Det-Tronics UD10 User Manual

Instructions 95-8661

FlexVu® Explosion-Proof

Universal Display Unit

Model UD10

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

4.2 |

|

|

|

|

|

|

|

Rev: 9/12 |

95-8661 |

|||||||||||||||

|

|

|

|

|

|

|

||||||||||||||||||||

Table of Contents

application . . . . . . . . . . . . . . . . . . . |

. . |

.1. . . |

.Appendix. . . . |

H — UD10 WITH pir9400 pointwatch |

. .H-1 |

|||

DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . |

. . |

|

..1. . . |

. Wiring . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

H-1 |

|

HART Communication |

|

|

3 |

|

Installation Notes . . . . . . . . . . . . . . . . . . . . . |

. . |

H-2 |

|

. . |

|

|

Orientation |

|

H-2 |

|||

Magnetic Switches . . . . . . . . . . . . . . . |

. |

|

|

|

. . |

|||

|

..3. . . . . . |

|

|

|

||||

Relays |

|

|

4 |

|

Changing Operating Modes . . . . . . . . . . . . . |

. . |

H-3 |

|

. . |

|

|

Calibration . . . . . . . . . . . . . . . . . . . . . |

. .H.-3. . . |

||||

4-20 mA Output Modes |

|

|

4 |

|

||||

. . |

|

|

Menu Structure |

|

H-4 |

|||

Modbus / Fieldbus Compatibility . . . . . . . . |

. |

|

..4. . . |

|

. . |

|||

|

|

|

|

|

|

|||

Device Enclosure . . . . . . . . . . . . . . . |

. . |

.4 . . . . . . |

|

|

I-1 |

|||

|

|

|

|

Appendix I — UD10 WITH model pirecl . . . . . . . |

. . |

|||

Device Display . . . . . . . . . . . . . . . . |

. . |

..4 . . . . . . . |

|

|

I-1 |

|||

Logging |

|

|

5 |

|

Wiring . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

|

. . |

|

|

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

.I-2 |

|||

IMPORTant SAFETY NOTES |

|

|

5 |

|

Calibration . . . . . . . . . . . . . . . . . . . . . |

. |

. .I.-3. . . . |

|

. . |

|

|

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . |

. . |

.I-4 |

|||

INSTallation . . . . . . . . . . . . . . . . . . . . . . . |

. . |

..6. . . |

Appendix J — UD10 WITH OPEN PATH MODEL OPECL . . . J-1 |

|||||

|

Wiring |

|

|

J-1 |

||||

Identification of Vapor(s) to be Detected |

|

|

6 |

|

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

||

. . |

|

|

Orientation |

|

J-3 |

|||

Identification of Detector Mounting Locations |

|

|

6 |

|

. . |

|||

. . |

|

|

Calibration . . . . . . . . . . . . . . . . . . . . . |

. |

. J.-3. . . . |

|||

WIRING |

|

|

7 |

|

OPECL Transmitter Lamp Fault Condition . . |

. . |

J-4 |

|

. . |

|

|

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . |

. . |

J-4 |

|||

Power Supply Requirements . . . . . . . . . . . . |

. . |

|

..7. |

Appendix K — UD10 WITH NTMOS H2S Sensor |

|

K-1 |

||

Wiring Cable Requirements |

|

|

7 |

. . |

||||

. . |

|

|

Wiring |

|

|

K-1 |

||

Shield Connections . . . . . . . . . . . . . . . |

. . |

.7. . . . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

||||

Installation Notes |

|

K-1 |

||||||

Jumper Setting for 4-20 mA Loop . . . . . . |

. |

. .7. . . |

|

. |

||||

|

Orientation |

|

K-4 |

|||||

Foundation Fieldbus |

|

|

7 |

|

. . |

|||

. . |

|

|

Calibration . . . . . . . . . . . . . . . . . . . . . |

. |

.K.-4. . . . |

|||

Wiring Procedure |

|

|

8 |

|

||||

. . |

|

|

Menu Structure |

|

K-5 |

|||

|

|

|

|

|

. . |

|||

STaRTUP . . . . . . . . . . . . . . . . . . . . . . . . . |

. |

|

|

Appendix L — UD10 WITH C706X ToXIC GAS SENSOR |

. L-1 |

|||

..12. . . . . |

|

|

|

|

||||

Troubleshooting . . . . . . . . . . . . . . . . . . . . . |

. . |

|

16 |

|

Wiring . |

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . |

L-1 |

SPECIFICATIONS |

|

|

19 |

|

Installation . . . . . . . . . . . . . . . . . . . . . . |

. |

. L.-3. . . |

|

. . |

|

|

Calibration . . . . . . . . . . . . . . . . . . . . . |

. |

. L.-4. . . . |

|||

Device Repair and Return |

|

|

22. |

|

||||

. . |

|

|

Menu Structure |

|

L-4 |

|||

Ordering Information . . . . . . . . . . . |

. .22. . . . . |

. . |

||||||

|

|

. . .M-1 |

||||||

|

|

|

|

Appendix M — UD10 with Model CGS Sensor |

||||

APPENDIX A — FM Approval description . . . . a-1 appendix b — csa certification description . b-1 appendix C — atex approval description . . . . . c-1 appendix d — iecEx approval description . . . . d-1 Appendix E — Additional Approvals . . . . . . . E.-.1.

Appendix F — UD10 WITH Handheld Hart

communicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . F-1

Appendix G — UD10 WITH gt3000 toxic gas detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1 Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2 Live Maintenance . . . . . . . . . . . . . . . . . . . . . . . G-2 Calibration . . . . . . . . . . . . . . . . . . . . . . .G.-3. . .

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . G-4

Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1 Important Notes . . . . . . . . . . . . . . . . . . . . . . . . M-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . M-3 K-Factor.. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. .. M-4 Menu Structure. . . . . . . . . . . . . . . . . . . . . . . . . M-4

Appendix N — UD10 WITH Model 505/CGS . . . . . . . .N-1

Wiring . . . . . . . . |

. . . . . . . . . . . . . . . . . . . . . . |

. . N-1 |

Installation . . . |

. . . . . . . . . . . . . . . . . . . |

. ..N.-2. . |

Orientation . . . . |

. . . . . . . . . . . . . . . . . . . . . . . |

. N-2 |

Calibration . . . |

. . . . . . . . . . . . . . . . . . |

. .N.-3. . . |

Menu Structure . |

. . . . . . . . . . . . . . . . . . . . . . . |

. N-4 |

Appendix O — UD10 WITH Generic 4-20 ma sensor O-1

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . O-1 Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . O-1

INSTRUCTIONS

FlexVu® Explosion-Proof

Universal Display Unit

Model UD10

Important

Be sure to read and understand the entire instruction manual before installing or operating the gas detection system. This product can be used with a variety of Det-Tronics gas detectors to provide early warning of the presence of a toxic or explosive gas mixture. Proper device installation, operation, and maintenance is required to ensure safe and effective operation. If this equipment is used in a manner not specified in this manual, safety protection may be impaired.

