Detroit Diesel Engine MBE4000 Service Manual

MBE 4000 SERVICE

MANUAL

REVISION NOTIFICATION

Modifications to this manual are announced in the form of Service Information

Bulletins. The

(www.detroitdiesel.com/svc/sibindex.htm).

Revisions to this manual will be sent marked with a revision bar (see Example 2). Sections

containing re

bulletins include attachment pages and are posted on the World Wide Web

visions will have a third line in the page footer (compare Examples 1 and 2).

ENGINE EXHAUST

Consider the following before servicing engines:

All information subject to change without notice.

6SE412 0403 Copyright © 2004 DETROIT DIES EL CORPORATION i

MBE 4000 SERVICE

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

MANUAL

PERSONAL INJURY

ii 6SE412 0403 Copyright © 2004 DETROIT DIES EL CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE

MANUAL

TABLE OF CONTENTS

GENERAL INFORMATION ...................................................................... 1

SCOPE AND USE

GENERAL DESCRIPTION ...................................................................... 3

ELECTRONIC ENGINE CONTROL SYSTEM ......................................... 4

ENGINE BRAK

GENERAL S PECIFICATIONS AND ENGINE VIEWS ............................. 7

ENGINE MODEL AND SERIAL NUMBER ............................................... 14

EXHAUST GA

SAFETY INSTRUCTIONS AND PRECAUTIONS .................................... 20

ENGLISH TO METRIC CO NVERSION .................................................... 32

DECIMAL AN

TORQUE SPECIFICATIONS ................................................................... 35

1ENGINE

1.1 CYLINDER

HEAD COVER ......................................................................

1.2 CYLINDER HEAD .................................................................................... 1-5

1.3 CYLINDER BLOCK .................................................................................. 1-24

1.4 EGR CYLI

NDER HEAD AND BLOCK .....................................................

1.5 EGR FRONT AND REAR LIFTER BRACKETS ....................................... 1-43

1.6 ENGINE BRAKE ...................................................................................... 1-45

1.7 FRONT R

ADIAL SEAL .............................................................................

1.8 REAR RADIAL SEAL ............................................................................... 1-54

1.9 CRANKSHAFT ASSEMBLY ..................................................................... 1-57

1.10 FRONT C

OVER HOUSING .....................................................................

1.11 CRANKSHAFT VIBRATION DAMPER ..................................................... 1-84

1.12 FLYWHEEL .............................................................................................. 1-86

1.13 RING G

EAR .............................................................................................

1.14 PILOT BEARING ...................................................................................... 1-100

1.15 ENGINE CRANKING TOOL ..................................................................... 1-102

1.16 FLYW

HEEL HOUSING .............................................................................

1.17 PISTON, PISTON RING, AND CONNECTING ROD ............................... 1-106

1.18 EGR P ISTON, PISTON RING, AND CONNECTING ROD ...................... 1-135

1.19 VALV

ES ....................................................................................................

1.20 EGR VALVES ........................................................................................... 1-161

1.21 ROCKER ARM ......................................................................................... 1-166

1.22CAM

SHAFT AND CAMSHAFT SENSOR ................................................

1.23 EGR CAMSHAFT ..................................................................................... 1-181

1.A ADDITIONAL INFO RMATION .................................................................. 1-183

OF TH IS MANUAL .....................................................

ING POWER ....................................................................

S REC IRCULATION (EGR) SYSTEM ...............................

D METRIC EQUIVALENTS ................................................

1-3

1-40

1-51

1-82

1-96

1-10

1-13

1-1

3

7

16

33

4

8

70

2FUELSYSTEM

2.1 INJECTOR UNIT PUMP ........................................................................... 2-3

2.2 EGR INJECTOR UNIT PUMP .................................................................. 2-11

3

2.

All information subject to change without notice.

6SE412 0403 Copyright © 2004 DETROIT DIES EL CORPORATION iii

EL INJECTOR LINE ............................................................................

FU

2-

13

MBE 4000 SERVICE

MANUAL

2.4 FUEL INJECTOR NOZZLE ...................................................................... 2-18

2.5 EGR FUEL INJECTOR NOZZLE ............................................................. 2-24

2.6 PROTECTIVE SL

EEVE ...........................................................................

2.7 DDEC ELECTRONIC CONTROL UNIT ................................................... 2-29

2.8 FUEL HEAT EXCHANGER ...................................................................... 2-34

2.9 FUEL FILTER ........................................................................................... 2-37

2.10 EGR FUEL FILTER .................................................................................. 2-41

2.11 FUEL PUMP ............................................................................................. 2-43

2.12 FUEL SYSTEM I

NSPECTION .................................................................

2.A ADDITIONAL INFORMATION .................................................................. 2-57

3 LUBRICATION SYSTEM

3.1 OIL PAN ................................................................................................... 3-3

3.2 OIL SPRAY NOZZLE ............................................................................... 3-9

3.3 EGR CAMSHAFT LUBRICATION SPRAYER .......................................... 3-13

3.4 OIL PU MP ................................................................................................ 3-14

3.5 EGR O IL PUMP AND PICK UP TUBE ..................................................... 3-21

3.6 OIL FILTER .............................................................................................. 3-23

3.7 OIL HEAT E

XCHANGER AND FILTER HOUSING ..................................

3.8 OIL PR ESSURE AND TEMPERATURE SENSOR .................................. 3-32

3.A ADDITIONAL INFORMATION .................................................................. 3-35

2-25

2-47

3-26

4 COOLING SYSTEM

4.1 COOLING SYSTEM ................................................................................. 4-3

4.2 COOLANT PUMP .................................................................................... 4-8

4.3 EGR COOL

ANT PUM P ............................................................................

4-20

4.4 FRONT IDLER AND TENSIONER SUPPORT ........................................ 4-22

4.5 THERMOSTAT ......................................................................................... 4-25

4.6 EGR THE

RMOSTAT HOUSING ...............................................................

4-30

4.7 COOLANT TEMPER ATURE SENSOR .................................................... 4-32

4.A ADDITIONAL INFORMATION .................................................................. 4-35

5 FUEL, LUBRICATING OIL, AND COOLANT

5.1 FUEL ........................................................................................................ 5-3

5.2 LUBRICATING OIL ................................................................................... 5-5

5.3 COOLA

NT ................................................................................................

5-7

5.A ADDITIONAL INFORMATION .................................................................. 5-13

6 AIR INTAKE SYSTEM

6.1 INTA

KE MANIFO LD .................................................................................

6-3

6.2 CHARGE PRESSUR E/TEMPERATURE SENSOR ................................. 6-5

6.3 TURBOCHARGER ................................................................................... 6-6

6.A ADD

7EXH

ITIONAL INFORMATION ..................................................................

AUST SYSTEM

6-1

7.1 EXHAUST MANIFOLD ............................................................................. 7-3

7.

2

HAUST BRAKE ASSEMBLY ...............................................................

EX

7-

7.3 EGR EXHAUST MANIFOLD .................................................................... 7-14

7.4 EGR COO LER AND COOLER SUPPORT BRACKET ............................ 7-26

7.

5

R CONTROL VALVE, GAS OUTLET PIPE, AND GAS MIXER ..........

EG

7-

43

7

6

iv 6SE412 0403 Copyright © 2004 DETROIT DIESEL COR P ORATION

All information subject to change without notice.

MBE 4000 SERVICE

MANUAL

7.6 EPV (ELECTRONIC PROPORTIONAL VALVE) AND WABCO®AIR

SOLENOID VALVE ................................................................................... 7-51

7.7 HENGST

®

BREATHER FILTER ............................................................... 7-55

7.A ADDITIONAL INFO RMATION .................................................................. 7-59

8 ELECTRICAL EQUIPMENT

8.1 DRIVE BELTS .......................................................................................... 8-3

8.A ADDITIONAL INFO RMATION .................................................................. 8-15

9 POWER TAKE-OFF

9.1 POWER TAKE-OFF ................................................................................. 9-3

10 SPECIAL EQUIPMENT

10.1 AIR CO MPRESSOR ................................................................................ 10-3

10.A ADDITIONAL INFO RM ATION .................................................................. 10-11

11 OPERATION A ND VERIFICATION

11.1 PREPARATION FOR A FIRST TIME START ........................................... 11-3

11.2 STARTING THE ENGINE ......................................................................... 11-7

11.3 RUNNING THE ENGINE .......................................................................... 11-10

11.4 STOPPING THE ENGINE ........................................................................ 11-12

12 ENGINE TUNE-UP

12.1 VALVE LASH CHECKING ........................................................................ 12-3

12.2 ADJUSTING VALVE LASH ....................................................................... 12-10

13 PREVENTIVE MAINTENANCE

13.1 SCHEDULED INTERVALS ....................................................................... 13-3

14 ENGINE STORAGE

14.1 PREPARING ENGINE FOR STORAGE ................................................... 14-3

15 MECHANICAL TROUBLESHOOTING

15.1 TROUBLESHOOTING THE ELECTRONIC ENGINE CONTROL

SYSTEM .................................................................................................. 15-3

15.2 GENERAL TROUBLESHOOTING ........................................................... 15-4

INDEX ................................................................................................. Index-1

All information subject to change without notice.

6SE412 0403 Copyright © 2004 DETROIT DIES EL CORPORATION v

MBE 4000 SERVICE

MANUAL

vi 6SE412 0403 Copyright © 2004 DETROIT DIESEL CORPORATION

All information subject to change without notice.

