and feed your material into the cutter

head.

Page 5

NOTE:Do not exceedthe TABLEA

recommendeddepthof cutfor _ _-_ MATERIAL y,,

various widths of material :: I REMOVAL i:: I

recommended on the material i¢;ia GAUGE L_ J

removal gauge (Table A). _-_J_ C3DEPTHI

Turret Stop ii ! i _, _

Your planer is equipped with a 3" 6" _' 13- Yi

turret stop (M), shown in Figure 11, \ w DT. -_.f

for repetitive planing of pre-set ..... . ...................

depths. Stops are set at 0", 1/4"

(6.4 mm), 1/2" ( 12.7 mm)and 3/4" (19.0 mm). Use the

0" setting when planing between 1/8" (3.2 mm) and 1/4"

(6.4 mm).

TO SET A PLANING DEPTH

1. Be sure the carriage is set above 1-1/4" (31.8 mm)

before trying to set the turret stop.

2. Turn the turret stop until the desired measurement

shows (Fig. 11).

3. Unlock the head lock lever (Fig. 8). Turn the depth

adjustment crank, lowering the carriage by the desired

increments, until it contacts the turret stop.

NOTE: DO NOT USE FORCE TO CRANK THE CARRIAGE

BELOW THE LEVEL THAT THE TURRET STOP INDICATES.

PERMANENT DAMAGE TO THE HEIGHT ADJUSTMENT

SYSTEM ON YOUR PLANER WILL RESULT.

NOTE: The 3/4" (19.0 mm) turret stop can be adjusted for

other planing thicknesses. Adjusting the 3/4" (19.0 mm)

turret stop does not affect the other turret stop settings.

TO ADJUST THE 3/4" (19.0 MM) STOP FOR OTHER

THICKNESSES

1. Unlock the head lock lever (Fig.8) and turn the adjustment

handle counterclockwise to raise the cutter head.

2. From the back of the tool, locate the turret adjustment

bolt (N) shown in Figure 11. This bolt is set for a 3/4"

(19.0 mm) depth of cut at the factory. Use the crescent

wrench provided to loosen the jam nut. Adjust the bolt

up or down to reach the desired planing depth.

3. Turn the depth adjustment crank, lowering the carnage

by the desired increments, until it contacts the turret

stop.

PLANING BASICS

Proper Planing Technique

_J,WARNING: DO NOT TURN THE UNIT ON WITH THE

MATERIAL ALREADY INSERTED UNDER THE CARRIAGE.

WAIT UNTIL THE ROLLERS AND CUTTER HEAD ARE UP

TO FULL SPEED BEFORE FEEDING YOUR MATERIAL

INTO THE MACHINE.

TO PLANE YOUR MATERIAL

Your planer works best on lumber with at least one flat

surface. If both sides of your workpiece are rough, use a

jointer to level one face.

_[_ 0FCUTI

FIG. 8

FIG. 9

FIG. 10

M

Support the workpiece adequately at all times. The maximum

depth of cut your planer can take in one pass is 1/8" (3.2

mm) [on material less than 6" (152 mm) wide]. Never attempt

to modify your planer to take a deeper cut. Follow the depth/

width of cut guidelines shown in Table A for best results.

1. Lower the carriage to the desired height for your first

pass.

2. Turn the unit on and feed the material into the feed

rollers.

3. Examine the finished cut and adjust the carriage to the

appropriate height for your next pass.

See the Troubleshooting Guide at the end of this section for

more information.

_,WARNING: Do not place your body between the

workpiece and a stationary structure while the material is

feeding out. Personal injury and/or damage to the work piece

may occur.

WARNING: This tool is designed to plane only wood. Do

not try to plane materials other than wood.

WARNING: Never plane wood which is shorter than 12"

(304.8 mm) in length.

_ WARNING: Plane only wood that is free from foreign

objects, with no loose knots and as few tight knots as

possible. Do not plane wood that is severely warped,

twisted, knotted or bowed.

WARNING: Do not feed wood across the grain, always

feed wood in the direction of the wood grain.

NOTE: For best results, plane both sides of the workpiece

to reach a desired thickness. For example, if you need to

remove 1/8" (3.2 ram) from your workpiece, remove 1/16"

(1.6 ram) from each side. This not only allows the workpiece

to dry with a even moisture content, it also produces finer

cuts.

NOTE: Always plane in the direction of the grain. Planing

material less than 3/4" (19.0 ram) wide is not recommended.

If you must plane narrow material, group the pieces together

and plane them as one wide workpiece whenever possible.

MINIMUM/MAXIMUM WIDTH/HEIGHT/DEPTH

NOTE: There is a certain area on the carriage of your planer

that will allow the 1/8" (3.2 ram) depth of cut on material less

than 6" (152.4 ram) wide. See Figure 12 for an approximate

location of this area. Your material must move under this

section of the carriage or planer will not take a 1/8" (3.2 ram)

depth of cut. If the material is wider than 6" (152.4 ram), it will

not fit through this area with an 1/8" depth cut.

Snipe

Snipe is a depression made when an unsupported end of

your material bends downward, causing the opposite end

to lift up into the cutter head. Ifyou are planing material that

is especially long, the use of additional material support is

recommended.

TO AVOID SNIPE

Feed the workpiece into the planer so it is level and remains

flat against the base at all times.

Page 6

FIG. 12 FIG. 17

FIG. 13

FIG. 14

FIG. 15

FIG. 16

BOWED WOOD WILL BE FLATTENED BY

FEED ROLLERS AND CUTTER HEAD...

...BUT BOW WILL RETURN AFTER

WOOD IS PLANED

TOP FLAT

BOTTOM FLAT

Keep long workpieces level throughout planing operation

by receiving or "catching" them from the rear of the planer.

WARNING: Do not place your body between the

workpiece and a stationary structure while the material is

feeding out. Personal injury and/or damage to the work piece

may occur.

Twisted, Cupped and Bowed Wood

If both sides of your material are very rough or if the material

is cupped, bowed or twisted, the planer may not produce

the desired result. Ideally, you should have at least one

level face/surface on your material before you plane. Your

thickness planer will work best with material that has been

run through a jointer to produce one flat surface. If you

do not have at least one flat surface or a jointer, see the

following recommendations:

TO PLANE TWISTED WOOD (FIG. 13)

_'_WARNING: TWISTED WOOD MAY JAM YOUR

THICKNESS PLANER. IF A JAM OCCURS, TURN THE

POWER OFF, DISCONNECT THE POWER SUPPLY AND

RAISE THE CARRIAGE TO RELEASE THE MATERIAL

FROM THE CUTTER HEAD.

To plane only slightly twisted material:

Plane both sides alternating from one to the other until the

desired thickness is reached.

TO PLANE CUPPED WOOD (FIG. 14)

To obtain the best possible results with cupped wood:

Rip the material down the middle and plane it as two

separate pieces.

NOTE: Ripping the material reduces the severity of the

cup and allows the machine to deliver better results. More

material will be removed on cupped wood to achieve the

desired thickness than on a normal board.

If ripping the material is not an option:

Plane one side of the material until flat, then plane the

opposite side until flat (Fig. 15).

NOTE: Do not flip the board back and forth between each

pass as recommended by the general planing directions.

TO PLANE BOWED WOOD (FIG. 16)

The feed rollers and cutter head in your planer will push

the bow out of the material as it feeds. When the material

exits the planer, the pressure of the rollers and cutter head

will release allowing the wood to spring back into a bowed

formation. To properly remove the bow, use a jointer.

CHANGING THE PLANER KNIVES

_WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source

before making any adjustments or removing/installing

attachments or accessories.

Your planer is equipped with a three-knife cutter head with

three blades that have two sharpened edges. These blades

can be rotated once and changed as needed.

FIG. 18

FIG. 19

|

FIG. 20

\

, \\

FIG. 21 O

Page 7

CHANGE BLADES WHEN:

• dull - may cause feeding issues.

• slow feed or no feed.

• motor overloading can also be an indication that knives

are dull and result in frequent breaker trips.

• excessive tearout of the wood material being planed

• nicked - blades can become nicked when planning very

knotty wood or when foreign material is not removed

from the wood being planed.

TO CHANGE PLANER KNIVES

1. Use the T-wrench to remove the tool tray. The cutter

head should now be exposed.

If the eight bolts in the knife clamp ARE NOT visible,

use a piece of scrap wood to carefully rotate the cutter

head until the bolts are accessible and the cutter head

locking lever engages as shown in Figure 21 (O).This will

prevent further rotation of the cutter head as you change

each knife (Fig. 17).