Application

The FlexVu® Model UD10 is recommended for applications that require a gas detector with digital readout of detected gas levels as well as analog 4-20 mA output with HART, relay contacts, and Modbus RS485 (foundation™ Fieldbus option available). The UD10 Universal Display Unit is designed for use with Det Tronics gas detectors listed in Table 1.

The display unit is designed and approved as a ‘stand alone’ device and performs all the functions of a gas controller.

When furnished with the CGS interface board, the device can be used only with a CGS sensor for detection of combustible gas. The UD10/CGS combination is certified as a “Gas Detector”.

Gas concentration and unit of measurement are displayed on a digital display. The display unit provides a linear isolated/non-isolated 4-20 mA DC output signal (with HART) that corresponds to the detected gas concentration.

All electronics are enclosed in an explosion-proof aluminum or stainless steel housing. The display unit is used with a single detector that may be either coupled directly to the UD10, or remotely located using a sensor termination box.

The UD10 features non-intrusive calibration. A magnet is used to perform calibration as well as to navigate the UD10’s internal menu.

4.2©Detector Electronics Corporation 2012

Description

The UD10 Universal Display can be used with various 4-20 mA gas detection devices, with or without HART. The unit provides display, output and control capabilities for the gas detector.

The UD10 utilizes the following I/O:

Signal Inputs: |

4-20 mA loop from the sensing device |

|

User Inputs: |

Magnetic switches (4) on the display |

|

|

panel |

|

|

HART communication (handheld field |

|

|

communicator or AMS) |

|

|

foundation™ Fieldbus (if selected) |

|

Signal Outputs: |

4-20 mA output loop with HART |

|

|

Modbus RS485 or foundation™ Fieldbus |

|

|

Three alarm relays and one fault relay |

|

Visible Outputs: |

Backlit LCD display |

|

|

HART slave interface via HART |

|

|

Communicator |

|

|

Rev: 9/12 |

95-8661 |

Table 1—Range and Default Values for Alarms and Calibration Gas Concentration

|

|

UD10 Alarm DaTA |

|

|

Calibration |

|

|

|

|

|

|

|

|

Gas Detector |

|

High Alarm Value |

Low Alarm Value |

Aux alarm Value |

Cal Gas |

|

|

|

|

|

|

|

|

GT3000-- |

Range |

10-90% |

5-50% |

5-90% |

30-90% |

|

Hydrogen Sulfide |

Default |

40% |

10% |

40% |

50% |

|

|

|

|

|

|

|

|

GT3000-- |

Range |

10-90% |

5-50% |

5-90% |

30-90% |

|

Ammonia |

Default |

40% |

10% |

40% |

50% |

|

|

|

|

|

|

|

|

GT3000--Chlorine |

Range |

10-90% |

5-50% |

5-90% |

30-90% |

|

|

|

|

|

|

||

Default |

40% |

10% |

40% |

50% |

||

|

||||||

|

|

|

|

|

|

|

GT3000-- |

Range |

10-60% |

5-50% |

5-90% |

30-90% |

|

Hydrogen |

Default |

40% |

10% |

40% |

50% |

|

GT3000--Oxygen |

Range |

5-20.5% v/v |

5-20.5% v/v |

5-20.5% v/v |

20.9% v/v |

|

|

|

|

|

|

||

Default |

18% v/v |

18% v/v |

18% v/v |

20.9% v/v |

||

|

||||||

|

|

|

|

|

|

|

GT3000--Carbon |

Range |

10-90% |

5-50% |

5-90% |

30-90% |

|

Monoxide |

Default |

40% |

10% |

40% |

50% |

|

|

|

|

|

|

|

|

GT3000--Sulfur |

Range |

10-90% |

5-50% |

5-90% |

30-90% |

|

Dioxide |

Default |

40% |

10% |

40% |

50% |

|

|

|

|

|

|

|

|

PIR9400 |

Range |

10-60% |

5-50% |

5-90% |

50% |

|

|

|

|

|

|

||

Default |

40% |

10% |

40% |

50% |

||

|

||||||

|

|

|

|

|

|

|

PIRECL |

Range |

10-60% |

5-50% |

5-90% |

30-90% |

|

|

|

|

|

|

||

Default |

40% |

10% |

40% |

50% |

||

|

||||||

|

|

|

|

|

|

|

OPECL |

Range |

1-3 LFL-meters |

0.25-3 LFL-meters |

NA |

NA |

|

|

|

|

|

|

||

Default |

2 LFL-meters |

1 LFL-meter |

NA |

NA |

||

|

||||||

|

|

|

|

|

|

|

C706x* |

Range |

10-90% |

5-50% |

5-90% |

30-90% |

|

|

|

|

|

|

||

Default |

40% |

10% |

40% |

50% |

||

|

||||||

|

|

|

|

|

|

|

CGS |

Range |

10-60% |

5-50% |

5-90% |

50% |

|

Combustible |

Default |

40% |

10% |

40% |

50% |

|

|

|

|

|

|

|

|

Model 505/CGS |

Range |

10-60% |

5-50% |

5-90% |

N/A |

|

Combustible |

Default |

40% |

10% |

40% |

N/A |

|

|

|

|

|

|

|

|

NTMOS-- |

Range |

10-90% |

5-50% |

5-90% |

50% |

|

Hydrogen Sulfide |

Default |

40% |

10% |

40% |

50% |

|

|

|

|

|

|

|

|

Generic Detector |

Range |

10-90% |

5-50% |

5-90% |

N/A |

|

|

|

|

|

|

||

Default |

40% |

10% |

40% |

50% |

||

|

||||||

|

|

|

|

|

|

Notes: All values are a percentage of full scale with the exception of Oxygen, which is the actual percent of Oxygen, and OPECL, which is the value in LFL-meters.

low alarm must be less than or equal to the high alarm.

