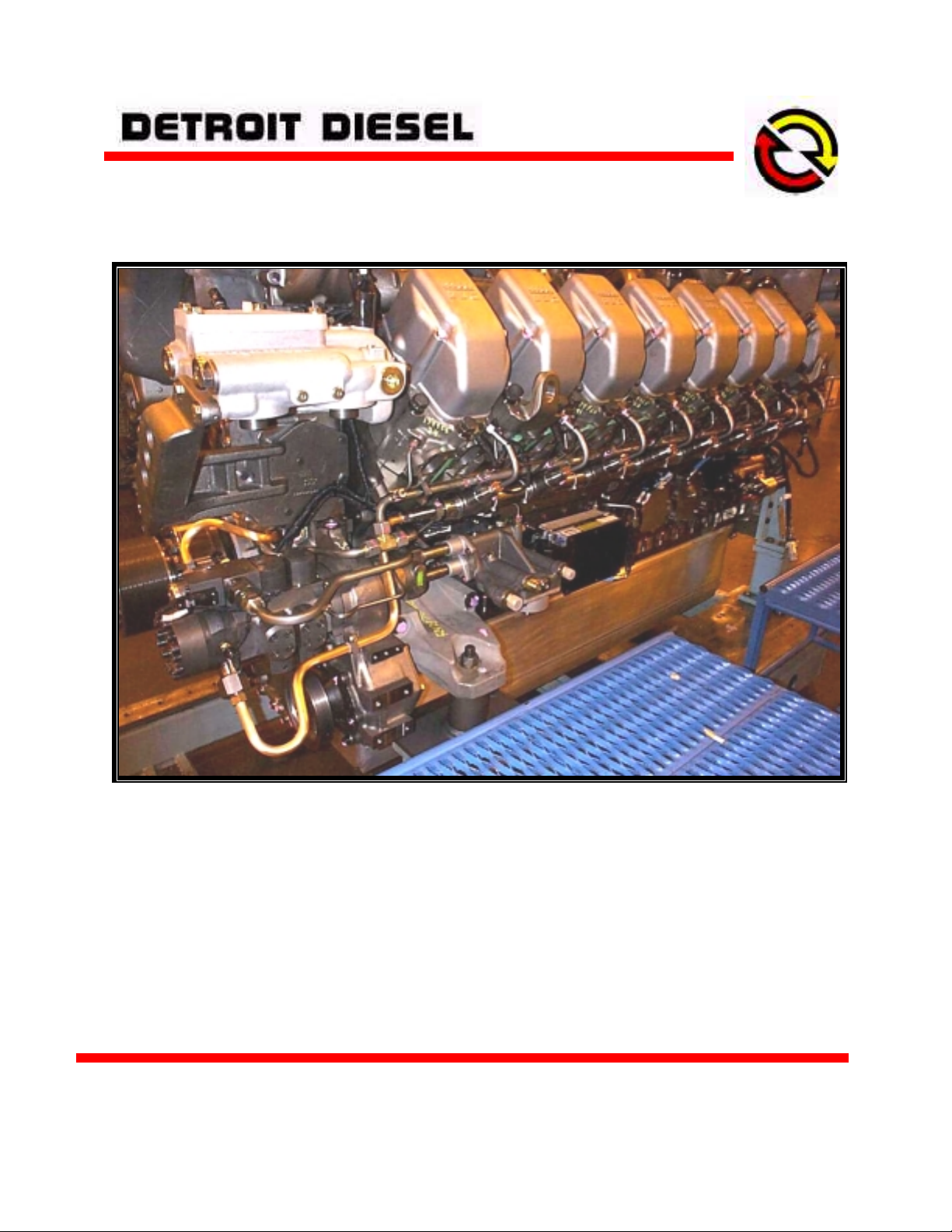

Page 1

®

TTEECCHHNNIICCIIAANN GGUUIIDDE

E

SSEER

RIIEESS 44000000

UEELL SSYYSSTTEE

FFU

C

C

O

O

M

M

M

M

O

O

M

M

N

N

R

AIILL

R

A

Page 2

Page 3

AATTTTEENNTTIIOONN

TThhiiss bbuulllleettiinn iiss aa gguuiiddeelliinnee ffoorr qquuaalliiffiieedd ppeerrssoonnnneell.. TThhee iinnffoorrmmaattiioonn ccoonnttaaiinneedd iinn tthhiiss

bbuulllleettiinn mmaayy nnoott bbee ccoommpplleettee aanndd iiss ssuubbjjeecctt ttoo cchhaannggee wwiitthhoouutt nnoottiiccee..

Page 4

Page 5

Page 6

Cautions

WORK SAFELY

!

CAUTION:

The service procedures

recommended by Detroit Diesel

Corporation and described in this

Technicians Guide are effective

methods of performing service and

repairs. Some of these procedures

require the use of tools specially

designed for this purpose.

Accordingly, anyone who intends to

use a replacement part, service

procedure or tool which is not

recommended by Detroit Diesel

Corporation must first determine that

neither their safety nor the safe

operation of the engine will be

jeopardized by the replacement part,

service procedure or tool selected.

This Technician’s Guide contains

various work procedures that must

be carefully observed in order to

reduce the risk of personal injury

during service or repair or the

possibility that improper service or

repair may damage the engine or

render it unsafe. It is also important

to understand that these work

procedures are not exhaustive,

because it is impossible for Detroit

Diesel Corporation to warn of all the

possible hazardous consequences

that might result from failure to follow

these instructions.

A service technician can be severely

injured if caught in the pulleys, belts

or rotating parts of an engine that is

accidentally started. To avoid

personal injury, take this precaution

before starting to work on an engine:

Disconnect the battery from the

starting system by removing one or

both of the battery cables

(disconnect negative [ground] cable

first). With the electrical circuit

disrupted, accidental contact with the

starter button will not produce an

engine start.

Follow all lockout procedures as

required.

i

Page 7

SAFETY PRECAUTIONS TO OBSERVE WHEN

WORKING ON THE ENGINE

1. Consider the hazards of the job and

wear protective gear such as safety

glasses, safety shoes, hard hats,

hearing protection, etc. to provide

adequate protection.

2. When using a lifting device, make

sure the lifting device is fastened

securely. Be sure the item to be

lifted does not exceed the capacity of

the lifting device.

3. Always use caution when using

power tools.

4. When using compressed air to clean

a component, such as flushing a

radiator or cleaning an air cleaner

element, use a safe amount of air.

Too much air can rupture or in some

other way damage a component and

create a hazardous situation that can

lead to personal injury. Always wear

adequate eye protection (safety

glasses, safety face shield) when

working with compressed air.

5. To avoid possible personal injury

when working with chemicals, steam

and/or hot water, wear adequate

protective clothing (face shield,

rubber apron, gloves, boots, etc.)

work in a well ventilated area, and

exercise caution.

6. Avoid the use of carbon tetrachloride,

carbon dissolved, methylene, chloride,

perchloroethylene and

trichloroethylene

as cleaning agents because of harmful

vapors they release. Use 1.1.1 –

trichlorethane.

Cautions

However, while less toxic than other

chlorinated solvents, use it with

caution. Be sure the work area is

adequately ventilated and wear

protective gloves, goggles or face

shield and an apron. Follow

chemical manufacturer’s use and

safety recommendations.

Mineral spirits or mineral spirits

based solvents are highly flammable.

They must be stored and used in “No

Smoking” areas away from sparks

and open flames.

7. Do not weld on or near the diesel fuel

tank until it has been thoroughly

emptied and ventilated. Possible

explosion could result if this

precaution is not taken.

8. Failure to inspect parts thoroughly

before installation, failure to install

the proper parts or failure to install

parts properly can result in

component or engine mal-function

and/or damage and may also result in

personal injury.

9. When working on an engine that is

running, accidental contact with the

hot exhaust manifolds or

turbochargers can cause severe

burns. Avoid making contact across

the two terminals of a battery, which

can result in severe arcing.

10. Turbocharger air inlet shields should

be used if operation of the

turbocharger is necessary without

normal piping, to avoid injury.

ii

Page 8

Series 4000 Fuel System Technician Guide

Table of Contents

INTRODUCTION 1

SAFETY 1

DESCRIPTION OF FUEL SYSTEM 3

COMMON RAIL FUEL SYSTEM OPERATION 5

DETROIT DIESEL ELECTRONIC CONTROL (DDECIV) 9

COMPONENT REVIEW (INDEX) 15

• HIGH-PRESSURE FUEL PUMP 17

• LOW-PRESSURE DELIVERY FUEL PUMP 25

• ELECTRONIC UNIT INJECTOR 31

• FUEL RAILS AND LINES 37

• FLOW LIMITER VALVES 53

• C&I FUEL JUNCTION BLOCK AND SECONDARY FILTERS 57

• MARINE SECONDARY FUEL FILTERS 61

• ECM COLD PLATE (S) 63

• FUEL LEAK MONITOR SYSTEM (MARINE) 65

• DDEC SENSORS 67

FUEL SYSTEM PLUMBING REQUIREMENTS 68

DAVCO FUEL PRO FILTERS 70

FUEL SYSTEM PRIMING PROCEDURE 72

FUEL SYSTEM TROUBLE SHOOTING 74

TORQUE SPECIFICATIONS FOR FUEL SYSTEM COMPONENTS 78

SERVICE PUBLICATIONS 80

NOTES

Page

Page 9

Series 4000 Fuel System Technician Guide

INTRODUCTION

The purpose of a properly designed fuel system is to provide clean fuel,

free from air, water or dirt, and to deliver fuel to the engine at correct amounts for

good combustion to provide optimum power, fuel economy and emissions

compliance.

A unique feature of the Series 4000 is the common rail fuel injection system.

This system relies on a single high-pressure fuel pump that provides a continuous

supply of fuel, at injection pressure, to all of the injectors at all times. This common

rail fuel system does not require cam driven unit injectors or injection pumps with

separate cam driven plungers to make fuel pressure for each injector. The unit

injectors in the Series 4000 common rail fuel system do not make fuel pressure.

DDECIV Electronics alone control injector timing, the amount of fuel and

atomization of fuel being supplied from the high-pressure rails. The Common Rail

Fuel System provides the Series 4000 with the most advanced fuel system

technology available today.

The Common Rail Fuel System consists of many unusual components not

found in other diesel fuel systems. Therefore, the Fuel System Technician Guide is

intended to help better understand the Common Rail Fuel System operation and

components as well as provide failure analysis to properly maintain this unique

system for maximum performance.

This manual is applicable to all engine sizes and product applications of the

Series 4000 and is intended to be expanded upon, as additional information

becomes available. It is also a good place for the technician to add helpful notes

on the fuel system for future reference.

SAFETY

Safety is always our first concern. To guard against safety mishaps while

working on the common rail fuel system, there are a couple of areas of caution to

be noted:

The common rail fuel system operates at pressures up to 19.6 KPSI (19,000

PSI). Fuel at this pressure can be very hazardous causing bodily injury or fire if

proper repair procedures are not followed. Fuel under high pressure creates a very

fine spray, which can penetrate the skin or cut! Appropriate safety equipment

should be worn to prevent injury. NEVER ATTEMPT REPAIRS OF HIGHPRESSURE FUEL LEAKS WHILE AN ENGINE IS IN OPERATION!

Under certain conditions the high-pressure fuel lines from the high-pressure

fuel rail to the injectors can become heated from combustion gases. Care should

be taken to prevent the possibility of burns from excessive contact with theses fuel

lines.