If the bolts ARE visible, be sure that the cutter head

locking lever is engaged so the cutter head does not

rotate while you are changing the knives. To do this, use

a piece of scrap wood to attempt to rotate the cutter

head. The locking lever will click into place if it is not

already engaged.

AWARNING: KEEP YOUR FINGERS AWAY FROM

THE CUTTER HEAD AT ALL TIMES. USE THE TOOL

PROVIDED TO HANDLE THE KNIVES.

2. Remove bolts from knife clamp.

3. Use the magnets on the top of the T-wrench to attract

the knife clamp and lift the knife off the cutter head

(Fig. 18). One of the knives should now be exposed.

4. Use the magnet on the top of the T-wrench to attract

and handle the knife. AVOID TOUCHING THE KNIFE

WITH YOUR FINGERS. The knives on your planer are

sharpened on both edges.

If only one edge of the knife is worn:

1. Turn the knife around so that the sharp, unused edge

hangs over the edge of the cutter head where it will cut

the material. Be sure to set the oblong holes in the knife

over the pins machined on the cutter head (Fig. 19).

2. To reset the knife clamp, align the beveled edge of the

knife clamp with the cutting edge of the knife (Fig. 20).

If these are not aligned correctly, the clamp will not

secure the knife properly.

3. Place the screws through the holes in the knife clamp

and knife into the cutter head.

4. Tighten the screws sufficiently.

To access and replace the other two knives:

1. Depress the cutter head lock lever (O) as shown in

Figure 21.

2. Use the piece of scrap wood to carefully turn the cutter

head until it locks into place revealing another knife

clamp and dull knife.

3. Repeat the procedure indicated above.

If the knives are dull on both edges:

1. Follow the same knife change procedure indicated

above. HOWEVER, discard the dull knives and install

new ones onto the cutter head. Blades can not be

sharpened.

2. Repeat the procedure for the remaining knives.

After installing or reversing the knives:

1. Replace the tool tray onto the unit.

2. Tighten the screws onto the tray.

NOTE: THE PLANER WILL NOT OPERATE IF THE TOOL

TRAY IS NOT INSTALLED CORRECTLY.

MAINTENANCE

_WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source

before making any adjustments or removing/installing

attachments or accessories.

Periodic Maintenance

AWARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source before

makinganyadjustmentsorremoving/installingattachments

or accessories.

1. Routinely check the tool for damage or broken parts.

2. Clean the unit of dust and debris that has collected in

all accessible areas of the planer from planning wood

material.

3. Wipe off infeed and outfeed rollers.

4. Clean base table. Light waxing will help wood material

pass through the planer.

5. Evaluate blade sharpness condition. Replace as

necessary.

6. Gauge Calibration, check thickness gauge calibration

and turret stop calibration.

7. Check brushes for wear and replace as necessary.

Installing a New Belt

NOTE: No tools are necessary to install a belt. The use of a

screwdriver or other tool to pry or stretch a belt may cause

damage to the pulleys and ultimately destroy the new belt.

1. Remove the crank handle.

2. Remove the two hex screws from the top, right side of

the planer.

3. Remove the two, small cross head screws securing the

side panels to the top of the planer.

4. Lift the side panel up out of the slot in the base and

remove the panel from the machine. Notice the grooves

inside the belt.

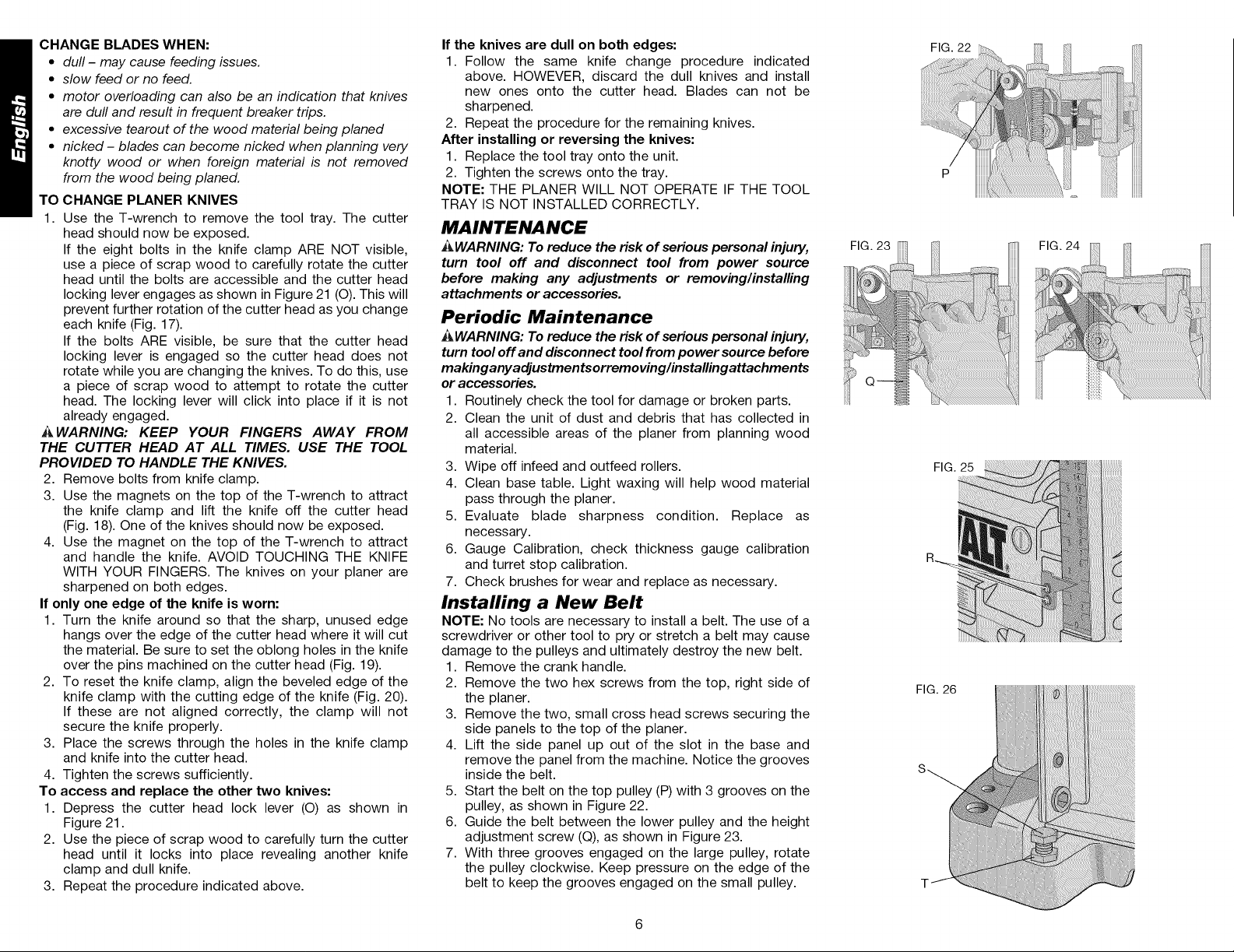

5. Start the belt on the top pulley (P) with 3 grooves on the

pulley, as shown in Figure 22.

6. Guide the belt between the lower pulley and the height

adjustment screw (Q), as shown in Figure 23.

7. With three grooves engaged on the large pulley, rotate

the pulley clockwise. Keep pressure on the edge of the

belt to keep the grooves engaged on the small pulley.

FIG. 22 _

p

FIG. 25

FIG. 26

Page 8

FIG.27

8. Continue pressure on the side of the belt and rotate

the large pulley while hopping the belt further onto the

pulleys, as shown in Figure 24.

9. All of the belt grooves should be engaged in the final

position and the pulleys should rotate smoothly.

10. Reinstall the side cover and the screws. Do not

overtighten the self-tapping screws.

FIG.28

Calibrating the Depth Adjustment

Scale

The depth adjustment scale on your planer is set at the

factory. However, with extended use, the depth adjustment

scale could show an incorrect measurement.