Changing the Measurement Range will reset all alarm and Cal Gas values to the default settings for the selected range.

Alarm relays are selectable for either normally energized or normally de-energized coils, with selectable latching or non-latching contacts. Fault relay is normally energized (with no faults).

*Does not support C7064C hydrogen sulfide or C7065E oxygen, but includes C7064E hydrogen sulfide, C7067E chlorine, C7066E carbon monoxide, and C7068E sulfur dioxide.

4.2 |

2 |

95-8661 |

HART communication

A HART interface provides device status information and field programming capability.

magnetic switches

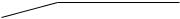

Four internal magnetic switches provide a non intrusive user interface that allows navigation through the menu and adjustment of configuration parameters in the field without the use of a HART handheld device. See Figure 1 for switch locations.

PREVIOUS

CANCEL / ESCAPE

CANCEL / ESCAPE

ENTER / SELECT

ENTER / SELECT

NEXT

B2426

Figure 1—Faceplate of UD10

These switches are used for device configuration, checking status and event logs, and performing calibration. The switches are labeled as follows:

CANCEL / ESCAPE

ENTER / SELECT / MeNU ACCESS

PrEVIOUS or if on Main Screen:

Fault Shortcut

Next

Next

To actuate a magnetic switch, lightly touch the magnet to the viewing window of the UD10 directly over the switch icon on the faceplate.

Caution

Handle magnets with care! Personnel wearing pacemakers/defibrillators should not handle magnets. Modern magnet materials are extremely strong magnetically and somewhat weak mechanically. Injury is possible to personnel, and magnets themselves can easily get damaged if allowed to snap towards each other, or if nearby metal objects are allowed to be attracted to the magnets.

note

Det-Tronics offers two magnet options for activating internal magnetic switches. While the two magnets can usually be used interchangeably, the best results will be achieved if they are used as follows: The Magnetic Tool (p/n 009700-001) is the stronger magnet and is recommended for activating the switches on the UD10 viewing window. The Calibration Magnet (p/n 102740 002) is recommended for applications that involve initiating calibration or resetting the detector by touching the side of a metal junction box or detector housing (PIRECL, OPECL, etc). Throughout this manual, the term “magnet” can refer to either device.

Access To Menus

To access the menus, use the magnet to activate the Enter/SeLECT button. This will display the Main Menu.

The actual menu structure varies depending upon the device that is connected to the UD10. Menus for the various devices can be found in the corresponding Appendix in this manual.

Some areas of the menu contain additional information, which is indicated by the presence of an arrow on that particular line. By placing the magnet to the glass over the Enter/SeLECT button, the next screen with the additional information will be shown.

The UD10 automatically returns to the main screen after 10 minutes if no activity occurs.

Quick Access/Shortcut: Fault Menu

To access the fault menu quickly, when a fault is present, touch the magnet to the glass by the PrEVIOUS button.

4.2 |

3 |

95-8661 |

Relays

The display unit has 4 output relays — high alarm, low alarm, auxiliary alarm, and fault. The relays have form C (SPDT) contacts. Low, auxiliary and high alarm relay contacts are selectable for latching or non latching operation, as well as normally energized or normally de energized (default) coils. During normal operation, the fault relay is energized.

IMportant

Direct connection of 120/240 VAC to the relay terminals inside the UD10 enclosure is not allowed, since switching relay contacts can induce electrical noise into the electronic circuitry, possibly resulting in a false alarm or other system malfunction. If the application requires that AC powered equipment be controlled by the transmitter, the use of externally located relays is recommended.

External relays, solenoids, motors, or other devices that can cause inductive transients should be transient suppressed. Place a diode across the coil for DC devices. See Figure 2.

+ |

|

POSITIVE |

|

|||

|

|

|

1N4004 |

DCV LOADS |

||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

|

|||

|

|

|

TYPICAL |

|

||

|

|

|

NEGATIVE |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

B0179 |

||

|

|

|

|

|||

|

|

|

|

|

|

|

Figure 2—Transient Suppression for Inductive Loads

4-20 mA OuTpuT Modes

The UD10 offers two operating modes for its 4-20 mA output circuit.

Note

A minimum output of 1 mA is required for proper HART communication.

In the Standard (default) Mode, the linear 4-20 mA output corresponds to 0-100% full scale gas detected at the sensor, with 3.8 mA indicating calibrate mode, and 3.6 mA or lower indicating a fault condition. This mode ensures that the current level is always high enough to support HART communication and must be selected when using HART communication for fault diagnostics.

In Replicate Mode, the output of the UD10 matches the output of the connected detector (except for loop test/trim, response test, calibration, or if the UD10 has an internal fault). This mode can be used with

detectors such as PIR9400 or PIRECL where multiple current levels below 4 mA are used for fault diagnostic purposes.

UD10 with Model PIRECL

PIRECL supports two fault modes: PIR9400 and Eclipse mode. PIR9400 fault mode uses fault codes below 1 mA, while Eclipse mode uses no levels below 1 mA. In the Standard (default) mode, the UD10 programs the PIRECL for Eclipse fault mode to ensure proper HART communication in the event of a fault. In the Replicate mode, the UD10 programs the PIRECL for PIR9400 fault mode.

MODBUS / fieldbus COMpATIBILITY

The UD10 supports RS485 Modbus RTU communication. See Addendum number 95-8639 for details. A model with Modbus RS485 or foundation™ Fieldbus communication (field selectable via jumpers) is also available.

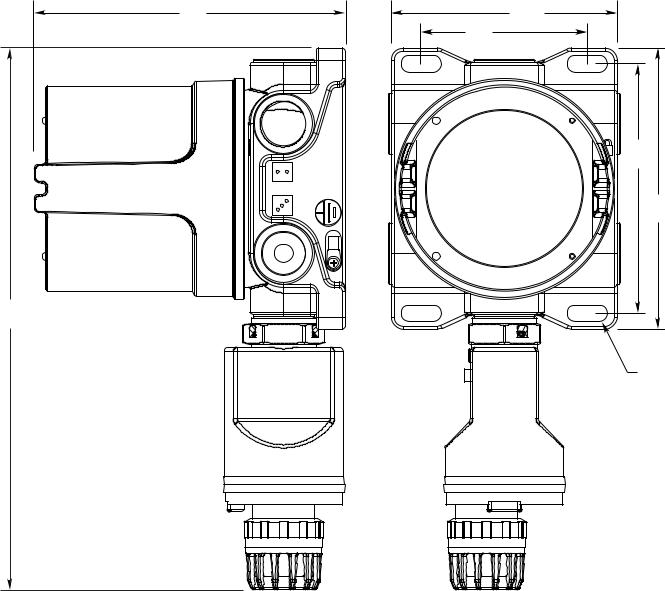

DeviCE ENCLOSURE

The UD10 housing is a 5 port aluminum or stainless steel explosion proof junction box with a clear viewing window.