GENERAL INFORMATION

Section Page

SCOPE A ND USE OF THIS MANUAL ....................................................... 3

GENERAL DESCRIPTION ......................................................................... 3

ELECTRONIC ENGINE CONTROL SYSTEM ............................................ 4

ENGINE BRAKING POWER ....................................................................... 7

GENERAL S PECIFICATIONS AND ENGINE VIEWS ................................ 7

ENGINE MODEL AND SERIAL NUMBER ................................................. 14

EXHAUST GAS RECIRCULATION (

SAFETY INSTRUCTIONS AND PRECAUTIONS ....................................... 20

ENGLISH TO METRIC CO NVERSION ...................................................... 32

DECIMAL AND METRIC EQUI

TORQUE SPECIFICATIONS ...................................................................... 35

EGR) SYSTEM ..................................

VALENTS ...................................................

16

33

MBE 4000 SERVICE MANUAL

2 6S

E412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

SCOPE AND USE OF THIS MANUAL

This manual contains complete instructions on oper ation, adjustment (tune-up), preventive

maintenance, and repair (including complete overhaul) for the MBE 4000 engine. This manual

was written primarily for persons servicing and overhauling the engine. In addition, this manual

contains all of the instructions essential to the oper ators and users. Basic maintenance and

overhaul procedures are common to all MBE 4000 engines, and apply to all engine models.

This manual is divided into numbered sections. Section one covers the engine (less major

assemblies). The following sections cover a complete system such as the fuel system, lubrication

system, or air system. Each section is divided into subsections which conta in comple te

maintenance and operating instructions for a specific engine subassembly. Each section begins

with a table of contents. Pages and illustrations are numbered consecutively within each section.

Information can be located by using the table of contents at the front of the manual or the table of

contents at the beginning of each section. Information on specific subassemblies or accessories

within the major section is listed immediately following the sec tion title.

GENERAL DESCRIPTION

The MBE 4000 Engine described in this manual is a water-cooled, four-stroke, direct injection

diesel engine. The cylinders are arranged in line. Each cylinder has a separate fuel injection pump

(unit pump) with a short injection line to the injection nozzle, which is located in the center of

the combustion chamber. The unit pumps are attached to the crankcase and are driven from the

camshaft. Each cylinder has two intake valves and two exhaust valves.

Charge-air cooling and an exhaust ga s turbocharger are standard equipment on all MBE 4000

engines.

The engine has a fully electronic control system, which regulates the injection quantity and timing

using solenoid valves, allowing extremely low-emission operation. The control system consists of

an engine-resident pump and nozzle c ontrol unit (the DDEC-ECU ) and a vehicle control unit (the

DDEC-VCU). The two are connected by a proprietary datalink.

Engine braking is controlled by a pneumatically-operated exhaust brake on the turbocharger and

by a constant-throttle system. For greater braking power, an optional turbo brake is available.

The cylinder block has integrated oil and water cha nnels. The upper section of the cylinder bore

is induction-hardened. The six individual cylinder heads are made of cast iron. The c ylinder head

gasket is an adjustment-free seal with rubber sealing elements.

The pistons are made of aluminum alloy with ring carriers and a shallow com bustion chamber

recess. The pistons are cooled b y oil spray nozzles.

The crankshaft is precision-forged with seven main bearings and eight custom-forged counter

weights, and a vibration damper at the front end.

The camshaft is made of induction-har dened steel and has seven main bearings. Each cylinder has

cams for intake and exhaust valves and a unit pump.

The valves are controlled by mushroom tappe ts, pushrods, and rocker arms. The intake and

exhaust valves are opened and closed by a valve-guided bridge.

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

3

MBE 4000 SERVICE MANUAL

There is a force-feed lubricating oil circuit supplied by a gear-type oil pump. This pump is

positioned at the rear of the oil pan and driven by gears from the crankshaft. The oil heat

exchanger is located near the front of the crankcase on the right-hand side ne ar the turbocharger.

The gear-type fuel pump is located near the front of the crankcase on the left hand side. The pump

is driven from the forward end of the cam shaft.

The air compressor, with a power-steering pump attached, is driven by a gear on the camshaft.

The engine is cooled by a closed s ystem using recirculated coolant; temperature is regulated

automatically by a t herm ostat.

There are three drive belts, each with its own automatic belt tensioner. The alternator and coolant

pump (and any other accessories) are driven by a main drive belt. The fan and the air conditioner

compressor are each driven by their own drive belt.

ELECTRONIC ENGINE CONTROL SYSTEM

The engine is equipped with a fully electronic control system. Besides the engine and its related

sensors, this system is composed of the DDEC-ECU, or engine c ontrol unit, and the DDEC-VCU,

or vehicle control unit. The two control units are connected by a proprietary datalink through

which all necessary data and information can be exchanged. The DDEC-VCU then broadcasts

all information on the J1587 and J1939 datalinks, where it can be read by minidiag2, Nexiq™

Diagnostic Data Reader (DDR), or Detroit Diesel Diagnostic Link

®

(DDDL) PC software.

The DDEC-ECU m onitors both the engine and the datalink. When a malfunc tion or other

problem is detected, the system selects an appropriate response; for example, the emergency

running mode may be activated.

4 6S

E412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

DDEC-ECU — Engine-Resident Control Unit

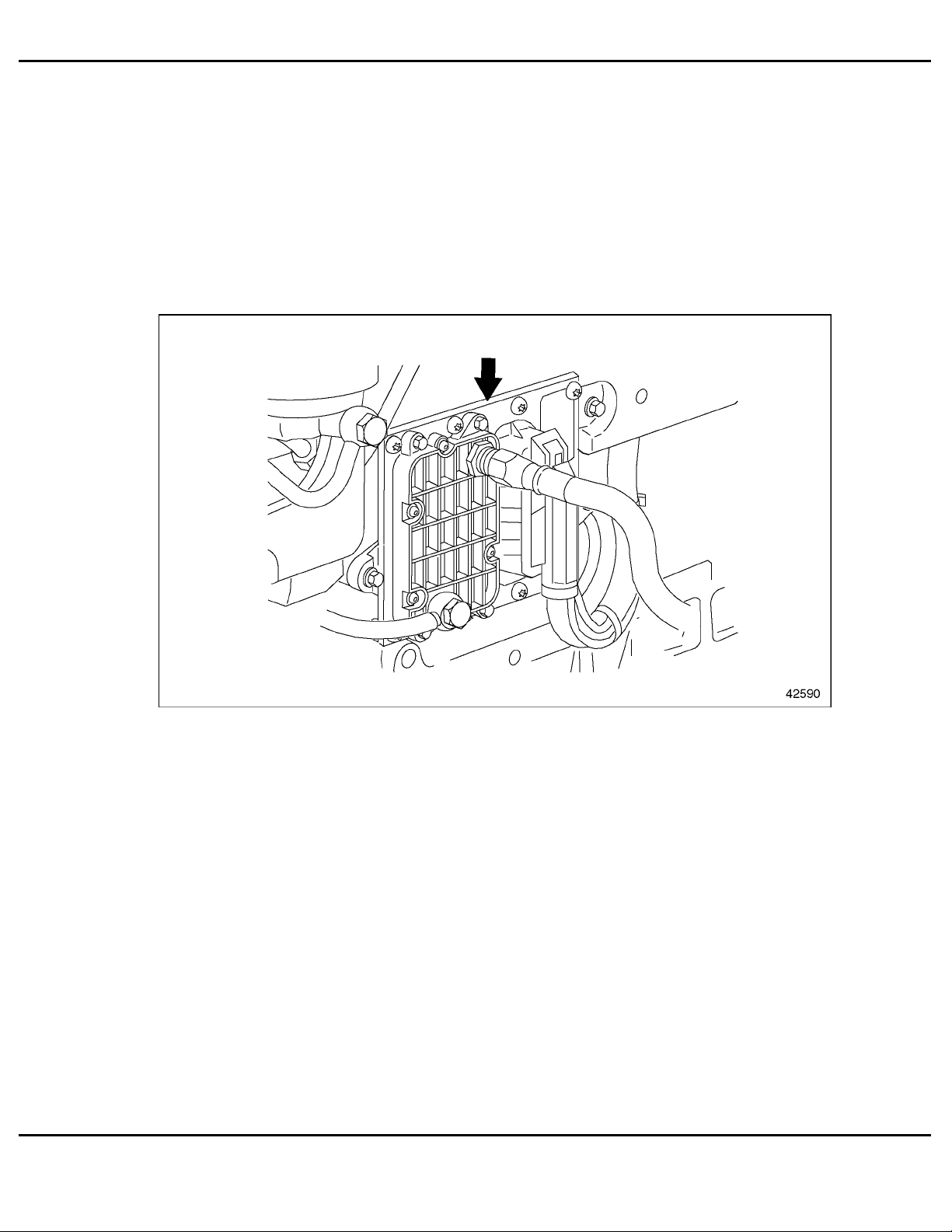

The DDEC-ECU control unit is loc ated on the left-hand side of the engine. See Figure 1. The

DDEC-ECU processes the data received from the DDEC-VCU, for example the position of the

accelerator p edal, engine brake, etc. These data are evaluated together with the data from the

sensors on the engine, such as, charge and oil pressure and coolant and fuel temperature. The

data is then compared to the characteristic maps or lines stored in the DDEC-ECU. From these

data, quantity and timing of injection are calculated and the unit pumps are actuated accordingly

through the solenoid valves.

Figure 1 DDEC-ECU Control Unit Location

NOTE:

To obtain a replacement DDEC-ECU, all the data given on the DDEC-ECU label are

required.