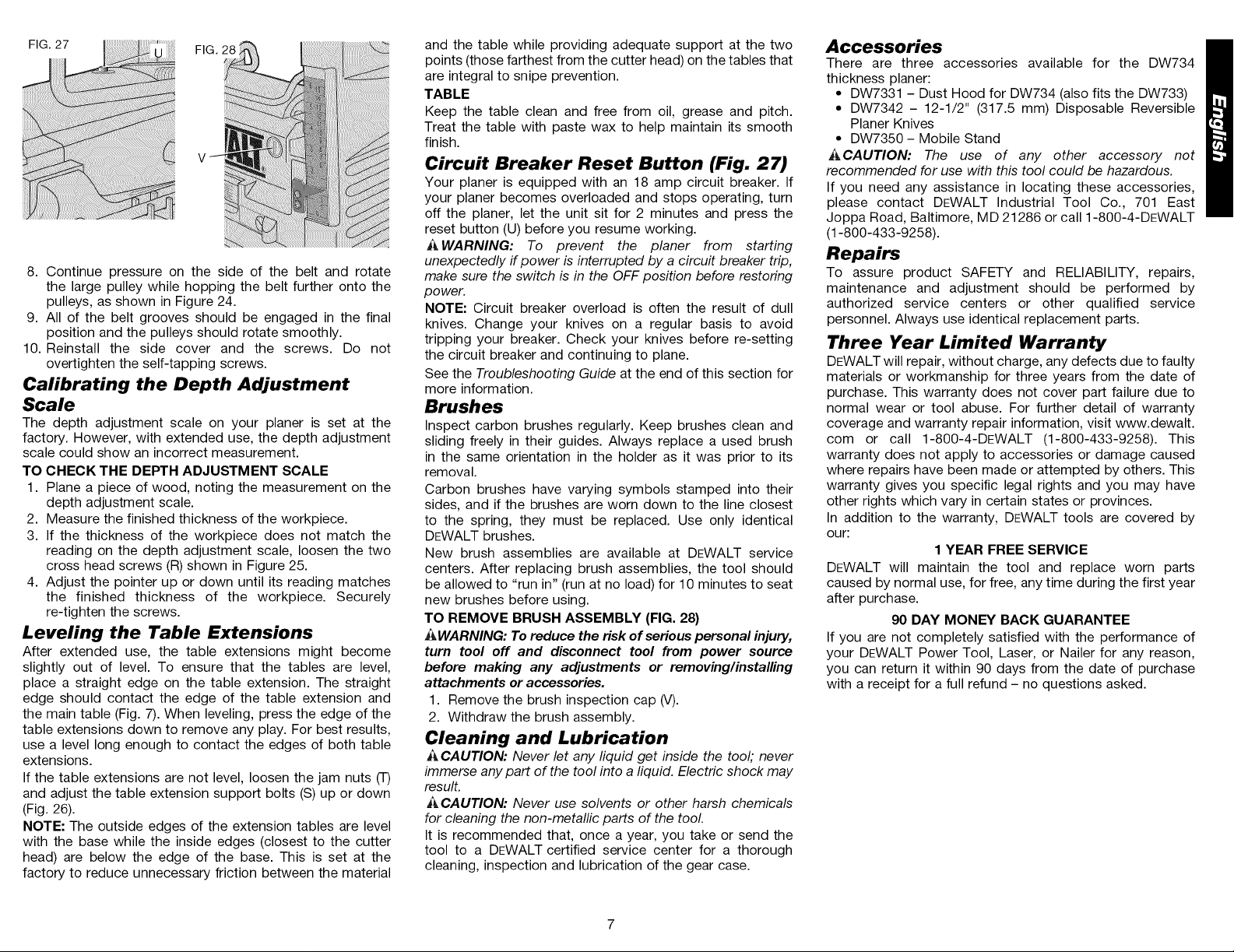

TO CHECK THE DEPTH ADJUSTMENT SCALE

1. Plane a piece of wood, noting the measurement on the

depth adjustment scale.

2. Measure the finished thickness of the workpiece.

3. If the thickness of the workpiece does not match the

reading on the depth adjustment scale, loosen the two

cross head screws (R) shown in Figure 25.

4. Adjust the pointer up or down until its reading matches

the finished thickness of the workpiece. Securely

re-tighten the screws.

Leveling the Table Extensions

After extended use, the table extensions might become

slightly out of level. To ensure that the tables are level,

place a straight edge on the table extension. The straight

edge should contact the edge of the table extension and

the main table (Fig. 7). When leveling, press the edge of the

table extensions down to remove any play. For best results,

use a level long enough to contact the edges of both table

extensions.

If the table extensions are not level, loosen the jam nuts (T)

and adjust the table extension support bolts (S) up or down

(Fig. 26).

NOTE: The outside edges of the extension tables are level

with the base while the inside edges (closest to the cutter

head) are below the edge of the base. This is set at the

factory to reduce unnecessary friction between the material

and the table while providing adequate support at the two

points (those farthest from the cutter head) on the tables that

are integral to snipe prevention.

TABLE

Keep the table clean and free from oil, grease and pitch.

Treat the table with paste wax to help maintain its smooth

finish.

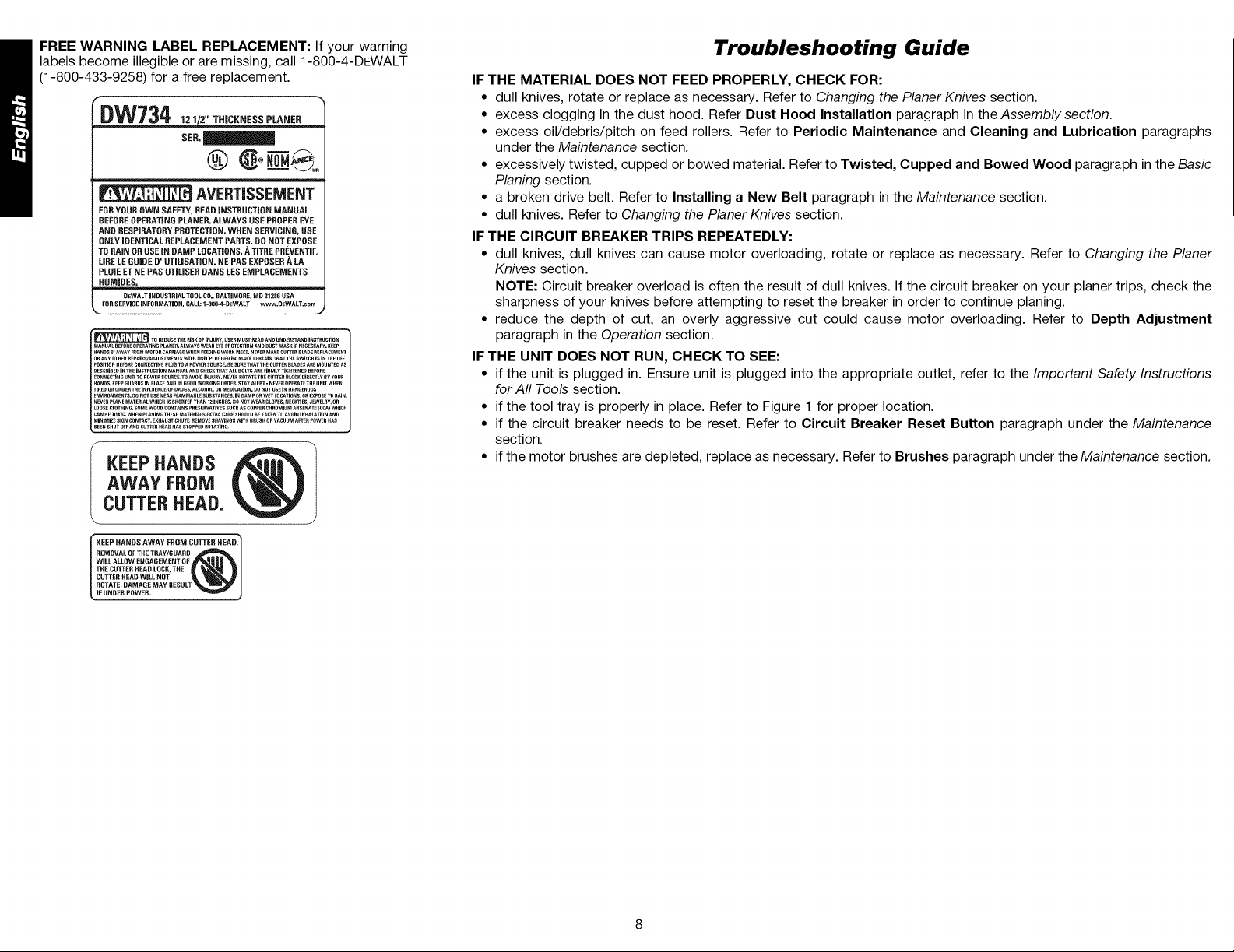

Circuit Breaker Reset Button (Fig. 27)

Your planer is equipped with an 18 amp circuit breaker. If

your planer becomes overloaded and stops operating, turn

off the planer, let the unit sit for 2 minutes and press the

reset button (U) before you resume working.

_ WARNING: To prevent the planer from starting

unexpectedly if power is interrupted by a circuit breaker trip,

make sure the switch is in the OFF position before restoring

power.