Device DISPLAY

The UD10 is provided with a 160 x 100 dot matrix backlit LCD display. See Figure 1.

During normal operation, the LCD continuously displays the detected gas level, gas type, and units of measurement. The real time clock can also be displayed if desired.

The display shows the following alarm information:

•High gas alarm

•Low gas alarm

•Aux alarm

The display indicates the following fault information:

•Device fault

•Display fault

The UD10 has smart capabilities to allow easy access to the following information:

•Detector information

•Measurement range

•Alarm setpoints

•Alarm and event logs

For detailed HART menu structure, refer to the appropriate Appendix.

4.2 |

4 |

95-8661 |

Logging

Events that can be logged in the UD10 include:

•Calibration (Date, time and success Y/N are logged for detectors that do not provide their own calibration logging capabilities.)

Faults that are logged in the UD10 include:

•Detector fault

•Low power

•General fault

Alarms that are logged in the UD10 for gas detector inputs include:

•High gas alarm

•Low gas alarm

•Aux alarm.

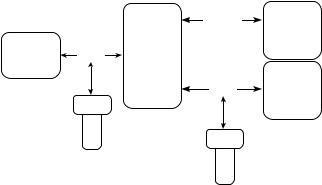

The UD10 has its own battery backed real time clock (RTC) and its own event logs. The RTC in the UD10 can be set from the UD10 display, Modbus or HART interfaces. The RTC in the gas detector (any HART detector having an RTC) can be set independently using the UD10 menu, or by using the synchronize command, which will set the detector RTC to the same time as the UD10 RTC. See Figure 3.

The UD10 can display the detector event and calibration logs (if available). The UD10 has its own 1,000 entry event log available under the Display Status >History >Event Log menu.

UD10 event logs can be read from the HART interface or the Modbus interface.

Detector calibration and event logs can also be read from the detector HART interface (where available).

|

|

MODBUS |

CONTROL |

|

|

or |

SYSTEM |

|

|

FOUNDATION FIELDBUS |

PLC/DCS |

|

|

|

|

GAS |

HART |

UD10 |

|

DETECTOR |

|

||

|

|

|

|

|

|

|

CONTROL |

|

|

HART |

SYSTEM |

|

|

PLC/DCS |

|

|

HART |

|

|

|

|

AMS |

|

|

Handheld |

|

|

|

|

|

|

|

|

HART |

|

|

|

Handheld |

|

important safety notes

CAUTIOn

The wiring procedures in this manual are intended to ensure proper functioning of the device under normal conditions. However, because of the many variations in wiring codes and regulations, total compliance to these ordinances cannot be guaranteed. Be certain that all wiring complies with the NEC as well as all local codes. If in doubt, consult the authority having jurisdiction before wiring the system. Installation must be done by a properly trained person.

CAUTIOn

This product has been tested and approved for use in hazardous areas. However, it must be properly installed and used only under the conditions specified within this manual and the specific approval certificates. Any device modification, improper installation, or use in a faulty or incomplete configuration will render warranty and product certifications invalid.

CAUTIOn

The device contains no user serviceable components. Service or repair should never be attempted by the user. Device repair should be performed only by the manufacturer.

LiabiLIties

The manufacturer’s warranty for this product is void, and all liability for proper function of the detector is irrevocably transferred to the owner or operator in the event that the device is serviced or repaired by personnel not employed or authorized by Detector Electronics Corporation, or if the device is used in a manner not conforming to its intended use.

Caution

Observe precautions for handling electrostatic sensitive devices.

caution

Unused conduit entries must be closed with suitably certified blanking elements upon installation.

Figure 3—UD10 Logging

4.2 |

5 |

95-8661 |

Installation

note

The gas detector housing must be electrically connected to earth ground. A dedicated earth ground terminal is provided on the UD10.

Note

Refer to the Model UD10 Safety Manual (number 95-8668) for specific requirements and recommendations applicable to the proper installation, operation, and maintenance of SILCertified Model UD10 displays.

The detector must always be installed per local installation codes.

Before installing the gas detector, define the following application details:

IdENTIFICATION of vapoR(s) to be detected

It is necessary to identify the vapor(s) of interest at the job site. The fire hazard properties of the vapor, such as vapor density, flashpoint, and vapor pressure should be identified and used to assist in selecting the optimum detector mounting location within the area.

For cross sensitivity information, refer to each gas detector’s corresponding instruction manual. Refer to Table 5 in the Specifications section for a list of gas detectors and their corresponding instruction manuals.

IdENTIFICATION of detector moUNTINg loCATIONS

Identification of the most likely leak sources and leak accumulation areas is typically the first step in identifying the best detector mounting locations. In addition, identification of air current/wind patterns within the protected area is useful in predicting gas leak dispersion behavior. This information should be used to identify optimum detector installation points.

If the vapor of interest is lighter than air, place the detector above the potential gas leak. Place the detector close to the floor for gases that are heavier than air. Note that air currents may cause a gas that is slightly heavier than air to rise under some conditions. Heated gases may also exhibit the same phenomenon.

The most effective number and placement of detectors varies depending on the conditions on site. The individual designing the installation must often rely on experience and common sense to determine the detector quantity and best locations to adequately protect the area. Note that it is typically advantageous to locate detectors where they are accessible for maintenance. Locations near excessive heat or vibration sources should be avoided.

Final suitability of possible gas detector locations should be verified by a job site survey.

The gas detector must be mounted with the sensor in the correct orientation as shown in Table 2.