Page 1

Page 10

Page 2

Page 11

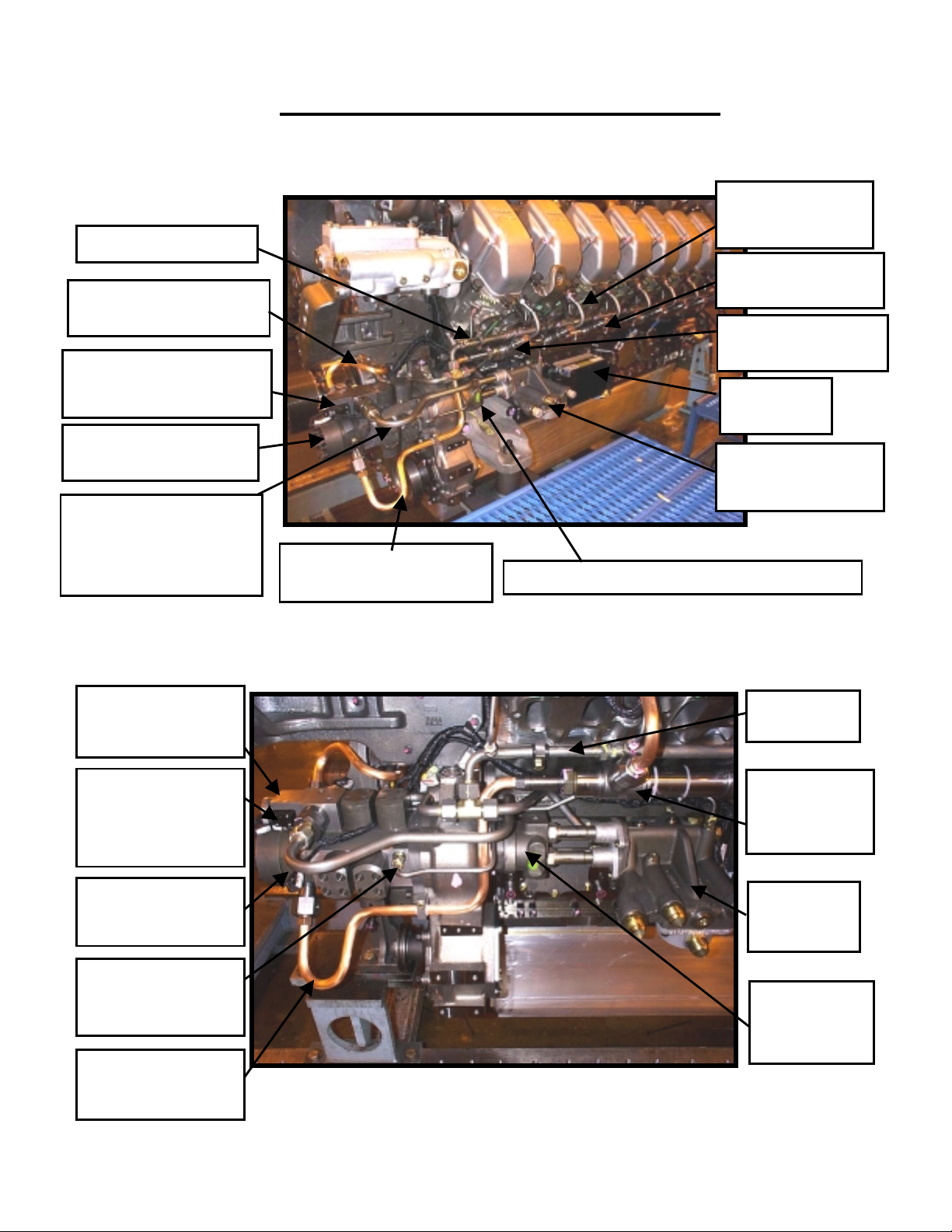

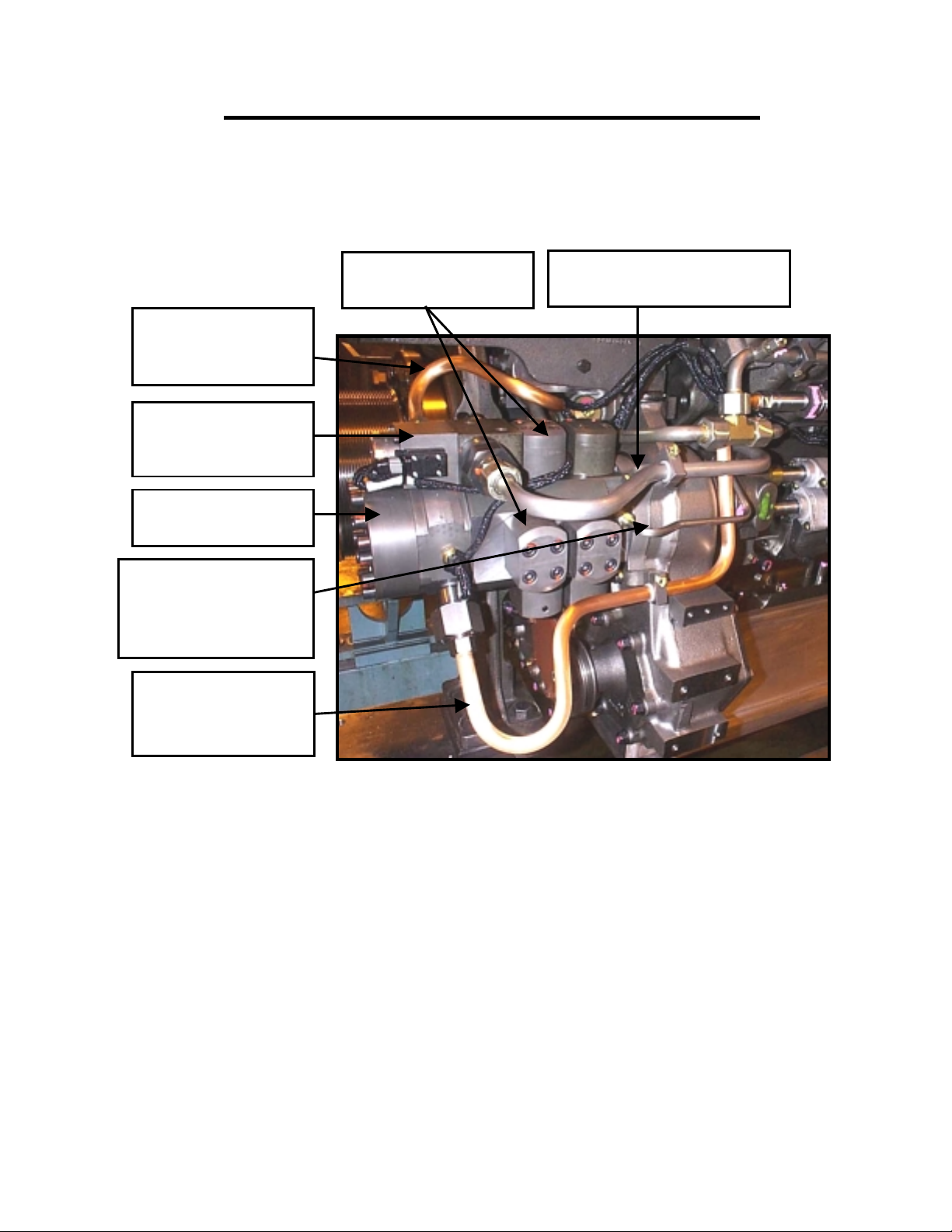

Common Rail Fuel System - A Bank

FUEL RETURN RAIL

Description of Fuel System

HIGH PRESSURE

INJECTOR FUEL

LINE

HIGH-PRESSURE FUEL

LINE TO B BANK RAIL

HIGH-PRESSURE FUEL

PUMP CONTROLLER

SOLENOID

HIGH-PRESSURE

HIGH-

FUEL PUMP

PRESSURE

LOW-PRESSURE FUEL

SUPPLY LINE FROM

FUEL JUNCTION

BLOCK TO HP PUMP

CONTROL SOLENOID

HIGH-PRESSURE

PUMP CONTROL

SOLENOID

Fig. 1

HIGH-PRESSURE FUEL

LINE TO A BANK RAIL

LOW-PRESSURE FUEL DELIVERY PUMP

Fuel Delivery System - A Bank

HIGH-PRESSURE

FUEL RAIL

FLOW LIMITER

VALVE LOCATION

ECM COLD

PLATE (S)

FUEL JUNCTION

BLOCK AND

FILTER ADAPTOR

RETURN

FUEL RAIL

DDEC

CONNECTION TO

HIGH-PRSSURE

PUMP CONTROL

LOW-PRESSURE

FUEL SUPPLY TO

HP PUMP

HP PUMP RETURN

FUEL TO FUEL

JUNCTION BLOCK

HIGH-PRESSURE

FUEL LINE TO A

Page 3

BANK RAIL

Fig. 2

HIGHPRESSURE

FUEL RAIL

CONNECTOR

FUEL

JUNCTION

BLOCK

LOWPRESSURE

DELIVERY

FUEL PUMP

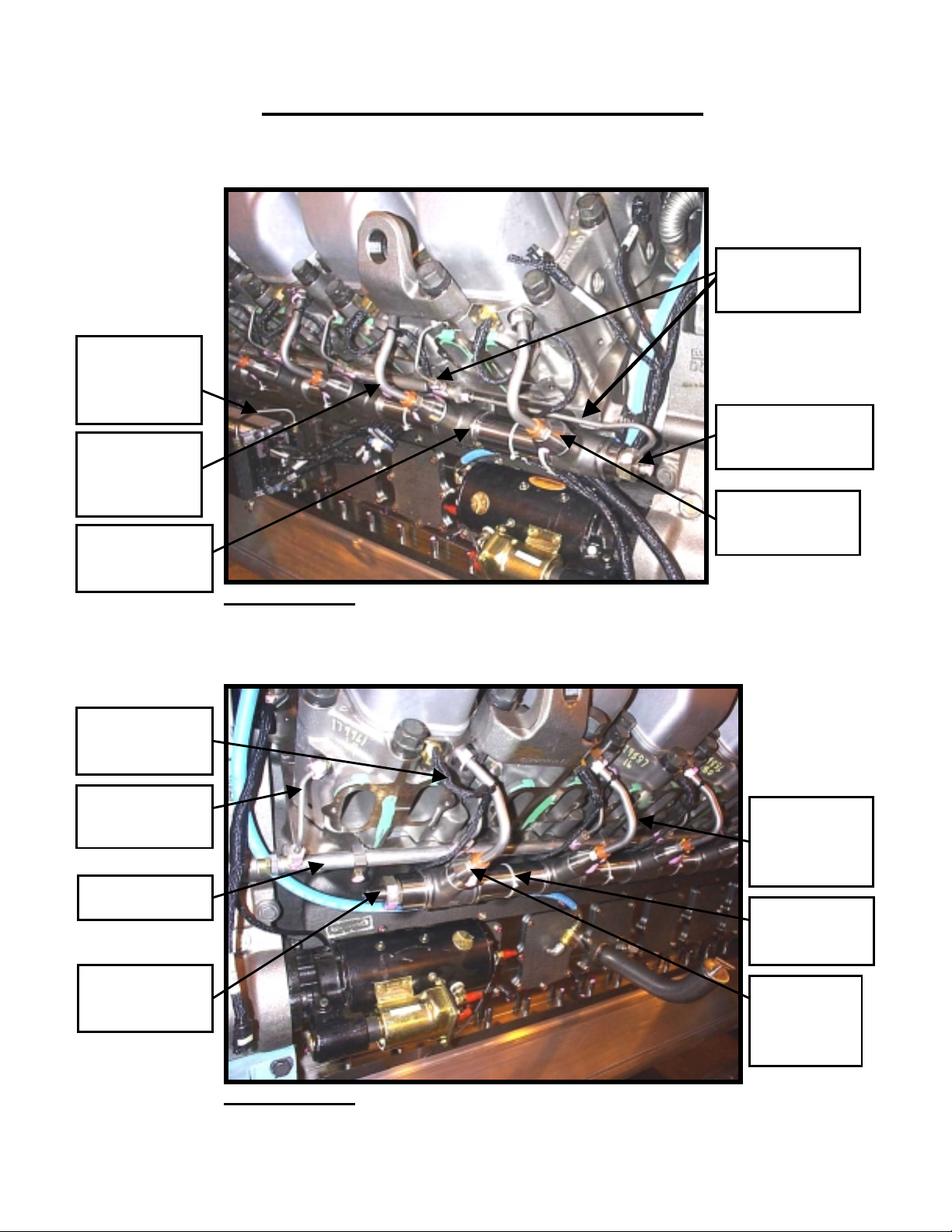

Page 12

U

V

OC

ECM COLD

PLATE

CROSSOVER LINE

HIGHPRESSURE

INJECTOR

FUEL LINE

HIGHPRESSURE

FUEL RAIL

Description of Fuel System

High-pressure Rail - A Bank

FUEL RETURN

LINES TO FUEL

RET

RN RAIL

HIGH-PRESSURE

RAIL RELIEF

ALVE

FLOW LIMITER

VALVE

L

ATION

Rear of Engine Fig. 3

High-pressure Rail B Bank

DDEC WIRING

HARNESS TO

INJECTOR

INJECTOR

FUEL RETURN

FUEL

HIGHPRESSURE

RAIL END

Rear of Engine Fig. 4

Page 4

HIGHPRESSURE

NJECTOR

I

FUEL LINE

HIGHPRESSURE

FUEL RAIL

FLOW

LIMITER

VALVE

LOCATION

Page 13

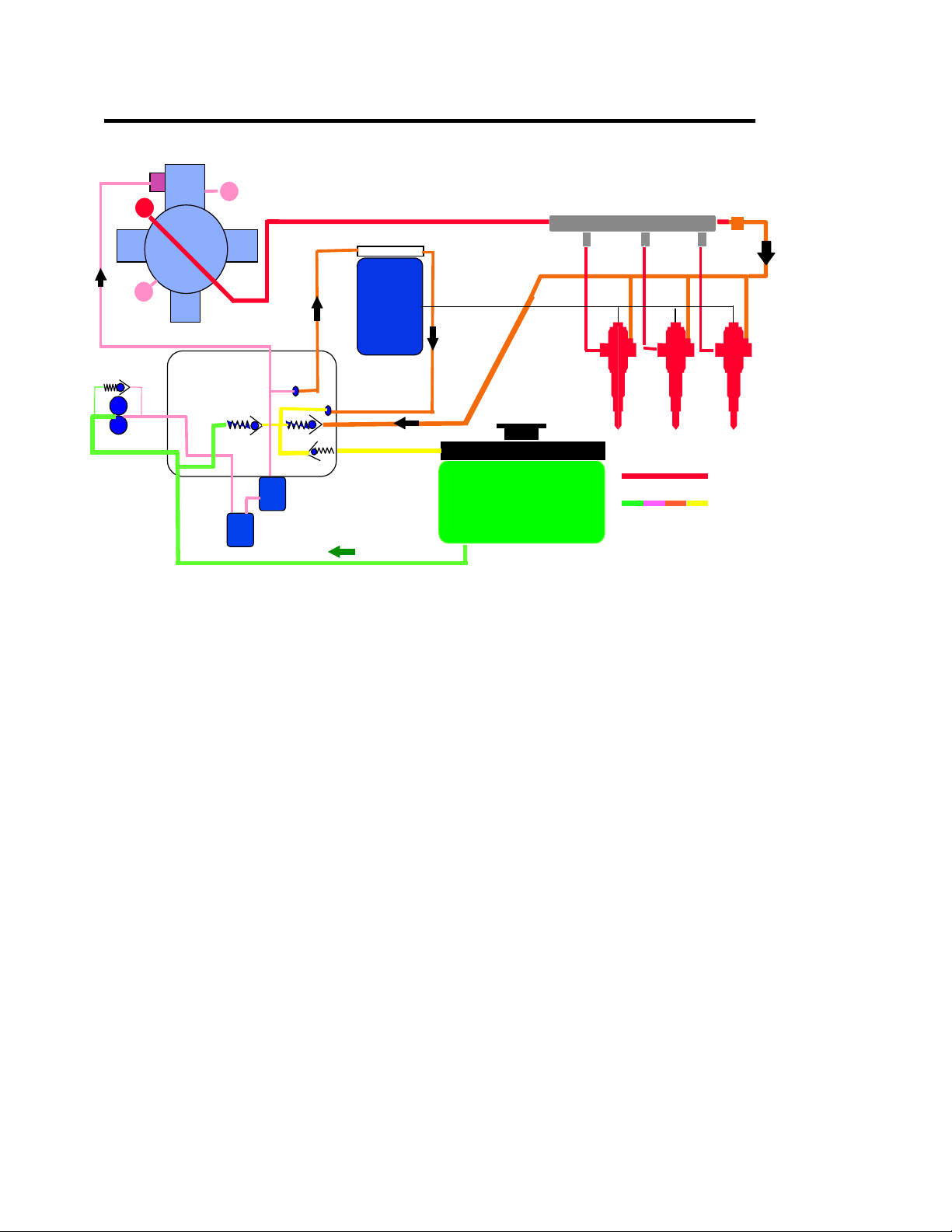

Com m on Rail Fuel System Operation

Limiter Safety

Limiting Safety

Valve 19.6 KPSI

Valve 1350 Bar

HP

LP

Common Rail

6.8 Bar

LT

High

Pressure

Pump

Fuel filter

Housing

1.7 Bar

2.0 Bar

DDEC IV

DDEC IV

ECM

ECM

Flow

Limiter

Injecto rs

.1 Bar

Fuel filters

Pro 40

Fuel Tank

The Common Rail Fuel System used on the Series 4000 is a two-stage fuel

distribution system. Gear driven fuel pumps maintain constant fuel supply

pressure. This pressure is supplied to the common rails then to all injectors.

Constant high-pressure is available regardless of crankshaft position or engine

speed.

The first stage is the fuel transfer side which brings fuel from the fuel tank,

through the filters, and provides low-pressure fuel supply of 65 PSI at idle to 85 PSI

at full load to the second stage high pressure system. Additionally, low-pressure

fuel is sent to the ECM Cold Plates to protect the ECM's from excessive heat (Refer

to page 63). An OEM supplied fuel cooler should be incorporated in the fuel system

to assist the cooling function for the ECM’s. Additionally, low-pressure fuel is used

for cooling and lubrication in the high-pressure fuel pump. However, unlike other

fuel systems, fuel temperature has no affects on engine power or performance due

to the extremely high fuel operating pressure, which prevents the fuel from boiling

and vaporizing.

The high-pressure system receives the low-pressure fuel at the control

regulator and further pressurizes it in the high-pressure pump from (8.3 KPSI at

idle to 17.4 KPSI) for non-low flow injectors and (7.25KPSI at idle to 13.1KPSI) for

low flow injectors at maximum load conditions to the high-pressure rails. (Refer to

page 17). Fuel pressure at Full No-Load averages about 11.4 KPSI. A 19.6 KPSI

safety-relief valve on the A-bank rail protects the fuel system components from

damage due to excessive pressure.