NOTE: Circuit breaker overload is often the result of dull

knives. Change your knives on a regular basis to avoid

tripping your breaker. Check your knives before re-setting

the circuit breaker and continuing to plane.

See the Troubleshooting Guide at the end of this section for

more information.

Brushes

Inspect carbon brushes regularly. Keep brushes clean and

sliding freely in their guides. Always replace a used brush

in the same orientation in the holder as it was prior to its

removal.

Carbon brushes have varying symbols stamped into their

sides, and if the brushes are worn down to the line closest

to the spring, they must be replaced. Use only identical

DEWALT brushes.

New brush assemblies are available at DEWALT service

centers. After replacing brush assemblies, the tool should

be allowed to "run in" (run at no load) for 10 minutes to seat

new brushes before using.

TO REMOVE BRUSH ASSEMBLY (FIG. 28}

_WARNING: To reduce the risk of serious personal injury,

turn tool off and disconnect tool from power source

before making any adjustments or removing/installing

attachments or accessories.

1. Remove the brush inspection cap (V).

2. Withdraw the brush assembly.

Cleaning and Lubrication

ZCCAUTION: Never let any liquid get inside the tool; never

immerse any part of the tool into a liquid. Electric shock may

result.

_ CAUTION: Never use solvents or other harsh chemicals

for cleaning the non-metallic parts of the tool.

It is recommended that, once a year, you take or send the

tool to a DEWALT certified service center for a thorough

cleaning, inspection and lubrication of the gear case.

Accessories

There are three accessories available for the DW734

thickness planer:

• DW7331 - Dust Hood for DW734 (also fits the DW733)

• DW7342 - 12-1/2" (317.5 mm) Disposable Reversible

Planer Knives

• DW7350- Mobile Stand

_CAUTION: The use of any other accessory not

recommended for use with this tool could be hazardous.

If you need any assistance in locating these accessories,

please contact DEWALT Industrial Tool Co., 701 East

Joppa Road, Baltimore, MD 21286 or call 1-800-4-DEWALT

(1-800-433-9258).

Repairs

To assure product SAFETY and RELIABILITY, repairs,

maintenance and adjustment should be performed by

authorized service centers or other qualified service

personnel. Always use identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. For further detail of warranty

coverage and warranty repair information, visit www.dewalt.

com or call 1-800-4-DEWALT (1-800-433-9258). This

warranty does not apply to accessories or damage caused

where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have

other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by

our:

1YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts

caused by normal use, for free, any time during the first year

after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your DEWALT Power Tool, Laser, or Nailer for any reason,

you can return it within 90 days from the date of purchase

with a receipt for a full refund - no questions asked.

Page 9

FREEWARNINGLABELREPLACEMENT: If your warning

labels become illegible or are missing, call 1-800-4-DEWALT

(1-800-433-9258) for a free replacement.

f

DW734,2,,2,,T.,c..E.sP .E.

SER.

®

L_ AVERTiSSEiViENT

FORYOUR OWN SAFETY,READiNSTRUCTiON MANUAL

BEFOREOPERATINGPLANER.ALWAYS USEPROPEREYE

AND RESPIRATORYPROTECTION.WHEN SERViCiNG, USE

ONLY iDENTiCAL REPLACEMENTPARTS.O0 NOT EXPOSE

TO RAIN ORUSEIN DAMP LOCATIONS.A TITRE PREVENTIF,

LIRELEGUIDE D' UTiLiSATi0N. NE PAS EXPOSER,_ LA

PLUiEET NE PAS UTiLJSERDANS LESEMPLACEMENTS

BUMiDES.

DEWALT iNDUSTRiAL TOOL CO. BALTIMORE, MD 21286 USA

FOR SERVICE iNFORMATiON, CALL 1-800-4-DEWALT www.B_WALT.com

_ TOREDUCETHERISKOFINJUffY,OSERMUSTR_AoANDUNDERSTANDINSTRU_TION]

.AN0S_°AWAYFH0_M0T011CAnRIAGEW_ENFEE01NGWORKpI_CE.N_ M_E currE_81A_EREPlaCEMENT

0RA_I_'0n_ff _p_IRS/AOJUSTM_NTSWITI_UNI_P_U_EDIN.M_ CER_I_IT.ATnf_ swrrcHIsI__.E 0FF

P0_nl0___F0R_Ce_I_EC_I_PL__ TOAPOWERS0U_CE._ ES_ T_ATT_ ct_rr_ _LA_S A_ Me_N_ AS

DESCribEDiNT.EI_STRUCOON_NOA_ _NOC_C_T_AT_LLt_0LTS_REFIRMLYTI_T_NEOB_F0_

H_DS. _r _UA_I_SiNpt_c__N_ ING_O0WOR_N_0_. m'_y ALE_T- NEW_OPERATETHEUNnWHeN

TIREO0__N_ T_IEI_I_LUENC_O_D_U_S.AL_O_O_O_M_IC_OON.O0NOTUS_INOA_ROOS

N_W_pt_E MAlariaLWHIC_IS SH0_T_T_ANlZI_C_S. _0 _0TWEA__OVES,_EClnlES.JEWELRY.0R

MANUA_BE_O_EOpERA_NGpLA_E_.ALWAY_W_ _E pROT_CllO_IA_I_._STMAS_IFN_CESSA_V._Er l

LOOS_C_OTHI_IG.SOMEWOO0COm_NSreESERVATIVESSUCHASCOPP__H_OMIOMA_S_N_I_{CCA_WHIC.

MINIMIZ_SKINC0_ACT._XHAUSTCHUTe;REM0WSI_A_NGSWIT._RUS.ORWCUU__Fr_ P0W_R_AS

BEENSHU_O_FA_IDCUttERH_ADHASSToppEDROTATINg.

KEEPHANDS

AWAY FROM

CUTTERHEAD.

Troubleshooting Guide

IF THE MATERIAL DOES NOT FEED PROPERLY, CHECK FOR:

• dull knives, rotate or replace as necessary. Refer to Changing the Planer Knives section.

• excess clogging in the dust hood. Refer Dust Hood Installation paragraph in the Assembly section.

• excess oil/debris/pitch on feed rollers. Refer to Periodic Maintenance and Cleaning and Lubrication paragraphs

under the Maintenance section.

• excessively twisted, cupped or bowed material. Refer to Twisted, Cupped and Bowed Wood paragraph in the Basic

Planing section.

• a broken drive belt. Refer to Installing a New Belt paragraph in the Maintenance section.

• dull knives. Refer to Changing the Planer Knives section.

IF THE CIRCUIT BREAKER TRIPS REPEATEDLY:

• dull knives, dull knives can cause motor overloading, rotate or replace as necessary. Refer to Changing the Planer

Knives section.

NOTE: Circuit breaker overload is often the result of dull knives. If the circuit breaker on your planer trips, check the

sharpness of your knives before attempting to reset the breaker in order to continue planing.

• reduce the depth of cut, an overly aggressive cut could cause motor overloading. Refer to Depth Adjustment

paragraph in the Operation section.

IF THE UNIT DOES NOT RUN, CHECK TO SEE:

• if the unit is plugged in. Ensure unit is plugged into the appropriate outlet, refer to the Important Safety Instructions

for AII Tools section.

• if the tool tray is properly in place. Refer to Figure 1 for proper location.

• if the circuit breaker needs to be reset. Refer to Circuit Breaker Reset Button paragraph under the Maintenance

section.

• if the motor brushes are depleted, replace as necessary. Refer to Brushes paragraph under the Maintenance section.

KEEP HANDS AWAY FROM CUTTER HEAD.

REMOVAL OF THE TRAY/GUARD

WiLL ALLOW ENGAGEMENTOF _|R|_

THE CUTTER HEAD LOCK, THE

CUTTER HEAD WiLL NOT

ROTATE, DAMAGE MAY RESULT

iF UNDER POWER.

Page 10

D_finitions : lignes directrices en mati_re de

s_curit_

Les definitions ci-dessous decrivent le niveau de gravite pour chaque symbole. Veuillez lire le

mode d'emploi et porter une attention particuliere & ces symboles.

_DANGER : Indique une situation dangereuse imminente qui, si elle n'est pas 6vit6e,

causera la mort ou des blessures graves.

_ A VERTISSEMENT : Indique une situation potentiellement dangereuse qui, si elle n'est pas

_vit6e, pourrait se solder par un d_c_s eu des blessures graves.

A ATTENTION : Indique une situation potentiellement dangereuse qui, si elle n'est pas 6vit6e

pourrait se solder par des blessures rnineures ou rnod_r_es.