If the UD10 faceplate is not correctly oriented, it can be rotated at 90 degree increments by pulling the electronic module from the four mounting posts that secure it to the junction box and repositioning it as desired. Note that the module is held in place by a compression fitting – no screws are involved.

|

Table 2—Device Orientation |

|

|

|

|

Device |

|

Orientation |

|

|

|

GT3000 |

|

Vertical with Sensor Pointing Down |

|

|

|

PIR9400 |

|

Horizontal |

|

|

|

PIRECL |

|

Horizontal |

|

|

|

OPECL |

|

Horizontal (Fixed to a vertical post) |

|

|

|

CGS |

|

Vertical with Sensor Pointing Down |

|

|

|

505/CGS |

|

Vertical with Sensor Pointing Down |

|

|

|

C706X |

|

Vertical with Sensor Pointing Down |

|

|

|

NTMOS |

|

Vertical with Sensor Pointing Down |

|

|

|

4.2 |

6 |

95-8661 |

WIRING

power SUPply requiremeNTS

Calculate the total gas detection system power consumption rate in watts from cold start-up. Select a power supply with adequate capability for the calculated load. Ensure that the selected power supply provides regulated and filtered 24 Vdc output power for the entire system. If a back-up power system is required, a float type battery charging system is recommended. If an existing source of 24 Vdc power is being utilized, verify that system requirements are met. The acceptable voltage range is 18-30 Vdc measured at the input to the UD10.

note

The power supply must meet the noise requirements for HART systems. If noise or ripple on the main power source could interfere with the HART function, an isolated power source (Figure 11) is recommended. (For detailed information regarding power supply specifications, refer to the HART Communication Foundation’s document “FSK Physical Layer Specification” HCF_SPEC-54.)

Wiring cable requiremeNTS

Always use proper cabling type and diameter for input power as well as output signal wiring. 14 to 18 AWG shielded stranded copper wire is recommended. Correct wire size depends on the device and wire length. Refer to the appropriate Appendix for additional information. The maximum cable length from power source to UD10 is 2000 feet. Maximum cable length from UD10 to sensor is 2000 feet.

note

The use of shielded cable in conduit or shielded armored cable is highly recommended. In applications where the wiring is installed in conduit, dedicated conduit is recommended. Avoid low frequency, high voltage, and non signaling conductors to prevent nuisance EMI problems.

caution

The use of proper conduit installation techniques, breathers, glands, and seals is required to prevent water ingress and/or maintain the explosion-proof rating.

ShIEld CoNNECTIONS

The UD10 provides terminals for proper grounding of wiring cable shields (located on the sensor, 4-20 mA, and operating power terminal blocks). These shield terminals are not connected internally, but are connected to ground through capacitors. The capacitors ensure an RF ground, while preventing 50/60 Hz ground loops.

Ground all shields as shown in the wiring examples throughout this manual.

important

For proper grounding, all junction boxes / metal enclosures must be connected to earth ground.

The following are required for installations requiring CE Mark compliance:

•For shielded cable installed in conduit, attach the wire shields to the “shield” connections on the terminal blocks, or to earth ground on the case.

•For installations without conduit, use double shielded cable. Terminate the outer shield to earth ground on the case. Terminate the inner shield to the “shield” connection on the terminal blocks.

JumpeR SeTTINg for 4-20 mA Loop

In order for the 4-20 mA current loop to operate properly, +24 Vdc must be applied to terminal P1-3. This can be accomplished in one of two ways:

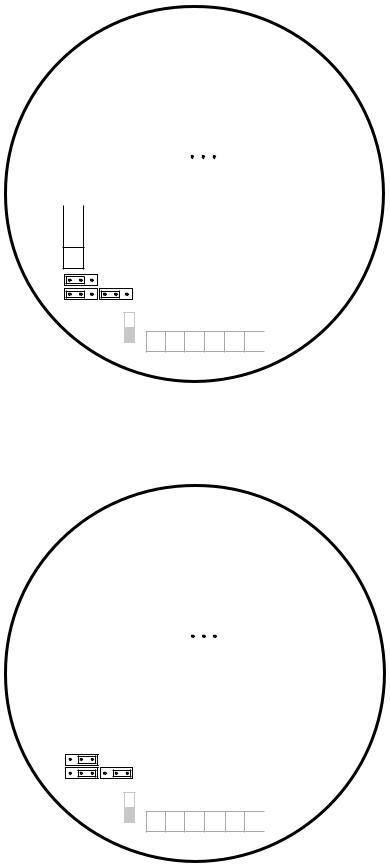

•For a non-isolated 4-20 mA loop, set jumper plug as shown in Figure 4. This applies +24 Vdc to P1-3 via an internal connection to terminals P2-2 and P2-5.

•If the 4-20 mA loop will receive power from a source other than the UD10’s main power source (isolated), set the jumper plug as shown in Figure 5 to remove the internal connection.

FoUNDATION FiEldbus (Optional)

Some UD10 models allow the use of either RS485/ MODBUS or Foundation Fieldbus communication via connection to J2 on the terminal board. Four jumpers are provided to select between the two protocols. If the device is equipped for Foundation Fieldbus, it will be shipped from the factory with the jumpers preset for that mode. If the user wants to switch to RS485/MODBUS (for example, to retrieve logs), the four jumpers can easily be moved. Figures 6 and 7 show the jumper settings for each mode of communication.

Note that the pin identification for the J2 connector is different for each communication protocol. For Foundation Fieldbus it is “– +”. For RS485/MODBUS it is “B A com”.

4.2 |

7 |

95-8661 |

Wiring Procedure

NOTE

The following section shows the output of the UD10 wired to a generic 4-20 mA signal receiver in various configurations. Since the UD10 can be used with a variety of different detection devices, information that is specific to each detector model (wiring, calibration, HART menus, etc.) is covered in an Appendix that is dedicated to that device. Refer to the appropriate Appendix at the back of this manual for specific information when wiring the detection system. For information on devices not covered in an Appendix, refer to the manual provided by the device’s manufacturer.

Figure 4 shows jumper plug P12 positioned to power the 4-20 mA loop from the main power source (non isolated output).

Figure 5 shows jumper plug P12 positioned for powering the 4-20 mA loop from an external wire/jumper of from a separate power source (isolated output).