Page 5

H. Pr Line

L. Pr Line

Fig. 5

Page 14

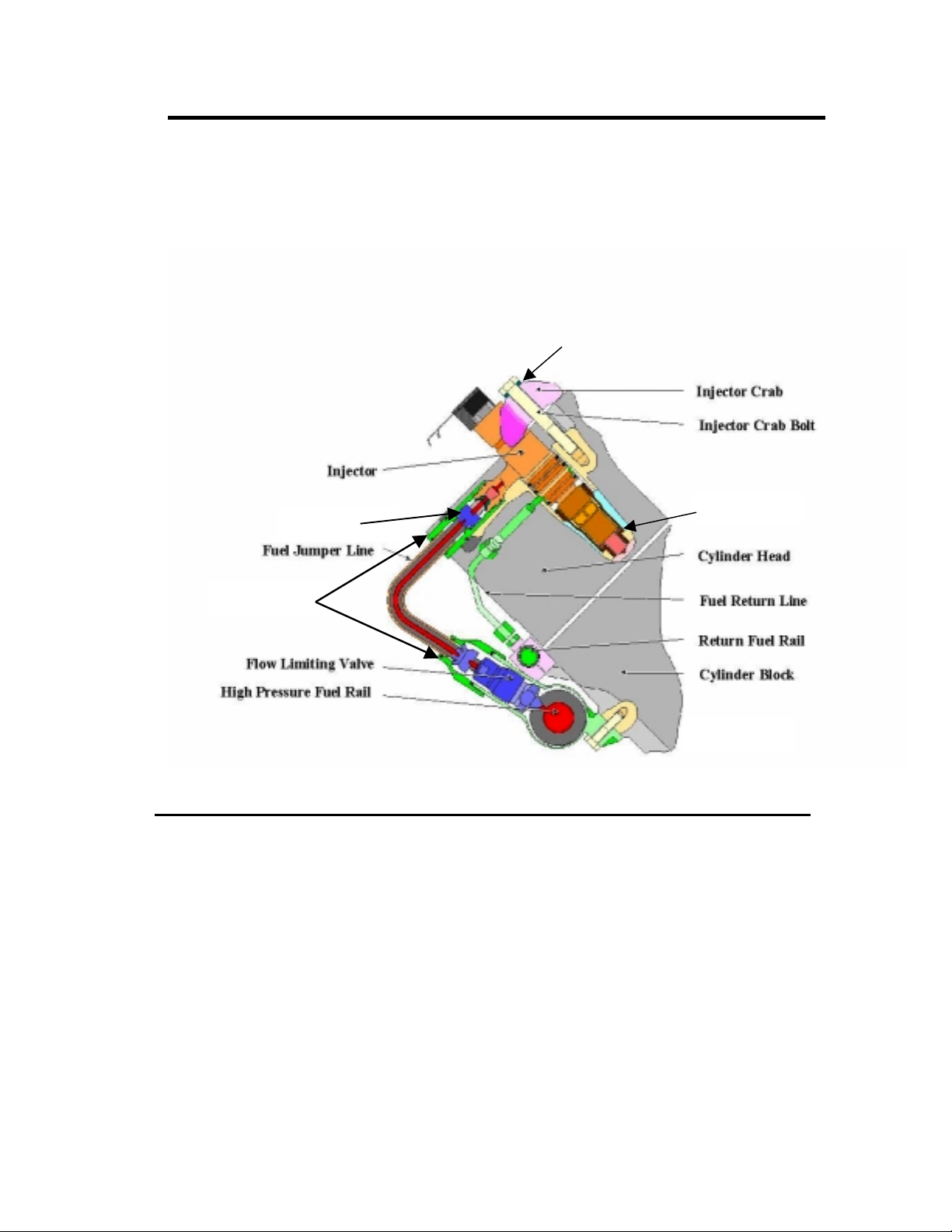

Common Rail Fuel System Operation

High-pressure fuel as received at each injector provides lubrication and

cooling of the injectors while awaiting the DDECIV signal from the ECM’s to the

injector solenoid to start the injection event. Approximately 90% of the fuel

received at the injectors is injected into the engine cylinder for combustion, while

10% of the fuel is returned to the fuel tank under full load conditions.

Washer

Inlet Filter

Retaining Nut

C-E Ring

Fig. 6

CROSS SECTION VIEW OF FUEL SYSTEM AT CYLINDER HEAD

The high-pressure fuel rails provide continuous pressure at all times to all

injectors within the engine. The high-pressure fuel rail at each cylinder location is a

port, which is fitted with a flow-limiter valve. High-pressure fuel passes from the

stainless steel high-pressure rails through flow limiter valves to the injectors. The

flow limiter valves operate by sensing fuel flow differential, which can shut off the

flow of fuel to prevent excessive over fueling of a cylinder in the event of a faulty

injector (Refer to page 53).

All of the joints from the high-pressure rail to the flow limiter valves to the

injectors are conical shaped metal-to-metal sealing (Refer to page 37).

Page 6

Page 15

Common Rail Fuel System Operation

V

The high-pressure fuel line to the injectors is double walled with an air gap

between the stainless steel inner tube and the outer copper protective tube (Refer

to page 44). This air gap is also a vent from the injector providing early warning of

poor injector C-E Ring sealing. The injector has a vent hole drilled in the body from

below the lower O-ring land out through the injector arm to the high-pressure line

joint surface, which aligns with the air gap in the high-pressure fuel line (Refer to

page 31).

The injector is retained in the cylinder head hole tube by the injector hold

down clamp and retaining bolt. The clamp load provided by this hold down crab

and bolt works with the C-E Ring located at the injector nozzle to provide a

compression seal with the injector hole tube inner surface. The high-pressure

injector fuel line fittings are held in position to the tube by retaining nuts on each

end (Refer to page 44). These retaining nuts have reverse threads, which requires a

special tool for installation.

At the inlet of the injector, recessed in the arm, is an inlet filter screen. This

screen is a safety element intended to trap foreign material, which could find its

way to the injector. The injector assembly has three O-ring seals between the

injector body and the cylinder head to control the flow of the return fuel from the

injector into the cylinder head return passage (Refer to page 31). Unused fuel from

the injector exits the injector through the passage between the second and third Oring land into the return port in the cylinder head. The return fuel then passes

through the external return fuel line from the cylinder head to the return fuel rail

back to the fuel tank.

ALVE OPERATING

MECHANISM

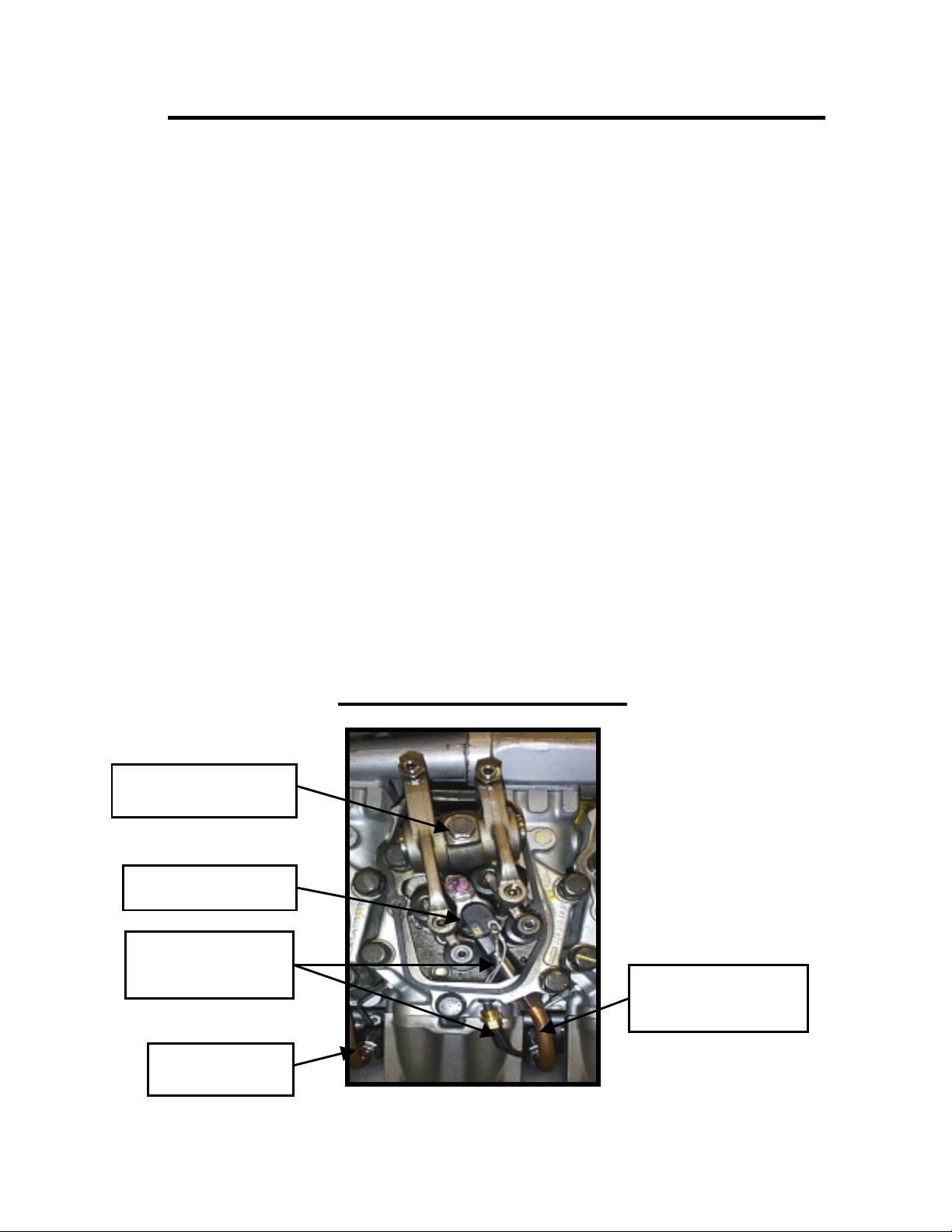

ELECTRONIC UNIT

DDEC WIRING

HARNESS TO

INJECTOR

RETURN FUEL

LINE

Cylinder Head View

HIGH-PRESSURE

FUEL LINE TO

INJECTOR

Fig. 7 Injector Installation in Cylinder Head

Page 7

Page 16

Page 8

Page 17

Detroit Diesel Electronic Controls

Flow

Limiter

Rail

Pressure

Sensor

Common Rail

Pressure

Limiting

Valve

Fuel Tank

Injectors

Controlled High

Pressure Pump with

Pre-Supply Pump

Filter

Sensors

MDEC

DDEC IV

OR

DDEC IV

ECM

ECM

DDECI

V

Fig. 8

DDECIV electronics control the beginning of injection or timing of the event

and the duration of the injection event, which determines the amount of fuel being

injected. Timing of the injection event is totally a function of DDECIV and not that

of the camshaft lobe profile as in other fuel systems.

DDECIV sends a signal to the injector solenoid to inject fuel into the

cylinders. To provide this control, DDECIV electronics utilize state of the art

microprocessors to gather information from the engine and its operating

environment to be used in determining the optimum schedule of fuel injection.

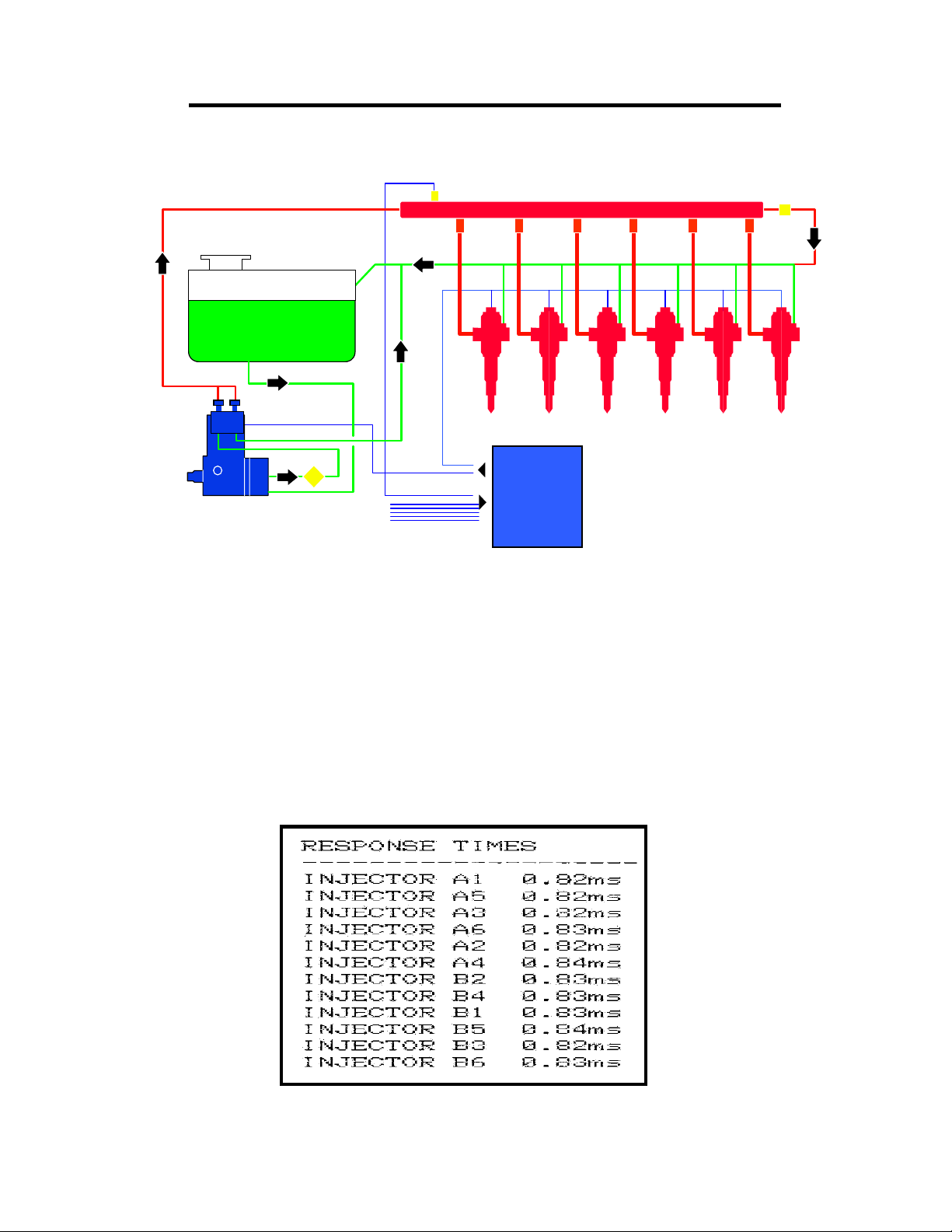

Part of the information gathered is from the fuel system itself. DDECIV receives

feedback for the injector solenoids as to their performance in the form of Response

Times as seen in the DDEC printout shown in Fig. 9.

Fig. 9 Injector Response Times Printout.

Page 9

Page 18

Detroit Diesel Electronic Controls

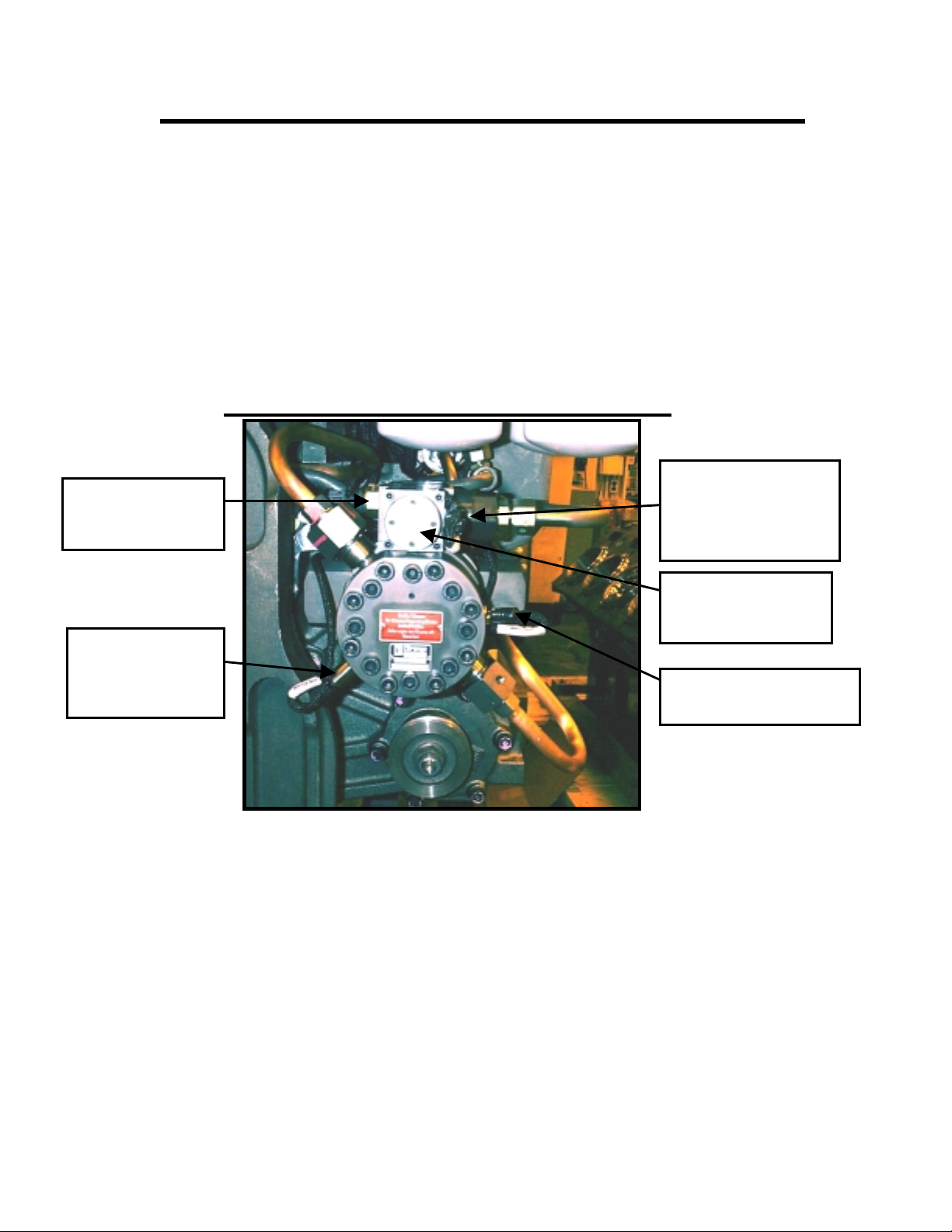

V

The Common Rail Fuel System consists of several sensors used to evaluate

its own performance. These sensors are; high fuel pressure, low fuel pressure and

fuel temperature, which are located on the high-pressure fuel pump as shown in

Fig. 10.