AVIS : Indique une pratique ne posant aucun risque de dommages corporels mais

qui par centre, si rien n'est fair pour 1'6viter, pourra# poser des risques de dommages

materiels.

\ J

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT AUTRE

OUTIL DEWALT, COMPOSER LE NUM#RO SANS FRAIS :

1 800 4-DEWALT (1 800 433-9258)

CONSERVER CES CONSIGNES

Consignes de s_curit_ g_n_rales pour tous les outils

_ AVERTISSEMENT : Pour sa propre s6curit6, il est important de fire le guide d'utilisation

avant d'utiliser la raboteuse. On dolt respecter les avertissements afin d'6viter de se

blesser ou d'endommager gravement la raboteuse. Pour r6parer cet outil, utiliser seulement

des pieces de rechange identiques. Faire remplacer les cordons d'alimentation endommag6s

par un centre de service autoris&

MISE A LA TERRE

En cas de d6faillance ou de bris, la mise a la terre procure un chemin de moindre r6sistance

au courant 61ectrique afn de r6duire le risque de secousses 61ectriques. L'outil est muni d'un

cordon comportant un conducteur de terre et d'une fiche de terre. II faut brancher la fiche

dans une prise correspondante bien install6e et mise a la terre selon les lois et reglements de

la r6gion. II ne faut pas modifier la fche de I'outil; Iorsque la fiche ne s'insere pas dans la prise,

faire installer une prise appropri6e par un 61ectricien certifi&

Une mauvaise connexion du fl de terre pr6sente des risques de secousses 61ectriques. Le

conducteur vert (ou vert et jaune) du cordon constitue la mise a la terre. Si la r6paration ou le

remplacement d'un cordon d'61ectrique ou d'une fiche s'averent n6cessaires, ne pas brancher

la mise a la terre dans une borne sous tension.

Consulter un 61ectricien certifi6 ou un repr6sentant du service a la clientele si les instructions

de mise a la terre ne sent pas parfaitement assimil6es ou si un doute r6side quanta la mise

la terre. Utiliser seulement des cordons de rallonge trifilaires ayant une fiche a 3 broches ainsi

qu'une prise a 3 trous acceptant la fiche de I'outil.

RI_PARER OU REMPLACER IMMI_DIATEMENT TOUT

CORDON ENDOMMAGI_ OU USI_.

Cet outil est congu pour _tre aliment6 par

un circuit dent la fiche ressemble a celle

illustr6e a la figure A. L'outil comporte une

fiche de raise a la terre qui ressemble a celle

illustr6e a la figure A. On peut utiliser un

adaptateur temporaire (figures Bet C) pour

brancher ce type de fiche dans des prises

deux trous (figure B). Utiliser I'adaptateur

temporaire uniquement en attendant

I'installation d'une prise raise a la terre par

un 61ectricien certifi& L'oreille ou la cosse

rigide et verte de I'adaptateur doit #tre reli6e a une mise a la terre permanente, comme une

prise bien mise a la terre. L'adaptateur (C) ne peut _tre utilis6 au Canada.

_AVERTISSEMENT : Afin de r_duire les risques d'incendie, de choc #lectrique et de

blessure durant I'utilisation d'outils _lectriques, il faut toujours respecter certaines mesures de

s_curit_ fondamentales, notamment :

A PRISE B C

MISEh LA DISPOSITIF

TERRE DEMISE h LA

TERRE

DAPTATEUR

BROCHE DE

PRISEMISE

h LA TERRE

Consignes de s_curit_ d'ordre g_n_ral

• S'ASSURER QUE LES PROTECTEURS SONT EN PLACE et en _tat de fonctionner.

• DE-POSER LES CLE-S DE RE-GLAGE OU DE SERRAGE. Prendre/'habitude de v_rifier si

les cl_s de r_glage et de serrage sent d_pos_es de I'outil avant de le mettre en marche.

• L'AIRE DE TRAVAIL DOlT eETREPROPRE. Les aires de travail et les _tablis encombr_s

peuvent entrafner des blessures.

• NE PAS UTILISER L'OUTIL DANS UN ENVIRONNEMENT DANGEREUX. Ne pas utiliser

les outils _lectriques dans des endroits humides ou d_tremp_s, et ne pas les exposer a la

pluie. L'aire de travail dolt _tre bien _clair_e. Toujours utiliser I'outil dans un endroit bien a_r_

et exempt de matieres combustibles, d'essence ou de vapeurs de solvants. Si des etincelles

viennent en contact avec des vapeurs inflammables, celles-ci risquent de prendre feu et

d'entrafner un incendie ou une explosion.

• TENIR LES ENFANTS A DISTANCE. Tous les visiteurs doivent _tre tenus a une distance

sore de I'aire de travail.

• PRE-PARER L'ATELIER DE FA_,ON A PROTE-GER LES ENFANTS a I'aide de cadenas

et de commutateurs principaux, ou en enlevant les cl_s de mise en marche.

• NE PAS FORCER L'OUTIL. II permettra de faire le travail de fagon plus efficace et plus

sore s'il fonctionne suivant la cadence pour laquelle il a #t# conqu.

• UTILISER L'OUTIL APPROPRIE-. Ne pas forcer un outil ou un accessoire a faire une tbche

pour laquelle il n'est pas conqu.

• UTILISER UNE RALLONGE APPROPRIE-E. V_rifier si la rallonge est en ben _tat. S'il y

a lieu d'utiliser une rallonge, s'assurer que celle-ci est de calibre suffisamment _lev_ pour

acheminer le courant n_cessaire au fonctionnement de I'outil. Une rallonge de calibre

trop faible pourrait causer une chute de tension se traduisant par une perte de courant

et une surchauffe. Le tableau qui suit indique le calibre appropri_ selon la Iongueur de la

rallonge et I'intensit_ indiqu_e sur la plaque signal_tique. En cas de doute, utiliser le calibre

sup_rieur suivant. Plus le num#ro de calibre est petit, plus le calibre de la rallonge est

_lev& Lorsqu'on utilise un outil _lectrique a I'ext_rieur, il faut employer une rallonge portant

I'inscription "W-A" ou "W". Ces rallonges sent conques pour I'utilisation a I'ext_rieur et

r_duisent le risque de choc _lectrique.

Page 11

Calibres

minimaux des rallonges

volts Longueur totale de cordon

en m_tres (pieds)

Intensit6 (en

amperes)

Sup6rieur Inf6rieur

0 6

6 10

10 12

12 16

120V 7,6 15,2 30,5 45,7(150)

(25) (50)(100)

240V 15,2 30,5 61,0 91,4(300)

(50) (100)(200)

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12 Non recommande

• PORTER DES VeL-TEMENTS APPROPRI£-S. E-viter de

porter des v_tements amples, des gants, une cravate,

des bagues, des bracelets et tout autre bijou pouvant

_tre happ6 par des pieces mobiles. II est recommand6

de porter des chaussures a semelles antid6rapantes et

de se couvrir la t_te pour retenir les cheveux longs. II faut

6galement se tenir a 1'6cart des 6vents qui recouvrent

souvent les pieces mobiles.

• PORTER DES LUNETTES DE SE-CURITE- EN

TOUT TEMPS. Porter 6galement un masque facial

ou antipoussiere si I'op6ration de coupe produit de

la poussiere. Les lunettes ordinaires sont seulement

pourvues de verres r6sistants a I'impact; ce ne sont pas

des lunettes de s6curit&

• LORSQU'IL EST EN MARCHE, L'OUTIL PEUT

PROJETER DES DE-BRIS, DU MATE-RIEL AMALGAME-

OU DE LA POUSSIt-RE POUVANT CAUSER DES

LE-SIONS OCULAIRES .4 L'OPE-RATEUR. L'op6rateur

et toutes les personnes dans la zone environnante

doivent porter des lunettes de s6curit6 avec 6crans

lat6raux fixes. Les lunettes de s6curit6 approuv6es sont

estampill6es avec la mention "Z87.1". L'employeur a

la responsabilit6 d'imposer le port d'6quipement de

protection des yeux a I'op6rateur eta toutes les autres

personnes dans la zone de travail.

• IMMOBILISER LA PIt-CE .4 RABOTER. Lorsque c'est

possible, utiliser des pinces ou un 6tau pour immobiliser

la piece sur laquelle on travaille. En plus de se prot6ger les

mains, I'op6rateur dispose ainsi de ses deux mains pour

manier I'outil.

• NE PAS TENDRE LE BRAS TROP LOIN.II faut demeurer

en 6quilibre en tout temps.

• VEILLER .4 ENTRETENIR CORRECTEMENT LES

OUTILS. AffOter et nettoyer les outils pour en obtenir un

rendement optimal et une s6curit6 maximale. Respecter

les instructions sur la lubrification et le remplacement des

accessoires.