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

5

MBE 4000 SERVICE MANUAL

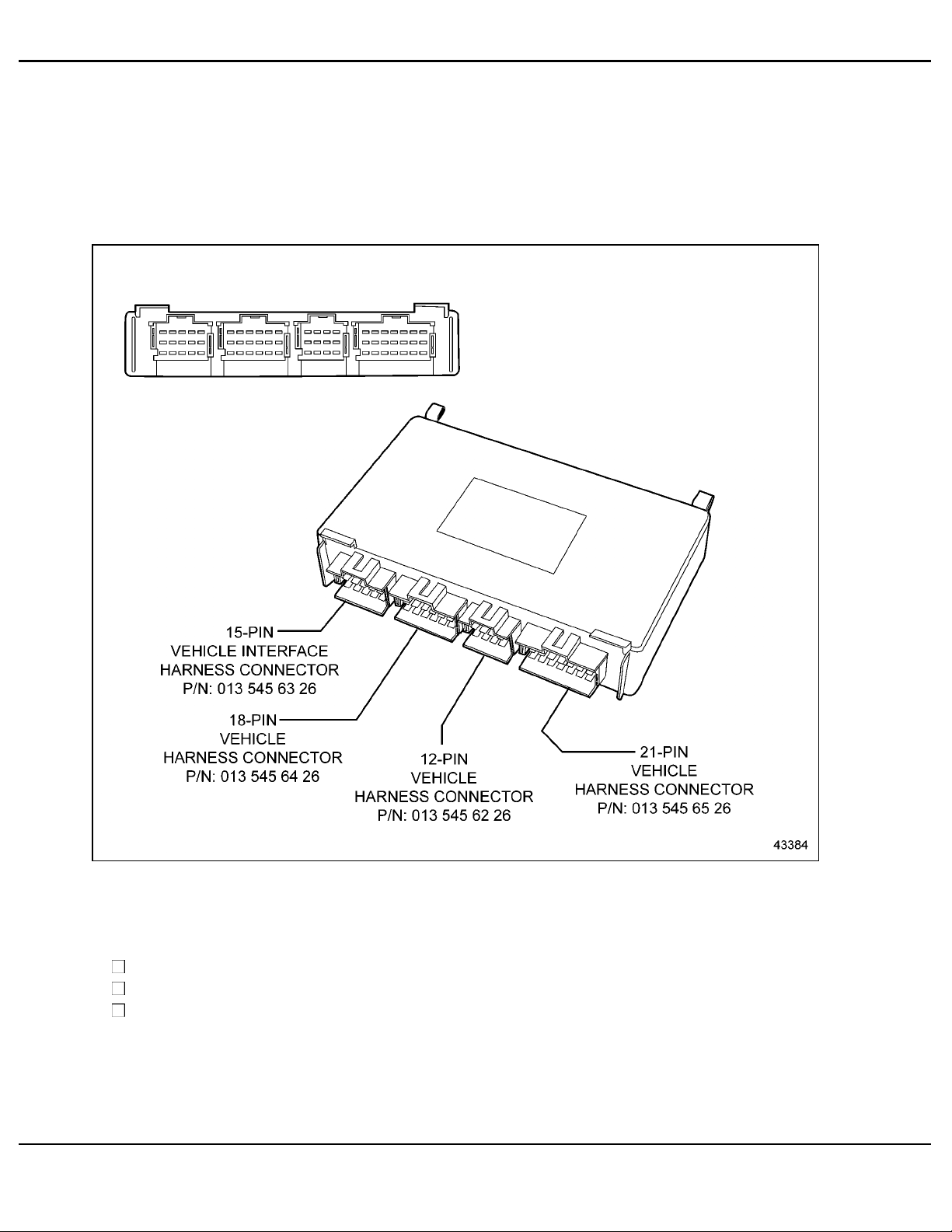

DDEC-VCU — Vehicle Control Unit

The vehicle control unit (DDEC-VCU) communicates w ith other electronic control units installed

on the vehicle over the J1587 datalink. See Figure 2. Within the DDEC-VCU, sets of data for

specific applications are stored. These include idle speed, ma ximum running speed, and speed

limitation.

Figure 2 Vehicle Control Unit (DDEC-VCU)

The DDEC-VCU rec

eives data from the following sources:

The operator (accelerator pedal position, engine brake switch)

Other electronic control units (for example, the antilock brake system)

The DDEC-ECU con

6 6S

trol unit (data such as oil pressure and coolant temperature)

E412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

From these data, instructions are computed for controlling the engine and transmitted to the

DDEC-ECU via the proprietary datalink. The DDEC-VCU controls various systems, for example,

communications with the datalink, the engine brake, and the constant-throttle valves. If the

engine control system detects a fault, the appropriate fault code is broadcast on the datalink

and can be read using minidiag2. When there is a fault, the code for the control unit reporting

the fault can be read directly on the display.

ENGINE BRAKING POWER

Exhaust B rake/Constant-Throttle Valves

To increase braking performa nce , the engine is equipped with an exhaust br ake on the

turbocharger in conjunction with constant-throttle valves on the cylinder head.

NOTE:

The constant-throttle values are activated by engine oil pressure.

The exhaust back-pressure is use d by the exhaust brake to increase braking performance.

Optional Turbo Brake

For high braking output, the MBE 4000 engine can be equipped with an optional turbo brake.

The turbo brake increases the air mass flow through the engine to provide up to 600 brake

horsepower. The turbo brake can be operated either manually or automatically, through the

cruise control function.

Because the charge air pressure is maintained at a high level during braking, full throttle r esponse

is available immediately, if the operator desires it, without any turbo lag.

The turbo brak e is maintenance-free, highly reliable, an d adds virtually no weight to the engine.