The low fuel pressure sensor provides information on the availability of lowpressure fuel being supplied to the high-pressure pump. The high fuel pressure

sensor provides information on the fuel pressure within the high-pressure rails

available for injection. The fuel temperature sensor provides information on the

temperature of the fuel being supplied to protect the ECM’s and high-pressure fuel

pump.

HIGH-PRESSURE FUEL PUMP

DDEC HARNESS

LOW-PRESSURE

FUEL PRESSURE

SENSOR

CONNECTION TO

HP PUMPCONTROL

SOLENOID (24-

OLT SUPPLY)

HIGH-PRESSURE

PUMP CONTROL

SOLENOID

HIGH-PRESSURE

FUEL RAIL

PRESSURE

SENSOR

FUEL TEMPERATURE

SENSOR

Fig. 10 High-pressure Pump Sensor Locations.

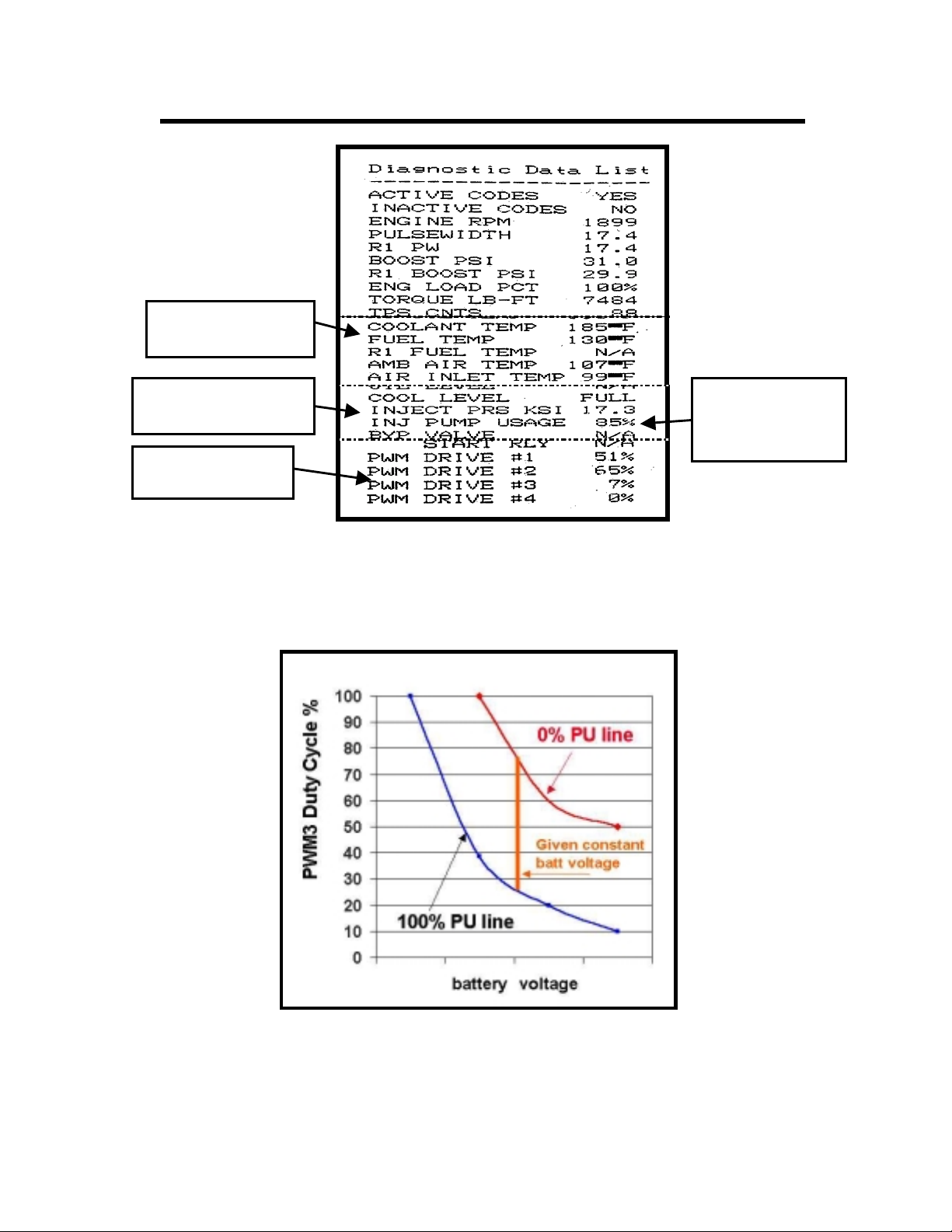

The high-pressure fuel pump receives low-pressure fuel from the fuel

delivery pump and controls the high-pressure fuel output with the control solenoid,

which receives input from the Master ECM and provides feedback information to

the Master ECM. This input and output can be read with a DDR as PWM3 and

Injection Pump Usage (Refer to Fig. 11).

The normal PWM3 operating range is 8-52%. Injection pump usage operates

between 2% and 98% range. The normal injection pump usage at 100% engine load

is in the 45-65% range at 1900 RPM. The control solenoid operates on 24 Volts DC

with a fuse located in the OEM supplied power circuit.

Page 10

Page 19

Detroit Diesel Electronic Controls

FUEL

TEMPERATURE

INJECTION RAIL

PRESSURE

PWM #3

PERCENTAGE

Fig. 11 Diagnostic Data List Printout.

HIGHPRESSURE

PUMP USAGE

Fig. 12 Relationship Between High-pressure Pump % (Percent) Usage and PWM3.

Page 11

Page 20

Detroit Diesel Electronic Controls

ELECTRONIC PILOT INJECTION (EPI)

Normal fuel injection has long ignition delays resulting in large quantities of

fuel to be injected before the beginning of combustion. With large amounts of fuel

at the beginning of combustion, there is a high rate of cylinder pressure rise, white

smoke from unburned fuel and excessive combustion noise.

DDEC controlled Electronic Pilot Injection (EPI) provides a small quantity of

fuel injection in advance of the normal injection beginning the combustion

process. This is followed by the main quantity of fuel injection to complete

combustion. EPI is a form of indirect injection reducing the ignition delay period

thereby reducing the rate of pressure rise effectively reducing the unburned fuel

and cylinder knock during startup.

Significant reduction in fuel consumption, peak cylinder pressure, rate of

pressure rise and emissions are all achieved with EPI.

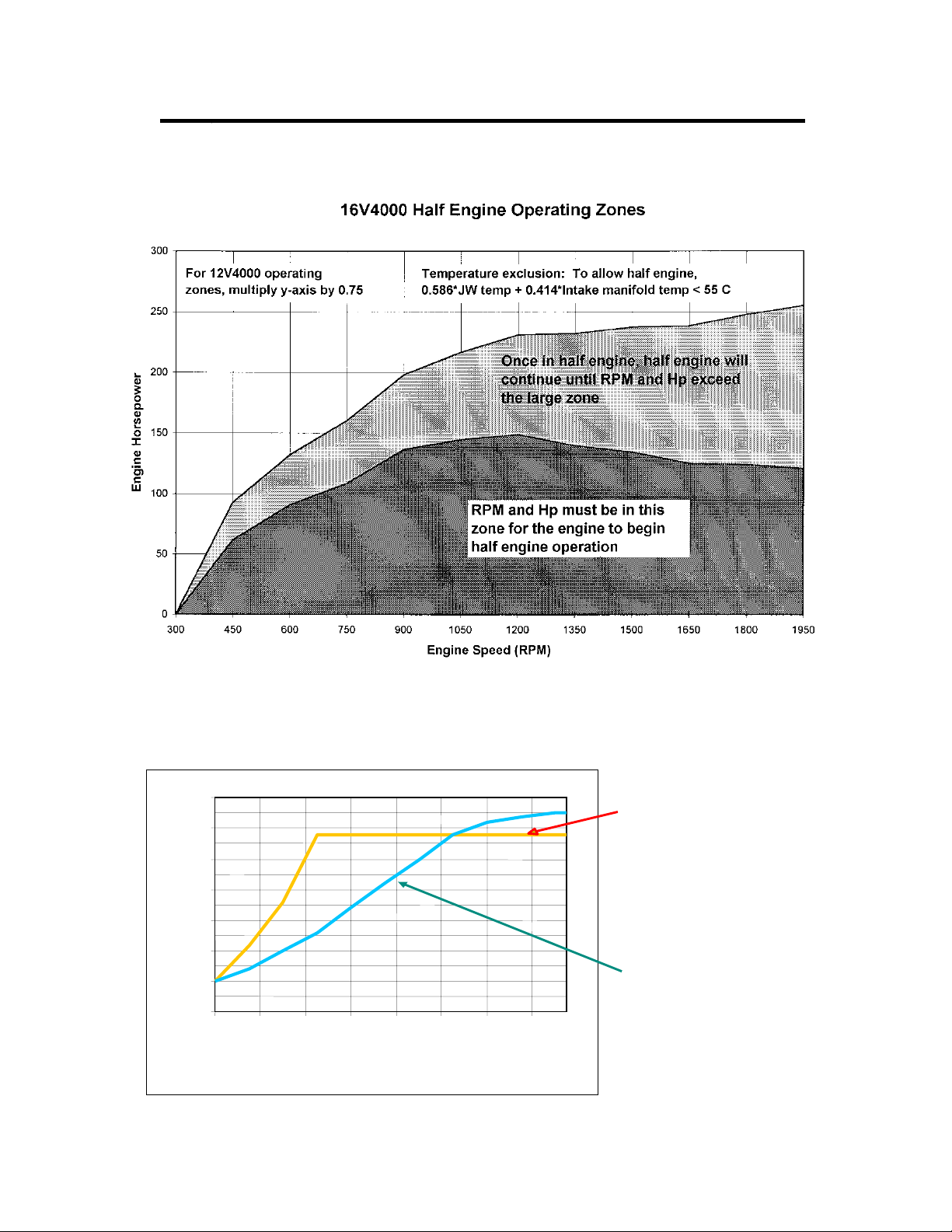

HALF ENGINE IDLE

The half engine idle feature controlled by DDEC enables the engine to

maintain higher cylinder temperature during idle to light load operating conditions.

Half engine idle is activated depending on the percent of load, air intake

temperature and engine coolant temperature. Half engine operation may occur up

to 1900-rpm engine speed.

Half engine operation differs with the 12V4000 from the 16V4000 models on

the 12V, only the master ECM fires the “A” bank cylinders; with the 16V, both

ECM’s control (4) cylinders each for either bank randomly.

Page 12

Page 21

Detroit Diesel Electronic Controls

Fig. 13

Series 4000 Low Pressure Fuel Limits

70

60

PSI

50

40

30

20

10

0

450 650 850 1050 1250 1450 1650 1850

Engine Speed

Fuel pressure drop Max

CEL activated

Max Fuel Temperature 140F

CEL activates.

Oil pressure

Fig. 14

Page 13

Page 22

Page14

Page 23

COMPONENT REVIEW INDEX

Page

• HIGH-PRESSURE FUEL PUMP 17

• LOW-PRESSURE FUEL DELIVERY PUMP 25

• ELECTRONIC UNIT INJECTOR 31

• FUEL RAILS AND LINES 37

• FLOW LIMITER VALVES 53

• C&I FUEL JUNCTION BLOCK AND

SECONDARY FUEL FILTERS 57

• MARINE SECONDARY FUEL FILTERS 61

• ECM COLD PLATE (S) 63

• FUEL LEAK MONITOR SYSTEM (MARINE) 65

• DDEC SENSORS 67

Page 15

Page 24

Page 16

Page 25

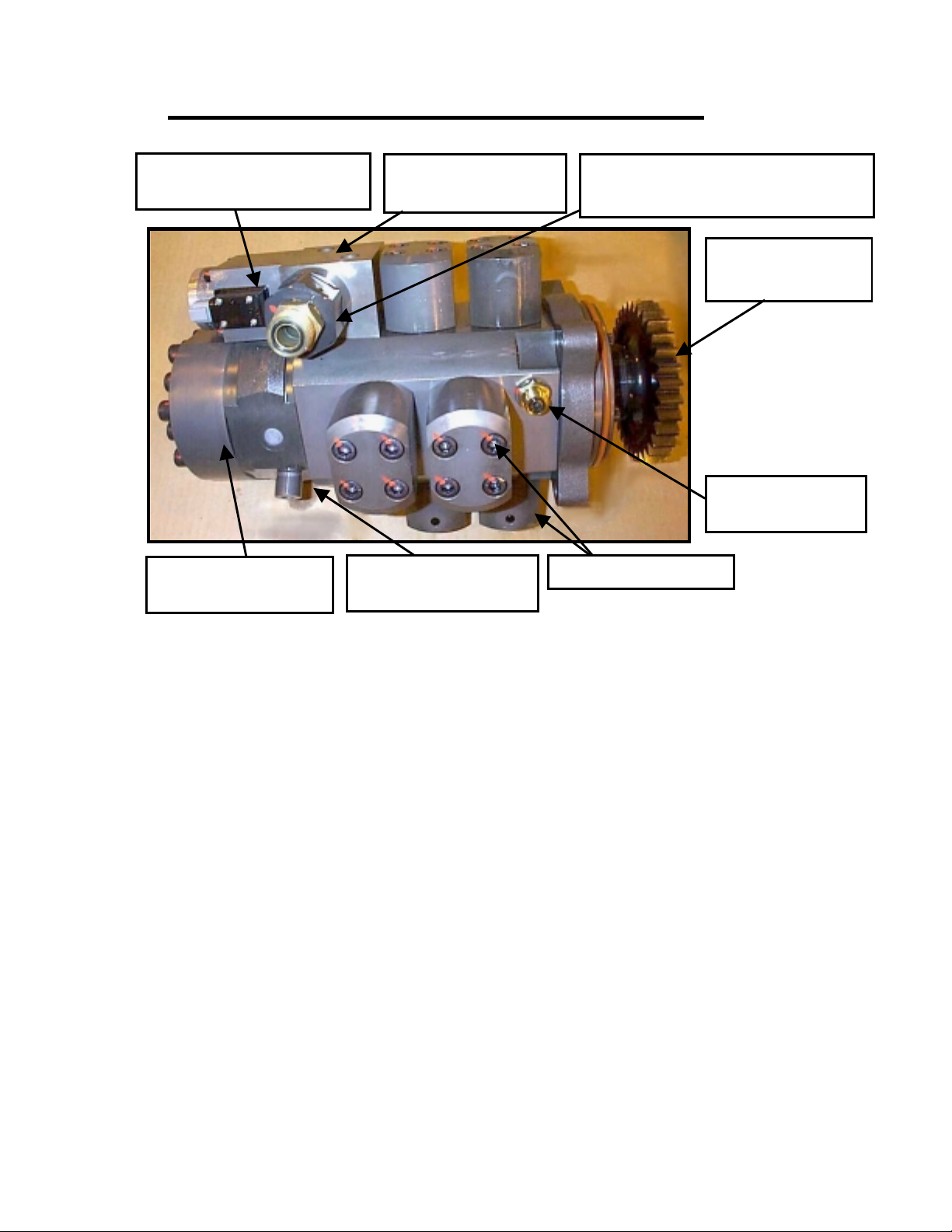

HIGH-PRESSURE FUEL PUMP

SO

The high-pressure fuel pump is mounted on the front side of the gear

case and is driven by the A-bank idler gear. The high-pressure pump utilizes a

break away driven gear, which disengages itself in the event of a pump failure to

prevent engine gear train damage.