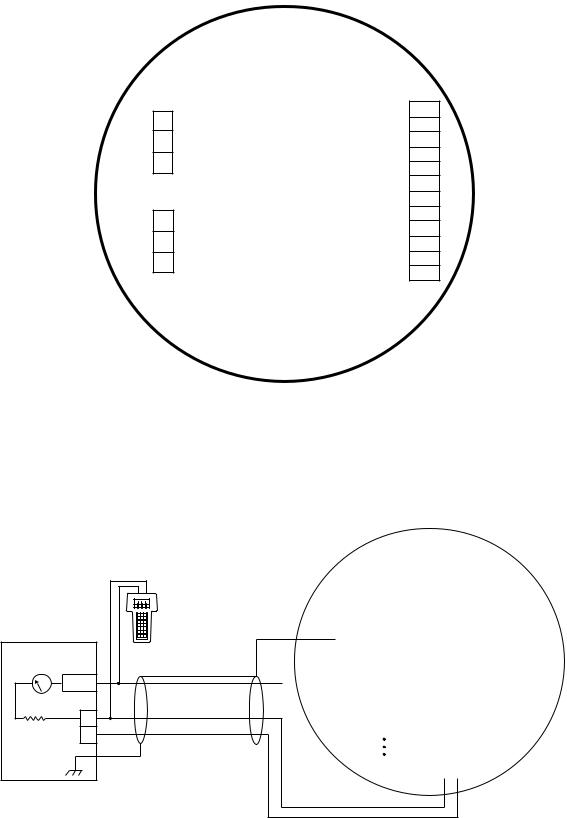

Figure 6 shows the correct jumper positions and J2 terminal identification for using Foundation Fieldbus communication.

Figure 7 shows the correct jumper positions and J2 terminal identification for using MODBUS communication.

Refer to Figure 8 for an illustration of the UD10 wiring terminal board (see Figure 6 for Foundation Fieldbus connections).

Figure 9 shows a UD10 Wired to a PLC using 3-Wire Shielded Cable with a 4-20 mA Non-Isolated Sourcing Output.

Figure 10 shows a UD10 Wired to a PLC using 4-Wire Shielded Cable with a 4-20 mA Non-Isolated Sourcing Output.

Figure 11 shows a UD10 Wired to a PLC with a 4-20 mA Isolated Sourcing Output.

GREASE/LUBRICATION

To ease installation and future removal, ensure that all junction box covers and sensor threads are properly lubricated. If the need arises for additional lubrication, use either Lubriplate grease (see Ordering Information for part number) or Teflon tape. Avoid the use of silicone grease.

WHEN P12 IS

IN THIS POSITION, P1-3 IS INTERNALLY CONNECTED TO P2-2 AND P2-5

Sensor Connector

|

|

|

|

|

-1 |

-2 |

-3 |

-4 |

-5 |

|

J3 |

|

|

|||||||

|

|

|

|

|

J3 |

|

J3 |

J3 |

|

J3 |

|

J3 |

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

SHIELD |

|

CALIBRATE |

24 VDC – |

|

4-20 mA |

|

24 VDC + |

|

|

|

|

|||

|

|

4-20 mA + |

|

|

HIGH ALARM COM |

J4-1 |

||||||||||||||

|

P1-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NC |

J4-2 |

||||

Output |

P1-2 |

4-20 mA – |

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NO |

J4-3 |

|||

Loop |

|

|

|

|

|

|

|

P3 |

|

|

|

|

|

|

|

|

|

AUX ALARM COM |

J4-4 |

|

Connector |

P1-1 |

SHIELD |

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NC |

J4-5 |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

P1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NO |

J4-6 |

|

|

J2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM COM |

J4-7 |

|

Fieldbus |

J2-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NC |

J4-8 |

|

Connector |

|

+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NO |

J4-9 |

|

J2-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT COM |

J4-10 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

J2-1 |

– |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NC |

J4-11 |

||

P5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NO |

J4-12 |

P9 |

|

|

|

|

|

–VDC24 |

|

+VDC24 |

|

|

SHIELD |

|

|

VDC24– |

|

+VDC24 |

|

SHIELD |

|

J4 |

|

|

|

|

P7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-6 |

|

-5 |

-4 |

|

-3 |

|

-2 |

|

-1 |

P2 |

|

|||

|

|

|

|

P12 |

|

P2 |

|

P2 |

|

P2 |

|

|

P2 |

|

P2 |

|

P2 |

|

|

|

Power Supply Connector

Relay Connector

B2525

WHEN P12 IS IN

THIS POSITION, A SEPARATE POWER SOURCE IS REQUIRED TO POWER THE

4-20 MA LOOP

Sensor Connector

|

|

|

|

|

|

|

|

|

|

-1 |

-2 |

-3 |

-4 |

-5 |

|

J3 |

|

||||

|

|

|

|

|

|

|

|

|

|

J3 |

|

J3 |

J3 |

|

J3 |

J3 |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

SHIELD |

|

CALIBRATE |

24 VDC – |

|

4-20 mA |

24 VDC + |

|

HIGH ALARM COM |

||

|

P1-3 |

4-20 mA + |

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NC |

|||||||

Output |

P1-2 |

4-20 mA – |

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NO |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||

Loop |

|

|

|

|

|

|

|

|

|

|

|

|

P3 |

|

|

|

|

|

|

AUX ALARM COM |

|

Connector |

P1-1 |

SHIELD |

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NC |

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

P1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NO |

|

|

|

J2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM COM |

|

Fieldbus |

|

J2-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NC |

|

Connector |

|

|

+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NO |

||

|

J2-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT COM |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J2-1 |