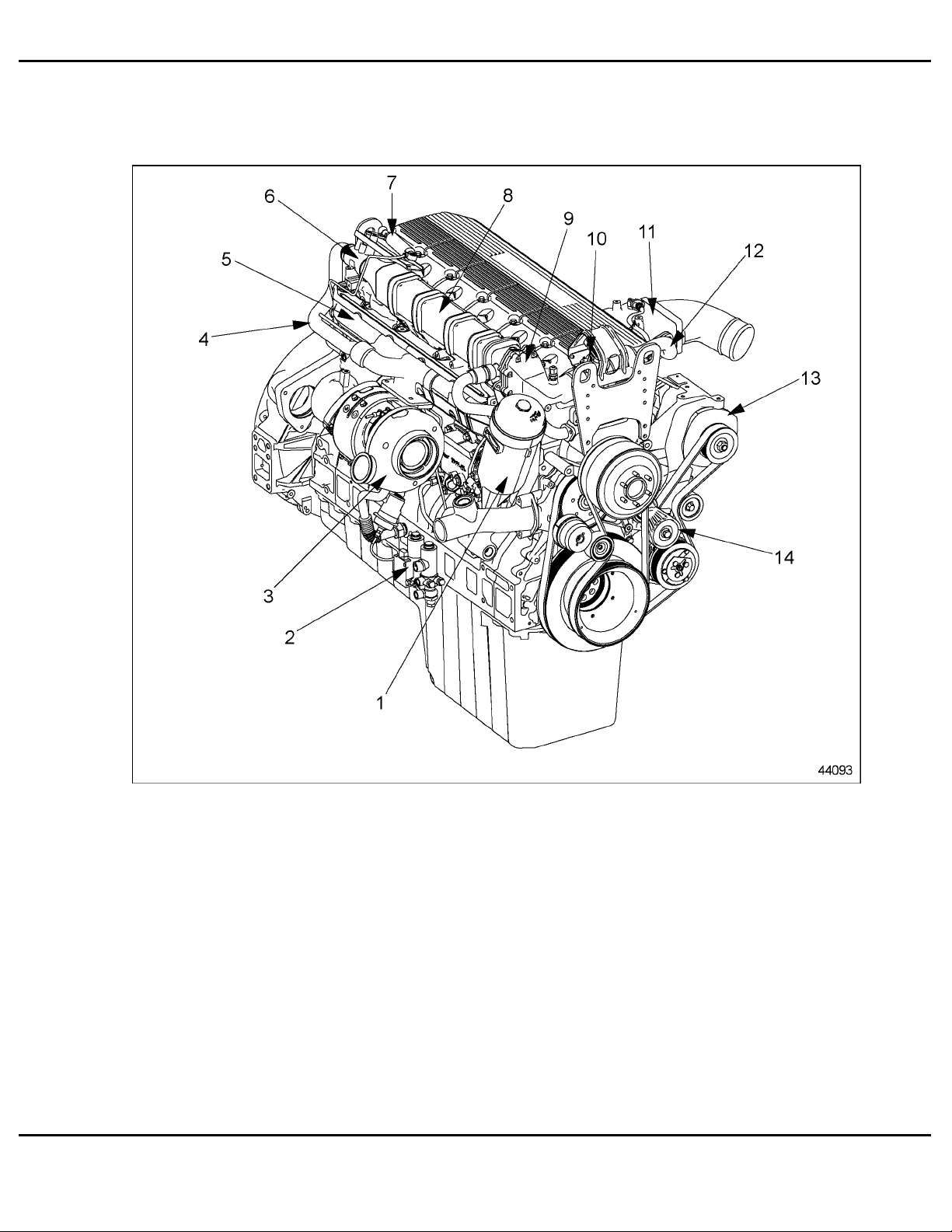

GENERAL S PECIFICATIONS AND ENGINE VIEWS

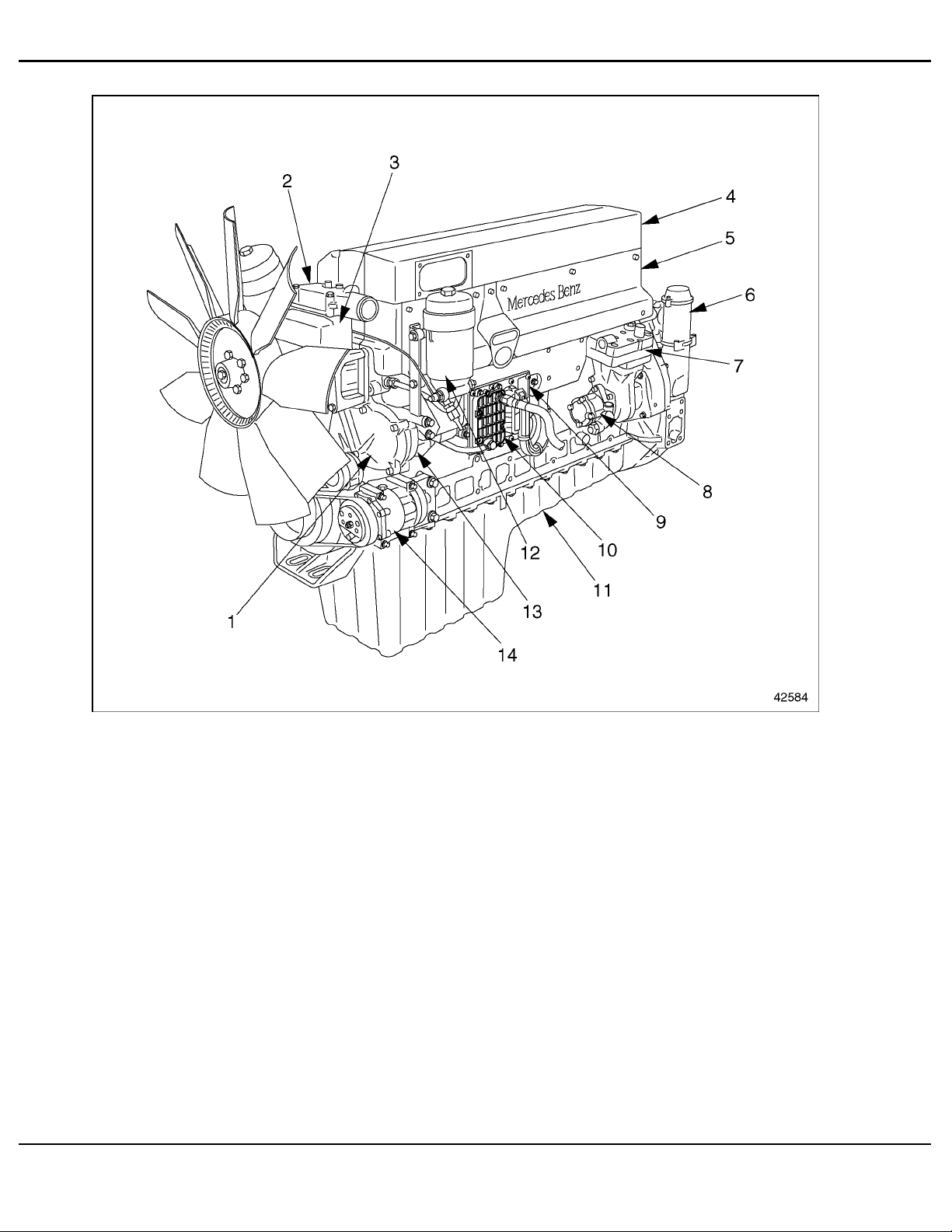

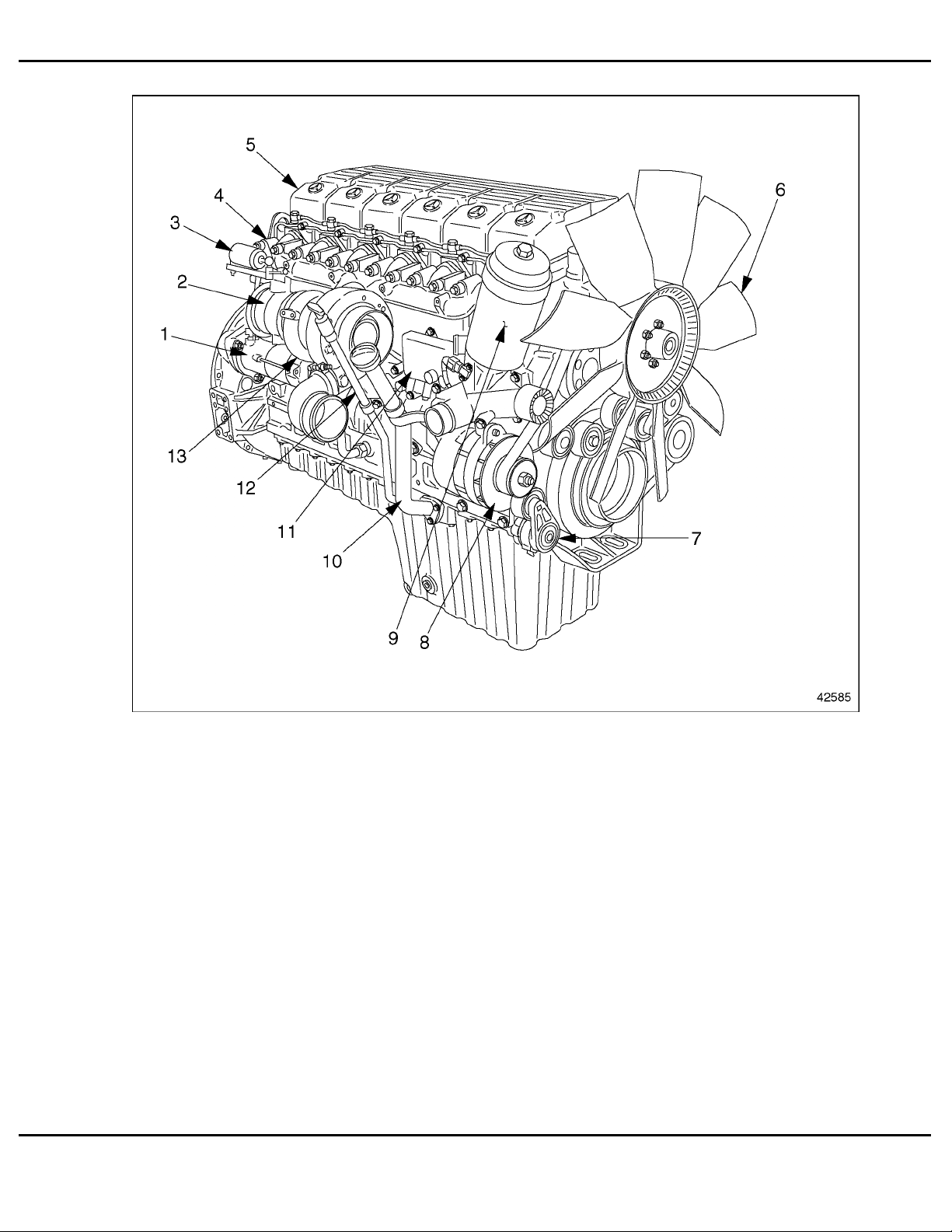

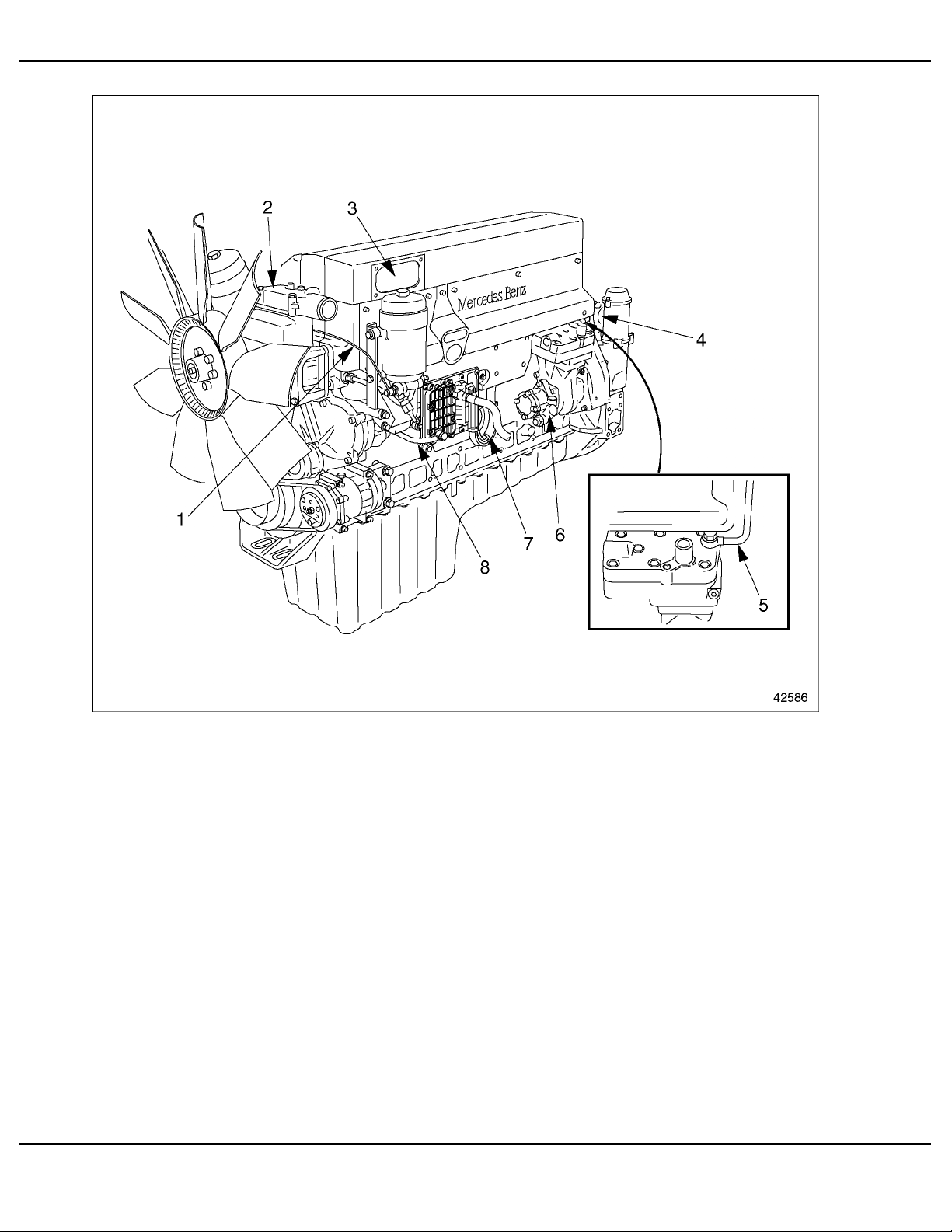

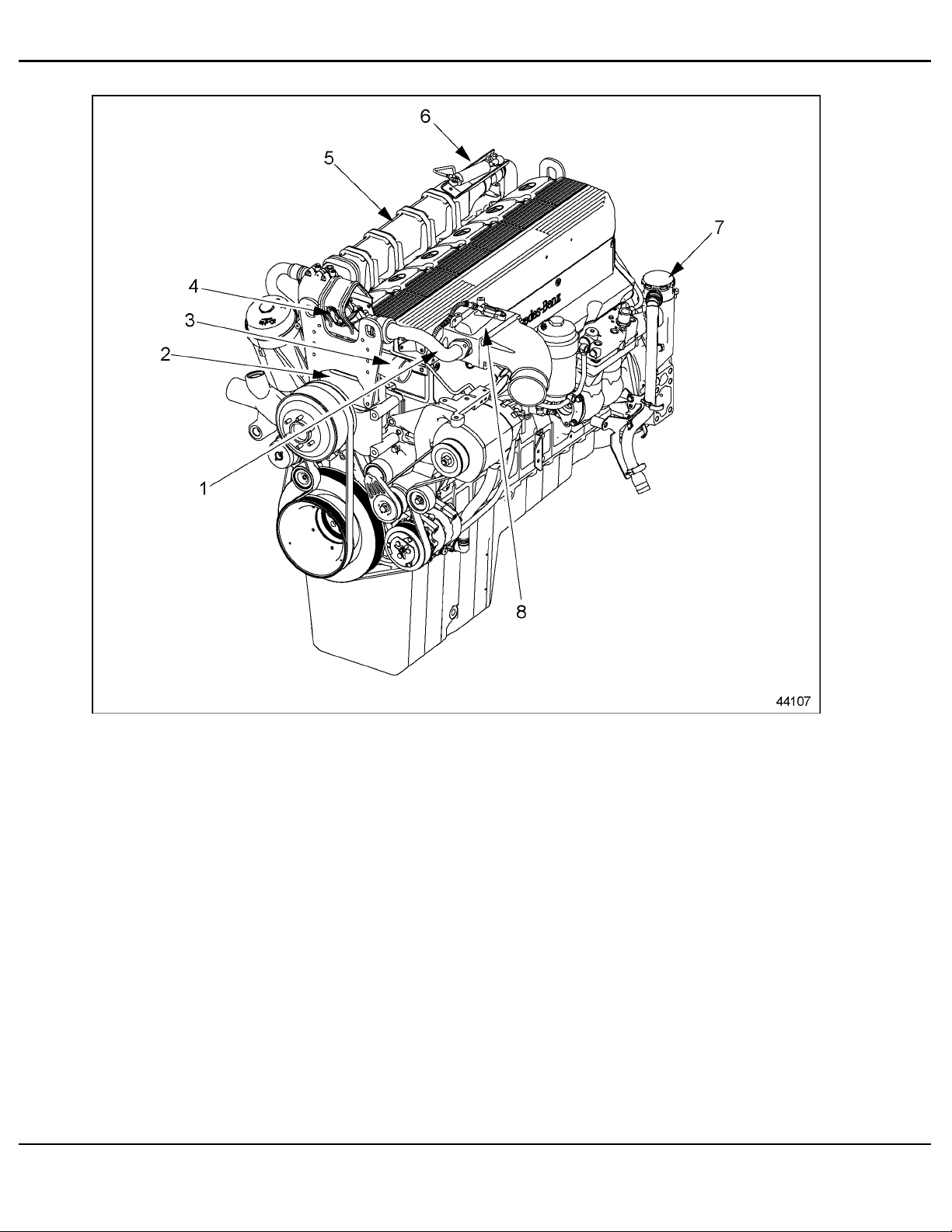

For a general view of the MBE 4000 engine, showing m a jor components, see Figure 3 f or the