HIGH-PRESSURE

RAIL SUPPLY

LINE, B-BANK

HIGH-PRESSURE

PUMP CONTROL

LENOID

HIGH-PRESSURE

PUMP

HIGH-PRESSURE

PUMPING UNITS

LOW-PRESSURE FUEL

SUPPLY LINE

HIGH-PRESSURE

PUMP BODY FUEL

RETURN LINE TO

JUNCTION BLOCK

HIGH-PRESSURE

RAIL SUPPLY

LINE, A-BANK

Fig. 15 High-pressure Fuel Pump Installation.

The high-pressure pump receives filtered low-pressure fuel from the fuel

delivery pump at the control solenoid. The high-pressure pump control solenoid

meters the amount of fuel entry to the high-pressure pump body and pumping

units. The control solenoid is 24 volt operated to close against spring pressure in

the open direction. (See Page 23).

Part of the fuel received by the high-pressure pump passes to the pump

crankcase where it provides lubrication and cooling to the pump camshaft

bearings and ceramic rings. The lubrication and cooling fuel exits the highpressure pump body by a fuel return line to the fuel junction block (See Fig. 15).

Page 17

Page 26

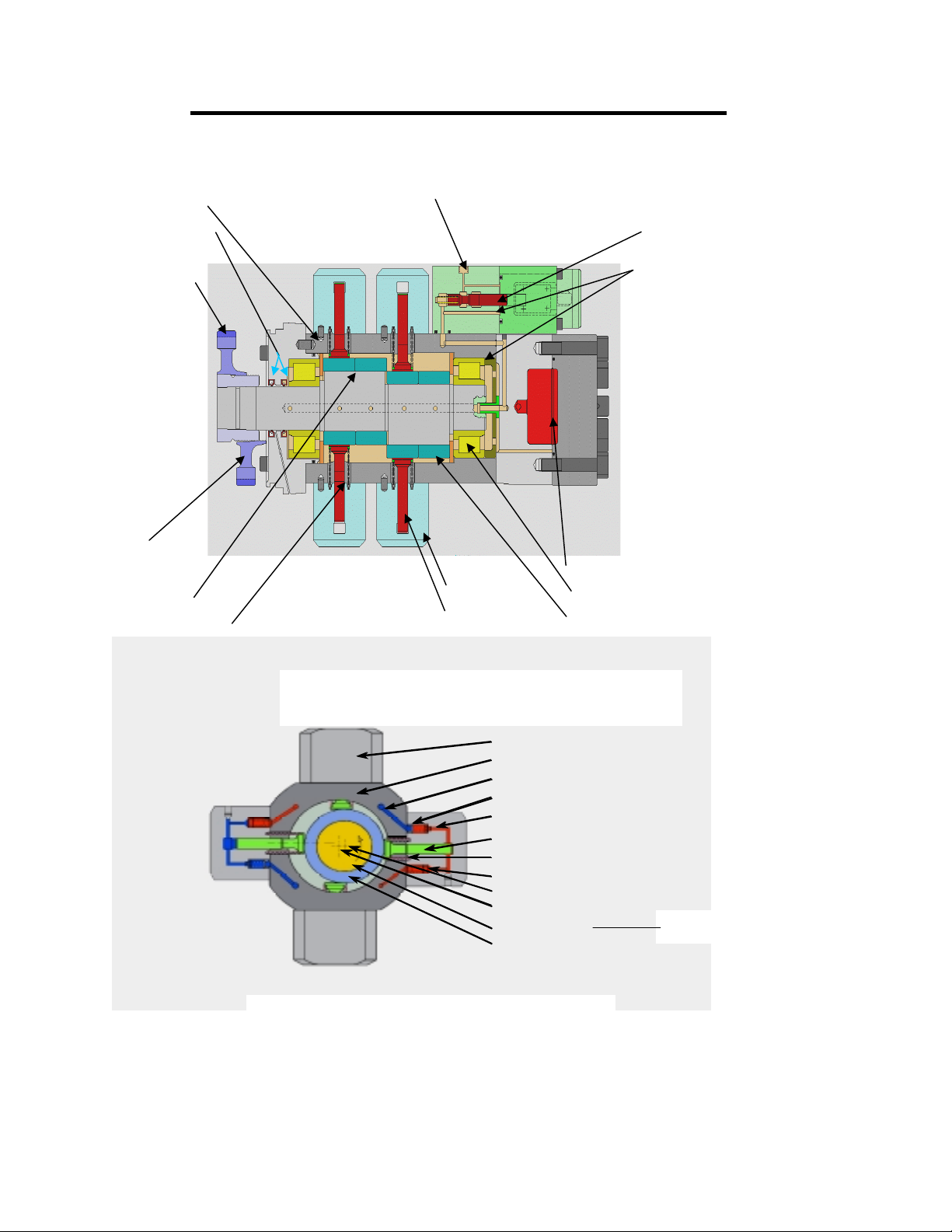

HIGH-PRESSURE FUEL PUMP

24-VOLT POWER

SUPPLY CONNECTOR

HIGH-PRESSURE

ACCUMULATOR

Fig. 16 High-pressure Fuel Pump Assembly

The majority of the fuel entering the high-pressure pump is directed to high

pressure pumping units for pressurization to the required operating pressure.

There are eight pumping units shown in Figure 16, which are operated by the

eccentric camshaft rings and controlled by inlet and outlet check valves. Fuel

enters the pumping unit through the inlet check valve, pressurized by the piston to

the high operating pressure, then exits through the outlet check valve to the

accumulator. There are two high-pressure outlet ports for transferring the

pressurized fuel to both the A-bank and B-bank high-pressure rails.

REGULATOR

VALVE

HIGH-PRESSURE

FUEL OUTLET

Page 18

LOW-PRESSURE FUEL INLET

CHECK VALVE AND FILTER

DRIVEN GEAR

(BR EAK AWAY)

FUEL RETURN

PORT

PUMPING UNITS

Page 27

HIGH-PRESSURE FUEL PUMP

CRANKCASE FUEL INLET

SHAFT SEALS

DRIVE GEAR

ENGAGED

HIGH PRESSURE

REGULATOR VALVE

COOLING AND

LUBRICATING FUEL

DRIVE GEAR

DISENGAGED

ECCENTRIC

PISTON SPRING

CYLINDER

PISTON

SIDE CUT AWAY VIEW

CYLINDER

CRANKCASE

SUPPLY FUEL

CHECK VALVE INLET

HIGH PRESSURE FUEL

PISTON

FOLLOWER SPRING

CHECK VALVE OUTLET

CENTER OF CAM

CENTER OF CRANK

CAMSHAFT

CERAMIC BEARING

HIGH PRESSURE ACCUMULATOR

CRANKSHAFT BEARING

CERAMIC BEARINGS

(Fig. 17)

(ECCENTRIC)

END CUT AWAY VIEW

Page 19

(Fig. 18)

Page 28

Page 20

Page 29

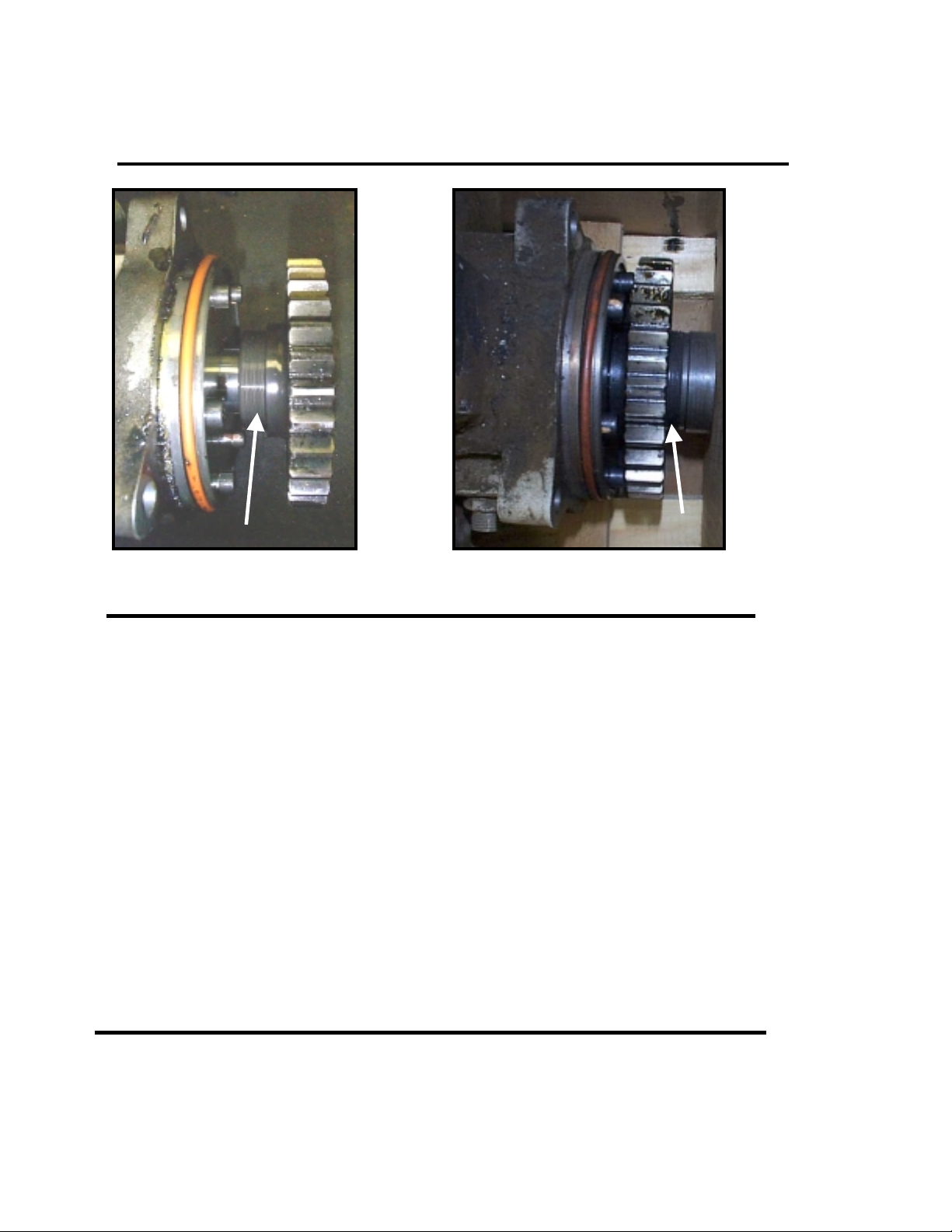

INSPECTION AND ANALYSIS

HIGH-PRESSURE FUEL PUMP

Fig. 19 Normal Gear Position Fig. 20 Disengaged Gear Position

CONDITION:

CAUSE:

restriction, which starved the high-pressure pump causing a lack of

lubrication or cooling condition.

RECOMMENDATION:

fuel system cleaning procedure in Maintenance Section. Evaluate fuel

system for source of low-pressure fuel flow restriction.

REUSE:

NOTICE: Do not disassemble the high-pressure fuel pump for any reason!

Do Not Reuse!

If the pump fails to rotate, replace the pump assembly. All highpressure fuel pumps are to be returned intact as Reliabilt® cores.

High-pressure pump seized, drive gear disengaged.

High-pressure fuel pump bearing failure. Low-pressure fuel flow

Replace High-pressure pump assembly and follow

Page 21

Page 30

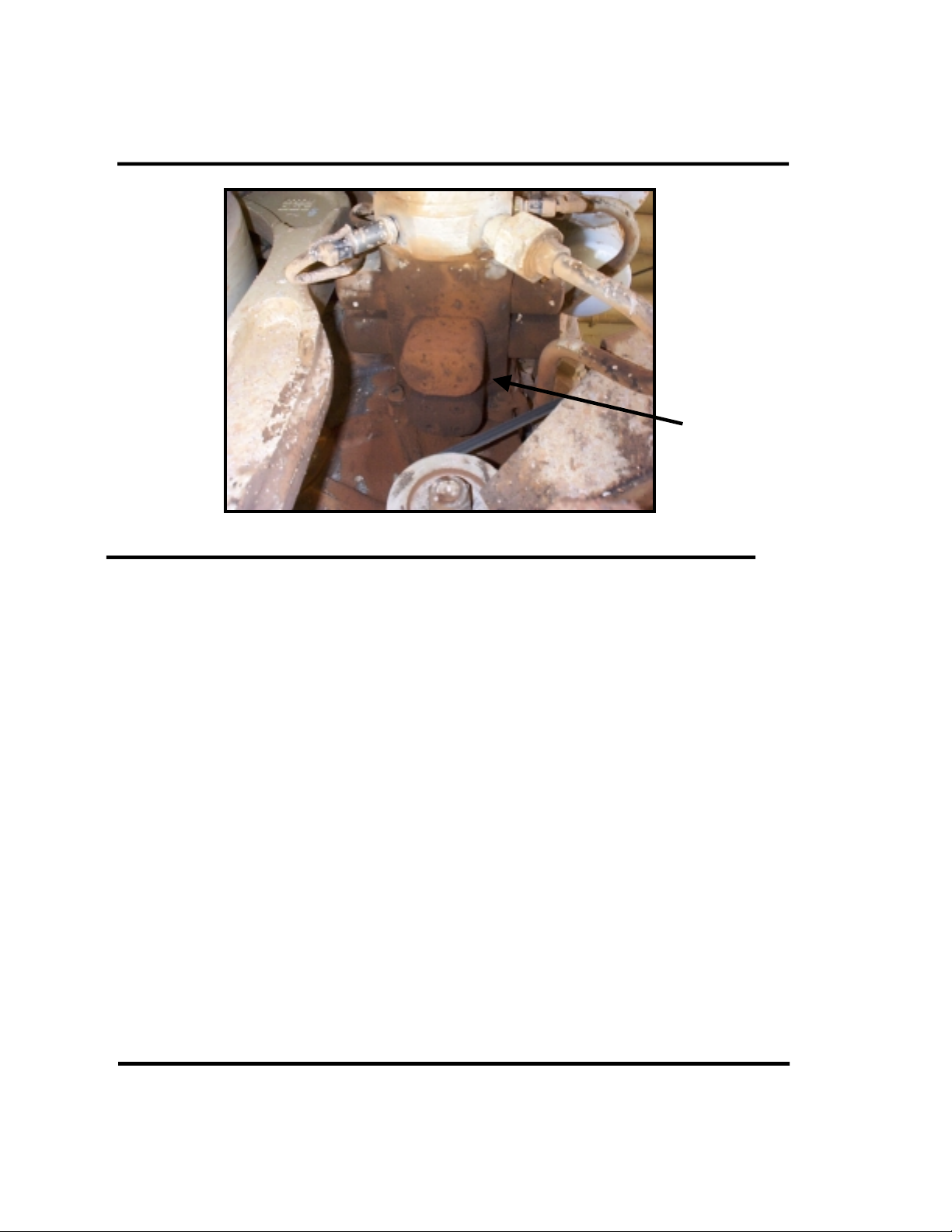

INSPECTION AND ANALYSIS

HIGH-PRESSURE FUEL PUMP

Fig. 21 High-pressure Fuel Pump Leak at Weep hole.

CONDITION:

pump weep hole is acceptable for service. Continuous dripping at the weep

hole would define a leak and require servicing.

CAUTION: Presence of excessive amount of diesel fuel could present a

safety hazard and should be addressed immediately.

CAUSE:

contaminates can contribute to this cause. Excessive fuel temperature or

dry operation of the pump may also result in seal damage.

RECOMMENDATION:

condition and condition of equipment fuel system for con tr ibuting factors.

Review events of dry operation and priming procedures being used.

REUSE:

NOTICE: Do not disassemble the high-pressure fuel pump for any reason!

All high-pressure fuel pumps are to be returned intact as Reliabilt® cores.

Do Not Reuse!