• DE-BRANCHER LES OUTILS avant toute r6paration ou

Iorsqu'on remplace des accessoires comme les lames,

les forets, les couteaux, etc.

• RE-DUIRE LES RISQUES DE MISE EN MARCHE

INTEMPESTIVE. Veiller ace que I'interrupteur soit en

position d'arr_t (OFF) avant de brancher I'outil.

• N'UTILISER QUE LES ACCESSOIRES

RECOMMANDE-S. Consulter le guide

d'utifisation pour les accessoires recommand6s.

L'utilisation d'accessoires inad6quats risque

d'entrafner des blessures.

• NE JAMAIS SE METTRE DEBOUT SUR L'OUTIL. On

risque alors de graves blessures si I'outil s'incline ou si

I'on entre accidentellement en contact avec I'outillage de

coupe.

• VE-RIFIER LES PIt-CES ENDOMMAGE-ES. Avant de

continuer a utiliser I'outil, inspecter attentivement le

protecteur ou toute autre piece endommag6e afin de

s'assurer qu'il fonctionnera ad6quatement et remplira sa

fonction - s'assurer que les pieces mobiles sont align6es

et qu'elles ne restent pas coinc6es, qu'aucune piece n'est

bris6e; v6rifier si le montage et tout autre facteur pouvant

avoir un impact sur son fonctionnement est appropri&

Les protecteurs et autres pieces endommag6s doivent

_tre ad6quatement r6par6s ou remplac6s.

• NE JAMAIS LAISSER L'OUTIL EN MARCHE SANS

SURVEILLANCE. LE METTRE HORS TENSION. Ne

jamais laisser I'outil avant qu'il ne soit completement

arr_t&

R_gles de s_curit_ suppl_mentaires

propres aux raboteuses

• Pour r_duire les risques de blessures, on doit life et

comprendre le guide d'utilisation avant d'utiliser la

raboteuse.

• Toujours porter des lunettes de s_curit_ et, au besoin, un

masque antipoussiere.

• Ne pas s'approcher les mains en dessous du chariot

porte-couteaux.

• Sens de I'entrafnement. Faire avancer le mat_riau

travailler dans le sens des fleches d'entrafnement situ_es

sur le dessus de I'appareil.

• Ne jamais tenter d'enlever des obstructions, de remplacer

un couteau ou d'effectuer une r_paration ou un r_glage

quelconque Iorsque I'appareil est branch,.

• On dolt s'assurer que I'interrupteur est en position

d'arr_t (OFF) avant d'ins_rer la fiche dans une prise

d'alimentation.

• S'assurer que les couteaux sont months conform_ment

aux instructions du guide d'utilisation et s'assurer que

tous les boulons sont bien serr#s avant de brancher

I'appareil a une source d'alimentation.

• Pour #viter les blessures, ne jamais se servir de ses mains

pour faire tourner I'arbre porte-couteaux.

• Maintenir les protecteurs en place et en bon _tat de

fonctionnement.

• Rester vigilant - ne jamais utiliser I'appareil si on est

fatigu# ou sous I'influence de drogues, d'alcool ou de

m_dicaments.

10

• Ne pas utiliser dans un environnement dangereux. Ne

pas utiliser pres de substances inflammables ou dans

des endroits humides ou d_tremp_s; ne pas exposer a la

pluie.

• Ne jamais raboter des mat_riaux de Iongueur inf_rieure

304,8 mm (12 po).

• Chute d'#vacuation : enleverles rognures avec une brosse

ou un aspirateur apres avoir mis I'appareil hors tension et

attendu que le porte-couteaux arr#te de tourner.

• Arrimer syst_matiquement la raboteuse a une surface de

travail stable a I'aide des trous de montage sur la base. Se

reporter a la section Fixation _ un _tabli.

• TOUJOURS PRE-VOIR UN DE-GAGEMENT APPROPRIE-

A LA SORTIE de la raboteuse afin d'#viter que la piece

de mat_riau rabot_e ne soit pinc_e ou coinc_e contre un

obstacle quelconque.

• Nettoyerl'outil fr_quemment, plusparticuli_rement s'il

est soumis a une utilisation intensive. De la poussiere

contenant des particules m_talliques s'accumule souvent

sur les surfaces int#rieures et pourrait entrafner de graves

blessures et provoquer un choc #lectrique ou m#me une

_lectrocution. PORTER DES LUNE7-i-ES DE SE-CURITE-

EN TOUT TEMPS.

AAVERTISSEMENT : II est recommand_ de se mettre

deux personnes pour soulever cet appareil afin d'_viter les

risques de blessures graves.

AAVERTISSEMENT : porter un disposfff personnel

approprie de protection auditive durant I'utilisation.

Sous certaines conditions et suivant la Iongueur d'utilisation,

le bruit _manant de ce produit pourrait contribuer a une

perte de I'acuit_ auditive.

t&AVERTISSEMENT : Certaines poussieres cr_es par le

ponqage, le sciage, le meulage et le forage m_caniques

ainsi que d'autres activit_s de construction contiennent

des produits chimiques dont on sait qu'ils causent le

cancer, des anomalies cong#nitales ou d'autres anomafies

li_es a la reproduction. Parmi ces produits chimiques,

citons notamment :

• le plomb des peintures au plomb;

• la silice cristalline provenant des briques, du b_ton et

autres mat_riaux de maqonnerie;

• I'arsenic et le chrome provenant du bois trait_ (ars_niate

de cuivre et de chrome).

Le risque associ_ aces expositions varie selon la fr#quence

de ces types de travaux. Pour r_duire I'exposition aux

produits chimiques : travailler dans un local bien ventil_

et utiliser du materiel de s#curit_ approuv_, comme les

masques antipoussiere sp_cialement conqus pour filtrer les

particules microscopiques.

• E-vfer le contact prolong_ avecla poussi_re

provenant du ponqage, du sciage, du meulage et

du forage m_canique ainsi que d'autres activit_s de

construction. Porter des v6tements de protection et

laver les parties du corps expos_es au savon et

Page 12

I'eau.Lefaitdepermettrealapoussieredep6n6trerdans

laboucheetlesyeuxoudesed6posersurlapeaupeut

favoriserI'absorptiondeproduitschimiquesnocifs.

,&AVERTISSEMENT : Toutes les personnes qui entrent

dans la zone de travail doivent porter un masque ou

un respirateur antipoussiere. Le filtre dolt _tre remplac6

quotidiennement ou chaque fois que la personne qui le

porte 6prouve des difficult6s a respirer. On peut se procurer

le masque antipoussiere approuv6 (NIOSH/OSHA) a la

quincaillerie locale.

• L'6tiquette appos6e sur I'outil peut comprendre les

symboles suivants. Voici les symboles et leurs d6finitions :

V......... volts A........ amperes

Hz....... hertz W....... watts

min .....minutes "_...... courant alternatif

--- .. courant continu _ ..... courant alternatif

@ ....... Construction de ou continu

classe I (mis a la terre) no ...... vitesse a vide

[] ....... Construction de _ ...... borne de terre

classe II A ...... symbole

(a double isolation) d'alerte

BPM... coups par minute la s6curit6

RPM... rotations ou alternance .../minpar minute

par minute

Caract_ristiques techniques

Alimentation ............................ 120 V c.a., 15 A

Vitesse &vide ......................... 10 000 tr / min

Vitesse d'alimentation ............ 7,9 m (26 pi) / min

Hauteur de rabotage .............. 152 mm (6 po) max.,

3,2 mm (1/8 po) min.

Largeur de rabotage .............. 317,5 mm (12,5 po) max.

Profondeur de rabotage ........3,2 mm (1/8 po) max.

(planches de 152 mm (6 po)

de large ou moins)

Raccordement _lectrique

S'assurer que I'alimentation corresponde aux valeurs

nominales inscrites sur la plaque signaletique de I'outil, soit

120 volts c.a. (courant alternatif seulement), 50/60 Hz. Une

diminution de tension de 10 % ou plus entrafnera une chute

de puissance et une surchauffe. Tousles outils DEWALT

sont mis & I'essai en usine. Si cet outil ne fonctionne pas,

verifier I'alimentation electrique.

Transport de la raboteuse

AAVERTISSEMENT : il est plus s6curitaire de transporter

I'outil a deux personnes, sans quoi on risque de se blesser

gravement.

Pour deplacer la raboteuse, la tenir par les poignees

laterales (B) ou par la base, I& oQ des creux (C) sont prevus

cet effet (fig. 2).