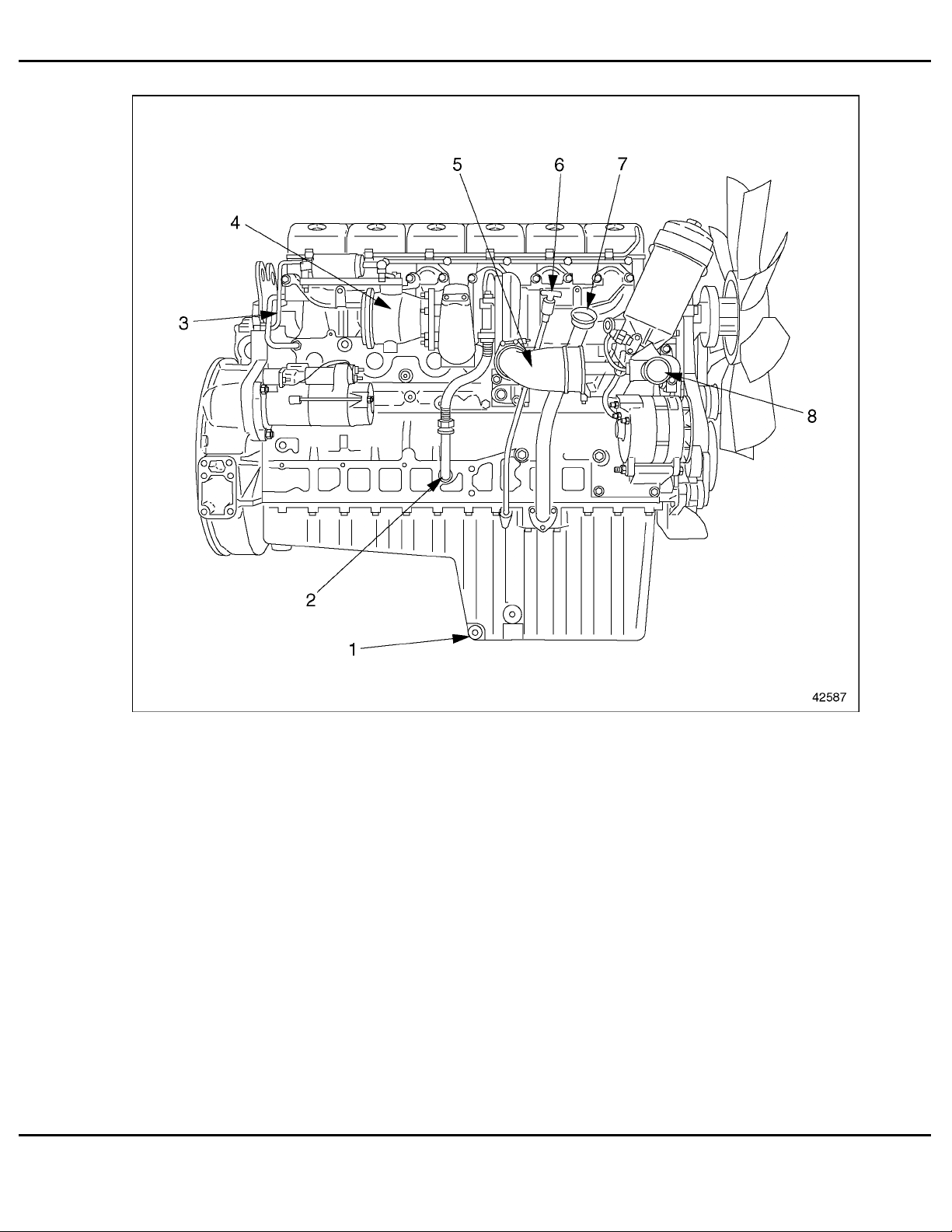

left-hand side, and see Figure 4 for the right-hand side.

For a general view of the MBE 4000 engine , showing ports and fluid lines, see Figure 5 for the

left-hand side and see Figure 6 for the right-hand side.