High-pressure pump leak at weep hole. A damp area at the

Pump drive shaft pump body seal leaking. Fuel system

Replace High-pressure pump assembly. Evaluate fuel

Page 22

Page 31

HIGH-PRESSURE FUEL PUMP

V

V

V

V

V

REGULATOR VALVE ASSEMBLY

SOLENOID

SOLENOID

ARMATUR

SOLENOID

COIL

Fig. 22

24-VOLT POWER

SUPPLY CONNECTOR

Low-pressure fuel is received at the control-valve fuel inlet port. The control

valve plunger is spring actuated in the full fuel position when 24-volt power supply

is not present at the solenoid. Depending on the supply voltage received, the

solenoid armature acts against the control valve plunger and spring to move to the

desired fuel inlet flow rate past the control valve determined by DDEC.

CONTROL-

ALVE

CONTROL-VALVE

FUEL INLET PORT

CONTROL

ALVE BODY

CONTROL-

ALVE SPRING

CONTROLVALVE BODY

SOLENOID

ASSEMBLY

Fig. 23

CONTROL-

ALVE

The regulator valve assembly is made up of the solenoid assembly and the controlvalve body assembly, which includes the control valve plunger and control valve

spring. Only the solenoid assembly is serviced separately from the complete

regulator valve assembly.

CONTROL-

ALVE SPRING

Page 23

Page 24

Page 32

Page 33

LOW-PRESSURE FUEL DELIVERY PUMP

LOW-PRESSURE

FUEL PUMP

INLET PIPE

Fig. 24

LOW-PRESSURE

FUEL DELIVERY

PUMP

The low-pressure fuel delivery pump receives fuel from the fuel junction

block through the low-pressure pump inlet pipe. The fuel is then pressurized by

the low-pressure fuel delivery pump to a normal operating pressure range of 64 PSI

to 85 PSI at rated speed. The pressurized fuel is then sent to the fuel junction

block via the low-pressure fuel pump outlet pipe. The fuel junction block directs

the low-pressure fuel through the primary and secondary fuel filter to the supply

line providing low-pressure fuel to the high-pressure fuel pump regulator valve

assembly inlet port.

LOW-PRESSURE

FUEL PUMP

OUTLET PIPE

Page 25

FUEL JUNCTION

BLOCK

Page 34

LOW-PRESSURE FUEL DELIVERY PUMP

case housing and is gear driven from the rear of the A-bank idler gear behind the

high-pressure pump drive. The delivery pump is a gear type mechanical pump

utilizing a drive gear with shaft and a driven gear in a two-piece housing (Fig. 26).

Pressurized fuel is regulated by a pressure regulator valve and spring mounted in

the pump cover (Fig. 25). The maximum pressure is regulated to 105-PSI output.

The body and cover of the fuel pump contain support bearings for the drive and

driven gears (Fig. 27).

PRESSURE

REGULATOR

VALVE

Fig. 25

WEEP HOLE

The low-pressure fuel delivery pump is mounted on the backside of the gear

PUMP DRIVE

DRIVEN GEAR

Fig. 26 Fig. 27

DRIVE GEAR

PUMP COVER SUPPORT BEARINGS

Page 26

Page 35

LOW-PRESSURE FUEL DELIVERY PUMP

V

V

V

There are two seals on the drive gear shaft (Fig. 28). The inner seal is used

to retain fuel in the pump from leaking past the drive sha ft into the engine. The

outer seal prevents engine oil from entering the fuel system through the fuel pump.

There is a small weep hole located in the pump body to allow for drainage and early

warning should either seal begin to leak (Refer to Fig. 25).

SPRING SET

REGULATOR

ALVE SPRING

Fig. 28 Fig. 29

SHAFT SEAL

REGULATOR

ALVE

Page 27

REGULATOR

ALVE BORE

PLUG

18

Page 36

Page 28

Page 37

INSPECTION AND ANALYSIS

LOW-PRESSURE FUEL PUMP

Fig. 30 Low-pressure fuel leak at weep hole.

CONDITION:

pump weep hole is acceptable for service. Continuous dripping at the weep

hole would define a leak and require servicing.

CAUTION: Presence of excessive amount of diesel fuel could present a

safety hazard and should be addressed immediately.

CAUSE:

contaminates can contribute to this cause. Excessive fuel temperature or

dry operation of the pump may also result in seal damage.

RECOMMENDATION:

condition and condition of equipment fuel system for con tr ibuting factors.

Review events of dry operation and priming procedures being used.

REUSE:

NOTICE: Do not disassemble the Low-pressure fuel pump for any reason!

If the pump fails to rotate, replace the pump assembly. All Low-

pressure fuel pumps are to be returned intact as Reliabilt® cores.

Low-pressure pump leak at weep hole. A damp area at the

Pump drive shaft pump body seal leaking. Fuel system

Replace Low-pressure pump assembly. Evaluate fuel

Do Not Reuse!

Page 29

Page 38

Page 30

Page 39

ELECTRONIC UNIT INJECTOR

Solenoid

Control Valve

Control Unit

O-RINGS

High Pressure Fuel

Inte rmed ia te V a lv e

Body

Filter

Vent

Sleeve

Rod

Fuel Return

Needle Valve

Nut

Nozzle

Fig. 31 Injector Assembly (Cutaway)

The Electronic Unit Injector delivers the fuel input into each cylinder.

The unit injector receives high-pressure fuel continuously from the highpressure rails. The unit injector does not need to make pressure, therefore,

there is no camshaft driven mechanism requiring adjustment or tune-up. The

amount of fuel and timing is controlled by DDECIV.

DDECIV controls the fuel flow in the injector by sending a signal to the

injector solenoid. The control valve is spring loaded in the closed position

and opens when the solenoid is energized. Each injector has its own

calibration code, which is factory determined and stamped on the injector

identification plate (Fig. 32 and Fig. 33). The calibration code can be any

number from 00 to 99 (Fig. 34). The calibration code is entered into DDECIV

with the DDR reader or DDDL, so that DDECIV can balance each injector for

uniform fuel output and performance.

Page 31

Page 40

ELECTRONIC UNIT INJECTOR

INJECTOR

INJECTOR NAME

PLATE WITH

CALIBRATION CODE

Fig. 32 Fig 33 Fig. 34

The energized solenoid lifts the control valve, which hydraulically

permits the rod to rise and the needle to lift from its seat. This action allows

fuel to flow from the injector tip into the combustion chamber. To end

fueling the solenoid is de-energized, allowing the control valve to fall against

the control unit, which causes hydraulic pressure to build above the rod

forcing it and the needle downward until the needle closes against its seat.

About 10% of the fuel, which entered the unit injector is used for

lubrication and cooling, exits the injector through the fuel return port. The

fuel return port is located between the second and third o-ring lands on the

injector body (Fig. 35). The return fuel exits the injector from the fuel return

port to a port in the cylinder head to the return fuel line to the return

manifold.

INJECTOR

ASSEMBLY

RETURN

FUEL PORT

INJECTOR

HOLE TUBE

(CUT AWAY)

C-E RING

Page 32

INJECTOR HOLD DOWN

BOLT AND WASHER

INJECTOR HOLD

DOWN CLAMP

CYLINDER HEAD

COOLANT PASSAGE

Fig. 35

Page 41

INSPECTION AND ANALYSIS

ELECTRONIC UNIT INJECTOR

O-RINGS

FUEL

RETURN

PORT

Fig. 36 NEW Fig. 37 HEAVY CARBONED FROM

FAILED C-E RING

CONDITION:

Injector damaged from compression and carbon. O-ring

damage can occur from combustion heat, which could result in return fuel

leaking past the o-rings into the engine oil or compression entering the return

fuel.

CAUSE:

Leaking C-E Ring. May be defective C-E Ring or a loose or broken

hold down bolt.

RECOMMENDATION:

Inspect injector hole tube for damage. Replace Injector

Assembly with new C-E Ring and o-rings. Insure proper hold down bolt

torque is used.

REUSE:

Do Not Reuse!

Page 33

Page 42

INSPECTION AND ANALYSIS

(

INJECTOR C-E RING

CARBON BUILD-UP

C-E RING

COPPER)

C-E RING (FORMER

STYLE STEEL)

Fig. 38 NORMAL

LEAKING COMBUSTION

Fig. 39 (FORMER STYLE TWO PIECE)

CONDITION

injector body and injector hole tube. Carbon will also in injector vent

passage and high-pressure fuel line. Injector O-rings may be burnt and

damaged. Injector hole tube may also be damaged from combustion gases.

CAUSE:

down bolt or defective C-E Ring.

RECOMMENDATION:

Inspect hold-down bolt and clamp. Replace if needed. Replace Injector hole

tube.

REUSE:

or high pressure fuel line. Replace both as the vent passage is plugged with

carbon.

Page 34

: C-E Ring leaking combustion causing carbon build-up on

Improper hold-down clamp bolt torque or missing washer on hold-

Replace Injector assembly, C-E Ring and O-rings.

If carbon is present in high-pressure fuel line, do not reuse injector

Page 43

INSPECTION AND ANALYSIS

CYLINDER HEAD FUEL INJECTOR TUBE

O-RING OVERHEATED

Fig. 40 Fig. 41 Fig. 42

NORMAL OPERATION OPERATION WITH C-E RING

WITH C-E RING OMITTED

SE AT AR EA

CONDITION:

Build-up in the tube and coolant leak from overheated injector tube o-ring.

CAUSE:

RECOMMENDATION:

area. Severe carbon buildup will require the replacement of the tube and orings. Clean thoroughly, insure C-E Ring seat area is flat and free of carbon.

REUSE:

are used when injector is installed.

Page 35

Combustion leaking into injector tube area causing carbon

C-E Ring was omitted during injector installation.

Inspect for signs of erosion inside tube area at seat

Replace injector tube if C-E ring has failed. Insure new C-E Rings

Page 44

INSPECTION AND ANALYSIS

FUEL INJECTOR HOLD-DOWN CLAMP & BOLT

BOLT HEAD

SE AT AR EA

ON HOLDDOWN CLAMP

BROKEN

HOLD-DOWN

BOLT

NORMAL

Fig. 43 Injector Hold-down Bolt Failure

CONDITION: Broken hold-down bolt.

CAUSE: Excessive torque during installation.

RECOMMENDATION: Replace bolt and add new hardened washer. Follow proper

torque specifications shown in the Torque Specifications section.

REUSE: Do not reuse! Inspect hold-down clamp bolt head seat area for signs of

fretting. If fretting is present, replace bolt even if bolt is not broken. Fretting is a

sign of the bolt working from possible being stretched, which could result in a

broken bolt and loss of clamp load on the injector. Replace the hold-down clamp if

it is severely fretted.

Page 36

Page 45

FUEL RAILS AND LINES

Fig. 44 Common Rail Fuel System

The rails of the Common Rail Fuel System include the high-pressure and the

low-pressure return rails. The high-pressure rails are of stainless steel

construction with port locations for each fuel limiter valve seat (Fig. 45). The front

of the high-pressure rails has fittings to accept a high-pressure fuel line. The rear

of the high-pressure rail is fitted with a safety relief valve assembly on the A-bank

or a plug assembly on the B-bank. The safety relief valve spills pressure at 19.6

KPSI to the A-bank return rail. The two low-pressure return rails accept the

injector return fuel from each cylinder head.

LOW-PRESSURE

RETURN RAIL

HIGH-PRESSURE

FUEL RAIL

Page 37

HIGH-PRESSURE

RAIL ADAP T E R

HIGH-PRESSURE

RAIL FLOW

LIMITER VALVE

SEAT

Fig. 45 View of High-pressure Rail Limiter Valve Seat.

Page 46

Page 38

Page 47

INSPECTION AND AN ALYSIS

HIGH-PRESSURE RAILS

Fig. 46 Fig. 47

LIMITER

VALVE SEAT

AREA

Fig. 48 Fig. 49

USED AND CORRODED

CONDITION:

CAUSE:

RECOMMENDATION:

Externally Corroded and Dirty.

Normal Operation.

Completely disassemble and clean. Sand rails so rail

CLEANED FOR REUSE

connector can be easily removed. Inspect seating areas for fuel limiter

valves and repair if needed. Follow repair procedures found in the

maintenance section.

REUSE:

Reuse if all sealing surfaces are in good condition.

Page 39

Page 48

INSPECTION AND ANALYSIS

HIGH-PRESSURE RAIL CONNECTOR

Fig. 50 NEW Fig. 51 USED, CORRODED

CONNECTOR

THREADS

DAMAGED

DURING ENGINE

DRAIN

Fig. 52 Protective Sleeve

(Marine & Hydro Frac Only!)

CONDITION:

Fig. 53

Corroded and Dirty. Damage form improper protection during

engine disassembly.

CAUSE:

Normal Operation. Damaged threads are from not using protective

caps when the fuel lines are removed.

RECOMMENDATION:

Clean and inspect for cracks or damaged high-pressure

fuel line connector threads.

REUSE:

Reuse if no damage is found. Do not attempt repair of connector

threads!

Page 40

Page 49

INSPECTION AND ANALYSIS

HIGH-PRESSURE RAIL RELIEF VALVE AND PLUG

Fig. 54 High-pressure Rail Plug

High Pressure Rail Relief Valve

Note: Do not disassemble Pressure Relief Valve! For Reference only!

Fig. 55 Fig. 56

CONDITION: Leaking fuel past seating surfaces.

CAUSE: Debris or cracks present on seating surfaces.

RECOMMENDATION: Inspect for damage to seating surfaces or presence of

debris.

DO NOT DISASSEMBLE THE PRESSURE RELIEF VALVE, AS IT CANNOT BE

READJUSTED WITHOUT SPECIAL TOOLS!

REUSE: Reuse unless found damaged or cracked.

Page 41

Page 50

Page 42

Page 51

HIGH PRESSURE FUEL LINE

Fig. 57 High-pressure Fuel Line System

HIGH-PRESSURE

LINE TO A-BANK

RAIL.

HIGH-PRESSURE

LINE TO B-BANK

RAIL

FUEL LEAK

DETECTION

LINE PORT

Fig.58 High-pressure line connector Fig. 59 High-pressure line from rails to

injectors

All the high-pressure fuel lines are designed to carry the fluctuating highpressures of this system by utilizing a unique double walled construction. This

double walled construction consists of a stainless steel inner wall with a copper

protective outer wall forming an air vent passage between them.

Care should be taken at anytime the high-pressure fuel line is removed from

an injector as breaking the torque on the outer retaining nuts will also loosen the

inner retaining nuts and could cause improper seating if not properly retorqued

before re-installation. Care must be taken to protect these sealing surfaces at any

time the high-pressure lines or flow-Limiter valves are removed as damage to these

sealing surfaces can result in a high-pressure fuel leaks.

Page 43

Page 52

HIGH PRESSURE FUEL LINE

(

HIGH-PRESSURE

OUTER WALL

(COPPER)

FUEL LEAK BACK

PASSAGES

Fig. 60 High-pressure fuel line construction (cross-section view).

FUEL PASSAGE

INNER WALL

STAINLESS STEEL)

Fig. 61 High-pressure fuel line construction (cutaway).

Check the counterclockwise turning collar ring after loosening of the union nut by

screwing completely backwards to the end of the tread and torquing to 10Nm using

DDC special tool J-45252.

UNION NUT

Fig. 62 High-pressure fuel line collar ring adjustment.

Page 44

COLLAR RING

SPECIAL TOOL

J-45252

Page 53

INSPECTION AND ANALYSIS

HIGH-PRESSURE FUEL LINES PUMP TO RAILS

Fig. 63 High-pressure Fuel Leak at the Connector.

CONDITION: Fuel line leaking at high-pressure fuel line connector from highpressure fuel pump to high-pressure fuel rail.

CAUSE: Debris, crack or damaged seat or improper adjustment of internal

collar ring at either connector on the ends of fuel line causing an improper

stack-up condition.

RECOMMENDATION:

Inspect for debris presence in connection, clean as required.

Check internal collar ring for proper adjustment and torque, correct.

Inspect all seat surfaces for damage or fretting, replace fuel line if

found.

REUSE: Reuse unless sealing surfaces are found damaged.

Page 45

Page 54

INSPECTION AND ANALYSIS

HIGH-PRESSURE FUEL LINES

INJECTOR TO RAILS

Fig.64 High-pressure Fuel Leak at the High-pressure Rail. Fig. 65

CONDITION: Fuel line leaking at high-pressure fuel line from injector to

high-pressure fuel rail.