– |

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NC |

|||||

P5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

– |

|

|

|

|

FAULT NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

P9 |

|

|

|

|

|

|

|

|

P7 |

|

|

SHIELD |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

24VDC– |

|

24VDC+ |

|

24VDC |

|

24VDC+ |

|

SHIELD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

-6 |

|

-5 |

-4 |

|

-3 |

-2 |

|

-1 |

P2 |

|

|

|

|

|

|

|

|

|

P12 |

|

|

P2 |

|

P2 |

P2 |

|

P2 |

|

P2 |

|

P2 |

|

Power Supply Connector

J4-1 |

|

J4-2 |

|

J4-3 |

|

J4-4 |

Connector |

J4-5 |

|

J4-6 |

|

J4-7 |

Relay |

J4-8 |

|

J4-9 |

|

J4-10 |

|

J4-11 |

|

J4-12 |

|

J4 |

|

B2526

Figure 4—Position of Jumper P12 for Non-Isolated 4-20 mA Loop Output

Figure 5—Position of Jumper P12 for Isolated 4-20 mA Loop Output

4.2 |

8 |

95-8661 |

Sensor Connector

|

|

|

J3-1 |

J3-2 |

|

J3-3 |

J3-4 |

J3-5 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SHIELD |

CALIBRATE |

|

24 VDC – |

4-20 mA |

24 VDC + |

||

|

P1-3 |

4-20 mA + |

|

|

|

|

|

|

|

|

Output |

|

4-20 mA – |

|

|

|

|

|

|

|

|

P1-2 |

|

|

|

|

|

|

|

|||

Loop |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P3 |

|

|

|

|

||

|

|

|

|

|

|

|

||||

Connector |

P1-1 |

SHIELD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

P1 |

|

|

|

|

|

|

|

|

|

|

J2 |

|

|

|

|

|

|

|

|

|

Fieldbus |

|

|

|

|

|

|

|

|

|

|

J2-3 |

|

|

|

|

|

|

|

|

|

|

Connector |

|

|

|

|

|

|

|

|

|

|

J2-2 |

+ |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

J2-1 |

– |

|

|

|

|

|

P5 |

|

|

|

|

|

|

P9 |

P7 |

– |

+ |

SHIELD |

– |

+ |

|

|

24 VDC |

24 VDC |

24 VDC |

24 VDC |

|

|

P12 |

P2-6 |

P2-5 |

P2-4 |

P2-3 |

P2-2 |

|

|

|

|

|

|

J3

HIGH ALARM COM |

J4-1 |

||

HIGH ALARM NC |

|

||

J4-2 |

|||

|

|

||

HIGH ALARM NO |

J4-3 |

||

|

|

||

AUX ALARM COM |

J4-4 |

||

|

|

||

AUX ALARM NC |

J4-5 |

||

|

|

||

AUX ALARM NO |

J4-6 |

||

|

|

||

LOW ALARM COM |

J4-7 |

||

|

|

||

LOW ALARM NC |

J4-8 |

||

|

|

||

LOW ALARM NO |

J4-9 |

||

|

|

|

|

|

|

FAULT COM |

J4-10 |

|

|

|

|

|

|

FAULT NC |

J4-11 |

|

|

FAULT NO |

|

|

|

J4-12 |

|

|

|

|

|

|

|

|

J4 |

SHIELD |

|

|

|

-1 |

|

P2 |

|

|

|

||

P2 |

|

|

|

|

|

|

|

|

|

|

|

Relay Connector

NOTE: FOUNDATION FIELDBUS IS AVAILABLE ON SELECT MODELS. REFER TO THE MODEL MATRIX IN THE ORDERING INFORMATION SECTION FOR DETAILS.

|

Power Supply Connector |

JUMPERS P3, P5, P7, AND P9 MUST BE POSITIONED AS SHOWN |

|

|

|

C2527 |

|

FOR FOUNDATION FIELDBUS COMMUNICATION |

Figure 6—Foundation Fieldbus Communication

Sensor Connector

|

|

|

J3-1 |

J3-2 |

|

J3-3 |

J3-4 |

J3-5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SHIELD |

CALIBRATE |

|

24 VDC – |

4-20 mA |

24 VDC + |

|

|

P1-3 |

4-20 mA + |

|

|

|

|

|

|

|

Output |

|

4-20 mA – |

|

|

|

|

|

|

|

P1-2 |

|

|

|

|

|

|

|||

Loop |

|

|

|

|

|

|

|

||

|

|

|

|

P3 |

|

|

|

||

|

|

|

|

|

|

||||

Connector |

P1-1 |

SHIELD |

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

P1 |

|

|

|

|

|

|

|

|

|

J2 |

|

|

|

|

|

|

|

|

MODBUS |

J2-3 |

COM |

|

|

|

|

|

|

|

Connector |

|

RS485 A |

|

|

|

|

|

|

|

J2-2 |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|||

|

|

RS485 B |

|

|

|

|

|

|

|

|

J2-1 |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

P5 |

|

|

|

|

|

|

P9 |

P7 |

– |

+ |

SHIELD |

– |

+ |

|

|

24 VDC |

24 VDC |

24 VDC |

24 VDC |

|

|

P12 |

P2-6 |

P2-5 |

P2-4 |

P2-3 |

P2-2 |

|

|

|

|

|

|

J3

HIGH ALARM COM |

J4-1 |

||

HIGH ALARM NC |

|

||

J4-2 |

|||

|

|

||

HIGH ALARM NO |

J4-3 |

||

|

|

||

AUX ALARM COM |

J4-4 |

||

|

|

||

AUX ALARM NC |

J4-5 |

||

AUX ALARM NO |

J4-6 |

||

|

|

||

LOW ALARM COM |

J4-7 |

||

|

|

||

LOW ALARM NC |

J4-8 |

||

LOW ALARM NO |

J4-9 |

||

|

|

|

|

|

|

FAULT COM |

J4-10 |

|

|

|

|

|

|

FAULT NC |

J4-11 |

|

|

FAULT NO |

|

|

|

J4-12 |

|

|

|

|

J4 |

SHIELD |

|

|

|

-1 |

|

P2 |

|

|

|

||

P2 |

|

|

|

|

|

|

|

|

|

|

|

Relay Connector

|

Power Supply Connector |

JUMPERS P3, P5, P7, AND P9 MUST BE POSITIONED AS SHOWN |

|

|

|

B2528 |

|

FOR MODBUS/RS485 COMMUNICATION |

Figure 7—MODBUS Communication

4.2 |

9 |

95-8661 |

Output Loop

Connector

P1-3 4-20 mA +

P1-2 4-20 mA –

P1-1 SHIELD

P1

J2

J2-3 COM

J2-2 RS485 A

J2-1 RS485 B

MODBUS

Connector

Sensor Connector

-1 |

-2 |

-3 |

-4 |

-5 |

|

J3 |

|

|||||

J3 |

|

J3 |

|

J3 |

|

J3 |

|

J3 |

|

|

||

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

SHIELD |

CALIBRATE |

|

24 VDC – |

|

4-20 mA |

|

24 VDC + |

HIGH ALARM COM |

||||

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NC |

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NO |

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM COM |

||

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NC |

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NO |

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM COM |

||

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NC |

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NO |

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT COM |

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NC |

|

– |

+ |

|

SHIELD |

|

– |

+ |

|

SHIELD |

FAULT NO |

||

|

24 VDC |

|

24 VDC |

|

|

24 VDC |

|

24 VDC |

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-6 |

|

-5 |

|

-4 |

|

-3 |

|

-2 |

|

-1 |

P2 |

|

P2 |

|

P2 |

|

P2 |

|

P2 |

|

P2 |

|

P2 |

|

|

|

|

|

|

|

|

||||||

Power Supply Connector

J4-1

J4-2

J4-3

J4-4

J4-5

J4-6

J4-7

J4-8

J4-9

J4-10

J4-11

J4-12

J4

Relay Connector

C2399

Figure 8—Wiring Terminals on UD10 Terminal Board

PLC 4-20 mA INPUT CARD

|

INPUT |

4-20 mA |

|

|

– |

250-600 |

24 VDC |

OHMS |

+ |

Notes: Resistor may be external if voltage input card is used. Sinking resistance at PLC must be 250-600 ohms

for HART communication.