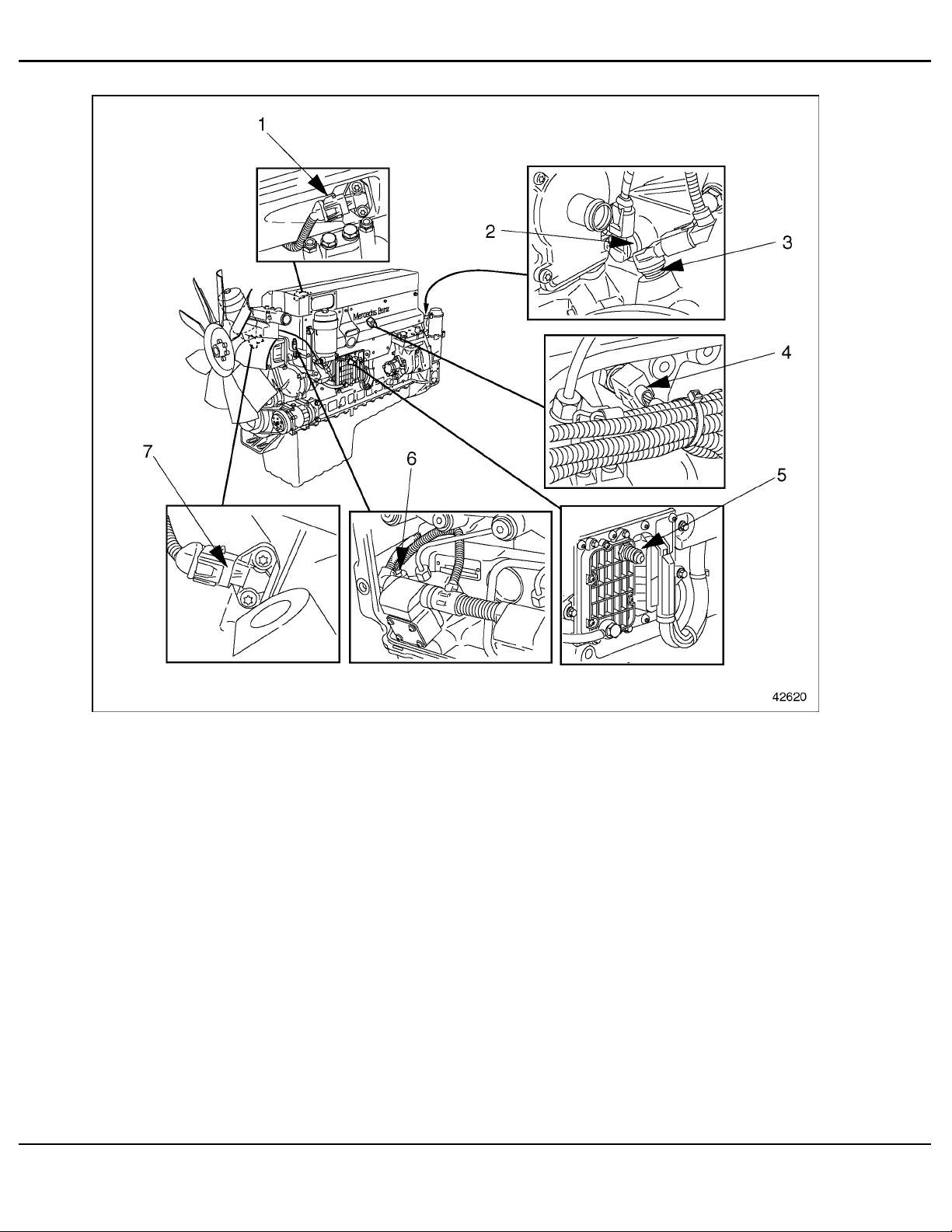

For a general view of the MBE 4000 engine, showing sensor locations, see Figure 7. Two sensors

are not easily visible from the left-hand side of the engine: the charge pressure/tem perature

sensor, located on the right-hand side of the charge air manifold, and the oil pressure/temperature

sensor loca ted at the base of the oil filter.

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

7

MBE 4000 SERVICE MANUAL

1. Front Camshaft Cover 8. Power Steering Pump

2. Thermostat Housing 9. DDEC-ECU Control Unit

3. Coolant Pump

4. Charge-Air (Intake) Manifold

5. Engine Trim Cover

6. Crankcase Breather

7. Air Compressor

10. Fuel Heat Exchanger

11. Oil Pan

12. Fuel Filter

13. Fuel Pump

14. Air Conditioner Compressor

Figure 3 Left Side, Major Engine Components

8 6S

E412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

1. Starter 8. Alternator

2. Exhaust Brake Valve 9. Oil Filter

3. Exhaust Brake Cylinder

4. Exhaust Manifold

5. Cylinder Head Cover

6. Fan

10. Oil Fill Tube

11. O il Heat Exchanger

12. Oil Dipstick

13. Turbocharger

7. Belt Tensioner

Figure 4 Right Side, Major Engine C omponents

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

9

MBE 4000 SERVICE MANUAL

1. Fuel Spill Line 5. Coolant Line (to air compressor)

2. Thermostat Outlet 6. Hydraulic Line (to power steering pump)

3. Charge Air Inlet 7. Electronic Engine Harness Connector

4. Open Breather Tube 8. Fuel Feed Line

Figure 5 Left Side, Ports and L ines

10 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

1. Oil Drain Plug 5. Turbocharger Outlet Pipe

2. Turbo Oil Return Line 6. Dipstick

3. Constant-Throttle Inlet 7. Oil Fill Cap

4. Exhaust Brake Valve Outlet 8. Coolant Pump Inlet Pipe

Figure 6 Right Side, Ports and Lines

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

11

MBE 4000 SERVICE MANUAL

1. Intake Manifold Pressure/Temperature Sensor 5. Barometric Pressure Sensor (integrated into

DDEC-ECU)

2. TDC Sensor (on camshaft) 6. Fuel Temperature Sensor

3. Crank Angle Position Sensor 7. Oil Pressure/Temperature Sensor

4. Coolant Temperature Sensor

Figure 7 Sensor Locations

12 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

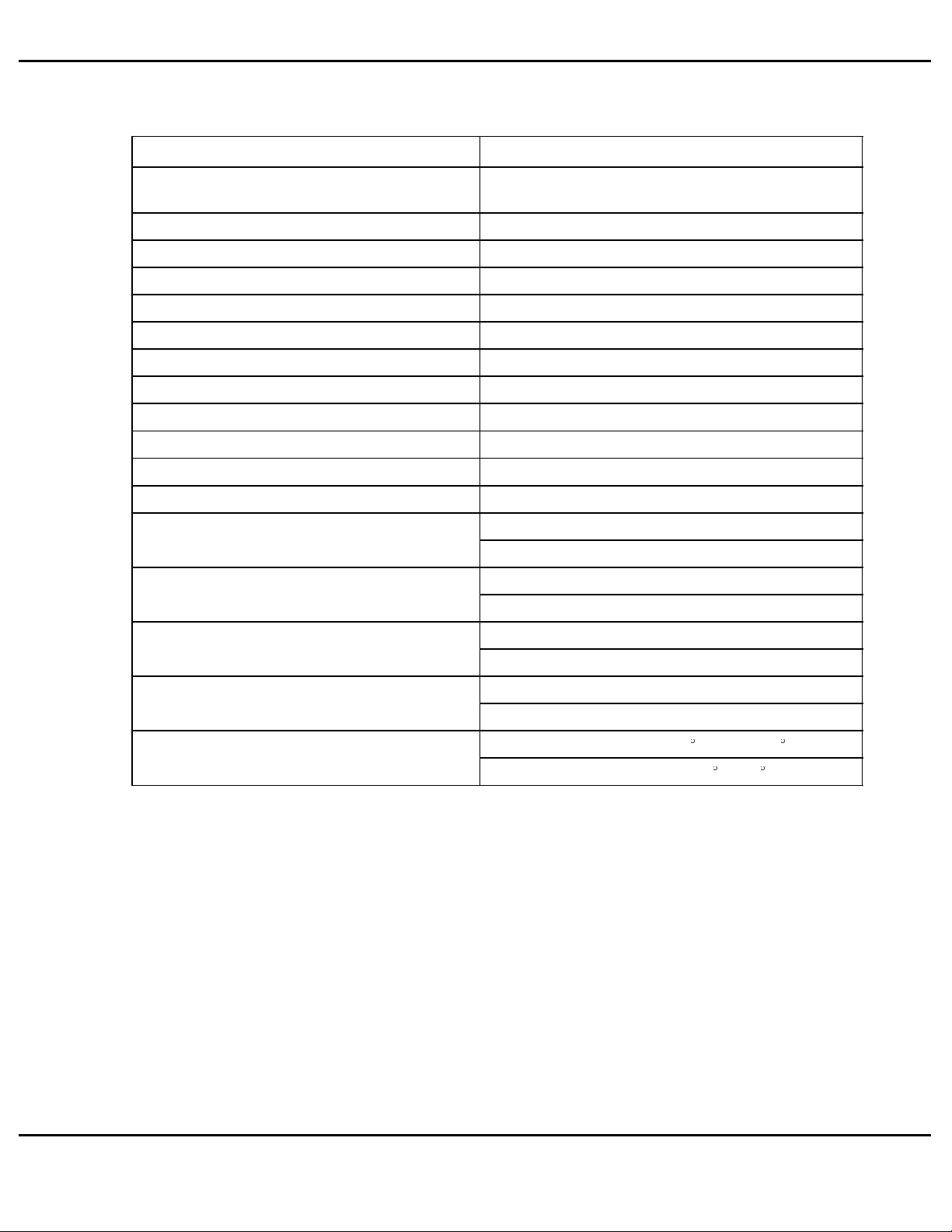

The general specifications for the MBE 4000 engine are listed in Table 1.

Description 6–Cylinder Engines

Engine Type Vertical, inline cylinder block with turbocharger and

charge-air cooler

Cooling System Liquid Circuit

Combustion Principle 4–Stroke direct-injection diesel

Number of Cylinders 6

Bore 128 mm (5.03 in.)

Stroke 166 mm (6.53 in.)

Displacement 12.8 liters (781 in.3)

Compression Ratio 17.25:1

Starting Speed Approximately 100 rpm

Direction of Engine Rotation (viewed from flywheel) Counterclockwise

Starter Electric Motor

Engine “Dry” Weight 930kg(2050lb)

Intake = 0.40 mm (0.016 in.)Valve Lash (with engine cool)

Exhaust = 0.60 mm (0.024 in.)

Intake = 11.546 mm (0.45 in.)Valve Lift (at maximum valve clearance)

Exhaust = 11.963 mm (0.47 in.)