CAUSE: Debris (carbon) or damaged seat connections at three possible

locations (Fuel line to injector, Fuel line to fuel limiter valve, limiter valve to

fuel rail) or improper adjustment of internal collar ring at either connector on

the ends of fuel line causing an improper stack-up condition.

RECOMMENDATION:

Inspect for debris (carbon) presence in connection, clean as required.

Check internal collar ring for proper adjustment and torque, correct.

Inspect all seat surfaces for damage or fretting, replace fuel line if

found.

REUSE: Reuse unless sealing surfaces are found damaged.

Page 46

Page 55

INSPECTION AND ANALYSIS

HIGH PRESSURE FUEL LINE TO INJECTORS

Fig. 66 Fig. 67

CARBON BUILD UP

BETWEEN THE INNER

AND OUTER TUBE

Fig. 68 NORMAL Fig. 69 OVERHEATED & CARBONED FROM

LEAKING C-E RING

CONDITION:

Fuel Line overheated and carbon filled between inner and outer

Fig. 70

tube. Refer to cut away to see carbon build up between tubes.

CAUSE:

Leaking or omitted Injector C-E Ring, improper hold down bolt

torque or defective C-E Ring.

RECOMMENDATION: Replace High Pressure Fuel Line, Injector and C-E

Ring. Under normal conditions, Clean, inspect sealing areas for damage,

replace o-rings, and tighten internal nuts before reuse.

REUSE:

Do Not Reuse! Cleaning is not possible.

Page 47

Page 48

Page 56

Page 57

RETURN RAILS AND LINES

RETURN FUEL

RAILS AND LINES

RETURN FUEL LINE

FROM RETURN RAIL

TO CYLINDER HEAD

RETURN

FUEL RAIL

Fig.71 Low-pressure Fuel Rails Fig. 72 Low-pressure Injector Fuel Return Line

The return fuel rails are located on each bank of the Series 4000 attached to the

cylinder block above the high-pressure rails. The return fuel rails provide a

common collection of all returned fuel from the injectors and the A-bank highpressure rail relief valve. (See Fig. 73) The return fuel rails are constructed of steel

with O-ring seals at each connection point. The return fuel lines from each

cylinder head have a flair type metal to metal joint at the re turn fuel rail fittings.

Fig. 73 High-pressure Fuel Rail Pressure Regulator Return Fuel Line.

Page 49

Page 58

Page 50

Page 59

INSPECTION AND ANALYSIS

RETURN FUEL LINES

BENT

Fig. 74 Fig. 75

BENT

CRACK

Fig. 76 Fig. 77

CONDITION: Bent, cracked or damaged return fuel lines.

CAUSE: Improper installation, lack of proper support or mishandling after

removal.

RECOMMENDATION: Inspect return fuel lines for signs of external damage

such as impact, electrical shorts or fretting. Bent or cracked fuel lines are

indications of being forced into position or over tightened during installation.

Sealing surfaces of the return fuel lines should be inspected for nicks,

scratches or cracks. Proper care should be taken in handling and storing to

prevent damage. Replace any found damaged.

REUSE: DO NOT REUSE!

Page 51

Page 60

Page 52

Page 61

FLOW- LIMITER VALVE

No Fuel t o

Injector

Fuel to

Injector

Fuel Volume

Limit

Spring

Valve

High Pressure

Fuel

Rail

Valve Open Valve Closed

There are flow-limiter valves for each injector to prevent over fueling of the

cylinder should something happen to an injector. The flow-limiter valves are

located on each bank between the injector high-pressure fuel lines and the highpressure fuel rail. These valves sense fuel flow and will shut off the flow of fuel to

the injector if the flow rate exceeds the spring tension of the flow-limiter valve.

This is normally 1.5 times the normal injector fueling rate.

Fig. 78

Fig. 79 FLOW-LIMITER VALVE DISASSEMBLED

The flow limiter valves consist of spring and a valve, which floats in the fuel

flow until the flow exceeds that of the spring, thereby causing the valve to close on

the seat of the body. The fuel inlet from the high-pressure rail is tapered to accept

the cone shaped nozzle of the flow-limiter valve. The outlet of the flow-limiter valve

also is cone shaped to accept the injector high-pressure fuel line. The conditions

of this cone shaped sealing areas are very important in the prevention of fuel leaks.

Anytime the injector high-pressure lines are removed; care should be taken to

protect all the sealing surfaces of the flow-limiter valve, high-pressure rail and the

injector high-pressure fuel line.

Page 53

Page 62

Page 54

Page 63

INSPECTION AND ANALYSIS

FLOW-LIMITER VALVE

Fig. 80 Fig. 81 Fig. 82

NORMAL OVERHEATED & CAR- CORRODED FROM WATER

BONED FROM LEAKING

C-E RING

CONDITION: Overheated or corroded.

CAUSE: Overheated from leaking C-E Ring or corroded from exposure to

water.

RECOMMENDATION: Normal condition, Inspect sealing surfaces for

damage. Overheated or corroded conditions replace flow-limiter valve

assembly.

REUSE: Reuse normal condition only! Replace if damaged sealing

surfaces.

Page 55

Page 56

Page 64

Page 65

C&I FUEL JUNCTION BLOCK AND

SECONDARY FUEL FILTERS

LOW-PRESSURE

FUEL DELIVERY

PUMP

LOW-PRESSURE

FUEL PUMP

CONNECTING PIPES

TO FUEL JUNCTION

BLOCK

FUEL JUNCTION

BLOCK

SECONDARY FUEL

FILTER ADAPTER

SECONDARY FUEL

FILTER ELEMENTS

and controls the direction of flow to the low-pressure fuel pump, filters and ECM

cold plate(s). The fuel junction block also accepts the return fuel from the highpressure pump. There are three check valves located in the fuel junction block to

aid in directing the fuel flow. See the fuel flow diagram in Fig. 86.

adapter, which accepts two spin-on 5-micron cartridge type fuel filters. Refer to

Fig. 87or exploded view of the fuel junction block and secondary fuel filter adapter

assembly.

Fig. 83 Fuel Junction Block and Secondary Fuel Filters.

The fuel junction block receives unfiltered fuel from the equipment fuel tank

Attached to the bottom of the fuel junction block is the secondary fuel filter

Page 57

Page 66

FUEL JUNCTION BLOCK

LOW-PRESSURE

PUMP INLET AND

OUTLET PORTS

HIGH-PRESSURE

PUMP INLET AND

OUTLET PORTS

FUEL FILTER

ADAPTER

MOUNTING PAD

CYLINDER BLOCK

ACCESS COVER

MOUNT FLANGE

Fig. 84 Fuel Junction Block without Filter Adapter.

HIGH-PRESSURE

PUMP FUEL

RETURN

LOW-PRESSURE

FUEL PUMP

CONNECTIONS

SECONDARY

FUEL FILTER

ADAPTER

Fig. 85 Fuel Junction Block Engine Fuel Line Connections.

Page 58

ECM COLD

PLATE FUEL

ECM COLD

PLATE FUEL

SUPPLY

Page 67

FUEL JUNCTION BLOCK

)(

LP Pump

Fuel Pro

/

Fuel Primer

X

)(

om Tank

Fr

1.1 bar

0.1 bar

To Tank

Fig. 86 Fuel Junction Block Fuel Flow Schematic (C&I).

(Note: Refer to Fuel System Plumbing for other applications.)

Filters

X

2 bar

Cold Plate

HP Pump

Vent

Cold Plate

Injector Spill

Check Valve

(2 Bar/ 29 PSI)

Check Valve

(0.1 Bar/ 1.4 PSI)

Fig. 87 Fuel Junction Block Assembly with Check Valve Locations

Page 59

Check Valve

(1.1 Bar/ 16 PSI)

Page 68

Page 60

Page 69

MARINE SECONDARY FUEL FILTERS

FUEL OUT

TO HIGHPRESSURE

PUMP

CONNECTION

PORT FOR

FUEL PRIMING

DUPLEX

DIVERTER

VALVE

FUEL FILTER

ELEMENTS

Fig. 88 Marine Secondary Fuel Filter Installation.

Marine engine applications utilize a different secondary fuel filter installation then

found on the C&I models. The marine secondary fuel filter is located on the front of

the engine mounted on a support bracket. The marine secondary fuel filter

incorporates a duplex diverter valve and a port to connect a fuel line to a fuel

priming pump. The duplex diverter valve permits switching filters for servi cing of

the fuel filters during engine operation.

Page 61

Page 62

Page 70

Page 71

ECM COLD PLATE (S)

FUEL CROSSOVER TUBE

BETWEEN COLD PLATES

COLD PLATE

JUNCTION BLOCK

ECM COLD PLATES

FUEL SUPPLY

FROM FUEL

JUNCTION BLOCK

ECM MOUNT BOLTS

Fig. 89

The ECM cold plate(s) provide protective cooling to the ECM(s) to remove

heat generated within the ECM(s). Also the ECM cold plate(s) act as a thermal

barrier to protect the ECM(s) from external heat sources.

The ECM(s) and cold plate(s) are located on the "A" bank of the cylinder

block between the intake manifold and the oil pan bolt rail. For an 8V4000, a single

ECM is mounted between the ECM cold plate and the cylinder block cover plate.

The 12V4000 and 16V4000 both have two ECM’s sandwiched between two ECM

cold plates connected by a fuel crossover tube, which are then mounted to cylinder

block cover plate.

The ECM cold plate(s) are made up of two aluminum plates assembled with

directional baffles to allow fuel flow between them. At one end is a junction block

made of 30% reinforced polyester, molded around brass fittings to receive the fuel

inlet and outlet fittings (refer to Fig. 91). The ECM cold plate(s) receive cooling

filtered low-pressure inlet fuel from the fuel junction block. On duel ECM

configurations, fuel passes through the inner ECM cold plate first and then

transfers via the fuel crossover tube to the outer ECM cold plate before returning

back to the fuel junction block. The return fuel is then returned back to the

equipment fuel tank.

Page 63

ECM (S)

FUEL RETURN TO FUEL

JUNCTION BLOCK

Page 72

ECM COLD PLATE (S)

Fig. 90 Cold Plates Mounted on ECM’s

RECEIVER ECM

COLD PLATE

JUNCTION BLOCK

MASTER ECM

COLD PLATE

JUNCTION BLOCK

COLD PLATE

JUNCTION

BLOCK

Fig. 91 Cold Plate Assembly

Fig. 92 Cold Plate Fuel Flow

Page 64

COLD PLATE

MOUNT SCREW

LOCATIONS TO

ECM

COLD PLATE

JUNCTION BLOCK

INLET PORT

COLD PLATE

JUNCTION BLOCK

OUTLET PORT

Page 73

FUEL LEAK MONITOR SYSTEM (MARINE)

FUEL COOLER

FUEL IN FROM

TRANSFER

PUMP

MDEC

CONTROLS

SECONDARY

FUEL FILTERS

Fig. 93 Marine Fuel System (MDEC Controls)

Marine applications have a high-pressure line leak monitoring system installed to

detect the occurrence of high-pressure fuel leaking at the high-pressure fuel pump

connectors (“A” and “B” bank). The leak monitor sensor is connected to the

electronic controls of the engine (MDEC or DDEC) and will provide an alarm if a

leak is detected. Two types of leak monitor junction blocks are used depending on

the electronic controls and fuel coolers used on the engine. (Fig. 94 and Fig. 95)

HIGH-PRESSURE

PUMP CONNECTOR

“A” BANK

FUEL

COOLER

FUEL OUT

TO FILTER

FUEL

COOLER

FUEL LEAK

MONITOR

SYSTEM

HIGHPRESSURE

PUMP FUEL

RETURN LINE

HIGH-PRESSURE

LEAK RETURN

LINE TO

JUNCTION BLOCK

Fig. 94 Fuel Leak Monitor System (MDEC Controls)

FUEL

MONITOR

SENSOR

FUEL

MONITOR

JUNCTION

BLOCK

Page 65

Page 74

FUEL LEAK MONITOR SYSTEM (MARINE)

TO FUEL

COOLER

HIGH-PRESSURE

LEAK RETURN LINE

TO JUNCTION BLOCK

HIGH-PRESSURE

LEAK RETURN LINE

TO “B” BANK

CONNECTOR

HIGH-PRESSURE

PUMP CONNECTOR

“B” BANK

Fig. 95 Fuel Leak Monitor System (DDEC Controls)

HIGH-PRESSURE

LINE TO “A”

BANK FUEL RAIL

FUEL RETURN

FROM RETURN

RAILS

HIGH-PRESSURE

PUMP FUEL

RETURN LINE

FUEL JUNCTION

BLOCK

HIGH-PRESSURE

PUMP CONNECTOR

“B” BANK

HIGH-PRESSURE

LEAK RETURN LINE

TO “B” BANK

CONNECTOR

Fig. 96 Fuel Leak Monitor Return Line “A” Bank Fig. 97 Fuel Leak Monitor Sensor

(Both MDEC or DDEC Controls) in junction block

Page 66

Page 75

DDEC SENSORS

Fig. 98 DDEC Sensor and Wire Identification Chart.

The common rail fuel system for the Series 4000 contains three sensors, the highpressure fuel pressure sensor (See Fig. 99), low-pressure fuel pressure sensor

(See Fig. 101) and a fuel temperature sensor (See Fig. 100). Refer to the Detroit

Diesel Electronic Controls section Fig. 10 for sensor locations. Additionally, a leak

monitor sensor utilized for marine applications (See Fig. 102).

Page 67

Page 76

DDEC SENSORS

Fig. 99 High-pressure Fuel Sensor (Cutaway View) Fig. 100 Fuel Temperature

Sensor

The fuel temperature sensor is not located in the fuel inlet, but instead in the highpressure pump it self. Therefore, the fuel temperature will assist in warning of

impending pump failures.

DIN CONNECTOR

Fig. 101 Low-pressure Fuel Sensors Fig. 102 Leak Monitor Sensor

PACKARD

CONNECTOR

Page 68

Page 77

FUEL SYSTEM PLUMBING REQUIREMENTS

Fig. 103 Fuel System Plumbing Schematic

Care should be taken not to exceed the maximum fuel pump suction limits of 6 in.

Hg (0.2 bar) for a clean system or 12 in. Hg (0.4 bar) for a dirty system. The

maximum restriction for the fuel return line to the fuel tank is 15 in. Hg (0.5 bar).

Page 68

Page 78

FUEL SYSTEM PLUMBING REQUIREMENTS

Fuel coolers are installed on engines to reduce the temperature of the fuel being

returned from the engine to the fuel tank. Such a cooler can be installed in the fuel

system between the fuel junction block and the fuel tank. Fuel coolers are effective

and can lower fuel tank temperatures by as much as 20° F (11°C).

Fuel coolers are required for construction and industrial applications were ambient

air temperatures exceed 95°F (35.0°C). Excessive fuel temperature can adversely

affect the high-pressure fuel pump and ECM’s. The maximum allowable fuel inlet

temperature is 140°F (60°C). DDEC activates a check engine light at 179.6°F (82

°C).

Fuel supply hoses must be SAE number 16 (25mm I.D.) or larger. The fuel return

hoses must be SAE number 12 (18mm I.D.) or larger. Route hoses at least 12 in.

away from all exhaust components and do not route against sharp edges or in an

area where the hose may rub or vibrate against vehicle parts.

Page 69

Page 79

DAVCO FUEL FILTERS

Fig. 104 Fuel Pro 40 Fuel/Water Separator with Filter

FUEL FILTER ADAPTER

MARKINGS

Fig. 105 C&I Fuel Junction Block Off-engine Fuel Line Connection Identification

Page 70

Page 80

DAVCO FUEL FILTERS

Fig. 105 Marine Sea Pro 600 Fuel/Water Separator with Filter

Page 71

Page 81

FUEL SYSTEM PRIMING PROCEDURE

DO NOT PRESSURIZE

THIS PORT

FUEL PRIMING

PORT

Fig. 106 Fuel Junction Block Fuel Priming Port Location

PRIMING PROCEDURE

1. Open the vehicle fuel supply and return valves, if applicable.

2. Connect an external pressurized fuel supply (0.5 to 2.0 bar pressure) to the

priming port shown in Fig. .