Lors du transport ou de I'entreposage de la raboteuse,

enrouler le cordon aux crochets (D) situ6s a I'arriere de I'outil

(fig. 3).

Fixation _ un _tabli

Des trous de tailles differentes (E), aux quatre coins de

la raboteuse, permettent la fixation de celle-ci a un etabli

(fig. 4). Utiliser les grands trous pour une fixation au moyen

d'ecrous, et les petits si on utilise des clous ou des vis. II

n'est pas necessaire d'utiliser les deux formats de trous.

La raboteuse doit _tre fixee a une surface immobile. Si on

desire pouvoir la deplacer aisement, on peut d'abord la

fixer a une planche de contreplaqu6 de 12,7 mm (0,5 po)

d'epaisseur ou plus, laquelle pourra ensuite _tre fixee au

moyen de pinces a divers plans de travail.

REMARQUE • si on opte pour la fixation a une planche,

on doit s'assurer que les vis de montage ne depassent pas

sous le contreplaqu6; celui-ci doit reposer bien a plat sur

le plan de travail.

_ATTENTION : la surface de montage ne doit _tre ni

d6form6e, ni in6gale de quelque faqon que ce soit.

ASSEMBLAGE

_AVERTISSEMENT : Pour r_duire tout risque de

dommages corporels graves, arr#ter et d_brancher I'outil

avant tout r_glage ou avant de retirer ou installer toute

piece ou tout accessoire.

Manivelle de r_glage de la

profondeur

FIXATION DE LA MANIVELLE DE R#GLAGE DE LA

PROFONDEUR

1. Inserer la manivelle (F) au-dessus de la tige (fig. 5).

2. Fixer la manivelle au moyen de la vis creuse & six pans

(star) et de la cle en T fournies.

INSTALLATION DE LA HOTTE ._,POUSSI#RE (FIG. 1)

1. Retirez les vis (AA, fig. 1), et les mettre de c6t&

2. Poussez a fond les clips (BB, fig. 1A) de la hotte

poussiere a I'avant du plateau a outils puis tournez la

hotte jusqu'a ce qu'elle s'enclenche en place.

3 Alignez les trous sur la hotte a poussiere sur les trous

du plateau a outils et le boftier du moteur, puis fixez-la

avec les vis retirees plus t6t.

REMARQUE : resserrer la vis inferieure d'abord puis les

deux vis de c6t&

4. Rattachez la hotte a poussiere a un systeme de

depoussierage. Reportez-vous au manuel de I'utilisateur

du systeme de depoussierage pour suivre la procedure

correcte ainsi que les directives de securit&

_ ATTENTION : Iorsque I'accessoire de d_poussi_rage est

utilis_, ne pas faire fonctionner I'appareil sans lui connecter

un tuyau et un systeme de d_poussi_rage en _tat de marche.

FONCTIONNEMENT

_AVERTISSEMENT : Pour r_duire tout risque de

dommages corporels graves, arr_ter et d_brancher I'outil

avant tout r_glage ou avant de retirer ou installer toute

piece ou tout accessoire.

FIG. 1

AA

FIG. 4

FIG. 6

FIG. 3

FIG. 2

FIG. 1A

FIG. 5

F

\

E

11

Page 13

Interrupteur

Pour faire demarrer la raboteuse, soulever I'interrupteur

(G), lequel reste automatiquement verrouille en position de

marche. Pour I'arr6ter, rabattre I'interrupteur. Un trou (H) situ6

sous I'interrupteur permet de verrouiller ce dernier en position

d'arr6t au moyen d'un cadenas (fig. 6).

Rallonges de plateau

Avant d'utiliser la raboteuse, rabattre les rallonges de plateau

situees & I'avant et & I'arriere de I'outil (fig. 7). Apres de

Iongues periodes d'utilisation, ces rallonges peuvent parfois

se decaler; le cas echeant, se reporter & la section relative &

la raise a niveau des rallonges de plateau, dans la section

Entretien.

REMARQUE • les c6tes externes de ces rallonges sont de

niveau avec la base de I'outil, tandis que les c6tes internes

(ceux les plus rapproches de I'organe de coupe) depassent

sous la base. Ces positions sont reglees en usine afin

d'eviter la friction inutile de rouvrage contre le plateau, tout

en procurant un soutien adequat en deux points (suit ceux

les plus eloignes de I'organe de coupe) sur le plateau, de

maniere & eviter de produire une depression dans I'ouvrage.

Verrouillage du chariot _ lame

La raboteuse est pourvue d'un levier de verrouillage (I)

pour le chariot & lame, laquelle se trouve sur le dessus

du moteur (fig. 8). Ce dispositif sert & bloquer le chariot

(contenant I'organe de coupe) contre les quatre montants

de la raboteuse, ce qui permet de reduire les mouvements

pouvant provoquer des depressions dans I'ouvrage.

R_glage de la profondeur

L'echelle de reglage de la profondeur (J) indique I'epaisseur

qu'aura I'ouvrage une fois rabote (fig. 9). Un tour de

manivelle permet de modifier la profondeur d'environ

1,6 mm (1/16 po), un demi-tour, de 0,8 mm (1/32 po), etc.

R#GLAGE DE L'#PAISSEUR VOULUE

1. Soulever le levier de verrouillage (I) de maniere &

debloquer I'organe de coupe (fig. 8), afin de pouvoir

regler la position de celui-ci.

2. Regler I'epaisseur voulue en tournant la manivelle (F)

vers la droite pour baisser I'organe de coupe, ou vers

la gauche pour I'elever. Un tour complet de manivelle

permet de modifier le reglage d'environ 1,6 mm

(1/16 po).

3. Baisser le levier de verrouillage afin de bloquer de

nouveau I'organe de coupe.

REMARQUE : ne jamais tenter de regler la hauteur du

chariot Iorsque le levier de verrouillage est engage, ce qui

pourrait endommager I'outil.

RI_GLAGE DE PRI_CISION

La manivelle de reglage permet un reglage d'une precision

allant de 1,6 mm (1/16 po) a 0,4 mm (1/64 po). Le reglage

de precision est ideal pour <<raser _>une mince pellicule

sur la surface d'un ouvrage. Par exemple, si une piece

d'une epaisseur de 77,8 mm (3 1/16 po) doit 6tre reduite

& 76,2 mm (3 po), on doit regler la raboteuse de la fagon

suivante :

FIG. 8

FIG. 9

FIG. 10

12

1. Raboter puis mesurer la piece & travailler; dans cet

exemple, I'epaisseur finale est de 77,8 mm (3 1/16 po).

2. Tourner I'etiquette ronde de la manivelle de reglage de la

profondeur jusqu'& ce que la marque <<0 _>suit alignee

avec la fleche situee sur le dessus de I'outil (ne pas

effectuer d'autres reglages).

3. Tourner la manivelle de reglage vers la droite, jusqu'&

ce que la marque 1.6 mm (1/16 po) suit alignee avec la

fleche.

4. Raboter la piece. L'epaisseur obtenue sera de 76,2 mm

(3 po).

Indicateur d'_paisseur voulue

La raboteuse est dotee d'un indicateur permettant de

determiner I'epaisseur qu'on obtiendra apres un passage en

function du reglage de la hauteur du chariot.

UTILISATION DE L'INDICATEUR D'I_PAISSEUR

VOULUE

AAVERTISSEMENT : NE JAMAIS FAIRE DE-MARRER

L'OUTIL LORSQUE L'OUVRAGE EST PLACE SOUS LE

CHARIOT, CE QUI POURRAIT CAUSER DE GRAVES

BLESSURES.

1. Glisser la piece, sur environ 76.2 mm (3 po), sous la

fleche (K)situee au milieu du chariot (fig. 10).

2. La piece doit reposer bien a plat contre la base de la

raboteuse; si elle est le moindrement inclinee, la lecture

risque d'6tre faussee.

3. Deverrouiller et abaisser le chariot, au moyen de la

manivelle, sur la piece jusqu'a ce que la barre de

I'indicateur d'epaisseur voulue s'engage sur la piece;

I'indicateur rouge (L) se deplacera jusqu'a I'indication de

I'epaisseur qu'on obtiendra en function de la hauteur du

chariot.

4. Regler la hauteur du chariot jusqu'a ce que I'epaisseur

voulue apparaisse sur I'indicateur.

5. Retirer la piece de sous le chariot.

6. Bloquer le levier de verrouillage.

7. Demarrer la raboteuse, puis faire avancer la piece sous

I'organe de coupe.

REMARQUE :ne pas depasser la

profondeur de coupe

recommandee pour chacune des

epaisseurs indiquees sur

I'indicateur d'epaisseur voulue

(tableau A).