UD10

DISPLAY UNIT

Sensor Connector

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-1 |

-2 |

-3 |

-4 |

|

|

-5 |

|

|

|

J3 |

|

|

|

||||||||

|

|

|

|

|

J3 |

|

J3 |

|

J3 |

|

J3 |

|

J3 |

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||||||||

Output Loop |

SHIELD |

|

CALIBRATE |

|

VDC24 – |

|

20-4mA |

|

VDC24 + |

|

|

|

|

|

||||||||||||

Connector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

4-20 mA + |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM COM |

J4-1 |

|

|||

|

P1-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NC |

J4-2 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

P1-2 |

4-20 mA – |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NO |

J4-3 |

|

|||

|

P1-1 |

SHIELD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM COM |

J4-4 |

Connector |

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NC |

J4-5 |

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

P1 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NO |

J4-6 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM COM |

J4-7 |

Relay |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

COM |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NC |

J4-8 |

||||

|

J2-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

RS485 A |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NO |

J4-9 |

|

|||

|

J2-2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT COM |

J4-10 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J2-1 |

RS485 B |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NC |

J4-11 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NO |

|

|

||||

|

|

|

|

|

|

|

– |

+ |

|

SHIELD |

|

|

– |

+ |

|

SHIELD |

J4-12 |

|

||||||||

|

MODBUS |

|

|

|

|

|

|

|

||||||||||||||||||

|

|

|

VDC24 |

|

VDC24 |

|

|

|

VDC24 |

|

|

VDC24 |

|

|

J4 |

|

||||||||||

|

Connector |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-6 |

|

-5 |

|

-4 |

|

-3 |

|

-2 |

|

-1 |

P2 |

|

|

|||||||

|

|

|

|

|

|

|

P2 |

|

P2 |

|

P2 |

|

|

P2 |

|

|

P2 |

|

P2 |

|

|

|||||

|

|

P12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

Power Supply Connector

D2439

Figure 9—UD10 Wired to PLC using 3-Wire Shielded Cable with 4-20 mA Non-Isolated Sourcing Output

4.2 |

10 |

95-8661 |

UD10

DISPLAY UNIT

Sensor Connector

|

|

Output Loop |

|

|

|

Connector |

|

|

|

P1-3 |

4-20 mA + |

|

|

P1-2 |

4-20 mA – |

PLC 4-20 mA INPUT CARD |

P1-1 |

SHIELD |

|

|

|

||

|

|

P1 |

|

|

|

J2 |

|

|

INPUT |

J2-3 |

COM |

|

|

|

|

4-20 mA |

J2-2 |

RS485 A |

|

|

|

||

|

– |

J2-1 |

RS485 B |

|

|

|

|

250-600 |

24 VDC |

MODBUS |

|

OHMS |

+ |

Connector |

|

|

|

|

P12 |

Notes: Resistor may be external if voltage input card is used. Sinking resistance at PLC must be 250-600 ohms

for HART communication.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-1 |

-2 |

-3 |

-4 |

|

-5 |

|

|

J3 |

|

|

||||||||

J3 |

|

J3 |

|

J3 |

|

J3 |

|

J3 |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|||||||||||

SHIELD |

|

CALIBRATE |

|

24 VDC – |

|

4-20 mA |

|

24 VDC + |

|

|

|

|

||||||

|

HIGH ALARM COM |

J4-1 |

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NC |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J4-2 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

HIGH ALARM NO |

J4-3 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM COM |

J4-4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NC |

J4-5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

AUX ALARM NO |

J4-6 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM COM |

J4-7 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NC |

J4-8 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

LOW ALARM NO |

J4-9 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT COM |

J4-10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NC |

J4-11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

FAULT NO |

|

|

|

– |

+ |

|

|

|

|

– |

+ |

|

|

J4-12 |

||||||

|

|

|

SHIELD |

|

|

|

SHIELD |

|

|

|||||||||

|

|

VDC24 |

|

VDC24 |

|

|

|

VDC24 |

|

|

VDC24 |

|

|

J4 |

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-6 |

|

-5 |

|

-4 |

|

-3 |

|

-2 |

|

-1 |

P2 |

|

|||||

|

|

P2 |

|

P2 |

|

P2 |

|

|

P2 |

|

|

P2 |

|

P2 |

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Power Supply Connector

Relay Connector

E2440

Figure 10—UD10 Wired to PLC using 4-Wire Shielded Cable with 4-20 mA Non-Isolated Sourcing Output

UD10

DISPLAY UNIT

Sensor Connector

|

|

Output Loop |

|

|

|

Connector |

|

|

|

P1-3 |

4-20 mA + |

|

|

P1-2 |

4-20 mA – |

PLC 4-20 mA INPUT CARD |

P1-1 |

SHIELD |

|

|

|

||

|

|

P1 |

|

|

|

J2 |

|

|

INPUT |

J2-3 |

COM |

|

|

|

|

4-20 mA |

J2-2 |

RS485 A |

|

|

|

||

|

– |

J2-1 |

RS485 B |

|

|

|

|

250-600 |

24 VDC |

MODBUS |

|

OHMS |

+ |

Connector |

|

|

|

|

P12 |

Notes: Resistor may be external if voltage input card is used. Sinking resistance at PLC must be 250-600 ohms

for HART communication.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

-1 |

-2 |

-3 |

-4 |

|

-5 |

|

|

J3 |

|

|

|

||||||||

J3 |

|

J3 |

|

J3 |

|

J3 |

|

J3 |

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|