AtIdlerpm=50kPa(7psi)Minimum Engine Oil Pressure

At Maximum rpm = 250 kPa (36 psi)

Minimum Opening Pressure = 27,500 kPa (3989 psi)Fuel Injectors

Maximum Opening Pressure = 30,000 kPa (4350 psi)

Opening Temperature = 81 to 85 C (177 to 185 F)Coolant Thermostat

Normal Operating Temperature = 95 C(203F)

Table 1 General Technical Information

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

13

MBE 4000 SERVICE MANUAL

ENGINE M ODEL AND SERIAL NUMBER

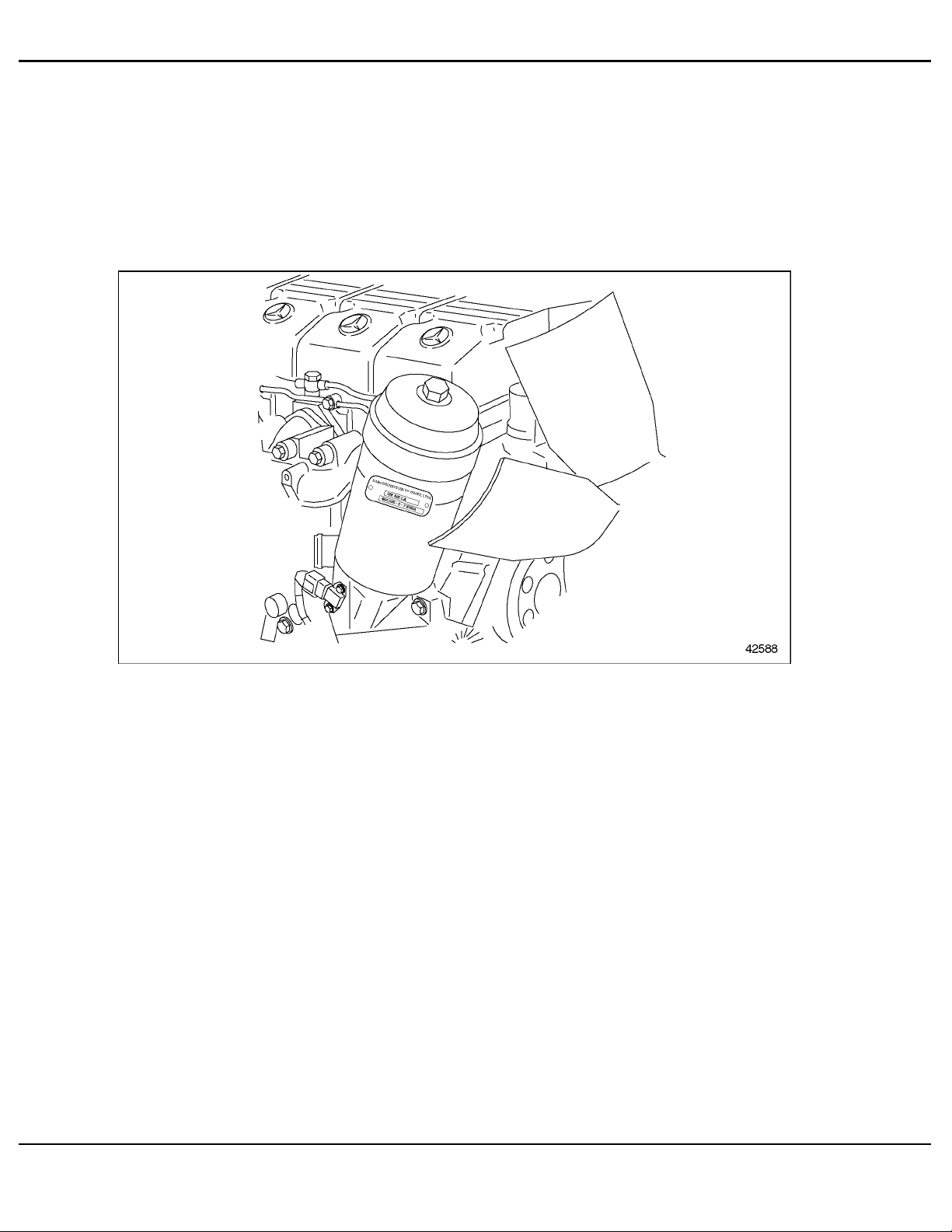

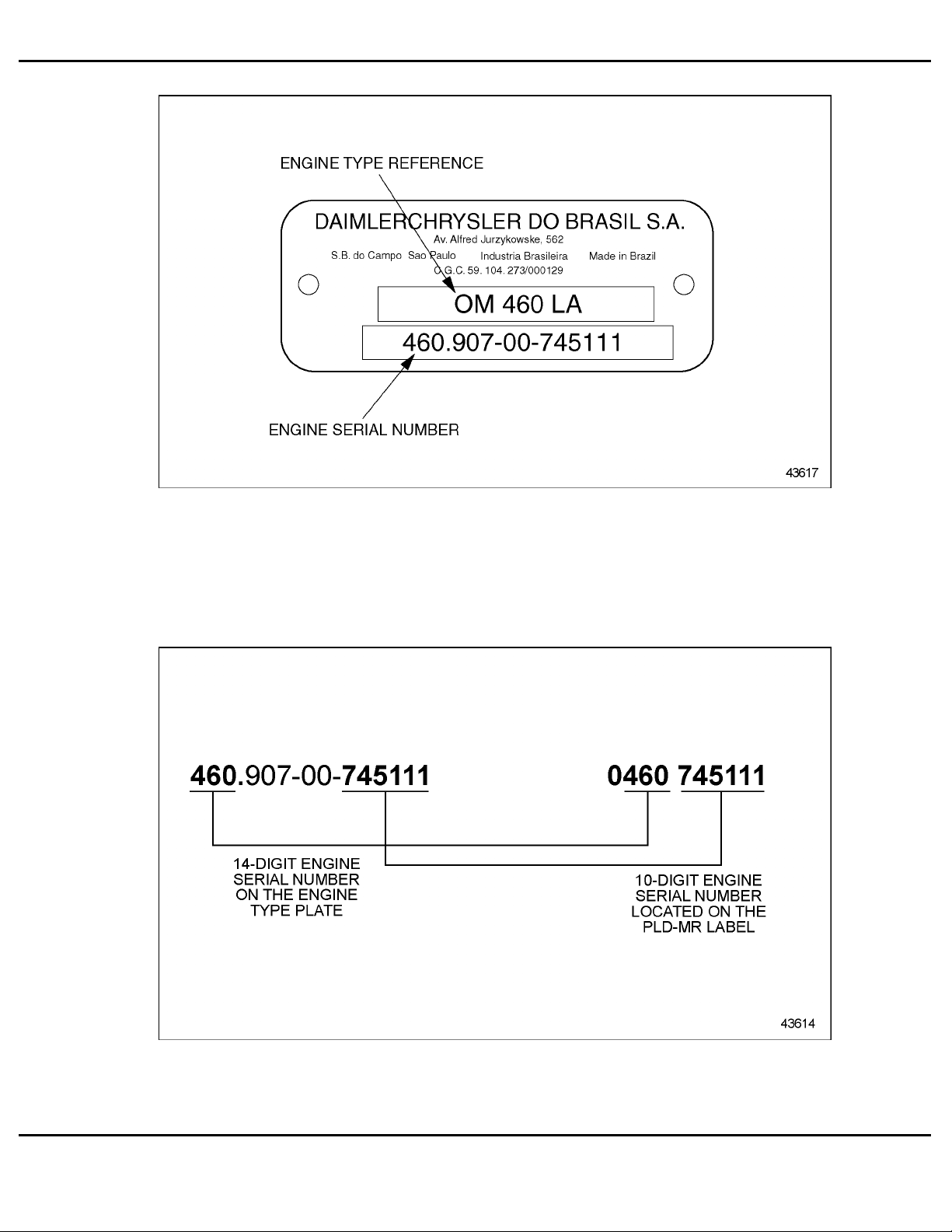

The engine model number and serial number are located on the engine type plate. It is located on

the oil filter housing on the right-hand side of the engine. See Figure 8. The engine type reference

and the complete engine serial number appear beside the name of the manufacturer. The engine

type reference, OM 460 LA is the production code. The engine serial number contains the type

reference followed by a sequential manufacturing number. See Figure 9.

Figure 8 Location of Engine Type Plate

14 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

Figure 9 Engine Type Plate Detail

In addition to the fourteen-digit number on the engine type plate, there is a ten-digit number used

for warranty and service that is found on the DDEC-ECU label. The ten-digit number is derived

from the fourteen-digit number. See Figure 10.