NOTICE: Do not skip step 3. Do not try to bleed air at another location.

Severe damage to the high-pressure fuel pump will occur if it is not full of fuel at

engine start-up.

Fig. 107 Fuel System Vent Valve Fig. 108 Vent Valve with Quick

Coupling and Hose Connected

Page 72

Page 82

FUEL SYSTEM PRIMING PROCEDURE

Fig. 109 High-pressure Pump Fuel Return Line Fitting

3. Connect a hose with quick disconnect coupling P/N PD 243 to the vent valve

located on the body of the high-pressure fuel pump. (See Fig.107and

Fig.108) Place the open end of the hose in a container to catch fuel

discharge. On older units, loosen the fitting of the return fuel line on the

high-pressure fuel pump to allow air to bleed out of the pump crankcase.

(See Fig.109) When fuel flows without air bubbles present, disconnect the

quick coupling or tighten the return line fitting.

4. Disconnect the priming fuel supply.

5. Crank the engine in 20-second intervals, up to four times.

6. If the engine did not start, repeat the steps beginning with step 2.

7. After three attempts and the engine still did not start, loosen the highpressure fuel lines from the injectors at cylinder locations A1 and B1, at the

high-pressure fuel rails. Repeat the steps beginning with step 2.

8. Tighten the high-pressure line at cylinder A1 and B1 at the high-pressure fuel

rail connectors. Torque to 100 Nm + 10 Nm (74 l b . ft + 7.4 lb. ft).

Page 73

Page 83

FUEL SYSTEM TROUBLE SHOOTING

To help determine the root cause of the fuel system problem, A complete DDEC data list or DDDL should be taken at the following three steady state points:

1. Idle, while the code is active

2. Full power, rated speed

3. Rated speed, no load

The data list must contain the following parameters:

- Engine S/N

- 6N4D

- Injection control pressure

- Fuel rail pump utilization

- Fuel delivery pressure

- Engine RPM

- Fuel temperature

- Percent engine load

- Battery voltage

- PWM3 output

The high-pressure fuel pump is directly affected by the availability of low-

pressure fuel being supplied. The lack of sufficient low-pressure fuel supply will

result in the control solenoid PWM3 demand signal being raised above normal

range and the pump usage exceeding 97 percent. Excessive high-pressure pump

usage above 97 percent will cause a PWM3 DDEC Code above normal range and

eventual failure of the high-pressure pump.

Hard Starting

Probable Causes Check Corrective Action

No fuel supply Fuel supply Replenish Bad seat at the high-

pressure rail relief valve

High-pressure rail relief

valve

Clean or replace as

needed

Engine Fires Erratically After Starting

Probable Causes Check Corrective Action

Fuel system is not vented Does engine fire steady

after short period

Fuel injector faulty Injector wiring, unit

injector solenoid, ECM’s

Open system vent

Replace injector, wiring

harness or ECM’s as

required

Page 74

Page 84

FUEL SYSTEM TROUBLE SHOOTING

Engine Does Not Reach Full-Load Speed

Probable Causes Check Corrective Action

Fuel Injectors faulty Injectors, wiring harness,

ECM’s

High-pressure fuel pump insufficient pressure

Check fuel supply

Check battery voltage to

controller

Replace as needed

Replenish

Correct cause for low

battery voltage

Engine Speed Not Steady

Probable Causes Check Corrective Action

Fuel Injectors faulty Injectors, wiring harness,

ECM’s

High-pressure fuel pump controller faulty

Excessive fuel inlet restriction

Check battery voltage to

controller

Plugged fuel filters

Incorrectly plumbed

remote fuel filters

Replace as needed

Correct cause for low

battery voltage

Replace controller

Replace filters

Correct remote fuel filter

plumbing

Code 63, PWM 3 Above Normal Range

Probable Causes Check Corrective Action

No battery voltage on 440 circuit to high-pressure pump controller

Short in ECM DDEC Codes Replace ECM Controller faulty Replace controller Restricted or low fuel

supply

High-pressure pump If low-pressure fuel

Page 75

Available battery voltage

Wiring harness and

connectors

Fuel Supply

Fuel Filters and lines for

obstruction

supply OK, disconnect

24-Volt power supply

Replace batteries

Repair or replace wiring

harness or connectors

Replenish

Replace filters

Repair fuel lines

Injection pressure does

not change, replace highpressure pump

Page 85

FUEL SYSTEM TROUBLE SHOOTING

Code 63, PWM 3 Below Normal Range

Probable Causes Check Corrective Action

440 Not on it’s own battery post

Controller faulty Replace controller

Wiring harness Repair wiring harness or

connectors

Fuel Leaks at Injector

Probable Causes Check Corrective Action

Fuel in oil Injector O-rings Replace O-rings Injector O-ring Leaking C-E ring leaking Replace C-E ring and O-

rings.

Loose fuel line Fuel line torque Retorque

Fuel line connector

internal nut adjustment

Connector internal nut

torque

Retorque

Fuel Leaks at Fuel Rail

Probable Causes Check Corrective Action

Fuel line connector internal nut adjustment

Limiter valve seat at highpressure fuel rail

Connector internal nut

torque

Limiter valve seat Repair seat or replace

Retorque

high-pressure fuel rail

Fuel Pressure Too High

Probable Causes Check Corrective Action

High-pressure fuel sensor faulty

High-pressure fuel pump controller faulty

Page 76

DDEC code

DDEC fuel pressure

reading

Check battery voltage to

controller

Replace sensor

Low battery voltage

Replace controller

Page 86

FUEL SYSTEM TROUBLE SHOOTING

High-pressure Fuel Pump Leaking at Weep Hole

Probable Causes Check Corrective Action

High-pressure pump leaking fuel

High-pressure pump leaking oil

Fuel temperature

Contaminated fuel

High-pressure pump

crankcase seal

Crankcase pressure

High-pressure pump drive

seal

Correct cause of high fuel

temperature

Clean fuel system and

replace contaminated fuel

Replace high-pressure

pump

Correct cause of high

crankcase pressure

Replace high-pressure

pump

Low Fuel Pressure

Probable Causes Check Corrective Action

Fuel level too low Fuel Supply Replenish

Fuel supply blocked Shut off valve in system Open

Fuel line leaking Seals and torque of

fittings

Fuel filter plugged Secondary and remote

filters

Fuel delivery pump faulty Fuel delivery pump and

drive

High-pressure fuel

pressure sensor faulty

High-pressure fuel pump controller faulty

High-pressure rail relief valve leaking

High-pressure fuel pump generating insufficient pressure

Page 77

DDEC codes Replace

Check battery voltage to

controller

Fuel return from relief

valve

DDEC fuel pressure

reading

Seal, replace if needed

Tighten fittings

Replace filters

Replace as needed

Correct cause for low

battery voltage

Clean or replace relief

valve as needed

Replace high-pressure

pump

Page 87

TORQUE SPECIFICATIONS

FOR FUEL SYSTEM COMPONENTS

DESCRIPTION SIZE CAT. USAGE DESCRIPTION TORQUE

(Nm)

BOLT M3 A INJECTOR TERMINAL 1.4 - 2.0

BOLT, CLASS 10.9

(P/N 5249902101)

METAL TO METAL CONE

SEAL

METAL TO METAL CONE

SEAL

FUEL LINE M24 X 1.5 C NUT, HP FUEL LINES

FUEL LINE M40 X 1.5 C NUT, HP FUEL LINES

FUEL LINE M42 X 1.5 A FUEL RAIL NUT 550 - 605

FUEL LINE C NUT, HP FUEL LINES

SENSOR M18 X 1.5 A FUEL MONITOR – MARINE 25 – 28

CATEGORY (CAT.) DESCRIPTIONS

A - LOAD WITHIN DESIGN CAPABILITY.

PROCESS VERIFICATION CONTROLLED BY CORRECT TOOLING.

VERIFIC ATION - TO MINIMUM TORQUE VALUE.

C - LOAD REQUIRED SENSITIVE TO BOTH LOW & HIGH VALUES.

PROCESS CONTROLLED BY SPECIAL TORQUE EQUIPMENT OR

PROCESS

VERIFIC ATION - TO GIVEN RANGE OF TORQUE VALUES.

F - JOINT SENSITIVE TO TORQUE SEQUENCE. SEE ENGINE BUILD

INSTRUCTIONS.

NOTE: TORQUE SPECIFICATION DOES NOT APPLY TO HOT ENGINES.

RECHECK OF TORQUE AT ROOM TEMPERATURE TO BE NOT LESS THAN 90

PERCENT OF MINIMUM ASSEMBLY VALUE.

Page 78

M12 A INJECTOR HOLD DOWN

CLAMP

M14 X 1.5 A HIGH PRESSURE FUEL

SENSOR

M16 X 1.5 A LOW PRESSURE FUEL RAIL

END CAP

(REFERENCE CATEGORY F)*

(REFERENCE CATEGORY F)*

(HP PUMP TO RAILS)

(REFERENCE CATEGORY F)*

115 - 125

30 - 40

30 - 33

100 -

110*

100 -

110*

100-110

Page 88

Page 79

Page 89

SERVICE INFORMATION

TECHNICAL SERVICE LETTERS

• NO.: 01 TS – 28 May 1, 2001

Addition of an Injector Hold-down Bolt Washer with Revised Torque

• NO.: 00 TS – 24 June 6, 2000

Injector Response Time (IRT) Long Codes

SERVICE INFORMATION BULLETINS

• 1-4000-99 February 1999

Injector Seal Installation Improvement

• 5-4000-99 August 1999

Fuel System Cleaning After High-pressure Pump Failure

• 6-4000-99 October 1999

New Floating Style Fuel Tubes Replace Brazed Fuel Tubes

• 3-4000-00 January 2000

Release of Low-pressure Fuel Tube Support

• 9-4000-00 March 2000

Model Year 2000 Emissions Requirements

• 20-4000-00 December 2000

Improved Injector C-E Ring Released

• 9-4000-01 May 2001

Improved Low-pressure Fuel Plumbing System

MTU SERVICE INFORMATION BULLETINS

• 4000-99/0028

HP Fuel Lines, Tightening of Thrust Rings after Disassembly

18SP INSTALLATION INSTRUCTIONS

• 18SP503

Installation of DIN Common Rail Fuel Pressure Sensor

Page 80

Page 90

Page 81

Page 91

NO.: 01 TS - 28

May 1, 2001

TO: All Detroit Diesel Distributors - Worldwide

FROM: S-4000 Technical Service Department

ATTN: General Service Manager

SUBJECT: Addition of an Injector Hold-down Bolt Washer with Revised Torque

To improve the injector clamp retention, Detroit Diesel released for production a hardened

injector hold-down bolt washer P/N 23509483 effective with Series 4000 engine serial numbers

(12V) 5262000340 and (16V) 5272000713.

Fig. 1) Cut-away showing injector installation with hardened washer installed.

Additionally, the torque for the injector hold-down bolt has been revised from 100-110 N-m to

115- 125 N-m (85-92 ft-lbs.).

At any time injectors are serviced, include the new hardened washer and revised torque

specification during re-installation of the injector.

With these changes and the use of the most current C-E ring (P/N 23540260), the need to

retorque the injector hold-down bolts during the 50-Hour Inspection is no longer required.

Floyd Pemberton

S-4000 Technical Service Department

World Headquarters - 13400 Outer Drive, West / Detroit, Michigan 48239-4001 / Telephone: 313-592-5000

An Equal Opportunity Employer

Page 92

Page 93

http://192.135.85.10/readonly/distribs_only/htms/00TS-24-5-06282000.htm

5/25/01

00 TS-24

Injector Response Time (IRT) long codes have a greater tendency for occurrence in certain cylinders as a result of increased electrical

ground wire, which runs back to battery,

To further help with response time problems and noisy injector operation, a third ground wire can be installed for the receiver power

Use one of the spare wires in the engine power harness to run 150 R #3 from pin B on the 5 pin receiver power harness connector to

pin S on the 16 pin Duetsch connector. This will equalize the power harness resistance for both ECM's and provide additional

Additionally, LeTourneau and Unit Rig installations will have pin S unused and plugged. These two OEMs would need to modify the

wire installed on the OEM side of the

wire will need to be installed from the

Repower installations should be rewired to take advantage of the additional ground. All repowers must have the correct size wire on

Updating former injectors to low flow style injectors P/N 23526589 and re-calibrating the ECM's (Reference Service Information Bulletin

June 6, 2000

TO: All Detroit Diesel Distributors - Worldwide

FROM: S-4000 Technical Service Department

ATTN: General Service Manager

SUBJECT: Injector Response Time (IRT) Long Codes

Applications: All Construction, Industrial and Generator Applications.

resistance being detected. This resistance can occur in the OEM power harness, injector harnesses or in the injector solenoids themselves.

To reduce the possibility of Injector Response Time long codes; Detroit Diesel has released the following improvements:

1. Engine Power Harness - 3rd receiver ground wire.

All applications have pin S of the 16-pin power harness connector populated with a 12 AWGground (just like the other #150 ground wires). All three have pin S labeled as wire 954.

harness.

protection against IRT codes on the receiver ECM.

harnesses for a 3rd 150 R wire. Units in the field would have to have an additional #12 AWGDuetsch power connector back to battery ground.

For Generator applications without the 16 pin power harness connector, an additional #12 AWGpin B of the 5 pin receiver power harness connector back to battery ground.

the power harness.

2. New equal resistance injector harnesses have been released in March (Refer to Service Information Bulletin 11-4000-00).

(12V- A bank) P/N 23540167, (12V- B bank) P/N 23540166

(16V- A bank) P/N 23540165, (16V- B bank) P/N 23540164

3.

9-4000-00), will reduce the DDEC sensitivity to Injector Response Times.

AUTHOR: Floyd Pemberton

AUTHOR'S TITLE: S-4000 Technical Service Department

Page 94

NUMBER: 1-4000-99 S.M. REF.: Information Only ENGINE: 4000 DATE: February 1999

SUBJECT:INJECTOR SEAL INSTALLATION IMPROVEMENT

INTRODUCTION

The fuel injector CE-ring assembly on Series 4000™ engines must be installed in the correct position to

provide reliable service.

DETAILS AND REASON

The current fuel injector CE-ring assembly 5240160419 replaces former CE-ring seal 0000160119. This CEring assembly must be mounted on the fuel injector with the flat side placed towards the spray tip nut. Correct

positioning of the injector CE-ring assembly insures proper sealing of the fuel injector into the cylinder head,

preventing oil leakage past the fuel injector into the cylinder bore. To aid installation of the CE-ring assembly,

apply a small amount of grease to the injector body.

ADDITIONAL SERVICE INFORMATION

Additional service information will be available in the Detroit Diesel Series 4000 Service Manual, 6SE4000,

which is currently in process. This manual will include the injector information.

Page 95

Detroit Diesel®, Detroit Diesel and Spinning Arrows Design® are registered trademarks of Detroit Diesel Corporation. Series 4000™ is a trademark of

Detroit Diesel Corporation.

© Copyright 1999 Detroit Diesel Corporation. All rights reserved. Printed in U.S.A.

Page 96

NUMBER: 5-4000-99 S.M. REF.: Information Only ENGINE: 4000 DATE: August 1999

SUBJECT: FUEL SYSTEM CLEANING AFTER HIGH-PRESSURE PUMP FAILURE

INTRODUCTION

Detroit Diesel has released a cleaning procedure for the U. S.-manufactured Series 4000™ engine fuel system to

be completed after a high-pressure fuel pump has failed. This condition requires that the entire fuel system be

thoroughly cleaned of ceramic particles to prevent further damage to the fuel system components.

DETAILS AND REASON

Detroit Diesel has released a cleaning procedure for the U. S.-manufactured Series 4000 engine high-pressure

fuel system in the event a high-pressure fuel pump fails. Should the idler gear be disengaged from the pump

shaft, this would indicate that the ceramic bearing has failed. If a bearing fails, the shaft of the high-pressure

pump will seize and will not rotate. If this condition is experienced, the following cleaning procedure must be

performed to prevent further damage to the fuel system components.

NOTICE:

Failure to clean the fuel system of ALL ceramic particles will result in the contamination