Butte de tourelle

La raboteuse est pourvue d'une

butee de tourelle (M, figure 11),

laquelle sert & fixer la profondeur

de rabotage pour des coupes repetitives. La butee peut 6tre

fixee & 0, a 6,4, & 12,7 ou & 19,0 mm (0, 1/4 po, 1/2 po ou

3/4 po). Choisir le reglage <<0 _>si la profondeur voulue se

situe entre 3,2 et 6,4 mm (1/8 et 1/4 po).

TABLEAUA

F F- MATERIAL r _,

_ I REMOVAL J _ I

i rT_ GAUGE L_ I

;--L-U..,_r-_ C3 DEPTH I

_r_ OFCUT

" 6" 9" 13"

_- w,.'r. U/

S']

Page 14

R#GLAGE DE LA BUT#E DE TOURELLE

1. S'assurer que le chariot soit regl6 a plus de 31,8 mm (1

1/4 po) avant d'utiliser la butee.

2. Tourner la butee jusqu'a ce que la mesure voulue soit

indiqu6e (fig. 11).

3. Debloquer le levier de verrouillage (fig. 8); tourner la

manivelle de reglage de la profondeur, ce qui fera

baisser le chariot, jusqu'a ce que dernier entre en

contact avec la butee.

REMARQUE : NE PAS EXERCER DE PRESSION SUR

LA MANIVELLE, CE QUI POURRAIT FAIRE BAISSER LE

CHARIOT EN-DESSOUS DU NIVEAU INDIQUI_ PAR LA

BUTI_E; CELA POURRAIT ENDOMMAGER DE FAQON

PERMANENTE LE SYSTI_ME DE RI_GLAGE DE LA

HAUTEUR DE L'OUTIL.

REMARQUE : on peut choisir la mesure 19.0 mm (3/4 po)

pour obtenir d'autres epaisseurs; cela n'affectera pas les

autres reglages de la butee.

RI_GLAGE DE LA BUTI_E A LA POSITION 19.0 MM

(3/4 PO) POUR D'AUTRES #PAISSEURS

1. Debloquer le levier de verrouillage (figure 8) puis tourner

la manivelle de reglage vers la gauche afin d'elever

I'organe de coupe.

2. Un ecrou de reglage (N, fig. 11), situ6 & I'arriere de

I'outil, est regle en usine & une profondeur de 19,0 mm

(3/4 po); desserrer le contre-ecrou au moyen de la cle

& molette Crescent fournie, puis le regler, vers le haut

ou vers le bas, de maniere & obtenir la profondeur de

rabotage voulue.

3. Tourner la manivelle de reglage de la profondeur ce qui

fera baisser le chariot, jusqu'& ce que dernier entre en

contact avec la butee.

TECHNIQUES DE RABOTAGE

DE BASE

Technique _ privil_gier

AAVERTISSEMENT : NE JAMAIS DE-MARRER L'OUTIL

LORSQUE L'OUVRAGE EST DE-JA INSERE SOUS LE

CHARIOT; ATTENDRE QUE LES ROULEAUX ET

L'ORGANE DE COUPE SE SOIENT COMPLETEMENT

IMMOBILISES AVANT D'INSERER UNE PIECE A

TRA VAILLER.

RABOTER UN OUVRAGE

La raboteuse donne de meilleurs resultats Iorsqu'on I'utilise

pour travailler une piece ayant au moins une surface plane.

Si les deux c6tes de la piece sont irreguliers, on peut utiliser

une varlope pour lisser un des c6tes.

L'ouvrage doit _tre bien supporte pendant la coupe. La

profondeur maximale pouvant _tre obtenue en un passage

est 3,2 mm (1/8 po) pour une piece d'une largeur de moins

de 152 mm (6 po). On ne doit pas tenter de modifier la

raboteuse dans le but d'obtenir une coupe plus profonde;

pour obtenir de bons resultats, les recommandations

relatives a la profondeur eta la largeur donnees au tableau A

doivent _tre suivies.

FIG. 12

FIG. 13

FIG. 14

FIG. 15 DESSUS PLAT

FIG. 16

LA PLANCHE DE BOIS BOMBI_E SERA APLATIE

PAR LES ROULEAUX D'ALIMENTATION ET LE

PORTE-COUTEAUX...

...MAIS LA CAMBRURE RI_APPARAJTAPRES

LE RABOTAGE DE LA PLANCHE

DESSOUS PLAT

1. Abaisser le chariot & la hauteur voulue pour le premier

passage de la raboteuse.

2. Faire demarrer I'outil et inserer I'ouvrage dans les

rouleaux d'entrafnement.

3. Examiner la coupe obtenue et regler le chariot & la

hauteur appropriee pour le passage suivant.

Se reporter au guide de depannage, & la fin des presentes,

pour en savoir davantage.

i_AVERTISSEMENT : ne jamais se placer entre I'ouvrage

et une structure immobile Iorsque la piece travaill6e ressort

de sous la raboteuse; cela pourrait causer des blessures ou

I'endommagement de I'ouvrage.

_AVERTISSEMENT : cet outil a 6t6 conqu pour raboter

le bois seulement. Ne pas tenter de raboter des mat6riaux

autres que le bois.

_ A VERTISSEMENT : ne jamais raboter des morceaux de

bois de Iongueur inf6rieure a 304,8 mm (12 po).

._,AVERTISSEMENT : ne raboter que des pieces de bois

fibres de tout corps 6tranger, ne pr6sentant aucun noeud

sautant et le moins de noeuds adh6rents que possible; ne

pas raboter des pieces de bois gauchies, tordues, noueuses

ou courb6es.

_AVERTISSEMENT : ne pas alimenter le bois contre le

grain, I'alimenter syst6matiquement dans la direction du

grain.

REMAROUE • pour s'assurer des meilleurs resultats, raboter

les deux c6tes de la piece jusqu'a ce que I'epaisseur voulue

soit obtenue. Par exemple, si on veut enlever 3,2 mm (1/8 po)

d'epaisseur a une planche, il est pref6rable de retirer 1,6 mm

(1/16 po) de chaque c6te et ce, non seulement par ce que

cela favorise un sechage plus uniforme, mais aussi parce que

cela permet d'obtenir une coupe plus exacte.

REMAROUE • on doit toujours raboter dans le sens naturel

du grain; le rabotage de pieces d'une epaisseur de moins de

19,0 mm (3/4 po) n'est pas recommande; si on doit raboter

des pieces plus etroites, on doit les regrouper ensemble et

les raboter simultanement (Iorsque cela est possible).

LARGEUR, HAUTEUR ET PROFONDEUR

MINIMALES/MAXIMALES

REMARQUE : une certaine zone du chariot permet de

raboter & une profondeur de 3,2 mm (1/8 po) les pieces

d'une largeur de moins de 152 mm (6 po); la figure 12

illustre I'emplacement de cette zone. La piece doit suivre

cette zone, sans quoi la raboteuse refusera d'effectuer la

coupe. Les pieces de plus de 152 mm (6 po) ne pourront pas

_tre inser6es dans cette zone.

Ddpressions

Des depressions se produisent Iorsqu'une extremite non

soutenue d'un ouvrage se courbe vers le bas et pousse

I'autre extremite, passant dans I'organe de coupe, vers

le haut. En consequence, Iorsqu'on rabote des pieces

tres Iongues, on doit s'assurer que celles-ci soient bien

supportees.

13

Page 15

COMMENT #VITER LES D#PRESSIONS

S'assurer que I'ouvrage inser6 dans la raboteuse soit de

niveau et qu'il reste bien & plat contre la base pendant

toute la coupe. La piece doit etre bien supportee, meme

Iorsqu'elle ressort a I'arriere de la raboteuse.

i_AVERTISSEMENT " ne jamais se placer entre I'ouvrage

et une structure immobile Iorsque la piece travaill6e ressort

de sous la raboteuse; cela pourrait causer des blessures ou

I'endommagement de I'ouvrage.

Pi_ces de bois tordues, concaves ou

courb_es

Si les deux c6tes de la piece & travailler sont tres irreguliers,

ou si la piece est concave, courbee ou tordue, la raboteuse

risque de ne pas procurer les resultats escomptes.

Idealement, il est preferable d'avoir une piece presentant

au moins une surface ou un c6te uniforme. La raboteuse

donnera de meilleurs resultats si la piece est d'abord egalisee

au moyen d'une varlope. Si aucun des c6tes d'une piece

n'est egal, on doit suivre les recommandations ci-dessous •

RABOTAGE DE PI#CES TORDUES (FIG.13)

AAVERTISSEMENT : LE BO/S TORDU R/SQUE DE