Figure 1 0 Engine Serial Number

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

15

MBE 4000 SERVICE MANUAL

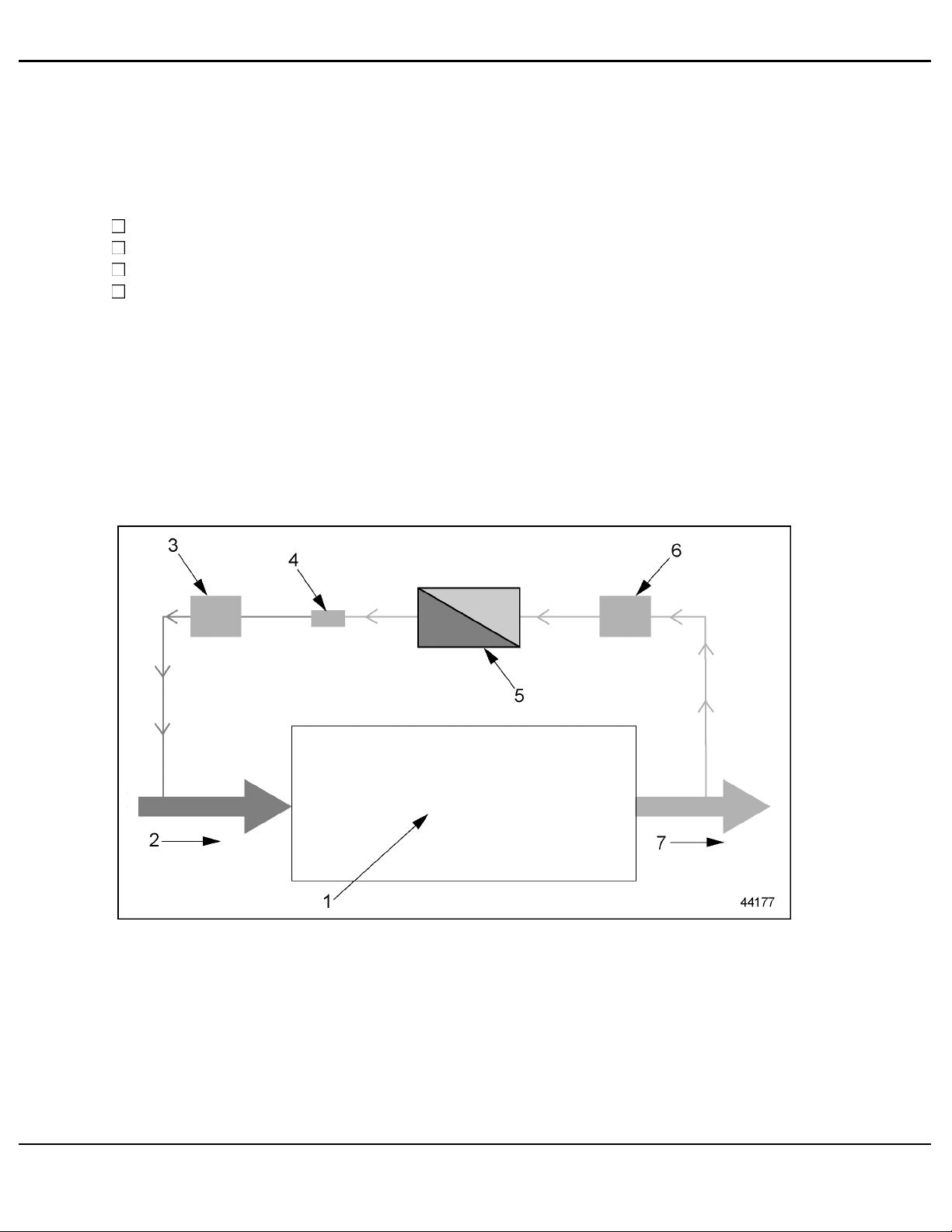

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

The purpose of the Exha ust Gas Recirulation (EGR) system is to reduce engine exhaust gas

emissions in accordance with EPA regulations.

The E GR system consists of:

EGR Cooler

EGR Control Valves

Reed Valves

EGR Charge Air Mixer

The MBE 4000 engines for on-highway EPA 2004 regulation applications use a cooled

EGR s ystem. Pa rt of the exhaust gasses from the front three c ylinders are routed from the

exhaust manifold through the EGR cooler, past control and reed valves, and are mixed with the

intake manifold charge air. The addition of cooled exhaust gasses back into the combustion

airflow reduces the peak in cylinder combustion temperature. Less oxides of nitrogen (NOx) are

produced at lower combustion temperatures.

The recycled exhaust gasses are cooled before engine consumption in a tube and shell engine

water cooler. See Figure 11.

1. Engine 5. EGR Cooler

2. Intake Air 6. EGR Shutoff Valve

3. EGR Modulated Valve 7. Exhaust Air

4. Reed Valves

Figure 11 Air flow Diagram through Engine with EGR System

16 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

For an general view of the MBE 4000 engine with an EGR system, See Figure 12 for a right side

view and see Figure 13 for a left side view.

1. Oil Filter 8. EGR Cooler

2. Solenoid Valve (Wabco®)

3. Turbocharger 10. EGR Modulated Control Valve

4. EGR Gas Inlet Pipe (Hot Pipe) 11. EGR Mixer

5. Exhaust Manifold 12. EGR Gas Outlet Pipe (Cold Pipe)

6. EGR Shutoff Valve 13. Alternator

7. EGR Air Cylinder 14. Belt Tensioner

9. Reed Valve Housing

Figure 1 2 EGR Engine with EGR Components and Revised Parts (Right View)

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

17

MBE 4000 SERVICE MANUAL

1. EGR Gas Outlet Pipe 5. EGR Cooler

2. Coolant Pump 6. EGR Shutoff Valve (hidden)

3. Thermostat Housing 7. Crankcase Breather (Hengst filter)

4. EGR Modulated Control Valve 8. EGR Mixer

Figure 13 EGR Engine with EGR Components and Revised Parts (Left View)

18 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

EGR Cooler

The EGR Cooler is equipped with a single-pass cooler. Part of the exhaust gasses from the first

three cylinders are directed through the EGR shutoff valve and through the cooler and reed valves,

past the EGR modulated control valve and the mixer and then back to the cylinder.

EGR Control Valves

There are two EGR valves on the MBE 4000 EGR engine — the EGR shutoff valve and the EGR

modulated control valve. The EGR shutoff valve is a pneumatically driven butterf ly valve,

located at the inlet of the EGR cooler. It closes when the exhaust flap or turbo-brake actuates,

avoiding exhaust gas flow and excessive pressure in the EGR cooler and reed valves. The EGR

modulated control valve is an electronically actuated butterfly valve loc ated after the EGR cooler

and r eed valves, controlled by the DDEC-EC U (formerly PLD-MR). This va lve controls the

exhaust gas flow for the intake manifold.

Reed Valves

The reed valves work like a check valve, allowing flow of gas only in one direction, avoiding gas

back flow when the intake pressure is higher than exhaust gas pressure. As the average exhaust

pressure is lowe r than the intake pressure, the gas flow through the reed valves is possible due to

exhaust gas pressure peaks — peaks slightly higher than the intake air pressure, which occur as

the engine exhaust valves open. During this peak of pressure, the reed valves open and allow gas

flow to the EGR modulated valve and mixer.

EGR Mixer

The purpose of the mixer is to ensure good mixing of the cooled E GR gasses with filtered charge

air. Once the exhaust gasses a re cooled and have completed their cycle through the EGR system,

they are released into the EGR mixer. The recycled exhaust gasses are combined with the charged

air and directed to the cylinders.

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

19

MBE 4000 SERVICE MANUAL

SAFETY INSTRUCTIONS AND PRECAUTIONS

The following safety measures are essential when working on the MBE 4000 engine.

To re duce the chance of personal injury and/or property damage, the following instructions

must be car efully observed:

Proper service and repair are important to the service technician and the safe, reliable

operation of the engine. If part replac ement is ne ce ssary, the par t must be replaced with

one of the same part number or with an equivalent part number. Do not use a replacement

part of lesser quality.

The service procedures recomme n ded and described in this manual are effective methods

of performing repair. Some of these procedures require the use of specially designed tools.

Accordingly, anyone who intends to use a replacement part, procedure or tool that is not

recommended, must first determine that neither personal safety nor the safe operation of the

engine will be jeopardized by the replacement part, procedure or tool selected.

It is important to note that this manual contains various “Cautions” and “Notice s” that

must be carefully observed in order to reduce the risk of personal injury during repair or

the possibility that improper repair may damage the engine or render it unsafe. It is also

important to understand that these “Cautions” and “Notices” a re not exhaustive, be cause it

is impossible to warn personnel of the possible hazardous consequences that might result

from f ailure to follow these instructions.

20 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

MBE 4000 SERVICE MANUAL

Exhaust (Start/Run Engine)

Before starting and running an engine, adhere to the following safety precautions:

PERSONAL INJURY

To avoid injury before starting and running the engine,

ensure the vehicle is parked on a level surface, parking

brake is set, and the wheels are blocked.

PERSONAL INJURY

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

Always start and operate an engine in a well ventilated

area.

If operating an engine in an enclosed area, vent the

exhaust to the outside.

Do not modify or tamper with the exhaust system or

emission control system.

Stands

Safety stands are required in conjunction with hydraulic jacks or hoists. Do not rely on either the

jack or the hoist to car ry the load. When lifting an engine, ensure the lifting device is fastened

securely. Ensure the item to be lifted does not exceed the capacity of the lifting device.

PERSONAL INJURY

To avoid injury when removing or installing a heavy engine

component, ensure the component is properly supported

and securely a tt ached to an adequate lifting device to

prevent the component from falling.

All information subject to change without notice.

412 0403 Copyright © 2004 DETROIT DIESE L CORPORATION

6SE

21

MBE 4000 SERVICE MANUAL

Glasses

Select appropriate safety glasses for the job. I t is especially important to w ear safety glasses when

using tools such as hammers, chisels, pullers or punches.

PERSONAL INJURY

To avoid injury when working on or near an operating

engine, wear protective clothing, eye protection, and

hearing protection.

Work Place

Organize your work area and keep it clean. A fall could result in a serious injury. Eliminate

the possibility of a fall by:

Wiping up oil spills

Keeping tools and parts off the floor

After s er vicing or adjusting the engine:

Reinstall all safety devices, guards or shields

Ensure that all tools a nd servicing equipment are removed from the engine

22 6

SE412 0403 Copyright © 2004 DETROIT DIES E L CORPORATION

All information subject to change without notice.

Loading...

Loading...